Patents

Literature

48 results about "Ethylidenediphosphonic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Descaling method of phospheric acid concentration heat exchanger

ActiveCN1724965AEfficient removalRemove completelyOrganic detergent compounding agentsSurface-active detergent compositionsHexamethylenetetraminePhosphoric acid

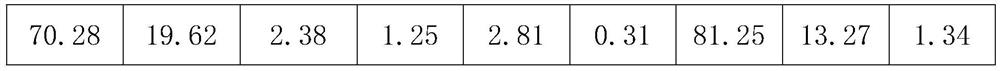

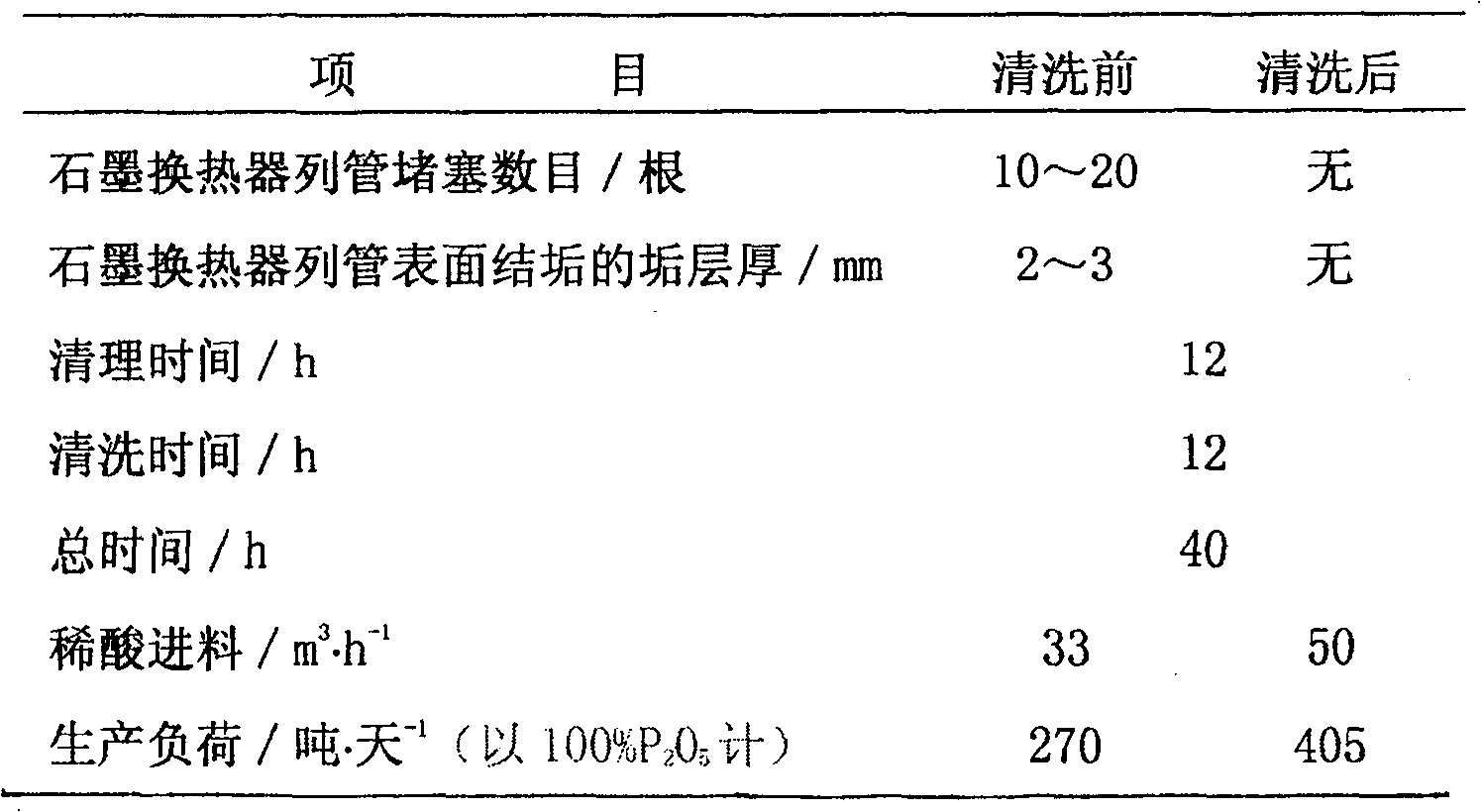

The invention discloses a method for decaling phosphoric acid concentration heat exchanger, namely a technique of adopting a washing-liquor composed of thin fluosilicic acid solution, organic phosphonic acid sustained-releasing agent and film forming matter and firstly washing the heat exchanger with water and then washing out the foul with the washing liquor. In the washing liquor, the fluosilicic acid is a 5%-20% thin acid, the organic phosphonic acid sustained-releasing agent includes amino tri- sub-methylene phosphoric acid, hydroxyl sub-ethyl di-phosphoric acid and hydroxyl-l, 1-subethyl di-phosphoric acid; the film forming matter includes nitrous phenylhydroxylamine ammonium salt and wuluotuopin as well as sodium molybdate. As using, adding in surface active agent alkyl sulphonate. The invention can make high efficiency and thorough decaling the graphite heat exchanger and simultaneously effectively control the corrosion of the washing liquor to the equipment and as compared with traditional washing methods, the invention improves the productivity of the equipment.

Owner:WENGFU (GRP) CO LTD +1

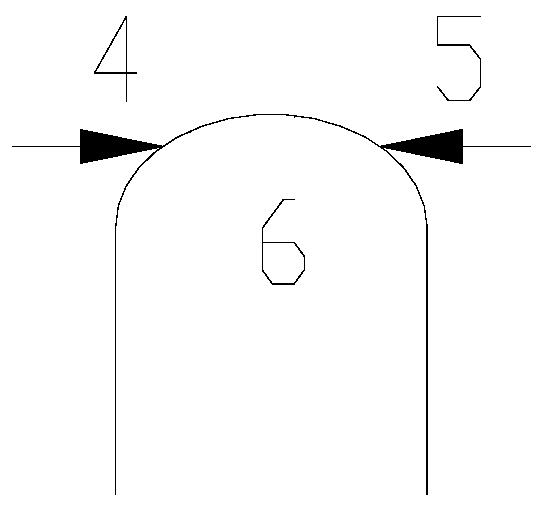

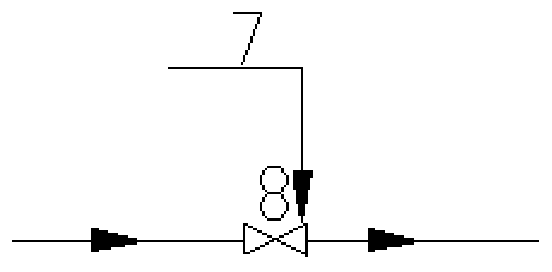

Continuous synthesis technique of hydroxyethylidenediphosphonic acid

ActiveCN102875594AIncrease productivityImprove utilization efficiencyChlorine/hydrogen-chlorideOrganic compound preparationO-Phosphoric AcidEthylic acid

The invention relates to a continuous synthesis technique of hydroxyethylidenediphosphonic acid, which comprises the following steps: 1. mixing raw materials: mixing phosphorus trichloride and acetic acid in a mol ratio of 1:(2.8-3.0) in a mixing kettle; 2. sending the mixture into a tubular reactor: pumping the mixture into the tubular reactor through a diaphragm pump; 3. carrying out esterification reaction while controlling the temperature of the tubular reactor at 70-130 DEG C; 4. separating the reaction mixture in a gas-liquid separator for recycling; 5. carrying out hydrolysis reaction to obtain the hydroxyethylidenediphosphonic acid; and 6. distilling out acetic acid under negative pressure to separate the acetic acid from the product, wherein the acetic acid enters an acetic acid storage tank as a raw material. In the invention, the hydroxyethylidenediphosphonic acid is continuously produced in a semi-closed system, thereby changing the existing intermittent production mode and enhancing the production efficiency; and the invention overcomes the defects of low product yield, too many side reactions and high contents of phosphorous acid and phosphoric acid in other preparation techniques, and implements complete cyclic utilization of acetic acids with different concentrations.

Owner:山东泰和科技股份有限公司

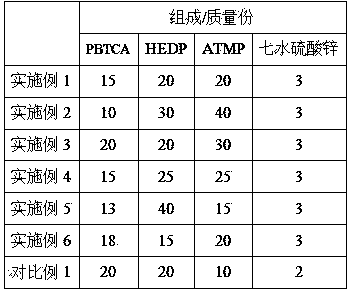

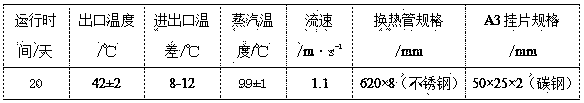

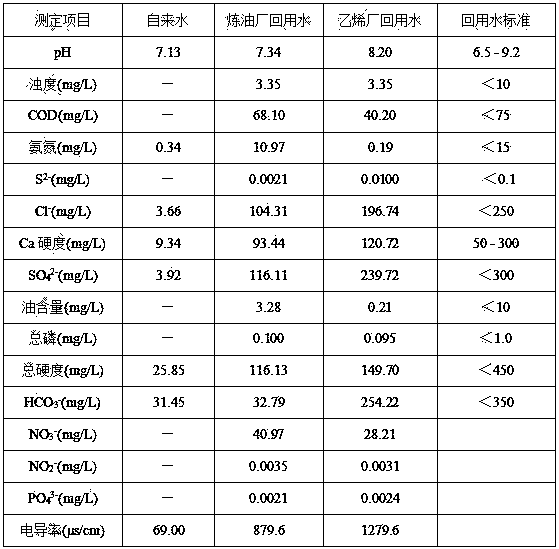

Composite slow-release scale inhibitor suitable for petrochemical wastewater reusing circulating water system

ActiveCN104230015AComply with corrosion rate less than 0.075 mm/a anti-corrosion requirementsAdd lessScale removal and water softeningAqueous corrosionPhosphate

The invention discloses a composite slow-release scale inhibitor suitable for a petrochemical wastewater reusing circulating water system. The composite slow-release scale inhibitor comprises 2-butane phosphate-1,2,4-tricarboxylic acid, hydroxy ethylidene diphosphonic acid, amino trimethylene phosphonic acid and zinc sulfate. After the composite slow-release scale inhibitor is adopted, by virtue of dynamic simulation experiment on oil refinery reuse water, the water quality inhibition rate is 86.18%; by virtue of the dynamic simulation experiment on ethylene plant reuse water, the water quality inhibition rate is 86.44%, and the scale inhibiting rate is 87.42%; the corrosion rate is reduced to 0.0168 mm / a and 0.0091 mm / a, which meets the anticorrosion requirement that the corrosion rate of China petrochemical circulating cooling water is less than 0.075 mm / a. Compared with the traditional polyphosphate carboxylate composite slow-release scale inhibitor, the composite slow-release scale inhibitor disclosed by the invention has the advantages of small addition amount and good corrosion inhibition effect and scale inhibition.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

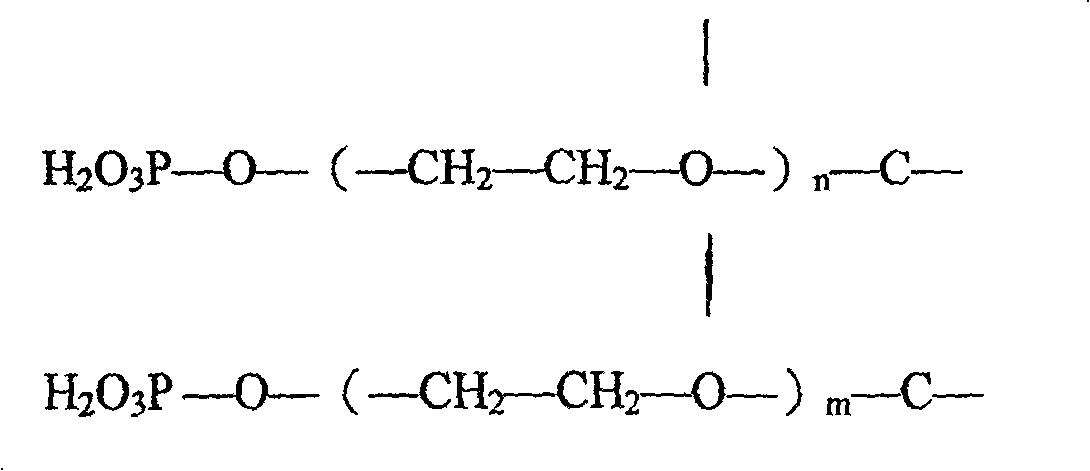

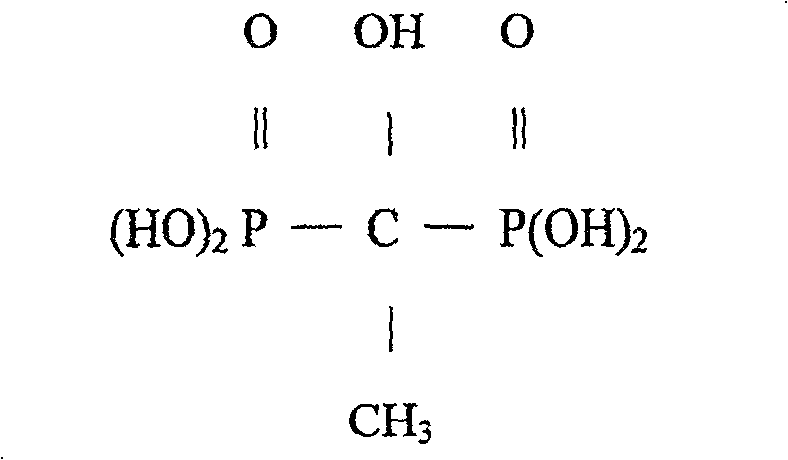

Process for synthesis of hydroxy ethidene diphosphoric acid

InactiveCN1827625ALess investmentSimple and safe operationGroup 5/15 element organic compoundsPhosphorous acidDistillation

A method for synthesizing hydroxyl ethylidenediphosphonic acid belongs to synthesis of organo-phosphonic acid and is used in water stabilization. The phsophorus trichloride and acetic acid react at a temperature between 80 DEG C and 150 DEG C with an absolute pressure less than 760 millimeters mercury column, and the byproducts of hydrochloride and a few acetyl chlorides free of condensation are respectively retrieved and reused by combined recovery system of acetic acid and hydrochloric acid. The product of this method is obtained by hydrolyzing the acetylated hydroxyl ethylidenediphosphonic acid at a temperature between 80 DEG C and 150 DEG C with an absolute pressure no more than 760 millimeters mercury column; the collected hydrolysate of acetic acid after the distillation and the condensation is selected as raw material together with the acetic acid solution from the reclamation tower of acetic acid. The autoclave of 1000 litres daily produces products of 2500 kilograms with 60 % of solid content and less than 0.15 % of phosphorous acid; the yield rate of the products is more than 98 % calculated by phsophorus trichloride and is more than 96 % calculated by acetic acid.

Owner:傅明珠

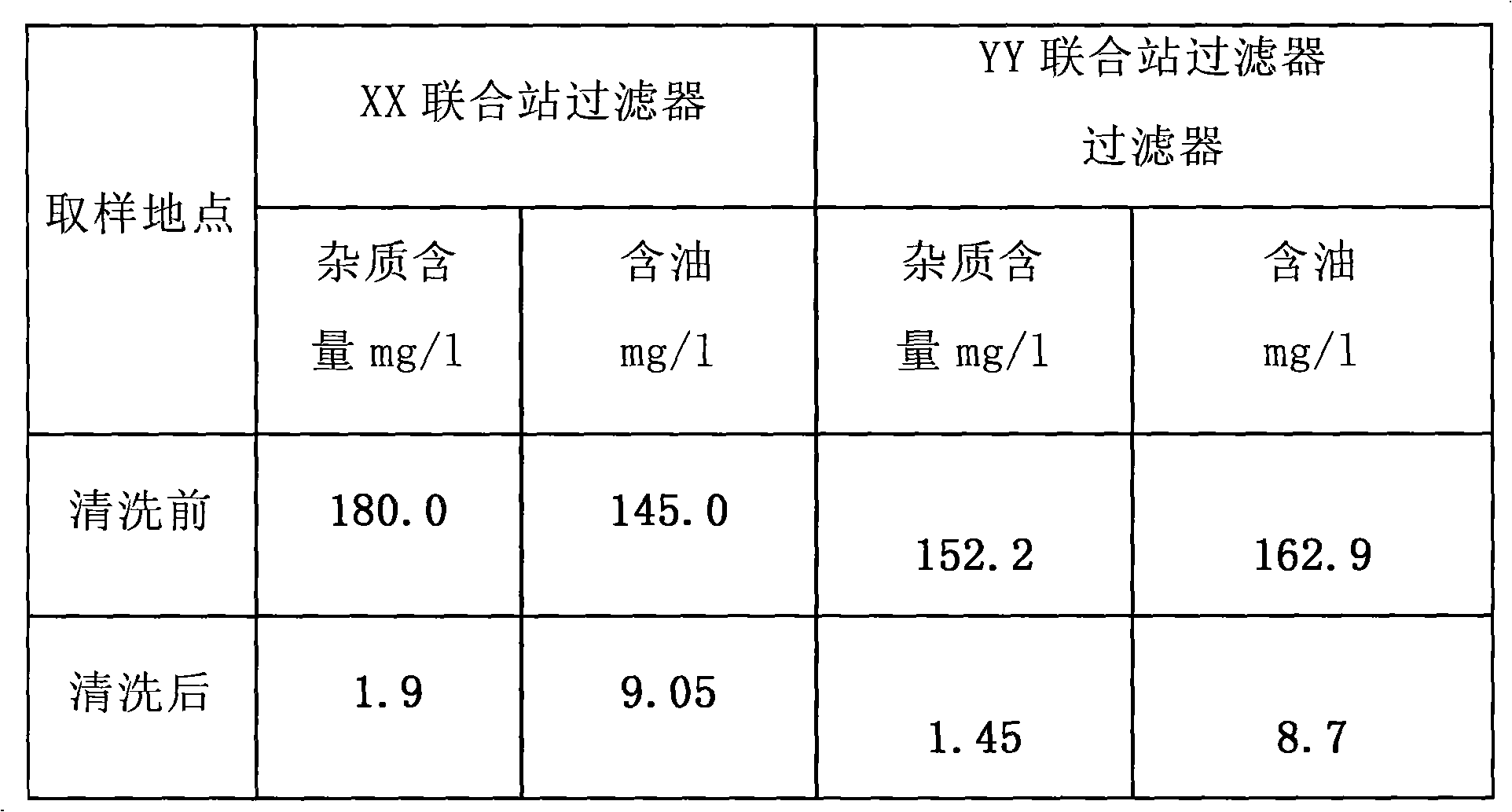

Sewage filter cleaning agent and preparation thereof

ActiveCN101328451AImprove filtration efficiencyNon-ionic surface-active compoundsDetergent compounding agentsCleansing AgentsPhenol

The invention provides a sewage filter cleaning agent. The cleaning agent is used in oil fields to remove crude oil and impurities deposited on filter screens. The cleaning agent consisting of the following components in weight percentage: a. 5 to 10 percent of citric acid; b. 3 to 5 percent of hydrochloric acid; c. 0.05 to 0.2 percent of hydroxide radical-1, 1-ethidene diphosphonic acid sulfonic acid; d. 4 to 6 percent of alkyl phenol polyoxyethylene(14) ether; and d. the remaining being water. The cleaning agent has the advantages that, the cleaning agent can remove the majority of crude oil and impurities deposited on filter materials, and the filtering efficiency of the sewage filter which is cleaned is improved by 20 percent, the oil content of the sewage which is filtered is less than 4mg / l, and the oil content of the mechanical impurity is less than 10mg / l.

Owner:PETROCHINA CO LTD

Special corrosion and scale inhibitor for surface evaporation air cooling

InactiveCN1459424AExcellent corrosion and scale inhibitionLittle effect of turbidityScale removal and water softeningTurbidityWater quality

A retarding-corrosion antiscaling compound for the surface-evaporating air cooler used in high-hardness and high-basicity circulating water system is prepared from zinc sulfate 15-25 wt. portions, acrylic acid-acrylate copolymer 30-36 portions, hydroxy-1-1-ethylene diphosphonic acid 34-46 portions, and benzotriazole 4-6 portions. It still exhibits good performance under the condition of relatively bad quality of circulating water. Its advantages are its effect little affected by turbidity, adapting to wide pH range, high effect, and low dosage.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

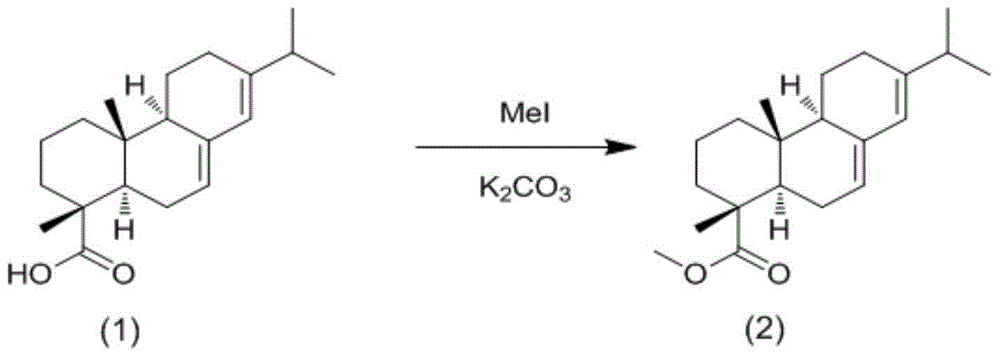

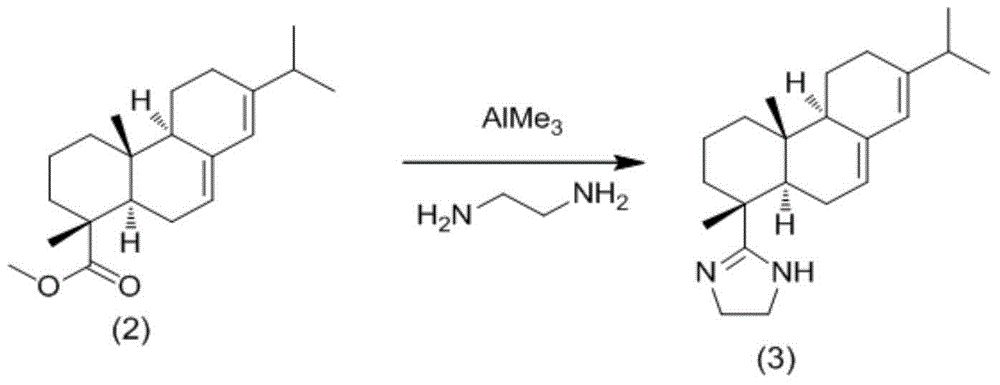

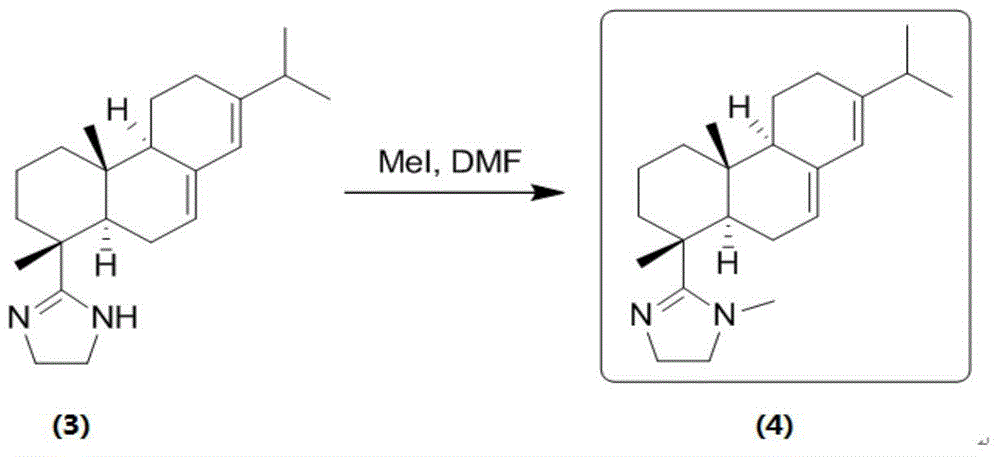

Novel rosin imidazoline corrosion inhibitor

ActiveCN105272916AImprove thermal stabilityLow toxicityOrganic chemistryBorehole/well accessoriesMetallic materialsRosin

The invention relates to the synthesis and application technology field of compounds used for metal anticorrosion, and concretely discloses a novel rosin imidazoline corrosion inhibitor, a synthetic method and applications. The initial raw material of the provided compound is rosin acid, the raw material is single and the synthetic route operation is simple. The method for preparing a corrosion inhibitor from the synthesized compound is simple, the compound is dissolved in dimethyl formamide, then the obtained solution is dissolved in water, then 1-hydroxyethylidene-1,1-diphosphonic acid is added, and uniform stirring is carried out. The corrosion inhibitor is safe and environmentally friendly, and has excellent corrosion inhibition effects. The corrosion inhibitor can be used for oil and gas field ground gathering and storage and transportation pipes, prevents damage of corrosive gases to metal materials of steel and the like and reduces corrosion loss.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

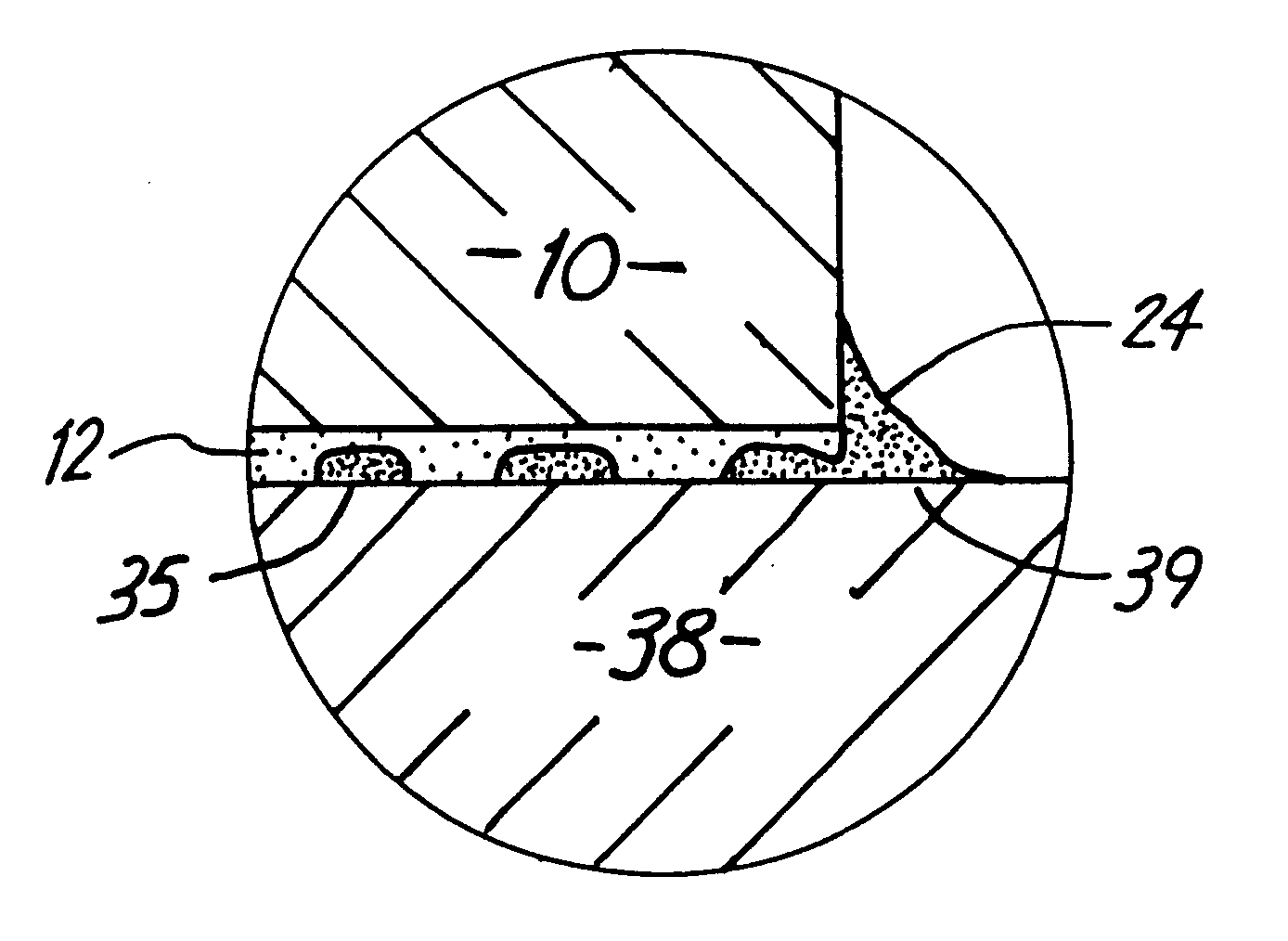

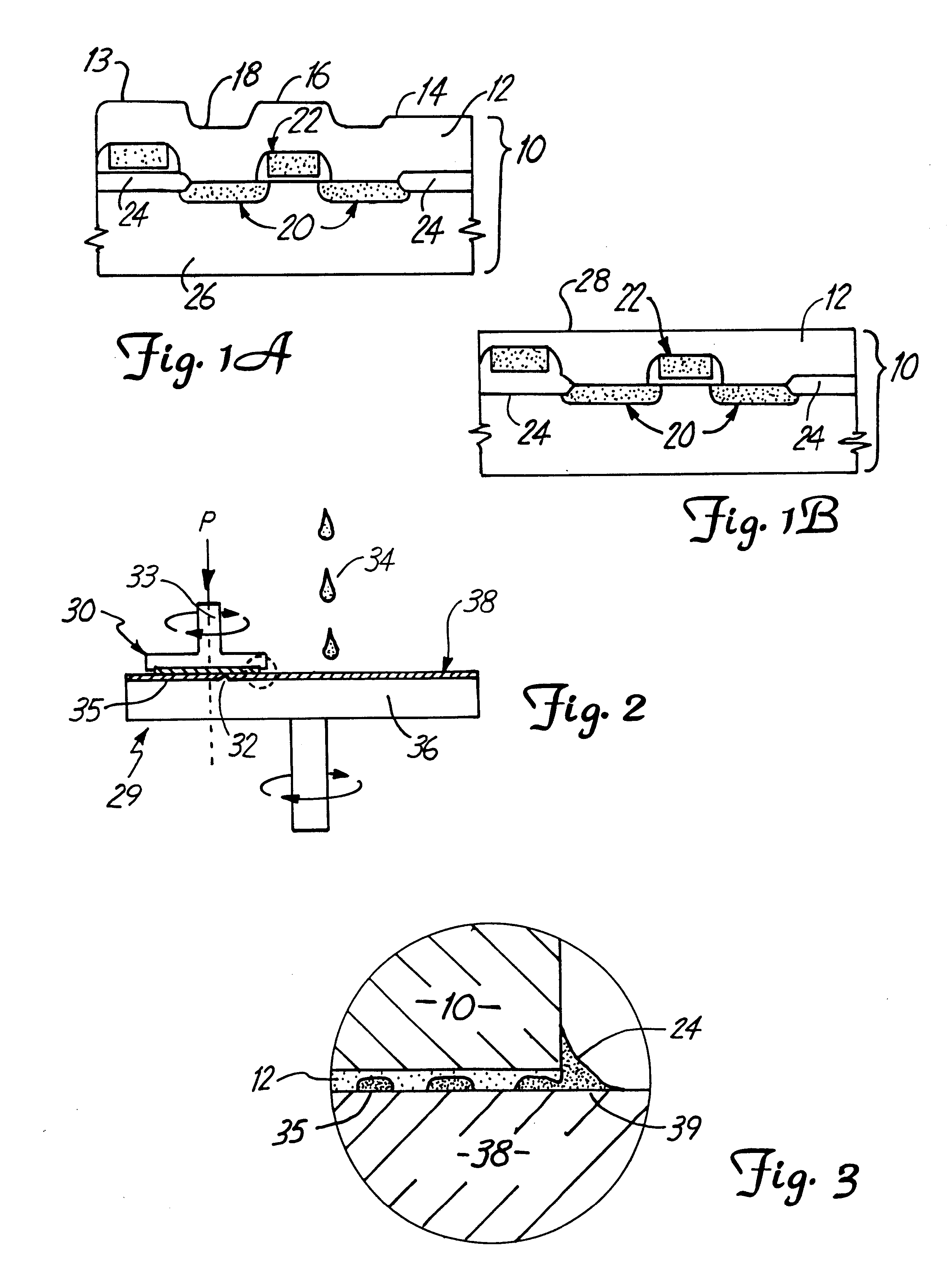

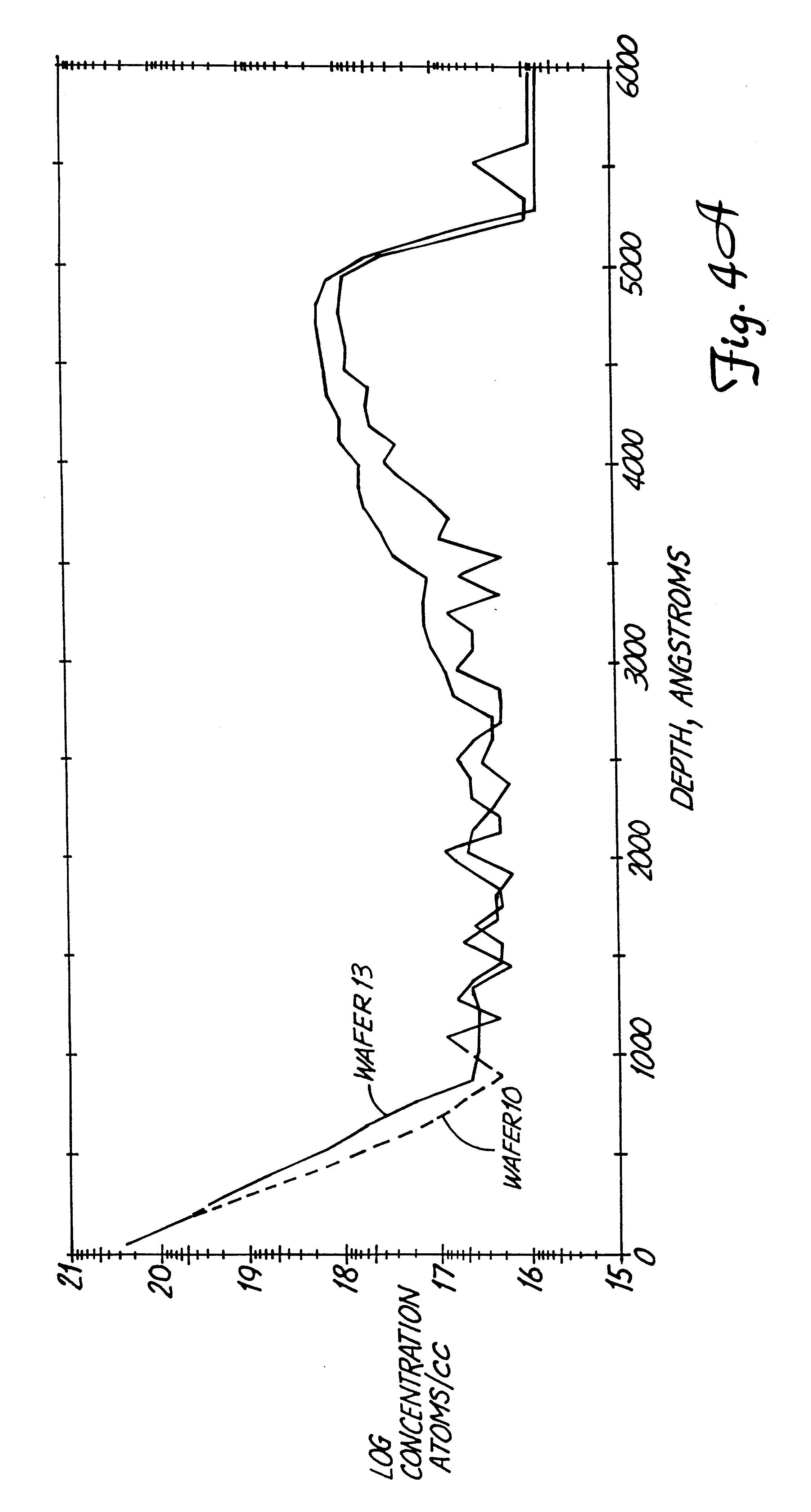

Planarization method using fluid composition including chelating agents

InactiveUS6280924B1Decorative surface effectsSemiconductor/solid-state device manufacturingWater solubleFluid composition

A planarization method including the provision of a wafer having a wafer surface. A pad is positioned for contact with the wafer surface and the wafer surface is planarized using the pad and a fluid composition that includes a chelating agent. The chelating agent is a water soluble multidentate chelating agent, preferably a water soluble bidentate ionic chelating agent, and more preferably 1,2-ethylenediphosphonic acid (EDP). A fluid composition for use in planarization of a surface of a wafer includes a chemically interactive component that interacts with the surface of the wafer and a chelating agent for reducing the metal ion contamination of the wafer during planarization. The chelating agent may be one of a water soluble multidentate chelating agent, preferably a water soluble bidentate ionic chelating agent, and more preferably 1,2-ethylenediphosphonic acid (EDP). Further, the fluid composition may include an abrasive component.

Owner:MICRON TECH INC

Environment-friendly water treatment barium-strontium anti-scaling agent and preparation method thereof

InactiveCN105036357AReduce usageGood corrosion inhibitionTreatment using complexing/solubilising chemicalsMeth-Ptru catalyst

The invention discloses an environment-friendly water treatment barium-strontium anti-scaling agent and a preparation method thereof. Acrylic acid, methyl acrylate, ammonium persulfate, amino trimethylene phosphonic acid, distilled water, ethylene diamine tetraacetic acid, unsaturated organic acid, sodium tripolyphosphate, maleic anhydride, hydroxyethylidene diphosphonic acid and a catalyst are weighed according to a weight ratio. According to the anti-scaling agent, calcium carbonate and calcium phosphate micro-crystals are dispersed; even if scales are generated, the scales are relatively loose and are easily washed away by flow; the anti-scaling agent is excellent in corrosion inhibition, non-toxic and high in thermal stability; the using amount of the anti-scaling agent is as small as 1 to 10mg / L, and the using cost is reduced; the effect is enduring, after the anti-scaling agent is placed for a month at the temperature of 50 to 60 DEG C, the anti-scaling effect is 98 to 100 percent, and the anti-scaling agent is mainly applied to a recycled sewage and oil delivery pipeline of an oil field and is used for preventing metal ions from scaling.

Owner:SUZHOU YOUJUN ENVIRONMENTAL SCI & TECH

Scale inhibitor for industrial cooling water system and preparation method thereof

InactiveCN106745844AExtensive sources of raw materialsGood water solubilitySpecific water treatment objectivesScale removal and water softeningIonEnvironmental chemistry

A scale inhibitor for an industrial cooling water system contains raw materials of ultrapure water, polyacrylic acid, binary acylic copolymer, benzotriazole, hydrolyzed polymaleic acid, ethanol, phenol polyoxyethylene, hydroxyethylidene-1,1-diphosphonic acid, dodecyl dimethyl benzyl ammonium chloride, amino trimethylene phosphonic acid and polyamino polyether methylene phosphonate. The scale inhibitor for the industrial cooling water system is applicable to industrial water systems, boiler systems and central air conditioning systems; the phosphorus value in exterior drainage water is 0.05-0.25 mg / L; the scale inhibitor for the industrial cooling water system achieves very good complexing ability for metal ions in the water and effectively stops scaling; the crystal lattice sequence of sediments is effectively destroyed, the corrosion rate of carbon steel is 0.001-0.005 mu m / a<-1>, the adhesive speed is 1.5-3 mcm and the scale inhibiting ratio of calcium carbonate is 99.5-99.9%, the dispersion effect is good and a very good inhibiting and eliminating effect on the sediments in the water is achieved.

Owner:JIANGSU JINGWEI TECH INNOVATION CONSULTING CO LTD

Preparation process for high-purity low-arsenic hydroxyethylidene diphosphonic acid

ActiveCN103509051ARealize continuous online productionMild process control conditionsGroup 5/15 element organic compoundsThio-Ethylic acid

The invention relates to a preparation process for high-purity low-arsenic hydroxyethylidene diphosphonic acid. The preparation process comprises the following steps: with phosphorus trichloride, acetic acid and ammonium thioacetate as raw materials, controlling process conditions at first, reacting acetic acid with phosphorus trichloride in a reaction vessel to produce hydroxyethylidene diphosphonic acid and adding ammonium thioacetate in the process of the reaction; and then subjecting an obtained material to concentration and air flushing to remove impurities, adding ammonium thioacetate and carrying out arsenic removal and centrifugation so as to obtain the high-purity low-arsenic hydroxyethylidene diphosphonic acid. According to the invention, scientific technology is employed for product purification, no other substance like a crystal nucleus and a crystallization promoter is added, so no new impurity is introduced. Hydroxyethylidene diphosphonic acid in the high-purity low-arsenic hydroxyethylidene diphosphonic acid prepared in the invention is more than 95%, and arsenic content in the high-purity low-arsenic hydroxyethylidene diphosphonic acid is less than 2 ppm; the preparation process overcomes problems in packaging, transporting and on-site application of liquid hydroxyethylidene diphosphonic acid and broadens the application fields of the high-purity low-arsenic hydroxyethylidene diphosphonic acid.

Owner:HENAN QINGSHUIYUAN TECH

Reverse osmosis membrane scale inhibitor and preparation method thereof

The invention discloses a reverse osmosis membrane scale inhibitor and a preparation method thereof. The scale inhibitor is prepared from polyepoxysuccinic acid, amino trimethylene phosphonic acid, diethylenetriamine pentaacetic acid pentasodium salt, hexadecyl tributyl phosphonium bromide, distilled water, dodecyl triphenyl phosphonium bromide, methoxymethyl triphenyl phosphonium bromide, 1, 2-benzisothiazolin-3-one, hydroxyethylidene-1,1-diphosphonic acid, polyacrylic acid and benzotriazole. The usage amount of the scale inhibitor is less and is only 1 to 5 mg / L; the effect is lasting, i.e., after the scale inhibitor is placed for one month at 60 to 80 DEG C, the scale inhibiting ratio is 96 to 100 percent; the reverse osmosis membrane scale inhibitor has a good sterilizing effect and positive effects in improving calcium scale resistance and iron dispersing property.

Owner:SUZHOU YOUJUN ENVIRONMENTAL SCI & TECH

Continuous production method of hydroxyethyl diphosphonic acid crystal

ActiveCN110642887AAchieve continuous recyclingIncrease productivityGroup 5/15 element organic compoundsLiquid productDistillation

The invention provides a continuous production method of a hydroxyethyl diphosphonic acid crystal. The specific operation method comprises the following steps: performing preheating and gas-liquid separation on a hydroxyethyl diphosphonic acid liquid product with active content being 50 to 65 percent, and throwing into a distilling kettle continuously at constant speed; when performing distillation and concentration until the material active content is more than or equal to 70 percent, completing step-by-step automatic material transfer on high-temperature materials among crystallization kettles which are connected in tail series after condensation, and performing step-by-step continuous crystallization under the conditions of stirring and naturally cooling; performing circular condensation and cooling in the n-stage crystallization kettle and maintaining the system temperature to 20+ / -2 DEG C; and after performing crystallization completely, performing separation and drying treatmentto obtain a hydroxyethyl diphosphonic acid crystal product with the active content being more than or equal to 98 percent. The traditional single-kettle closed crystallization method is changed into aflow line crystallization method more suitable for industrialization, so the prepared crystallization granularity is proper, crystal aids and crystal nucleuses are not added in the crystallization process, explosive crystallization is avoided, and the continuous production method of the hydroxyethyl diphosphonic acid crystal is suitable for industrialization.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

Continuous synthesis technique of hydroxyethylidenediphosphonic acid

ActiveCN102875594BIncrease productivityImprove utilization efficiencyChlorine/hydrogen-chlorideOrganic compound preparationO-Phosphoric AcidEthylic acid

The invention relates to a continuous synthesis technique of hydroxyethylidenediphosphonic acid, which comprises the following steps: 1. mixing raw materials: mixing phosphorus trichloride and acetic acid in a mol ratio of 1:(2.8-3.0) in a mixing kettle; 2. sending the mixture into a tubular reactor: pumping the mixture into the tubular reactor through a diaphragm pump; 3. carrying out esterification reaction while controlling the temperature of the tubular reactor at 70-130 DEG C; 4. separating the reaction mixture in a gas-liquid separator for recycling; 5. carrying out hydrolysis reaction to obtain the hydroxyethylidenediphosphonic acid; and 6. distilling out acetic acid under negative pressure to separate the acetic acid from the product, wherein the acetic acid enters an acetic acid storage tank as a raw material. In the invention, the hydroxyethylidenediphosphonic acid is continuously produced in a semi-closed system, thereby changing the existing intermittent production mode and enhancing the production efficiency; and the invention overcomes the defects of low product yield, too many side reactions and high contents of phosphorous acid and phosphoric acid in other preparation techniques, and implements complete cyclic utilization of acetic acids with different concentrations.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

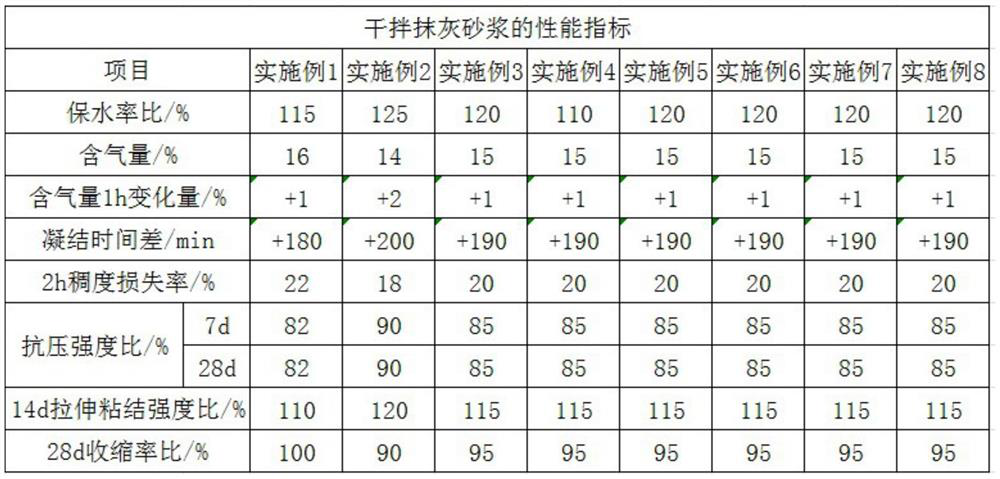

Composite dry-mixed mortar admixture and preparation method thereof

The invention relates to a composite dry-mixed mortar admixture, which comprises the following components in parts by weight: 100 parts of a flocculating agent, 180-220 parts of redispersible latex powder, 13-15 parts of whiskers, 45-55 parts of a water reducing agent, 1-2 parts of an air entraining agent, 10-15 parts of sodium hexametaphosphate, 8-10 parts of hydroxyethylidene diphosphonic acid,and 117-122 parts of a carrier. The invention also relates to a preparation method of the composite dry-mixed mortar admixture. The whiskers in the composite dry-mixed mortar admixture are helpful forimproving the sagging resistance of a dry-mixed mortar mixture and improving the tensile bonding strength of hardened plastering mortar; besides, the hydroxyethylidene diphosphonic acid has the effects of thickening, water retention and the like, and the phenomena of layering and bleeding of a dry-mixed mortar mixture can be effectively avoided; in addition, the sodium hexametaphosphate has better compatibility with a dry-mixed mortar cement system, and the setting time of a mortar mixture can be effectively prolonged.

Owner:CHONGQING JURONG CONSTR GRP

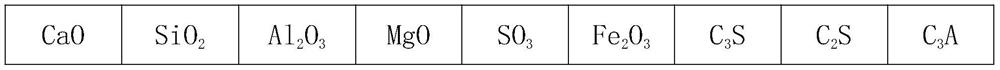

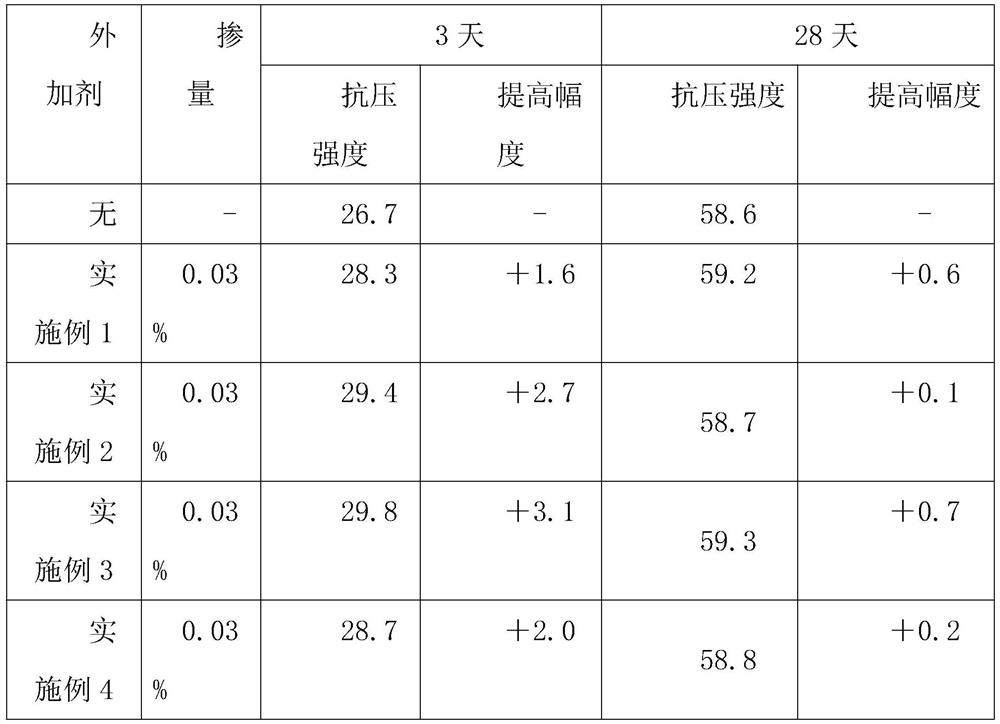

Additive for improving early strength of white cement and preparation method and application of additive

PendingCN111825363AImprove early strengthIncrease the concentration of soluble calcium ionSodium thiocyanatePhysical chemistry

The invention discloses an additive for improving early strength of white cement, a preparation method and application thereof, and belongs to the technical field of additives. The additive is mainlycomposed of phosphonoglycolic acid, Hydroxyethylidene-1,1-diphosphonic acid, ethylenediamine tetramethylene phosphonic acid, disodium hydroxyethylidene diphosphonate, tetrasodium aminotrimethylene phosphonate, sodium thiocyanate and water; through the chelating effect of organic phosphonate ions with an extremely strong chelating effect in the additive and calcium ions, the concentration of soluble calcium ions of white cement in hydrated slurry is increased, and then the dissolution and hydration rates of mineral components of the white cement are promoted, and the effect of improving the early strength of the white cement is achieved; the addition amount of the additive is 0.03%-0.2% of the weight of the white cement, and the 1-day strength and the 3-day strength can be improved by 5-15%.

Owner:XINYANG LINGSHI TECH CO LTD +1

Process for synthesis of hydroxy ethidene diphosphoric acid

InactiveCN100348603CSimple and safe operationShort generation cycleGroup 5/15 element organic compoundsPhosphorous acidDistillation

A method for synthesizing hydroxyl ethylidenediphosphonic acid belongs to synthesis of organo-phosphonic acid and is used in water stabilization. The phsophorus trichloride and acetic acid react at a temperature between 80 DEG C and 150 DEG C with an absolute pressure less than 760 millimeters mercury column, and the byproducts of hydrochloride and a few acetyl chlorides free of condensation are respectively retrieved and reused by combined recovery system of acetic acid and hydrochloric acid. The product of this method is obtained by hydrolyzing the acetylated hydroxyl ethylidenediphosphonic acid at a temperature between 80 DEG C and 150 DEG C with an absolute pressure no more than 760 millimeters mercury column; the collected hydrolysate of acetic acid after the distillation and the condensation is selected as raw material together with the acetic acid solution from the reclamation tower of acetic acid. The autoclave of 1000 litres daily produces products of 2500 kilograms with 60 % of solid content and less than 0.15 % of phosphorous acid; the yield rate of the products is more than 98 % calculated by phsophorus trichloride and is more than 96 % calculated by acetic acid.

Owner:傅明珠

Descaling method of graphite for phospheric acid concentration

ActiveCN100573027CEfficient removalRemove completelyOrganic detergent compounding agentsSurface-active detergent compositionsHexamethylenetetraminePhosphoric acid

The invention discloses a method for decaling phosphoric acid concentration heat exchanger, namely a technique of adopting a washing-liquor composed of thin fluosilicic acid solution, organic phosphonic acid sustained-releasing agent and film forming matter and firstly washing the heat exchanger with water and then washing out the foul with the washing liquor. In the washing liquor, the fluosilicic acid is a 5%-20% thin acid, the organic phosphonic acid sustained-releasing agent includes amino tri- sub-methylene phosphoric acid, hydroxyl sub-ethyl di-phosphoric acid and hydroxyl-l, 1-subethyl di-phosphoric acid; the film forming matter includes nitrous phenylhydroxylamine ammonium salt and wuluotuopin as well as sodium molybdate. As using, adding in surface active agent alkyl sulphonate. The invention can make high efficiency and thorough decaling the graphite heat exchanger and simultaneously effectively control the corrosion of the washing liquor to the equipment and as compared with traditional washing methods, the invention improves the productivity of the equipment.

Owner:WENGFU (GRP) CO LTD +1

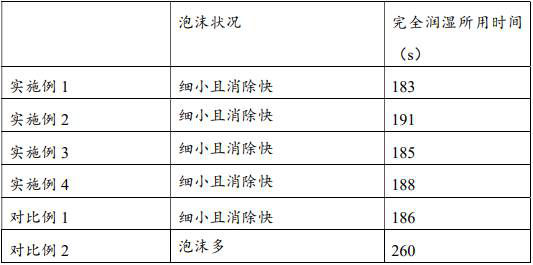

Farm foam cleaning agent

PendingCN113943613AStrong adhesionRich and fine foamInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBiotechnologyDisinfectant

The invention provides a farm foam cleaning agent and belongs to the technical field of detergents. The farm foam cleaning agent is prepared from the following raw materials by mass: 6%-8% of a degreaser, 7.5-8.5% of sodium alpha-olefin sulfonate, 20-28% of an AOS surfactant, 16-20% of sodium hydroxide, 3%-5% of a bactericide, 1-5% of an ampholytic surfactant, 1-3% of 1-hydroxyethylidene-1, 1-diphosphonic acid, 1-3% of phosphonobutane tricarboxylic acid and deionized water, wherein the deionized water is used as the balance. The farm foam cleaning agent is rich and fine in foaming, good in visibility, free of dead angles and high in foam adhesive force; the farm foam cleaning agent is non-corrosive, can prolong the service life of metal equipment; with a phosphorus-free formula adopted, the farm foam cleaning agent is green and environment-friendly; the farm foam cleaning agent contains no heavy metal and is high in safety; and the farm foam cleaning agent is efficient in penetration to remove dirt and is efficient in disinfection. With the disinfectant adopted, the pathogenic microorganism pollution degree can be reduced to be lower than the disinfection standard, and the pathogenic concentration of an external environment is practically reduced.

Owner:ZHENGZHOU HUAMEI WANBANG CLEANING TECH CO LTD

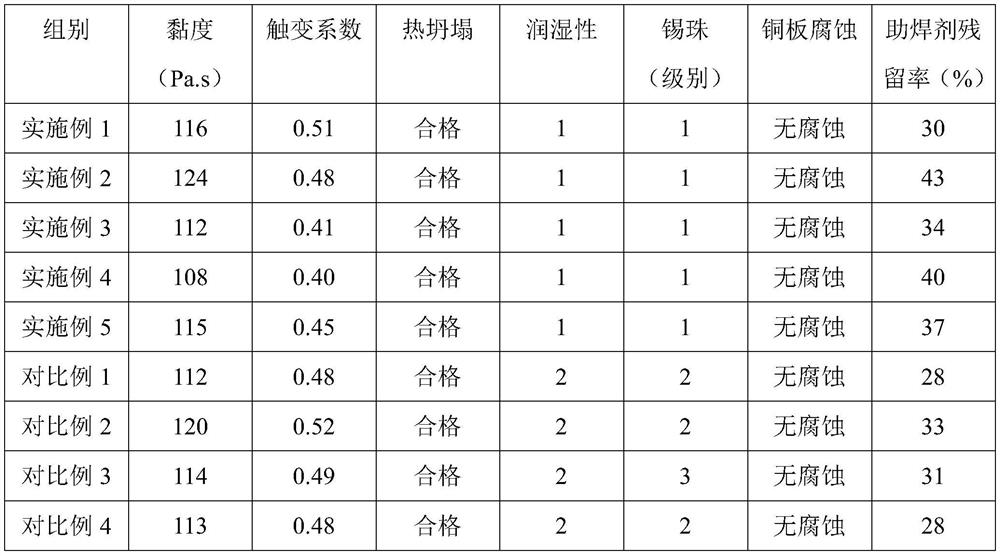

A kind of high-performance halogen-free lead-free solder paste and preparation method thereof

ActiveCN110202293BHigh activityEfficient removalWelding/cutting media/materialsSoldering mediaPhosphoric acidSolder paste

The invention discloses a high-performance halogen-free lead-free solder paste and a preparation method thereof. The halogen-free lead-free solder paste includes the following components in mass percentage: 80-90% of tin-based alloy powder, 2-5% of metal salt of hydroxy acid, 1-2% of acidic alkyl phosphate, hydroxyethylene 0.2-1% of diphosphonic acid, 0.5-1.5% of polyaniline, 0.1-0.5% of amine antioxidant, 0.5-2% of rheological additive, 2-4% of film forming agent and 3-8% of cosolvent. The solder paste of the present invention has high activity, low corrosiveness, and less residue, which can well solve the common problems of current low-temperature lead-free solder paste such as blackening of the periphery after soldering, a large number of tin beads, and a large number of residues, and can greatly reduce Reduce the defective rate of printing and improve the reliability of welding.

Owner:深圳市可为锡业有限公司

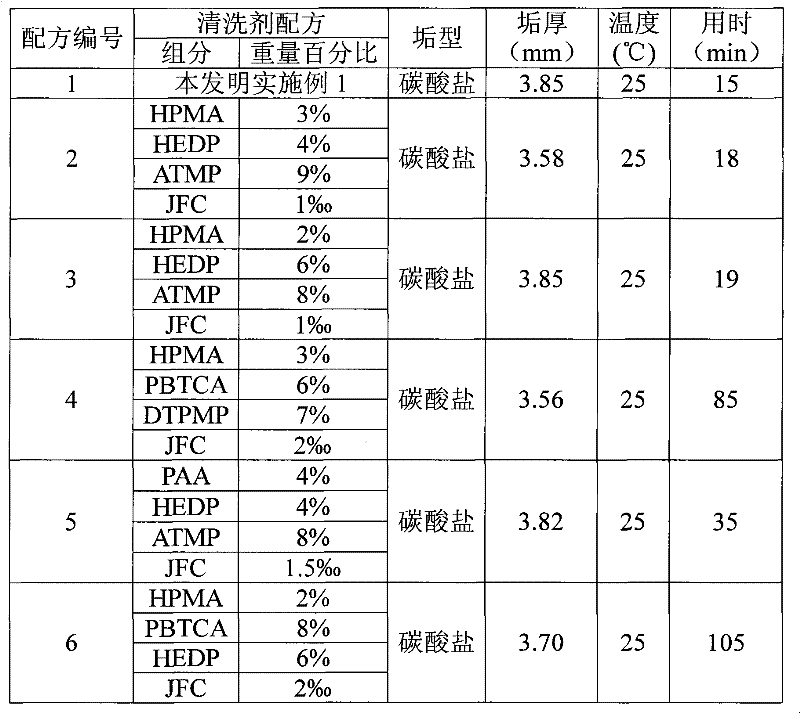

Organic descaling composition, preparation method and application thereof

ActiveCN101565660BFast descalingDescaling speed comparisonHollow article cleaningOrganic non-surface-active detergent compositionsMeth-Diphosphenes

The invention provides an organic descaling composition, which includes an organic cleaning agent and a corrosion inhibitor CM-911, and the weight ratio of the organic cleaning agent and the corrosioninhibitor is 100:0.1-0.3. The organic cleaning agent includes the follow components by weight: 1%-15% of maleic acid-crylic acid copolymer (MA-AA), 1%-25% of 1-hydroxyethylidene-1,1-diphosphonic acid(HEDP), 2%-30% of amino trimethylene phosphonic acid (ATMP), 0.03%-0.5% of penetrating agent JFC and balance of water. The organic descaling agent provided by the present invention has advantages offast reaction speed, small corrosivity for material and high descaling efficiency.

Owner:河南伯淼水处理有限公司

Polishing composition

InactiveCN1854224AOther chemical processesLapping machinesAluminium nitrateEthylenediamine tetraacetate

A polishing composition for polishing a disk substrate, comprising (A) selected from the group consisting of phosphoric acid, phosphate and pyrophosphoric acid, phosphonic acid, phosphinic acid, hydroxyethylene diphosphonic acid, nitrilotri( (Methylenephosphonic acid), phosphonobutanetricarboxylic acid, and salts thereof, (B) colloidal silicon dioxide, (C) water, and (E) diammonium iron edetate .

Owner:FUJIMI INCORPORATED

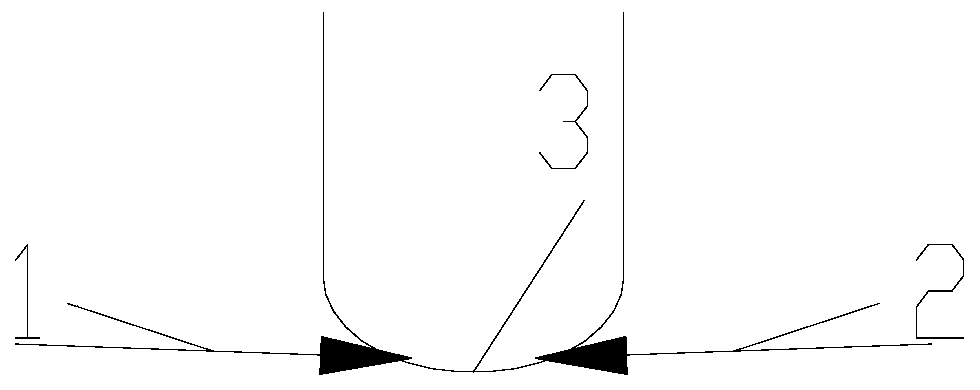

A process and design method for removing coke and deposits in hydrogenation process

ActiveCN108384570BImprove performanceChange structureLiquid hydrocarbon mixture productionTreatment apparatus corrosion/fouling inhibitionMeth-Diethylenetriamine

The invention provides a process for eliminating hydrogenation process coking materials and deposits and a design method thereof. A removal agent is used for dredging on easy coking and depositing positions, and is prepared from additives and 250 to 520 DEG C distillate oil generated in the hydrogenation process; the additives are prepared from one or several kinds of materials from benzene sulfonate or naphthenate accounting for 0.1 to 0.7 weight percent of the total mass of the removal agents, one or several kinds of materials in amino amino trimethylene phosphonic acid, diethylenetriamine pentamethylphosphonic acid, edetic acid and HEDP accounting for 0.1 to 0.5 weight percent. A viscosity and pressure difference detection instrument is arranged in the easy coking and depositing positions for monitoring the viscosity and pressure difference change in real time; when the viscosity is higher than 750cSt or the pressure difference is higher than or equal to 100KPa, the dredge speed is10 to 15m / s, and the dredge temperature is higher than or equal to 200 DEG C; when the viscosity is higher than 250cSt but lower than or equal to 750cSt, or the pressure different is higher than 40KPabut lower than 100KPa, the dredge speed is 5 to 10m / s.

Owner:CATECH TECH

A kind of preparation technology of high-purity low-arsenic hydroxyethylidene diphosphonic acid

ActiveCN103509051BRealize continuous online productionMild process control conditionsGroup 5/15 element organic compoundsThio-Ethylic acid

The invention relates to a preparation process of high-purity and low-arsenic hydroxyethylidene diphosphonic acid. It uses phosphorus trichloride, acetic acid and ammonium thioacetate as raw materials. Firstly, the process conditions are controlled, and the acetic acid and phosphorus trichloride are React in a reactor to generate hydroxyethylene diphosphonic acid, add ammonium thioacetate during the reaction process; then concentrate the material, aerate, remove impurities, add ammonium thioacetate during the process, remove arsenic, and finally centrifuge to obtain High purity low arsenic hydroxyethylene diphosphonic acid. The present invention adopts a scientific process to purify the product without adding other substances, such as crystal nuclei and crystal aids, and without introducing new impurities. The hydroxyethylene diphosphonic acid in the high-purity and low-arsenic hydroxyethylene diphosphonic acid obtained by the present invention reaches more than 95%, and the arsenic content is lower than 2ppm, which not only solves the problem of liquid hydroxyethylene diphosphonic acid packaging, The problem of circulation and on-site application, and broaden the application field of the product.

Owner:HENAN QINGSHUIYUAN TECH

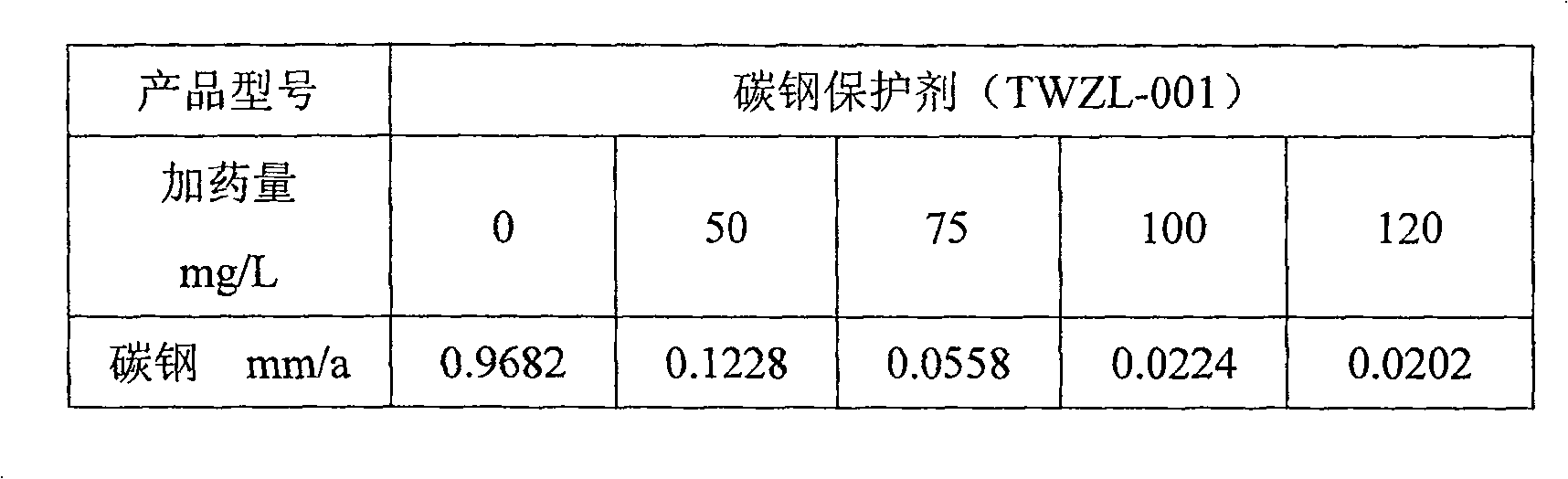

Carbon steel protectant for open-circuit water softening system and preparation method and application thereof

InactiveCN100516308CEliminate the disadvantage of easy hydrolysisThe disadvantage of easy hydrolysis preventsChemical industryPhosphoric Acid Esters

Owner:北京能泰高科环保技术有限公司

Method for preparing biodiesel by microwave solid alkali ester exchange method

InactiveCN102125876BEasy to separateReduce energy consumptionFatty acid esterificationOrganic-compounds/hydrides/coordination-complexes catalystsBiodieselMicrowave

The invention discloses a method for preparing a pyrazine hydroxy ethidene sodium copper bisphosphonate-sodium hydroxide solid base catalyst for preparing biodiesel from soybean oil by a microwave solid alkali ester exchange method. The method is characterized by comprising the following steps of: hydrothermally synthesizing pyrazine hydroxy ethidene sodium copper bisphosphonate by using copper salt, hydroxy ethidene bisphosphonate, sodium hydroxide and pyrazine as raw materials, filtering, drying, grinding, sieving, soaking in sodium hydroxide solution, baking for 3 to 6 hours at the temperature of between 250 and 320 DEG C, and finally obtaining the pyrazine hydroxy ethidene sodium copper bisphosphonate-sodium hydroxide solid base catalyst. The solid catalyst prepared by the method has high catalytic activity, high biodiesel yield can be obtained in the process of preparing the biodiesel by the ester exchange method by using the catalyst and combining a microwave heating technology, and the yield can reach about 94 percent. The method for preparing the biodiesel from the soybean oil is high in reaction speed, simple in operation, low in energy consumption and low in pollution, and has high popularization and application value.

Owner:LUDONG UNIVERSITY

A kind of oil well water-based wax remover and preparation method thereof

ActiveCN110257036BEnhance the effect of wax removal and anti-wax treatmentImprove wax removal and anti-wax effectWater/sewage treatment by magnetic/electric fieldsDrilling compositionSODIUM METAPHOSPHATESodium phosphates

Owner:西安环博新材料科技有限公司

A kind of rigid contact lens care solution and preparation method thereof

ActiveCN110819464BAdhesion blockingBlock connectionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsDisodium EdetateGlycerol

The invention discloses a care solution for rigid gas permeable contact lenses and a preparation method of the care solution. The care solution includes lifitegrast, polyaminopropyl biguanide, disodium edetate, poloxamer, polyoxyethylene hydrogenated castor oil, 1-hydroxyethylidene-1,1-diphosphonicacid, hydroxypropyl-beta-cyclodextrin, hydroxypropyl methylcellulose, propylene glycol, glycerol, mannitol, boric acid, sodium chloride and tris(hydroxymethyl)aminomethane, and can successfully treat proteins and bacteria adhered to the lenses, and achieve the effect of cleaning the lenses and residual proteins; the care solution blocks connection of ICAM-1, prevent corneal cells from proliferating to cause inflammation, has good lubricity to reduce the discomfort of wearers in the early stage, and has a good oxygen transmission rate.

Owner:SHAANXI RENKANG PHARMA

Care solution for rigid gas permeable contact lenses and preparation method of care solution.

ActiveCN110819464AAdhesion blockingBlock connectionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsRigid gas permeable lensDisodium Edetate

The invention discloses a care solution for rigid gas permeable contact lenses and a preparation method of the care solution. The care solution includes lifitegrast, polyaminopropyl biguanide, disodium edetate, poloxamer, polyoxyethylene hydrogenated castor oil, 1-hydroxyethylidene-1,1-diphosphonicacid, hydroxypropyl-beta-cyclodextrin, hydroxypropyl methylcellulose, propylene glycol, glycerol, mannitol, boric acid, sodium chloride and tris(hydroxymethyl)aminomethane, and can successfully treat proteins and bacteria adhered to the lenses, and achieve the effect of cleaning the lenses and residual proteins; the care solution blocks connection of ICAM-1, prevent corneal cells from proliferating to cause inflammation, has good lubricity to reduce the discomfort of wearers in the early stage, and has a good oxygen transmission rate.

Owner:SHAANXI RENKANG PHARMA

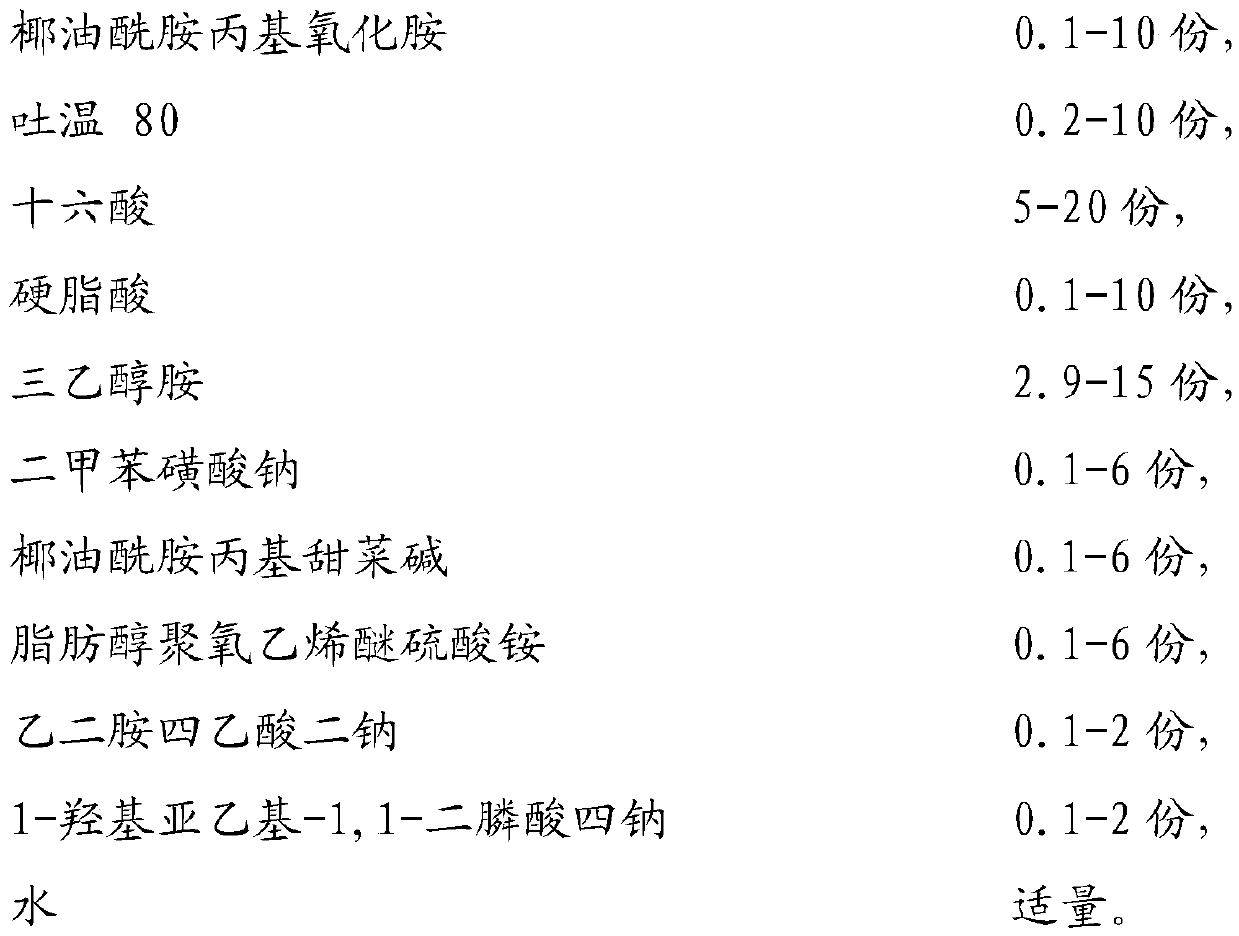

A kind of foam stabilizer and preparation method thereof

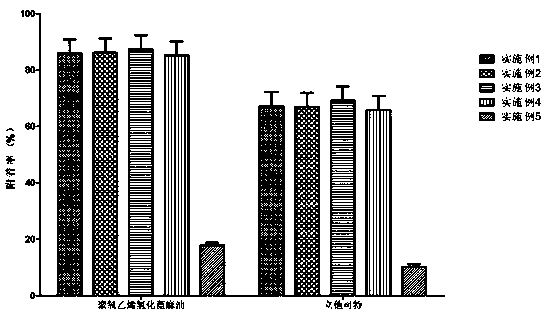

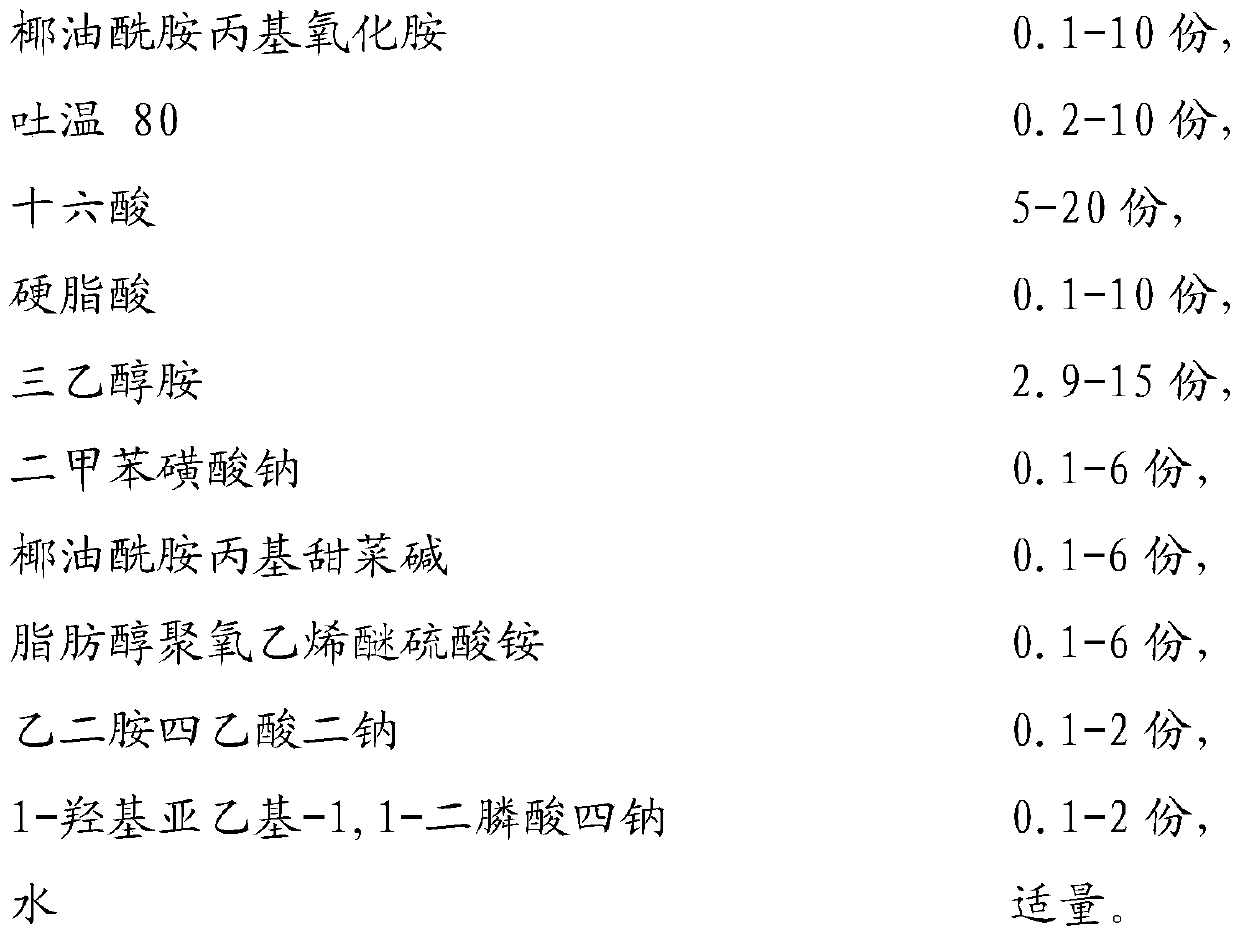

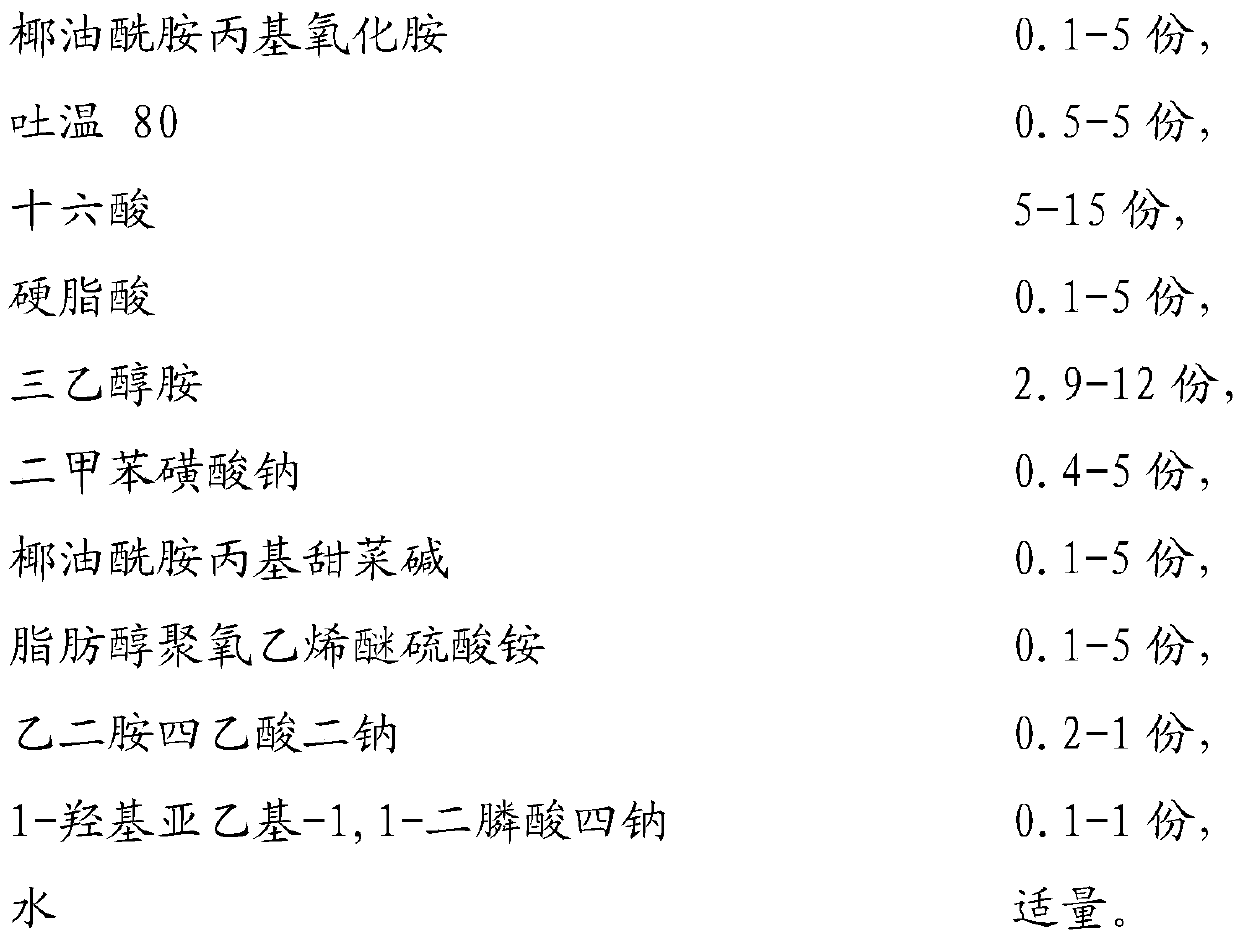

ActiveCN107828076BGood foaming effectGood foam stabilization effectCocamidopropyl dimethylamineOil phase

The invention discloses a foam stabilizer and a preparation method thereof. The foam stabilizer comprises 0.1-10 parts of cocamidopropyl dimethylamine oxide, 0.2-10 parts of tween 80, 5-20 parts of hexadecanoic acid, 0.1-10 parts of stearic acid, 2.9-15 parts of triethanolamine, 0.1-6 parts of sodium dimethyl benzene sulfonate, 0.1-6 parts of cocamidopropyl betaine, 0.1-6 pars of ammonium fatty alcohol polyoxyethylene ether sulfate, 0.1-2 parts of disodium ethylene diamine tetraacetate, 0.1-2 parts of 1-hydroxyethylidene-1,1-bis-phosphonic acid tetrasodium salt and water. The preparation method comprises the following steps: heating water, adding disodium ethylene diamine tetraacetate, 1-hydroxyethylidene-1,1-bis-phosphonic acid tetrasodium salt, ammonium fatty alcohol polyoxyethylene ether sulfate, cocamidopropyl betaine, cocamidopropyl dimethylamine oxide, sodium dimethyl benzene sulfonate and triethanolamine, stirring and dissolving to obtain a water phase; heating and melting tween80, hexadecanoic acid and stearic acid to obtain an oil phase; and rapidly mixing the water phase and the oil phase and stirring and cooling so as to obtain the foam stabilizer.

Owner:山东丽波日化股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com