Patents

Literature

254 results about "Diethyl phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dimethylphosphate, also known as dimethyl hydrogen phosphate, is classified as a member of the Dialkyl phosphates. Dialkyl phosphates are organic compounds containing a phosphate group that is linked to exactly two alkyl chain.

Low-odour polypropylene composite

The invention relates to a low-odour polypropylene compound, the compound comprises (by weight ratio) polypropylene 55-95, talcum powder 0-40, fatty acid ester compound 0.5-3, nano zinc oxide 0.5-3, nano titanium oxide 0.5-3, heat stabilizer DSTP 0.1-1.0, heat stabilizer 3114 0.1-1.0, heat stabilizer 618 0.1-0.5, wherein the fatty acid ester compound being C25-C45 long-chain fatty acid ester, the heat stabilizer DSTP being octadecyl thiodipropionate, the heat stabilizer 3114 being 3,obtaining 5-ditert-butyl-4-hydroxy benzylphosphonate diethylate, the heat stabilizer being dioctadecyl pentaerythritol diphosphite.

Owner:SHANGHAI PRET COMPOSITES +1

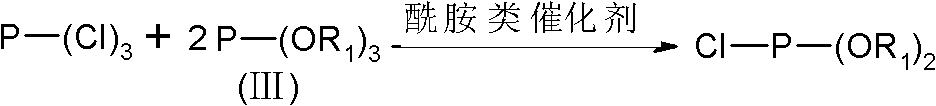

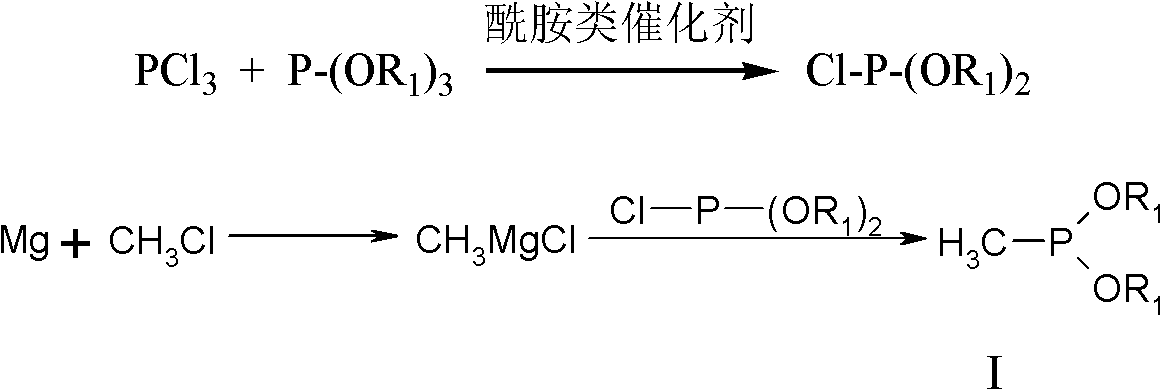

Improved synthesis method for glufosinate and analogue thereof

InactiveCN102399240AReduce generationReduce processing costsGroup 5/15 element organic compoundsDiethyl phosphateHydrogen halide

The invention discloses a comprehensive method for synthesizing glufosinate and analogue thereof by using phosphorus trichloride, triethyl phosphate and chloromethane as initiative raw materials. The method comprises the following steps of: performing Grignard, disproportionation and coupling; introducing a proper amount of hydrogen halide; and synthesizing to obtain two intermediates, namely methyl diethyl phosphate (intermediate I) and methyl phosphinate (intermediate II), wherein the two intermediates can synthesize the glufosinate and the analogue thereof. By the method, the glufosinate and the analogue thereof are synthesized by completely utilizing the methyl diethyl phosphate and the methyl phosphinate synthesized by a Grignard route; yield is increased; production cost is reduced; and three wastes are reduced.

Owner:JIANGSU YOUTH CHEM +1

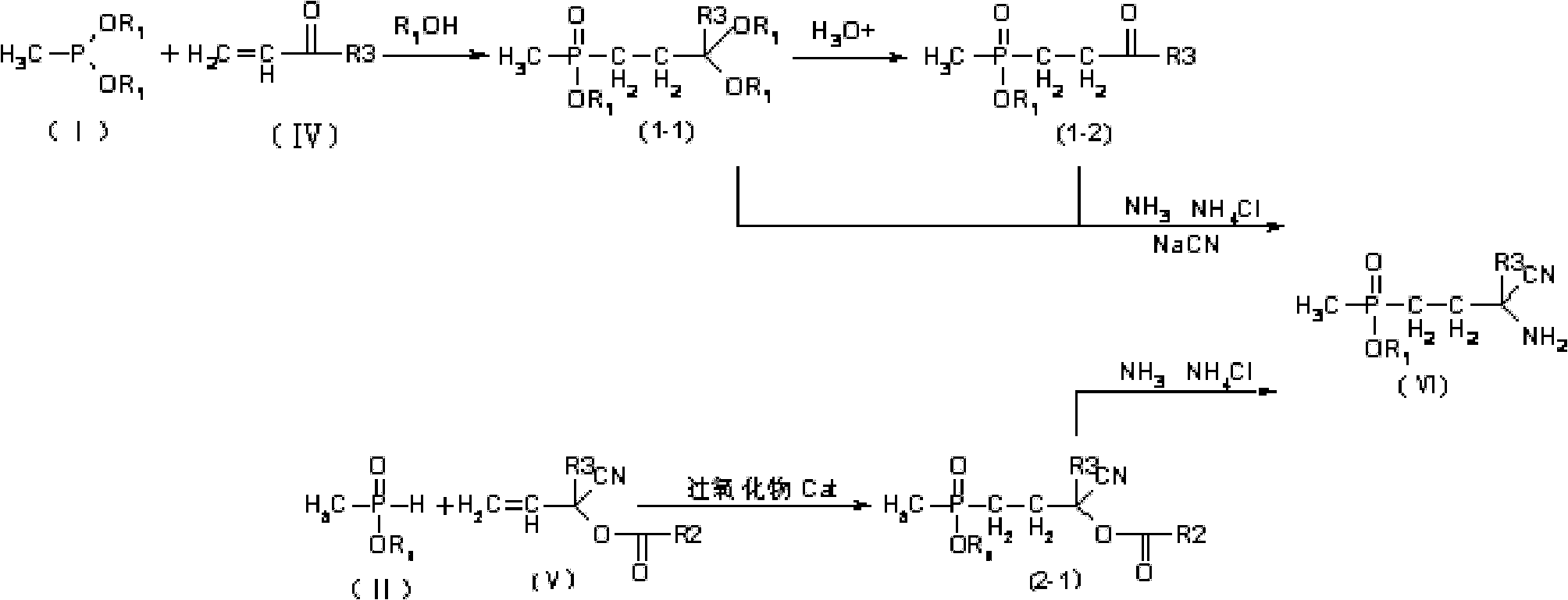

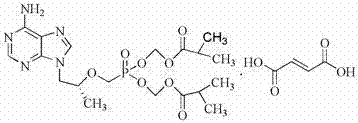

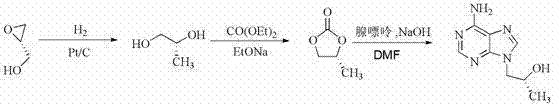

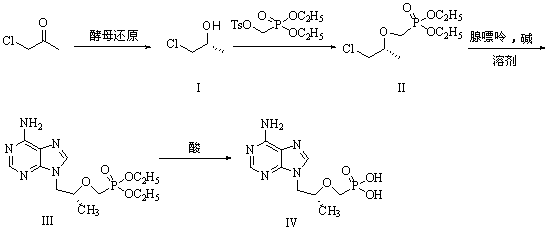

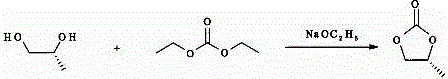

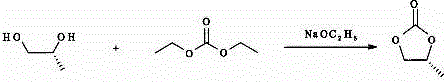

Synthetic process of tenofovir

InactiveCN102295660AHigh yieldEasy post-processingGroup 5/15 element organic compoundsDiethyl phosphatePurine

The invention relates to a synthesis technique of tenofovir, and relates to the field of medicinal chemistry. Using natural (R)-lactate as the starting material, chiral R-1,2-propanediol is obtained through reduction, and then reacted with diethyl carbonate under the action of alkali to obtain the key reaction intermediate R-propylene carbonate ester. Use adenine and R-propylene carbonate to prepare R-9-(2-hydroxypropyl)adenine; Gained R-9-(2-hydroxypropyl)adenine and diethyl p-toluenesulfonyloxyphosphate Under the catalysis of magnesium tert-butoxide, the condensation reaction is carried out to obtain R-9[(diethylphosphorylmethoxy)propyl]purine; the obtained R-9[2-(diethylphosphorylmethoxy) Propyl]purine is hydrolyzed to obtain Tenofovir. The process has short reaction steps, short required reaction time, high quality yield and good product quality, and is suitable for industrialized production.

Owner:CHANGZHOU UNIV

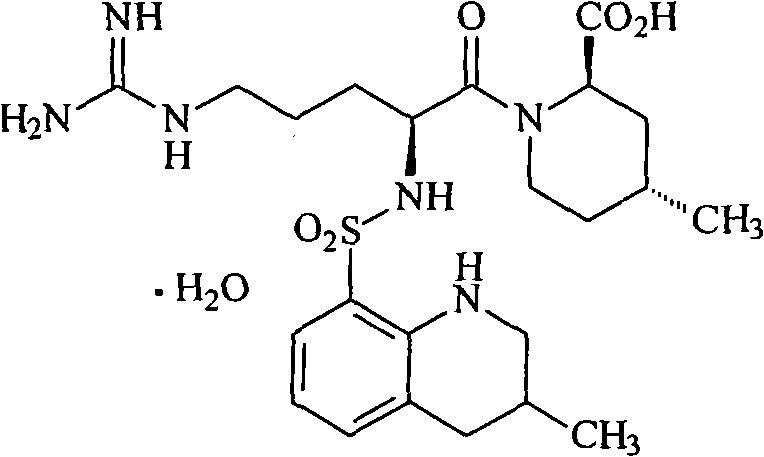

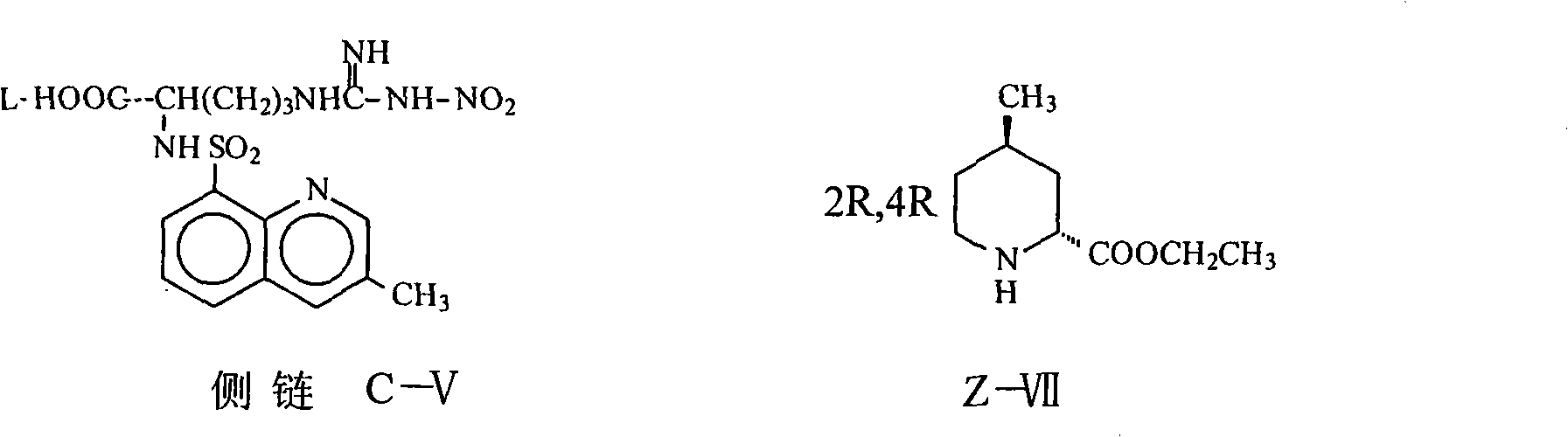

Argatroban and preparation thereof

InactiveCN101348481AThe synthesis process is simpleEasy to operateOrganic chemistryDiethyl phosphateOrganic solvent

The invention relates to a method for synthesizing argatroban. The method comprises the following steps that nitryl L-arginie and quinoline sulfonchloride are condensed, and undergo amidation with piperidine ethyl formate, followed by hydrolysis and hydrogenation to obtain argatroban; the amidation is to make carboxylate (c-v) and (2R, 4R) 4MPE (Z-VII) react in an organic solvent in the presence of condensing agent, or the presence of both condensing agent and dehydration promoter, in which the molecular ratio of carboxylate (c-v): (2R, 4R) 4MPE (Z-VII): condensing agent: dehydration promoter is 1: 0.8-1.2: 0.8-1.2: 0-1.2. The condensing agent adopted by the invention is diphenylphosphoryl azide, diethylthiophosphoryl, chlorophosphoric acid diethyl or bromophosphoric acid diethyl. The invention has simplified operation, lowered cost, decreased pollution, increased yielding rate, and is suitable for large-scale industrialized production of argatroban.

Owner:TIANJIN TAIPU PHARMA SCI & TECH DEV +1

Conjugate polyether, polyurethane raw material composition, polyurethane foams and applications thereof

InactiveCN102030977ALow densityLight in massPolyurea/polyurethane coatingsDiethyl phosphateThermal insulation

The invention provides conjugate polyether, comprising 6-8 parts of polyether polyol EP-330N, 2-4 parts of polyether polyol SU-450L, 0.06-0.15 parts of non-hydrolytic surface active agent, 1.5-2 parts of water, 0.8-1.5 parts of nonyl phenol polyoxyethylene ether NP-10, 0.03-0.05 part of foaming catalyst PC52, 0.3-0.5 part of foaming catalyst NE300 and 1.3-2 parts of ethyl diethyl phosphate. The invention further provides a polyurethane raw material composition, polyurethane foams and applications thereof. Compared with the conventional polyurethane foams, the polyurethane foams in the invention have low density, low mass, proper aperture ratio, good sound-proofing effect, and good heat insulating effect, and compared with the polyurethane foams with middle and high density, the cost of the polyurethane foams in the invention is lower. While the polyurethane foams in the invention have low density, the polyurethane foams can reach the application standards of thermal insulation materials, sound-proofing materials, sandwich panels for construction, spraying materials for ceilings of automobiles or filling materials and the like. The conjugate polyether is a total-moisture foaming system, has no damage to ozone layer and has the advantage of environmental protection.

Owner:SHANGHAI DONGDA POLYURETHANE

Fiber glass enhanced polypropylene material with high ageing ressistance of anti heat and oxygen

InactiveCN1696187AExcellent thermal and oxidative aging resistanceImproved resistance to thermo-oxidative agingDiethyl phosphatePolypropylene composites

A glasls fibre reinforced polypropene material with high refractory, antioxidizing and antiageing performance is prepared proportionally from polypropene, maleic anhydride grafted polypepen, glass fibres, stabilizer DSTP, stabilizer '3114' and stabilizer '618'.

Owner:SHANGHAI PRET COMPOSITES

Modified high-flame-retardation weather-resistant polyurethane cable material and preparing method thereof

ActiveCN103467971AImprove flame retardant performanceGood weather resistancePlastic/resin/waxes insulatorsPolymer sciencePtru catalyst

The invention relates to the technical field of cable materials, in particular to a modified high-flame-retardation weather-resistant polyurethane cable material and a preparing method thereof. The modified high-flame-retardation weather-resistant polyurethane cable material comprises modified polyurethane elastomer, ethylene-vinyl ethylene copolymer, nitrile rubber, chlorinated polyethylene, antimony trioxide, calcium chloride, ethyl phosphoric acid diethyl ester, a lubricating agent, a dispersing agent, an antioxidant, a rat-proof master batch, a termite-proof master batch and an ultraviolet light absorber. The modified polyurethane elastomer is formed by anionic polyurethane of lateral chain band sulfonic group or / and carboxylic group, tetra-n-butyl titanate, organic solvent, deionized water and a catalyst. According to the preparing method of the modified high-flame-retardation weather-resistant polyurethane cable material, as the modified polyurethane elastomer is used as the main raw material, the modified polyurethane cable material prepared by the method has high flame retardation and weather resistance.

Owner:GUANGDONG ZHONGDE CABLE

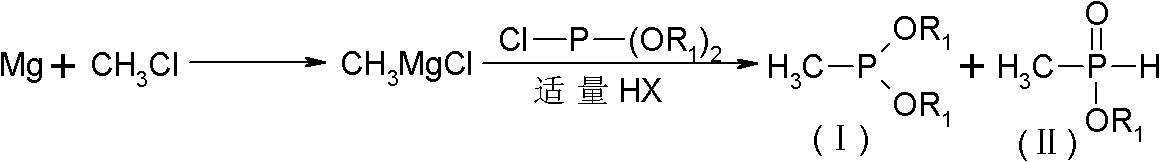

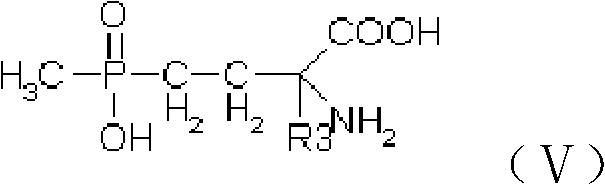

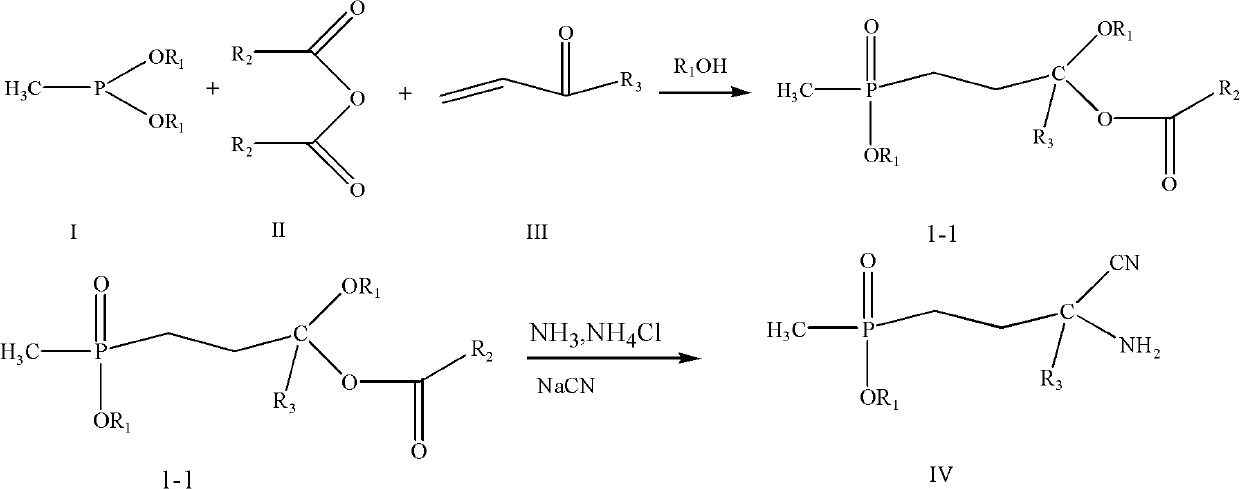

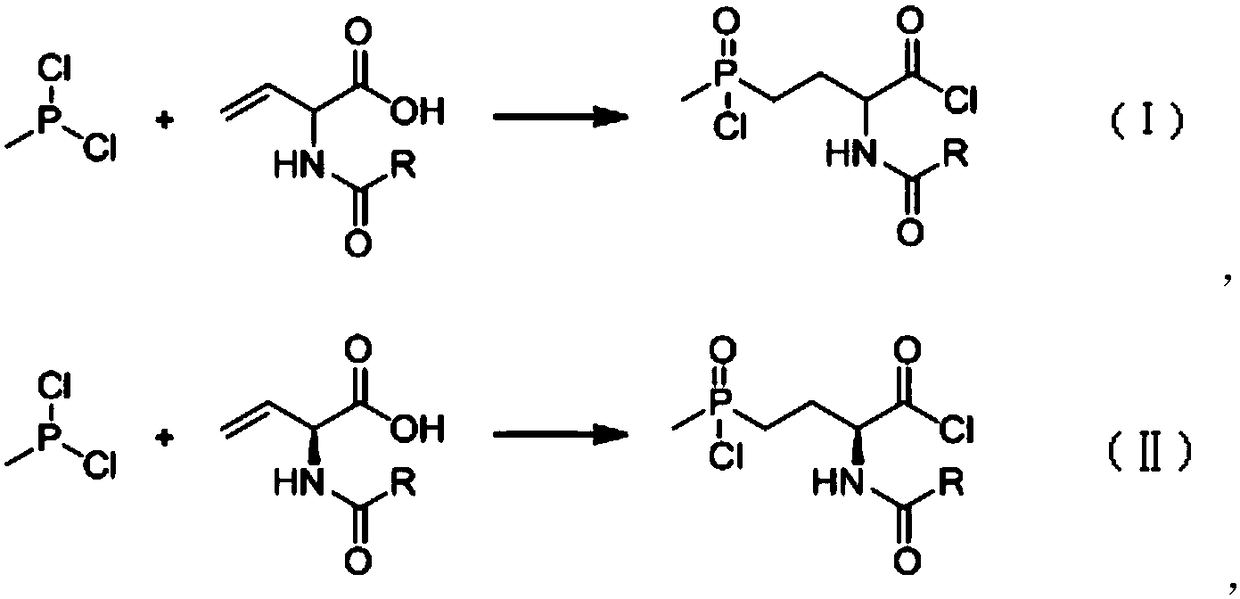

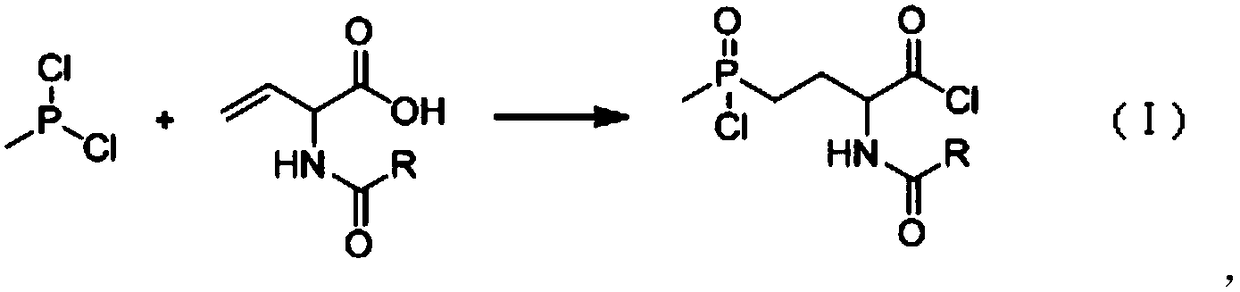

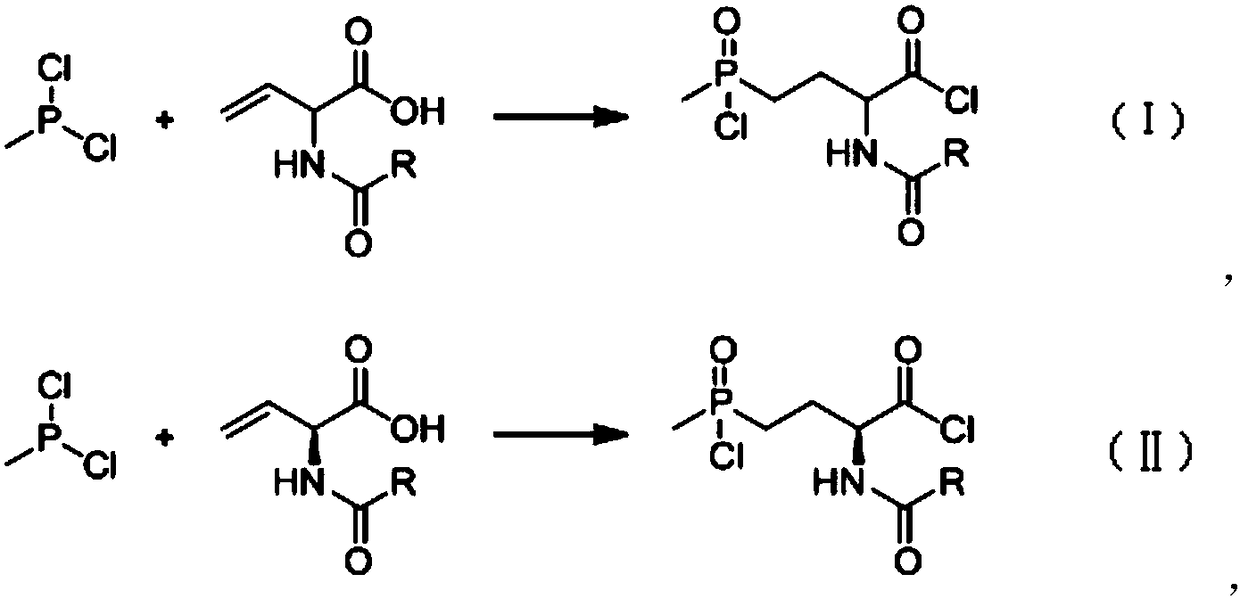

Synthesis method for glufosinate and analogue thereof

InactiveCN102399239AReduce generationReduce processing costsGroup 5/15 element organic compoundsDiethyl phosphateSynthesis methods

The invention provides a synthesis method for glufosinate shown as a formula (V) and an analogue thereof. The method comprises the following steps of: preparing an intermediate such as methyl diethyl phosphate by Grignard, disproportionation and coupling and with phosphorus trichloride, triethyl phosphate and chloromethane as initiative raw materials; condensing the methyl diethyl phosphate, anhydride and acrolein substances; performing Strecker reaction and hydrolysis and thus obtaining the glufosinate and the analogue thereof. In the synthesis method, the reaction condition is mild; safety is high; and yield is obviously increased.

Owner:JIANGSU YOUTH CHEM +1

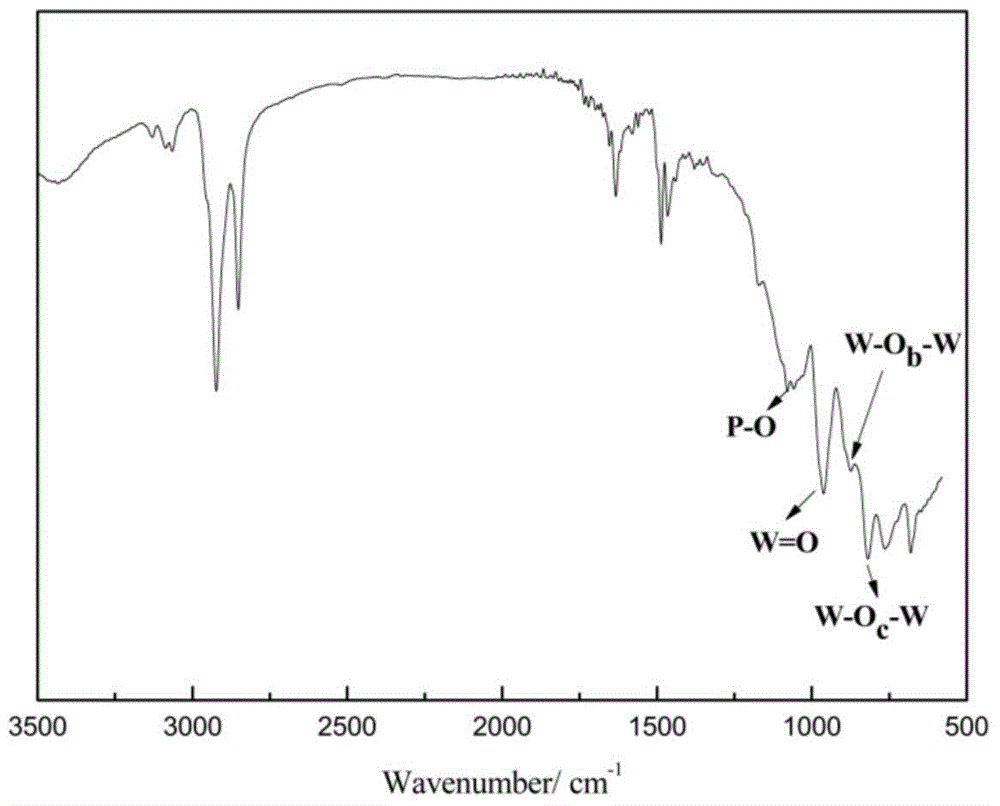

Castor oil-based flame retardation polyol composition, and preparation method and applications thereof

ActiveCN103319675AImprove flame retardant performanceGood emulsifying effectGroup 5/15 element organic compoundsDiethyl phosphatePolyol

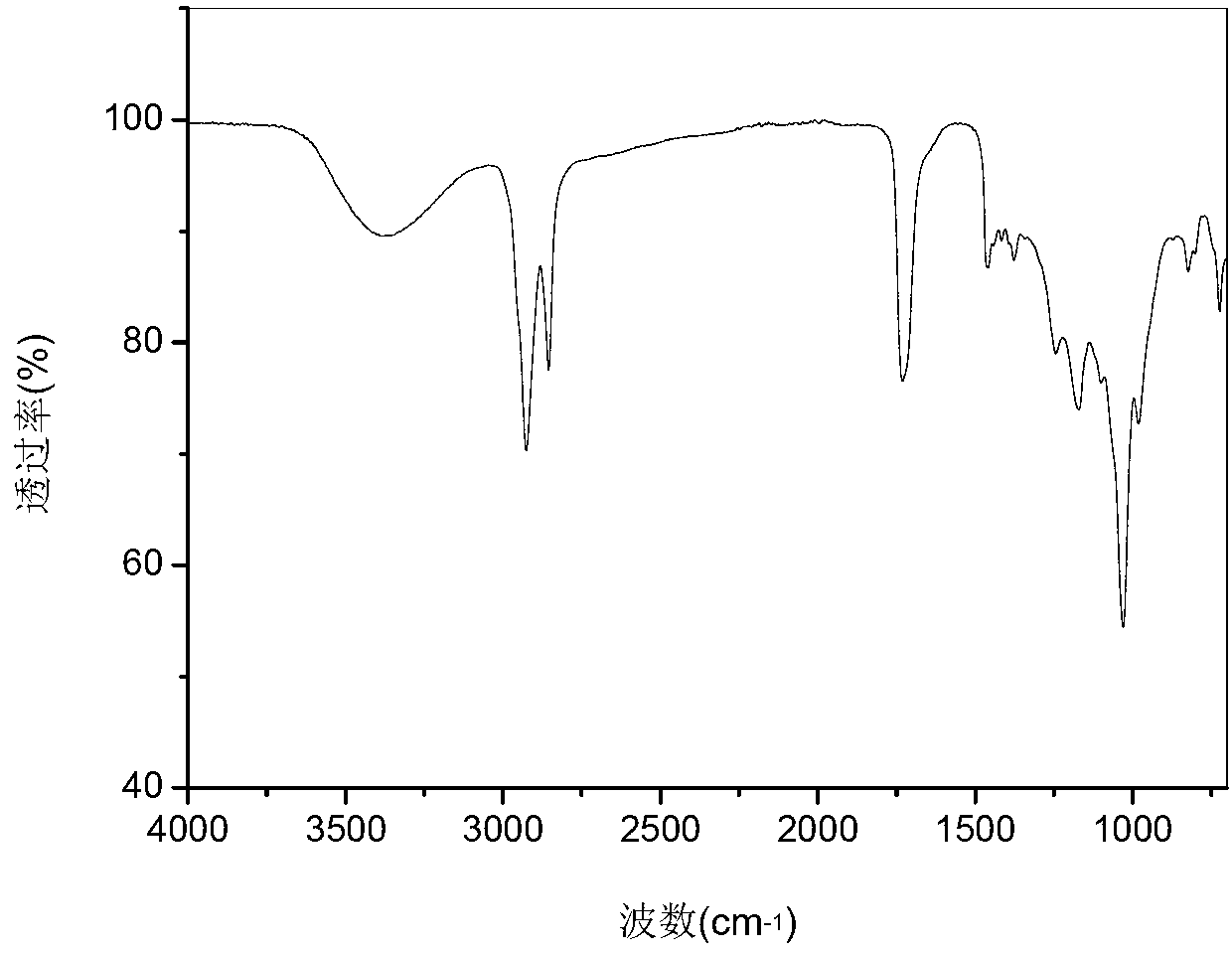

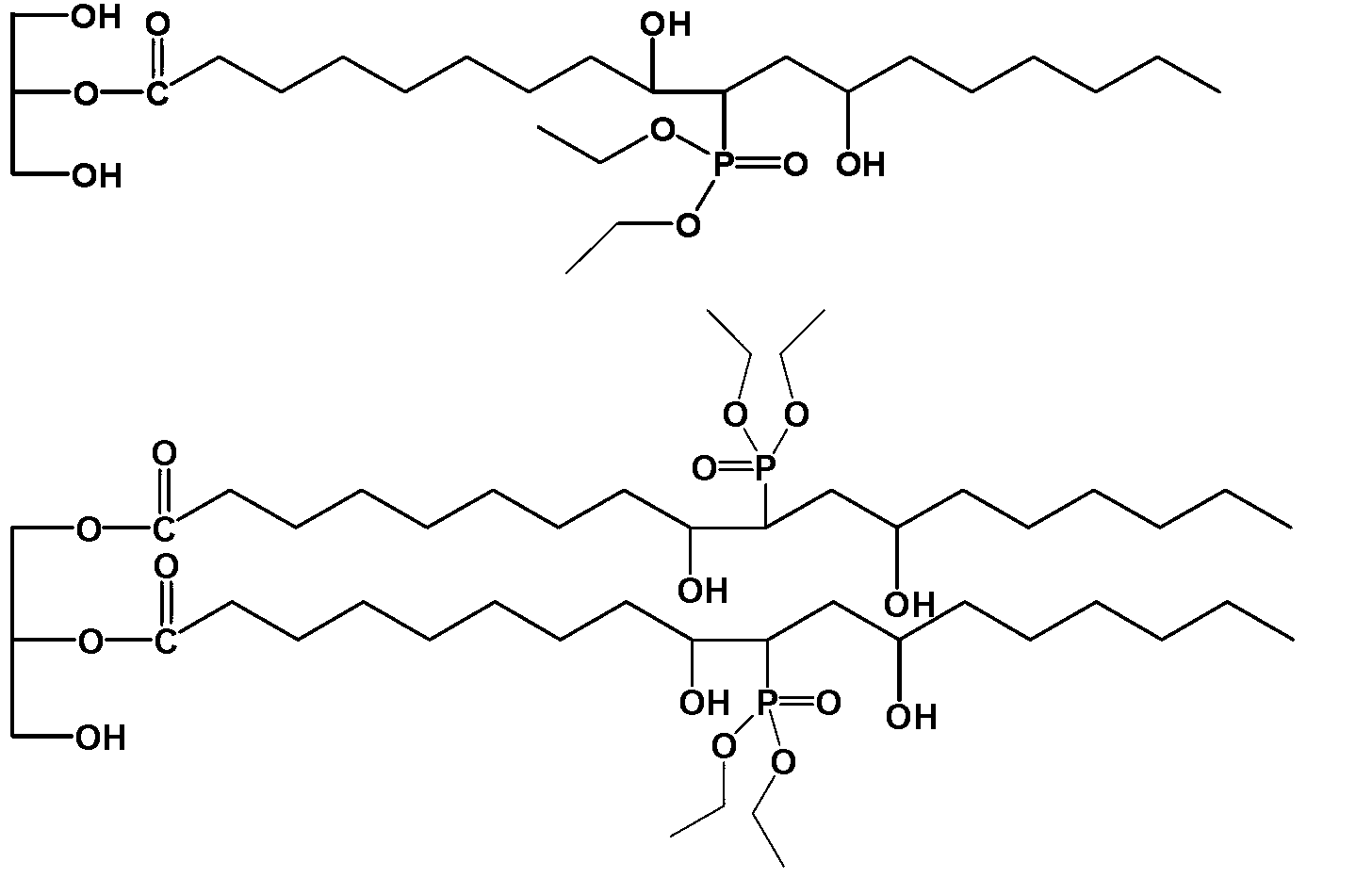

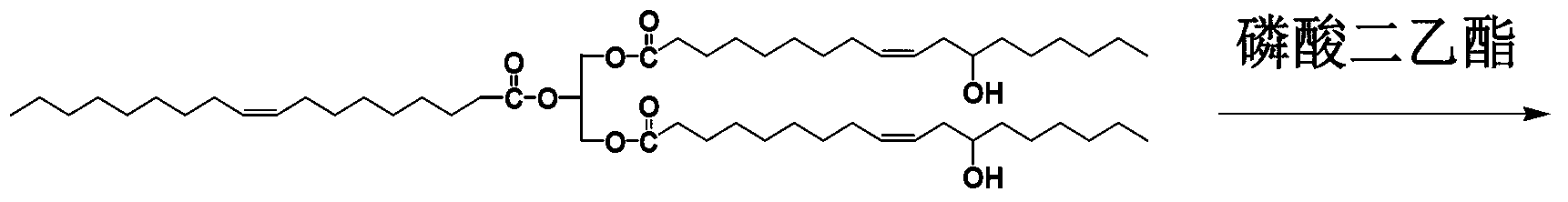

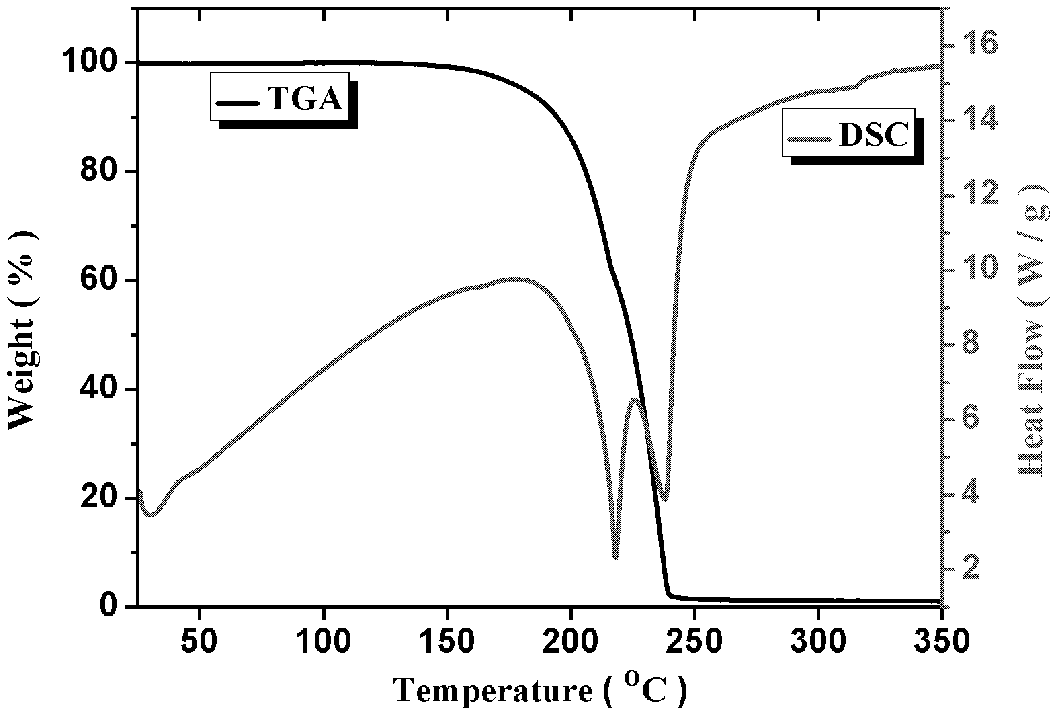

The invention provides a castor oil-based flame retardation polyol composition, and a preparation method and applications thereof. A composition composed of two followed polyols by reacting diethyl phosphate with oxidized castor oil, wherein a mol ration of the two compositions is 2.5:1, and a structural formula is characterized in that: a structure modifying method is used in the castor oil-based flame retardation polyols, diethyl phosphate containing the flame retardation element P into a castor oil structure for synthesizing a flame retardation type hard polyurethane foam, which has higher flame resistance, wherein an oxygen index can reach 25-27%. The castor oil-based flame retardation polyol composition has wide application prospects on the fields of construction and insulation, and some special occasions.

Owner:山东天洋新材料有限公司

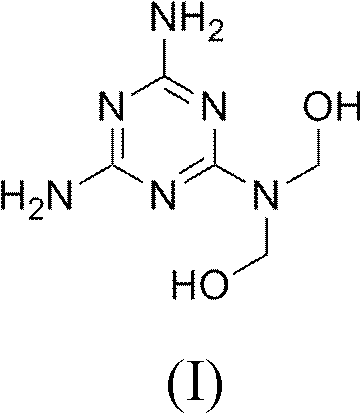

Efficient neutral formaldehyde capture agent and preparation method

ActiveCN102671336AStable in natureNo secondary pollutionChemical protectionActivated carbonDiethyl phosphate

The invention provides efficient neutral formaldehyde capture agent, which consists of deionized water, melamine, formalin solution, methyl salicylate, isoamyl alcohol, polysorbate, diethyl phosphate, sodium dodecyl benzene sulfonate and activated carbon. The invention further provides a method for preparing the efficient neutral formaldehyde capture agent. The efficient neutral formaldehyde capture agent can rapidly react with formaldehyde to form innocuous and unpoisonous colorless transparent liquid with excellent stability, and can not produce secondary pollution for environment at the same time. The efficient neutral formaldehyde capture agent is low in cost of raw materials, simple and easy in production process, and simple and convenient to use.

Owner:WENZHOU WINTOP BIOLOGICAL TECH

Polyurethane sponge and processing method thereof

InactiveCN106957408AWith flame retardant functionGood flame retardant functionDiethyl phosphateHalogen

The invention discloses polyurethane sponge and a processing method thereof. Polyether polyol with a flame retardant function is directly added to a material A, and a diethyl ethylphosphonate fire retardant is selectively added to a material B, so that the polyurethane sponge does not contain halogen, is low in viscosity and very stable in a two-component system of the material A and the material B, and a product is endowed with good fireproof and flame-retardant properties while the process is simple. The product is endowed with good mildew-proof and antibacterial effects through an antibacterial agent and a mildew preventive added to the material B; and through addition of nanoscale inorganic material tourmaline powder, the product has the function of lastingly emitting anions. The production technology and the formula are relatively simple on the premise that all performance indexes reach the expected requirements; the production process and the formula are relatively simple; the processes such as heating or refrigerating do not need to be specifically carried out in the production process and foaming and curing in a natural state can be carried out; the production success rate of sample post-detection is very high; the produced polyurethane sponge has obvious fireproof and flame-retardant functions, antibacterial and anti-mildew functions and continuous anion release function, and is beneficial to improvement of the competitiveness of the product.

Owner:东莞恒生高分子科技有限公司

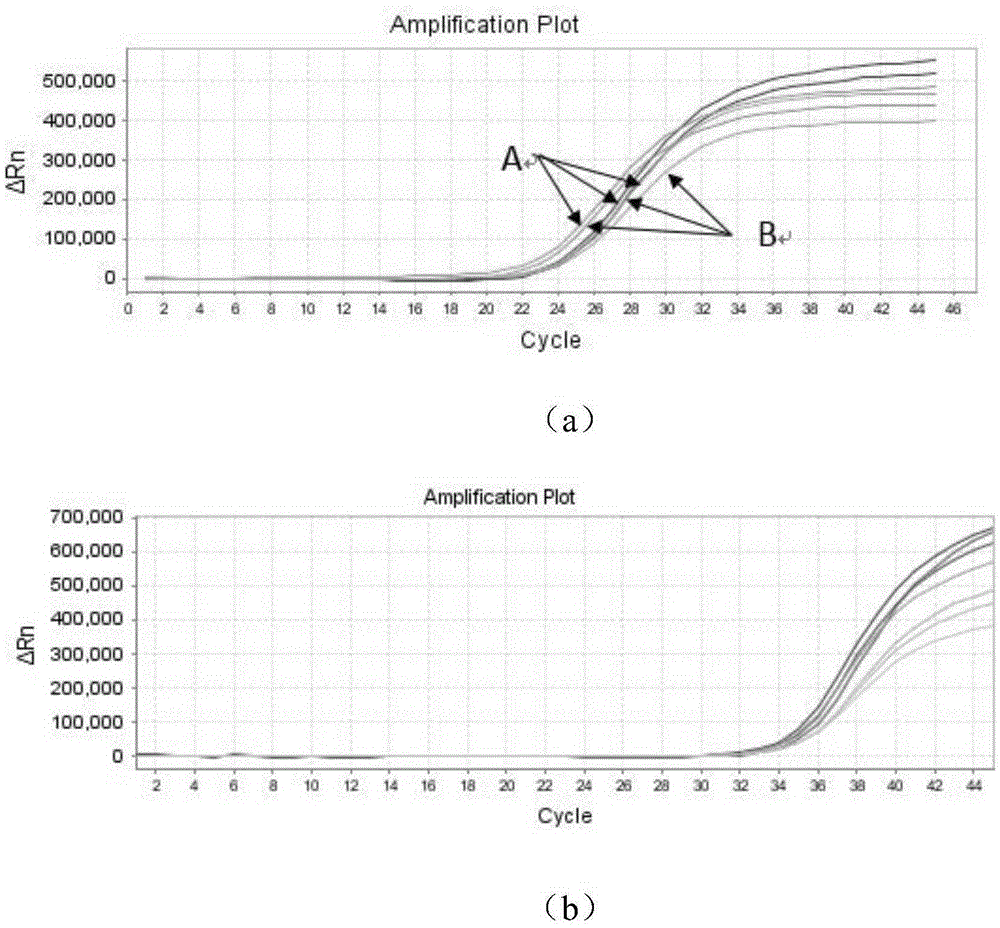

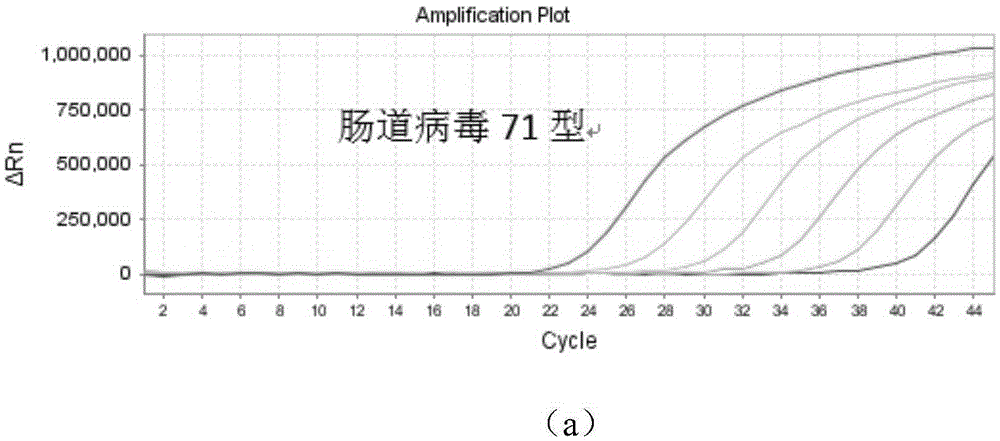

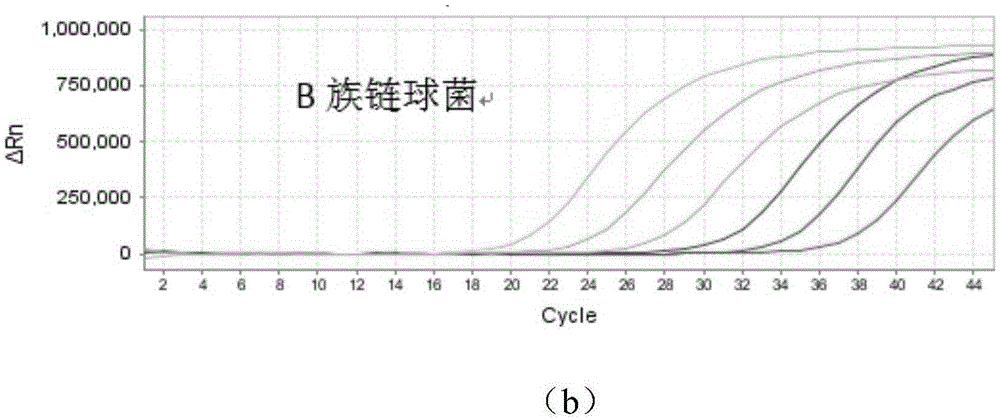

Freeze-drying protective agent applied to nucleic acid amplification system

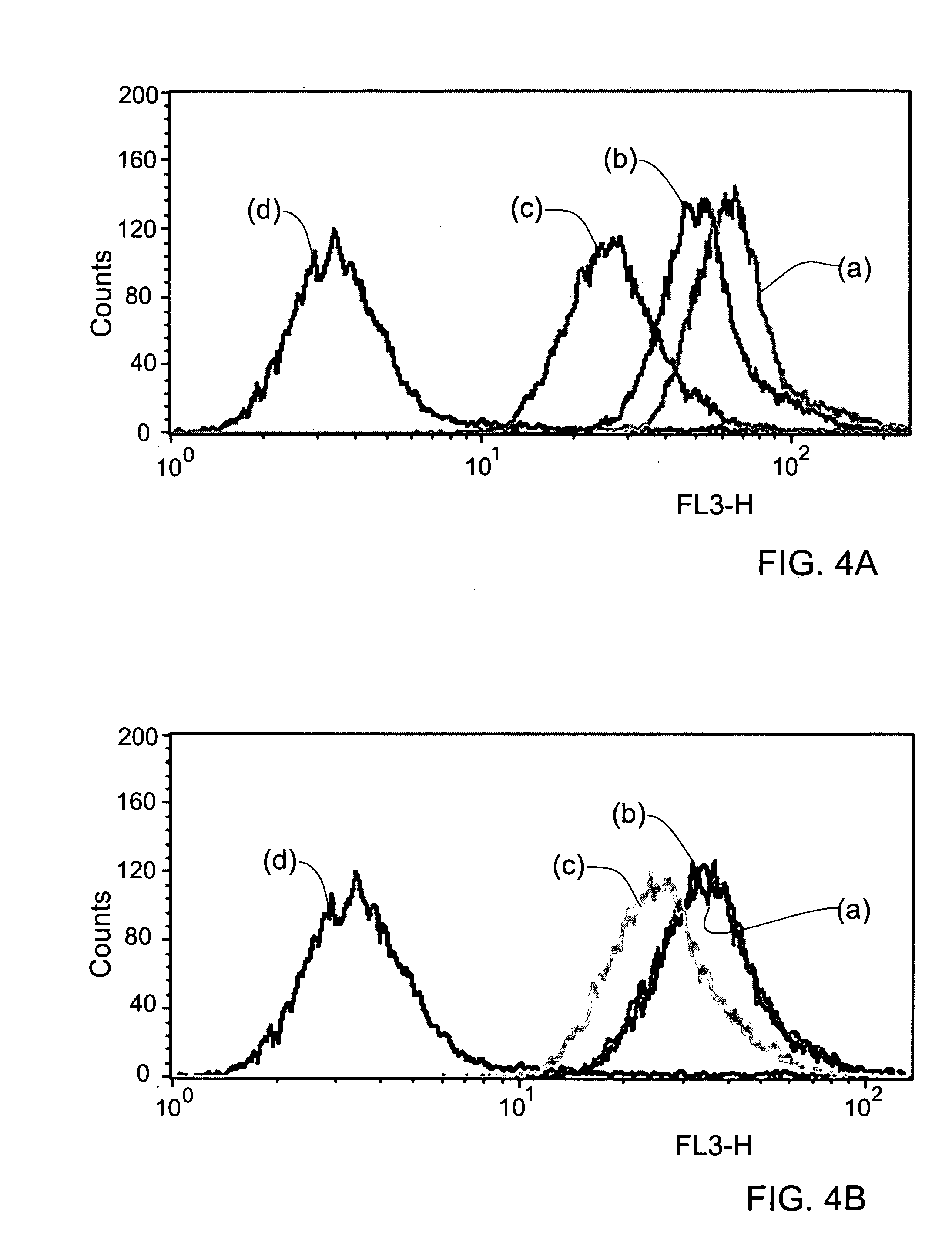

InactiveCN105349529AHigh sensitivityAchieving Freeze DryingMicrobiological testing/measurementDNA preparationConcentration ratioFluorescence

The invention discloses a freeze-drying protective agent applied to a nucleic acid amplification system. The freeze-drying protective agent is prepared from one or more of trehalose and water treated through diethylpyrocarbonate. The freeze-drying protective agent applied to the nucleic acid amplification system further comprises cane sugar and / or lactose. A preparing method of the freeze-drying protective agent applied to the nucleic acid amplification system includes the following steps that the components are mixed accordingly the use concentration ratio to be even, and the freeze-drying protective agent is obtained. By means of the freeze-drying protective agent, the fluorescence quantitative nucleic acid diagnostic reagent system of RNA / DNA can be detected in a freeze-drying mode, freeze drying can be achieved, the detecting aim can be achieved only through one-step hydration, and the normal-temperature transportation aim and the normal-temperature storage aim which can not be achieved through a nucleic acid diagnostic reagent at the present stage can be achieved.

Owner:江苏正大天创生物工程有限公司

Concise glufosinate ammonium synthesizing method

ActiveCN108727427ASolve application problemsReduce labor intensityOrganic chemistry methodsGroup 5/15 element organic compoundsDiethyl phosphateGlufosinate-ammonium

The invention discloses a concise glufosinate ammonium synthesizing method and aims at solving the problem that an existing method needs to use toxic sodium cyanide to synthesize glufosinate ammonium.Being different from an existing method of using diethyl methyl phosphite to prepare the glufosinate ammonium, the concise glufosinate ammonium synthesizing method disclosed by the invention can effectively avoid using toxic chemicals; thus, the problem of using the sodium cyanide is solved. By means of the synthesizing method, use of toxic chemicals is reduced, operation steps are simplified, equipment investment is reduced, the amount of three wastes is reduced, a requirement for clean production is met, and more environmental friendliness is achieved. Meanwhile, the synthesizing method disclosed by the invention not only can synthesize racemate glufosinate ammonium, but also can synthesize optical pure-chirality glufosinate ammonium, so that the synthesizing method has obvious progressive significance. According to the synthesizing method disclosed by the invention, technique connection is orderly, no solid material is used, convenience in operation is achieved, a technological process is simple, automatic production is achieved, labor intensity of workers is greatly reduced, and a production efficiency is improved; thus, the synthesizing method has a better application prospect and is worth of popularizing and applying in a large scale.

Owner:LIER CHEM CO LTD

Antibacterial and mothproof silk composite fibers and manufacturing method thereof

InactiveCN104233505AIncrease elasticityHigh strengthConjugated artificial filamentsArtifical filament manufactureDiethyl phosphateMoisture

The invention discloses antibacterial and mothproof silk composite fibers. The antibacterial and mothproof silk composite fibers are characterized by comprising the following materials in parts by weight: 17-20 parts of mulberry silk, 10-13 parts of tencel, 12-15 parts of chicken feather down fibers, 4-7 parts of acrylic fibers, 6-9 parts of aloe fiber, 7-10 parts of kawo kawo fiber, 1.2-3.2 parts of chitin fibers, 2-3 parts of epoxidized soybean oil, 0.3-0.5 part of calcium carbonate, 0.1-0.3 part of sodium sec-alkyl sulfonate, 1-3 parts of mica powder, 100-110 parts of 1-butyl-3-methylimidazole dibutyl phosphate, 120-125 parts of 1-ethyl-3-methylimidazole diethyl phosphate, 1.2-3.2 parts of folium cortex eucommiae, 1-3 parts of rhizoma corydalis, 2-4 parts of radix rubiae, 2-5 parts of additives and a proper amount of water. Due to addition of the multiple plant fibers and Chinese herbal medicines, the silk composite fibers have good antibacterial, mothproof, breathable, moisture-absorbing and heat-preserving functions, and the prepared silk composite fibers are also high in elasticity, strength and washing durability.

Owner:TONGCHENG SHUANGLONG SILK

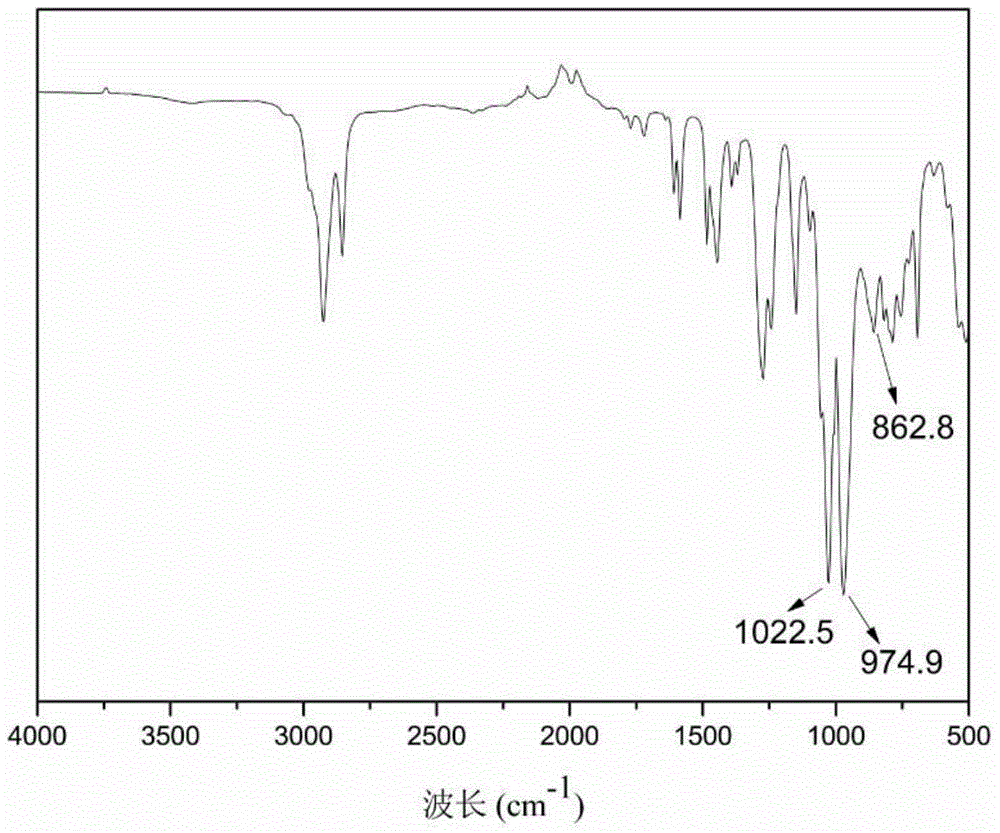

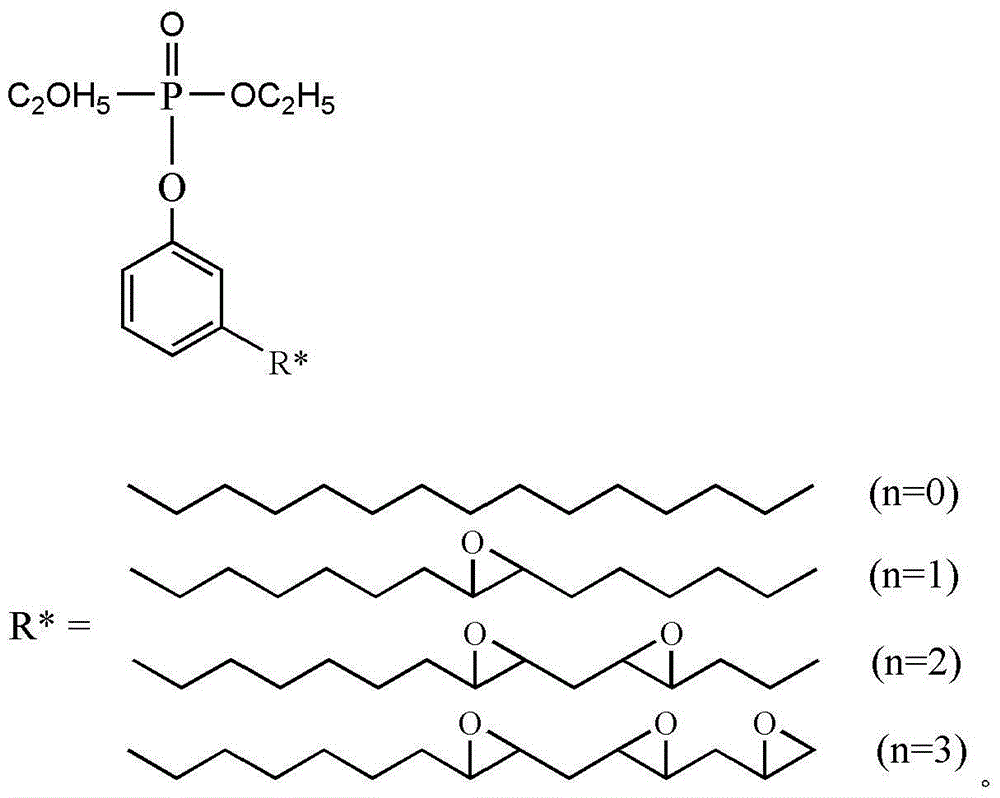

Cardanol-based phosphatefire-retardant plasticizer and preparation method thereof

InactiveCN104610571AImprove flame retardant performanceGood thermal stabilityGroup 5/15 element organic compoundsDiethyl phosphatePhosphoric acid

The invention discloses a cardanol-based phosphatefire-retardant plasticizer and a preparation method thereof. The preparation method comprises the following steps: with cardanol and diethyl chlorophosphate as main raw materials, carrying out substitution reaction in the presence of an acid binding agent to synthesize cardanol-based diethyl phosphate; further with cardanol-based phosphoric acid as a raw material, in the presence of a peracetic phosphotungstate phase transfer catalyst, adding a peracetic source dropwise for epoxidation to prepare crude epoxy cardanol-based diethyl phosphate, and filtering, washing and dehydration to obtain a finished epoxy cardanol-based glycidyl ether plasticizer. According to the cardanol-based phosphatefire-retardant plasticizer and the preparation method disclosed by the invention, as the cardanol is taken as the raw material, the cost is low, and the source is wide; the preparation process is simple, the energy consumption is low; the product is low in toxicity, is environmentally friendly, is capable of endowing a polymer substrate with excellent flame retardancy and flexibility and has good application prospect.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

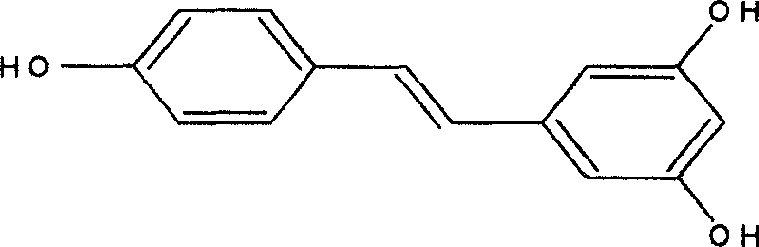

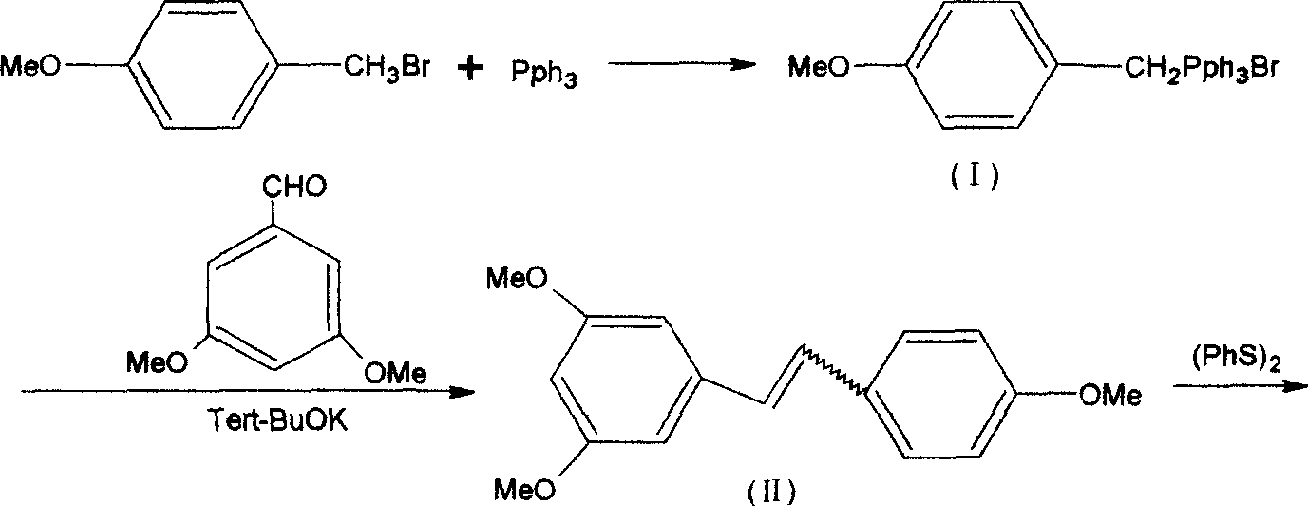

Method for synthesizing veratric alcohol

InactiveCN1907931AThe synthesis process is simpleThe synthesis process is easier to industrializeOrganic chemistryOrganic compound preparationDiethyl phosphateTriethylphosphite

The invention discloses a synthesis method for resveratrol, including (1) discharging hydrogen bromide gas to benzene solution of p-methoxy benzyl alcohol to obtain p-methoxy benzyl bromide, (2) carrying out reaction of p-benzyl bromide with triethyl phosphate to obtain diethyl p-methoxy benzyl phosphate, (3) carrying out reaction of diethyl p-methoxy benzyl phosphate with sodium amide and 3,5-dimethoxybenzaldehyde to obtain (E)-3, 4', 5-trimethoxystilbene, and (4) carrying out reaction of (E)-3, 4', 5- trimethoxystilbene with aluminum iodide to obtain the final product. The invention has the advantages of raw materials easy to get, lowered cost, mild reaction conditions, simplified operation, and enhanced yield.

Owner:JINAN UNIVERSITY

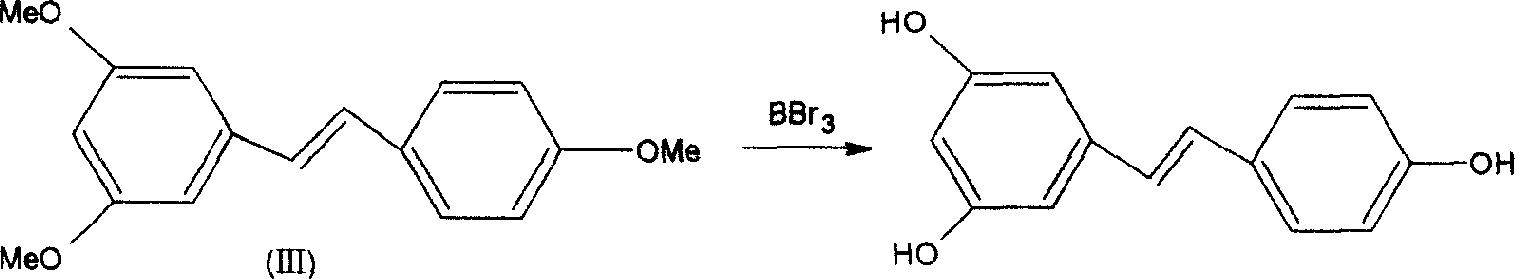

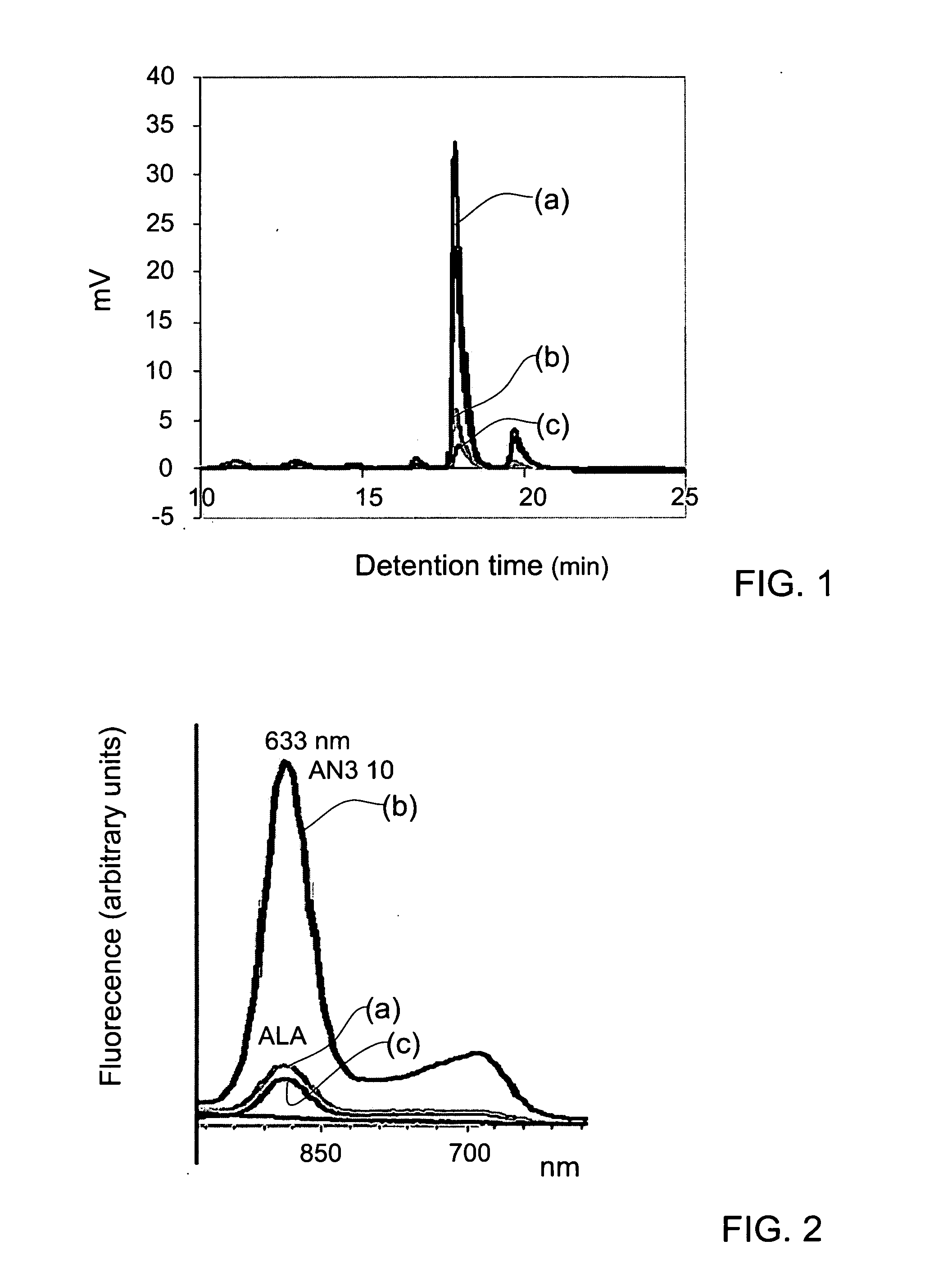

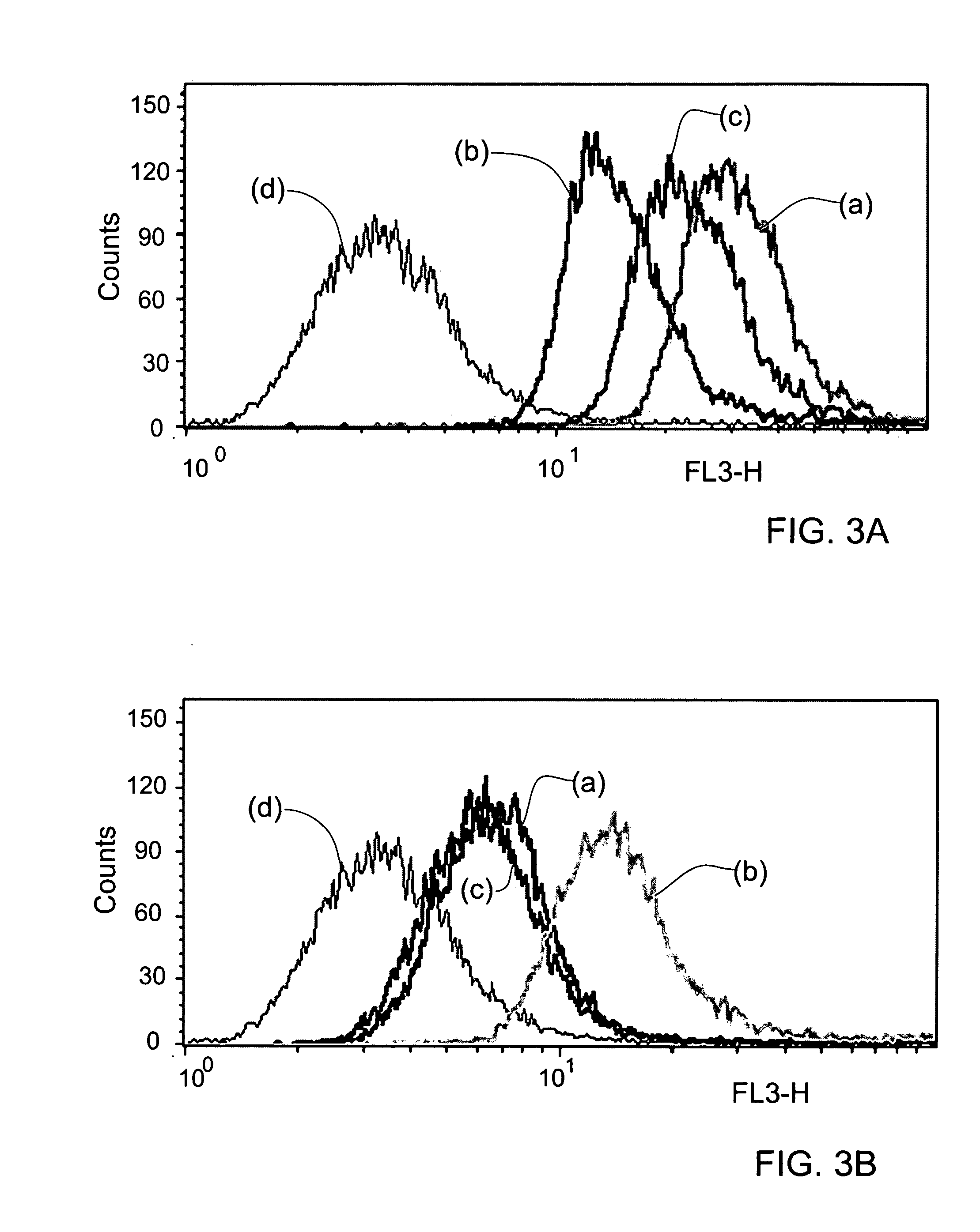

5-Aminolevulinic acid salts and their use

The invention provides salts of 5-Aminolevulinic acid (ALA) of formula (I): wherein RY is an organic acid moiety; Y is selected from the group consisting of a sulfonic acid residue, mono- or di-phosphoric acid residue, mono- or di-carboxylic acid residue and R is selected from the group consisting of saturated, unsaturated, straight or branched C2-C20 chains, aryl, aralkyl or naphthyl. In preferred embodiments, RY is selected from benzenesulfonic acid (besylate), 2-naphthalene sulfonic acid (napsyate), p-toluenesulfonic acid (tosylate), diethyl phosphate, dibenzyl phosphate, di-(2-ethylhexyl) phosphate, caproic or stearic acids. The invention also provides methods for preparing the ALA salts of the invention, pharmaceutical compositions containing the ALA salts of the invention, and use of the ALA salts of the invention in photodynamic therapy (PDT).

Owner:BAR ILAN UNIV +1

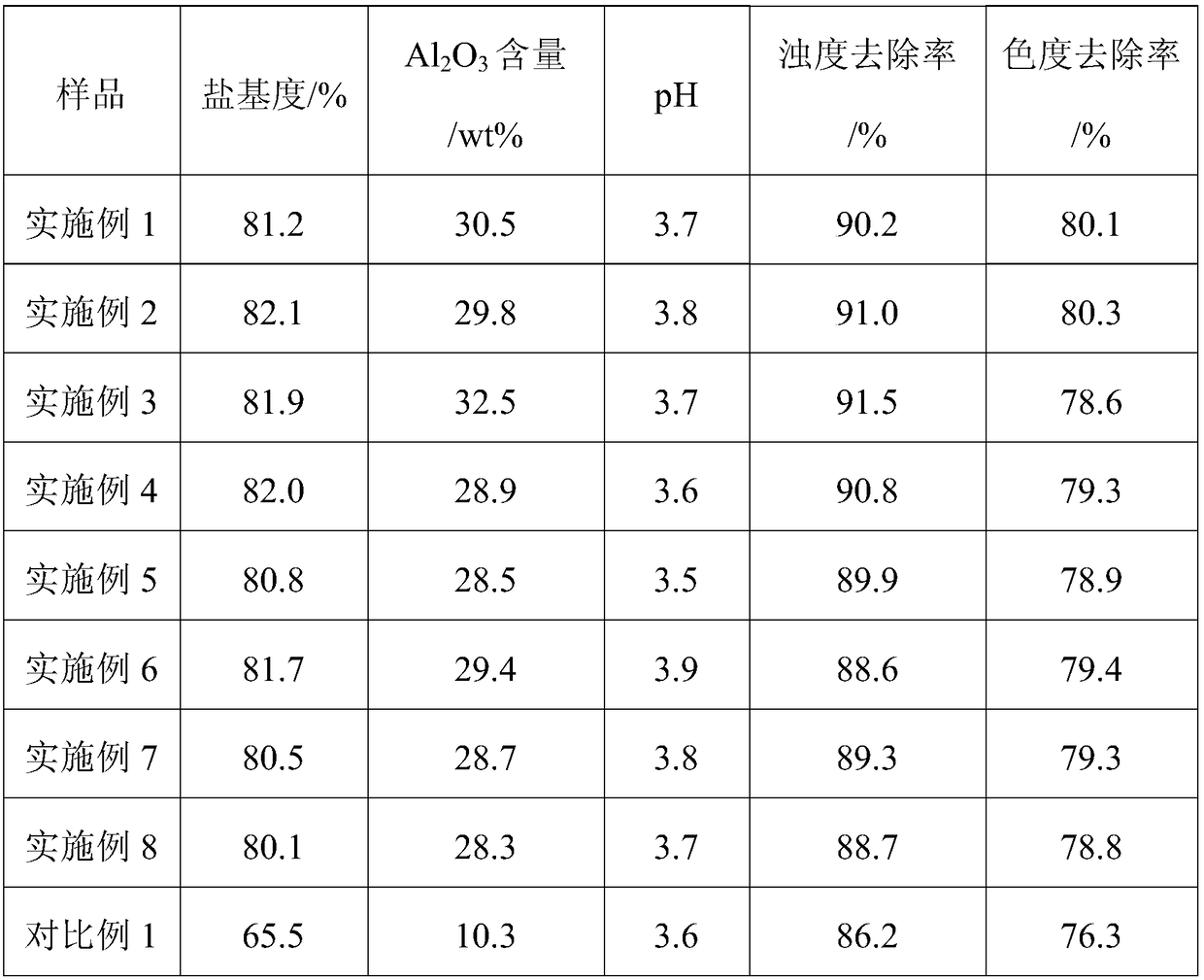

Method for preparing aluminum polychlorid from byproduct generated in methyl diethyl phosphate production

ActiveCN109052444AResolve disposal issuesHigh value-added productsAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorideDiethyl phosphate

The invention provides a method for preparing aluminum polychlorid from byproducts generated in methyl diethyl phosphate production. The method comprises the following steps: (1) dispersing byproductsolid dregs into a solvent, analyzing, and collecting a solution; (2) cooling the solution with water, and separating aluminum chloride hydrate crystal; (3) hydrolyzing and polymerizing the aluminum chloride hydrate crystal, and aging, thereby obtaining the aluminum polychlorid. By adopting the method, solid dregs rich in sodium tetrachloroaluminate are adopted as a raw material, an inorganic polymeric flocculant, namely the aluminum polychlorid, is successfully prepared through steps of simple processes, and not only is the problem of waste disposal solved, but also a high additional value product can be successfully made.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

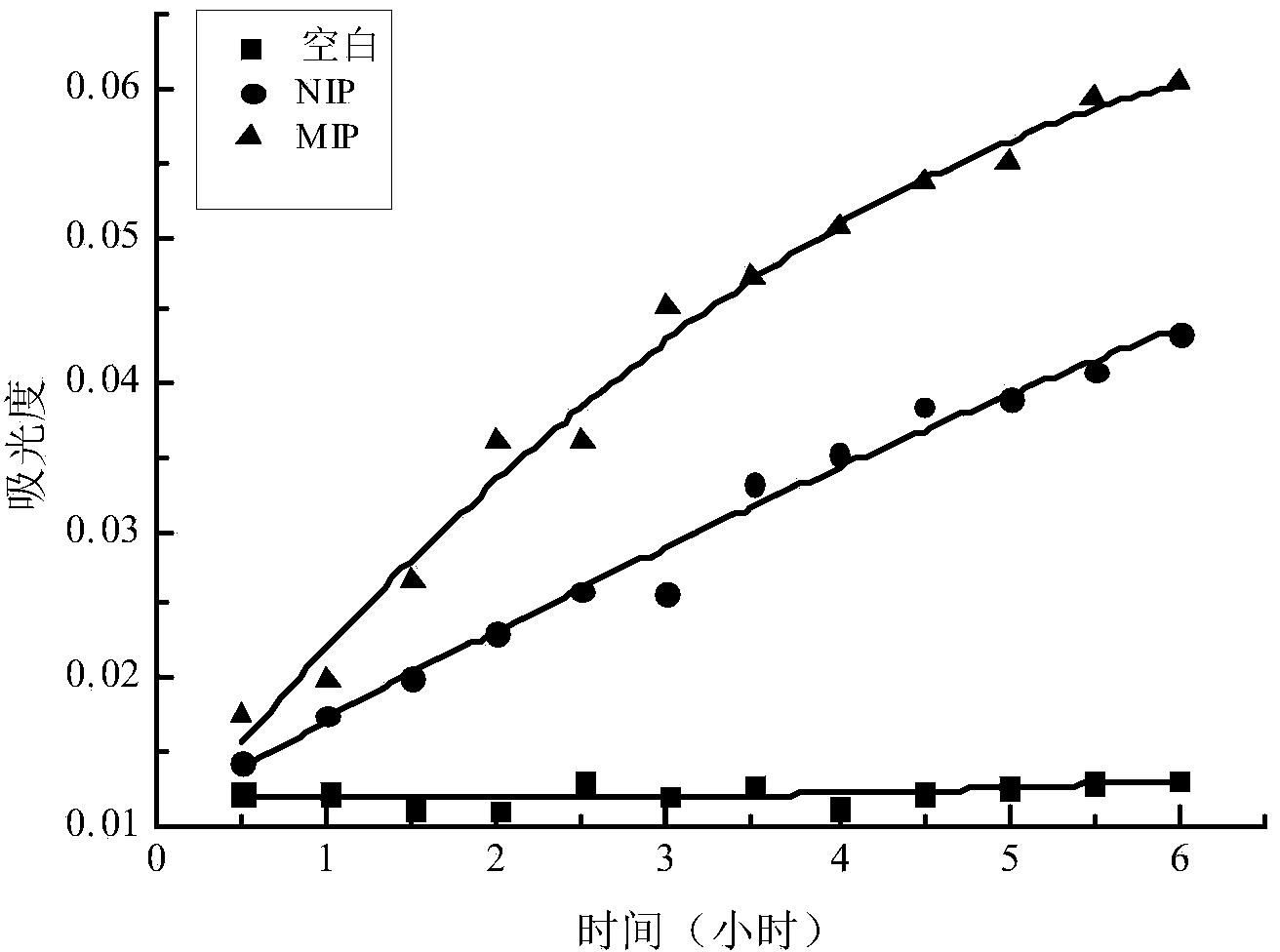

Method for preparing mimic enzyme molecularly imprinted polymer microsphere for hydrolyzing organophosphorus

InactiveCN104140494AFlexiblePromote formationOther chemical processesAlkali metal oxides/hydroxidesDiethyl phosphateFunctional monomer

The invention discloses a method for preparing a mimic enzyme molecularly imprinted polymer microsphere for hydrolyzing organophosphorus. A paraoxon transient state analogue (4-nitro benzyl) phosphoric acid diethyl ester serves as a template molecule, 1-vinyl imidazole and methacrylic acid are functional monomers, a molecular imprinting technology is used, a precipitation polymerization method is adopted, and therefore the mimic enzyme molecularly imprinted polymer microsphere for hydrolyzing the organophosphorus is prepared, wherein the mimic enzyme molecularly imprinted polymer microsphere for hydrolyzing the organophosphorus is good in dispersibility and uniform in particle size. The paraoxon hydrolytic enzyme activity of the prepared molecularly imprinted polymer microsphere and the paraoxon spontaneous hydrolyzing are compared, the hydrolyzing efficiency can be improved by 188 times to the maximum and is also improved by 2.3 times compared with the catalyzing efficiency of a non-imprinted polymer synthesized under the condition of not adding template molecules, a measured Km value and a measured Vmax value are 0.064 mmol / L min and 2.41 mmol / L respectively, and Kcat is 0.237 / S. The prepared mimic enzyme molecularly imprinted polymer microsphere for hydrolyzing the organophosphorus can be used for efficiently hydrolyzing organophosphorus pesticide and can also be used for degrading and destroying organophosphorus nervous toxic agent chemical weapons.

Owner:SHAANXI NORMAL UNIV

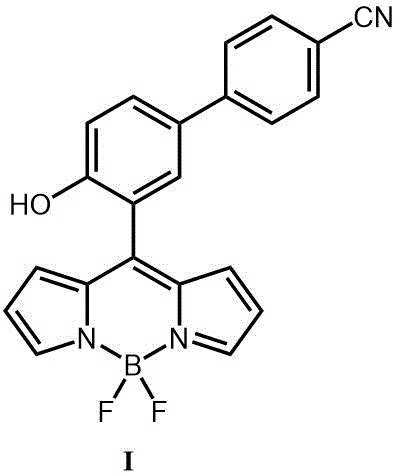

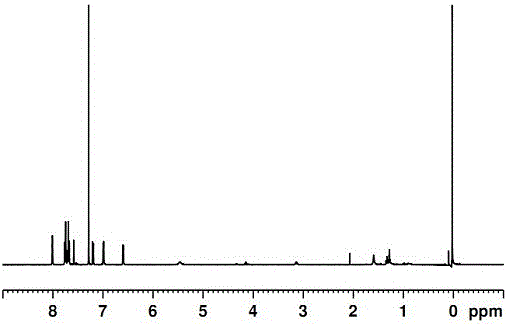

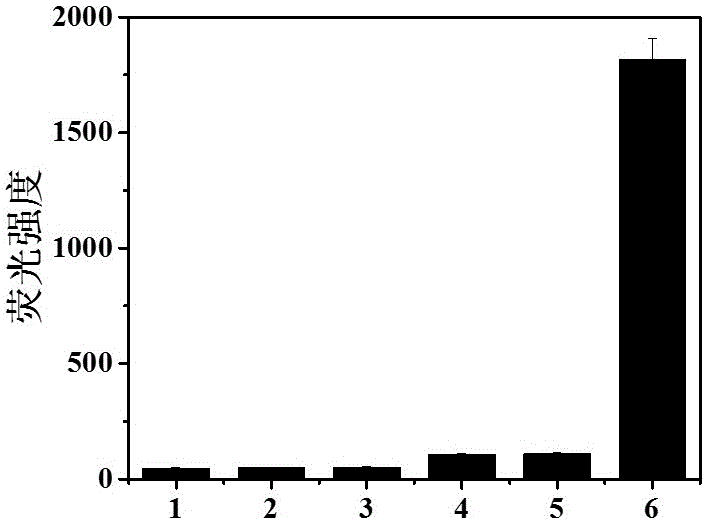

Preparation and application of boron-dipyrromethene-based diethyl chlorophosphate fluorescent probe

InactiveCN106588968AInnovative designGood choiceGroup 3/13 element organic compoundsFluorescence/phosphorescenceDiethyl phosphatePhosphoric acid

The invention relates to a detection diethyl chlorophosphate (DCP) fluorescent probe compound based on boron dipyrromethene (BODIPY) and preparation and application of the detection diethyl chlorophosphate (DCP) fluorescent probe compound. The detection diethyl chlorophosphate (DCP) fluorescent probe compound has the structure shown in the formula I. A preparation method includes the steps that an acetonitrile solution containing 4-(4-hydroxyphenyl)benzonitrile, anhydrous magnesium chloride, paraformaldehyde and triethylamine is subjected to heating and refluxing under protection of nitrogen to obtain white solid III; the obtained solid III and pyrrole are mixed and dissolved in dichloromethane; grey white solid II is obtained under catalysis of trifluoroacetic acid; and the obtained grey white solid II is subjected to DDQ oxydehydrogenation and boron trifluoride diethyl etherate coupling to obtain orange solid I. The probe compound has very good selectivity and sensitivity for DCP, the detection limit is low, and the probe compound can be applied to DCP content measurement.

Owner:UNIV OF JINAN

Phosphorus-nitrogen synergistic flame-retardant polyester diol and preparation method thereof

ActiveCN107417898AEffective dilution concentrationAct as protection against oxygen and heat insulationPolyesterDiethyl phosphate

The invention provides phosphorus-nitrogen synergistic flame-retardant polyester diol and a preparation method thereof. The phosphorus-nitrogen synergistic flame-retardant polyester diol is prepared through reaction of the following raw materials of dibasic acid, dibasic alcohol, [[bis(2-ethoxyl]amino)methyl]diethyl phosphate (FRC-6), a catalyst and azeotrope at a certain ratio. The phosphorus-nitrogen synergistic flame-retardant polyester diol is stable in structure and adjustable in content of phosphorus and nitrogen elements, the hydroxyl value is 120-160mgKOH / g, the phosphorus-nitrogen synergistic flame-retardant polyester diol is good in heat stability, high in char yield and good in flame retardant property, simple in preparation technology and environment-friendly, and can be used as a main reaction material of polymer materials, such as polyurethane.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

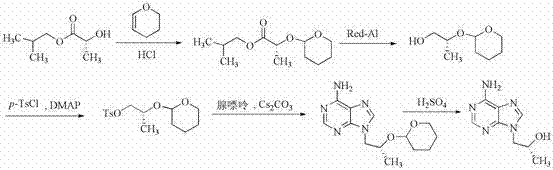

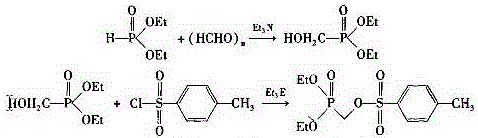

Method for synthesis of PMPA by combining biological technique and chemical technique

ActiveCN102899367AHigh yield of reductionEasy post-processingGroup 5/15 element organic compoundsMicroorganism based processesBiotechnologyDiethyl phosphate

Belonging to the technical field of medicine synthesis, the invention relates to a method for synthesis of PMPA by combining a biological technique and a chemical technique. The method comprises: taking chlorinated acetone as a starting raw material, conducting yeast fermentation reduction so as to obtain chiral chloropropanol (I), then subjecting the chiral chloropropanol (I) and diethyl p-toluenesulfonyloxyphosphonate to a condensation reaction under the action of alkali so as to obtain a reaction intermediate (II); preparing R-9-(2-hydroxypropyl)adenine (III) from adenine and the reaction intermediate (II); and hydrolyzing the obtained R-9[2-(diethylphosphonomethoxy)propyl]purine, thus obtaining the PMPA (IV). The method combines the biological technique and the chemical technique and obtains a key chiral alcohol by means of a biological means, i.e. fermentation. The method has the characteristics of short reaction process, short reaction time, high mass yield, and can produce products with good quality, thus being suitable for industrialized production.

Owner:黄石福尔泰医药科技有限公司

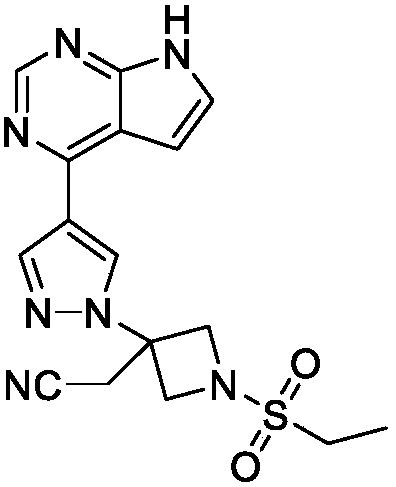

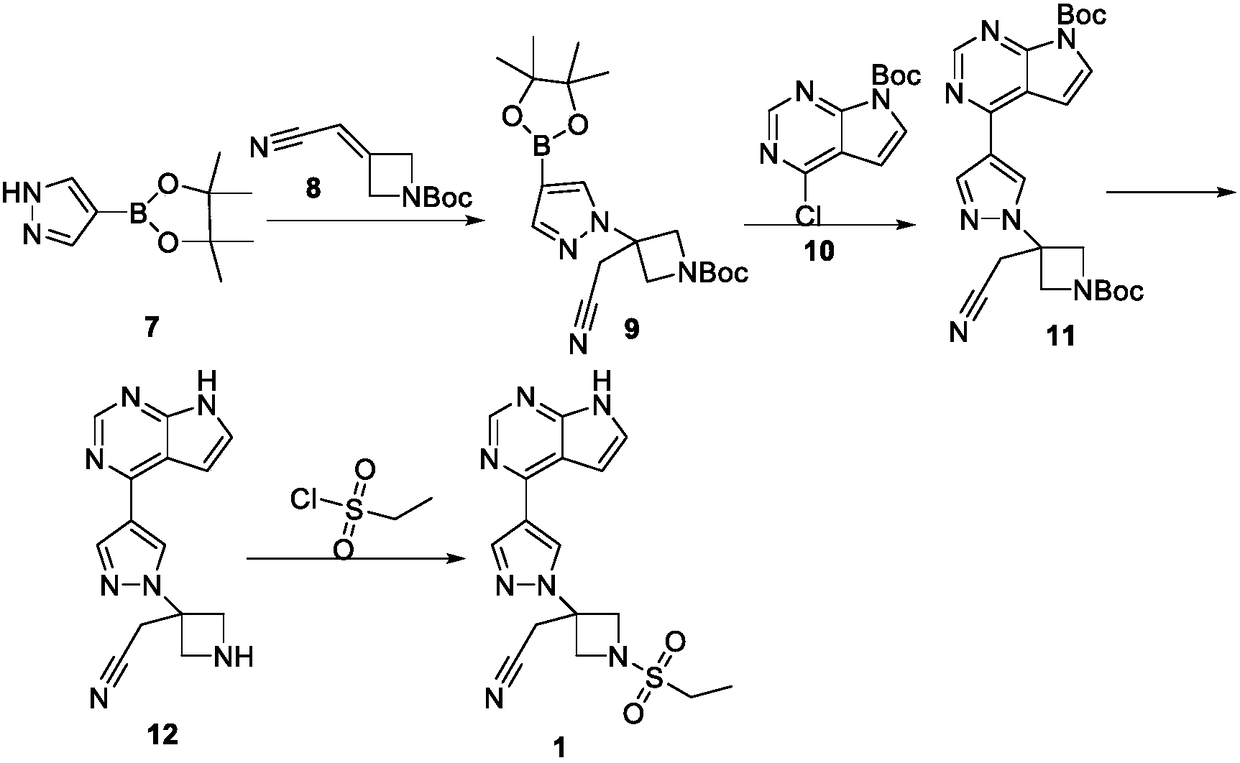

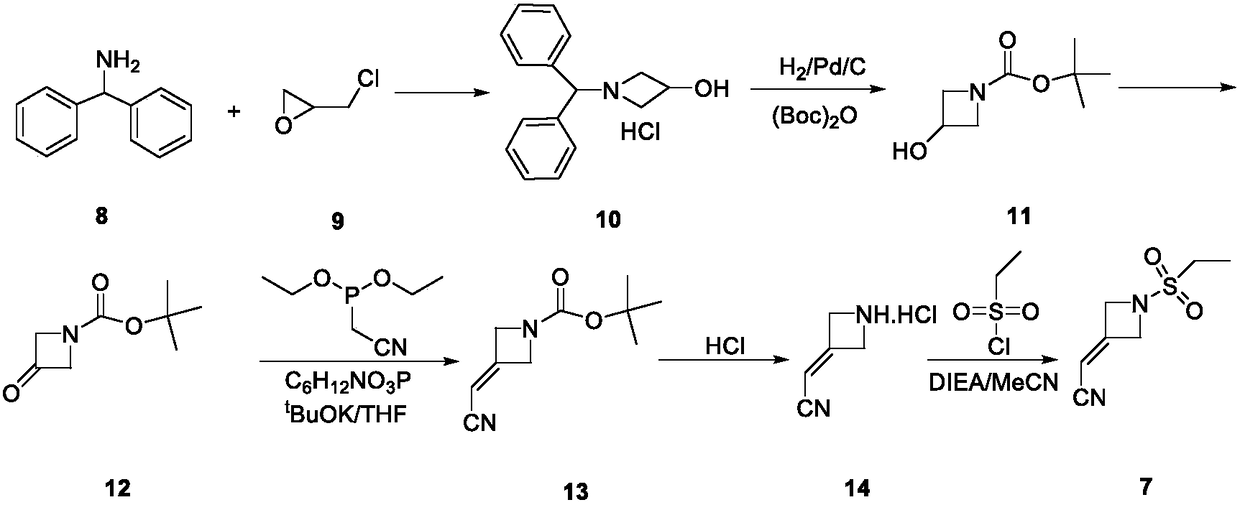

Preparation method of baricitinib

InactiveCN108129482ALow costAvoid participating in the reactionOrganic chemistryBulk chemical productionDiethyl phosphatePurification methods

The invention discloses a preparation method of baricitinib and belongs to the technical field of drug preparation. The method comprises that 4-chloropyrrolopyrimidine as a starting raw material is subjected to amino protection, the product, hydrazine hydrate and acrolein undergo a one-pot displacement reaction and a cyclization reaction to produce an intermediate 4, a starting raw material 1, 3-dibromoacetone and ethylene glycol undergo a condensation reaction to produce an intermediate 5, the intermediate 5 and ethyl sulfonamide undergo a condensation reaction to produce an intermediate 6, the intermediate 6 and diethyl cyanomethylphosphonate undergo a reaction under action of a strong base to produce an intermediate 7, the intermediate 4 and the intermediate 7 undergo an addition reaction under the action of a catalyst, and the product undergoes a deprotection reaction to produce a desired product 1. The preparation method needs mild reaction conditions. The intermediate purification method is simple and easy, has a total yield of 40-55% and is suitable for industrial production.

Owner:JIANGSU ZHONGBANG PHARMA

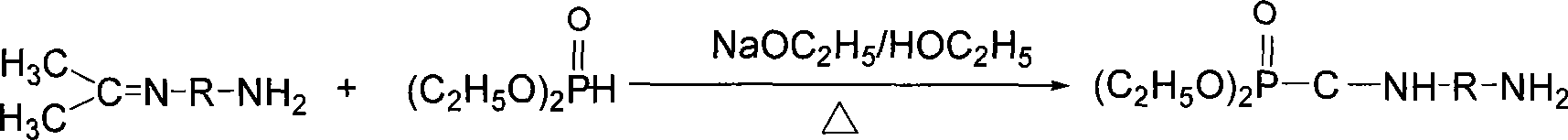

Organic phosphorus active flame-proof epoxy resin curing agent amine group phosphonate and preparation method thereof

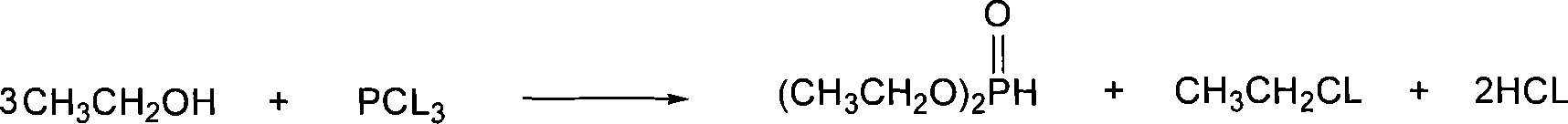

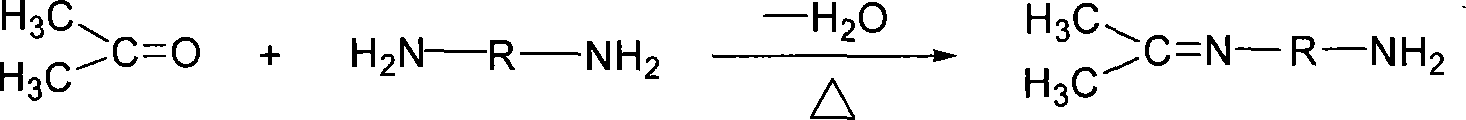

The invention discloses an organophosphorus active flame-proof epoxide resin solidifying agent amino phosphonate ester and the preparing method. The amino phosphonate ester comprises the following parts: 3:1:1:1 absolute ethyl alcohol, phsophorus trichloride, organic amine (the structural formula is H2N-R-NH2)and acetone. The organic amine is diethylenetriamine, triethylene tetraamine, tetraethylene pentamine or 4, 4-diaminodiphenylmethane. The method comprises the following steps: 1, synthesizing diethyl phosphate with alcohol and phsophorus trichloride; 2, generating ketoimine with acetone and the organic amine by adding the anhydrating agent; 3, generating amino phosphonate with diethyl phosphate and ketoimine. The oxygen index of the product is more than 20 and less than 34.6. The invention is provided with the simple method and the simple operation.

Owner:HEILONGJIANG INST OF PETROCHEM

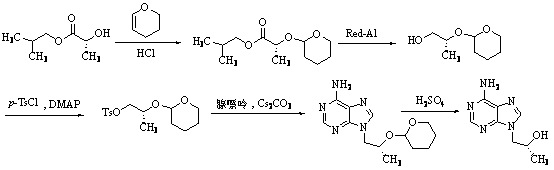

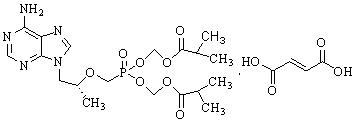

Industrialization production technology for tenofovir disoproxil fumarate

InactiveCN105859781AHigh yieldHigh purityGroup 5/15 element organic compoundsDiethyl phosphateDiethyl methylphosphonate

An industrial production process of tenofovir, the production process steps are as follows: add R-1,2-propylene glycol, diethyl carbonate and sodium ethylate into the reaction kettle; add absolute ethanol and diphosphite Ethyl ester, stirring, after the stirring is completed, put in paraformaldehyde and triethylamine, after the reaction is complete, add anhydrous sodium sulfate, dry, filter, and distill out, the distilled product is diethyl p-toluenesulfonyloxymethylphosphonate Fine product; add adenine, R-propylene carbonate, DMF and NaOH in the reaction kettle, after the reaction is complete, add magnesium tert-butoxide, drop diethyl p-toluenesulfonyl phosphate, after the reaction is complete, add acetic acid, Concentrate under reduced pressure, add hydrochloric acid, filter, filter out the solid and dry under normal pressure to obtain PMPA fine product. The method has the advantages of high yield, high product purity and low impurity content, and can be fully industrialized.

Owner:JINGMEN SHUAIBANG CHEM SCI & TECHCO

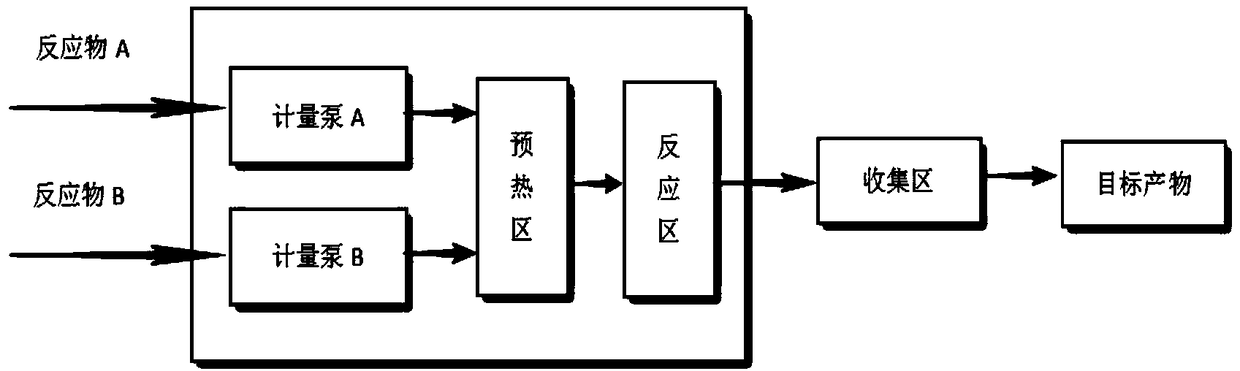

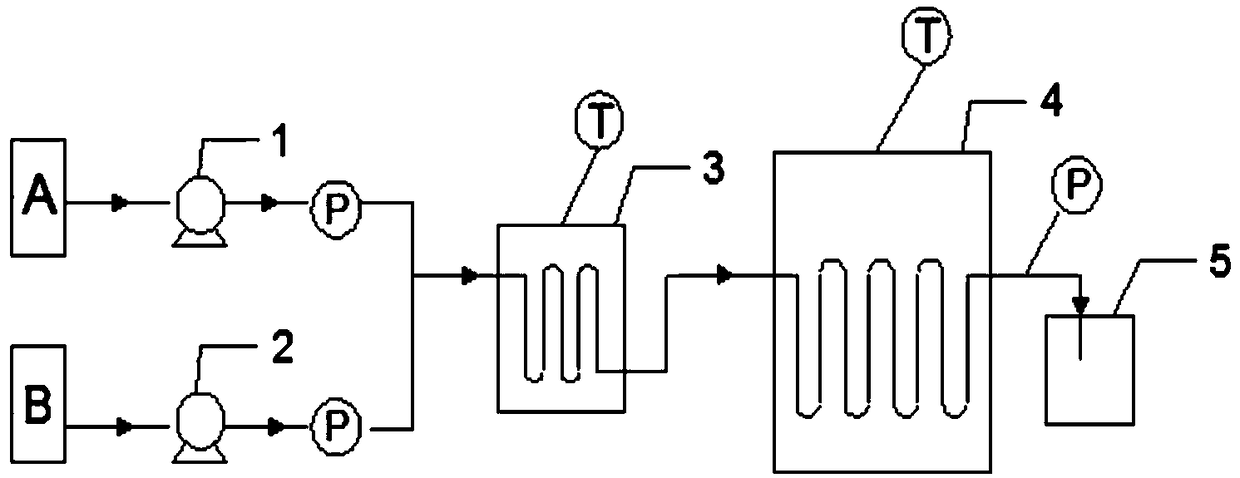

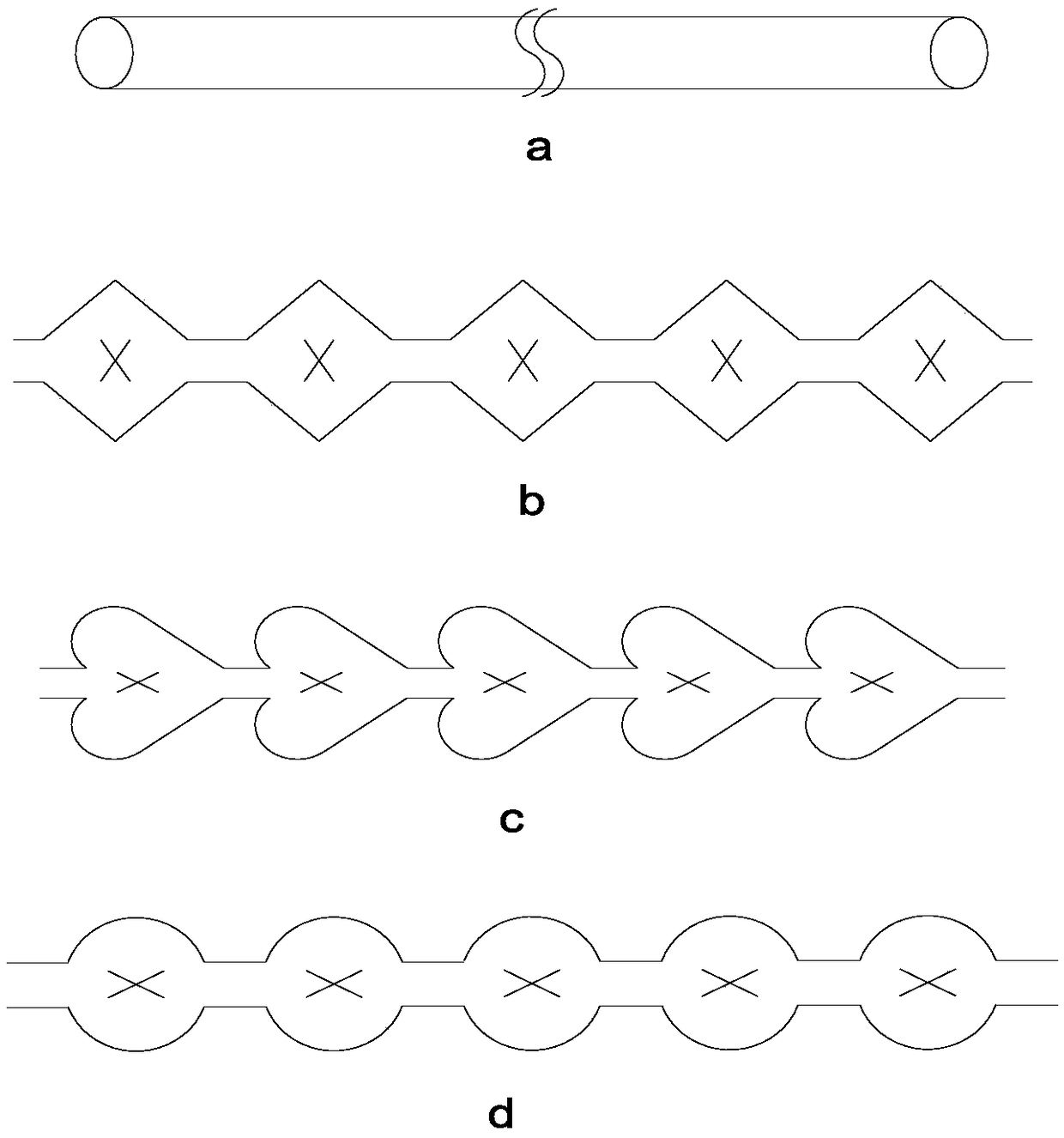

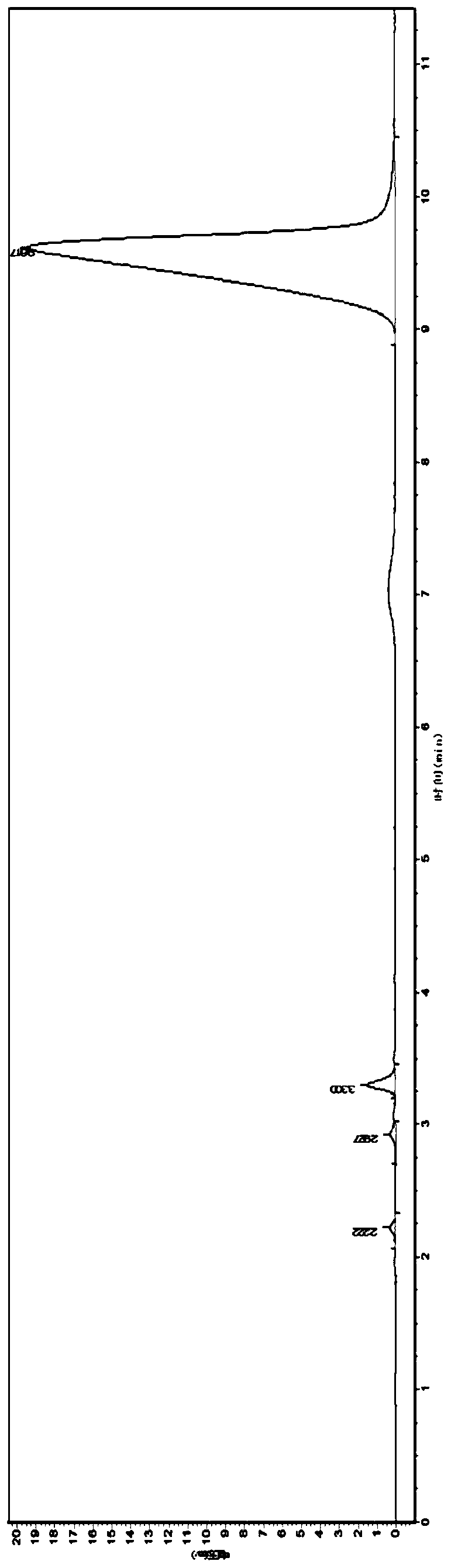

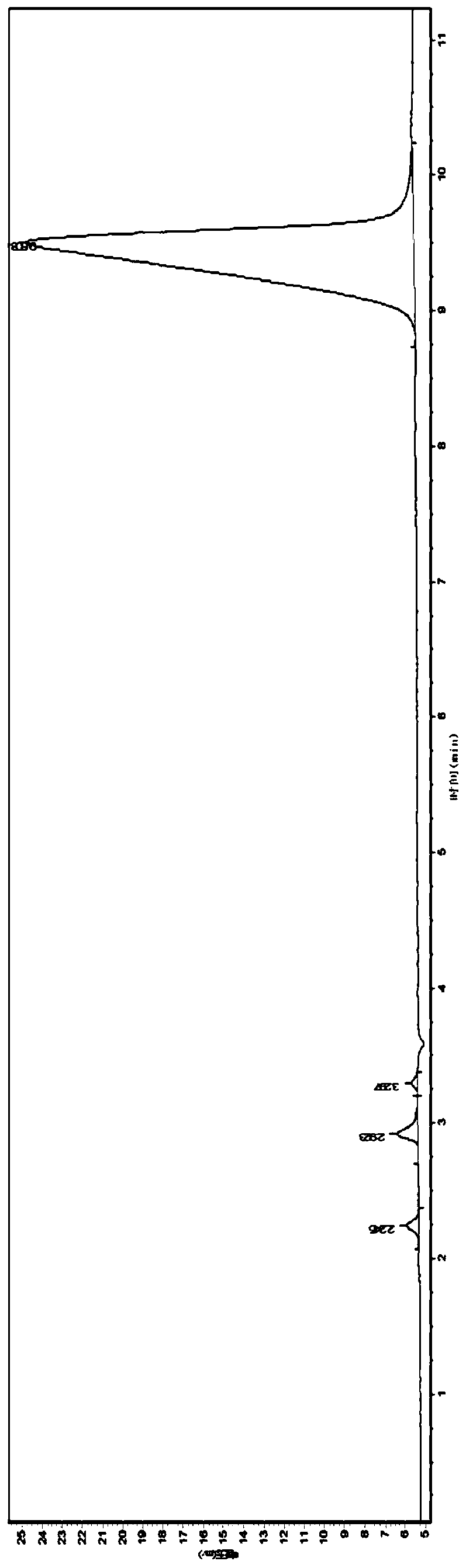

Method for continuously synthesizing diethyl phosphite in microchannel reactor

InactiveCN109096328AShort reaction timeIncrease temperatureGroup 5/15 element organic compoundsChemical industryDiethyl phosphateOrganic synthesis

The invention discloses a method for continuously synthesizing diethyl phosphite in a microchannel reactor, and belongs to the technical field of organic synthesis processes. More specifically, the method is a method for generating diethyl phosphite by a continuous reaction in a microchannel continuous flow reactor using anhydrous ethanol and phosphorus trichloride as a substrate and chloroform asa solvent, wherein the mixed solution of the chloroform and the phosphorus trichloride is a material A, the anhydrous ethanol solution is a material B, and the material A and the material B simultaneously enter a microchannel through a metering pump. According to the method, the efficient mass transfer and heat transfer efficiency of the microchannel reactor are utilized to effectively strengthenthe mass transfer rate between two-phase materials, and the safety and operability of an experiment are greatly improved.

Owner:CHANGZHOU UNIV

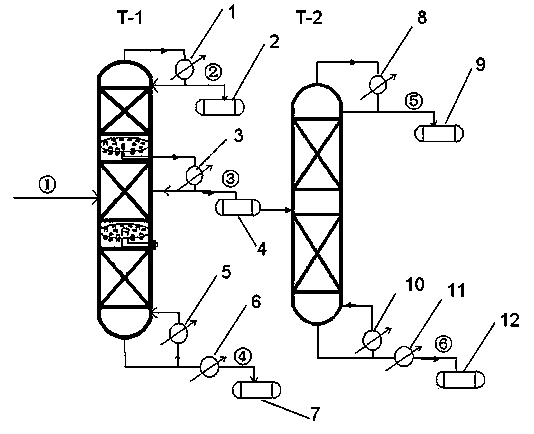

Method for recovering useful constituents in mixed waste solvent during glufosinate ammonium production process

InactiveCN103880786AReduce one evaporation processLow costGroup 5/15 element organic compoundsDistillation purification/separationGlufosinate-ammoniumDiethyl phosphate

The invention discloses a method for recovering useful constituents such as tetrahydrofuran, methyl diethyl phosphate, triethyl phosphate and trimethylbenzene in a mixed waste solvent during a process of producing glufosinate ammonium by an integrated rectification process. The method comprises the following steps: using an integrated rectification process of discharging and rectifying in a single-tower side line and then connecting a single tower to rectify, directly extracting tetrahydrofuran from the top of the rectification tower in the side line and obtaining trimethylbenzene from the bottom of the tower; extracting the mixed solution of methyl diethyl phosphate and triethyl phosphate from the side line simultaneously, conveying the mixed solution to the rectification tower and carrying out single-tower separation, thereby obtaining methyl diethyl phosphate from the top of the tower and obtaining triethyl phosphate from the bottom of the tower. According to the method disclosed by the invention, the useful constituents in the mixed waste solvent during the glufosinate ammonium production process are recovered by the integrated rectification process, the total recovery rate of the mixed solvent exceeds 98%, and the quality achieves reuse standards. Compared with the conventional three-tower rectification method, the equipment cost and energy consumption of the method disclosed by the invention are obviously lowered.

Owner:江苏威格瑞斯化工有限公司

Polyurethane foam with heat conductivity coefficient enhanced by hollow glass beads

InactiveCN106244084AHigh oxygen indexImprove flame retardant performancePolyureas/polyurethane adhesivesDiethyl phosphateGlycerol

The invention discloses polyurethane foam with heat conductivity coefficient enhanced by hollow glass beads. The polyurethane foam is prepared from, by weight, 150-160 parts of diphenyl-methane-diisocyanate, 100-105 parts of propoxylated glycerin, 100-110 parts of castor oil, 5-6 parts of glycerol, 40-43 parts of diethyl phosphate, a proper amount of 1 mol / L sodium hydroxide solution, 13-15 parts of diatomite, 5-6 parts of distilled water, 2-3 parts of triethanolamine, 3-4 parts of dibutyltin dilaurate, 4-5 parts of polyacrylamide, 3-4 parts of ethoxylated lauryl alcohol sulfate, 6-7 parts of hollow glass beads, 20-23 parts of cyclohexane, 0.2-0.22 part of n-propylamine, 0.6-0.7 part of silane coupling agent KH550 and a proper amount of deionized water. The prepared foam can be foamed on the spot, has the characteristics of being uniform in foaming, high in cell density and low in heat conductivity coefficient, is used for sealing of a switch cabinet, and is high in binding strength, good in sealing and excellent in heat preservation performance.

Owner:HEFEI E CHON METAL PLATE TECH CO LTD

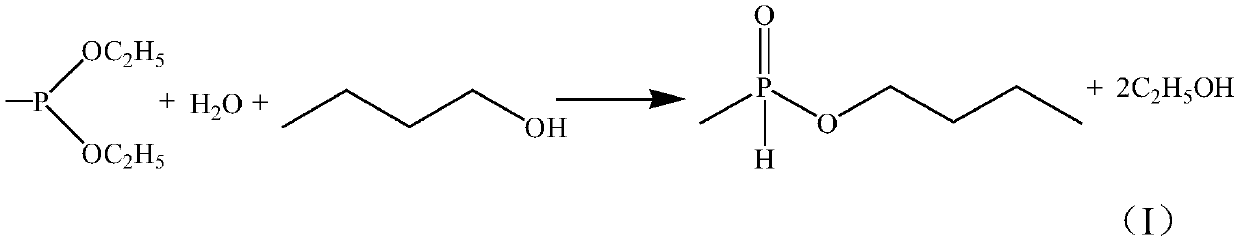

Method for synthesizing glufosinate ammonium salt

InactiveCN110386950AReduce separation and purification processReduce outputGroup 5/15 element organic compoundsDiethyl phosphateN-Butanol

The invention discloses a method for synthesizing a glufosinate ammonium salt. The method comprises the following steps that (1) methyldiethoxyphosphine and n-butanol are used as raw materials to produce an intermediate I by hydrolysis and transesterification; (2) the intermediate I is subjected to a free radical addition reaction with acrolein cyanohydrin acetate to form an intermediate II; (3) the intermediate II is subjected to an aminolysis reaction with ammonia gas to form a mixture of an intermediate III and an intermediate IV; (4) the intermediate III and the intermediate IV are subjected to acid hydrolysis with hydrochloric acid to form an intermediate V; and (5) the intermediate V is neutralized, purified and crystallized to obtain the glufosinate ammonium salt. The method does not need to use toxic raw materials, avoids the large-scale use of ammonia water and ammonium chloride, not only greatly reduces the safety hazard, but also reduces the quantity of by-products and the amount of waste water generated, and the environmental protection risk is greatly reduced; and the purification process is simple, the product content and the yield coefficient are obviously increased,and the method is suitable for industrial scale production.

Owner:石家庄瑞凯化工有限公司

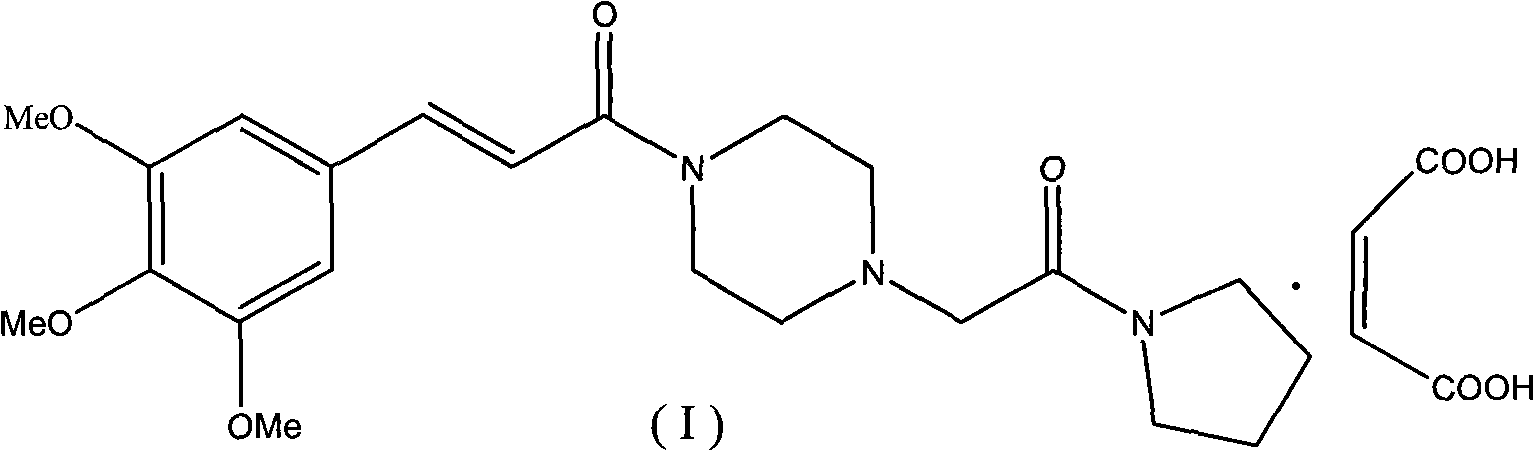

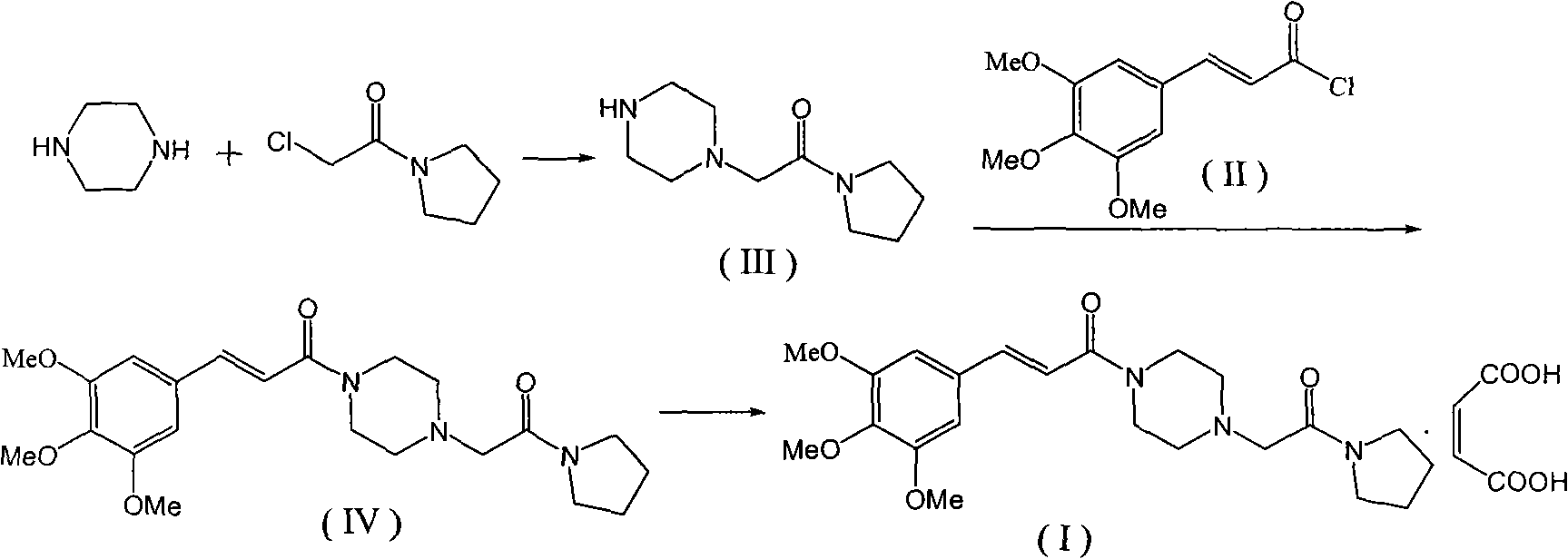

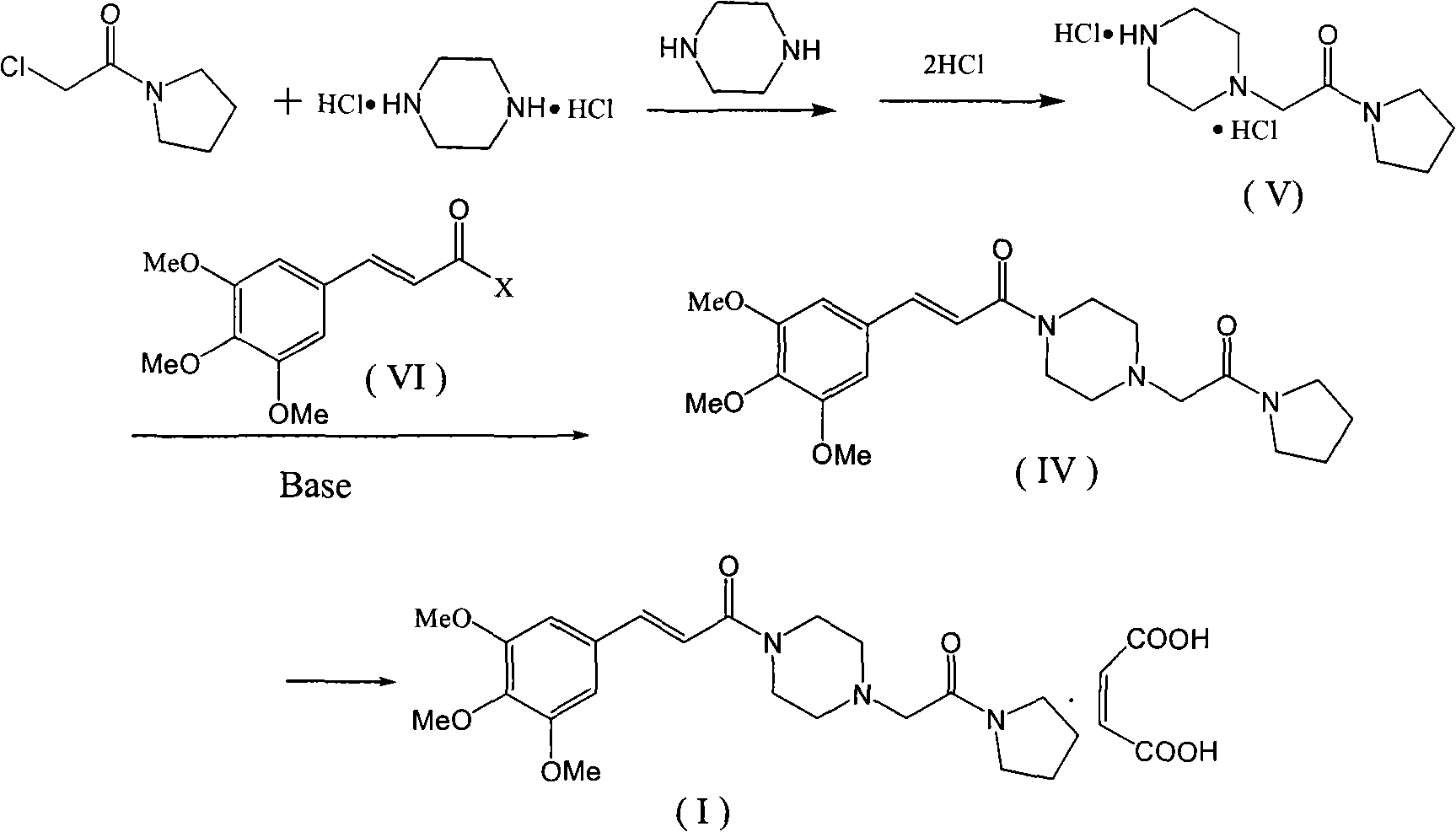

Method for preparing cinepazide maleate

InactiveCN101492431AGroup 5/15 element organic compoundsSulfonic acid preparationDiethyl phosphateMethyl group

The invention relates to a preparation method of cinepazide maleate, comprising the following steps: 3, 4, 5-trimethoxycinnamylic acid reacts with chlorinating agent, chloro diethyl phosphate and benzenesulfonyl chloride for preparing corresponding acyl active matters of the 3, 4, 5-trimethoxycinnamylic acid. The acyl active matters react with 1-[(1-pyrrolidine carbonyl) methyl] piperazine double hydrochloride for preparing 1-[(1-pyrrolidine carbonyl) methyl]-4-(3, 4, 5-trimethoxycinnamylic acid acyl) piperazine which is separated and forms salt with maleic acid for preparing cinepazide maleate or can be directly used in ethanol or acetone solution for forming salt with maleic acid. And after the crystallization, the cinepazide maleate with high melting point and stable crystal form is prepared. Chloroacetyl pyrrole perimidine reacts with mixture of piperazine and double hydrochloride of the piperazine with the ratio of 1 to 1 in lower alcohol, and then the chlorine hydride is pumped in to obtain the 1-[(1-pyrrolidine carbonyl) methyl] piperazine double hydrochloride. The process has the advantages of simple operation and high yield.

Owner:SHIJIANGZHUANG ZHIHENG PHARMACY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com