Patents

Literature

114results about How to "Reduce local resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

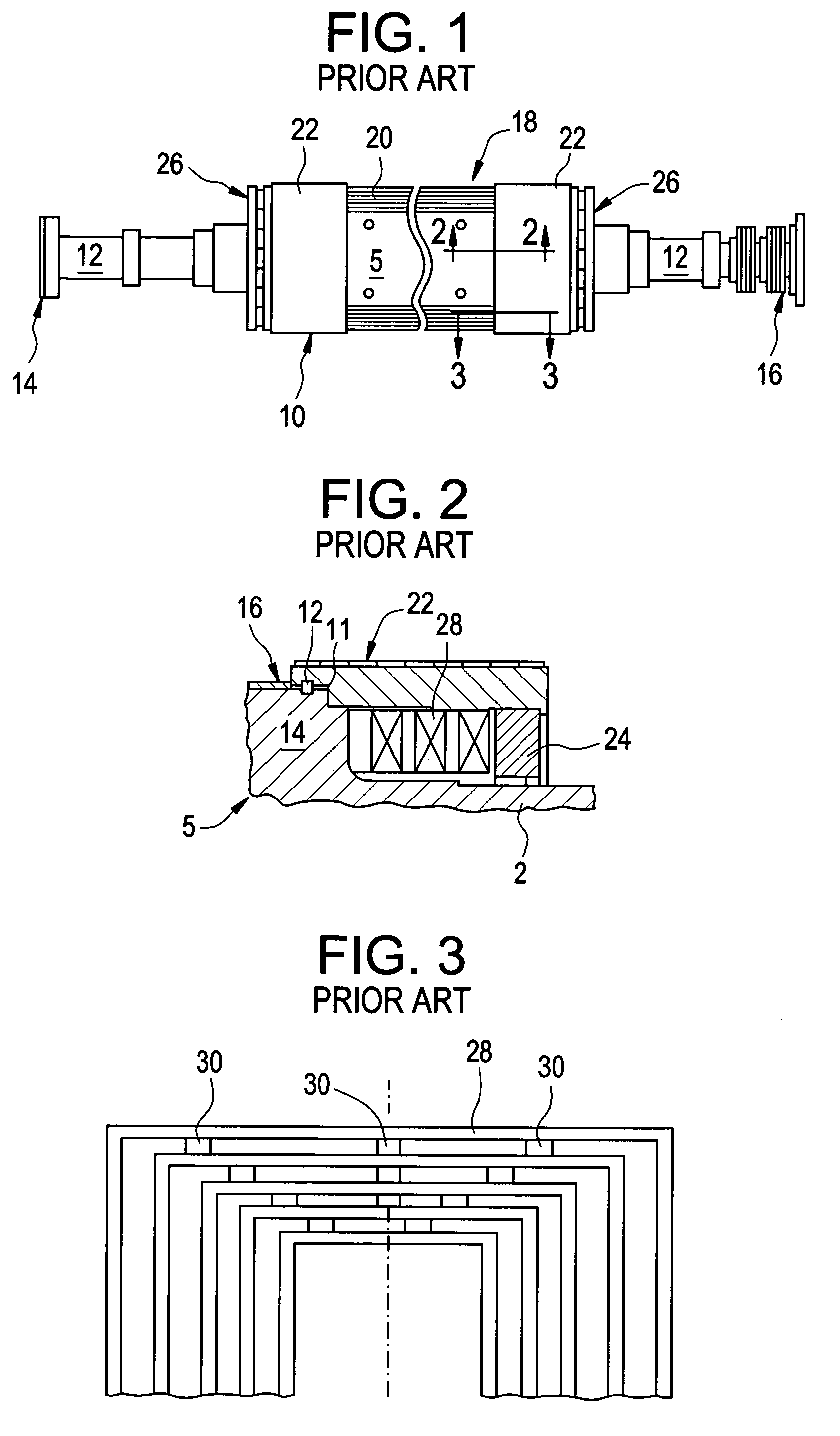

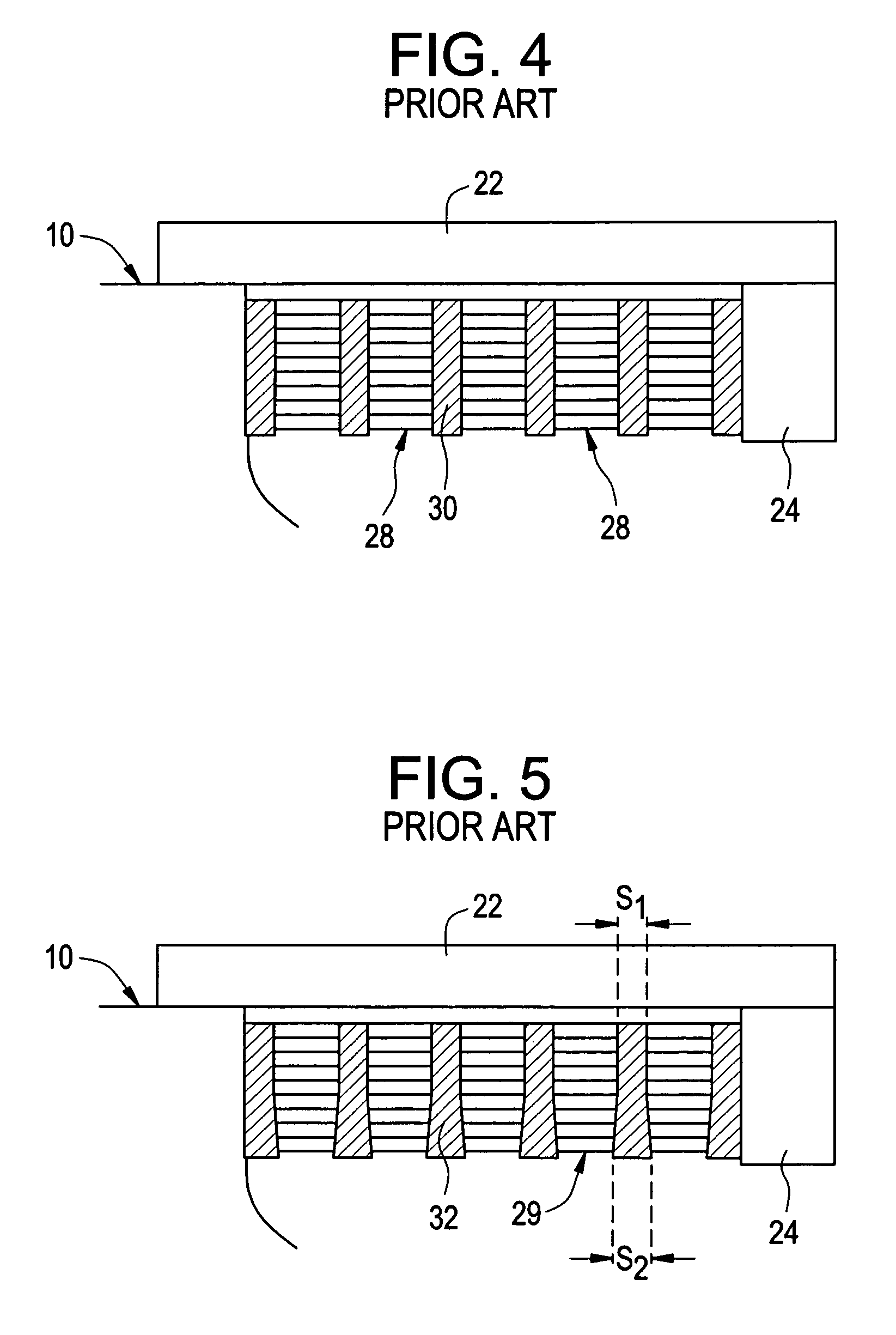

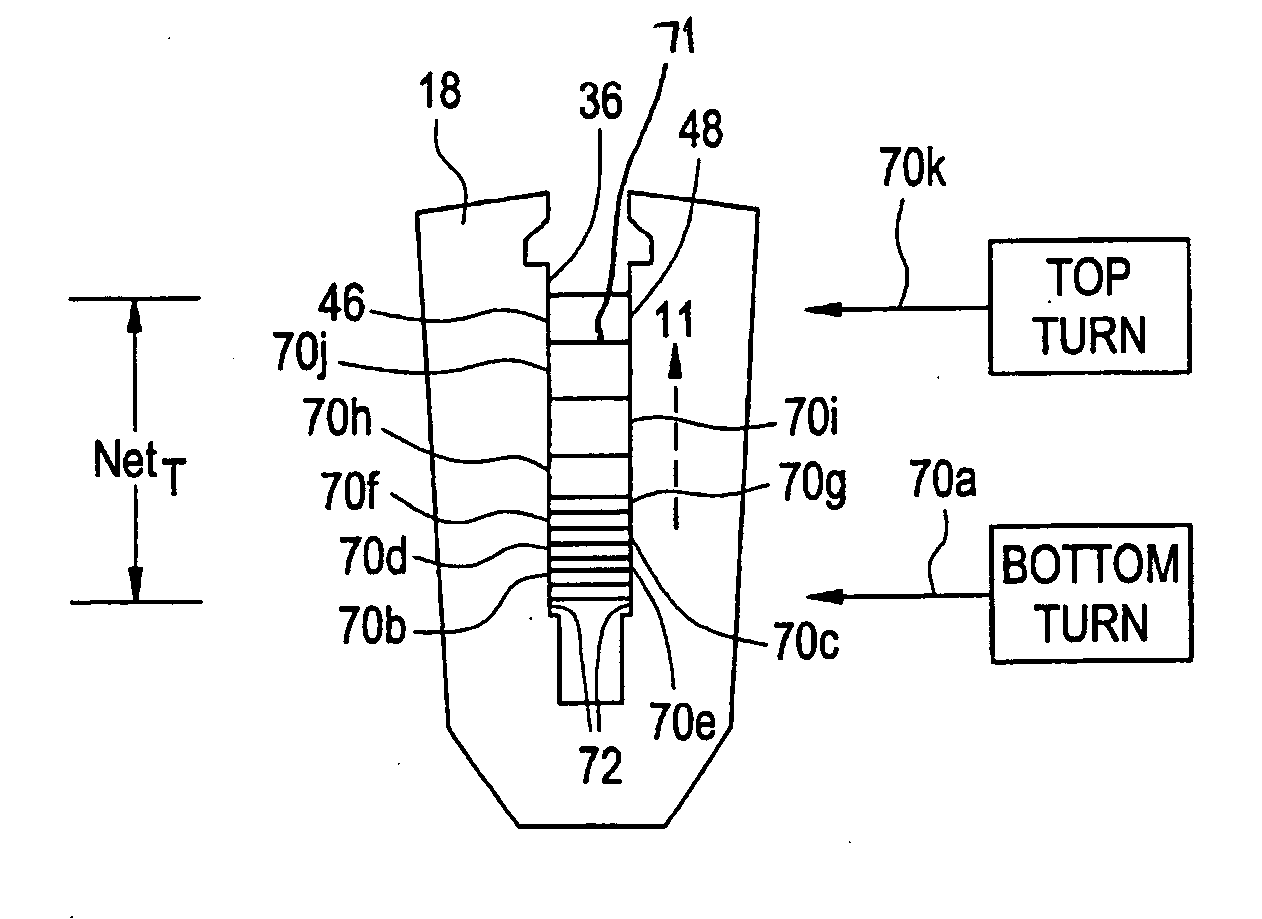

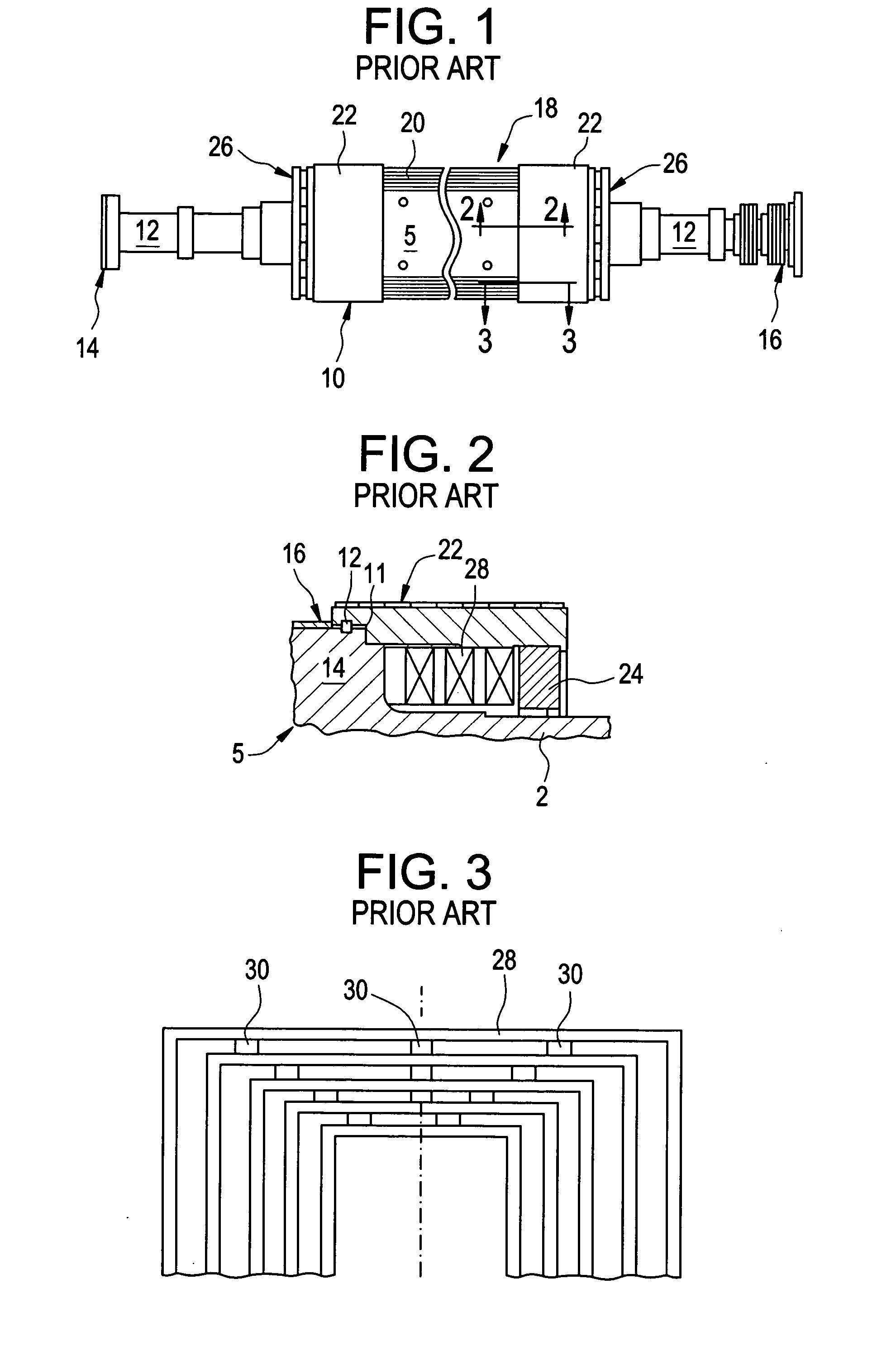

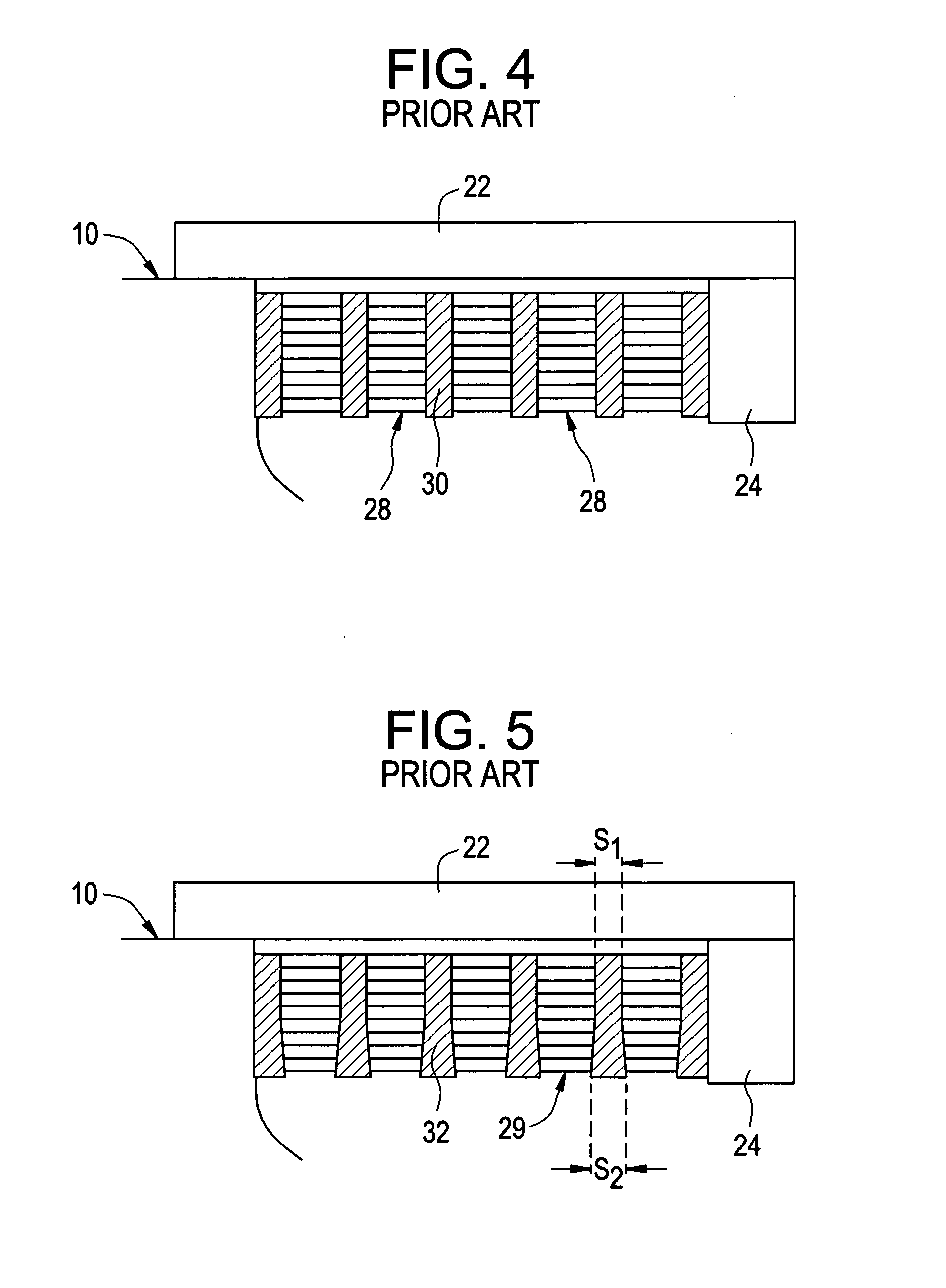

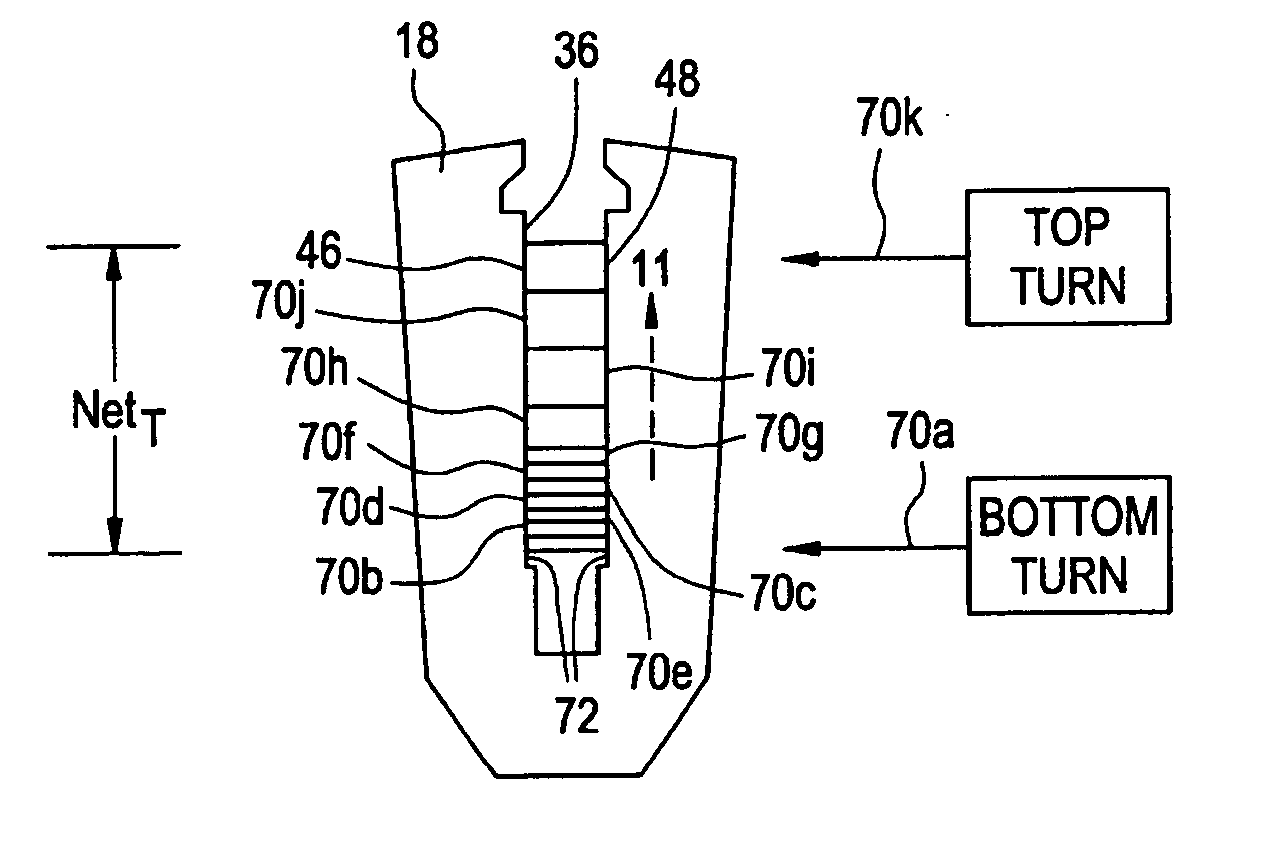

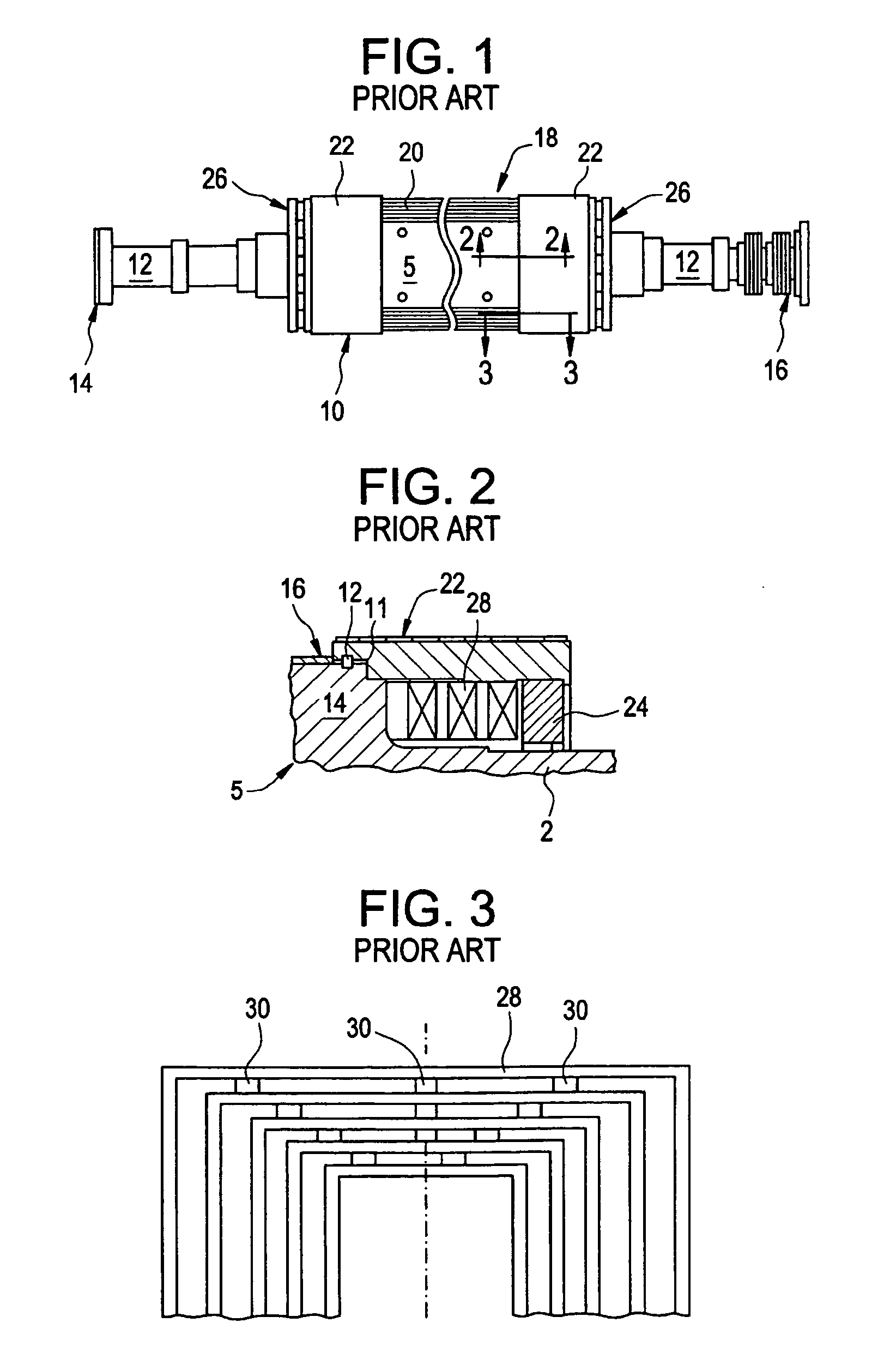

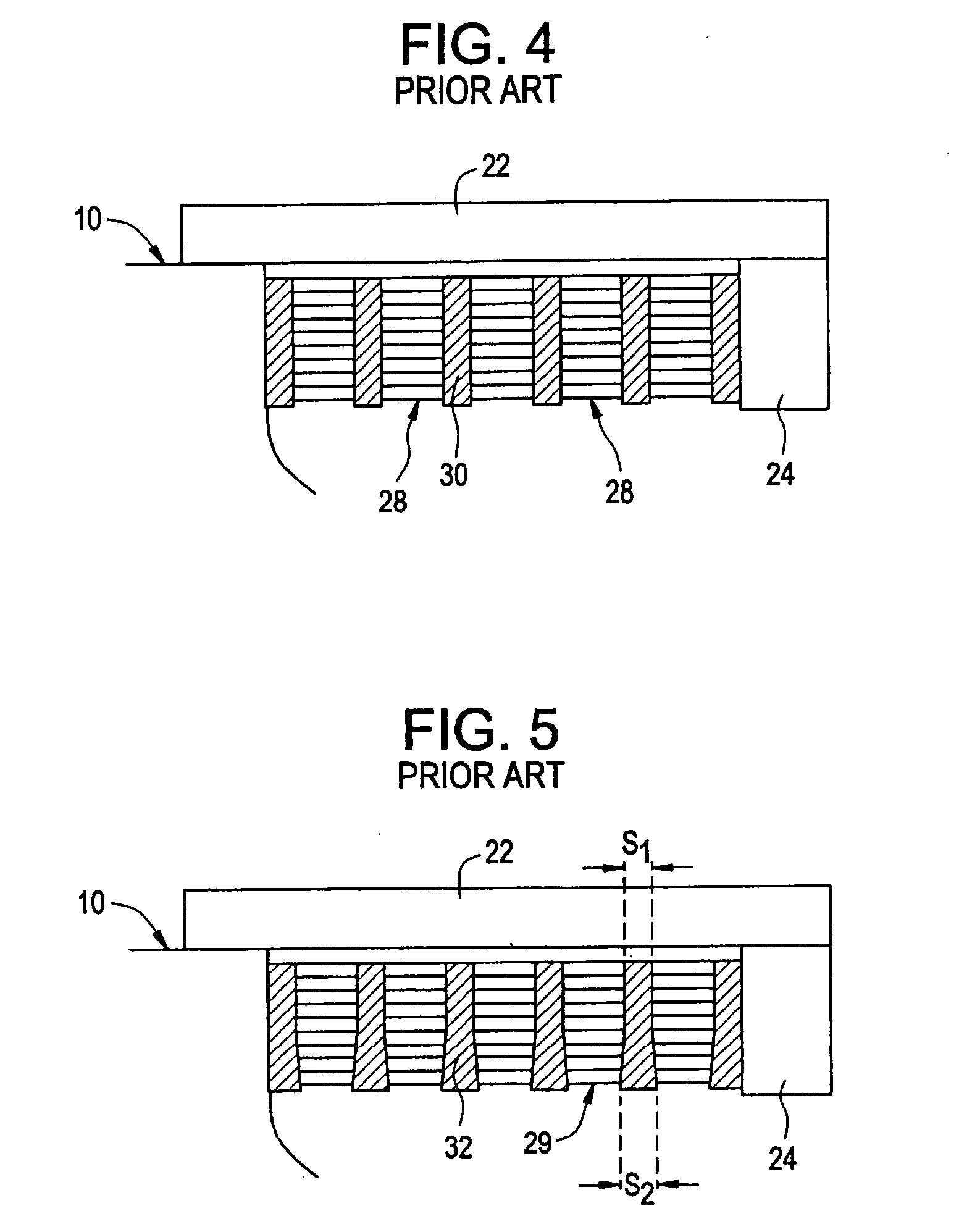

Method and apparatus for reducing hot spot temperatures on stacked field windings

ActiveUS6956313B2Reduce local resistanceReducing field hot spot temperaturesMagnetic circuitSynchronous machinesEngineeringConductor Coil

Owner:GENERAL ELECTRIC CO

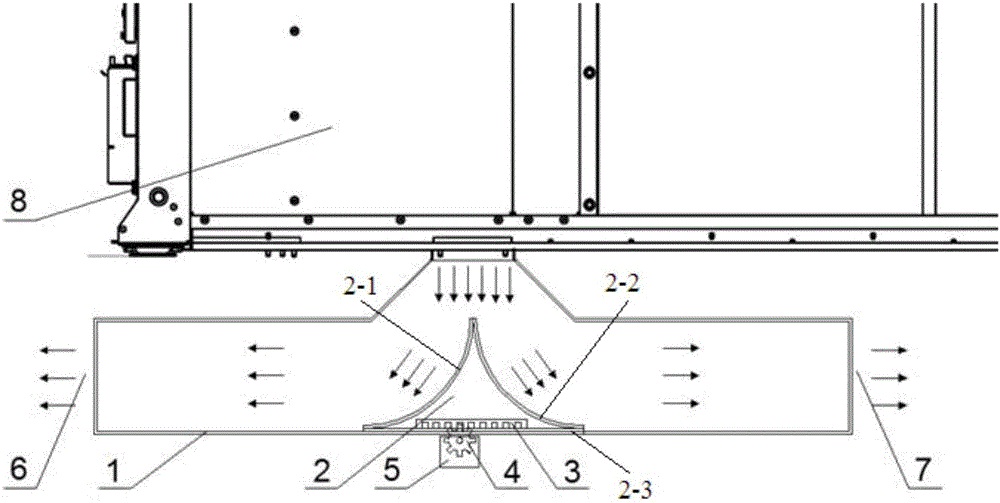

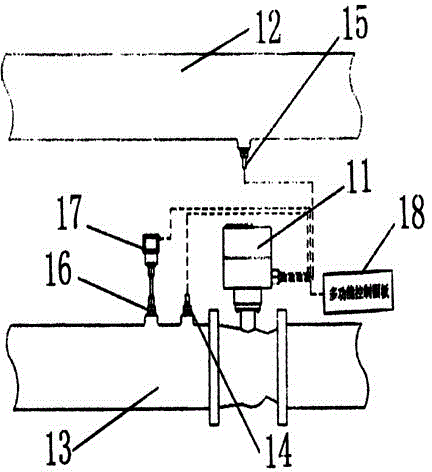

Adjustable distribution air flue for rail transit air conditioner and control method of adjustable distribution air flue

ActiveCN106274942AGuaranteed air volumeMeet heat load demandsRailway heating/coolingRailway transportAir volumeNoise level

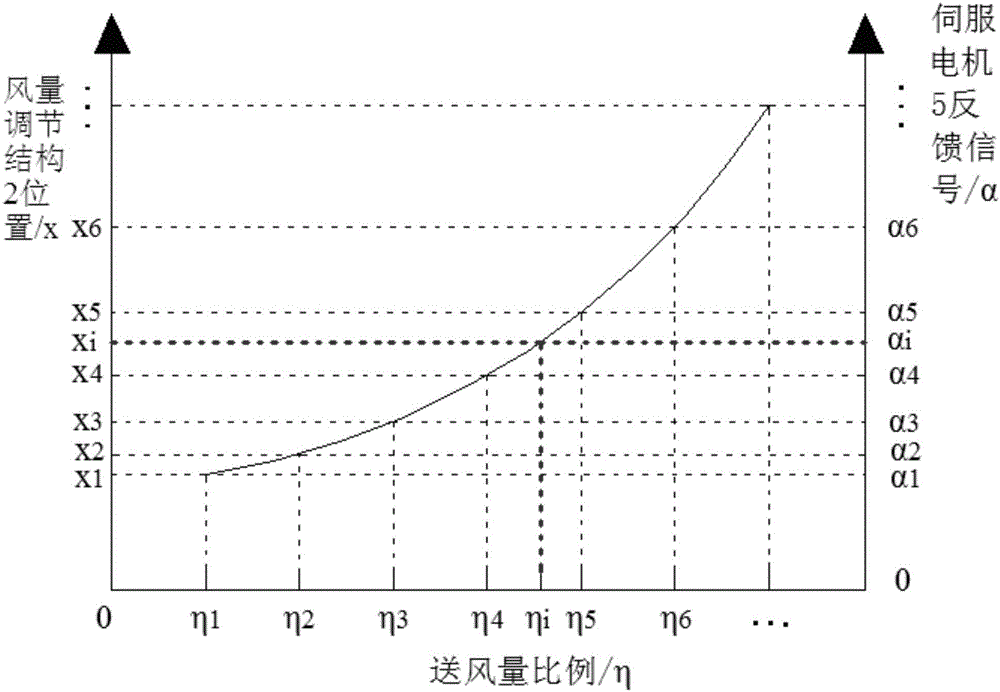

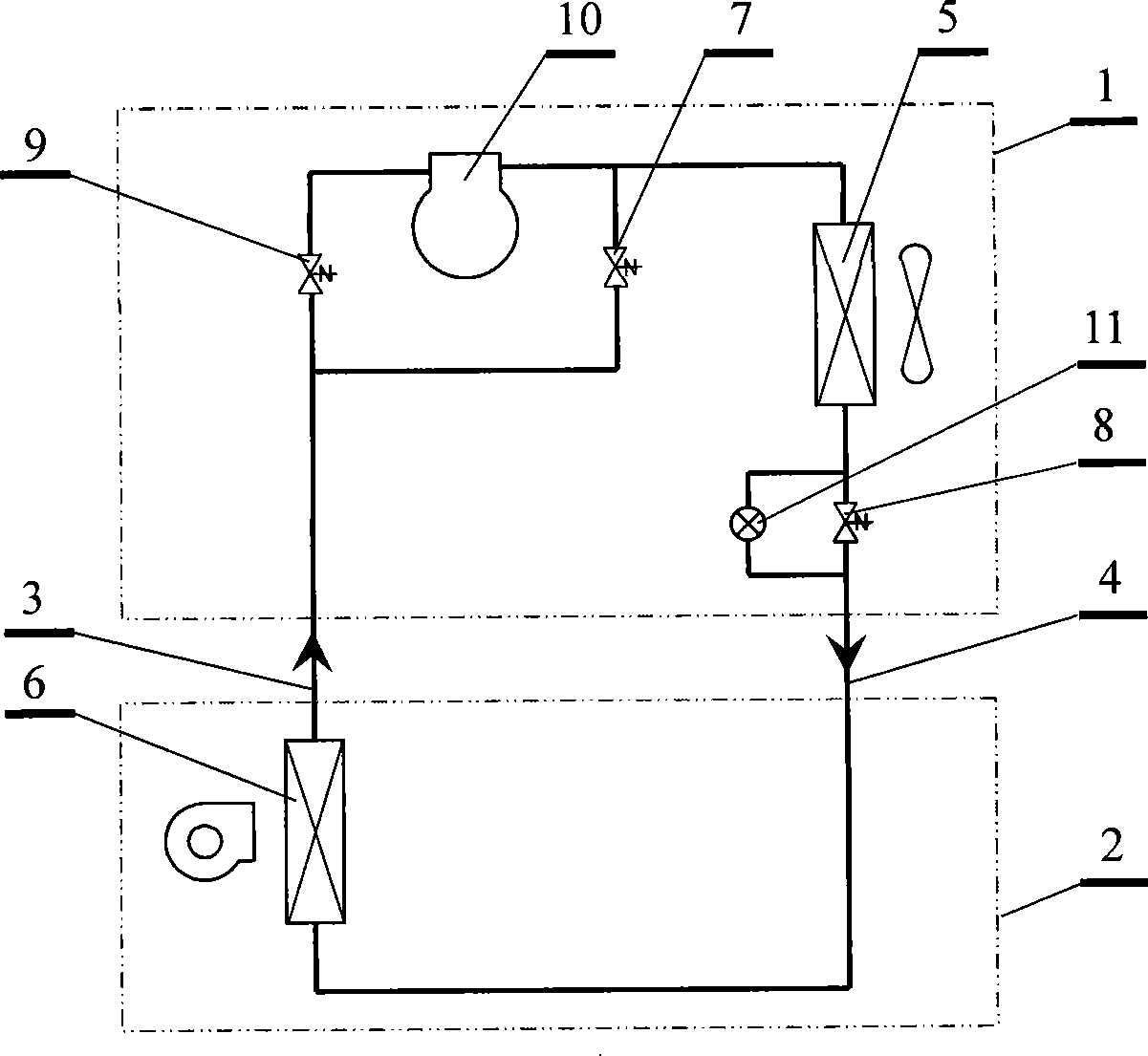

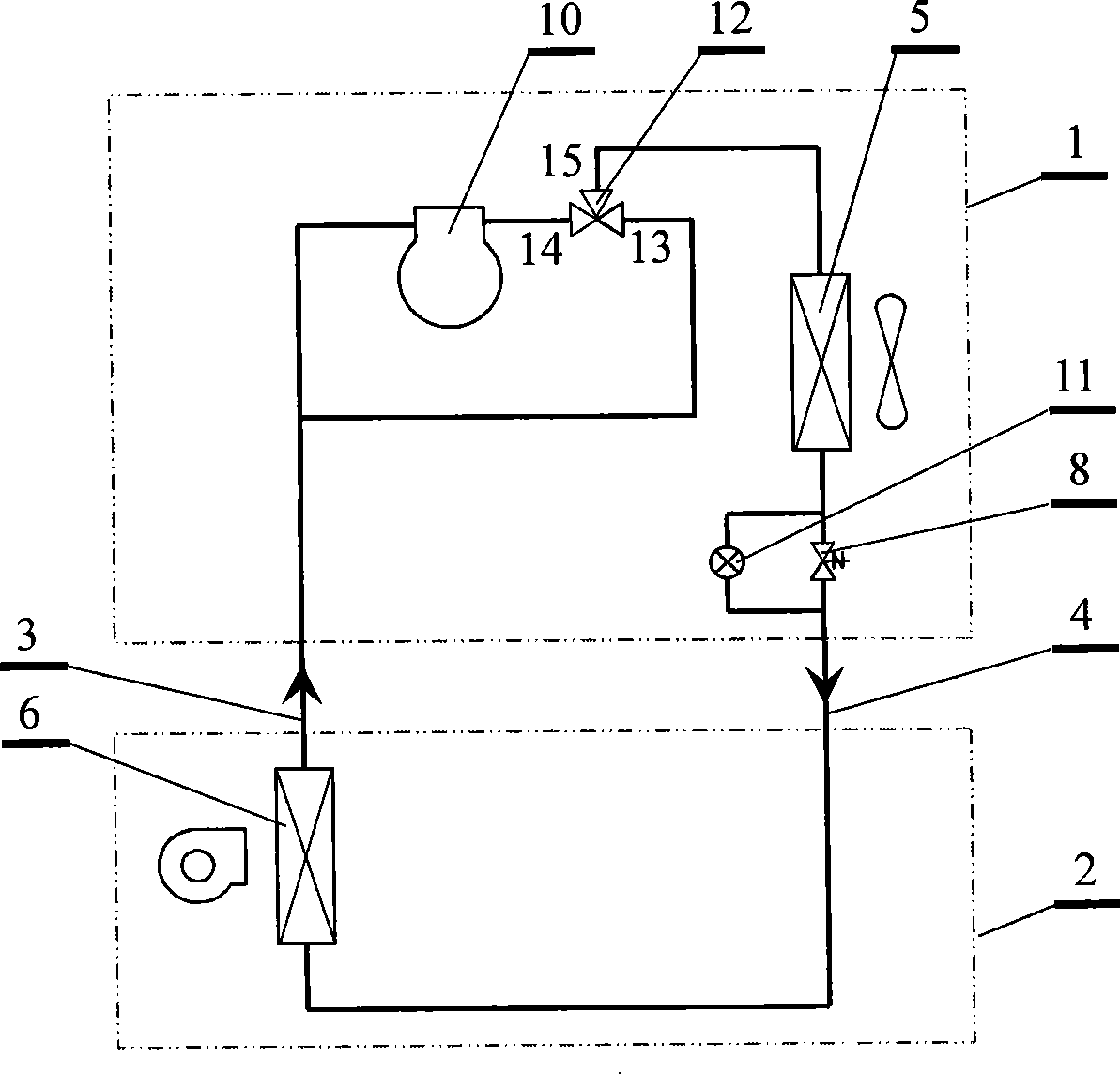

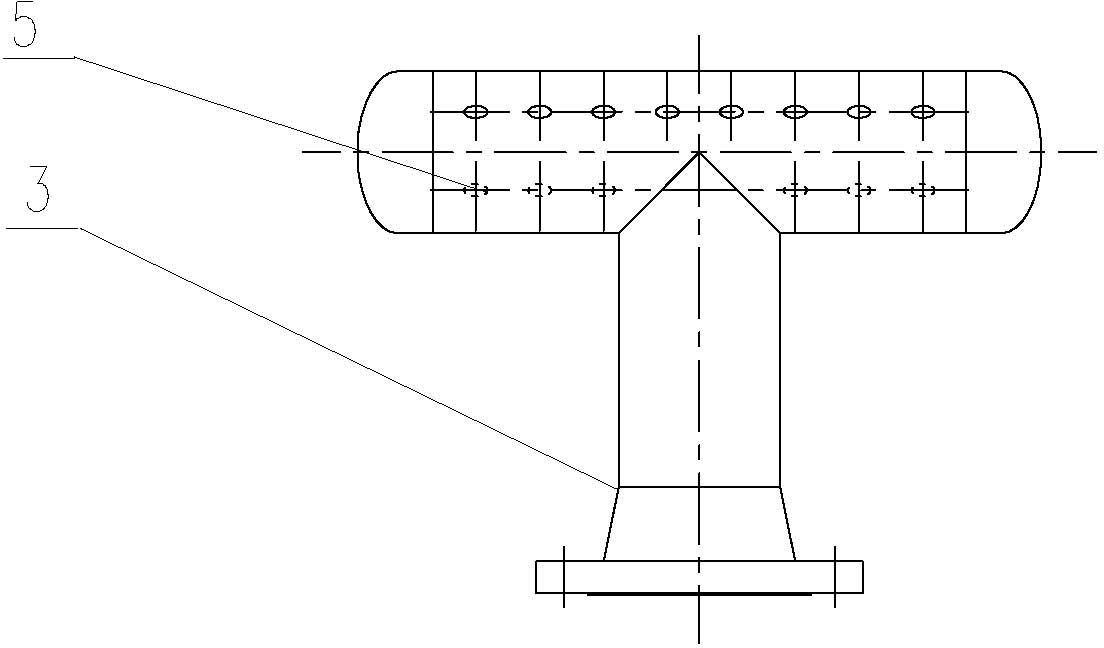

The invention relates to an adjustable distribution air flue for a rail transit air conditioner and a control method of the adjustable distribution air flue. The adjustable distribution air flue comprises a distribution air flue body. An air inlet of the distribution air flue body is connected with an air conditioner unit. The two ends of the of the distribution air flue body are provided with a first air outlet and a second air outlet correspondingly. The adjustable distribution air flue has the characteristics that an air regulation structure used for regulating the air outlet volume of the first air outlet and the second air outlet is installed in the distribution air flue body; the air regulation structure comprises a first flow guide plate and a second flow guide plate which guide outlet air to be discharged through the first air outlet and the second air outlet correspondingly; the upper end of the first flow guide plate is connected with the upper end of the second flow guide plate; the lower end of the first flow guide plate is connected with the lower end of the second flow guide plate through a connection plate; a tooth-shaped guide rail is fixed to the connection plate of the air regulation structure; a servo motor is installed on the outer side of the distribution air flue body; a power output shaft of the servo motor is connected with a gear; and the gear meshes with the tooth-shaped guide rail. According to the adjustable distribution air flue for the rail transit air conditioner and the control method of the adjustable distribution air flue, air distribution in a carriage can be optimized, and the noise level in the air flue can also be lowered effectively.

Owner:MERAK JINXIN AIR CONDITIONING SYST (WUXI) CO LTD

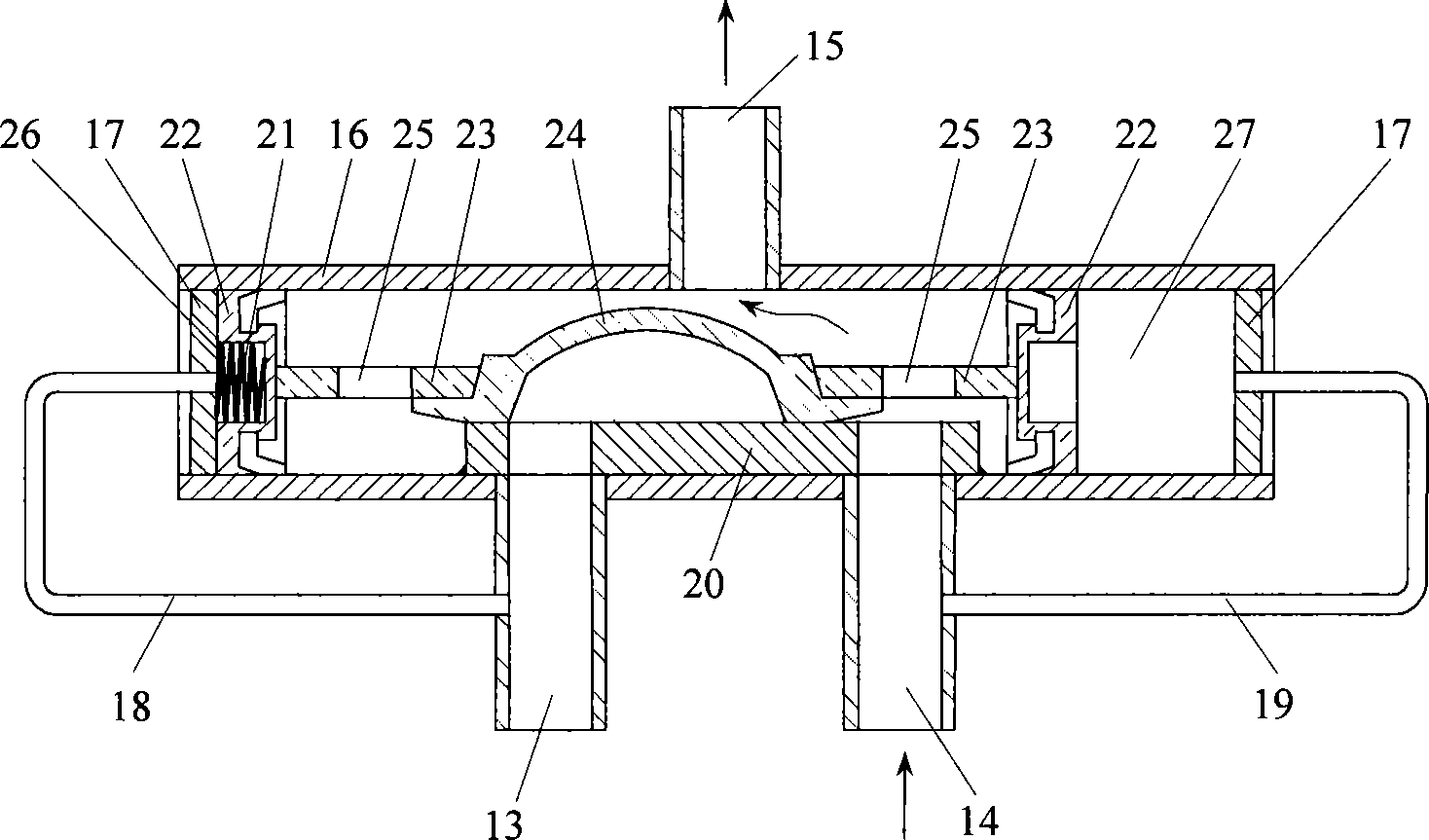

Self-operated three-way valve used for coolant circulating type machine room special machine

InactiveCN101245864AImprove reliabilityOvercome frictionOperating means/releasing devices for valvesMultiple way valvesSpring forceEngineering

The invention provides a self-operated three-way valve used for a special machine in a refrigerant circulation parallel machine room. The three-way valve comprises a valve body, a low pressure air inlet pipe, a high pressure air inlet pipe and an exhaust pipe. The valve body is internally provided with a piston component, a valve seat and a sliding valve. The internal chamber of the valve body is divided into a low pressure chamber and a high pressure chamber by a piston which can axially move. A low pressure capillary is connected between the low pressure chamber and the low pressure air inlet pipe. A low pressure capillary is connected between the high pressure chamber and the high pressure air inlet pipe. The low pressure chamber and / or the high pressure chamber are / is internally provided with a spring. By the pressure difference of the suction and exhaust when a spring force and a compressor are stated, the piston component which is arranged in the valve body drives the sliding valve to be closely attached to the surface of the valve seat to slide, thus achieving the communication between the high pressure air inlet pipe and the exhaust pipe and the communication between the low pressure air inlet pipe and the exhaust pipe. The three-way valve needs no outside power, can achieve the free switching of refrigerant refrigeration circulation and the natural circulation just according to the running state of the compressor, thus sufficiently displaying the energy-saving advantage of the special machine in the refrigerant circulation parallel machine room and improving the operation reliability.

Owner:和雄科技(北京)有限公司

Method and apparatus for reducing hot spot temperatures on stacked field windings

ActiveUS20050162032A1Reduce local resistanceReducing field hot spot temperaturesMagnetic circuitSynchronous machinesEngineeringConductor Coil

Owner:GENERAL ELECTRIC CO

Energy storage battery container temperature control system utilizing underground water

ActiveCN112436210AAvoid damageImprove temperature uniformityGeothermal energy generationSecondary cellsWater storage tankHigh energy

The invention discloses an energy storage battery container temperature control system utilizing underground water, which comprises an energy storage battery container, a heat exchange chamber arranged on the outer side wall of the periphery of the energy storage battery container and a water storage tank arranged below the energy storage battery container, and the water storage tank is communicated with the external underground water through a pipeline; a water inlet-outlet pipe of the energy storage battery container and a water inlet-outlet pipe of the heat exchange chamber are communicatedwith the water storage tank; a plurality of energy storage battery stacks are arranged in the energy storage battery container, and each energy storage battery stack is a polygon defined by a plurality of energy storage battery packs; and each energy storage battery pack is composed of a plurality of single lithium batteries, and a water cooling plate is arranged between every two adjacent singlelithium batteries. According to the system, when the battery works, underground water is used as a cold source to cool the battery, and before the battery is started in winter, the underground wateris used as a heat source to preheat the battery stack, so that the damage to the battery caused by low-temperature starting is avoided,the system takes underground water as a heat exchange source, theenergy consumption of the system is greatly reduced, the problem of high energy consumption caused by using a central air conditioner is avoided, and the energy utilization rate is increased.

Owner:JIANGSU UNIV OF SCI & TECH

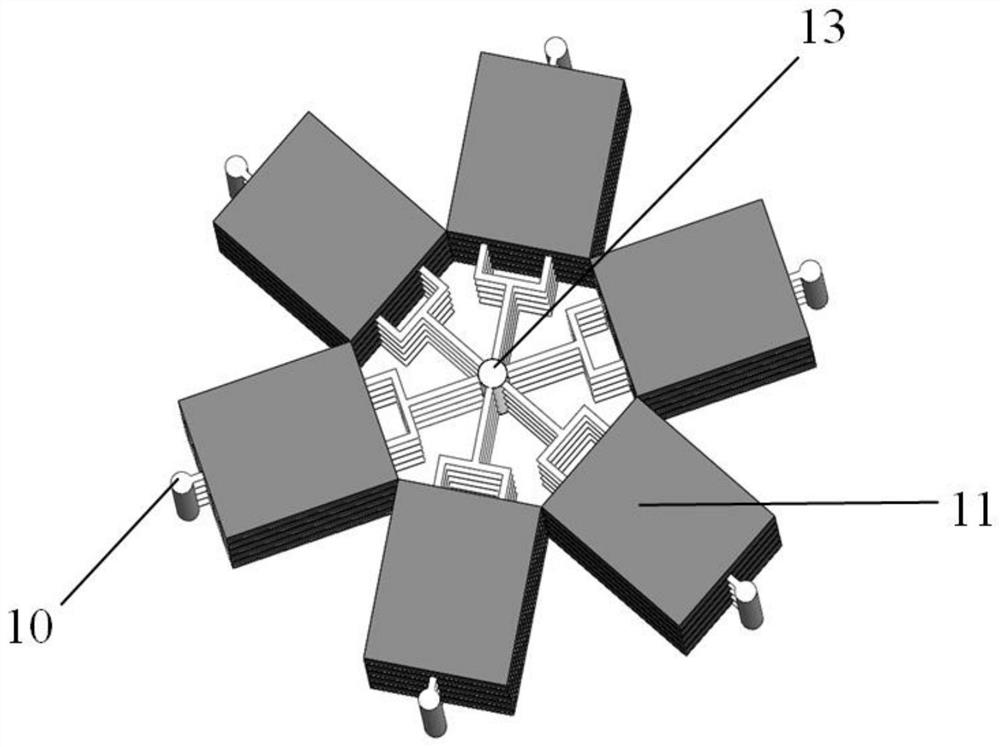

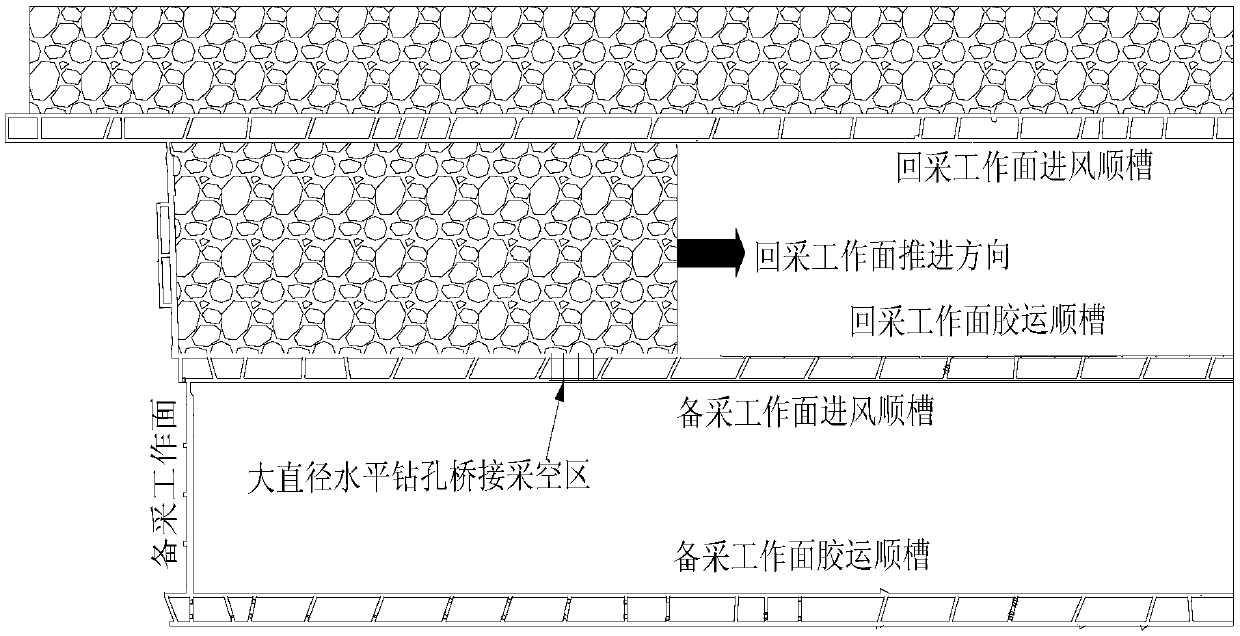

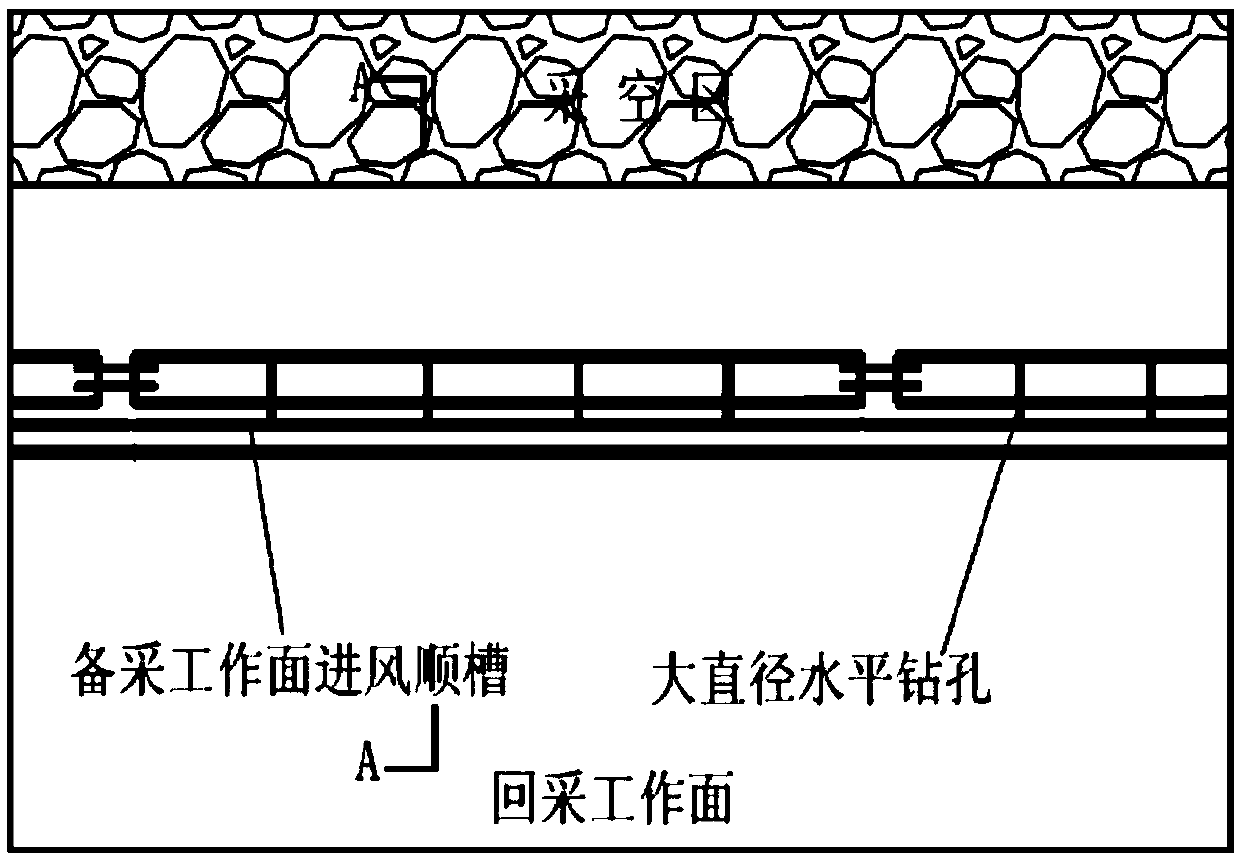

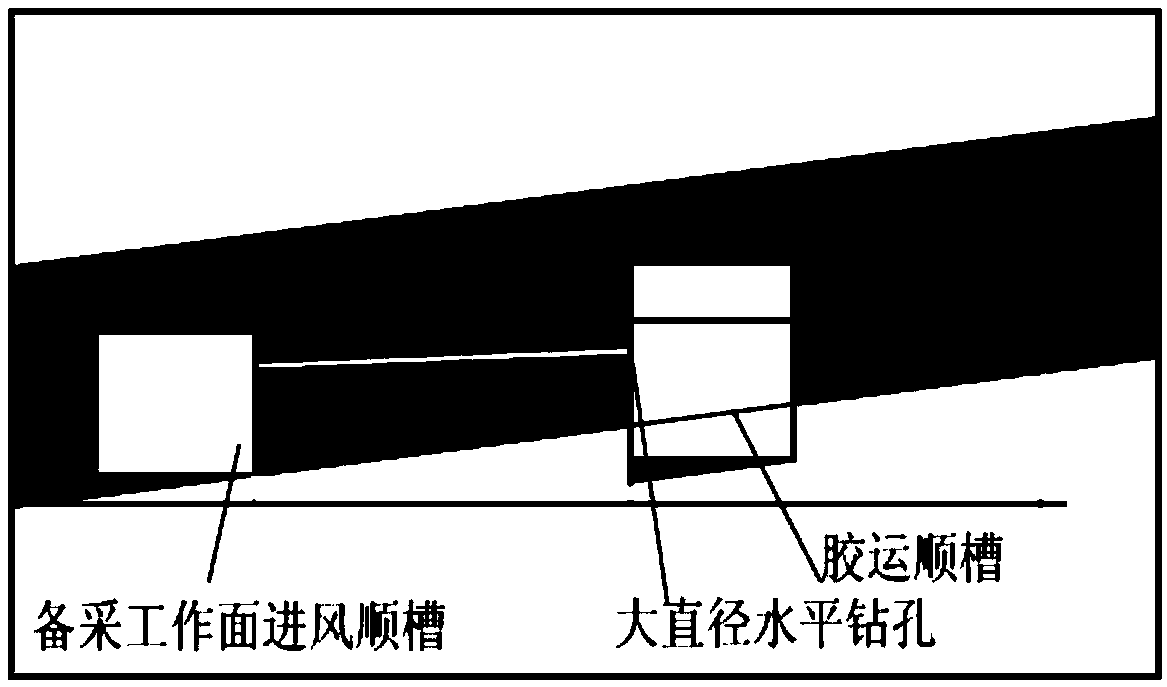

Device and method for large-diameter horizontal borehole bridging goaf gas extraction

PendingCN109519212AAchieve isolationAvoid direct inflowMining devicesGas removalSpontaneous combustionMultiple point

The invention relates to a device and method for large-diameter horizontal borehole bridging goaf gas extraction, and belongs to the technical field of coal mine gas safety. The device comprises a casing, a butterfly valve, a three-way joint and a pumping pipe. The butterfly valve is mounted on the casing, and the casing is connected to the pumping pipe through the three-way joint; the casing is placed inside a horizontal borehole; the horizontal borehole is formed in a coal pillar between a belt transporting crossheading of the working face and an air inlet duct of the adjacent working face and penetrates the coal pillar; a device for determining the flow rate, the temperature and the gas and carbon monoxide gas concentration is installed on the pumping pipe to monitor the gas extractionin a horizontal borehole bridging goaf. The device and method solve the difficulty in gas control of the return air corner on the high-strength working face under the condition of the 'Y' type ventilation mode, achieves multiple-point continuous controllable pumping of the gas in the goaf and monitors spontaneous combustion of the residual coal in the goaf in real time while effectively controlling corner gas emission.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

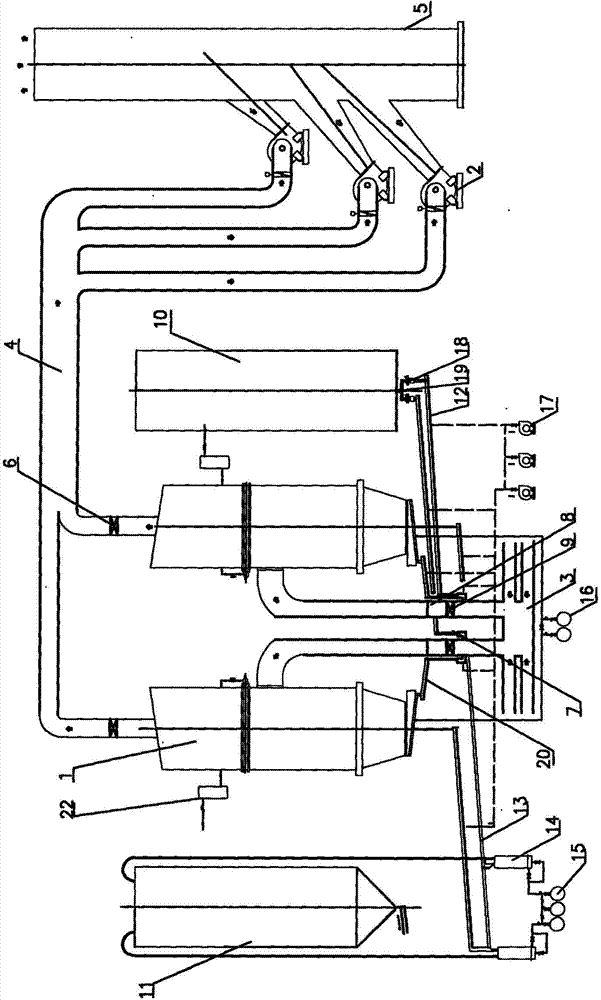

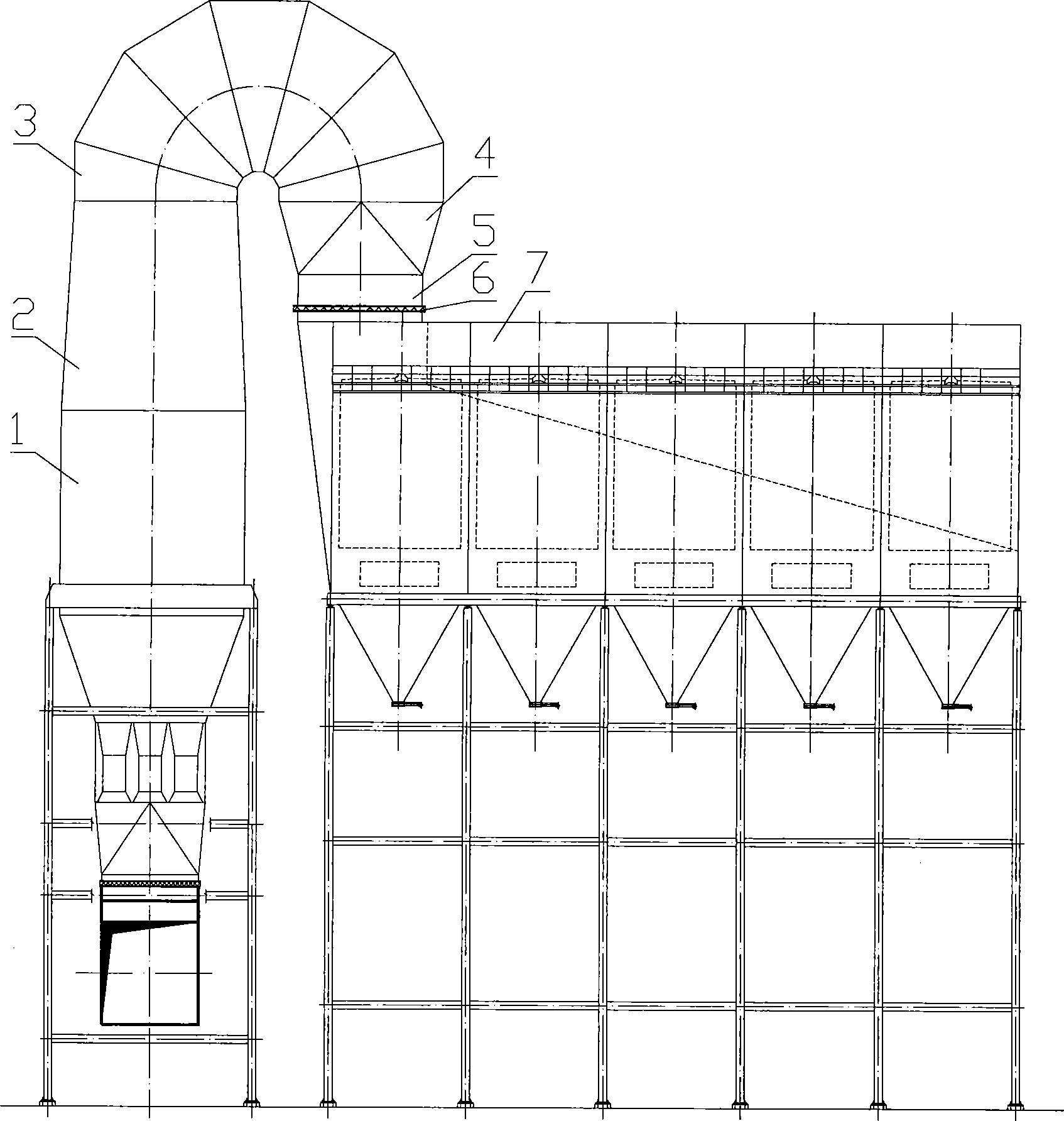

Electrolysis flue gas dry-purification system

ActiveCN102851706AReduce drag along the wayRealize mutual backupHuman health protectionDispersed particle filtrationElectrolysisFlue gas

The invention relates to a purification system, and particularly relates to an electrolysis flue gas dry-purification system. The electrolysis flue gas dry-purification system structurally comprises a dust remover, a dust remover outlet pipeline arranged at the top of the dust remover, a reactor connected with the dust remover and a gathering pipeline connected with the reactor, wherein the bottom of the dust remover is communicated with a fluorine-carrying aluminum oxide storage bin, the reactor is communicated with a fresh aluminum oxide storage bin, and the dust remover outlet pipeline is communicated with a chimney through a main draught fan. The invention has the following advantageous effects: the configuration form of the pipelines is changed to reduce local resistance, thereby reducing the whole on-way resistance of the purification system and saving energy; the purification effect is enhanced; and the advantages of small occupied area, high purification efficiency, low energy consumption, low maintenance workload, high control degree and the like are achieved.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

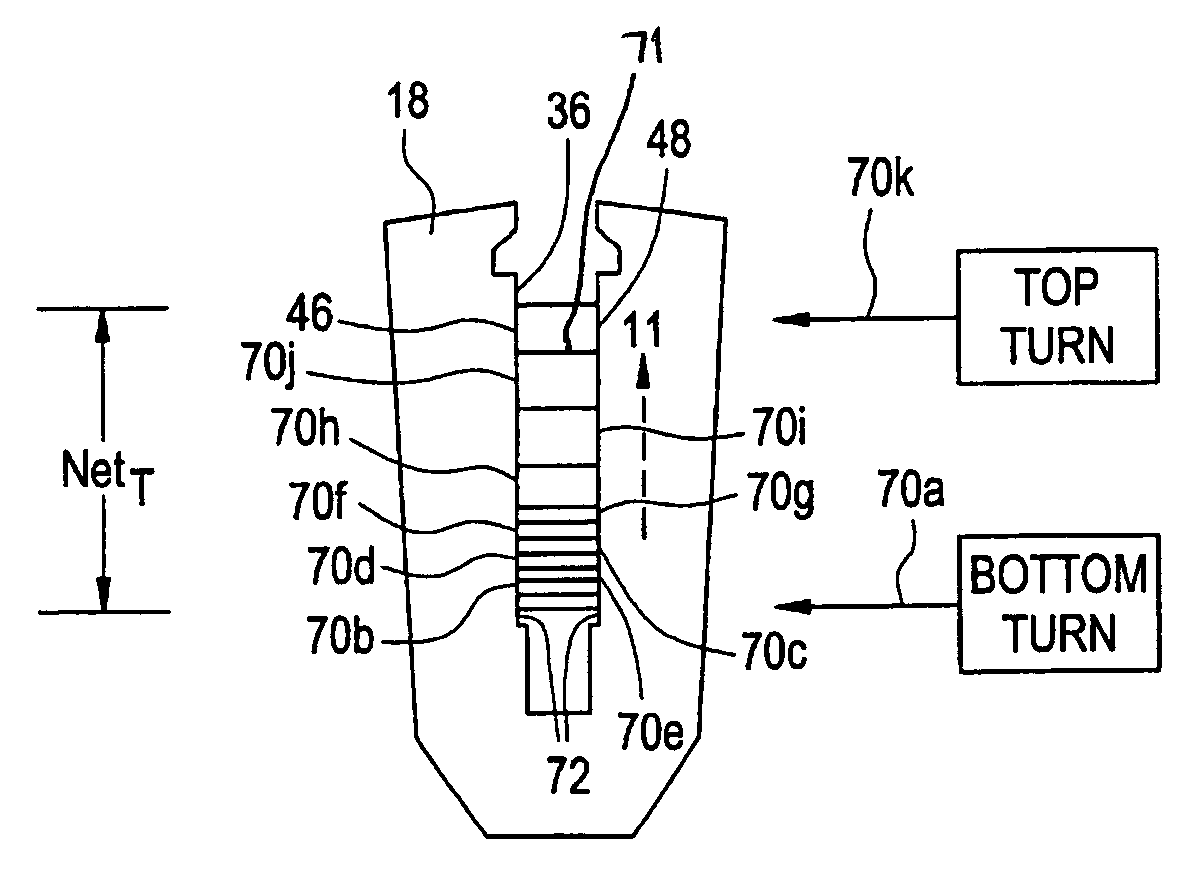

Method and apparatus for reducing hot spot temperatures on stacked field windings

InactiveUS20050275304A1Reduce local resistanceReducing field hot spot temperaturesMagnetic circuit rotating partsSynchronous machinesEngineeringConductor Coil

Owner:EL GABRY LAMYAA ABDEL ALLE +1

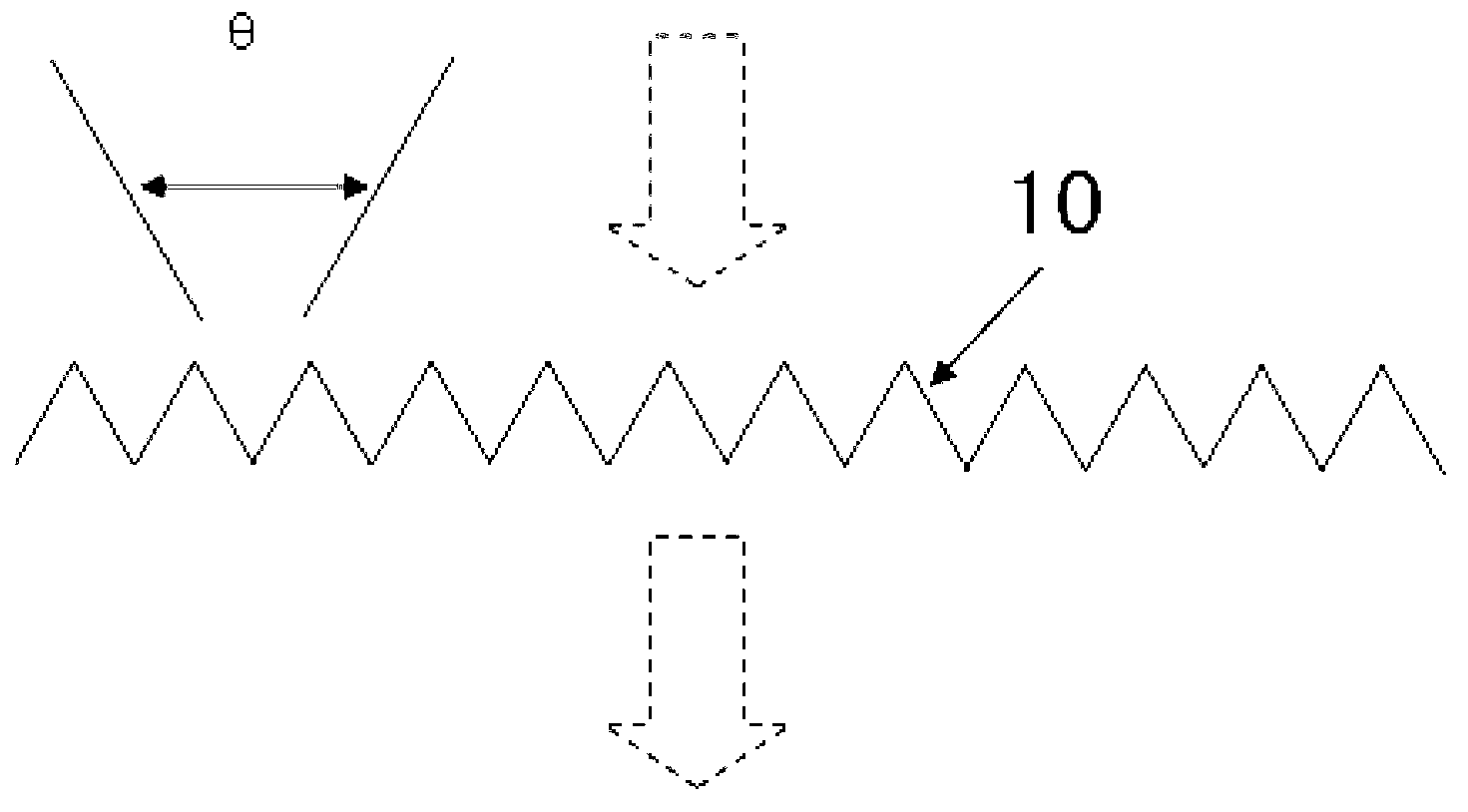

Dustproof mouth mask with dynamic breathing function

ActiveCN102793312AIncrease the effective filter areaSmall flow resistanceProtective garmentInhalationRespirator

The invention provides a dustproof mouth mask with a dynamic breathing function for a dust work environment. A filter material of the dustproof mouth mask adopts corrugated filter sponge, the adopted corrugated angle theta of the filter material is less than 60 DEG, a corrugated generating line is parallel to the gravity direction, and an air outlet and the downstream part of the filter material at an air inlet of the mouth mask are provided with a high-speed centrifugal fan respectively. On the premise of meeting the air flow for breathing of a human body, the effective filter area of the filter material is increased, the air speed is reduced, the flow resistance of the filter material is reduced, and the inhalation resistance is reduced. A micro electric air supplying and exhausting system and the micro high-speed centrifugal fan are adopted; and the requirement of the pressure in the inhaling process of the human body can be fully met, and the increment of the pressure in the inhaling process of the human body is controlled to be in the reasonable range at the same time. The breathing pressure difference of the novel mouth mask is controlled to be within 30 Pa, the structure design and the control of the whole system are simplified while the safety is met and the comfort is improved, and the mouth mask is small in volume, light in weight and convenient to carry.

Owner:BEIJING HUACHUANG KUANGAN TECH CO LTD

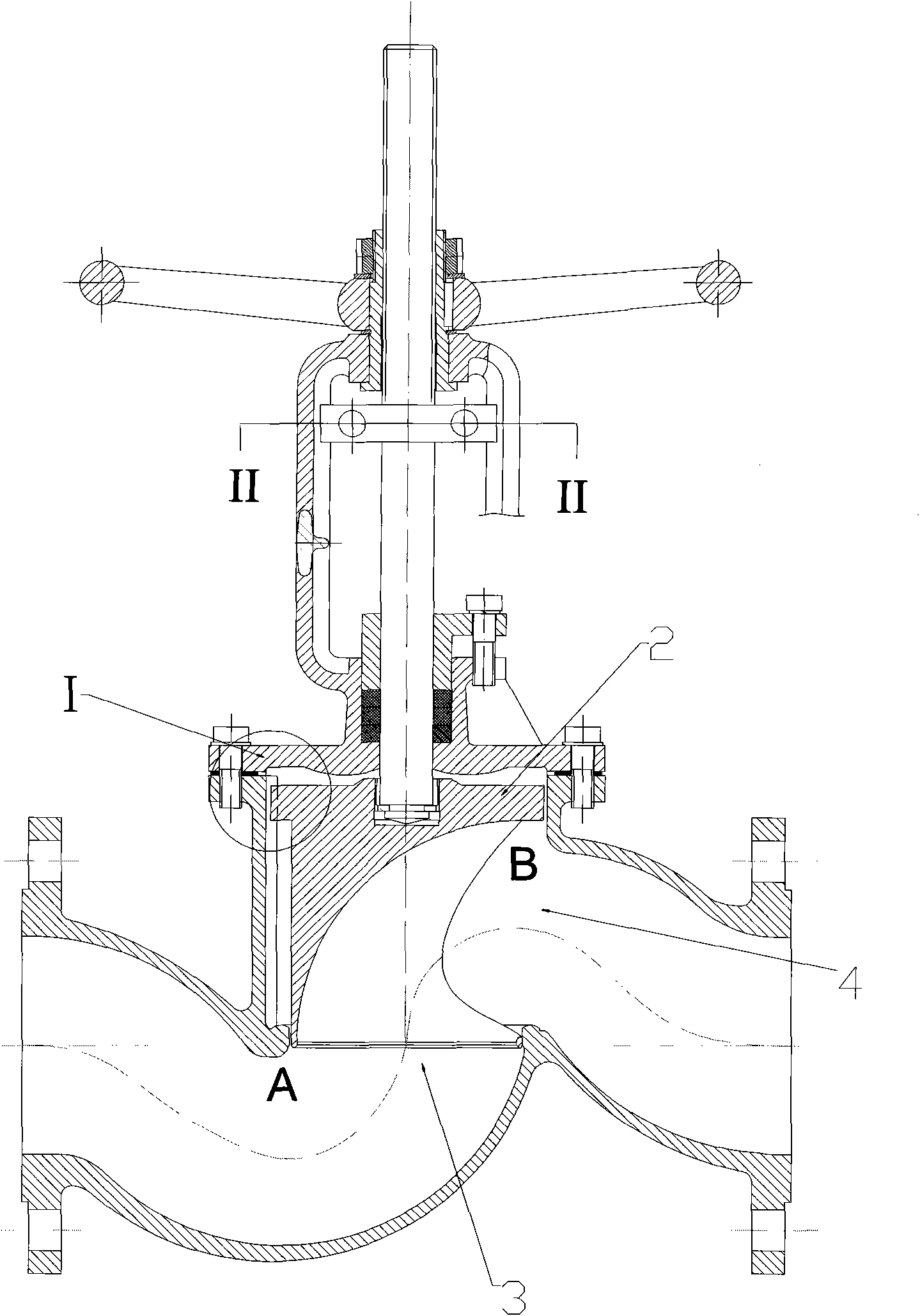

Stop valve of pipeline

The invention discloses a stop valve of a pipeline, which comprises a valve clack, wherein the valve clack comprises a sealed valve plate and a lower cylindrical body which is vertical to the valve plate; the internal surface of the lower cylindrical body of the valve clack is a cylindrical ring surface, the cylindrical ring surface is vertical to the sealed surface of a valve seat at a fluid inlet, and an outlet is tangential to an inlet of a valve body, i.e. the tangential line of the center line of the cylindrical ring surface at the outlet is superposed with the tangential line of the center line of the section at the inlet of the valve body. The cylindrical ring surface can be a cylindrical ring with equal diameter and can be also a cylindrical ring with variable diameter. The valve clack of the stop valve structure can lower the local resistance of the valve obviously, lower the pressure of a medium on a valve rod because the structure of the valve clack enables the medium to smoothly flow from an inlet of a valve cavity to an outlet, reduce the energy loss of the pipeline valve greatly, save the running cost of the pipeline and play an indispensable positive role in the aspects of environmental protection and energy saving.

Owner:GUANGDONG LIANSU TECH INDAL

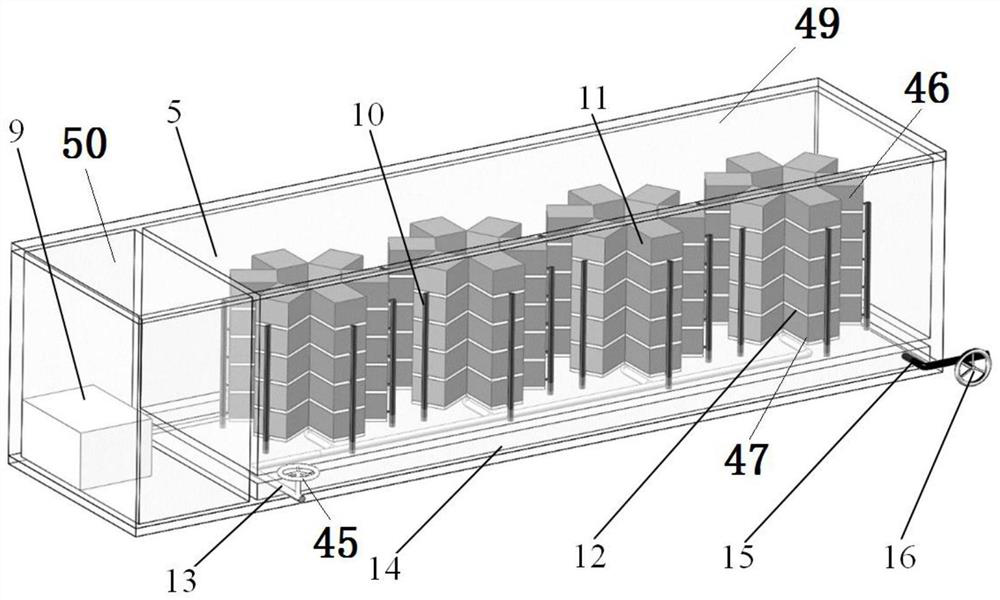

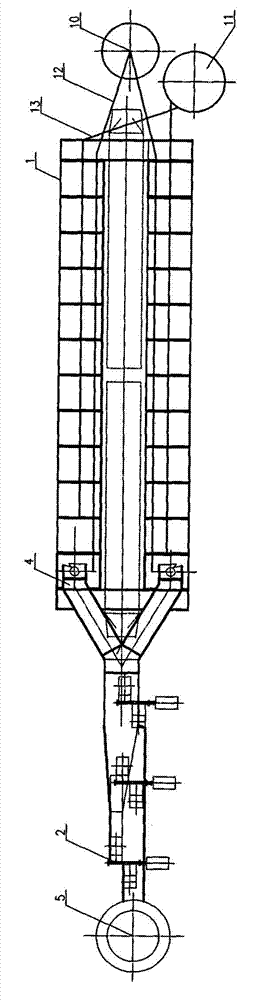

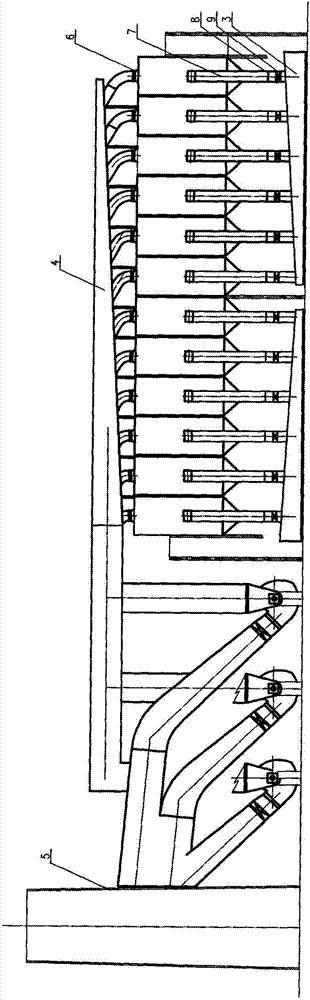

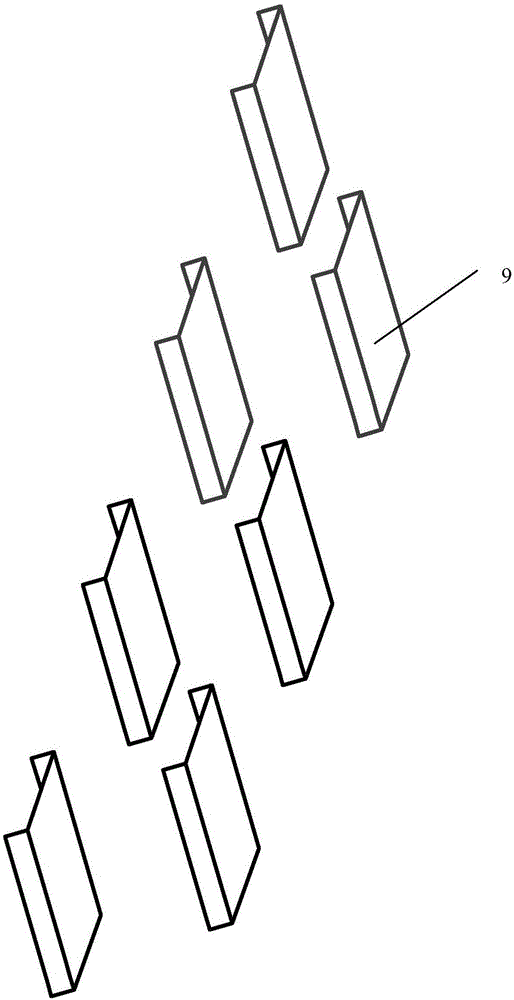

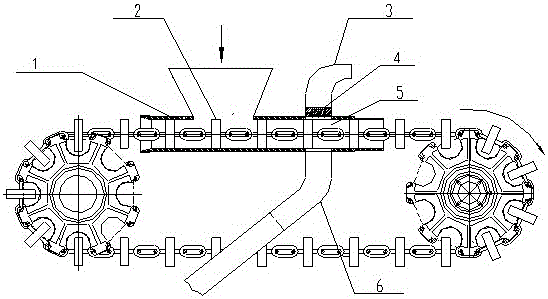

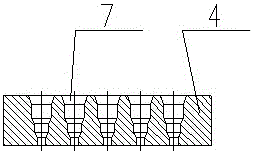

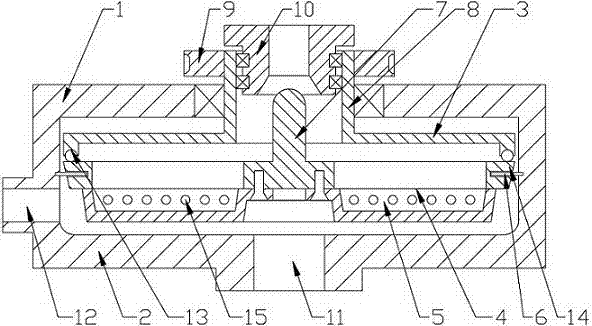

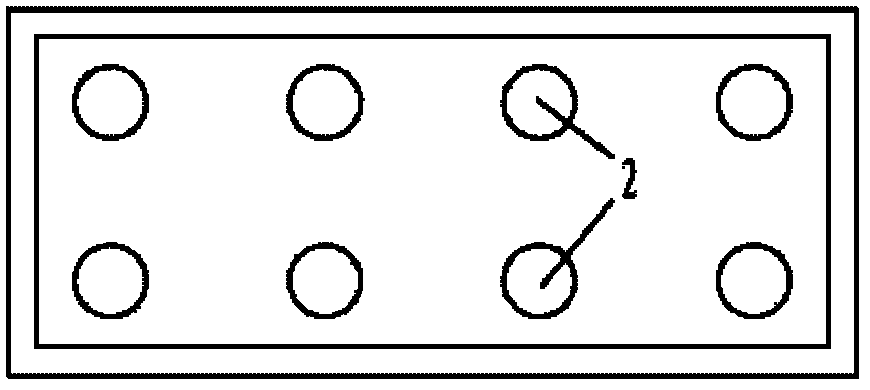

Electrochemical descaling device containing parallel scraper

InactiveCN105923709AAvoid short circuitImprove scraping effectSpecific water treatment objectivesWater/sewage treatment by electrochemical methodsDrive shaftDrive motor

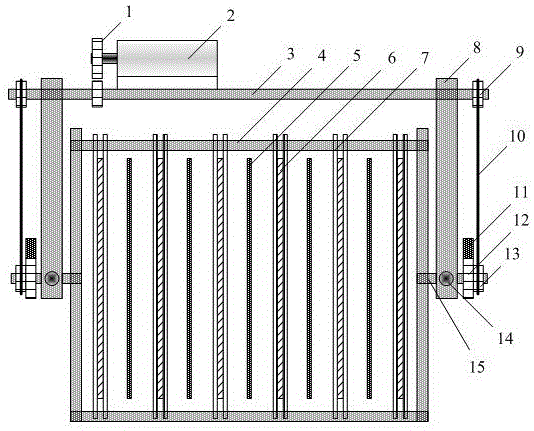

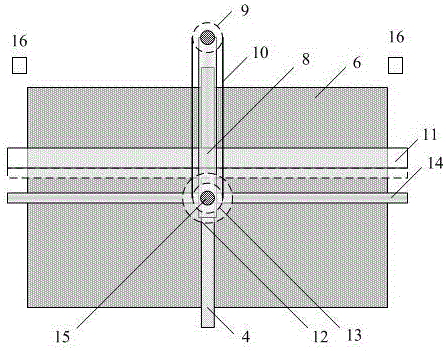

The invention relates to an electrochemical descaling device containing a parallel scraper. The electrochemical descaling device comprises a main driving gear 1, a driving motor 2, a driving shaft 3, a scraper fixing frame 4, an anode plate 5, a cathode plate 6, a scraper 7, a main driving frame 8, an upper driving gear 9, a chain 10, a rack 11, a sliding gear 12, a lower driving gear 13, a sliding rod 14, a connecting rod 15, and an infrared sensor 16, wherein a linkage mechanism drives the scraper 7 to go across the surface of the surface of the cathode plate 6, so as to remove scale adhered onto the surface of the cathode plate 6; the infrared sensor 16 senses the distance between the infrared sensor 16 and the main driving frame 8; when the main driving frame 8 approaches the infrared sensor 16, the driving motor 2 can perform contrarotation, and the scraper 7 can go across the surface of the cathode plate 6 in the opposite direction. The electrochemical descaling device adopts the scraper which is parallel with the cathode plates and slides back and forth, improves the descaling efficiency, and enhances the reliability of a mechanical structure.

Owner:卫士循环水处理(北京)有限公司

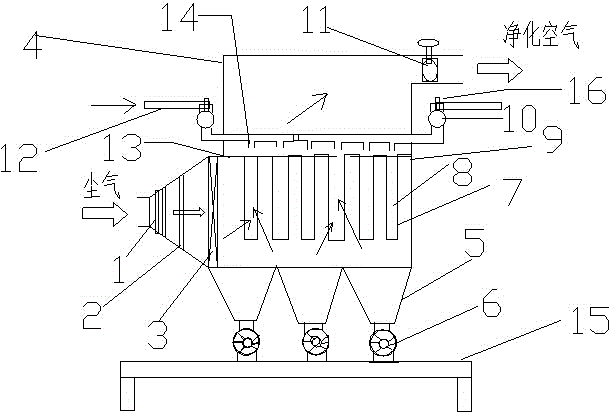

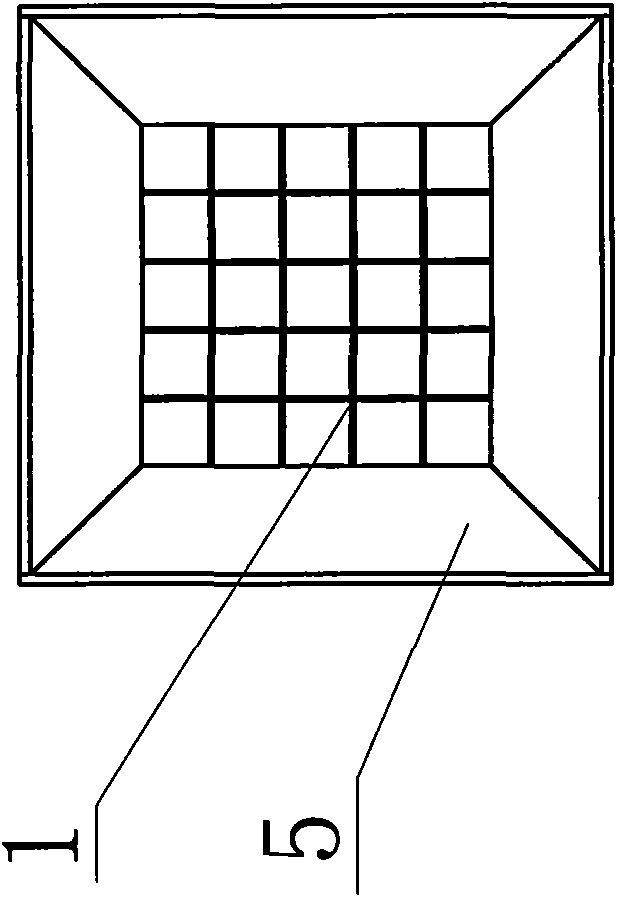

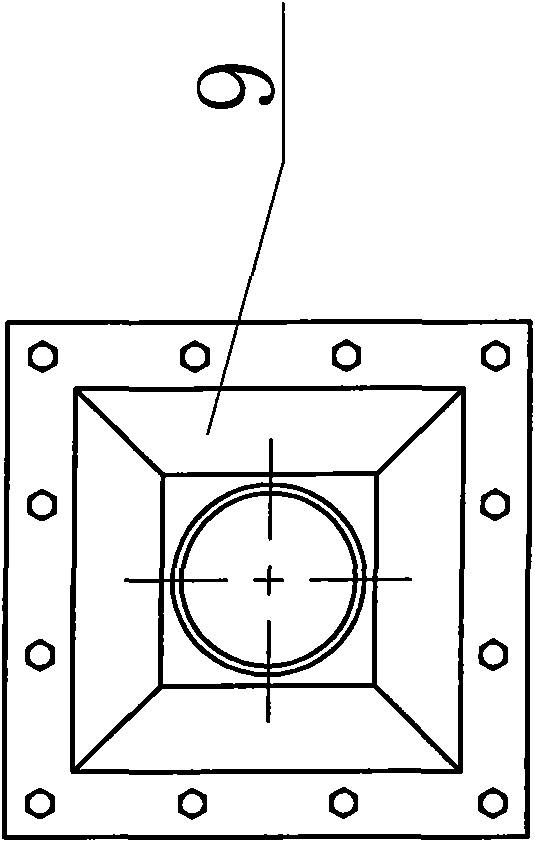

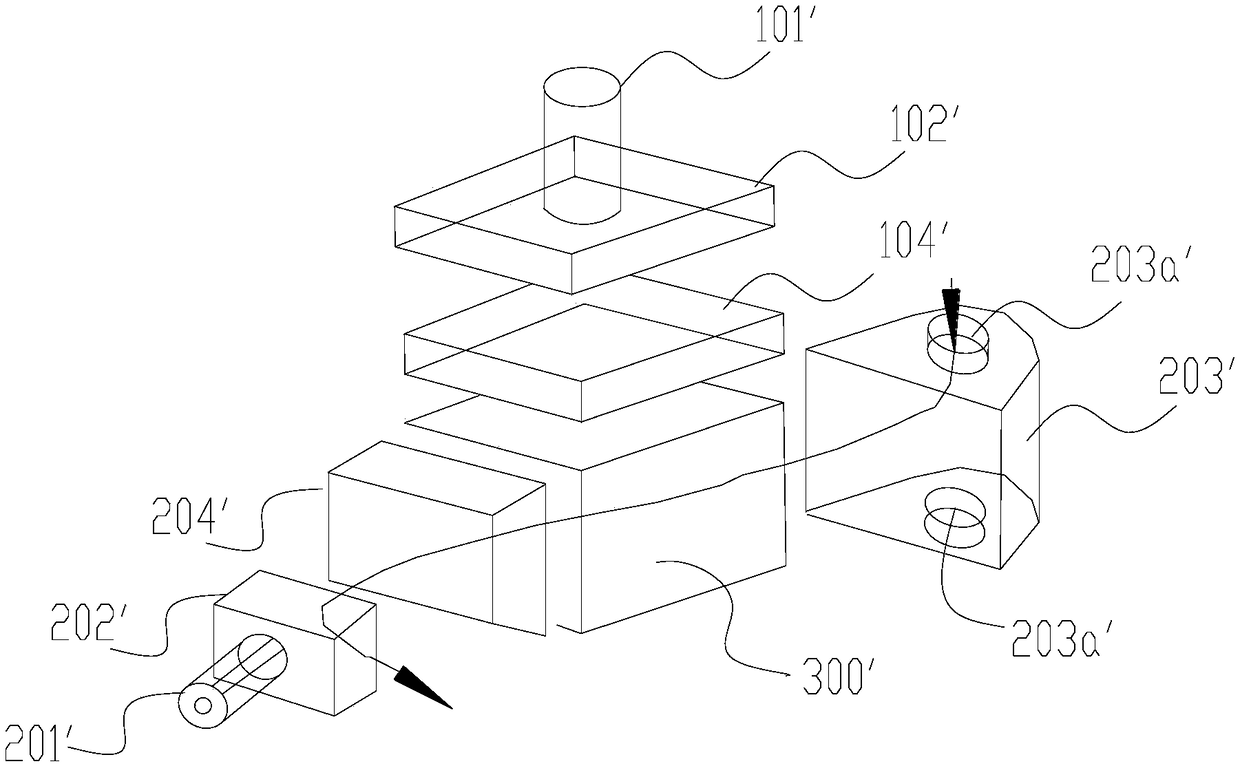

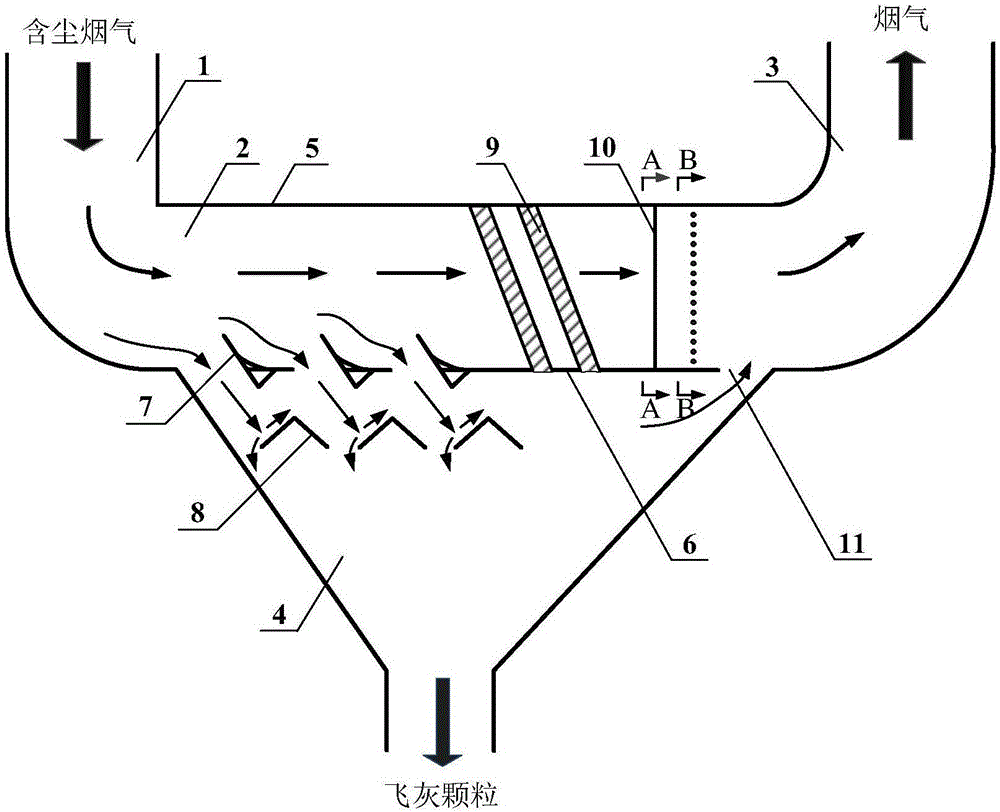

Direct-connection even-flow pulse bag type dust collector

PendingCN106823598AImprove cleaning efficiencySmooth air flowDispersed particle filtrationTransportation and packagingAir compressionAutomatic control

The invention relates to a direct-connection even-flow pulse bag type dust collector, which comprises an upper box body, a middle box body, an ash bucket, a skid mount package and an automatic control system. After dust air enters, the dust air which passes through a low efficient filter directly enters an air flow distribution device to be shunted; a filtering frame is arranged in each filtering bag to support the filtering bag to enable filtered purified air to flow to the upper box body; the automatic control system automatically controls a cabinet to close an air inlet valve when the resistance of the filtering bag reaches a certain value, pulse jet is carried out to remove dust on the surface of the filtering bag; an air compression bag and a pulse valve are opened, air filtered by a high efficiency filter directly enters an injection pipe, and dust on the filtering bag which is under the function of pulse external force falls. The air flow distribution device of the direct-connection even-flow pulse bag type dust collector has a reasonable structure, airflow which contains dust is conveyed to the filtering bags on different positions from a front side, side surfaces and the bottom surfaces, so that the washing of the airflow which contains dust for the filtering bags is avoided, and the flowing of the airflow which contains dust from bottom to top is slowed down so as to reduce the secondary attachment of the dust and guarantee the dust removal efficiency of the filtering bags.

Owner:易能环境技术有限公司

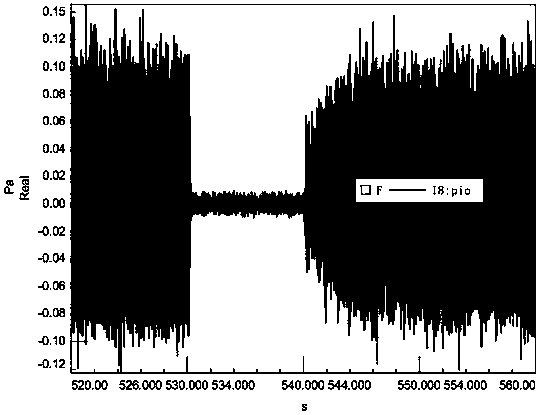

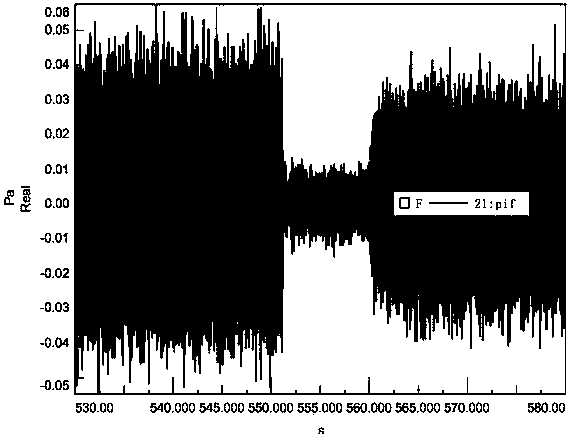

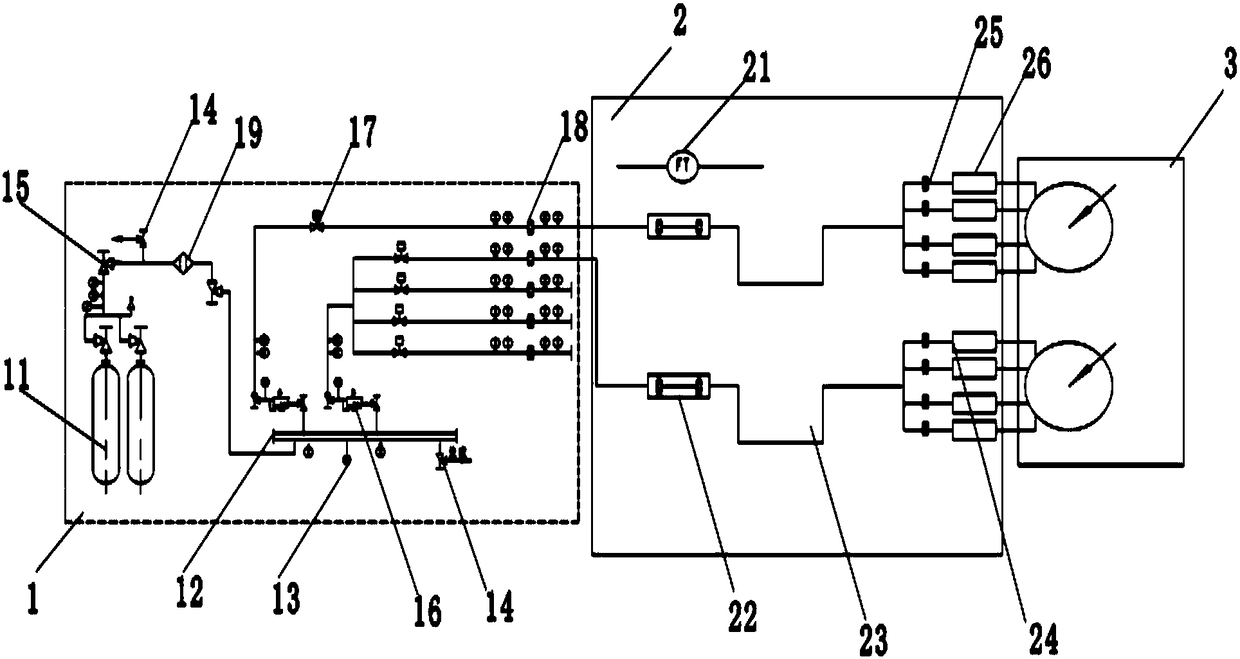

Engine test propellant supply low frequency ripple suppression method and system

ActiveCN108387378AEvenly distributedSelf-pulsation regulationGas-turbine engine testingJet-propulsion engine testingHeliumGas mixing

The invention relates to an engine test propellant supply low frequency ripple suppression method and system. Accurate helium injection is performed on the propellant supply pipeline, the inherent frequency of the propellant supply system is changed through gas mixing, and the ripple of the propellant can be adjusted through accurate control of the injection gas volume, the gas distribution and the injection gas form and the coupling situation of the propellant supply system and the engine can be reduced. With application of the method, the propellant supply ripple can be reduced, the propellant supply stability can be enhanced and thus the stability of the whole engine pump system can be enhanced. The method and the system are applied to the engine test.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

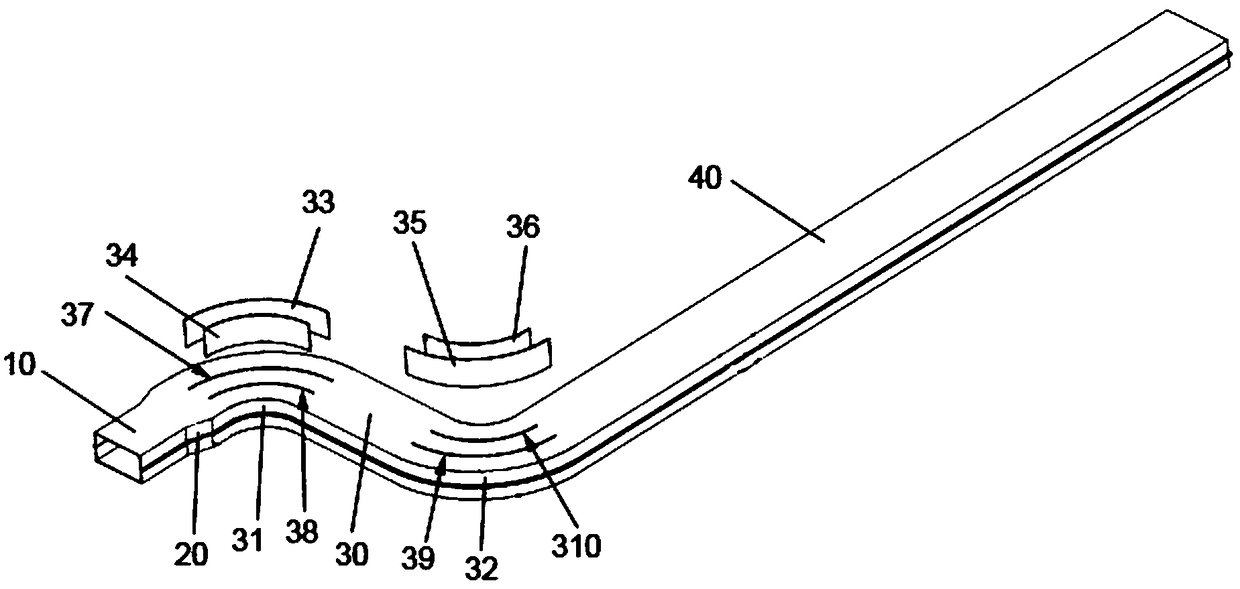

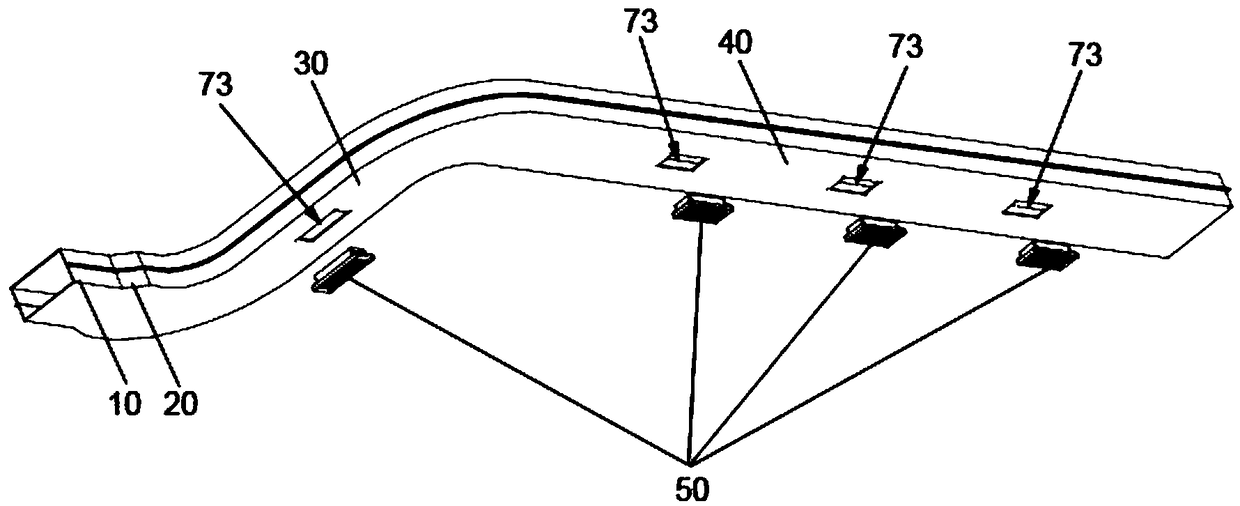

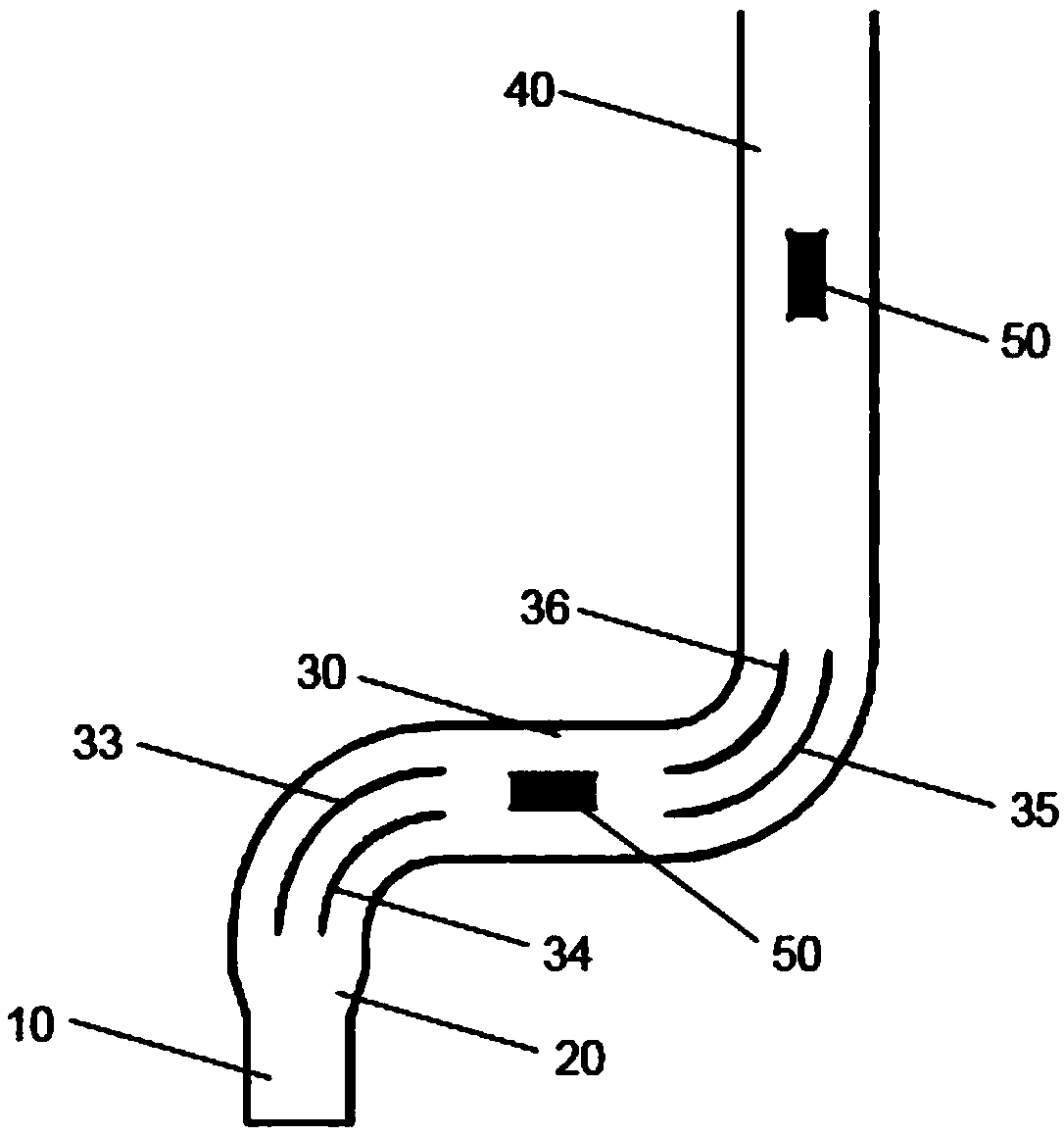

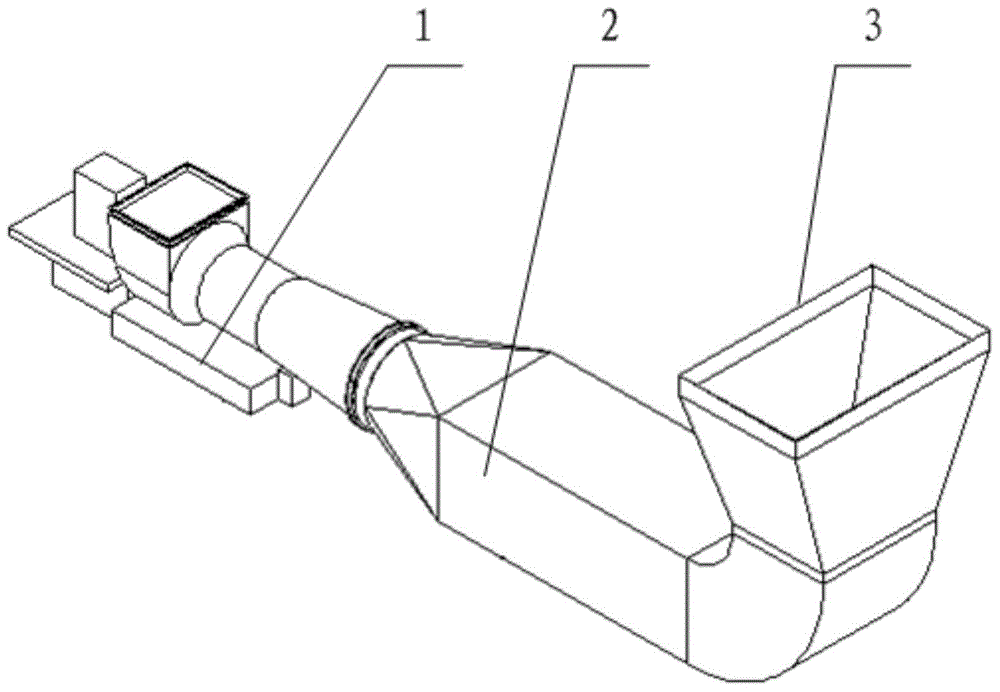

Noise reduction air duct of an automobile air conditioner

PendingCN108944340AReduce flow rateReduce aerodynamic noiseAir-treating devicesVehicle heating/cooling devicesAutomobile air conditioningEngineering

The invention provides a noise reduction air duct of an automobile air conditioner, which can solve the problems that the existing noise reduction air duct has complex structure, high manufacturing cost, and is not conducive to processing, installation and mass production. The invention aims at reducing the aerodynamic noise by reducing the airflow velocity in the air duct and avoiding the generation of the vortex. the noise reduction air duct comprises a noise reduction air duct body, the noise reduction air duct body comprises an air inlet section, a transition pipe section, a straight pipesection and a Z-shaped elbow section provided with two corners, The bottom surfaces of the Z-shaped elbow section and the straight pipe section are provided with grille-type air outlets, the air inletsection is butted with the air outlet of the automobile air conditioner, the two ends of the Z-shaped elbow pipe section are respectively connected with the transition pipe section and the straight pipe section, the transition pipe section is in the shape of a flared opening with a variable section, the small opening end of the transition pipe section is connected with the air inlet section, andthe large opening end is connected with the Z-shaped elbow pipe section.

Owner:SUZHOU JIANGNAN AEROSPACE MECHANICAL& ELECTRICAL IND CO LTD

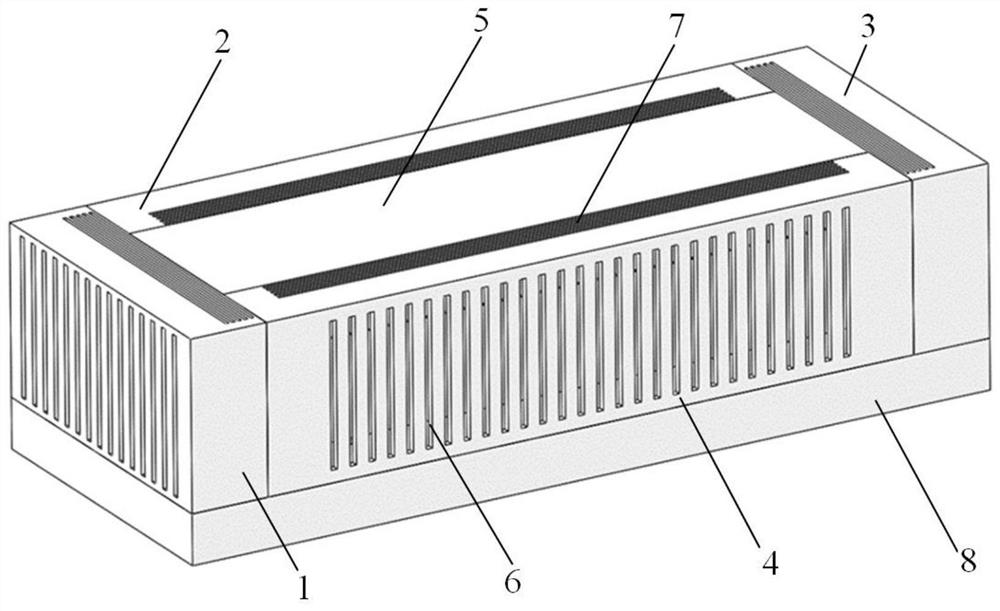

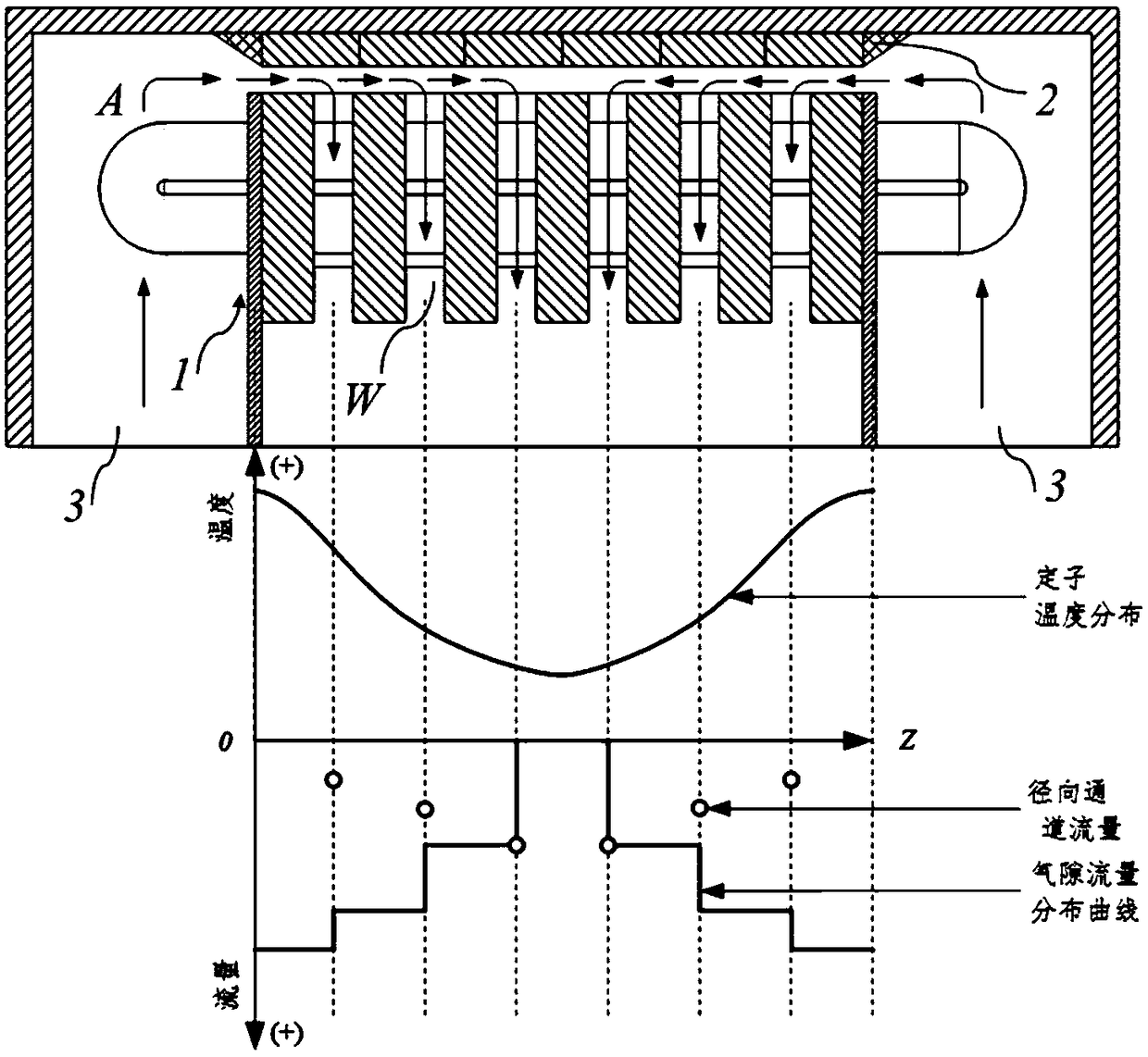

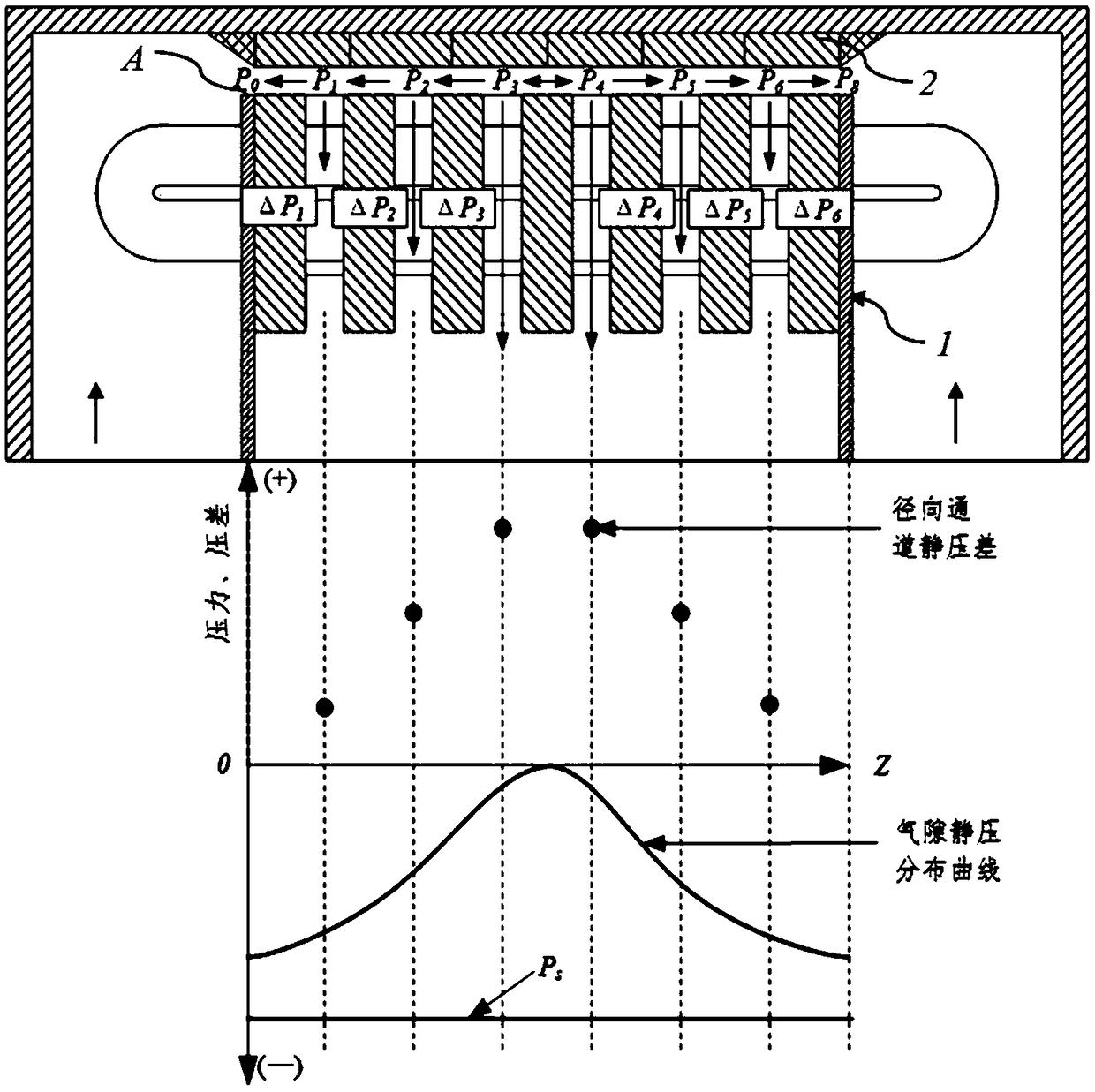

Slot wedge element, stator device, motor and wind turbine generator set

ActiveCN109149828AImprove cooling effectImprove power densityEngine fuctionsMagnetic circuit stationary partsCooling effectConductor Coil

The invention relates to a slot wedge element, a stator device, a motor and a wind turbine generator set. The slot wedge element is used for a stator device, the slot wedge element extends in a firstdirection and has opposite first and second edges, the slot wedge element has a first surface and a second surface in a thickness direction of the slot wedge element itself, and the slot wedge elementis attached to a winding of the stator device through the first surface; and the second surface includes a first portion, a second portion and a third portion sequentially distributed in the first direction; wherein a second thickness between the second portion and the first surface is greater than a first thickness between the first portion and the first surface and a second thickness is greaterthan or equal to a third thickness between the third portion and the first surface, the first thickness being distributed in a decreasing direction from the second portion to the first edge. The invention makes the cooling air in the radial channel of the stator device distribute more uniformly along the axial direction by setting the slot wedge element, and improves the cooling effect of the motor.

Owner:XINJIANG GOLDWIND SCI & TECH

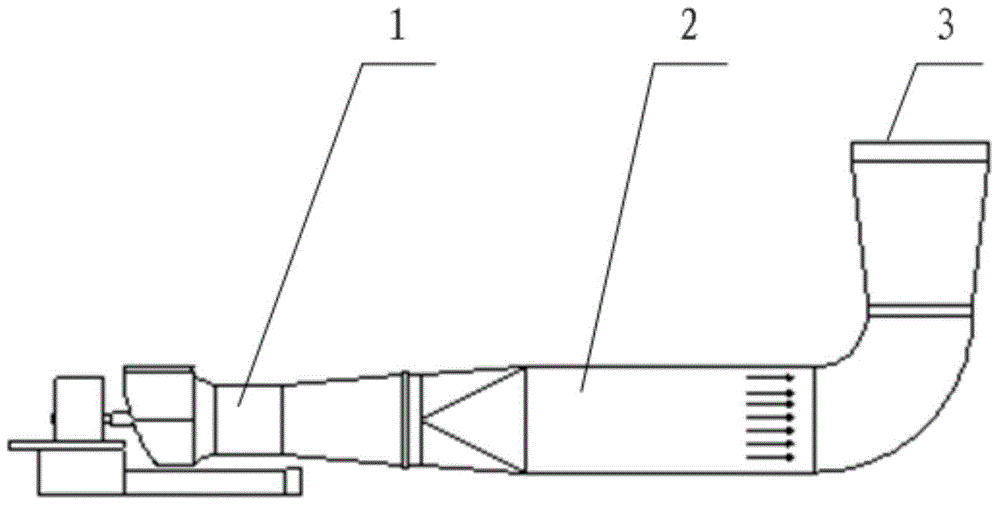

Flue-gas and air system and flow guide device, of flue-gas and air system, at cold secondary air inlet of air preheater

ActiveCN105042624AImprove heat transfer effectGuaranteed uniformityCombustion processIndirect carbon-dioxide mitigationAir preheaterFlue gas

The invention discloses a flow guide device at a cold secondary air inlet of an air preheater. The flow guide device is used for a thermal power plant and comprises a first connecting device which is used for being connected with an air feeder and has a certain dispersion angle. The outlet end of the first connecting device is circular. The flow guide device further comprises a flow dividing piece, bent pipes and square circular sections. The flow dividing piece is used for flow dividing and comprises a plurality of circular air pipes, and the inlet end of the flow dividing piece is connected with the outlet end of the first connecting device. The bent pipes are connected with the outlet ends of the circular air pipes of the flow dividing piece, and the number of the bent pipes is equal to the number of the circular air pipes of the flow dividing piece. The square circular sections are connected with the outlet ends of the bent pipes, and the number of the square circular sections is equal to the number of the bent pipes. According to the flow guide device, an original circular air pipe is changed into the multiple circular air pipes through the flow dividing piece, the evenness of air flow at the cold secondary air inlet of the air preheater is improved accordingly, and the heat exchange effect of the air preheater is improved accordingly. The invention further discloses a flue-gas and air system.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

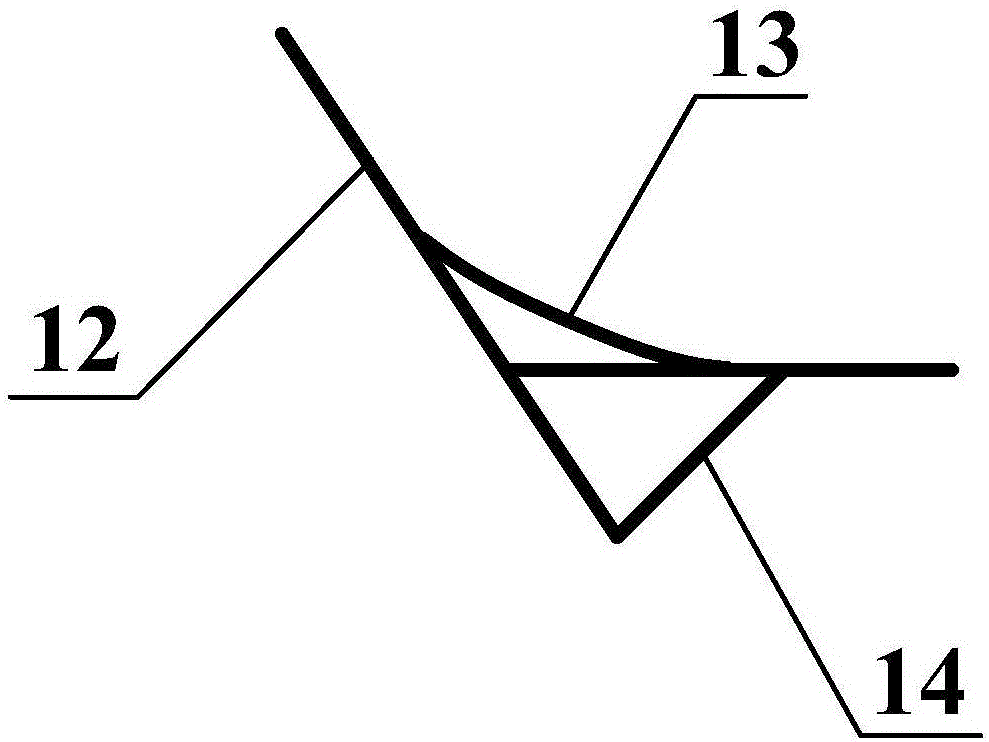

Flare gas system baffle molecular sealer

InactiveCN102287833AAvoids the danger of plugging flare gas ventsReduce resistanceIncinerator apparatusEngineeringFlare

A baffle molecular sealer for a flare gas system, which includes a housing (8), an inlet flange (1) is installed at the lower end of the housing (8), and an outlet flange (10) is installed at the other end of the housing (8). The feature is that an upward upward baffle (12) is installed at the entrance of the lower end of the housing (8), and the upward baffle (12) is connected by one end to the entrance of the lower end of the housing (8). The inclined arc plate is composed of an upward straight plate connected with the arc plate, and a downward descending baffle (9) is installed at the outlet of the upper end of the housing (8), and the descending baffle ( 9) It is composed of a downward-sloping arc plate connected at one end to the outlet of the upper end of the casing (8) and a downward straight plate connected with the arc-shaped plate. The upward baffle (12), the downward baffle An upward channel (16) and a downward channel (17) for flare gas are formed between the flow plate (9) and the inner wall of the casing (8). The invention has the advantages of simple structure, light weight and good safety.

Owner:JIANGSU SUNPOWER TECH

Open experiment device for teaching local resistance measurement during air flowing

InactiveCN101635109AReduce local resistanceReduce resistanceFluid speed measurement using pressure differenceFluid pressure measurement by electric/magnetic elementsElectricityEngineering

An open experiment device for teaching the local resistance measurement during air flowing relates to an experiment device for measuring the local resistance during the air flowing. The open experiment device aims at measuring the change of local flowing resistance in the flowing process, which happens together with the change of a flow passage and the change of flowing speed, so as to further obtain a flow passage structure with the minimum flowing resistance in the same wind speed. A frequency-variable speed-regulating draught fan is communicated with a small end of a retraction section tube. An experiment section is arranged between two measurement section tubes and detachably communicated with one end of each of the two measurement section tubes. Each measurement section tube is provided with a Pitot tube. Each Pitot tube is connected with an electronic microtasimeter. The middle part of the lateral wall of each measurement section tube is provided with at least two pressure obtaining holes. The pressure obtaining holes on the two measurement section tubes are respectively communicated with pipelines and connected with the electronic microtasimeters for measuring pressure difference. Due to the open experiment device, the flow passage structure with the minimum flowing resistance in the same wind speed can be obtained. The resistance in the flowing process is reduced so that the power of the fan for driving the flow is greatly lowered, the electricity consumption is reduced, and the energy is saved.

Owner:HARBIN INST OF TECH

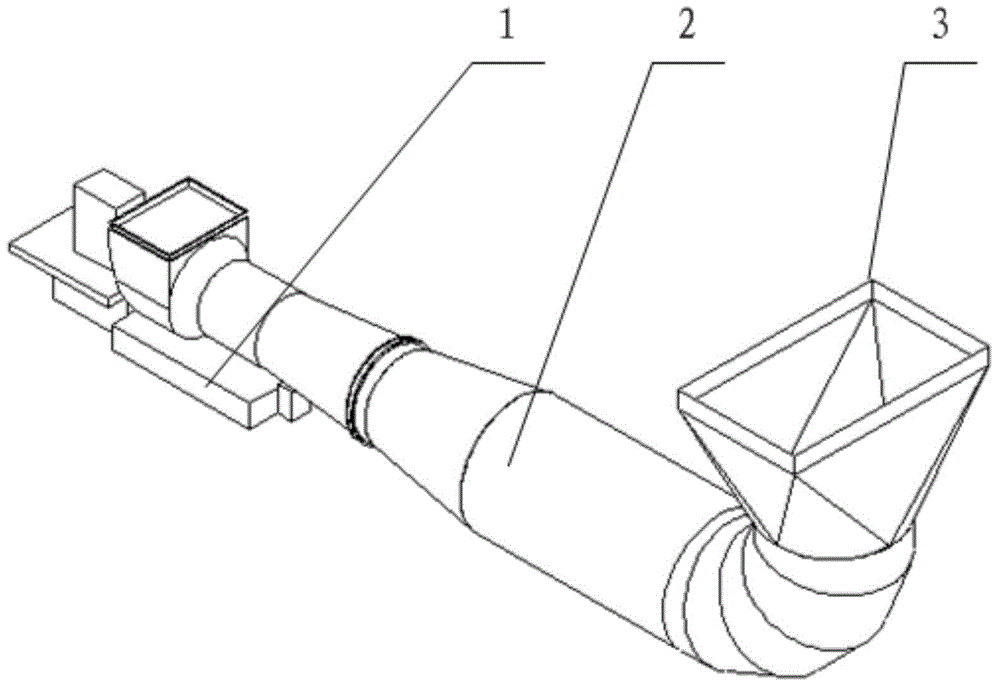

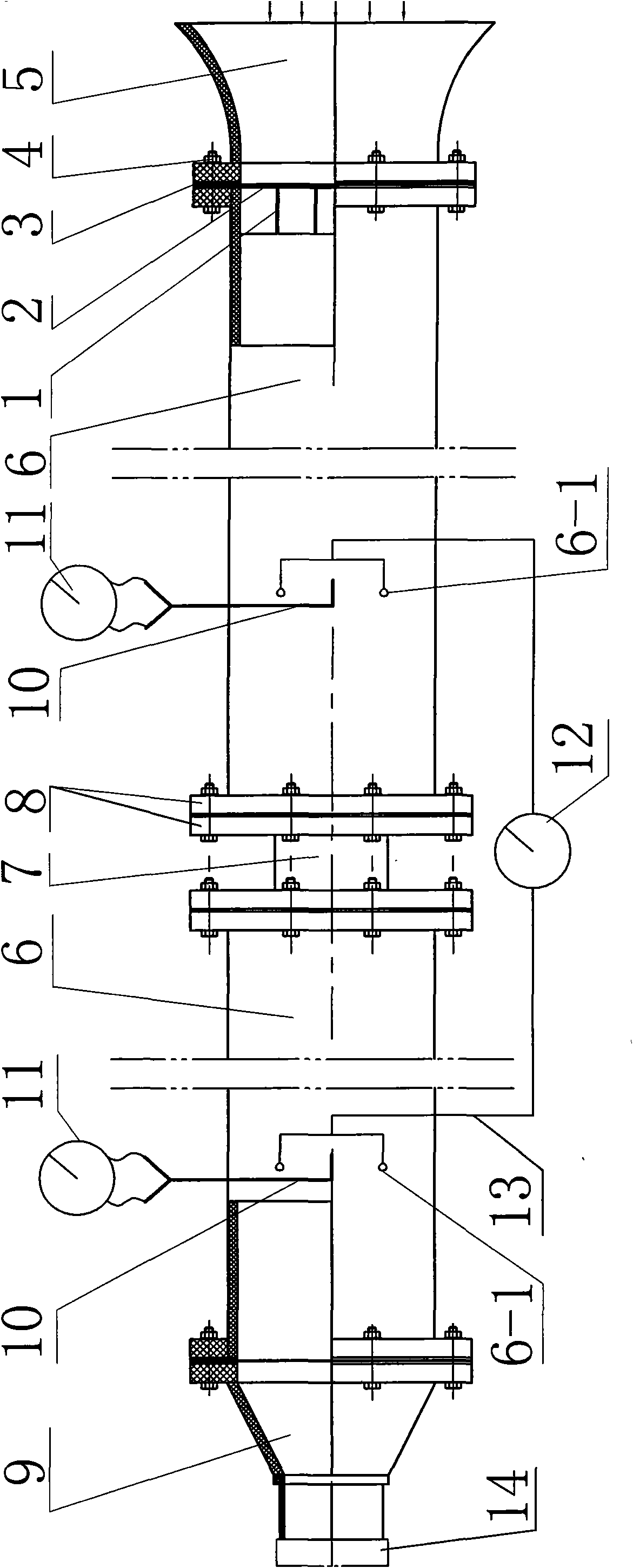

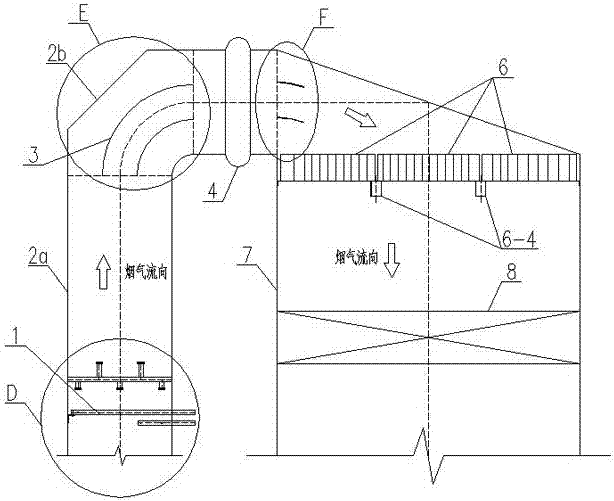

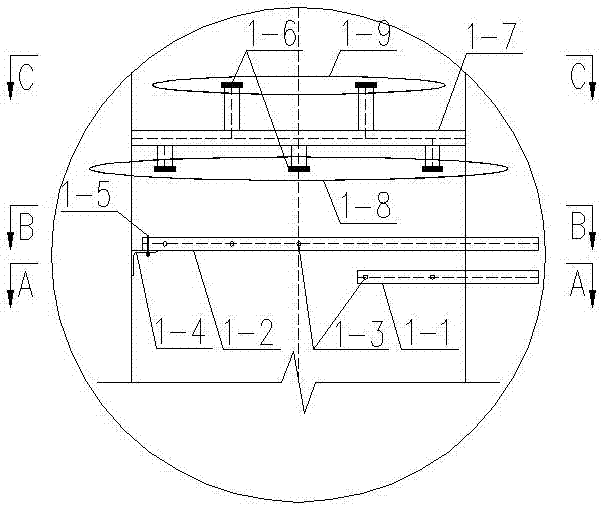

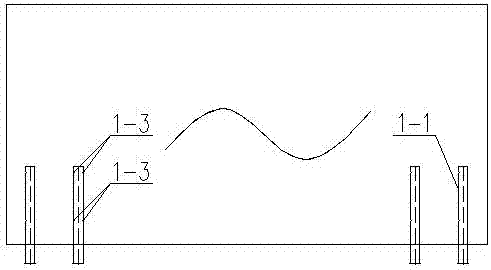

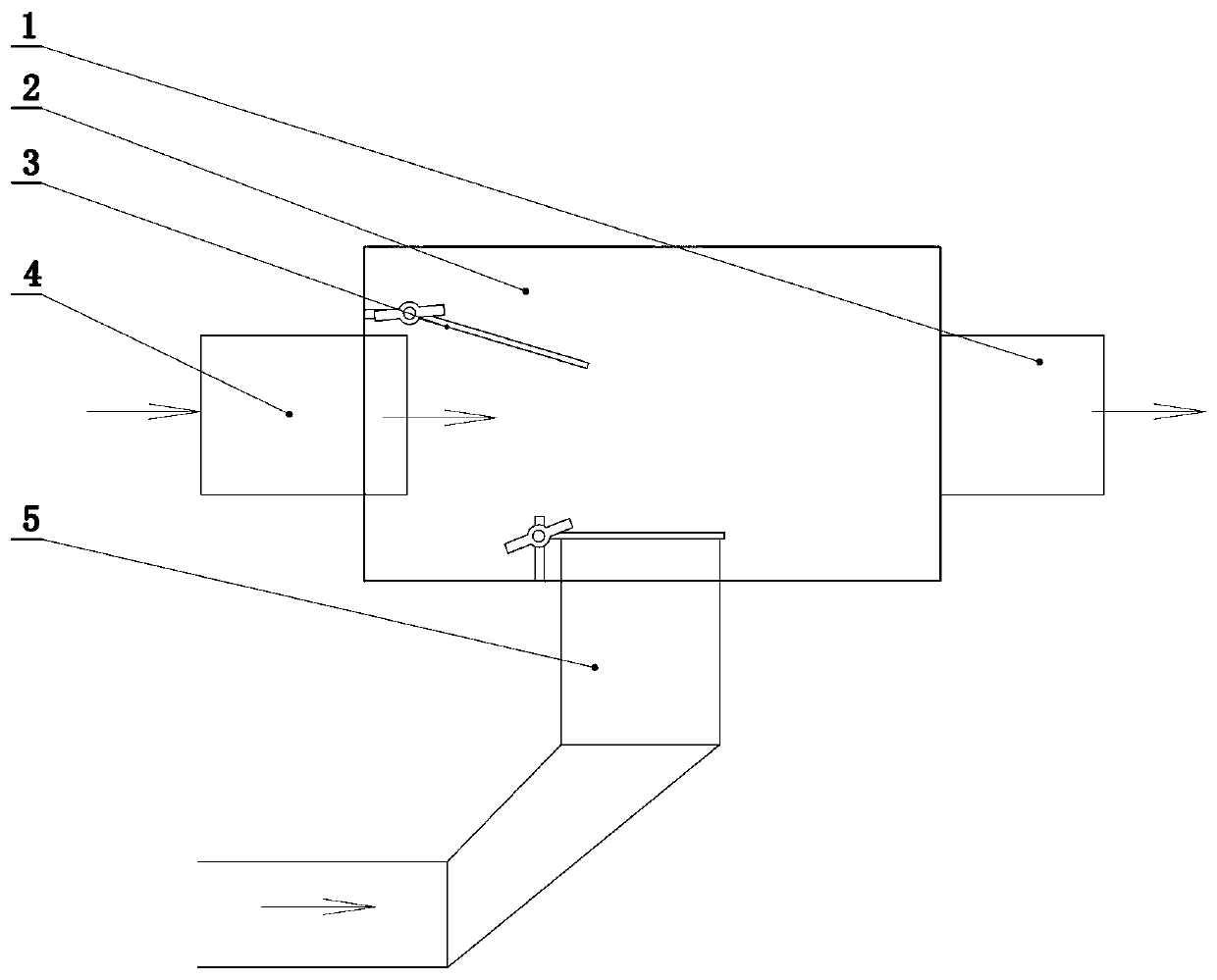

SCR denitrification ammonification and flow field homogeneous structure and operating method thereof

PendingCN107126835AEfficient mixingImprove the flow fieldGas treatmentDispersed particle separationMixed flowFlue gas

The invention provides an SCR denitrification ammonification and flow field homogeneous structure and an operating method thereof. The structure has the advantages of high mixing uniformity between ammonia gas and flue gas, reasonable flow field, low local resistance and simple configuration. Ammonification pipe series are fixed in a linear-segment flue; the ammonification pipe series are provided with ammonification holes; the outer bend of the bend flue is composed of an outer-chamfer plate; the inner bend of the bend flue is composed of an inner arc plate; a front guide plate is fixed in the bend flue; a back guide plate is fixed to the inside of an inlet of a reactor; and a rectifier unit module is fixed in the reactor. Ammonia gas is quickly ejected via the ammonification holes of the ammonification pipe series, and is subjected to opposed-flow diffusion and taken away by the flue gas; ammonia molecules are further diffused under the barrier action of mixed flow plates of mixed flow assemblies, are divided to the two sides of the mixed flow plates at higher speed, are subjected to slow guiding after sufficient mixing, and finally, are uniformly dispersed in the flue gas; and the flue gas is adjusted and distributed uniformly by the rectifier unit module and reaches the catalyst on the first layer.

Owner:CHINA UNITED ENG

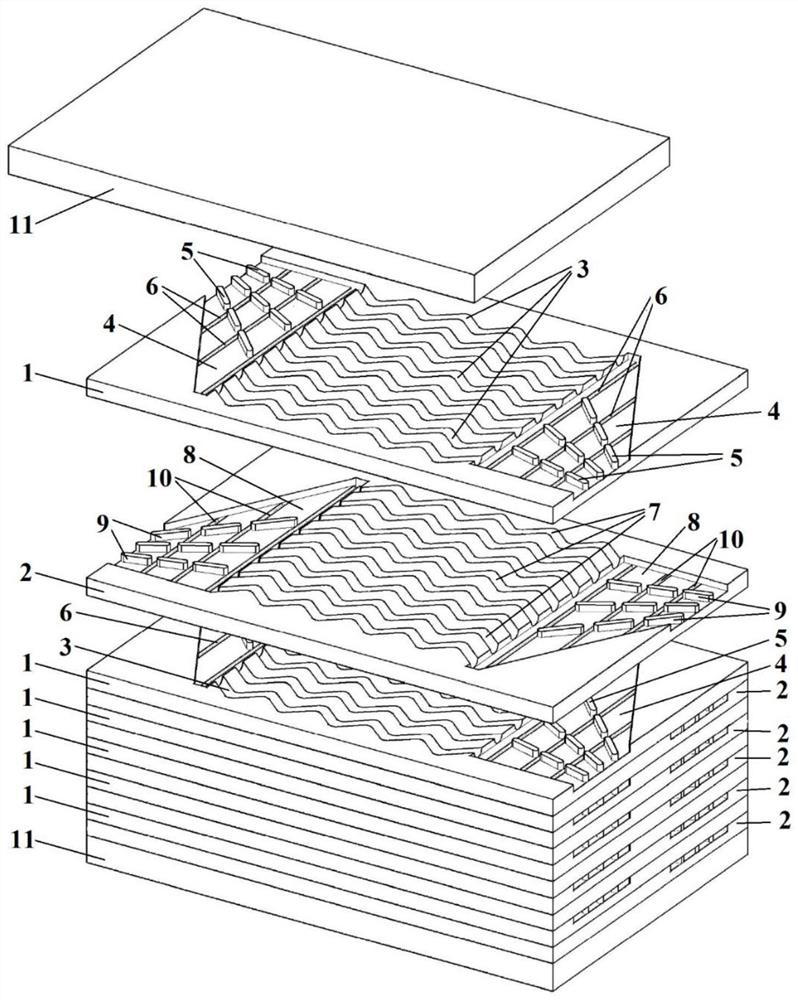

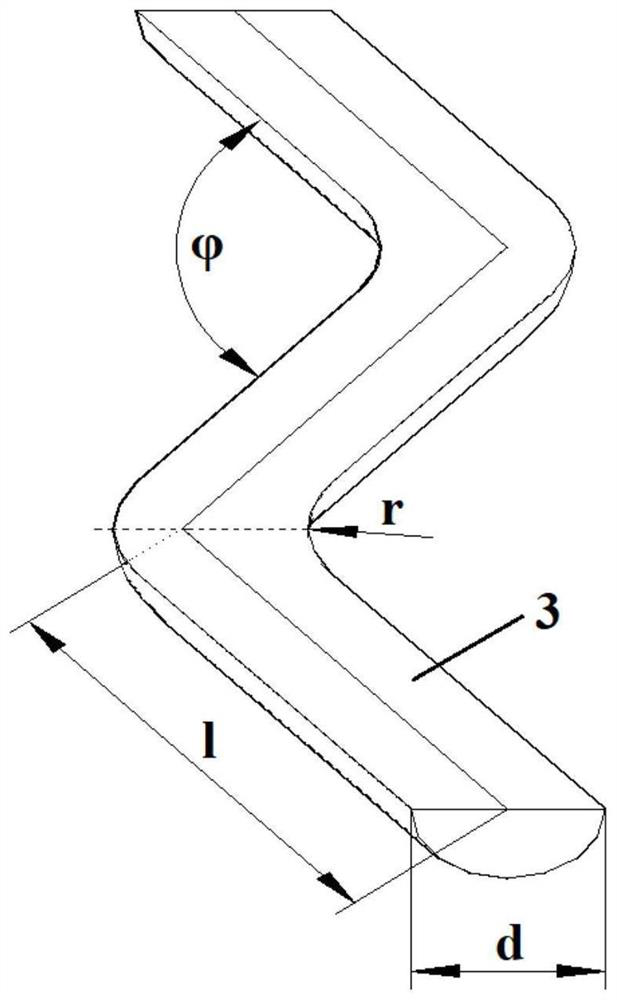

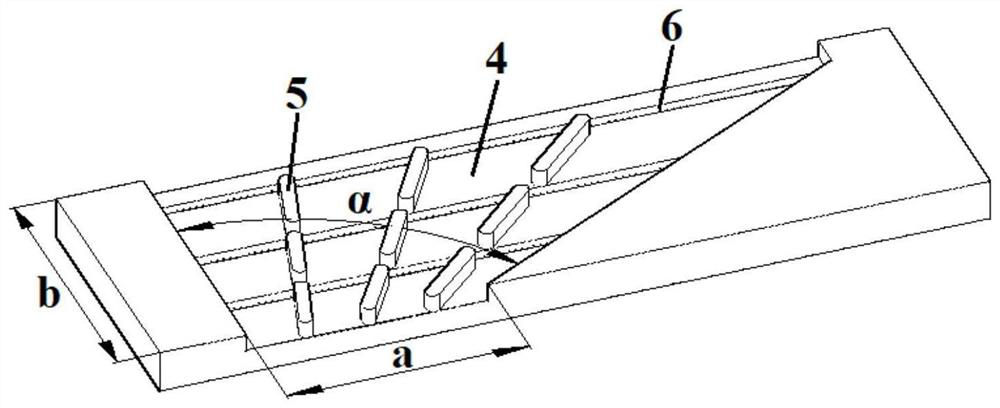

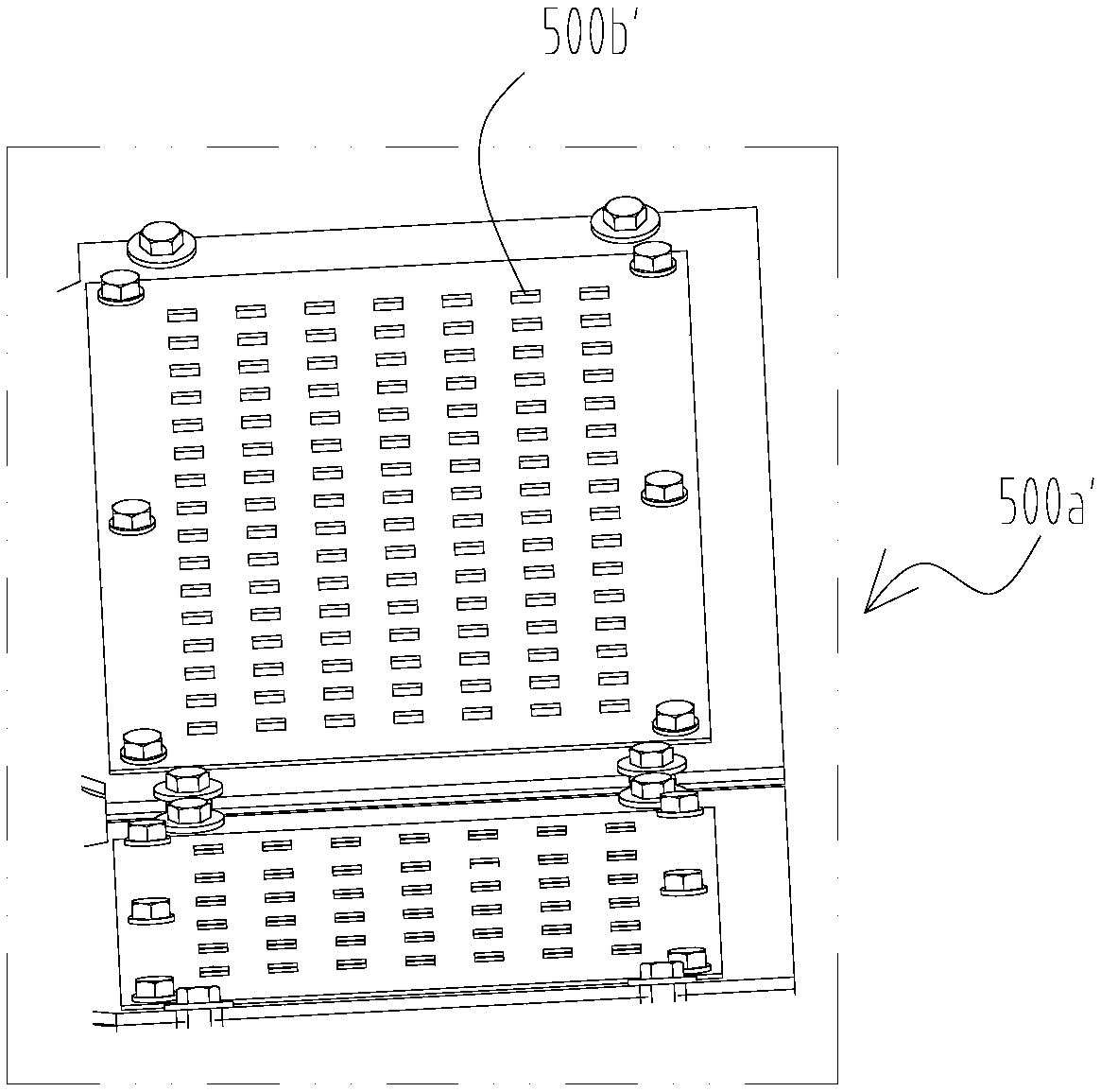

Micro-channel plate heat exchanger core with flow guide areas and fillets and manufacturing method of micro-channel plate heat exchanger core

PendingCN112033193AImprove heat transfer performanceLower heat transfer coefficientCorrosion preventionLaminated elementsPlate heat exchangerEngineering

The invention discloses a micro-channel plate heat exchanger core with flow guide areas and fillets and a manufacturing method of the micro-channel plate heat exchanger core. The micro-channel plate heat exchanger core is formed by stacking and combining a plurality of high-temperature medium plates, a plurality of low-temperature medium plates and a plurality of end plates in the plate thicknessdirection; high-temperature medium runners and high-temperature medium flow guide areas are arranged on the upper surfaces of the high-temperature medium plates, and high-temperature medium flow guidefins and high-temperature medium collection grooves are arranged in the high-temperature medium flow guide areas; and low-temperature medium runners and low-temperature medium flow guide areas are arranged on the upper surfaces of the low-temperature medium plates, and low-temperature medium flow guide fins and low-temperature medium collection grooves are arranged in the low-temperature medium flow guide areas. The micro-channel plate heat exchanger core is high in heat transfer capacity, low in resistance loss, uniform in fluid distribution and high in heat efficiency.

Owner:XIAN THERMAL POWER RES INST CO LTD

Intelligent flow balancing device

InactiveCN105736778AReduce local resistanceRealize real-time monitoring functionEqualizing valvesSafety valvesValve actuatorProcess engineering

The invention discloses an intelligent flow balancing device. The intelligent flow balancing device comprises an intelligent water valve actuator, temperature sensors, a water supply pressure sensor, flow balancing valves and pilot tube flowmeters, wherein the intelligent water valve actuator is arranged on a pipeline, the temperature sensors are arranged on a water supply pipeline and a water return pipeline, the water supply pressure sensor is arranged on the water supply pipeline, the flow balancing valves are arranged on the water supply pipeline and the water return pipeline and controlled by the intelligent water valve actuator, the pilot tube flowmeters are arranged between the flow balancing valves and the intelligent water valve actuator, and a calculation chip is arranged in the intelligent water valve actuator. By the adoption of the intelligent flow balancing device, a straight-through type valve is used for reducing local resistance; flow sensors and the temperature sensors are arranged on all branched pipes, and the calculation chip is arranged in the intelligent water valve actuator so that the balance of a system can be re-adjusted according to the actual operating condition while the monitoring function is achieved, the maintenance cost is reduced, the structure is simple, and operation is convenient.

Owner:常州金利智能科技有限公司

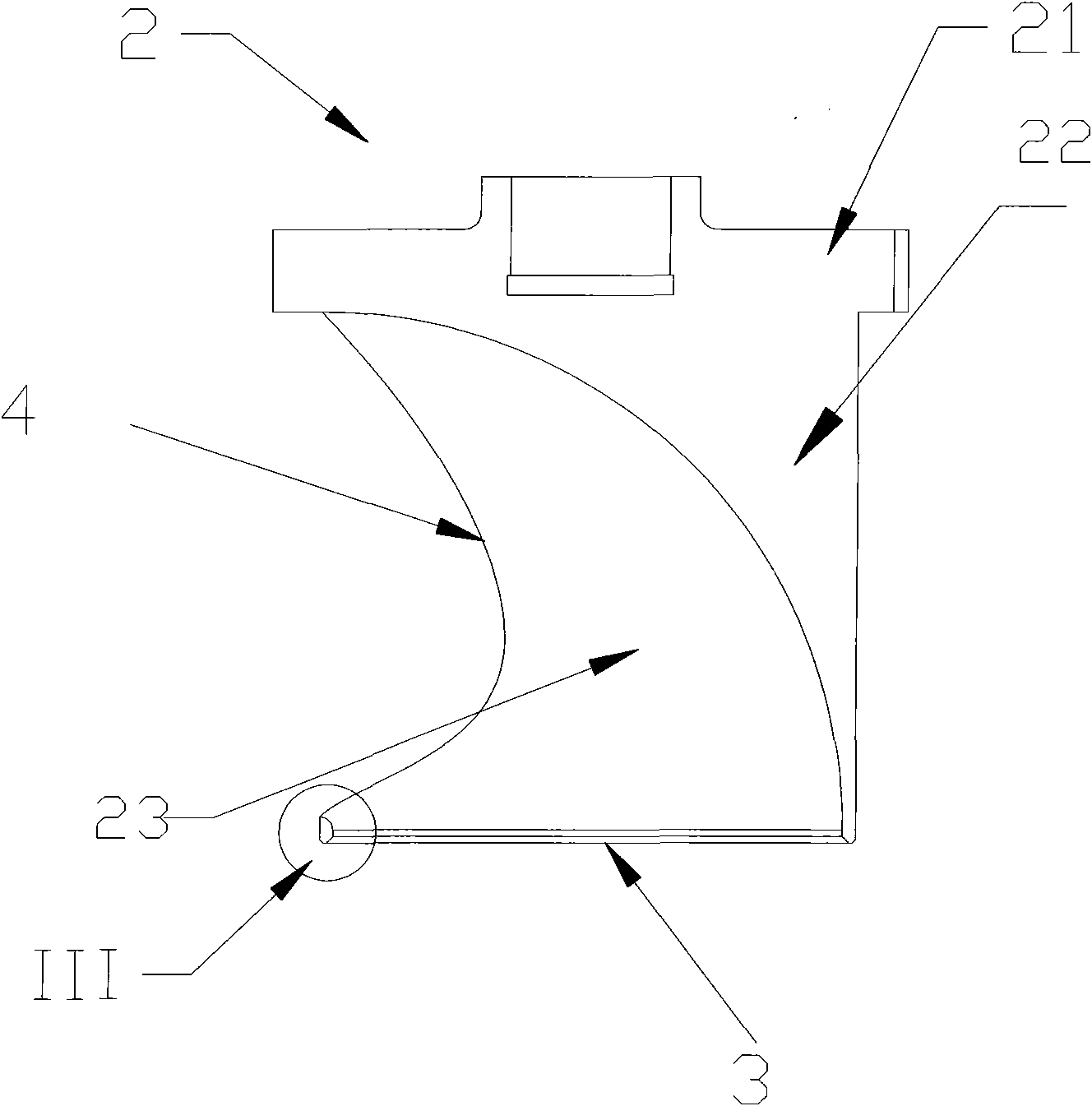

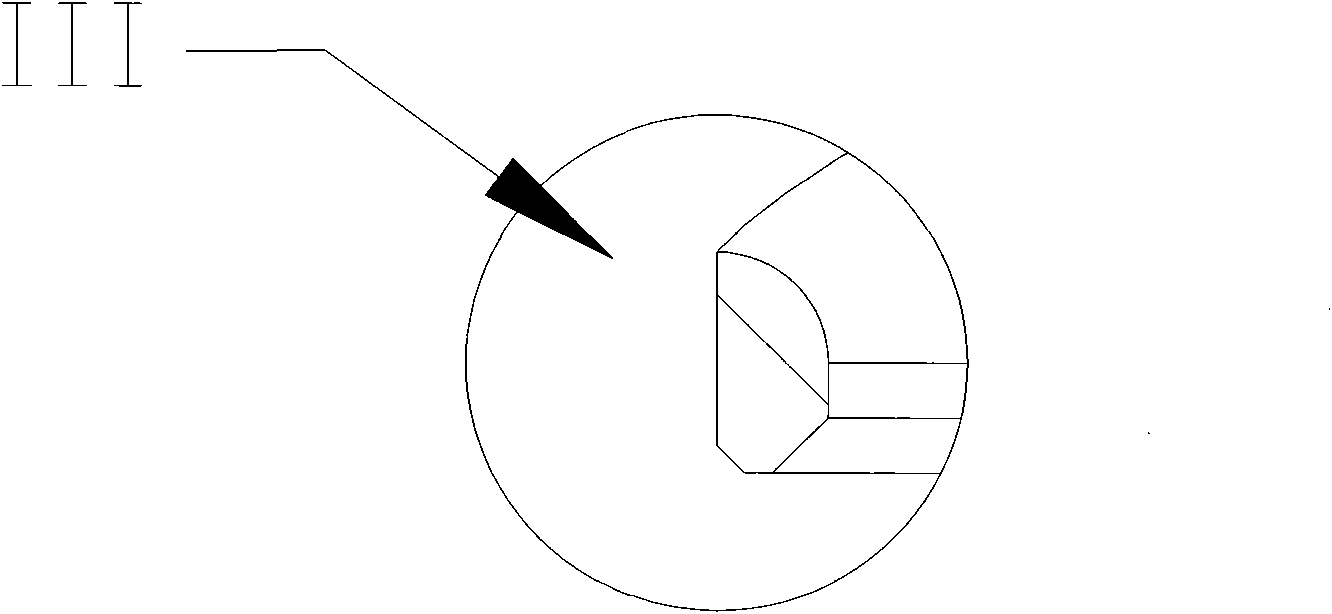

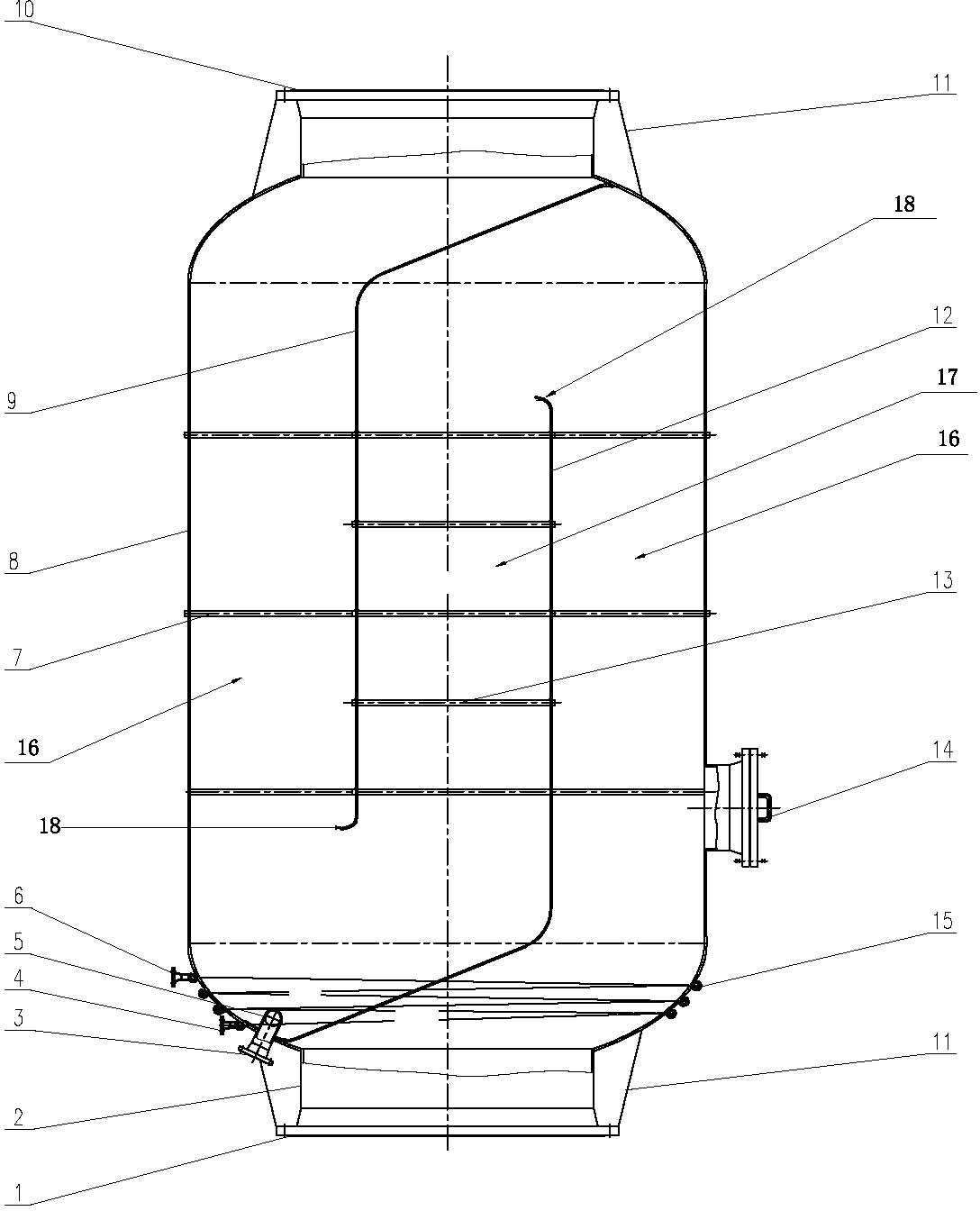

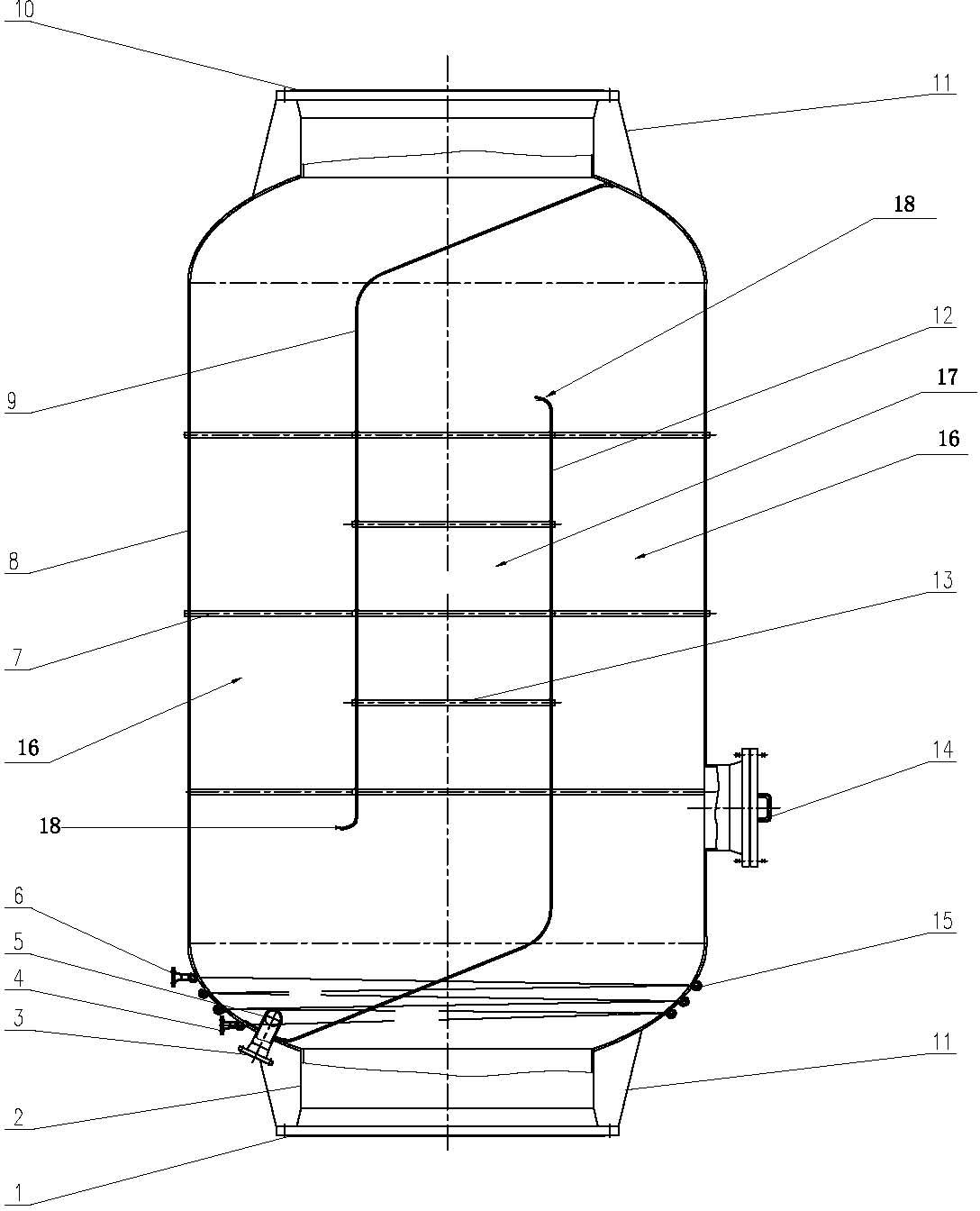

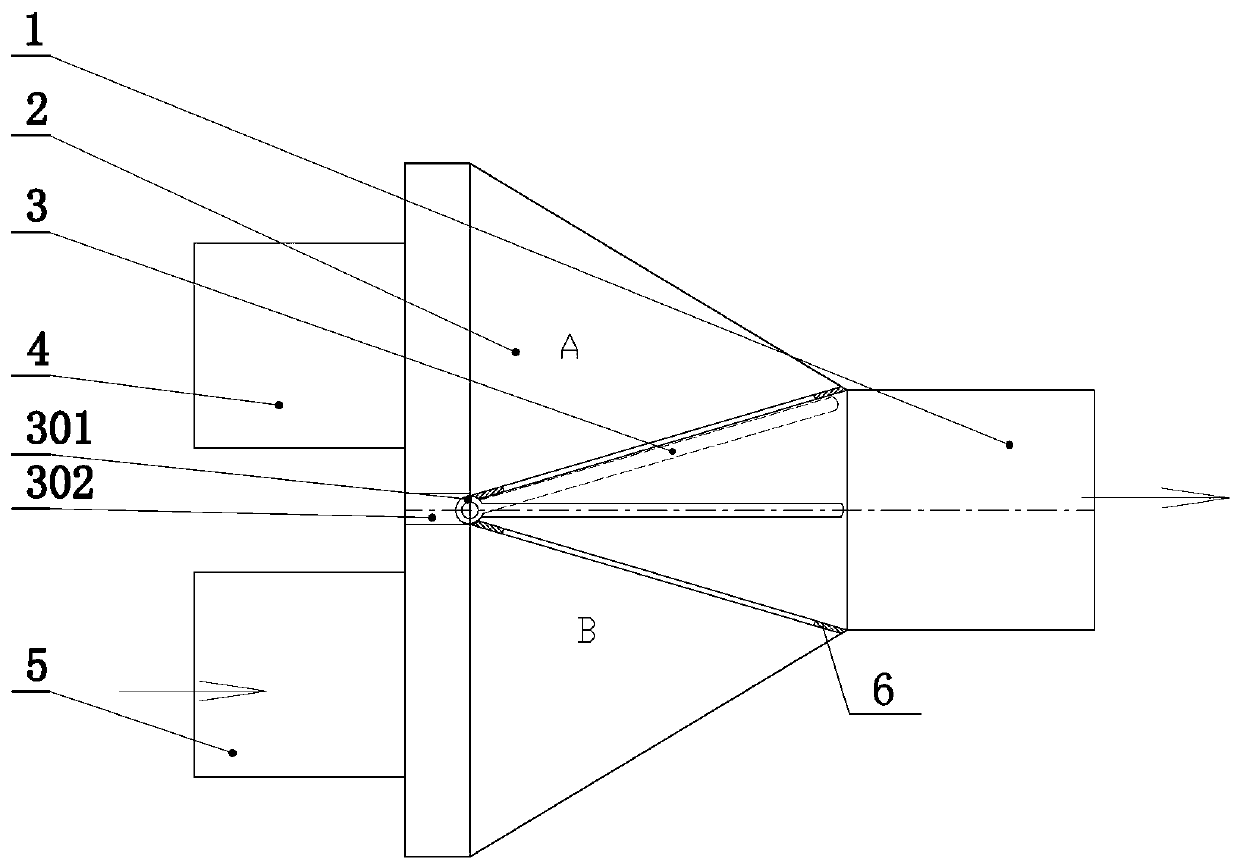

Dry desulfurization absorbing tower with top circular winding pipe exit

The invention discloses a dry method desulphurization absorption tower with a top round bent pipe outlet. In order to solve the problems that the square outlet of the prior dry method desulphurization absorption tower has overlarge local resistance, inordinate flue gas flow field, easy generation of solid particle accumulation on a local part and the like. The upper part of a main body section (1) of the absorption tower is connected with a reducing section (2); the upside of the reducing section (2) is provided with an outlet flue (3) which adopts a round bent pipe flue and is connected with a round square section (4); and the underside of the round square section (4) is provided with an adjusting section (5) which is connected with the inlet of a dust collector (7). The design of the absorption tower not only greatly reduces the local resistance of the outlet, optimizes the flue gas flow field and reduces the local solid particle accumulation, but also can remarkably reduce the construction cost; besides, the absorption tower has the advantages of simple manufacture, convenient maintenance, long service life and the like.

Owner:上海融新能源环境科技有限公司 +4

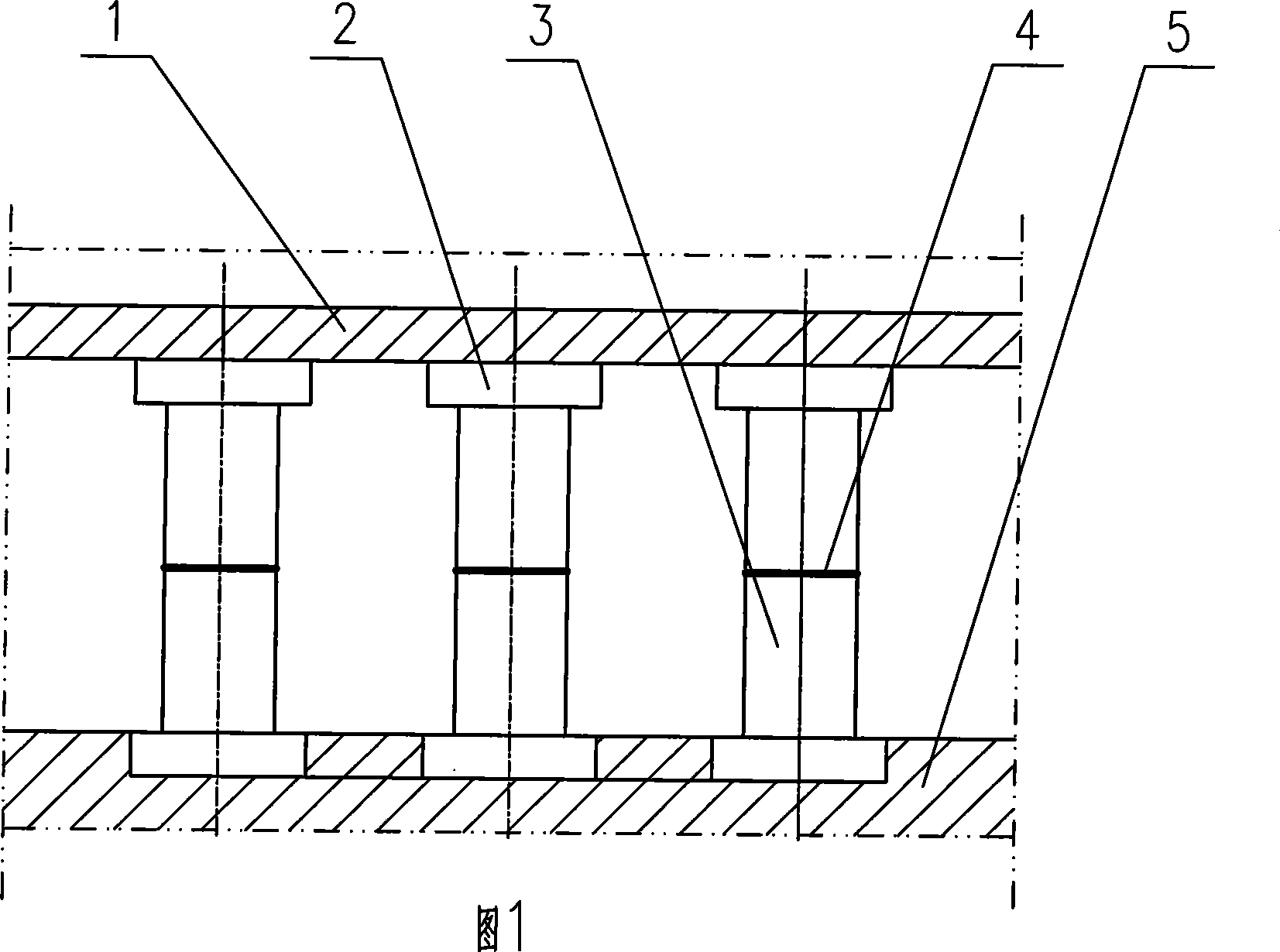

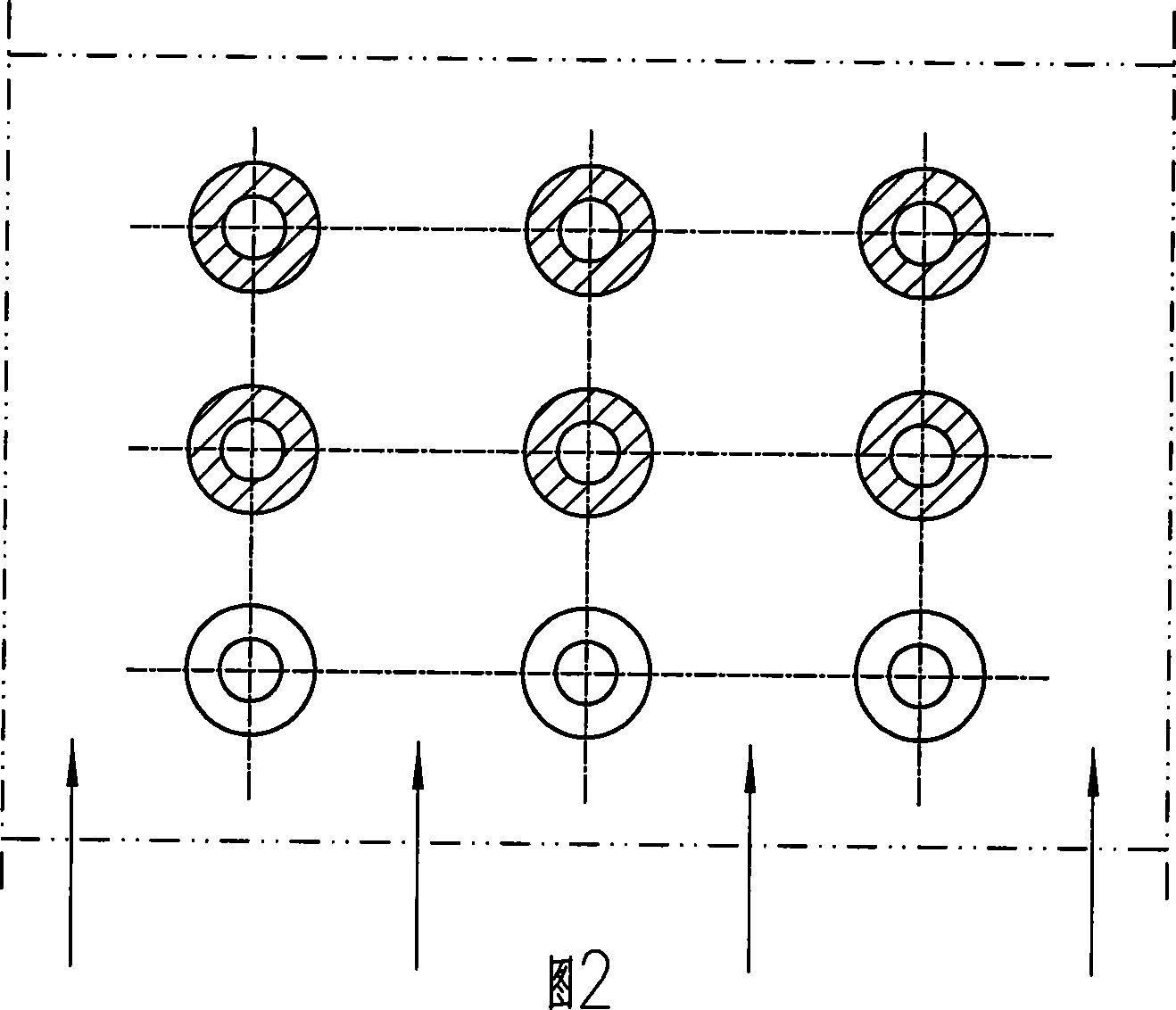

Bottom flue gas passage structure of electrode calcination furnace with cap

InactiveCN101398259AReduce local drag lossIncrease the circulation areaMaintainance of heating chambersWaste heat treatmentBrickGraphite electrode

The invention discloses an electrode roasting furnace with a lid in the field of graphite electrode production, particularly relates to a furnace floor flue gas channel structure of the electrode roasting furnace with the lid. The furnace floor flue gas channel structure is realized by the following steps: an ondol pier is arranged between a furnace floor masonry and ondol surface bricks and is composed of an upper ondol pier brick section and a lower ondol pier brick section. The calandria arrangement in the furnace floor flue gas channel that is formed by the ondol pier bricks with circular sections greatly lowers the local resistance loss of flue gas. As the furnace is a running system consisting of a plurality of furnace chambers, the accumulated reduction value of local resistance loss is very remarkable. As section size of the ondol pier bricks is reduced and the calandria flue gas channel structure is additionally arranged, the flue gas circulation area in the channel is increased, and the friction resistance loss in the flue gas circulation process is effectively reduced.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

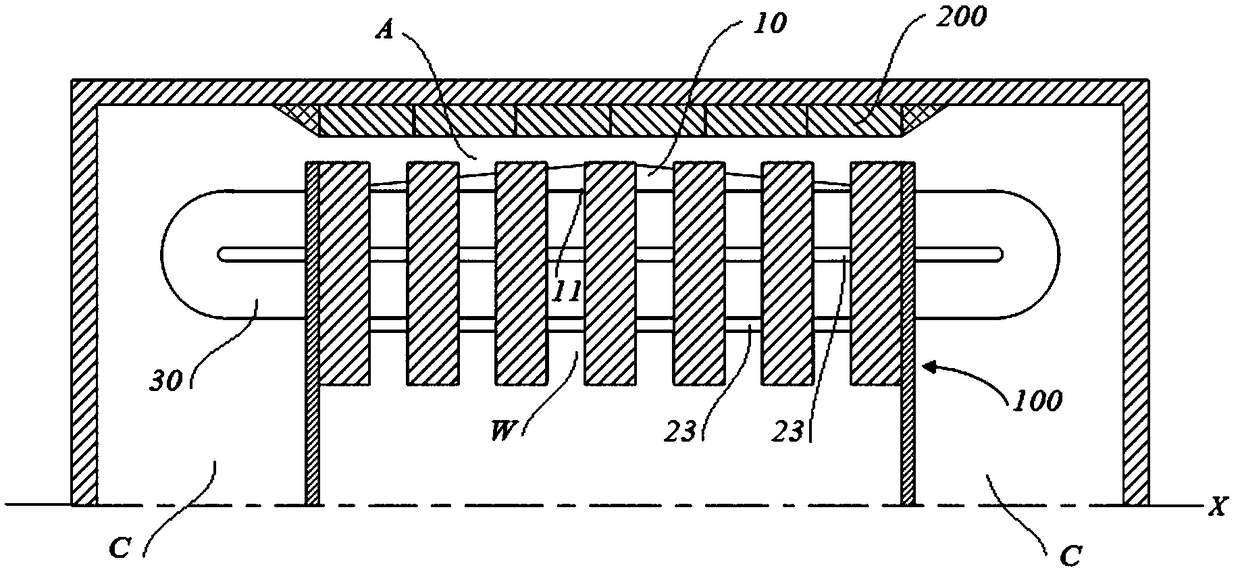

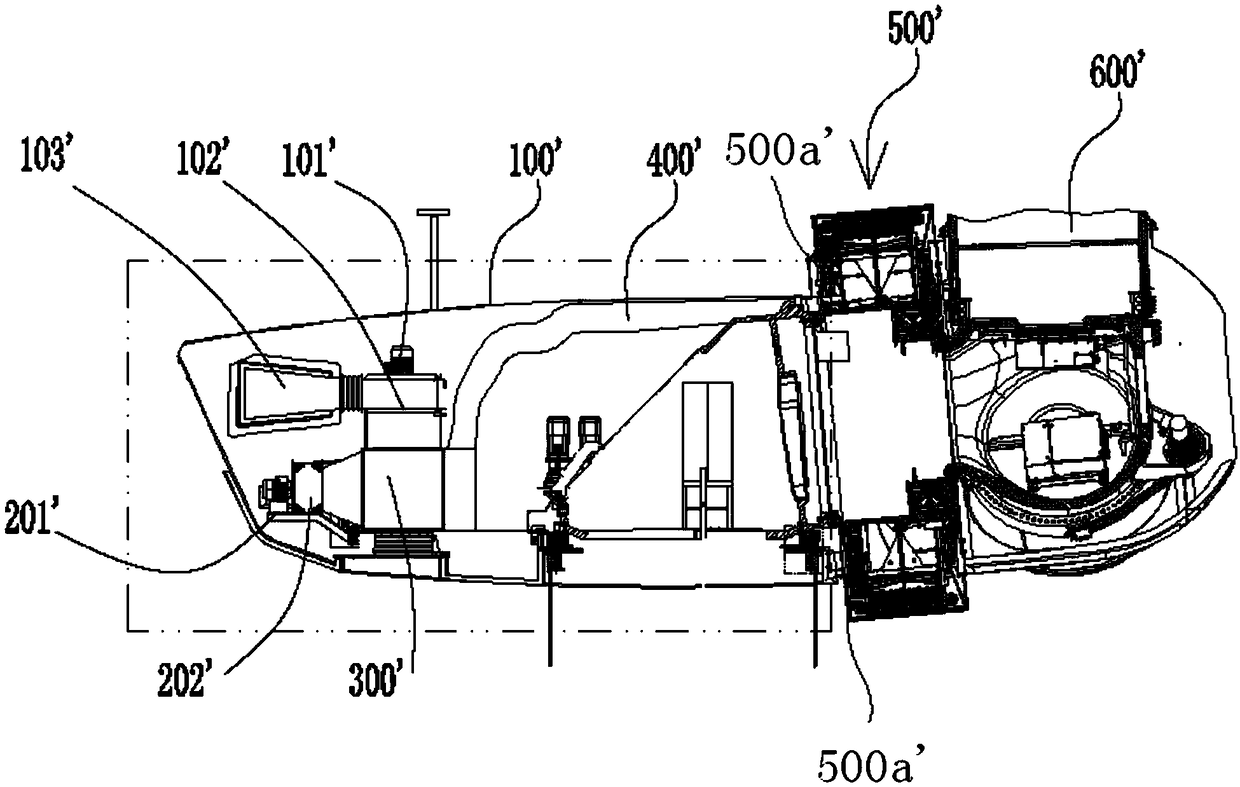

Wind-driven generator set, motor and air flow transfer device for motor air gap

ActiveCN109120104AReduce local resistanceQuality improvementEngine fuctionsMachines/enginesWind drivenEngineering

The invention discloses a wind-driven generator set, a motor and an air flow transfer device for a motor air gap. The air flow transfer device for the motor air gap comprises an annular air distribution chamber; the annular air distribution chamber is located at least one end of the air gap; and the annular air distribution chamber has a transfer opening facing the air gap to as to transfer hot orcold air flow to the air gap. According to the air flow transfer device for the motor air gap, the annular air distribution chamber is arranged at the end of the air gap; required air flow is injected into the annular air distribution chamber, and the annular air distribution chamber can output accumulated air flow to the air gap, so that the air flow can be facilitated to smoothly pass through the air gap, and the flow rate of the air gap can be controlled with easiness, and therefore, the air flow can be effectively outputted into the air gap, and the local resistance of the air flow entering the air gap can be decreased; and the air flow entering the air gap can contact the outer circumference of an entire core, so that the cooling and drying effect of the core can be improved.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Novel automatic bidirectional air regulating device

PendingCN109899100AGuaranteed original performanceGuaranteed normal functionTunnel/mines ventillationEngineeringAir blower

The invention discloses a novel automatic bidirectional air regulating device, and provides the bidirectional air regulating device for automatic switching between a local fan and a standby local fanduring normal operation; the maintenance rate of the local fan air regulating device is reduced, and internal air leakage of the regulating device is completely eradicated. According to the followingtechnical scheme, the novel automatic bidirectional air regulating device includes a main hair dryer, a standby hair dryer, a three-links shell body, and a chimney fan, wherein an air guiding valve for switching air sources is installed in the three-links shell body; the novel automatic bidirectional air regulating device is characterized in that the three-links shell body is a Y-shaped shell body, the main hair dryer and the standby hair dryer are installed at the wider end of the three-links shell body, and the chimney fan is installed at the other end of the three-links shell body, and themain hair dryer and the standby hair dryer are respectively connected with a main air blower and a standby air blower; and the air guiding valve is installed between the main hair dryer and the standby hair dryer in the three-links shell body, and a valve baffle of the air guiding valve is installed above a valve baffle seat through an articulated shaft.

Owner:XINAN COAL IND ZAOZHUANG COAL MINING GROUP

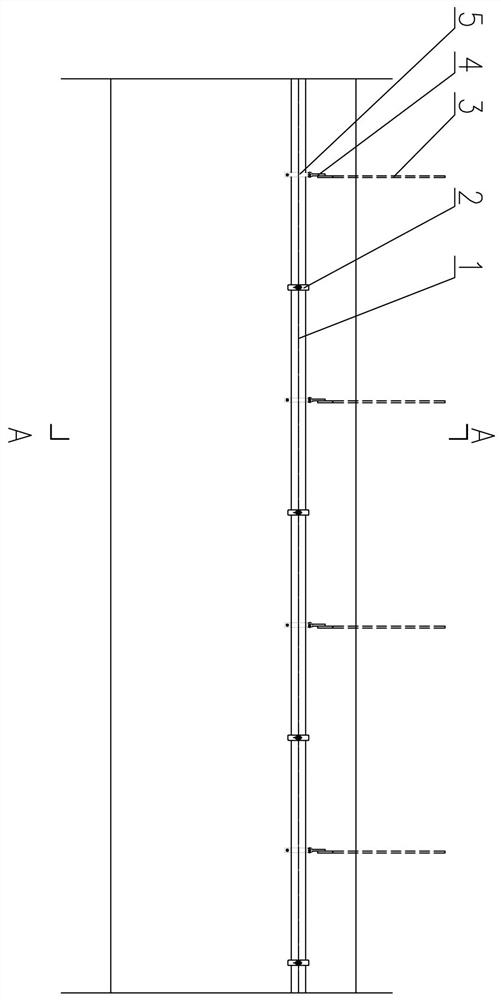

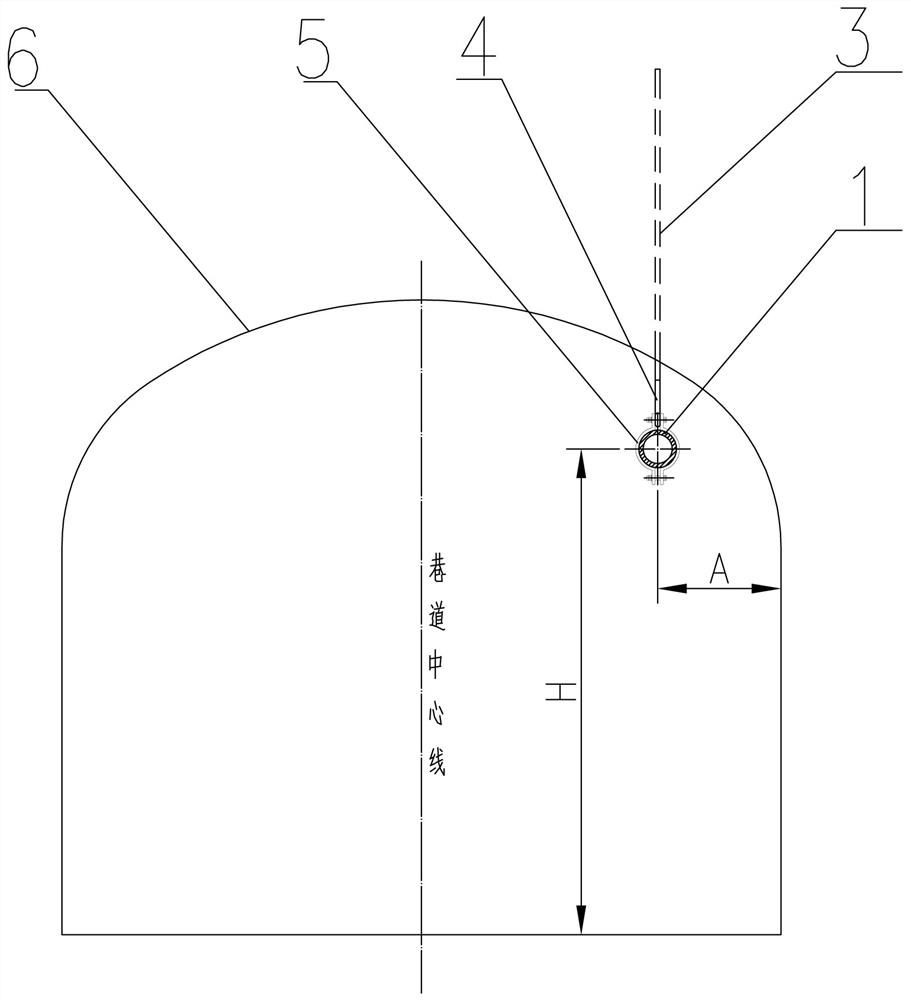

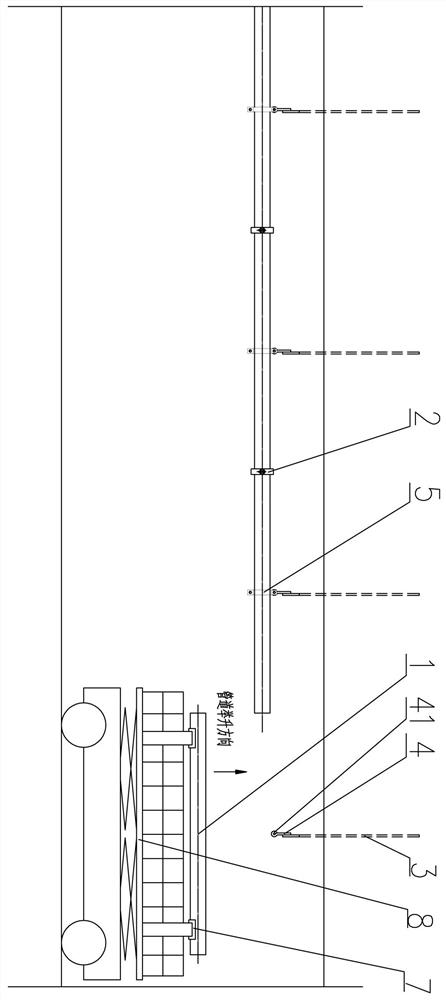

Erecting method of underground roadway filling pipeline

The invention relates to an erecting method of an underground roadway filling pipeline. The erecting method is characterized by comprising the following steps that (1) the height from a filling pipeline to a bottom plate of a roadway is determined; (2) a row of anchor rods are preset on a vault of the roadway at equal intervals in the flowing direction of slurry in the filling pipeline, a pipelinehanging bracket pull rod is arranged at the lower ends of the anchor rods in a welded mode, a tail ring is arranged at the lower part of the pipeline hanging bracket pull rod in a welded mode, and the upper ends of the anchor rods are anchored on the vault of the roadway through cement mortar; and (3) the filling pipeline is composed of a plurality of pipe sections, each section of filling pipeline is connected with an upstream filling pipeline by adopting a clamp type connector, pipe clamping clamps are arranged in the middle of each section of filling pipeline, and the pipe clamping clampsare fixedly connected with the tail ring of the hanging bracket pull rod through a bolt, a gasket and a nut until the tail end of the filling pipeline in a filling stope is reached. The erecting method of the underground roadway filling pipeline has the advantages that the pipeline is convenient to mount and dismount, the width and the sectional area of a roadway can be reduced, the engineering quantity is saved, and the local resistance of filling slurry conveying can be further reduced.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Device and method for pre-removing popcorn ash of SCR denitration system

The invention discloses a device for pre-removing popcorn ash of an SCR denitration system. The device comprises a vertical shaft flue, a horizontal flue and an uptake shaft which are connected in sequence, wherein the turning connection positions between the horizontal flue and the vertical shaft flue and the uptake shaft respectively have streamline appearances, an ash hopper is arranged on the lower side of a base plate of the horizontal flue, and a catcher, a separator and a filter screen are sequentially arranged on the side in the smoke flowing direction. A smoke circulating port is formed in a base plate of the tail portion of the horizontal flue and is communicated with the ash hopper. The invention further provides a method for pre-removing popcorn ash of the SCR denitration system. The flinging wall characteristics at the connection positions of the streamline vertical shaft flue and the horizontal flue which are installed without guiding plates are utilized to form a high-ash-concentration flue airflow, and popcorn ash and smoke are efficiently separated by sequentially adopting the catcher, the separator and the filter screen based on streaming impact type separation, gravity settling separation and intercepting separation principles. Rapid and effective separation of high-temperature and high-concentration popcorn ash is achieved by adopting the method, and the device has the advantages of being simple in structure and safe and stable in operation.

Owner:SOUTHEAST UNIV

Push chain type concrete spraying machine with distributor

InactiveCN104989431AIncrease flow rateReduce local resistanceUnderground chambersFoundation engineeringEngineeringChain type

Provided in the invention is a push chain type concrete spraying machine with a distributor. The spraying machine comprises a chain type piston, an injection cylinder, a high-pressure pipe, a mixing chamber, and a spraying elbow. The mixing chamber is arranged in the middle of the injection cylinder; and the chain type piston penetrates the injection cylinder. The machine is characterized in that a distributor is arranged above the mixing chamber; the high-pressure pipe is connected to the top of the distributor; the spraying elbow is linked below the mixing chamber; air injection holes are formed in the middle of the distributor and the lower ends of the air injection holes are opposite to the upper space of the chain type piston in the mixing chamber, so that attachments of the chain type piston can be cleaned. The distributor is arranged on the mixing chamber; the high-pressure pipe is arranged on the distributor; the chain type piston passes through the injection cylinder; and compresses air is processed by flow acceleration of the distributor and thus the concrete is blown to the spraying elbow. Compared with the prior art, the spraying machine has the following beneficial effects: with the reducing injection pipe type distributor, the outlet injection speed of the compressed air is improve, thereby enhancing the injection capability; a problem that hanging materials can not be blown completely by the chain type piston can be solved; and the machine has the great popularization value.

Owner:李艮

Improved minitype oil pump

InactiveCN107237757AIncrease contactAvoid stickingSpecific fluid pumpsPump componentsMicrocomputerImpeller

The invention relates to an improved miniature oil pump, which includes a pump casing, a pump cover and a centrifugal impeller located in the pump casing and the pump cover, wherein the pump casing includes a disk-shaped flow guide cavity, and the side wall of the flow guide cavity There is a discharge nozzle whose axis is on the tangent line of the guide cavity, and a rotating hole for connecting the driving mechanism of the centrifugal impeller is arranged in the middle of the pump cover; the centrifugal impeller includes a driving disc and a centrifugal disc, and a driving ring is arranged on the periphery of the driving disc , a cylindrical connecting ring is set in the middle of the side of the driving disc facing away from the driving ring, the liquid inlet is located in the middle of the connecting ring, the connecting ring and the rotating hole are connected by bearing rotation, and the connecting ring extends out of the outer wall of the rotating hole The drive gear is also coaxially fixedly connected to the top, and a contact ring is arranged on the periphery of the centrifugal disc, and the contact ring is in contact with the drive ring. The side of the centrifugal disc surface facing away from the contact ring is provided with a number of fan-shaped hollow protrusions in an annular array. The column is densely covered with oil discharge holes on the side wall of the raised column.

Owner:JIANGSU HENGLI MACHINE TOOL

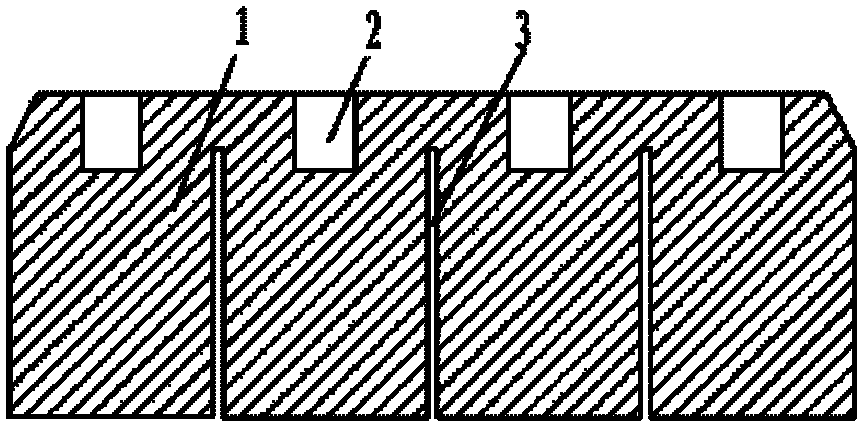

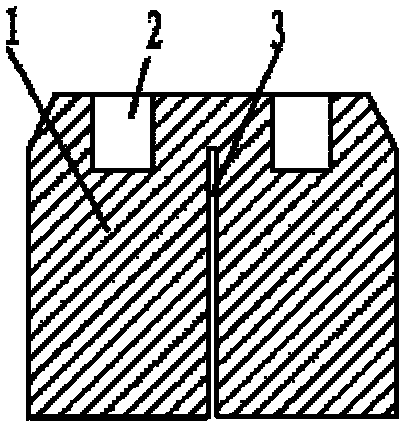

Aluminium electrolysis cell anode carbon block

InactiveCN102330113ASmall discharge resistanceReduce local resistanceWork periodAluminium electrolysis

The invention discloses an aluminium electrolysis cell anode carbon block. The upper surface of the anode carbon block is a plane, wherein the plane of the upper surface of the anode carbon block is provided with concave carbon bowls connected with steel talons below an anode guide rod; the carbon bowls are arranged in one row or two rows at equal distances along the length direction of the anode carbon block, and each row comprises 2-4 carbon bowls; and a groove is arranged from the position which is 50-200mm below the upper surface of the anode carbon block in the middle of two adjacent carbon bowls on the anode carbon block to an anode bottom palm. According to the aluminium electrolysis cell anode carbon block, CO2 gas generated on the bottom surface of the anode in the electrolysis process can be smoothly discharged into a space formed by the upper surface of an electrolyte melt to the top of the groove in the whole anode working period or during most time; and when the upper part of the top of a lateral groove in the middle of the length direction of the carbon anode is provided with a vertically through narrow slit, the narrow slit has the function of reducing anode end tip damage because the narrow slit releases expansion force on the carbon anode connected with the anode steel talons on the end part by the thermal expansion of the beam with the upper steel talons of the anode in the electrolytic cell at a high temperature.

Owner:冯乃祥

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com