Electrolysis flue gas dry-purification system

一种干法净化、烟气的技术,应用在净化系统领域,能够解决提高烟气净化效率困难、运行维护费用高、备用程度低等问题,达到提高气固混合效果、占地面积小、节省能耗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The following is a detailed description of the present invention.

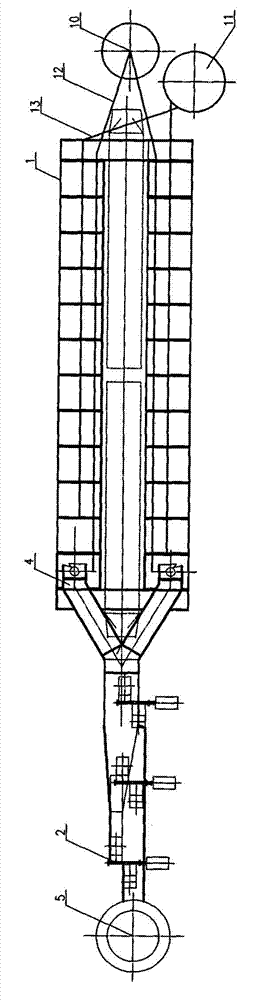

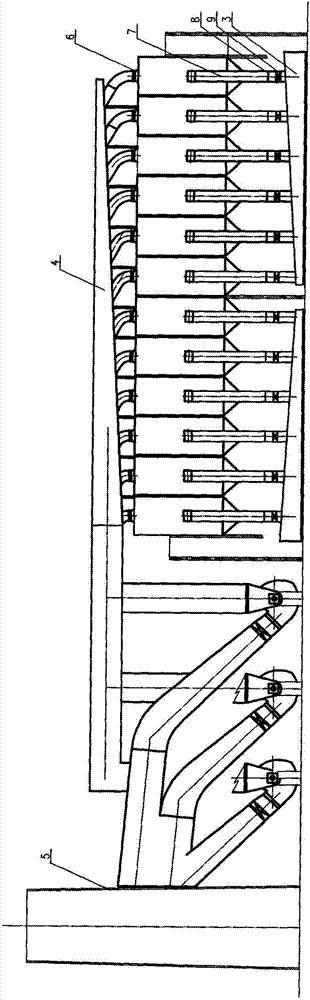

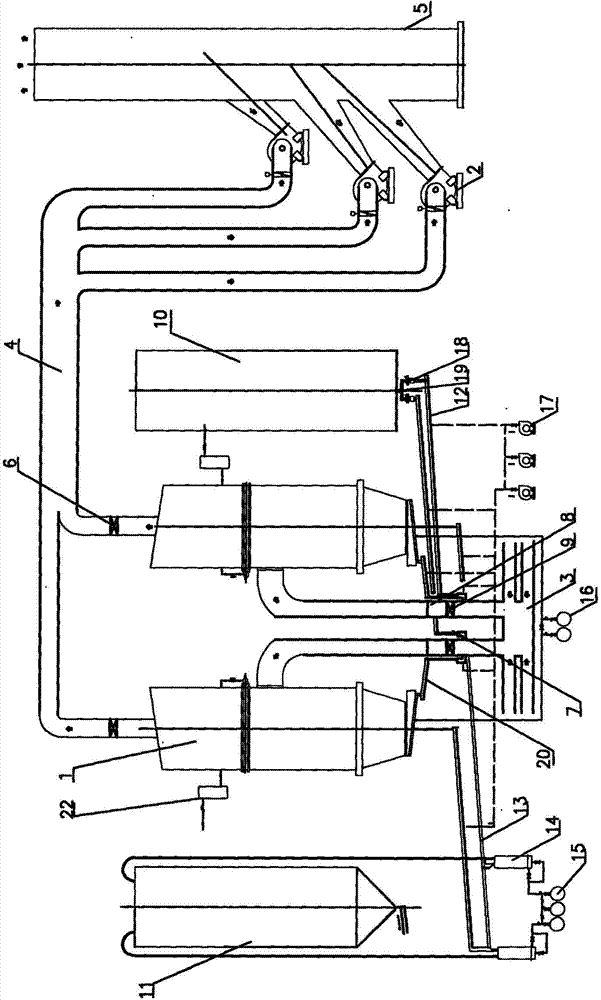

[0068] like Figure 1-3 The refreshment of the drying of the electrolytic flue gas is composed of the following structure: the dust collector 1, the dust collector export pipe 4 located at the top of the dust collector 1, the reactor 8 connected to the dust collector 1, the summary of the reactor 8 connectionPipeline 3, the bottom of the dust collector 1 is connected to the 11 -connected aluminum oxide storage warehouse, the reactor 8 is connected with the fresh aluminum storage warehouse 10, the dust collector export pipe 4 is connected to the chimney 5 through the main firm 2, and the main fans 2 as the main fans 2 as the main fans 2 to the main campaign.3-6 units, the sink pipe 3 and the reactor 8 have the front pipeline 7 of the reactor, the reactor 8 and the front pipeline 7 of the reactor 7 are provided with reaction front valve 9;Export valve 6, fresh aluminum storage warehouse 10 connects to the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com