Slip-sheet for rotary compressor

A technology of rotary compressors and sliding vanes, which is applied in the direction of rotary piston machines, rotary piston pumps, rotary piston/swing piston pump components, etc., which can solve the problem of affecting the reliability of compressors and increasing mechanical friction power Loss, reduce compressor and other issues, to achieve the effect of reducing mechanical friction power loss, improving the COP of the compressor, and reducing friction power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

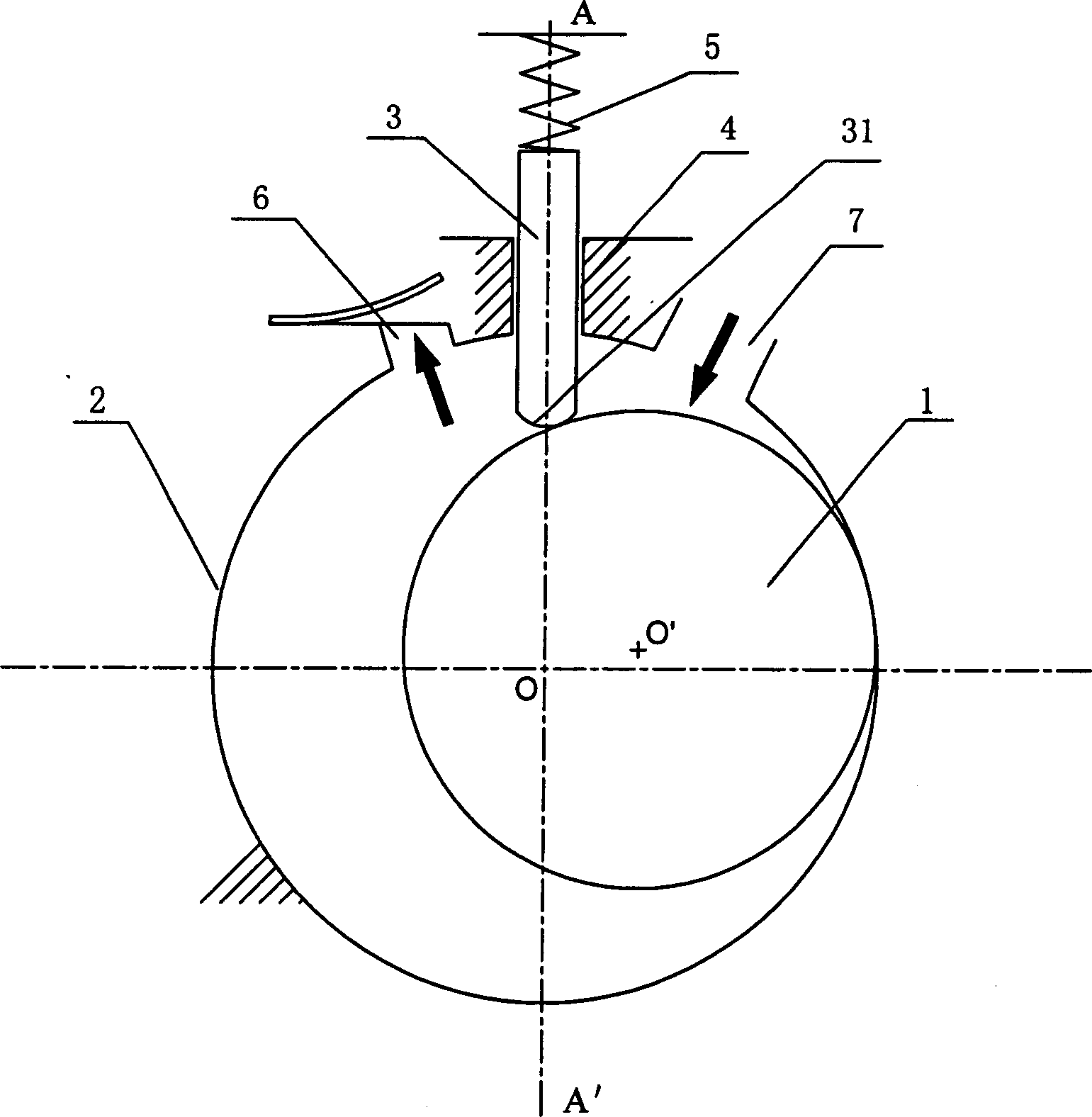

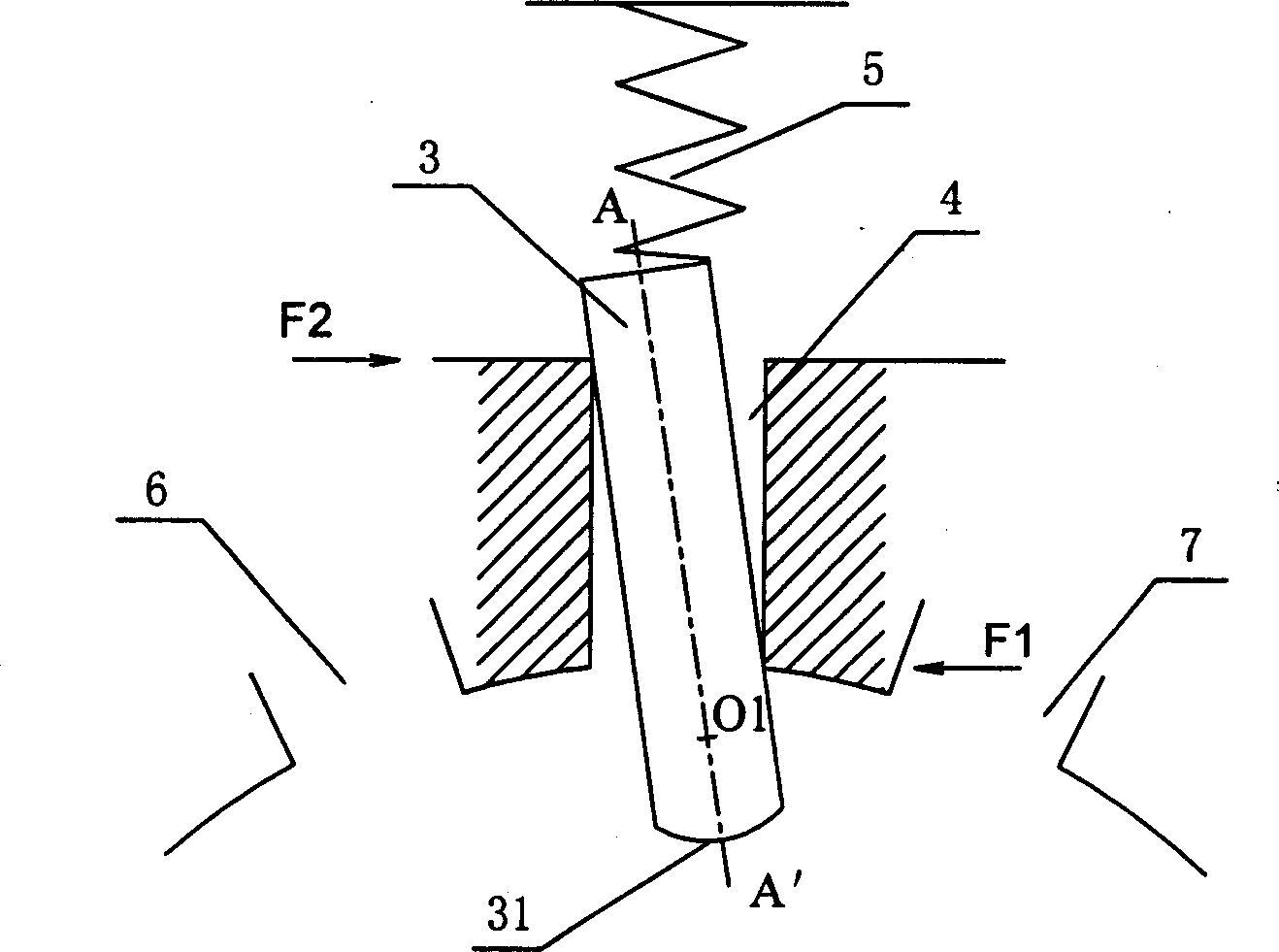

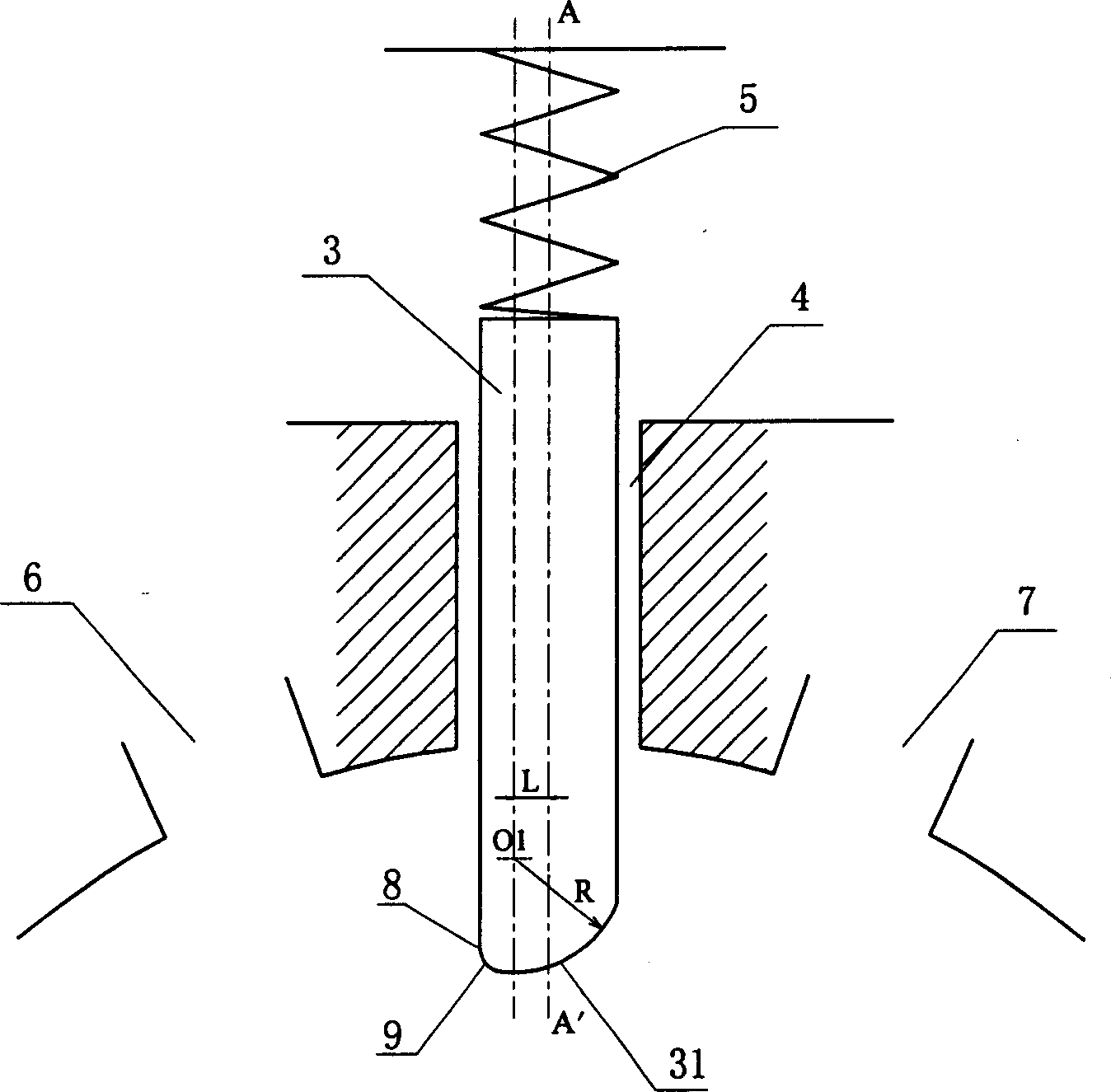

[0029] image 3 Shown is one of the embodiments of the present invention, the bottom end surface 31 of the slide piece 3 is arc-shaped, the center O1 of the arc shape is biased towards the exhaust port 6, the bottom end of the bottom end surface 31 of the slide piece is in line with the outside of the slide piece The inflection points 8 are transitioned by a smooth arc 9, so as to raise the position of the inflection point at the bottom of the sliding plate, avoid contact with the piston, and reduce the friction and wear between the sliding plate and the piston. The distance L between the center of circle O1 and the vertical center line AA' of the slider is 1 / 8 to 1 / 3 times of the width of the slider, preferably 1 / 4 of the width of the slider. The bottom end surface 31 of the slider is in the shape of a continuous arc and intersects with the edges on both sides of the slider 3. The radius R is 0.6-2 times the width of the slider, preferably 1.58 times the width of the slider. ...

Embodiment 2

[0039] Figure 4 Shown is the second embodiment of the present invention, which is different from the first embodiment in that: due to the processing of grinding tools or cutters, the radius of curvature R of the arc-line end surface 31 at the bottom of the slide plate may be smaller than the center of curvature O1 to the slide plate The vertical distance from the edge of the suction side, that is, the end surface 31 of the arc line at the bottom of the slide will not directly intersect with the edge of the suction side of the slide, and there is a connecting end surface 32 between the two, so the bottom of the slide presents a combined form , but the object of the present invention can also be achieved. The connection end surface 32 can be a straight line or a curved line, which is completely determined by the shape of the grinding tool or cutter for processing the bottom curve of the slide plate, and does not affect the implementation of this embodiment. The distance L betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com