Patents

Literature

796 results about "Phosphorus trichloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

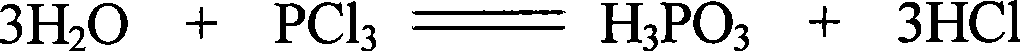

Phosphorus trichloride is a chemical compound of phosphorus and chlorine, having the chemical formula PCl₃. It has a trigonal pyramidal shape. It is the most important of the three phosphorus chlorides. It is an important industrial chemical, being used for the manufacture of organophosphorus compounds for a wide variety of applications. It has a ³¹P NMR signal at around +220 ppm with reference to a phosphoric acid standard.

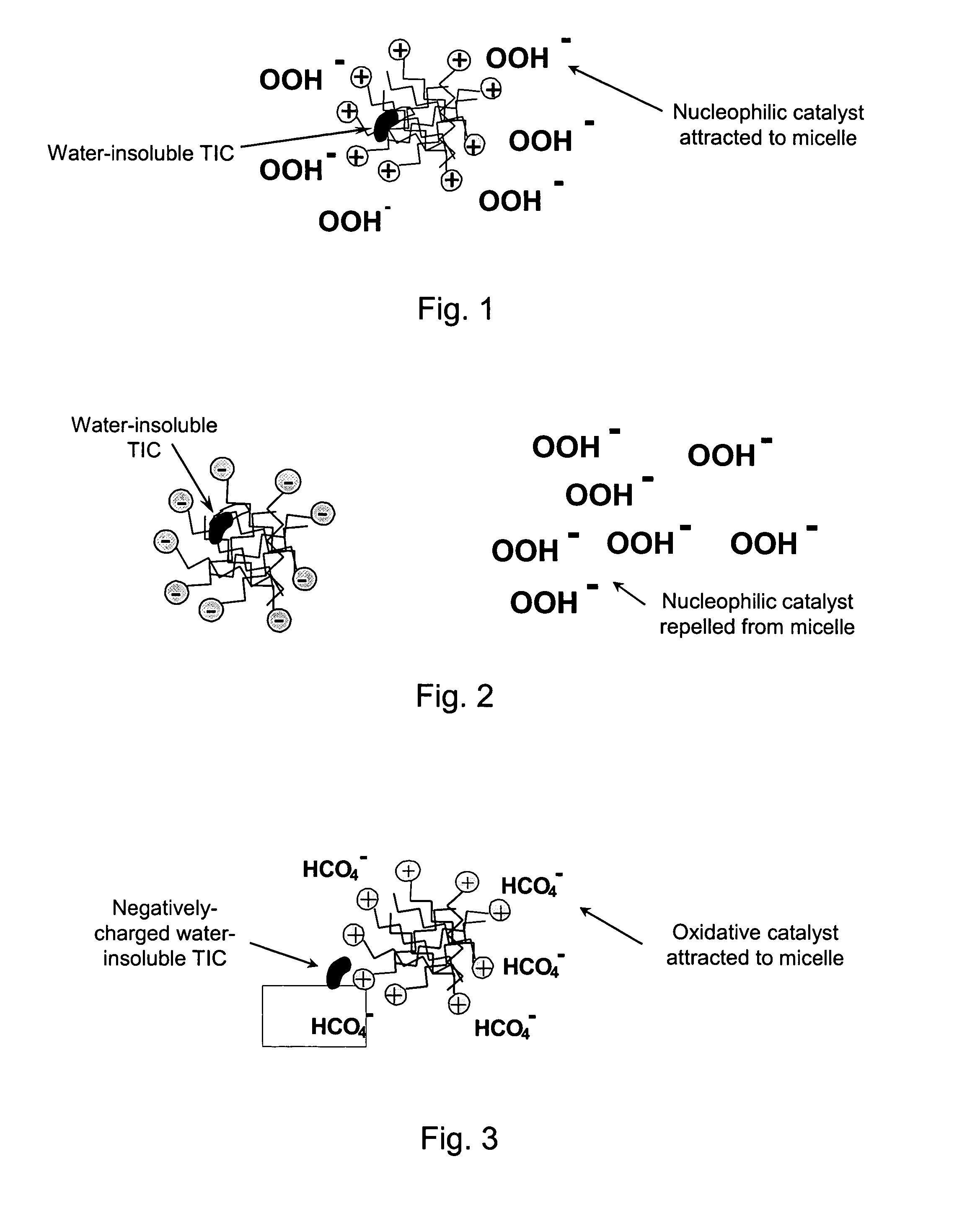

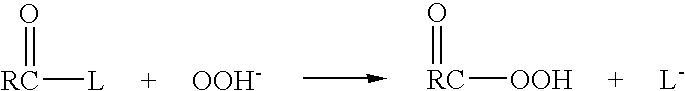

Reactive formulations for a neutralization of toxic industrial chemicals

InactiveUS7125497B1Efficiently neutralizedHydrogen peroxideLiquid degasificationBoron trichlorideMalathion

Decontamination formulations for neutralization of toxic industrial chemicals, and methods of making and using same. The formulations are effective for neutralizing malathion, hydrogen cyanide, sodium cyanide, butyl isocyanate, carbon disulfide, phosgene gas, capsaicin in commercial pepper spray, chlorine gas, anhydrous ammonia gas; and may be effective at neutralizing hydrogen sulfide, sulfur dioxide, formaldehyde, ethylene oxide, methyl bromide, boron trichloride, fluorine, tetraethyl pyrophosphate, phosphorous trichloride, arsine, and tungsten hexafluoride.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

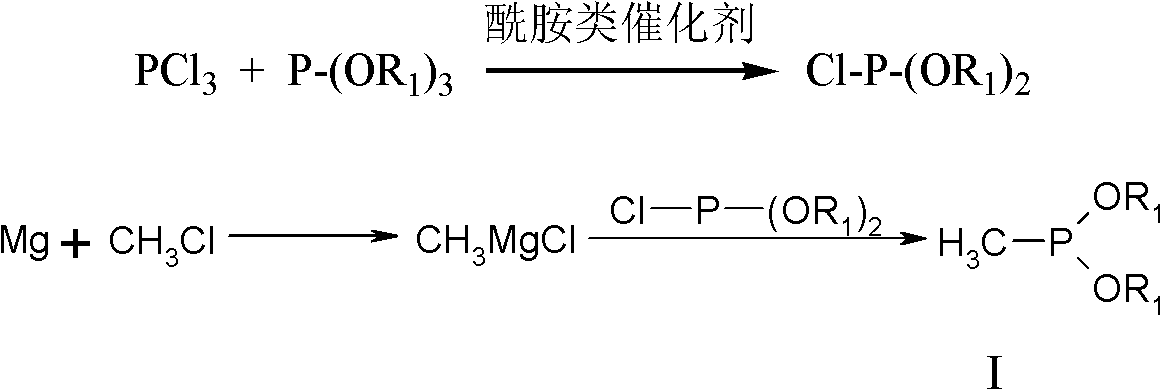

Improved synthesis method for glufosinate and analogue thereof

InactiveCN102399240AReduce generationReduce processing costsGroup 5/15 element organic compoundsDiethyl phosphateHydrogen halide

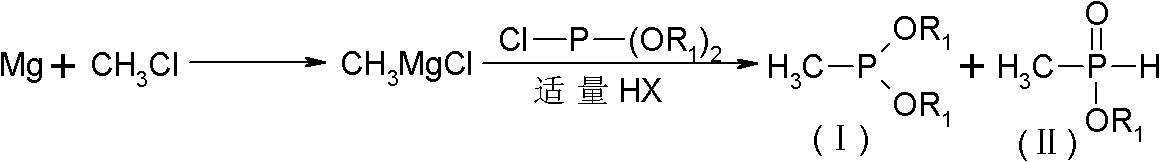

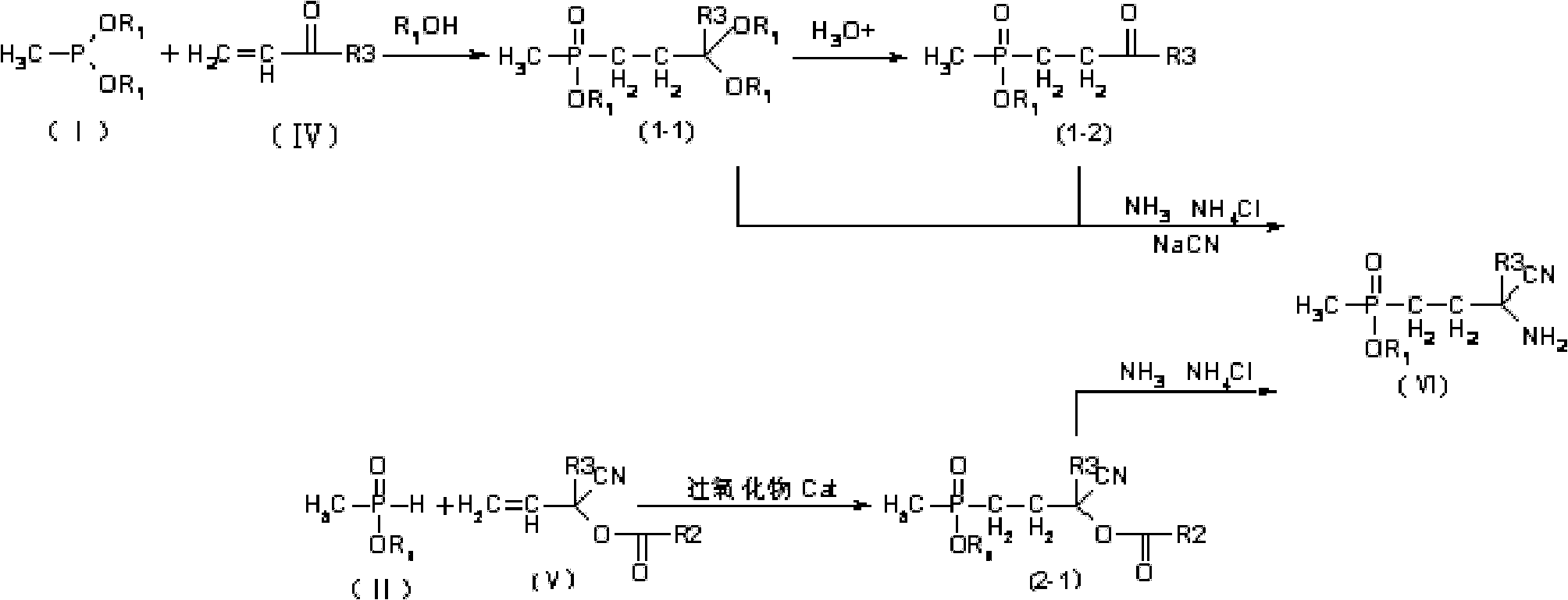

The invention discloses a comprehensive method for synthesizing glufosinate and analogue thereof by using phosphorus trichloride, triethyl phosphate and chloromethane as initiative raw materials. The method comprises the following steps of: performing Grignard, disproportionation and coupling; introducing a proper amount of hydrogen halide; and synthesizing to obtain two intermediates, namely methyl diethyl phosphate (intermediate I) and methyl phosphinate (intermediate II), wherein the two intermediates can synthesize the glufosinate and the analogue thereof. By the method, the glufosinate and the analogue thereof are synthesized by completely utilizing the methyl diethyl phosphate and the methyl phosphinate synthesized by a Grignard route; yield is increased; production cost is reduced; and three wastes are reduced.

Owner:JIANGSU YOUTH CHEM +1

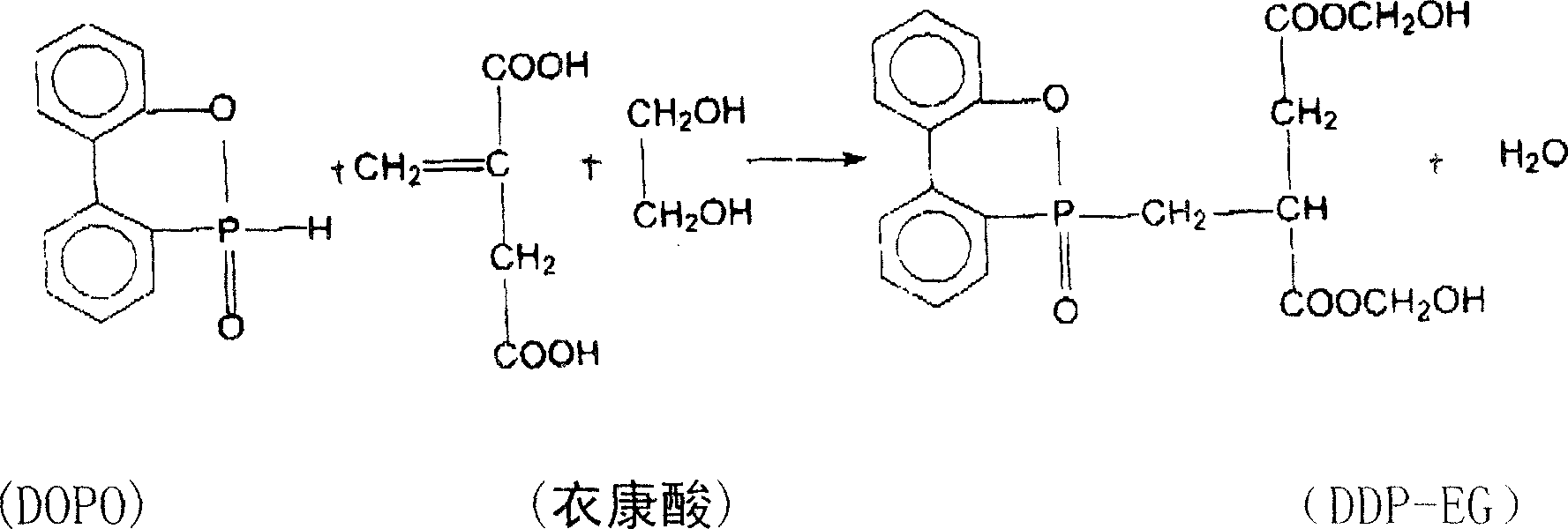

9, 10- dihydro-9- oxa -10- phosphine hetero- phenanthrene -10- oxide compound and its derivant and method of preparing the same

InactiveCN101108864ALight colorHigh yieldGroup 5/15 element organic compoundsGlycol synthesisPhosphorus trichloride

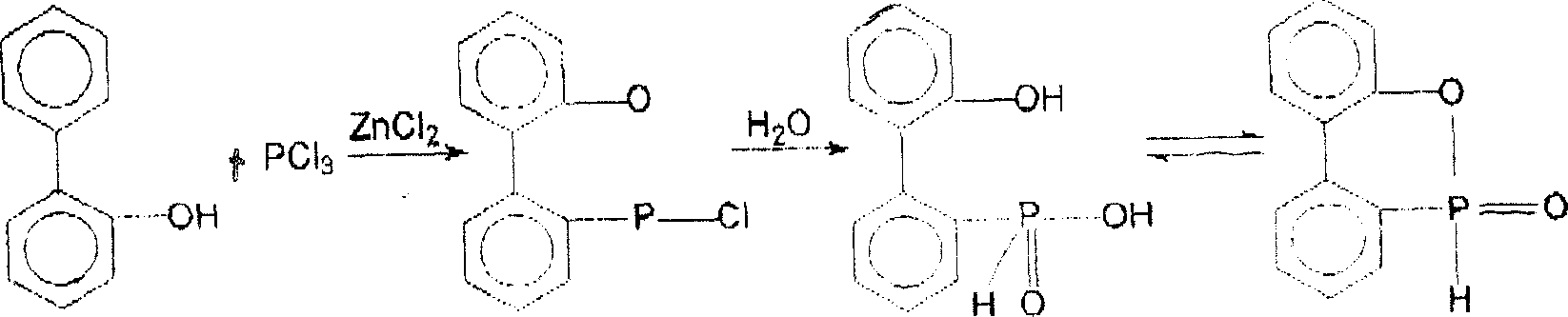

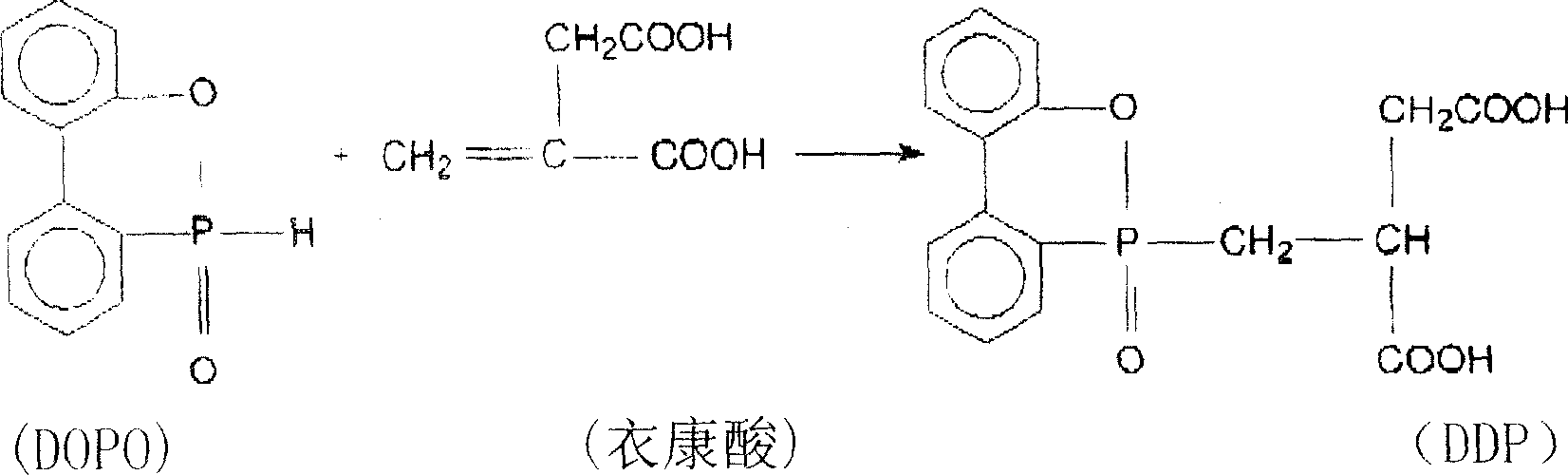

The invention discloses a preparation method of the 9, 10-dihydro-9-oxa-10-phosphahenanthrene-10-oxide and the derivatives DDP, DDP-EG and DOPO-BQ. The invention has three steps to synthesize the DOPO: (1) preparation of CDOP, the O-phenylphenol (OPP) reacts with the Phosphorus trichloride (PCl3) with ZnCl2 as the catalyst. (2) purification of CDOP, vacuum distillation is carried out. (3) DOPO with high purity and yield is gained through the hydrolysis and crystallization. The preparation materials comprises the O-phenylphenol, the Phosphorus trichloride, the toluene, the alcohol, the deionized water, the itaconic acid, the ethylene glycol, the p-benzoquinone and the acetone. The invention simplifies the process conditions, improves the product purity with good production stability and repeatability. The purity of the product reaches over 99.0 per cent, the content of the chloride is below 50ppm, the OPP is about 0.01 per cent, the color is about 10 (10 per cent solution of acetone), the zinc-ion is less than 10ppm. The preparation method of the derivatives DDP, DDP-EG, DOPO-BQ is simple, good in stability and high in yield.

Owner:魏铭杉

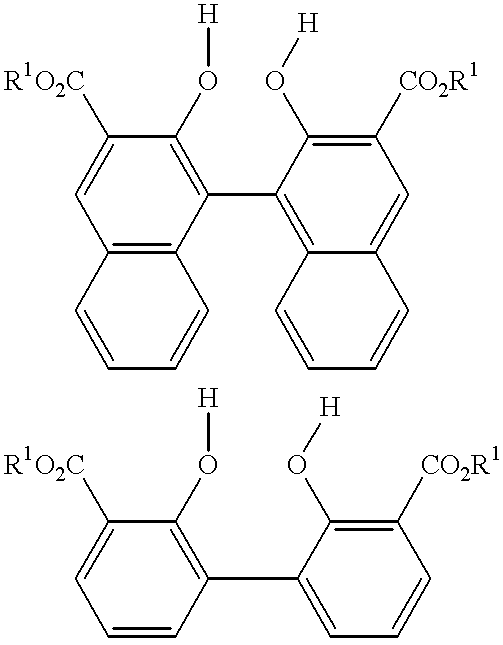

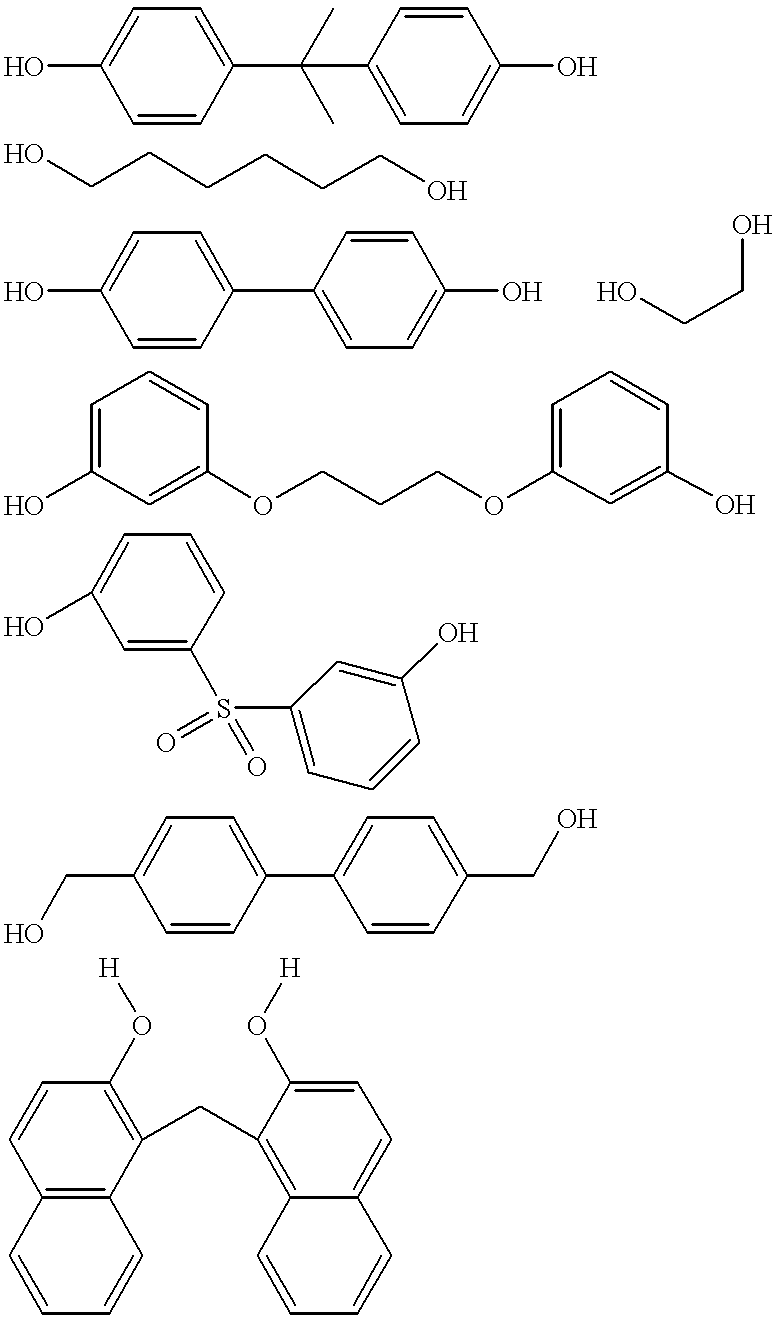

Polymeric phosphite composition and hydrocyanation of unsaturated organic compounds and the isomerization of unsaturated nitriles

InactiveUS6855799B2Reduce solubilityOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsIsomerizationOrganic compound

A polymeric composition, a process for producing the composition, and a process for using the composition in, for example, hydrocyanation or isomerization are disclosed. The composition comprises repeat units derived from (1) a carbonyl compound, a monomer, and phosphorochloridite; (2) phosphorus trichloride, a polyhydric alcohol, and an aromatic diol; or (3) combinations of (1) and (2) in which the monomer can be a polyhydric alcohol, an amine, combinations thereof. The composition can further comprise a Group VIII metal and optionally a Lewis acid. The composition can be produced by (1) contacting a carbonyl compound with the monomer to produce an intermediate and contacting the intermediate with phosphorochloridite; (2) contacting phosphorus trichloride with a second polyhydric alcohol under a condition sufficient to produce a phosphorus-containing polymer and contacting the phosphorus-containing polymer with an aromatic diol; or (3) contacting an N,N-dialkyl dichlorophosphoramidite with a second polyhydric alcohol to produce a polymer phosphoramidite, contacting the polymer phosphoramidite with an acid such as HCl to produce the phospphorus-containing polymer, which is then contacted with an aromatic diol. The composition can be used as catalyst, for example, for converting an unsaturated organic compound to a nitrile and isomerizing a nitrile.

Owner:INVISTA NORTH AMERICA R L

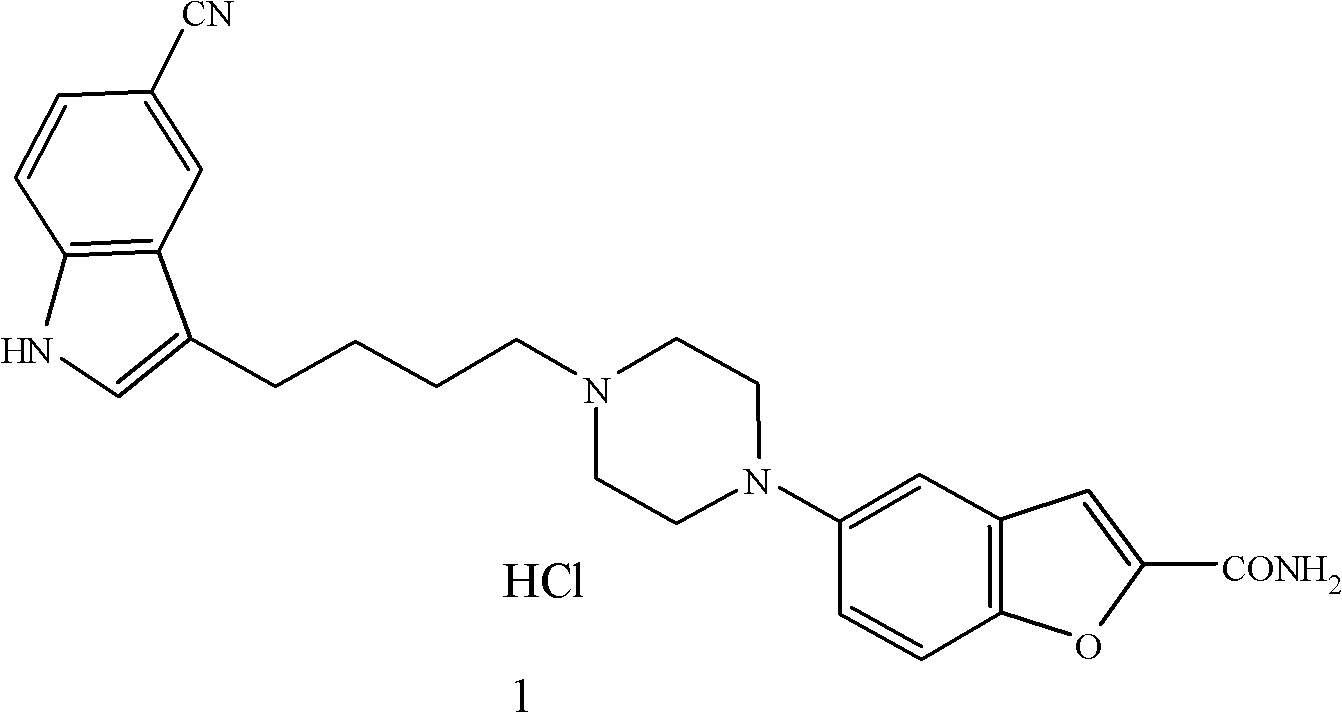

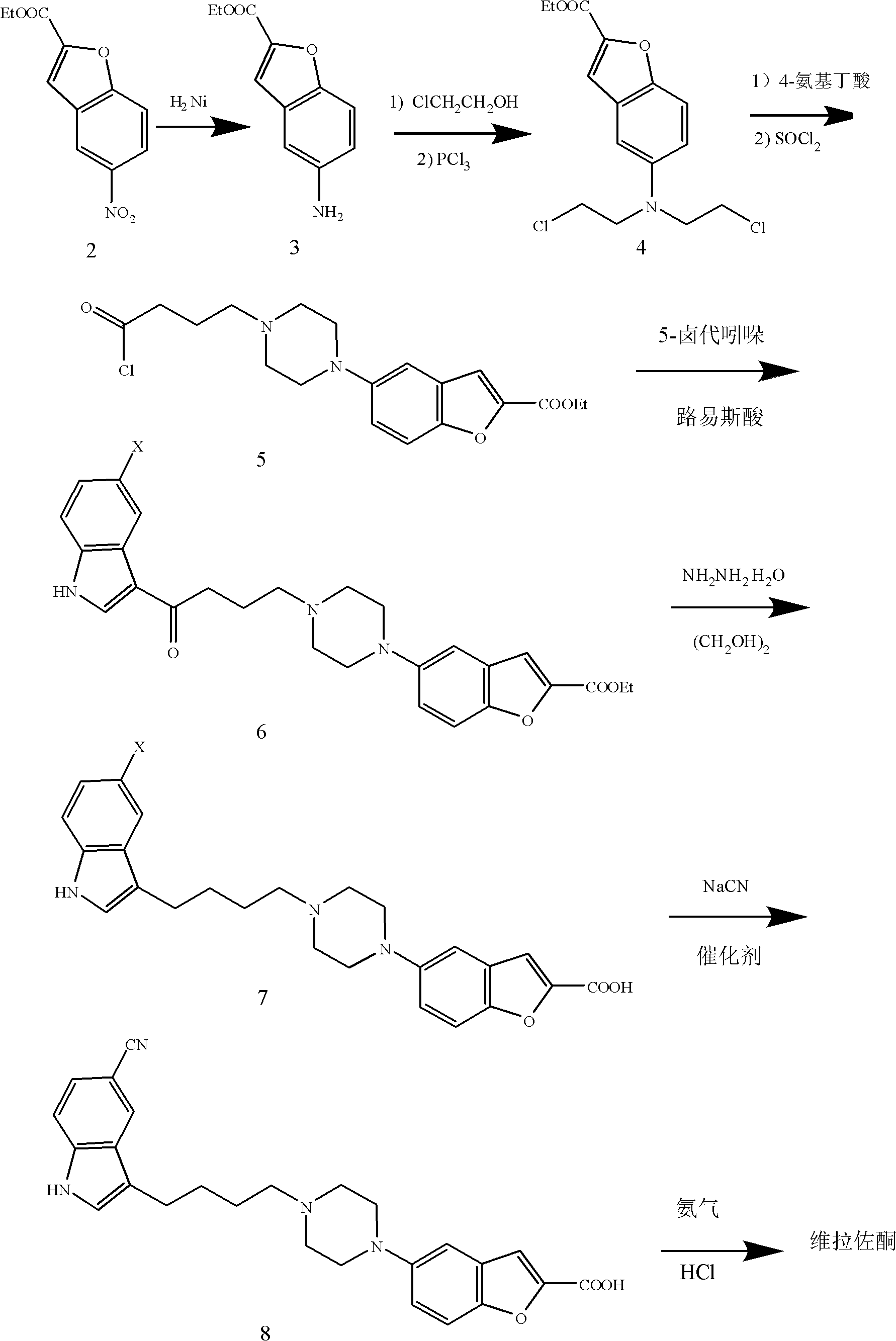

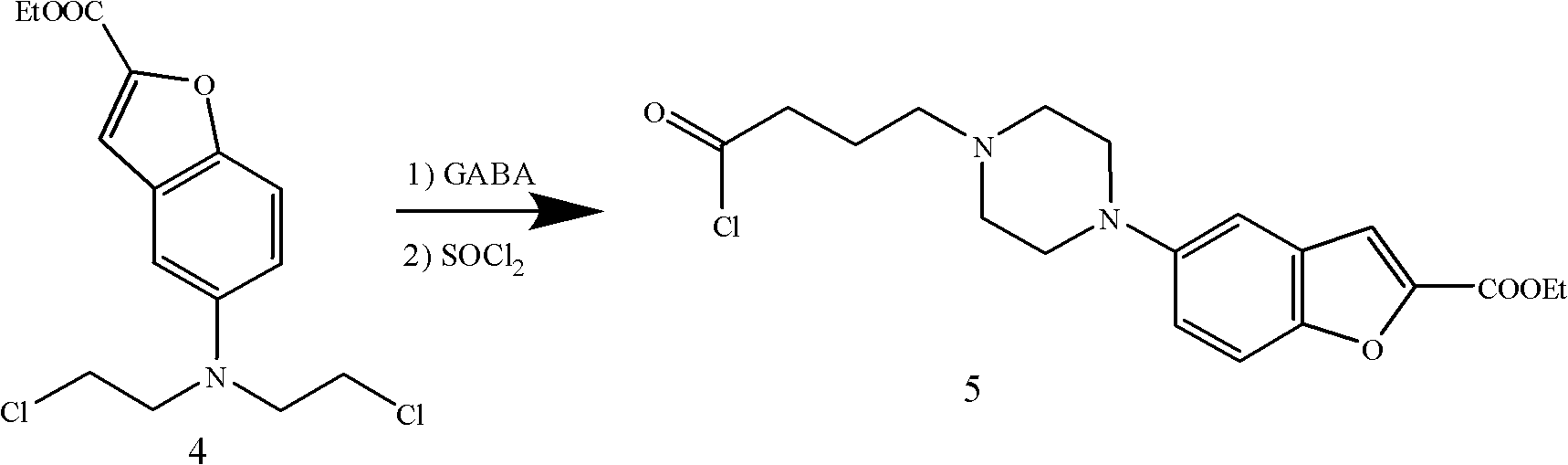

Method for preparing anti-depression medicine vilazodone

InactiveCN102180868AOvercome costsHigh reaction yieldOrganic chemistryCarboxylic acidPhosphorus trichloride

The invention provides a method for preparing an anti-depression medicine vilazodone, which comprises the following steps of: performing nitro reduction on 5-nitrobenzofuran-2-ethyl carboxylate serving as a raw material, conjugating with chlorohydrin, chlorinating by using phosphorus trichloride, cyclizing with 4-aminobutyric acid to generate a piperazine ring, performing acylchlorination, condensing with halogenated indole, performing carbonyl reduction, cyaniding, performing amidation, and the like to obtain the vilazodone. The method overcomes the defects in the prior art, is suitable for industrial production and has high application value, the used raw material is readily available, operating cost is low, and reaction yield is high.

Owner:SCI GENERAL MATERIAL & CHEM

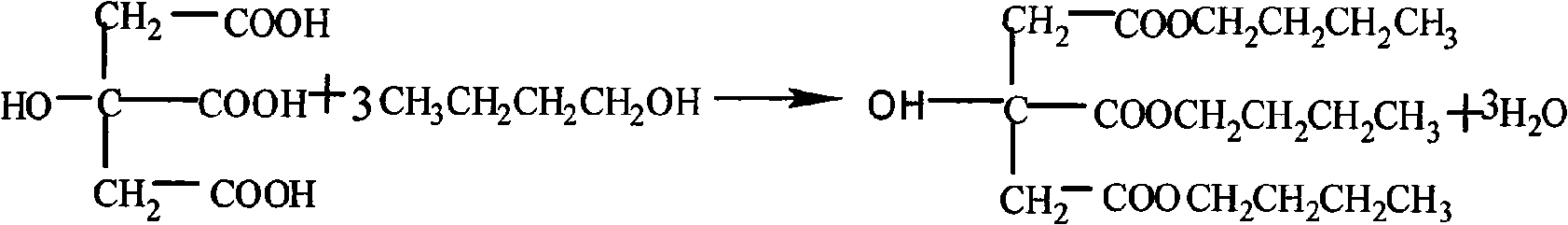

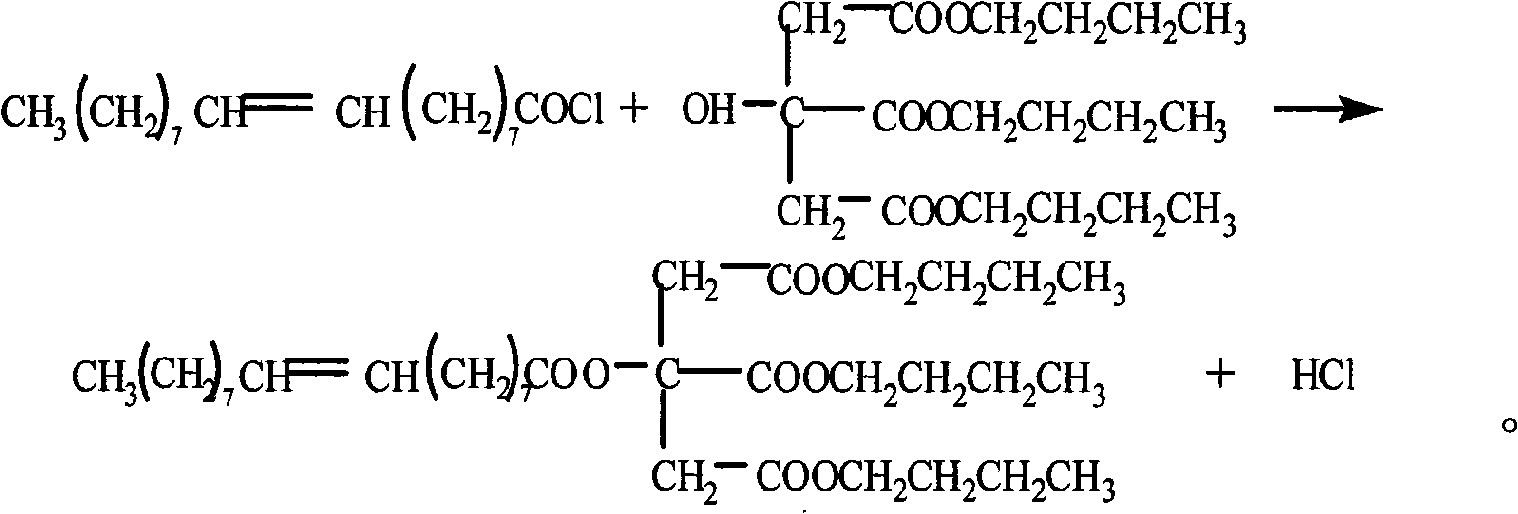

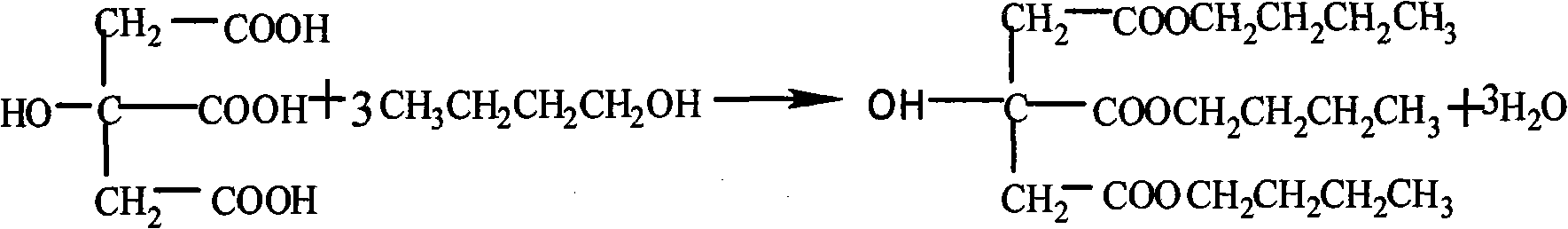

Method for preparing oleoyl tributyl citrate plasticizer

InactiveCN101255114AOrganic compound preparationCarboxylic acid esters preparationRoom temperatureChloride

The invention provides a method for preparing oleoyl tributyl citrate plasticizer, comprises: adding citric acid, n-butanol, water-carrying agent and catalytic agent into a reactor, stirring and heating up, controlling the temperature for reaction at 96 degree C until no water is generated again, and obtaining tributyl citrate; adding oleate into the reactor, stirring and heating up, dropping phosphorus trichloride into the reactor, reacting for 3h at 60 degree C, cooling to room temperature, standing for 2h, and separating to obtain; and a step 3, synthesizing oleoyl tributyl citrate; adding tributyl citrate and a catalytic agent into the reactor, stirring and heating up to 70 degree C, dropping oleoyl chloride, absorbing the generated hydrogen chloride by introducing the drier into base, stopping the reaction until the pH value of base has no change, and obtaining oleoyl tributyl citrate by neutralizing with sodium carbonate solution, water washing, and vacuum filtrating.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

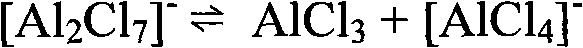

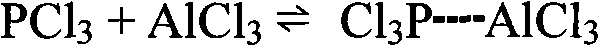

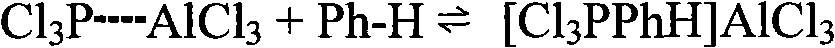

Synthesis method of methyl phosphorus dichloride

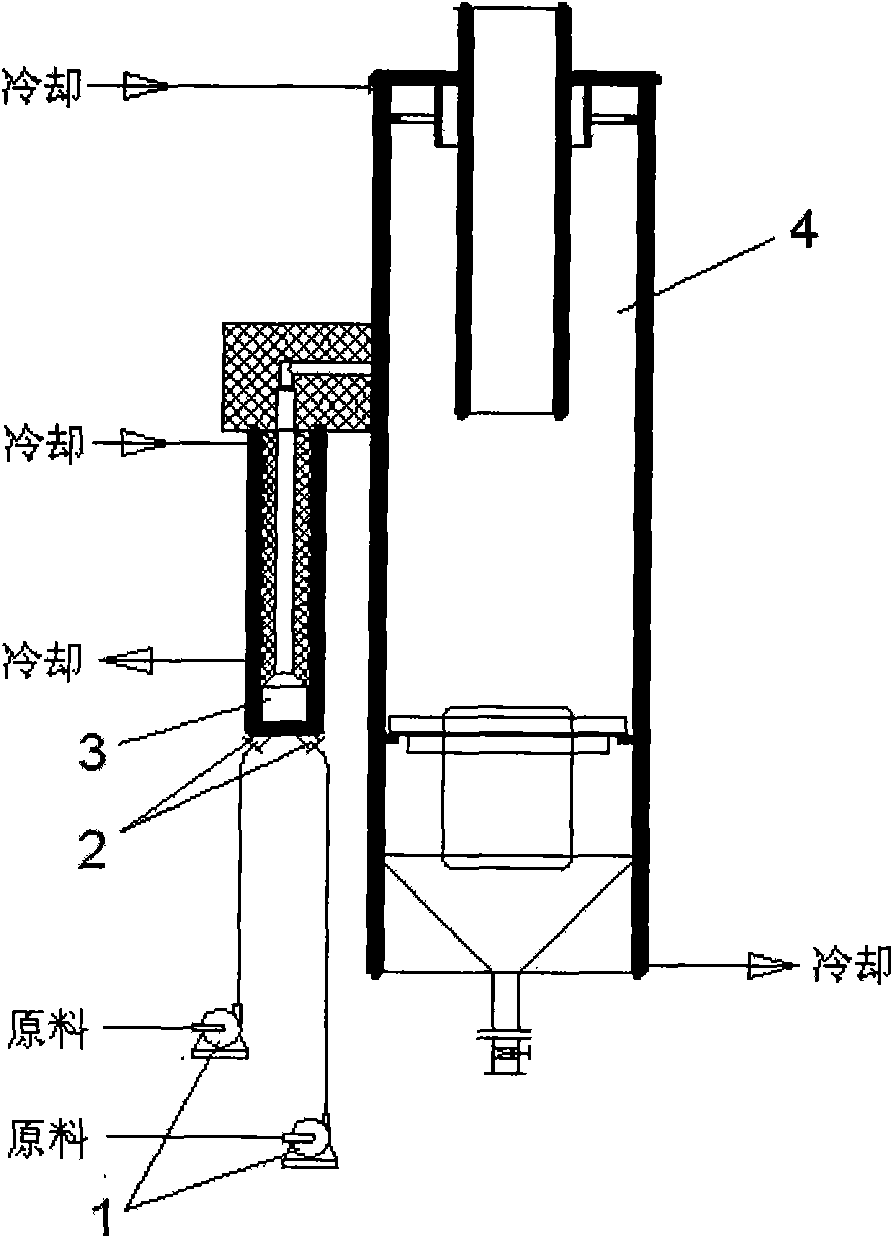

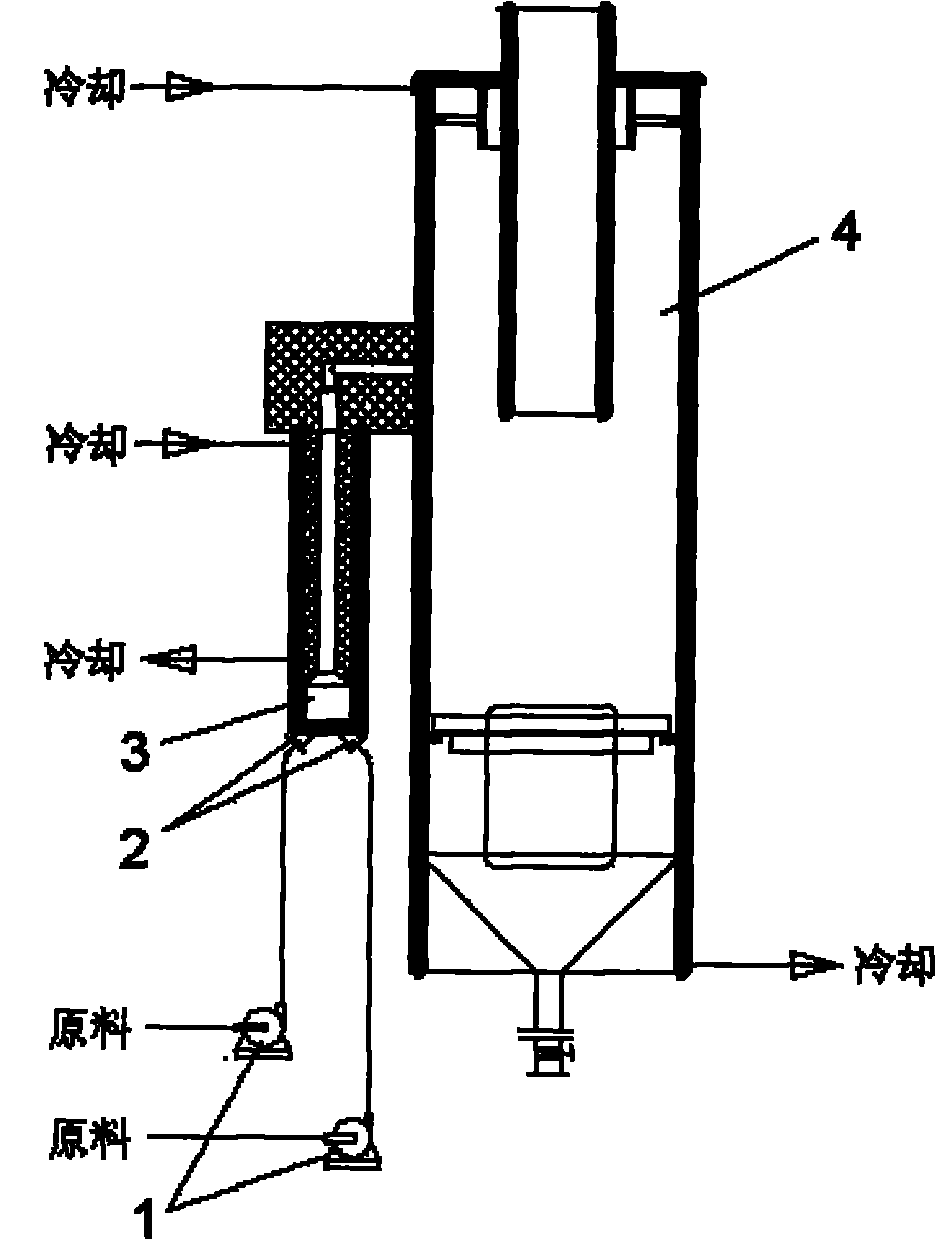

ActiveCN105669748ANo emissionsIn line with the principles of cleaner productionGroup 5/15 element organic compoundsSynthesis methodsDistillation

The invention discloses a synthesis method of methyl phosphorus dichloride. According to the synthesis method, methyl chloride, aluminum trichloride and phosphorus trichloride serve as raw materials, petroleum ether serves as a solvent, ligands CH3PCl4.AlCl3 are generated through reaction, after petroleum ether is recycled through distillation, aluminum powder and petroleum ether are added, and the methyl phosphorus dichloride is obtained through reduction under the action of a catalyst. The synthesis method of methyl phosphorus dichloride can replace an existing technology to solve the problem of emission of organic waste gas in the preparation process, and the method is a complete synthesis technology process according with the clean production principle better. Besides, compared with the prior art, the synthesis method has a better production effect, and in other words, the yield of the methyl phosphorus dichloride can reach 91% (denoted by phosphorus dichloride).

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD

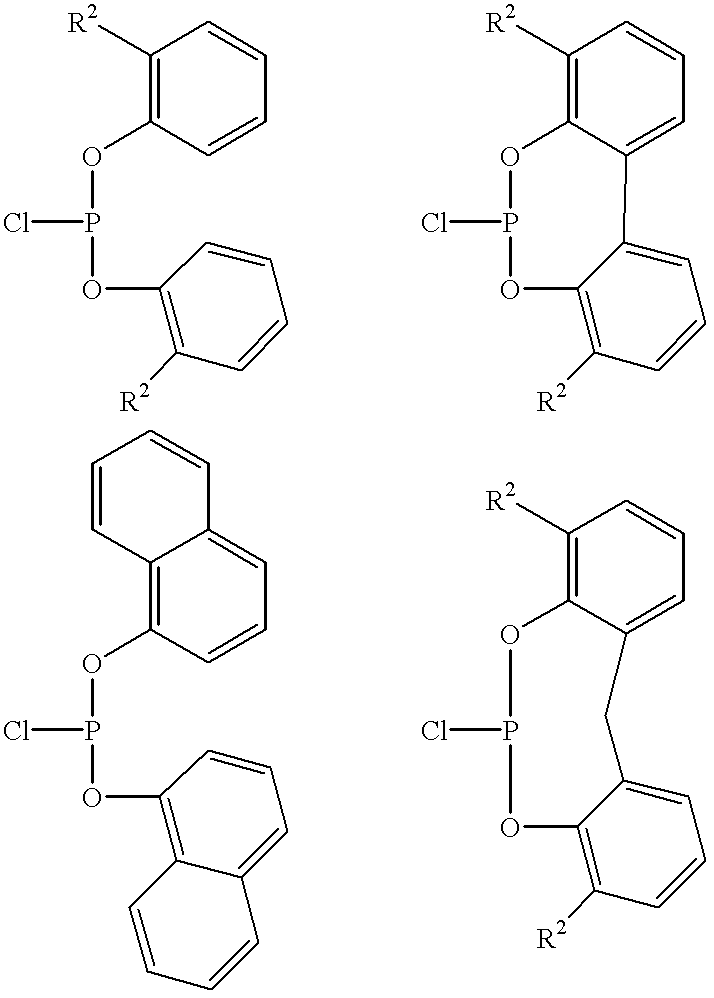

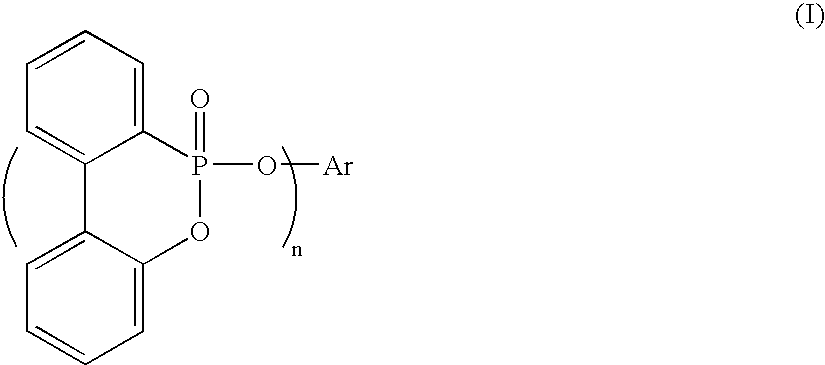

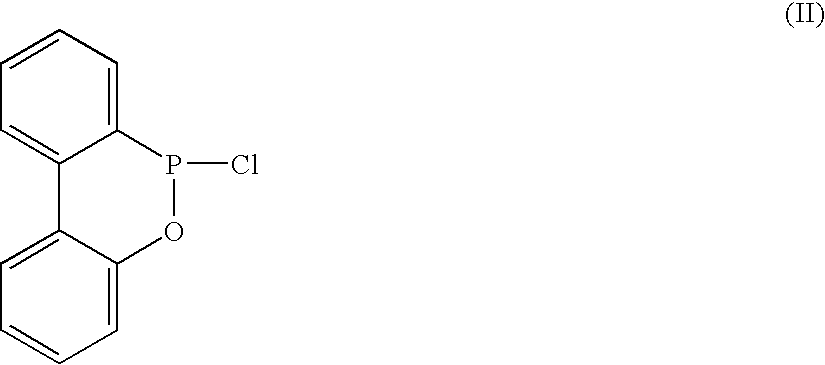

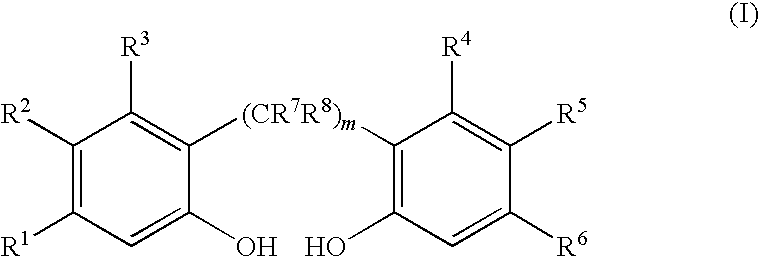

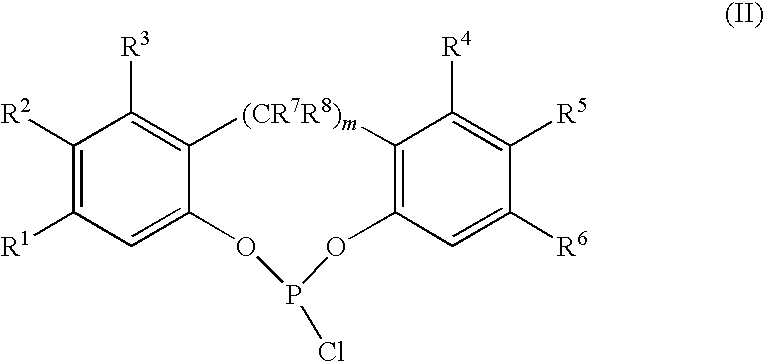

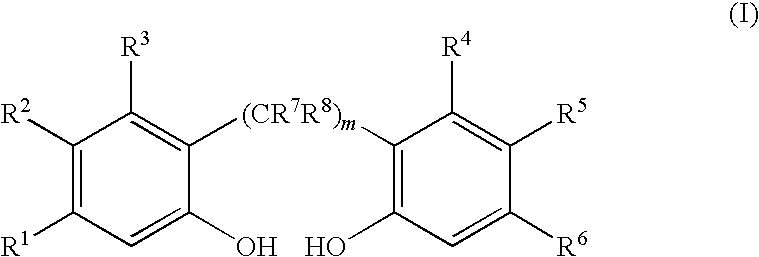

Method for preparing a biphenylphosphonate compound

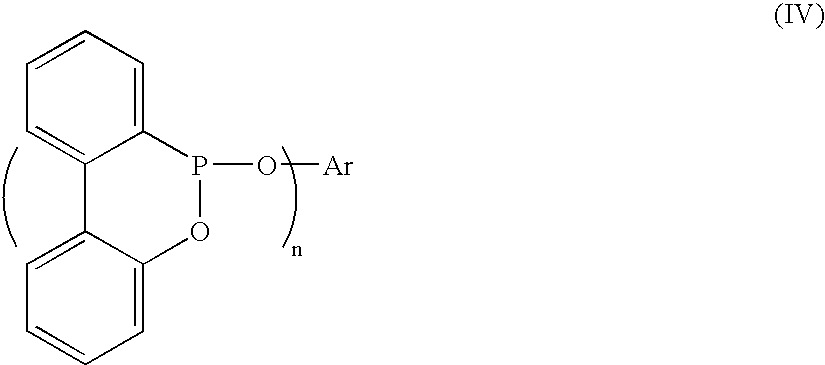

A method for preparing a biphenylphosphonate compound of the following formula (I): wherein n is 2 or 3; Ar is a C6-C16 aromatic group; which comprising (a) reacting an o-phenylphenol with a phosphorus trichloride in the presence of a zinc chloride catalyst to form a 6-chloro-6H-dibenz [c,e][1,2] oxaphosphorin of the following formula (II); (b) reacting a polyhydroxybenzene compound of the formula (III) (HO)n—Ar (III) wherein n and Ar are defined the same as the above, with the compound of formula (II) to form a compound of the following formula (IV) wherein n and Ar are defined the same as the above; and (c) oxidizing the compound of formula (IV) in the presence of water and ozone to form the compound of formula (I).

Owner:NAT CHUNG SHAN INST SCI & TECH

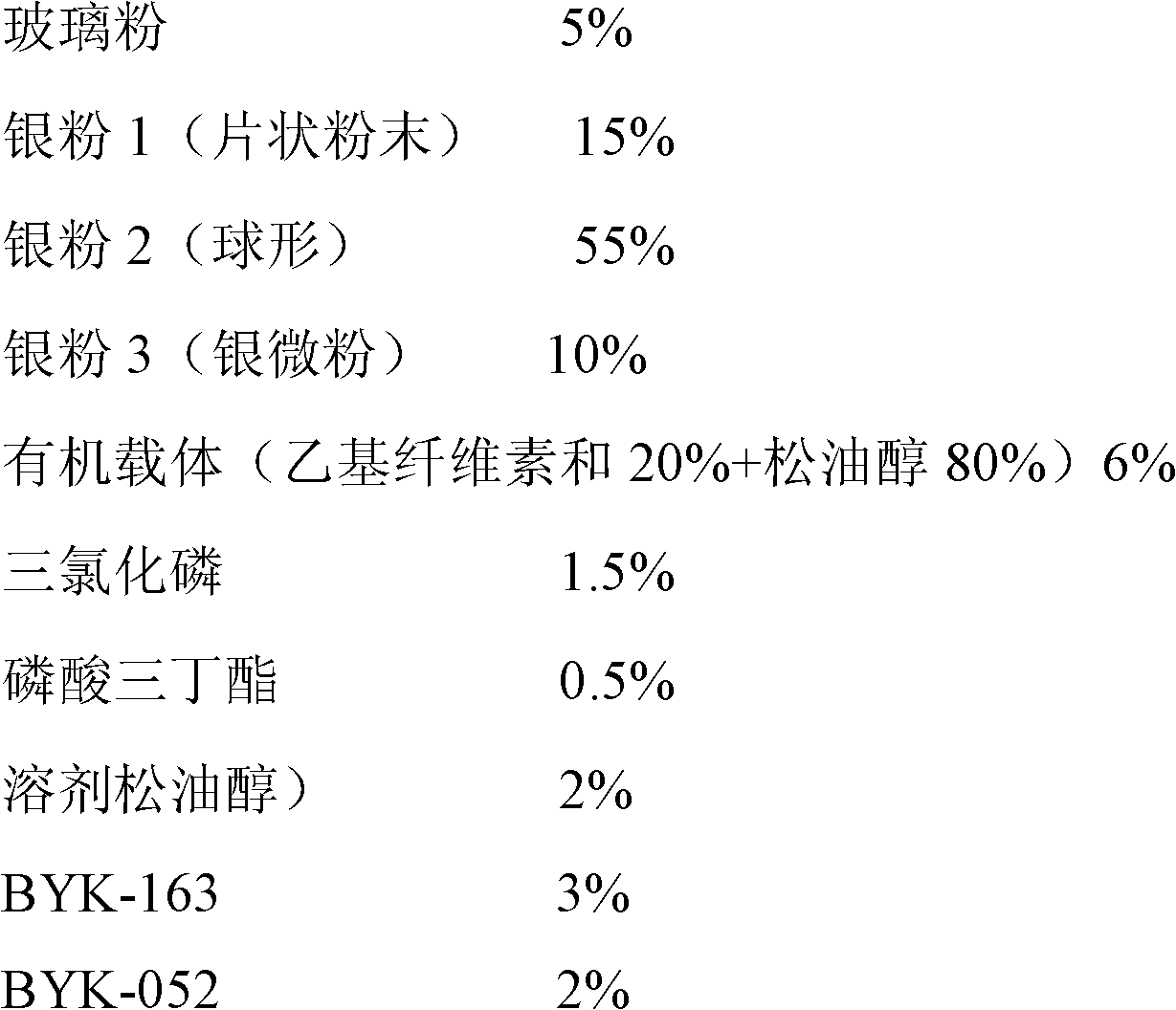

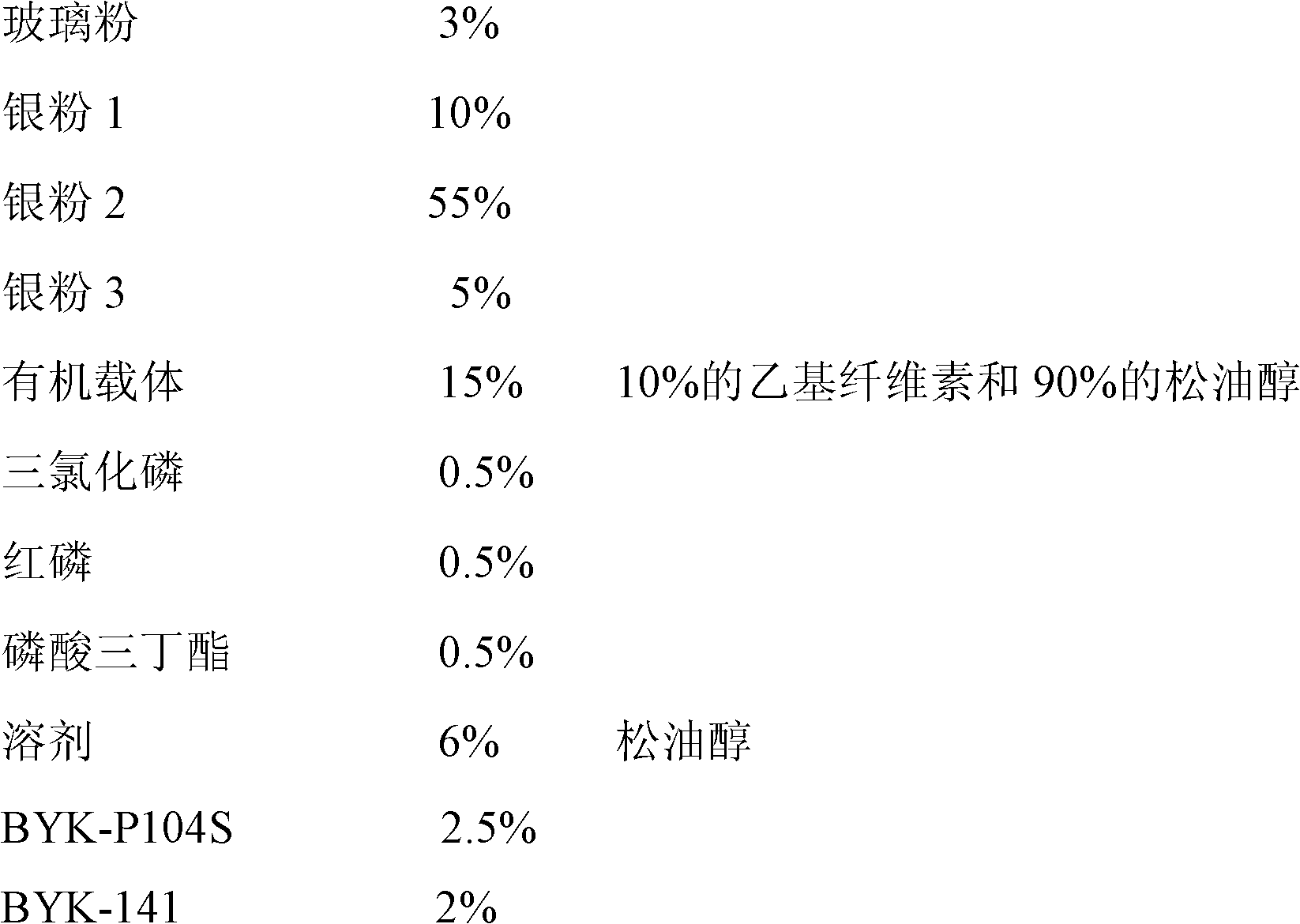

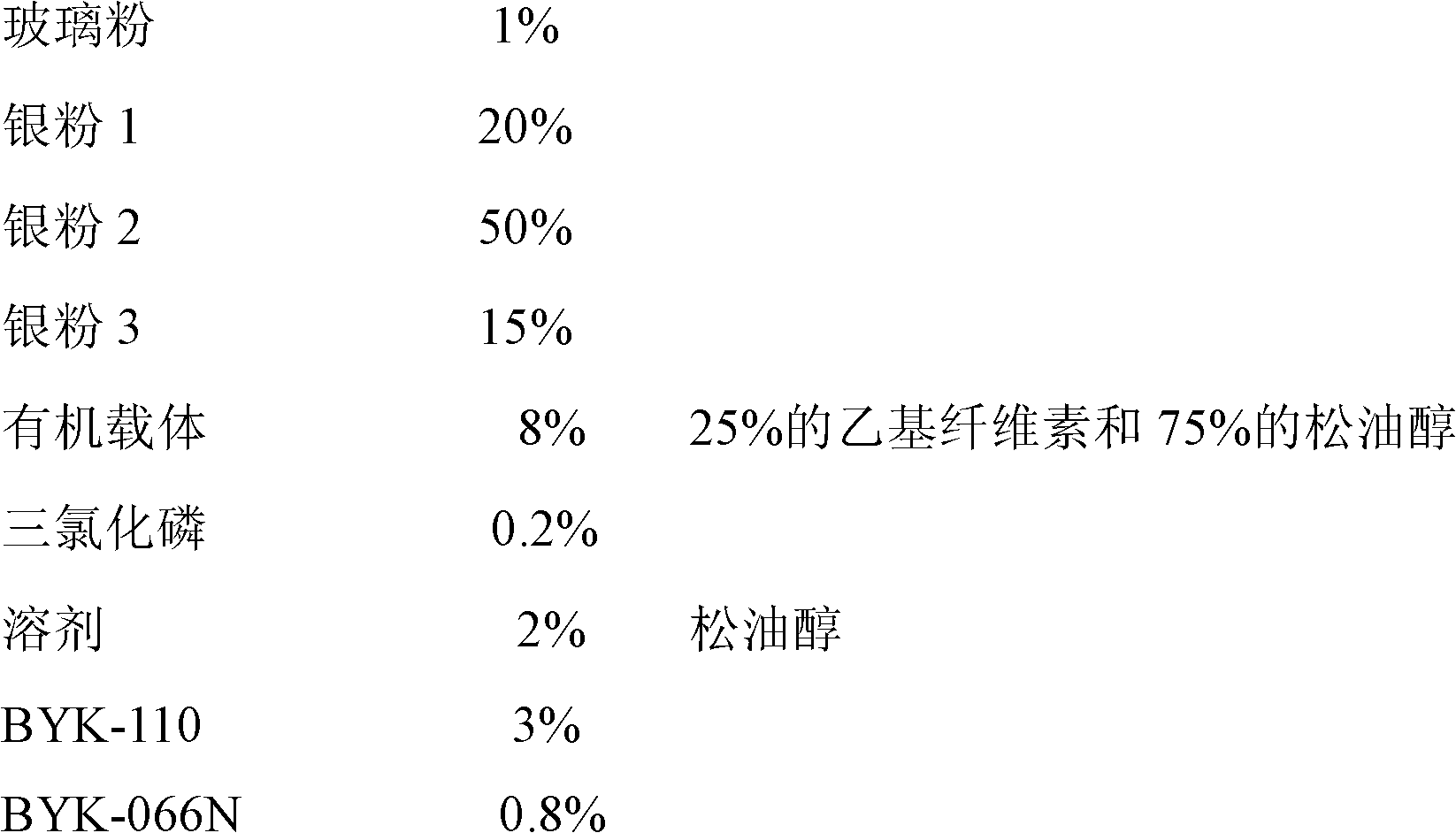

Front silver paste for silicon solar cells and preparation method thereof

InactiveCN102426874AImprove photoelectric conversion efficiencyImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureConductive pasteSilver paste

The invention relates to front silver paste for silicon solar cells and a preparation method thereof. The silver paste is characterized by comprising the following components by weight percent: 6-15% of organic carrier, 1-5% of binders, 2-6% of solvents, 0.5-5% of auxiliaries, 0.1-2% of additives and the balance of conductive silver powder. The invention relates to conductive paste for front electrodes of silicon solar cells. The paste comprises conductive silver powder, an organic carrier, binders, solvents and auxiliaries. The paste also comprises additives selected from one or more of phosphorus trichloride, red phosphorus and tributyl phosphate. The additives in the conductive paste can conduce to improvement of the conductivity of the conductive paste, therefore the finally prepared solar cells have higher photoelectric conversion efficiency.

Owner:IRICO

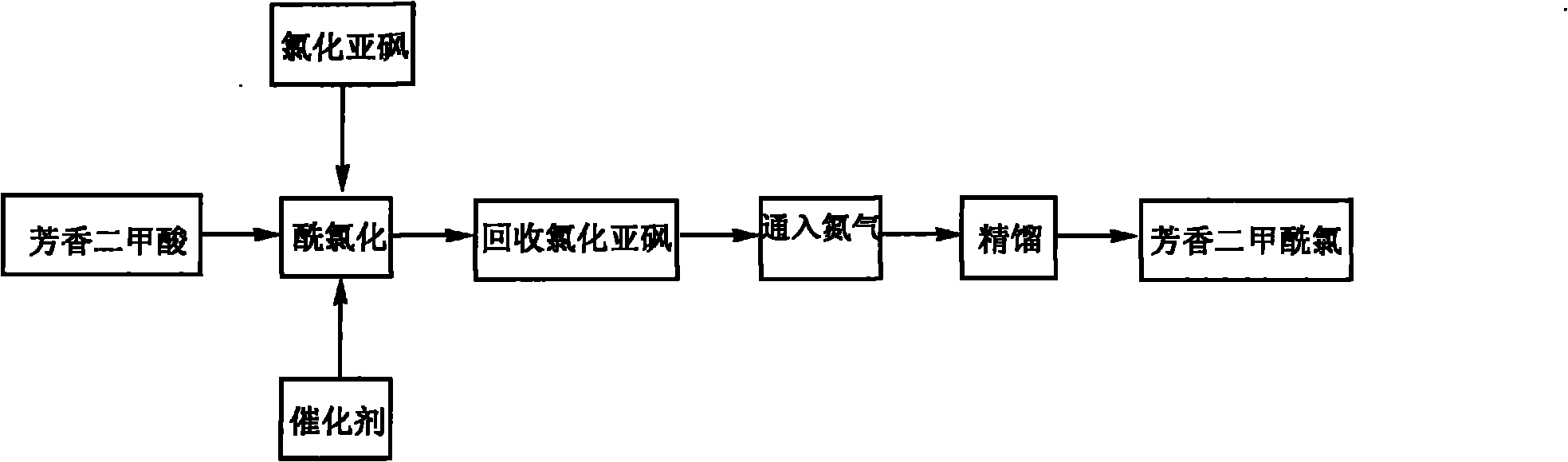

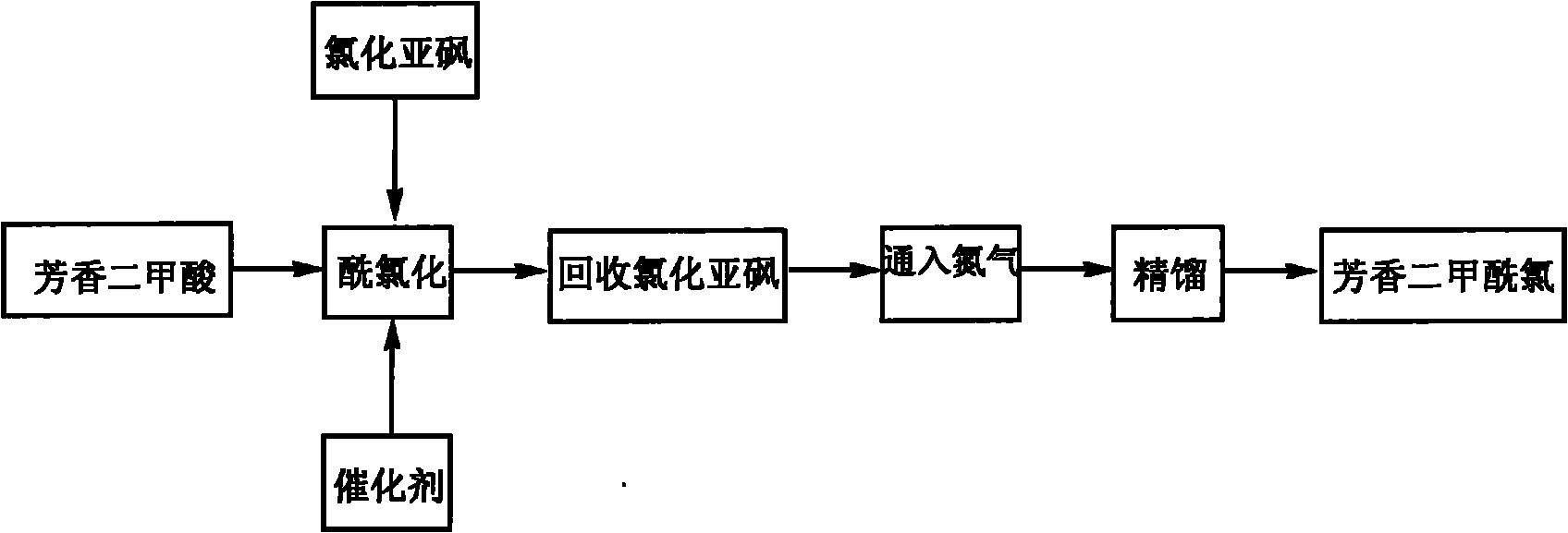

Method for preparing aromatic dimethyl chloride

InactiveCN102093209AHigh yieldHigh purityOrganic compound preparationCarboxylic compound preparationPyridinePhosphorus pentachloride

The invention discloses a method for preparing aromatic dimethyl chloride, which relates to the technical field of preparation methods of aromatic chloride. The method comprises the following steps of: reacting aromatic dioctyl phthalate with a chlorinating agent to generate the aromatic dimethyl chloride; evaporating the chlorinating agent; exhausting tail gas; and distilling the obtained aromatic dimethyl chloride, wherein the reaction of the aromatic dioctyl phthalate and the chlorinating agent is performed in the presence of a catalyst, namely pyridine or N-methyl pyrolidone; and the chlorinating agent is one or more of chlorine, phosphorus trichloride, phosphorus pentachloride and thionyl chloride. Compared with the prior art, the method for preparing the aromatic dimethyl chloride has the advantages that: the yield and the purity of the aromatic dimethyl chloride are increased, transformation rate is up to 95 percent, and the purity is up to 99.9 percent.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

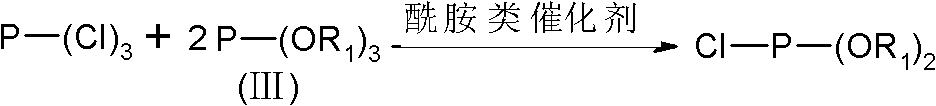

Preparation method of antioxidant product with stable performance

ActiveCN101798325ASimple production processHigh yieldGroup 5/15 element organic compoundsDistillationSolvent

The invention provides a preparation method of antioxidant product with stable performance. 2, 4-di-tert-butylphenol and phosphorus trichloride are taken as raw materials, organic amino compound is taken as catalyst, organic solvent is taken as reaction solvent, esterification is carried out to prepare tri(2,4-ditertrabutyl phenyl) phosphite ester crystal product, namely antioxidant crude product; after reaction is completed, the organic solvent is added into a kettle, so that the antioxidant crystal product is completely dissolved into the organic solvent, an amount of triethylamine is added to react with HCl remained in product mixture, so as to generate triethylamine hydrochloride crystal, filter aid is added to remove solids triethylamine hydrochloride and organic amine catalyst hydrochloride by heat filtering, reduced pressure distillation is carried out to remove the organic solvent, and crystal is washed by low carbon fatty alcohol, thus obtaining the antioxidant product with stable performance. The invention has the advantages of simple production technology, high product yield and good quality; and the obtained product has long time hydrolytic resistance, pyrolysis resistance and good oxidation resistance.

Owner:溧阳常大技术转移中心有限公司

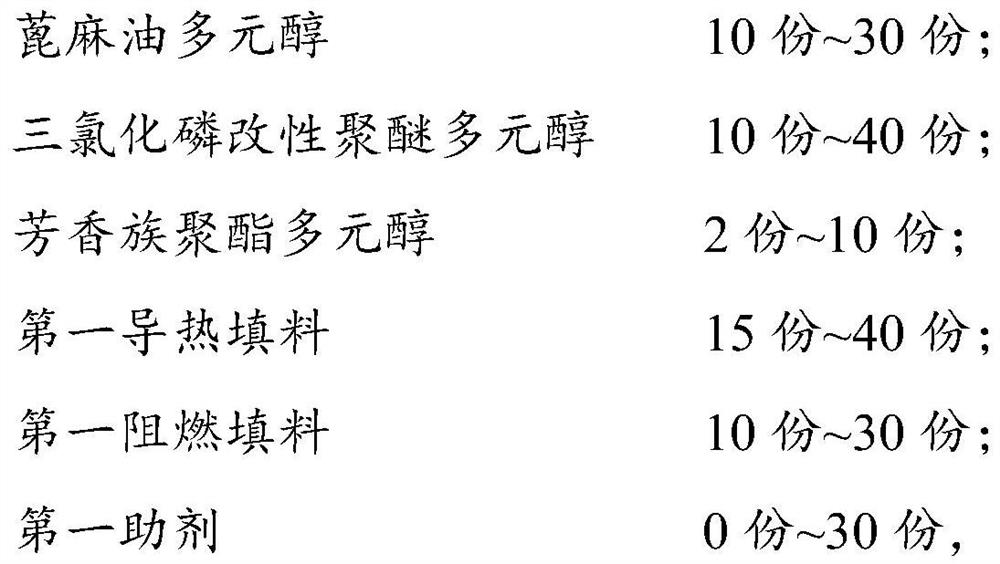

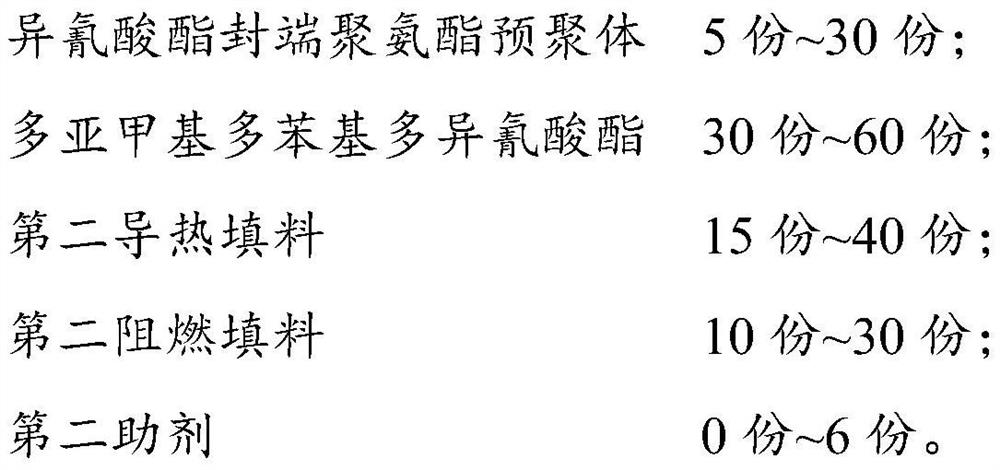

Two-component polyurethane structural adhesive and preparation method thereof

ActiveCN112608707AHigh ignition pointReduced thermal stabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPhosphoric Acid Esters

The invention discloses a two-component polyurethane structural adhesive and a preparation method thereof. The two-component polyurethane structural adhesive is prepared from a component A and a component B. The component A comprises castor oil polyol, phosphorus trichloride modified polyether polyol, aromatic polyester polyol, a first heat conduction filler, a first flame-retardant filler and a first assistant, and the component B comprises an isocyanate-terminated polyurethane prepolymer, polymethylene polyphenyl polyisocyanate, a second heat-conducting filler, a second flame-retardant filler and a second auxiliary agent; the two components are mixed according to a certain volume ratio to prepare the double-component polyurethane structural adhesive. The phosphorus trichloride modified polyether polyol is a special alkyl phosphite stabilizer and is also a phosphorus-containing polyol flame retardant, so that the use amount of flame-retardant filler can be reduced, the component density can be reduced, and the crosslinking density of the system can be improved; the bi-component polyurethane structural adhesive has the advantages of low density, and high flame retardancy, heat conductivity, high-temperature shear strength and low-temperature curing property.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD +1

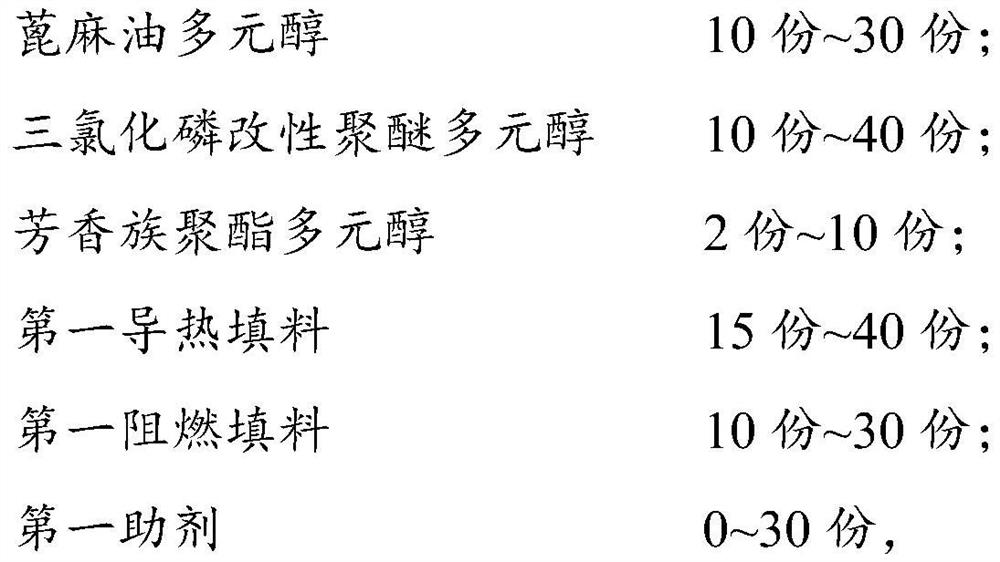

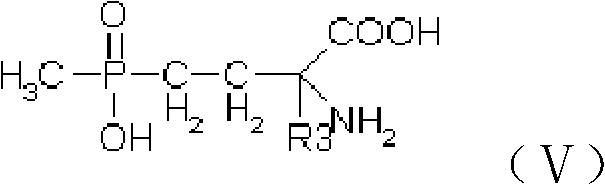

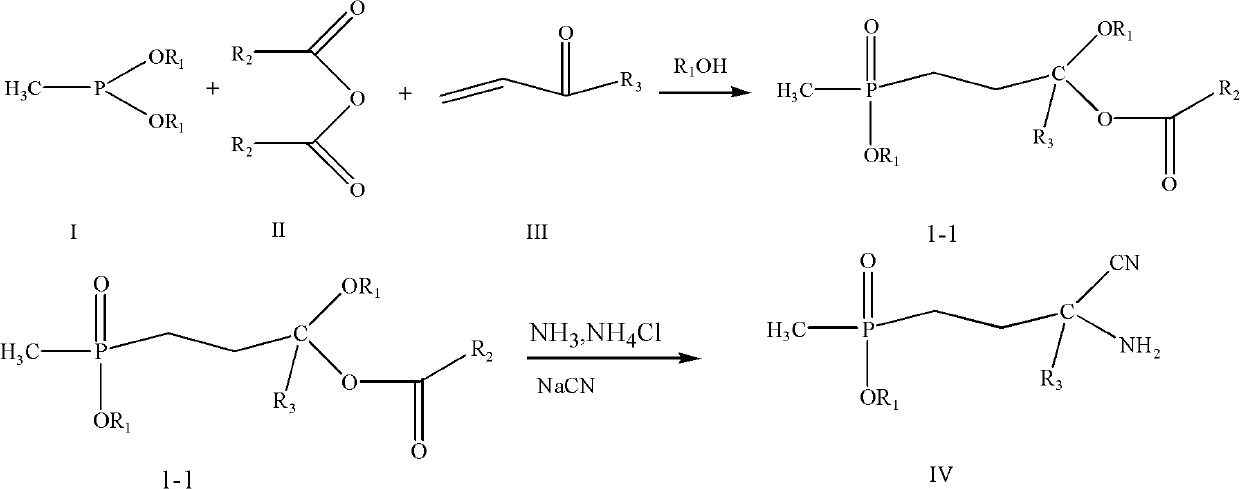

Synthesis method for glufosinate and analogue thereof

InactiveCN102399239AReduce generationReduce processing costsGroup 5/15 element organic compoundsDiethyl phosphateSynthesis methods

The invention provides a synthesis method for glufosinate shown as a formula (V) and an analogue thereof. The method comprises the following steps of: preparing an intermediate such as methyl diethyl phosphate by Grignard, disproportionation and coupling and with phosphorus trichloride, triethyl phosphate and chloromethane as initiative raw materials; condensing the methyl diethyl phosphate, anhydride and acrolein substances; performing Strecker reaction and hydrolysis and thus obtaining the glufosinate and the analogue thereof. In the synthesis method, the reaction condition is mild; safety is high; and yield is obviously increased.

Owner:JIANGSU YOUTH CHEM +1

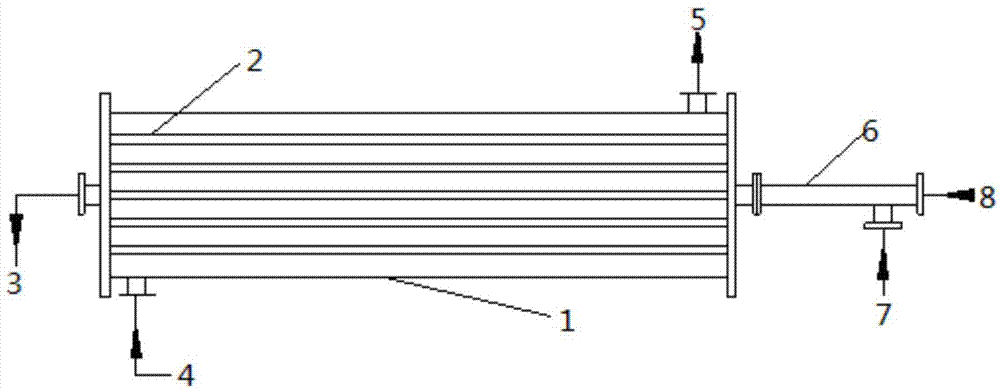

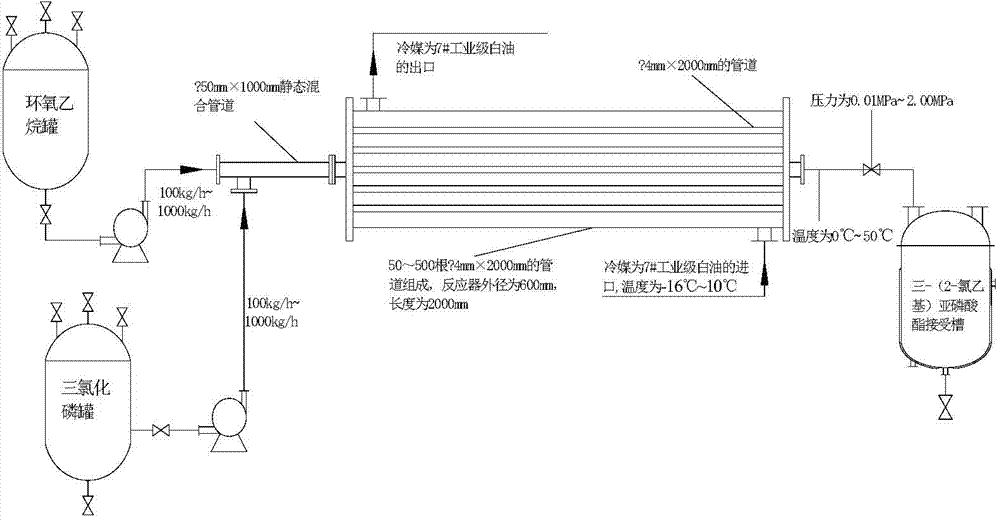

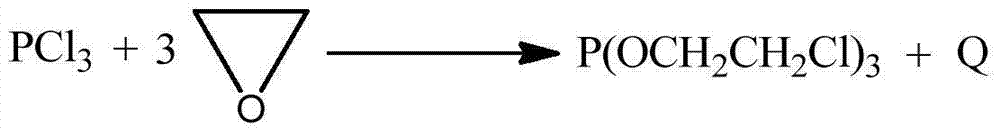

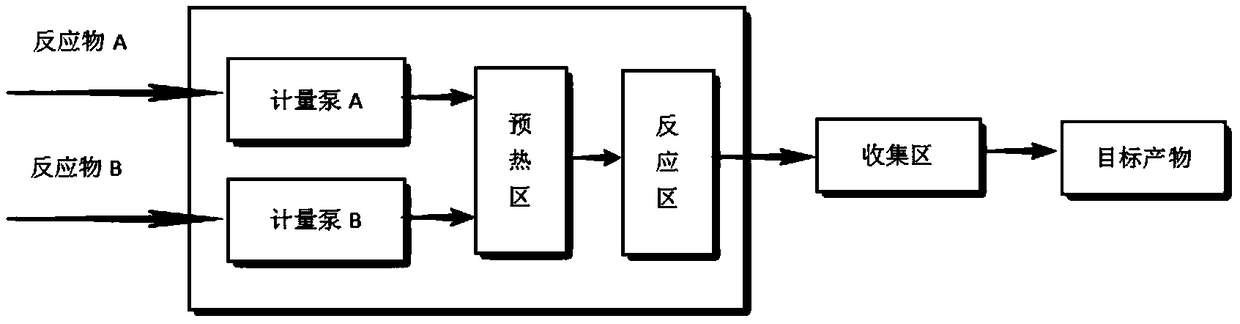

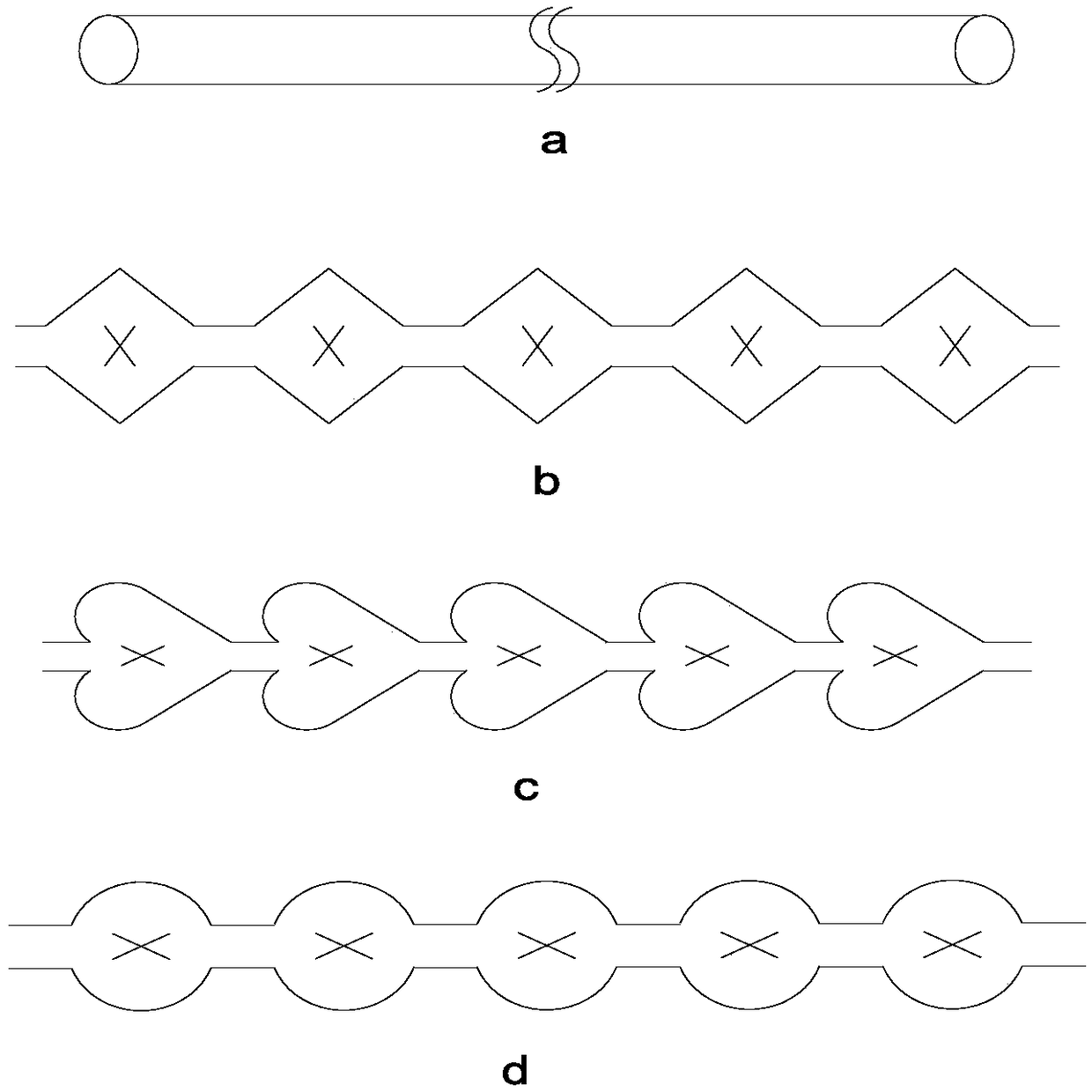

Method utilizing micro-channel to prepare tris(2-chloroethyl)phosphite

ActiveCN104119374AIncrease contentPrevent oxidationGroup 5/15 element organic compoundsEthylene oxidePhosphorus trichloride

The invention discloses a method utilizing micro-channel to prepare tris(2-chloroethyl)phosphite. The method comprises the following steps: taking phosphorus trichloride and ethylene oxide as the raw materials, and then carrying out reactions in a micro-channel reaction system composed of a micro-channel reaction device which is formed by coupling a pipeline-type pre-mixer and cooling-medium cooling equipment; and specifically comprises the following steps in sequence: first continuously pumping phosphorus trichloride and ethylene oxide into a pipeline-type pre-mixer to carry out premixing, then introducing the mixture into a micro-channel reaction device, starting the cooling-medium cooling equipment of a micro-channel reaction system, and collecting the effluent liquid from the micro-channel reaction device after the reactions finish, wherein the effluent liquid is tris(2-chloroethyl)phosphite. The method can largely increase the esterification product content, the production efficiency is increased by 500 to 1000 times compared to that of common tank reactor, and the standing time of the esterification products in the reactor is reduced from 110 hours to dozen minutes.

Owner:SHAOXING EASTLAKE HIGH TECH CO LTD

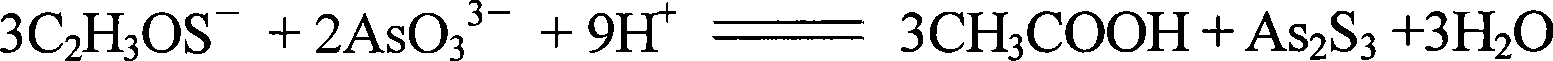

Hydroxylethylidene diphosphonic acid with arsenic content <=3ppm and preparation technique thereof

ActiveCN101386628AReduce arsenic levelsReduce pollutionGroup 5/15 element organic compoundsAcetic acidEtidronic acid

The invention discloses an etidronic acid with the content of arsenic less than or equal to 3ppm and a process for preparing the same. The method is to use phosphorus trichloride, acetic acid and ammonium thioacetamide as raw materials and comprises the following steps of: putting one-third of the acetic acid and the ammonium thioacetamide into a reaction kettle, stirring to control the temperature and the pressure, slowly dropping one-third of the phosphorus trichloride and putting one-third of the ammonium thioacetamide into the reaction kettle, stopping stirring and keeping stand; controlling the temperature and the pressure; dropping the remaining phosphorus trichloride into the reaction kettle; then stirring for 1 hour with the rotational speed of 50 to 60 revolutions per minute, raising the temperature slowly and reflowing; controlling the temperature and the pressure while reflowing; hydrolyzing the esters produced after reflowing under the negative pressure; concentrating the materials, filling air, removing impurities, reducing the temperature, putting the remaining phosphorus trichloride into the reaction kettle, sealing the reaction kettle and keeping stand, and then putting the materials into a mixing tank; regulating and filtering the materials so as to obtain an HEDP product. The product has extremely little arsenic with less than or equal to 3ppm, which not only reduces the environmental pollution, but also expands the application fields.

Owner:HENAN QINGSHUIYUAN TECH

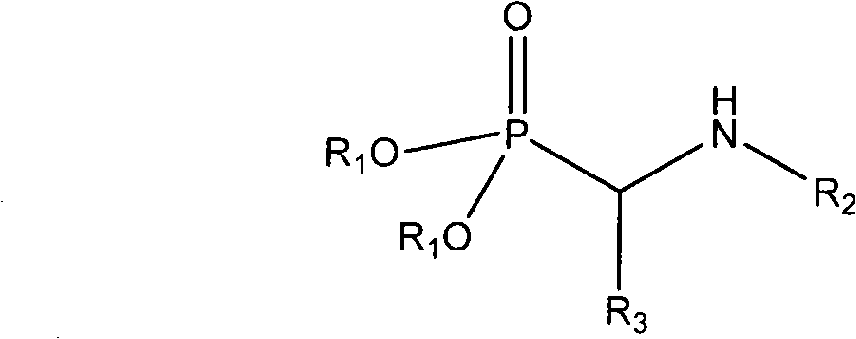

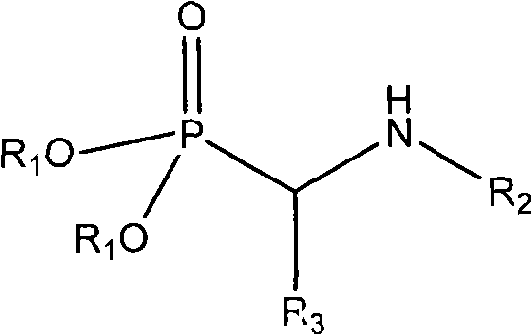

Isothermal process for phosphoromonochloridite synthesis

The present invention relates to a process for preparation of a phosphoromonochloridite in high yield by contacting phosphorus trichloride (PCl3) with an aromatic diol in a solution of one or more organic solvents under reaction conditions sufficient to produce the phosphoromonochloridite. The reaction is carried out by adding a feed solution containing the aromatic diol dissolved in a first organic solvent into a reaction zone containing PCl3, and optionally one or more second organic solvents, the addition being conducted so as to maintain substantially isothermal process conditions. The reaction solution comprises greater than 0.01 to less than 5 mole percent of a nitrogen base.

Owner:UNION CARBIDE CORP

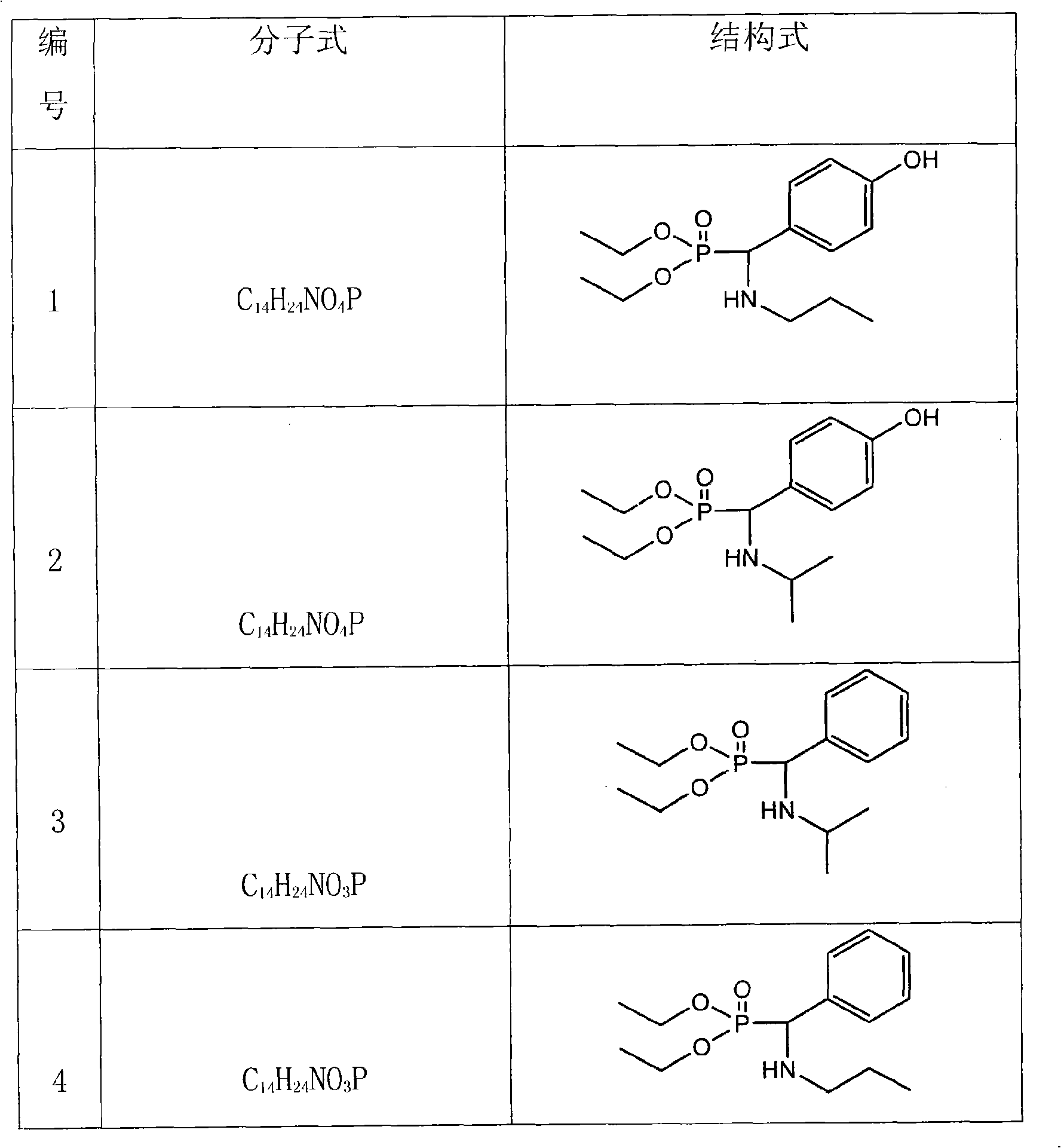

Synthetic method of floating agent of organophosphorous compound and organophosphorous floating agent

InactiveCN101537395AThe synthesis method is simpleEasy to operateGroup 5/15 element organic compoundsFlotationOrganophosphorous compoundsDistillation

The invention discloses a synthetic method of a floating agent of organophosphorous compound and the organophosphorous floating agent, belonging to the technical field of mineral separation. The synthetic method comprises the steps of: taking phosphorus trichloride as a phosphorus source, dissolving parahydroxyben-zaldehyde in ethanol, slowly dropping excess propylamine, reacting at room temperature, then obtaining product imine, using the mixture of the phosphorus trichloride and petroleum ether to prepare phosphite ester in a mixing liquid of the ethanol and the petroleum ether, then using the phosphite ester, the imine and anhydrous ether to prepare the mixture of phosphoramidic acid, imine, small amount of phosphite ester and solvent ether, and then conducting distillation, column chromatography and separation to obtain the organophosphorous floating agent phosphoramidic acid, therefore the method obtains 20 types of phosphoramidic acid compounds, and from which, 2-3 efficient and novel organophosphorous floating agents can be selected for use. The invention has simple synthetic method, easy operation and short period, and the obtained organophosphorous floating agent is widely applied to mineral dressing due to special structure thereof.

Owner:TSINGHUA UNIV

Method for synthesizing diphenyl phosphonium chloride

InactiveCN102942591AReduce dosageDoes not destroy activityGroup 5/15 element organic compoundsChemical recyclingLiquid layerBenzene

The invention discloses a method for synthesizing diphenyl phosphonium chloride. The method includes: performing reaction on raw materials of phosphorus trichloride and excessive benzene under catalyzing effect of Lewis acid ionic liquid, wherein after the reaction, the reaction liquid is divided into two layers, one layer is an ionic liquid layer, and the other layer is a mixed liquid layer. Through direct liquid separation, the ionic liquid layer is extracted, the extract liquor is mixed with the mixed liquid layer, and the mixture is respectively performed with normal pressure distillation and decompression distillation to obtain the target object diphenyl phosphonium chloride and byproduct phenyl phosphonium chloride. The ionic liquid is performed with normal pressure and decompression distillation so as to remove impurities and recover the diphenyl phosphonium chloride. Compared with the existing industrial process, the method has the advantages of being small in catalyst amount, requiring no decomplexing procedure, being easy to operate and control, not generating large amount of waste residue, being low in production cost, environment-friendly in production process and the like, and the catalyst is recoverable.

Owner:SHANDONG UNIV OF SCI & TECH

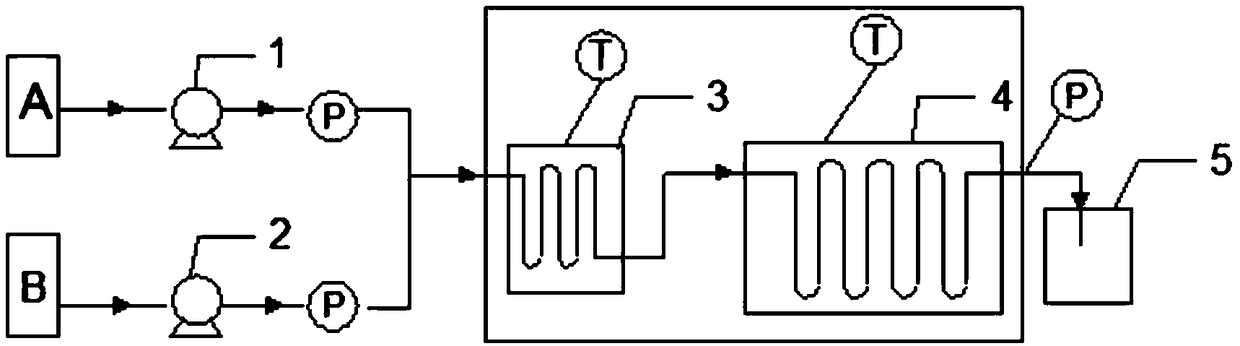

Method for continuous synthesis of dialkyl phosphite in micro-channel reactor

InactiveCN108840884AShort reaction timeIncrease temperatureGroup 5/15 element organic compoundsChemical industryAlcoholDolichyl phosphate

The invention discloses a method for continuous synthesis of dialkyl phosphite in a micro-channel reactor and belongs to the technical field of organic synthesis technologies. The method is used for generating the dialkyl phosphite through continuous reaction in the micro-channel continuous-flow reactor by using alcohol and phosphorus trichloride as substrates. Phosphorus trichloride is used as the material A, an alcohol solution is used as the material B, and the material A and the material B enter a micro-channel simultaneously through a metering pump for the continuous esterification reaction. According to the technological method, the high mass and heat transfer efficiency of the micro-channel reactor is utilized, the mass transfer rate between the two phase materials is effectively increased, and the safety and the operability of a test are greatly improved.

Owner:CHANGZHOU UNIV

Synthesis method of palmitoyl amino acid sodium

ActiveCN102863348AAdvanced process routeHigh reaction yieldOrganic compound preparationCarboxylic acid amides preparationPalmitoyl chlorideActive agent

The invention relates to a synthesis method of palmitoyl amino acid sodium in the surfactant field, in particular relates to a method for preparing palmitoyl amino acid sodium by using palmitoyl chloride synthesized by a phosgene method. The synthesis method comprises the following steps: by taking palmitic acid and phosgene as raw materials, preparing palmitoyl chloride through reaction in the presence of an organic amide catalyst; dropwise adding palmitoyl chloride in an amino acid alkaline solution to obtain palmitoyl amino acid through reaction; and dissolving obtained palmitoyl amino acid with ethanol and adding the ethanol solution of sodium hydroxide to finally obtain palmitoyl amino acid sodium. In the synthesis method, a lot of phosphorus-containing wastewater is not produced even though phosphorus trichloride is used as a chlorination agent; sulfur dioxide generated by a thionyl chloride method can heavily pollute the environment; and the synthesis method reasonable in process, high in reaction yield and good in product quality, and the product does not contain residual phosphorus and sulfur and can be widely used in high-end anti-aging cosmetics.

Owner:CHANGSHA PUJI BIOTECH

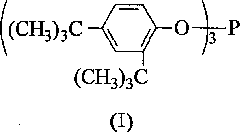

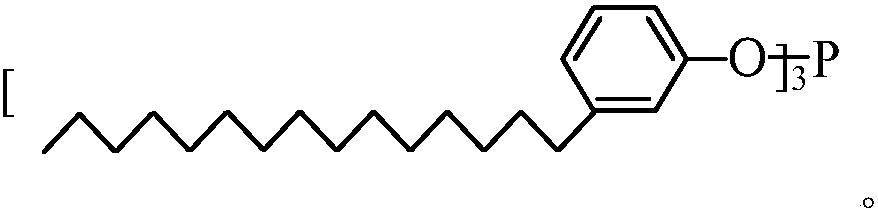

Novel biological based phosphite ester type antioxidant and preparation method thereof

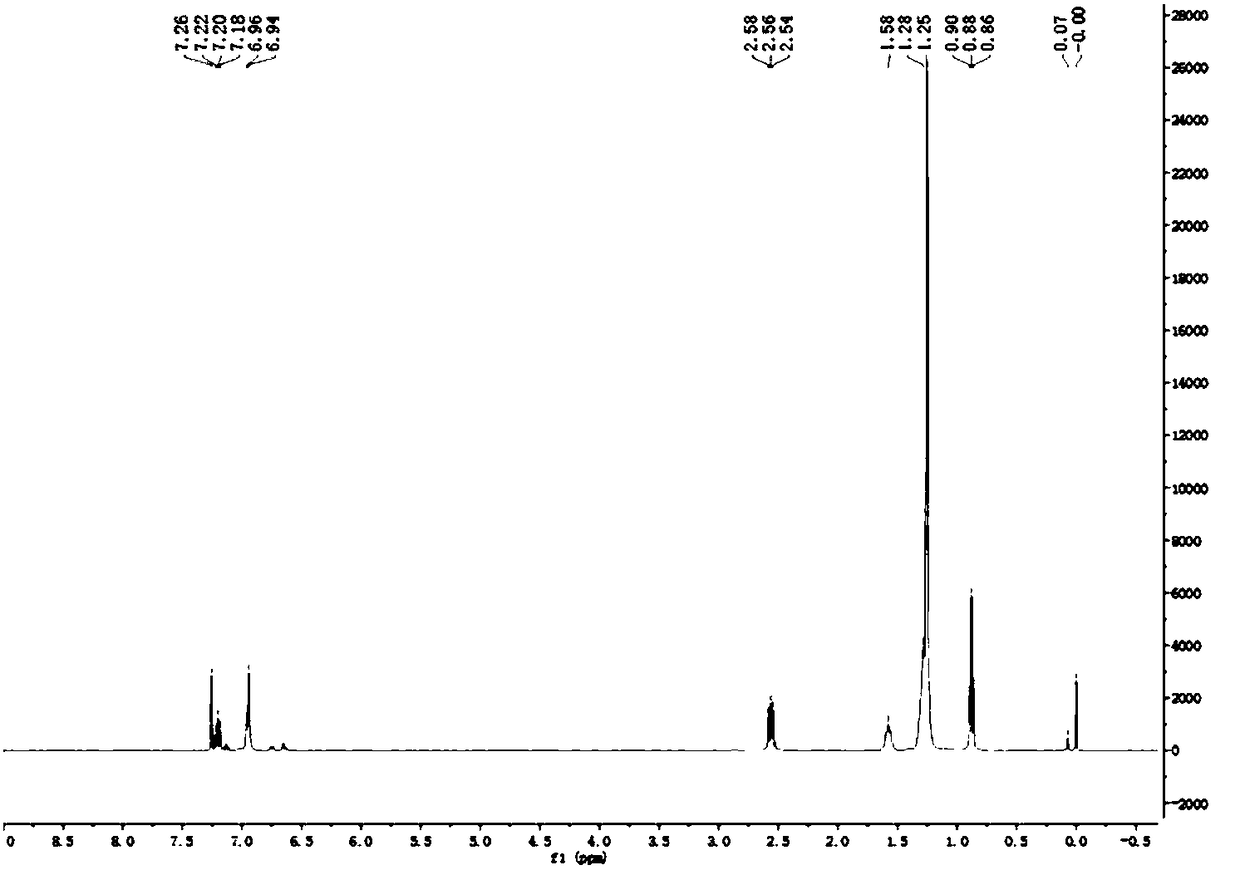

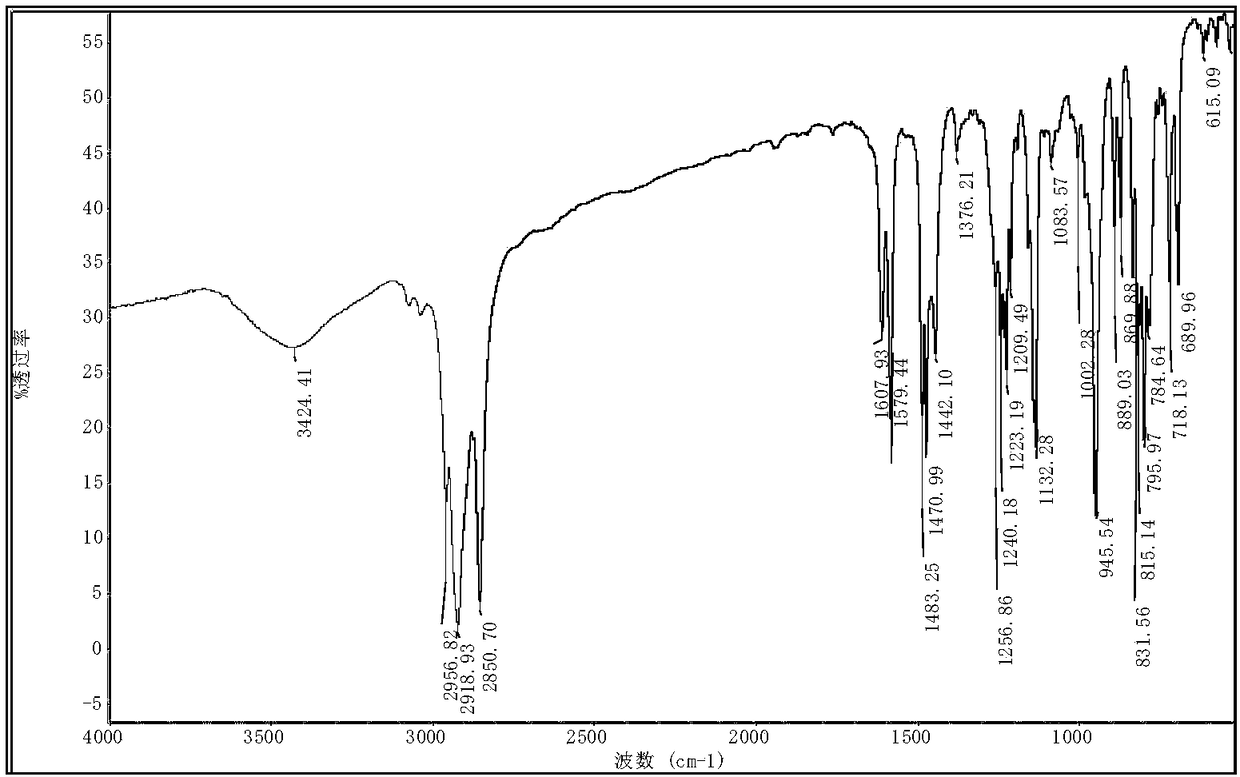

ActiveCN108586522ADoes not consume energy resourcesRelatively stable against hydrolysisGroup 5/15 element organic compoundsAntioxidantStructural formula

The invention discloses a novel biological based phosphite ester type antioxidant and a preparation method thereof. A compound I has a structural formula as shown in the description. The novel biological based phosphite ester type antioxidant is free of nonyl phenol, large in molecular weight and green, environmental-friendly and safe. The invention provides a preparation method of the biologicalbased phosphite ester type antioxidant. The preparation method comprises the following steps: by taking biological-based cardanol as a raw material, carrying out a hydrogenation reaction so as to convert the cardanol into m-pentadecyl phenol, and further carrying out an esterification reaction on the m-pentadecyl phenol, obtained through the reaction and phosphorus trichloride in the presence of acatalyst under the action of negative pressure, thereby obtaining the biological based phosphite ester type antioxidant. The antioxidant prepared by using the method comprises three P-O bonds, has atrivalent bond P, has steric hindrance approximate to that of TNPP (Tris-Nonyl Phenyl Phosphite), has hydrolytic stability equivalent to that of TNPP, and is a good antioxidant because of a large molecular weight and high thermal resistance stability.

Owner:SHANDONG LINYI SUNNY WEALTH CHEM CO LTD +1

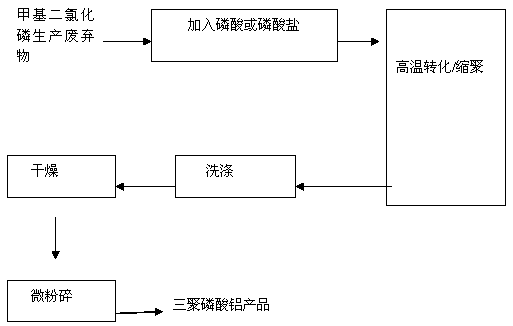

Method for producing aluminum triphosphate by utilizing methyl phosphorus dichloride production waste

ActiveCN105502326ARealize resource utilizationAvoid pollutionPhosphorus compoundsTernary complexPhosphate

The invention provides a method for producing aluminum triphosphate by utilizing methyl phosphorus dichloride production waste. With methyl chloride, aluminum trichloride and phosphorus trichloride as raw materials, a complex generated through reaction is reduced under the catalysis of aluminum powder, phosphoric acid or phosphate is added into the waste left after a product methyl phosphorus dichloride is evaporated out, condensation reaction is performed at the high temperature of 250-450 DEG C, and after the reaction is completed, washing, drying and micro-grinding are performed to obtain the aluminum tripolyphosphate product. Resource utilization that methyl phosphorus dichloride production waste is utilized to prepare ternary complexes is achieved.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD

Production method of dimethyl phosphite

ActiveCN101870712AAvoid acidolysis side effectsImprove effective conversion rateGroup 5/15 element organic compoundsChemical/physical/physico-chemical nozzle-type rreactorsLiquid productCyclone

The invention relates to a production method of dimethyl phosphate, which takes phosphorus trichloride and methyl alcohol as raw materials for reaction. The method comprises the steps of: in a reaction chamber space having cross injection angle and the injection structures of the raw materials, respectively and continuously injecting and sending the phosphorus trichloride and the methyl alcohol which are based on the molar ratio of 1: (3.0-3.1) into the reaction chamber space through respective injection structures by corresponding pumping mechanisms for mixing together and reaction; then, introducing reaction material into a centrifugal cyclone separator with the pressure lower than that of the reaction chamber space along the tangential direction, and leading noncondensable gas and condensing liquid product to have centrifugal cyclone separation; and collecting the liquid dimethyl phosphate product descending along the inner wall of the centrifugal cyclone separator. The method can rapidly complete the reaction and the separation for products, effectively reduces the contact between HCl and the dimethyl phosphate, inhibits the occurrence of side reaction, improves the yield and the quality of the product, and greatly reduces the energy consumption.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD +1

Environmentally-friendly synthesis method for phenylphosphonic dichloride

InactiveCN101671366AReduce dosageDoes not destroy activityGroup 5/15 element organic compoundsChemical recyclingBenzeneSynthesis methods

The invention provides an environmentally-friendly synthesis method for phenylphosphonic dichloride. Phosphorus trichloride and benzene used as raw materials are reacted under the catalytic action ofLewis acid ionic liquid; after the reaction is finished, the reaction solution is divided into two layers, wherein one layer is an ionic liquid layer, and the other layer is a mixed solution layer ofphenylphosphonic dichloride, benzene and phosphorus trichloride; through direct solution separation, the ionic liquid layer is extracted, and the extract and the mixed solution layer are combined andthen are distilled at normal pressure and distilled at reduced pressure to obtain a phenylphosphonic dichloride target product respectively; and the ionic liquid is reclaimed after evaporation at thenormal pressure and the reduced pressure for removing imprity. Compared with the traditional industrialized process, the method has the characteristics of little using amount of a catalyst, reclaimable catalyst, easy operation and control, low production cost, environmentally-friendly production process and the like, does not need a de-complexing step, and does not produce a large amount of wasteslag.

Owner:王忠卫

Preparation of neutral compound scale inhibitor used for oil field reinjection water

ActiveCN101607767AMeet the use requirements of reinjection waterStrong synergyScale removal and water softeningPotassium hydroxidePhosphorus trichloride

The invention provides a neutral compound scale inhibitor used for oil field reinjection water. The dosing is added according to the following parts by weight: adding 18-20 parts of self-made inhibitor, 25-30 parts of amino trimethylene phosphonic acid, 8-10 parts of acrylic acid-acrylic ester-2-acrylamide-2-ATBS ternary polymer and 20-22 parts of pure water into a reaction kettle for stirring for 30-60min with the temperature controlled at 20-35 DEG C; adding 14-16 parts of KOH within 30-45min, controlling the temperature below 60 DEG C, stirring for 90-120min, when cooling to below 30 DEG C, adding 8-10 parts of absolute alcohol, evenly stirring to obtain the compound scale inhibitor; synthesizing the self-made inhibitor, adding 25-30 parts of industrial acetic acid and 20-23 parts of pure water into the reaction kettle, stirring and slowing adding 33-37 parts of phosphorus trichloride within 30-40min, controlling the temperature below 40 DEG C for constant temperature for 15-30min, slowly raising the temperature to 110-120 DEG C within 30-60min, refluxing for 55-65min, carrying out cooling and reduced pressure distilling, when descending the temperature to 50 DEG C, slowly adding 15-18 parts of KOH within 30-60min, stirring for 60-90min with the temperature controlled below 50 DEG C, and cooling to room temperature. The addition of reinjection water in the preparation is 10-50mg / L. The preparation is also suitable for circulating water.

Owner:XINJIANG DELAND

Environment-friendly synthesis method for diphenyl phosphine chloride

InactiveCN102399243AReduce pollutionIncrease incomeAluminium compoundsGroup 5/15 element organic compoundsNitrogen gasBottle

The invention discloses an environment-friendly synthesis method for diphenyl phosphine chloride and aims to solve the problem of environmental pollution in the conventional process. The method comprises the following steps of: adding phosphorus trichloride, benzene and aluminium trichloride into a three-mouth bottle respectively; introducing nitrogen for protection; stirring intensely; heating to 140 to 150 DEG C; maintaining reflux; discharging a large amount of white smoke until the white smoke disappears; cooling to room temperature; and performing aftertreatment operation comprising the steps of adding an organic solvent into reaction liquid in the step A, stirring for 0.5 hour, adding a decomplexing agent beta-chlorophosphate triethyl ester dropwise for 0.5 hour, stirring for 1.0 hour, standing for 1.0 hour, removing the lower layer of the decomlexing agent layer, distilling the organic solvent layer under reduced pressure to obtain a crude product diphenyl phosphine chloride, and distilling the crude product diphenyl phosphine chloride under high vacuum to obtain the pure product diphenyl phosphine chloride. By the method, the aluminium trichloride is recovered through an environment-friendly idea, so environmental pollution is reduced, a byproduct is increased, and yield is increased. The method is high in yield, low in cost and short in reaction time.

Owner:GANSU RES INSTION OF CHEM IND GRICI +1

Circulation production process for glyphosate

ActiveCN101402652AHigh removal rateReduce pollutionGroup 5/15 element organic compoundsPhosphatePhosphorus trichloride

The invention discloses a technology for the circular production of glyphosate, which pertains to the technical field of pesticide. An alkyl ester process is adopted to produce the glyphosate; chlorine and yellow phosphorus are used for producing phosphorus trichloride; the phosphorus trichloride and methanol react to produce dimethyl phosphate which is taken as a raw material to prepare the glyphostate and glyphostate mother solution; triethylamine separated from the glyphostate mother solution is reused and after the triethylamine is separated, alkali mother solution is then obtained; after sodium is removed by a membrane process, the alkali mother solution is divided into strong solution and weak solution, with the strong solution being used for preparing a glyhosate ammonium aqua and the weak solution being electrolyzed to obtain sodium hydroxide solution, chlorine and hydrogen, wherein, sodium hydroxide is used for recovering the triethylamine, the sodium hydroxide solution is used for neutralizing thin methanol, the chlorine is used for synthesizing phosphorus trichloride and the hydrogen is used for other purposes. The technology for the circular production of glyphosate has good effect in triethylamine recovery, high recovery rate, low cost and high removal rate of sodium chloride in the alkali mother solution, forms large-scale circular production of the glyphosate, and is characterized by reduction in logistics cost, high comprehensive utilization, less environmental pollution, compliance with the development concept by industrial recycling economy and remarkable comprehensive benefits.

Owner:JIANGXI JINLONG CHEM

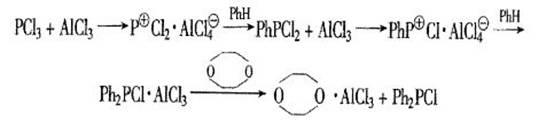

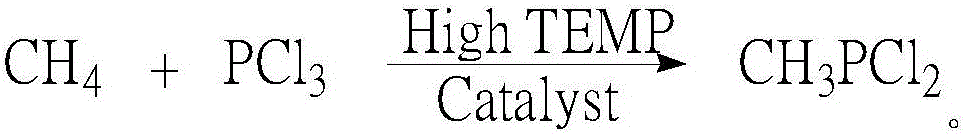

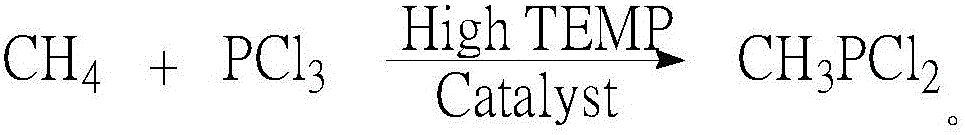

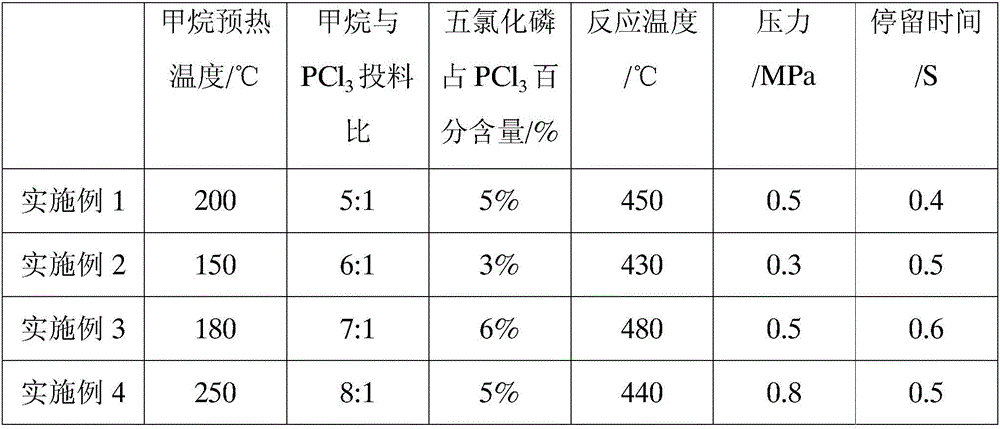

Green synthesis method of methyl phosphorus dichloride

InactiveCN106117267AImprove conversion rateImprove protectionGroup 5/15 element organic compoundsPhosphorus pentachloridePhosphorus trichloride

The invention discloses a green synthesis method of methyl phosphorus dichloride. The method comprises the following steps: by taking phosphorus pentachloride as a catalyst, heating phosphorus trichloride and phosphorus pentachloride into vapor, and preheating to 150-250 DEG C and mixing with methane and then entering a tubular reactor, and reacting for 0.1-1.0s under the conditions that the temperature is at 400-500 DEG C and the pressure is 0.3-1.2MPa, to obtain methyl phosphorus dichloride. After the catalyst is applied to methane and phosphorus trichloride to synthesize methyl phosphorus dichloride, the conversion rate of the phosphorus trichloride is effectively improved to 40%-50%, and the yield is 90%-95%; the adopted catalyst phosphorus pentachloride is decomposed into phosphorus trichloride and chlorine gas, the catalyst and the product is not required for separation, three wastes are not generated during the whole preparation, and all the materials are recycled, so that the resources are saved, the environment is beneficially protected, and the synthesis method is green.

Owner:ANHUI COSTAR BIOCHEM CO LTD

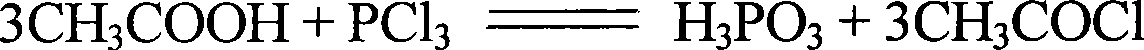

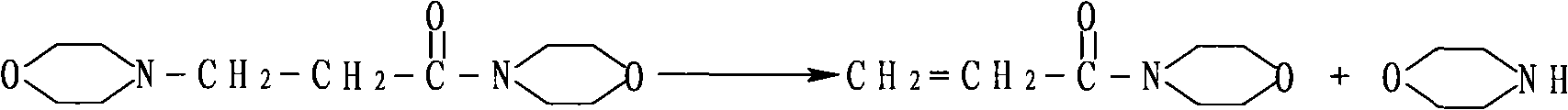

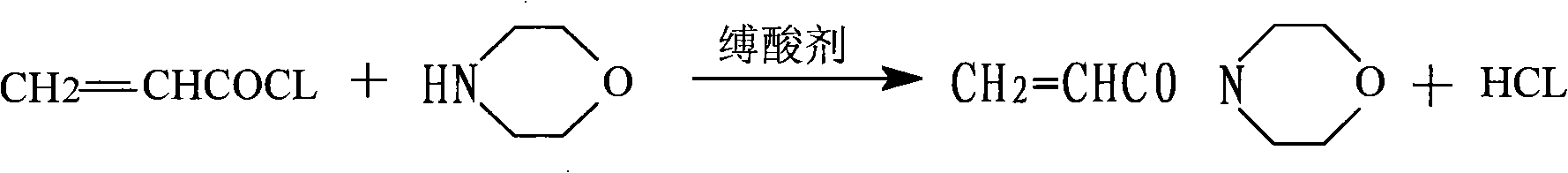

Synthesizing method for preparing N-acryloyl morpholine

ActiveCN101293880ARaw materials are easy to getMild reaction conditionsOrganic chemistryMorpholineSolvent

The invention relates to a method for synthesizing high-purity N-acryloyl-morpholine, comprising the steps of: dropwise mixing acrylic acid and phosphorus trichloride within 0.5-1 hours, and allowing reaction at 40-45DEG C for 3-4 hours under stirring speed of 80-100rpm to obtain acryloyl chloride; and dropwise mixing morpholine, an acid-binding agent and a solvent within 3-4 hours to obtain a mixed liquid, allowing reaction at 0-5DEG C for 3 hours under stirring speed of 80-100rpm, collecting supernatant, and distilling in the presence of a compound polymerization inhibitor under reduced pressure to obtain an N-acryloyl-morpholine product with purity over 99%, wherein the molar ratio of phosphorus trichloride and acrylic acid is 1:(3-3.5), the molar ratio of acryloyl chloride and morpholine is 1:(1-1.5), the addition amount of the acid-binding agent is 50-150 wt% of morpholine, the solvent addition amount is 100-200 wt% of morpholine, and the addition amount of the compound polymerization inhibitor is 0.1-1 wt% of morpholine.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

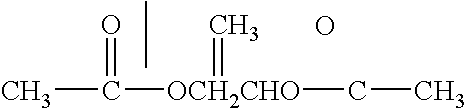

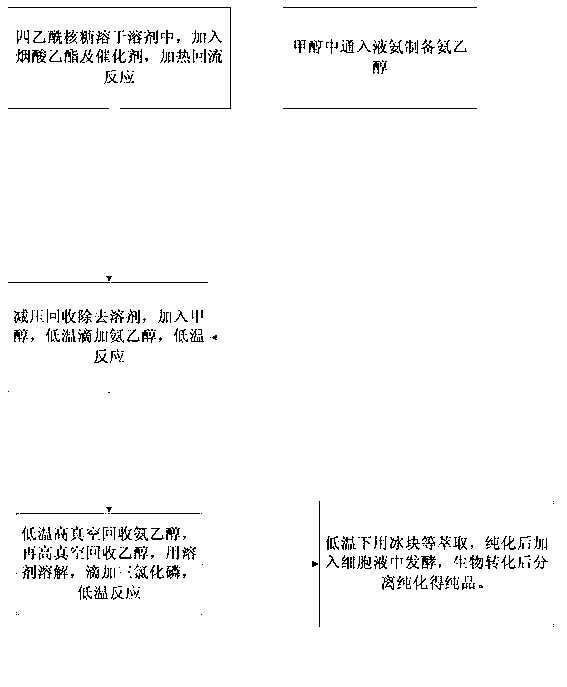

Chemical and biological synthesis method for large-scale preparation of nicotinamide adenine dinucleotide

ActiveCN103233051ALow costReduce the difficulty of productionFermentationSynthesis methodsEthyl ester

The invention relates to a chemical and biological synthesis method for large-scale preparation of nicotinamide adenine dinucleotide (NAD). According to the invention, ribofuranose tetraacetate and ethyl nicotinate are adopted as initial raw materials, and the following steps are carried out that: (1) a refluxing reaction is carried out; (2) ammonia ethanol is dropped under a low temperature, such that a reaction is carried out; (3) phosphorus trichloride is dropped under a low temperature, such that a reaction is carried out; and (4) extraction, separation, and purification are carried out, and the material is added into cell fluid and is biologically converted into nicotinamide adenine dinucleotide; and a pure product is obtained by purification and drying.

Owner:ZHEJIANG JIAHUA CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com