Sinter cooler low temperature waste gas residual heat boiler and power generating system thereof

A technology of sintering cooler and waste heat boiler, which is applied to steam boilers, steam boiler accessories, components of steam boilers, etc. Low loss, low heat transfer effect, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

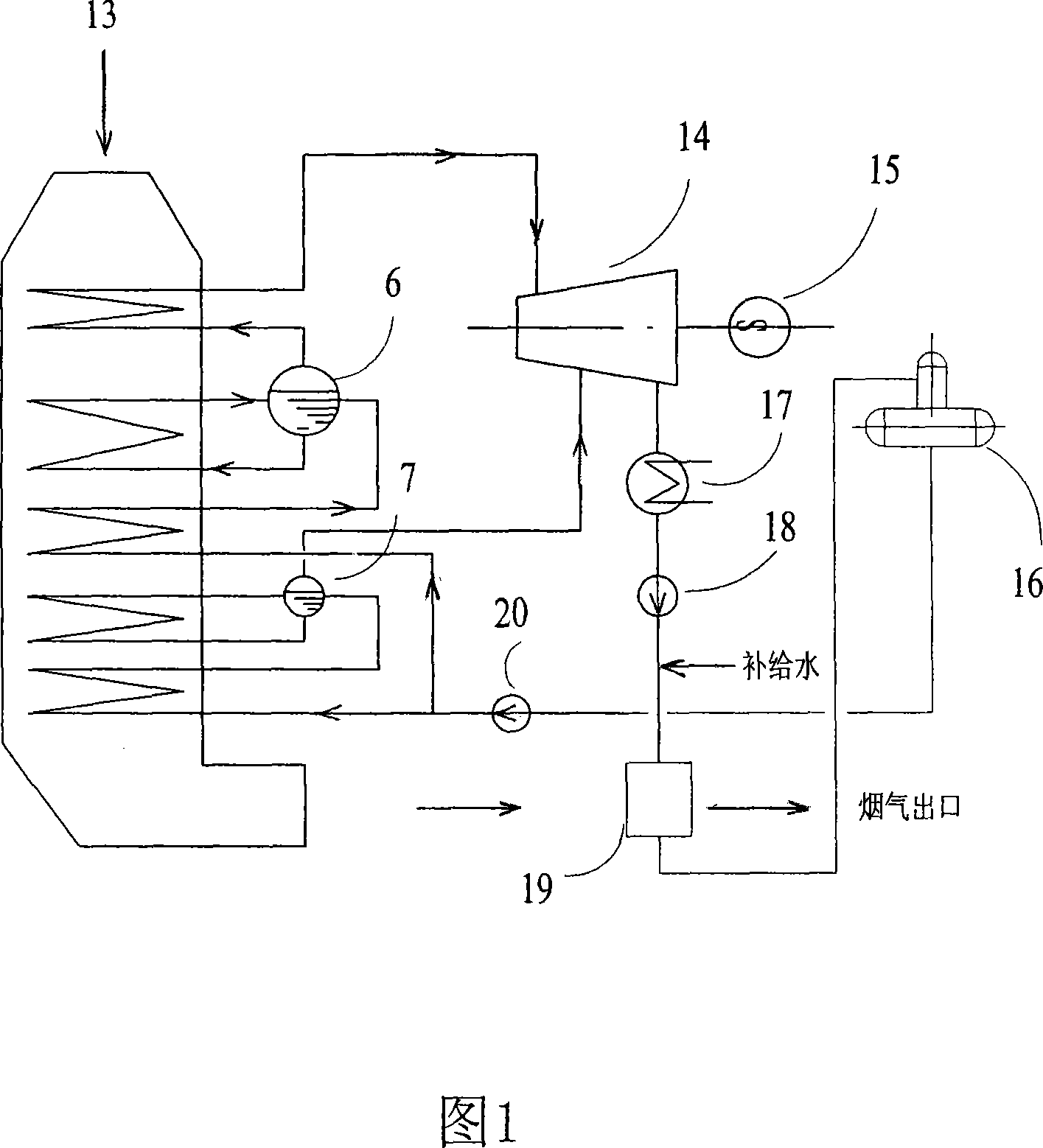

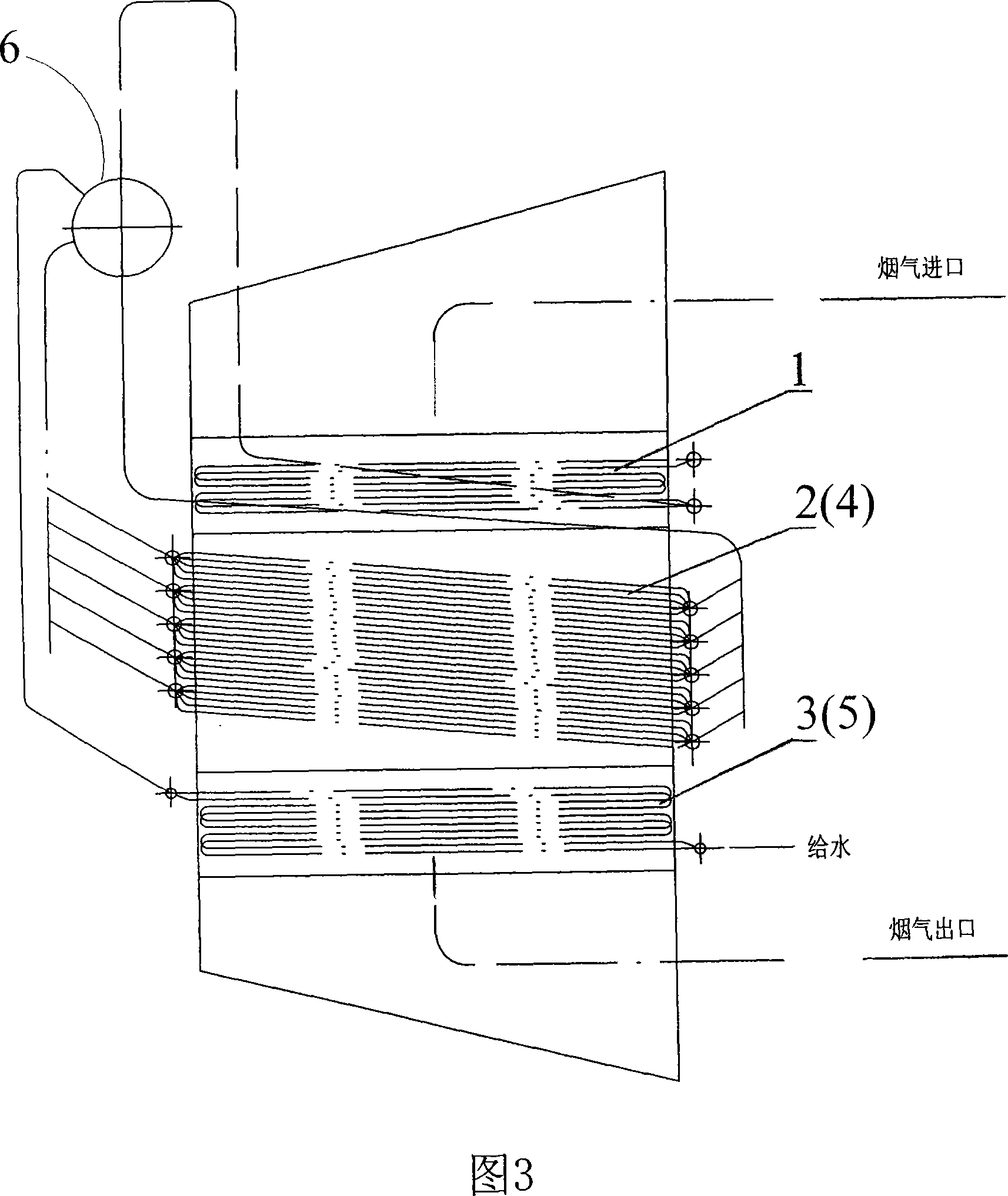

[0041] Dual-pressure system: a dual-pressure single-stage supplementary steam system using a supplementary steam turbine. The waste heat boiler is equipped with a superheater 1, an evaporation zone 2, a low-pressure evaporation zone 4, a soft water heater (economizer) 3, and a low-pressure soft water heater (low pressure Economizer) 5, flue gas passes through superheater 1, evaporation zone 2, low pressure evaporation zone 4, soft water heater (coal economizer) 3, low pressure soft water heater (low pressure economizer) 5 from top to bottom. The sintering waste heat boiler produces two kinds of steam with different parameters, one is main steam and the other is low-pressure supplementary steam. Due to the low-pressure evaporation section, the low-pressure steam pressure is 0.55MPa, the saturation temperature of the low-pressure steam is 162°C, and the exhaust gas temperature can drop to about 110°C.

Embodiment 2

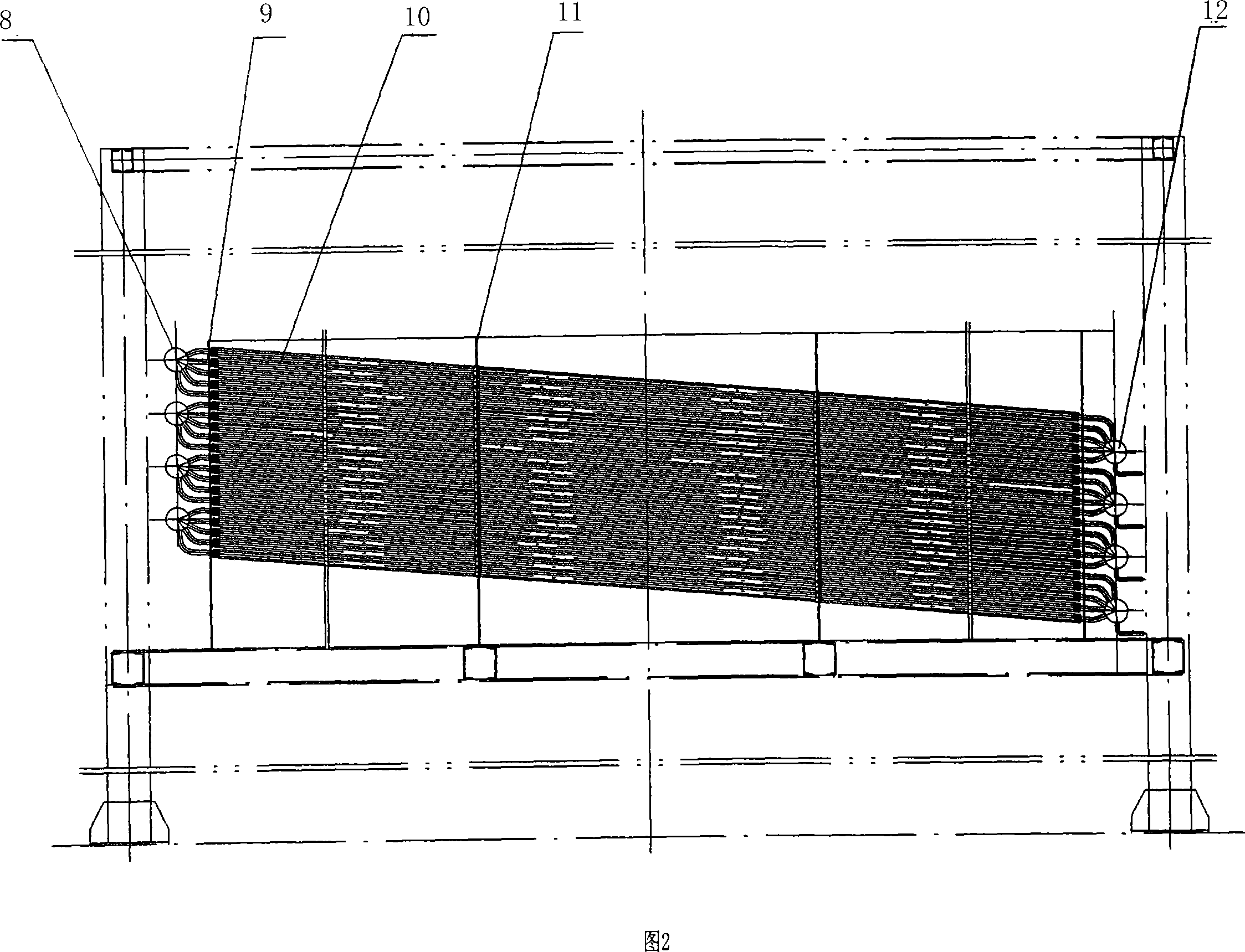

[0043] In Fig. 2, the steam-water mixture produced in the evaporation zone 2 is collected into the upper header 8 and enters the waste heat boiler drum 6 through the outlet pipe, and the water supply in the evaporation zone 2 is distributed to the lower header 12 by the steam drum 6 through the downcomer. , thus forming a reliable water circulation loop. The steam drum 6 separates the steam-water mixture, and the saturated steam enters the superheater 1 to be heated into superheated steam. The heating surfaces of the economizers 3 and 5 adopt the structure of spiral finned tubes 10, and the feed water enters the steam drums 6 and 7 after being heated.

[0044] In Fig. 3, the evaporation section 2 is designed as a lantern tube structure, that is, the upper and lower headers 8, 12 and the convection tube bundle 10 structure.

Embodiment 3

[0046] A low-temperature exhaust gas waste heat boiler with a sintered cooler, including a superheater, an evaporation zone, a low-pressure evaporation zone, an economizer, and a low-pressure economizer. There are connecting flues and water vapor pipes between the equipment. The waste heat boiler adopts a vertical layout as a whole. Tube box structure, the boiler tube box is equipped with superheater 1, evaporation area 2, low pressure evaporation area 4, economizer 3 and low pressure economizer 5 from top to bottom, among which the evaporation area and low pressure evaporation area are equipped with multiple Group evaporator, the evaporator is placed obliquely in the flue, the inclination angle is 5°~15°; the evaporator is a lantern tube structure, the evaporator is equipped with an upper header, a lower header and a convection tube bundle, the upper and lower headers The staggered convection tube bundles are formed by longitudinal rows of spiral finned tubes. Each evaporator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com