Multi-purpose hole head for screwdriver

A technology for hole heads and hole formers, applied in the direction of drill bits, drill pipes, casings, etc., which can solve problems such as affecting the entry of hole formers, excessive transmission capacity, and wear at joints, so as to enhance structural strength and facilitate connection operations , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

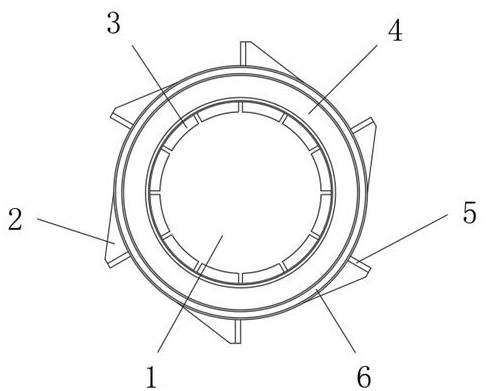

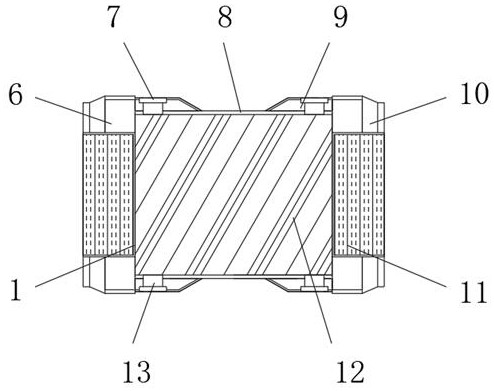

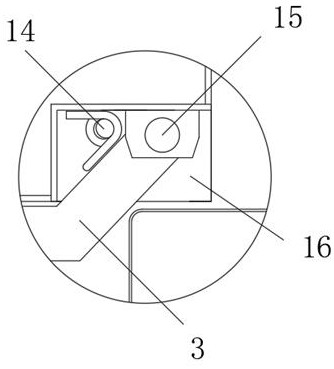

[0023] Please refer to figure 2 As shown, the present invention provides a multi-purpose hole head for a screwdriver, including a hole former joint 6, a connecting column 8 and a connecting rod joint 10, and the hole former joint 6 and the connecting rod joint 10 are respectively fixed on both ends of the connecting column 8, forming a hole. The end faces of the tool joint 6 and the connecting column 8 are provided with mounting holes 1, the inner wall of the mounting hole 1 is provided with an internal thread 11, and both sides of the hole former joint 6 and the connecting rod joint 10 are provided with bolt holes 13. The outer wall of the port of the hole 13 is fixedly connected with a reinforcing rib 9, and the reinforcing rib 9 is provided with a receiving slot 7 at the outer port of the bolt hole 13. The hole former and the connecting rod are respectively connected with the multi-purpose hole head of the screwdriver. The connection operation is convenient, using bolts Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com