Patents

Literature

328results about How to "Reduce separation energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Separation method for glycol, propylene glycol and butylene glycol

ActiveCN102372600AReduce separation energy consumptionEasy to separateOrganic compound preparationHydroxy compound separation/purificationHigh energyPropylene glycol

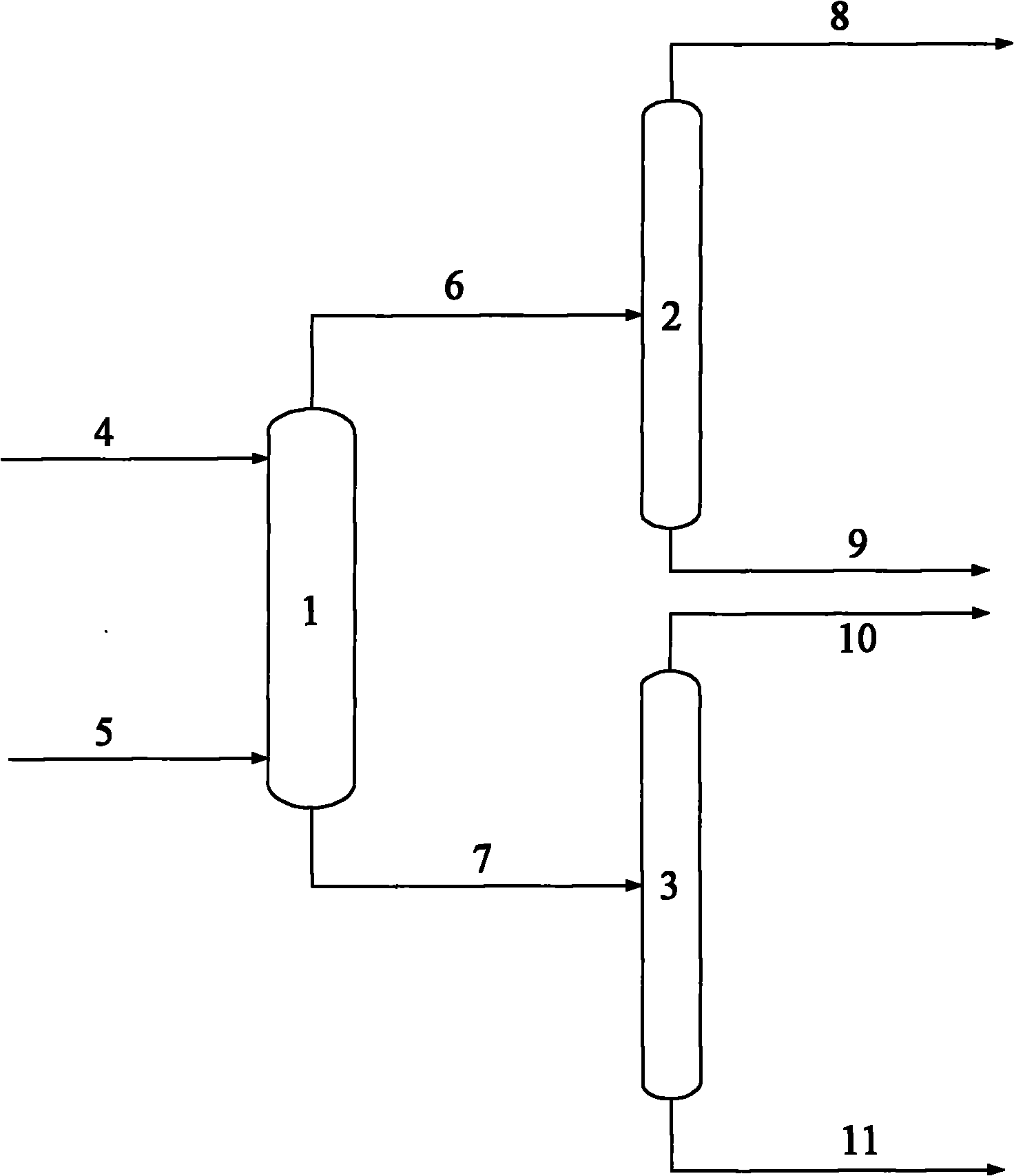

The invention relates to a separation method for glycol, propylene glycol and butylene glycol and mainly aims to solve the problem of high energy consumption in separation of glycol, propylene glycol and butylene glycol by using azeotropic rectification in the prior art. The invention comprises the following sequential steps that: a raw material containing glycol, propylene glycol and butylene glycol and an extractant enter into an extraction tower (1) respectively from the top and the bottom of the extraction tower, an extractant material flow I containing butylene glycol is obtained at tower top, and glycol material flow II containing propylene glycol is obtained at tower bottom; the material flow I enters into the central part of an extractant recovery tower (2), the recovered extractant is obtained at tower top, and an extractant solution containing butylene glycol is obtained at tower bottom; the material flow I enters into the central part of a glycol treating tower (3), a solution containing propylene glycol and the extractant is obtained at tower top, and the product of glycol is obtained at tower bottom. The method provided in the invention enables the above-mentioned problem to be well overcome and can be used in industrial production for separation of glycol, propylene glycol and butylene glycol.

Owner:CHINA PETROLEUM & CHEM CORP +1

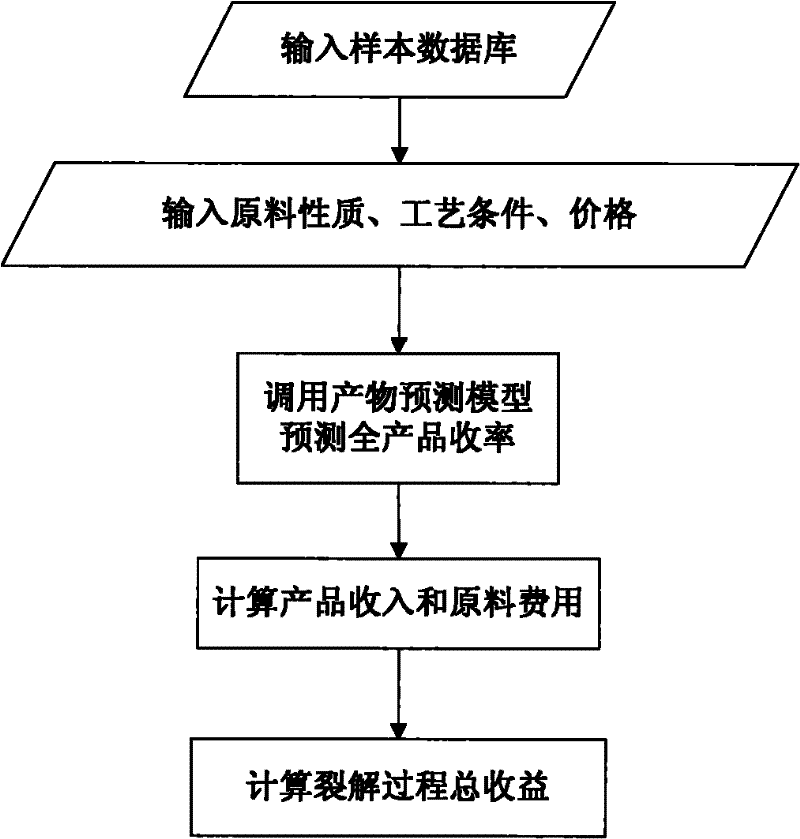

Method for optimizing value of ethylene device

ActiveCN102213949AExtended operating cycleSmall cleaning costThermal non-catalytic crackingAdaptive controlEconomic benefitsProcess engineering

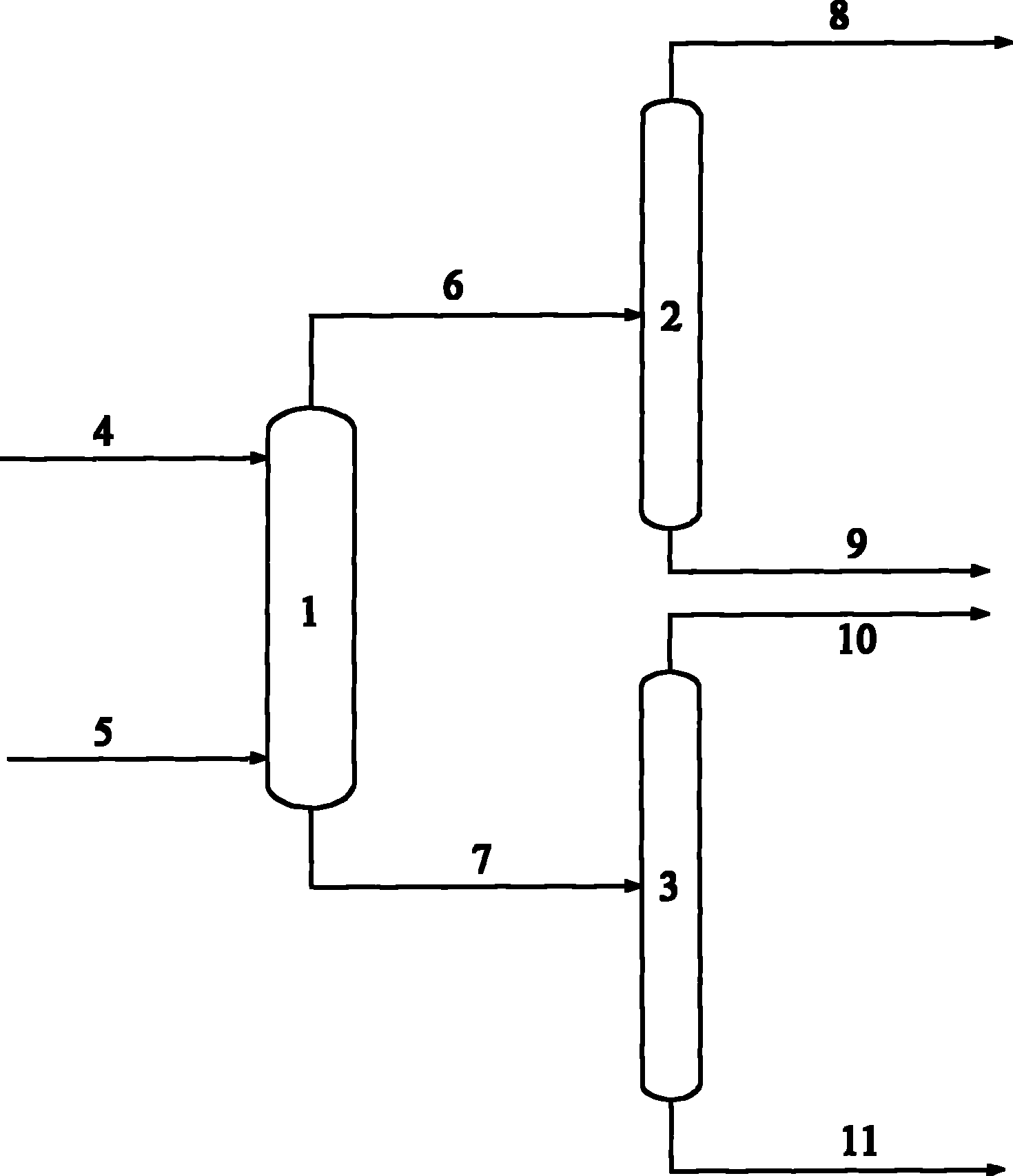

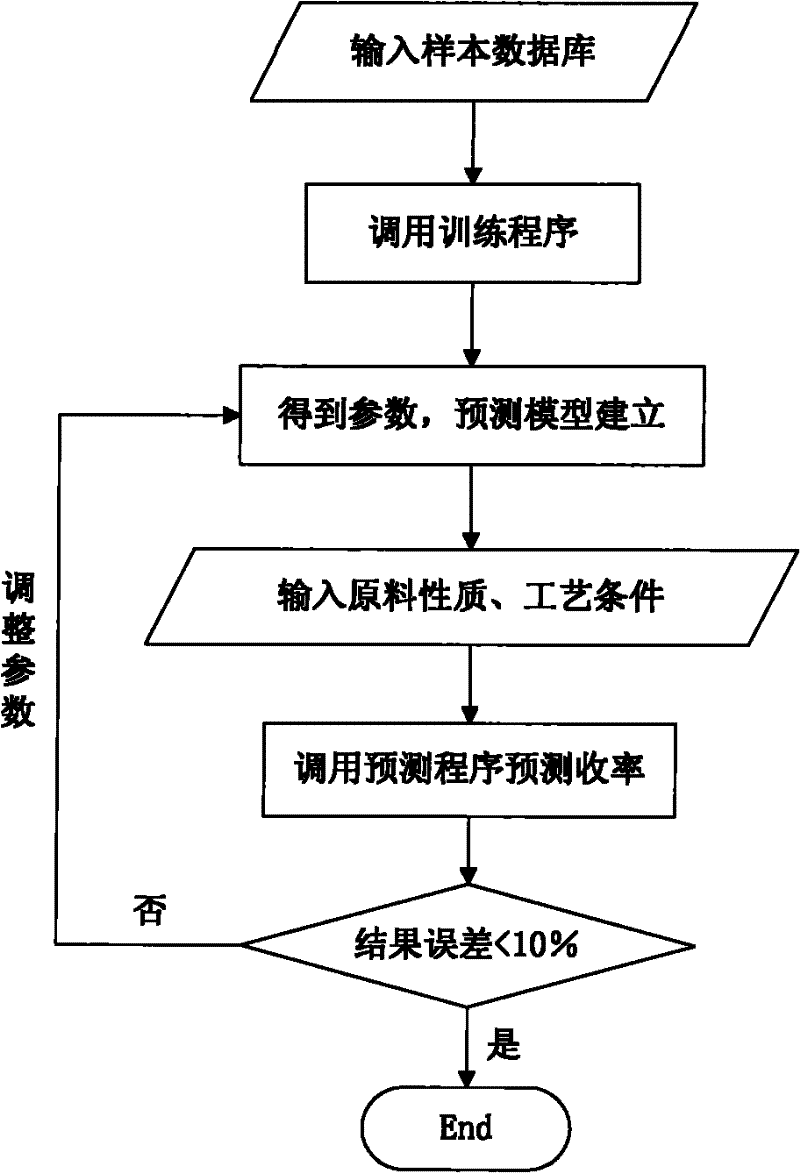

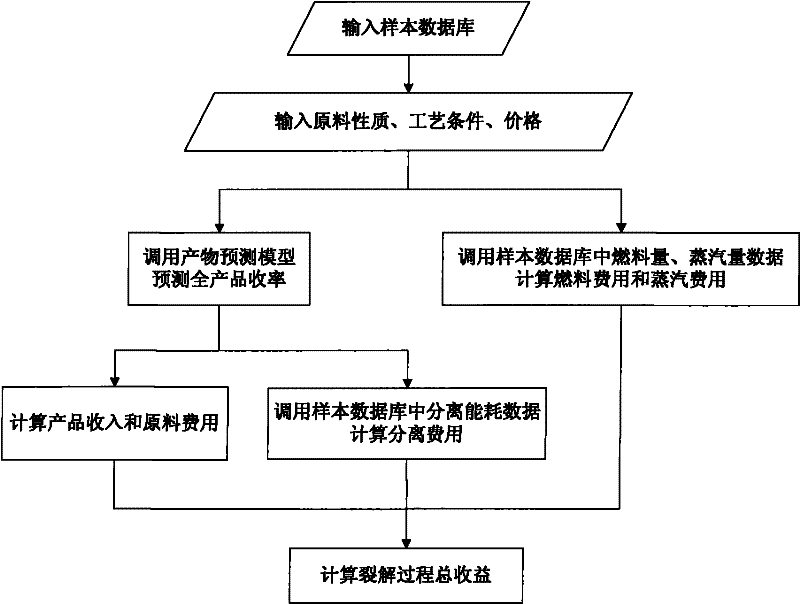

The invention belongs to the field of chemical reaction engineering and particularly relates to a method for optimizing the operation of an ethylene cracking device. In the method provided by the invention, value maximization is utilized as a scale and the operation optimization scheme of a cracking furnace is formulated aiming at the constitution and market price of different raw materials and the process characteristics of the device by virtue of establishing a yield prediction model, a value prediction model and a value optimization model. After the optimization scheme provided by the invention is adopted, the optimal cracking temperature is lower than the cracking temperature obtained by the optimization scheme which is formulated by the maximum yield of principal products such as ethylene and the like; the operating period of the device is effectively prolonged; the decoking cost is lower; the separation energy consumption is reduced; the potential of the processing capability of the device is further enhanced; and the highest economic benefits are simultaneously obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

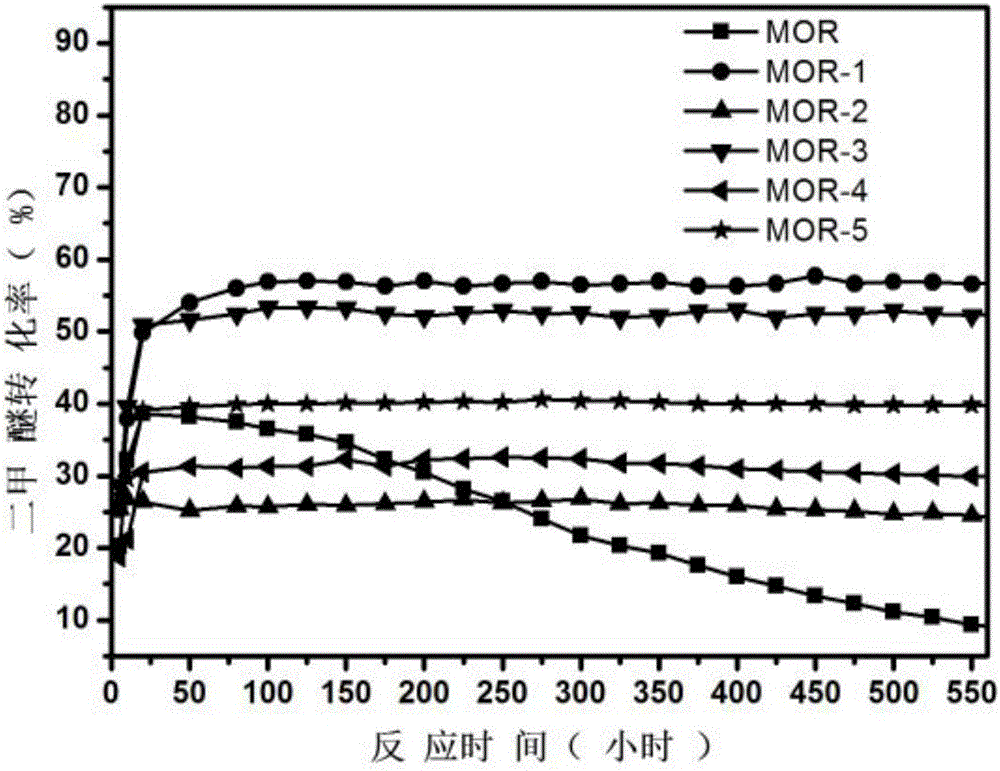

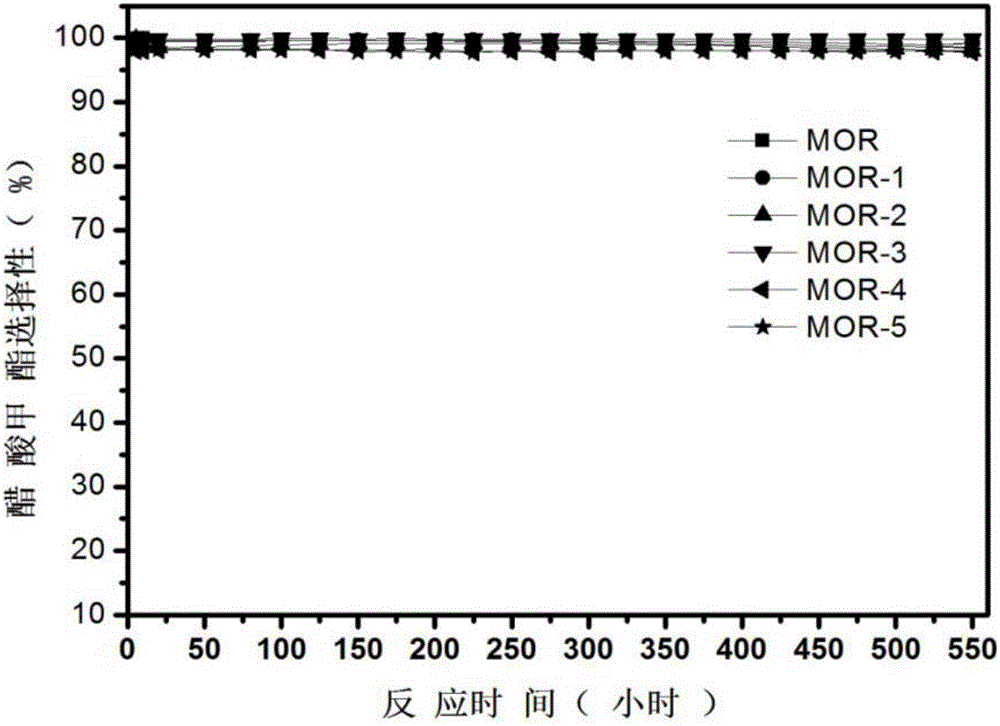

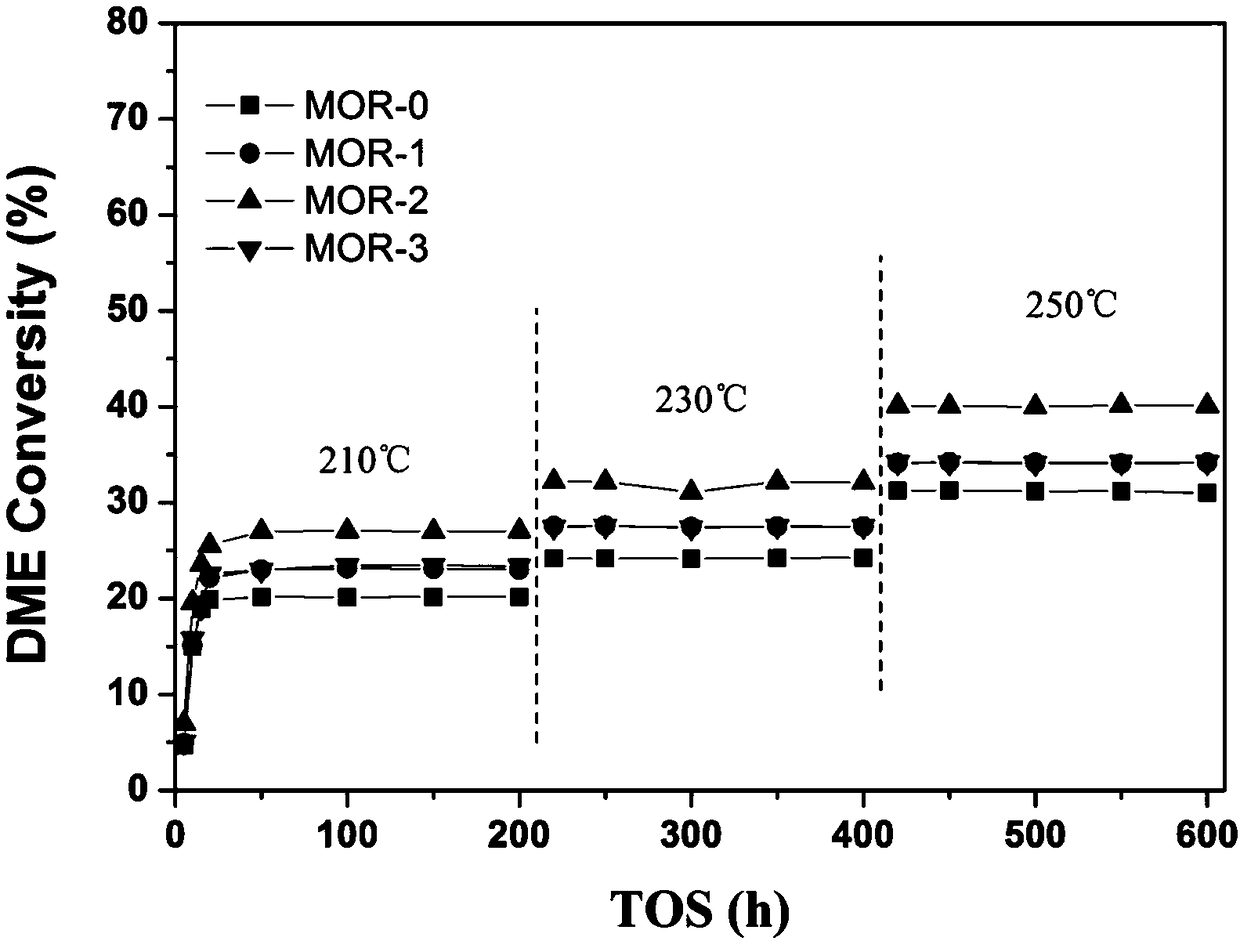

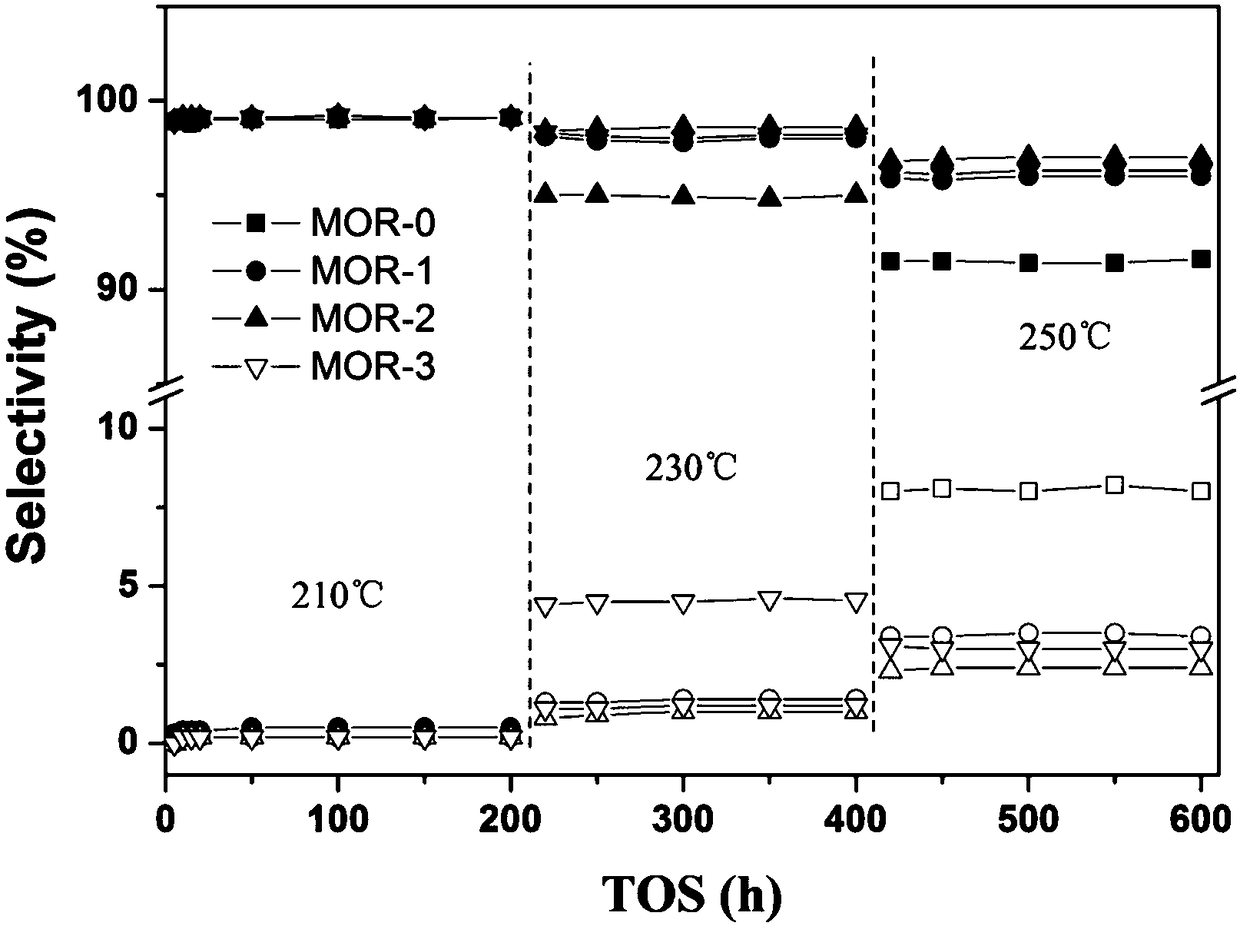

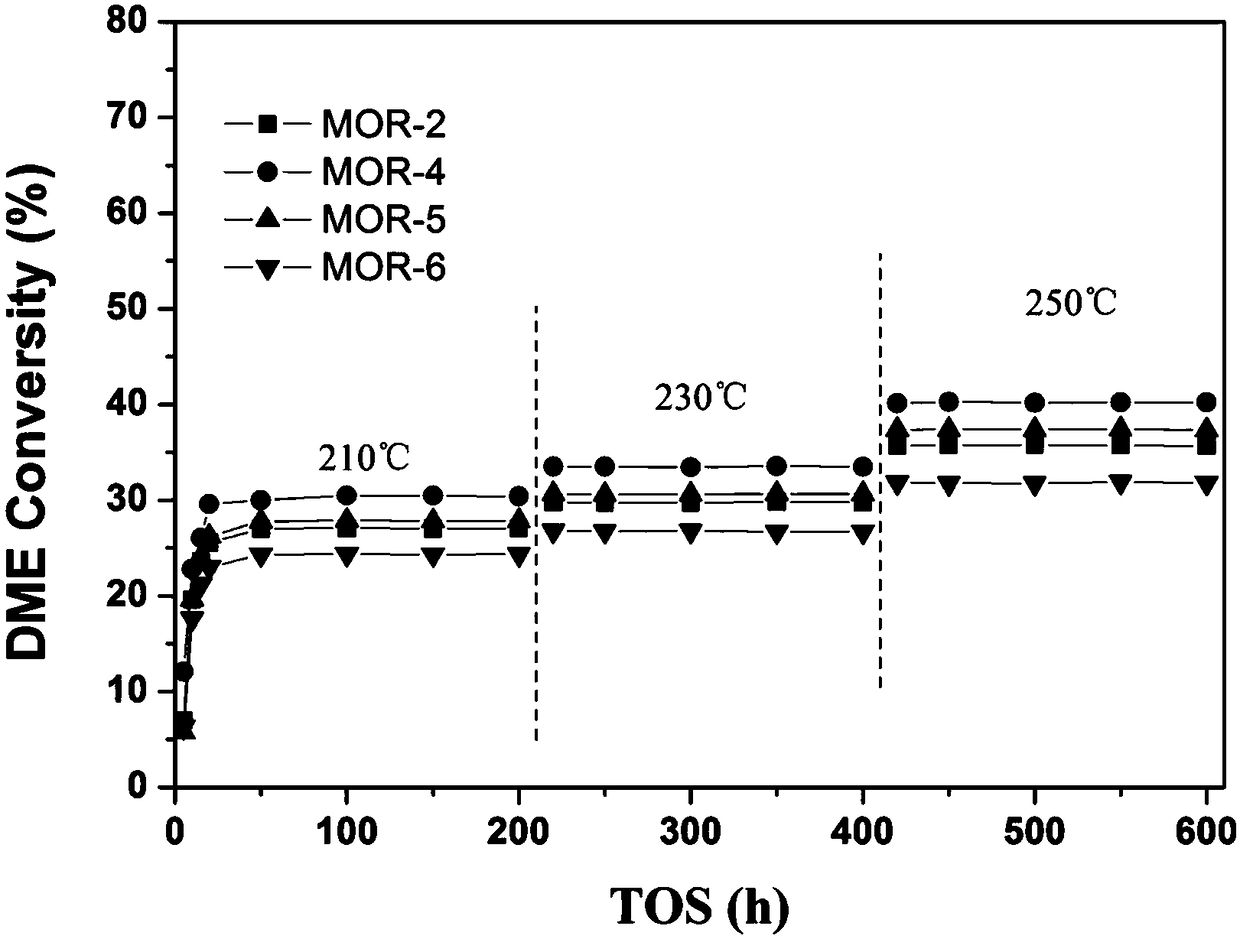

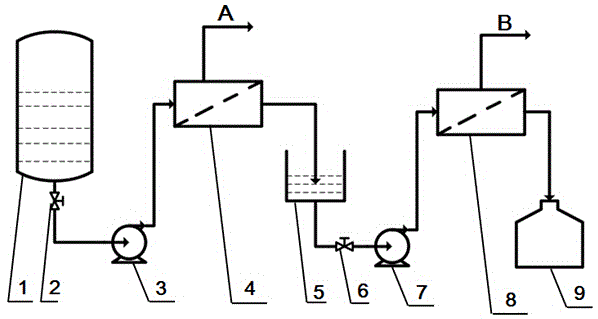

Method for making methyl acetate through carbonylation of dimethyl ether and the modified molecular sieve catalyst and modification method thereof

ActiveCN106311336AExtend your lifeImprove conversion rateCatalyst protectionMolecular sieve catalystsMolecular sieveHydrogen

The invention discloses a method for making methyl acetate through carbonylation of dimethyl ether and the modified molecular sieve catalyst and modification method thereof. The modification method is to pass the modified substance that is diluted by the diluent gas through the reactor filled with hydrogen type zeolite molecular sieve catalyst at an adsorbent temperature of 100-400 oC under normal pressure condition, so that the modified substance can have chemisorption on the hydrogen type zeolite molecular sieve catalyst to obtain modified molecular sieve catalyst; the modified substance can be liquid modified substance and / or gaseous modified substance. The modified molecular sieve catalyst can be obtained by using the modification method in which the modified molecular sieve catalyst for making methyl acetate through carbonylation of dimethyl ether can be obtained. The method for making methyl acetate through carbonylation of dimethyl ether is to pass the raw gas consisting of dimethyl ether, carbon monoxide and hydrogen through the reactor filled with the modified molecular sieve catalyst for reaction to obtain the methyl acetate. Through the modification of hydrogen type zeolite molecular sieve catalyst by the modified substance, the method can effectively inhibit the side-reaction of carbon deposit and greatly prolong the service life.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

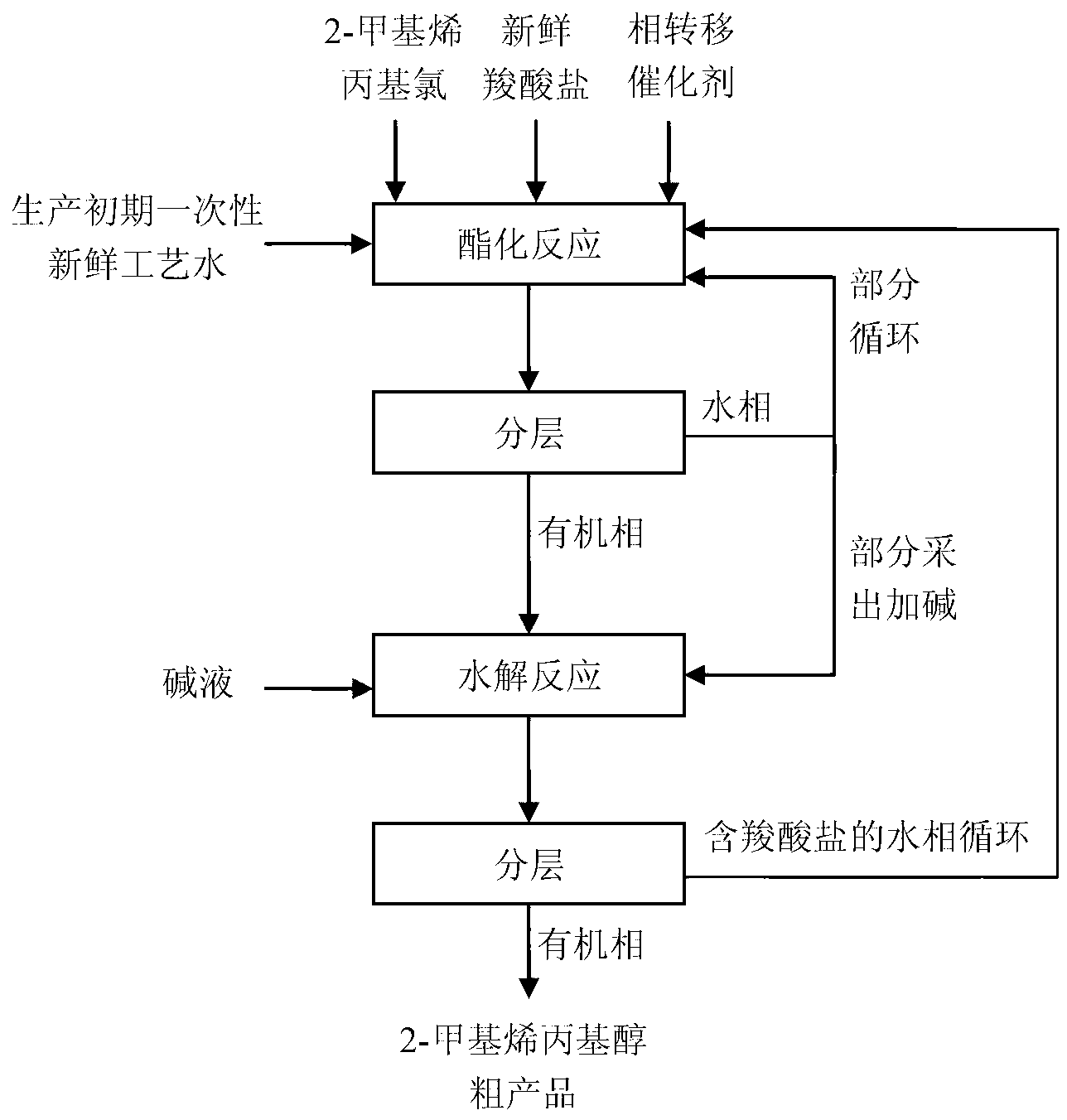

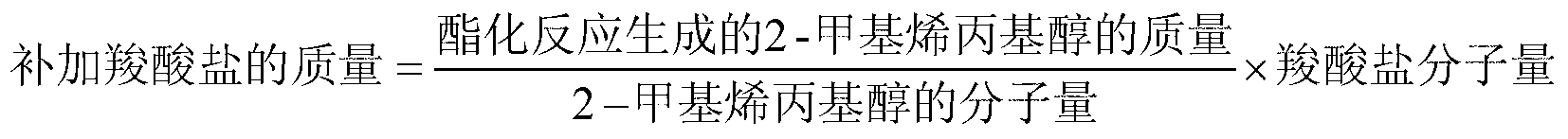

Method for preparing 2-methyl allyl alcohol by esterification and hydrolysis

ActiveCN103242139AImprove conversion rateHigh selectivityOxygen-containing compound preparationOrganic compound preparationChemical industryCarboxylic salt

The invention belongs to the field of chemical industry, and discloses a method for preparing 2-methyl allyl alcohol by esterification and hydrolysis. The method comprises the following steps of: first, performing esterification reaction of 2-methyl allyl chloride and carboxylate; and then, kalifying for hydrolysis reaction to synthesize 2-methyl allyl alcohol. The synthesizing steps are as follows: (1) esterification reaction: under the effect of a phase transfer catalyst, adding carboxylate, water and 2-methyl allyl chloride into a high pressure kettle for esterification reaction; after esterification reaction, cooling, standing and layering the reaction liquor to obtain an organic layer and a water layer, wherein the organic layer is a mixture which takes 2-methyl allyl carboxylate as a main product; (2) hydrolysis reaction: adding alkali liquor to the organic layer obtained in the esterification reaction stage for hydrolysis reaction; cooling, standing and layering the mixed liquor obtained by hydrolysis to obtain an organic layer and a water layer, wherein the organic layer is a target product, namely 2-methyl allyl alcohol. The method is high in material conversion ratio and product selectivity, the product yield is improved, and the separation energy consumption and material consumption are reduced.

Owner:NANJING UNIV OF TECH

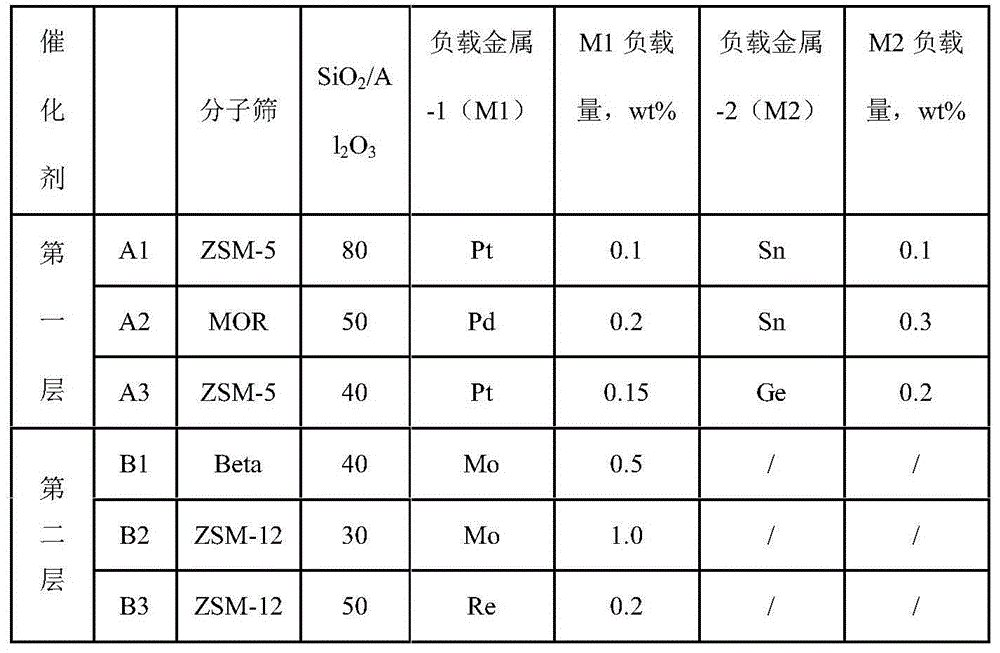

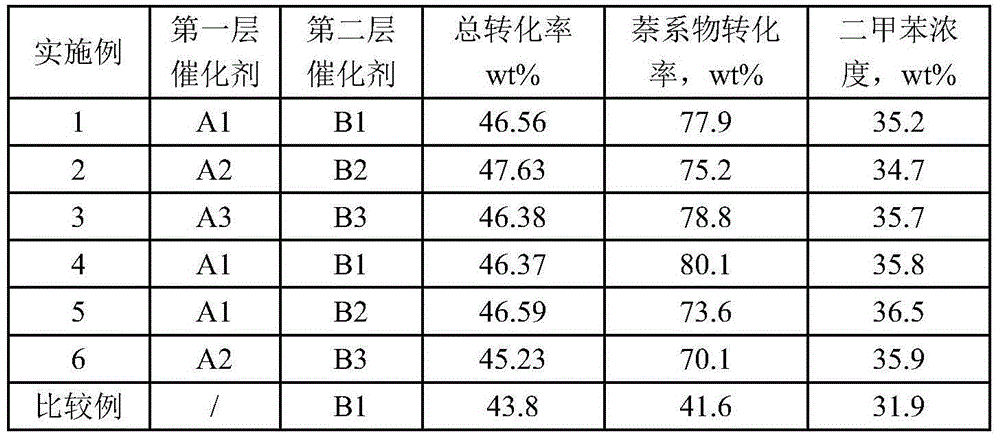

Method for disproportionation and transalkylation of toluene and heavy aromatic hydrocarbon

ActiveCN105272803ASimple processReduce separation energy consumptionHydrocarbonsHydrocarbon preparationPolycyclic aromatic hydrocarbonHydrogen

The invention relates to a method for disproportionation and transalkylation of toluene and heavy aromatic hydrocarbon. The method mainly solves the problem of inadequate ability of treating polycyclic aromatic hydrocarbon in the prior art. A technical scheme of the invention adopts the method for disproportionation and transalkylation of toluene and heavy aromatic hydrocarbon, and the method comprises the following steps: with toluene and heavy aromatic hydrocarbon with carbon nine or more containing polycyclic aromatic hydrocarbon as reaction raw materials, carrying out mixing with hydrogen and then carrying out preheating, then allowing the obtained mixture to successively pass through two layers of catalysts, subjecting reactants to heavy aromatic hydrocarbon light fraction reaction on a first layer of the catalysts so as to generate a first reaction product rich in monocyclic aromatic hydrocarbon, and subjecting the first reaction product to disproportionation and transalkylation reaction through a second layer of the catalysts so as to produce xylene; thus, the problem is well solved, and the method can be applied in industrial production of disproportionation and transalkylation of toluene and heavy aromatic hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

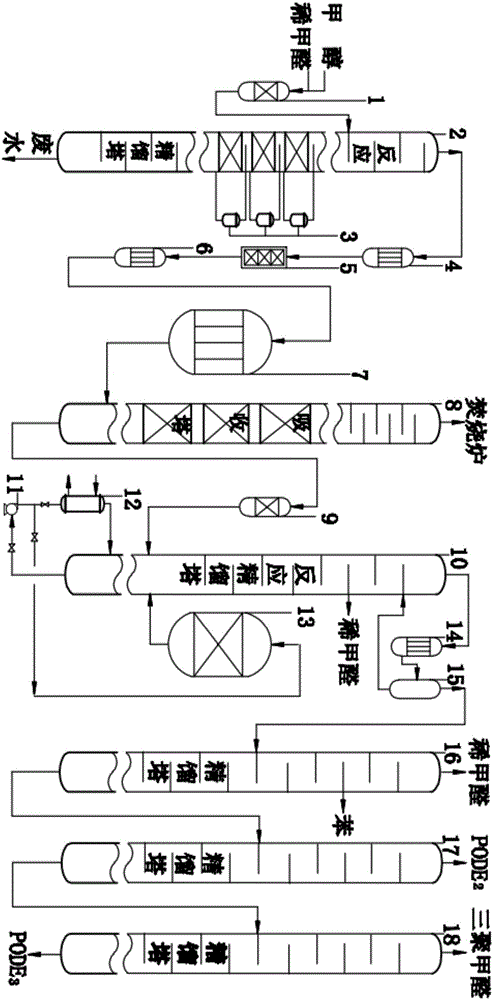

Method for synthesizing trioxymethylene by methanol through condensation, oxidation and polycondensation

InactiveCN106256822AEasy to separateReduce separation energy consumptionOrganic chemistryChemical industryHigh concentrationHigh energy

The invention relates to a method for synthesizing trioxymethylene by methanol through condensation, oxidation and polycondensation. According to the invention, methanol and dilute formaldehyde with concentration of 5-30% separated from a trioxymethylene apparatus are taken as raw materials to synthesize methylal with concentration of 85-99.9%; methylal and air are subjected to catalyst oxidation to generate formaldehyde through an iron molybdenum method, through refining water and methylal unit tower waste water absorption, a formaldehyde aqueous solution with concentration of 70% is generated; high-concentration formaldehyde is introduced into a trioxymethylene synthetic tower, and the trioxymethylene is synthesized under existence of a strong-acid cation exchange resin catalyst, and trioxymethylene with content of 99.9% can be obtained through steps of rectification and concentration, extraction, rectification, and purifying. The method solves the problems of low conversion rate, selectivity and low yield during a trioxymethylene production process, solves the problems of low catalyst reaction efficiency and corrosivity, and solves the problems of complex technology and high energy consumption. The method provides good raw materials for producing PODE, and realization of industrialization of PODE can solve the problem of excess production capacity of methanol in our country.

Owner:XIAN SHANGHUA TECH DEV CO LTD

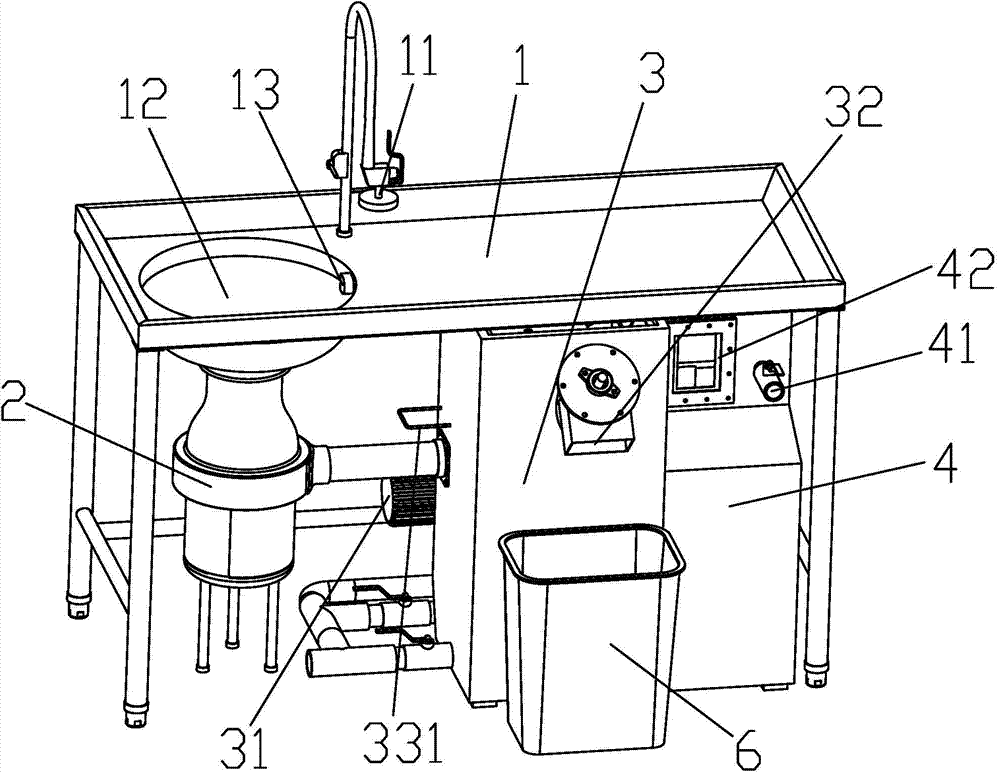

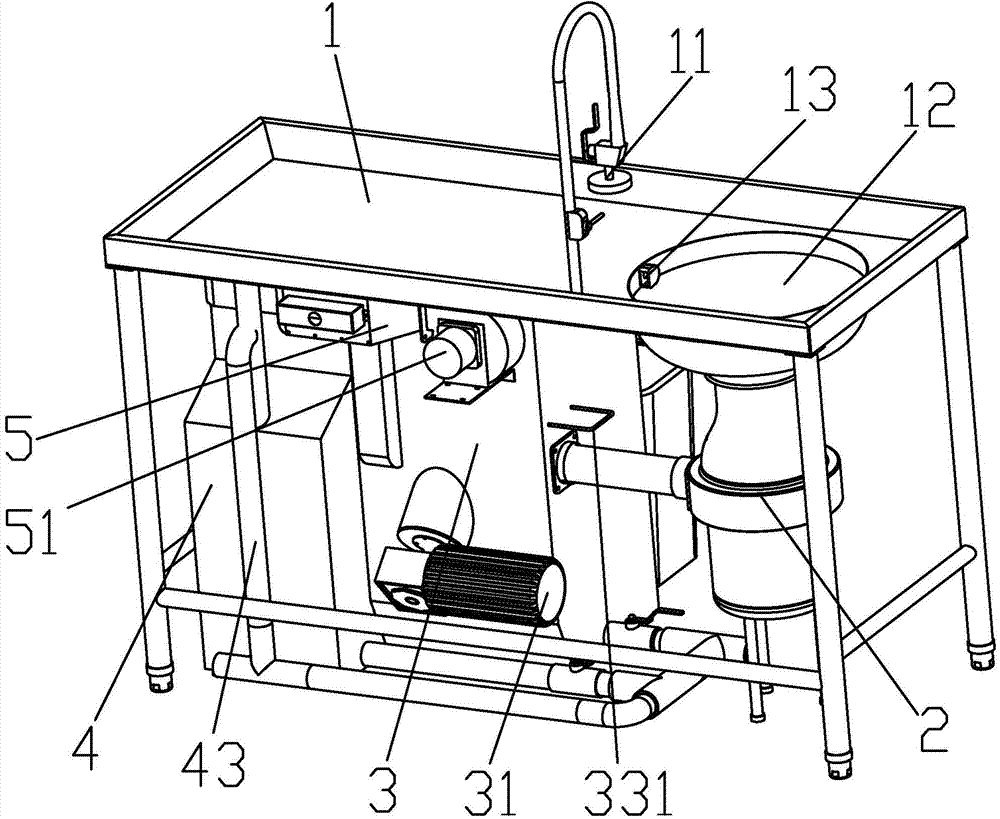

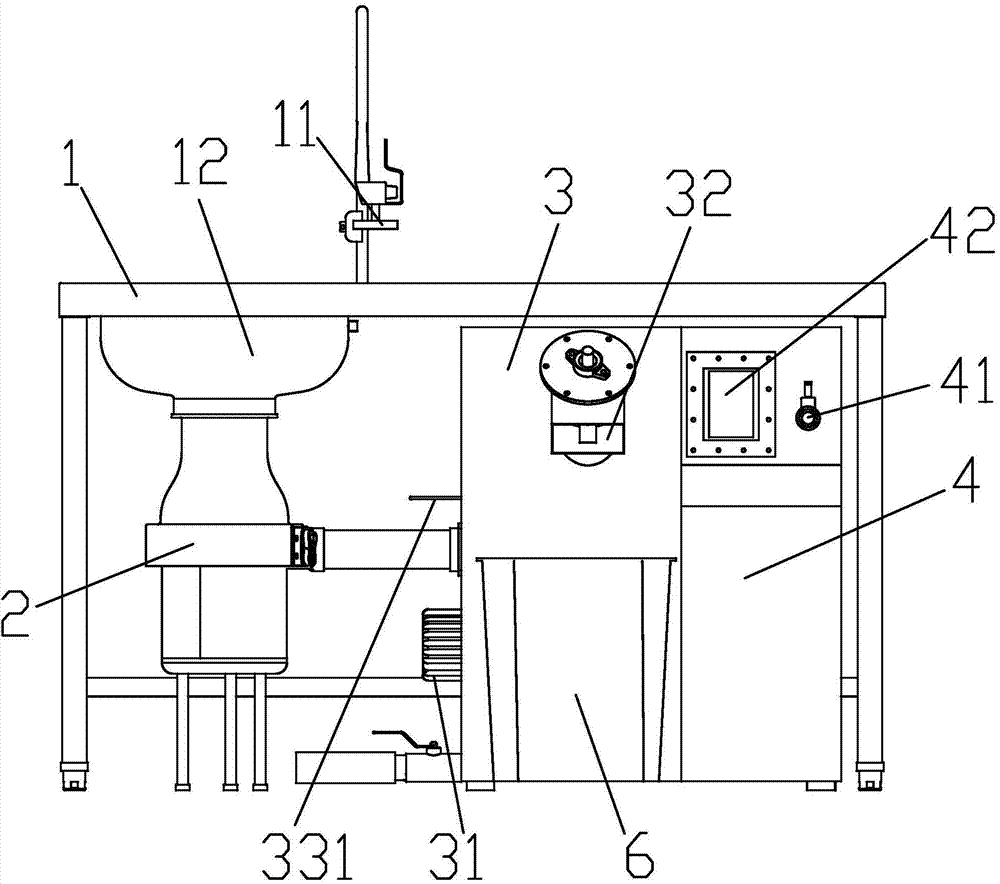

Waste processor

InactiveCN104741358AReduce separation energy consumptionWith self-cleaning functionSolid waste disposalAir heatersSlagOil water

The invention discloses a waste processor which comprises a worktable, a waste crusher, a solid-liquid separator, an oil-water separation tank, a heater and an electric cabinet, wherein the waste crusher, the solid-liquid separator, the oil-water separation tank, the heater and the electric cabinet are arranged below the worktable; a secondary solid-liquid separator is arranged in the solid-liquid separator; a spray header and a collection basin are arranged on the worktable; a discharging port is formed in the center of the bottom of the collection basin; a diversion nozzle is arranged on the side surface of the collection basin; a feeding port and a discharging port are formed in the waste crusher; the feeding port of the waste crusher is fixedly connected with the discharging port of the collection basin; a slag inlet is formed in the solid-liquid separator; the slag inlet is connected with the discharging port of the waste crusher through a pipeline; and a diversion port and a ventilation opening are formed between the solid-liquid separator and the oil-water separation tank. Through the manner, the waste processor is capable of effectively crushing the waste, carrying out solid-liquid separation and oil-water separation on the waste, collecting the waste slag and oil-water and realizing the energy-saving idea of waste recycle; and the waste processor is simple in structure and reliable in work.

Owner:钱海荣

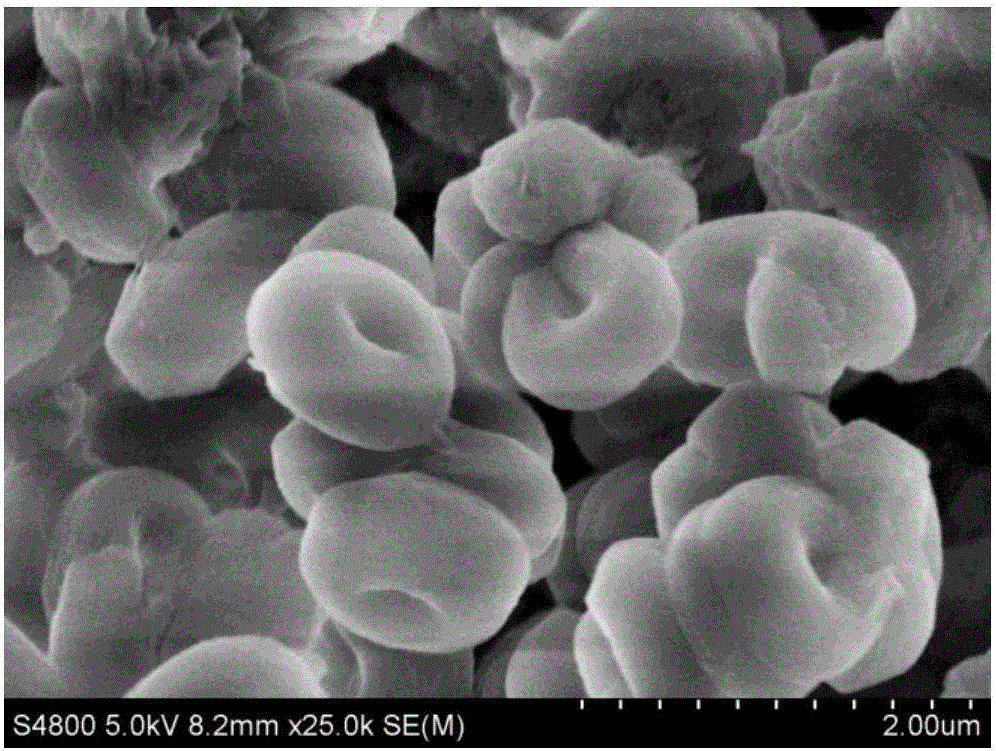

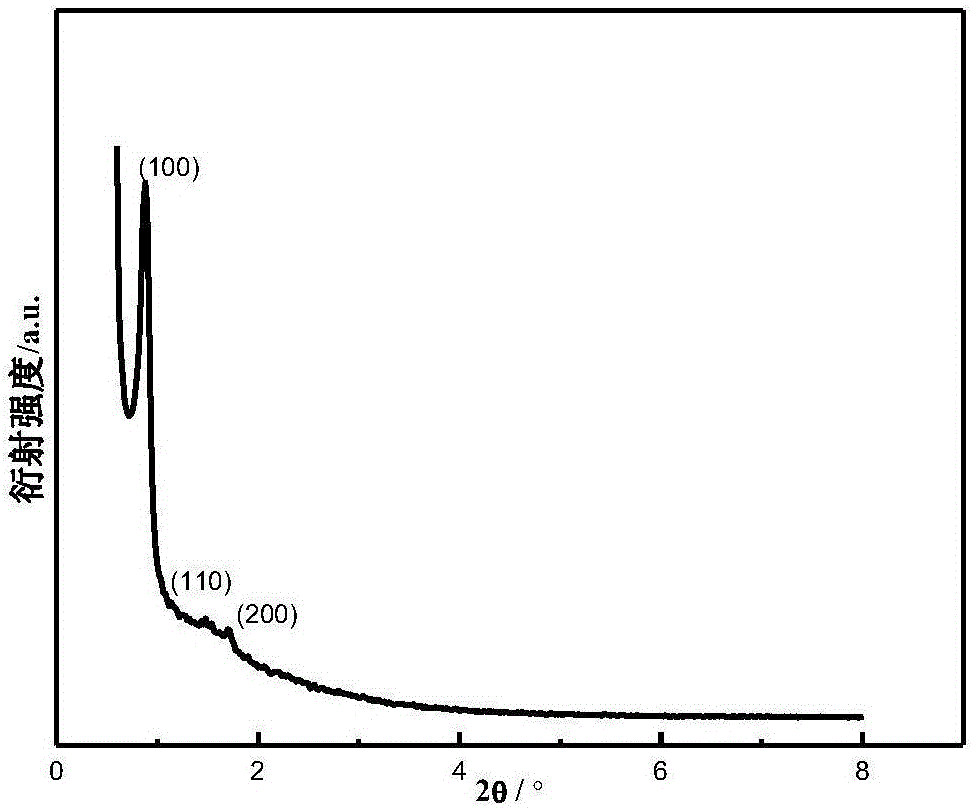

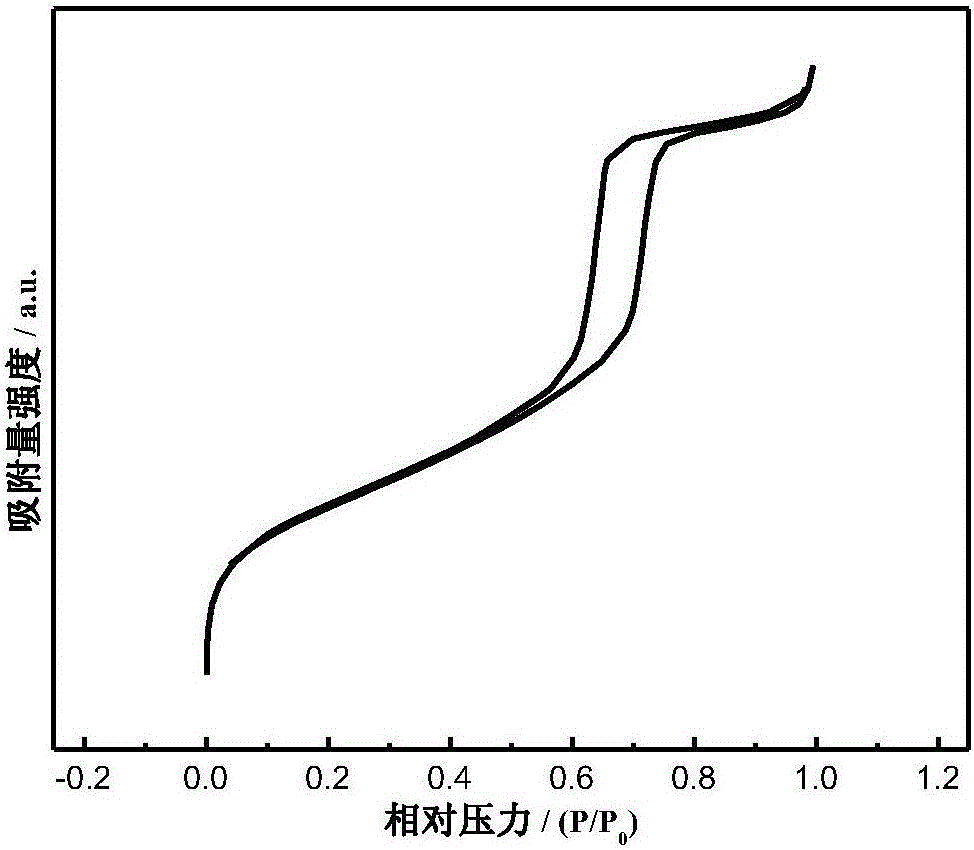

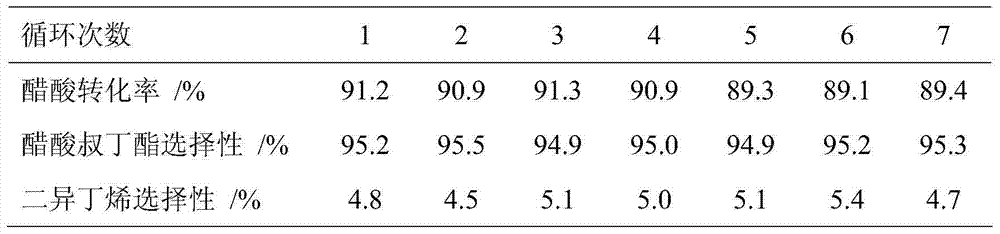

SO3H-SBA-15 molecular sieve catalyst for catalyzing isobutene and carboxylic acid to synthesize carboxylic acid tert-butyl ester and preparation method and application thereof

ActiveCN106040282AEfficient and stable synthesisReduce separation energy consumptionMolecular sieve catalystsOrganic compound preparationMolecular sieveCarboxylic acid

The invention discloses a SO3H-SBA-15 molecular sieve catalyst for catalyzing isobutene and carboxylic acid to synthesize carboxylic acid tert-butyl ester. The molecular sieve catalyst is prepared by adopting a template agent, a morphology regulator, a silicon source, a sulfonic acid source and an oxidizing agent through a one-step co-condensation method or a two-step sulfonic acid group post-synthesis method. In the SO3H-SBA-15 molecular sieve catalyst, by the molar ratio of a sulfonic acid group to silicon oxide, the sulfonic acid group supporting amount accounts for 30%-50%. The invention further discloses a method of using the SO3H-SBA-15 molecular sieve catalyst to catalyze the isobutene and the carboxylic acid for carboxylic acid tert-butyl ester synthesis. The molecular sieve catalyst is adjustable in shape, orderly in mesoporous pore passage and capable of efficiently and stably catalyzing the isobutene and the carboxylic acid to selectively synthesize the carboxylic acid tert-butyl ester under the conditions of higher temperature and polymerization inhibitor absence, meanwhile the separation energy consumption and equipment investment of reaction products are reduced, and the SO3H-SBA-15 molecular sieve catalyst has an important significance on development and utilization of atomic economic reaction.

Owner:NANJING UNIV OF TECH +1

Method for sequential separation and azeotropic recovery of ethyl benzene/styrene

ActiveCN101734999AReduce polymerization lossLow operating pressureDistillation purification/separationOperating energyPhysical chemistry

The invention relates to a method for sequential separation and azeotropic recovery of ethyl benzene / styrene and mainly aims to solve the problems existing in the prior art that the reduction of the polymerization loss of styrene and the reduction of the operating energy consumption cannot be simultaneously achieved in an ethyl benzene / styrene separation industrial device. The method comprises the following steps of: a) making ethyl benzene and styrene containing tower bottoms of a benzene-toluene tower enter an ethyl benzene / styrene separating tower to obtain ethyl benzene containing tower top gas material current I and styrene containing tower bottom material current II; b, putting the material current II in a refined styrene separation tower for separation, putting the material current I in an ethyl benzene / water azeotropic evaporator, heating an ethyl benzene / water mixture from the outside to obtain the ethyl benzene / water azeotropic material current III exchanging heat, partially returning the condensed material current I to the tower top, and partially circulating the condensed material current I to a reaction area; and c), compressing the material current III, and transferring the compressed material current III to the reaction area, wherein an operating pressure of the ethyl benzene / styrene separation tower top is 5 to 20kPaA. The technical scheme better solves the technical problems and can be applied to the industrial production requiring the separation of the ethyl benzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for producing crotonaldehyde

InactiveCN101462044ANo corrosionShort processMolecular sieve catalystsOrganic compound preparationCrotonaldehydeAlkali metal oxide

The invention provides a catalyst for producing crotonaldehyde, which takes a complex consisting of alkaline earth metal oxide and a molecular sieve or alumina as a carrier, and is prepared by supporting alkaline metal oxide by adopting an impregnation method. Alkaline earth metal is magnesium, calcium or barium, the molecular sieve is an HZSM-5, Hbeta, HY, USY or rare earth Y(ReY) molecular sieve, the alumina is gamma-Al2O3, and alkaline metal is lithium, sodium, potassium or cesium. The mass ratio of the alkaline earth metal oxide and the molecular sieve or the alumina which are taken as the carrier of the catalyst is 1: 20-20: 1, and the mass of the alkaline metal oxide is 1 to 30 percent of the total mass of the complex consisting of the alkaline earth metal oxide and the molecular sieve or the alumina. Compared with a solid catalyst reported by literature, the catalyst has better low-temperature activity, namely the reaction temperature is lower than that of the catalyst reported by literature when the conversion rate of acetaldehyde is equivalent to the selectivity of the crotonaldehyde. The method also additionally produces tolyl aldehyde with higher added value when synthesizing a main product, namely the crotonaldehyde, and further promotes the economic benefit of the catalyst.

Owner:SINOPEC YANGZI PETROCHEM

Method for synthesizing diethyl carbonate and coproducing diol by using carbon dioxide

ActiveCN104418701ARapid responseEasy to optimizeProductsOxygen-containing compound preparationEpoxyReaction temperature

The invention discloses a method for synthesizing diethyl carbonate and coproducing diol by using carbon dioxide, belonging to the field of synthesis of organic chemicals. An epoxy compound, the carbon dioxide and ethanol are used as raw materials and directly esterified in the presence of a catalyst to prepare the diethyl carbonate, and the diol is also coproduced; and the catalyst is characterized by consisting of an alkali metal halide and an alkali catalyst which are used as active ingredients, wherein the weight ratio of the epoxy compound to the catalyst is 100: (1-5), the reaction temperature is 80-230 DEG C, the reaction pressure is 0.5-15MPa, and the reaction time is 0.01-5h. The diethyl carbonate is synthesized by directly using the CO2, the epoxy compound and the ethanol, so the yield and selectivity of the target product are relatively high, the production cost of the diethyl carbonate can be reduced, and the diethyl carbonate has good industrial application value.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

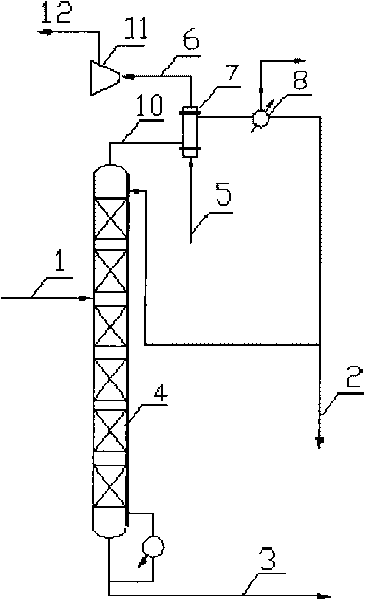

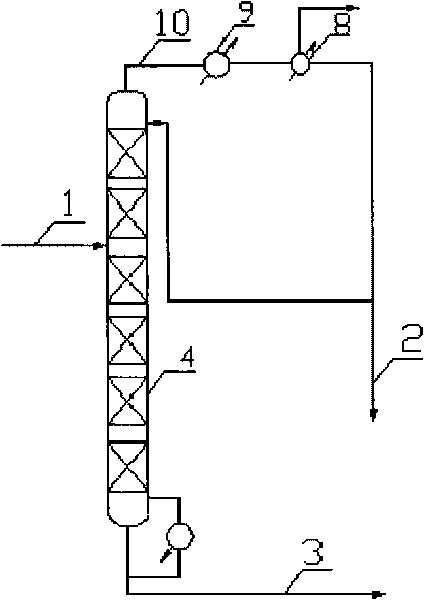

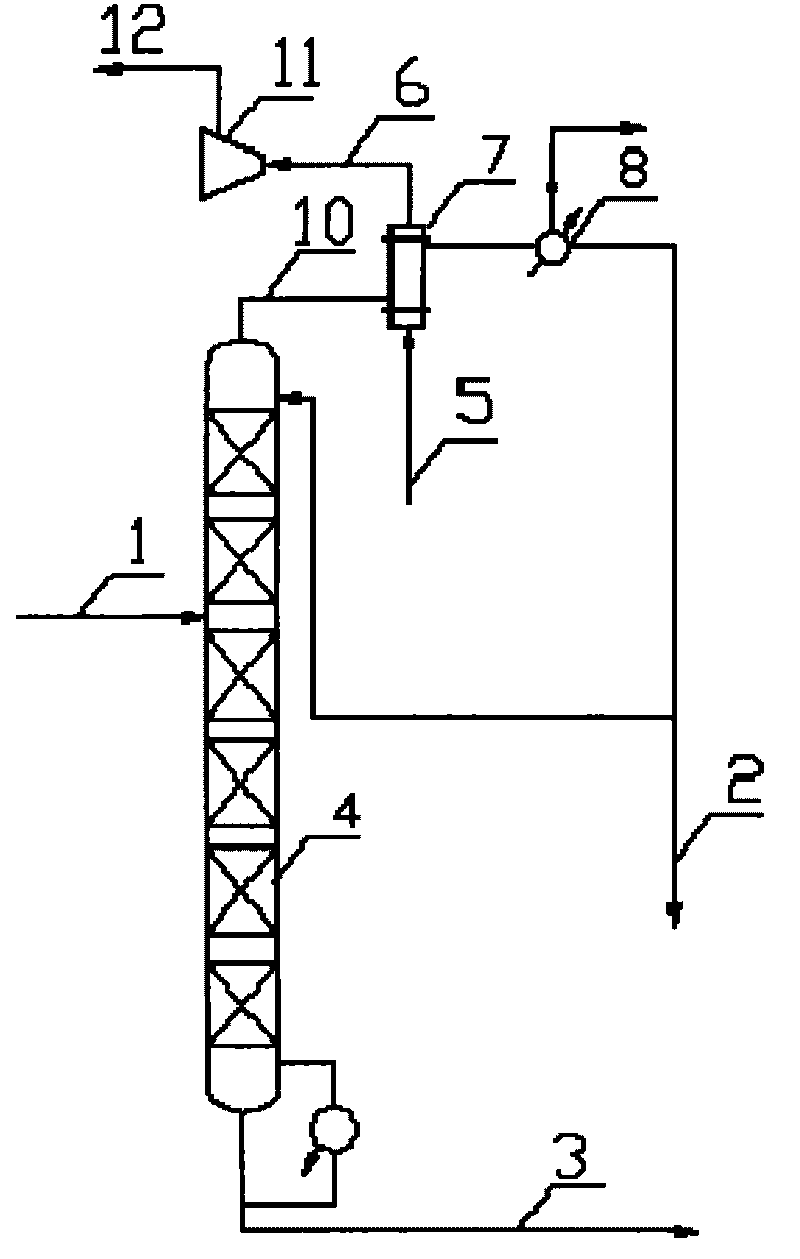

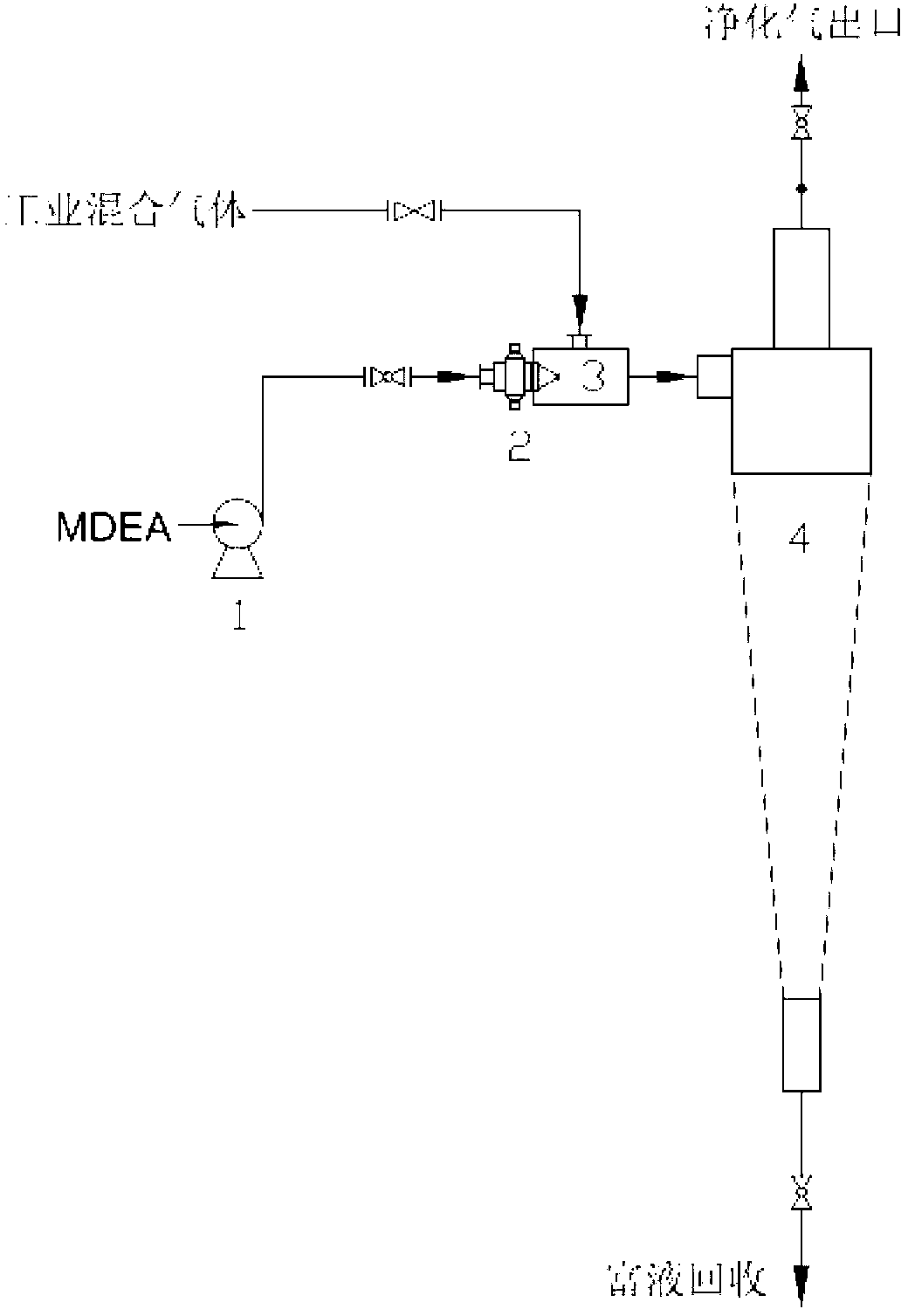

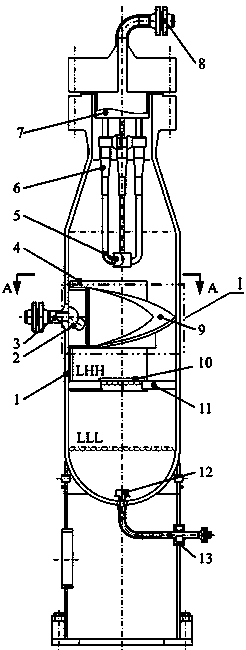

Method and device for selectively removing hydrogen sulfide from gas by utilizing amine droplets

The invention relates to a method and a device for selectively removing hydrogen sulfide from gas by utilizing amine droplets, and provides the method for selectively removing hydrogen sulfide from gas by utilizing amine droplets. The method comprises the steps of (1) atomizing N-methyldiethanolamine solution into droplets with particle size of not larger than 50 micrometer; (2) uniformly mixing the droplets with hydrogen sulfide-containing mixed gas, and introducing into a micro-swirler; (3) allowing thorough contact and reaction between N-methyldiethanolamine droplets and hydrogen sulfide in the micro-swirler to transfer hydrogen sulfide into the droplets, and meanwhile separating the hydrogen sulfide-absorbed droplets from gas; and (4) enriching the hydrogen sulfide-absorbed droplets, recycling, regenerating, and circulating to the step (2). The invention also provides the device for selectively removing hydrogen sulfide from gas by utilizing amine droplets.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

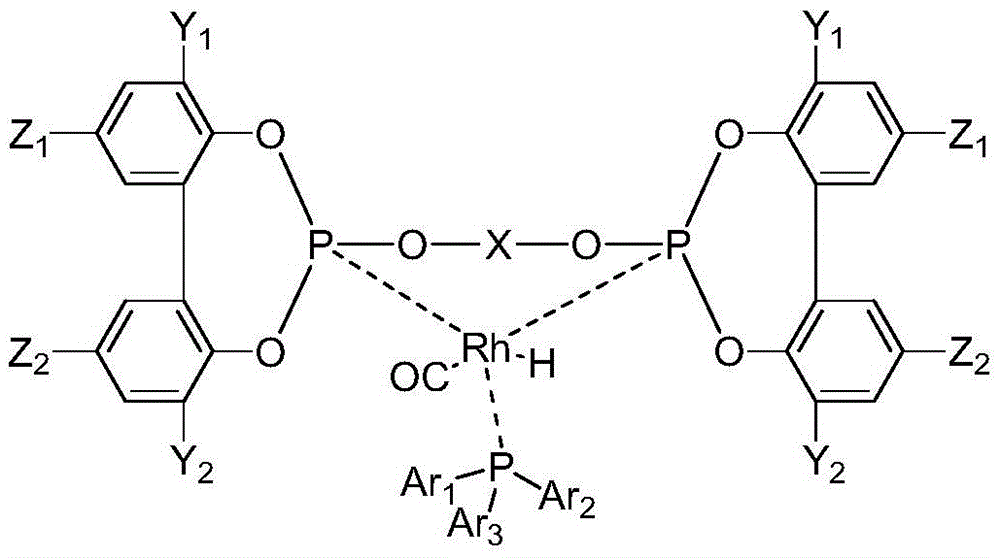

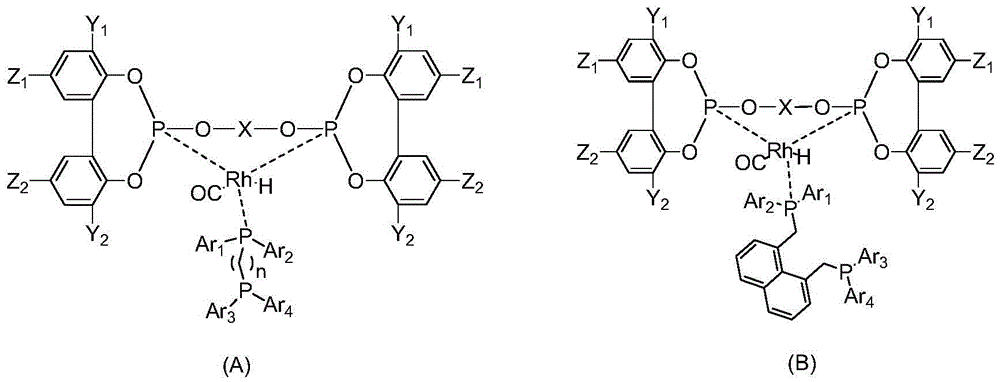

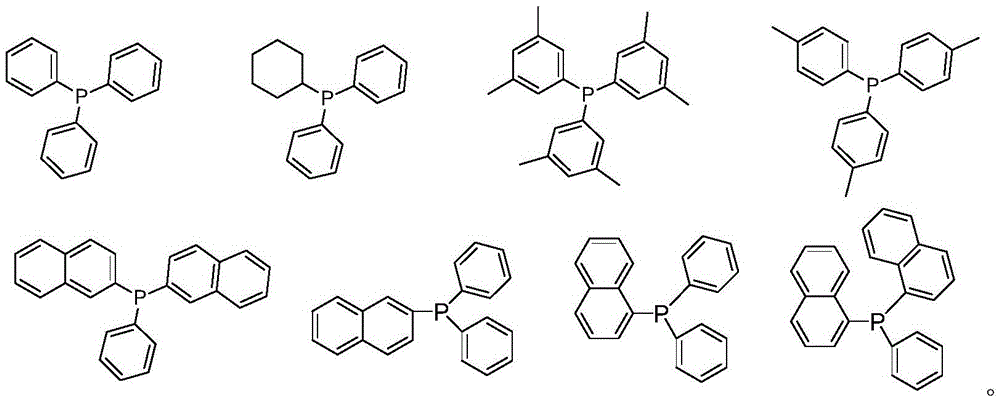

Method for preparing aldehyde through olefin hydroformylation

InactiveCN105566081AImprove isotropic selectivityImprove economyOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsFormylation reactionOrganic chemistry

The invention relates to a method for preparing aldehyde through olefin hydroformylation, aiming at mainly solving the problems in the prior art that the normal / isomeric ratio of the product is relatively low and the stability of a catalyst is poor. According to the method for preparing the aldehyde through adopting the olefin hydroformylation, in an olefin hydroformylation reaction, the catalyst is at least one of a complex catalyst I and a complex catalyst II. With the adoption of the technical scheme, the problems above are solved very well and the method can be used for the olefin hydroformylation reaction.

Owner:SHANGHAI HUAYI GRP CO

Production method of epoxy propane

This invention relates to a preparation method of propylene oxide. In existing technology takes low concentration H2O2 water solution as oxidizer, phosphorus tungsten heteropoly acid quaternary ammonium salt as catalyzer to prepare propylene oxide. This invention mainly solve the problem in existing technology of separation energy high caused by water, as well as catalyst stability low caused by decompound of phosphorus tungsten heteropoly acid quaternary ammonium salt, and problem of H2O2 activity factor descending. This invention takes propylene and aqueous hydrogen peroxide solution of weight percent concentration 40 to 80 as raw material, takes phosphorus tungsten heteropoly acid quaternary ammonium salt as catalyzer, takes at least one of toluene, benzene, ethylbenzene, cumene or chloroform as solvent, under 20 to 100deg reaction temperature and 0 to 3.0 Mpa reaction pressure, to carry out reaction for 0.5 to 24 hours. It best solve existing problem, can be used in industrial production of propylene oxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

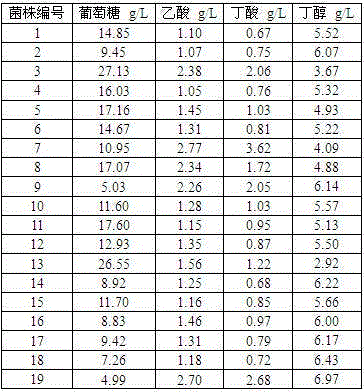

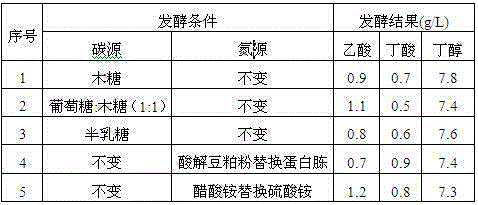

Clostridium beijerinckii and application thereof

The invention discloses clostridium beijerinckii XH0906 producing butanol and application thereof. The classification term of the clostridium beijerinckii XH0906 is clostridium beijerinckii which is preserved in CGMCC on 4th, May, 2014 and has the preservation number of CGMCCNo.9124. The strain can growth in a non-strict anaerobic environment and ferment to produce butanol. No sodium hydrosulfite needs to be added to remove oxygen into a fermenting culture medium. In the fermenting process, N2 needs not to be introduced to maintain the anaerobic environment, so that the phenomenon that thalli do not grow as a result of halfway oxygen removal is avoided, and the energy consumption is reduced; moreover, the clostridium beijerinckii XH0906 has the characteristics of high output of butanol, few acetone and ethanol byproducts and the like, the pressure of follow-up butanol recovery is alleviated, and the separating energy consumption is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing 5-hydroxymethyl furfural by utilizing biomass as raw material

InactiveCN102617524AHigh yieldReduce generationOrganic chemistryAlternative fuelsHydroxymethylfurfural

The invention provides a method for efficiently preparing 5-hydroxymethyl furfural (HMF) utilizing biomass widely existing in a natural world as a raw material. The method includes the following steps: utilizing a two-phase system composed of low-boiling point organic matter and water, adopting acid salt of sulfuric acid and sulfuric acid metal normal salt as a catalyst in synergy mode to form a catalyst system, adding the biomass raw material capable of being degraded to hexose to a reaction system and preparing the HMF by reaction. The reaction process of the method has high HMF selectivity. The catalyst is low in price, mild in operation condition, simple in process and low in separation energy consumption. The biomass raw material with a wide source is utilized as the reaction raw material, preparation of biomass-based chemical and alternative fuel with the biomass as the raw material can be favorably promoted, and the method has high industrialized prospect.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

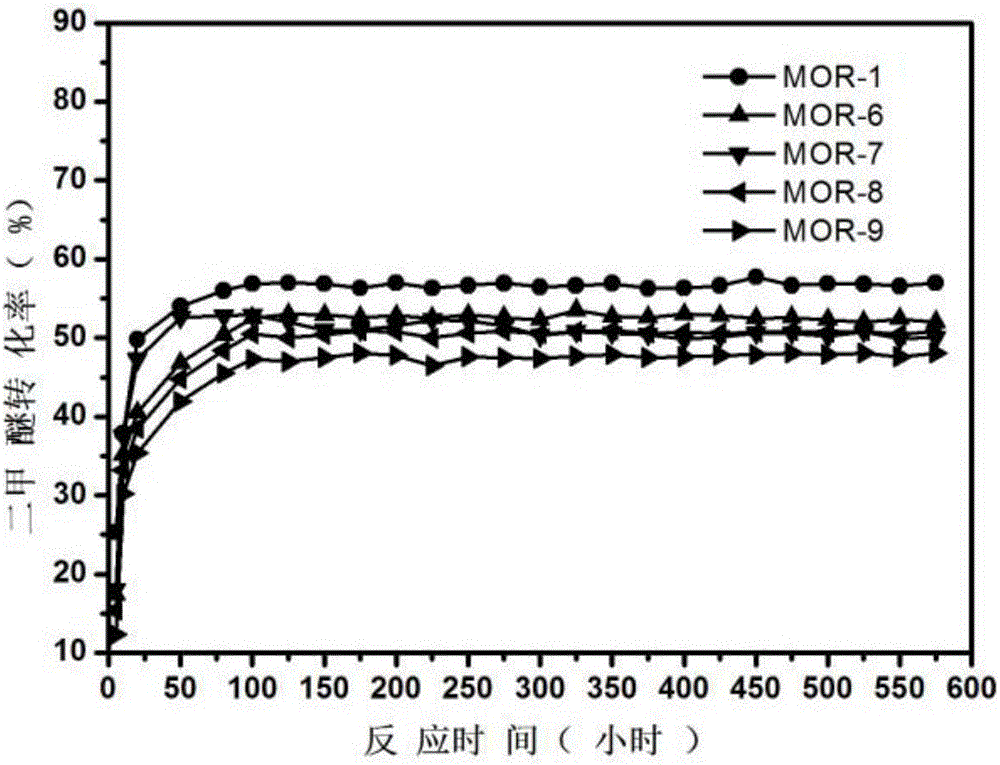

Methyl acetate molecular sieve catalyst prepared by carbonylation of dimethyl ether, modification method and application

InactiveCN108160100AEfficient modificationSimple methodMolecular sieve catalystsPreparation by carbon monoxide or formate reactionMolecular sieveChemical reaction

The invention discloses a modification method for a methyl acetate molecular sieve catalyst prepared by carbonylation of dimethyl ether, and solves the problem that in the prior art, the catalyst activity and the selectivity are reduced with the increase of the reaction temperature. The modification method provided by the invention comprises the following steps: firstly, carrying out a reaction onnon-metal modified substances with B acid sites on a 12-membered ring pore channel of a catalyst and selectively modifying the 12-membered ring pore channel, then modifying an 8-membered ring pore channel of the catalyst by adopting a metal modified substance, and carrying out ion exchange on the metal ions of the metal modifying substance and the H+ on the 8-membered ring pore channel to preparethe modified molecular sieve catalyst. The invention also discloses the methyl acetate molecular sieve catalyst prepared by carbonylation of dimethyl ether and an application of the methyl acetate molecular sieve catalyst. The preparation method provided by the invention is simple, the operation is simple and convenient, the methyl acetate molecular sieve catalyst prepared by carbonylation of dimethyl ether can be effectively modified, and high catalytic activity and high selectivity of the catalyst can be maintained at a higher reaction temperature.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Method for fully recycling yellow water in white spirit production process

ActiveCN104312881AImprove recycling efficiencyEfficient separationBy-product recoveryAlcoholic beverage preparationAlcoholEnergy consumption

The invention discloses a method for fully recycling yellow water in a white spirit production process. The method comprises the following steps: firstly, separating yellow water in a raw material tank by virtue of a porous separating membrane system; feeding yellow water clean liquor permeating a porous separating membrane into a pervaporation membrane for further separation; enriching most alcohol, aldehyde and ester matters through the pervaporation membrane on the other side of the membrane in the form of gas state; recovering the matters which are condensed by using a condenser of a pervaporation membrane system to a product storage tank for blending white spirit; increasing fragrant component and the like in original spirit; and further recovering intercepted porous separating membrane permeating liquor and pervaporation membrane permeating liquor. The method disclosed by the invention has the remarkable characteristic that the yellow water recovery efficiency is improved by virtue of two membrane separating and integrating methods including the porous separating membrane and the pervaporation membrane, so that the effective matters of the yellow water are utilized to a maximum extent, thereby thoroughly solving the outlet problem of the yellow water. In addition, the method further has the advantages of being simple in equipment and low in separating energy consumption and has strong practicality.

Owner:JIANGSU JIUMO HIGH TECH CO LTD

Method for preparing tert-butyl carboxylate by using dual-modified SBA mesoporous molecular sieve catalyst

ActiveCN103936583AImprove conversion rateHigh selectivityMolecular sieve catalystsOrganic compound preparationCarboxylic acidSolvent

The invention discloses a method for preparing tert-butyl carboxylate by using a dual-modified SBA mesoporous molecular sieve catalyst. According to the method, carboxylic acid and isobutylene are subjected to addition esterification by using a dual-modified SBA mesoporous molecular sieve as a catalyst to synthesize the tert-butyl carboxylate. The molecular sieve catalyst is a metal-doped sulfonate-grafted dual-modified SBA mesoporous molecular sieve catalyst prepared by a one-step cocondensation process. When the dual-modified SBA mesoporous molecular sieve catalyst is used in the addition esterification reaction process of synthesizing tert-butyl carboxylic acid from carboxylic acid and isobutylene, no polar solvent (such as tert-butyl alcohol, methyl tert-butyl ether or the like) is needed as an isobutylene polymerization inhibitor, and the quantity of the carboxylic acid is not excessive, thereby reducing the energy consumption for separating the reaction product. The catalyst has the advantages of high conversion rate, high selectivity, non-homogeneous phase, no corrosiveness, adjustable acid quantity and acid center and the like, and is recyclable.

Owner:安徽百昊晟科技有限公司

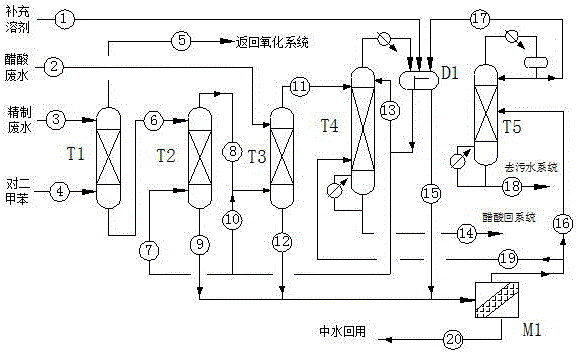

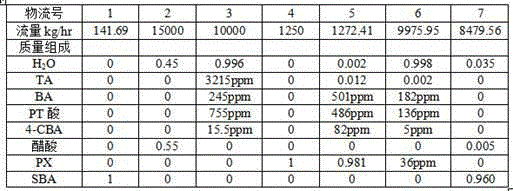

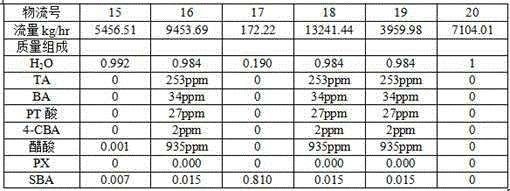

Novel process for recovering PTA (purified terephthalic acid) wastewater

ActiveCN105037131ASolve the technical problems of broken reverse osmosis membraneSolve operational problemsCarboxylic compound separation/purificationReverse osmosisEthylic acid

The invention a novel process for recovering PTA (purified terephthalic acid) wastewater (including refinement wastewater and acetic acid wastewater), which comprises the following steps: (1) extracting and recovering polybasic organic acids in refinement wastewater by using paraxylene; (2) extracting the trace paraxylene dissolved in the refinement wastewater by using a solvent, and deeply extracting and recovering residual organic acids in the refinement wastewater; (3) by using the extract phase in the step (2) as the solvent, recovering acetic acid in acetic acid wastewater by an extraction+azeotropy rectification technique; and (4) recovering reclaimed water by ultrafiltration+reverse osmosis. The process recovers most organic matters in the wastewater, achieves the goal of recovering wastes, and avoids waste of resources. By organically combining the double-extraction processes, extraction+azeotropy rectification process and membrane system, the process can simultaneously treat the PTA refinement wastewater and acetic acid wastewater, achieves the goal of deeply recovering organic acids in the PTA wastewater, obviously lowers the energy consumption of the azeotropy rectification tower and solvent dehydration tower, implements recovery of reclaimed water, and has the advantages of low energy consumption, high resource recovery rate, simple procedure and the like.

Owner:FUZHOU UNIV

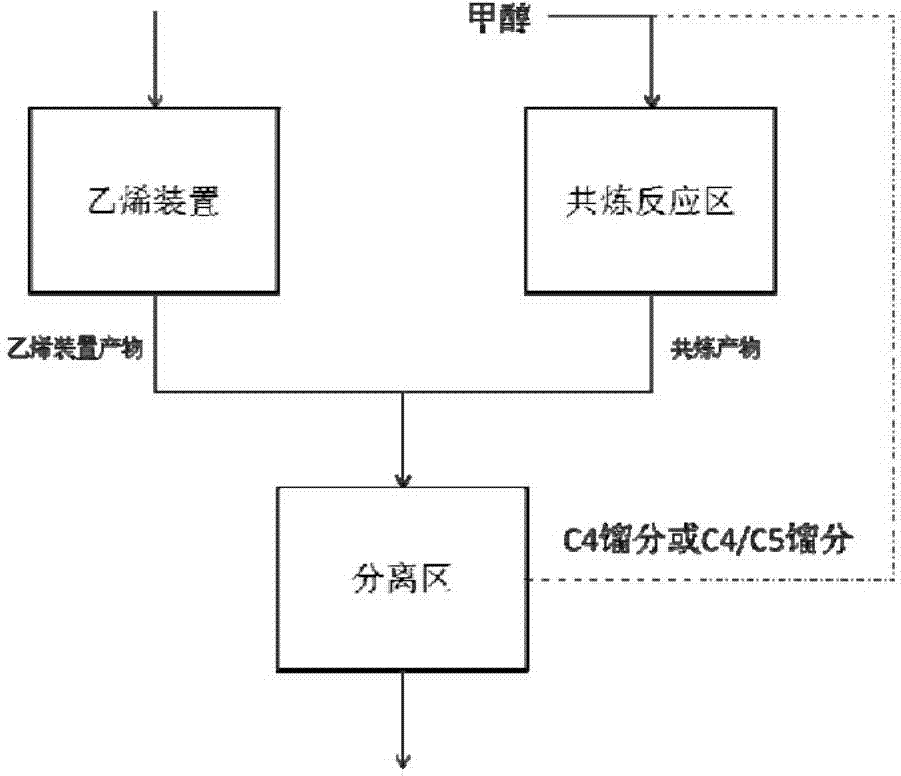

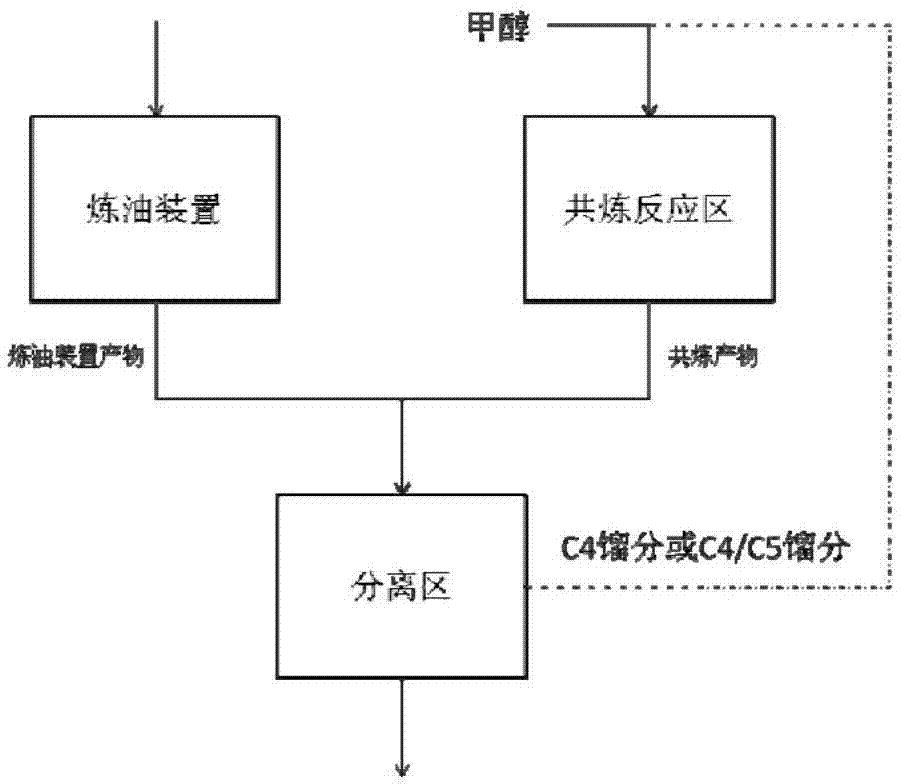

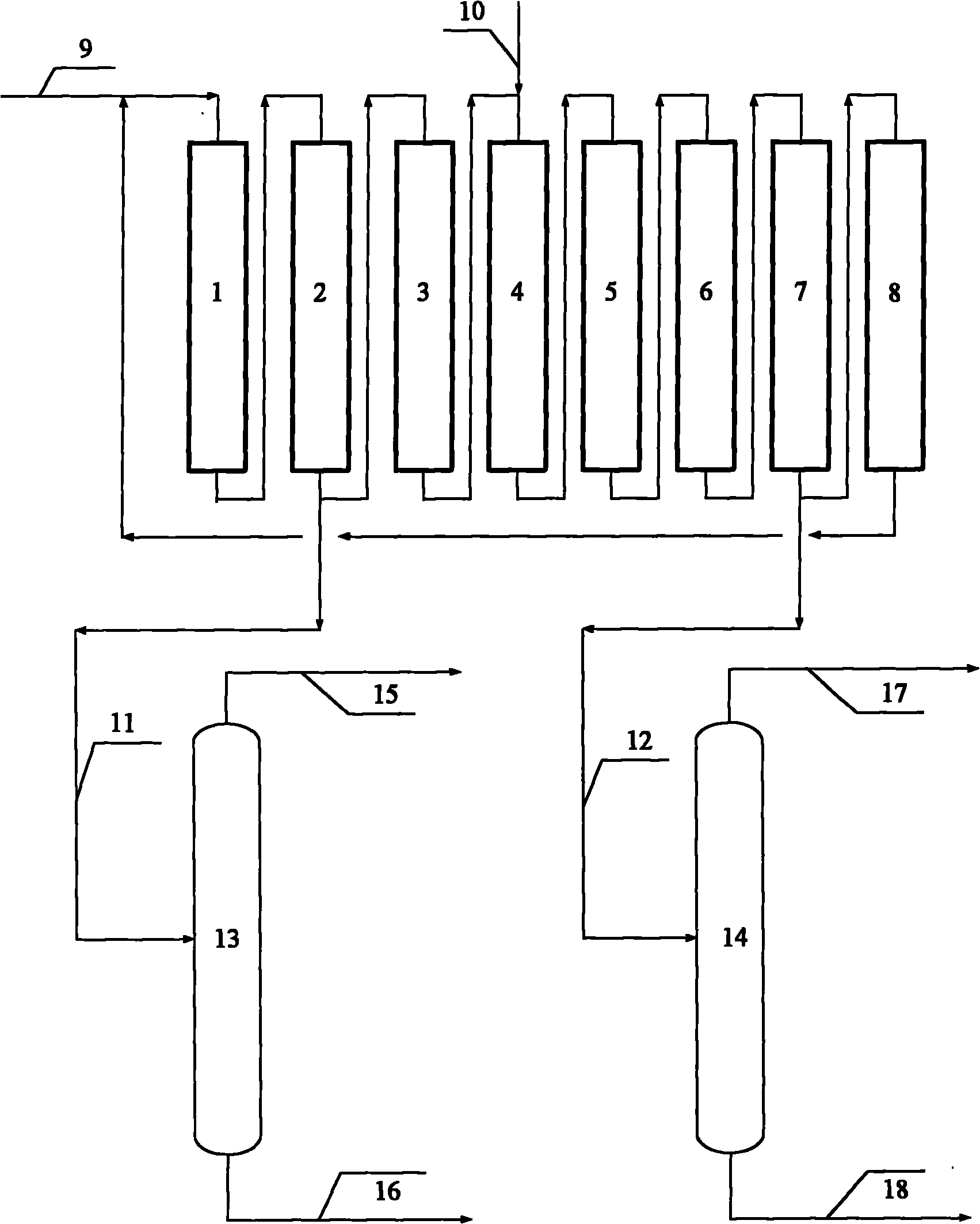

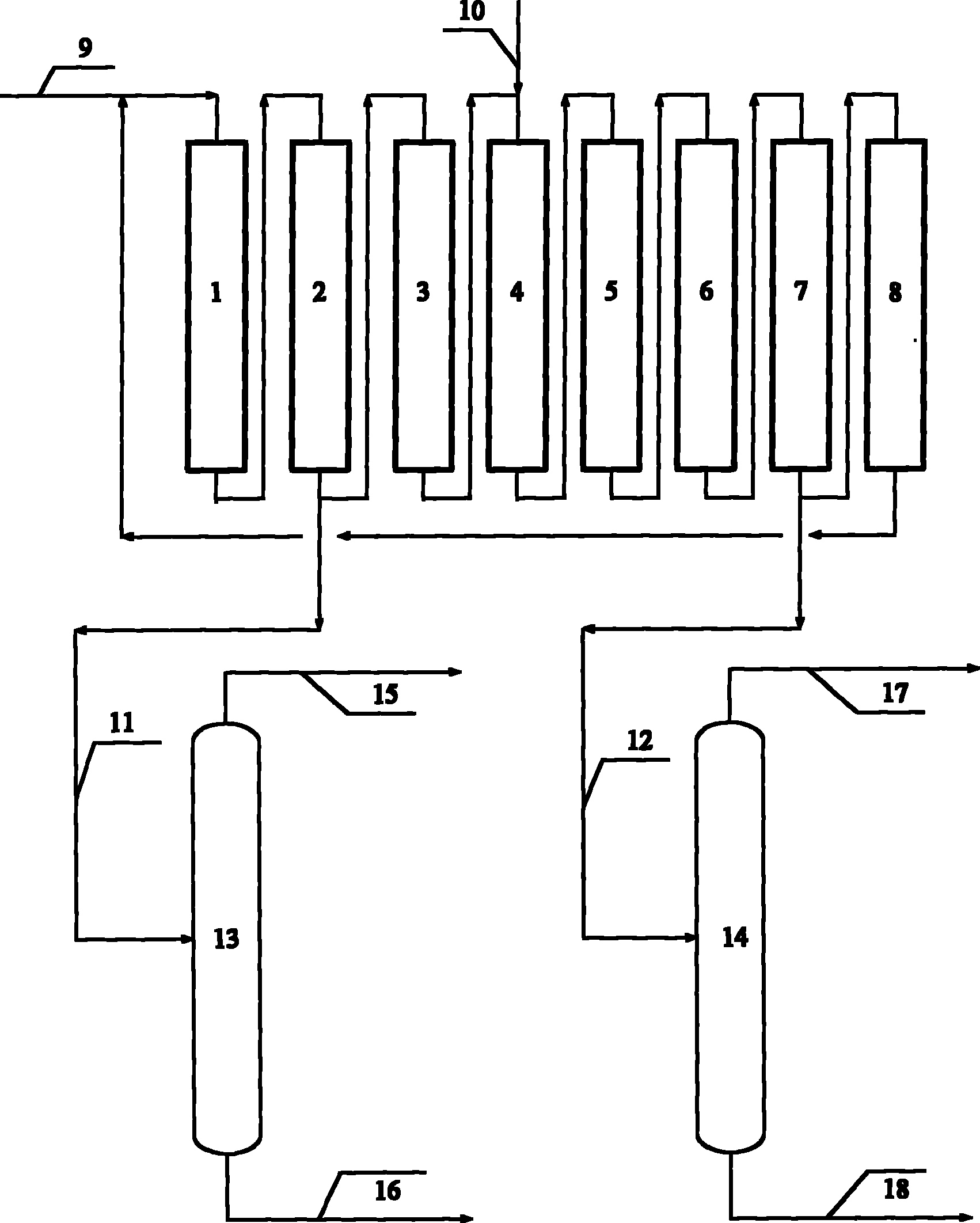

Process for producing propylene by using alcohol-hydrocarbon co-refining technology

InactiveCN103755510AReduce heat exchange difficultyReduce the difficulty of temperature controlHydrocarbon from oxygen organic compoundsEthylene productionOxideDimethyl ether

The invention discloses a process for producing propylene by using an alcohol-hydrocarbon co-refining technology. The process comprises the steps of (1) introducing a raw gas consisting of methanol and / or dimethyl ether, and C4 or C4 / C5 cut fractions and diluent gas into a co-refining reaction zone to have a co-refining reaction in contact with a catalyst, thereby obtaining a co-refining reaction product; and (2) putting the co-refining reaction product obtained in the step (1) and a product of an oil refining device or ethylene unit into a separation zone, performing dehydration and oxide removal, and then separating to obtain a product namely propylene and other hydrocarbon byproducts, wherein the C4 and C5 cut fractions in the hydrocarbon byproducts are returned to the co-refining reaction zone after crude separation. According to the process disclosed by the invention, methanol and / or dimethyl ether and C4 or C4 / C5 cut fractions are subjected to co-refining, so that a strong thermal effect existing in separate reactions of the two components is effectively neutralized, and the heat exchange difficulty is reduced; the separation zone is shared by the process and the oil refining device or ethylene unit, so that integrated production is realized, the added values of the C4 or C4 / C5 cut fractions of the oil refining device or ethylene unit are improved.

Owner:ZHEJIANG UNIV

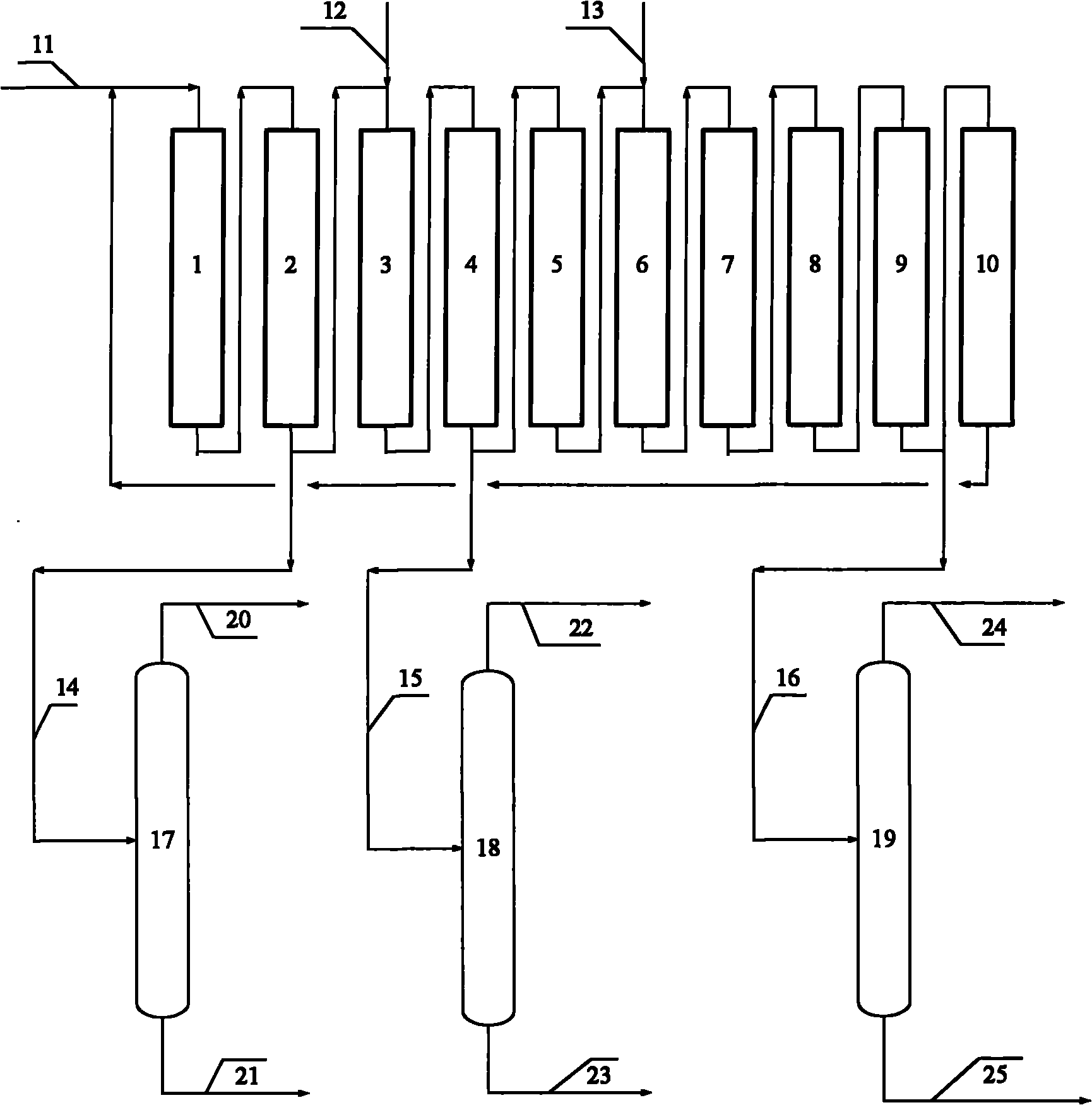

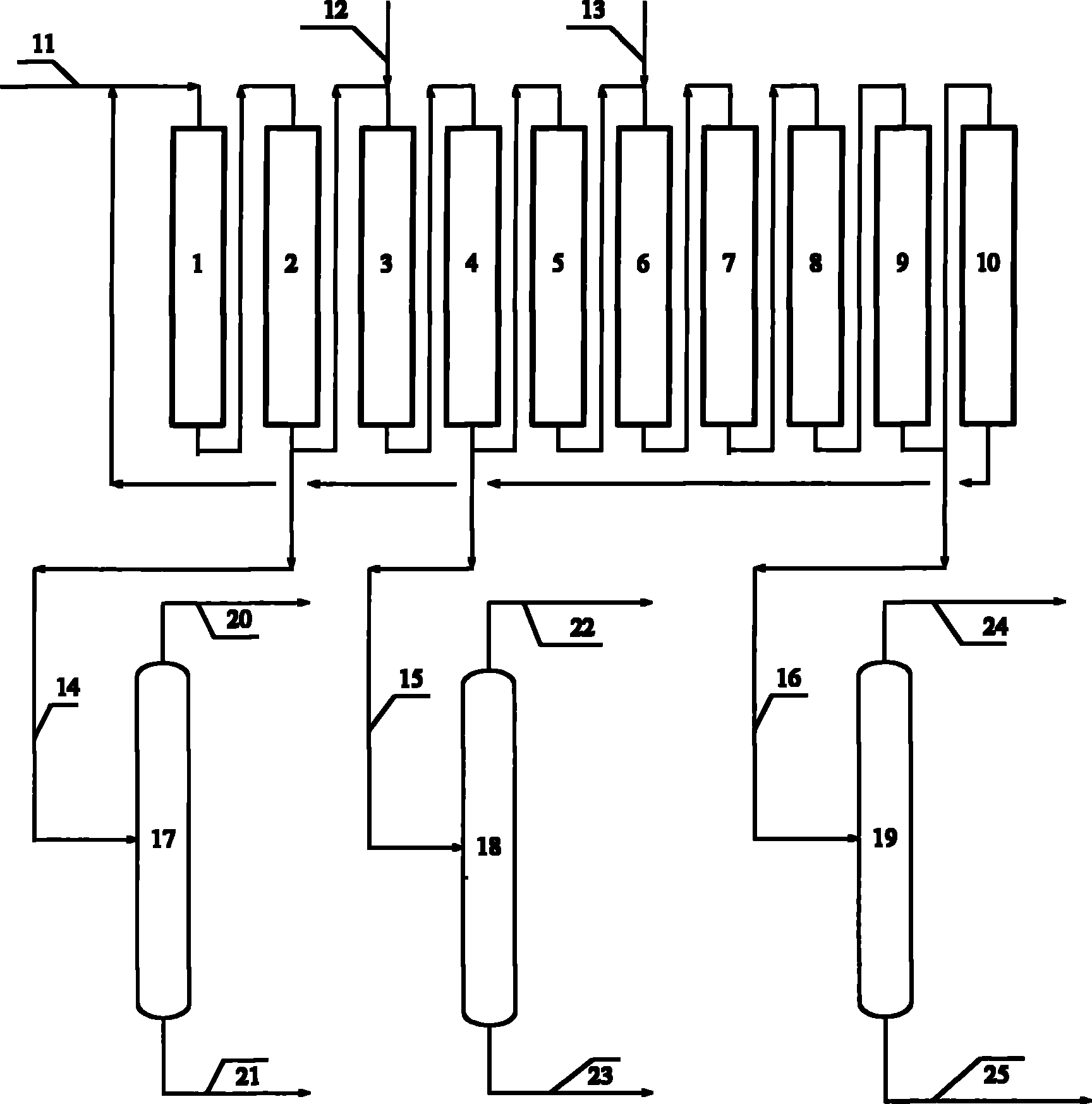

Method for separating glycol and butylene glycol

ActiveCN102372599AReduce separation energy consumptionReduce overall energy consumptionHydroxy compound separation/purificationMolecular sieveSimulated moving bed

The invention relates to a method for separating glycol and butylene glycol, and mainly aims to solve the problem of high separation energy consumption in separation of glycol and butylene glycol through azeotropic rectification. The method comprises the steps of: putting a glycol solution with butylene glycol content higher than 1% and a strippant into the raw material feeding bed and the strippant feeding bed of a simulated moving bed instrument loaded with an adsorbent, with the extraction solution mixed by the strippant and butylene glycol, and the raffinate mixed by the strippant and glycol, subjecting the extraction solution to separation in a butylene glycol separation tower, recovering the strippant from the tower top, and collecting butylene glycol from the tower kettle, delivering the raffinate into a glycol separation tower, recovering the strippant from the tower top, and collecting glycol from the tower kettle, with the adsorbent selected from at least one of nonfunctional resin or a molecular sieve, and the strippant selected from at least one of polar solvents. The technical method provided in the invention solves the problem well, and can be used in industrial production of glycol and butylene glycol separation.

Owner:CHINA PETROLEUM & CHEM CORP +1

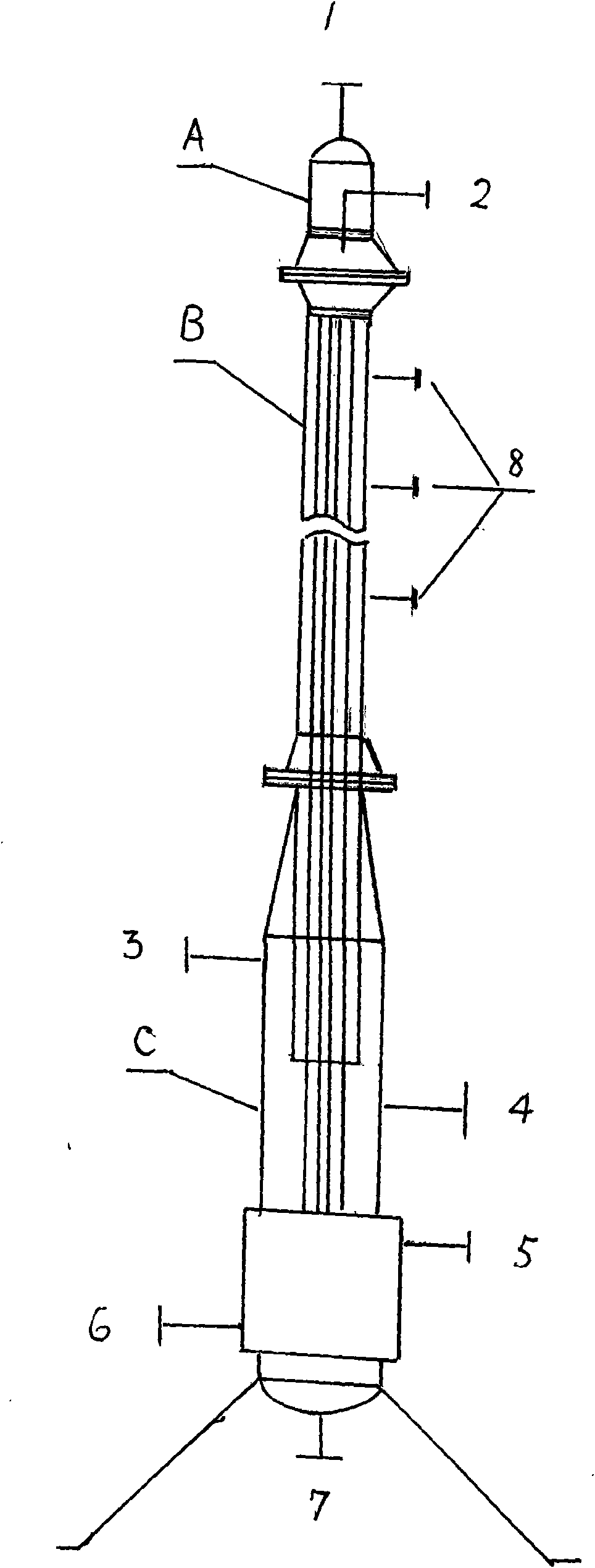

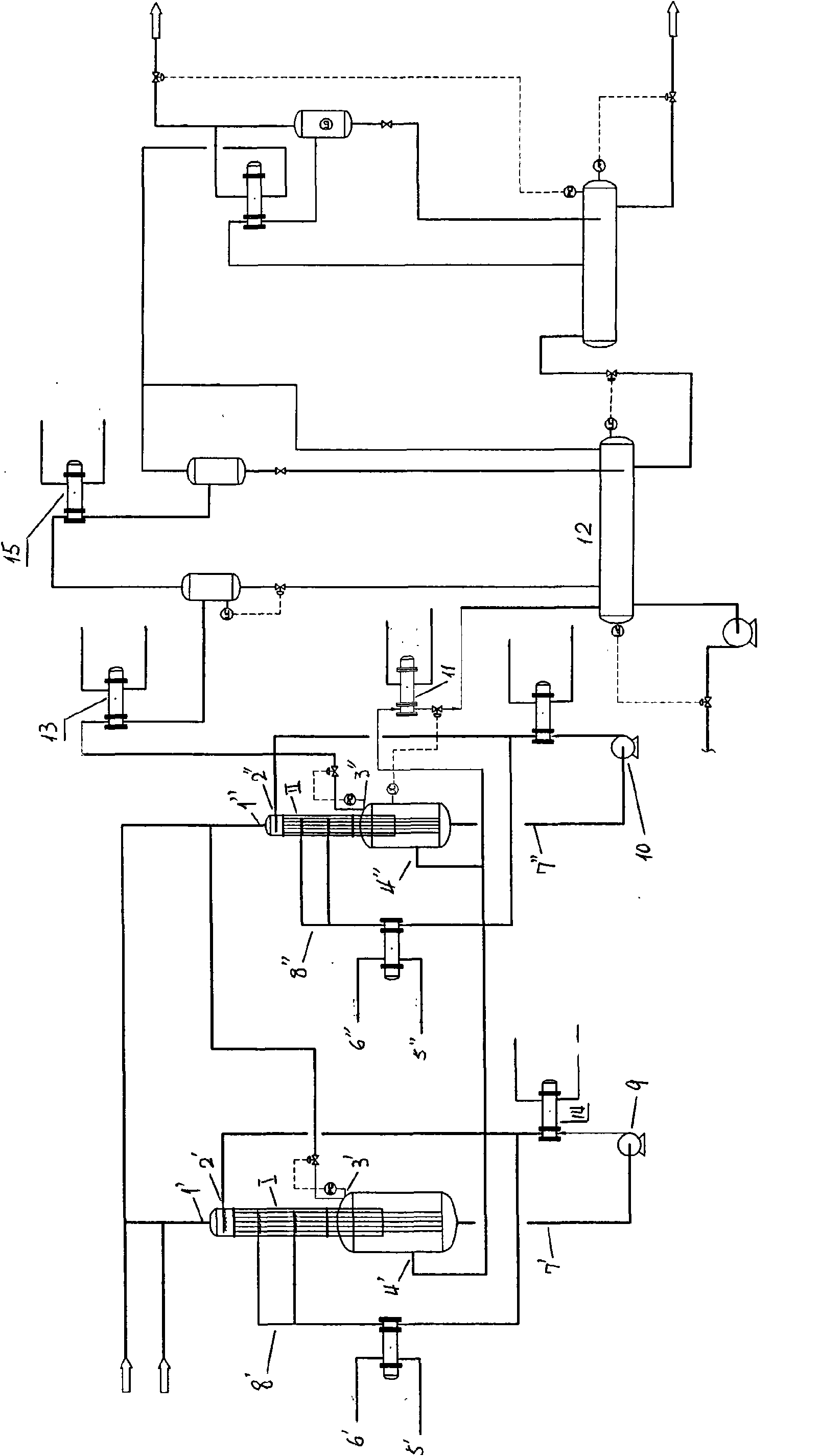

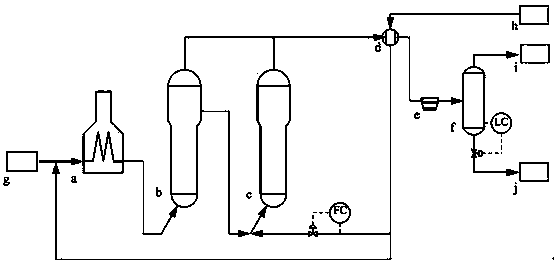

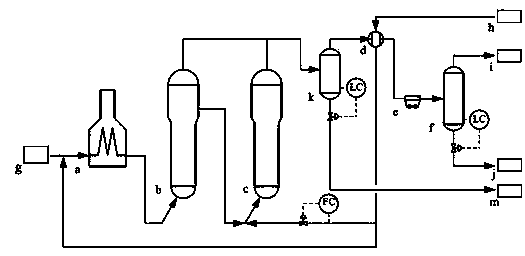

Process for continuously producing corresponding aldehyde by alkene hydroformylation reaction

ActiveCN101575272AFully playAdequate responsePreparation by carbon monoxide reactionFormylation reactionGas phase

The invention discloses a process for continuously producing corresponding aldehyde by alkene hydroformylation reaction. The process comprises the following steps: heating a water-soluble alkene hydroformylation catalyst water solution to between 80 and 95 DEG C and then making the water-soluble alkene hydroformylation catalyst water solution enter NO. 1 and NO.2 alkene hydroformylation continuous reactors (I and II) from liquid distributors (2' and 2'); when the catalyst water solution is cyclically stable, introducing mixed gas of alkene and synthesis gas of purified hydrogen and carbon monoxide to the NO.1 reactor, and carrying out hydroformylation reaction on the alkene on an interface of a cyclical catalyst liquid membrane; discharging unreacted mixed gas at the end of a separation section of the bottom of the NO.1 reactor and a gas-phase byproduct from the NO.1 reactor; automatically separating an aldehyde product from the catalyst water solution, discharging the aldehyde product and the catalyst water solution from liquid aldehyde outlet (4') of the NO.1 reactor, and making the aldehyde product and the catalyst water solution enter a coarse aldehyde tank (12); and supplementing the mixed gas of the alkene and the synthesis gas of the hydrogen and the carbon monoxide by the unreacted mixed gas which is discharged from a reaction residual gas outlet (3') of the NO.1 reactor and the gas-phase byproduct, and introducing the mixed gas into the NO.2 reactor (II) to further react.

Owner:南京荣欣化工有限公司 +3

Method for preparing epoxypropane by epoxidation of propene

ActiveCN101279957AIncrease concentrationEasy to separateOrganic chemistryMolecular sieve catalystsReaction temperatureSolvent

The invention relates to a method to prepare propylene oxide through the epoxidation of propylene, mainly solving the problems of complex operation and large energy consumption during the separation process in prior art which introduces a large amount of solvent during the preparation of propylene oxide. The method takes peroxide and propylene as material and ti-si molecular sieveTS-1 as catalyzer, and the materials contact with the catalyzer to produce propylene oxide; wherein the mol ration of propylene to peroxide is 1-162:1; the weight ratio of peroxide to catalyzer is 0.2-200:1; the temperature for the reaction is 10-100 DEG C, the absolute pressure is 1.0-3.0MPa and the reaction lasts for 0.1-48h. The technical proposal of the method solves above problems and is applicable to the industrial production of preparing propylene oxide through the epoxidation of propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for separating ethylene glycol, propanediol and butanediol

ActiveCN102372601AReduce separation energy consumptionAchieve the purpose of separationHydroxy compound separation/purificationHigh energyDesorption

The invention relates to a method for separating ethylene glycol, propanediol and butanediol. By the method, the problem of high energy consumption during azeotropic distillation separation of the ethylene glycol, the propanediol and the butanediol at present is mainly solved. The method sequentially comprises the following steps that: raw materials containing the ethylene glycol, the propanediol and the butanediol, a desorption agent I and a desorption agent II enter a raw material feed bed, a desorption agent I feed bed and a desorption agent II feed bed of a simulation moving bed device filled with an adsorbent, wherein extraction liquid I is a mixture of the propanediol and the desorption agents, extraction liquid II is a mixture of the butanediol and the desorption agents, and raffinate is a mixture of the ethylene glycol and the desorption agents; and the extraction liquid I, the extraction liquid II and the raffinate are rectified normally to form the ethylene glycol, the propanediol and the butanediol. Through the technical scheme, the problem is better solved. The method can be used for the industrial production of separating the ethylene glycol, the propanediol and the butanediol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of ethyl benzene by adopting alkylation exhaust gas generated in process of preparing styrene by adopting catalytic dry gas

ActiveCN103965009AAchieve self-sufficiencyLow costHydrocarbonsAbsorption purification/separationDehydrogenationEthylene

The invention belongs to the technical field of preparation of ethyl benzene through catalytic dry gas, and discloses a preparation method of ethyl benzene by adopting alkylation exhaust gas generated in the process of preparing styrene by adopting catalytic dry gas. The method comprises the following steps: separating ethane, demethanizing, deethanizing, performing oxidative dehydrogenation, dehydrating and depickling, performing hydrocarbylation reaction, and separating ethyl benzene. A preferred adsorbent and the cyclic utilization technology of ethane and the adsorbent can minimize the preparation cost of ethyl benzene, the technology is simple and the recyclability is high. Under appropriate technological conditions, the total conversion rate of ethane can reach above 88%, the overall selectivity of ethylene generating ethyl benzene can reach above 80%, the purity of ethyl benzene can reach above 83%, and the recovery rate of the adsorbent can reach above 99%.

Owner:陕西延长石油(集团)有限责任公司炼化公司

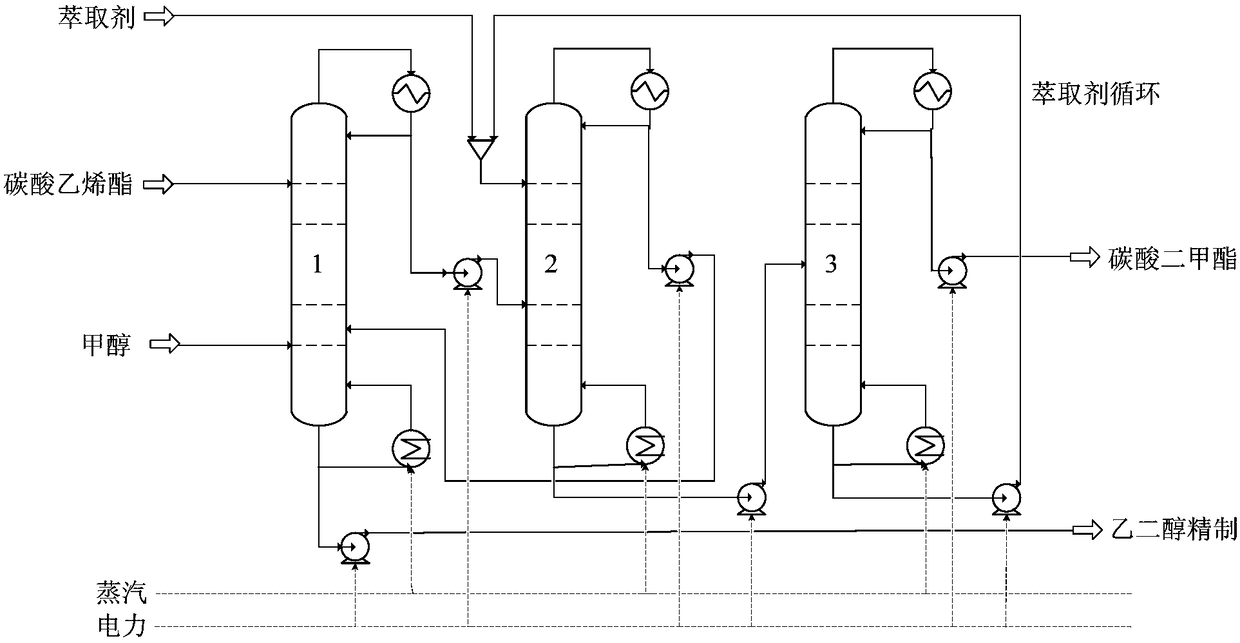

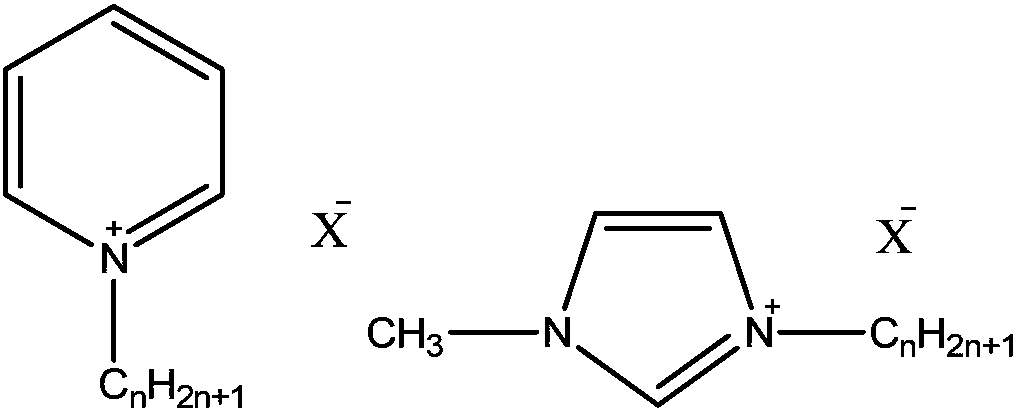

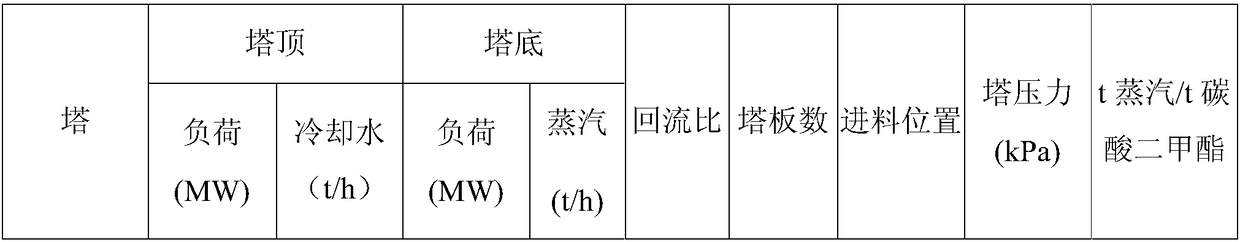

Extraction agent for extracting, rectifying and separating methanol and dimethyl carbonate azeotrope, application of extraction agent, and treatment method

ActiveCN108067012AReduced cycle lossChanging the relative volatilityOrganic compound preparationChemical industryLoss rateMethyl carbonate

The invention provides an extraction agent for extracting, rectifying and separating methanol and dimethyl carbonate azeotrope, application of the extraction agent, and a treatment method. The extraction agent is a mixed extraction agent containing ionic liquid. A system for extracting, rectifying and separating methanol and dimethyl carbonate azeotrope comprises a reaction rectifying tower, an extraction rectifying tower and an extraction agent regeneration tower which are sequentially connected, wherein the extraction rectifying tower uses the extraction agent to perform extraction and rectification. The extraction agent has the advantages that the extraction agent can effectively change the relative volatility of methanol and dimethyl carbonate azeotrope, increase the separation effectof the methanol and dimethyl carbonate azeotrope, the purity of obtained dimethyl carbonate can reach 99.8wt% or above, and the circulating loss rate of the extraction agent can be lowered to 0.01% orbelow; the extraction agent can guarantee the conversion rate of ethylene carbonate and lower the concentration of circulating methanol, and accordingly thermal load is reduced, and separation energyconsumption is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for purifying m-phenylenediamine

ActiveCN107286023APrinciples of ScienceIncrease profitAmino compound purification/separationChemistryDiaminotoluene

The invention relates to the technical field of production of m-phenylenediamine and particularly discloses a method for purifying m-phenylenediamine. The method for purifying m-phenylenediamine is characterized by comprising the following steps: continuously feeding pre-molten m-phenylenediamine ash into a rectifying tower to be rectified, and extracting partial liquid through an extraction pipe; directly injecting the extracted m-phenylenediamine into a crystallizer, heating until the m-phenylenediamine is totally molten, cooling, crystallizing and cooling, draining the mother solution by a drain valve of the crystallizer, feeding to the next-stage crystallizer to be continuously molten and crystallized, wherein the operation process is the same as that in the previous step; and collecting the feed liquid obtained by multistage melting and crystallizing, cooling and slicing in an inert protection atmosphere, thereby obtaining the finished purified m-phenylenediamine product. According to the m-phenylenediamine purified by the method disclosed by the invention, the content of the impurity, namely diaminotoluene, in the m-phenylenediamine is less than 50ppm, the requirements on synthesis of aramid fibers 1313 and other high-purity applications can be met, the principle is scientific, the utilization rate of the materials is improved, the separation energy consumption and equipment investment are reduced, and the method is green and economical.

Owner:QINGDAO UNIV OF SCI & TECH

Rotational-flow purifying device for gaseous product in fluidized-bed residual oil hydrogenation reactor and method for purifying gaseous product by same

The invention relates to a rotational-flow purifying device for a gaseous product in a fluidized-bed residual oil hydrogenation reactor. The device comprises the fluidized-bed residual oil hydrogenation reactor and a thermal high-pressure gas / hydrogen heat exchanger, wherein a thermal high-pressure flash tank is arranged between the reactor and the heat exchanger, and comprises a thermal high-pressure flash tank shell and an inlet distribution ring arranged in the shell; the inlet distribution ring has a spiral structure and defines a spiral channel together with the thermal high-pressure flash tank shell; a gaseous product inlet is formed in the thermal high-pressure flash tank shell; a tangential inlet guide pipe is mounted on the gaseous product inlet; the thermal high-pressure flash tank also comprises a micro-rotational-flow separator set arranged at the top in the thermal high-pressure flash tank shell. According to the device, the gaseous product in the fluidized-bed residual oil hydrogenation reactor is subjected to stepped rotational-flow separation, so that the entrainment quantity of liquid and catalysts in the gaseous product during a cold high-pressure separation process is reduced, the problem of blockage of the high-pressure heat exchanger is avoided, the energy consumption of a fluidized-bed hydrogenation device is greatly reduced, and the running cycle of the device is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +2

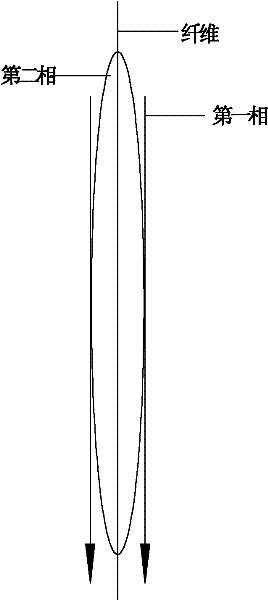

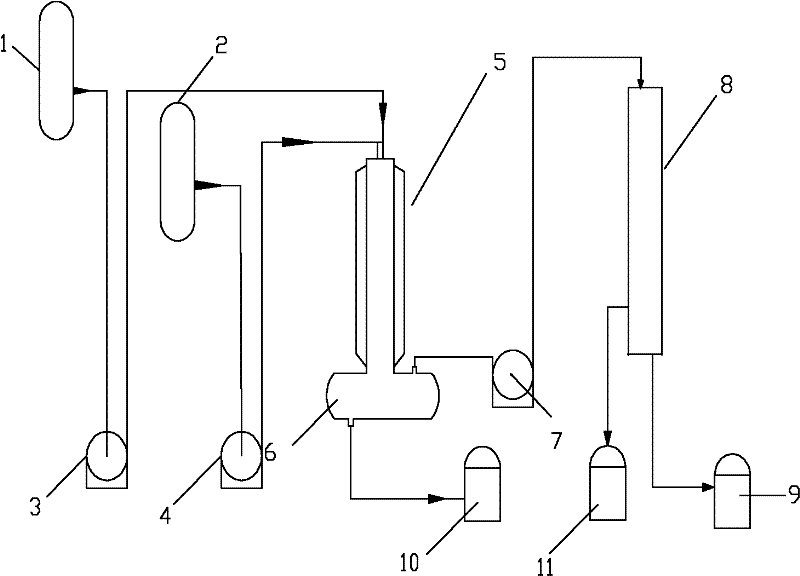

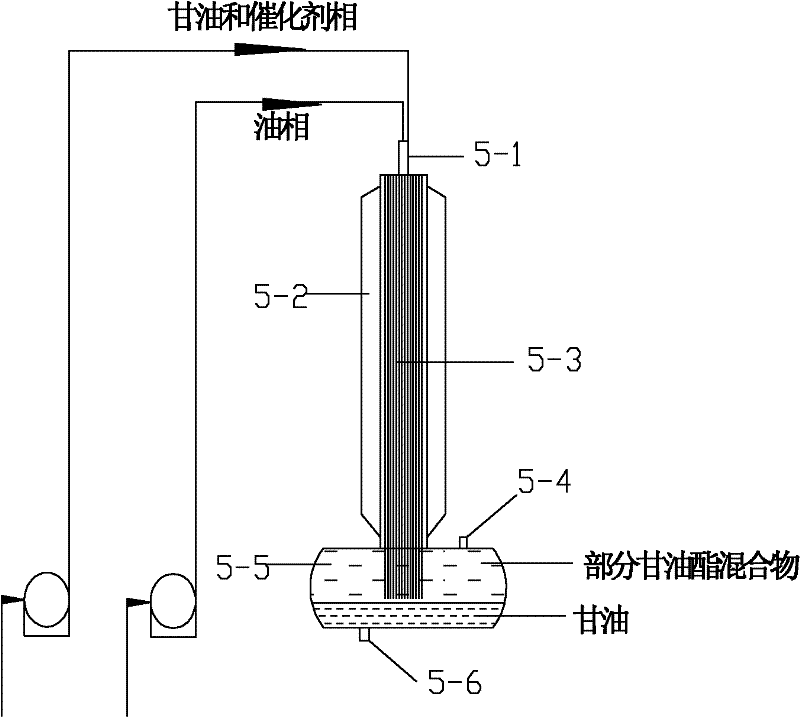

Preparation method of partial glyceride

InactiveCN102191134AIncrease contact areaEnhanced mass transferFatty acid esterificationFermentationFiberMonoglyceride

The invention belongs to the technical fields of chemical food and biological medicine and relates to a preparation method of partial glyceride. The method is characterized by comprising the following steps: mixing glycerin and catalyst to form glycerin-catalyst mixed solution, wherein the catalyst refers to alkali catalyst or enzyme catalyst; separately preheating raw material oil and the glycerin-catalyst mixed solution to 30-200 DEG C according to a ratio of raw material oil to glycerin, pumping the two materials in a fiber reactor at the same time, controlling the temperature of the fiber reactor to 0-200 DEG C, controlling the reaction temperature, using the mixed solution obtained by the reaction to perform molecular distillation or vacuum distillation and obtain monoglyceride and diglyceride. In the preparation method, the raw material oil and glycerin realizes liquid film contact on the surface of fiber in the fiber reactor, ester exchange reaction is performed under the action of the catalyst to prepare partial glyceride; and the reaction system is used to couple the reaction and separation step and ensure that the reaction is shifted in the direction of the product. Fiber contact is adopted to increase the contact area of the reactants, thus the reaction time can be shortened and the conversion rate and the separation efficiency can be increased.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com