Multifunctional energy resource system

An energy system and multi-functional technology, applied in energy input, chemical modification of combustible gas, gas production, etc., can solve the problems of thermal efficiency reduction, etc., and achieve the effect of improving utilization rate, efficient utilization, simple utilization and reasonable utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

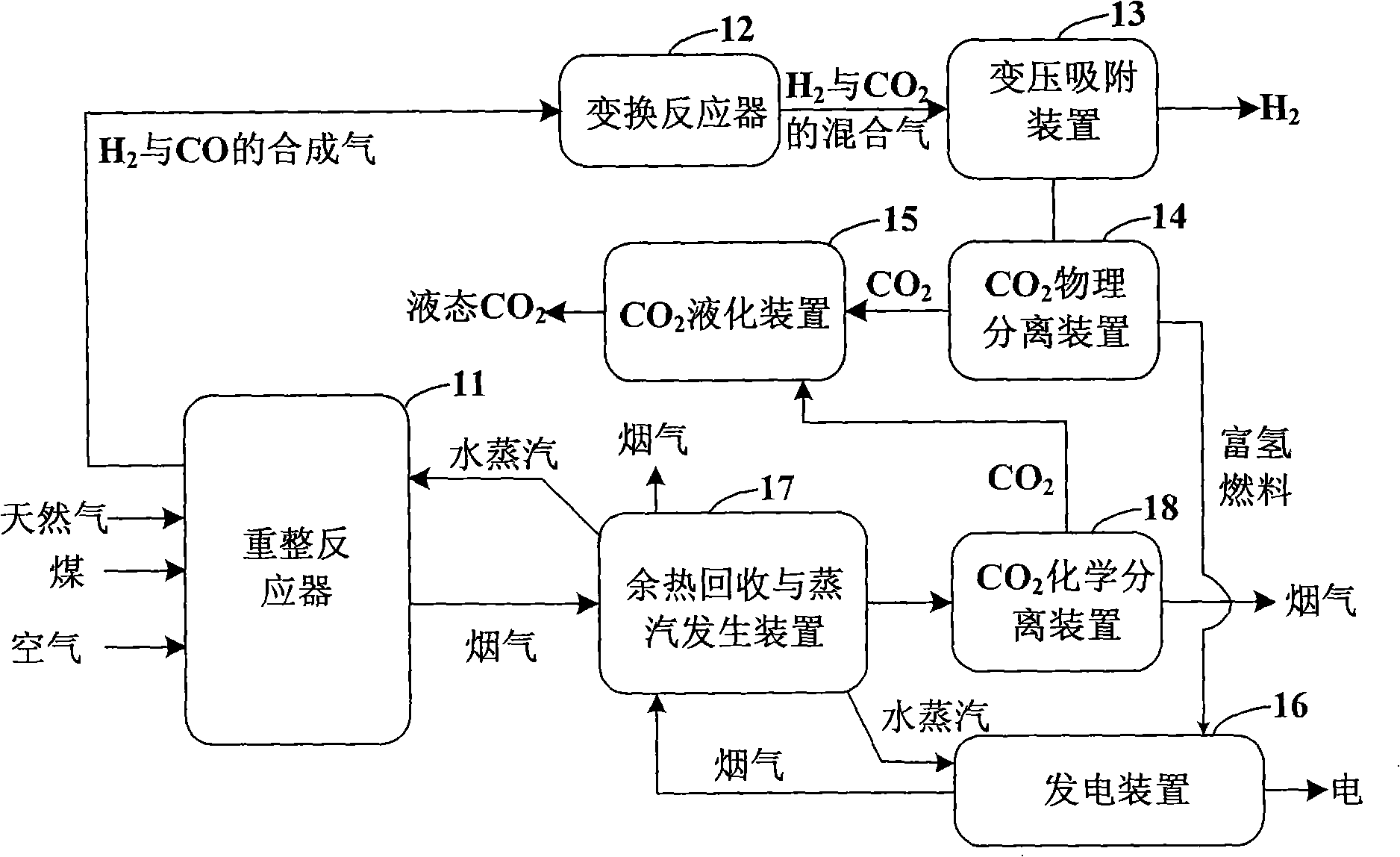

[0062] Such as figure 2 as shown, figure 2 It is a schematic structural diagram of the multifunctional energy system provided by the present invention. The multifunctional energy system includes a reforming reactor 11, a shift reactor 12, a pressure swing adsorption device (PSA) 13, a carbon dioxide physical separation device 14, a carbon dioxide liquefaction device 15, a power generation device 16, a waste heat recovery and steam generation device 17 and a carbon dioxide Chemical separation unit 18.

[0063] Among them, the reforming reactor 11 is used to prepare hydrogen and carbon monoxide synthesis gas from coal and natural gas, and output the prepared synthesis gas to the shift reactor 12 after being cooled. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com