A rotary biofuel combustion furnace

A biofuel and combustion furnace technology, applied in the direction of rotary grate, combustion equipment, combustion method, etc., can solve the problems of frequent ash discharge, affecting combustion, and difficult operation of ash discharge, so as to improve combustion efficiency, save energy, and discharge Ash quick and easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

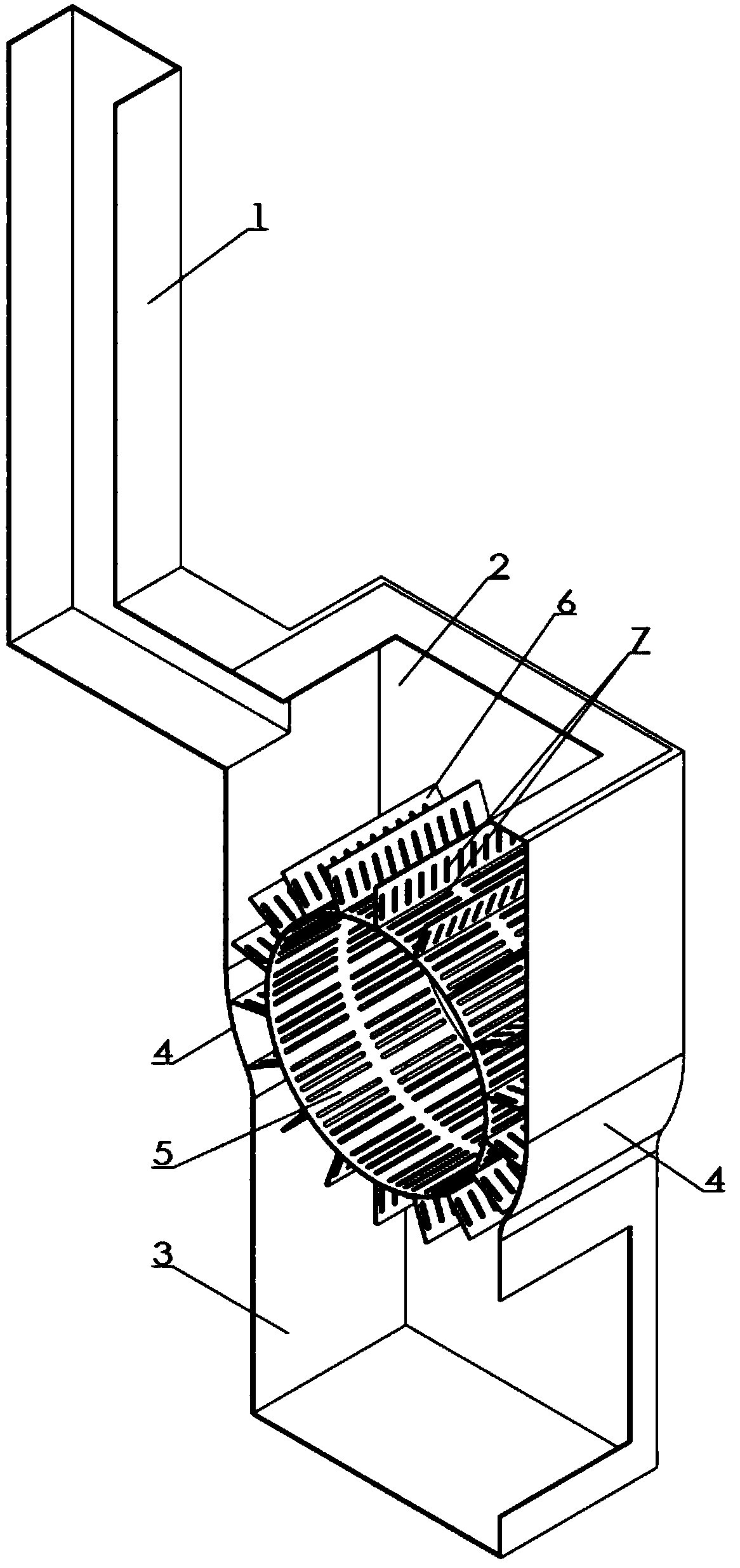

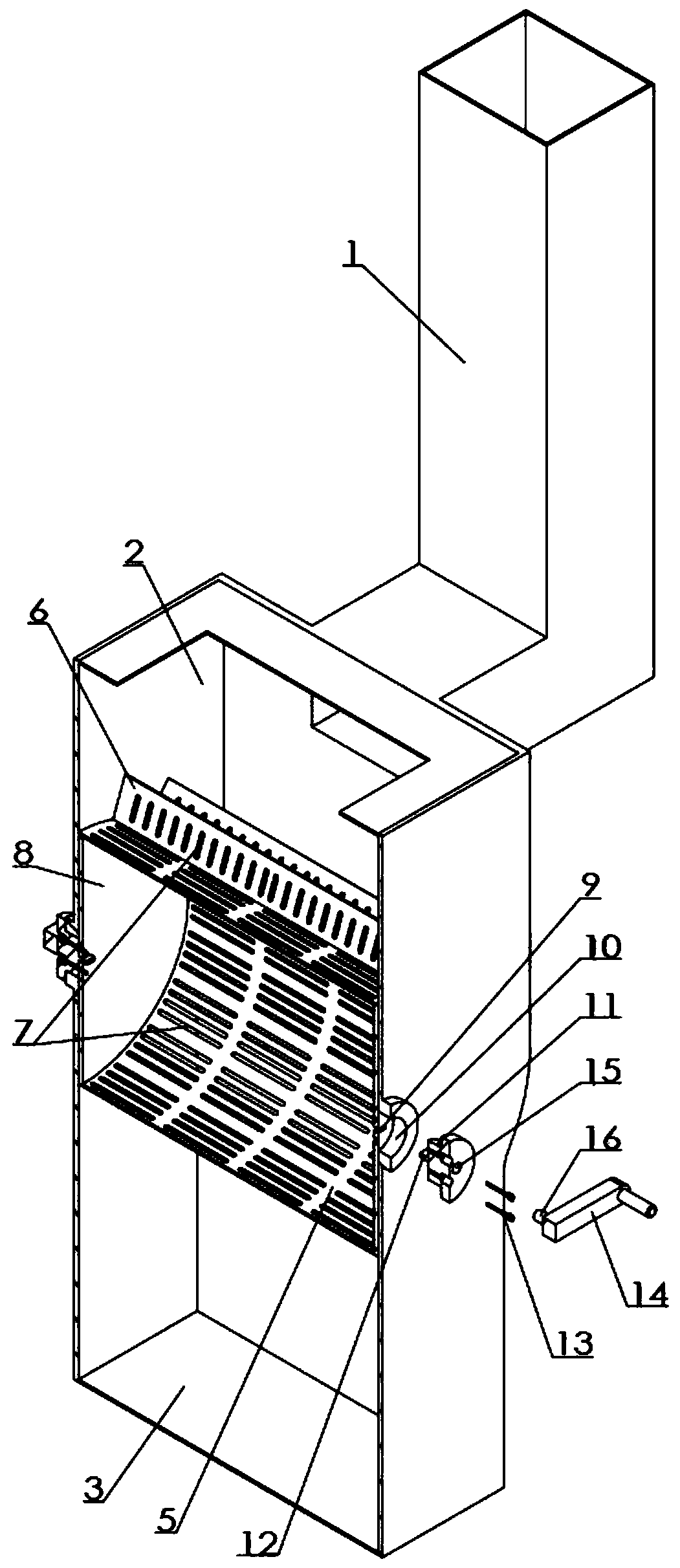

[0013] Examples of the present invention figure 1 , 2 As shown, the rotary biofuel combustion furnace is provided with a furnace chamber and a smoke exhaust pipe 1, the furnace chamber is provided with a combustion chamber 2 and an ash storage chamber 3, the ash storage chamber is located at the lower part of the combustion chamber, and the front and rear walls of the combustion chamber are respectively The arc-shaped transition plate 4 of the same size is transitionally connected with the front and rear walls of the ash storage chamber. A hollow drum 5 coaxial with the arc-shaped transition plate in the left and right directions of the axis is provided in the combustion chamber, and the outer wall of the drum is provided with circumferentially distributed The diaphragm 6 extending radially outward and parallel to the axis of the drum, the number of partitions facing the arc-shaped transition plate on one side of the drum at any angle is at least two, to avoid open air, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com