Patents

Literature

548 results about "Boiler tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boiler Tubes are metal tubes located inside of boilers that heat water in order to produce steam.

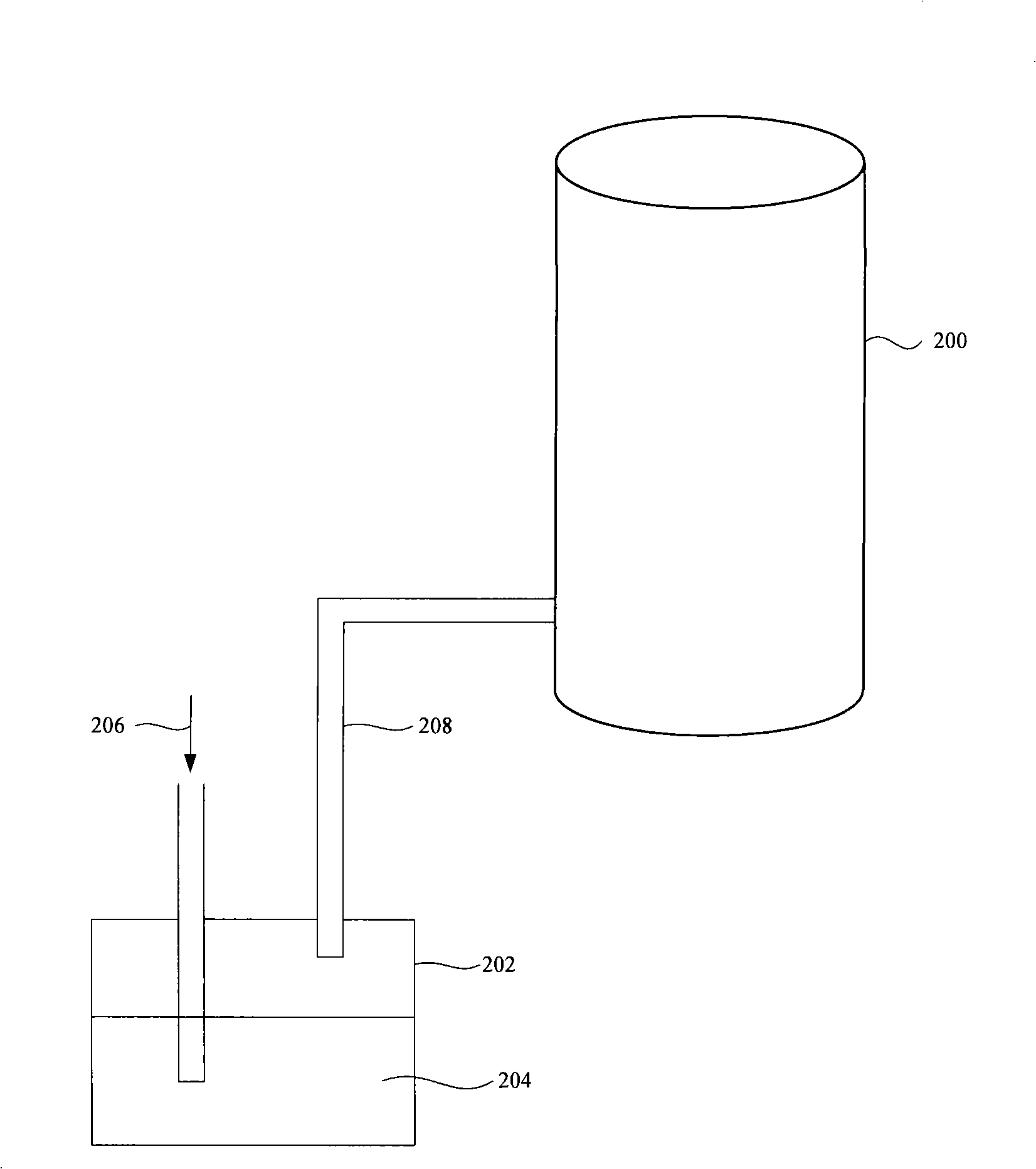

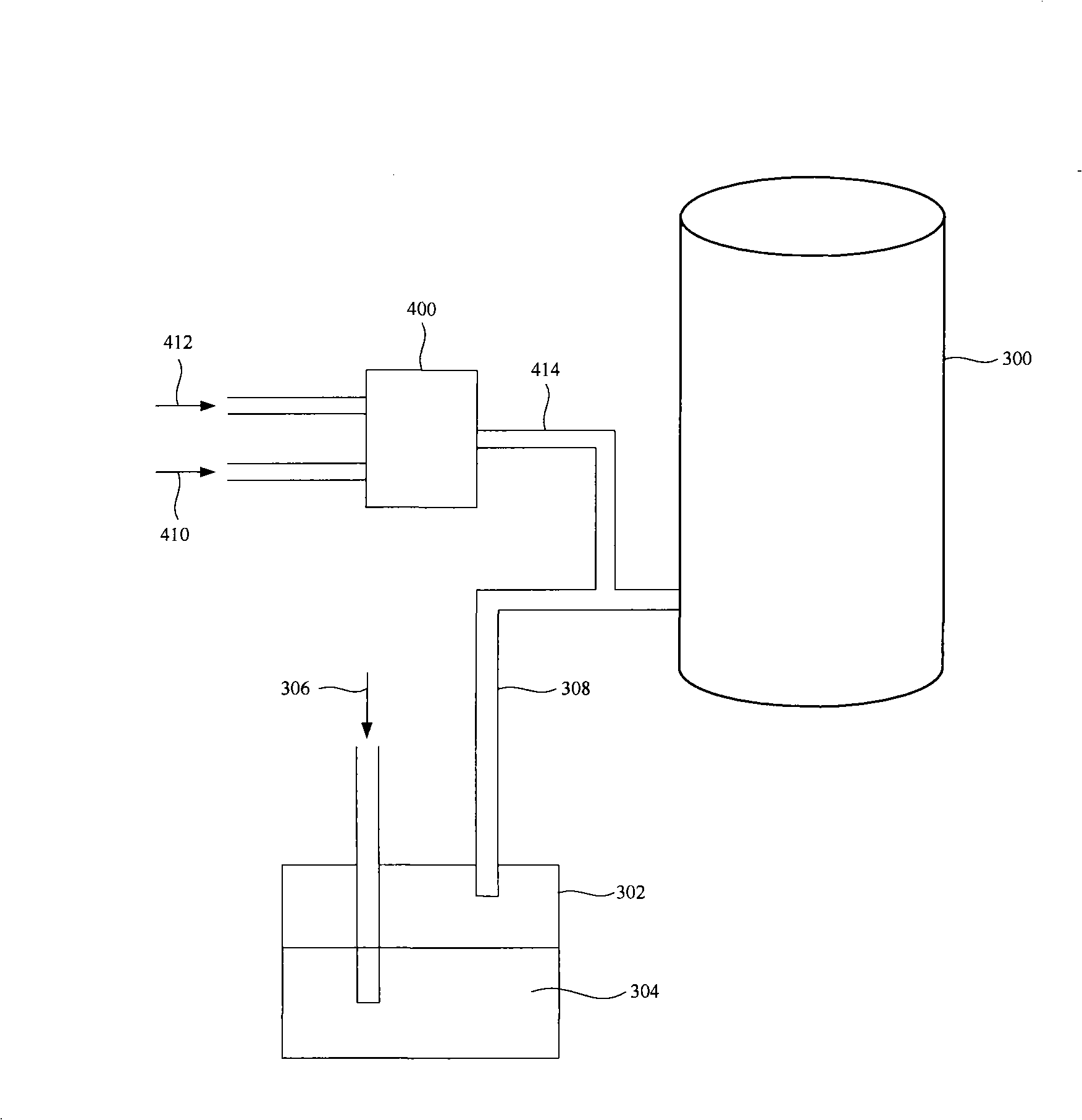

Solar Thermal Power System

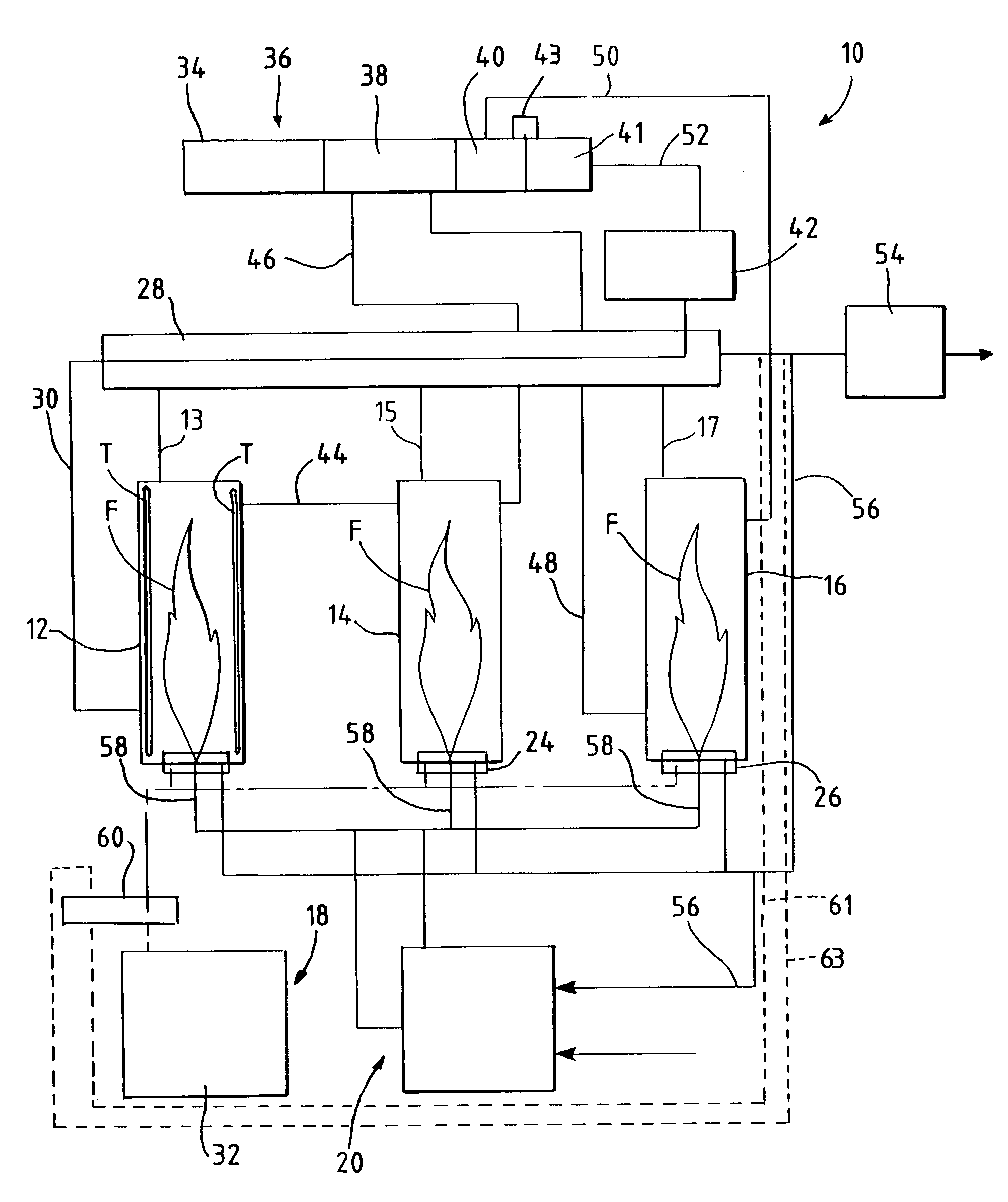

InactiveUS20090199557A1Simple efficiencyTechnology being suitableAuxillary drivesSteam separation arrangementsThermal energy storageEngineering

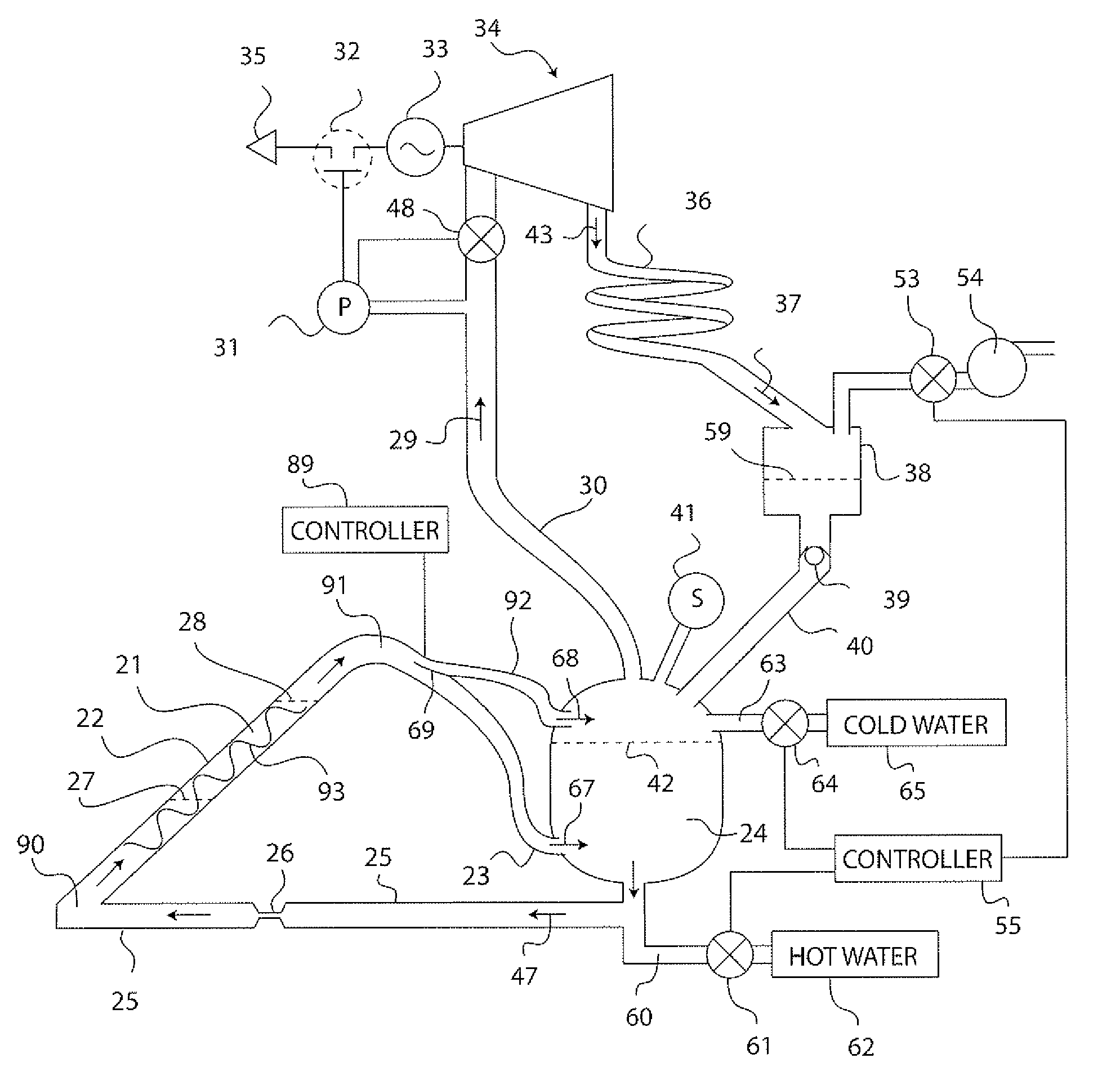

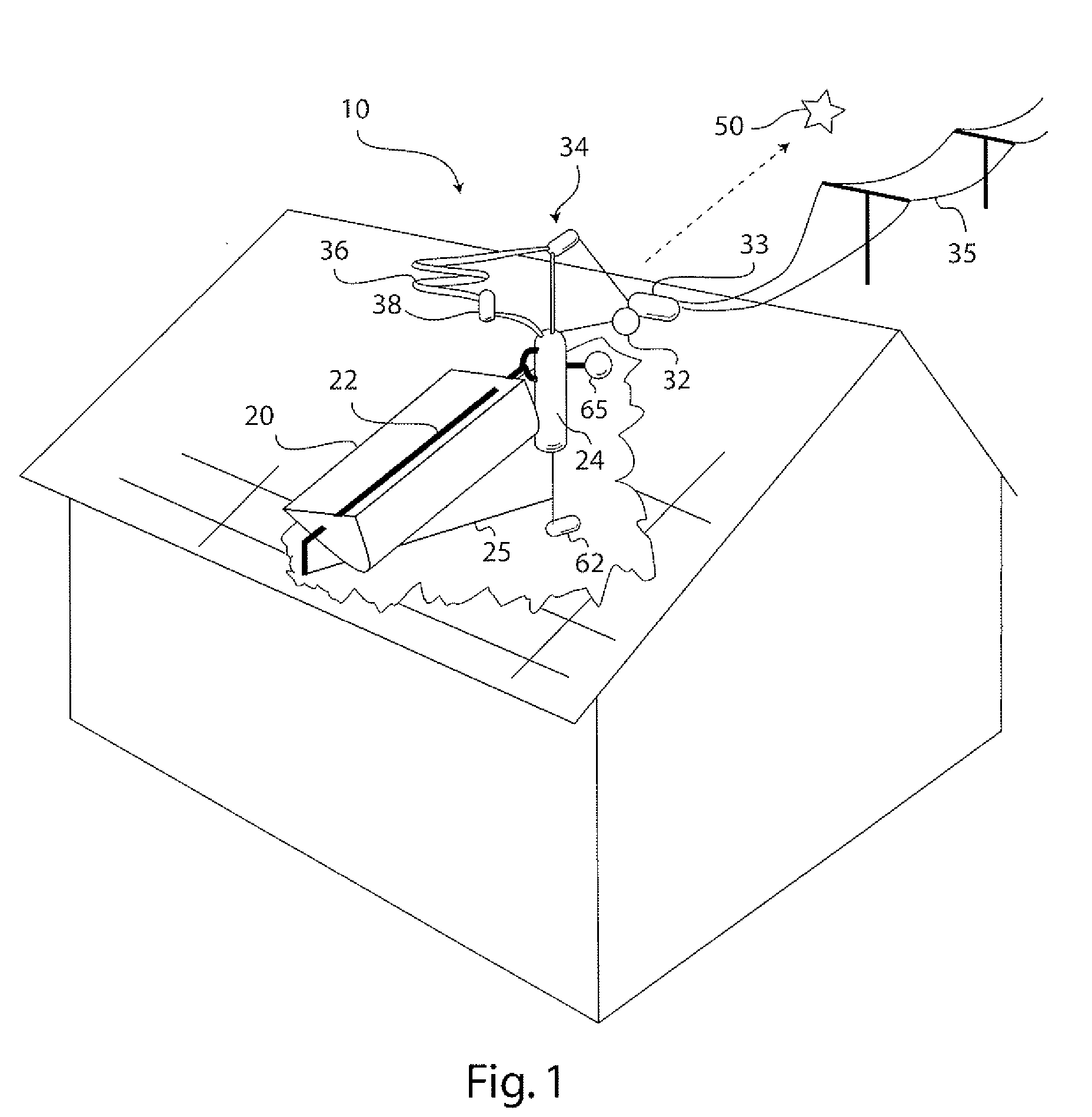

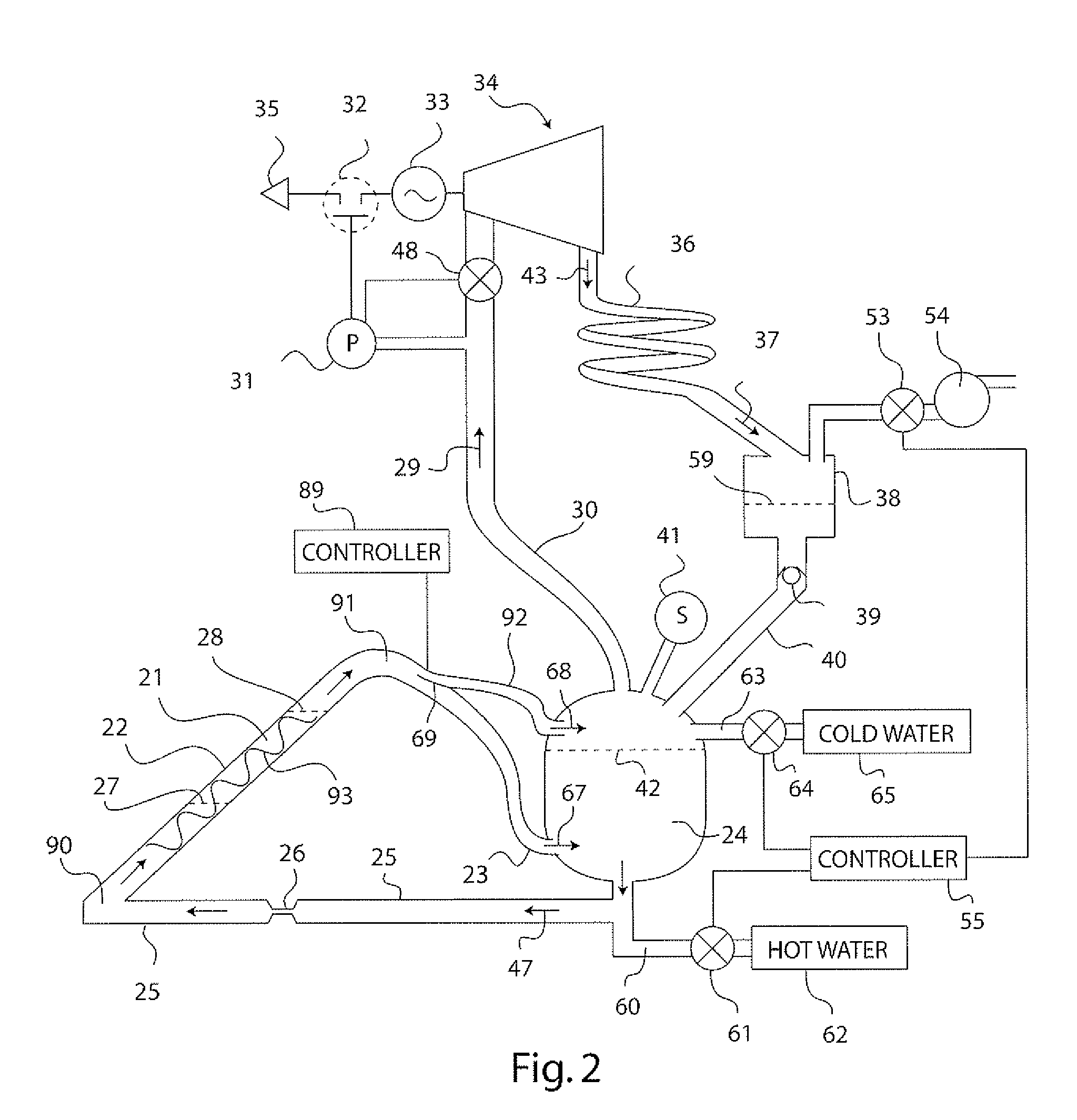

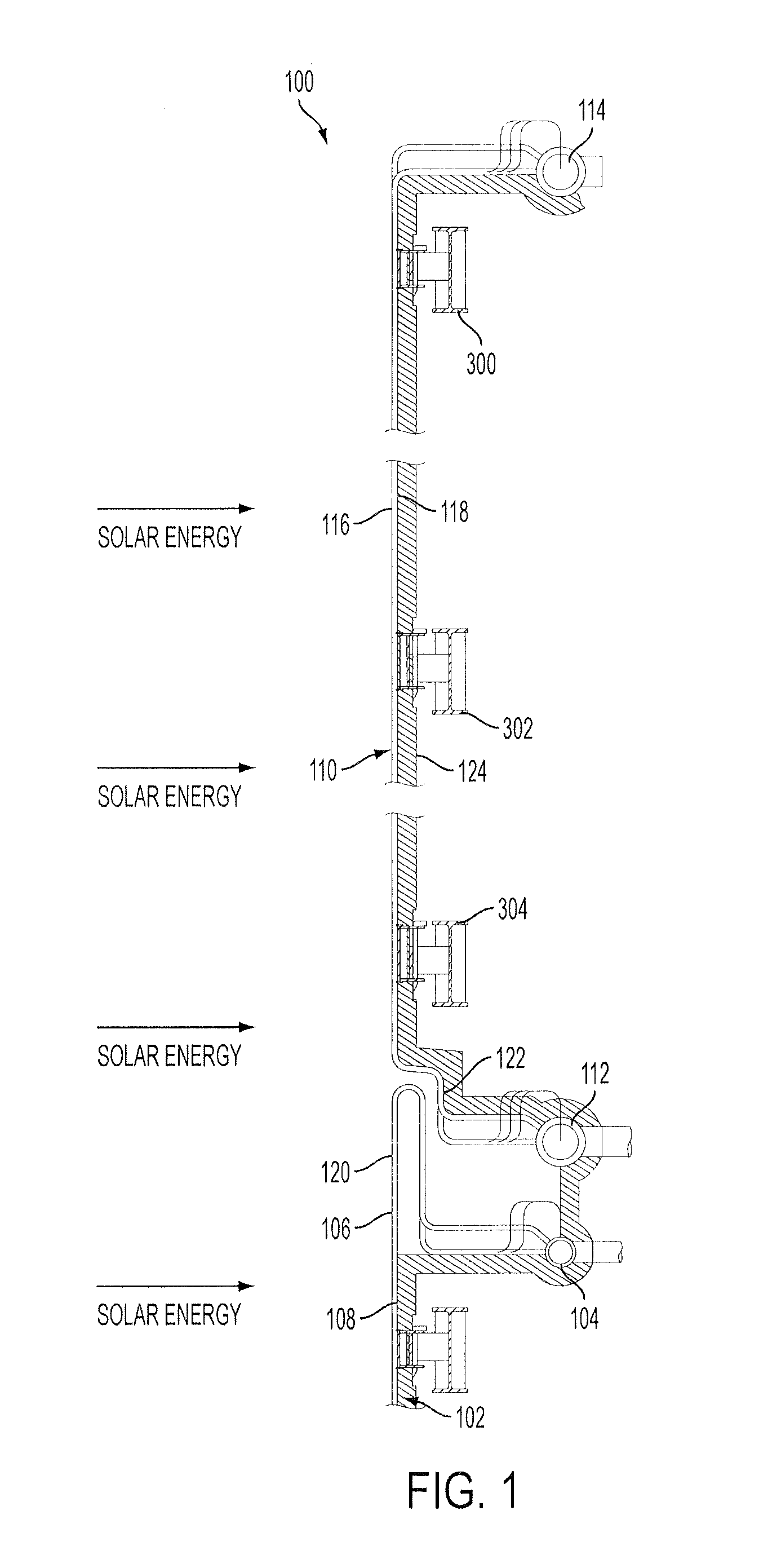

A solar thermal power generator includes an inclined elongated boiler tube positioned in the focus of a solar concentrator for generating steam from water. The boiler tube is connected at one end to receive water from a pressure vessel as well as connected at an opposite end to return steam back to the vessel in a fluidic circuit arrangement that stores energy in the form of heated water in the pressure vessel. An expander, condenser, and reservoir are also connected in series to respectively produce work using the steam passed either directly (above a water line in the vessel) or indirectly (below a water line in the vessel) through the pressure vessel, condense the expanded steam, and collect the condensed water. The reservoir also supplies the collected water back to the pressure vessel at the end of a diurnal cycle when the vessel is sufficiently depressurized, so that the system is reset to repeat the cycle the following day. The circuital arrangement of the boiler tube and the pressure vessel operates to dampen flow instabilities in the boiler tube, damp out the effects of solar transients, and provide thermal energy storage which enables time shifting of power generation to better align with the higher demand for energy during peak energy usage periods.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

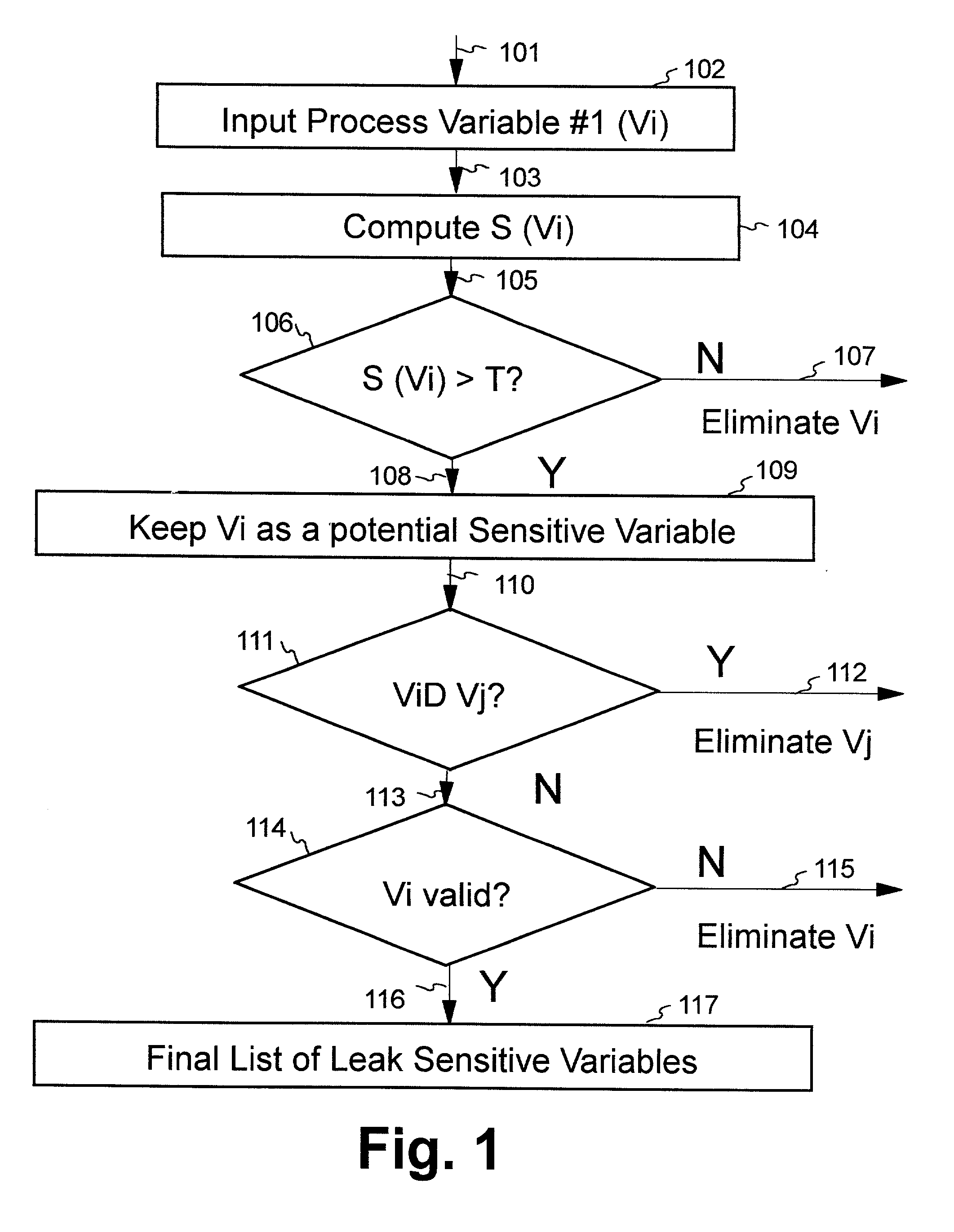

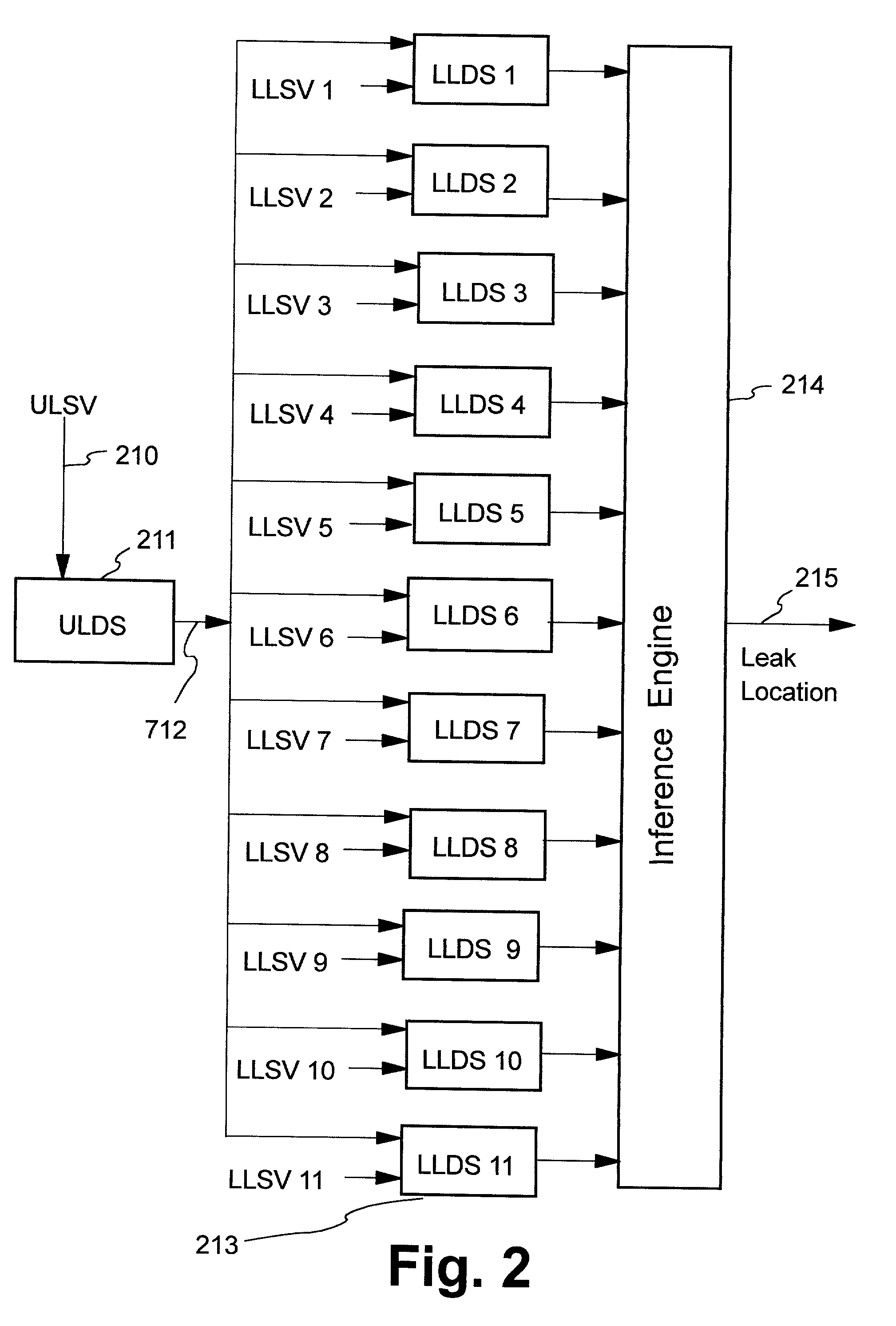

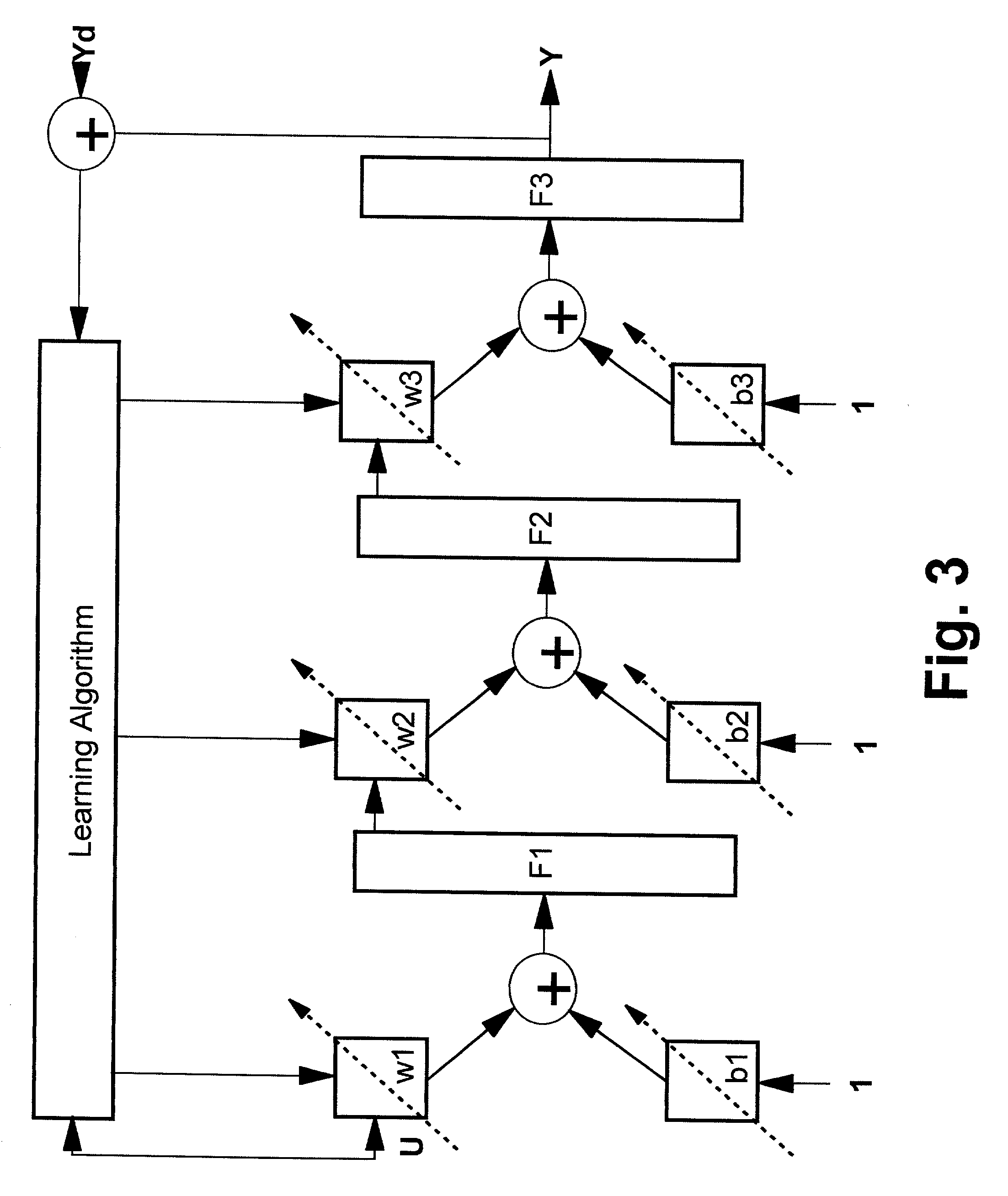

Artificial neural network and fuzzy logic based boiler tube leak detection systems

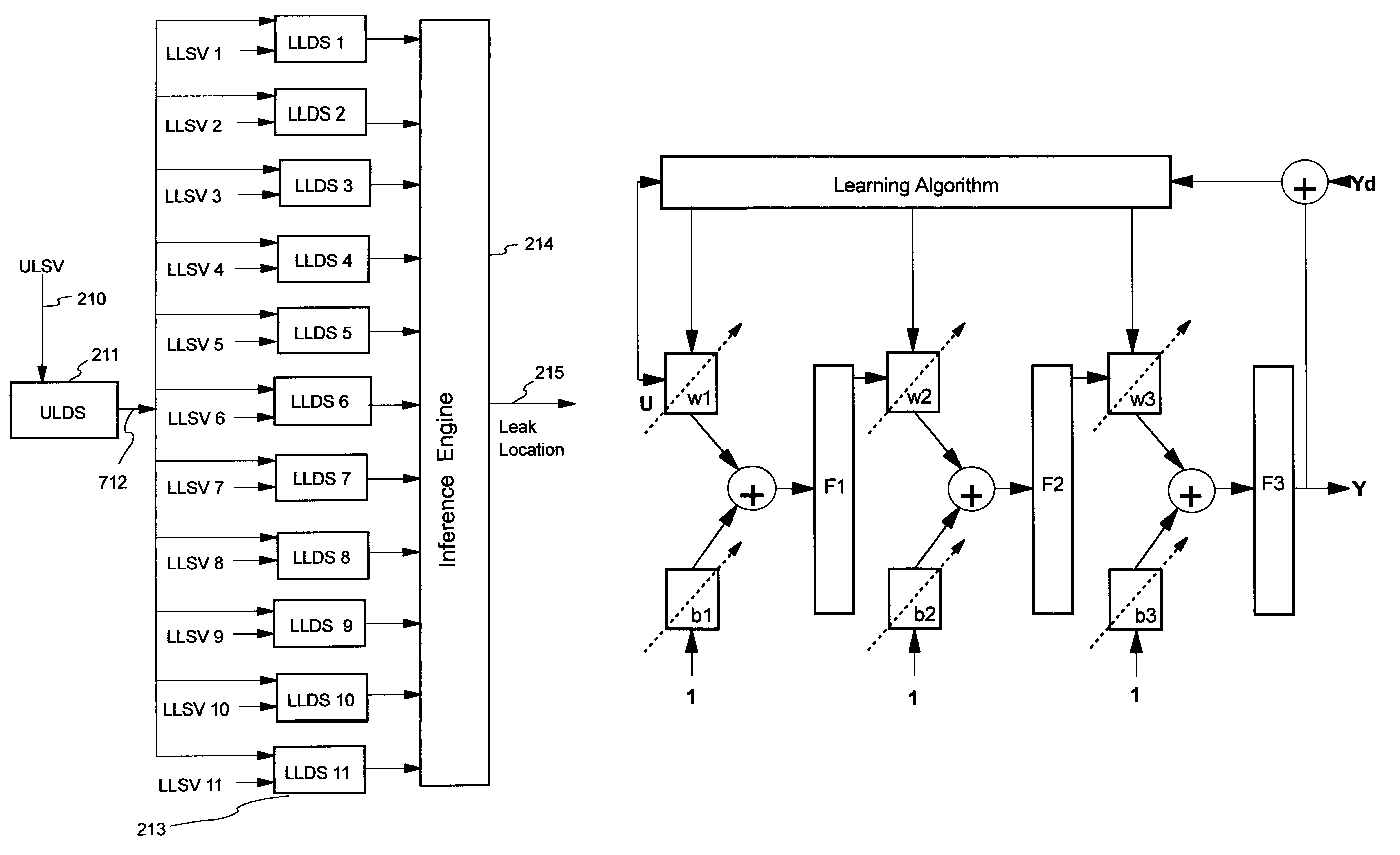

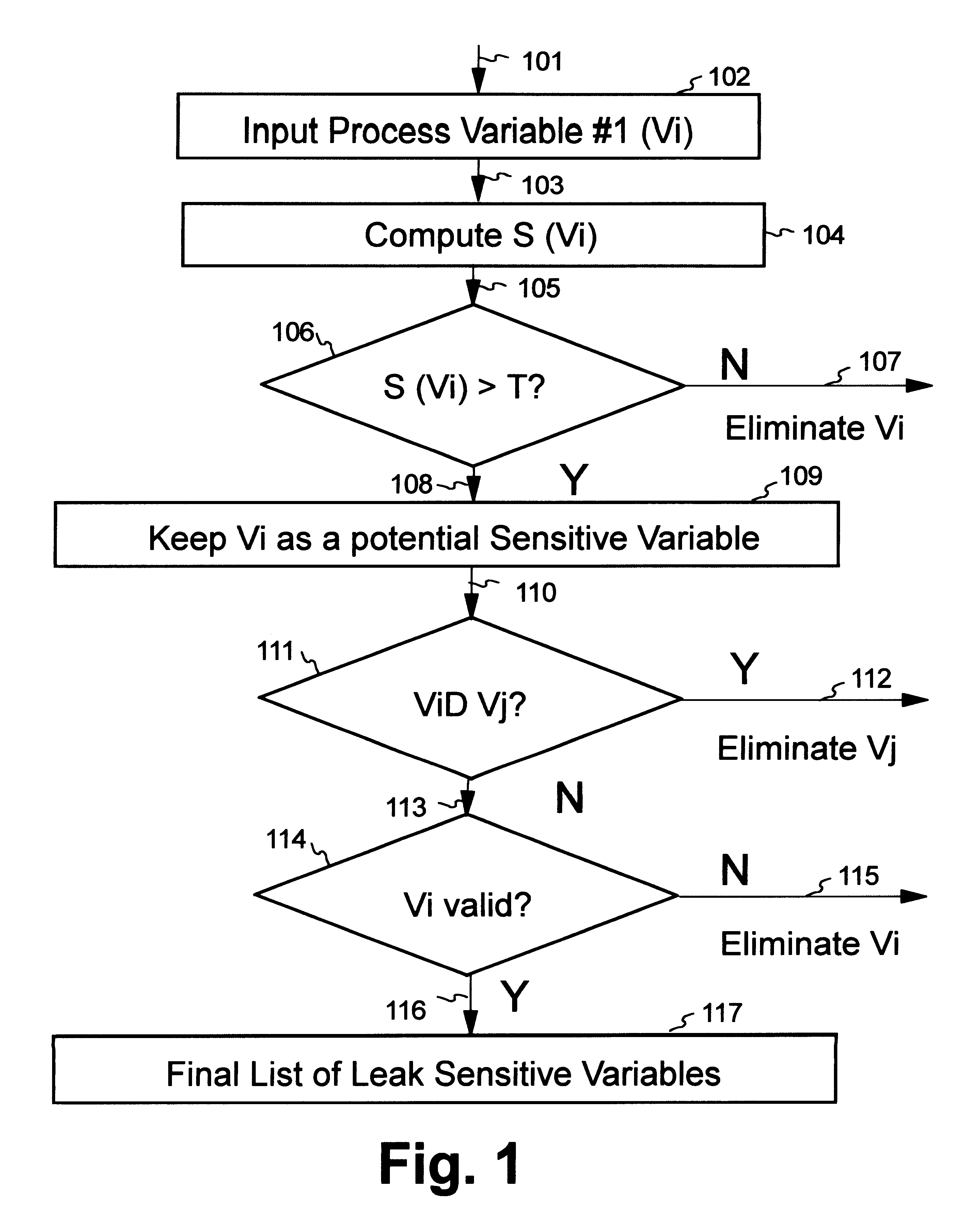

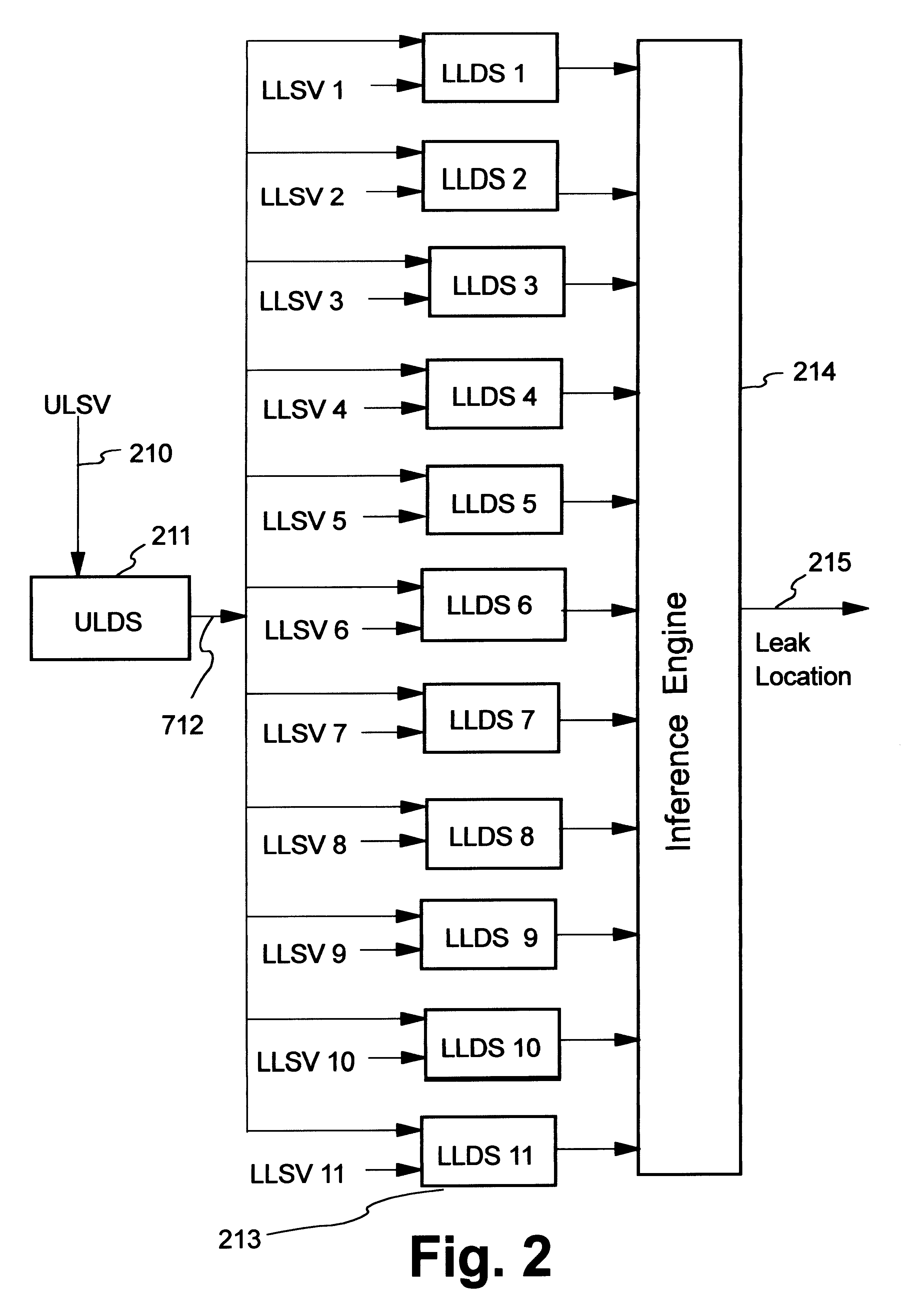

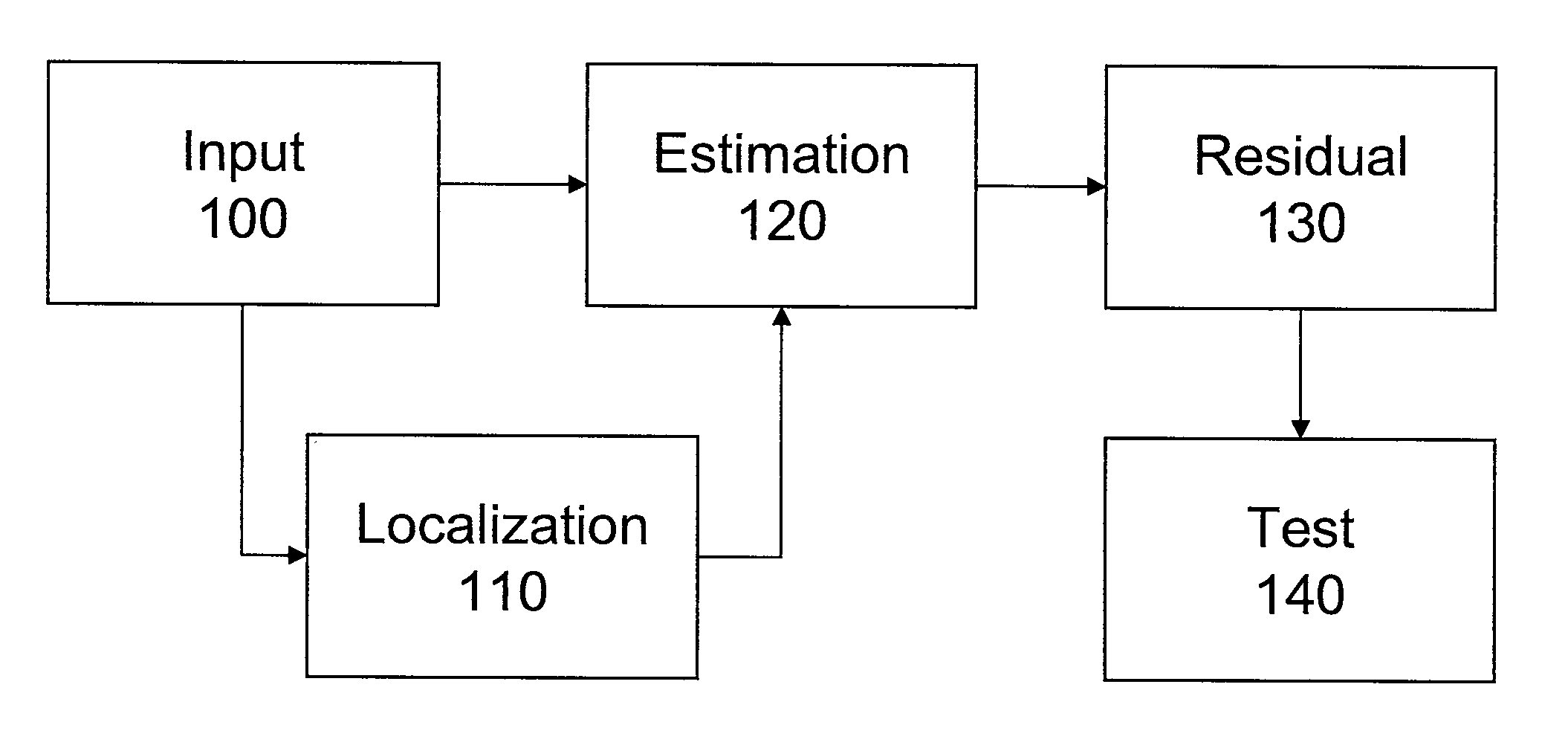

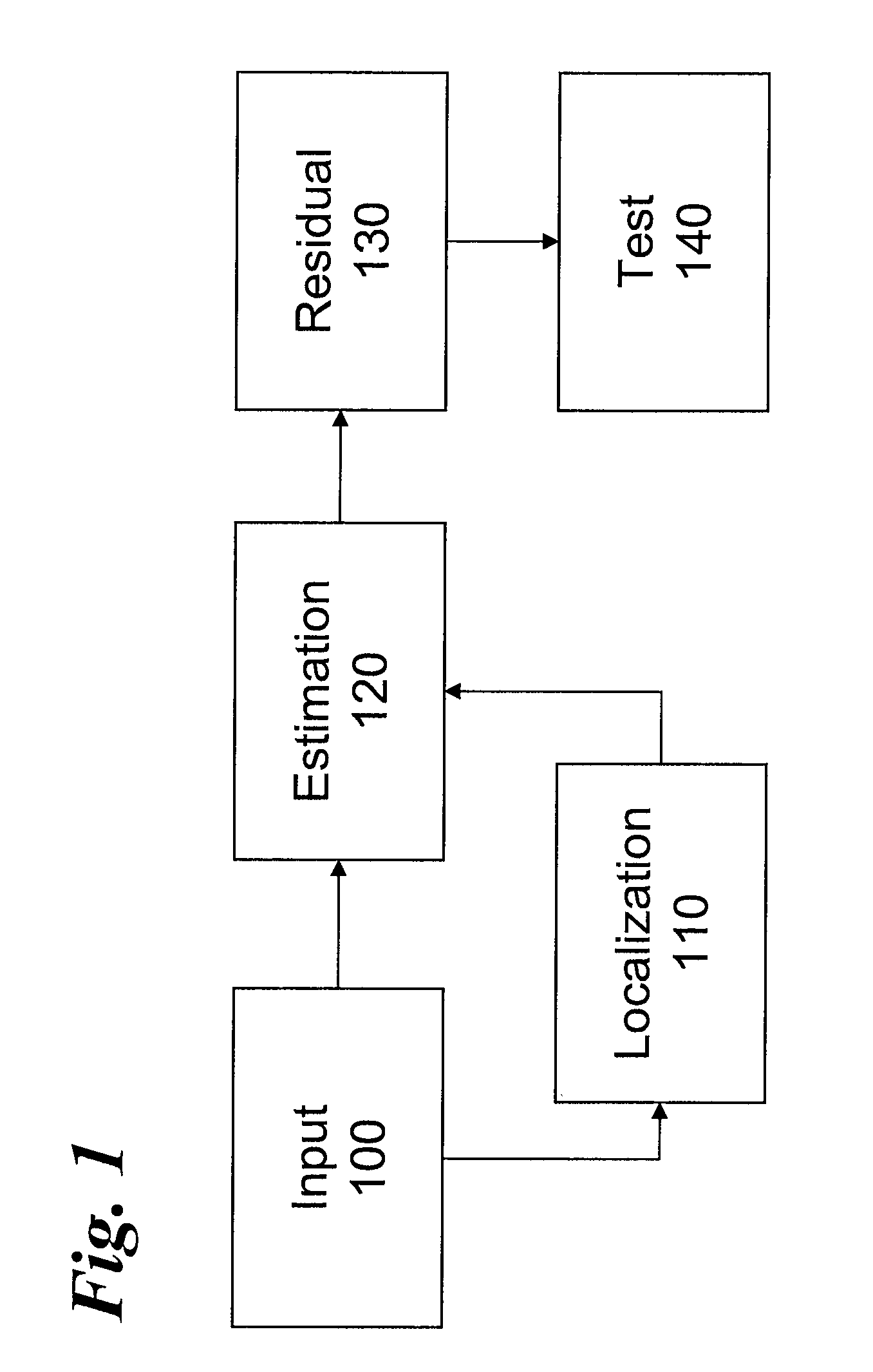

Power industry boiler tube failures are a major cause of utility forced outages in the United States, with approximately 41,000 tube failures occurring every year at a cost of $5 billion a year. Accordingly, early tube leak detection and isolation is highly desirable. Early detection allows scheduling of a repair rather than suffering a forced outage, and significantly increases the chance of preventing damage to adjacent tubes. The instant detection scheme starts with identification of boiler tube leak process variables which are divided into universal sensitive variables, local leak sensitive variables, group leak sensitive variables, and subgroup leak sensitive variables, and which may be automatically be obtained using a data driven approach and a leak sensitivity function. One embodiment uses artificial neural networks (ANN) to learn the map between appropriate leak sensitive variables and the leak behavior. The second design philosophy integrates ANNs with approximate reasoning using fuzzy logic and fuzzy sets. In the second design, ANNs are used for learning, while approximate reasoning and inference engines are used for decision making. Advantages include use of already monitored process variables, no additional hardware and / or maintenance requirements, systematic processing does not require an expert system and / or a skilled operator, and the systems are portable and can be easily tailored for use on a variety of different boilers.

Owner:TENNESSEE VALLEY AUTHORITY +1

Method and apparatus for detecting external cracks from within a metal tube

InactiveUS6271670B1Resistance/reactance/impedenceFlaw detection using microwavesRadarScattering loss

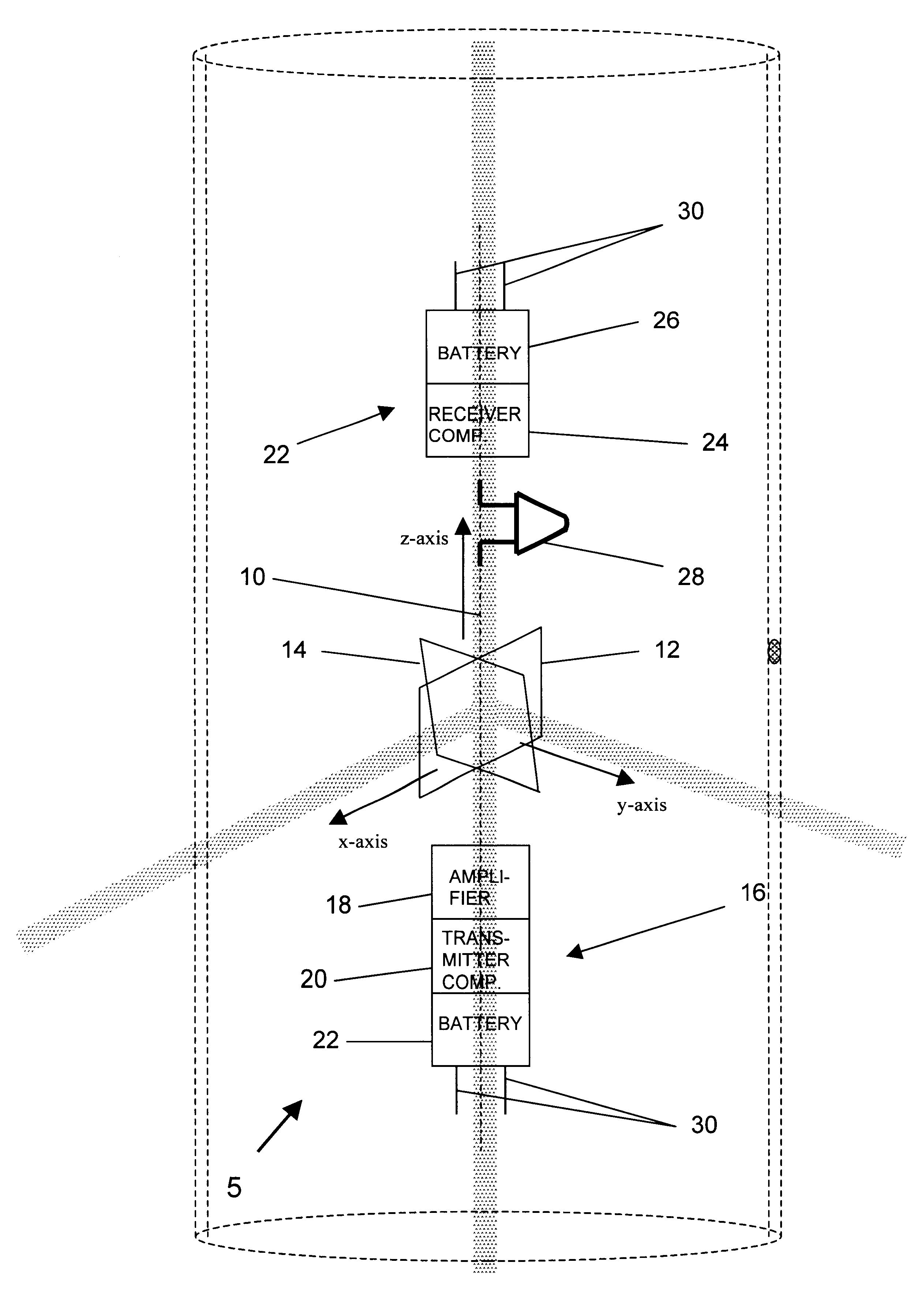

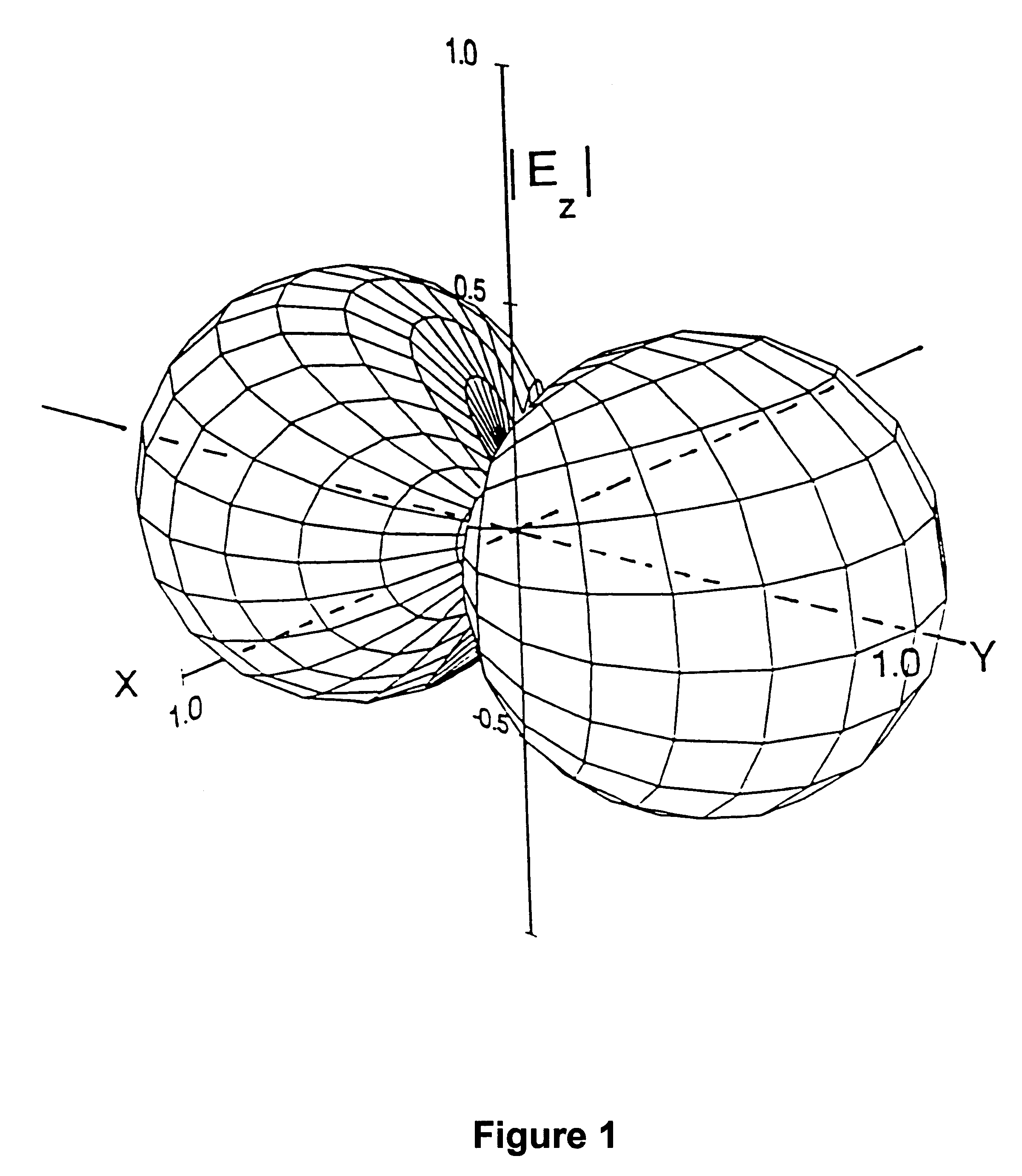

A method and tool using a continuous electromagnetic wave from a transverse magnetic-dipole source with a coaxial electric-dipole receiver is described for the detection of external sidewall cracks and other anomalies in boiler tubes and other enclosures. The invention utilizes the concept of radar backscatter rather than eddy-currents or ultrasound, which are sometimes used in prior art crack-detection methods. A numerical study of the distribution of the fields shows that the direct transmission from the source to the receiver is reduced from that in free space. Further, if the diameter of the receiver dipole is made sufficiently small, it should be possible to detect cracks with a scattering loss of up to -40 dB in thin-walled boiler tubes.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Reducing mercury emissions from the burning of coal

ActiveUS7758827B2Reduce waste disposal costsReduce concrete costsSolid waste managementUsing liquid separation agentCombustionHalogen

Sorbent components containing calcium, alumina, silica, and halogen are used in combination during coal combustion to produce environmental benefits. Sorbents are added to the coal ahead of combustion and / or are added into the flame or downstream of the flame, preferably at minimum temperatures to assure complete formation of the refractory structures that result in various advantages of the methods. When used together, the components ● reduce emissions of mercury and sulfur; ● reduce emissions of elemental and oxidized mercury; ● increase the efficiency of the coal burning process through de-slagging of boiler tubes; ● increase the level of Hg, As, Pb, and / or Cl in the coal ash; ● decrease the levels of leachable heavy metals (such as Hg) in the ash, preferably to levels below the detectable limits; and ● make a highly cementitious ash product.

Owner:NOX II LTD

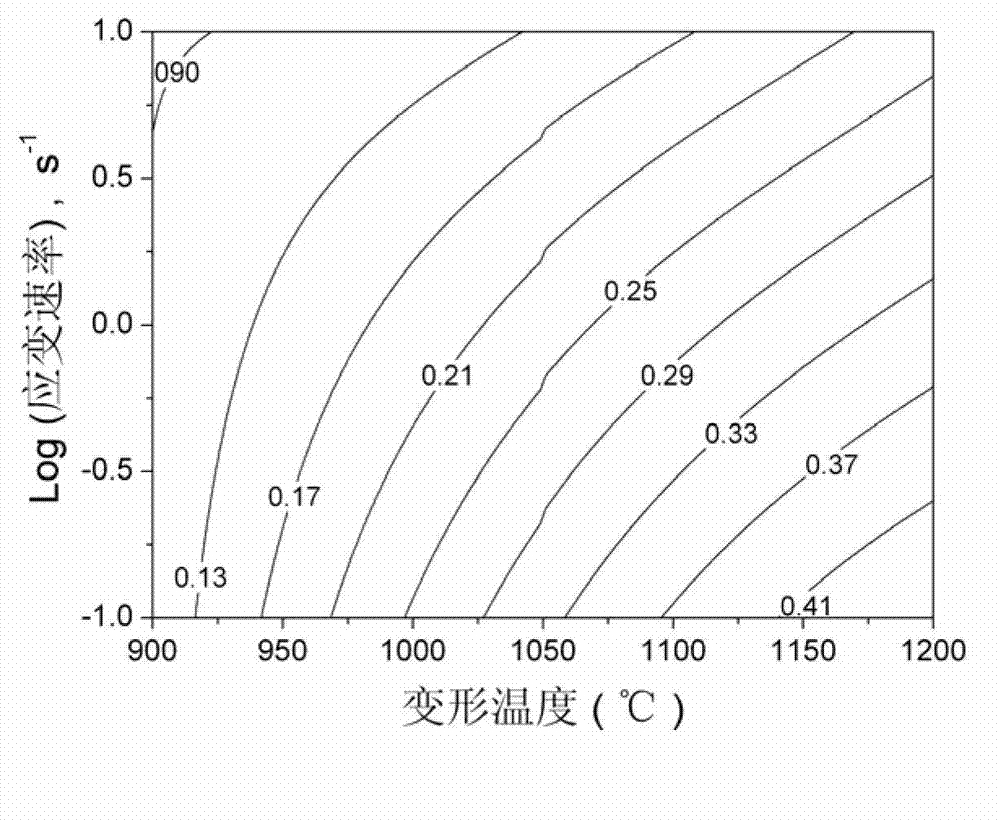

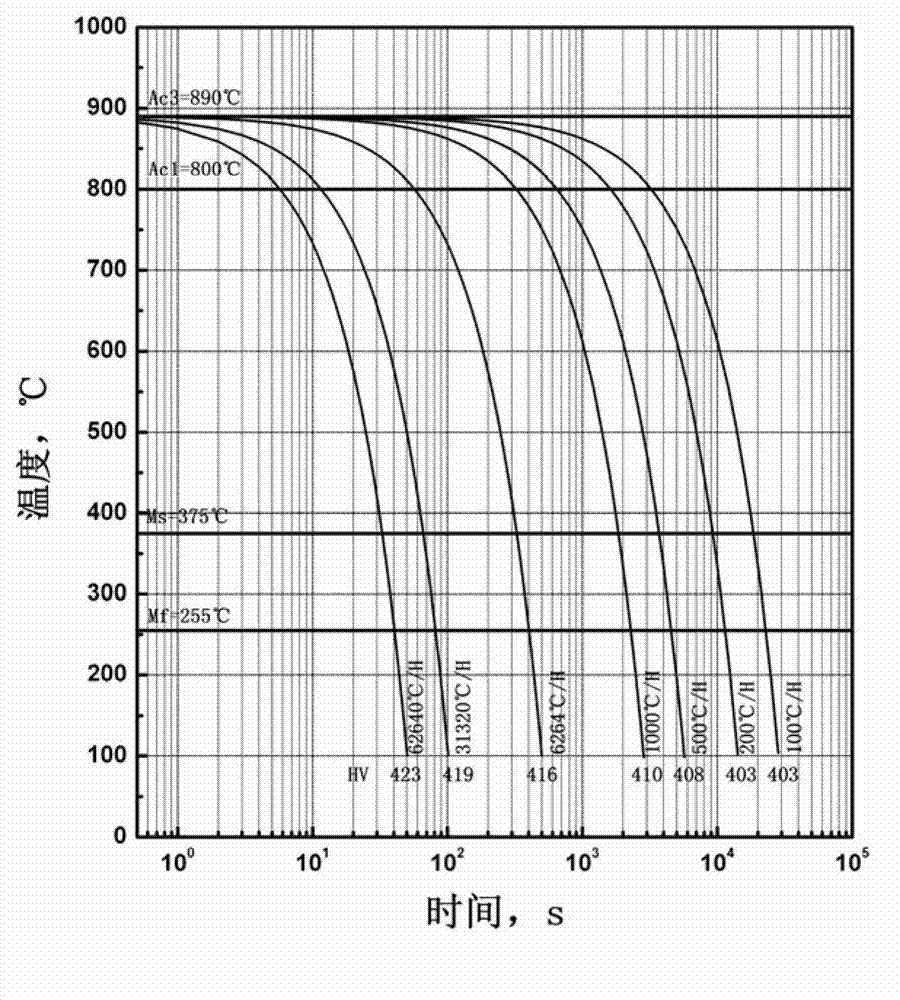

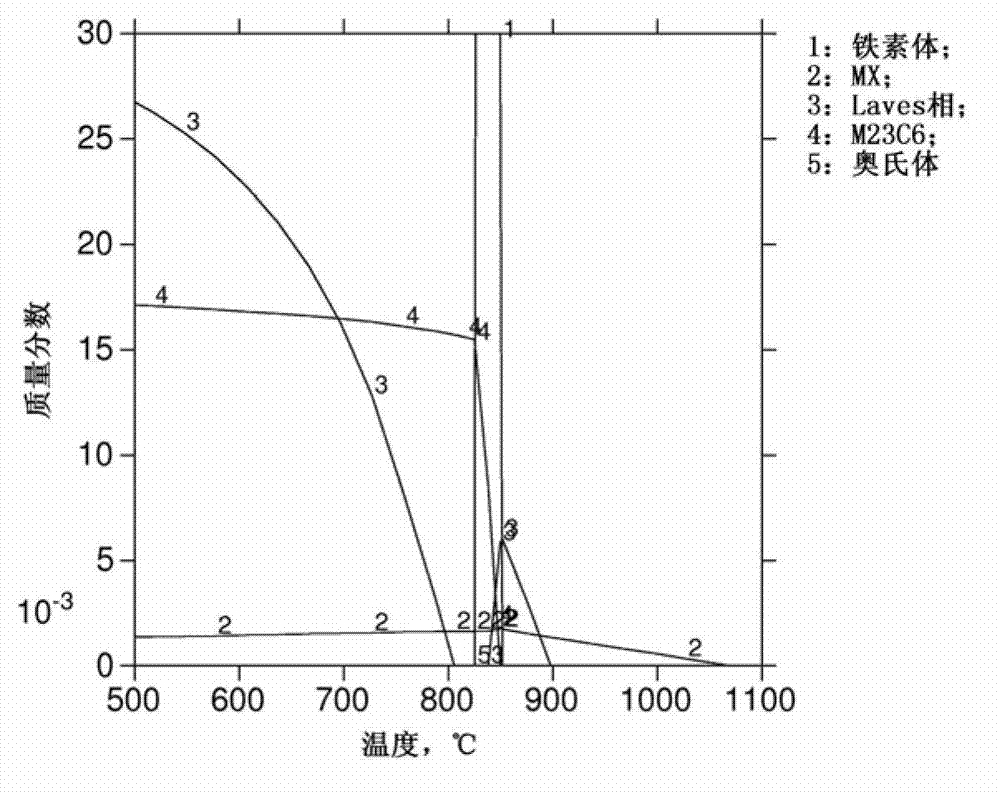

Steel for steam-temperature ultra-supercritical thermal power unit and preparation method thereof

The invention relates to steel for a steam-temperature ultra-supercritical thermal power unit and a preparation method thereof, belonging to the technical field of heat resistant steel. The steel comprises the following chemical compositions by weight percentage: 0.06-0.10 percent of carbon, 0.1-0.5 percent of silicon, 0.2-0.8 percent of manganese, not more than 0.004 percent of phosphorous, not more than 0.002 percent of sulfur, 8.0-9.5 percent of chromium, 2.5-3.5 percent of tungsten, 2.5-3.5 percent of cobalt, 0.03-0.07 percent of niobium, 0.10-0.30 percent of vanadium, 0.80-1.20 percent of copper, 0.006-0.010 percent of nitrogen, 0.010-0.016 percent of boron, 0.01-0.04 percent of rare-earth cerium, not more than 0.01 percent of nickel, not more than 0.005 percent of aluminum, not more than 0.01 percent of titanium, not more than 0.01 percent of zirconium and the balance of ferrum and inevitable impurity elements. The steel has the advantages that the steel can be used for preparing G115 steel of 650 DEG C of steam-parameter ultra-supercritical thermal power unit and a large-diameter boiler tube thereof, and the room-temperature mechanical property, the impact property, the high-temperature mechanical property and the permanence property of the steel are much higher than those of P92 steel in the Gb5310 and ASME standard.

Owner:CENT IRON & STEEL RES INST

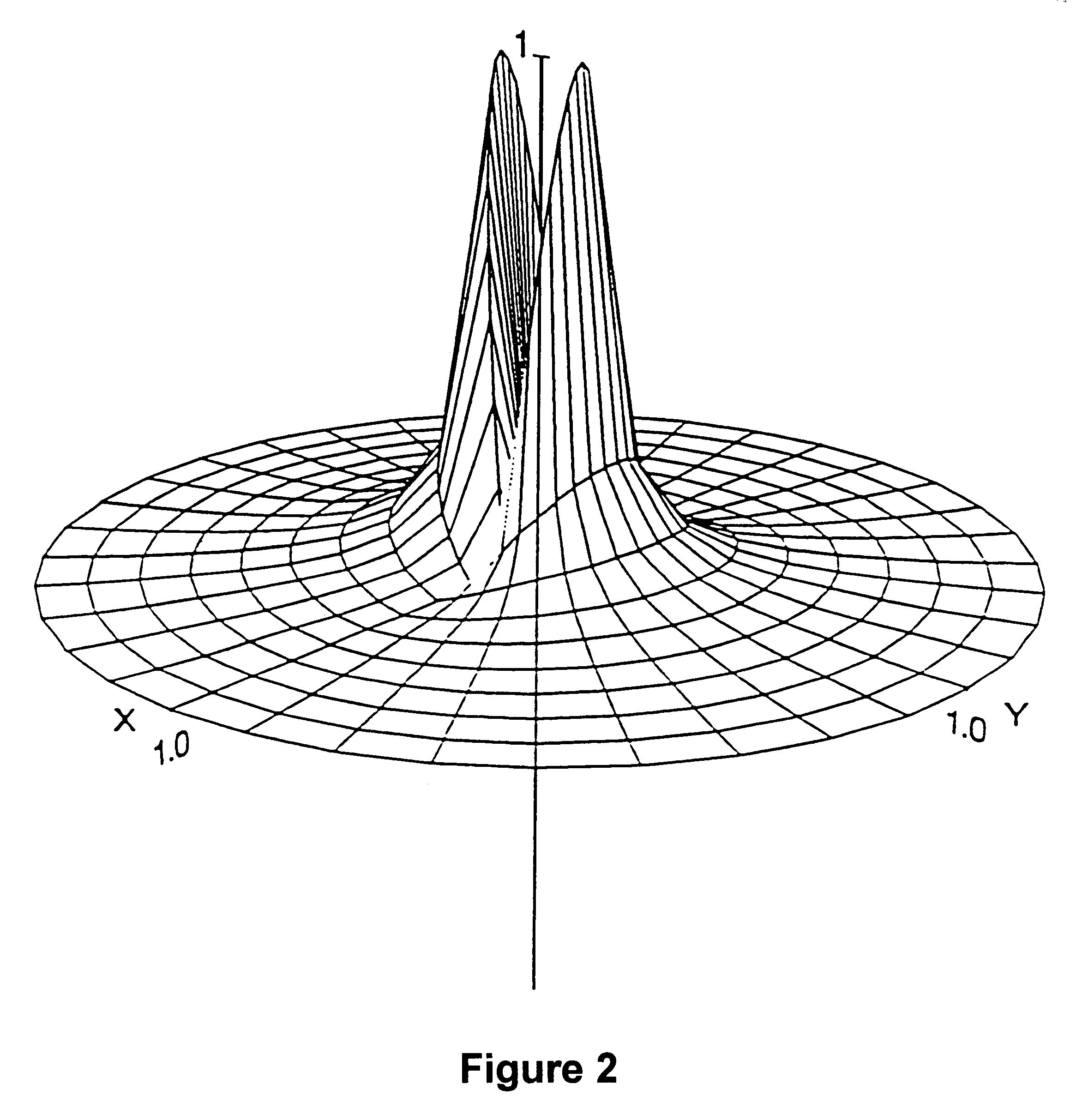

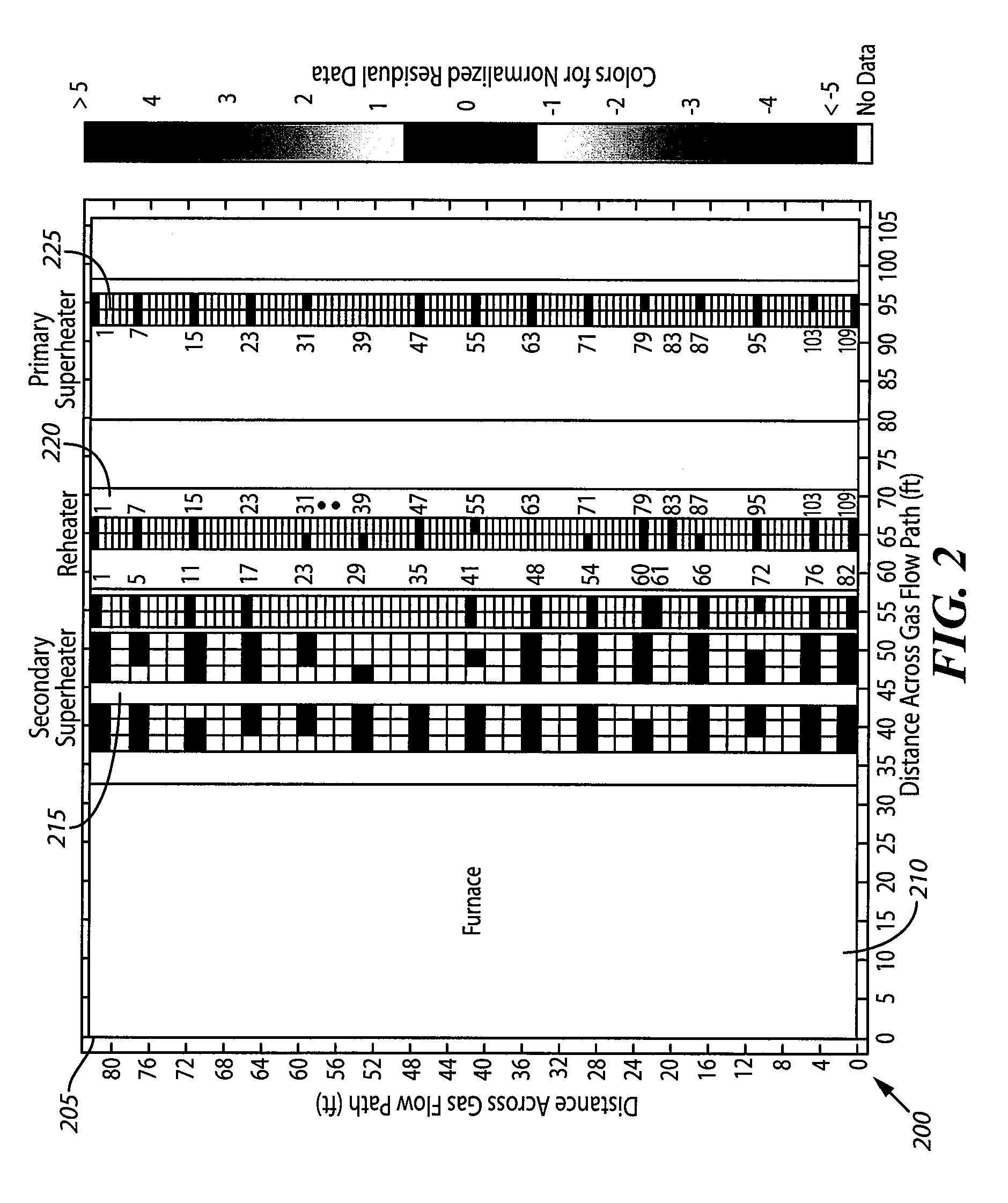

Kernel-based method for detecting boiler tube leaks

ActiveUS8275577B2Accurate accountingBoiler water tubesSafety devices for heat exchange apparatusMonitoring systemData source

Owner:SMARTSIGNAL CORP

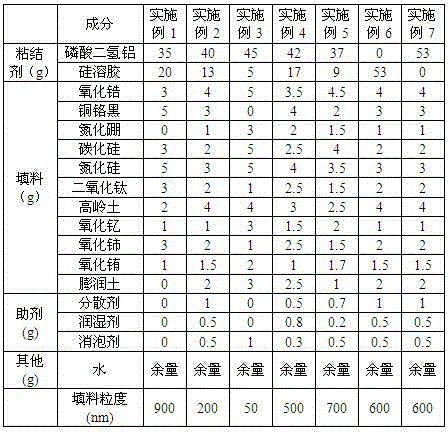

High temperature, contamination and slagging resistant ceramic paint as well as preparation method and application of high temperature, contamination and slagging resistant ceramic paint

ActiveCN104446325AImprove heat transfer efficiencyImprove heat transfer effectCeramic coatingRare earth

The invention provides high temperature, contamination and slagging resistant ceramic paint, as well as a preparation method and an application of the high temperature, contamination and slagging resistant ceramic paint and belongs to the technical field of special paint. The ceramic paint comprises the following ingredients by mass percentage: 15-30% of filling, 40-65% of adhesive agent and the balance of water, wherein the filling comprises 3-5% of zirconia, 3-5% of silicon carbide, 3-5% of silicon nitride, 1-3% of titanium dioxide, 2-4% of kaoline and 3-8% of rare earth oxide. The preparation method of the paint comprises the steps of mixing the adhesive agent with the water to prepare adhesive agent liquid, adding the filling refined into a particle size to be up to 50-900nm into the adhesive agent liquid, adding an assistant, uniformly mixing, filtering and packaging. The paint can be applied on the external surfaces of a boiler tube and a heater tube to form a ceramic coating to prepare the high-performance boiler tube and the heater tube.

Owner:QINGDA SAISIDI NEW MATERIAL TECH BEIJING

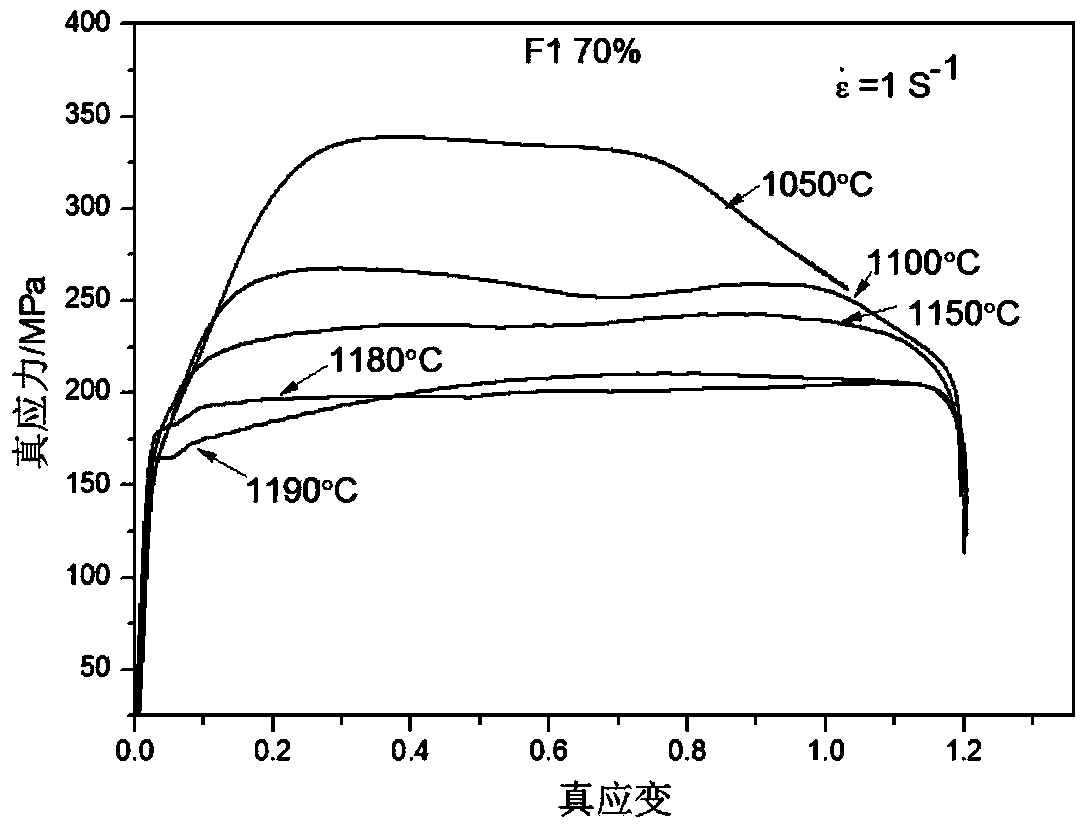

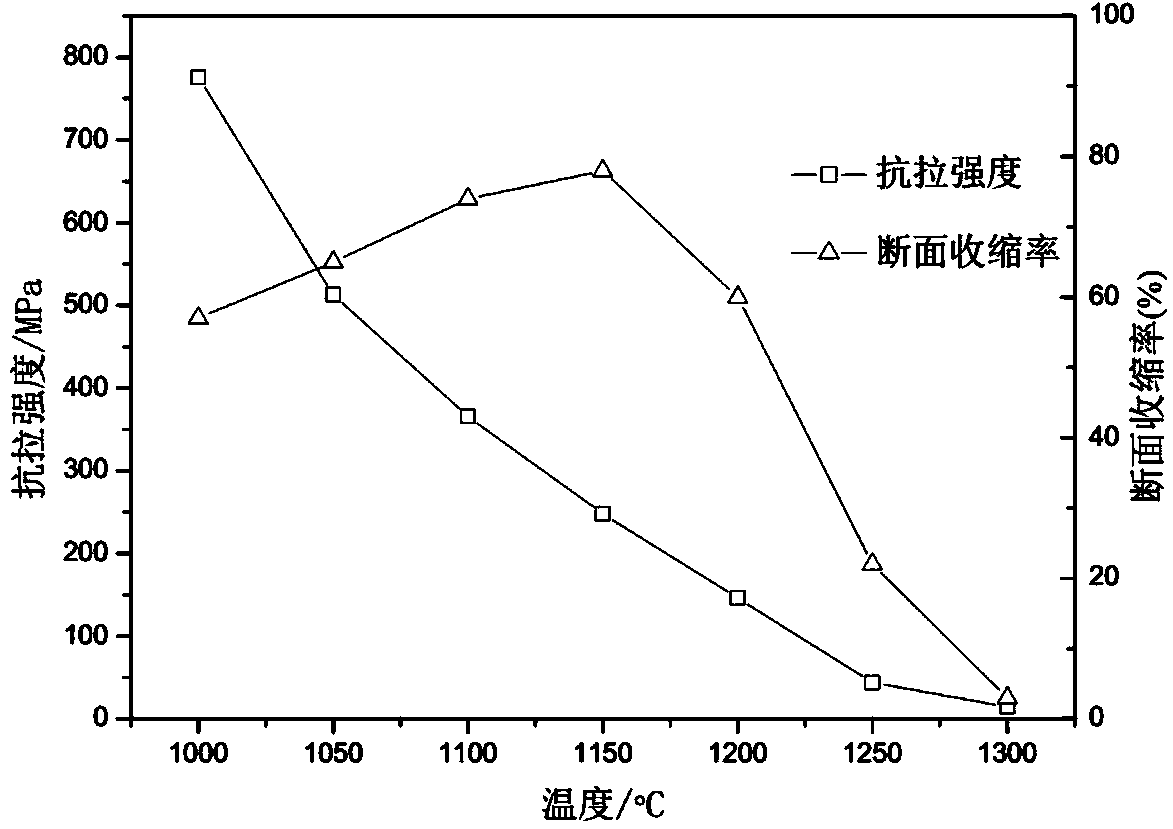

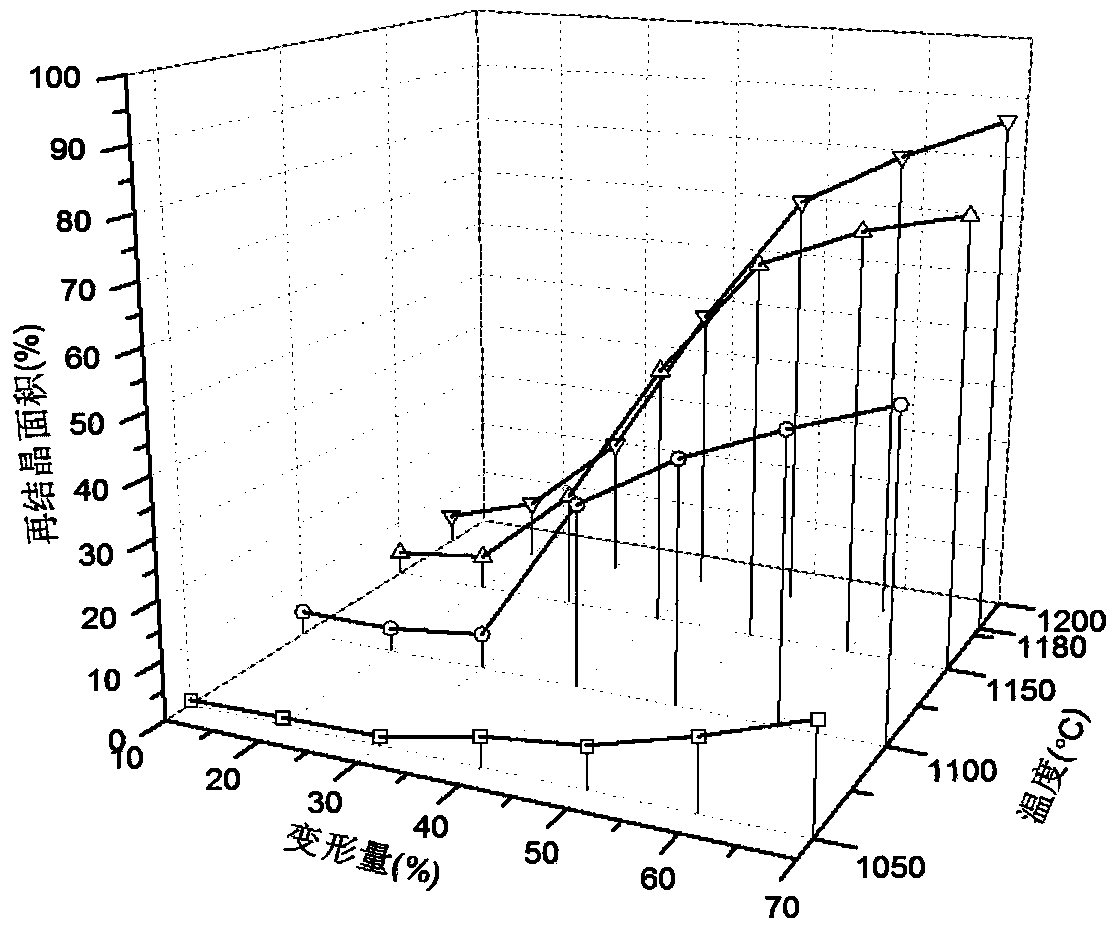

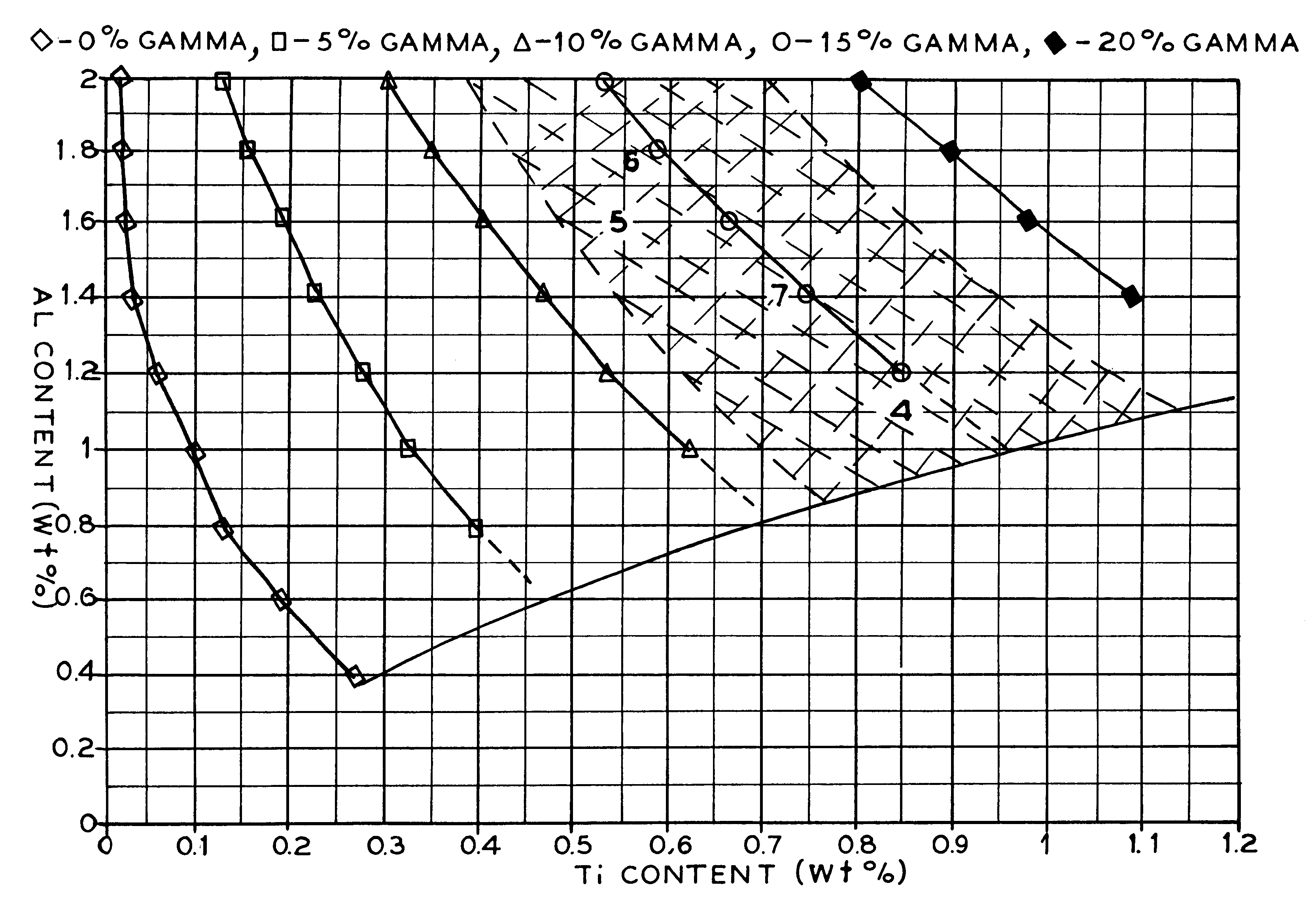

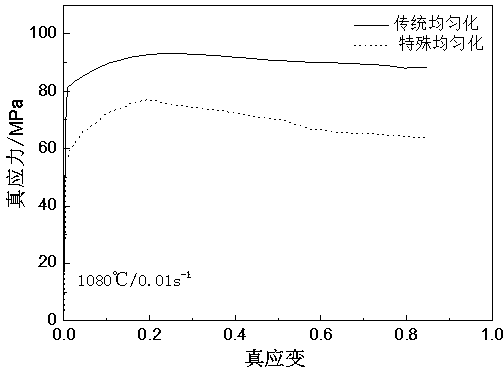

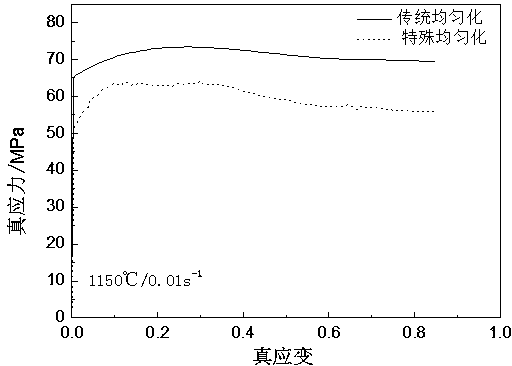

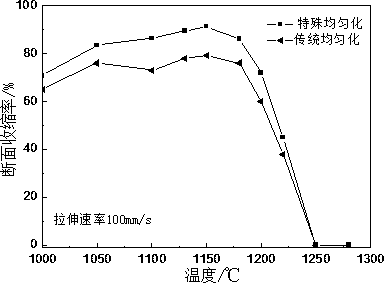

Nickel-chromium-cobalt-molybdenum heat resisting alloy and pipe manufacturing process thereof

The invention provides a nickel-chromium-cobalt-molybdenum heat resisting alloy and a pipe manufacturing process thereof and belongs to the technical field of the heat-resisting alloys. The alloy comprises the following chemical components in percentage by weight: 21-23% of Cr, 0.05%-0.07% of C, less than or equal to 0.3% of Mn, 11-13% of Co, 6.0-9.0% of Mo, 0.3-0.5% of Ti, 0.8-1.3% of Al, 0.1-1.0% of W, 0.002-0.005% of B, 0.03-0.15% of Zr, 0.2-0.6% of Nb+V and 0.01-0.05% of Nb, less than or equal to 0.15% of Cu, less than 0.008% of P, less than 0.002% of S, less than or equal to 0.015% of N, 0.005-0.02% of Mg, less than or equal to 0.01% of Ca, less than or equal to 0.01% of As, less than or equal to 0.07% of Pb, less than or equal to 0.001% of Bi and the balance of nickel and inevitable impurity elements. The nickel-chromium-cobalt-molybdenum heat resisting alloy has the advantages that the room-temperature mechanical properties, the high-temperature mechanical properties, the low cycle fatigue properties and the durability of a large-diameter thick-wall boiler pipe produced from the nickel-chromium-cobalt-molybdenum heat resisting alloy are all over ASME standard requirements and the technical requirements of CCA617 alloys; the formulation of HAZ liquation cracks and stress relaxation cracks is greatly reduced, and the HAZ long term rupture strength and the tenacity after long term aging both are excellent.

Owner:CENT IRON & STEEL RES INST

Suppressing and slowing method of coking in ethylene cracking furnace tube

InactiveCN1546609AReduce coking rateExtended service lifeThermal non-catalytic crackingAdhesiveDecomposition

The invention discloses a method for suppressing and slowing coking in ethylene cracking furnace tube comprising the steps of, (1) atmosphere processing, using the gaseous mixture produced from liquid ammonia decomposition as reducing gas to process the boiler tube atmosphere, (2) alloying treatment, preparing the alloy powder and adhesive into pulp, coating onto the surface of the processed furnace tube, drying and solidifying at 50-120 deg. C, placing into heating-furnace for diffusion treatment, cooling the furnace tube after the completion of the treatment, and removing the alloy powder coating on the furnace tube surface.

Owner:CHINA PETROCHEMICAL CORP +1

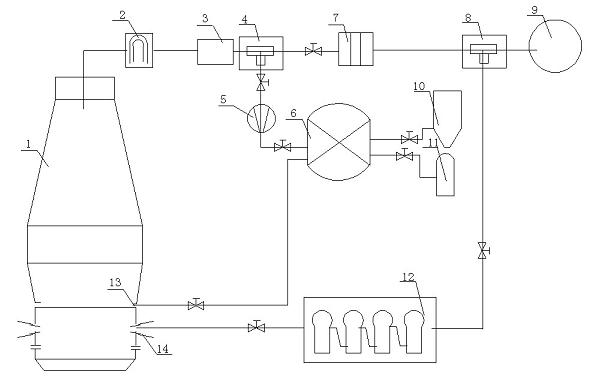

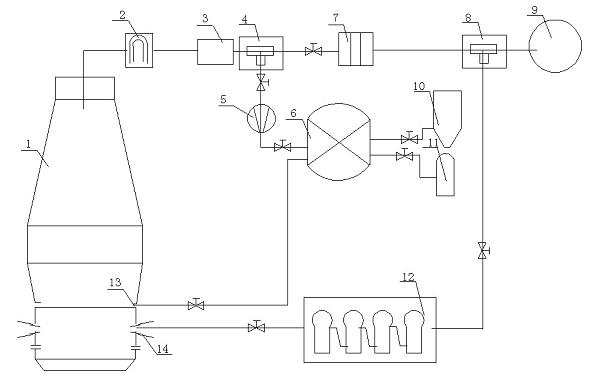

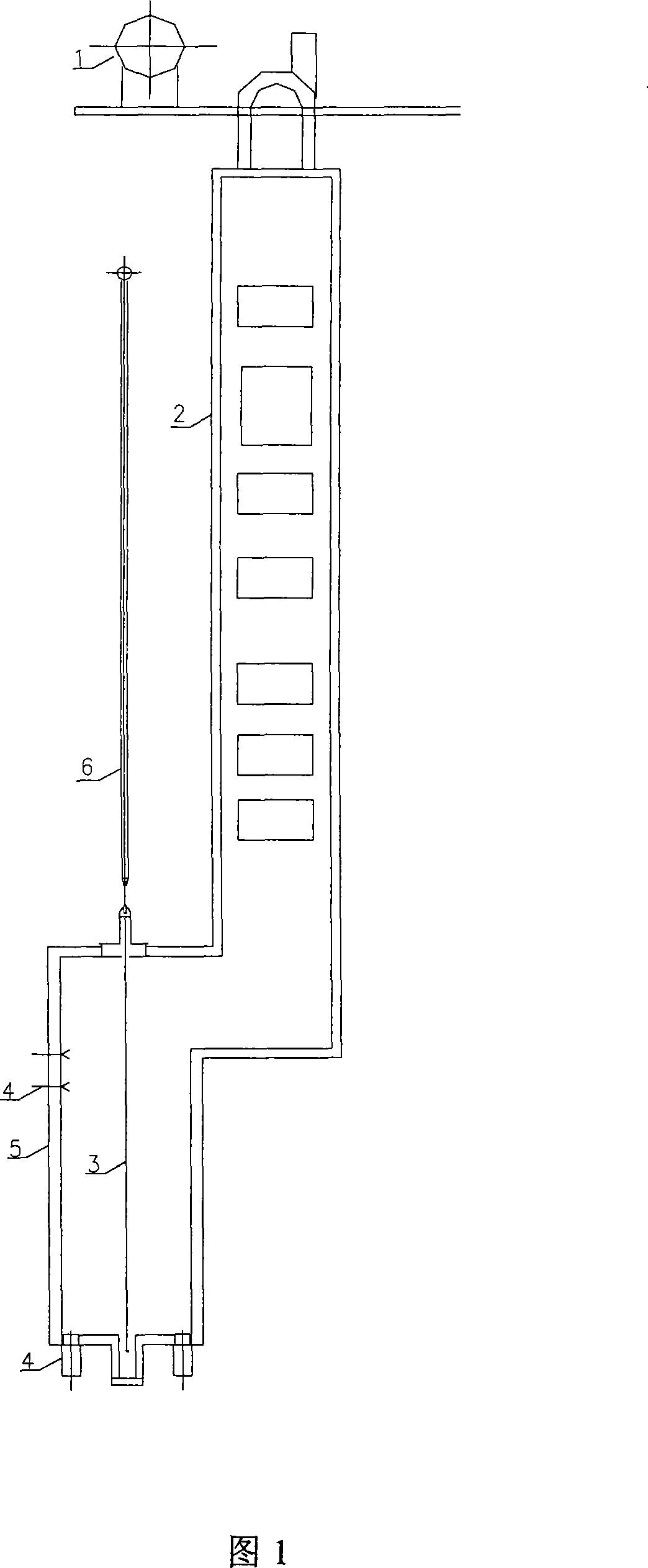

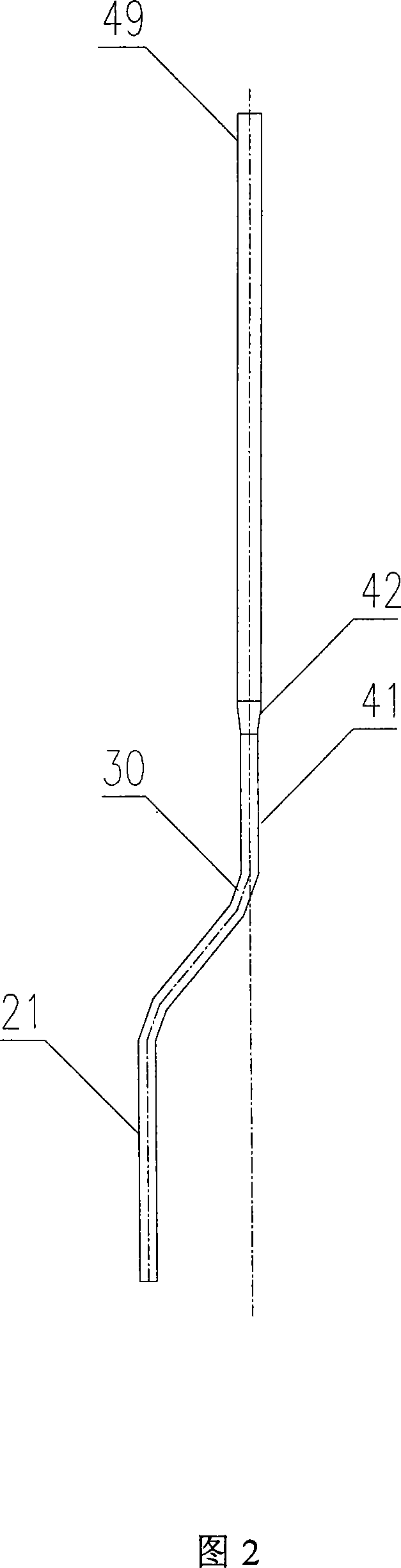

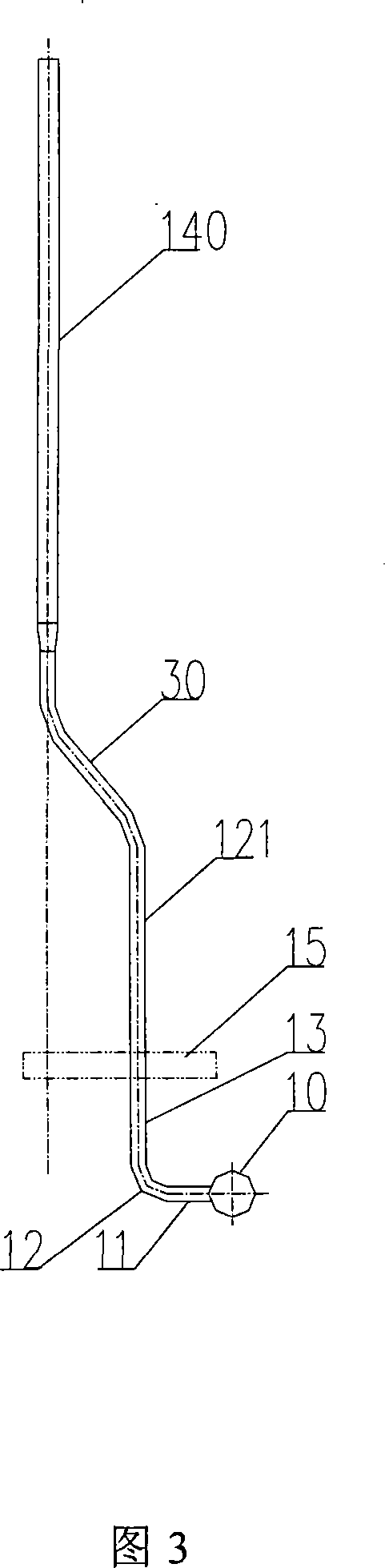

Device and method for top gas enrichment utilization of blast furnace

InactiveCN102220443AReduce cloggingAvoid damageBlast furnace detailsIncreasing energy efficiencyReduction rateEngineering

The invention relates to a device and method for top gas enrichment utilization of a blast furnace, in particular to a device and method for using top gas in a blast furnace production process, belonging to the field of smelting pig iron with the blast furnace. The device is characterized in that: a tee joint is arranged on a pipeline between a gas purifying and de-dusting system and an excess pressure power generation device; a gas pressurization device, a gasification furnace and a gas back-eject hole which is formed on the blast furnace are connected through the pipeline and a valve to form one way of the tee joint; the gasification furnace is provided with an oxygen supply pipeline and a coal blending device; the enriched gas, after being pressurized, enters the gasification furnace and is subjected to gasification reaction with oxygen and powder coal in the pressurized gasification furnace; a reaction product is ejected into the blast furnace for smelting iron through the back-eject hole which is formed on the blast furnace; the excess pressure power generation device is respectively connected with a hot blast heater, a power plant boiler pipeline and a valve through a gas distributor to form another way of the tee joint; and the generated hot air is fed into the blast furnace through a nozzle. The device has the advantages of novel conception, simple process flow, easiness in implementation, safety and reliability in operation and capabilities of increasing the calorific value of gas, ejecting back to smelt iron, increasing the indirect reduction rate, reducing the coal ratio, reducing blast furnace slag and CO2 emission, regulating and controlling the width of a cohesive zone of the blast furnace, ensuring long-term smooth running of the blast furnace, avoiding diffusion of the top gas, saving energy and contributing to environment friendliness.

Owner:MAANSHAN IRON & STEEL CO LTD

Method and system for cleaning boiler tube

InactiveCN101327487AEasy to cleanHigh purityHollow article cleaningMaintainance of heating chambersEngineeringCleaning methods

The invention discloses a furnace tube cleaning system and method. Nitrogen gas enters into a cleaning agent tank, wherein, the cleaning agent carried by the nitrogen gas enters into the furnace tube via a pipeline to clean the furnace tube; hydrogen and oxygen are mixed to produce water vapor which enters into the furnace tube to clean the furnace tube. The furnace tube cleaning method of the invention is capable of effectively removing the metallic and non-metallic impurity sediments inside the furnace tubes in the semiconductor calcar pipes.

Owner:SEMICON MFG INT (SHANGHAI) CORP

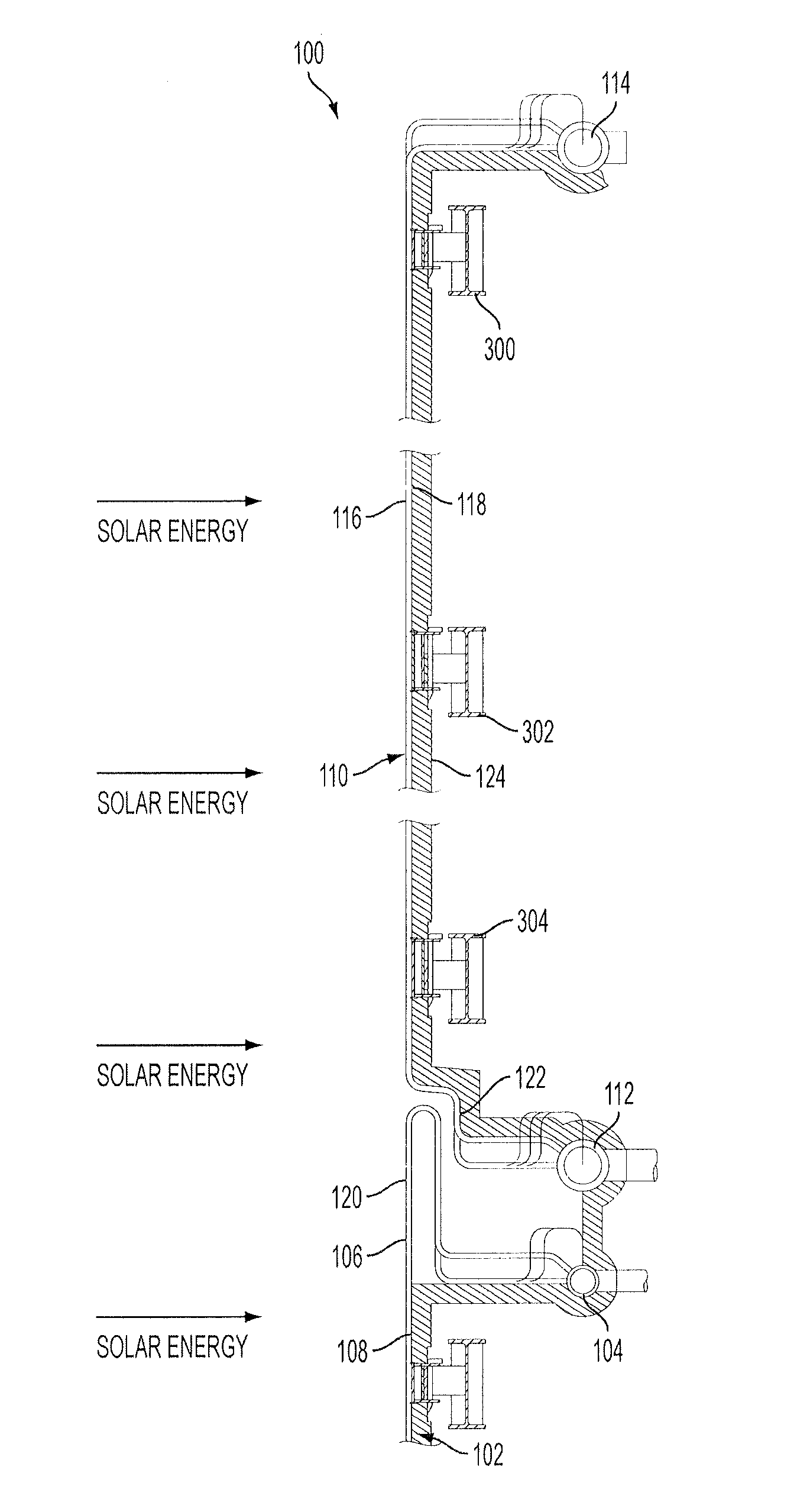

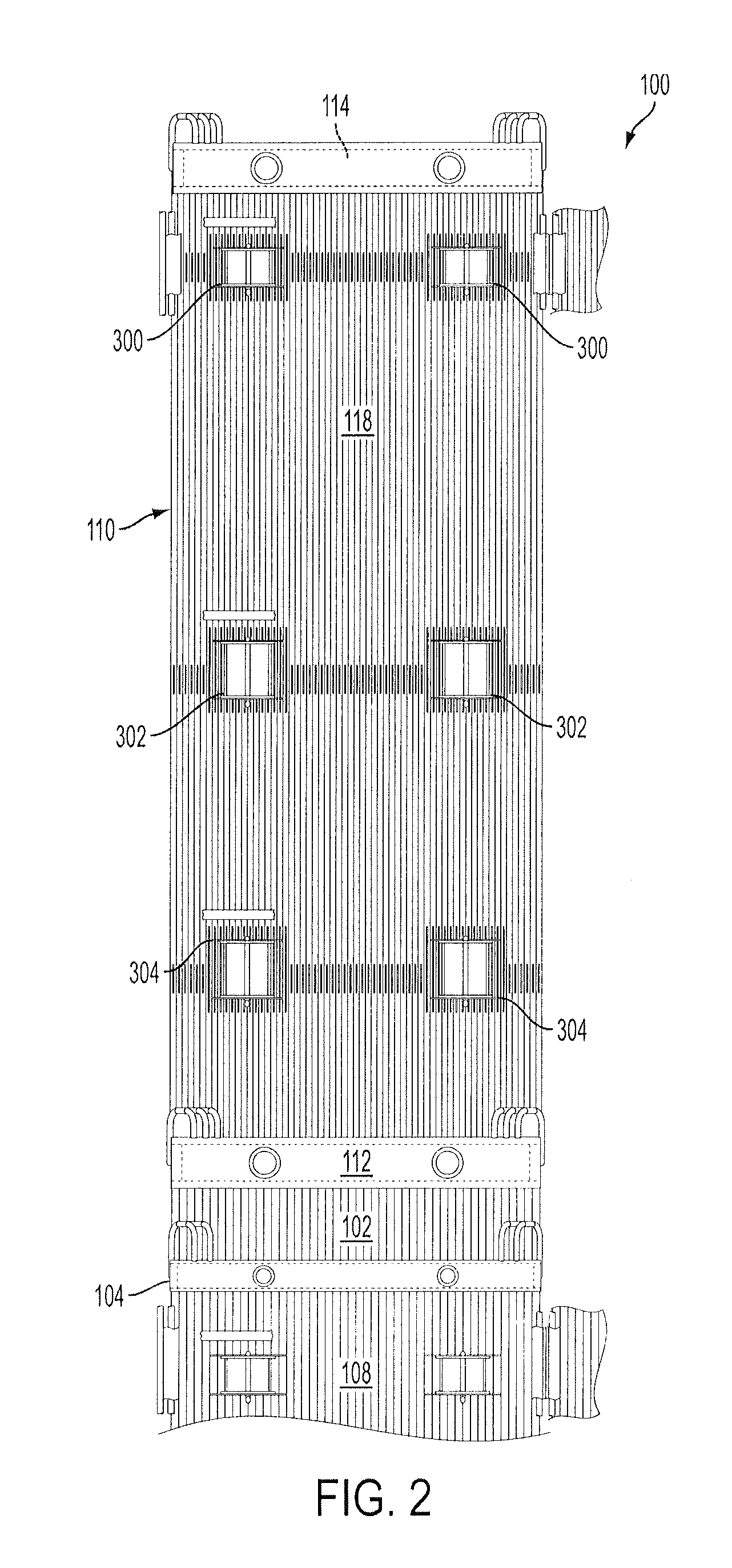

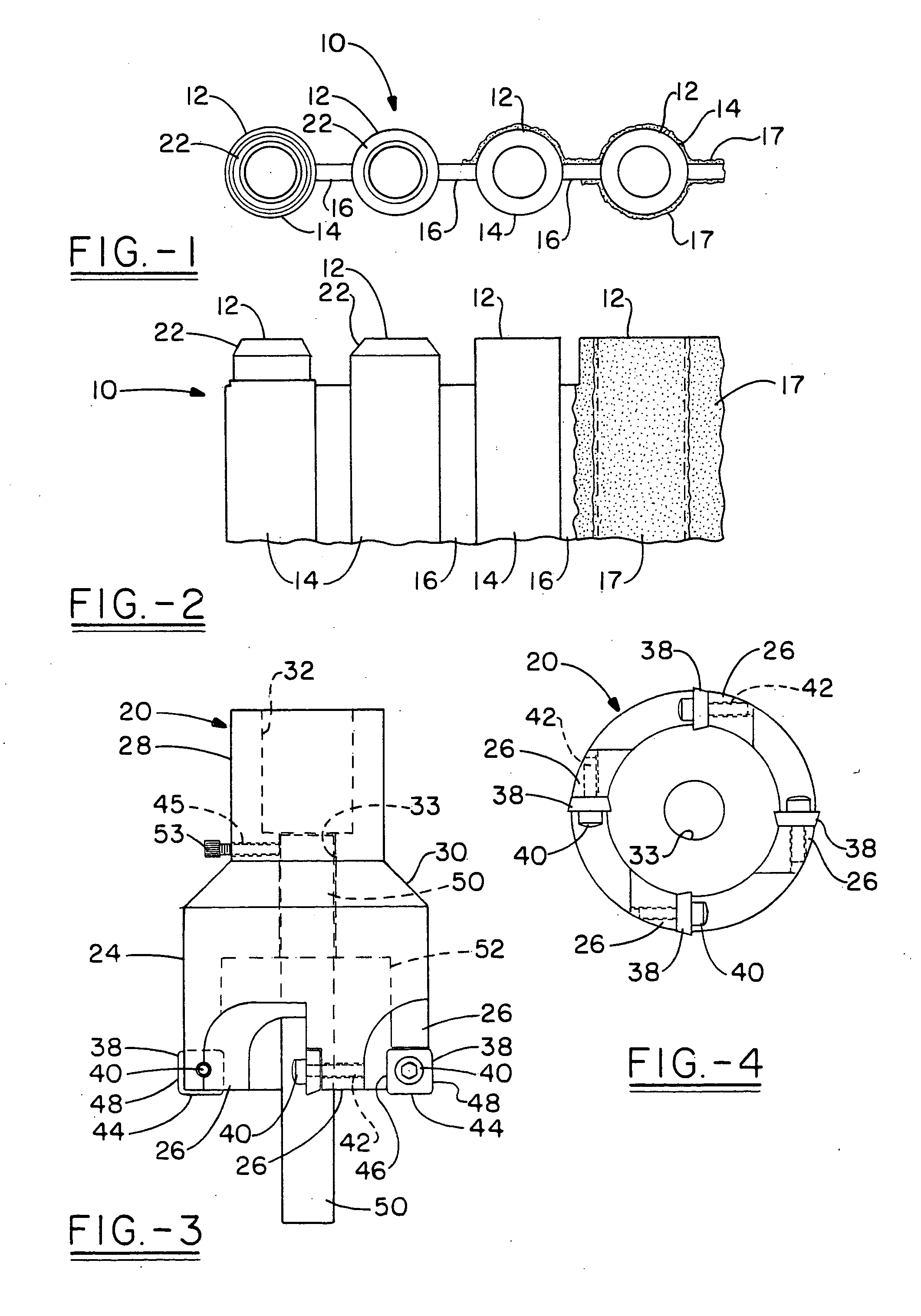

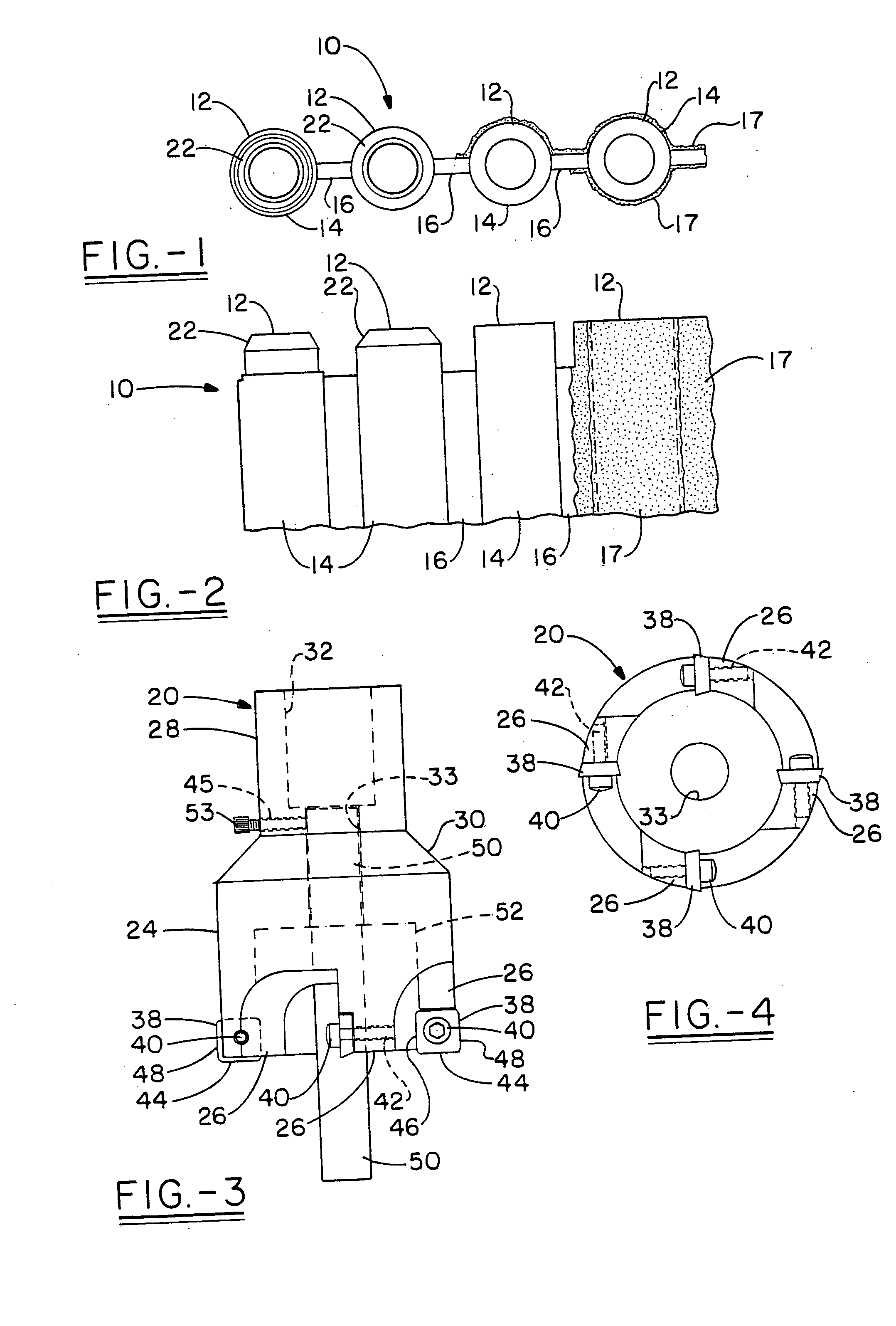

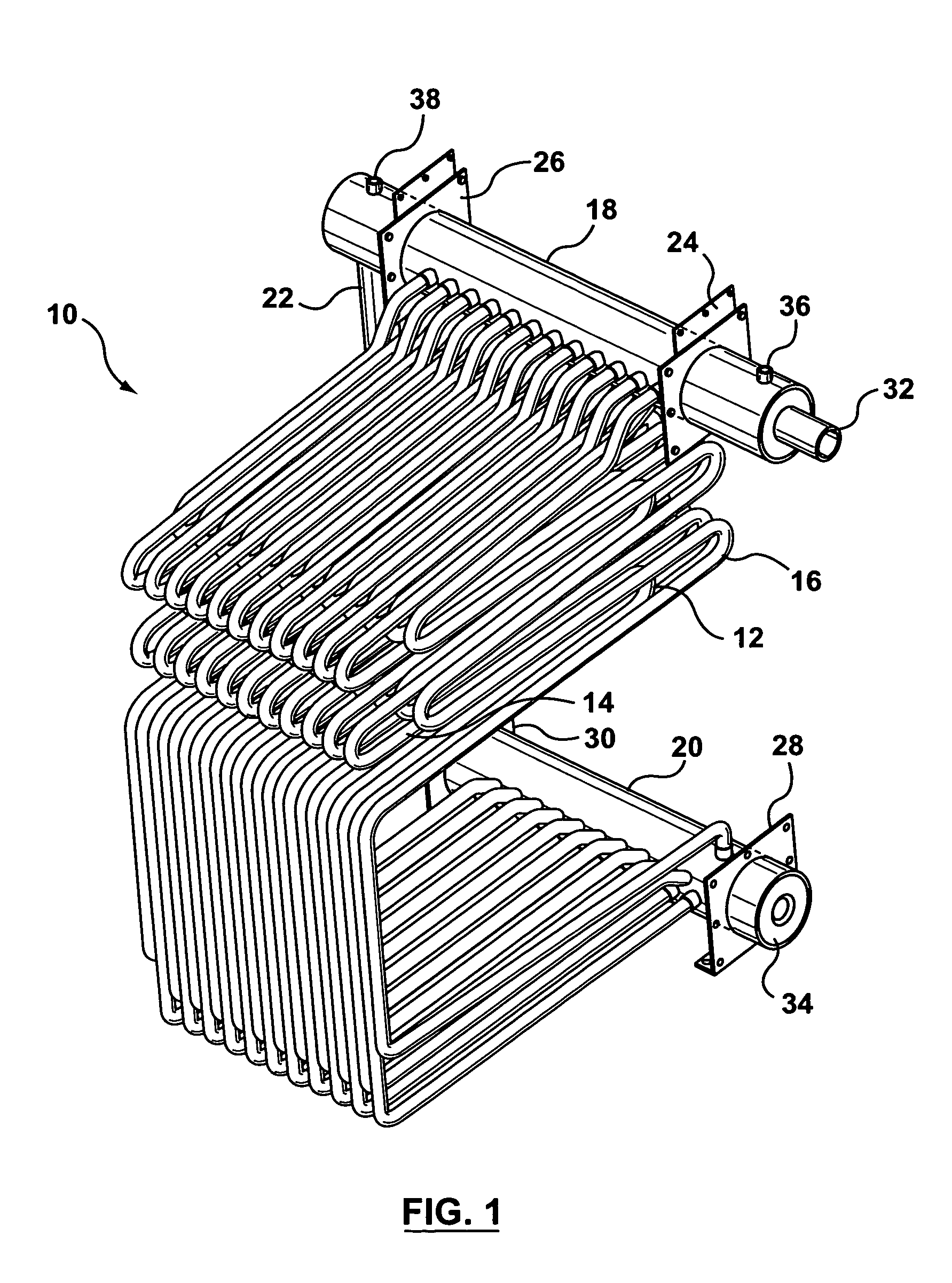

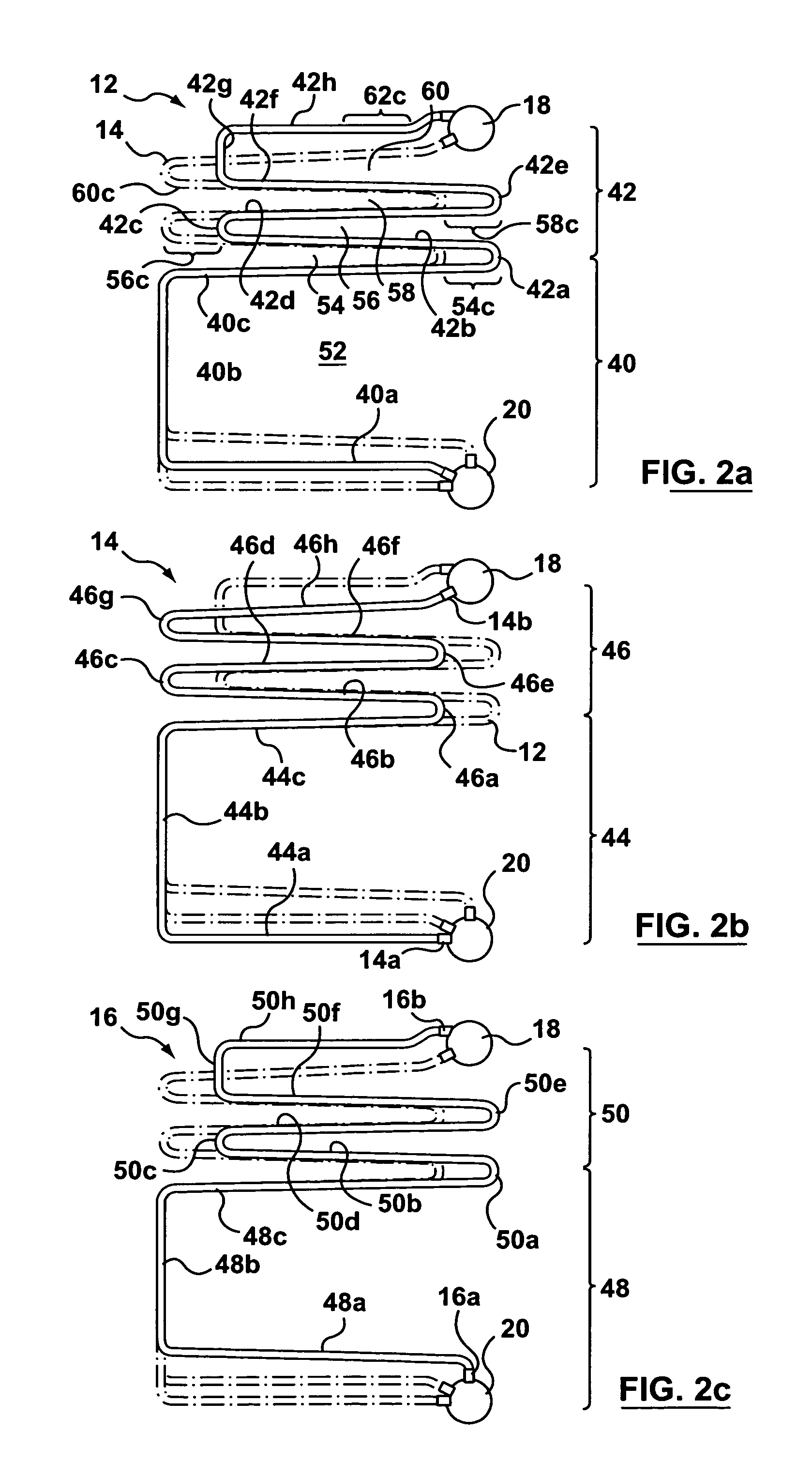

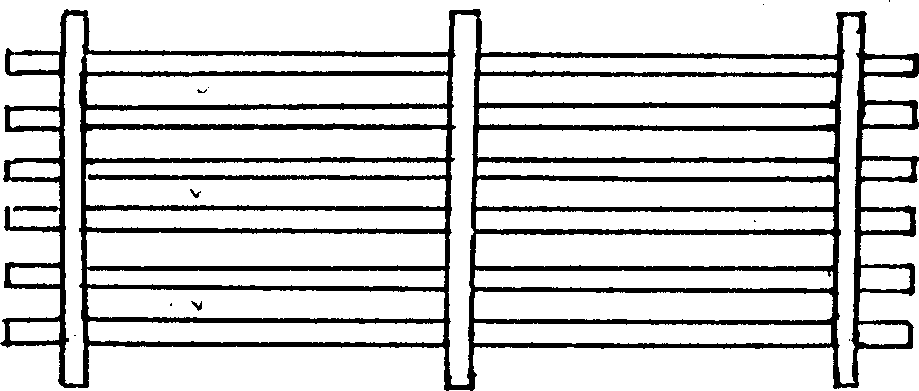

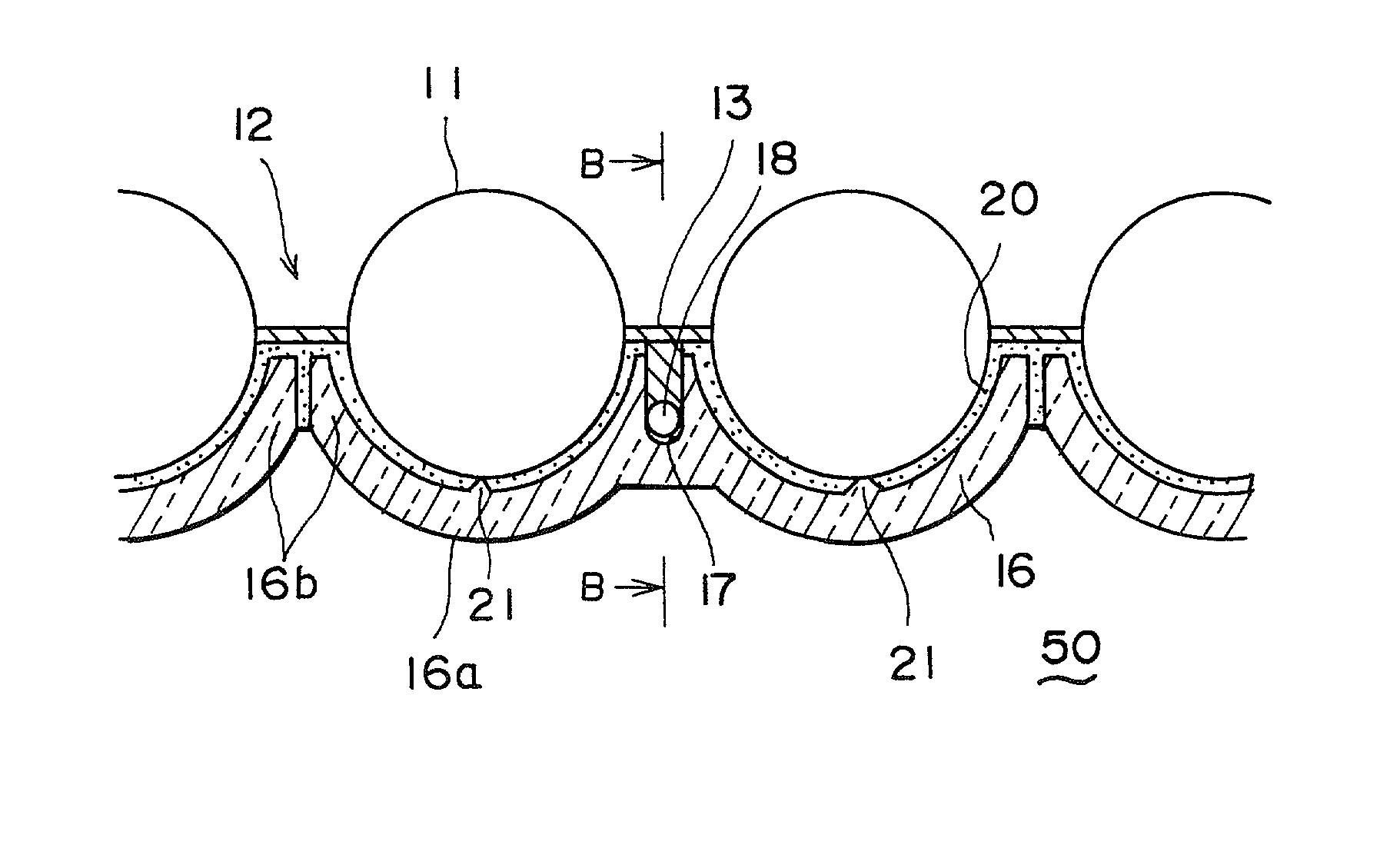

Expansion joints for panels in solar boilers

A boiler for a solar receiver includes a first receiver panel having a plurality of substantially parallel boiler tubes fluidly connecting an inlet header of the panel to an outlet header of the panel. A second receiver panel has a plurality of substantially parallel boiler tubes fluidly connecting an inlet header of the panel to an outlet header of the panel. The boiler tubes of the second receiver panel are substantially parallel to the boiler tubes of the first receiver panel. The first and second receiver panels are separated by a gap. A panel expansion joint is connected to the first and second receiver panels across the gap, wherein the panel expansion joint is configured and adapted to allow for lengthwise thermal expansion and contraction of the receiver panels along the boiler tubes, and to allow for lateral thermal expansion and contraction of the receiver panels toward and away from one another, while blocking solar radiation through the gap.

Owner:BABCOCK POWER SERVICES

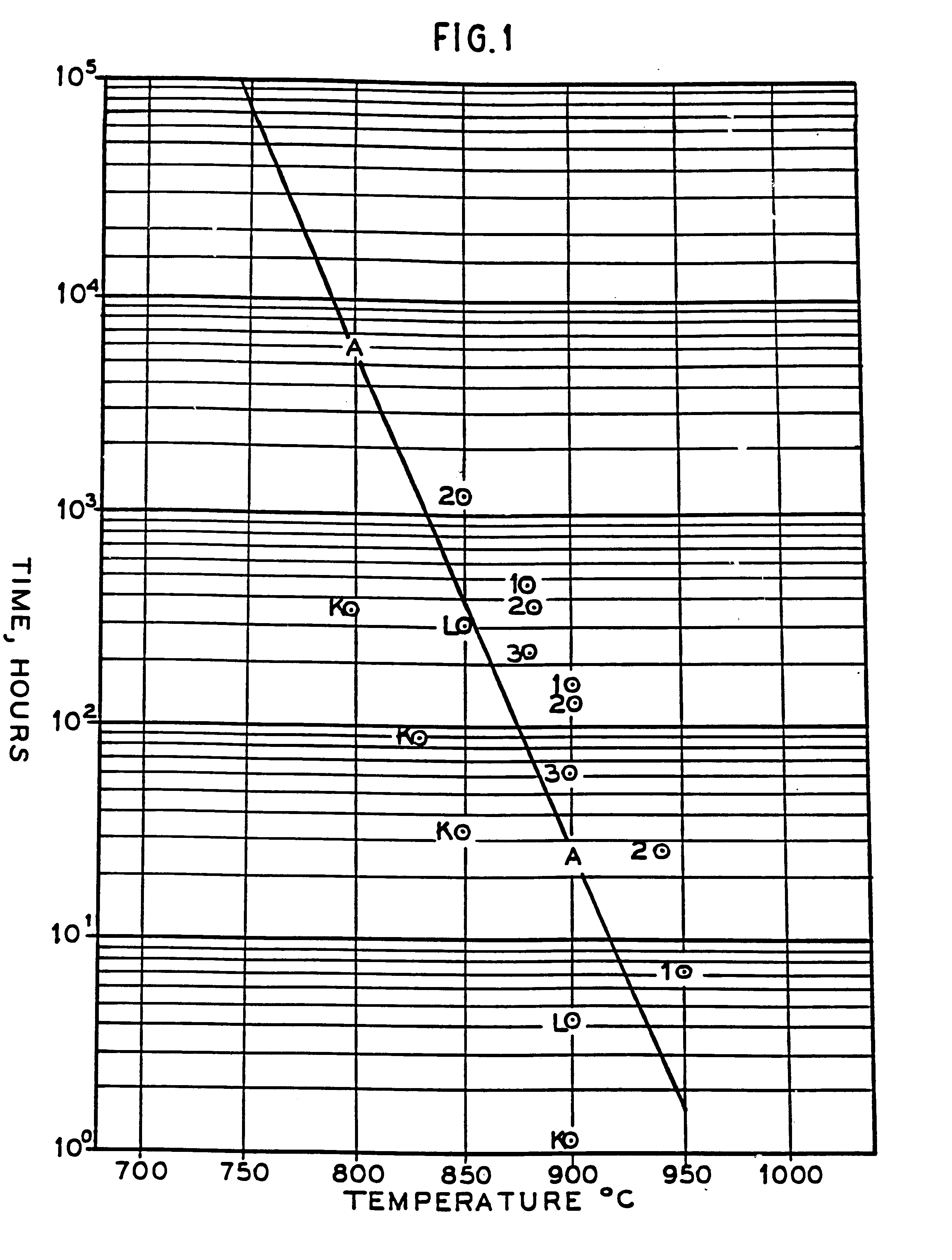

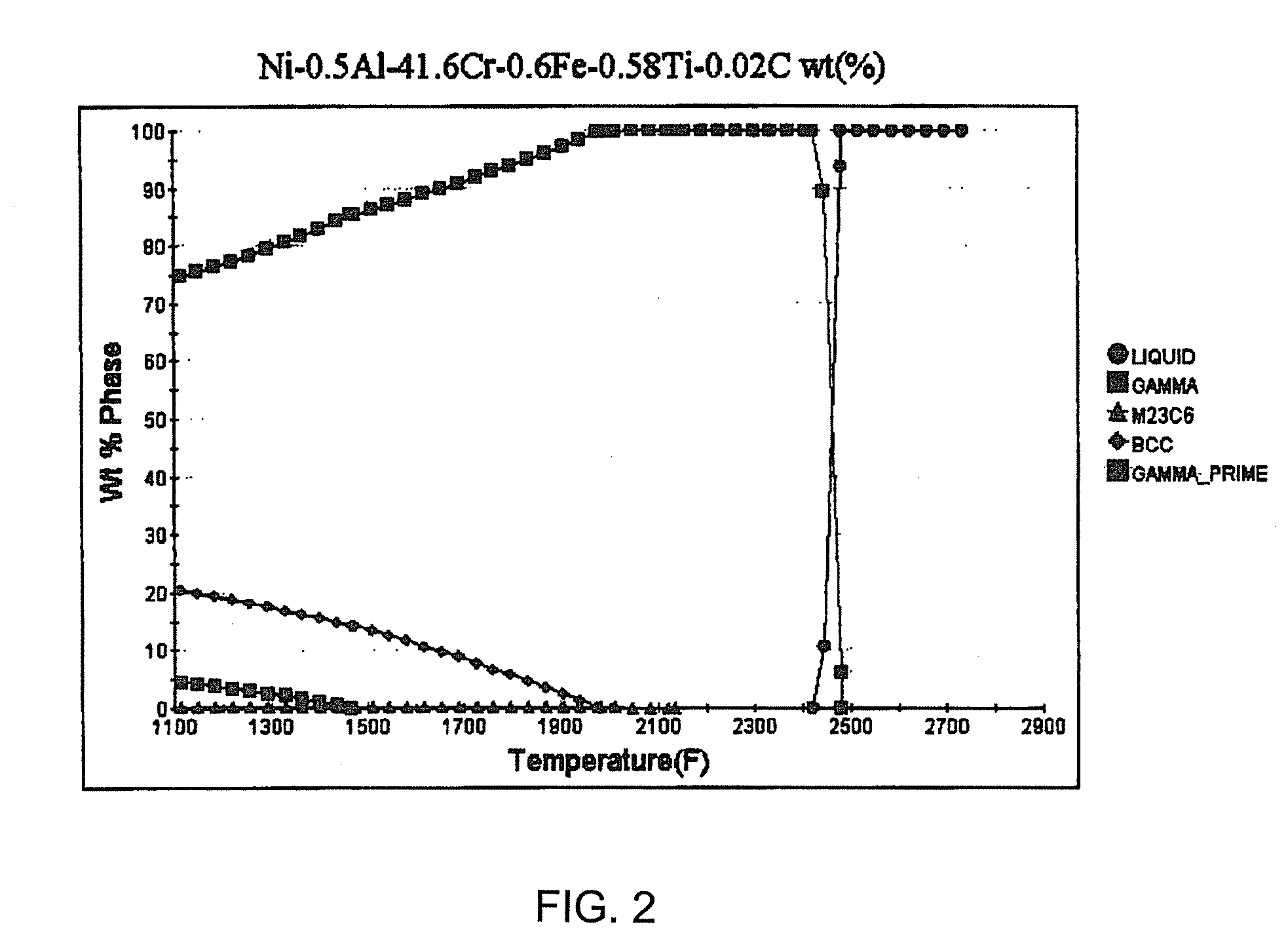

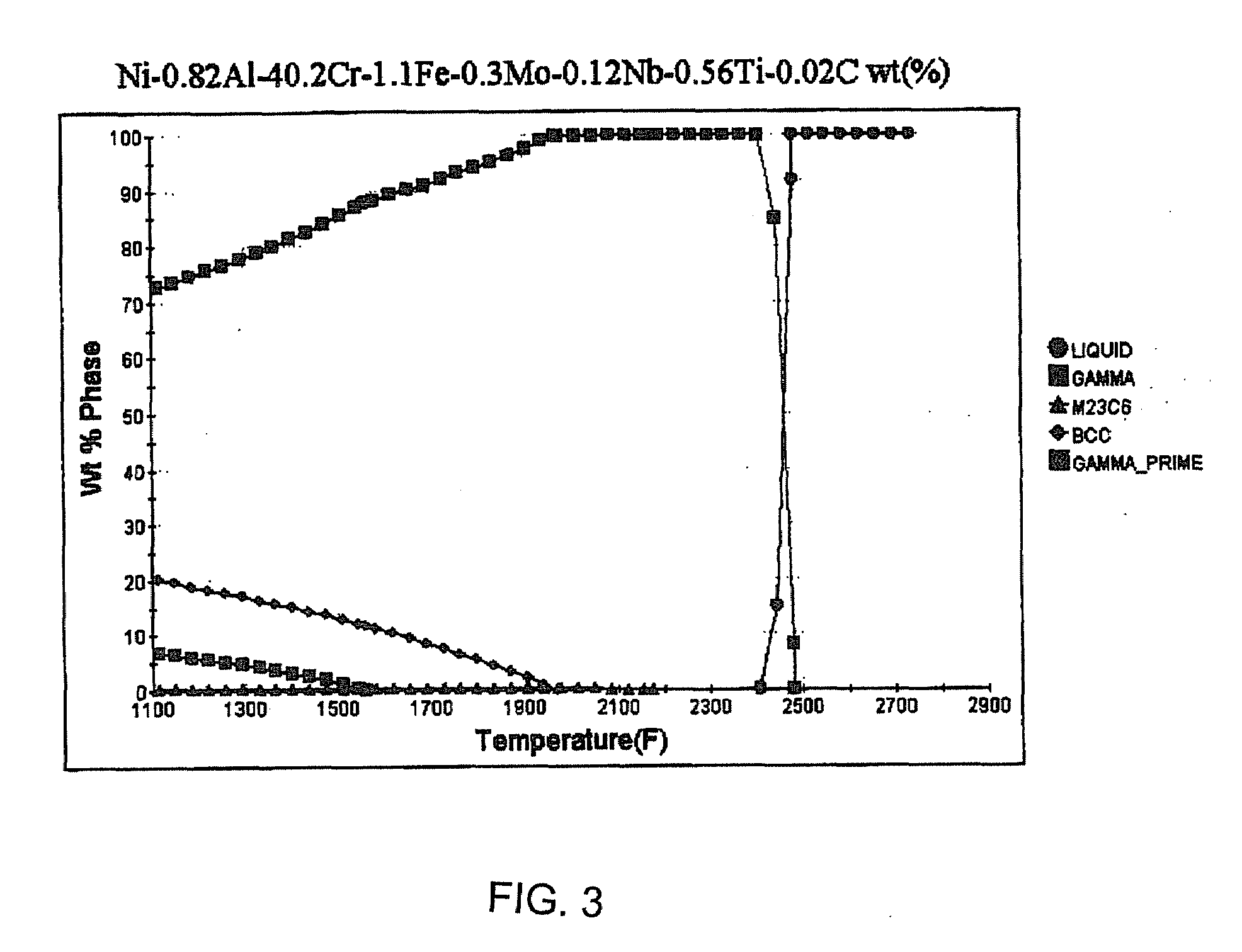

Advanced ultra-supercritical boiler tubing alloy

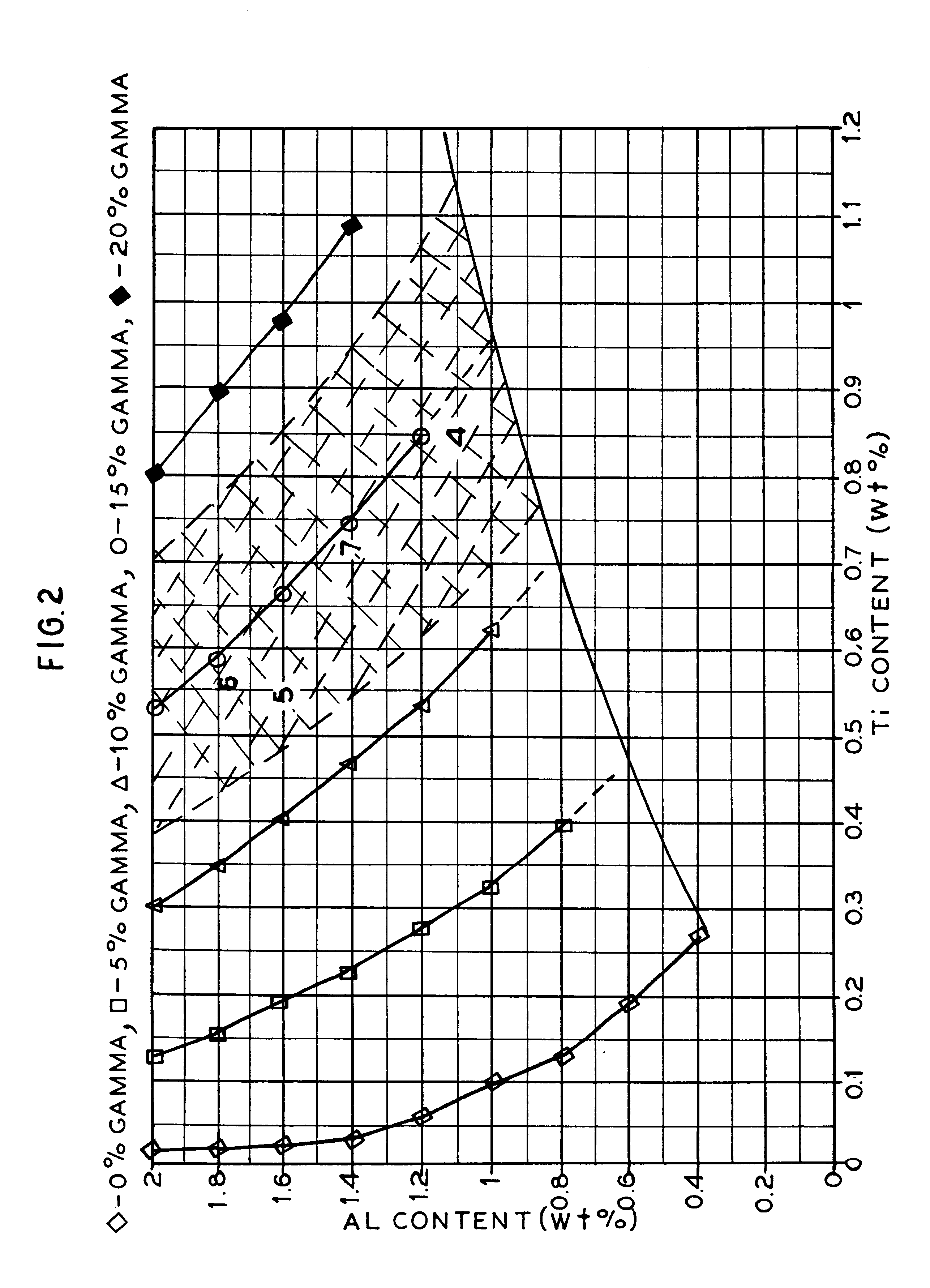

An ultra supercritical boiler tubing alloy characterized by a microstructure stabilized and strengthened for 375 bar / 700.degree. C. steam, in weight percent, service and alloyed to resist coal ash / flue gas corrosion for 200,000 hours consisting of 10 to 24 cobalt, 22.6 to 30 chromium, 2.4 to 6 molybdenum, 0 to 9 iron, 0.2 to 3.2 aluminum, 0.2 to 2.8 titanium, 0.1 to 2.5 niobium, 0 to 2 manganese, 0 to 1 silicon, 0.01 to 0.3 zirconium, 0.001 to 0.01 boron, 0.005 to 0.3 carbon, 0 to 4 tungsten, 0 to 1 tantalum and balance nickel and incidental impurities.

Owner:HUNTINGTON ALLOYS CORP (US)

Nickel-based alloy for tubes of boiler of ultra-supercritical power station and preparation method thereof

ActiveCN103993202AImprove stabilityMeet the requirements of the use environmentPower stationSuperheater

The invention provides a nickel-based alloy for tubes of a boiler of an ultra-supercritical power station and a preparation method thereof and belongs to the field of metallurgy. The nickel-based alloy comprises the following chemical components in percentage by weight: 23.5-25.5% of Cr, 19.0-23.0% of Co, 1.4-1.9% of Al, 1.05-1.4% of Ti, 1.2-1.5% of Nb, 0.3-0.5% of Mo, 0.03-0.06% of C, 0.002-0.006% of B, 0.04-0.07% of Zr, not more than 0.5% of Si, not more than 0.5% of Mn, not more than 0.003% of S, not more than 0.005% of P, not more than 4.0% of Fe and the balance of Ni and inevitable impurity elements, wherein, the amount of Al and Ti is not less than 2.45% and the ratio of Ti / Al is 0.75-0.95. The nickel-based alloy tubes obtained according to the preparation method provided by the invention can meet the requirements of using environments of boiler superheaters / reheaters of advanced ultra-supercritical power stations.

Owner:TAIYUAN IRON & STEEL GROUP

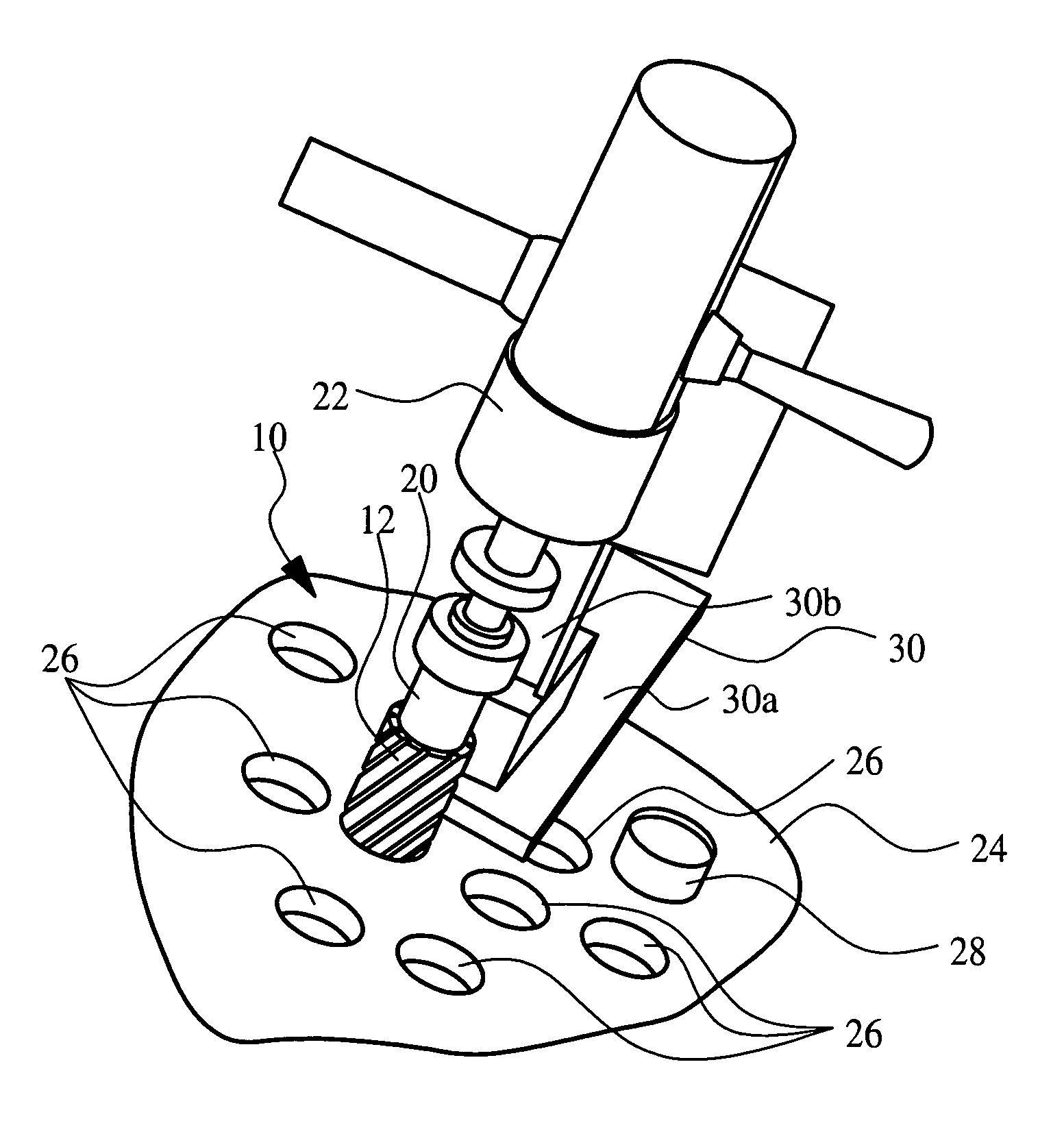

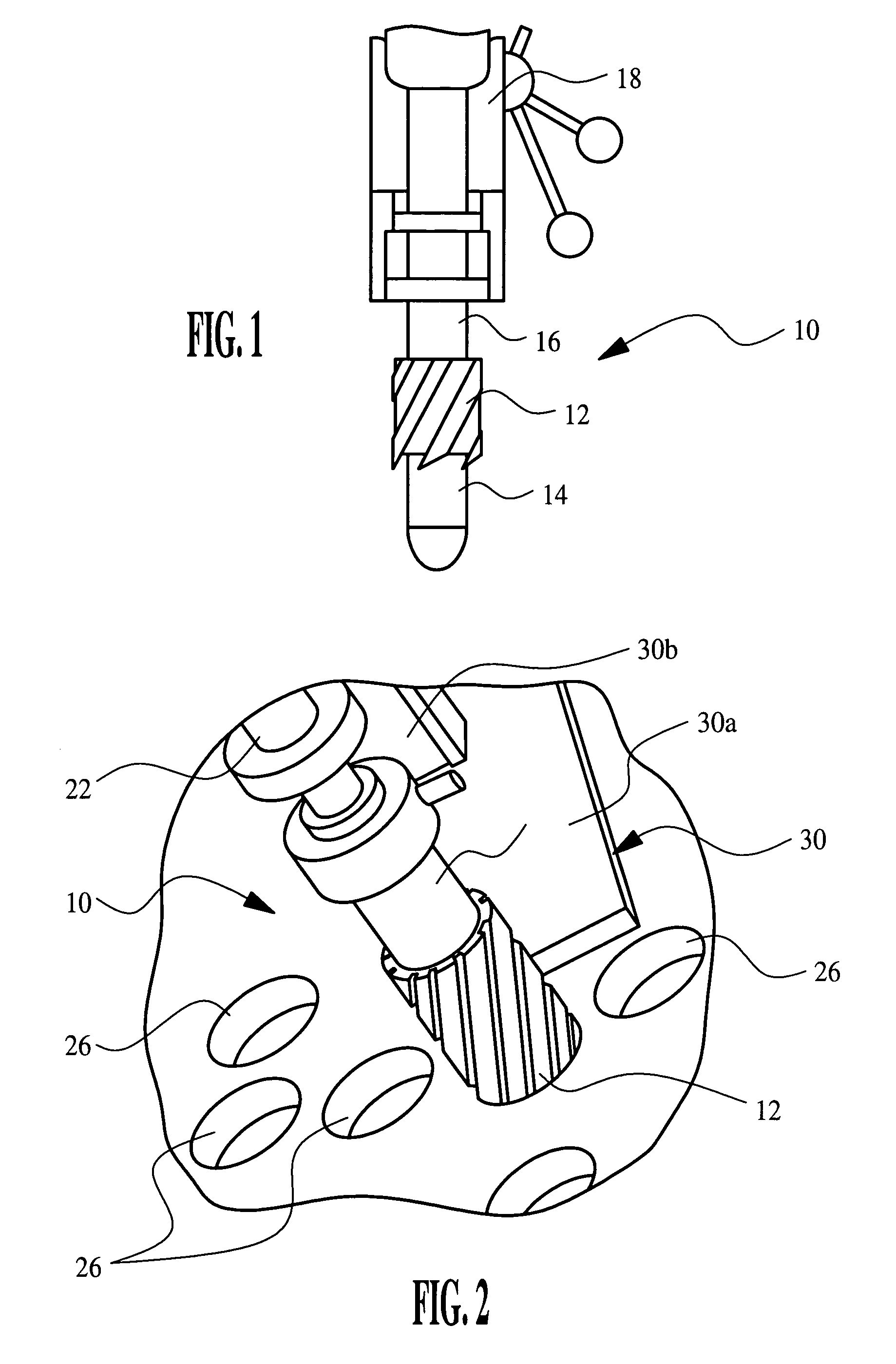

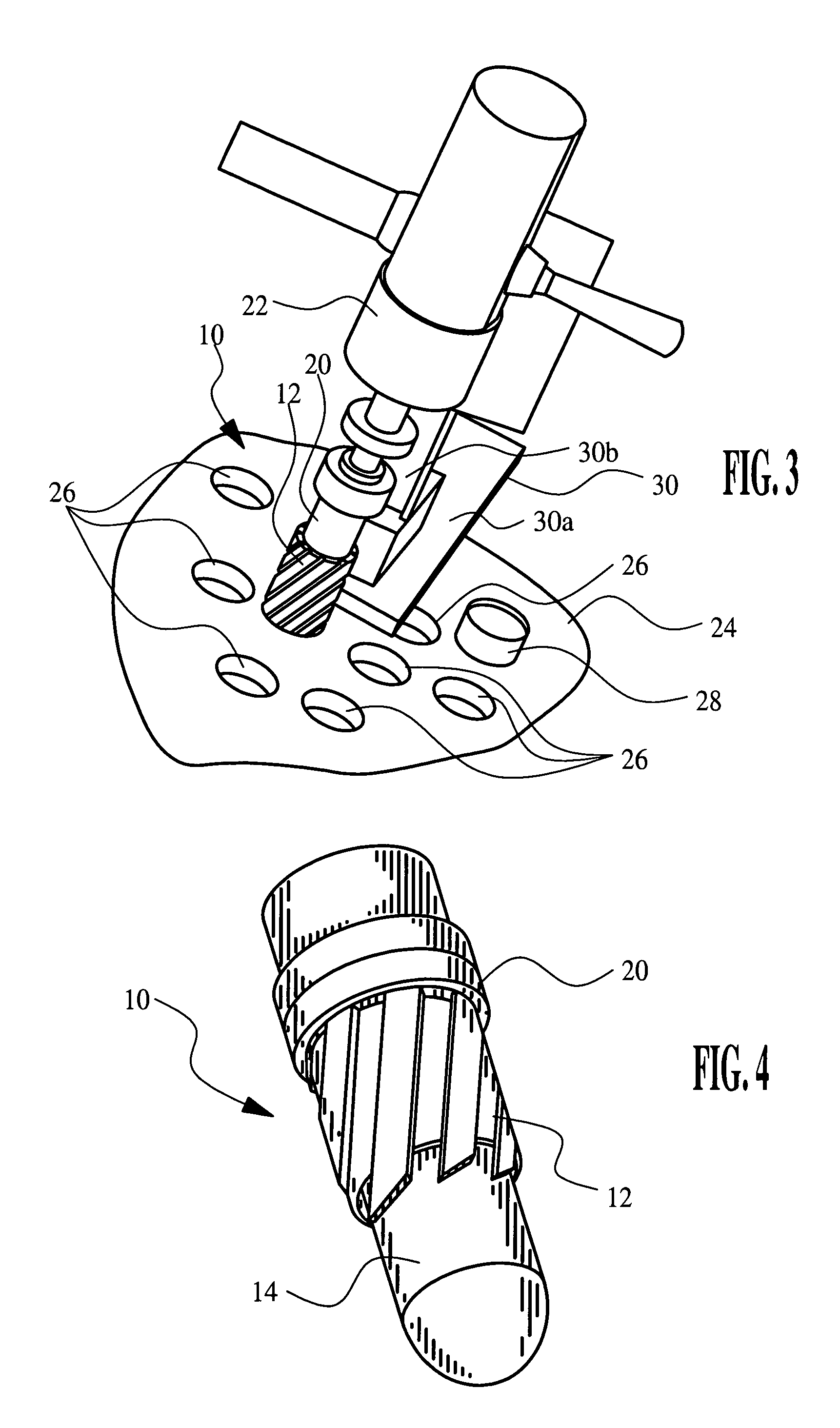

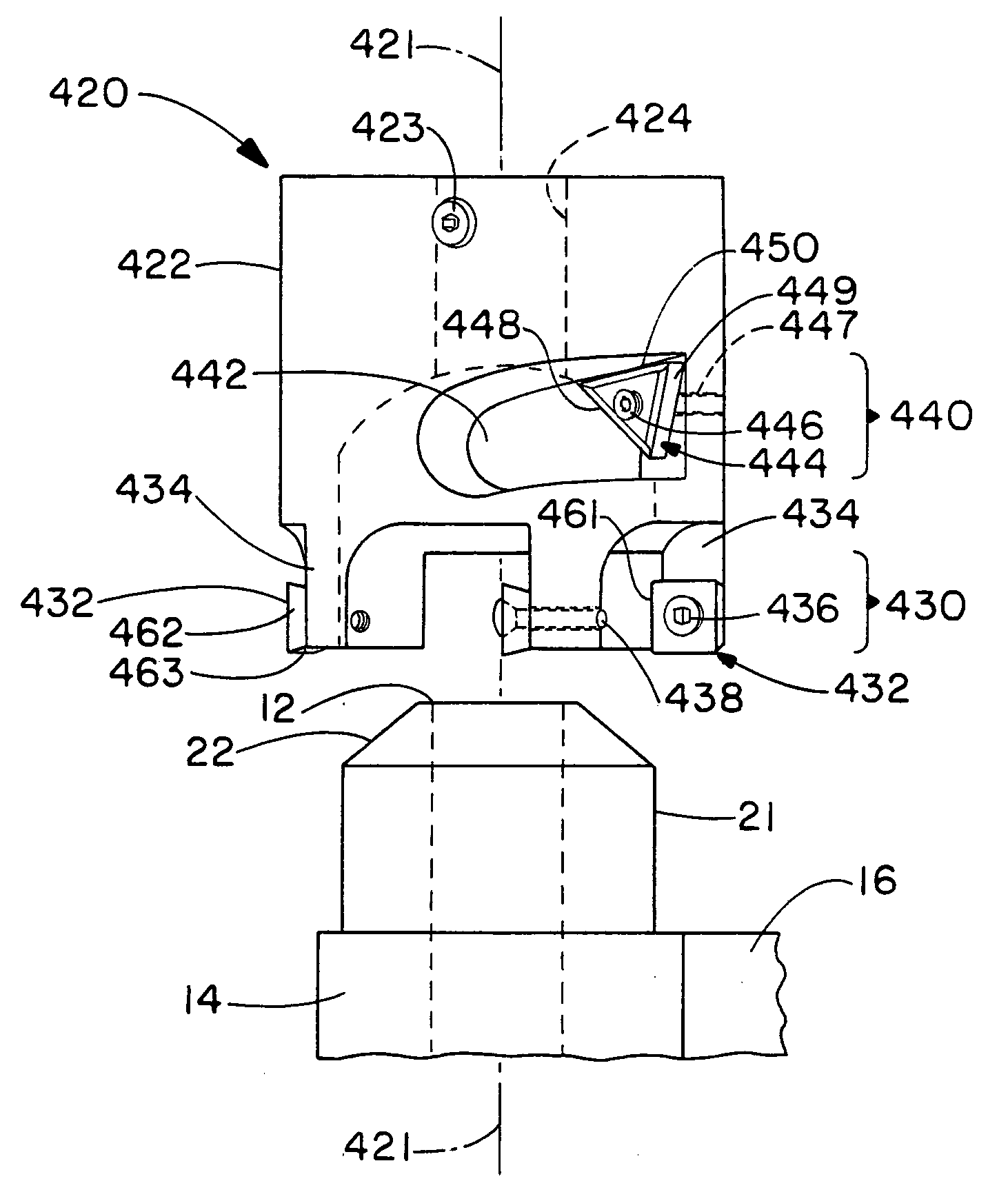

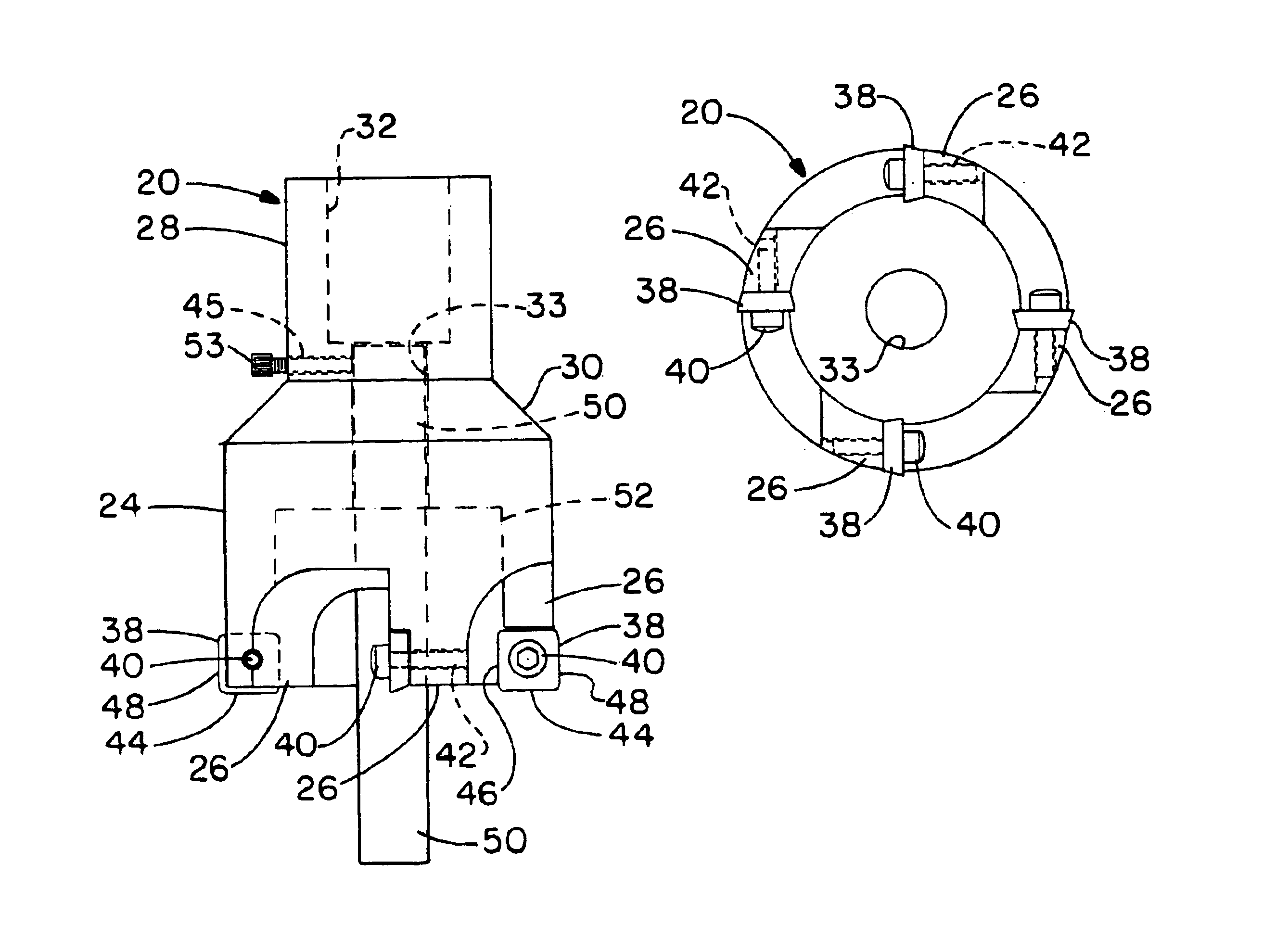

Method of removing boiler tubes

Boiler tubes are removed from a boiler vessel without damaging the vessel by severing the boiler tube near the exterior periphery of the vessel, and using a piloted rotary cutting tool fixtured with respect to the longitudinal axis of the severed boiler tube to remove all but a very thin shell of the severed tube. The rotary cutting tool is then withdrawn, and the remaining thin shell of the boiler tube is manually peeled away from the periphery of the boiler vessel opening. In a preferred implementation, the rotary cutting tool is annular, and a tapered cylindrical pilot having an outside diameter slightly smaller than the inside diameter of the expanded portion of the boiler tube is retractably mounted within the annulus of the cutting tool.

Owner:CRAIG MERRILL C

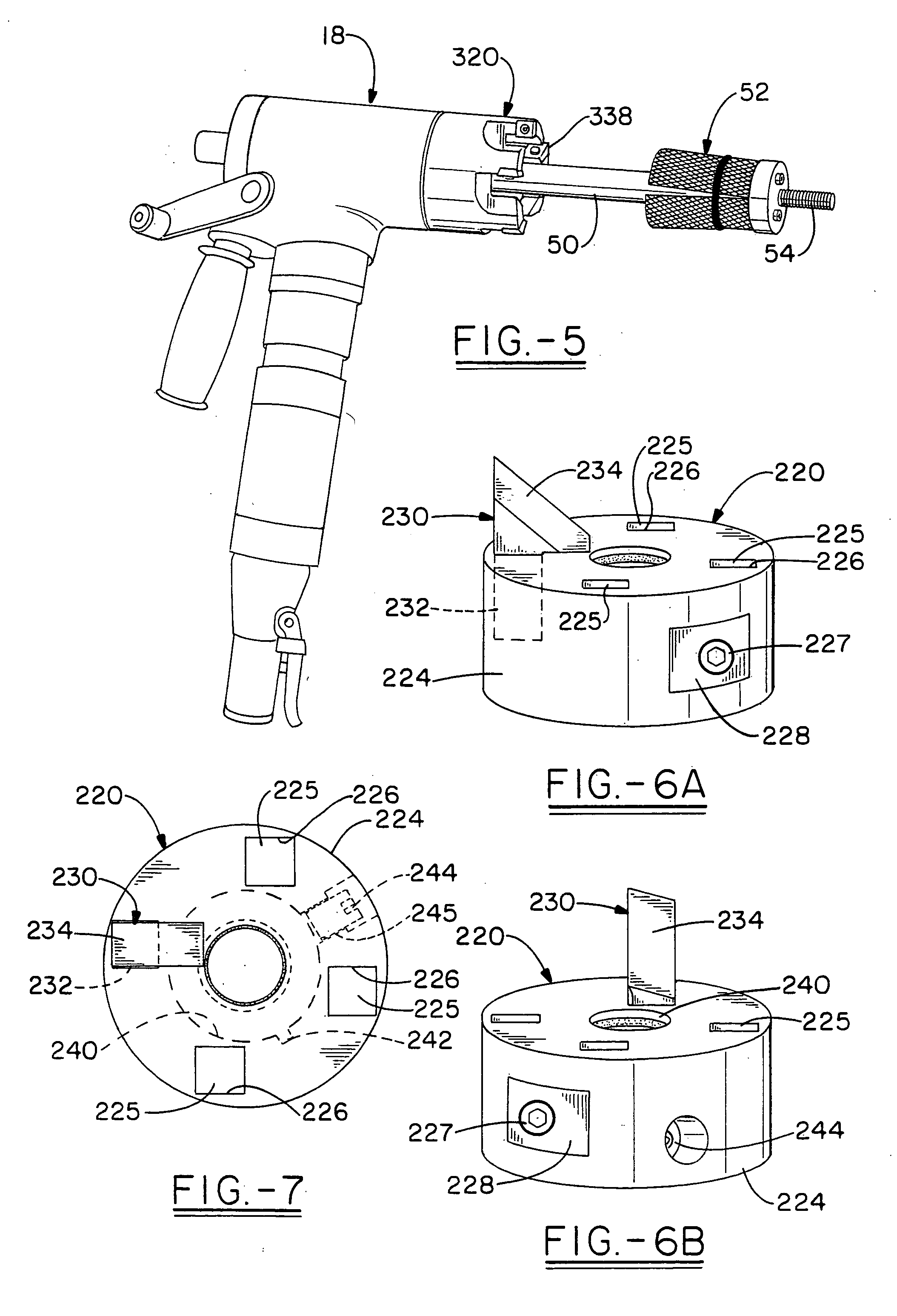

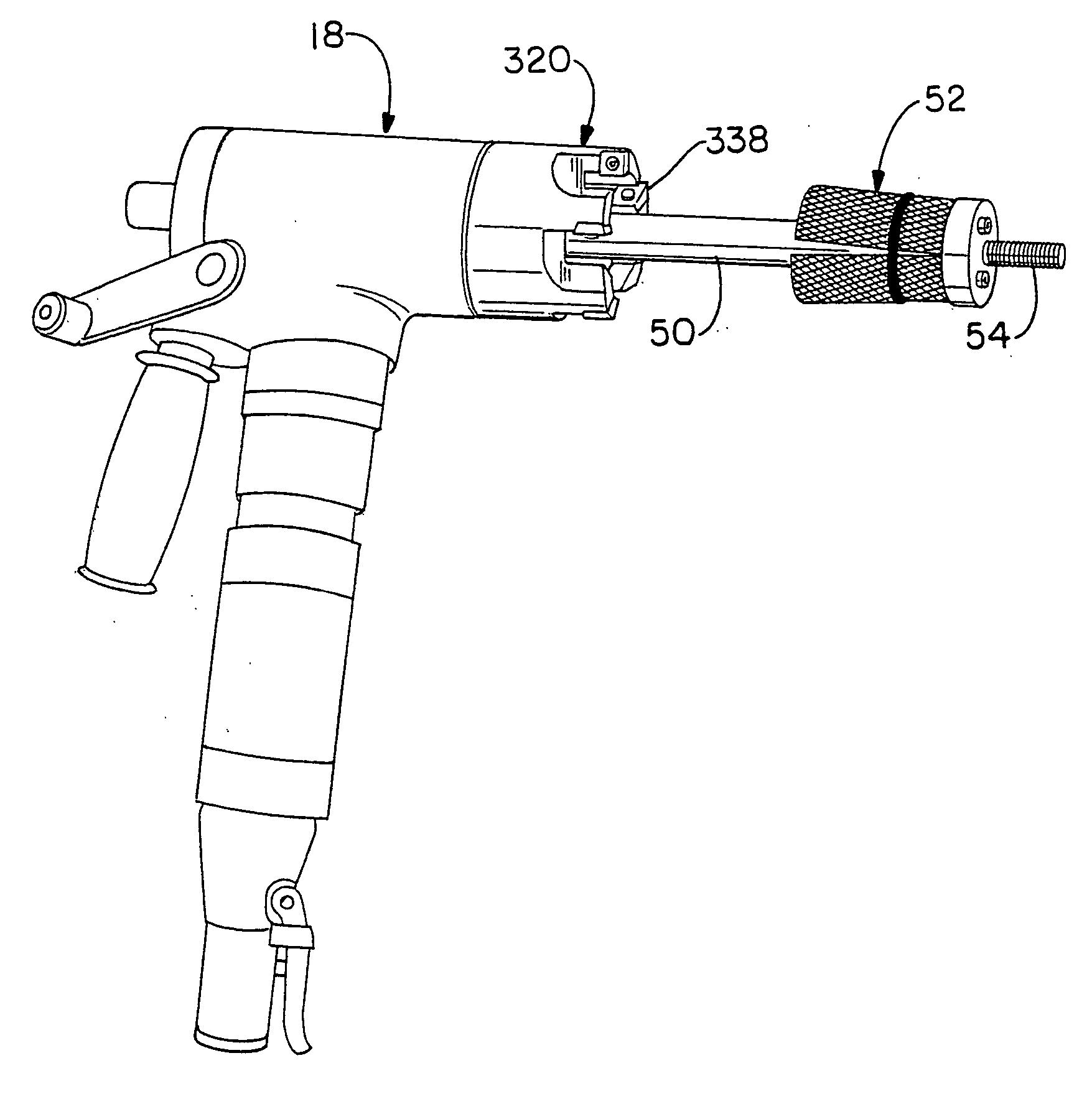

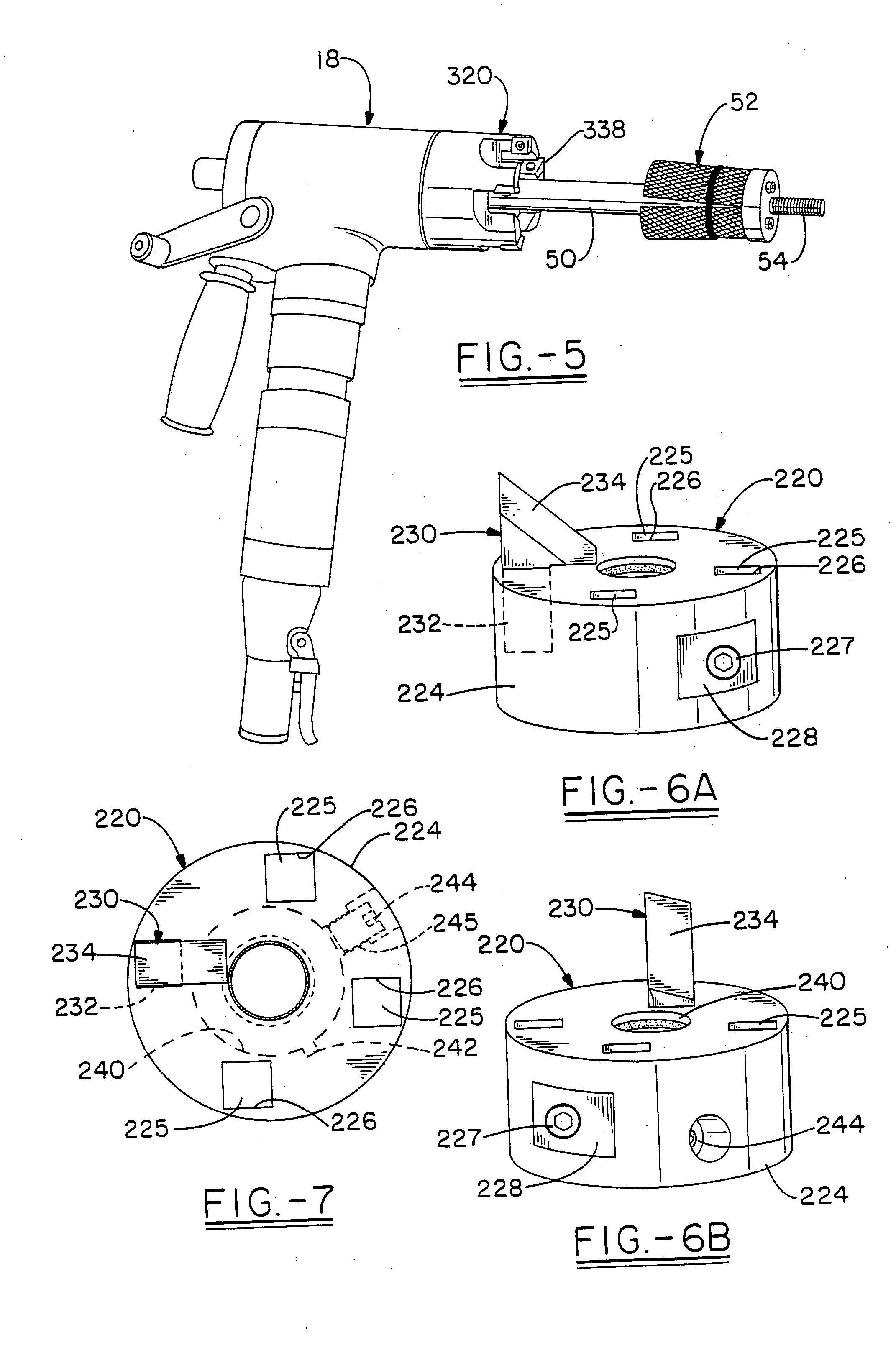

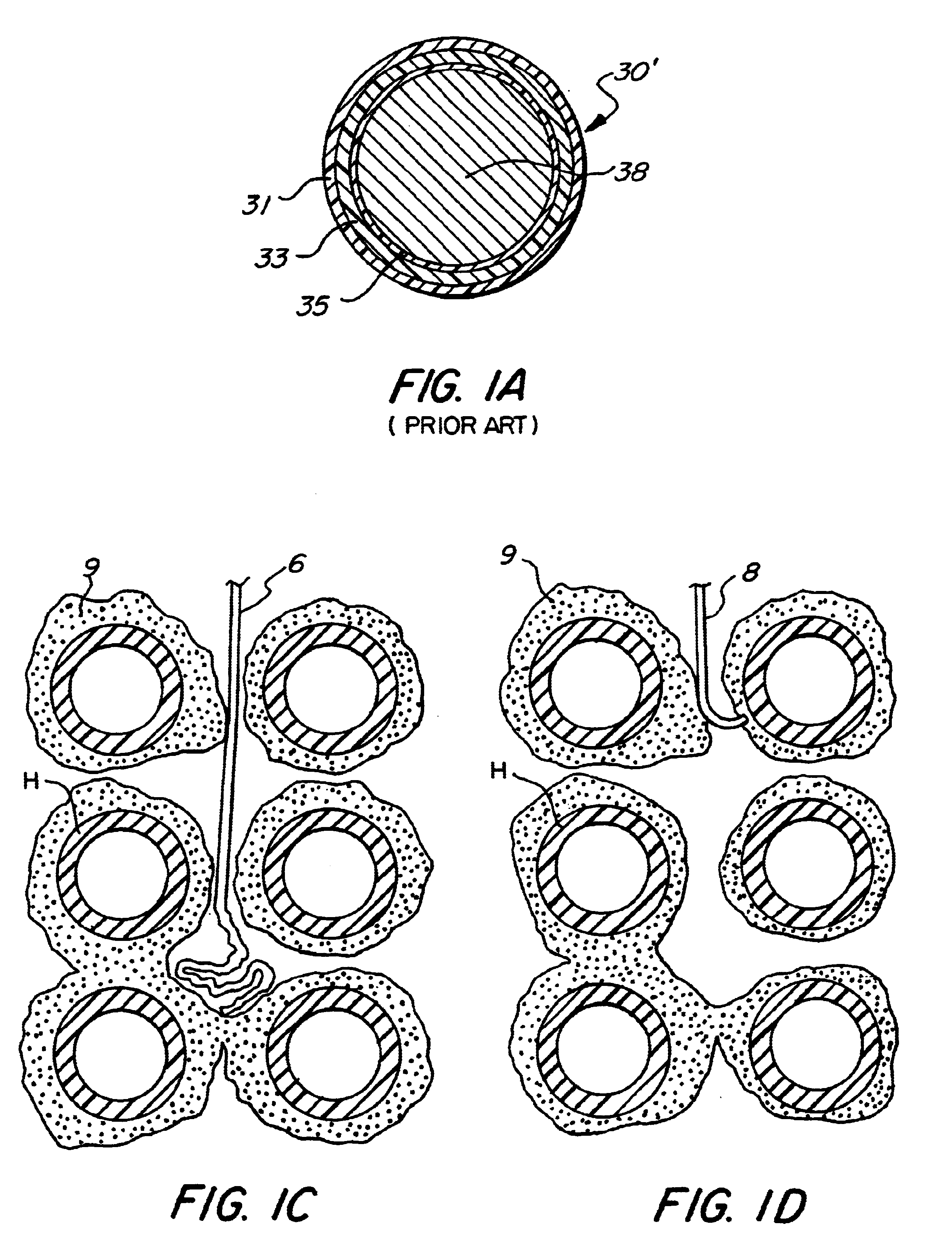

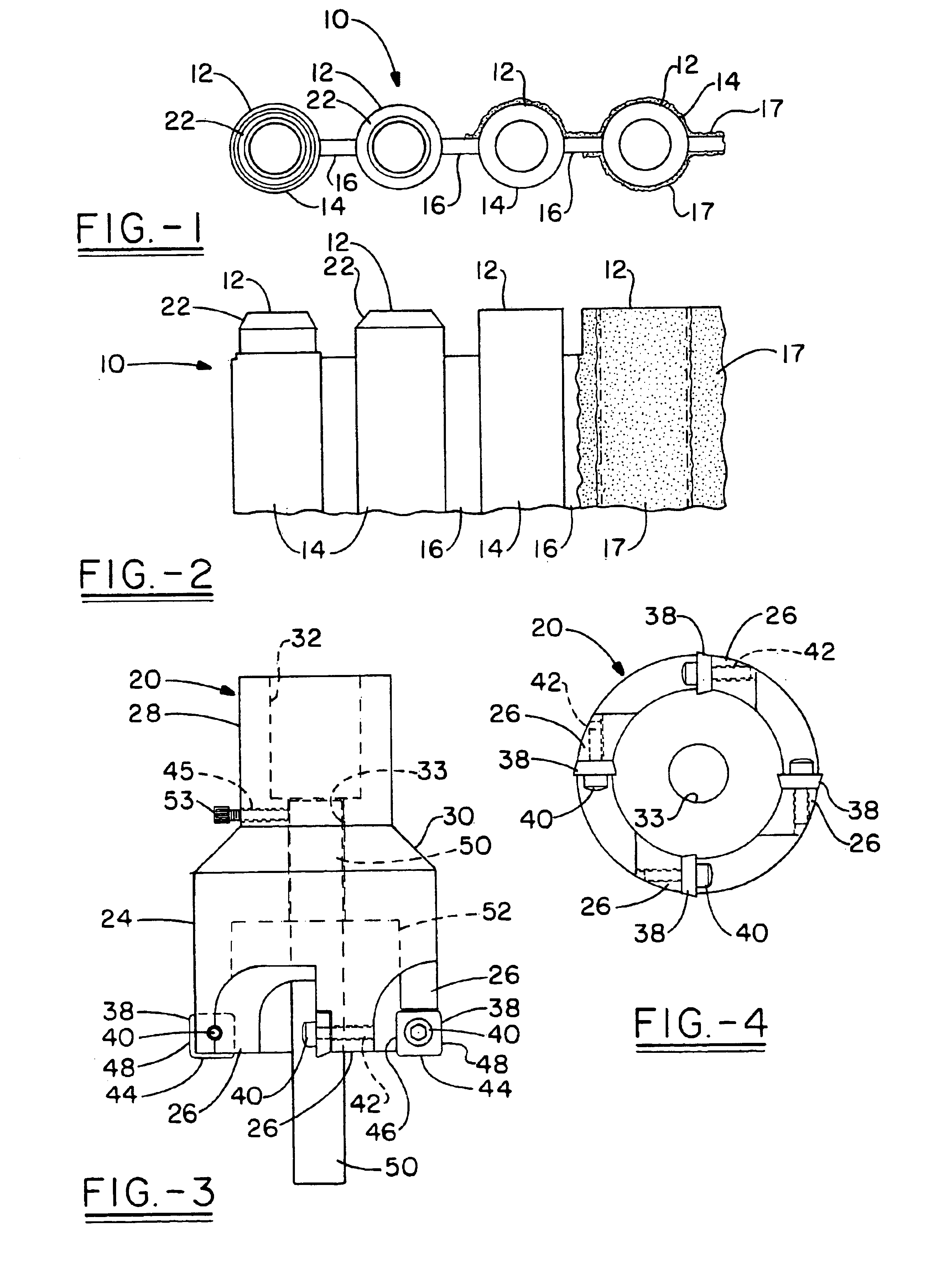

Tube milling head

ActiveUS20050053432A1Improve relationshipSave downtimeMilling cuttersWorkpiecesEngineeringKnife blades

Tube ends such as those of boiler tube banks, are prepared utilizing any of various combinations of processes which include a step of micro-diameter tube film removal from a portion of a tube end, including an area below a beveled segment, or segment to be beveled. The micro-diameter film removal step provides the tube with an exposed, clean metal surface which is conducive to a subsequent welding or bonding operation performed on the tube. Preferably, the process is performed with a tube milling tool having interchangeable milling or cutting heads. A specialized milling head is also disclosed and, in one embodiment, is at least used to perform the micro-diameter tube film removal step. Advantageously, the tube film removal milling head also removes a weld overlay on one or both sides of a tube in one embodiment. The tube film removal milling head includes an attached blade having a planar face configuration which enables tube film removal.

Owner:CLIMAX PORTABLE MACHINE TOOLS

Artificial neural network and fuzzy logic based boiler tube leak detection systems

Power industry boiler tube failures are a major cause of utility forced outages in the United States, with approximately 41,000 tube failures occurring every year at a cost of $5 billion a year. Accordingly, early tube leak detection and isolation is highly desirable. Early detection allows scheduling of a repair rather than suffering a forced outage, and significantly increases the chance of preventing damage to adjacent tubes. The instant detection scheme starts with identification of boiler tube leak process variables which are divided into universal sensitive variables, local leak sensitive variables, group leak sensitive variables, and subgroup leak sensitive variables, and which may be automatically be obtained using a data driven approach and a leak sensitivity function. One embodiment uses artificial neural networks (ANN) to learn the map between appropriate leak sensitive variables and the leak behavior. The second design philosophy integrates ANNs with approximate reasoning using fuzzy logic and fuzzy sets. In the second design, ANNs are used for learning, while approximate reasoning and inference engines are used for decision making. Advantages include use of already monitored process variables, no additional hardware and / or maintenance requirements, systematic processing does not require an expert system and / or a skilled operator, and the systems are portable and can be easily tailored for use on a variety of different boilers.

Owner:TENNESSEE TECHNOLOGICAL UNIVERSITY +1

Method for tube end preparation and milling head therefore

InactiveUS20050053440A1Improve relationshipSave downtimeThread cutting toolsTransportation and packagingEngineeringMetal

Tube ends such as those of boiler tube banks, are prepared utilizing any of various combinations of processes which include a step of micro-diameter tube film removal from a portion of a tube end, including an area below a beveled segment, or segment to be beveled. The micro-diameter film removal step provides the tube with an exposed, clean metal surface which is conducive to a subsequent welding or bonding operation performed on the tube. Preferably, the process is performed with a tube milling tool having interchangeable milling or cutting heads. A specialized milling head is also disclosed and, in one embodiment, is at least used to perform the micro-diameter tube film removal step. Advantageously, the tube film removal milling head also removes a weld overlay on one or both sides of a tube in one embodiment. The tube film removal milling head includes an attached blade having a planar face configuration which enables tube film removal.

Owner:CLIMAX PORTABLE MACHINE TOOLS

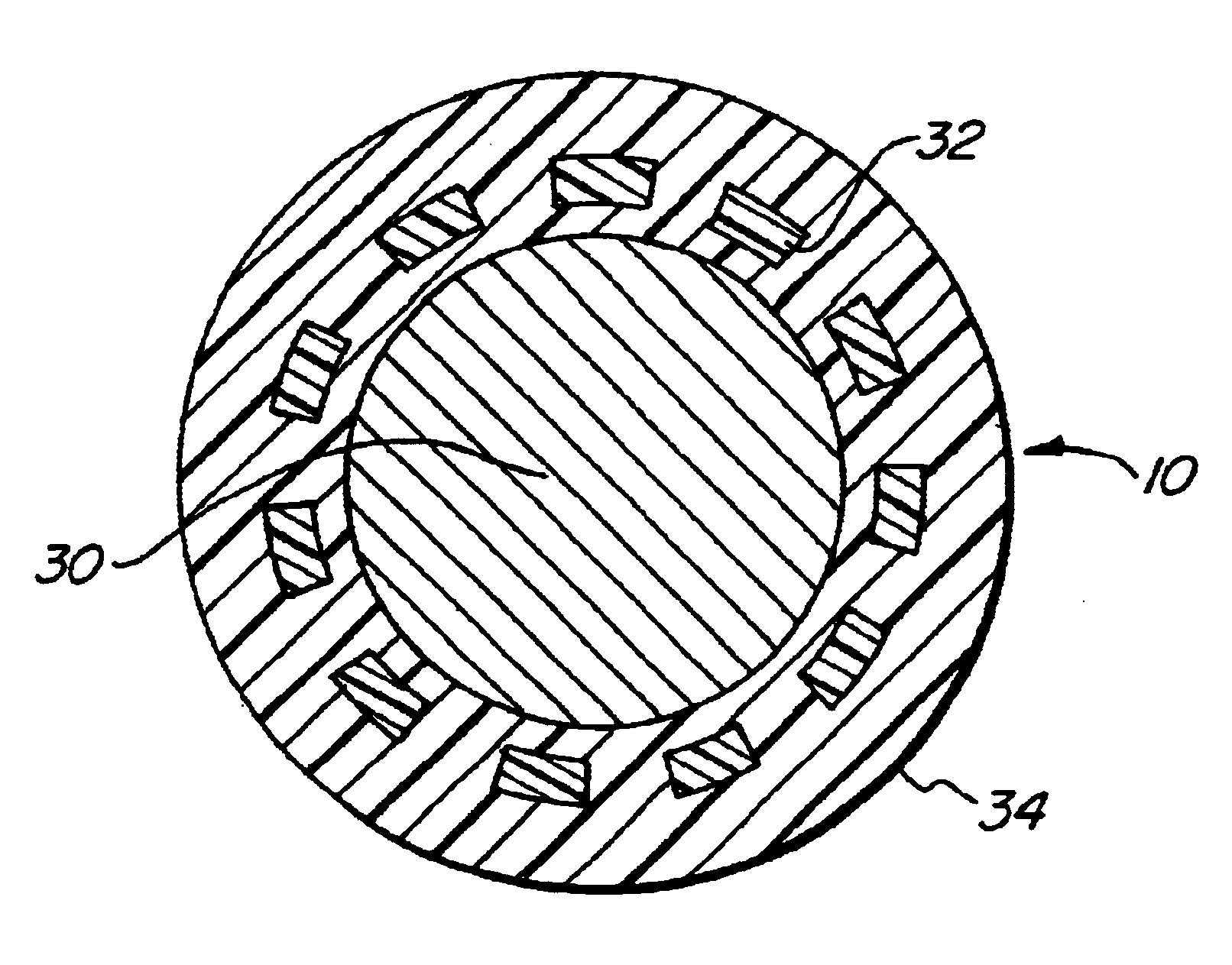

Rigid reactive cord and methods of use and manufacture

The present invention provides a rigid reactive cord such as a detonating cord (10) that includes a core (38) of an energetic material and a rigid non-metal sheath (40) disposed about the core. The cord (10) is sufficiently rigid so that it can be inserted through a material to be fractured or through passages formed therein. A method of using the rigid reactive cord for the removal of combustion residue from boiler tubes is also presented.

Owner:DYNO NOBEL INC

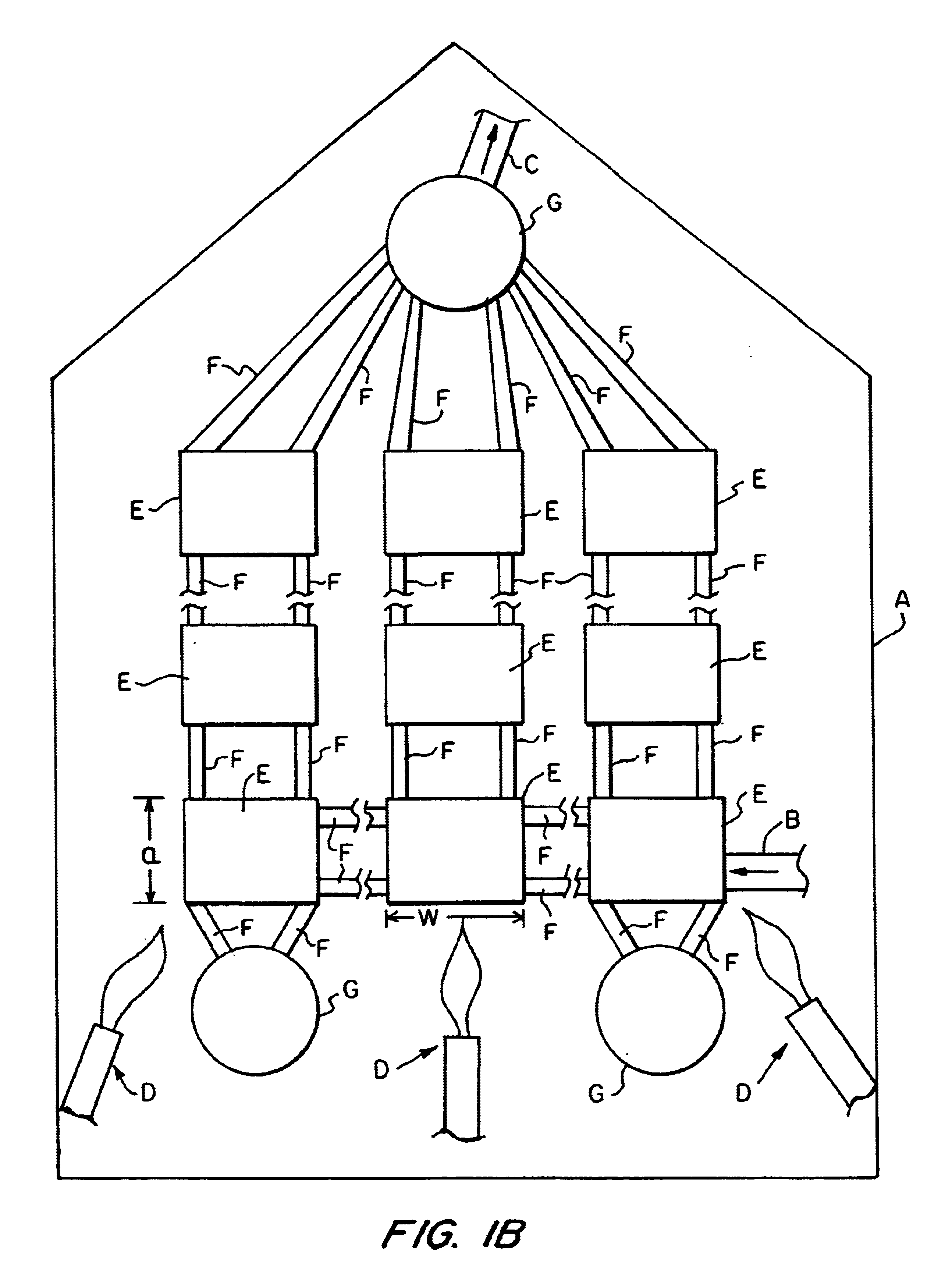

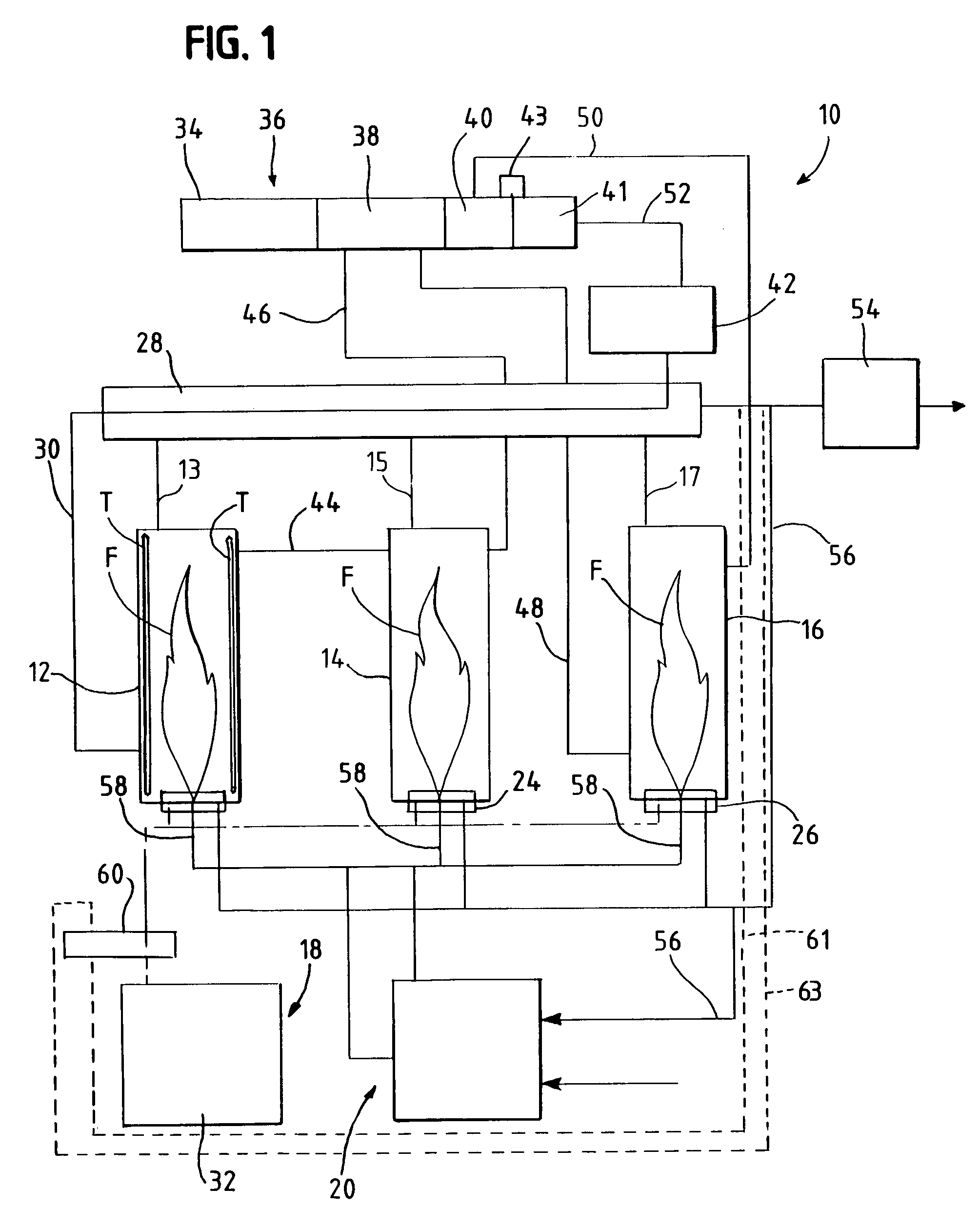

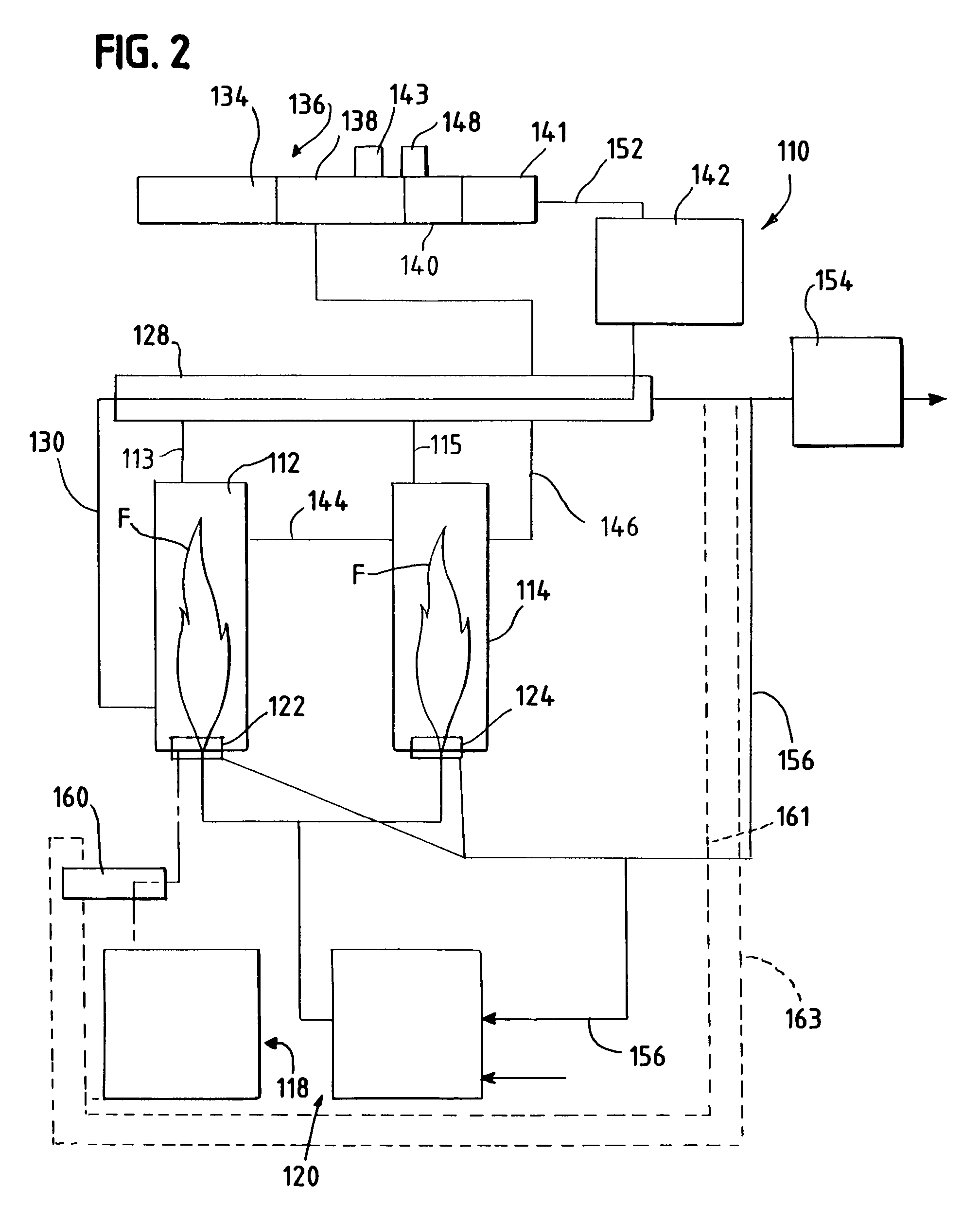

Module-based oxy-fuel boiler

InactiveUS7516620B2Avoid introducingFluidized bed combustionSteam useCombustion systemEnergy transfer

Owner:JUPITER OXYGEN CORP

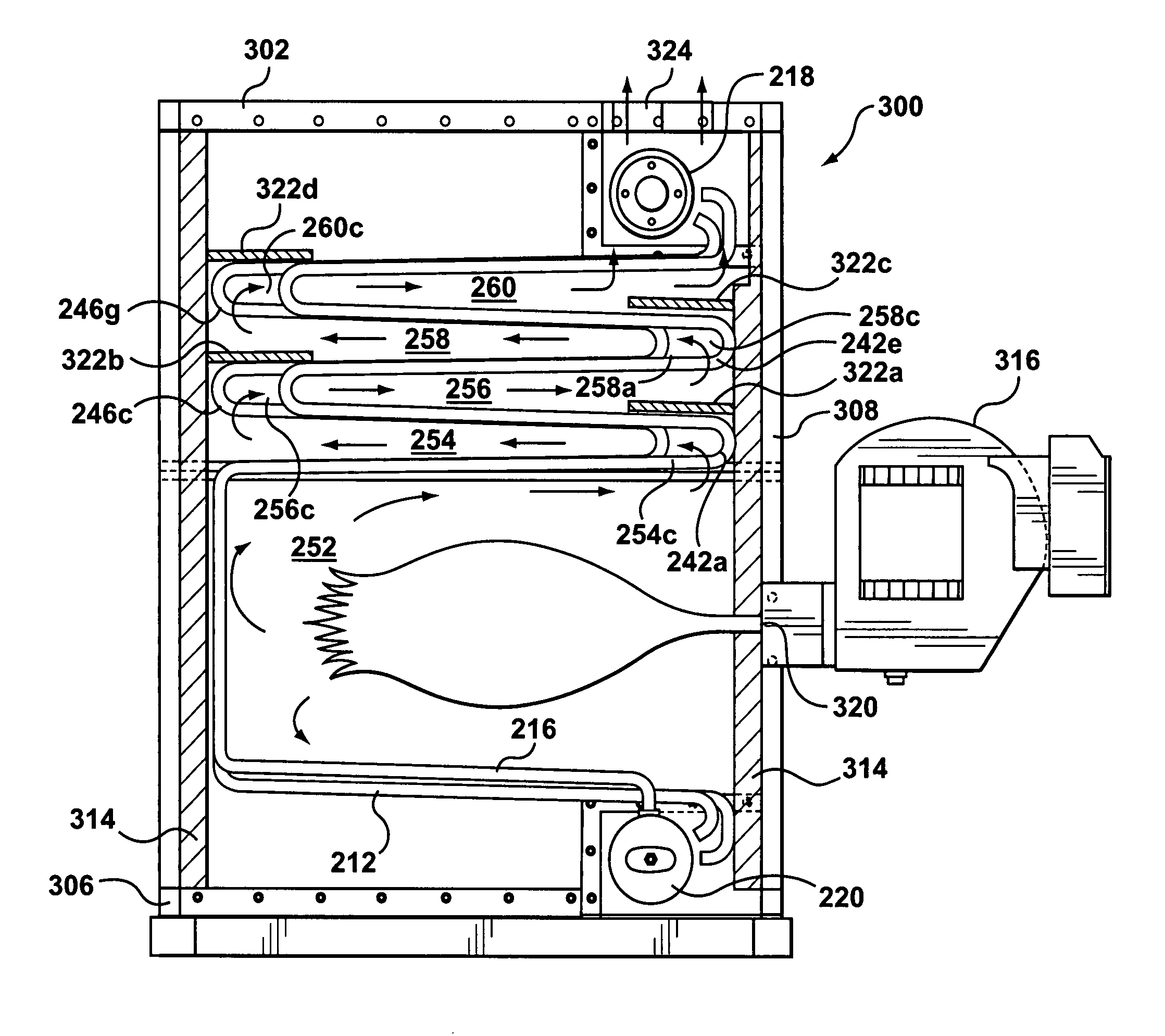

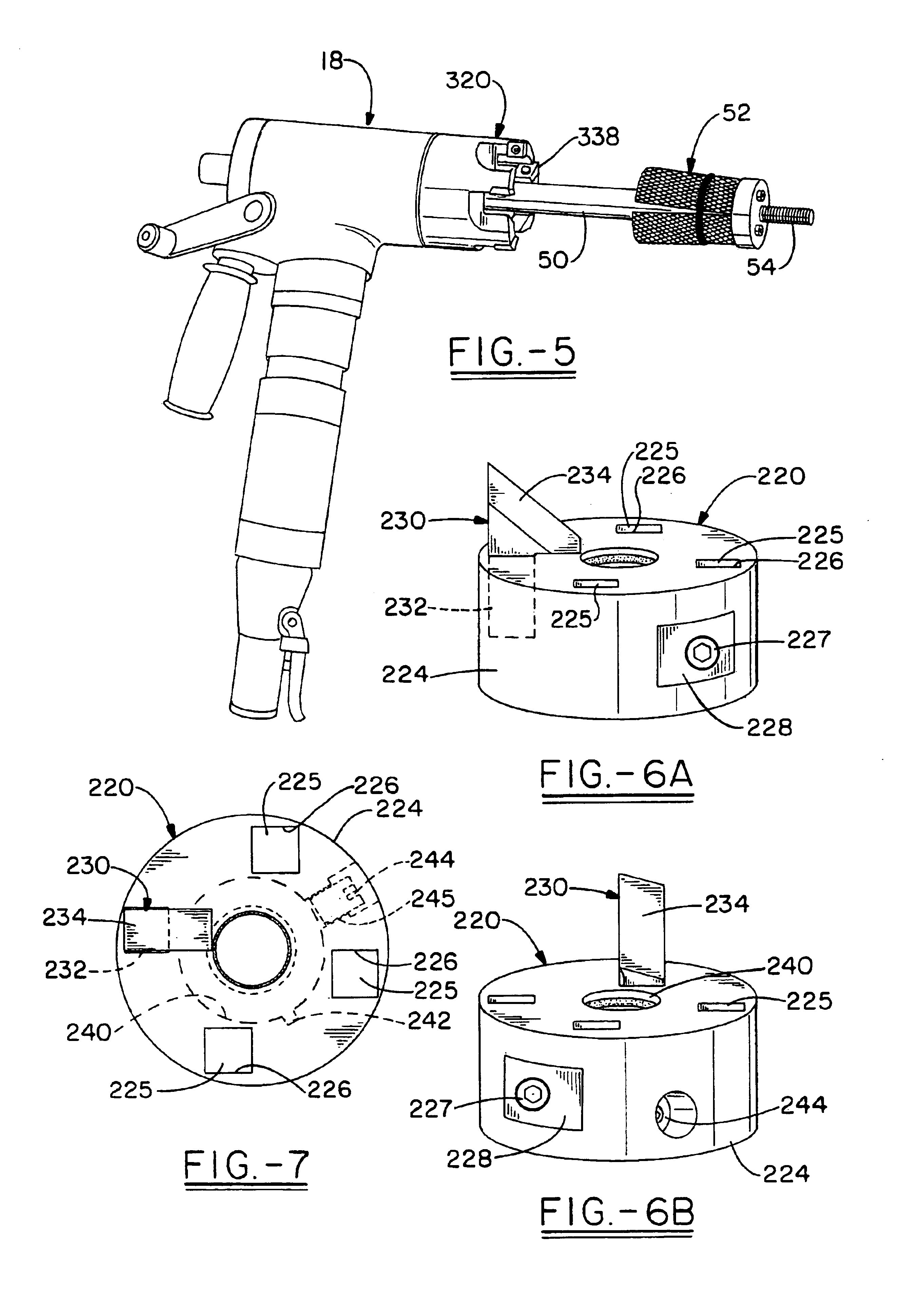

Tube assembly for a boiler

InactiveUS7137360B1Improve boiler efficiencyGood coefficientBoiler water tubesEnergy industryFlue gasEngineering

A boiler is described comprising a housing with a flue gas inlet for receiving a hot gas flame and an outlet for venting a hot gas produced by the hot gas flame, and a tube assembly mounted within the housing. The tube assembly comprises a lower manifold for receiving a liquid, an upper manifold for receiving a heated version of the liquid; and, a plurality of tubes disposed between the lower and upper manifolds. Each tube is shaped to provide a hot gas pathway that travels in a parallel fashion along at least a lower portion of the longitudinal extent of each tube in the tube assembly to the outlet, whereby the liquid introduced into the lower manifold travels in the plurality of tubes and receives heat from the hot gas along the extent of the hot gas pathway.

Owner:PRIME BOILERS

Tube milling head

Tube ends such as those of boiler tube banks, are prepared utilizing any of various combinations of processes which include a step of micro-diameter tube film removal from a portion of a tube end, including an area below a beveled segment, or segment to be beveled. The micro-diameter film removal step provides the tube with an exposed, clean metal surface which is conducive to a subsequent welding or bonding operation performed on the tube. Preferably, the process is performed with a tube milling tool having interchangeable milling or cutting heads. A specialized milling head is also disclosed and, in one embodiment, is at least used to perform the micro-diameter tube film removal step. Advantageously, the tube film removal milling head also removes a weld overlay on one or both sides of a tube in one embodiment. The tube film removal milling head includes an attached blade having a planar face configuration which enables tube film removal.

Owner:CLIMAX PORTABLE MACHINE TOOLS

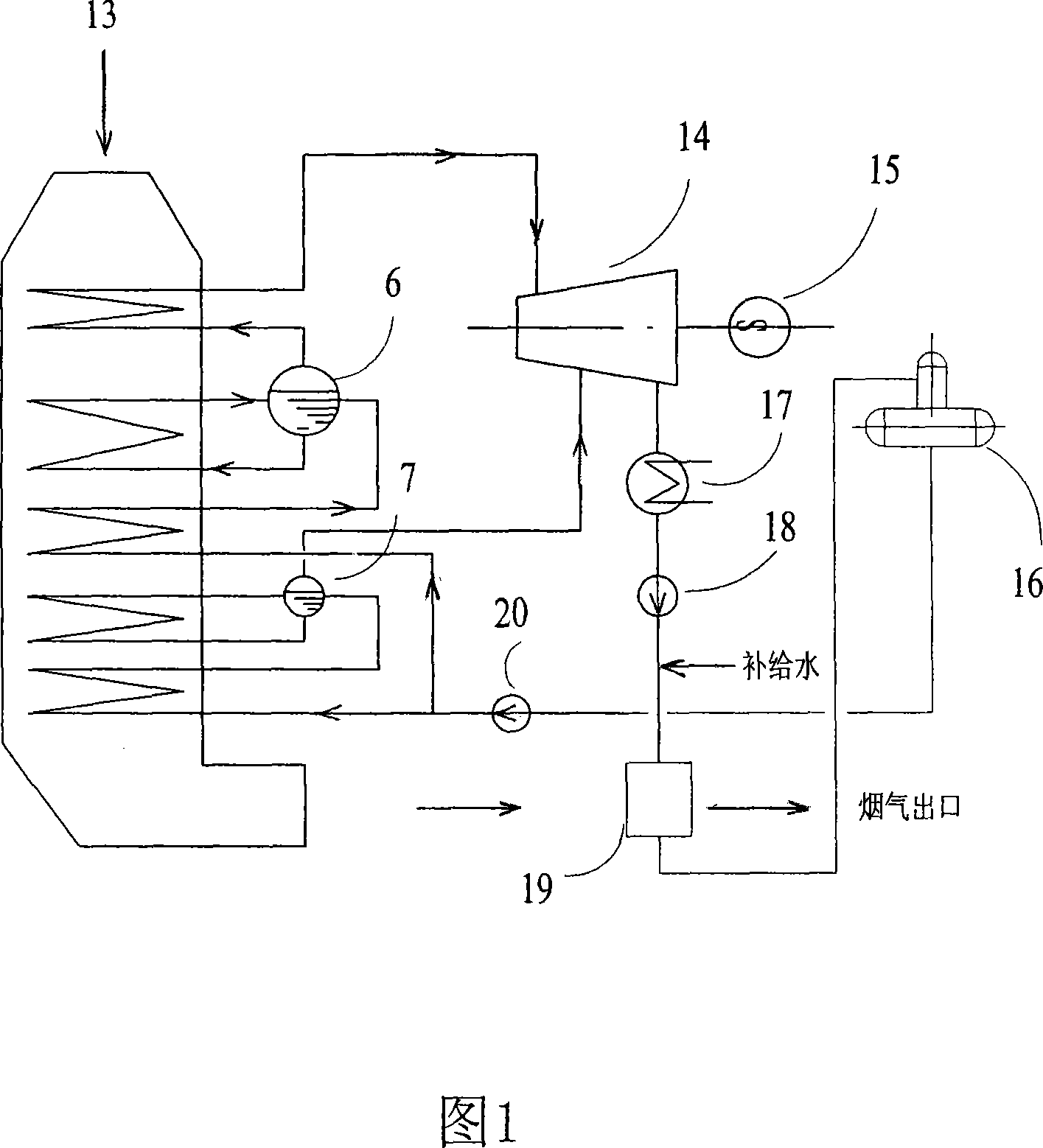

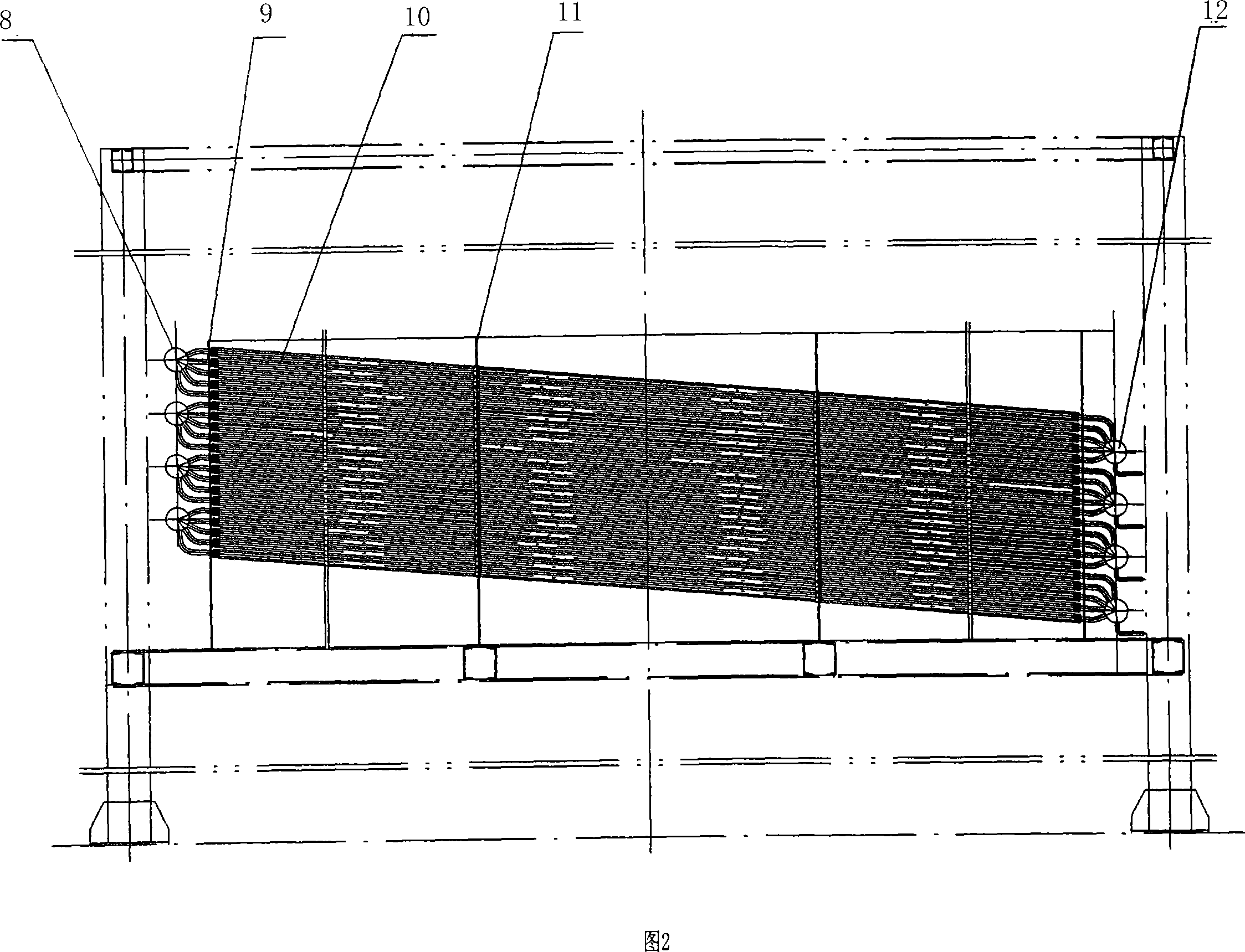

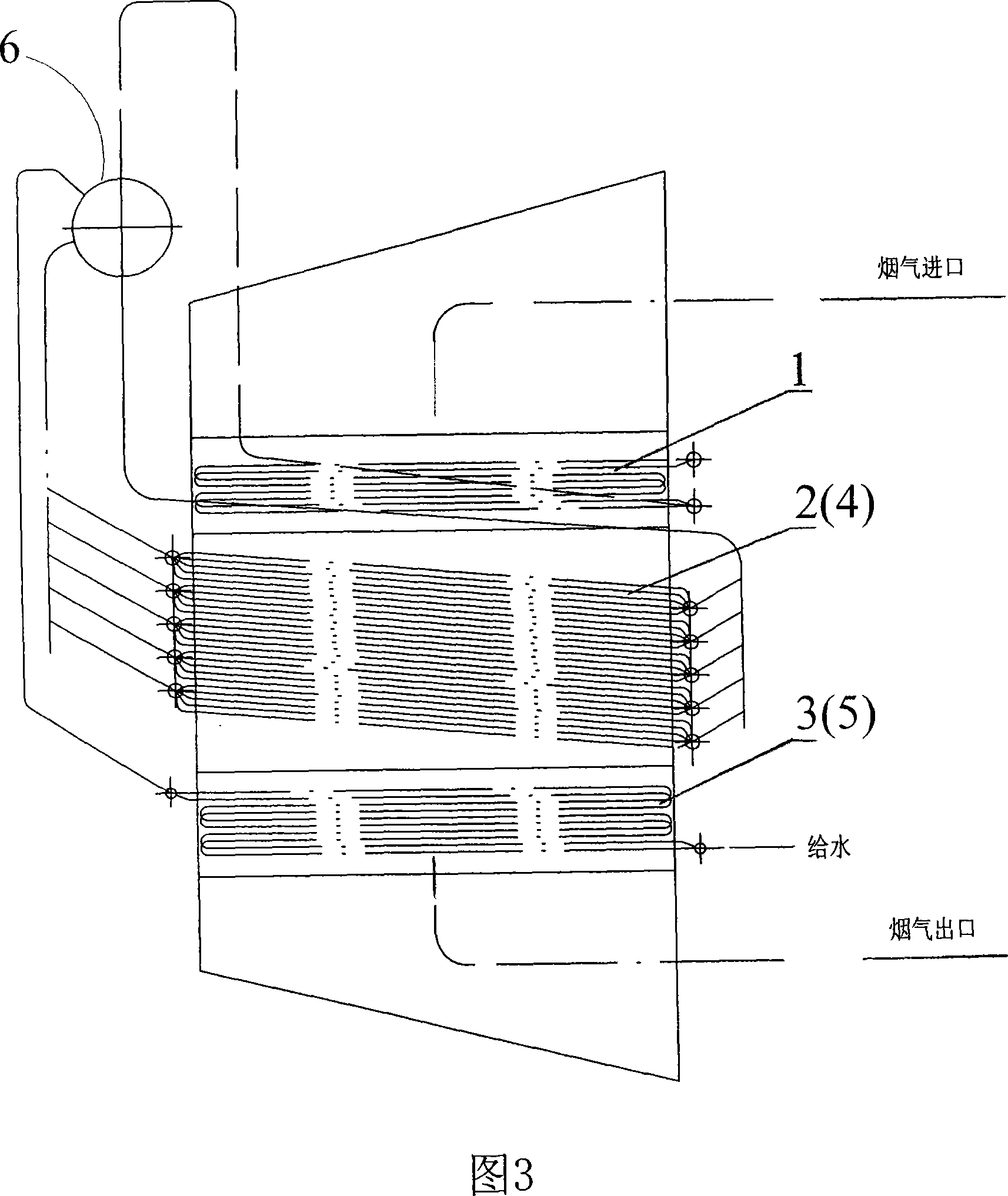

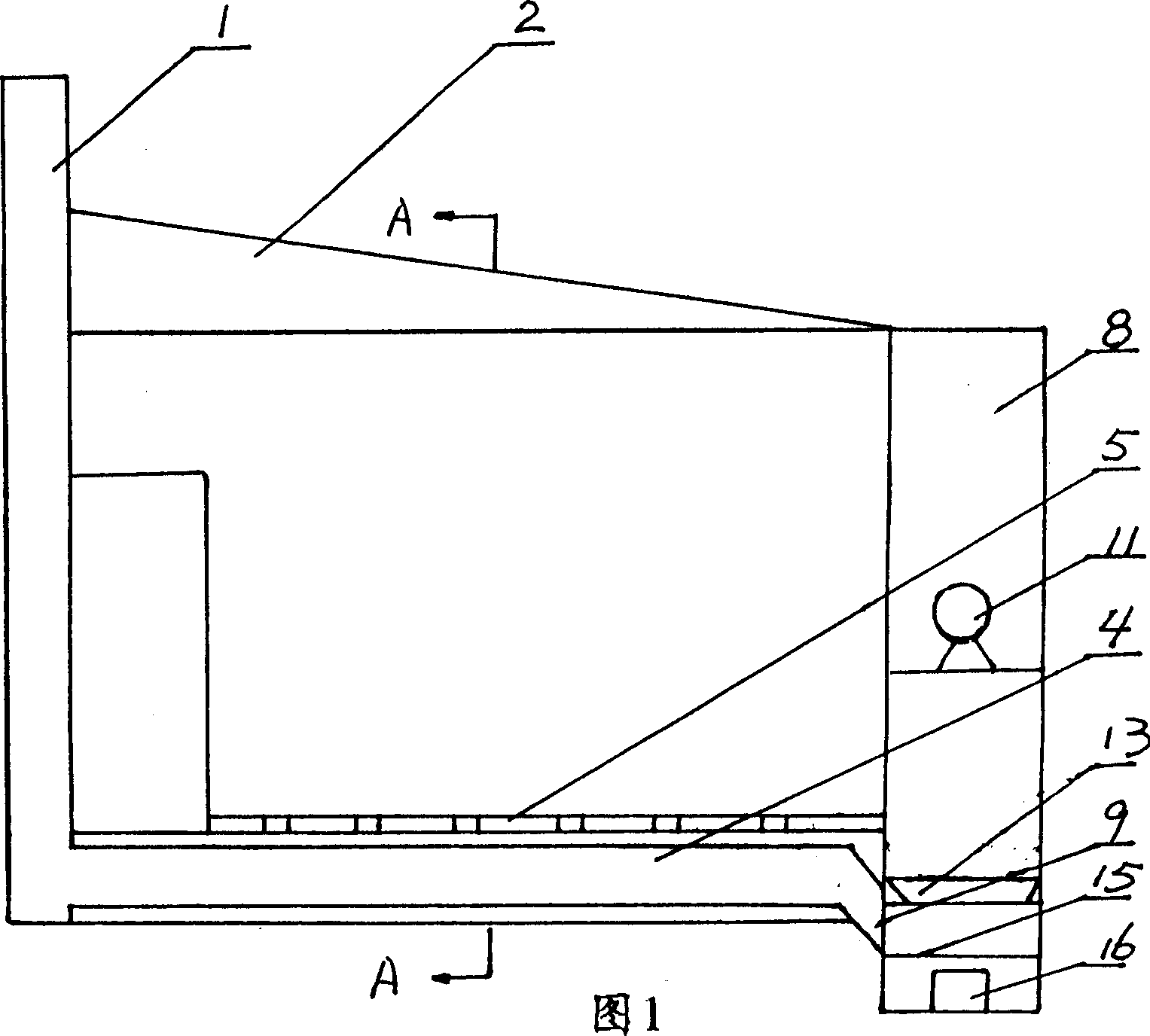

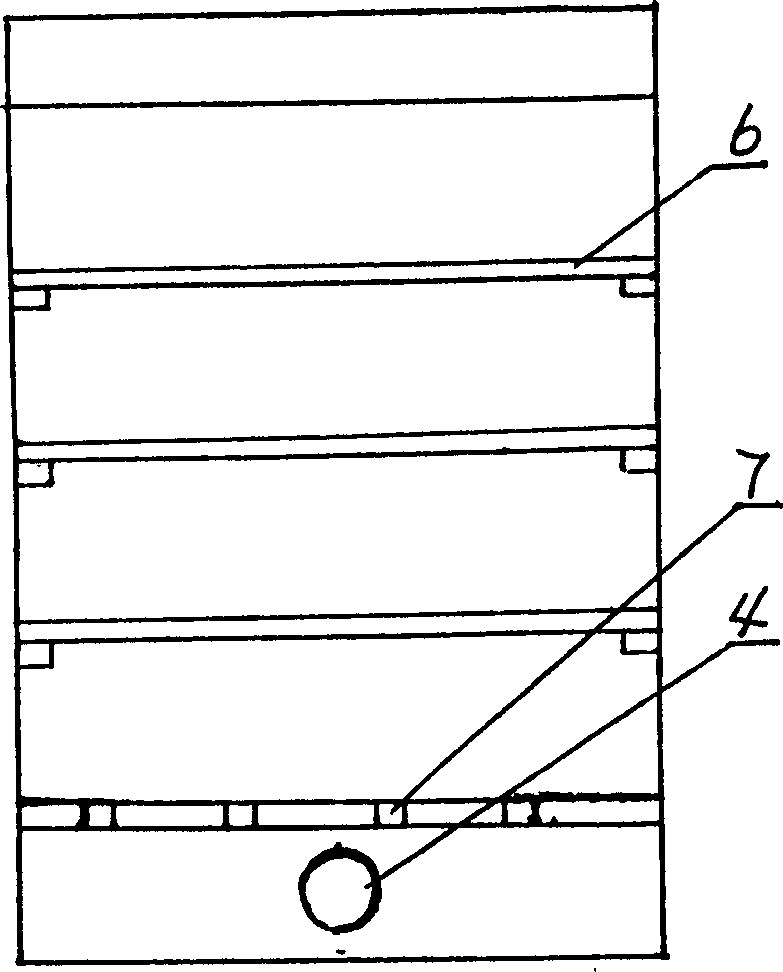

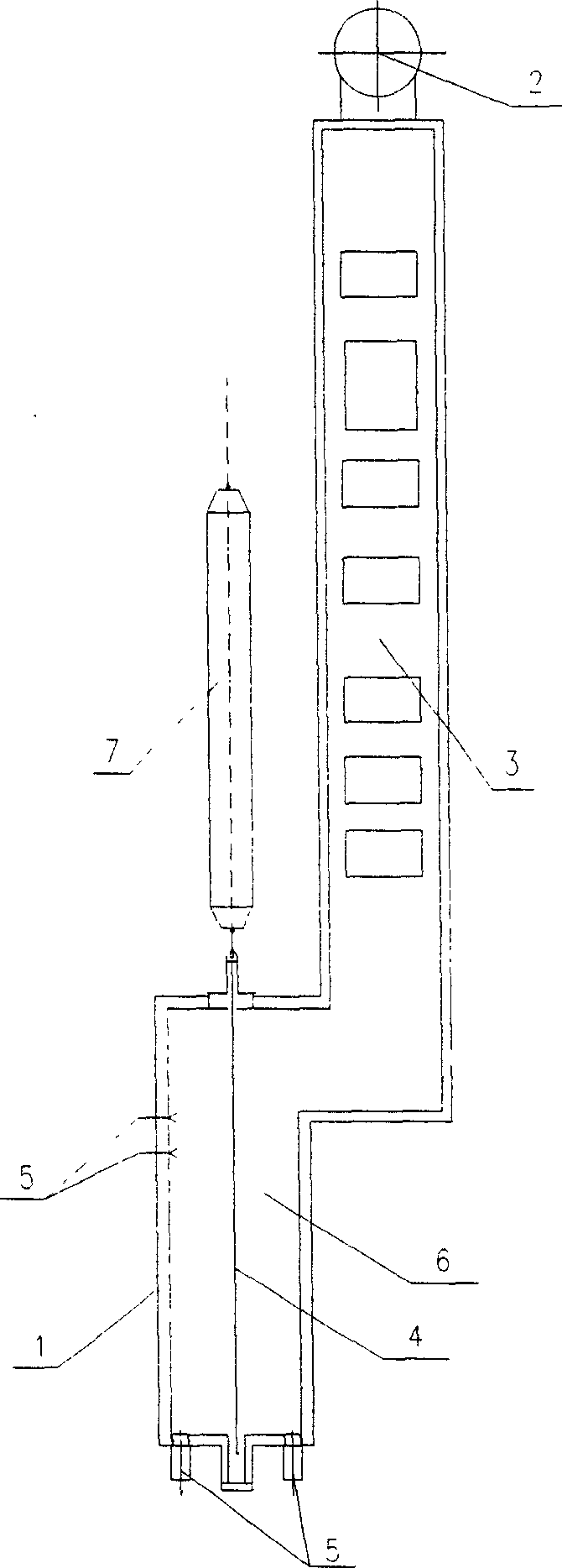

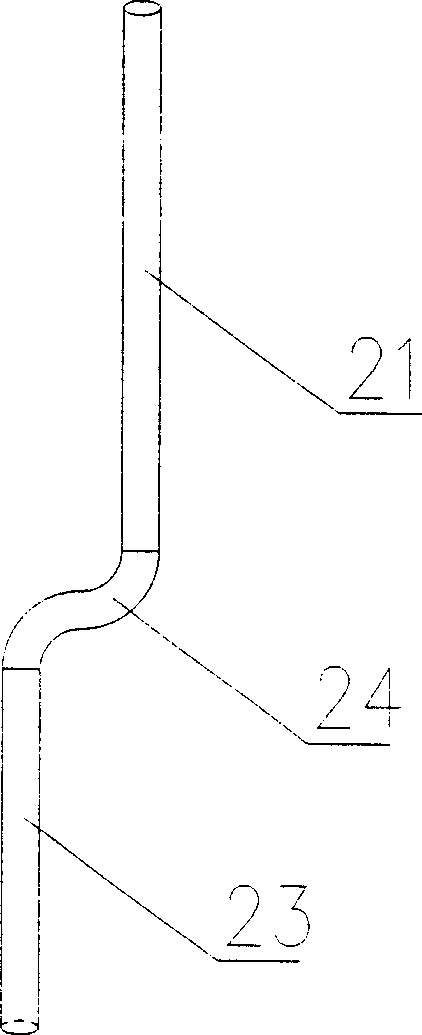

Sinter cooler low temperature waste gas residual heat boiler and power generating system thereof

InactiveCN101021305AEasy to discharge ashSmall footprintSteam boilersSteam boilers componentsWhole bodyEvaporation

The present invention provides an exhaust-heat boiler capable of effectively utilizing low-temperature heat transmission to make power generation and its power generation system. Said exhaust-heat boiler whole body adopts vertical type arrangement and tube-box type structure, in the boiler tube-box interior are successively set super heater, evaporation zone, low-pressure evaporation zone, coal economizer and low-pressure coal economizer from top to bottom, in which the evaporation zone and low-pressure evaporation zone have several groups of evaporators, these evaporators are obliquely placed in smoke flue, their inclination angle is 5 deg-15 deg. Said invention also provides the concrete structure of every evaporator, and provides the working principle of said exhaust-heat boiler and its power generation system and their concrete operation method.

Owner:JIANGSU DONGJIU HEAVY IND

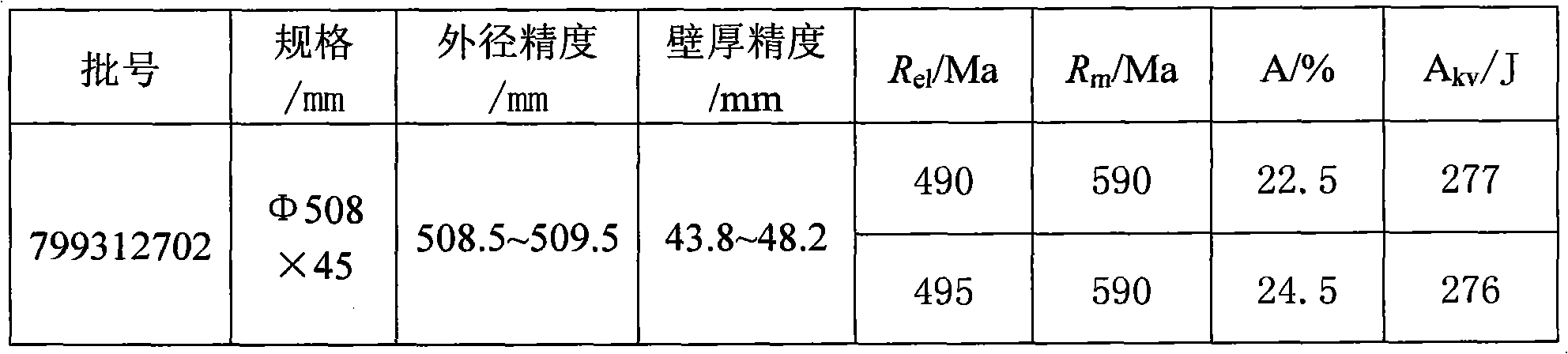

Production method of large-caliber high-pressure boiler tube

InactiveCN101890432AImprove internal and external qualityGuaranteed dimensional accuracyMetal rolling arrangementsPunchingEddy current

The invention provides a production method of a large-caliber high-pressure boiler tube, comprising the following steps: inspecting blank; saw cutting blanking; heating by an annular furnace; punching by a Mannesmann punching machine or punching by hydraulic pressure and punching by utilizing the Mannesmann punching machine; pre-punching a mandril; rolling by a pilger mill; carrying out hot-sawing on pilger heads; reheating by a walking beam furnace; externally descaling by high pressure water; sizing by a sizing mill; cooling by a cooling bed; carrying out thermal treatment; sampling; passing physical and chemical inspection; straightening; cutting head and end parts; carrying out manually initial check; polishing an inner surface and an outer surface or internally boring and externally raking; blowing soot; carrying out ultrasonic and eddy-current combination detection; manually rechecking; carrying out spectral inspection; measuring length and weighing; jet-printing; and finally packaging and warehousing. In the method, a steel billet is heated in the annular furnace, which comprises three processes of preheating, heating and soaking; and heating temperature and time in each process are rationally distributed to prevent heating unevenness and heating defects. During the tube rolling process, the feeding system of the pilger mill completes feeding release with the feeding quantity less than 0.5mm, thus achieving uniform and accurate feeding quantity in each rolling cycle.

Owner:HENGYANG VALIN STEEL TUBE

New-type tobacco flue-curing room and the tobacco flue-curing process

InactiveCN1403035ACompatible with growth physiological characteristicsSelection quality improvementTobacco preparationThree stageSmall footprint

Owner:刘志峰

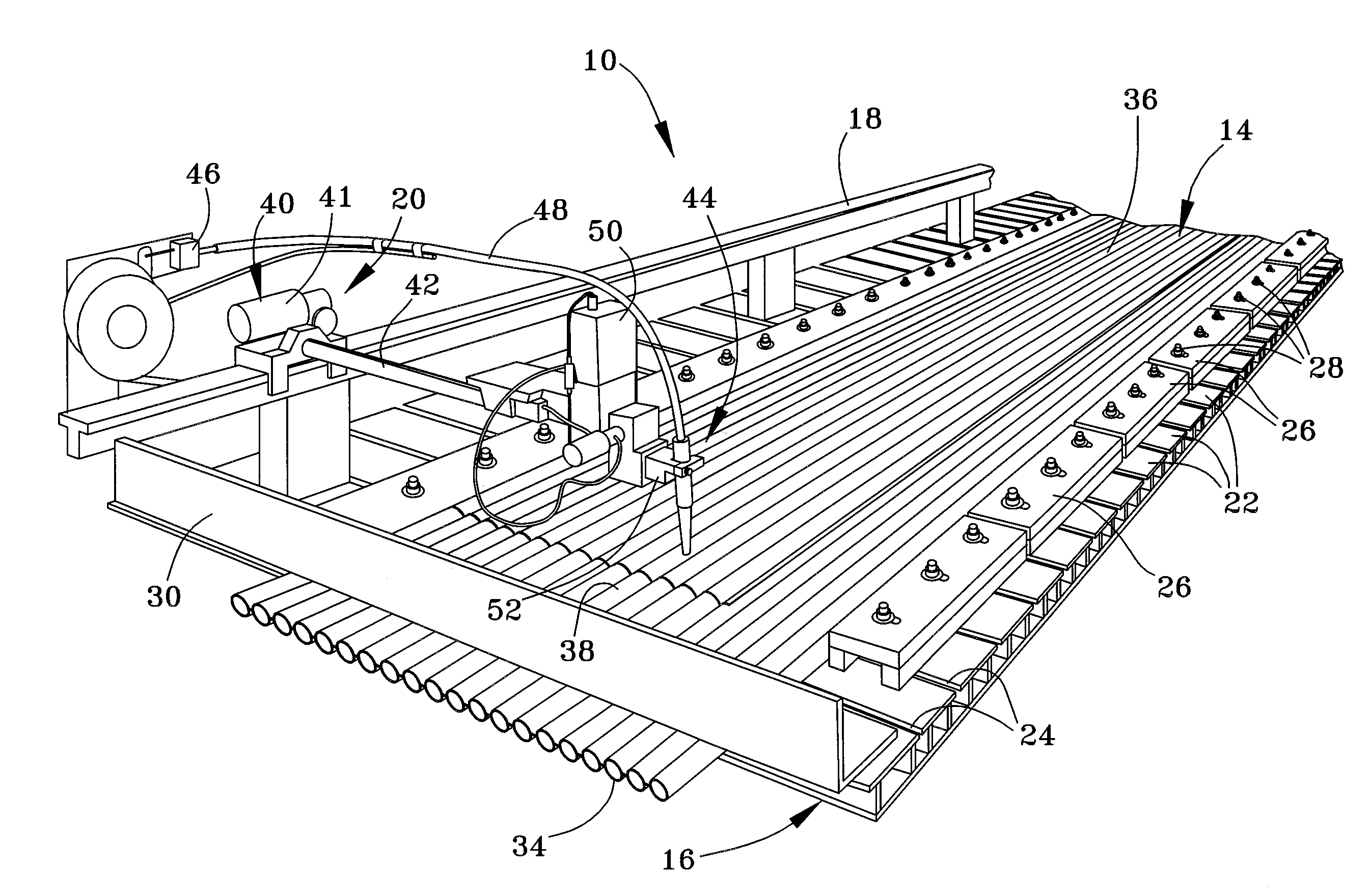

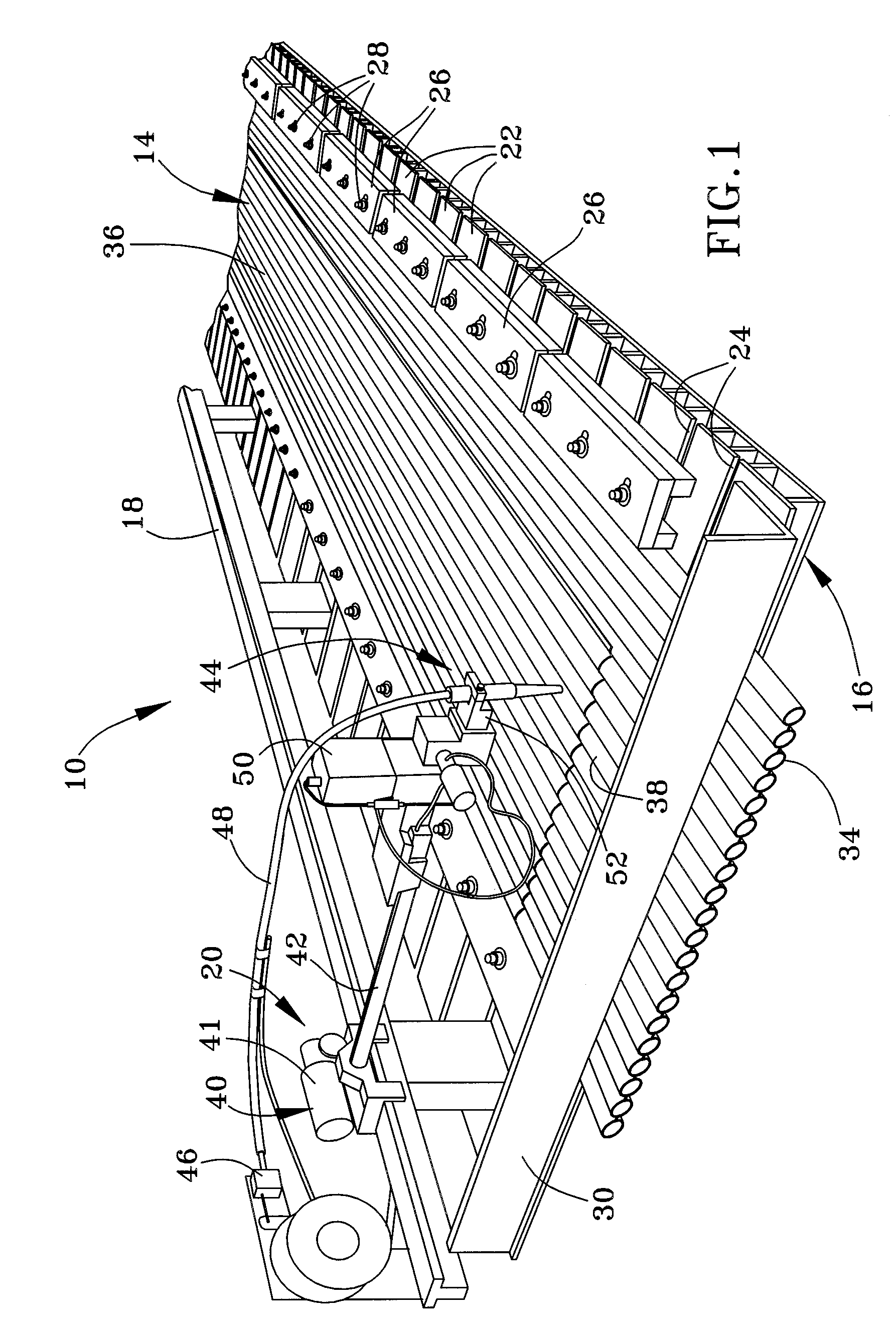

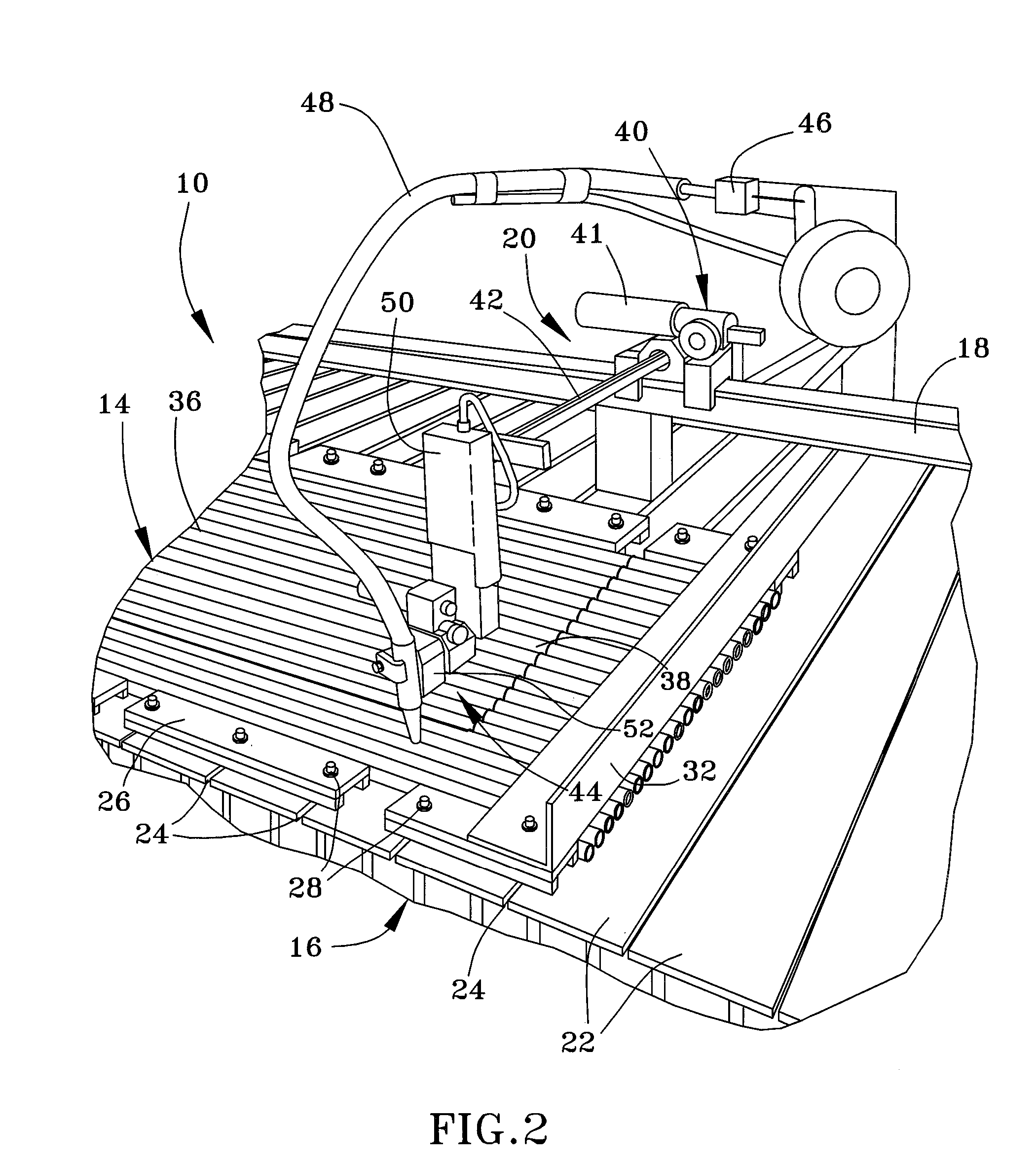

Process and apparatus for boiler tube panel welding and straightening

ActiveUS20050167468A1Reduce morbidityEasy to controlAutomatic control devicesPrecision positioning equipmentEngineeringMembrane configuration

An apparatus and process for depositing an overlay weld on a boiler tube panel comprising a plurality of tubes with adjacent tubes joined together with membranes therebetween, and then straightening the panel in response to bowing that occurs as a result of depositing the overlay weld. The apparatus generally comprises an overlay welding apparatus that deposits an overlay weld on a surface of a boiler tube panel, and a straightening apparatus for straightening the panel following deposition of the overlay weld. The straightening process entails placing the boiler tube panel between two members, and the pressing a portion of the panel therebetween.

Owner:GENERAL ELECTRIC CO

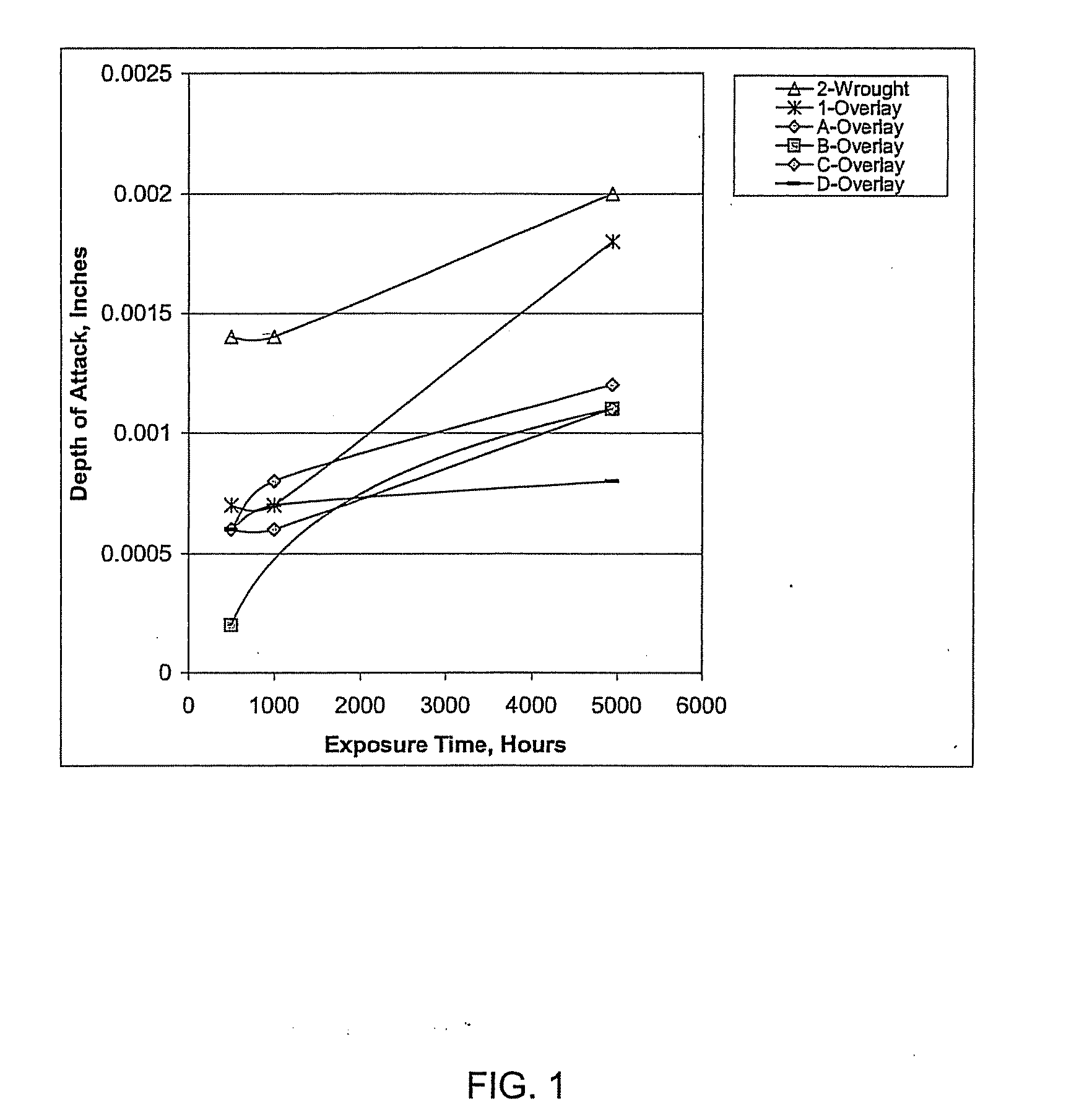

Filler Metal Composition and Method for Overlaying Low NOx Power Boiler Tubes

ActiveUS20080241580A1Solve the lack of corrosion resistanceEnvelopes/bags making machineryElectric discharge heatingAlloyOxygen

An alloy for use as a welding overlay for boiler tubes in a low NOx coal-fired boiler comprising in % by weight: 36 to 43% Cr, 0.2 to 5.0% Fe, 0-2.0% Nb, 0-1% Mo, 0.3 to 1% Ti, 0.5 to 2% Al, 0.005 to 0.05% C, 0.005 to 0.020% (Mg+Ca), 0-1% Mn, 0-0.5% Si, less than 0.01% S, balance substantially Ni and trace additions and impurities. The alloy provides exceptional coal ash corrosion resistance in low partial pressures of oxygen. The alloy also increases in hardness and in thermal conductivity at service temperature over time. The increased hardness improves erosion resistance of the tubes while the increased thermal conductivity improves the thermal efficiency of the boiler and its power generation capabilities.

Owner:HUNTINGTON ALLOYS CORP (US)

Cracking furnace of boiler tube with one-way reducing diameter

ActiveCN1766042AHigh cleavage selectivityModerate cycleThermal non-catalytic crackingVertical tubeCombustor

The invention provides a cracking furnace for one-way variable-diameter furnace tube, special to crack oil and produce olefin industry, which comprises: a furnace body, a high-pressure steam drum, a convection section, a one-way vertical tube with inner diameter of out-feed end larger than the feed-in end, a combustor, and a waste heat boiler. This invention has longer cycle of operation and higher yield.

Owner:CHINA PETROLEUM & CHEM CORP +3

Novel configured single-stroke furnace tube ethylene cracking furnace

ActiveCN101062881AExtended operating cycleImprove mechanical propertiesHydrocarbon by hydrocarbon crackingCombustorEngineering

The invention discloses a new type configuration single-pass furnace tube ethylene cracking furnace, which comprises the following steps: comprising high pressure steam drum, convection section, radiant section furnace tube, combustor, radiant section and chill boiler; setting the inner diameter of discharge pipe port of one-pass reducing vertical furnace tube bigger than the inner diameter of feed pipe inlet; assembling a bend in the middle of the furnace pipe; arranging an angle head in collecting tube; connecting a plurality of furnace tubes to a collecting tube; getting a nest of boiler tube. This invention can be used to ethylene installation.

Owner:CHINA PETROLEUM & CHEM CORP +2

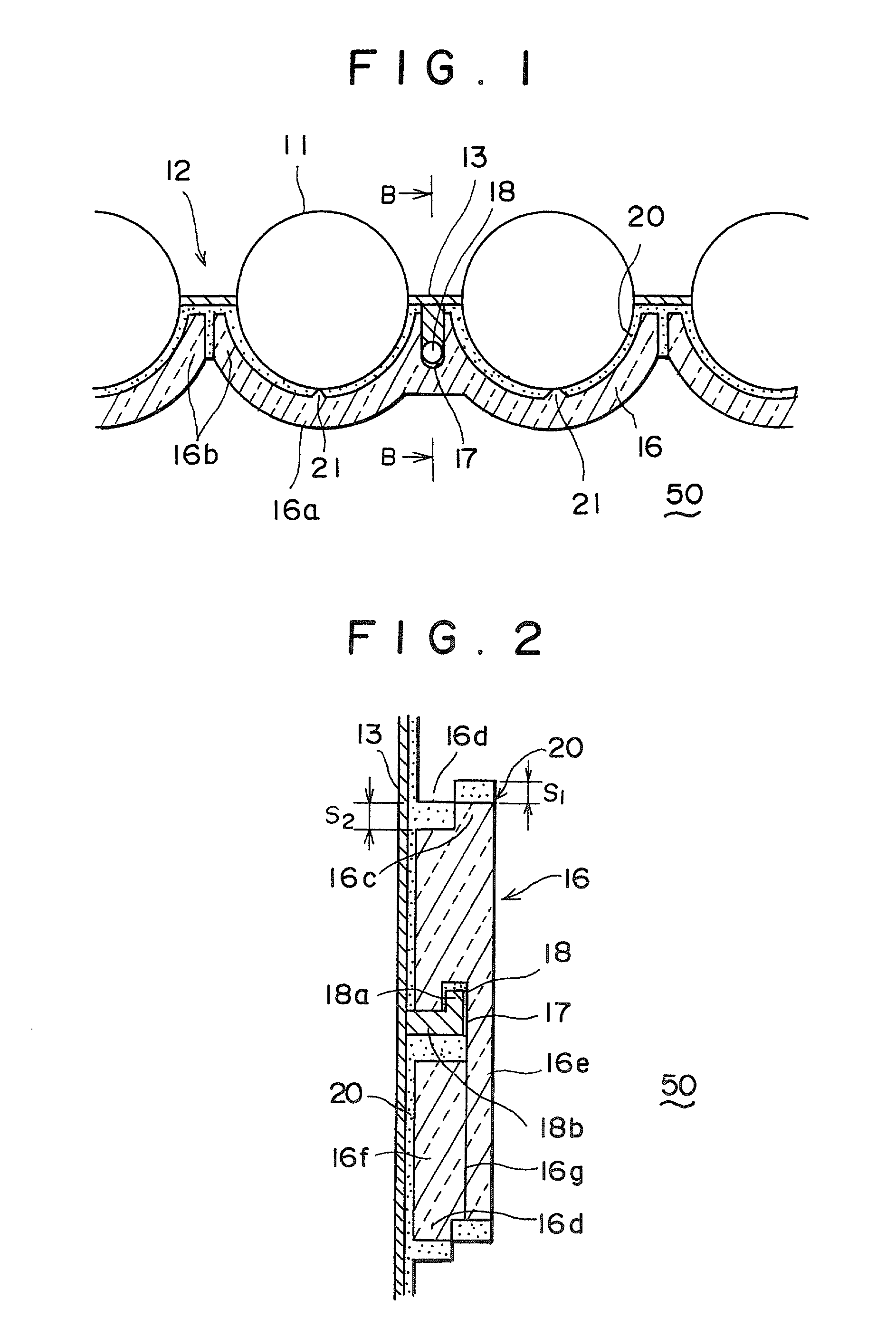

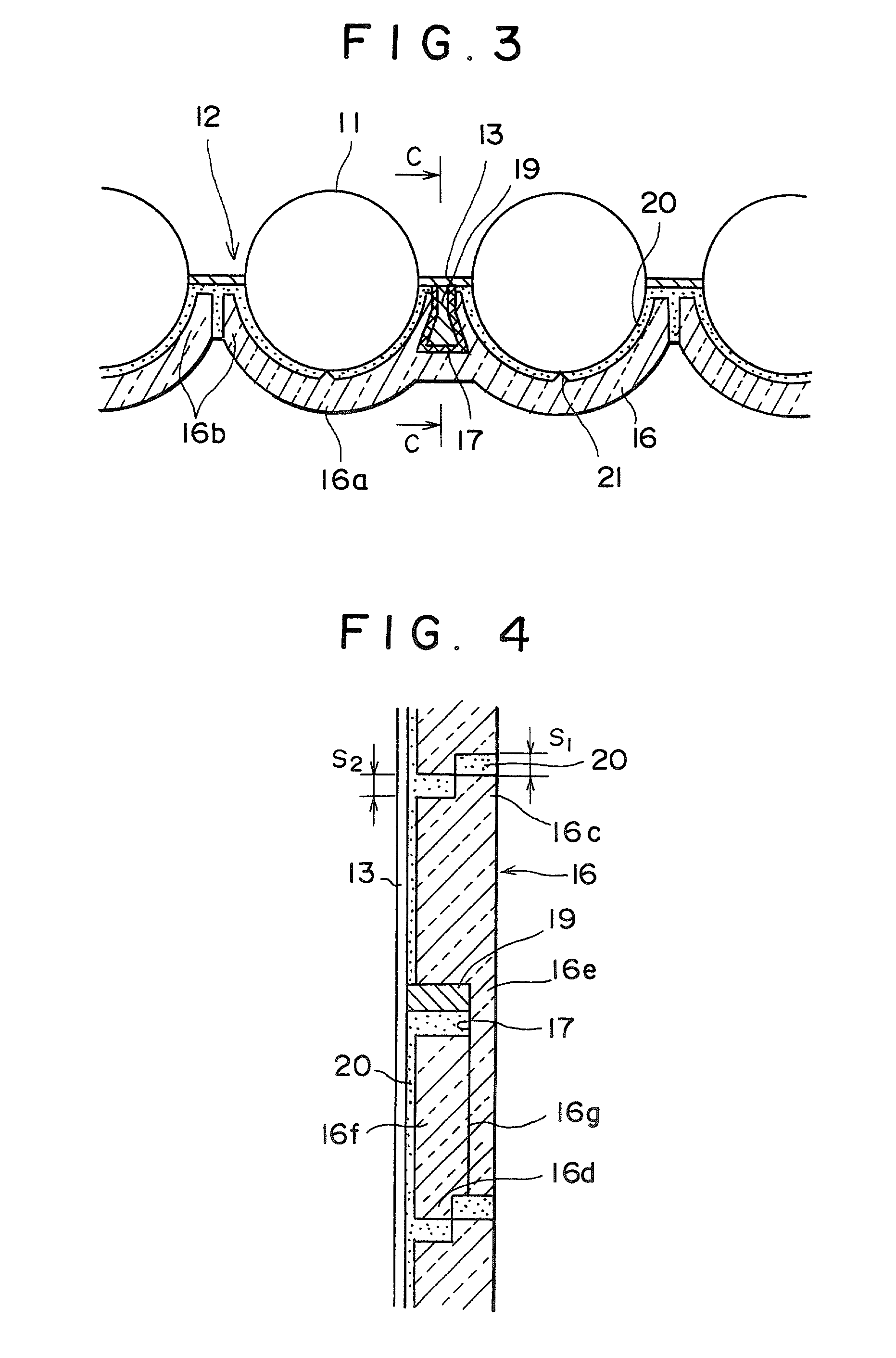

Heat-resistant assembly for protecting boiler tubes and method of assembling same

InactiveUS20020077767A1Thermometer detailsBoiler supporting/setting arrangementsEngineeringMechanical engineering

This invention concerns a heat-resistant assembly having a heat-resistant block conformed to the contours of boiler tubes and the surface of their connecting rib. The heat-resistant assembly has an arm which protrudes from the surface of the rib toward the heat-resistant block and which has a catch on the end. The block has an indentation in which the catch on the arm engages. The block can be hung on or removed from the tube assembly by means of the arms and indentations. The heat-resistant assembly is further distinguished by the fact that a space is created between the end of the arm and the indentation of the block. A fusible substance, which will melt when the temperature of the arm exceeds a given value, is placed in the space. The heat-resistant assembly is further distinguished by the fact that an indentation is formed in the block in which a heat-resistant sleeve is adhered to engage the arm. This arrangement makes it possible to manufacture the heat-resistant block using press molding.

Owner:MITSUBISHI HEAVY IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com