Separation method for glycol, propylene glycol and butylene glycol

A separation method, ethylene glycol technology, applied in chemical instruments and methods, separation/purification of hydroxyl compounds, preparation of organic compounds, etc., can solve the problem of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

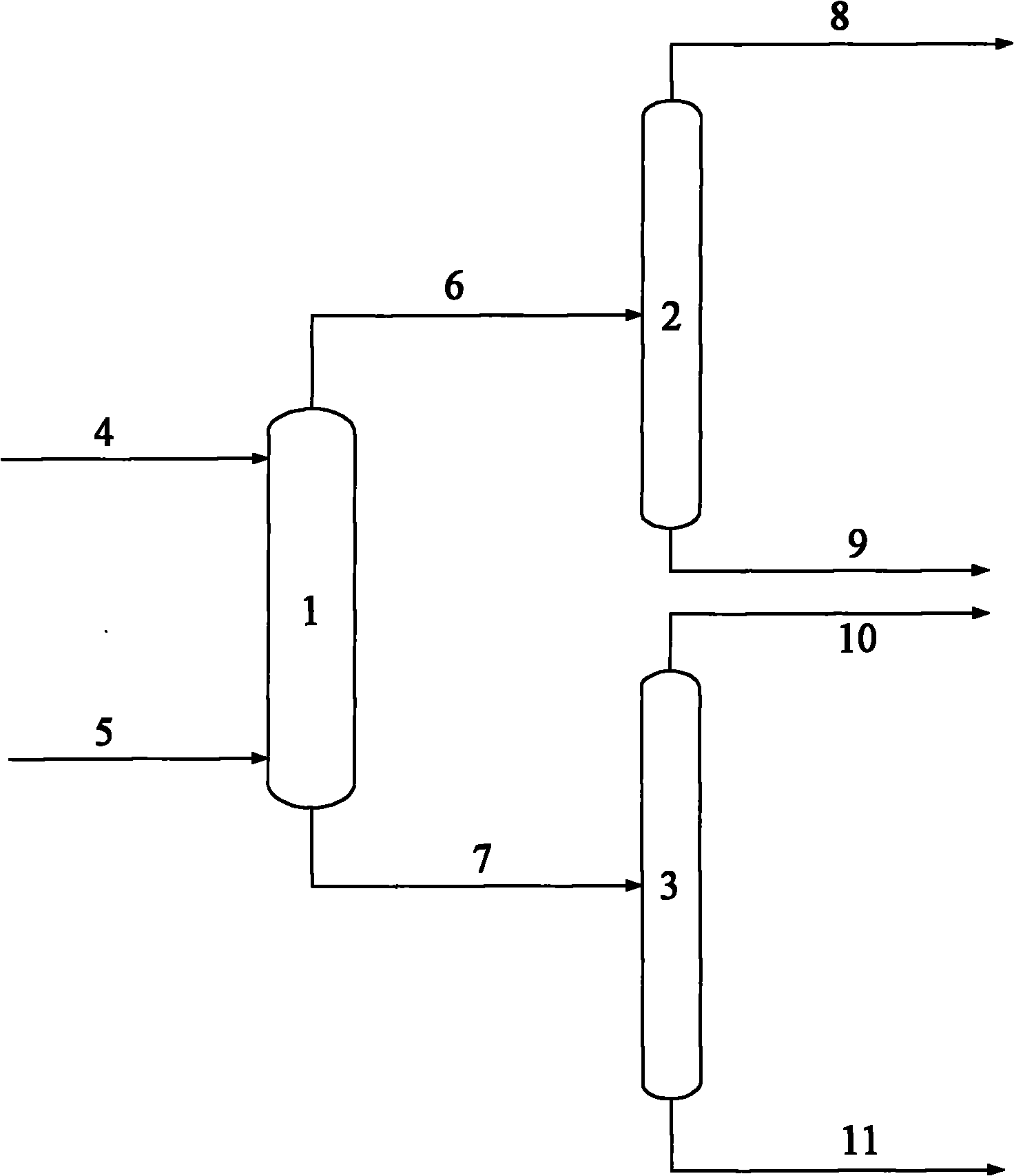

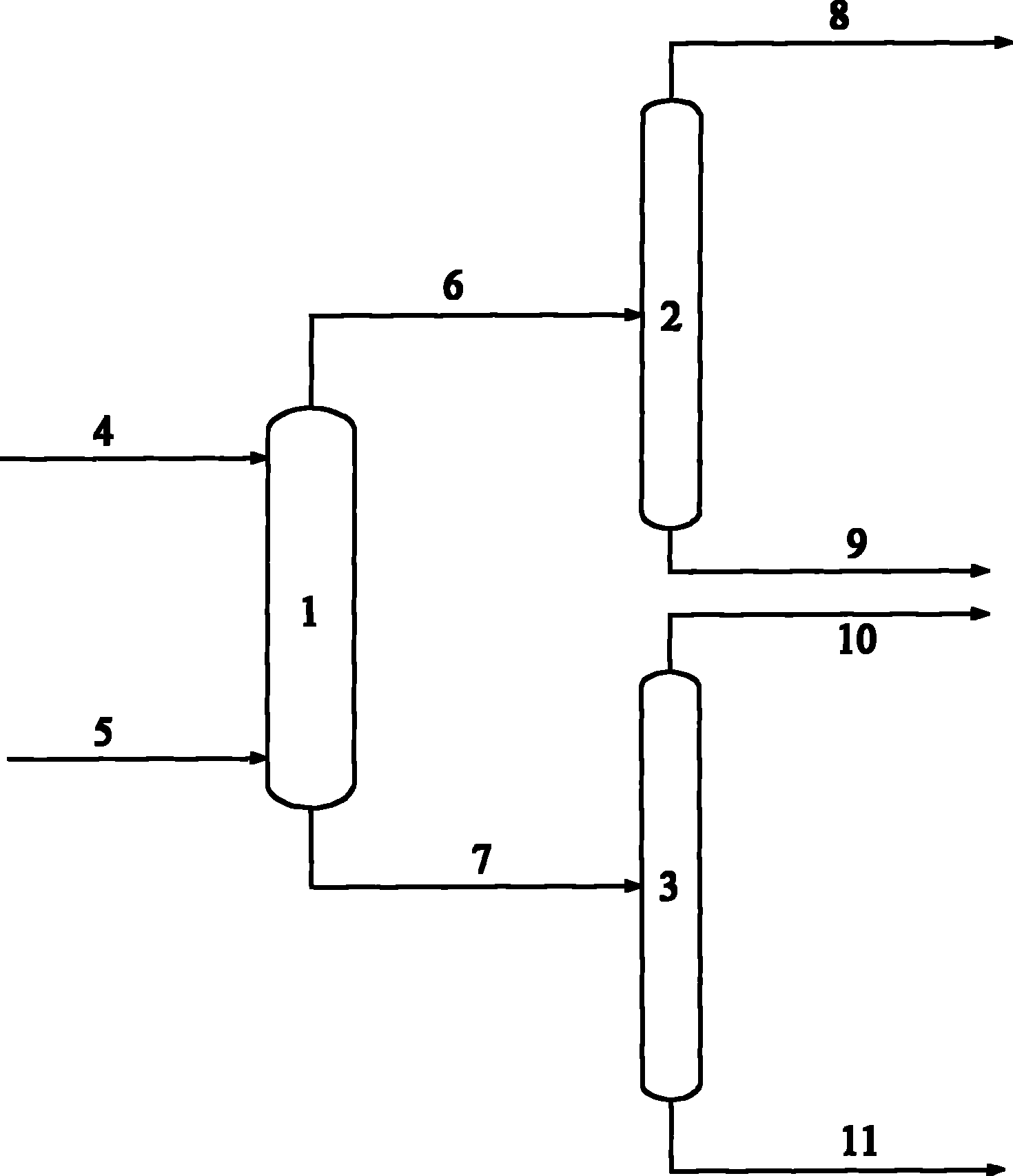

[0014] press figure 1 In the process shown, raw material 4 (90% ethylene glycol, 7% 1,2-propanediol, 3% 1,2-butanediol) and extractant 5 are calculated from the theoretical plates. The 15 extraction tower 1 enters the top and bottom, the raw material flow rate is 5 g / min, the extractant is toluene, the mass ratio of the extractant to the raw material is 0.5, the operating pressure is normal pressure, and the operating temperature is 40°C. The top of the tower is extracted Phase 6, the bottom of the tower obtains the raffinate phase 7; the extraction phase 6 enters the 15th plate of the extraction agent recovery tower 2 with a theoretical plate number of 20, the operating pressure is 10KPa, the reflux ratio is 0.5, and the top production control does not contain 1, 2-Butanediol, extractant 8 is recovered at the top of the tower, and a toluene solution rich in 1,2-butanediol 9 is obtained from the bottom of the tower; the raffinate phase 7 enters the second stage of the ethylene ...

Embodiment 2

[0016] press figure 1 In the process shown, the raw material 4 (the mass fraction of ethylene glycol is 60%, the mass fraction of 1,2-propanediol is 15%, the mass fraction of 1,4-butanediol is 25%) and the extractant 5 are calculated from the theoretical plates. The top and bottom of the extraction tower 1 of 40 enter, the raw material flow rate is 5 g / min, the extractant is o-xylene, the mass ratio of the extractant to the raw material is 2, the operating pressure is normal pressure, the operating temperature is 50 ℃, and the top of the tower The extraction phase 6 is obtained, and the raffinate phase 7 is obtained at the bottom of the tower; the extraction phase 6 enters the 15th plate of the extraction agent recovery tower 2 with a theoretical plate number of 40, the operating pressure is 50KPa, the reflux ratio is 0.2, and the top extraction control does not contain 1,4-butanediol, extracting agent 8 is recovered from the top of the tower, o-xylene solution 9 rich in 1,4-bu...

Embodiment 3

[0018] press figure 1 In the process shown, raw material 4 (50% ethylene glycol, 30% 1,3-propanediol 30%, and 20% 1,3-butanediol) and extractant 5 are calculated from theoretical plates. The top and bottom of the extraction tower 1 of 5 enter, the raw material flow rate is 5 g / min, the extractant is cumene, the mass ratio of the extractant to the raw material is 5, the operating pressure is normal pressure, and the operating temperature is 20℃. The extraction phase 6 is obtained, and the raffinate phase 7 is obtained at the bottom of the tower; the extraction phase 6 enters the sixth plate of the extraction agent recovery tower 2 with a theoretical plate number of 10, the operating pressure is 5KPa, the reflux ratio is 5, and the top production control does not contain 1,3-Butanediol, extractant 8 is recovered at the top of the tower, cumene solution 9 rich in 1,3-butanediol is obtained from the bottom of the tower; raffinate phase 7 enters the ethylene glycol refinement with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com