Patents

Literature

148results about How to "Reduced clearance volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

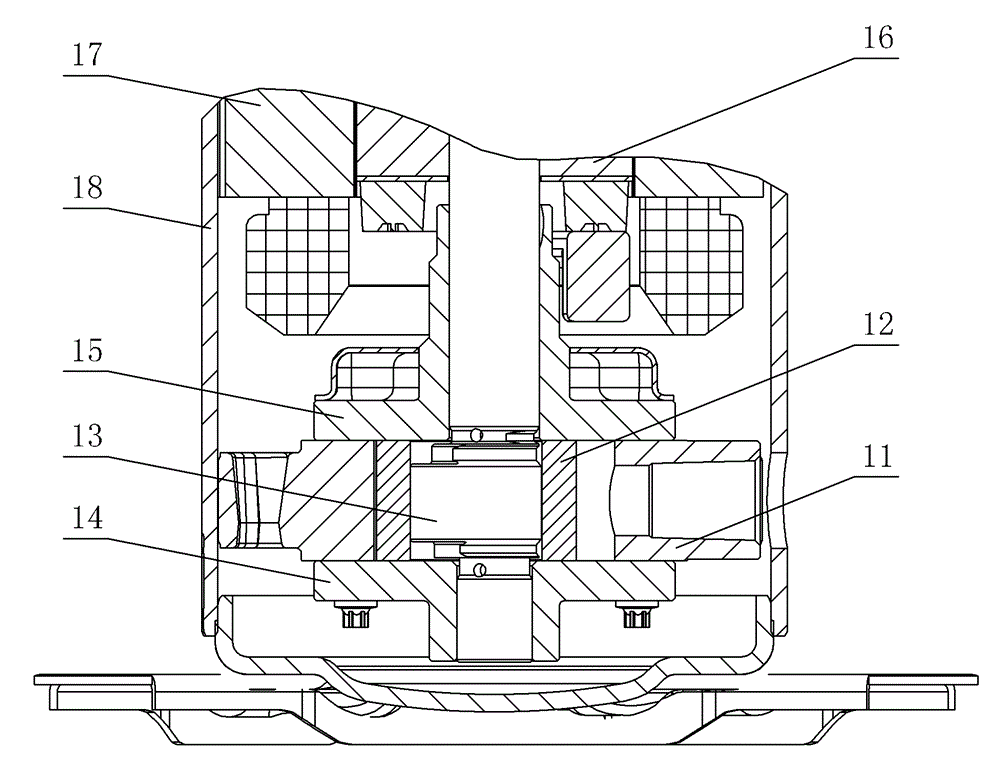

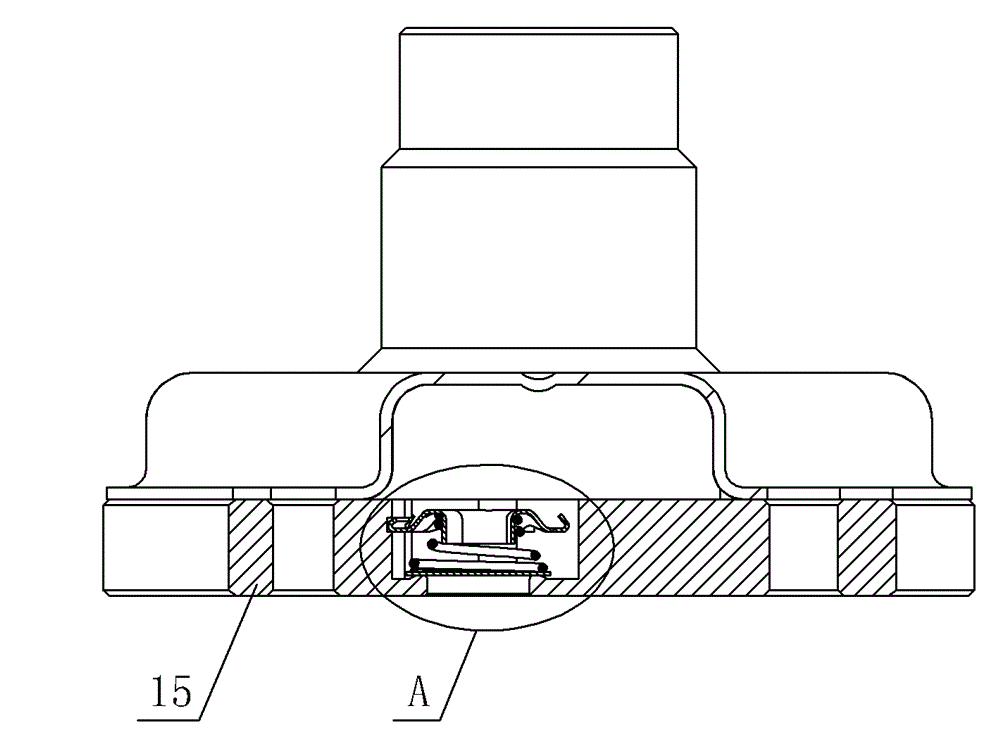

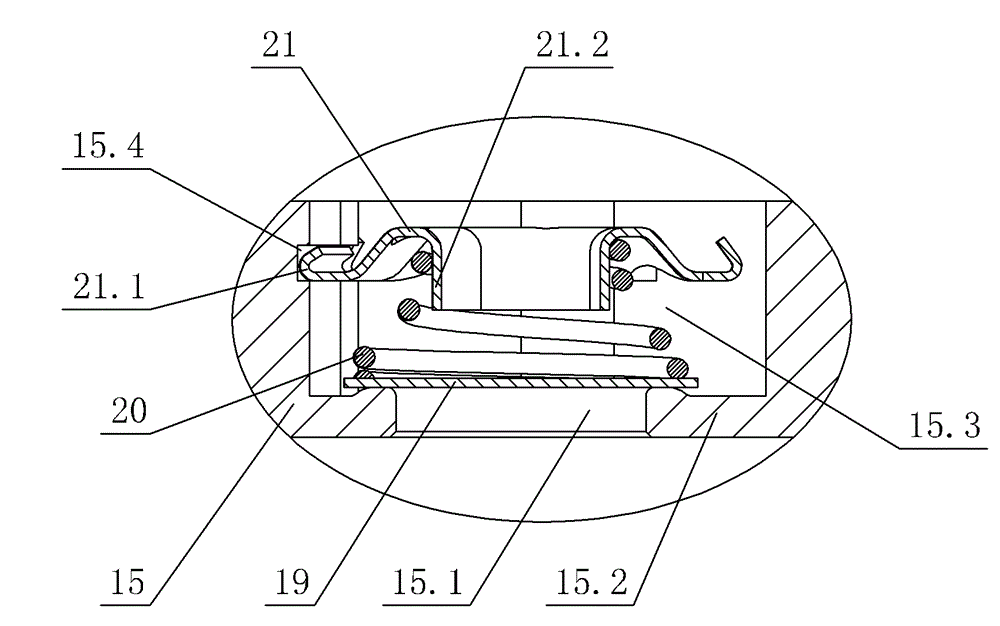

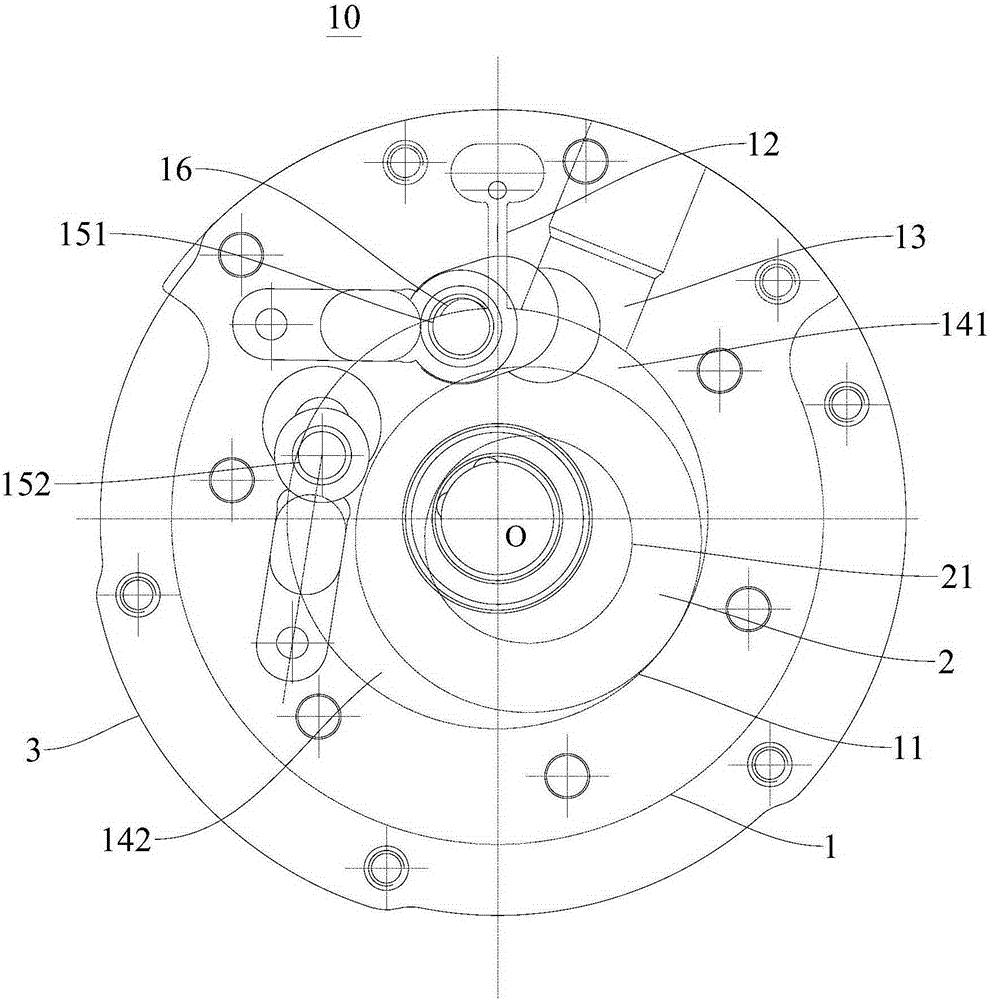

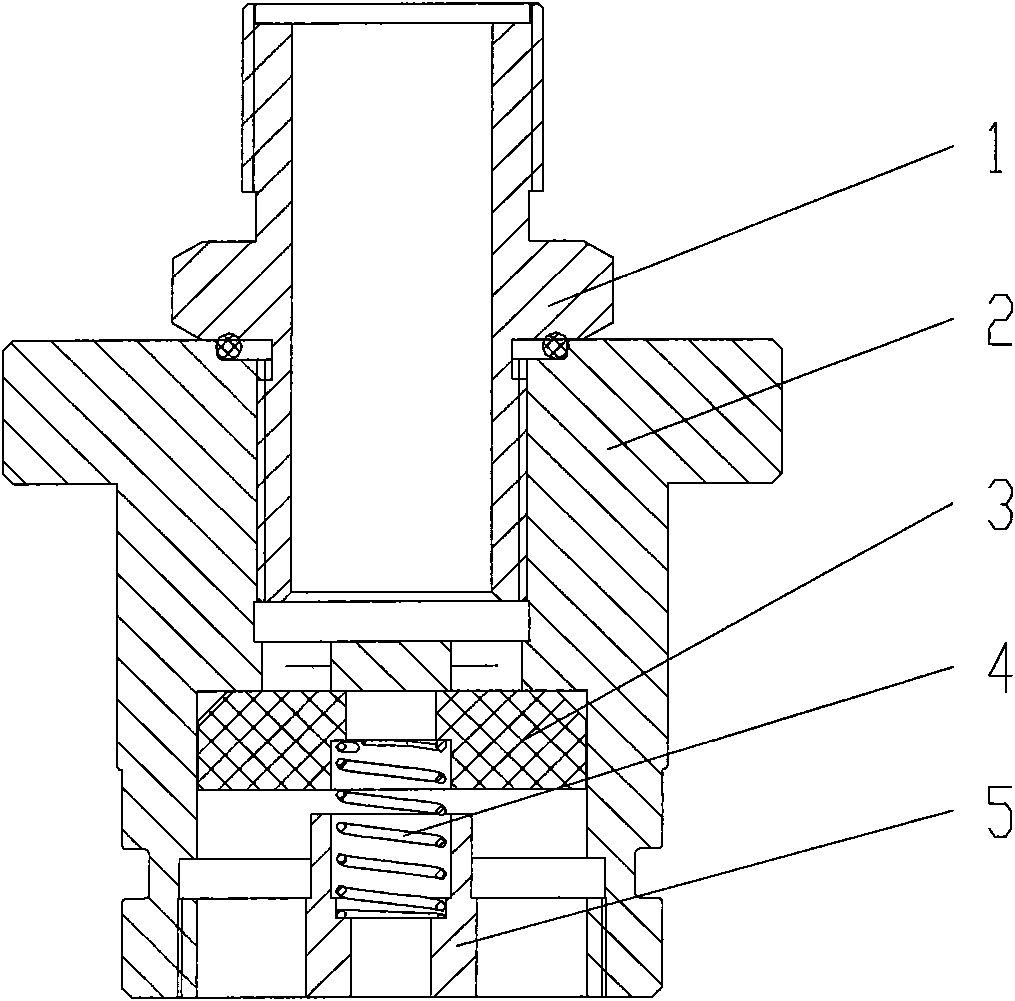

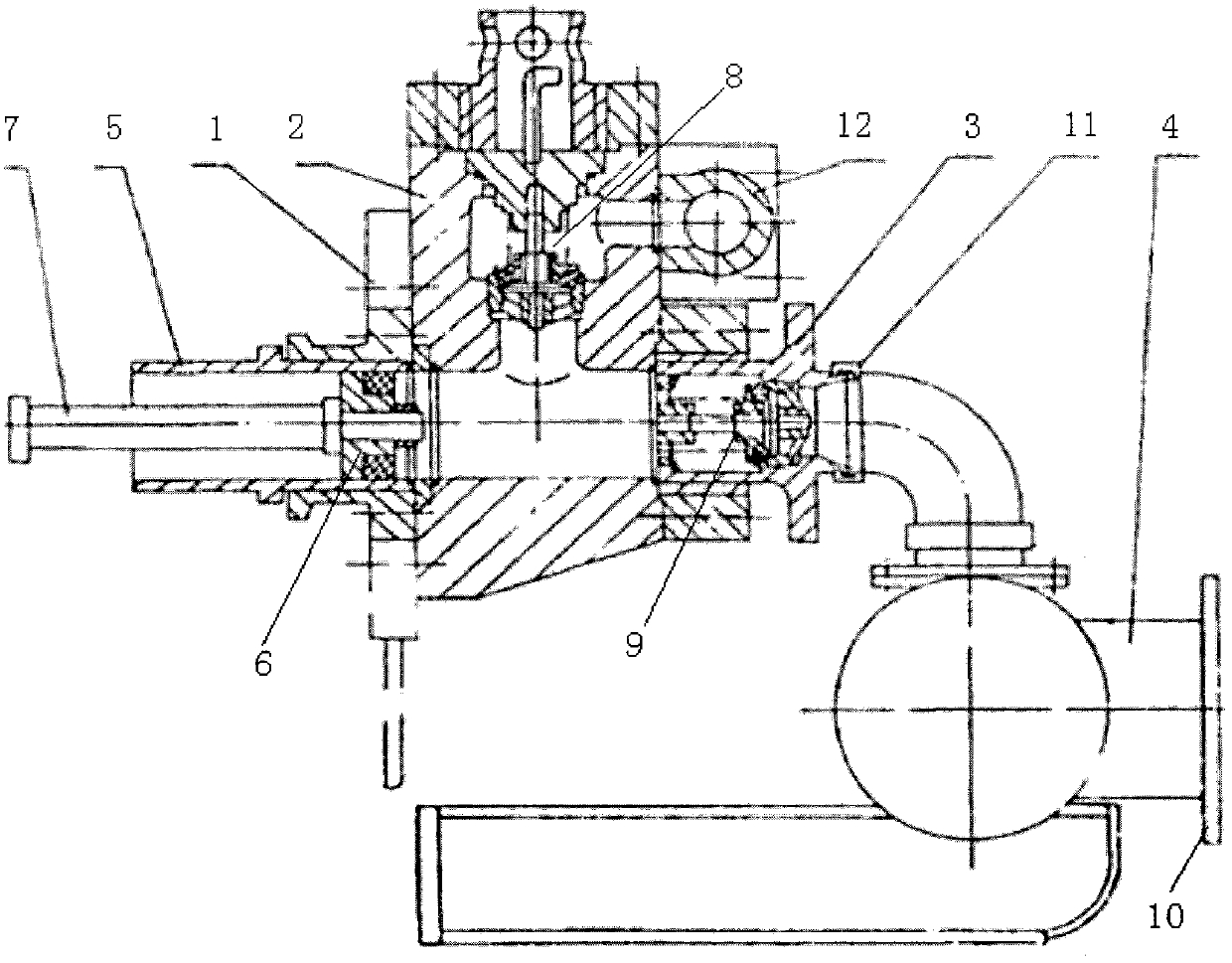

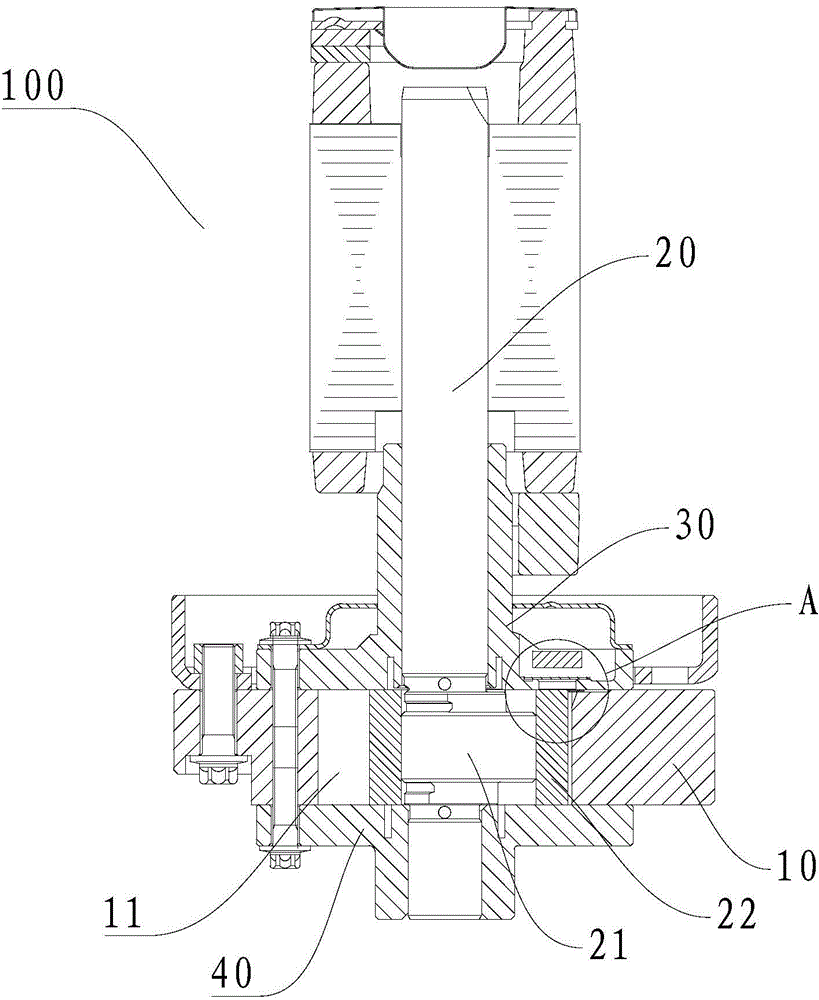

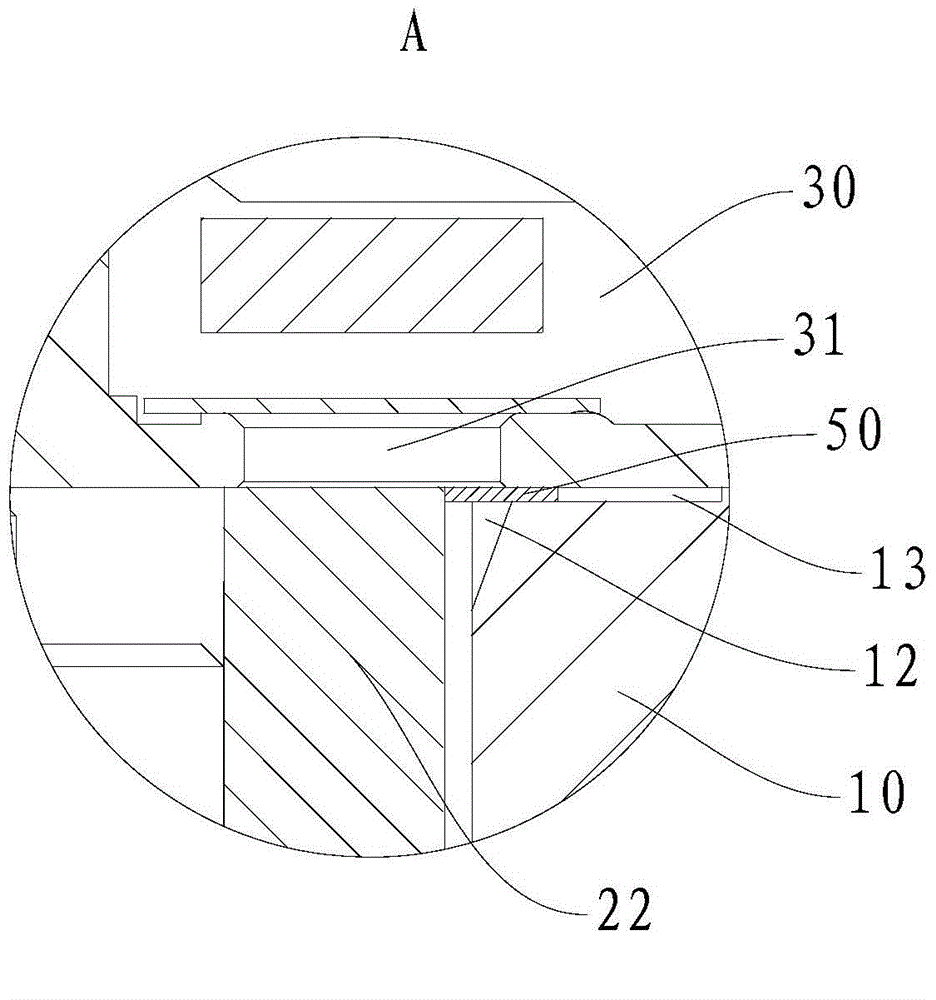

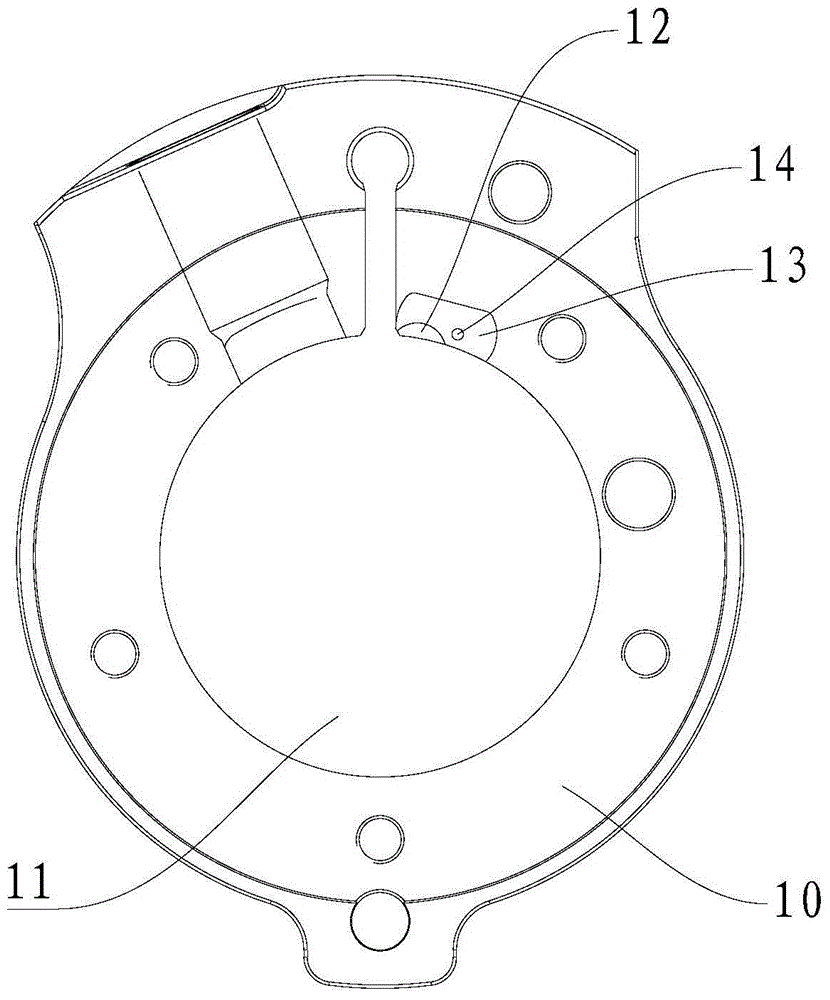

Compressor exhaust apparatus

InactiveCN102748297AImprove rigidityReduce thicknessRotary/oscillating piston pump componentsLiquid fuel engine componentsBall bearingExhaust valve

The invention relates to a compressor exhaust apparatus, the compressor comprises a compression component and a motor component arranged in a closed casing; the compression component comprises a cylinder, a piston arranged in the cylinder, an eccentric crankshaft capable of driving the eccentric rotation of the piston, a slide plate arranged in a slide plate groove of the cylinder, a main bearing and an auxiliary bearing respectively arranged at two sides of the cylinder; the exhaust apparatus comprises a bearing valve seat arranged on the base bearing, and an exhaust valve sheet, a spring and a stopper which are arranged in the bearing valve seat; a valve seat steam vent is provided at the lower part of the bearing valve seat, a spacing hole is provided at the upper part of the valve seat steam vent; the exhaust valve sheet is carried on the valve seat steam vent, and is capable of moving up and down along an axial direction of the spacing hole; the stopper is positioned at the upper part of the exhaust valve sheet, and is fixedly connected to the spacing hole inner wall; the spring is subjected to pressure welding between the exhaust valve sheet and the stopper. The exhaust apparatus has the advantages of compact structure and simple assembling, can effectively reinforce the rigidity of the bearing valve seat; simultaneously the valve seat thickness is reduced, the clearance volume of the valve seat steam vent is reduced, and the cold amount can be increased.

Owner:GUANGDONG MEIZHI COMPRESSOR

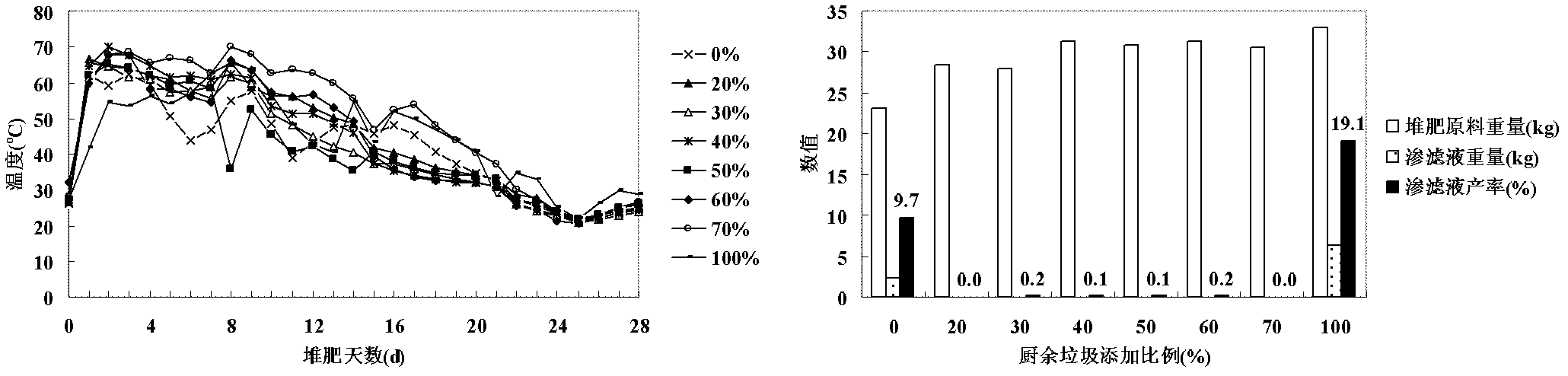

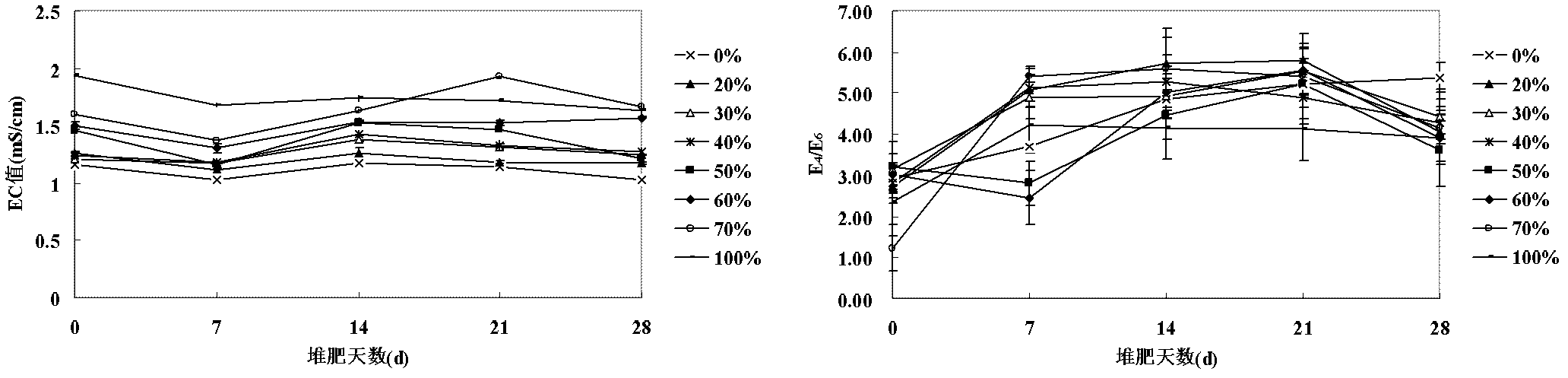

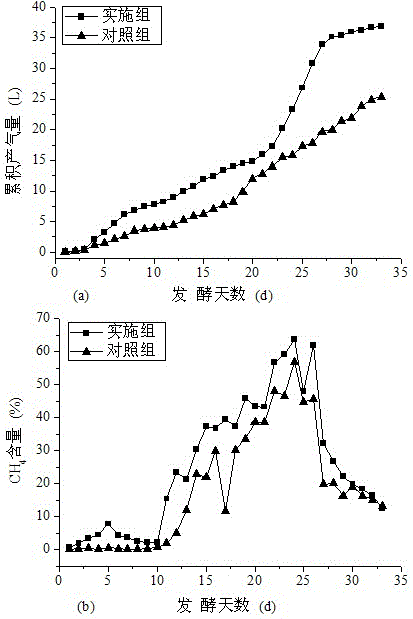

Method for changing kitchen garbage into fertilizer

ActiveCN102826878AFast heating rateReduce generationBio-organic fraction processingOrganic fertiliser preparationFecesLivestock manure

The invention discloses a method for changing kitchen garbage into a fertilizer. The method provided by the invention comprises the following steps of: mixing livestock manure, crop straw and kitchen garbage to obtain a mixture; and fermenting the mixture to obtain the fertilizer. An appropriate proportion of kitchen garbage is added into pig manure and straw which are used as main materials of compost, thus solving problems of unventilated defect, slow heating and generation of a lot of leachate and the like by individually composting. It shows through a fermenter composting test that heating speed of compost can be accelerated by the addition of residual kitchen garbage into straw and pig compost and simultaneously the generation of leachate can be greatly minimized. Germination rate indexes of residual kitchen garbage compost products added in any proportion are all greater than 80%, and the compost products all reach the putrescibility standard. Considering temperature, leachate, putrescibility and odor discharge together as a whole, the percentage of the added residual kitchen garbage is supposed to be controlled within 30% to 60%. In addition, by the adoption of the method, delivering quantity of house refuse can be effectively minimized, resources are saved, generation of malodorous gases is controlled, and the goal of energy saving and emission reduction is realized.

Owner:CHINA AGRI UNIV

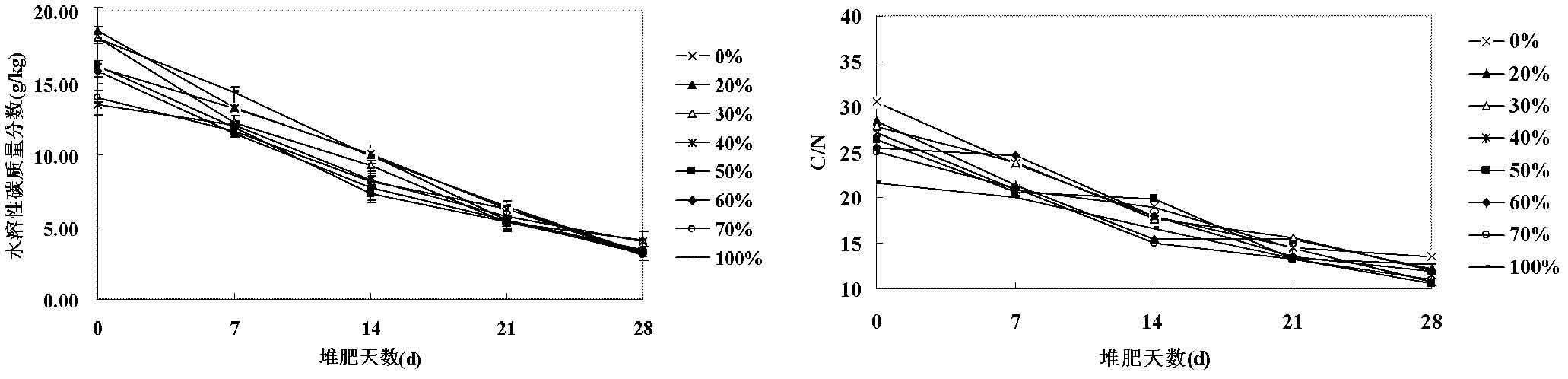

Heat pump air-conditioning system for electric or hybrid vehicle

ActiveCN104121722AIncrease profitImprove energy efficiency ratioMechanical apparatusEfficient regulation technologiesFour-way valveEngineering

The invention discloses a heat pump air-conditioning system for an electric or hybrid vehicle. The heat pump air-conditioning system for the electric or hybrid vehicle comprises a compressor with the air supplying and enthalpy increasing function, a four-way valve, an external heat exchanger, a bidirectional thermal expansion valve, a middle heat exchanger, an expansion valve, a block valve, an internal heat exchanger, an air return pipeline, an air supplying pipeline, an air blower and an air distributing system. According to the heat pump air-conditioning system for the electric or hybrid vehicle, the flowing direction of refrigeration circulation is made to be opposite to the flowing direction of heating circulation by means of the four-way valve and the bidirectional thermal expansion valve, in this way, both the refrigeration mode and the heating mode are achieved on the electric or hybrid vehicle, PTC heating and electric heating tube heating are not needed for heating, the energy efficiency ratio is high, and the performance is reliable.

Owner:庹明慧

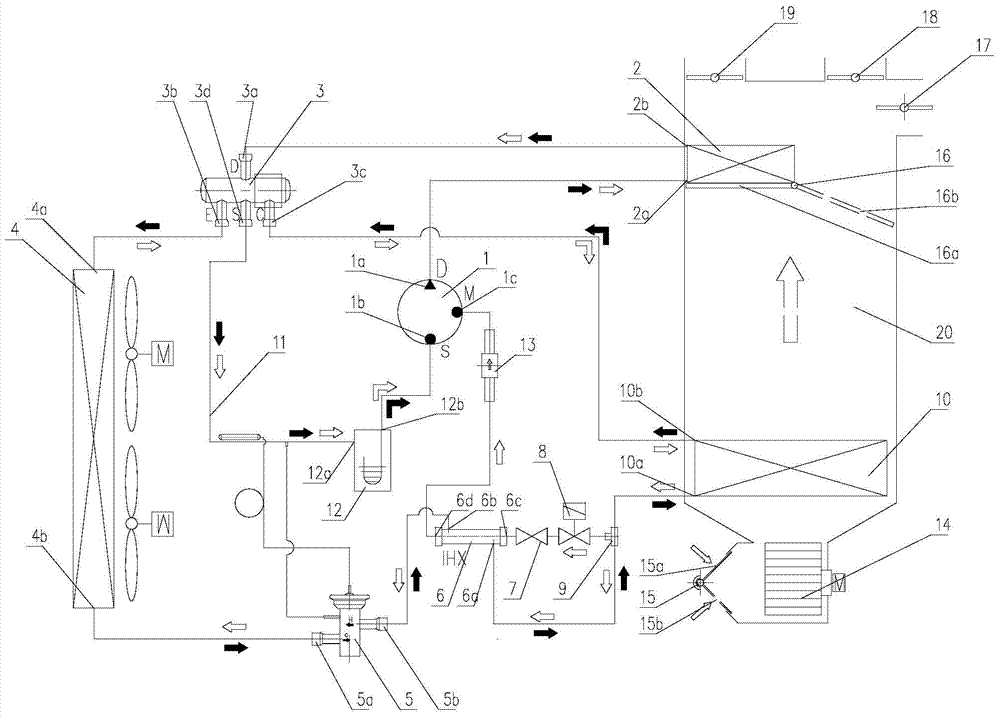

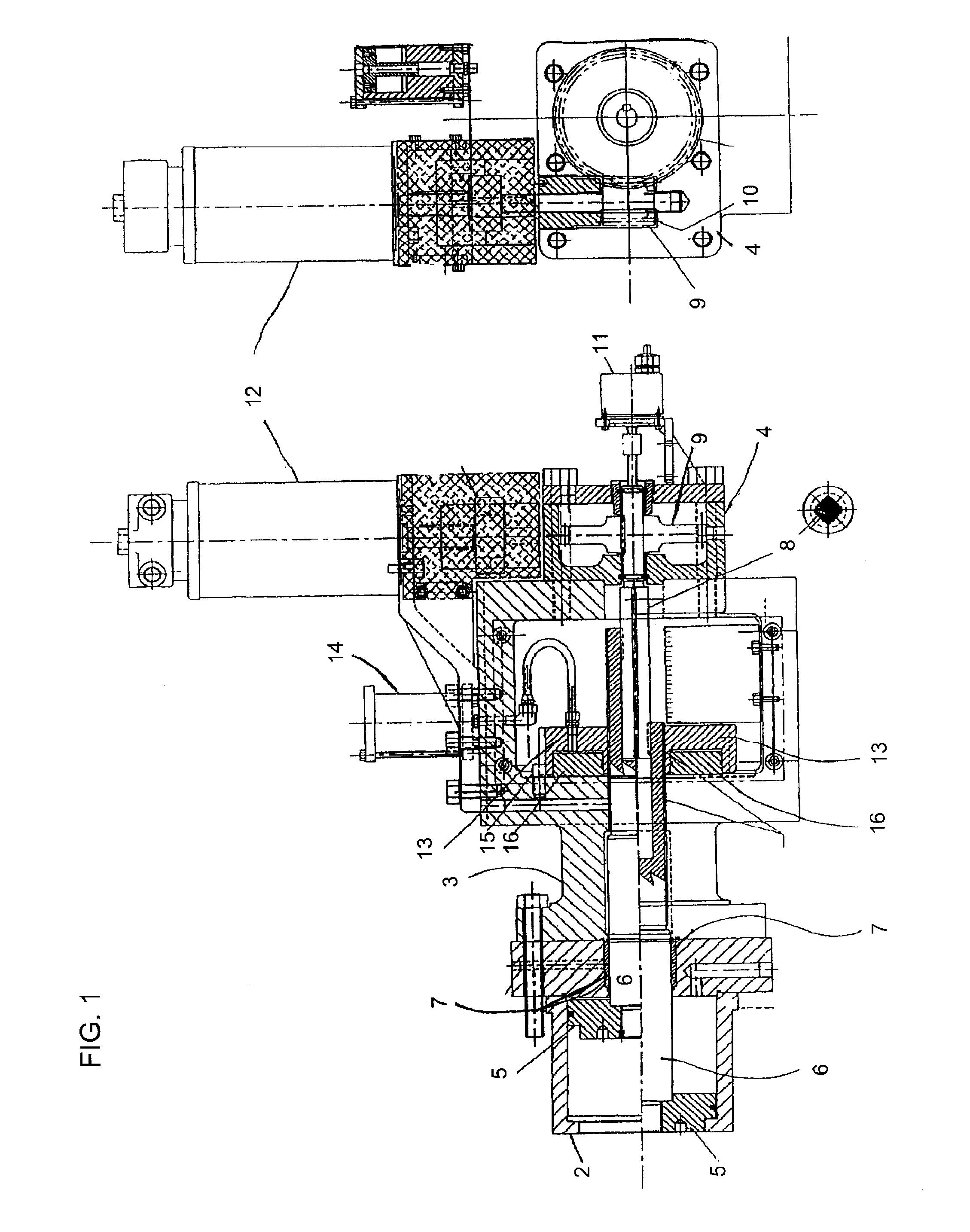

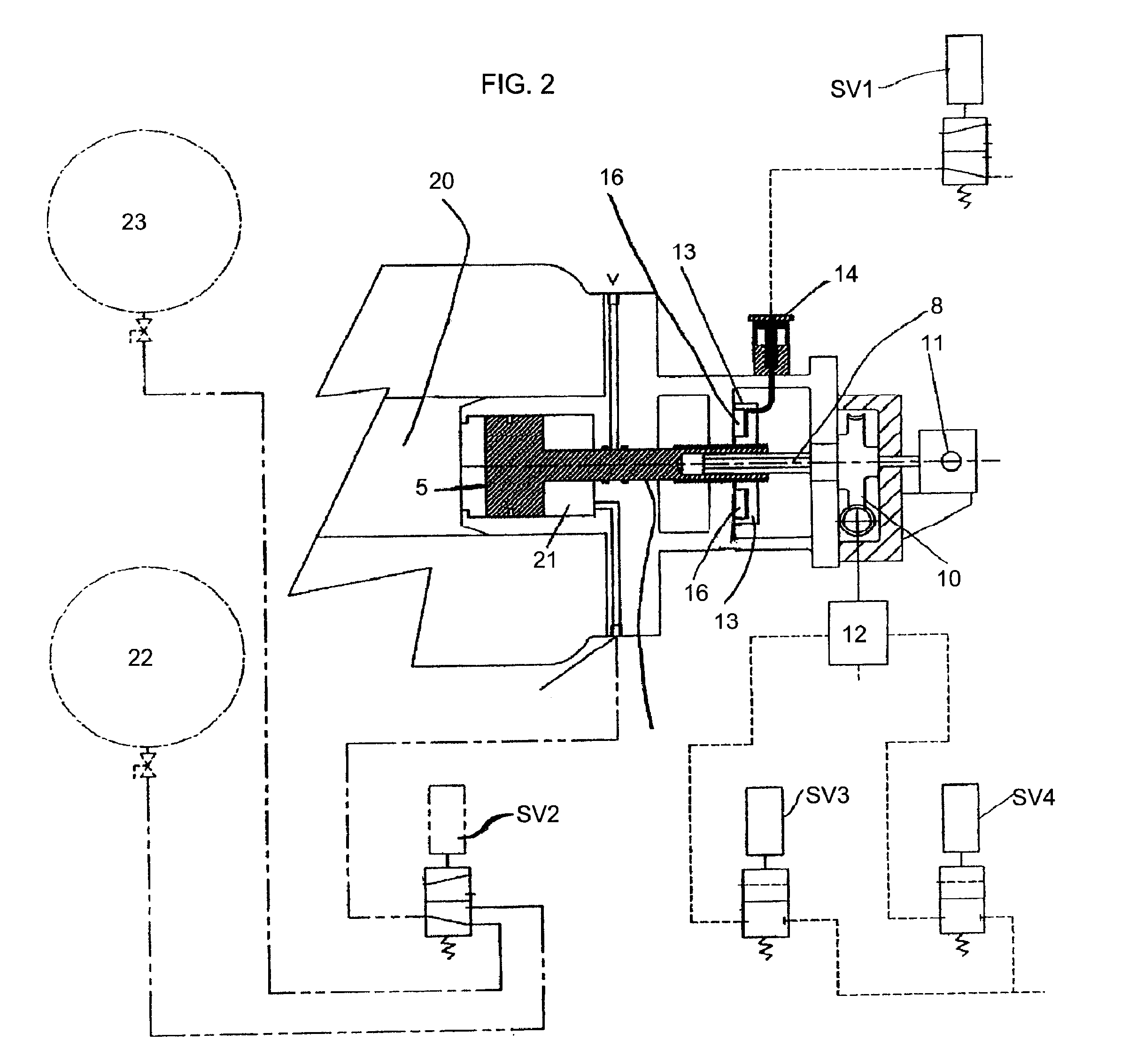

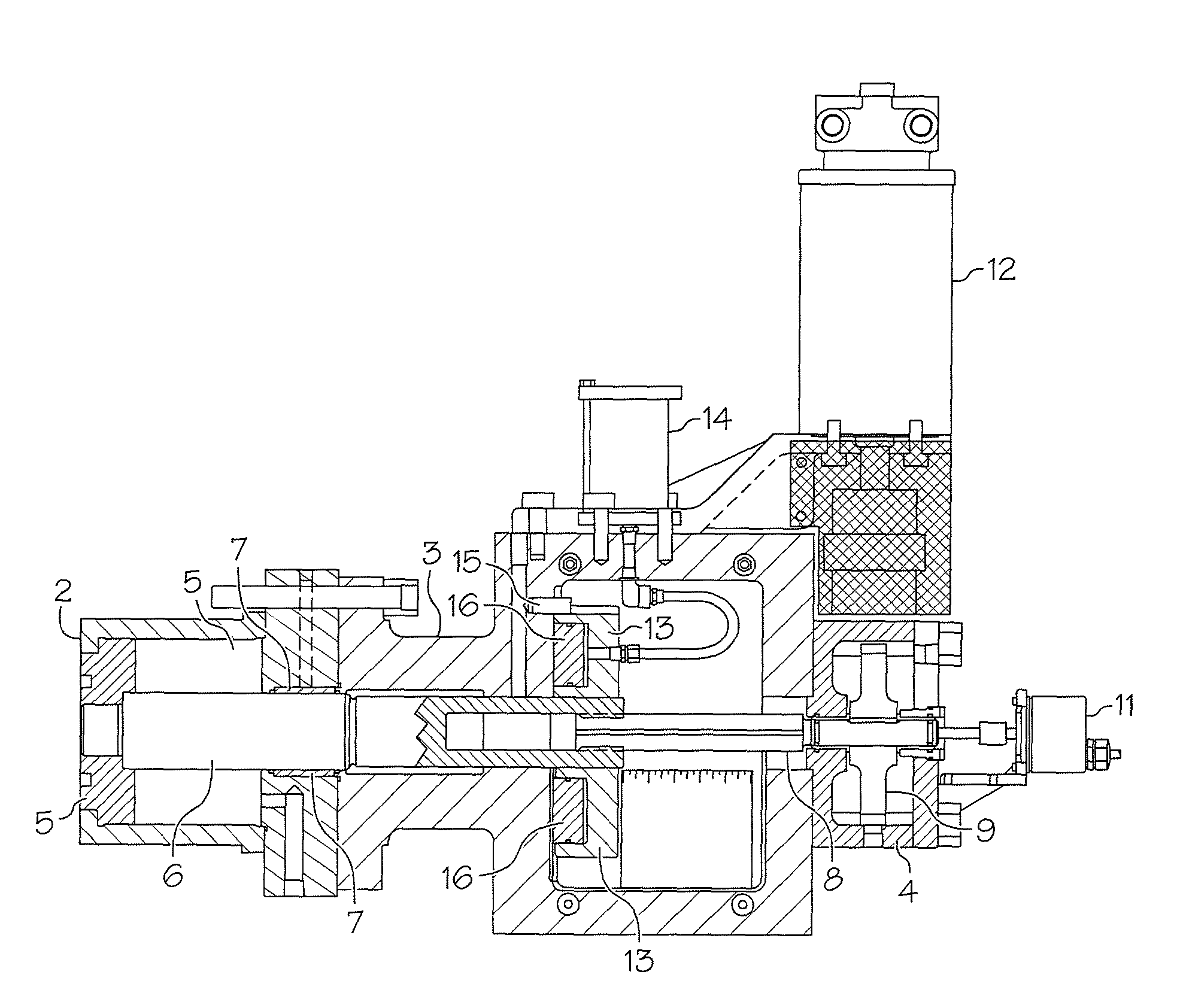

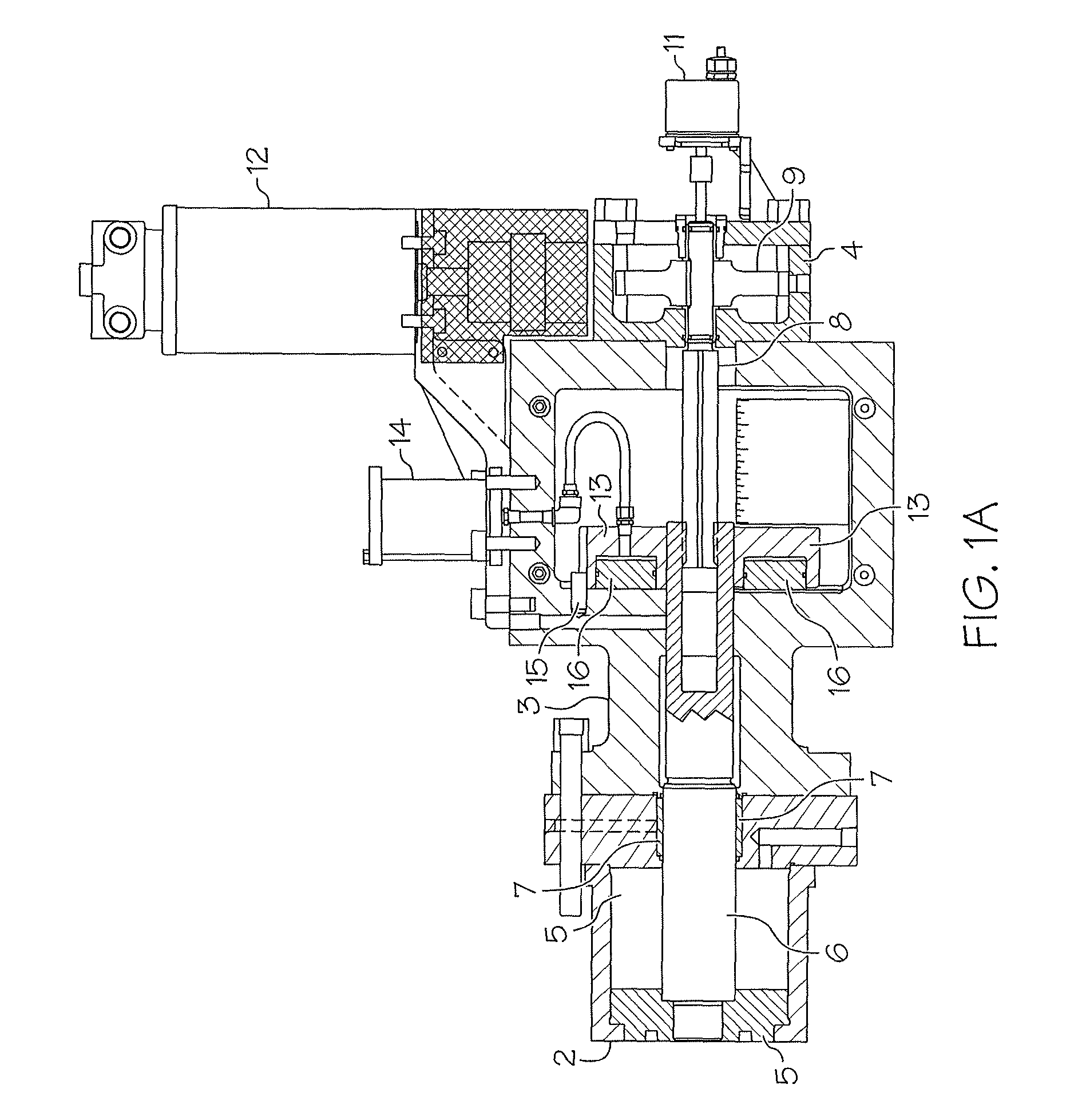

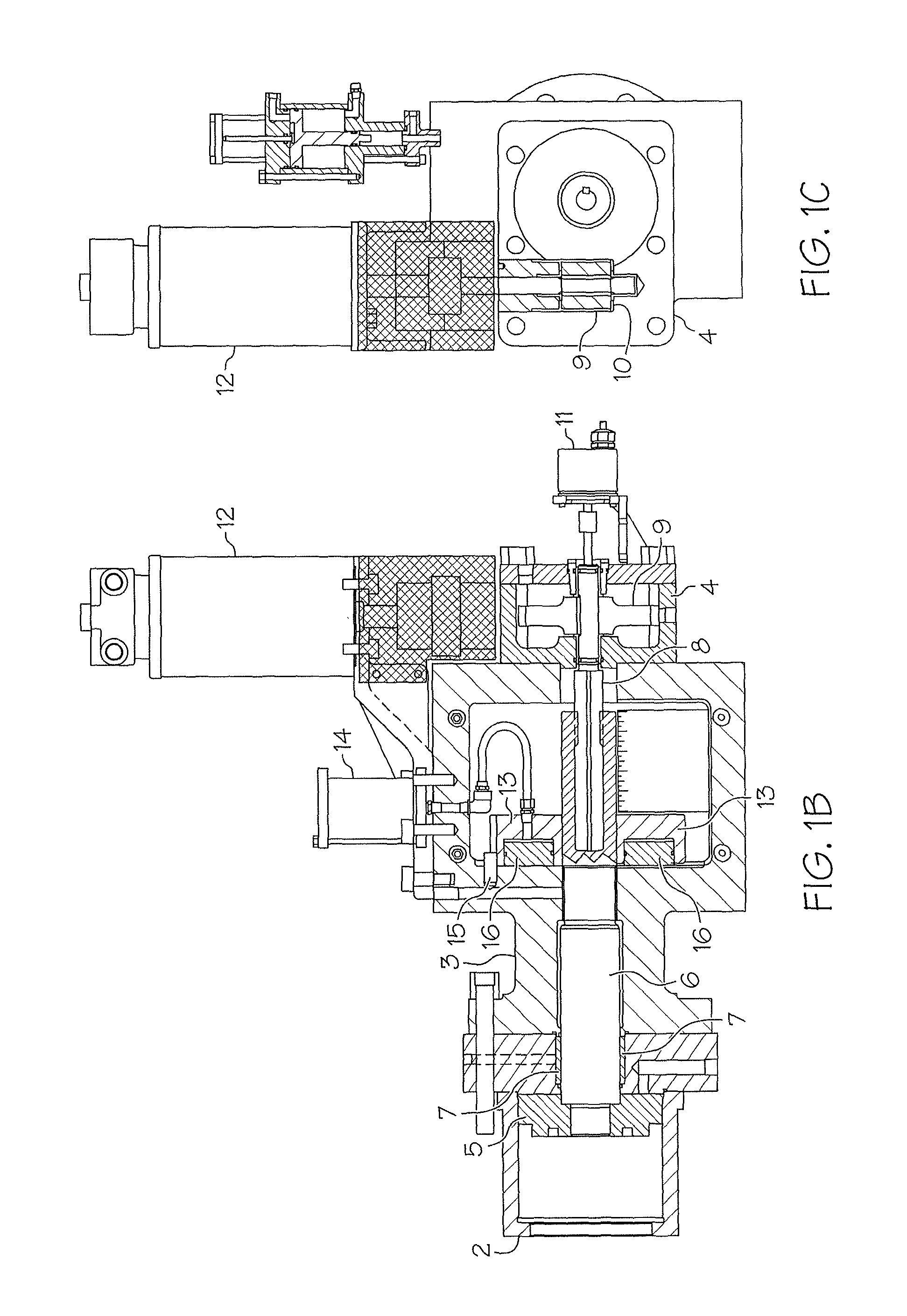

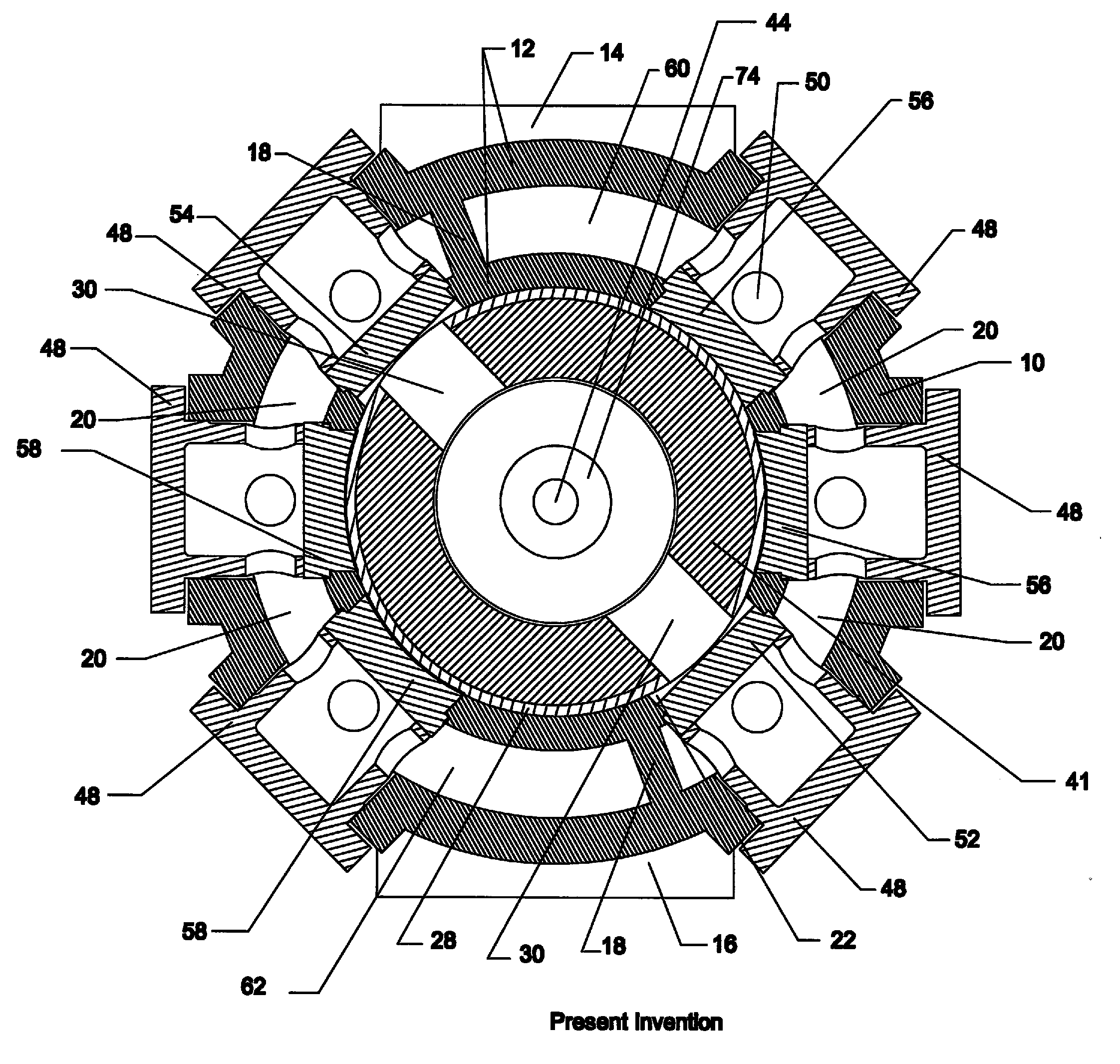

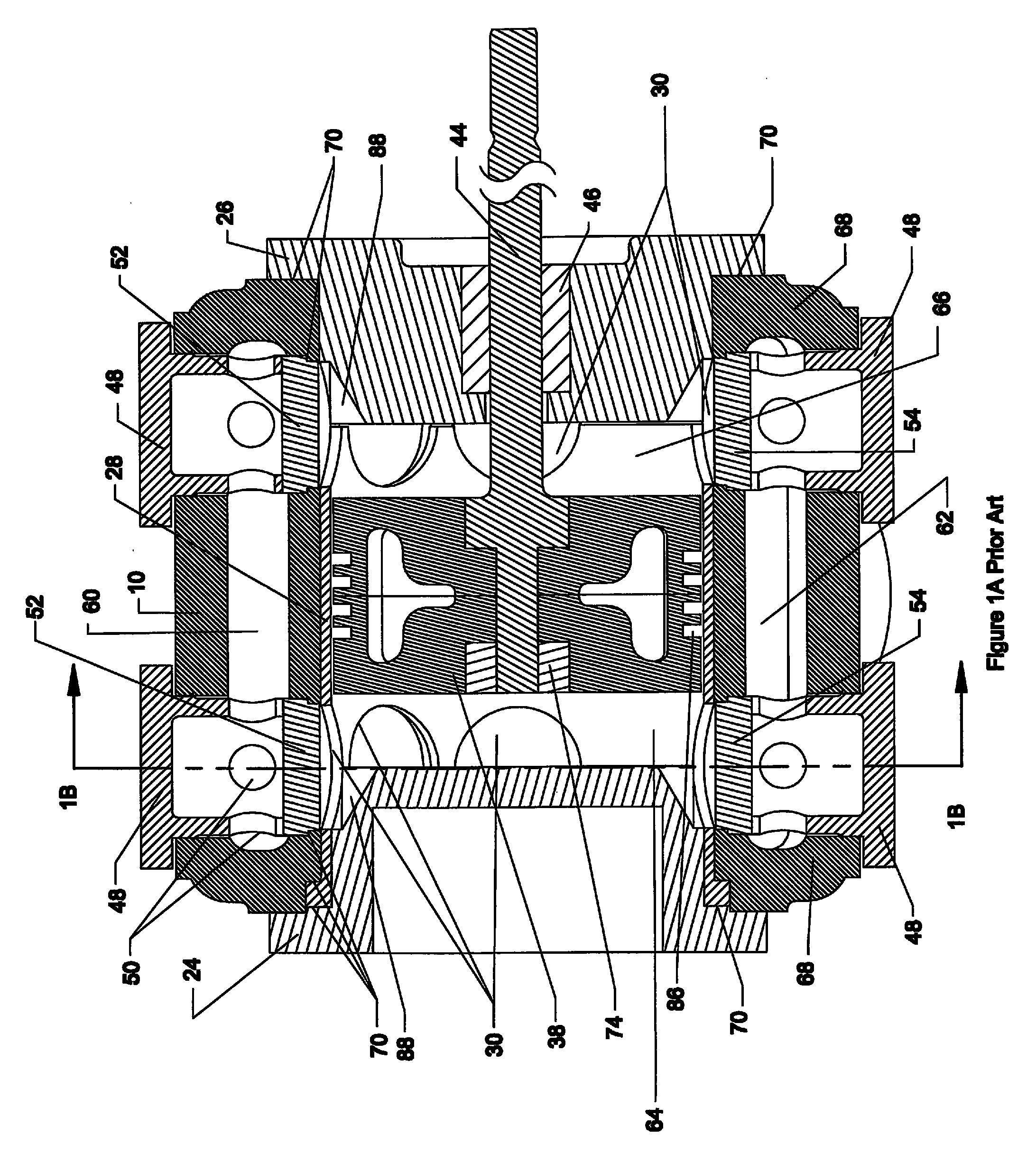

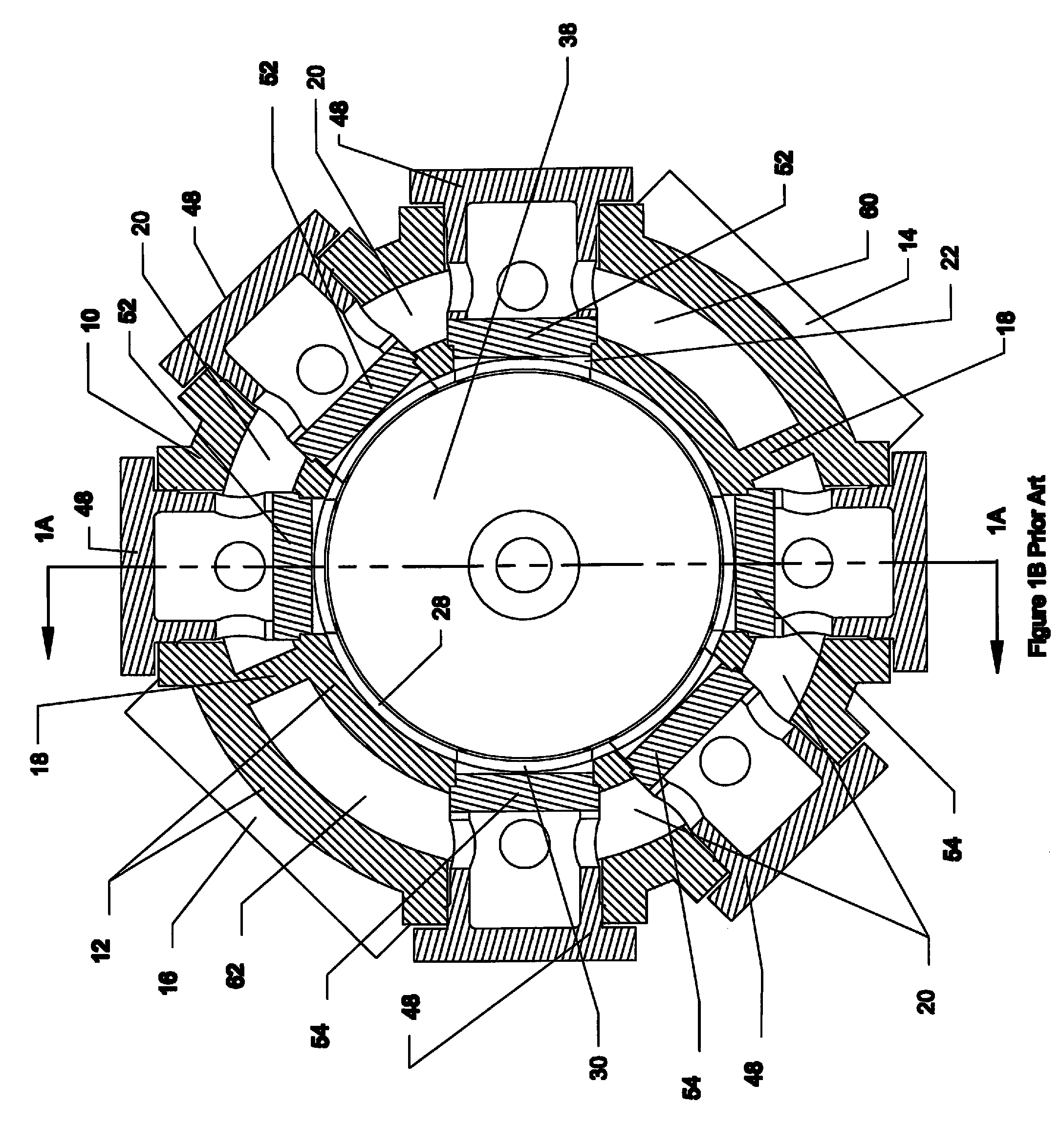

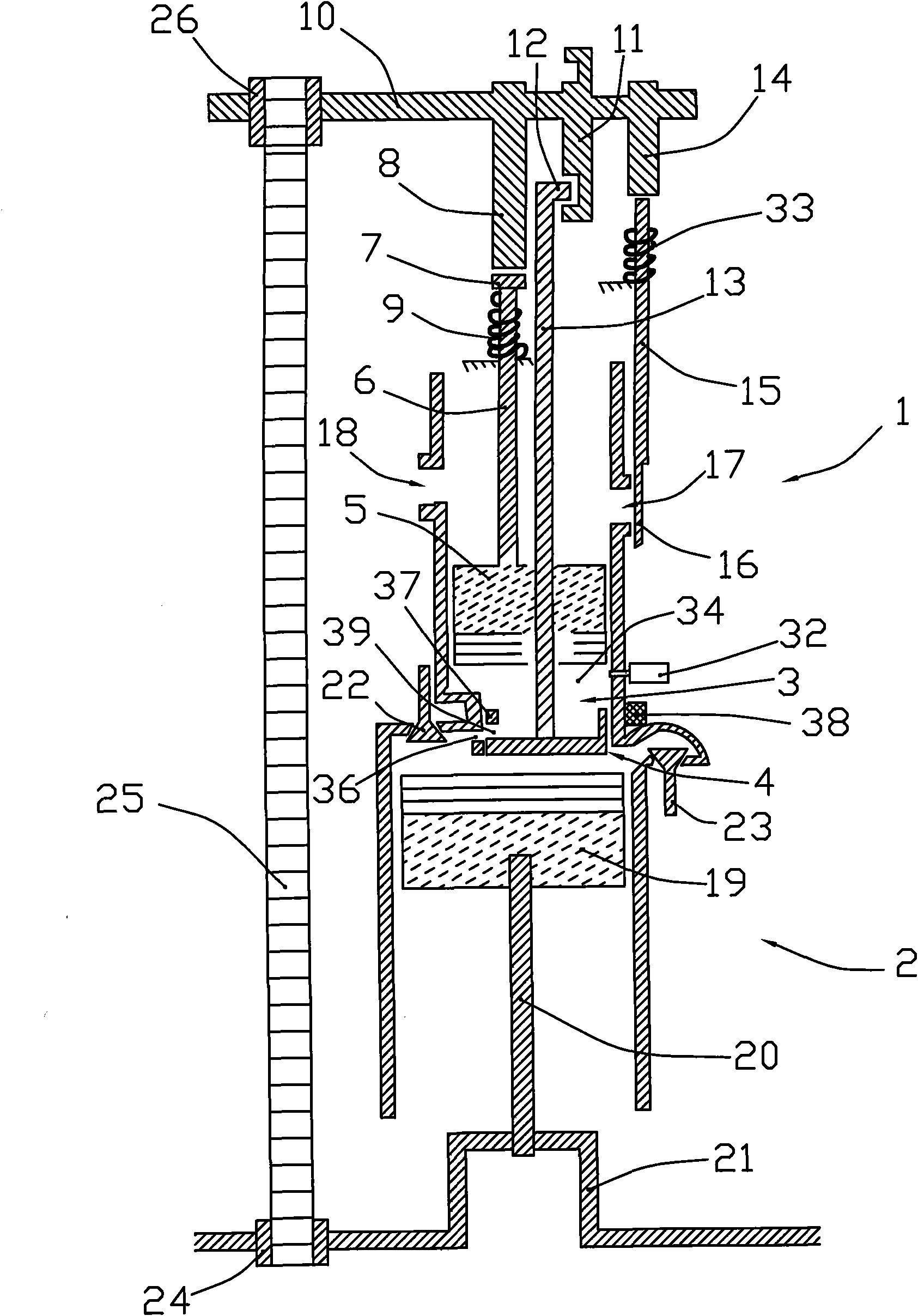

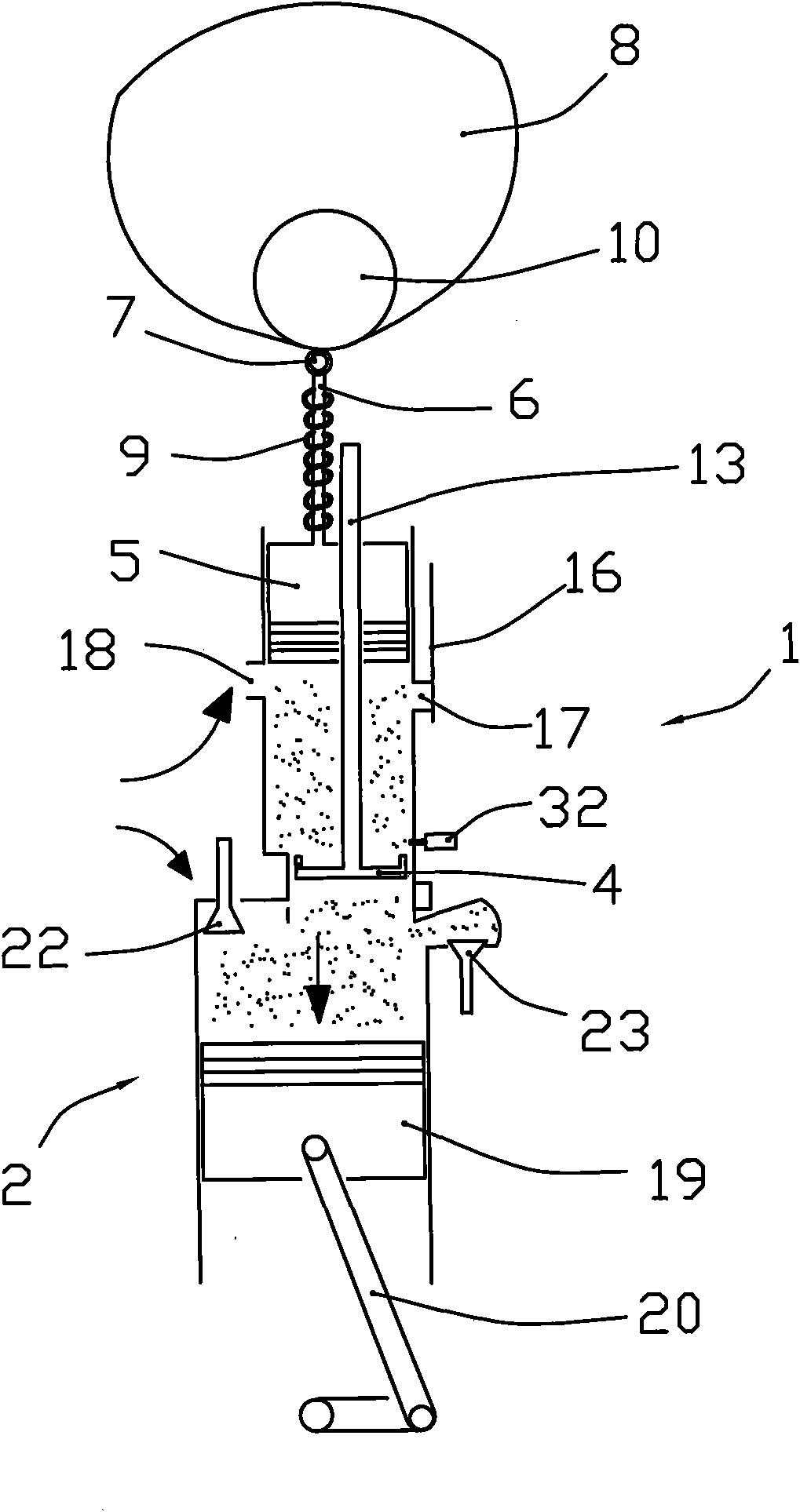

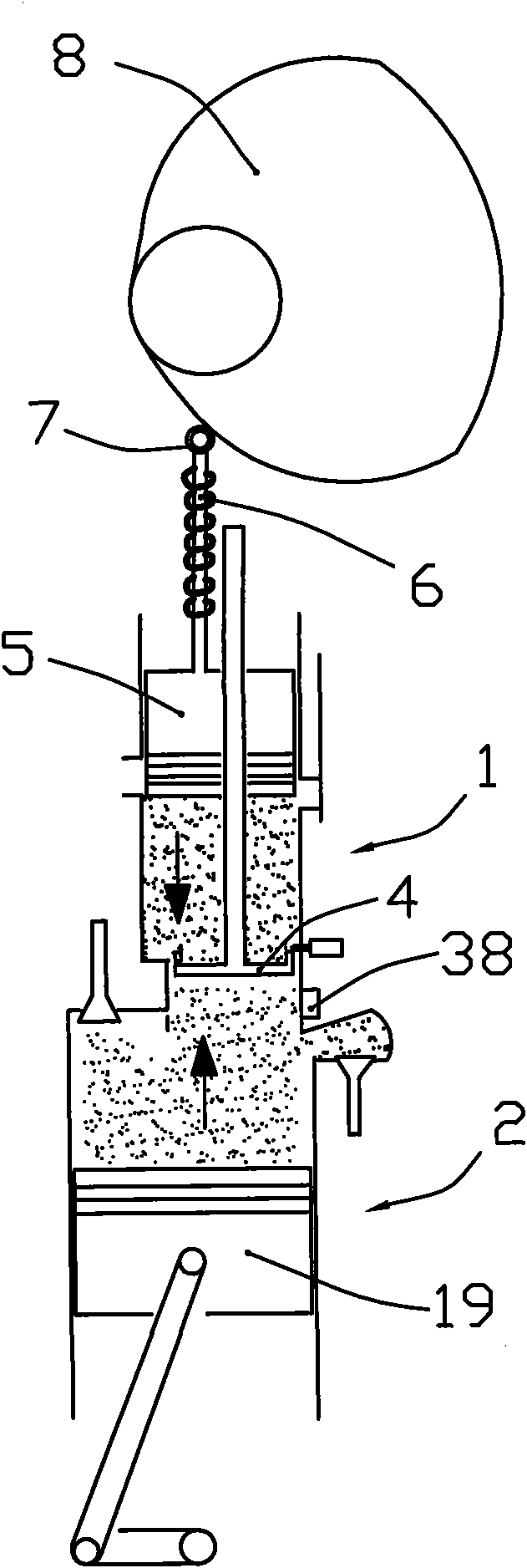

Variable volume clearance pocket for a reciprocating compressor cylinder

ActiveUS20100040484A1Decrease clearance volumeIncrease clearance volumePositive displacement pump componentsFluid-pressure actuatorsEngineeringReciprocating compressor

A controllable variable volume clearance pocket for reciprocating compressor cylinders is disclosed. The invention includes a device for varying the clearance volume of a variable volume clearance pocket in a controlled manner. The device can be used repeatedly to change the compressor cylinder clearance volume as required to control compressor capacity and power required from the compressor driver. The device is typically mounted on the outer or head end of a reciprocating compressor cylinder, but can also be scaled and configured for use either in conjunction with a variable clearance volume unloader operating over a reciprocating compressor valve pocket or a special port in a reciprocating compressor body.

Owner:ACI SERVICES

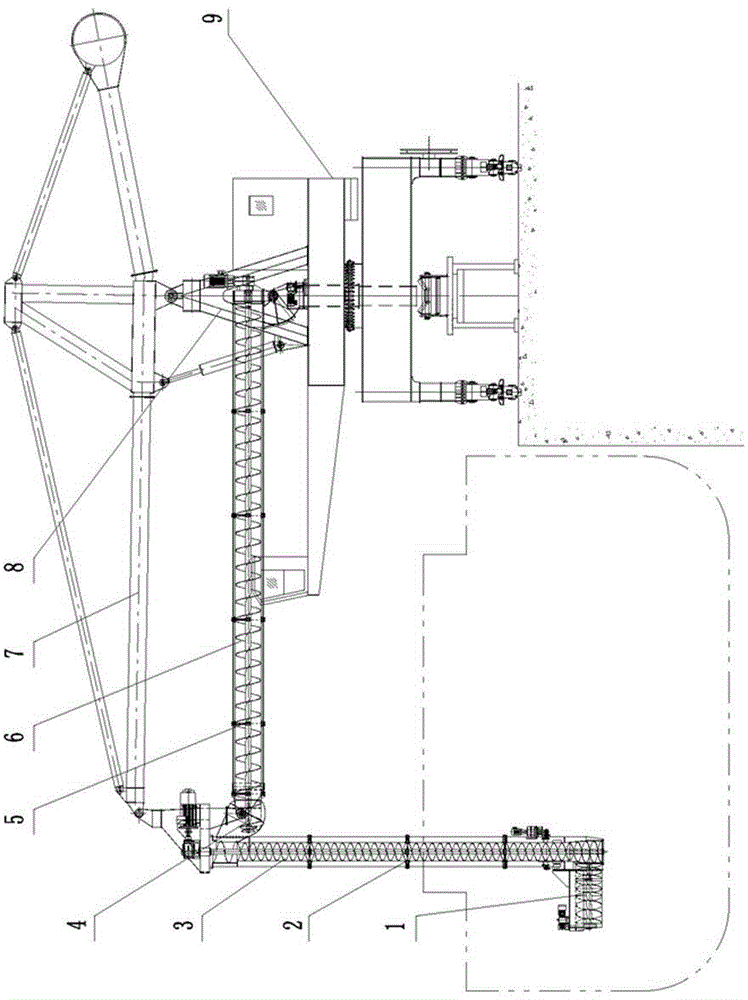

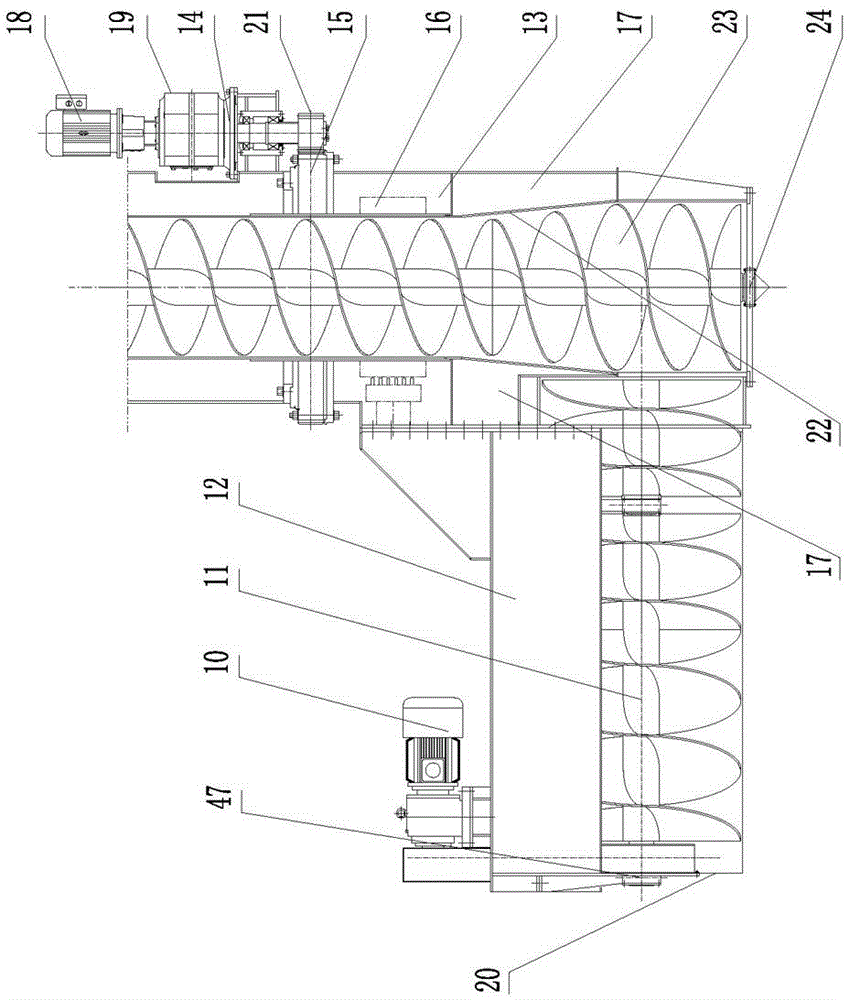

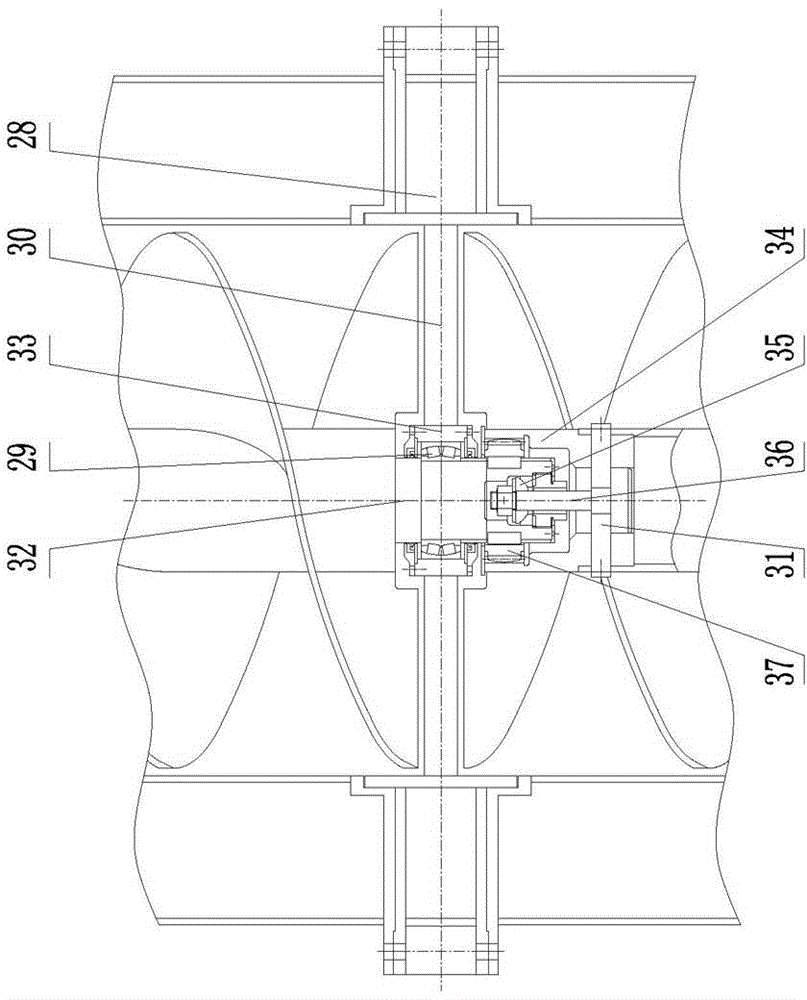

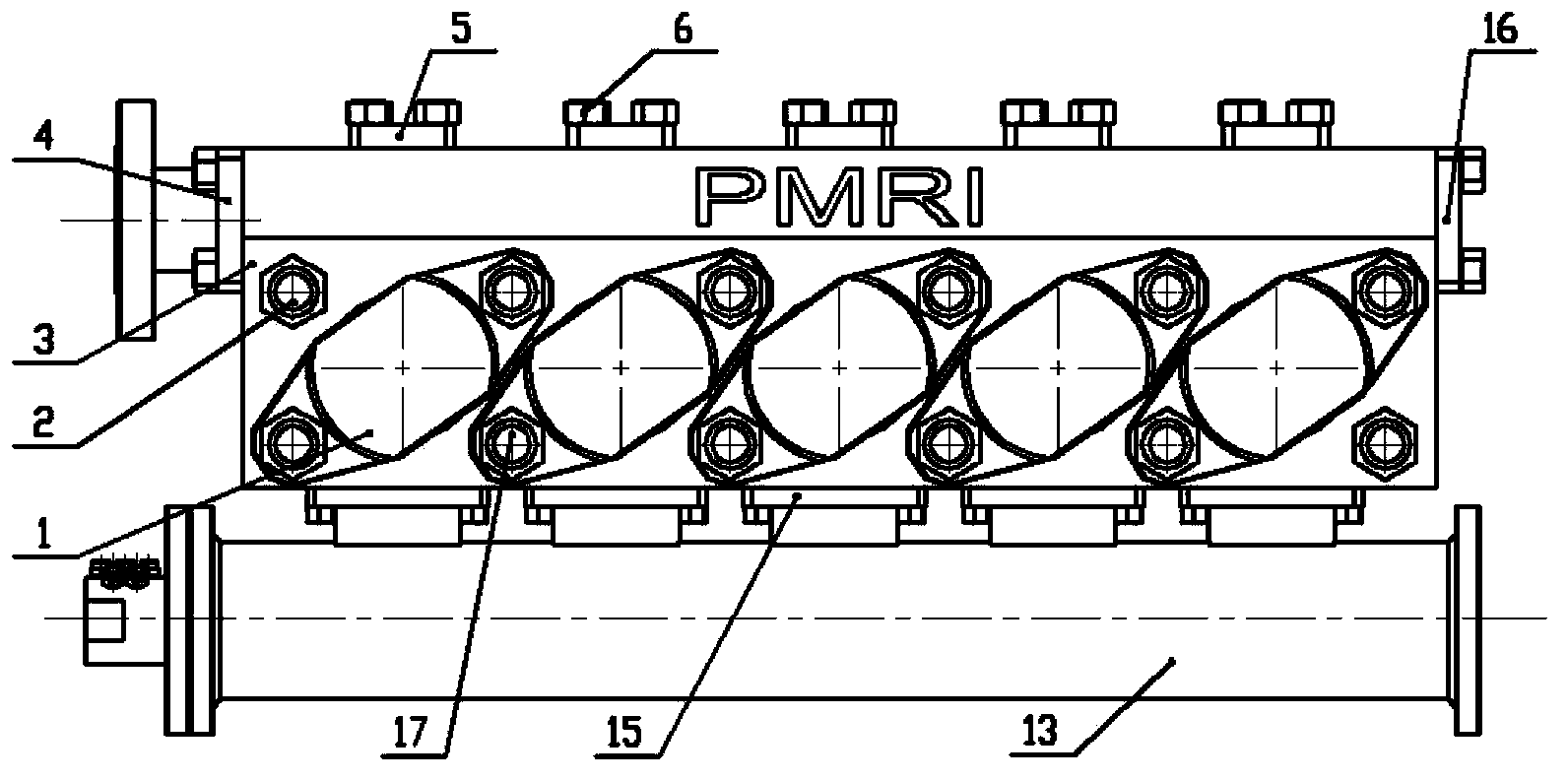

L-shaped screw ship unloader

ActiveCN104627700AImprove feeding capacityImprove unloading capacityLoading/unloadingLoad carryingScrew conveyor

The invention discloses an L-shaped screw ship unloader which can improve material taking capacity and efficiency, improve ship unloading capacity, increase the utilization rate, improve the material flow smoothness of a conveying system, improve the load-carrying capacity of a supporting structure, lower ship clearing quantity, lower the energy consumption of the ship unloader and lower the requirement for the manufacturing and mounting accuracy of a vertical screw shaft. The L-shaped screw ship unloader comprises a vertical milling type screw material taking device, a reverse screw spoke middle supporting device, a vertical screw conveyor, a coaxial annular material groove material transferring device, a horizontal screw conveyor, a balance beam, a Y-shaped frame and a supporting frame. The vertical screw conveyor, the horizontal screw conveyor, the balance beam and the Y-shaped frame form a parallel four-connecting-rod mechanism. By means of the scheme, the L-shaped screw ship unloader achieves the purposes of improving the material taking capacity and efficiency, improving the ship unloading capacity, increasing the utilization rate, improving the material flow smoothness of the conveying system, improving the load-carrying capacity of the supporting structure, lowering the ship clearing quantity, lowering the energy consumption of the ship unloader and lowering the requirement for the manufacturing and mounting accuracy of the vertical screw shaft.

Owner:WUHAN UNIV OF TECH +1

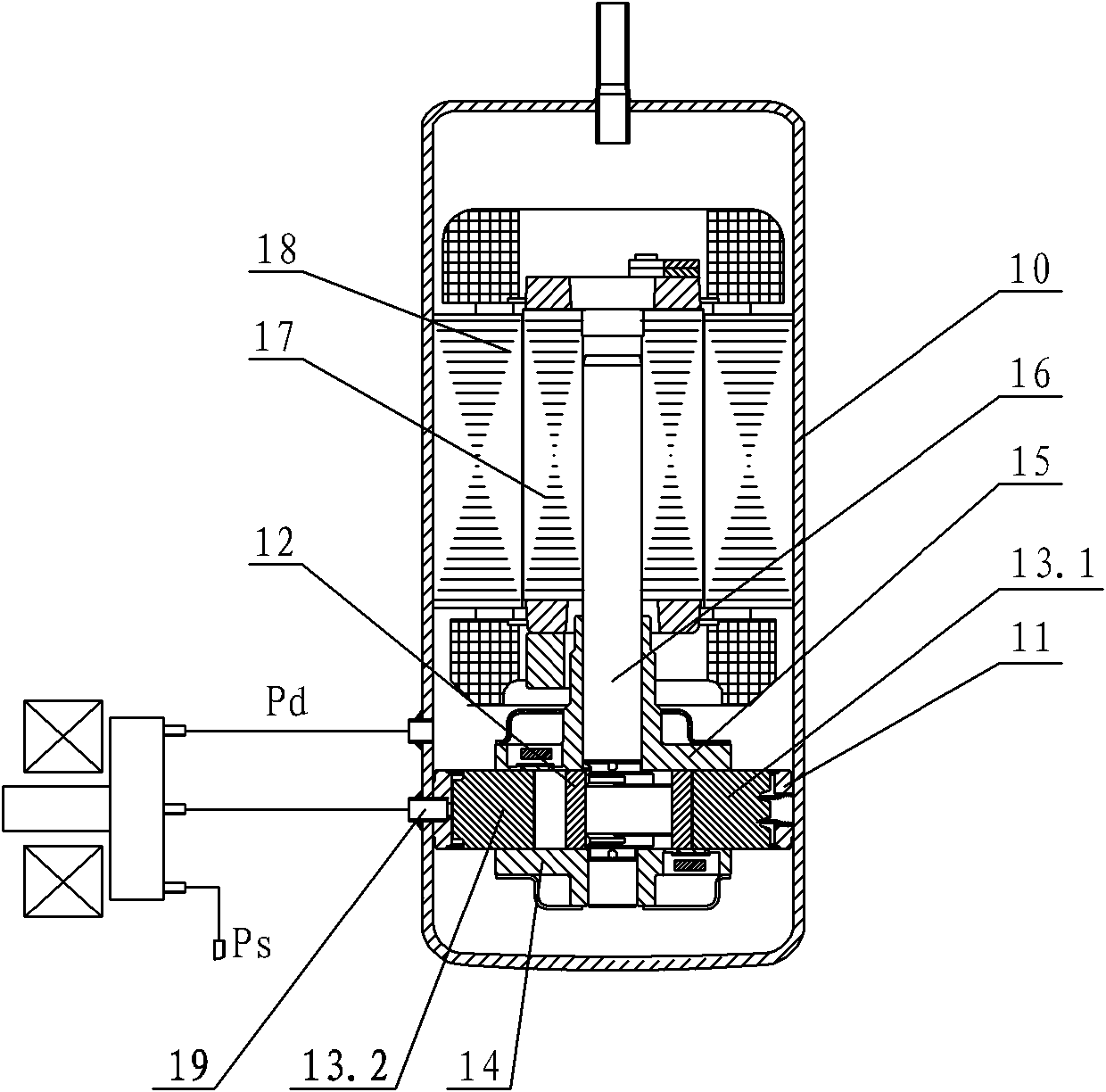

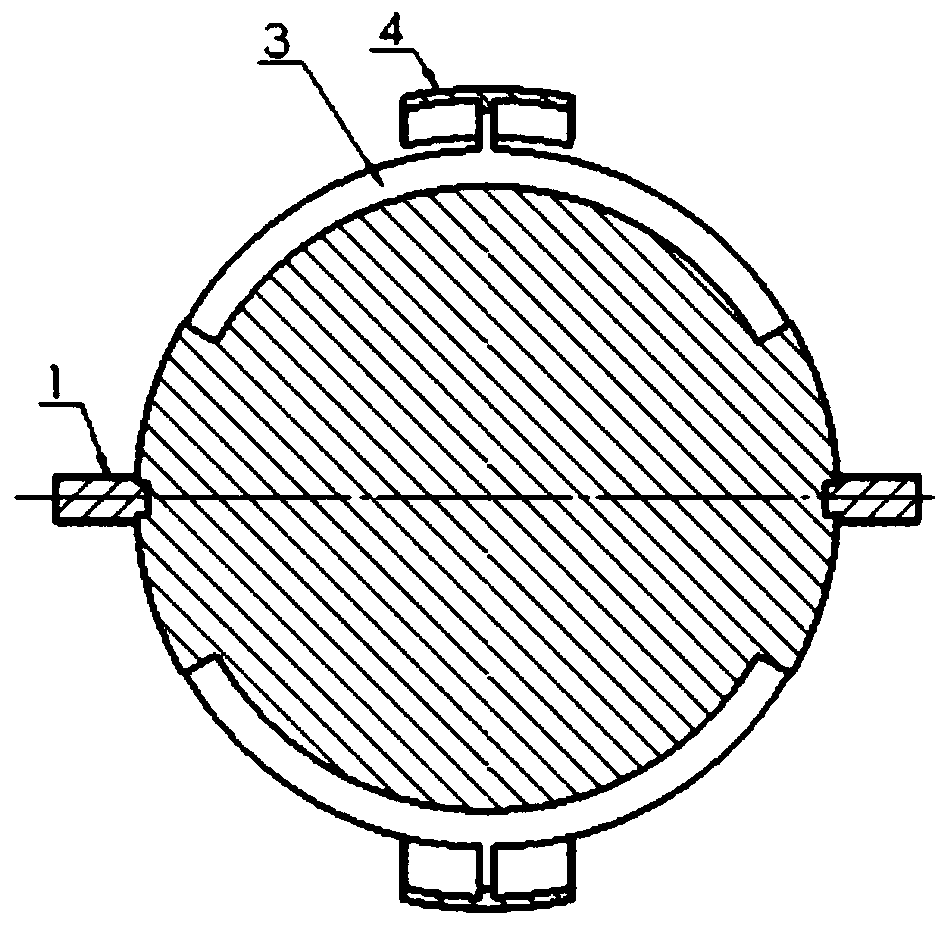

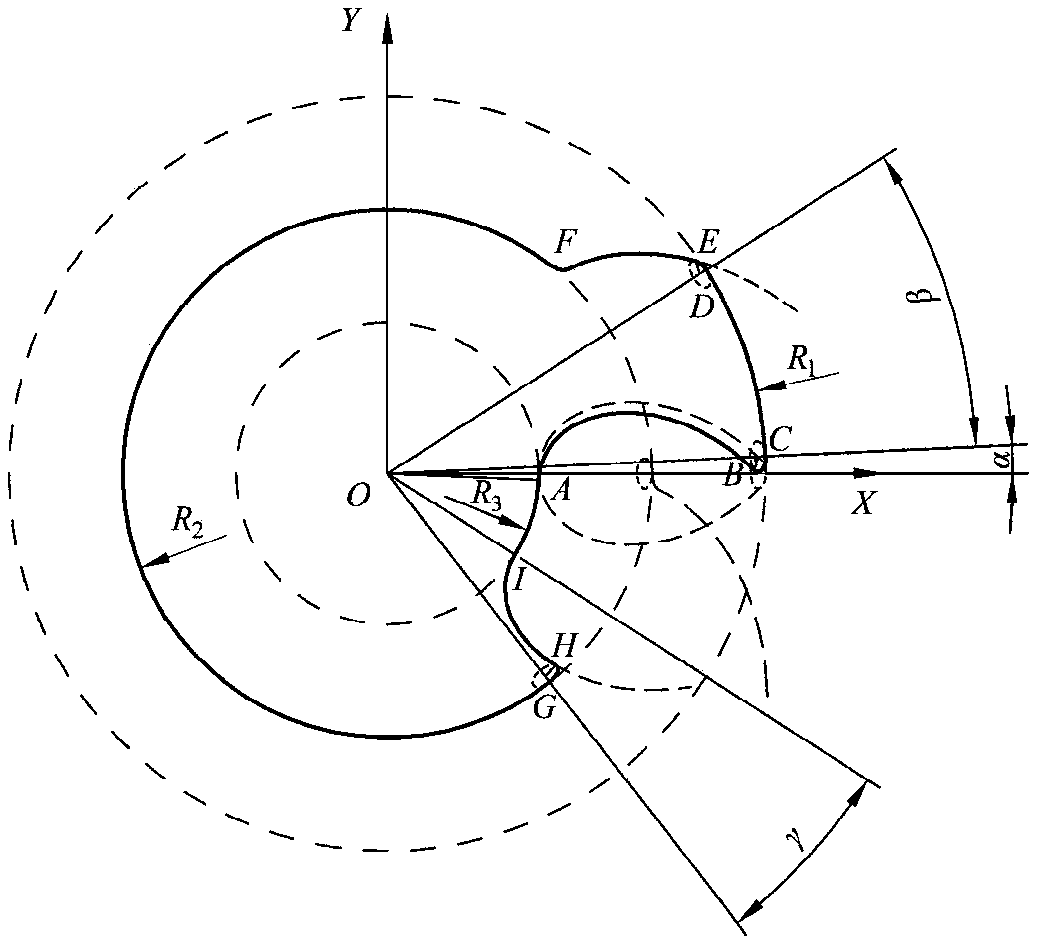

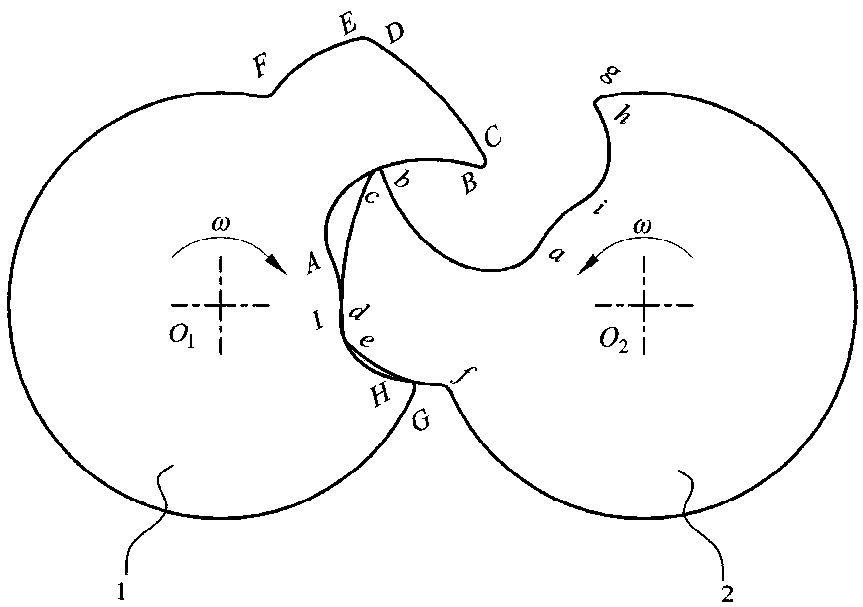

Double-slip-sheet type rotary compressor

ActiveCN102828951AShorten exhaust strokeSmall compression strokeRotary piston pumpsRotary piston liquid enginesSlip sheetEngineering

The invention relates to a double-slip-sheet rotary compressor, comprising a motor assembly and a compression assembly which are arranged in a housing, wherein the compression assembly comprises a piston disposed in an air cylinder; the air cylinder is provided with a first slip sheet groove for accommodating a first slip sheet and a second slip sheet groove for accommodating a second slip sheet; the first slip sheet groove is communicated with a first slip sheet cavity; the second slip sheet groove is communicated with a second slip sheet cavity; the second slip sheet cavity is communicated with a pressure-switch pipe and realizes volume change by switching the pressure of the second slip sheet cavity; the air cylinder is provided with a first exhaust notch and a second exhaust notch; a main bearing is provided with an upper exhaust hole; an auxiliary bearing is provided with a lower exhaust hole; an angle beta is formed by connecting lines between the center of the first exhaust notch and the center of the air cylinder and between the center of the second exhaust notch and the center of the air cylinder; and on basis of the center line of the first exhaust notch and in a counter-clockwise direction, the angle beta meets the following relationship. With the double-slip-sheet rotary compressor, clearance volume of a low-capacity working mode is effectively decreased; and volume efficiency of the compressor is improved.

Owner:GUANGDONG MEIZHI COMPRESSOR

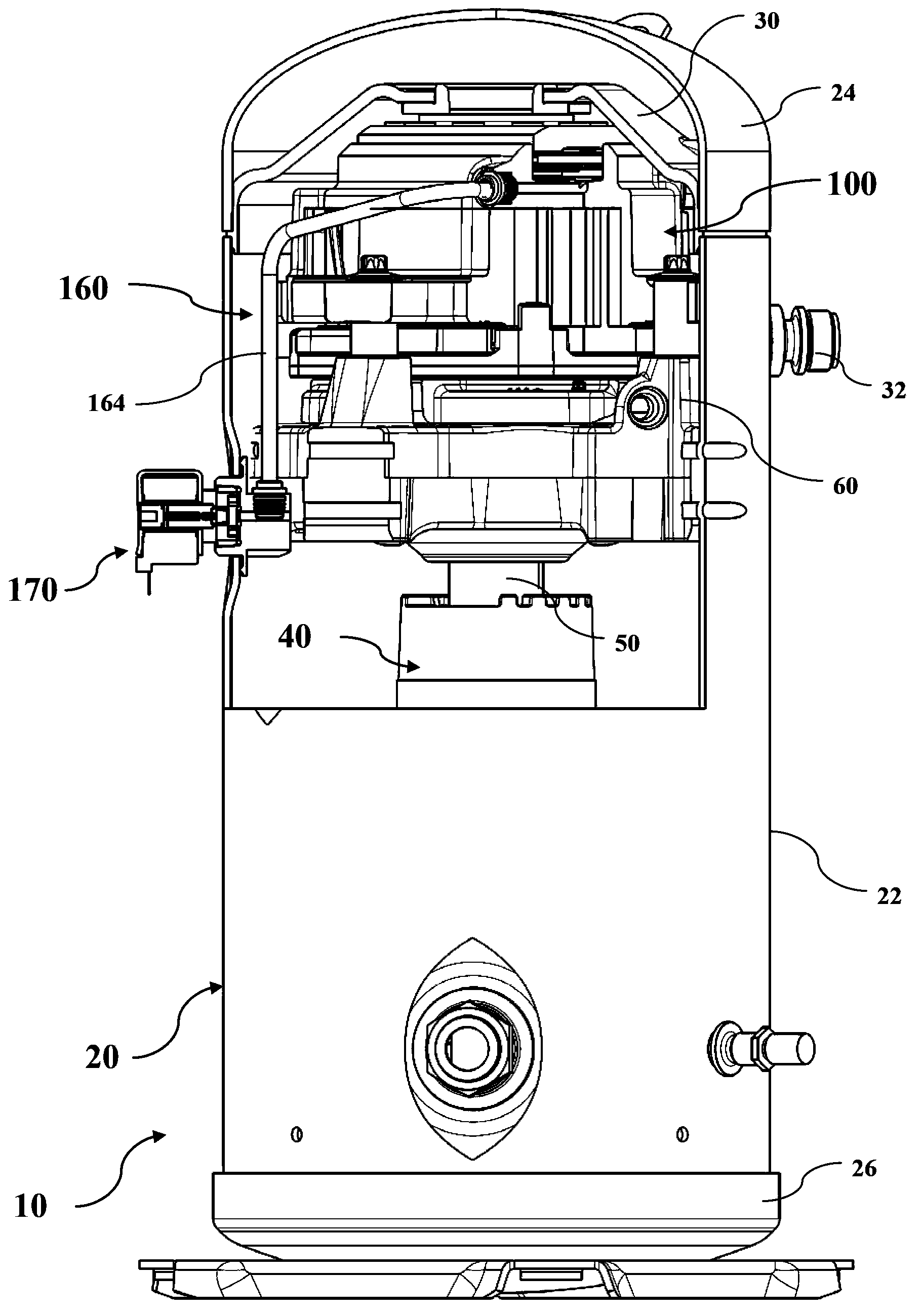

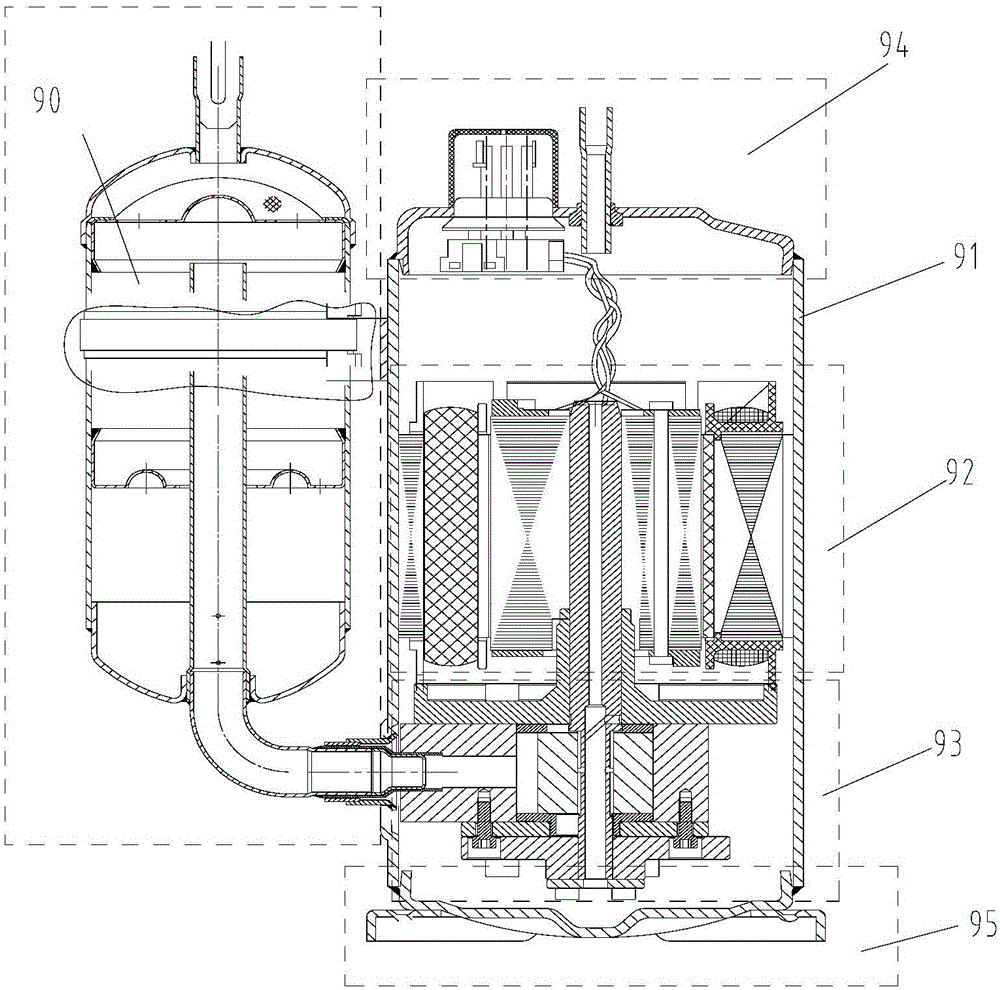

Compressor

ActiveCN103790831AImprove work efficiencySimple structureRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringThrottle

Owner:EMERSON CLIMATE TECH (SUZHOU) CO LTD

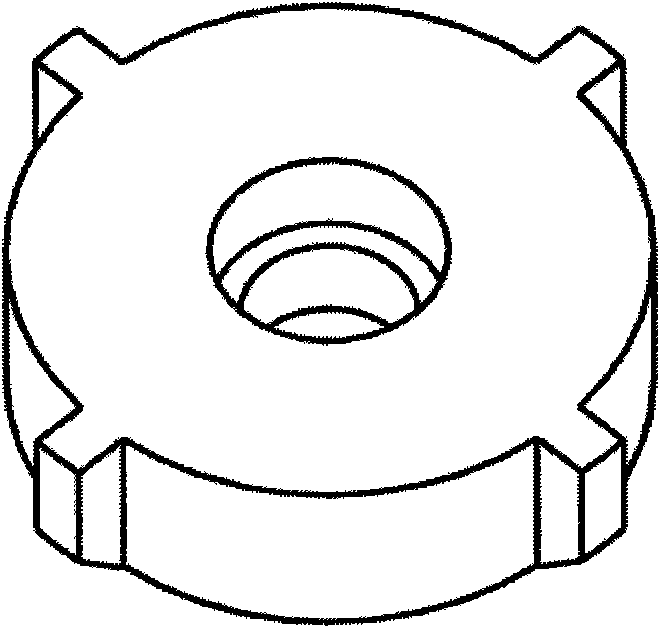

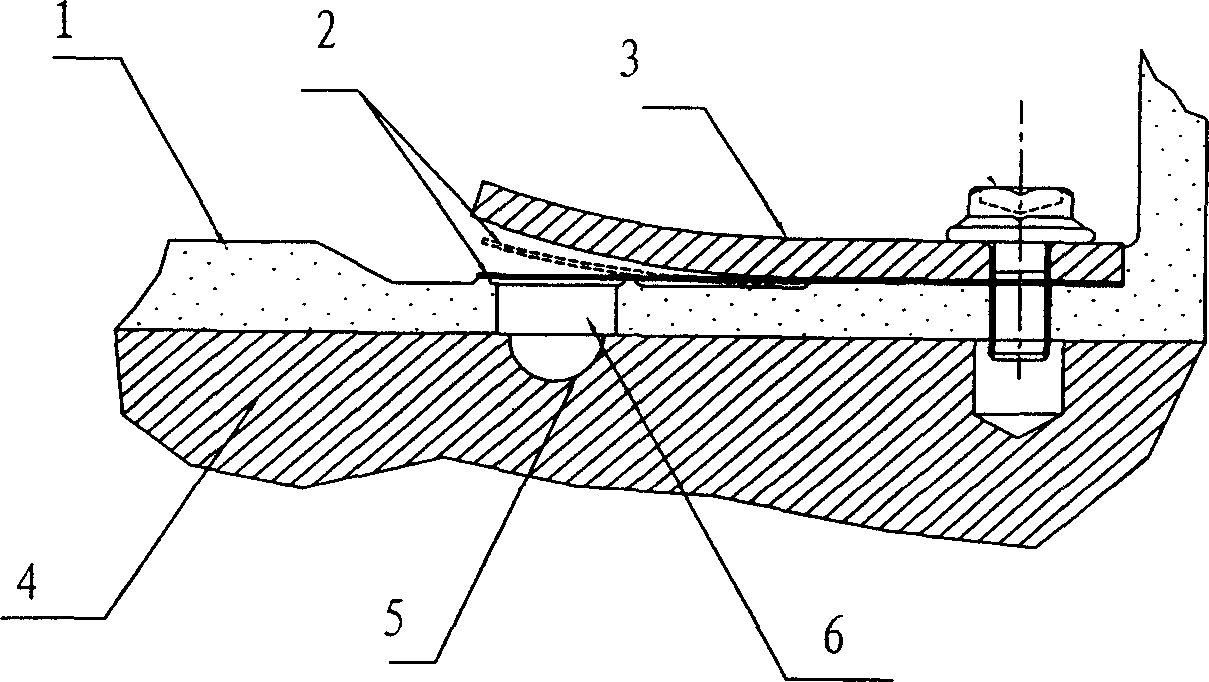

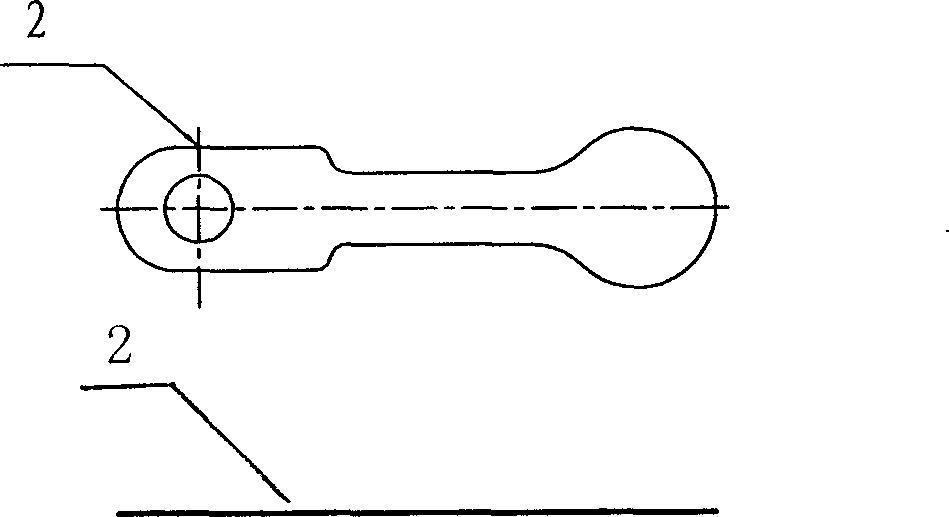

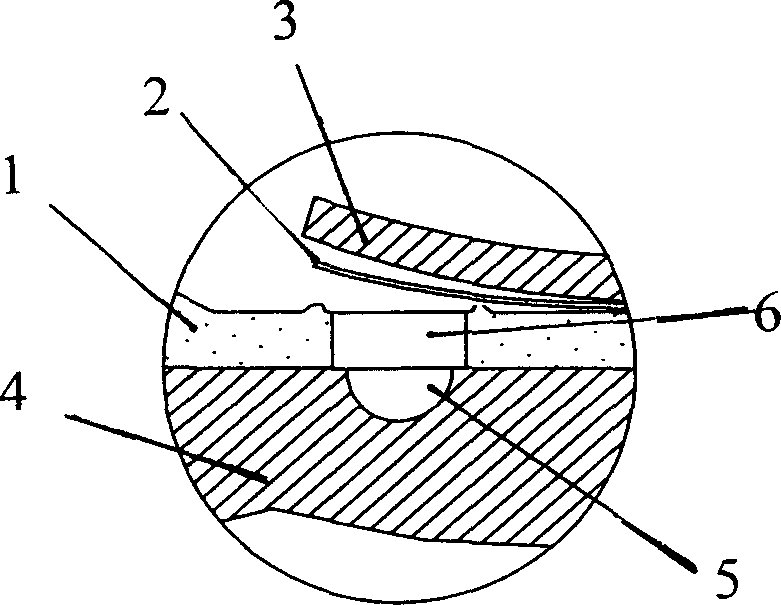

Slip-sheet for rotary compressor

InactiveCN1815029AImprove COPReduced clearance volumeRotary piston pumpsRotary piston liquid enginesEngineeringSlip sheet

Present invention discloses a slide piece for rotary compressor. Said end surface end surface contour is smooth curve, the curvature centre of said curve deviated to air outlet, the end surface of slide piece bottom being not symmetric along slide piece center line, but one side corresponded air suction port being higher than one side corresponded air outlet. When compressor is in operation, said asymmetrical shape can relieve slide piece tilted position, thereby reducing frictional wear and mechanical friction power loss between slide piece and slide piece trough, reducing slide piece blocking duo to assembly deformation, raising compressor reliability and COP.

Owner:李玉斌

Rotary compressor and compression mechanism thereof

InactiveCN105201830AReduce exhaust resistanceReduce noiseRotary piston pumpsRotary piston liquid enginesSlide plateCrankshaft

The invention discloses a rotary compressor and a compression mechanism thereof. The compression mechanism comprises an air cylinder, a piston and a bearing, wherein an air cylinder hole and a slide plate groove are formed in the air cylinder; the piston is arranged on an eccentric part of a crankshaft in a sleeving manner and is stored in the air cylinder hole in a way of eccentrically rotating surrounding the center of the air cylinder hole; the bearing is arranged on the upper end or the lower end of the air cylinder, an air cylinder cavity is collectively formed between the end surface of the bearing and the air cylinder hole, a plurality of exhaustion holes which are communicated with the air cylinder cavity are formed in the bearing, and the plurality of exhaustion holes are arranged at intervals along a rotating path of the piston. The compression mechanism is small in ventilation resistance, low in noise, small in exhaustion clearance volume, simple in structure and low in cost.

Owner:GUANGDONG MEIZHI COMPRESSOR +1

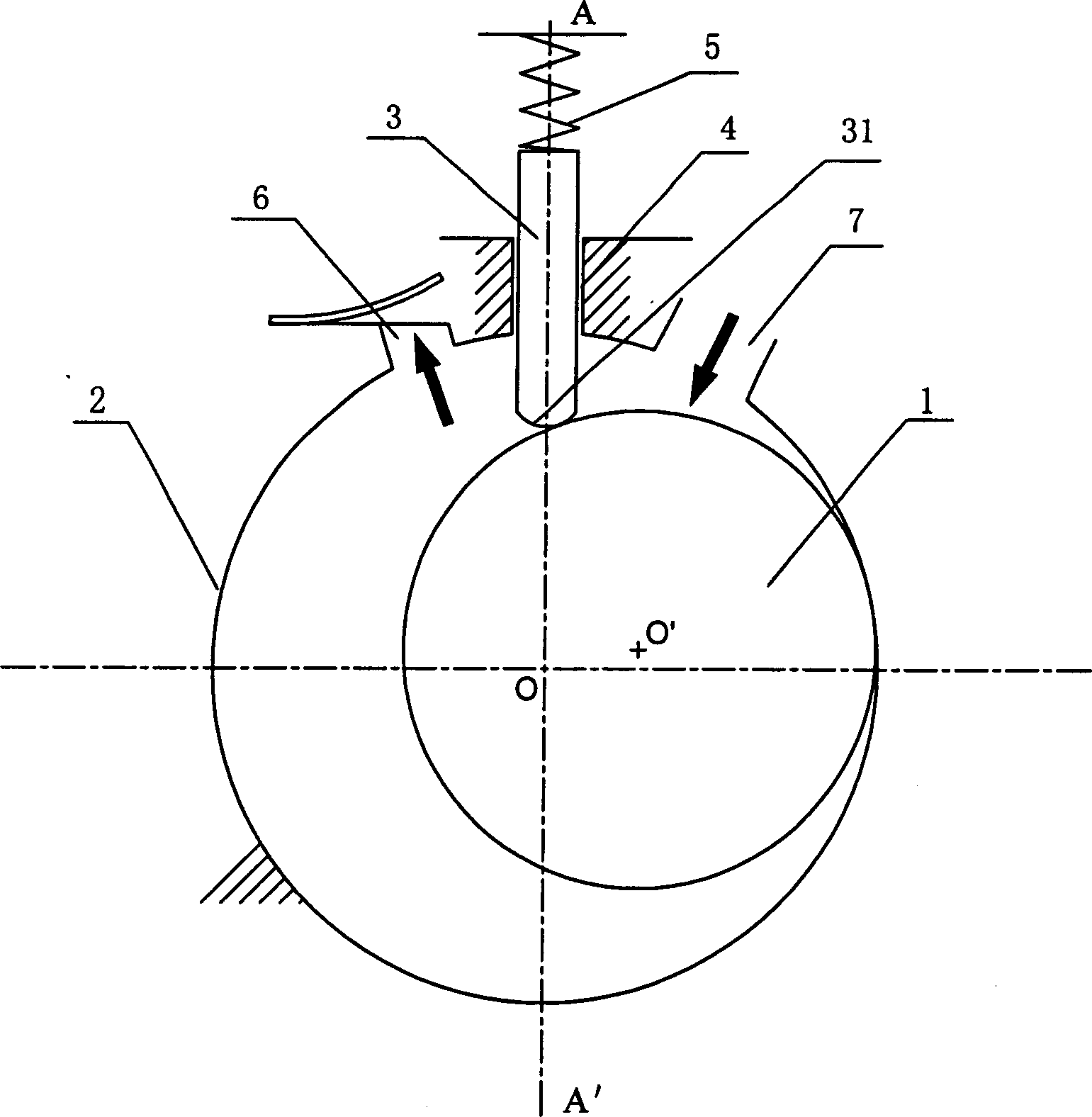

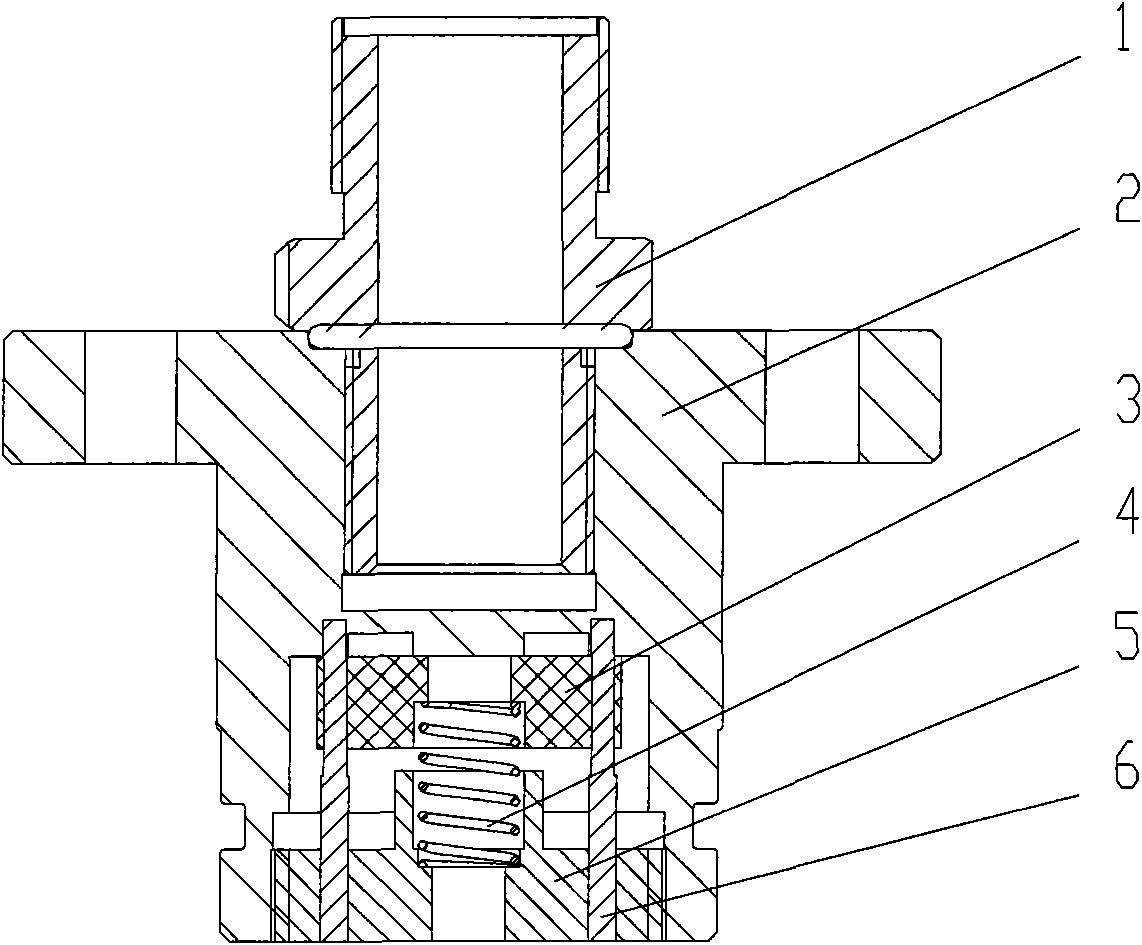

Exhaust device of rotary compressor

ActiveCN101644266AReduced clearance volumeImprove efficiencyRotary/oscillating piston pump componentsLiquid fuel engine componentsRefrigeration compressorEngineering

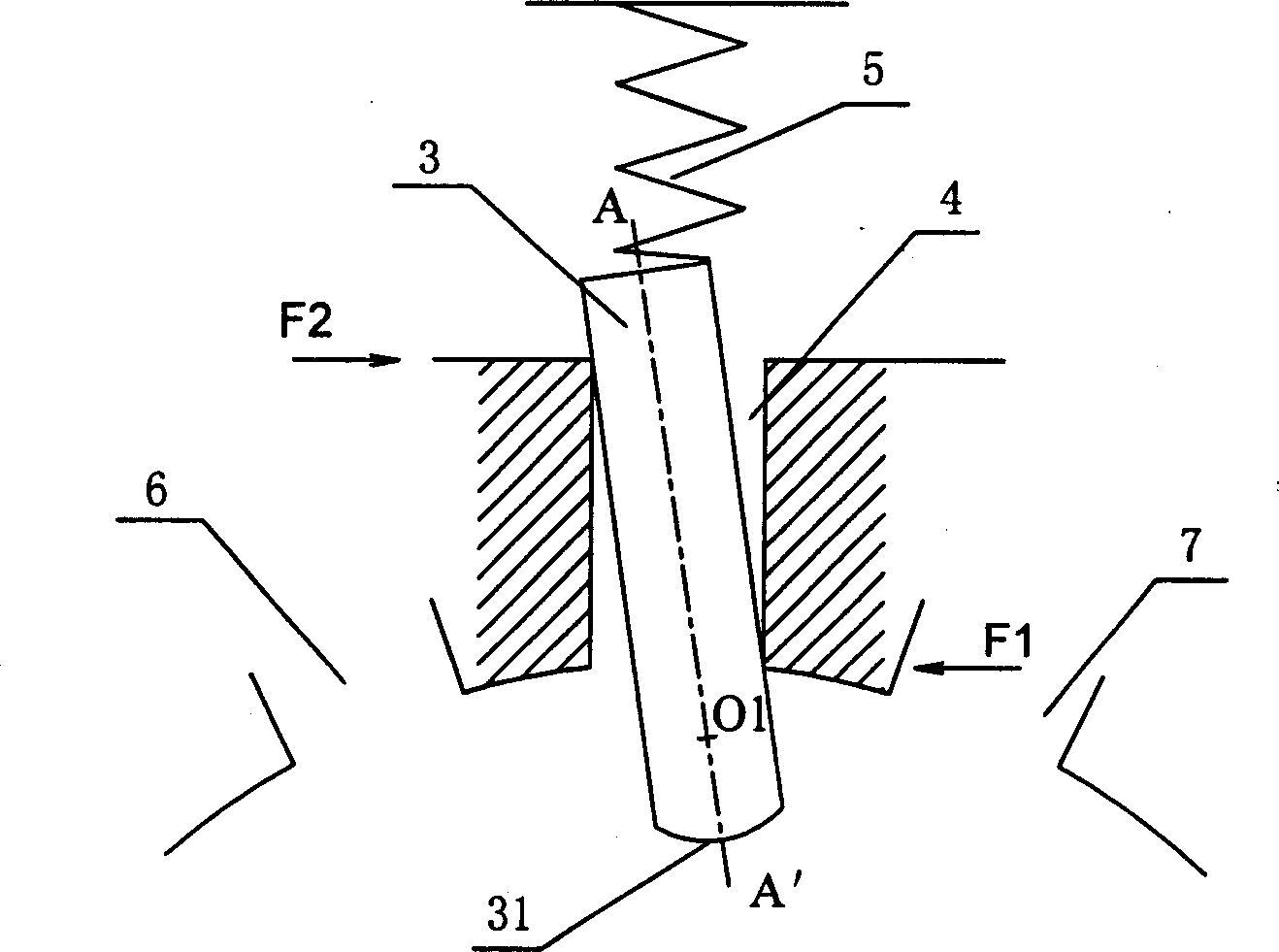

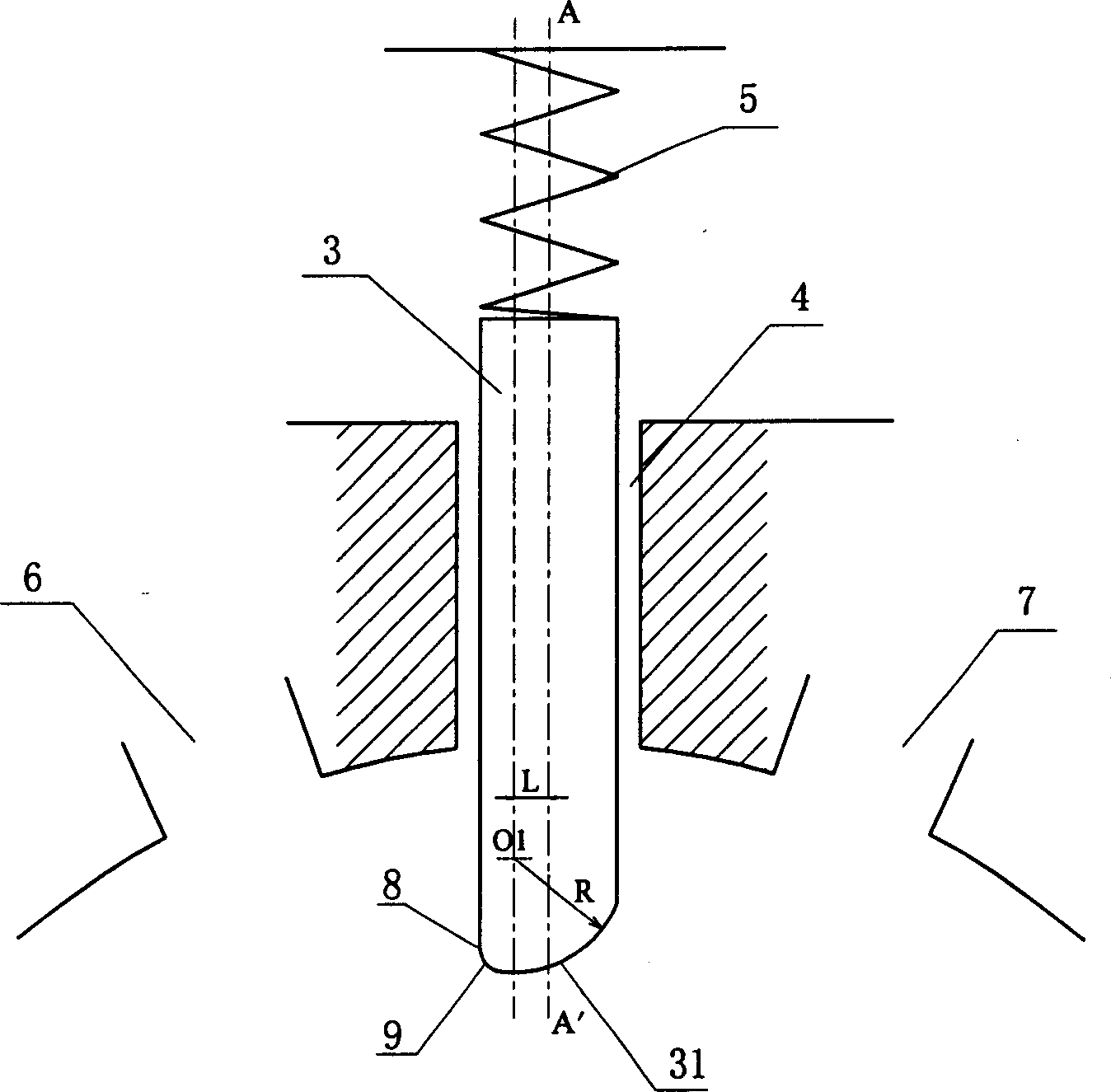

The invention relates to the technical field of refrigeration compressors, in particular to an exhaust device of a rotary compressor; in the exhaust device of the rotary compressor, a piston channel is arranged on a wall of an air cylinder, the bottom part of the air cylinder is provided with an exhaust port communicated with an air cylinder cavity, the inner end of a piston is tightly close to and blocks the exhaust port under the action of spring thrust; when the compressor exhausts air in the working process, the piston slides outwards in a piston channel, so as to remove blocking to the exhaust port, at the moment, high-pressure air in the air cylinder cavity is exhausted outside a compressing cavity through the exhaust port and an exhaust pipeline; the exhaust device in the inventioncan reduce clearance volume of the compressor in the exhaust process, and the efficiency of the compressor is improved; the mechanical noise generated by repeat beating is avoided when the traditionalcompressor is exhausted; in addition, a plurality of exhaust devices are arranged on the air cylinder wall according to needs, so as to bear the exhaust pressure respectively, reduce the exhaust resistance and reduce energy loss.

Owner:GREE ELECTRIC APPLIANCES INC +1

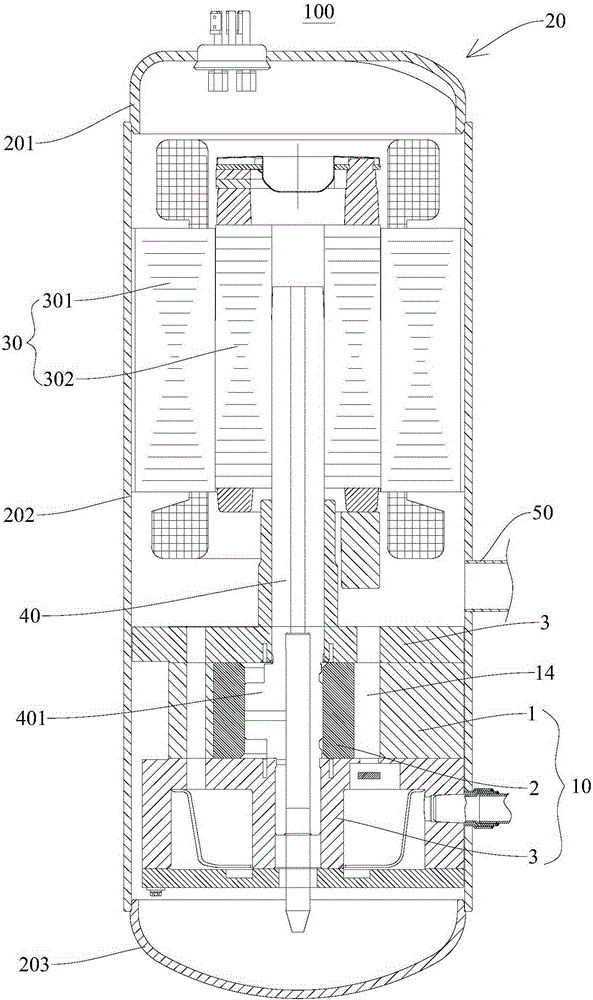

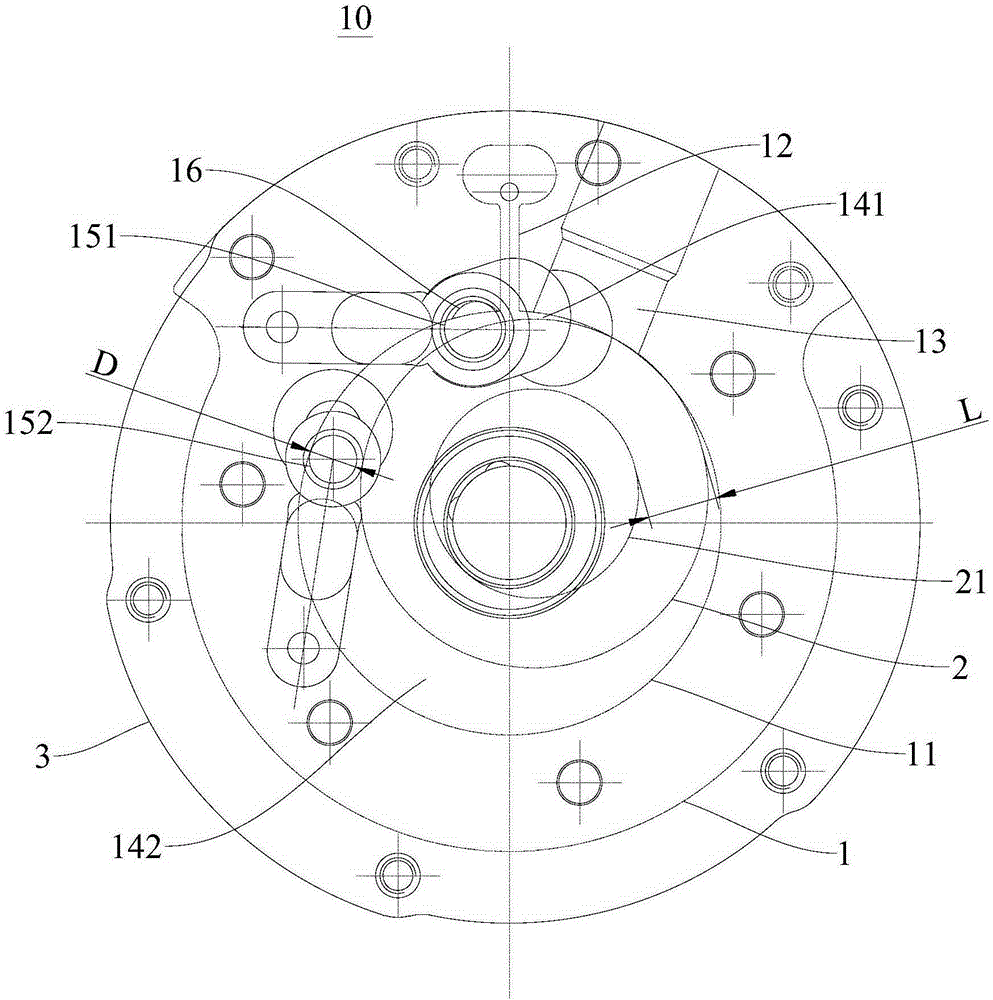

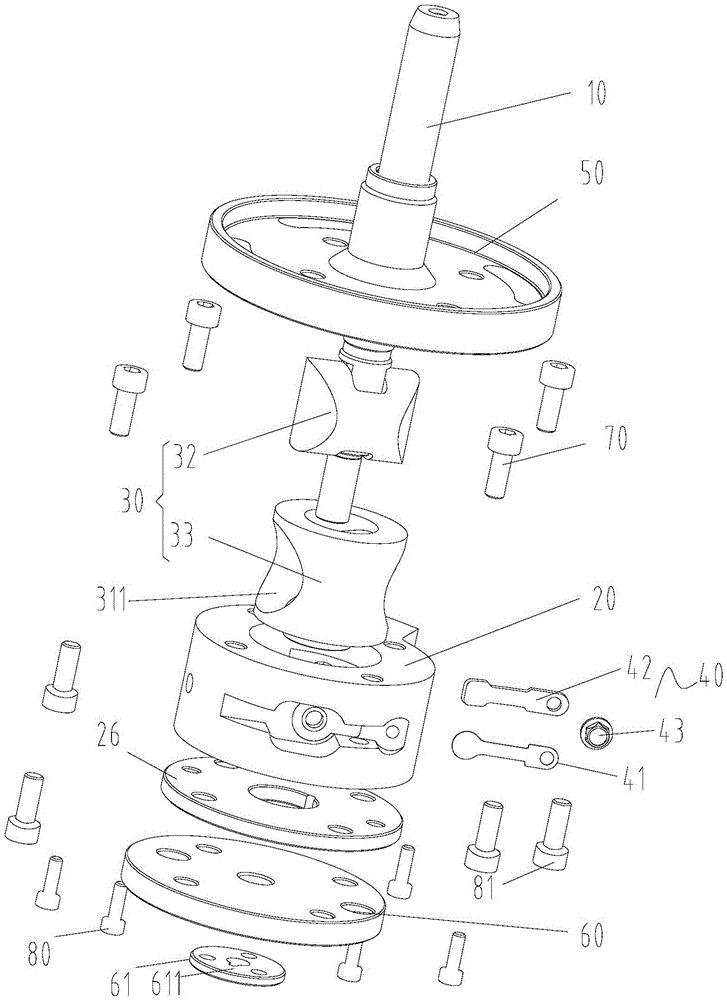

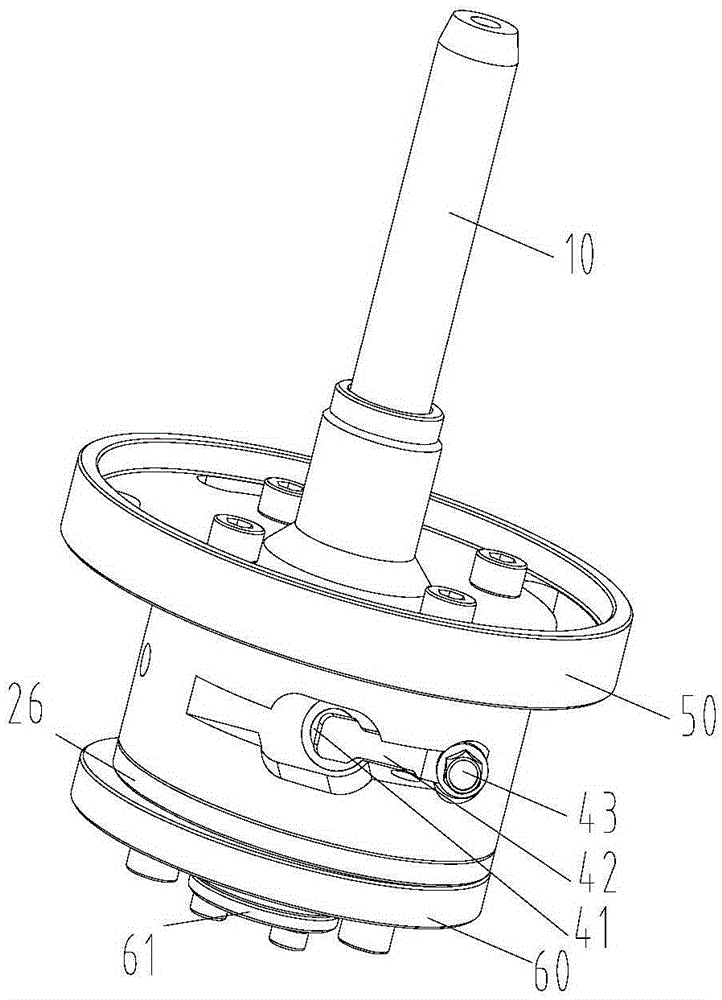

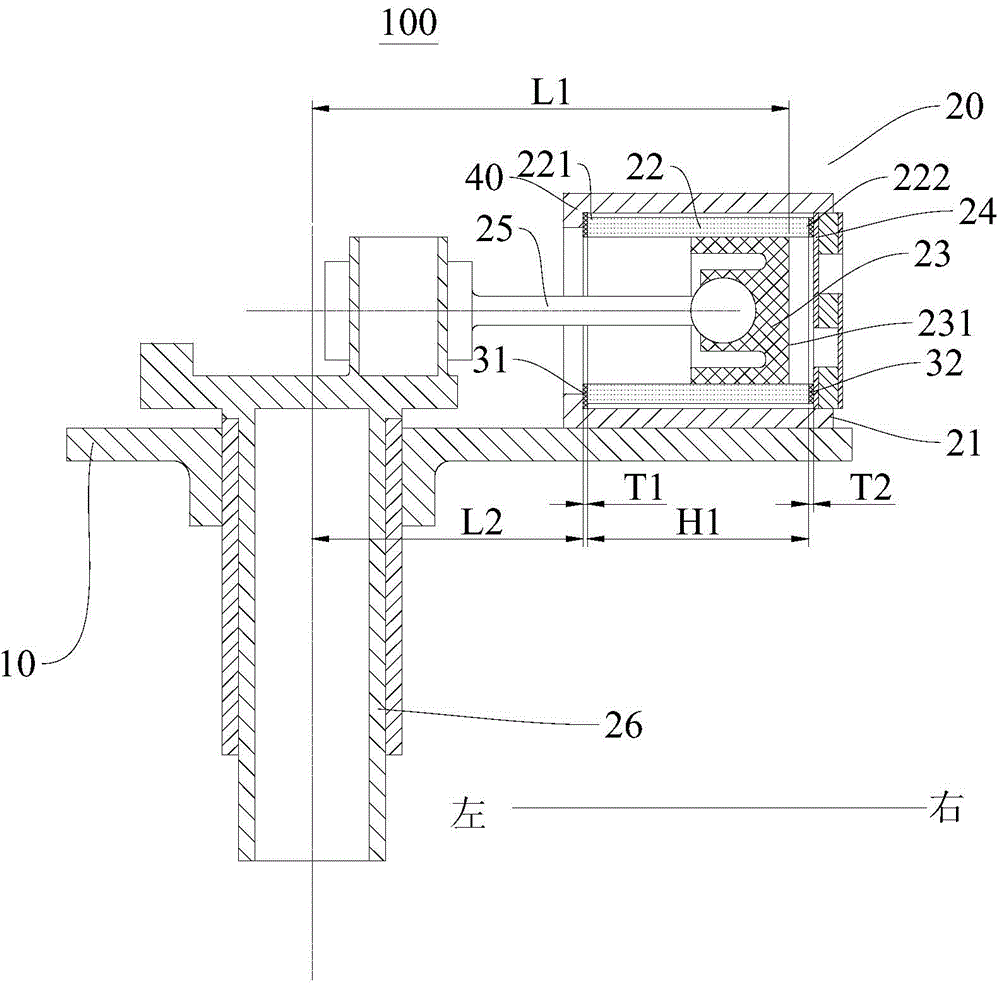

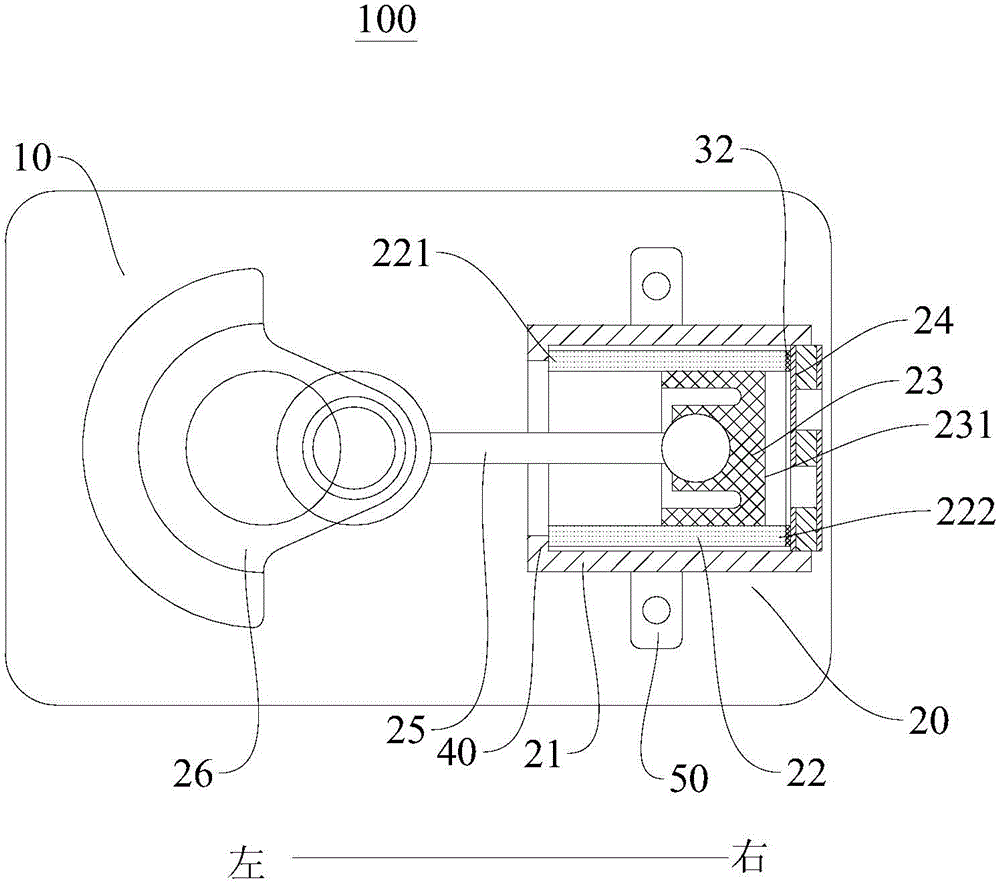

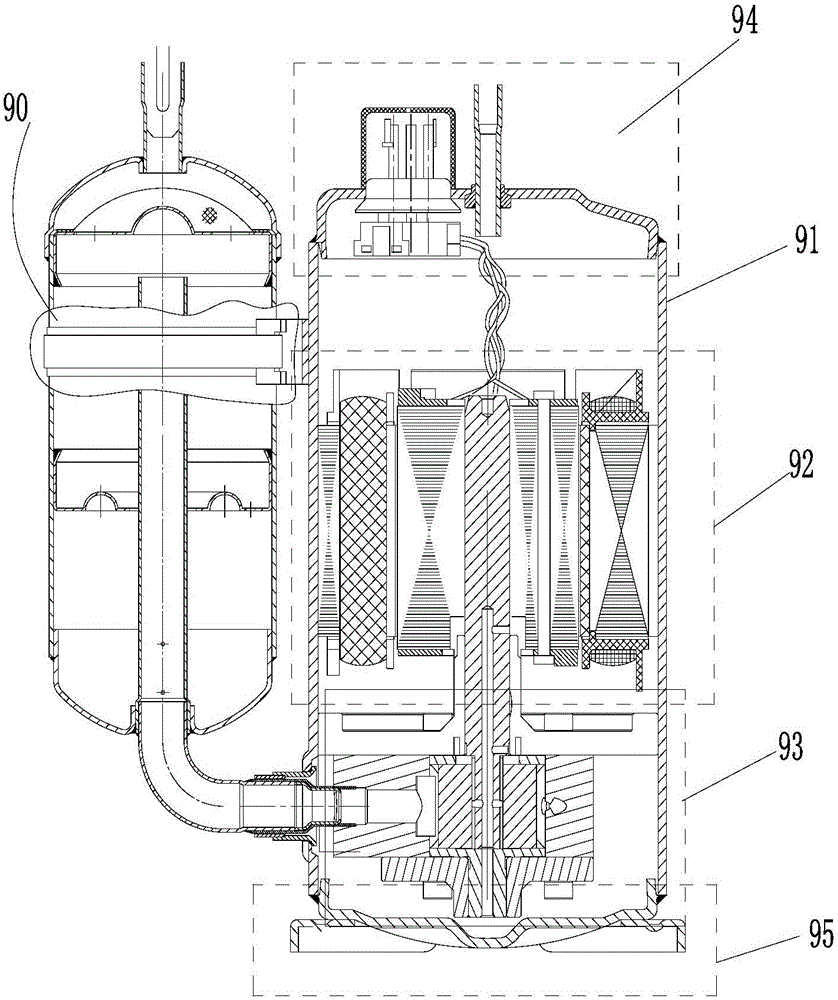

Fluid machine, heat exchange equipment and running method of fluid machine

ActiveCN106704182AStable and continuous volumeImprove running stabilityPositive displacement pump componentsRotary piston pumpsEngineeringPiston

The invention provides a fluid machine, heat exchange equipment and a running method of the fluid machine. The fluid machine comprises an upper flange, a lower flange, a cylinder arranged between the upper flange and the lower flange in a sandwiched manner, a rotating shaft and a piston assembly, wherein the axis of the rotating shaft and the axis of the cylinder are eccentrically arranged and the eccentric distance is fixed, and the rotating shaft sequentially penetrates the upper flange, the cylinder and the lower flange; and the piston assembly has a variable-volume cavity and is arranged in the cylinder in a pivotal manner, and the rotating shaft is connected with the piston assembly in a driving manner to change to the volume of the variable-volume cavity. Because the eccentric distance between the rotating shaft and the cylinder is fixed, the rotating shaft and the cylinder rotate around the axis of the rotating shaft and the axis of the cylinder correspondingly, the mass center position does not change, thus, when the piston assembly moves in the cylinder, the piston assembly can stably and continuously rotate, vibration of the fluid machine is effectively relieved, it is guaranteed that the volume change of the variable-volume cavity has a rule, the clearance volume is reduced, and therefore the running stability of the fluid machine is improved, and the working reliability of the heat exchange equipment is improved.

Owner:GREE ELECTRIC APPLIANCES INC

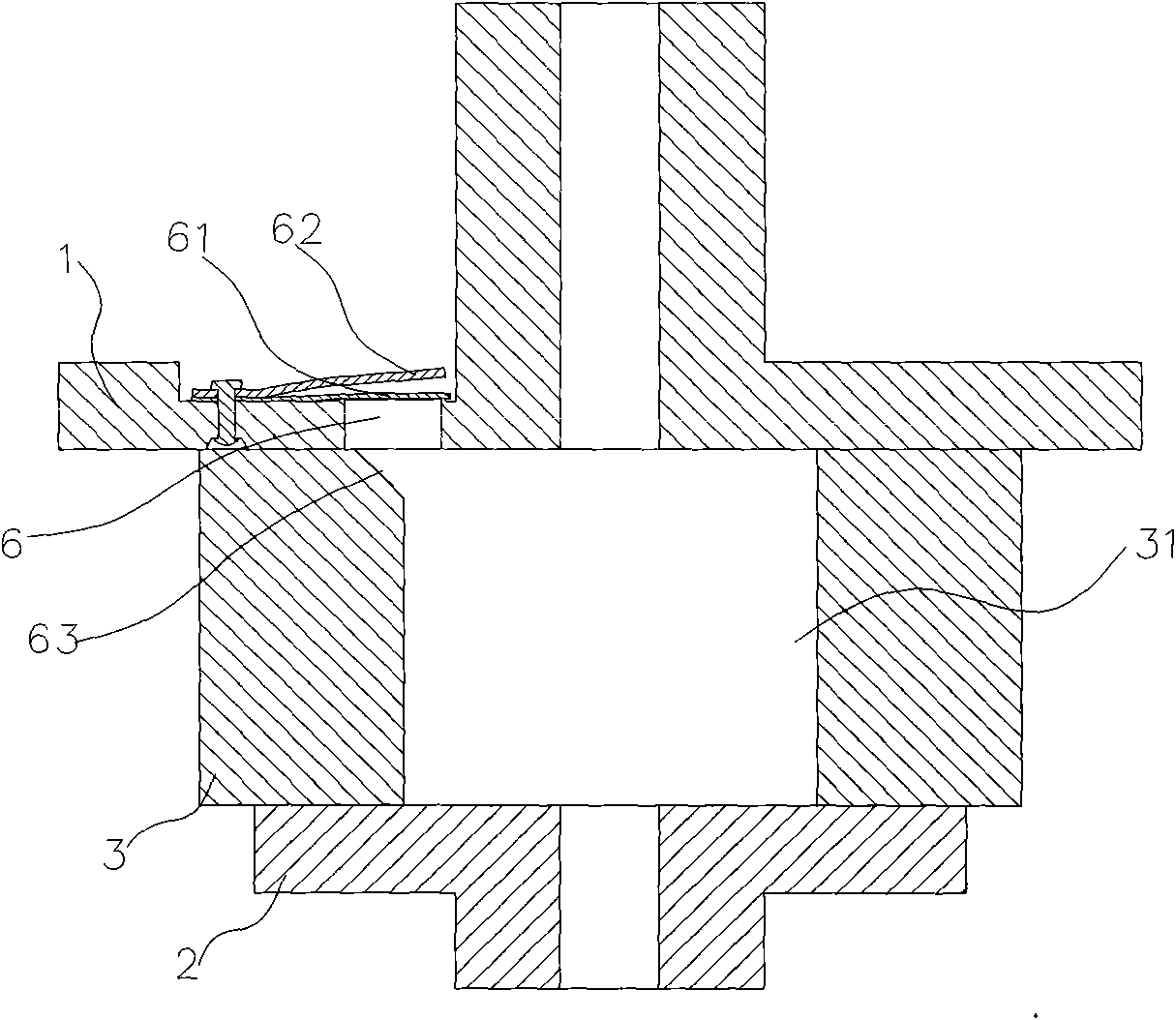

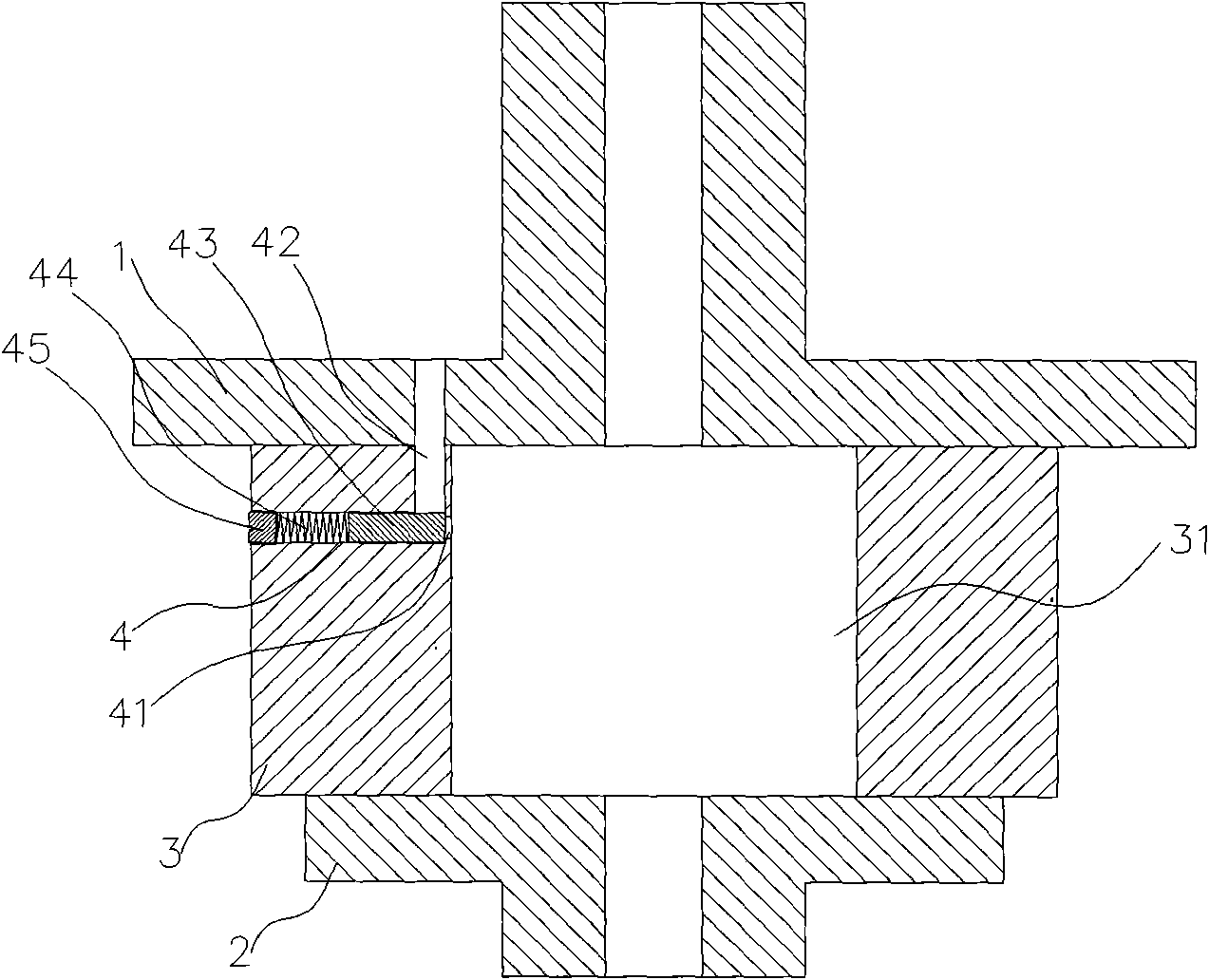

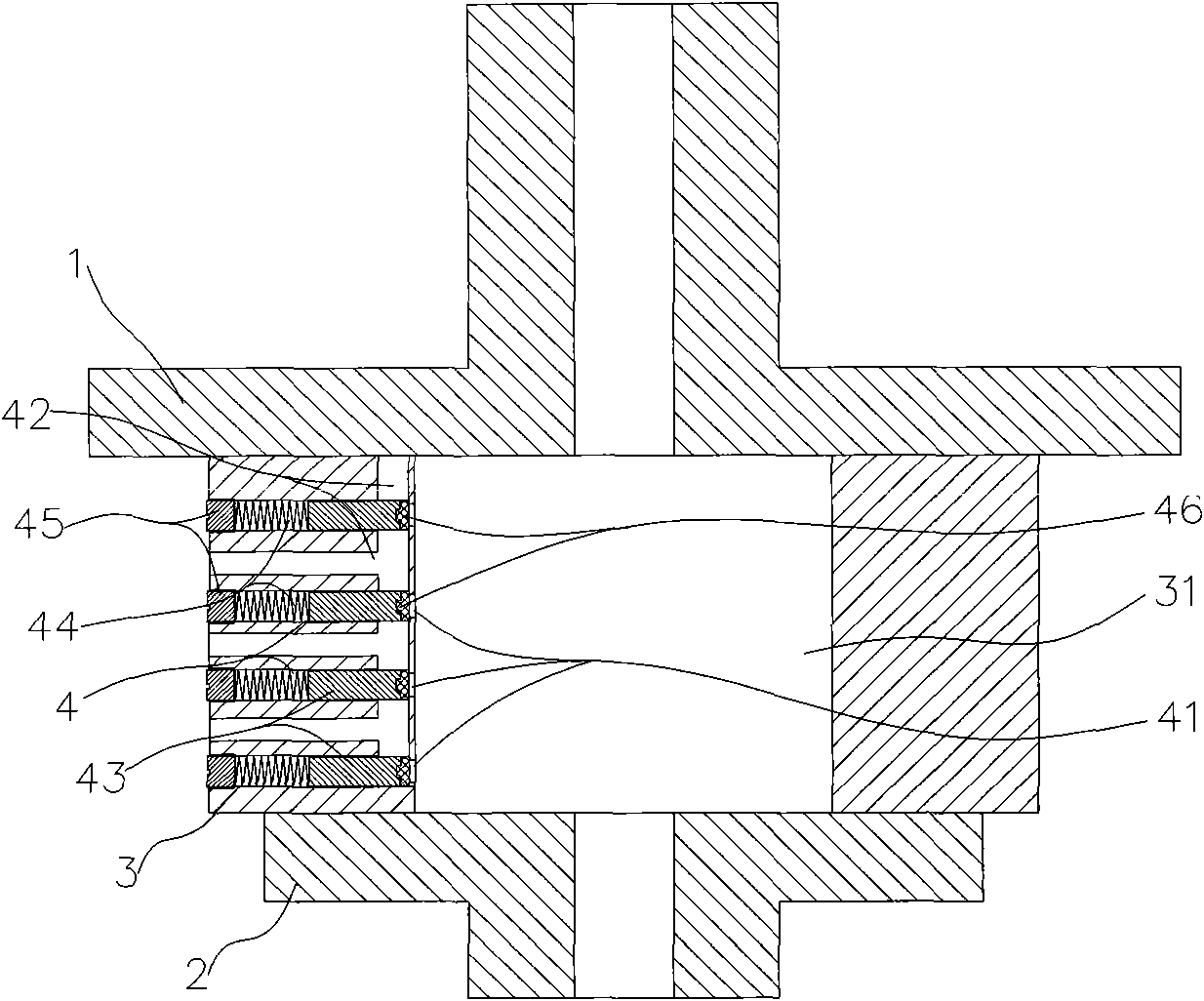

Reciprocating compressor

ActiveCN104963830AImprove convenienceImprove assembly efficiencyPositive displacement pump componentsPositive-displacement liquid enginesEngineeringMechanical engineering

The invention discloses a reciprocating compressor. The reciprocating compressor comprises a rack, a compressor pump body and an adjusting gasket. The compressor pump body comprises an air cylinder support, an air cylinder, a piston, a valve block, a connecting rod and a crankshaft, wherein the piston is movably arranged in the air cylinder, the connecting rod is used for connecting the crankshaft and the piston, the valve block is arranged at the end, far away from the crankshaft, of the air cylinder and is right opposite to the end face of the piston, the air cylinder support is arranged on the rack, the air cylinder support and the air cylinder are of a split structure, and the air cylinder is assembled into the air cylinder support. The adjusting gasket is arranged on the first end face and / or the second end face of the air cylinder to adjust the distance between the end face of the piston and the valve block, the first end face is the end face of the end, near to the crankshaft, of the air cylinder, and the second end face is the end face of the end, far away from the crankshaft, of the air cylinder. The reciprocating compressor is easy to assemble and high in efficiency.

Owner:ANHUI MEIZHI COMPRESSOR +1

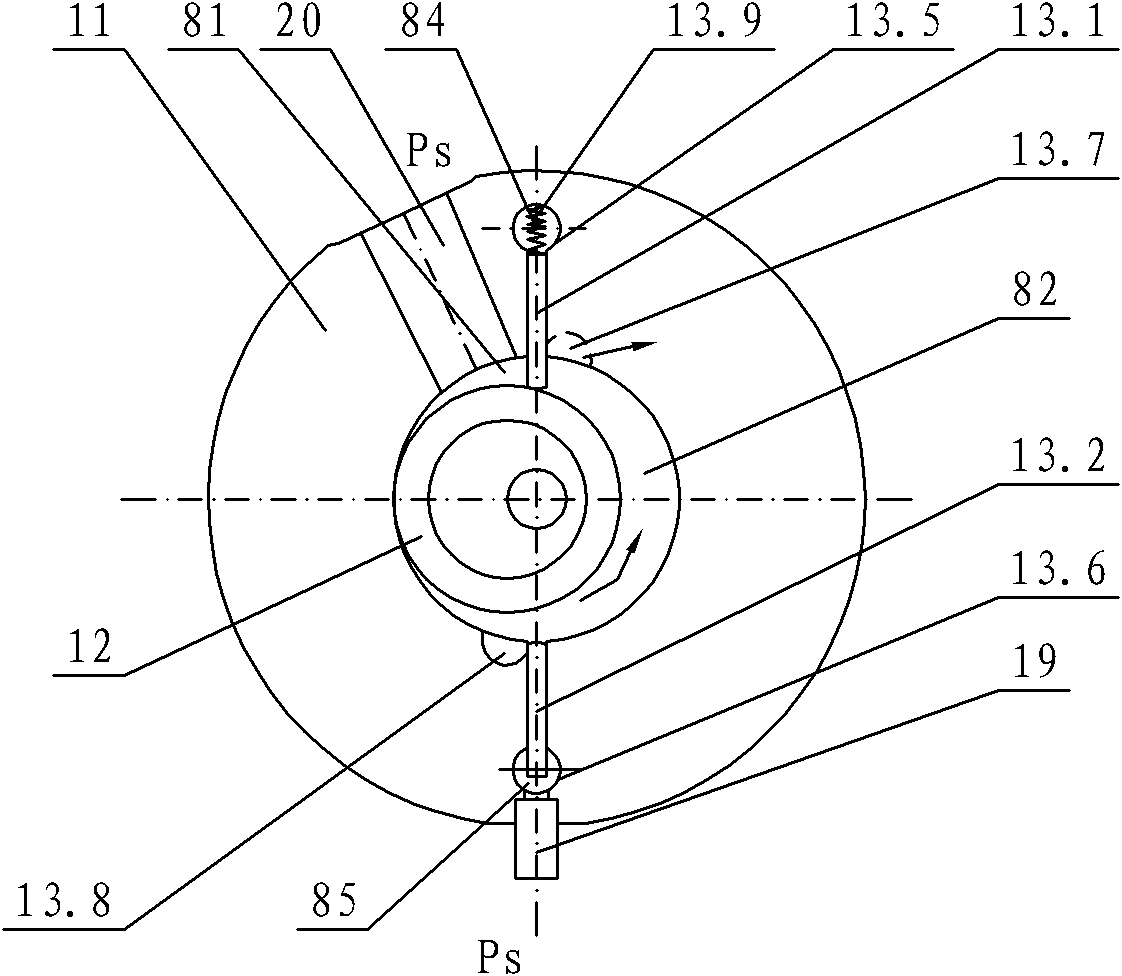

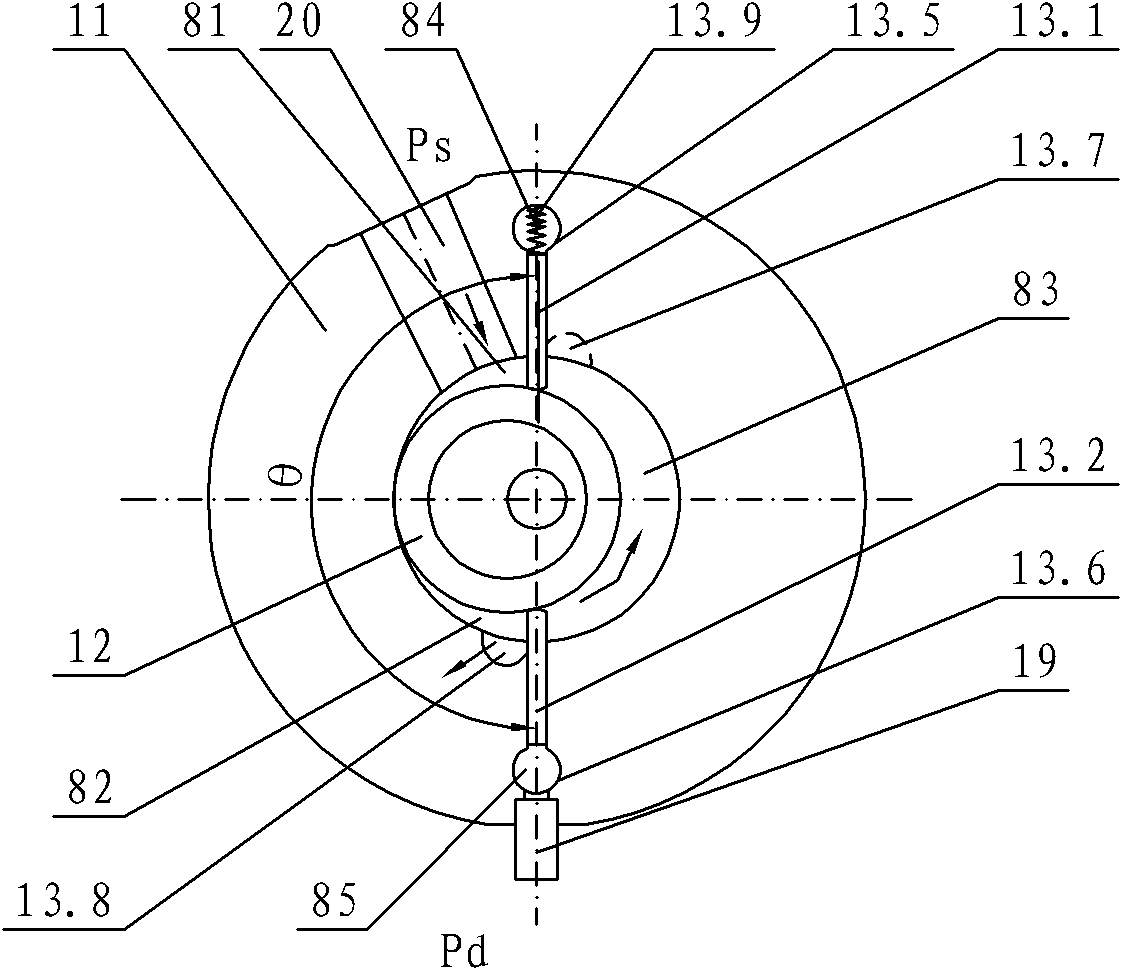

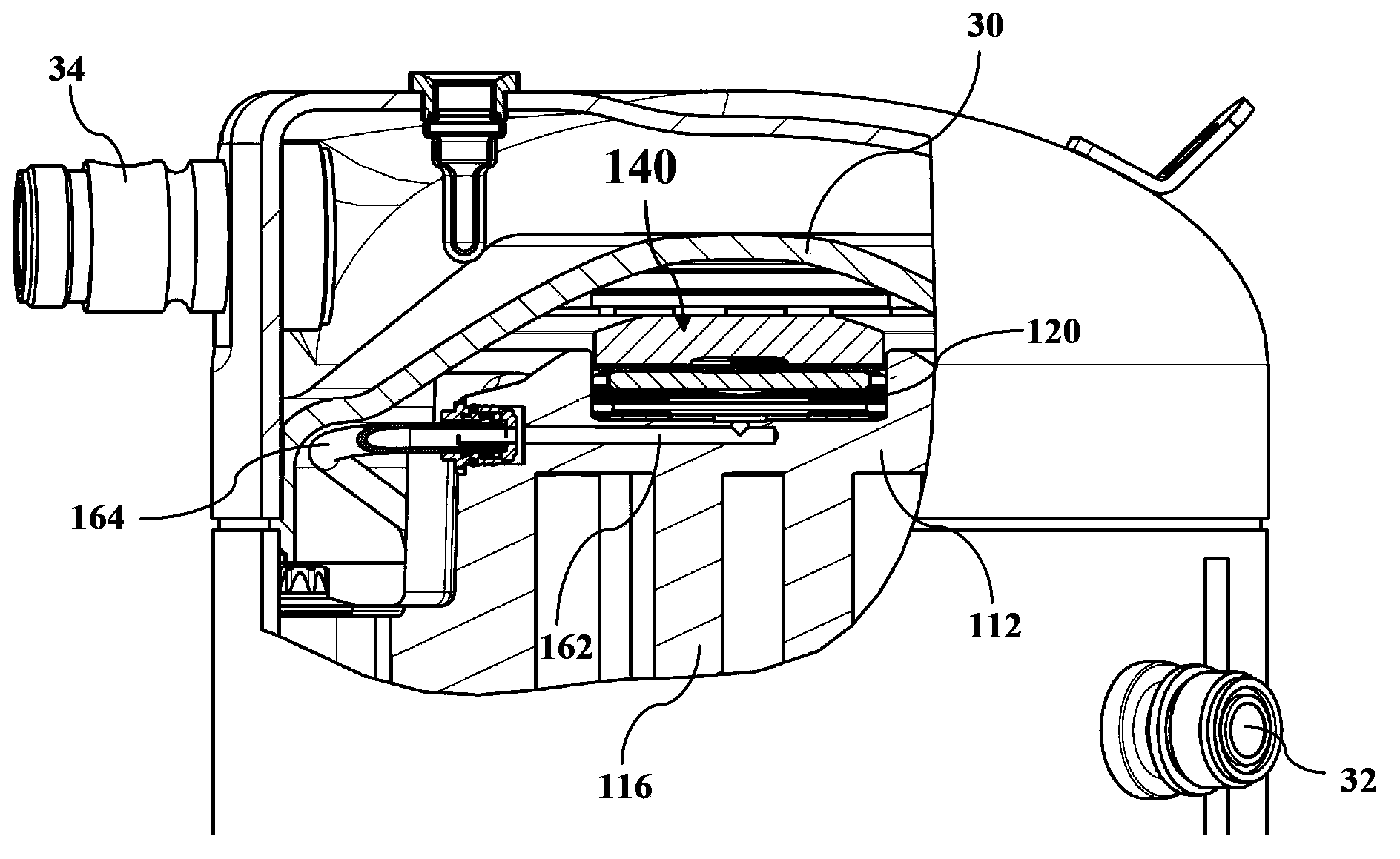

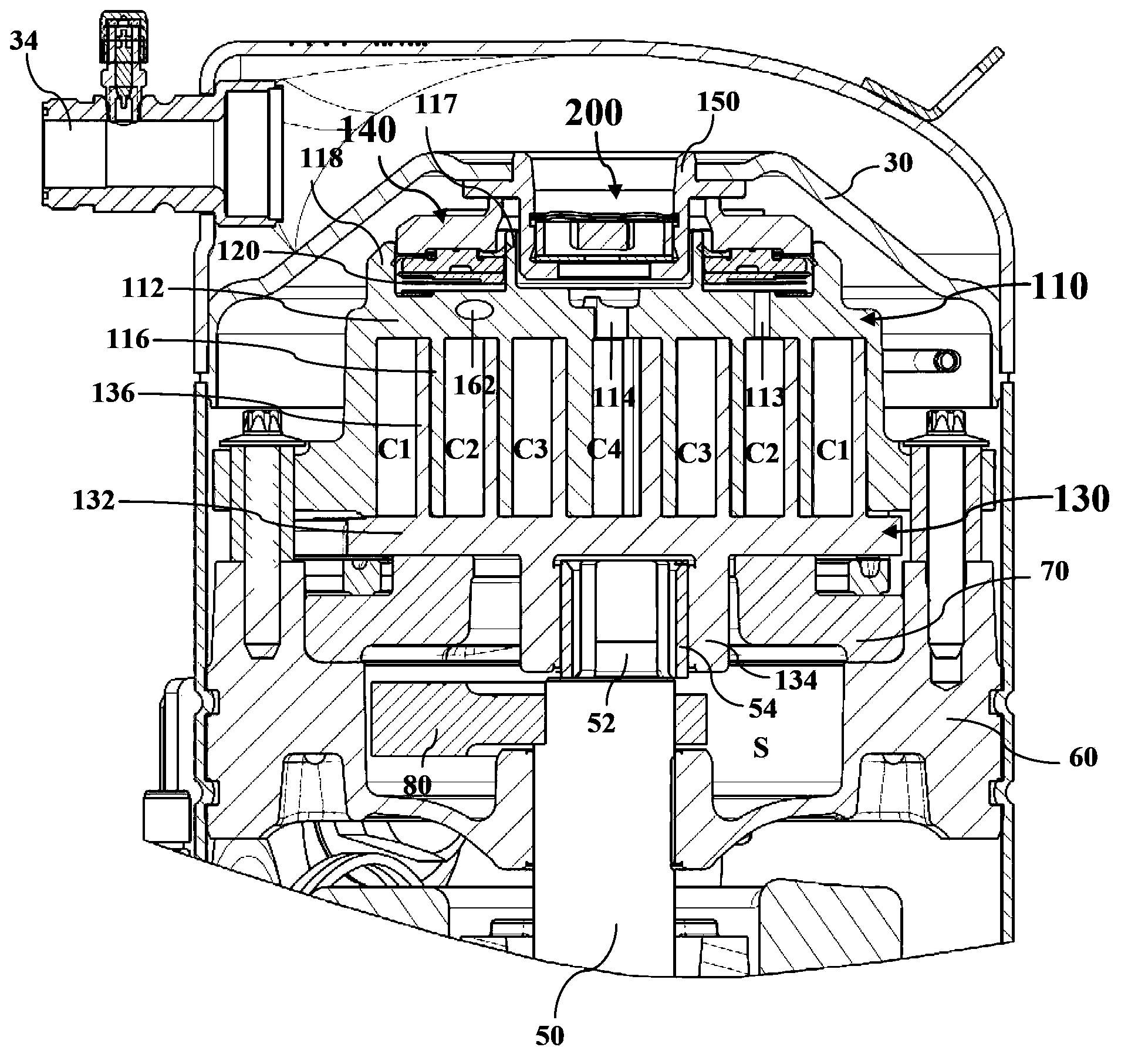

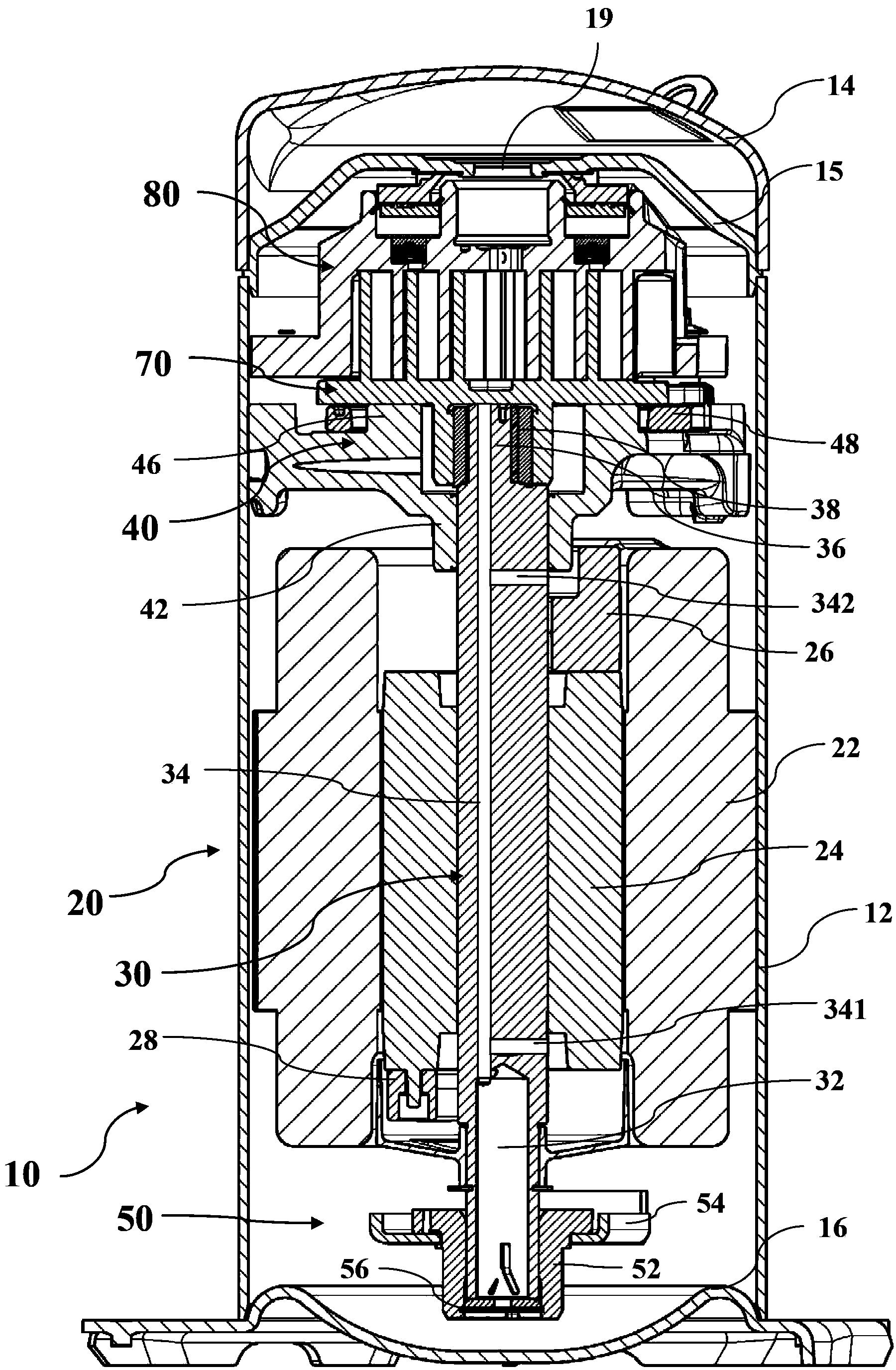

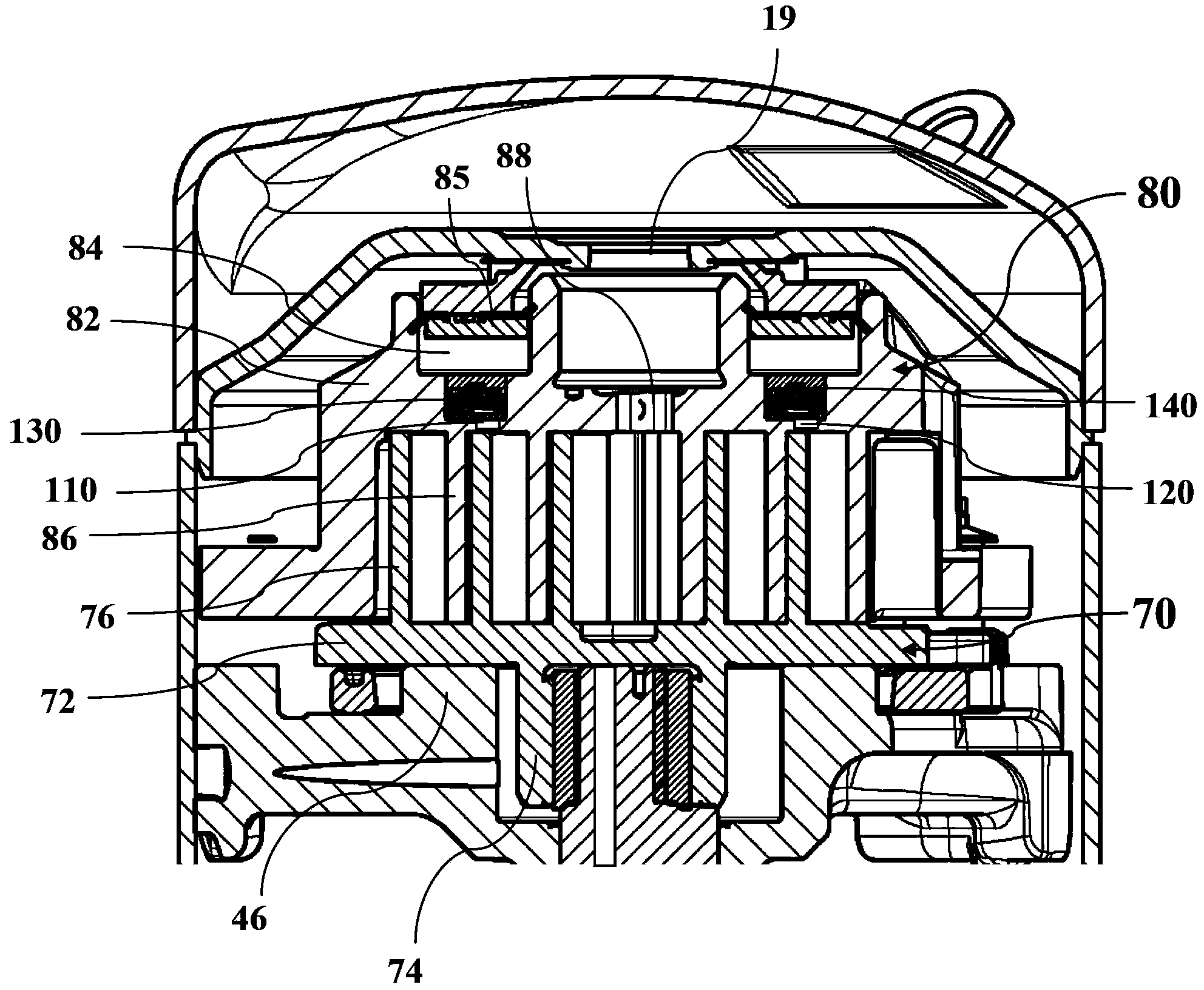

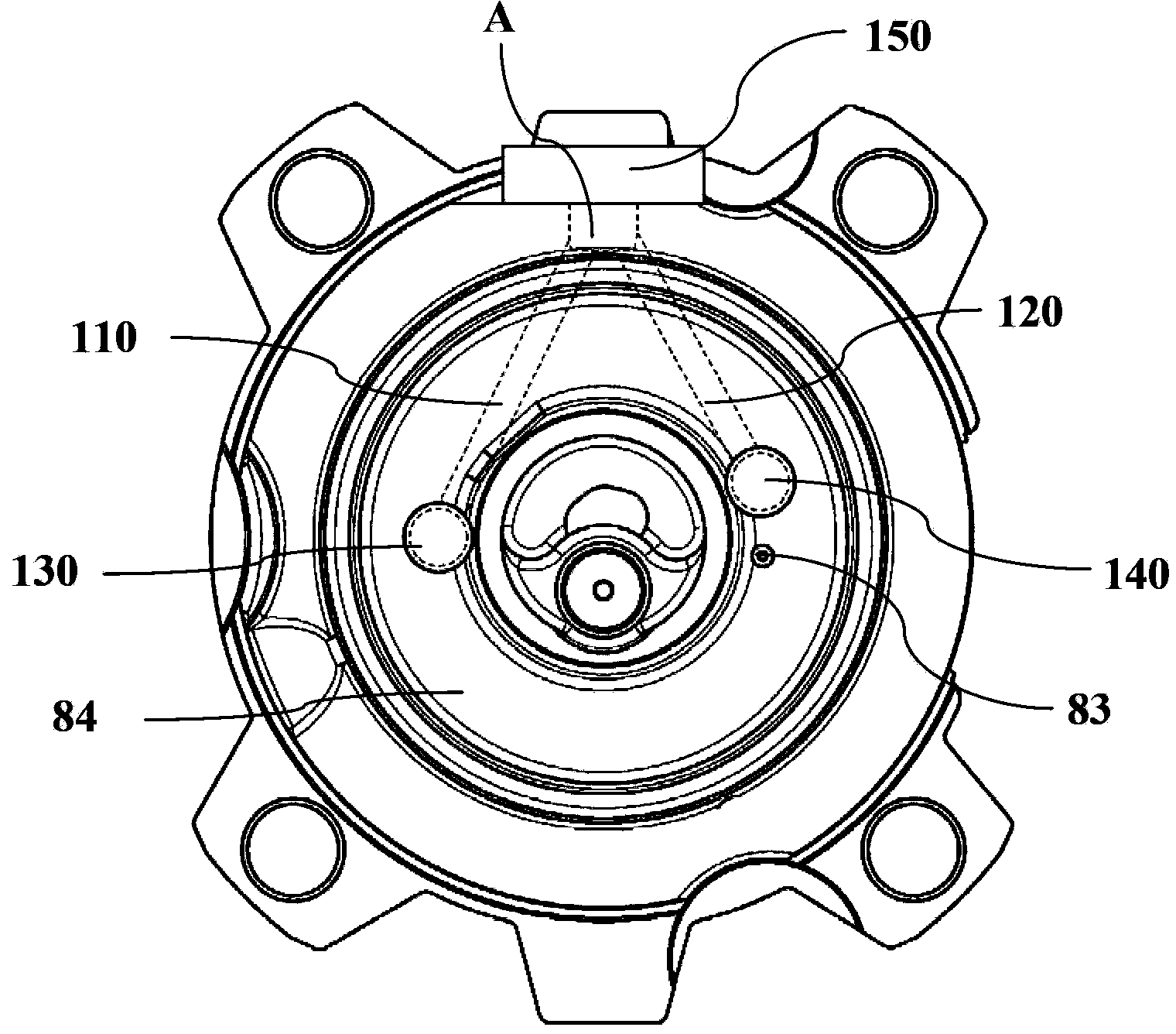

Compressor

ActiveCN103573619ASave design costSave manufacturing costRotary piston pumpsRotary piston liquid enginesControl valvesDischarge pressure

A disclosed compressor (10) comprises: a shell (12) in which an inspiratory pressure zone and an exhaust pressure zone are defined, and a compression mechanism arranged in the shell; and the compression mechanism comprises: a first vortex part (80) comprising a first end plate (82) and a first vortex blade (86), a second vortex part (70) comprising a second end plate (72) and a second vortex blade (76), a first communication channel (110) which is arranged between a first compression chamber (C1) and the inspiratory pressure zone and selectively provides fluid communication, and a first control valve (150). When the first control valve closes the first communication channel, the compressor works with full capacity, and when the first valve opens the first communication channel, the compressor works with reduced capacity. The compressor provided by the invention helps to realize capacity adjusting of compressors by employing a relatively simple manner.

Owner:EMERSON CLIMATE TECH (SUZHOU) CO LTD

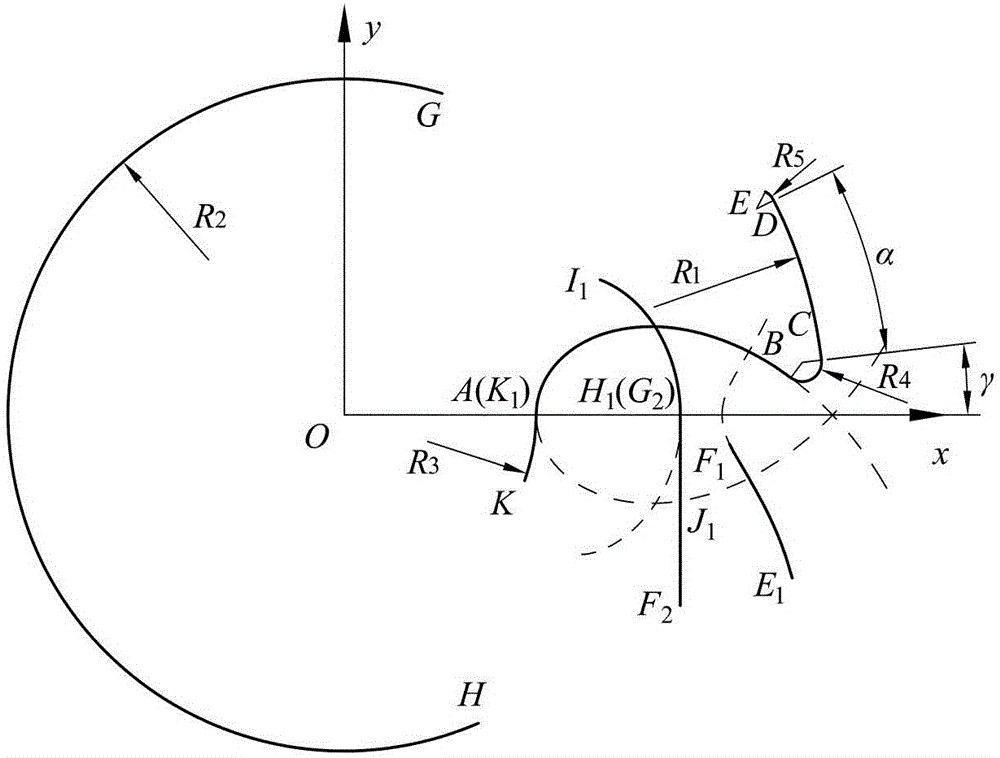

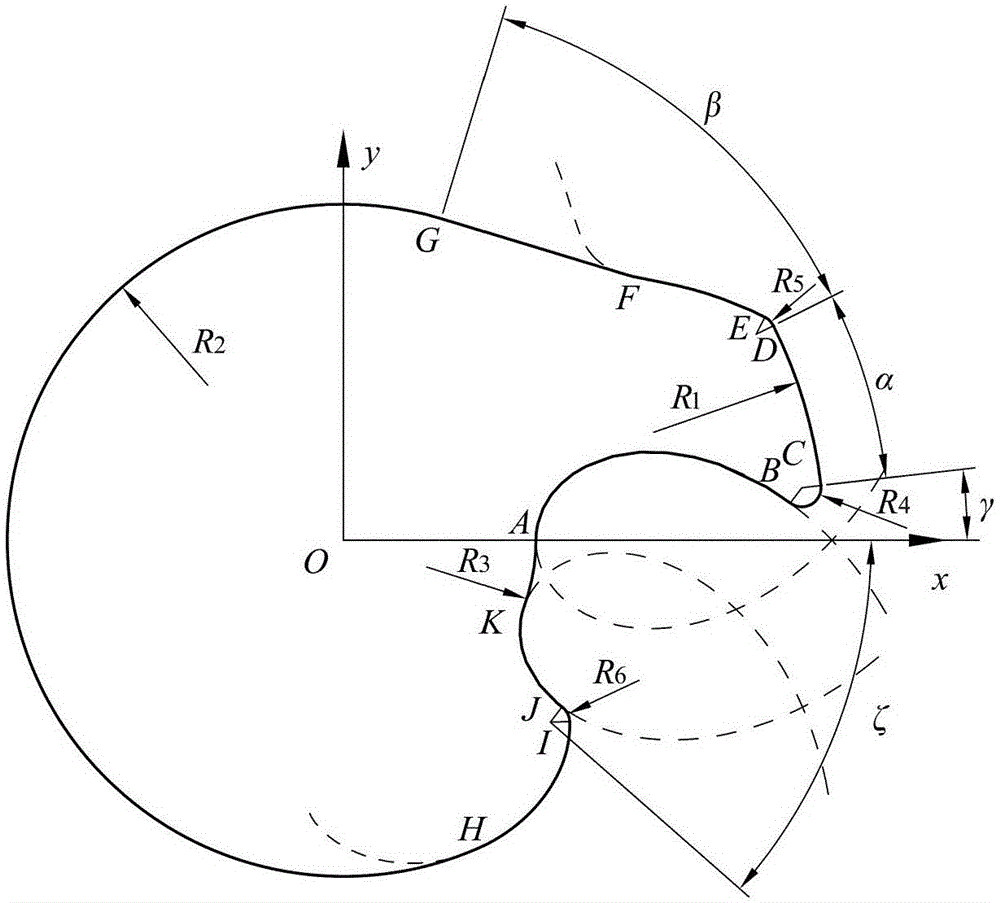

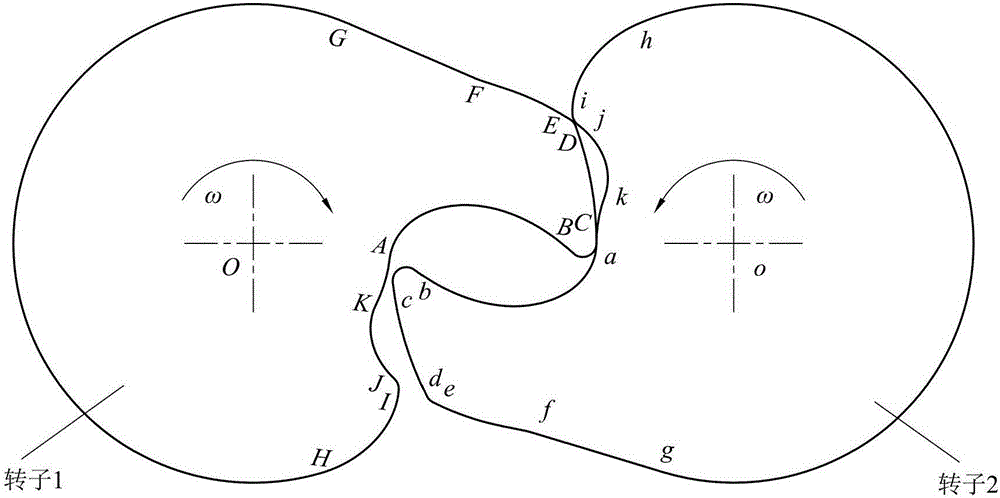

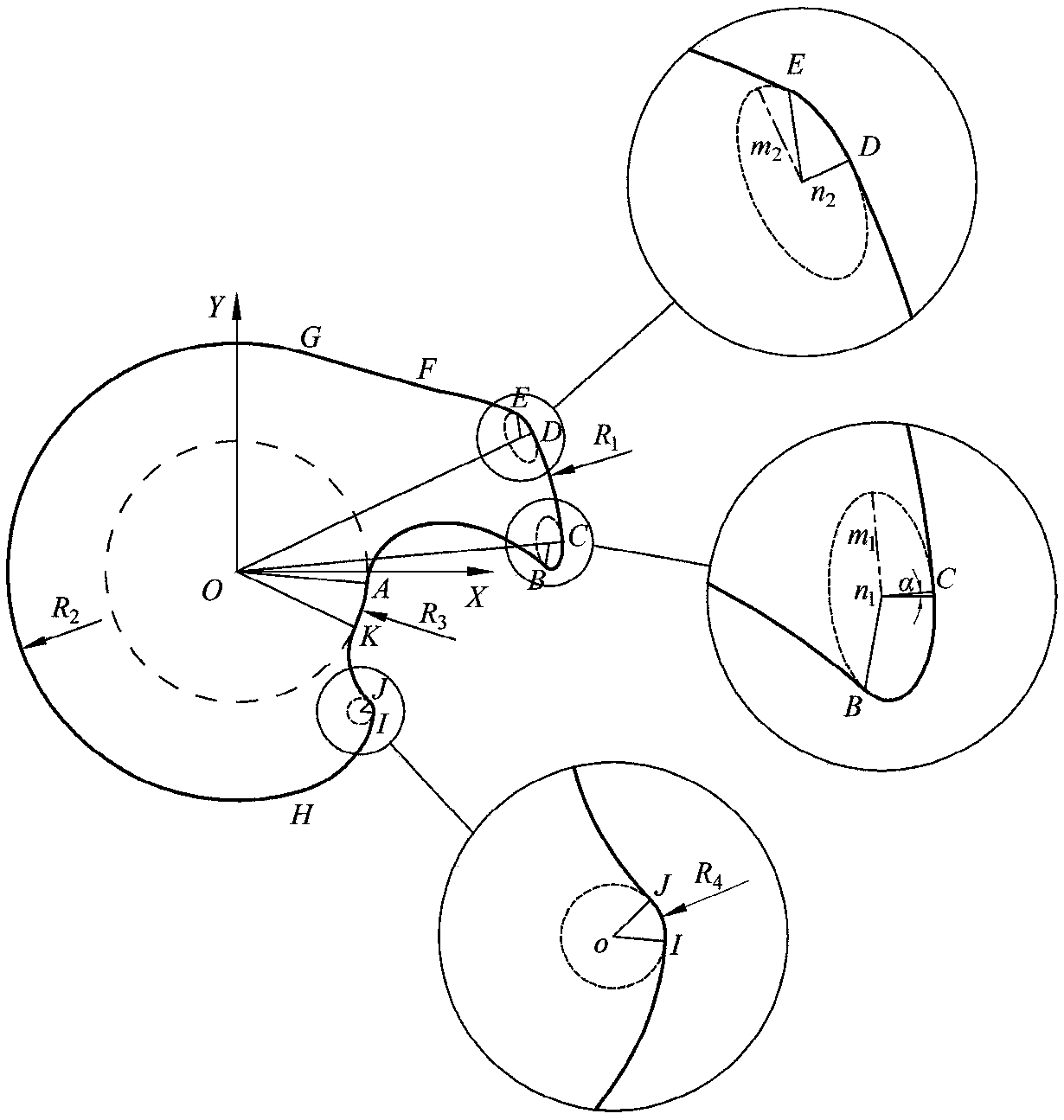

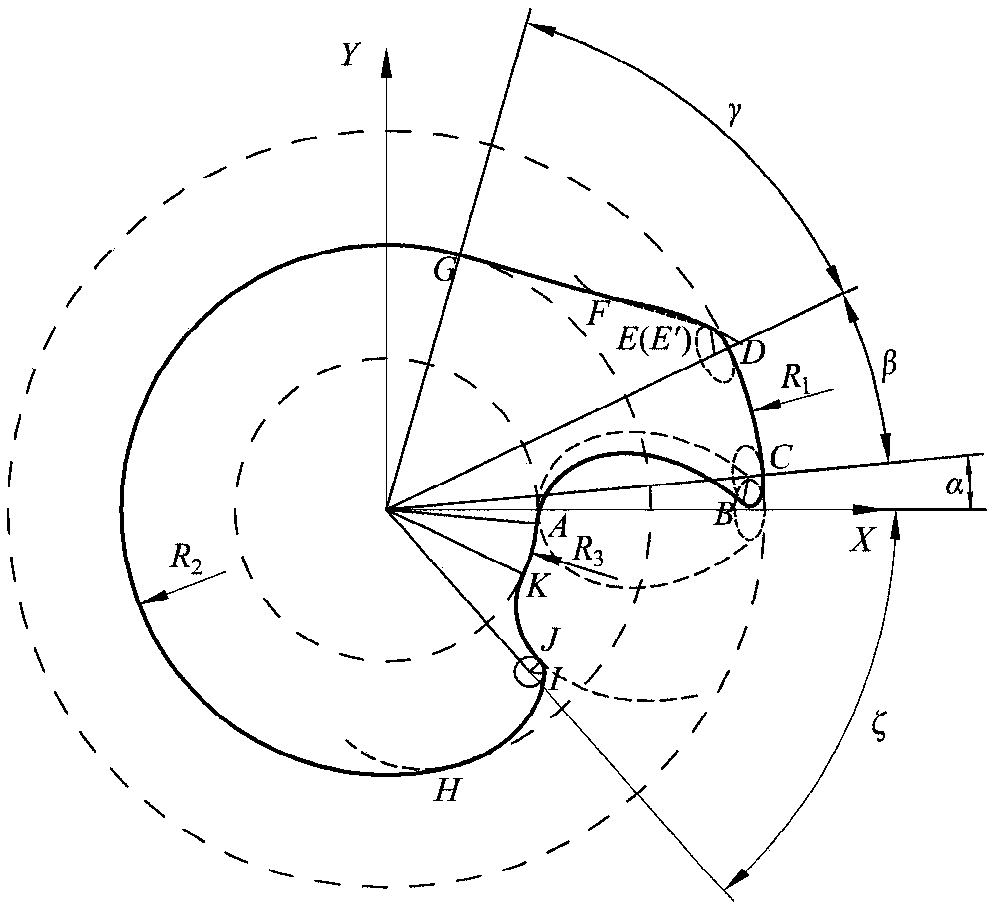

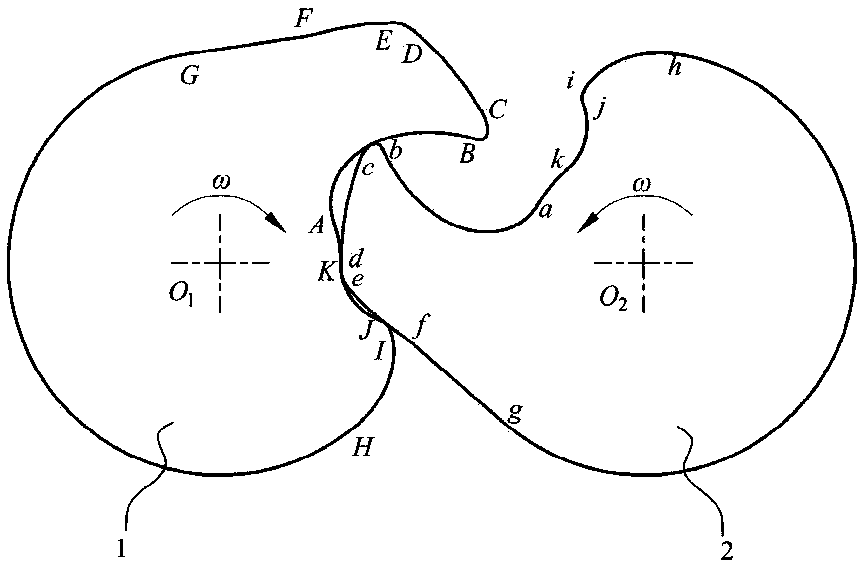

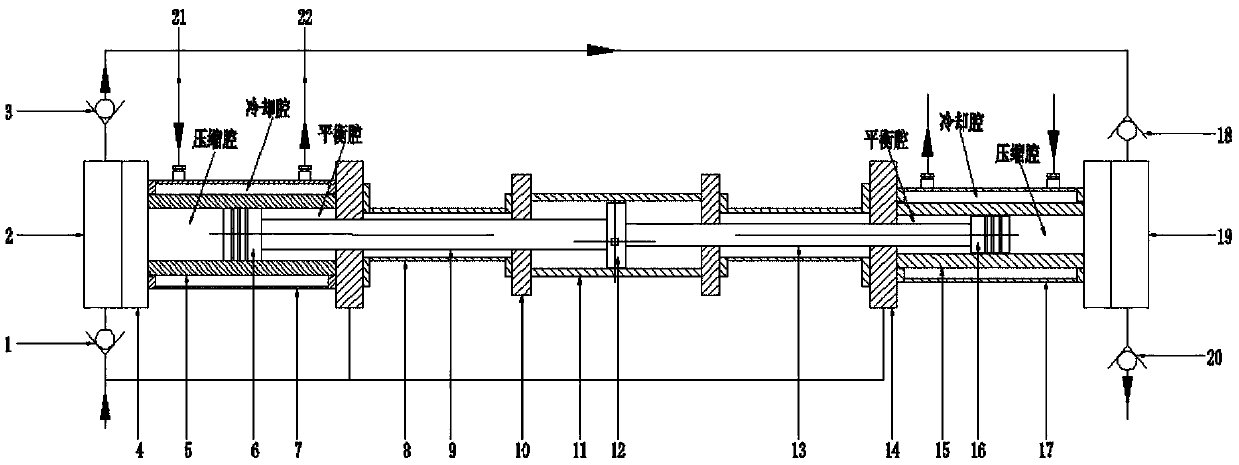

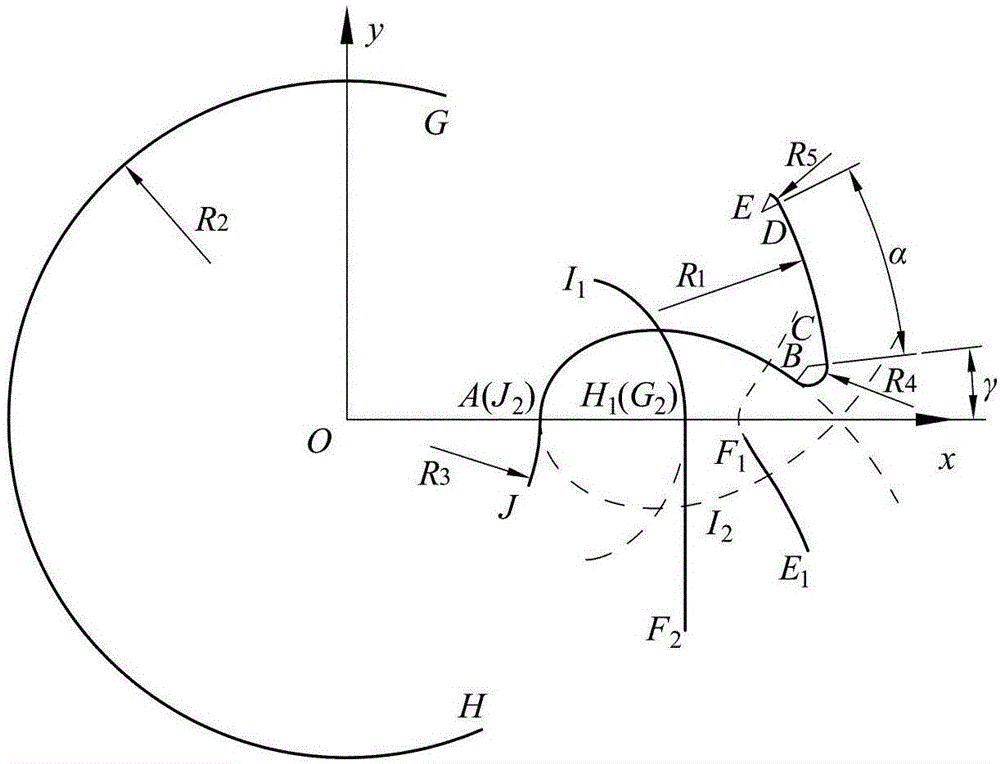

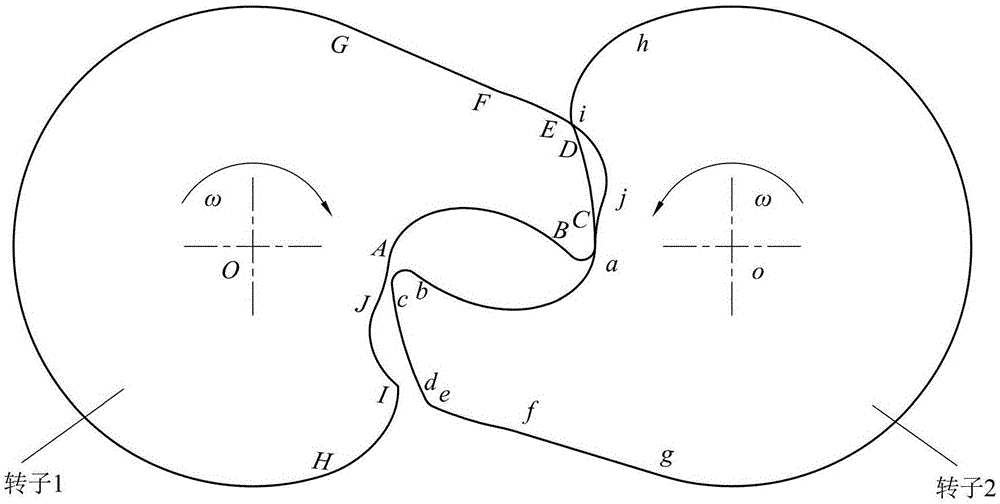

Full-smooth straight claw type rotor

ActiveCN106194728AAchieve full engagementPrevent leakageEngine of intermeshing engagement typeRotary piston pumpsLine segmentEngineering

The invention discloses a full-smooth straight claw type rotor. The full-smooth straight claw type rotor is composed of 11 curves including six circular arcs, equidistant curves of three cycloid curves, one line and an envelope curve of one line; from beginning of the pitch circle, the pitch circle circular arc GH, the envelope curve HI of the line, the third claw tip circular arc IJ, the equidistant curve JK of one cycloid curve, the claw bottom circular arc KA, the equidistant curve AB of another cycloid curve, the first claw tip circular arc BC, the claw top circular arc CD, the second claw tip circular arc DE, the equidistant curve EF of another cycloid curve and the line FG are sequentially connected in the anticlockwise direction; the adjacent curves are all in smooth connection, non-smooth tip points do not exist, two engaged claw type rotors are completely same, in the work process, complete correct engaging and smooth connection of lines of the claw type rotor can be achieved, the problem that claw back segment curves do not participate in engaging completely is solved, and work efficiency and work performance of claw type fluid machines are improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Variable volume clearance pocket for a reciprocating compressor cylinder

ActiveUS8430646B2Increase volumeReduced clearance volumePositive displacement pump componentsPump controlControl mannerMechanical engineering

A controllable variable volume clearance pocket for reciprocating compressor cylinders is disclosed. The invention includes a device for varying the clearance volume of a variable volume clearance pocket in a controlled manner. The device can be used repeatedly to change the compressor cylinder clearance volume as required to control compressor capacity and power required from the compressor driver. The device is typically mounted on the outer or head end of a reciprocating compressor cylinder, but can also be scaled and configured for use either in conjunction with a variable clearance volume unloader operating over a reciprocating compressor valve pocket or a special port in a reciprocating compressor body.

Owner:ACI SERVICES

Variable bore convertible compressor cylinder

InactiveUS20120107144A1Easy to removeMinimizing clearance volumePositive displacement pump componentsFlexible member pumpsEngineeringReciprocating compressor

A variable bore reciprocating compressor cylinder, with a family of removable liners of various diameters that can accommodate significant changes in bore diameters without significant increases in fixed clearance volume. In one embodiment of the invention, valves are added or subtracted as required in conjunction with optimizing the flow area of the liner and head ports to minimize clearance volume and to keep overall flow losses within acceptable values. In another embodiment of the invention, smaller valves and valve extension insert / adapters are incorporated to further extend the practical operating range with smaller bore diameters.

Owner:KEIFER ERIC G

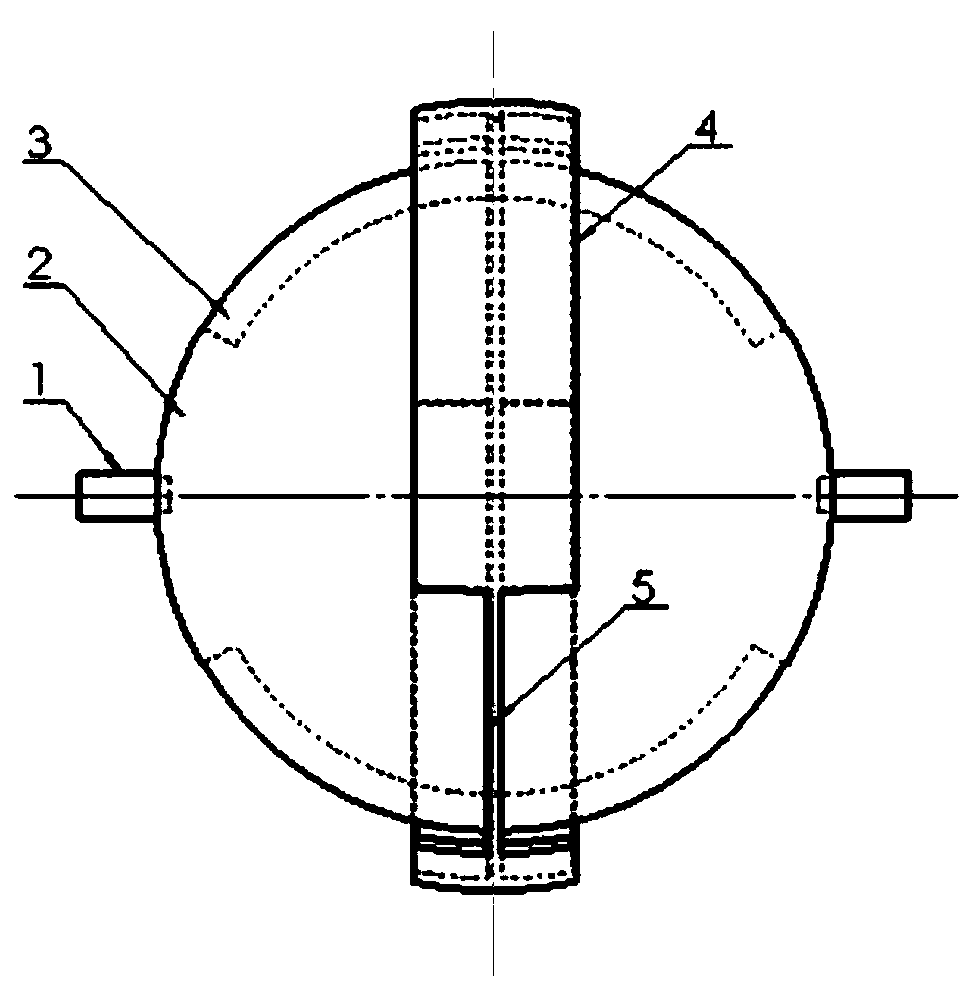

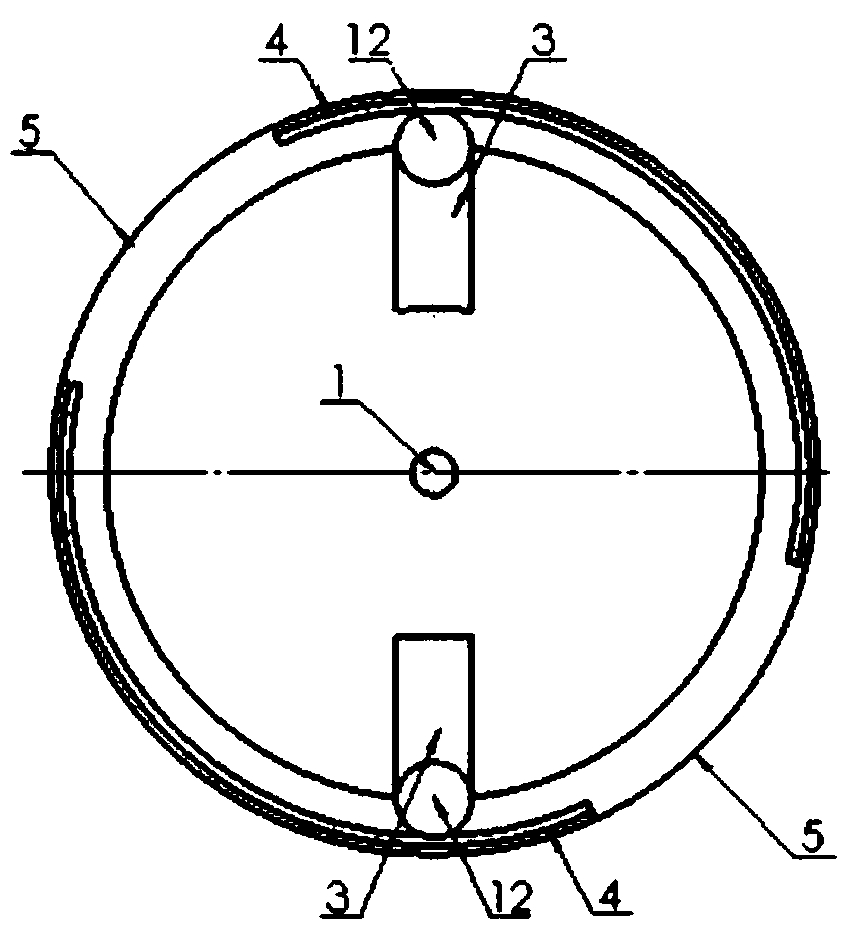

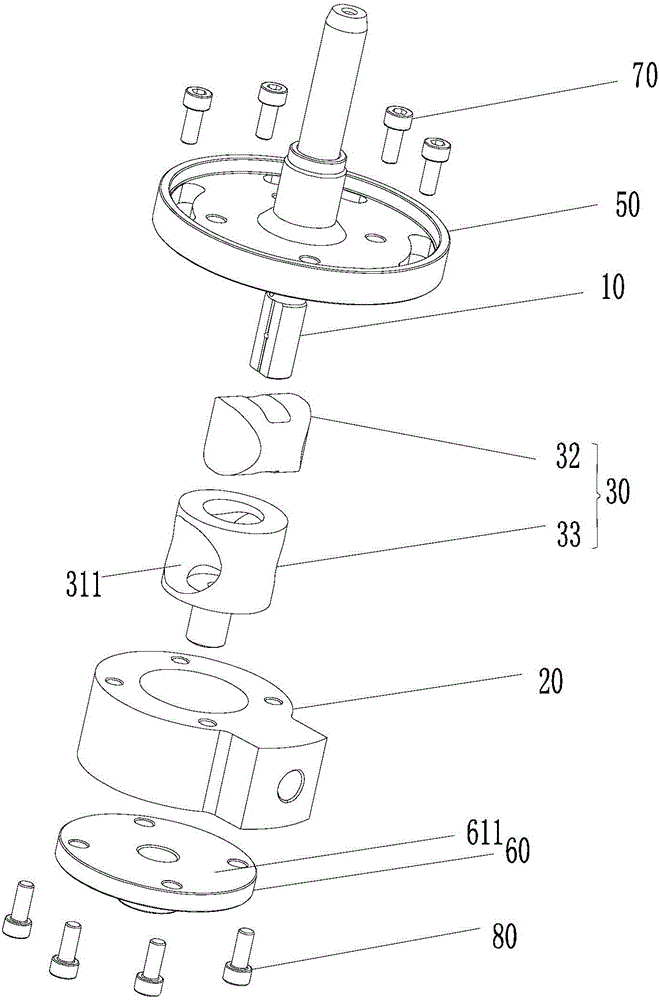

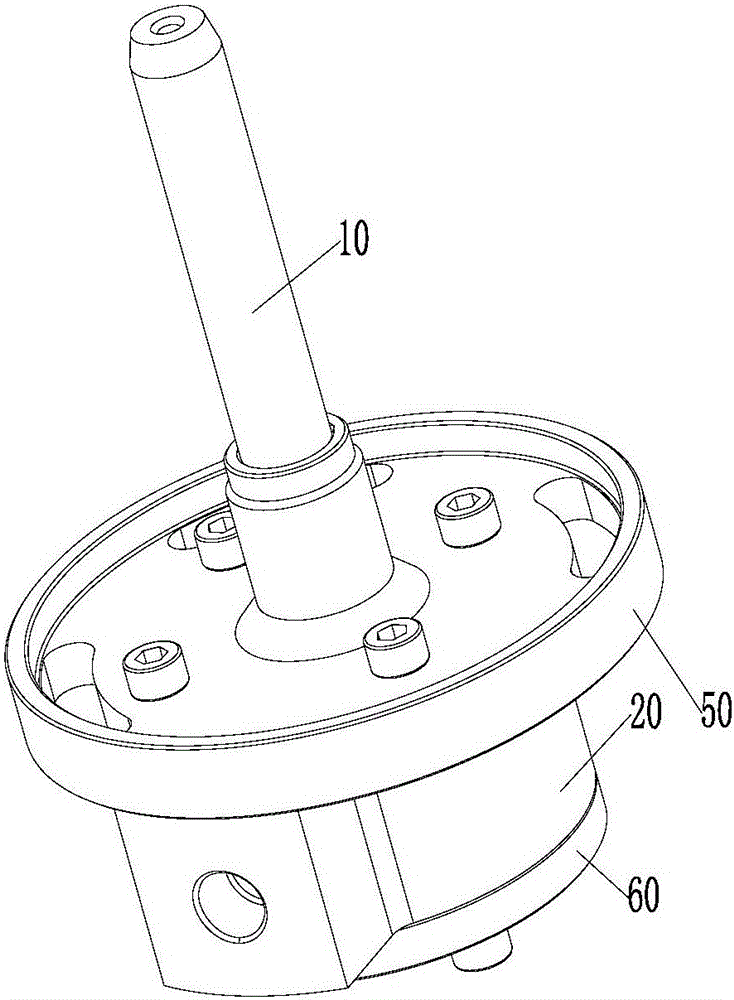

Spherical ball expander

ActiveCN109162762AReduce settingsReduce in quantityEngine componentsRotary piston enginesMachine partsInlet channel

The invention provides a spherical ball expander. The spherical ball expander comprises a sphere, a spherical shell and two balls, wherein the sphere and the spherical shell are concentric; a whole sphere bulge ring and two inward concave arc sphere grooves are arranged on the outer surface of the sphere, and the whole sphere bulge ring is formed by alternately connecting two T-shaped sphere bulgerings and two rectangular sphere bulge rings; an inward concave T-shaped spherical shell concave ring and an inward concave annular spherical shell groove are arranged on the inner surface of the spherical shell; an air inlet channel and an air outlet channel which communicate the outside with the annular spherical shell groove are formed in the spherical shell; the T-shaped spherical shell concave ring is embedded with the whole sphere bulge ring; the air inlet channel is stopped from communicating the outside with the annular spherical shell groove when the T-shaped sphere bulge rings passthe air inlet channel; the air inlet channel is enabled to communicate the outside with the annular spherical shell groove when the rectangular sphere bulge rings pass the air inlet channel. Accordingto the spherical ball expander, the function of an air inlet valve is realized by the sphere bulge rings, arrangement of the air inlet valve is omitted, manufacture cost is reduced, and the sphericalball expander further has the advantages of fewer machine parts, small clearance volume, compact structure and good motion balance.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Air inlet and exhaust valve of compressor

ActiveCN101592145AReduce weightAvoid breakingPositive displacement pump componentsPositive-displacement liquid enginesExhaust valveReciprocating motion

The invention discloses an air inlet and exhaust valve of a compressor, which comprises a valve body, an air valve plate, a spring, a spring seat and an air inlet and exhaust connector, wherein the valve body is arranged on the valve seat; the spring applies a pretightening force during installation to press the air valve plate onto the valve seat tightly; seal is formed between the air valve plate and the valve seat to separate the channels positioned above and below the air valve plate; the air valve plate is made of an impact-resistance nonmetal material and is provided with a guide structure preventing the sidewise inclination of the air valve plate during reciprocal motion of the air valve plate; the valve body is provided with a structure matched with the guide structure; and the center of the air valve plate is provided with a central hole for reducing the weight of the air valve plate and increasing circulation area at the same time. The air valve has the advantages of compact arrangement, simple structure, small resistance to air flow, low vibration noise, high reliability and the like and is particularly suitable for use in medium and small flow reciprocating piston type compressors.

Owner:SHANGHAI MICROPOWERS

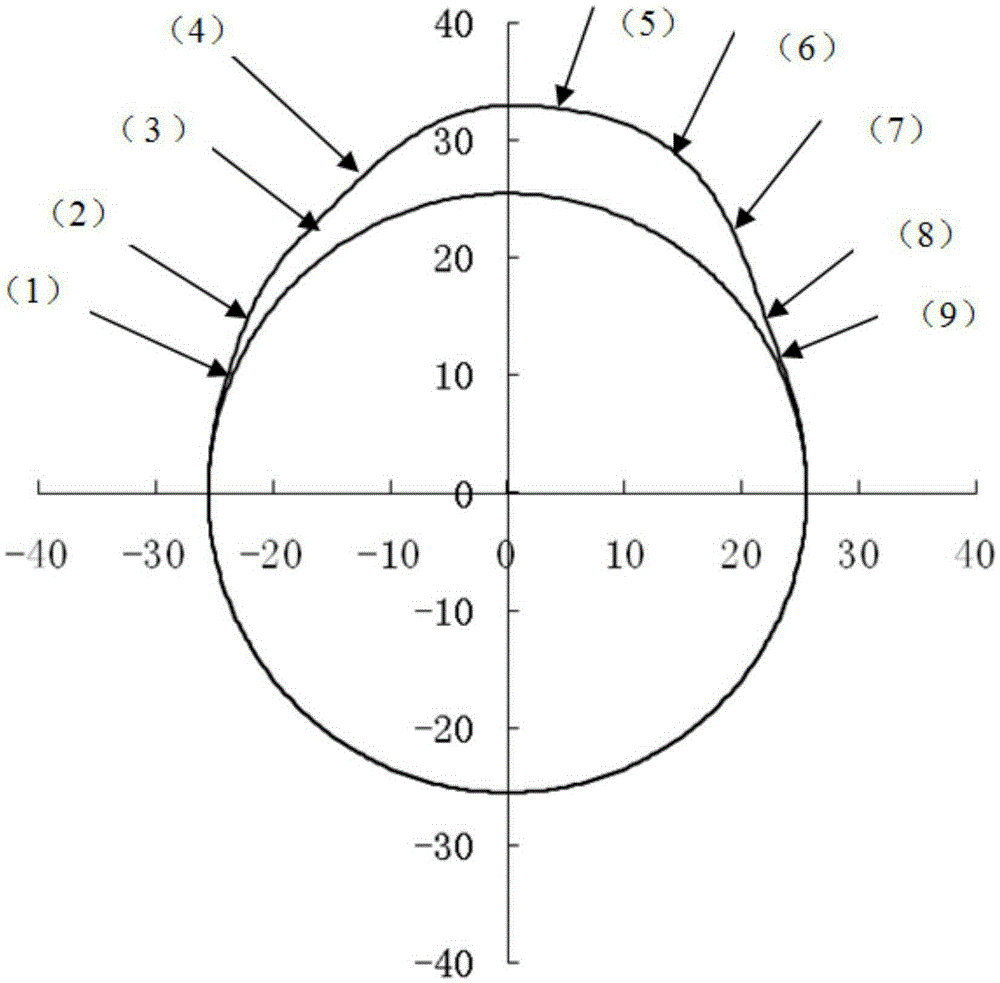

Straight jaw rotor of claw type vacuum pump and profile design method of straight jaw rotor

ActiveCN108757464AIncreased engagement rangeEngagement wire lengthGeometric CADRotary piston pumpsEllipseCycloid

The invention discloses a straight claw rotor of a claw type vacuum pump and a profile design method of the straight claw rotor. The straight claw rotor is composed of eleven segments of curves comprising four segments of arcs, two segments of elliptical arcs, two segments of elliptical arc envelope lines, one segment of equidistant curve of a cycloid, one segment of line segment and one segment of envelope line. The rotor uses the elliptical arcs and the envelope lines of the elliptical arcs to construct the profile at the top of a claw and the tip of the claw, and uses the arcs and the equidistant curve of the cycloid to construct the profile at the bottom of the claw, adjacent curves are all connected smoothly, no non-smooth connection point exists, and the mechanical properties, the meshing performance and the sealing performance of the straight jaw rotor are improved. Two rotors meshing with each other are identical and the correct meshing of the profile can be achieved. The rotorhas a smaller clearance volume and improves the compression ratio of the claw vacuum pump. The top of the claw is more flat, the meshing range is large, a mesh line is long, and abrasion is further reduced. The rotor enriches profile types of claw type rotors and promotes the development of claw type vacuum pumps.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

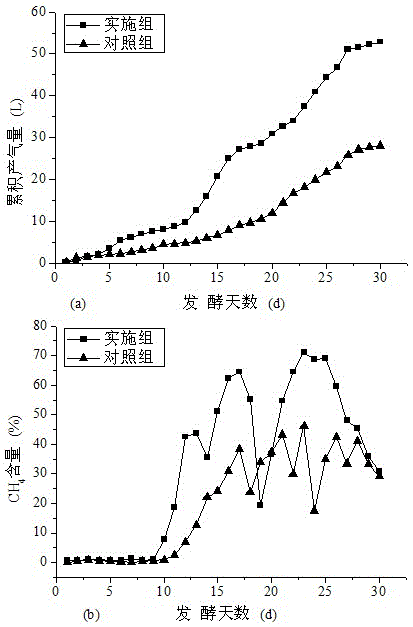

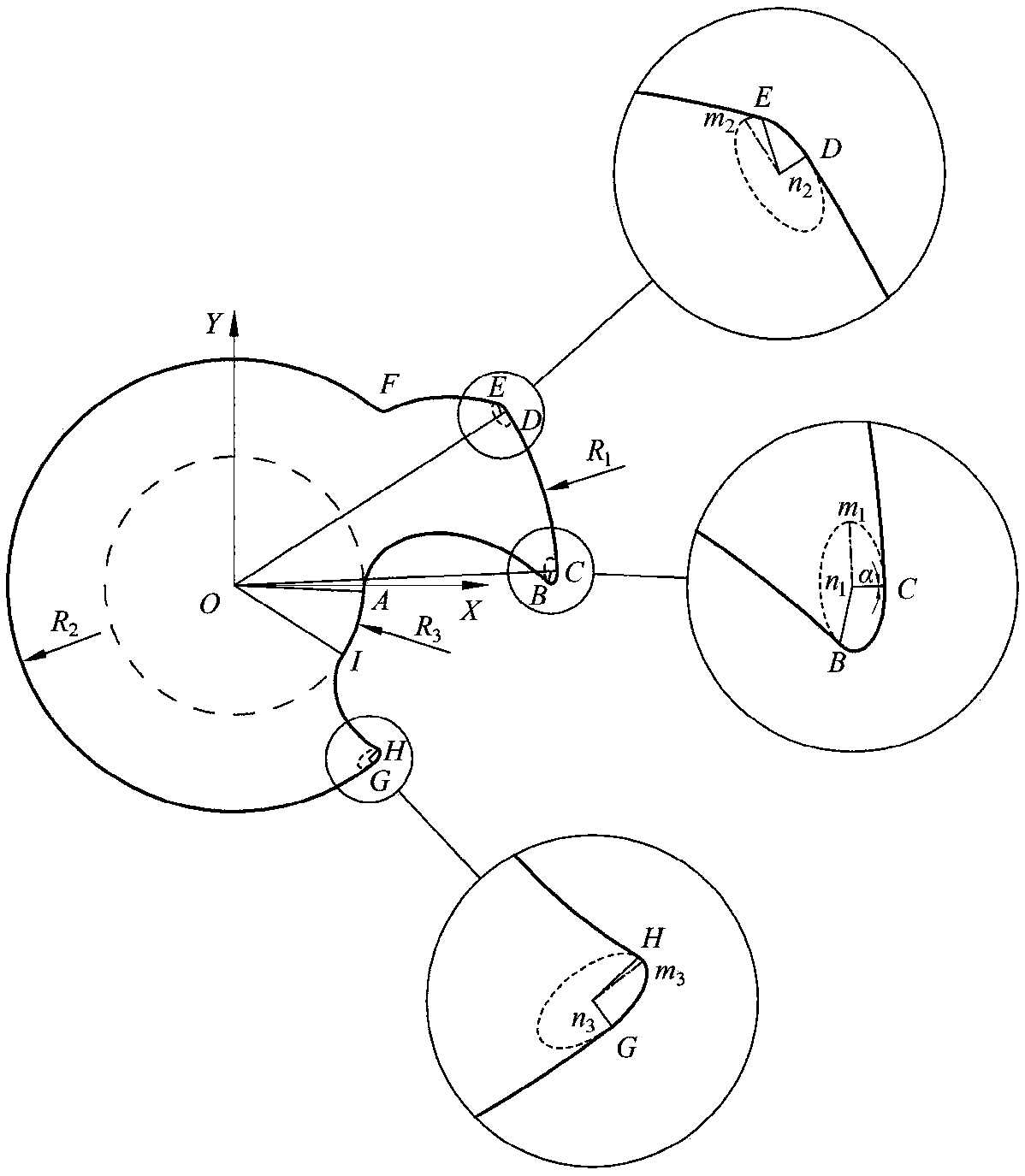

Method for preparing biogas through activated carbon, kitchen garbage and faeces

InactiveCN105063094AReduce outputIncrease productionBio-organic fraction processingEnergy inputActivated carbonFeces

The invention relates to a method for preparing biogas through activated carbon, kitchen garbage and faeces, and belongs to the technical field of renewable energy. The method specifically comprises the following steps that the kitchen garbage and the faeces are put into a pretreatment tank to be mixed and heated at constant temperature, and a mixture is obtained; the mixture, the activated carbon and inoculums are put into at least one anaerobic fermentation tank to be heated at constant temperature, stirring and fermentation are carried out, and biogas and fermentation residues are obtained. The method has the advantages that the allothigene active carbon is added, so that the efficiency of fermentatively producing biogas and methane with kitchen garbage and faeces as raw materials is greatly improved, and running is stable; meanwhile, production cost can be lowered, and the method is suitable for large-scale popularization; in addition, the amount of cleared household garbage can be effectively reduced, resources can be saved, generated foul gas can be controlled, and energy saving and emission reducing can be achieved.

Owner:HUAIYIN TEACHERS COLLEGE

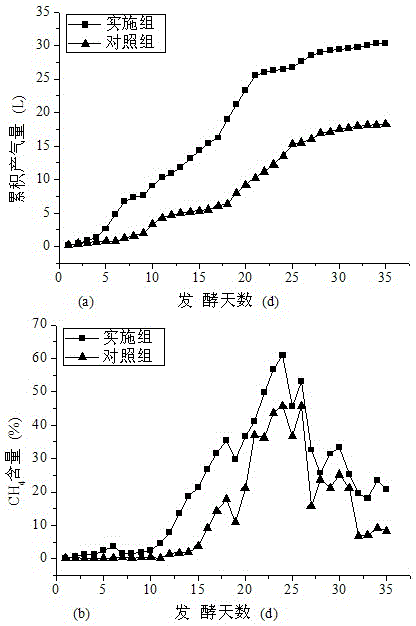

Hydrogen compressor host and compression method

InactiveCN109653985ANot pollutedAvoid pollutionPositive displacement pump componentsPiston pumpsHydrogenEngineering

The invention relates to a hydrogen compressor host and a compression method. The hydrogen compressor host comprises a primary air cylinder, a secondary air cylinder and an oil cylinder, wherein a first compression cavity is disposed in the primary air cylinder; a second compression cavity which communicates with the first compression cavity is disposed in the secondary air cylinder; the oil cylinder internally comprises two independent auxiliary oil cavities which are separated by an oil cylinder piston; and the two sides of the oil cylinder piston are connected with a primary piston of the primary air cylinder and a secondary piston of the secondary air cylinder through a primary piston rod and a secondary piston rod correspondingly. The hydrogen compressor host and the compression method have the beneficial effects that the air cylinder compression cavities and the pistons are of an oil-lubrication-free structure, and process gas is protected and not contaminated; hydraulic oil is completely separated from the process gas, and thus the hydraulic oil can be prevented from contaminating the gas; the hydrogen gas entering pressure range is wide, and a pressure regulator is not needed at an inlet; through the scheme, during air cylinder working, the piston stroke is long, the speed is low, the clearance volume is small, and volume efficiency is high; and by adopting the water cooled air cylinders, the running temperature is lowered, and the service life is prolonged.

Owner:WUHAN QIDAKANG ENVIRONMENTAL PROTECTION TECH CO LTD

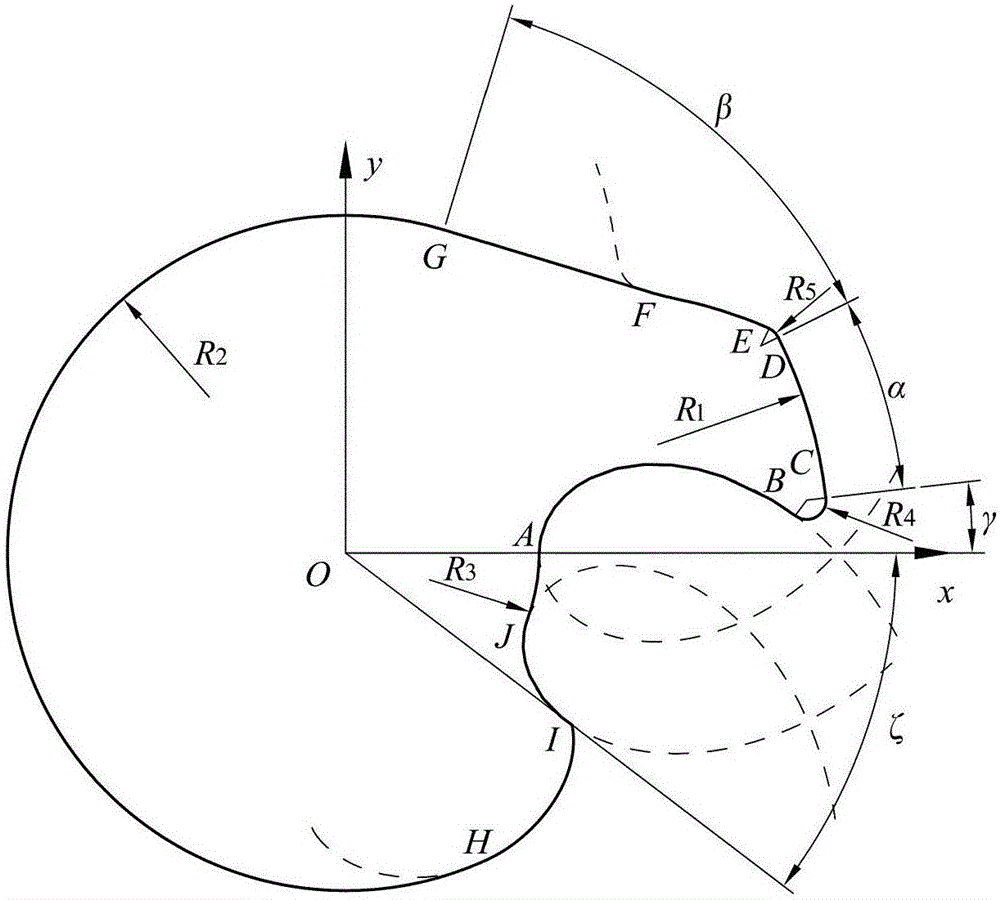

Curved claw rotor of claw type vacuum pump and molded line design method thereof

PendingCN108678954AIncreased engagement rangeEngagement wire lengthGeometric CADRotary piston pumpsEllipseEngineering

The invention discloses a curved claw rotor of a claw type vacuum pump and a molded line design method thereof. The rotor is composed of nine curved lines: three circular arcs, three elliptic arcs andthree elliptic arc envelope lines. Molded lines are constructed at the top, tip and bottom of the claw of the rotor by adopting the elliptic arcs and the elliptic arc envelope lines. Two rotors engaged to each other are totally same and the molded lines can be correctly engaged; adjacent curved lines are smoothly connected without unsmooth connecting points, so that the mechanical property, the engaging property and the sealing property of the curved claw rotor are improved. The rotor has a smaller clearance volume, the compression power consumption is reduced effectively, and the compressionratio of the claw type vacuum pump is improved. The tip of the claw of the rotor is more flat, large in engaging range and long in engaging line, so that wear is further reduced; the rotor is small in area, and the pumping speed and the volume utilization ratio of the vacuum pump are improved; the types of the molded lines of the claw type rotor are enriched according to the rotor, and the rotoris of important significance to development of the claw type vacuum pump.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Straight claw rotor

InactiveCN106246539ASimple compositionAchieve full engagementEngine of intermeshing engagement typeRotary piston pumpsEngineeringWork Performances

The invention discloses a straight claw rotor which comprises ten curves: five arcs, two equidistant curves of a cycloid, a cycloid, a line segment and an envelope line of the line segment; the pitch circle arc GH, the envelope line HI of the line segment, the equidistant curve IJ of the cycloid, the claw foot arc JA, the equidistant curve AB of the cycloid, the first claw tip arc BC, the claw top arc CD, the second claw tip arc DE, the cycloid EF and the line segment FG are sequentially connected counterclockwise from a pitch circle; and all the other molded lines are smoothly connected except for a connection point I of the envelope line HI of the line segment and the equidistant curve IJ of the cycloid. two mutually engaged claw rotors are identical; all the molded lines of the claw rotor can be engaged correctly during working; the problem that a claw back curve does not participate in engagement completely is solved; and the working efficiency and working performance of a claw fluid machine are improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Fluid machine, heat exchange apparatus and running method of fluid machine

ActiveCN106704183AVibration reliefReduced clearance volumeRotary piston pumpsRotary piston liquid enginesPistonEngineering

The invention provides a fluid machine, a heat exchange apparatus and a running method of the fluid machine. The fluid machine comprises: an upper flange; a lower flange; a cylinder clamped between the upper flange and the lower flange; a rotating shaft, wherein the axle center of the rotating center and the axle center of the cylinder are eccentrically arranged, the eccentric distance is constant, and the rotating shaft sequentially traverses through the upper flange and the cylinder; and a piston assembly, wherein the piston assembly has a variable volume chamber, the piston assembly is pivotally arranged in the cylinder, and the rotating shaft is in driving connection with the piston assembly to change the volume of the variable volume chamber. The eccentric distance between the rotating shaft and the cylinder is constant, the rotating shaft and the cylinder rotate around respective axle centers in the movement process, and the positions of mass centers do not change, so the piston assembly stably and continuously rotates when moving in the cylinder, vibration of the fluid machine is effectively alleviated, regular volume change of the variable volume chamber is guaranteed, and the clearance volume is reduced, thereby the running stability of the fluid machine is improved, and the working reliability of the heat exchange device is improved.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Drilling pump with T-type pump head and supercharging method thereof

InactiveCN103104473ACompact structureReduce size and massPositive displacement pump componentsLiquid fuel engine componentsPistonEngineering

The invention discloses a drilling pump with a T-type pump head. The drilling pump with the T-type pump head is mainly formed by a shell body, a discharge liquor cylinder arranged on the shell body, a discharging pipe connected and communicated with the discharge liquor cylinder, a suction liquor cylinder connected and communicated with the discharge liquor cylinder, and a suction pipe connected and communicated with the liquid suction cylinder. A piston device communicated with the discharge liquor cylinder is arranged inside the shell body. The invention further discloses a supercharging method based on the drilling pump. The drilling pump with the T-type pump head is in a compact structure and a suction chamber is canceled, the volume and the quality of the drilling pump with the T-type pump head are both reduced by 25% - 30%. The drilling pump with the T-type pump head is easy to process and manufacture, convenience is brought to flaw detect and inspection, and can ensure the quality of pump head products. Slurry is sucked horizontally, the clearance volume in the pump head cylinder is small, the suction efficiency and the volumetric efficiency of the drilling pump are improved; liquid flow is smooth, pressure fluctuation and pressure vibration are reduced, and drilling pump impact loads are also reduced. The change of a suction valve is very convenient and time-saving, and the workload of dismounting and changing is little.

Owner:谢月

Rotary type compressor exhaust apparatus

InactiveCN1632320AImprove volumetric efficiencyIncrease the exhaust areaRotary/oscillating piston pump componentsLiquid fuel engine componentsExhaust valveSpherical shaped

The invention provides a rotary compressor exhaust device, which includes a compressor main bearing, a stopper, a compressor cylinder, a cylinder exhaust hole, a partially spherical exhaust valve plate and a conical exhaust hole. The main bearing is fixed on the compressor cylinder, and the compressor cylinder is provided with a cylinder exhaust hole. The above-mentioned partial spherical exhaust valve plate is fixed on the compressor main bearing, and a conical exhaust hole is arranged on the compressor main bearing. The local sphere of the partially spherical exhaust valve plate is aligned with the conical exhaust hole, and the above-mentioned limiter is arranged on the upper surface of the partially spherical exhaust valve plate and fixed on the main bearing of the compressor. The beneficial effects of the present invention are: the cylindrical exhaust hole is designed as a conical exhaust hole, which expands the exhaust area under the same circumstances, relatively reduces the clearance volume caused by the existence of the exhaust hole, and improves Improve the volumetric efficiency of the compressor and reduce noise.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Reciprocating type internal-combustion engine with low fuel oil and micro discharge

InactiveCN101566091AReduced clearance volumeIncrease the compression ratioInternal combustion piston enginesIgnition delayFuel oil

The invention discloses a reciprocating type internal-combustion engine with low fuel oil and micro discharge, which comprises a combustion cylinder, a power output cylinder, a communication cylinder and a blocker which is controlled by a blocking control mechanism and can reciprocate between the combustion cylinder and the power output cylinder so as to open and close the communication cylinder. The blocker reciprocating in the communication cylinder of the reciprocating type internal-combustion engine is used for controlling different working substances of the combustion cylinder and the power output cylinder to separately or cooperatively work. When the power output cylinder has a smallest clearance volume, fuel gas close to a highest temperature period after doing work in the combustion cylinder is put in the power output cylinder, and pure air which is compressed isothermally and compressed with a high-pressure compression ratio and is several times or even tens of times of the amount of the fuel gas in the power output cylinder is isasterically heated. The processes and the power of the ignition delay period and the rapid combustion period of the reciprocating type internal-combustion engine are similar to those of a conventional internal-combustion engine, and the thermal efficiency of the reciprocating type internal-combustion engine is improved by multiples. The reciprocating type internal-combustion engine has micro discharge, low fuel oil, large push moment and flexible working.

Owner:王建全

Combined cam

InactiveCN105332749AIncrease the compression ratioReduced clearance volumeValve drivesCombustion chamberEngineering

The invention provides a combined cam. A cam profile of the combined cam is composed of multiple segments of function cam profiles. Multi-segment combined function design is adopted, the combined cam sequentially comprises an ascending buffer segment, a first ascending work segment, a second ascending work segment, a third ascending work segment, a flat segment, a first descending work segment, a second descending work segment and a descending buffer segment, and the descending buffer segment is composed of a constant-speed segment and a constant-acceleration segment. By the adoption of the combined cam, the requirement for collision prevention of a diesel engine air valve and a piston can be flexibly met, the clearance volume of the piston is reduced, the compression ratio of a diesel engine can be increased, and therefore the comprehensive requirements for the structure of an engine combustion chamber, the inflation performance and the power performance are met.

Owner:CHINA NORTH ENGINE INST TIANJIN

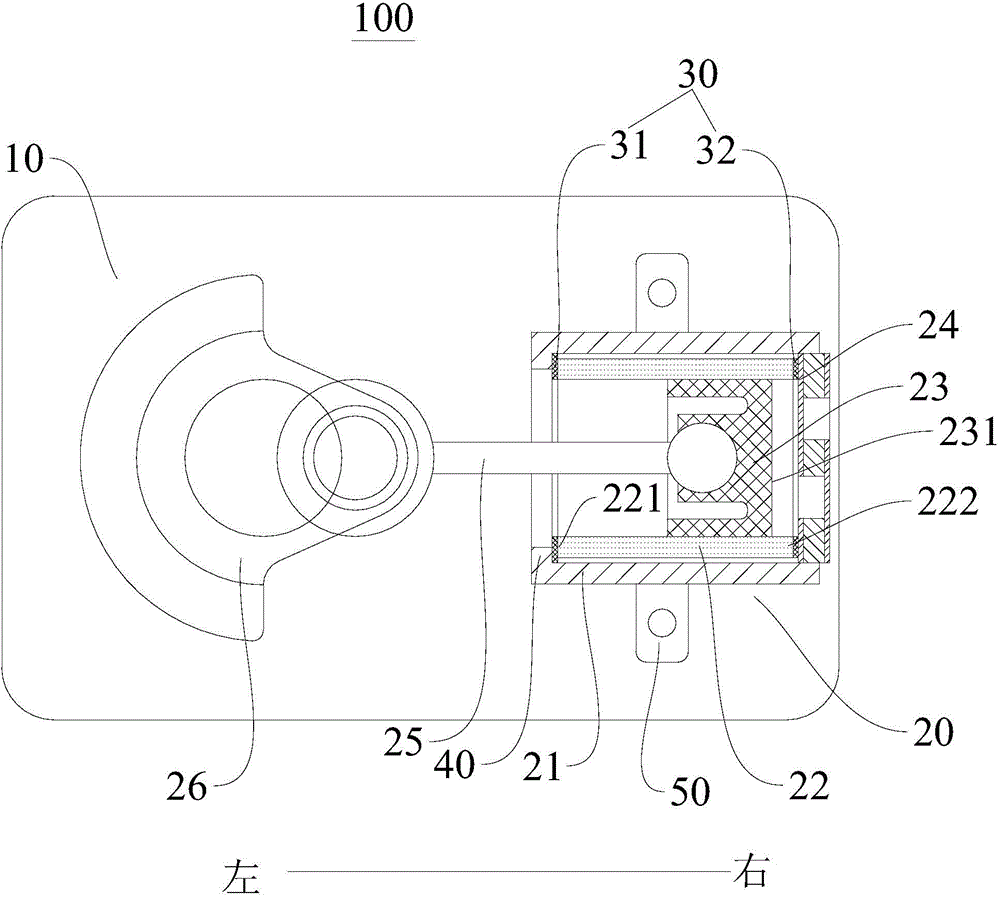

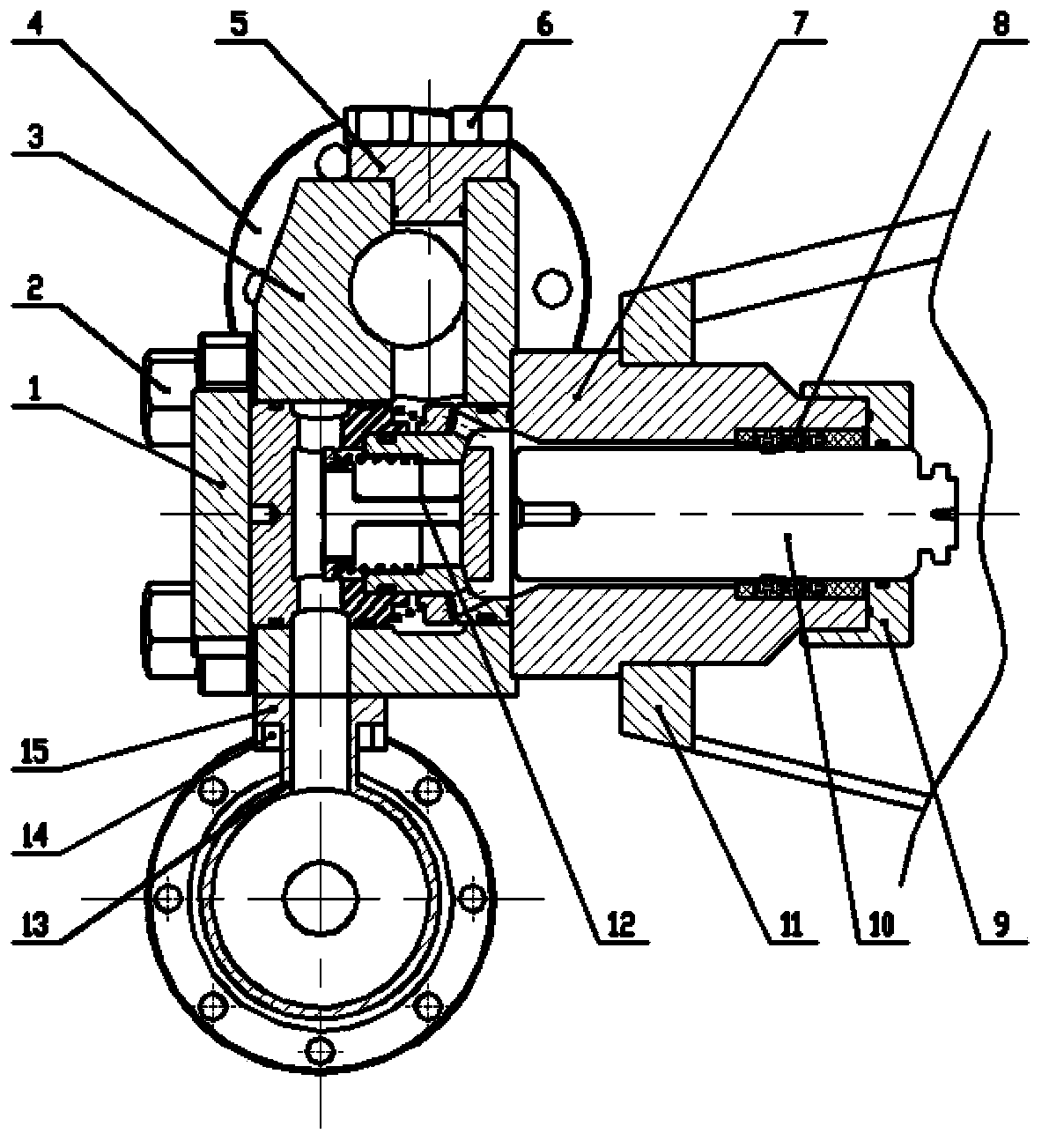

Compression mechanism and compressor provided with same

InactiveCN104564690AReduced clearance volumeGuaranteed exhaust effectRotary piston pumpsRotary piston liquid enginesPulp and paper industryCrankshaft

The invention discloses a compression mechanism and a compressor provided with the compression mechanism. The compression mechanism comprises a cylinder, a crankshaft, an upper bearing, a lower bearing and a switch valve plate, wherein a compression chamber is defined in the cylinder, and a tapered cut communicated with the compression chamber is formed in the upper end or the lower end of the inner wall surface of the cylinder; the crankshaft penetrates through the compression chamber along the axial direction of the cylinder and can rotate around the central axis of the crankshaft, the part, extending into the compression chamber, of the crankshaft is provided with an eccentric shaft, and a roller is arranged on the eccentric shaft; the upper bearing and the lower bearing are arranged at the upper end and the lower end of the cylinder respectively, and an exhaust hole corresponding to the tapered cut in position is formed in the upper bearing or the lower bearing and is connected with the tapered cut; and the switch valve plate is arranged between the upper end of the cylinder and the upper bearing or between the lower end of the cylinder and the lower bearing, and can move between a first position and a second position to connect or disconnect the tapered cut and the exhaust hole, the tapered cut is connected with the exhaust hole when the switch valve plate is at the first position, and the tapered cut is disconnected with the exhaust hole when the switch valve plate is at the second position.

Owner:GUANGDONG MEIZHI COMPRESSOR

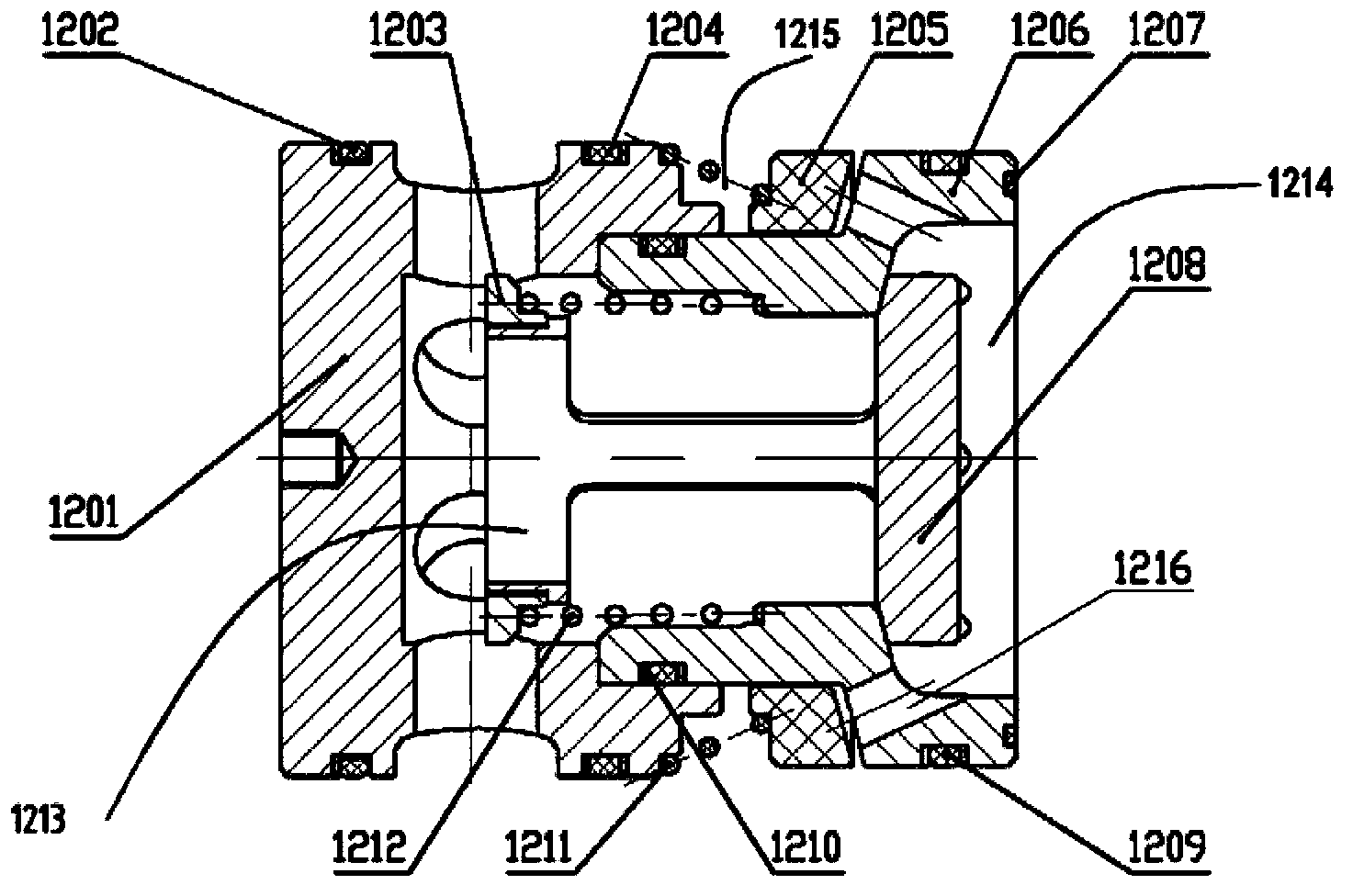

Fluid end device of plunger pump

ActiveCN103410721ACompact structureEasy to disassemblePositive displacement pump componentsLiquid fuel engine componentsPump headBiomedical engineering

The invention relates to a fluid end device of a plunger pump. The fluid end device of the plunger pump comprises a pump head body (3), a cartridge combination valve (12), a stuffing box (7) and a plunger (10). The pump head body (3) is provided with a suction inlet and an exhaust outlet, and the cartridge combination valve (12) is arranged inside the pump head body (3); a liquid inlet cavity (1213) communicated with the suction inlet and a liquid outlet cavity (1215) communicated with the exhaust outlet are formed between the pump head body (3) and the cartridge combination valve (12); the end surface of the stuffing box (7) is closely adhered to the pump head body (3), and the plunger (10) can move inside the stuffing box (7) in a reciprocating mode; the cartridge combination valve (12) comprises a pressing sleeve (1201), a valve core (1206), a suction valve (1208) and a discharge valve (1205). The fluid end device of the plunger pump improves the overflowing performance of the combination valve and the guide performance between the suction valve and the valve core and meanwhile is compact and simple in structure; the pump head body is small in size; the fluid end device of the plunger pump is high in volume efficiency, easy to assemble and disassemble and rapid in maintenance and replacement.

Owner:INST OF SINOPEC OILFIELD EQUIP CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com