Extraction agent for extracting, rectifying and separating methanol and dimethyl carbonate azeotrope, application of extraction agent, and treatment method

A dimethyl carbonate, extractive distillation technology, applied in the field of organic matter separation, can solve the problems of large reflux, increased energy consumption of extraction agent regeneration, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

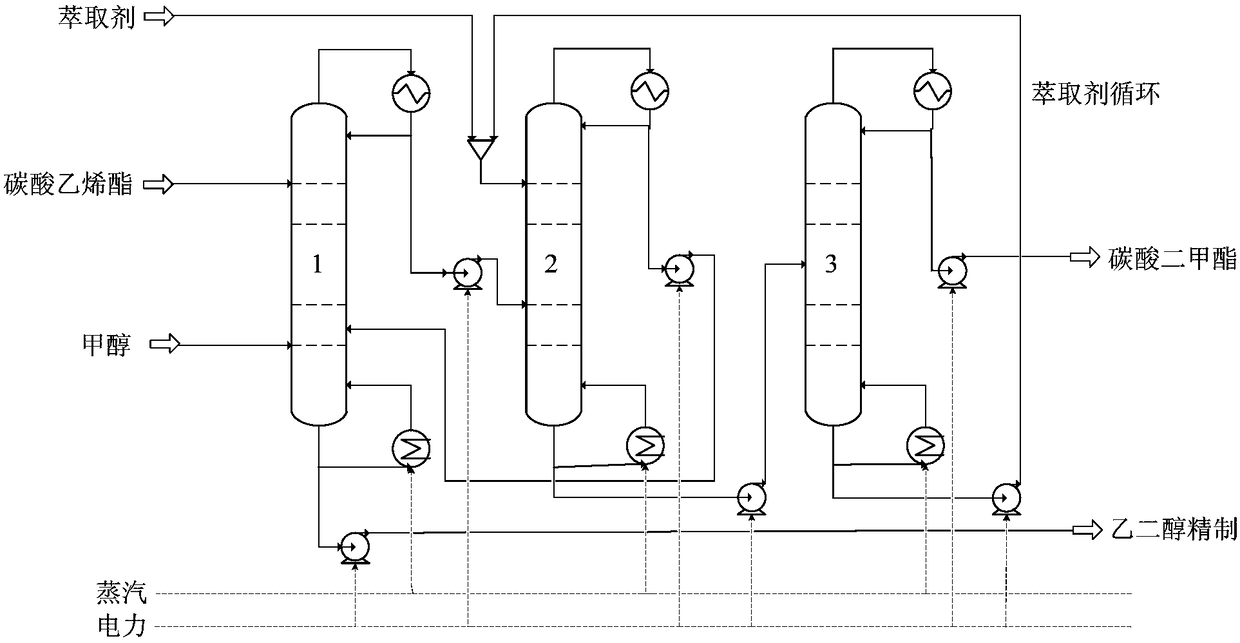

Method used

Image

Examples

Embodiment 1

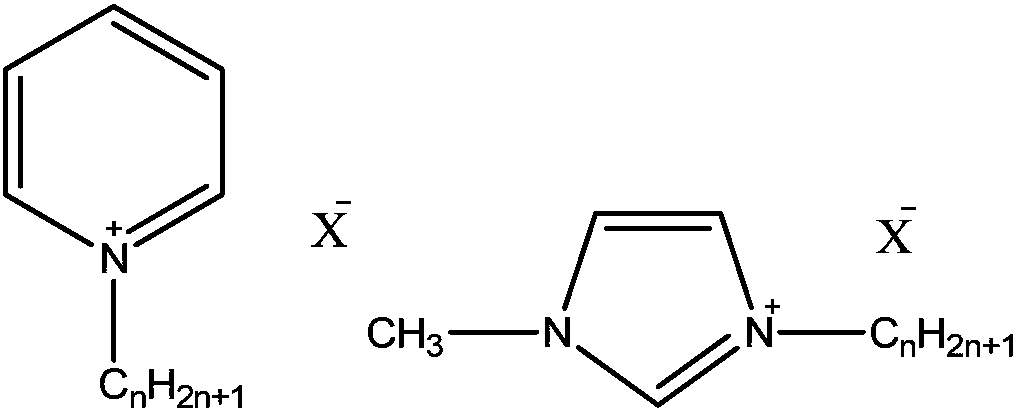

[0064] The present embodiment provides a kind of extraction agent that is used for extractive distillation separation methanol and dimethyl carbonate azeotrope, described extraction agent is made up of ethylene carbonate and ionic liquid, the molar ratio of described ethylene carbonate and ionic liquid is 6:1; wherein the cation of the ionic liquid is 1-butyl-3-methylimidazole (BMIM), and the anion is two trifluoromethanesulfonimide salts (Tf 2 N), so the ionic liquid is [BMIM]Tf 2 N.

Embodiment 2

[0066] This embodiment provides an extractant for extracting and rectifying the separation of methanol and dimethyl carbonate azeotrope, the extractant is composed of ethylene glycol and ionic liquid, and the molar ratio of ethylene glycol and ionic liquid is 12 : 1; wherein the cation of the ionic liquid is 1-ethyl-3-methylimidazole (EMIM), and the anion is diethyl phosphate (DEP), so the ionic liquid is [EMIM] DEP.

Embodiment 3

[0068] The present embodiment provides a kind of extraction agent that is used for extractive distillation separation methanol and dimethyl carbonate azeotrope, described extraction agent is made up of ethylene carbonate and ionic liquid, the molar ratio of described ethylene carbonate and ionic liquid 1:1; wherein the cation of the ionic liquid is N-ethylpyridine, and the anion is hexafluorophosphate (PF 6 ), so the ionic liquid is N-ethylpyridine hexafluorophosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com