Farm foam cleaning agent

A foam cleaning agent, a technology for breeding farms, applied in the directions of detergent compositions, detergent compounding agents, surface active detergent compositions, etc. The effect of reducing the concentration of pathogens, no dead angle of visibility, and strong foam adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

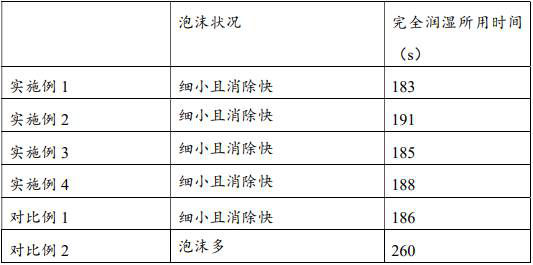

Examples

Embodiment 1

[0019] A kind of farm foam cleaning agent, comprises the raw material of following mass percentage: dodecylbenzene sulfonic acid 7g, α-alkenyl sulfonate sodium 8 g, α-alkenyl sulfonate 24 g, sodium hydroxide 16 g, p-Chloro-m-dimethylphenol 3 g, phosphobetaine and imidazoline 2 g, hydroxyethylidene diphosphonic acid 2 g, phosphonobutane tricarboxylic acid 1.5 g and deionized water, deionized water is 36.5 g .

[0020] The preparation method is as follows: add 7 g of dodecylbenzenesulfonic acid, 8 g of sodium α-alkenyl sulfonate, and 24 g of α-alkenyl sulfonic acid salt into a reaction vessel, mix and stir evenly, and then add hydroxide Sodium 16 g and deionized water 36.5 g, then add phosphatidyl betaine and imidazoline 2 g, hydroxyethylene diphosphonic acid 2 g, phosphonobutane tricarboxylic acid 1.5 g and p-chloro-m-xylenol 3 g. After stirring for 3 minutes, cool down naturally. After cooling to room temperature, add an appropriate amount of 10mol / L sodium hydroxide solution...

Embodiment 2

[0022] A kind of farm foam cleaning agent, comprises the raw material of following mass percentage: dodecylbenzene sulfonic acid 6g, α-alkenyl sulfonate sodium 7.5 g, α-alkenyl sulfonate 20 g, sodium hydroxide 18g, para Chloro-m-dimethylphenol 4 g, phosphobetaine and imidazoline 3 g, hydroxyethylidene diphosphonic acid 1 g, phosphonobutane tricarboxylic acid 1 g and deionized water, deionized water is 39.5 g.

[0023] The preparation method is: add 6 g of dodecylbenzenesulfonic acid, 7.5 g of sodium α-alkenyl sulfonate, and 20 g of α-alkenyl sulfonic acid salt into a reaction vessel, mix and stir evenly, and then add hydroxide Sodium 18g and deionized water 39.5g, then add phospholipid betaine and imidazoline 3g, hydroxyethylene diphosphonic acid 1g, phosphonobutane tricarboxylic acid 1g and p-chloro-m-xylenol 4g, stir for 3 After 10 minutes, cool down naturally. After cooling to room temperature, add 10mol / L sodium hydroxide solution to adjust the pH value between 11.5-12.5 t...

Embodiment 3

[0025] A foam cleaning agent for farms, comprising the following raw materials in mass percentages: 8.5 g of dodecylbenzenesulfonic acid, 27 g of sodium α-alkenyl sulfonate, 20 g of α-alkenyl sulfonate, 17 g of sodium hydroxide, 5 g of p-chloro-m-dimethylphenol, 5 g of phosphatidyl betaine and imidazoline, 3 g of hydroxyethylidene diphosphonic acid, 3 g of phosphonobutane tricarboxylic acid and deionized water, the deionized water is 11.. 5g.

[0026] The preparation method is as follows: add 7 g of dodecylbenzenesulfonic acid, 8.5 g of sodium α-alkenyl sulfonate, and 20 g of α-alkenyl sulfonate into a reaction vessel, mix and stir evenly, and then add hydroxide Sodium 17 g and deionized water 11.5 g, then add phosphatidyl betaine and imidazoline 5 g, hydroxyethylene diphosphonic acid 3 g, phosphonobutane tricarboxylic acid 3 g and p-chloro-m-xylenol 5 g After stirring for 3 minutes, cool down naturally. After cooling to room temperature, add an appropriate amount of 10mol / L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com