A kind of metal solid waste recycling and processing equipment

A solid waste, recycling and processing technology, applied in the direction of improving process efficiency, can solve the problems of high environmental protection processing cost and hidden safety hazards, and achieve the effect of non-polluting discharge and recycling and reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the present invention, the solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

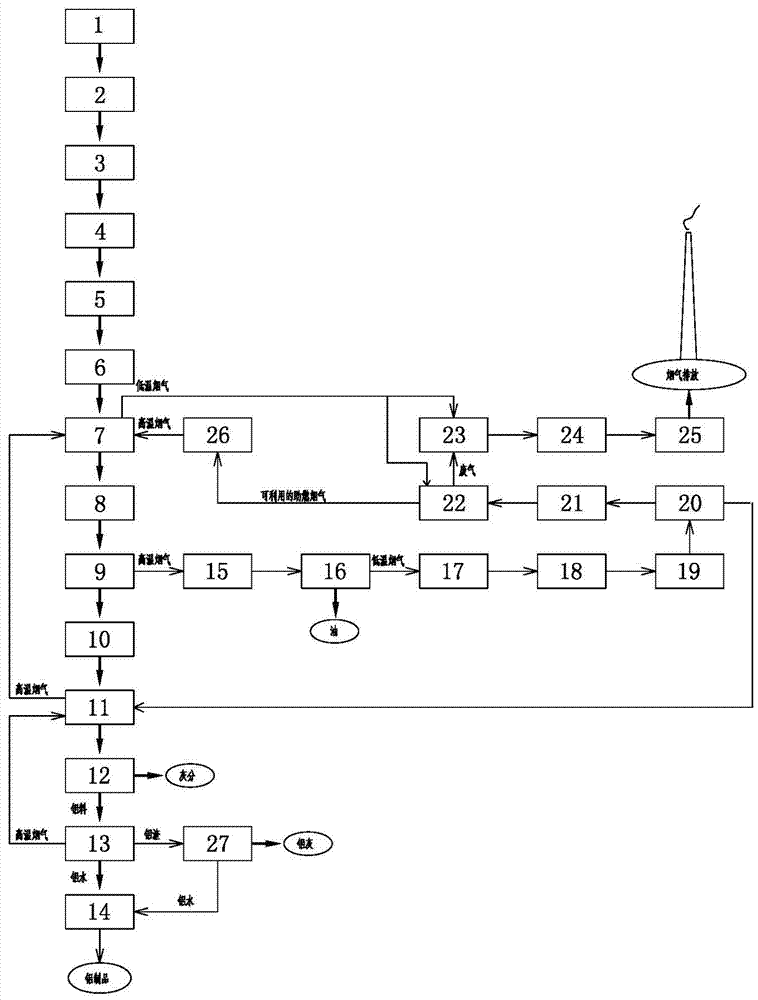

[0022] see figure 1 As shown, a metal solid waste recycling and processing equipment according to an embodiment of the present invention includes a silo 1, a crusher 2, a magnetic separator 3, a hoist 4, a blocking silo 5, a hydraulic feeding mechanism 6, and a low-temperature pyrolysis furnace 7. Discharging mechanism 8, gas-solid separation tower 9, conveying mechanism 10, high temperature decarburization furnace 11, screening machine 12, side well double chamber furnace 13, heat preservation refining furnace 14, condenser 15, oil tank 16, primary water Seal 17, secondary water seal 18, high-pressure induced draft fan 19, flue gas incineration 20, flue gas quenching chamber 21, heat exchanger 22, cyclone dust collector 23, bag dust colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com