Patents

Literature

38results about How to "Easy to discharge ash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

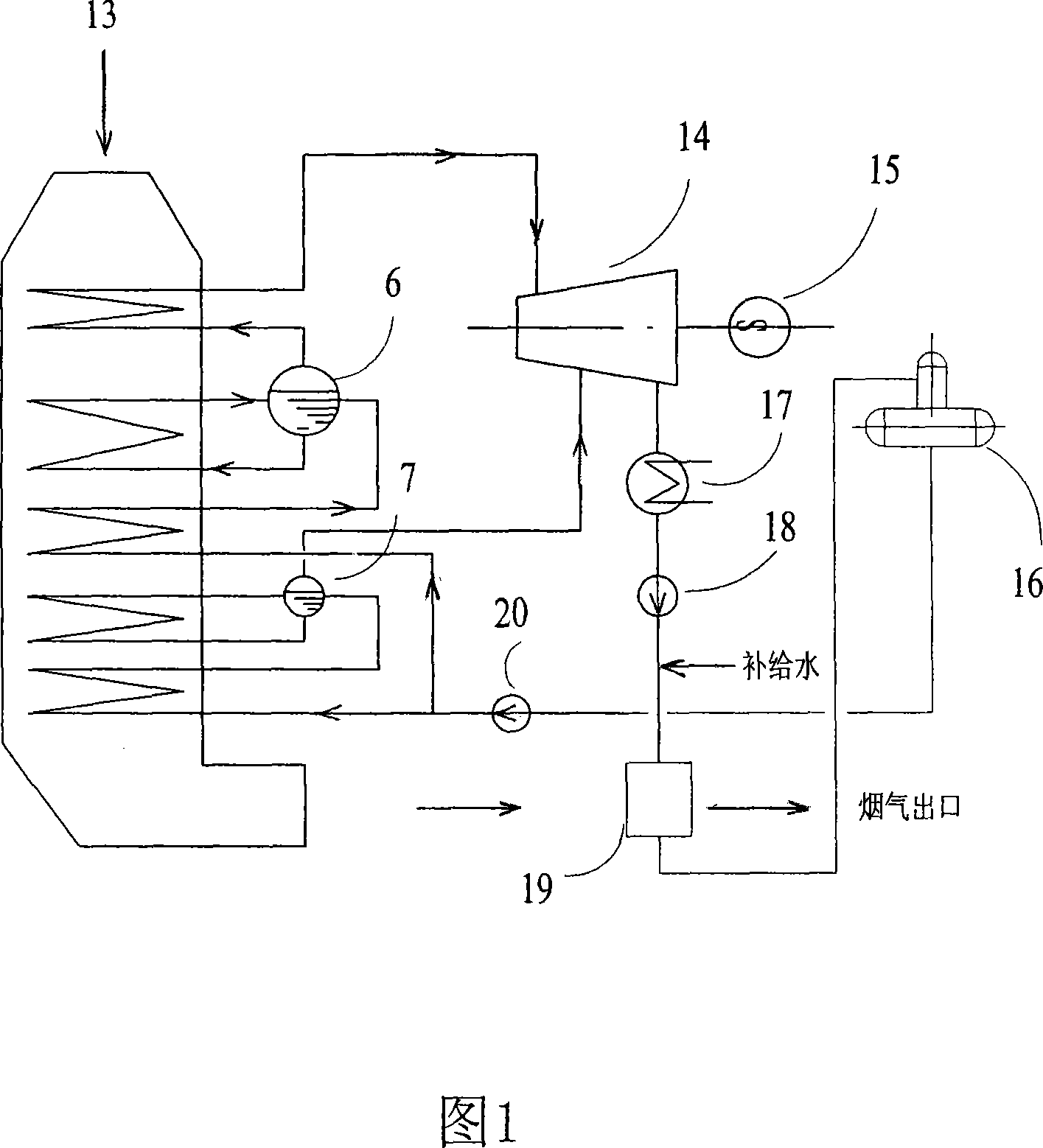

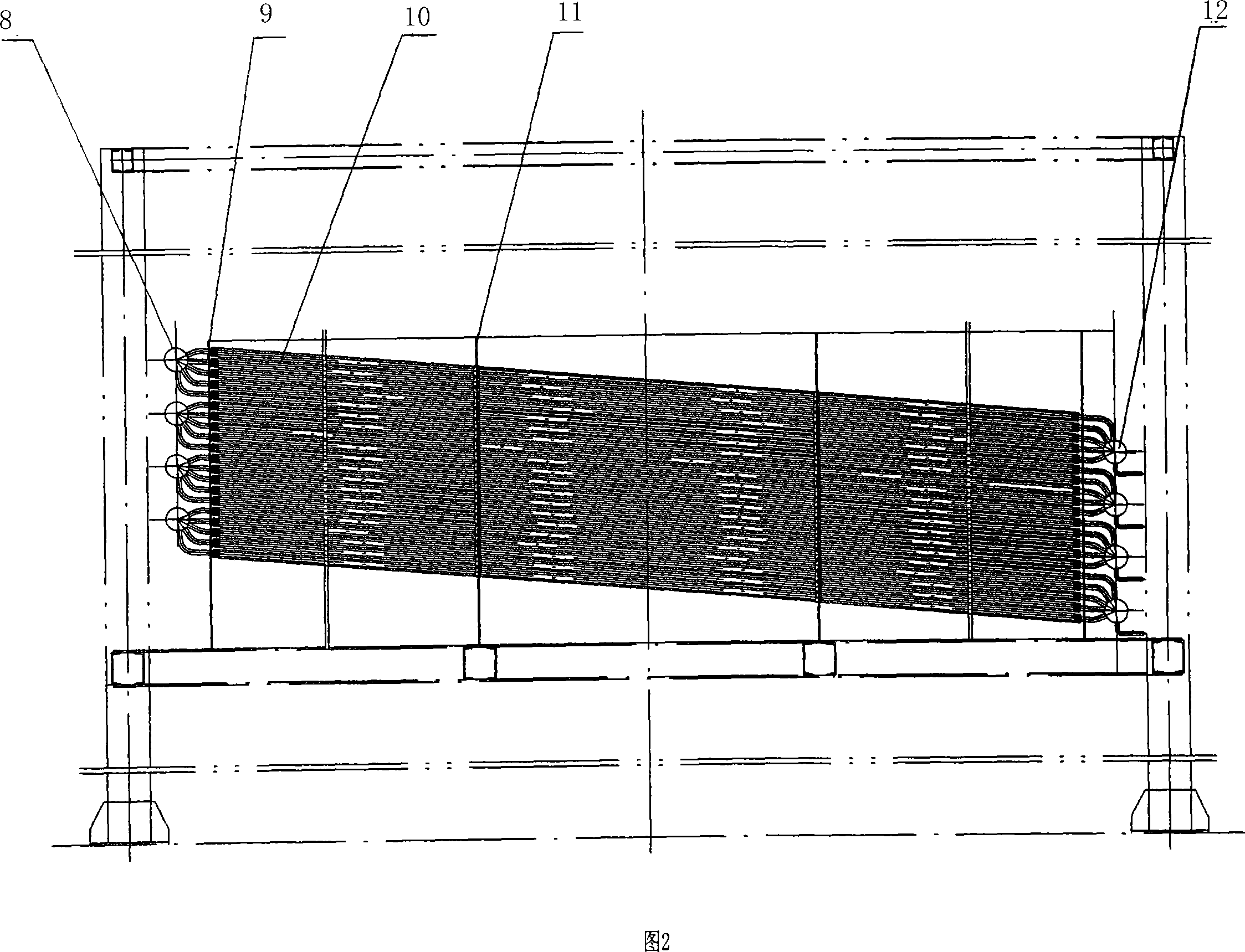

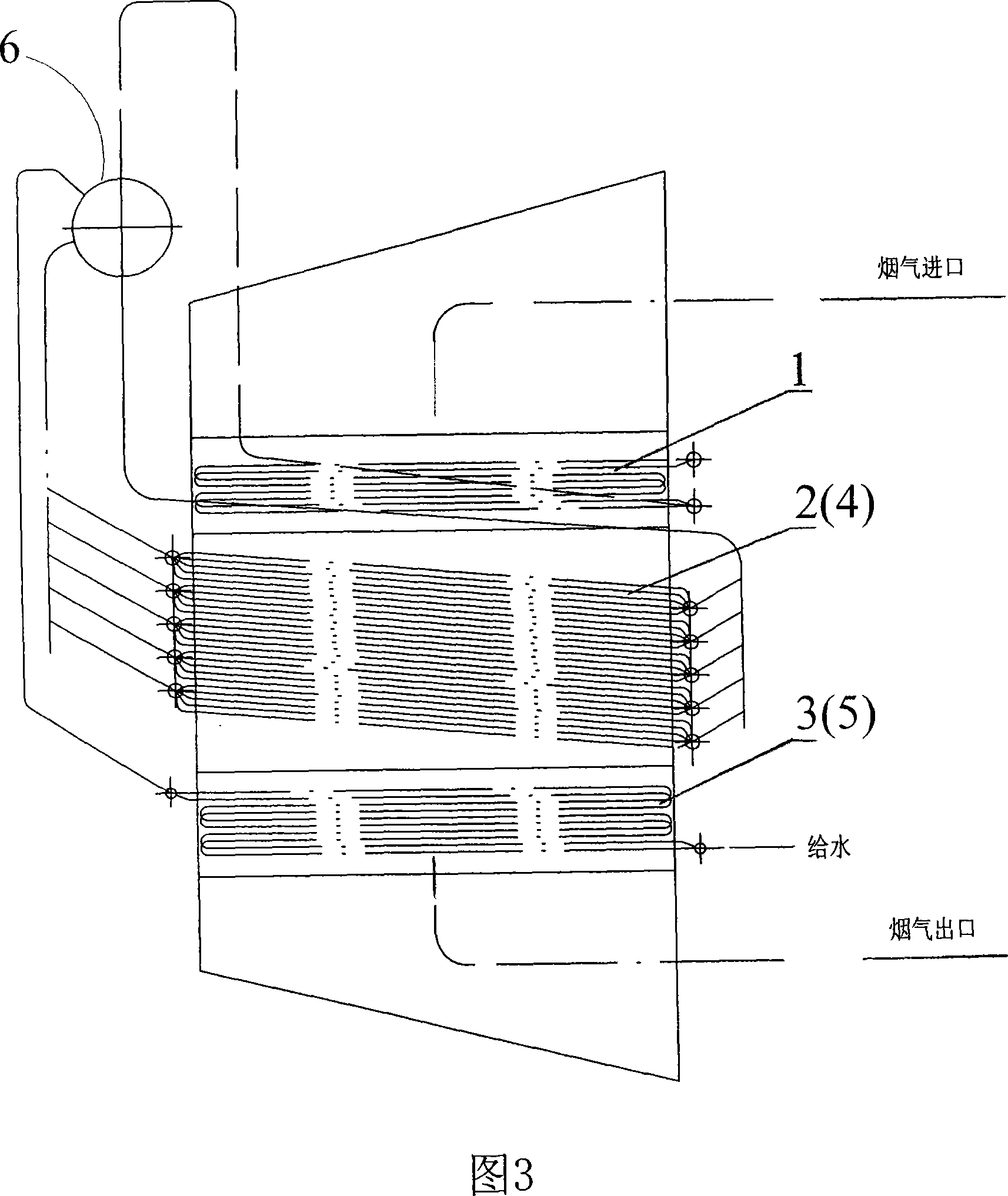

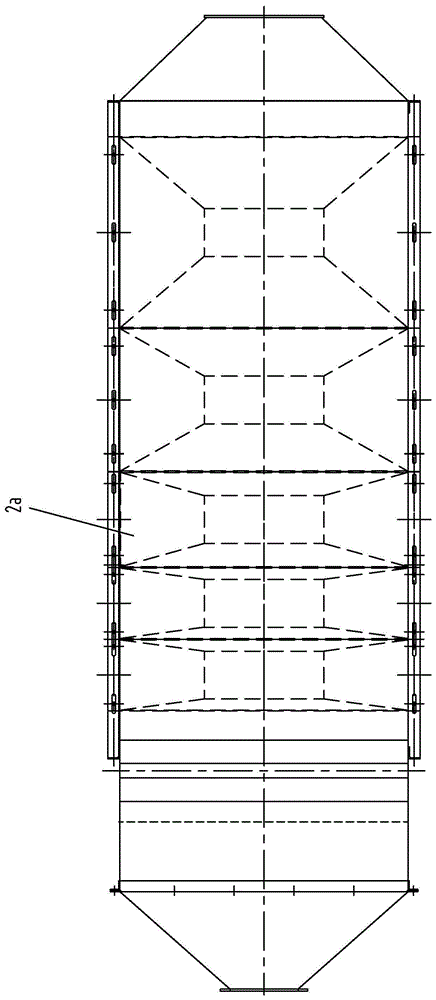

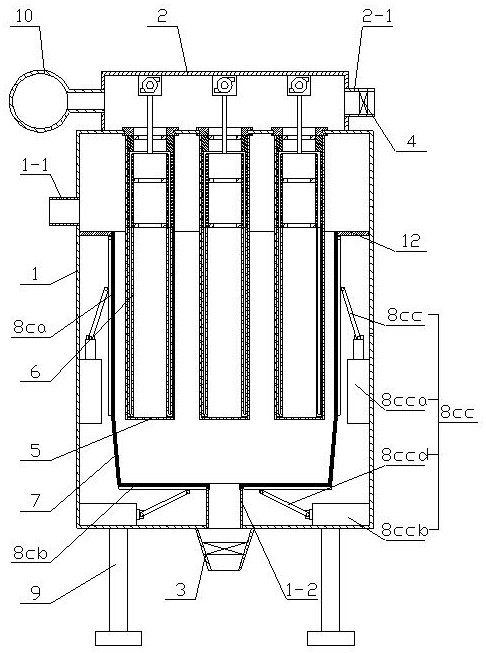

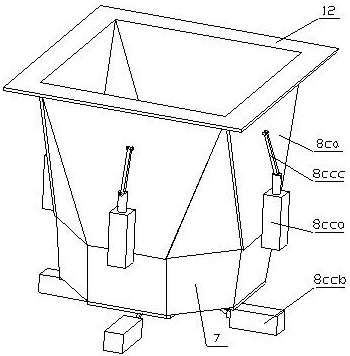

Sinter cooler low temperature waste gas residual heat boiler and power generating system thereof

InactiveCN101021305AEasy to discharge ashSmall footprintSteam boilersSteam boilers componentsWhole bodyEvaporation

The present invention provides an exhaust-heat boiler capable of effectively utilizing low-temperature heat transmission to make power generation and its power generation system. Said exhaust-heat boiler whole body adopts vertical type arrangement and tube-box type structure, in the boiler tube-box interior are successively set super heater, evaporation zone, low-pressure evaporation zone, coal economizer and low-pressure coal economizer from top to bottom, in which the evaporation zone and low-pressure evaporation zone have several groups of evaporators, these evaporators are obliquely placed in smoke flue, their inclination angle is 5 deg-15 deg. Said invention also provides the concrete structure of every evaporator, and provides the working principle of said exhaust-heat boiler and its power generation system and their concrete operation method.

Owner:JIANGSU DONGJIU HEAVY IND

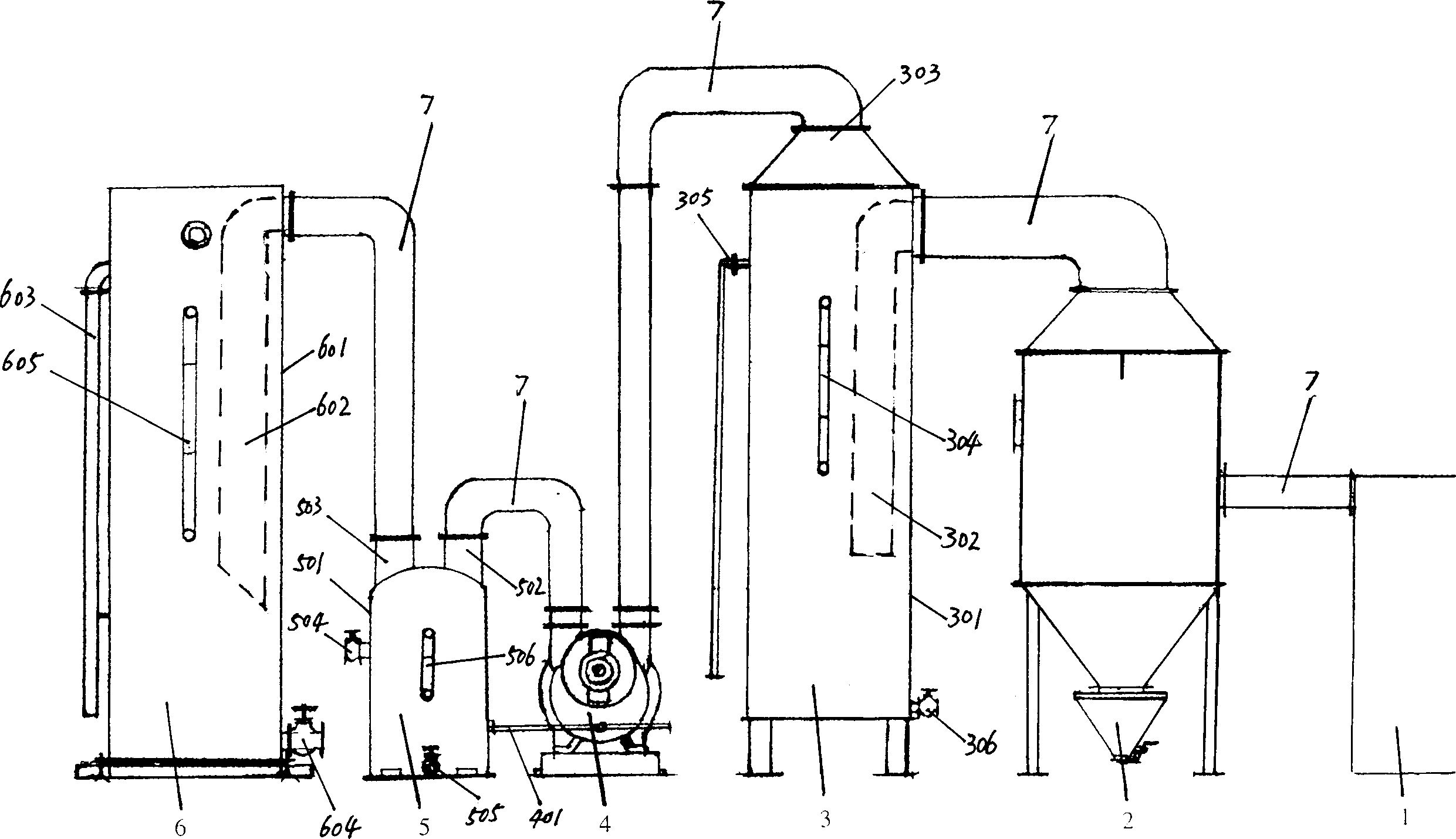

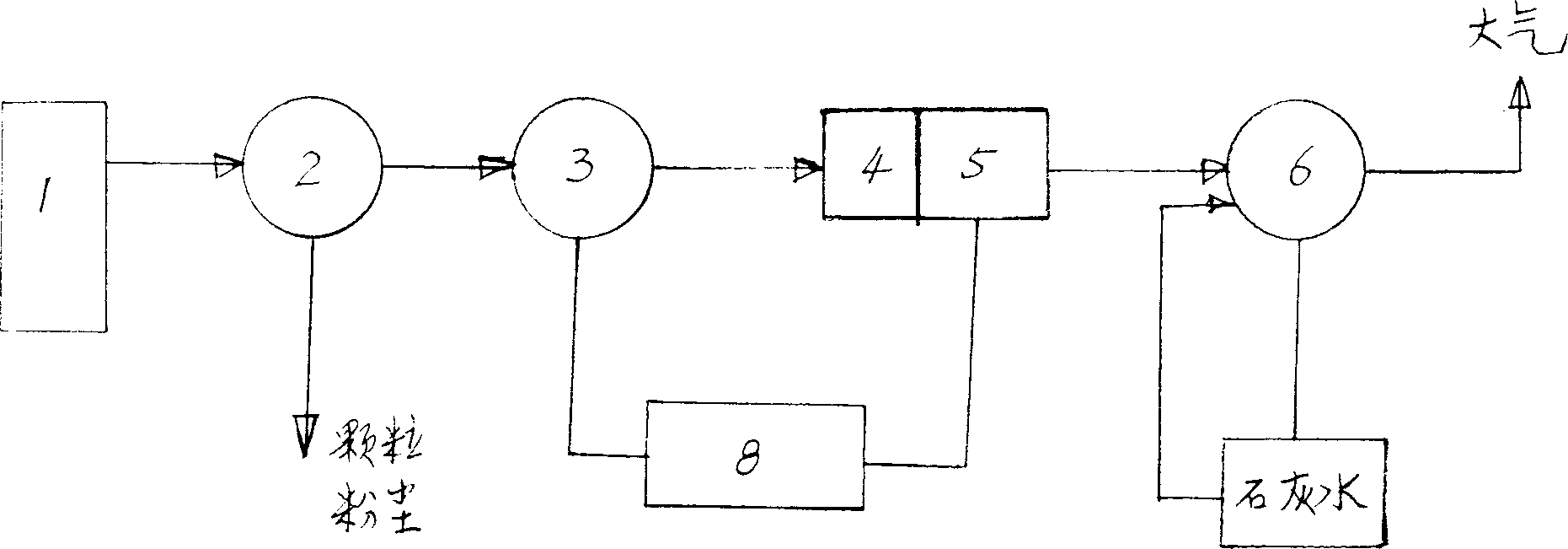

Apparatus and method for removing smoke of boiler

InactiveCN1395979AExtended service lifeEasy to discharge ashCombination devicesImpellerChemical reaction

A smoke cleaner for boiler and its cleaning method are discloosed. The smoke from boiler flows through cyclone dust collector for removing dust, hydraulic draught fan, wet dust for further removing dust and sulfuride, and gas-water separator for separating water from gas. The water containing dust powder flows in depositing pool. The gas flows into lime milk in desulfurizer to obtain chean gas for exhausting. Its advantages are high effect and low corrosion to equipment.

Owner:张福生

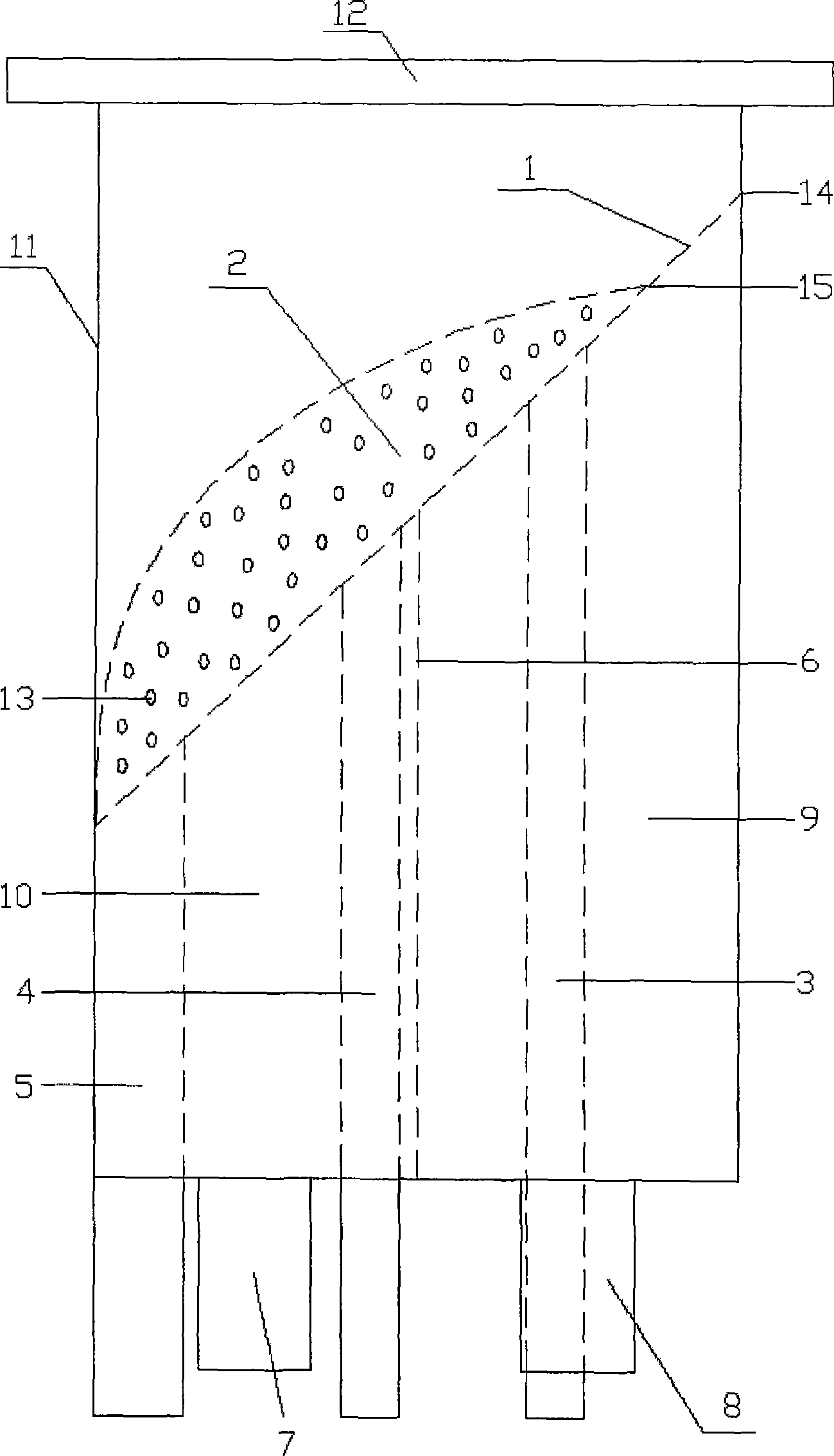

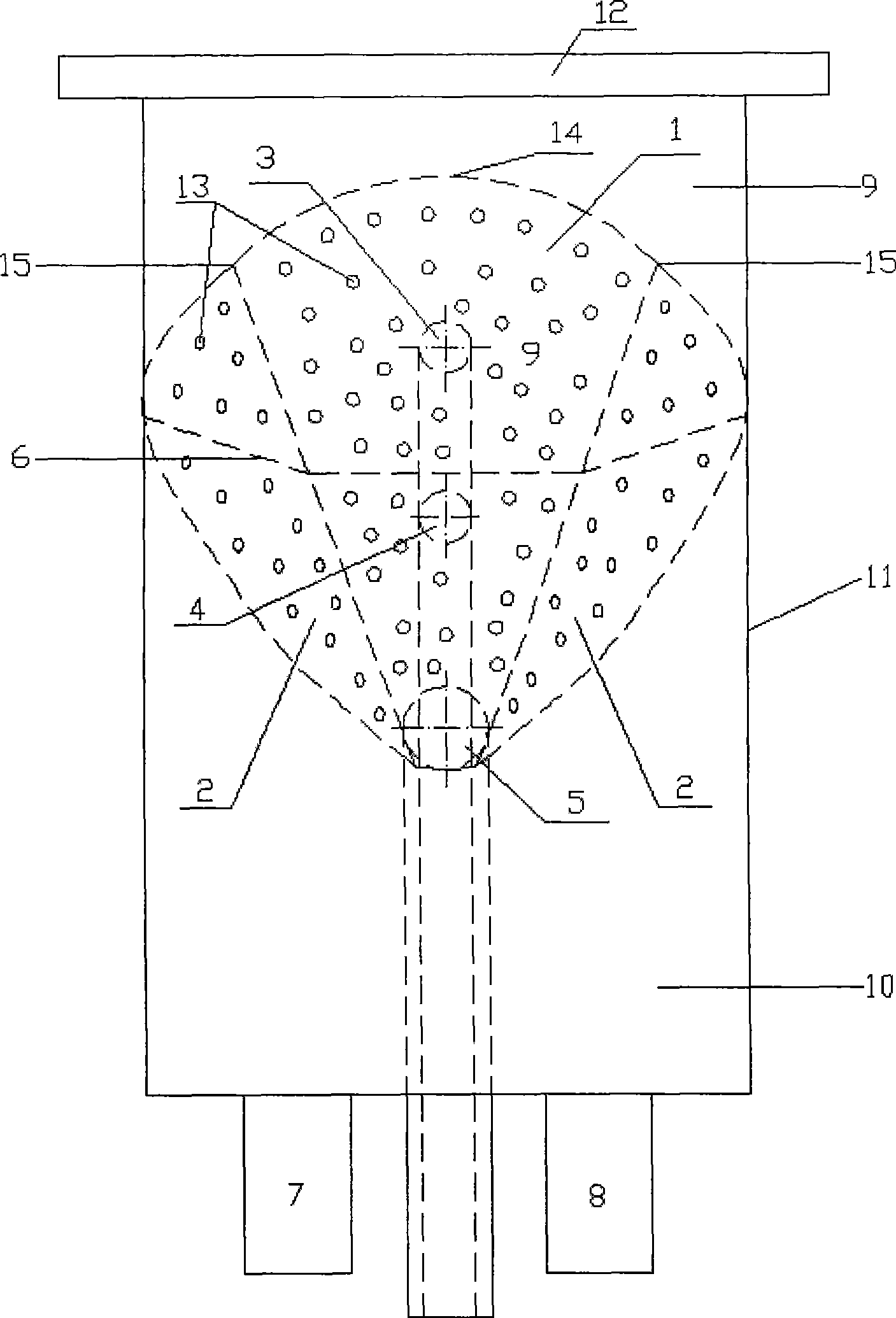

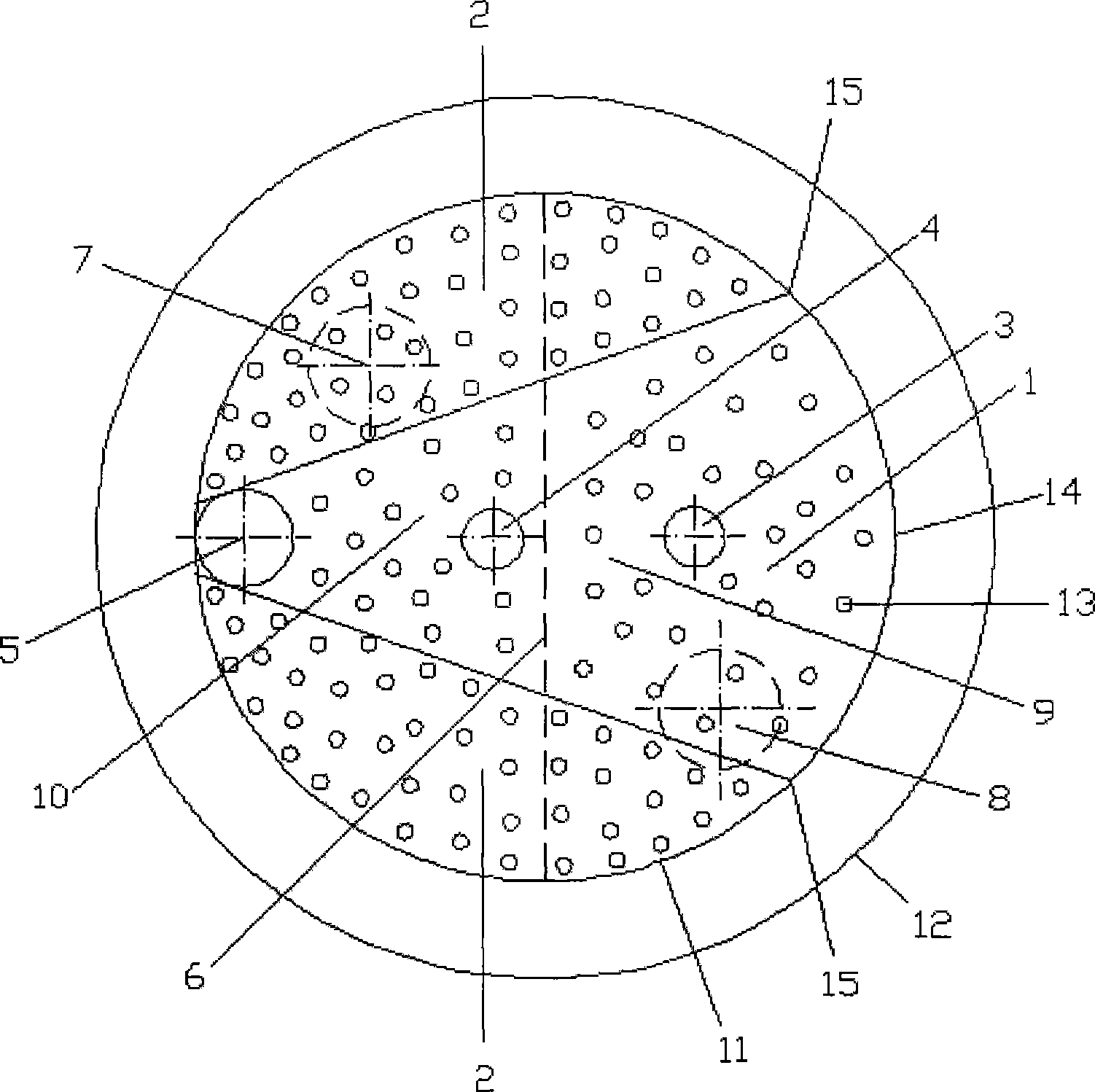

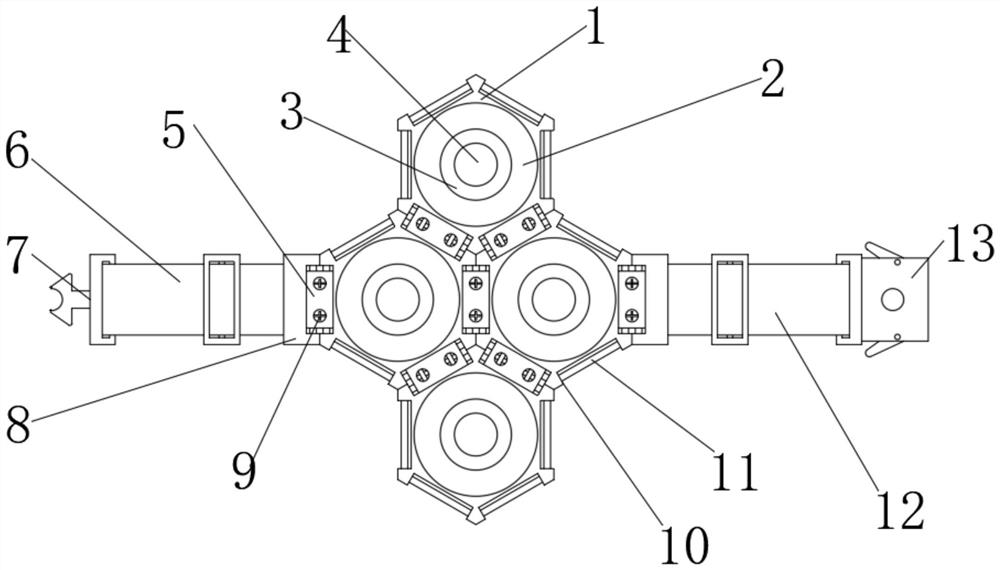

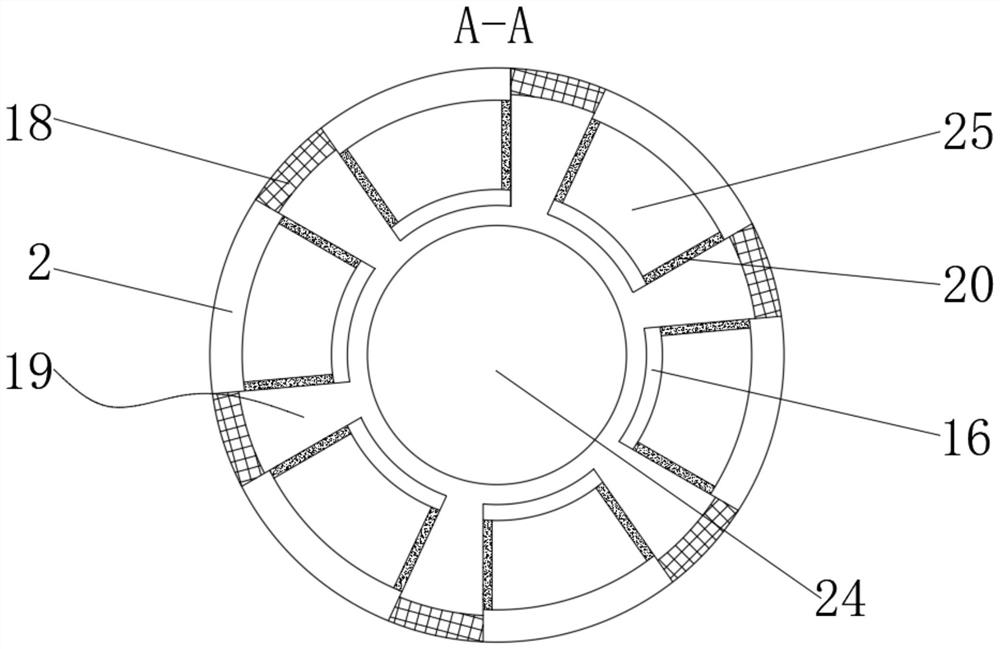

Gas distribution device

ActiveCN101519606AEnhanced lateral mixingExtended stayCombined combustion mitigationGranular/pulverulent flues gasificationEngineeringGas chamber

The invention relates to a gas distribution device which comprises a main board (1), lateral wings (2), a jet pipe ash-exhausting pipe (5), a baffle (6), a gas inlet pipe gas chamber, a cylinder (11) and a flange (12). A gas distribution board is formed by the main board (1) and the lateral wings (2), and the main board (1) forming an angle of 25 degrees to 60 degrees with the horizontal direction is obliquely arranged in the cylinder (11) and is connected with the wall surface of the cylinder (11); vertical upward small holes (13) are respectively arranged on the main board (1) and the lateral wings (2), and the ash-exhausting pipe (5) is communicated with an ash-exhausting hole on the main board (1); two jet pipes (3) and (4) are arranged in the cylinder (11), and the centers are respectively arranged on two equipartition points which uniformly divide the diameter of the cylinder (11) after the diameter of the ash-exhausting pipe (5) is removed; one end of the jet pipe (3) and one end of the jet pipe (4) are communicated with the main board (1), and the baffle (6) which is arranged on a midline in the cylinder (11) divides the gas chamber into two gas chambers (9) and (10) which are communicated with two gas inlet pipes (7) and (8). The invention has the advantages of easy operation, high gasification efficiency and wide material range of application.

Owner:ENN SCI & TECH DEV

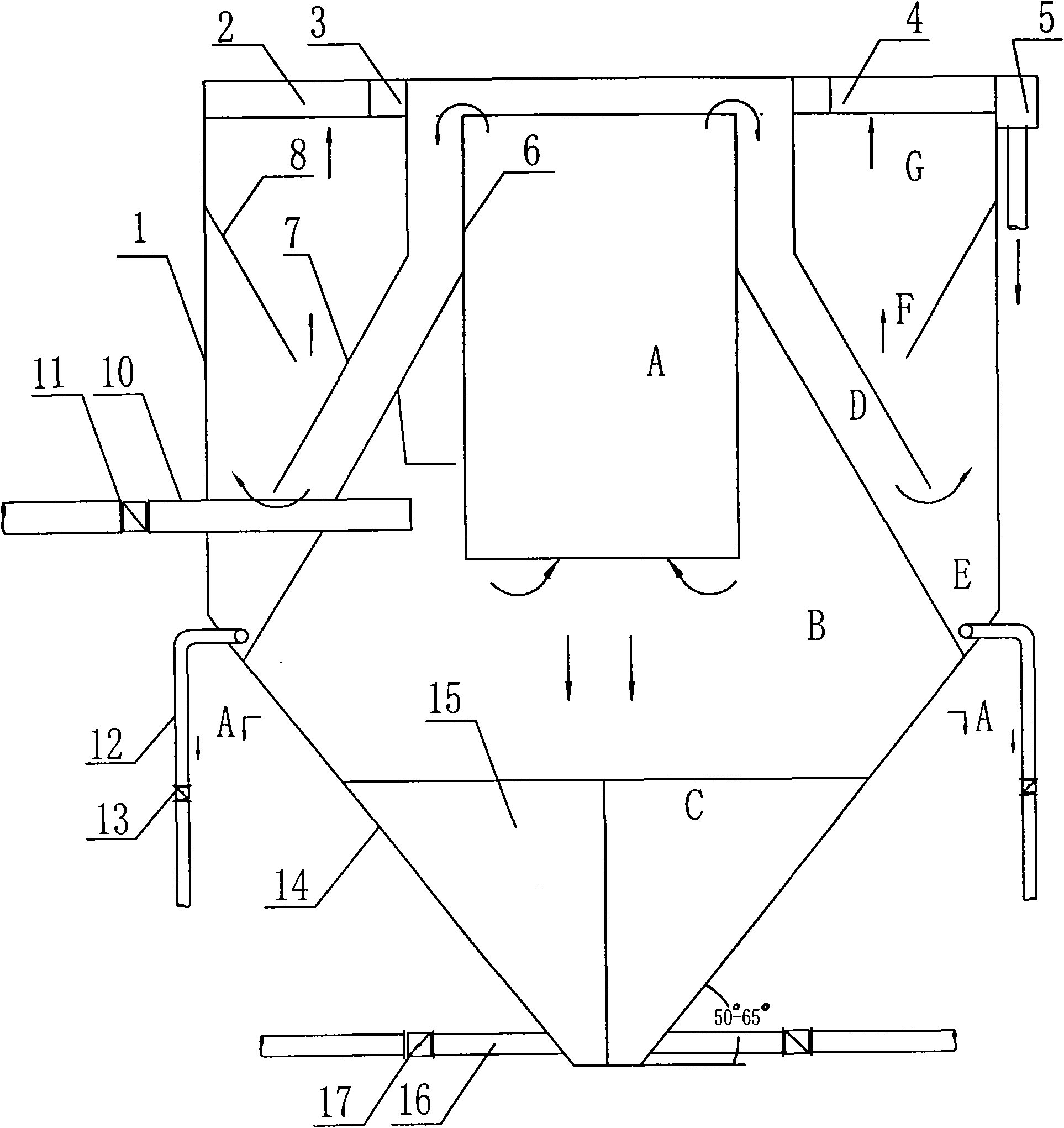

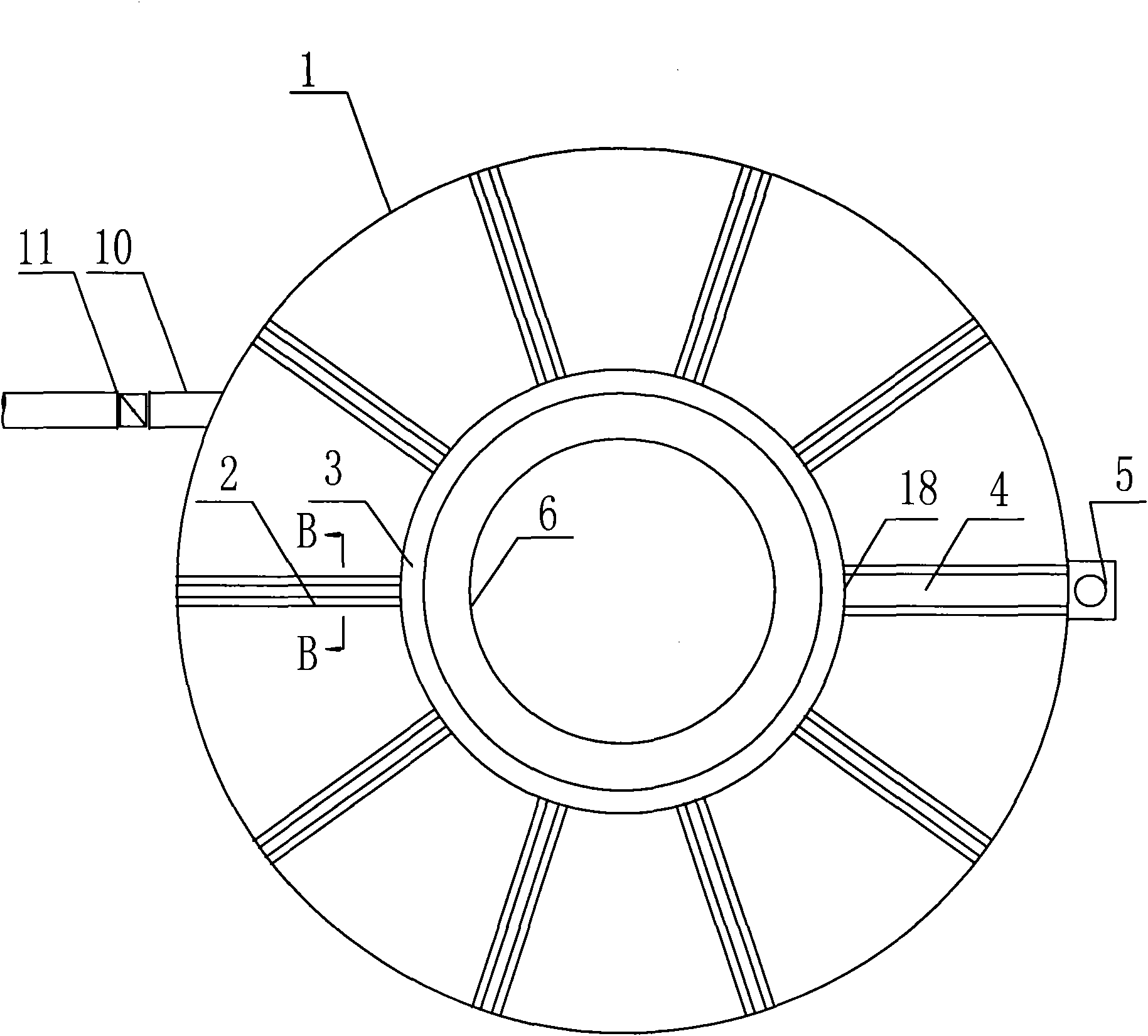

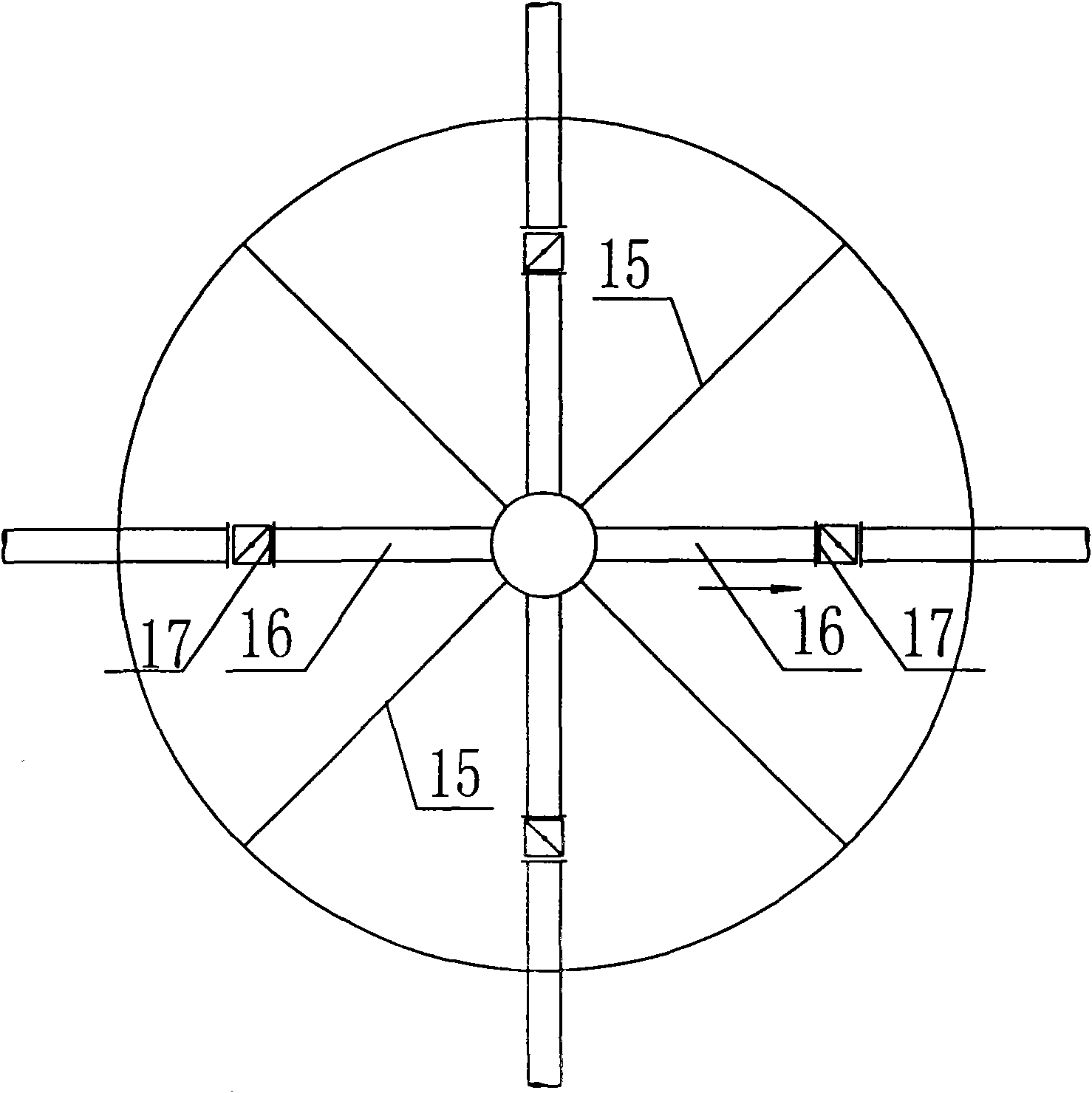

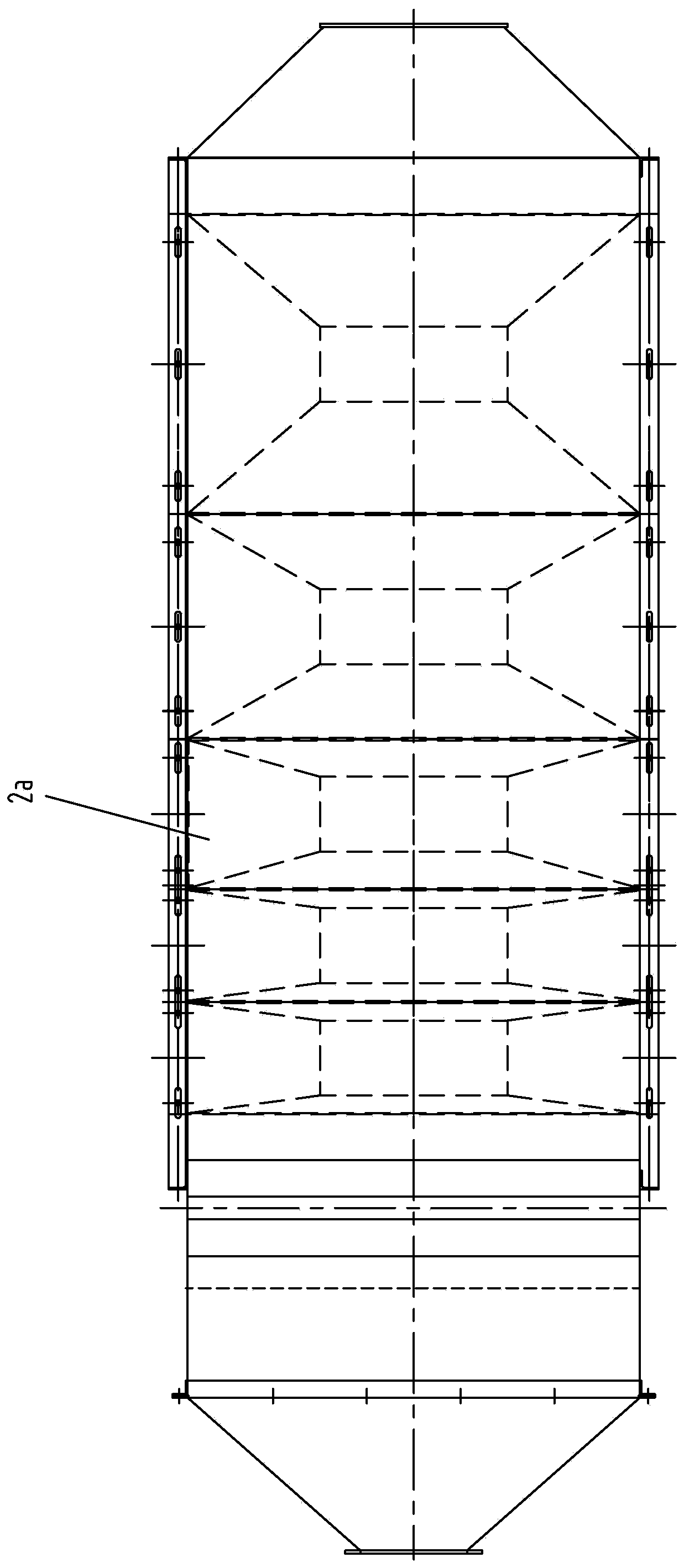

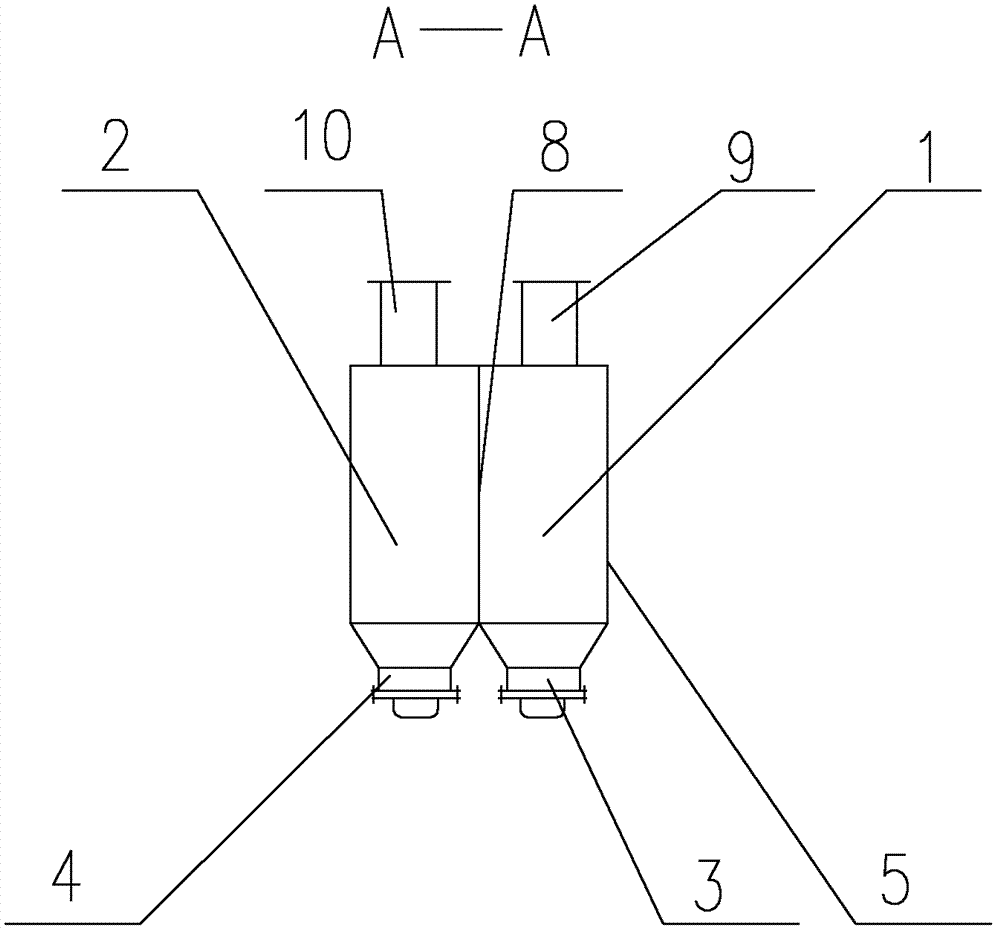

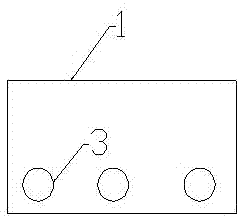

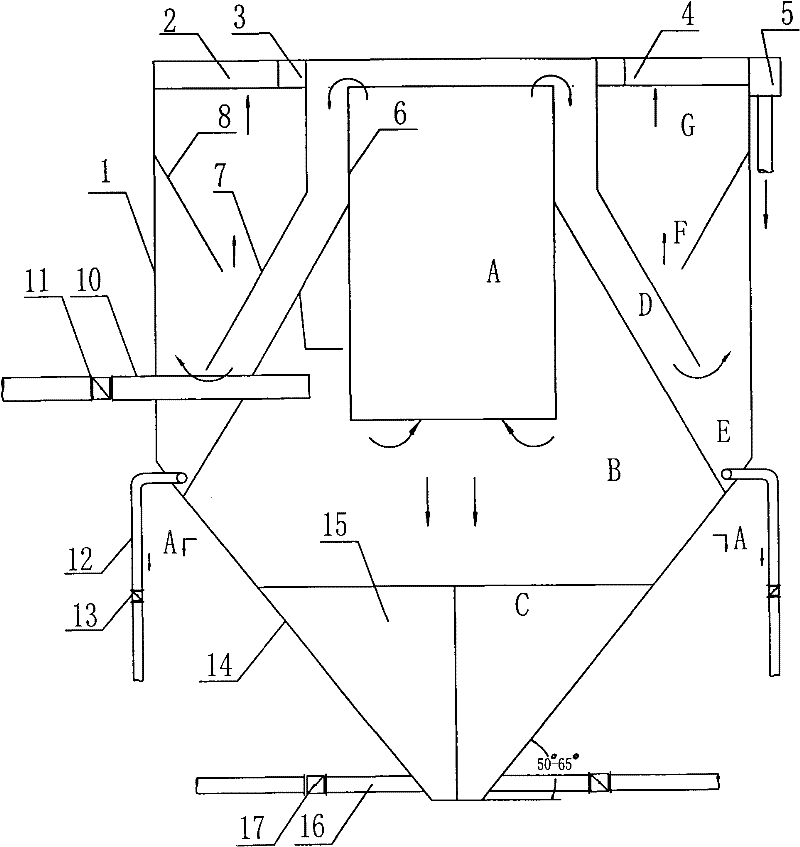

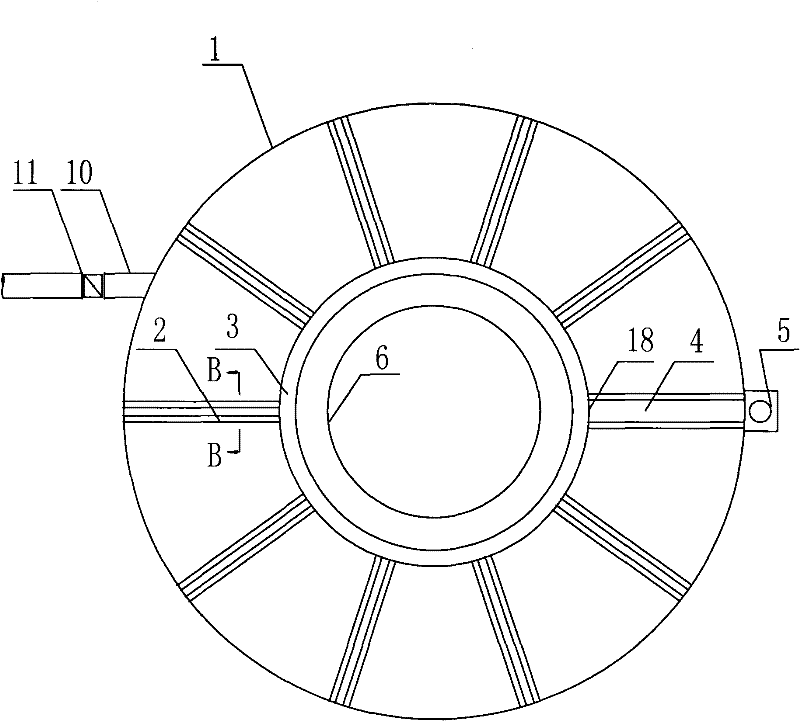

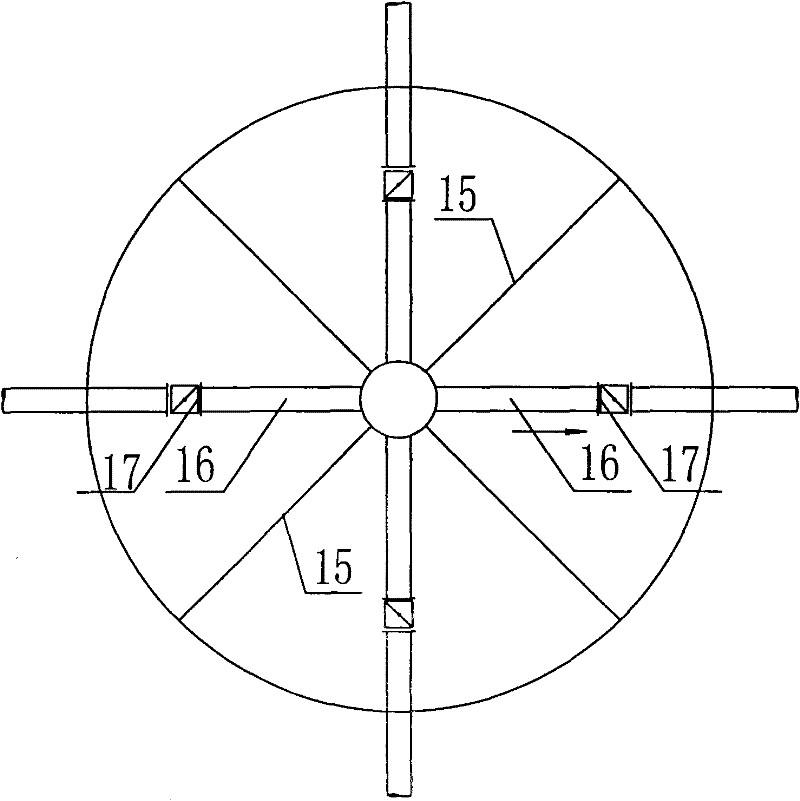

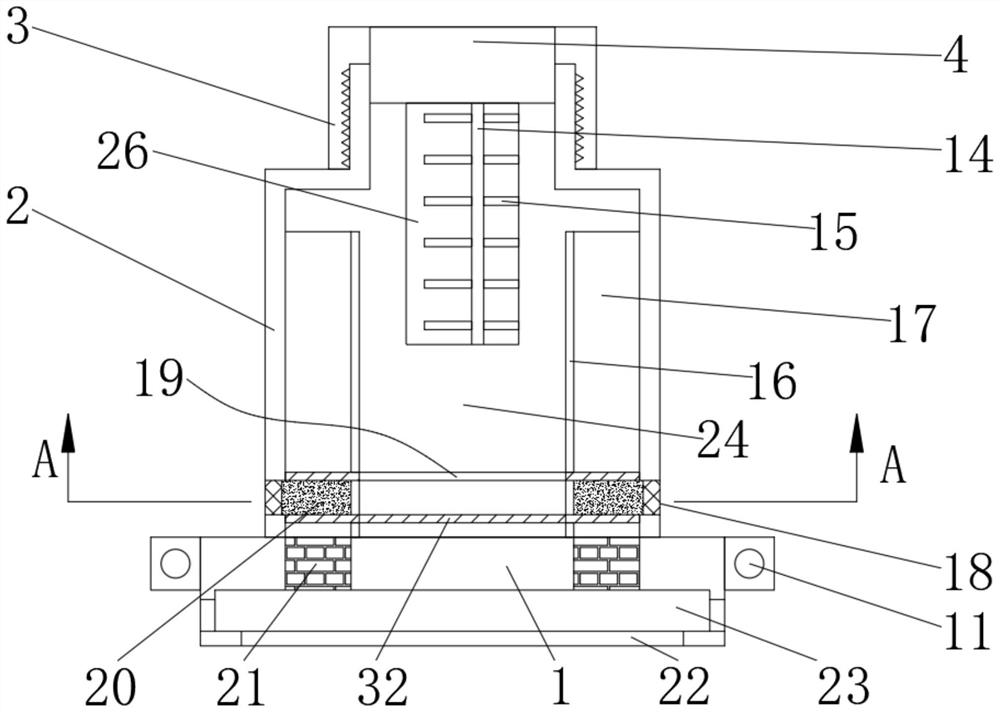

Cinder soaking water concentrating and separating tank

ActiveCN101612489AReduce energy consumption and operating costsGood for ash dischargeSedimentation settling tanksCinderEngineering

The invention relates to a concentration and separation processing facility for flushing cinder soaking water from a fuel electric plant, in particular to a cinder soaking water concentrating and separating tank which is mainly characterized in that a separated tapered cinder hopper (14) of the concentration and separation tank is arranged below a concentration and separation tank body (1) and is internally provided with a cinder separating plate (15); the middle part of the concentration and separation tank body (1) is provided with a straight reaction cylinder (6) which is a reaction region A on the upper part, a rotational flow settling region B in the middle and a first concentration region C at the lower part; the outer wall of the straight reaction cylinder (6) is fixedly connected with a tapered reaction cylinder (9); the concentration and separation tank body (1), the separated tapered cinder hopper (14) of the concentration and separation tank and the tapered reaction cylinder (9) forms a second concentration region E which is connected with a second cinder discharging pipe (12) and a valve (13) arranged on the second cinder discharging pipe (12); a flow guiding cylinder (7) is arranged outside the straight reaction cylinder (6) and forms a flow guiding region D together with the straight reaction cylinder (6) and the tapered reaction cylinder (9); a tapered cinder baffle (8) is arranged on the concentration and separation tank body (1), and a separation region F is formed between the tapered cinder baffle (8) and the flow guiding cylinder (7).

Owner:GANSU GOLDEN BRIDGE GRP CO LTD

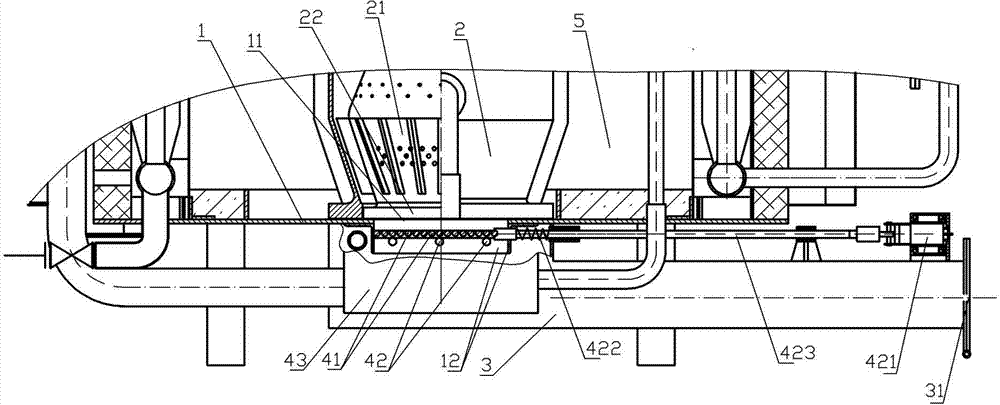

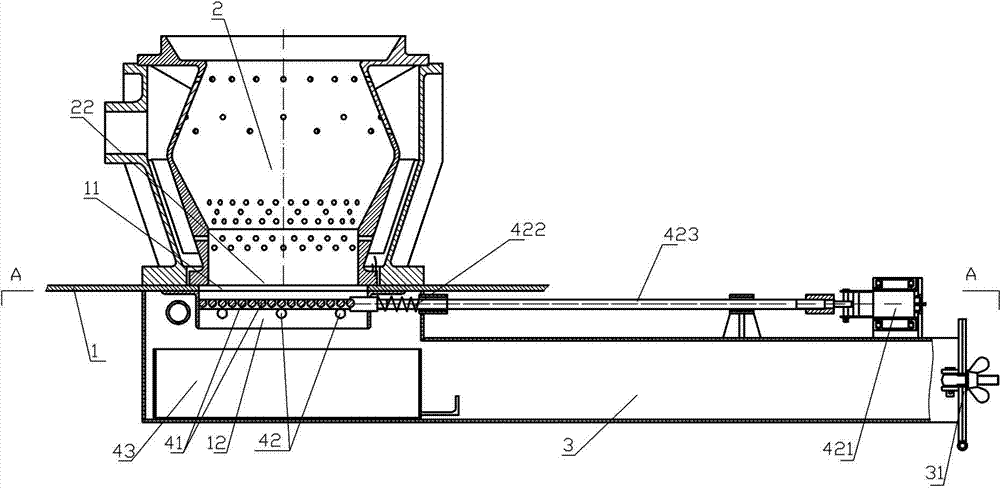

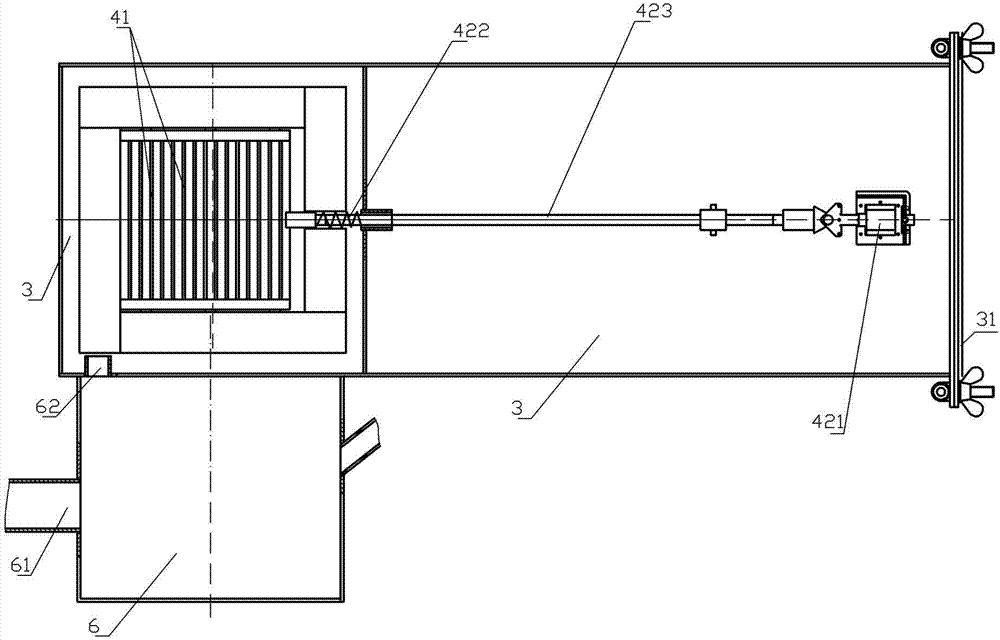

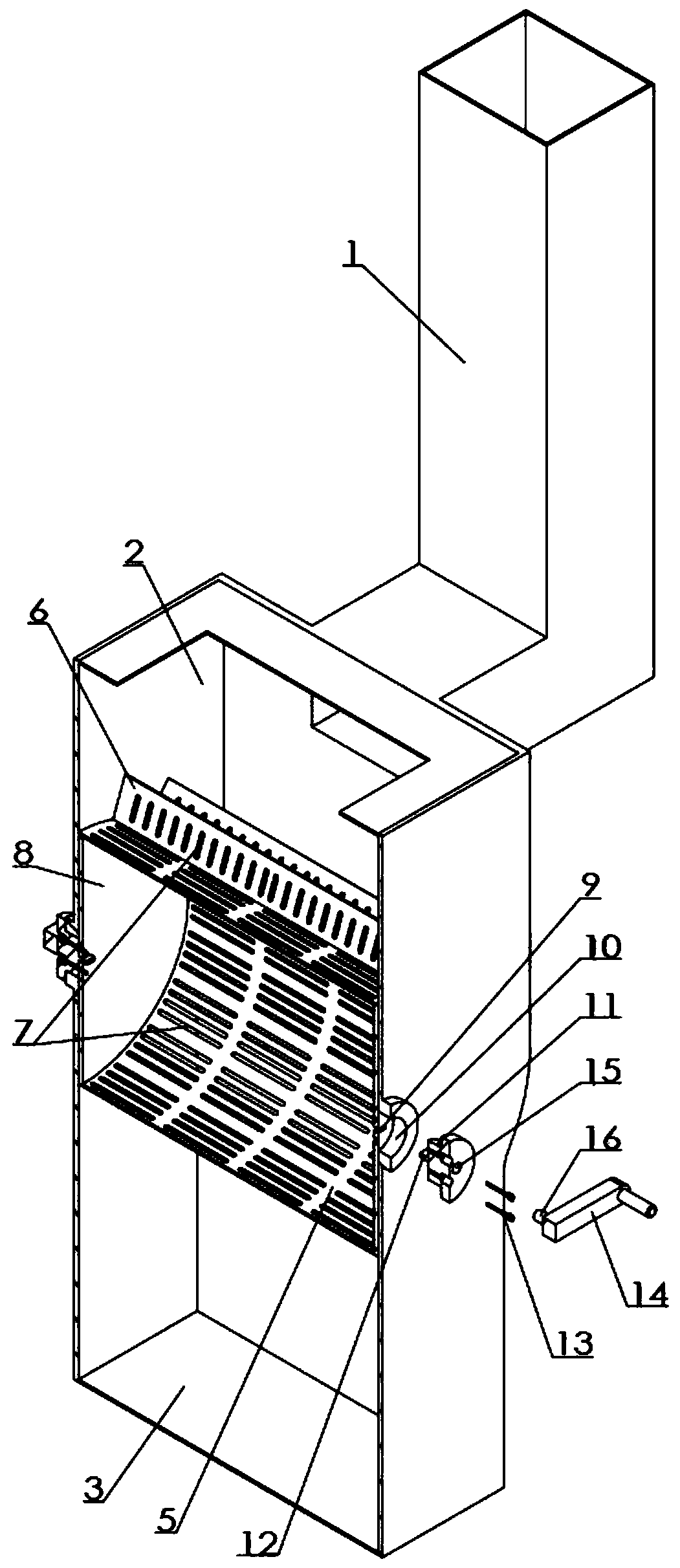

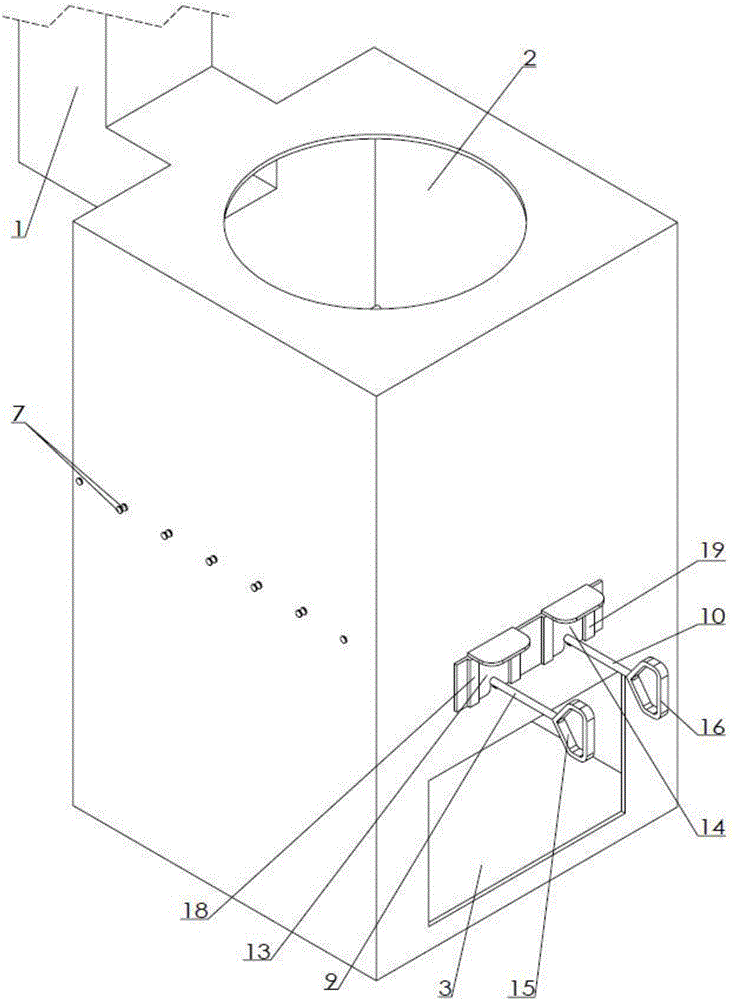

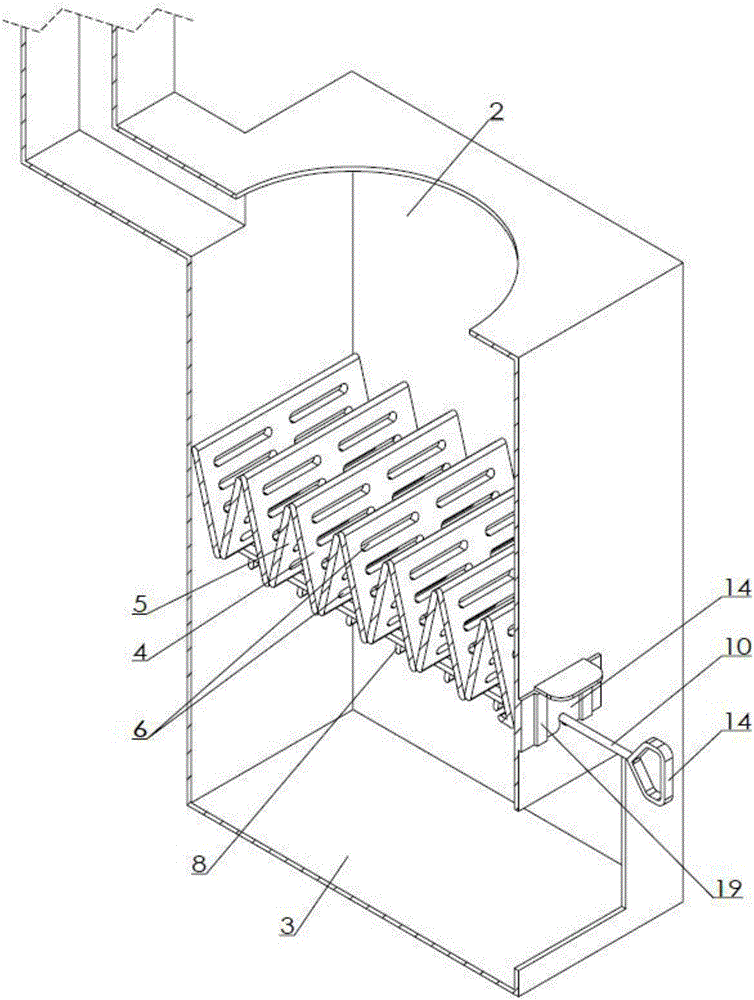

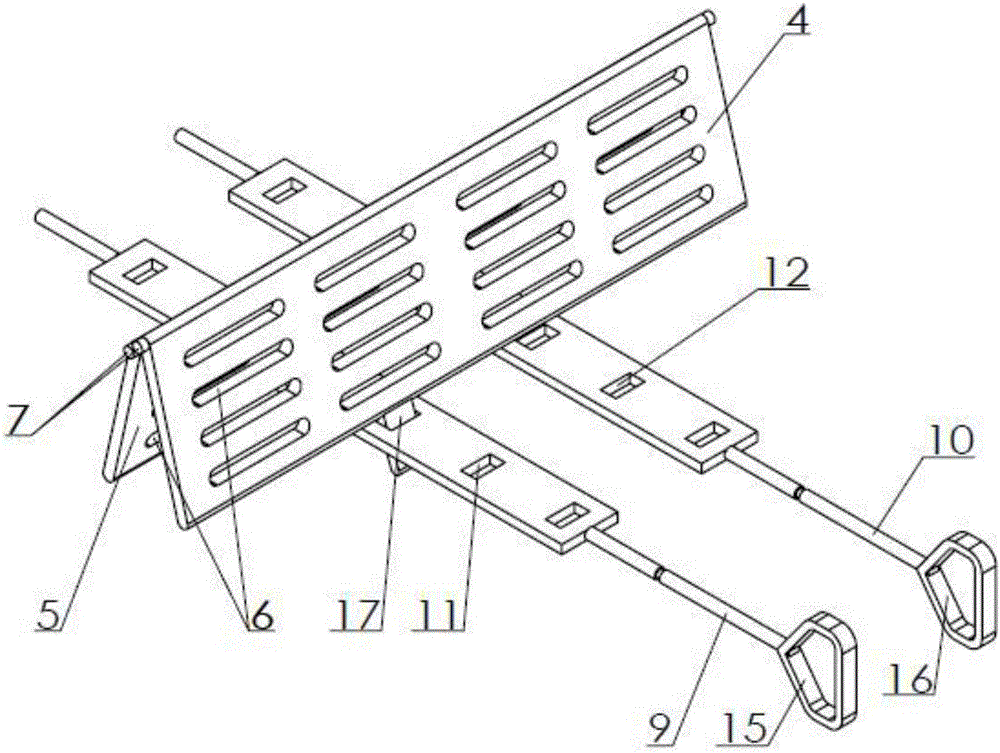

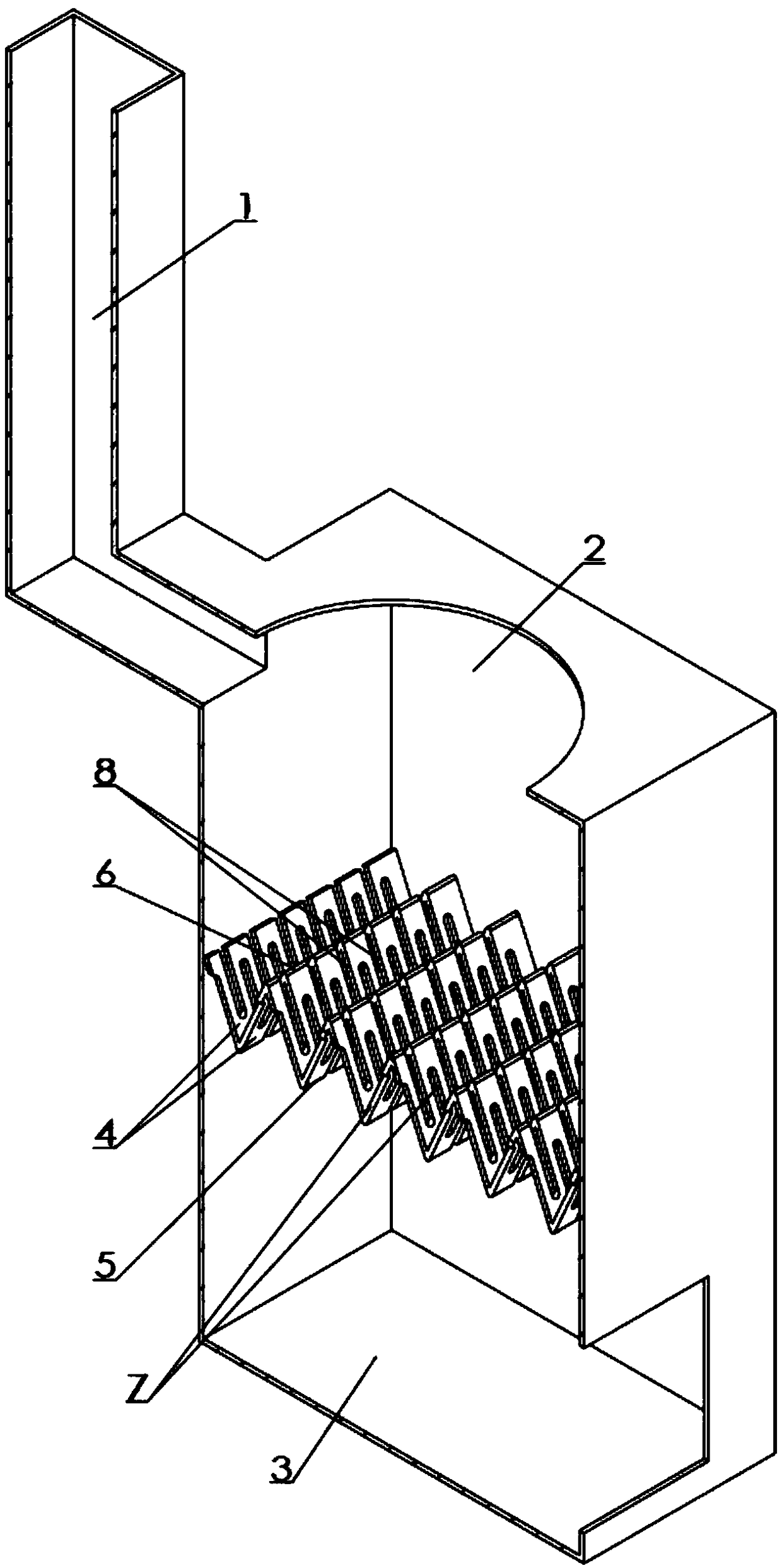

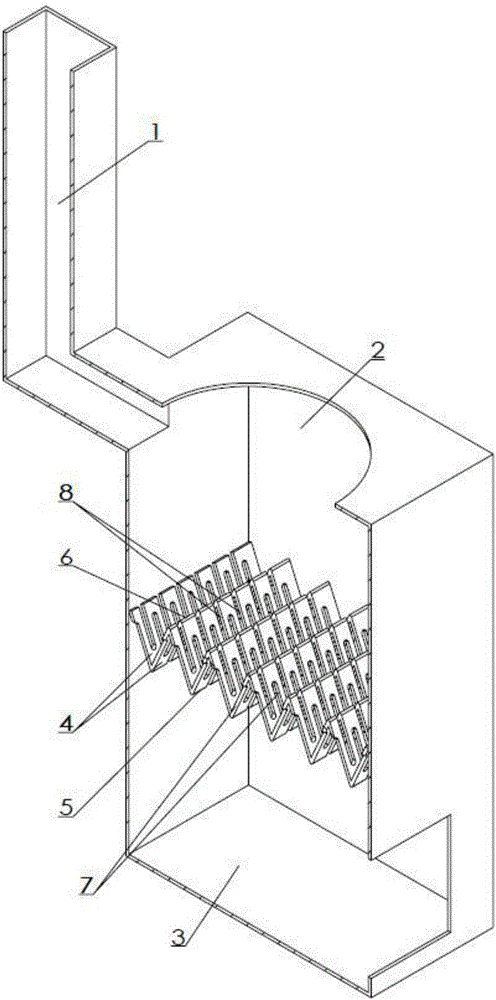

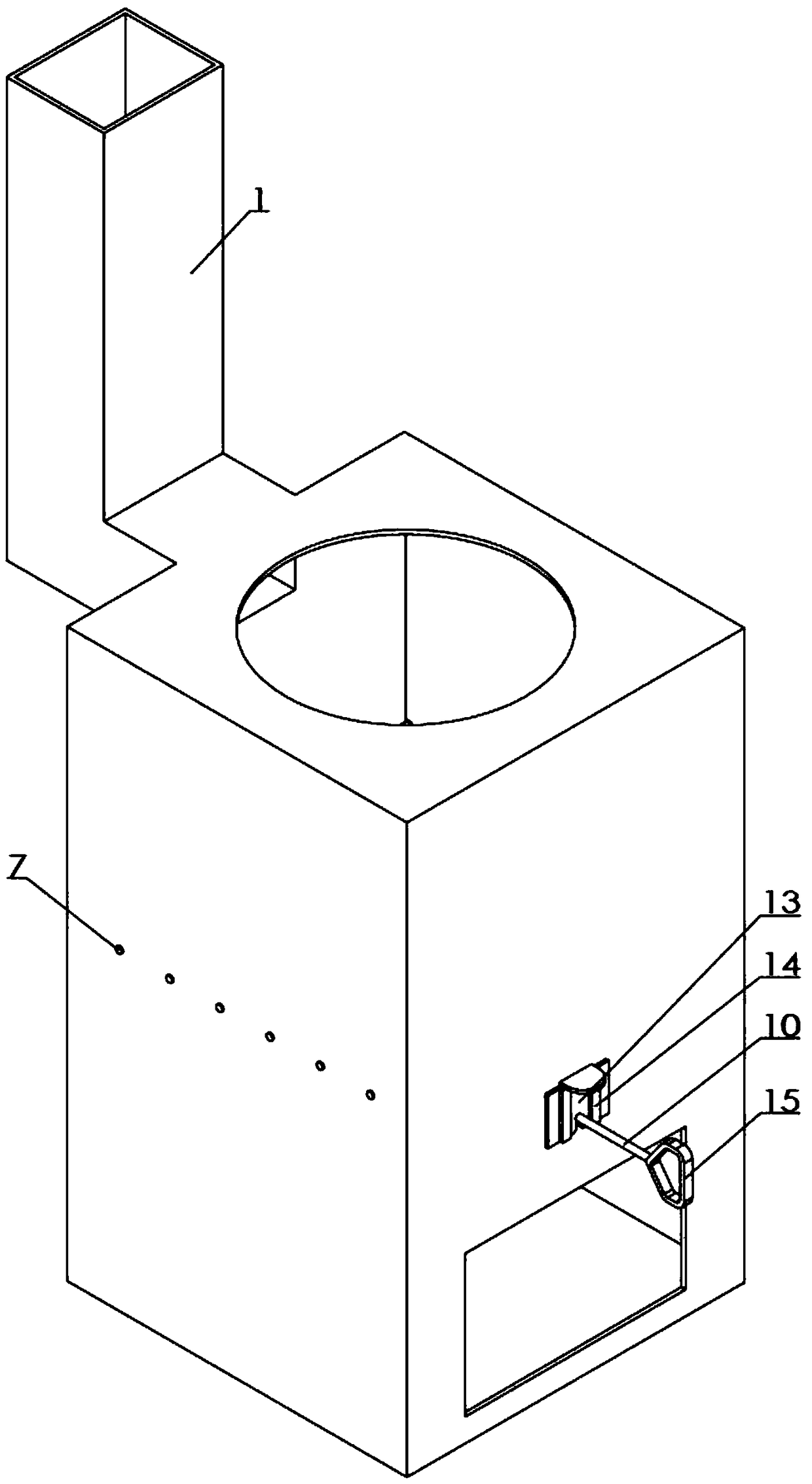

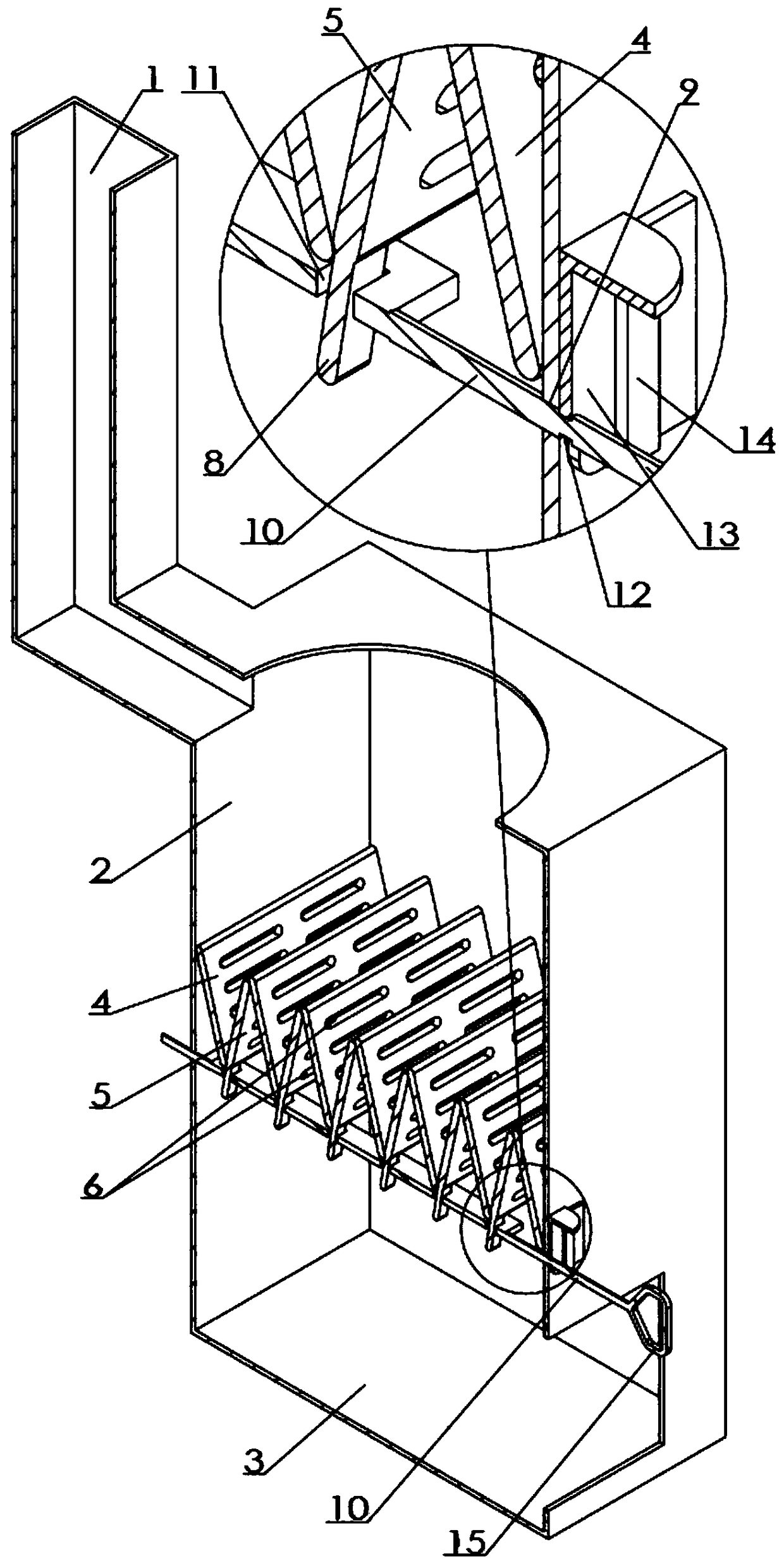

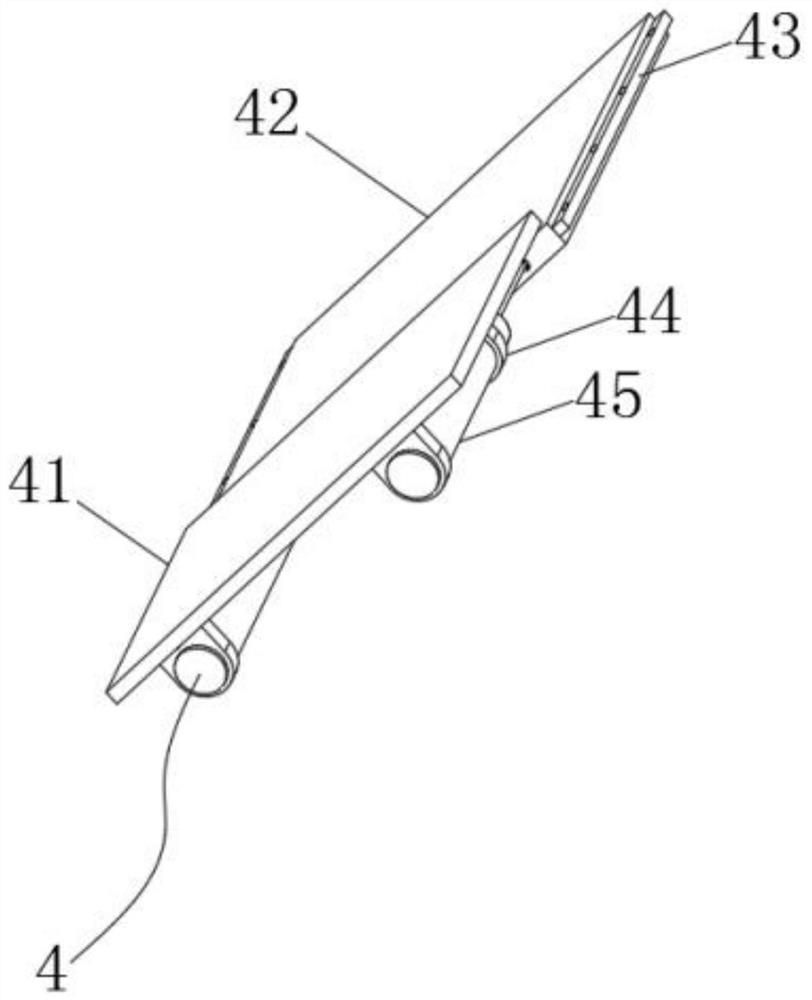

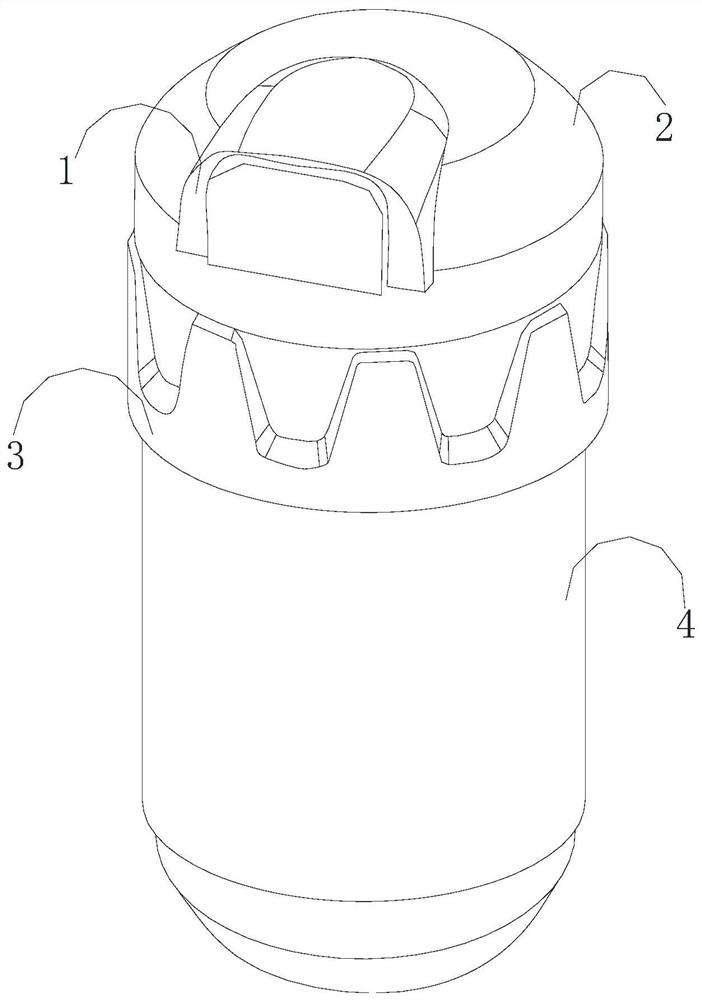

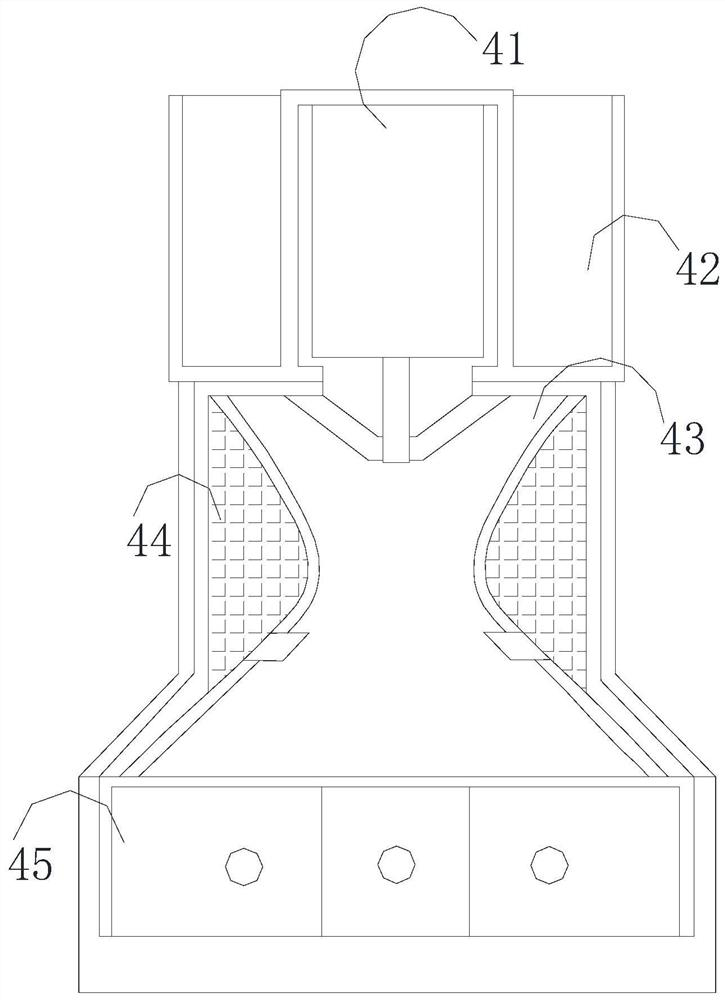

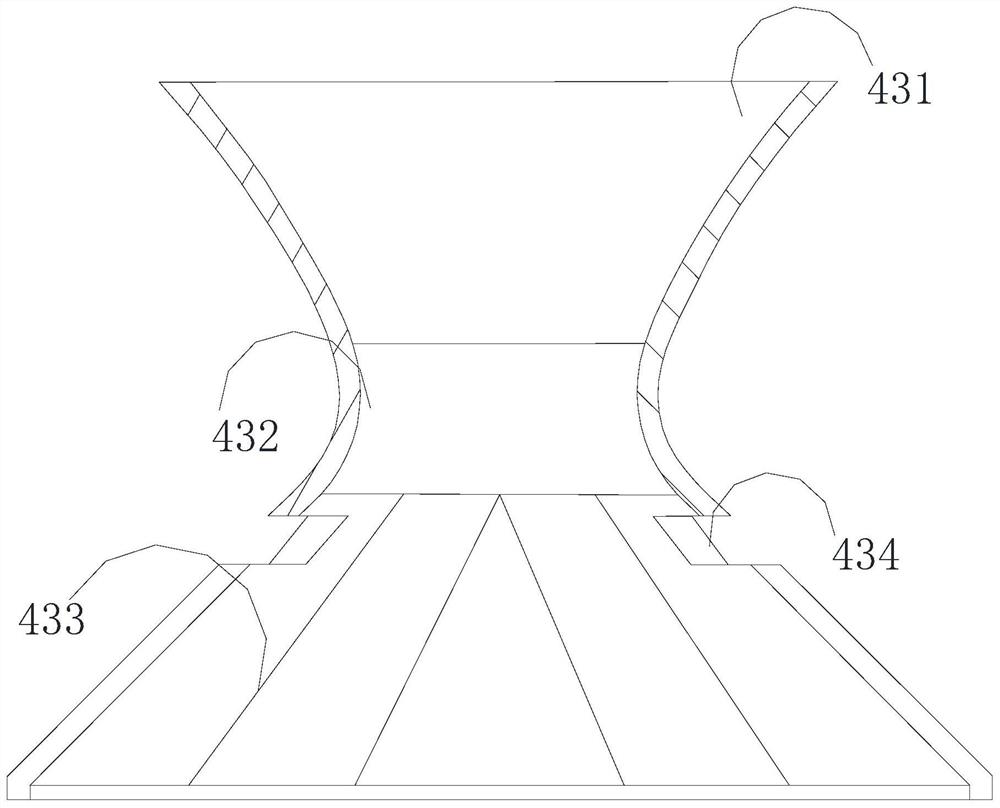

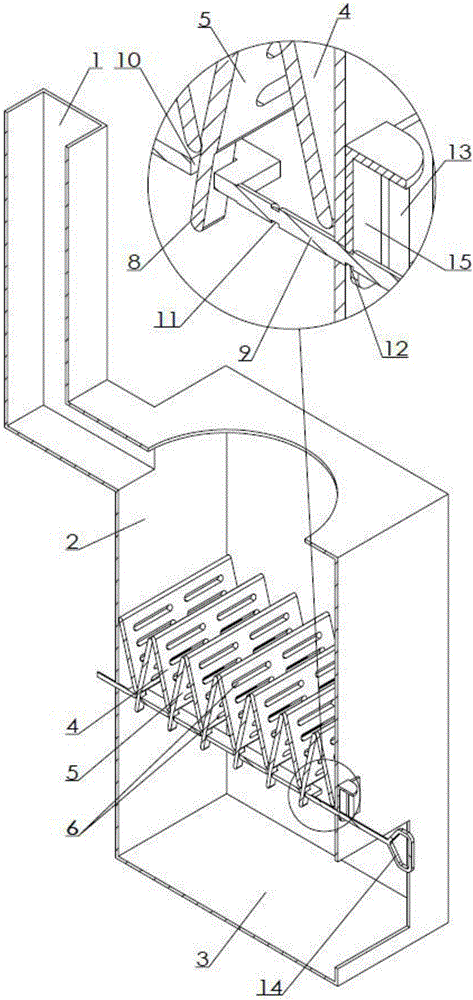

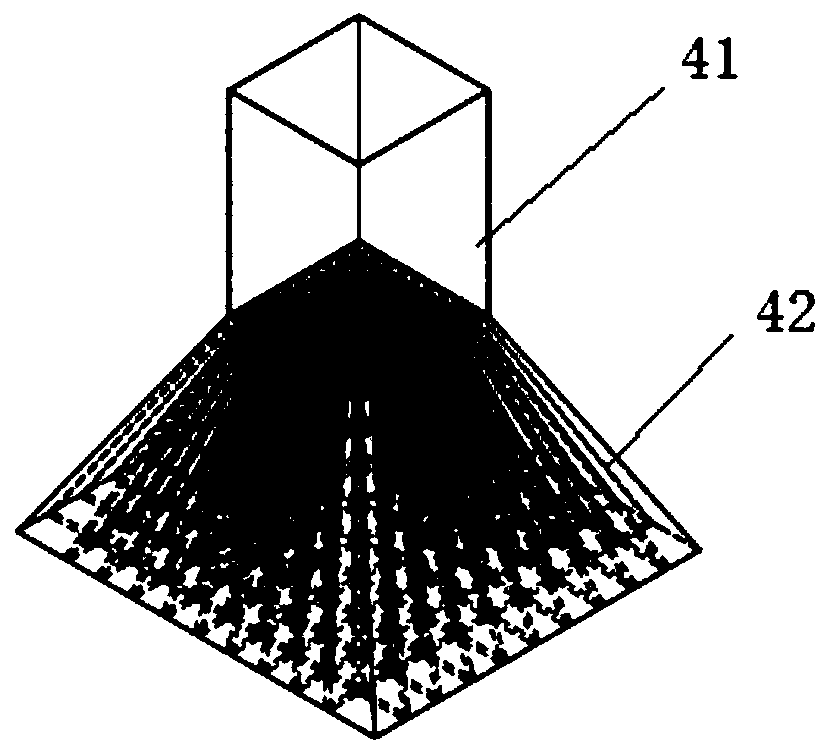

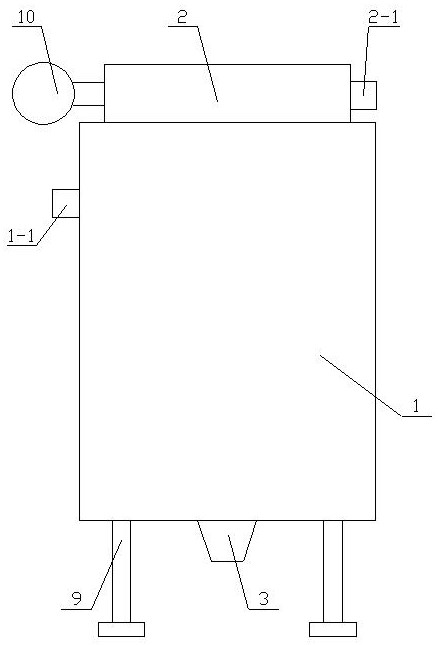

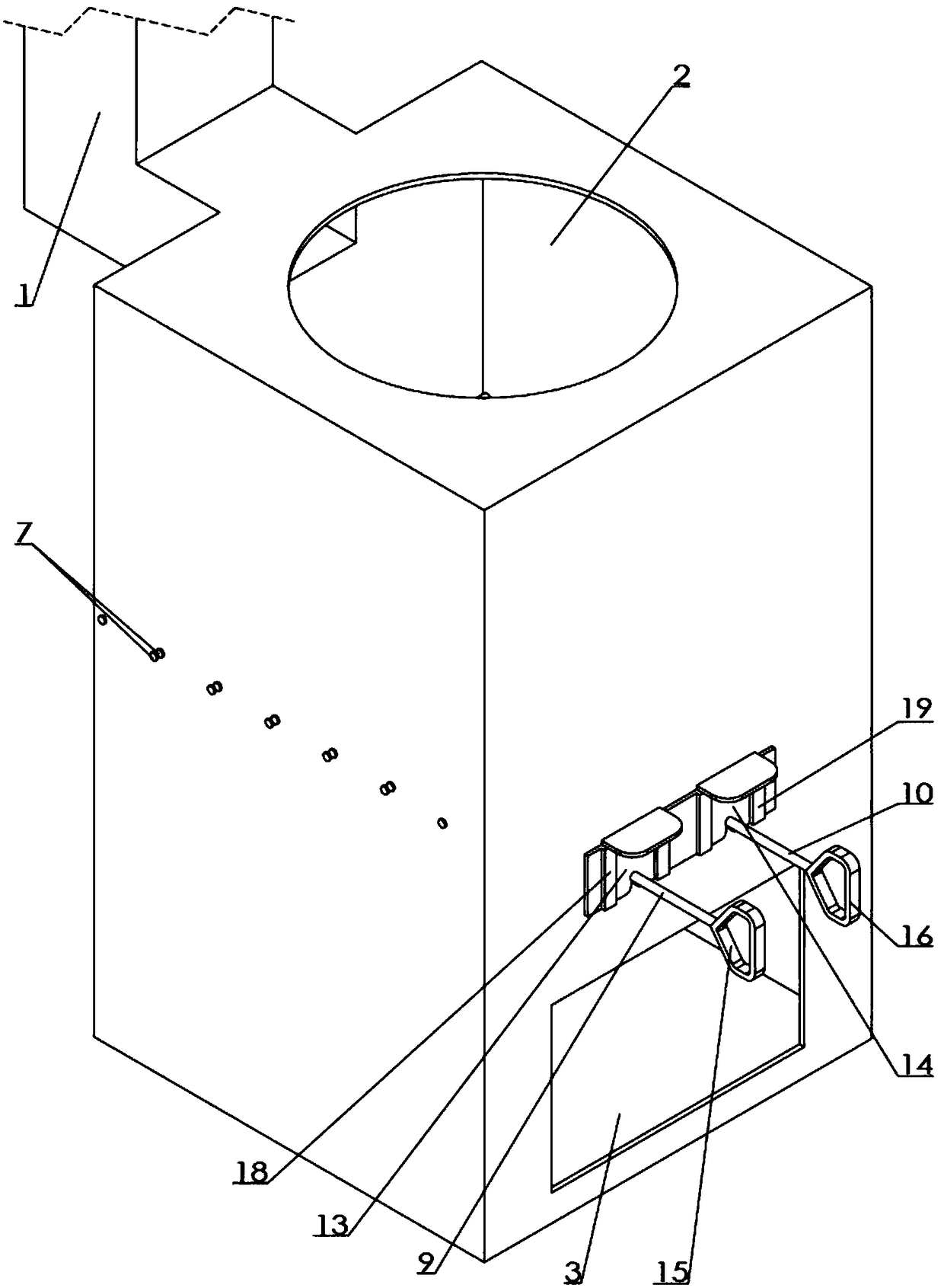

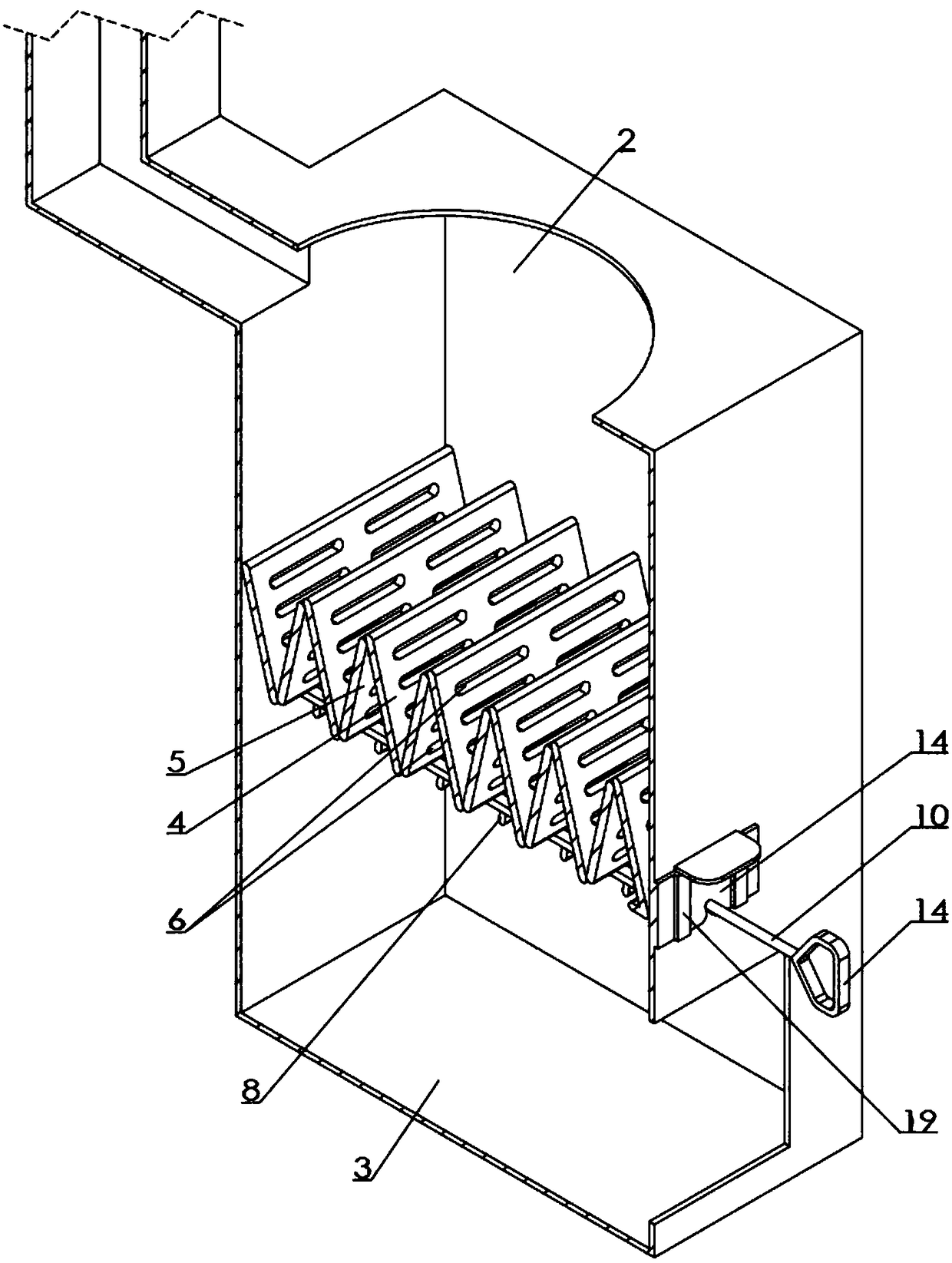

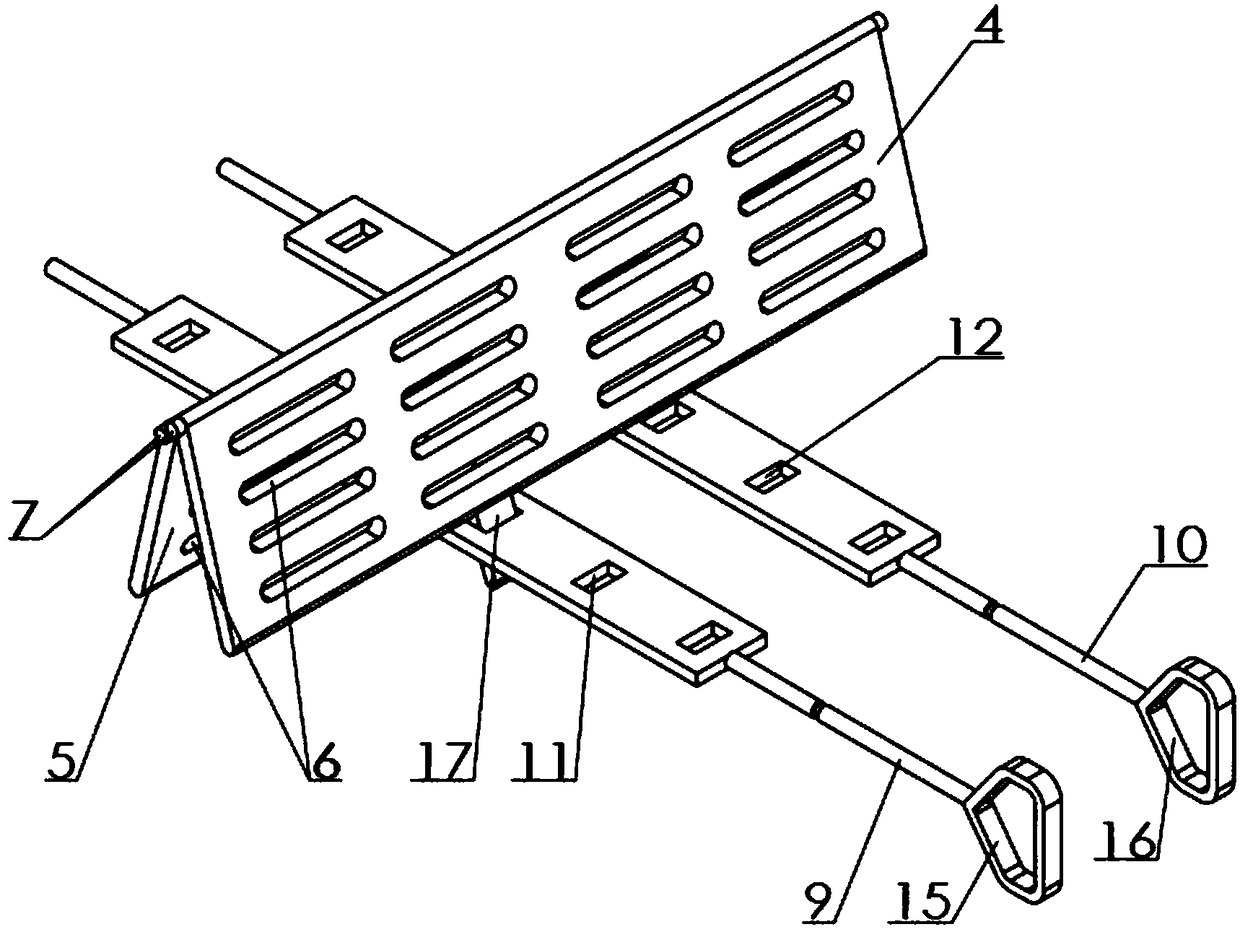

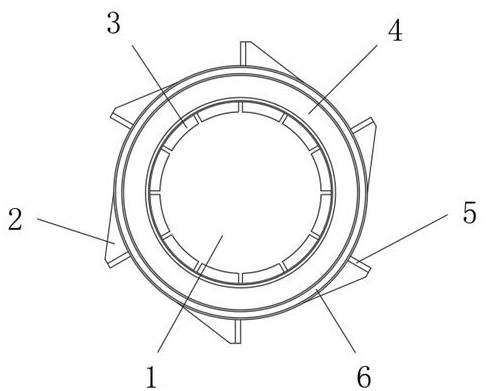

Ash discharge structure of solid particle fuel stove

ActiveCN103900114AEasy dischargeAvoid blockingDomestic stoves or rangesLighting and heating apparatusCombustorSolid particle

The invention discloses an ash discharge structure of a solid particle fuel stove. The ash discharge structure of the solid particle fuel stove comprises a stove bottom (1), a combustor (2), a bottom box (3) and an ash discharge device. The combustor (2) is located in a hearth (5) of the stove and installed on the stove bottom (1). An ash outlet (22) is formed in the lower portion of the combustor (2). An ash discharge and air inlet hole (11) is formed in the position, corresponding to the ash outlet (22) of the combustor (2), of the stove bottom (1). The bottom box (3) is located below the stove bottom (1) and installed on the stove bottom (1), and an inner cavity of the bottom box (3) is communicated with the ash discharge and air inlet hole (11) of the stove bottom (1). The ash discharge device comprises a fire grate (41) and a fire grate shaking device, the fire grate (41) is a separation net capable of leaking ash and stopping material, and the fire grate (41) is movably installed on the stove bottom (1) or the bottom box (3), located in the bottom box (3) and located below the ash discharge and air inlet hole (11). The fire grate shaking device is connected between the bottom box (3) and the fire grate (41) and can drive the fire grate (41) to vibrate or shake. According to the ash discharge structure of the solid particle fuel stove, ash can be discharged conveniently, and fuel can be prevented from coking.

Owner:湖南宏南节能科技有限公司

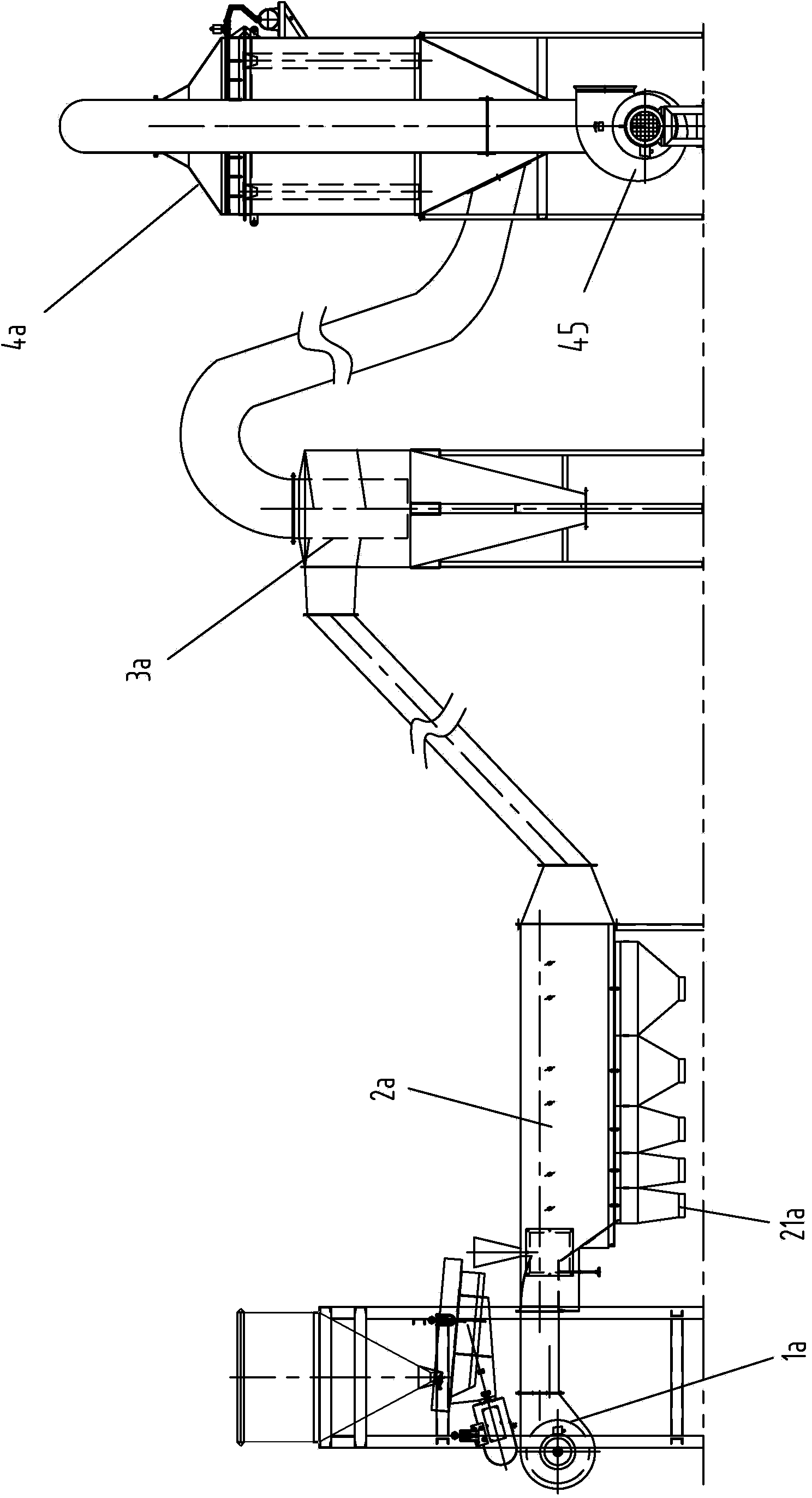

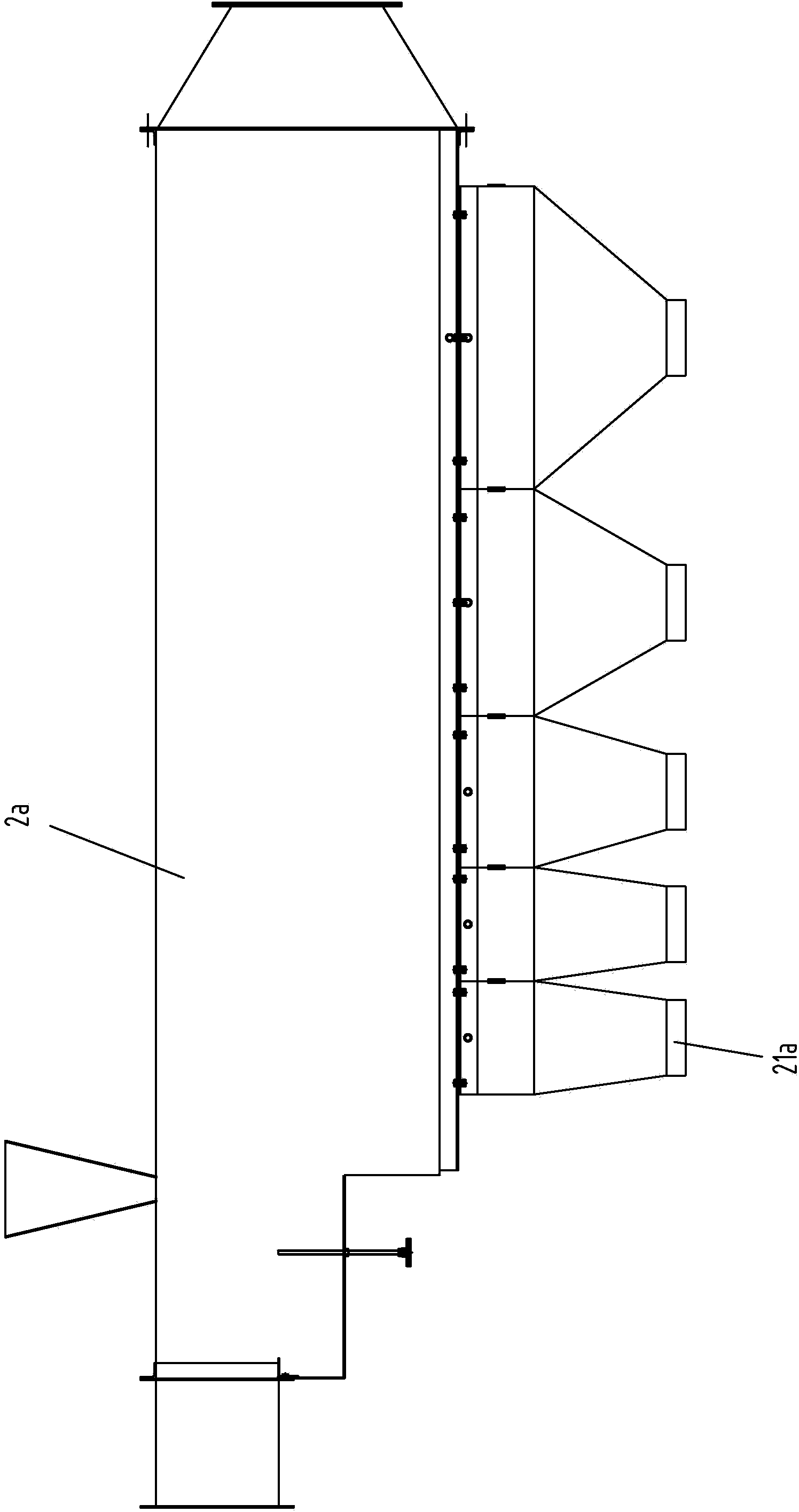

Concrete dry aggregate continuous multistage air classification method

InactiveCN103521445AQuality improvementExemption from washingGas current separationClassification methodsMaterials science

The invention discloses a concrete dry aggregate continuous multistage air classification method which is achieved by means of the following steps that mixed aggregate is thrown into the same sealed space, multistage air classification is carried out continuously on the mixed aggregate, and the mixed aggregate is divided into classified aggregate within multiple particle diameter ranges. According to the concrete dry aggregate continuous multistage air classification method, multistage air classification is carried out on the mixed aggregate continuously to enable particle sizes of classified aggregate to be more concentrated; soil and stone powder blended in the mixed aggregate are separated from the classified aggregate through continuous multistage air classification and are discharged, the classified aggregate is clean, the steps of water washing and dewatering can be omitted, the technological process is shortened, cost is reduced, and quality of concrete finished products is improved.

Owner:XINJIANG YUXIN CONCRETE

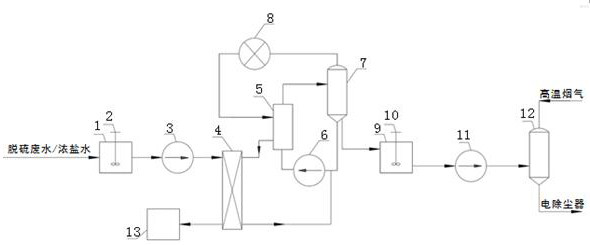

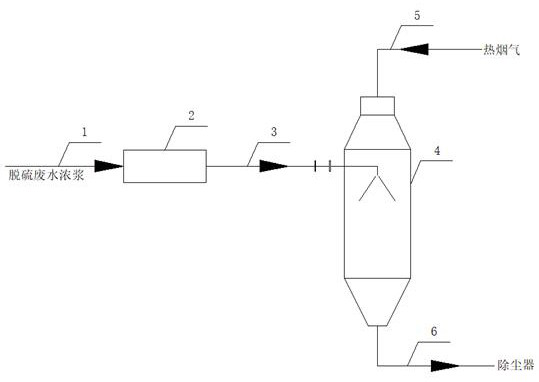

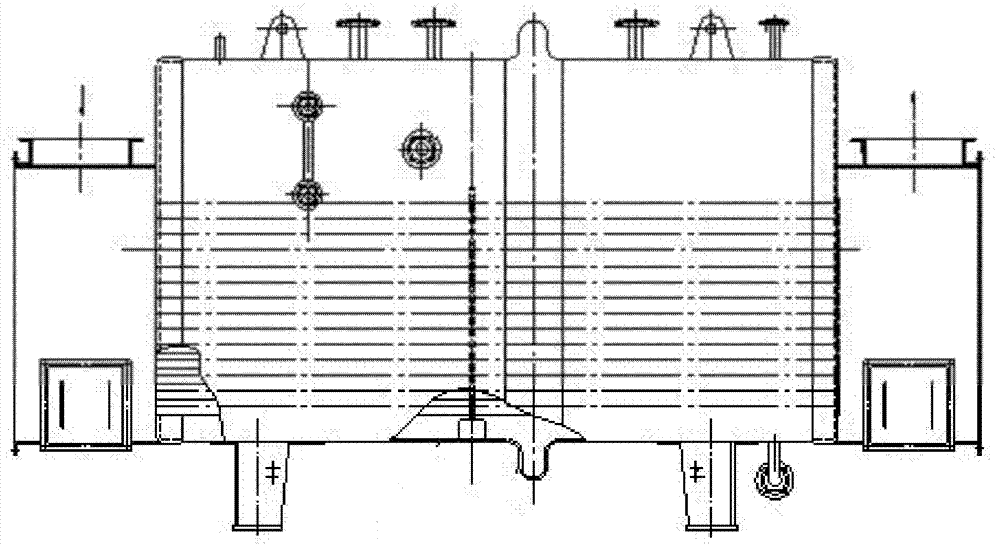

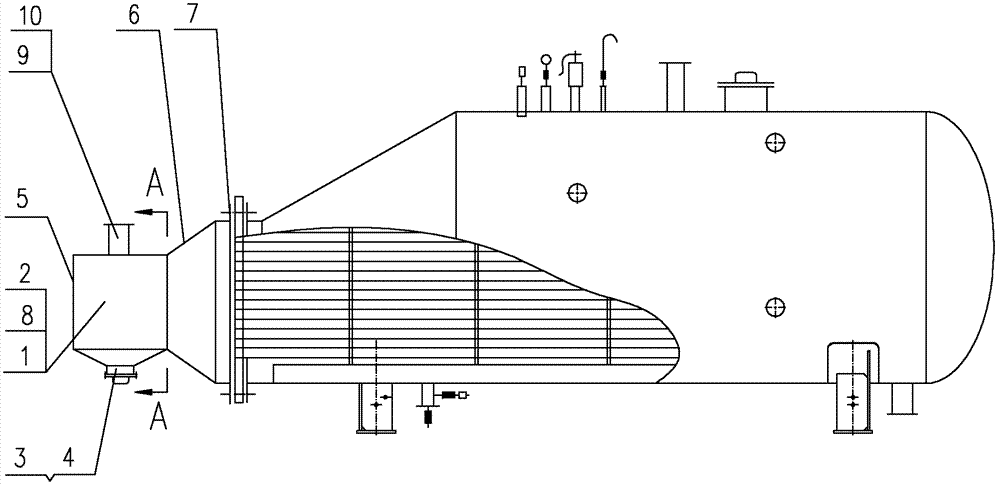

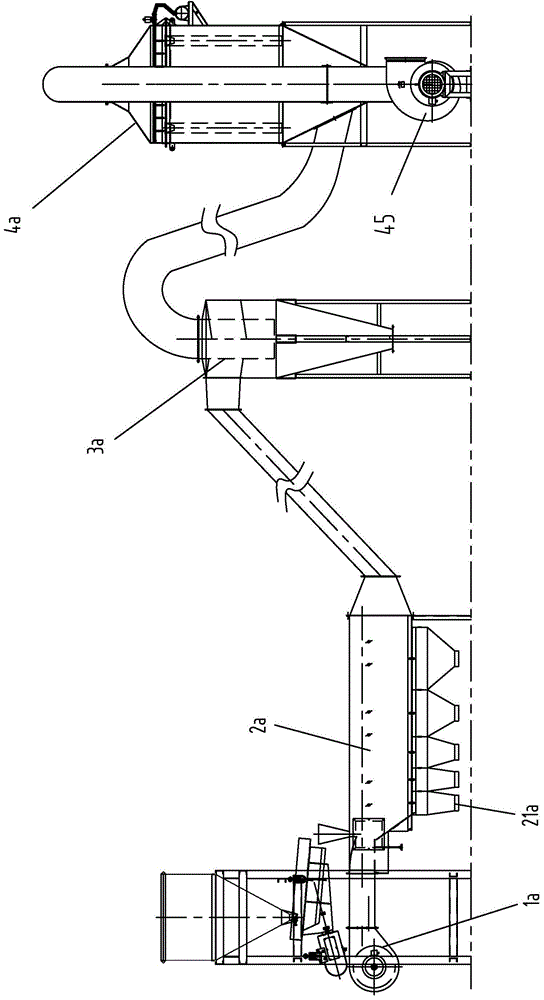

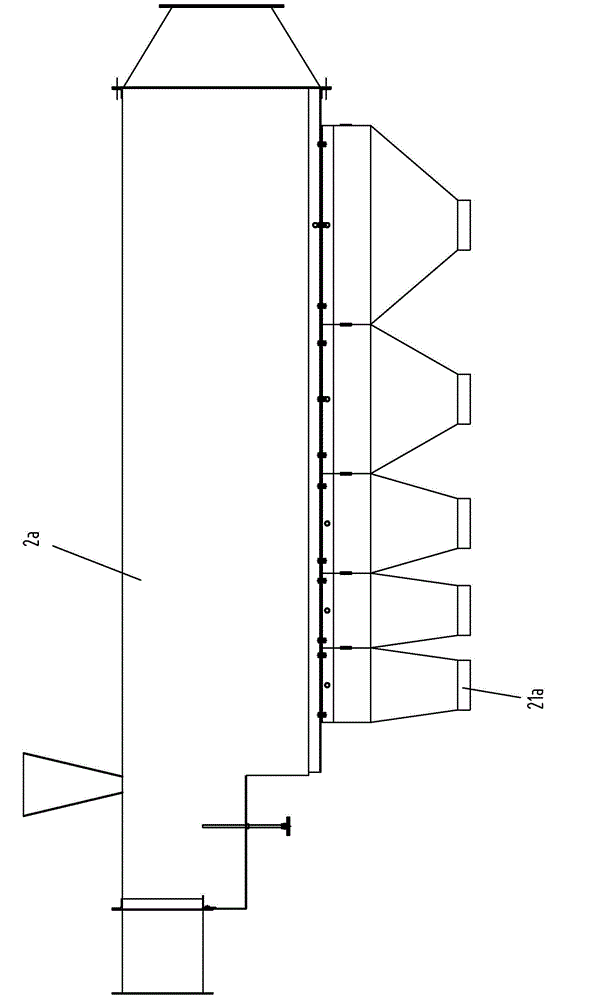

Wastewater zero discharge system based on efficient concentrating and spray drying integrated treatment

PendingCN113264564AHigh speed flowPrevent fouling and pluggingSpecific water treatment objectivesWaste water treatment from gaseous effluentsWastewaterSpray dried

The invention provides a wastewater zero discharge system based on efficient concentrating and spray drying integrated treatment, which is characterized in that desulfurization wastewater is collected into a wastewater collection tank, the wastewater collection tank and a wastewater lifting pump are in liquid level linkage, the wastewater lifting pump conveys desulfurization wastewater stock solution to a preheater, the preheater preheats the desulfurization wastewater, the preheated desulfurization wastewater flows to an inlet of a forced circulation pump, feed liquid is driven by the pressure of a forced circulation pump to enter a heater, the desulfurization wastewater is heated, evaporated and concentrated in the heater, and when the density of a densimeter arranged in a vapor-liquid separator reaches a set value, part of concentrated liquid is discharged into a concentrated liquid collecting box; and the desulfurization wastewater is evaporated and concentrated, then the concentrated solution is evaporated and dried by an evaporation drying tower, salt particles generated by drying enter a dust remover, and the system has the characteristics of short process flow, high concentrating ratio, no scaling in long-time stable operation, avoidance of auxiliary dosing, capability of recovering fresh water, diversification of heat sources and the like.

Owner:国能朗新明环保科技有限公司

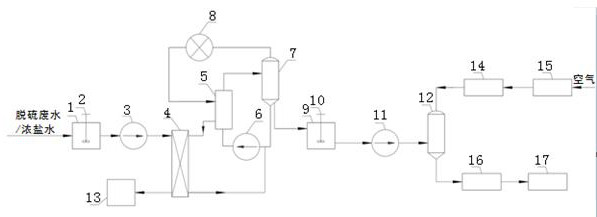

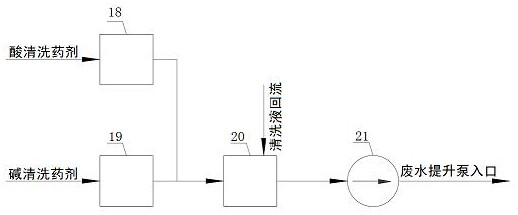

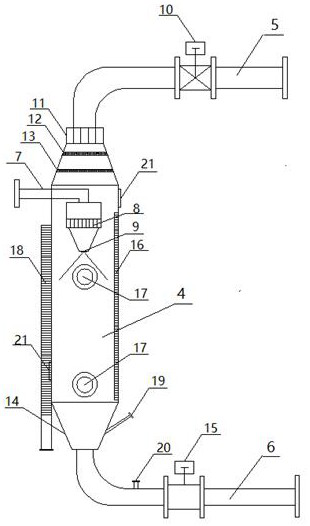

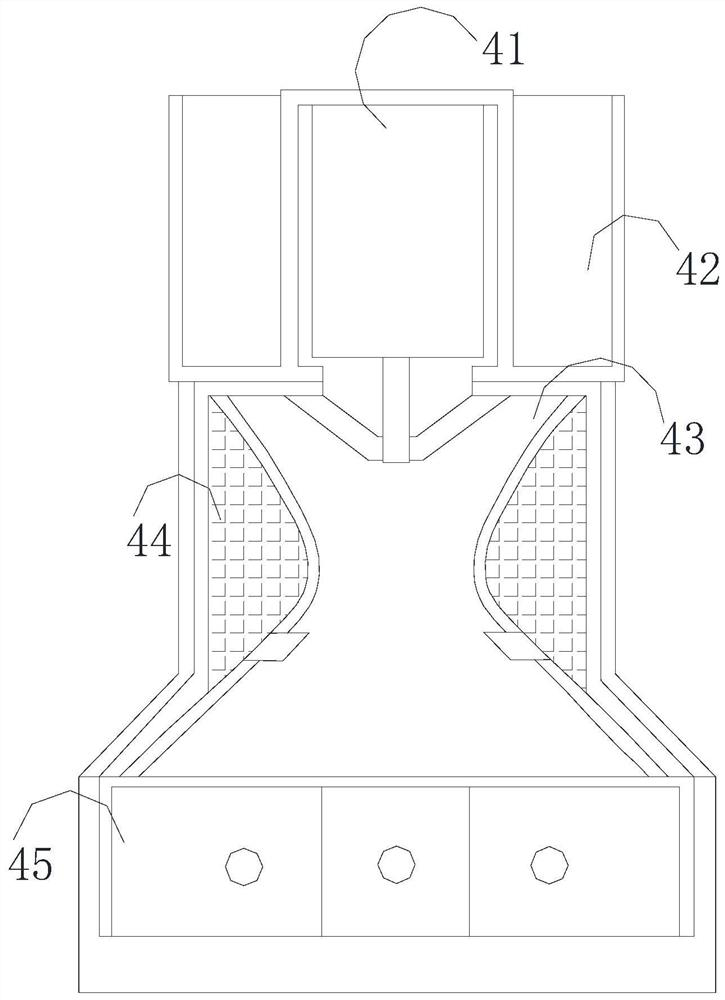

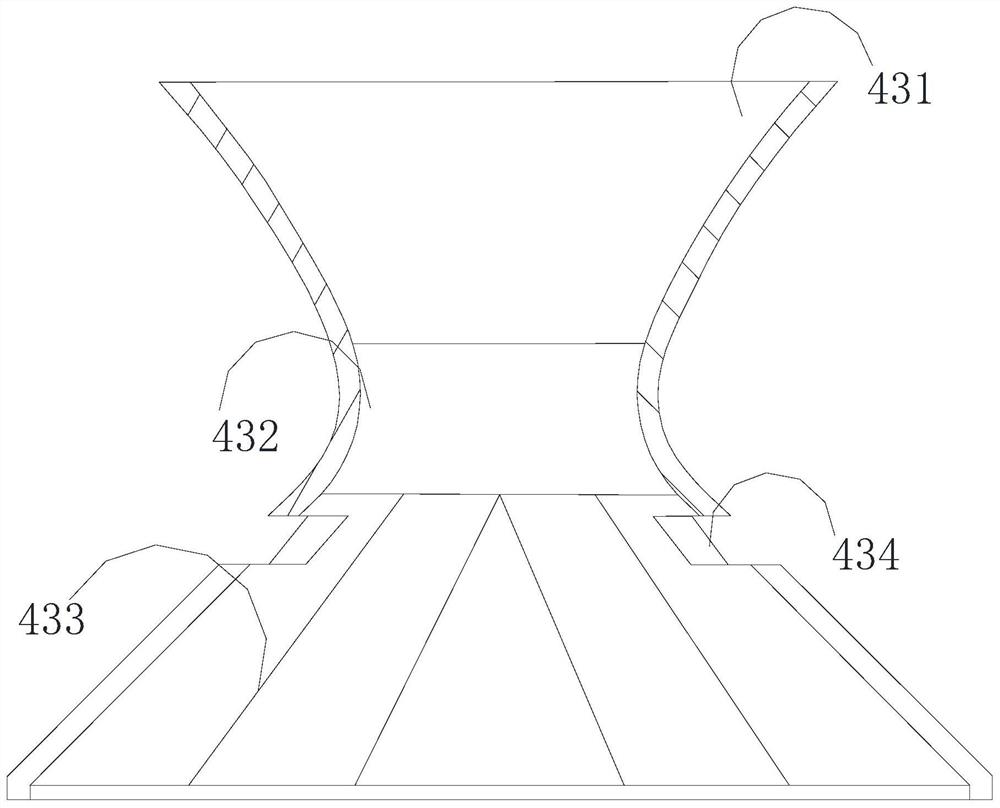

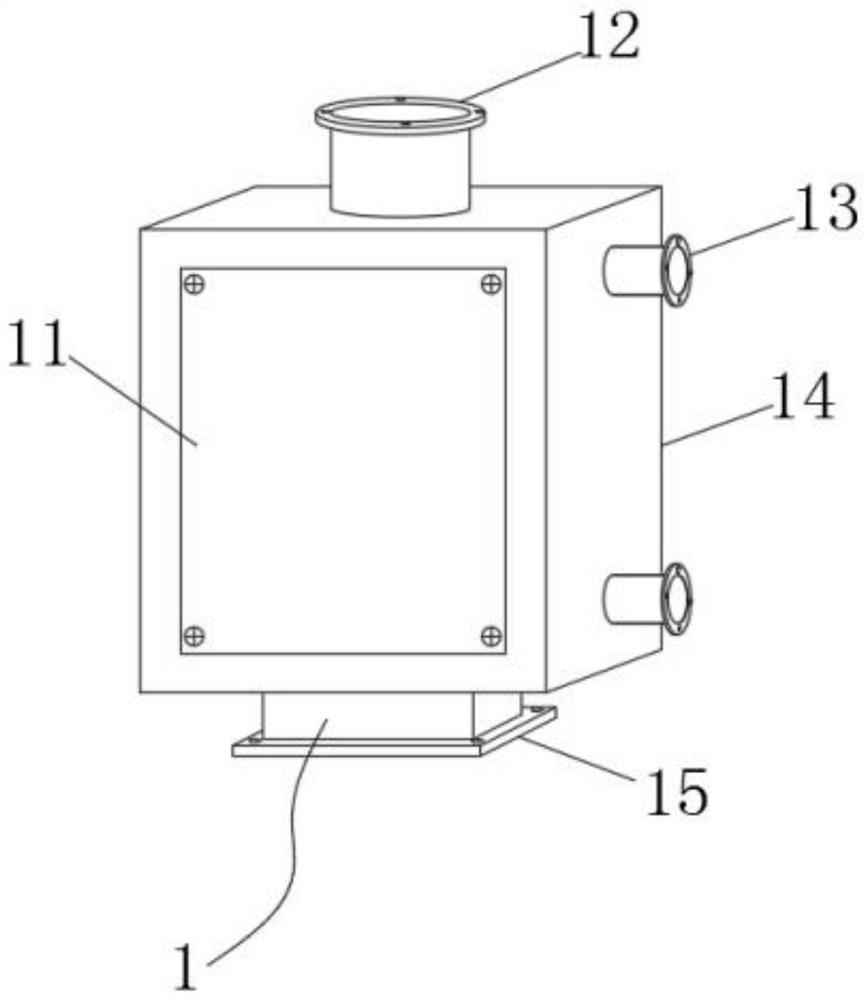

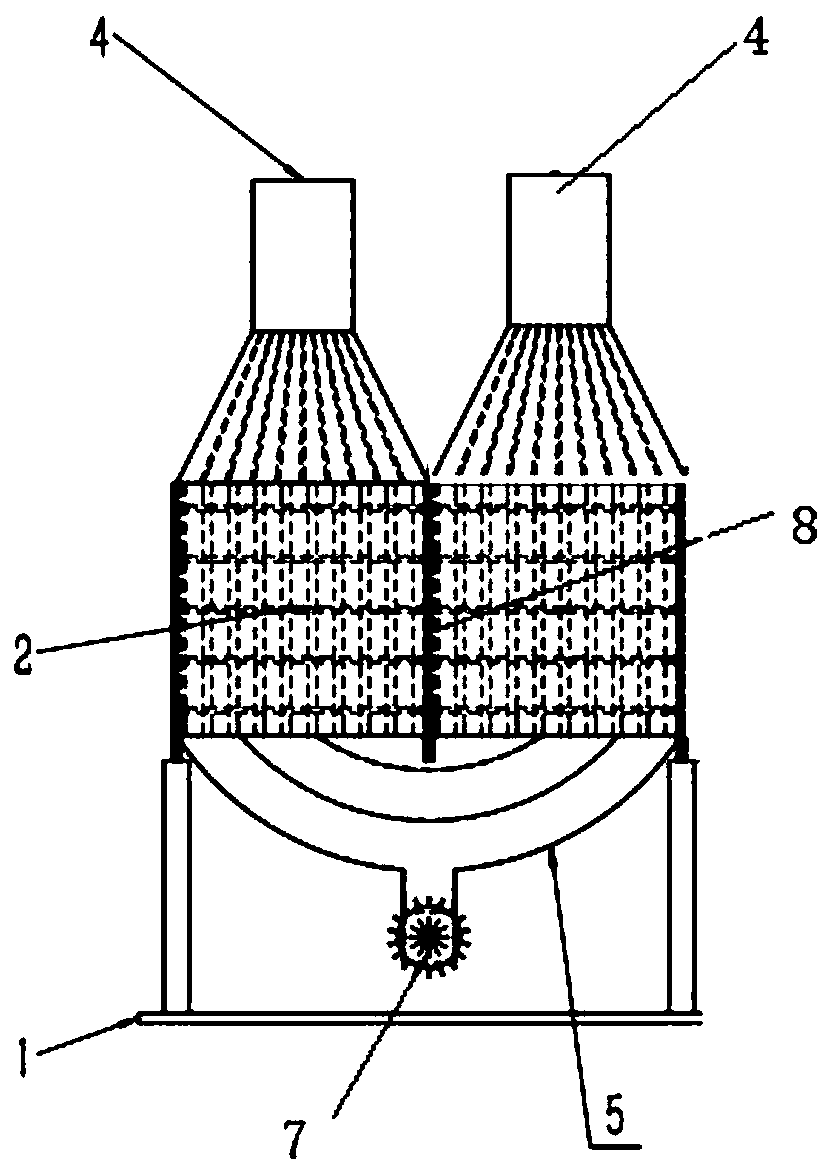

Efficient spray drying system for desulfurization wastewater

PendingCN113830853AGuaranteed uptimeAvoid defectsWater/sewage treatmentWaste water treatment from gaseous effluentsFlue gasWastewater

The invention provides an efficient spray drying system for desulfurization wastewater, which is characterized in that two ends of a slurry conveying pipeline are respectively connected with an external desulfurization wastewater concentrated solution and a liquid inlet of a slurry conveying pump, and a liquid outlet of the slurry conveying pump is communicated with a feeding hole of a spray drying tower through a high-pressure connecting pipeline; a material outlet of the spray drying tower is connected with a dust remover through a negative pressure dry powder conveying pipeline, and an air inlet of the spray drying tower is connected with external hot flue gas through a flue. According to the invention, the spray drying tower is improved in design, and the improved rectifying plate of the hot flue gas and hot air distributor is turbo-type; the flow guide plate is a groove disc type flow guide grid, after hot flue gas enters the drying tower and before the hot flue gas is in contact with atomized desulfurization wastewater, a flue gas flow field is uniformly designed without dead angles, the hot flue gas is uniformly diffused in the drying tower and is uniformly contacted with a concentrated solution, and the powder bin is improved to be a dead-angle-free conical ash hopper, so that ash discharge is facilitated, and ash particles are prevented from caking and adhering to the wall; the emptying section at the bottom of the powder bin is designed to be large in radius, and pipeline scaling and blocking can also be effectively avoided.

Owner:国能朗新明南京环保科技有限公司 +1

Easy-ash-discharge smoke evaporator

The invention relates to an easy-ash-discharge smoke evaporator. The evaporator comprises a channel, the channel comprises a smoke entrance room and a smoke depart room, a smoke entrance and ash discharge port is arranged below the smoke entrance room, a smoke depart and ash discharge port is arranged below the smoke depart room, and each of the smoke entrance and ash discharge port and the smoke depart and ash discharge port is a funnel type ash discharge port. The smoke entrance and depart rooms in a tube pass segment have large spaces, so the flow section area is enlarged, thereby the smoke flow speed is substantially reduced, and smoke grits can naturally sediment from the smoke flow through utilizing the gravity action; and each of the smoke entrance and ash discharge port and the smoke depart and ash discharge port is the funnel type ash discharge port, so the ash discharge is easy.

Owner:冯锦宇

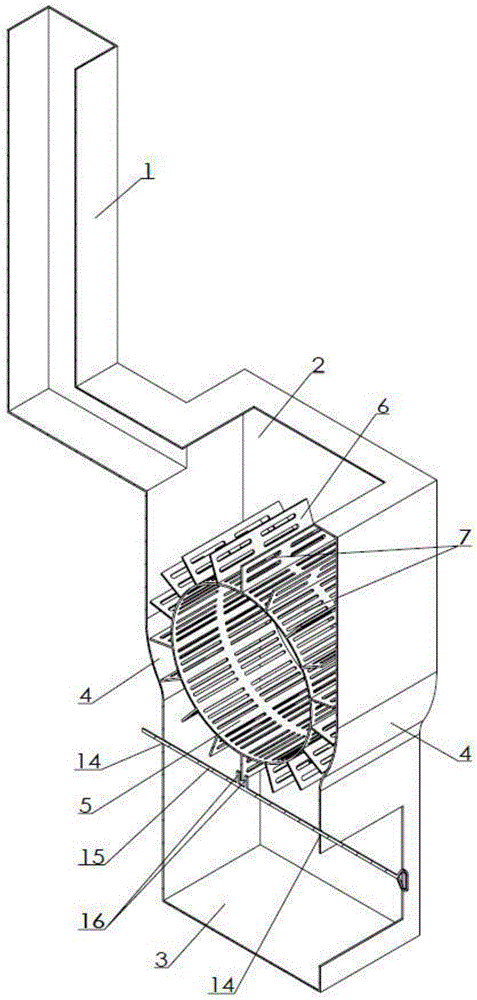

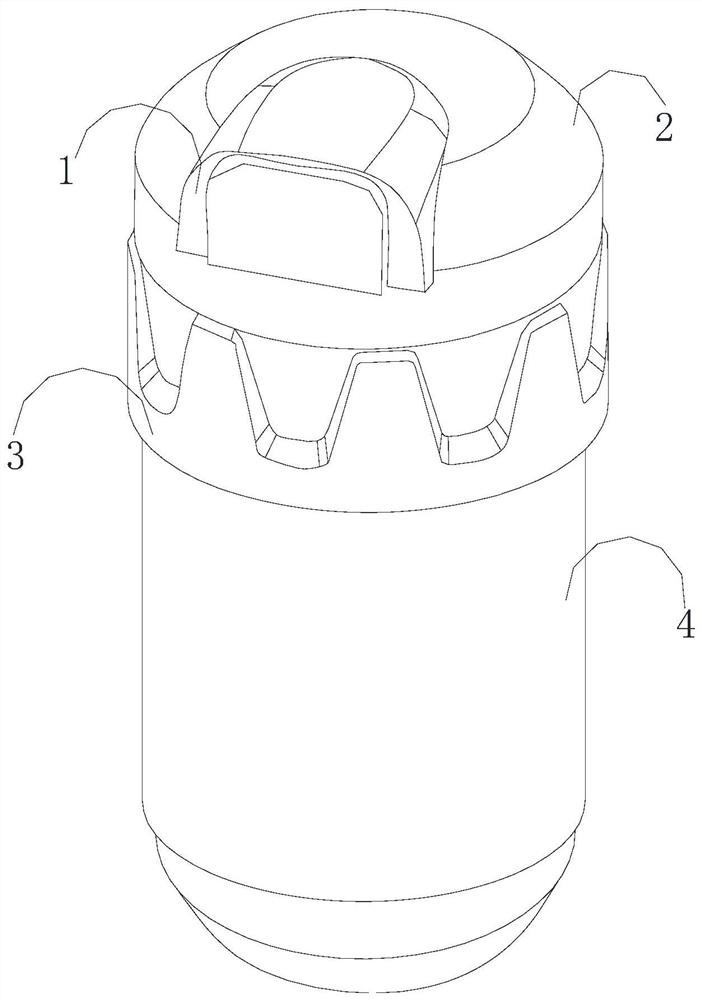

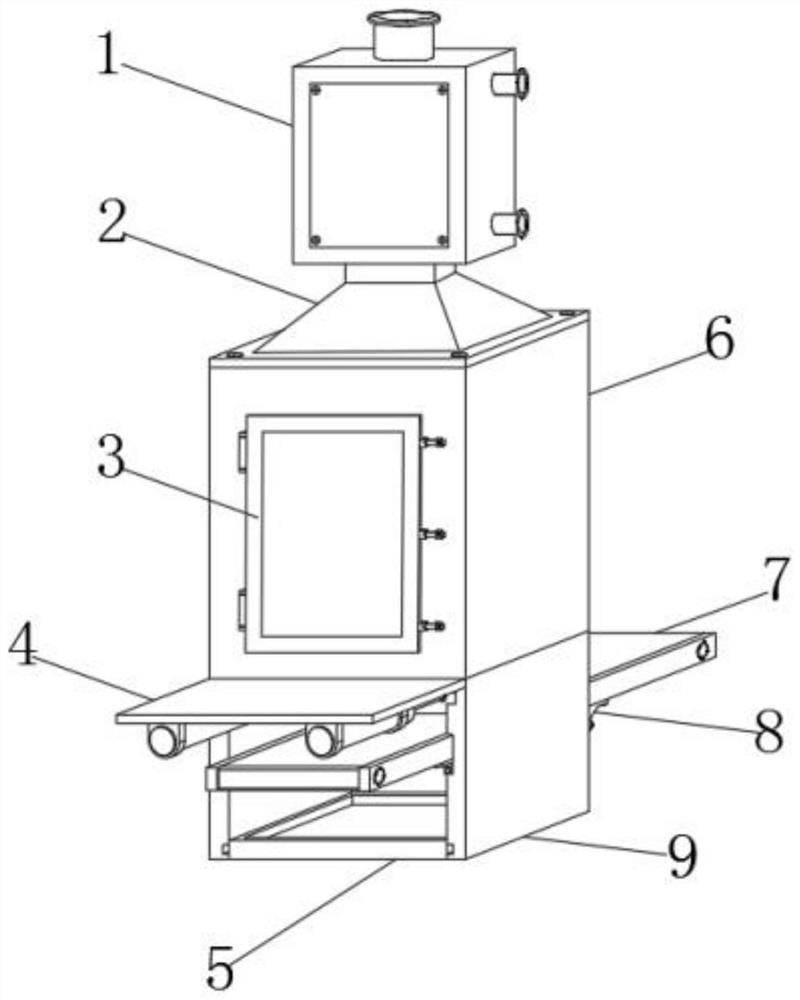

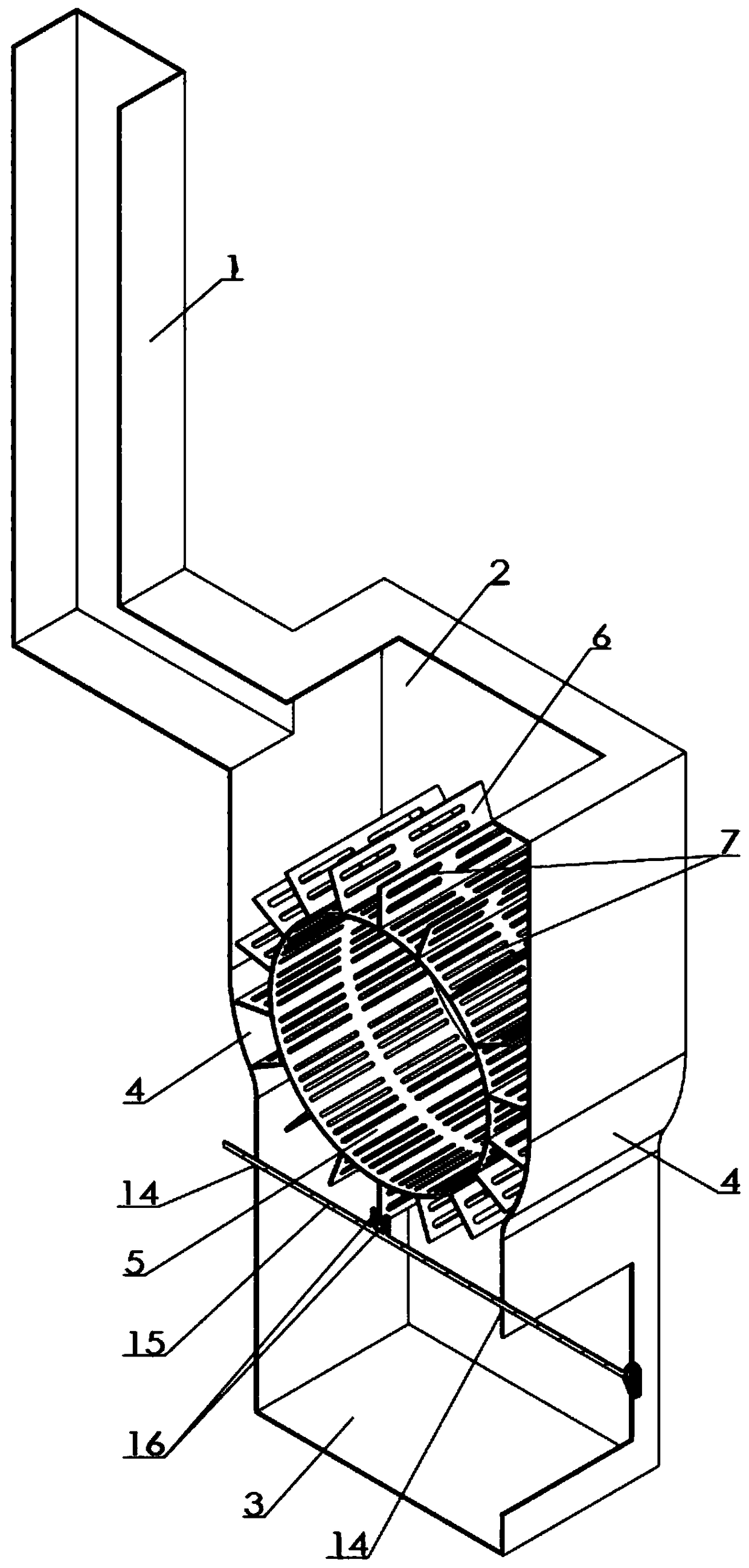

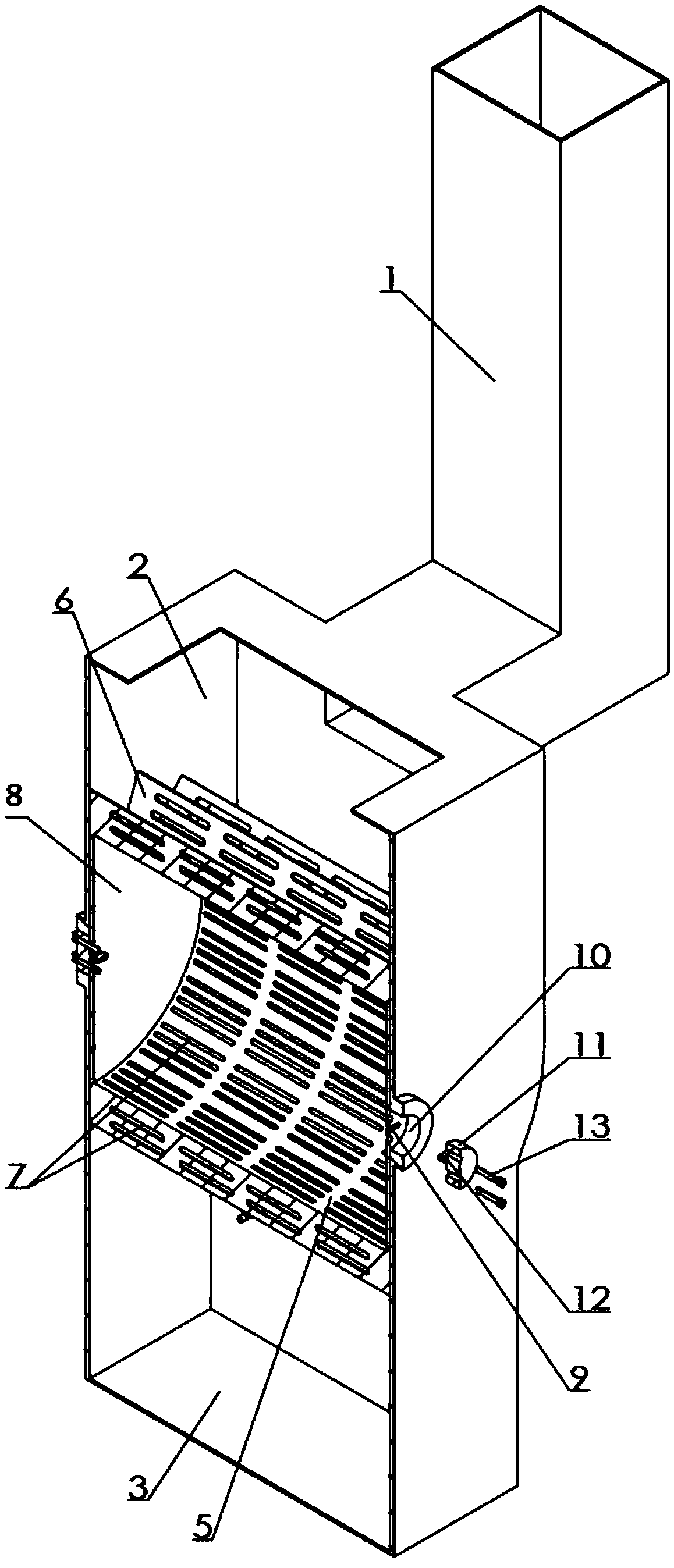

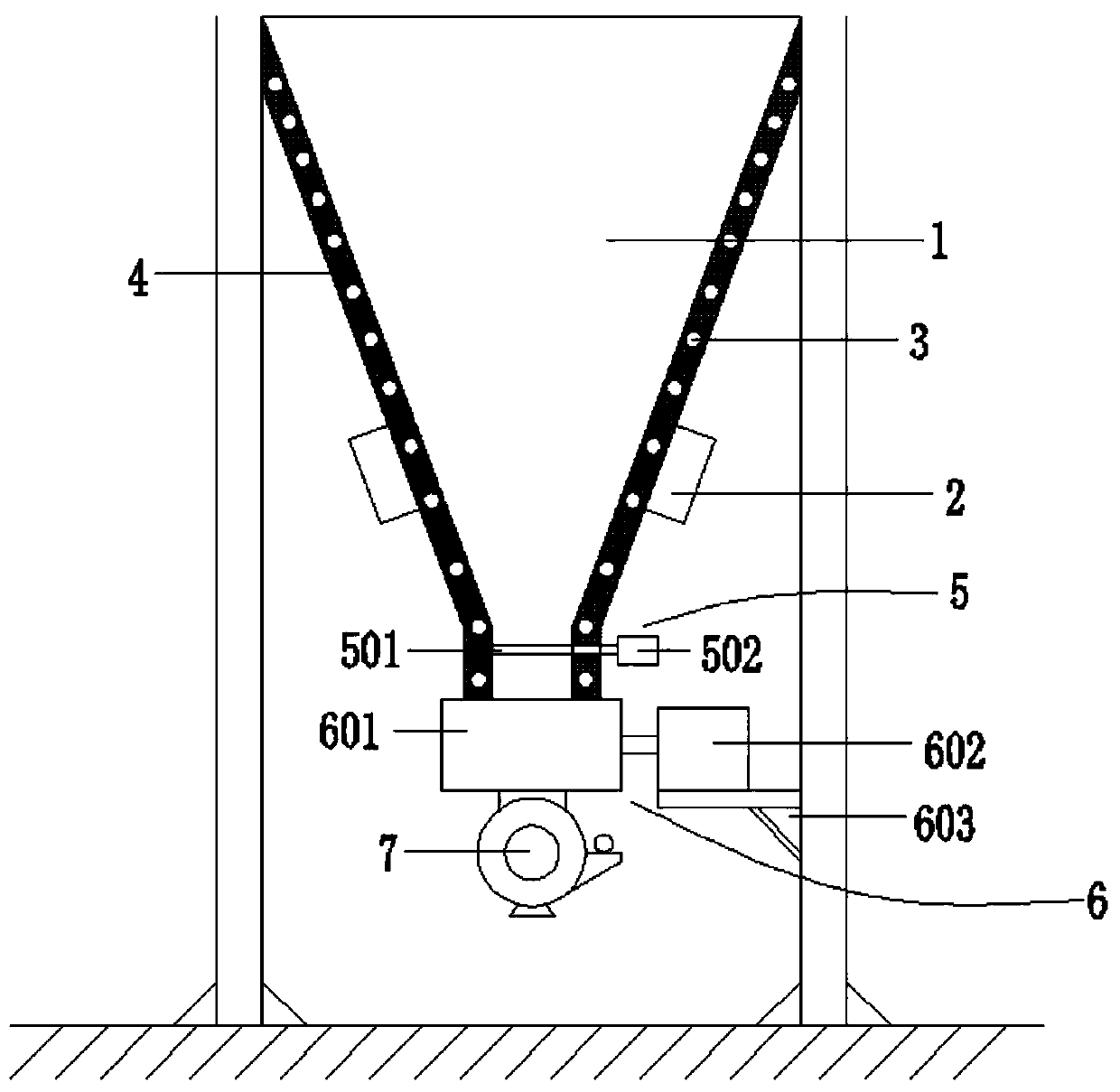

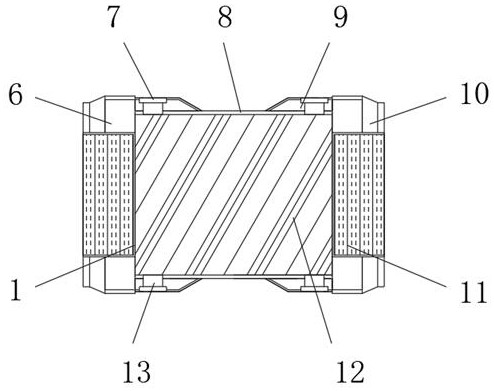

Improved biofuel burning furnace

ActiveCN106524229ABurn helpsEasy to discharge ashDomestic stoves or rangesLighting and heating apparatusCombustion chamberBiofuel

The invention disclosed an improved biofuel burning furnace. The improved biofuel burning furnace is characterized in that a hollow roller of which the axis is arranged in the left-right direction is arranged in a burning chamber, and the hollow roller and an arc-shaped transition plate are coaxial; the outer wall of the roller is provided with partition plates which are distributed in the circumferential direction, extend outwards in the radial direction and are parallel to the axis of the roller; a gap is formed between the outer edge of each partition plate and the arc-shaped transition plate; the roller and the partition plates are provided with via holes; end plates are connected to the two ends of the roller; prism holes are formed in the axes of the end plates; the left and right side walls of the burning chamber are provided with shaft holes coaxial with the end plates correspondingly, and rotary bodies are arranged in the shaft holes in a matched mode; the front and rear walls of a dust storage chamber are provided with opposite via holes; a transmission rod capable of rotating penetrates through the via holes; a shift fork is connected to the middle of the transmission rod and can be screwed into the partition plates along with the transmission rod; a handle is connected to the front end of the transmission rod; and operation on the front portion is more convenient. According to the improved biofuel burning furnace, ash can be quickly and conveniently discharged, and the burning efficiency can be effectively improved, so that people would like to use biofuel particles, and energy sources are saved advantageously.

Owner:CHONGQING HUAWANLUN BIOLOGICAL NEW ENERGY TECH CO LTD

A rotary biofuel combustion furnace

ActiveCN106524227BBurn helpsEasy to discharge ashDomestic stoves or rangesRevolving grateCombustion chamberBiofuel

Owner:CHONGQING HUAWANLUN BIOLOGICAL NEW ENERGY TECH CO LTD

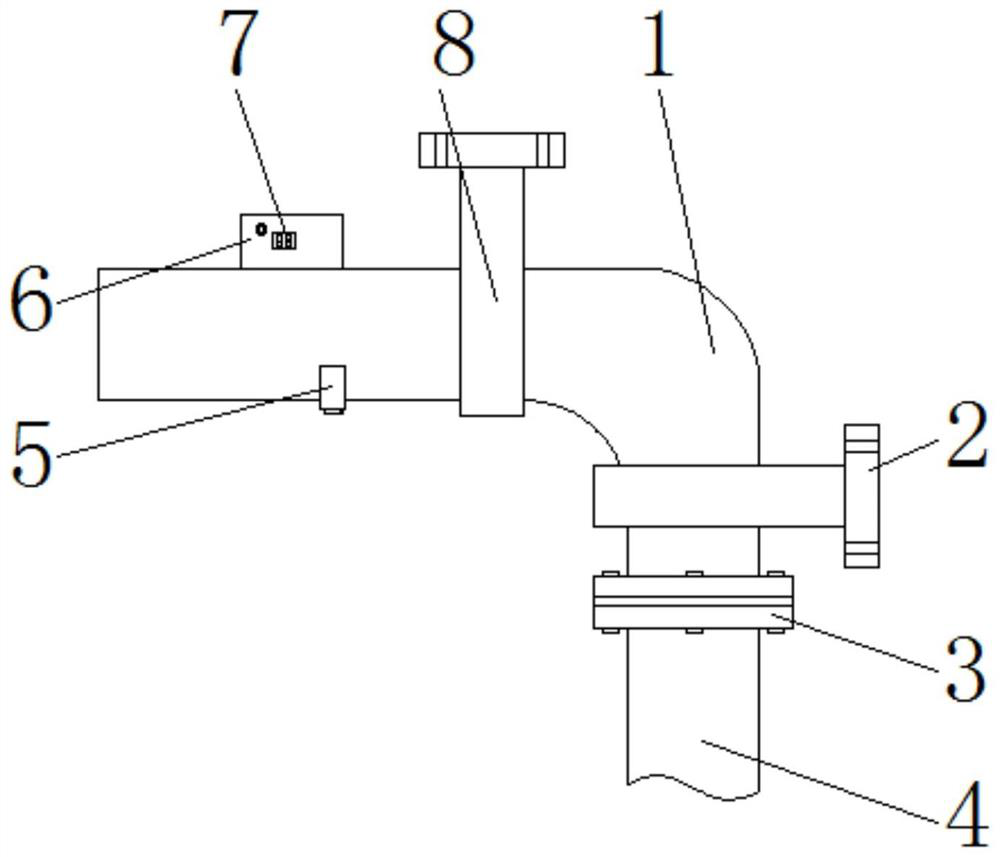

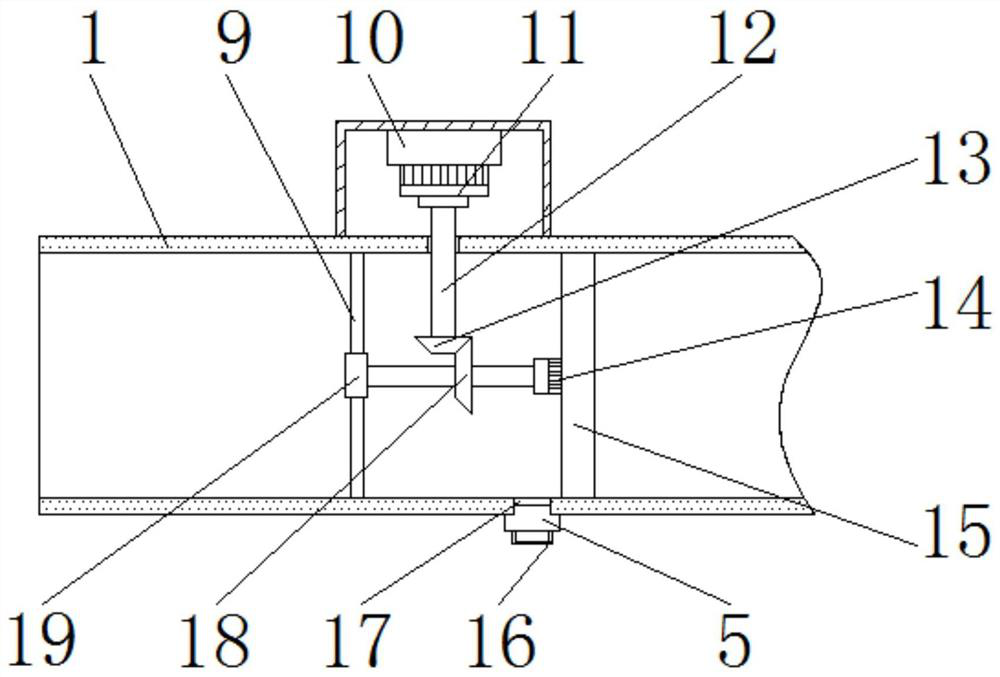

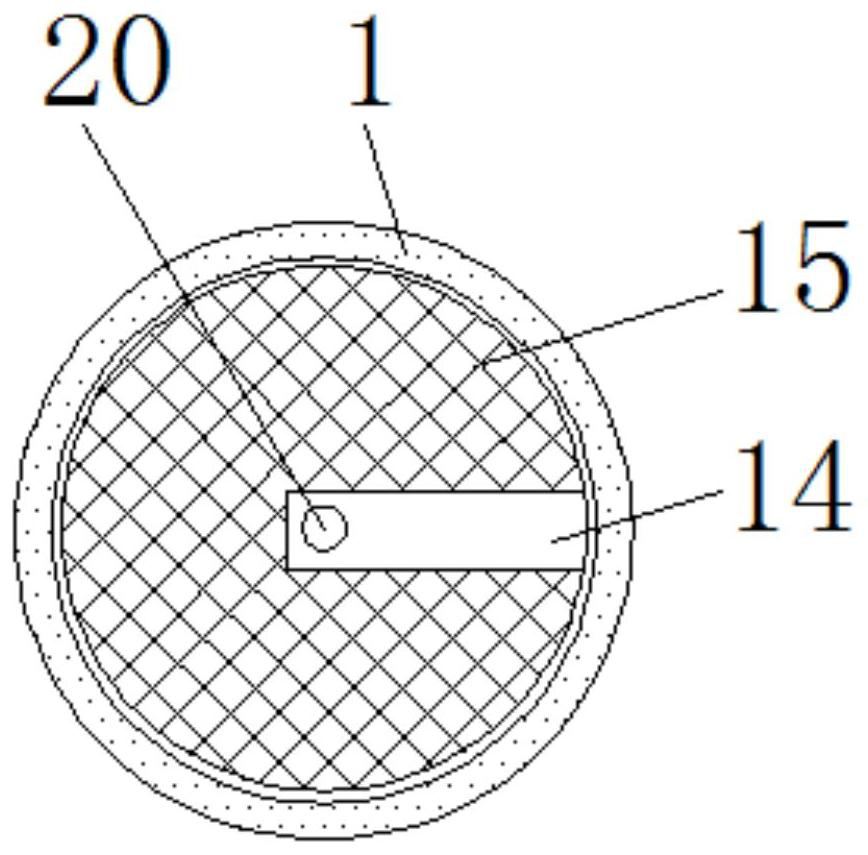

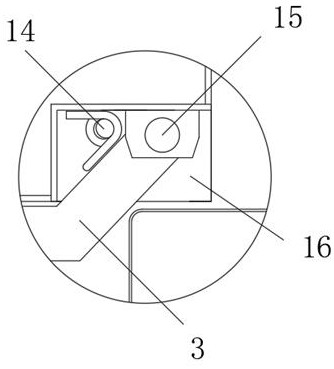

Ventilation pipeline capable of preventing particles from entering interior to precipitate and accumulate

InactiveCN113390173AAffect liquidityPrevent accumulation and cloggingDucting arrangementsMechanical apparatusElectric machineGear wheel

The invention discloses a ventilation pipeline capable of preventing particles from entering the interior to precipitate and accumulate. The ventilation pipeline comprises an air inlet pipe, a flange is arranged at the lower end of the air inlet pipe, a connecting pipe is arranged at the lower end of the flange, a machine box is fixedly connected to the upper end of the left side of the air inlet pipe, a rotating motor is arranged at the upper end of an inner cavity of the machine box, the output end of the rotating motor is fixedly connected with a power rod, the lower end of the power rod penetrates through the air inlet pipe and is provided with a driving gear in a sleeved mode, and a transmission rod is arranged below the driving gear. According to the ventilation pipeline, through the arrangement of a filter screen, filtering can be carried out on circulating air, so that the phenomenon that dust enters a bent part to cause accumulation and blockage is avoided; and through the arrangement of the machine box, the rotating motor, the power rod, the driving gear, a cleaning brush, a dust discharging opening, a driven gear and the transmission rod, and cleaning can be automatically carried out on the surface of the filter screen, so that dust is prevented from being gathered on the surface of the filter screen to influence air circulation, and cleanness and circulation of the interior of the air inlet pipe are effectively kept.

Owner:丽水大广通环保科技工程有限公司

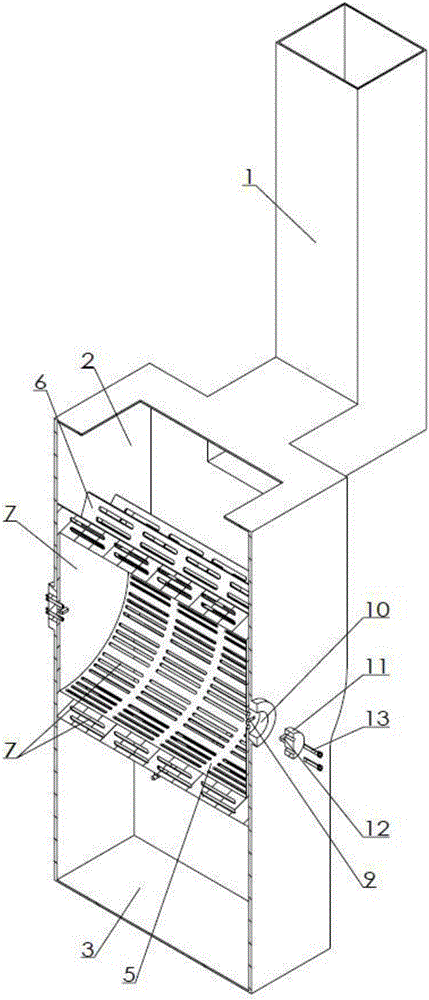

Double-turnover-plate type biofuel furnace

ActiveCN106482163AEasy to discharge ashEasy access from the frontDomestic stoves or rangesLighting and heating apparatusCombustion chamberRight shift

The invention discloses a double-turnover-plate type biofuel furnace. The double-turnover-plate type biofuel furnace is characterized in that the lower edge of each front turnover plate contacts with the lower edge of a corresponding rear turnover plate adjacent to the front turnover plate and located on the other side or a gap below 1cm is reserved between the lower edge of each front turnover plate and the lower edge of the corresponding rear turnover plate adjacent to the front turnover plate and located on the other side, two ends of the turnover plates adjacent to the front wall and the rear wall of an ash storage chamber are fixedly connected with the lateral wall of a combustion chamber, two ends of the upper edges of the rest of turnover plates are connected with the lateral wall of the combustion chamber through rotary shafts, a left shifting rod extending downwardly is connected to the left of the middle of the lower edge of each front turnover plate, a right shifting rod extending downwardly is connected to the right of the middle of the lower edge of each rear turnover plate, a drawable left transmission rod and a drawable right transmission rod which penetrate the front wall and the rear wall of the ash storage chamber are arranged, left shifting holes allowing the left shifting rods to insert into are formed in the left transmission rod, and right shifting holes allowing the right shifting rods to insert into are formed in the right transmission rod. The double-turnover-plate type biofuel furnace has the advantages that the biofuel furnace is fast and convenient in ash discharge, combustion efficiency can be increased effectively, people are willing to use biofuel particles, and energy saving is facilitated.

Owner:CHONGQING HUAWANLUN BIOLOGICAL NEW ENERGY TECH CO LTD

Industrial environment-friendly bag type dust collector for dust removal

ActiveCN112044186APlay the role of elastic lockingPrevent stretching and shakingDispersed particle filtrationDust controlEnvironmental engineering

The invention discloses an industrial environment-friendly bag type dust collector for dust removal. The bag type dust collector structurally comprises an air suction opening, an upper cover, a filtercartridge and a dust collector, the upper cover is located at one end of the filter cartridge, the air suction opening is fixedly formed in one side of the upper cover, the filter cartridge is in butt joint with the dust collector, the interiors of the filter cartridge and the dust collector are communicated, a binding sleeve is in threaded locking connection with a dust collecting bag through anannular top plate, and the binding sleeve plays a role in elastically locking the dust collecting bag under the action of an opening and expanding piece, so that the phenomenon that the elastically locked cloth bag is stretched and shaken due to the impact force of smoke when the dust collecting bag is sprayed to the opening and expanding piece from a supporting and guiding device due to downwardimpact waste gas is prevented; and a dust collecting bucket is of a tapered structure with a big top and a small top to facilitate dust discharge, and through cooperation of a dispersing structure and a dispersing pipe, the wind direction is more dispersed, waste gas and dust in the dust collecting bucket are distributed more evenly, and meanwhile, the dispersing structure can play a certain rolein buffering, so impact borne by the dispersing structure can be reduced.

Owner:扬州市光大机械制造有限公司

A kind of continuous multi-stage air separation and classification method of concrete dry aggregate

InactiveCN103521445BQuality improvementShort processGas current separationClassification methodsStone dust

The invention discloses a concrete dry aggregate continuous multistage air classification method which is achieved by means of the following steps that mixed aggregate is thrown into the same sealed space, multistage air classification is carried out continuously on the mixed aggregate, and the mixed aggregate is divided into classified aggregate within multiple particle diameter ranges. According to the concrete dry aggregate continuous multistage air classification method, multistage air classification is carried out on the mixed aggregate continuously to enable particle sizes of classified aggregate to be more concentrated; soil and stone powder blended in the mixed aggregate are separated from the classified aggregate through continuous multistage air classification and are discharged, the classified aggregate is clean, the steps of water washing and dewatering can be omitted, the technological process is shortened, cost is reduced, and quality of concrete finished products is improved.

Owner:XINJIANG YUXIN CONCRETE

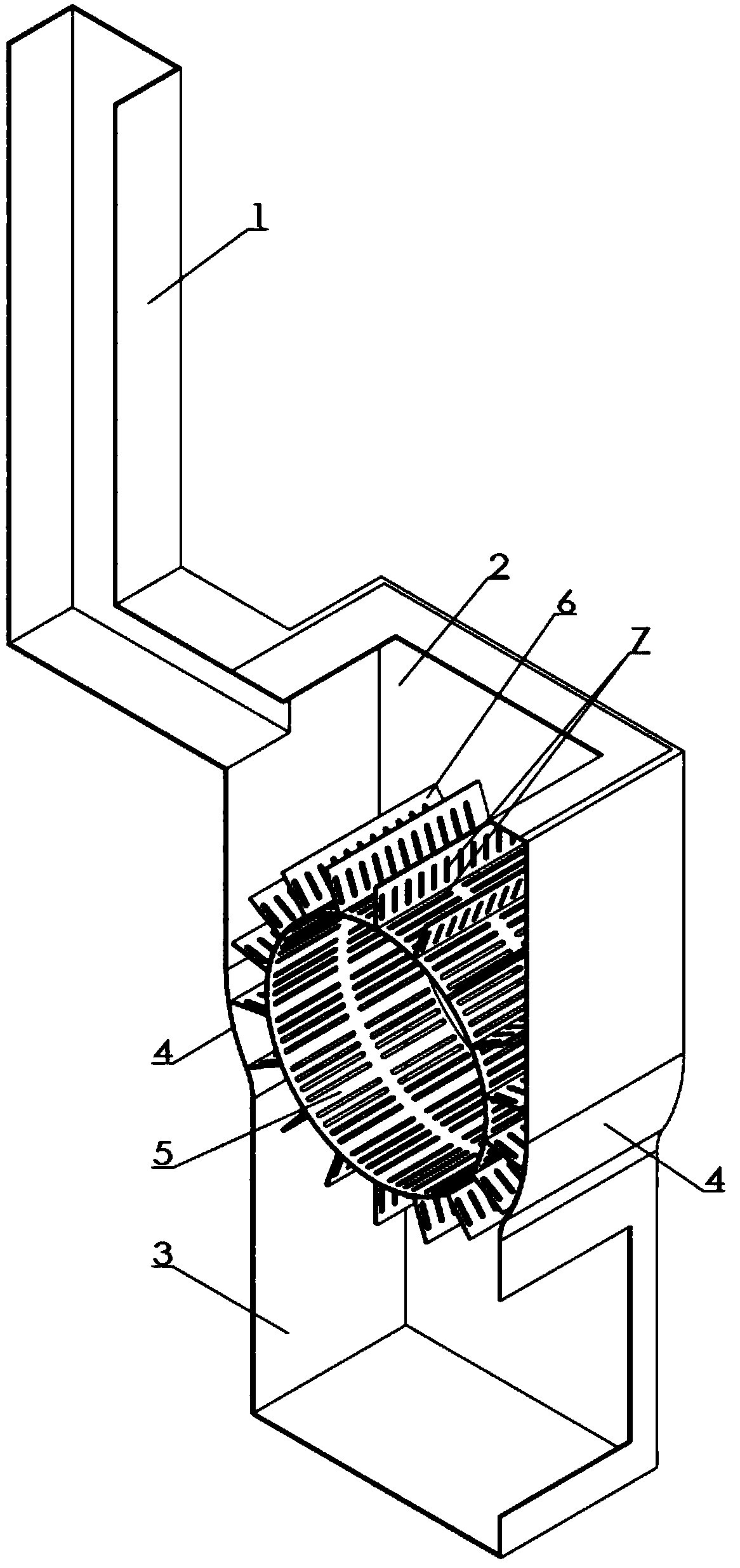

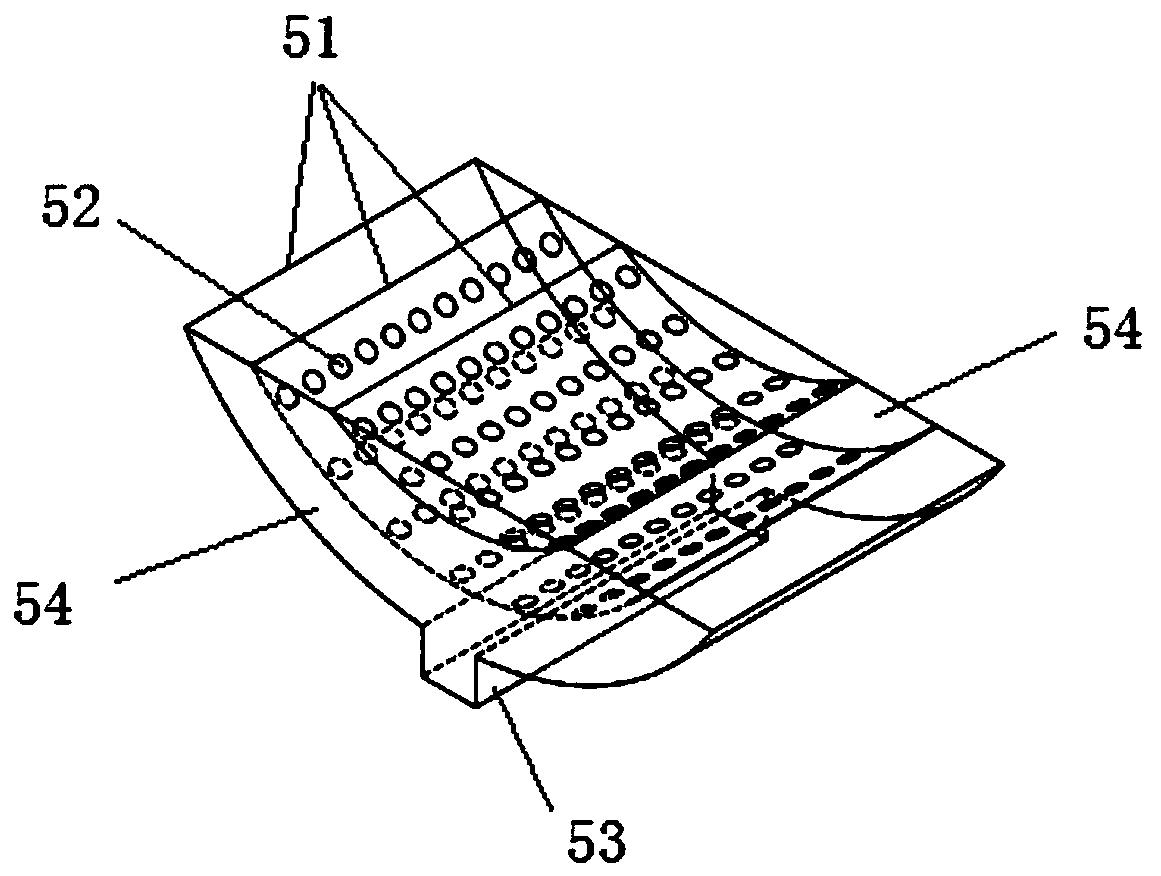

A Corrugated Grate Biofuel Stove

ActiveCN106482160BIncrease the ventilation areaIncrease the ash fall areaDomestic stoves or rangesLighting and heating apparatusCombustion chamberBiofuel

The invention discloses a wavy grate biofuel furnace. The wavy grate biofuel furnace comprises a furnace chamber and an exhaust pipe, and is characterized in that the furnace chamber is provided with a combustion chamber and an ash storage chamber of which the horizontal sections are rectangular; the ash storage chamber is below the combustion chamber; a grate is arranged between the ash storage chamber and the combustion chamber; the grate is composed of inclined plates which are arranged from the inner wall on one side to the opposite side wall at equal intervals and are connected end to end; the lower edges of the adjacent inclined plates are connected to form wave troughs; the upper edges of the adjacent inclined plates are connected to form wave crests; lower notches which are distributed along the wave troughs and downwards penetrate through the bottoms of the wave troughs are arranged in the bottoms of the wave troughs; and upper notches which are distributed along the wave crests, upwards penetrate through the tops of the wave crests and are staggered with the lower notches are arranged at the tops of the wave crests. According to the wavy grate biofuel furnace, the ventilation and ash falling area is increased, and combustion and ash discharge are facilitated; and besides, the V-shaped notches have inclination, ash collapses and slides during the combustion process, ash falls through the V-shaped notches more easily during the sliding process, and ash discharge is quicker and more convenient.

Owner:CHONGQING HUAWANLUN BIOLOGICAL NEW ENERGY TECH CO LTD

Wavy grate biofuel furnace

ActiveCN106482160AIncrease the ventilation areaIncrease the ash fall areaDomestic stoves or rangesLighting and heating apparatusCombustion chamberBiofuel

The invention discloses a wavy grate biofuel furnace. The wavy grate biofuel furnace comprises a furnace chamber and an exhaust pipe, and is characterized in that the furnace chamber is provided with a combustion chamber and an ash storage chamber of which the horizontal sections are rectangular; the ash storage chamber is below the combustion chamber; a grate is arranged between the ash storage chamber and the combustion chamber; the grate is composed of inclined plates which are arranged from the inner wall on one side to the opposite side wall at equal intervals and are connected end to end; the lower edges of the adjacent inclined plates are connected to form wave troughs; the upper edges of the adjacent inclined plates are connected to form wave crests; lower notches which are distributed along the wave troughs and downwards penetrate through the bottoms of the wave troughs are arranged in the bottoms of the wave troughs; and upper notches which are distributed along the wave crests, upwards penetrate through the tops of the wave crests and are staggered with the lower notches are arranged at the tops of the wave crests. According to the wavy grate biofuel furnace, the ventilation and ash falling area is increased, and combustion and ash discharge are facilitated; and besides, the V-shaped notches have inclination, ash collapses and slides during the combustion process, ash falls through the V-shaped notches more easily during the sliding process, and ash discharge is quicker and more convenient.

Owner:CHONGQING HUAWANLUN BIOLOGICAL NEW ENERGY TECH CO LTD

A flap type biofuel stove

ActiveCN106439918BEasy to discharge ashImprove combustion efficiencyDomestic stoves or rangesLighting and heating apparatusCombustion chamberBiofuel

The invention discloses a flip plate type biofuel furnace. The flip plate type biofuel furnace is characterized in that a grate is composed of parallel fixed grate bodies arranged from front to back in an equal distance mode and movable grate bodies distributed among adjacent fixed grate bodies, the fixed grate bodies and the movable grate bodies are provided with ash falling holes, two ends of each fixed grate body are fixedly connected with the side wall of a combusting chamber, the upper edge of each movable grate body is in contact with or is spaced from the upper edge of the fixed grate body adjacent to the movable grate body and located on one side for a gap of below 1 cm, the lower edge of each movable grate body is in contact with or is spaced from the lower edge of the fixed grate body adjacent to the movable grate body and located on the other side for a gap of below 1 cm, two ends of the upper edge of each movable grate body are connected with the side wall of the combusting chamber through rotary shaft, the middle of the lower edge of each movable grate body is connected with a shifting rod stretching downwards, a shifting hole for the shifting rod to be inserted is formed in the driving rod, a clamping groove is formed in the driving rod, the front wall of an ash storage chamber is connected with a movable insert plate which can be inserted into the clamping groove, and the front end of the driving rod is connected with a handle. The flip plate type biofuel furnace makes ash discharge quick and convenient, can effectively improve the combustion efficiency, makes people willing to adopt biofuel particles and is conductive to energy saving.

Owner:嘉兴久珥科技有限公司

Degradable environment-friendly bag incineration treatment system for garbage recycling

PendingCN113685819AReduce labor intensityEasy to cleanIncinerator apparatusCombined combustion mitigationBottom ashCombustion

The invention discloses a degradable environment-friendly bag incineration treatment system for garbage recycling. The degradable environment-friendly bag incineration treatment system comprises a conical top cover and a combustion furnace body, the conical top cover is fixedly installed at the upper end of the combustion furnace body, a waste heat utilization box is arranged at the upper end of the conical top cover, a closed furnace door is arranged at the front end of the conical top cover, and a bottom ash discharging seat is arranged at the lower end of the combustion furnace body. According to the degradable environment-friendly bag incineration treatment system for garbage recycling, an ash blocking plate is stretched out and drawn back to be opened, so that ash of the combustion furnace body falls into an ash conveyor and can be conveyed to the outside, an automatic ash discharging system is formed, automatic cleaning is achieved, and cleaning is more efficient; and the labor strength of personnel is effectively reduced, a bottom ash collecting bin plate can effectively collect ash falling from the ash conveyor, hot air generated by combustion in the combustion furnace body is discharged into the waste heat utilization box, a water pipe in the waste heat utilization box is effectively heated, and therefore the waste heat utilization effect is achieved.

Owner:杭州兆银医疗用品有限公司

A bag type dust collector for industrial environmental protection dust removal

ActiveCN112044186BPlay the role of elastic lockingPrevent stretching and shakingDispersed particle filtrationDust controlEnvironmental engineering

The invention discloses a bag-type dust collector for industrial environment-friendly dust removal. Its structure includes an air suction port, an upper cover, a filter cylinder, and a dust collector. The filter cartridge is docked with the dust collector, and the two are connected internally. The bundle sleeve is threaded and locked with the dust bag through the ring top plate, and is stretched under the action of the expansion part to elastically lock the dust bag. It can prevent the dust bag from stretching and shaking due to the impact force of the dust when the exhaust gas that impacts downward is ejected from the support and guide device to the expansion part. The structure of the dust collection bucket is The upper and lower conical shapes are convenient for ash discharge, and through the cooperation of the dispersion structure and the dispersion pipe, the wind direction is more dispersed, and the exhaust gas and dust in the dust collection bucket are more evenly distributed, and the dispersion structure can play a certain buffer function, so that the impact on itself will be reduced.

Owner:扬州市光大机械制造有限公司

Warped plate type biofuel furnace

ActiveCN106482161AFast ash removalEasy to discharge ashDomestic stoves or rangesLighting and heating apparatusCombustion chamberBiofuel

The invention discloses a warped plate type biofuel furnace. The warped plate type biofuel furnace is characterized in that a furnace grate is composed of parallel fixed grates which are arranged at equal intervals from front to back and parallel movable grates, wherein each movable grate is distributed between every two adjacent fixed grates, the fixed grates and the movable grates are each provided with ash holes, the two ends of each fixed grate are fixedly connected with the side walls of a combustion chamber, and the middles of the two ends of each movable grate are connected with the side walls of the combustion chamber through a rotating shaft; a transmission rod is provided with an inner limiting clamping slot and an outer limiting clamping slot, a movable insertion plate capable of being alternatively inserted into the inner limiting clamping slot and the outer limiting clamping slot is connected to the front wall of an ash storage chamber, and a handle is connected to the front end of the transmission rod. According to the warped plate type biofuel furnace, the movable grates can be rapidly turned by manipulating the transmission rod, ash can be discharged rapidly and conveniently, the combustion efficiency can be effectively improved, people prefer to adopting biofuels particles, and energy saving is promoted.

Owner:嘉兴久珥科技有限公司

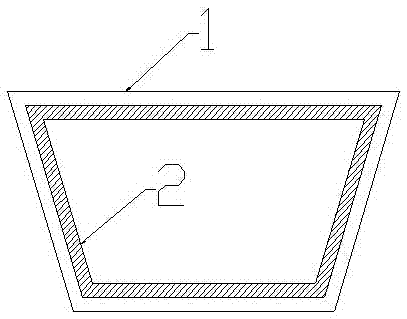

Smoke pipeline facilitating ash discharging

The invention discloses a smoke pipeline facilitating ash discharging. The smoke pipeline facilitating ash discharging comprises a horizontally mounted pipeline body. The two side faces of the pipeline body are both designed into slopes. The bottom of the pipeline body is horizontally arranged. A plurality of observation holes are horizontally formed in the lower end of one side face of the pipeline body. The cross section of the smoke pipeline facilitating ash discharging is designed to be in a trapezoid, thus, ash in the pipeline can conveniently glide along the slopes for collection, so that the effects of facilitating ash discharging and not prone to pipeline blockage are achieved.

Owner:DEYANG YIYOU METALLURGICAL EQUIP MFG CO LTD

Combined heat storage unit

PendingCN111043888AImprove uniformityEasy to discharge ashHeat storage plantsDispersed particle separationThermodynamicsFlue gas

The invention discloses a combined type heat storage unit which comprises a heat storage device and an ash discharging channel. Two independent heat exchange spaces are arranged in the heat storage device in parallel, and an opening allowing gas to pass through is formed in the top of each heat exchange space; the ash discharging channel is arranged at the bottom of the heat storage device and used for communicating the two heat exchange spaces, and an ash discharging valve is arranged at the bottom of a middle section of the ash discharging channel; one heat exchange space, the ash dischargechannel and the other heat exchange space sequentially form a gas flowing channel, each heat exchange space is used for storing heat or releasing heat for gas, the ash discharge channel is used for providing a deposition space for dust in the gas, and the ash discharging valve is used for discharging deposited dust. The problems that existing heat storage equipment is mainly suitable for clean gasand dust cannot be discharged during heat exchange of dusty flue gas are solved.

Owner:思安新能源股份有限公司

An improved biofuel combustion furnace

ActiveCN106524229BBurn helpsEasy to discharge ashDomestic stoves or rangesLighting and heating apparatusCombustion chamberBiofuel

The invention disclosed an improved biofuel burning furnace. The improved biofuel burning furnace is characterized in that a hollow roller of which the axis is arranged in the left-right direction is arranged in a burning chamber, and the hollow roller and an arc-shaped transition plate are coaxial; the outer wall of the roller is provided with partition plates which are distributed in the circumferential direction, extend outwards in the radial direction and are parallel to the axis of the roller; a gap is formed between the outer edge of each partition plate and the arc-shaped transition plate; the roller and the partition plates are provided with via holes; end plates are connected to the two ends of the roller; prism holes are formed in the axes of the end plates; the left and right side walls of the burning chamber are provided with shaft holes coaxial with the end plates correspondingly, and rotary bodies are arranged in the shaft holes in a matched mode; the front and rear walls of a dust storage chamber are provided with opposite via holes; a transmission rod capable of rotating penetrates through the via holes; a shift fork is connected to the middle of the transmission rod and can be screwed into the partition plates along with the transmission rod; a handle is connected to the front end of the transmission rod; and operation on the front portion is more convenient. According to the improved biofuel burning furnace, ash can be quickly and conveniently discharged, and the burning efficiency can be effectively improved, so that people would like to use biofuel particles, and energy sources are saved advantageously.

Owner:CHONGQING HUAWANLUN BIOLOGICAL NEW ENERGY TECH CO LTD

Cinder soaking water concentrating and separating tank

ActiveCN101612489BSmall footprintImprove concentration efficiencySedimentation settling tanksEngineeringRotational flow

The invention relates to a concentration and separation processing facility for flushing cinder soaking water from a fuel electric plant, in particular to a cinder soaking water concentrating and separating tank which is mainly characterized in that a separated tapered cinder hopper (14) of the concentration and separation tank is arranged below a concentration and separation tank body (1) and isinternally provided with a cinder separating plate (15); the middle part of the concentration and separation tank body (1) is provided with a straight reaction cylinder (6) which is a reaction regionA on the upper part, a rotational flow settling region B in the middle and a first concentration region C at the lower part; the outer wall of the straight reaction cylinder (6) is fixedly connected with a tapered reaction cylinder (9); the concentration and separation tank body (1), the separated tapered cinder hopper (14) of the concentration and separation tank and the tapered reaction cylinder (9) forms a second concentration region E which is connected with a second cinder discharging pipe (12) and a valve (13) arranged on the second cinder discharging pipe (12); a flow guiding cylinder (7) is arranged outside the straight reaction cylinder (6) and forms a flow guiding region D together with the straight reaction cylinder (6) and the tapered reaction cylinder (9); a tapered cinder baffle (8) is arranged on the concentration and separation tank body (1), and a separation region F is formed between the tapered cinder baffle (8) and the flow guiding cylinder (7).

Owner:GANSU GOLDEN BRIDGE GRP CO LTD

A crusher dust collector

ActiveCN112774336BEasy detachable connectionIncrease the lengthDispersed particle filtrationTransportation and packagingFiltrationPlastic surgery

The present invention disclosed a crusher dust collector, including the shell and exhaust chamber. The air inlet was opened on the shell, and the bottom was connected to the ash through the gray outlet.The shell is columnar, with a filter bag in the shell; a deformation support mechanism is set inside the filter bag; the ash carrier made of elastic material below the air inlet, the outer edge of the outer edge is connected to the inner wall of the shell to the inner wall connectionInner edge to connect to the ash outlet; the back of the ash to the side of the filter bag is connected to a plastic surgery mechanism. The gray film has two shapes. The first shape is the bucket shape of the opening, and the second shape is a cone -shaped shape.The crusher dust collector can facilitate the length of the filter bag through the cylindrical shell and the first -shaped gray film, thereby expanding the filtration area, enhancing the filtering effect, and extending the use cycle.Falling dust, combined with the blowing system, improve the dredging effect of the filter bag, and adjust the gray film to the second shape to facilitate the gray.

Owner:WUHAI XISHUI CEMENT

A double flap biofuel stove

ActiveCN106482163BEasy to discharge ashEasy access from the frontDomestic stoves or rangesLighting and heating apparatusCombustion chamberRight shift

The invention discloses a double-turnover-plate type biofuel furnace. The double-turnover-plate type biofuel furnace is characterized in that the lower edge of each front turnover plate contacts with the lower edge of a corresponding rear turnover plate adjacent to the front turnover plate and located on the other side or a gap below 1cm is reserved between the lower edge of each front turnover plate and the lower edge of the corresponding rear turnover plate adjacent to the front turnover plate and located on the other side, two ends of the turnover plates adjacent to the front wall and the rear wall of an ash storage chamber are fixedly connected with the lateral wall of a combustion chamber, two ends of the upper edges of the rest of turnover plates are connected with the lateral wall of the combustion chamber through rotary shafts, a left shifting rod extending downwardly is connected to the left of the middle of the lower edge of each front turnover plate, a right shifting rod extending downwardly is connected to the right of the middle of the lower edge of each rear turnover plate, a drawable left transmission rod and a drawable right transmission rod which penetrate the front wall and the rear wall of the ash storage chamber are arranged, left shifting holes allowing the left shifting rods to insert into are formed in the left transmission rod, and right shifting holes allowing the right shifting rods to insert into are formed in the right transmission rod. The double-turnover-plate type biofuel furnace has the advantages that the biofuel furnace is fast and convenient in ash discharge, combustion efficiency can be increased effectively, people are willing to use biofuel particles, and energy saving is facilitated.

Owner:CHONGQING HUAWANLUN BIOLOGICAL NEW ENERGY TECH CO LTD

Ash hopper dust removal device

InactiveCN109847942AGuaranteed temperatureAvoid cakingElectrostatic separation detailsEngineeringElectrical and Electronics engineering

The invention discloses an ash hopper dust removal device comprising an ash hopper, wherein the ash hopper adopts an interlayer heat preservation structure, a plurality of vibrators are respectively arranged on an outer wall of the ash hopper, a heating device is arranged in the interlayer heat preservation structure of the ash hopper, a connecting gap of the heating device and the interlayer heatpreservation structure of the ash hopper is filled with a heat preservation filler, a partition device is arranged at the bottom end of the ash hopper in a penetration manner, a crushing drum deviceis arranged at the bottom end of an ash discharge valve, and the ash discharge valve is arranged at the bottom end of the crushing drum device. The ash hopper dust removal device provided by the invention is capable of preventing the agglomeration of an ash body due to condensation caused by temperature reduction and preventing the ash body from being attached to the inner wall of the ash hopper,and is also capable of efficiently crushing the ash body.

Owner:FOSHAN SANSHUI HUAXING GLASS

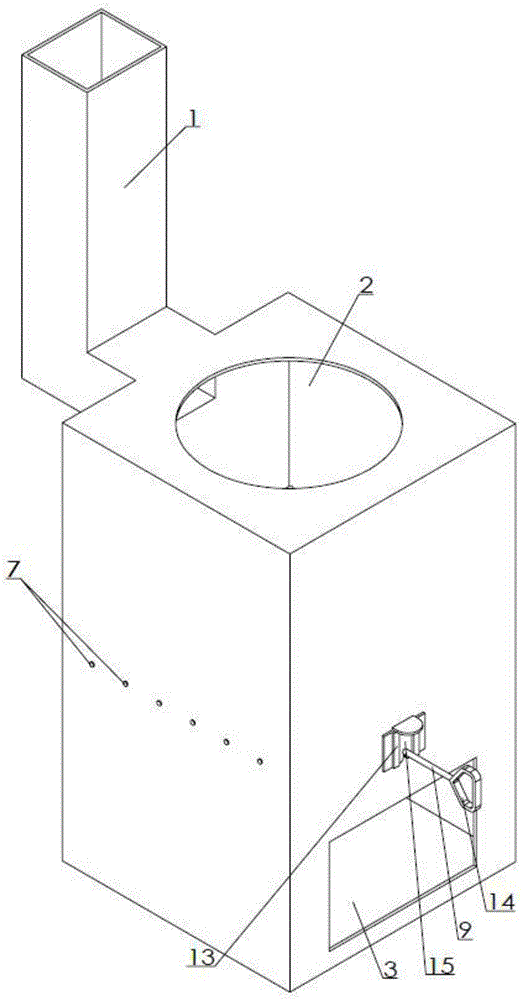

Moxibustion therapy device capable of discharging ash conveniently

PendingCN114869744AEasy to installAdjustable lengthHuman health protectionDevices for heating/cooling reflex pointsPharmacy medicineMedicine

The invention relates to a moxibustion therapy device convenient to discharge ash, which is characterized in that a mounting cylinder is mounted on a mounting seat, a mounting top cover is mounted at the top of the mounting cylinder, a mounting top seat is embedded in the mounting top cover, a first connecting belt is mounted on one side of the mounting seat through a connecting block, and a second connecting belt is mounted on the other side of the mounting seat through a connecting block; a smoke outlet cavity is formed in the inner side of the mounting cylinder, a plurality of flow guide cavities evenly distributed at equal angles are formed in the position, close to the periphery of the smoke outlet cavity, of the inner side of the middle of the mounting cylinder, a plurality of air inlet cavities evenly distributed at equal angles are formed in the position, close to the periphery of the smoke outlet cavity, of the inner side of the bottom of the mounting cylinder, and the air inlet cavities and the smoke outlet cavity are correspondingly arranged in an up-down staggered mode. A smoke exhaust cavity is formed in the mounting seat, a heat conduction net pad is embedded in the bottom of the mounting seat, moxa smoke penetrates through the flow guide groove to enter the smoke exhaust cavity of the mounting seat, medicine components and heat in the moxa smoke penetrate through the heat conduction net pad to reach the skin surface of the acupuncture points of the human body to treat the human body, no ash is discharged in the whole process, and pollution is reduced.

Owner:安徽奇乃尔医疗科技有限公司

Multi-purpose hole head for screwdriver

ActiveCN112392411BImprove structural strengthEasy to fixDrill bitsDrilling rodsEngineeringScrew thread

The invention discloses a multi-purpose hole head of a screwdriver, comprising a hole former joint, a connecting column and a connecting rod joint. The end faces of the columns are all provided with mounting holes, the inner walls of the mounting holes are provided with internal threads, the two sides of the hole former joint and the connecting rod joint are provided with bolt holes, and the outer walls of the ports of the bolt holes are fixedly connected There is a reinforcing rib, and the reinforcing rib is provided with a receiving slot at the outer port of the bolt hole; the hole former and the connecting rod are respectively threaded with the multi-purpose hole head of the screwdriver, and the connection operation is convenient. The connector and the connecting rod and the connecting rod joint are firmly fixed, and the reinforcing ribs effectively enhance the structural strength of the bolt hole to prevent cracking during the fixing process. Wear and tear on the connecting part during the process.

Owner:ZOUCHENG YANKUANG TAIDE IND & TRADE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com