Method for sequencing batch type nitrogen, phosphorus, and COD pollution burthen of high concentration waste water

A high-concentration wastewater and pollution load technology, applied in the field of environmental engineering, can solve problems such as increased processing costs, excessive land occupation, and easy blockage of stripping towers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

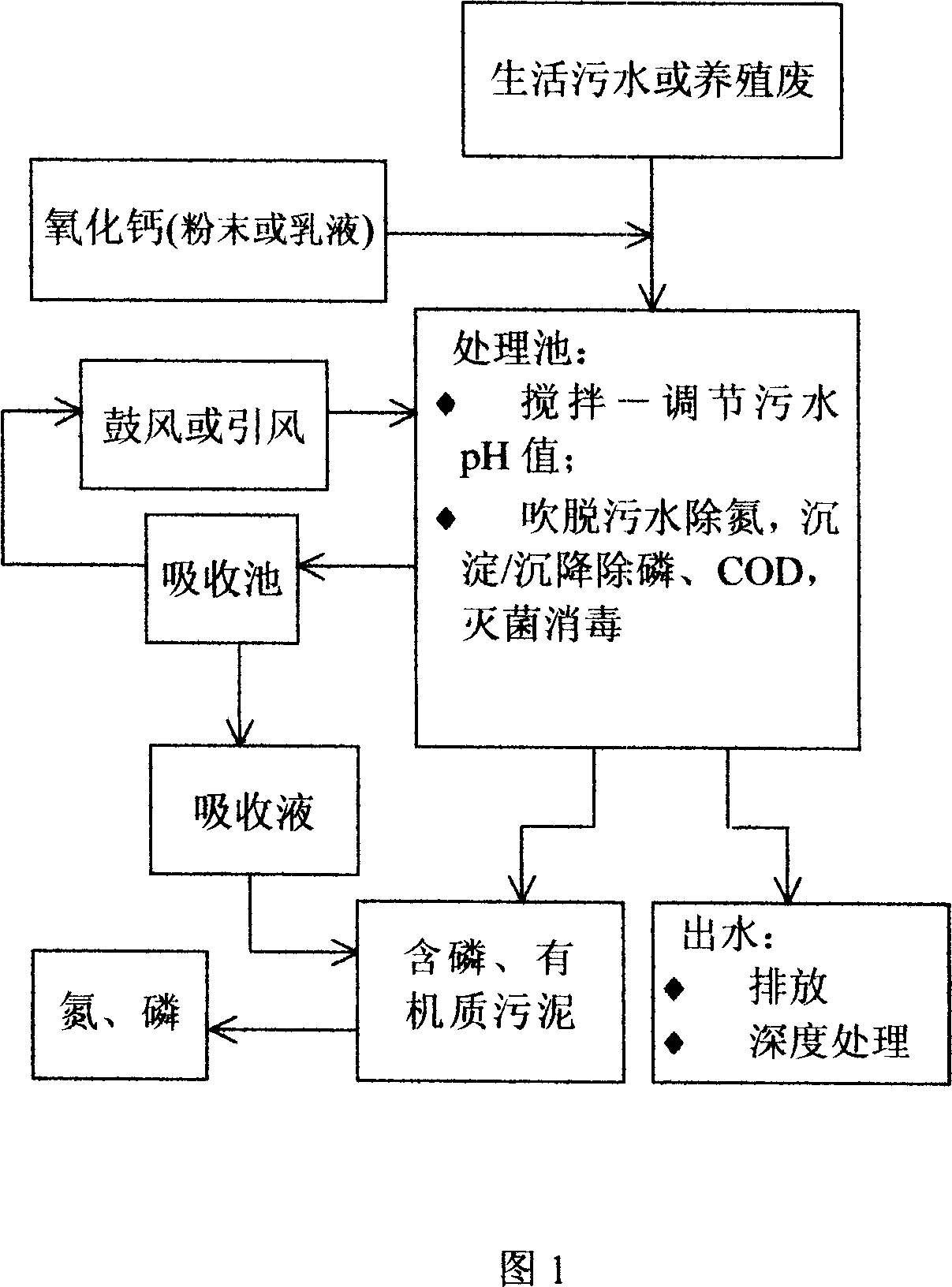

Method used

Image

Examples

Embodiment 1

[0014] 10L of farm wastewater was placed in the stripping tank. The pH value of the wastewater was 7.90, the ammonia nitrogen was 823.67mg / l, the total nitrogen was 831.32mg / l, the total phosphorus was 29.83mg / l, and the COD was 5679.9mg / l. Using milk of lime with a mass ratio of calcium oxide to water of 1:20, the pH value of the wastewater was adjusted to 10.56 under stirring conditions, the stripping time was 20 hours, and the gas-liquid ratio was 5000:1. After treatment, the pH value of the effluent was 9.35, and the removal rates of pollutant indicators ammonia nitrogen, total nitrogen, total phosphorus and COD were 82.9%, 83.0%, 85.0% and 75.4%, respectively.

Embodiment 2

[0016] 20L of farm wastewater was placed in the stripping tank. The pH value of the wastewater was 8.26, the ammonia nitrogen was 947.67mg / l, the total nitrogen was 950.67mg / l, the total phosphorus was 52.94mg / l, and the COD was 5896.2mg / l. Using milk of lime with a mass ratio of calcium oxide to water of 1:50, the pH value of the wastewater is adjusted to 10.39 under stirring conditions, the stripping time is 20 hours, and the gas-liquid ratio is 5000:1. After treatment, the pH value of the effluent was 8.66, and the removal rates of pollutant indicators ammonia nitrogen, total nitrogen, total phosphorus and COD were 66.4%, 66.3%, 77.9% and 59.6%, respectively.

Embodiment 3

[0018] 20L of farm wastewater was placed in the stripping tank. The pH value of the wastewater was 8.04, the ammonia nitrogen was 903.38mg / l, the total nitrogen was 910.6mg / l, the total phosphorus was 31.16mg / l, and the COD was 6328.7mg / l. Using milk of lime with a mass ratio of calcium oxide to water of 1:50, the pH value of the wastewater was adjusted to 11.18 under stirring conditions, the stripping time was 20 hours, and the gas-liquid ratio was 5000:1. After treatment, the pH value of the effluent was 8.66, and the removal rates of pollutant indicators ammonia nitrogen, total nitrogen, total phosphorus and COD were 98.5%, 98.4%, 88.5% and 69.2%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com