Patents

Literature

110 results about "Water ph" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PH is a measurement of the acidity of your water. The lower the pH, the more acidic your water; the higher, the more alkaline. The pH of water should be 7 to be neutral.

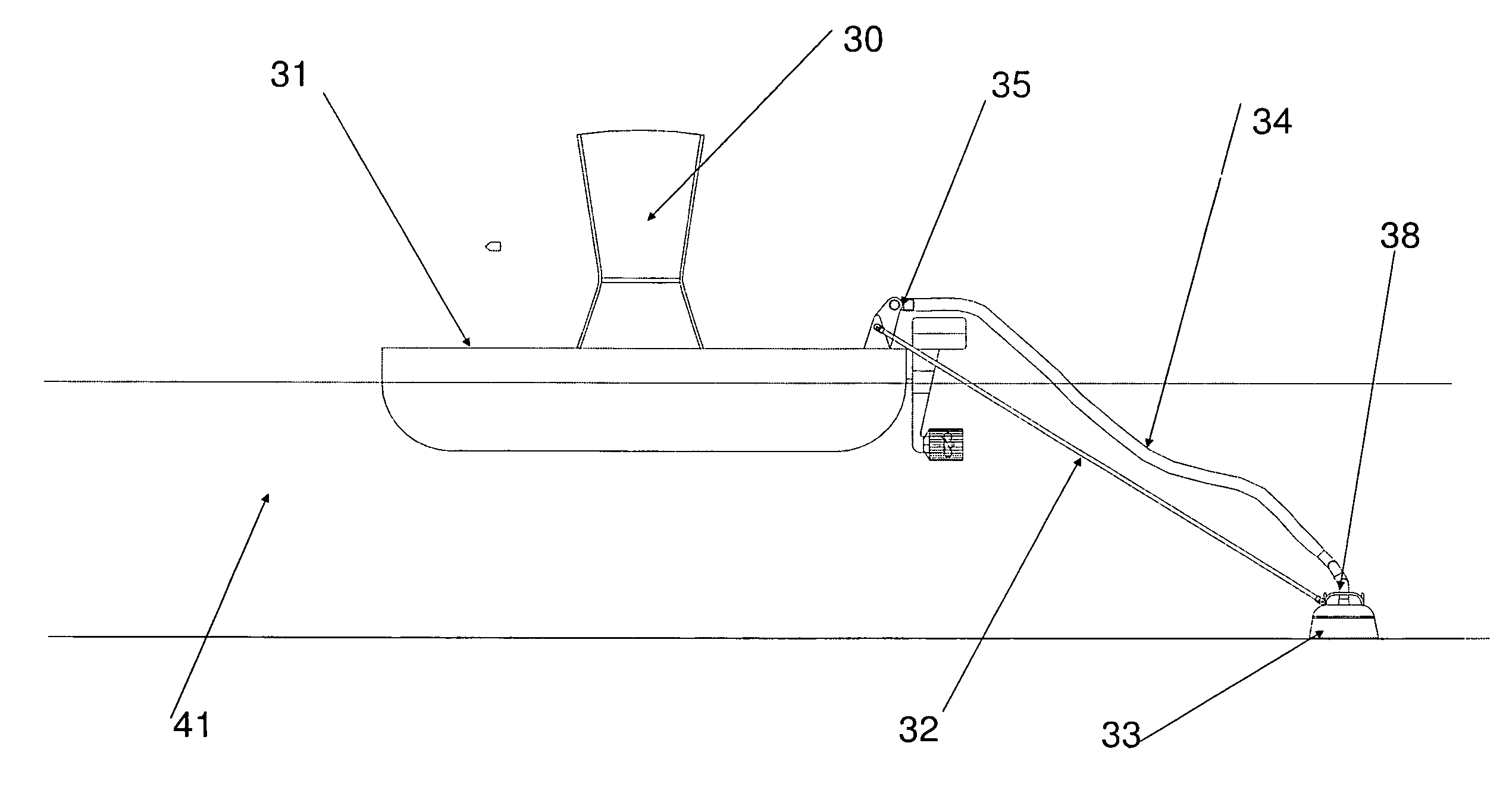

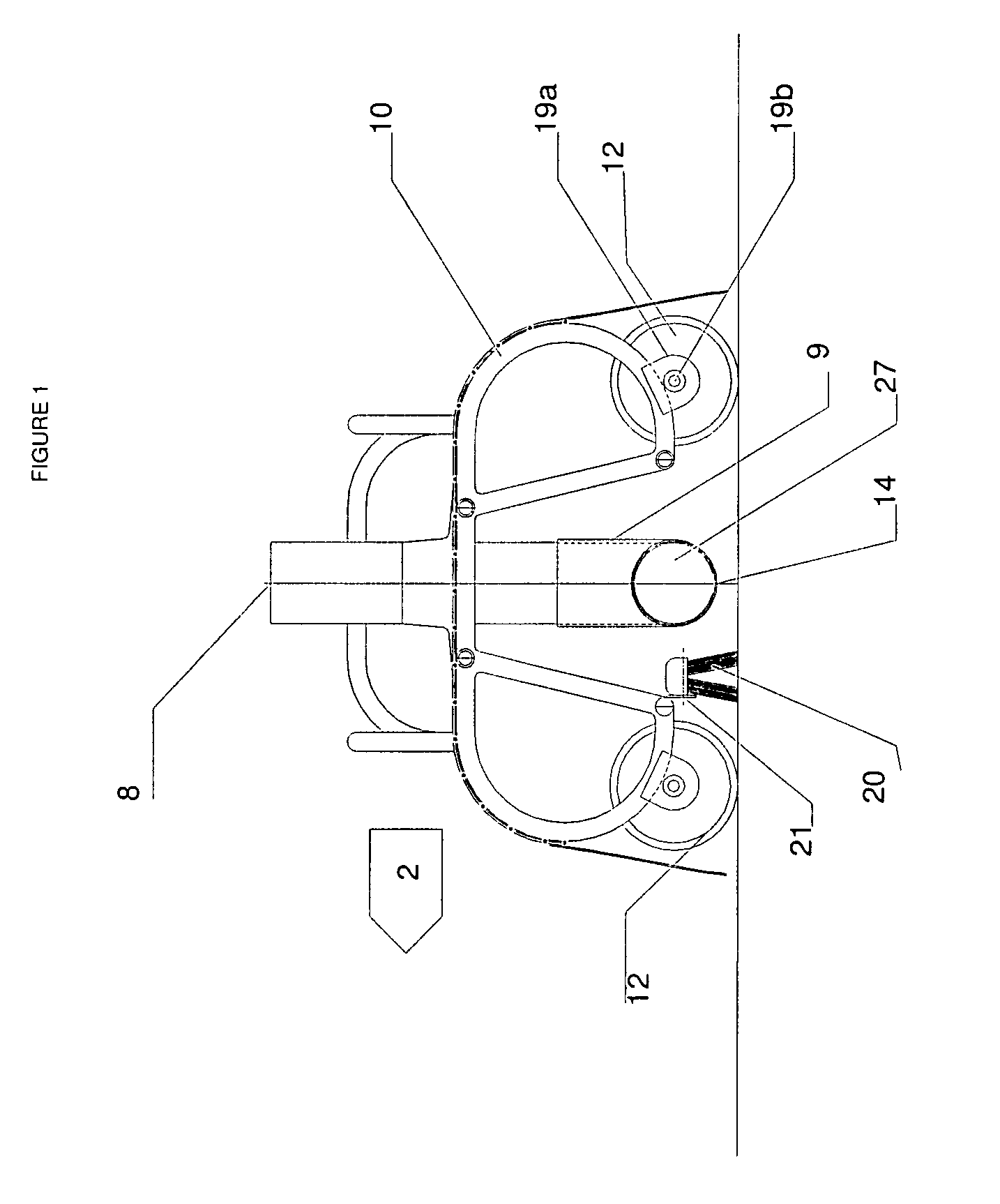

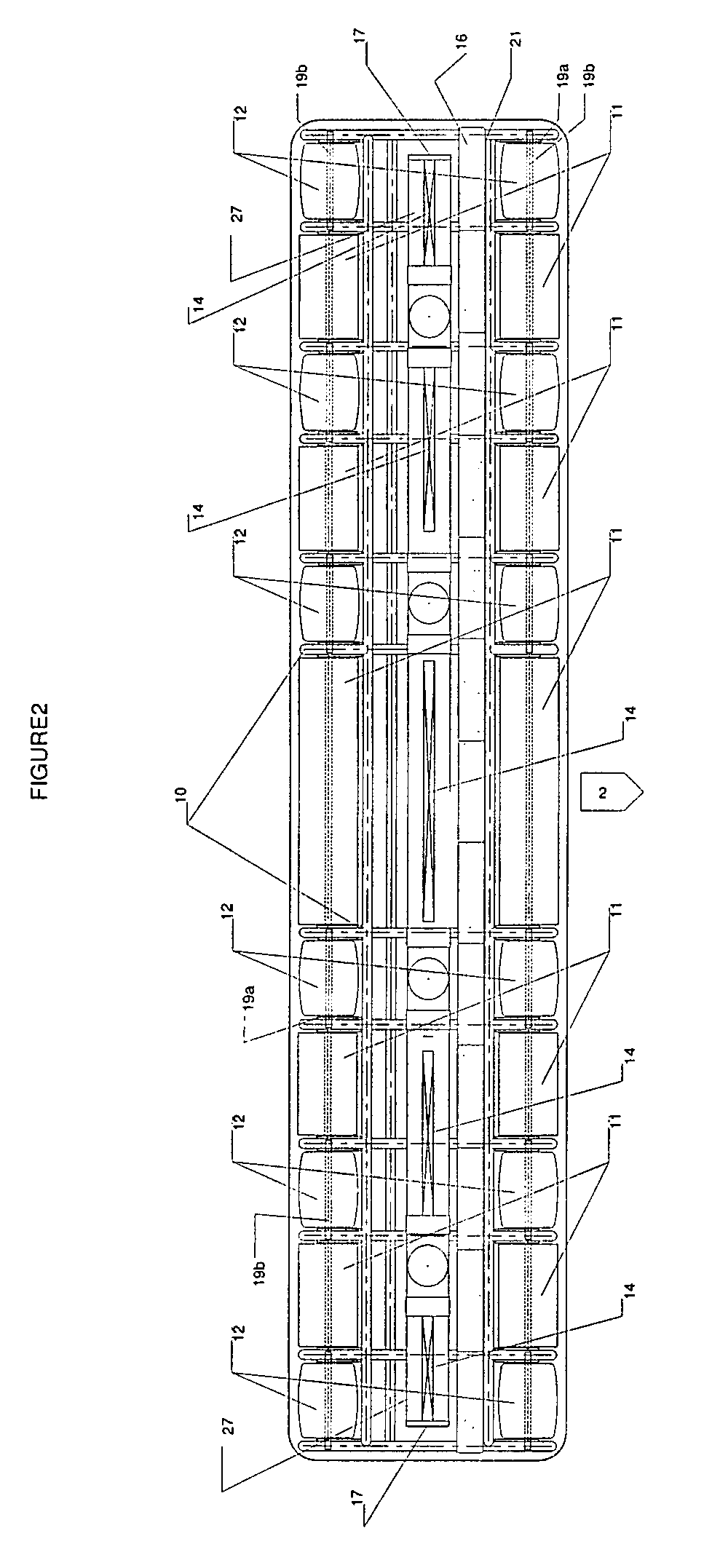

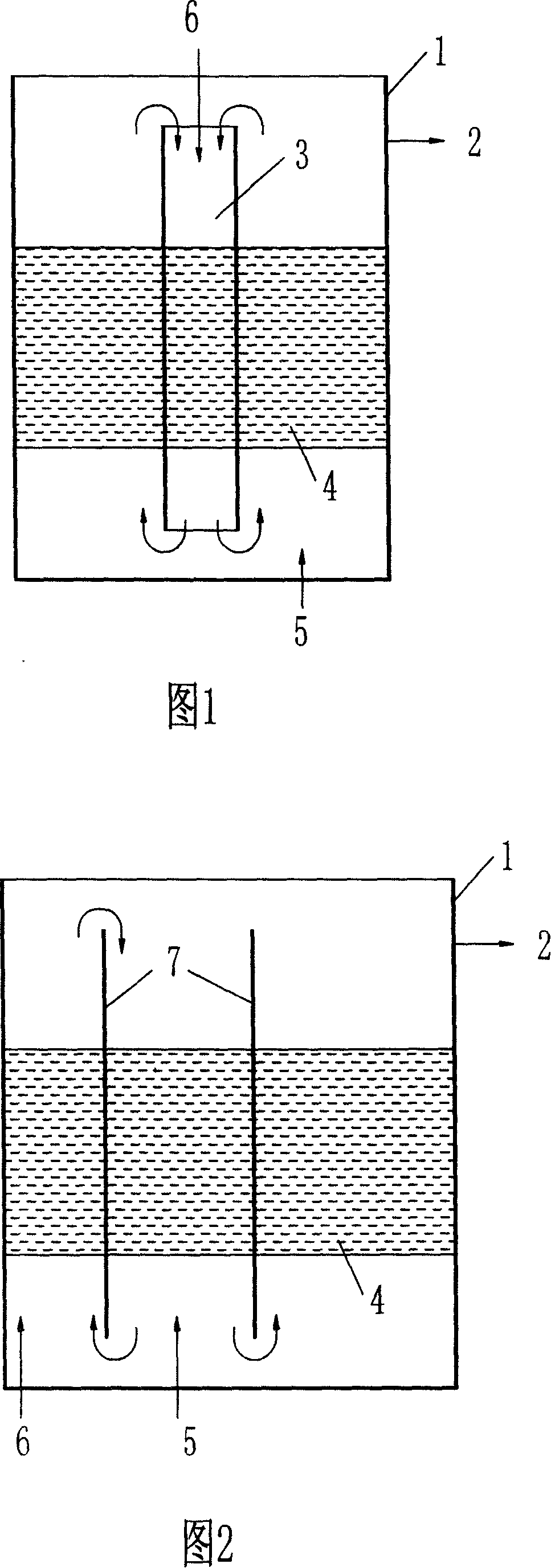

Process to maintain large clean recreational water bodies

The invention discloses a process to implement and maintain water bodies larger than 15,000 m3 for recreational use, such as lakes or artificial lagoons, with excellent color, transparency and cleanness properties at low cost, which comprises the following steps:a.—providing a structure able to contain a large water body larger than 15,000 m3;b.—feeding the structure of step (a) with inlet water having iron and manganese levels lower than 1.5 ppm and turbidity lower than 5 NTU;c.—measuring water pH, ideally it should be within a range lower than 7.8;d.—adding an oxidizing agent to the water contained in the structure of step (a), with which a 600 mV minimal ORP is controlled in water for a minimal period of 4 hours and in maximal cycles of 48 hours;e.—adding a flocculating agent in concentrations within 0.02 and 1 ppm with maximal frequencies of 6 days and cleaning the bottom of the structure of step (a) with a suction device to remove precipitated impurities from the bottom of said structure, together with the additional flocculants and;f.—generating a displacement of surface water containing impurities and surface oils by means of the injection of inlet water according to step (b), which generates said displacement in such a way to remove said surface water by means of a system for impurities and surface oils removal arranged in the structure of step (a), which together with step (e) replaces traditional filtering.The present invention also discloses a structure to contain large water bodies comprising a system for the removal of impurities and surface oils by means of skimmers and the suction device to clean said structure.

Owner:CRYSTAL LAGOONS TECH INC

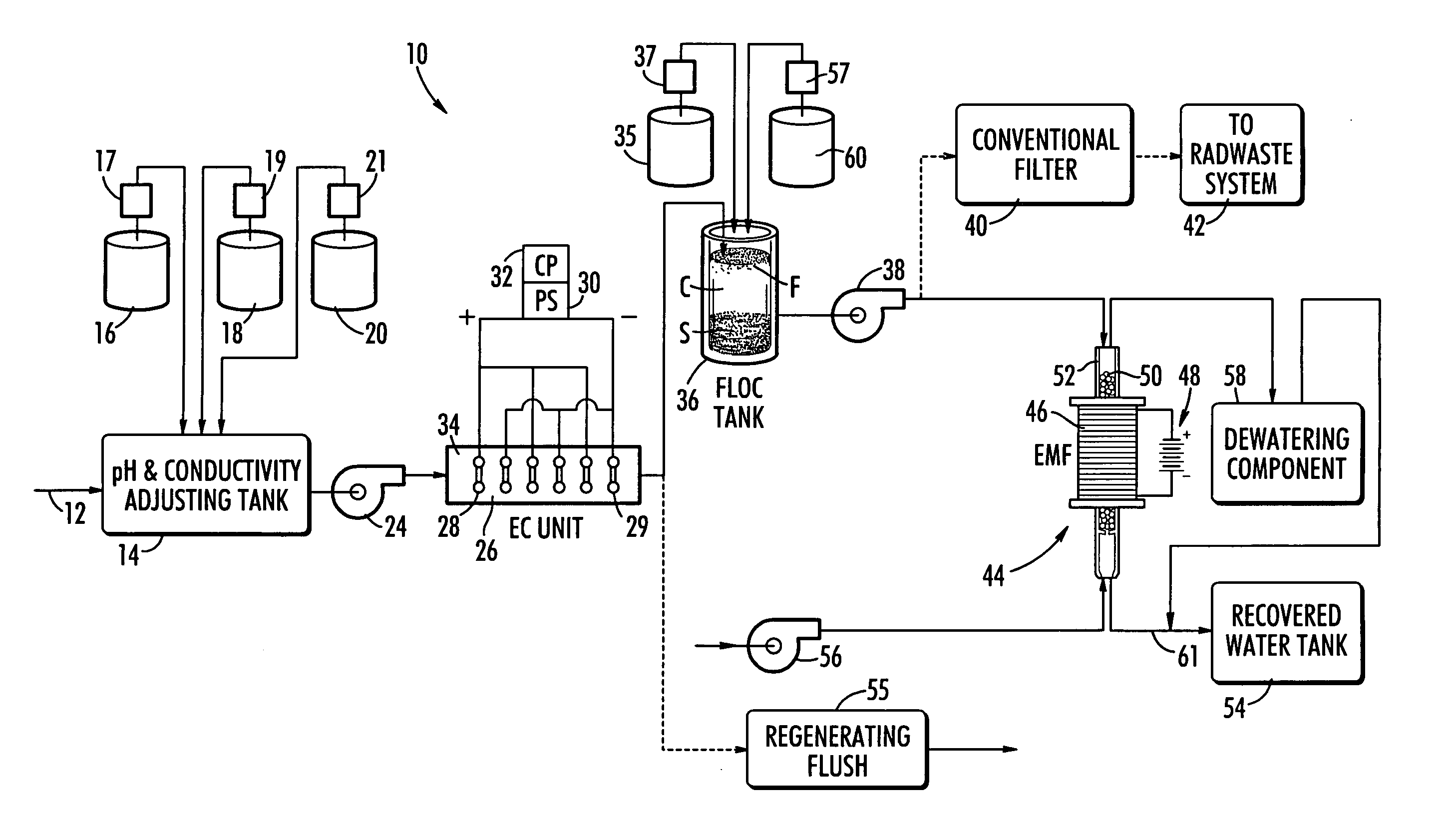

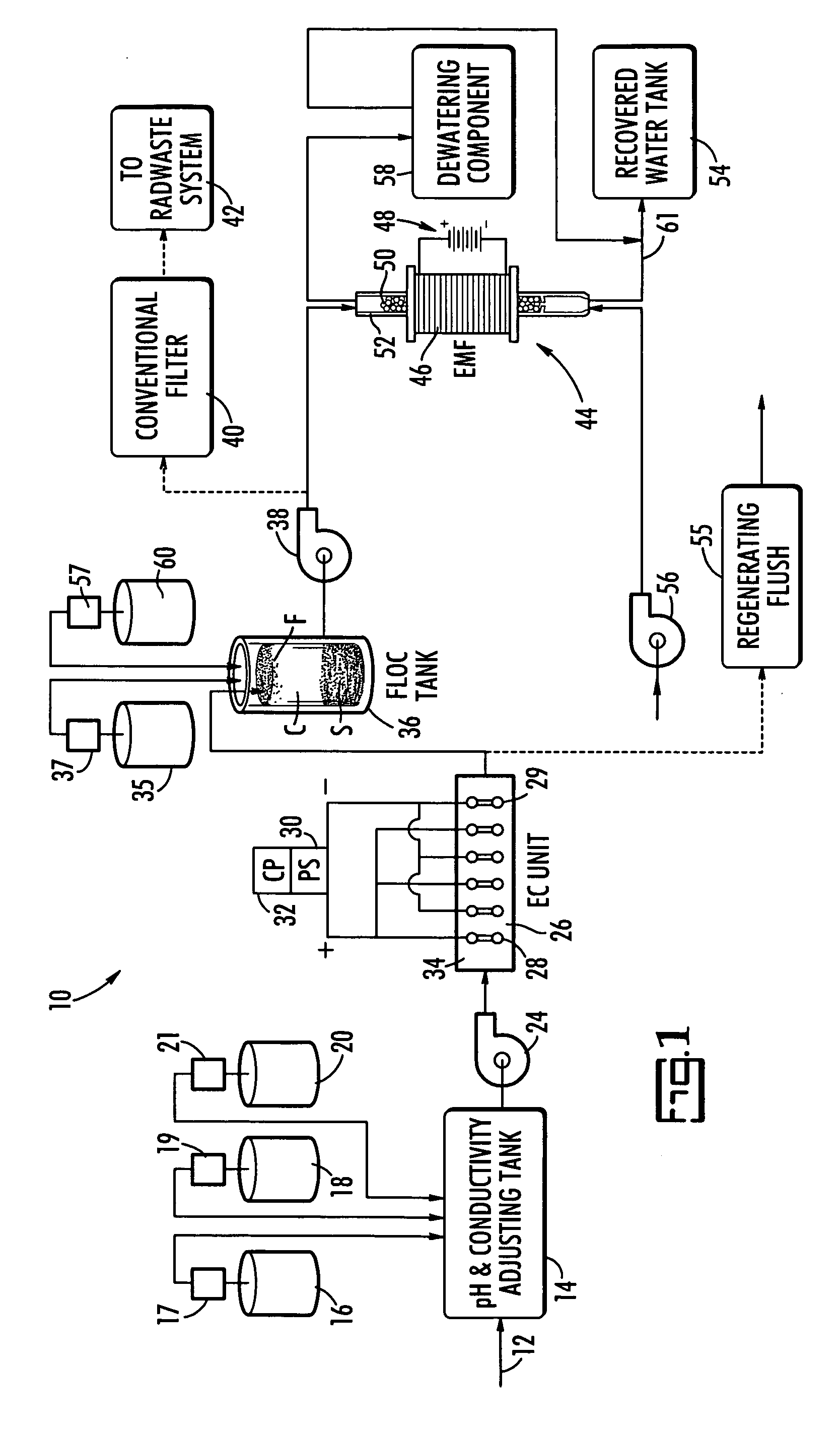

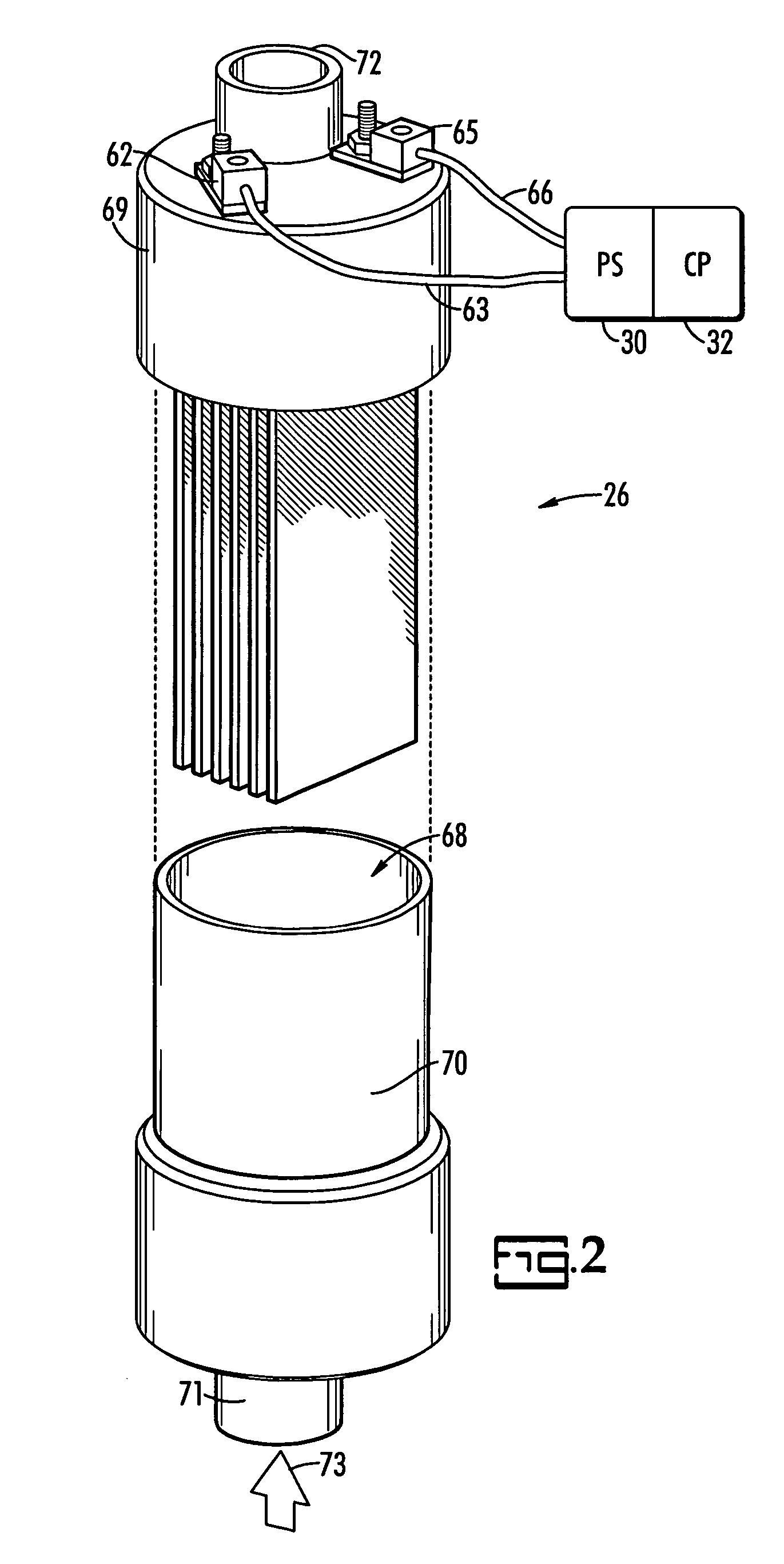

Method and system for treating radioactive waste water

ActiveUS20070131621A1Easy to useLoss in efficiencyElectrolysis componentsLiquid separation by electricityFiltrationElectro coagulation

A method and apparatus for treating radioactive waste water containing contaminating ions, colloids and suspended solids having like (usually negative) charges preventing their precipitation. An electric current is passed through the waste water in an EC assembly to cause electro-coagulation of the contaminants and anodes of this assembly are made of a metal that dissolves to provide cations for neutralizing the negative charges and forming precipitates containing neutralized contaminants. Precipitates are then separated from waste water by an electro-magnetic or other filtering unit. The water pH and conductivity may be adjusted before the EC assembly and additives may be introduced into its effluent for enlargement of precipitate particles, improvement of filtration, improvement of dewaterability, and / or enhancement of magnetism.

Owner:ENERGYSOLUTIONS LLC

Nuisance free big sized river crab ecological cultivation method

ActiveCN1568677AFull use of production potentialImprove the level of standardized farmingClimate change adaptationPisciculture and aquariaDiseaseAlkalinity

The invention relates to nuisance free large-size river crab ecological breeding method. The method comprises: exposing breeding pool in sun after drainage, fertilizing the pool, planting aquatic grass, migrating seashell for mixed breeding, determining breeding density according to a certain quality and quantity proportion, choosing uniform size ,vigorous individual, regulating and controlling the water quality, insuring oxygen content and the slight alkalinity of water pH. The pool has optimal breeding density, crabs are not influenced by disease, and antibiotics is not needed.

Owner:潘洪强 +1

Microorganism advanced treatment for oil refining waste water

ActiveCN101148293AAvoid pollutionStable waterTreatment using aerobic processesBacteriaInitial treatmentBacillus megaterium

The present invention relates to deep treating process of refinery waste water after initial treatment. Refinery waste water is deeply treated biologically with microbial flora comprising Pseudomonas sp., Zoogloea sp., Plesiomonas sp., Bacillus, Bacillus megaterium and Rhodopseudomonas globiformis in a biological aeration filtering pond and / or a bioreaction pond while controlling the intake water pH value in 6-9. The deep treating process has simple path, high safety, low power consumption, low running cost and other advantages, and the water output can reach the reuse standard stably including CODcr not more than 60 mg / l, oil not more than 2 mg / l, NH3-N not more than 2 mg / l and SS not more than 10 mg / l.

Owner:JIANGSU BODA ENVIRONMENTAL PROTECTION

Method for increasing waste water treating efficiency by improving activity of sulfate reducing bacteria

InactiveCN1458083ARaise the pHImprove adaptabilityTreatment with anaerobic digestion processesWater/sewage treatment by neutralisationSulfate-reducing bacteriaHigh activity

The present invention belongs to the waste water treating technology utilizing sulfate reducing bacteria. Upwards flowing anaerobic composite bed bioreactor and mixed sulfate reducing bacteria are used in treating acid waste water containing Cr2O72-, CrO42-, Cu2+, Zn 2+, Mn2+ and other heavy metal ions. The present invention has high activity of sulfate reducing bacteria and high waste water treating efficiency. The present invention features that inside the reactor or waste water tank, simple substance iron is added to result in waste water pH value of 5.5-8.5, and that the biochemical reaction is performed at 25-30 deg.c. The present invention has the advantages of addition of simple substance iron, raised waste water pH value, improved bacteria living environment, high metabolic activity of the bacteria, reinforced capacity of the sulfate reducing bacteria, raised bacteria adaptability and waste water treating capacity.

Owner:TIANJIN UNIV

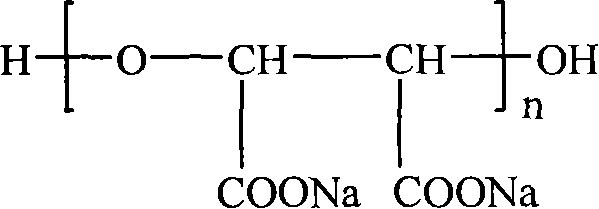

Environment-friendly type composite pre-film reagent used for recirculated cooling water system pre-film processing and method of use thereof

InactiveCN101182643AReduce total usageUse low concentrationScale removal and water softeningLiquid wasteTricarboxylic acid

The invention belongs to the circulating cooling water treatment technical field, and refers in detail to an environment-protecting composite pretreatment filming agent used for the pre-treatment filming in a circulating cooling water system and a use method thereof. The environment-protecting composite pretreatment filming agent comprises the main components of 2-phosphonobutane- 1, 2, 4-tricarboxylic acid and sodium of polyepoxysuecinic acid as well as a proper amount of carboxylic acid copolymer, benzotriazole, sodium molybdate, zinc sulphate and so on. When used, the composite pre-treatment filming agent is added into the circulating cooling water directly, and a corrosion-resistant protecting film is formed after 48 years of operation, the corrosion resistance of which to the standard copper sulphate drip solution is far better than the traditional phosphor-zinc pretreatment filming agent. The total phosphor content of the environment-protecting composite pretreatment filming agent is less than 7.5mg / l, and the water pH value does not have to be adjusted. After the pretreatment filming, the water is clear and transparent, and the normal operation can be started without replacing the water. Thus, not only the water to be replaced is saved, but also the chemical base investment expense during the normal operation after the water replacement is reduced. Meanwhile, no waste liquor of pretreatment filming is discharged, so the invention belongs to the environment-friendly pretreatment filming method.

Owner:TONGJI UNIV

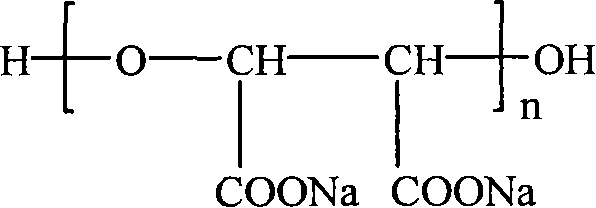

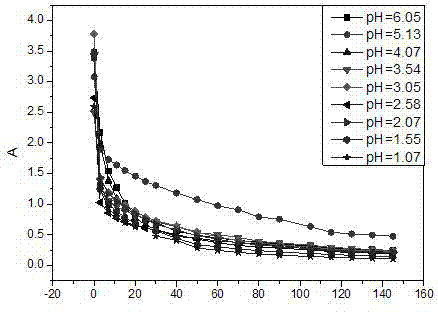

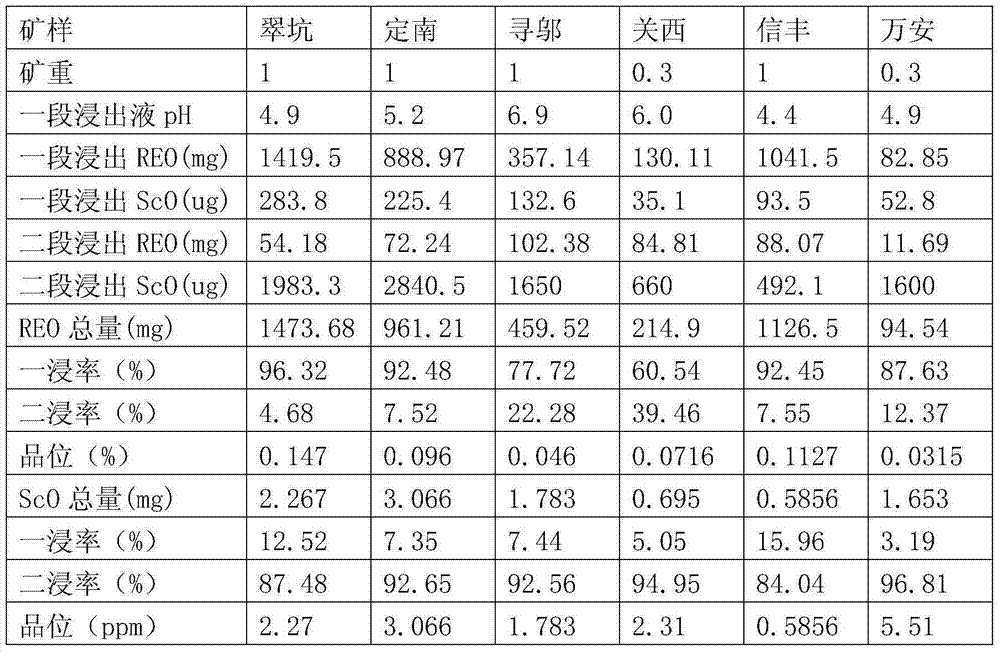

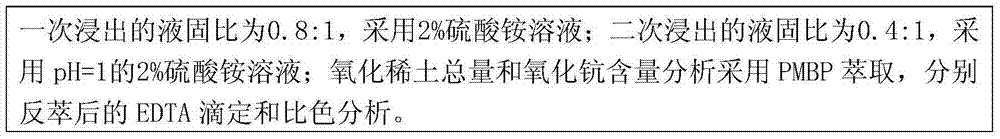

Method for improving ionic rare earth extraction rate and mine tailing safety

InactiveCN103695670AEnhanced exchange leachingImprove leaching efficiencyProcess efficiency improvementSulfateRare earth

The invention discloses a method for improving an ionic rare earth extraction rate and mine tailing safety. According to the characteristics of ionic rare earth ore, 1, most of rare earth is subjected to extraction according to a ratio of rare earth raw ore to a nearly neutral ammonium salt ore-leaching agent and then an acid sulfate ore-leaching agent is supplied so that rare earth having high leaching difficulty is extracted by leaching, rather than at the beginning, a pH value of the ore-leaching agent is adjusted to less than 4, and 2, after acid sulfate ore-leaching agent-based extraction, tailings are cared respectively by water and a lime milk aqueous solution so that residual acid in the ore is neutralized and adsorbed excess ammonium is transferred to the solution and thus ammonium residues in the tailings are reduced and an ammonium recovery utilization rate is improved. Through the method, rare earth extraction efficiency is improved by 2-30% and the rare earth extraction efficiency is related to content of difficult exchange ingredients in ore, ammonium consumption is reduced by about 20%, content of rare earth and ammonium residues in mine tailings is reduced by above 50%, and content of rare earth, ammonium, uranium and thorium in mine tail water is reduced by above 70%. The method guarantees a tail water pH value of 7 and reduces risk of landslip caused by mine tailing puffing.

Owner:NANCHANG UNIV

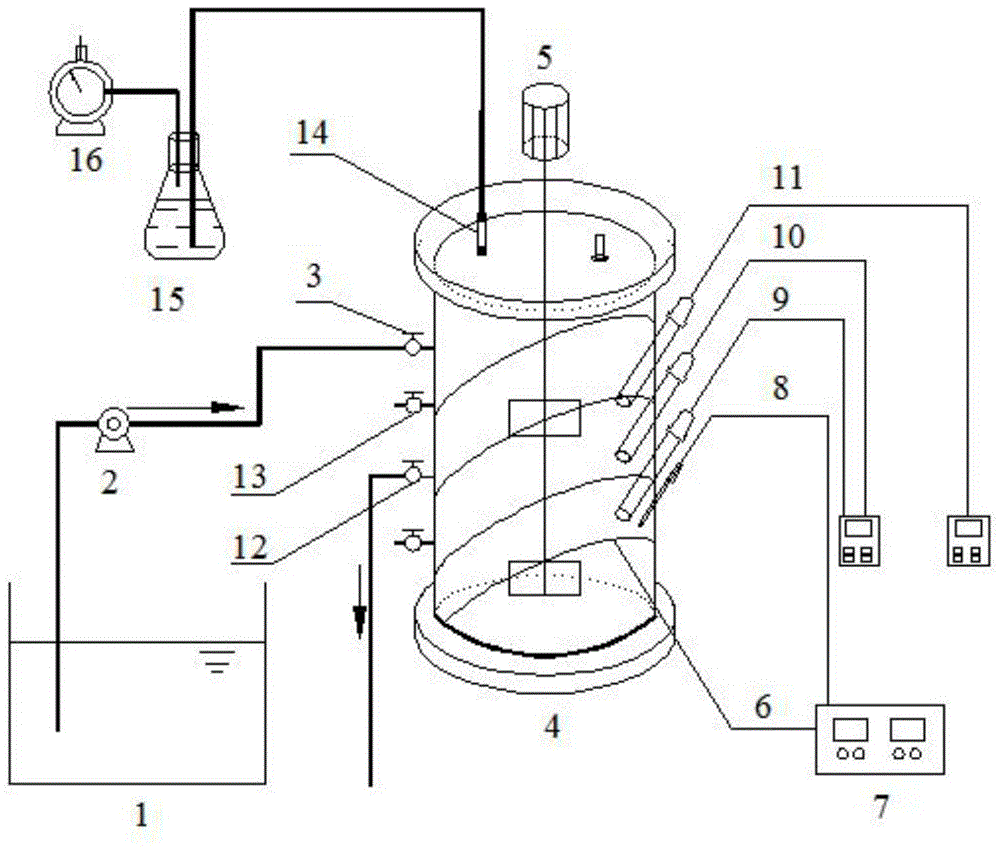

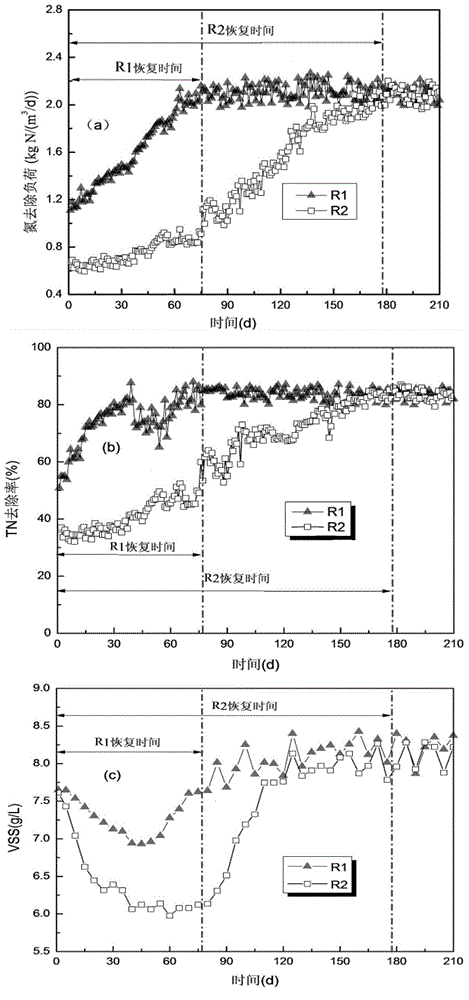

Method for relieving anaerobic ammonium oxidation system salinity shock with betaine as additive

ActiveCN104909455AShorten the timeImprove removal rateTreatment with anaerobic digestion processesBetaineSludge

The invention relates to a method for relieving anaerobic ammonium oxidation system salinity shock with betaine as an additive. According to the invention, a successfully started anaerobic ammonium oxidation SBR reactor is used for processing salt-containing wastewater, wherein a volatile suspended sludge concentration is maintained at 6-9g / L, an inlet water NH4<+>-N concentration is 180-220mg / L, and the molar ratio of NH4<+>-N to NO2<->-N is controlled at 1:1-1:1.32 through adding (NH4) 2SO4 and NaNO2; the betaine concentration in the reactor is maintained at 0.1-5mmol / L through adding betaine; with a heating band, the temperature of the reactor is controlled at 30-35 DEG C; DO is controlled at 0-0.1mg / L; inlet water pH is stabilized at 7.0-8.5 through dropping NaOH / HCl; anoxic stirring is carried out for 4-8h after water feeding; when stirring is finished, the material is allowed to stand and to precipitate; when precipitation is finished, a supernatant is discharged. With the method provided by the invention, anaerobic ammonium oxidation activity recovery time when the anaerobic ammonium oxidation system is under salinity load shock can be effectively shortened, nitrogen removal rate can be improved, and a higher total nitrogen removal rate can be realized.

Owner:BEIJING UNIV OF TECH

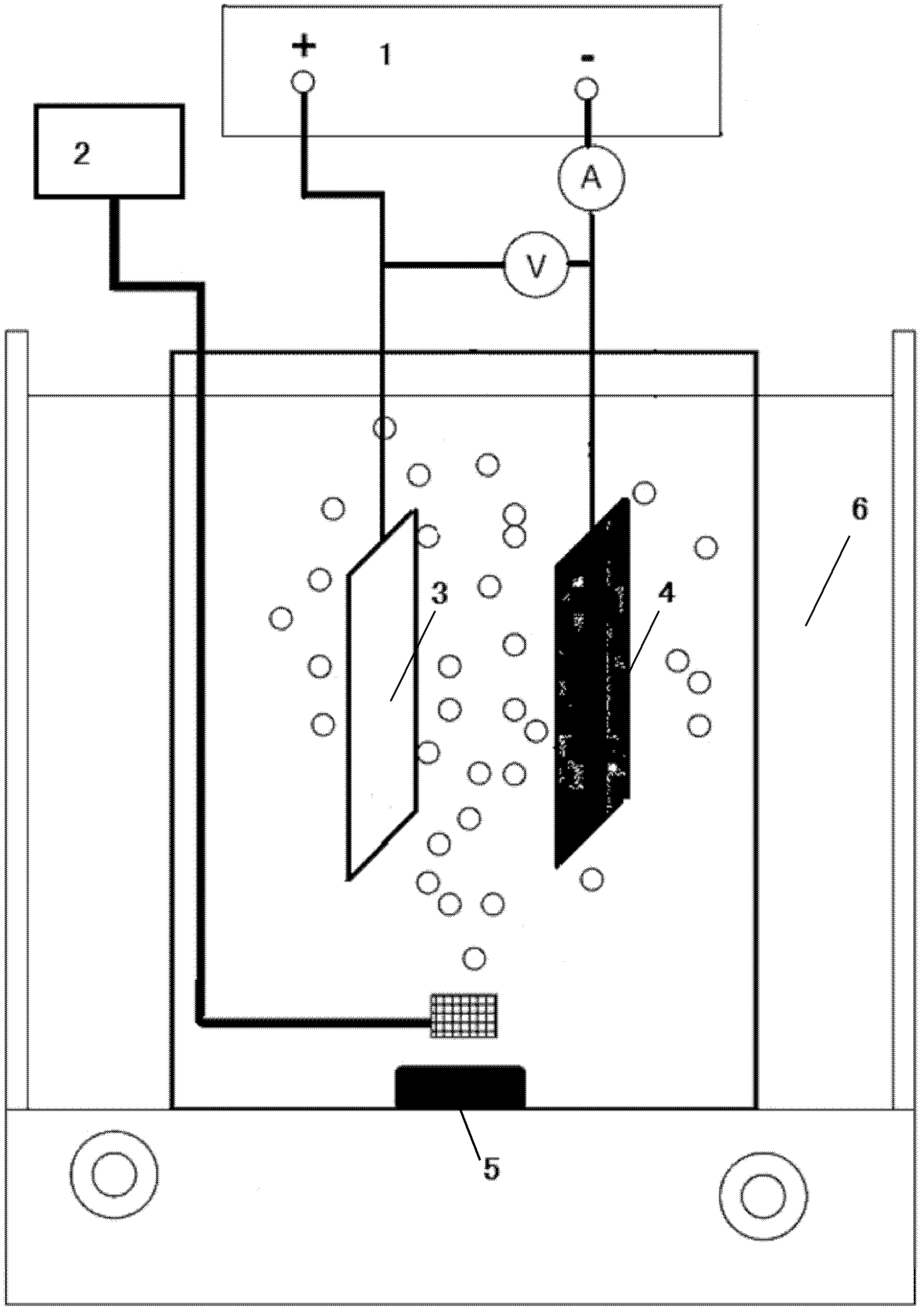

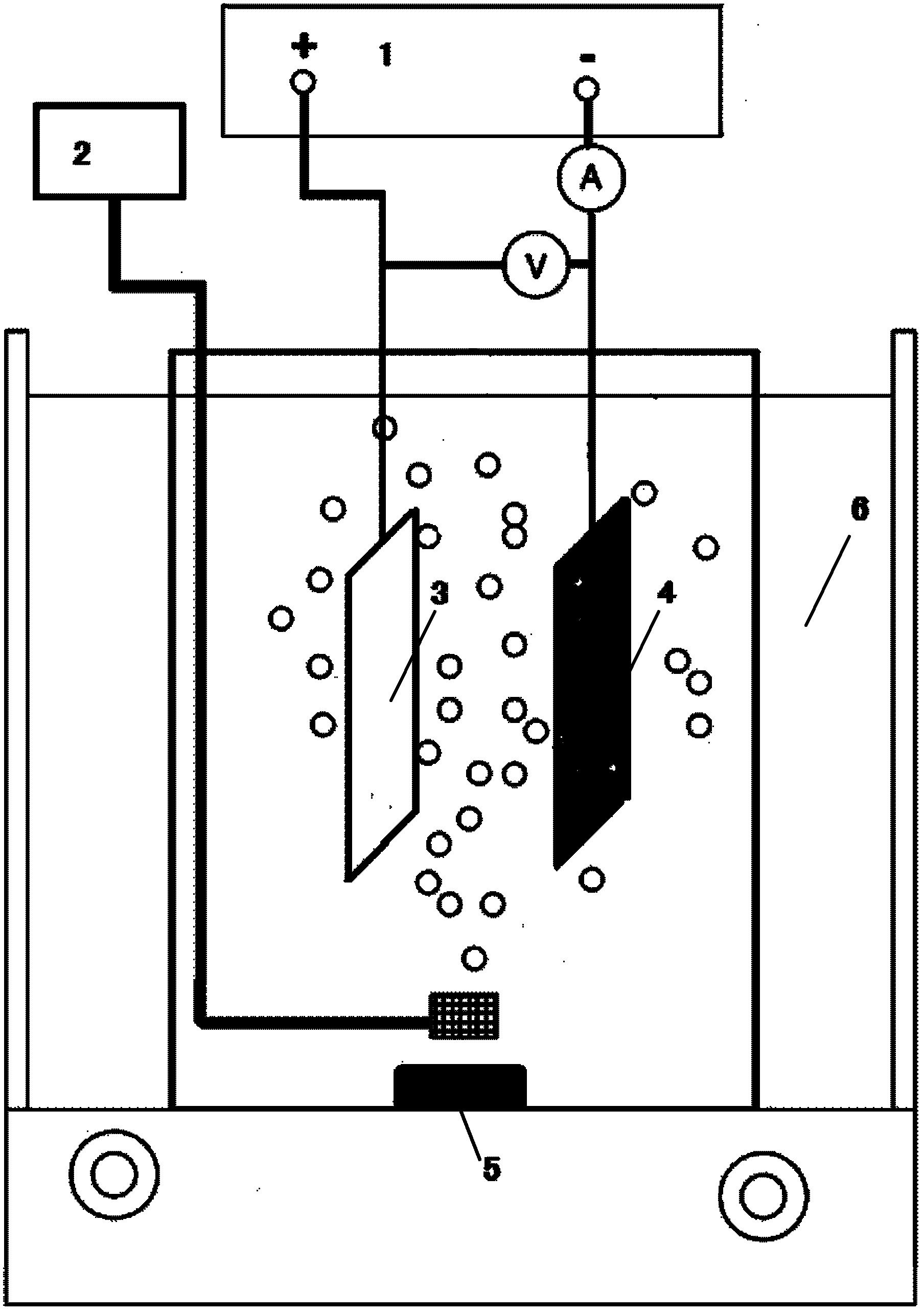

Semi-coke waste water pretreatment method based on Electro-Fenton oxidization technology

InactiveCN102633322AAvoid the danger of storage and transportationImprove degradation efficiencyWater/sewage treatmentPretreatment methodElectrolysis

The invention provides a semi-coke waste water pretreatment method based on a Electro-Fenton oxidization technology, which comprises the steps of: using an efficient graphite gas diffusion electrode as a cathode, and using a stainless steel plate as an anode to form an electrochemical oxidization system, controlling such conditions as current density, pole plate distance, waste water pH value andventilatory capacity, to enable the filled air to generate hydrogen peroxide in the cathode region, and forming a Fenton reagent through the Fe<2+> generated by anode electrolysis so as to generate ahydroxyl radical with strong oxidability to oxidize and degrade the organic pollutants, greatly reduce the waste water COD (chemical oxygen demand), improve the biodegradability of the waste water inthe successive processing process, fully remove the pollutants and improve the removal rate; and the pretreatment method provided by the invention is also suitable for the electrolytic treatment process of non-biodegradable organic waste water of spinning, dyeing and the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Feed and management technique of Penaeus vannamei Boone

InactiveCN101715746AGrow fastIndividual bigClimate change adaptationPisciculture and aquariaEcological environmentPrawn

Cultured Penaeus vannamei Boone has the advantages of high growth speed, strong adaptability and high yield and becomes one of the main cultured varieties in northern areas of China. (1) pond water color control: the ideal color of water for culturing the Penaeus vannamei Boone is yellow green or yellow brown formed by green algae or diatoms; the algae or diatoms are benign biocenosis in the micro-ecological environment of a pond and play a role of purifying water quality; (2) control of pond water pH value, dissolved oxygen and transparency: the pH value suitable for the Penaeus vannamei Boone is 7.8-8.5, but the peak value of 9.2 is generated at the middle and final stages culturing, and therefore, the pH value control is especially focused in the culturing process; the pH value is not suitable to be high, otherwise, the toxicity of ammonia nitrogen can be increased, thereby restraining the growth of the Penaeus vannamei Boone; (3) scientific bait casting: generally, low-cost iced fish cream or small shells are fed, and some formula feeds are also fed; the formula feeds can be manually compounded; the formula feeds contain the following components: 17 percent of fish meal, 40 percent of soya-bean cake, 28 percent of bran, 10 percent of wheat middling, 3 percent of bone meal and 2 percent of additive; and (4) pond patrol: the pond is patrolled in the morning, at night and in the midnight every day to observe the water color change and whether Penaeus vannamei Boone raise above water to breathe or not; the activity condition, the growth condition and the repletion rate of the Penaeus vannamei Boone are observed by adopting two methods of lamplight observing and spoon-net inspection so as to regulate the bait casting amount and decide whether to start an oxygen-enriching machine or not.

Owner:刘瀚昌

Pretreatment of industrial wastewater with high concentration and of difficult degradation

InactiveCN1680199AEasy to collectEasy to superviseWater/sewage treatment by irradiationMultistage water/sewage treatmentHigh concentrationPretreatment method

A pretreatment method for hardly degradable high-concentration industrial waste water consists of pH value regulation, oxidization, coagulation and separation. It is characterized by combining each of treatment to form integrated pretreatment according to the order of regulating waste water pH value. It is carried out by chemical oxidizing, photolytic oxidizing and microelectrolytic decomposing at pH 2-4, air float separating tailing at pH 6-7, and coagulating separating settling at pH 8-9. The treatment of every unit is combined by initial pH value of waste water. It achieves higher biological degradability.

Owner:陈平

Anoxybiotic/aerobic two-section internal electrolysis organic waste water treating method

InactiveCN1935681AReduce concentrationImprove hydrophobicityWater/sewage treatmentTreatment with aerobic and anaerobic processesActivated carbonElectrolysis

The invention relates to an anoxic / aerobic, two-stage, internal- electrolysis organic waste water treating method, fully mixing iron chips and activated carbon / copper chips in a certain mass ratio, and placing their mixture into a reactor, regulating waste water pH value and then adding the waste water into the reactor in the fixed solid-liquid ratio, firstly making anoxic internal electrolysis reation for a certain period of time and then making aerobic reaction for a certain period of time, adding alkali in the effluent water to make mixing coagulation settlement and discharging supernatant. And the treating mode can adopt a single- groove static flow mode or double-groove continous flow mode. And it fully uses redox reaction to degrade organic matters, and has stronger ability to degreade organic matters difficult to degrade and more remarkable decoloring effect.

Owner:SHANGHAI JIAO TONG UNIV

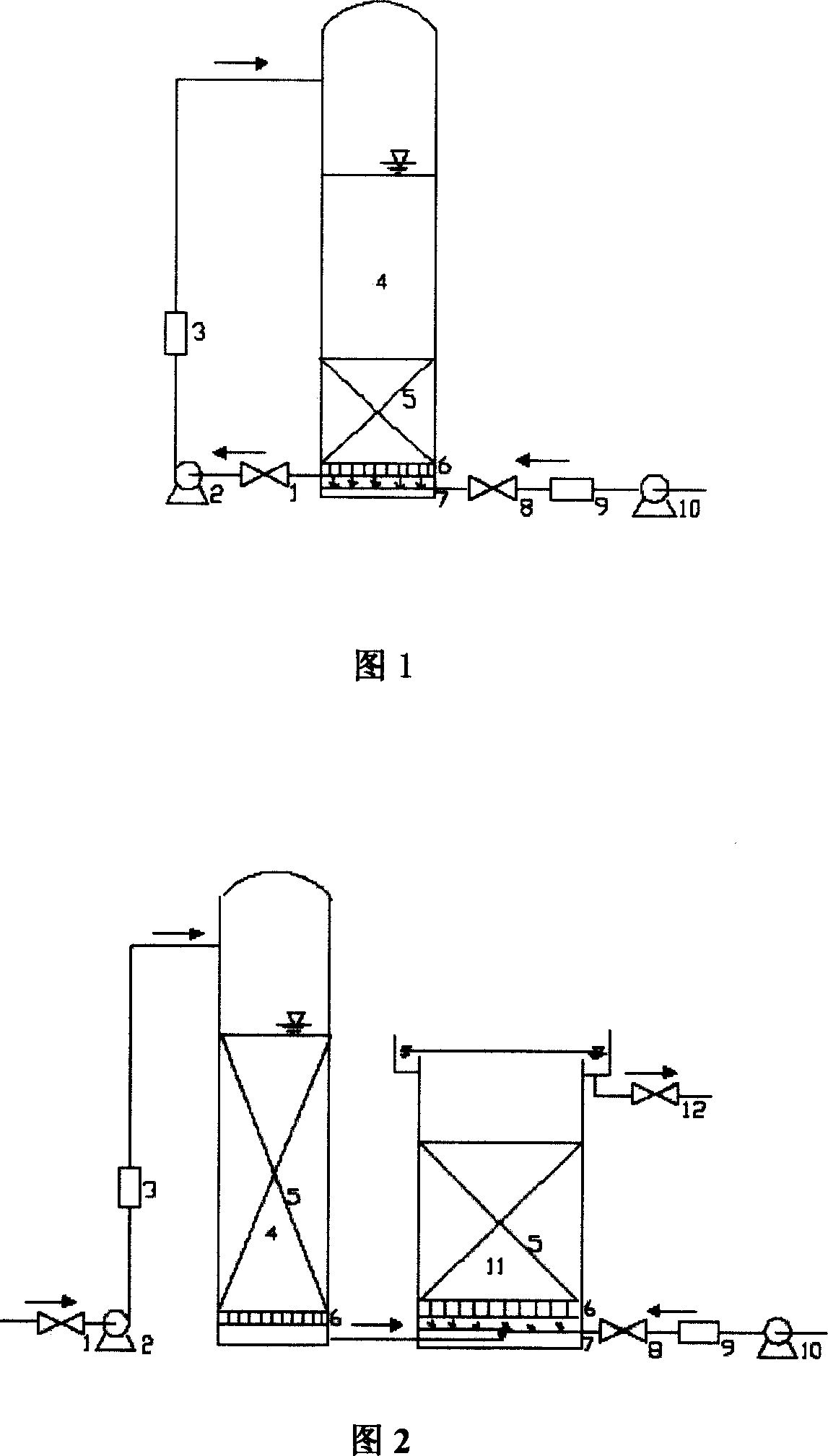

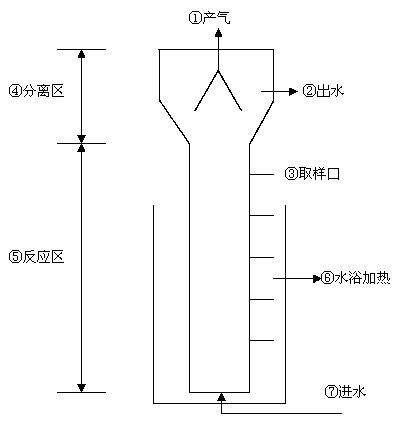

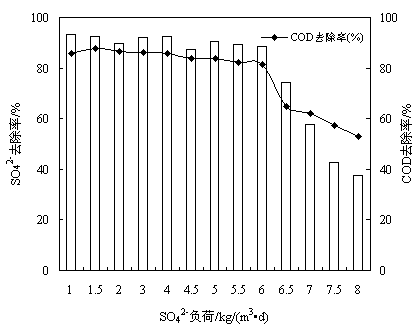

Anaerobic biological treatment method of heat-engine plant desulphurization waste water

InactiveCN103739065AImprove running stabilityEfficient removalWaste based fuelTreatment with anaerobic digestion processesChemical treatmentChemical oxygen demand

The invention provides an anaerobic biological treatment method of heat-engine plant desulphurization waste water, and relates to the field of heat-engine plant wet flue gas desulfurization waste water treatment. A sulfate reducing bacteria (SRB) anaerobic biological treatment method is used for treatment of the heat-engine plant desulphurization waste water, SO4<2-> is reduced into H2S by use of SRB, dissolved form S<2-> reacts with heavy metals in the waste water to produce a sulfide precipitate meanwhile to achieve the purposes of removal of the SO4<2-> and the heavy metals in the waste water and improvement of discharged water pH value. By the sulfate reducing bacteria (SRB) anaerobic biological treatment method, up-to-standard release of the SO4<2->, the heavy metals, COD (chemical oxygen demand) and the discharged water pH value of the desulphurization waste water can be realized. The anaerobic biological treatment method is simple in technology process and high in sulfate and heavy metal removal efficiency, and can significantly improve the discharged water pH value, effectively solves the problems of complex operation, high treatment cost, low tendency to cause secondary pollution and the like of a traditional physical and chemical treatment method, and has good economic and environmental benefits.

Owner:JILIN ELECTRIC POWER RES INST LTD +2

Efficient treatment method for electroplating nickel-containing waste water

InactiveCN105800841AAvoid secondary pollutionEasy to operateWaste water treatment from metallurgical processMultistage water/sewage treatmentWastewaterWater ph

The invention discloses an efficient treatment method for electroplating nickel-containing waste water.The method comprises the following steps that 1, under the acidic condition, the electroplating nickel-containing waste water is subjected to a microelectrolysis reaction in a microelectrolysis reactor till the pH value of the electroplating nickel-containing waste water ranges from 4.0 to 5.0; 2, an oxidizing agent is added, and the electroplating nickel-containing waste water is subjected to secondary microelectrolysis in the microelectrolysis reactor continuously; 3, an alkaline solution is added, and the pH value of the electroplating nickel-containing waste water ranges from 9.5 to 11.0; 4, coagulant and flocculant are added to the electroplating nickel-containing waste water in sequence for coagulating sedimentation, and final supernate is treated waste water capable of being discharged.The efficient treatment method for the electroplating nickel-containing waste water is easy to operate and stable in effect, chemicals such as a heavy metal chelating agent and sodium sulfide which are bad for the environment do not need to be added, and secondary pollution to environment is avoided; the occupied area is saved, the requirements on reaction conditions are low, the waste water pH can be increased in the reaction process, the alkali quantity needed by follow-up alkali adjustment is decreased, and a product obtained through treatment can be recycled.

Owner:李小琴

Preparation method and application of load-type metal phthalocyanine catalyst

InactiveCN101804361ASimple methodLow costOrganic-compounds/hydrides/coordination-complexes catalystsWater/sewage treatmentVolumetric Mass DensityPhthalocyanine

The invention discloses a preparation method of load-type metal phthalocyanine catalyst, comprising: directly dipping a molecular sieve into phthalocyanine aqueous solution of which the molar volume density is 10-500 mu mol / L; adjusting the pH value to be 10-12; dipping at room temperature; stirring at interval; and centrifuging and drying to prepare the load-type metal phthalocyanine catalyst. The invention discloses an application of the catalyst in removing organic pollutants in water. The load-type metal phthalocyanine catalyst prepared with the invention has simple method, environment protection and low cost, the catalytic activity thereof is far higher than that of unloaded phthalocyanine catalyst, and the reaction condition is moderate and is not limited by waste water pH value. The load-type metal phthalocyanine catalyst does not generate secondary pollution, can be used for oxidation treatment of organic waste water systems and has industrial application prospect.

Owner:ZHEJIANG UNIV

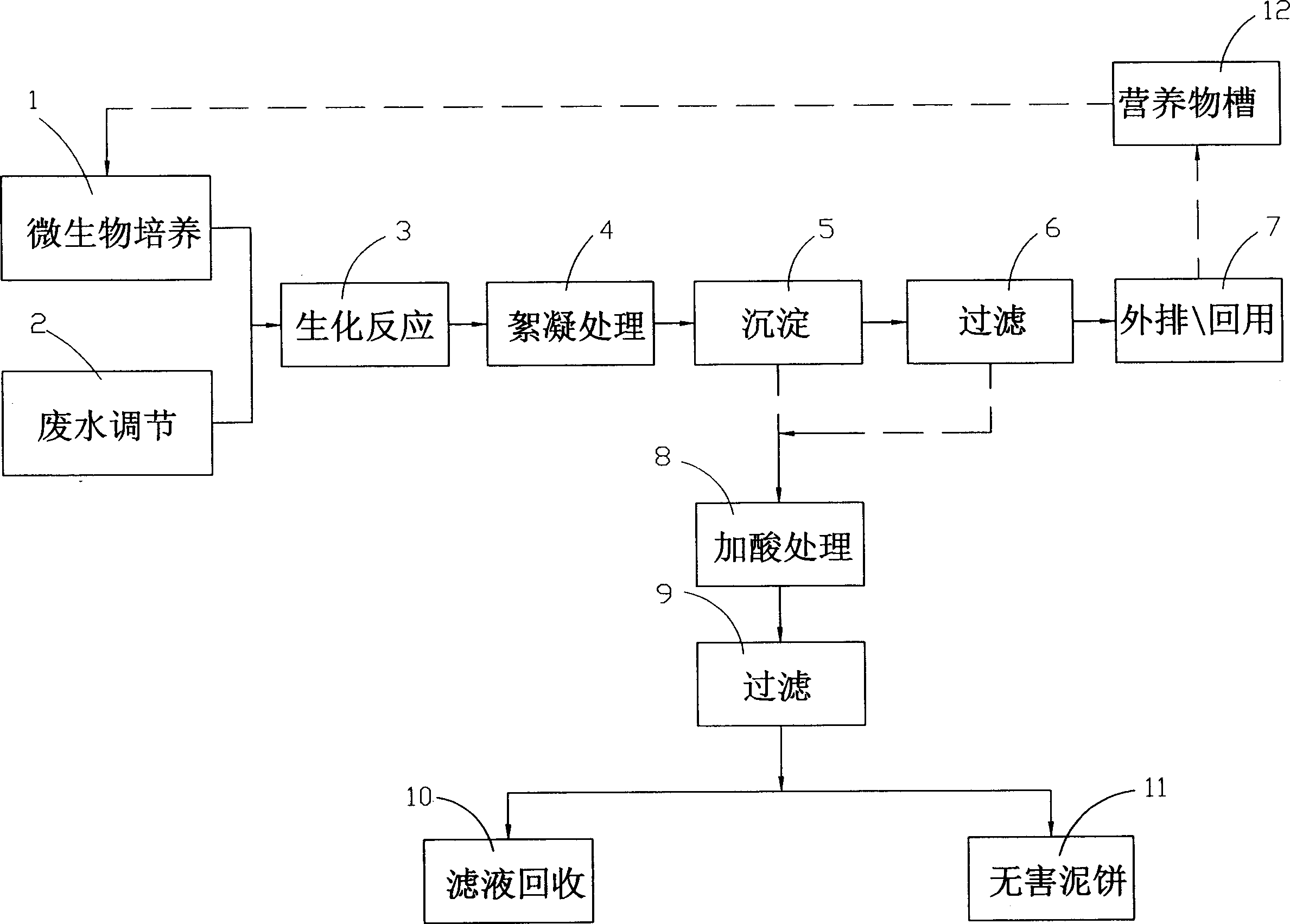

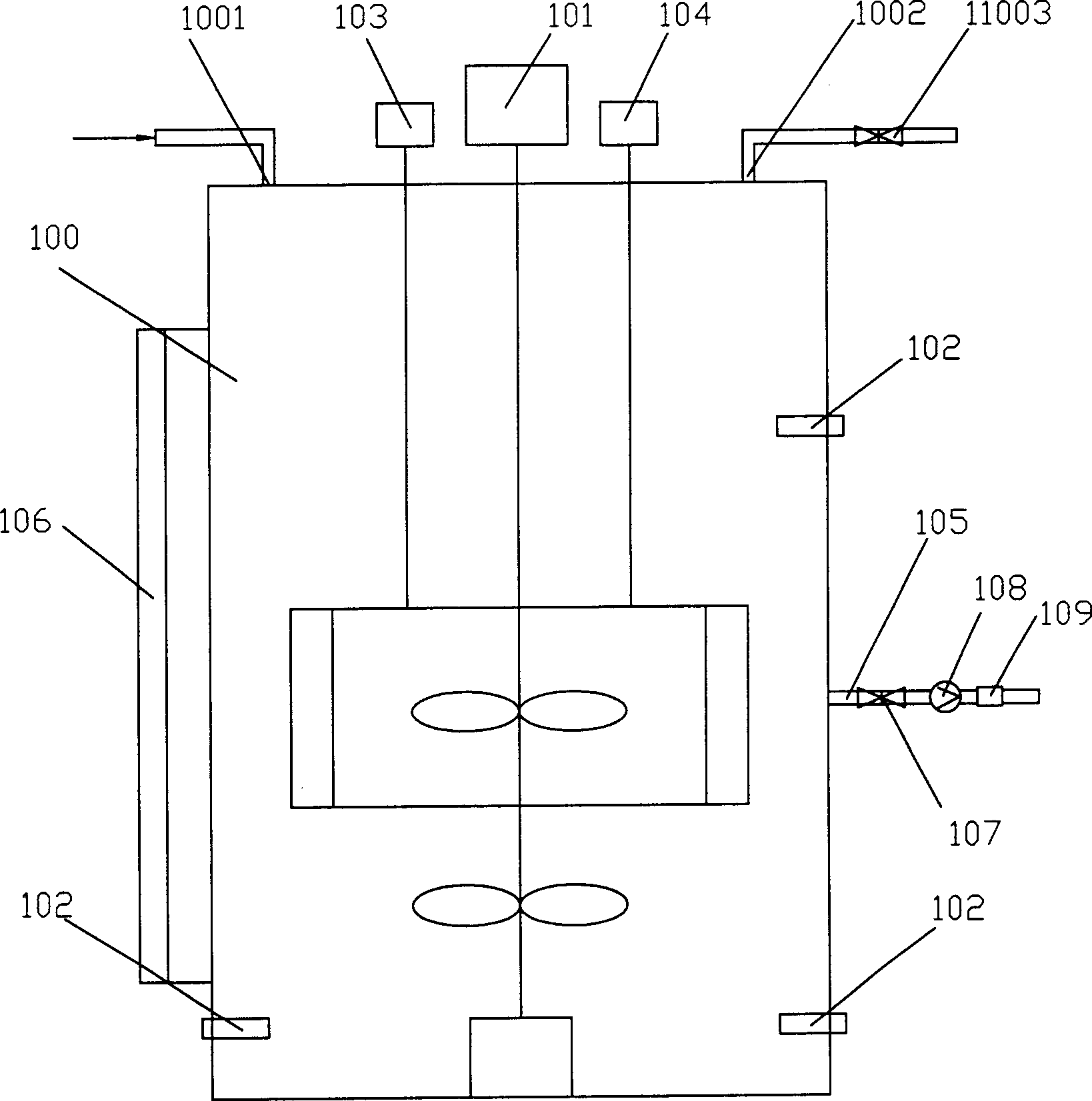

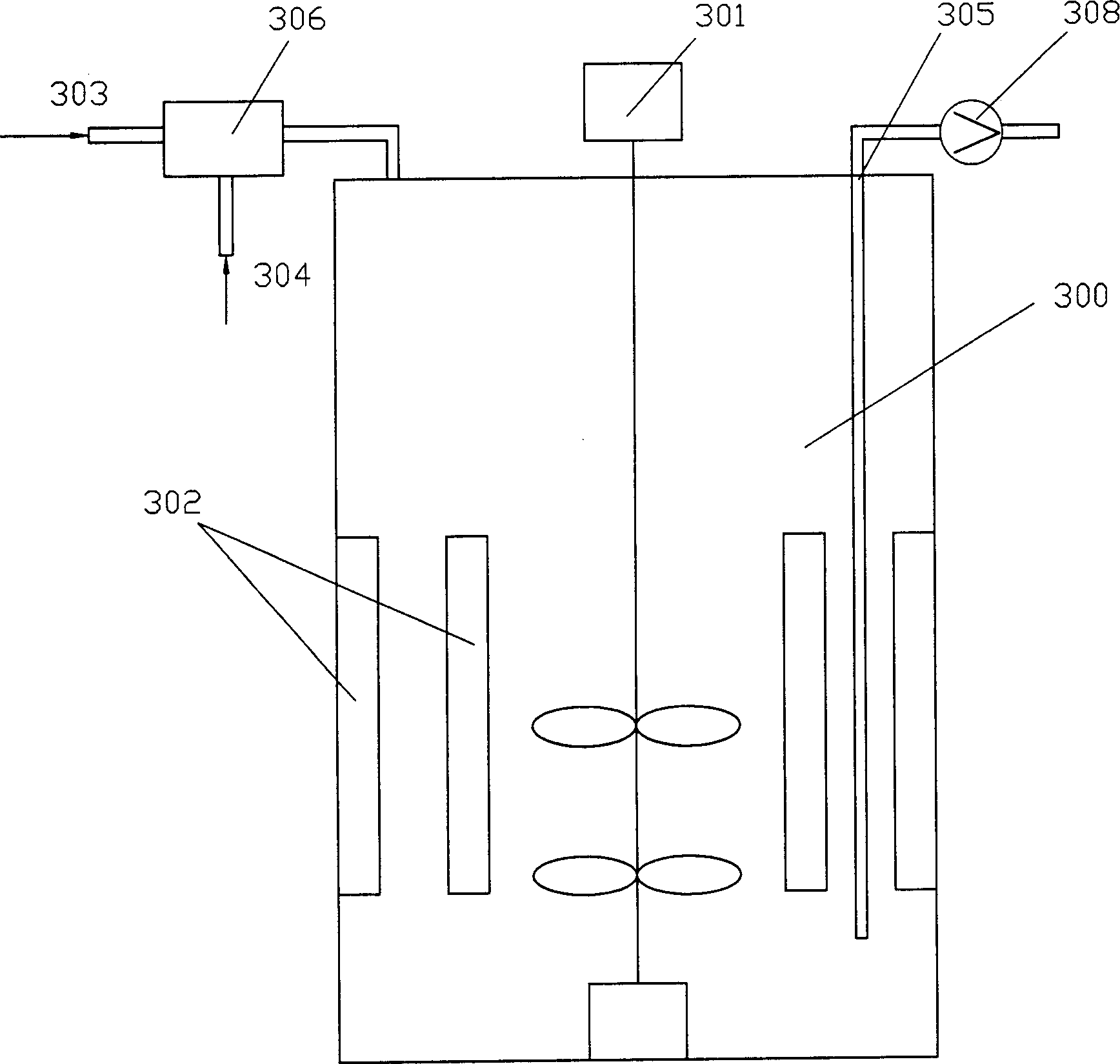

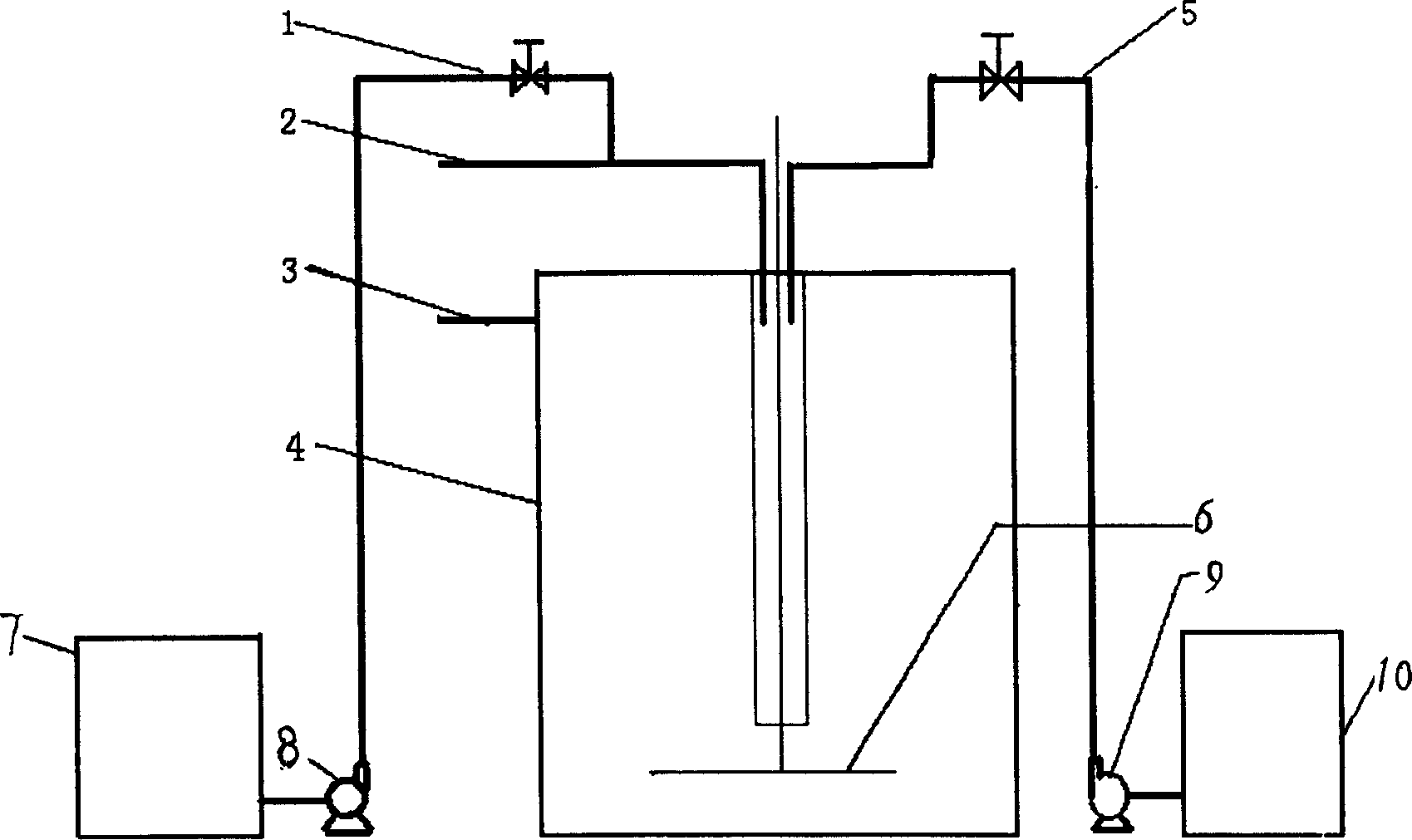

Technique and equipment for treating waste liquor containing high concentration chromium by microorganisms

InactiveCN1689982ARealize resourcesReduce energy consumptionBiological water/sewage treatmentHigh concentrationLiquid waste

The microbe treating process of high concentration chromium containing waste water includes culturing microbe in culture medium containing C, N and P in the ratio of 100 to 1-5 to 0.1-1 at temperature of 15-50 deg.c pH 7-8 and growth period of 24-48 hr; controlling the waste water pH value in 2-4; mixing waste water with microbial liquid for biochemical reaction for 30 min, flocculating with PAM flocculating agent, depositing to separate, filtering, and draining or reusing; and treating separated sludge with acid, filtering and draining or recovering. The said process makes the high concentration chromium containing waste water reach the draining standard while recovering Cr, Zn, Fe and other metals.

Owner:BAOSHAN IRON & STEEL CO LTD +1

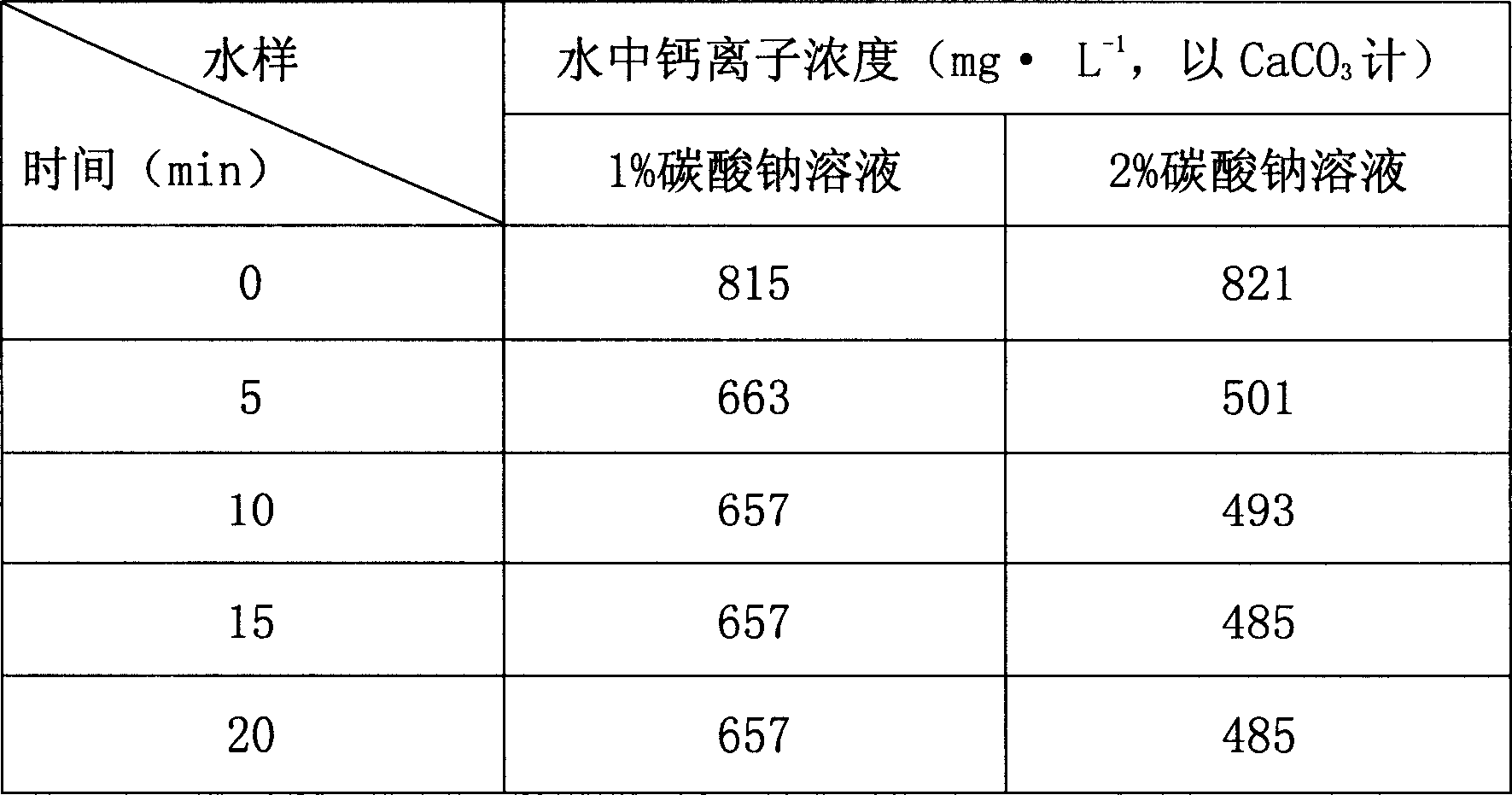

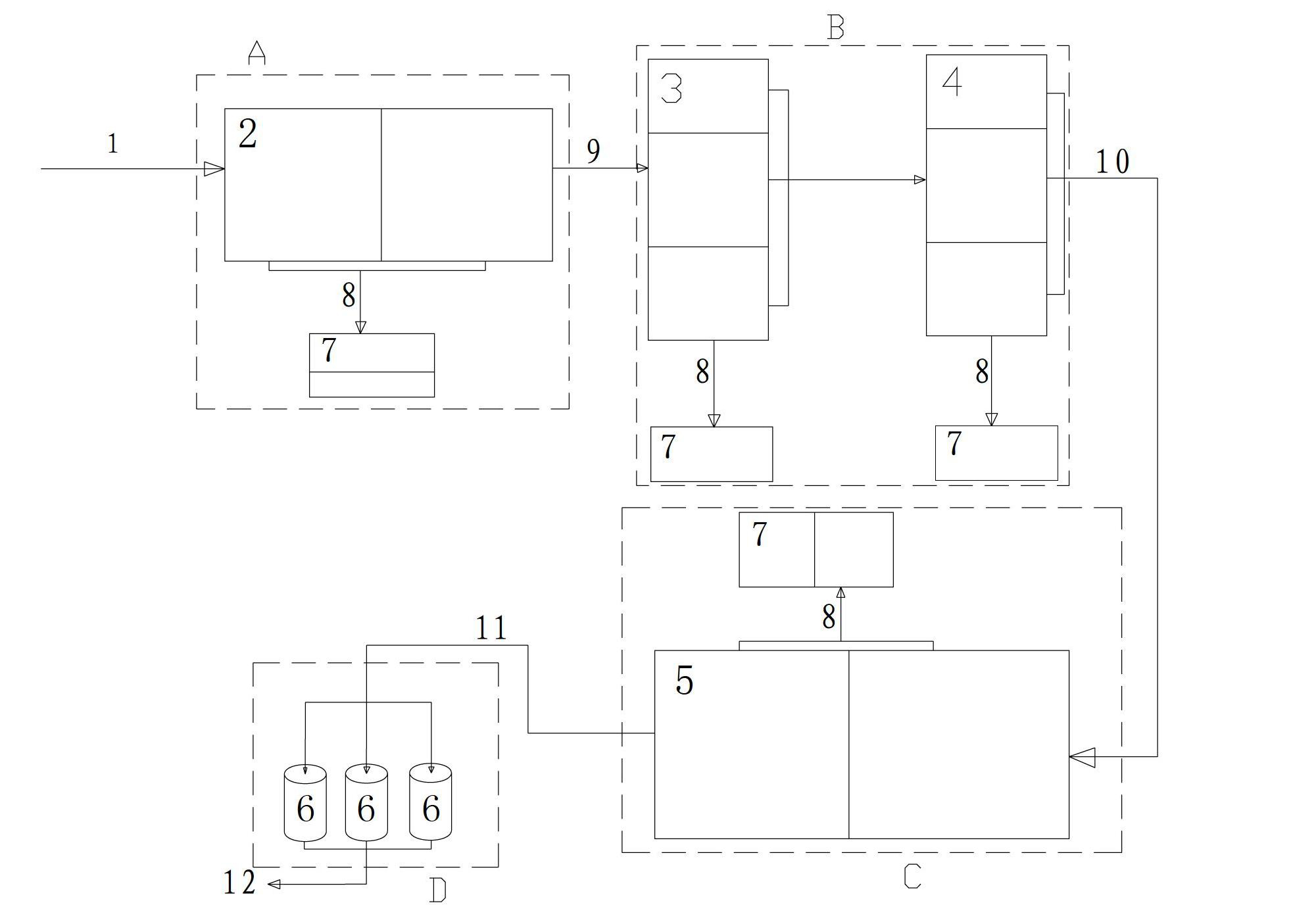

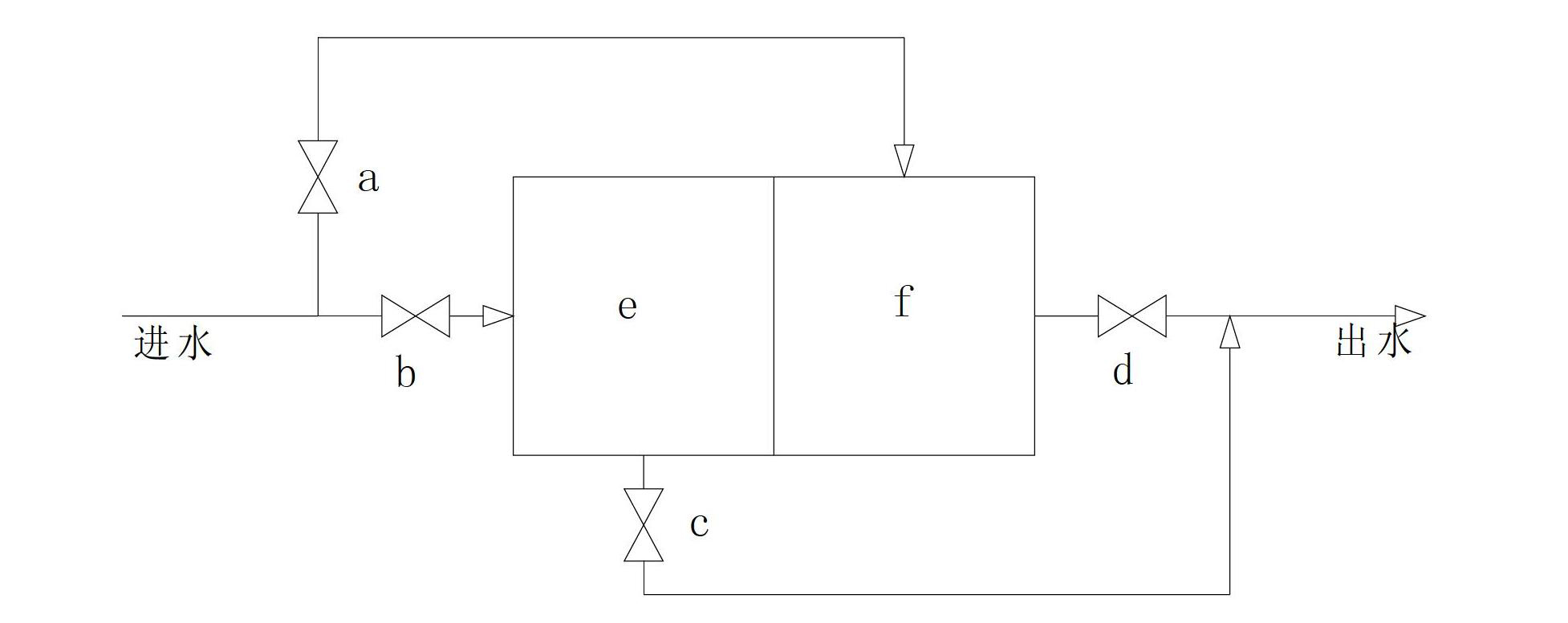

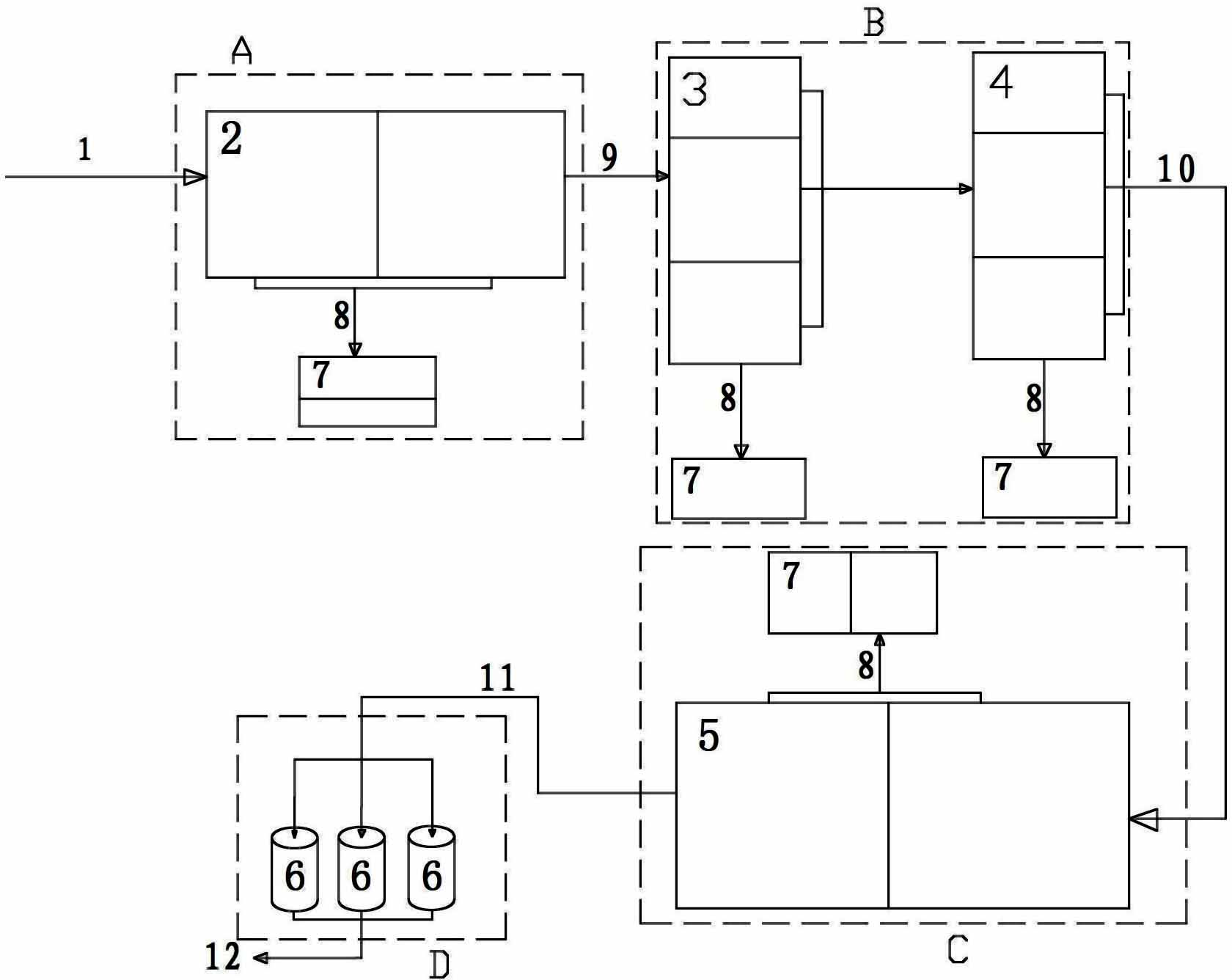

Softening and coagulating treatment process of gas scrubbing water

InactiveCN1526662AReduce hardnessReduce calcium hardnessWater softeningWater/sewage treatment by flocculation/precipitationSolid matterCalcium carbonate crystals

The softening and coagulating treatment process of gas scrubbing water with high calcium hardness and high solid suspension content is one simultaneous softening and coagulating process, in which sodium carbonate solution of 1-15 % concentration is added in proper position of coagulating deposition tank and the created calcium carbonate crystal and the suspended solid matter coagulate under the action of the coagulant. The present invention features that under the condition of maintaining the water pH unchanged, the concentration of calcium ion and suspended solid in water is reduced in simplified technological process, not expanded apparatus capacity and long term stable operation of the system. The present invention is also suitable for the coagulation and deposition treatment of other industrial effluent with high calcium hardness and high solid suspension content.

Owner:SHANGHAI HUAYI ENERGY CHEM +1

Process method for treating mine acidic waste water

InactiveCN102649608AGood removal effectEasy to operateWaste water treatment from quariesMultistage water/sewage treatmentFiltrationWastewater

The invention discloses a process method for treating mine acidic waste water. The method comprises the steps of performing primary precipitation, performing primary filtration, performing secondary precipitation and performing secondary filtration. By the method, the pH value of the mine acidic waste water can be regulated to 6 to 8, the national standard of the mine waste water pH emission is achieved, and the antimony content of the antimony well waste water can be reduced below 0.5 mg / L provided by 'Guizhou Province Environmental Pollutant Emission Standard'. The method has a good effect of treating the heavy metal mine waste water.

Owner:GUIZHOU NORMAL UNIVERSITY

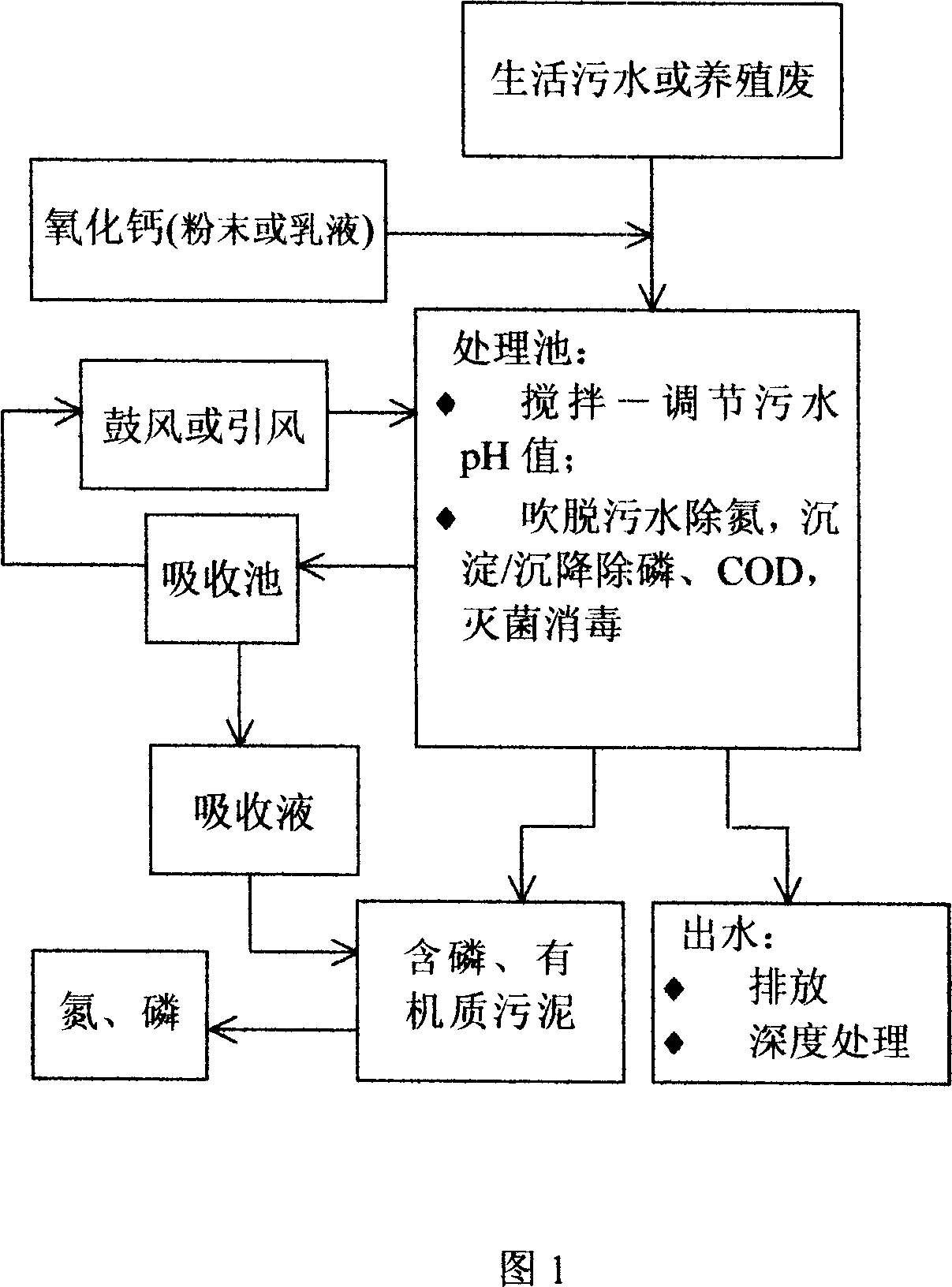

Method for sequencing batch type nitrogen, phosphorus, and COD pollution burthen of high concentration waste water

InactiveCN101041499AWater contaminantsWaste water treatment from animal husbandryHigh concentrationSludge

The invention discloses a highly effective denitrification, synchronizing dephosphorize, sterilization disinfection, effectively remove COD contaminant and one-step realize pH discharge disposing method of high concentration septic tank domestic sewage and breeding waste water in environmental engineering technology domain, which comprises the following steps: making calcium oxide as dominant water treatment agent; adjusting pH value of waste water; transforming nitrogen compound to free ammonia; proceeding blending flocculation and chemical precipitation with deposit contaminant; proceeding surface blow-off continually; dissolving free ammonia into absorption liquid; reclaiming. The contaminant clearance is 82.2%-90.3% ammonia nitrogen, 82.0%-90.2% total nitrogen, 84.4%-97.0% total phosphor, 52.5%-78.8% COD, waste water pH<=9, which can realize synchronizing disinfection. The discharging water can discharge directly or proceed future dispose.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

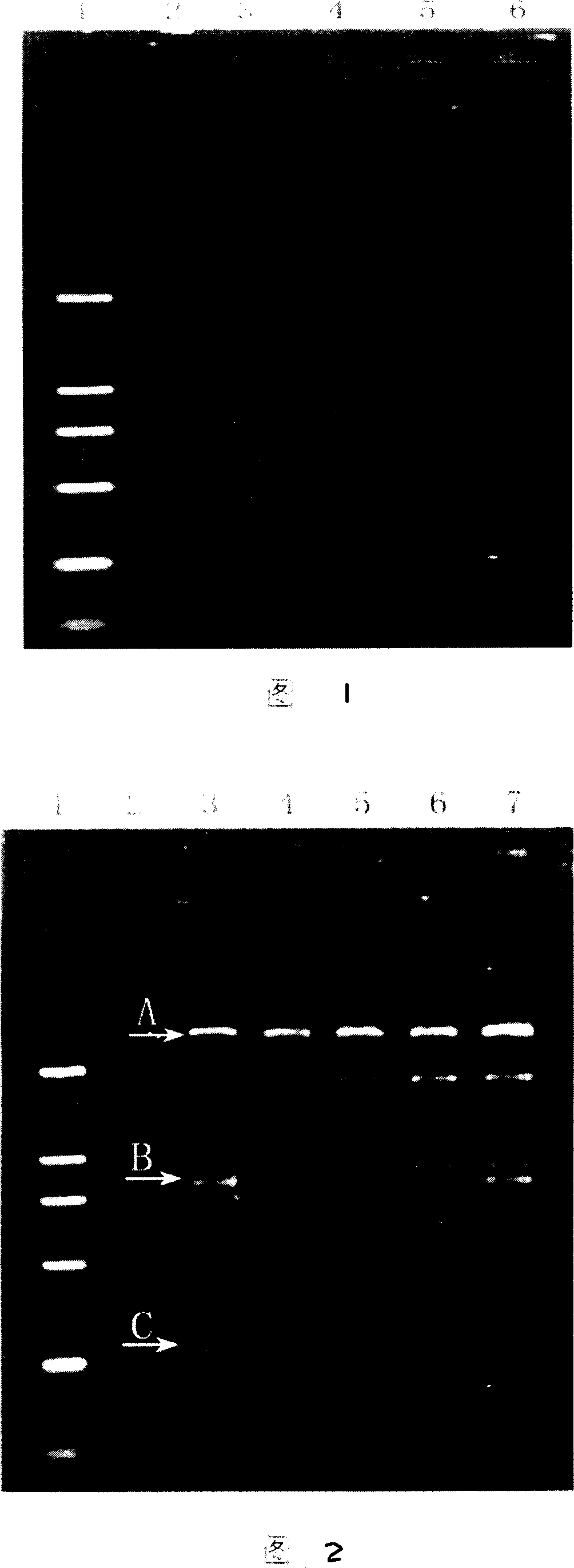

Biological reinforcing technology for increasing stability of oil-contained waste water treatment system

InactiveCN101024542AAccurate trackingQuick resultsBiological water/sewage treatmentMaterial analysisProcess systemsOptimal control

The invention relates to a biology strengthening technology to improve oily wastewater processing system stability. It tests the waste quality, system running parameter and key biological indicator by ERIC-PCR. It selects microbiology compound fungus agent or the compound, when system running normally, enduring high load or impacted by toxic pollutant, according 1013-1015 per cubic meter, adding 1013-1016 live fungus special effect degradation functional fungus, adding compound microbiology fungus agent or the compound into the system, controlling system parameter: dissolved oxygen 2-5mg / L, taking water pH 6.5-9.0, inner system pH 6.5-8.5, biomass 109-1016CFU, and dehydrase activity 10U. The invention realizes optimal control to process system, fully improves dislodging efficiency and stability of the process system. And it also achieves high environment social and economic benefits.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

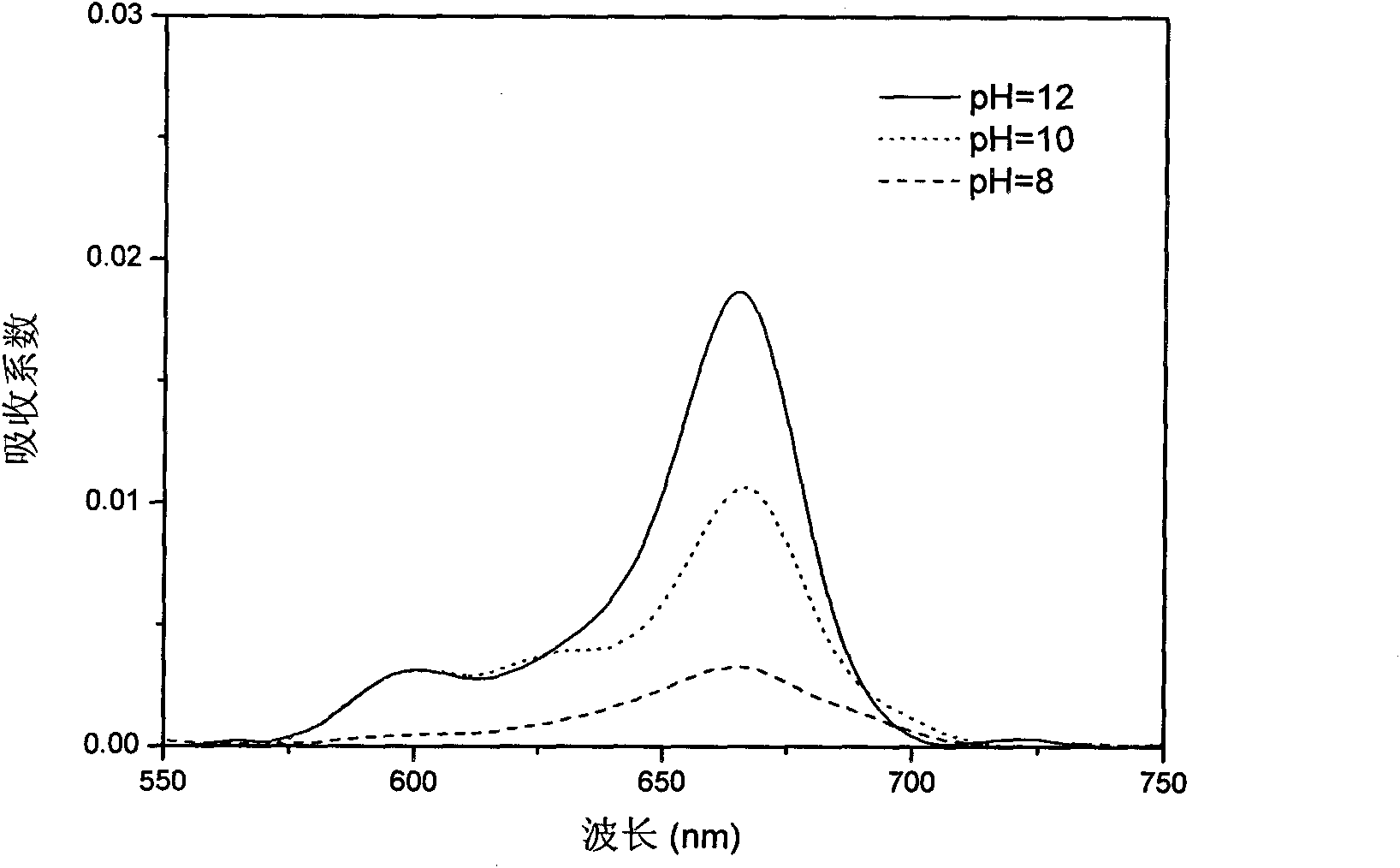

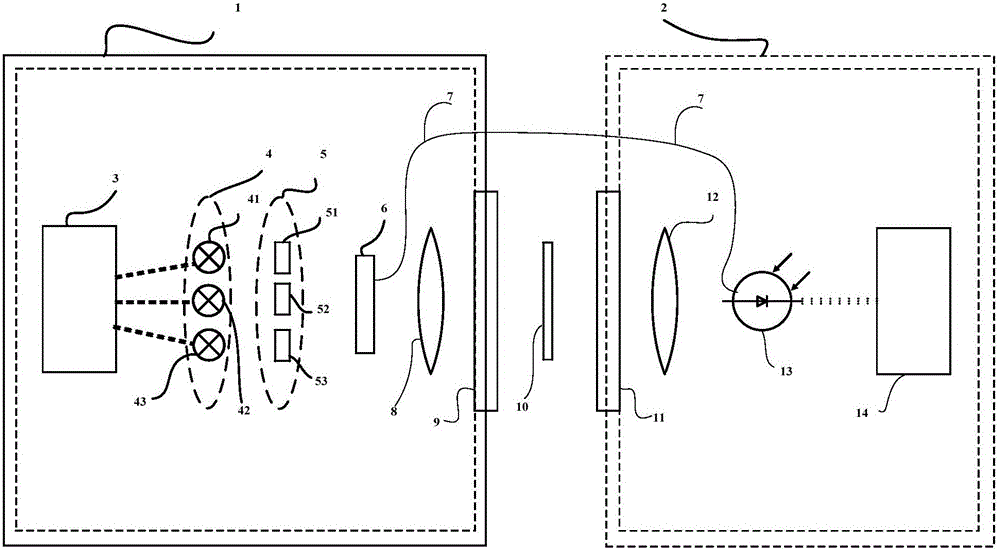

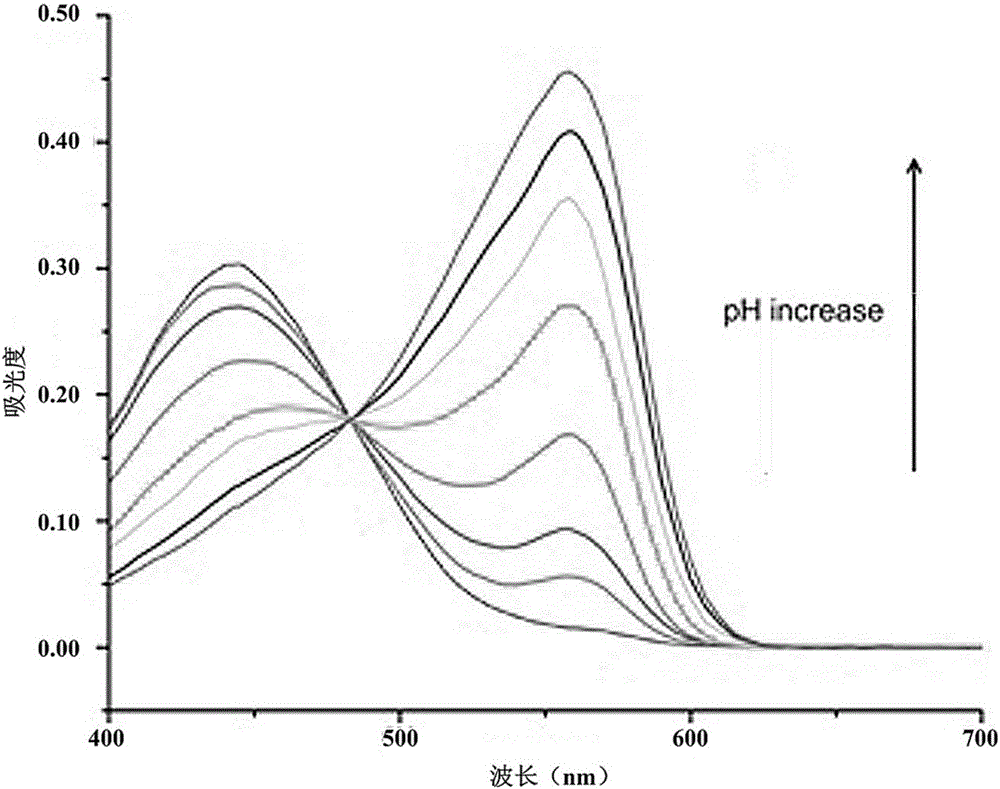

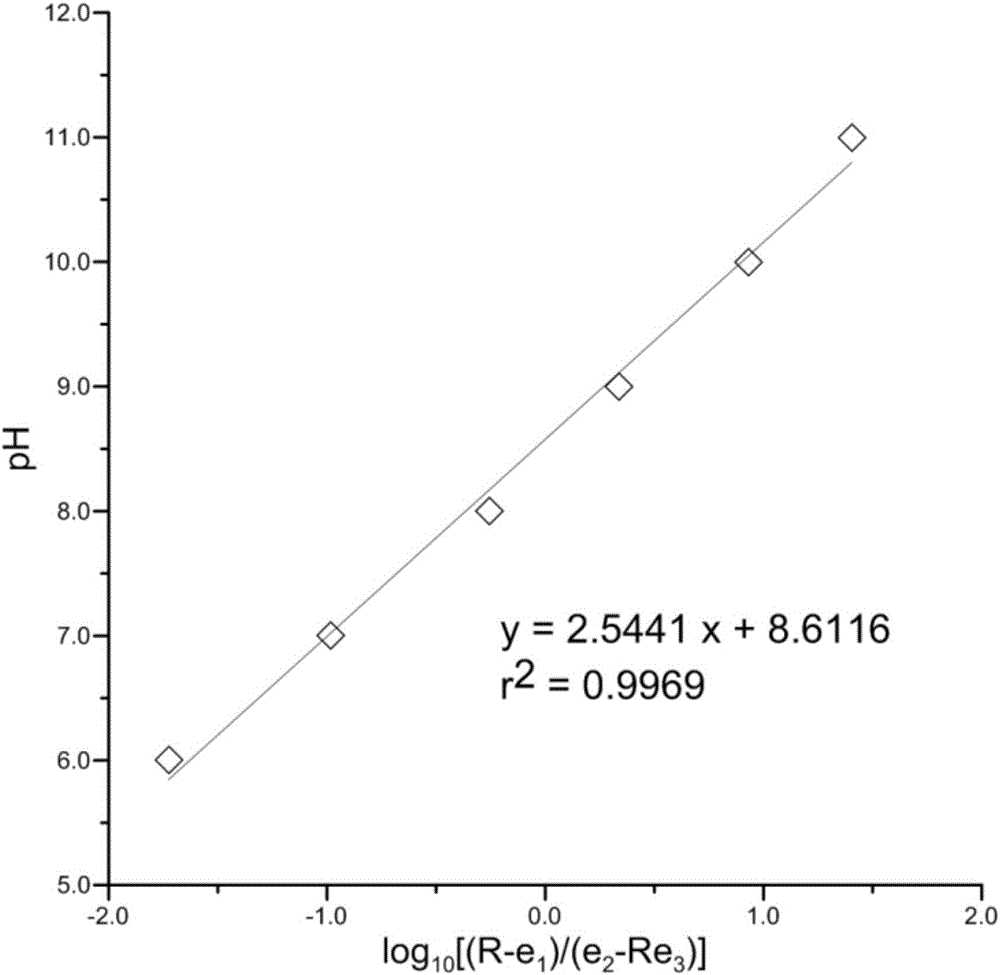

Method and detecting device for online detecting water pH value based on sensitive membranes

InactiveCN105675521AHighly integratedReduce volumeColor/spectral properties measurementsLuminosityLinear regression

The invention provides a method for online detecting the water pH value based on sensitive membranes.The method includes the following steps that the sensitive membranes are prepared; buffer solutions with the different pH values are prepared, and absorption spectra of the sensitive membranes are obtained; the molar-absorption-coefficient ratios e1, e2 and e3 and multiple absorbance ratios R are calculated; linear regression curves are prepared through the molar-absorption-coefficient ratios and the multiple absorbance ratios to obtain the slope 1 / n and the intercept pK of the linear regression curves; the sensitive membranes are immersed into to-be-detected water, and the absorbance ratio R under the present condition is calculated; the molar-absorption-coefficient ratios e1, e2 and e3, the slope 1 / n, the intercept pK and the absorbance ratio R<x> under the present condition are substituted into the formula to calculate the pH value of the to-be-detected water.The invention further provides a detecting device for online detecting the water pH value based on the sensitive membranes.The method has the advantages of being high in detection accuracy and flexible in use.

Owner:NAT DEEP SEA CENT

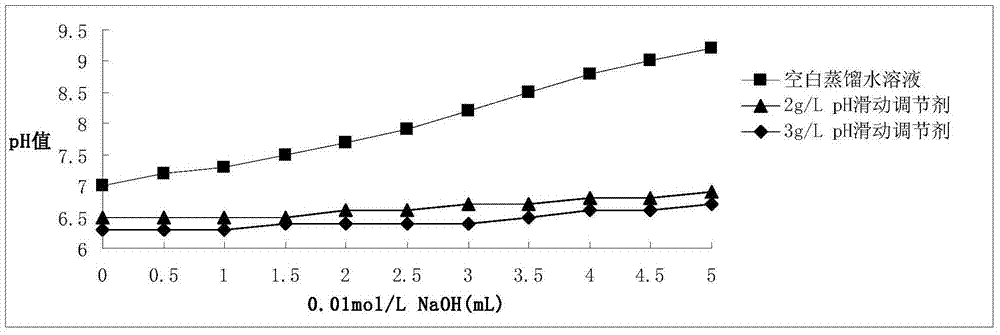

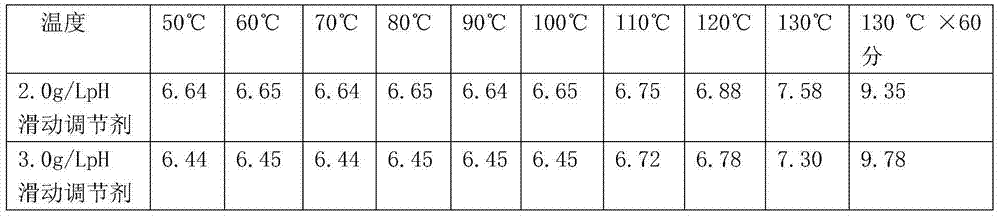

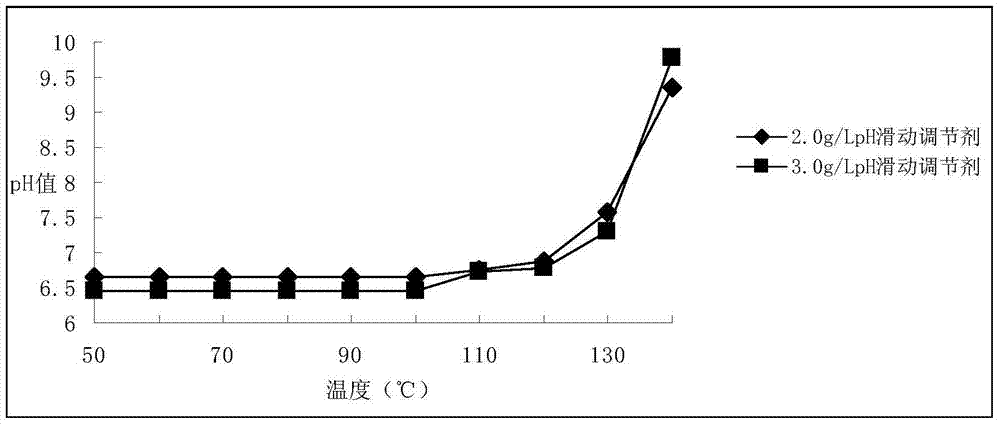

Temperature-controlled nanoscale microcapsule water pH sliding conditioning agent

ActiveCN103774463AEmission reductionImprove securityDyeing processMicroballoon preparationTemperature controlDistilled water

The invention belongs to the technical field of pH sliding conditioning agents in basic dyestuff dying, and in particular relates to a temperature-controlled nanoscale microcapsule water pH sliding conditioning agent which is characterized by comprising the following components by weight parts: 8-16 parts of a microcapsule prepolymer, 5-15 parts of aminophosphonic acid, 25-40 parts of an amide compound, 1.5-2.5 parts of caustic alkali, and 26.5-60.5 parts of distilled water, wherein the microcapsule prepolymer is prepared from C3-5 unsaturated fattyacid, an initiator, isopropyl alcohol and the distilled water by reaction. By adopting the method, the production technology process is shortened, the energy consumption and the waste water discharging are reduced, the safety is high, the cost is low, and the stability is high. The application range of dye types and technology conditions can be widened during dyeing.

Owner:义乌市中力工贸有限公司

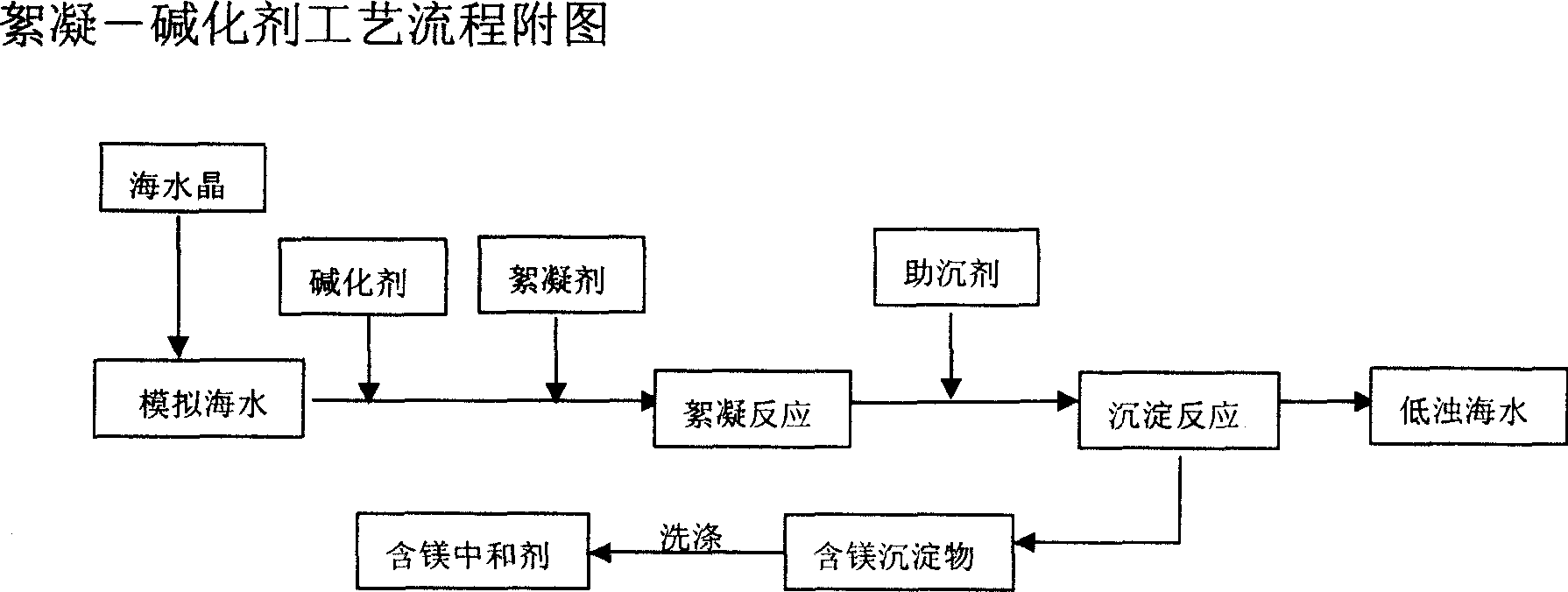

Method for removing cloud point of sea water drasticlly and producing acid waste-water neutralizer

InactiveCN1982230AReduce turbidityQuick filterSeawater treatmentWater/sewage treatment by neutralisationWater desalinationMagnesium salt

Alkali treatment for sea water with sodium hydrate as basifier is carried out by regulating sea-water pH value by basifier addition, reacting magnesium salt with alkali to generate magnesium hydrate with strong adsorptive function, and adsorbing rapidly electric colloid, suspended substance, microbe, bacterial and algae. It has faster flocculation depositing speed, gentle reactive condition, simple process and less investment. It can be used as acid waster-water neutralizer and magnesium hydrate slurry.

Owner:TIANJIN UNIV OF SCI & TECH

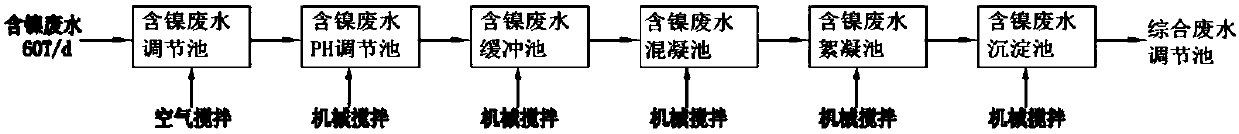

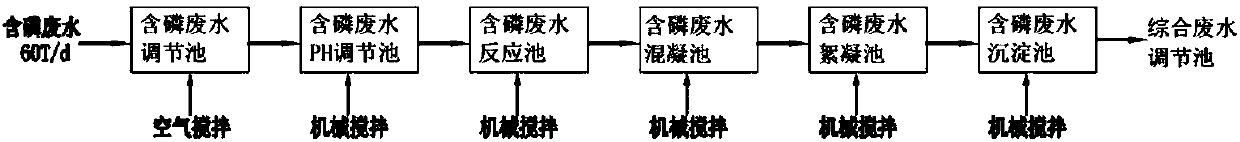

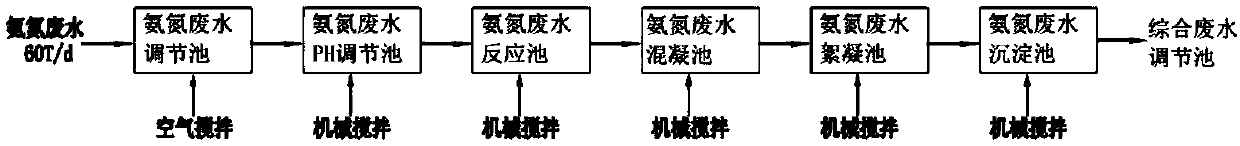

Electroplating waste water zero discharge system

PendingCN108033651AImprove removal efficiencyGuaranteed uptimeGeneral water supply conservationTreatment involving filtrationSludgeMembrane technology

The invention provides an electroplating waste water zero discharge system and relates to the technical field of sewage treatment. The bottoms of a nickel-containing waste water regulating pool, a nickel-containing waste water PH regulating pool, a nickel-containing waste water buffer pool, a nickel-containing waste water coagulating pool, a nickel-containing waste water flocculating pool and a nickel-containing waste water settling pool are connected with a nickel-containing sludge concentration pool through pipelines; the nickel-containing sludge concentration pool is connected with a nickel-containing sludge compressor; concentrated liquid in the nickel-containing sludge compressor is connected with the nickel-containing waste water regulating pool through a pipeline; a phosphorus-containing waste water regulating pool, a phosphorus-containing waste water PH regulating pool, a phosphorus-containing waste water reaction pool, a phosphorus-containing waste water coagulating pool, a phosphorus-containing waste water flocculating pool and a phosphorus-containing waste water settling pool are connected through pipelines. The electroplating waste water zero discharge system is high inremoval rate of pollutants and stable to operate, reasonably utilizes an advanced membrane technology, reduces membrane blockage, guarantees the service life of the membrane, increases the water production rate of the membrane, can reduce evaporation cost and has higher practicability.

Owner:SHENZHEN RUIWEISHENG ENVIRONMENTAL PROTECTION TECH

Paint spray waste water treatment agent and its application

InactiveCN100999350ASuperior Viscosity ReductionVisbreaking fastWater/sewage treatment by flocculation/precipitationWastewaterWater ph

This invention belongs to flocculating agent field. It is especially used to process flocculating agent of spray painting waste water and its application. Flocculating agent of spray painting waste water, of which characteristic is: it is made up of DZ-11 flocculating agent and DZ-12 polycoagulant. Wherein, DZ-11 has strong charge neutralization function. It can quickly neutralize oil paint particle electric charge, and remove glutinosity; DZ-12 polycoagulant has strong condensation, which can gather oil paint particle that lose glutinosity; proportion by weight of DZ-11 flocculating agent and DZ-12 polycoagulant is between 0.5-2:1. Spray painting waste water method, of which characteristic is: independently deposit above DZ-11 flocculating agent and DZ-12 polycoagulant, dissolve respectively, and utilize at then same time; adjust waste water PH to 8.5-10.5, add DZ-11 flocculating agent which is 5-8% of paint content of waste water at circulating water pump entrance; decrease glutinosity of circulating water that contains paint by using spray painting flocculating agent, add DZ-12 polycoagulant which is 6-10% of paint content of waste water at circulating water pump exit.

Owner:TIANJIN SHUANGJIE CHEM TECH

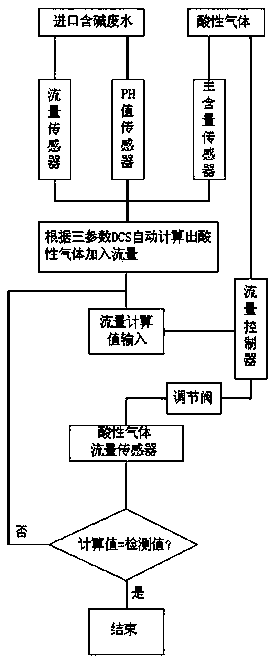

DCS control method for adjusting alkaline waste water pH

InactiveCN105366791AEasy to controlAvoid corrosionWater treatment parameter controlWater/sewage treatment by neutralisationAcid corrosionEconomic benefits

The invention relates to a DCS control method for adjusting an alkaline waste water pH. The method comprises 1, reading three parameter values, 2, calculating acid gas addition flow, 3, inputting the flow calculated value and 4, comparing the current detected pH and preset calculated pH, if the current detected pH is equal to the preset calculated pH, feeding the alkaline waste water subjected to pH adjustment into the next process so that the current process is finished, and carrying out the above circulation from the step 3. The DCS control method for adjusting the alkaline waste water pH realizes easy control of alkaline waste water pH adjustment, reduces a safety risk, prevents liquid acid corrosion and safety problems, reduces an operation cost and has substantial environment and economic benefits.

Owner:XINJIANG TIANZHI CHENYE CHEM +1

Composite water deoxidizing agent for wet steam generator

InactiveCN1351966AReduce processing costsMeet environmental protection requirementsWater/sewage treatment by degassingFoam dispersion/preventionWet steamWater quality

A composite water-deoxidizing agent as a kind of compositve water treating agent consists of ammonium sulfite 15-40 wt% and organic amine 0-10 wt% beside the rest of water. It is used in water treatment of steam boiler and can reduce oxygen content in water from 0.1-0.4 mg / l to less than 0.01 mg / l and raise water pH value from 7.0-7.5 to 8.3-9.0. The treated water has no corrosion to pipeline and no damage to oil layer. Its ammonium sulfite may be produced by absorbing SO2 in waste gas with ammonia water, and this can protect environmental and reduce water treating cost. The composite water deoxidizing agent of the present invention has high deoxidizing effect and reduced corrosion to pipeline.

Owner:YUHUA CHEM PLANT BINZHOUSNDONG PROV

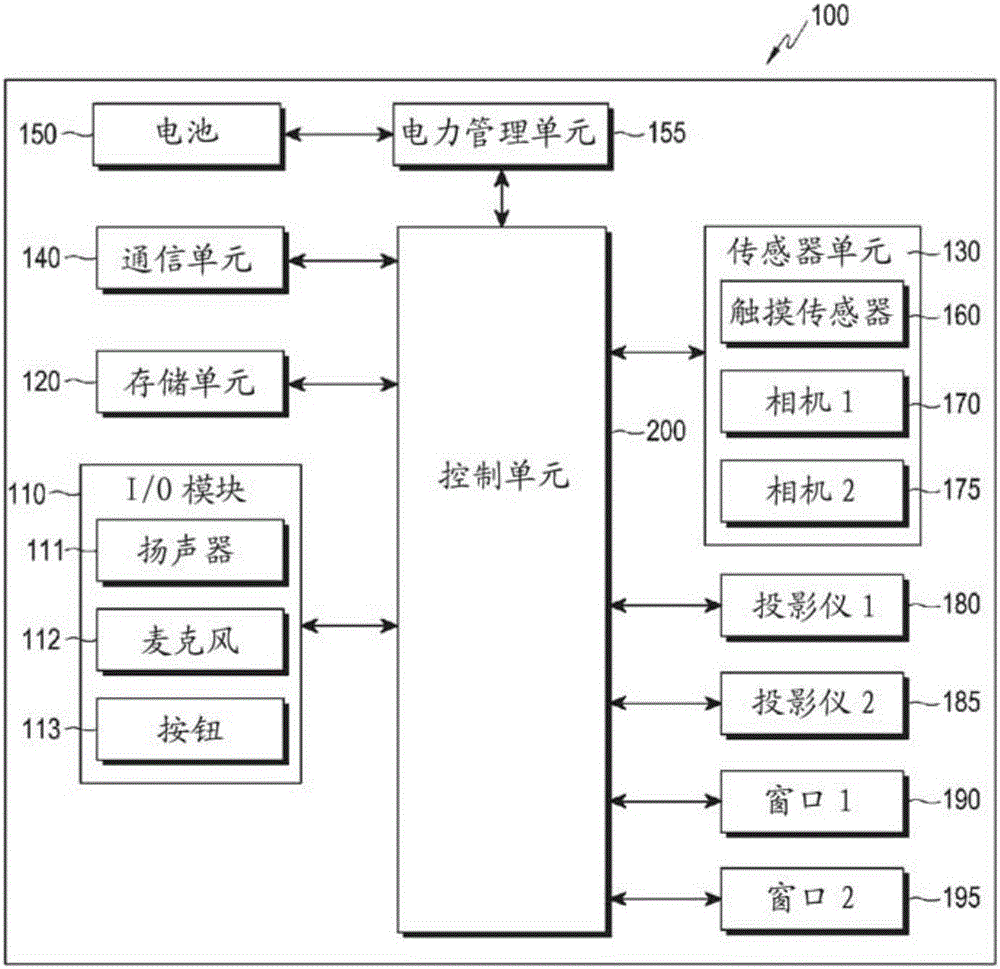

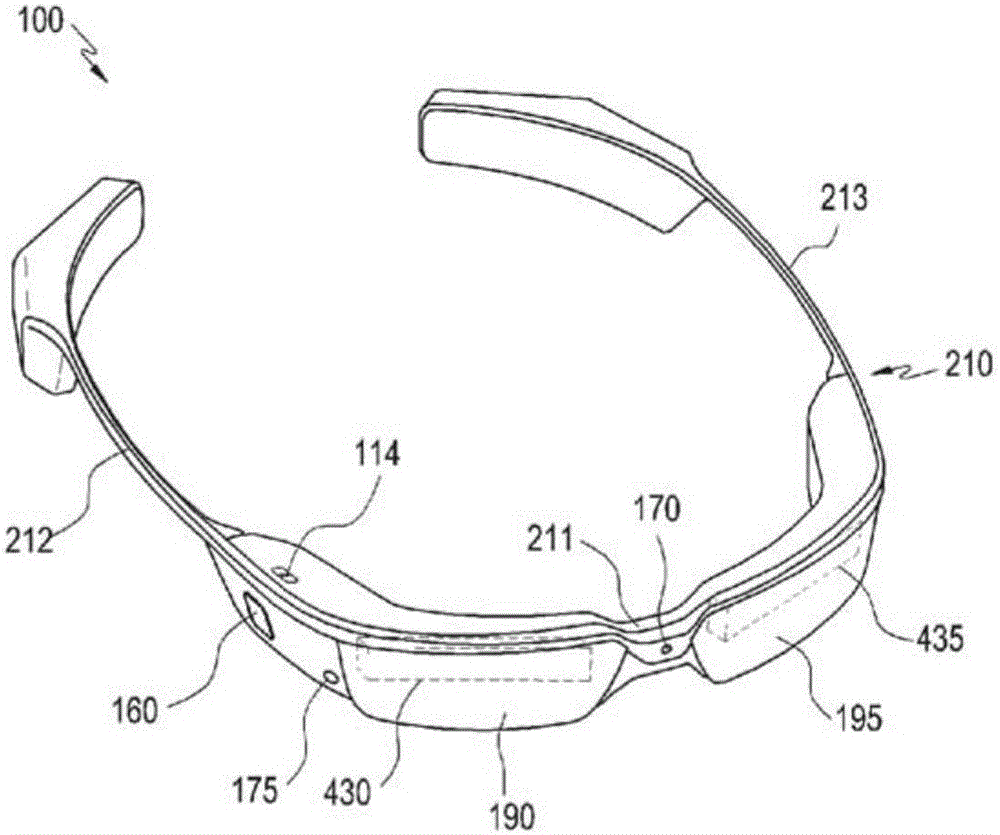

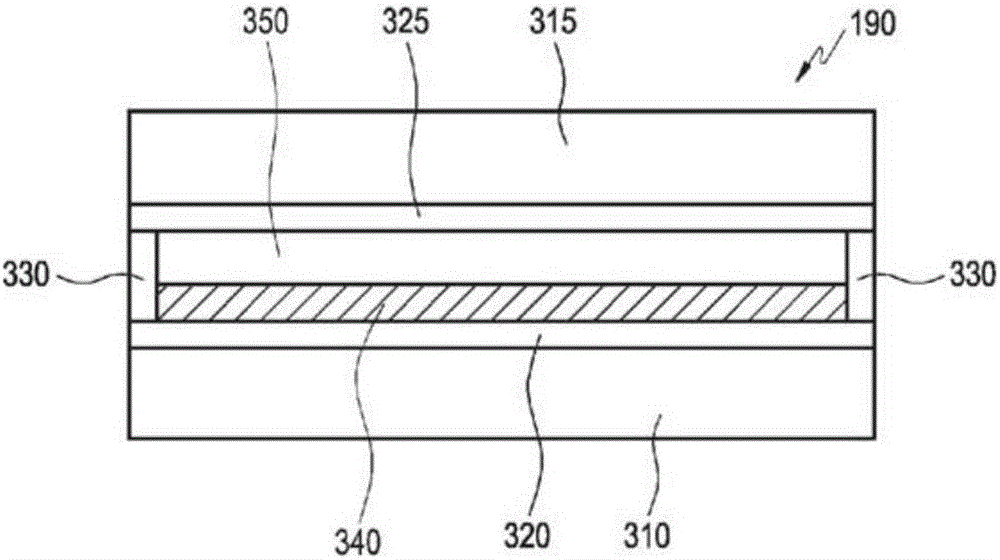

Scrubber and engine system

ActiveCN105899998AOptical light guidesAcquiring/reconising fingerprints/palmprintsWater storageSpray nozzle

This scrubber (40) is provided with: a water storage section (42) for collecting rinsing solution sprayed from spray nozzles (41) and storing same and discharging some of the stored rinsing solution to the outside; a neutralizing agent-injecting device (44) for injecting a neutralizing agent in the flow channel of a circulation pipe (43); and a control device (70). The control device (70) determines the amount of neutralizing agent to be injected from the neutralizing agent-injecting device (44) on the basis of the difference between the pH value of the rinsing solution sprayed from the spray nozzles (41) and the specified target spray pH value and the difference between the pH value of the rinsing solution stored in the water storage section (42) and a specified target stored water pH value.

Owner:SAMSUNG ELECTRONICS CO LTD

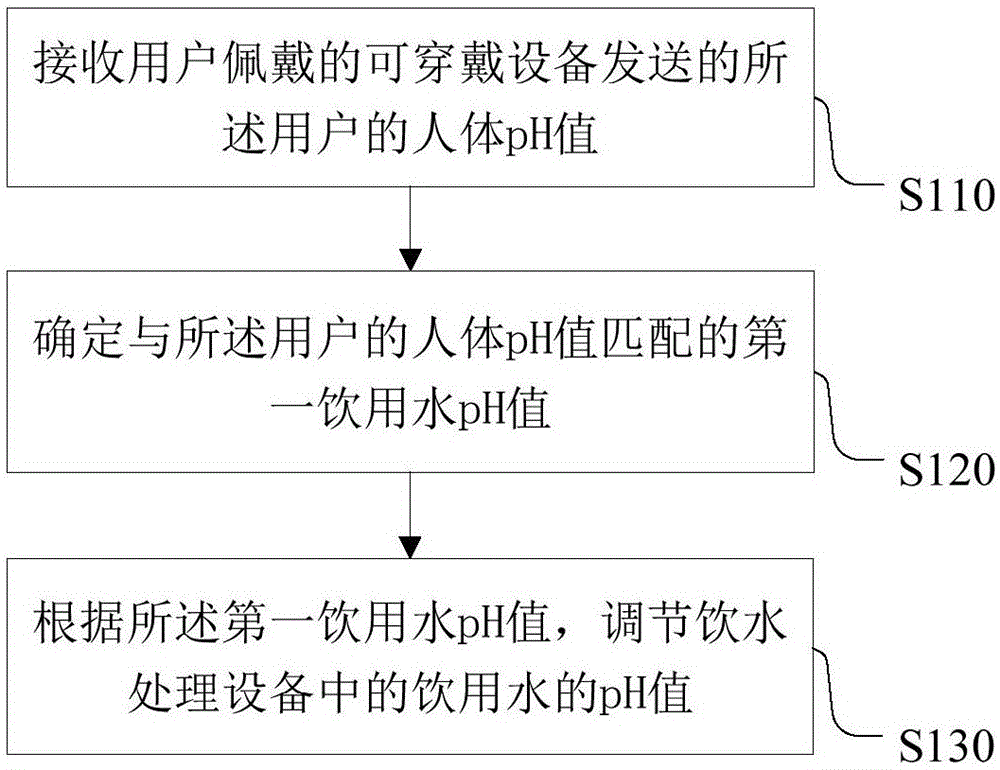

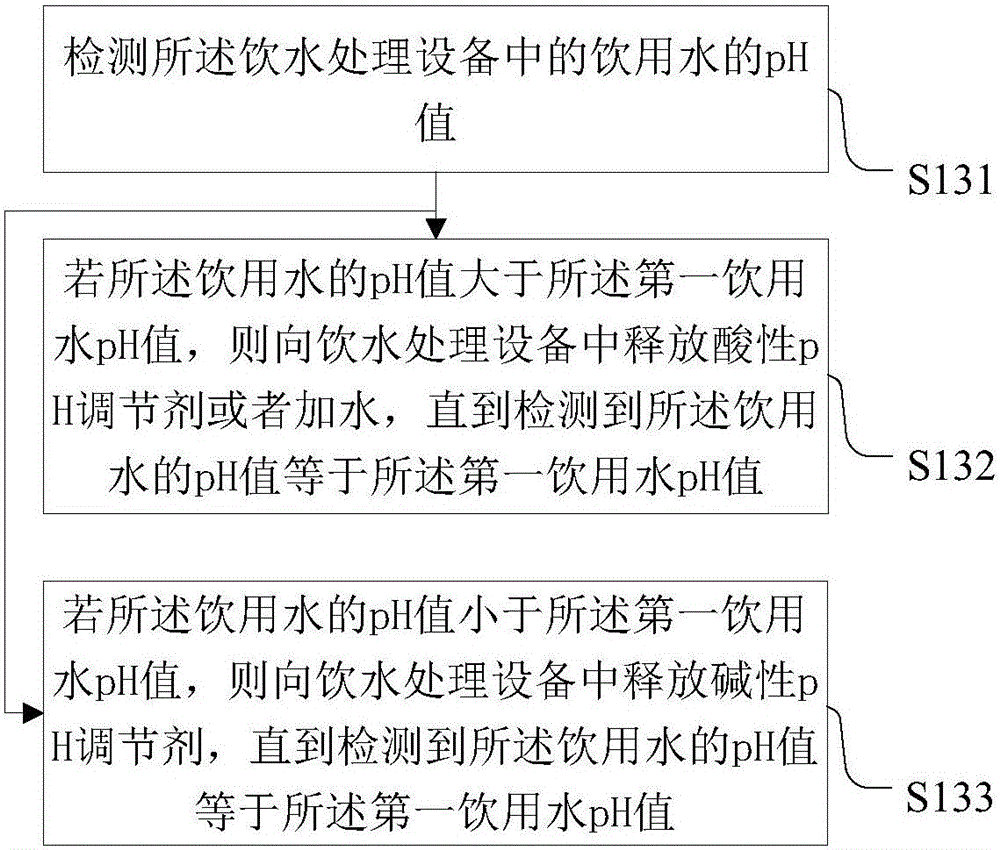

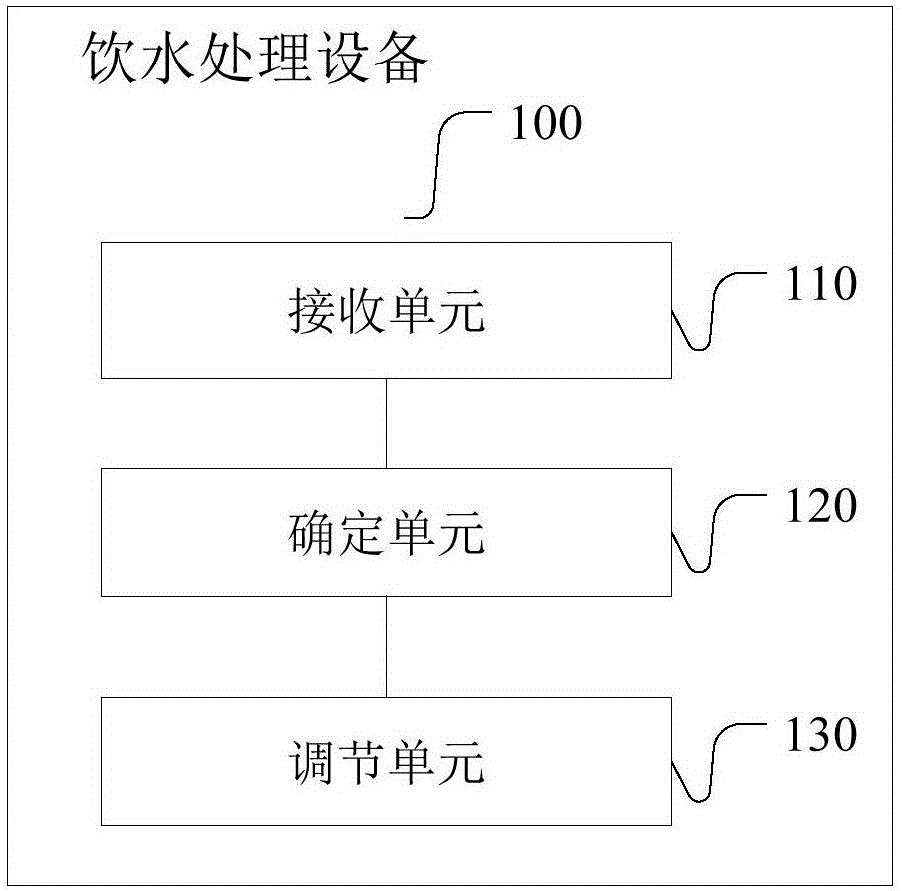

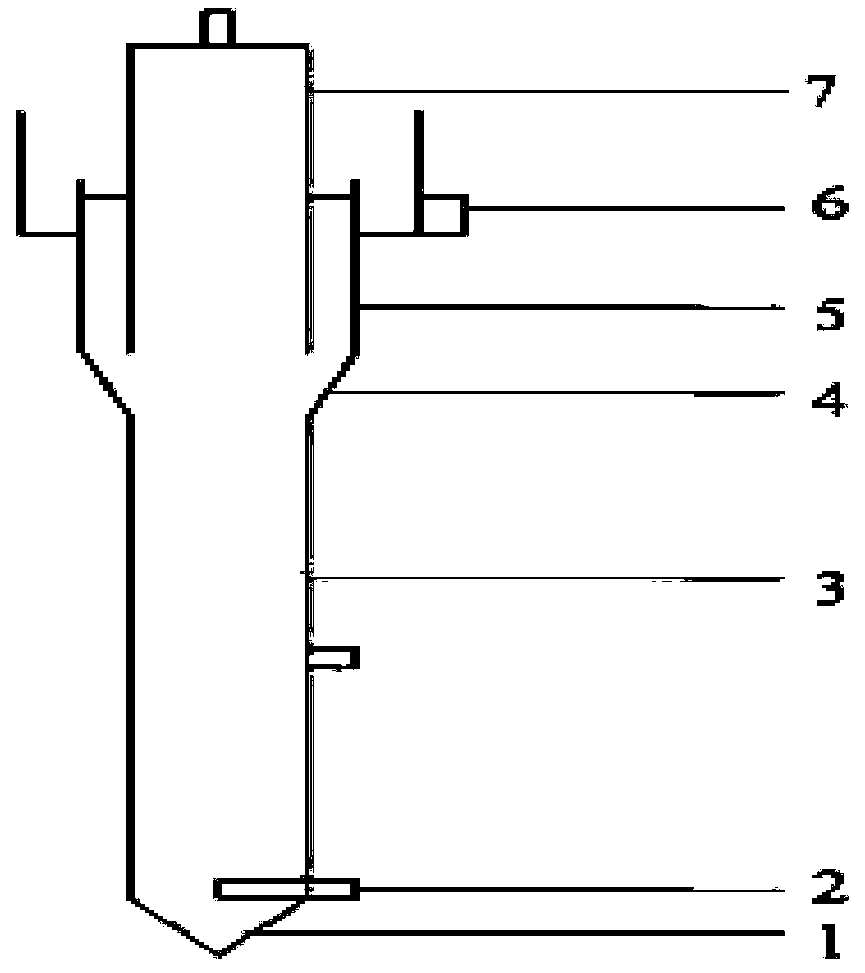

Method and device for regulating pH of drinking water in drinking water treatment equipment as well as drinking water treatment equipment

InactiveCN106673167AFit for drinkingWater treatment parameter controlWater/sewage treatment by neutralisationPotable waterWater ph

The invention provides a method and a device for regulating pH of drinking water in drinking water treatment equipment as well as the drinking water treatment equipment. The method comprises the steps of receiving a human pH, sent by a wearable device worn by a user, of the user; determining a first drinking water pH matched with the human pH of the user; regulating the pH of the drinking water in the drinking water treatment equipment according to the first drinking water pH. According to the technical scheme, the pH of the drinking water in the drinking water treatment equipment can be regulated to be suitable for the user to drink according to the human pH of the user.

Owner:GREE ELECTRIC APPLIANCES INC

Method for enhancing anammox activity by adding manganese dioxide

InactiveCN108264145AIncrease operating loadWater treatment compoundsTreatment with anaerobic digestion processesHigh activityAnaerobic sludge

The invention provides a method for enhancing anammox activity by adding manganese dioxide. The method includes: adopting an upflow anaerobic sludge bed reactor, taking anaerobic ammonium oxidation granule sludge as the inoculation source, taking simulation wastewater containing ammonia nitrogen and nitrite nitrogen as the influent water, also adding an inorganic salt buffer solution and trace elements maintaining microorganism growth, after stable operation under anaerobic and dark conditions with a temperature of 35+ / -1DEG C, an influent water pH of 7.70-7.80, and a hydraulic retention timeof 0.9-1.0h, adding manganese dioxide into the influent water of the reactor in a phased increasing way, performing culture until the activity of the reactor sludge is 2.4-2.6 times that of inoculatedsludge, thus completing culture. The anaerobic ammonium oxidation granule sludge culture by the method provided by the invention has the advantages of high activity, good nitrogen removal performance, high microorganism concentration and the like.

Owner:HANGZHOU NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com