Oil field produced water heat pump technique

A technology for producing water and heat pump, which is applied in the directions of heat pump, production fluid, earthwork drilling, etc., can solve the problems such as the temperature not reaching 80 °C, serious scaling, etc., and achieve the effect of improving COP and reducing fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

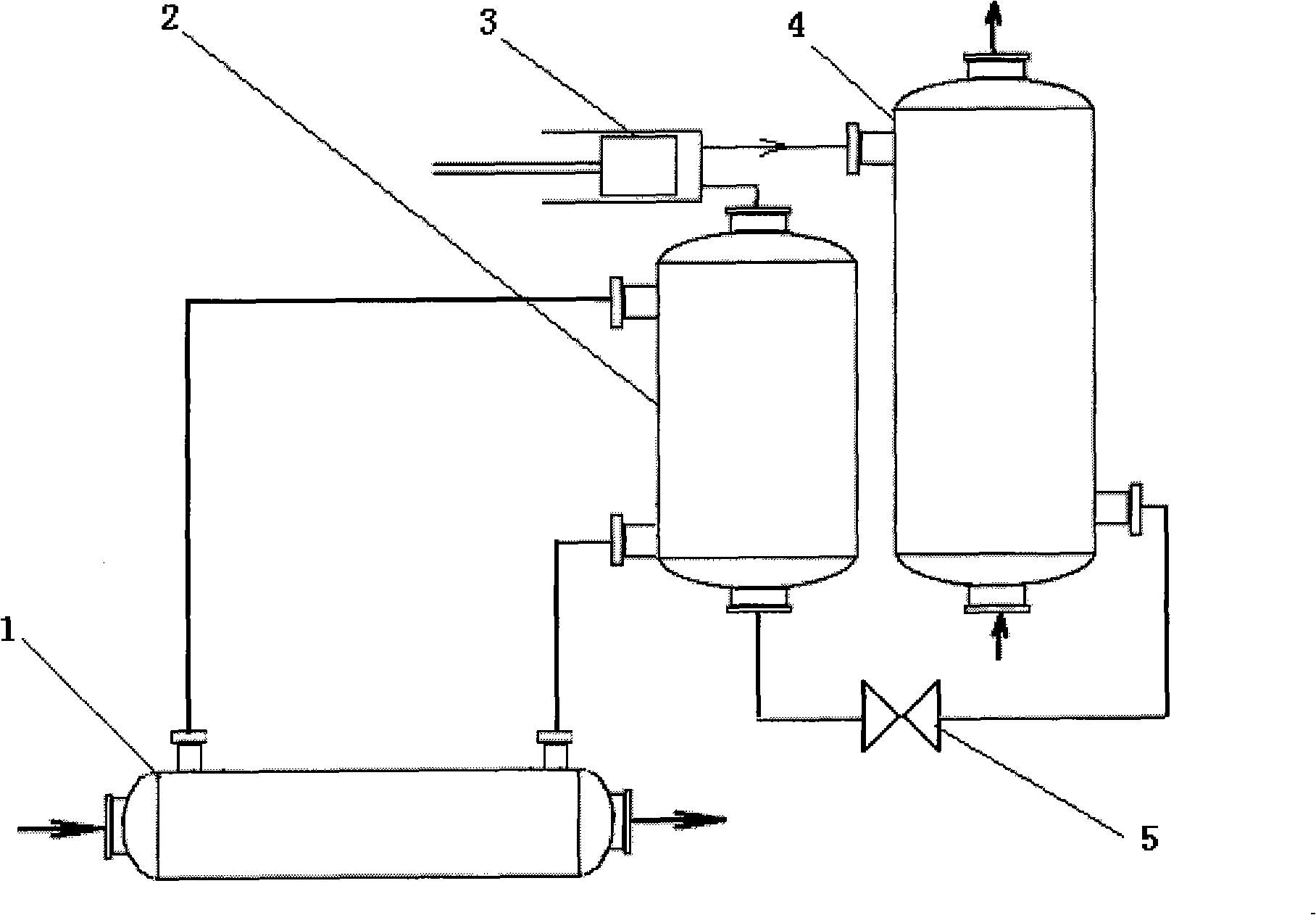

[0011] combined with figure 1 , the present invention is further described, comprising the following steps: the oil field produced water is sent to the tube side of the produced water boiling heat exchanger 1 from the sewage tank (generally, the gauge pressure of the tank is 0.06MPa), and the oil field produced water is discharged after cooling. Enter the produced water discharge pumping station pipeline: the shell side of the produced water boiling heat exchanger 1 is filled with low boiling point working fluid, which absorbs heat and vaporizes and enters the shell side of the heat pump working medium evaporator 2, releases heat and condenses into a liquid before flowing back to the produced water The shell side of the boiling heat exchanger 1: the heat pump working medium in the evaporator 2 tube is the heat pump working medium, which absorbs heat and vaporizes into steam, and sends the steam to the compressor 3 through the pipeline to increase the pressure and heat up; throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com