Anaerobic biological treatment method of heat-engine plant desulphurization waste water

An anaerobic biological and desulfurization wastewater technology, applied in anaerobic digestion treatment, gaseous discharge wastewater treatment, waste fuel, etc., can solve the problems of secondary pollution, high treatment cost, and difficult treatment of high-concentration sulfate-containing desulfurization wastewater. , to achieve the effect of saving treatment costs, reducing the concentration of heavy metals, and good operating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

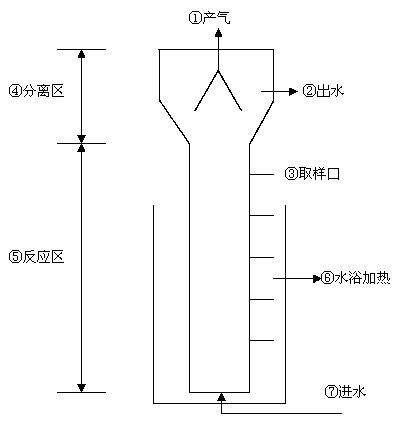

[0032] The diagram of the experimental setup is shown in figure 1 , figure 1 Among them, the sulfate reduction reactor is a UASB reactor, made of plexiglass, with a total height of 1300mm and an effective volume of 7.8L. The reactor is composed of two parts: the reaction zone and the settling zone (separation zone). The gas-liquid-solid three-phase separator installed on the upper part of the reactor avoids the installation of sedimentation and separation devices, auxiliary degassing devices and reflux for granular sludge. Sludge equipment simplifies the process and saves investment and operating costs. At the same time, thermal insulation measures were taken for the reactor, and the temperature was kept at 35°C.

[0033] figure 1 Among them, ① is the gas production port; ② is the water outlet; ③ is the sampling port; ④ is the separation area (three separators); ⑤ is the reaction area, the upper part is the sludge layer area, and the lower part is the sludge bed area; ⑥ is ...

experiment example 2

[0037] In this experiment, within the optimum temperature range (25~40°C) of mesophilic anaerobic digestion, the present invention investigated the effect of different temperatures on SO 4 2- effect on removal efficiency. Experimental parameters: SO 4 2- Concentration is 1000mg / L, HRT is 12h, ρ(COD) / ρ(SO 4 2- ) ratio is 3, and the influent pH is 7.

[0038] temperature / ℃ SO 4 2- Removal rate / % 25 63.05 28 70.31 30 78.02 33 84.46 35 86.21 38 80.08 40 74.05

[0039] SO 4 2- The removal rate showed a trend of first increasing and then decreasing with the increase of temperature. When the temperature increased to 35 °C, SO 4 2- The removal rate is the largest, which can reach about 86%; but with the continuous increase of temperature, SO 4 2- The removal rate started to drop. It shows that the growth and metabolism of SRB is the strongest at 35℃, so the maximum sulfate reduction rate is obtained.

experiment example 3

[0041] Different HRTs have different effects on sulfate bioreduction ability, and the present invention reduces HRT from 30h to 6h for SO 4 2- Study on the effect of removal rate, experimental parameters: temperature is 35°C, SO 4 2- The concentration is 1000mg / L, ρ(COD) / ρ(SO 4 2- ) ratio is 3, and the influent pH is 7.

[0042] HRT / h SO 4 2- Removal rate / % 6 54.29 8 68.52 12 87.87 14 89.54 18 90.29 24 90.86 30 90.64

[0043] When HRT drops from 30h to 12h, SO 4 2- The removal rates were all greater than about 87%; when the HRT continued to drop from 12h to 6h, SO 4 2- The removal rate dropped rapidly to 54%. On the basis of ensuring a good treatment effect, considering that shortening the treatment time can effectively reduce the cost of desulfurization wastewater treatment, it can be considered that HRT=12h is the best HRT under this experimental condition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com