Fischer-Tropsch synthesis catalyst and preparation method and application thereof

A Fischer-Tropsch synthesis and catalyst technology, which is used in catalyst activation/preparation, chemical instruments and methods, preparation of liquid hydrocarbon mixtures, etc., can solve the problems of poor product selectivity, unfeasible, low activity, etc., and achieve mild production conditions. , low production cost, and the effect of improving the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

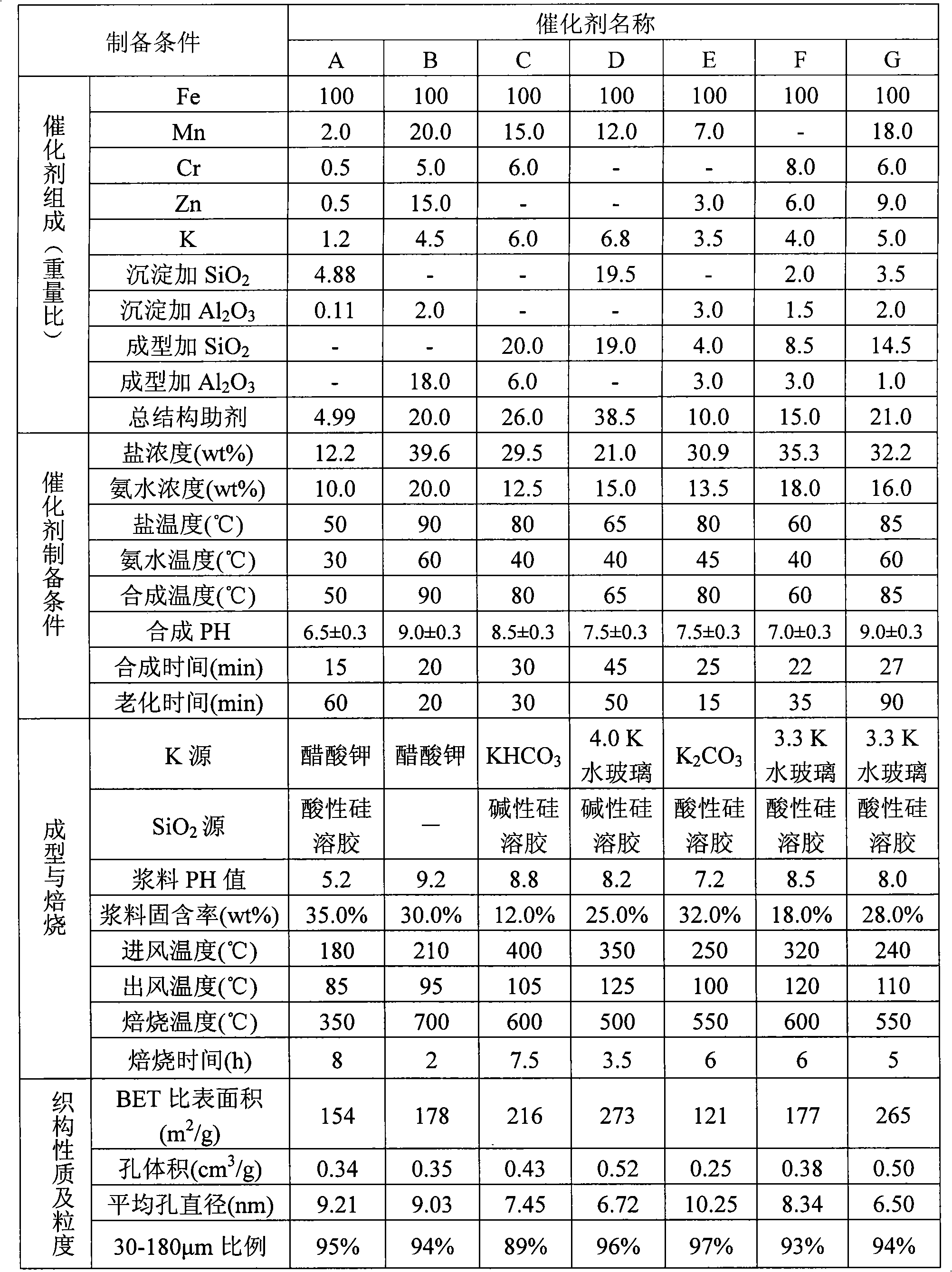

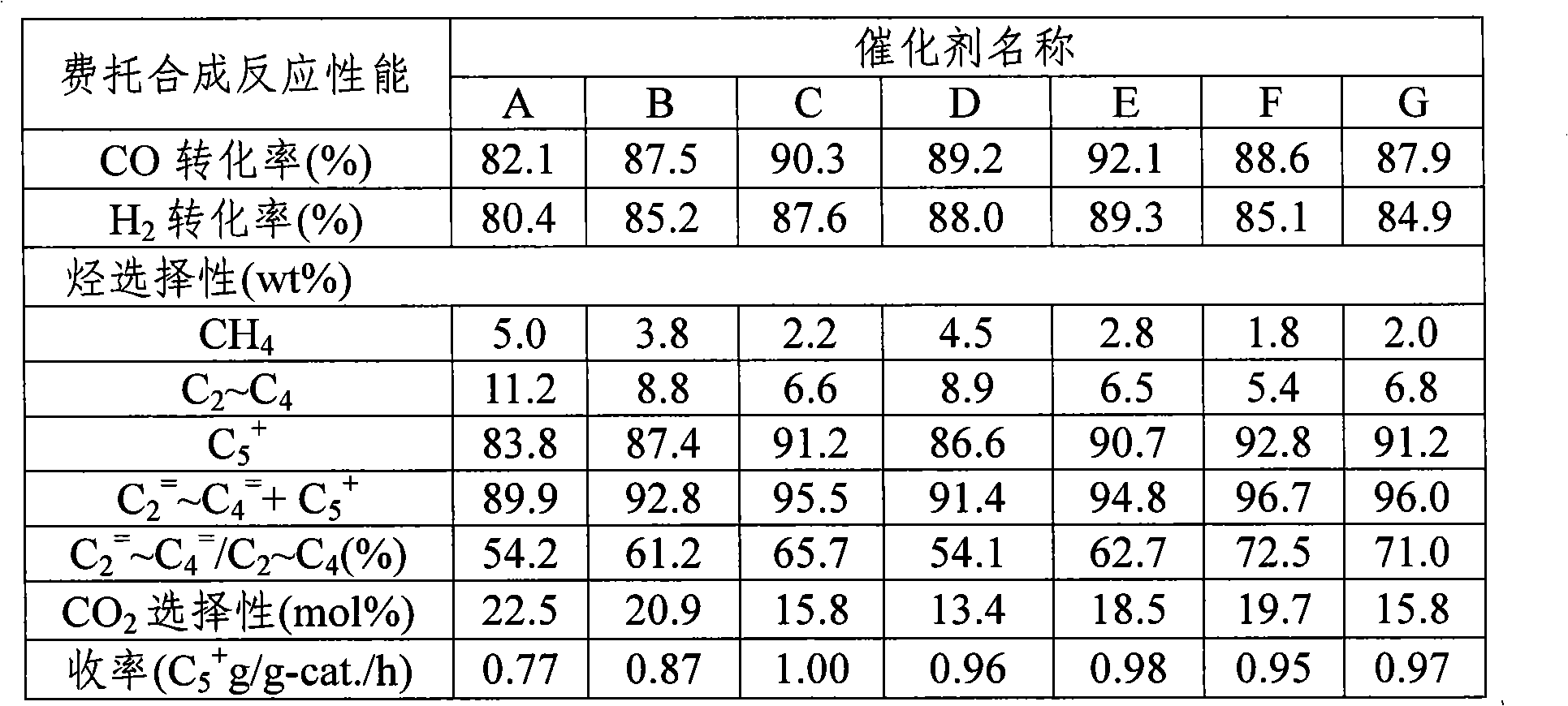

Embodiment 1

[0038] 2000 kg Fe(NO 3 ) 3 9H 2 O, 36 kilograms of 50wt% Mn (NO 3 ) 3 Aqueous solution, 10.65 kg Cr(NO 3 ) 3 ·3H 2 O and 6.3 kg of Zn(NO 3 ) 2 ·6H 2 O was dissolved in 1050 kg of deionized water, and after fully dissolved, SiO was added to the mixed salt solution 2 45 kg of silica sol with a content of 30 wt%, Al 2 o 3 Content is 1.2 kilograms of aluminum sols of 25wt%, this solution is warmed up to 50 ℃ under stirring, and the total concentration of nitrate in the gained mixed solution is 12.22wt%, and the weight ratio of each component in the described mixed salt solution is Fe: Mn :Cr:Zn:SiO 2 :Al 2 o 3 =100:2.0:0.5:0.5:4.88:0.11.

[0039] Prepare 10.0wt% ammonia solution at the same time and heat up to 30°C. Preset 1500 kg of deionized water in the precipitation tank and preheat it to 50°C. After the temperature rises to the set temperature, add the salt solution and ammonia solution Co-current co-precipitation, keeping the temperature of the slurry in the ...

Embodiment 2

[0043] 2000 kg Fe(NO 3 ) 3 9H 2 O, 324 kg of 50wt% Mn (NO 3 ) 3 Aqueous solution, 127.5 kg Cr(NO 3 ) 3 ·3H 2 O and 201.5 kg of Zn(NO 3 ) 2 ·6H 2 O was dissolved in 1360 kg of deionized water, and after fully dissolved, Al was added to the mixed salt solution 2 o 3 Content is 24.0 kilograms of silica sols of 25.0wt%, this solution is warmed up to 90 ℃ under stirring, and the total concentration of nitrate in the gained mixed solution is 39.6wt%, and the weight ratio of each component in the described salt solution is Fe: Mn :Cr:Zn:Al 2 o 3 =100:20.0:5.0:15.0:2.0.

[0044] Prepare 20.0wt% ammonia solution at the same time and heat up to 60°C. Preset 1500 kg of deionized water in the precipitation tank and preheat to 90°C. After the temperature rises to the set temperature, add the salt solution and ammonia solution For co-current co-precipitation, the temperature of the slurry in the precipitation tank is kept at 90° C., the pH of the mixed synthetic slurry is 9.0±...

Embodiment 3

[0048] 2000 kg Fe(NO 3 ) 3 9H 2 O, 270 kg of 50wt% Mn (NO 3 ) 3 Aqueous solution, 127.5 kg Cr(NO 3 ) 3 ·3H 2 O is dissolved in 2500 kilograms of deionized water, after fully dissolving, this solution is warmed up to 80 ℃ under stirring, and the total concentration of nitrate in the gained mixed salt solution is 29.5wt%, and the weight ratio of each component in this salt solution is Fe:Mn:Cr=100:15.0:6.0.

[0049] Prepare 12.5wt% ammonia solution at the same time and heat up to 40°C. Preset 1500 kg of deionized water in the precipitation tank and preheat it to 80°C. After the temperature rises to the set temperature, add the salt solution and ammonia solution For co-precipitation, the temperature of the slurry in the precipitation tank is kept at 80° C., the pH of the mixed synthetic slurry is 8.5±0.3, and the mixing and co-precipitation process is completed within 30 minutes. Leave to age for 30 minutes.

[0050] The aged slurry was washed with deionized water until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com