Acid washing corrosion inhibitor

A technology of pickling corrosion inhibitor and active agent, which is applied in the field of pickling corrosion inhibitor, can solve the problems of high production cost, environmental pollution, three wastes, etc., and achieve the effect of simple production process, low production cost and excellent water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

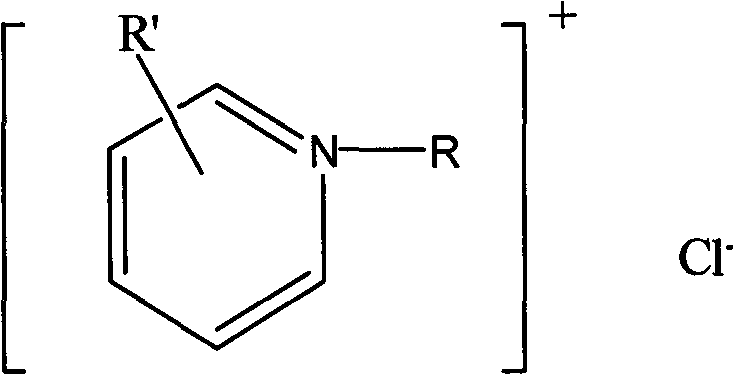

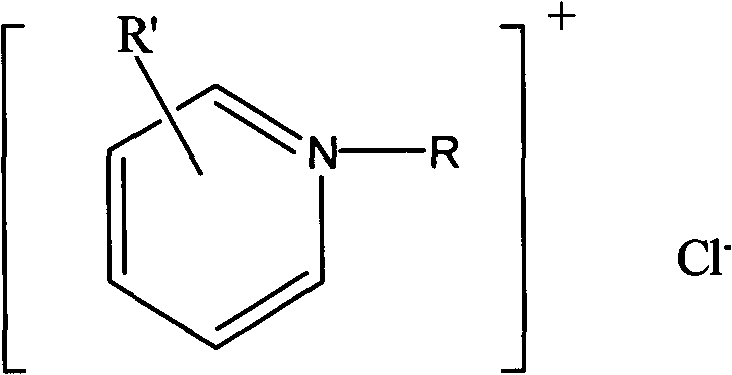

Method used

Image

Examples

Embodiment 1

[0023] Preparation of the present embodiment corrosion inhibitor;

[0024] Take a 500ml four-neck flask, add 100g of mixed alkylpyridine, 80g of ethanol or methanol, stir, heat to about 80°C, and reflux for 0.5h (h refers to the unit of time hour, that is, English hour, the same below), to make the mixed alkyl Pyridine is fully dissolved in ethanol; after the dissolution is complete, add about 70g of benzyl chloride dropwise for 0.5 to 1 hour. After the drop is complete, control the reaction temperature at 80°C and continue to stir and reflux for about 8-12 hours to obtain brown to black The oily liquid is prepared into mixed alkylpyridine quaternary ammonium salt, then add 5g of nonionic surfactant OP-10 (OP-10 refers to alkylphenol polyoxyethylene ether, the same below), stir evenly, and prepare It has become a corrosion inhibitor for mixed alkylpyridine quaternary ammonium salts.

[0025] Different mixed alkylpyridine quaternary ammonium corrosion inhibitors can be prepare...

Embodiment 2

[0029] Corrosion inhibitor composition: mixed alkyl allyl pyridinium quaternary ammonium salt 50g, 1g nonionic surfactant OP-10,

[0030] Hydrochloric acid: 15%, 20%

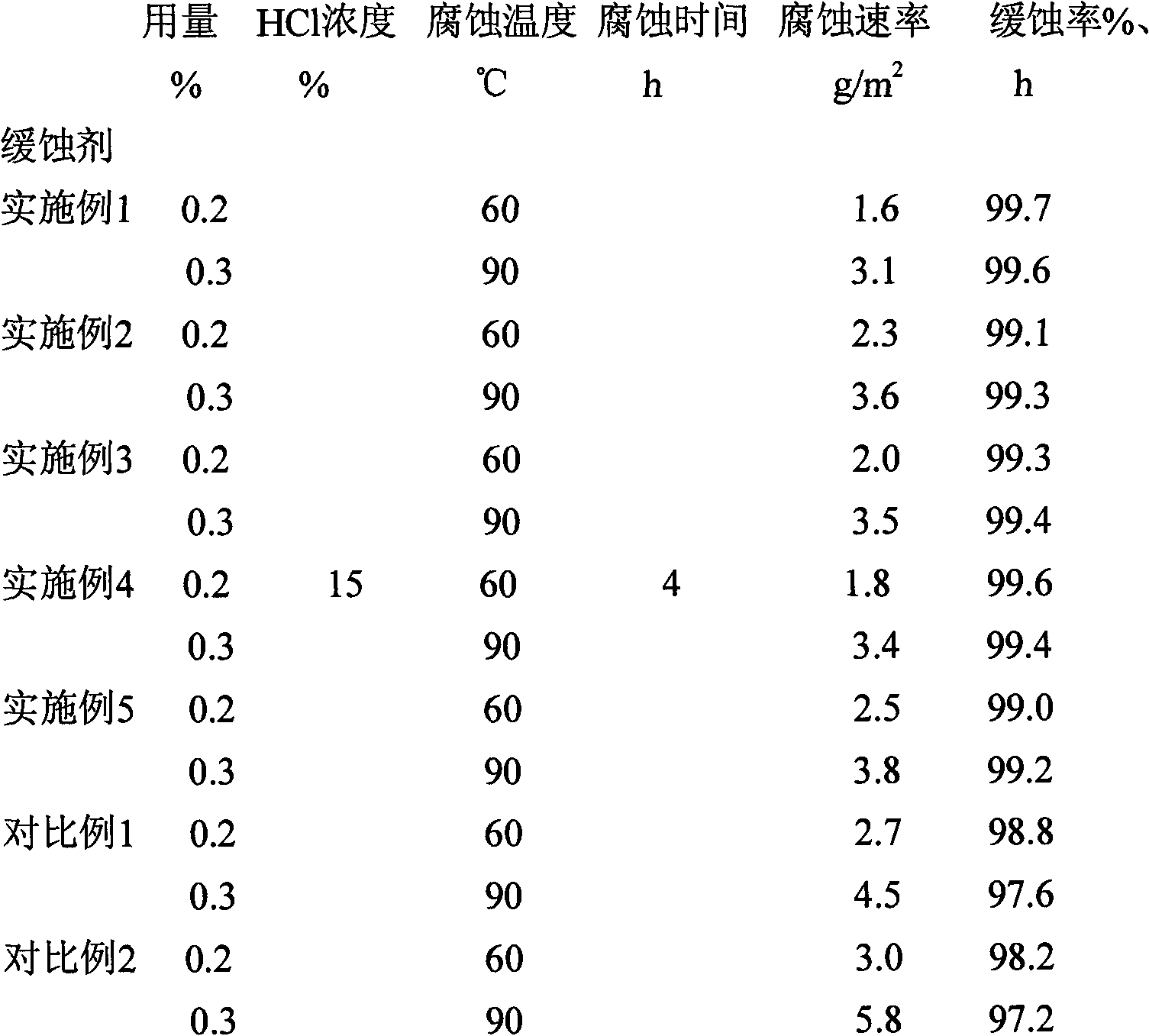

[0031] Use the above corrosion inhibitor and hydrochloric acid to carry out normal pressure static corrosion test, refer to China National Petroleum Corporation "Acidification Corrosion Inhibitor Performance Test Method and Evaluation Index" SY / T5405-1996, test temperature 60 ℃, 90 ℃, corrosion time 4h , the results are shown in Table 1 and Table 2 below.

Embodiment 3

[0033] Corrosion inhibitor composition: 50g of mixed alkyl epoxypropylene pyridinium quaternary ammonium salt, 1g of nonionic surfactant OP-10

[0034] Hydrochloric acid: 15%, 20%

[0035] Use the above corrosion inhibitor and hydrochloric acid to carry out normal pressure static corrosion test, refer to China National Petroleum Corporation "Acidification Corrosion Inhibitor Performance Test Method and Evaluation Index" SY / T5405-1996, test temperature 60 ℃, 90 ℃, corrosion time 4h , the results are shown in Table 1 and Table 2 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com