Organic phosphorus active flame-proof epoxy resin curing agent amine group phosphonate and preparation method thereof

An epoxy resin curing and amino phosphonate technology, which is applied in the field of organophosphorus active flame retardant epoxy resin curing agent amino phosphonate and its preparation, can solve the problem of unsatisfactory flame retardant effect of epoxy resin cured products, etc. problem, to achieve the effect of simple method and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

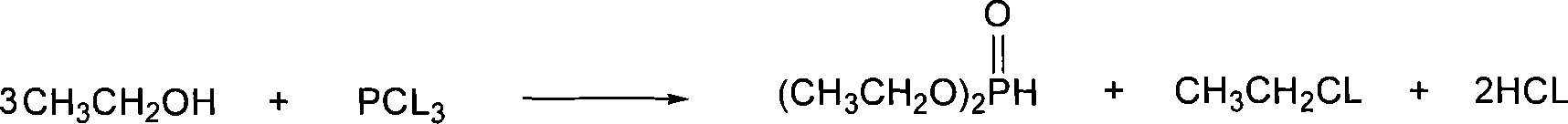

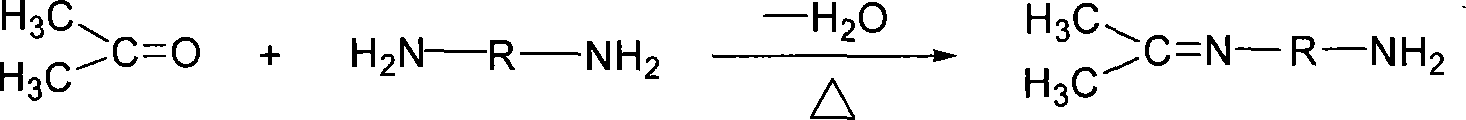

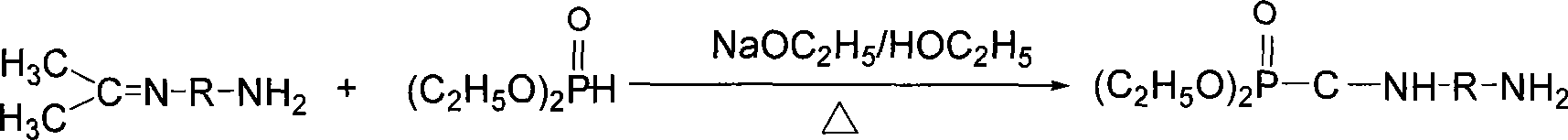

[0015] Specific embodiment one: the present embodiment amino phosphonate is made of dehydrated alcohol, phosphorus trichloride, organic amine (structural formula is H 2 N-R-NH 2 ) and acetone at a molar ratio of 3:1:1:1; the organic amine is diethylenetriamine, triethylenetetramine, tetraethylenepentamine or 4,4-diaminodiphenylmethane.

specific Embodiment approach 2

[0016] Specific embodiment two: the preparation method steps of organophosphorus active flame retardant epoxy resin curing agent amino phosphonate in the present embodiment are as follows: 1, synthetic diethyl phosphite: add 3mol anhydrous in every 100ml anhydrous benzene Proportion of ethanol Mix anhydrous ethanol and anhydrous benzene until uniform, then cool to 5-15°C, start the agitator, stir at a speed of 300-600r / min, and add dropwise at a speed of 3-5 drops per second The mixture of phosphorus trichloride and anhydrous benzene, wherein the mixture of phosphorus trichloride and anhydrous benzene is mixed according to the ratio of adding 1mol of distilled phosphorus trichloride per 100ml of anhydrous benzene, and absolute ethanol and three The molar ratio of phosphorus chloride is 3:1, the reaction temperature is kept between 5-15°C, and the reaction time is 0.8-1h; the reaction product is quickly moved into a vacuum distillation device, and under the condition of a water ...

specific Embodiment approach 3

[0018] Embodiment 3: In this embodiment, in step 1, the mixture of absolute ethanol and anhydrous benzene is cooled to 5-10°C. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com