A double flap biofuel stove

A bio-fuel and flap-type technology, which is applied to solid heating fuel, household stoves/stoves, lighting and heating equipment, etc., can solve the problems of large amount of burnt ash, poor airflow, and affecting combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

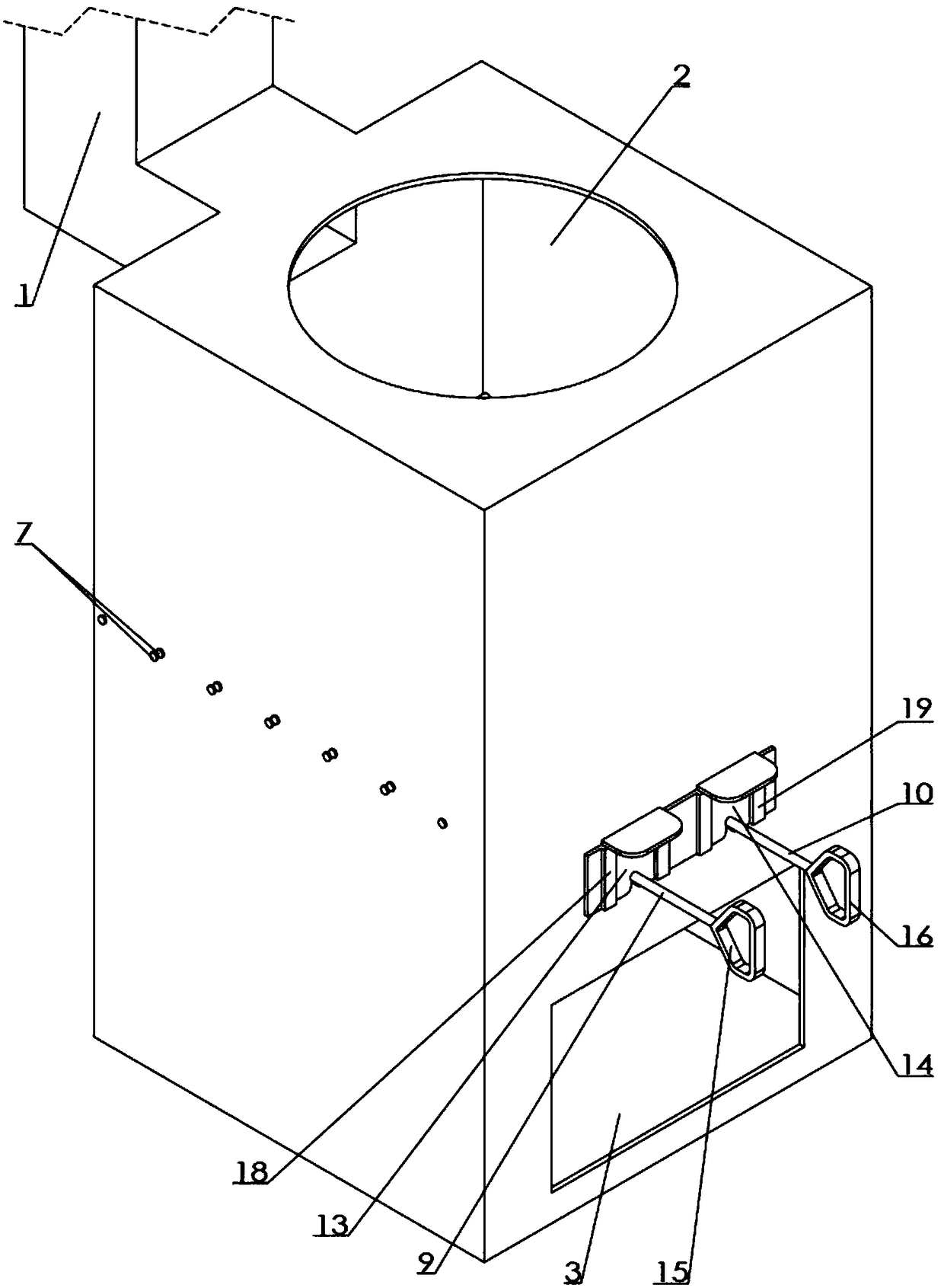

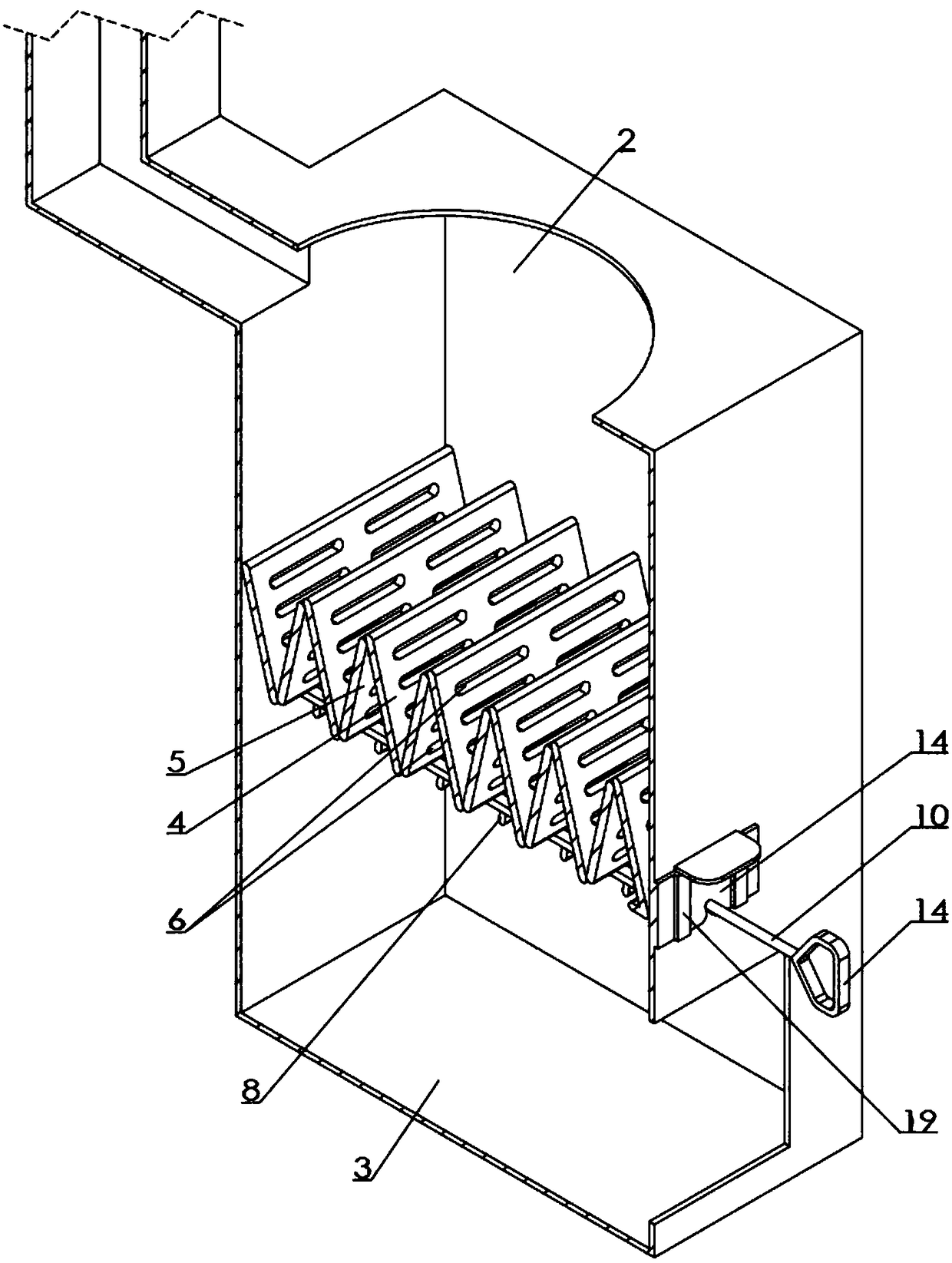

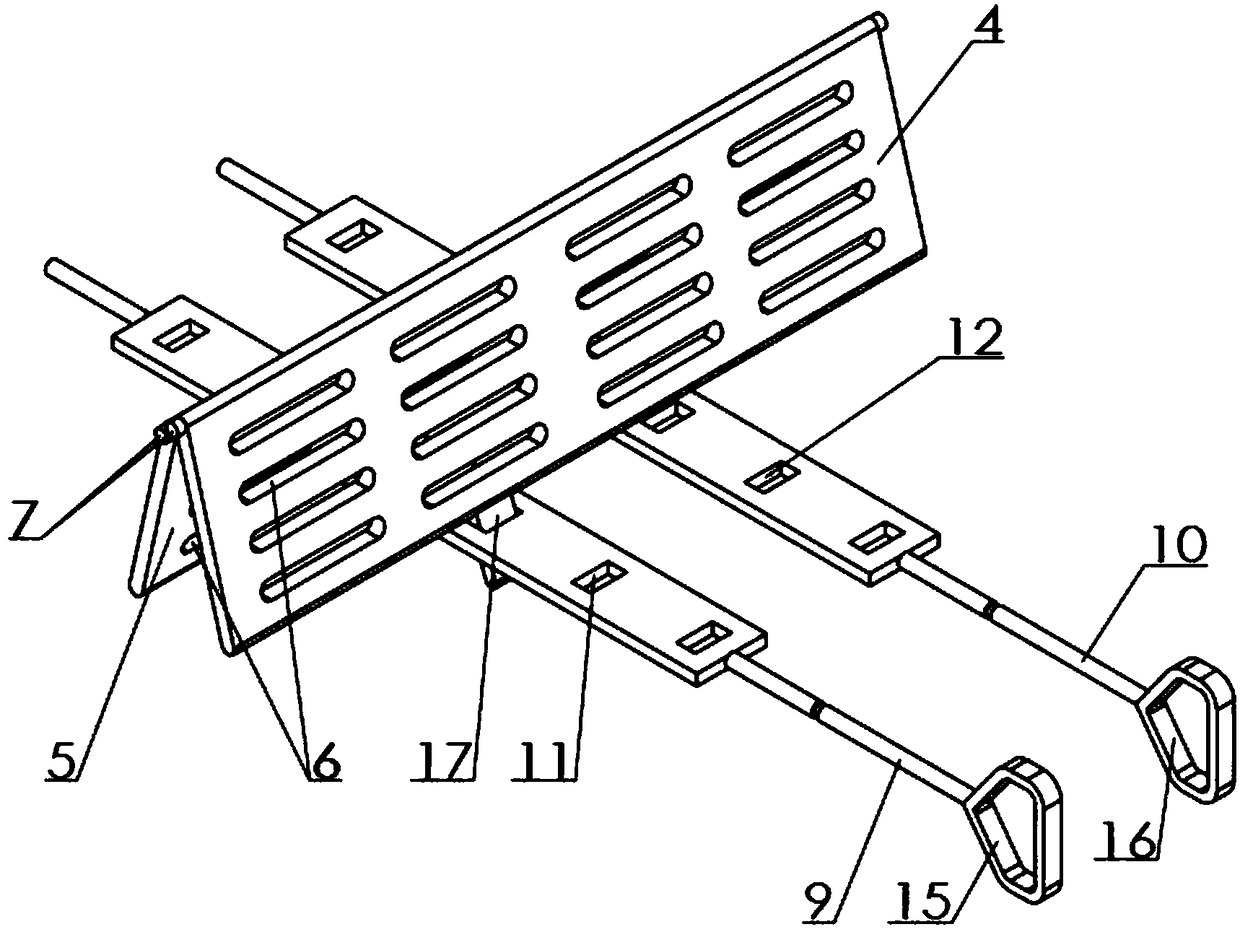

[0012] Examples of the present invention figure 1 , 2 , 3, the double-flap type biofuel furnace is provided with a furnace cavity and a smoke exhaust pipe 1, and the furnace cavity is provided with a combustion chamber 2 and an ash storage chamber 3, and the ash storage chamber is located at the bottom of the combustion chamber, between the ash storage chamber and the combustion chamber There is a fire grate in between; the fire grate is composed of a front flap 4 and a rear flap 5 arranged at equal intervals from the front to the rear. The front flap and the rear flap are equipped with ash drop holes 6, and the ash drop holes can be horizontal. Or vertically, the upper edge of the front flap is in contact with the upper edge of the rear flap on the adjacent side or maintains a gap of less than one centimeter, and the lower edge of the front flap is in contact with the lower edge of the rear flap on the other adjacent side. Contact or keep a gap of less than one centimeter, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com