Method for producing aluminum triphosphate by utilizing methyl phosphorus dichloride production waste

A technology of methylphosphorus dichloride and aluminum tripolyphosphate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of easy spontaneous combustion, inability to directly purchase, difficult to store, etc., to avoid environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

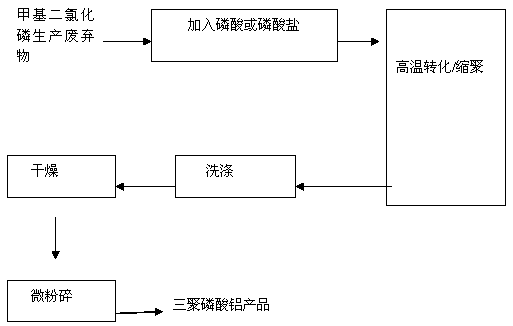

Image

Examples

Embodiment 1

[0017] A method for preparing aluminum tripolyphosphate from waste produced by methyl phosphorous dichloride, using methyl chloride, aluminum trichloride and phosphorous trichloride as raw materials, and the resulting complex is reduced under the catalysis of aluminum powder and steamed Phosphoric acid is added to the waste after the product methyl phosphorous dichloride, and a condensation reaction occurs at a high temperature of 250-450°C. After the reaction is completed, it is washed, dried, and finely pulverized to obtain an aluminum tripolyphosphate product.

Embodiment 2

[0019] A method for preparing aluminum tripolyphosphate from waste produced by methyl phosphorous dichloride, using methyl chloride, aluminum trichloride and phosphorous trichloride as raw materials, and the resulting complex is reduced under the catalysis of aluminum powder and steamed Phosphate is added to the waste after the product methyl phosphorous dichloride, and condensation reaction occurs at a high temperature of 250-450°C. After the reaction is completed, it is washed, dried, and finely pulverized to obtain an aluminum tripolyphosphate product.

[0020] The phosphoric acid or phosphate is added to make the molar ratio of phosphorus and aluminum in the material 2.9:1.

Embodiment 3

[0022] A method for preparing aluminum tripolyphosphate from waste produced by methyl phosphorous dichloride, using methyl chloride, aluminum trichloride and phosphorous trichloride as raw materials, and the resulting complex is reduced under the catalysis of aluminum powder and steamed Phosphoric acid is added to the waste after the product methyl phosphorous dichloride, and a condensation reaction occurs at a high temperature of 250-450°C. After the reaction is completed, it is washed, dried, and finely pulverized to obtain an aluminum tripolyphosphate product.

[0023] The phosphoric acid or phosphate is added to make the molar ratio of phosphorus and aluminum in the material 3.2:1.

[0024] Add the waste into the batching kettle, after heating to 40°C, stop heating, add phosphoric acid or phosphate under stirring, control the reaction temperature at 70°C, react for 4hrs, then transfer to the high temperature polycondensation kettle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com