Patents

Literature

955results about How to "Good corrosion inhibition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

No-phosphate corrosion and scale inhibitor and its application

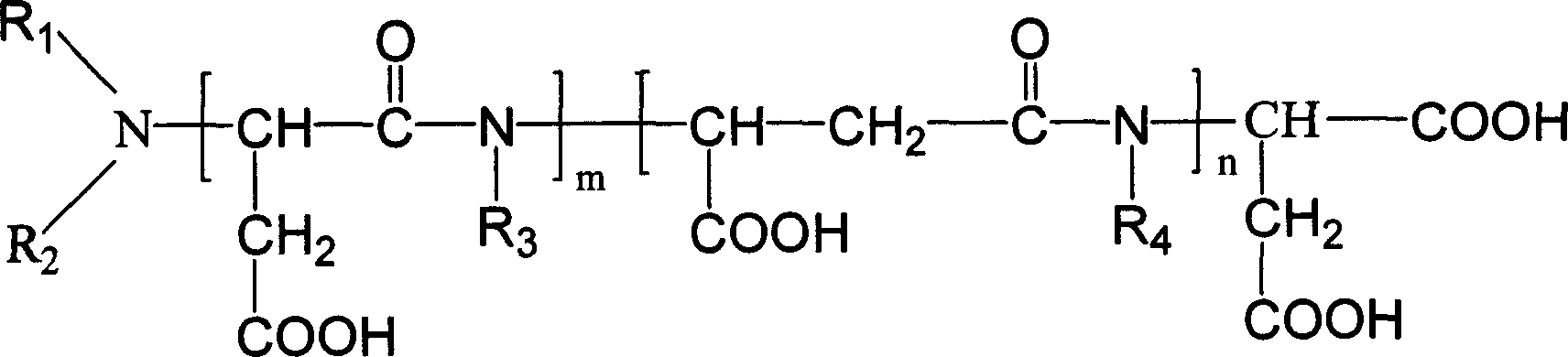

InactiveCN101066811AExcellent corrosion inhibition performanceIncrease polarityScale removal and water softeningNon-contaminated water treatmentPolyaspartic acidPhosphate

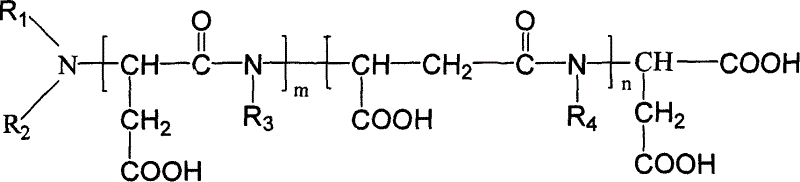

The present invention relates to no-phosphate corrosion and scale inhibitor and its application. The no-phosphate corrosion and scale inhibitor consists of polyaspartic acid and / or polyepoxy succinic acid 10-20 wt%, polymaleic anhydride 20-30 wt%, copolymer of acrylic acid and 2-acrylamido-2-methyl propenyl sulfonic acid 15-20 wt%, zinc salt 3-5 wt%, natural organic high molecular compound 5-12 wt%, molybdate 5-8 wt%, and other components 5-20 wt%. It has excellent corrosion retarding performance, high scale inhibiting performance and environment friendship.

Owner:WUHAN JINPO CHEM TECH

Acid-cleaning inhibiter for cleaning boiler and use method thereof

ActiveCN101634030ASlow down the dissolution rateIncrease activation energyBoiler cleaning apparatusThioureaPhosphoric acid

The invention discloses an acid-cleaning inhibiter for cleaning a boiler and a use method thereof. The acid-cleaning inhibiter comprises the following components by weight percent: 2.0%-10.0% of acid liquor, 0.08-0.25% of urotropine, 0.04-0.15% of dimethylbenzene thiourea or thiourea, 0.01-0.05% of thiocyanate, 0.03-0.12% of dodecyl-cetyl phenmethyl chloride or bromide, 0.05-0.12% of a surface active agent and the balance of water. Acids suitable for the acid-cleaning inhibiter include hydrochloric acid, citric acid, sulphuric acid, hydrofluoric acid, aminosulfonic acid and phosphoric acid, which are suitable for boiler steel, mild steel, alloy steel and steam steel. The inhibition effect of the invention is over 98% with less toxicity under the boiler chemical cleaning condition, the value of LD50 (orally taken by mice) is 5.74 g / kg. The invention can be stored for 2 years, resistant Fe<3+> ion is 800 mg / kg in the acid cleaning. The preparation method has simple steps, easily obtained raw materials and convention operation.

Owner:湖南省湘电试验研究院有限公司 +2

Non-Phosphorus composite anti incrustation eorrosion snhibiter and its application in water treatment

ActiveCN1785853AImprove performanceExcellent resistance to CaCO

<sub>3</sub>

Dirt performanceScale removal and water softeningMolybdatePolyaspartic acid

The present invention relates to a phosphorus-free composite antiincrustation corrosion inhibitor. It includes polyaspartic acid and / or polyepoxysuccinic acid and at least one kind of scale inhibition and dispersion agent, in which the scale inbibition and dispersion agent is polymer containing carboxylic acid group, or it includes polyaspartic acid and / or polyepoxysuccinic acid, zinc salt, molybdate or tungstate and polymer containing carboxylic acid group. Said invention is applicable to treatment of circulating cooling water.

Owner:BEIJING YANHUA PETRO CHEM

Phosphorus-free corrosion and scale inhibitor

InactiveCN101607763AReduce dosagePlay a role in corrosion inhibitionTreatment using complexing/solubilising chemicalsChelationPrecipitation types

The invention relates to a phosphorus-free corrosion and scale inhibitor, which is prepared from sodium molybdate, zinc salt, citrate, triethanolamine, benzotriazole (BTA), polyaspartic acid (PASP), polyepoxysuccinic acid (PESA), AA / AMPS terpolymer, solid alkali and water. The phosphorus-free corrosion and scale inhibitor inhibits corrosion of metals by forming oxidization type and precipitation type films on the surfaces of the metals, has the effect of inhibiting scale through chelation and dispersive action on salts causing scale in cooling water, is non-toxic and phosphorus-free, has easily biodegradable major organic compositions, does not cause environmental pollution and is not limited by phosphorus in emission.

Owner:SHANGHAI WEILAI ENTERPRISE

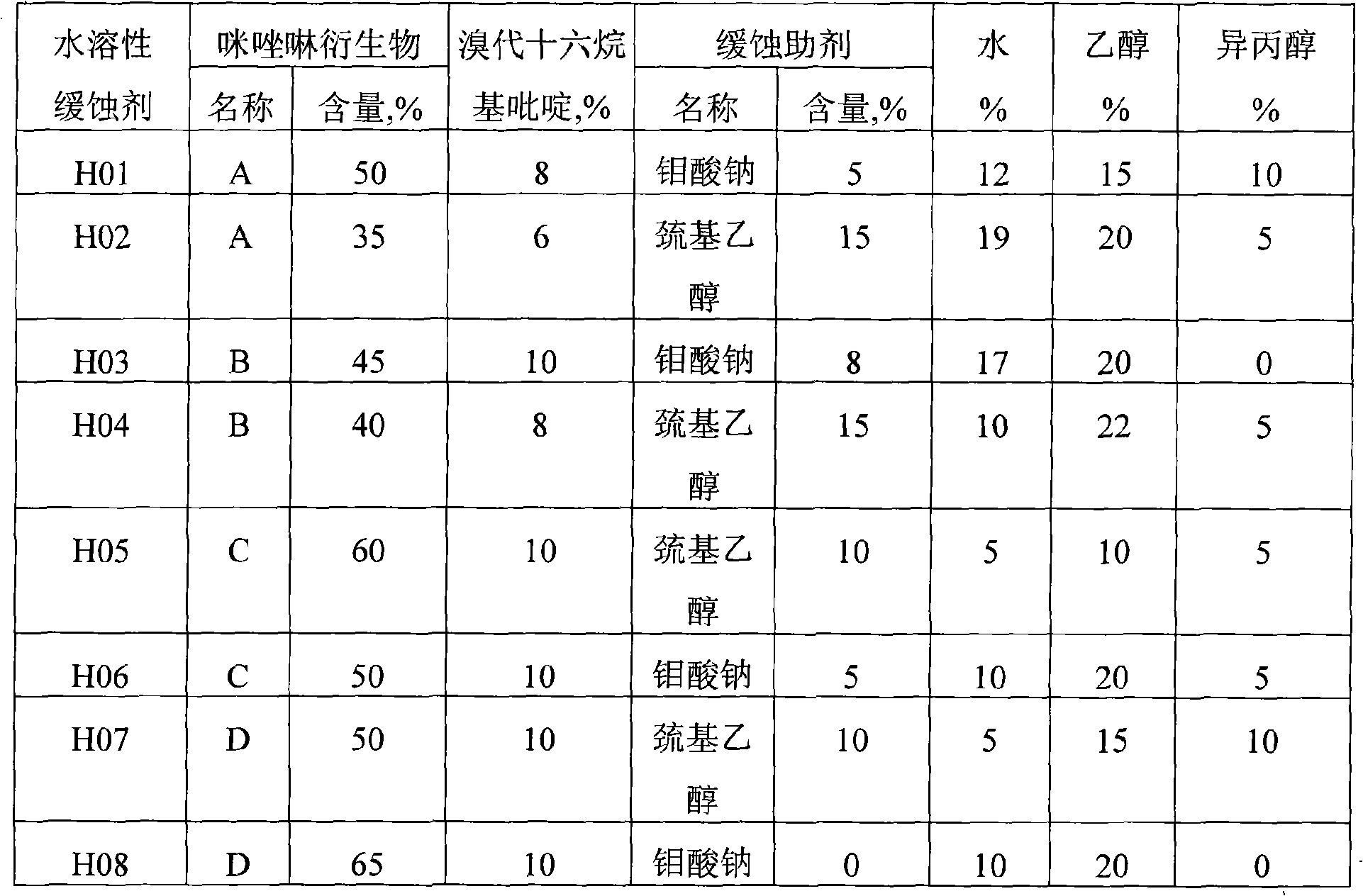

Water-soluble corrosion inhibitor, preparation and application thereof

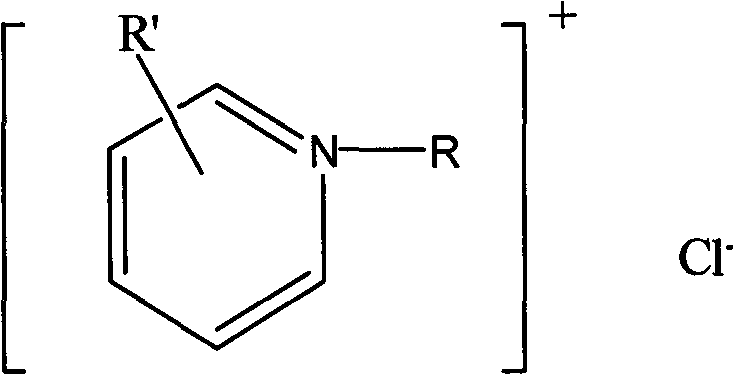

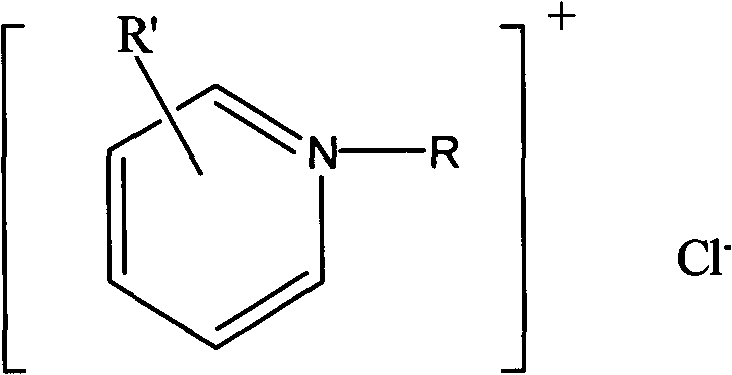

InactiveCN101280222AHigh corrosion inhibition efficiencyGood chemical stabilityTreatment apparatus corrosion/fouling inhibitionWater solubleImidazoline derivatives

The invention discloses a water soluble corrosion inhibitor, the preparation method and the application of the corrosion inhibitor, solving the defect of narrow application range of the corrosion inhibitor pH in the prior art; the water soluble corrosion inhibitor is composed of 20-70 weight proportion of imidazolines derivates, 1-10 weight proportion of pyridine derivates, 1-20 weight proportion of corrosion inhibition auxiliary agent and 10-50 weight proportion of solvent, based on the total weight of the corrosion inhibitor as the reference. The water soluble corrosion inhibitor in the invention has corrosion inhibition effect on the metal material in the medium with wide PH variation range (pH equals to 1-10) and good metal surface film formation property.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

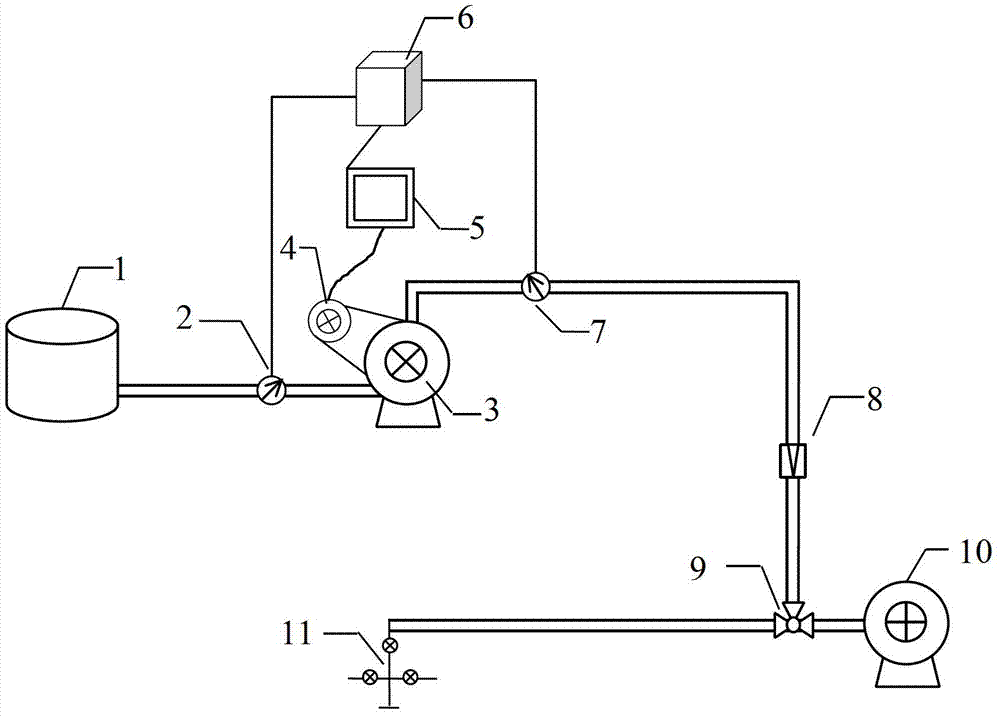

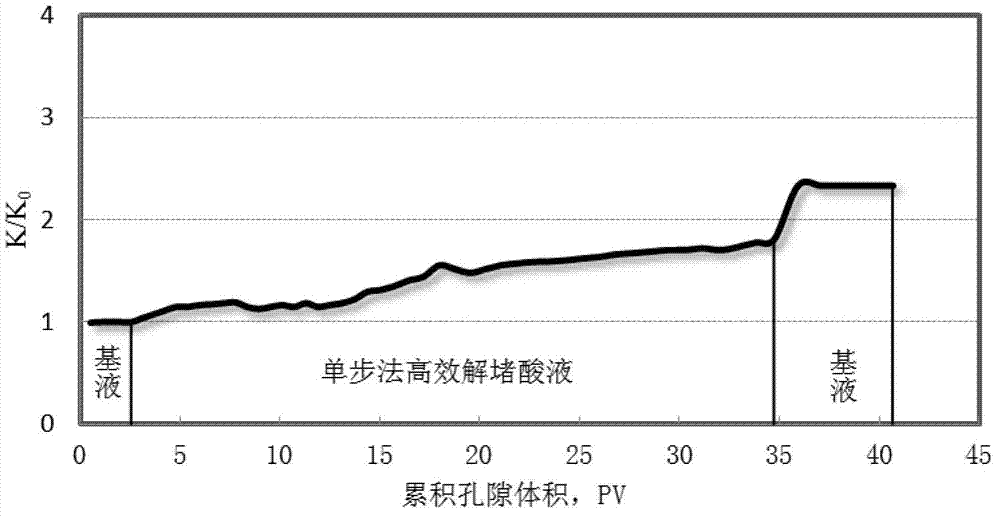

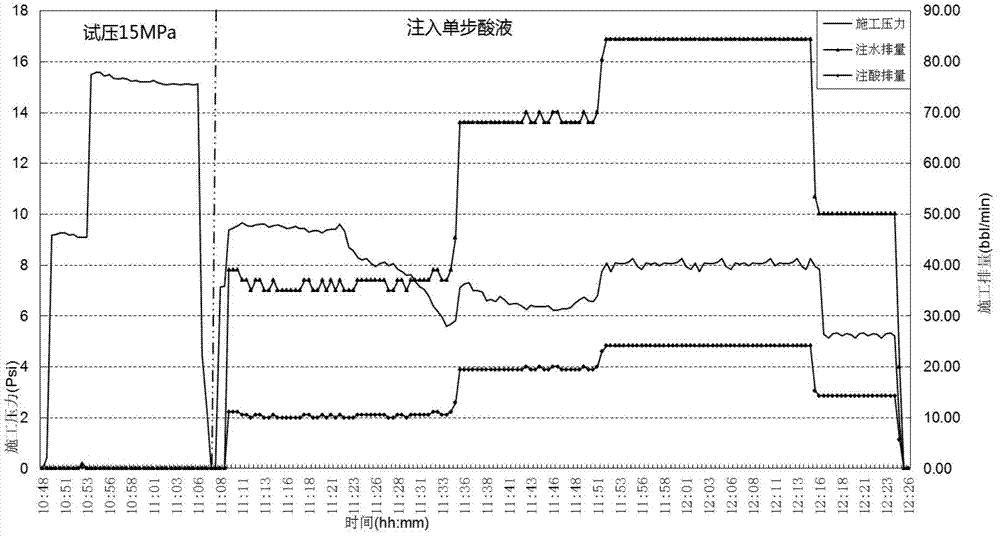

Offshore oilfield water injection well online one-step-process acidification technology

ActiveCN102828734ASimplified recipeSimplify the construction processFluid removalDrilling compositionHydrogen fluorideAcetic acid

The invention relates to an offshore oilfield water injection well online one-step-process acidification technology, which comprises following steps of (1) preparing one-step acid liquor, wherein the one-step acid liquor consists of following components by weight percent: 20 to 40 percent of industrial acetic acid, 15 to 40 percent of industrial hydrochloric acid, 3 to 15 percent of deposition inhibitor, 5 to 15 percent of discharging aiding agent, 3 to 15 percent of corrosion inhibitor, 5 to 15 percent of antiswelling agent, 5 to 15 percent of iron ion stabilizer and 2 to 10 percent of hydrogen fluoride; (2) storing the acid liquor into an acid storage tank of an injection system, wherein the injection system consists of the acid storage tank, an acid resistant pump, a motor, a frequency converter, a flow sensor, a pressure sensor, a computer, a check valve, a three-way pipe and an acid injection pipe; (3) utilizing the acid resistant pump to pump the acid liquor into the water injection flow; (4) monitoring the variation of the pressure and the flow of the injected acid, and calculating skin coefficients in real time; and (5) keeping the water injection after stopping the acid injection. Due to the adoption of the offshore oilfield water injection well online one-step-process acidification technology, high efficiency, rapidness and large scale in plug removal of an offshore oilfield water injection well can be realized, the water injection pressure can be reduced, and the water injection quantity can be improved.

Owner:SOUTHWEST PETROLEUM UNIV +1

Corrosion-and scaling-inhibiting water treating agent

InactiveCN1435384AInhibition of localized corrosionPrevent rustFatty acids production/refiningScale removal and water softeningWater useLiquid state

A corrosion-inhibiting and scale-inhibiting agent for treating the water used as circulated cooling water or for boiler is prepared from liquid-state dielectric hydrophobic substance, oil-soluble corrosion inhibitor, water-soluble disperser, and composite sensitive emulsifier. Its advantages are high effect and low dosage.

Owner:BEIJING UNIV OF CHEM TECH

Low-phosphorus composite antiincrustation corrosion inhibitor and its use for water treatment

ActiveCN1743282AImprove performanceExcellent resistance to CaCO

<sub>3</sub>

Dirt performanceScale removal and water softeningPhosphorAspartic acid

This invention relates to a sort of low-phosphor scale-corrosion inhibitor which includes PBTCA, (and / or HPAA), poly-aspartic acid and / or polyepoxysuccinic acid and carboxyl-containing polymer. This inhibitor can be used to treat recirculated cooling water in ways such as inhibiting the forming of CaCO3 scale, inhibiting corrosion and stabilizing Zn2+ in water. Its phosphor concentration in recirculated water is no more than 1mg / L, reducing the hazard of phosphor discharge to environment.

Owner:BEIJING YANHUA PETRO CHEM +1

Aluminum alloy semisynthesis cutting liquid and preparation method thereof

ActiveCN102925269AResistant to corruption and odorWill not corrodeLubricant compositionActive agentSurface-active agents

The invention discloses aluminum alloy semisynthesis cutting liquid and a preparation method thereof. The aluminum alloy semisynthesis cutting liquid is composed by weight of 12%-20% of mineral oil, 9%-15% of surfactant, 8%-12% of antirust agent, 1%-2% of aluminum corrosion inhibitor, 3%-7% of lubricant, 8%-12% of extreme pressure agent, 0.5%-1% of defoamer, 0.5%-1% of fungicide and the balance, water. The preparation method includes sequentially adding the surfactant, the antirust agent, the aluminum corrosion inhibitor, the lubricant, the extreme pressure agent, the defoamer, the fungicide and the water into the mineral oil and evenly stirring and mixing the mixture to obtain the aluminum alloy semisynthesis. The aluminum alloy semisynthesis cutting liquid has excellent performance on aluminum corrosion inhibition performance, corrosion resistance, lubricant performance, anti-rust performance, defoaming performance, use period and the like.

Owner:SHANGHAI INST OF TECH

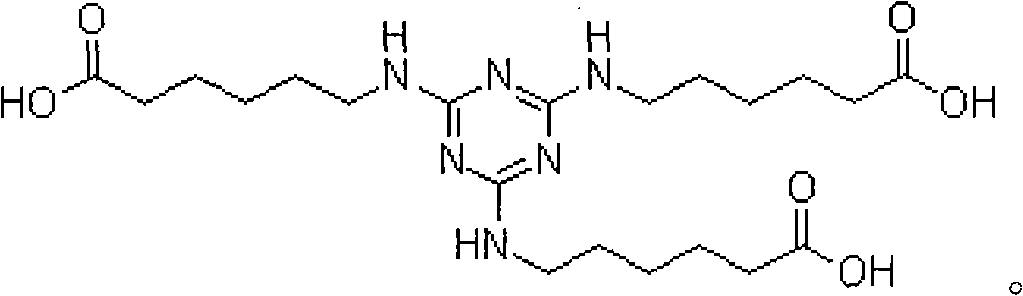

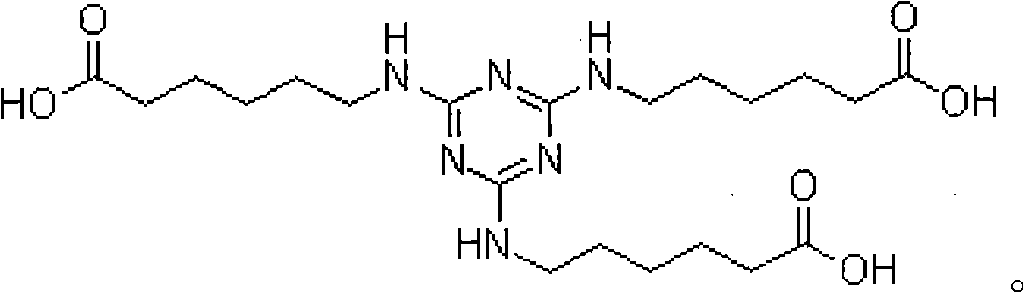

Engine coolant

ActiveCN101768428AAvoid corrosionGood corrosion inhibitionHeat-exchange elementsIonAutomotive engineering

The invention provides an all-organic type engine coolant which comprises glycol, fat carboxylic acid, tricarboxylic acid, benzoic acid, tri (2-ethylhexoic acid) phosphonate, imidazoles compound, defoamer and deionized water. The engine coolant of the invention contains no inorganic salts, such as amines, borate, nitrate, nitrite, silicate, and the like, so the engine coolant is environment-friendly, can prevent all the contacted metal and nonmetal materials in the engine cooling system from being corroded, has an obvious engine coolant effect on various metals, particularly solves the problem that the cast aluminum using a traditional organic acid engine coolant becomes black generally, can be stabled in a relative low density and bigger PH value range, and has the advantages of long-time storage and use.

Owner:北京蓝星清洗有限公司

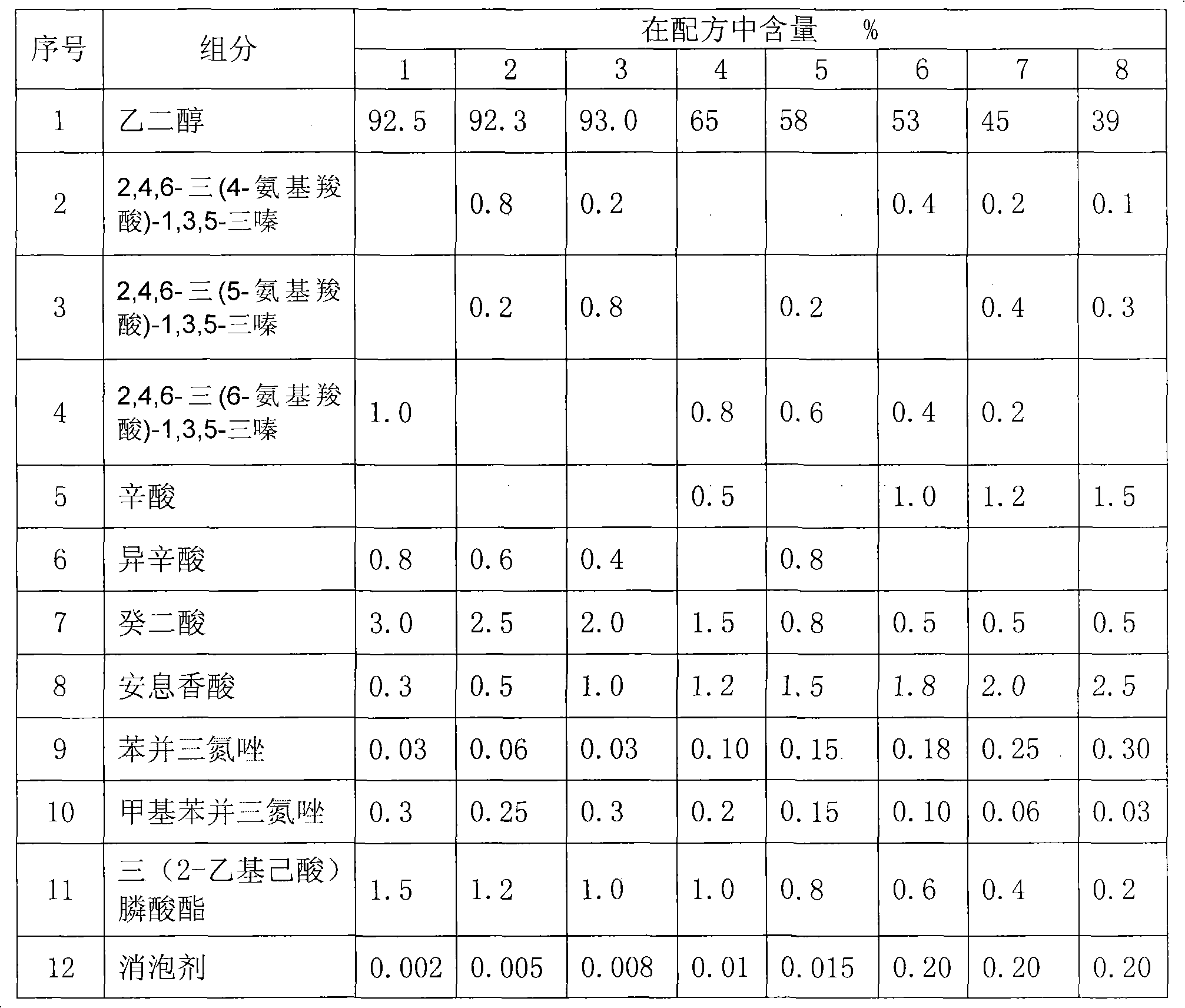

Corrosion inhibitor for inhibiting corrosion of magnesium alloy in automobile cooling liquid

The invention provides a corrosion inhibitor for inhibiting corrosion of magnesium alloy in automobile cooling liquid. The corrosion inhibitor consists of specific adsorption organic substance or / and film-forming inorganic substance, and water or / and ethanol. The corrosion inhibitor is a compound efficient anti-scale corrosion inhibitor, can well inhibit the corrosion of a magnesium alloy material in the cooling liquid in a wider temperature range, and has the characteristics of wide application range, low using amount, high efficiency, no toxicity or peculiar smell, full water dissolution, simple and convenient preparation, low cost, wide applicable temperature range, strong synergistic effect, convenient use, good comprehensive performance and the like. 100 to 1,000ppm corrosion inhibitor directly added into the automobile cooling liquid can inhibit the corrosion of the magnesium alloy, effectively inhibit the corrosion of the magnesium alloy material in the automobile cooling liquid at a normal temperature and a high temperature, and effectively protect the magnesium alloy.

Owner:HUAZHONG UNIV OF SCI & TECH

Phosphorus-free green composite corrosion and scale inhibitor

ActiveCN101805067AGood corrosion inhibitionReduce usageSpecific water treatment objectivesNature of treatment waterChemistryPolyaspartic acid

The invention discloses a phosphorus-free green composite corrosion and scale inhibitor, which comprises polyaspartic acid or polyepoxysuccinic acid, maleic acid homopolymers, acrylic copolymers, inorganic zinc salt, an ECH inhibition synergist and water. The ECH inhibition synergist is mixture of lanthanum nitrate and sodium gluconate mixed according to a mass ratio of 1:10-1:5. The phosphorus-free green composite corrosion and scale inhibitor of the invention is phosphorus-free, non-toxic and highly biodegradable, and not only can overcome the defects of water body eutrophication and high toxicity caused by water treatment agents containing phosphorus, chromium, nitrite and the like, but also can be used for treatment of corrosive water with low alkalinity and low concentration and can satisfy the requirements of circulating water with high temperature, high alkalinity, high hardness and high pH value at present. Moreover, the invention is a multifunctional security and environmental protection type water treatment agent with a function of inhibiting both corrosion and scale.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

Green compound corrosion and scale inhibitor

InactiveCN101746902ASolve the shortcomings of low scale inhibition efficiencySolving compatibility problemsScale removal and water softeningEutrophicationPhosphate

The invention discloses a green compound corrosion and scale inhibitor used in a circulating cooling water system. The green compound corrosion and scale inhibitor comprises sodium humate, starch, polyaspartic acid or polyepoxysuccinic acid, maleic anhydride-acrylic acid copolymer, acrylic acid-2-acrylamide-2-methylpropanesulfonic acid or acrylic acid-acrylate-sulfonate, zinc salt (zinc sulfate or zinc chloride) and tdlyltriazole. The green compound corrosion and scale inhibitor not only solves the problems that the frequently-used organic phosphate type corrosion and scale inhibitor used in the circulating cooling water system easily causes eutrophication of surrounding waters due to the phosphorus discharge to further lead to red tide, environmental pollution and the like, but also achieves the same high scale-preventing rate and corrosion inhibiting efficiency of the organic phosphate type corrosion and scale inhibitor.

Owner:成都澳贝龙科技发展有限公司

Low phosphine compound slow corrosion antisludging agent

InactiveCN1781858AImprove corrosion inhibition effectReduce dosageScale removal and water softeningCarbon steelChemistry

Owner:NANJING UNIV OF SCI & TECH

Phosphorus-free composite corrosion and scale inhibitor containing natural biodegradable substances

InactiveCN102627359AGood scale resistanceGood corrosion inhibitionTreatment using complexing/solubilising chemicalsIonChemistry

The invention introduces a phosphorus-free composite corrosion and scale inhibitor containing natural biodegradable substances. The phosphorus-free composite corrosion and scale inhibitor consists of the following raw materials in a mixing way: zinc sulfate or zinc nitrate, alkyl glycoside, polyaspartic acid, carboxymethylcellulose, polyepoxysuccinic acid, polymerized amino acid, sodium gluconate, methylbenzotriazole or benzotriazole, and water or deionized water. The raw materials are nontoxic, natural, renewable and degradable. The phosphorus-free composite corrosion and scale inhibitor has the advantages of no toxicity, no harm, biodegradability, stable performance, wide raw material source and the like. The synergistic effect of all compositions is fully utilized to improve the performance and reduce dosage. When the phosphorus-free composite corrosion and scale inhibitor is used for circulating cooling water treatment, calcium carbonate, calcium sulfate and calcium phosphate can be prevented from being deposited, the scale inhibition effect is obvious and the corrosion inhibition performance is excellent. The eutrophication of the water body can be effectively avoided, the used amounts of germicide and algaecide are reduced and the economic benefit is remarkable.

Owner:HUNAN ELECTRIC POWER CORP RES INST +2

Low-phosphorous environment-friendly composite corrosion and scale inhibitor

InactiveCN101746901AImprove toleranceGood dispersionScale removal and water softeningHigh concentrationTricarboxylic acid

The invention discloses a low-phosphorous environment-friendly composite corrosion and scale inhibitor that is used in a circulating cooling water system. The low-phosphorous environment-friendly composite corrosion and scale inhibitor comprises 2-phosphonic butane- 1,2,4 -tricarboxylic acid, plyaspartic acid or polyepoxysuccinic acid, maleic anhydride-acrylic acid copolymer, acrylic acid-2-acrylamide-2-methyl propanesulfonic acid or acrylic acid-acrylate-sulfonate, acrylic acid-acrylate-phosphonic acid-sulfonate quaternary copolymer, zinc salts (zinc sulfate or zinc chloride) or hydroxy benzotriazole. The invention is particularly suitable for the circulating cooling water system with high concentration multiple, which needs to control the phosphorous content (the total phosphorous content is lower than 0.5mg / l) due to environmental pressure.

Owner:成都澳贝龙科技发展有限公司

Environment-friendly water quality stabilizer

InactiveCN1463935AGood inhibitory effectGood corrosion inhibitionScale removal and water softeningHigh concentrationWater quality

The environment protecting water quality stabilizer consists of scale inhibitor, corrosion inhibitor, assistant compounded together, and has the features of high efficiency, low toxicity and environment friendship. The water treating agent may be used in water system to produce corrosion inhibiting and scale inhibiting dispersion effect and may be used in the conditions of high hardness, high pHand high concentration multiple. The water treating agent may be used in circulating cooling water system with calcium hardness up to 750-1300 ppm, and in make-up water calcium hardness of 120 ppm, the concentration multiple may reach 10, being in zero-exhaust level.

Owner:CHUANHUA GRP

Low-foam middle-cloud-point environment-friendly water base metal cleaner composition and preparing method thereof

The invention provides a low-foam middle-cloud-point environment-friendly water base metal cleaner composition and a preparing method thereof, and belongs to the field of metal cleaners. The low-foam middle-cloud-point environment-friendly water base metal cleaner composition is composed of low-foam low-cloud-point nonionic surface active agents, low-foam anion surface active agents, triethanolamine oleic soap, triethanolamine, styrene acrylic three azole nitrogen, ethylene diamine tetraacetic acid, sodium carbonate, polyether, organosilicone, sodium hydroxide and deionized water, wherein solid-phase raw material and liquid-phase raw material are sequentially added to a reaction container according to a formulation and metering, the organosilicone and the deionized water are finally added to the reaction container, stirring is conducted for 10min to 20min under the condition of indoor temperature, and clear products with a pH value ranging from 9 to 10 are obtained. The triethanolamine oleic soap is a cloud point improving agent, good water solubility is achieved after the triethanolamine oleic soap and the triethanolamine are re-compounded according to the ratio, solubilizing ability of the low-foam low-cloud-point nonionic surface active agents is enhanced, therefore the temperature of the solution cloud point of the cleaner is improved to 45 DEG C, cleaning efficiency of the cleaner is improved, and the low-foam middle-cloud-point environment-friendly water base metal cleaner particularly suitable for high-pressure spraying cleaning is obtained.

Owner:BOER TECH WUHAN

Corrosion inhibitor and preparation method

InactiveCN102234502AGood water solubilityImprove bindingBorehole/well accessoriesHexamethylenetetramineThiourea

The invention discloses a corrosion inhibitor, comprising the following ingredients: modified imidazoline derivative, 1,4-butynediol, thiourea, sodium dodecyl benzene sulfonate, urotropine and solvent, wherein, the weight ratio of modified imidazoline derivative to 1,4-butynediol to thiourea to sodium dodecyl benzene sulfonate to urotropine is (20-50):(1-2):(1-12):(1-5):(2-4), and the quality of the solvent accounts for 30-70% of the total mass of the corrosion inhibitor. The invention also discloses a preparation method of the corrosion inhibitor, comprising the following steps: adding the modified imidazoline derivative, 1,4-butynediol, thiourea, sodium dodecyl benzene sulfonate, urotropine in the solvent, stirring uniformly to obtain the corrosion inhibitor. The corrosion inhibitor disclosed in the invention has good corrosion inhibition effect for CO2 corrosion in the near neutral oil field water system (PH value: 5-6.8).

Owner:HUAZHONG UNIV OF SCI & TECH +1

Acid washing corrosion inhibitor

The invention discloses an acid washing corrosion inhibitor, which is characterized by comprising the following components in percentage by weight: 30 to 70 percent of mixed alkyl pyridine quaternary ammonium salt, 25 to 50 percent of alcohol, 1 to 4 percent of nonionic surfactant and the balance of water. Compared with the prior art, the acid washing corrosion inhibitor has the advantages that: a pharmaceutical byproduct is mixed with alkyl pyridine to perform modification so as to research the corrosion inhibitor; the acid washing corrosion inhibitor has higher water solubility; the corrosion inhibition effect of the acid washing corrosion inhibitor is superior to that of the common aldehyde ketone amine type corrosion inhibitor; the application temperature range of the acid washing corrosion inhibitor is wider than that of the aldehyde ketone amine type corrosion inhibitor; the aldehyde ketone amine type corrosion inhibitor is easy to carbonize under the condition of high temperature, so that the corrosion inhibition effect is influenced; and in addition, the acid washing corrosion inhibitor is lower in production cost compared with the aldehyde ketone amine type corrosion inhibitor, has a simple production process, has no generation of three wastes (waste water, waste gas and industrial residues) and meets the requirement for environmental friendliness.

Owner:浙江爱迪亚营养科技开发有限公司

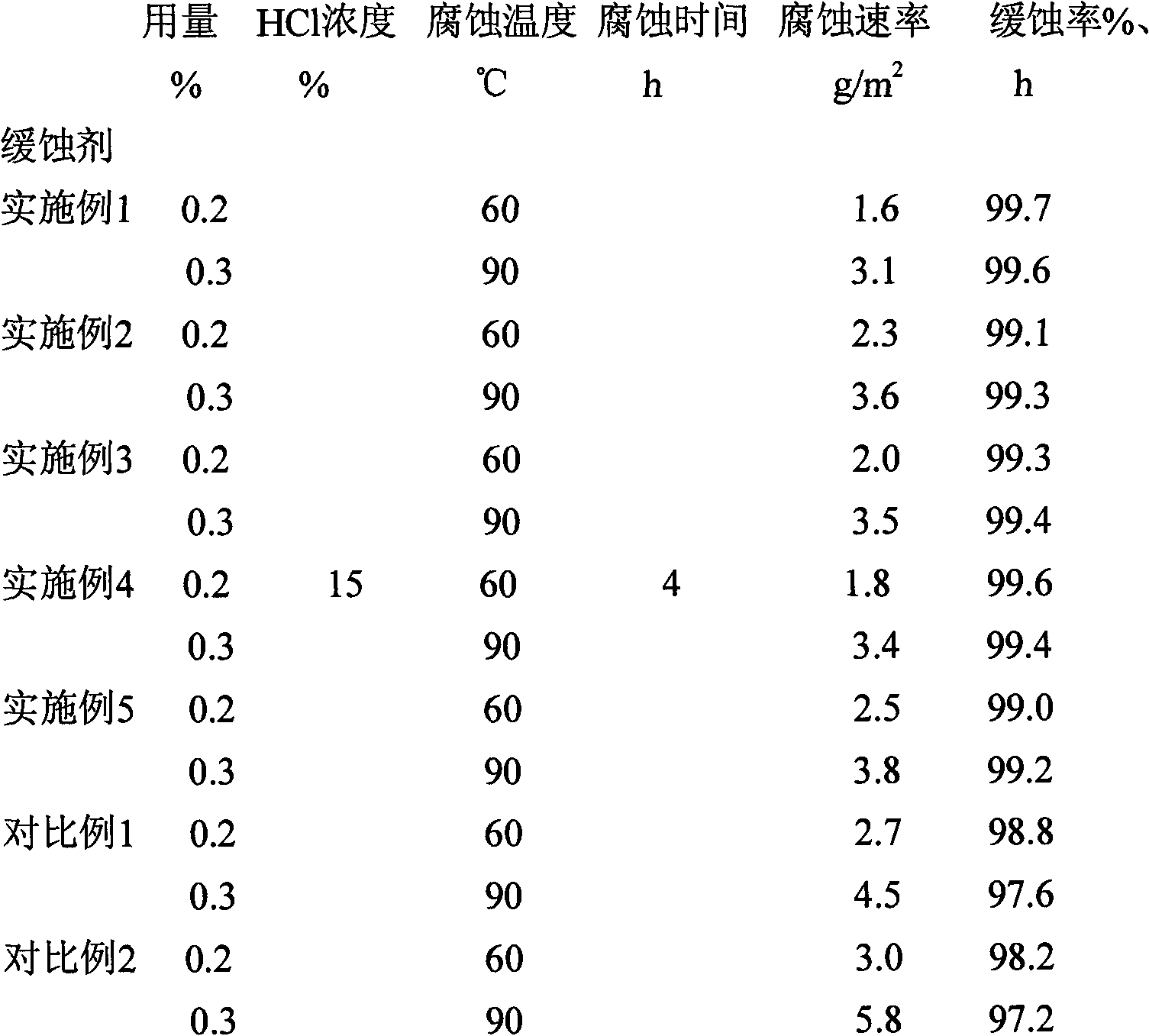

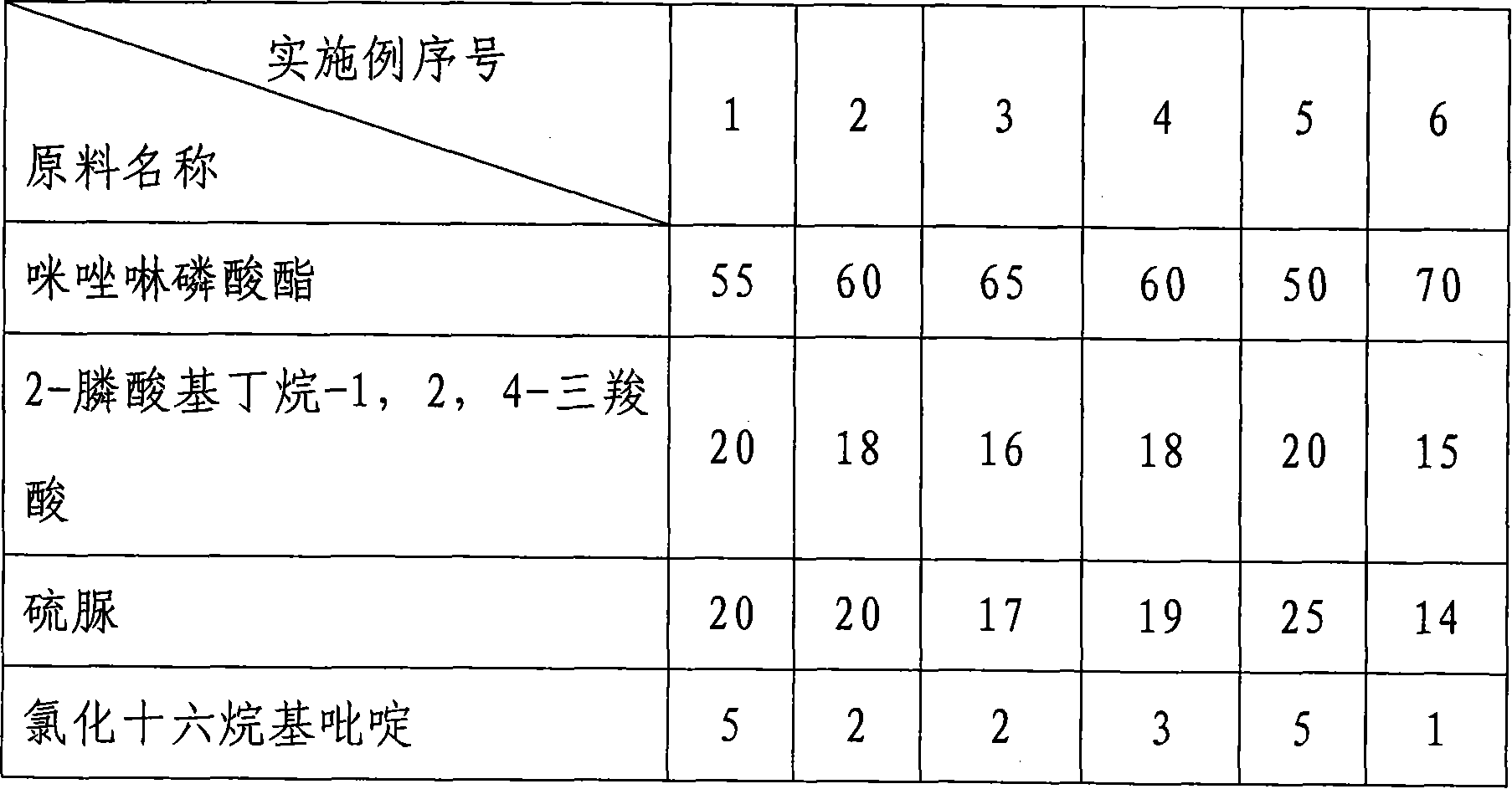

Compound inhibitor for exploitation of oil-gas field and preparation method thereof

ActiveCN101230260AGood corrosion inhibitionPrevents foulingBorehole/well accessoriesPhosphateThiourea

The invention discloses an oil gas field exploitation used compound inhibitor and the preparation method. The compound inhibitor contains imidazolinyl organic phosphate, 2 - N-acid butyrate -1, 2, 4-tricarboxylic acid, thiourea, cetylpyridinium chloride. The mixture proportions of all constituents by weight can meet the specified contents of all active substances. The preparation method is that the 2 - N-acid butyrate -1, 2, 4 - tricarboxylic acid is added into imidazolinyl organic phosphate; thiourea is added into and dissolved into water; the solutions obtained by sub-steps are mixed together and are added into the cetylpyridinium chloride; after evenly stirring for 50-90 minutes and keeping the temperature rang within 15-45 DEG C, the inhibitor of the invention is produced. The compound inhibitor uses multifold medicaments for synergia, can prevent scale formation, can kill bacteria or inhabit bacteria from growing with less usage, can be applied to wide range, and can perform excellent efficiency under complex water quality condition.

Owner:XINJIANG DELAND

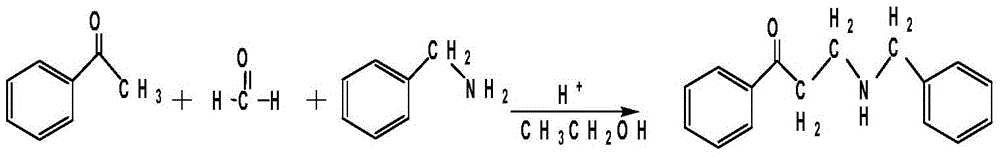

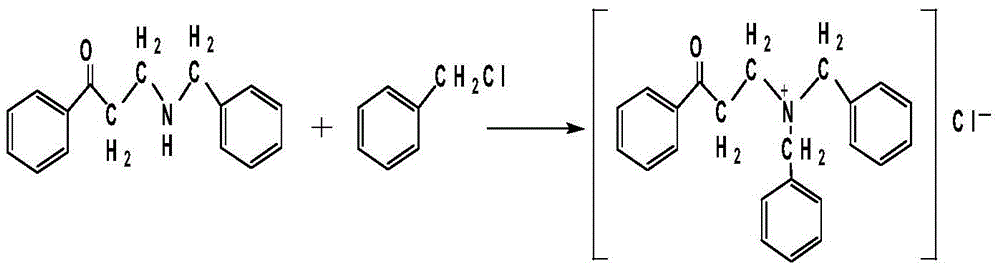

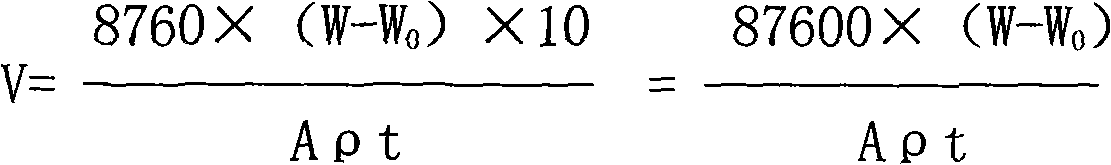

Preparation method of acidizing corrosion inhibitor in high-temperature and concentrated acid environment

InactiveCN105419774AImprove high temperature resistanceImprove solubilityDrilling compositionSolubilityAlcohol

The invention relates to a preparation method of acidizing corrosion inhibitor in a high-temperature and concentrated acid environment. The preparation method is used for an acidification technology in carbonate oil reservoir exploration and overcomes the problem that existing high-temperature acidification corrosion inhibitor is poor in solubility and dispersion in use and prone to coking. According to the technical scheme, firstly, formaldehyde, benzene methanamine, absolute ethyl alcohol and concentrated hydrochloric acid are added into a three-necked flask, and then the three-necked flask is placed into an oil bath pan with the temperature being 110 DEG C for conducting a reaction for 2 hours; then, acetophenone is added, the pH is adjusted to 4 through concentrated hydrochloric acid, a reaction is conducted for 4 hours, and a coarse mannich base is obtained; thirdly, a vacuum rotary evaporation instrument is utilized for purification, separation is conducted, and a mannich base intermediate is obtained; fourthly, after the intermediate obtained in step 3 is washed, benzyl chloride is added, a reaction is conducted for 6 hours at the temperature of 110 DEG C, evaporation and separation are conducted through the vacuum rotary evaporation instrument, and mannich base quaternary ammonium salt is obtained; finally, potassium iodide is added in the mannich base quaternary ammonium salt stirring process for conducting mixed distribution, and the high-temperature acidizing corrosion inhibitor is obtained. The acidizing corrosion inhibitor has good solubility and dispersion, can further improve corrosion inhibition efficiency and is good in stability.

Owner:SOUTHWEST PETROLEUM UNIV

Compound corrosion and scale inhibitor

InactiveCN101560022AGood sedimentationImprove the coordination effectScale removal and water softeningCalcium biphosphateSulfonate

The invention relates to a compound corrosion and scale inhibitor which comprises the following raw materials according to mass ratio: 15%-30% of organic phosphonic acid, 10%-20% of acrylic acid or acrylic acid copolymer, 2%-10% of poly-maleic acid, 1%-3% of azole ramifications, 15%-30% of multivariate organic sulfonate, 2%-6% of dimethyl formamide and 20%-35% of water. The compound corrosion and scale inhibitor of the invention is used for a system which employs normal water as circulating cooling water, so as to solve corrosion problem caused by circulating water of normal-water to equipment. Corrosion rate of copper product is lower than the national standard of 0.005mm / a, thereby generating no equipment scaling caused by calcium phosphate deposition. Compared with corrosion inhibitors of the same kind, the compound corrosion and scale inhibitor has a lower dosage and is effective in corrosion and scale inhibiting. The compound corrosion and scale inhibitor is simple in operation, convenient, quick, safe and efficient.

Owner:XIAN XIELI POWER TECH

Preparation method of metal corrosion inhibitor

The invention relates to a preparation method of a metal corrosion inhibitor. Fatty acid and polyamine are used as initiative raw materials in the method, and the novel metal corrosion inhibitor is synthesized by amidation, quaternization and substitution reaction. The corrosion inhibition rate of the metal corrosion inhibitor prepared by the method is more than 99 percent, the corrosion inhibitor is easily biodegraded, the pH value of the corrosion inhibitor is 6 to 8 and close to neutrality, and the corrosion inhibitor is convenient to transport and use.

Owner:大庆高新区华龙祥化工有限公司

Composite anti-dirty corrosion inhibiting agent and application thereof

ActiveCN1603253AStrong scale resistanceImprove performanceScale removal and water softeningAlkalinityHardness

The invention relates to a compound encrustation-blocking corrosion inhibitor. It includes phosphonic acid containing poly aspartic acid and at least one corrosion inhibitor. It has good complex encrustation-blocking corrosion inhibitor combination property. It has good function to blocking CaCO3 and Ca3(PO4)2, stabilizes Zn2+ in water and corrosion inhibits. The invention can be used to circulating cooling water process to increase the condense multiple. For example, it can be used under the situation of the sum of calcium hardness and total alkalinity reached to 1200mg / L after condense of the circulation cooling water.

Owner:中国石油化工股份有限公司北京燕山分公司研究院

Phosphorus-free corrosion-inhibition antiscalant used for industrial circulation cooling water

InactiveCN101700935AGood corrosion inhibitionGood synergyScale removal and water softeningWater/sewage treatment bu osmosis/dialysisCarboxylic saltCarboxylic acid

The invention relates to a phosphorus-free corrosion-inhibition antiscalant used for industrial circulation cooling water treatment, which is characterized by comprising the following medicament components by weight: 10-40% of N-alkyl group-N-fat acyl amino fatty acid salt, 5-25% of hydroxy carboxylate, 5-20% of carboxylic acid copolymer, 1-4% of metal salt and the balance water.

Owner:CHINA NAT OFFSHORE OIL CORP +1

High-efficiency phosphino-carboxylic acid dirt dispersion agent

InactiveCN1837101APrevent precipitationGood corrosion inhibitionScale removal and water softeningTricarboxylic acidCarboxylic acid

The invention provides a PBTC anti-scaling disperser, which comprises 2-phosphonobutane-1,2,4-tricarboxylic acid, acroleic acid-acrylate-petroleum sulfonate copolymer, zinc chloride, benzotrizaole and water, which can be operated under high pH, and can be used for forming a layer of thin and compact anti-corrosive film on the surface of metals, thus effectively inhibiting metallic corrosion.

Owner:SHANGHAI WANSEN WATER TREATMENT CO LTD

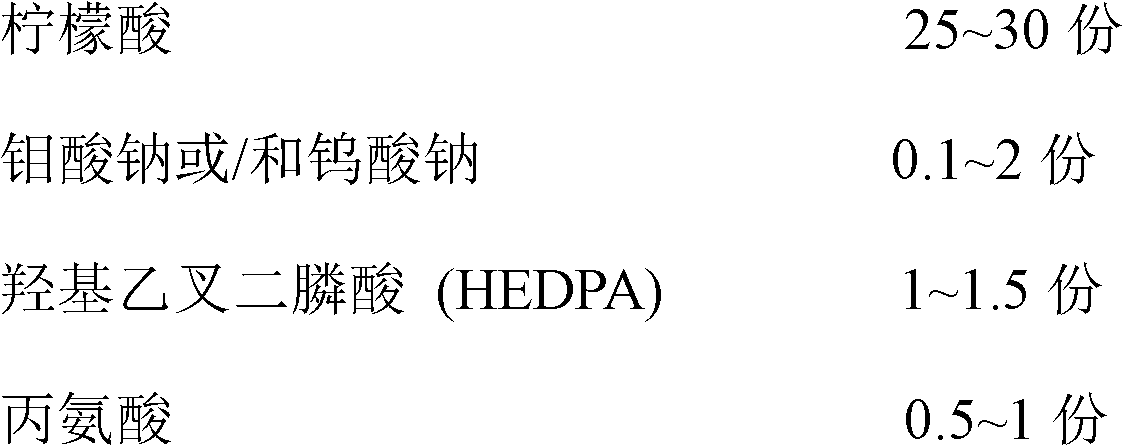

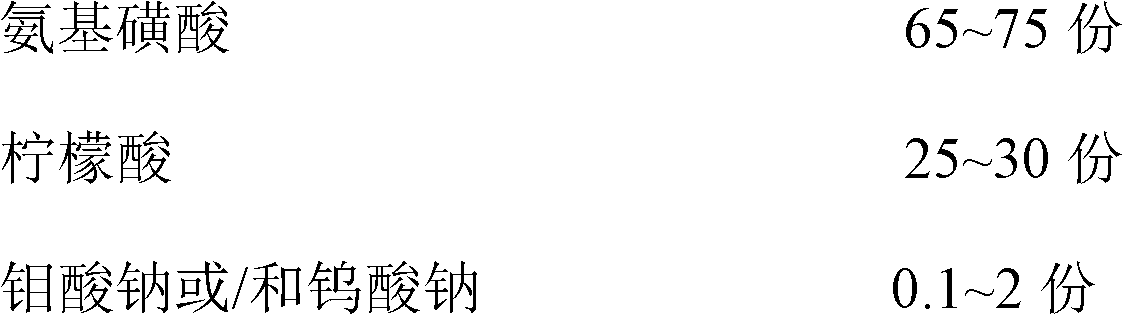

Novel acidic detergent for container of food industry

ActiveCN102358875AStrong decontamination abilityGood descalingOrganic non-surface-active detergent compositionsTungstenAmino acid

The invention discloses a novel acidic detergent for a container of food industry. A formula of the detergent comprises, by weight, 65-75 parts of sulfamic acid, 25-35 parts of citric acid, 0.1-2 parts of molybdenum corrosion inhibitor or / and tungsten corrosion inhibitor and 0.1-2 parts of amino acid or / and organophosphorus corrosion and scale inhibitor. The acidic detergent of the present invention has strong decontamination capability to remove scale thoroughly, good rust inhibition, practically no corrosion on a stainless steel water tank with a stainless steel heating pipe, and is foam free, suitable for machinery cleaning and residual free; besides, the acidic detergent has stable property, low toxicity and no generation of microbe breeding, and is suitable for cleaning containers of food industry, especially a barreled water packing (barrel of 5 gallons and 3 gallons).

Owner:GUANGDONG HUANKAI MICROBIAL SCI & TECH

Solid corrosion and scale inhibitor for oil field

InactiveCN101805597ALow cost of corrosion and scale inhibitionReduce filling operationsDrilling compositionBorehole/well accessoriesPolyethylene glycolTricarboxylic acid

The invention discloses a solid corrosion and scale inhibitor for an oil field, which relates to the technical field of chemical medicine reagents used for the oil field. The solid corrosion and scale inhibitor comprises the following ingredients: 2-phosphonic acid butane 1, 2, 4-tricarboxylic acid PBTCA, polyethyleneglycol, sodium hexametahposphate, span-60 and stearic acid, wherein each ingredient accounts for the mass percent of the sum of all the ingredients as follow: 30 percent to 40 percent of 2-phosphonic acid butane 1, 2, 4-tricarboxylic acid PBTCA, 10 percent to 15 percent of polyethyleneglycol, 10 percent to 15 percent of sodium hexametahposphate, 15 to 25 percent of span-60 and 20 percent to 30 percent of stearic acid. The invention is particularly suitable for well tubes of oil-gas wells with server corrosion and scale conditions, and has good corrosion and scale inhibition effects on underground pipe posts and equipment.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Phosphorus-free composite corrosion and scale inhibitor for bitter circulating water and preparation method thereof

ActiveCN104891684AGood synergyNo distractionScale removal and water softeningWater treatmentCorrosion

The invention relates to a phosphorus-free composite corrosion and scale inhibitor for bitter circulating water and a preparation method thereof, belonging to the technical field of water treatment. The phosphorus-free composite corrosion and scale inhibitor for bitter circulating water is prepared from the following raw materials in percentage by weight: 5-20% of sodium molybdate, 5-20% of urotropine, 10-30% of polyepoxysuccinic acid, 1-5% of azole derivative, 5-20% of hydroxypropyl methacrylate, 5-15% of acrylic acid-acrylate-sulfonate terpolymer, 5-15% of sodium humate, 0.1-1% of fluorescent tracer, 0.5-2% of caustic soda flakes and the balance of deionized water. The phosphorus-free composite corrosion and scale inhibitor for bitter circulating water can not interfere with other water treatment agents, is free of phosphorus, zinc and other components harmful to the environment, and can effectively solve the problems of corrosion and scales in the bitter-based high-salt-content high-pH system. The invention also relates to a simple and convenient preparation method.

Owner:INLEN CHEM TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com