Polyamide-imide resin insulating varnish and insulated wire using the same

一种聚酰胺酰亚胺树脂、绝缘涂料的技术,应用在塑料/树脂/蜡绝缘体、绝缘体、有机绝缘子等方向,能够解决绝缘特性降低、实用性低等问题,达到低介电常数的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

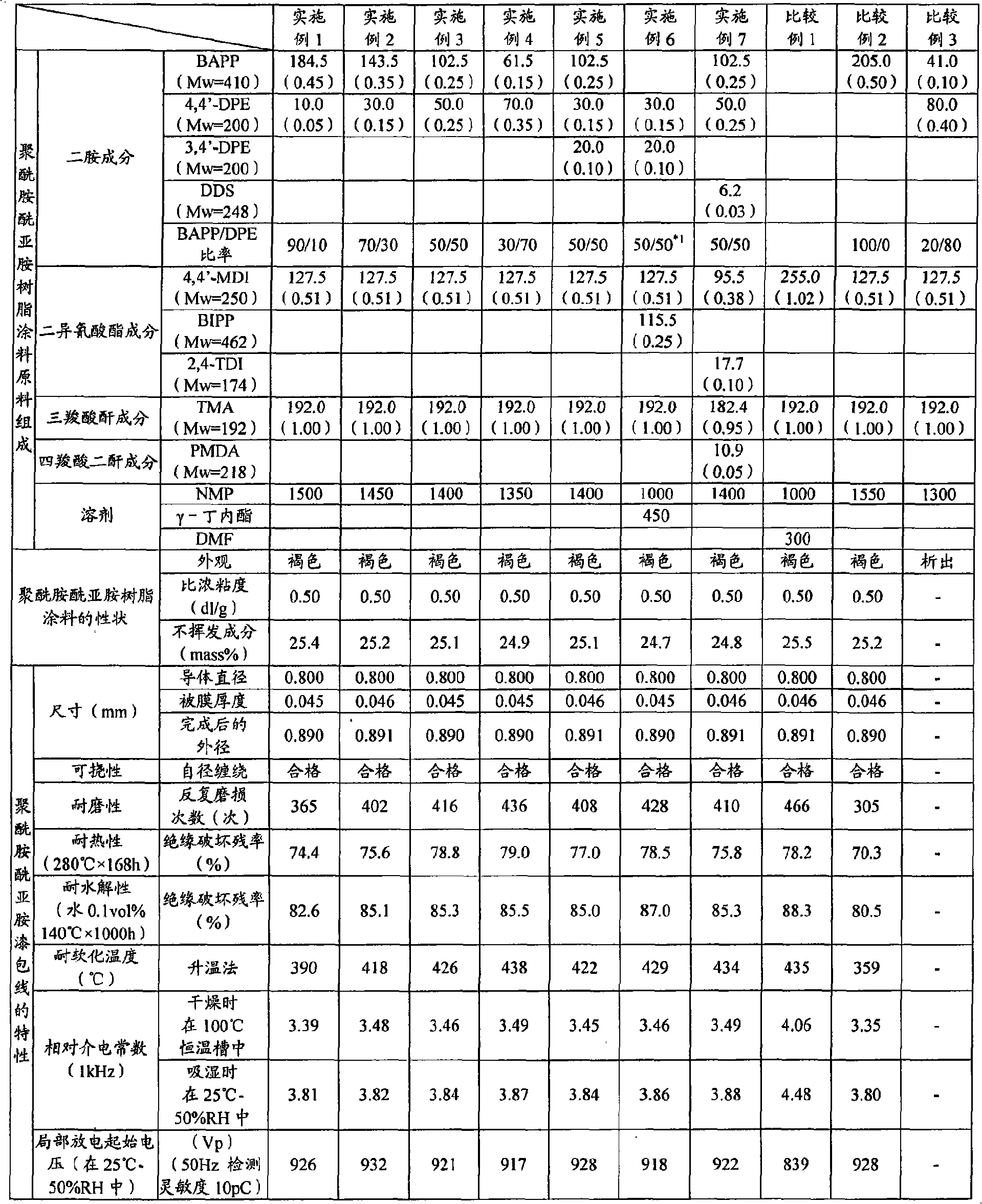

[0056] Examples 1-7 and Comparative Examples 2-3 are the synthesis|combination of the polyamide-imide resin insulating paint which used the diamine component (aromatic diamine component), and implemented the synthesis of 2 stages as follows.

[0057] Prepare a flask equipped with a stirrer, a reflux condenser, a nitrogen gas introduction tube, and a thermometer, and as a synthesis reaction of the first stage, inject the diamine component, the acid component, and about 50 to The 80% solvent was heated to 180° C. in about 1 hour while stirring in a nitrogen atmosphere, and reacted at this temperature for 4 hours while discharging the water generated by the dehydration reaction to the outside of the system. After cooling to 60°C while maintaining the nitrogen atmosphere, add the diisocyanate component and the remaining solvent, and heat to 140°C for about 1 hour while stirring in the nitrogen atmosphere as the second-stage synthesis reaction. A polyamide-imide resin solution with...

Embodiment 1

[0073] In the first stage of synthesis, 184.5 g (0.45 moles) of BAPP, 10.0 g (0.05 moles) of 4,4'-DPE, 192.0 g (1.0 moles) of TMA, and 1000 g of NMP as a solvent were put in, and water Synthesis was carried out while discharging to the outside of the system. After cooling to 60°C while maintaining a nitrogen atmosphere, as the second stage of synthesis, 127.5 g (0.505 moles) of MDI as an aromatic diisocyanate component and 500 g of NMP as a solvent were put in and heated at 140°C. The synthesis was carried out under the following conditions, and a polyamide-imide resin insulating coating with a reduced viscosity of about 0.5 dl / g and a resin component concentration of about 25% by weight was obtained.

Embodiment 2

[0075]For the synthesis of the first stage, 143.0 g (0.35 moles) of BAPP, 30.0 g (0.15 moles) of 4,4'-DPE, 192.0 g (1.0 moles) of TMA, and 1000 g of NMP as a solvent were charged, and water was added at 180°C. Synthesis was carried out while exhausting the system, and after cooling to 60°C while maintaining a nitrogen atmosphere, as the second stage of synthesis, 127.5 g (0.505 moles) of MDI as an aromatic diisocyanate component and 450 g of NMP as a solvent were put in and heated at 140°C. The synthesis was carried out under the following conditions, and a polyamide-imide resin insulating coating with a reduced viscosity of about 0.5 dl / g and a resin component concentration of about 25% by weight was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com