Composite inhibiter and preparation method and application thereof

A kind of corrosion inhibitor and composite technology, which is applied in the fields of processing equipment corrosion/fouling inhibition, petroleum industry, processing hydrocarbon oil, etc. It can solve the problems of single application range, narrow application range of corrosion inhibitor and poor dispersion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

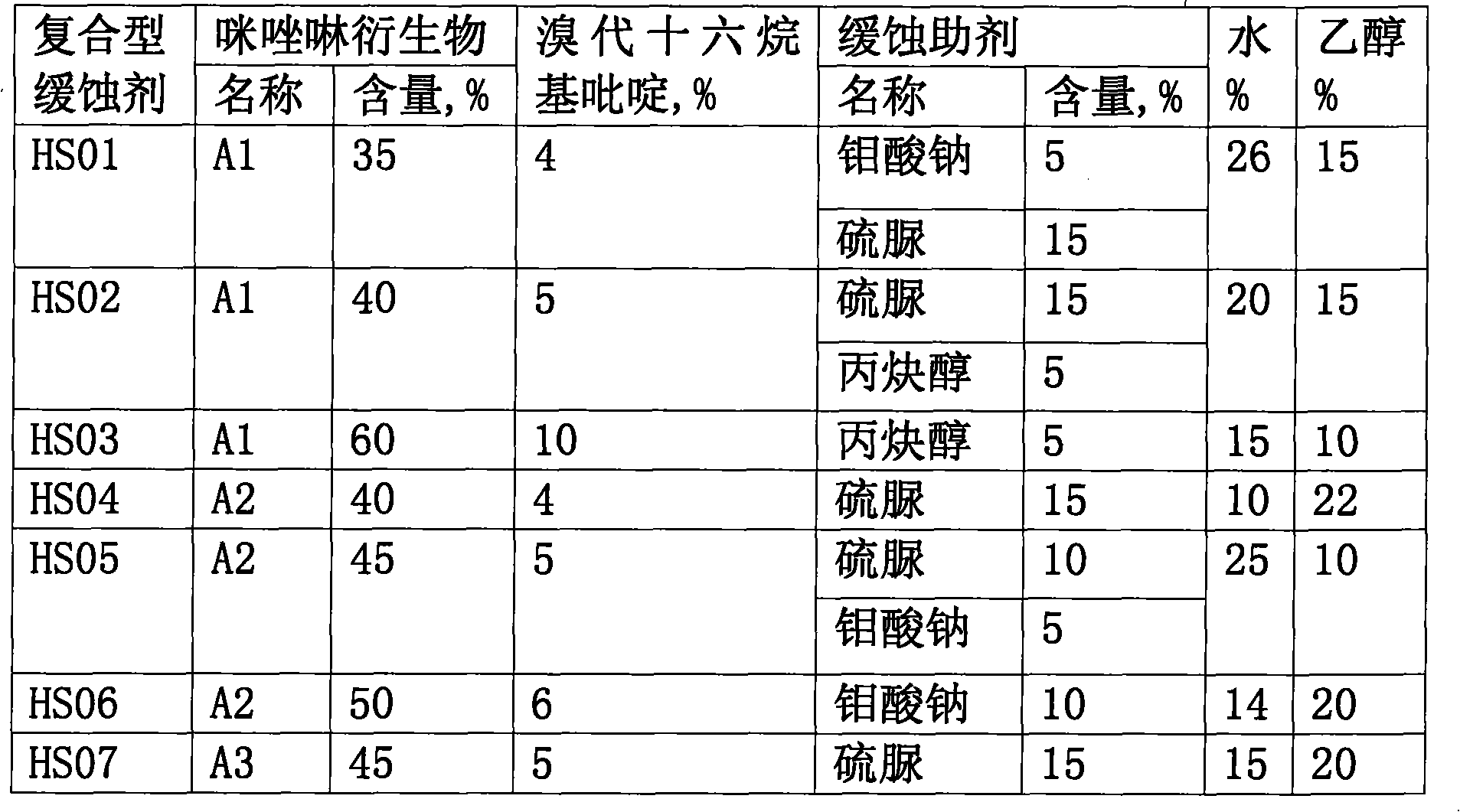

Examples

Embodiment 1~3

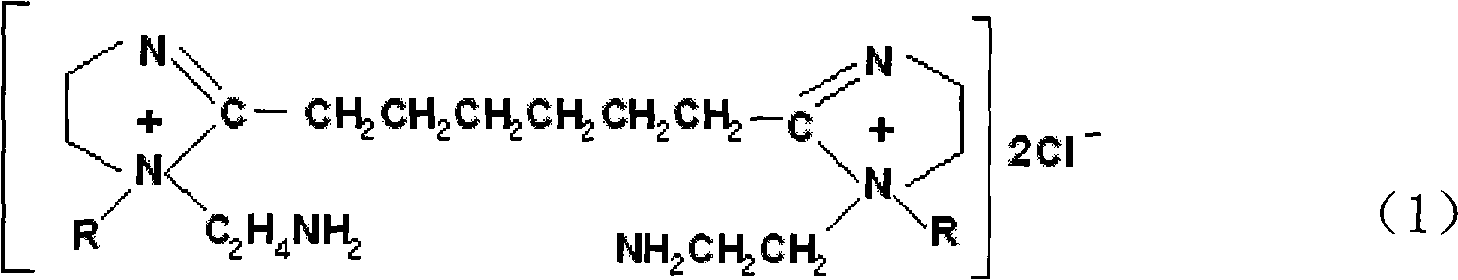

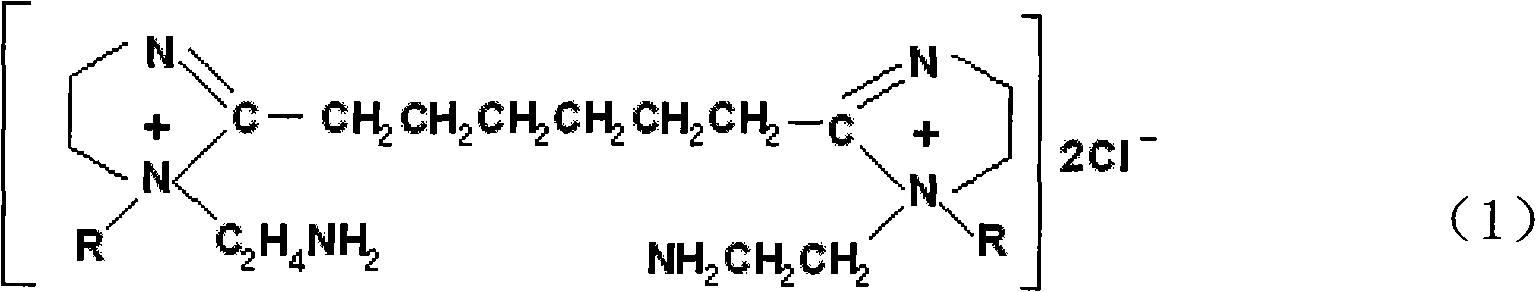

[0037] Embodiment 1~3 is the preparation example of two imidazoline quaternary ammonium salts:

Embodiment 1

[0039] Put adipic acid and diethylenetriamine into the reactor according to the molar ratio of 1:2.2, add boric acid accounting for 0.2% by weight of the feeding amount, and gradually heat up to 230°C under constant stirring, and the temperature rise reaction time is 4 hours to obtain bis-imidazoline Intermediate: After cooling to below 60°C, slowly add benzyl chloride reagent according to the molar ratio of 1:2. After the addition, react at a temperature of 90-110°C for 3 hours, and obtain bis-imidazoline quaternary ammonium salt A1 after cooling.

Embodiment 2

[0041] According to the similar method of preparing bis-imidazoline quaternary ammonium salt A1 in Example 1, the benzyl chloride reagent is replaced by hypochlorous acid and sodium hypochlorite mixture with a molar ratio of 1: 2, and the bis-imidazoline intermediate and the quaternization reagent mol ratio are 1 : 3, prepared bis-imidazoline quaternary ammonium salt A2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com