Patents

Literature

1645 results about "Waste heat recovery unit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A waste heat recovery unit (WHRU) is an energy recovery heat exchanger that transfers heat from process outputs at high temperature to another part of the process for some purpose, usually increased efficiency. The WHRU is a tool involved in cogeneration. Waste heat may be extracted from sources such as hot flue gases from a diesel generator, steam from cooling towers, or even waste water from cooling processes such as in steel cooling.

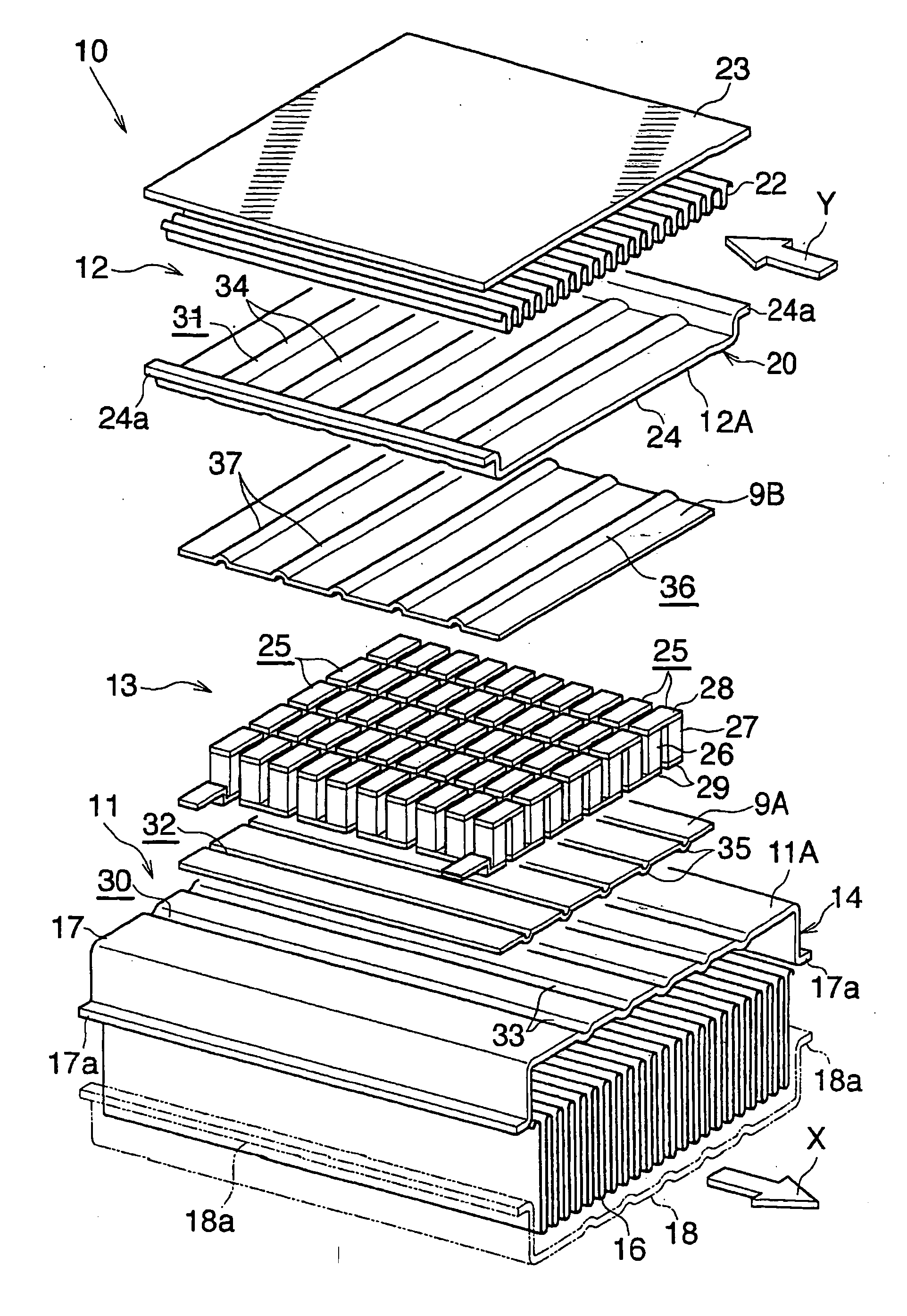

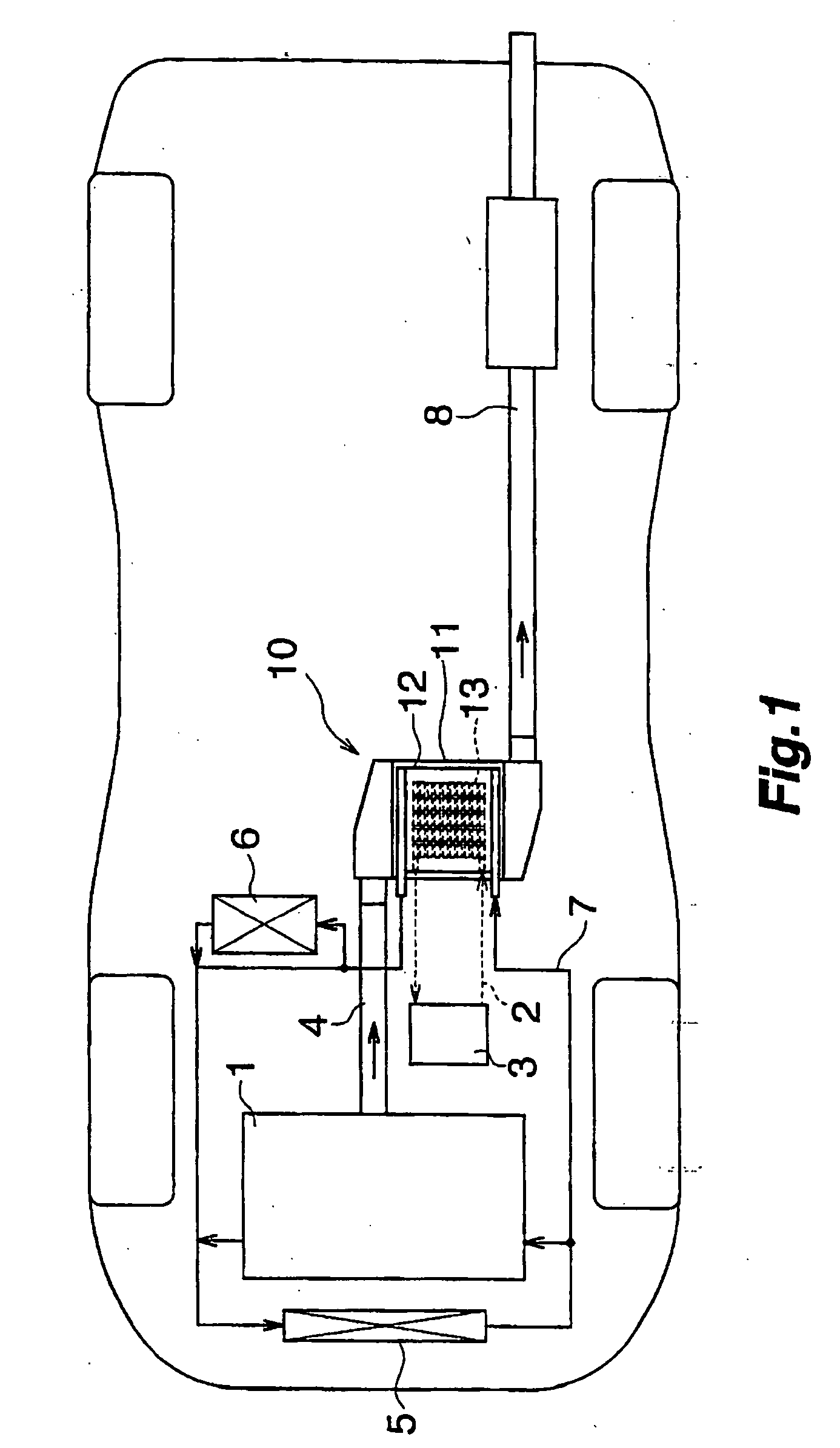

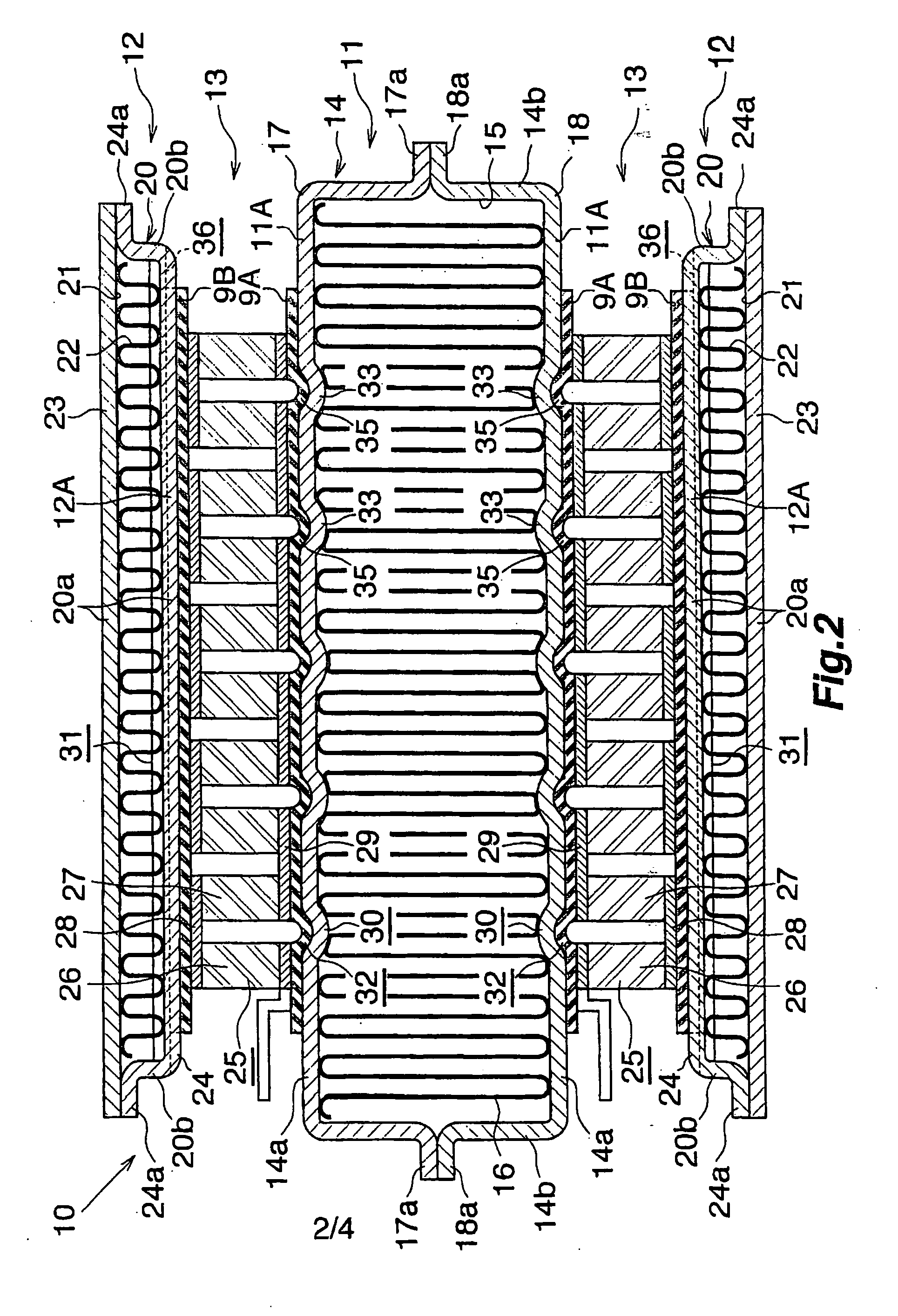

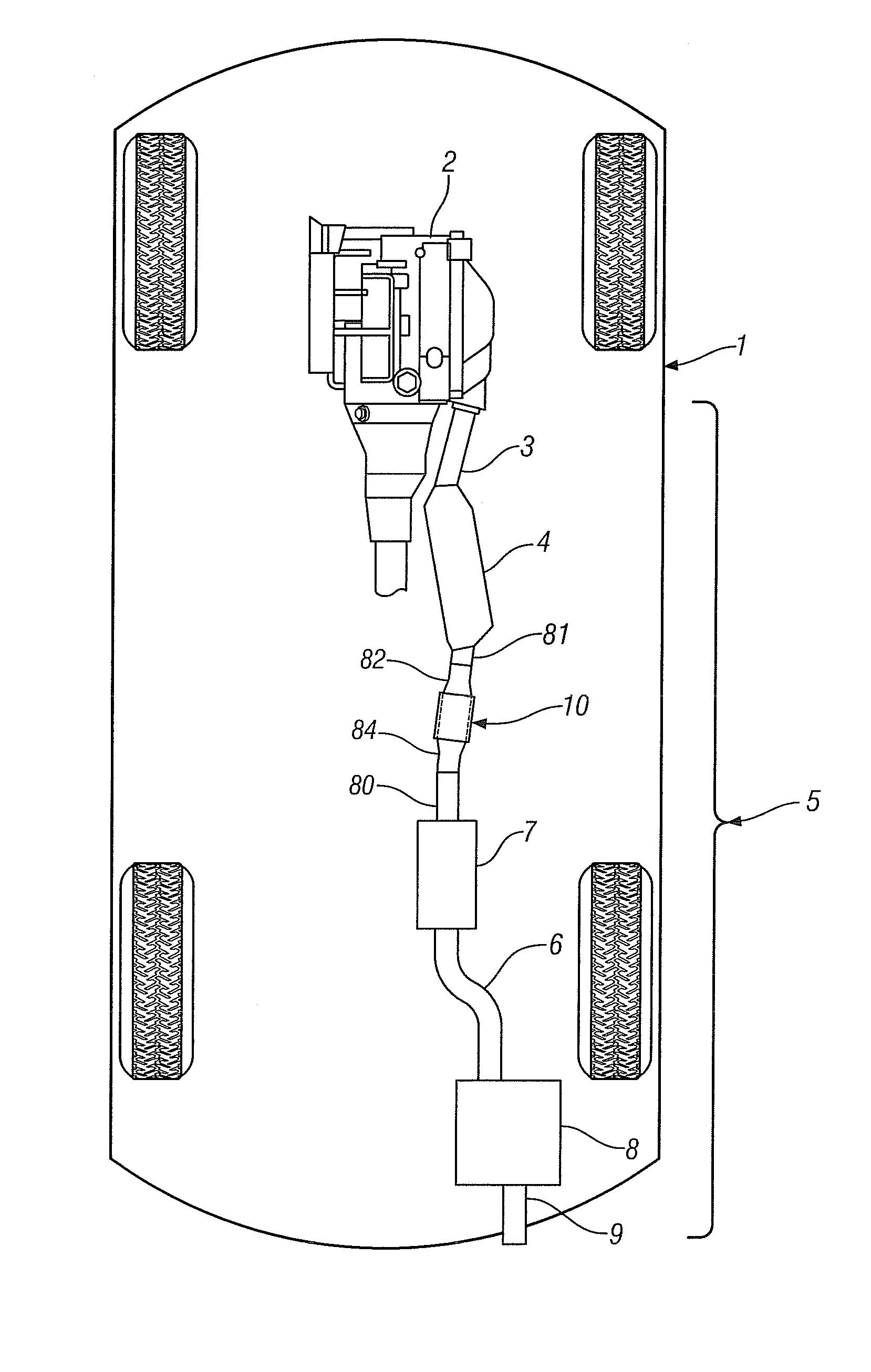

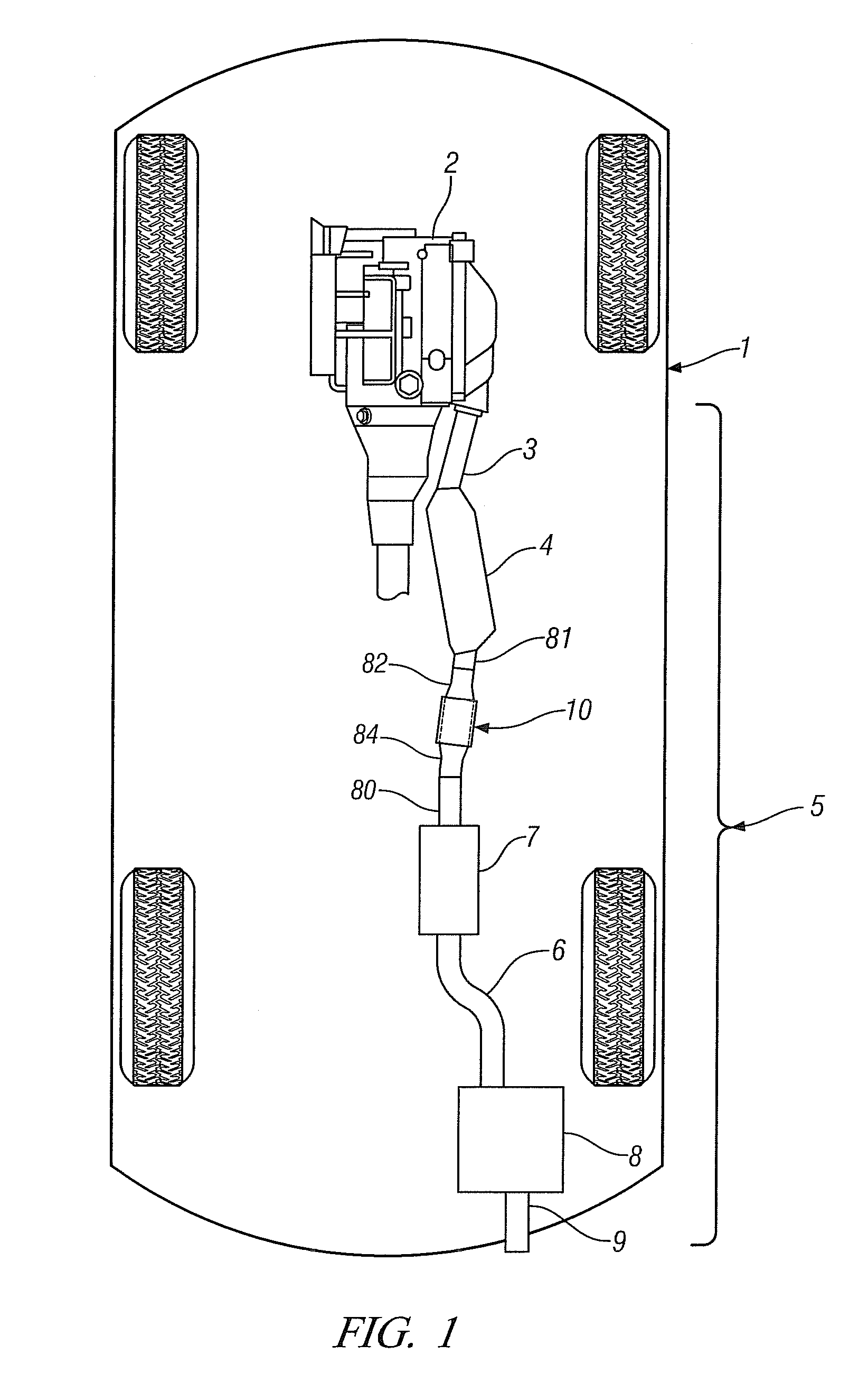

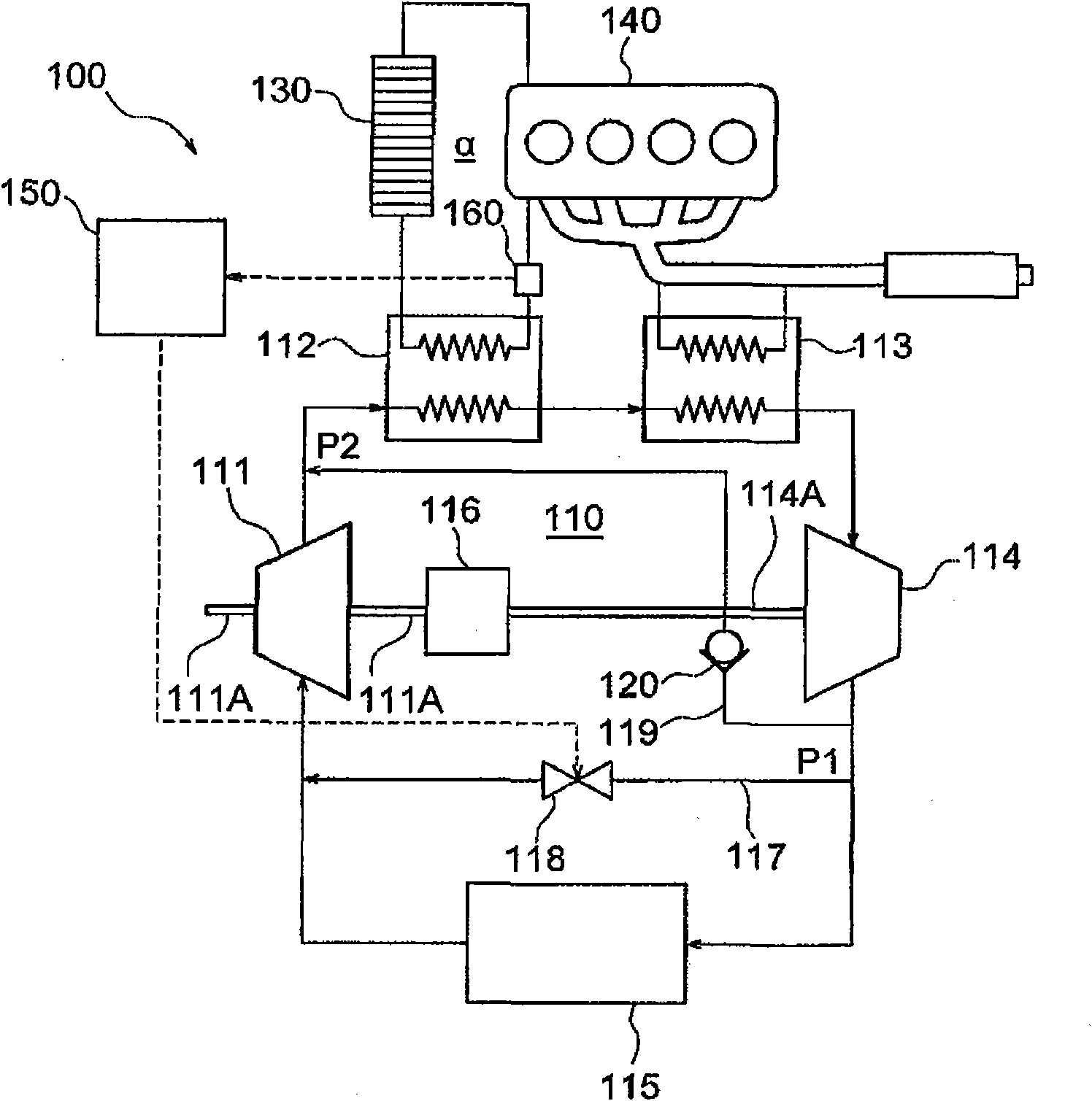

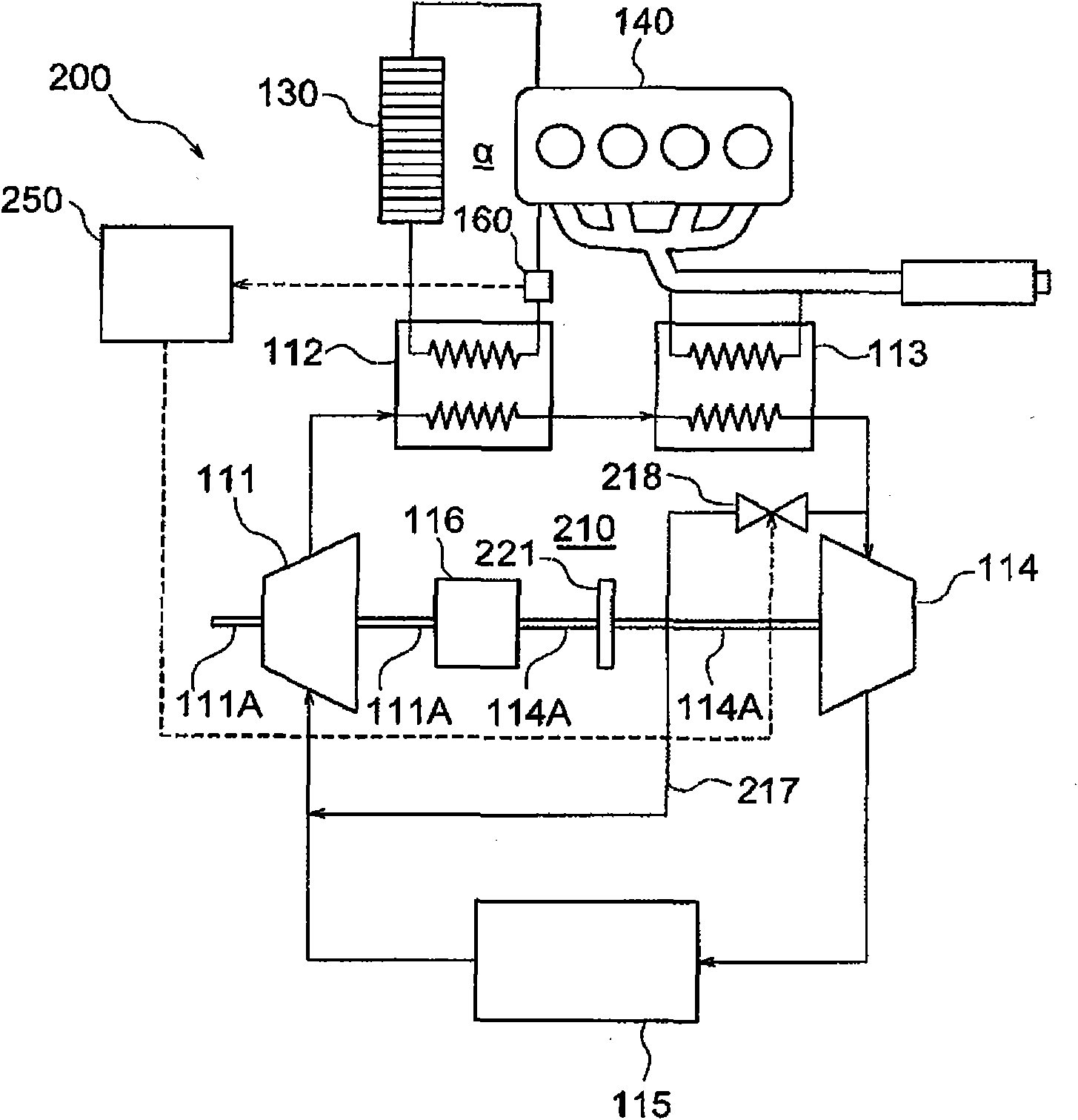

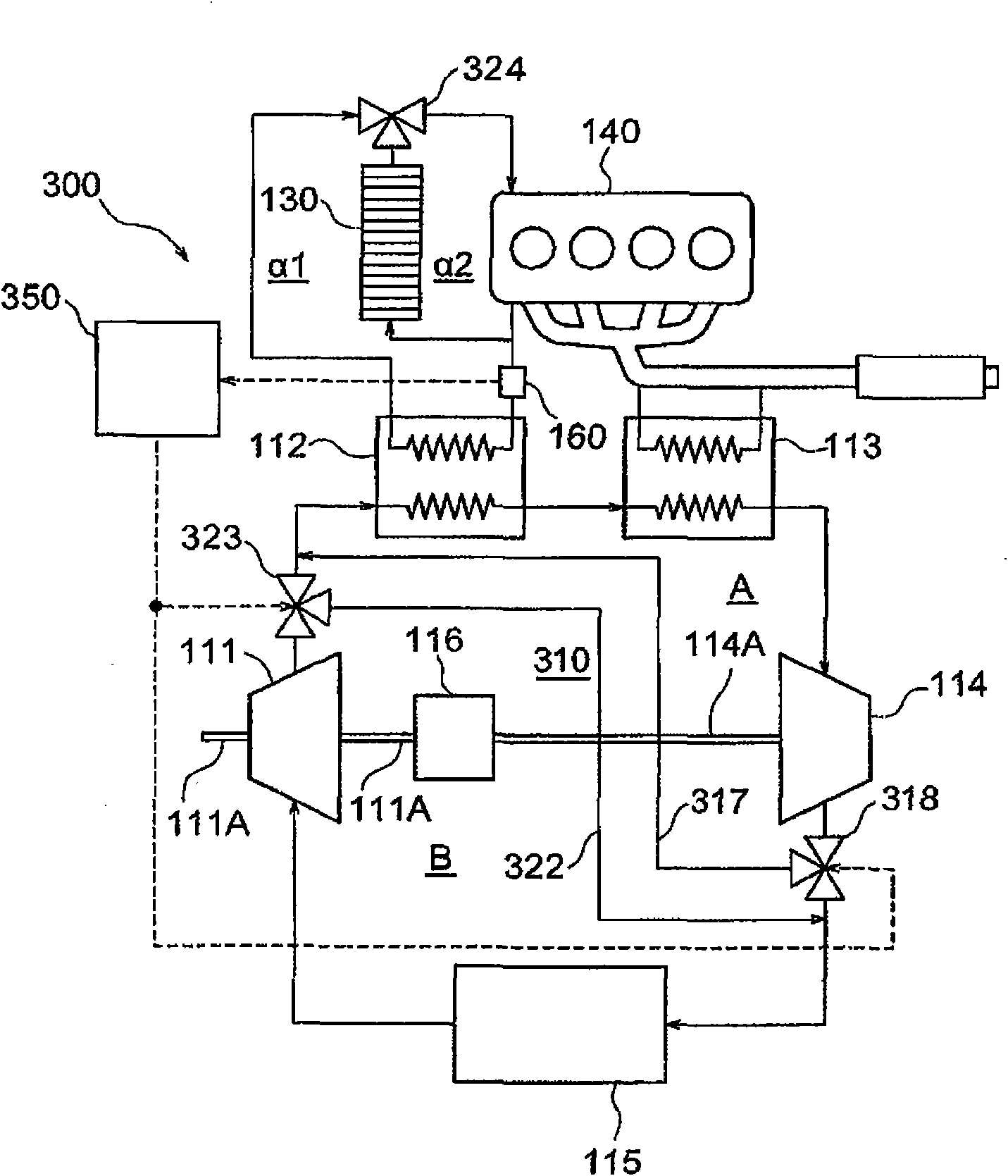

Waste heat recovery system and thermoelectric conversion system

InactiveUS20060157102A1Increase powerImprove efficiencyInternal combustion piston enginesThermoelectric device with peltier/seeback effectWaste heat recovery unitFuel cells

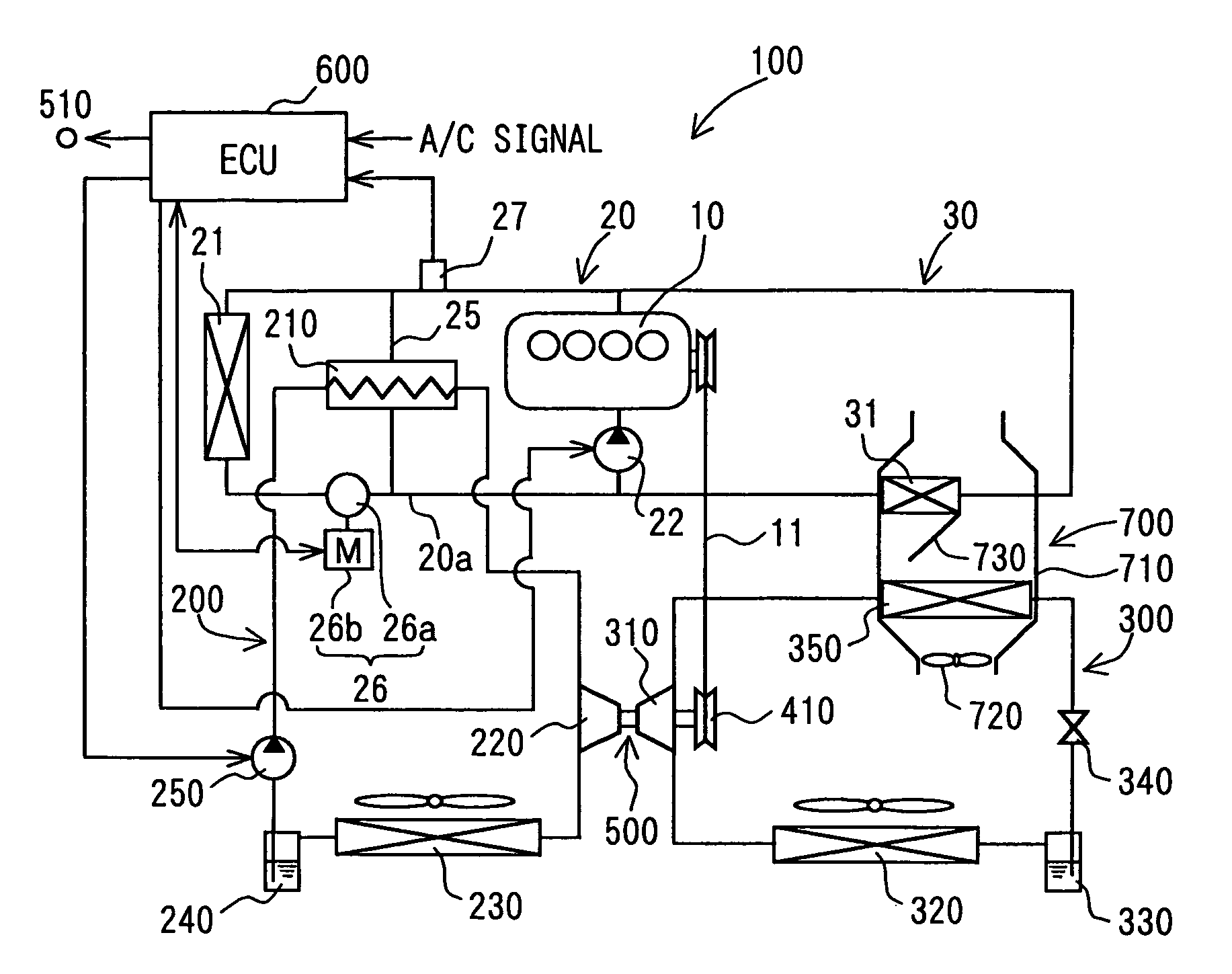

A waste heat recover system includes a mechanism for supplying power by use of a thermoelectric conversion unit, and a mechanism for utilizing heat released from the thermoelectric conversion unit. Heat released from the thermoelectric conversion unit is utilized for, for example, heating, defrosting, defogging, temperature keeping of fuel, temperature keeping of an internal combustion engine, and temperature keeping of a fuel cell. The waste heat recovery system is equipped in, for example, cars, incinerators, fuel cells, and industrial machinery.

Owner:SHOWA DENKO KK

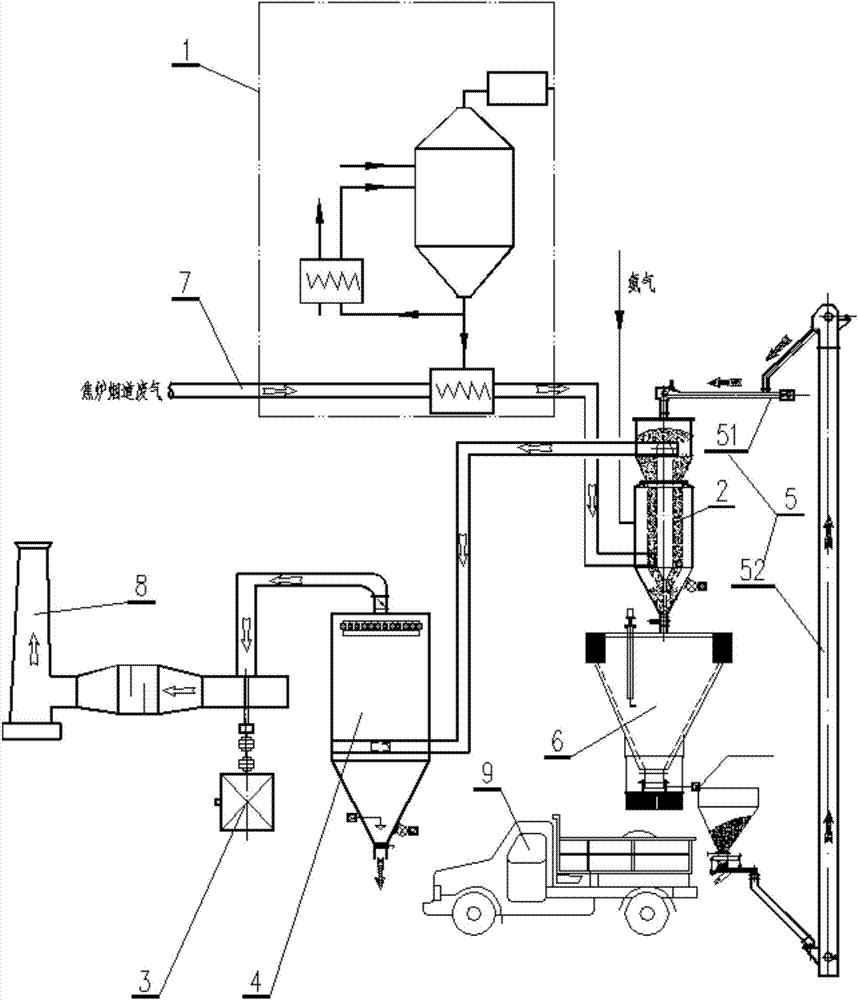

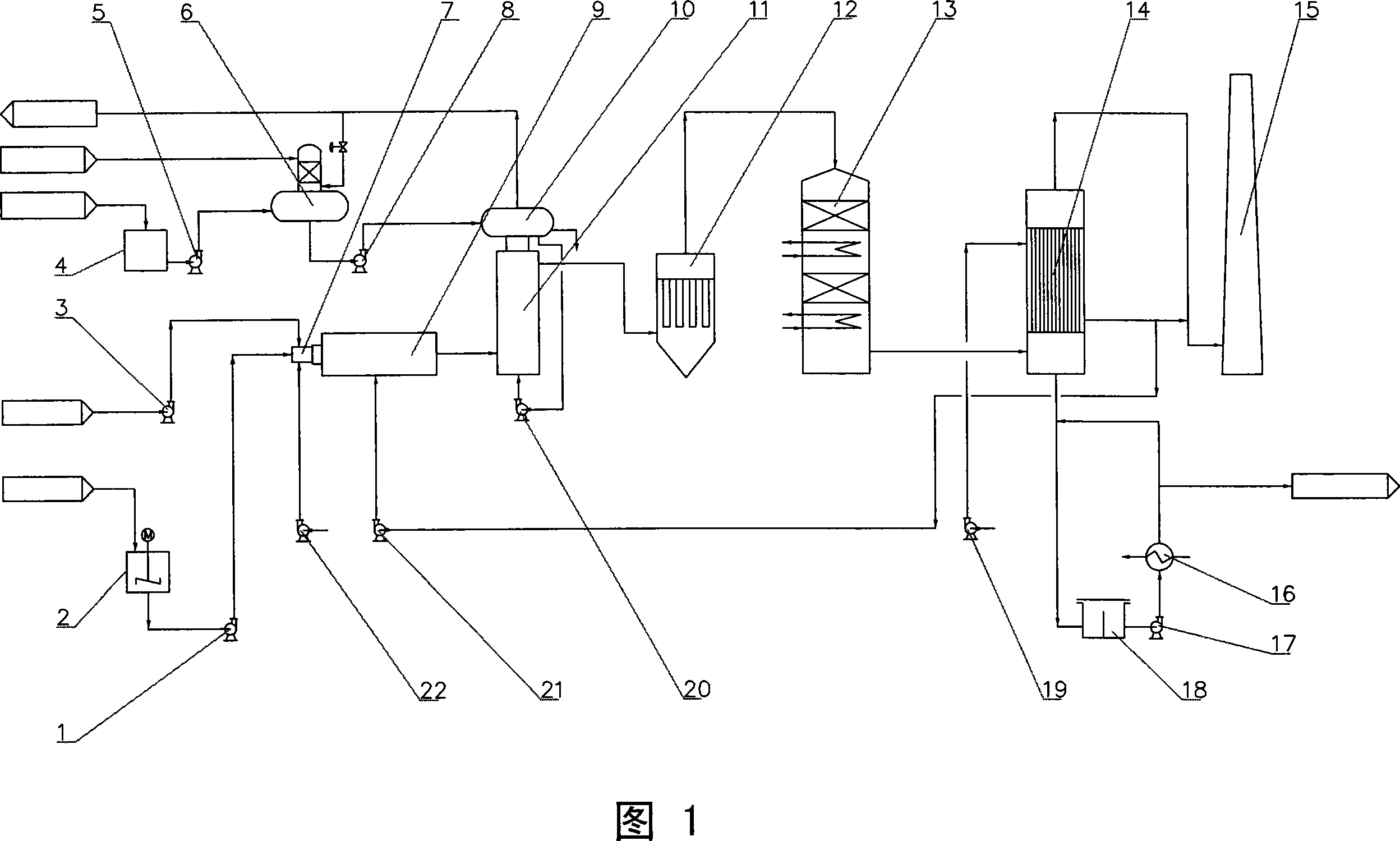

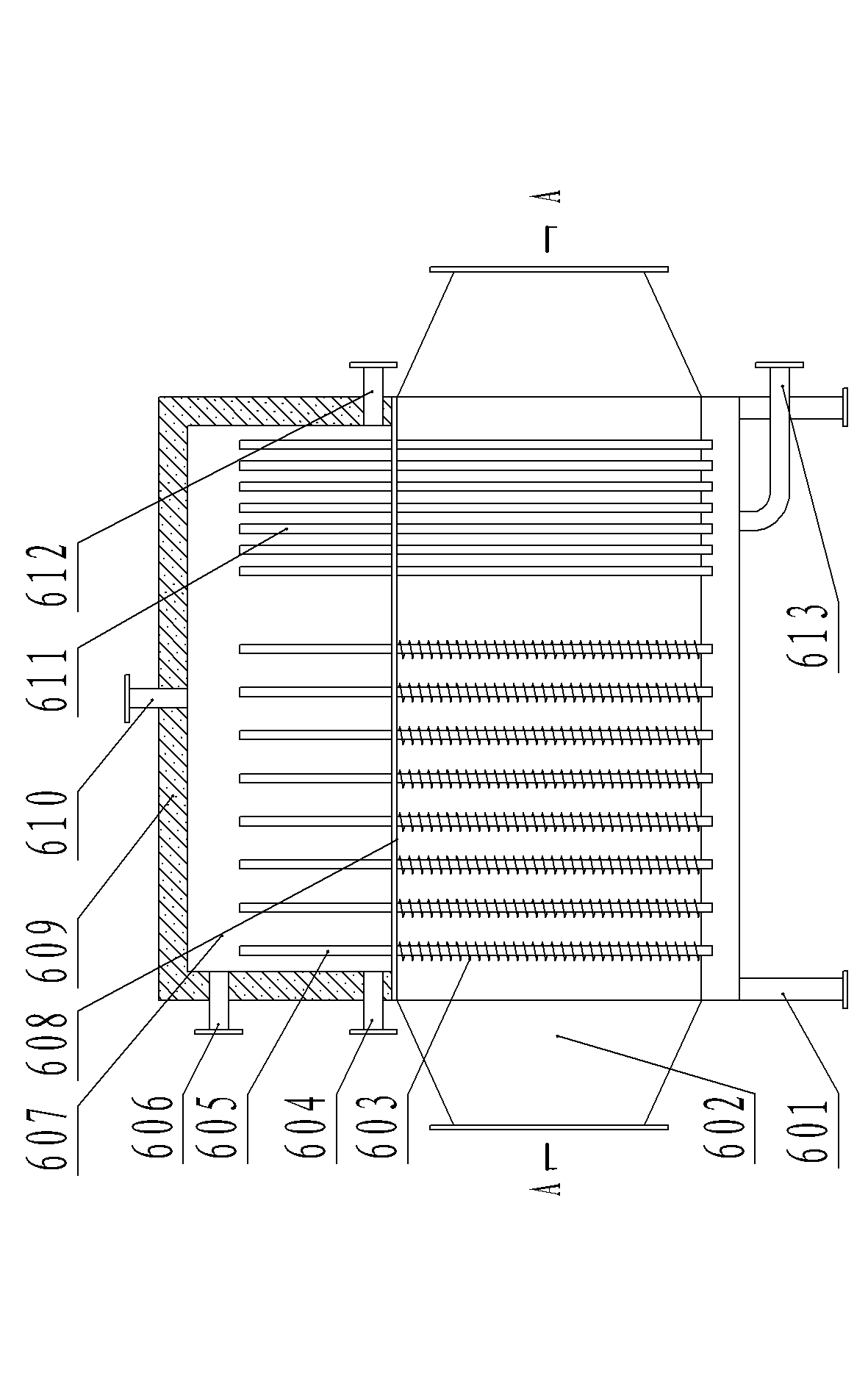

Coke oven flue gas waste heat utilization and purification method

ActiveCN103877856AReduce consumptionEfficient governanceDispersed particle separationPurification methodsCoking plant

The invention relates to the technical field of coke oven flue gas integrated utilization and pollution treatment and in particular relates to a coke oven flue gas waste heat utilization and purification method. The method is characterized in that flue gas waste heat is recovered by utilizing a flue gas waste heat recovery device, the temperature of the flue waste gas is reduced, and integrated desulfurization and denitration of the flue waste gas is realized by utilizing the activated adsorption capacity and low-temperature denitration catalytic capability of the coke. Compared with an existing process, the method has the beneficial effects that the flue waste gas desulfurization and denitration is performed under low-temperature working conditions, an additional heating system is not needed, and the energy consumption is reduced. In order to realize the desulfurization and denitration under low-temperature working conditions, the flue waste gas is cooled through the waste heat recovery device, so that the waste heat of the flue waste gas is fully utilized. The coke serves as a main catalyst for desulfurization and denitration and comes from a coking plant, the source is sufficient, and waste loss is avoided. The method disclosed by the invention can be widely applied to pollution treatment and integrated utilization of coke oven heated flue waste gas in coking production enterprises.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

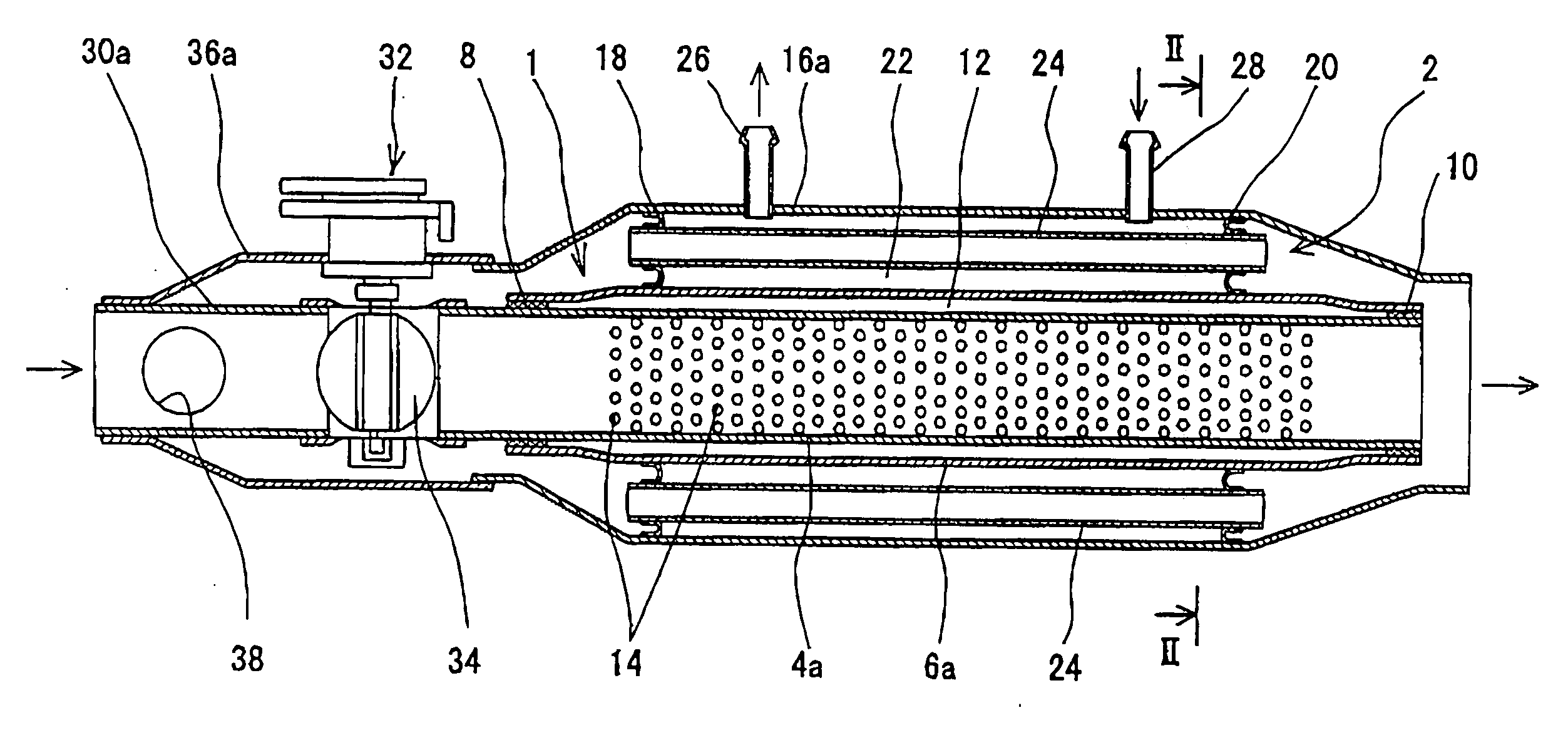

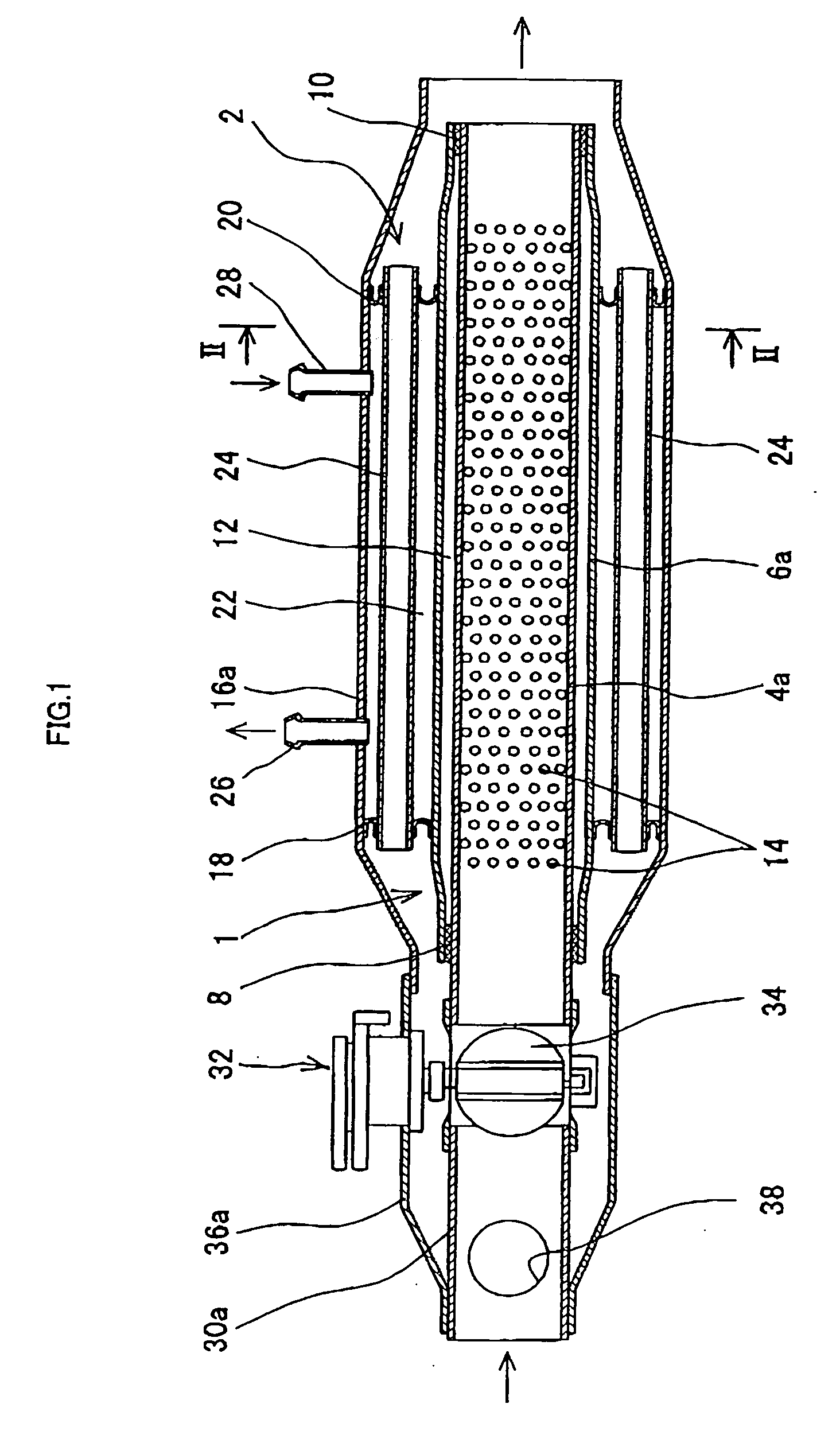

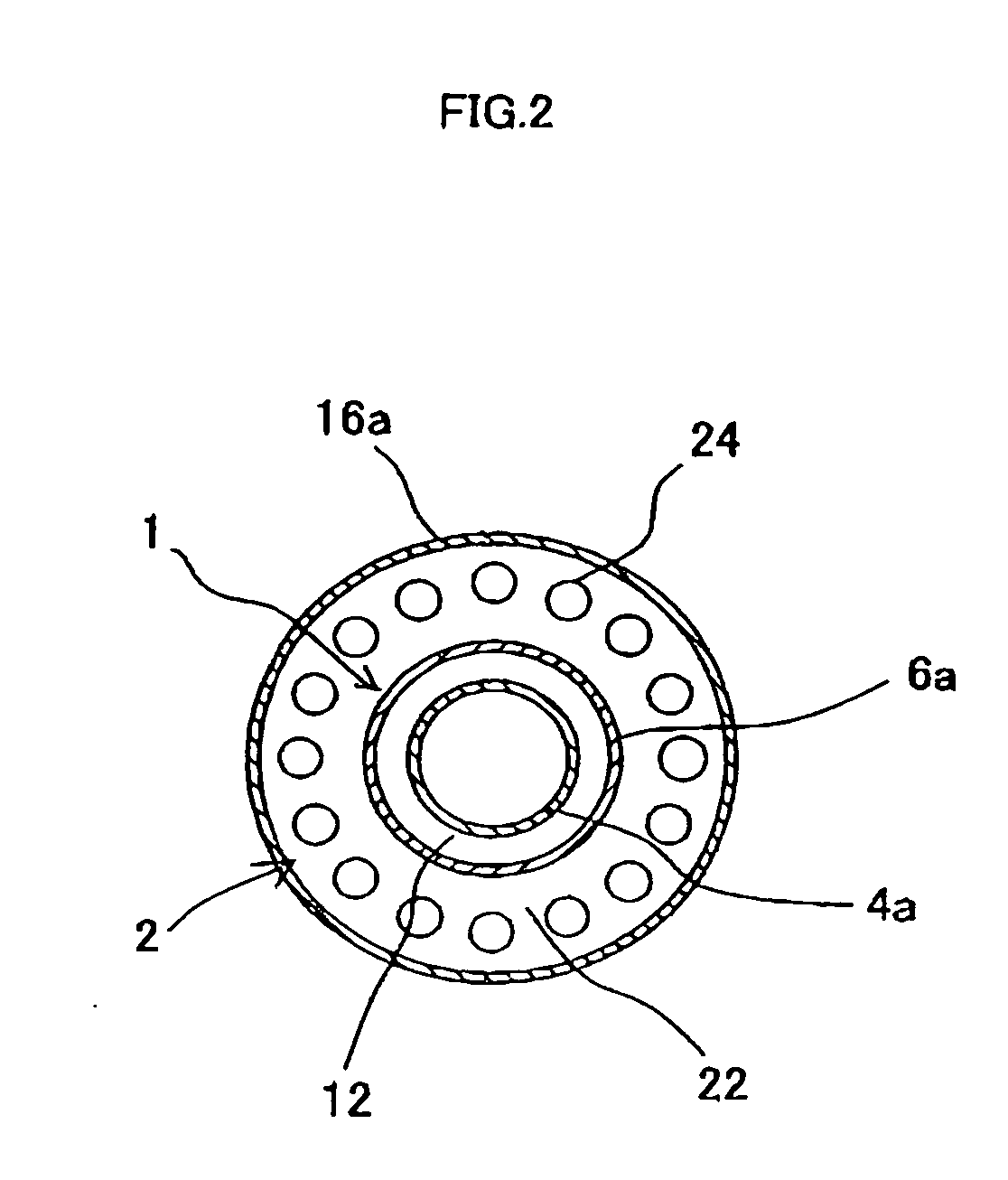

Exhaust heat recovery muffler

InactiveUS20060054381A1Easy to manufactureIncrease the cross-sectional areaInternal combustion piston enginesRecuperative heat exchangersWaste heat recovery unitEngineering

The exhaust heat recovery muffler includes a muffler unit having the outer surface thereof covered, an exhaust heat recovery unit disposed integrally with the muffler unit, and a switching valve that switches the flow of exhaust gas into the muffler unit and into the exhaust heat recovery unit. An outer pipe of the muffler unit and a cylindrical shell of the exhaust heat recovery unit, covering the outer circumference of the outer pipe, are coaxially disposed. The exhaust heat recovery unit includes a heat exchange chamber, formed by a pair of partitions provided between the inner circumference of the shell and the outer circumference of the outer pipe, and small-diameter pipes penetrating through the pair of partitions and extending through the heat exchange chamber. A heat exchange medium flows inside of the heat exchange chamber.

Owner:FUTABA IND CO LTD

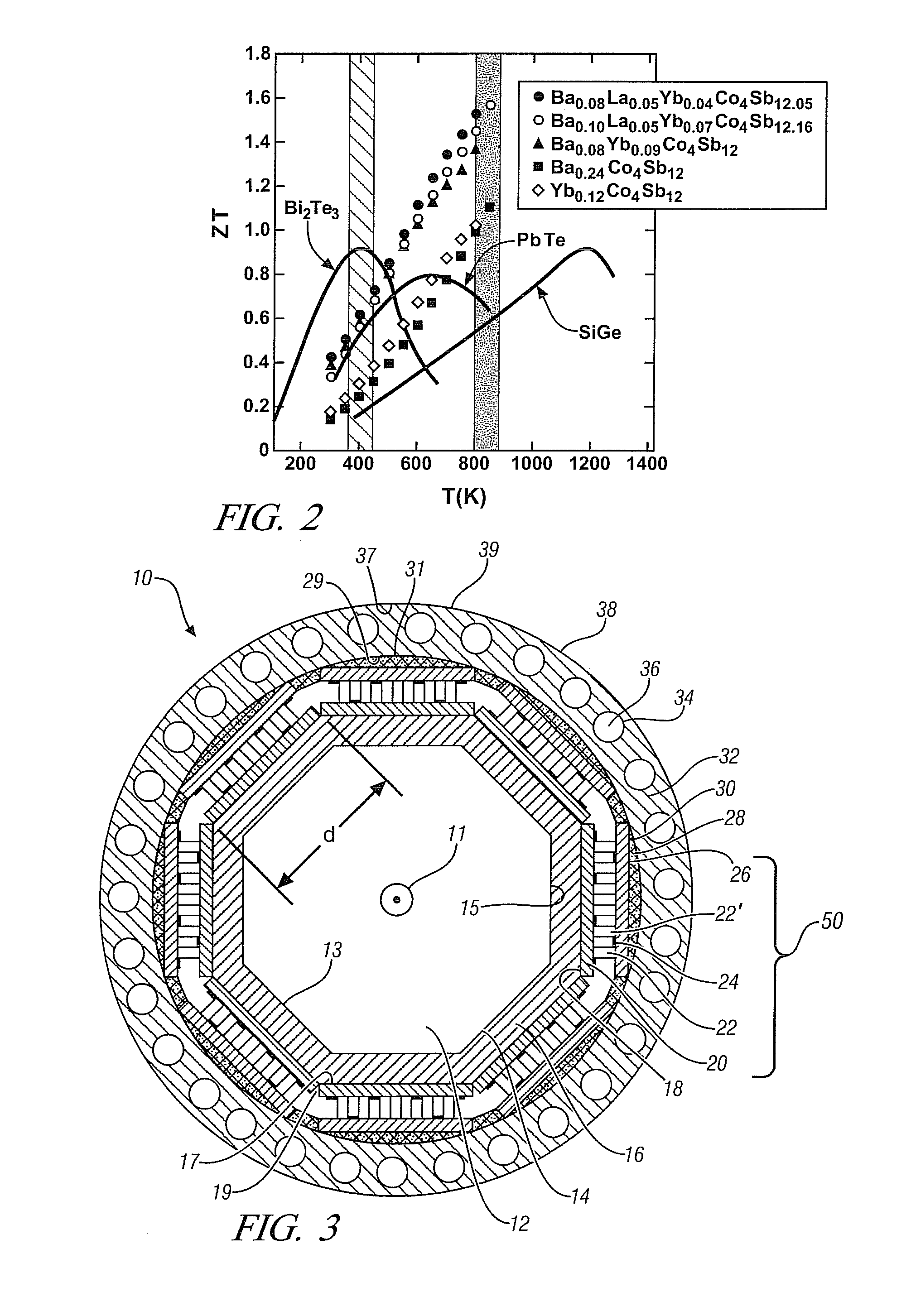

Thermoelectric generators incorporating phase-change materials for waste heat recovery from engine exhaust

ActiveUS20120073276A1Efficient extractionThermoelectric device with peltier/seeback effectExhaust apparatusEngineeringInternal combustion engine

Thermoelectric devices, intended for placement in the exhaust of a hydrocarbon fuelled combustion device and particularly suited for use in the exhaust gas stream of an internal combustion engine propelling a vehicle, are described. Exhaust gas passing through the device is in thermal communication with one side of a thermoelectric module while the other side of the thermoelectric module is in thermal communication with a lower temperature environment. The heat extracted from the exhaust gasses is converted to electrical energy by the thermoelectric module. The performance of the generator is enhanced by thermally coupling the hot and cold junctions of the thermoelectric modules to phase-change materials which transform at a temperature compatible with the preferred operating temperatures of the thermoelectric modules. In a second embodiment, a plurality of thermoelectric modules, each with a preferred operating temperature and each with a uniquely-matched phase-change material may be used to compensate for the progressive lowering of the exhaust gas temperature as it traverses the length of the exhaust pipe.

Owner:GM GLOBAL TECH OPERATIONS LLC

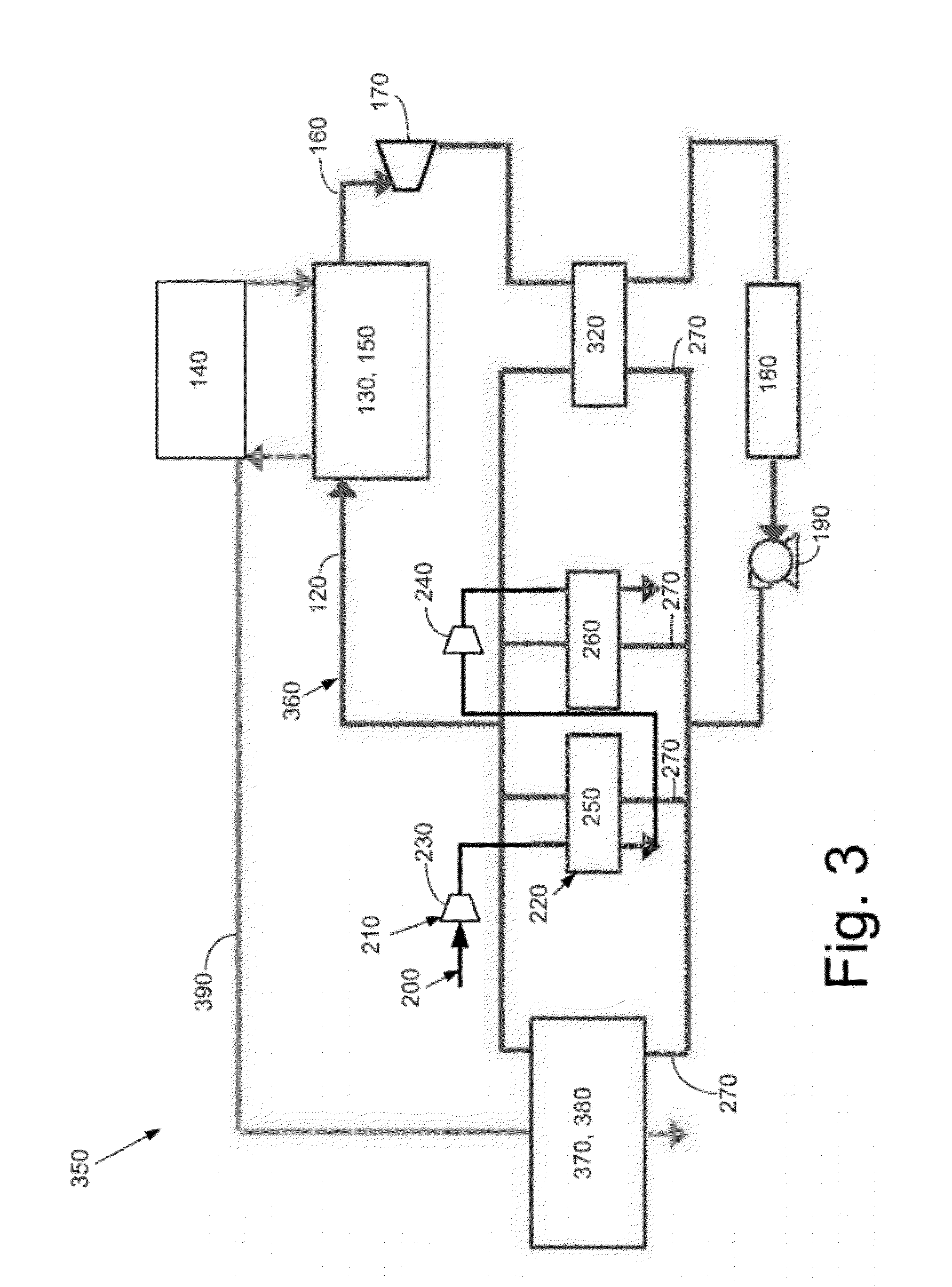

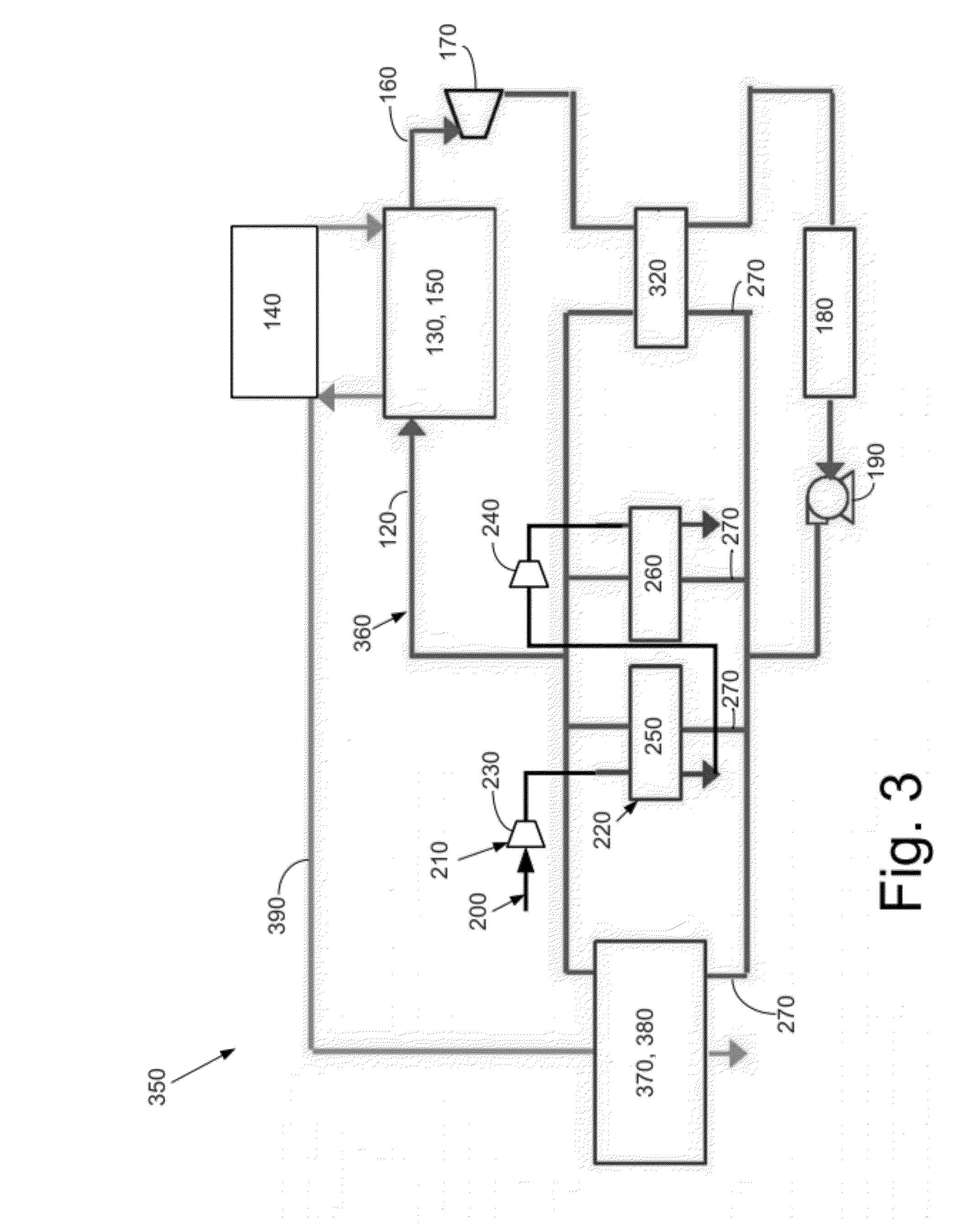

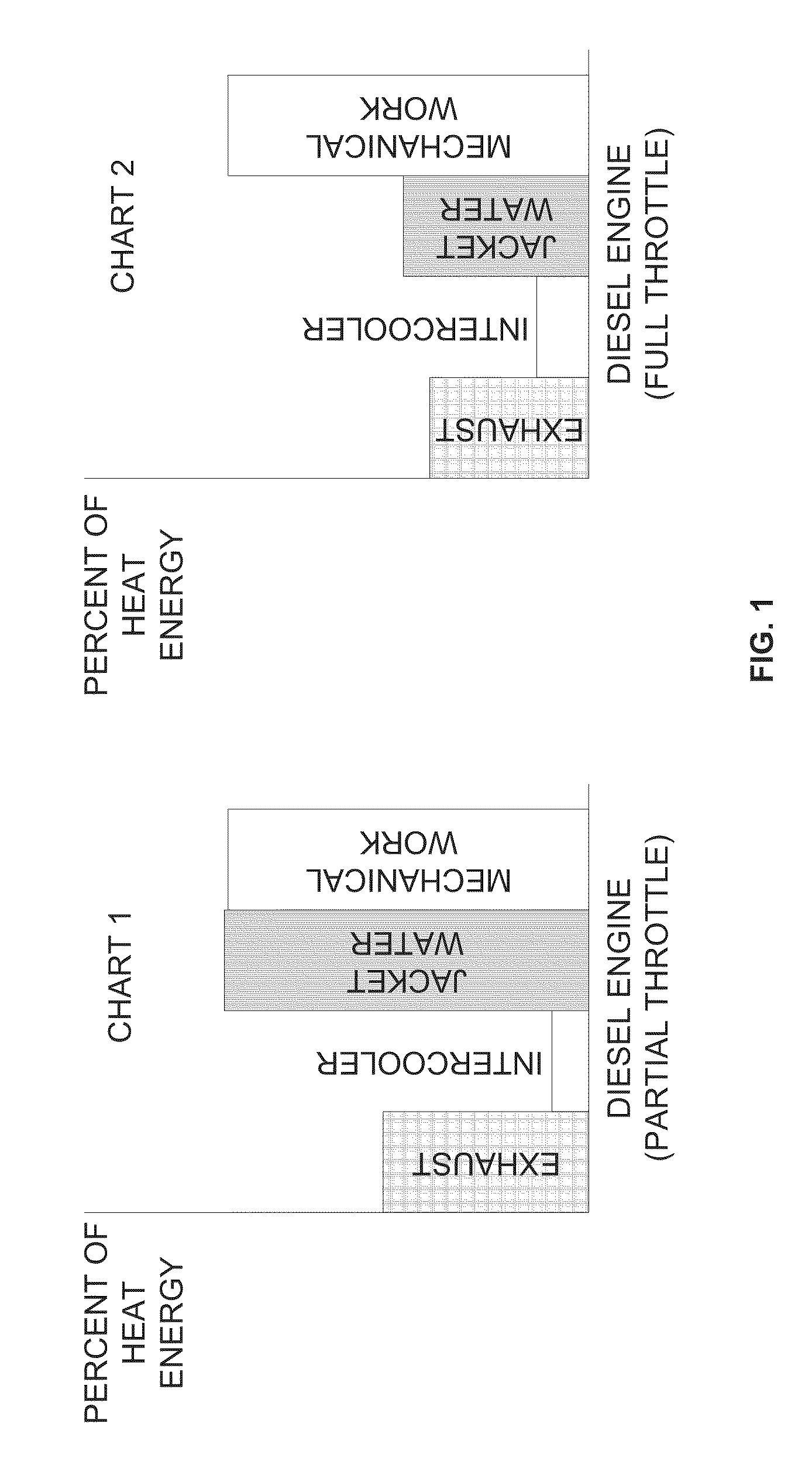

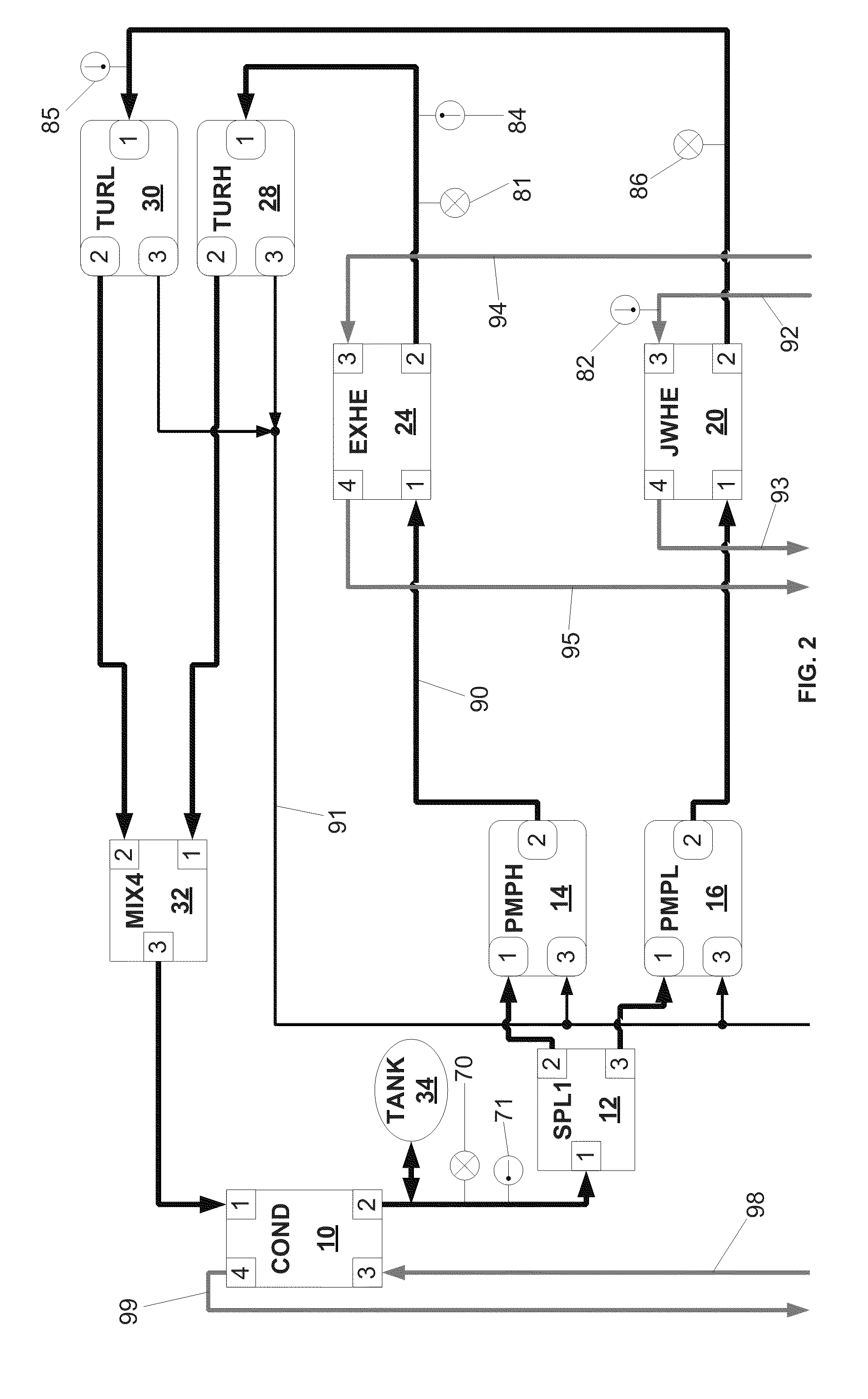

Organic rankine cycle systems using waste heat from charge air cooling

InactiveUS20120285169A1Internal combustion piston enginesExhaust apparatusWaste heat recovery unitOrganic Rankine cycle

The present application and the resultant patent provide a waste heat recovery system for recovering heat from a number of turbocharger stages. The waste heat recovery system may include a simple organic rankine cycle system and a number of charge air coolers in communication with the turbocharger stages and the simple organic rankine cycle system. The charge air coolers are positioned in a number of parallel branches of the simple organic rankine cycle system.

Owner:AI ALPINE US BIDCO INC

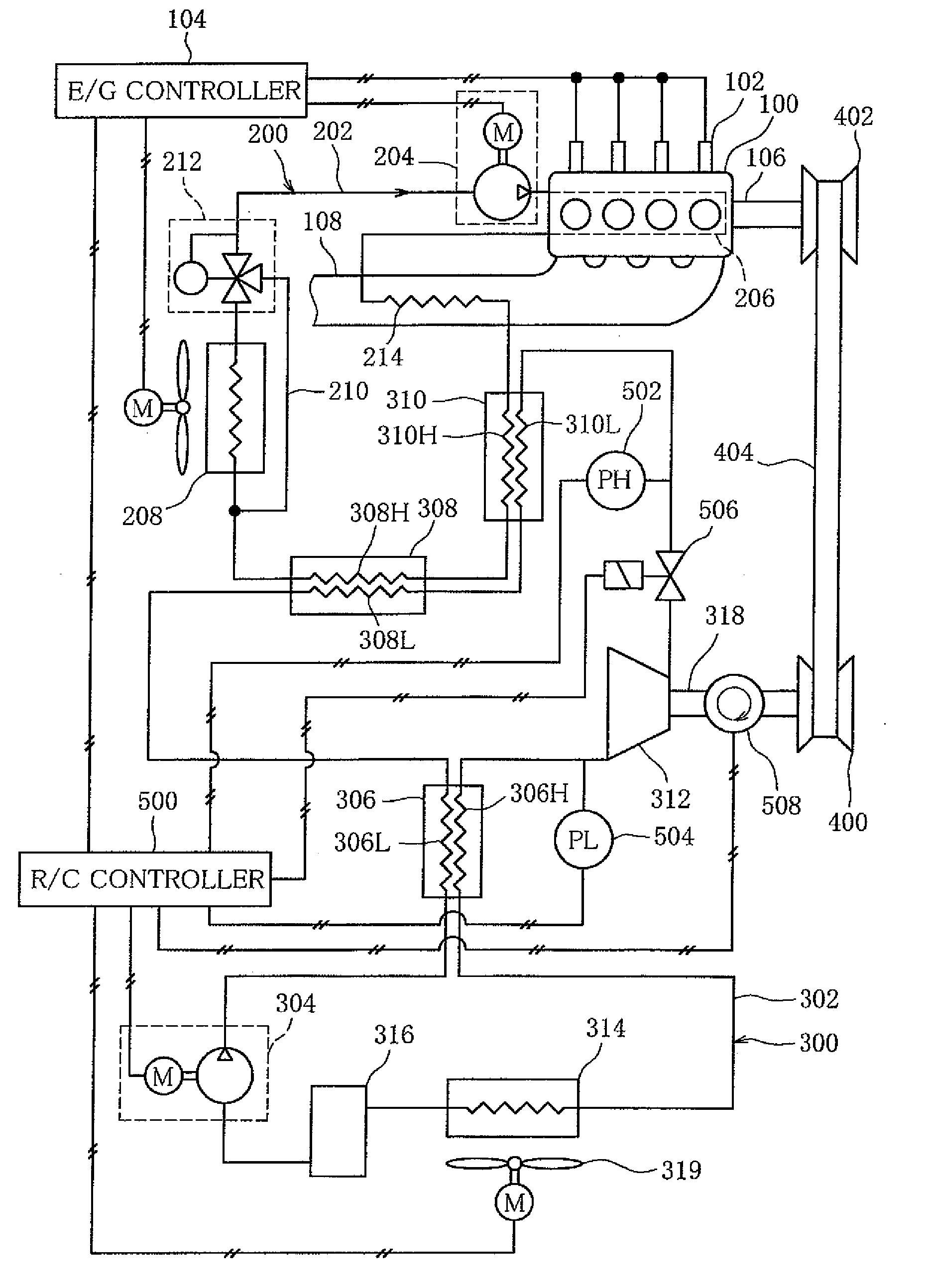

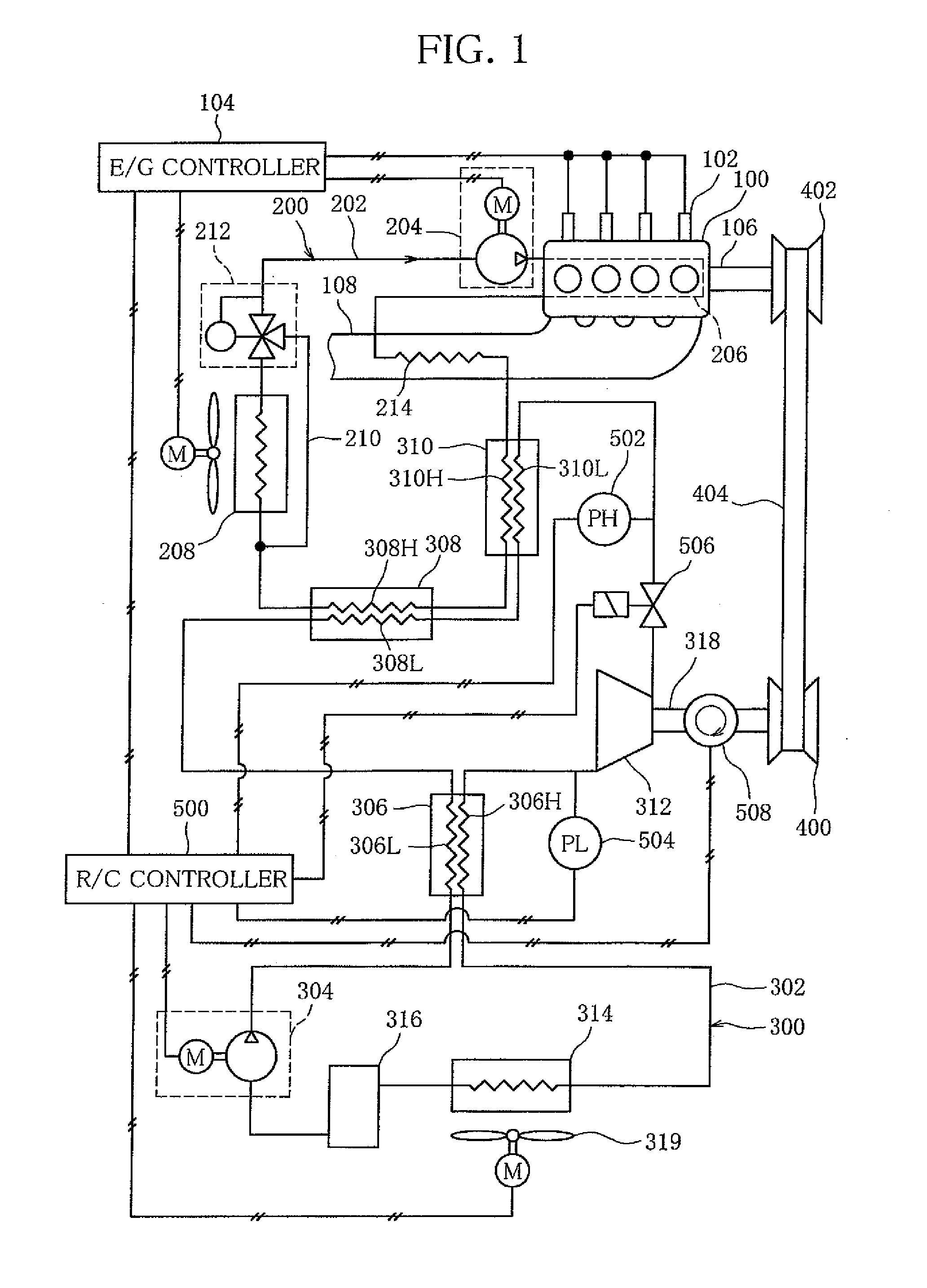

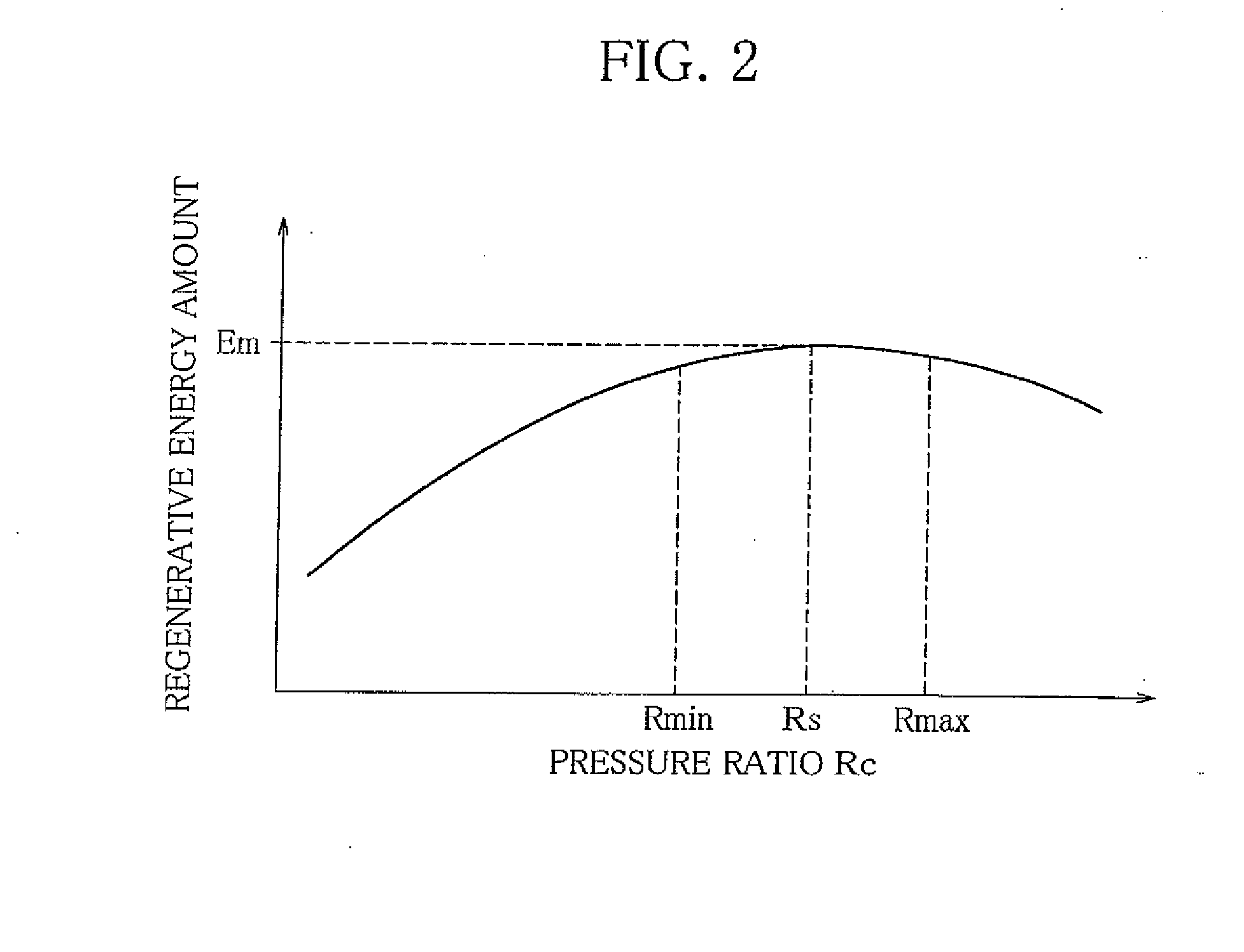

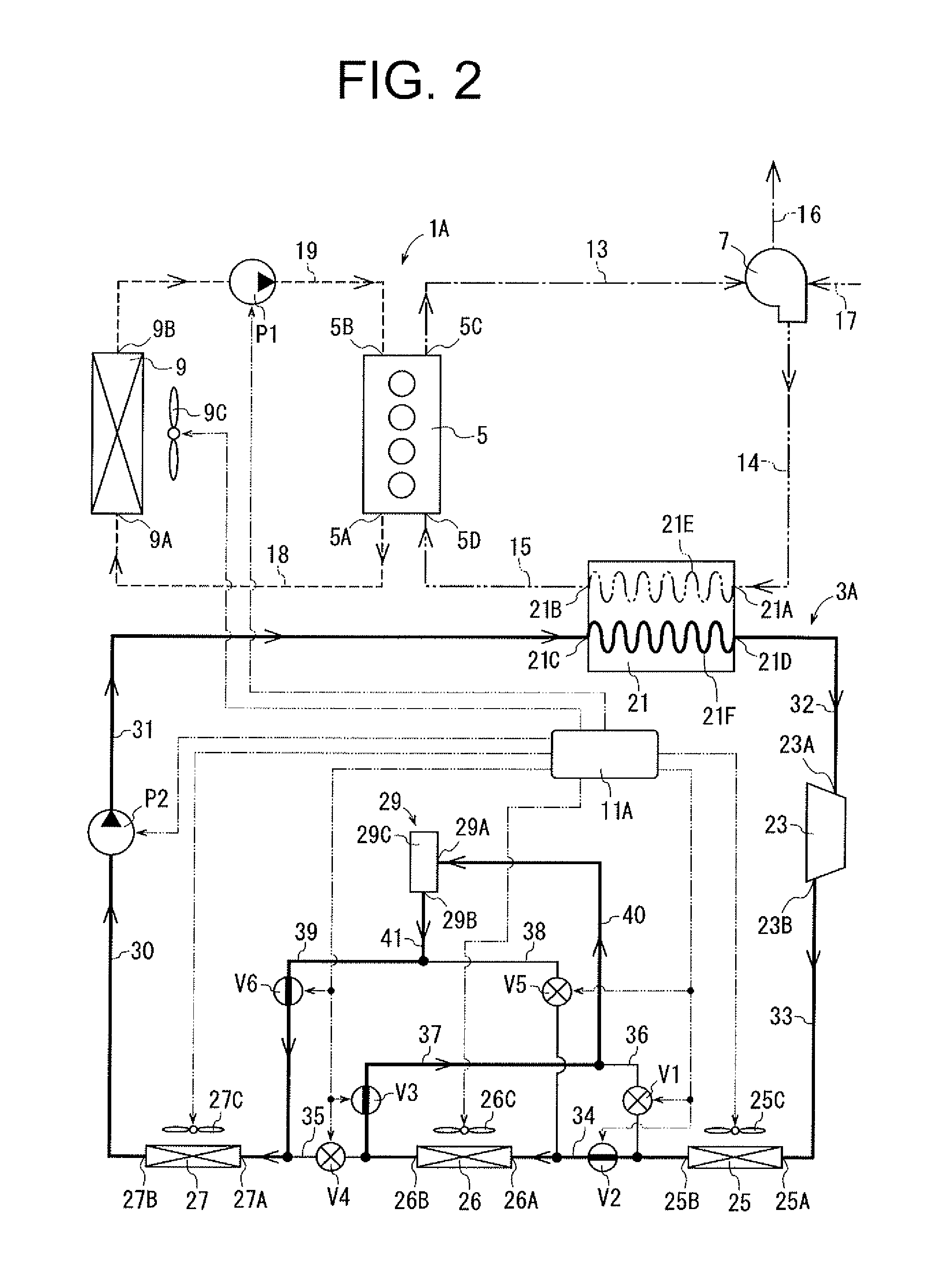

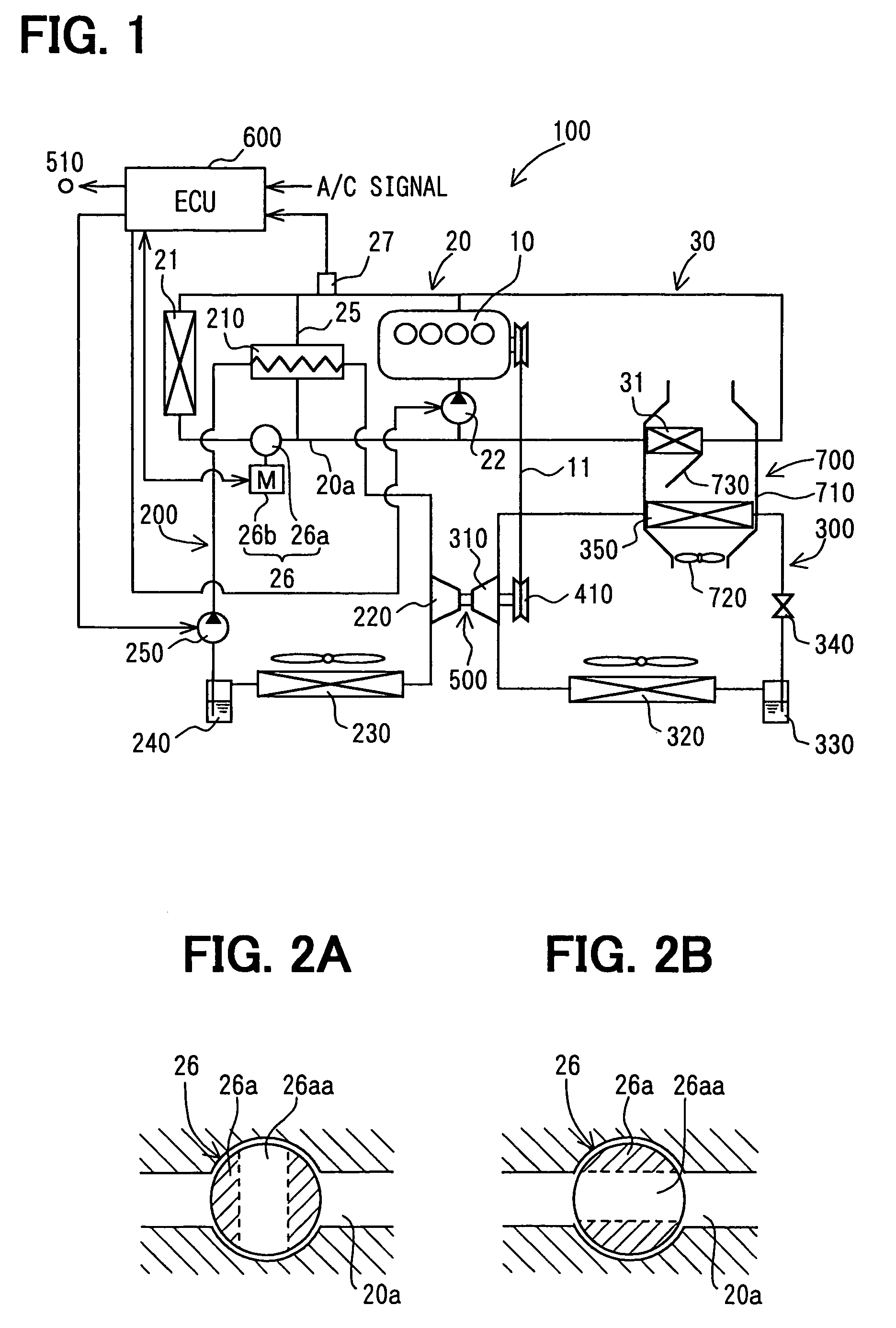

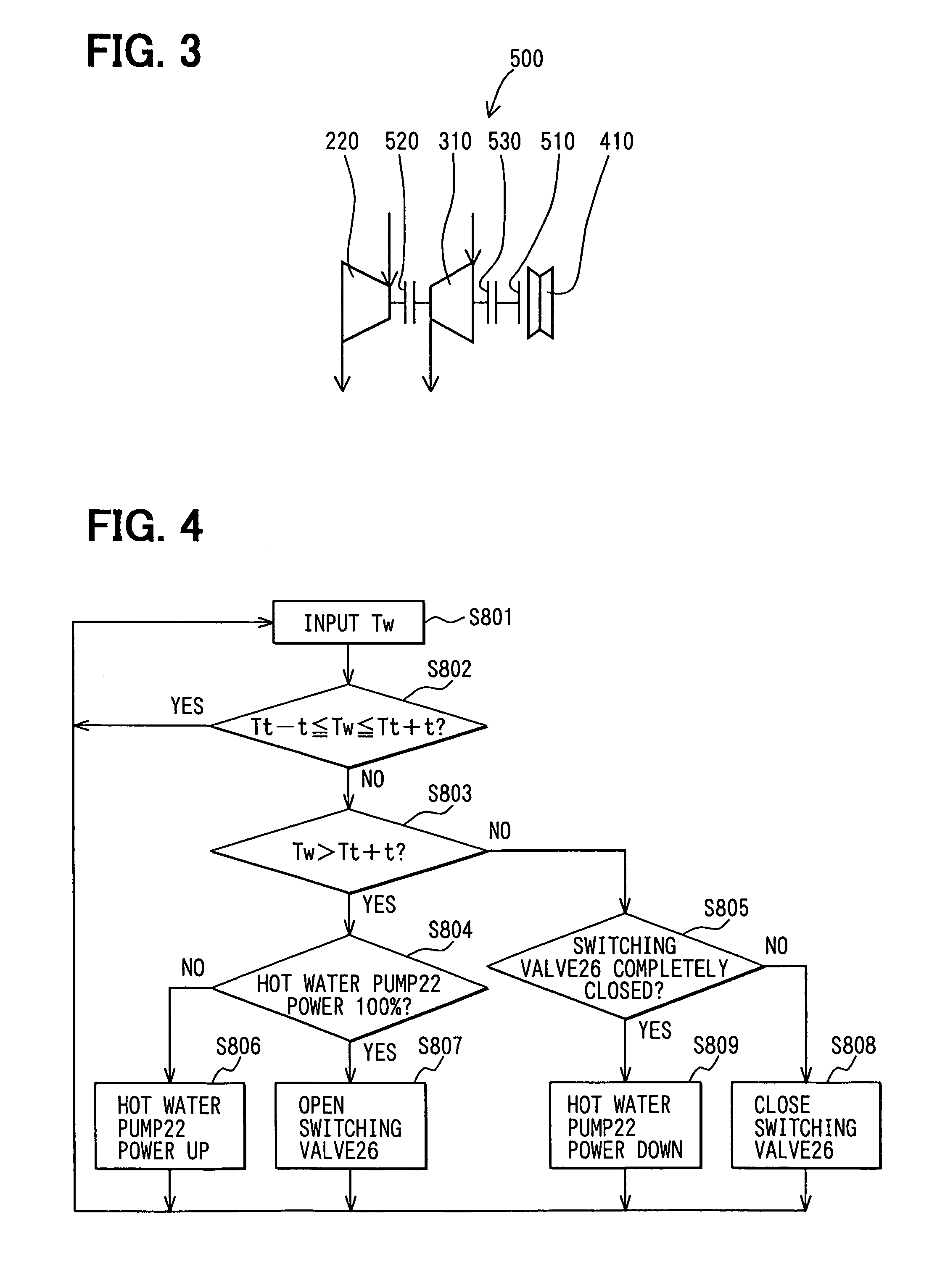

Waste Heat Recovery System of Internal Combustion Engine

InactiveUS20110192163A1Prevent pressure dropReduction in regenerative energy amountInternal combustion piston enginesExhaust apparatusWaste heat recovery unitExternal combustion engine

A waste heat recovery system of an internal combustion engine, in which the amount of regenerative energy transmitted to the internal combustion engine is increased with a simple mechanism. A controller of the waste heat recovery system of an internal combustion engine has at least determination means that makes a determination as to whether it is necessary to increase the pressure of heat-transfer media in a heat exchanger, on the basis of the pressure detected by the high-pressure sensor. When the determination means determines that it is necessary to increase the pressure in the heat exchanger, the controller causes a flow-rate regulating valve (506) to start regulating the flow rate of the heat-transfer media while leaving the pump working. The controller causes the flow-rate regulating valve to continue the regulation at least until the determination means determines that it is not necessary to increase the pressure in the heat exchanger, and then terminates the regulation.

Owner:SANDEN CORP

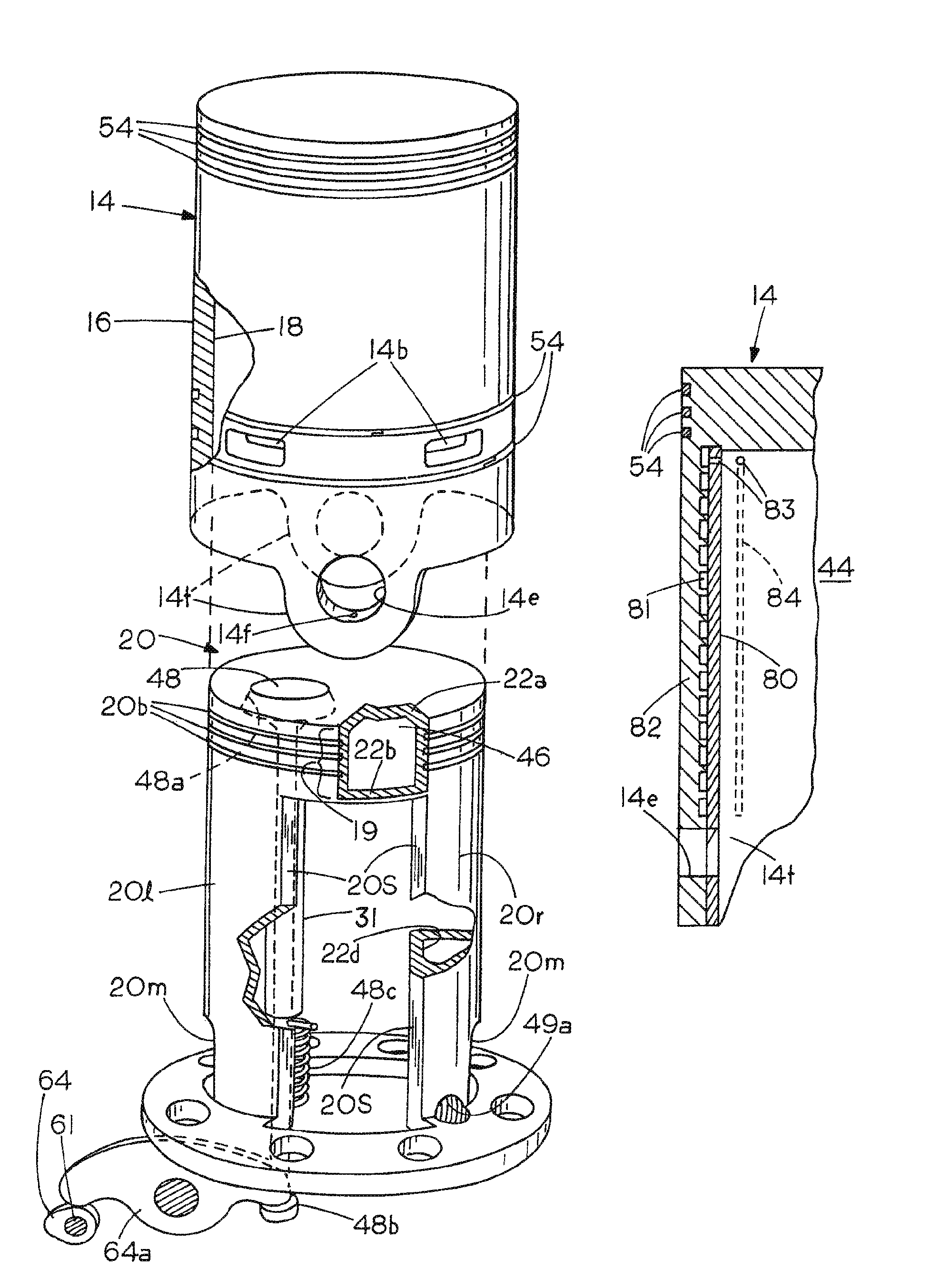

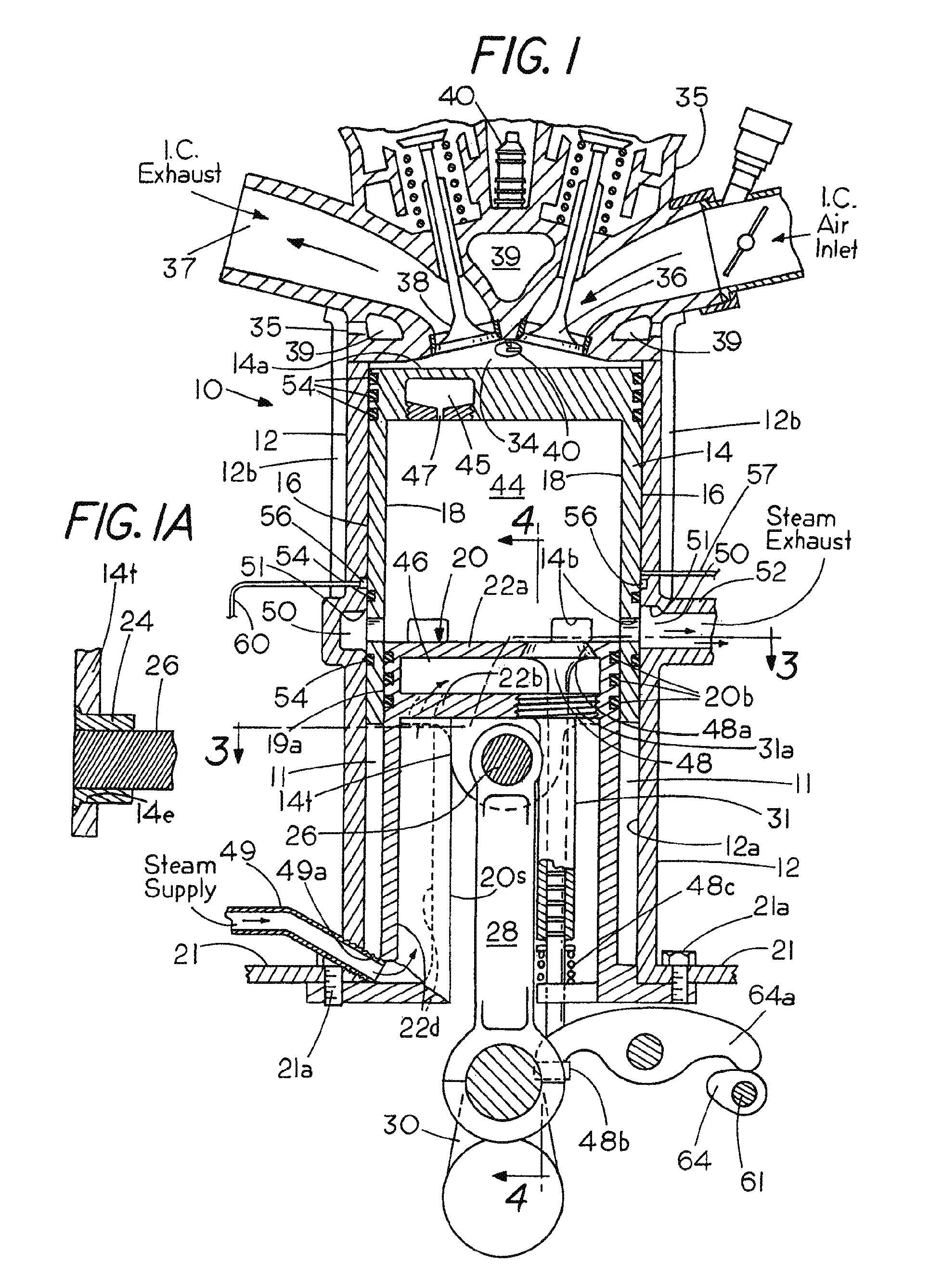

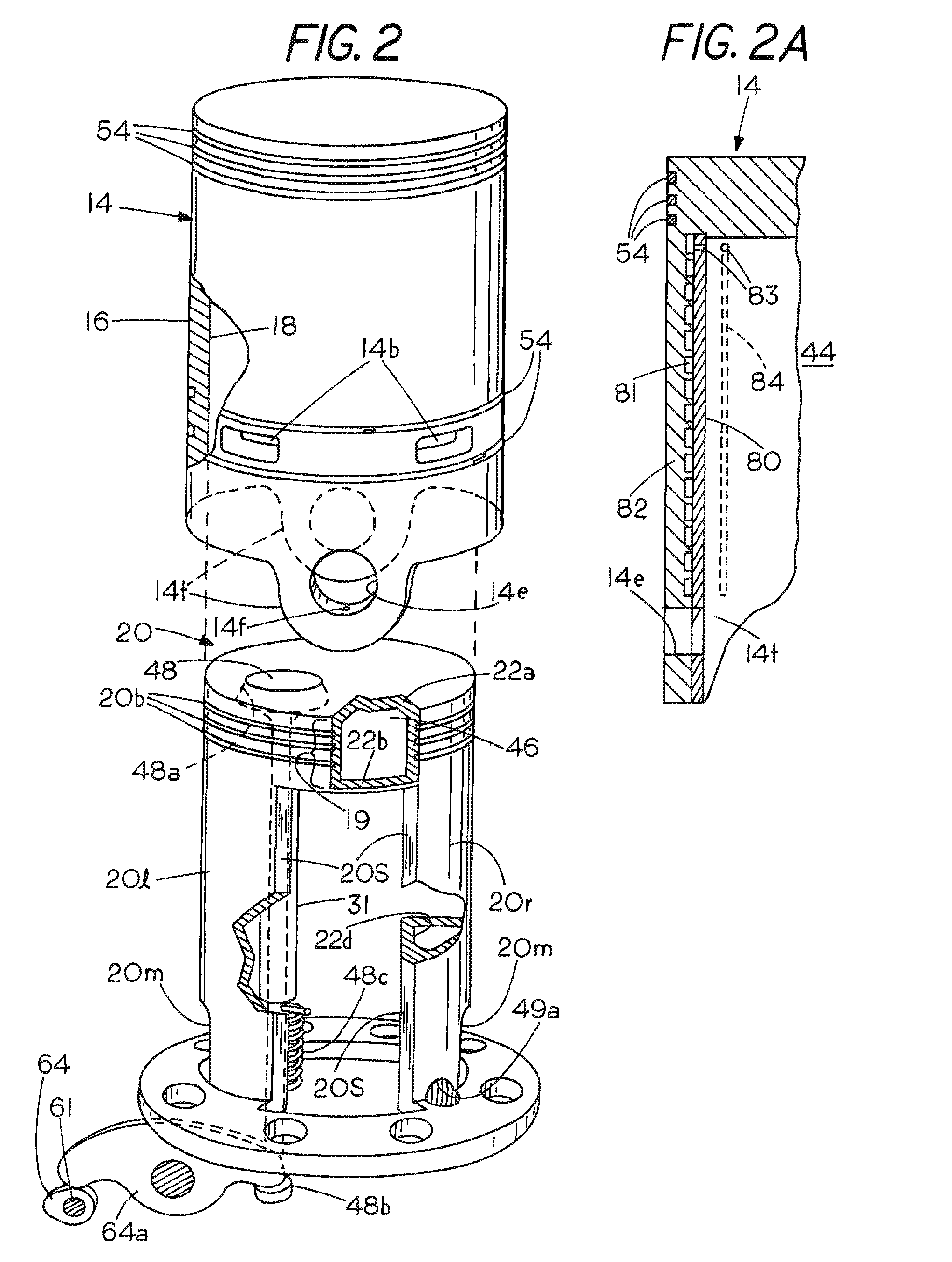

High efficiency multicycle internal combustion engine with waste heat recovery

ActiveUS8061140B2Effective recoveryIncrease enthalpyReciprocating combination enginesInternal combustion piston enginesCombustion chamberInlet valve

A high efficiency combined cycle internal combustion and steam engine includes a cylinder and a piston with an internal combustion chamber outward of the piston, a fixed cylinder cap and a steam expansion chamber inside the piston. The cylinder cap can be heated to reduce condensation of steam entering from a steam generator fired by waste combustion heat. Following exhaust, residual steam can be recompressed prior to admitting the next charge of steam. A wrist pin connected to an inner end of the piston skirt inwardly of the cylinder cap is coupled to a connecting rod secured to a crankshaft. One valve or a pair of steam inlet valves are connected to communicate in series within the cylinder cap inside the piston. The steam mass admitted is regulated to reduce fuel consumption. Coolant can be superheated in the combustion exhaust manifold.

Owner:THERMAL POWER RECOVERY

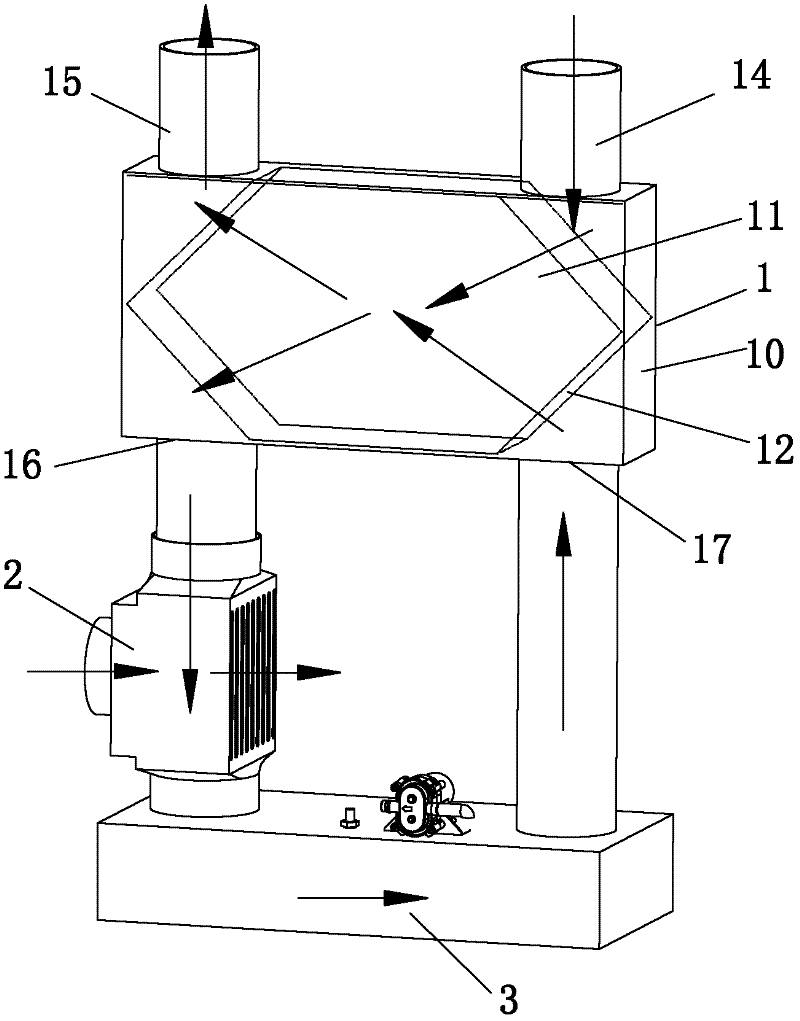

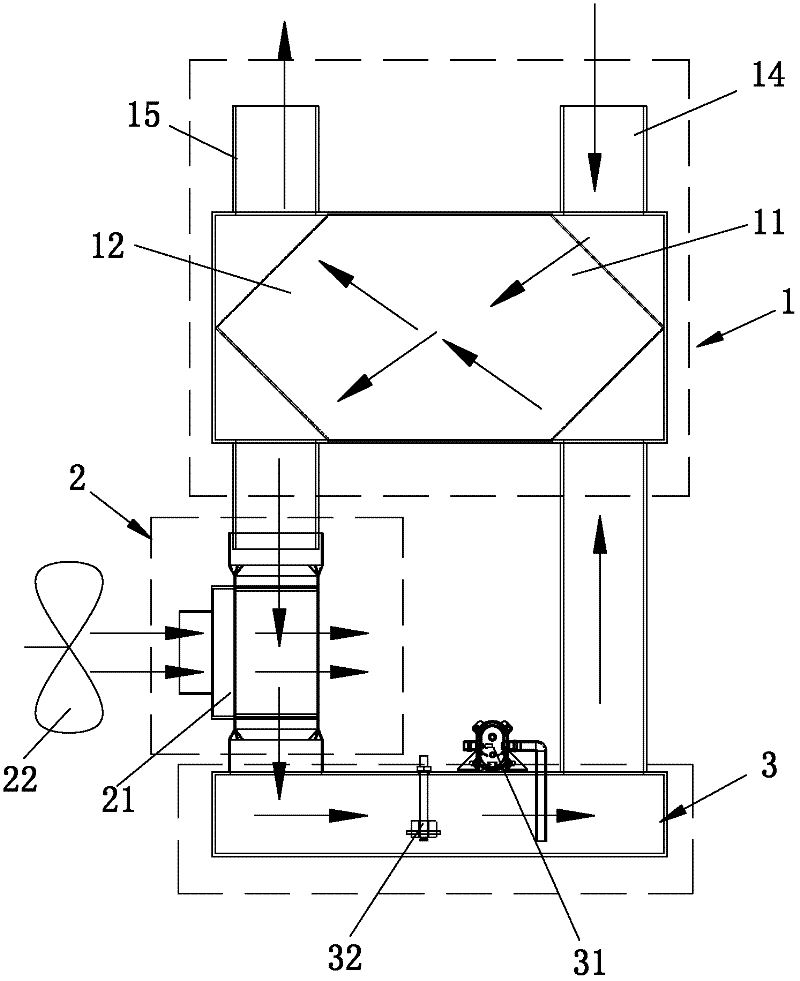

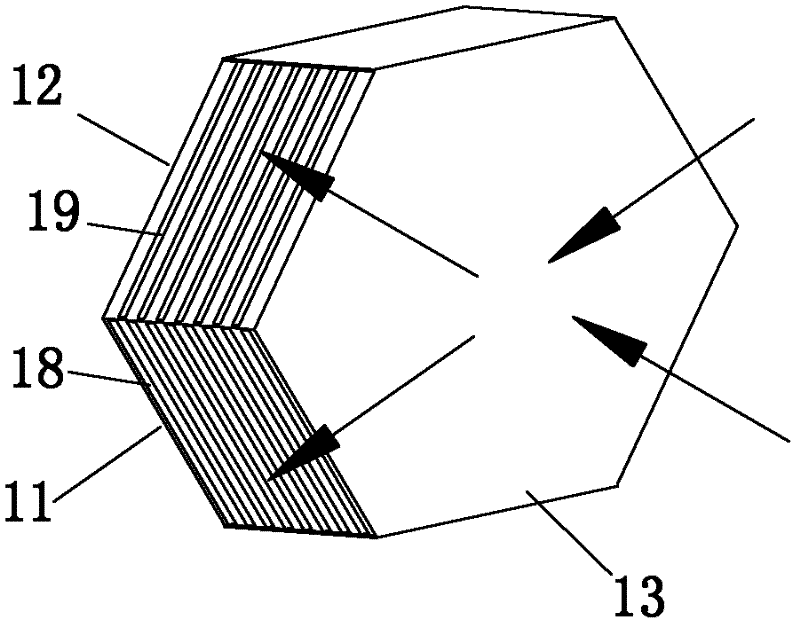

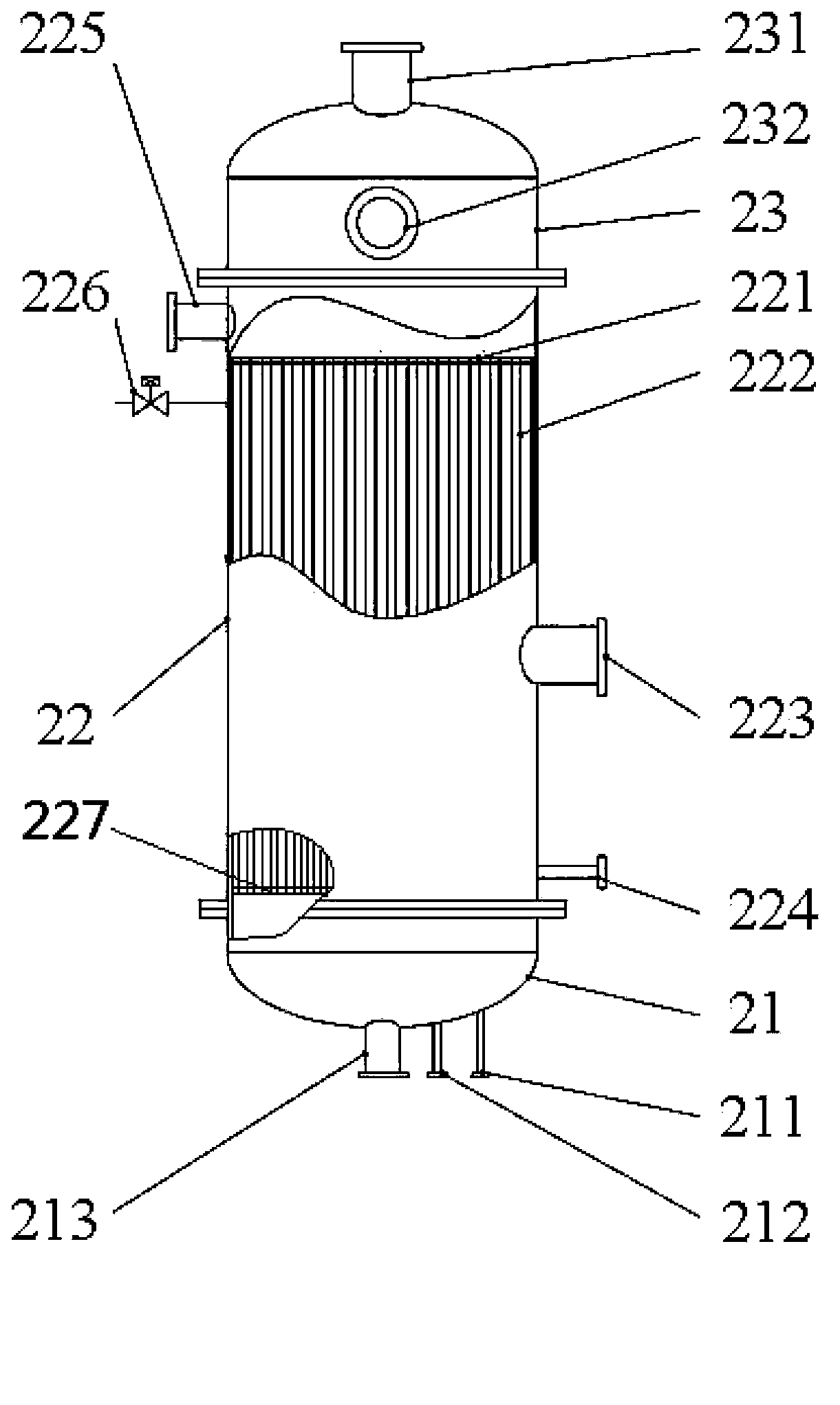

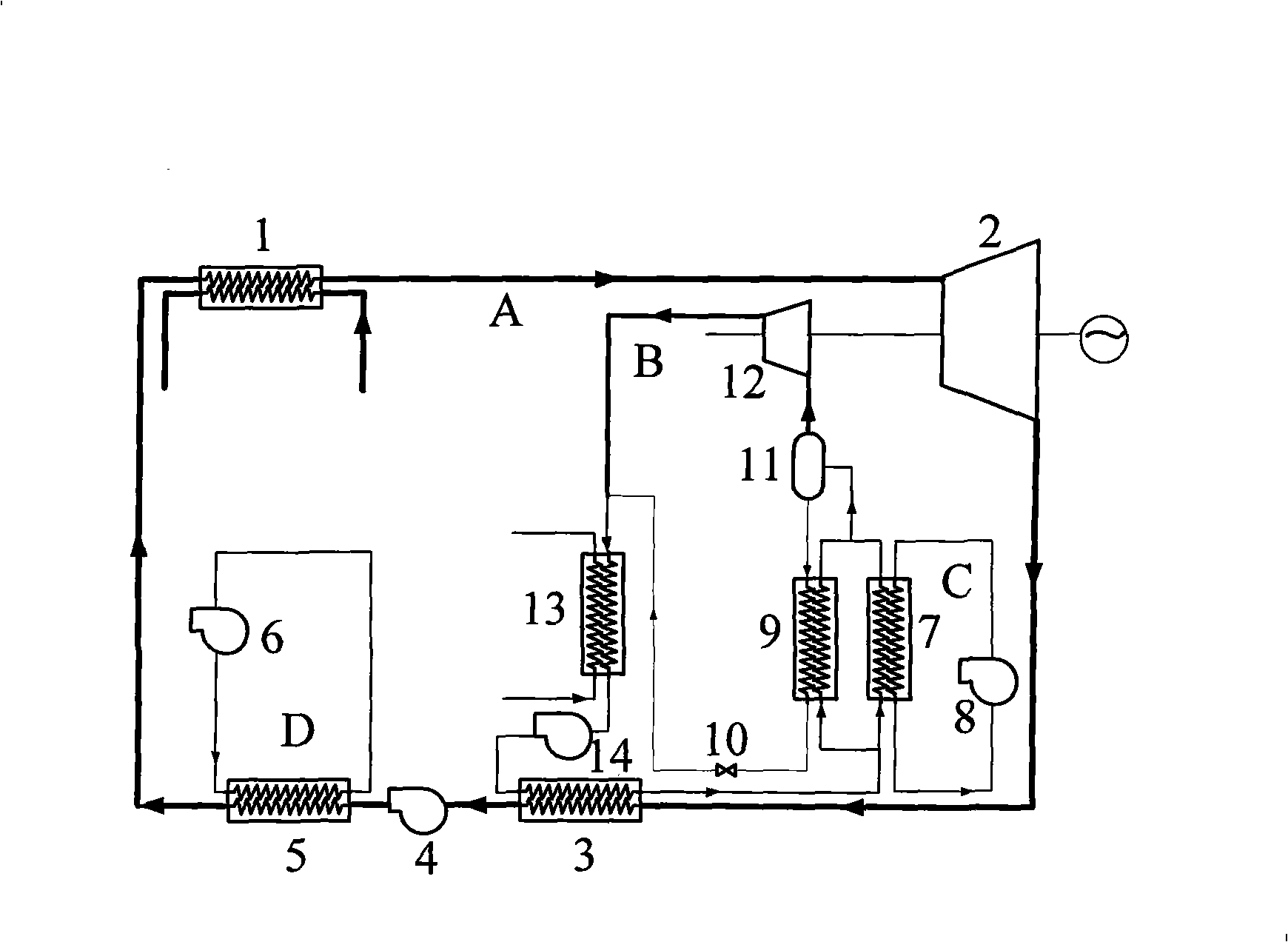

Heat-exchange system with waste heat recovery function for dry clothes condensation and cloths dryer

ActiveCN102517857AReduce trafficReduce energy lossTextiles and paperLaundry driersWaste heat recovery unitRecovery function

The invention discloses a heat-exchange system with the waste heat recovery function for dry clothes condensation and a clothes dryer. The heat-exchange system comprises a waste heat recovery device, a condenser and a water-collecting box, wherein the waste heat recovery device comprises two groups of airflow air ways, i.e. a damp and hot-air air way and a waste heat recovery air way; the two groups of airflow air ways form a heat-exchange structure; and damp and hot air passes through the damp and hot-air air way of the waste heat recovery device, the condenser and the water-collecting box in sequence and then passes through the waste heat recovery air way of the waste heat recovery device to finish water heat recovery. An air outlet of the clothes dryer is communicated with the damp and hot-air air way of the waste heat recovery device through an air outlet duct and is then communicated with an air inlet through an air inlet duct after the damp and hot air passes through the condenser and the water-collecting box in sequence and then passes through the waste heat recovery air way of the waste heat recovery device to finish the waste heat recovery; a filter is arranged in the air inlet duct; and a drying fan and a heating device are arranged in the air inlet duct. The heat-exchange system has the beneficial effect that the electric energy and the time are saved by utilizing waste heat, and the clothes drying efficiency is improved.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

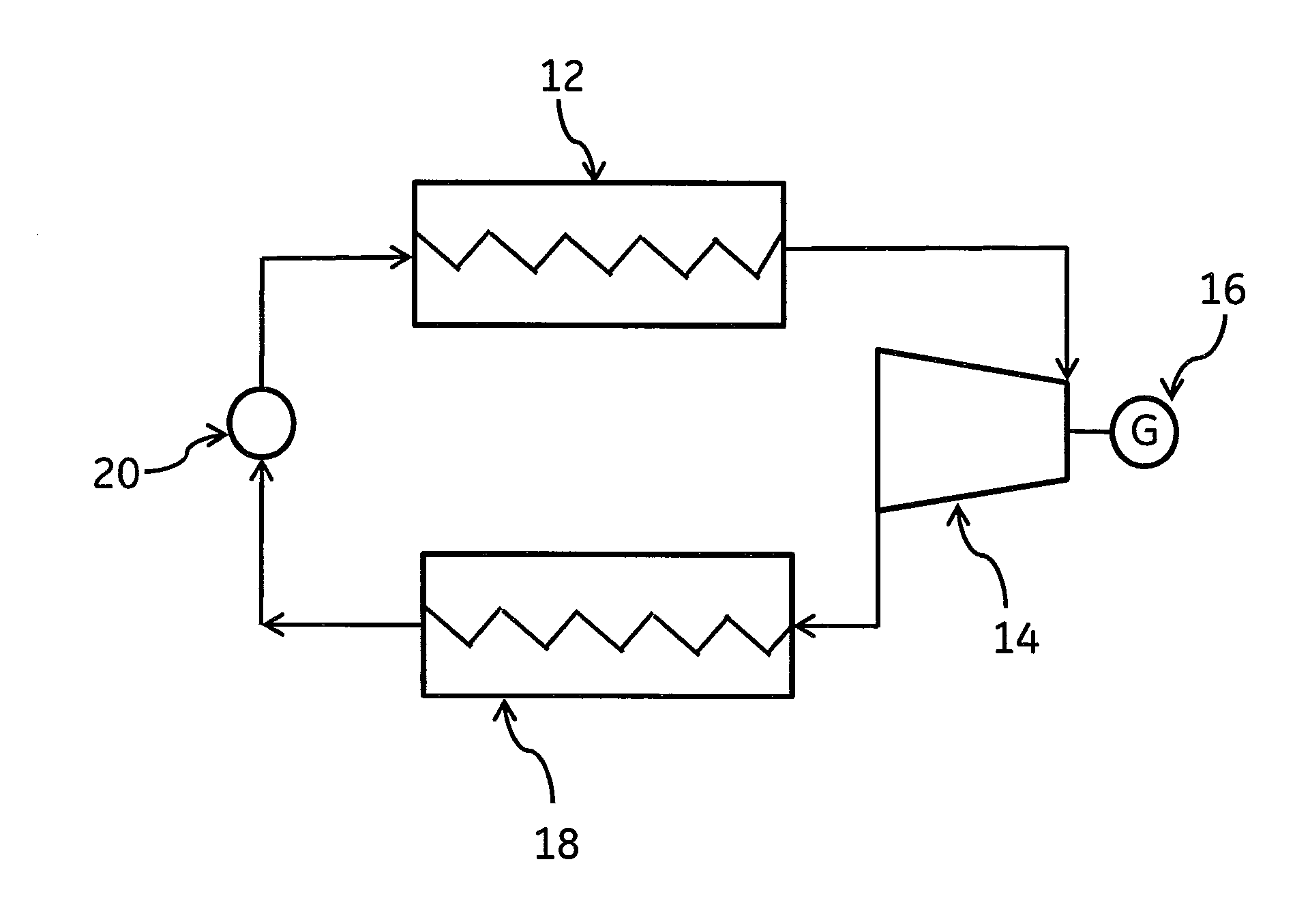

Waste heat recovery system

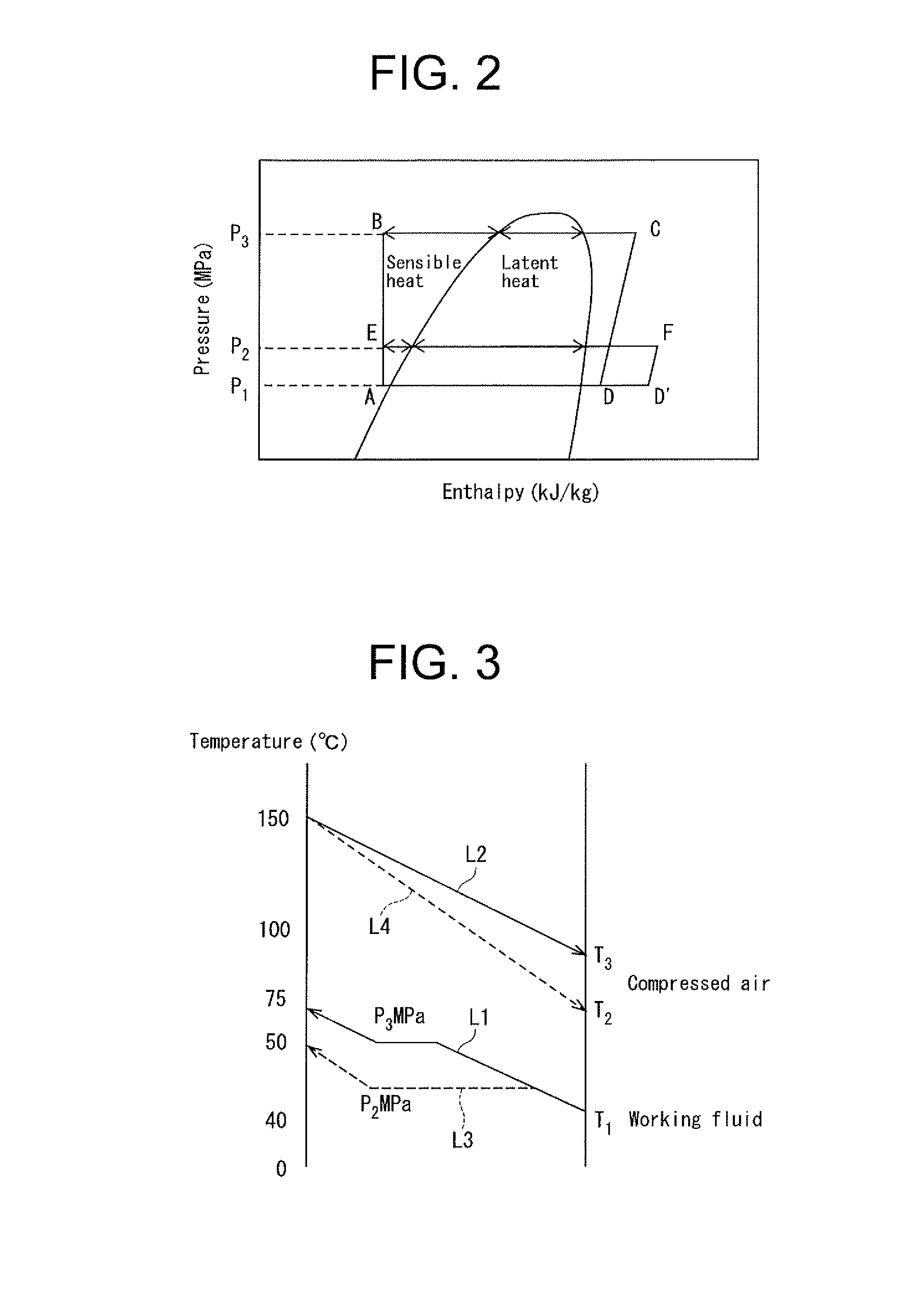

InactiveUS20130067910A1Non-fuel substance addition to fuelInternal combustion piston enginesWaste heat recovery unitWorking fluid

The waste heat recovery system includes a Rankine cycle device in which working fluid circulates through a pump, a boiler, an expander and then through a heat exchanging device, heat exchange occurs in the boiler between the working fluid and intake fluid that is introduced into an internal combustion engine while being cooled. The heat exchanging device includes a condenser condensing the working fluid, a receiver connected downstream of the condenser and storing liquid-phase working fluid, a subcooler connected downstream of the receiver and subcooling the liquid-phase working fluid, and a selector device serving to change the ratio of the condenser to the subcooler. The waste heat recovery system further includes a determination device for determining required cooling load for the intake fluid, and a controller for controlling the selector device depending on the required cooling load determined by the determination device.

Owner:TOYOTA IND CORP

Waste heat recovery device of air compressor and control method of waste heat recovery device

ActiveCN104061680AGuaranteed heat exchange effectEfficient use ofHeat pumpsPositive displacement pump componentsAxial compressorWaste heat recovery unit

The invention discloses a waste heat recovery device of an air compressor and a control method of the waste heat recovery device. The waste heat recovery device comprises heat exchanging modules and enhanced heat exchanging modules, wherein the heat exchanging modules are arranged in parallel at the two ends of an oil-channel electric valve; the reinforcing heat exchanging modules are arranged in parallel at the two ends of the air-channel electric valve; the heat exchanging modules and the reinforcing heat exchanging modules are utilized to recover and store the heat energy in circulating oil and the heat energy in compressed air lost and wasted when the air compressor operates; the heat energy of the compressed air can be recycled at highest efficiency under the premise that the operation of the air compressor is not impacted. According to the waste heat recovery device of the air compressor and the control method of the waste heat recovery device, the collected data are analyzed and operated so as to realized effective high intelligent control; not only is the efficiency of the operation of the air compressor improved, but also the energy input of the heat energy utilizing modules can be reduced, the energy consumption or fuels for heating are lowered, and energy comprehensive utilizing degree is improved. Therefore, the waste heat recovery device has the advantages that the energy-saving effect is good, the intelligent degree is high, and the stability is excellent.

Owner:ZHEJIANG UNIV

Multifunctional energy resource system

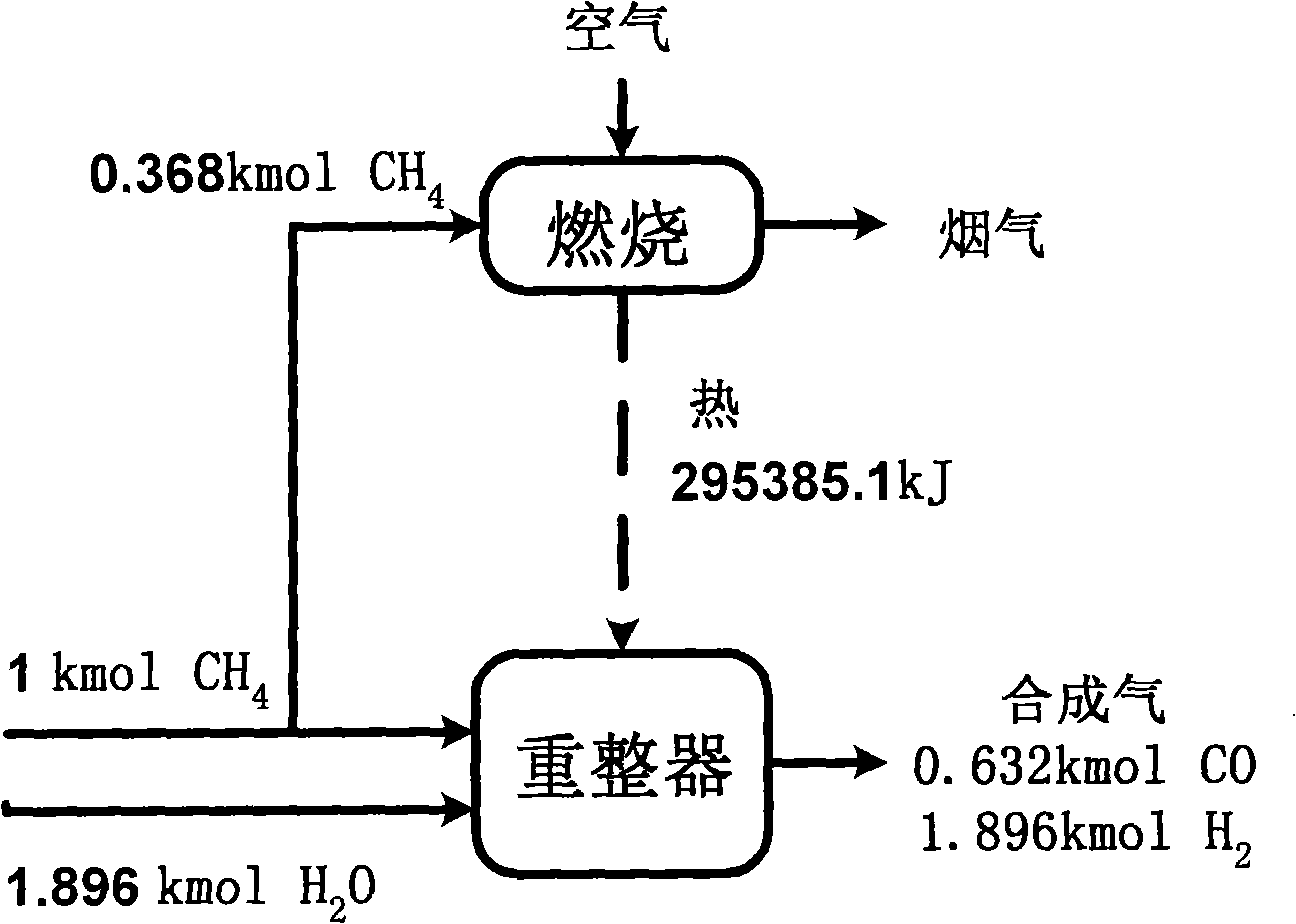

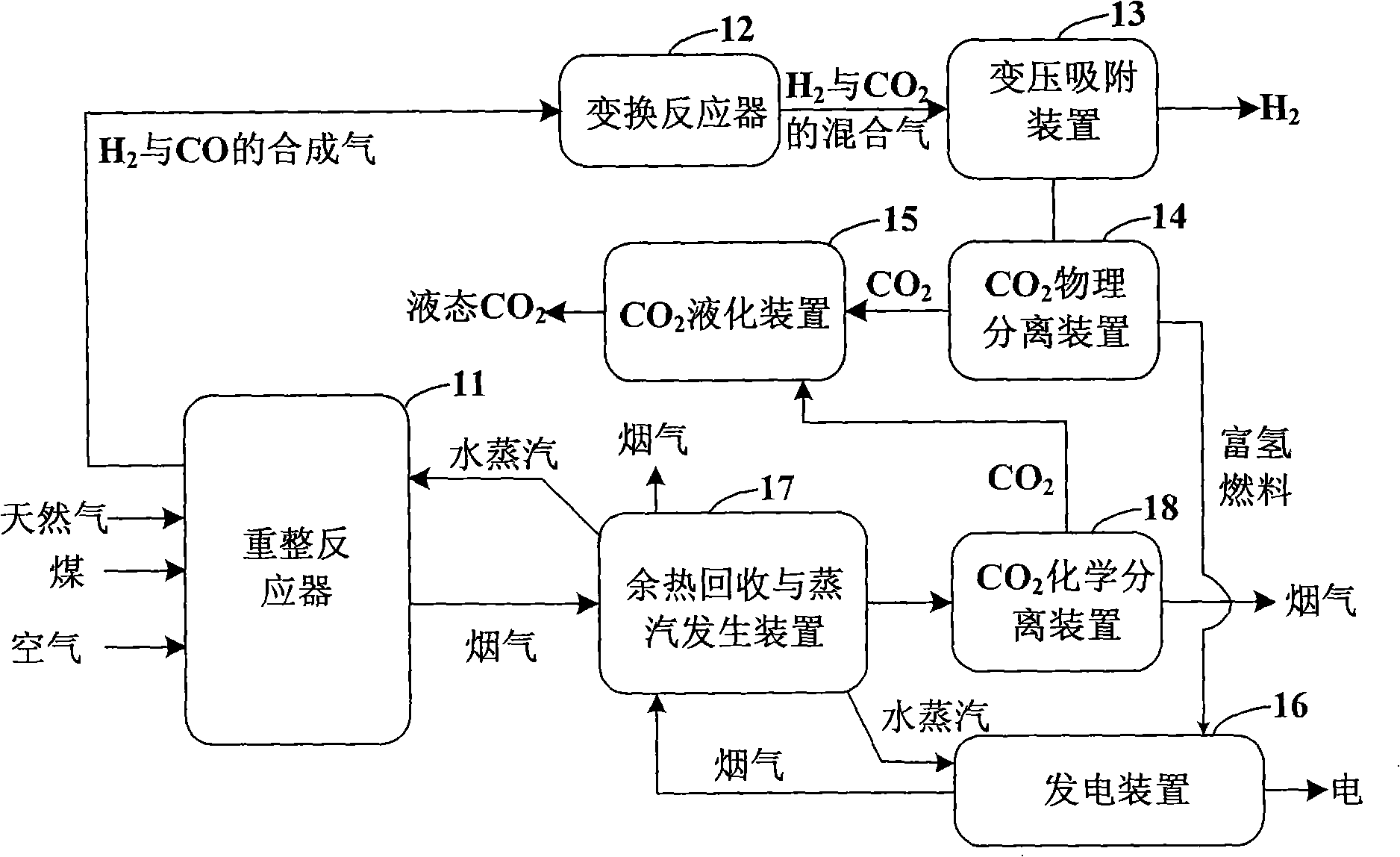

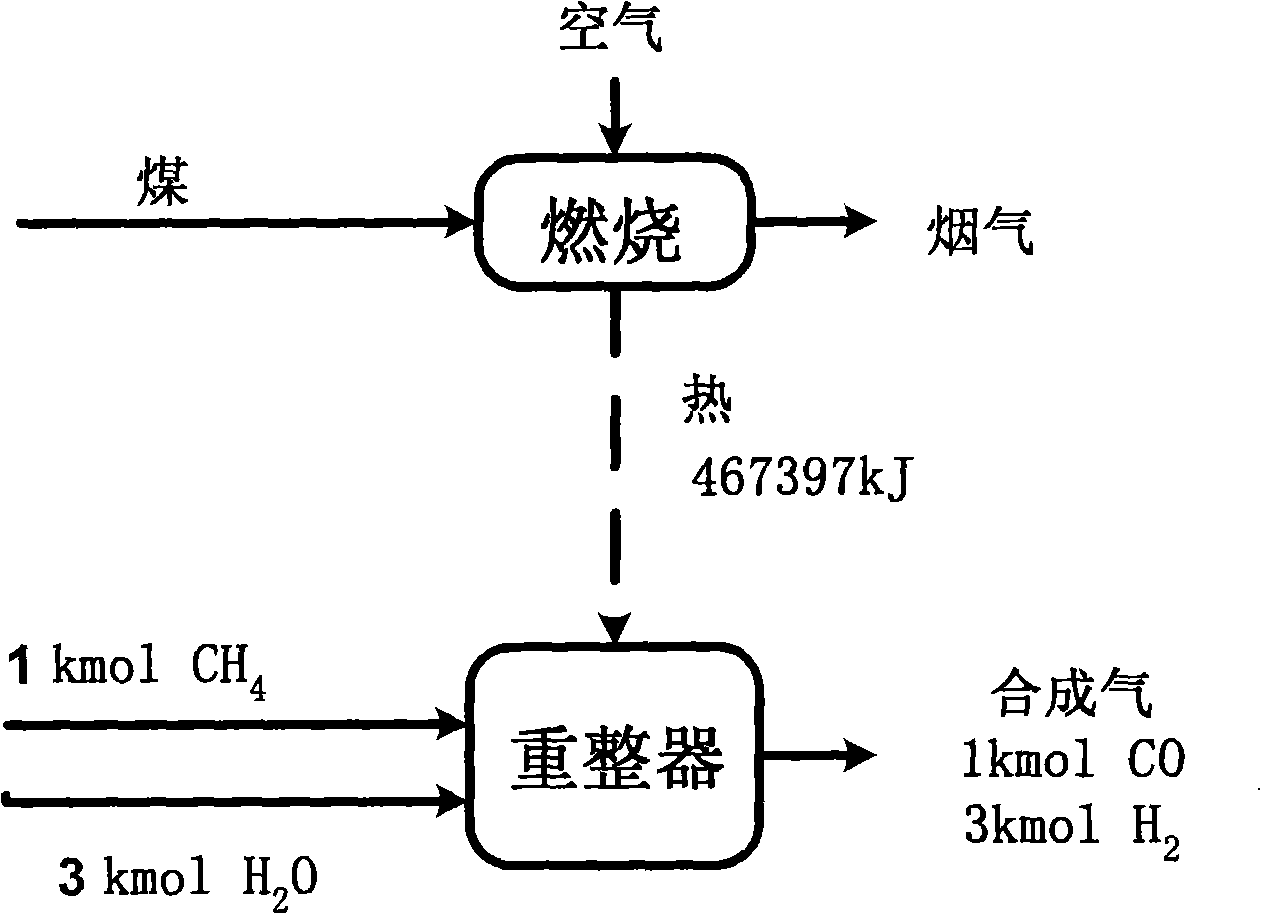

ActiveCN101285004AHuge lossReasonable useCombustible gas chemical modificationEnergy inputAtmospheric airNatural gas

The invention discloses a multifunctional energy system. In the system, coal and natural gases simultaneously enter a reforming reactor, and the coal fires in the reforming reactor to drive the reforming reaction of natural gases, which generates synthetic gases of H2 and CO; the synthetic gases pass through a shift converter to convert CO into CO2, and then enter a pressure swing adsorption device(PSA) for preparing hydrogen gases; tail gases generated in the PSA device are sent to a CO2 separator to separate out a majority of CO2, and then compressed and cooled to become liquid CO2, which is convenient for transportation and storage; hydrogen rich fuel gases remained after the separation of CO2 are sent to a generating set, and high-temperature flue gases enter a waste heat recovery and a steam generation device, and the flue gases, the waste heat of which is recovered, are discharged in air; the flue gases discharged by a dual fuel reformer are also enter the waste heat recovery and steam generation device for recovering the waste heat, and then enter the CO2 separator to separate CO2 contained in flue gases; purified CO2 is compressed and liquefied, and finally the flue gases are discharged in air. The multifunctional energy system has the advantages of improving the utilization rate of the fuel and realizing the control and recovery of CO2 with zero energy consumption.

Owner:中科思道(南京)储能技术有限公司

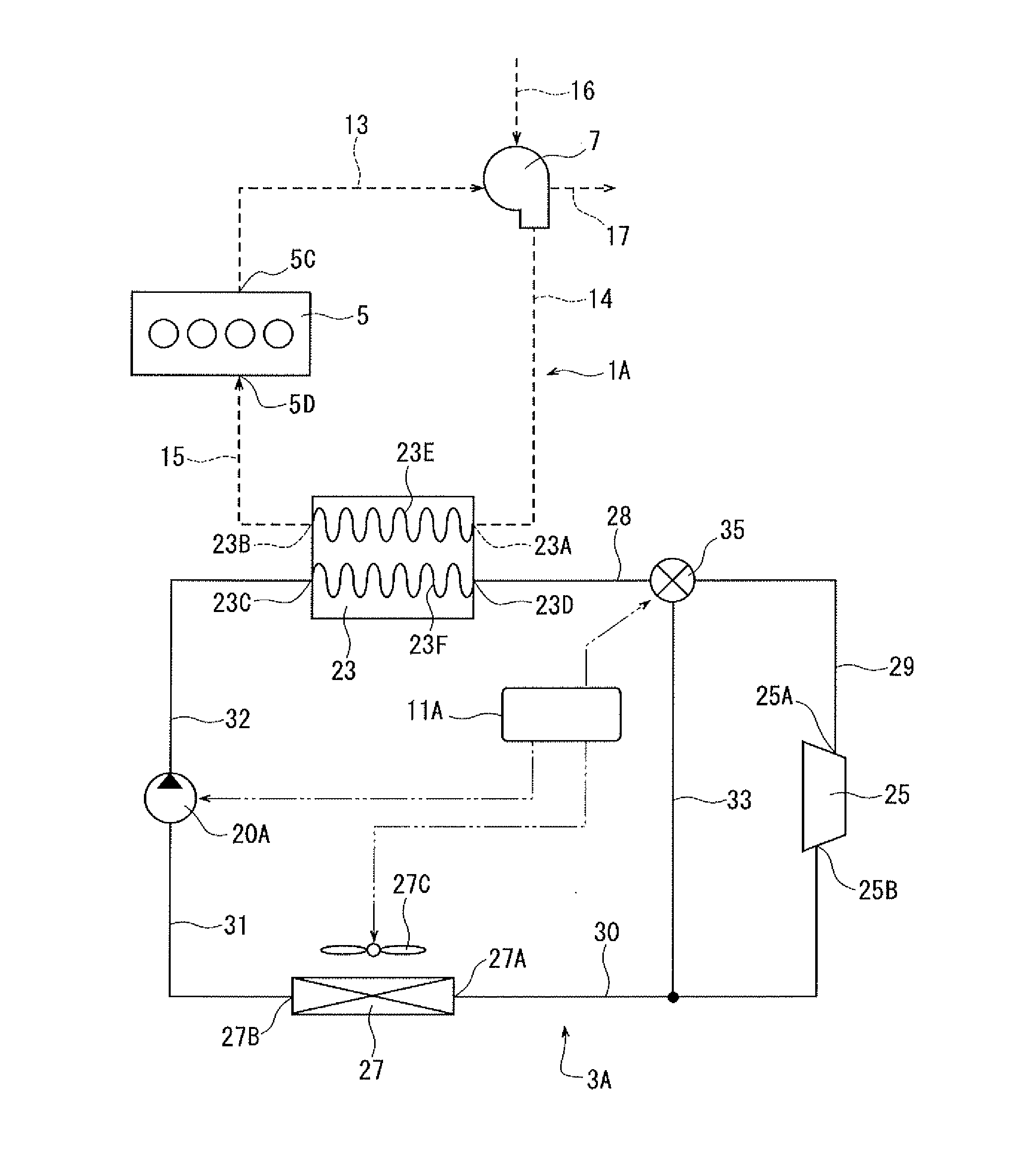

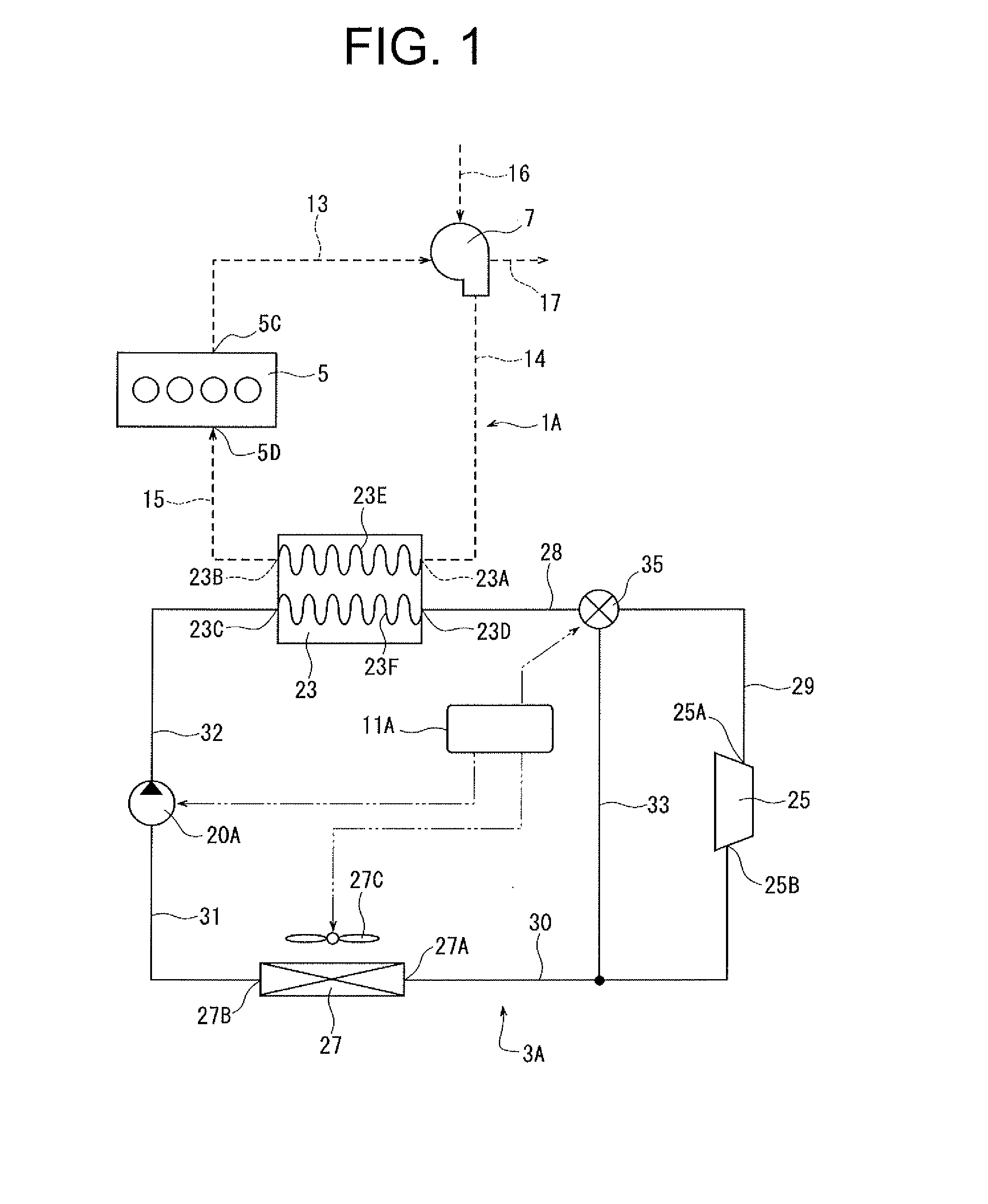

Waste heat recovery system of heat source, with Rankine cycle

InactiveUS7454910B2Easy to useReduce heatInternal combustion piston enginesEngine componentsWaste heat recovery unitWorking fluid

A waste heat recovery system of an engine has a cooling water circuit and a Rankine cycle. Cooling water is circulated between the engine and a radiator in the cooling water circuit. The Rankine cycle has a heater and an expansion device. The heater performs heat exchange between the cooling water heated by the engine and an operation fluid so as to heat the operation fluid in the Rankine cycle. The expansion device expands the heated operation fluid, so as to generate driving power. The heater is arranged in a bypass circuit so as to be in parallel with the radiator with respect to the cooling water flow. Thus, waste heat of the cooling water heated by the engine can be effectively recovered without reducing a cooling capacity of the radiator.

Owner:DENSO CORP

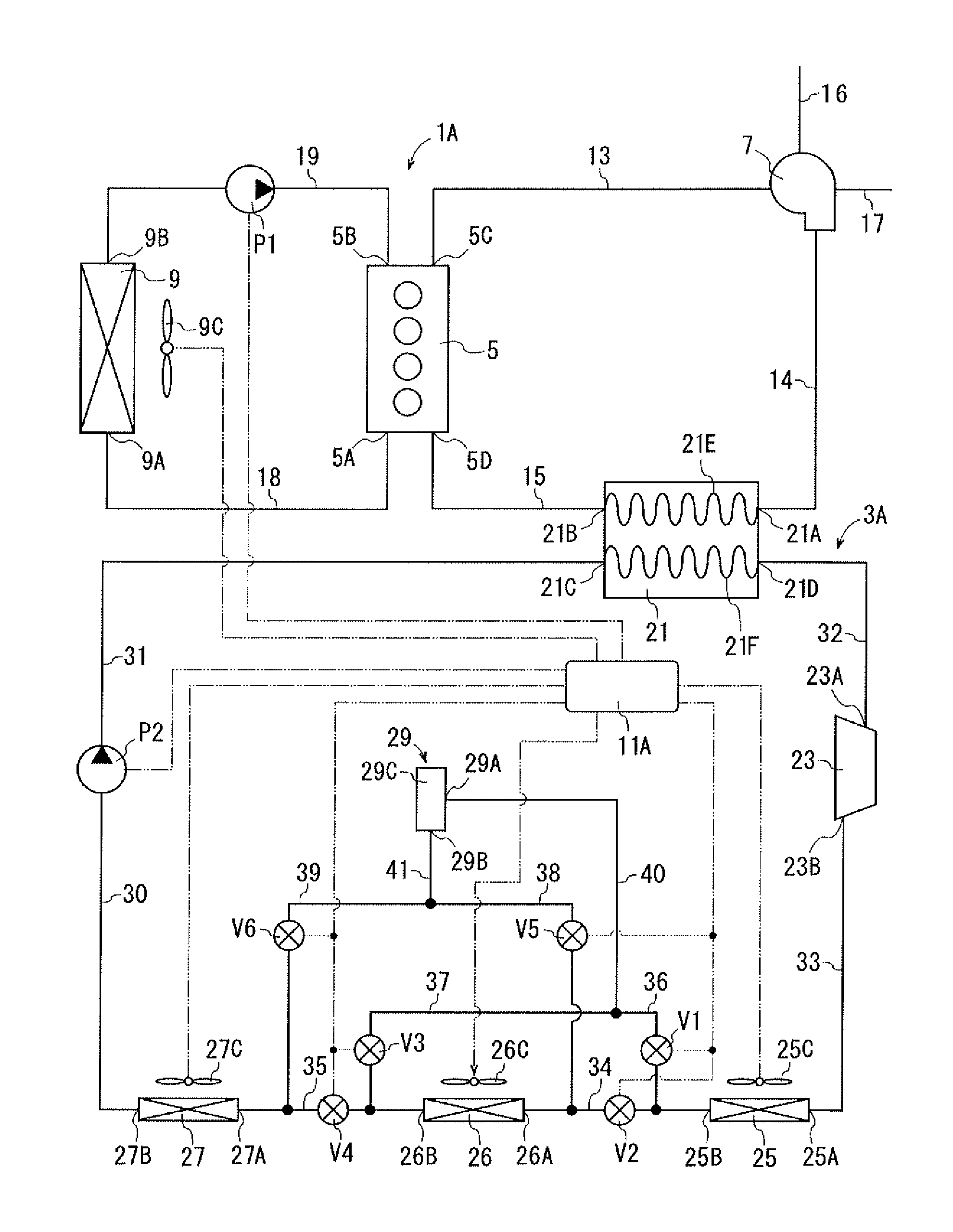

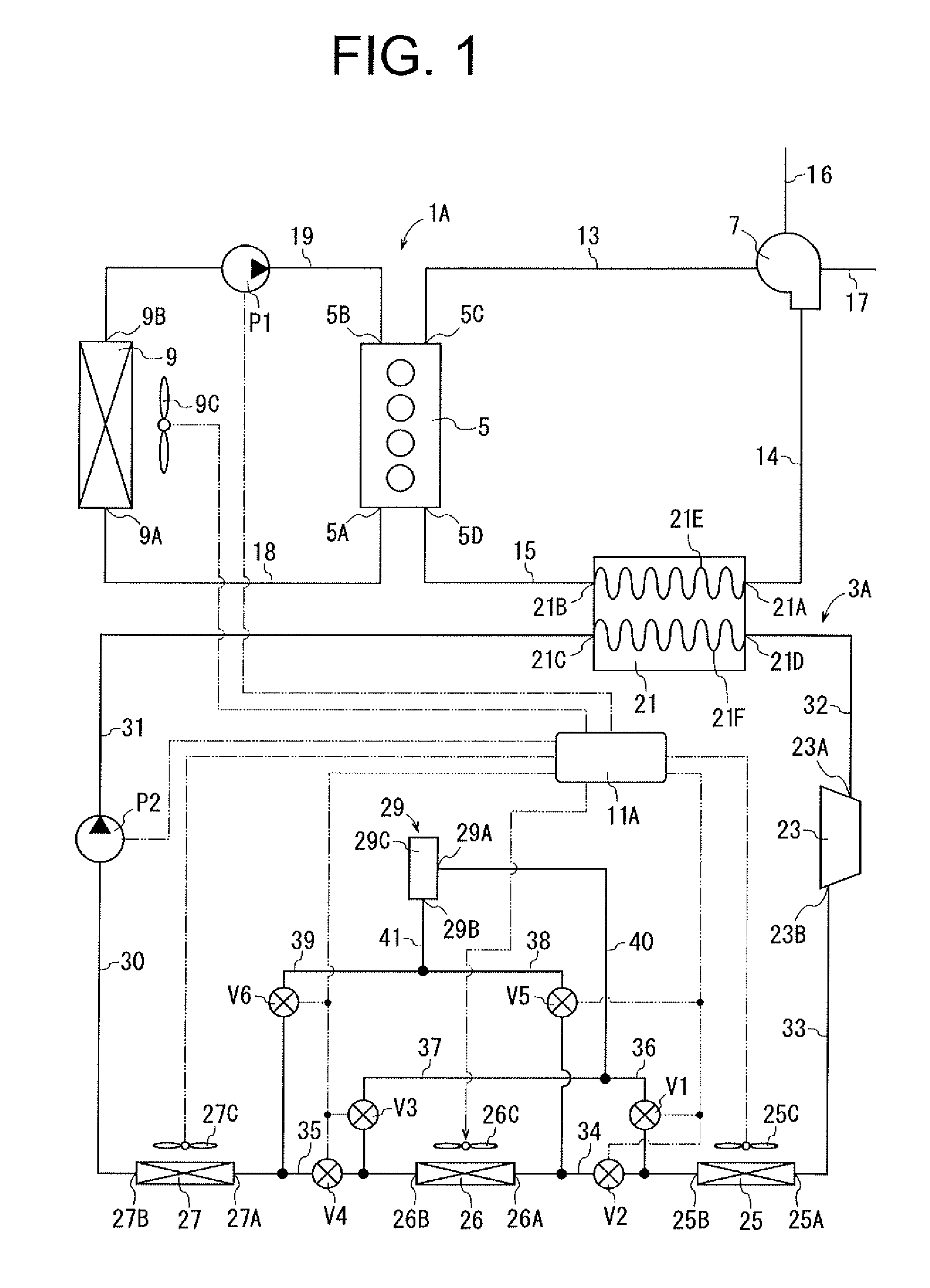

Waste heat recovery system

InactiveUS20130074497A1Reduce evaporating pressureNon-fuel substance addition to fuelInternal combustion piston enginesWorking fluidExternal combustion engine

A waste heat recovery system is for use with a power unit that includes an internal combustion engine. The waste heat recovery system includes a Rankine cycle device in which working fluid circulates through a pump, a boiler, an expander and then through a condenser, heat exchange occurs in the boiler between the working fluid and intake fluid that is introduced into the internal combustion engine while being cooled, a determination device for determining required cooling load for the intake fluid, a pressure reducing device for reducing evaporation pressure in the Rankine cycle device, and a controller for controlling the pressure reducing device so as to reduce the evaporation pressure below a predetermined evaporation pressure if the required cooling load determined by the determination device exceeds a threshold.

Owner:TOYOTA IND CORP

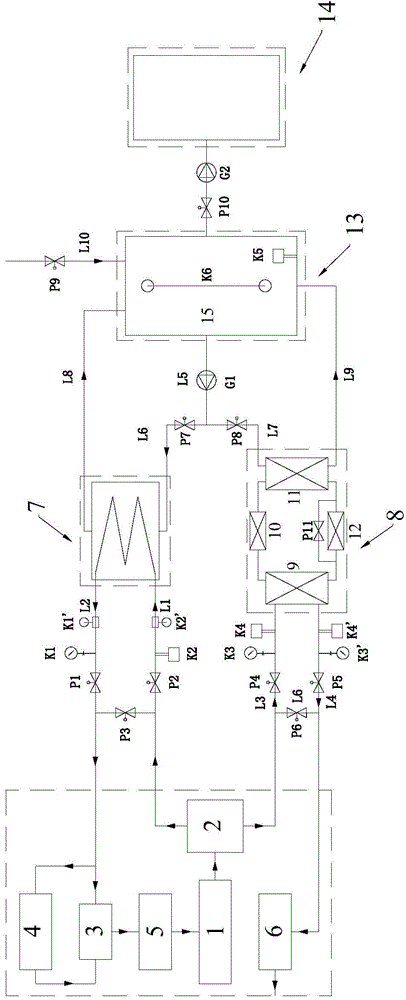

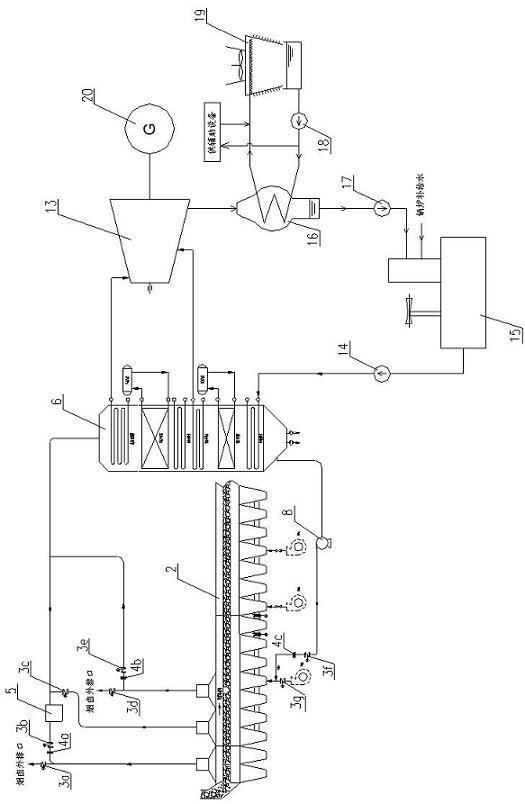

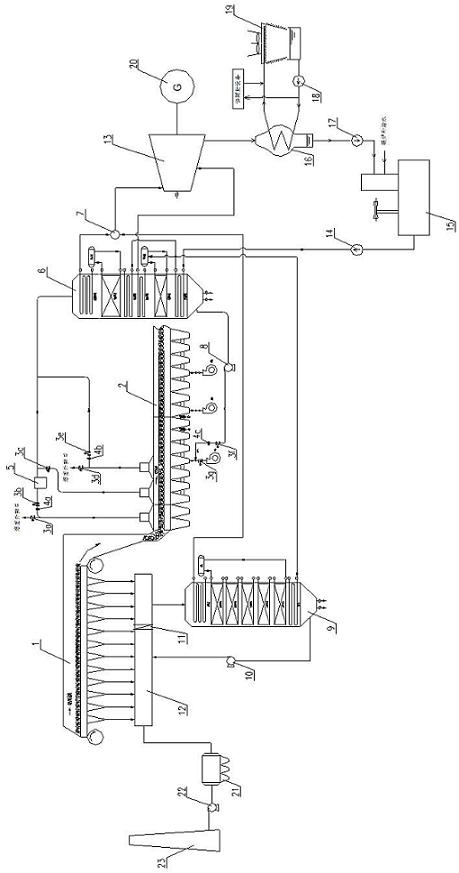

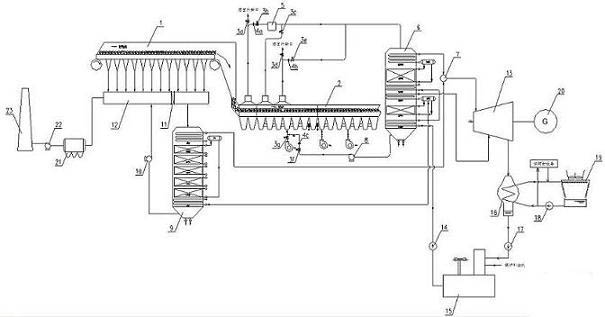

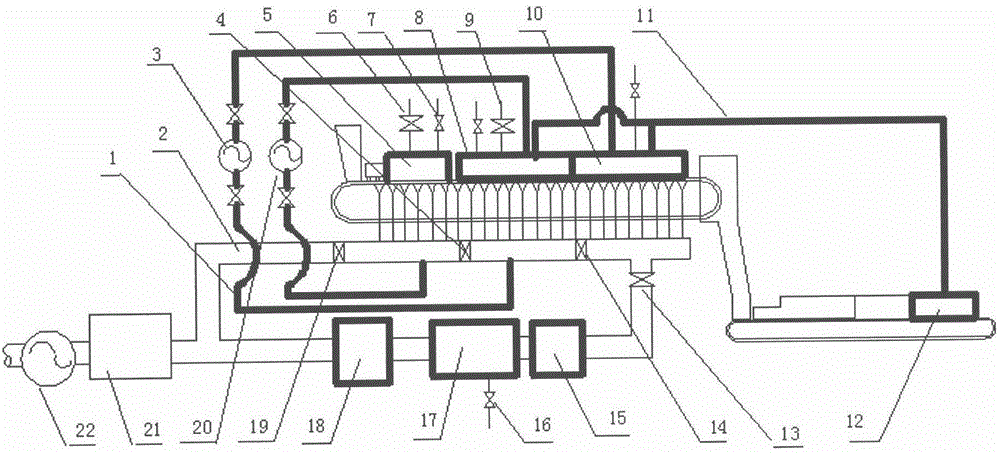

System and method for power generating by jointly recovering waste heat of flue gas of sintering machine and exhaust gas of cooling machine

ActiveCN102012167AImprove the efficiency of waste heat recovery and utilizationIncrease feed water temperatureEnergy industryIncreasing energy efficiencyWaste heat recovery unitIron plant

The invention discloses a system and method for power generating by jointly recovering the waste heat of a flue gas of a sintering machine and an exhaust gas of a cooling machine, belonging to the technical field of power generation by using waste sintering heat of a steel and iron plant. The power generating system comprises a sintering machine flue gas waste heat utilizing system, a cooling machine exhaust gas waste heat utilizing system, a turbine generating system and a relevant auxiliary system, wherein a main waste heat discharging boiler is utilized to recover the waste heat of the flue gas of a high-temperature segment of the tail part of the sintering machine; a cooling machine waste heat boiler is utilized to recover the waste heat of the high-temperature exhaust gas of the cooling machine; and a high-temperature electric butterfly valve is arranged between the high-temperature segment and a low-temperature segment of a large flue positioned on the tail part of the sintering machine to prevent the wind pickup temperature of the flue gas from being reduced because a low-temperature flue gas and a high-temperature flue gas are directly mixed so as to ensure the high-temperature flue gas to enter the main waste heat discharging boiler for waste heat recovery. The system and method effectively utilizes the waste heat resources of the high-temperature flue gas of the machine tail of the sintering machine and a hot gas of the high-temperature segment of the cooling machine, enhances the waste heat recovery and utilization efficiency of a sintering process and increases the power generation capacity of the waste heat power generating system.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

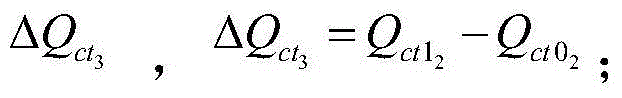

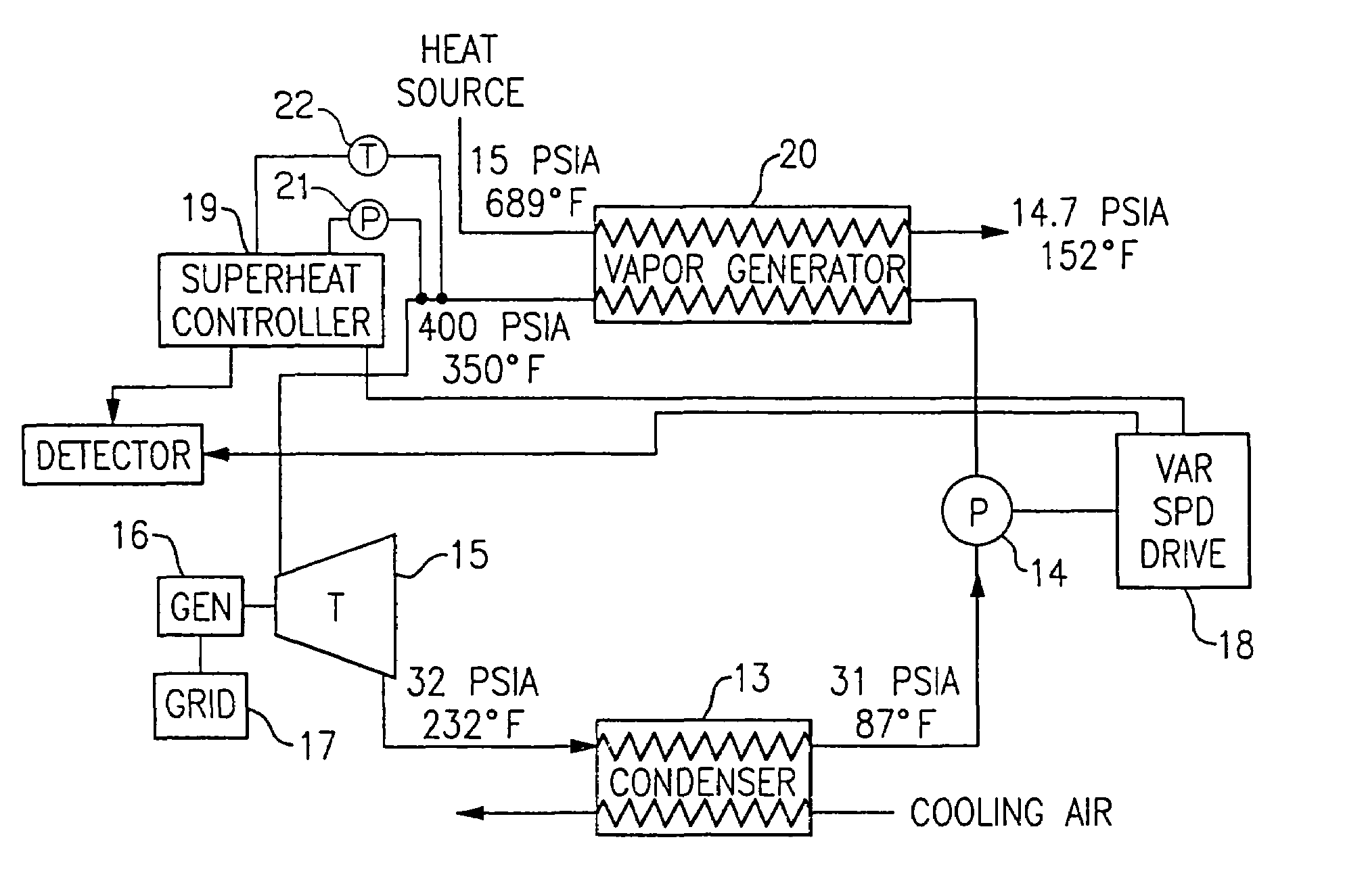

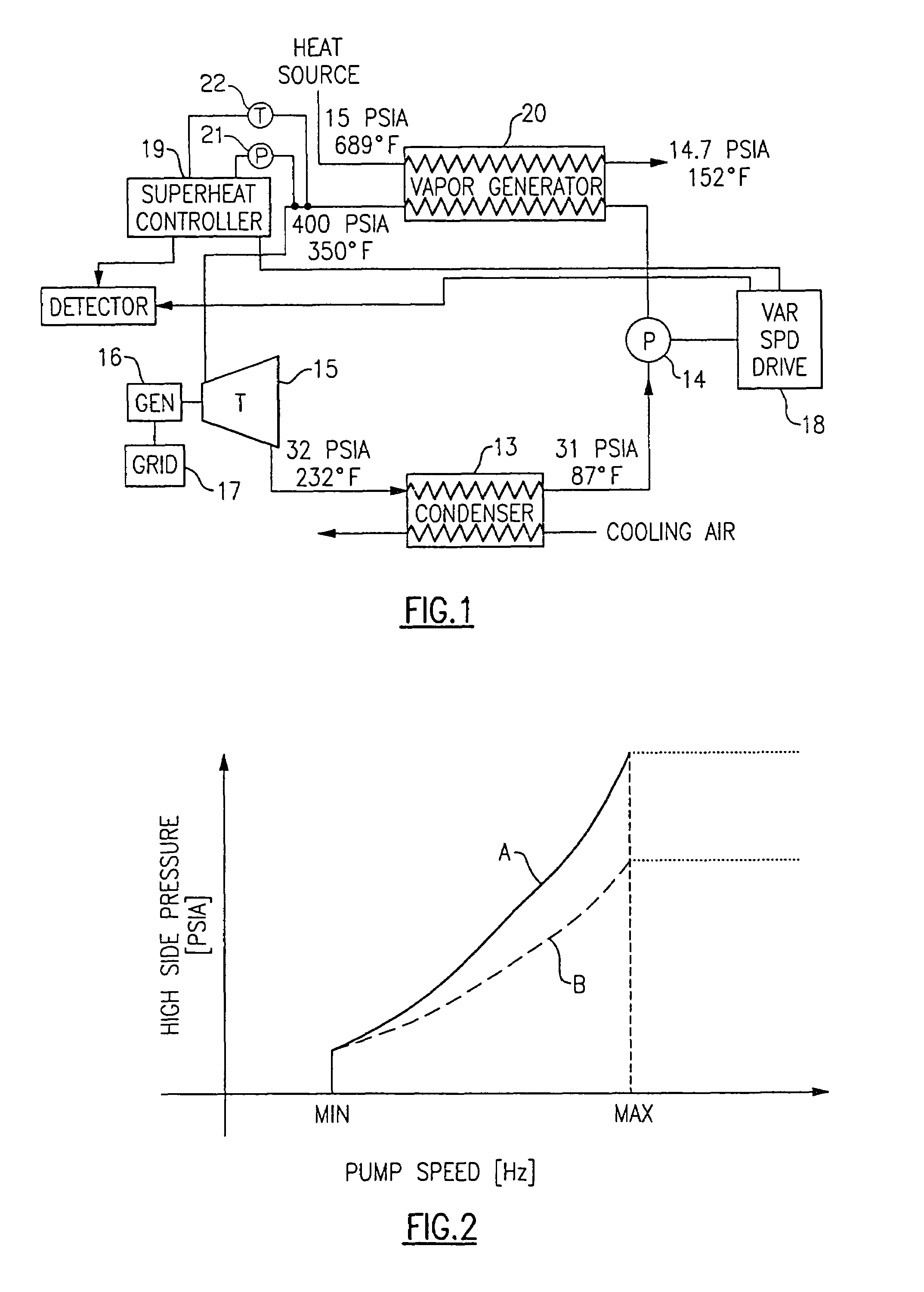

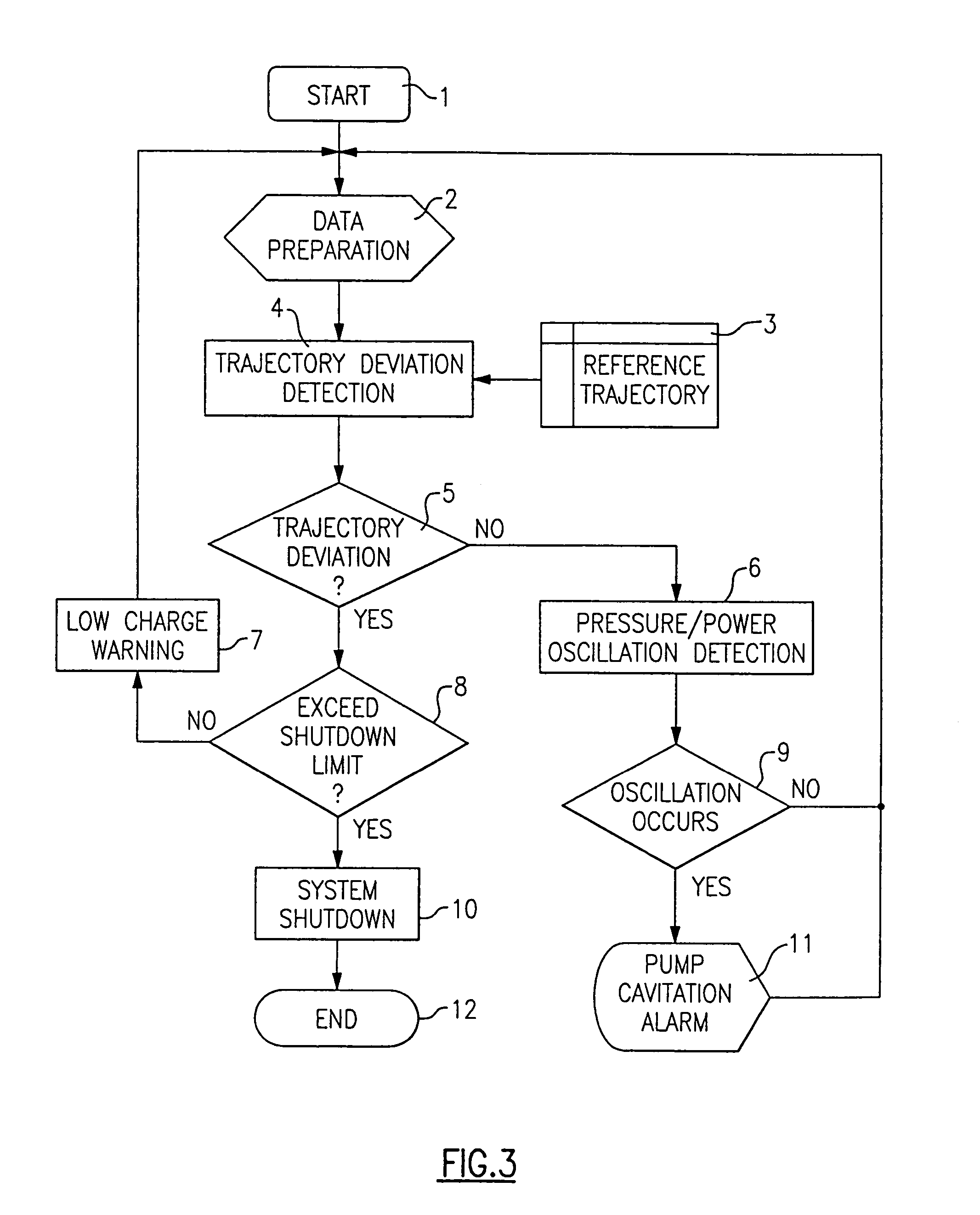

Apparatus and method for detecting low charge of working fluid in a waste heat recovery system

In a waste heat recovery system having a superheat controller, a reference superheat controller operating trajectory is established and compared with operational superheat controller trajectories from time to time and measuring the deviation therebetween to determine whether a low charge condition exists. If such a condition does exist, warning steps and possibly shut down steps can be taken. As a verification of a low charge condition, the absence or presence of oscillations in the pressure and / or pump power conditions can be observed.

Owner:RTX CORP

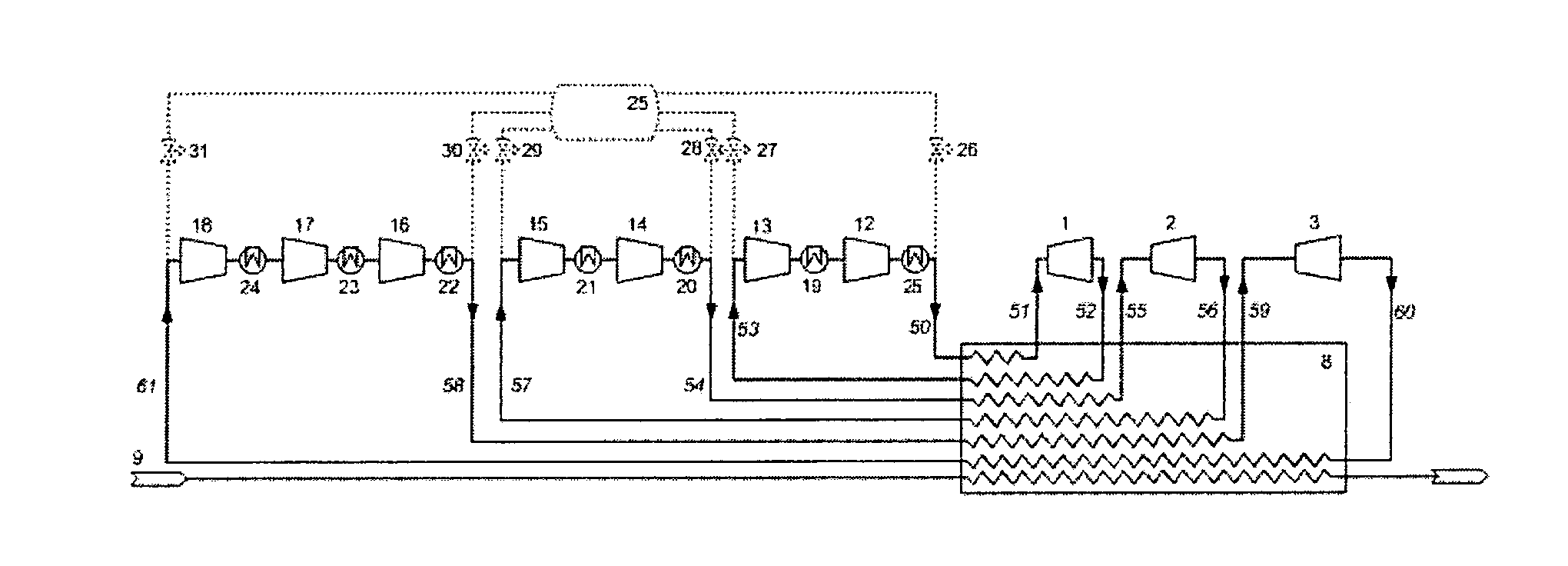

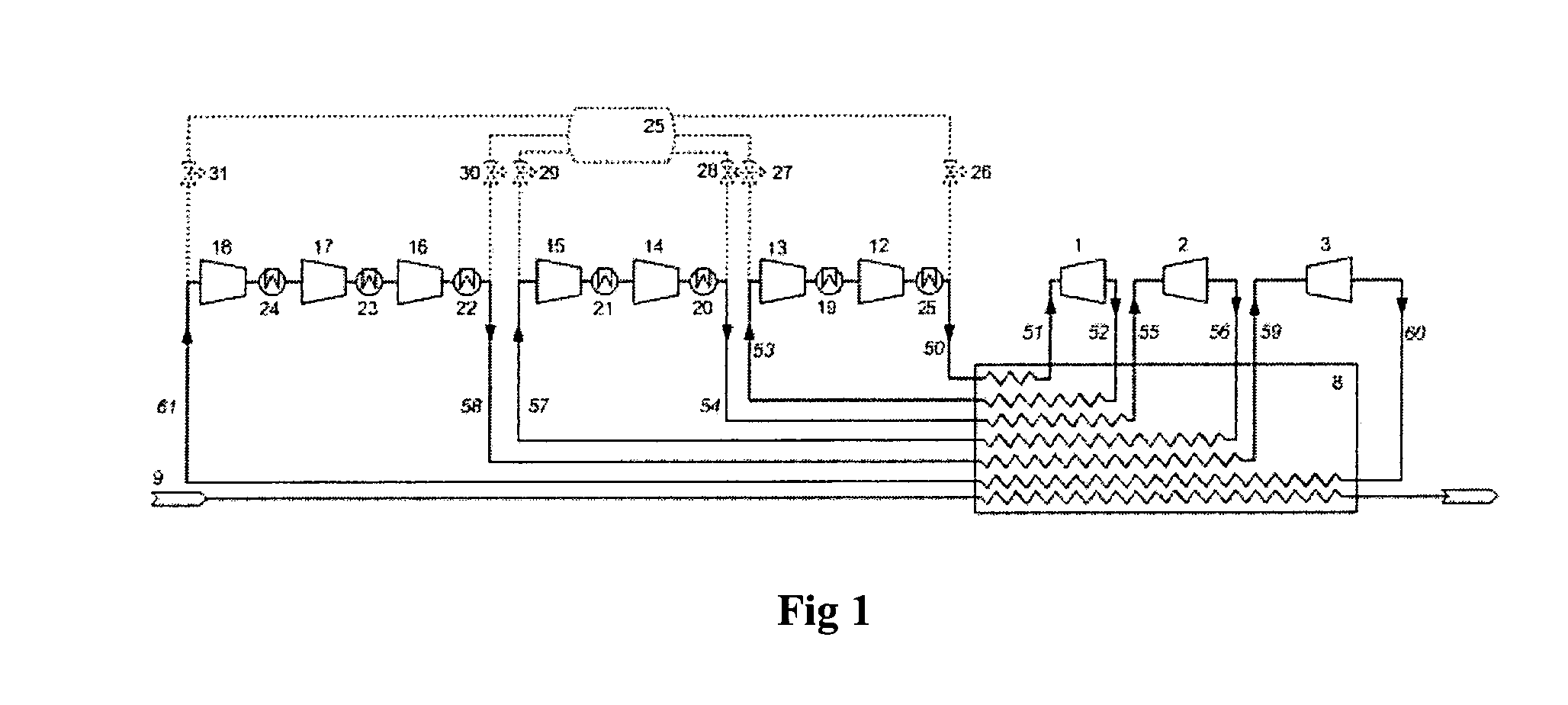

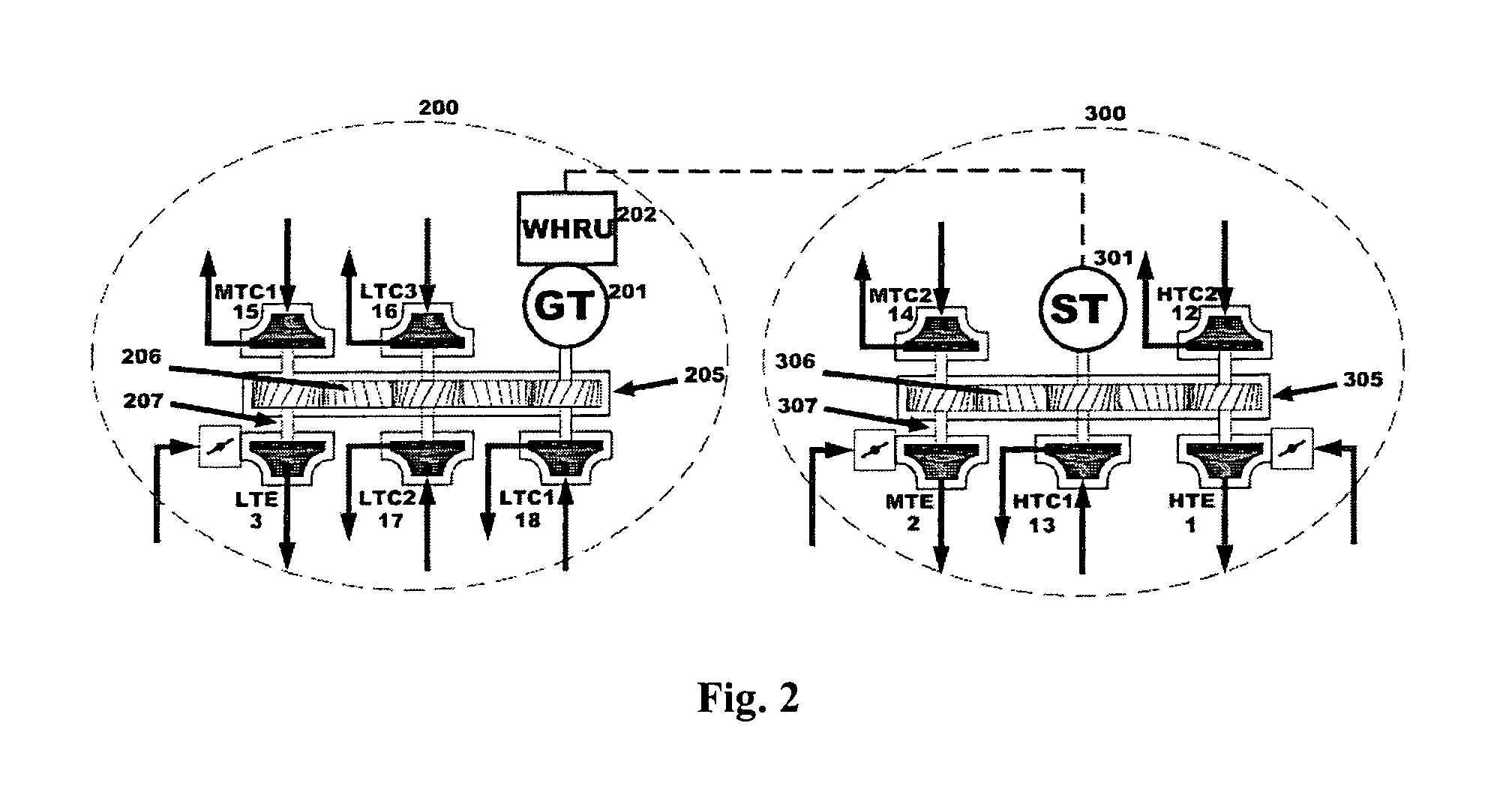

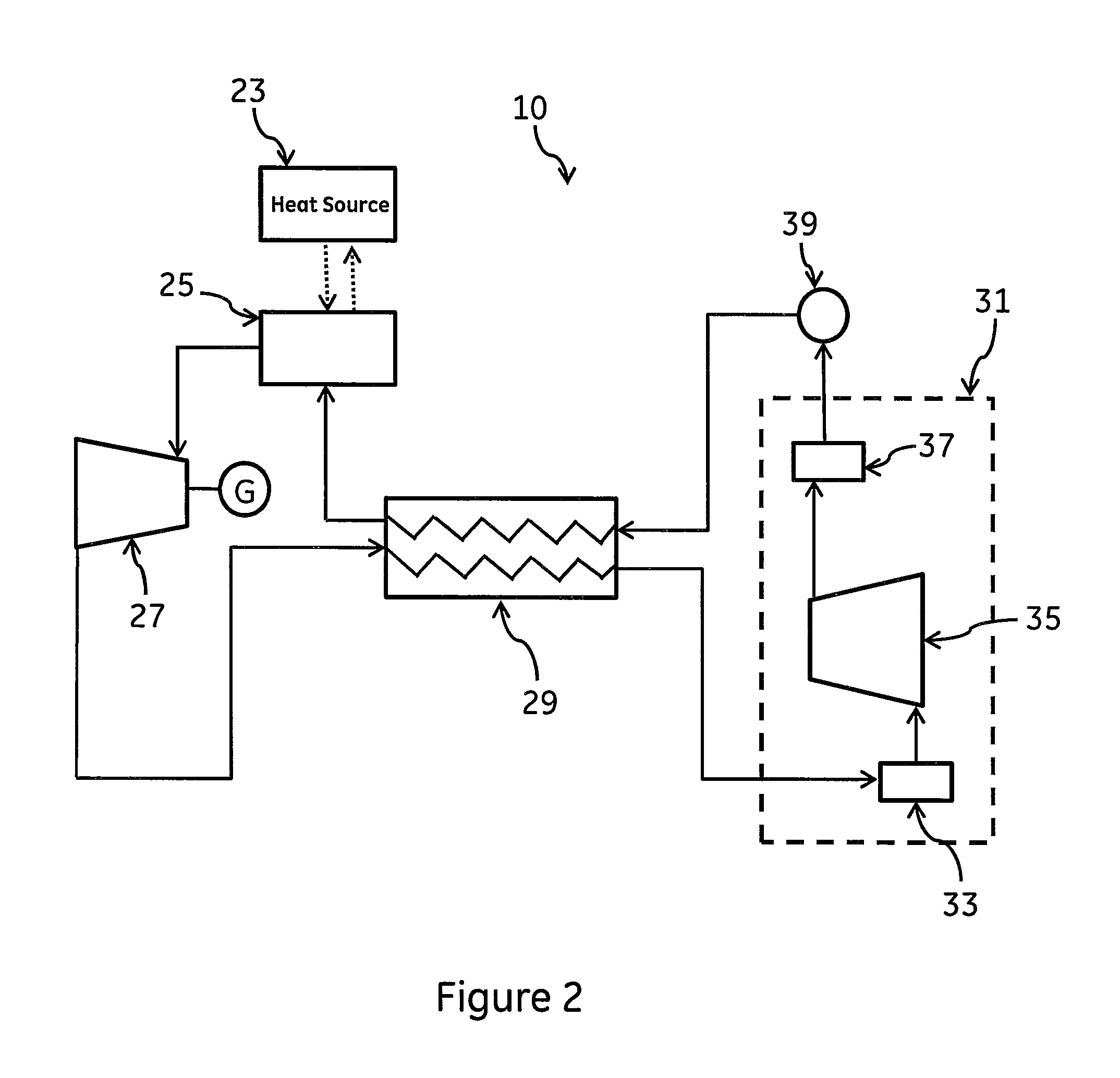

System for combined cycle mechanical drive in cryogenic liquefaction processes

InactiveUS20110209496A1Reduce operating costsReduce fuel requirementsSolidificationLiquefactionHeat rejectionNatural gas

A system for producing liquefied and sub-cooled natural gas by means of a refrigeration assembly using a single phase gaseous refrigerant comprises at least two expanders; a compressor assembly; a heat exchanger assembly for heat absorption from natural gas; and a heat rejection assembly, in which the expanders are arranged in expander loops and the refrigerant to the respective expander is served in a compressed flow by means of the compressor assembly having compressors or compressor stages enabling adapted inlet and outlet pressures for the respective expander. According to the present the expanders and compressors assembly are assembled in two mechanically connected compressor and expander packages of which one is driven by a gas turbine and the other is driven by a steam turbine, the steam primarily being generated by exhaust gases from the gas turbine in a waste heat recovery unit, and in that the expanders and compressors assemblies are distributed between the two compressor and expander packages to optimize the steam utilization and to balance the power generated by the gas turbine and the steam turbine.

Owner:HAMWORTHY OIL & GAS SYST AS

Organic rankine cycle systems using waste heat from charge air cooling

InactiveUS8302399B1Internal combustion piston enginesExhaust apparatusWaste heat recovery unitOrganic Rankine cycle

The present application and the resultant patent provide a waste heat recovery system for recovering heat from a number of turbocharger stages. The waste heat recovery system may include a simple organic rankine cycle system and a number of charge air coolers in communication with the turbocharger stages and the simple organic rankine cycle system. The charge air coolers are positioned in a number of parallel branches of the simple organic rankine cycle system.

Owner:AI ALPINE US BIDCO INC

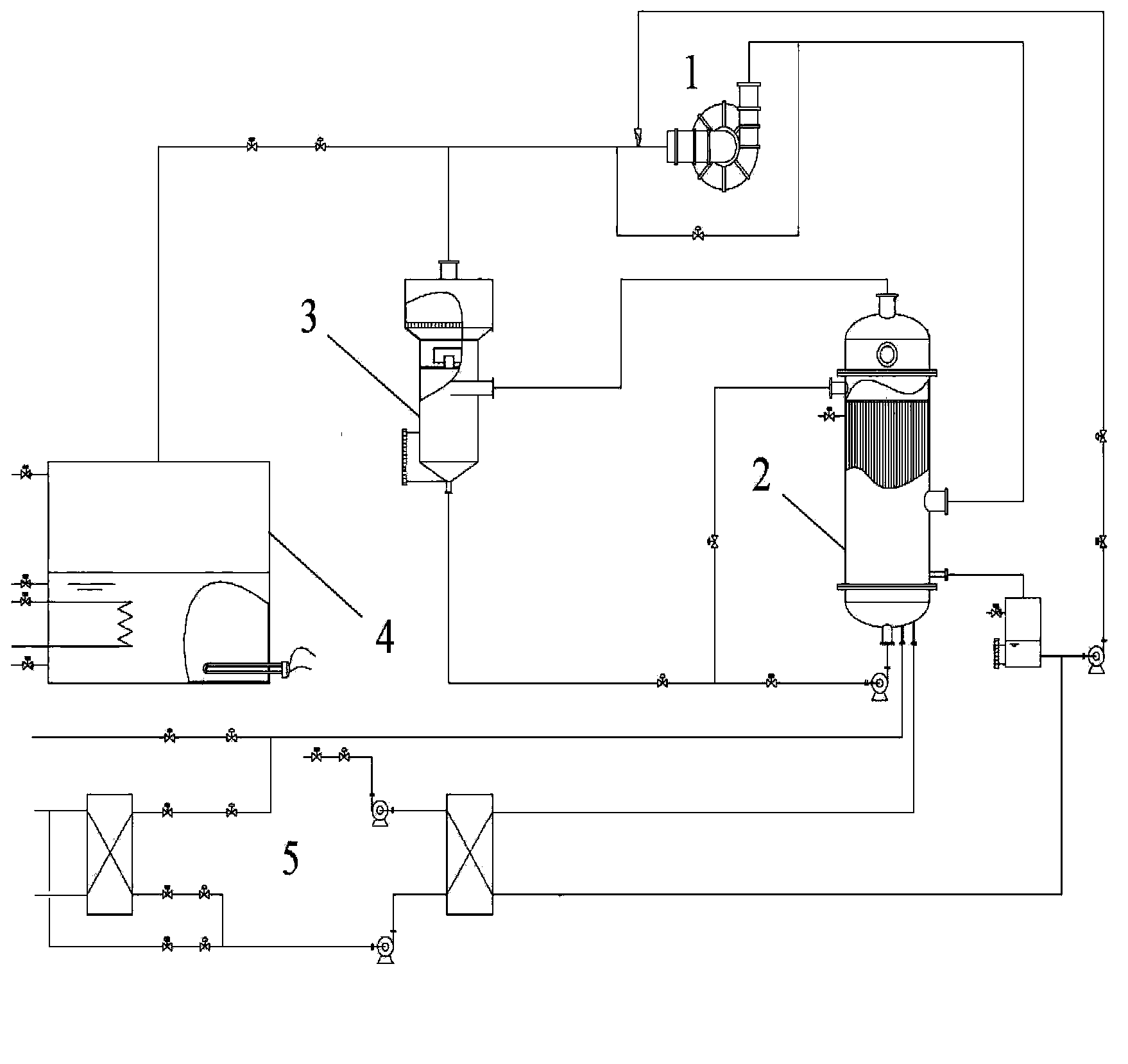

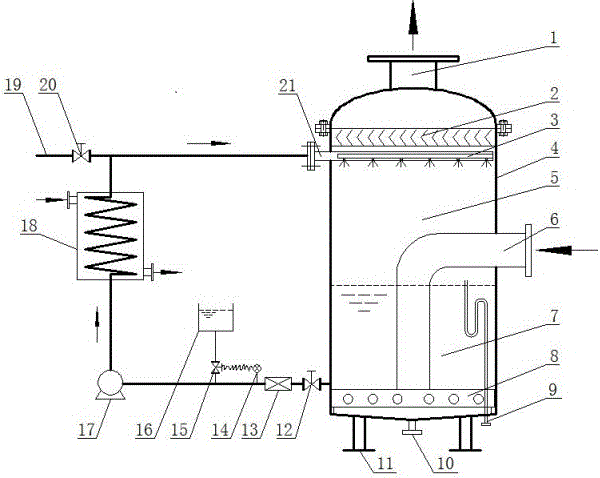

MVR heat pump evaporation system

ActiveCN103908788AReduce consumptionFast startupEvaporator accessoriesEvaporators with vertical tubesWater vaporEvaporation

The invention discloses an MVR heat pump evaporation system, which comprises a water vapor compression system, an evaporator, a separator, an energy storage water tank and a waste heat recovery system. The vapor outlet of the energy storage water tank and the vapor outlet of the separator are both in connection with the vapor inlet of the water vapor compression system, the vapor outlet of which is connected to the vapor inlet of the evaporator. The vapor outlet of the evaporator is connected to the vapor inlet of the separator, and the stock solution inlet and the concentrated solution outlet of the evaporator are both in connection with the waste heat recovery system. The MVR heat pump evaporation system provided by the invention recovers low grade waste heat, i.e. makes use of the energy storage water tank to convert hot water sensible heat into low-pressure vapor latent heat for recycling during starting, thus enhancing the start-up speed of the system, avoiding the influence of non-condensable gas air circulation in the system on compressor performance, recovering all the latent heat of secondary vapor generated in a solution evaporation process, saving primary energy, greatly reducing the energy consumption during solution evaporation, and avoiding pollution.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Closed Cycle System for Recovering Waste Heat

A closed cycle system for waste heat recovery is provided. The system comprises: a heat exchanger configured to transfer heat from an external heat source to a working fluid; an expander fluidly connected to an outlet of the heat exchanger and configured to expand the working fluid and produce mechanical energy; a recuperator fluidly connected to an outlet of the expander and configured to remove heat from the working fluid; a condensing unit fluidly connected to an outlet of the recuperator and configured to condense the working fluid; and a pump fluidly connected to an outlet of the condensing unit and configured to pump the condensed working fluid back to the recuperator, wherein the recuperator is fluidly connected to the heat exchanger such that the working fluid follows a closed path.

Owner:NUOVO PIGNONE SPA

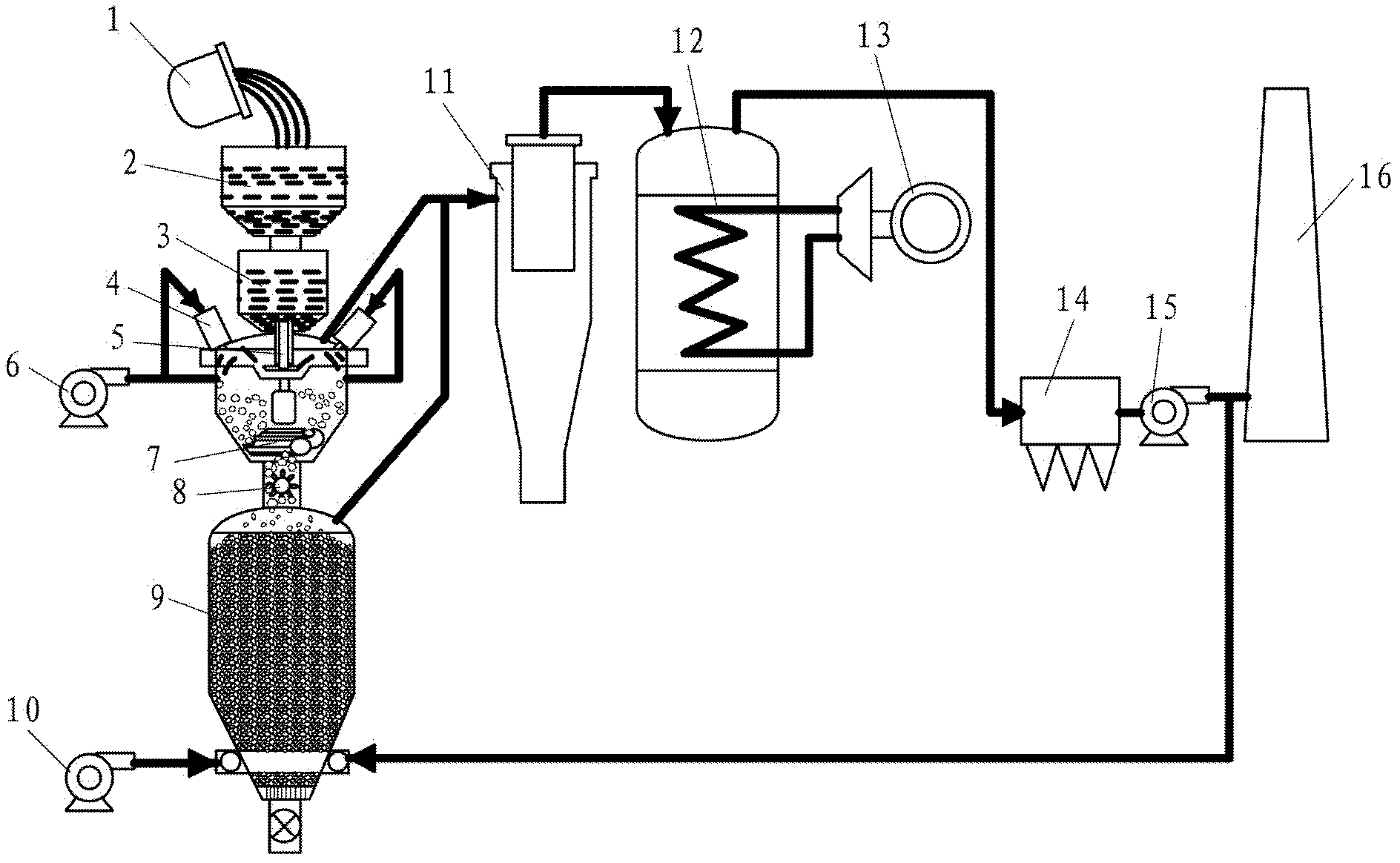

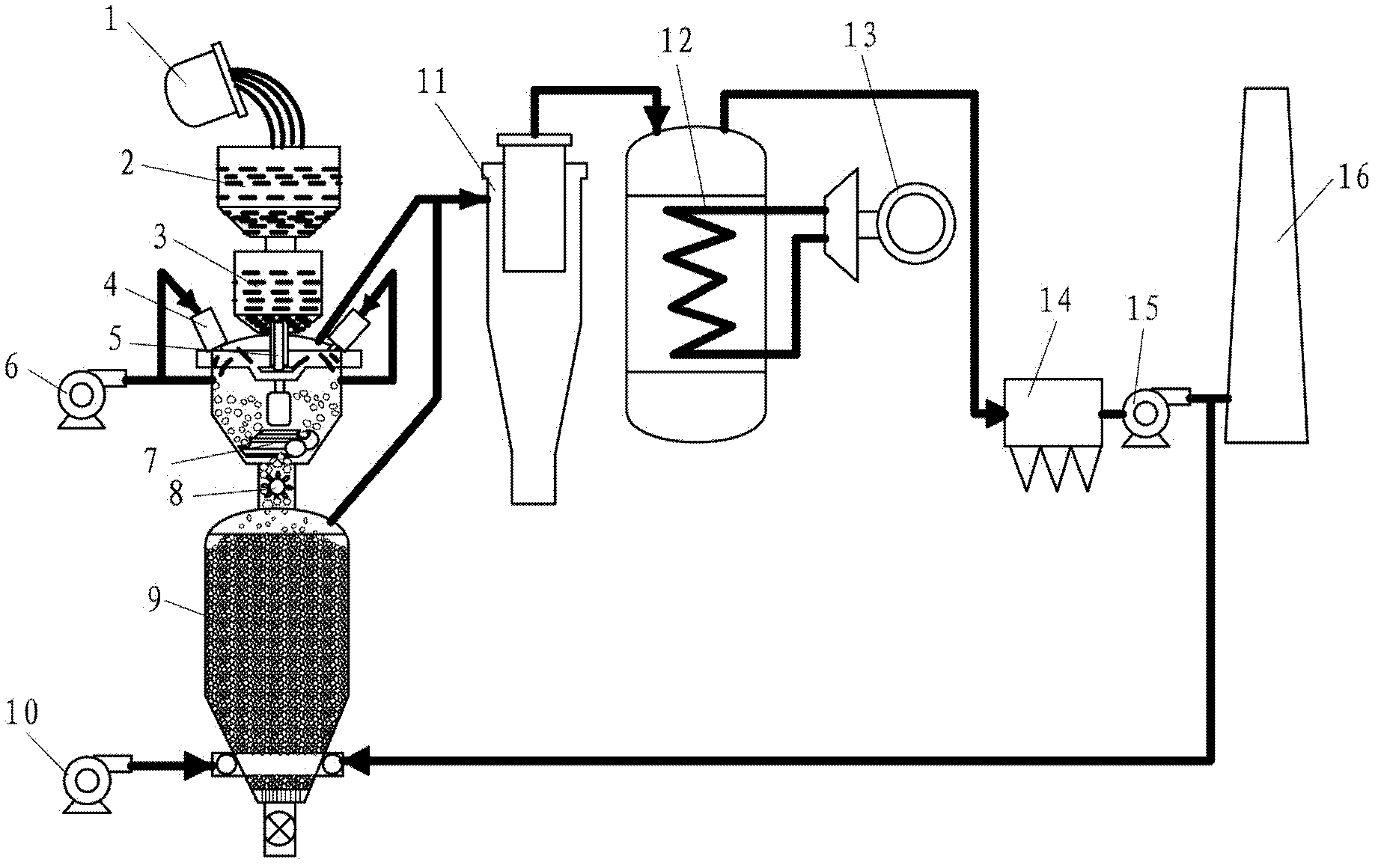

Technique and equipment for preparing sulfuric acid by using sulfur and waste liquid generated from coal gas wet type oxidation sweetening technique

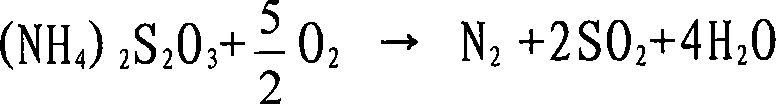

ActiveCN101092577ASimple processSimplify Process Gas Cleaning ProcessSulfur compoundsEnergy inputLiquid wasteSulfur containing

This invention relates to method and apparatus for preparing sulfuric acid by using sulfur and waste solution generated in wet oxidation desulfurization of coal gas. The method comprises: mixing sulfur and sulfur-containing salt solution, incinerating wastewater, recovering waste heat, dry-cleaning, wet-contact-converting, and condensing. The apparatus comprises: an incineration unit, a waste heat recovery unit, a dry-type purification unit, a wet-type contact conversion unit, and a condensation unit, while does not comprise drying unit or tail gas treatment unit. Only one dry-type high-temperature purification deduster is used for dry purification, thus the purification process is simplified. The method has low cost, and no waste solution discharge.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

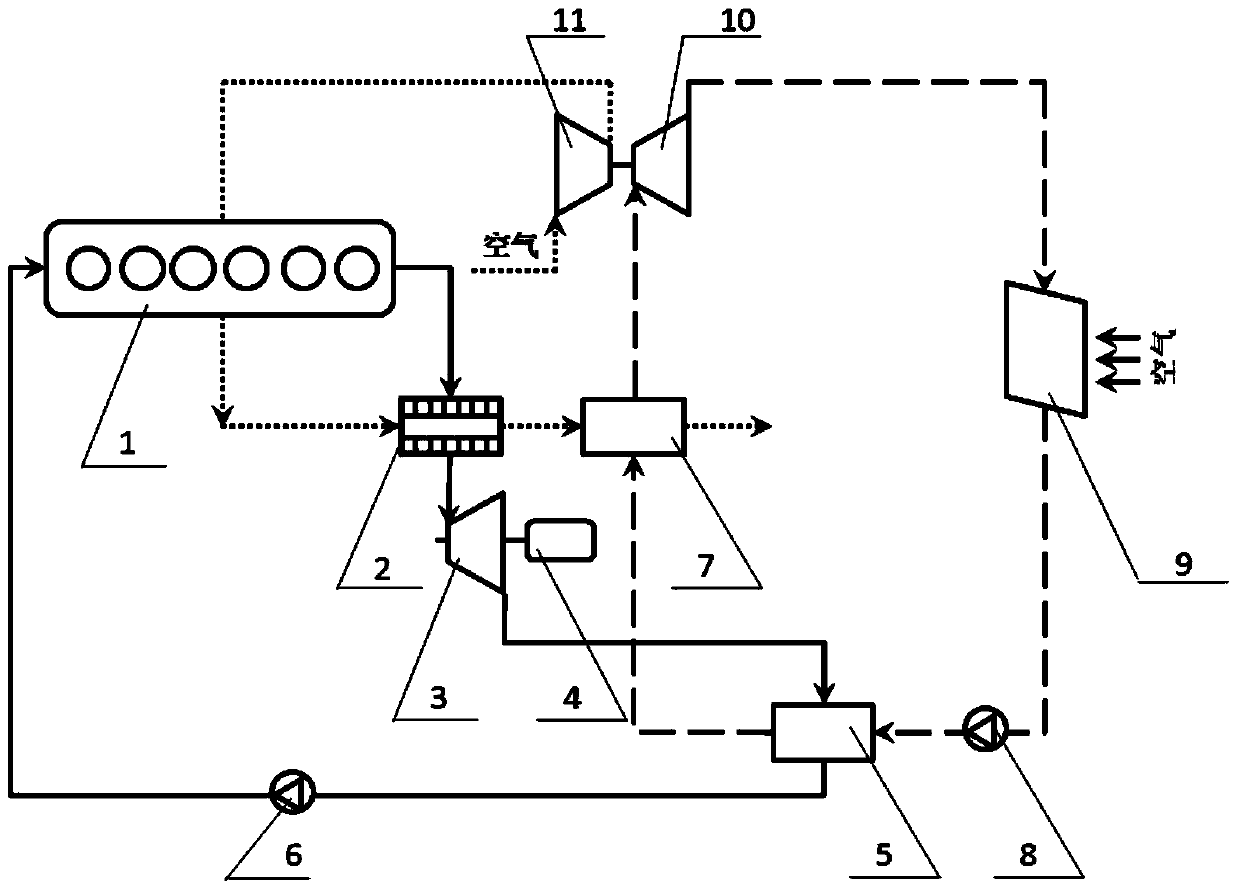

Thermodynamic cycle system suitable for waste heat recovery of engine for automobile

InactiveCN101408115AAchieve warm-upImprove waste heat recovery efficiencyInternal combustion piston enginesEngine componentsWaste heat recovery unitCoupling

The invention relates to a thermodynamic circulating system which is applicable to the recycling of waste heat of a vehicle engine. The thermodynamic circulating system is a coupling of low-temperature Kalina cycle used for recycling the waste heat of the cooling water of the engine and high-temperature organic Rankine cycle used for recycling the waste heat of the exhaust of the engine and the waste heat of the lubricating oil, and comprises an exhaust heat exchanger, an expansion machine, a heat exchanger, a pump, a lubricating oil heat exchanger, a lubricating oil circulating pump, a cooling water heat exchanger, a cooling water circulating pump, a heat regenerator, a throttle valve, a separator, the expansion machine, a low-pressure condenser and a pump. The system can overcome the defects that the utilization ratio of the waste heat is not high in the traditional utilization method of the waste heat of the engine, thus obviously improving the recycling efficiency of the waste heat of the vehicle engine.

Owner:XI AN JIAOTONG UNIV

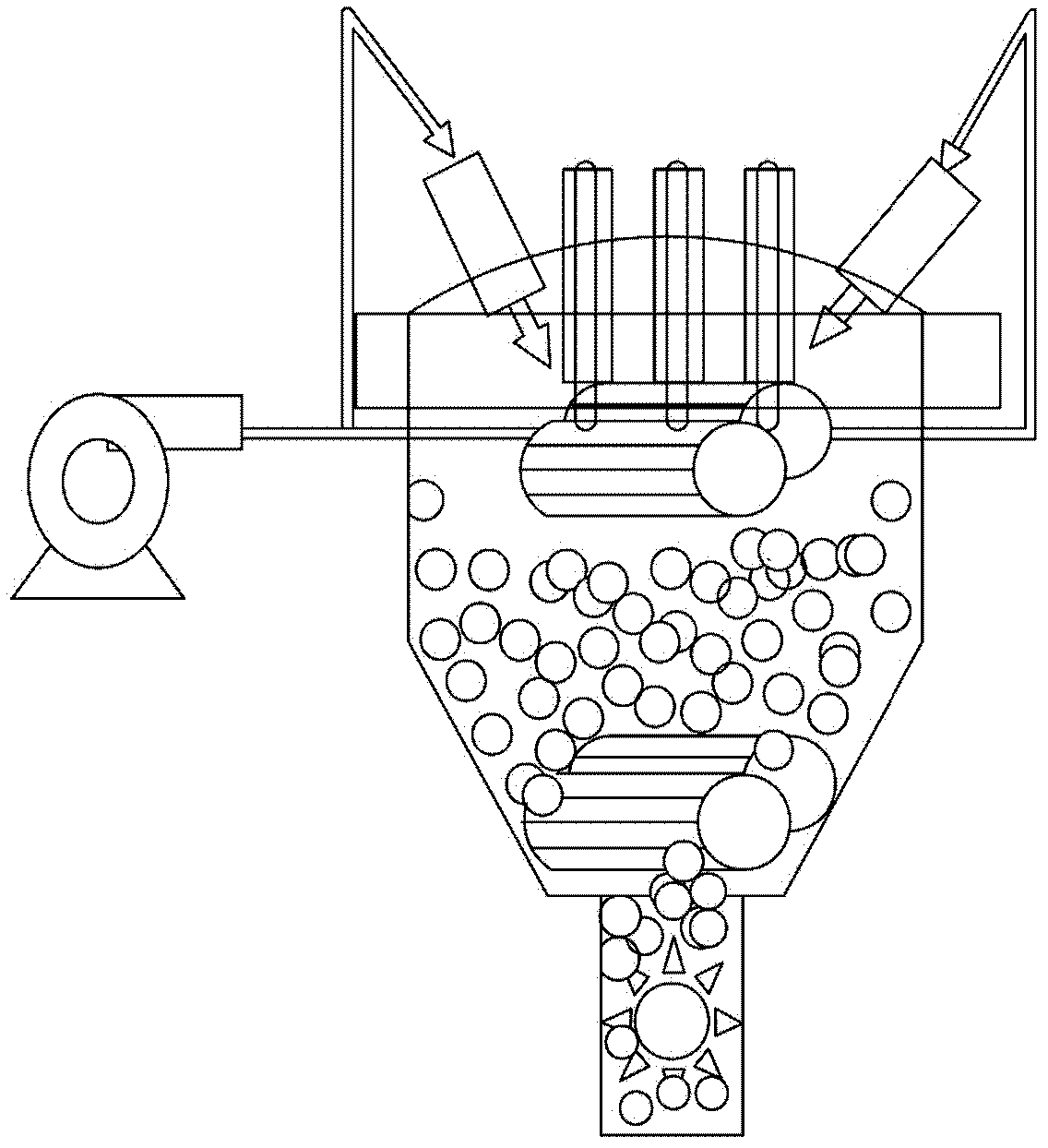

Slag granulating and waste heat recovery device

InactiveCN102424867ARecycling and recovery technologiesProcess efficiency improvementSlagShaft furnace

The invention provides a slag granulating and waste heat recovery device, comprising a slag pot, a slag ladle, a granulating device, a primary cooling fan, a discharge device, a secondary cooling fan, a heat exchange shaft furnace, a cyclone dust collector, a waste heat boiler, a dust collector and a chimney, wherein the slag pot is used for containing slag; a water port is arranged at the lower part of the slag ladle; the granulating device is used for granulating the slag in the slag ladle; the primary cooling fan is used for providing primary cooling air; the discharge device is used for discharging granulated slag; the secondary cooling fan is used for providing secondary cooling air; the heat exchange shaft furnace is used for performing heat exchange between the granulated slag discharged by the discharge device and the secondary cooling air; the cyclone dust collector is used for removing fine particle slag from the primary cooling air and the secondary cooling air; the waste heat boiler is used for generating high-temperature stream; the dust collector is used for collecting dust in the tail gas generated by the waste heat boiler; and the chimney is used for discharging the tail gas after dust collection. By using the slag granulating and waste heat recovery device according to the invention, no new water is consumed in the slag granulating process, the slag waste heatcan be effectively recovered for power generation, and the slag vitreous body after treatment can be used as a construction raw material.

Owner:CENT IRON & STEEL RES INST

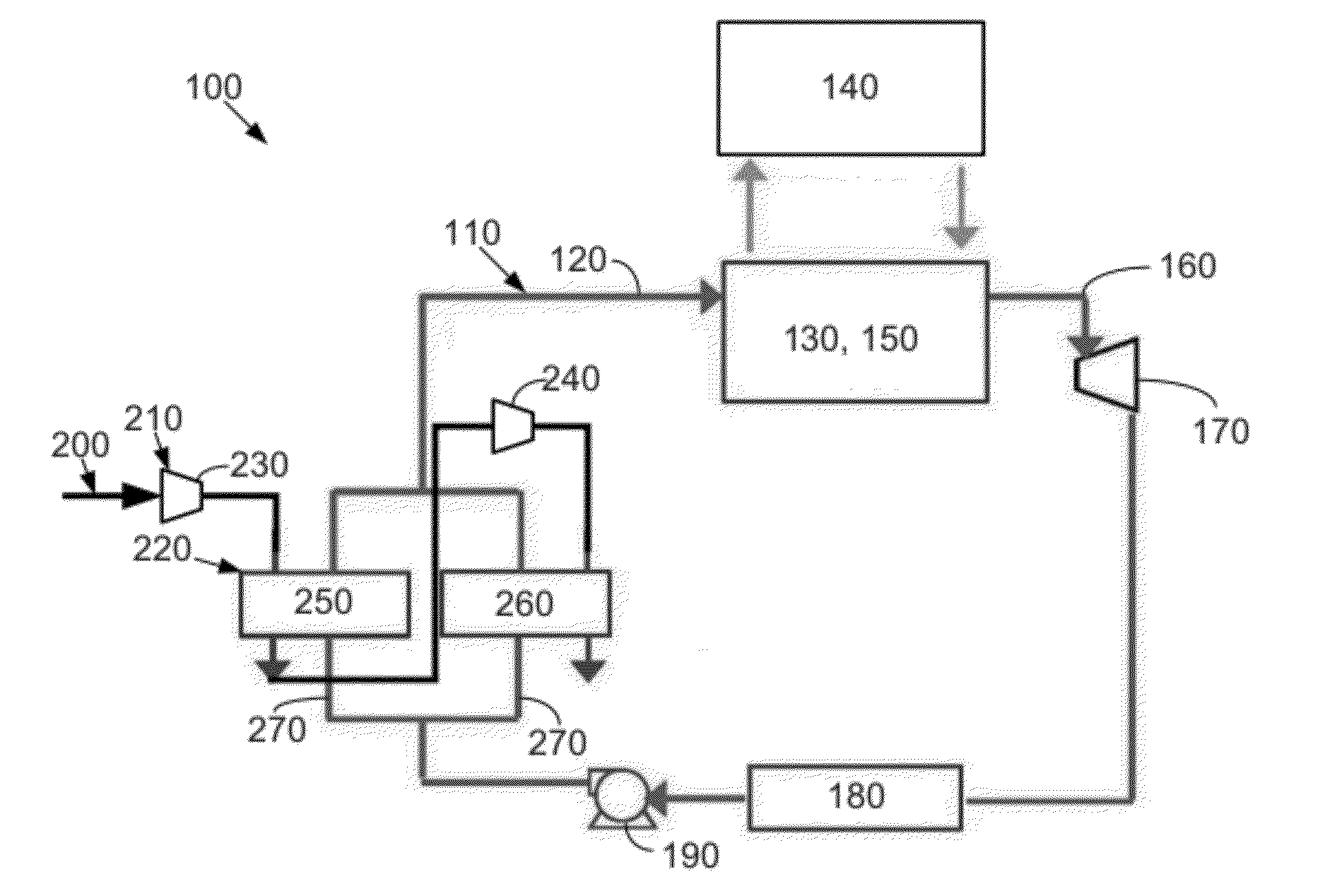

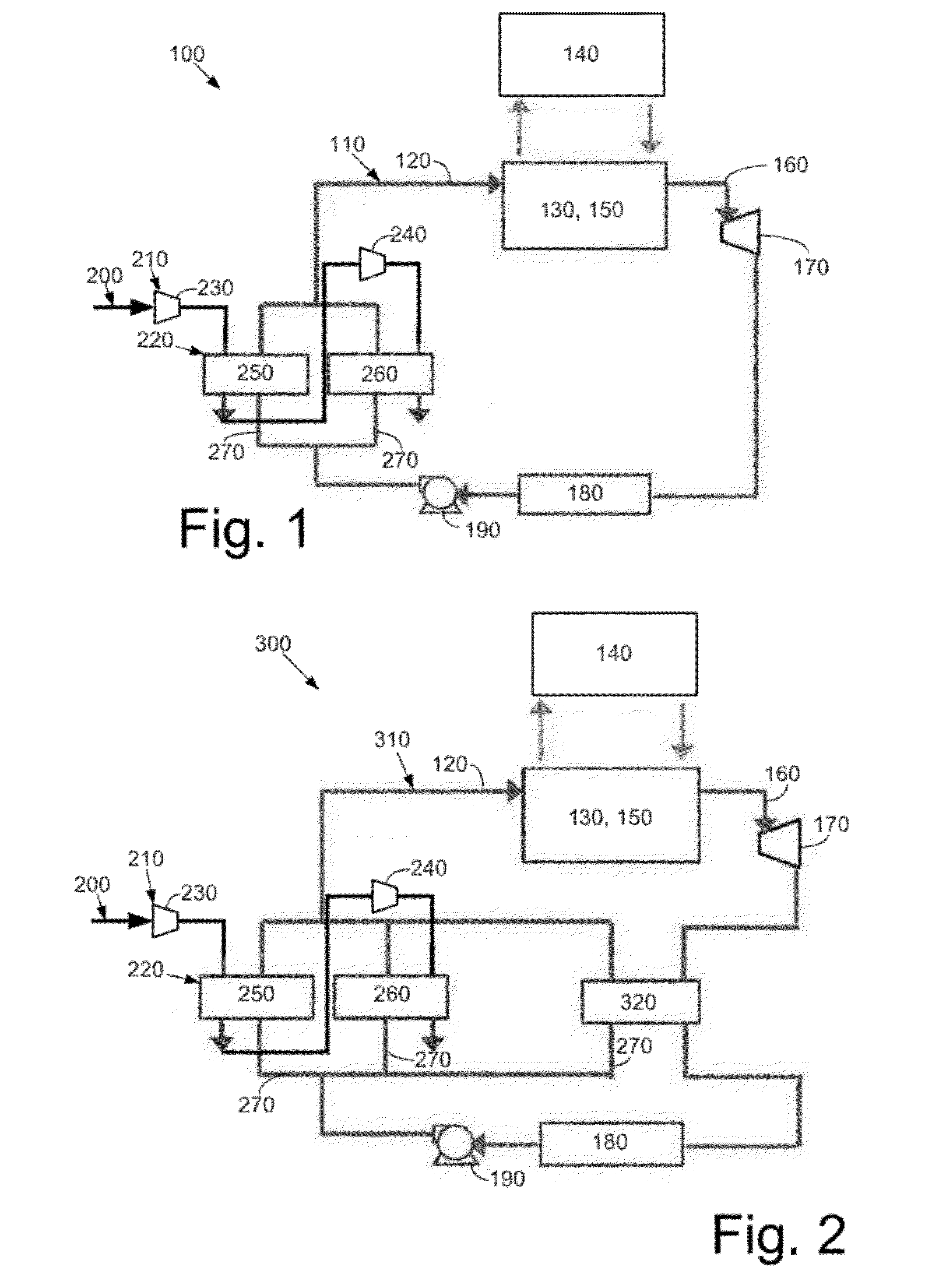

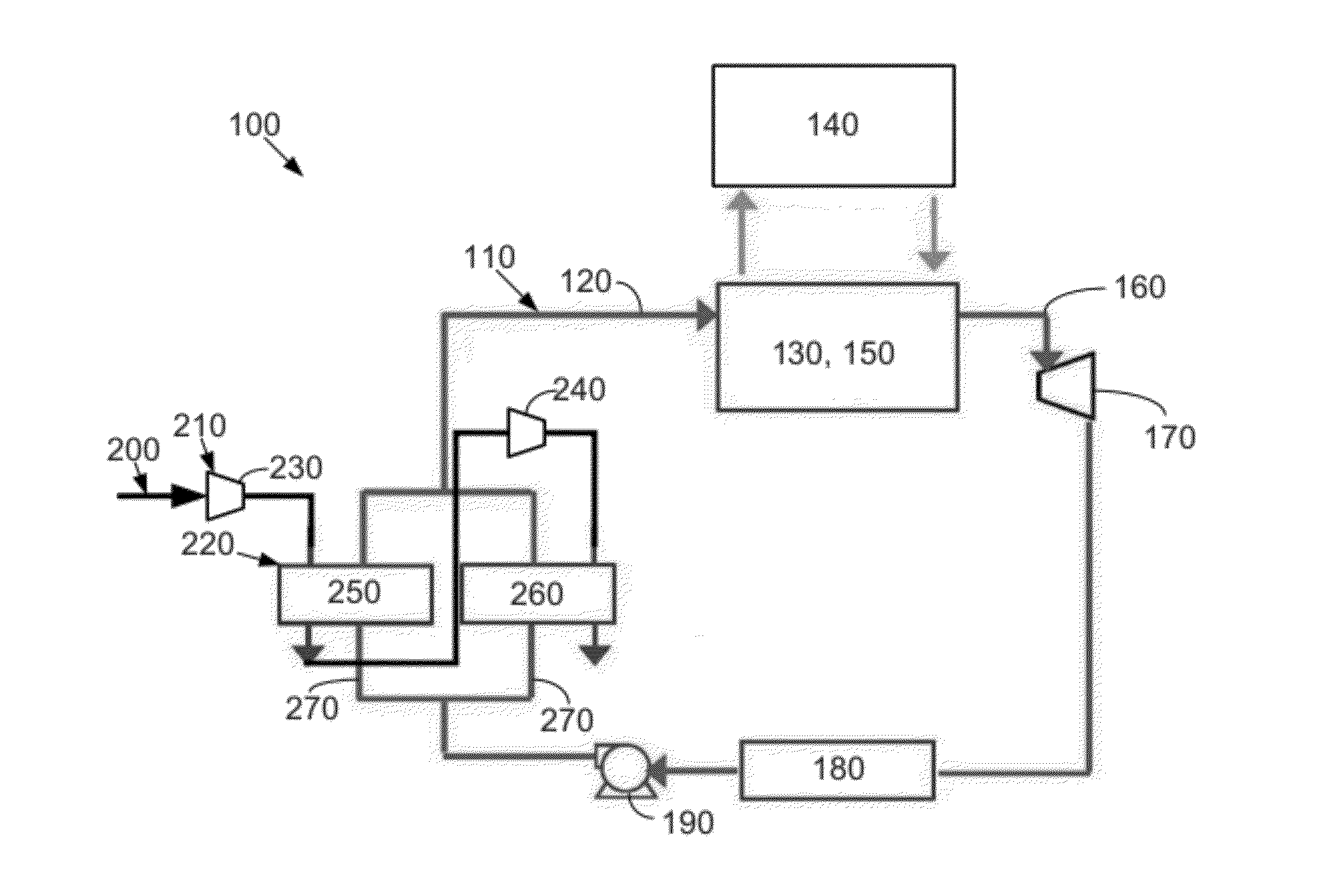

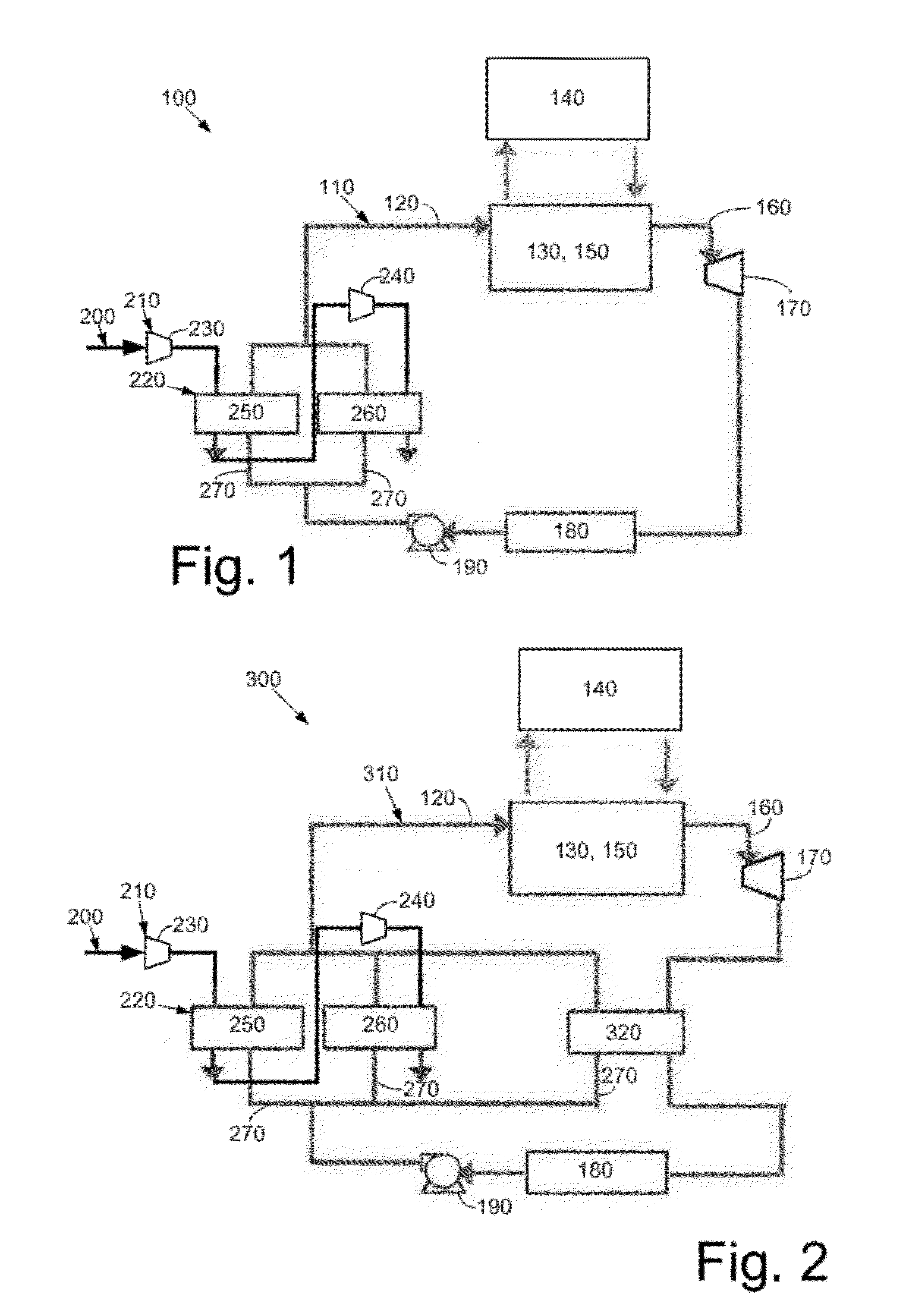

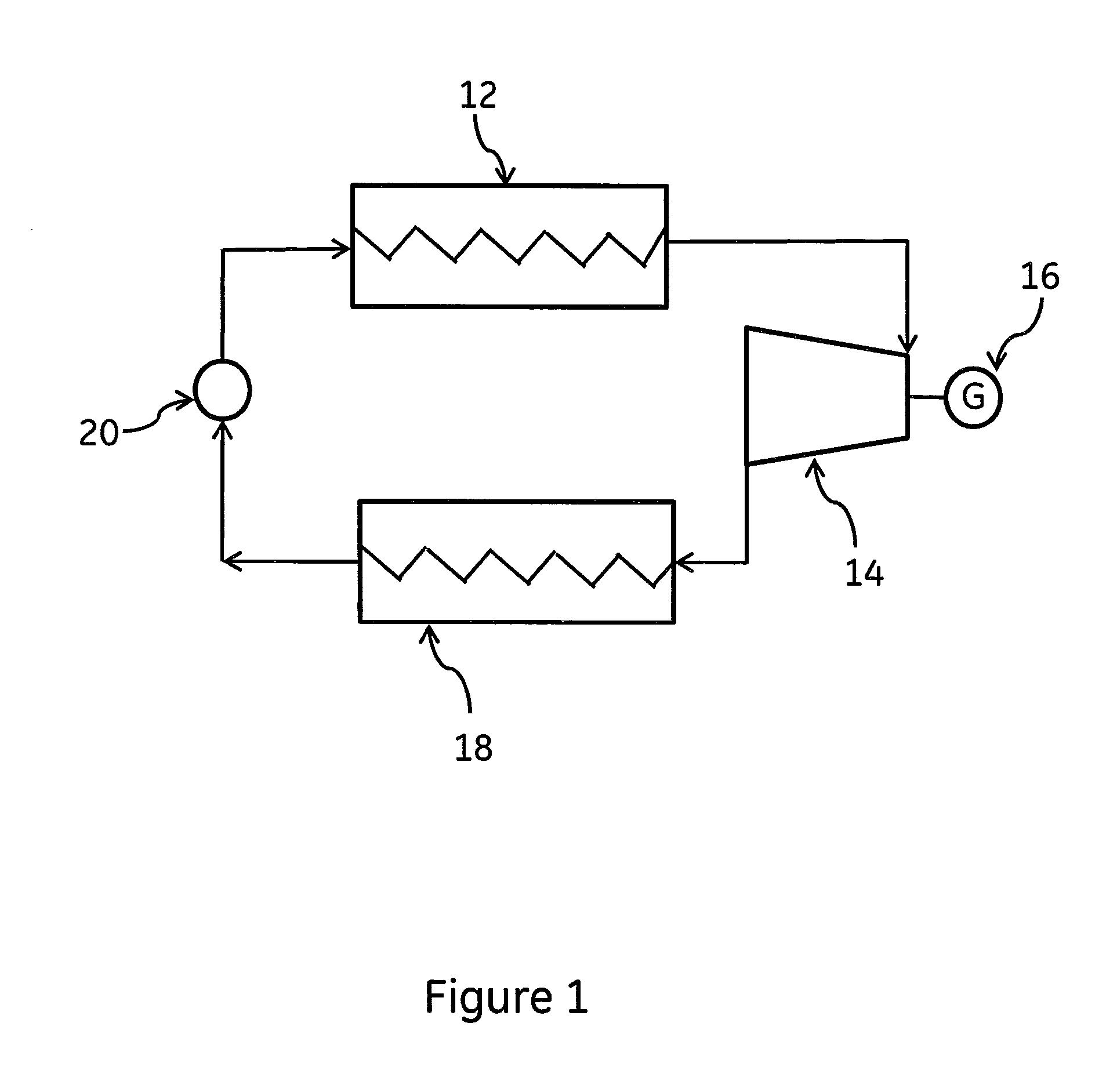

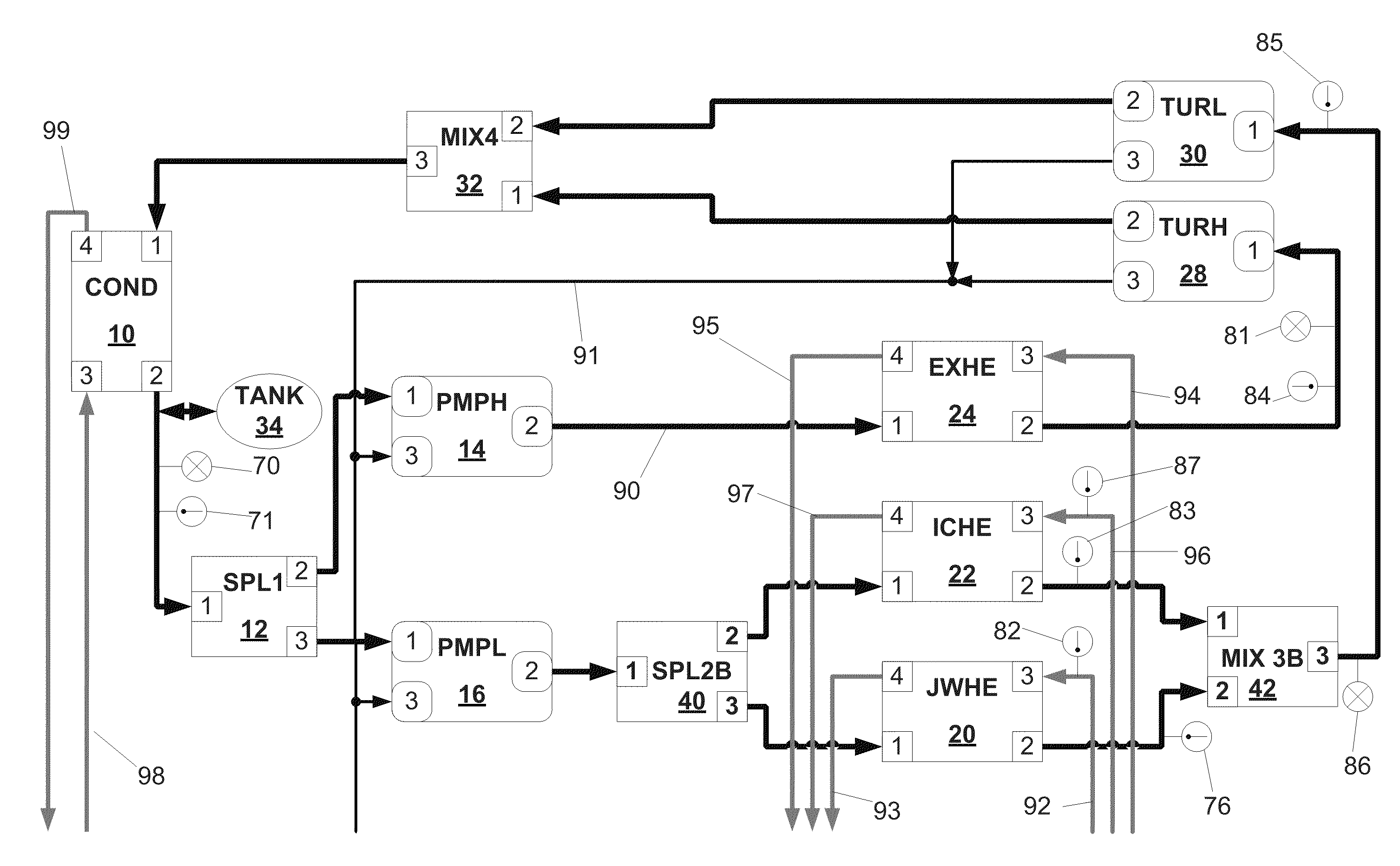

Waste heat recovery system

ActiveUS20110072818A1Reduce complexityLow costSteam engine plantsWorking fluidExternal combustion engine

To mitigate the potential significant impact on our society due to the continued reliance on high-cost diesel hydrocarbon fuel and the implementation of increasingly strict emission controls, an apparatus is disclosed which provides the means for extracting additional heat from an internal combustion engine while providing the cooling needed to meet stricter emissions standards. The present disclosure describes an apparatus operating on a Rankine cycle for recovering waste heat energy from an internal combustion engine, the apparatus including a closed loop for a working fluid with a single shared low pressure condenser serving a pair of independent high pressure circuits each containing zero or more controlled or passive fluid splitters and mixers, one or more pressure pumps, one or more heat exchangers, and one or more expanders, and the means for controlling said apparatus.

Owner:SANCHEZ SANDRA I

Heat supplying device for smoke purification and waste heat recovery

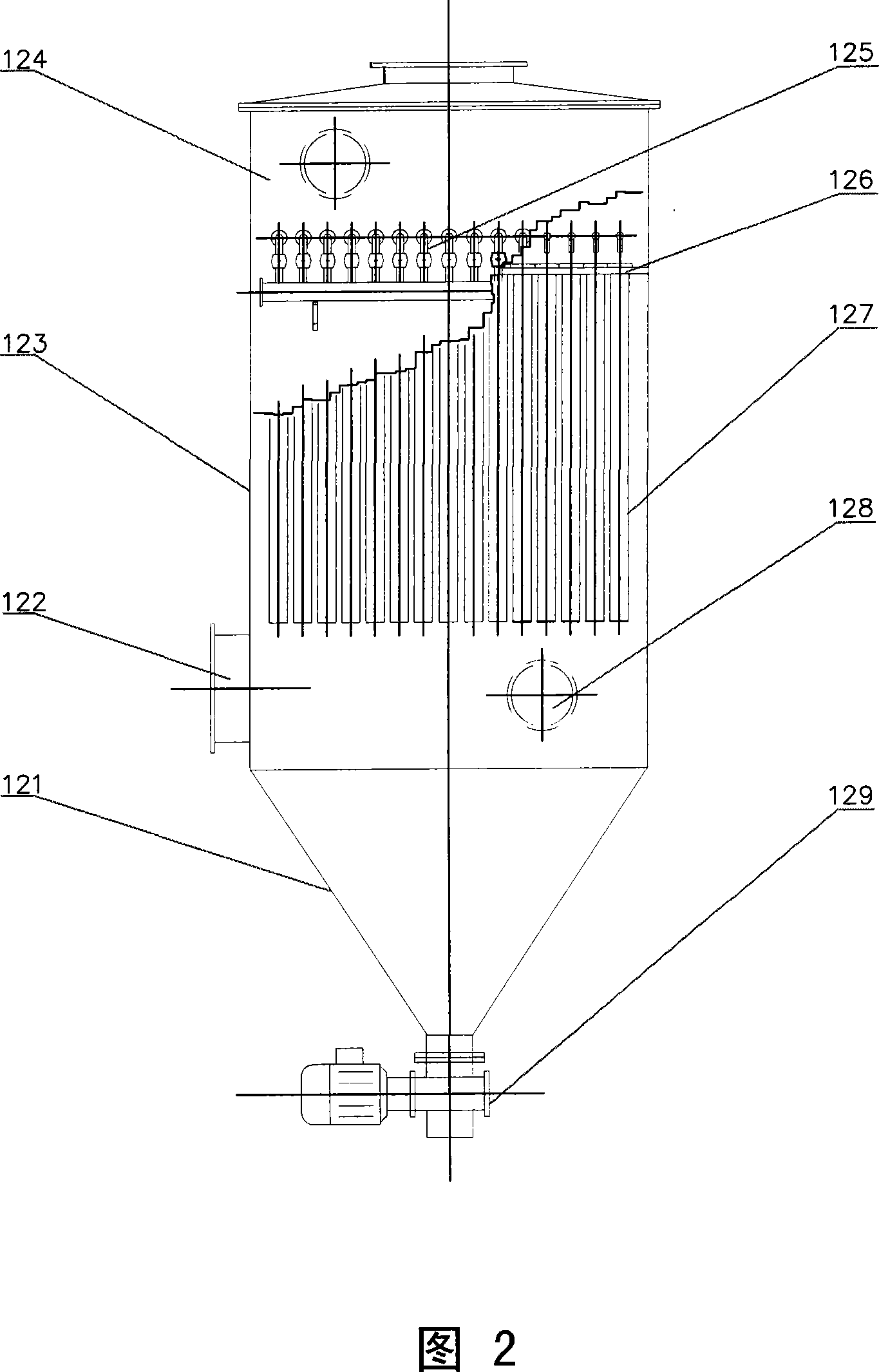

InactiveCN104791823AEvenly distributedReduce resistanceCombustion technology mitigationWater heatersThermal engineeringWaste heat recovery unit

The invention discloses a heat supplying device for smoke purification and waste heat recovery. The heat supplying device comprises a direct contact type waste heat recovery device and a circulating water system and is characterized in that the direct contact type waste heat recovery device comprises a bubbler, a smoke inlet pipe, an overflow pipe, a cylinder, a bubbling section, a spraying section, a sprayer, a water inlet pipe, a demister and a smoke exhaust pipe. The high temperature smoke enters cooling water in the bubble form through the bubbler and carries out direct contact type heat and mass transfer in the bubbling section; smoke discharged from the cooling water enters the spraying section and is in direct contact with the cooling water sprayed out of the sprayer again to transfer heat and mass; the cooling water absorbing heat enters the circulating water system, and a heat medium is heated through a heat exchanger in the circulating water system so as to supply heat outwards; the purified and cooled smoke is exhausted from a chimney at the upper portion of the cylinder. Two-section type direct contact of the smoke and the cooling water is adopted in the heat supplying device to transfer heat and mass, so that the smoke is fully cooled and completely purified, and the heat supplying device is suitable for smoke purification and waste heat recovery of all gas thermal engineering equipment.

Owner:ZHENGZHOU UNIV

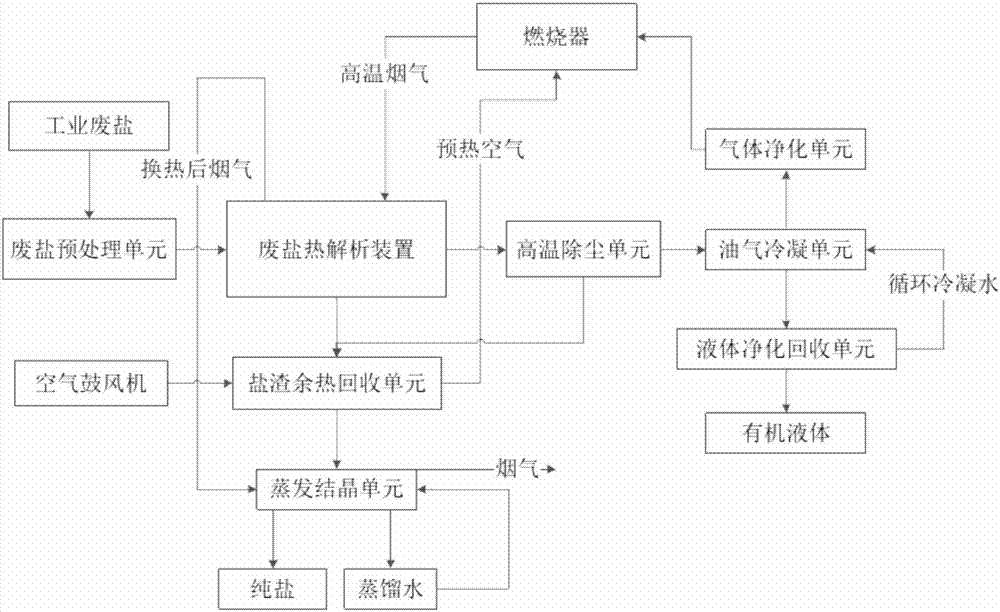

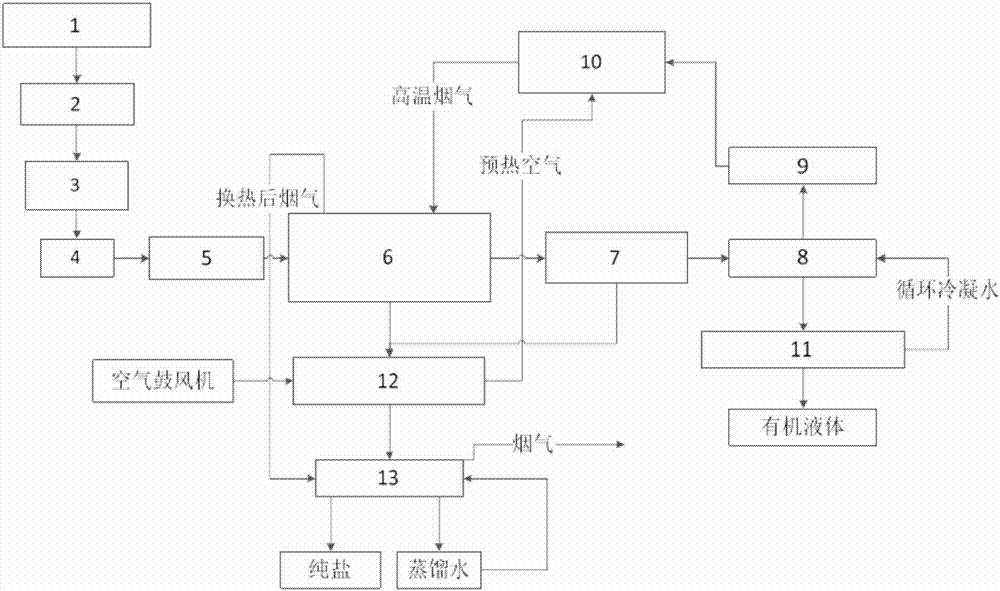

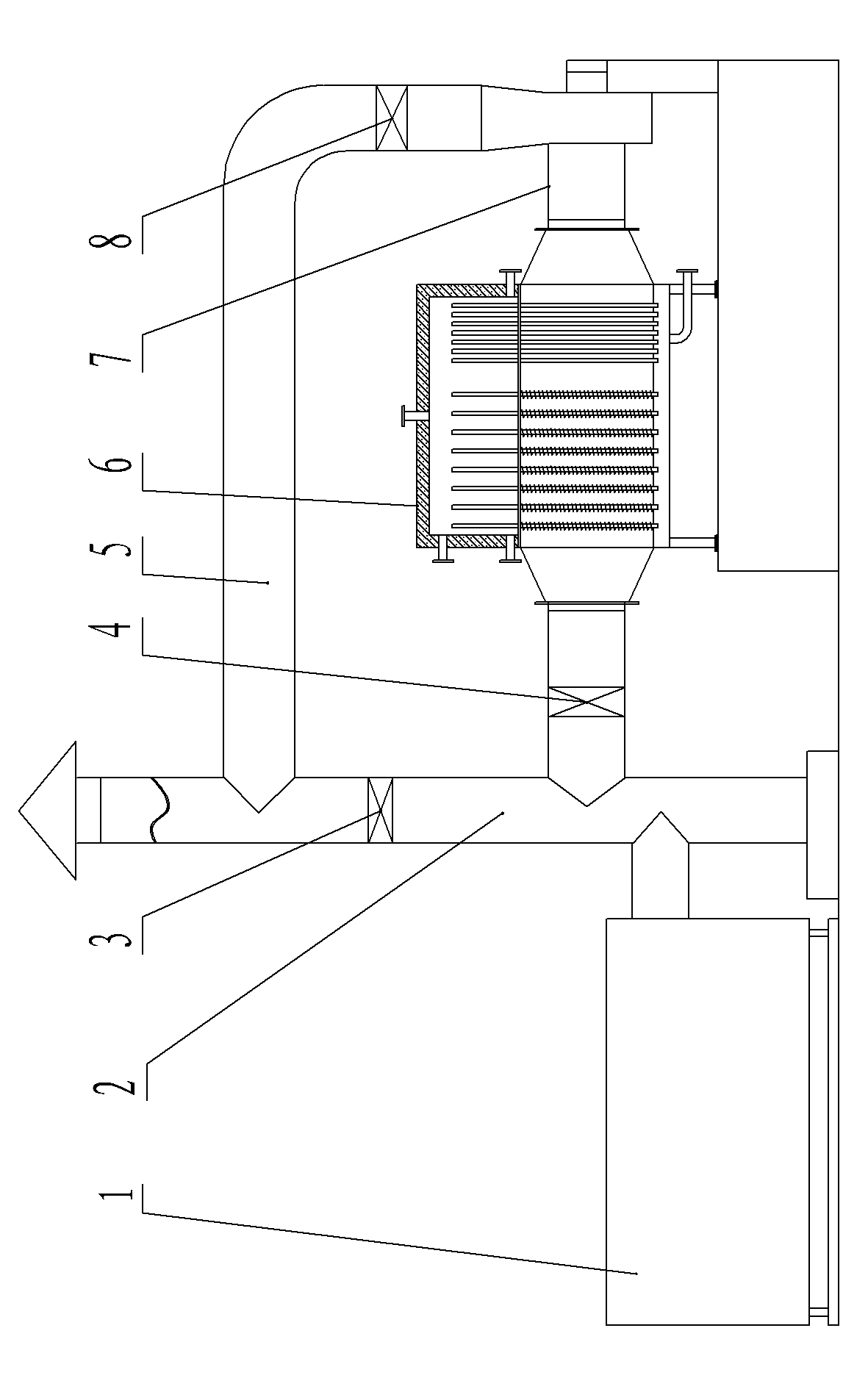

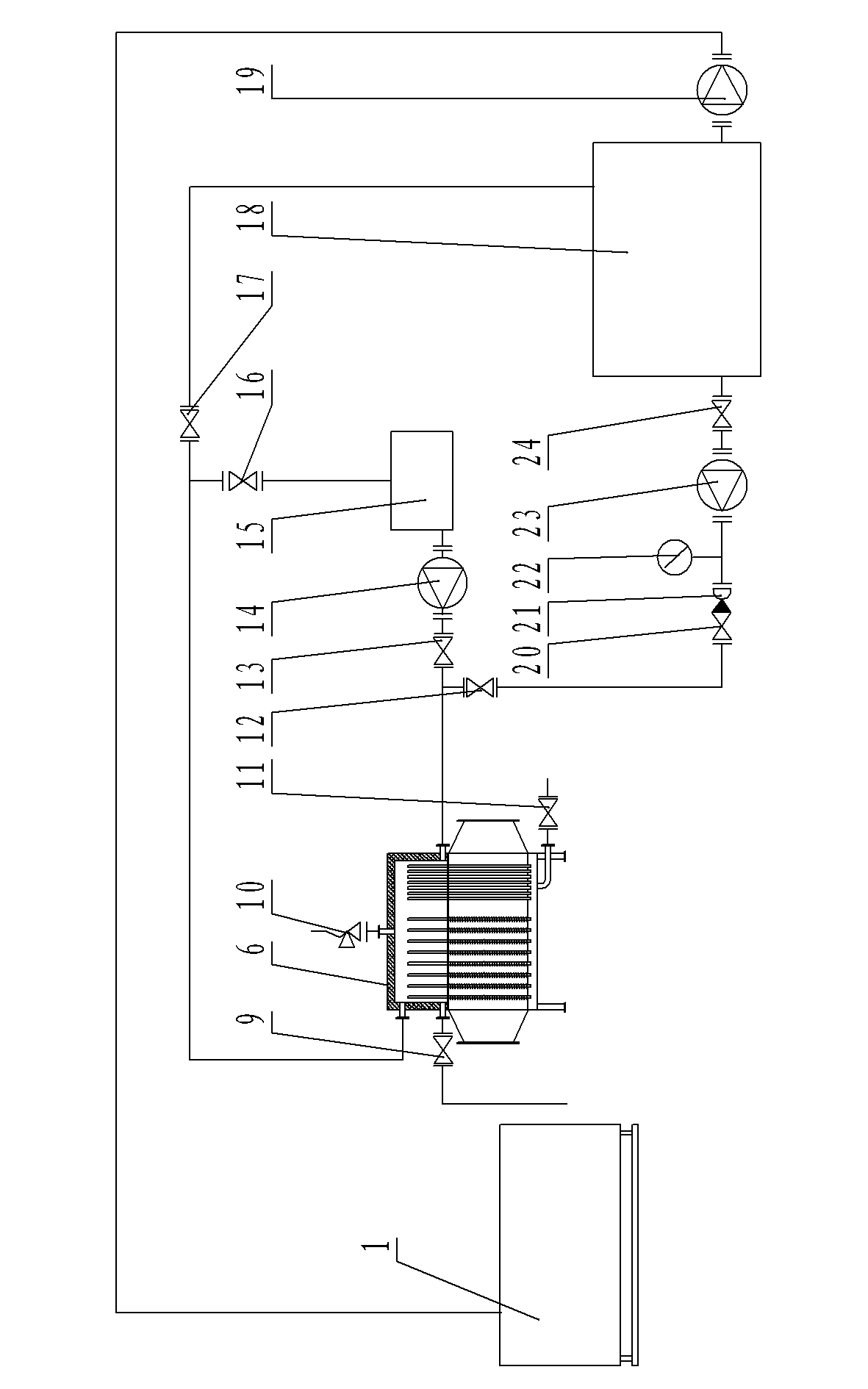

Industrial waste salt system and method

The invention belongs to the technical field of environmental protection, and particularly relates to an industrial waste salt system and method. The industrial waste salt system comprises a waste salt pretreatment unit, a waste salt thermal analysis device, a high temperature dust removal unit, an oil and gas condensing unit, a gas purification unit, a liquid purification and recovery unit, a burner, an evaporation and crystallization unit, and a salt slag waste heat recovery unit. The industrial waste salt system and method is complete in harmless treatment, high in resource recovery rate, and low in treatment energy consumption, and the recovery rate of the waste salt after the treatment of the system can reach 80%.

Owner:BEIJING BIOTECHINA ENVIRONMENT CORP

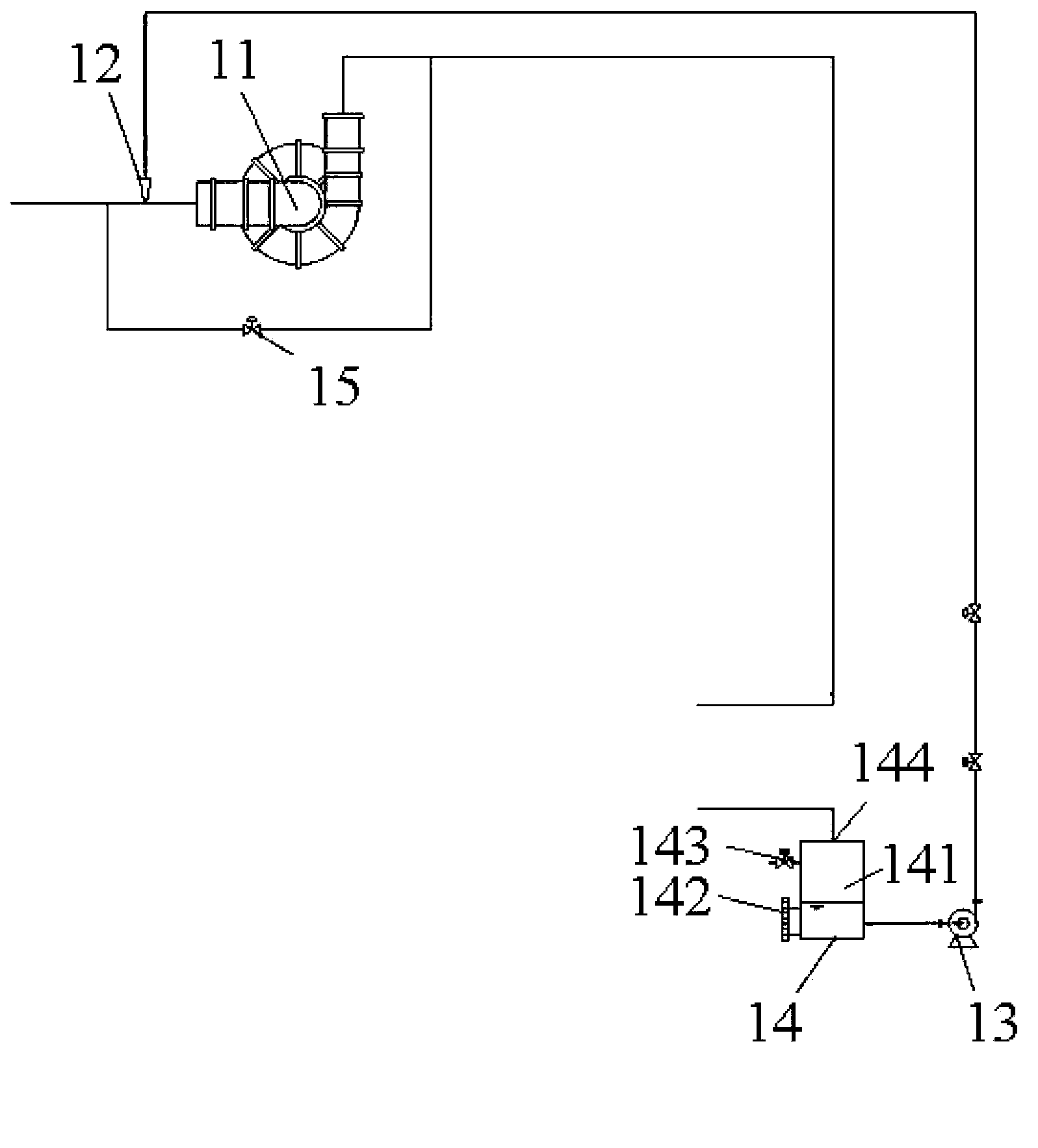

Waste heat recovering system of boiler

InactiveCN102183007ACombustion conditions unchangedWill not affect normal production and operationCombustion technology mitigationFeed-water heatersWaste heat recovery unitEngineering

The invention discloses a waste heat recovering system of a boiler, which comprises the boiler (1), a chimney (2), a main flue and a smoke waste heat recovering device (6) of the boiler, wherein the main flue is from a smoke outlet of the boiler (1) to a smoke outlet of the chimney (2), a cooling water tank is arranged in the smoke waste heat recovering device (6) of the boiler, a bypass flue is connected to the main flue, a draught fan (7) and the smoke waste heat recovering device (6) of the boiler are connected in series to the bypass flue, and a switching valve (3) used for selecting one of the main flue and the bypass flue for the smoke of the boiler is arranged on the main flue. Compared with the traditional waste heat recovering system of the boiler, the waste heat recovering system disclosed by the invention can be used for solving the problems of low waste heat recovery rate, inconvenience for maintenance, and need of stopping the boiler for maintenance when the smoke waste heat recovering device of the boiler is in failure.

Owner:GUANGXI ZHIYUAN ENERGY SAVING & ENVIRONMENTAL PROTECTION EQUIP

Waste heat regeneration system

The waste heat recovery system of an engine includes a Rankine cycle, a first bypass passage, a first valve and a control unit. The Rankine cycle allows a working fluid to circulate therethrough. The Rankine cycle has a first heat exchanger, a second heat exchanger, an expander and a condenser. The first heat exchanger exchange heat between the working fluid and the engine or a first intermediatemedium exchanging heat with the engine. The first bypass passage allows the working fluid to pass therethrough. One end of the first bypass passage is located at an upstream side of the condenser andthe other end is located at a downstream side of the condenser. The first valve opens and closes the first bypass passage. When temperature of the engine or the first intermediate medium is lower than a first predetermined value, the control unit opens the first valve.

Owner:TOYOTA IND CORP

Internal combustion engine vapor supercharging waste heat recovery system

ActiveCN103742293AIncrease the effective working rangeEfficient use ofInternal combustion piston enginesEngine componentsWaste heat recovery unitOrganic Rankine cycle

The invention discloses an internal combustion engine vapor supercharging waste heat recovery system. According to the technical scheme, internal combustion engine cylinder sleeve cooling water is in tandem connection with the cold end of a thermoelectric generator, an expansion machine, a preheater and a circulating water pump sequentially through pipelines to form into a cooling water heat utilization circulating system; air performed air suction compression through a compressor is sent to an internal combustion engine; an exhaust pipe of the internal combustion engine is in tandem connection with the thermal end of the thermoelectric generator, the gas side of an evaporator sequentially to form into an exhaust thermal utilization system; a preheater is in tandem connection with the working medium side of the evaporator, a turbine expansion machine, the working medium side of the condenser and a working medium pump sequentially to form into an organic rankine cycle system; the compressor is in shaft connection with a turbo machine to form into a turbosupercharger. The internal combustion engine vapor supercharging waste heat recovery system has the advantages of breaking the temperature limit of the recycle source of the organic rankine cycle, recycling the waste heat energy of the exhaust and the cooling water, achieving efficient utilization of the waste heat, avoiding the condition that the exhaust energy is not enough to drive a supercharging system when the load is low, increasing the effective working range of the supercharging system and achieving the purpose of efficiently recycling the waste heat energy.

Owner:TIANJIN UNIV

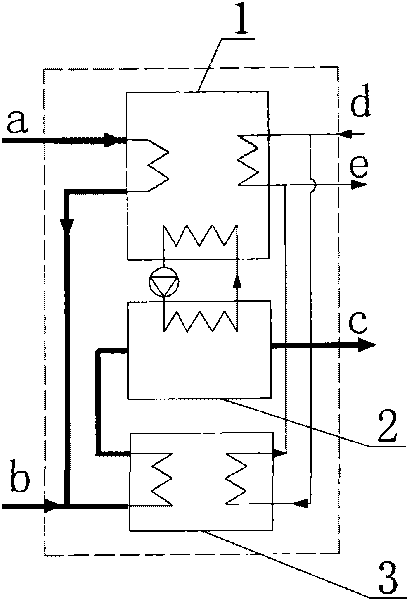

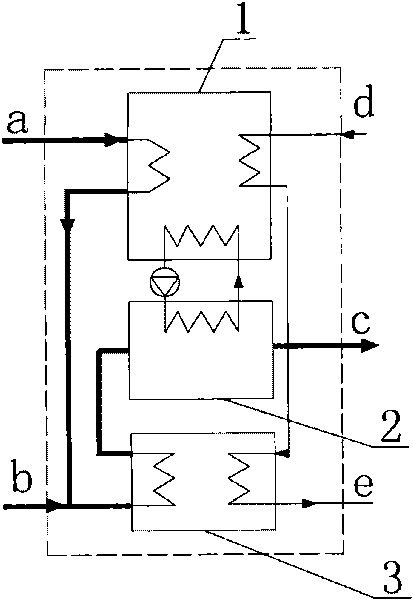

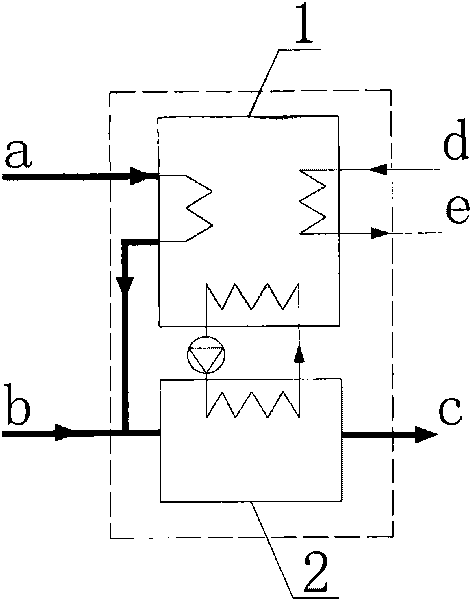

Heatpump type gas-fired boiler waste heat recovery unit

ActiveCN101726110ARealize cascade utilizationEmission reductionHeat recovery systemsClimate change adaptationEngineeringAbsorption heat pump

The invention belongs to the field of energy technology application, particularly relates to a heatpump type gas-fired boiler waste heat recovery unit. The unit comprises an absorption heat pump, a flue gas-water heat exchanger, a flue gas condensation heat exchanger, various connecting pipelines and accessories. The connecting pipelines comprise a first side pipeline, a middle water circulating pipeline and a second side pipeline. First side natural gas as a driving heat source enters a generator of the absorption heat pump and then enters the flue gas-water heat exchanger and the flue gas condensation heat exchanger with smoke exhausted by the gas fired boiler, the natural gas firstly passes through a water side circulating pipeline of the flue gas-water heat exchanger to heat second side return hot water and then exchanges heat with the generator side of the absorption heat pump to be as a low level heat source through the middle water circulating pipeline of the flue gas condensation pipeline, and the heat is transferred to a second side heating network by the absorption heat pump. The unit realizes cascade utilization for flue gas heat, greatly reduces the temperature of exhausted smoke, improves the energy utilization efficiency and is mainly used for gas-fired boiler waste heat recovery in a heating system.

Owner:TSINGHUA UNIV +1

Sintering flue gas energy-saving type denitrification system

ActiveCN104792186AIncrease waste heat recoveryRealize joint denitrification processEnergy industryIncreasing energy efficiencyWaste heat recovery unitFlue gas

The invention discloses a sintering flue gas energy-saving type denitrification system. The sintering flue gas energy-saving type denitrification system comprises a denitrification device, a heat exchanger, a circulating fan and an ammonification device. The sintering flue gas energy-saving type denitrification system fully uses waste heat of a sintering process, the sintering flue gas efficient denitrification is achieved, and the flue gas waste heat is recovered. The sintering flue gas energy-saving type denitrification system can greatly reduce nitrogen oxide discharge amount of sintering flue gas and improve the waste heat recovery level of the sintering process.

Owner:孙慕文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com