Patents

Literature

45results about How to "Reduce drag along the way" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

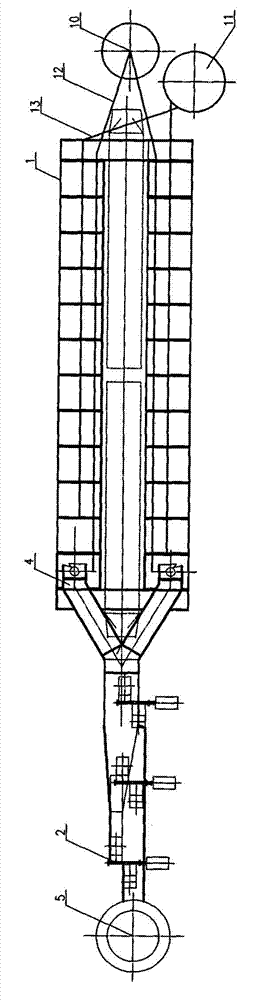

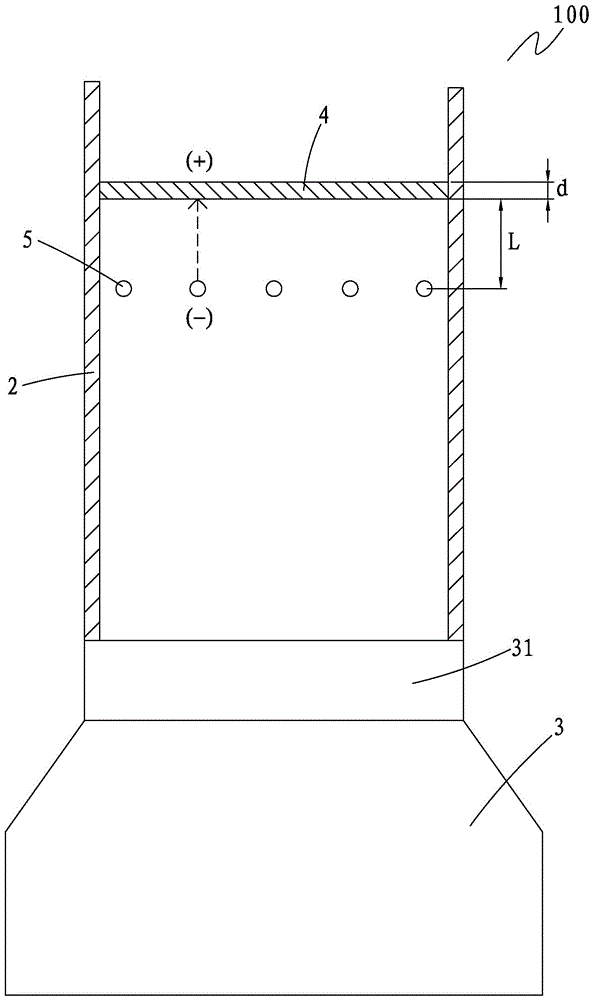

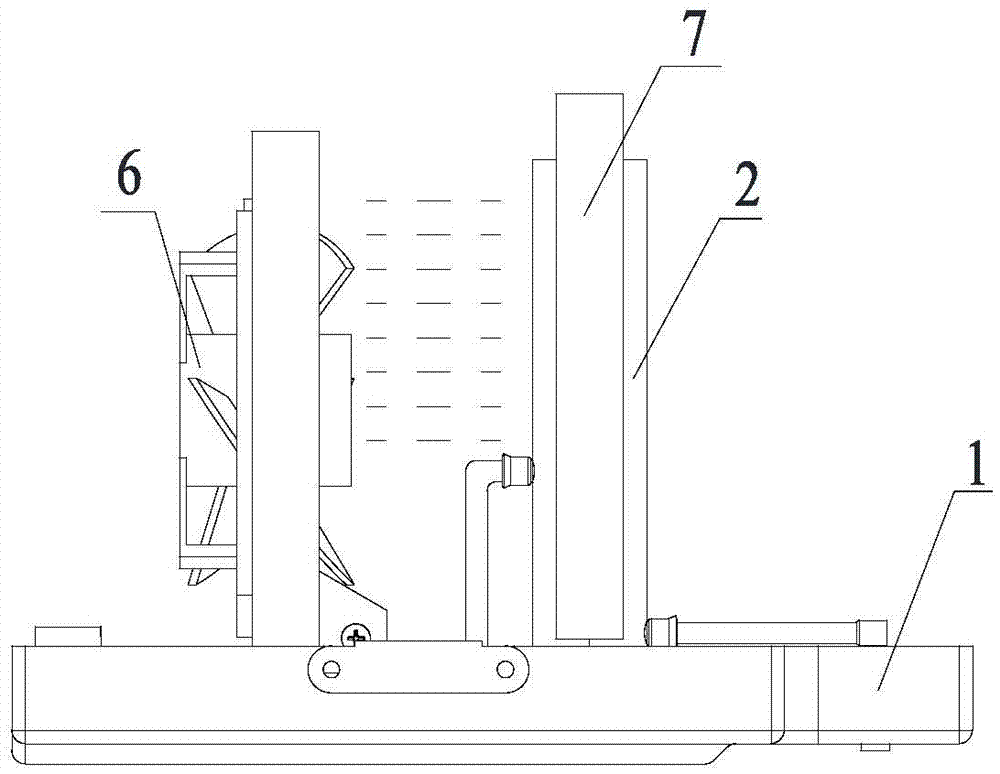

Electrolysis flue gas dry-purification system

ActiveCN102851706AReduce drag along the wayRealize mutual backupHuman health protectionDispersed particle filtrationElectrolysisFlue gas

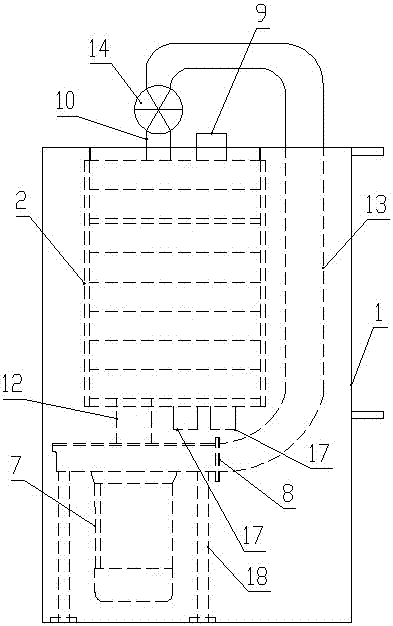

The invention relates to a purification system, and particularly relates to an electrolysis flue gas dry-purification system. The electrolysis flue gas dry-purification system structurally comprises a dust remover, a dust remover outlet pipeline arranged at the top of the dust remover, a reactor connected with the dust remover and a gathering pipeline connected with the reactor, wherein the bottom of the dust remover is communicated with a fluorine-carrying aluminum oxide storage bin, the reactor is communicated with a fresh aluminum oxide storage bin, and the dust remover outlet pipeline is communicated with a chimney through a main draught fan. The invention has the following advantageous effects: the configuration form of the pipelines is changed to reduce local resistance, thereby reducing the whole on-way resistance of the purification system and saving energy; the purification effect is enhanced; and the advantages of small occupied area, high purification efficiency, low energy consumption, low maintenance workload, high control degree and the like are achieved.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

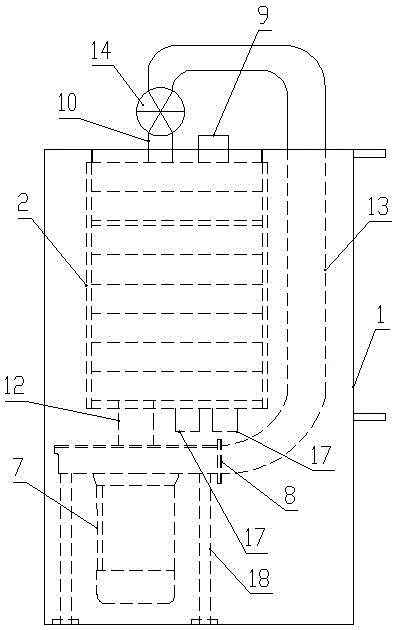

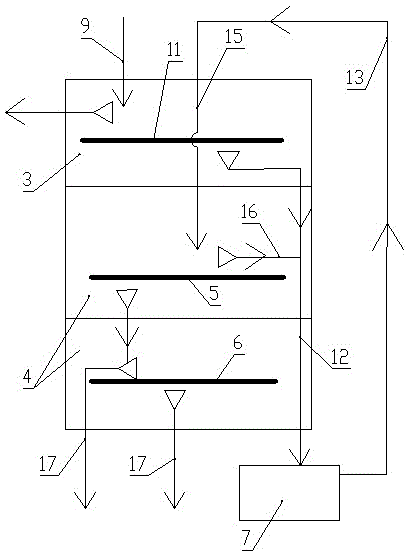

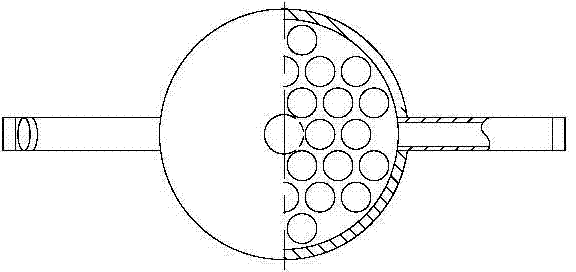

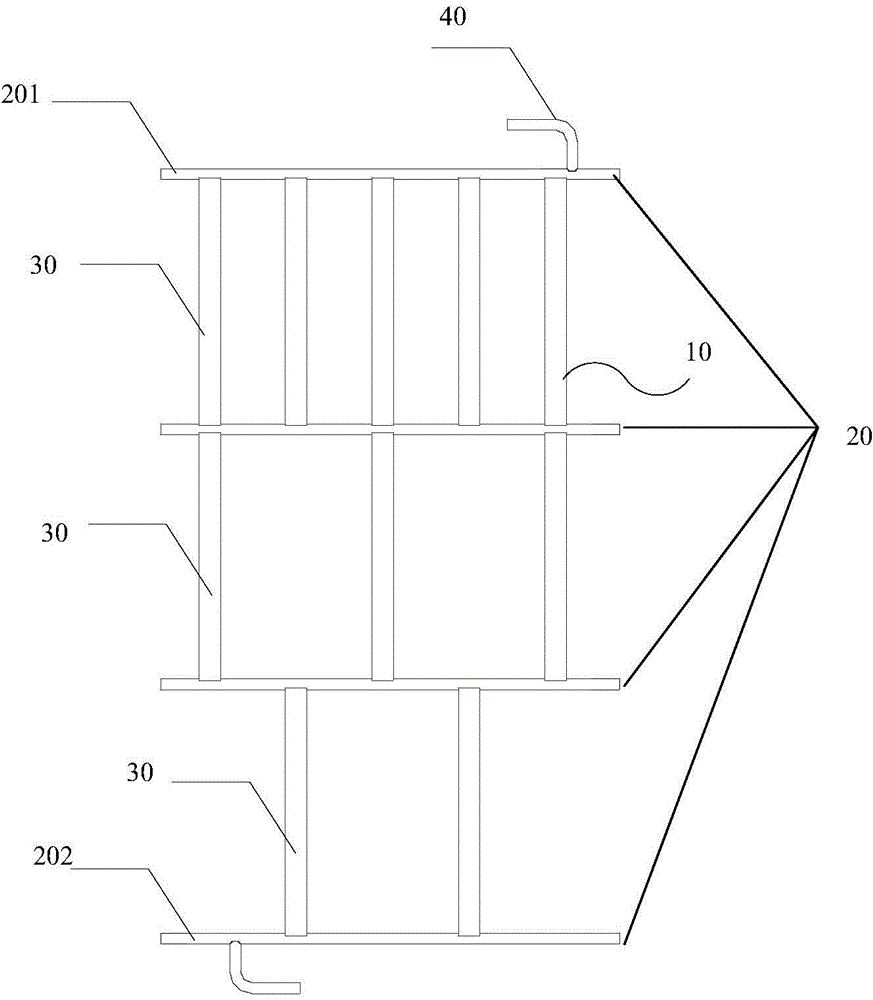

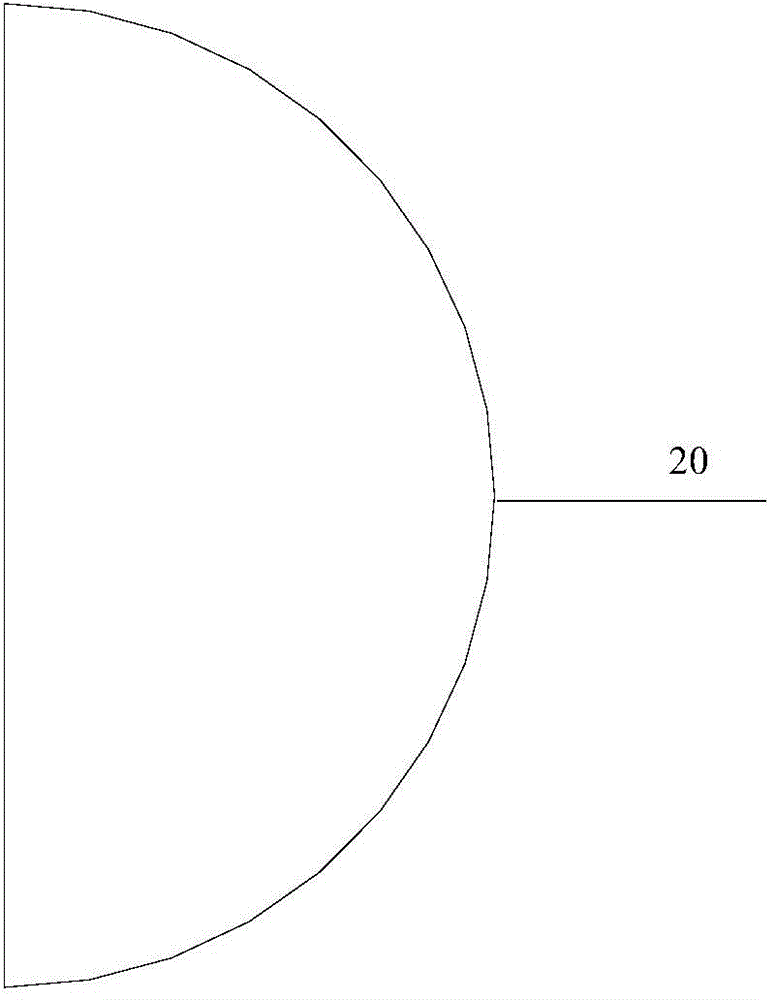

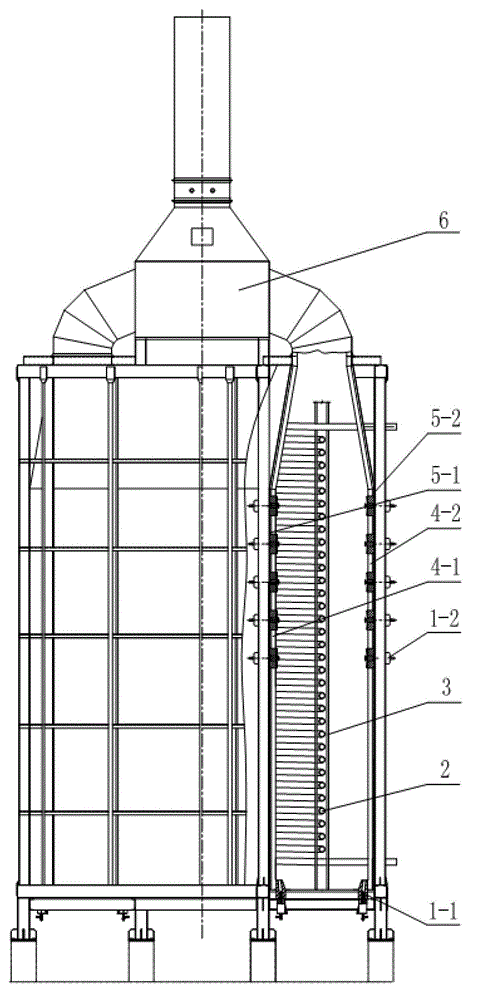

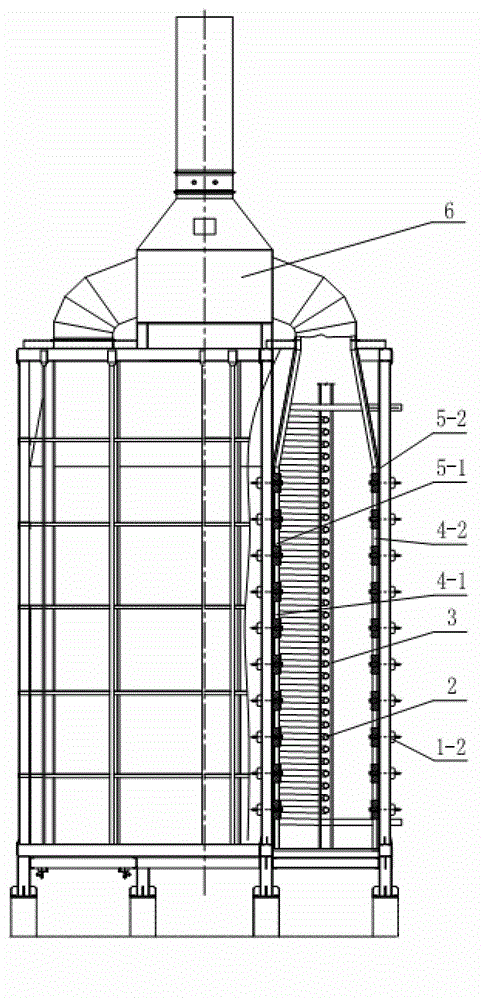

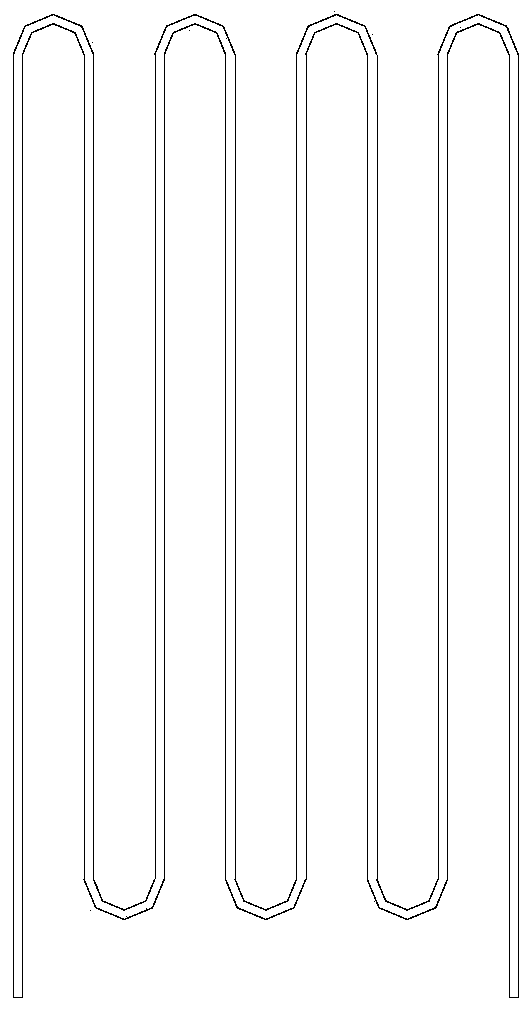

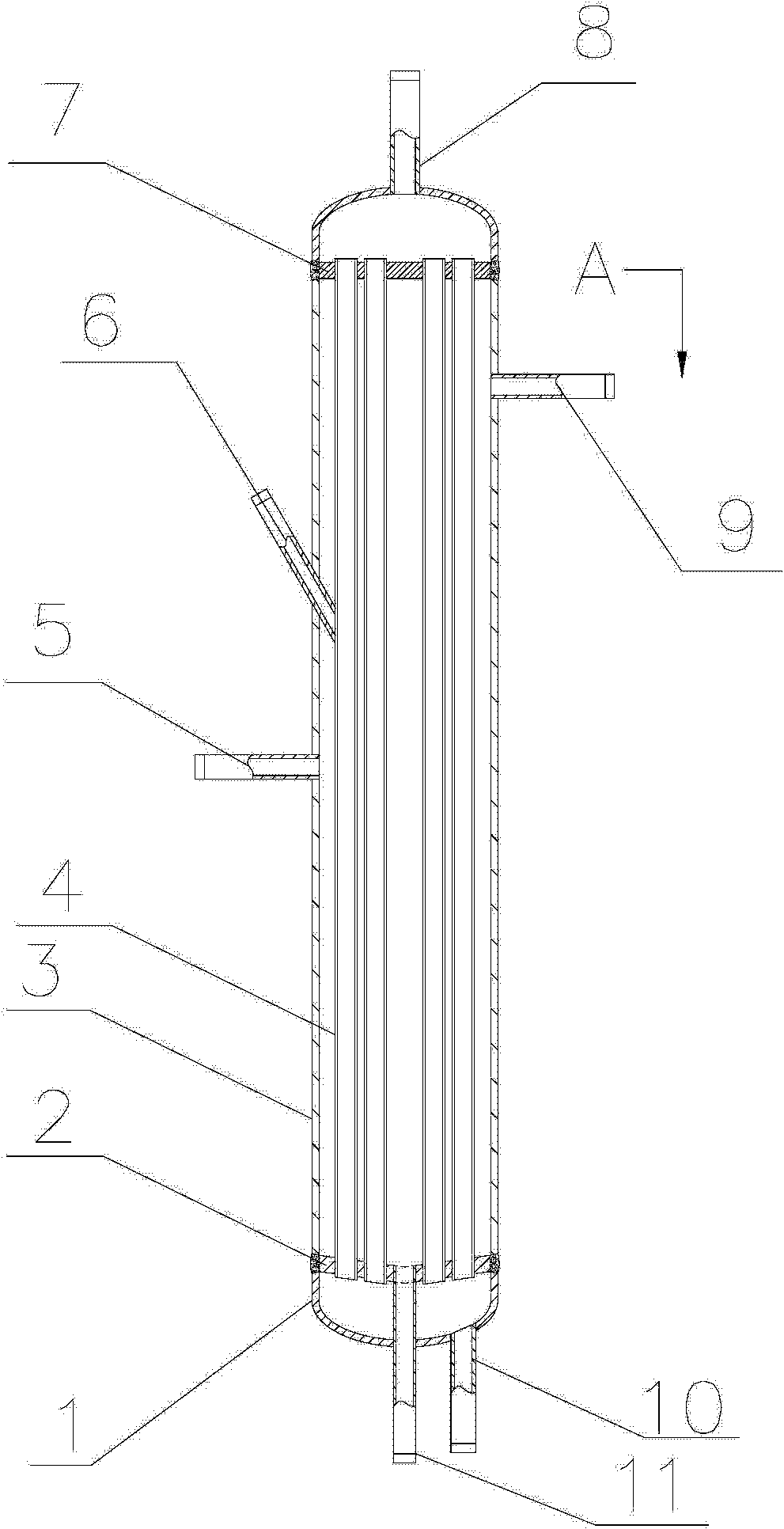

Multi-layer vertical flow methane biological oxidation device

InactiveCN101053766AObvious beneficial effectReduce global warming potentialDispersed particle separationAir quality improvementBiological oxidationGreenhouse

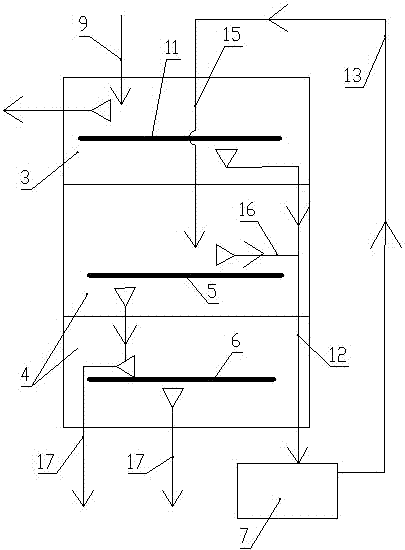

The invention discloses a multilayer vertical methane biological oxidation device, relating to the technical field of greenhouse gasses abatement, wherein the device is composed of a reactor, methane supply system and air supply system. Methane and air is forcibly led to flow along the pores of filling medium up to down in the device by the gas supply system. Plurality of gas-arranging layers are vertically mounted in the reactor to realize the frequent mixing for the gas to reduce the short flow of the gas, provide growth advantage for methane oxidation bacteria in the filling medium, and make the methane to be continuously decomposed in the device to transform into CO2 and discharge from the outlet at last.

Owner:张相锋

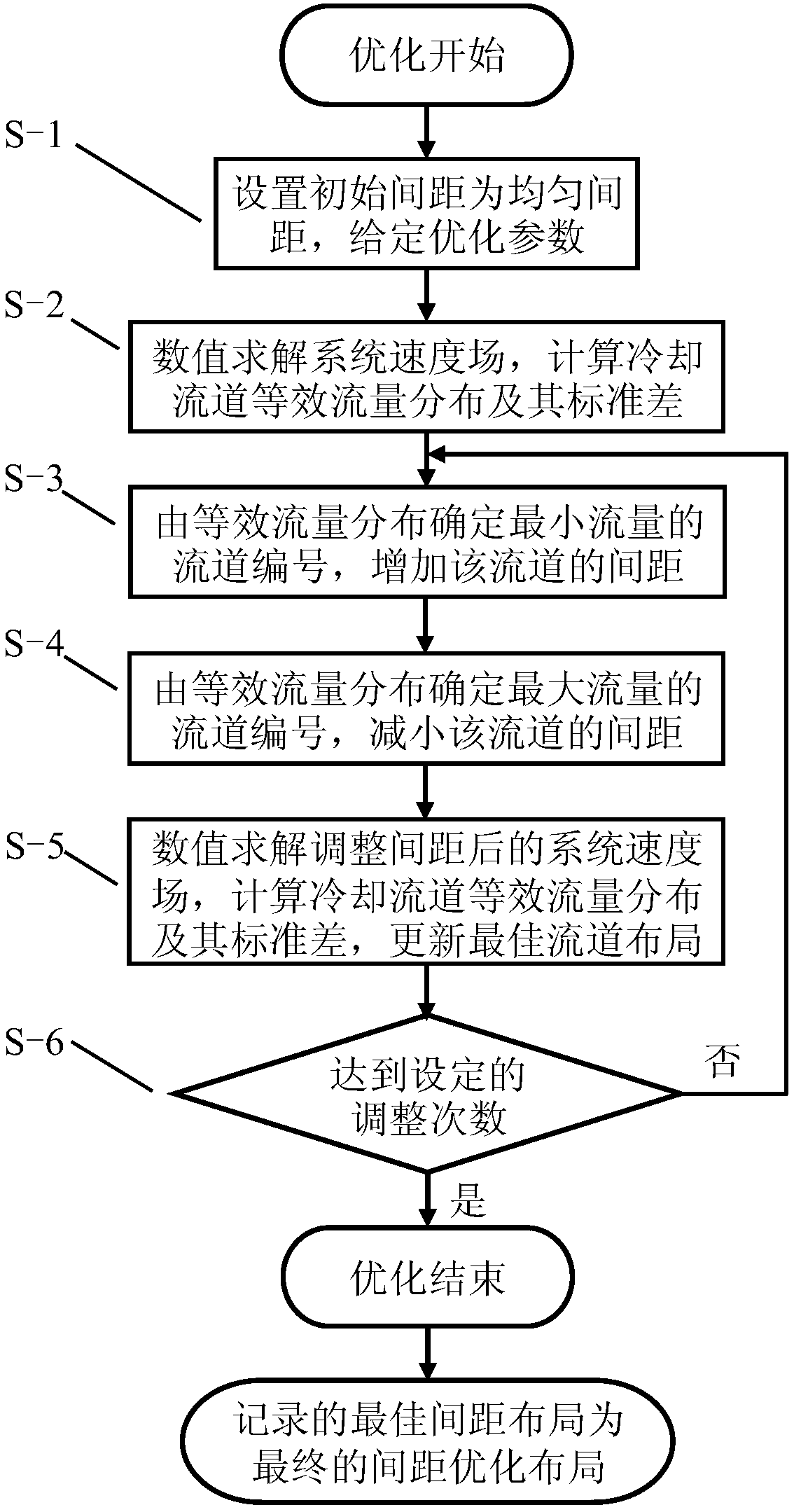

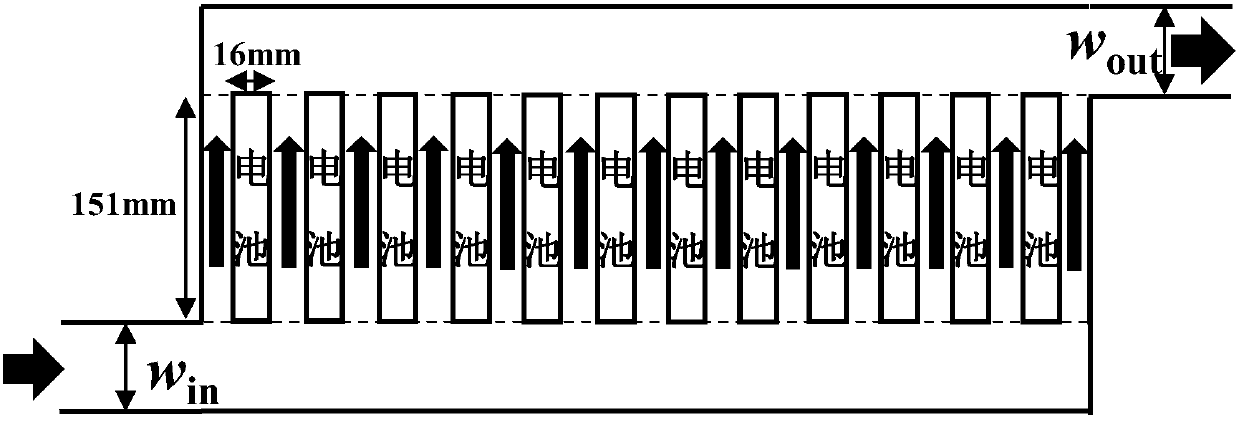

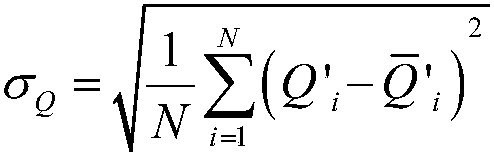

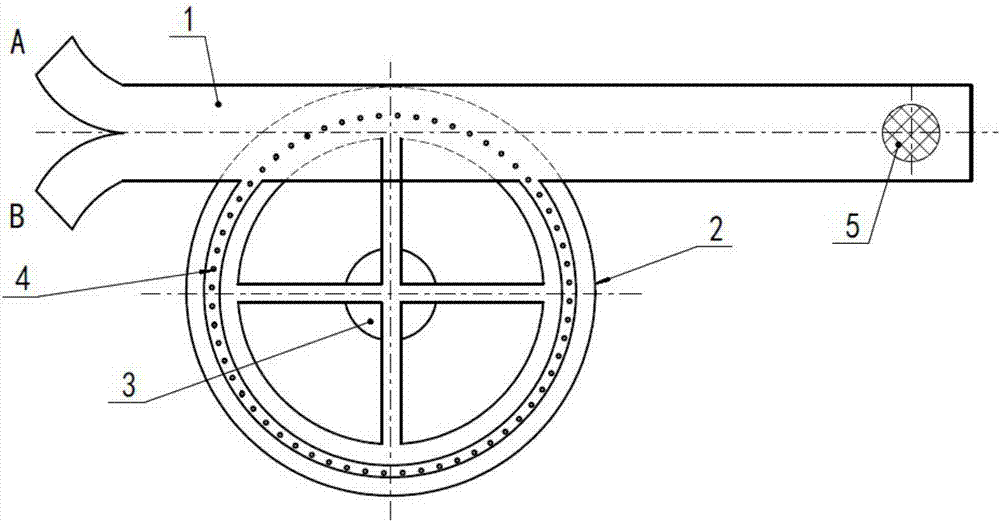

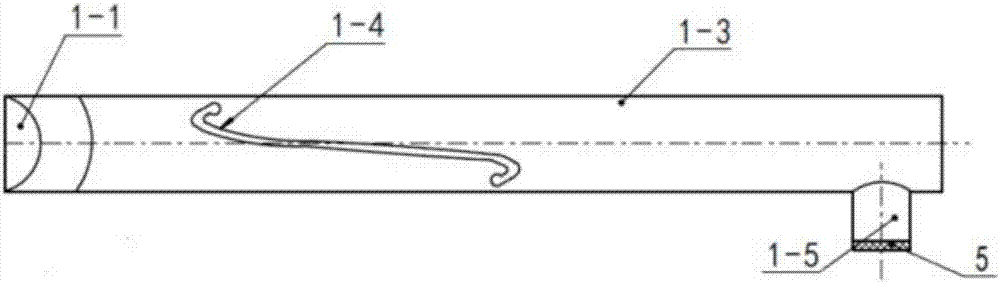

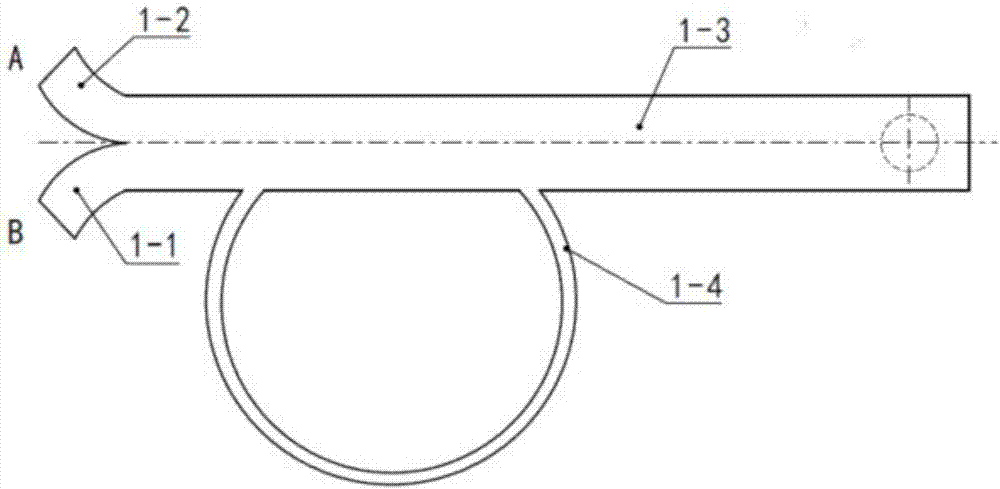

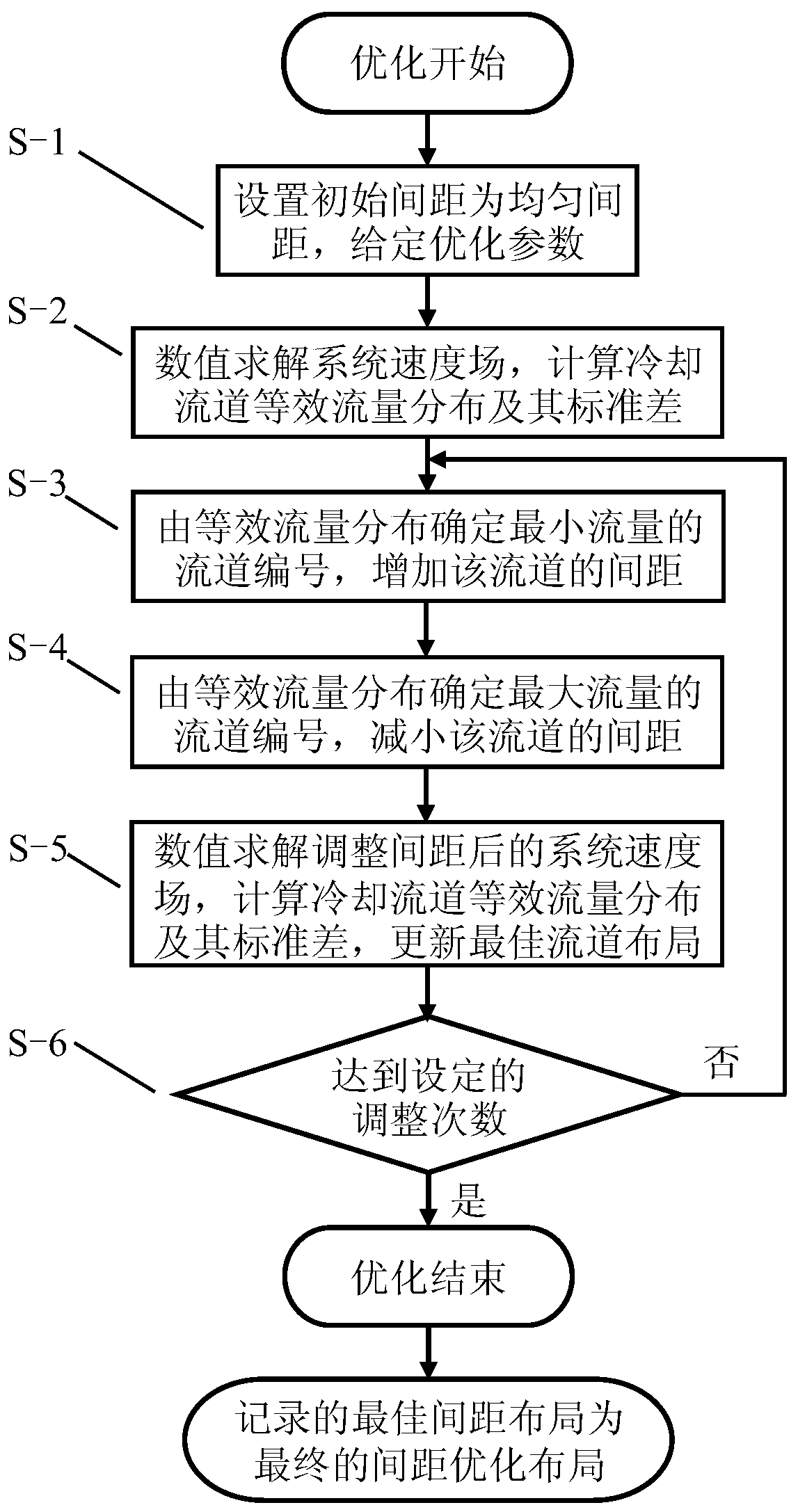

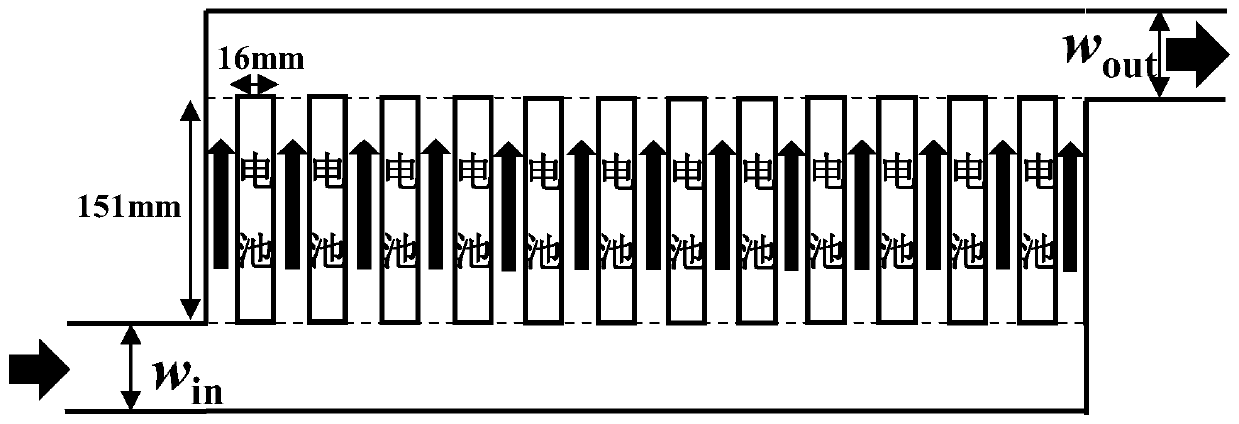

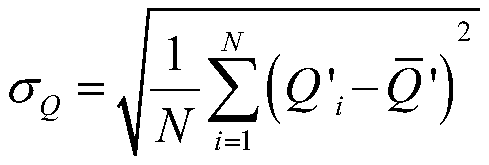

Rapid optimization method for power battery air cooling system runner interval

ActiveCN108038261AIncreased runner spacingReduced runner spacingSecondary cellsForecastingPower batteryMaximum flux

The invention discloses a rapid optimization method for a power battery air cooling system runner interval. The method comprises the steps that beginning from the uniform runner interval, velocity distribution of an air cooling system is solved through numerical values, by analyzing the flow distribution between cooling runners, the runner with the minimum flow and the runner with the maximum floware determined, then, the interval of the runner with the minimum flow is increased, and the interval of the runner with the maximum flow is decreased; speed distribution of the system is calculatedagain every time the runner interval is adjusted, and therefore the next runner interval adjustment is performed; when the frequency for runner interval adjustment reaches the set frequency, the layout of the runner interval with the minimum cooling runner equivalent flow standard deviation in the process is adjusted, and the final runner interval optimization result is obtained. The rapid optimization method has the advantages of being simple in optimization process, high in optimization speed, good in performance index, good in expansibility, high in practicability and the like.

Owner:SOUTH CHINA UNIV OF TECH

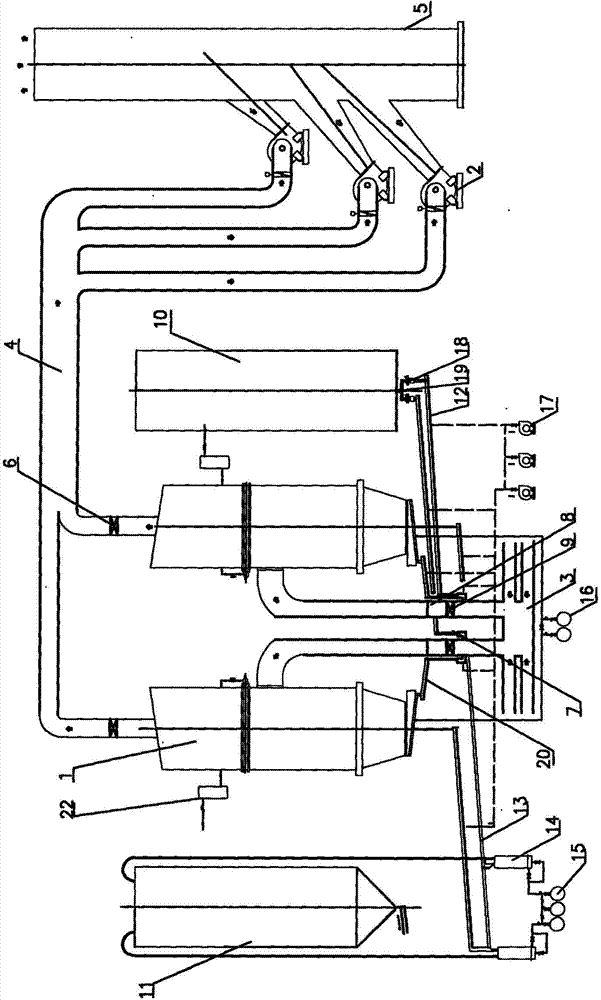

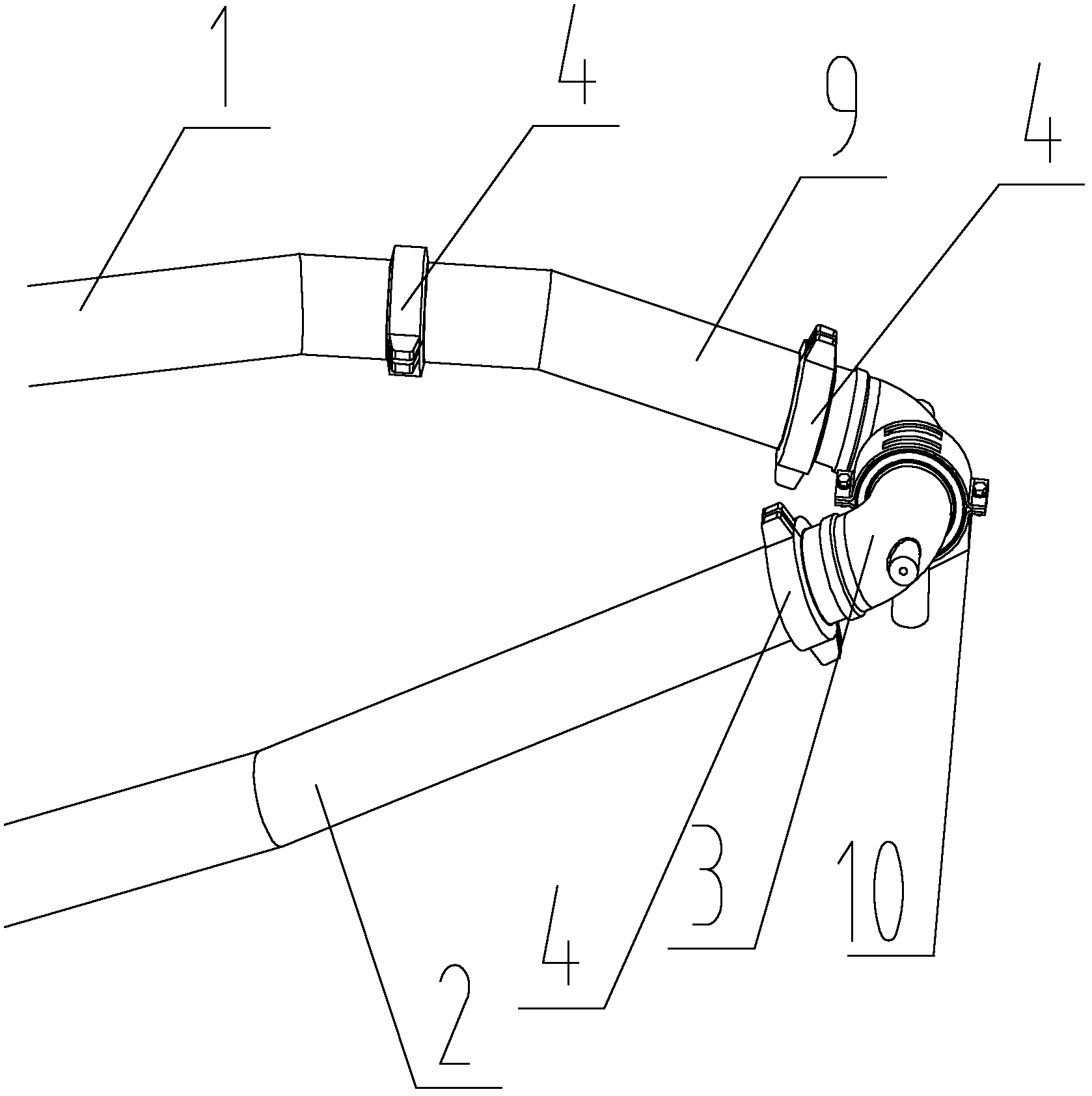

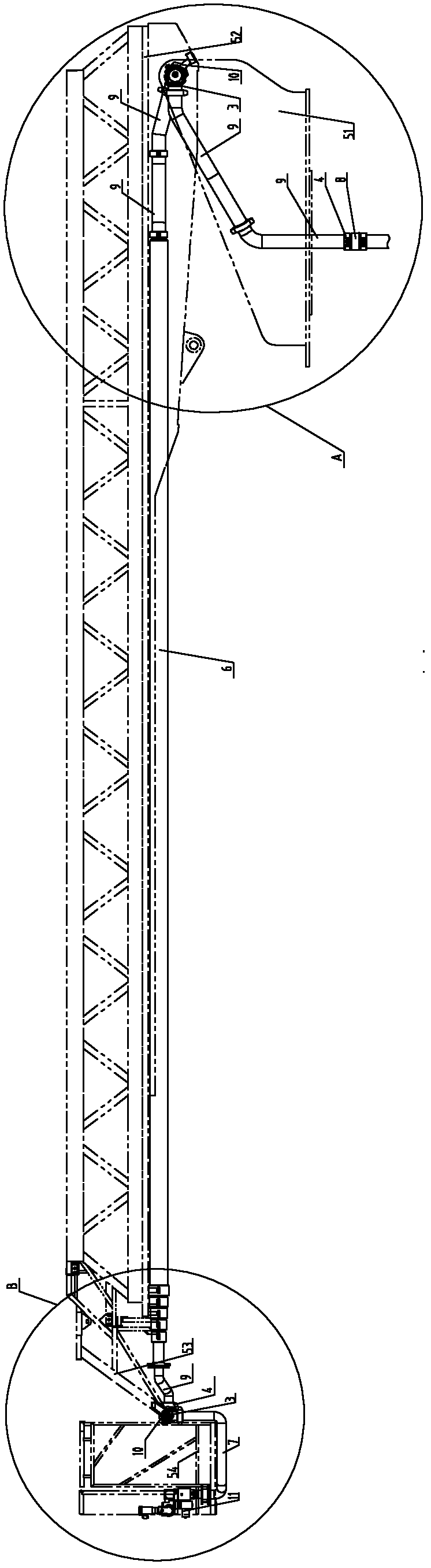

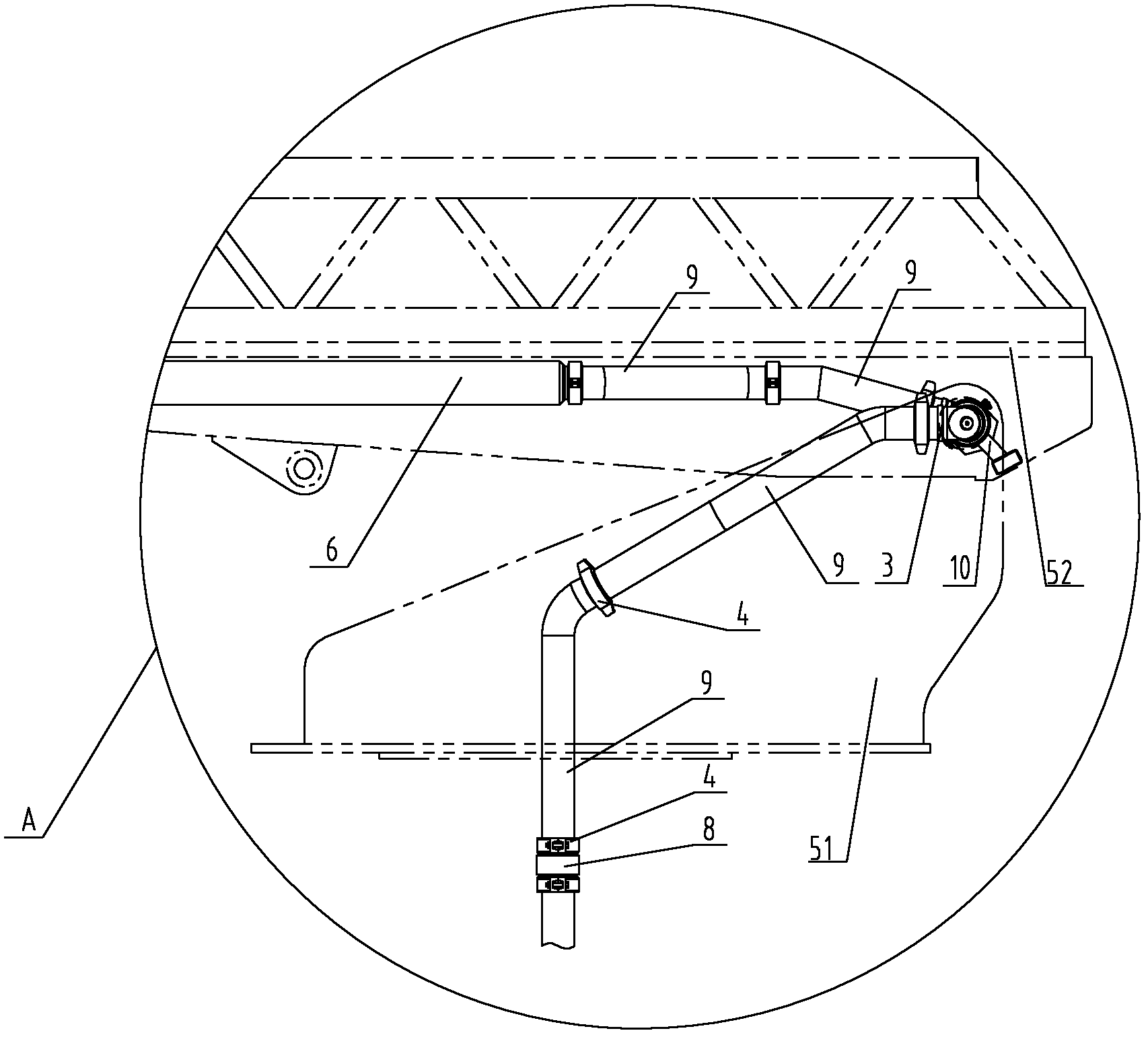

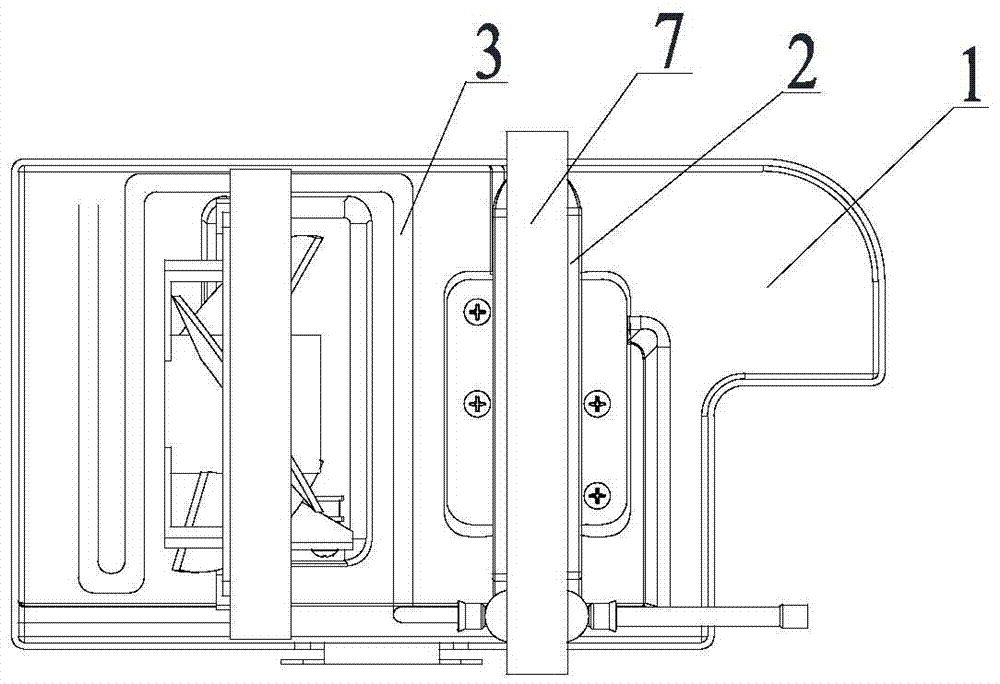

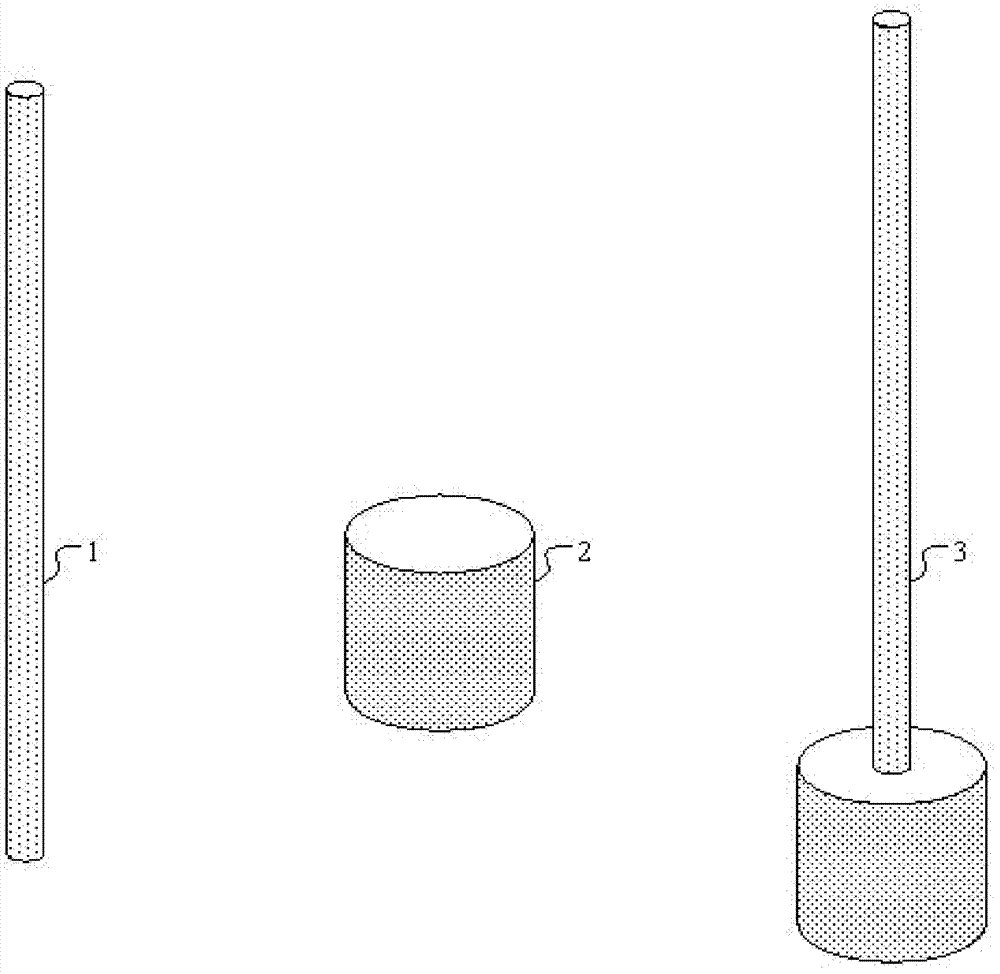

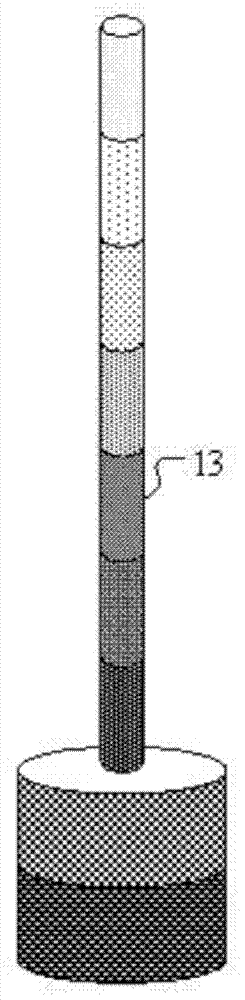

Water pipeline connecting structure for fire truck and fire truck with same

The invention discloses a water pipeline connecting structure for a fire truck. The water pipeline connecting structure comprises a first pipe (1) and a second pipe (2), which can rotate relatively around a rotating axis, the rotating axis is vertical to the axial directions of the first pipe and the second pipe; in addition, the water pipeline connection structure also comprises a rotary joint (3), one end of the rotary joint is communicated with the first pipe, the other end of the rotary joint is connected with the second pipe and the rotation center of the rotary joint is coaxial with the rotating axis. The invention also discloses a fire truck provided with the water pipeline connecting structure. Through adoption of the technical scheme, the on-way resistance of a water pipeline can be reduced greatly, pressure loss can be lowered and the injection distance and flow of water injected from a vehicle-mounted water spraying device can be improved; moreover, the water pipeline connecting structure has good fire resistance and is hardly aged; in addition, the water pipeline consisting of hard pipes has excellent sealing performance and the pressure resistance and the safety of the water pipeline of the fire truck can be improved remarkably.

Owner:CHANGSHA ZOOMLION FIRE FIGHTING VEHICLE

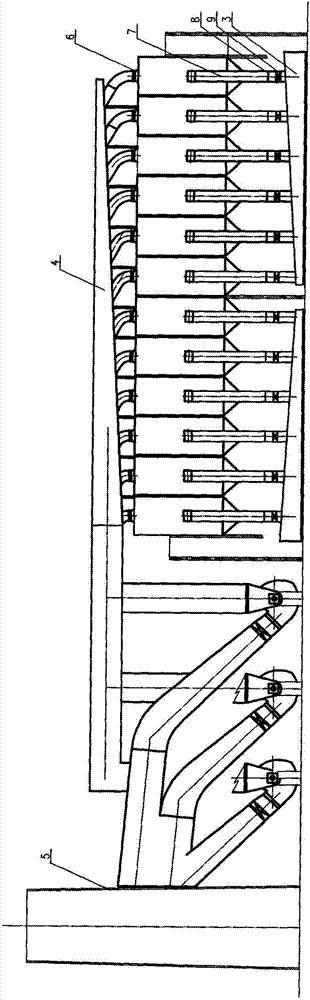

Circulating impact flour milling machine unit and circulating impact flour milling method by using circulating impact flour milling machine

InactiveCN105149045AAvoid damageEliminate the phenomenon of mixing in finished productsGrain treatmentsForeign matterEngineering

The invention discloses a circulating impact flour milling machine unit and a circulating impact flour milling method by using a circulating impact flour milling machine. The unit comprises a machine housing; a screen is mounted in the machine housing; a cleaning bin and a screening bin are arranged in the screen; a circulating screen mesh and a grading screen mesh mechanism are arranged in the screening bin; the impact flour milling machine is arranged in the machine housing; a screen body feed opening and a circulating feed opening are formed in the top of the screen; the cleaning screen mesh used for separating impurities is arranged in the cleaning bin; the discharge opening of the impact flour milling machine is connected with a flour milling machine discharging pipe; after being bent, the upward extending flour milling machine discharging pipe is connected with a discharger; the circulating feed opening is connected with a sieving feed passage; a circulating discharging passage is arranged above the circulating screen mesh, and is communicated with a flour milling machine feed passage; a plurality of screen discharging pipes are connected to each grading screen mesh in the grading screen mesh mechanism. The circulating impact flour milling unit is small in occupied space, low in cost, small in energy consumption, and capable of avoiding damage from large foreign impurities, realizing circulating processing and continuous discharging, avoiding the generation of pulverized materials which cannot reach size requirements, and classifying the processed materials to finished products with different grain sizes to be conveyed out.

Owner:王毅

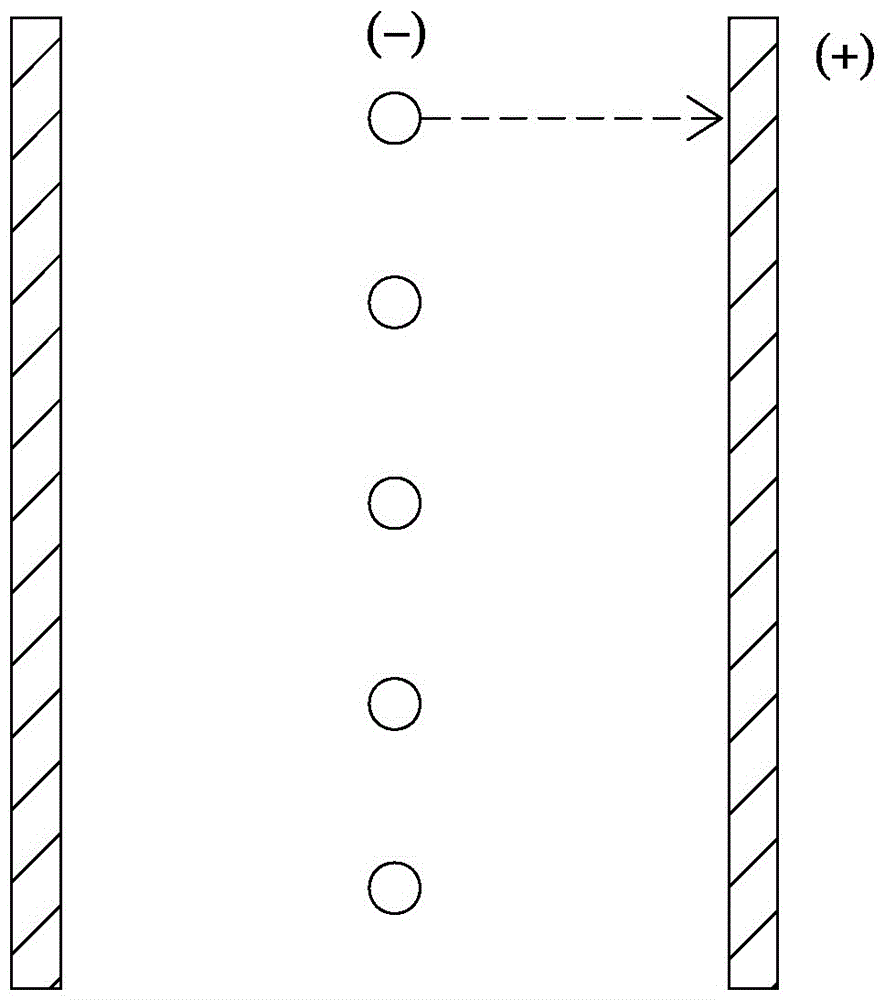

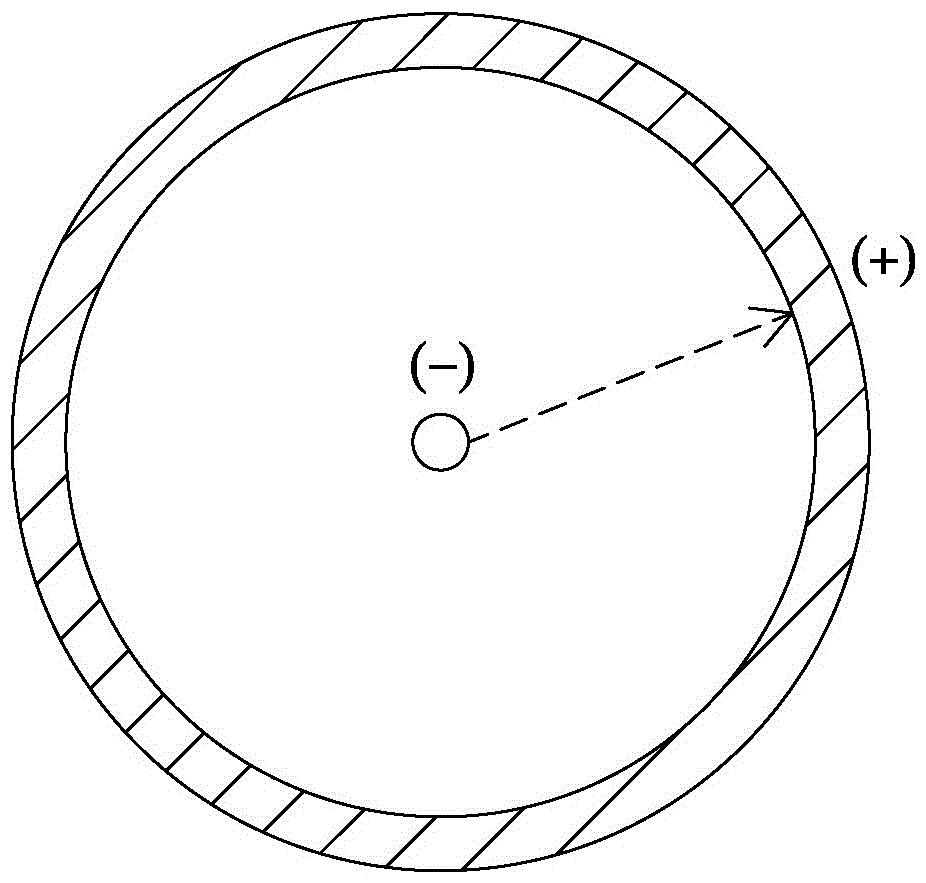

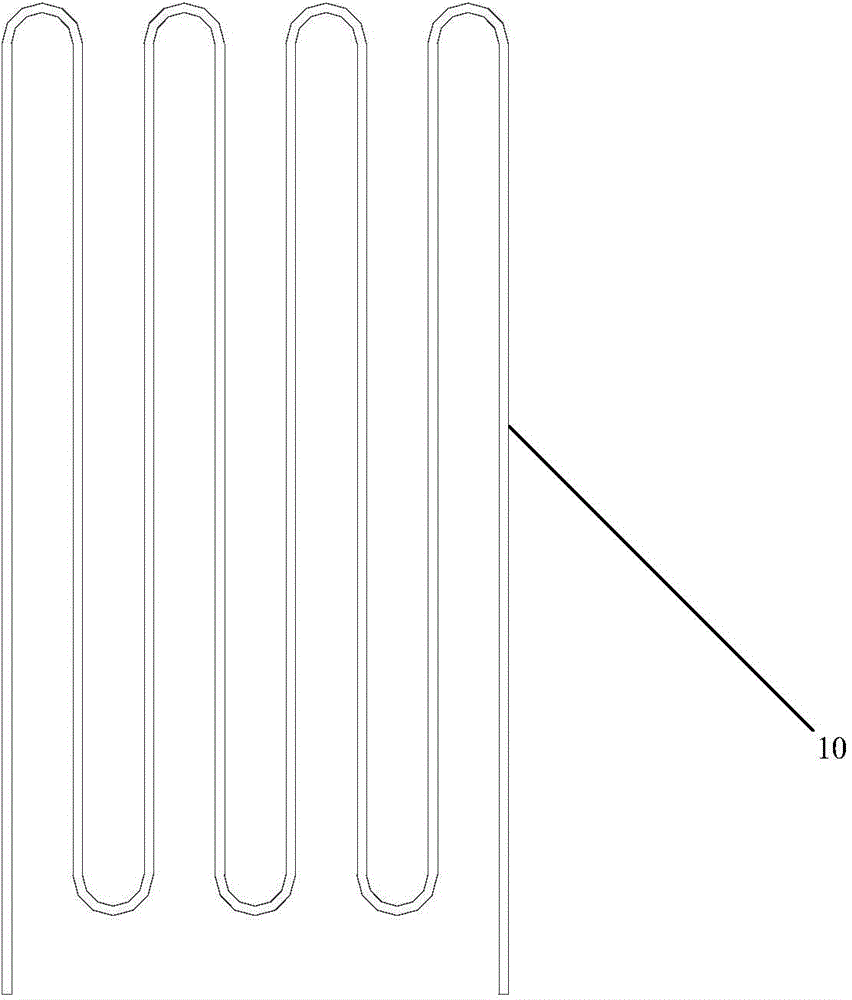

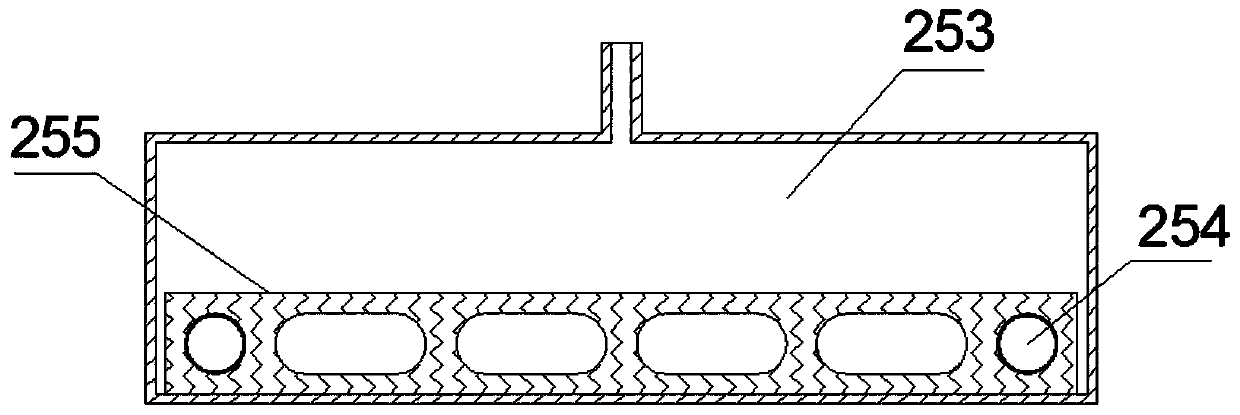

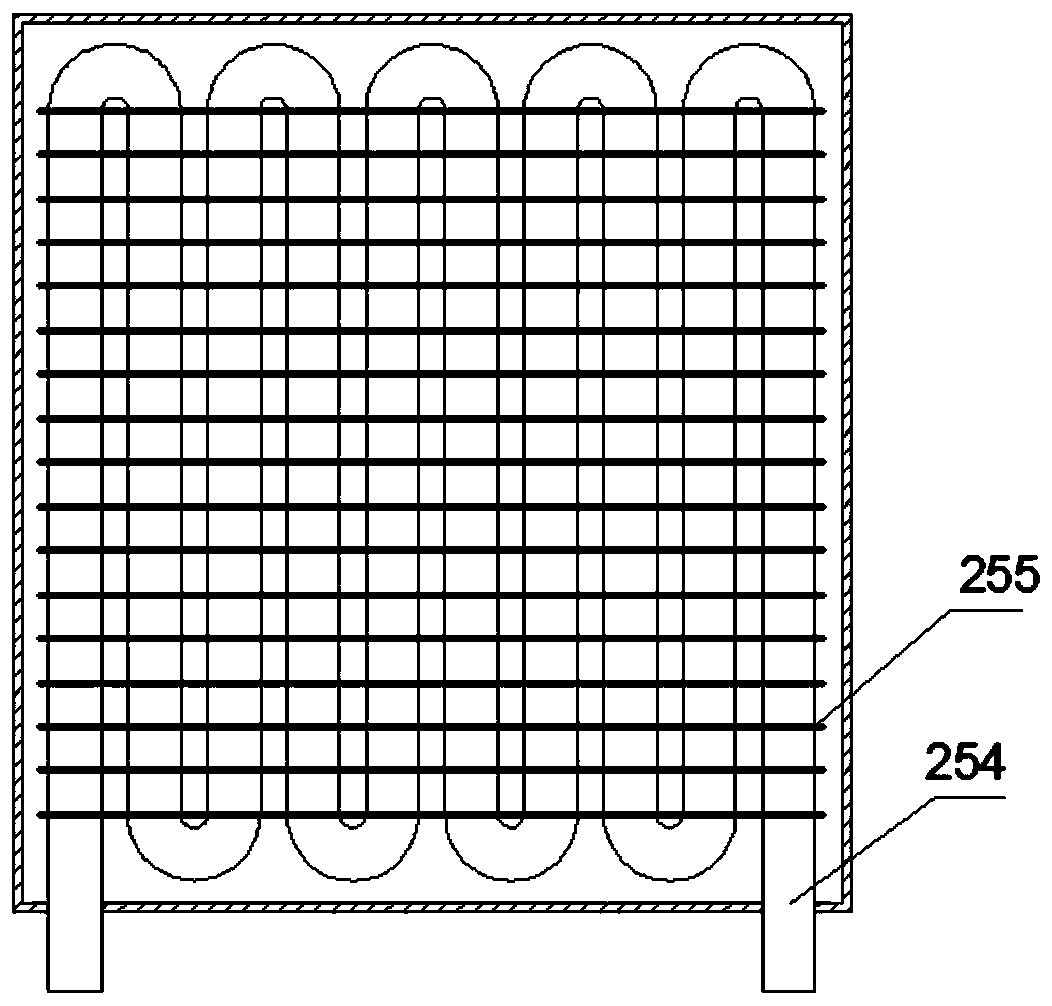

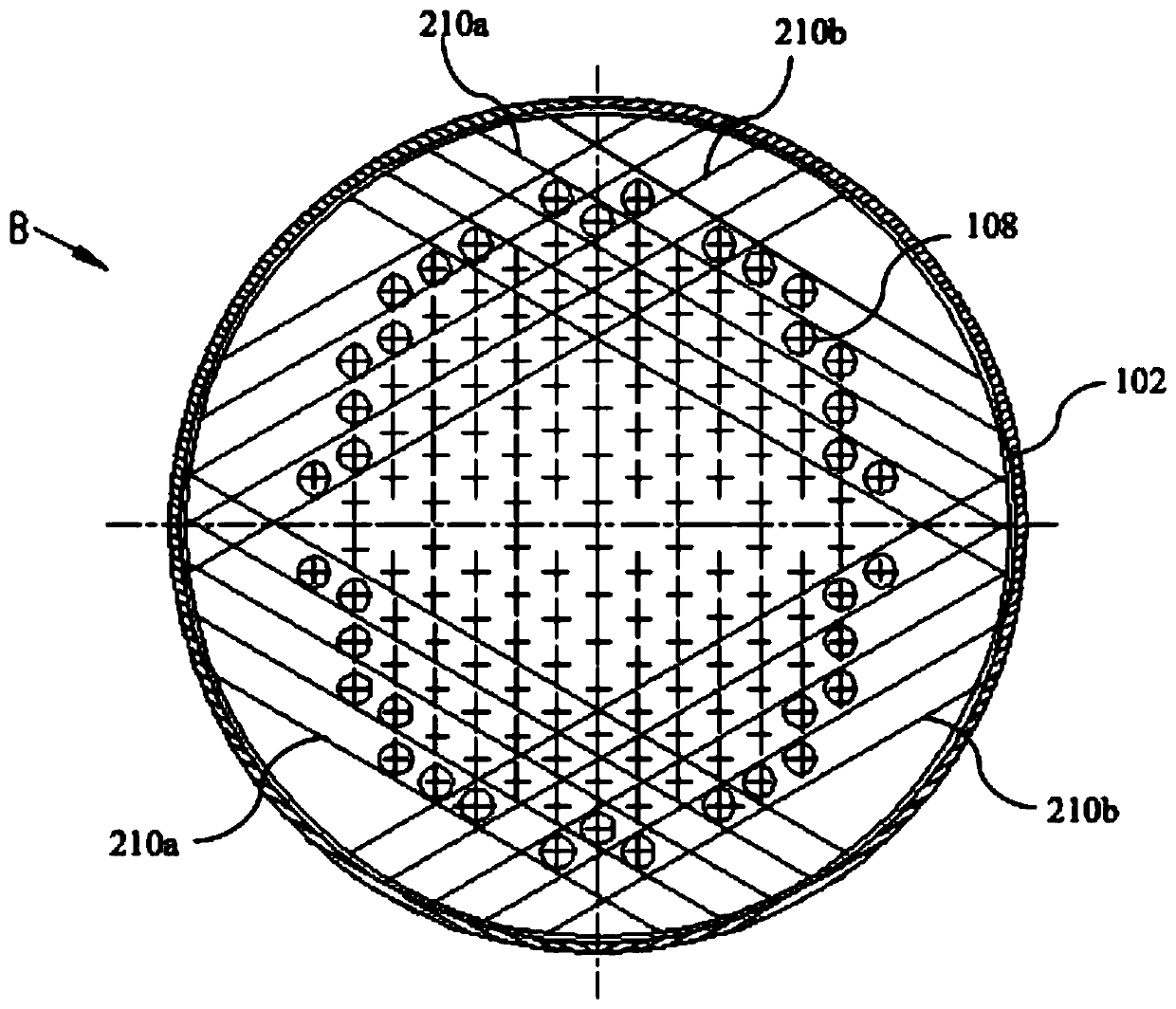

Micro-channel anode water mist removing device

InactiveCN106492988AShort pitchReduce drag along the wayElectrode constructionsElectric energyEngineering

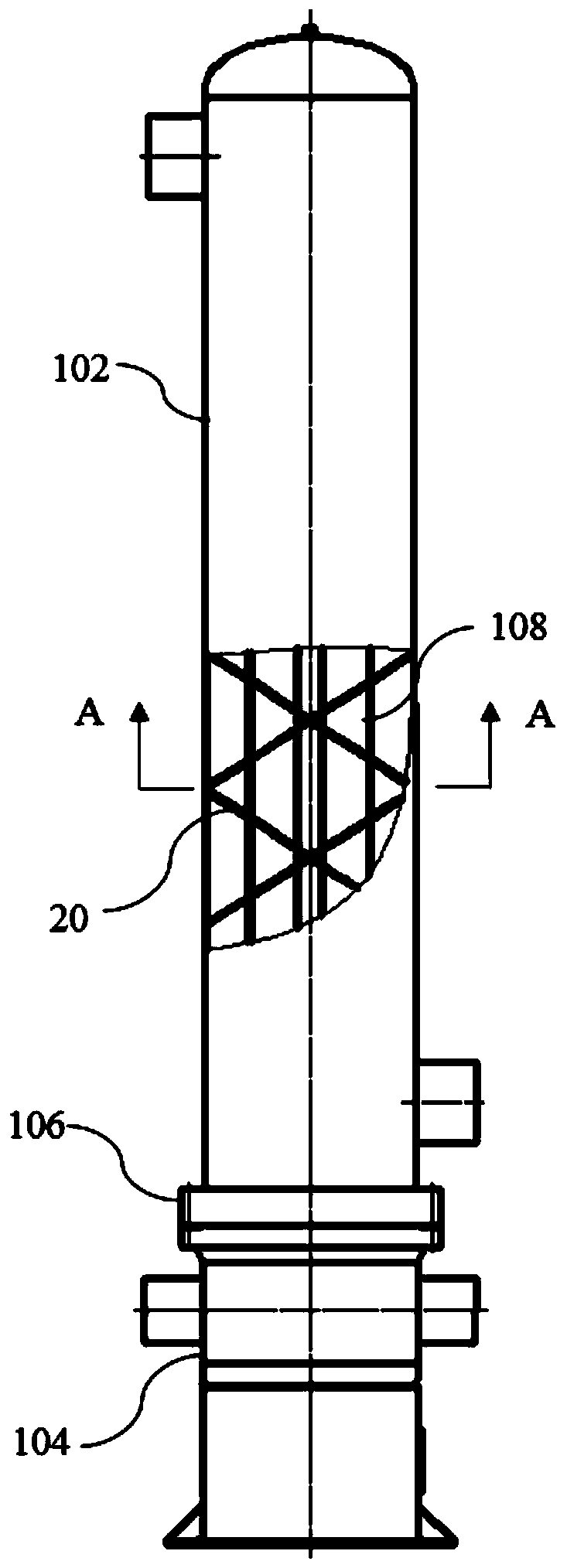

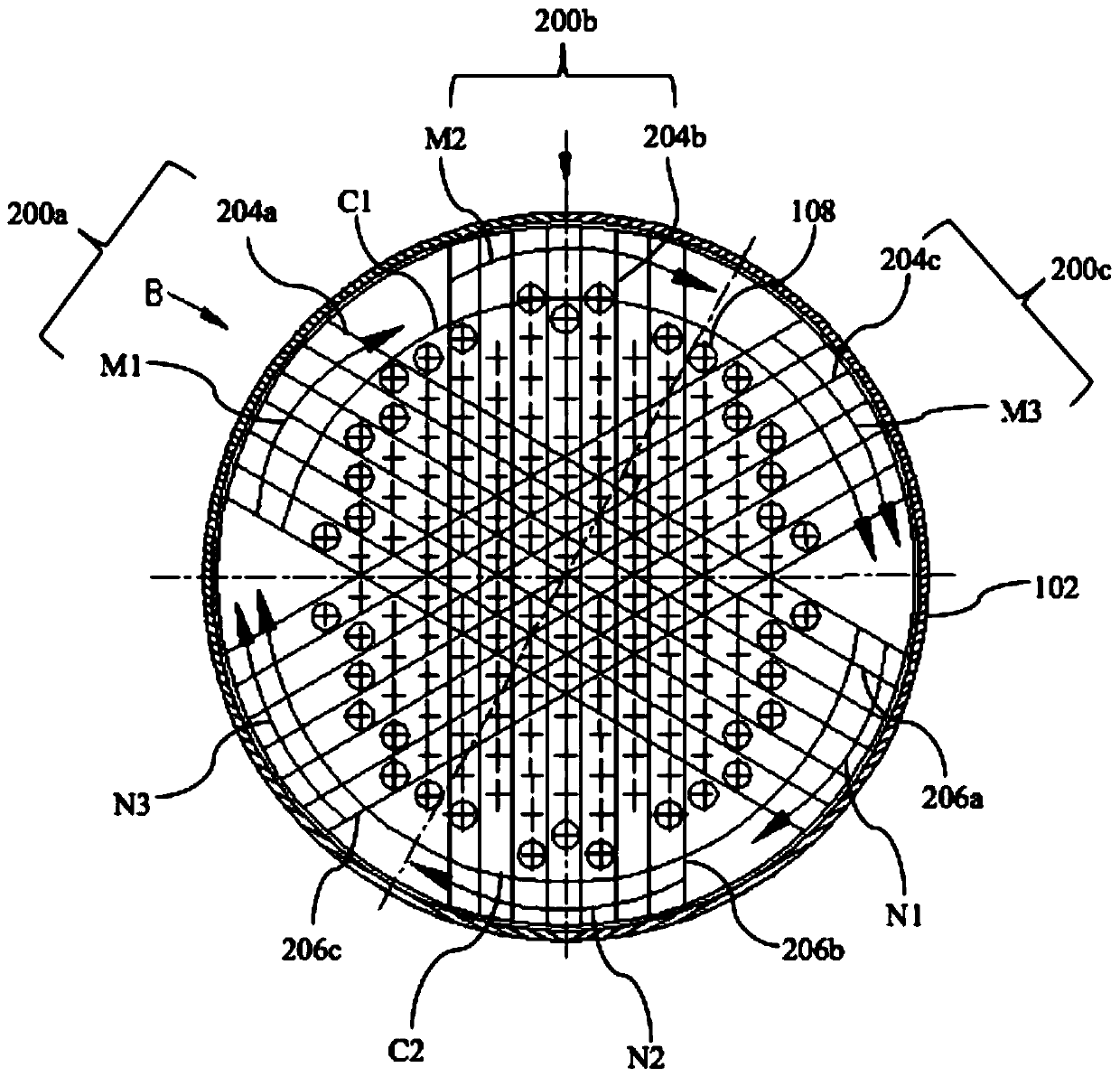

The invention provides a micro-channel anode water mist removing device. The micro-channel anode water mist removing device comprises a high-voltage electrostatic power supply, a columnar cylinder body, concentrated water mist discharging equipment, a wire mesh anode plate and a plurality of cathode lines; the wire mesh anode plate is an anode plate with a micro-channel which is formed by piling up a plurality of metal wires in an interweaved manner; the columnar cylinder body is communicated with the concentrated water mist discharging equipment; the wire mesh anode plate is transversely arranged inside the columnar cylinder body; the cathode lines are all transversely arranged inside the columnar cylinder body, and located in the air inlet direction of the wire mesh anode plate; the negative electrode of the high-voltage electrostatic power supply is connected with the cathode lines to form a cathode, and the wire mesh anode plate is correspondingly formed as an anode. The micro-channel anode water mist removing device disclosed by the invention has the advantages of being capable of greatly reducing the on-way resistance of water mist particles to improve the adsorption rate so as to reduce the time consumption, and only requiring to provide micro voltage of 10 to 20KV to meet adsorption requirements, thereby being capable or reducing the consumption of electric energy, and further being capable of effectively preventing the water mist particles from running away, and being very excellent in water mist removing effect.

Owner:福建省沃特宝环保科技有限公司

Condenser assembly for refrigerator, refrigerator refrigeration system and refrigerator

InactiveCN105444472AEnhanced turbulenceSmall pressure lossEvaporators/condensersEngineeringRefrigeration

The invention discloses a condenser assembly for a refrigerator, a refrigerator refrigeration system and the refrigerator, and belongs to the technical field of refrigerators. The condenser assembly for the refrigerator comprises a water receiving disc and a parallel flow condenser arranged on the water receiving disc. The parallel flow condenser comprises a first collecting main, a second collecting main and a plurality of flat tubes arranged between the first collecting main and the second collecting main in parallel. A partition plate is arranged in at least the first collecting main, a plurality of micro-channels are formed in each flat tube, and fins are arranged between the flat tubes. The condenser assembly for the refrigerator is high in heat exchange efficiency, the filling amount of refrigerants is small, occupied space is small, and the structure is more compact. Due to the fact that the refrigerator refrigeration system and the refrigerator comprise the condenser assembly for the refrigerator, the refrigerator refrigeration system and the refrigerator are smaller in size, more compact in structure and more convenient to mount.

Owner:HEFEI KINGHOME ELECTRICAL CO LTD

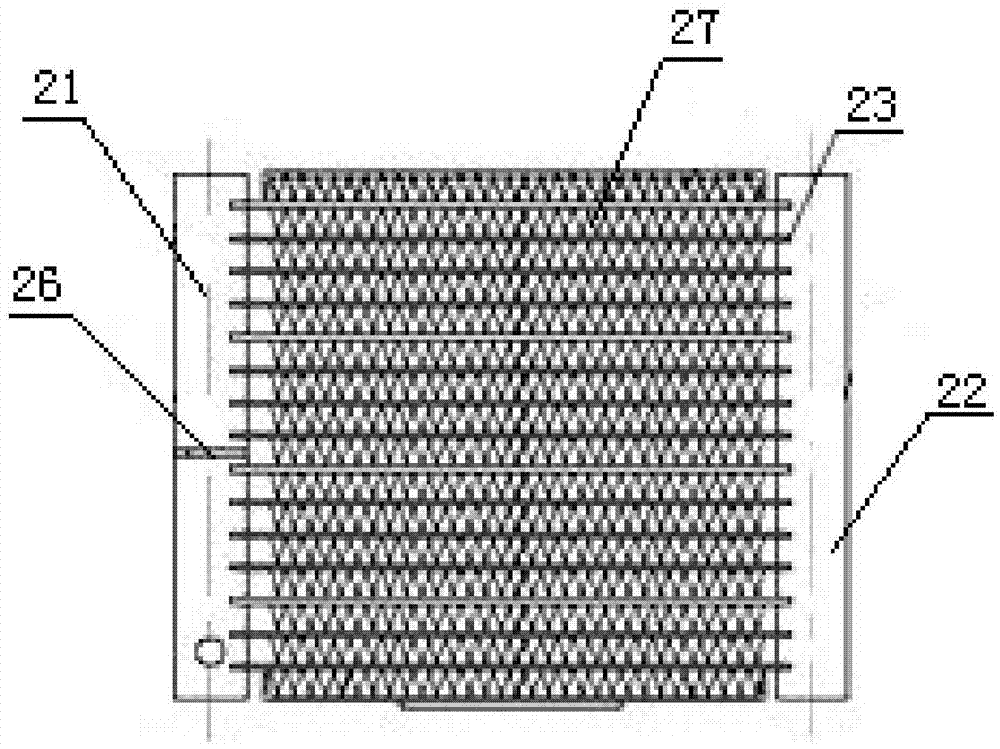

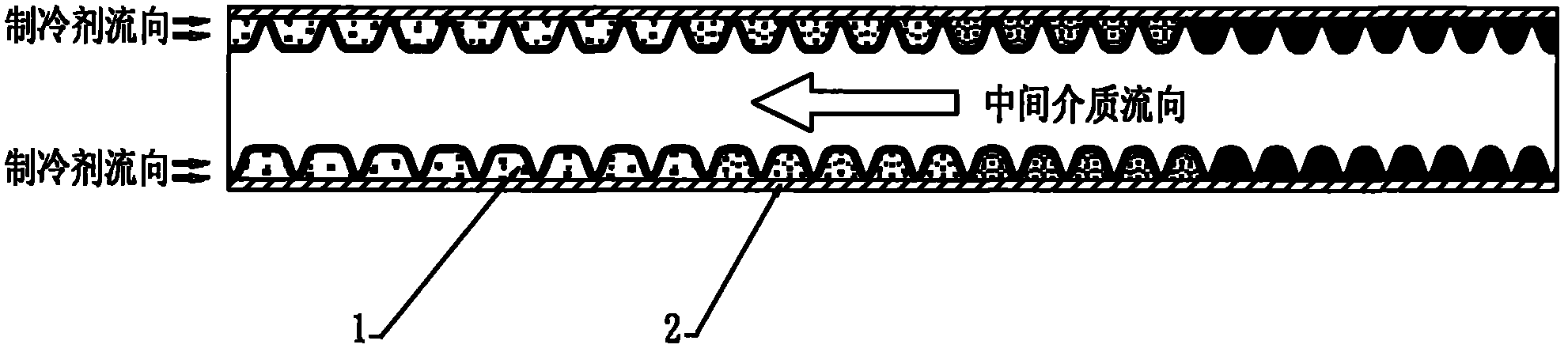

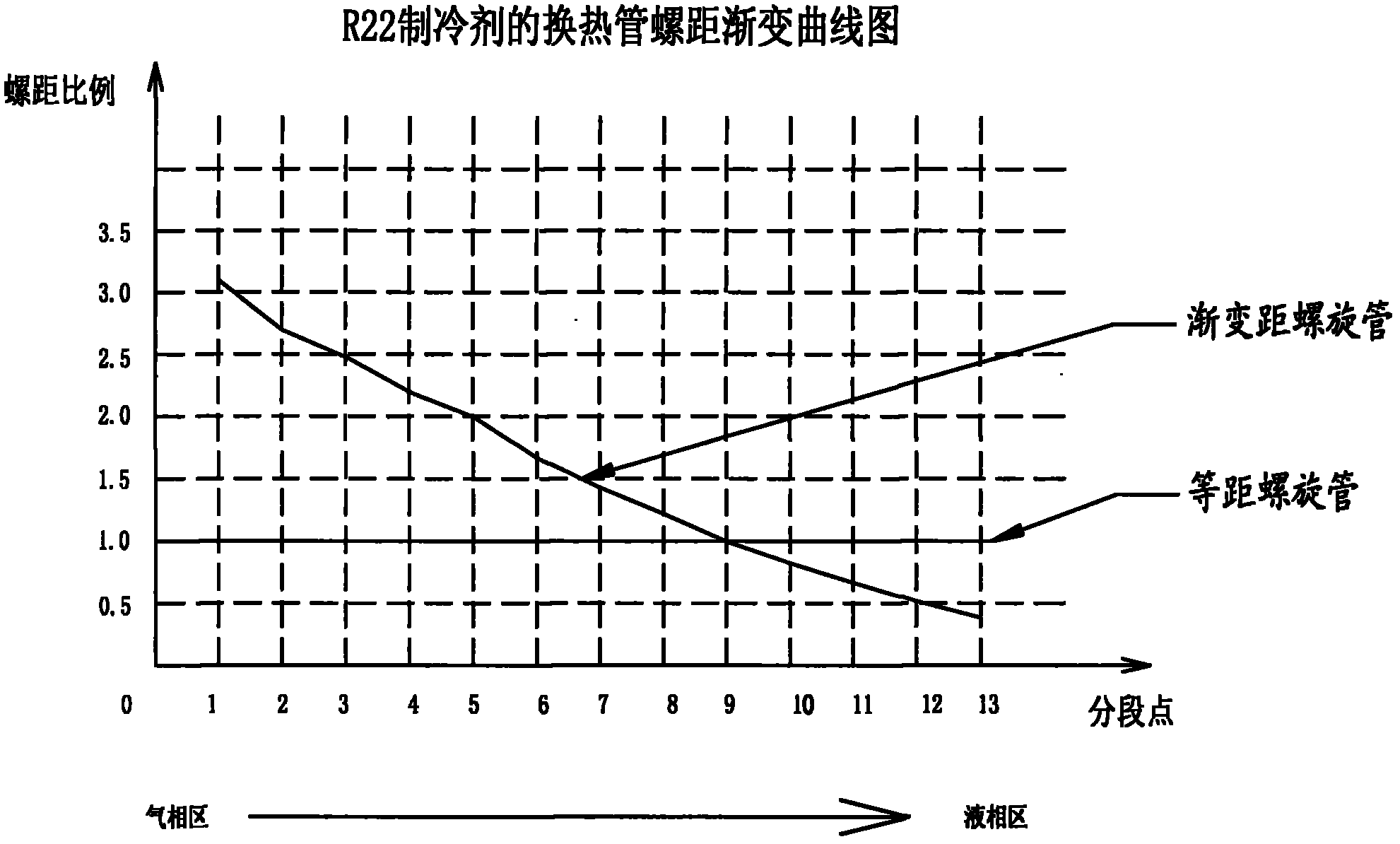

Air-conditioning heat exchanger

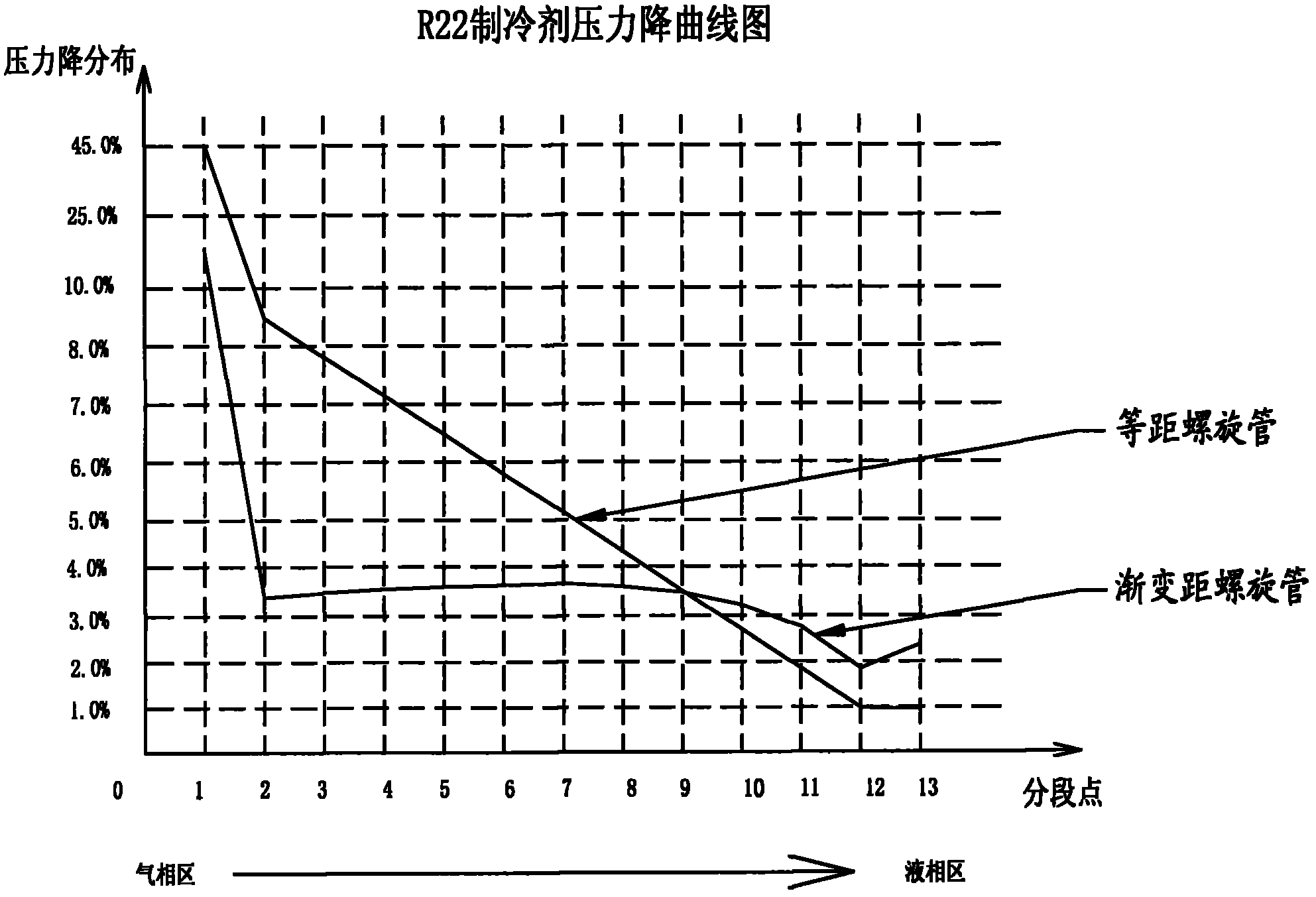

InactiveCN102116544AStable pressureStable flow rateEvaporators/condensersStationary tubular conduit assembliesEngineeringAir conditioning

The invention discloses an air-conditioning heat exchanger which comprises an outer pipe and an inner pipe, wherein the outer pipe is a straight pipe, the inner pipe is a spiral pipe, and the outer pipe and the inner pipe are mutually sleeved. The inner wall of the outer pipe and the outer spiral wall of the inner pipe are enveloped to form a spiral pipeline, a refrigerant enters through an inlet of the spiral pipeline and flows across the spiral pipeline, a refrigerating intermediate medium relatively flows in the inner pipe, the refrigerant exchanges heat with the intermediate medium through the wall of the inner spiral pipe, and the thread pitch of the inner spiral pipe is designed as gradual change according to the change situation of volume and pressure drop caused by the phase change of the refrigerant in the heat exchange process. Through the gradual change design for the thread pitch of the inner spiral pipe of the heat exchanger, a refrigerant channel can be adapted to the volume and pressure change of the refrigerant due to heat exchange, the stable pressure and the flow velocity of the refrigerant in the heat exchanger can be ensured, and the efficiency of the heat exchanger can be guaranteed; meanwhile, pressure loss in the heat exchange process is reduced, and the working load of a compressor is reduced; in addition, the total way resistance of the refrigerant is simultaneously reduced, and the delivery power of the refrigerant is reduced.

Owner:NINGBO HICON IND

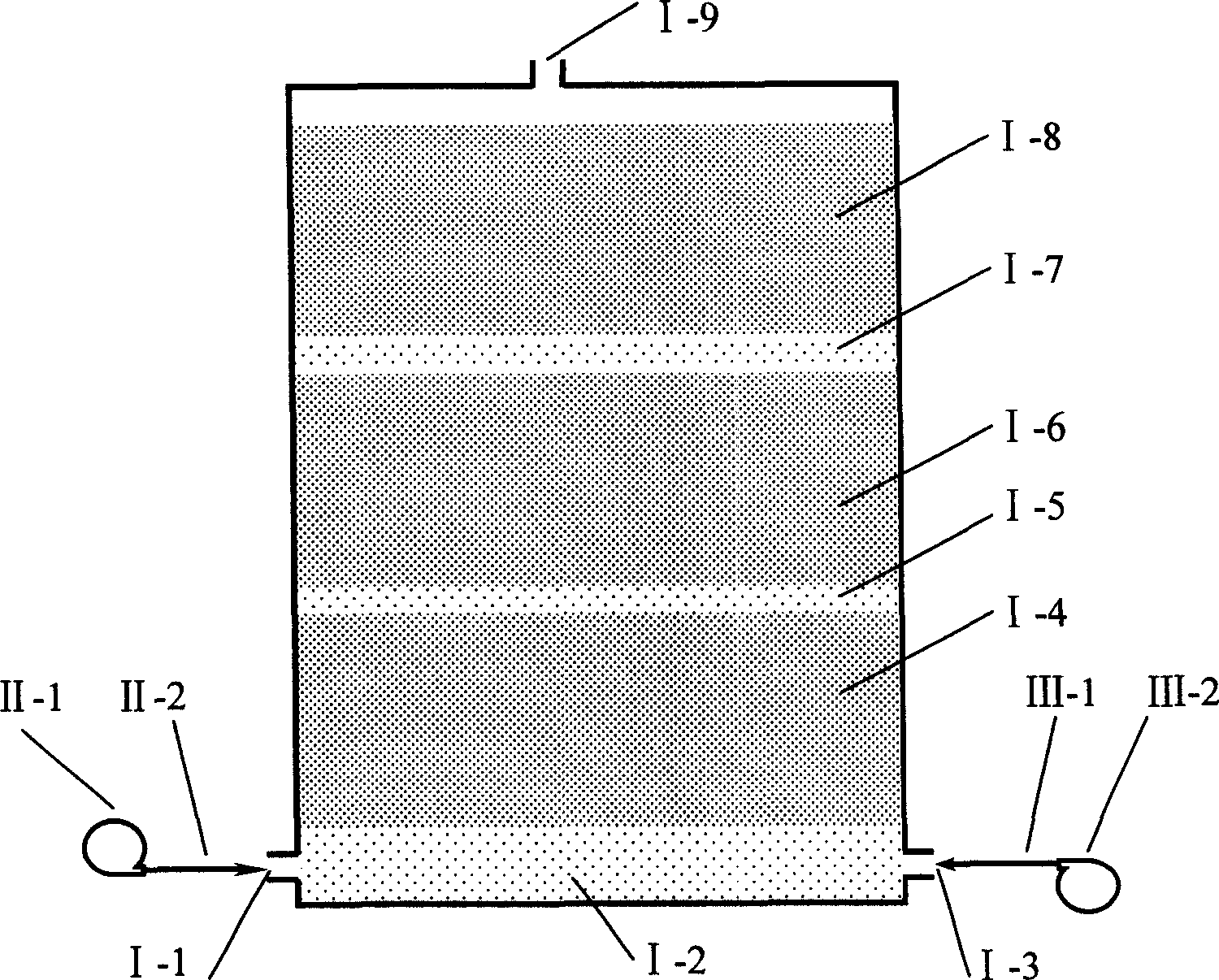

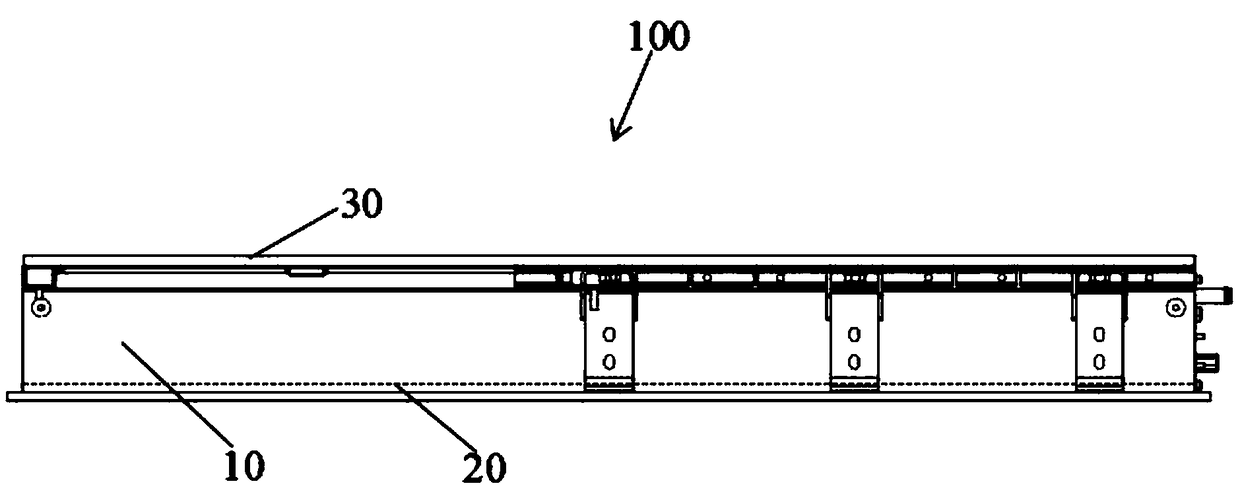

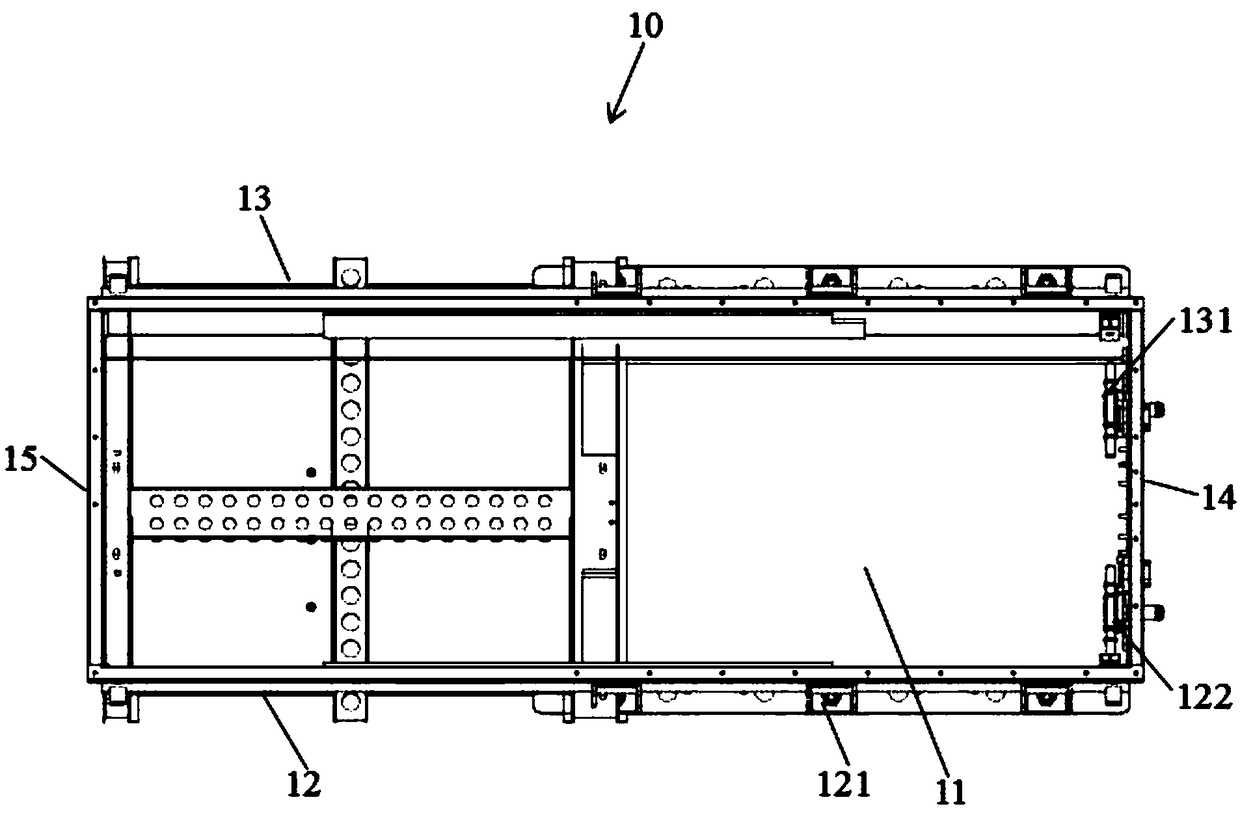

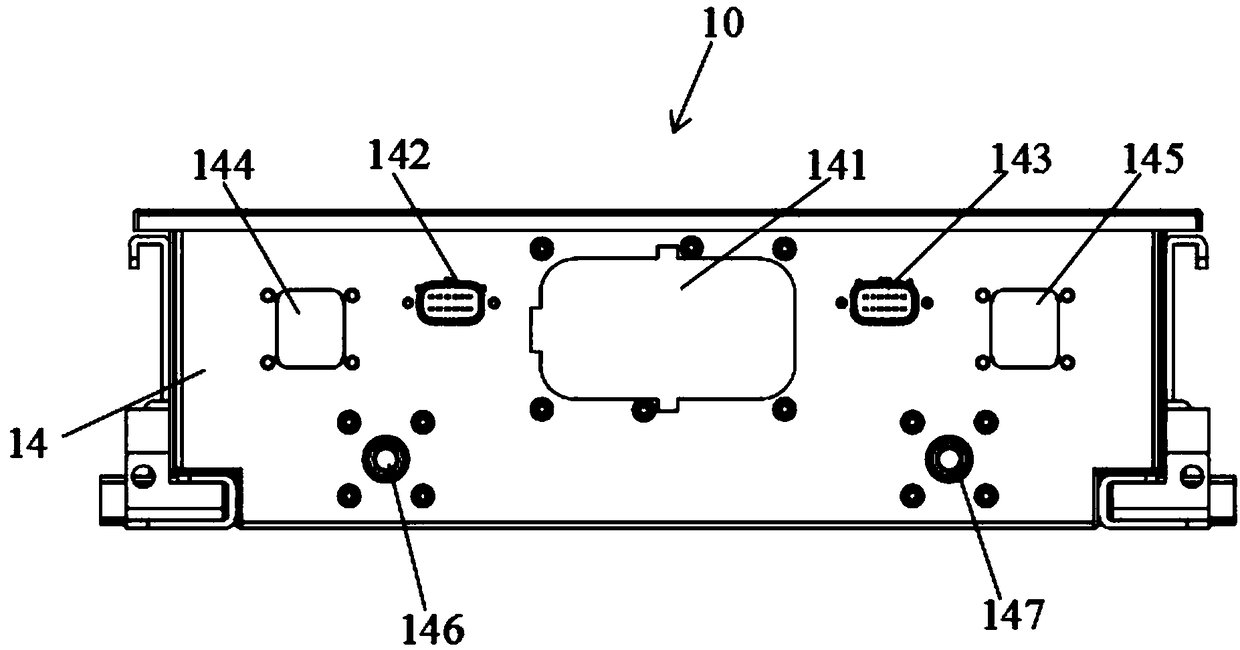

Lithium ion battery box for electric automobile

PendingCN108428835AIncrease energy densityReduce volumeSecondary cellsCell component detailsEngineeringLithium-ion battery

The invention provides a lithium ion battery box for an electric automobile. The lithium ion battery box is characterized by comprising a box body, a water cooling plate, and a cover, wherein the boxbody is square and comprises a bottom plate enclosing a space for accommodating a lithium ion battery module, two long side plates and two short side plates; the water cooling plate is arranged at thebottom of the space and used for cooling the lithium ion battery module, and is provided with an inlet and an outlet; the cover is detachably mounted at the top of the box body and used for sealing the space; one short side plate is provided with a water inlet and a water outlet, which are communicated with the inlet and the outlet respectively, and are used for enabling an external cooling liquid to flow into the water cooling plate from the inlet and flow out from the outlet; a temperature sensor is arranged on the long side plate; when the temperature sensor senses that the temperature inthe space is higher than 40 DEG C, the external cooling liquid flows into the water cooling plate and flows out; the water cooling plate comprises a first pipeline and a second pipeline arranged sideby side and a plurality of side-by-side third pipelines communicated with the first pipeline and the second pipeline; the diameter of the inlet is larger than that of the outlet.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Compressor and sliding vane thereof

InactiveCN104100526AIncrease inspiratory volumeReduced clearance volumeRotary piston pumpsRotary piston liquid enginesHigh pressureMechanical engineering

The invention provides a compressor and a sliding vane thereof. The sliding vane of the compressor comprises a sliding vane body which comprises a low-pressure side surface and a high-pressure side surface, wherein volume-increasing notches are formed in the low-pressure side surface of the sliding vane body and formed in the bottom of the sliding vane body. The sliding vane of the compressor can increase the air suction volume of the compressor and reduce the clearance volume, so that the problem of smaller air suction volume of the compressor in the prior art is solved; besides, when the compressor finishes previous air suction through rotation, a refrigerant in an air suction pipe can directly enter an air suction cavity for storage firstly, the compressor can finish the air suction quantity directly from the air suction cavity during next air suction, further, air suction quantity from the air suction pipe is reduced, on-way resistance is reduced, and the air suction resistance of the compressor is reduced.

Owner:郑州凌达压缩机有限公司

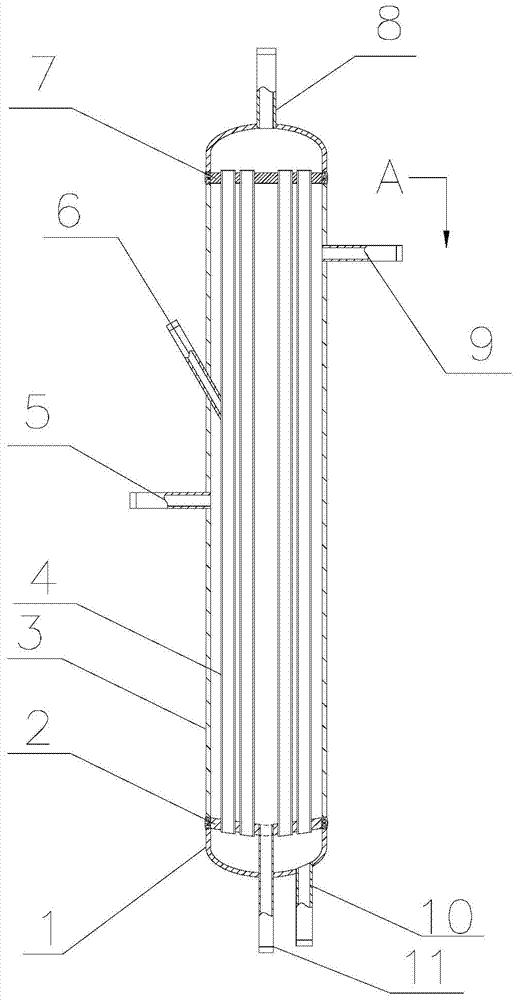

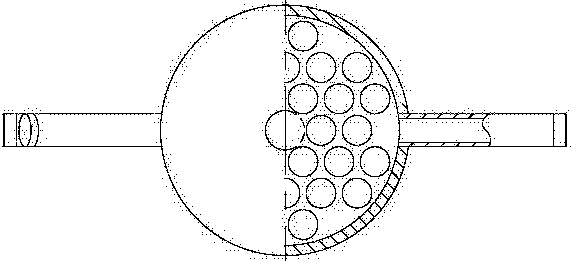

Air separator for refrigeration system

InactiveCN104748459AEffective contactIncrease condensation areaRefrigeration componentsEngineeringProduct gas

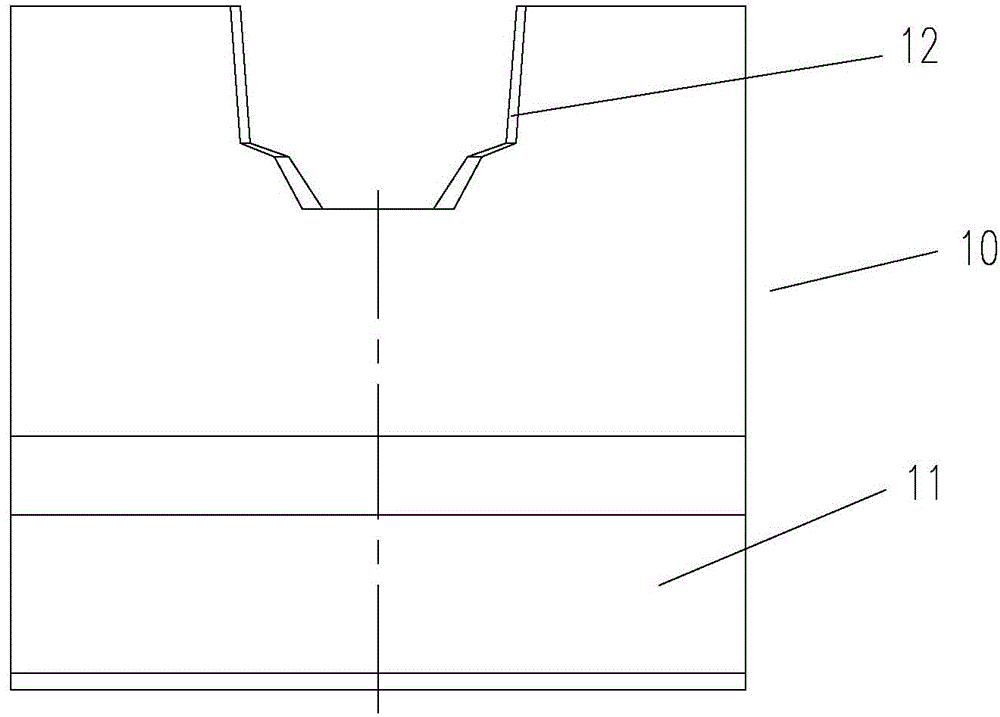

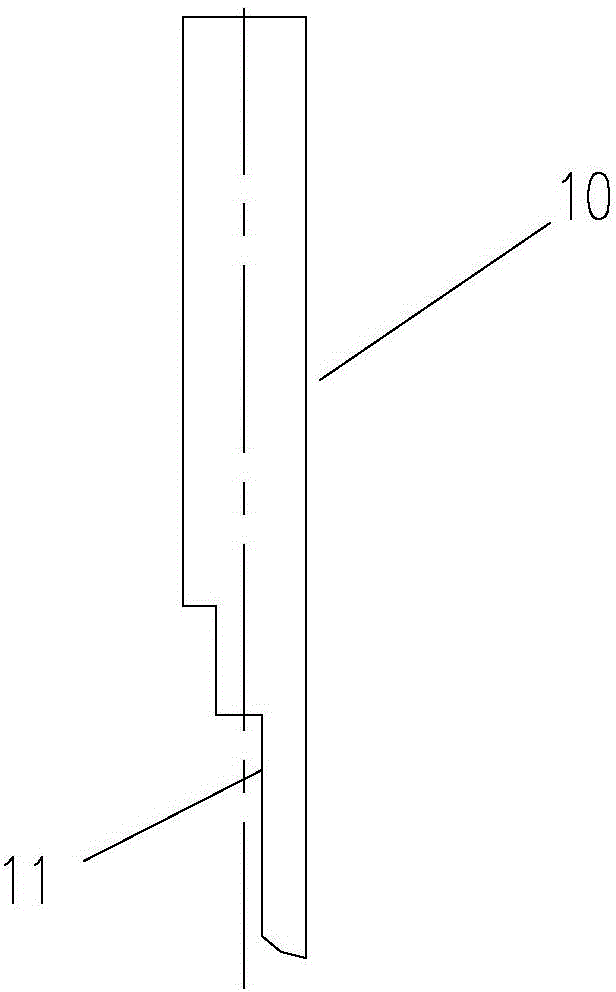

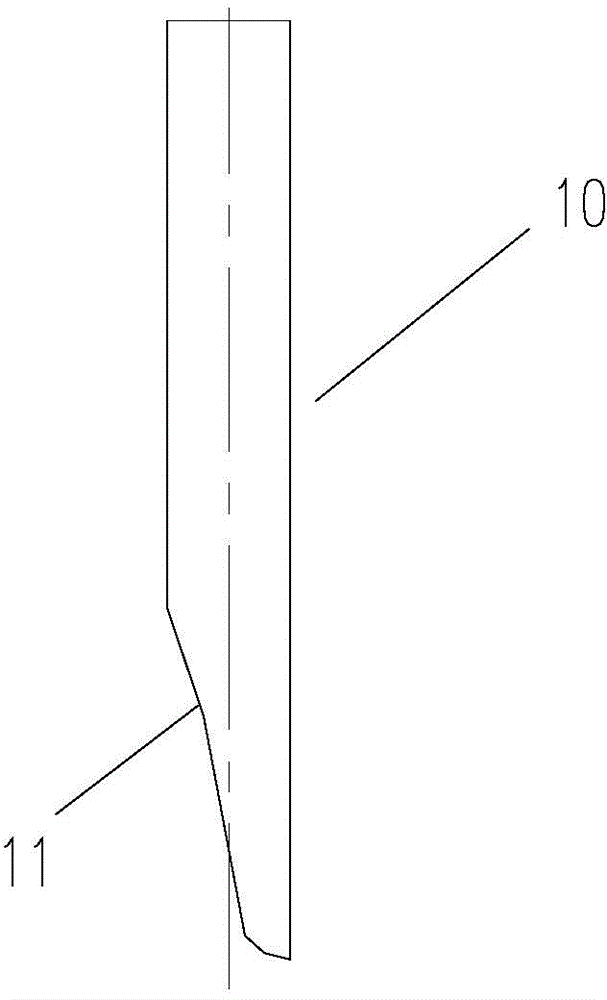

The invention provides an air separator for a refrigeration system. The air separator comprises a sealing head, a lower tube plate, a cylinder, multiple heat exchange tubes, a mixed gas inlet, a temperature probe inserting hole, an upper tube plate, a liquid outlet, a gas outlet, a liquid supply tube and a condensed liquid outlet, wherein the liquid supply tube and the condensed liquid outlet are positioned at the lowermost side of the cylinder; the liquid outlet is positioned at the top of the cylinder; the heat exchange tubes are connected with the upper tube plate and the lower tube plate, and are triangularly arranged in the cylinder; the mixed gas inlet is positioned in the middle of one side of the cylinder; the gas outlet is positioned at the upper part of the other side of the cylinder; and a low-temperature refrigerant circulates in the heat exchange tubes. The air separator can remove air and other non-condensable gas in the refrigeration system, so that the efficiency of the refrigeration system is improved, and the purpose of energy-saving operation of the refrigeration system is achieved.

Owner:上海宝丰机械制造股份有限公司

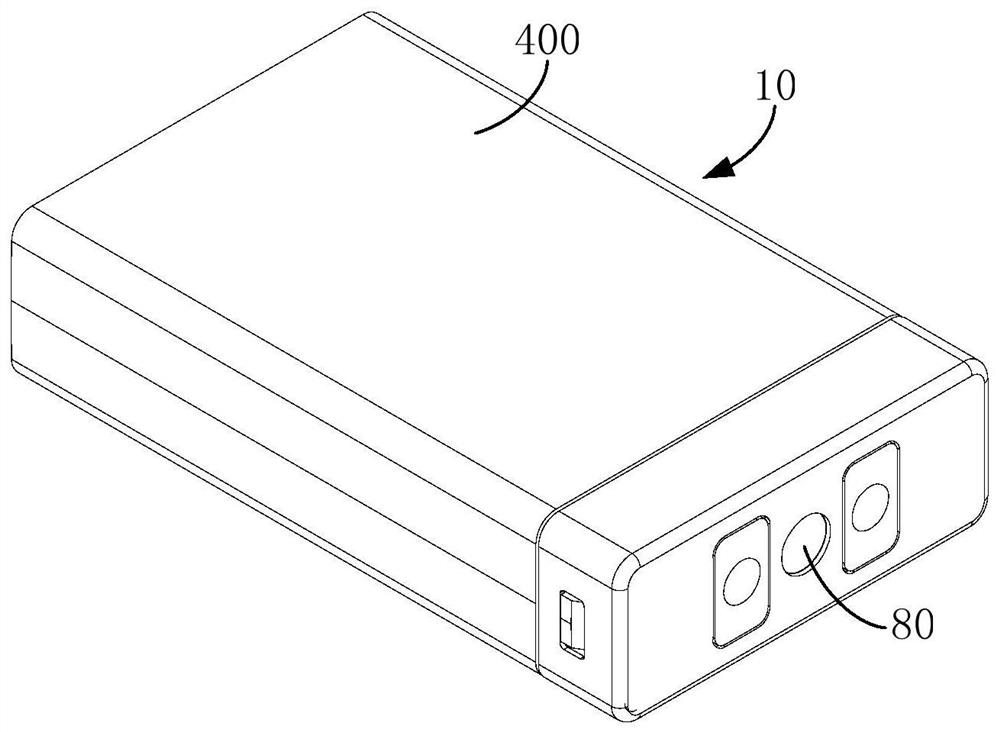

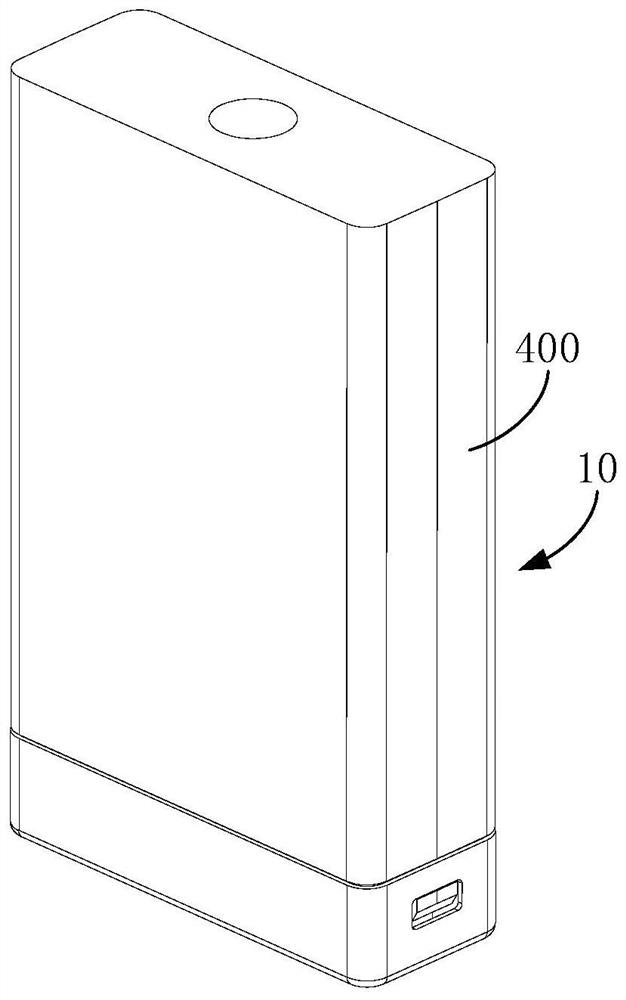

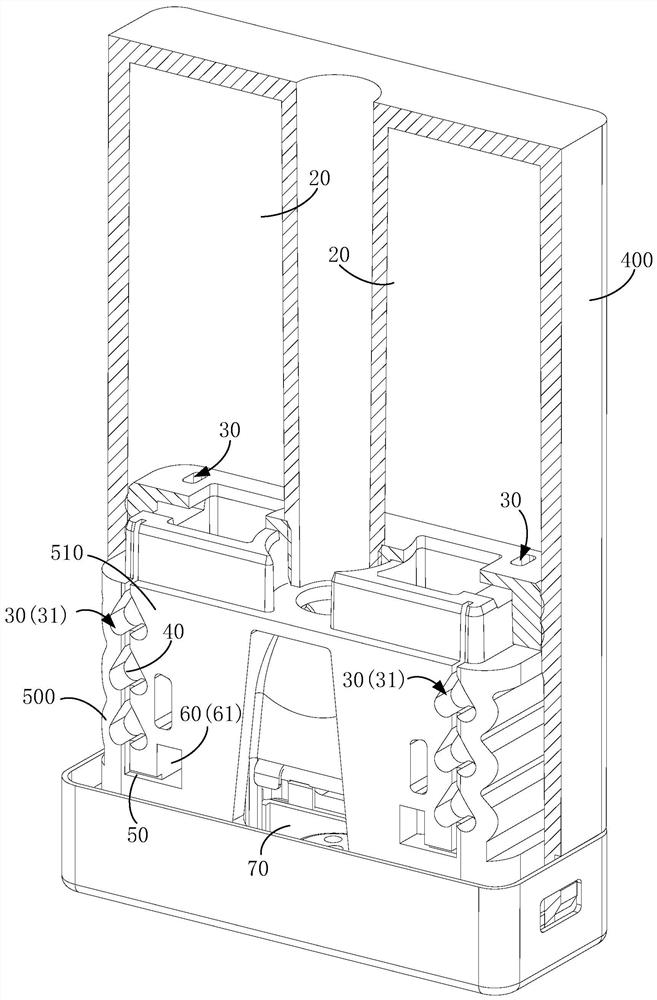

Atomizer and electronic atomization device

The invention relates to an atomizer and an electronic atomization device, the atomizer is provided with a liquid storage cavity and a ventilation channel, the ventilation channel comprises a first sub-channel and a second sub-channel, the first sub-channel comprises a throttling channel and a buffer channel, the liquid storage cavity is communicated with the throttling channel, the second sub-channel is communicated with the buffer channel and the outside, the buffer channel comprises an expansion section and a buffer section, the two ends of the expansion section are directly communicated with the throttling channel and the buffer section respectively, the minimum cross section size of the expansion section is larger than or equal to the cross section size of the throttling channel, thebuffer section can store leaked liquid from the throttling channel, and external gas can enter the liquid storage cavity through the second sub-channel, the buffer channel and the throttling channel in sequence. Therefore, the manufacturing cost can be reduced and liquid leakage can be prevented on the basis of ensuring smooth air exchange of the atomizer.

Owner:SHENZHEN SMOORE TECH LTD

Condenser and refrigerator

InactiveCN104359257AReduce consumptionReduce power consumptionEvaporators/condensersRefrigeration devicesMaterial consumptionEngineering

The invention provides a condenser and a refrigerator. The condenser comprises a plurality of mutually parallel collector tubes and condenser pipes, wherein the condenser pipes are arranged between any two adjacent collector tubes, and the amount of the condenser pipes between any two adjacent collector tubes is different from that of condenser pipes between any other two adjacent collector tubes. Through the condenser and the refrigerator, the total circulation cross section of the condenser can be gradually decreased along with the decrease of the specific volume and flow rate of a refrigerating fluid on the basis of meeting the radiating requirement of the refrigerator, so that the material consumption of the condenser can be reduced, the on-way resistance of the refrigerating fluid in the condenser can also be reduced, and the power consumption of a compressor and the complete machine of the refrigerator is reduced.

Owner:HEFEI HUALING CO LTD

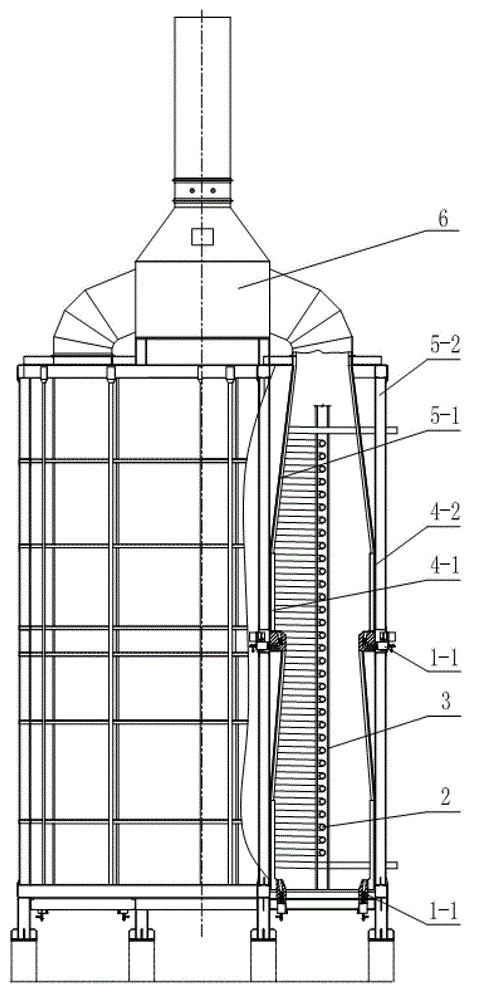

Double-sided radiation spiral pipe heating furnace

The invention relates to the technical field of tube heating furnaces for petroleum refining, petrochemical industry and coal chemical industry, particularly to a double-sided radiation spiral pipe heating furnace which comprises a steel framework, an outer ring radiation wall, a spiral pipe, an inner ring radiation wall and a flame combustor, wherein the outer ring radiation wall is attached inside the steel frame, the spiral pipe is positioned on the inner side of the outer ring radiation wall; the inner ring radiation wall is positioned on the inner side of the spiral pipe; and the flame combustor heats for enabling the inner ring radiation wall and the outer ring radiation wall to reach a high temperature to form radiations, and then the inner ring radiation wall and the outer ring radiation wall supply heat to the spiral pipe in a double-sided radiation mode. The double-sided radiation spiral pipe heating furnace can heat furnace pipes evenly, improve average heat strength of radiations of the furnace pipes, save cost, shorten the hydraulic length of the furnace pipe, increase the flow speed of medium inside the pipes, and avoid cock inside the pipes. Meanwhile, abrasions caused by high solid content medium inside the pipes to the inner walls of bending pipes can be avoided, and potential risks caused by the abrasions can be eliminated.

Owner:BEIJING PETROCHEM ENG

Condenser and refrigeration device

InactiveCN104329834AMeet cooling needsImprove cooling effectEvaporators/condensersRefrigeration devicesRefrigerationRefrigerant

The invention provides a condenser and a refrigeration device. The condenser comprises N collecting pipes and M sets of flat pipes, wherein each set of flat pipes are arranged between the adjacent collecting pipes in a parallel form; the flat pipes are mounted on the collecting pipes; the two ends of the flat pipes are respectively communicated with the adjacent collecting pipes; N is an integer more than or equal to 3; M is an integer more than or equal to 2. Through the technical scheme provided by the invention, on the one hand, the heat exchange area is increased, the heat exchange effect is enhanced, and the radiating property of the condenser is further improved; on the other hand, materials are effectively saved, and the pressure drop of a compressor and the on-way resistance of refrigerant are reduced, so that the overall power consumption is reduced and the charging quantity of the refrigerant is reduced.

Owner:HEFEI HUALING CO LTD

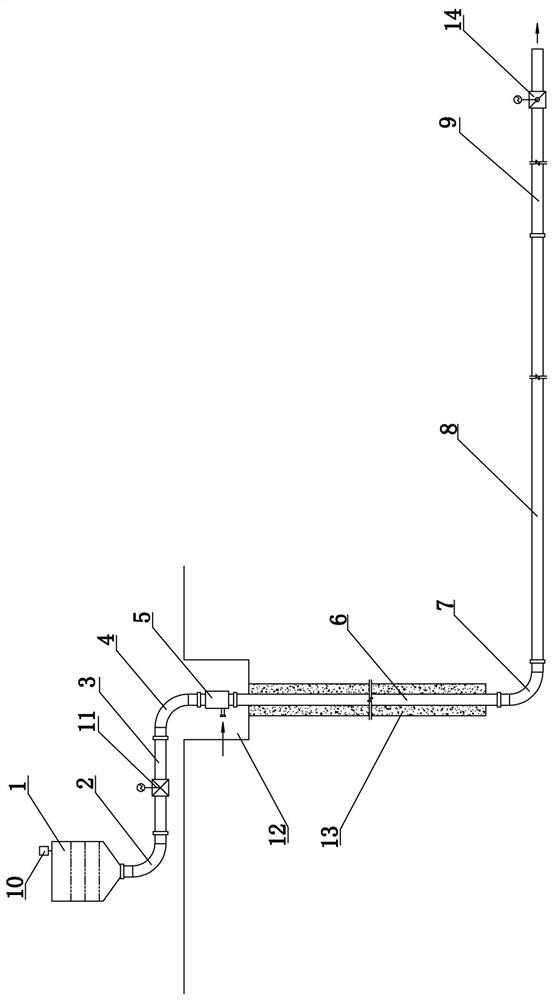

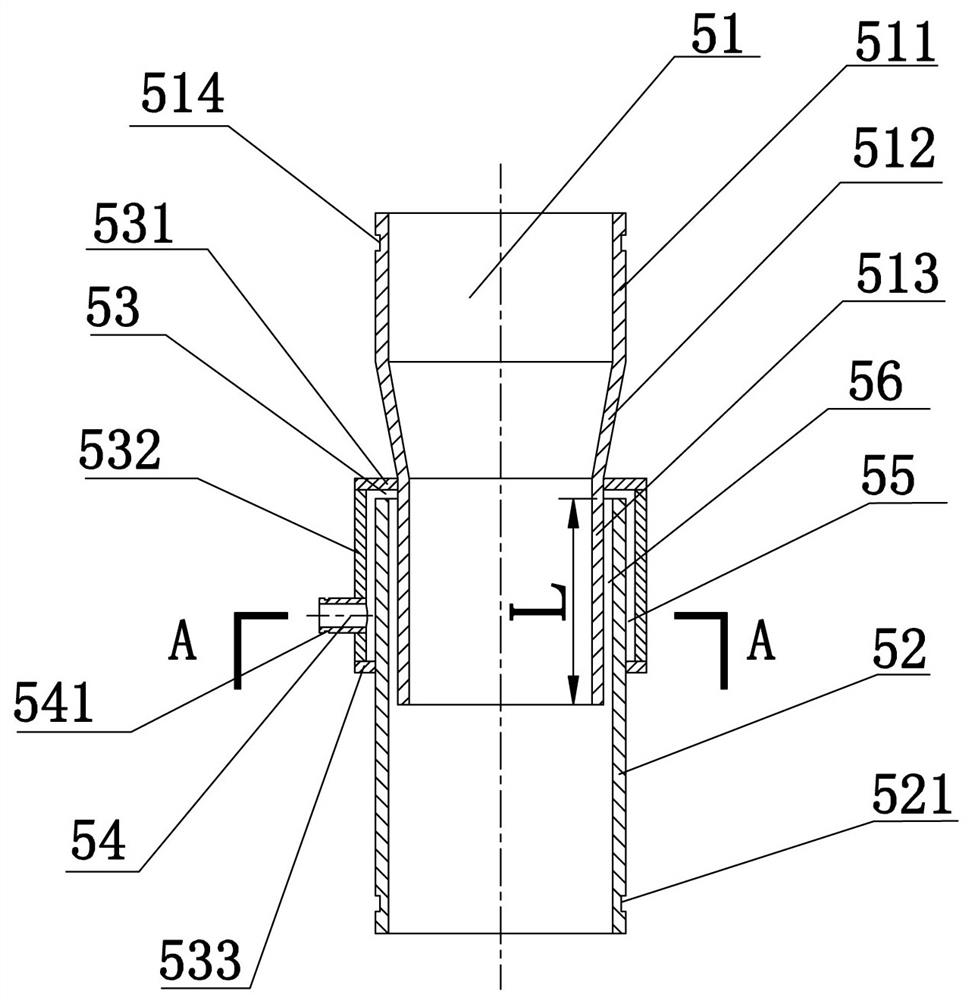

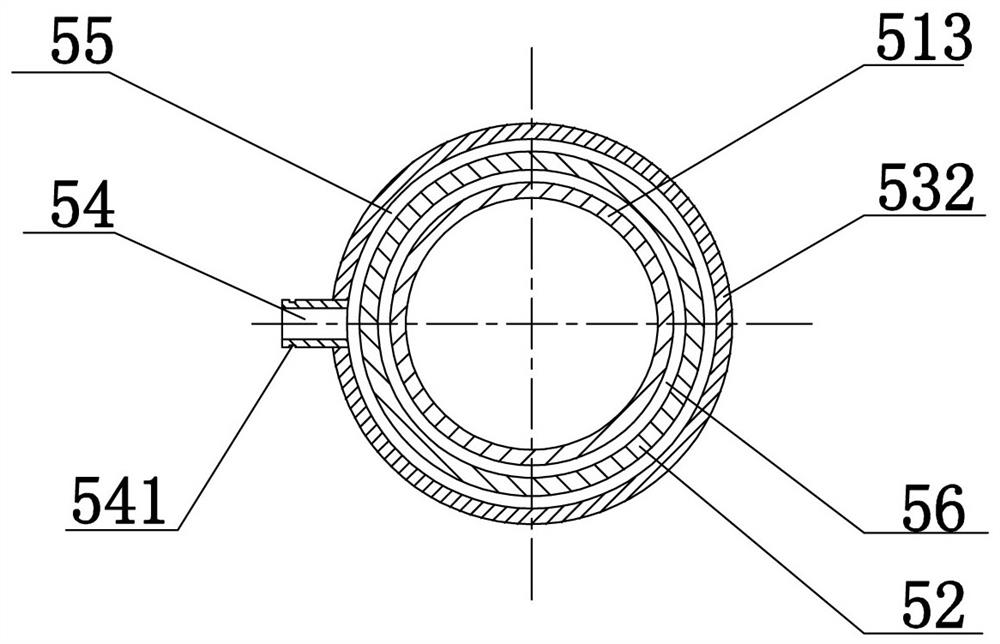

Filling slurry low-resistance free-flow pipeline conveying system

PendingCN111981209AMake full use of gravitational potential energyHigh concentricityPipeline systemsFlexible pipesAutomatic controlControl system

The invention relates to a filling slurry low-resistance free-flow pipeline conveying system which comprises a receiving hopper, a filling guide pipe, a filling vertical pipe, an underground filling pipeline and an automatic control system. The filling slurry low-resistance free-flow pipeline conveying system is characterized in that the receiving hopper is arranged corresponding to a discharge hole of a stirring device; a liquid level monitoring device is arranged on the receiving hopper; a water ring damping device is arranged at the upper end of the filling vertical pipe; one end of the filling guide pipe communicates with a discharge hole of the receiving hopper; the other end of the filling guide pipe communicates with the feed end of the water ring damping device; a motor switch valve is arranged on the filling guide pipe; the underground filling pipeline is arranged in a main roadway and a branch roadway and is suspended on top plates of the roadways; the lower end of the filling vertical pipe communicates with the starting end of the underground filling pipeline; the tail end of the underground filling pipeline extends to an underground goaf to be filled; and an electric adjusting valve is arranged at the position close to the tail end of the underground filling pipeline. The filling slurry low-resistance free-flow pipeline conveying system has the advantages that the structure design is simple and reasonable, the gravitational potential energy is fully played, the on-way resistance and the local resistance of pipeline conveying is reduced, and the conveying distance is lengthened.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

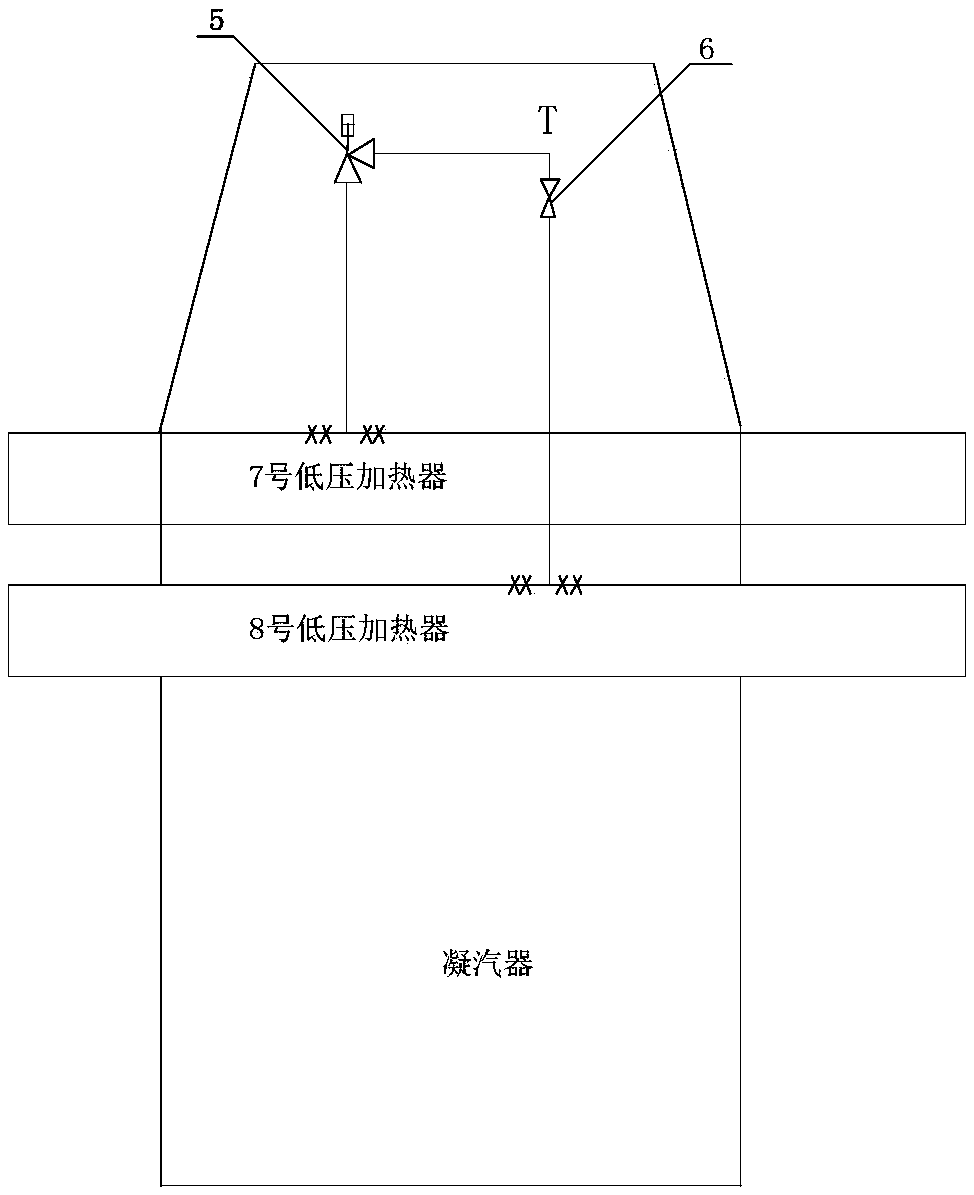

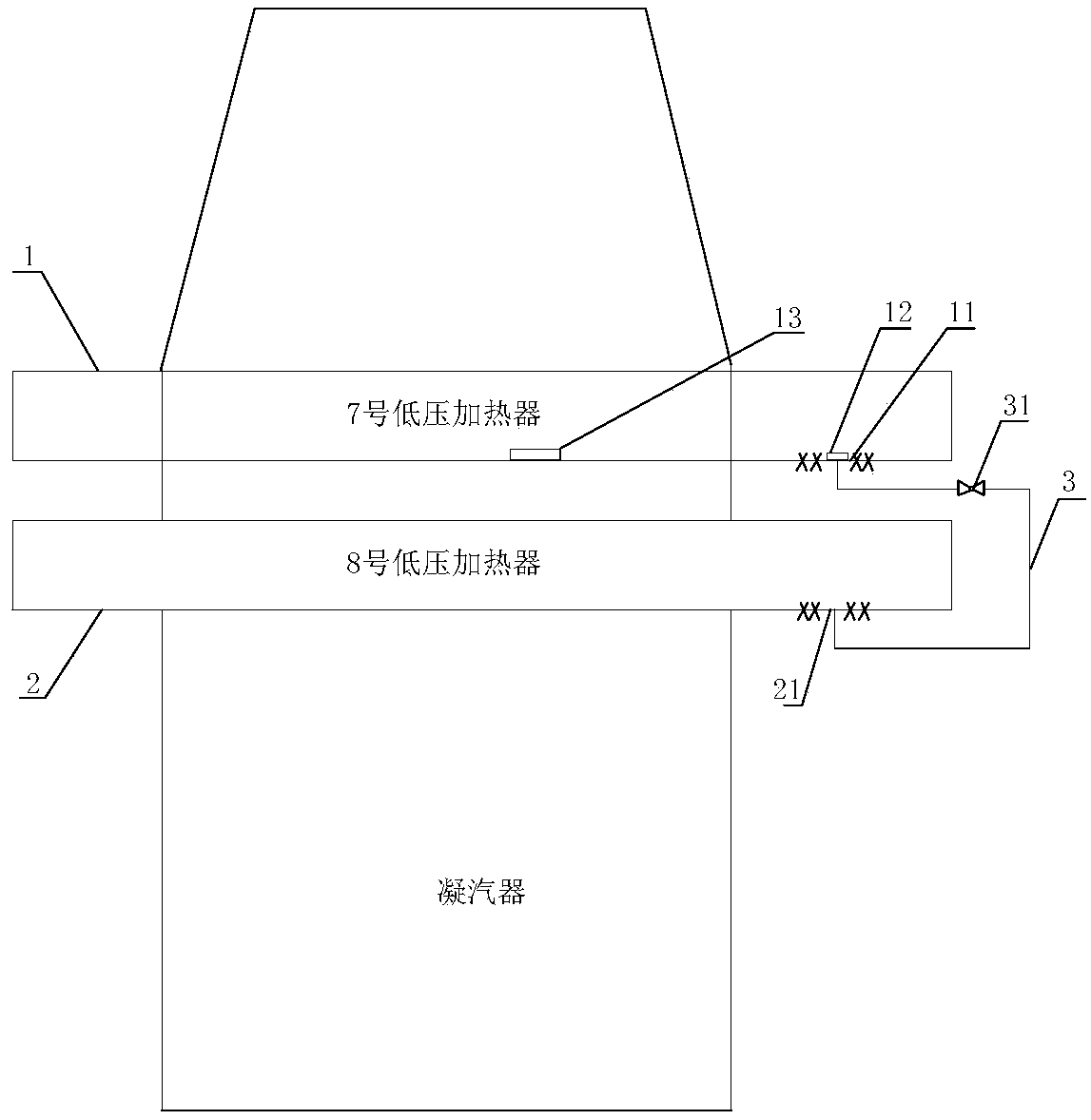

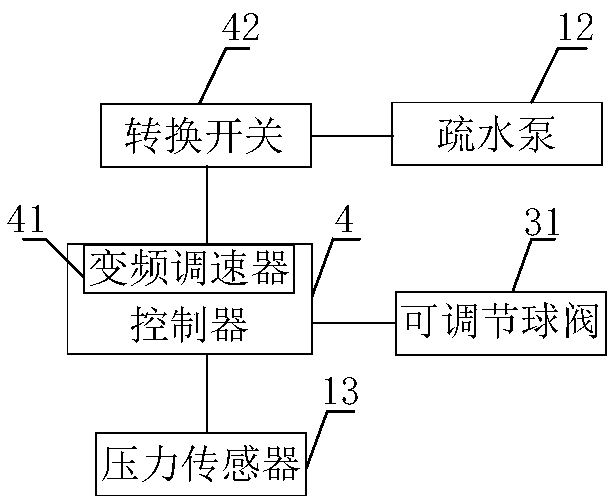

Drainage system for low-pressure heaters

The invention provides a drainage system for low-pressure heaters. The drainage system comprises the No.7 low-pressure heater and the No.8 low-pressure heater which are positioned at the last two stages of a unit. A drainage outlet of the No.7 low-pressure heater is positioned in the bottom of a No.7 low-pressure heater shell. A drainage inlet of the No.8 low-pressure heater is positioned in the lower side of the horizontal symmetry axis of a No.8 low-pressure heater shell, and the drainage outlet is communicated with the drainage inlet through a pipeline. An adjustable ball valve is arrangedon the pipeline. The drift diameter of a valve core of the adjustable ball valve is the same as that of the pipeline in front of the valve and that of the pipeline behind the valve, and the bends of the pipeline are communicated through elbows. A drainage pump is arranged at the drainage outlet. A pressure sensor is arranged at the bottom in the No.7 low-pressure heater shell, and the adjustable ball valve, the pressure sensor and the drainage pump are connected with a controller. By changing the position of a drainage joint and the pipeline arrangement of the low-pressure heaters, the problemof poor drainage between the low-pressure heaters at the last two stages can be effectively solved, meanwhile the automatic adjustment of the water level can be realized, and the economic efficiencyof the unit can be improved.

Owner:CHINA ENERGY CONSTR GRP SHAANXI ELECTRIC POWER DESIGN INST CO LTD

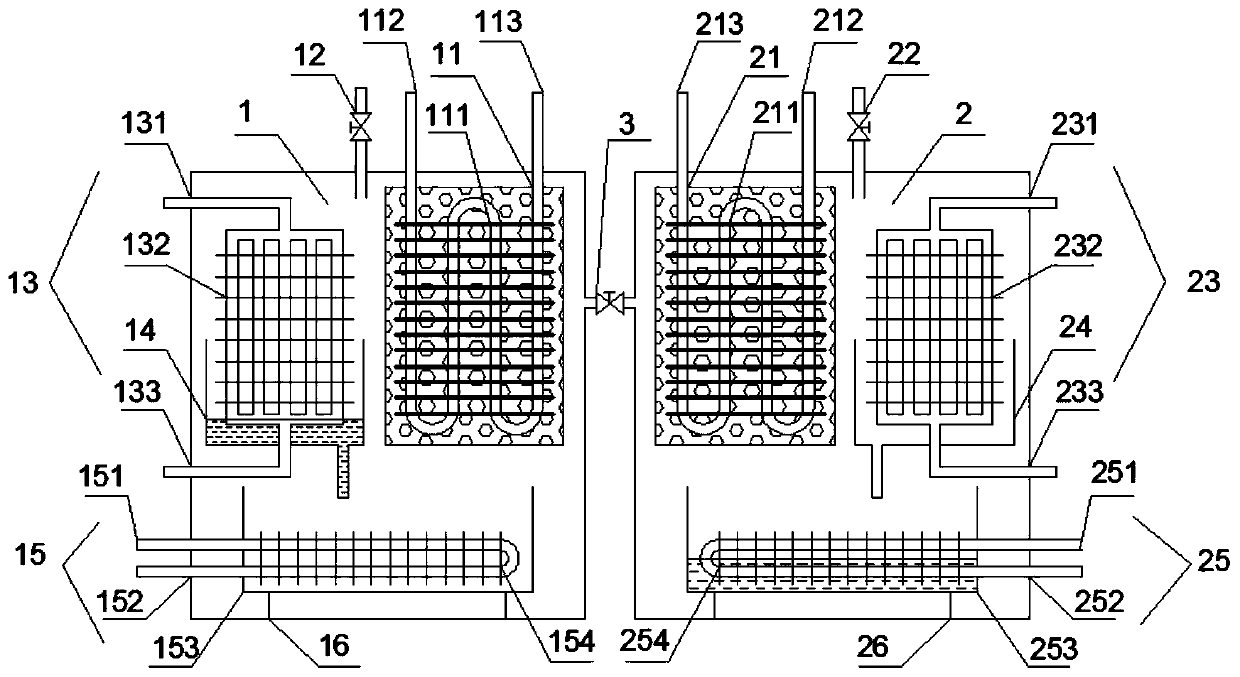

Adsorption type refrigeration system based on enhanced mass transfer

InactiveCN109959183AOptimize and enhance heat transferReduce drag along the wayClimate change adaptationEnergy efficient heating/coolingResource utilizationEnhanced heat transfer

The invention discloses an adsorption type refrigeration system based on enhanced mass transfer. The adsorption type refrigeration system based on enhanced mass transfer comprises a first work chamberand a second work chamber. The first work chamber and the second work chamber are both independent cavities and connected through a vacuum valve. The first work chamber comprises a first adsorption tool, a first condenser, a first liquid storage device and a first evaporator. The first condenser is arranged in the horizontal direction of the first adsorption bed. The first liquid storage device is located at the lower end of the first condenser. The first evaporator is arranged on the lower side of the first adsorption bed. All units in the first work chamber and the second work chamber are identical in structure and symmetrically arranged. The adsorption bed is of a tube-fin type structure, and a plurality of sub-adsorption beds can be connected in parallel according to different refrigeration amounts. Silica gel / calcium chloride is used as the adsorbing agent, so that the mass transfer performance of the adsorption bed can be enhanced, the volume of a unit can be reduced, and theperformance of the unit is improved. The adsorption type refrigeration system based on enhanced mass transfer can utilize solar energy and other low-grade heat sources and improves resource utilization rate.

Owner:SOUTH CHINA UNIV OF TECH

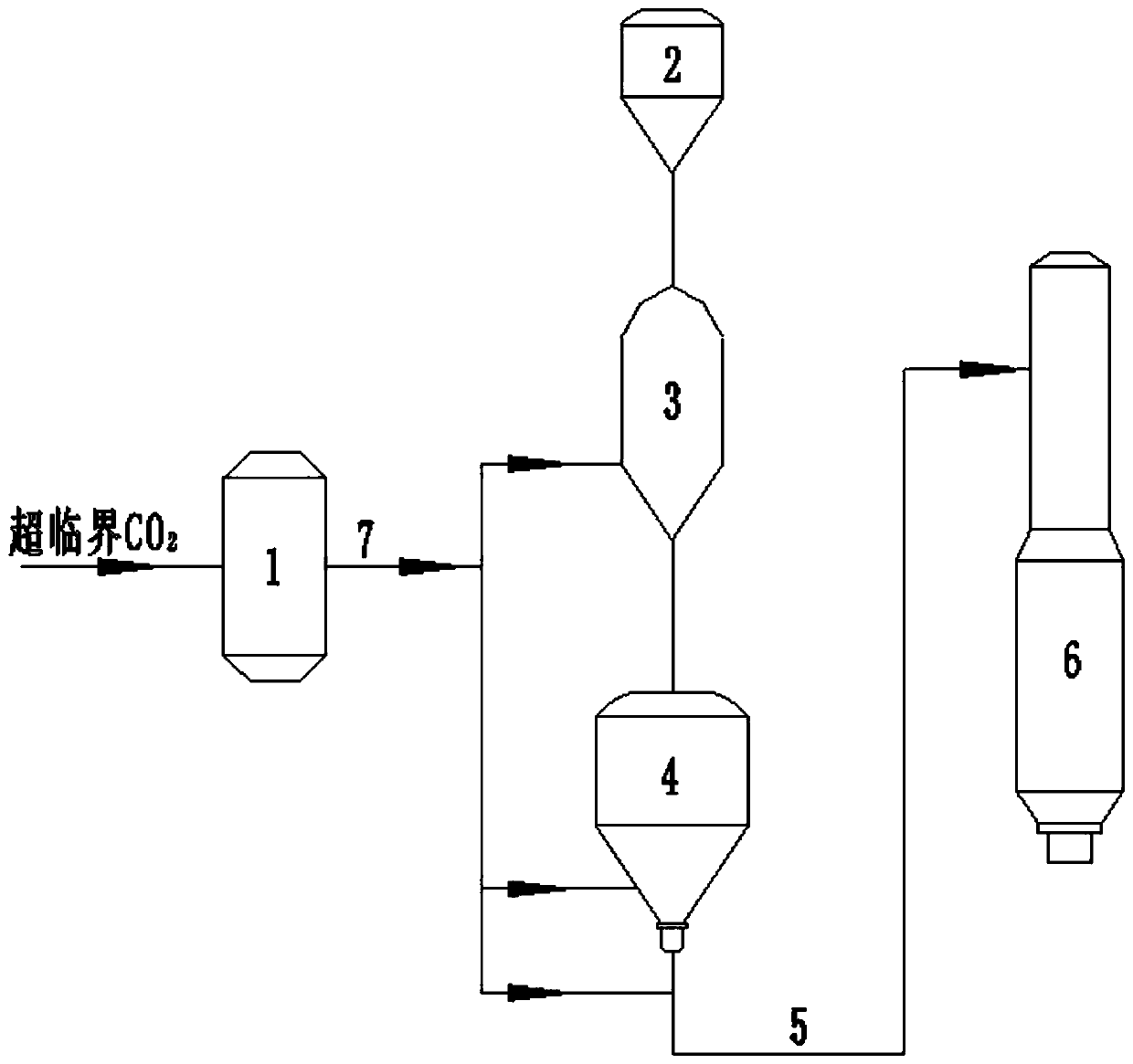

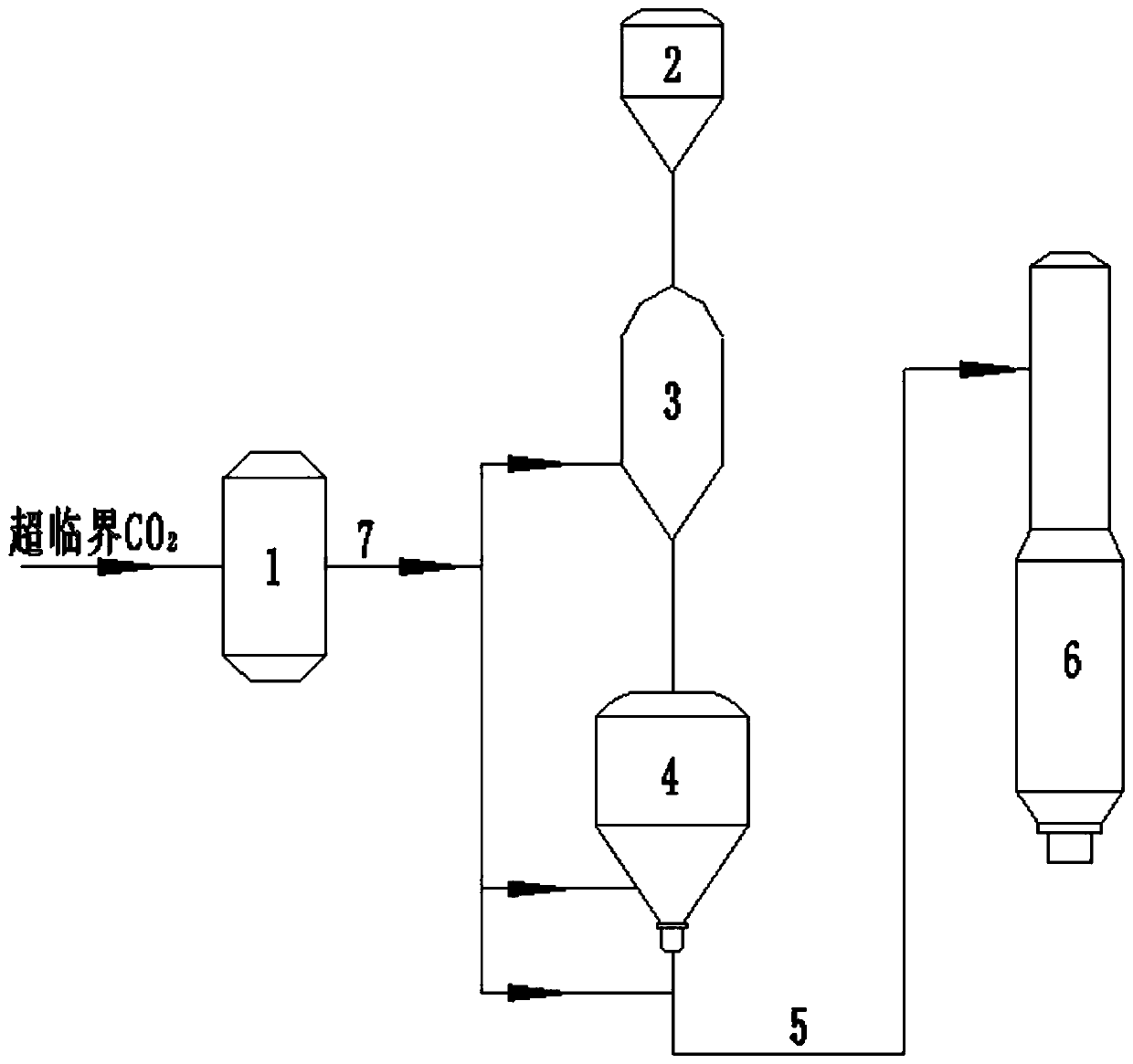

System for conveying solid raw materials by using supercritical carbon dioxide and conveying method thereof

PendingCN110040518ALow densityReduce drag along the wayBulk conveyorsPackagingChemical industryLine tubing

The invention discloses a system for conveying solid raw materials by using supercritical carbon dioxide and a conveying method thereof, and relate to the technical field of energy and chemical industry. The system for conveying the solid raw materials by using the supercritical carbon dioxide and the conveying method thereof aims to achieve the technical effects that the problem that a solid rawmaterial conveying and gasifying device is low in pressure can be solved, the system steam or power consumption is reduced, and the material conveying stability is high. According to the adopted technical scheme, the system comprises a buffering device, a storage bin, a pressurizing device, a material issuing device and a material issuing conveying pipeline, the buffering device is provided with asupercritical CO2 inlet, moreover, an outlet is connected with a supercritical CO2 supply pipeline, a discharging port at the lower end of the storage bin communicates with a feeding port at the upper end of the pressurizing device, the pressurizing device is provided with a pressurized gas inlet, moreover, the pressurized gas inlet communicates with the supercritical CO2 supply pipeline, the discharging port of the pressurizing device communicates with the feeding port of the material issuing device, and the discharging port of the material issuing device communicates with a feeding port ofa high-pressure gasification furnace through the material issuing conveying pipeline.

Owner:宁夏神耀科技有限责任公司

Circular impact mill unit and cycle impact mill method using impact mill

InactiveCN105149045BAvoid damageEliminate the phenomenon of mixing in finished productsGrain treatmentsForeign matterEngineering

The invention discloses a circulating impact pulverizing unit and method. The unit includes a casing, a screen is installed in the casing, a cleaning bin and a screening bin are arranged in the screen, and a circulating screen and a grading screen are arranged in the screening bin. There is an impact mill in the casing, and the top of the sieve is provided with a sieve body feed port and a circulating feed port; the cleaning bin is provided with a cleaning screen for separating impurities; the discharge port of the impact mill is connected to the mill. The discharge pipe of the pulverizer, the discharge pipe of the pulverizer extends upward and is connected with a discharger after being bent; the circulating feeding port is connected with a screening feeding channel, and a circulating discharging channel is arranged above the circulating screen, and the circulating The discharging channel is communicated with the feeding channel of the pulverizer; the grading screen mechanism is connected with a number of sieve discharge pipes at each grading screen. The invention occupies less area, has low cost and low energy consumption, can avoid the damage of large foreign objects, can process cyclically and continuously discharge materials, avoid that the pulverized materials fail to meet the particle size requirements, and divide the processed materials into different particle sizes. Finished product sent.

Owner:王毅

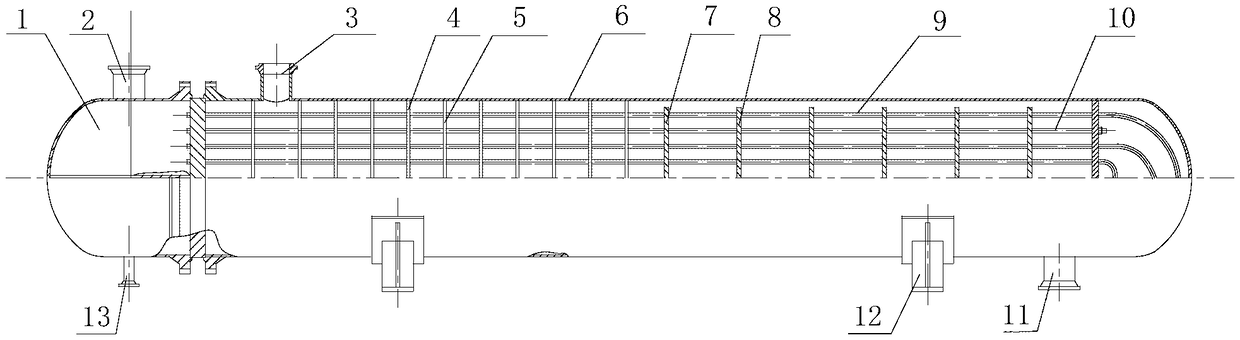

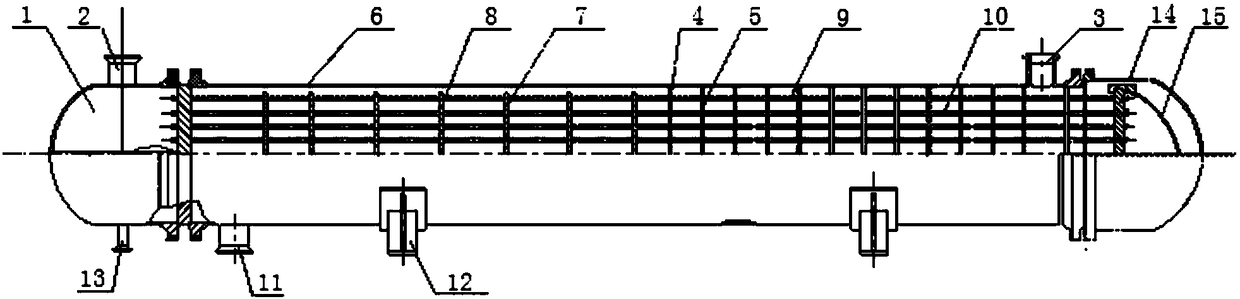

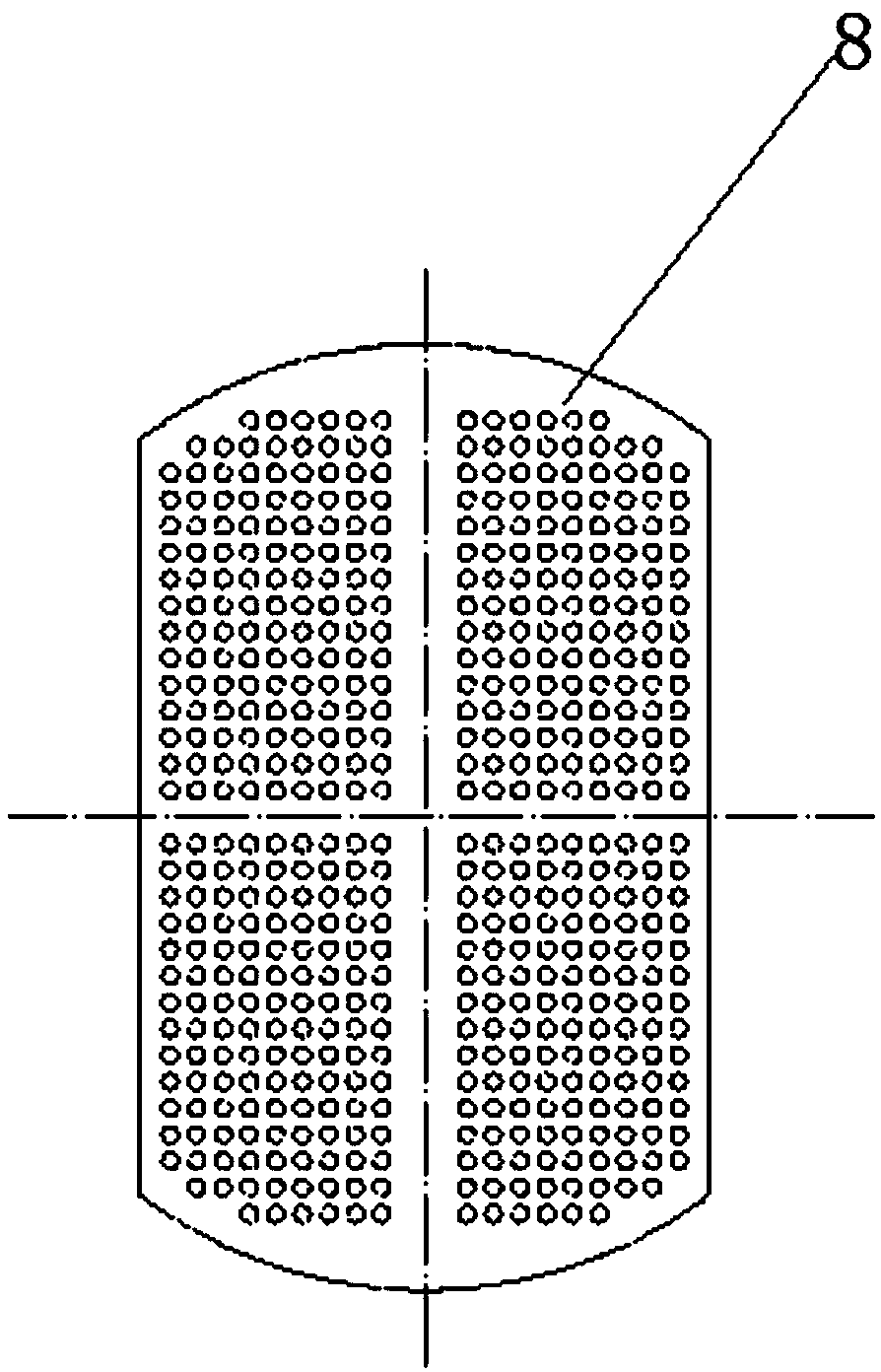

Shell and Tube Heat Exchanger

ActiveCN107883803BImprove applicabilityReduce lateral impactCorrosion preventionHeat exchanger casingsPlate heat exchangerShell and tube heat exchanger

The invention discloses a pipe-shell-type heat exchanger. The pipe-shell-type heat exchanger comprises a shell-side cylinder body, a pipe-box cylinder body, a pipe plate and a heat exchanging pipe. The heat exchanging pipe is fixed to the pipe plate, and a main body of the heat exchanging pipe is arranged in the shell-side cylinder body. A baffling rod assembly is arranged in the shell-side cylinder body and comprises a plurality of first baffling rods and a plurality of second baffling rods. Each first baffling rod comprises a connecting part, a first baffling part and a second baffling part,wherein the first baffling part and the second baffling part are connected with the two ends of the connecting part correspondingly. The first baffling rods are used for forming a double helix flow channel. Compared with the prior art, the pipe-shell-type heat exchanger has the following advantages that a shell-side fluid is arranged along with the first baffling rods and forms a double helix flow on the shell side, thus the shell-side fluid rotates and flushes a heat exchanging pipe bundle along with the double helix flow channel formed between the first baffling rods while passing through the first baffling rods and obliquely skimming over the heat exchanging pipe, the effect of heat transfer enhancing is improved, isochronous flow dead zones of the bow-shaped baffling rods are reduced,and the heat exchanging effect is enhanced.

Owner:CHINA NUCLEAR POWER DESIGN COMPANY +2

Air separator for refrigerating

InactiveCN107869882AEffective contactIncrease condensation areaSolidificationLiquefactionEngineeringRefrigerant

The invention provides an air separator for refrigeration, which includes a head, a lower tube plate, a cylinder body, a plurality of heat exchange tubes, a mixed gas inlet, a temperature probe socket, an upper tube plate, a liquid outlet, an outlet Air port, liquid supply pipe and condensate outlet; among them, the liquid supply pipe and condensate outlet are located at the bottom of the cylinder, and the liquid outlet is located at the top of the cylinder; the heat exchange tube is connected with the upper tube sheet and the lower tube sheet, and the The body is arranged in a triangle; the mixed gas inlet is located in the middle of one side of the cylinder, and the gas outlet is located in the upper part of the other side of the cylinder; low-temperature refrigerant circulates in the heat exchange tube. The invention can remove air and other non-condensable gases in the refrigeration system, improves the efficiency of the refrigeration system, and achieves the purpose of energy-saving operation of the refrigeration system.

Owner:潜江传家电子商务有限公司

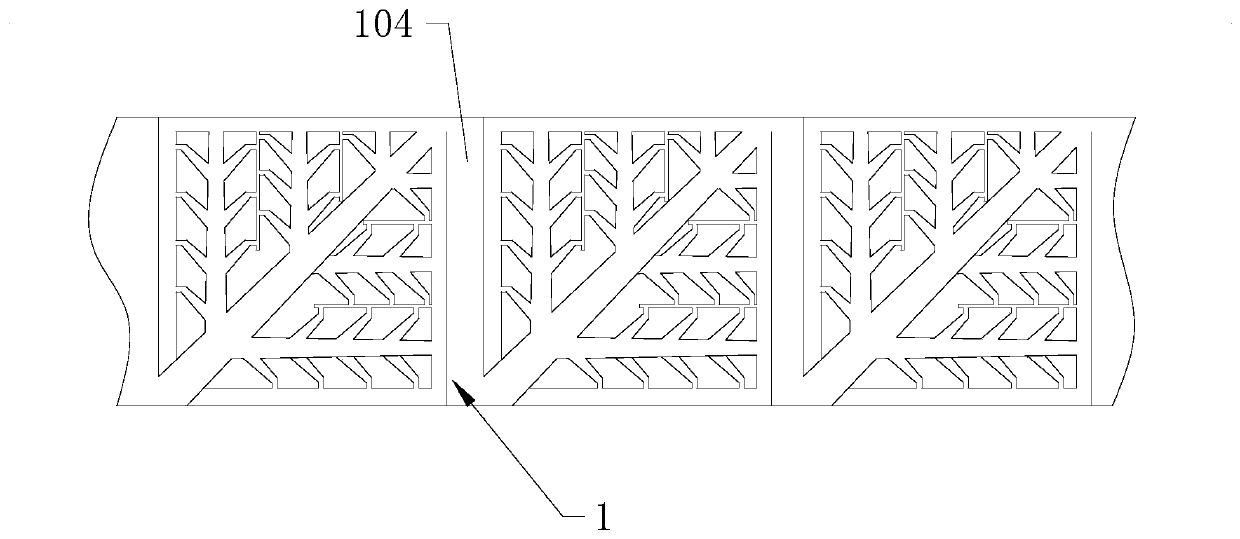

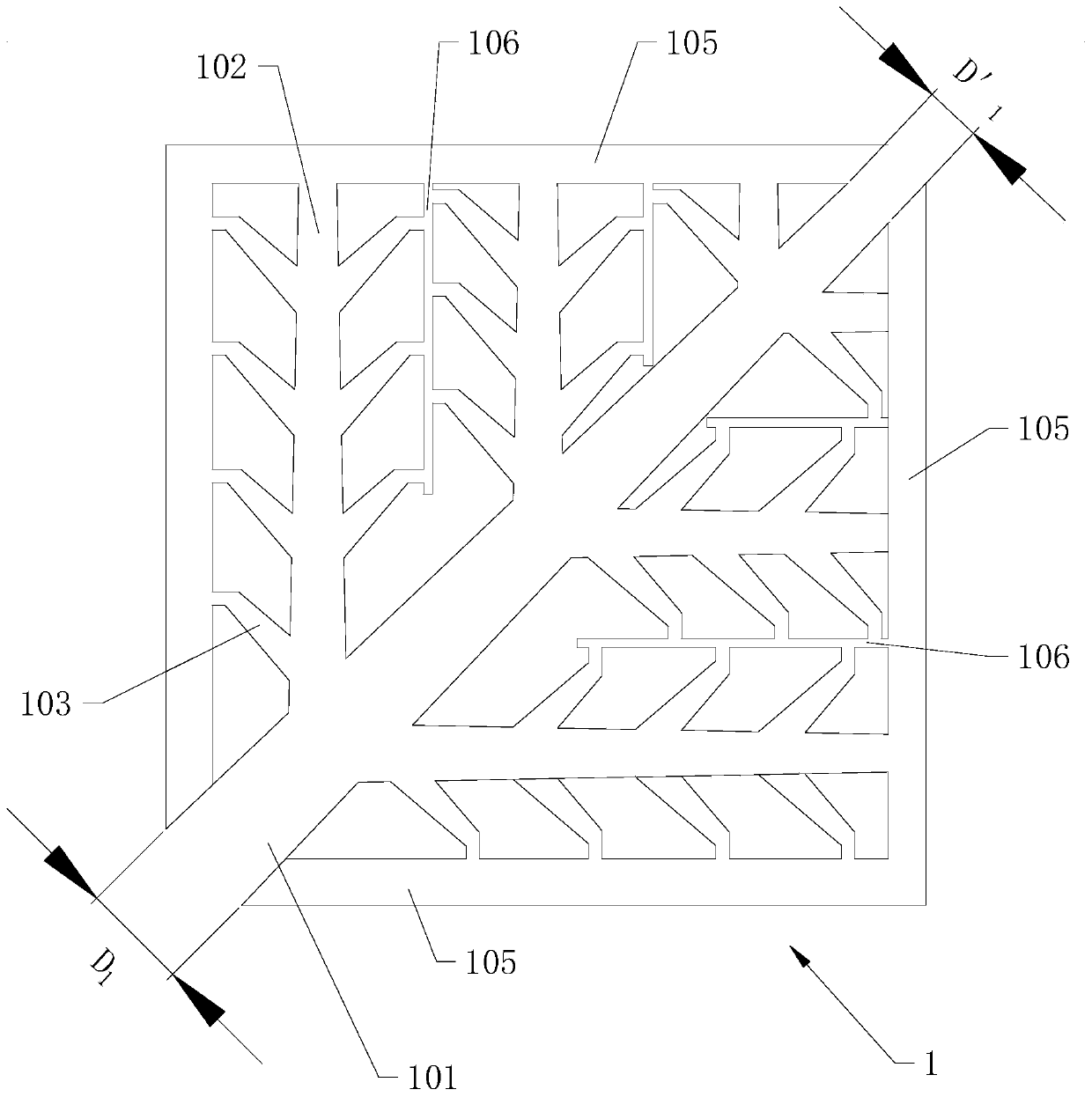

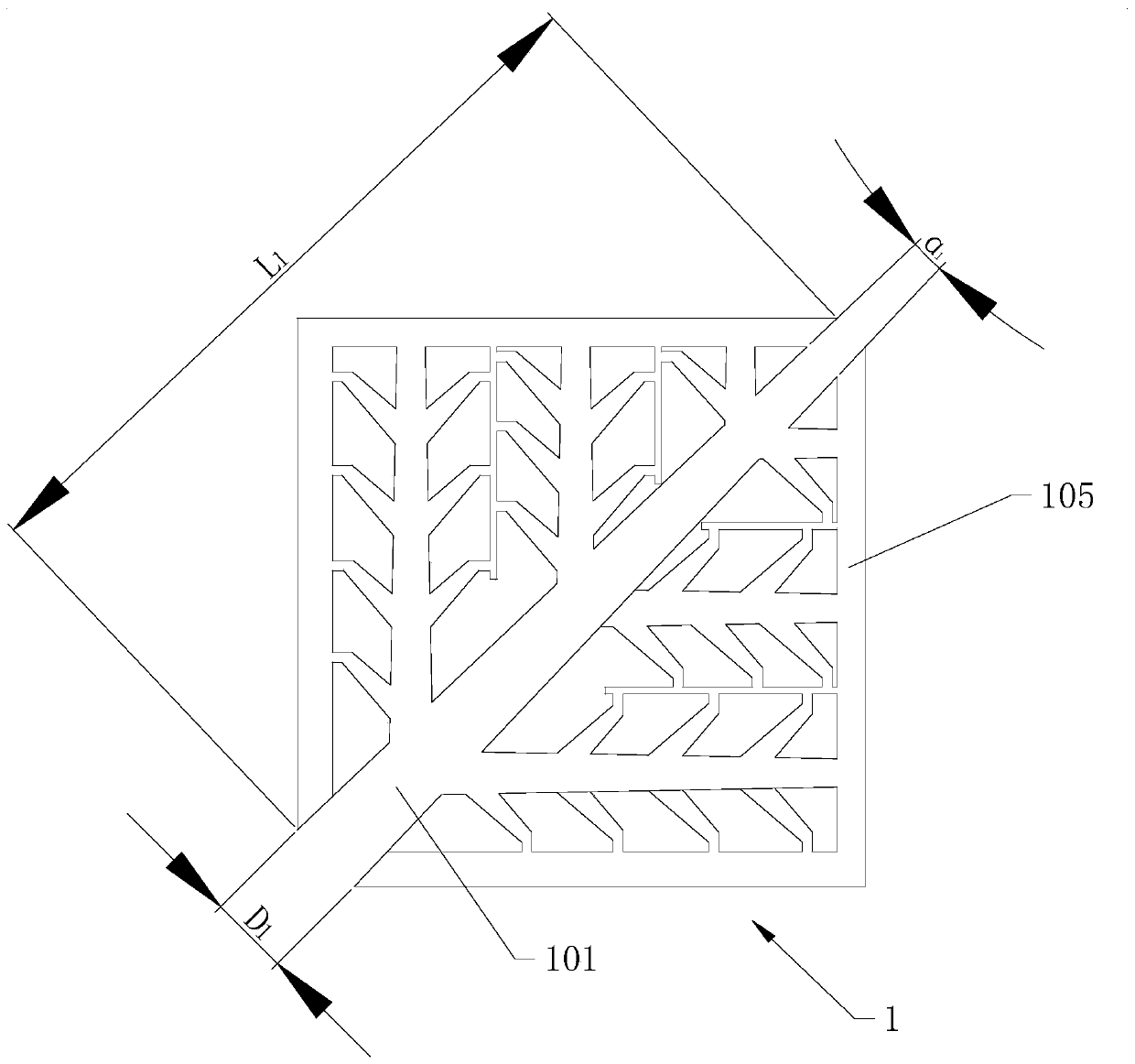

Tree-shaped channel structure based double pole plate of hydrogen cell

The invention discloses a tree-shaped channel structure based double pole plate of a hydrogen cell, relates to the technical field of fuel cells. The double pole plate comprise rectangular areas, eachrectangular area comprises an outlet channel and n levels trapezoid channels in tree-shaped distribution, the ith level of trapezoid channel is communicated with the inlet of the (i+1)th trapezoid channel, the length Li of the ith level of trapezoid channel is greater than the length Li+1 of the (i+1)th trapezoid channel, the inlet width Di of the ith level of trapezoid channel is greater than the outlet width D'i of the same, the inlet width Di of the ith level of trapezoid channel is greater than the inlet width Di+1 of the (i+1)th trapezoid channel, and the outlet of the nth level of trapezoid channel is communicated with an outlet channel. The tree-shaped channel structure based double pole plate of the hydrogen cell can effectively improve the power density of an electric pile.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

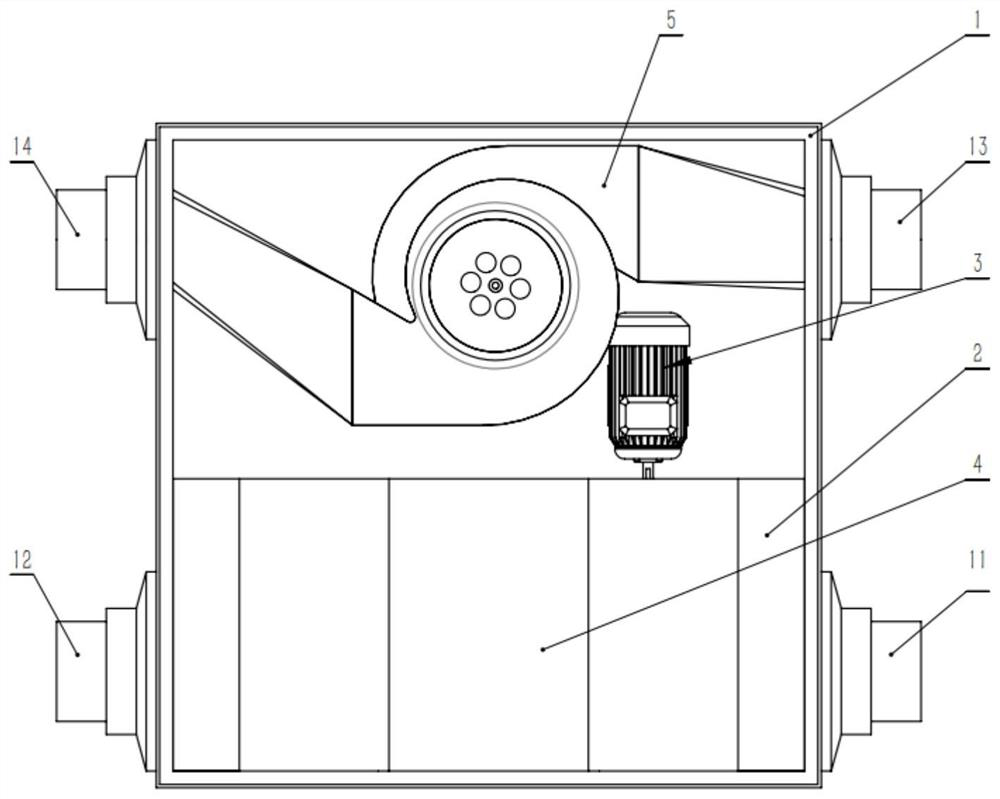

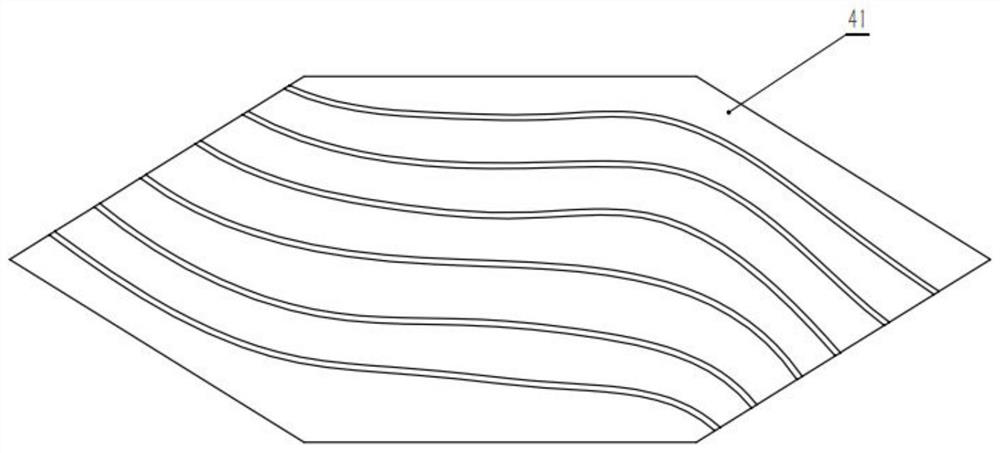

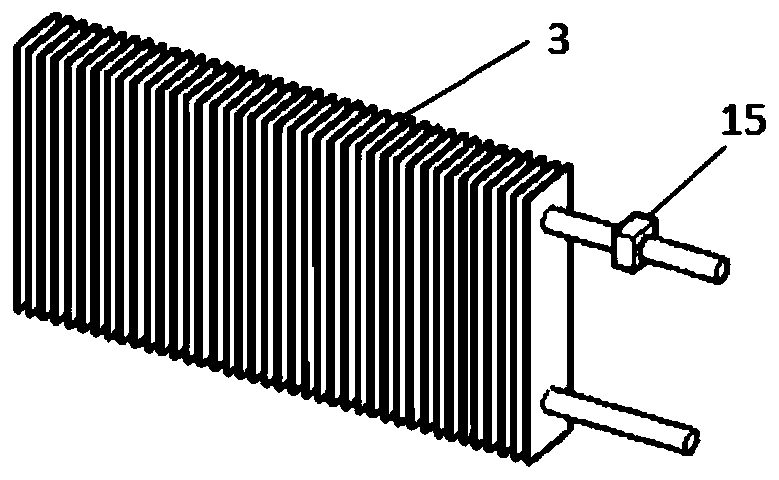

Vibration total heat exchanger for enhancing heat transfer

PendingCN113405196ALess internal supportReduce drag along the wayEnergy recovery in ventilation and heatingLighting and heating apparatusEngineeringNoise reduction

The invention discloses a vibration total heat exchanger for enhancing heat transfer. The vibration total heat exchanger comprises a noise reduction machine shell, an outdoor air inlet, an indoor air outlet, an indoor air inlet, an outdoor air outlet, a pair of filter screens, a heat exchange core and a double-layer fan, wherein the outdoor air inlet and the indoor air outlet are formed in one side of the noise reduction machine shell, the indoor air inlet and the outdoor air outlet are formed in the other side of the noise reduction machine shell, the pair of filter screens are arranged on the noise reduction machine shell, the heat exchange core is arranged between the pair of filter screens, and the double-layer fan is used for connecting the indoor air outlet and the outdoor air outlet; and a heat exchange plate is arranged in the heat exchange core and is of a special-shaped structure, and corrugations are arranged on the surface of the heat exchange plate. Through the arrangement of the heat exchange plate special-shaped structure, inner supports are reduced, on-way resistance is small, wind pressure loss is small, maximization of the heat transfer area is guaranteed, and therefore the maximum heat exchange efficiency is achieved.

Owner:ZHEJIANG SCI-TECH UNIV

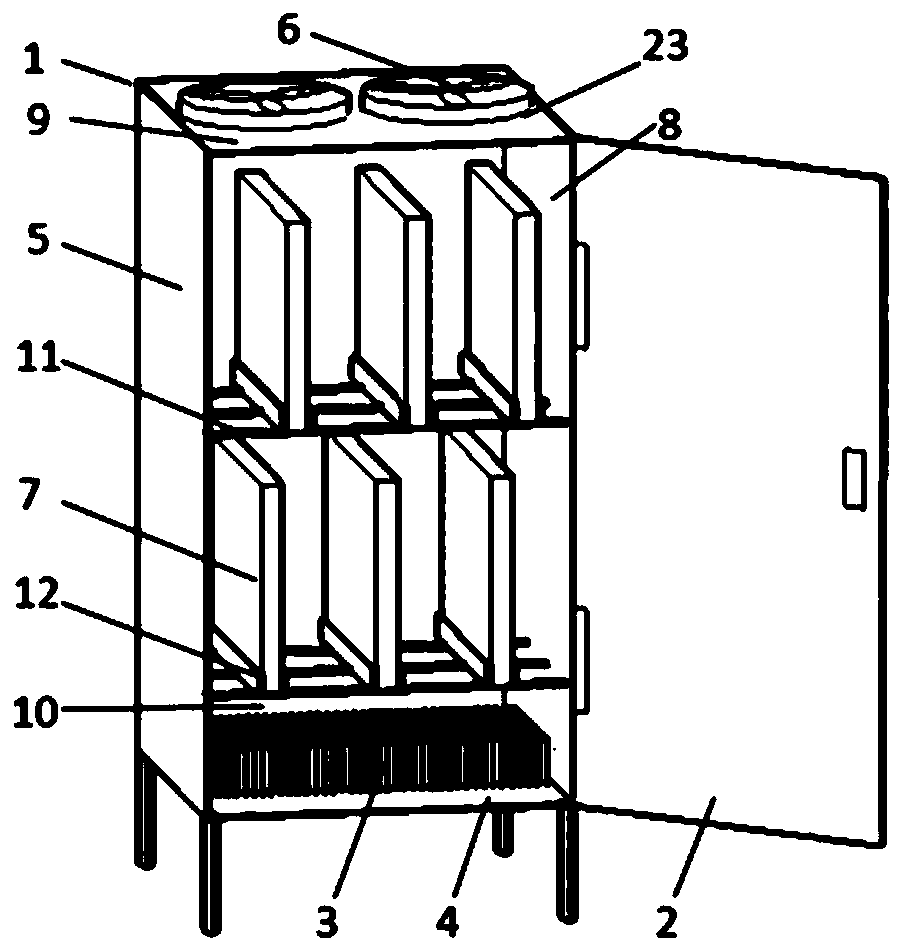

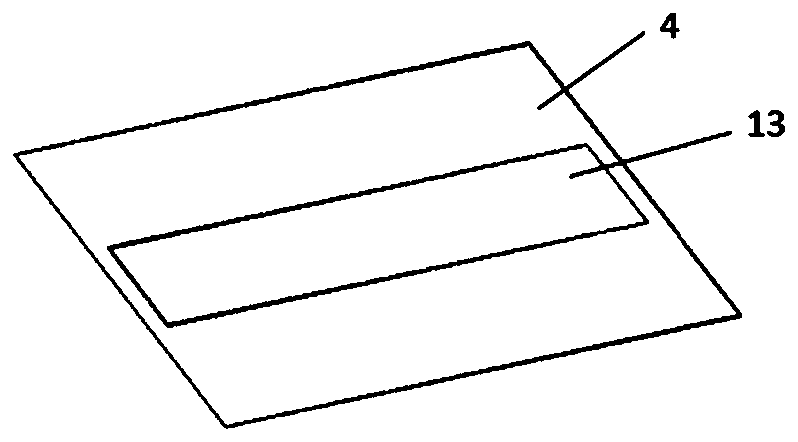

A data center cabinet with its own temperature control device and servers arranged vertically

ActiveCN109379883BEvenly distributedImprove heat transfer effectServersCooling/ventilation/heating modificationsTemperature controlCooling effect

The invention relates to a data center cabinet with its own temperature control device and vertically arranged servers, including a cabinet body, a server and a temperature control device. The cabinet body is provided with an air inlet channel, a heat dissipation area and an air outlet channel in sequence from bottom to top. The air inlet channel is equipped with a cooling device, and the air outlet channel is equipped with an air induction device. The servers are arranged in the heat dissipation area and arranged vertically. , the temperature control device is used to regulate the temperature inside the cabinet body within the preset temperature range. Based on the concept of creating a non-uniform environment, the present invention adopts a distributed cooling terminal to transform the existing uniform environment cooling mode into a quantitative and precise on-demand cooling mode, which improves the cooling capacity supply efficiency and cooling effect, and effectively reduces Reduced transmission and distribution energy consumption and cooling waste. The vertical staggered arrangement of the servers reduces the resistance along the airflow, and utilizes the principle of rising hot air to enhance the heat dissipation effect. At the same time, it cooperates with the temperature control device to realize the automatic adjustment of cooling on demand.

Owner:NORTHEASTERN UNIV LIAONING

Forcing mixer

ActiveCN107983244AIncrease delivery flowAvoid a series of problems such as agingTransportation and packagingMixer accessoriesEngineeringPositively charged particle

The invention discloses a forcing mixer. The forcing mixer comprises a mixed pipeline, a particle driving disc, a rotary motor and a particle recycling disc, wherein a first inlet and a second inlet are formed at the front end of the mixing pipeline and are respectively used for connecting two liquid to be mixed; a mixing ring is arranged on an abdominal part of the mixing pipeline; projection ofthe mixing ring is a circular arc structure; two ports of the mixing ring are staggered and are connected with the mixing pipeline; disturbance particles are put in the mixing ring; the particle driving disc is positioned under the mixing ring and is concentric to the mixing ring; the particle driving disc comprises an insulated support and a circular orbit fixed to the insulated support; positively charged particles are put on the circular orbit at intervals; the insulated support of the particle driving disc is driven by the rotary motor to rotate; a cylindrical particle collection hole is formed in the tail part of a straight pipe of the mixing pipeline; a particle recycling disc is mounted at the particle collection hole. The forcing mixer is mainly applied to mixing of different substances in channels with small sizes, and has the characteristics of simple structure, high mixing efficiency, small on-way resistance and the like.

Owner:大庆诺思环保科技有限公司

A rapid optimization method for the flow channel spacing of the power battery air cooling system

ActiveCN108038261BIncreased runner spacingReduced runner spacingSecondary cellsForecastingPower batteryThermodynamics

The invention discloses a rapid optimization method for a power battery air cooling system runner interval. The method comprises the steps that beginning from the uniform runner interval, velocity distribution of an air cooling system is solved through numerical values, by analyzing the flow distribution between cooling runners, the runner with the minimum flow and the runner with the maximum floware determined, then, the interval of the runner with the minimum flow is increased, and the interval of the runner with the maximum flow is decreased; speed distribution of the system is calculatedagain every time the runner interval is adjusted, and therefore the next runner interval adjustment is performed; when the frequency for runner interval adjustment reaches the set frequency, the layout of the runner interval with the minimum cooling runner equivalent flow standard deviation in the process is adjusted, and the final runner interval optimization result is obtained. The rapid optimization method has the advantages of being simple in optimization process, high in optimization speed, good in performance index, good in expansibility, high in practicability and the like.

Owner:SOUTH CHINA UNIV OF TECH

Liquid sucking core component of AMTEC (alkali metal thermoelectric converter) and manufacturing method thereof

InactiveCN102306556BReduce production processThe process steps are simpleTemperature-sensitive devicesCapacitor detailsCore componentMetal powder

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

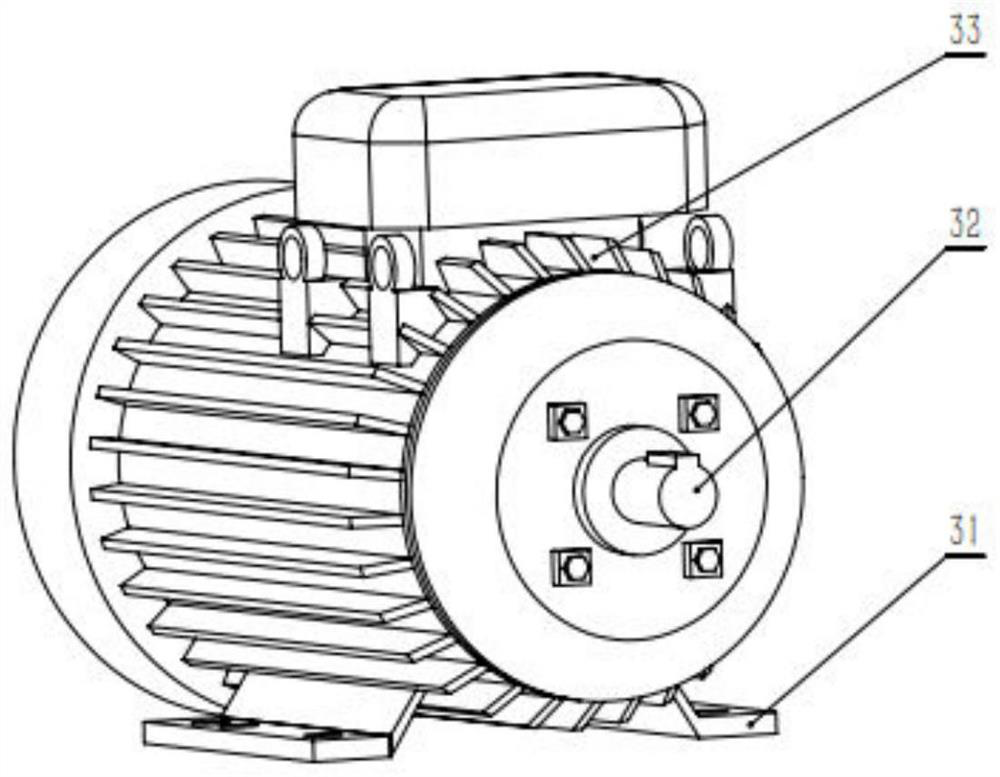

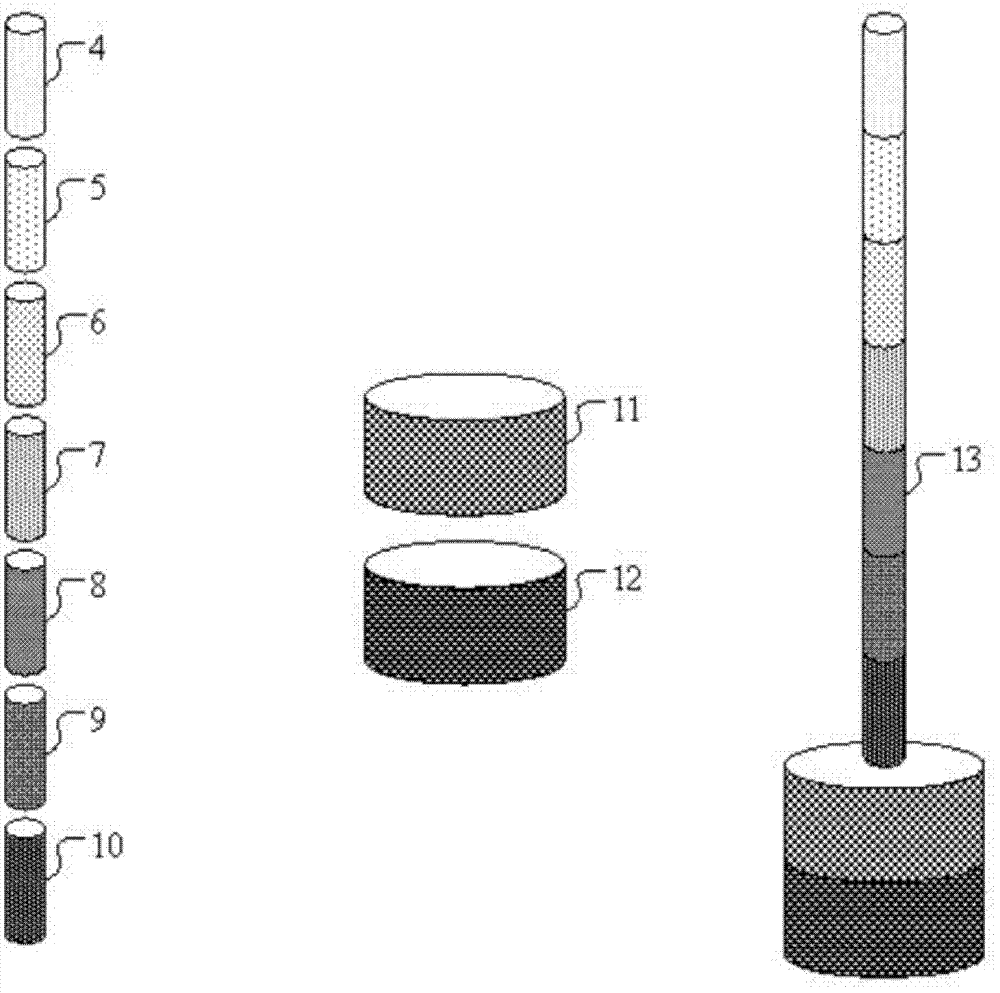

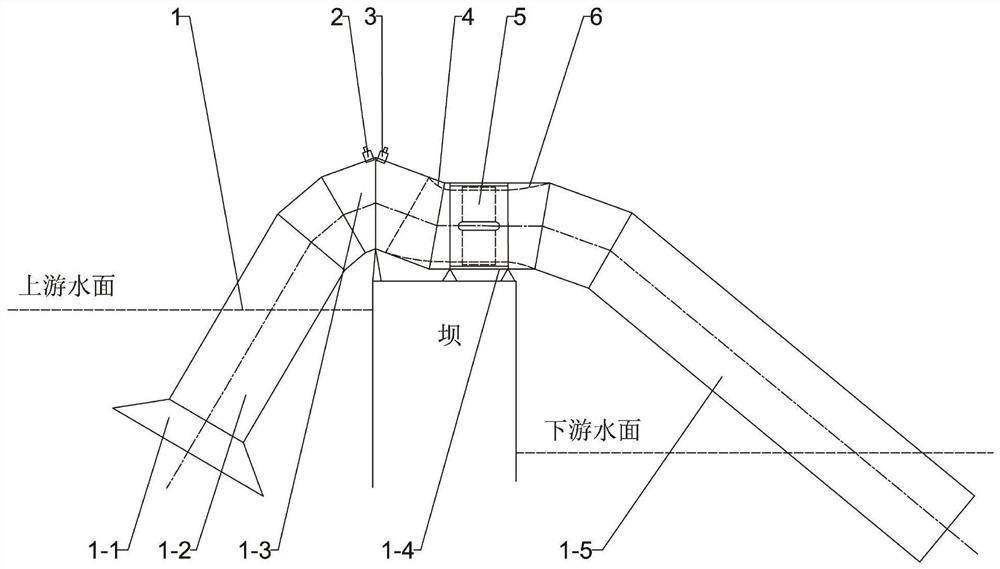

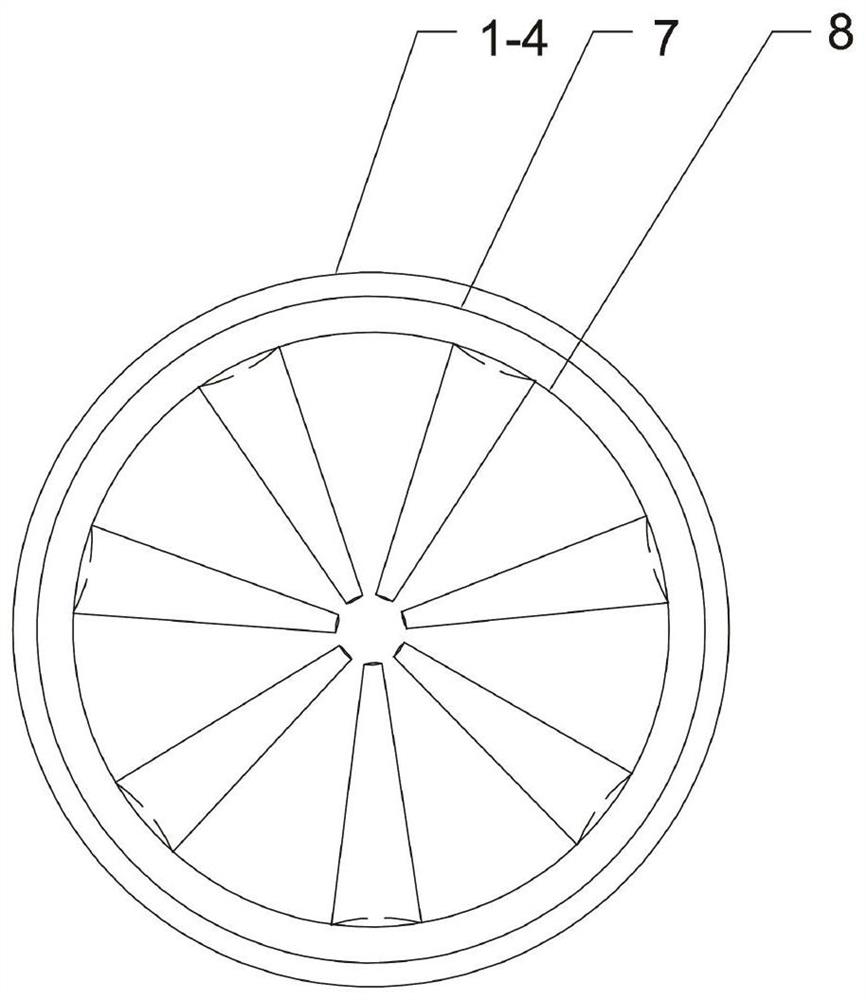

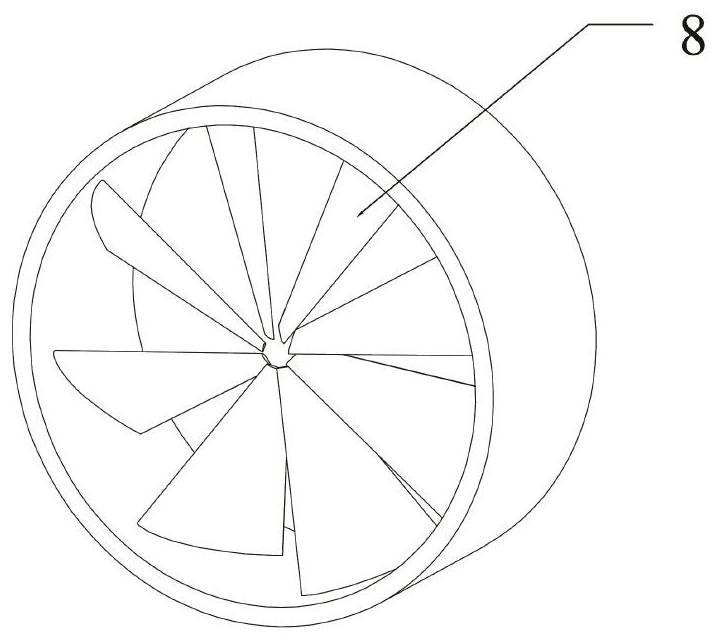

Siphon type direct-driven through-flow turbine suitable for low water head or ultra-low water head

PendingCN112360659AReduce drag along the wayEasy to processHydro energy generationReaction enginesStatorSiphonium

The invention discloses a siphon type direct-driven through-flow turbine suitable for a low water head or an ultra-low water head. The siphon type direct-driven through-flow turbine comprises a siphonpipe, wherein a direct-driven generator set is mounted in the siphon pipe; a stator of the direct-driven generator set is fixedly mounted on the inner wall of the siphon pipe; and a rotating wheel ofthe direct-driven generator set is connected with the stator through a bearing. The siphon type direct-driven through-flow turbine suitable for the low water head or the ultra-low water head solves the problem of loose sealing between dynamic and static parts caused by the fact that a main shaft of a siphon type water turbine penetrates through the siphon pipe in the prior art.

Owner:XIAN UNIV OF TECH

A mixed baffle reboiler

ActiveCN106643227BReduce drag along the wayStable supportHeat exchanger casingsStationary tubular conduit assembliesReboilerEngineering

The invention discloses a mixed baffling stream type reboiler. The mixed baffling stream reboiler comprises a shell body and a support which is arranged at the lower part of the shell body and is used for supporting the shell body, shell side in-out ports are correspondingly arranged at two ends of the shell body, multiple groups of tube bundles are arranged at intervals in the axial direction of the shell body in the shell body, baffling stream plates and baffling stream fences are arranged in the radial direction of the tube bundles in the shell body, and the baffling stream plates and the baffling stream fences are used for supporting the tube bundles and conducting stream guidance on shell side fluid. The mixed baffling stream type reboiler is reasonable in structure and safe and efficient in work, and combines an optimal heat transfer property and a minimum flow-induced vibration property.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com