Method for utilizing waste heat of low-concentration combustible materials in tail gas of Slapple furnace

A Slep activation furnace and low-concentration technology, which is applied in the field of waste heat utilization of low-concentration combustibles, can solve the problem of not involving low-concentration tail gas combustibles supplementary combustion and incineration, unable to fully utilize tail gas low-concentration combustibles, and polluting atmospheric energy. and other problems, to achieve the effect of solving the problem of furnace wall temperature resistance, fully incinerating and utilizing, and reducing pollution emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

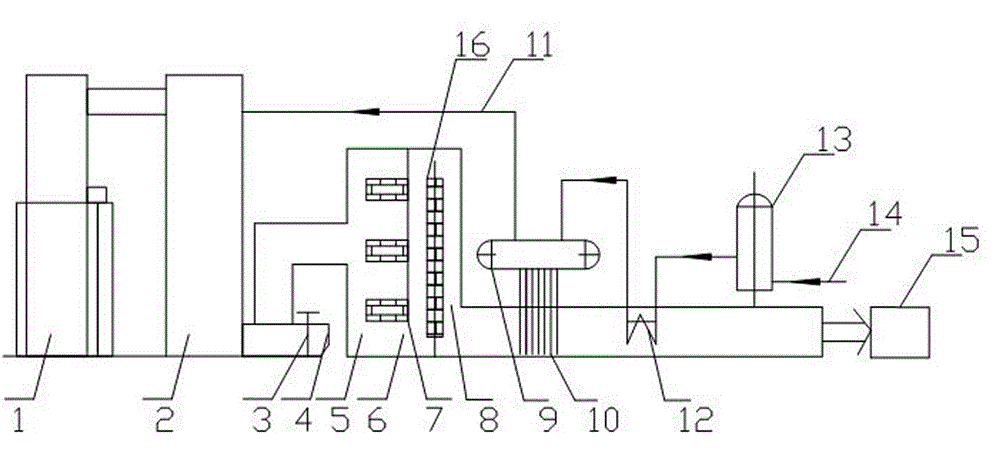

[0012] The present invention will be further described below in conjunction with the accompanying drawings and examples (taking a 3000 kg / d output activated carbon production line as an example).

[0013] Such as figure 1 As shown, a method for utilizing waste heat of low-concentration combustibles in the tail gas of Sleep furnace, the calorific value is lower than 450Kcal / m 3 The low-concentration exhaust gas enters the "U"-shaped settling chamber (5) for inertial separation and then enters the supplementary combustion chamber (6). 16) Ignite to ignite the combustible tail gas and fully burn it in the long flue incineration chamber (8), the tail gas gradually expands in the long flue, and the high-temperature flue gas after combustion enters the heat pipe heat exchanger (10) at a low flow rate, The internal resistance of the heat exchanger is lower than 10mmH 2 0. The economizer (13) performs heat exchange, and finally the tail gas is discharged into the atmosphere after pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com