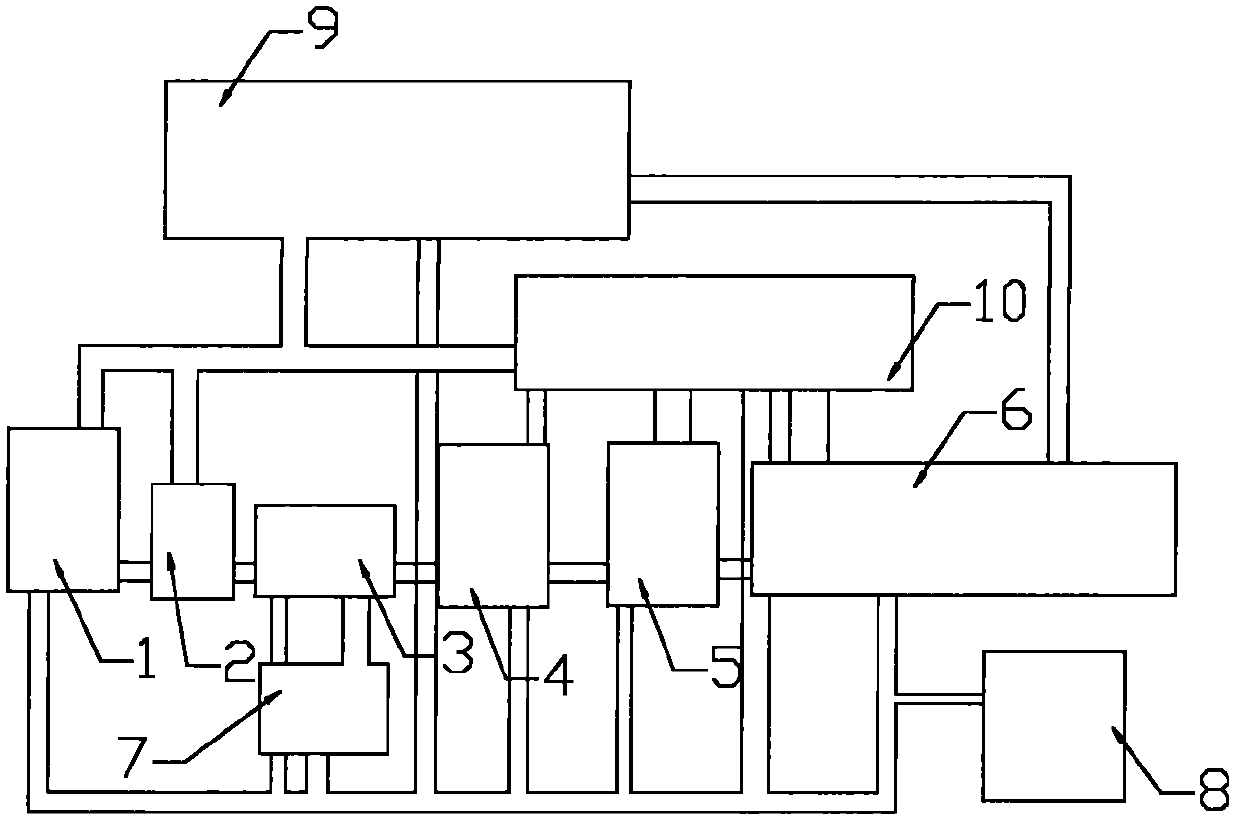

Recovery process of PX oxidation residues and recovery system device thereof

A technology for recycling system and residues, which is applied to the improvement of process efficiency, the preparation of organic compounds, the separation/purification of hydroxyl compounds, etc. Recycling, low production equipment requirements, and the effect of solving environmental protection pressures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

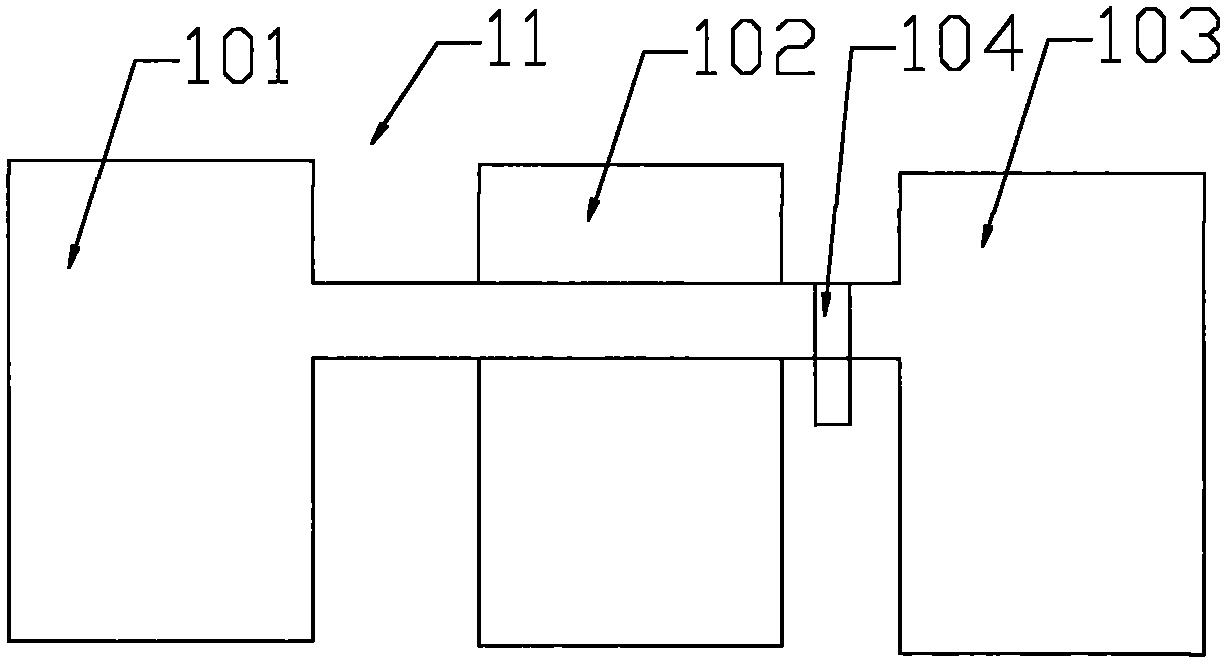

Method used

Image

Examples

Embodiment 1

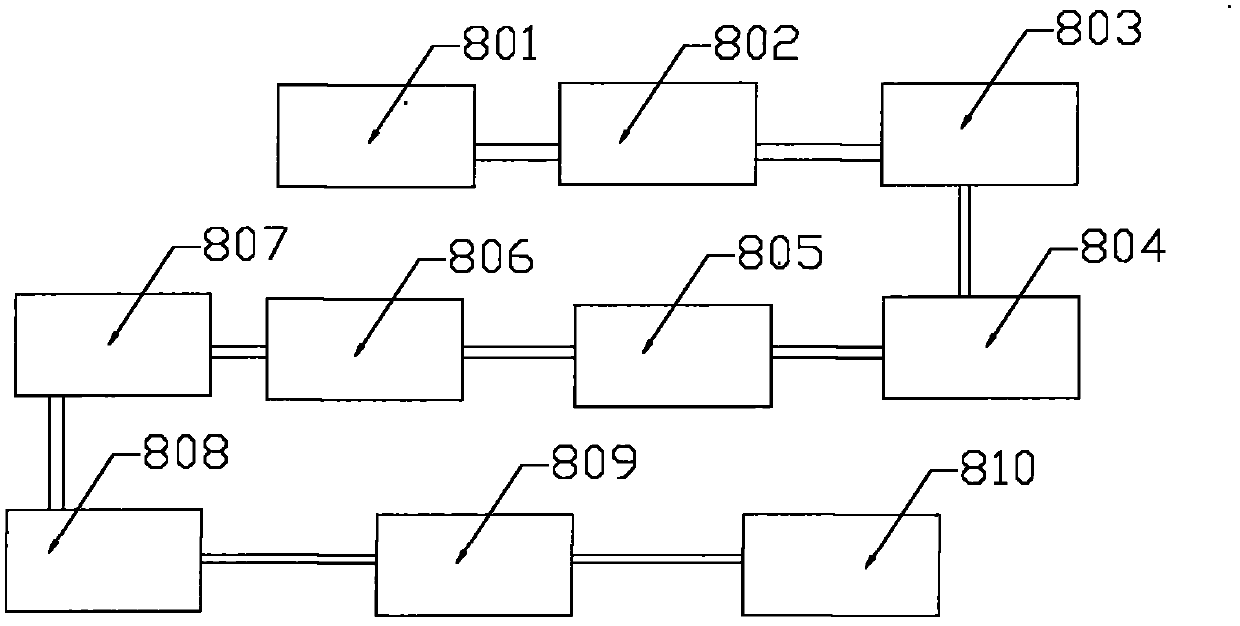

[0122] A kind of recovery technology of PX oxidation residue, it is characterized in that comprising the following steps:

[0123] The first step is to carry out preliminary treatment of PX oxidation residue:

[0124] (1), the PX oxidation residue is flash-dried at high temperature until the moisture contained in the residue is 2%;

[0125] (2), pulverization treatment, the residue after pulverization treatment is 10 orders;

[0126] (3), be made into slurry with water, stir evenly, put into dissolving kettle and heat and constant temperature 5 minutes, filter while hot, directly cool to crystallization, obtain mixed acid residue and filtration residue after filtration;

[0127] The second step is to recycle the mixed acid residue:

[0128] (1), carry out secondary esterification reaction:

[0129] The first esterification reaction: in the mixed acid residue, add methanol according to the molar ratio of 1:7 and iron sulfate according to the total mass ratio of 5‰. At this t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com