Patents

Literature

78results about How to "Solve environmental pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high-adsorption nano-crystalline cellulose polyvinylamine microgel by using biomass

InactiveCN105080503ALarge specific surface areaWon't breakOther chemical processesWater contaminantsFiberMicrosphere

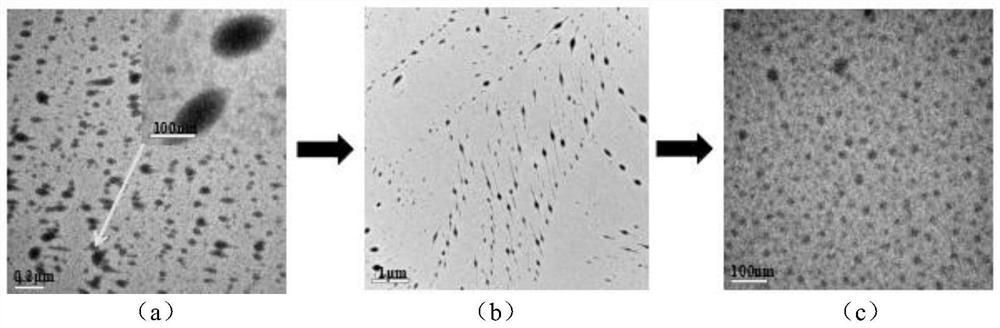

The invention relates to a method for preparing a high-adsorption nano-crystalline cellulose polyvinylamine microgel by using a biomass. The method comprises the steps of acid-treating lignocellulosic materials, and performing ultrasonic treatment to obtain nano microcrystalline cellulose colloidal suspension liquid; adding periodate in the nano microcrystalline cellulose colloidal suspension liquid, adjusting pH to be 3 to 4, and reacting under a dark condition, thus obtaining a dialdehyde nano microcrystalline cellulose; dropwise adding the dialdehyde nano microcrystalline cellulose into polyvinylamine, and stirring for reacting, thus obtaining the nano-crystalline cellulose polyvinylamine microgel. The nano-crystalline cellulose polyvinylamine microgel consists of microsphere particles with the particle size of 200 to 300 nm, has a greater specific surface area, contains a great amount of free amino groups on the surface, is used for adsorbing an anionic dye and heavy metal ions in wastewater, and has higher adsorption capacity.

Owner:QILU UNIV OF TECH

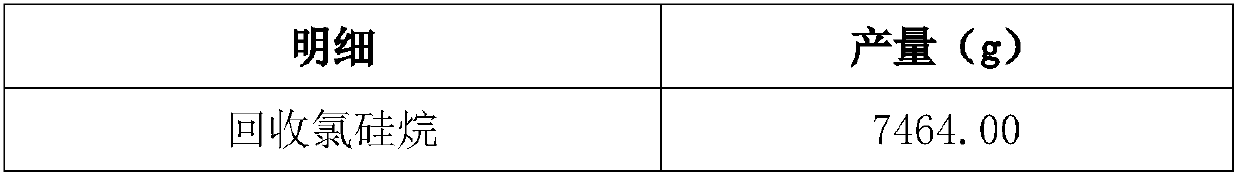

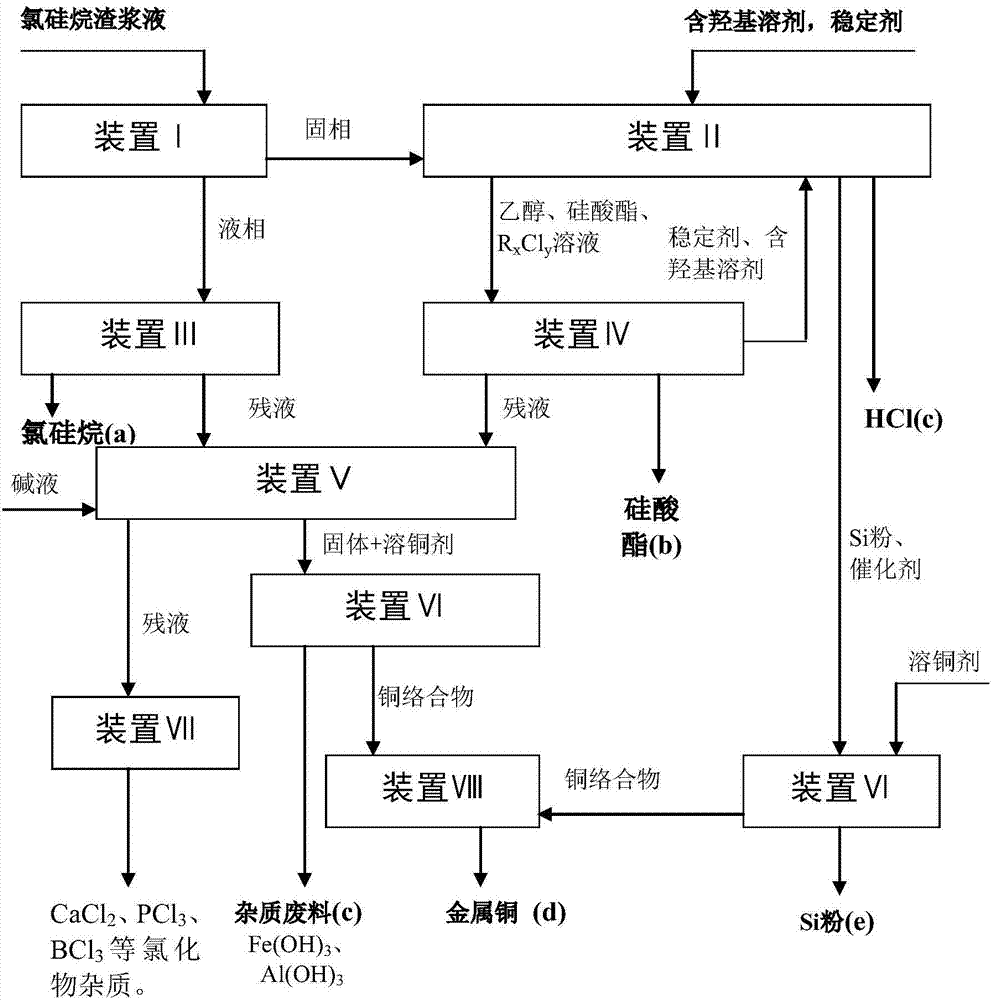

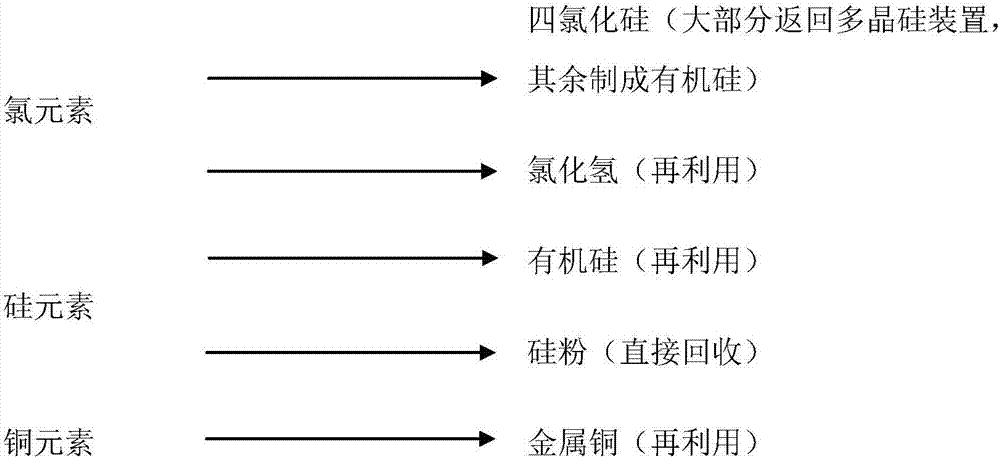

Method for treating chlorosilane slurry residual liquid

InactiveCN107628623AGood placeHigh recovery rateSilicon organic compoundsPreparation from chloridesSlurrySolvent

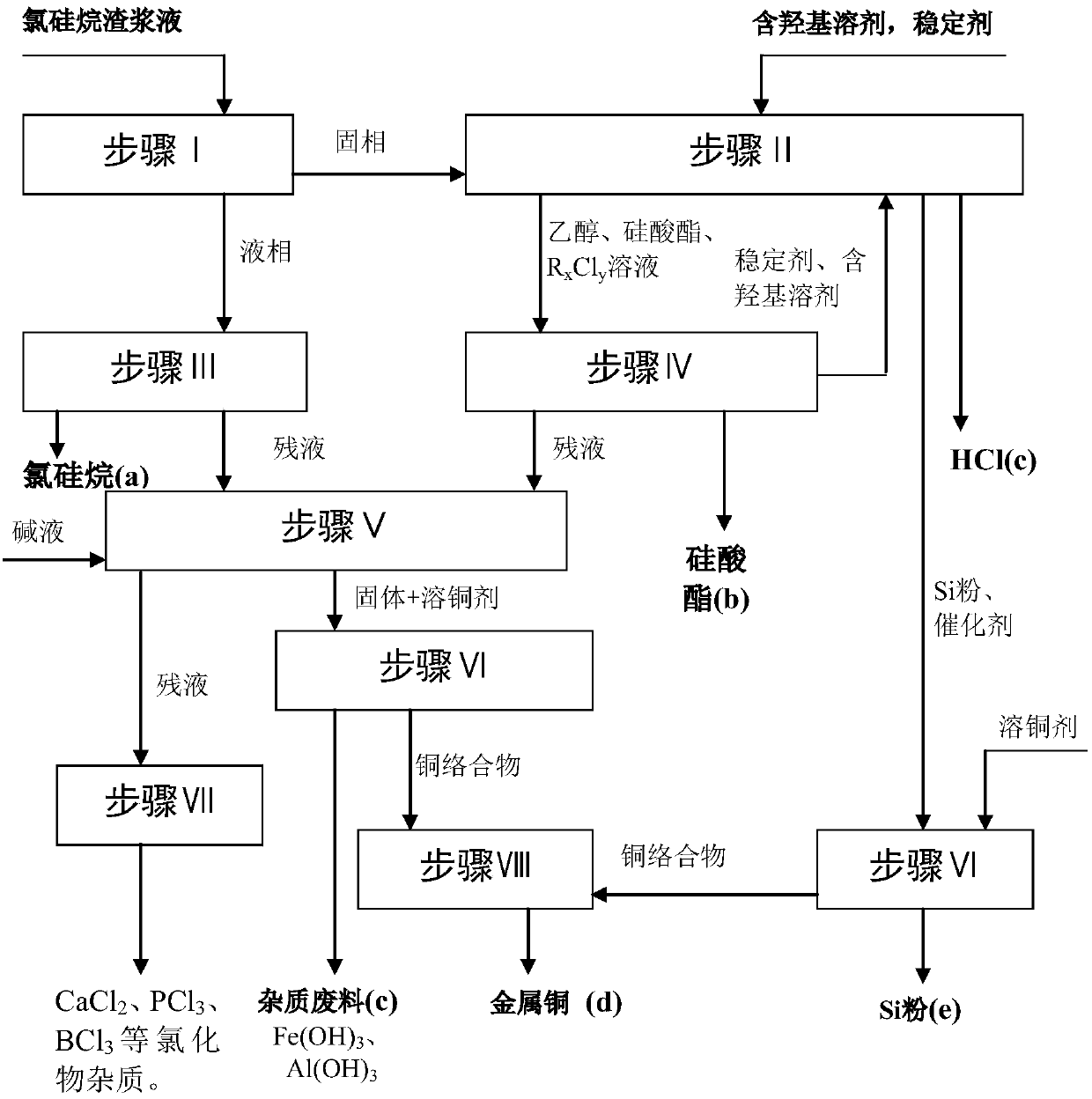

The invention provides a method for retrieving silicon tetrachloride, silicon powder and copper or / and preparing silicate ester by treating chlorosilane slurry residual liquid. The method comprises the following steps: separating chlorosilane slurry residual liquid through solid-liquid separation in step I; directly feeding a liquid phase into a silicon tetrachloride storage tank or purifying silicon tetrachloride in a step III; reacting the solid phase in the step II to lead residual chlorosilane to react and generate silicate ester and hydrogen chloride, and dissolving other chlorides in anorganic solvent; distilling and reclaiming silicate ester from the reacting liquid phase in the step IV, returning the reclaimed hydroxyl-containing solvent and stabilizer to step II for recycling, hydrolyzing and neutralizing kettle bottom solution in the step V; and adding an alkaline liquor, reacting metal chloride to generate hydroxide precipitate, directly removing the Three Wastes from the neutralized reacting liquid phase in the step VII, extracting copper from the hydroxide precipitate through the step VI, and further treating in the step VIII to obtain metal copper; and treating the solid, which is copper-containing silicon powder, obtained in the step II to reclaim silicon powder and copper after step VI and step VIII treatment.

Owner:四川绿源聚能环保科技有限责任公司

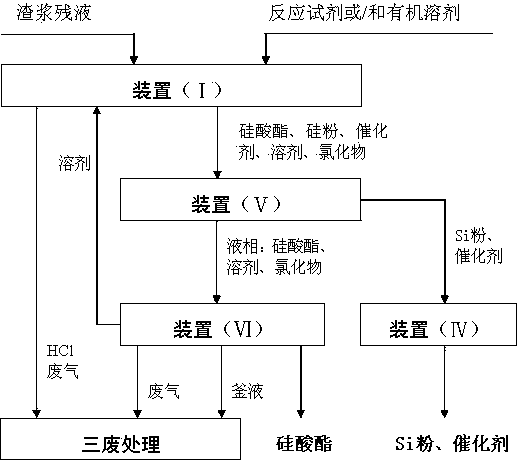

Method for preparing silicate ester by recycling chlorosilane slag slurry residual liquid

ActiveCN103951691ARecycled successfullySolve resource problemsSilicon organic compoundsSiliconPtru catalystSilicic acid

The invention provides a method for recycling silicon powder and catalysts and / or preparing silicate ester by treating chlorosilane slag slurry residual liquid by virtue of an organic solvent. By using the special characteristics that chlorosilane is easy to react with some materials to generate corresponding ester and the characteristics that impurity materials in slag slurry residual liquid are easy to be dissolved into some organic solvents, impurities in the chlorosilane slag slurry residual liquid can be effectively removed by adopting the method disclosed by the invention so as to ensure that the silicon powder and / or the catalysts are completely recycled, and valuable silicate ester also can be produced. The method is simple in involved device and convenient and fast in operation; the problems of serious raw material waste and three-waste treatment in the production of polysilicon and various chlorosilanes at present can be solved by adopting the method.

Owner:吴娟

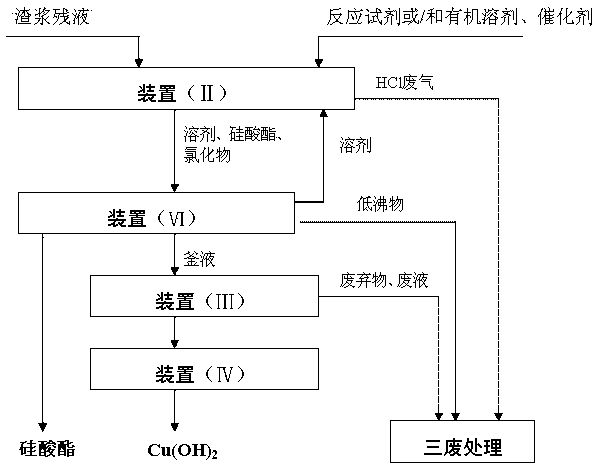

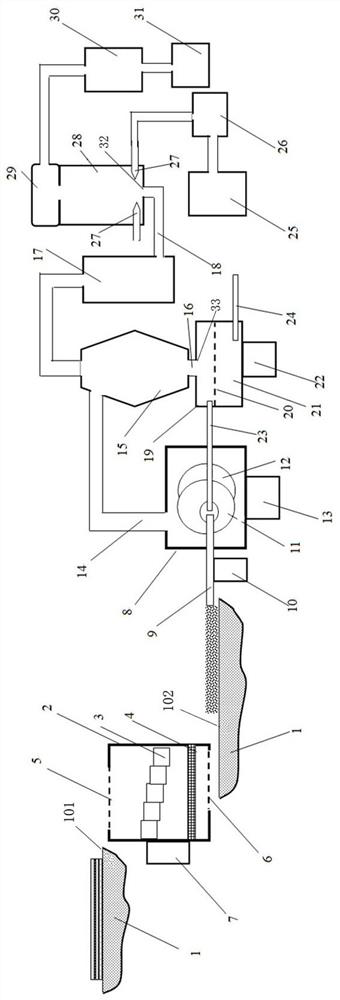

Device system for treating chlorosilane slag slurry raffinate

InactiveCN107539991ADoes not introduce secondary pollutionSolve resource problemsSilicon organic compoundsSiliconSlagSlurry

The invention provides a device system for treating chlorosilane slag slurry raffinate to recycle silicon tetrachloride, silicon powder, copper or / and preparing silicate ester. The chlorosilane slag slurry raffinate is added into a solid-liquid separation device I; after separation, a liquid phase directly flows into a silicon tetrachloride storage tank or a silicon tetrachloride purification device III, and a solid phase is discharged into a reaction device II, so that residual chlorosilane and an organic solvent react to generate the silicate ester and hydrogen chloride, and other chloridesare dissolved into the organic solvent; after the solid-liquid separation, the liquid phase is distilled by a device IV, so that the silicate ester is separated out; an extracted material at the top of a tower returns into the reaction device II, and kettle base solution flows into a hydrolysis and neutralization device V; alkali liquor is added into the device V and is in reaction with the metalchlorides to generate a hydroxide precipitate and chlorate solution, a liquid phase flows into a three wastes treatment device VII, a solid phase is transferred to a copper extraction device VI for copper extraction, and copper is further treated by a device VIII, so as to obtain recovery copper; a solid phase in the device II is copper-contained silicon powder and is treated by the device VI andthe device VIII, so as to recovery silicon powder and copper.

Owner:四川绿源聚能环保科技有限责任公司

Reusable modified guar gum fracturing fluid system

InactiveCN105567212ASolve water pressureSolve environmental pressureDrilling compositionFracturing fluidWater resources

The invention relates to a reusable modified guar gum fracturing fluid system. According to the technical scheme, the system comprises a primary mixed solution and a secondary mixed solution, wherein chemicals of a reusable fracturing system are adopted as the primary mixed solution and include compound modified guar gum, an organo-boron cross-linking agent, a low-temperature activator, a cleanup activator, a gel breaker removal adhesion preserving agent, an ionic equilibrium regulator, a molecular remodeling carding agent and a gel breaker. The base fluid formula of the secondary mixed solution includes an antibacterial agent formaldehyde, a gel breaker removal adhesion preserving agent, an ionic equilibrium regulator, thickening agent guar gum and a cleanup activator. The system has the advantages that the problems about water lack and environmental protection pressure during oilfield development in dry and rainless regions are solved, and secondary utilization of flowback fluid of fracturing fluid is achieved. On the premise that the requirements for safe fracturing construction and reservoir protection are met, fracturing fluid is easy to maintain and process and can be repeatedly used, the treatment amount of the flowback fluid is reduced, and water resources are saved.

Owner:DONGYING SPRING PETROLEUM ENG TECH

Preparation method of silver tin oxide electric contact materials

ActiveCN104117684ASmall particle sizeImprove dispersion uniformityContactsSilver carbonateAqueous solution

The invention provides a preparation method of silver tin oxide electric contact materials. Firstly, a method for preparing a solution is adopted, an aqueous solution containing silver nitrate and tin nitrate reacts with a sodium carbonate aqueous solution containing a sodium hexametaphosphate dispersing agent, a mixture containing silver carbonate and tine carbonate is obtained under the action of high-speed stirring and the sodium hexametaphosphate dispersing agent, silver tin oxide compound powder with fine particles is obtained through the processing of filtering, forging and mechanical grinding, the preparation of the silver tin oxide electric contact materials uniform in component in the subsequence powder metallurgy process is facilitated, and the preparing process is environmentally friendly. The preparation method of the silver tin oxide electric contact materials is simple and easy to control, short in production cycle, low in pollution, low in cost and favorable for industrial production.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

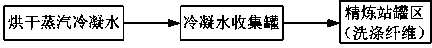

Waste water heat energy utilization method applicable to viscose staple fiber industry

InactiveCN104264255APromote energy saving and consumption reductionTake advantage ofArtificial thread manufacturing machinesTextile/flexible product manufactureFiberSocial benefits

The invention discloses a waste water heat energy utilization method applicable to the viscose staple fiber industry. The waste water heat energy utilization method applicable to the viscose staple fiber industry comprises processes of performing heat exchange and recycling on waste hot water during viscose staple fiber production, wherein the waste hot water comprises plasticizing tank overflow water; the processes comprise utilizing the plasticizing tank overflow water to perform step-by-step heat exchange sequentially on plasticizing tank make-up water, desulfurizing liquid and packaged cooling water, the packaged cooling water is conveyed to a cutting machine after heat exchange is performed, and then utilized by a refiner to obtain green cut water, and the green cut water returns to the cutting machine or is conveyed to a plasticizing tank water supplementing tank to serve as plasticizing tank supplement water. The waste water heat energy utilization method applicable to the viscose staple fiber industry achieves comprehensive recycling and utilization of various types of waste hot water and meanwhile achieves heat exchange treatment on specific mediums requiring heating during the viscose staple fiber production, thereby making full use of waste heat of the waste hot water, promoting energy conservation and consumption reduction for enterprises on the basis of existing process waste water treatment and under the premise of no flow losses, and obtaining high social benefits and economic benefits.

Owner:YIBIN GRACE +2

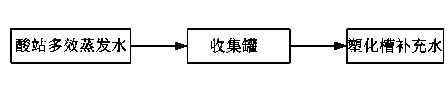

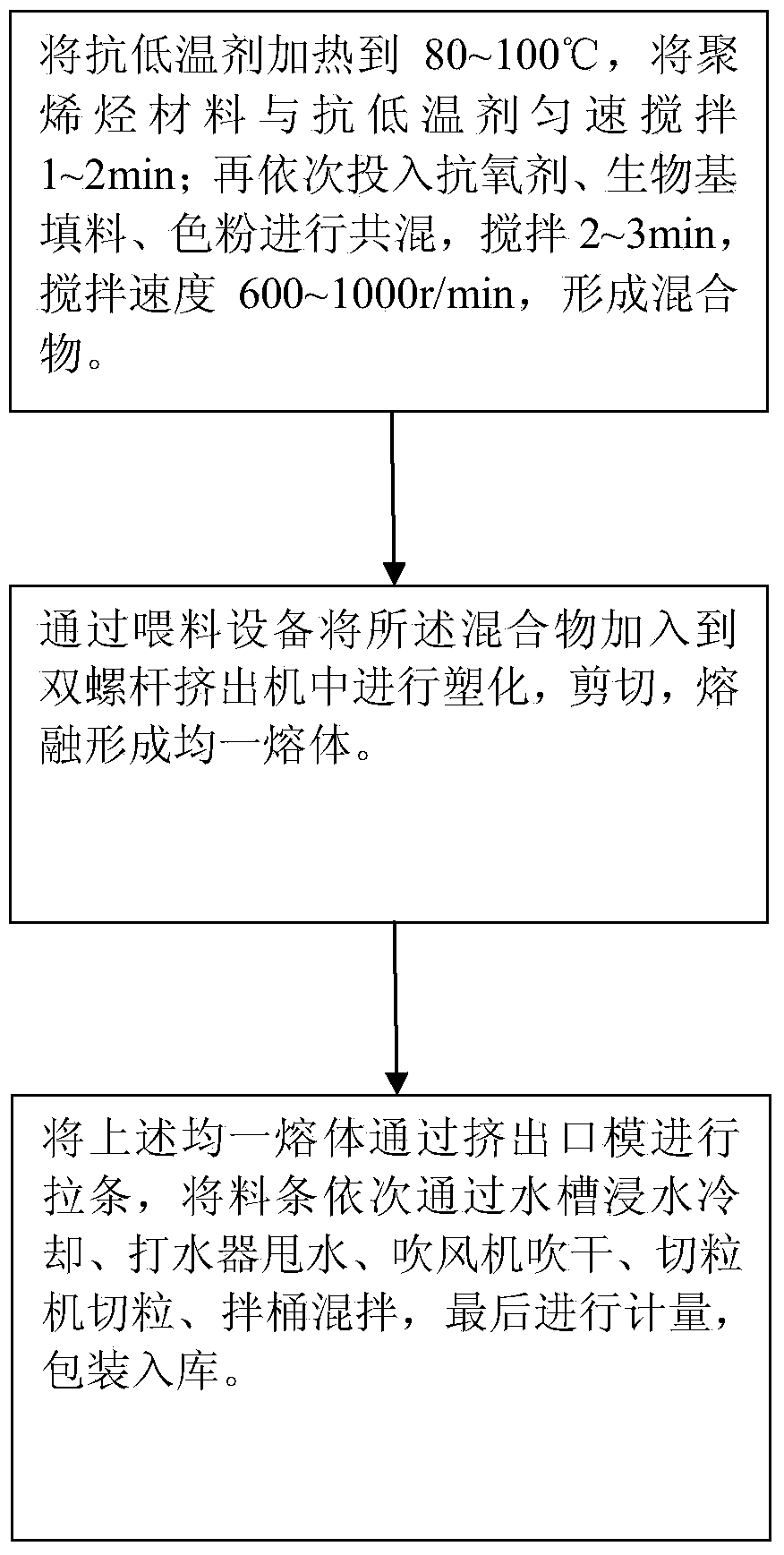

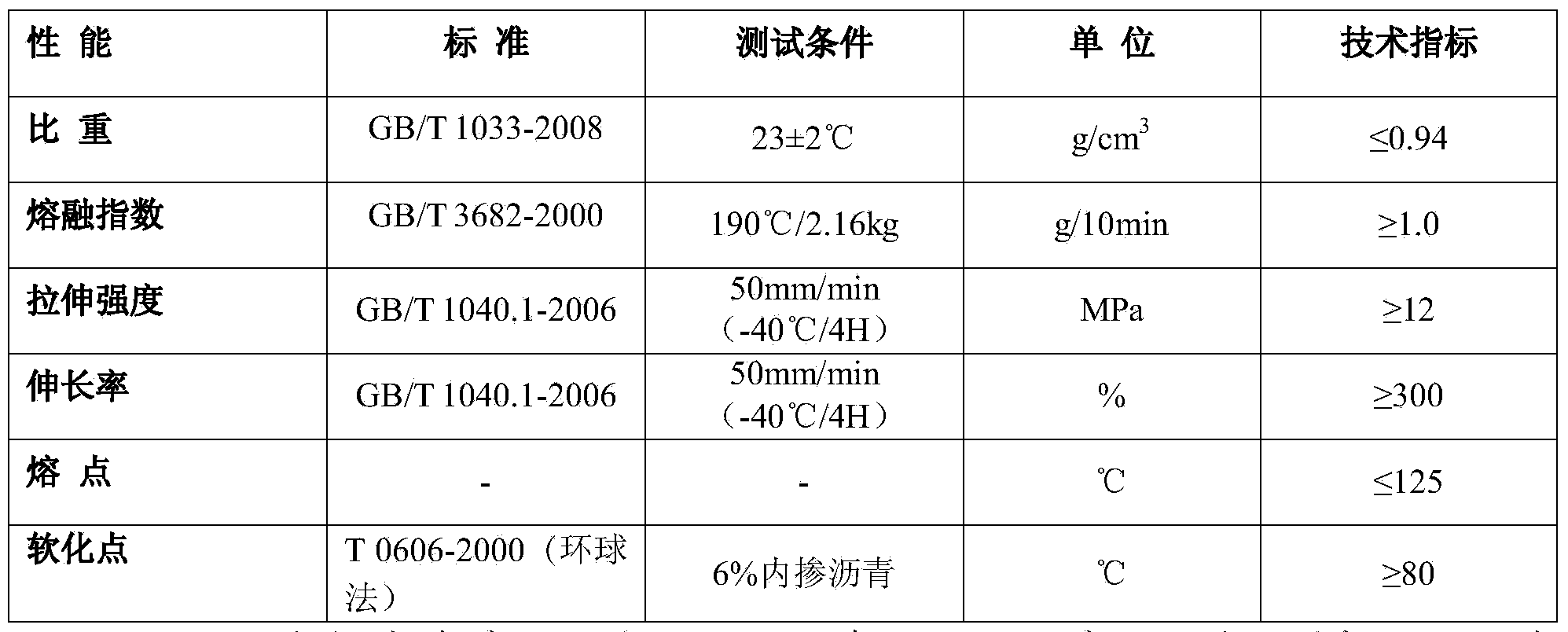

Bio-based asphalt mixture modifier, preparation method and application

ActiveCN104262752AAvoid easy segregation problemsAvoid quality problemsBuilding insulationsPolyolefinAntioxidant

The invention discloses a bio-based asphalt mixture modifier, a preparation method and an application. The method comprises steps as follows: heating a low-temperature-resistant agent to the temperature of 80-100 DEG C, and stirring a polyolefin material and the low-temperature-resistant agent at the constant speed for 1-2 min; sequentially adding antioxidants, novel bio-based filler and toner for blending, and stirring the mixture for 2-3 min at the stirring speed of 600-1000 r / min to form a mixture, wherein formula ranges of all the materials are as follows: 60-90% of the polyolefin, 10-30% of the novel bio-based filler, 0.1-0.6% of an antioxidant 01, 0.1-0.6% of an antioxidant 02, 0-10% of the low-temperature-resistant agent and 0.4-0.8% of the toner; adding the mixture into a twin-screw extruder through feeding equipment to be plasticized, sheared and molten into a uniform melt, pulling the melt into strips through a die, and shearing the strips into granules through a granulator. With the adoption of the method, needed machining processes when SBS modified asphalt is adopted are reduced, the quality problem of a pavement due to the fact that the SBS modified asphalt is separated easily is solved, and the cost is saved.

Owner:深圳市博富隆新材料科技有限公司

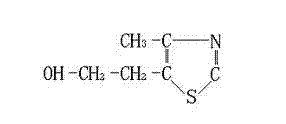

Synthesis method for 4-methyl-5-(2-ethoxyl)-thiazole

ActiveCN102584740AHigh yieldMeet market quality requirementsOrganic chemistrySynthesis methodsDistillation

The invention provides a preparation method for 4-methyl-5-(2-ethoxyl)-thiazole. The 4-methyl-5-(2-ethoxyl)-thiazole is synthesized from 2-acetylbutyrolactone serving as a raw material through amination, chloration, condensation and oxidative reaction. The preparation method comprises the following steps of: introducing chlorine into 2-acetylbutyrolactone and hydrolyzing to obtain 3-acetyl chloride propyl alcohol; introducing ammonia gas into carbon bisulfide to obtain ammonium salt; oxidizing a condensation product of 3-acetyl chloride propyl alcohol and the ammonium salt with hydrogen peroxide or oxygen to obtain a product; extracting with dichloromethane; removing the dichloromethane; then performing reduced pressure distillation; and collecting fraction at 120-127 DEG C under the pressure of 395-400 Pa. The synthesis method has the advantages of readily available raw material, low production cost, simple process, mild reaction conditions and yield of reaching up to 82 percent.

Owner:WUTONG AROMA CHEM CO LTD

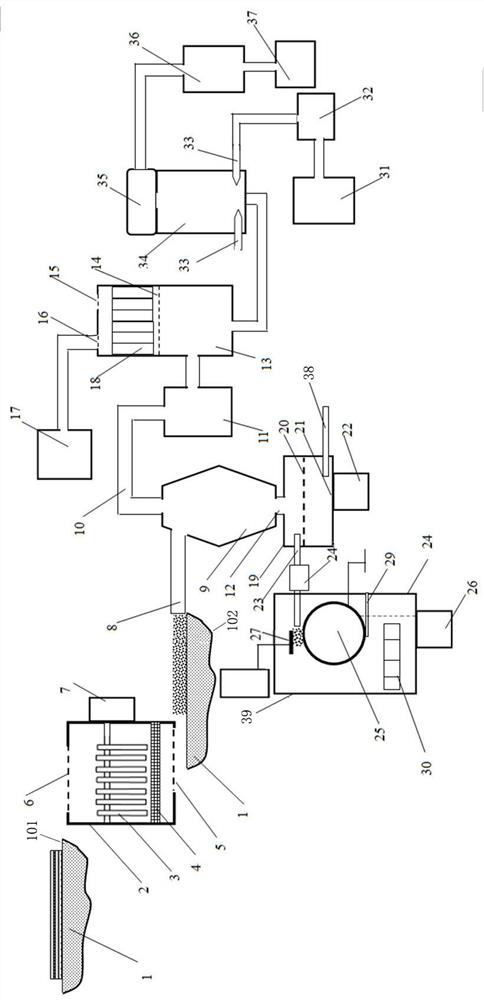

Equipment and method for crushing and sorting solar cell components

InactiveCN111790738ASolve environmental pressureSolve the repeatabilityWaste processingGlass recyclingElectrical batteryProcess engineering

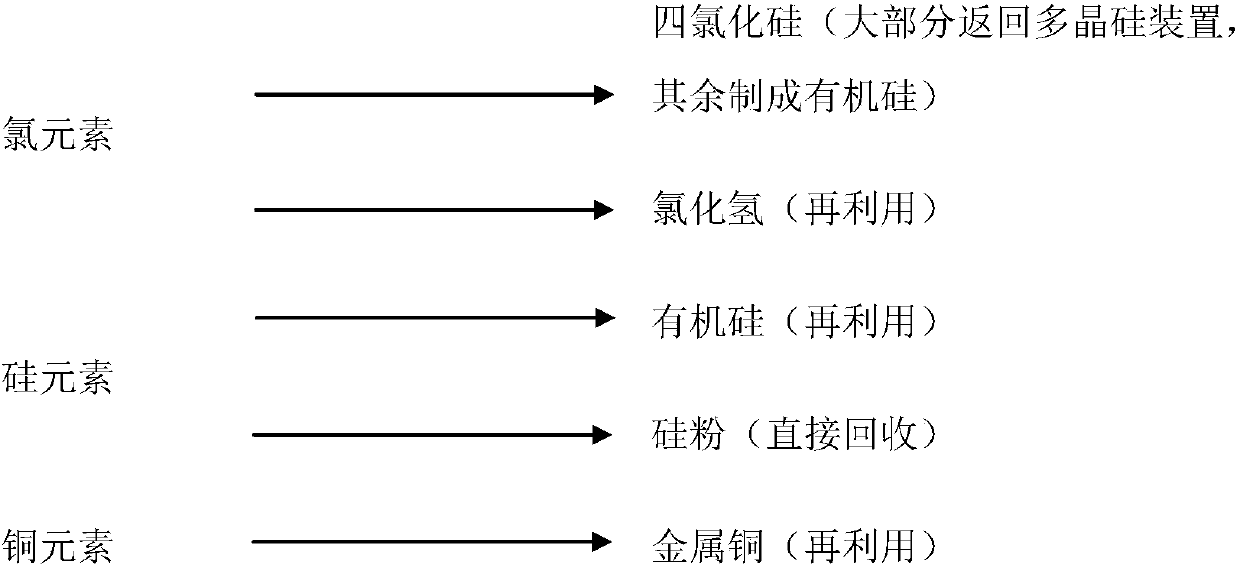

The invention provides an equipment and method for crushing and sorting solar cell components. The equipment for crushing and sorting the solar cell components comprises a hammering and splitting device, a winnowing separation device, a vibratory screening device, an electrostatic sorting device and an airflow crushing and grading device. A physical environmental protection method is adopted. Thesolar cell components, which remove aluminum frames and glass, are hammered into particle mixtures by the hammering and splitting device, and plastic particles are screened for recycling and meanwhilecopper materials such as metal solder strip particles and metal bus bar particles are screened and recycled in advance. The remaining particle mixtures are crushed into powder through the airflow crushing and grading device, so that the separation and sorting of silicon, silver, aluminum and other elements in cells is realized. The equipment has high processing speed, can automatically realize environmentally-friendly recycling of waste solar cell components, especially crystal silicon components on a larger scale, and solves the problems of environmental pressure and resource reuse caused bylarge-scale decommissioning of the solar cell components are solved.

Owner:HEBEI UNIVERSITY

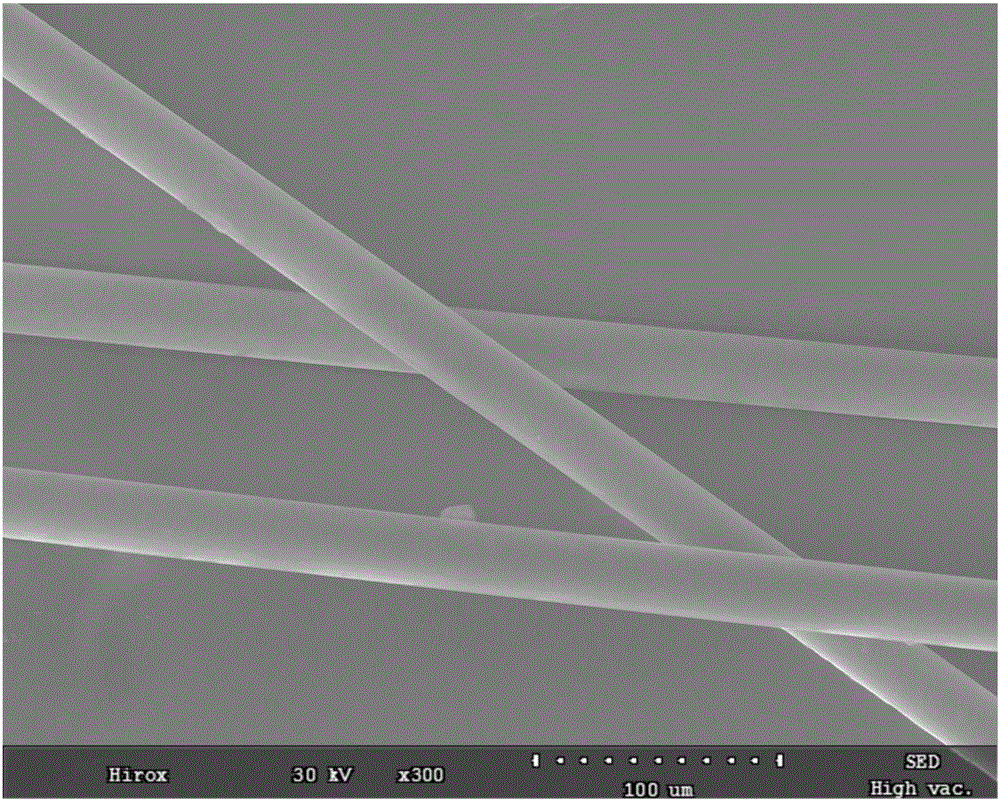

Ferromagnetic glass fiber, preparation method, and application of same

ActiveCN105906214AWith absorbing functionHigh strengthGlass making apparatusInorganic material magnetismSlagDolomite

The invention relates to a ferromagnetic glass fiber, a preparation method, and an application of the same. The glass fiber is composed of the chemical components comprising, by mass, 25-45% of Fe2O3, 20-50% of SiO2, 2-10% of Al2O3, 0-8% of B3O3, 2-15% of CaO, and 1-6% of MgO. The preparation method includes the steps of: preparing a uniformly mixed compound material from pyrite slag, quartz sands, aluminum oxide powder, boric acid, calcium carbonate and dolomite; melting, clarifying, homogenizing and cooling the compound material; and wire-drawing and drying the material. By means of the method, the industrial waste residue, pyrite slag, generated during industrial sulfuric acid production can be completely utilized in one time, so that a problem of waste residue treatment in preparation of sulfuric acid by roasting pyritic in chemical engineering is fundamentally solved, thereby achieving the targets of utilizing waste residues, improving environment and reducing production cost. The method greatly increases additional value of glass fibers and has great economic and social benefits.

Owner:QILU UNIV OF TECH

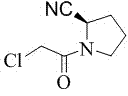

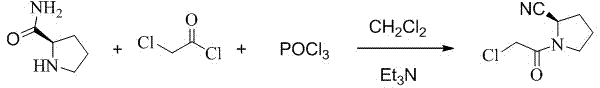

Preparation method of (S)-1-(2-chloracetyl)pyrrolidine-2-carbonitrile

ActiveCN104262227ALow raw material costShort reaction stepsOrganic chemistryDichloromethaneChemical synthesis

The invention discloses a preparation method of (S)-1-(2-chloracetyl)pyrrolidine-2-carbonitrile, which is applied to the field of chemical synthesis. The preparation method comprises the following steps of (1) dropwise adding chloracetyl chloride into a mixed solution composed of L-prolinamide, organic alkali and dichloromethane, and reacting after finishing the dropwise adding operation to obtain a reaction solution I containing 1-chloroacetylpyrrolidine-2-carboxamide; and (2) enabling the reaction solution I to react with phosphorus oxychloride serving as a dehydrating agent to obtain (S)-1-(2-chloracetyl)pyrrolidine-2-carbonitrile. In the step (1), the temperature of the mixed solution I composed of L-prolinamide, organic alkali and dichloromethane ranges from 10 DEG C below zero to 60 DEG C, the temperature of reaction carried out after the dropwise adding operation is finished ranges from 50 DEG C below zero to 10 DEG C below zero, the reaction carried out after the dropwise adding operation is finished lasts for 0.5-4h, and the molar ratio of L-prolinamide to chloracetyl chloride is 1:(1.05-1.31). The preparation method is short in reaction step and simple in operation and has the advantages that the raw material cost is low, the yield is high, the product quality is good, little environment pollution can be caused, green resources can be favorably protected, the required equipment is simple, and the dosage of the used organic solvent is low.

Owner:NORTHEAST PHARMA GRP

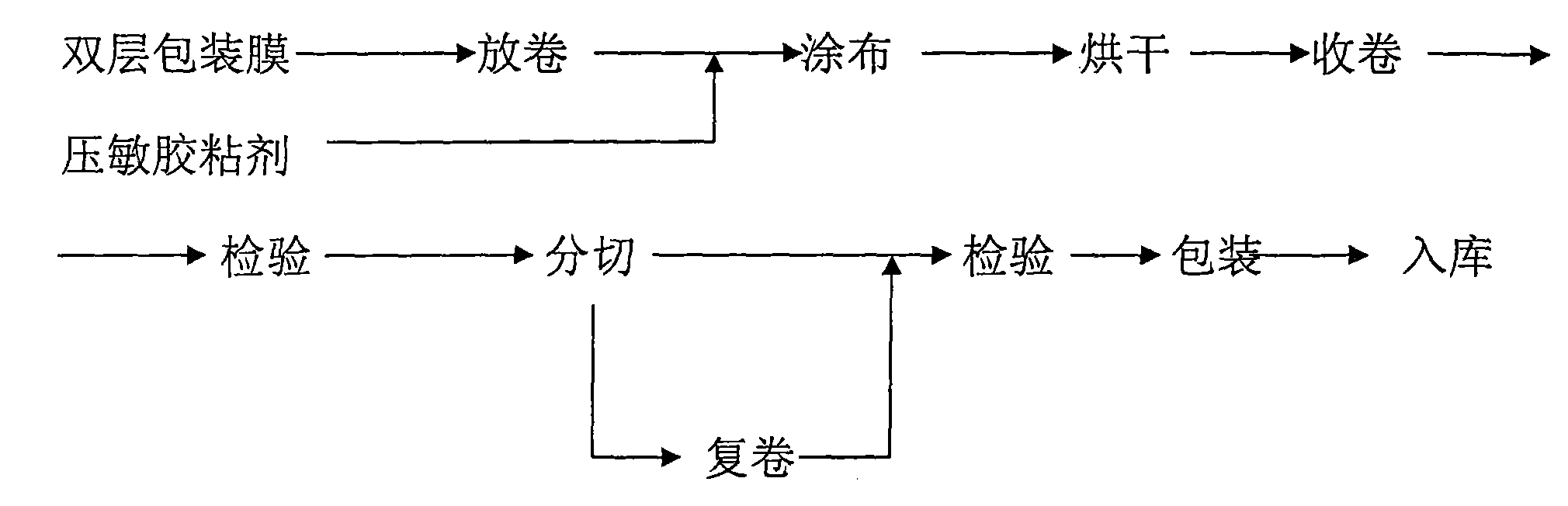

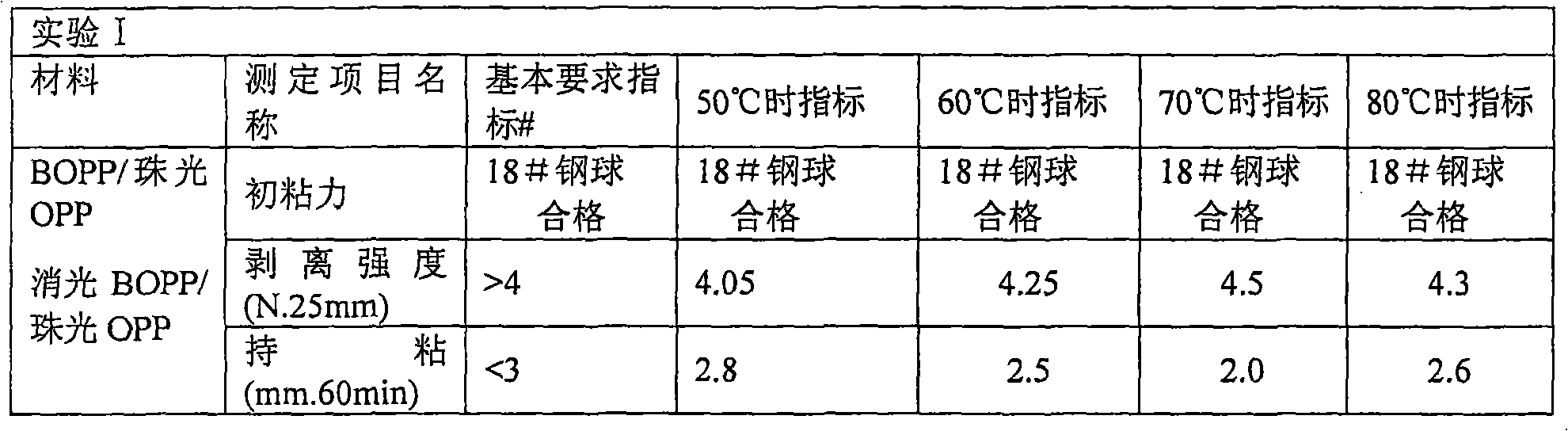

Adhesive tape for sealing boxes and manufacturing method thereof

ActiveCN101671531AReduce manufacturing costReduce financial lossFilm/foil adhesivesWrapper twisting/gatheringPressure sensitivePolypropylene

The invention provides an adhesive tape for sealing boxes. The adhesive tape is obtained by adopting a cold drink product packaging film as a substrate and coating a pressure-sensitive adhesive. The cold drink product packaging film is a composite thin film; and the inner surface of the cold drink product packaging film is a heat-sealing layer, while an outer surface is a biaxially tensioned polypropylene thin film layer and is printed with patterns and characters. The embodiment of the invention utilizes the waste composite packaging film in cold drink production, thereby effectively solvingthe problems of waste and overstocked products brought by the waste packaging film; the property of the obtained adhesive tape completely meets the application requirement; and the adhesive tape has quite significant economic benefit.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

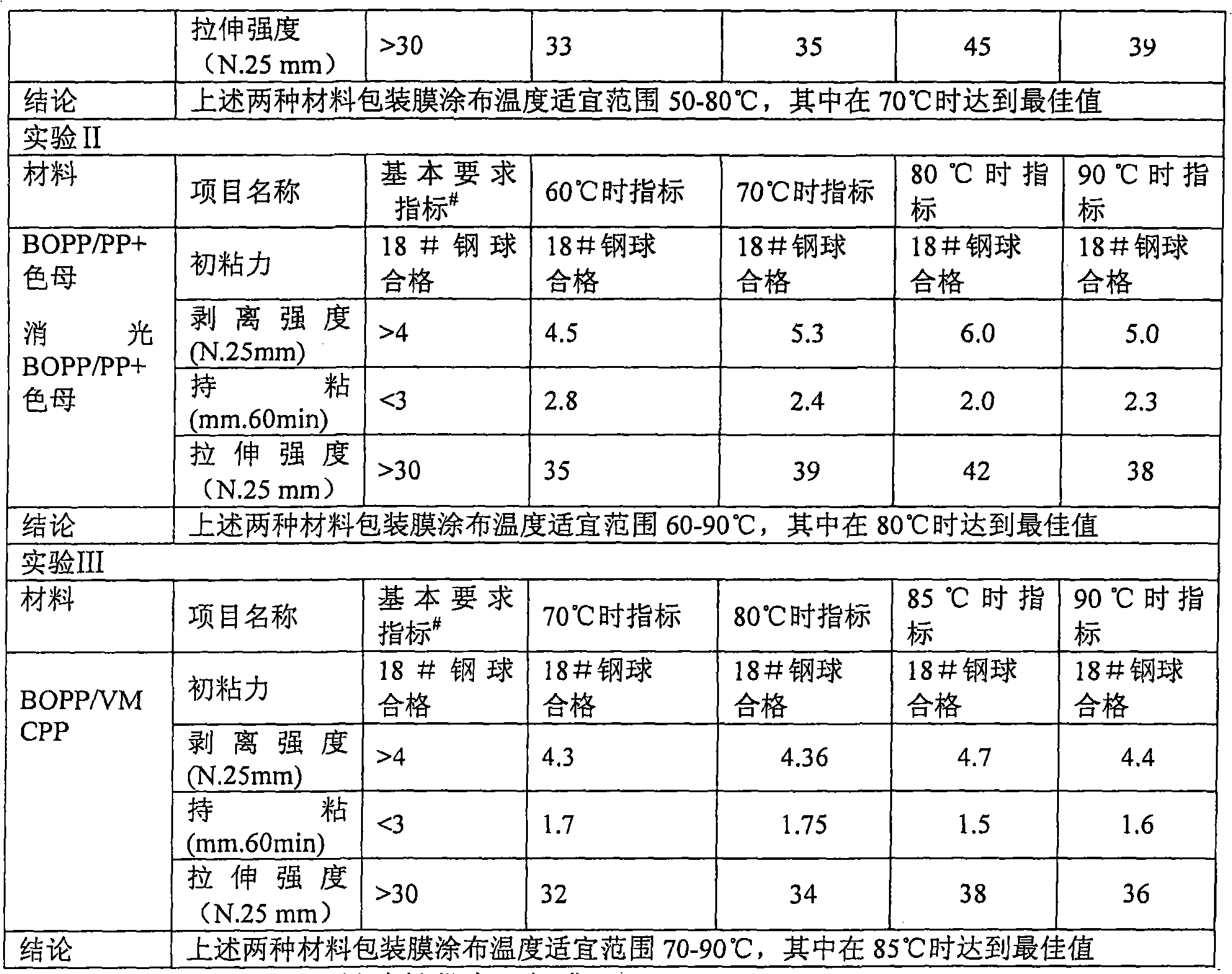

Method for preparing high-purity lithium fluoride

The invention discloses a method for preparing high-purity lithium fluoride, comprising the following steps of 1) sufficiently mixing lithium carbonate powder and hydrochloric acid for reaction to obtain a lithium chloride solution with the pH value of 6 to 7; 2) adding excessive hydrofluoric acid solutin into the lithium chloride solution obtained in the step 1) for sufficient mixing, and reacting to obtain a mixed solution containing lithium fluoride precipitate; 3) standing the mixed solution obtained in the step 2) and filtering to obtain a lithium fluoride wet solid and hydrochloric acidmother liquor; 4) washing and performing vacuum drying on the lithium fluoride wet solid obtained in the step 3) to obtain the high-purity lithium fluoride solid. According to the method provided by the invention, cheap and available hydrochloric acid is taken as an intermediate raw material for preparing lithium fluoride, lithium chloride with good water solubility is firstly prepared using hydrochloric acid and lithium carbonate, then lithium chloride is reacted with hydrogen fluoride to obtain lithium fluoride and the hydrochloric acid mother liquor, and the hydrochloric acid solution withlithium fluoride separated out is recycled to be reacted with lithium carbonate; the method has the advantages that the raw material cost is low, the process is simple, and the product conversion rateis high.

Owner:GUIZHOU INST OF TECH +1

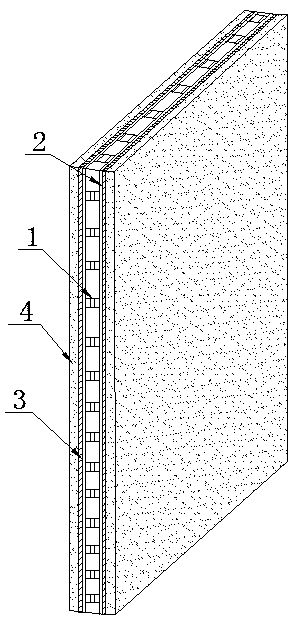

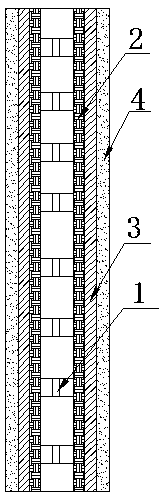

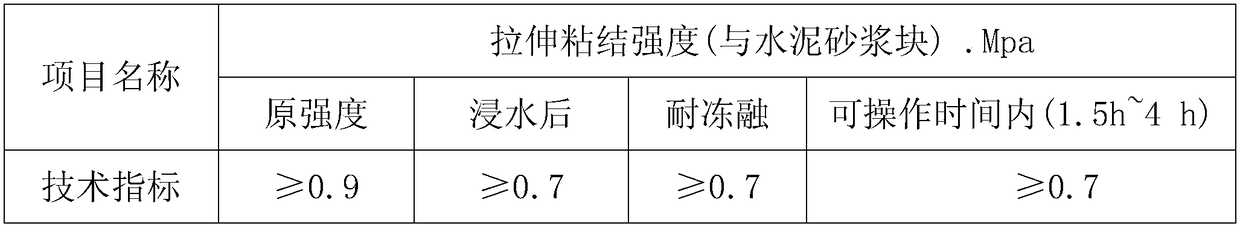

Fireproof protection and decoration integrated structure on steel member

PendingCN108775097AImprove fire performanceSimple and fast constructionWallsHeat proofingMetallurgyJoist

The invention discloses a fireproof protection and decoration integrated structure on a steel member. The fireproof protection and decoration integrated structure comprises the steel member, a steel structure interface mortar layer, a steel wire mesh and a wall spraying mortar layer, wherein the steel member is a bearing structure of a steel structure building; the steel structure interface mortarlayer is applied to the surface of a to-be-sprayed wall spraying mortar layer of the steel member; the steel wire mesh is laid on the surface of the steel structure interface mortar layer; the wall spraying mortar layer is sprayed to the surface of the steel wire mesh and wraps the steel member, the steel structure interface mortar layer and the steel wire mesh completely, and a fireproof protection and decoration integrated layer is formed. Compared with the traditional wrapping and decoration for the steel member through fireproof paint and a light-gauge steel joist system, the novel wall spraying mortar structure for the steel member has the advantages that the system is excellent in fireproof performance, good in overall performance and free of hollowing and cracking, the wall is light in mass, dense, fireproof, sound-insulating, heat-insulating, comfortable, simple and fast to construct, high in practicability and easy to popularize and use, and a construction environment is clean and tidy.

Owner:SHANGHAI KENAI NEW MATERIAL TECH CO LTD

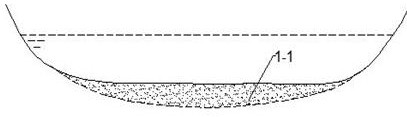

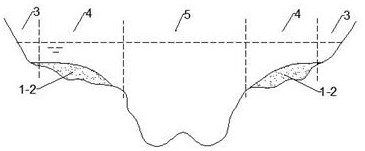

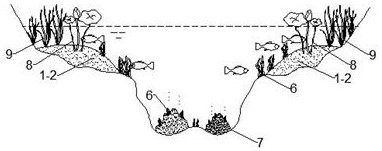

Large shallow lake deep and shallow bottom layer landform reconstruction and benign stable ecological system

PendingCN112759088AReduce disturbanceRestore self-cleaning abilityFlowers cultivationClimate change adaptationLophatherumShallow lake

The invention relates to a large shallow lake deep and shallow bottom layer landform reconstruction and benign stable ecosystem which is characterized in that bottom mud a is excavated to form a shallow water type lake deep water area, the excavated bottom mud a is buried in other areas of the lake, bottom mud b formed after the bottom mud a is conveyed is accumulated to form a shallow water area, the periphery of the shallow water area is a lakeside zone, the lakeside zone is located in a land and water interlaced zone of the shallow lake, ecological reefs are put in the deep water zone, submerged plants and ornamental lophatherum gracile are planted in the shallow water zone, and emergent aquatic plants are planted in the lakeside zone. The ecological principle is utilized, and the self-cleaning capacity of the shallow lake is restored by reconstructing deep and shallow bottom layer landforms, constructing a biocenosis structure of a damaged water body ecological system and restoring biodiversity, so that the virtuous circle of self-maintenance and self-succession of the ecological system is realized.

Owner:华川技术有限公司

Method for treating steel slag

InactiveCN110129492ARealize resource utilizationHigh value-added utilizationRecycling and recovery technologiesProcess efficiency improvementEnvironmental resistanceLiquid state

The invention relates to a method for treating steel slag, and belongs to the technical field of steel slag treatment. The method comprises the following steps that 1, liquid-state converter steel slag is discharged, and operation of slag splashing for converter protection is conducted; 2, reduction smelting is conducted on the liquid-state steel slag obtained in the step 1, slag discharging is conducted, reduced slag is obtained, iron discharging is conducted, reduced molten iron is obtained, and the reduced slag is recycled; 3, the reduced molten iron obtained in the step 2 is subjected to desulfuration and / or desilicication and / or dephosphorization operation, purified molten iron and slag are obtained, and the purified molten iron is smelted and then recycled; 4, the slag obtained in the step 3 is cooled with water and then filtered, filtrate and filter residues are obtained, and the filter residues are dried, smelted and recycled; 5, acid is added into the filtrate obtained in thestep 4 till the PH is neutral, precipitates and gas are produced, the precipitates are filtered and recycled, and filtrate obtained through filtering is retained for use; and 6, the gas and the filtrate which are obtained in the step 5 are treated through a FeCl3 solution. The method for treating the steel slag has the characteristics of being high in efficiency and environmentally friendly.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

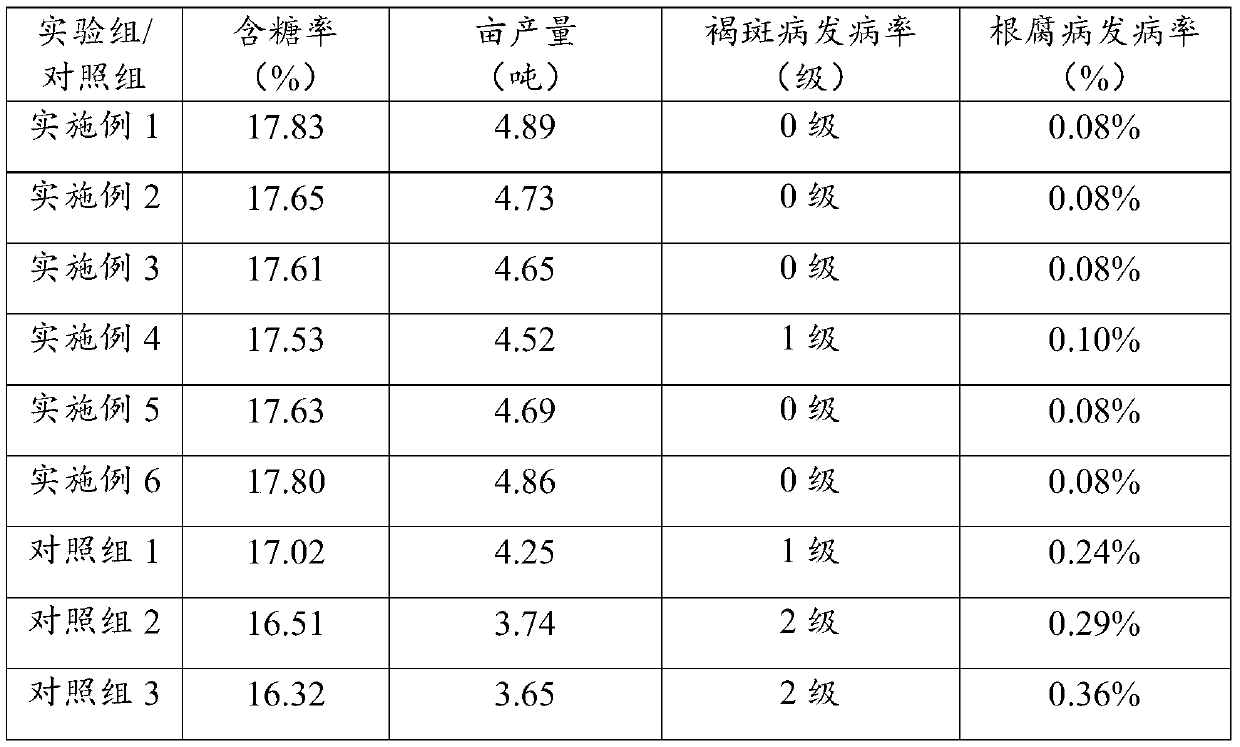

Special beet liquid fertilizer prepared from yeast concentrate

PendingCN110054516ALow COD valueHigh in sugarBio-organic fraction processingAlkali orthophosphate fertiliserPhosphateChelated zinc

The invention provides a special beet liquid fertilizer prepared from yeast concentrate. The special beet liquid fertilizer is prepared by a method including the steps: (1) adding sulfuric acid solution into the yeast concentrate and performing stirring reaction to obtain first reaction liquid; (2) performing aeration treatment on the first reaction liquid to obtain second reaction liquid; (3) naturally precipitating the second reaction liquid by standing to obtain precipitates and suspension liquid; (4) dissolving the suspension liquid, fulvic acid, urea, potassium sulphate, monoammonium phosphate, monopotassium phosphate, borax, chelated zinc, ammonium molybdate and synergists in water to obtain the liquid fertilizer. The yeast concentrate is prepared into the special suitable for beet growth, the problem of water environment pollution caused by the yeast concentrate is solved, the requirements of beets for nutrients in all growth periods can be met, and the nutrients taken away by the beets in the growth process are returned to lands. Moreover, waste can be comprehensively used and turned into wealth, and the environmental protection pressure of enterprises is relieved.

Owner:内蒙古佰惠生新农业科技股份有限公司 +1

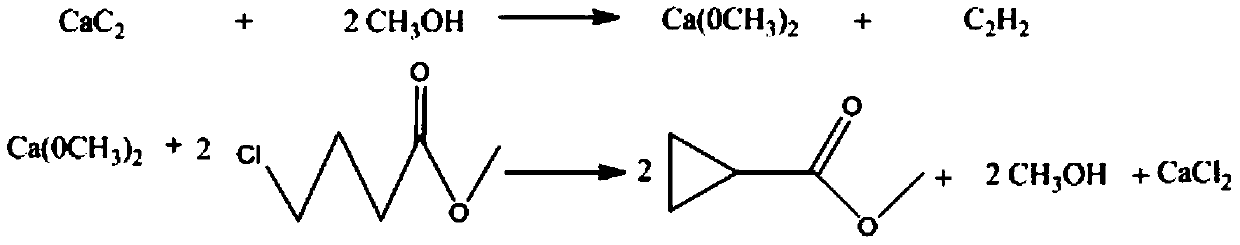

A kind of preparation method of cyclopropylamine intermediate methyl cyclopropanate

ActiveCN107673973BLow costOmit strong baseOrganic compound preparationCarboxylic acid esters preparationButyrateDistillation

The invention discloses a method for preparing cyclopropylamine midbody cyclopropanecarboxylic acid methyl ester. First in a sealed reaction kettle, methanol is added dropwise into calcium carbide, togenerate calcium methoxide and acetylene; gamma-chloro methyl butyrate is added into calcium methoxide at 60-120 DEG C, the temperature is controlled to be constant in the reaction process, methanolgenerated in the process is collected, and the cyclopropanecarboxylic acid methyl ester is obtained through distillation. The method is simple in process, types of raw materials necessary for production are fewer, some of the raw materials can be reused, the yield is high, the quality is good, and the method is safe and environmentally friendly.

Owner:SHANDONG GUOBANG PHARMA

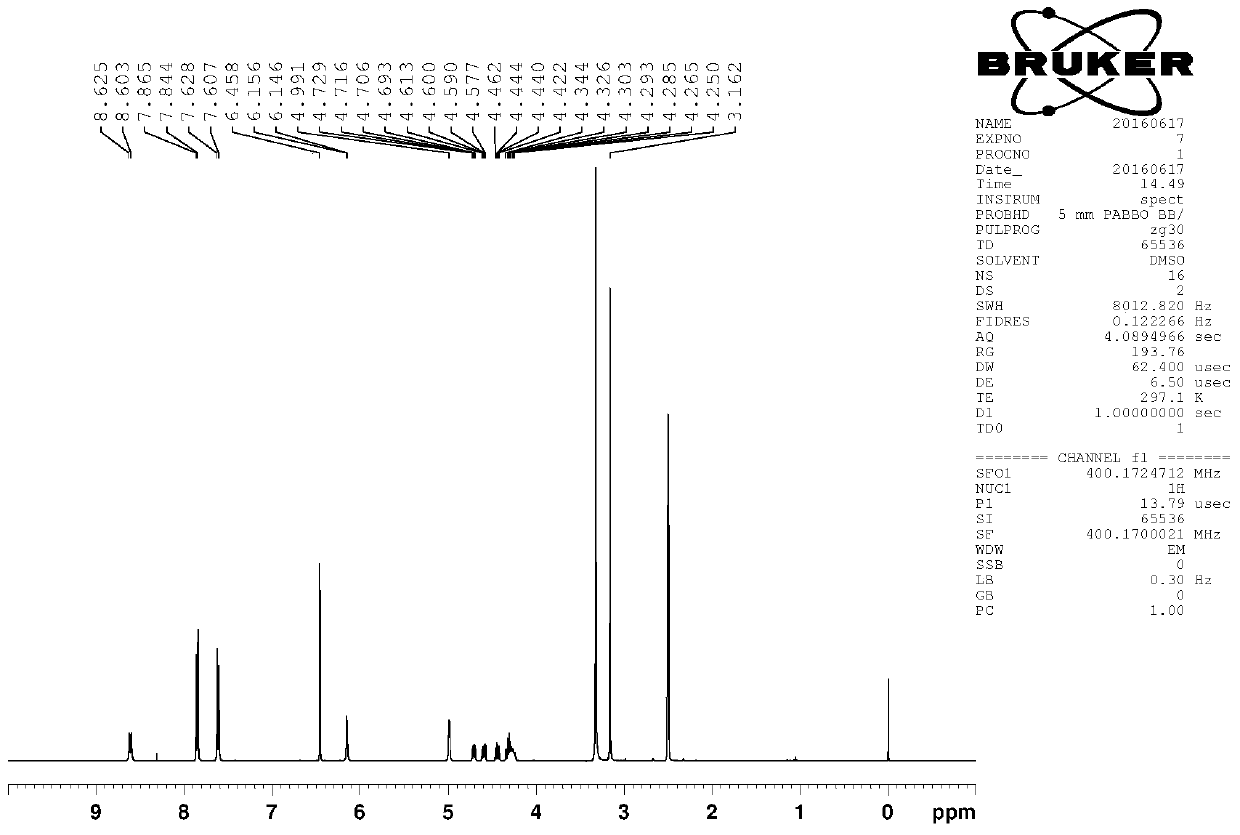

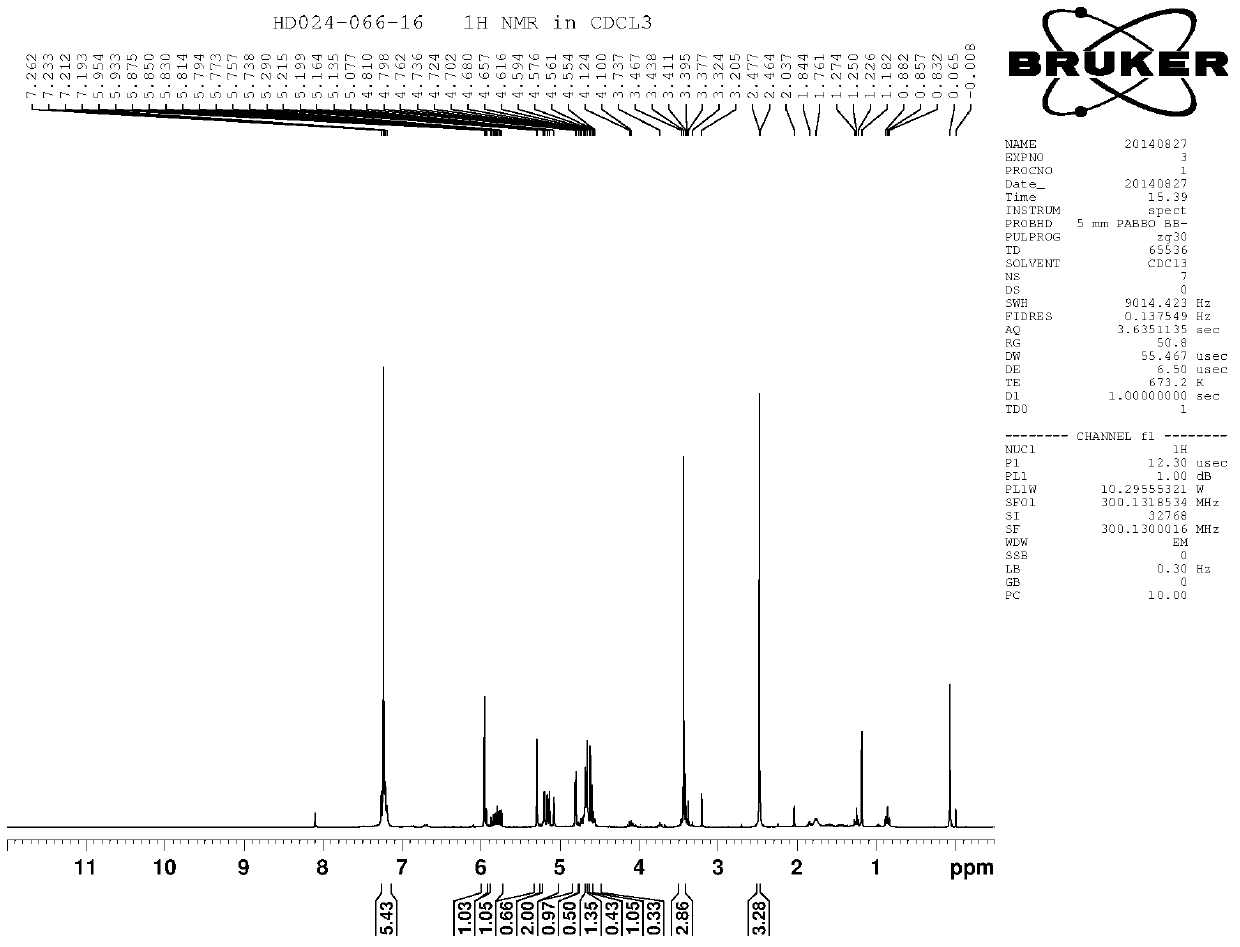

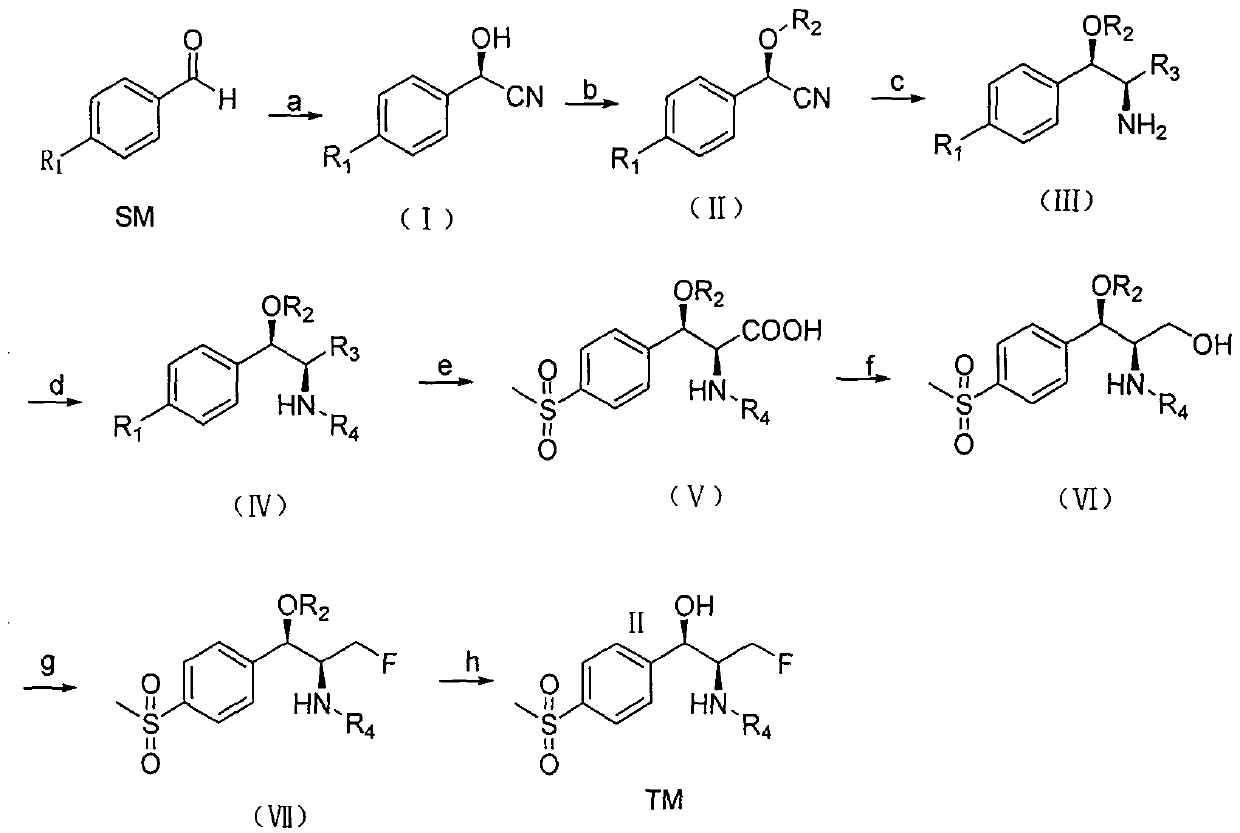

A kind of Florfenicol intermediate, its preparation method and the preparation method of Florfenicol

ActiveCN106187837BSimple chemical reactionLow costGroup 4/14 element organic compoundsOrganic compound preparationMethiodideTert-Butyloxycarbonyl protecting group

The invention discloses a florfenicol midbody, a preparation method thereof and a preparation method of florfenicol, and belongs to the field of veterinary drug preparation. The invention provides the florfenicol midbody shown in a formula IV, wherein R1 is dimethyl sulfide or methylene sulphonyl or methyl sulphonyl, R2 is TBS- or TMS- or MOM- or THP-, R3 is shown in the description, and R4 is dichloroacetyl or benzoyl or t-butyloxycarboryl. The invention further provides a preparation of the florfenicol midbody shown in the formula IV and a preparation method of florfenicol. The obtained florfenicol is low in cost, simple in technology and high in yield, and the product chirality purity reaches up to 98%.

Owner:HEADING NANJING PHARMTECH CO LTD

Device and method for crushing and sorting solar cell modules

InactiveCN112058872AProcessing speedAchieve separationWaste processingTransportation and packagingCrystalline siliconMechanical engineering

The invention provides a device and a method for crushing and sorting solar cell modules. The device comprises a shearing device, a grinding device, a winnowing separation device, a vibration screening device and an airflow crushing and grading device. According to the device and the method for crushing and sorting the solar cell modules, a physical environment-friendly method is adopted, the solar cell modules with aluminum frames and the glass removed are cut into fragments through the shearing device, the fragments are ground into a particle mixture through the grinding device, and then plastic particles in the particle mixture are sorted out and collected through the winnowing separation device and the vibration screening device. Battery piece particles are crushed into powder throughthe airflow crushing and grading device, separation and sorting of silicon, silver, aluminum, copper and other elements in battery pieces are achieved, the separation purity of the silicon, silver, aluminum, copper and other elements is high, the treatment speed is high, environment-friendly recycling of waste solar cell modules, especially crystalline silicon modules, can be automatically achieved on a large scale, and the problem of environmental pressure and resource reutilization caused by large-scale retirement of the solar cell modules is solved.

Owner:HEBEI UNIVERSITY

Tea saponin shampoo and preparation method thereof

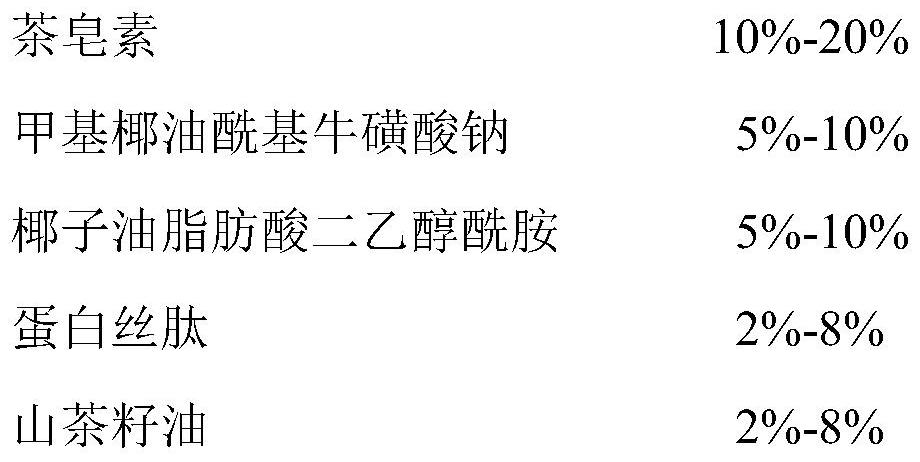

PendingCN111686040AImprove surface activityRelieves itchingCosmetic preparationsHair cosmeticsBiotechnologyNaturally occurring surfactants

The invention discloses tea saponin shampoo and a preparation method thereof. The shampoo takes a natural surfactant tea saponin as a main surfactant, and the tea saponin has good emulsifying, dispersing, wetting and foaming capacities, and has physiological activities of removing dandruff, resisting bacteria, relieving itching and the like. A micelle co-dissolution technology is adopted, a micromolecular amphiphilic surfactant is compounded to serve as a micelle inducer, macromolecular micelles are converted into micromolecular micelles, and the defects that the surfactant is prone to remaining and not easy to wash are overcome; and on the basis of the physiological activities of the tea saponin, camellia oil, a rosemary extracting solution, a cacumen biotae extracting solution, a white willow bark extracting solution, a chamomile extracting solution, a gentian extracting solution, a witch hazel extracting solution, octacosanol, squalene and other naturally extracted effective functional components are added to prepare the shampoo which is green and natural, has the effects of killing bacteria, relieving itching and removing dandruff, and has excellent conditioning performance onhair and scalp.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

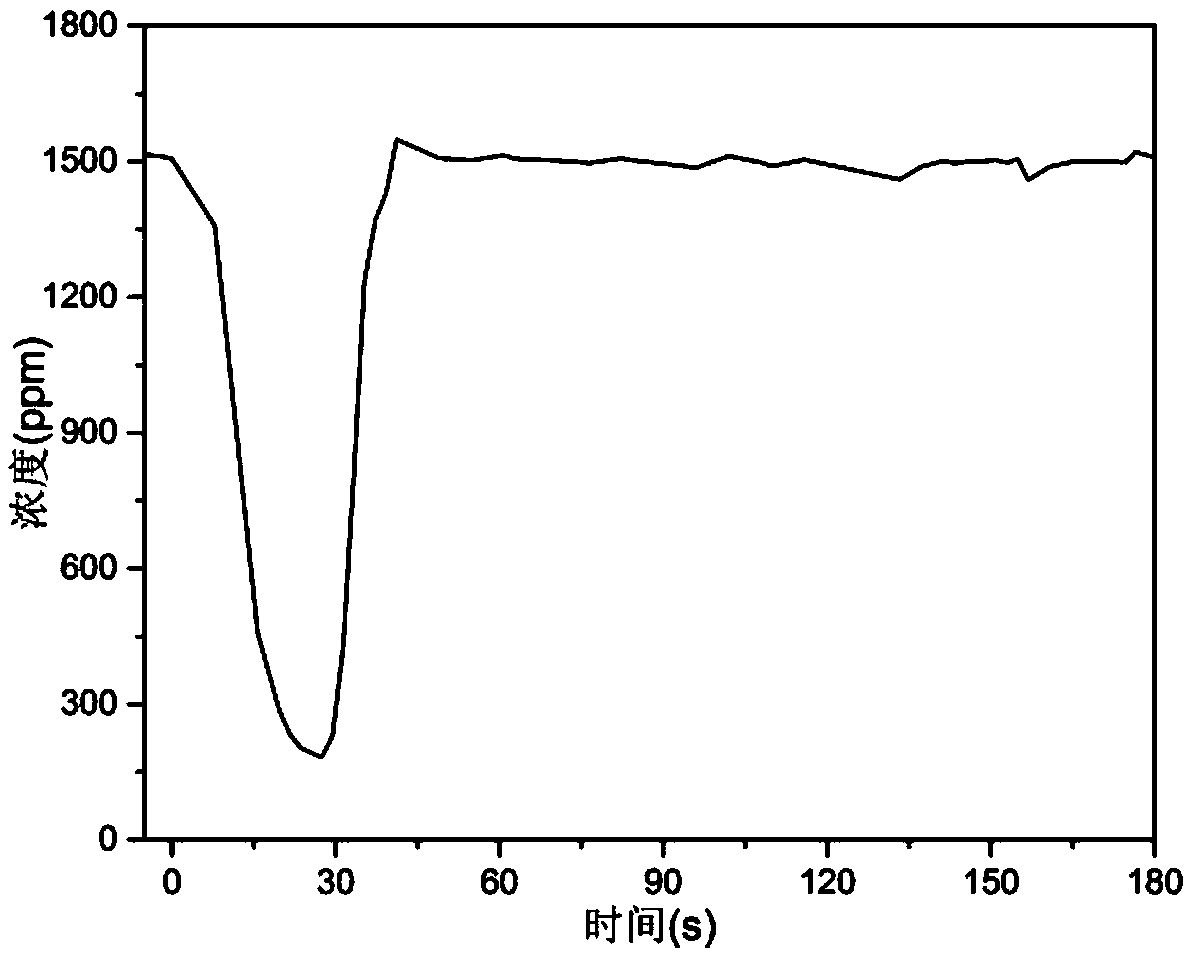

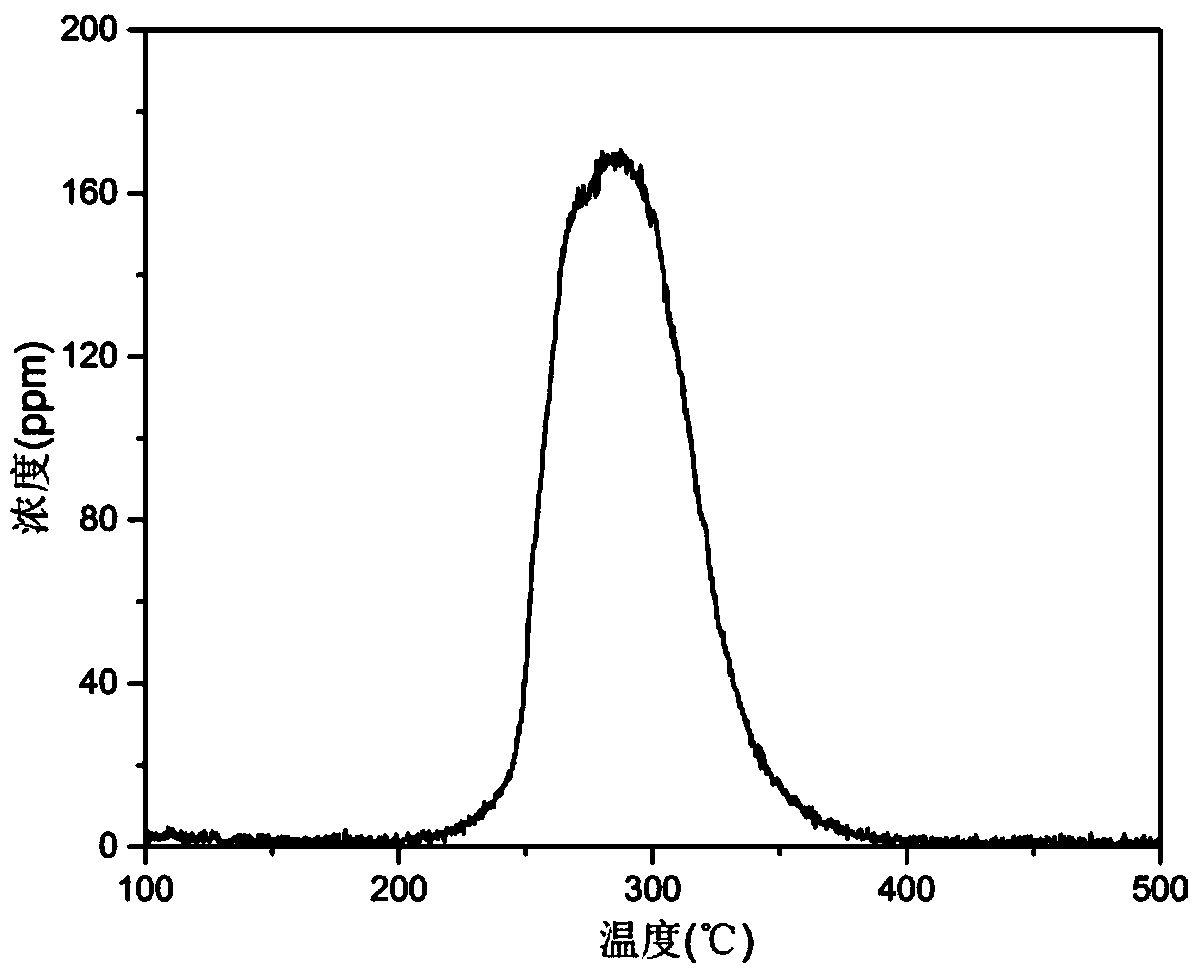

Method for eliminating and recycling nitric oxide in combustion tail gas

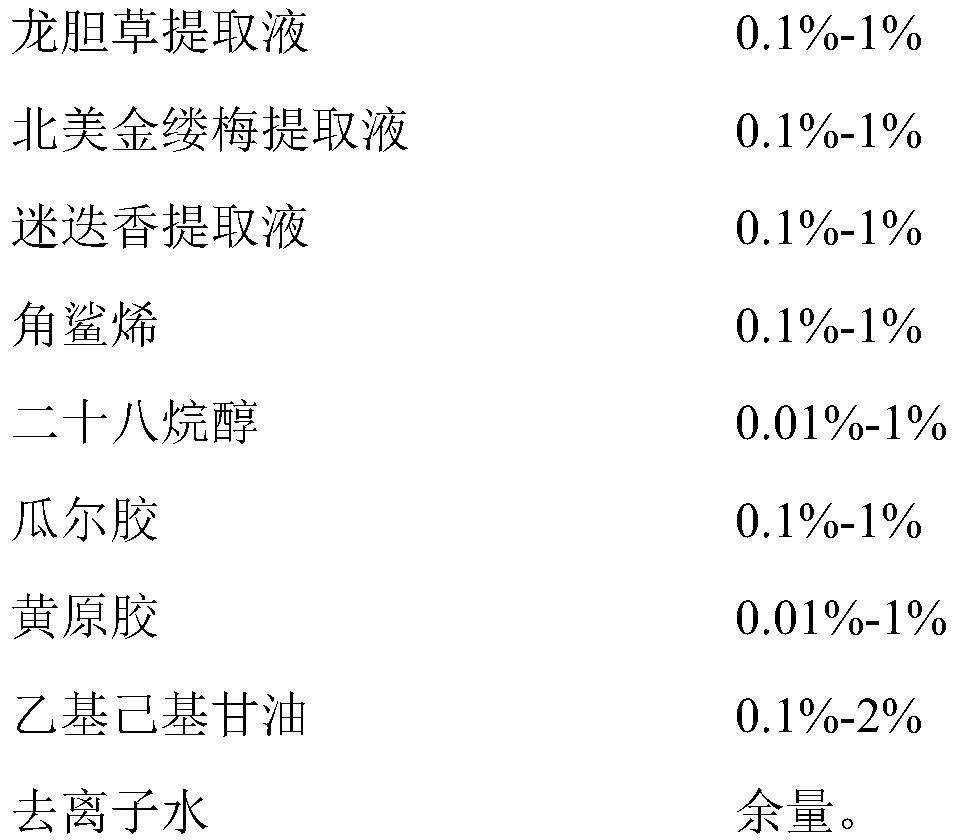

ActiveCN109621627ARealize pollution dischargeLow costGas treatmentDispersed particle separationCombustion chamberSorbent

The invention relates to a method for eliminating and recycling nitric oxide in combustion tail gas. The method includes the following steps that A, the combustion tail gas containing the nitric oxideand an adsorbing agent make contact with each other under the temperature smaller than 150 DEG C to adsorb the nitric oxide in the combustion tail gas, wherein the adsorbing agent comprises active components loaded onto a molecular sieve carrier, the active components comprise precious metal, rare earth metal or transition metal, and by elementary content, the active components account for 0.1-20wt% of the total mass of the adsorbing agent; B, high-temperature air which has the temperature larger than 125 DEG C is injected into the adsorbing agent so that the adsorbed nitric oxide can be desorbed and conveyed into a combustion room along with the high-temperature air to be used as combustion-assisting air. The method is suitable for all kinds of fire coal, fuel gas, oil burning boilers and automobile engines, NOx pollution is eliminated, NOx is also used as a combustion-assisting oxidant, and recycling of contaminants is realized.

Owner:TIANJIN UNIV

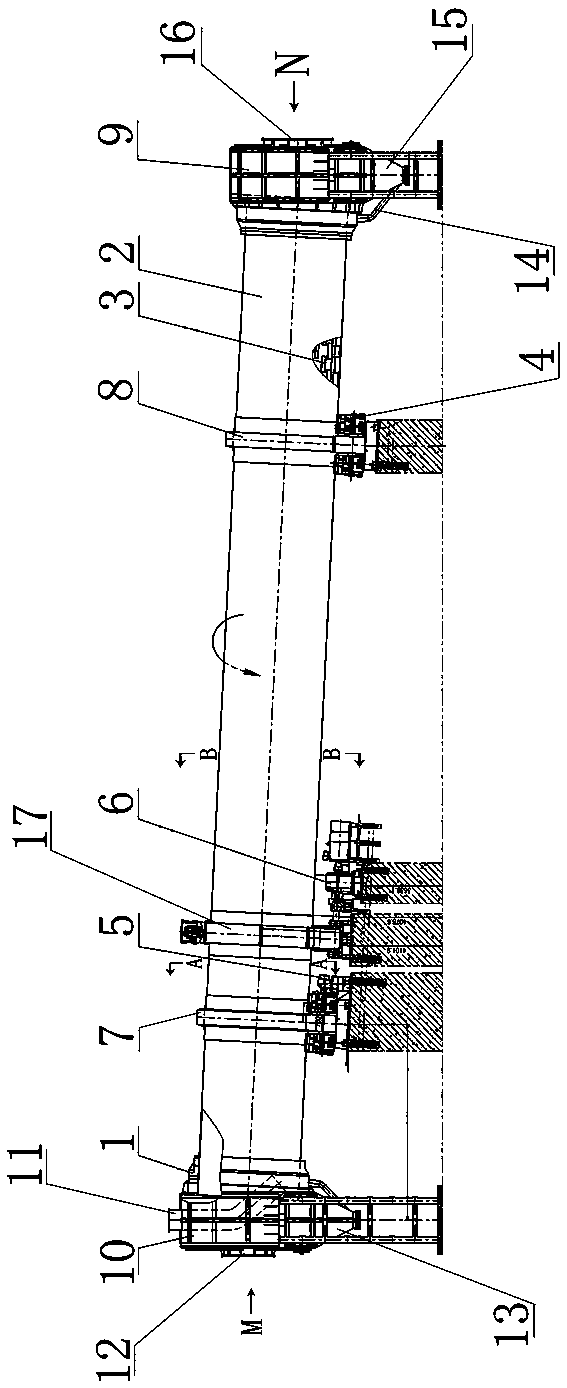

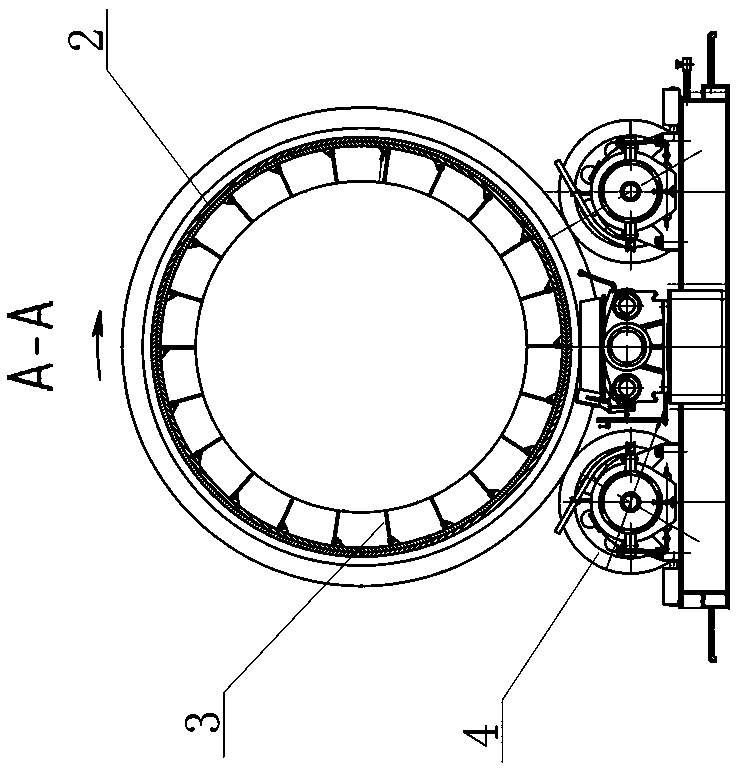

Dry kiln interior desulfurizer for smelting ferronickel through RKEF method

PendingCN107746973AKeep dryImprove desulfurization effectRotary drum furnacesMechanical engineeringMaterials science

The invention discloses a dry kiln interior desulfurizer for smelting ferronickel through an RKEF method. The dry kiln interior desulfurizer comprises a cylinder internally provided with a lifting board. The cylinder is oblique, and the front end of the cylinder is lower than the rear end of the cylinder. An air inlet and an air outlet are formed in the front end and the rear end of the cylinder.The front end and the rear end of the cylinder are rotationally connected with a kiln head cover and a kiln tail cover correspondingly. A feeding pipe is arranged on the top of the kiln head cover, and an ash unloading hopper is arranged at the bottom of the kiln head cover. A discharging hopper is arranged on the kiln tail cover. Rolling rings are arranged at the front portion and the rear portion of the cylinder correspondingly and rotationally connected with supporting wheels. A rotation tooth disk is arranged at the outer diameter position of the middle portion of the cylinder. Materials enter the cylinder from the position of the feeding pipe, a desulfurizing agent and sulfur oxides are subjected to the sufficient reaction till the purpose of desulfuration is achieved, and desulfurized materials are discharged out of the position of the discharging hopper. The lifting board in the cylinder sufficiently raises materials, and the reaction effect is improved. Purified gas enters thecylinder from the position of the air inlet, high-temperature heat is provided for the interior of the cylinder, and the material drying and desulfuration effects are promoted.

Owner:临沂鑫海新型材料有限公司

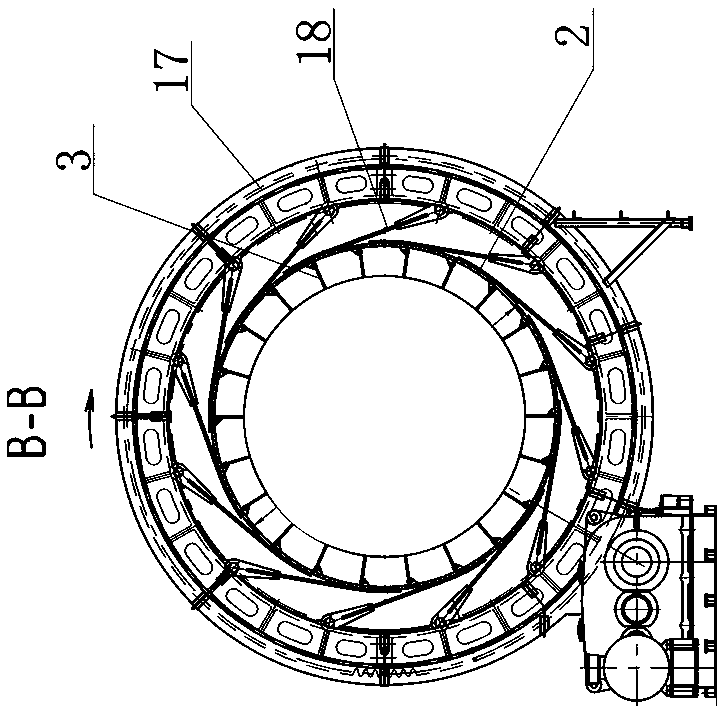

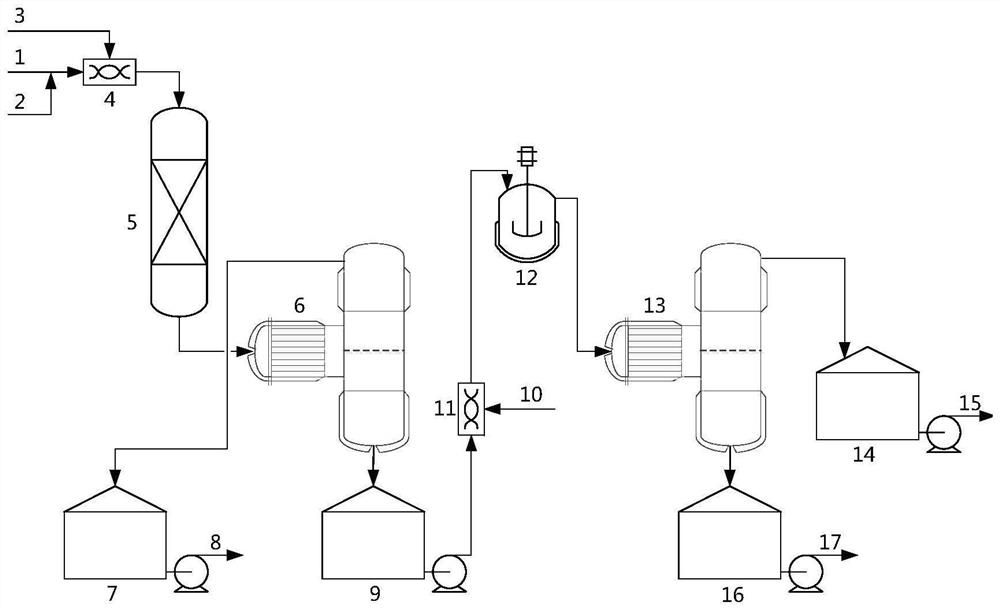

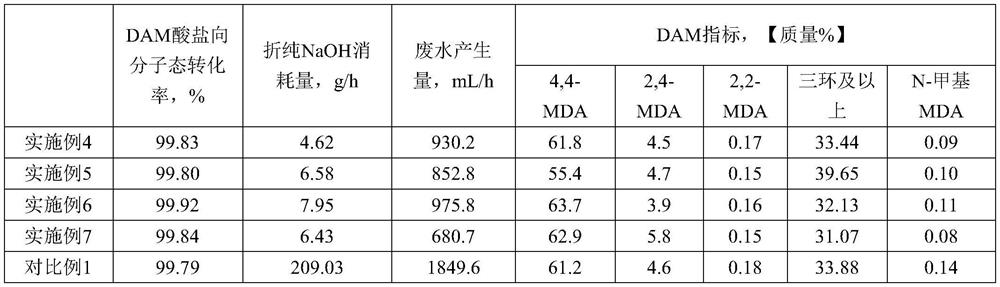

Catalyst for catalyzing amine salt conversion, preparation method of the catalyst and preparation method of DAM

ActiveCN111905753ALimit migrationAvoid reunionAmino compound purification/separationOrganic compound preparationDiphenylmethaneChromium sesquioxide

The invention relates to a catalyst for catalyzing amine salt conversion and a preparation method thereof, and a preparation method of DAM. The catalyst comprises a carrier and active components whichcomprise following four components: praseodymium oxide, cuprous oxide, chromium sesquioxide and tin oxide. The preparation method of the DAM comprises the following steps: (a) mixing aniline acid salt with a formaldehyde solution and performing a condensation reaction; (b) transferring H<+> in salified-state amino groups on diphenylmethane series diamine and polyamine in the reaction solution prepared in the step (a) to amino groups of aniline existing in a molecular form in the reaction solution prepared in the step (a) by adopting the catalyst, so that the diamine and the polyamine in the reaction solution are converted into the molecular form; and (c) carrying out phase splitting on the reaction liquid obtained in the step (b). According to the method disclosed by the invention, the manufacturing cost of diphenylmethane series diamine and polyamine (DAM) and the yield of effluent brine are remarkably reduced, and meanwhile, the stable quality of the DAM is ensured.

Owner:WANHUA CHEM GRP CO LTD +1

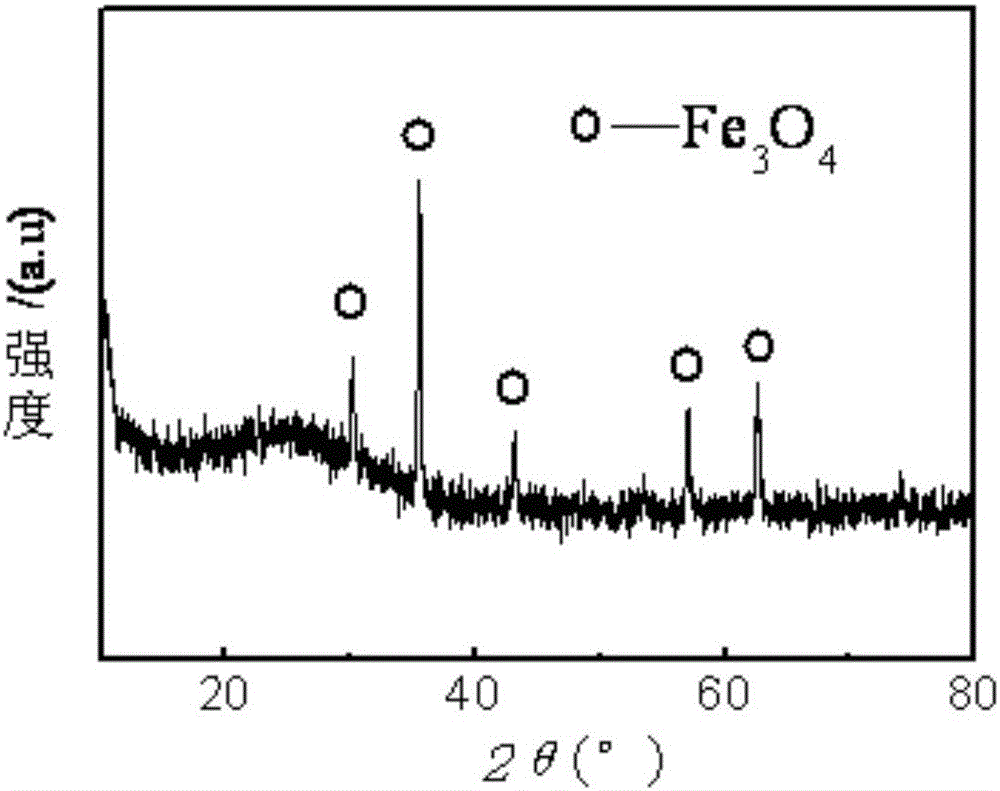

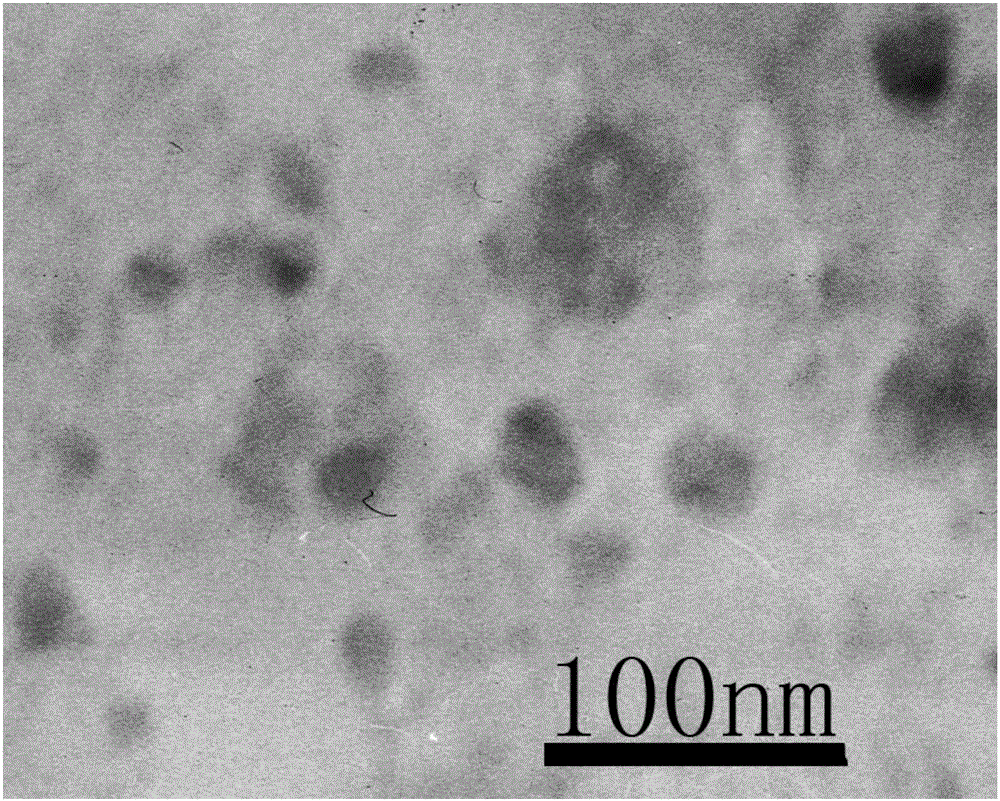

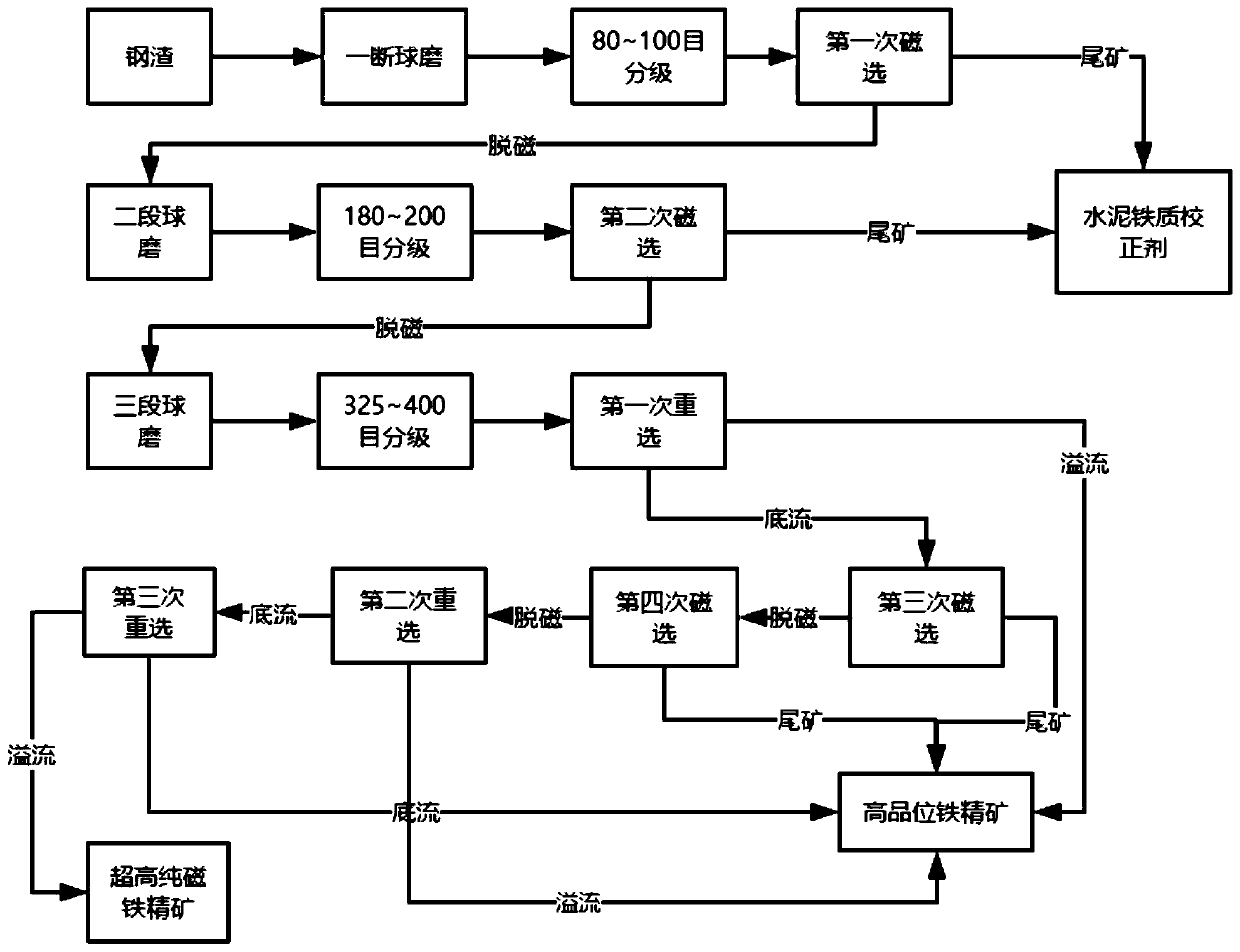

Steel slag selecting method

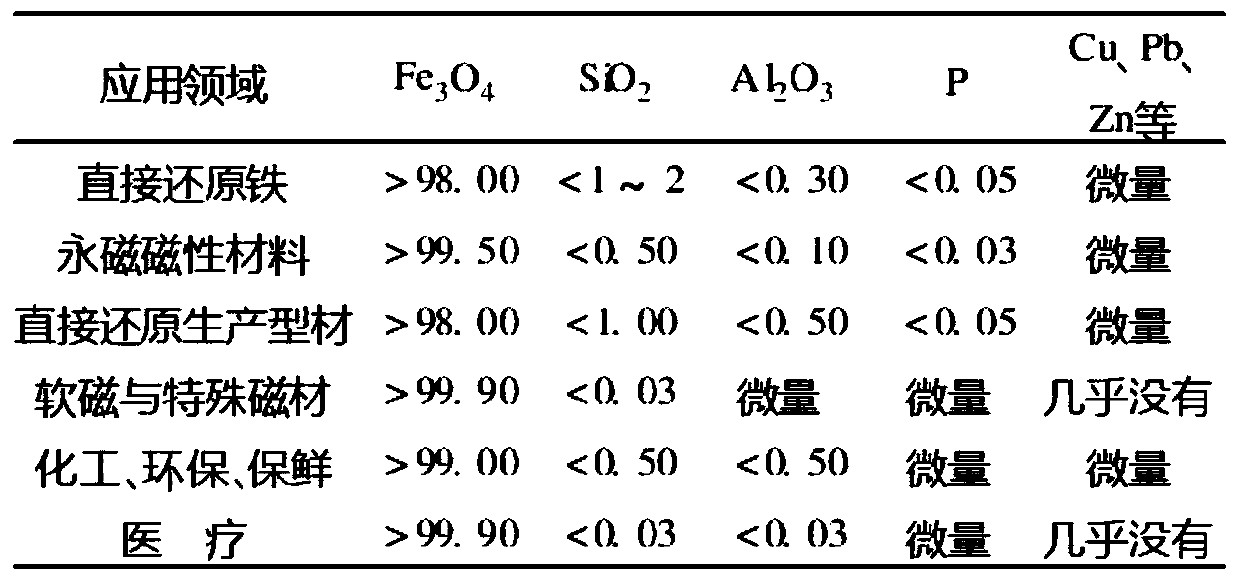

InactiveCN110216009AImprove protectionSolve environmental pressureSolid separationMechanical material recoverySlagEconomic benefits

The invention discloses a steel slag selecting method. The steel slag selecting method is characterized by comprising the following steps that S1, primary magnetic separation is carried out after steel slag is subjected to primary ball milling until the particle size of the steel slag is 80-100 meshes, and a primary magnetic separation concentrate and tailings are obtained for later use; S2, demagnetic treatment is carried out on the primary magnetic separation concentrate, secondary ball milling is carried out on the demagnetized primary magnetic separation concentrate until the particle sizeis 180-200 meshes, and secondary magnetic separation is carried out on the concentrate subjected to ball milling to obtain secondary magnetic separation concentrate and tailings for later use; and S3, demagnetic treatment is carried out on the secondary magnetic separation concentrate, then three-section ball milling and multiple times of magnetic separation and reselection treatment are carriedout on the demagnetized concentrate to obtain an ultrahigh-purity magnetite concentrate and a high-grade iron ore concentrate. The steel slag selecting method is mainly used for selecting the ultrahigh-purity magnetite concentrate from the steel slag, belongs to a pure physical method, does not use a chemical agent in the production process, and is green and environment-friendly; and the production cost is 35% of the production cost of a traditional chemical method for producing the ultrahigh-purity magnetite concentrate, and the method has remarkable economic benefits and market popularization values.

Owner:周涛 +2

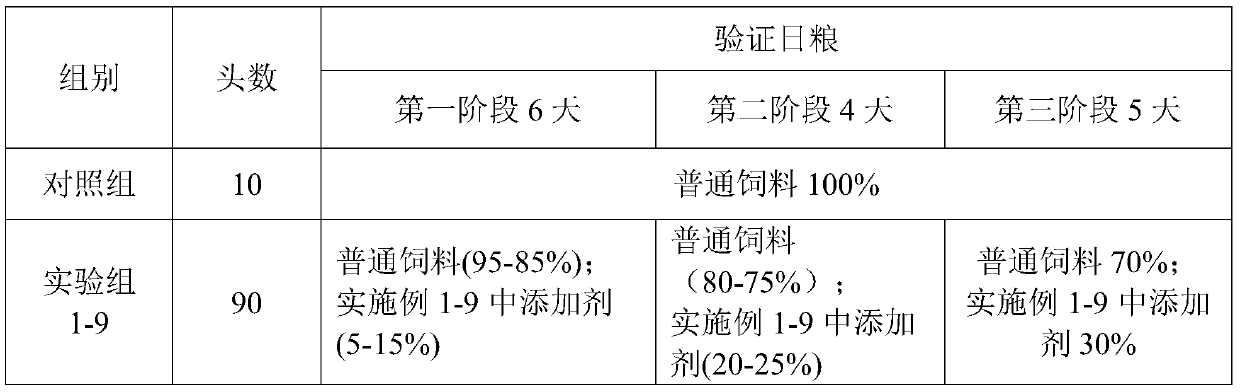

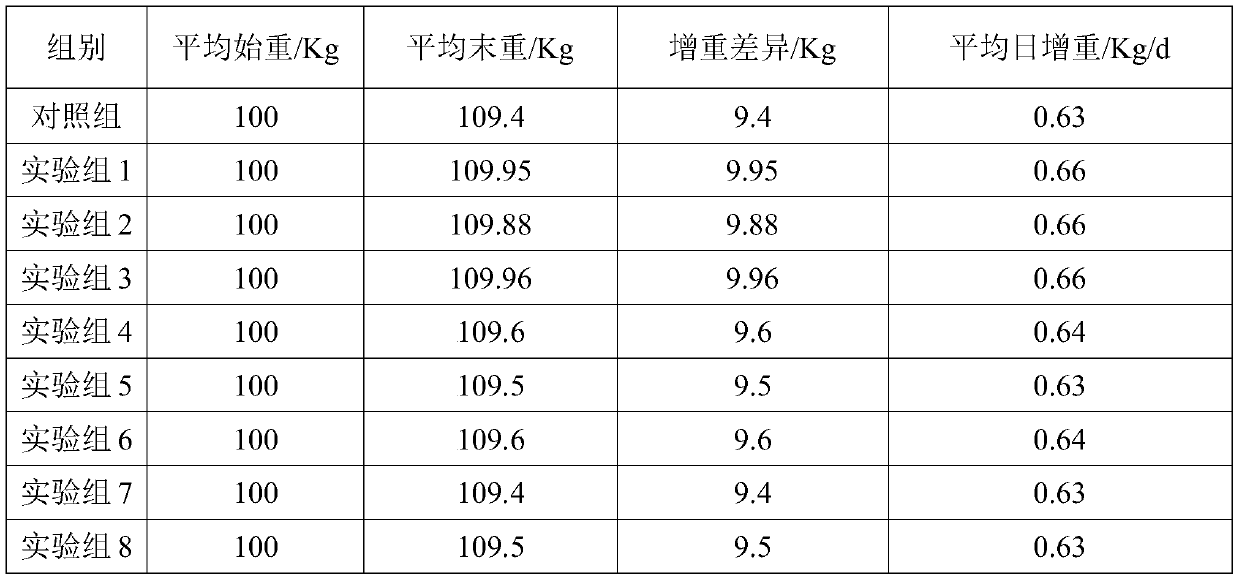

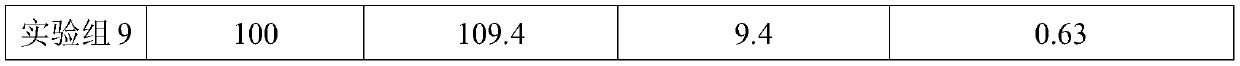

Pig feed additive and preparation method and application thereof

InactiveCN110150488AGood effectEnsure balanceFood processingAnimal feeding stuffWeight gainingAnimal science

The invention relates to a pig feed additive and a preparation method and application thereof. The preparation method comprises the steps that co-culture is performed on mixed flora to obtain a fermentation inoculant, cornstalk is preprocessed to obtain a standard ferment, finally, the fermentation inoculant, the standard ferment and fermentation auxiliary materials are mixed, facultative anaerobic fermentation is performed, and the pig feed additive is obtained. The prepared additive can partially replace full-value feed, and therefore the cultivation cost is lowered; the animal intestinal flora can be maintained to be balanced, and the diarrhea rate is lowered; the animal immunity can be improved, resistance can be enhanced, the animal survival slaughtering rate is increased, and excessive use of antibiotic is avoided; weight gaining of animals can be promoted, the metabolism way and the fatty acid structure of animal fat are changed, and the pork quality is improved; the air qualityof the feeding environment is improved, and the environment protection pressure of the breeding industry is solved; the safety food can be traced truly.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI +2

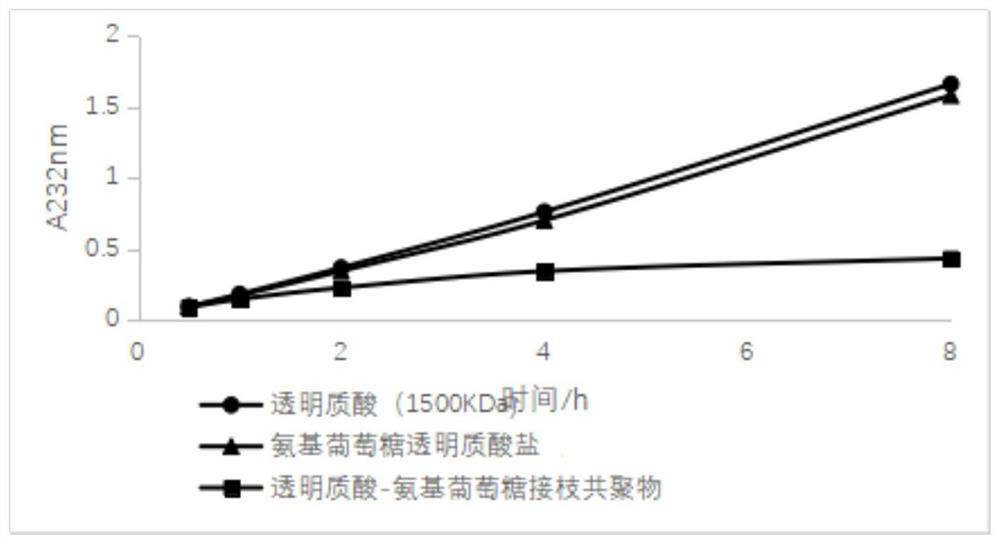

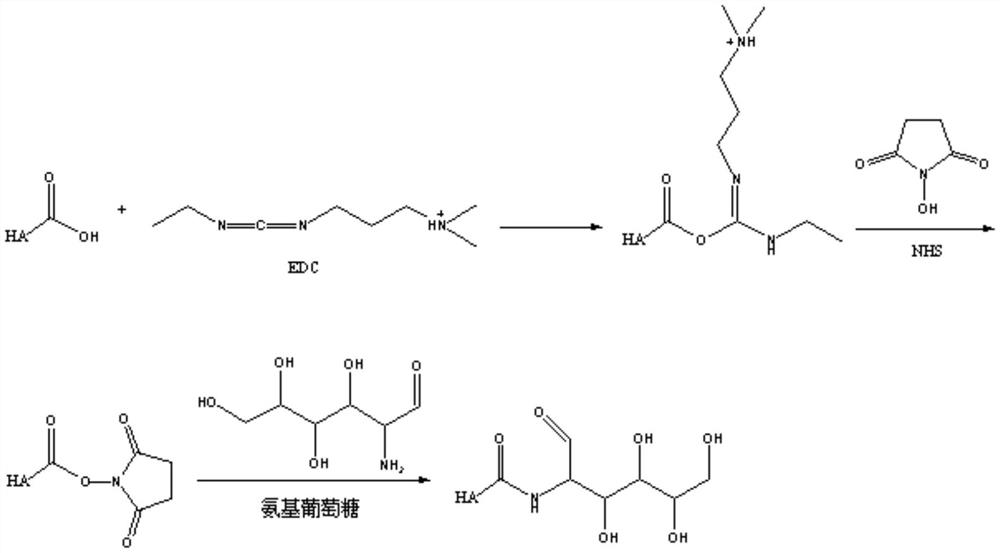

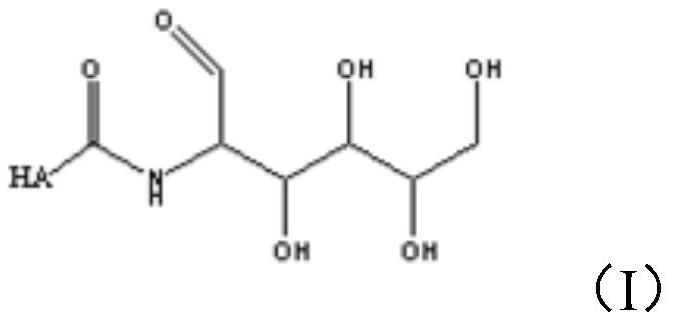

Hyaluronic acid-glucosamine grafted copolymer, and preparation method and application thereof

PendingCN111732675AReduce releaseCan maintain long-acting mechanism of actionOrganic active ingredientsSkeletal disorderArticular cavityLong chain

The invention discloses a hyaluronic acid-glucosamine grafted copolymer, and a preparation method and application thereof. The preparation method of the hyaluronic acid-glucosamine grafted copolymer comprises the following steps: mixing a condensing agent, glucosamine or salt thereof and water to obtain a mixed solution; adjusting the pH value of the mixed solution, then adding hyaluronic acid orsalt thereof, and performing an amidation reaction to obtain the hyaluronic acid-glucosamine grafted copolymer. The preparation method is simple and efficient; the method is performed in an aqueous solution to avoid environmental protection pressure caused by using an organic solvent; reaction conditions are mild, so long chains and molecular structures of hyaluronic acid or salt thereof in a reaction system cannot be damaged, and high molecular weight can be maintained; and through mediation of the condensing agent, hyaluronic acid and glucosamine are connected through a stable covalent bond,so the obtained hyaluronic acid-glucosamine grafted copolymer is injected into an articular cavity to directly recover the viscoelasticity of synovial fluid, and the hyaluronic acid-glucosamine grafted copolymer has the effects of lubricating and nourishing joints and has slow absorptivity.

Owner:SHANDONG BLOOMAGE HYINC BIOPHARM CORP LTD

Preparation method of lithium hexafluorophosphate

ActiveCN101570326BImprove product qualityRich sourcesLead-acid accumulatorsPhosphorus compoundsOleumPhosphoric acid

The invention relates to a preparation method of lithium hexafluorophosphate. The method comprises the following steps: (1), enabling anhydrous hydrogen fluoride and strong phosphoric acid to react under the protection of inert gas to prepare hexafluorophosphoric acid; (2), adding oleum to the hexafluorophosphoric acid prepared in the step (1) under cooling stirring to prepare phosphorus pentafluoride gas; (3), dissolving high-purity lithium fluoride in an anhydrous hydrogen fluoride solution to form an anhydrous hydrogen fluoride solution containing the lithium fluoride; (4), cooling and guiding the phosphorus pentafluoride gas into the anhydrous hydrogen fluoride solution containing the lithium fluoride, reacting, crystallizing, separating and drying to obtain a pure lithium hexafluorophosphate product; and (5), continuously guiding the unreacted and cooled phosphorus pentafluoride gas to the anhydrous hydrogen fluoride solution containing the lithium fluoride and continuously reacting to obtain a lithium hexafluorophosphate finished product. The phosphorus pentafluoride in the process is cooled to fully react so as to prevent incomplete reacted phosphorus pentafluoride powder from causing environmental-protection pressure.

Owner:DO FLUORIDE CHEM CO LTD

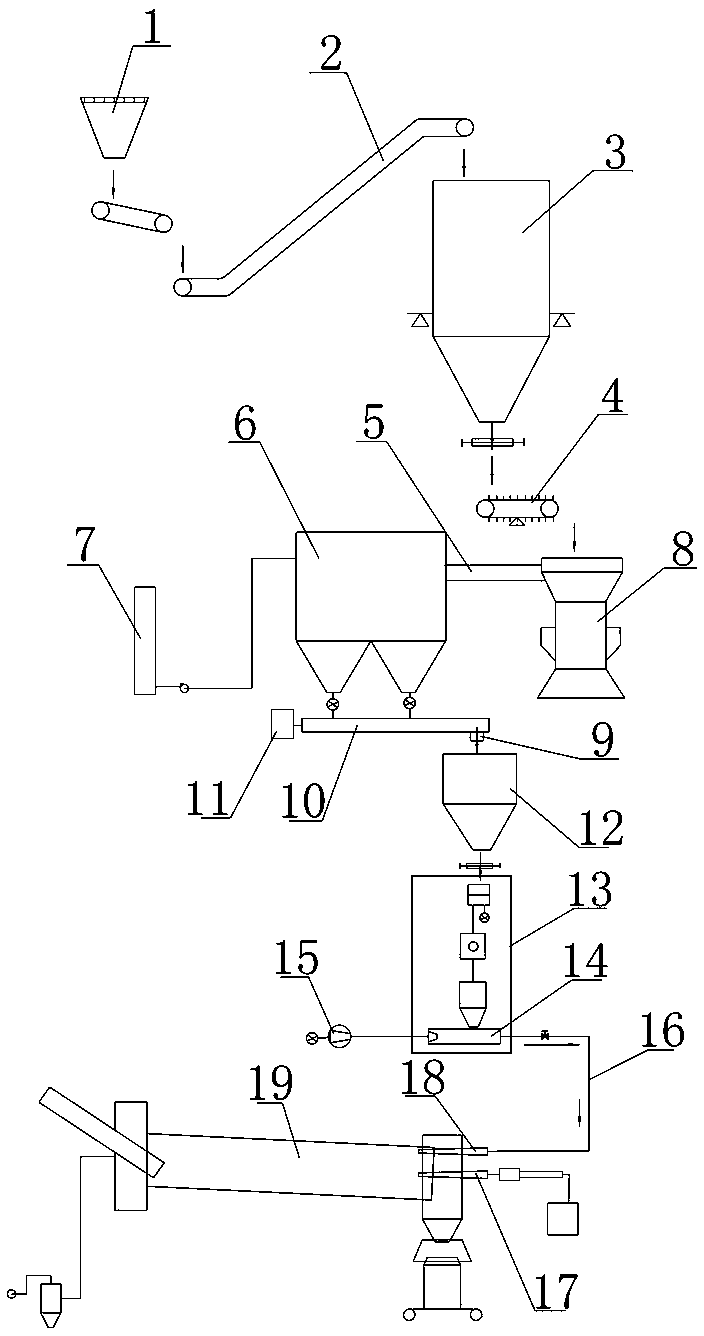

Internal pre-reduction desulfurization device for rotary kiln during ferronickel smelting by virtue of RKEF process

The invention discloses an internal pre-reduction desulfurization device for a rotary kiln during ferronickel smelting by virtue of an RKEF process. The internal pre-reduction desulfurization device comprises a massive material bin, wherein a quantitative feeding conveyer belt is arranged below the massive material bin; the tail end of the quantitative feeding conveyer belt corresponds to a feeding hole of a vertical mill machine; a discharging hole of the vertical mill machine is communicated with a feeding hole in the upper part of a powder collecting machine; the bottom of the powder collecting machine is communicated with a material conveying pipe; a discharging hole in the tail end of the material conveying pipe corresponds to a feeding hole in the top of a finished product bin; the finished product bin is communicated with a feeding hole of a quantitative feeding machine; one end of the quantitative feeding machine is communicated with a roots blower, and the other end of the quantitative feeding machine is communicated with a material nozzle; and a material nozzle is communicated with the rotary kiln. A desulfurizer and a reducer are ground and conveyed together and are finally blown into the interior of the rotary kiln, reaction is carried out when a burner jets flame into the rotary kiln, pre-reduction desulfurization is carried out in a high temperature and water vapor environment, desulfurization treatment can be carried out in the rotary kiln, a subsequent purification load is reduced, and purification effect also can be obviously improved, so that emission indexes are essentially improved.

Owner:临沂鑫海新型材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com