Patents

Literature

79 results about "Phosphorous trichloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of triethyl phosphite

ActiveCN101624400AIncrease production capacityImprove product qualityGroup 5/15 element organic compoundsAmmonium halidesTriethylphosphiteDistillation

The invention relates to a production method of triethyl phosphite, which belongs to the technical field of chemical production. Absolute ethyl alcohol, phosphorous trichloride are taken as main material, pure benzol is taken as solvent, triethylamine is taken as acid-binding agent, liquid ammonia is taken as reducing agent, and the triethyl phosphate is prepared through the processes of three-complex liquor preparing, synthetic reaction, water scrubbing reaction, layering, drying, crude distillation, rectifying, recovering and ammonia recovery and the like. The method adopts continuous production process of triethylamine, the material charging and the product discharging are continuous, the production capacity is strong, and the product quality is stable. With equal equipment and investment, the capacity of the method can be 6 to 7 times as the capacity of intermittent method. The method solves the problems of the prior production method that the production capacity is small, the production cycle of the product is long, the material consumption is large, the quality is unstable, the discharge amount of 'three wastes' is large, and the yield can not be guaranteed. The method has the advantages that the liquid ammonia is taken as reducing agent, the cost is low, the recovery factor of excess ammonia can reach more than 90 percent, the recovered ammonium chloride can be used as the crude product of ammonium fertilizer, the production cost is lowered, and the environmental pollution is reduced.

Owner:荆州三才堂化工科技有限公司

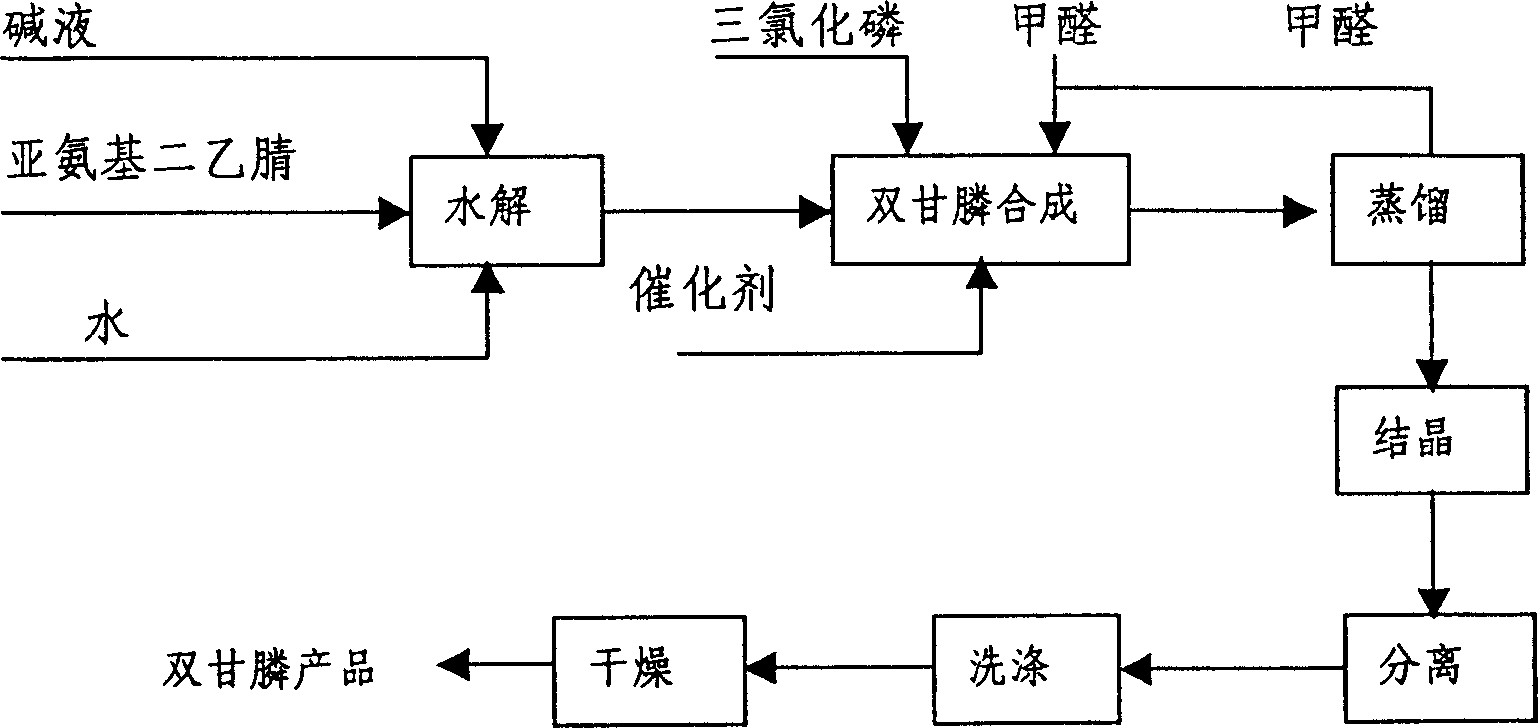

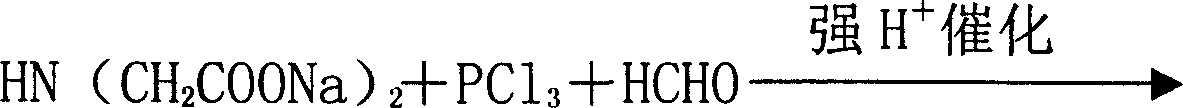

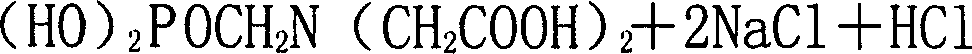

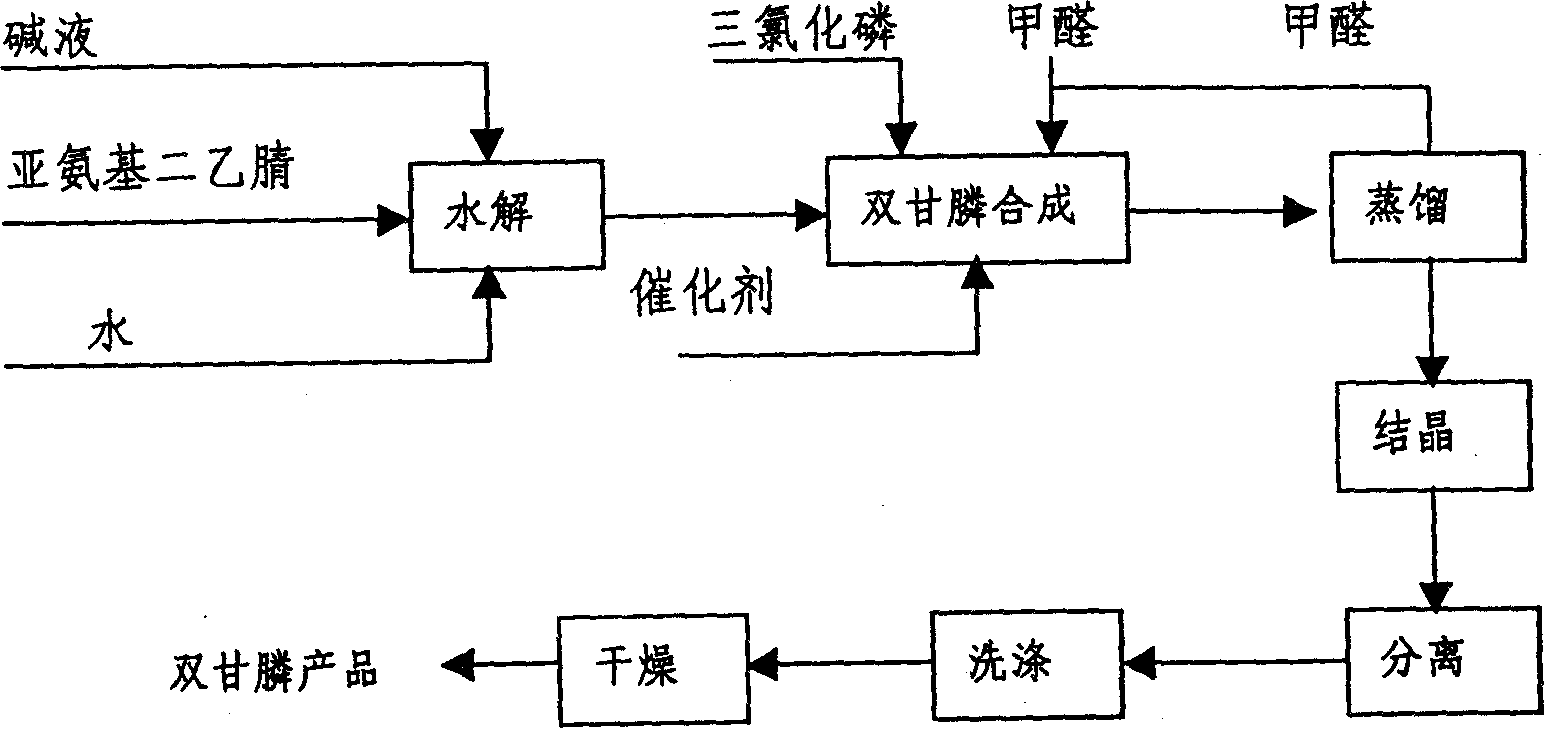

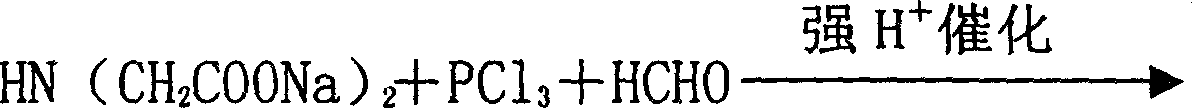

Method for preparing Phosphonomethyl iminodiacetic acid (PMIDA) through hydrolysis of imino diacetonitrile

InactiveCN1916005AShort process routeSave investmentGroup 5/15 element organic compoundsSaline waterIminodiacetic acid

This invention discloses a method for preparing N-phosphonomethyl iminodiacetic acid (PMIDA) by iminodiacetonitrile hydrolysis. The method comprises: (1) hydrolyzing iminodiacetonitrile (greater than or equal to 95 wt.%) in an alkali solution under stirring at 20-100 deg.C and -(0.01-0.04) MPa to obtain iminodiacetate solution; (2) dropping phosphorous trichloride (1.0-1.5 mol times of iminodiacetonitrile) to the iminodiacetate solution at 20-100 deg.C and -(0.01-0.04) MPa with an acidic catalyst added before or after the phosphorous trichloride addition; (3) adding formaldehyde at a temperature not lower than 80 deg.C; (4) reacting at 100-120 deg.C for 1-7 h to obtain PMIDA suspension; (5) vacuum-distilling to recover formaldehyde; (6) crystallizing, separating, washing and drying to obtain PMIDA with a purity higher than 98%. The method has such advantages as simple process, low cost and high yield.

Owner:SICHUAN BEIER CHEM GROUP

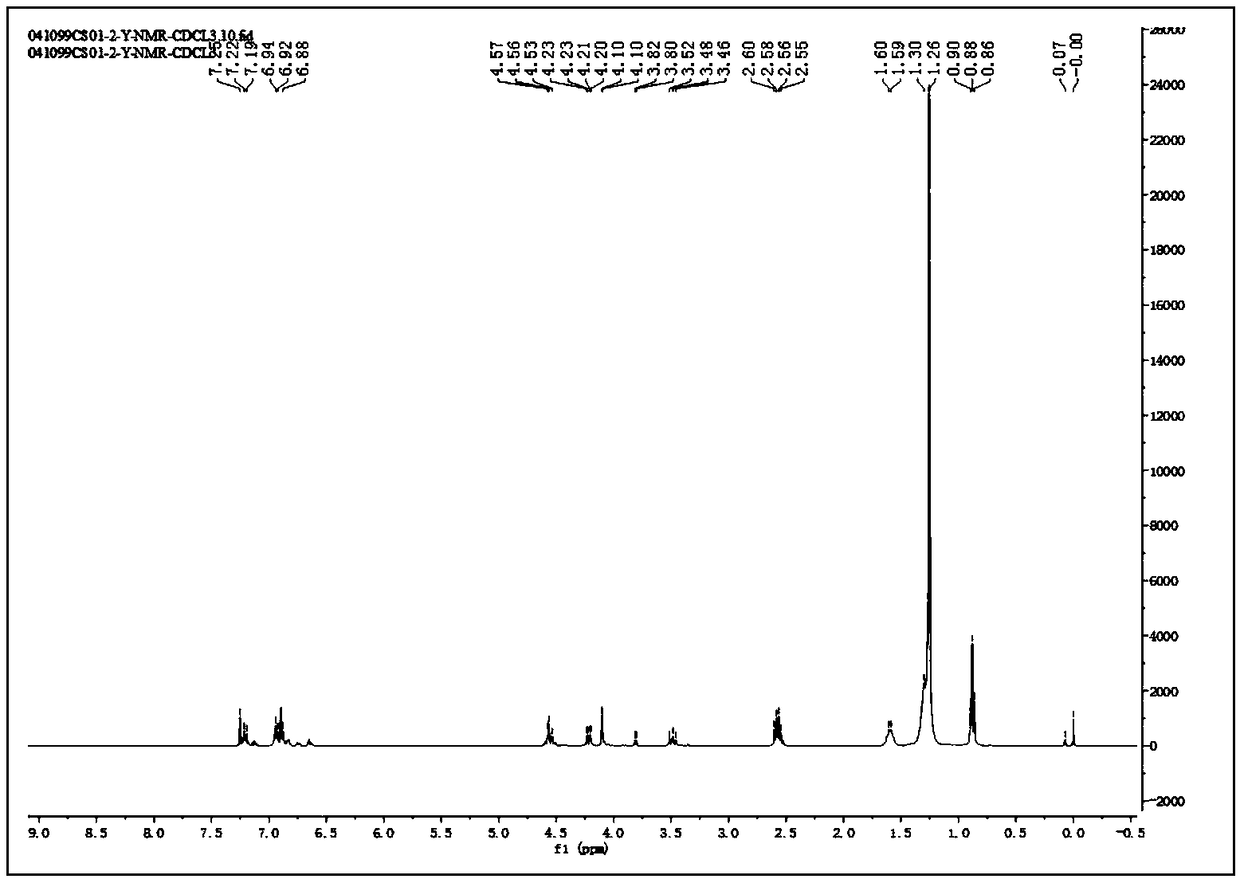

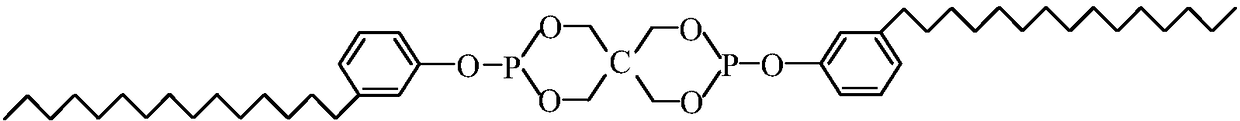

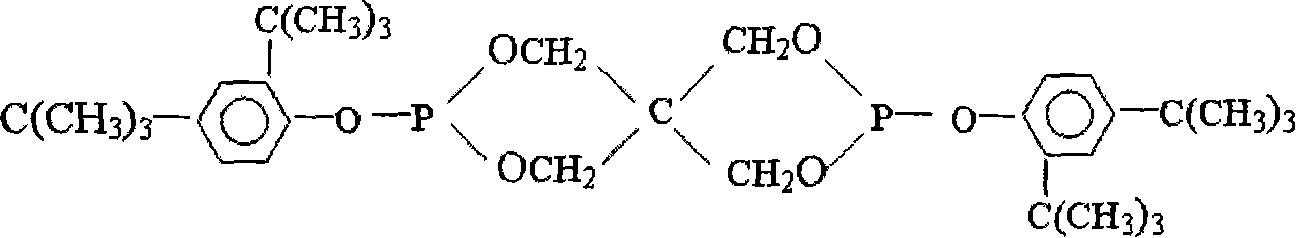

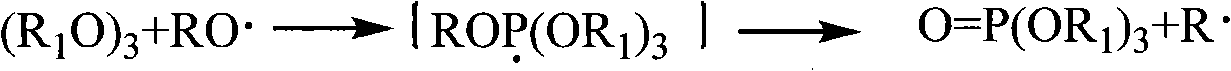

Novel efficient biology-based phosphite ester antioxidant and preparation methods thereof

ActiveCN108530485ADoes not consume energy resourcesHigh molecular weightGroup 5/15 element organic compoundsAntioxidantStructural formula

The invention discloses a novel efficient biology-based phosphite ester antioxidant and two preparation methods thereof. The structural formula of the antioxidant is as shown in the specification. Thepreparation methods are characterized in that cardanol is subjected to hydrogenation to obtain 3-pentadecyl-phenol, and the 3-pentadecyl-phenol, phosphorus trichloride and quaternary pentane are allowed to have esterification reaction under certain reaction conditions to obtain the biology-based phosphite ester antioxidant. The novel efficient biology-based phosphite ester antioxidant has the advantages that the antioxidant does not contain nonyl phenol and is large in molecular weight, green, environmentally friendly and safe; due to the fact that the antioxidant contains two trivalent phosphorus, each trivalent phosphorus contains three P-O bonds, and P is positively trivalent, the antioxidant can combine with instable components in polymer to generate oxide, and the antioxidant is goodin effect.

Owner:SHANDONG LINYI SUNNY WEALTH CHEM CO LTD +1

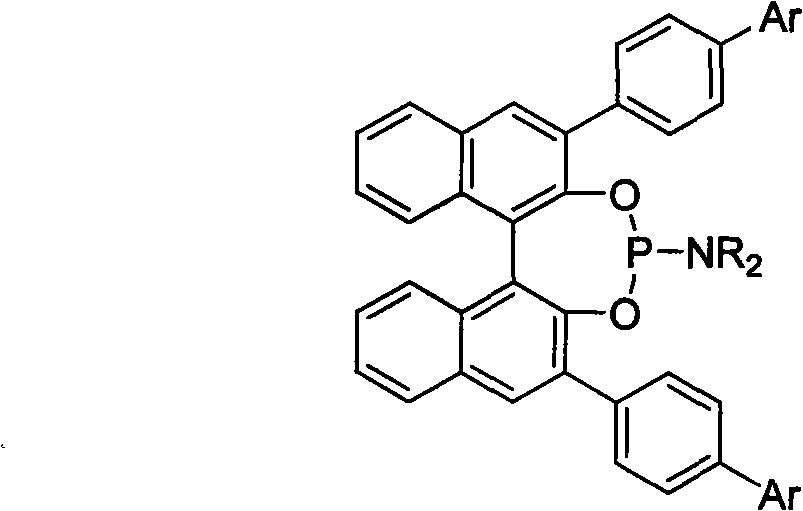

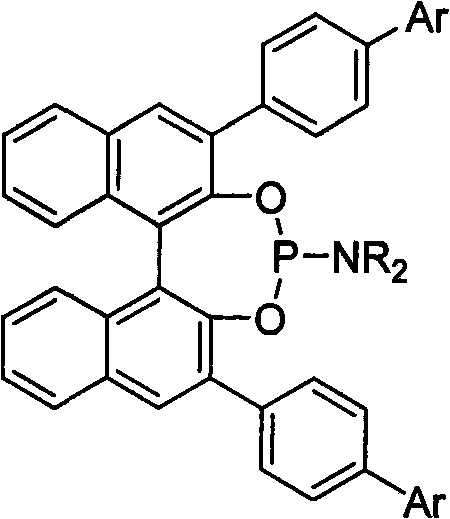

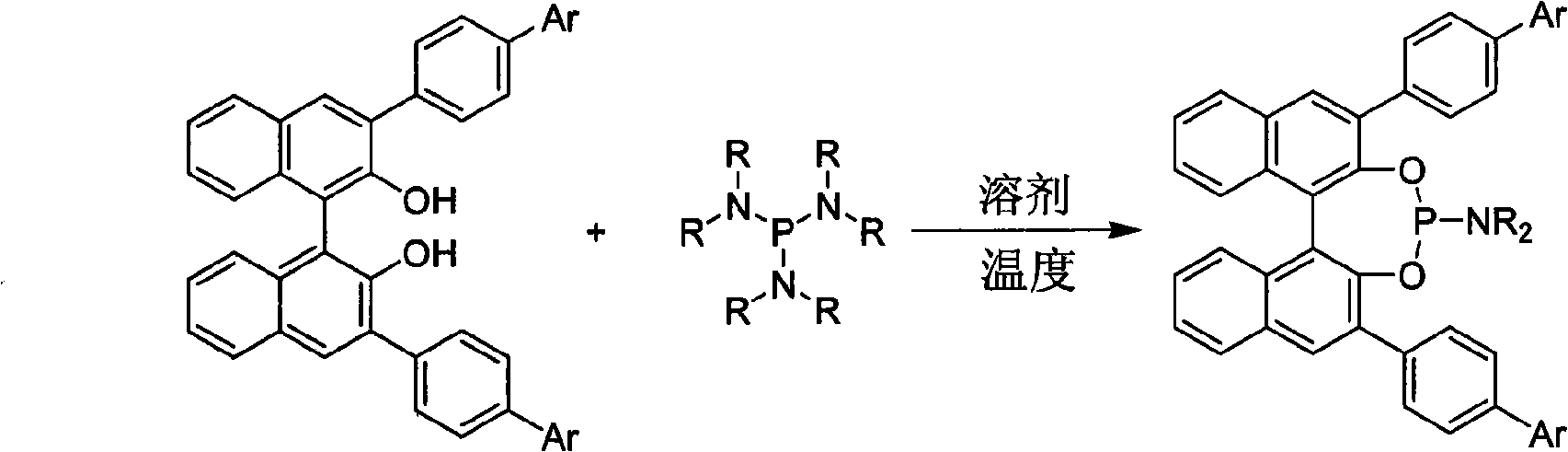

3, 3'-position biaryl group binaphthyl shaft chiral phosphoramidite ligand and preparation method thereof

InactiveCN101565436AGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsOrganic solventPhosphorus trichloride

The invention relates to a 3, 3'-position binaphthyl shaft chiral phosphoramidite ligand containing biaryl group and a preparation method thereof. The preparation method comprises the following steps of: leading 3, 3'-dual-biaryl group-2, 2'-dinaphthol to react with hexagon-alkyl group phosphoramidite in organic solvent at the temperature of 0-120 DEG C according to the mol rate of 1:1, or leading 3, 3'- dual-biaryl group-2, 2'-dinaphthol to react with phosphorus trichloride and dialkyl amine in steps, and after complete reaction, the object chiral phosphoramidite ligand can be obtained through washing, extraction and separation. After going through complexation with metallic copper salt, the chiral phosphoramidite ligand can be used for catalyzing the conjugate addition reaction of zinc alkyl with alpha, beta-unsaturated carbonyl compounds, and an additional product is prepared with high yield up to 78-98% and high enantioselectivity ee value up to 80-98%.

Owner:TIANJIN UNIV

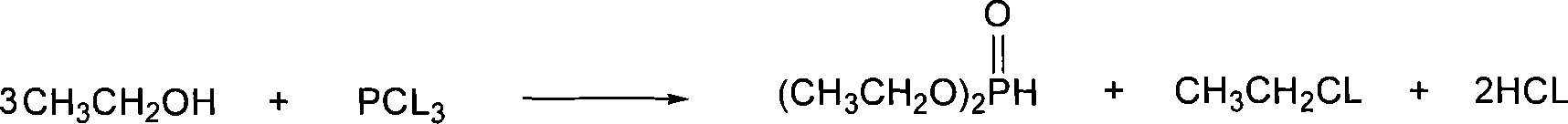

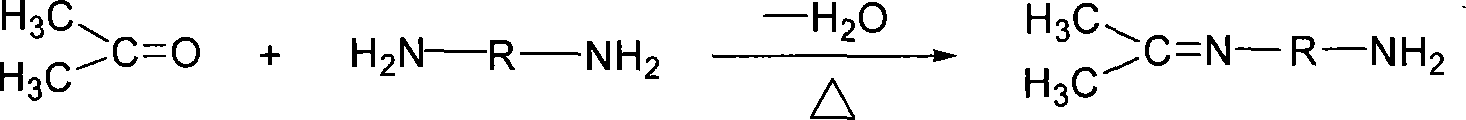

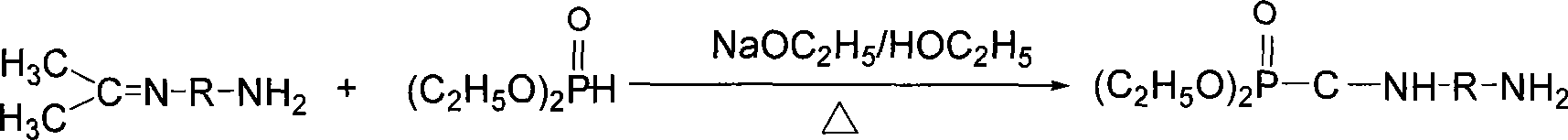

Organic phosphorus active flame-proof epoxy resin curing agent amine group phosphonate and preparation method thereof

The invention discloses an organophosphorus active flame-proof epoxide resin solidifying agent amino phosphonate ester and the preparing method. The amino phosphonate ester comprises the following parts: 3:1:1:1 absolute ethyl alcohol, phsophorus trichloride, organic amine (the structural formula is H2N-R-NH2)and acetone. The organic amine is diethylenetriamine, triethylene tetraamine, tetraethylene pentamine or 4, 4-diaminodiphenylmethane. The method comprises the following steps: 1, synthesizing diethyl phosphate with alcohol and phsophorus trichloride; 2, generating ketoimine with acetone and the organic amine by adding the anhydrating agent; 3, generating amino phosphonate with diethyl phosphate and ketoimine. The oxygen index of the product is more than 20 and less than 34.6. The invention is provided with the simple method and the simple operation.

Owner:HEILONGJIANG INST OF PETROCHEM

Process for synthesis of hydroxy ethidene diphosphoric acid

InactiveCN1827625ALess investmentSimple and safe operationGroup 5/15 element organic compoundsPhosphorous acidDistillation

A method for synthesizing hydroxyl ethylidenediphosphonic acid belongs to synthesis of organo-phosphonic acid and is used in water stabilization. The phsophorus trichloride and acetic acid react at a temperature between 80 DEG C and 150 DEG C with an absolute pressure less than 760 millimeters mercury column, and the byproducts of hydrochloride and a few acetyl chlorides free of condensation are respectively retrieved and reused by combined recovery system of acetic acid and hydrochloric acid. The product of this method is obtained by hydrolyzing the acetylated hydroxyl ethylidenediphosphonic acid at a temperature between 80 DEG C and 150 DEG C with an absolute pressure no more than 760 millimeters mercury column; the collected hydrolysate of acetic acid after the distillation and the condensation is selected as raw material together with the acetic acid solution from the reclamation tower of acetic acid. The autoclave of 1000 litres daily produces products of 2500 kilograms with 60 % of solid content and less than 0.15 % of phosphorous acid; the yield rate of the products is more than 98 % calculated by phsophorus trichloride and is more than 96 % calculated by acetic acid.

Owner:傅明珠

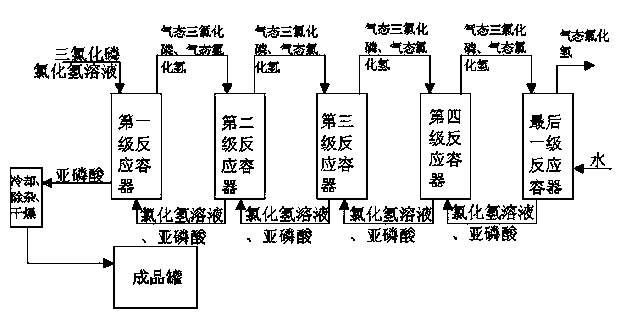

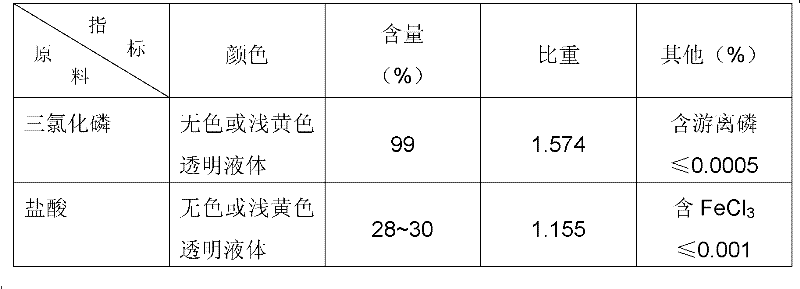

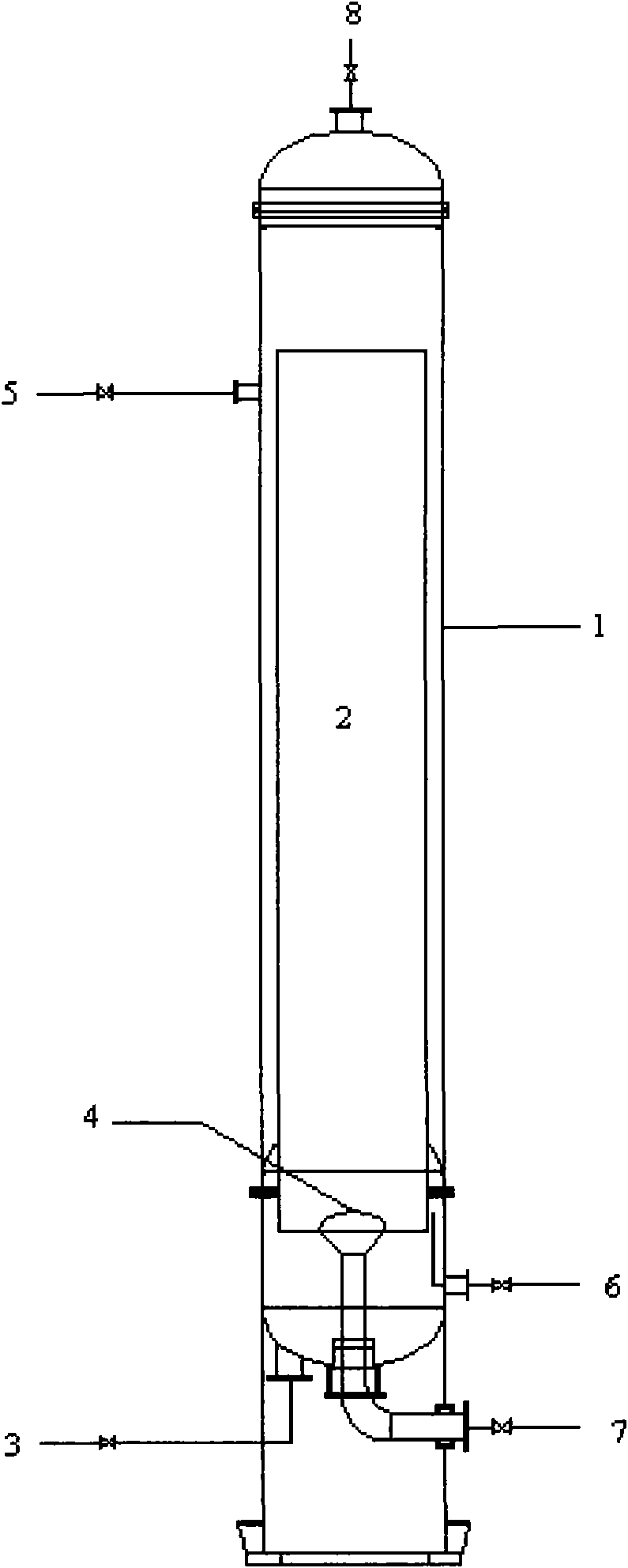

Process for preparing phosphorous acid by hydrolyzing phosphorus trichloride

The invention relates to a process for preparing phosphorous acid by hydrolyzing phosphorus trichloride, and in particular relates to a process for preparing phosphorous acid by hydrolyzing phosphorus trichloride under a mild reaction condition. According to the process, phosphorus trichloride and a hydrogen chloride solution are subjected to hydrolysis reaction in sequence in at least four stages of cascade reaction vessels under the condition that the temperature is 65-85 DEG C and the pressure is not more than 0.1Mpa to generate a phosphorous acid solution and gaseous hydrogen chloride. In the process, the phosphorus trichloride reacts with the water in a hydrochloric acid solution, the phosphorus trichloride is subjected to an exothermic reaction, the temperature of the process can reduce the hydrolysis rate to ensure that the reaction is performed mildly, and at least four stages of cascade bubbling reactions are adopted by the process, so that the utilization ratio of raw materials is improved, the phosphorus trichloride in the reaction vessel of the previous stage can enter the reaction vessel of the next stage, the content of the phosphorus trichloride in the reaction vessel of the previous stage is reduced in other ways, the intensity of the reaction is reduced again, the production safety is improved, and the service life of equipment is prolonged.

Owner:HENAN QINGSHUIYUAN TECH

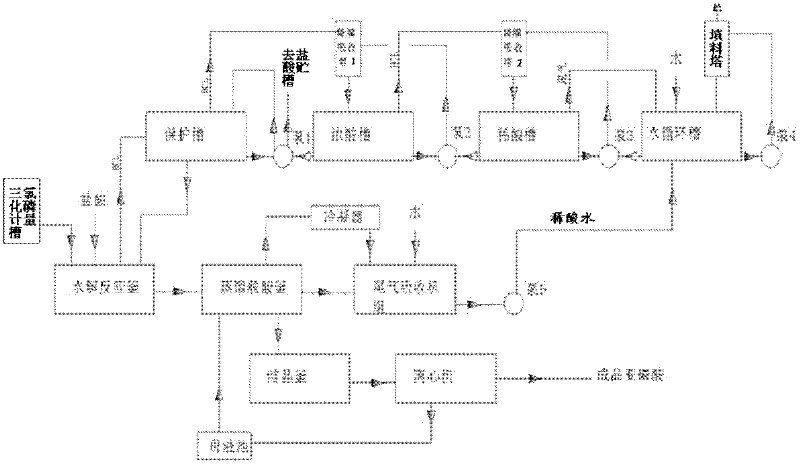

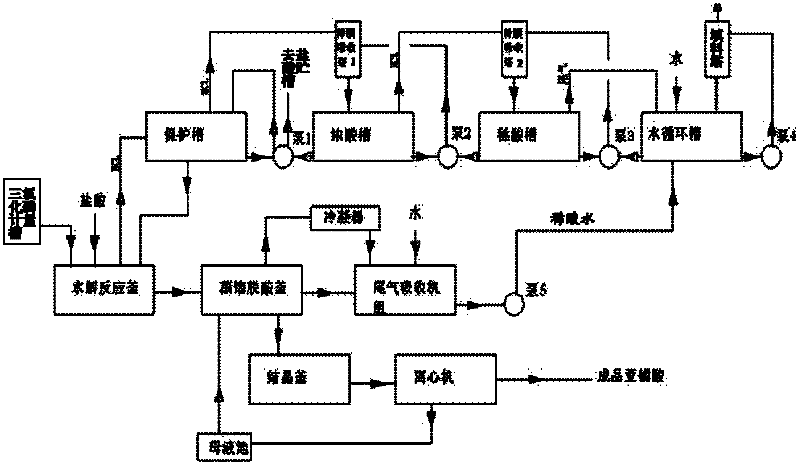

Preparation process for synthesizing phosphorous acid by hydrolyzing phosphorous trichloride

InactiveCN102249202AControl the speed of the hydrolysis reactionReaction is easy to controlChemical industryPhosphorous acidPhosphorous acidChemical industry

The invention belongs to the field of chemical industries, and in particular relates to a preparation process for synthesizing phosphorous acid by hydrolyzing phosphorous trichloride. The preparation process comprises the specific steps of: adding hydrochloric acid into a hydrolysis reaction kettle, dripping phosphorous trichloride into the hydrolysis reaction kettle, pumping a phosphorous acid mixture synthesized by hydrolysis reaction into a distillation and deacidification kettle with a stirrer through a pump to perform negative-pressure distillation concentration, cooling and crystallizing a concentration solution to prepare a crystallized phosphorous acid product; and absorbing an HCL gas generated through reaction through a protective trough and a hydrochloric film type absorbing system in sequence to obtain hydrochloric acid. According to the preparation process disclosed by the invention, a bubble absorbing trough (the protective trough) is additionally provided before a hydrolysis reaction film reducing hydrochloric acid absorbing system so that the HCL gas generated through reaction is more rapidly discharged, and thus the effects on the dripping quantity and the speed of the phosphorous trichloride in the hydrolysis reaction are greatly reduced. The mechanical stirrer is used in the distillation and deacidification kettle so as to implement the mechanical transmission stir, carry out the reduced-pressure distillation, enhance the heat transfer, improve the heat transfer efficiency and accelerate the deacidification speed, and thus the deacidification time is shortened and the capacity is increased.

Owner:JIANGSU DAMING TECH

Octadecanoyl tributyl citrate plasticizer and preparation thereof

InactiveCN101255240AIncrease the relative molecular massHigh plasticizing efficiencyCarbonyl chlorideStearic acid

The invention provides octade carbonyl tributyl citrate plasticizer and preparation method thereof. The composition of octade carbonyl tributyl citrate plasticizer (in mass percent): tributyl citrate 43.5-53.8%, octade carbonyl chloride 45.2-55.0%, catalyst 1.0-1.5%. The preparation method comprises: (1) adding citric acid, butylalcohol, water-carrying agent and catalyst into reaction kettle, stirring, heating up until reflowing to obtain tributyl citrate; (2) adding stearic acid into reaction kettle, stirring, heating up to 50 degree and then adding phosphorous trichloride and heating up to 75 degree to perform thermal insulating reaction for 3 hours and layering to obtain octade carbonyl chloride; (3) adding tributyl citrate and catalyst in the reaction kettle, stirring, heating up to 70 degree and then adding octade carbonyl chloride to obtain chlorine hydride and the chlorine hydride being absorbed in water containing soda in drier, when the pH of the water containing soda is constant, the reaction being stopped and the product being subjected to neutralizing, cleaning, pump filtering under reduced pressure to obtain octade carbonyl tributyl citrate.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

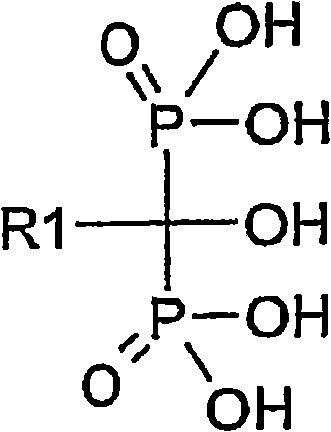

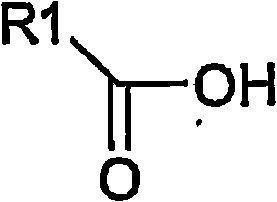

Methylene phosphonic carboxylic acid, its preparation process and its application in water treatment

InactiveCN1413913AAlso has corrosion inhibition effectGroup 5/15 element organic compoundsWater/sewage treatmentWater qualityCarboxylic acid

A methylene phosphocarboxylic acid as water quality stabilizer is prepared from carboxy-contained amine, PCl3 (or phosphonous acid and concentrated hydrochloric acid) and water through heating and adding solution of formaldehyde. It has high output rate.

Owner:RES INST OF BEIJING YANSHAN PETROCHEM

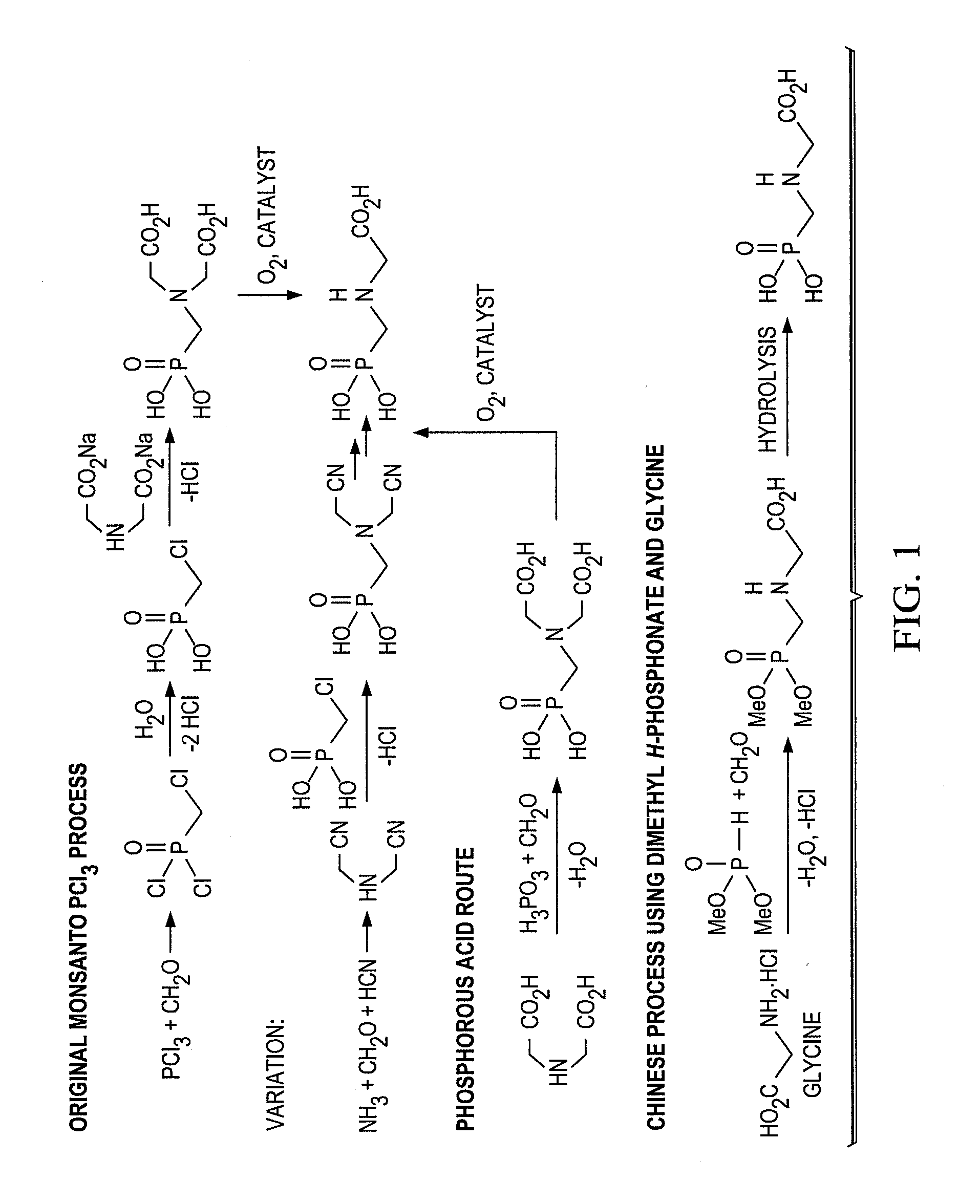

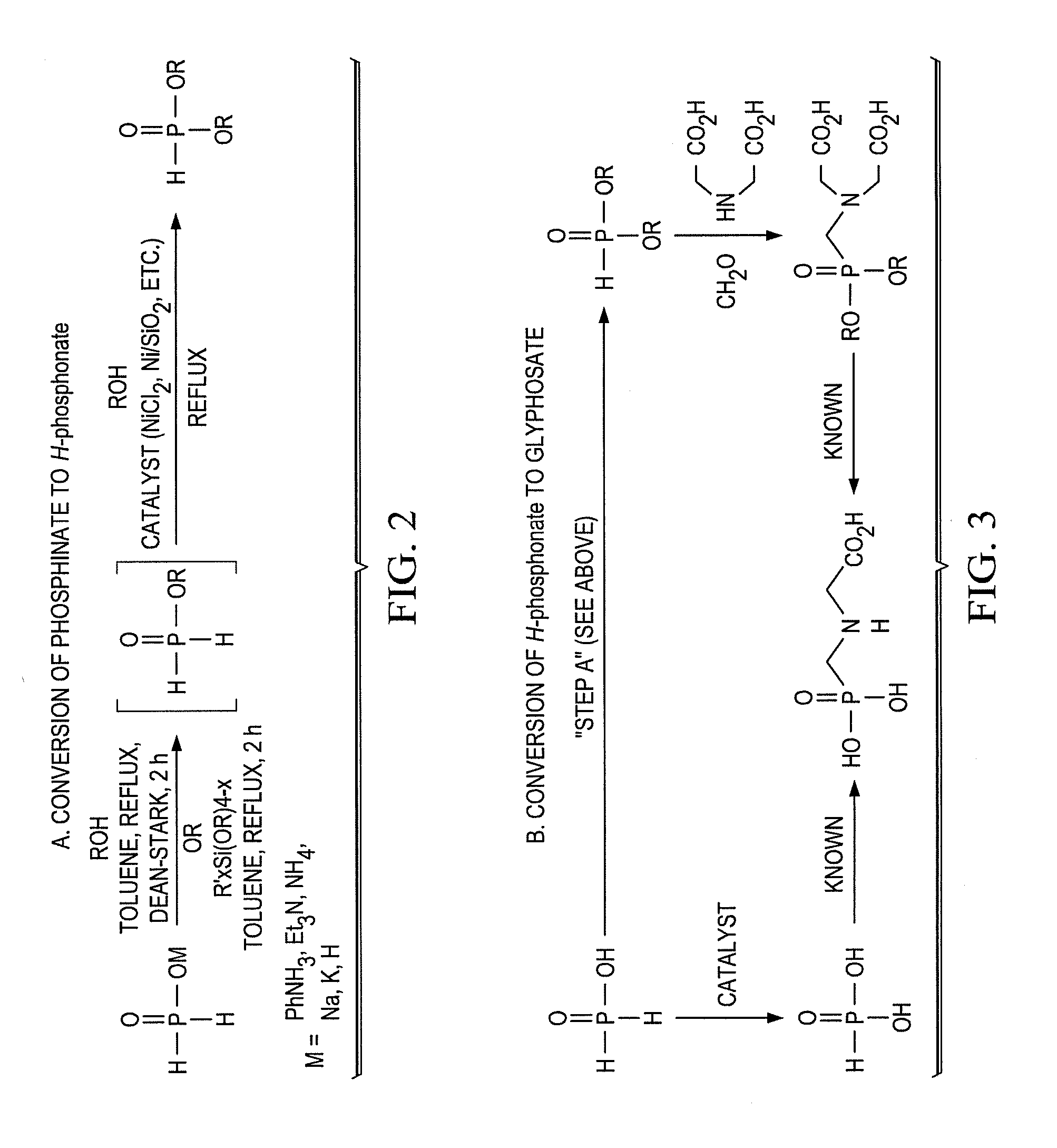

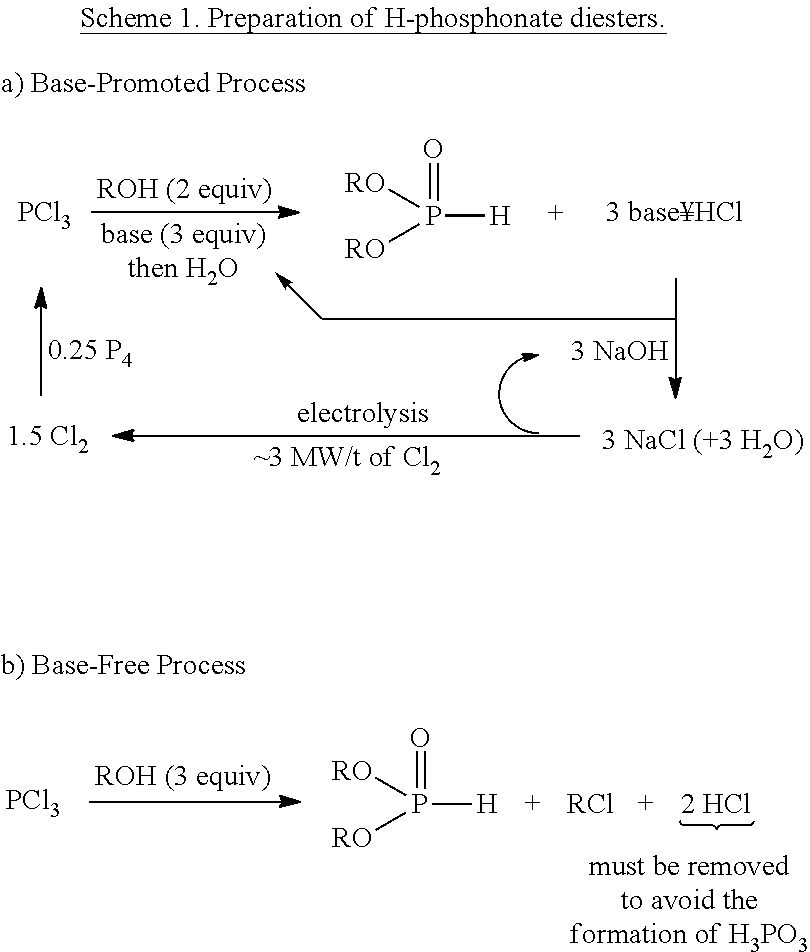

Synthesis of H-phosphonate intermediates and their use in preparing the herbicide glyphosate

The esterfication of hypophosphorous acid is followed by reaction with another molecule of alcohol under the action of a nickel catalyst to provide a green method for the preparation of H-phosphonate diesters. This method avoids the need for any stoichiometric chlorine unlike those based on phosphorous trichloride.

Owner:TEXAS CHRISTIAN UNIVERSITY

Prepn process of phosphorous acid and lower alkane halide

InactiveCN1486967AHigh recovery process requirementsIncrease contentPhosphorous acidHalogenated hydrocarbon preparationPhosphorous acidAlkane

The present invention is the production process of phosphorous acid and lower alkane halide with phosphorous trichloride and alkyl alcohol (phenol) as material. Phosphorous trichloride and alkyl alcohol (phenol) are reacted to produce phosphorous acid and lower alkane halide. The lower alkane halide is separated via proper method and the product is concentrated and crystallized to obtain phosphorous acid, with the mother liquor being circularly used. The phosphorous acid is used in producing other product. The production process is simple and low in cost.

Owner:李建兵

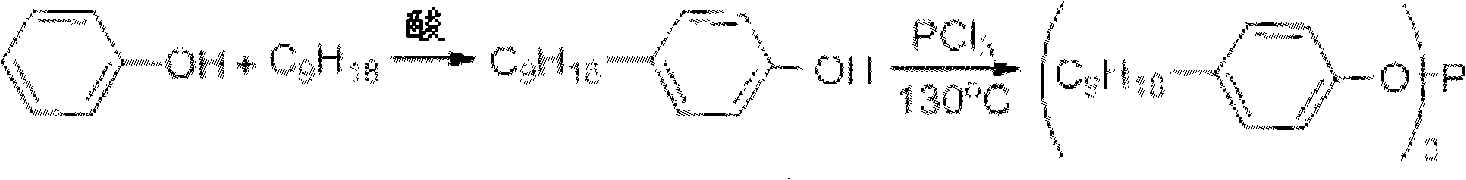

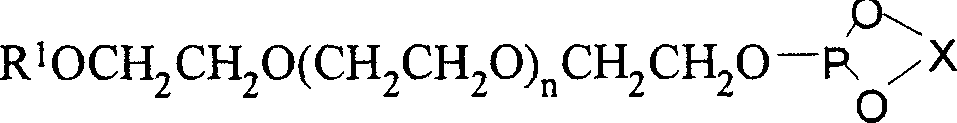

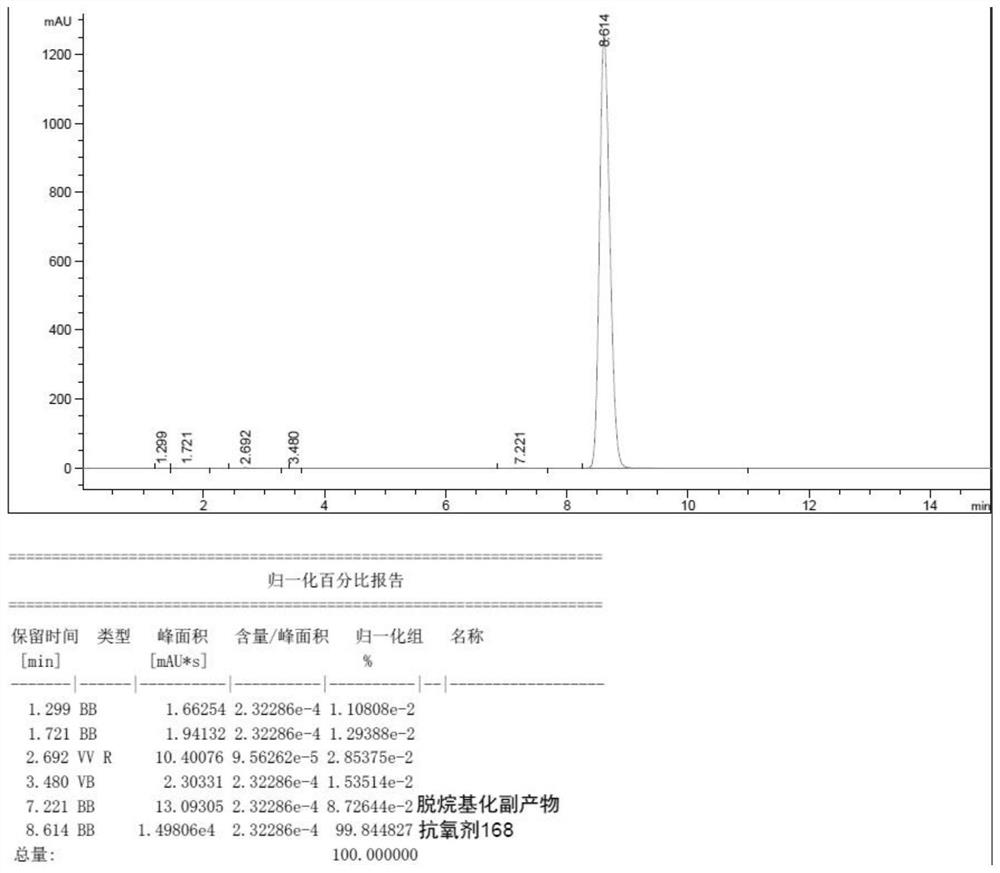

Efficient synthesis method of antioxidant 168

InactiveCN104370956AGood effectReduce dosageGroup 5/15 element organic compoundsTert butyl phenolSynthesis methods

The invention discloses an efficient synthesis method of antioxidant 168. The synthesis method specifically comprises the following steps: adding 2,4-di-tert-butyl phenol and a catalyst in a container, and then slowly adding a mixed solution of xylene and phosphorous trichloride, heating to 50-60 DEG.C, and reacting for 2-5 hours, wherein the catalyst is a mixture of 4-dimethylamino pyridine and triethylamine; then, heating a reaction solution to 130-160 DEG.C, reacting for 1.5-5 hours, distilling off hydrogen chloride and xylene at reduced pressure, and then cooling to 90 DEG.C, adding isopropanol, stirring for 0.5-1.5 hours, cooling to room temperature, carrying out suction-filtering, and drying to obtain the antioxidant 168. The 4-dimethylamino pyridine and triethylamine are mixed to serve as a catalyst, the use amount of the catalyst is low, the effect is good, the process is simple, the product yield is high and can reach 97% and more (counted by phosphorous trichloride), and the purity is high, the efficient synthesis method has good industrial production prospect. And the method can be used for the synthesis of the antioxidant 168.

Owner:JIANGMEN DENGZHONGTAI ENG PLASTICS CO LTD

Method for preparing Phosphonomethyl iminodiacetic acid (PMIDA) through hydrolysis of imino diacetonitrile

InactiveCN100400543CHigh yieldShort process routeGroup 5/15 element organic compoundsIminodiacetic acidSaline water

This invention discloses a method for preparing N-phosphonomethyl iminodiacetic acid (PMIDA) by iminodiacetonitrile hydrolysis. The method comprises: (1) hydrolyzing iminodiacetonitrile (greater than or equal to 95 wt.%) in an alkali solution under stirring at 20-100 deg.C and -(0.01-0.04) MPa to obtain iminodiacetate solution; (2) dropping phosphorous trichloride (1.0-1.5 mol times of iminodiacetonitrile) to the iminodiacetate solution at 20-100 deg.C and -(0.01-0.04) MPa with an acidic catalyst added before or after the phosphorous trichloride addition; (3) adding formaldehyde at a temperature not lower than 80 deg.C; (4) reacting at 100-120 deg.C for 1-7 h to obtain PMIDA suspension; (5) vacuum-distilling to recover formaldehyde; (6) crystallizing, separating, washing and drying to obtain PMIDA with a purity higher than 98%. The method has such advantages as simple process, low cost and high yield.

Owner:SICHUAN BEIER CHEM GROUP

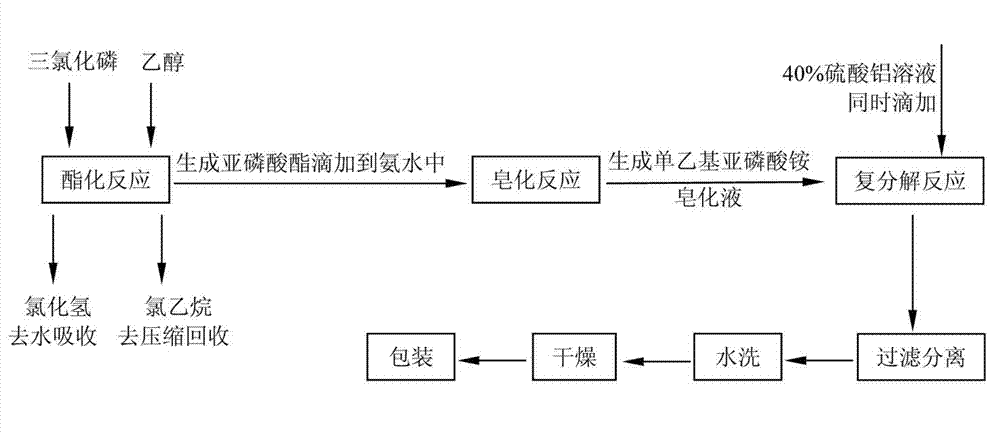

Method for producing technical-grade fosetyl-aluminum

ActiveCN102766157AReduce dosageReduce manufacturing costGroup 5/15 element organic compoundsPhosphoric Acid EstersPhosphorous acid

The invention discloses a method for producing technical-grade fosetyl-aluminum, comprising the steps of continuously mixing phosphorus trichloride and ethanol and esterifying to generate a phosphite ester liquid; continuously saponifying the phosphite ester liquid and inorganic alkali to generate an ammonium phosphite liquid; carrying out continuous double-decomposition on the ammonium phosphate liquid and water-soluble aluminum salt to generate fosetyl-aluminum slurry; precipitating the fosetyl-aluminum slurry, continuously separating and drying to obtain a product with fosetyl-aluminum content of 98% and total yield of 95% (based on phosphorus trichloride). The method has the advantages of simple process, easiness in implementation, high reaction speed, less side reaction, friendly field environment and notable economic benefit.

Owner:利民化学有限责任公司

A kind of preparation method of quaternary phosphonium salt

InactiveCN102268039AThe synthesis process is simpleSave human effortGroup 5/15 element organic compoundsPhosphonium saltGrignard reagent

The invention relates to a preparation method of a phosphonium salt, in particular relates to improvement of a preparation process of a phosphonium salt. The preparation method is characterized by comprising the following steps: carrying out a reaction on an alkane Grignard reagent and phosphorous trichloride so as to generate trialkyl phosphine; directly adding alkyl halide in the reaction in the former step without hydrolysis and separation so as to synthesize the phosphonium salt; and finally, separating and purifying by utilizing a principle that the phosphonium salt can be transferred in an organic phase and a water phase under a certain condition. Compared with the existing technology that the phosphonium salt is synthesized by a Grignard method, the hydrolysis step after trialkyl phosphine is synthesized is omitted in the preparation method provided by the invention, thereby simplifying the synthesis process, saving labor power and material resources and avoiding the side reaction and loss which are possibly brought by a middle operation so that the yield is improved; and the final yield is up to about 80%.

Owner:NANKAI UNIV

Method for preparing phosphorous acid and hydrogen chloride

The invention provides a method for preparing phosphorous acid and hydrogen chloride in an inner circulation tower by using phosphorus trichloride. The method comprises the following steps of: intermittently or continuously adding the phosphorus trichloride to the inner circulation tower, and then making the phosphorus trichloride react with a water solution in the tower to prepare a phosphorous acid water solution and a hydrogen chloride gas with large scale and high efficiency and yield and smoothly export the hydrogen chloride gas and heat. The method has the advantages of high reaction conversion rate and yield, steady reaction, high safety and the like and can be used for continuous production.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD

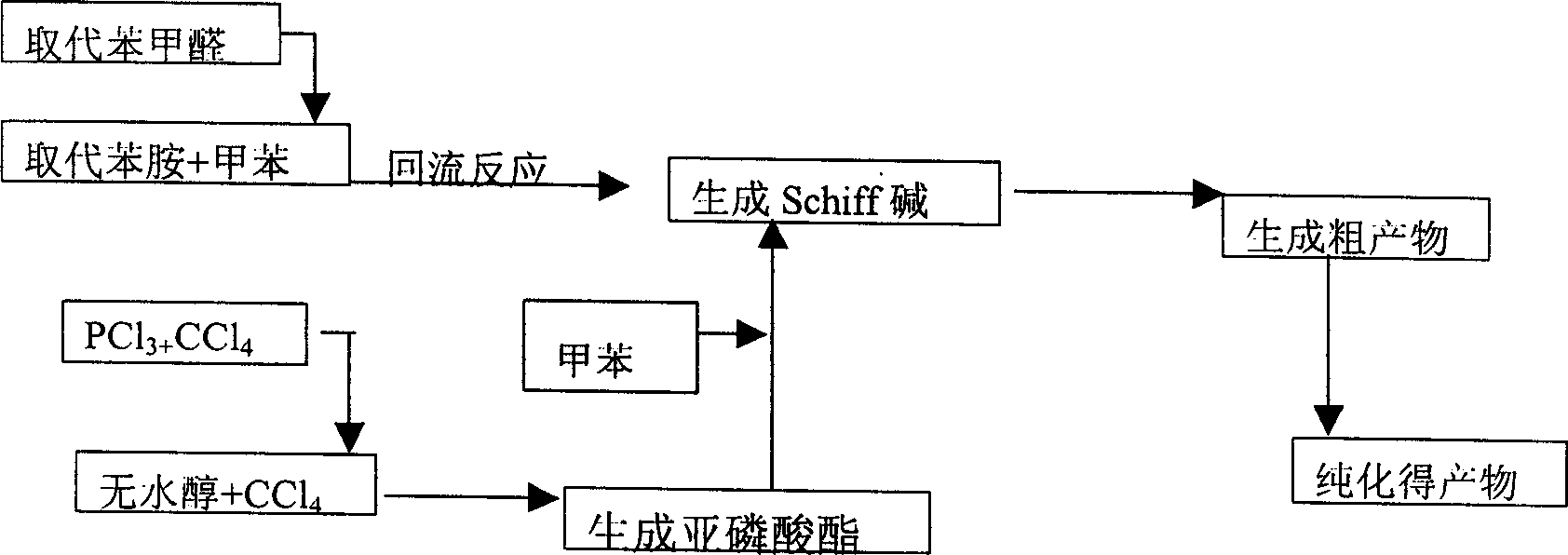

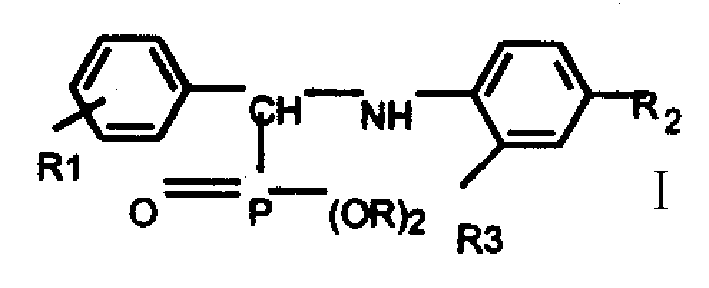

Fluoric alpha-aminoalkyl phosphonate with agricultural antiviral activity and its synthesis

The present invention relates to fluoric derivative of alpha-aminoalkyl phosphonate compound and its synthesis. Through active group splicing method, fluorine atom is introduced into alpha-aminoalkylphosphonate to synthesize serial fluoric alpha-aminoalkyl phosphate compounds. The synthesis features that substituted aniline, substituted banzaldehyde, anhydrous alcohol and phosphorus trichloride as materials in synthesized through a three-step process into fluoric alpha-aminoalkyl phosphonate compounds in solvent of toluene, benzene, ethanol, methanol, etc. The said derivatives have improved physical and chemical performance, increased liposolubility in organism, membrane permeability, etc.

Owner:GUIZHOU UNIV

Preparation method of N-(phosphonomethyl)iminodiacetic acid

ActiveCN102101873AAvoid it happening againReduce investmentGroup 5/15 element organic compoundsAmmonium halidesPhosphorous acidReaction temperature

The invention discloses a preparation method of N-(phosphonomethyl)iminodiacetic acid, which comprises the following steps: (1) putting iminodiacetonitrile into water, dropwisely adding phosphorus trichloride while controlling the temperature at 40-70 DEG C and stirring, heating to 80-130 DEG C after the dropwise adding process is finished, keeping the temperature for 1-4 hours to generate a mixed solution containing iminodiacetic acid hydrochloride, phosphorous acid, ammonium chloride and hydrochloric acid, adding formaldehyde into the mixed solution to carry out condensation reaction at 90-120 DEG C, cooling to crystallize, and carrying out solid-liquid separation to obtain an N-(phosphonomethyl)iminodiacetic acid product and a reaction mother solution containing ammonium chloride; and (2) adding ammonia into the reaction mother solution, regulating the pH value to 3-7, dehydrating by evaporation to concentrate until the ammonium chloride is oversaturated to precipitate, cooling to crystallize, carrying out solid-liquid separation to obtain ammonium chloride and a concentrated mother solution, and concentrating the mother solution for cyclic use. The invention fundamentally avoids the generation of a great deal of waste liquor containing sodium chloride, saves the investment into ammonia recovery equipment, simplifies the technique, increases the equipment utilization rate, and meanwhile recycles the byproduct ammonium chloride and the mother solution successfully.

Owner:捷马化工股份有限公司

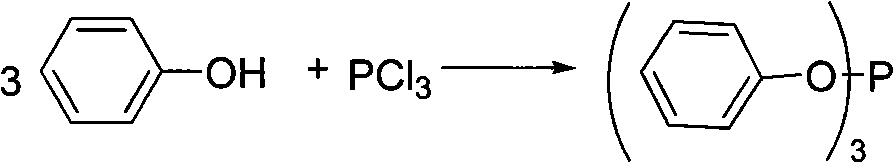

Method for synthesizing bis-(2,4-di-tert-butyl phenyl) pentaerythritol diphosphite

InactiveCN101250200ALow priceImprove responseGroup 5/15 element organic compoundsPentaerythritolSynthesis methods

The invention discloses a synthesis method of bis (2, 4-dibutylbenzene) pentaerythritol diphosphite, which comprises 1, synthesizing dichloropentaerythritol diphosphite: using xylene as solvent, adding pentaerythritol and catalyst, feeding nitrogen gas, adding phosphorous trichloride and absorbing generated hydrogen chloride gas via sodium hydroxide solution, and purifying reaction product to obtain the dichloropentaerythritol diphosphite, 2, synthesizing bis (2, 4-dibutylbenzene) pentaerythritol diphosphite: adding 2, 4-bis-tert-butylphenol into the reaction product of step 1, feeding nitrogen gas and mixing, absorbing generated hydrogen chloride gas via sodium hydroxide solution, and purifying the reaction product to obtain final product. The invention uses 2, 4-bis-tert-butylphenol, pentaerythritol and phosphorous trichloride as main materials, with low cost, easily processed reaction and high reaction yield.

Owner:SOUTH CHINA UNIV OF TECH

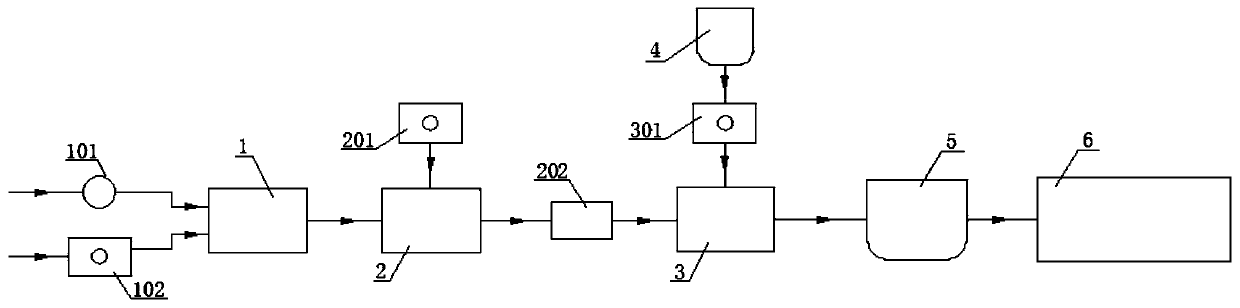

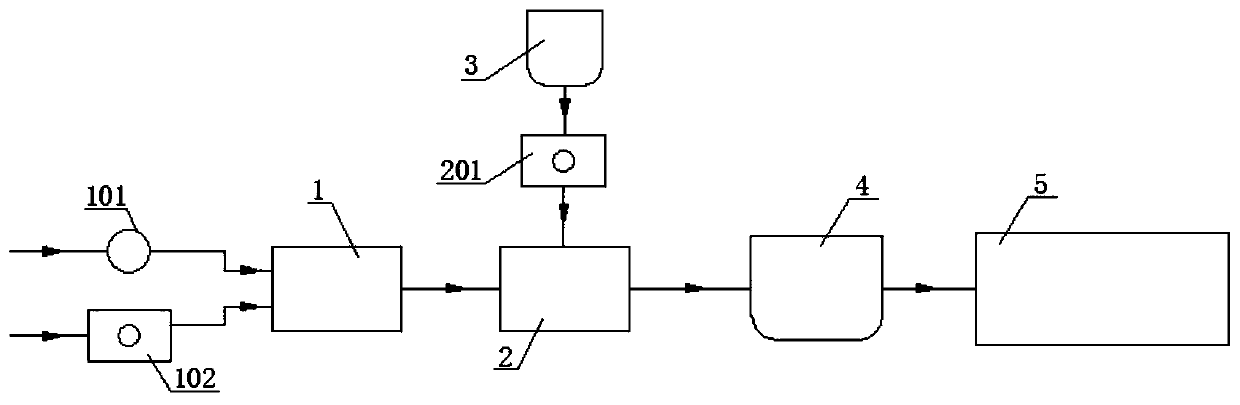

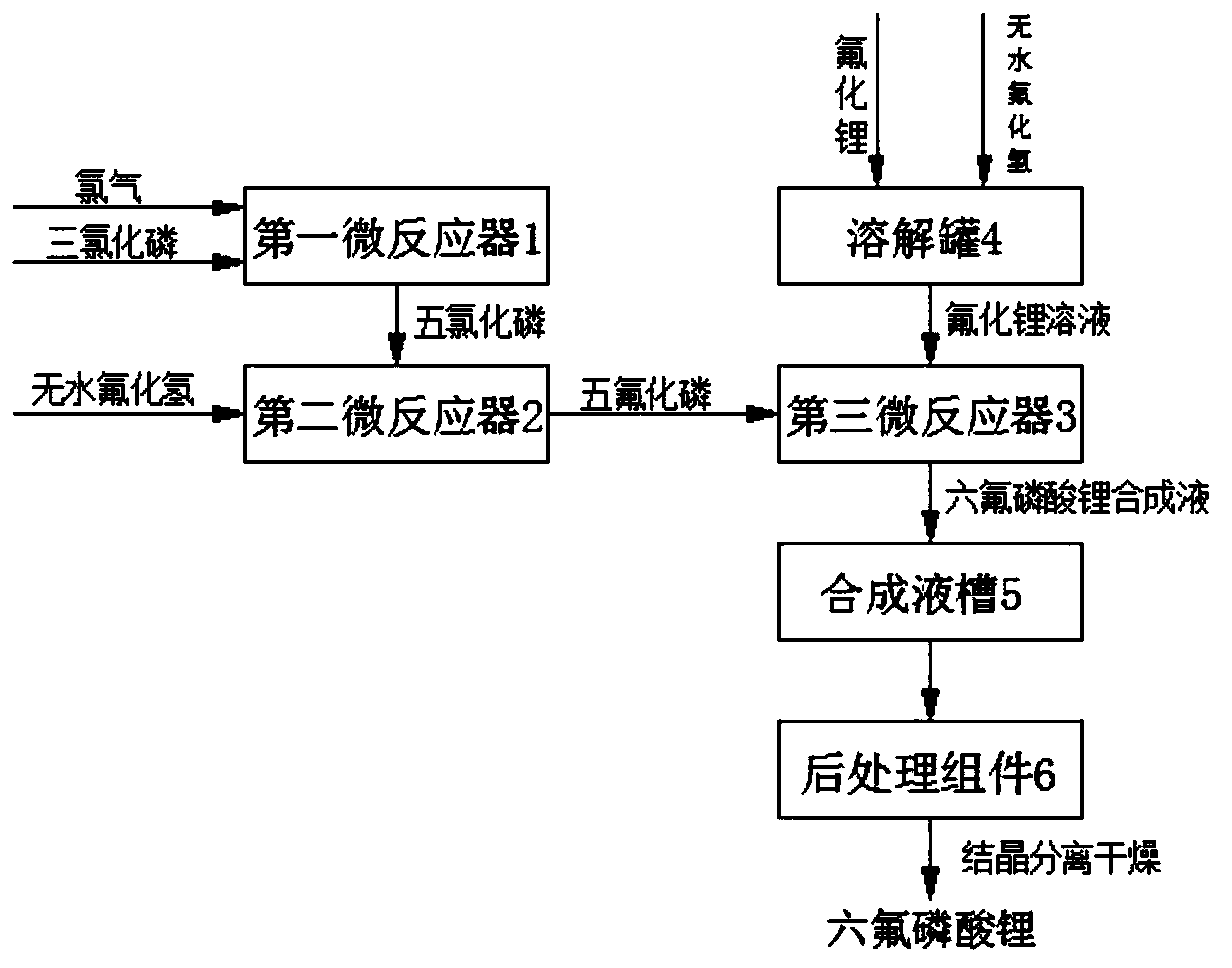

Continuous synthesis method and continuous synthesis device of lithium hexafluorophosphate

PendingCN110817831AImprove heat transfer efficiencyImprove mass transfer efficiencyLithium hexafluorophosphatePhosphorus compoundsPhosphoric acidLithium hexafluorophosphate

The invention provides a continuous synthesis method and a continuous synthesis device of lithium hexafluorophosphate, and belongs to the technical field of lithium hexafluorophosphate synthesis. According to the invention, the synthesis method comprises: introducing chlorine, phosphorus trichloride, hydrogen fluoride and lithium fluoride into a microreactor to achieve an instantaneous uniform mixing and rapid reaction of the materials, and exporting reaction heat; the synthesis device comprises a first micro-reactor for synthesizing phosphorus pentachloride through a reaction of chlorine andphosphorus trichloride, and a second micro-reactor for a reaction of the phosphorus pentachloride; and the chlorination reaction and the fluorination reaction are carried out by adopting the microreactor, so the intermolecular heat transfer and mass transfer efficiency of the reaction materials is high, the reaction efficiency is improved, and the reaction heat can be exported so as to ensure thesafety.

Owner:湖北迈可凯科技有限公司

High-temperature diesel antioxidant and preparation method thereof

The invention belongs to a diesel additive, and in particular relates to a phosphite compound high-temperature diesel antioxidant and a preparation method thereof. The preparation method of a trialkyl diphosphite diesel antioxidant comprises the following steps of: reacting pentaerythritol with phosphorus trichloride to generate dichloropentaerythritol diphosphite; and reacting the dichloropentaerythritol diphosphite with long-chain alkane alcohol to generate the trialkyl diphosphite diesel antioxidant. The antioxidant has the prominent effects of preventing oxidation, improving color and the like. The novel trialkyl phosphite compound has low toxicity and volatility and high compatibility with diesel, is environmental-friendly, and has a wide application prospect in the field of diesel additives.

Owner:JINAN DEV ZONE XINGHUO SCI & TECH RES INST

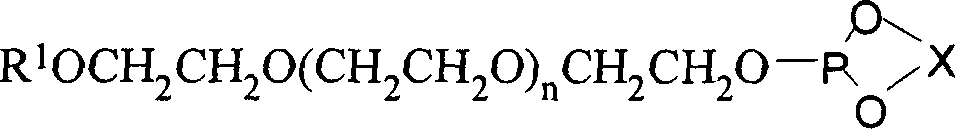

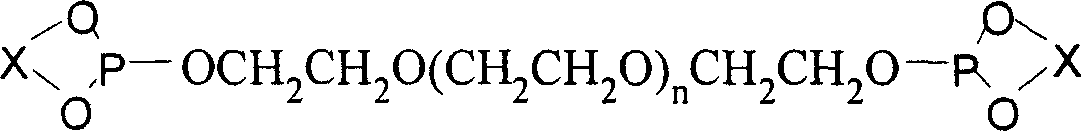

Chiral monodentate phosphite ligands, its preparation method and uses

InactiveCN1951946AStable air and humidityEasy to store and operateOrganic reductionOrganic compound preparationDouble bondDichloromethane

The invention discloses a chiral monodentate phosphite ester ligand and preparing method, which comprises the following steps: a) placing chiral glycol and phsophorus trichloride in the reacting bottle; adding 2-methyl pyrrolidone; heating and refluxing until the chiral glycol is dissolved completely; decompressing to remove solvent; recrystallizing residual skellysolve B; obtaining the needed phosphorochloridous acid ester; b) dissolving phosphorochloridous acid ester in the dichloromethane; adding carbowax methyl ether or carbowax methyl ester and trimethylamine carrene solution at 0-5 deg.c; heating reacting liquid to 18-25 deg.c; stirring to react for 10-30h; filtering; removing solvent to obtain the product. The invention improves catalyzing activity, which makes TON at 10000.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of phosphonium salt

InactiveCN102268039BThe synthesis process is simpleSave human effortGroup 5/15 element organic compoundsPhosphonium saltGrignard reagent

The invention relates to a preparation method of a phosphonium salt, in particular relates to improvement of a preparation process of a phosphonium salt. The preparation method is characterized by comprising the following steps: carrying out a reaction on an alkane Grignard reagent and phosphorous trichloride so as to generate trialkyl phosphine; directly adding alkyl halide in the reaction in the former step without hydrolysis and separation so as to synthesize the phosphonium salt; and finally, separating and purifying by utilizing a principle that the phosphonium salt can be transferred in an organic phase and a water phase under a certain condition. Compared with the existing technology that the phosphonium salt is synthesized by a Grignard method, the hydrolysis step after trialkyl phosphine is synthesized is omitted in the preparation method provided by the invention, thereby simplifying the synthesis process, saving labor power and material resources and avoiding the side reaction and loss which are possibly brought by a middle operation so that the yield is improved; and the final yield is up to about 80%.

Owner:NANKAI UNIV

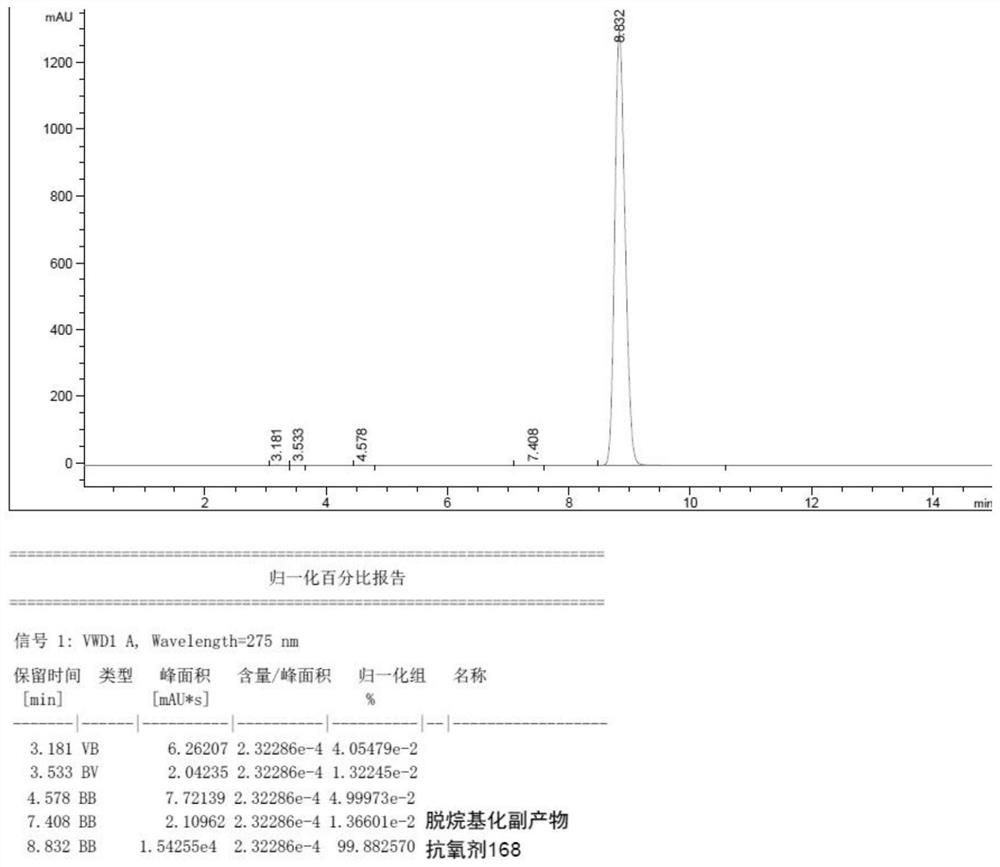

Preparation method of antioxidant tris(2,4-di-tert-butylbenzene) phosphite

ActiveCN112661787AHigh selectivityImprove hydrolysis resistanceGroup 5/15 element organic compoundsBulk chemical productionPhosphorous acidTert butyl phenol

The invention relates to a preparation method of an antioxidant tris(2,4-di-tert-butylbenzene) phosphite, which comprises the following steps: reacting 2,4-di-tert-butyl-phenol and phosphorus trichloride used as raw materials at 50-145 DEG C, and removing HCl gas generated in the reaction process; heating a reaction liquid obtained in the previous step until HCl gas is stopped being discharged, increasing the reaction temperature to 145-160 DEG C, controlling the reaction pressure to 90-101.3 kPa, continuing the reaction until the pH value of the reaction liquid reaches 3 or above, and ending the reaction to prepare the antioxidant tris(2,4-di-tert-butylbenzene) phosphite. The method adopts micro-negative pressure and by-products generated by reaction are avoided, so that the purity of the product is improved, and the hydrolysis resistance of the product is improved; and the crystallization mother liquor is simply distilled and recycled and then is reused.

Owner:RIANLON ZHONGWEI NEW MATERIAL CO LTD +2

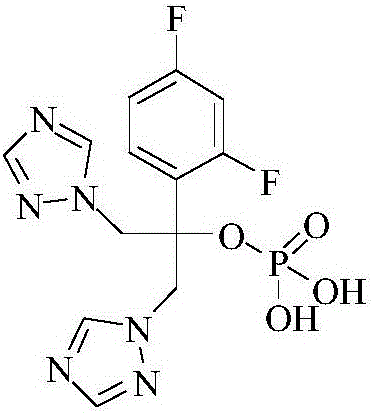

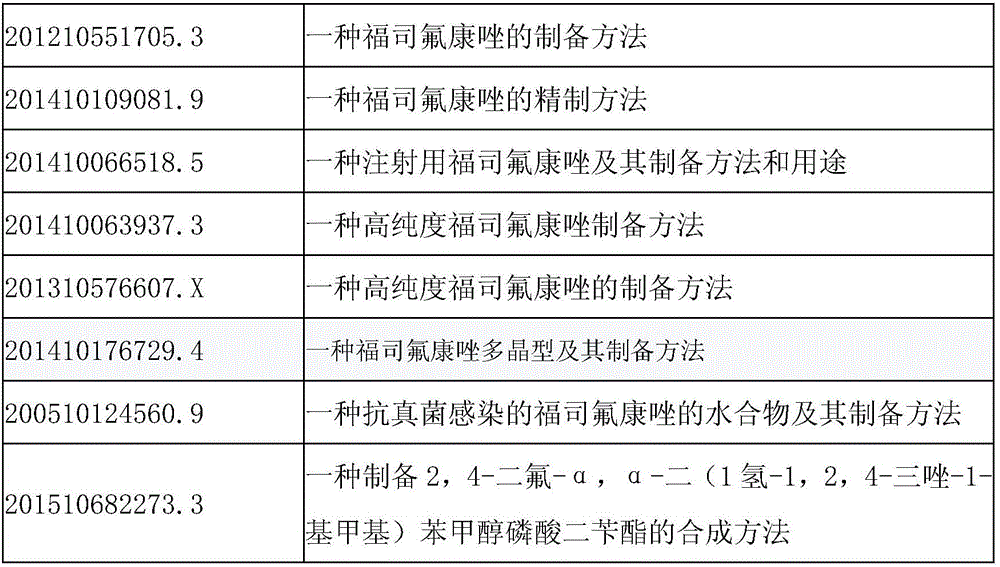

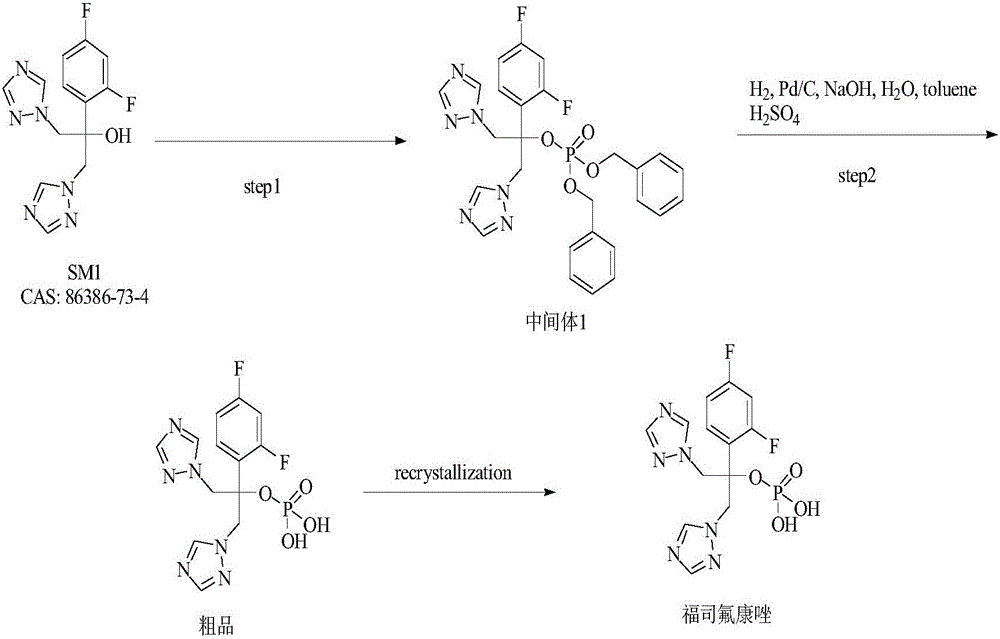

Method for preparing fosfluconazole

ActiveCN105753902ALow impurity contentImprove stabilityGroup 5/15 element organic compoundsPhosphorus trichlorideBENZYL ALCOHOL/WATER

The invention relates to a method for preparing fosfluconazole. The method comprises the following steps: 1, preparing a fosfluconazole midbody 1, namely, by taking fluconazole as a raw material, enabling fluconazole to react with phosphorus trichloride and benzyl alcohol so as to obtain the midbody 1; 2, preparing a crude product of fosfluconazole, namely, hydrogenating the fosfluconazole midbody 1 so as to obtain the crude product of fosfluconazole; 3, preparing a fine product of fosfluconazole, namely, recrystallizing the crude product of fosfluconazole by using a mixed solvent of acetone and dichloromethane in a ratio of 1:2 (v / v), thereby obtaining the fine product of fosfluconazole.

Owner:ZHEJIANG CHENGYI PAHRMACEUTICAL

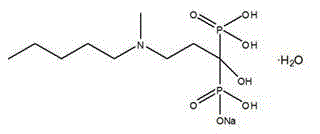

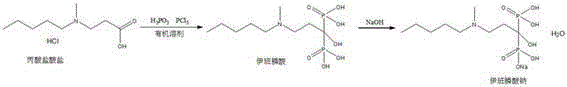

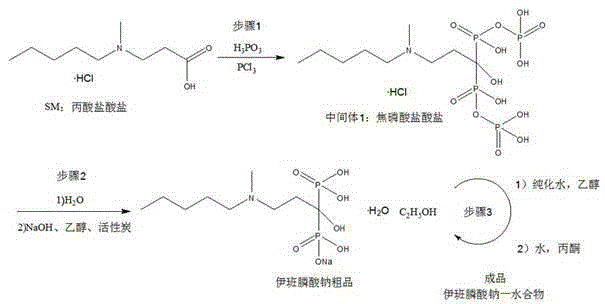

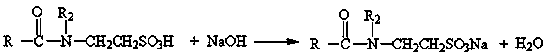

Preparation method of sodium ibandronate

InactiveCN104628768ALow toxicityAvoid reaction stirring difficultiesGroup 5/15 element organic compoundsPhosphorous acidChlorobenzene

The invention relates to a drug synthesis method, and in particular relates to a preparation method of sodium ibandronate. The preparation method comprises the following steps of: directly reacting 3-(N-methyl-N-n-amylamine) propionic hydrochloride, phosphorous acid with phosphorus trichloride to obtain 1-hydroxyl-3-(methyl amylamine)-dimethylmethane-1,1-bipyrophosphoric acid hydrochloride, directly forming salt with sodium hydroxide after hydrolyzing so as to obtain crude sodium ibandronate, and respectively re-crystallizing for one time through mixed solvents of ethanol and water and acetone and water so as to obtain sodium ibandronate. Any solvent is not used in the step of synthesizing pyrophosphoric acid hydrochloride; solid-liquid reaction is carried out without stirring and post-treatment; products are directly used in the next step; a reaction system is dispersed by using organic solvents, such as chlorobenzene and diethyl carbonate, in some reported methods; products are shaped as oil blocks and are not beneficial to stirring and post-treating after reacting; in contrast, the kinds of impurities in the products are reduced; toxicity due to the organic solvents, such as chlorobenzene and diethyl carbonate, is eliminated; furthermore, the stirring difficulty is avoided; sodium ibandronate is prevented from being stuck on a stirrer and a bottle wall; and thus, industrial production is conveniently carried out.

Owner:JIANGSU QINGJIANG PHARMA

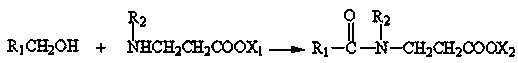

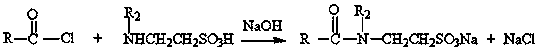

Synthesis method of surfactant

PendingCN111004142AReduce selectionEmission reductionOrganic compound preparationTransportation and packagingActive agentWater chlorination

The invention discloses a synthetic method of a surfactant. The synthetic method comprises the following steps: (1) adding fatty alcohol, a catalyst and amino acid ester into a reactor; (2) closing the reactor, and slowly heating to 200-300 DEG C; (3) carrying out a heat preservation reaction for 2-10 hours; (4) degassing; and (5) treating to obtain a finished product. According to the invention,fatty alcohol is directly selected as an acylation reagent to perform a reaction, so that the step of fatty acid acylation is omitted, the selection of dangerous substance acylation reagents such as phosgene, thionyl chloride, trichloromethyl chloroformate, phosphorus trichloride, phosphorus pentachloride and phosphorus oxychloride is reduced, the emission of byproducts such as phosphorous acid and the like is reduced, and the method is feasible from the aspect of reaction mechanism; and fatty alcohol and amino acid ester are selected to be subjected to a direct reaction, so that impurities such as chlorine ions and the like are not introduced in the process, and the target product is obtained through the direct reaction so as to eliminate the steps of acidification, salification or waterwashing desalination and reduce the use and discharge of salt-containing wastewater or an organic solvent.

Owner:ZHANGJIAGANG GREAT CHEM

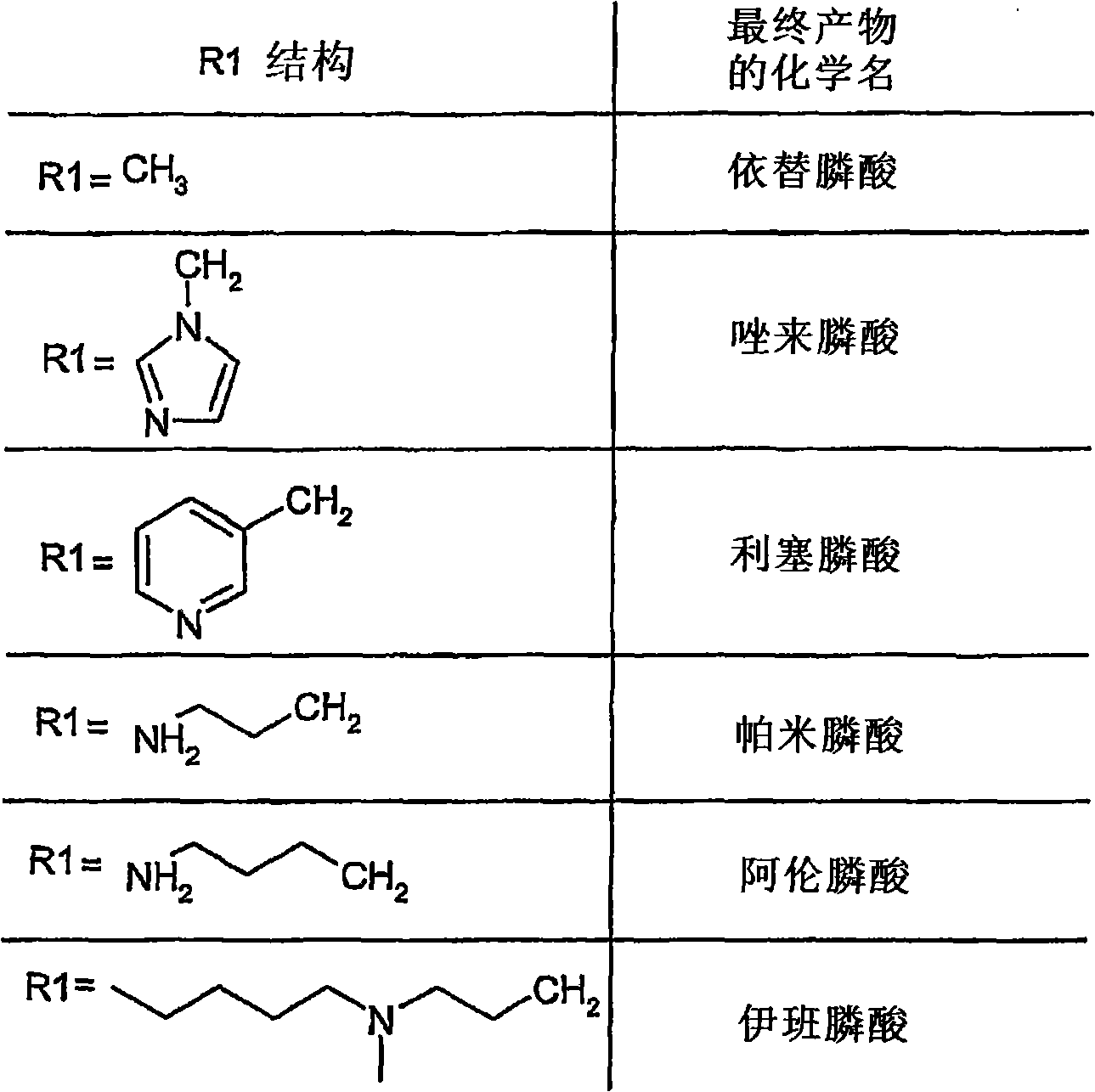

Process for the preparation of biphosphonic acids and salts thereof

A process for the preparation of biphosphonic acids and pharmaceutical acceptable salts thereof, comprises reacting a carboxylic acid with phosphorous trichloride and phosphorous acid in the presence of an aprotic polar solvent.

Owner:霍维奥恩联合有限公司

Production method of dimethyl phosphite

InactiveCN107082786ASimple production processHigh purityGroup 5/15 element organic compoundsDimethyl phosphiteChloride

The invention discloses a production method of dimethyl phosphite. The method includes the steps that phosphorus trichloride and methyl alcohol are adopted as raw materials to be put into a reaction still for reaction; after adding catalysts, the raw materials are reacted under the temperature of 20-30 DEG C for 10-20 h to obtain the dimethyl phosphite; ferric chloride is adopted as a catalyst and added into concentrated sulfuric acid for surface treatment, and meanwhile, the time of the surface treatment is controlled within 30-40 seconds; the mole ratio of the phosphorus trichloride to methyl alcohol is (0.8-1.1) : (3.2-3.3); the pressure inside the reaction still is controlled at 1.2 Mpa, and the stirring speed is controlled at 100 r per min. The production method of dimethyl phosphite has the advantages of simple production process and high product purity, and is suitable for large-scale industrial production.

Owner:XUZHOU JIANGHAIYUAN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com