Patents

Literature

890 results about "Tricarboxylic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tricarboxylic acid is an organic carboxylic acid whose chemical structure contains three carboxyl functional groups (-COOH). The best-known example of a tricarboxylic acid is citric acid.

Lercanidipine salts

The present invention relates to new addition salts of lercanidipine comprising lercanidipine and an acid counterion wherein the acid counterion is selected from the group consisting of: (i) inorganic acids, (ii) sulfonic acids, (iii) monocarboxylic acids, (iv) dicarboxylic acids, (v) tricarboxylic acids, and (vi) aromatic sulfonimides, with the proviso that said acid counterion is not hydrochloric acid.

Owner:RECORDATIE IRELAND LTD

Bleaching composition

PCT No. PCT / US97 / 04957 Sec. 371 Date Mar. 24, 1999 Sec. 102(e) Date Mar. 24, 1999 PCT Filed Mar. 25, 1997 PCT Pub. No. WO97 / 36989 PCT Pub. Date Oct. 9, 1997Bleach compositions comprising a percarbonate bleach and an amino tricarboxylic acid exhibit a reduced tendency to deposit calcium carbonate insolubles on substrates being bleached. Laundry compositions comprising percarbonate bleach and methyl glycine diacetic acid are provided.

Owner:THE PROCTER & GAMBLE COMPANY

Process for relaxing or straightening hair, using weak dicarboxylic acids with heat

ActiveUS20110256084A1Facilitate chemical reactionsStraighter and more relaxedCosmetic preparationsHair cosmeticsHair straighteningCompound (substance)

A process for straightening or relaxing hair comprising the following steps: (a) providing a hair straightening or relaxing composition having a pH ranging from 8 to 11.5, and containing, in a cosmetically acceptable medium, at least one weak acid chosen from monocarboxylic, dicarboxylic and tricarboxylic acids, their salts, and mixtures thereof; (b) contacting the hair with the hair straightening or relaxing composition to form treated hair; and (c) straightening or relaxing the treated hair by applying heat, wherein hydroxide-containing compounds are not used. Disclosed herein is also a preferred hair straightening or relaxing composition.

Owner:LOREAL SA

Scale inhibitor for an aqueous system

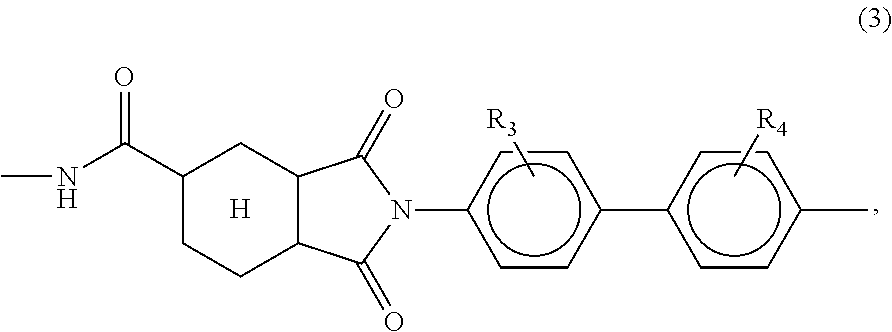

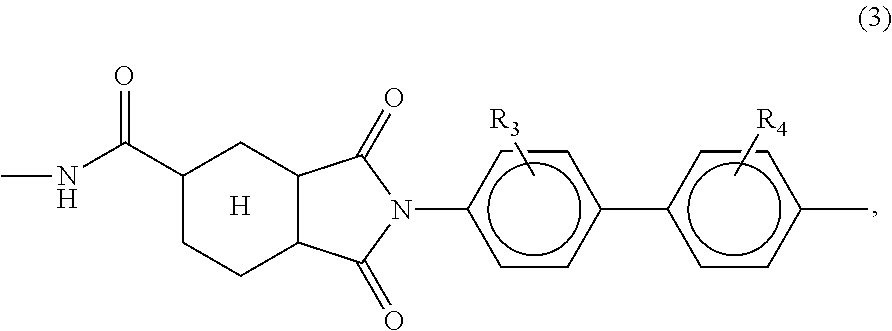

InactiveUS20030091467A1Less-expensive to useInhibition formationOther chemical processesScale removal and water softeningSulfonateTricarboxylic acid

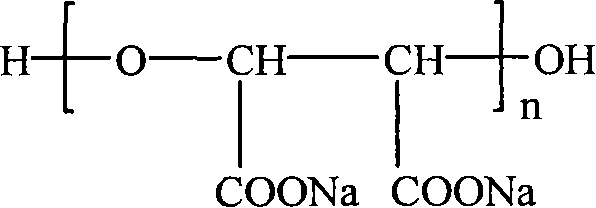

This invention relates to a composition and a method for inhibiting the formation of scale, particularly complex scale, in an aqueous system where more than one type of scale is present. The scale typically present in the aqueous system includes silica, silicates, and carbonates. The scale inhibiting composition comprises (1) 2-phosphonobutane-1,2,4-tricarboxylic acid and salts thereof, and (2) a copolymer of (1) one or more allyloxybenzenesulfonate monomers, and (2) one or more water-soluble acrylic monomers, substituted acrylic monomers, or mixtures thereof.

Owner:SOLENIS TECH CAYMAN

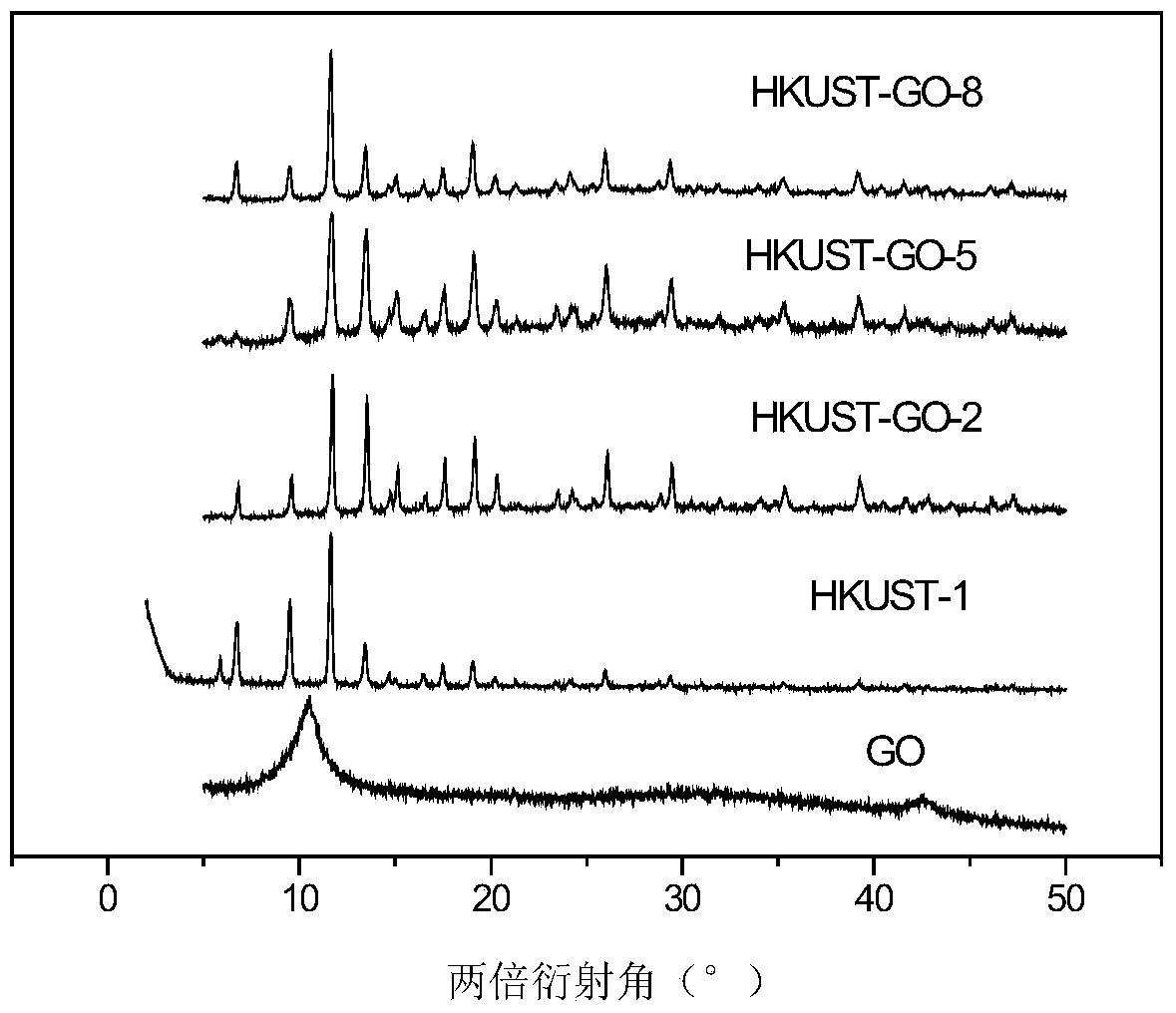

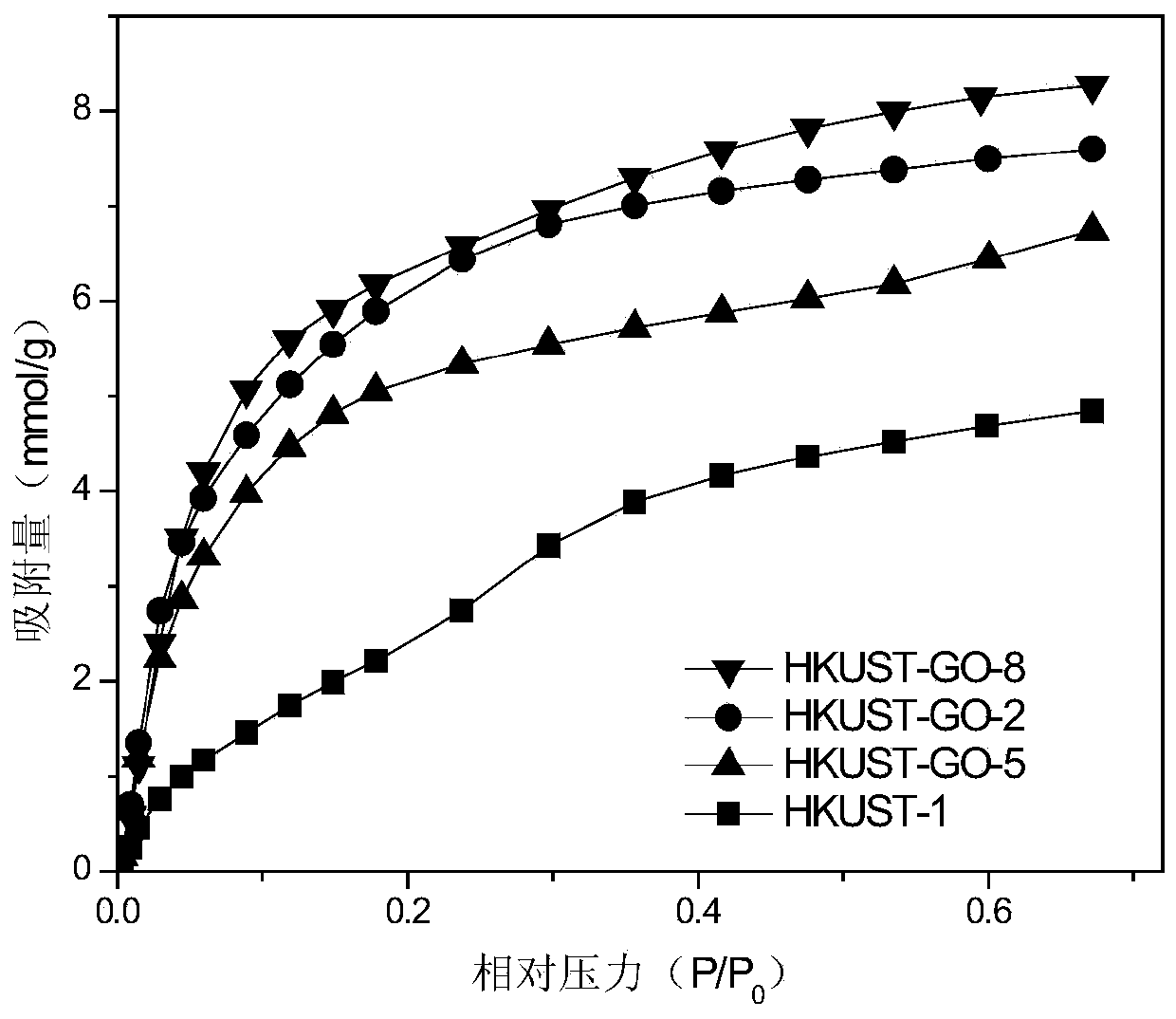

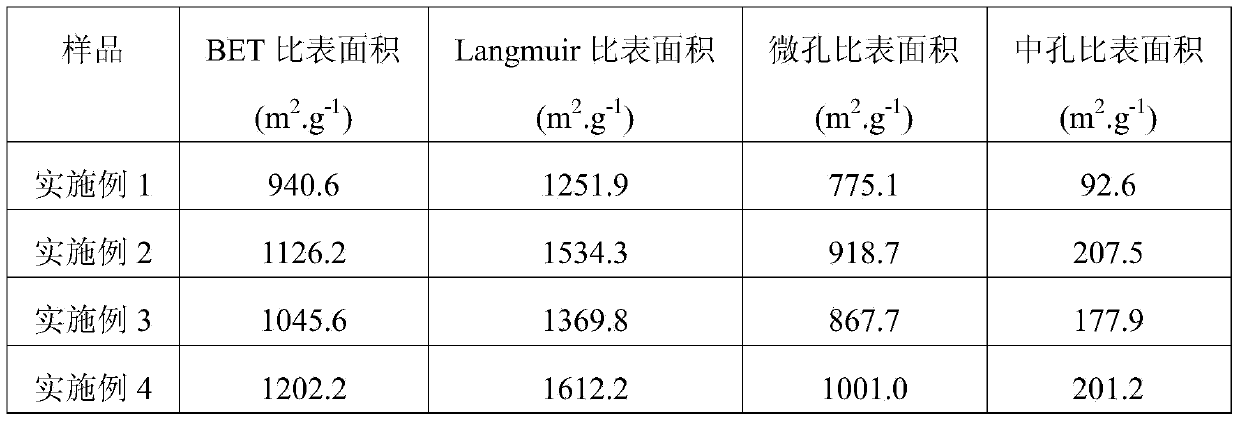

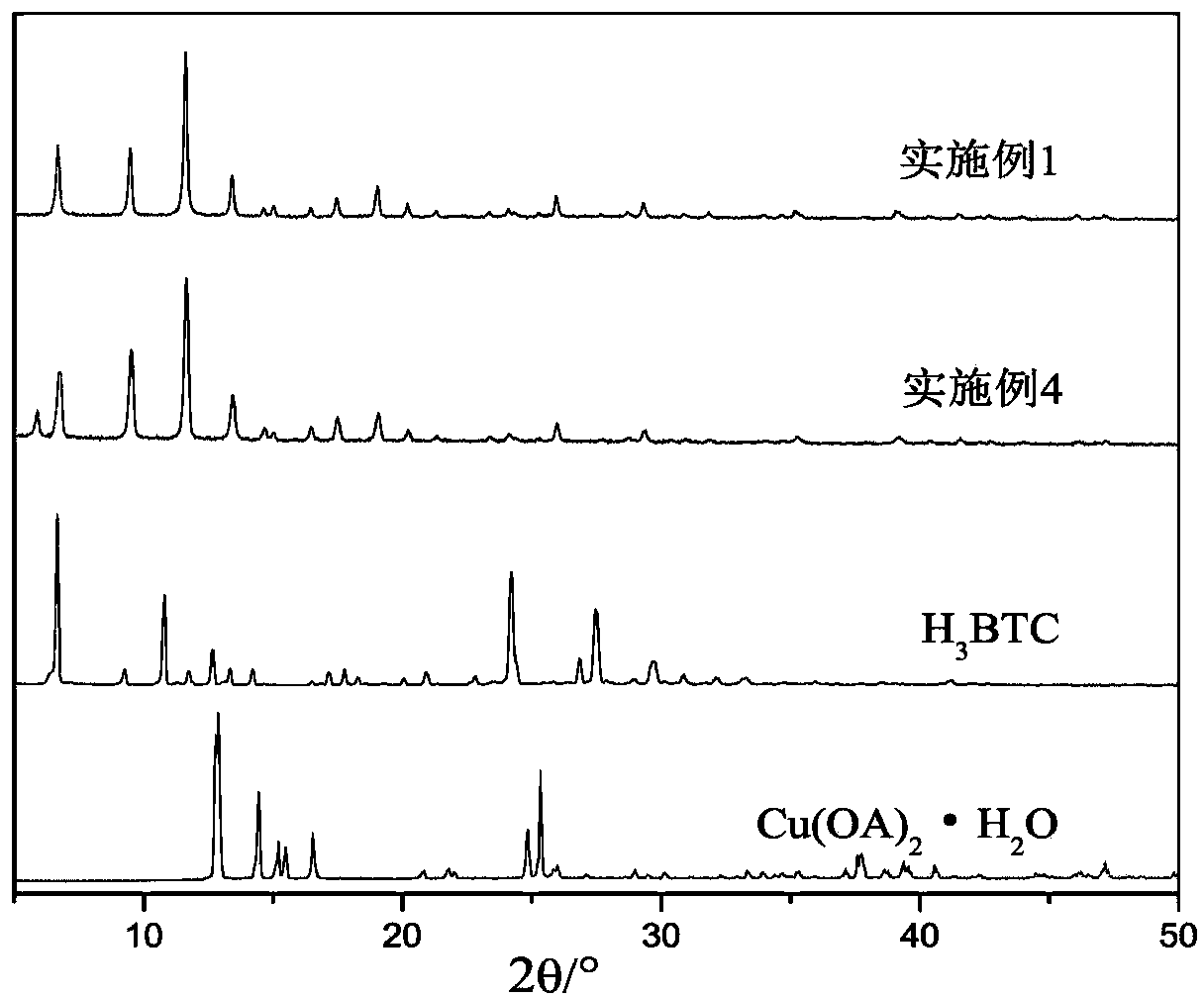

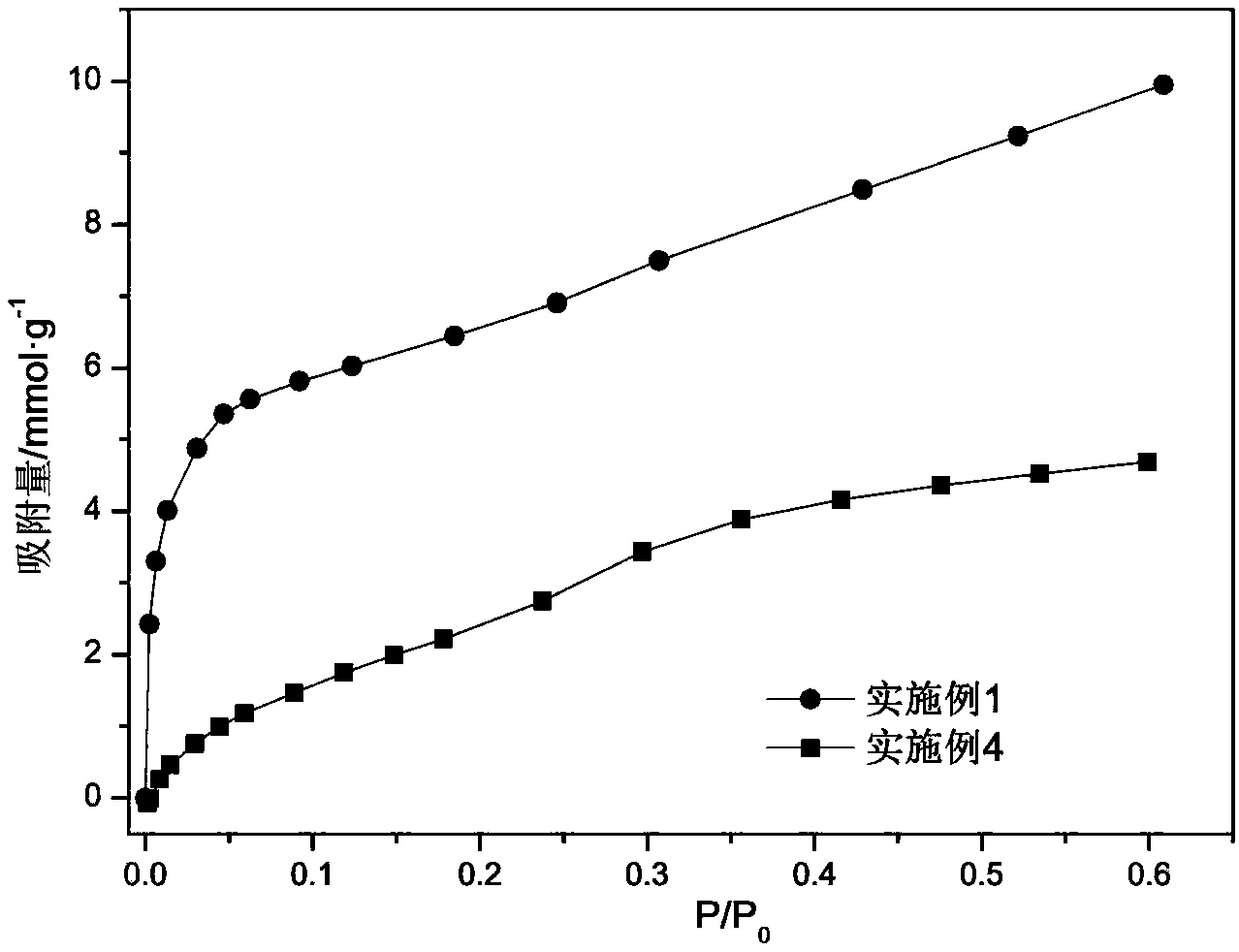

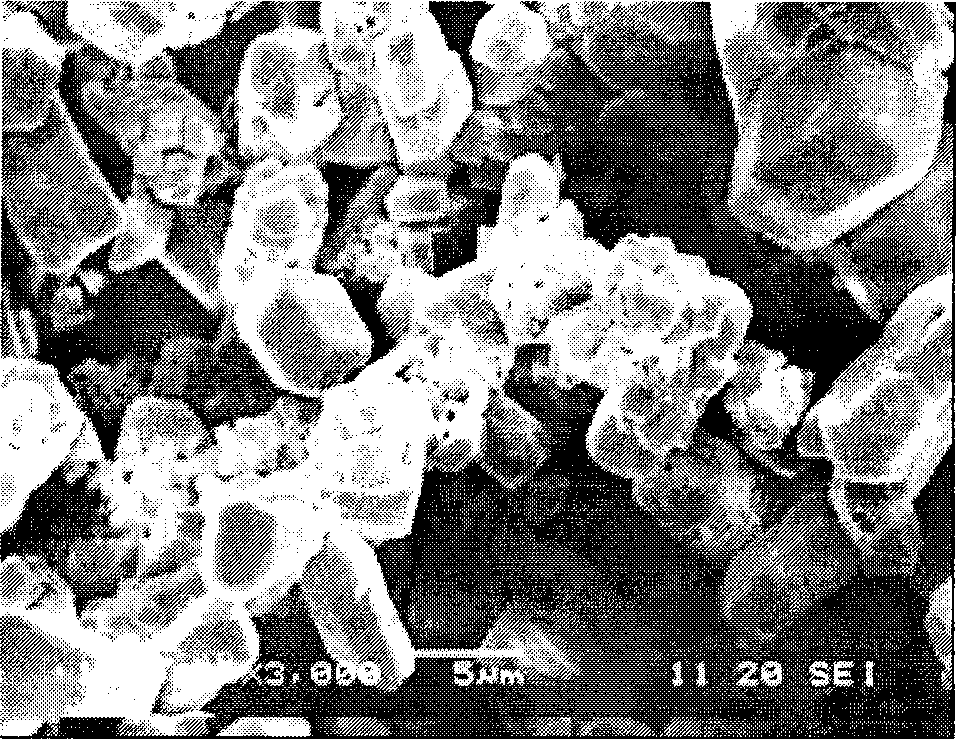

Cu-based organic skeleton-graphene oxide composite porous material and preparation method thereof

ActiveCN103432997AEasy to cleanReduce the activation energy of the interactionOther chemical processesMolecular sieveBenzene

The invention belongs to the technical field of metal organic skeletal materials, and discloses a Cu-based organic skeleton-graphene oxide composite porous material and a preparation method and application thereof. The preparation method particularly comprises the following steps of uniformly mixing copper acetate, 1,3,5-benzene tricarboxylic acid and graphene oxide; carrying out ball milling; washing; centrifugalizing; and drying to obtain the Cu-based organic skeleton-graphene oxide composite porous material. The preparation method disclosed by the invention has the advantages of short reaction time (only 30 minutes), no solvent, large preparation quantity, low energy consumption, simple operation method, and the like, is a high-efficiency, clean and environment-friendly novel green synthetic method. The obtained Cu-based organic skeleton-graphene oxide composite porous material greatly increases the adsorption capacity on hydrocarbon VOCs (Volatile Organic Compounds) and achieves the purposes that the adsorption capacity on methanol is 2.06 times of the adsorption capacity on the methanol caused by a Na-ZSM molecular sieve, 2.54 times of the adsorption capacity on the methanol caused by flexible-MOF(E), and 1.79 times of the adsorption capacity on the methanol caused by HKUST-1 under the same condition.

Owner:SOUTH CHINA UNIV OF TECH

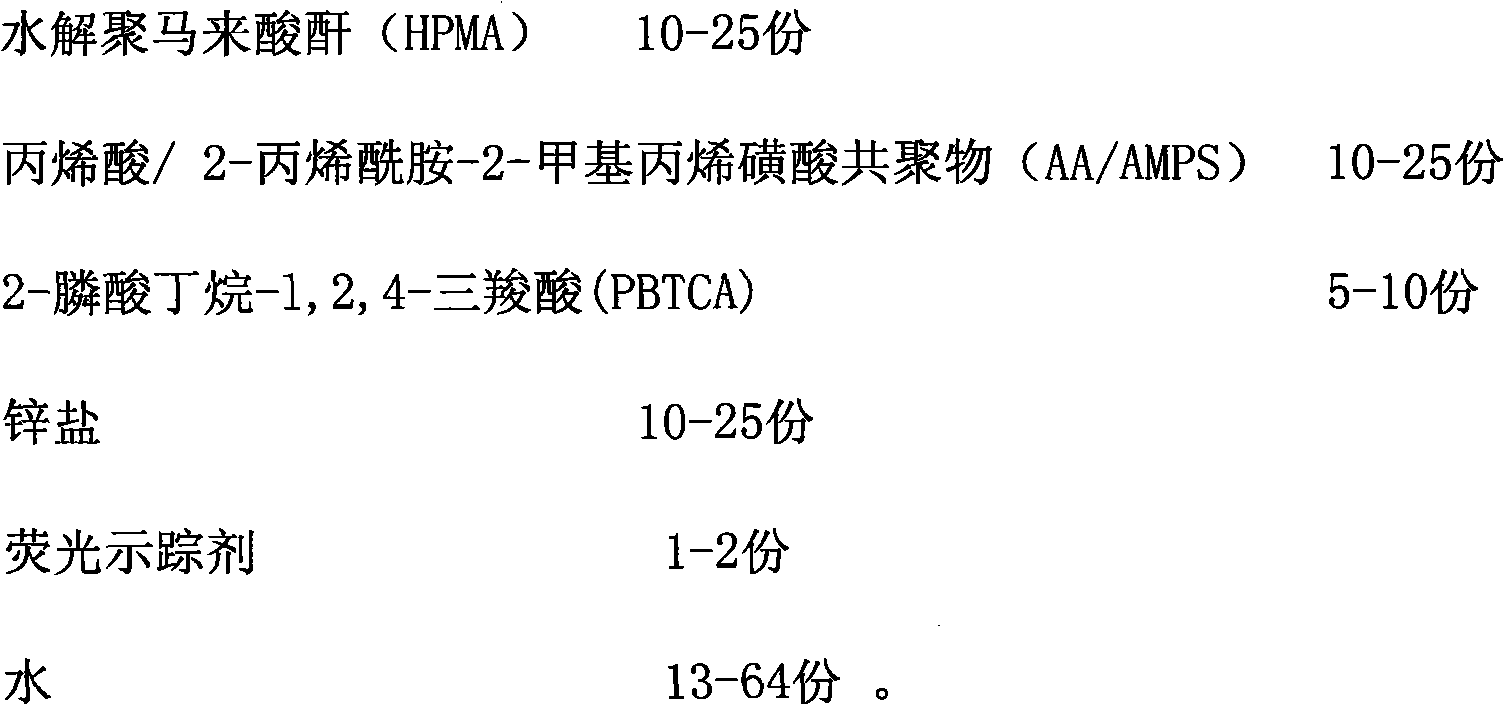

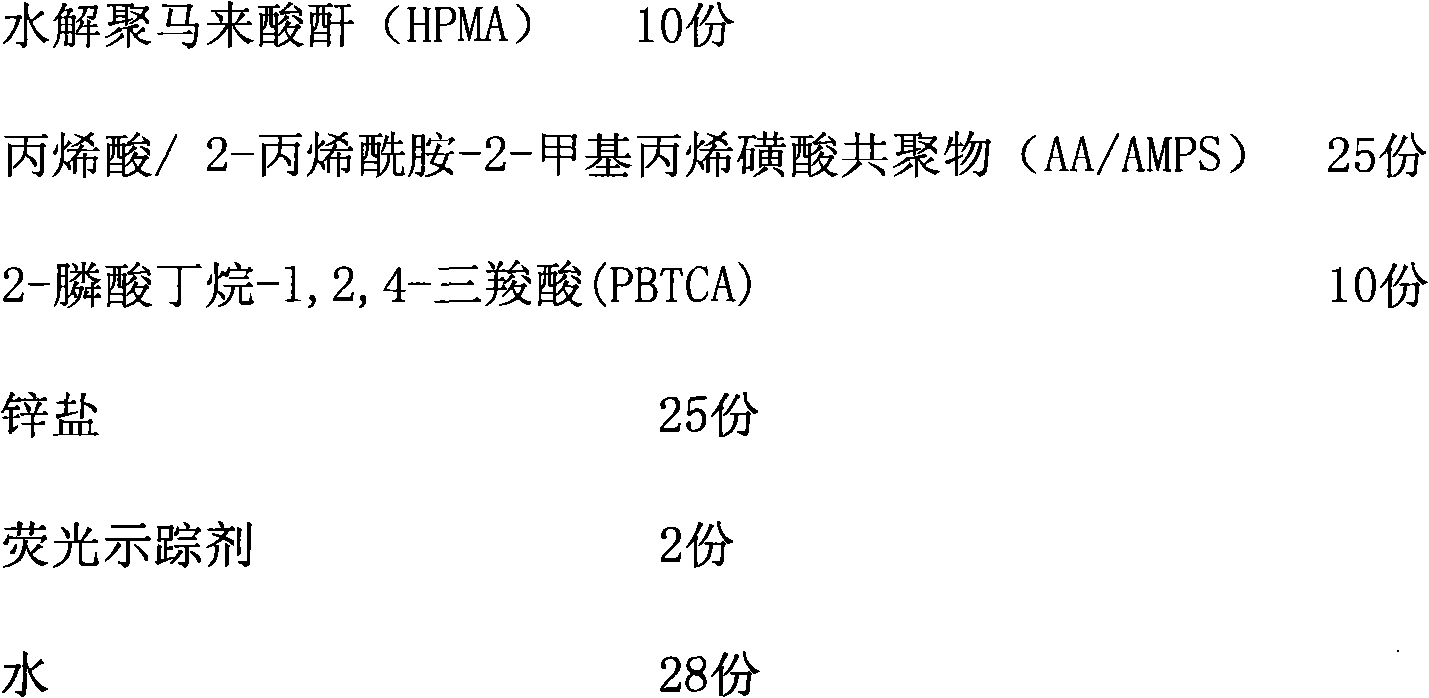

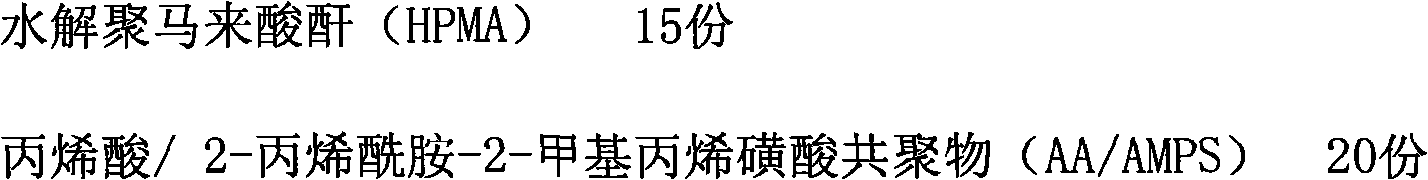

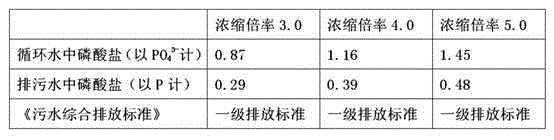

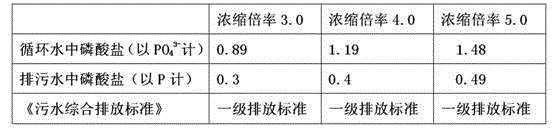

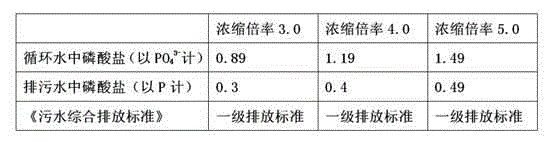

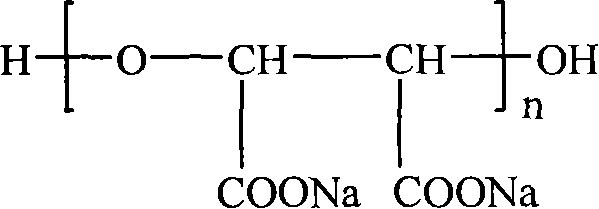

Composite low-phosphorus corrosion and scale inhibitor and application thereof

InactiveCN102674570ALow A phosphorus contentReduce dosageScale removal and water softeningTricarboxylic acidGluconic acid

The invention provides a composite low-phosphorus corrosion and scale inhibitor and application thereof. The composite low-phosphorus corrosion and scale inhibitor is prepared from a corrosion and scale inhibitor A and a corrosion and scale inhibitor B, wherein the corrosion and scale inhibitor A is prepared from 20-40 parts of polyepoxysuccinic acid (PESA), 20-40 parts of sodium gluconate and 20-60 parts of water; and the corrosion and scale inhibitor B is prepared from 10-25 parts of hydroxypropyl methacrylate (HPMA), 10-25 parts of acrylic acid / 2-acrylamido-2-methylacrylsulfonic acid copolymer (AA / AMPS), 5-10 parts of 2-phosphonobutyl-1,2,4-tricarboxylic acid (PBTCA), 10-25 parts of zinc salt, 1-2 parts of fluorescent tracer and 13-64 parts of water. The technical scheme is as follows: the corrosion and scale inhibitor A and the corrosion and scale inhibitor B in a weight ratio of 1:2 are compounded with water. The composite low-phosphorus corrosion and scale inhibitor has excellent corrosion and scale inhibition effects, and thus, the phosphorus content in the product is low, thereby reducing the phosphorus discharge and having favorable environmental protection performance.

Owner:CHINA PETROLEUM & CHEM CORP

Polyglycerol partial esters of polyricinoleic acid and polyfunctional carboxylic acids and the use thereof for producing emulsions and dispersions

ActiveUS20060165627A1Low viscosityFeel lightCosmetic preparationsFatty acid chemical modificationEmulsionTricarboxylic acid

The invention relates to polyglycerol partial esters of polyricinoleic acid and polyfunctional carboxylic acids, obtainable by esterification of a a) polyglycerol mixture with b) at least one polyricinoleic acid and c) at least one di- and / or tricarboxylic acid and optionally d) at least one fatty acid having 6 to 22 carbon atoms by methods known per se, and to the use thereof for producing cosmetic or pharmaceutical emulsions or dispersions.

Owner:EVONIK DEGUSSA GMBH

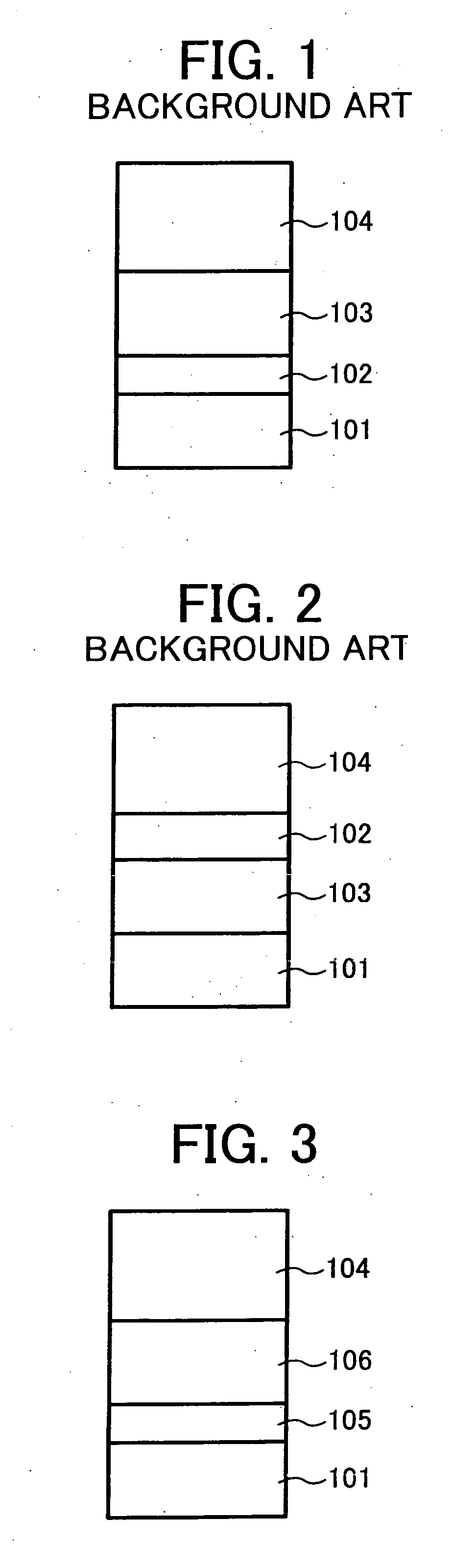

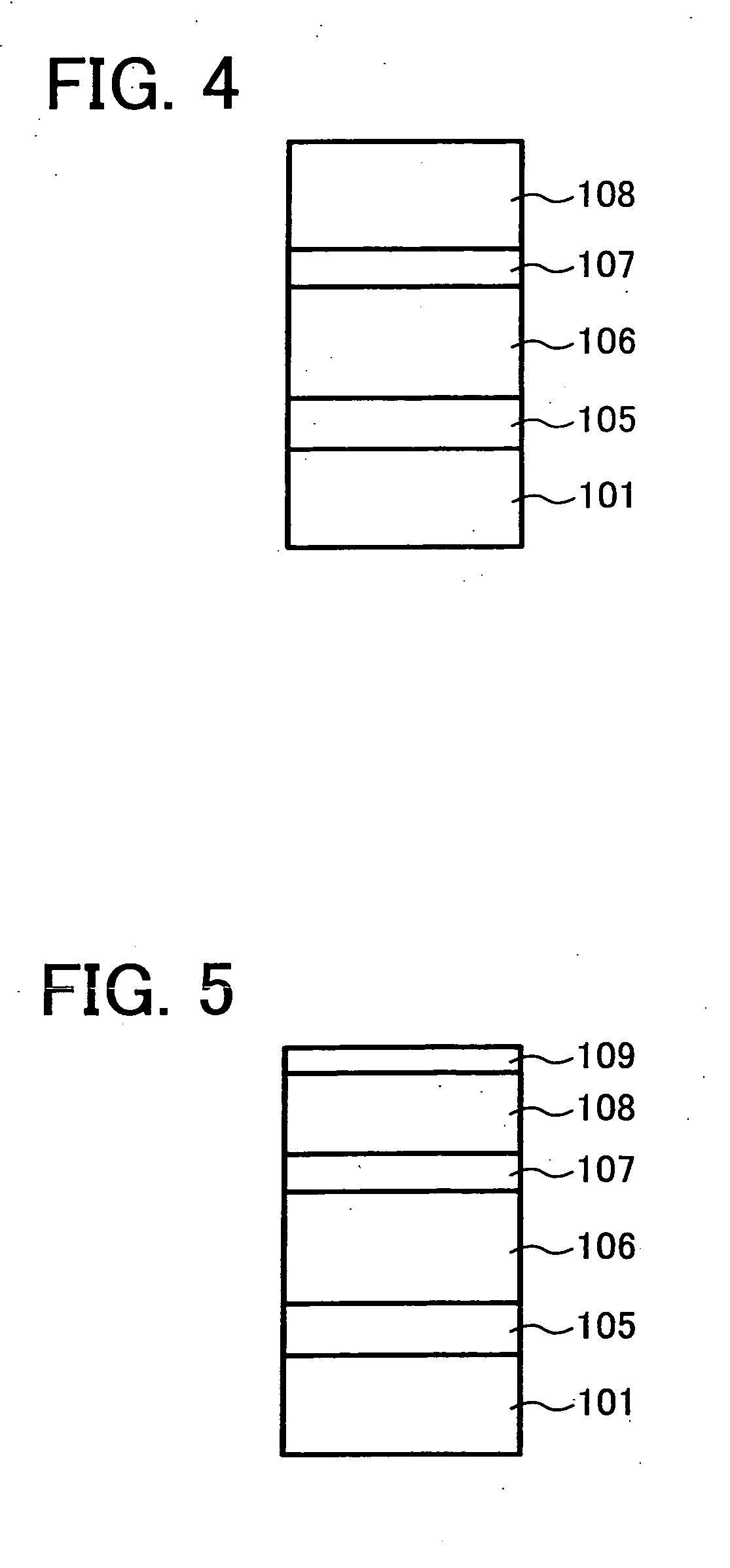

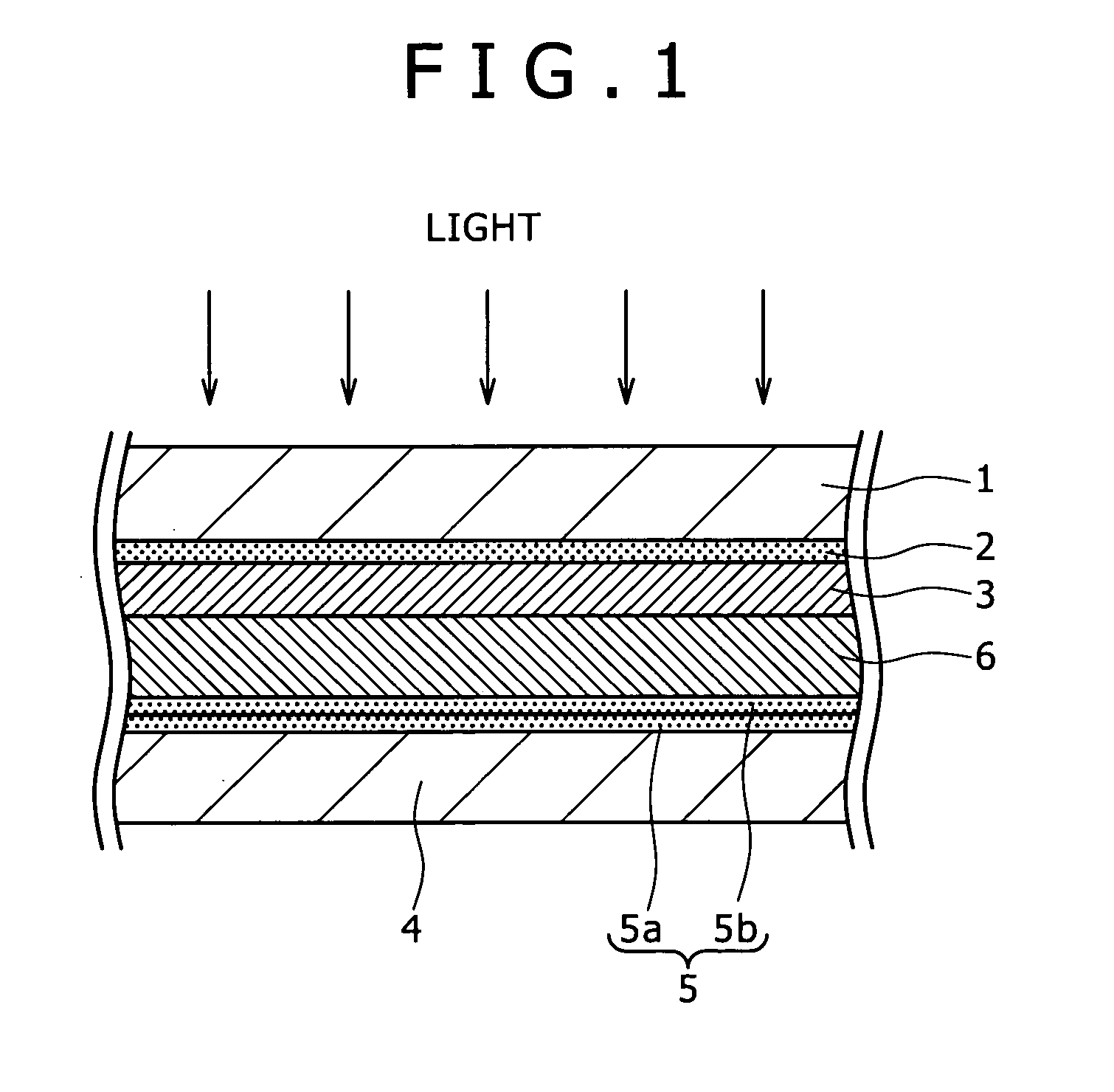

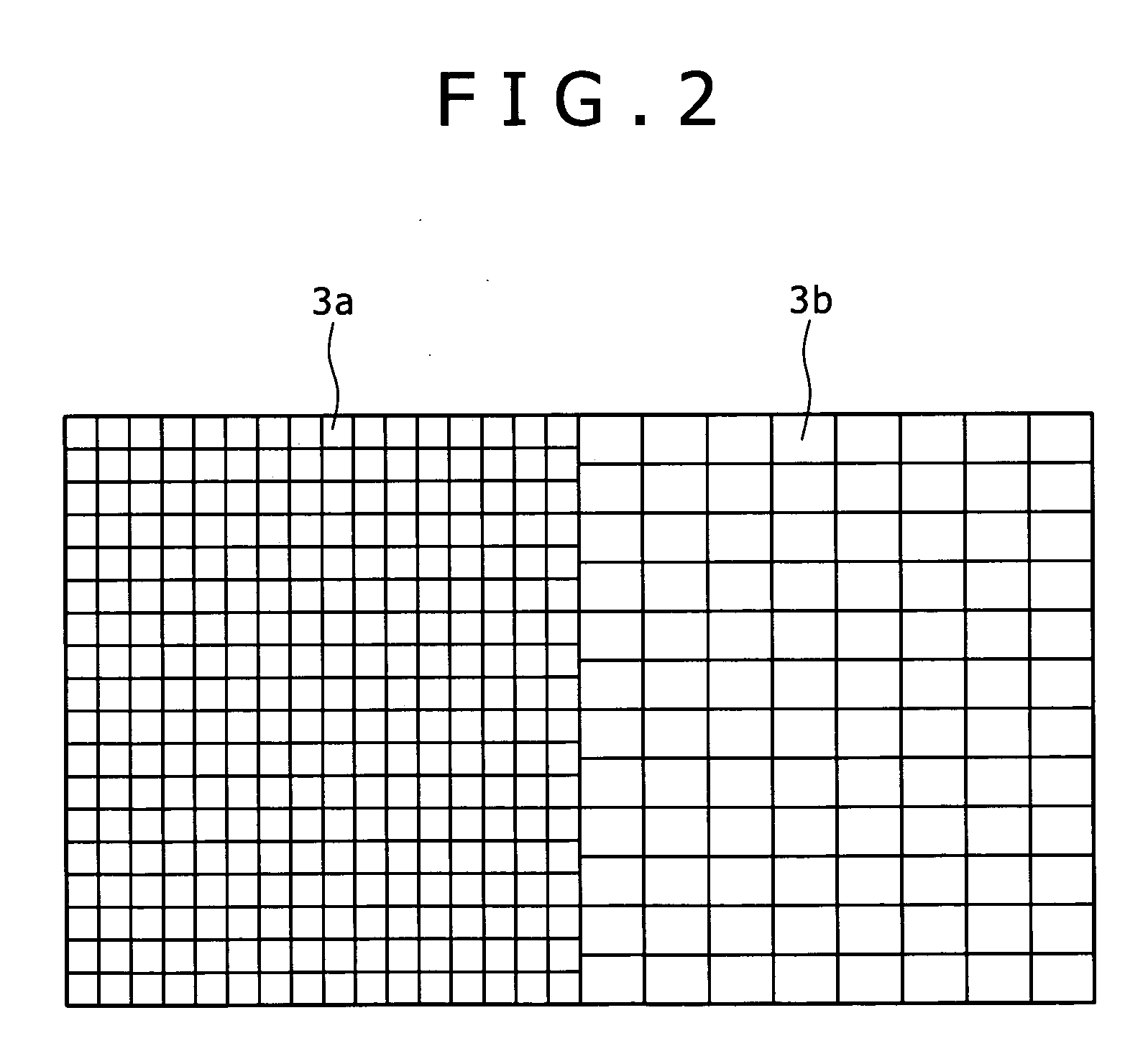

Image bearing member, and image forming apparatus and process cartridge using the same

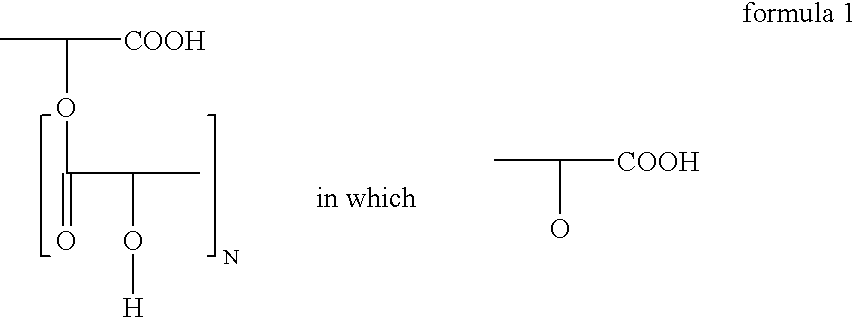

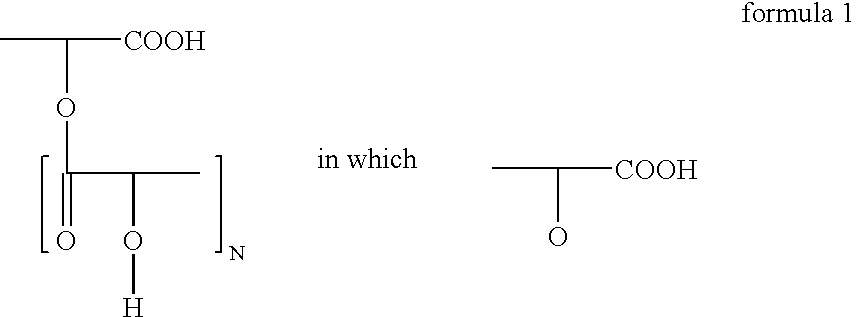

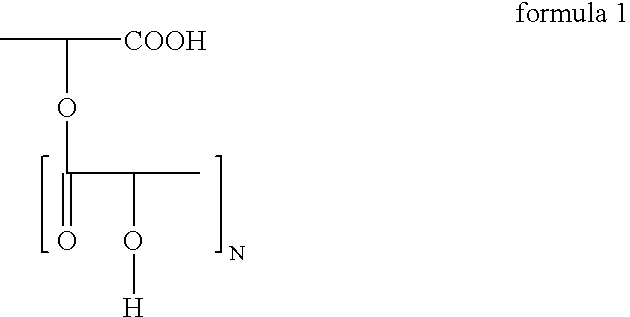

ActiveUS20060240346A1Image stabilizationElectrographic process apparatusCorona dischargePolymer scienceTricarboxylic acid

An image bearing member including an electroconductive substrate, a charge blocking layer disposed overlying the electroconductive substrate, a moire prevention layer disposed overlying the charge blocking layer, and a photosensitive layer disposed overlying the moire prevention layer. The charge blocking layer contains N-alkoxymethylized nylon and optionally at least one of an aliphatic dicarboxylic acid and an aliphatic tricarboxylic acid. The moire prevention layer contains a titanium oxide having a purity not less than 99.0% and a cross-linking resin.

Owner:RICOH KK

Method for restraining corrosion by circulating cooling water of containing sulphur

This invention provides a method for inhibiting the corrosion of sulfur-containing circulating cooling water. The method comprises: controlling the alkalinity of sulfur-containing circulating cooling water at 250-350 mg / L, and adding composite corrosion inhibitor 5-40 times of leaked sulfur ions in sulfur-containing circulating cooling water. The composite corrosion inhibitor comprises: organic corrosion inhibitor (one or more of hydroxyethylidene-1,1-diphosphonic acid, hydroxyphosphonoacetic acid, aminotrimethylene phosphonic acid, ethylene diamine tetramethylene phosphonic acid, 2-phosphono-1,2,4-tricarboxylic acid-butane and its potassium salt or sodium salt, polyol phosphate, and polyether alcohol amine phosphate) 2-24 wt.% and water 76-98 wt.%. The method has obvious effect on treating sulfur-containing circulating cooling water without changing the reagents used, and can control leaked sulfur ion concentration to 2mg / L and carbon steel corrosion rate to below 0.075 mm / a.

Owner:CHINA PETROLEUM & CHEM CORP

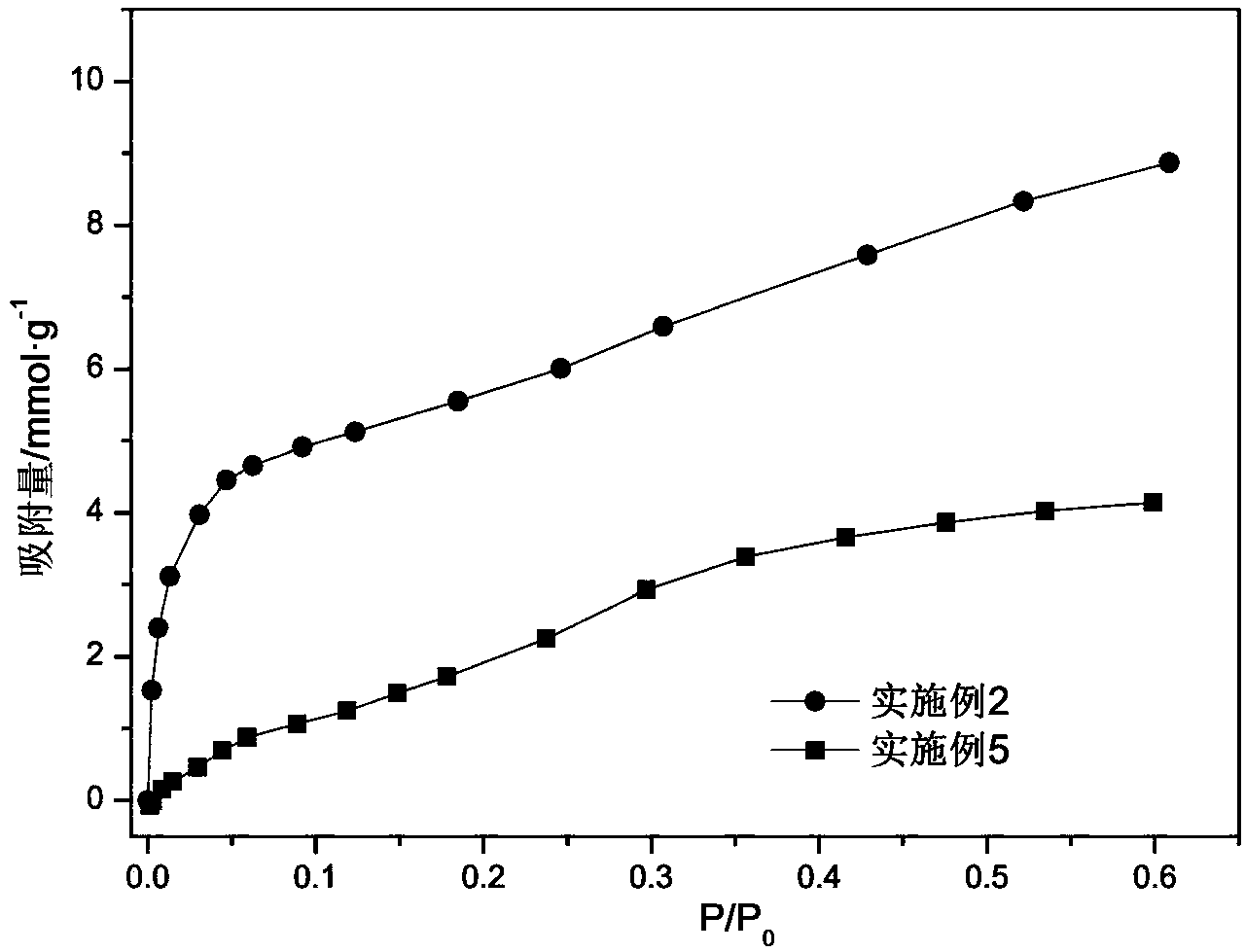

Copper-based metal-organic framework porous material and preparation method and application thereof

InactiveCN104138746ALower surface free energyHigh purityOther chemical processesAlkali metal oxides/hydroxidesPorositySynthesis methods

The invention belongs to the technical field of metal-organic framework materials and discloses a copper-based metal-organic framework porous material and a preparation method and application of the copper-based metal-organic framework porous material. The preparation method comprises the following steps that copper acetate and 1,3,5-benzene tricarboxylic acid are mixed evenly and then subjected to ball milling; the mixture is washed 2-3 times with ethanol water and then is soaked, centrifuged and dried, and finally the copper-based metal-organic framework porous material is obtained. By means of the preparation method, solvents do not need to be added in the reaction process, the reaction is quick, operation is simple, and the organic solvents which are cheap and easy to get are adopted as exchange solvents in the activation process, so the preparation method is a novel efficient and economical green synthesis method. The copper-based metal-organic framework porous material obtained through the preparation method has a large specific surface area and high porosity, can well adsorb volatile organic compounds and has higher adsorbing capacity to methanol than activated carbon, zeolite and other traditional adsorbing agents on the same conditions, the adsorbing capacity of the copper-based metal-organic framework porous material is about twice that of a metal-organic framework material HKUST-1 prepared through a hydrothermal synthesis method.

Owner:SOUTH CHINA UNIV OF TECH

Process for relaxing or straightening hair, using weak dicarboxylic acids with heat

ActiveUS8513200B2Facilitates straightening and relaxingLess irritating and damaging to a user's skin and hair.Cosmetic preparationsHair cosmeticsHair straighteningTricarboxylic acid

A process for straightening or relaxing hair comprising the following steps: (a) providing a hair straightening or relaxing composition having a pH ranging from 8 to 11.5, and containing, in a cosmetically acceptable medium, at least one weak acid chosen from monocarboxylic, dicarboxylic and tricarboxylic acids, their salts, and mixtures thereof; (b) contacting the hair with the hair straightening or relaxing composition to form treated hair; and (c) straightening or relaxing the treated hair by applying heat, wherein hydroxide-containing compounds are not used. Disclosed herein is also a preferred hair straightening or relaxing composition.

Owner:LOREAL SA

Efficient low-phosphorus compound water treatment agent

InactiveCN102718333AReduce manufacturing costPrevent scalingScale removal and water softeningPolyaspartic acidTricarboxylic acid

The invention provides an efficient low-phosphorus compound water treatment agent and belongs to the technical field of industrial circulating cooling water treatment. The water treatment agent consists of the following raw materials: polyaspartic acid (PESA), 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA), zinc salt, azoles, maleic acid-acrylic copolymer (MA / AA) and deionized water, wherein PESA is taken as a main scale inhibitor, PBTCA and MA / AA are taken as auxiliary scale inhibitors, a corrosion inhibitor is formed by the zinc salt, the azoles, PBTCA and PESA, and MA / AA is taken as a dispersing agent. By fully utilizing the synergistic effect of various components, a multifunctional low-phosphorus compound water treatment agent with scale and corrosion inhibition functions is formed.

Owner:SHANDONG TIANQING TECH DEV

Preparation of corrosion and scale inhibitor used for high alkaline high chlorine circulating cooling water

ActiveCN101607766AStrong chelating abilityStrong corrosion inhibitorScale removal and water softeningEpoxyPhosphoric acid

The invention provides a preparation of a corrosion and scale inhibitor used for high alkaline high chlorine circulating cooling water which is prepared according to the following parts by weight: 23-25 parts of PESA, 23-25 parts of 2-phosphonic acid butane-1, 2, 4-tricarboxylic acid, 12-15 parts of corrosion and scale inhibitor, 10-15 parts of sodium gluconate, 5-8 parts of alkyl epoxy carboxylate, 2-3 parts of BTA, and 10-20 parts of pure water. The preparation comprises the following steps: adding industrial phosphoric acid of 400-420kg into a reaction kettle for stirring, adding triethanolamine of 140-160kg slowly within 30-35min, stirring for 50-60min, keeping the temperature at 40-80 DEG C, adding pure water of 385-400kg and stirring for 20-30min; adding zinc oxide of 45-55kg under stirring, stirring for 90-120min, and keeping the temperature at 40-80 DEG C to obtain the corrosion inhibition potentiating agent, adding PESA into the 2-phosphonic acid butane-1, 2, 4-tricarboxylic acid to mix with the solution of the corrosion inhibition potentiating agent, sequentially adding alkyl epoxy carboxylate, pure water and sodium gluconate to stir for 30-40min, keeping the temperature at 20-35 DEG C, then adding BTA, stirring for 30-60 min, and keeping the temperature at 20-35 DEG C to obtain the composite corrosion and scale inhibitor.

Owner:XINJIANG DELAND

Environment-friendly type composite pre-film reagent used for recirculated cooling water system pre-film processing and method of use thereof

InactiveCN101182643AReduce total usageUse low concentrationScale removal and water softeningLiquid wasteTricarboxylic acid

The invention belongs to the circulating cooling water treatment technical field, and refers in detail to an environment-protecting composite pretreatment filming agent used for the pre-treatment filming in a circulating cooling water system and a use method thereof. The environment-protecting composite pretreatment filming agent comprises the main components of 2-phosphonobutane- 1, 2, 4-tricarboxylic acid and sodium of polyepoxysuecinic acid as well as a proper amount of carboxylic acid copolymer, benzotriazole, sodium molybdate, zinc sulphate and so on. When used, the composite pre-treatment filming agent is added into the circulating cooling water directly, and a corrosion-resistant protecting film is formed after 48 years of operation, the corrosion resistance of which to the standard copper sulphate drip solution is far better than the traditional phosphor-zinc pretreatment filming agent. The total phosphor content of the environment-protecting composite pretreatment filming agent is less than 7.5mg / l, and the water pH value does not have to be adjusted. After the pretreatment filming, the water is clear and transparent, and the normal operation can be started without replacing the water. Thus, not only the water to be replaced is saved, but also the chemical base investment expense during the normal operation after the water replacement is reduced. Meanwhile, no waste liquor of pretreatment filming is discharged, so the invention belongs to the environment-friendly pretreatment filming method.

Owner:TONGJI UNIV

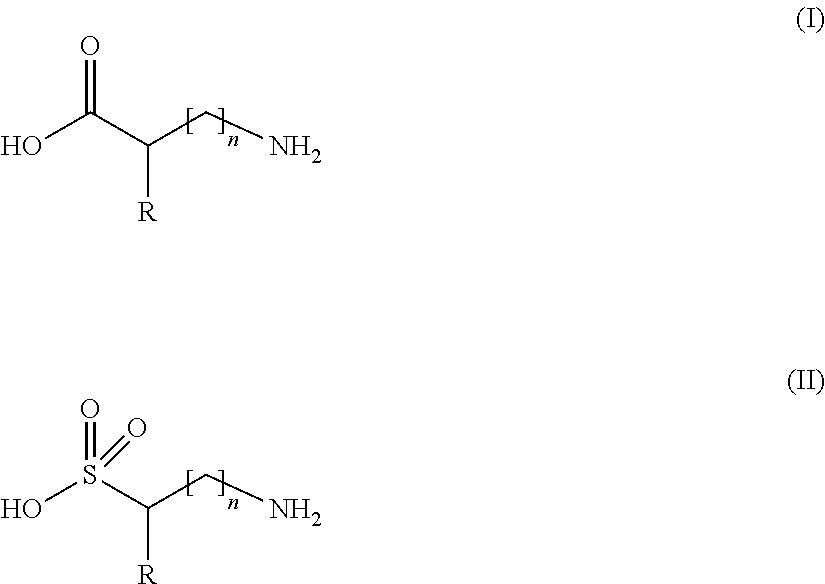

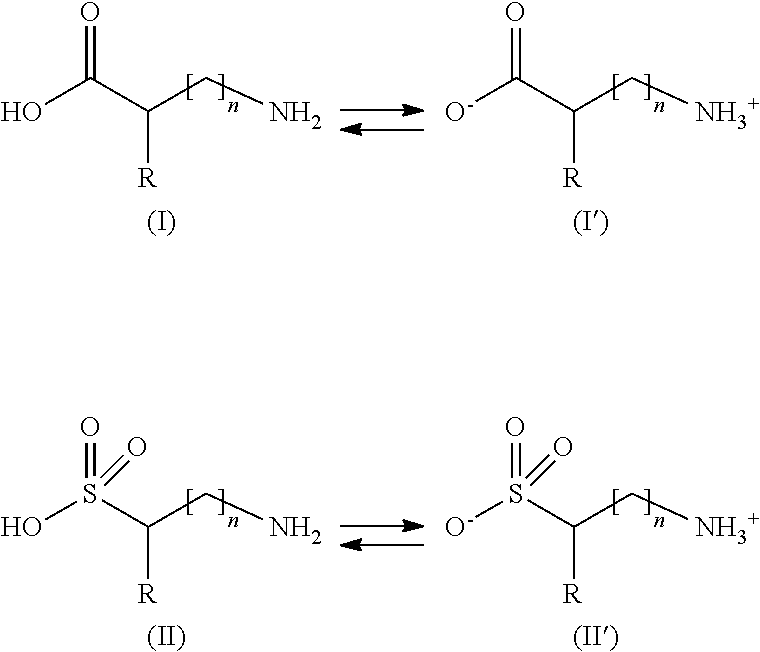

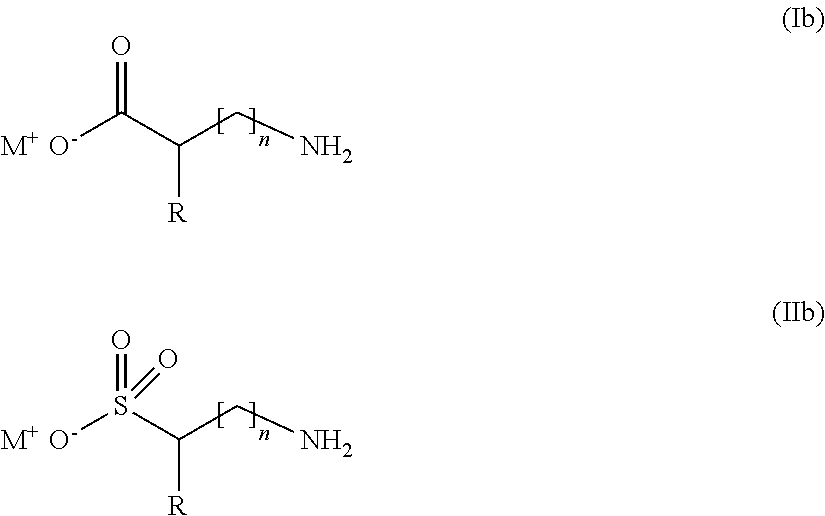

Hair-treatment compositions

PendingUS20180280270A1Condition protectProtection from damageCosmetic preparationsHair cosmeticsPolymer scienceTricarboxylic acid

The present disclosure relates to hair-treatment compositions, which are particularly useful for repairing, strengthening, and protecting hair from damage. The hair-treatment composition include at least 0.5 wt. % of at least one amino acid or amino sulfonic acid, and / or a salt thereof, and optionally, at least 0.5 wt. % of at least one non-polymeric mono, di, or tricarboxylic acid, and / or a salt thereof. Additional components such as surfactants and water may also be included. The unique components of the hair-treatment compositions restructure the hair fibers and result in the hair exhibiting improved properties such as increased hair fiber strength, better discipline, and more curl definition.

Owner:LOREAL SA

Low-phosphorous environment-friendly composite corrosion and scale inhibitor

InactiveCN101746901AImprove toleranceGood dispersionScale removal and water softeningHigh concentrationTricarboxylic acid

The invention discloses a low-phosphorous environment-friendly composite corrosion and scale inhibitor that is used in a circulating cooling water system. The low-phosphorous environment-friendly composite corrosion and scale inhibitor comprises 2-phosphonic butane- 1,2,4 -tricarboxylic acid, plyaspartic acid or polyepoxysuccinic acid, maleic anhydride-acrylic acid copolymer, acrylic acid-2-acrylamide-2-methyl propanesulfonic acid or acrylic acid-acrylate-sulfonate, acrylic acid-acrylate-phosphonic acid-sulfonate quaternary copolymer, zinc salts (zinc sulfate or zinc chloride) or hydroxy benzotriazole. The invention is particularly suitable for the circulating cooling water system with high concentration multiple, which needs to control the phosphorous content (the total phosphorous content is lower than 0.5mg / l) due to environmental pressure.

Owner:成都澳贝龙科技发展有限公司

Preparation method and applications of mesoporous metal organic complex base composite material

InactiveCN104324756AAvoid reunionHigh catalytic activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryTricarboxylic acid

The present invention relates to a preparation method and applications of a mesoporous metal organic complex base composite material, and belongs to the technical fields of material science, nanometer materials, chemical industry, catalysis and the like. According to the present invention, copper nitrate, a cyanuric chloride tricarboxylic acid H3L and tetraethyl orthosilicate are subjected to one-step ultrasound to prepare Cu-MOF@SiO2, the Cu-MOF@SiO2 is impregnated in a silver nitrate solution, and ultraviolet irradiation is adopted to reduce Ag<+> to prepare the magnetic metal organic polymer-supported noble metal catalyst with the nanometer Ag anchored on the surface, wherein the catalyst is the Cu-MOF@SiO2@Ag. The catalysis has the excellent performance of catalytic reduction of unsaturated organic compounds, and has good application prospects in heterogeneous catalytic reduction reactions.

Owner:UNIV OF JINAN

Lubricating and cutting fluid

InactiveCN101768502AImprove the lubrication effectImprove rust resistanceAdditivesWater basedPhosphoric acid

The invention relates to a lubricating and cutting fluid, which contains 12-20% of naphthene base crude oil, 15-25% of castor grease, 20-30% of poly-ester of polybasic acid and polyalcohol, 12-18% of sodium alkyl benzene sulfonate, 5-10% of refined tall oil, 1-3% of alkyl phosphoric acid and 1-4% of tricarboxylic acid salt. A surfactant used in the lubricating and cutting fluid has excellent properties of lubricating, washing and rust protection; an extreme-pressure lubricant and a rust preventer are added into water-based cutting fluid, so as to further improve the properties of lubricating and rust protection of the water-based cutting fluid, so that the water-based cutting fluid has good lubricity, rust protection, cooling property and washing property and can obviously improve the surface finishment of a workpiece and reduce the wear effect of a cutter.

Owner:SHANGHAI AORUNKE LUBRICANT

Corrosion and scale inhibitor for industrial recirculated cooling water

InactiveCN101302060AGood anti-scaling effectGood synergyScale removal and water softeningEutrophicationTricarboxylic acid

The invention provides a corrosion and scale inhibitor for industrial circulated cooling water, which is applicable to a composite for mitigating metal corrosion added into a water body with ultra-low hardness, low alkalinity and strong corrosiveness. The corrosion and scale inhibitor is characterized by comprising the following compositions in percentage by weight: 5 to 20 percent of 2-hydroxyphonoacetic acid, 5 to 25 percent of 2-phosphonobutane-1, 2, 4 - tricarboxylic acid, 10 to 40 percent of acrylic acid-2-acrylamido-2-methylpropane sulfonic acid copolymer, 1 to 8 percent of zinc chloride, 1 to 5 percent of copper corrosion inhibitor, and the balance being water. The corrosion and scale inhibitor has lower contents of inorganic phosphorus and zinc salt, can prevent scale sedimentation of medicine on one hand, and can reduce eutrophication of the water body and heavy metal pollution on the other hand, thereby facilitating the environmental protection.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD +1

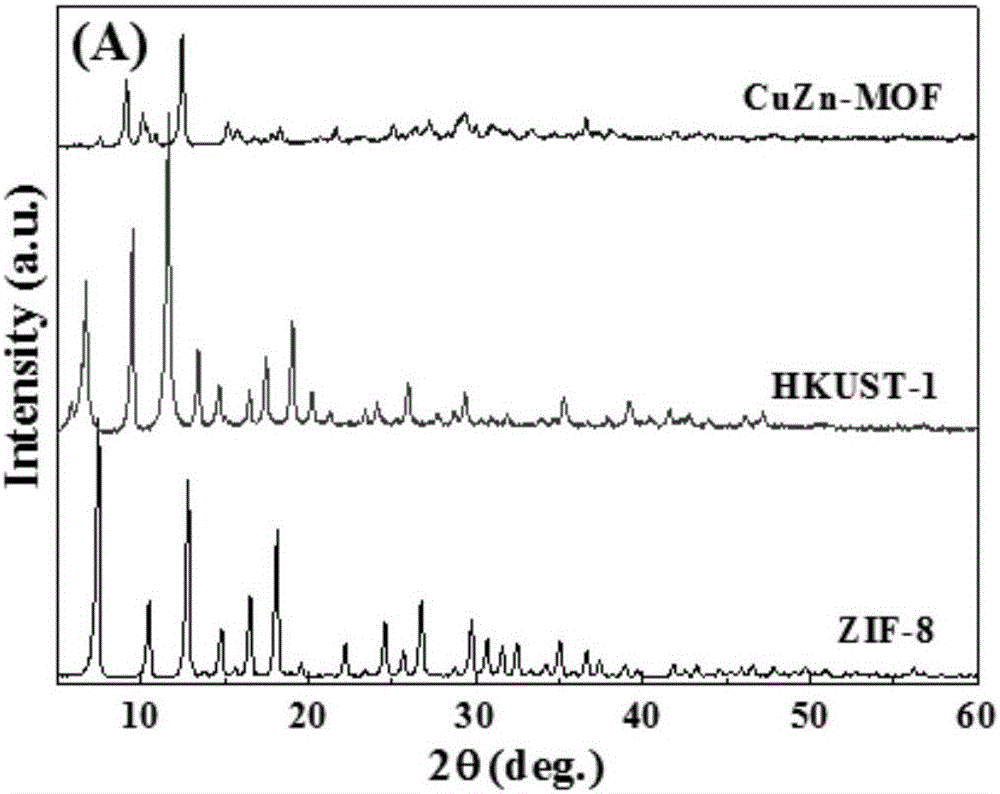

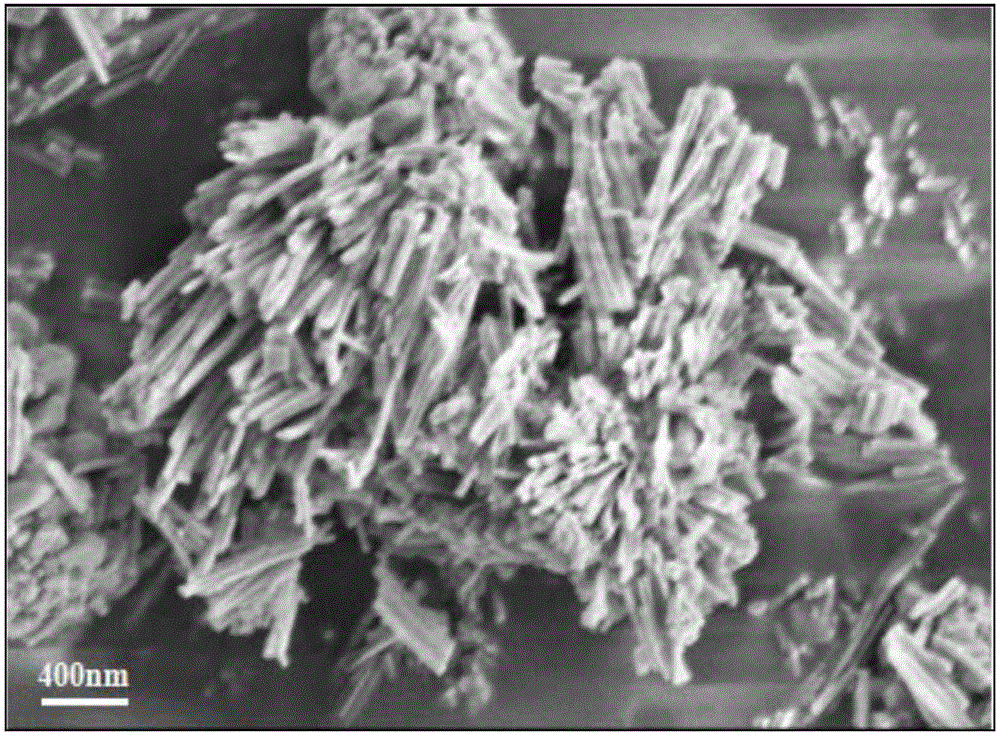

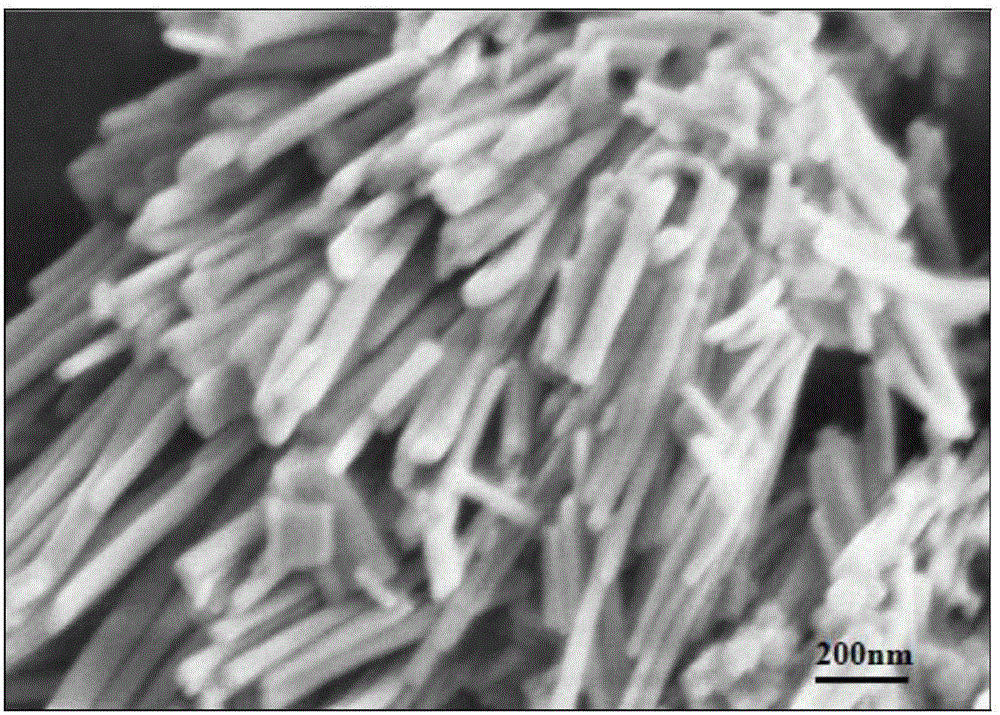

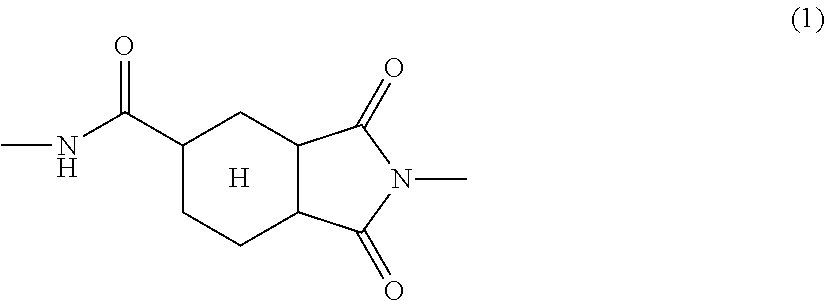

CuZn bi-metal organic framework material and preparing method thereof

The invention discloses a CuZn bi-metal organic framework material and a preparing method thereof.The metal organic framework material ZIF-8 containing metal Zn and soluble copper salt are dissolved in a mixed solvent containing H2O, ethyl alcohol and N,N-dimethylformamide, and then 1,3,5-benzene tricarboxylic acid is added for hydrothermal crystallization, separation, washing and drying, so that the CuZn bi-metal organic framework material is obtained.Different from traditional bi-metal MOF preparing methods, the preparing method has the advantages that preparing time is short, replacement rate is high, and the crystal structure of the product varies.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Polyamideimide resin, as well as a colorless and transparent flexible metal-clad laminate and circuit board obtained therefrom

ActiveUS20100018756A1Excellent heat resistance and flexibilitySufficient colorless and transparent propertySynthetic resin layered productsTransparent dielectricsHeat resistancePolyamide-imide

[Object] To provide a flexible metal-clad laminate having excellent heat resistance, flexibility and low thermal expansion together with sufficient colorless transparency and a flexible printed circuit board using the same.[Constitution] A colorless and transparent flexible metal-clad laminate where metal foil is directly laminated or is laminated via an adhesive layer on at least one side of the polyamideimide resin layer in which cyclohexane tricarboxylic acid anhydride is a main monomer, characterized in that said polyamideimide resin has an inherent viscosity of 0.8 dl / g or more and 2.5 dl / g or less.

Owner:TOYOBO CO LTD

C10/C7 ester mixtures based on 2-propylheptanol

Ester mixture comprising at least one ester of an aliphatic or aromatic di- or tricarboxylic acid having a C10 alcohol component composed of 2-propylheptanol or composed of a C10 alcohol mixture composed of 2-propylheptanol and of at least one of the C10 alcohols 2-propyl-4-methylhexanol, 2-propyl-5-methylhexanol, 2-isopropylheptanol, 2-isopropyl-4-methylhexanol, 2-isopropyl-5-methylhexanol, and / or 2-propyl-4,4-dimethylpentanol, and comprising at least one ester of an aliphatic or aromatic di- or tricarboxylic acid having a C7 alcohol component composed of n-heptanol or composed of an alcohol mixture composed of n-heptanol with at least one of the C7 alcohols 2-methylhexanol and / or 2-ethylpentanol, where the aliphatic or aromatic di- or tricarboxylic acid has been selected from the group consisting of citric acid, phthalic acid, isophthalic acid, terephthalic acid, and trimellitic acid, and polyvinyl chloride composition comprising this ester mixture.

Owner:BASF CORP

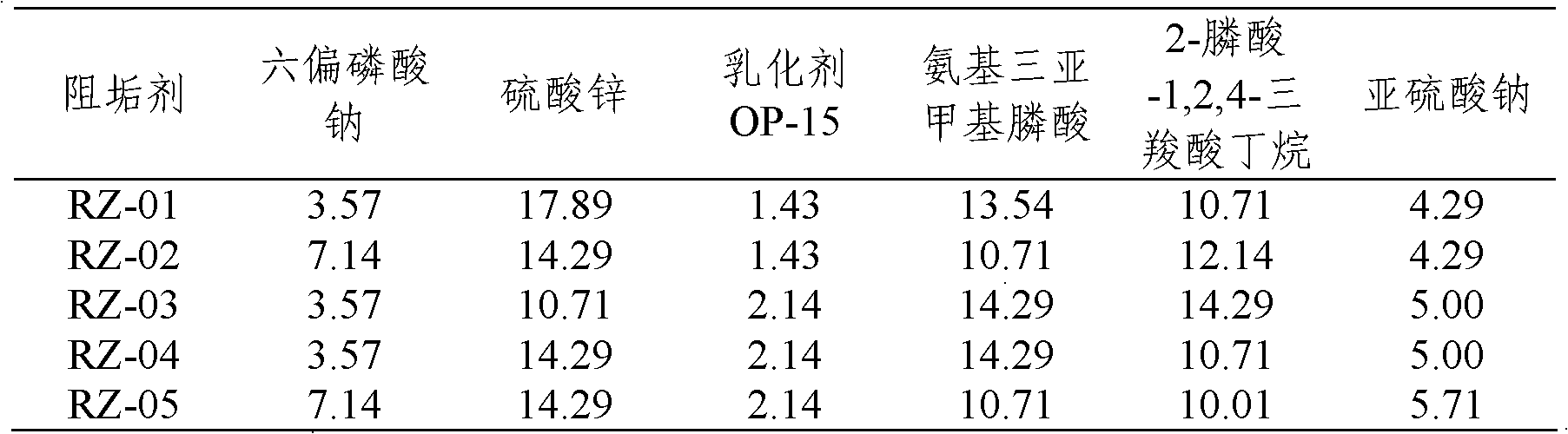

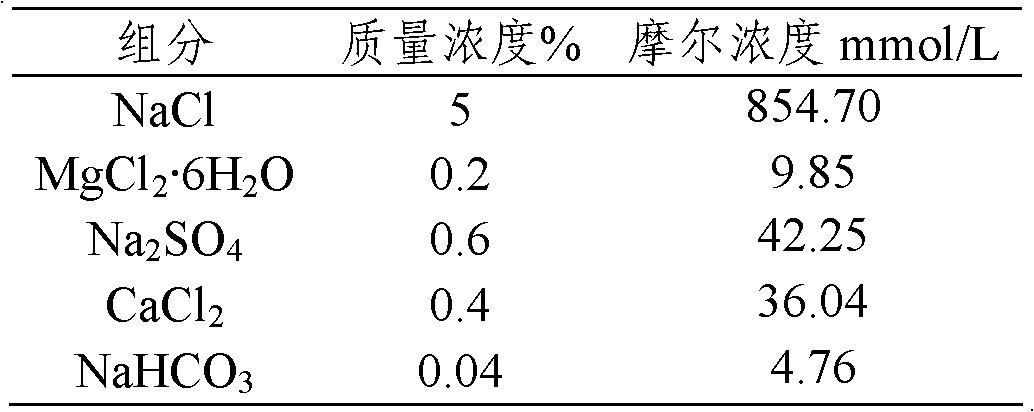

High-temperature resisting oil field scale inhibitor with emulsifying function and preparation method thereof

InactiveCN103030216ASuppress generationEmulsification hasScale removal and water softeningChemical industrySulfate

The invention relates to the petroleum chemical industry field and in particular to a high-temperature resisting oil field scale inhibitor with an emulsifying function and a preparation method thereof. The scale inhibitor comprises the following components by weight percent: 2-9% of sodium hexametaphosphate, 13-20% of zinc sulfate, 1-3% of emulsifying agent OP-15, 10-18% of amino trimethylene phosphonic acid, 8-16% of 2-phosphonic acid-1,2,4-tricarboxylic acid butane, 4-6% of sodium sulfite and the balance of water. The scale inhibitor provided by the invention has the emulsifying function, the inhibition rate of the high-temperature resisting oil field scale inhibitor is larger than 97%, and the scale inhibiting ratio is larger than 92% in a high temperature environment of 85 DEG C; and the high-temperature resisting oil field scale inhibitor has better scale inhibiting effect on typical scaling of a watering tube of an oil field gathering and transportation system.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

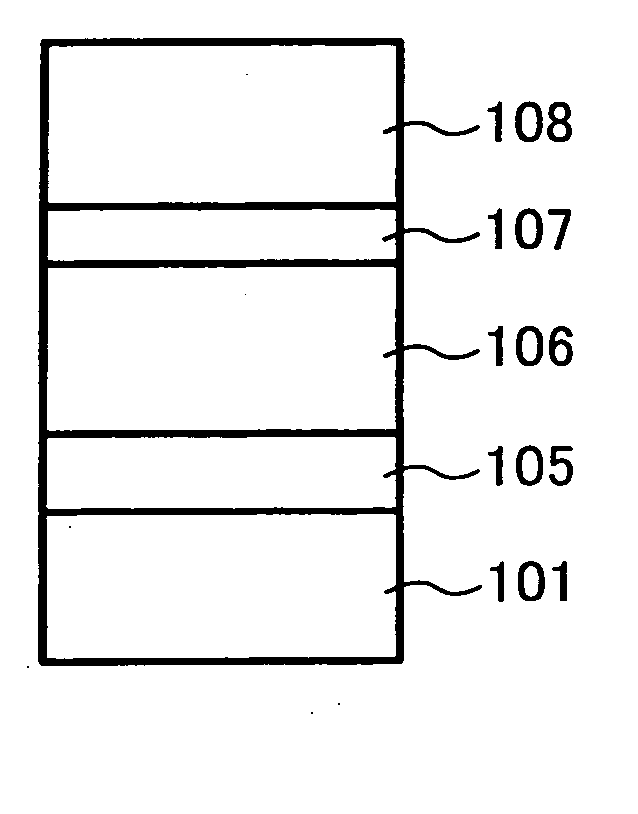

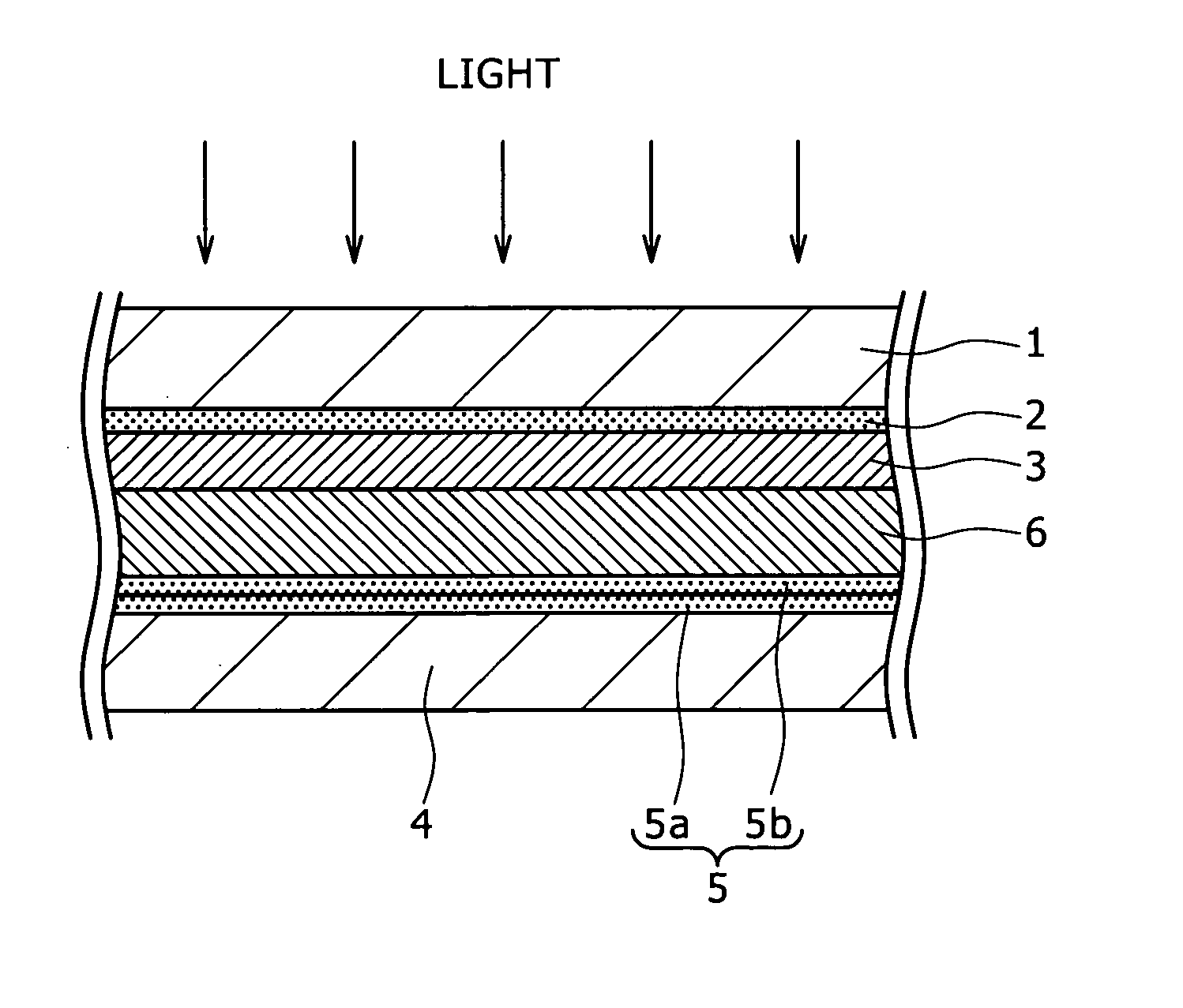

Dye sensitized photoelectric conversion device and manufacturing method thereof, electronic equipment, and semiconductor electrode and manufacturing method thereof

InactiveUS20100116340A1Degrade detection efficiency or photoelectric conversion efficiencyReduce quantum yieldElectrolytic capacitorsSemiconductor/solid-state device manufacturingSemiconductor electrodeTricarboxylic acid

In a dye sensitized photoelectric conversion device having an electrolyte layer (6) between a semiconductor electrode (3) including, for example, fine semiconductor particles to which a sensitizing dye is adsorbed and a counter electrode (5), two kinds of dyes are used as the dye, and the two kinds of dyes are adsorbed onto the surface of the semiconductor electrode (3) at the sites different from each other. The fine semiconductor particles include, for example, TiO2. Tris(isothiocyanate)-ruthenium(II)-2,2′:6′,2″-terpyridine-4,4′,4″-tricarboxylic acid and 2-cyano-3-[4-[4-(2,2-diphenylethenyl)phenyl]-1,2,3,3a,4,8b-hexahydrocyclopent[b]indol-7-yl]-2-propenoic acid are used, for example, as the two kinds of dyes. Thereby, a dye sensitized photoelectric conversion device such as a dye sensitized solar cell capable of obtaining higher light absorption rate and photoelectric conversion efficiency than in a case of using one kind of dye at high purity, as well as a manufacturing method thereof are provided.

Owner:SONY CORP

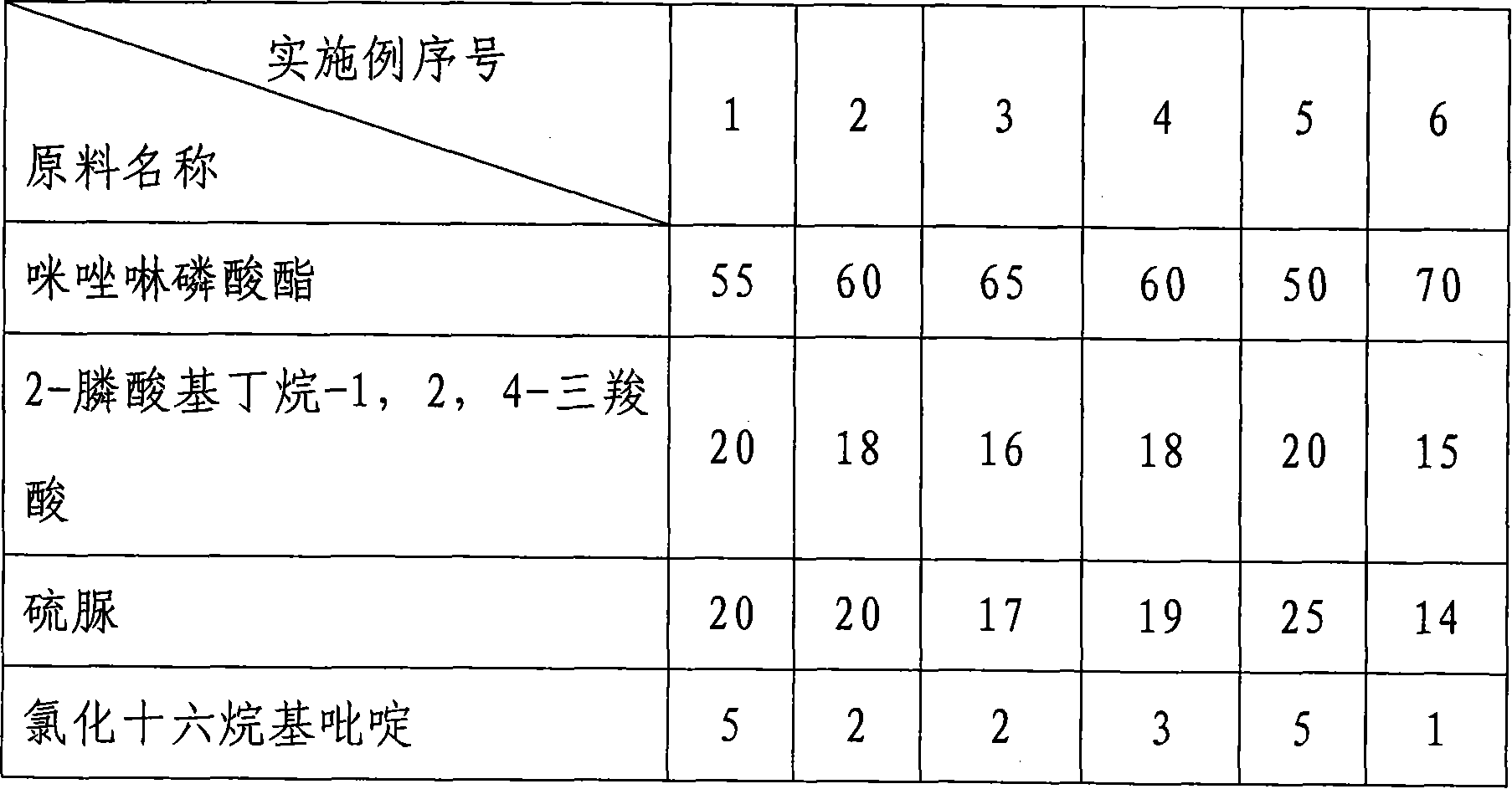

Compound inhibitor for exploitation of oil-gas field and preparation method thereof

ActiveCN101230260AGood corrosion inhibitionPrevents foulingBorehole/well accessoriesPhosphateThiourea

The invention discloses an oil gas field exploitation used compound inhibitor and the preparation method. The compound inhibitor contains imidazolinyl organic phosphate, 2 - N-acid butyrate -1, 2, 4-tricarboxylic acid, thiourea, cetylpyridinium chloride. The mixture proportions of all constituents by weight can meet the specified contents of all active substances. The preparation method is that the 2 - N-acid butyrate -1, 2, 4 - tricarboxylic acid is added into imidazolinyl organic phosphate; thiourea is added into and dissolved into water; the solutions obtained by sub-steps are mixed together and are added into the cetylpyridinium chloride; after evenly stirring for 50-90 minutes and keeping the temperature rang within 15-45 DEG C, the inhibitor of the invention is produced. The compound inhibitor uses multifold medicaments for synergia, can prevent scale formation, can kill bacteria or inhabit bacteria from growing with less usage, can be applied to wide range, and can perform excellent efficiency under complex water quality condition.

Owner:XINJIANG DELAND

Wet-mixed mortar modifier

The invention provides a wet-mixed mortar modifier. Every 1,000 parts of the wet-mixed mortar modifier comprises 15-20 parts of sodium tripolyphosphate, 1-2 parts of sodium hexametaphosphate, 4-5 parts of phosphonobutane tricarboxylic acid, 32-44 parts of glucose, 24-33 parts of citric acid, 50-80 parts of zeolite powder, 80-100 parts of silica fume, 200 parts of heavy calcium carbonate, 10-15 parts of starch ether, 20-40 parts of hydroxyethyl methyl cellulose ether, 1-2 parts of sodium dodecyl sulfate, 28-50 parts of a polycarboxylate superplasticizer, 20-25 parts of a polycarboxylate slump retaining agent, 40-80 parts of a naphthalene-based superplasticizer, 20-25 parts of redispersible latex powder, 8-10 parts of beta-cyclodextrin and the balance of fly ash. The plasticity-maintaining time of the wet-mixed mortar modifier is prolonged to 36 h, the later strength and bondability of the wet-mixed mortar are improved simultaneously, the mortar durability is improved, the problems of high probability of hollowing, cracking, leaking and the like of plastering mortar are solved, and the wet-mixed mortar modifier has low energy consumption and is free of chemical and radioactive contamination.

Owner:ZHEJIANG JIANKE NEW MATERIAL DEV

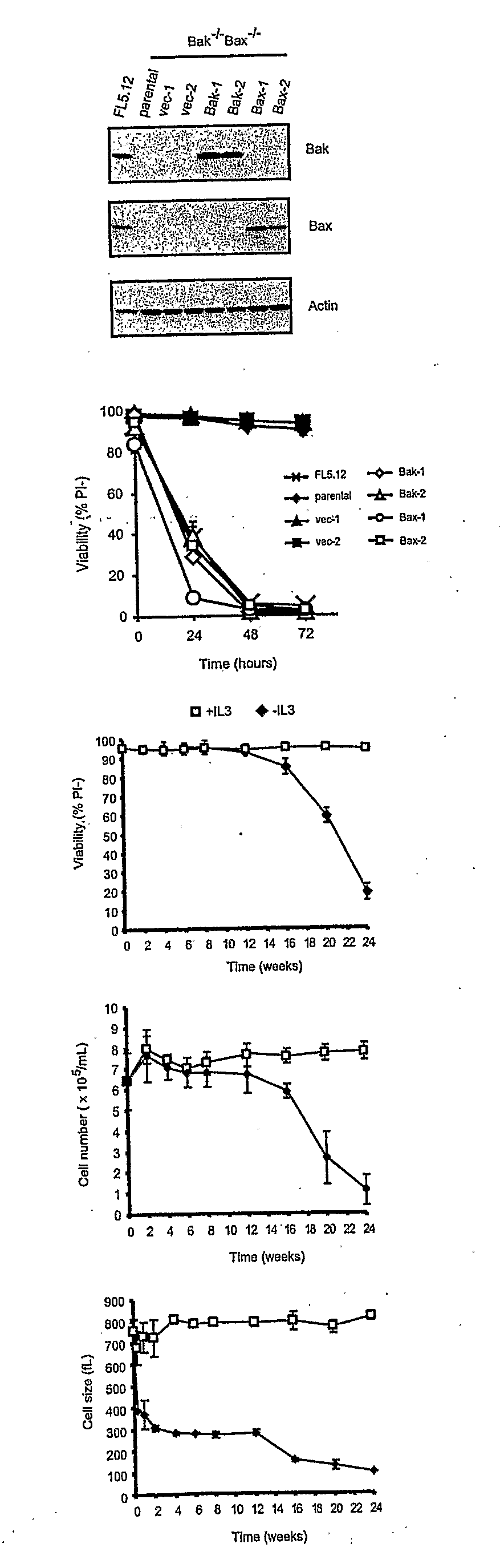

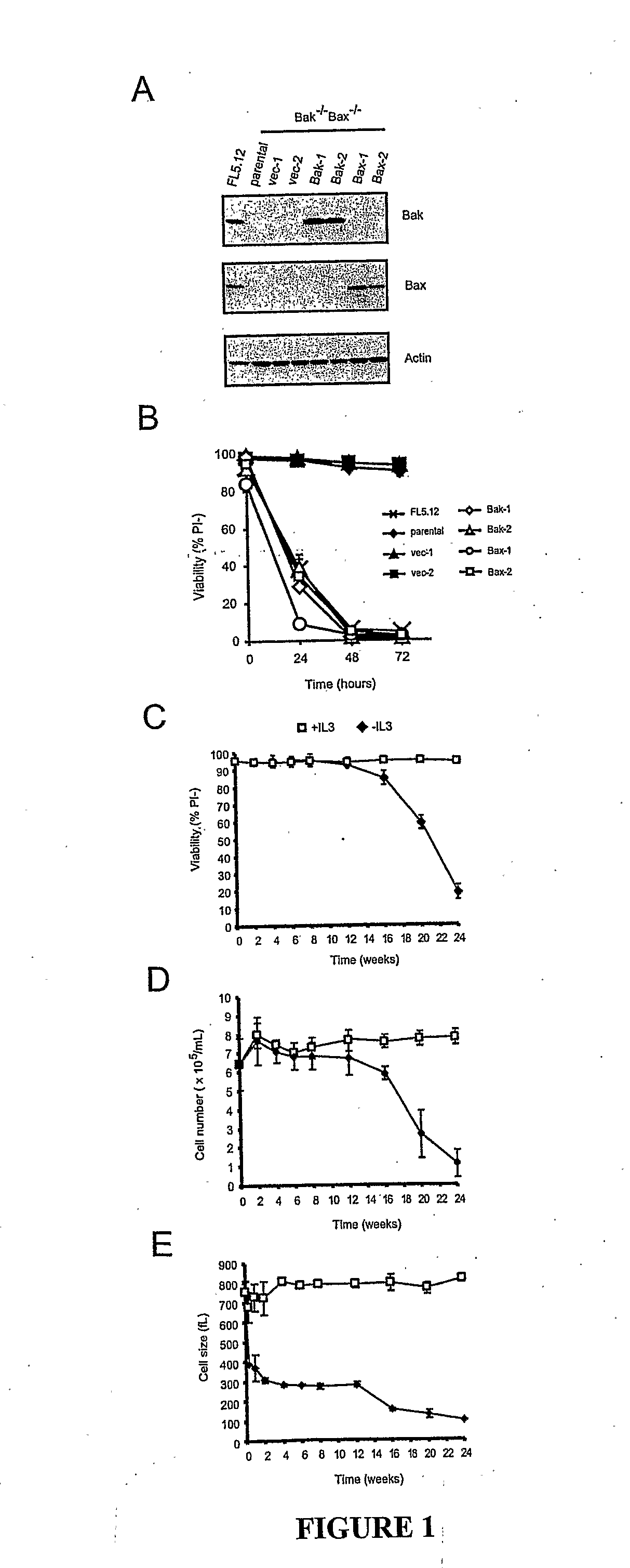

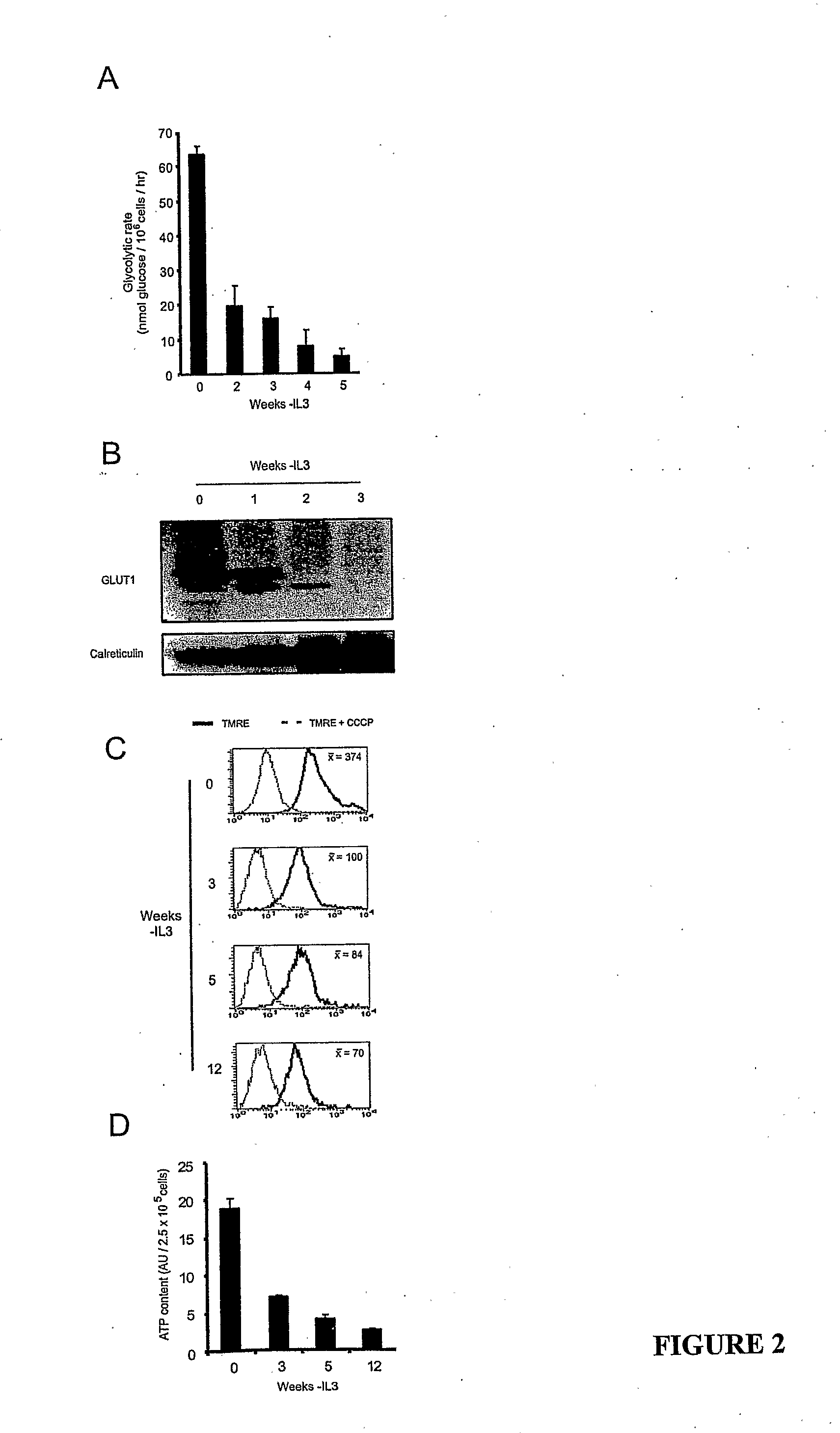

Regulation of Autophagy and Cell Survival

Methods of treating an individual who has been identified as having glycolysis dependent cancer are disclosed. The methods comprise the step of: administering to such an individual a combination of an anti-cancer composition that renders the cancer incapable of glycolysis and an autophagy inhibitor. Pharmaceutical compositions and kits comprising that renders the cancer incapable of glycolysis and an autophagy inhibit are also disclosed. Methods of treating an individual who has a disease characterized b cell degeneration and cell death due to autophagy are disclosed. The methods comprise administering to the individual a permeable form of a metabolic substrate that can be oxidized in the tricarboxylic acid cycle to produce NADH. Methods for identifying an autophagy inhibitor comprising performing a test assay using an apopto sis-resistant cell are disclosed.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

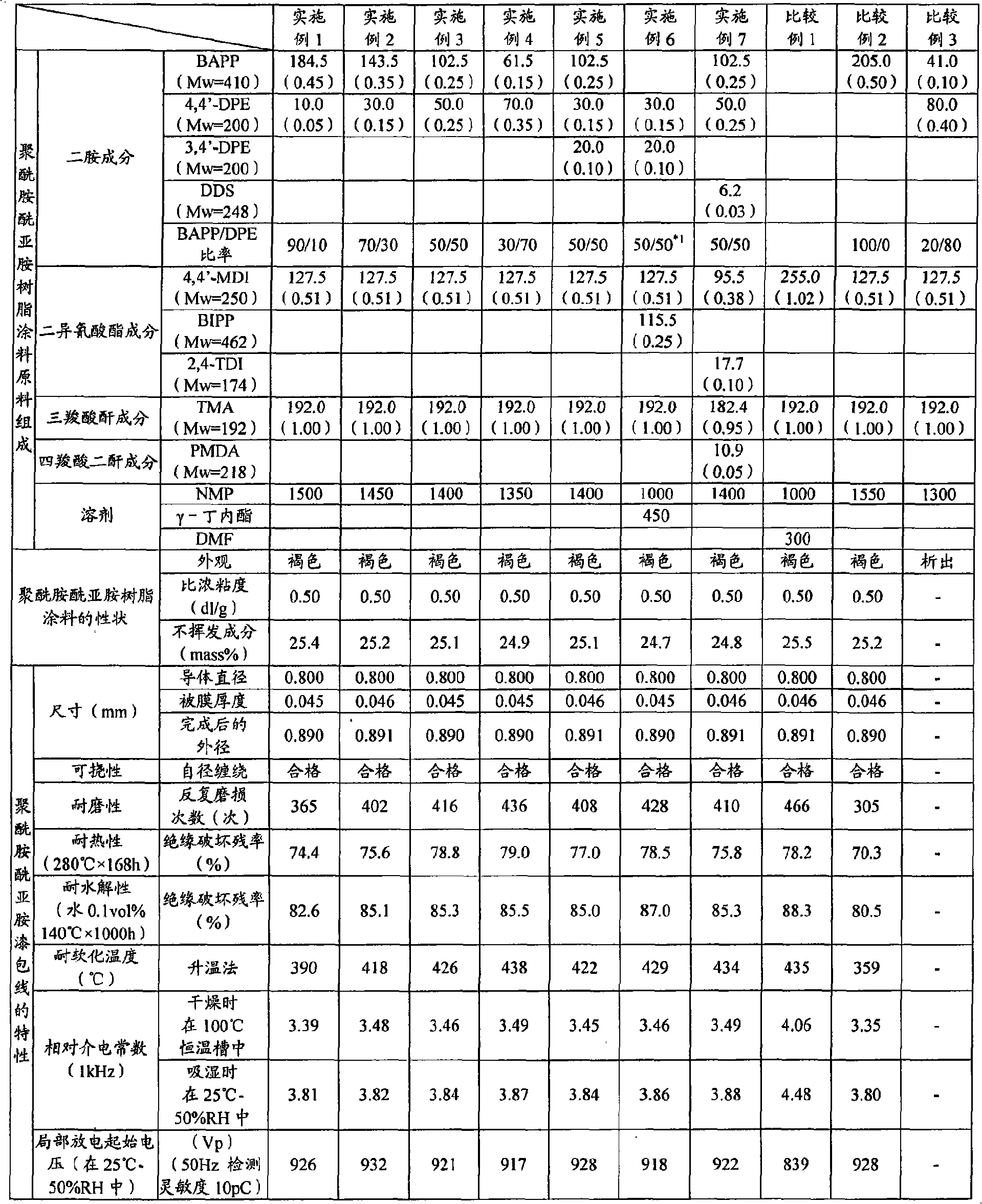

Polyamide-imide resin insulating varnish and insulated wire using the same

ActiveCN101597462AHigh partial discharge inception voltageNo reduction in softening temperaturePlastic/resin/waxes insulatorsCoatingsHeat resistancePolyamide-imide

This invention relates to a polyamide-imide resin insulating varnish and an insulated wire using the polyamide-imide resin insulating varnish. A polyamide-imide resin insulating varnish includes an aromatic diamine component, an aromatic diisocyanate component, an acid component including an aromatic tricarboxylic acid anhydride, and a solvent. The aromatic diamine component includes an aromatic diamine with three or more benzene rings and an aromatic diamine with two or less benzene rings. The polyamide-imide resin insulating varnish allows reduction in permittivity while retaining its heat resistance, mechanical performance, oil resistance etc. for producing a covering with a high partial discharge inception voltage.

Owner:HITACHI MAGNET WIRE CORP +1

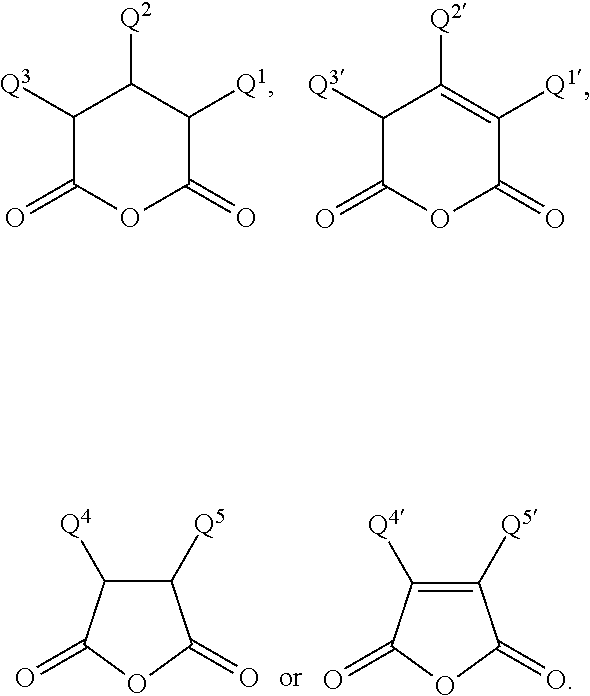

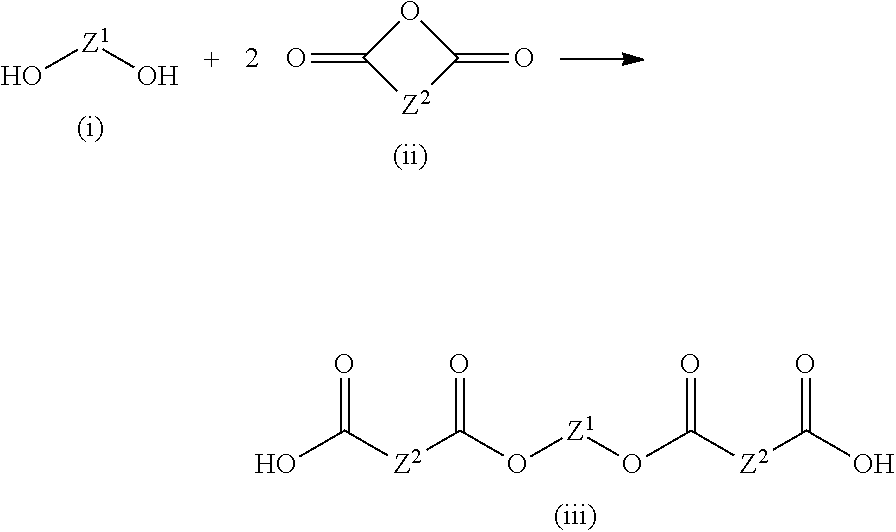

Reaction products based on amphiphilic block copolymers and their use as impact modifier

InactiveUS20110114257A1High tensile strengthTensile shear strengthLamination ancillary operationsLaminationTricarboxylic acidCarboxylic acid

Novel impact modifiers obtained by the reaction of amphiphilic block copolymers. These impact modifiers are suitable for use in thermosetting epoxy resin adhesives. The impact modifiers include a carboxylic acid group prepared from the reaction of an intramolecular anhydride of a di- or tricarboxylic acid with at least one amphiphilic block copolymer including at least one hydroxyl group. A method for adhesively binding heat-stable substrates includes applying a single-component thermosetting epoxy resin composition to the surface of a first heat-stable substrate; contacting the epoxy resin composition with the surface of second heat-stable substrate; heating the epoxy resin composition to 20-100° C.; bringing the two substrates and the epoxy resin composition into contact with a wash liquid; and heating the epoxy resin composition to 140-220° C.

Owner:SIKA TECH AG

Scale and corrosion inhibitor suitable for reclaimed water reuse system

The invention discloses a scale-corrosion inhibitor for a reclaimed water recycling system. The scale-corrosion inhibitor is prepared from polyepoxysuccinic acid, 2-phosphonobutane -1,2,4-tricarboxylic acid, alicyclic amine having 6 to 24 carbon atoms and nonionic surfaceactive agent sequentially by combination according to a ratio of 1 to 1.0-2.0 to 0.5-1.0 to 1.0-2.0. The water treatment agent has good scale-corrosion resistant effect and is applicable to contraindicated water sources and waters in awful conditions such as municipal wastewater. Water treated by the scale-corrosion inhibitor can be used as industrial circulating cooling water, and can be particularly used as circulating cooling water for condensers of a power plant, with effects of improving heat exchange rate, reducing equipment maintenance and prolonging the service life of equipment.

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com