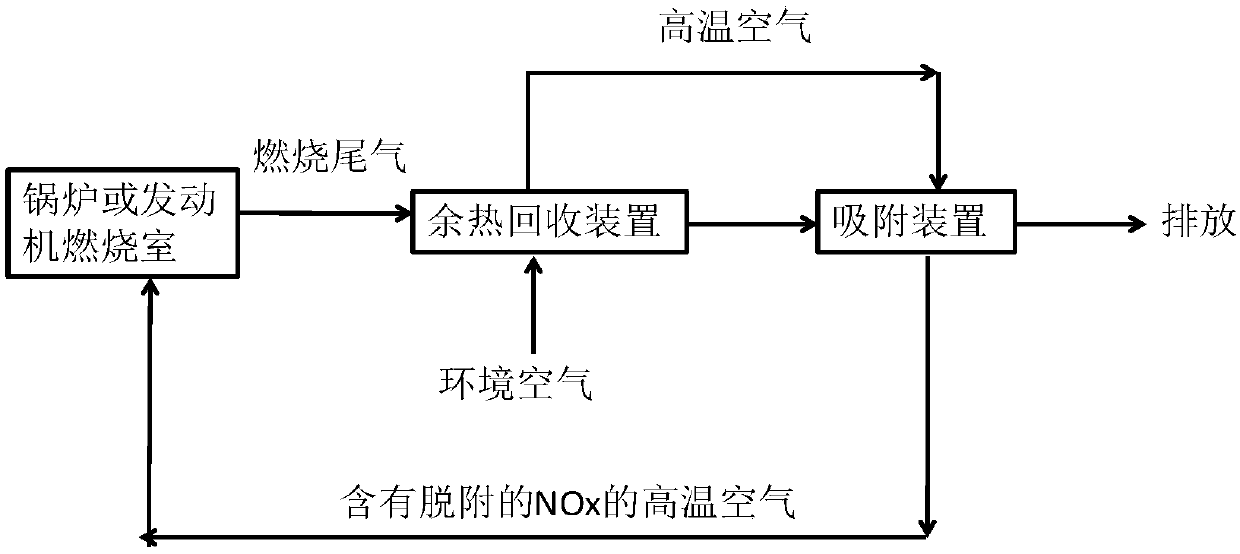

Method for eliminating and recycling nitric oxide in combustion tail gas

A nitrogen oxide and tail gas technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of complex systems, high equipment and raw material costs, and difficulty in meeting the needs of zero nitrogen oxide emissions, and achieve elimination. The effect of NOx pollution, raw material and equipment cost reduction, equipment investment cost and maintenance cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

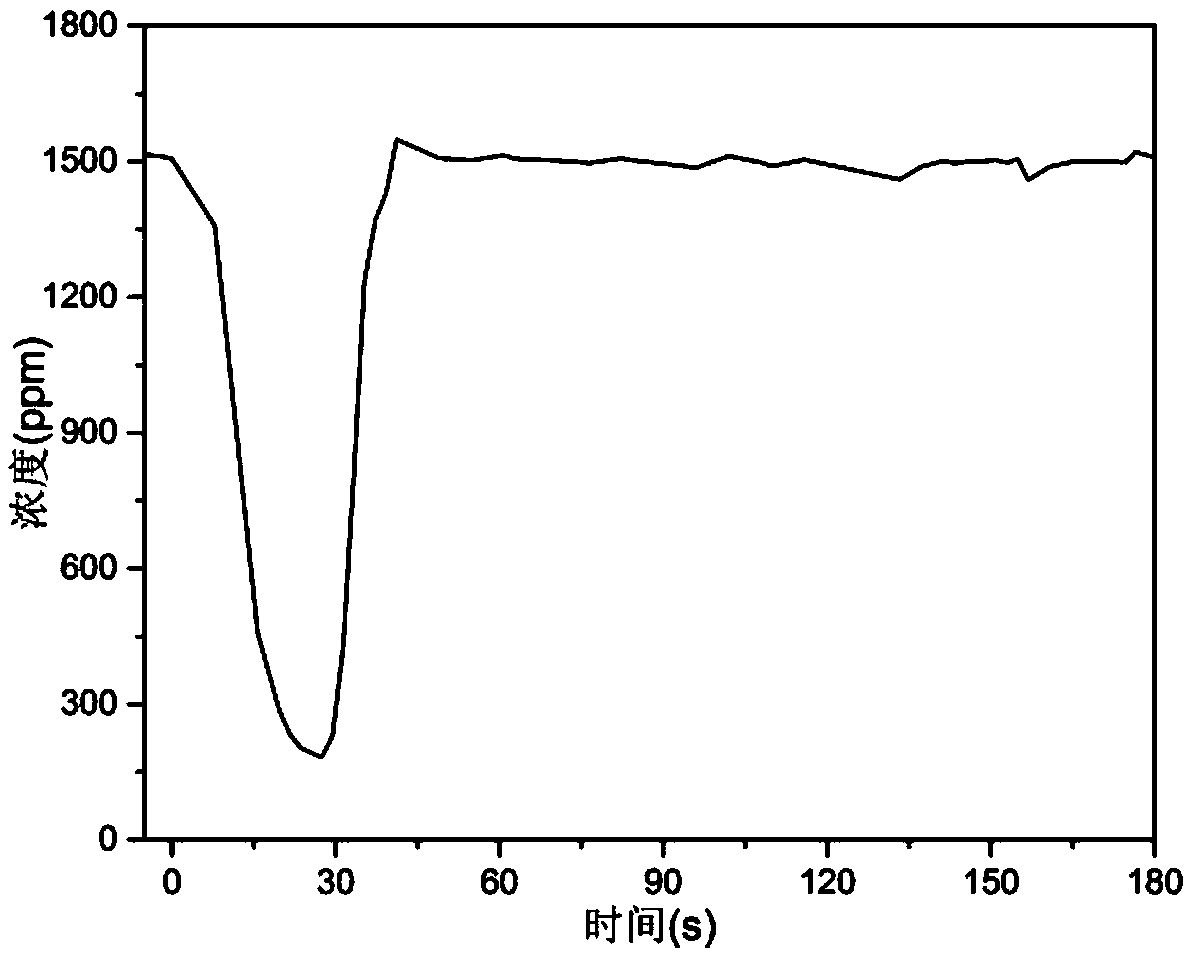

[0040] Take the combustion tail gas discharged from a coal-fired boiler used to smelt silica in a glass factory as an example.

[0041] After the combustion tail gas has been dedusted and desulfurized, it contains 1500ppm NOx, 16.5% CO 2 , 8% O 2 , 11.5%H 2 O, the balance is N 2 . The combustion tail gas sample was taken for experiments, the amount of molecular sieve adsorption material was 0.589g, the total gas flow rate was 900mL / min, the adsorption temperature was 100°C, and the space velocity was 11,000h -1 . The adsorbent used is Ce / Beta means that Ce is loaded on the Beta molecular sieve, and the composition expression method of the remaining adsorbents is similar to this), wherein the percentage content of Ce is 2wt%, and the NOx adsorption results are as follows figure 2 As shown, it takes about 41 seconds to reach adsorption saturation, and the saturated adsorption amount of NOx reaches 32.8 μmol / g adsorbent.

[0042] After the adsorption is saturated, stop fee...

Embodiment 2

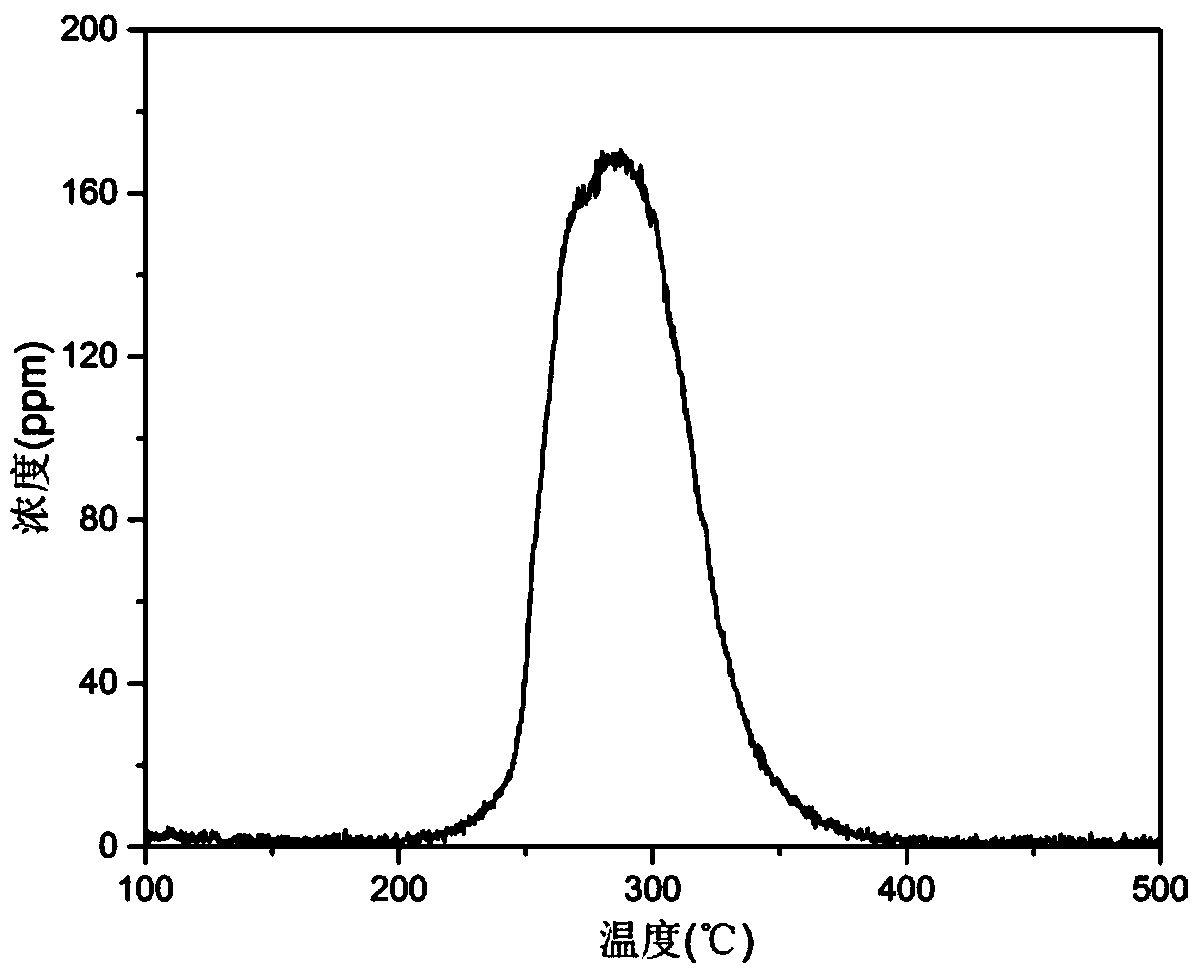

[0046] Take the combustion tail gas discharged from a coal-fired boiler in a cement plant as an example.

[0047] After the combustion tail gas has been dedusted and desulfurized, it contains 1000ppm NOx, 12.5% CO 2 , 9.2% O 2 , 6%H 2 O, the balance is N 2 . The combustion tail gas sample was taken for experiments, the amount of molecular sieve adsorption material was 0.288g, the total gas flow rate was 1000mL / min, the adsorption temperature was 150°C, and the space velocity was 25,000h -1 . The adsorbent used is La / Beta, wherein the percentage content of La is 5wt%, and the NOx adsorption results are as follows Figure 4 As shown, the adsorption saturation is reached after about 34 seconds, and the saturated adsorption amount of NOx reaches 33.4 μmol / g adsorbent.

[0048] After the adsorption is saturated, stop feeding the combustion tail gas, and change to feed air into the adsorbent and carry out the temperature-programmed desorption experiment. The results are as fol...

Embodiment 3

[0052] Take the combustion tail gas discharged from a gas-fired boiler in a power plant as an example.

[0053] After the combustion tail gas has been dedusted and desulfurized, it contains 500ppm NOx, 5% CO 2 , 8% O 2 , 5%H 2 O, the balance is N 2 . The combustion tail gas sample was taken for experiments, the amount of molecular sieve adsorption material was 0.144g, the total gas flow rate was 1000mL / min, the adsorption temperature was 80°C, and the space velocity was 50,000h -1 . The adsorbent used is Cu / ZSM-5, wherein the percentage content of Cu is 10wt%, and the NOx adsorption results are as follows Figure 6 As shown, the adsorption saturation is reached after about 47 seconds, and the saturated adsorption capacity of NOx reaches 33.6 μmol / g adsorbent.

[0054] After the adsorption is saturated, stop feeding the combustion tail gas, and change to feed air into the adsorbent and carry out the temperature-programmed desorption experiment. The results are as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com