Patents

Literature

524results about How to "No three wastes produced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing low-sulfur methyl tertiary butyl ether

ActiveCN102491882ASatisfy to reconcileFulfil requirementsEther separation/purificationSulfur contentRaw material

The invention provides a method for producing low-sulfur methyl tertiary butyl ether (MTBE), which is used for producing low-sulfur MTBE products by re-rectifying MTBE containing sulfur. The method can use the MTBE with 10-150 ppm of sulfur content as a raw material to produce the MTBE products with containing sulfur content less than 10 ppm or even less than 5 ppm, and can use the MTBE with sulfur content more than150 ppm to produce the MTBE products with sulfur content less than 150 ppm. Especially, produced MTBE with the sulfur content less than 10 ppm or even less than 5 ppm can not only meet blend requirements of state V clean gasoline, but also requirements of industrial chemical raw materials can be met.

Owner:HEBEI REFINING TECH CO LTD

Foam extingusher with covering function

InactiveCN1413749AImprove fire extinguishing effectGood anti-reburning effectFire extinguisherPROPYLENE GLYCOL BUTYL ETHERPreservative

A fire-extinguishing foaming chemical with covering function features that it contains F1157N or F1203, F3 or OBS or FC-4, JR-400 or sodium algate or CMC or HEC or cationic starch or chitosan or xanthan gum, CAB or LAB or MZL or K12 or APG, ethanediol butylether or propanediol butylether, glycol or diglycol or propanetriol, urea, anticorrosion agent and water through proportioning and compounding. Its advantages are high fire-extinguishing power, strong covering function and high effect on preventing evaporation of oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for hydrolyzing lignocellulose

The invention discloses a method for hydrolyzing lignocellulose. Lignocellulose is pulverized into particles, and the particles are mixed with water to form even seriflux; the seriflux is preheated to60-150 DEG C by using ultrasonic waves or microwaves; the preheated even seriflux is quickly heated to 120-300 DEG C, solid alkali is added and used as a catalyst, and stirring and catalytic reactionare simultaneously carried out for 15-300 minutes. The use of the ultrasonic waves or microwaves radiation in synergism with solid alkali for catalyzing and hydrolyzing the lignocellulose can greatlyreduce the reaction time as well as energy consumption. The solid alkali catalyst can be repeatedly used, is easily separated from an aqueous solution, and has the advantages of high mechanical strength, high durability, certain selectivity, relative singularity of catalytic hydrolyzate, high hydrolyzing efficiency and good market application prospect.

Owner:XISHUANGBANNA TROPICAL BOTANICAL GARDEN CHINESE ACAD OF SCI

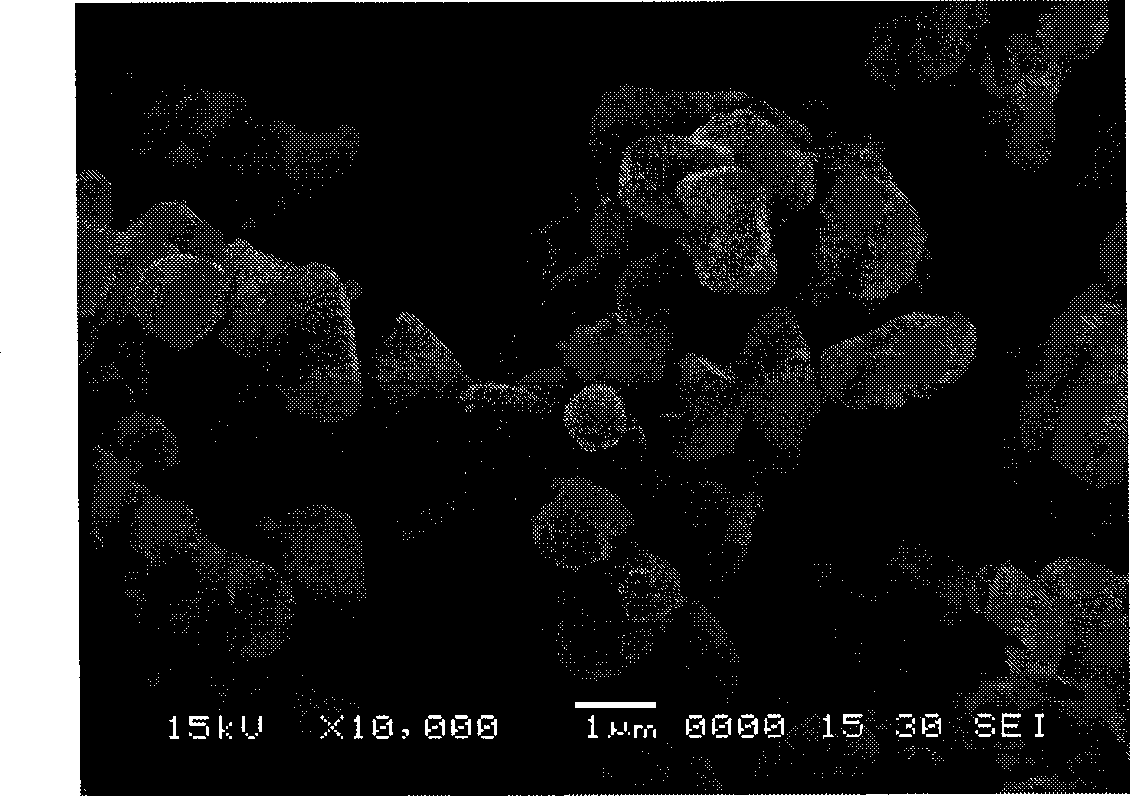

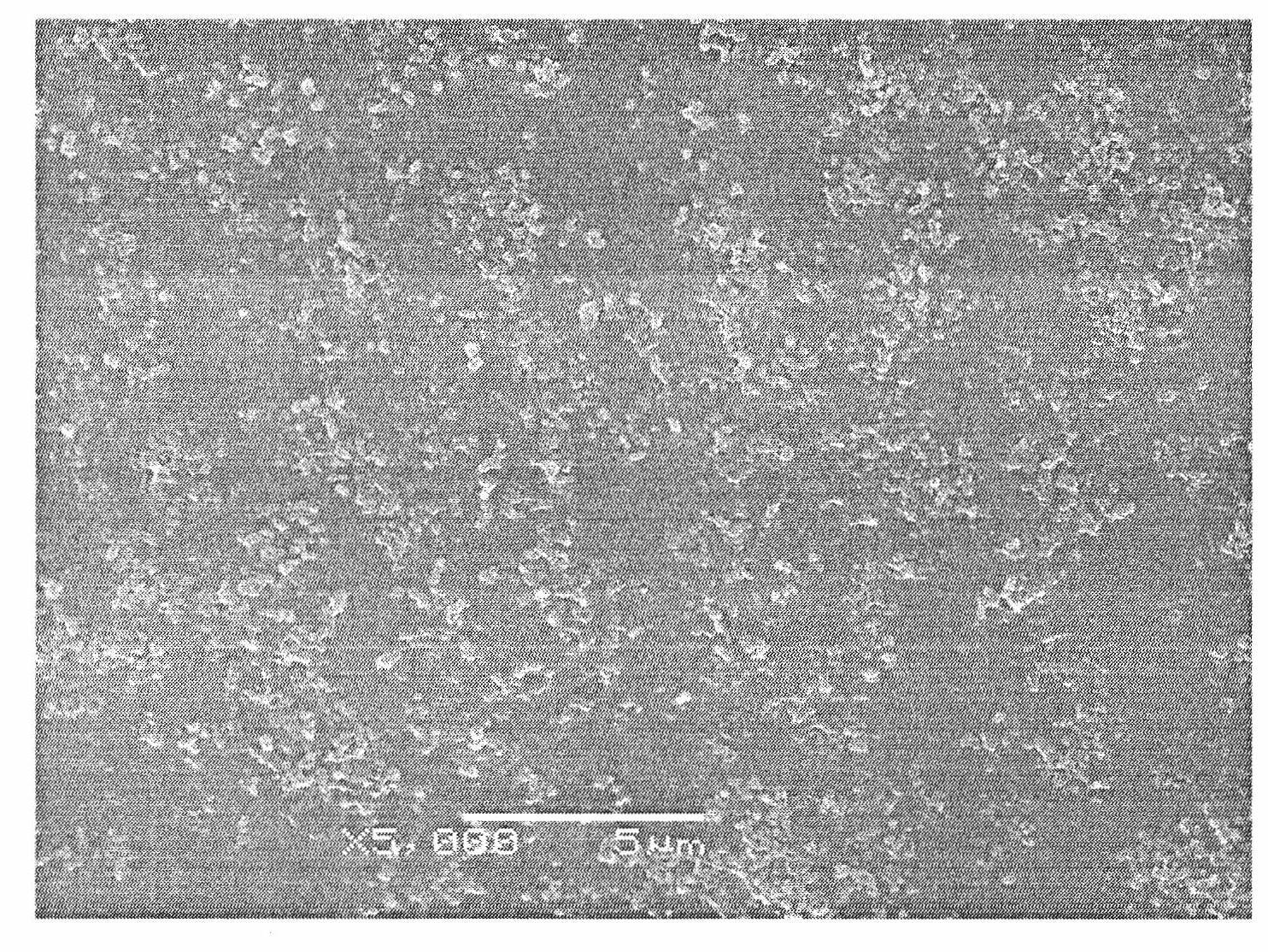

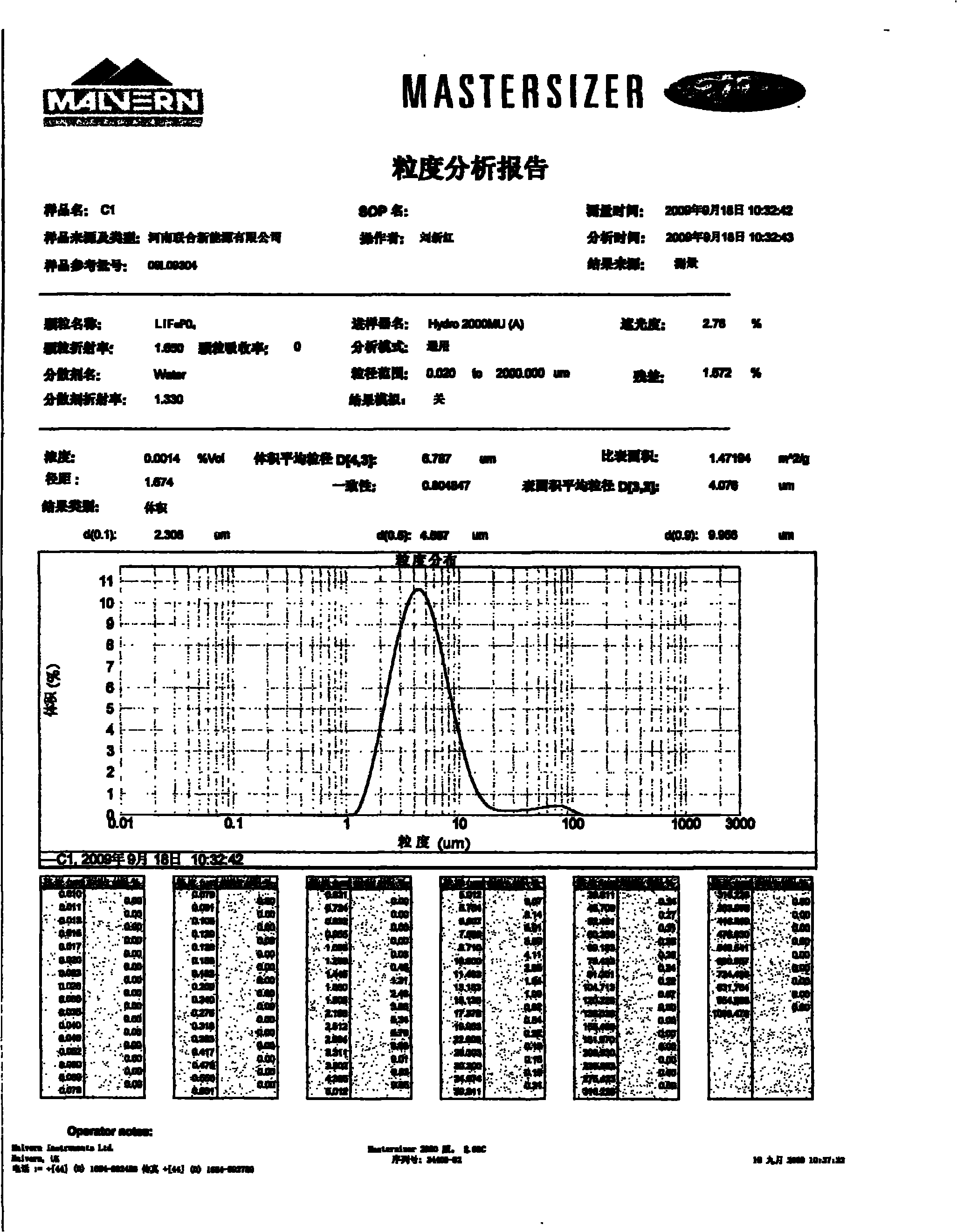

Process for producing lithium ion battery negative pole material of lithium titanate

InactiveCN101428851ARaw materials are cheap and easy to getLow costCell electrodesTitanium compoundsIonSolvent

The invention relates to the preparation method of Li4Ti5O12 as the negative electrode material of Li-ion battery. The preparation method comprises the following steps: dissolving nanoscale TiO2 and Li salts in a solvent at a molar ratio of 5:4 to 5:4.5, mixing completely, drying to remove the solvent to obtain a pre-mixture, heating the pre-mixture to melt the salt, soaking for 2 to 5 h, and calcining at 600 to 1,000 DEG C for 6 to 16 h to obtain Li4Ti5O12 with spinel structure and particle diameter of 0.3 to 2 mum. The preparation method has the advantages of easily-obtained raw materials, low cost, simple preparation process, low energy consumption, easy industrial production, no generation of the three wastes, no environmental pollution, and wide application prospect. By adopting a eutectic mixture as the molten medium, the preparation method can prepare high-performance and high-dispersion nanoscale Li4Ti5O12 with high specific surface area at lower temperature.

Owner:SHANGHAI UNIV

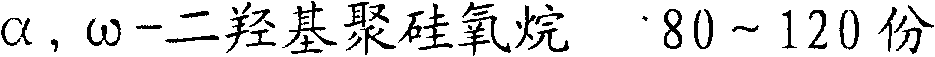

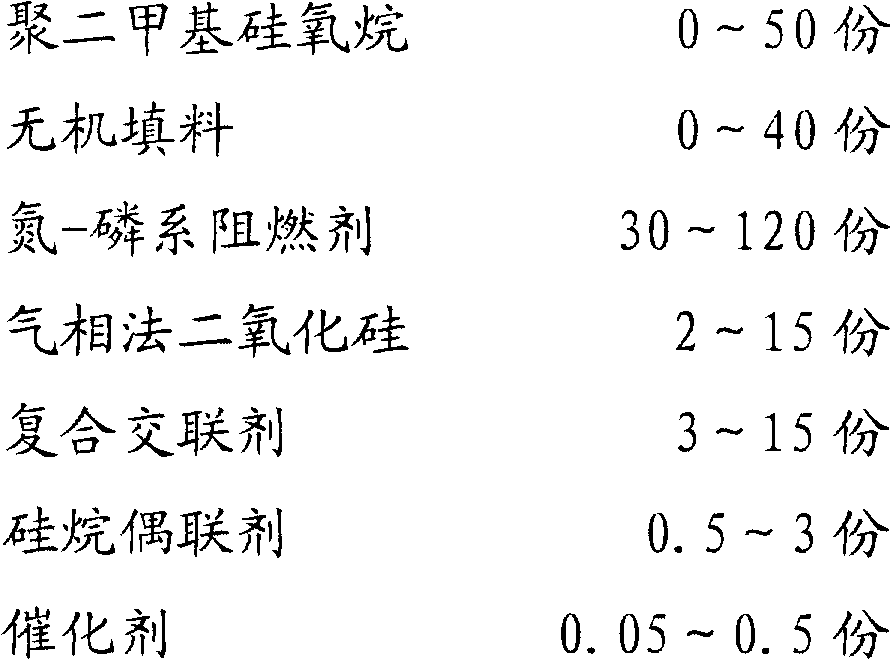

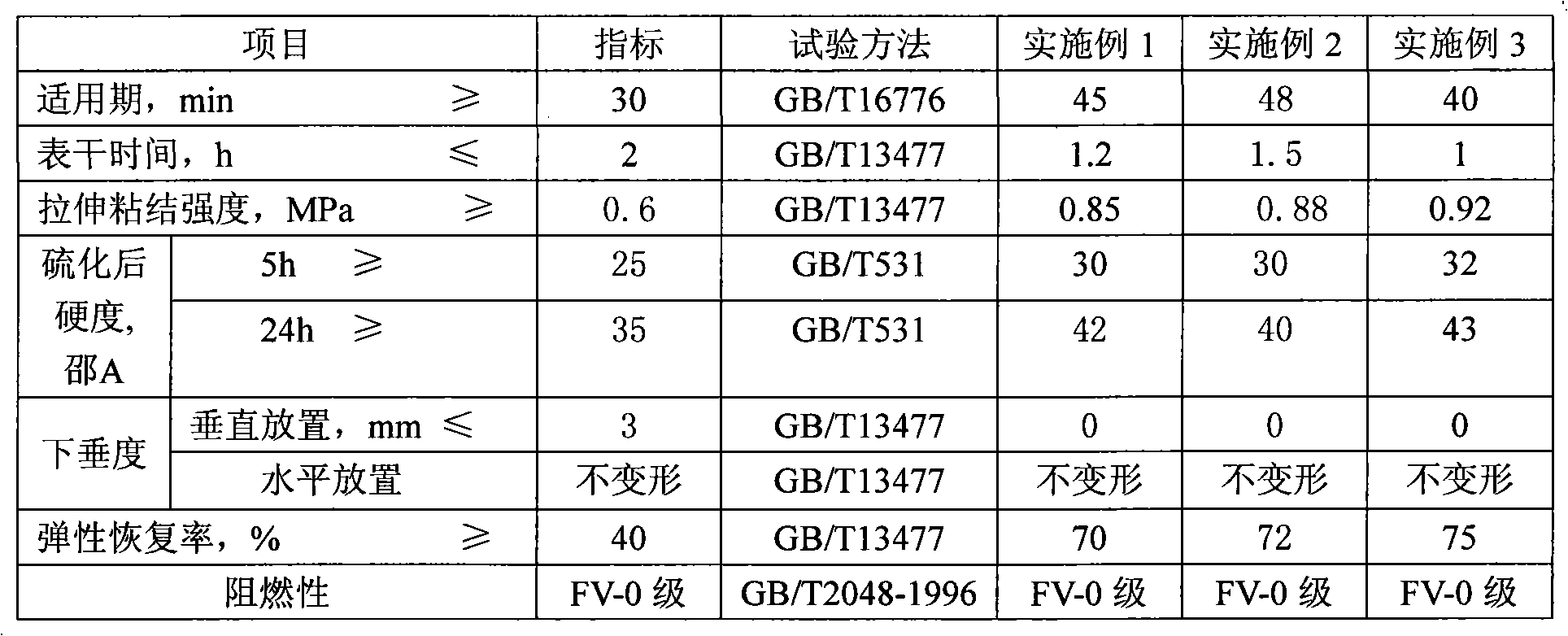

High-displacement-ability silicone fire-proof sealing glue and manufacturing method of the same

ActiveCN103160239AImprove fire performanceLow smoke productionNon-macromolecular adhesive additivesOther chemical processesChemical reactionGas phase

The invention discloses high-displacement-ability silicone fire-proof sealing glue and a manufacturing method of the high-displacement-ability silicone fire-proof sealing glue. The high-displacement-ability silicone fire-proof sealing glue and the manufacturing method of the high-displacement-ability silicone fire-proof sealing glue are characterized in that 100 parts of alpha, omega-dihydroxyl polysiloxane, 0-50 parts of polydimethylsiloxane, 0-40 parts of inorganic fillers, and 30-120 parts of nitrogen-phosphorus-based flame retardants are added into a kneading machine under the temperatures of 80-150 DEG C and the vacuum degree of 0.06-0.099MPa, dehydrated and mixed together for 30-300 minutes, and cooled to obtain a basic material. At room temperature, the basic material is added into a planetary mixer or a high-speed scattering stirring machine, and then 2-15 parts of gas phase method silica, 3-15 parts of compound cross-linking agents, 0.5-3 parts of silane coupling agents, and 0.05-0.5 part of catalytic agents are added into the stirring machine and react with the basic material for 30-180 minutes under the vacuum degree of 0.06-0.099MPa and the rotating speed of 10-800rpm to prepare the high-displacement-ability silicone fire-proof sealing glue. The high-displacement-ability silicone fire-proof sealing glue has good cohesiveness and water-proof cohesiveness, and displacement ability of the high-displacement-ability silicone fire-proof sealing glue can reach the 25th level. The high-displacement-ability silicone fire-proof sealing glue has effective sealing effect under the condition of normal elasticity and cutting deformation of a curtain wall.

Owner:GUANGZHOU BAIYUN CHEM IND

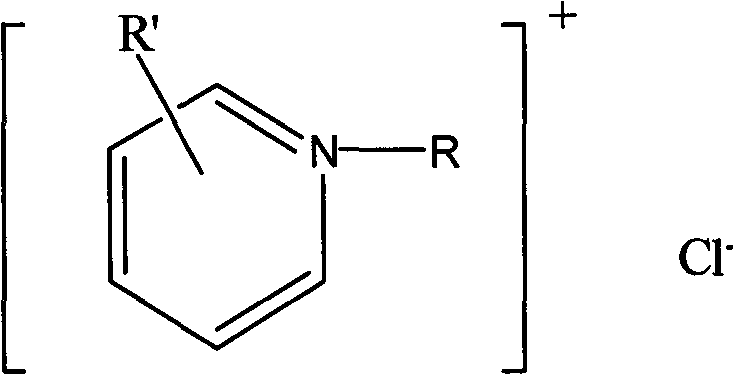

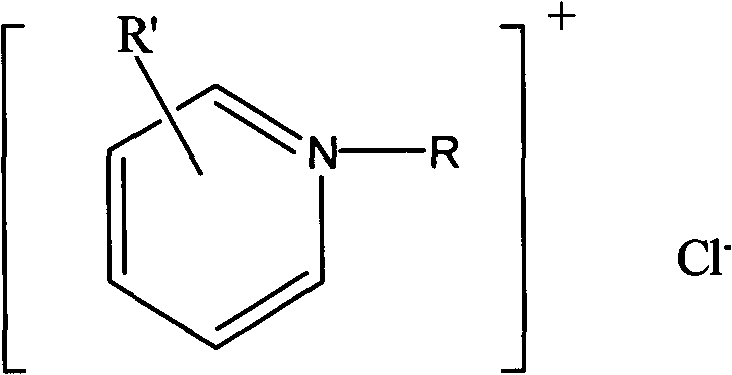

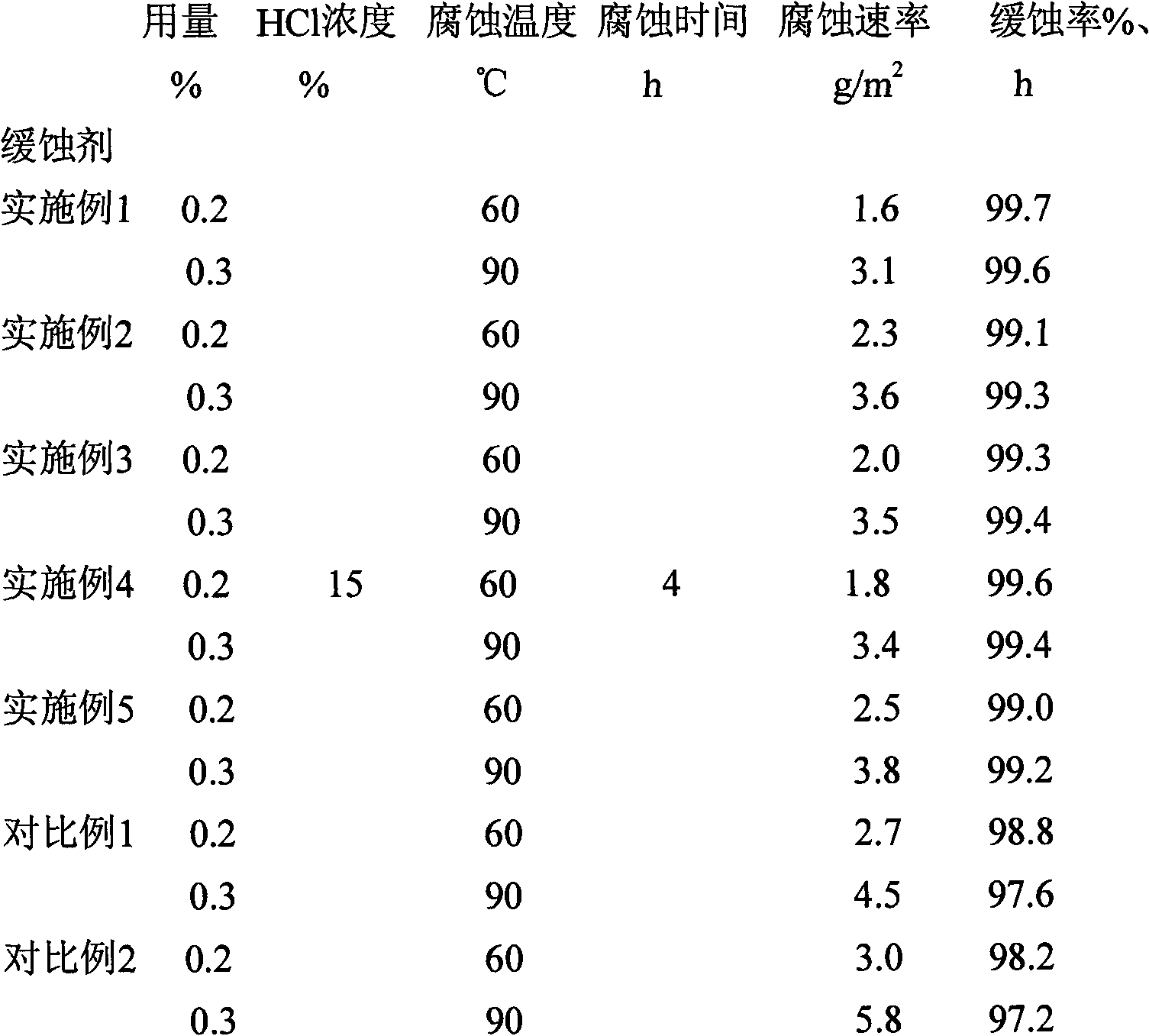

Acid washing corrosion inhibitor

The invention discloses an acid washing corrosion inhibitor, which is characterized by comprising the following components in percentage by weight: 30 to 70 percent of mixed alkyl pyridine quaternary ammonium salt, 25 to 50 percent of alcohol, 1 to 4 percent of nonionic surfactant and the balance of water. Compared with the prior art, the acid washing corrosion inhibitor has the advantages that: a pharmaceutical byproduct is mixed with alkyl pyridine to perform modification so as to research the corrosion inhibitor; the acid washing corrosion inhibitor has higher water solubility; the corrosion inhibition effect of the acid washing corrosion inhibitor is superior to that of the common aldehyde ketone amine type corrosion inhibitor; the application temperature range of the acid washing corrosion inhibitor is wider than that of the aldehyde ketone amine type corrosion inhibitor; the aldehyde ketone amine type corrosion inhibitor is easy to carbonize under the condition of high temperature, so that the corrosion inhibition effect is influenced; and in addition, the acid washing corrosion inhibitor is lower in production cost compared with the aldehyde ketone amine type corrosion inhibitor, has a simple production process, has no generation of three wastes (waste water, waste gas and industrial residues) and meets the requirement for environmental friendliness.

Owner:浙江爱迪亚营养科技开发有限公司

Bi-component polysulfide fireproofing flame retardant sealant and preparation method thereof

ActiveCN101575493AImprove fire performanceNot corrosiveNon-macromolecular adhesive additivesOther chemical processesPolysulfide rubberPlasticizer

The invention relates to a bi-component polysulfide fireproofing flame retardant sealant and a preparation method thereof, wherein the bi-component polysulfide fireproofing flame retardant sealant is prepared from the following components according to parts by weight: component A: 50-100 parts of liquid polysulfide rubber, 30-70 parts of flame retardant plasticizer, 50-150 parts of flame retardant filler, 60-200 parts of calcium carbonate, 0.3-1.2 parts of main agent micro-molecular finishing agent and 0.5-1.5 parts of silane coupling agent; component B: 10-30 parts of manganese dioxide, 20-60 parts of plasticizer, 1-3 parts of semi-strengthening agent carbon black and 0.4-1.5 parts of accelerant. The preparation method comprises the following steps of: mixing, stirring, vacuumizing, inspecting and packaging all the ingredients of component A; and mixing, stirring, vacuumizing, grinding, inspecting and packaging all the ingredients of component B. The sealant can be used by uniformly mixing A and B according to the mass rate of A: B being equal to 100:6-100:12. the sealant has good flame retardant property that is tested to be FV-0 level according to GB / T 2408-1996, and the oxygen index is tested to be 36.6 percent according to GB / T 2406-1993, and the both levels reach or exceed state-specified standards,.

Owner:ZHENGZHOU ZHONGYUAN SILANDE HIGH TECH CO LTD

Method of producing chip copper interconnection high-purity copper sulfate electroplate liquid

A method for producing a chip copper interconnection high-purity copper sulfate electroplating solution of the present invention firstly includes an electrolysis step: in the process of electrolysis, an electrolytic cell is used, and an anode and a cathode are arranged in the electrolytic cell, the anode adopts an electrolytic copper plate, and the cathode Platinum plates are used, separated by a one-way membrane between the cathode and the anode, sulfuric acid is used as the electrolyte in the electrolytic cell, and metallic copper is dissolved by electrochemical methods; secondly, a superfiltration purification step is included to obtain a total amount of metal impurities less than 10PPM, high-purity copper sulfate mixed plating solution with organic impurities less than 10PPM. The present invention adopts a purification method combining electrochemistry and membrane technology. By adjusting process parameters and combining semiconductor ultra-purification and ultrafiltration technology, other indicators of the product can be controlled, and the product can be purified without evaporation and crystallization, and the qualified product can be directly produced. High-purity copper sulfate electroplating solution for copper interconnection.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

Method for producing aqueous dual-component polyurethane waterproofing paint

ActiveCN101200616AReduce lossNo irritating odorAntifouling/underwater paintsPaints with biocidesCalcium hydroxideToluene

The present invention provides a production method of an aqueous bi-component waterproof polyurethane coating and a production method of a waterproof coating used for the construction. Component A is made from the raw materials of polyether polyol, tartaric acid and isocyanate; component B is made from rubber oil, emulsifying agent, water, catalyst, solid filler, calcium hydroxide and other additives. When being used, the components A and B are mixed. The waterproof coating does not contain the materials such as coal tar, toluene and vinyl acetate, does not have pungent odour and toxicity; nearly no three-waste is produced during the production and the construction; the waterproof coating has little material loss and consumption, good environmental protective effect, stable quality, low production cost and convenient construction and can be applied to the waterproof disposal construction of the wet grassroots.

Owner:滨州市良友防水材料有限责任公司

Special washing salt for pesticide residues in fruits and vegetables

ActiveCN103436391AHas a bactericidal effectPollutedSurface-active non-soap compounds and soap mixture detergentsInorganic non-surface-active detergent compositionsPesticide residuePollution

The invention discloses a special washing salt for pesticide residues in fruits and vegetables. The special washing salt comprises the following raw materials by weight: 65 to 95 parts of refined salt, 2 to 5 parts of sodium dodecyl benzene sulfonate, 3 to 4 parts of cinnamic acid, 1 to 2 parts of green tea powder, 2 to 3 parts of chitosan, 2 to 4 parts of sodium carbonate, 2 to 3 parts of sodium alpha-allylsulfonate and 0.005 to 0.01 part of essence. The special washing salt provided by the invention has the characteristics of a simple production process, no generation of waste gas, waste water and industrial residues, environment friendliness and the like and can improve performance of products of a same kind on the washing market at present and realize green washing. Compared with other washing agents, the washing salt uses salt as a basic raw material, so production cost for the washing salt is reduced and the washing salt performs a synergistic effect with a surfactant to reinforce a removal effect on pesticide residues; moreover, the washing salt uses salt has certain sterilization and disinfection effects, the advantages of no pollution, no toxicity, high-efficiency removal of pesticide residues, etc. and wide development prospects in fields like washing products.

Owner:中盐东兴盐化股份有限公司

Tunnel fireproof paint

InactiveCN101747675AGood construction performanceConstruction stabilityFireproof paintsCalcium formateToxic material

The invention relates to fireproof paint, in particular to tunnel fireproof paint, which is prepared from the following ingredients: a major bonding agent (ordinary Portland cement), inorganic heat insulation filling materials (expanded perlite, expanded vermiculite, meerschaum, kaoline and wollastonite powder) and addition agents (calcium formate, starch ether, redispersible latex powder, methyl cellulose ether and polypropylene fiber). Through the unique addition agent combination and the prescription mixture ratio, the tunnel fireproof paint has the advantages that the construction performance is obviously improved, at the same time, the integral overall performance of the tunnel fireproof paint is greatly improved, and the tunnel fireproof paint has the characteristics of stable fireproof performance, high adhesion intensity and stable physicochemical performance. Simultaneously, the product per se generates no toxic substance in the construction and burning processes, has the effects of environment protection and high practicability, and can be widely used for the fireproof protection of buildings such as highways, railways, subway tunnels and the like.

Owner:江西三星气龙新材料有限公司

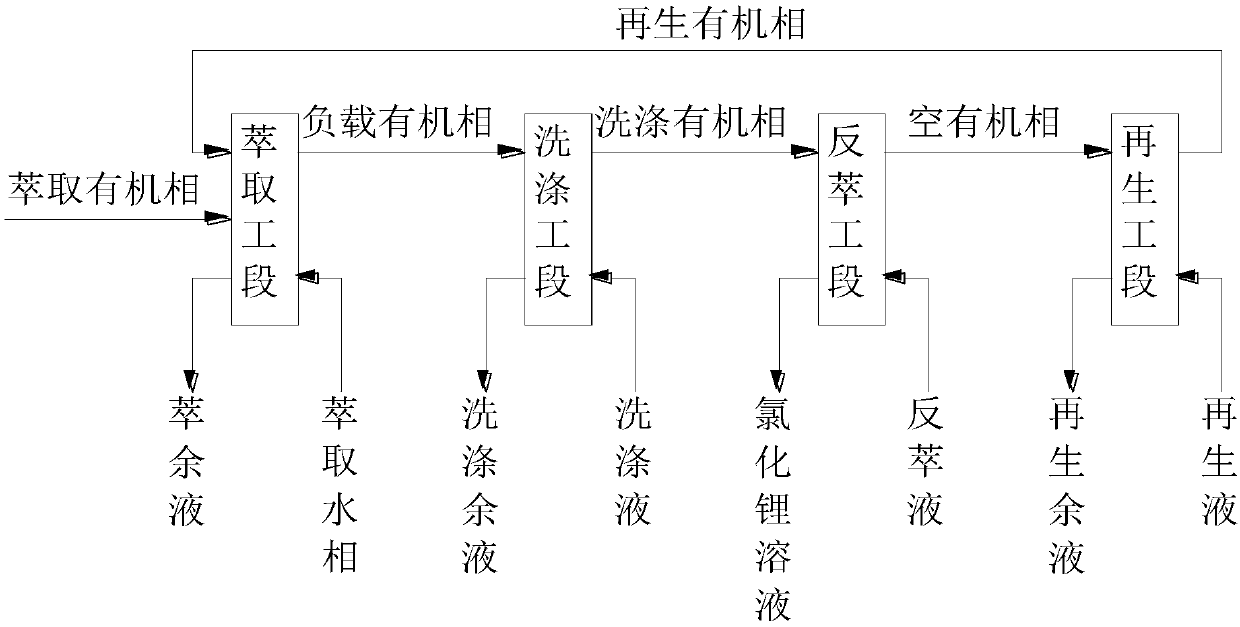

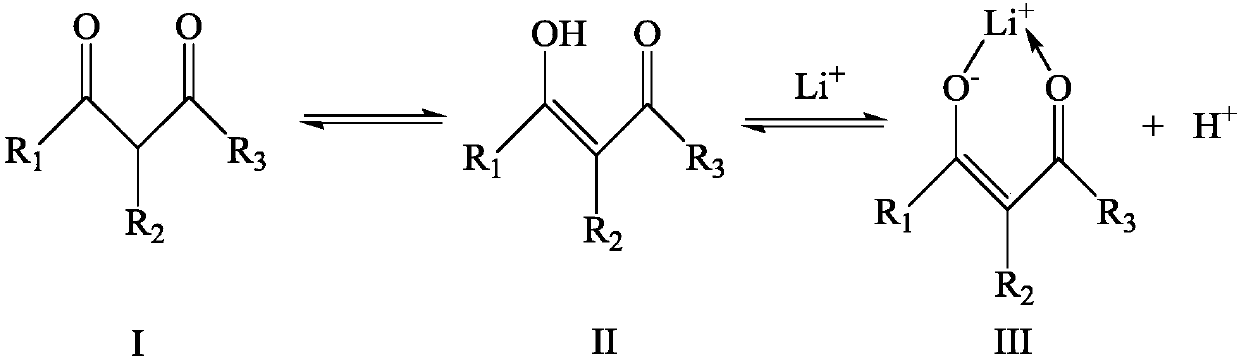

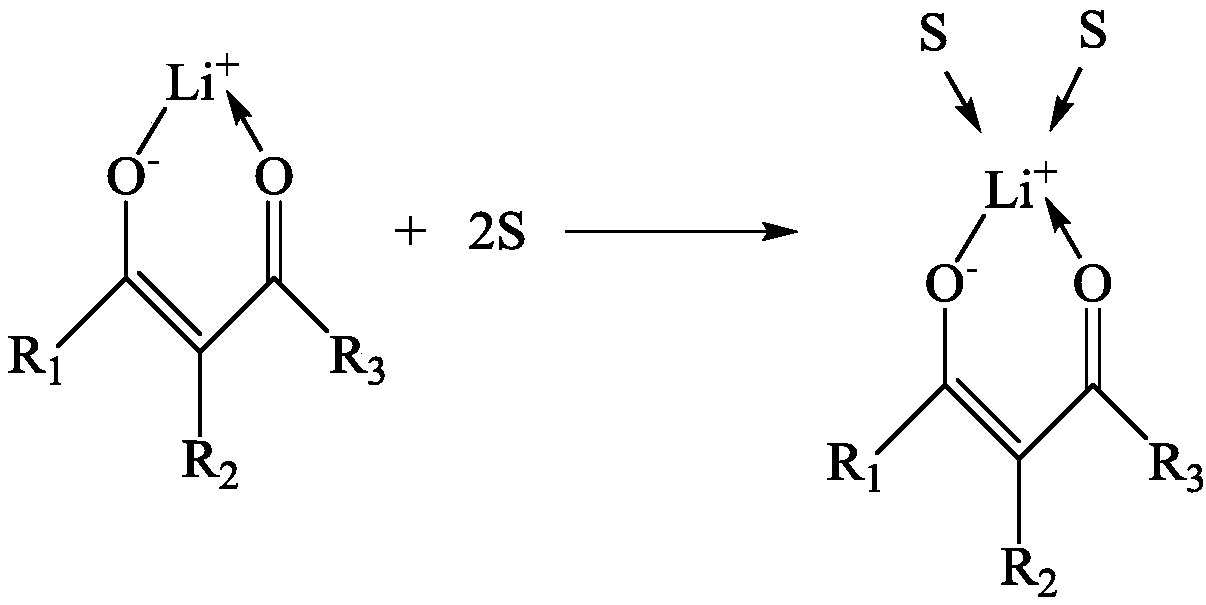

Technology for extracting lithium from alkaline bittern

ActiveCN107779612AReduce usageLow water solubilityProcess efficiency improvementLithium chlorideLithium carbonate

The invention discloses a technology for extracting lithium from alkaline bittern. The technology comprises the following steps of supplying an aqueous phase extraction, supplying an organic phase extraction, extracting, washing, reverse extracting and regeneration. The technology adopts an extraction system different from the tradition, and can extract lithium from an alkaline bittern system, meanwhile a complete process comprising the steps of extraction, washing, reverse extraction and regeneration is determined for the first time while not staying at basic researching of an extraction section, technology parameters such as the series of each section, the phase ratio and the concentration of each agent matched with the extraction system are finally determined, and a basic technology route is provided for industrialized expanded production. The technology for extracting lithium from the alkaline bittern is particularly suitable for a system that filter liquid is generated in the preparation process of a lithium carbonate product by using a lithium chloride solution, so that lithium is further extracted from the alkaline filter liquid bittern system where lithium carbonate is saturated, accordingly rear comprehensive cyclic utilization of salt lake bittern can be achieved, and the technology has practical meaning.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

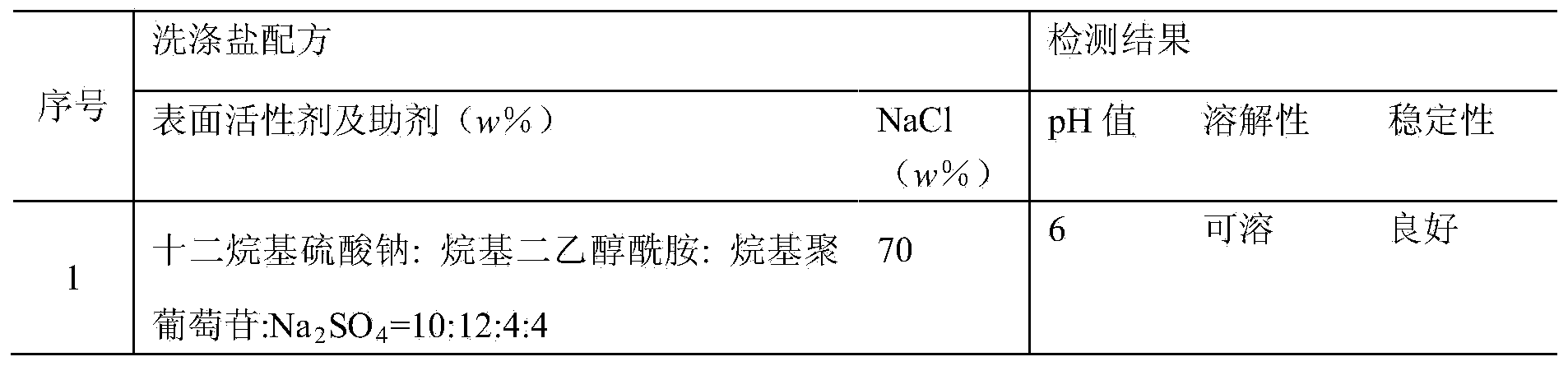

Fruit and vegetable washing salt and preparation method thereof

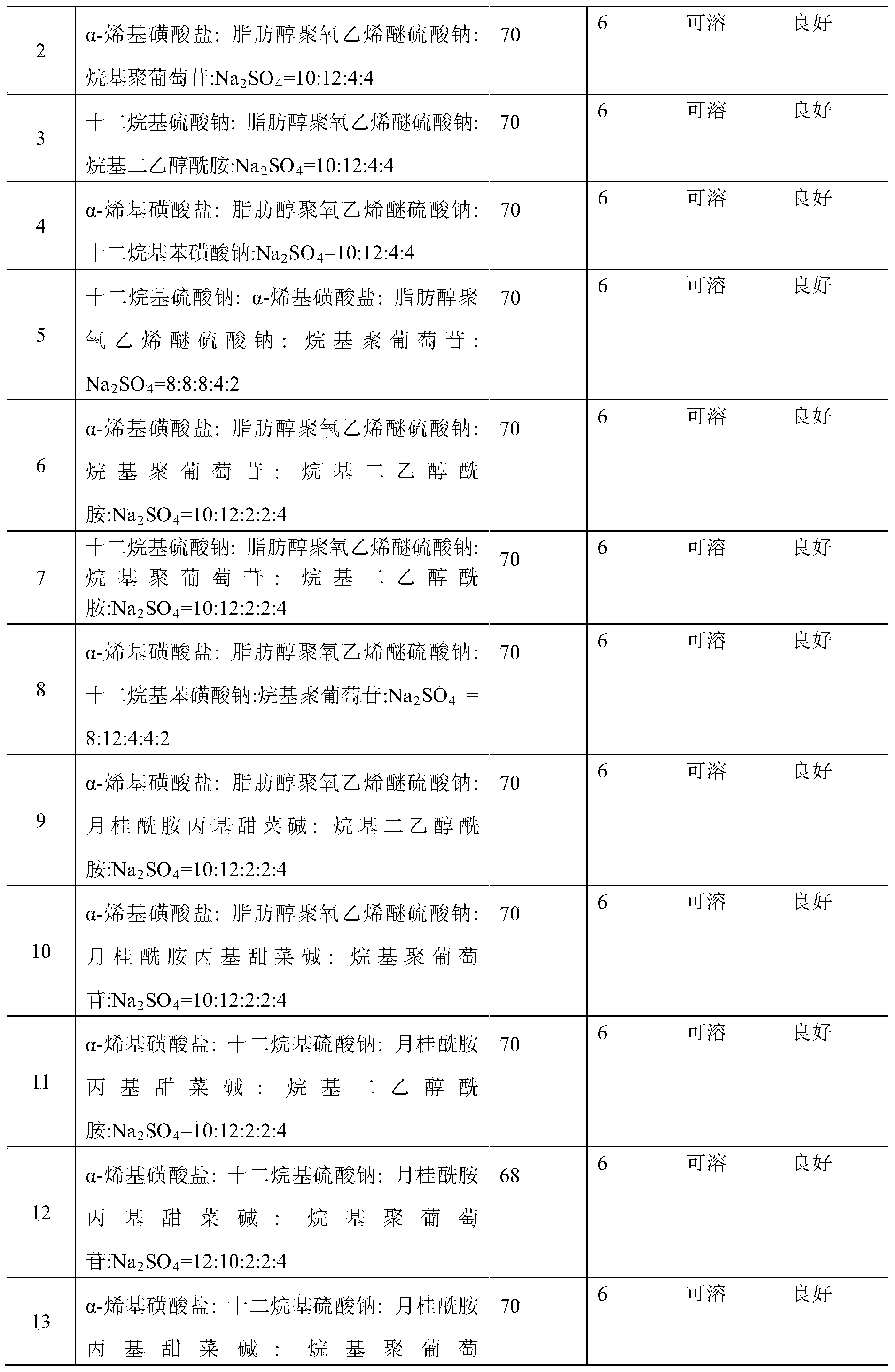

InactiveCN104312801AHigh technology contentImprove or solve pesticidesSurface-active non-soap compounds and soap mixture detergentsAdditive ingredientSURFACTANT BLEND

The invention discloses fruit and vegetable washing salt. The fruit and vegetable washing salt is prepared from the following raw materials in percentage by weight: 68-72% of table salt, 26-28% of a surfactant, and 2-4.0% of a stabilizer. According to the preparation method disclosed by the invention, the table salt is used as the main raw material, and compounded with the surfactant and other ingredients to prepare safe, non-toxic and efficient environment-friendly fruit and vegetable washing salt with washing performance and a high value added at a certain temperature. The washing salt product is stable, non-toxic, appropriate in the pH value, moderate, not harmful to hands, and capable of meeting contract requirements for sense organs and other physicochemical indexes.

Owner:中盐安徽润华强旺盐业有限公司

Degradable material, preparation method and application

The invention relates to a degradable material and a preparation method. Biomass resources are used as raw materials, are mixed with auxiliary materials and are placed into a mold to be sterilized, then, microbes are inoculated for culture, and the degradable material can be obtained through drying. The production raw materials of the degradable material have rich sources and low price, no three waste is generated in the production process, and the environment is not polluted. Products produced by using the technical scheme of the invention have the advantages that the weight is light, the pressure-resistance intensity and shock-resistance intensity are good, the damp-proof and mildew-proof effects are realized, in addition, the degradation is easy, the degradable material can be recovered to be used as organic fertilizers after being degraded, and the degradable material is suitable for industrial production.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI +1

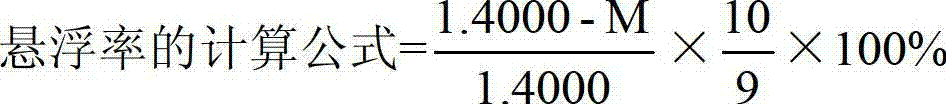

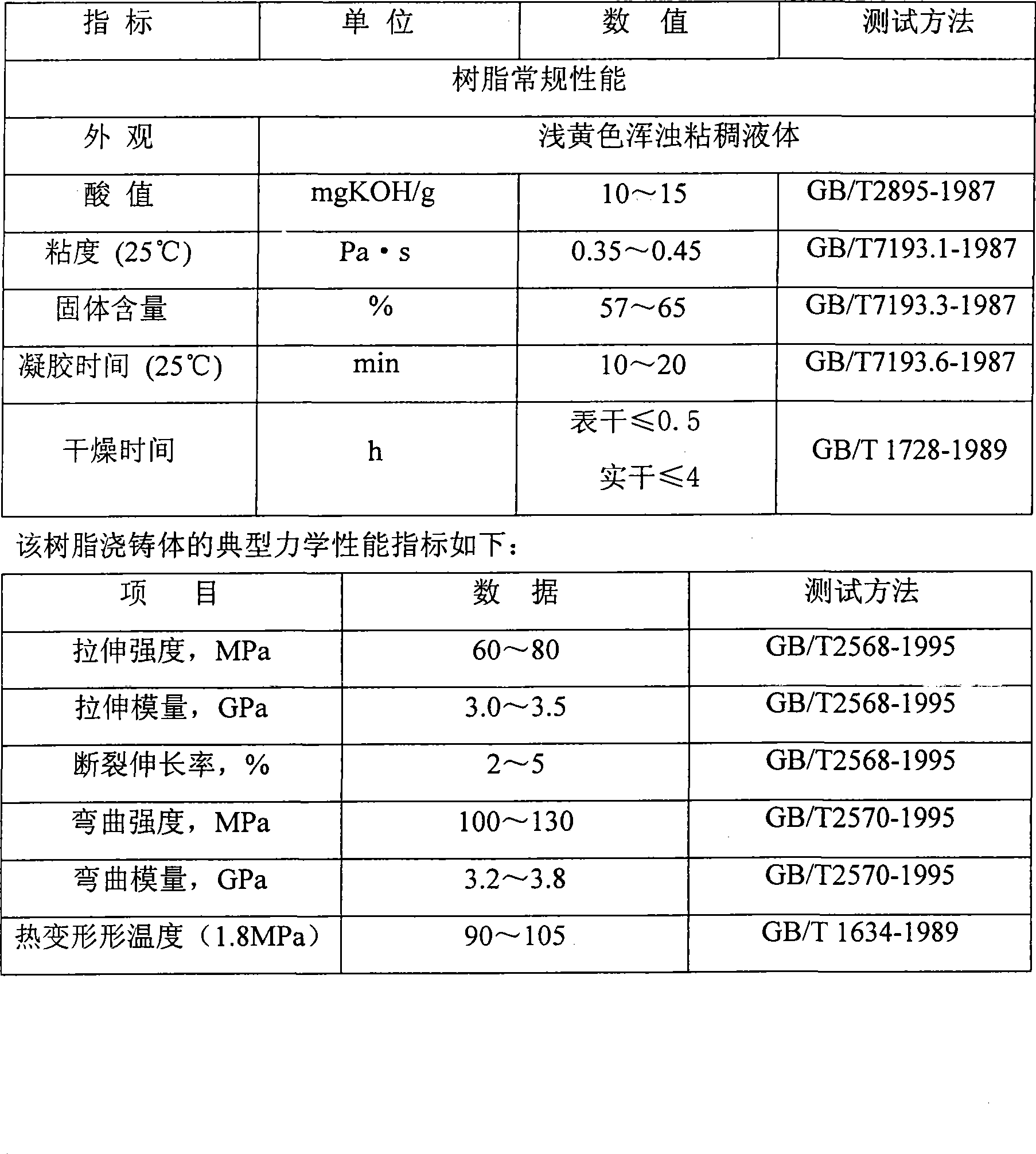

Synthesis technique of alkide resin modified epoxy vinyl esters resin

The invention relates to the technique to synthesize alkide resin modified epoxy vinyl resin. According to a certain compounding ratio, diphyenylol propane epoxy resin, organic monobasic unsaturated carboxylic acid, biatomic acid, catalyst agent and inhibitive substance are fed into a reactor to do ring cleavage esterification, then based on the existence of inhibitive substance, crosslinked monomer is added to deliquate and modified alkide resin and accelerating agent are added to accelerate in advance. The invention has the beneficial effects that: in ring cleavage esterification, the biatomic acid is employed as chain extender, and the alkide resin is added in the deliquating process (45 to 120 mg KOH / g hydroxyl value and 5 to 15 mgKOH / g acid value) to mix and modify, which largely strengths resin ductility, causes resin casting tension set is more than 8 percent, impact strength is above 20 KJ / m2; meanwhile largely reduces the resin solidification shrinkage ratio, improves the bonding strength, meets special compound material need as a result. The synthetic technique of the invention is simple, conformity with environmental protective and has good production stability without producing waste gas, waste water, and waste residue.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

A kind of Moringa water purifier

InactiveCN102259965ARealize comprehensive utilizationHigh technology contentWater/sewage treatment by flocculation/precipitationRural populationWater quality

The invention provides a moringa oleifera water purifying agent. The water purifying agent is characterized in that: the water purifying agent is prepared from components of, by mass: 90% to 100% of moringa oleifera extract, and 0 to 10% of a chemical water purifying agent. According to the invention, moringa oleifera oil extraction residuals are adopted; moringa oleifera effective components areextracted; and a complete and comprehensive utilization of moringa oleifera seeds is realized. The moringa oleifera water purifying agent is a pure plant extract. When the moringa oleifera water purifying agent is used for purifying water, no toxicity or harm is brought in. Therefore, harms to human and secondary pollutions to the environment brought by chemical water purifying agents can be solved from the source. The moringa oleifera water purifying agent is suitable for rural water purification. With the water purifying agent, a problem of drinking-water safety of rural population can be solved. The water purifying agent is applied in the purifications of turbid waters such as river water, lake water and rainwater, and brings better purification effects than chemical water purifying agents. The moringa oleifera water purifying agent can be blended with chemical water purifying agents for purifying urban sewage. Therefore, adoption amount of chemical water purifying agents is greatly reduced.

Owner:THE RES INST OF RESOURCES INSECTS RIRI OF THE CHINESE ACADEMY OF FORESTRY

Simple high-performance modification process for attapulgite clay

InactiveCN101337678ASimple processing technologyImprove productivitySilicon compoundsMaterials scienceHeat processing

The invention discloses a simple and efficient attapulgite clay modification method. The method comprises the steps of dipping the attapulgite clay; extruding the dipped attapulgite clay for twice; adding a modifying agent solution; refrigerating; performing heat processing; and pulverizing to obtain the modified attapulgite clay. The method is a semidry process. The crystal bundle separation of the attapulgite clay and the modification procedure are integrated as one procedure; the modification is complete and no three-waste is produced; and the processing efficiency is high.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

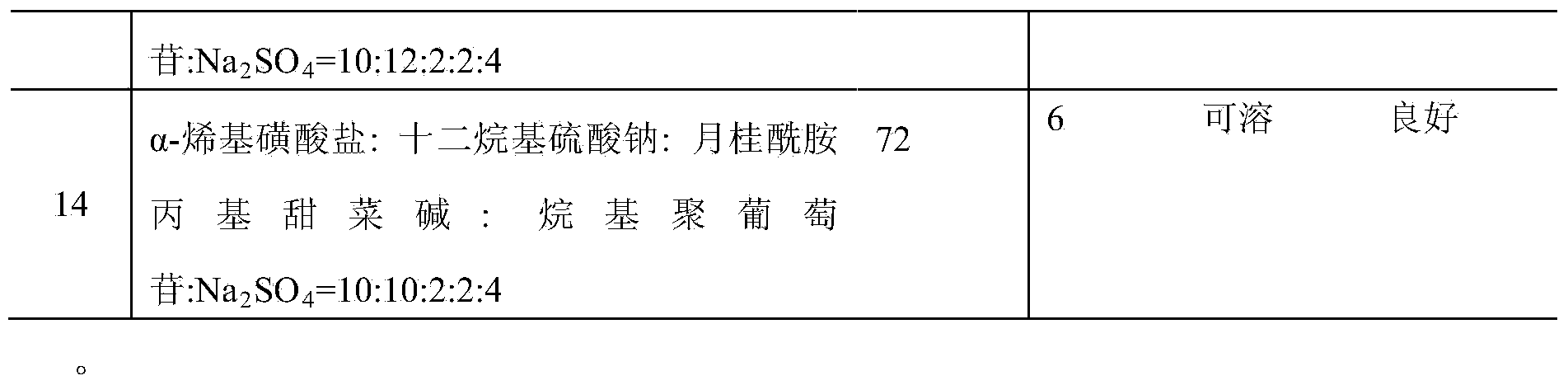

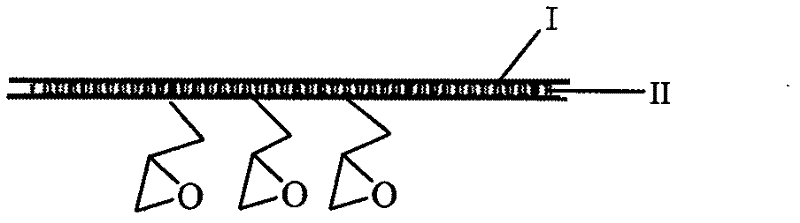

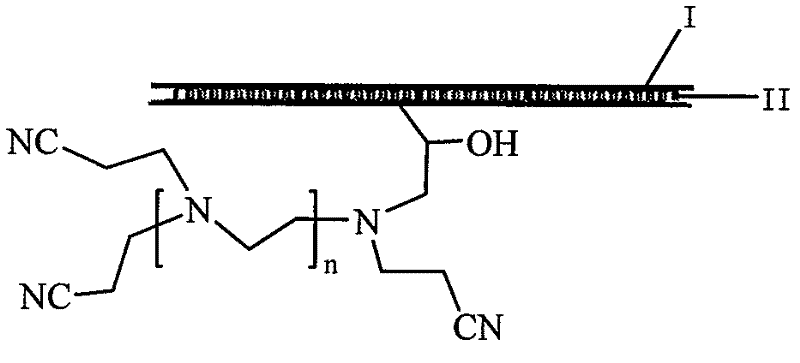

Chelation ion exchange fiber capable of resisting marine organism stain and preparation method thereof

InactiveCN102631954AEasy to prepareFast adsorption and desorptionFibre treatmentComplex ion-exchangersIon exchangeIon

The invention provides a chelation ion exchange fiber capable of resisting marine organism stain and a preparation method thereof. Synthetic fibre or synthetic fibre and cotton and hemp blend fiber serve as base material fibres dipped with the polyacrylic ester function resin solution containing an epoxy group to prepare the epoxy function fibre; and then, the epoxy function fibre successively carries out ring-opening reaction with the organic polyamine, carries out Micheal addition reaction with acrylonitrile, carries out quaternization reaction with 5-chloromethyl methyl salicylic aldehyde and carries out hydroxylamine addition reaction. A quaternary ammonium group, salicylaldoxime and an amidoxime function group are successively increased and led in the base material fibre surface to obtain the Chelation ion exchange fiber capable of resisting marine organism stain.

Owner:HUAIHAI INST OF TECH

Method of pimiento preparing hungarian pepper red powder

ActiveCN101248865AHigh yieldPromote absorptionAnimal feeding stuffAccessory food factorsFood additiveAntioxidant

The invention provides a method for preparing capsanthin powder from red peppers, belonging to the field of coloring agent in food additives or feed additives. The method comprises the following steps of drying red pepper with a drying machine, pulverizing into 60-80 mesh powder, adding into a pressure extractor, adding antifoaming agent and antioxidant, vacuuming to -0.06 to -0.1 MPa, adding compressed No.4 solvent oil, extracting under pressure of 0.3-1MPa for 20-60 min for 3-6 times to obtain mixed oil, heating, and concentrating under reduced pressure to obtain capsanthin resin; and mixing the capsanthin resin with alkaline solution, heating for saponifying, mixing the saponified capsanthin resin with adsorbent at a weight ratio of 1:(0.4-10) to obtain capsanthin powder, and embedding with starch by using fluidized bed. The inventive capsanthin powder has the advantages of good fluidity, stable quality, high yield, and no pollution.

Owner:山东天音生物科技有限公司

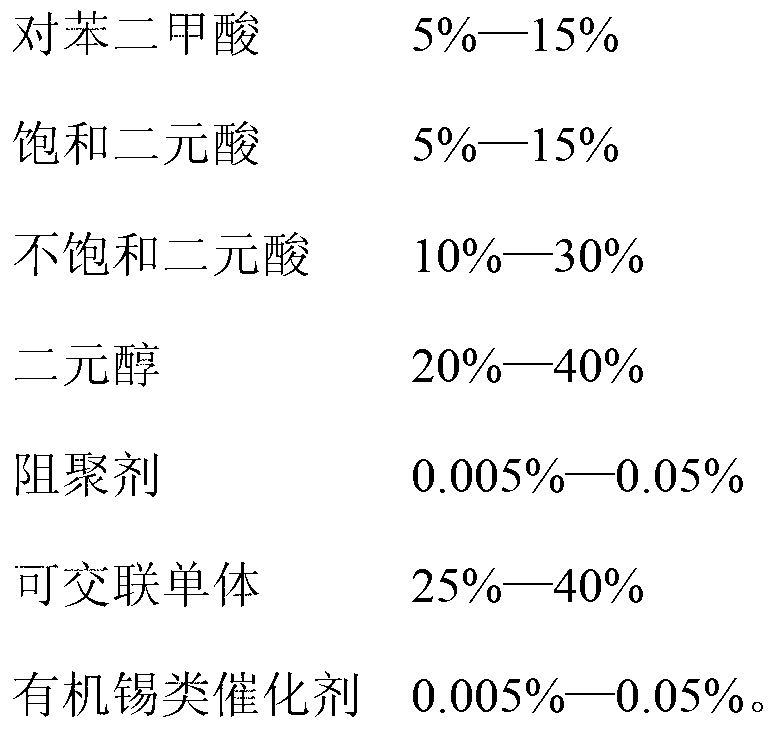

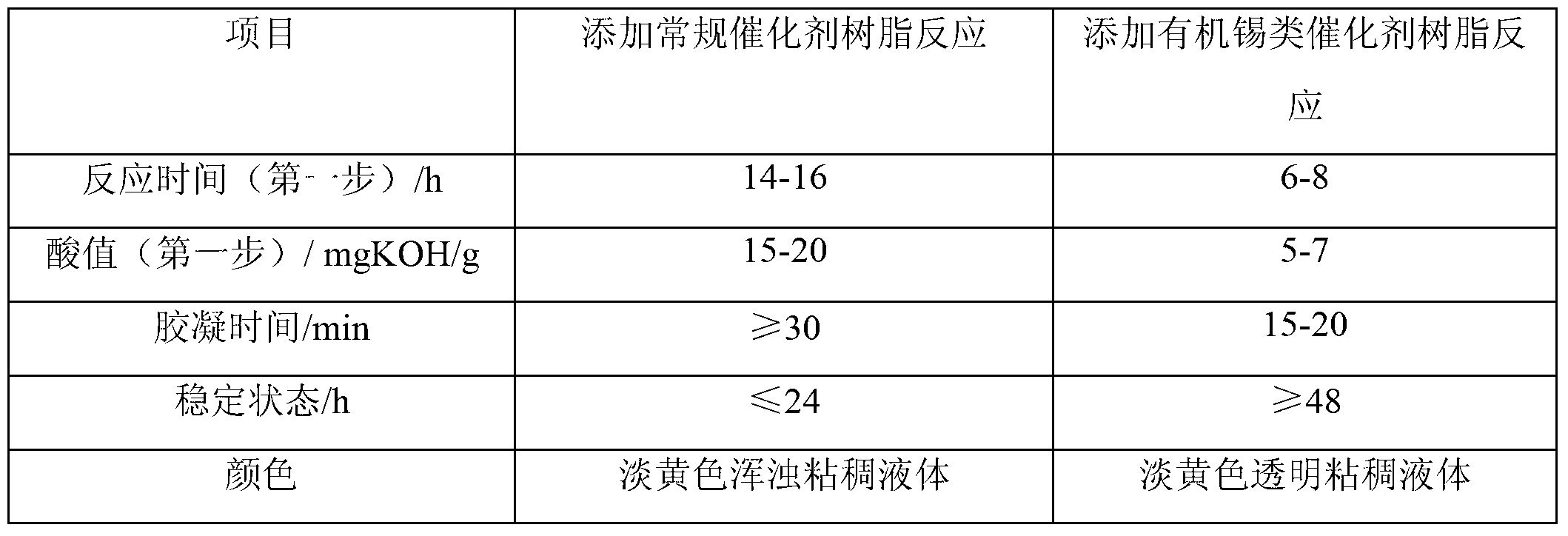

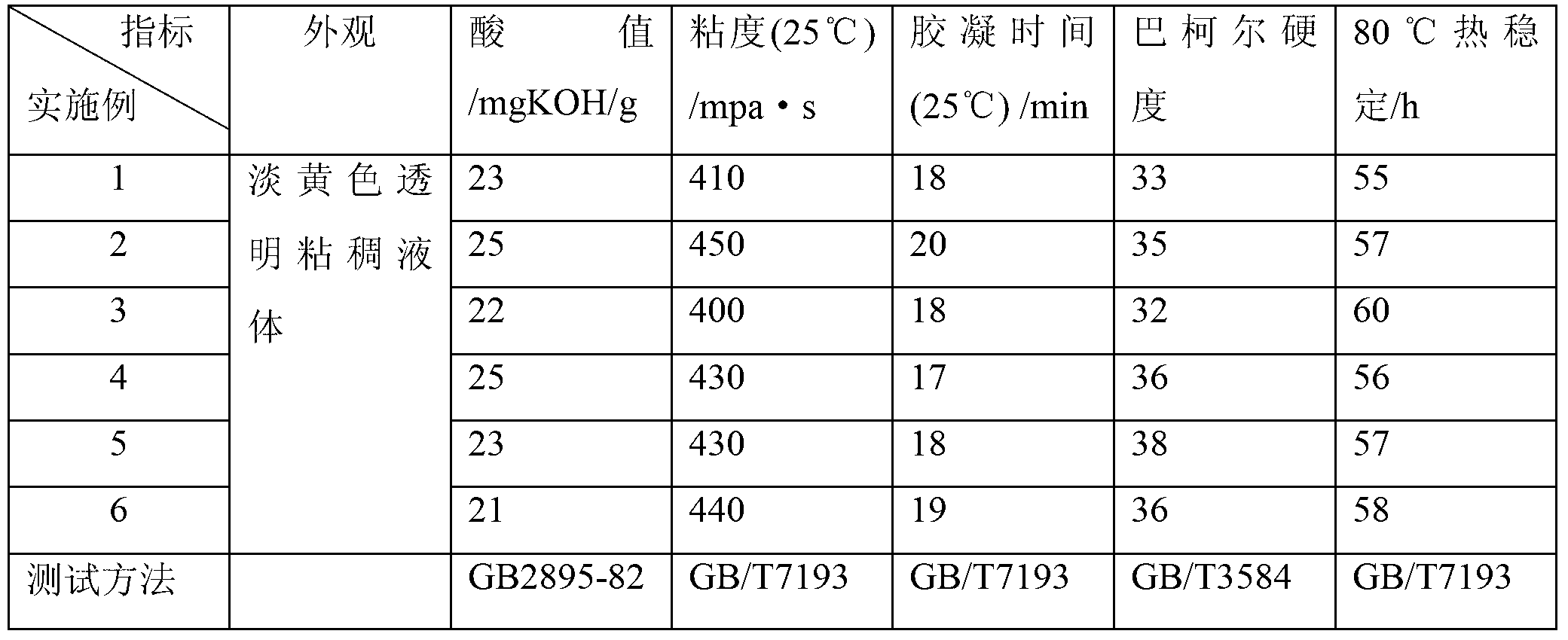

Preparation method of terephthalic type unsaturated polyester resin

The invention relates to a preparation method of unsaturated polyester resin and particularly relates to a preparation method of terephthalic type unsaturated polyester resin. The preparation method comprises an esterification-polycondensation reaction and a cross linking reaction, wherein saturated binary acids and organic tin catalysts are added in the esterification-polycondensation reaction. The problem of poor compatibility between styrene and polyesters generated by the reaction among terephthalic acid, other acids and dihydric alcohol with a symmetric structure is solved through adjusting the quantities of terephthalic acid and other acids. The saturated binary acids are used in the preparation method, so that the compatibility between styrene and the polyesters is greatly improved, and the flexibility of the resin is enhanced; and unsaturated polyester resin prepared by using the organic tin catalysts is high in reaction activity and easy to completely cure. The preparation method has the advantages of simple synthesis process, low production cost, excellent product performance, environmental friendliness and no generation of three wastes.

Owner:山东宏信化工股份有限公司

Deep eutectic solvent and preparation method thereof and application thereof in process of preparing glucose by hydrolyzing celluloses

ActiveCN108950091ARaw material environmental protectionDifficult to volatilize and less pollutionSugar juice extraction using extracting agentsGlucose productionCelluloseSolvent

The invention discloses a deep eutectic solvent. A hydrogen bond donor of the deep eutectic solvent is a protonic acid; a hydrogen bond acceptor of the deep eutectic solvent is an ammonium salt containing a specific functional group; and the specific functional group is alkylene, a sulfonic acid group, a carboxyl group, an ether group, an amino group or a sulfhydryl group. The deep eutectic solvent can efficiently hydrolyze celluloses to glucose. The invention also discloses a method of preparing the glucose by using the deep eutectic solvent to hydrolyze cellulose biomasses. The method comprises the following steps of: adding the cellulose biomass and the deep eutectic solvent to a reactor, and reacting at the temperature of 80-120 DEG C for 0.5-10h to obtain the hydrolysate glucose. Themethod has the characteristics of high reduction selectivity and high yield of glucose products in the process of using the cellulose biomass to prepare the glucose, can ensure that the glucose product meets the production quality requirements, and has very good economic, environmental and social benefits.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Degradable environment-friendly plant fiber product and manufacturing method thereof

The invention relates to a degradable environment-friendly plant fiber product and a manufacturing method of the degradable environment-friendly plant fiber product, in particular to a flowerpot, tableware, a compressed panel or a tray made of the degradable environment-friendly plant fiber and the manufacturing method of the flowerpot, the tableware, the compressed panel or the tray made of the degradable environment-friendly plant fiber. The raw materials comprise plant fibers from crop straws, food processing wastes, annual wild plant stem parts, bamboos, and woods. The raw materials are added with modified starch and organic pigments to be molded at high temperature to produce the plant fiber product. The degradable environment-friendly plant fiber product has the advantages that the main raw materials can be completely from the wastes of agricultural products; the materials are simple; the cost is low; the product is green and environment-friendly and can be naturally degraded in a natural environment; the production method is simple and high-efficiency; and the product is mild in surface color, high in strength, waterproof and not easy to deform, and can be used for substituting the current products made of plastic, argil and wood, so that the plant fiber product is an ideal degradable environment-friendly plant fiber product.

Owner:李宁

Bio-based dimer fatty acid base vinyl ester resin as well as preparation method and application thereof

The invention discloses a bio-based dimer fatty acid base vinyl ester resin as well as a preparation method and application thereof. The preparation method comprises the following steps of: enabling dimer fatty acid and unsaturated carboxylic acid base glycidyl ester to have reflux reaction in an anaerobic environment under the condition that polymerization inhibitor and catalyst exist, so as to obtain dimer fatty acid base unsaturated diglyceride; enabling the obtained dimer fatty acid base unsaturated diglyceride to have reflux reaction with a modifying agent, carrying out decoloration by activated carbon to obtain a dimer fatty acid base vinyl ester resin monomer; and carrying out copolymerization on the dimer fatty acid base vinyl ester resin monomer and other crosslinking monomers to obtain the dimer fatty acid base vinyl ester resin. The dimer fatty acid base vinyl ester resin can be used for preparing corresponding products and materials after being treated by ultraviolet-curing and heating-curing. The vinyl ester resin curing product has the advantages of good toughness, corrosion resistance, weather fastness and product stability; the preparation technology is simple in route, mild in conditions and free from generation of the three wastes; and bio-based dimer fatty acid base vinyl ester resin is made of an environmentally-friendly regenerative oil resource, so that the product price is low.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

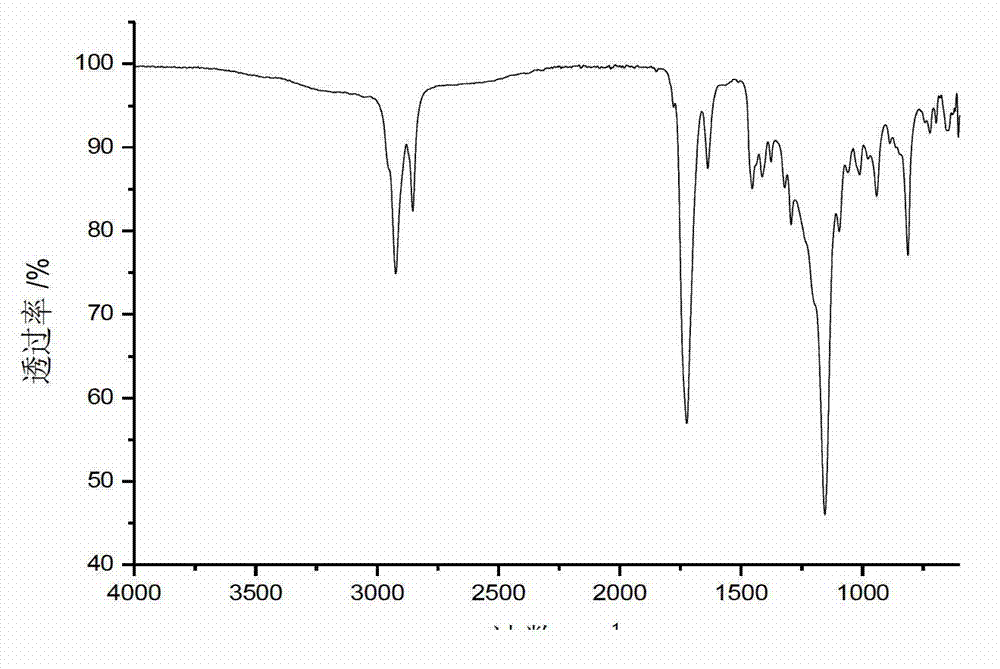

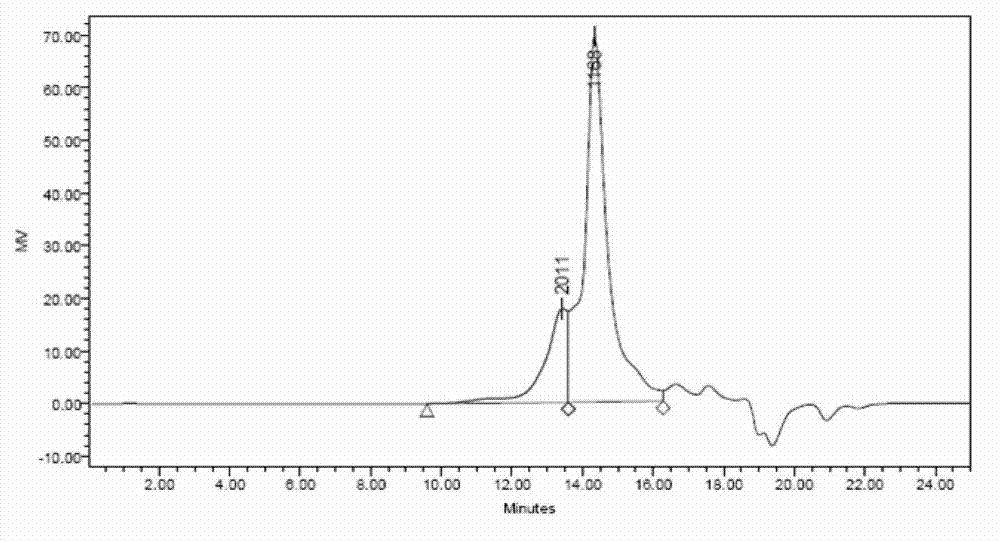

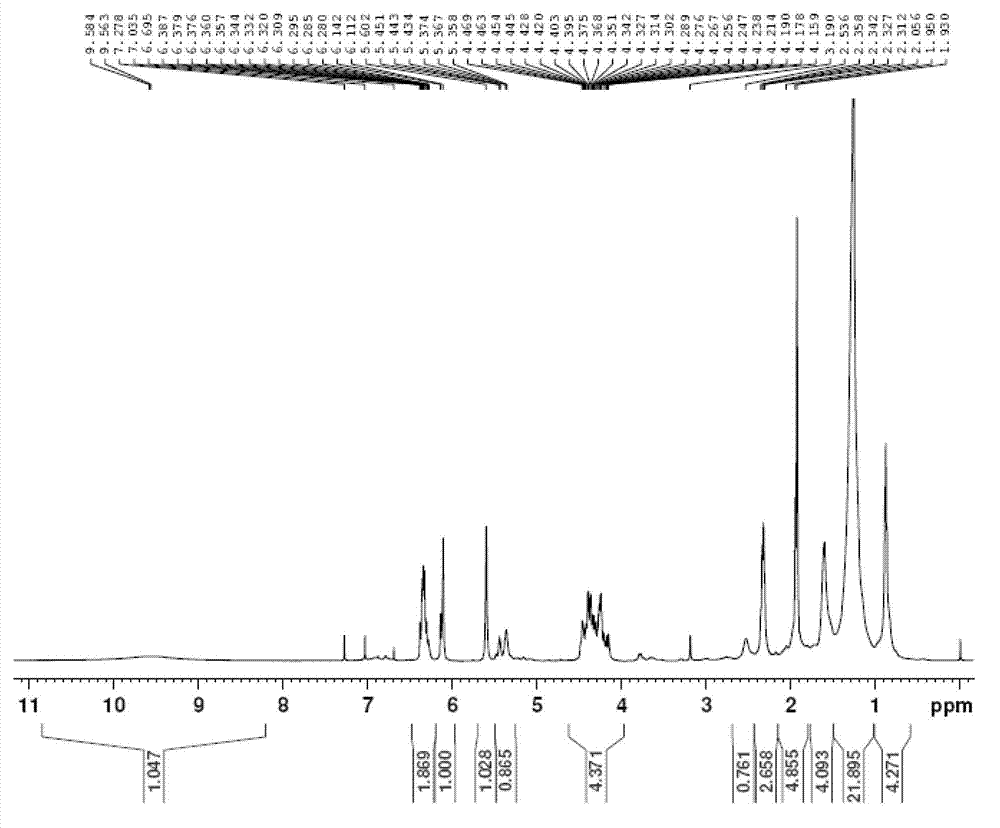

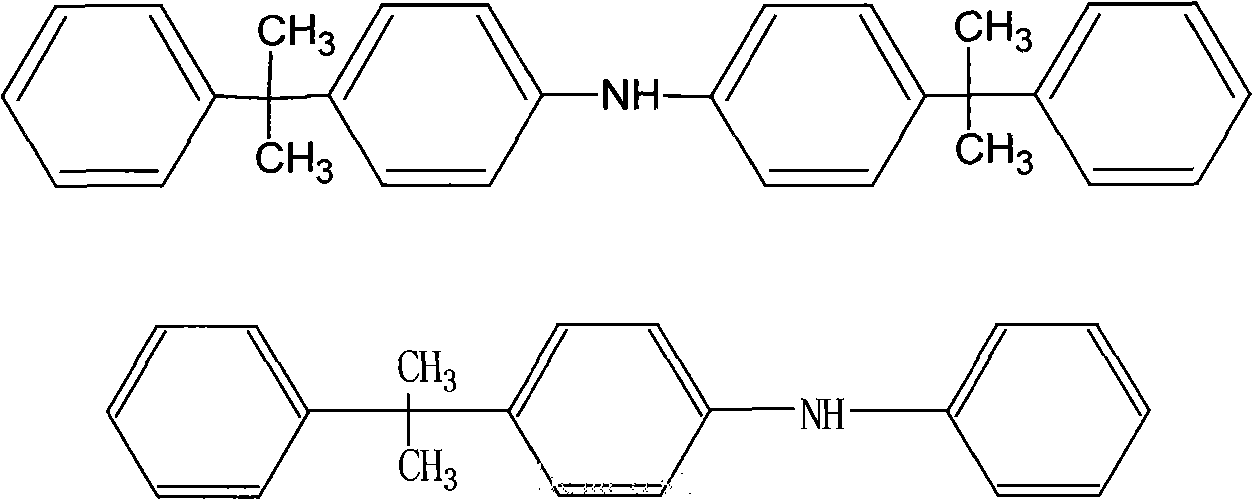

Method for preparing mixture of 4-(alpha, alpha-dimethylbenzyl) diphenylamine and 4,4-bis (alpha, alpha-dimethylbenzyl) diphenylamine

ActiveCN101538208ANo three wastes producedMild reaction conditionsAmino compound preparation by condensation/addition reactionsChemistryStyrene

The invention discloses a method for preparing mixture of 4-(alpha, alpha-dimethylbenzyl) diphenylamine and 4,4-bis(alpha, alpha-dimethylbenzyl) diphenylamine, relating to a preparation method of alkylated diphenylamine. The method comprises the following steps: diphenylamine and excessive a-methyl styrene carry out alkylate reaction at 120-175 DEG C in the presence of catalyst of activated clay to produce a coarse product, i.e. a mixture of 4-(alpha, alpha-dimethylbenzyl) diphenylamine and 4,4-bis(alpha, alpha-dimethylbenzyl) diphenylamine, and the mixture is filtered, distilled in decompression condition, prilled or crushed to produce mixture of 4-(alpha, alpha-dimethylbenzyl) diphenylamine and 4,4-bis(alpha, alpha-dimethylbenzyl) diphenylamine. The invention is a high-efficiency and clean synthetic process and has the advantages of long-term oxidization resistance, heat resistance, disturbance resistance and favorable stability.

Owner:JIANGSU FEIYA CHEM IND

Preparation method of dispersing agent containing sulfo polycarboxylate

ActiveCN103030730AMolecular weight is easy to controlImprove adaptabilityBiocideAnimal repellantsPolymer sciencePersulfate

The invention relates to a preparation method of a dispersing agent containing sulfo polycarboxylate. The method comprises the steps that acrylamide-2-methyl propanesulfonic acid, acrylic acid, and 2-acryamide-2-methyl propanesulfonic acid are copolymerized in an aqueous solution; persulfate serves as an initiating system; and the water-soluble polymer dispersing agent is formed. The polymer dispersing agent contains sulfonic groups, and has good heat resistance, salt tolerance and environmental adaptability. The method is simple and practicable, short in production cycle, safe and environment-friendly; and the prepared dispersing agent is used for dispersing iron oxide, titanium dioxide, and atrazine in circulating water.

Owner:山东宝龙达新材料有限公司

Microwave radioradiation crosslinked complete biodegradable material and its processing method

The invention relates the microwave radio-frequency radiation cross-linking biodegradation material, comprising starch, cellulose, A, aminocaprolactam or polyatomic alcohol, B, coupling agent, C, nucleation agent, D, undecylenic acid, calcium carbonate, natrii chloridum, and urea. The method comprises the following steps: mixing the raw material, cross linking with microwave radio-frequency device, foaming, forming, and getting the product. The invention solves the problems of no degradation, complex procedure, high cost and hard technology. The product has the advantages of good draftability, suppleness and obstructing property. The invention has the advantages of wide application area, completely degradation and non pollution. The invention also has the advantages of simple technology, easy operation and low cost.

Owner:杨军现

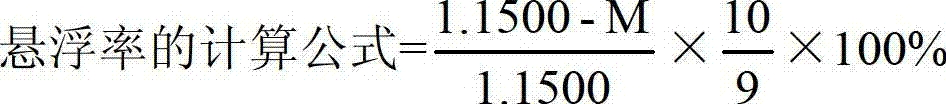

Method for preparing air drying epoxy vinyl ester resin

The invention relates to a preparation method for air-drying epoxy vinyl ester resin. The preparation method is as follows: bisphenol A epoxide resin, acrylic acid or methacrylic acid and boletic acid are reacted; and then the generated epoxy vinyl ester resin is modified with dicyclopentadiene; the dicyclopentadiene is added in the reaction system and reacts for 1 hour to 3 hours at the temperature of 110 DEG C to 130 DEG C till the acid value falls below 20 mg KOH / g and the reaction products are cooled below 110 DEG C; styrene is added into the products for dilution and well blended. Compared with the prior art, the invention has the advantages that the epoxy vinyl ester resin has good air-drying property; for the coating with the thickness of 0.1 mm, the surface drying time is less than and equal to 0.5 hour and the hard drying time is more than and equal to 4 hours; the surface hardness can reach 3 H; the modified raw material formulation of the dicyclopentadiene has low cost; the preparation method is simple, environmentally friendly and does not generate waster water, waste gas and industrial residue; the products have good stability, good performances of normal temperature cure, rapid curing rate, high paint film adhesion, low shrinkage factor and good corrosion resistance.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

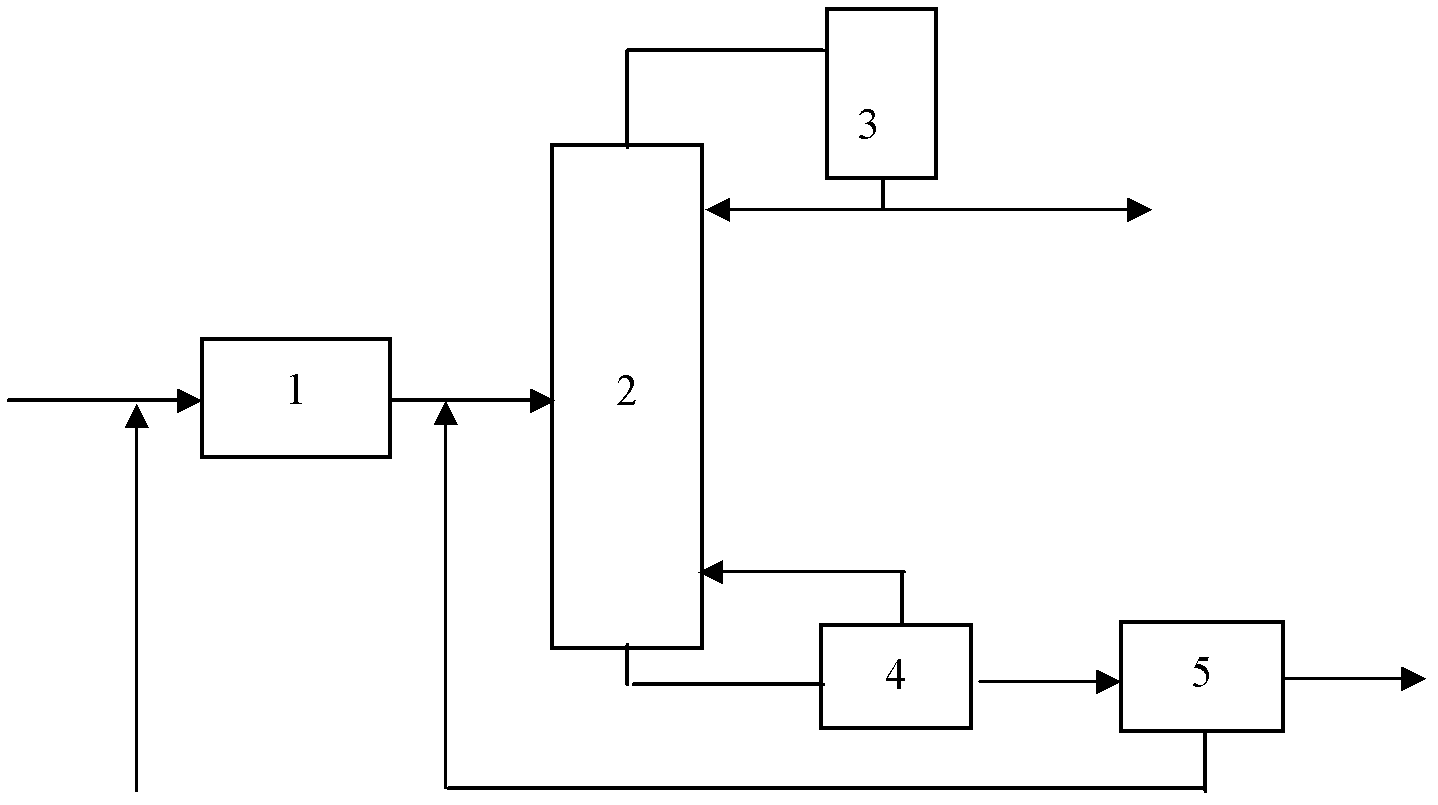

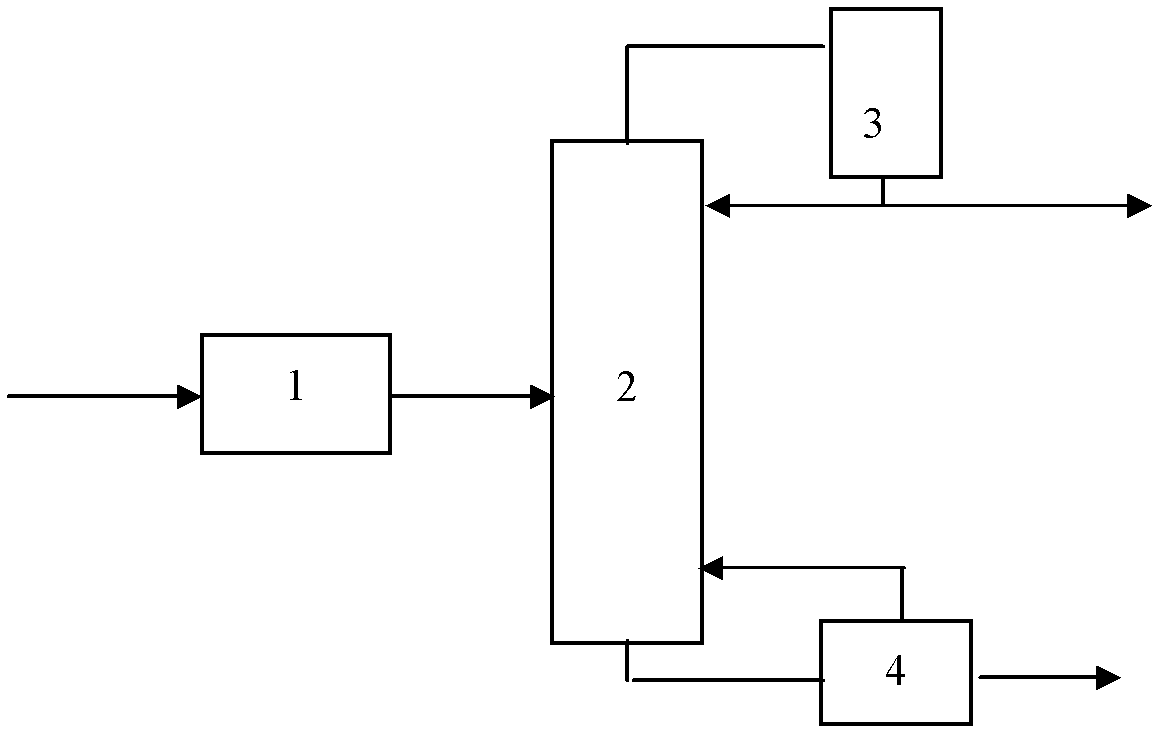

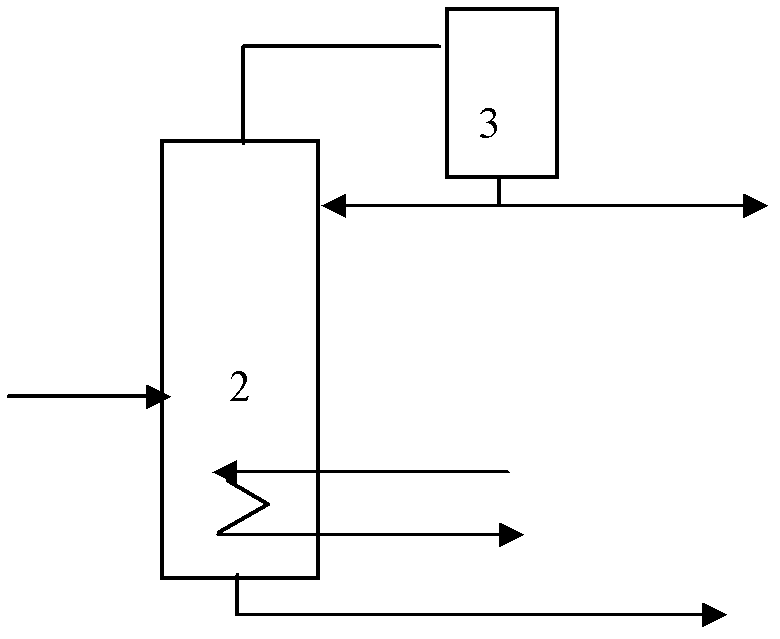

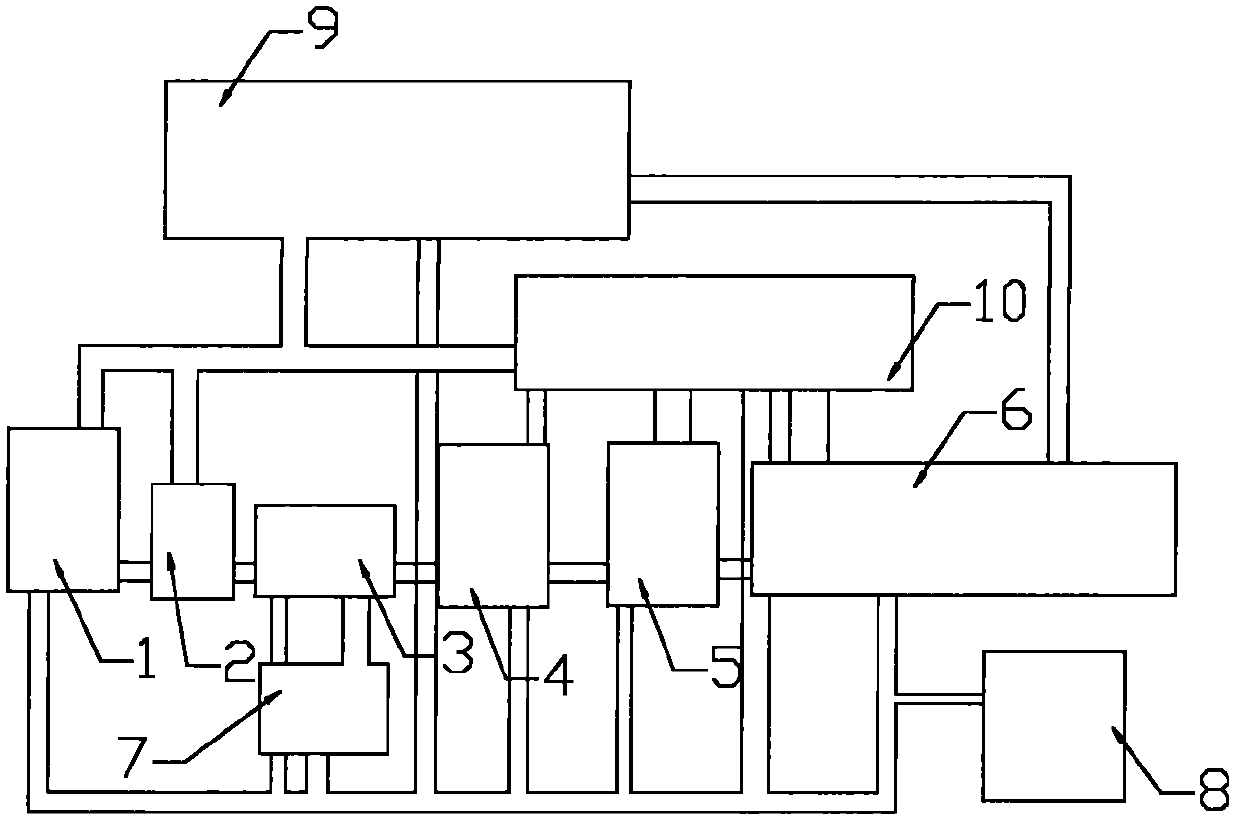

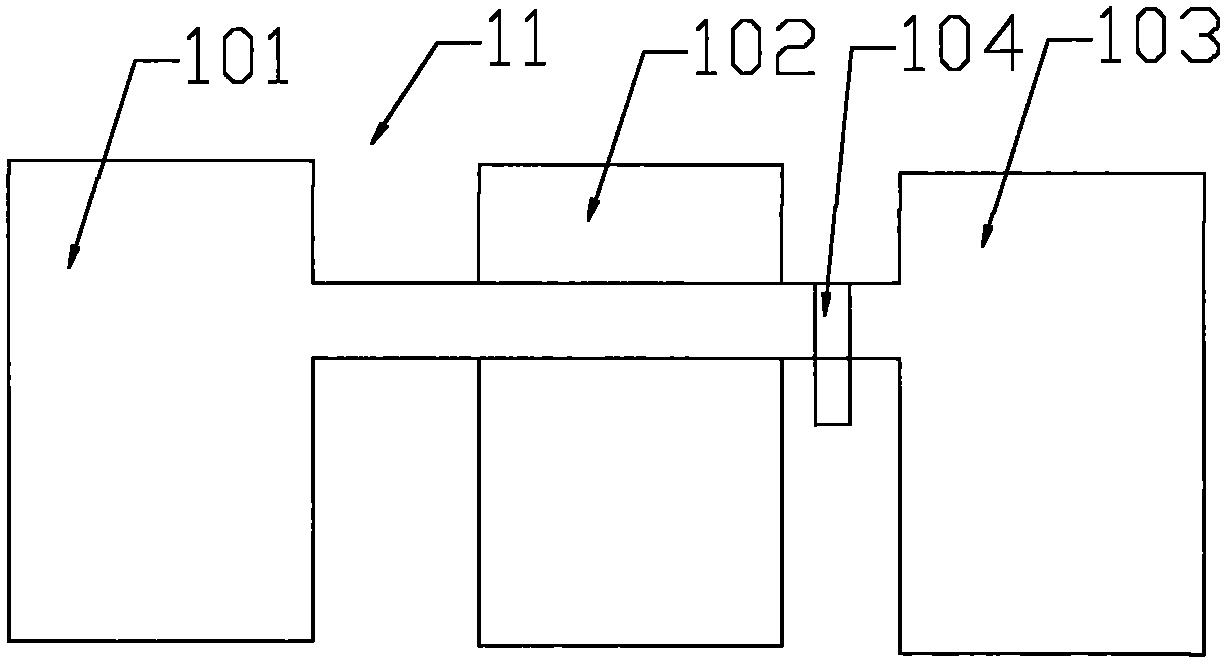

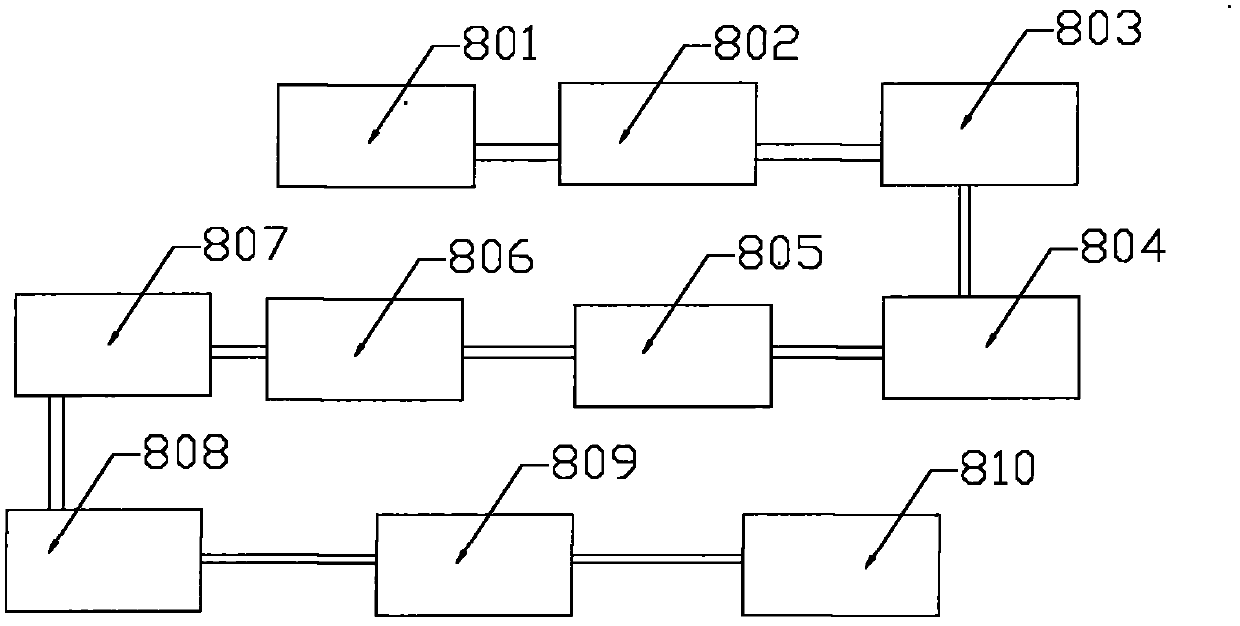

Recovery process of PX oxidation residues and recovery system device thereof

InactiveCN102516080AAchieve recyclingLarge resourcesOrganic compound preparationCarboxylic acid esters preparationDistillationResource utilization

The invention discloses a recovery process of PX (p-xylene) oxidation residues, and the process comprises primary treatment, secondary esterification, fine distillation, ion exchange, and subsequent treatment of wastewater, exhaust gas and waste residues. The invention also discloses a recovery system device used for the recovery process of PX oxidation residues. The device consists of a high temperature flash dryer, a pulverizer, a reaction dissolving kettle, a first esterification instrument, a second esterification instrument, series of rectification towers, an ion exchange instrument, a wastewater treatment instrument and a tail gas absorption tower that are connected in order, and also includes a methanol recovery system. The process of the invention can extract various material components in large amounts and high purity, has low requirement for production equipment and basically no corrosion, and realizes recycling of wastes, which can achieve resource utilization to the utmost and a highest utilization rate. Meanwhile, the process in the invention solves the environmental protection pressure of enterprises, basically realizes no three wastes, thus being consistent with the green environmental protection concept of low carbon and having competitive edges.

Owner:白英

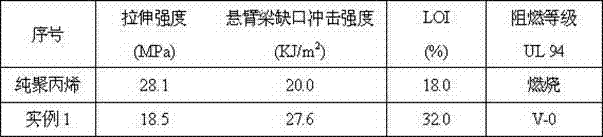

Halogen-free flame-retardant polypropylene material and preparation method thereof

The invention relates to a high polymer material and a preparation method thereof, particularly a halogen-free flame-retardant polypropylene material and a preparation method thereof. The halogen-free flame-retardant polypropylene material is prepared from the following components in parts by weight: 170-200 parts of polypropylene resin, 380-400 parts of inorganic composite flame retardant, 30-50 parts of toughener POE (ethylene-octylene copolymer), 10-15 parts of compatilizer POE-g-MAH (POE grafted maleic anhydride), 3-5 parts of lubricant and 2-4 parts of anti-ultraviolet agent. The preparation method comprises the following steps: proportionally mixing polypropylene resin, toughener, compatilizer, lubricant, anti-ultraviolet agent and the like at high speed, granulating by extrusion, and carrying out injection molding to obtain the halogen-free flame-retardant polypropylene composite material. The tests of vertical burning, limited oxygen index, tensile property, impact property and the like prove that the composite material has excellent flame retardancy and mechanical properties, and has favorable industrial application value.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

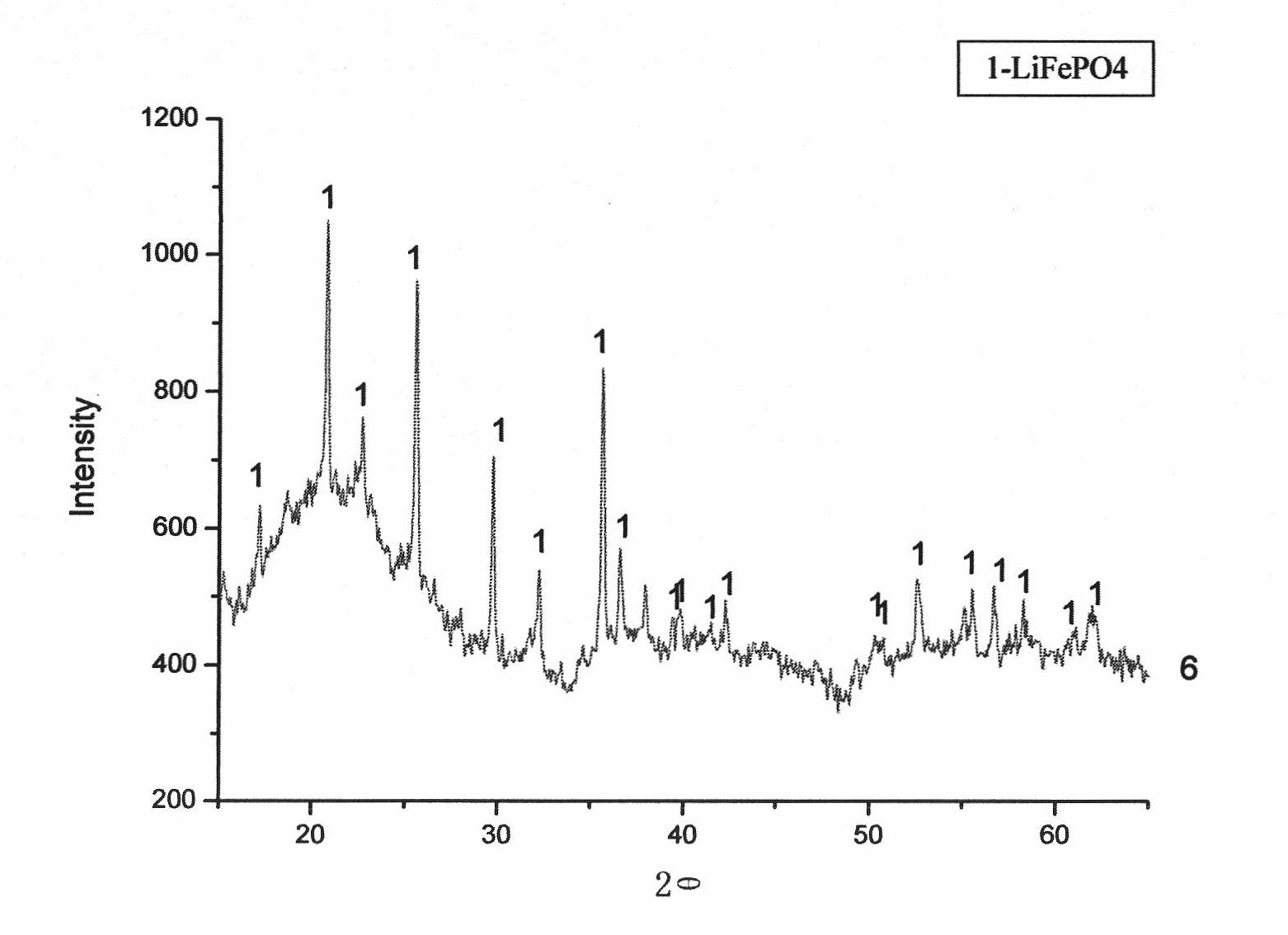

Method for preparing lithium iron phosphate by sintering lithium iron phosphate precursor and microwave sintering equipment

InactiveCN102092699APromote densificationEvenly distributedCell electrodesPhosphorus compoundsLithium iron phosphateControl treatment

The invention discloses a method and equipment for preparing lithium iron phosphate from a lithium iron phosphate precursor. The method comprises the three process steps of pretreatment of the lithium iron phosphate precursor material, pre-sintering and sintering; and in a non-oxidizing environment, the precursor material is heated by a certain number of microwave heaters, and the three process steps are finished by controlling treatment temperature and treatment time to finally prepare the lithium iron phosphate product. The equipment comprises a material inlet, a material feeding ventilation chamber, a pretreatment unit furnace, a pre-sintering unit furnace, a sintering unit furnace, a material discharging ventilation chamber, a cooling material discharging mechanism, a material outlet,a vacuumizing device, a protective gas input device and an equipment control circuit. In the method, the pretreatment and pre-sintering process steps are added to optimize a lithium iron phosphate microwave sintering process and solve keys problems on product quality control. The equipment provided by the invention realizes continuous microwave sintering by a plurality of unit furnaces so as to improve the sintering efficiency and realize large-scale industrial production.

Owner:HENAN UNION NEW ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com