Microorganism advanced treatment for oil refining waste water

A technology for advanced treatment of oil refining wastewater, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of shortening the treatment residence time, eliminating pollution, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment one class (6), different treatment process comparisons:

[0027] Using the same refinery oily wastewater, after preliminary treatment to the average inflow of various indicators as shown in the table below, they are treated according to different processes, and the treatment results are shown in Table 1. Wherein embodiment 1-embodiment 5 adopts United Synthetic group 1 : Pseudomonas sp, Zoogloea sp., Plesiomonas sp., Bacillus, Bacillus megaterium, Rhodopseudomonas sp. (Rhodopseudomonas globiformis); Example 6 uses Combined flora 2 : Pseudomonas sp, Zoogloea sp., Plesiomonas sp., Bacillus, Bacillus megaterium, Rhodopseudomonas sp. (Rhodopseudomonas globiformis), Pseudomonas alcaligenes, Flavobacterium sp., microbial activity ≥10 11 per gram, the test treatment device is 20 tons / day, the average water temperature is 22°C, and the gas-water ratio is 1:3-5.

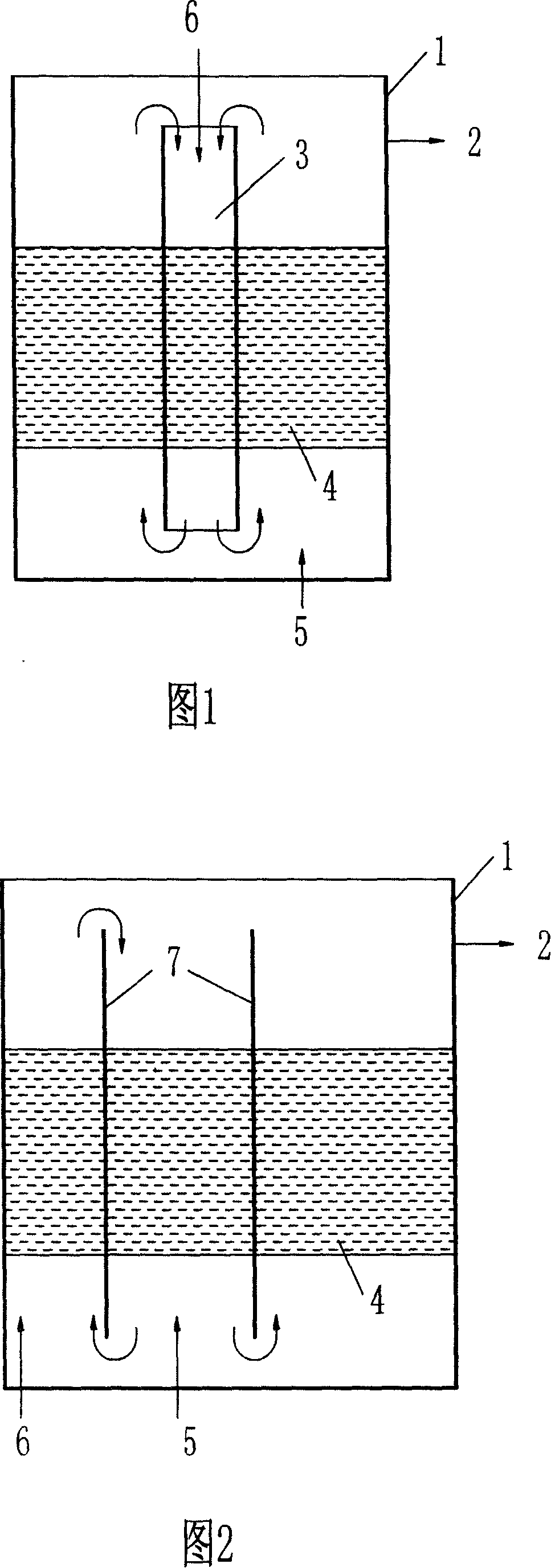

[0028] The internal circulation fluid biological aeration device (Fig. 1) consists of an aeration ...

Embodiment 1

[0034] Embodiment 1: adopt flora 1, mix and inoculate in common biological aeration filter carrier filler;

Embodiment 2

[0035] Example 2: Bacteria 1 was used and mixed inoculated in the contact oxidation reaction tank; it showed that the effect was basically the same as that of Example 1, indicating that the biological aeration filter had basically the same treatment effect as the biological reaction tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com