Patents

Literature

1109 results about "Oil refinery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An oil refinery or petroleum refinery is an industrial process plant where crude oil is transformed and refined into more useful products such as petroleum naphtha, gasoline, diesel fuel, asphalt base, heating oil, kerosene, liquefied petroleum gas, jet fuel and fuel oils. Petrochemicals feed stock like ethylene and propylene can also be produced directly by cracking crude oil without the need of using refined products of crude oil such as naphtha.

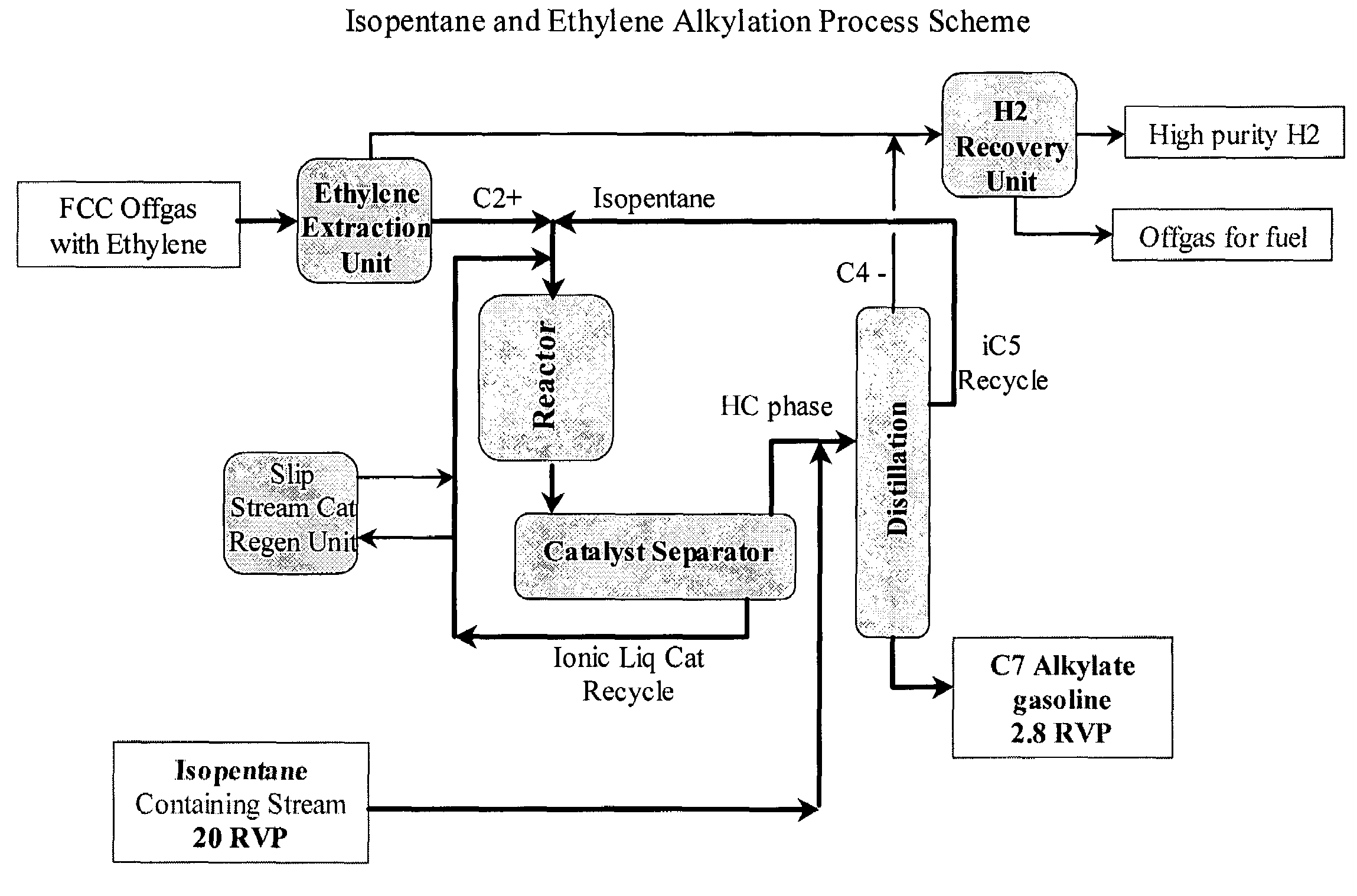

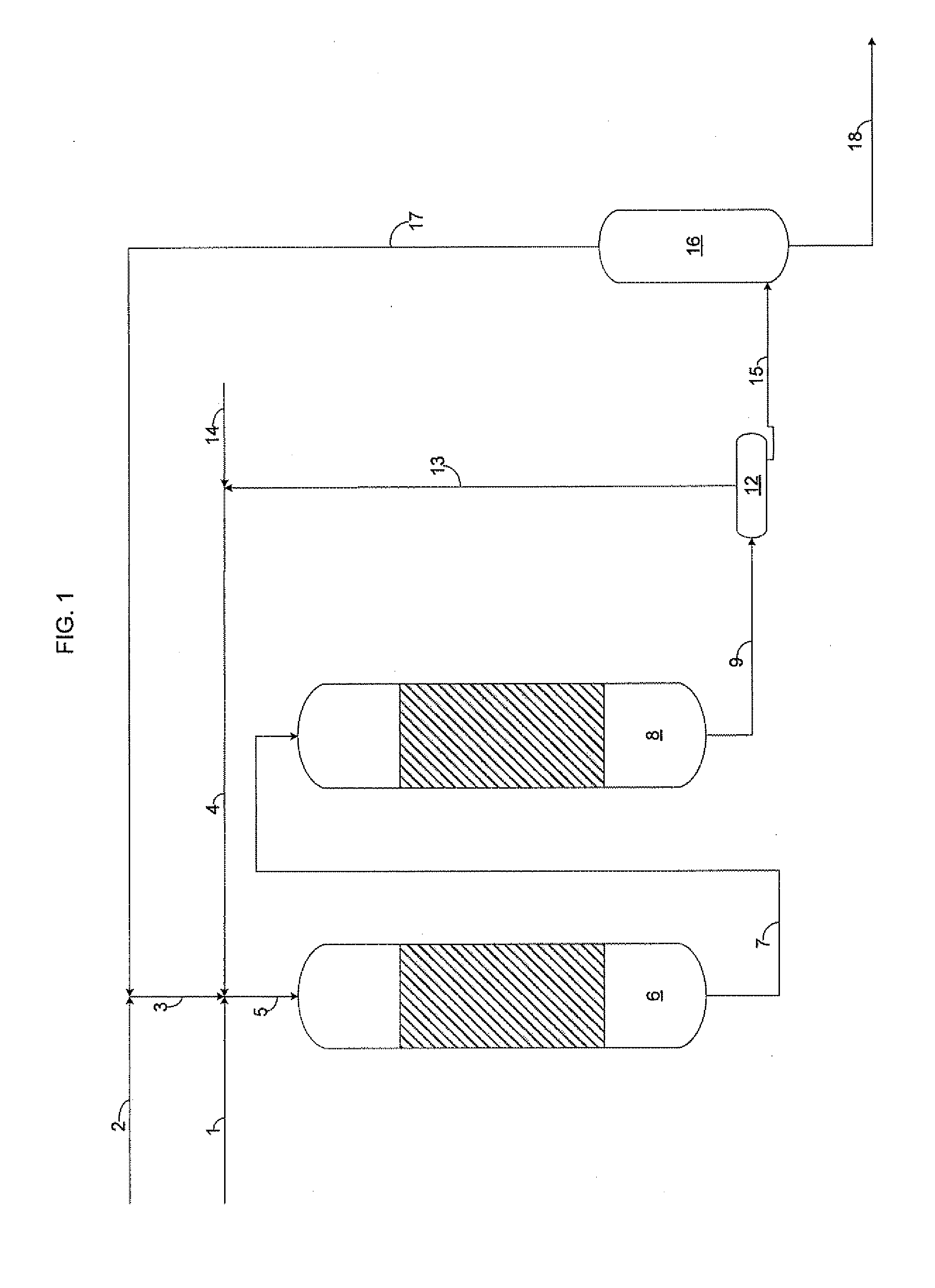

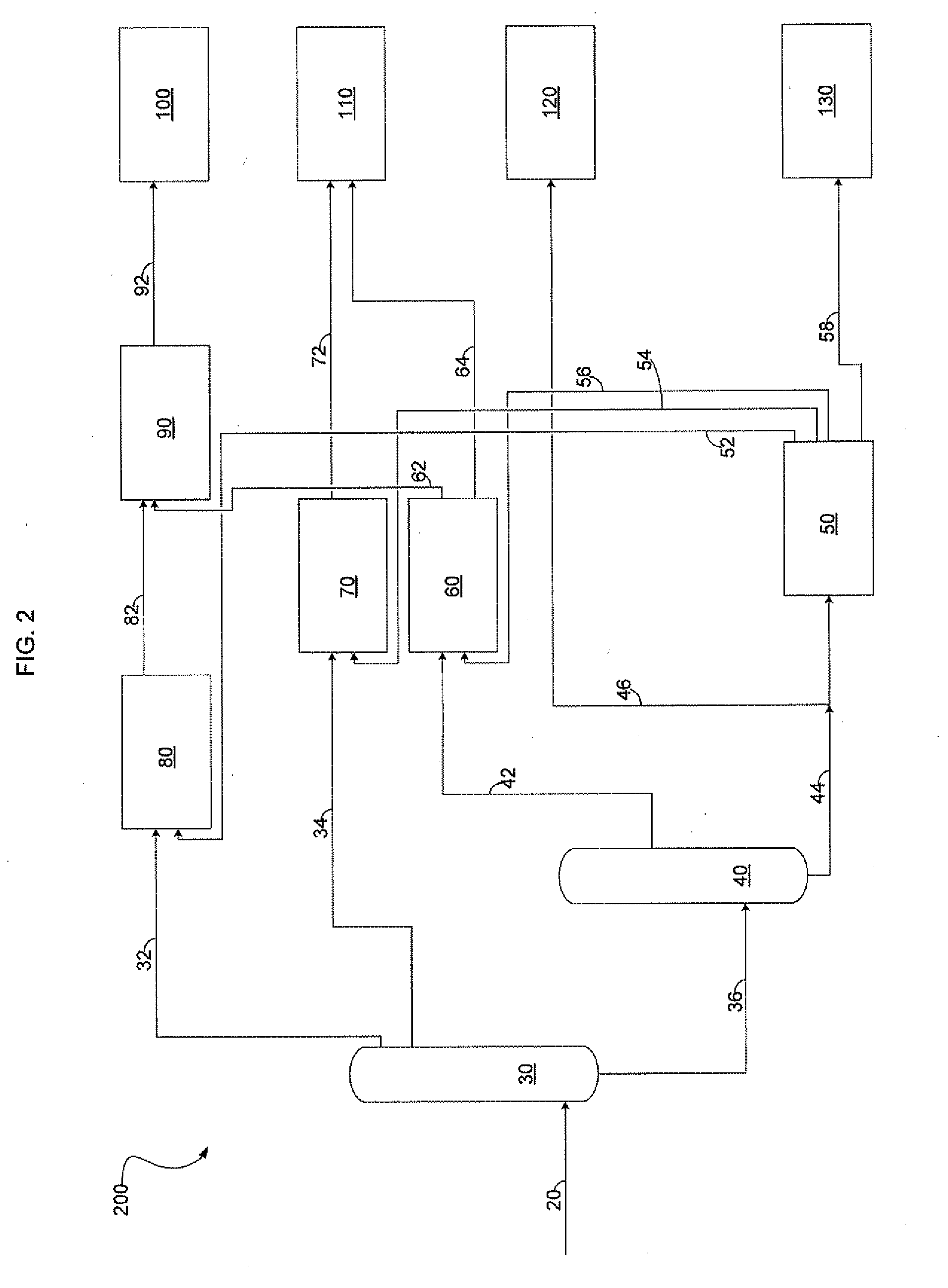

Integrated alkylation process using ionic liquid catalysts

ActiveUS7432408B2Easy to operateReduce gas productionLiquid hydrocarbon mixtures productionRefining with metal saltsAlkyl transferGasoline

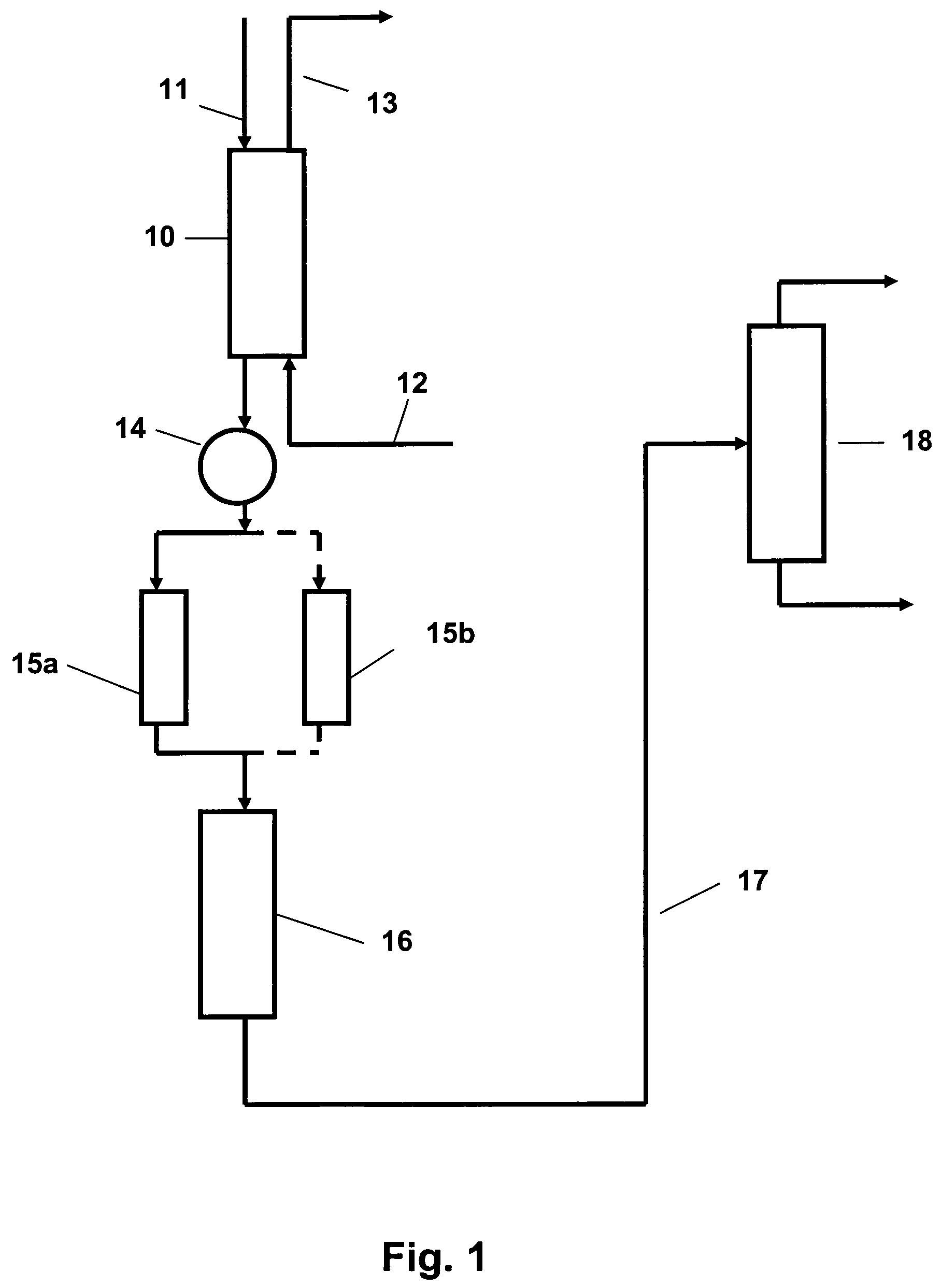

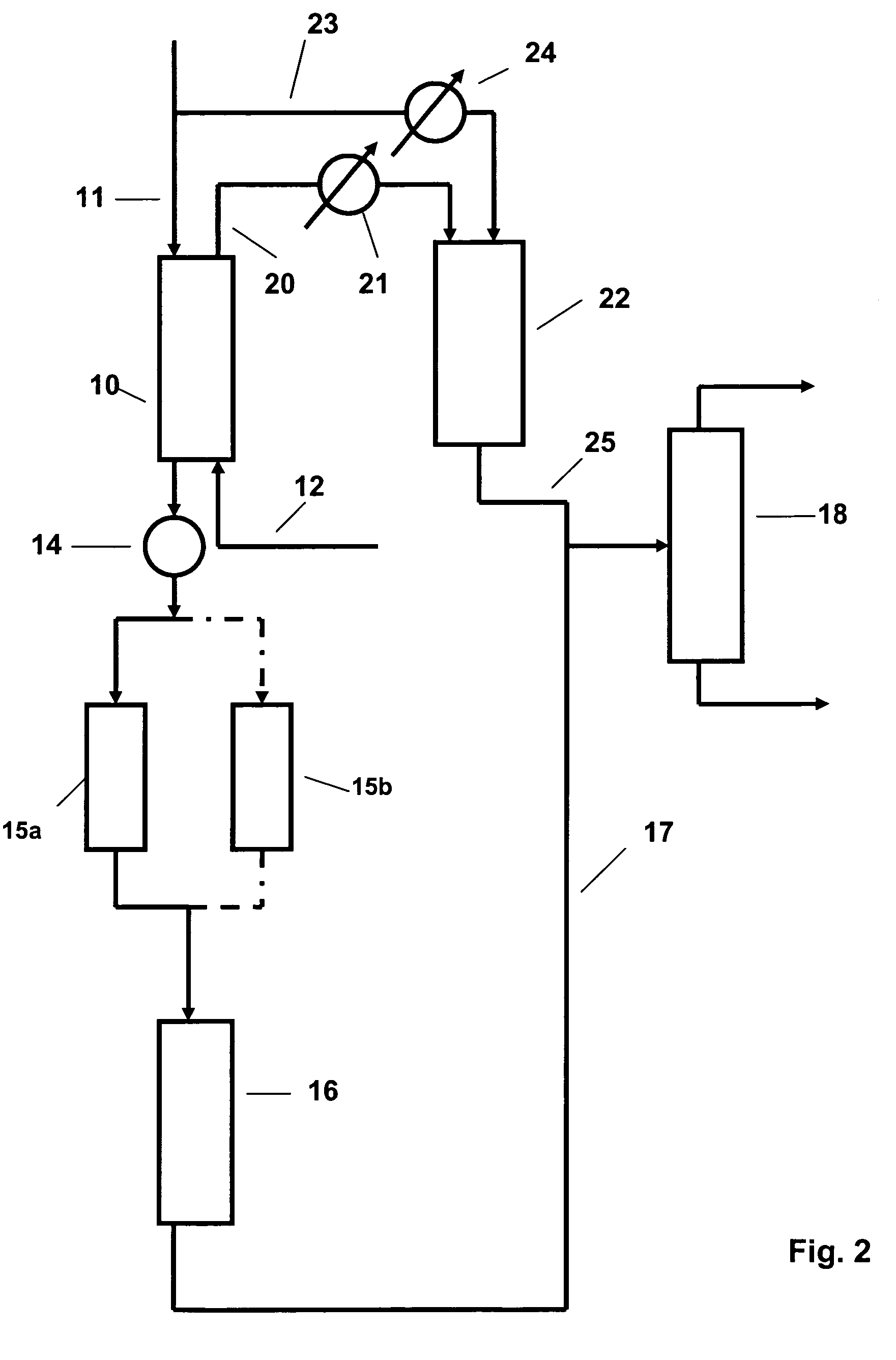

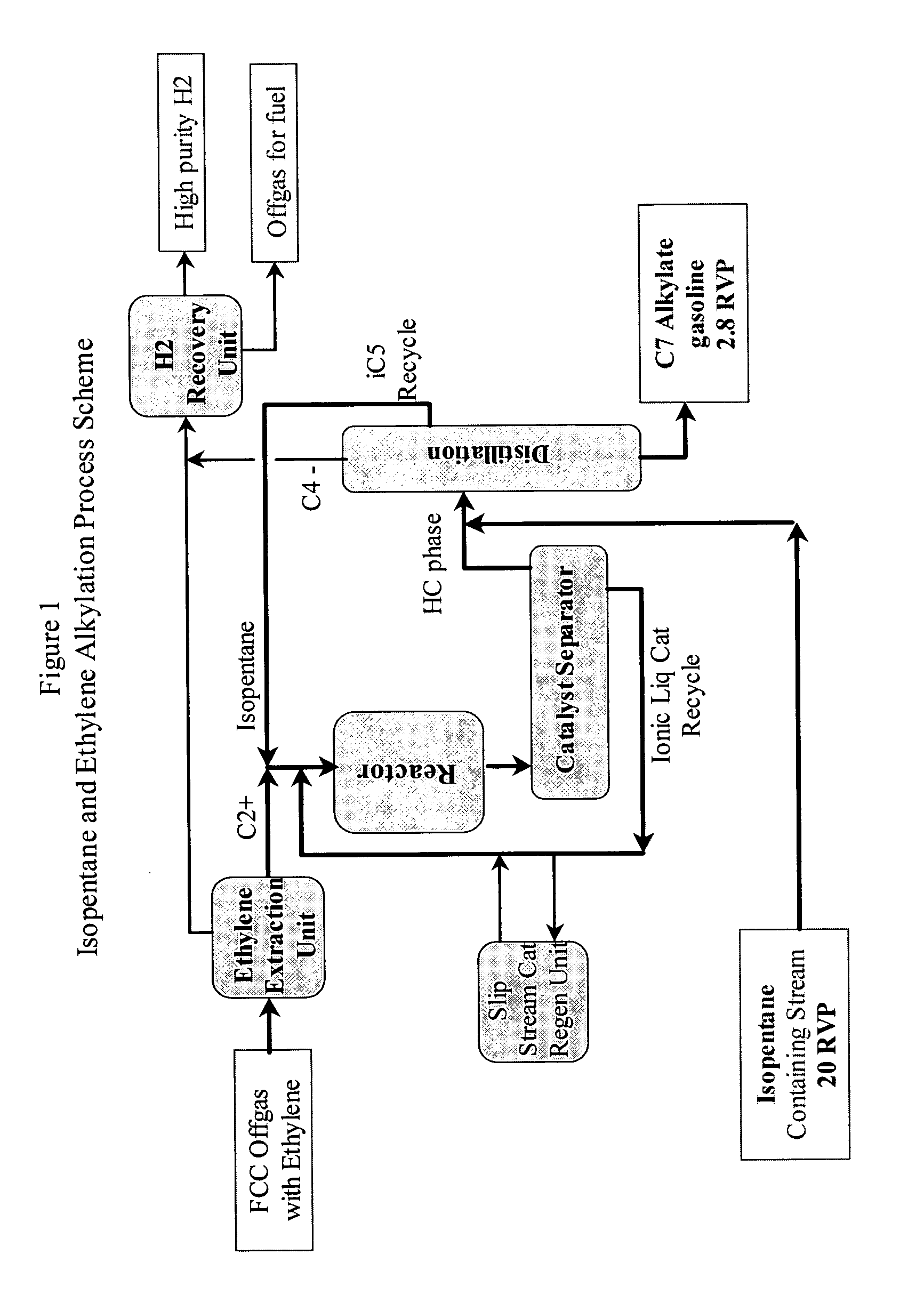

An integrated refining process for the production of high quality gasoline blending components from low value components is disclosed. In addition there is disclosed a method of improving the operating efficiency of a refinery by reducing fuel gas production and simultaneously producing high quality gasoline blending components of low volatility. The processes involve the alkylation of a refinery stream containing pentane with ethylene using an ionic liquid catalyst.

Owner:CHEVROU USA INC

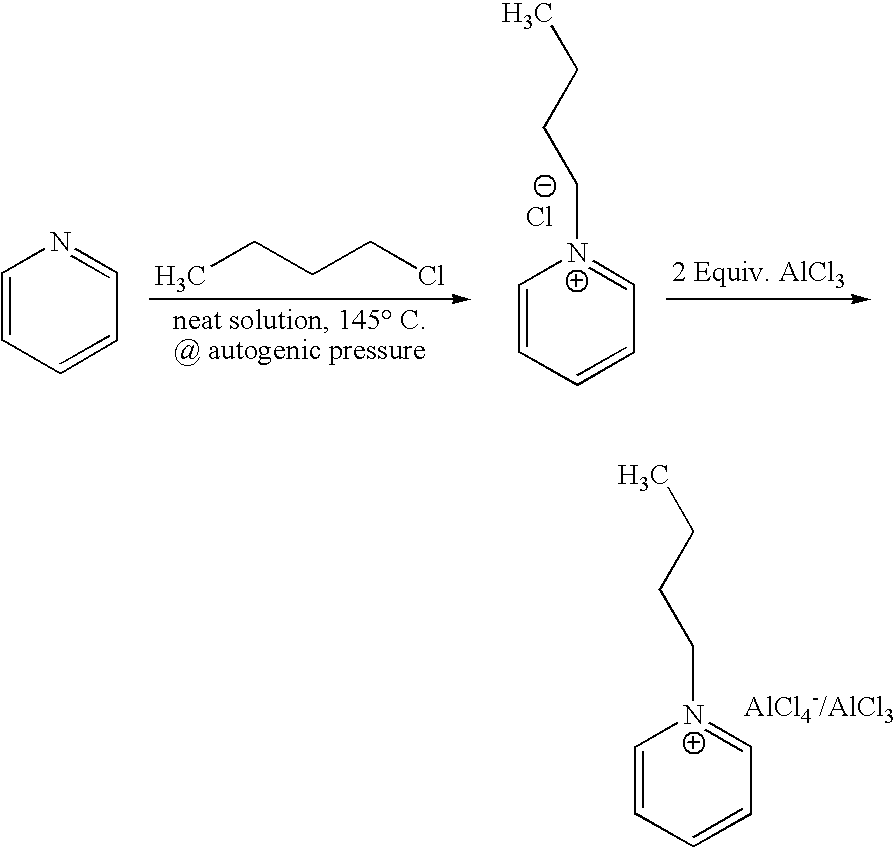

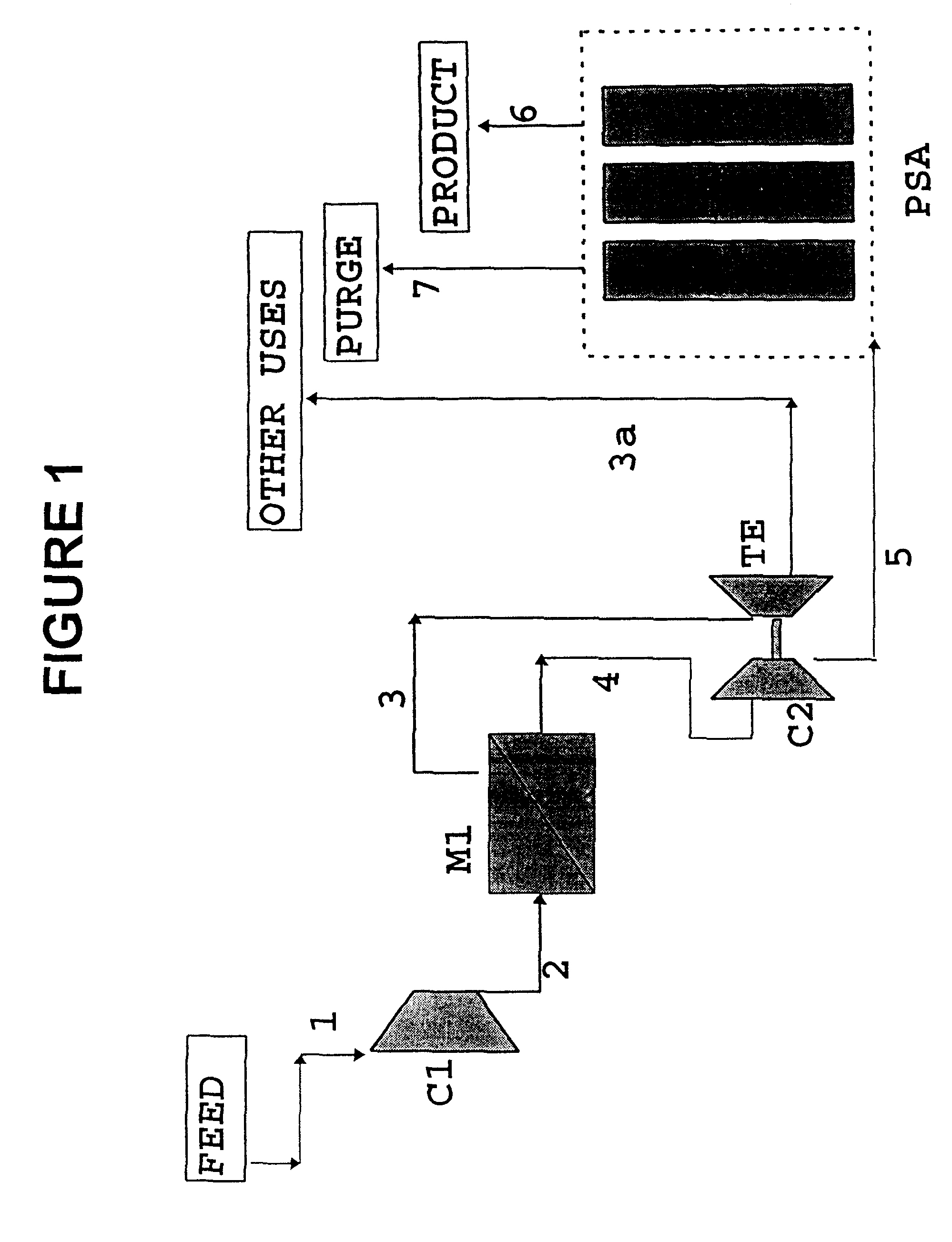

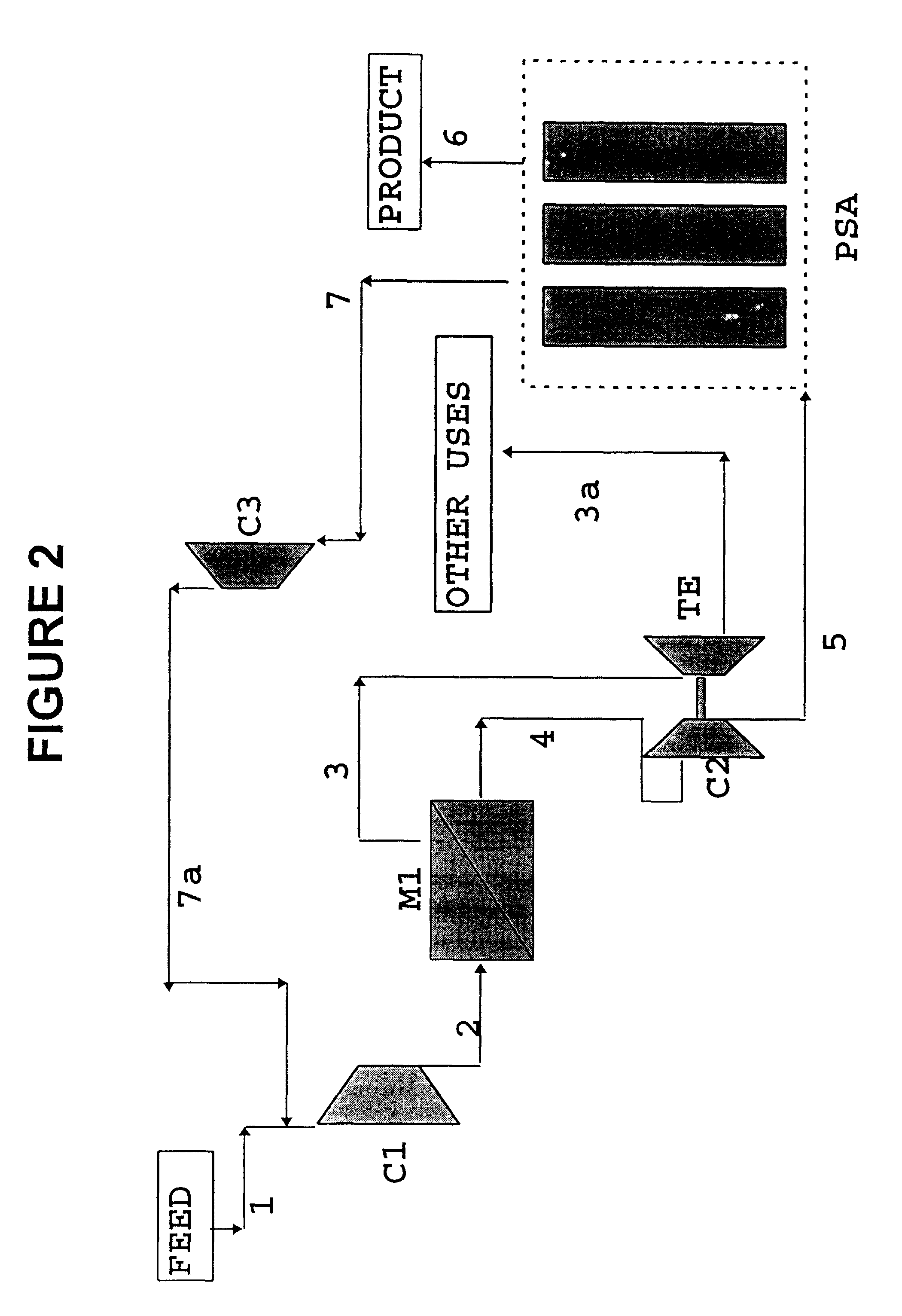

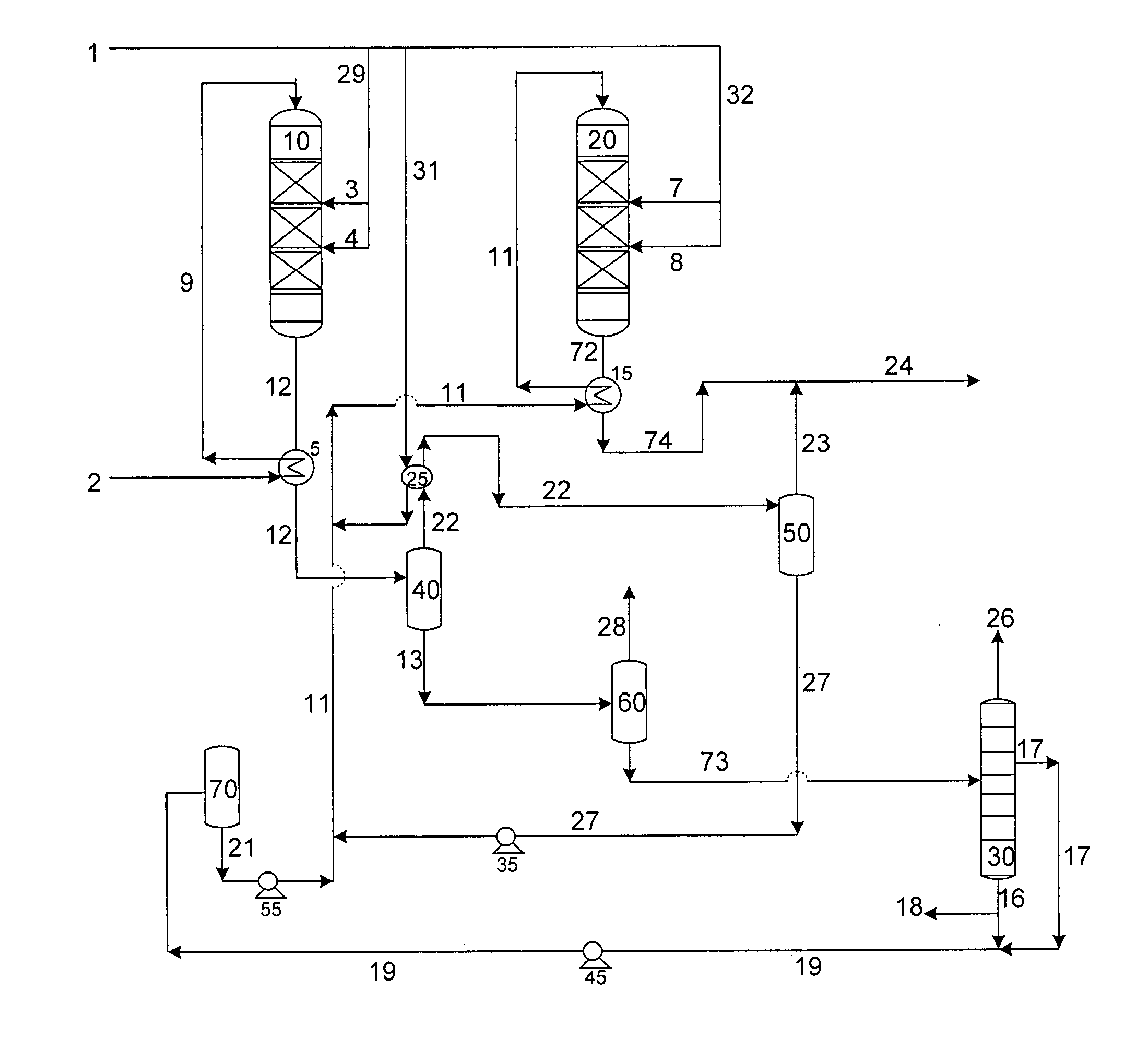

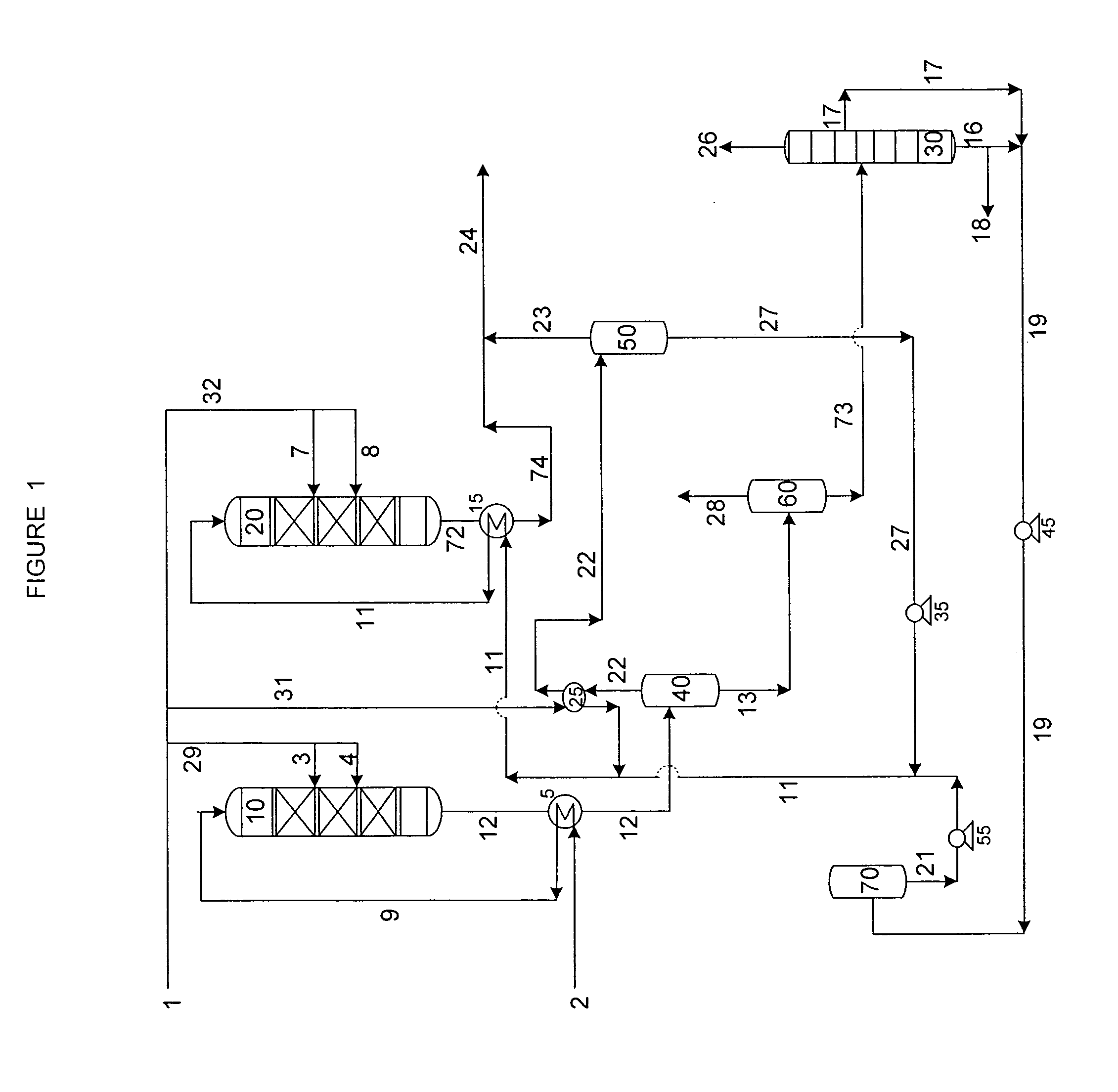

Process for the separation/recovery of gases

InactiveUS6179900B1Low costHigh purityNitrogen purification/separationGas treatmentHydrogenHigh pressure

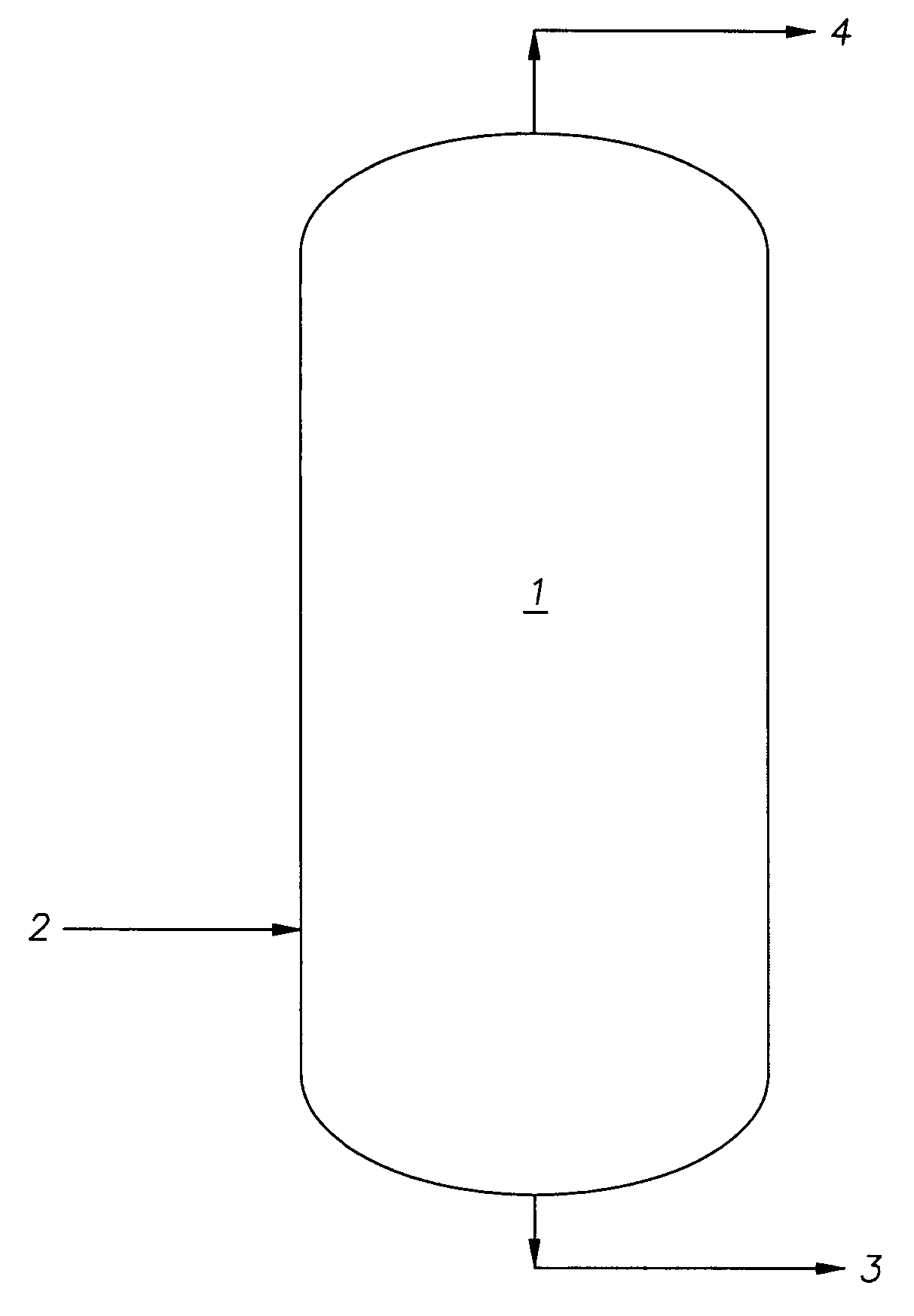

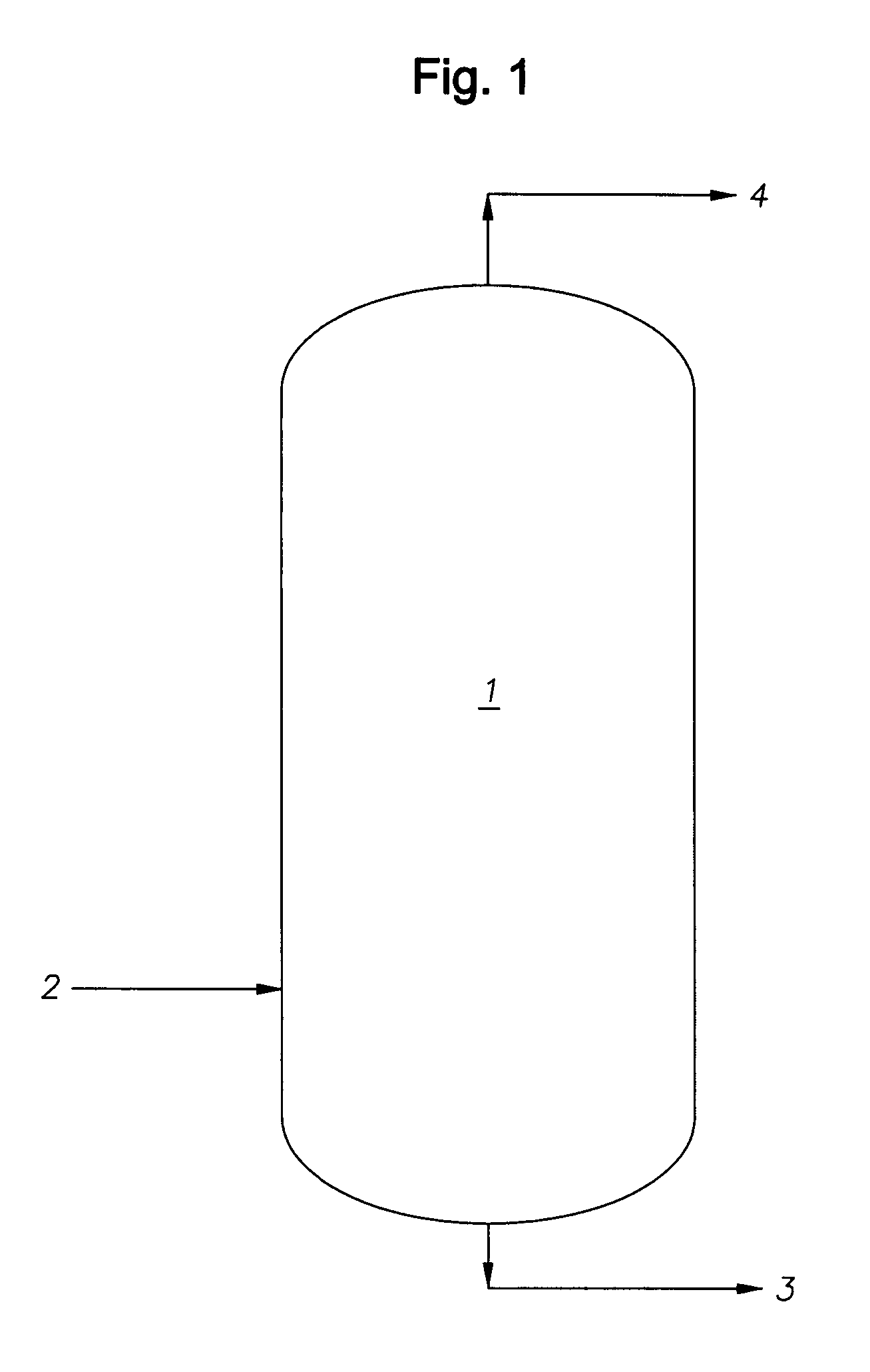

A process for the separation / recovery of gases is described where the desired component to be separated from the gaseous mixture is present in low / very low molar amount and / or low / moderate pressure, the process comprising contacting the gaseous mixture with a separation membrane unit containing high permeability / medium selectivity membranes which separate the feed stream into a permeate stream, enriched in the desired component and at a lower pressure and a retentate stream lean in the desired component and at a higher pressure. The retentate stream is made to convey its pressure to the permeate stream which then is directed to an adsorption PSA unit for further purification of the permeate stream so that the effluent stream from the PSA unit which contains the purified component has a purity of up to 99.90%. The process is useful for separating hydrogen from refinery off gases such as FCC gases and can also be applied to other gases such as helium and any other valuable gases present in gaseous streams in low to very low molar contents and low to moderate pressures.

Owner:GKSS FORSCHUNGSZENTRUM GEESTHACHT GMBH +1

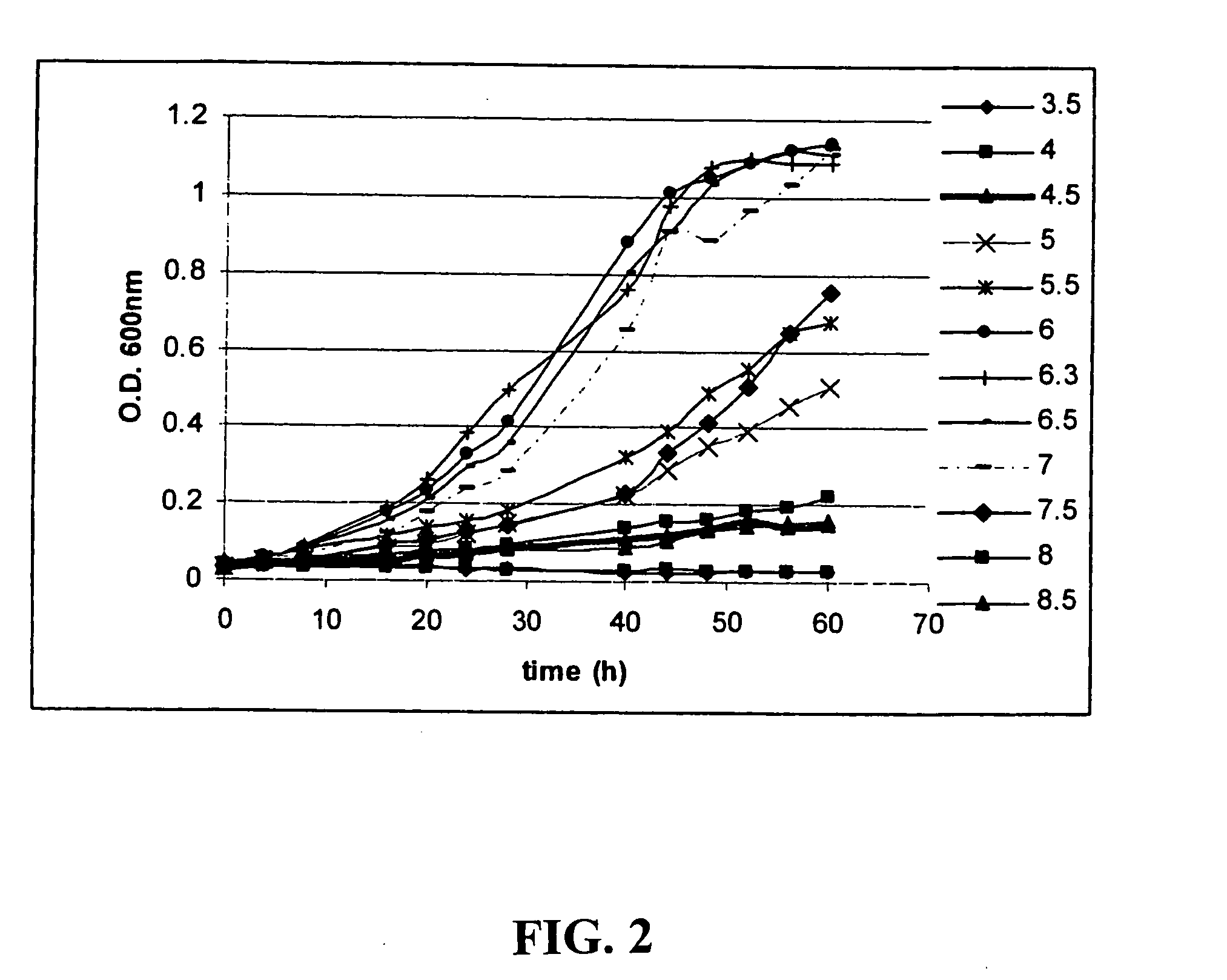

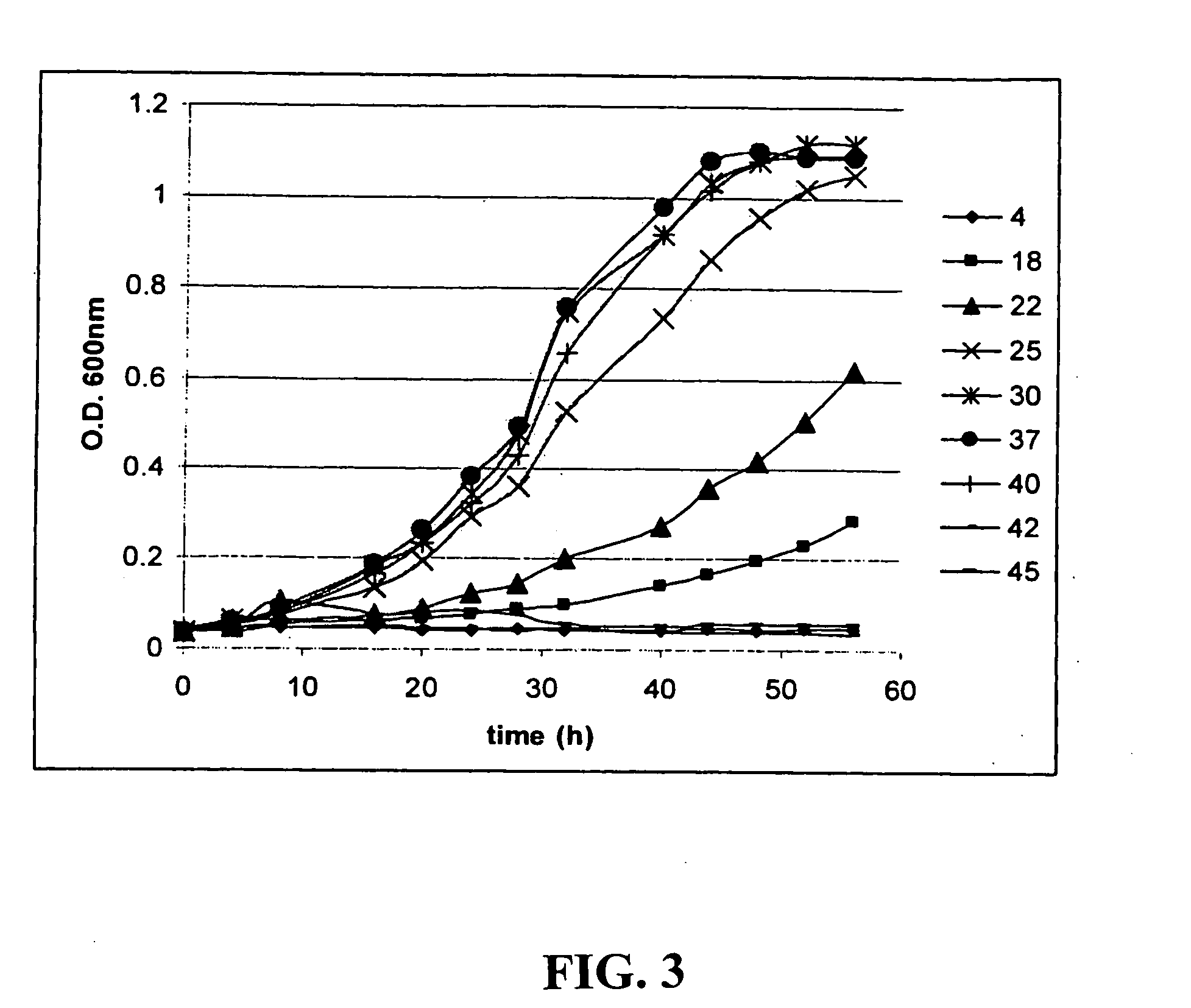

Isolation and characterization of novel clostridial species

InactiveUS20080057554A1High yieldReadily availableBioreactor/fermenter combinationsBiological substance pretreatmentsBacteroidesAcetic acid

A novel clostridia bacterial species (Clostridium ragsdalei, ATCC BAA-622, “P11”) is provided. P11 is capable of synthesizing, from waste gases, products which are useful as biofuel. In particular, P11 can convert CO to ethanol. Thus, this novel bacterium transforms waste gases (e.g. syngas and refinery wastes) into useful products. P11 also catalyzes the production of acetate.

Owner:BOARD OF REGENTS FOR OKLAHOMA STATE UNIVERSITY +1

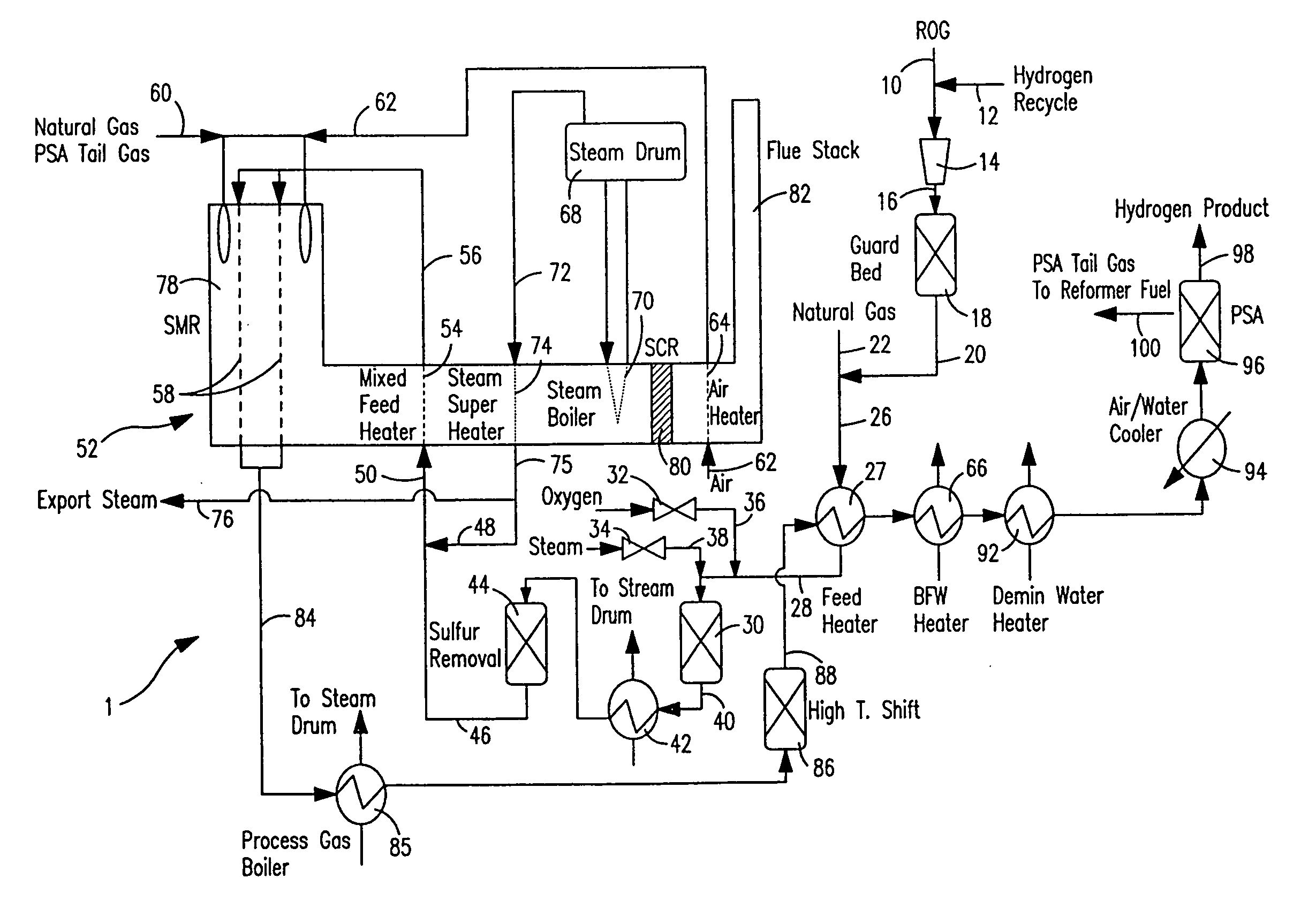

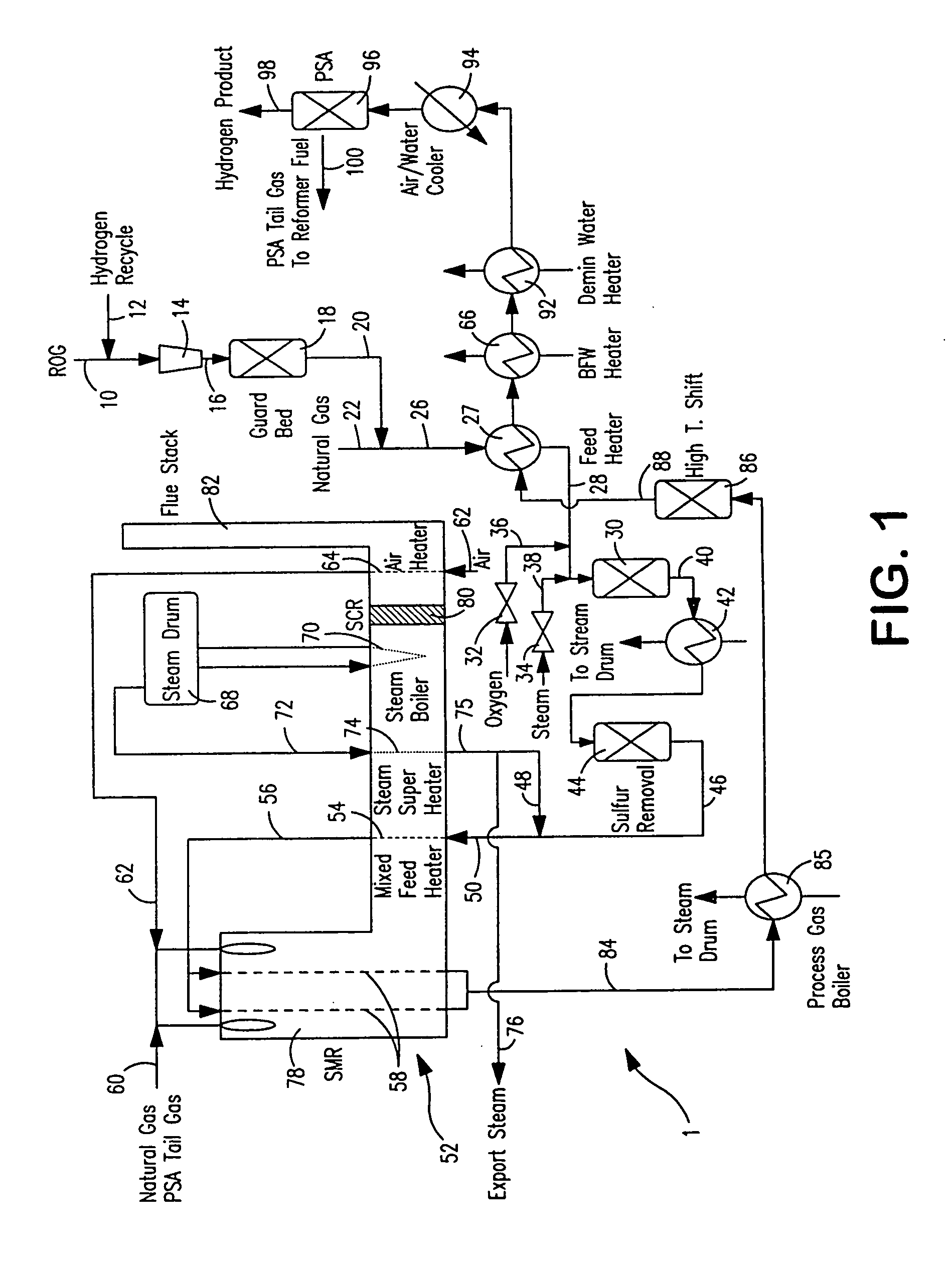

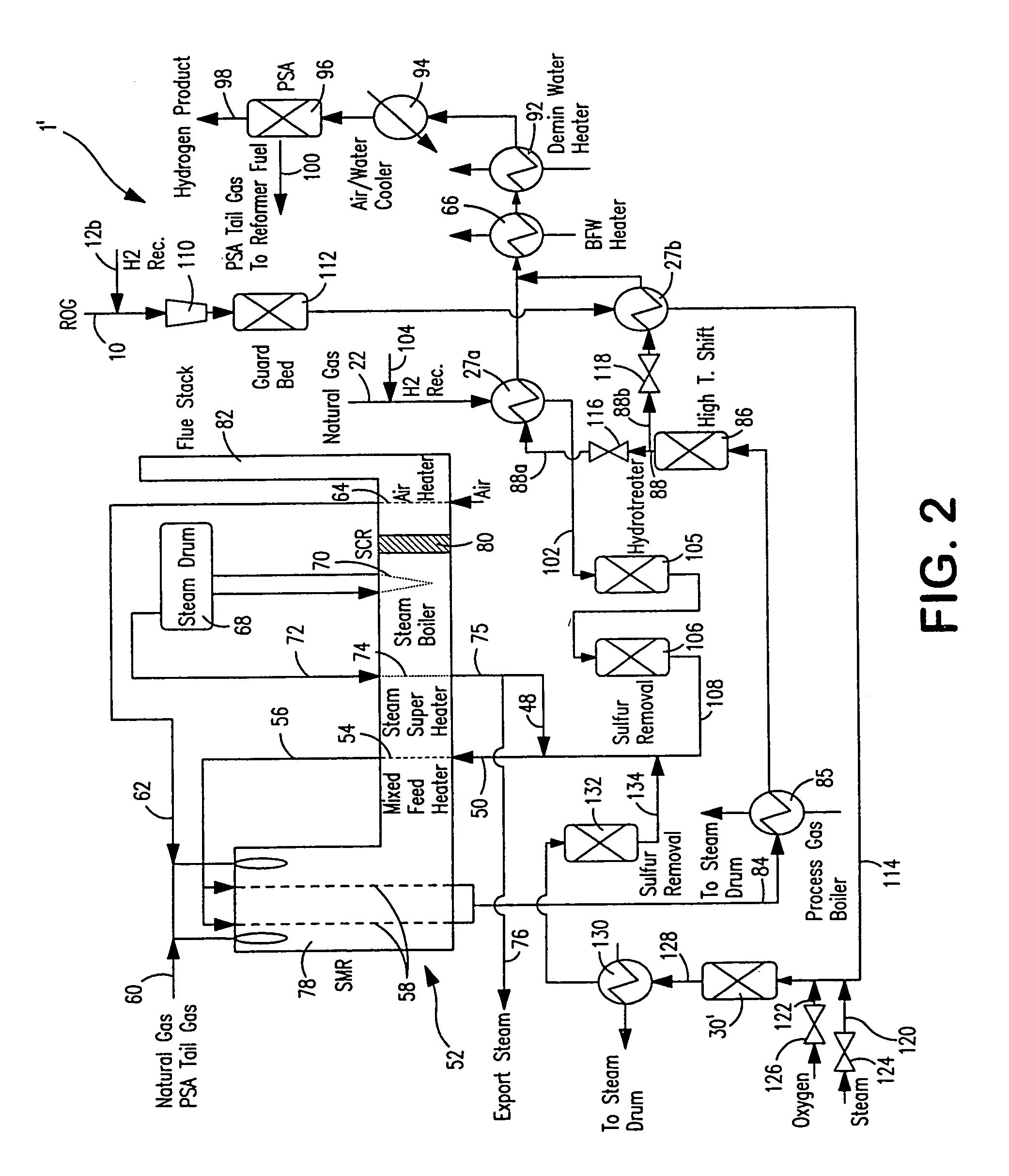

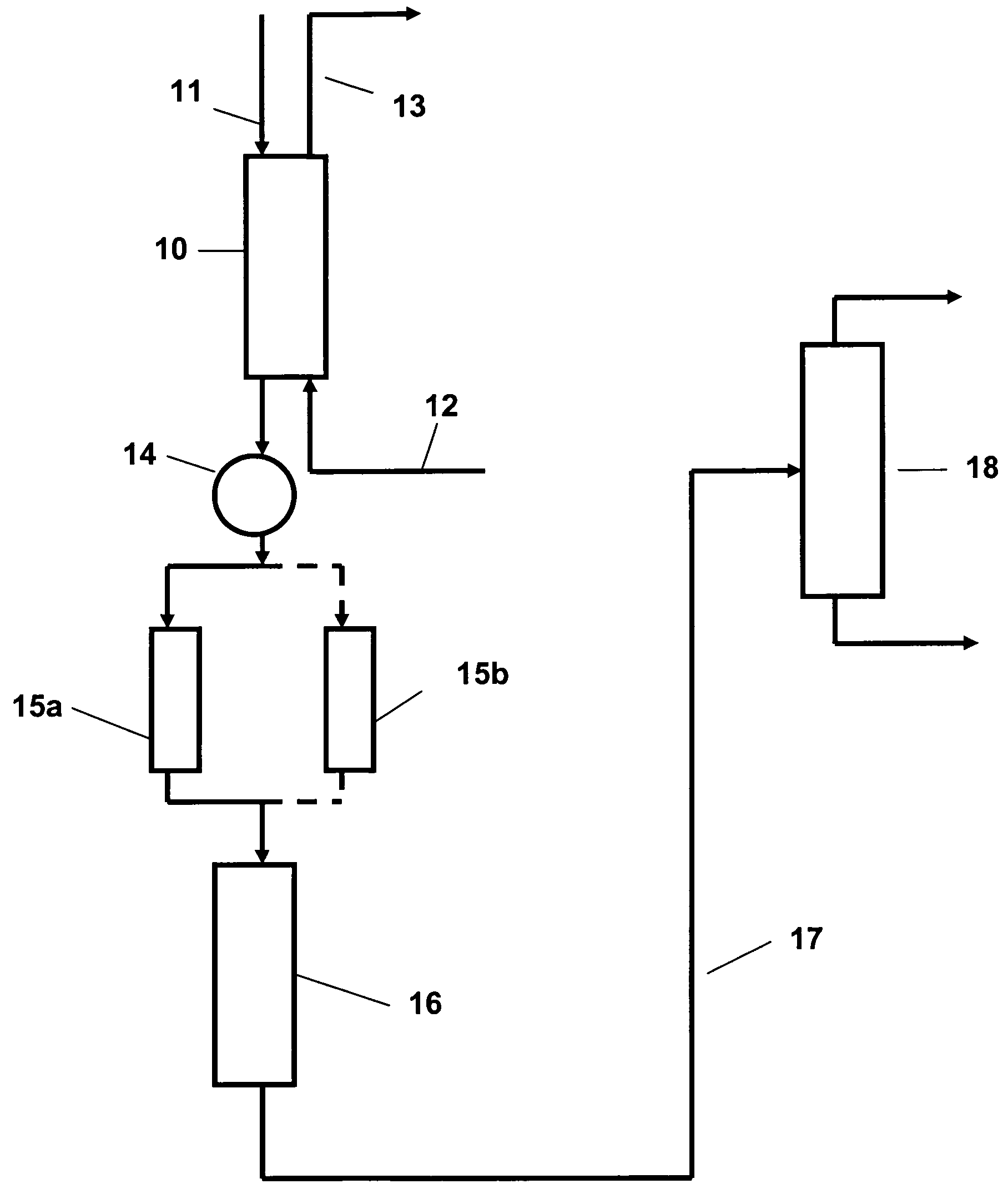

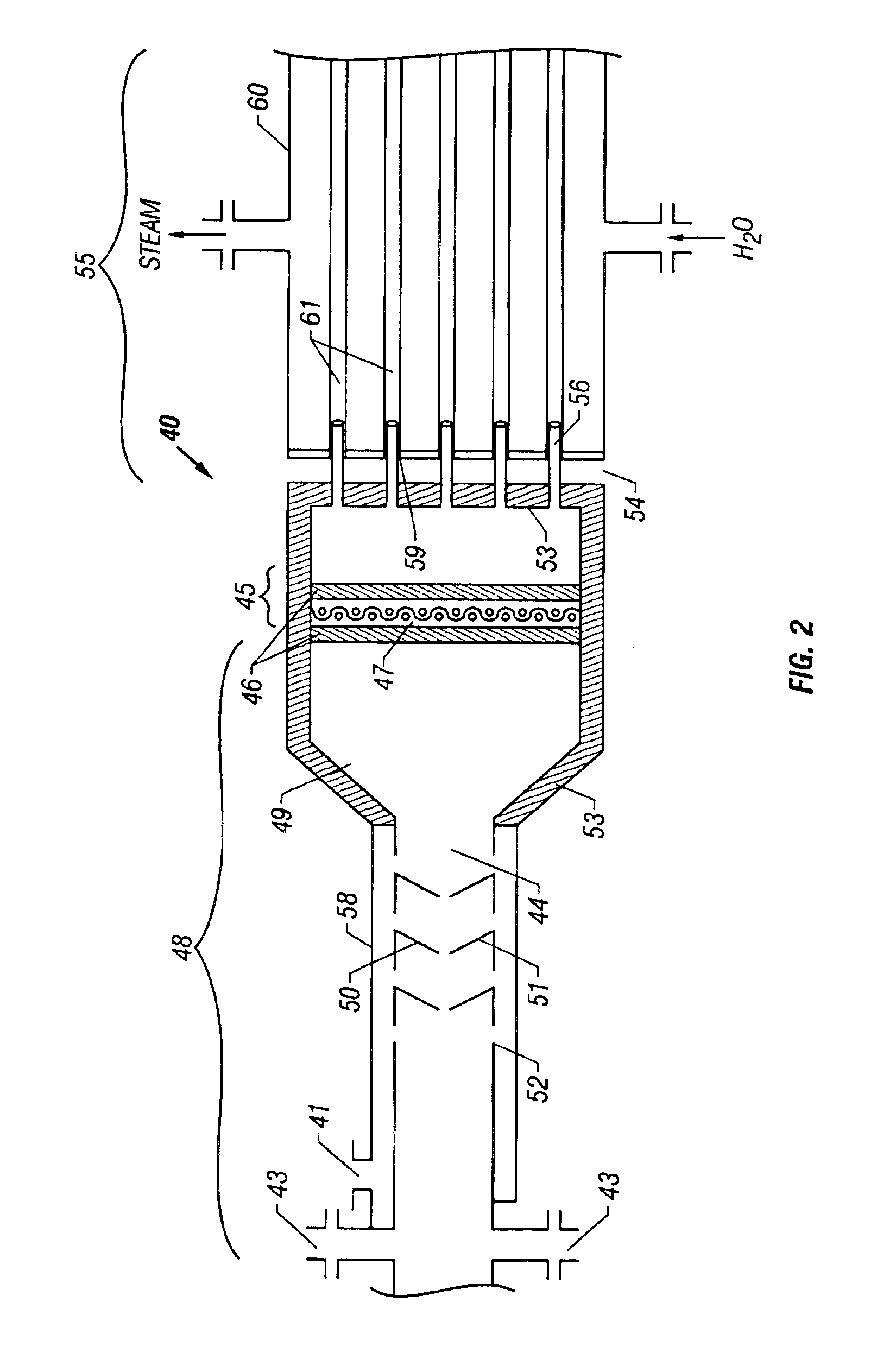

Steam methane reforming method

ActiveUS7037485B1Reduce fuel usageReduce firing rateHydrocarbon from carbon oxidesHydrogen separation using solid contactMethane reformerAlkane

A steam methane reforming method in which a feed stream is treated in a reactor containing a catalyst that is capable of promoting both hydrogenation and partial oxidation reactions. The reactor is either operated in a catalytic hydrogenation mode to convert olefins into saturated hydrocarbons and / or to chemically reduce sulfur species to hydrogen sulfide or a catalytic oxidative mode utilizing oxygen and steam to prereform the feed and thus, increase the hydrogen content of a synthesis gas produced by a steam methane reformer. The method is applicable to the treatment of feed streams containing at least 15% by volume of hydrocarbons with two or more carbon atoms and / or 3% by volume of olefins, such as a refinery off-gas. In such case, the catalytic oxidative mode is conducted with a steam to carbon ratio of less than 0.5, an oxygen to carbon ratio of less than 0.25 and a reaction temperature of between about 500° C. and about 860° C. to limit the feed to the steam methane reformer to volumetric dry concentrations of less than about 0.5% for the olefins and less than about 10% for alkanes with two or more carbon atoms.

Owner:PRAXAIR TECH INC

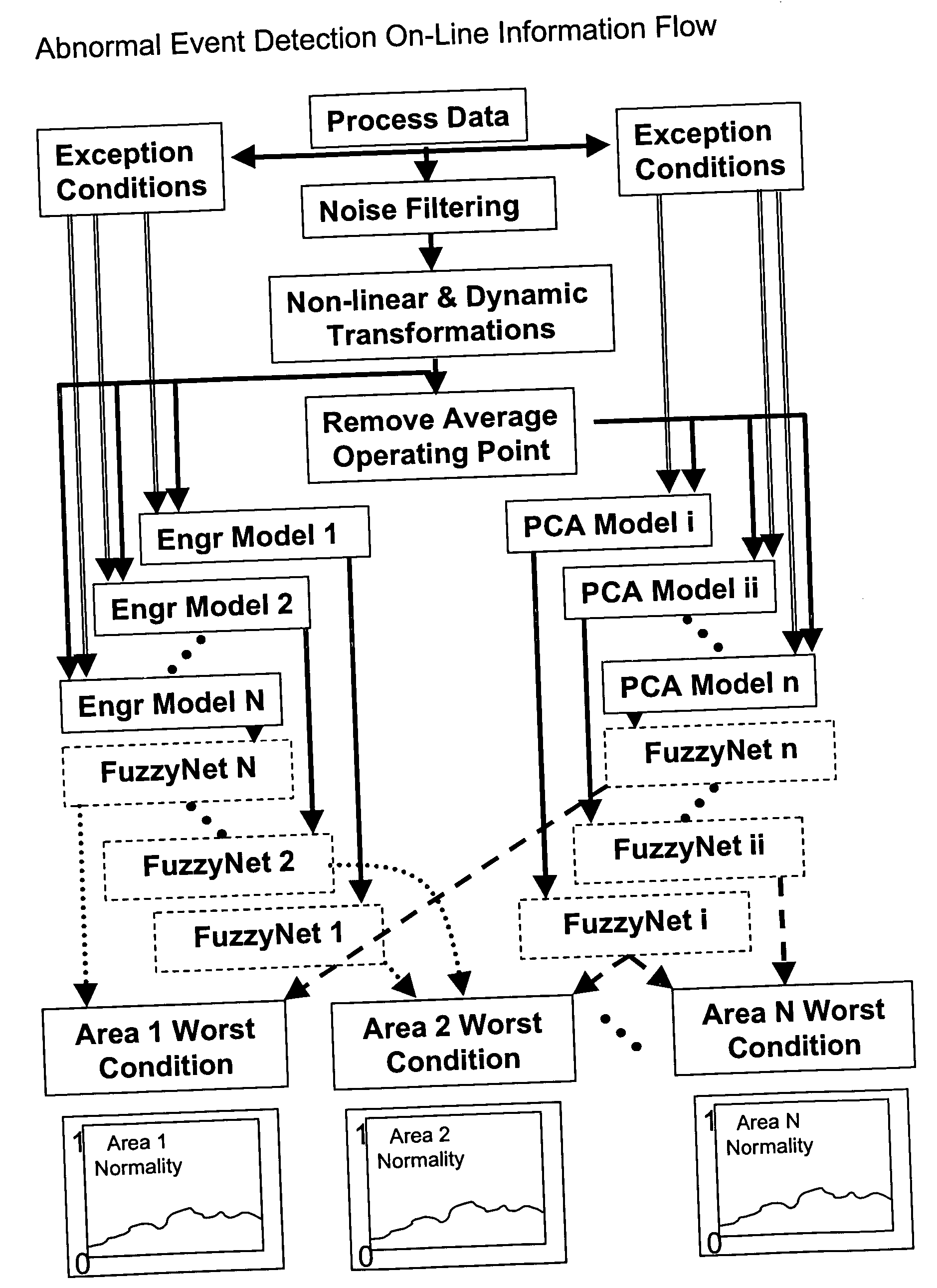

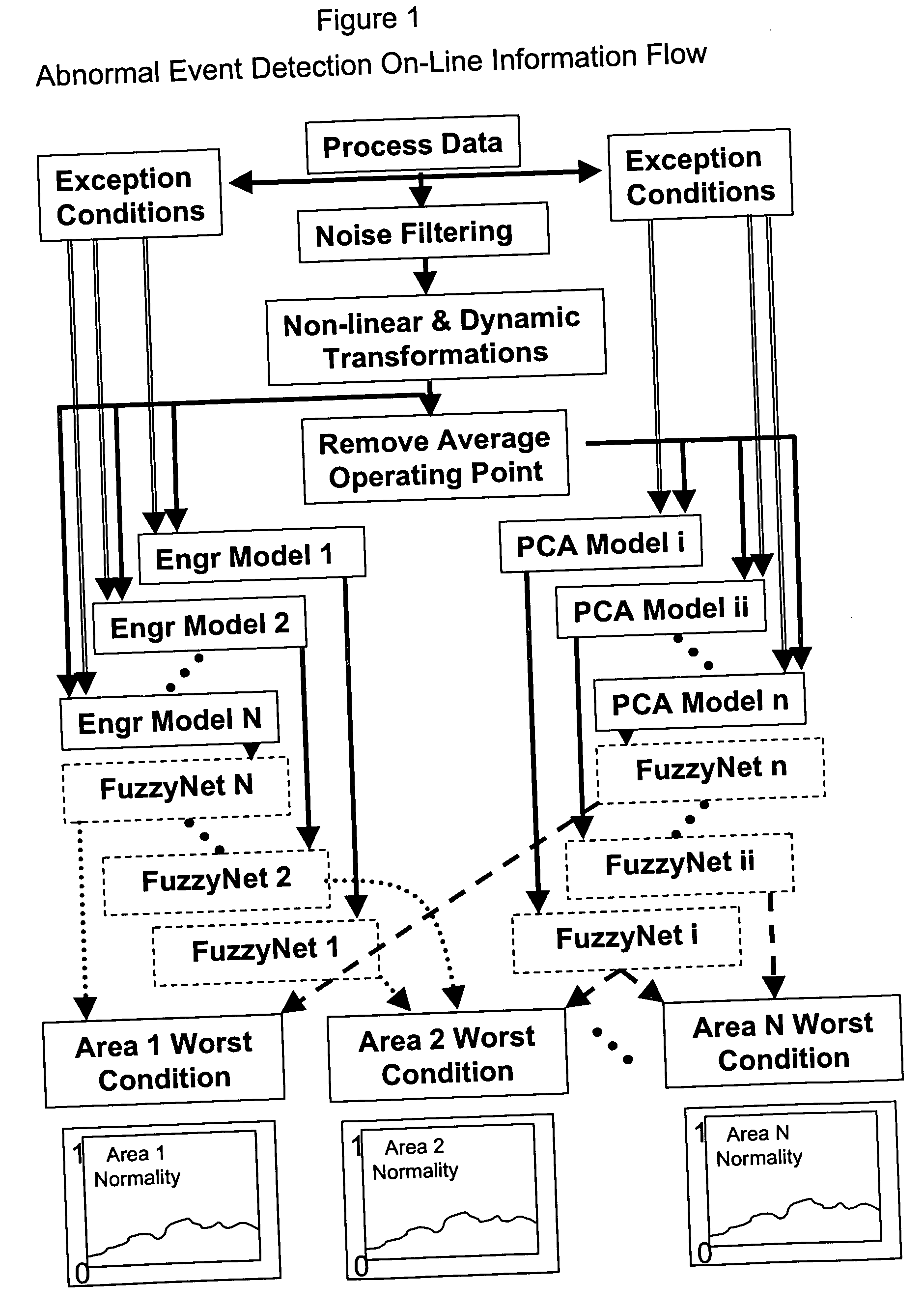

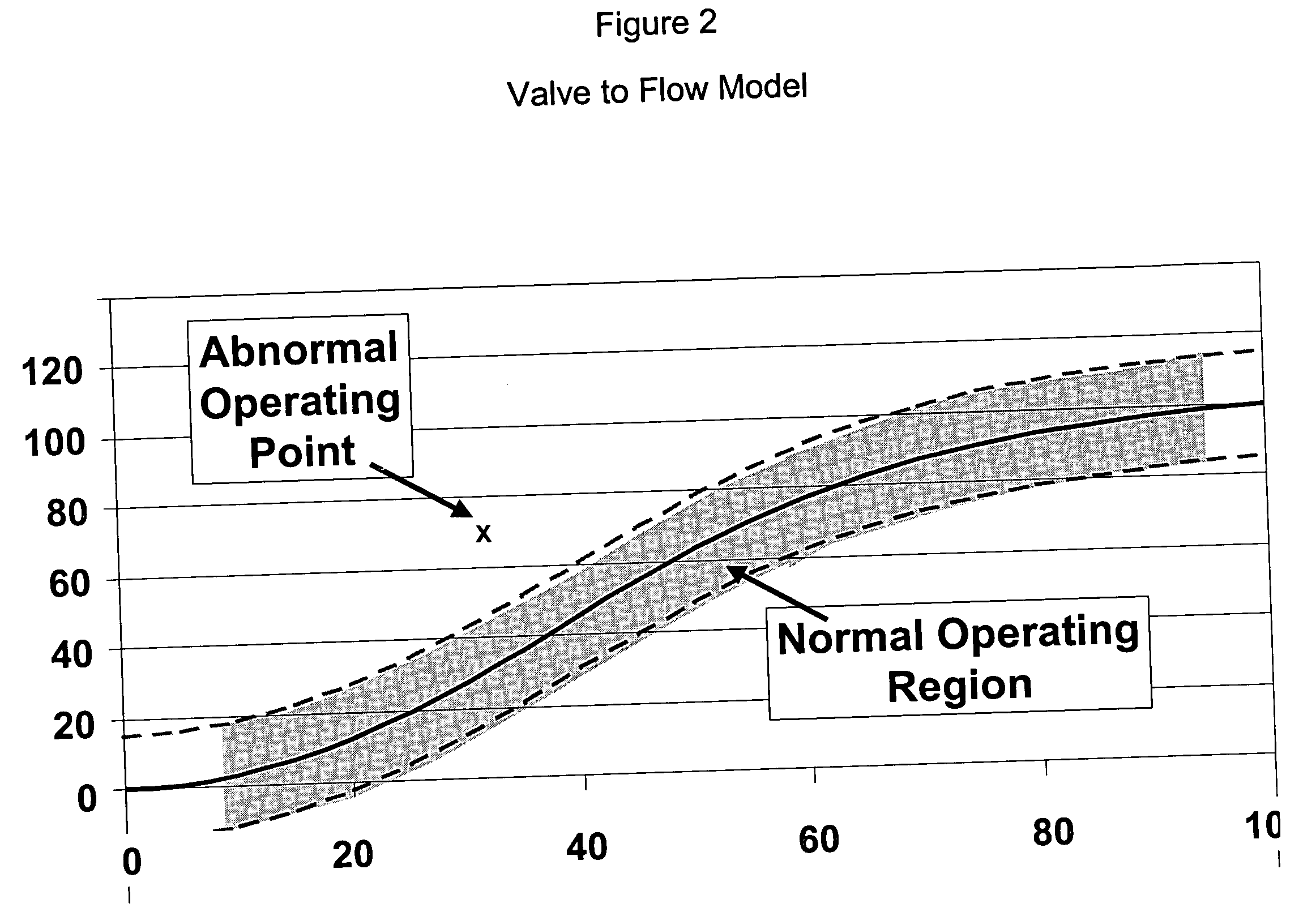

System and method for abnormal event detection in the operation of continuous industrial processes

ActiveUS20060058898A1Eliminate the effects ofEasy to monitorCatalytic crackingTesting/monitoring control systemsMultivariate statisticsPrincipal component analysis

Thousands of process and equipment measurements are gathered by the modern digital process control systems that are deployed in refineries and chemical plants. Several years of these data are historized in databases for analysis and reporting. These databases can be mined for the data patterns that occur during normal operation and those patterns used to determine when the process is behaving abnormally. These normal operating patterns are represented by sets of models. These models include simple engineering equations, which express known relationships that should be true during normal operations and multivariate statistical models based on a variation of principle component analysis. Equipment and process problems can be detected by comparing the data gathered on a minute by minute basis to predictions from these models of normal operation. The deviation between the expected pattern in the process operating data and the actual data pattern are interpreted by fuzzy Petri nets to determine the normality of the process operations. This is then used to help the operator localize and diagnose the root cause of the problem.

Owner:EXXON RES & ENG CO

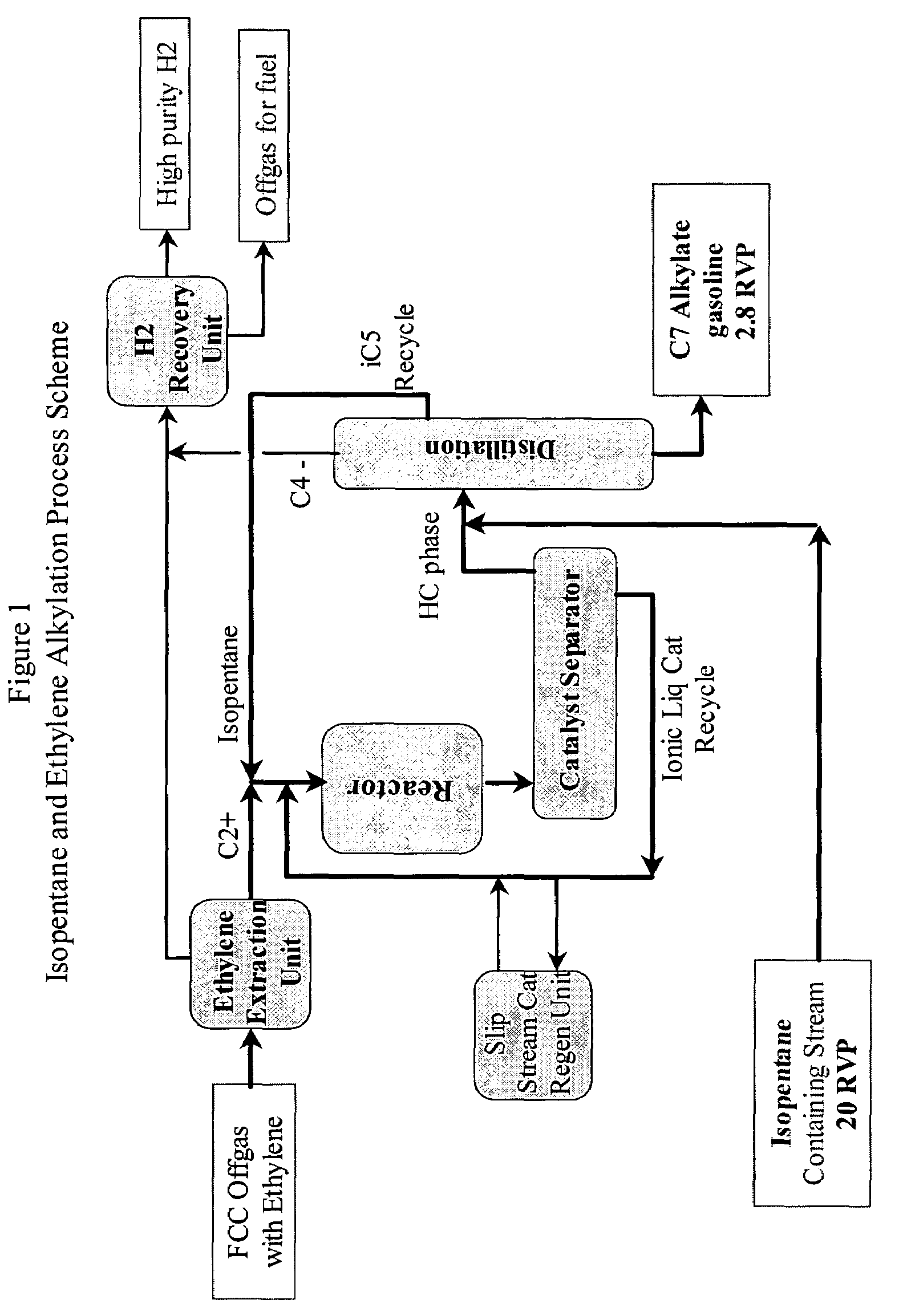

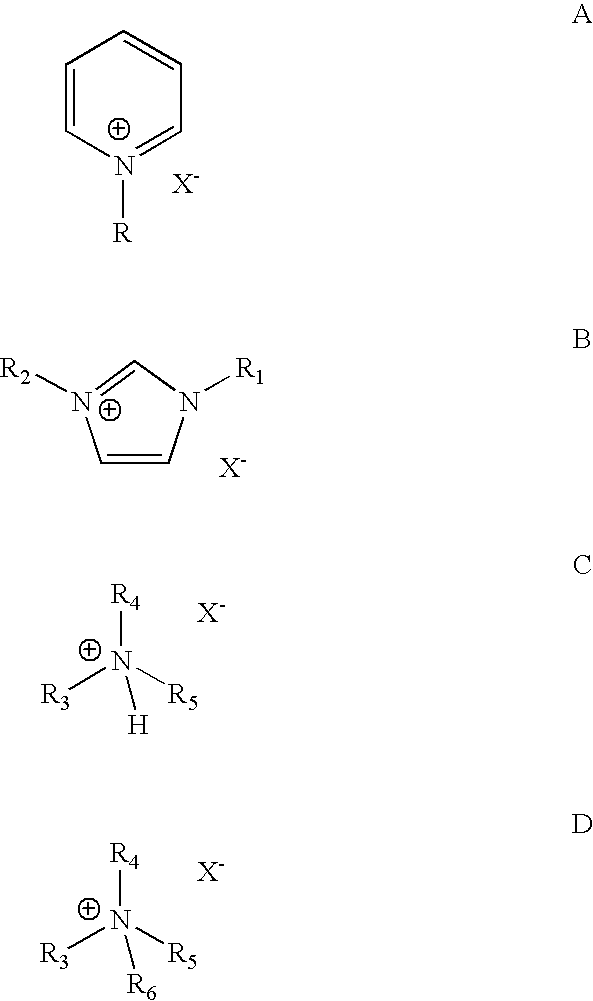

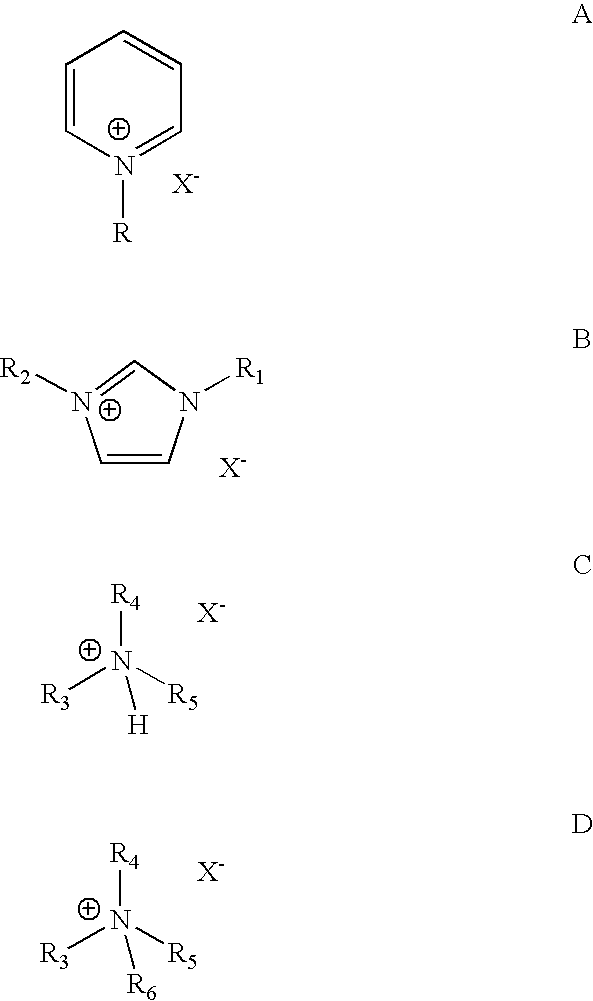

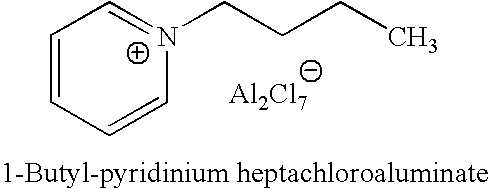

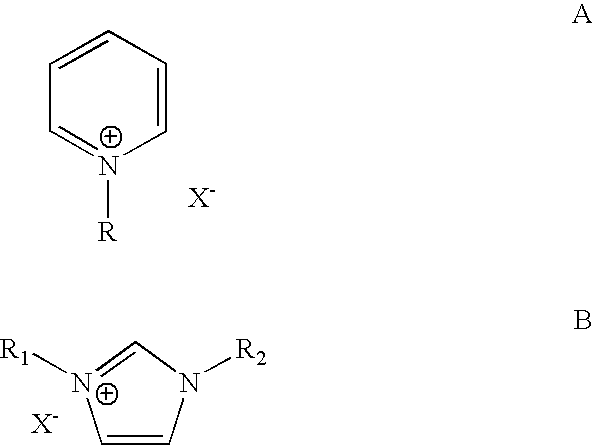

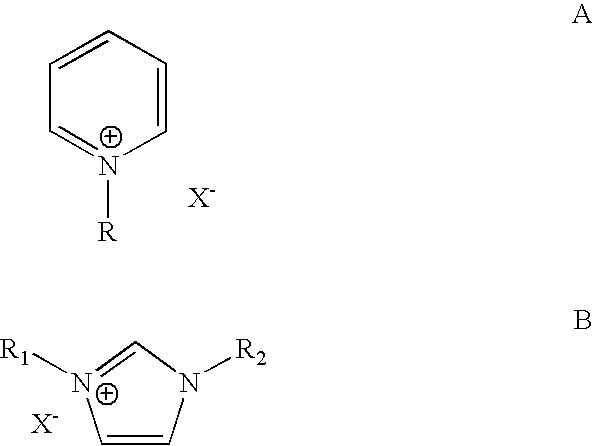

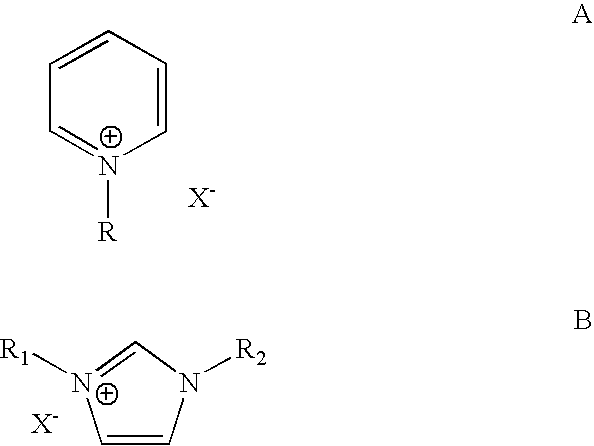

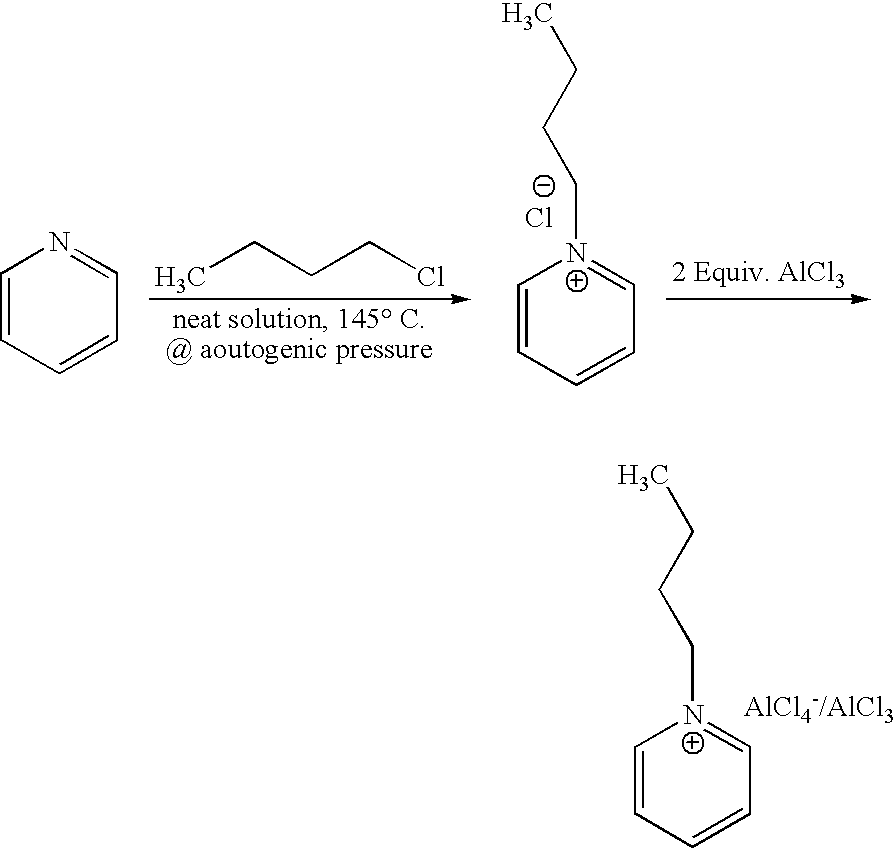

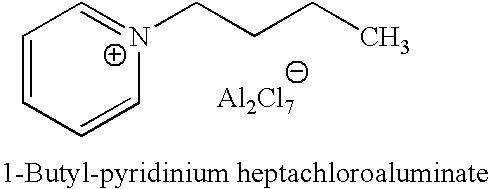

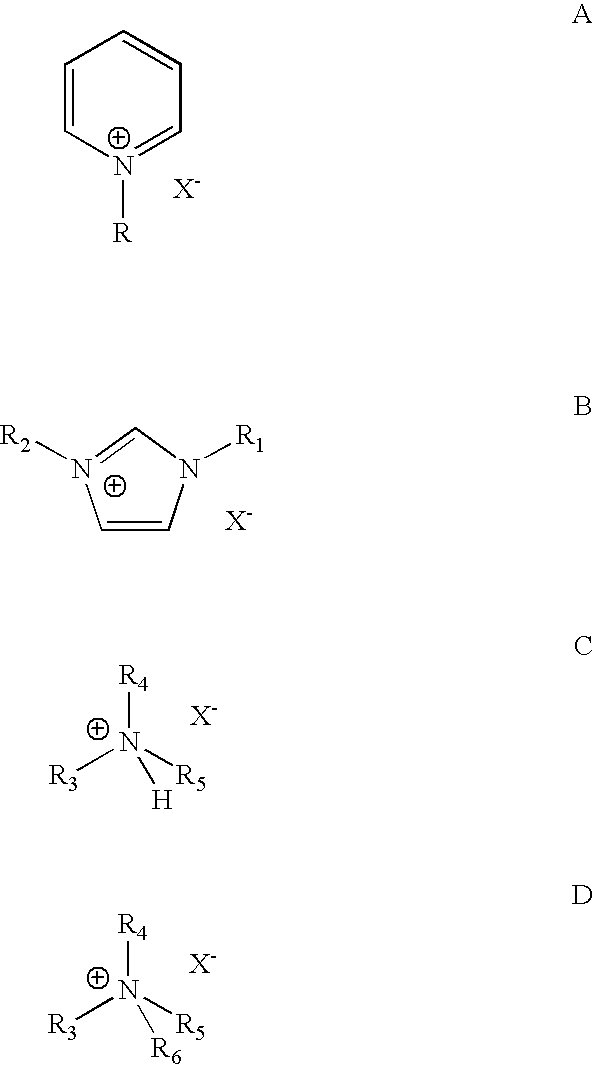

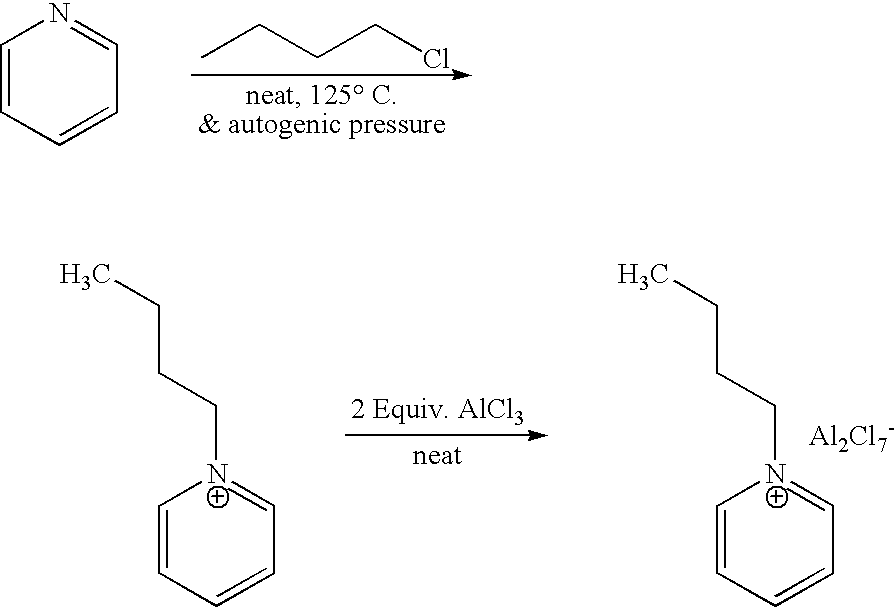

Alkylation process using an alkyl halide promoted ionic liquid catalyst

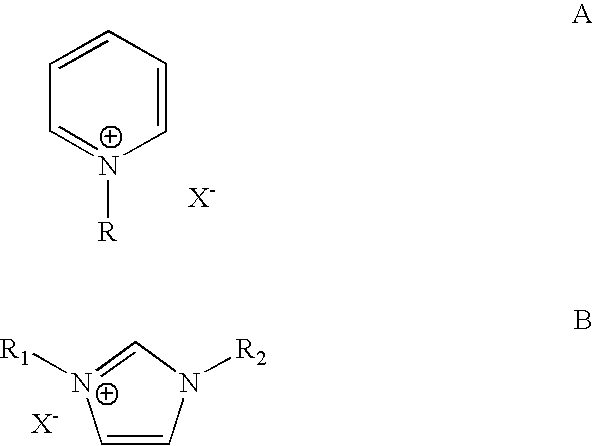

A process for the production of a high quality gasoline blending components from refinery process streams by the alkylation of light isoparaffins with olefins using an ionic liquid catalyst is disclosed. The alkylation process comprises contacting a hydrocarbon mixture comprising at least one olefin having from 2 to 6 carbon atoms and at least one isoparaffin having from 3 to 6 carbon atoms under alkylation conditions, said catalyst comprising a mixture of at least one acidic ionic liquid and at least one alkyl halide. In one embodiment, the acidic ionic liquid is chloroaluminate ionic liquid prepared by mixing aluminum trichloride (AlCl3) and a hydrocarbyl substituted pyridinium halide, a hydrocarbyl substituted imidazolium halide, trialkylammonium hydrohalide or tetraalkylammonium halide of the general formulas A, B, C and D, respectively,where R=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and X is a halide and preferably a chloride, and R1 and R2=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and where R1 and R2 may or may not be the same, and R3, R4, and R5 and R6=methyl, ethyl, propyl, butyl, pentyl or hexyl group and where R3, R4, R5 and R6 may or may not be the same.

Owner:CHEVROU USA INC

Alternative Process for Treatment of Heavy Crudes in a Coking Refinery

ActiveUS20110083996A1Increasing API gravityReduce the amount of metalThermal non-catalytic crackingRefining with metalsFuel oilPre treatment

The present invention relates to a process for the pretreatment of heavy oils using a catalytic hydrotreating process prior to introduction to a refinery. More specifically, the invention relates to the use of an HDM reactor and an HDS reactor in order to improve the characteristics of the heavy oil, such that when the oil is introduced into the refinery, the refinery can achieve improved throughputs, increased catalysts life, increased life cycles, and a reduction in overall operation costs.

Owner:SAUDI ARABIAN OIL CO

Upgrading of tar using POX/coker

ActiveUS8083931B2Reduce and eliminate needThermal non-catalytic crackingTreatment with plural serial cracking stages onlyNaphthaPartial oxidation

The invention is directed to a process wherein a feedstock or stream comprising steam cracker tar is passed to a vacuum pipestill. A deasphalted cut of tar is obtained as an overhead (or sidestream) and a heavy tar asphaltenic product is obtained as bottoms. In preferred embodiments, at least a portion of the bottoms product is sent to a partial oxidation unit (POX) wherein syn gas may be obtained as a product, and / or at least a portion of the bottoms product is used to produce a light product stream in a coker unit, such as coker naphtha and / or or coker gas oil. In another preferred embodiment at least a portion of the overheads product is added to refinery fuel oil pools and in yet another preferred embodiment at least a portion of the overheads product is mixed with locally combusted materials to lower soot make. Two or more of the aforementioned preferred embodiments may be combined.

Owner:EXXONMOBIL CHEM PAT INC

Liquid phase aromatics alkylation process

InactiveUS7476774B2Improve overall utilizationEasy to useLiquid carbonaceous fuelsHydrocarbonsAlkylationChemistry

A process for the production of high octane number gasoline from light refinery olefins and benzene-containing aromatic streams such as reformate. Light olefins including ethylene and propylene are extracted from refinery off-gases, typically from the catalytic cracking unit, into a light aromatic stream such as reformate containing benzene and other single ring aromatic compounds which is then reacted with the light olefins to form a gasoline boiling range product containing akylaromatics. The alkylation reaction is carried out in the liquid phase with a catalyst which preferably comprises a member of the MWW family of zeolites such as MCM-22 using a fixed catalyst bed.

Owner:EXXON RES & ENG CO

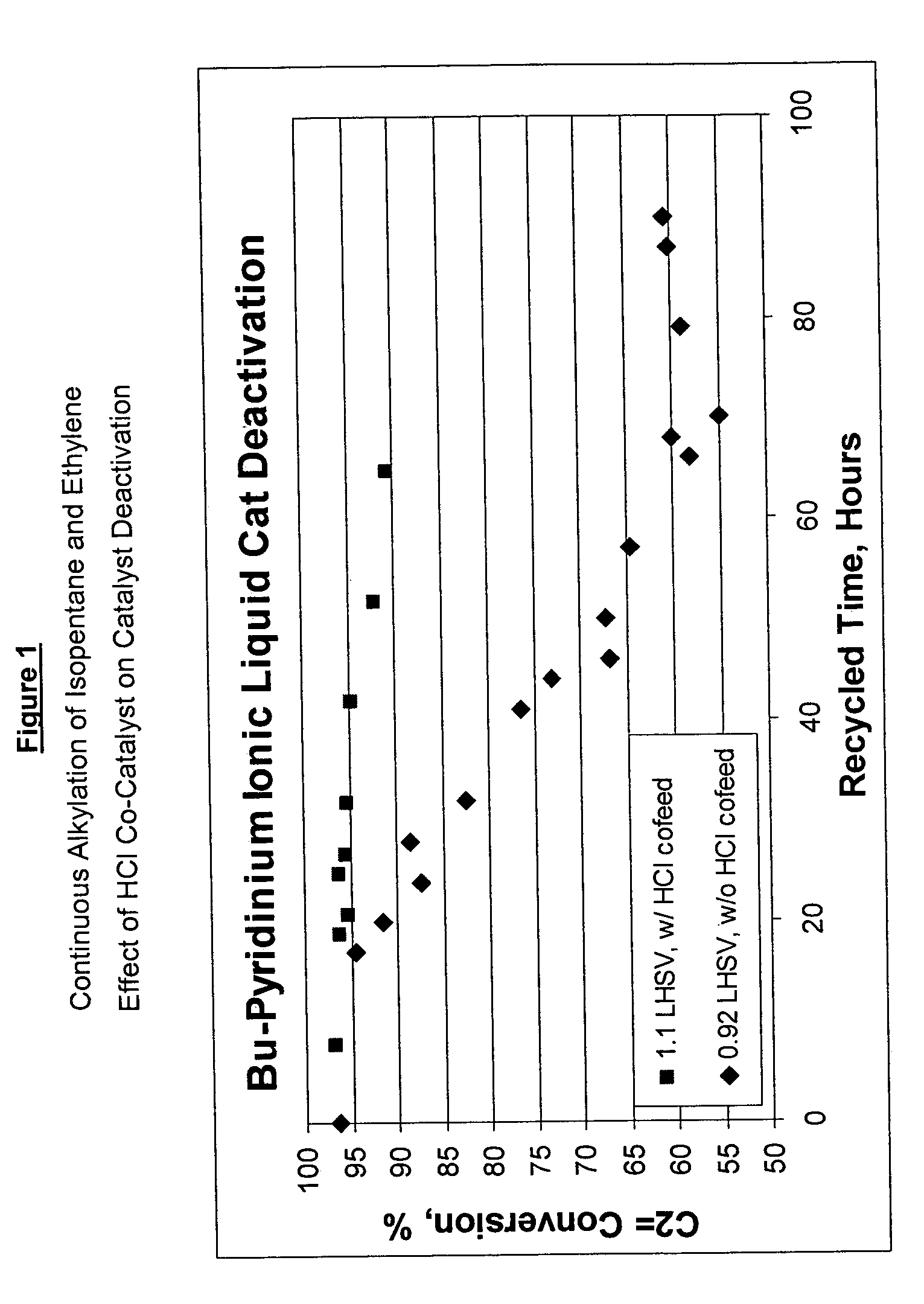

Alkylation process using chloroaluminate ionic liquid catalysts

A process for the production of a high quality gasoline blending components from refinery process streams by the alkylation of light isoparaffins with olefins using an ionic liquid catalyst is disclosed. The process includes reacting a refinery stream containing isopentane and / or isobutane with a refinery stream containing ethylene and / or propylene and butylenes under alkylation conditions in the presence of a chloroaluminate ionic liquid catalyst comprising a hydrocarbyl substituted pyridinium chloroaluminate or a hydrocarbyl substituted imidazolium chloroaluminate of the general formulas A and B, respectively.Where R═H, methlyl, ethyl, propyl, butyl, pentyl or hexyl group and X is a chloroaluminate, and R1 and R2=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and where R1 and R2 may or may not be the same.

Owner:CHEVROU USA INC

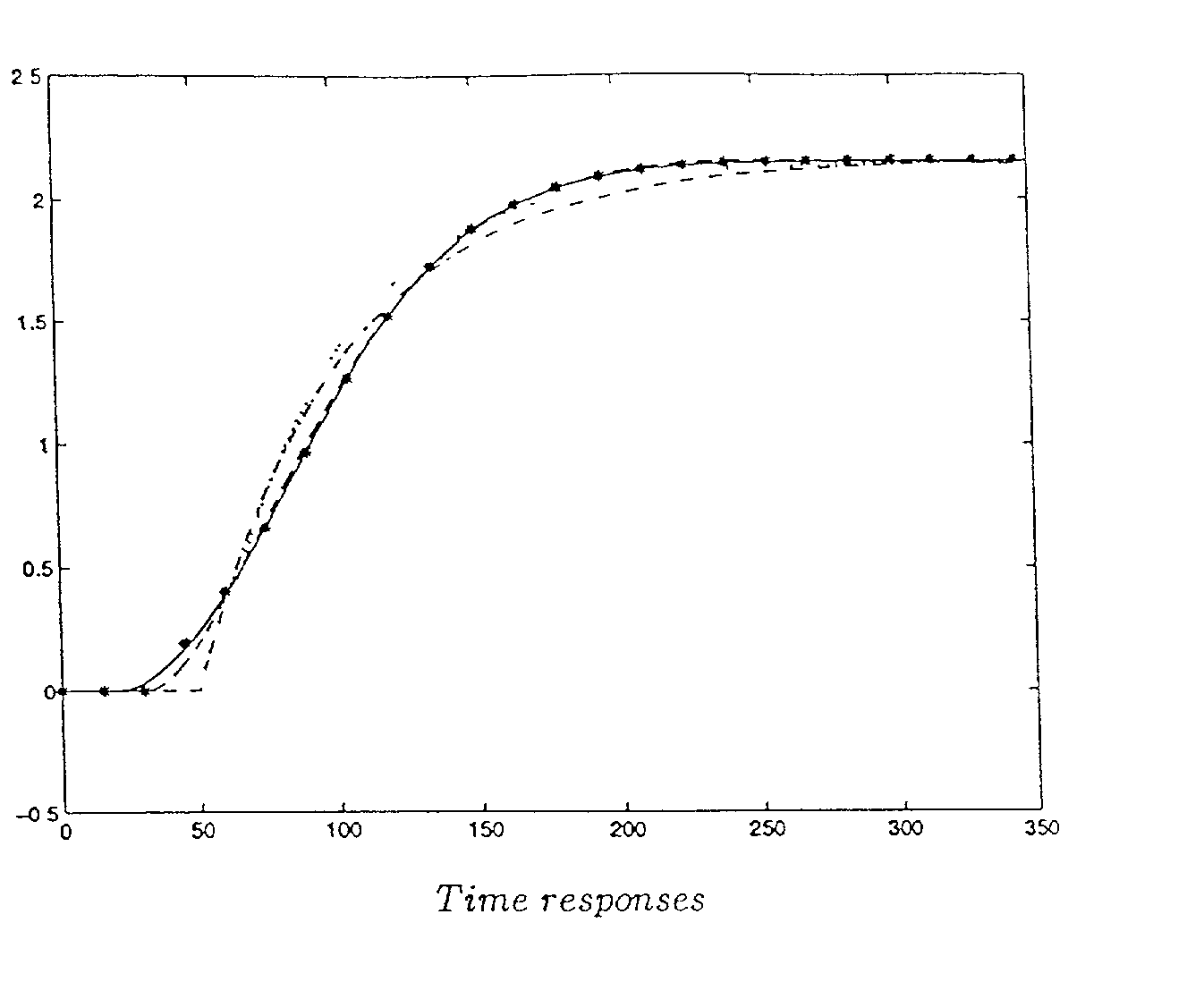

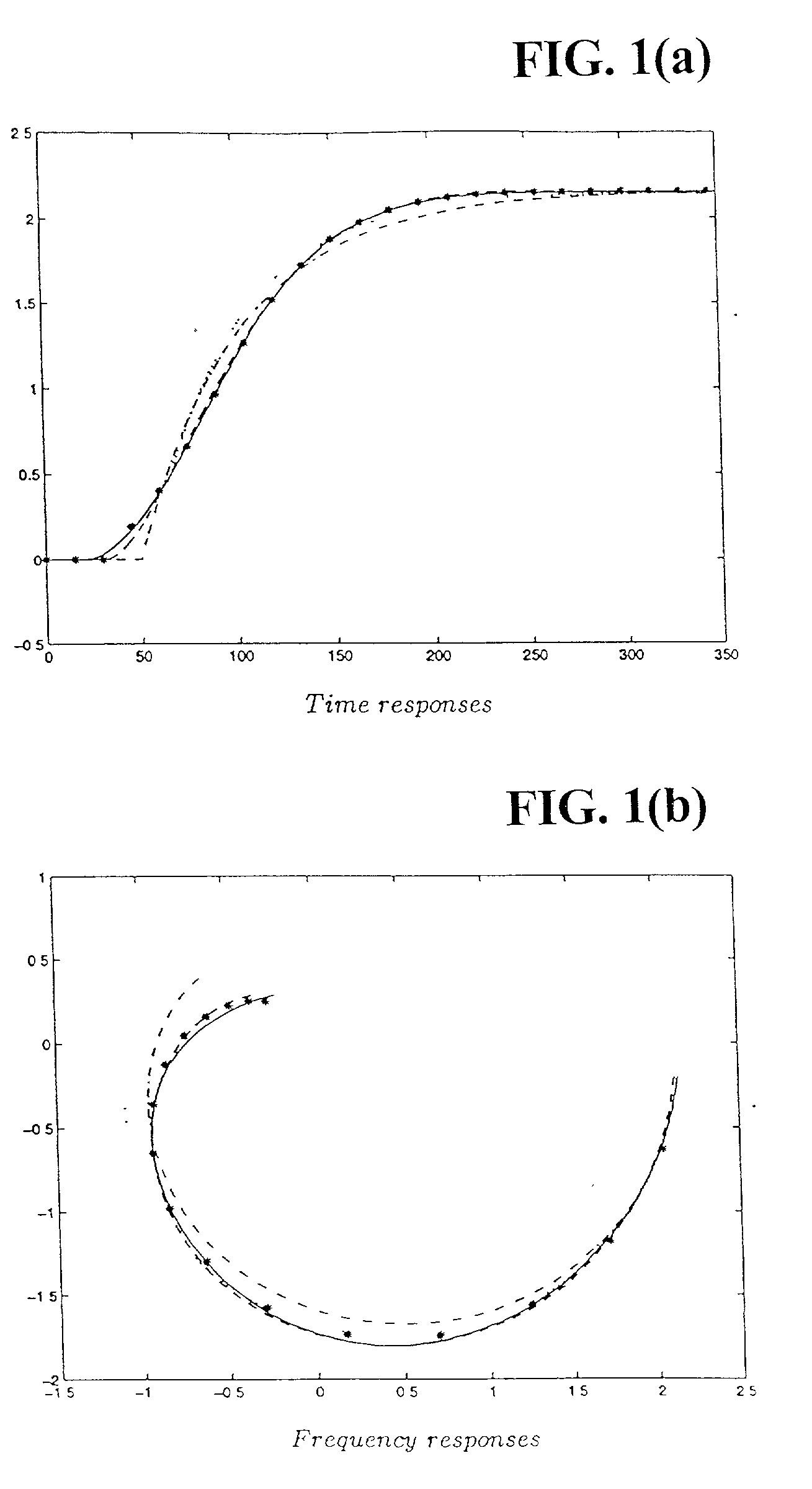

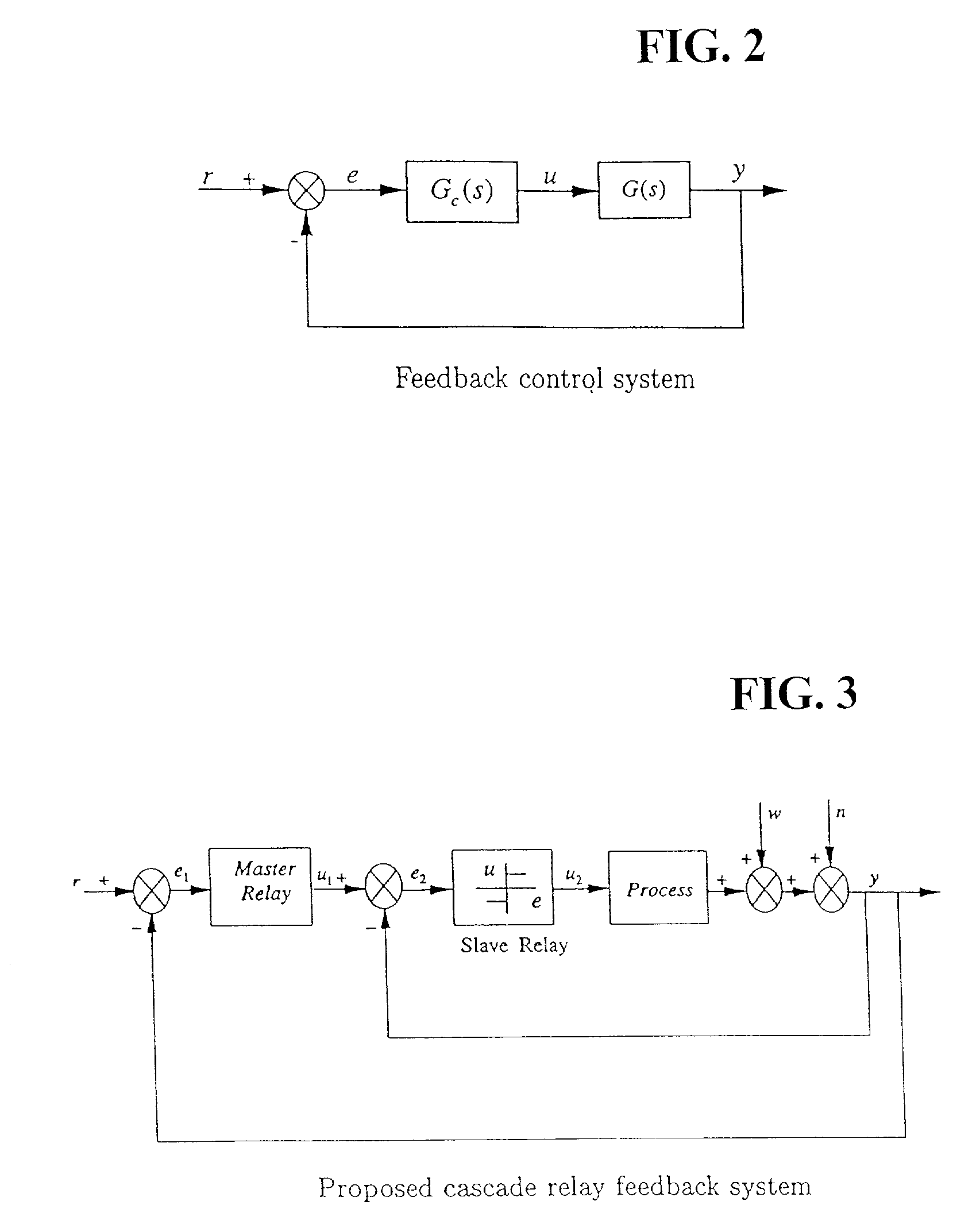

Robust process identification and auto-tuning control

InactiveUS20020111758A1Accurate estimateImprove performanceAmplifier modifications to reduce noise influenceVoltage-current phase angleGuidelineTime delays

A simple yet effective and robust identification method is presented using process step responses for process identification that can provide a continuous transfer function with time-delay without iteration. A cascade relay provides accurate and reliable more points on the process frequency response. The internal model principle is employed to design single-loop controller of PID or high-order types with best achievable control performance for controller tuning, e.g. both single and multivariable cases are covered. The process identification and control design portions can be easily integrated into a control system auto-tuning package. Further, a general control scheme for disturbance rejection is given which can significantly improve disturbance rejection performance over conventional feedback systems with time delays. Practical issues such as noises, real-time implementation and tuning guidelines are also provided. The present invention provide general, systematic, effective, and applicable methods for process identification and control for a wide range of industries such as process and chemical plants, food processing, waste water treatment and environmental systems, oil refinery, servo and mechatronic systems, where a system model is needed for analysis, prediction, filtering, optimization and management, and / or where control or better control is required for their systems.

Owner:NAT UNIV OF SINGAPORE

Alkylation process using chloroaluminate ionic liquid catalysts

ActiveUS20060135839A1Quality improvementLiquid hydrocarbon mixtures productionHydrocarbons2-methylbutanePyridinium

A process for the production of a high quality gasoline blending components from refinery process streams by the alkylation of light isoparaffins with olefins using an ionic liquid catalyst is disclosed. The process includes reacting a refinery stream containing isopentane and / or isobutane with a refinery stream containing ethylene and / or propylene and butylenes under alkylation conditions in the presence of a chloroaluminate ionic liquid catalyst comprising a hydrocarbyl substituted pyridinium halide or a hydrocarbyl substituted imidazolium halide of the general formulas A and B, respectively. Where R=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and X is a halide and preferably a chloride, and R1 and R2=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and where R1 and R2 may or may not be the same.

Owner:CHEVROU USA INC

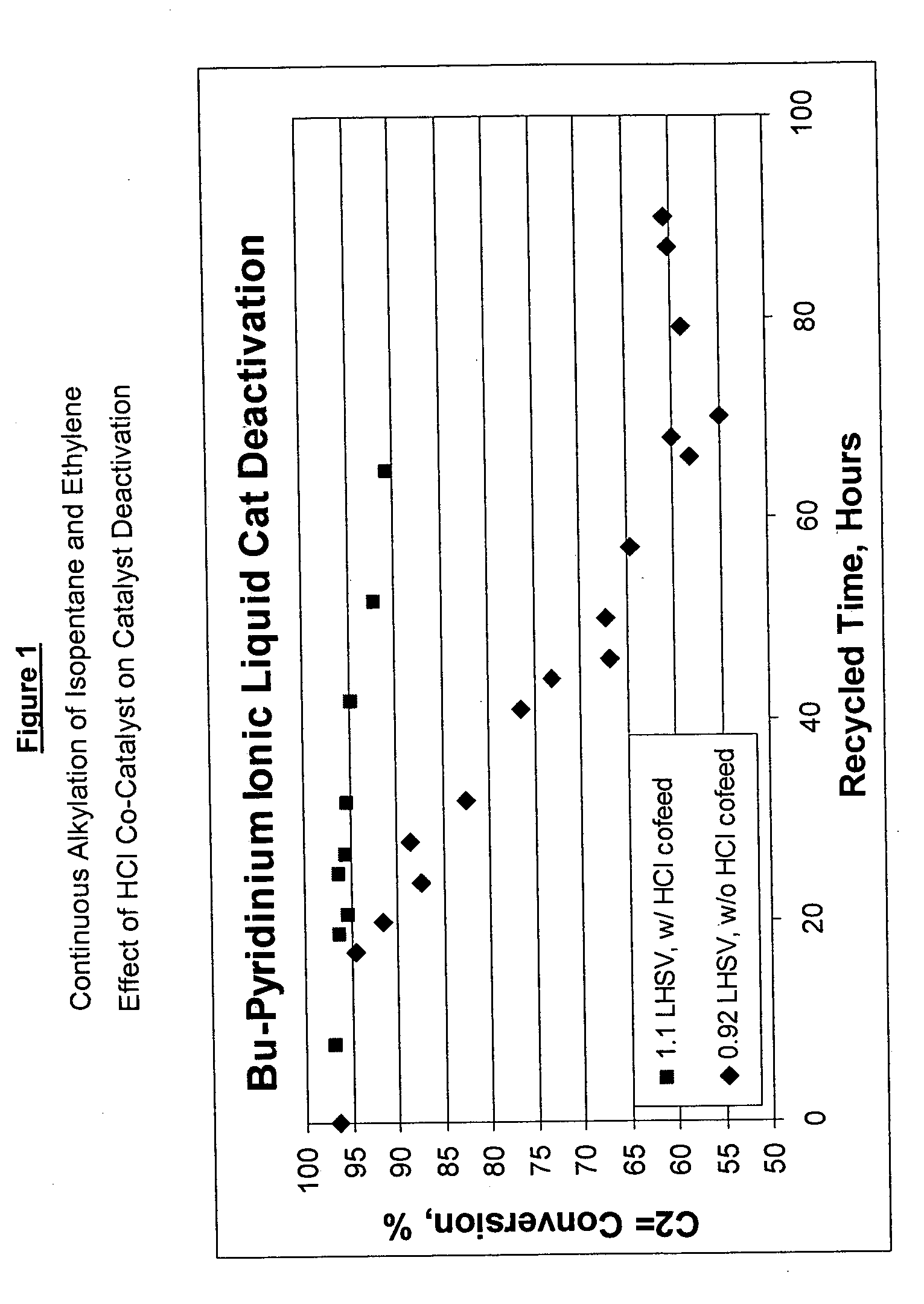

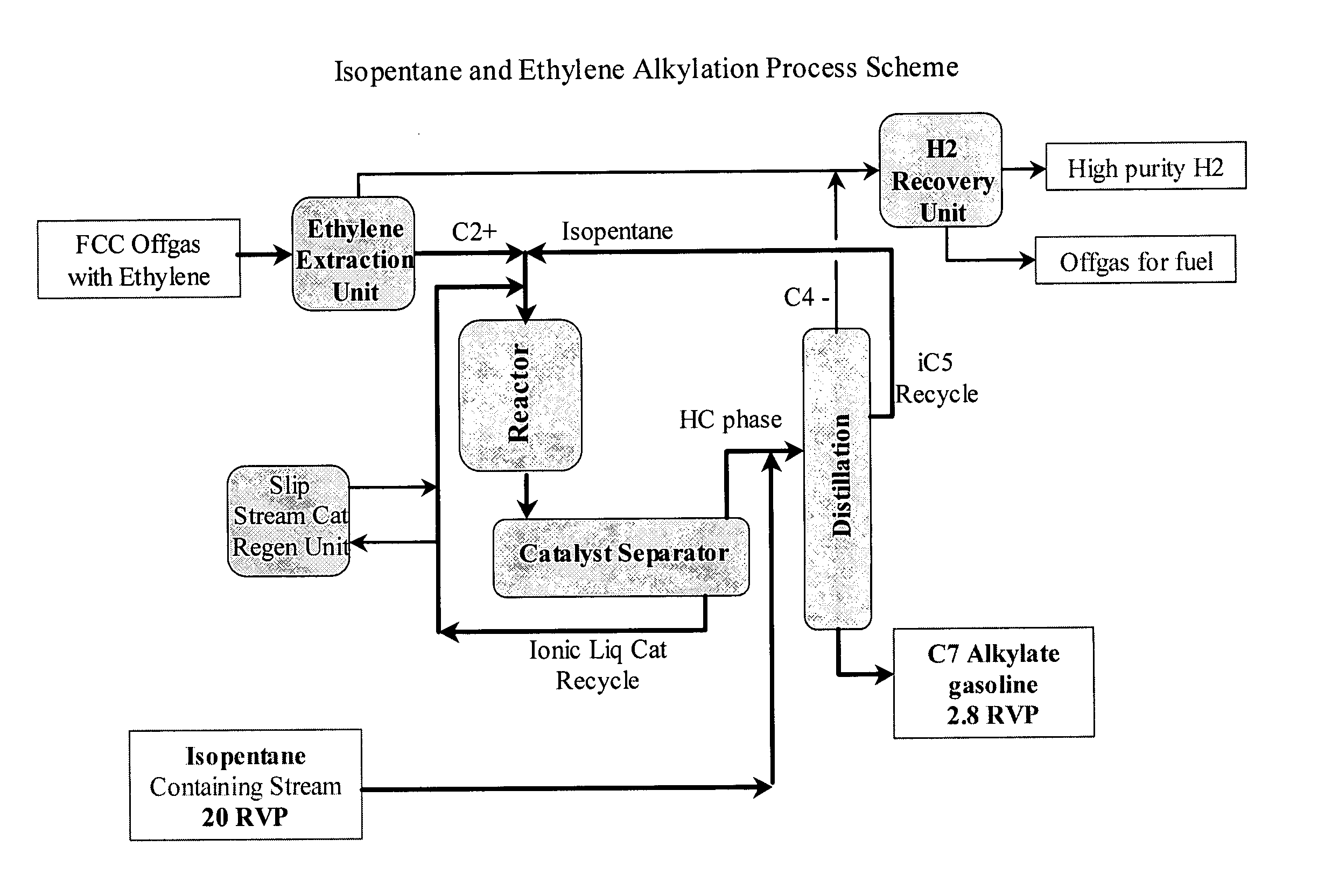

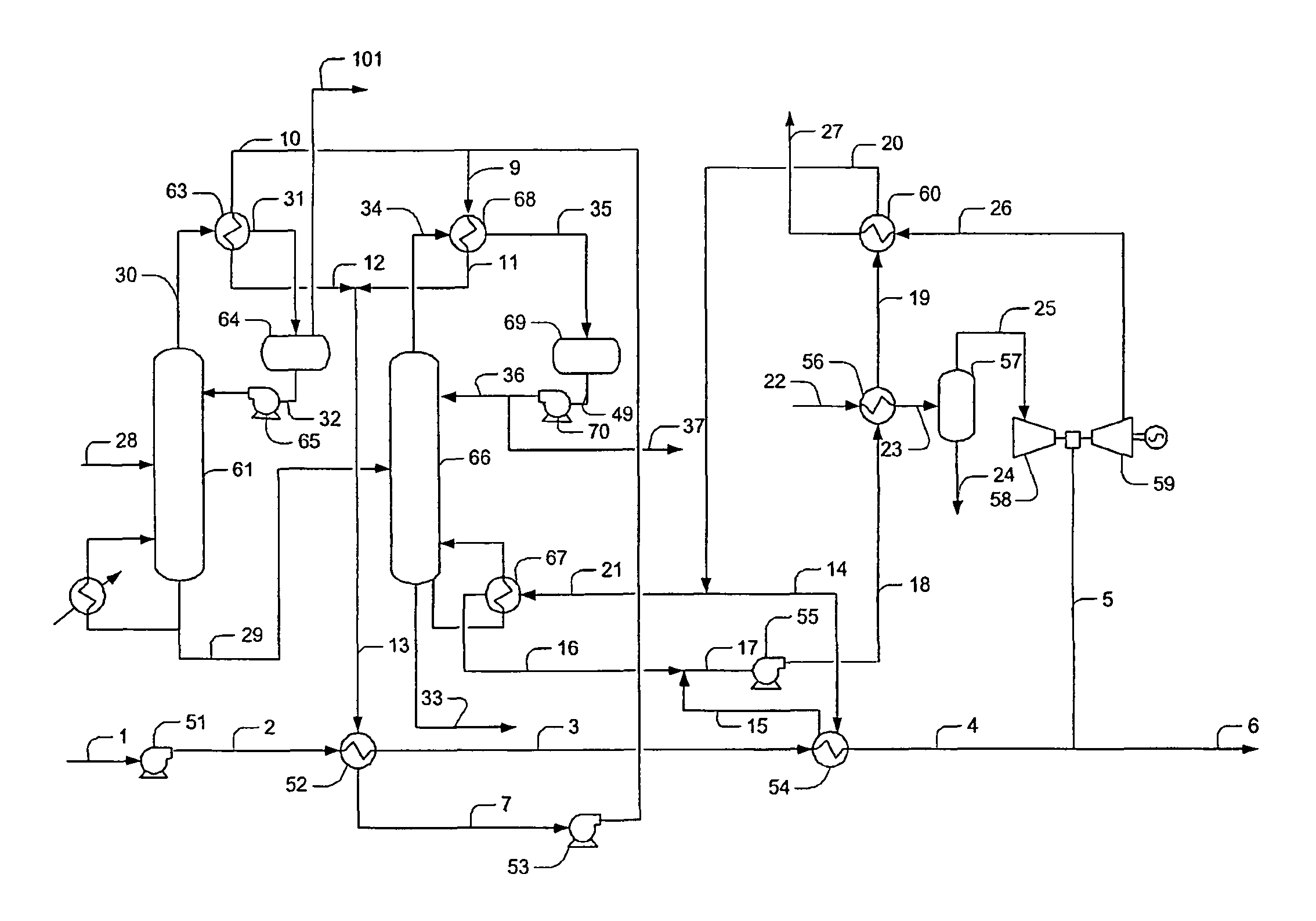

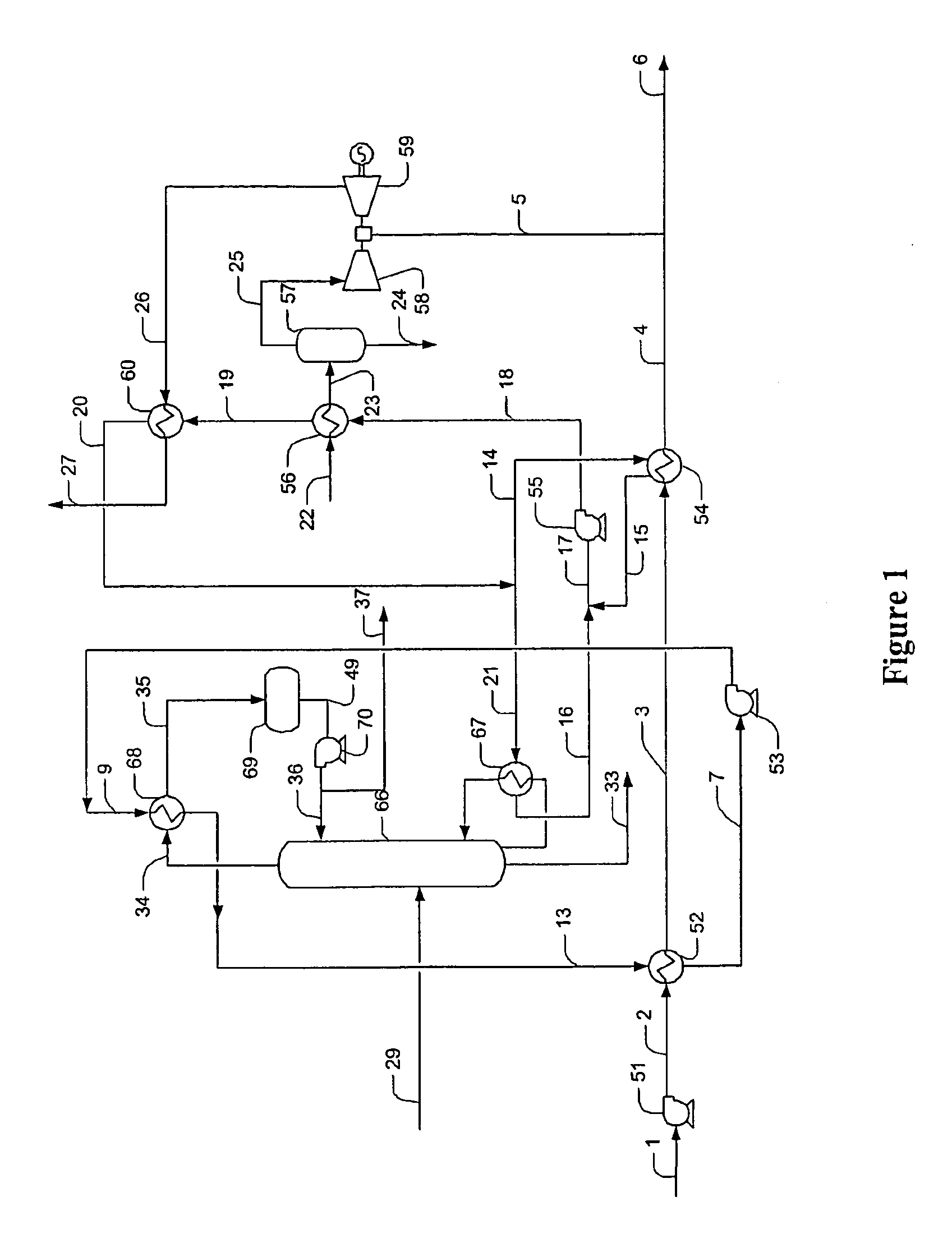

Integrated alkylation process using ionic liquid catalysts

ActiveUS20060131209A1Easy to operateReducing fuel gas productionLiquid hydrocarbon mixtures productionRefining with metal saltsAlkyl transferGasoline

An integrated refining process for the production of high quality gasoline blending components from low value components is disclosed. In addition there is disclosed a method of improving the operating efficiency of a refinery by reducing fuel gas production and simultaneously producing high quality gasoline blending components of low volatility. The processes involve the alkylation of a refinery stream containing pentane with ethylene using an ionic liquid catalyst.

Owner:CHEVROU USA INC

Alkylation process using an alkyl halide promoted ionic liquid catalyst

ActiveUS7531707B2Organic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsHydrogen halideAlkane

A process for the production of a high quality gasoline blending components from refinery process streams by the alkylation of light isoparaffins with olefins using an ionic liquid catalyst is disclosed. The alkylation process comprises contacting a hydrocarbon mixture comprising at least one olefin having from 2 to 6 carbon atoms and at least one isoparaffin having from 3 to 6 carbon atoms under alkylation conditions, said catalyst comprising a mixture of at least one acidic ionic liquid and at least one alkyl halide. The alkylhalide by reacting to at least a portion of the olefin with a hydrogen halide.

Owner:CHEVROU USA INC

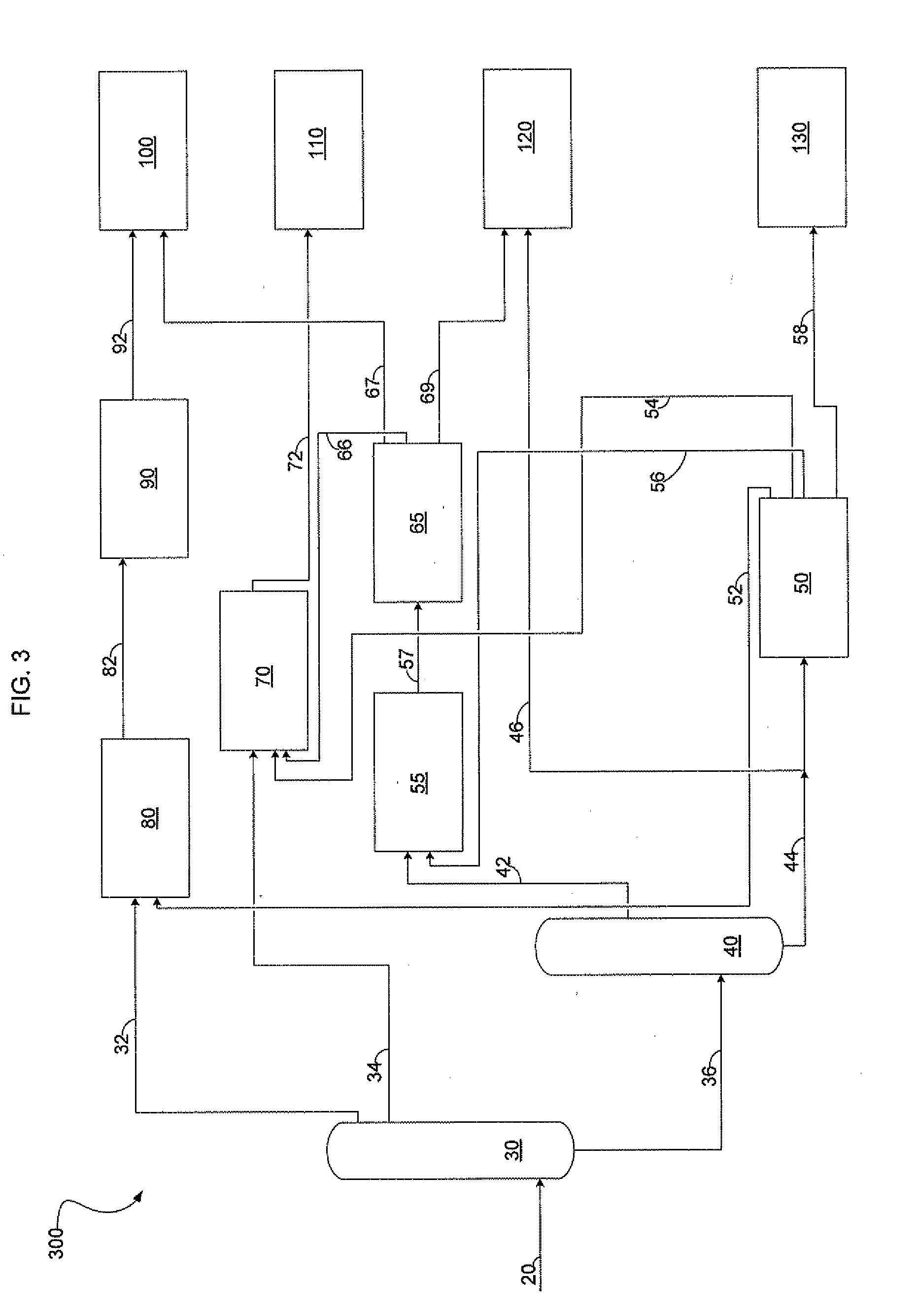

Integration of LNG regasification with refinery and power generation

Contemplated plants thermally integrate operation of a refinery component, and most preferably of a hydrocarbon splitter with LNG regasification to provide refrigeration duty and with a power cycle to provide the reboiler duty of the component. It should be noted that such configurations advantageously allow operation of the splitter at a reduced temperature and at reduced pressure, thereby increasing separation efficiency, while the power output is boosted using air intake chilling. Most notably, such process advantages are achieved by satisfying the heating duty of LNG regasification.

Owner:FLUOR TECH CORP

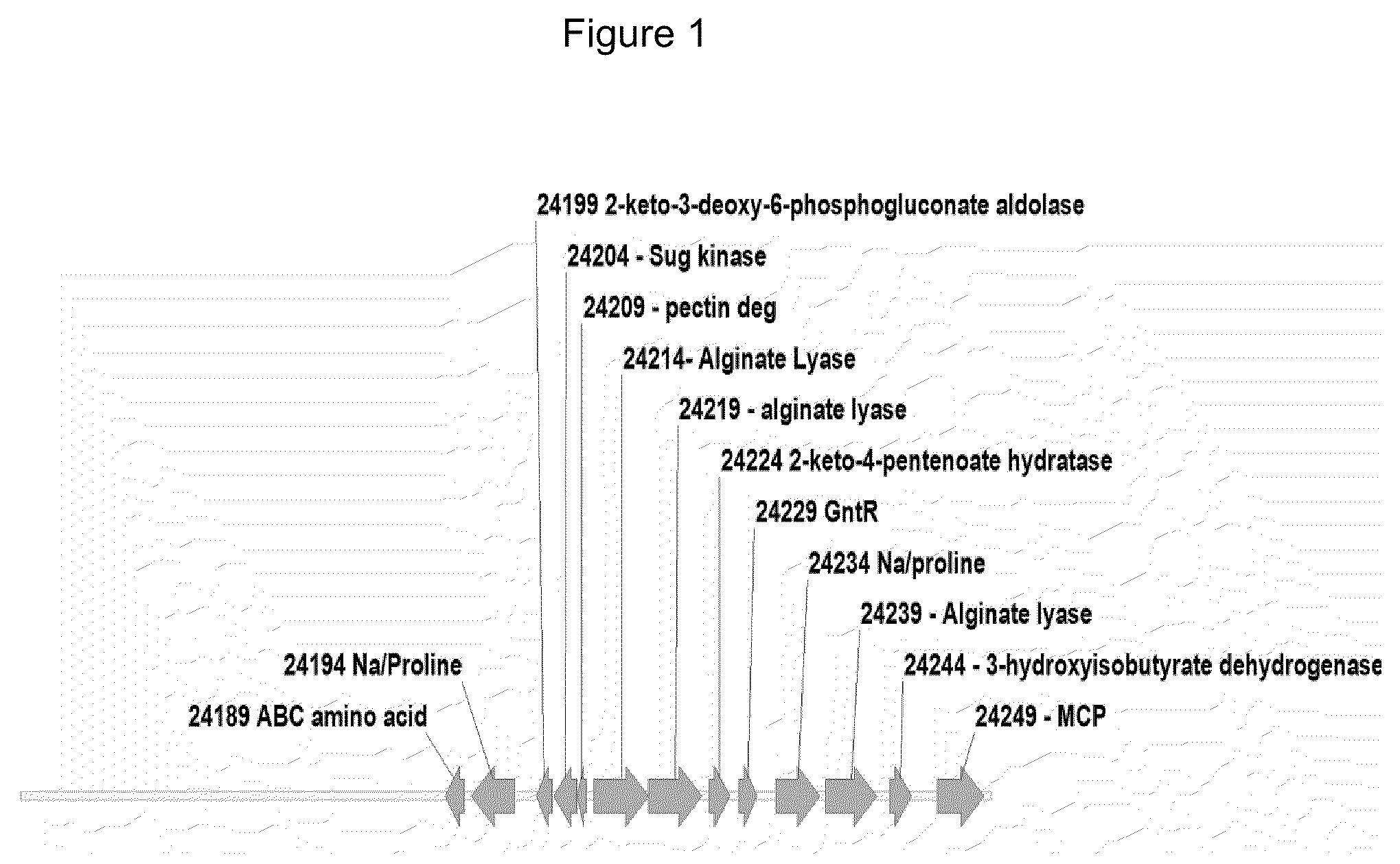

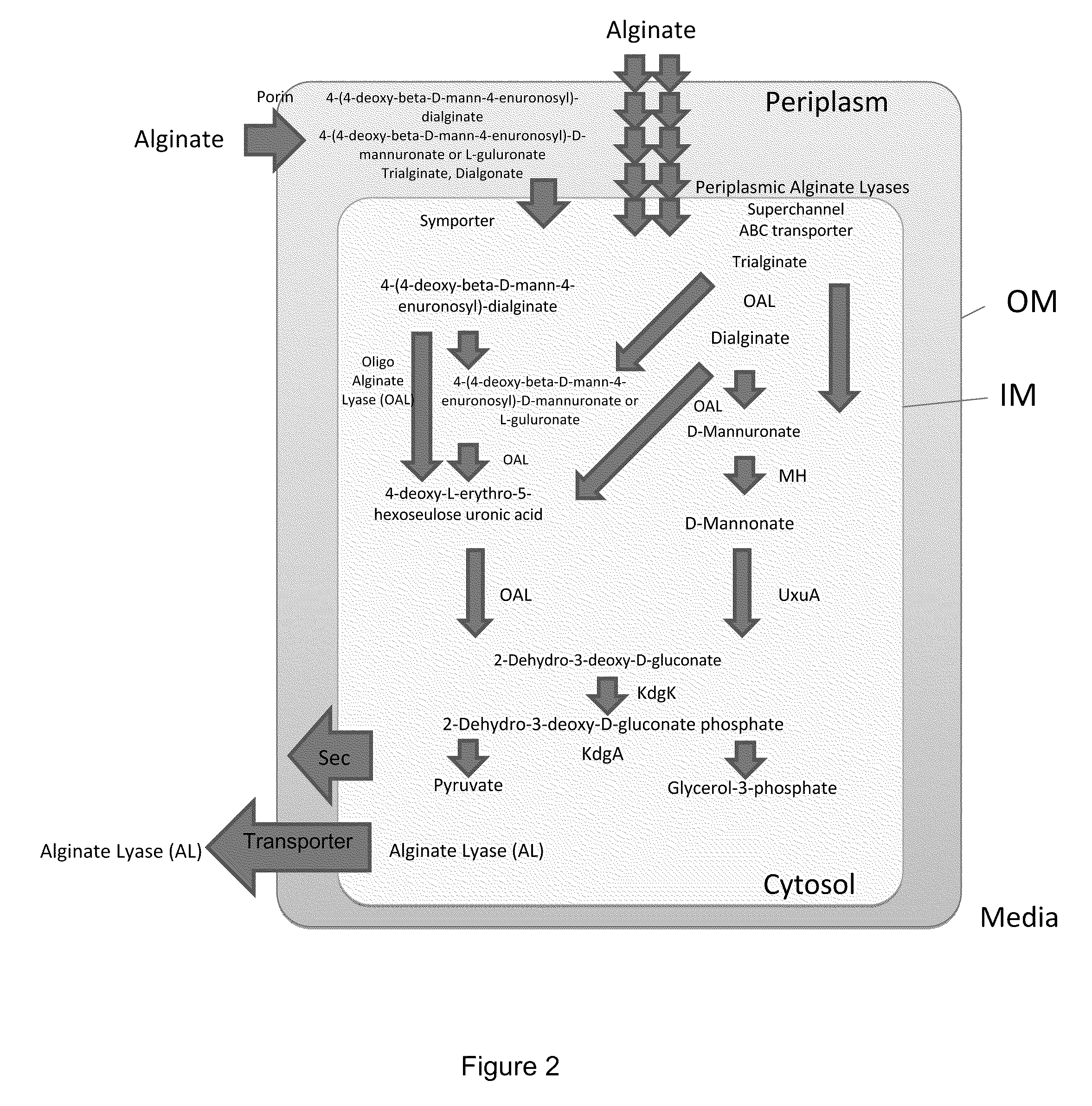

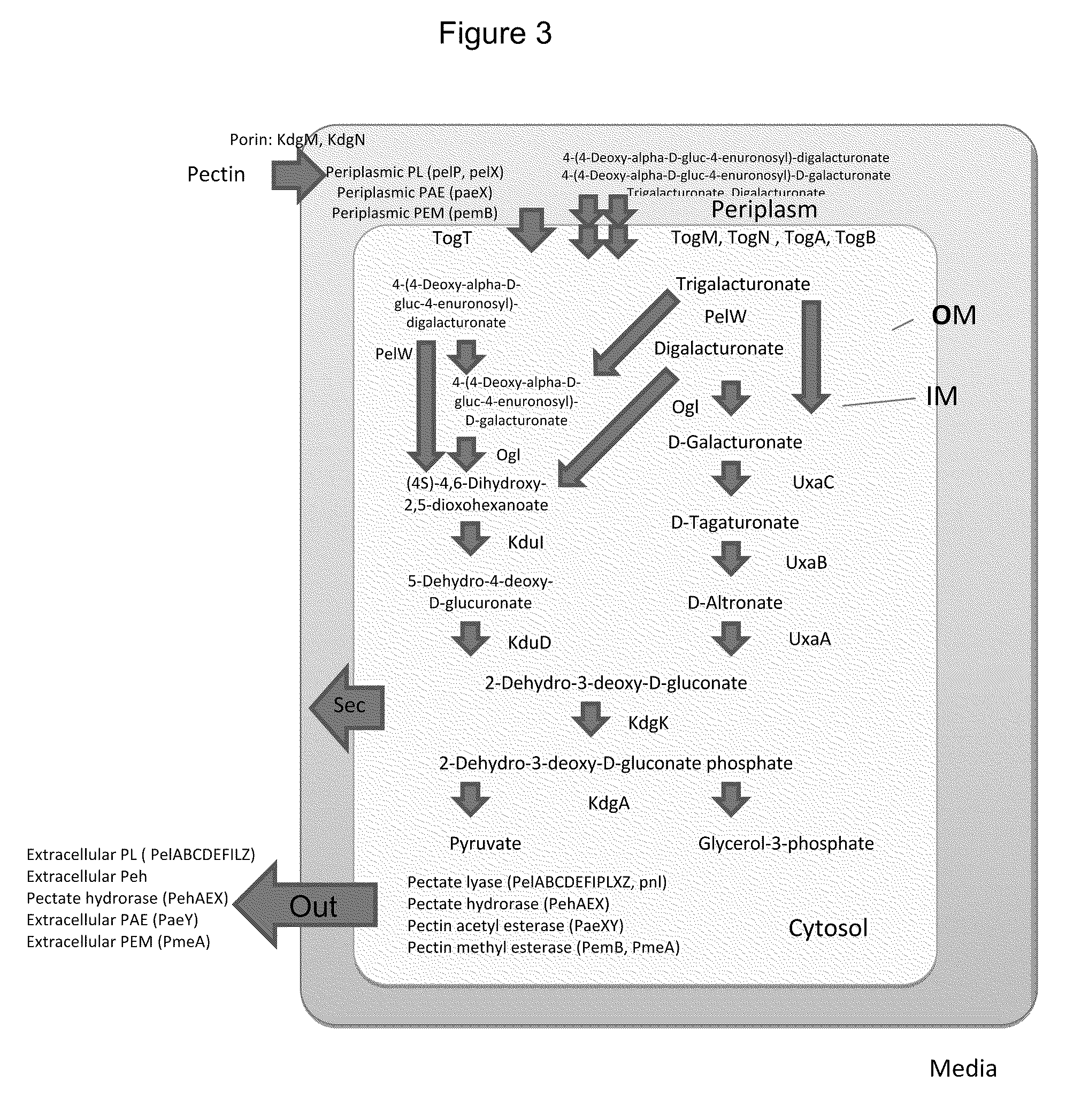

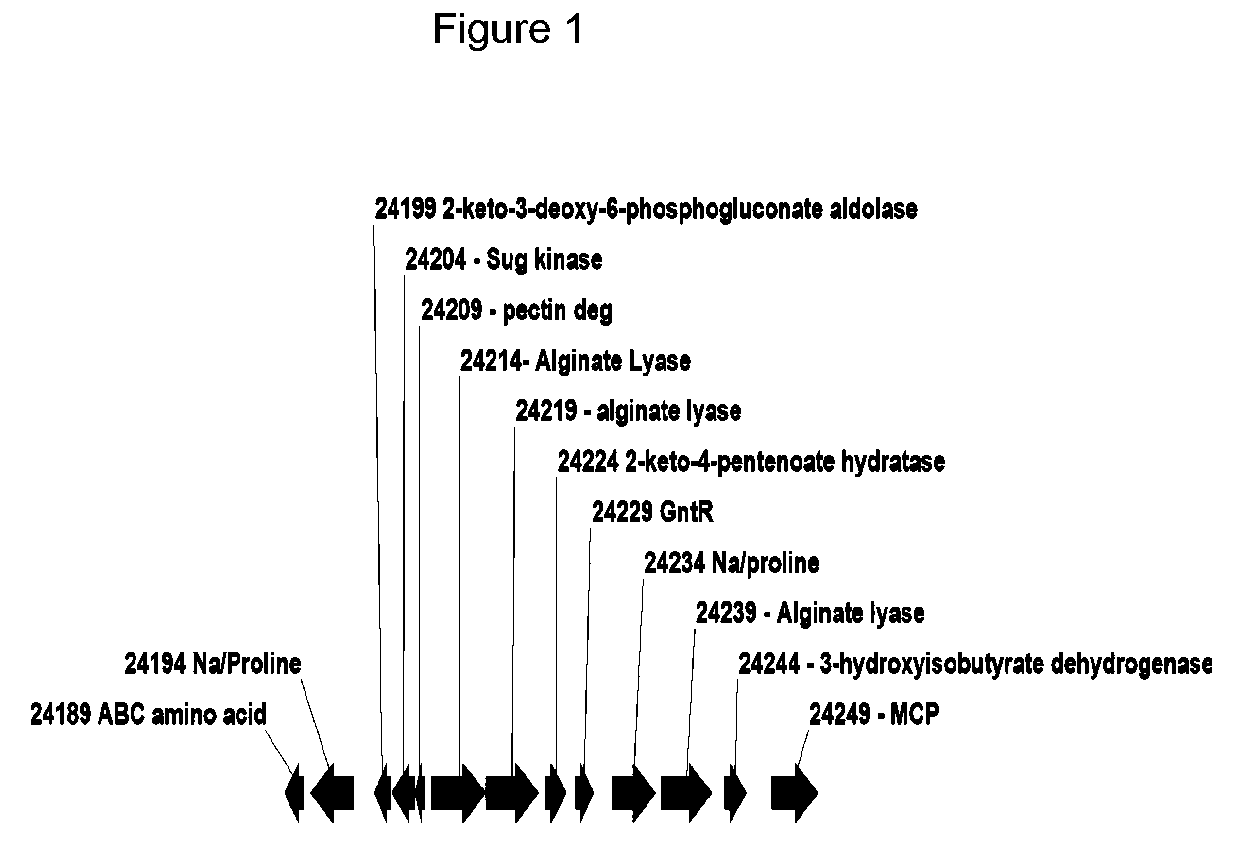

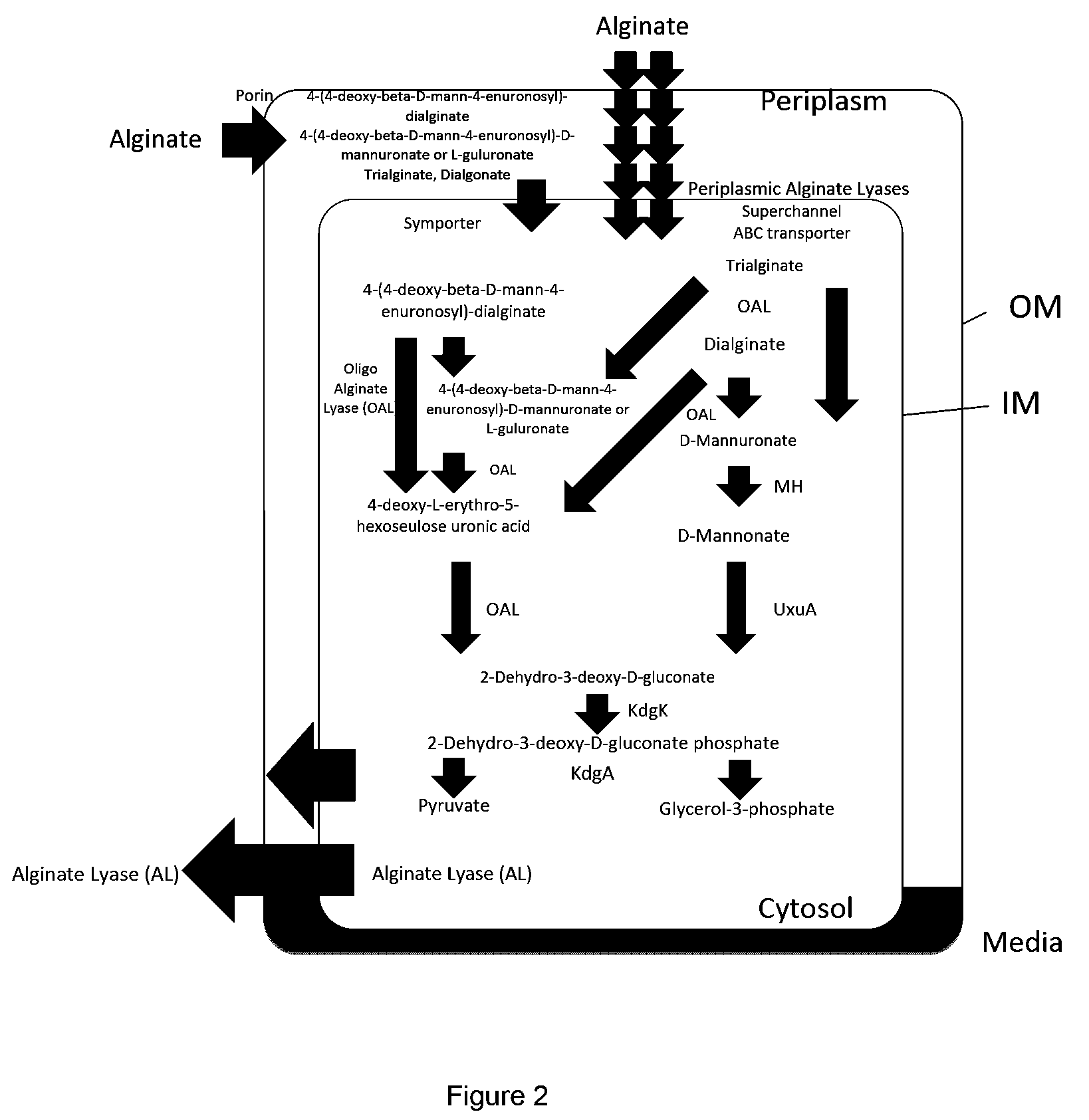

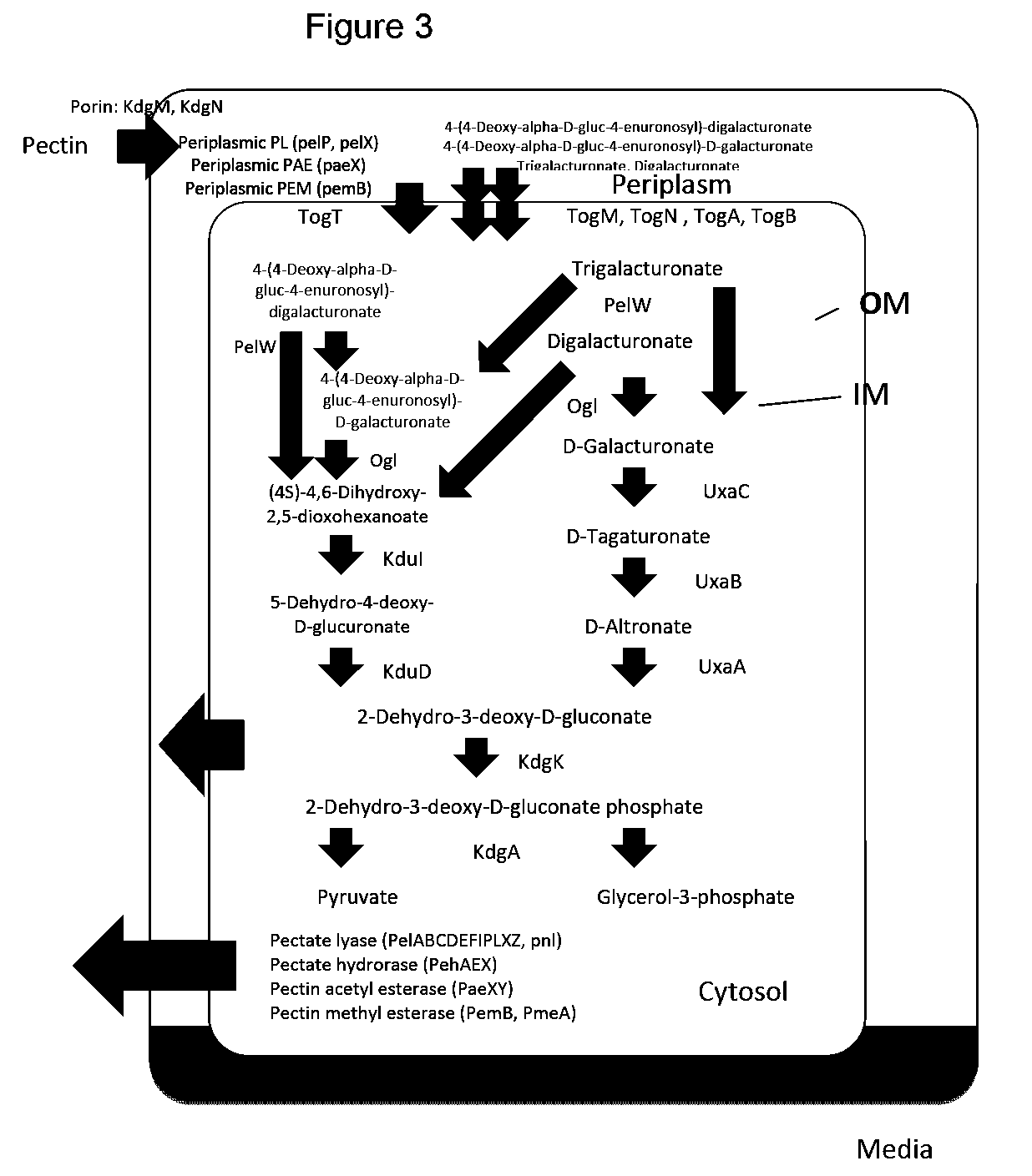

Biofuel production

Methods, enzymes, recombinant microorganism, and microbial systems are provided for converting polysaccharides, such as those derived from biomass, into suitable monosaccharides or oligosaccharides, as well as for converting suitable monosaccharides or oligosaccharides into commodity chemicals, such as biofuels. Commodity chemicals produced by the methods described herein are also provided. Commodity chemical enriched refinery-produced petroleum products are also provided, as well as methods for producing the same.

Owner:BIO ARCHITECTURE LAB +1

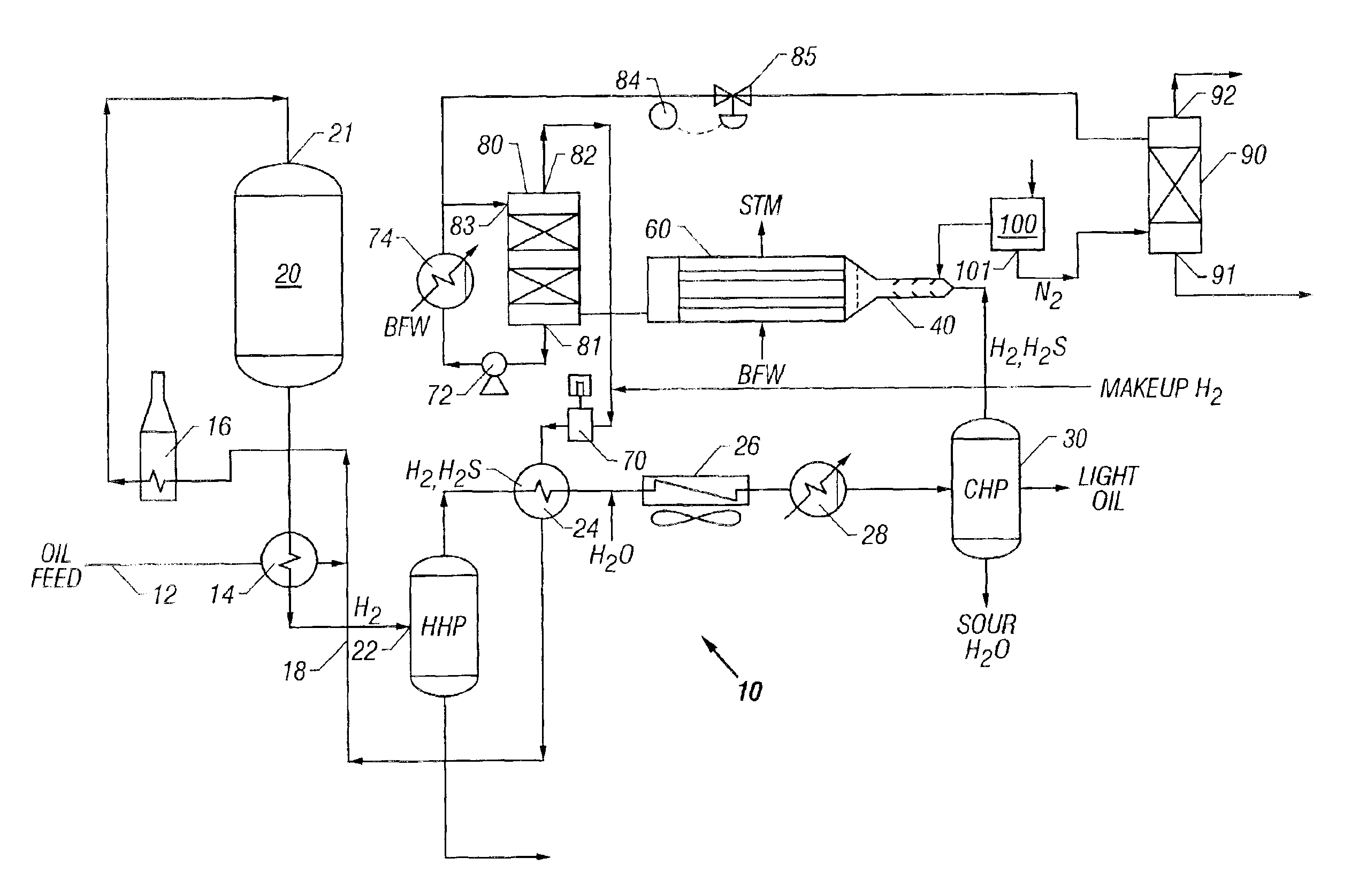

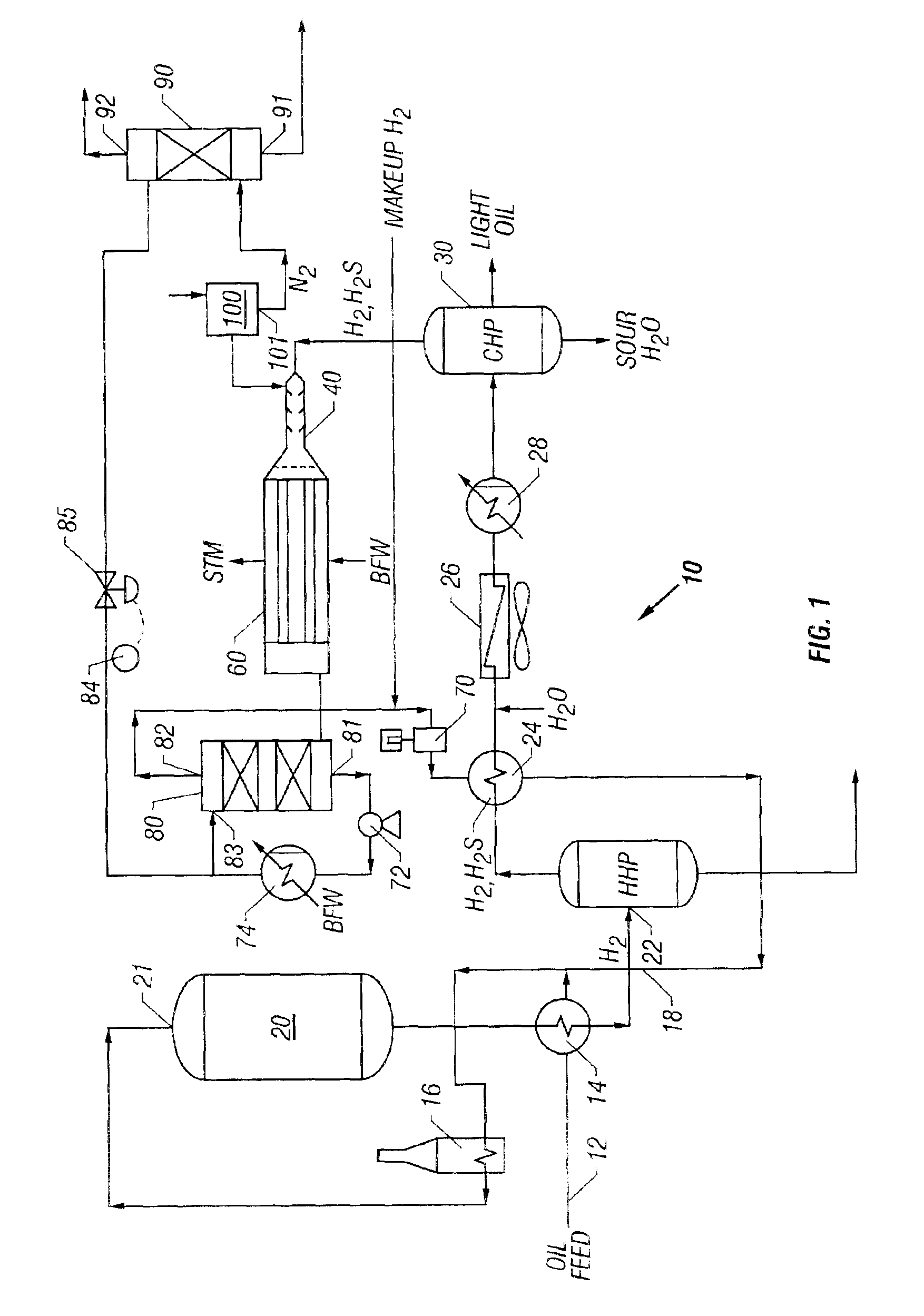

Targeted hydrogenation hydrocracking

InactiveUS20090159493A1Hydrocarbon oil crackingTreatment with hydrotreatment processesProcess engineeringEngineering

This invention is directed to a process scheme in which a partial conversion hydrocracking (HCR) unit, preferably preceded by a hydrotreating unit, feeds unconverted oil to a FCC (fluid catalytic cracking ) unit. Most refineries run the FCC unit at the full capacity for optimal asset utilization. During shutdowns of Residue Desulfurization unit(s) which feed an FCC unit, it is desirable to reduce the conversion in the FCC feed hydrocracker. In this way, the feed to FCC unit is maximized. Jet and Diesel products that conform to specifications may be produced during low conversion HCR operation. Furthermore, undesirable over-saturation of the unconverted oil (UCO) from the HCR unit feeding the FCC unit can be avoided. Excess hydrogen consumption can also be avoided. Normally, further aromatic saturation of the middle distillate products from a low conversion HCR is achieved in a separate, post treatment, unit.

Owner:CHEVROU USA INC

Biofuel production

Methods, enzymes, recombinant microorganism, and microbial systems are provided for converting polysaccharides, such as those derived from biomass, into suitable monosaccharides or oligosaccharides, as well as for converting suitable monosaccharides or oligosaccharides into commodity chemicals, such as biofuels. Commodity chemicals produced by the methods described herein are also provided. Commodity chemical enriched, refinery-produced petroleum products are also provided, as well as methods for producing the same.

Owner:BIO ARCHITECTURE LAB

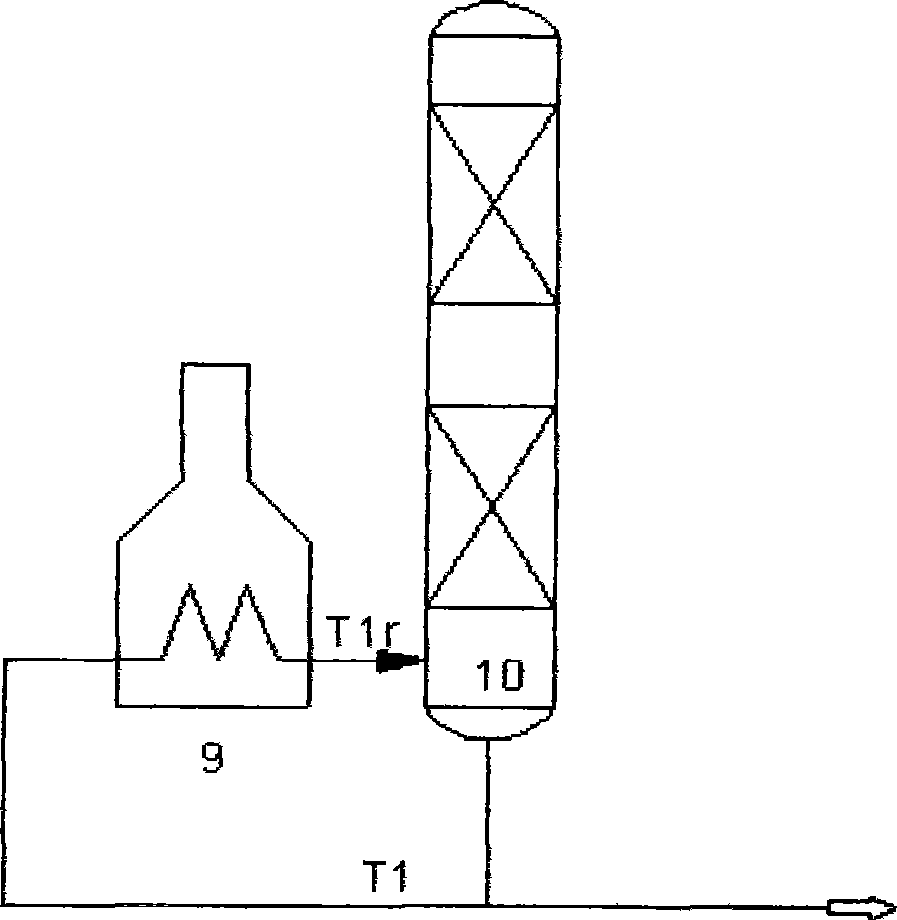

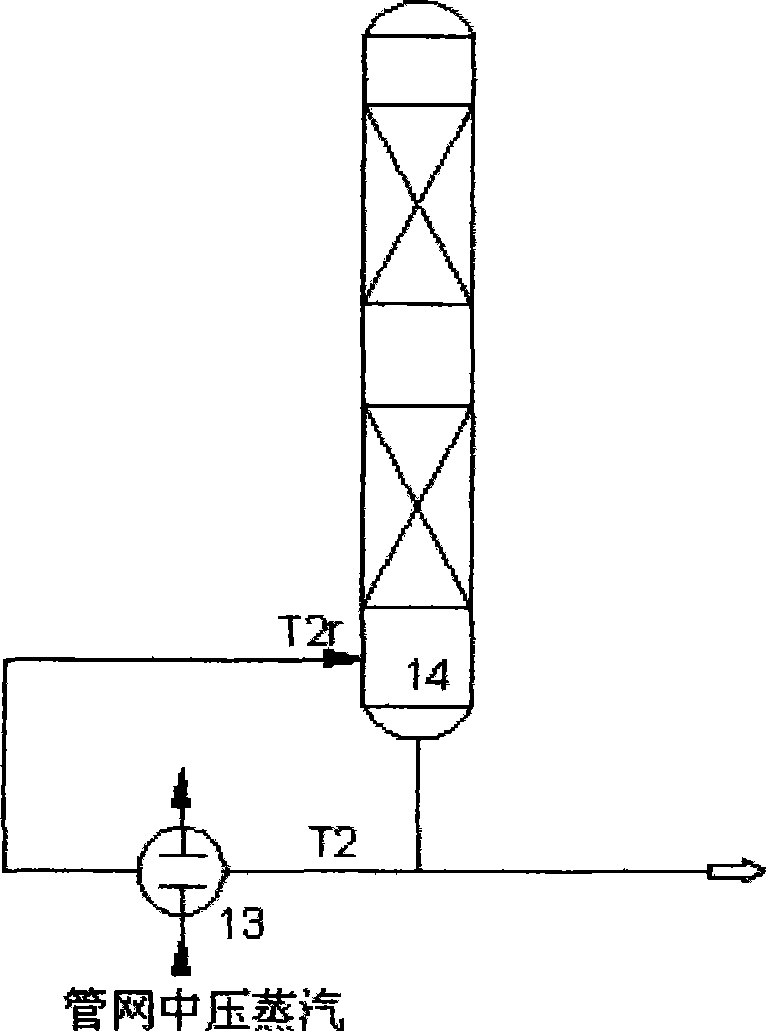

Improvement method of needle coke used refined aromatic hydrocarbon oil

InactiveCN104560082AIncrease contentSimple processCoke ovensTreatment with polymerisationVapor–liquid separatorRoom temperature

The invention relates to an improvement method of needle coke used refined aromatic hydrocarbon oil. The improvement method of the needle coke used refined aromatic hydrocarbon oil comprises the following steps: taking oil rich in aromatic hydrocarbon, heating the oil to 400-490 DEG C by a heating furnace, introducing the oil into a polymerization tower, taking the material at the bottom of the polymerization tower and introducing the material into a flash tower, taking the flashed material at the bottom of the flash tower, cooling the material to the room temperature, introducing the material into a gas-liquid separator, controlling the vacuum degree in the gas-liquid separator to be 5-10kpa, taking the material at the bottom of the gas-liquid separator, and enabling the material to flow into a refined aromatic hydrocarbon oil buffering tank to prepare the raw material which is refined aromatic hydrocarbon oil for producing needle coke. The improvement method of the needle coke used refined aromatic hydrocarbon oil is simple in process; the oil rich in aromatic hydrocarbon with low content of aromatic hydrocarbon in domestic oil refining plant is processed, the content of the aromatic hydrocarbon is increased; the prepared refined aromatic hydrocarbon oil is applicable to production of the needle coke.

Owner:SHANDONG YIDA NEW MATERIAL

Catalytic cracking process for production of diesel from seeds of oleaginous plants

ActiveUS20080313955A1Production is possibleCatalytic crackingFatty acid chemical modificationEngineeringCracking reaction

The present invention comprises a thermocatalytic cracking process for the production of diesel oil from a charge of vegetable origin made from seeds of oleaginous plants in refineries possessing at least two FCC reactors. At least -one of such reactors processes heavy gas oil or residue under conventional conditions whilst at least one of such reactors processes the charge of vegetable origin made from seeds of oleaginous plants under conditions suitable, for production of diesel oil. Said process employs the same catalyst utilised in the fluid catalytic cracking process which, simultaneously, processes a conventional charge.The diesel, or biodiesel, oil produced by means of said process is of superior quality having a cetane number exceeding 40 given that the cracking reactions occur at low temperatures and the products obtained are less oxidised and consequently purer than products obtained by means of existing technology.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

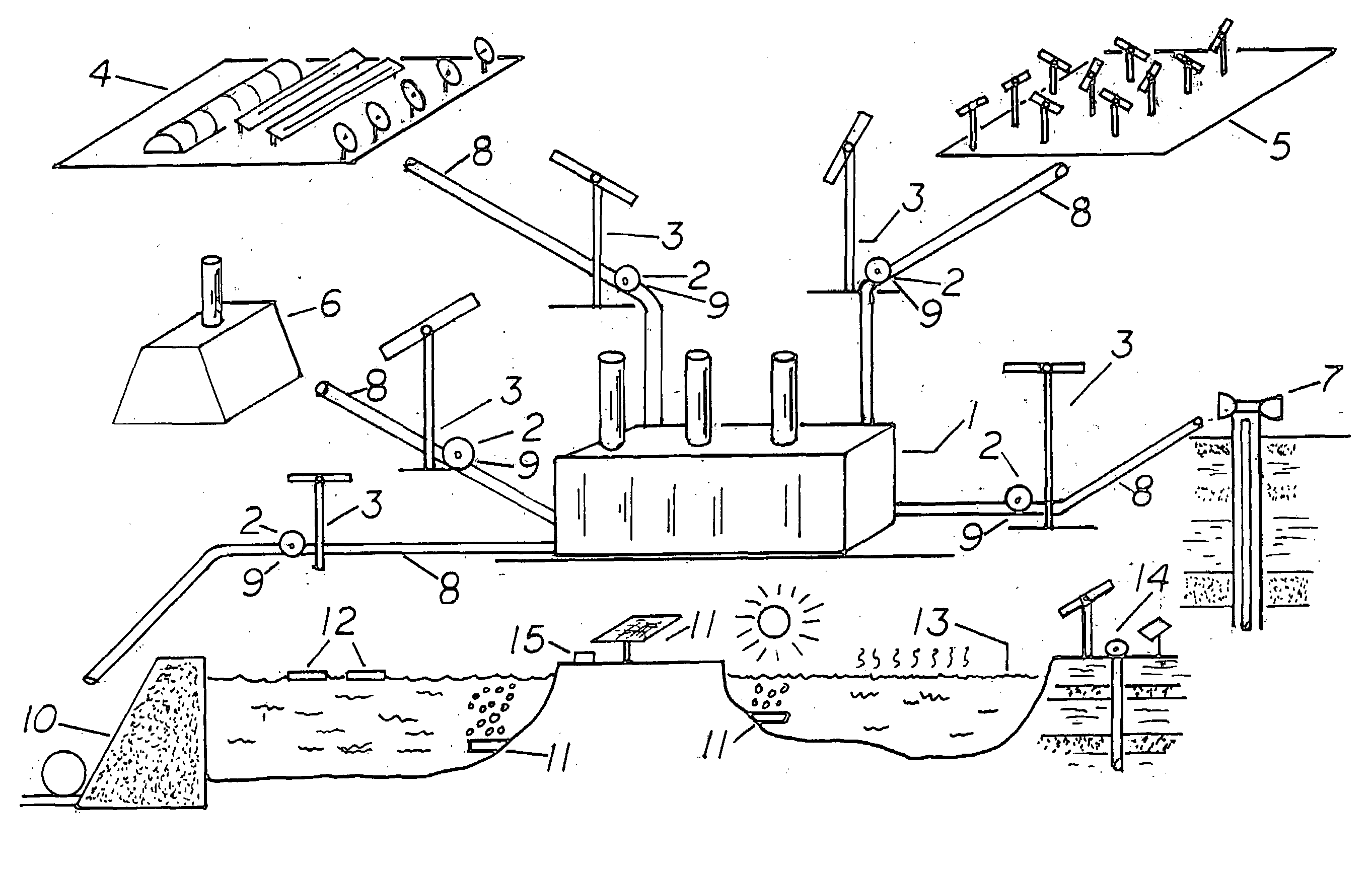

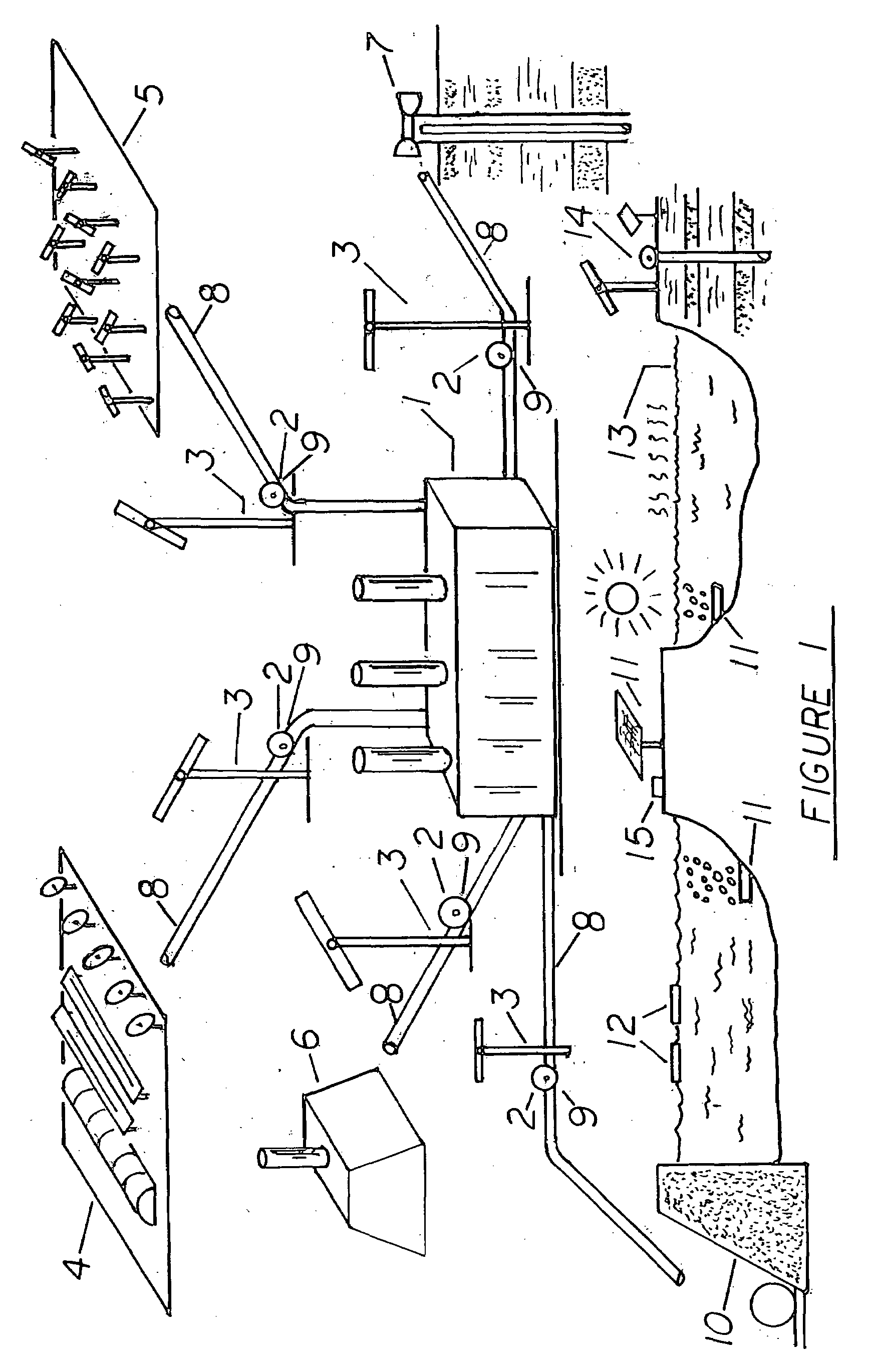

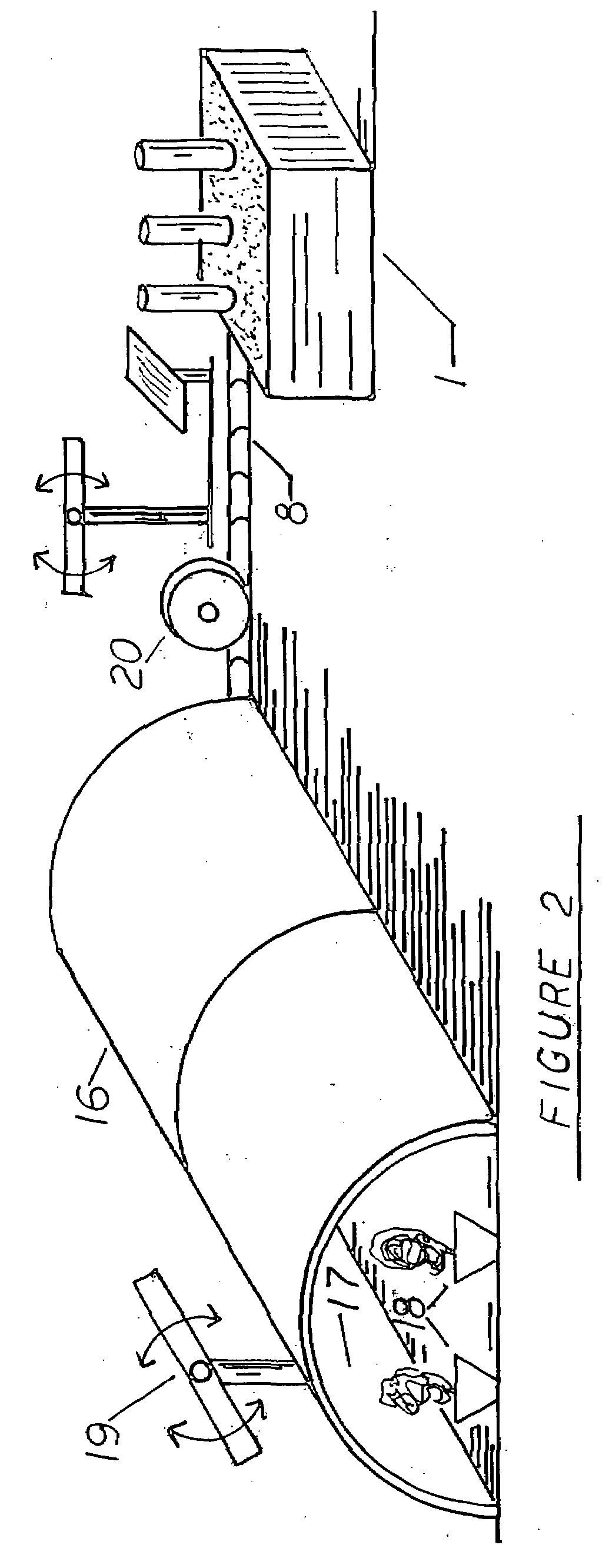

Use of renewable energy like solar, wind, geothermal, biomass, and hydropower for manufacturing combustion air for a fossil fuel burner and firebox

InactiveUS20080131830A1Reduce the amount requiredCarbon reductionSolar heating energyFuel heating with wind energyCombustion chamberEvaporation

Invented is a method of making combustion air for a fossil fuel burner, as a coal burning power plant, oil refinery or gas fired household appliance. Combustion air is made from solar, wind, biomass, hydropower or geothermal. A staged progression using lower cost greenhouses, or flatplates, or solarponds, feed warm air to higher cost concentrator solar collectors. Wind energy, biomass, geothermal energy heat and compress combustion air. Hydropower also heats and compresses combustion air. Solar evaporation from salt or impure water creates water or local rain for the hydropower system. Combustion air thus is made economically hot, compressed and high velocity, and placed into a heavily insulated pipes for long distance transmission to a distant power plant.

Owner:NIX MARTIN E

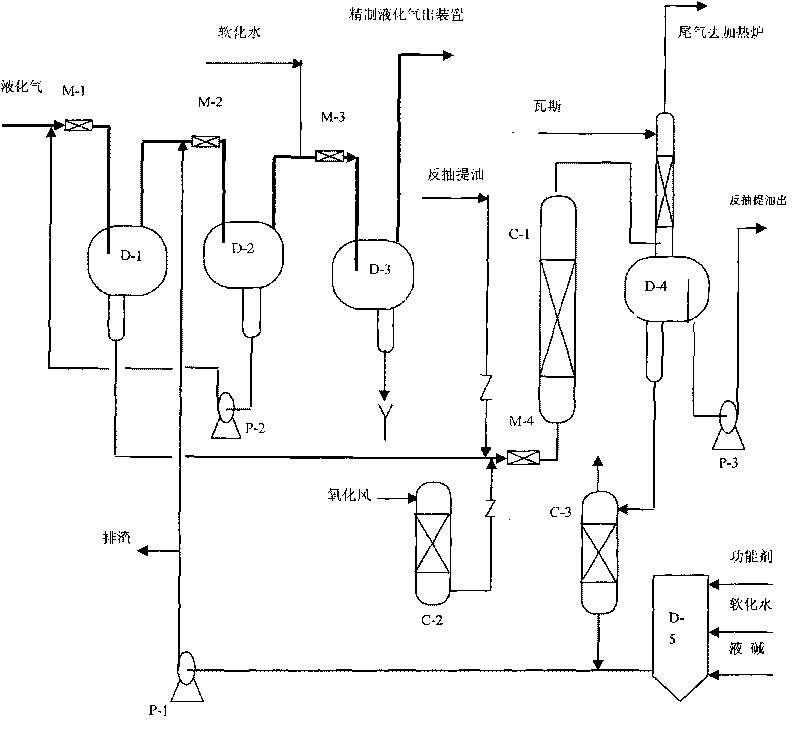

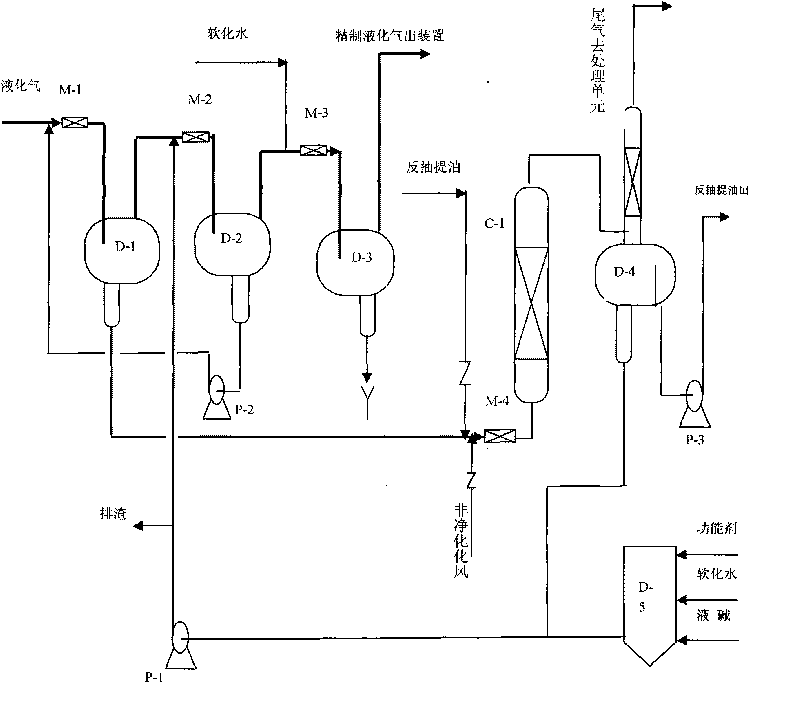

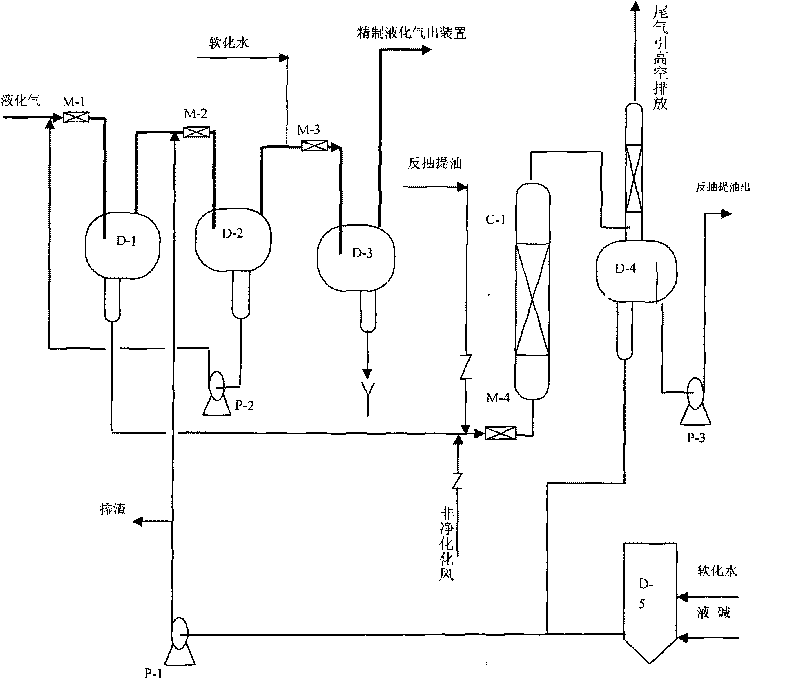

Liquid hydrocarbon mercaptan removal technique capable of deeply removing total sulfur

ActiveCN101705108AImprove abilitiesHigh activityGaseous fuelsRefining with aqueous alkaline solutionsSlagCarbonyl sulfide

The invention relates to a liquid hydrocarbon mercaptan removal technique capable of deeply removing total sulfur, in particular to a sweetening technique for liquefied gas in an oil refinery. The oil refining liquid hydrocarbon refers to components of liquefied gas and light gasoline, wherein the liquefied gas is a raw material for producing MTBE, and the light gasoline is a component for producing high-cleanness gasoline. In order to solve the problem of high total sulfur in the oil refining MTBE and the light gasoline, according to the shape and the distribution rule of sulfocompounds in the liquid hydrocarbon, processes such as functional reinforcement of a recycle solvent, three-phase mixed reinforced regeneration, regenerated catalyst and extractant separation and recycle solvent deoxidization and the like are adopted in the conventional process of liquid hydrocarbon extraction, oxidization and mercaptan removal, so the technical effects of reinforcing the mercaptan removal depth, improving carbonyl sulfide removal rate, and avoiding forming disulphide in the extracting, saving energy and reducing emission and the like are achieved. Thus, the liquid hydrocarbon can be deeply desulfurated, the problem of high total sulfur in the oil refining MTBE and the light gasoline is solved and the slag discharging quantity in the conventional process is greatly reduced.

Owner:HEBEI REFINING TECH CO LTD

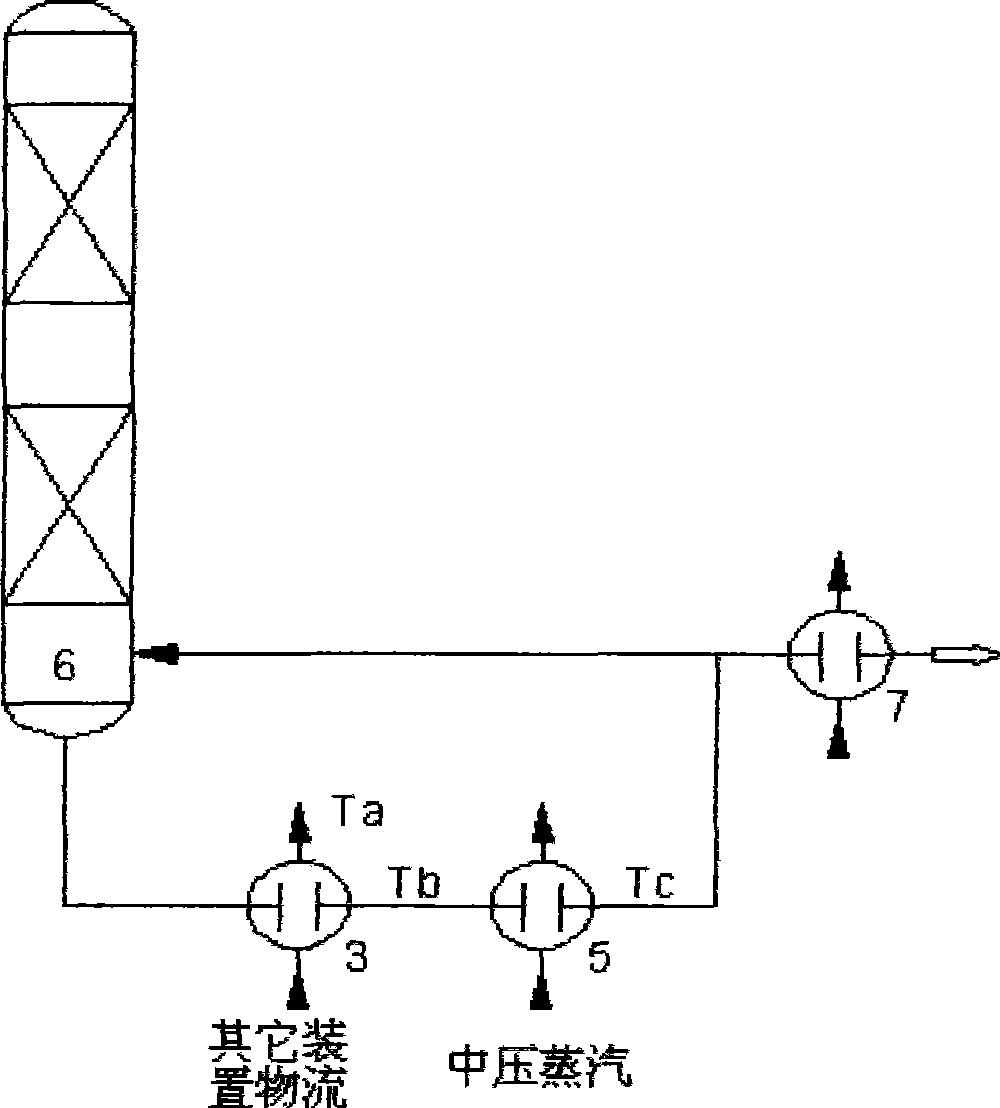

High temperature heat integration system for oil-extraction plant and use thereof

ActiveCN101424453ASave medium pressure steamOptimize heat exchange networkStorage heatersStationary tubular conduit assembliesSystems designExchange network

The invention relates to a heat exchange system for high temperature heat of a plant, in particular to an oil refining plant high-temperature heat integration system designed for using high-temperature mass flow heat. The system is characterized in that three independent heat source devices are connected through thermal medium pipes and heat-conducting oil in the thermal medium pipes are used as a heat-transfer medium to form heat integration, so as to collect and use high-temperature heat. Compared with the prior art, the system optimizes a heat exchange network, saves fuel gases and steam in a reboiler at the tower bottom, reduces energy consumption of equipment, lowers oil refining cost and improves economic benefits.

Owner:SHANGHAI YOUHUA PROCESS INTEGRATED TECH CO LTD

Method for starting operation of catalyst for hydrocracking in oxidation state

InactiveCN101003749AStrong resistance to sulfur poisoningImprove hydrogenation performanceHydrotreatment operations starting-upOxidation stateNitrogen gas

This invention relates to a start-up method for oxidation-state hydrocracking catalyst used in oil refinery process. The method comprises: loading the oxidation-state hydrocracking catalyst into a reactor, introducing nitrogen to replace air in the reactor and pipelines, pressurizing to meet the pressure requirement of hydrocracking, switching to hydrogen after nitrogen flow is stable, raising the temperature of the catalyst bed to meet the temperature requirement of catalyst reduction after hydrogen flow is stable, keeping the temperature, adjusting the temperature of the catalyst bed to meet the temperature requirement of hydrocracking, adjusting hydrogen flux to meet the flux requirement of hydrocracking, and introducing hydrocarbon reactants. The method does not need pre-sulfurization of the catalyst with additional sulfurization agent, thus can avoid the problems caused by pre-sulfurization, and partially reduced catalyst has higher hydrocracking activity.

Owner:XIAMEN UNIV

Short contact time catalytic partial oxidation process for recovering sulfur from an H2S containing gas stream

InactiveUS6946111B2Avoid contactExcess buildupHydrogenDispersed particle separationPartial oxidationSulfur

A process for removing sulfur from a H2S-containing gas stream is disclosed. A preferred embodiment of the process comprises incorporating a short contact time catalytic partial oxidation reactor, a cooling zone, and a condenser into a conventional refinery or gas plant process, such as a natural gas desulfurizer, a hydrotreater, coker or fluid catalytic cracker, in which sulfur removal is needed in order to produce a more desirable product. An H2S-containing gas stream is fed into a short contact time reactor where the H2S is partially oxidized over a suitable catalyst in the presence of O2 to elemental sulfur and water.

Owner:PHILLIPS 66 CO

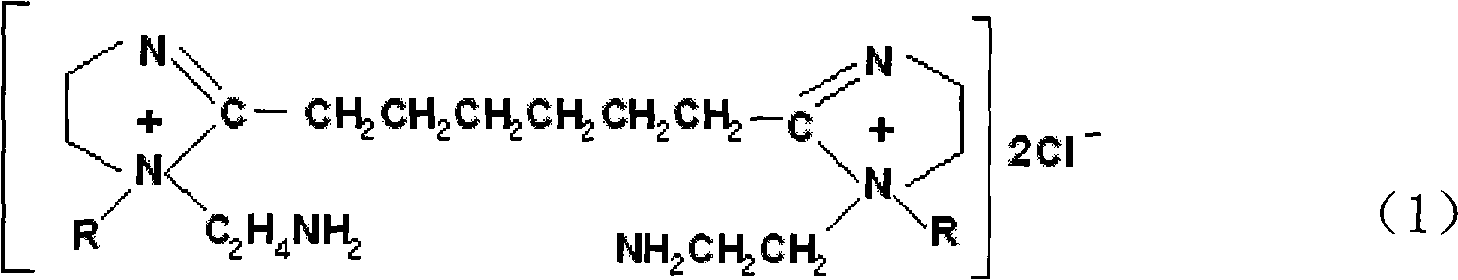

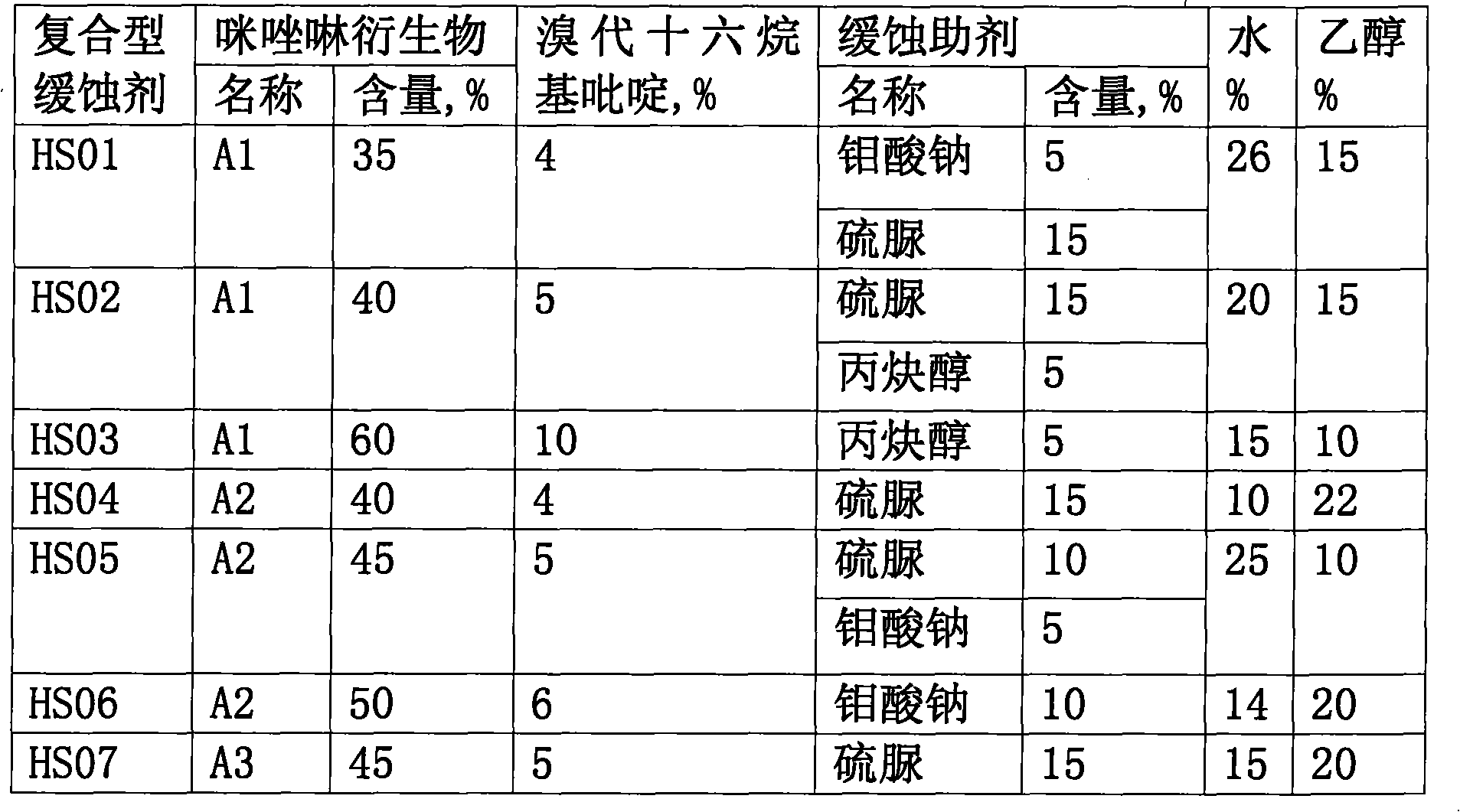

Composite inhibiter and preparation method and application thereof

ActiveCN101613622AGood corrosion inhibitionGood film formingTreatment apparatus corrosion/fouling inhibitionSolventPyridine

The invention discloses a composite inhibiter and a preparation method and an application thereof. The composite inhibitor is a composition with the components and contents being as follows: (A) 10wt%-60wt% of auaternary ammonium bis-imidazoline; (B) 1wt%-10wt% of pyridine derivatives; (C) 1wt%-30wt% of corrosion inhibition assistant; and (D) 10wt%-50wt% of solvent. The inhibitor in the invention has fine effect on preventing low-temperature lightweight oil part equipment from being corroded in an oil refinery.

Owner:CHINA PETROCHEMICAL CORP +2

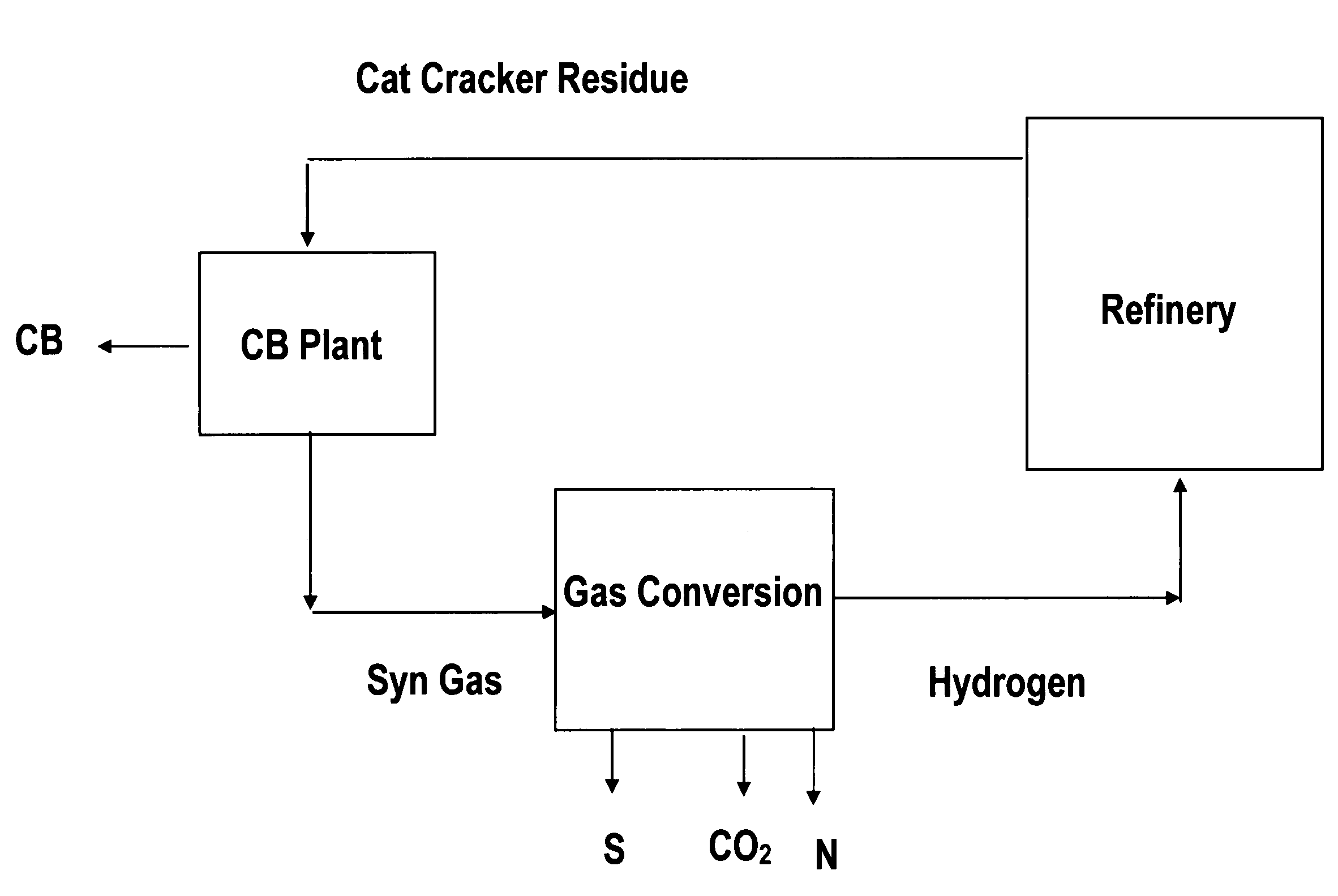

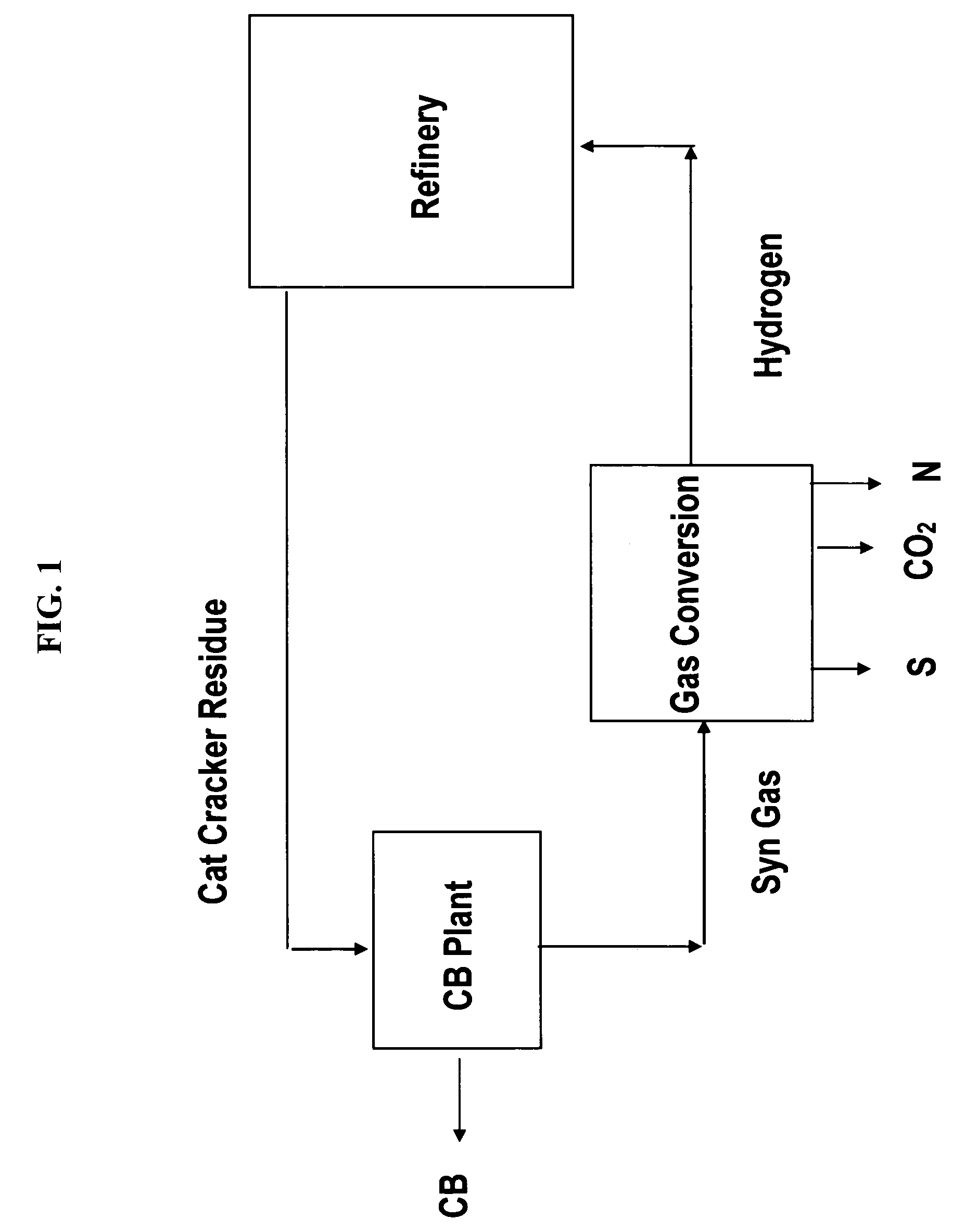

Method to produce hydrogen or synthesis gas and carbon black

InactiveUS7666383B2Emission reductionPigmenting treatmentHydrogen separation using solid contactHydrogenOil refinery

Owner:CABOT CORP

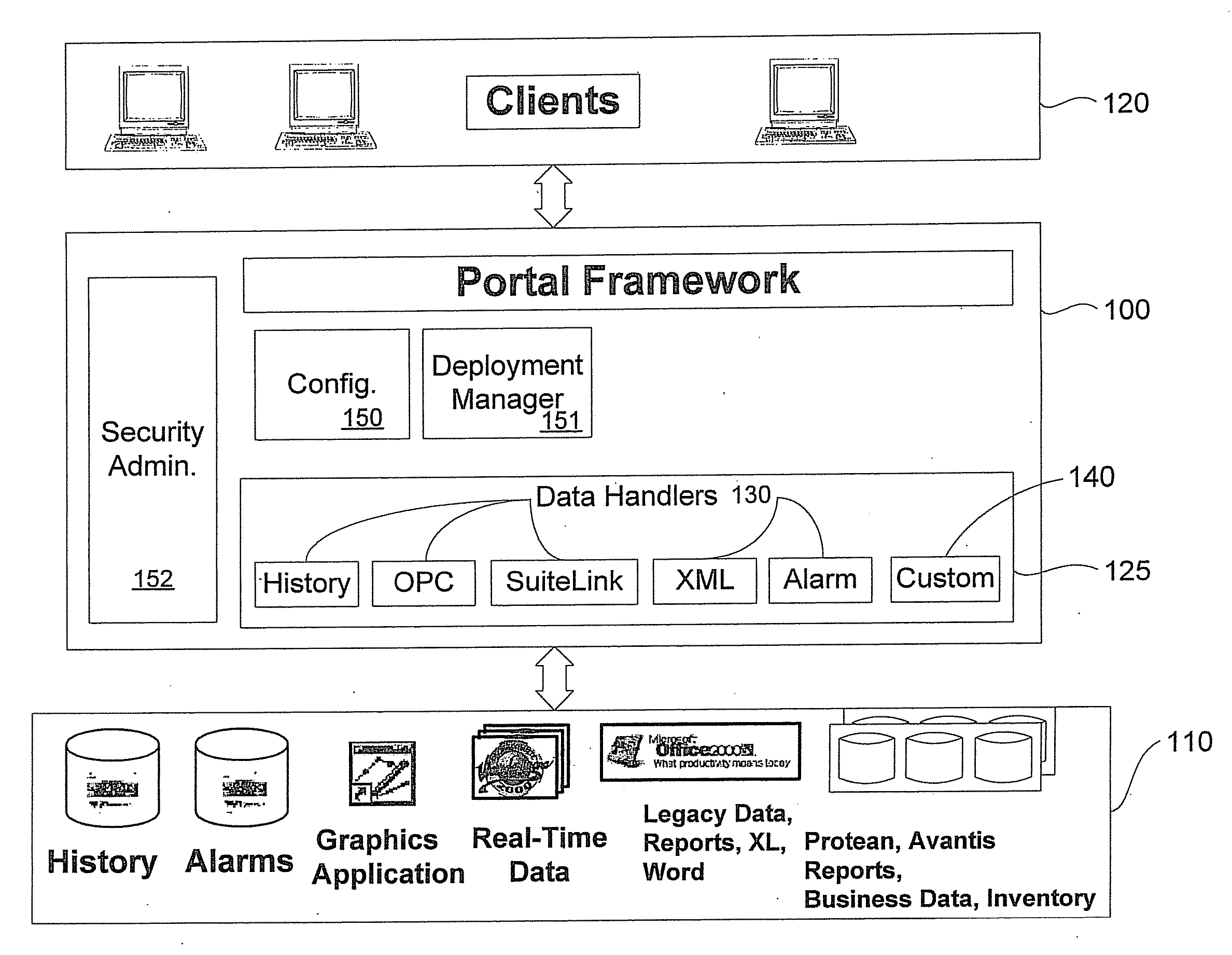

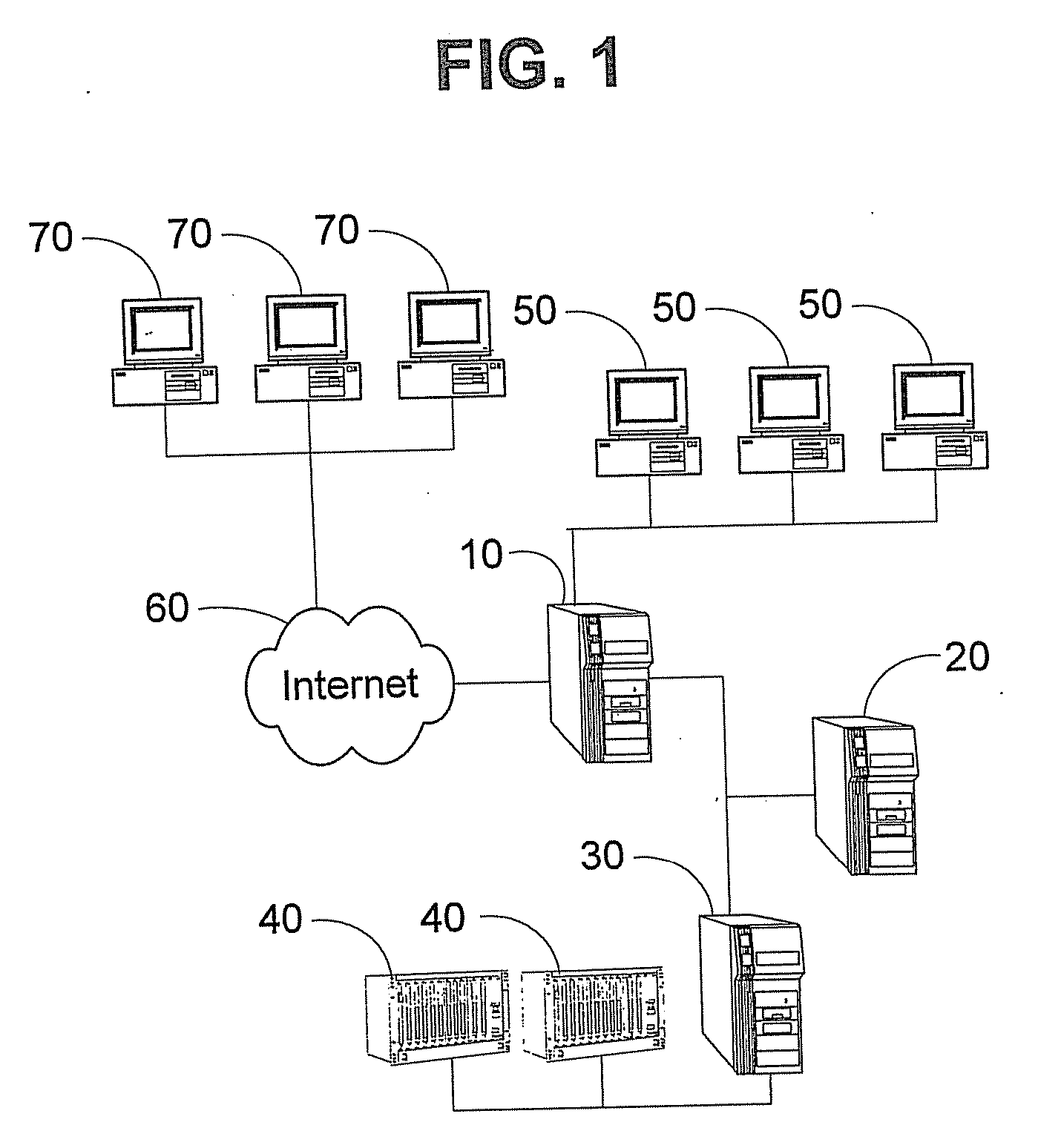

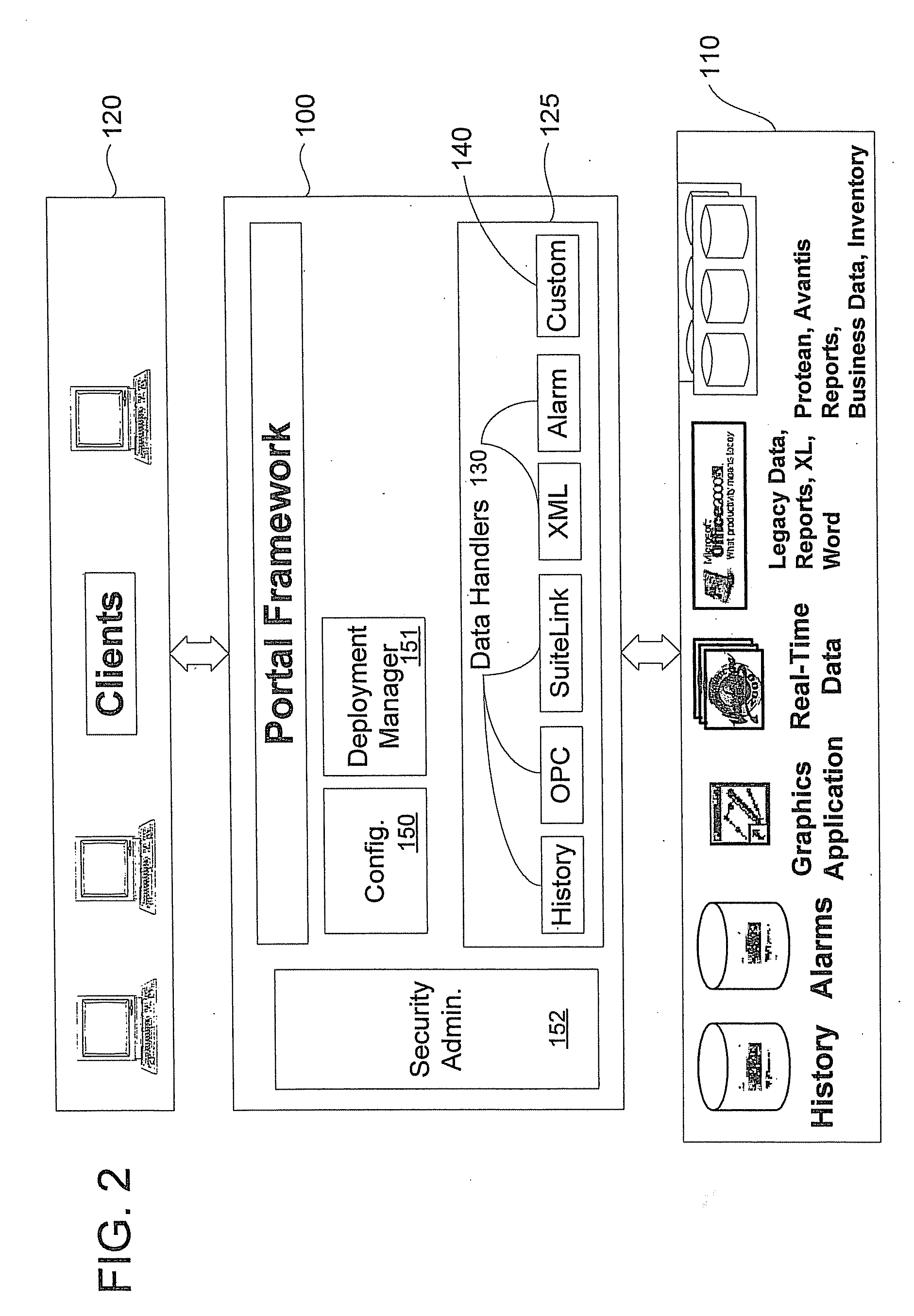

Extensible manufacturing/process control information portal server

InactiveUS20080097622A1Easy to customizeComputer controlCathode-ray tube indicatorsData providerInformation access

A manufacturing / process control system information access provider architecture is disclosed. Manufacturing / process control system data provider flexibility is achieved through a user-configurable manufacturing / process control information portal server that comprises multiple selectable data provides (sources) and / or data types that a particular data provider accommodates. A user configures the portal server to deliver manufacturing / process control information associated with a controlled process environment, such as a food processing plant floor or an oil refinery reactor, to the user via a browser client over the Internet or a corporate intranet. Furthermore, an extensible architecture is provided that enables adding new components to the portal server. Such extensions include new data sources and new data types / handlers. The new architecture enables a user to select particular ones of the available data handlers and then their associated data sources thereby facilitating customizing the configuration of the portal server to the particular needs / interests of the user.

Owner:INVENSYS SYST INC

Method for simultaneously desulfurating, denitrating and decarbonizing coal-fired flue gas

InactiveCN101816886APromote regenerationSolve pollutionDispersed particle separationAir quality improvementMass ratioSorbent

The invention provides a method for simultaneously desulfurating, denitrating and decarbonizing coal-fired flue gas. The method comprises the following steps: dedusting and cooling the coal-fired flue gas containing SO2, NOx and CO2; leading the gas into an adsorbent for saturated adsorption at the adsorption temperature of 50-100 DEG C and the adsorption pressure of 50-10000Pa; evacuating the coal-fired flue gas, desorbing the adsorbent by means of pressure reduction or temperature rise, and then repeatedly using; leading the desorbed gas into ammonia water for absorption treatment, wherein, the mass ratio of the ammonia water to the mixed gas containing SO2, NOx and CO2 is 2-6:1, the absorption temperature is 30-50 DEG C, and the absorption pressure is 5000-12000Pa; and recycling the gas to generate ammonium sulfate, ammonium nitrate and ammonium carbonate. The method can achieve simultaneouse desulfuration, denitration and decarbonization, and has small investment, low cost and low energy consumption; and the method can be widely applied to purification treatment of SO2, NOx and CO2 in the waste gas discharged from fixed fire coal sources such as thermal power plants, smelting plants, oil refinery, chemical plants and the like.

Owner:KUNMING UNIV OF SCI & TECH

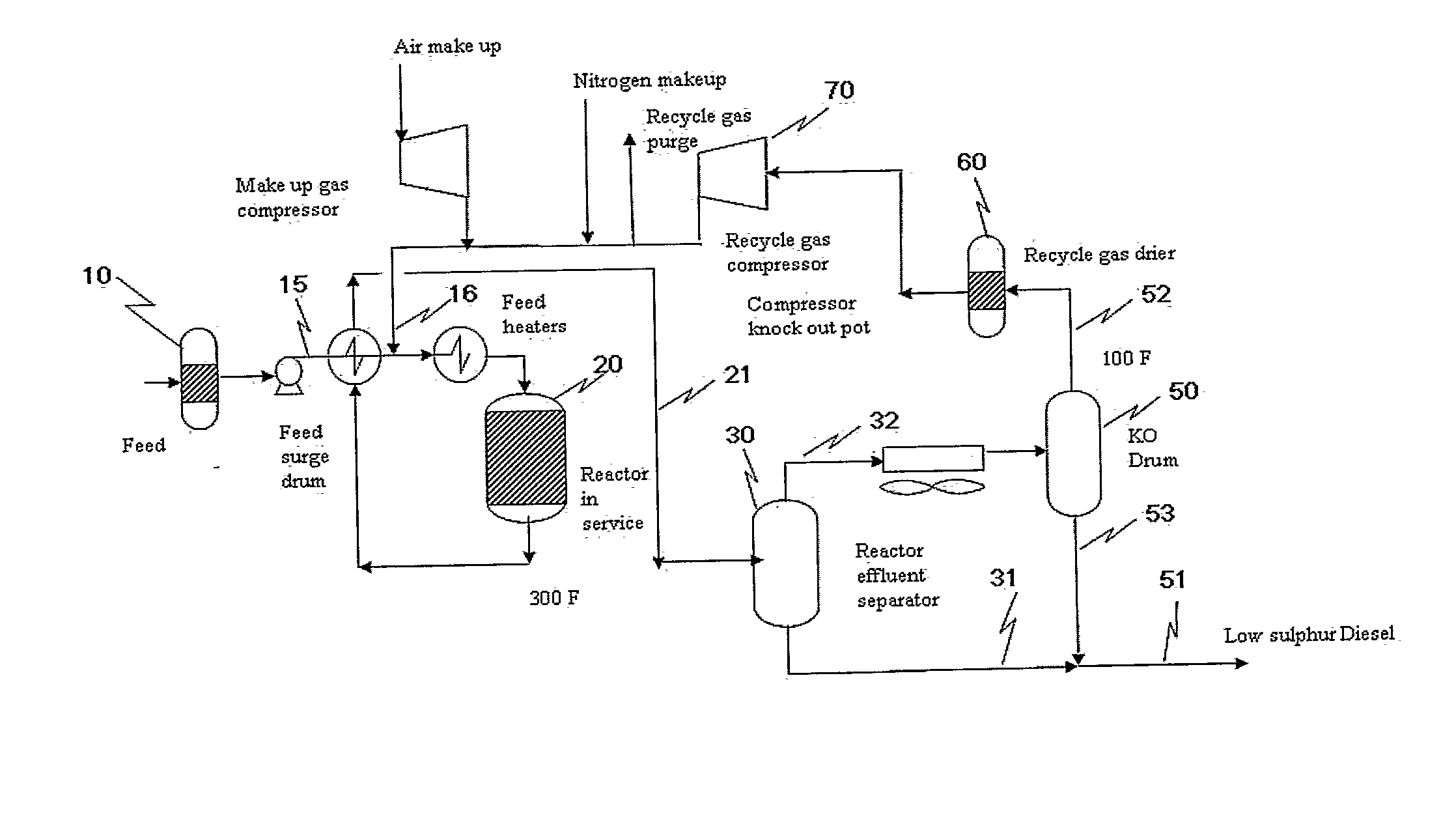

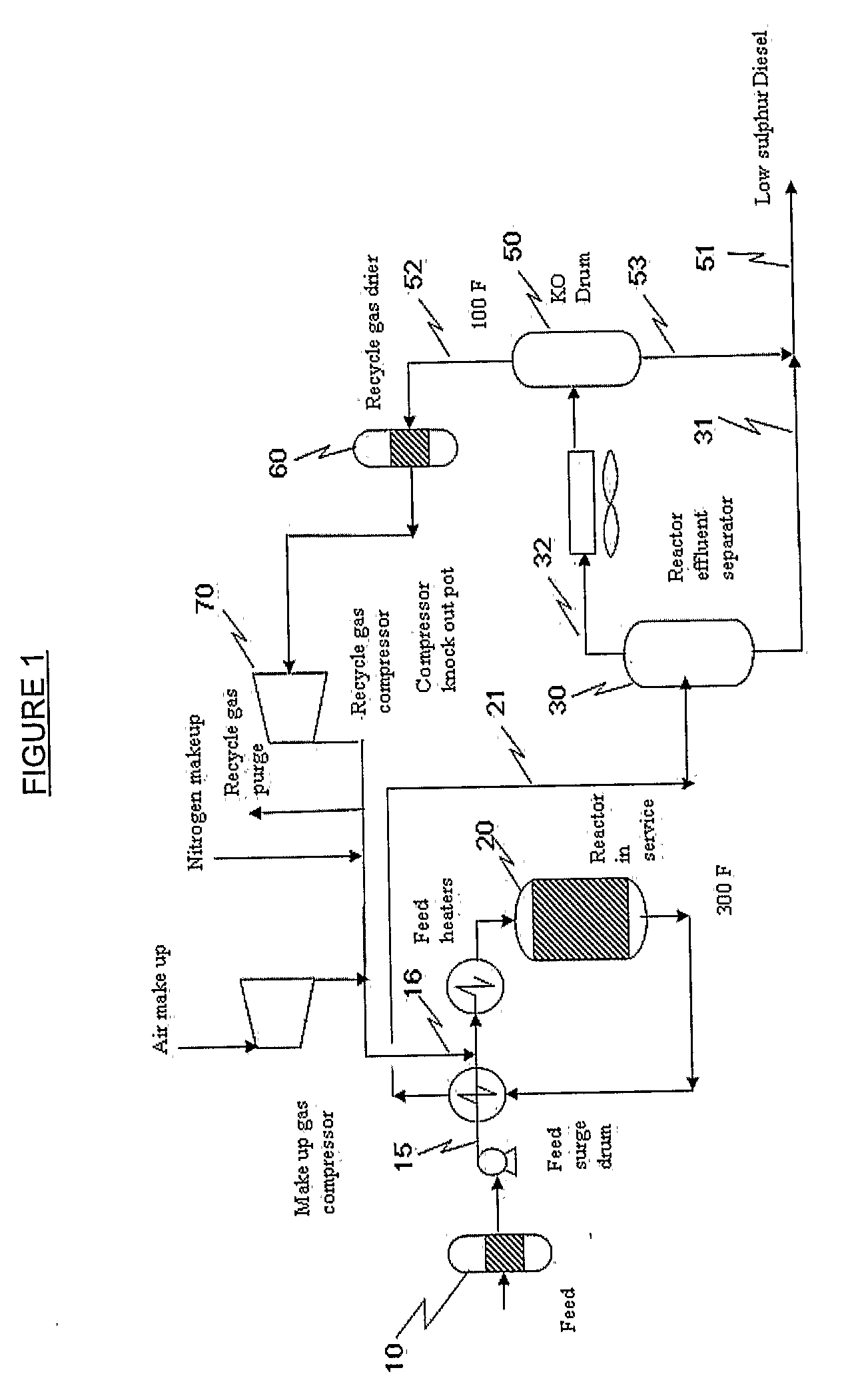

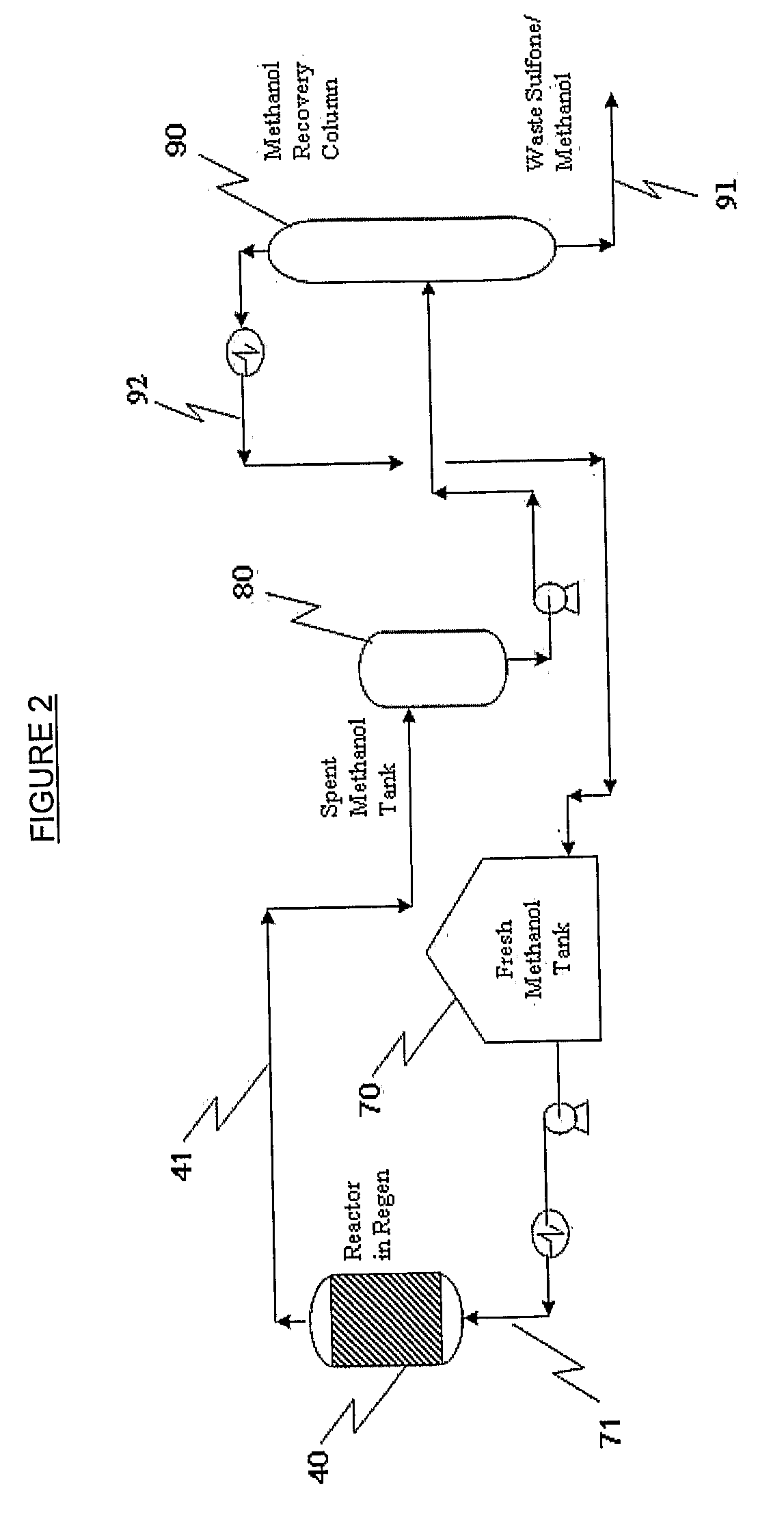

Oxidative Desulfurization Process

InactiveUS20080308463A1Reduce sulfur contentRefining with metalsMolecular sieve catalystsSulfurNitrogen

Disclosed is a process which reduces the sulfur and / or nitrogen content of a distillate feedstock to produce a refinery transportation fuel or blending components for refinery transportation fuel, by contacting the feedstock with an oxygen-containing gas in an 5 oxidation / adsorption zone at oxidation conditions in the presence of an oxidation catalyst comprising a titanium-containing composition whereby the sulfur species are converted to sulfones and / or sulfoxides which are adsorbed onto the titanium-containing composition.

Owner:BP CORP NORTH AMERICA INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com