Patents

Literature

65results about How to "Increase the exhaust area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

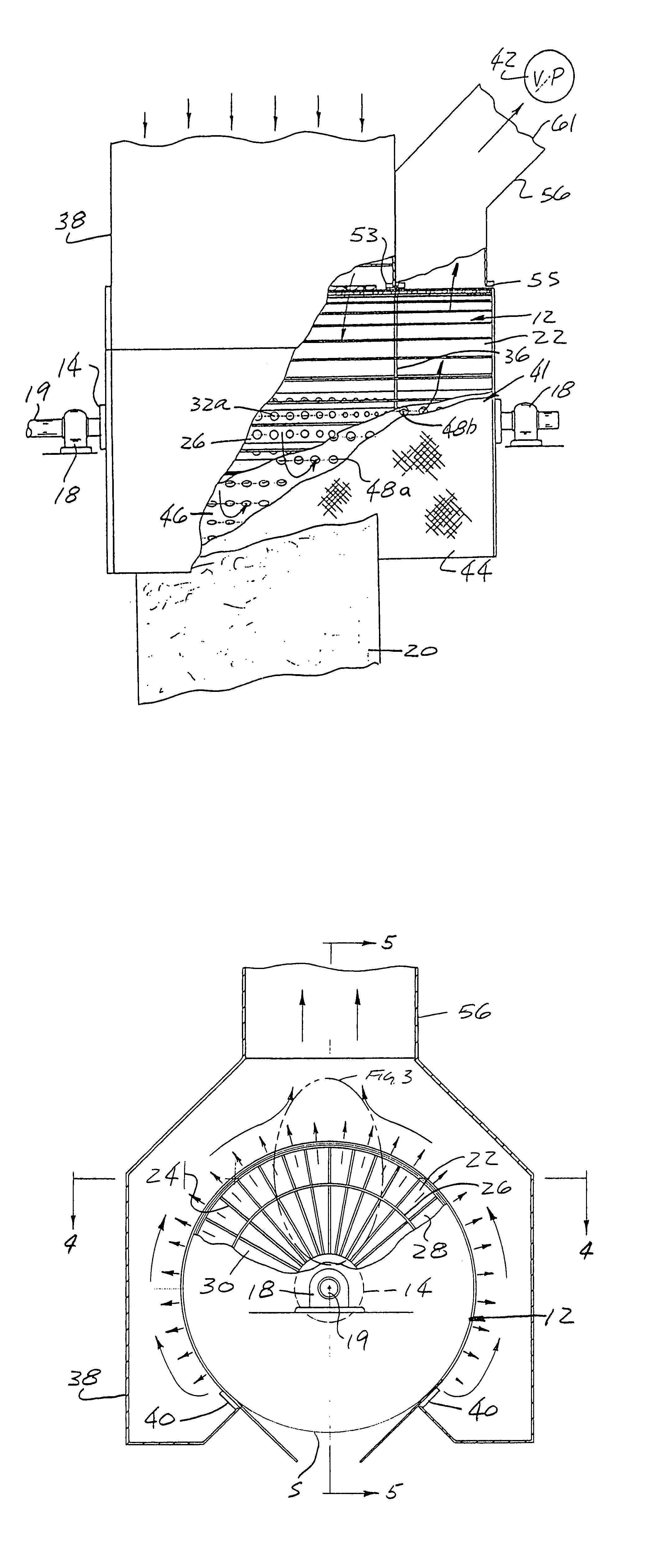

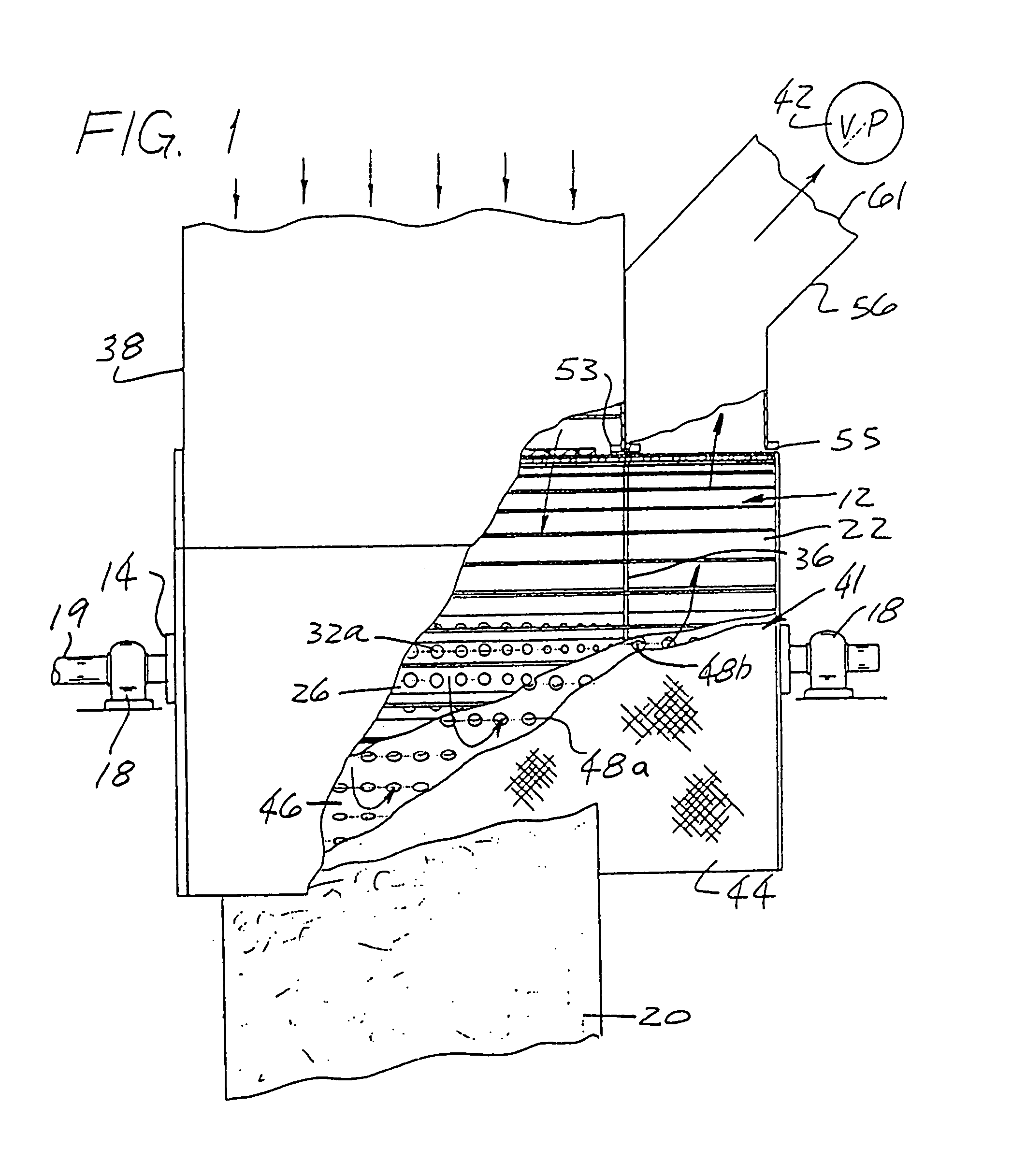

Apparatus for processing permeable or semi-permeable webs

InactiveUS7040038B1Enhance and control air flowBig economyDryer sectionMachine wet endNetwork onEngineering

An air processing cylinder useful in drying, curing, thermal bonding, cooling, and web transferring materials such as fabrics, papers, and the like. Air is exhausted out of the cylinder surface through a plurality of conduits equipped with distribution means for profiling the flow of air. The drying cylinder further includes a duct network on its outer shell for exhausting air out of one axial area only or, alternatively, the drying cylinder may contain multiple duct networks for exhausting air out of several axial areas, each having its own flow characteristics.

Owner:VALMET OY

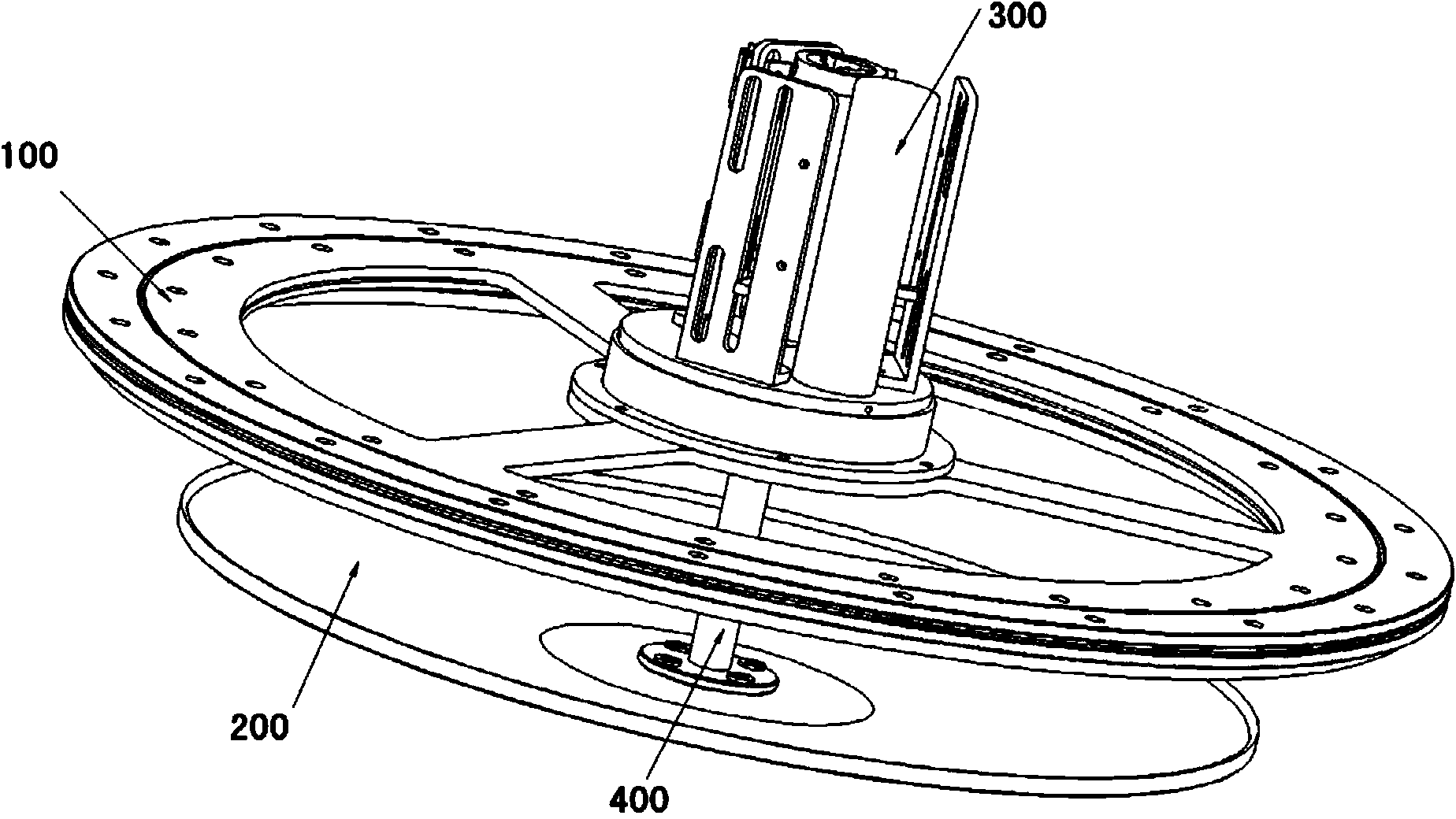

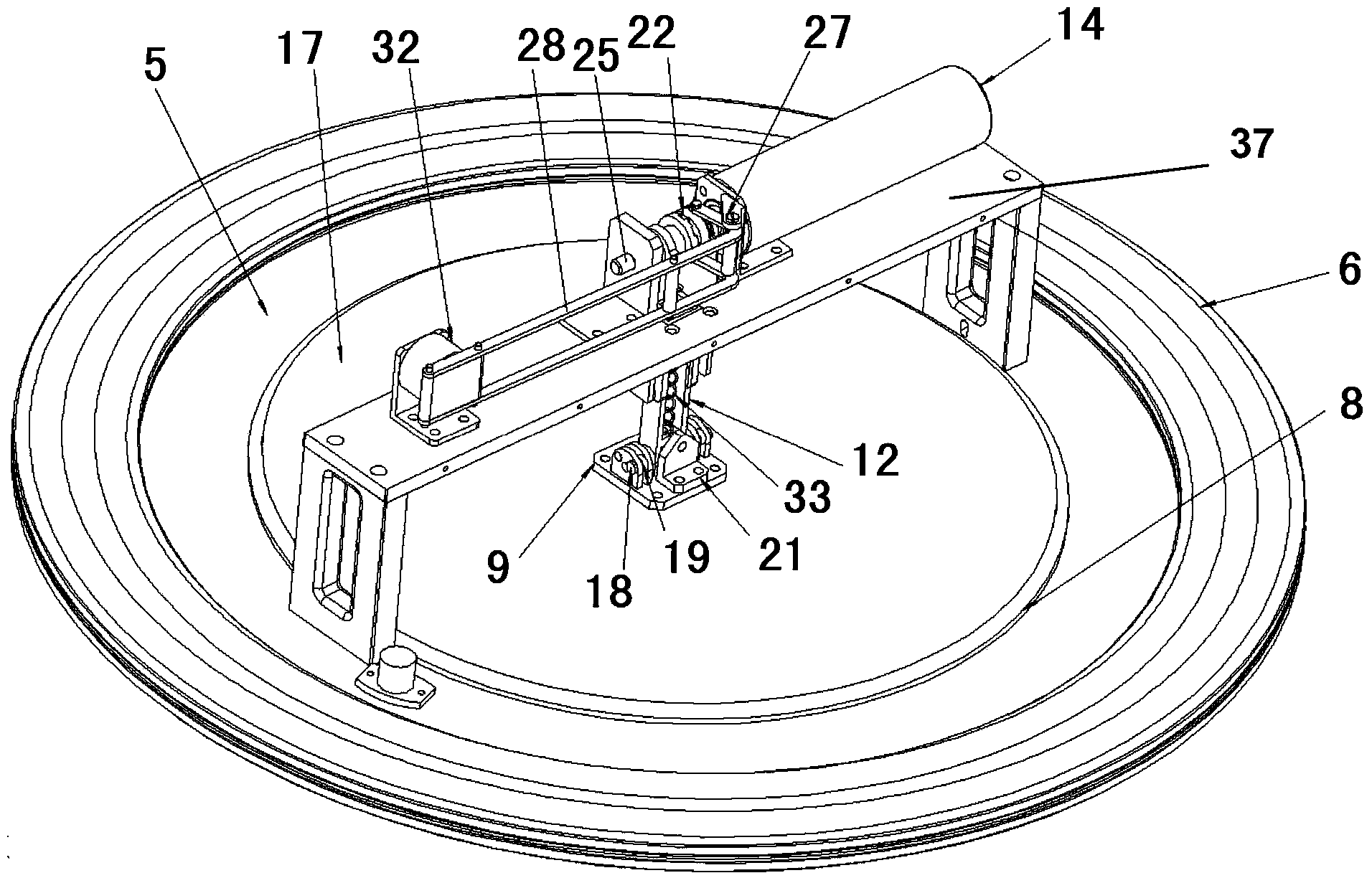

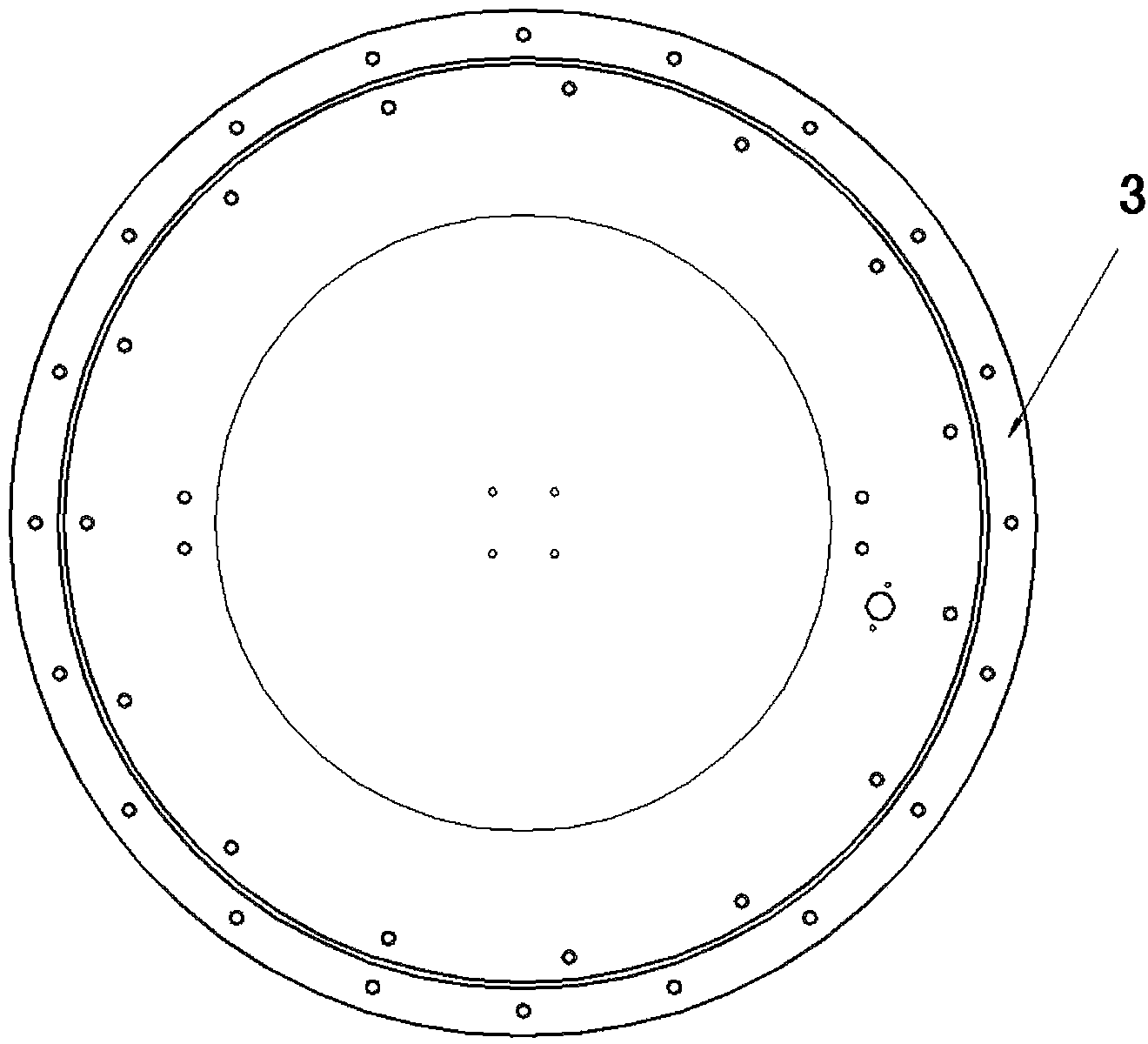

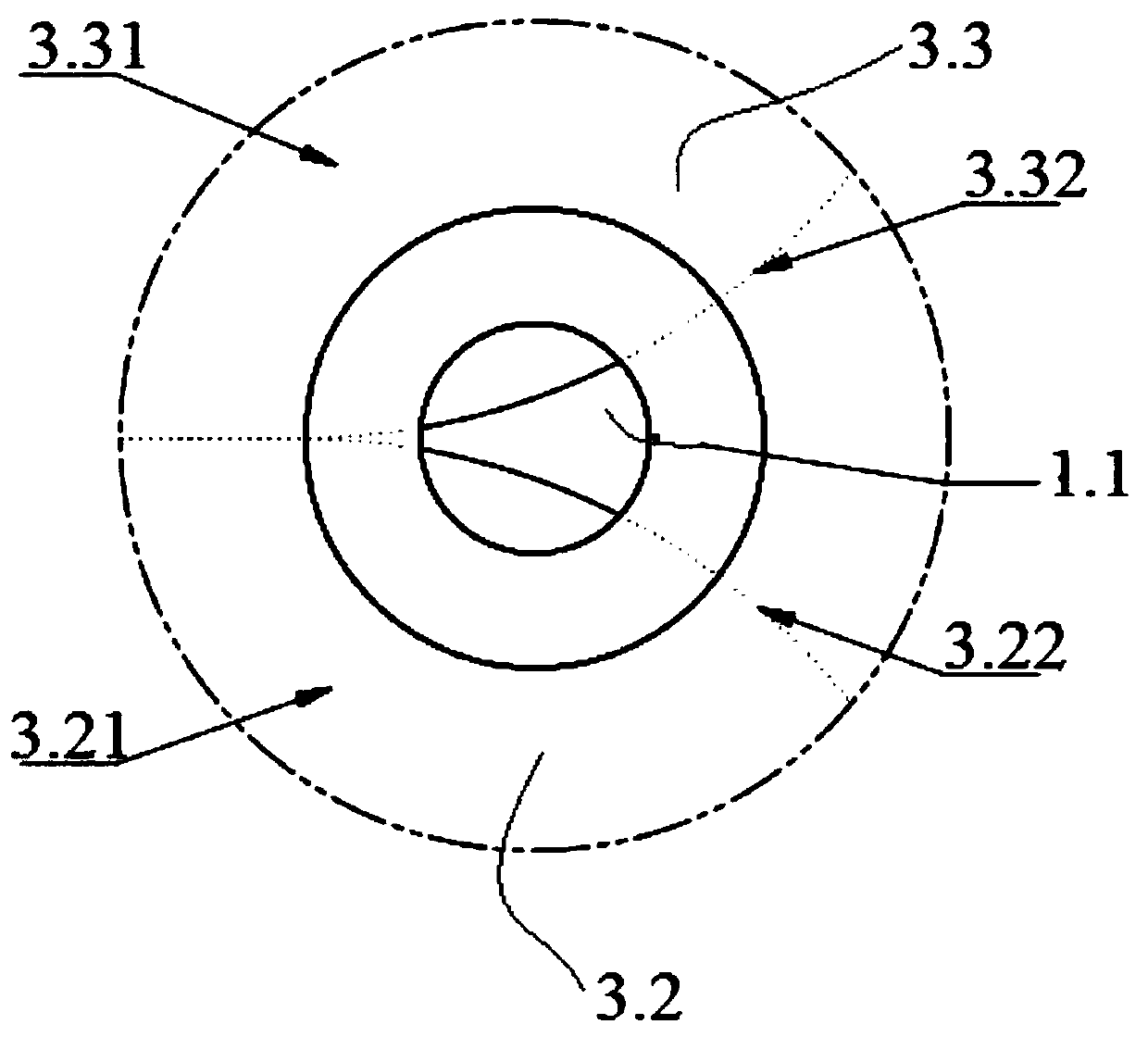

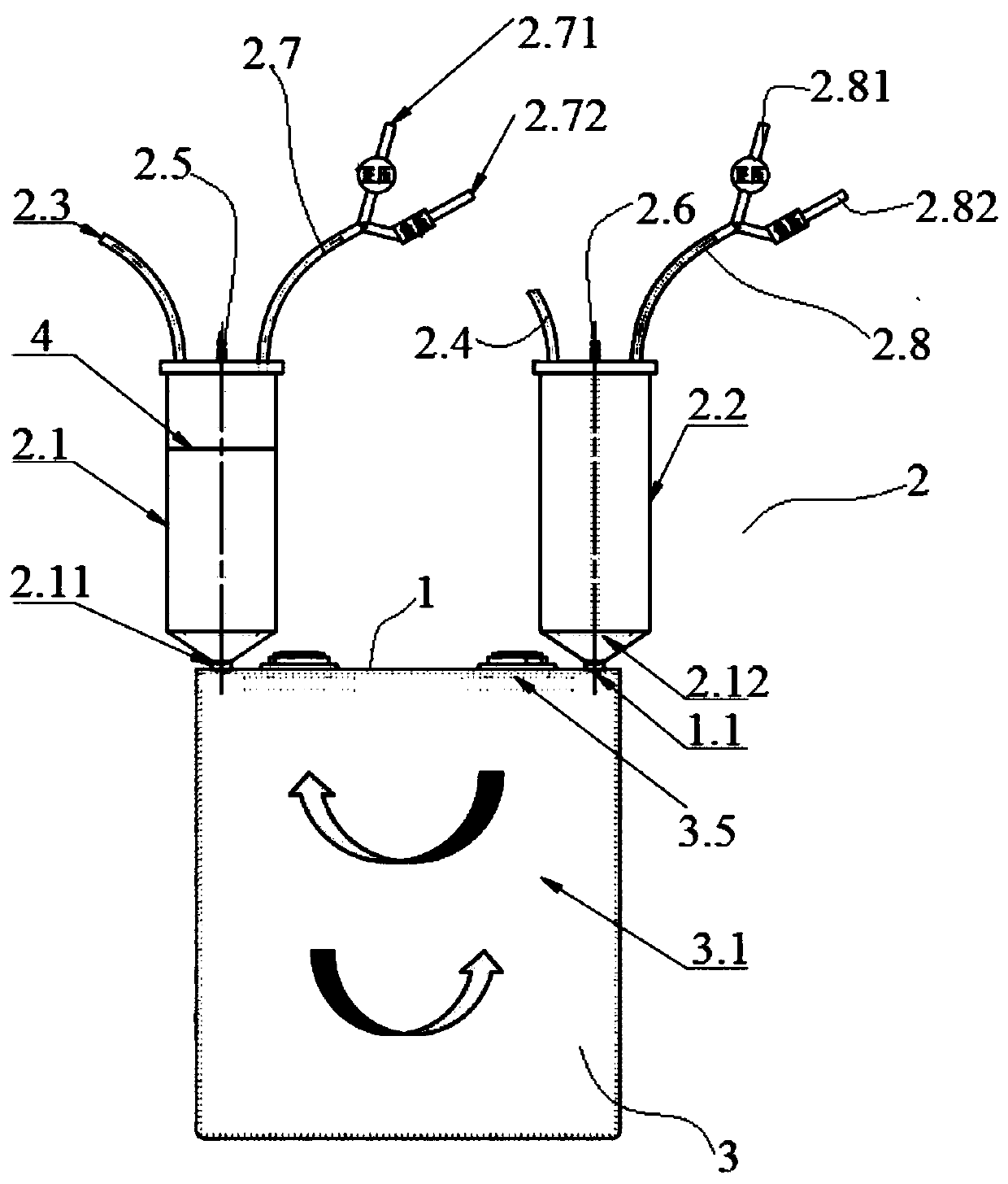

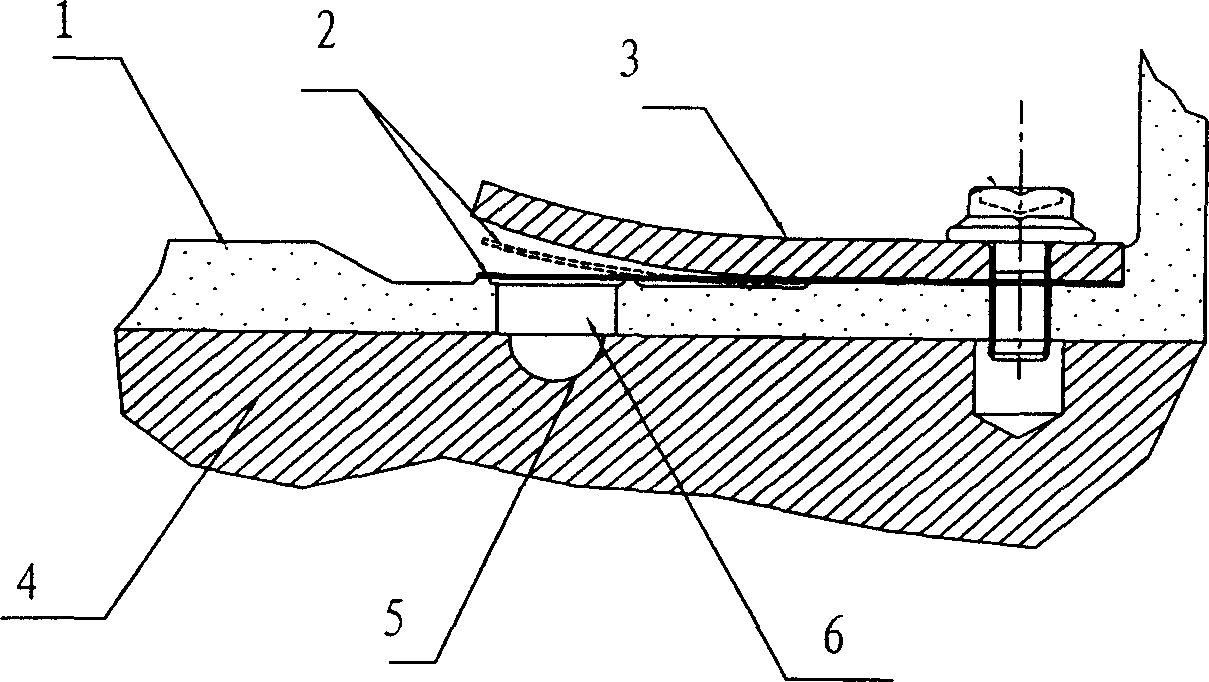

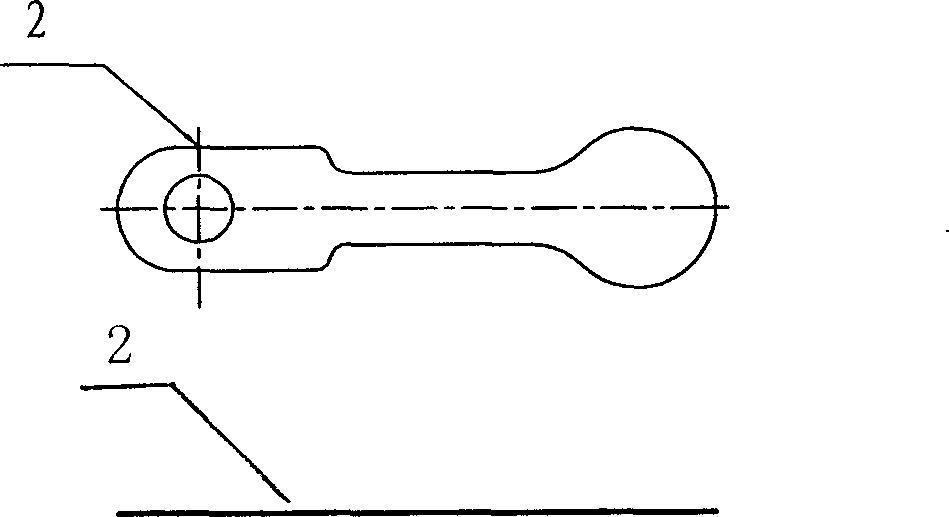

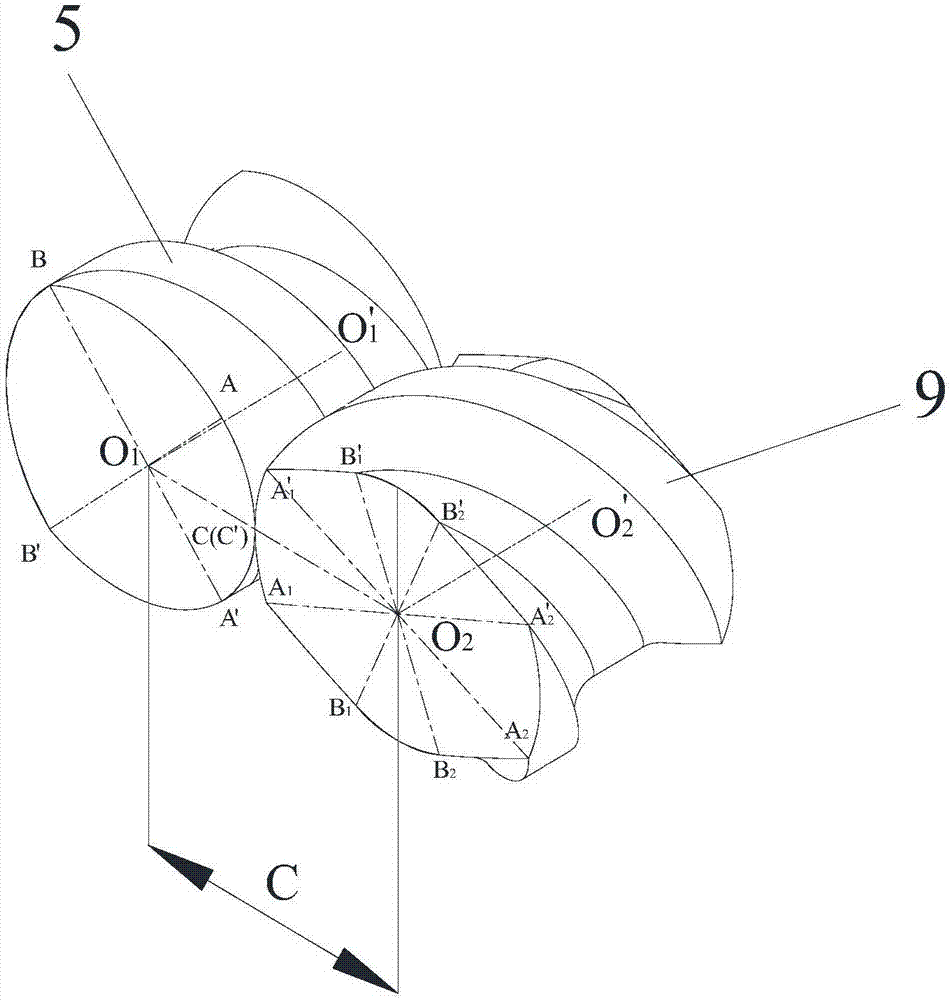

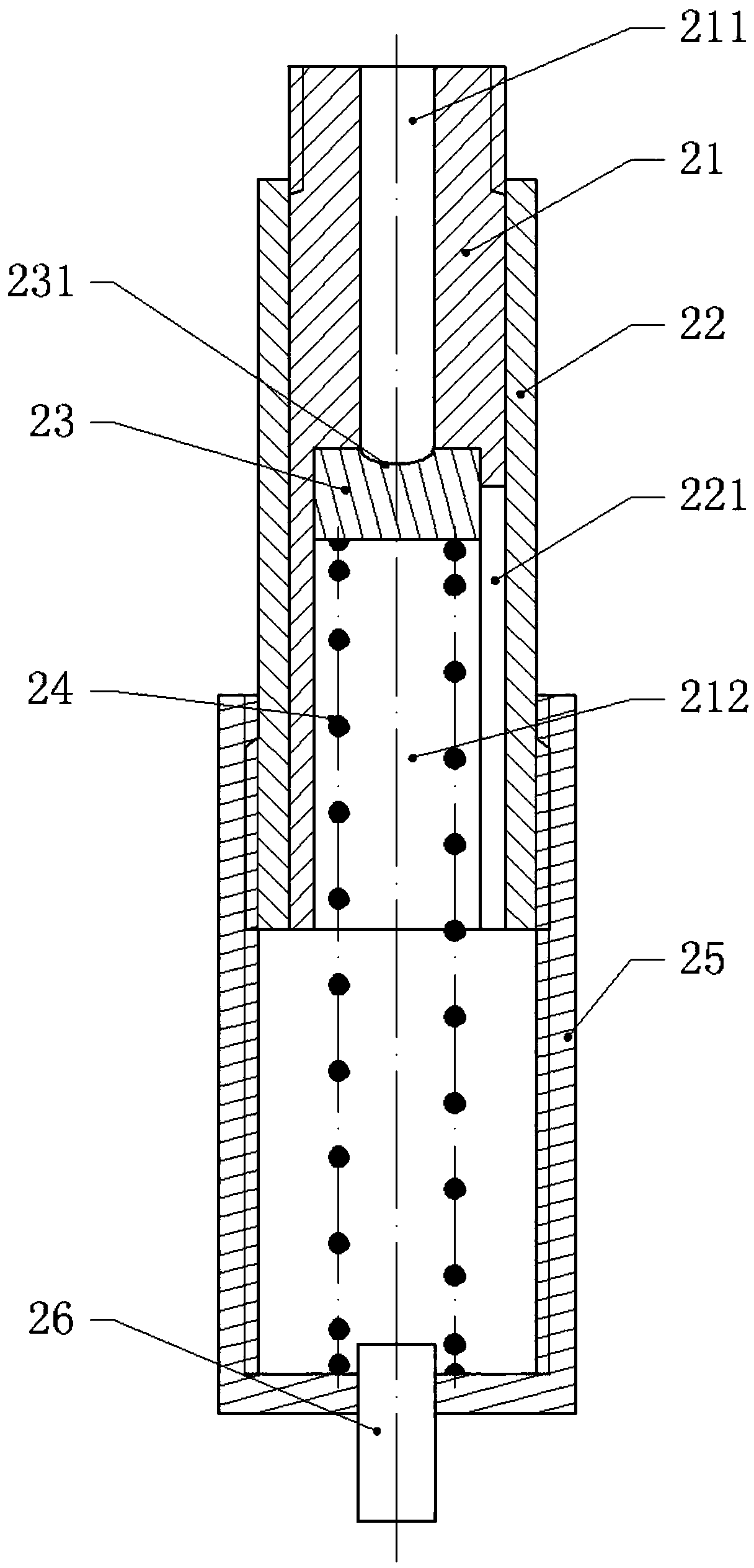

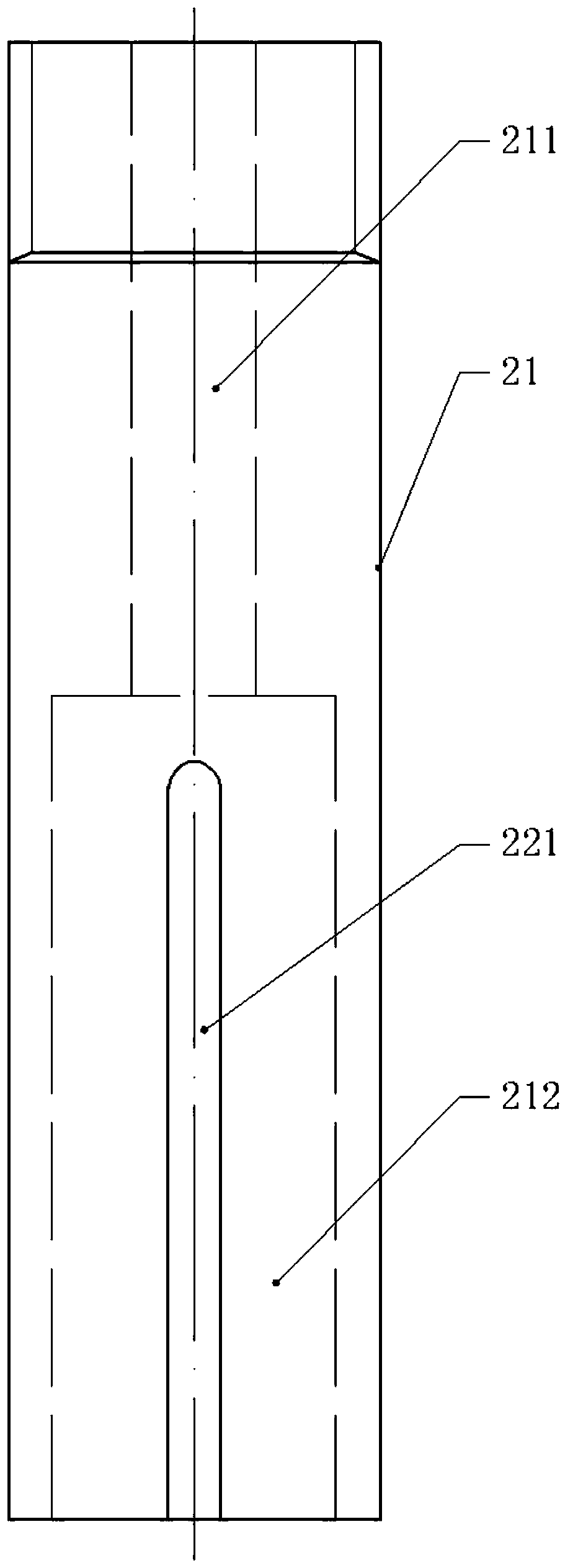

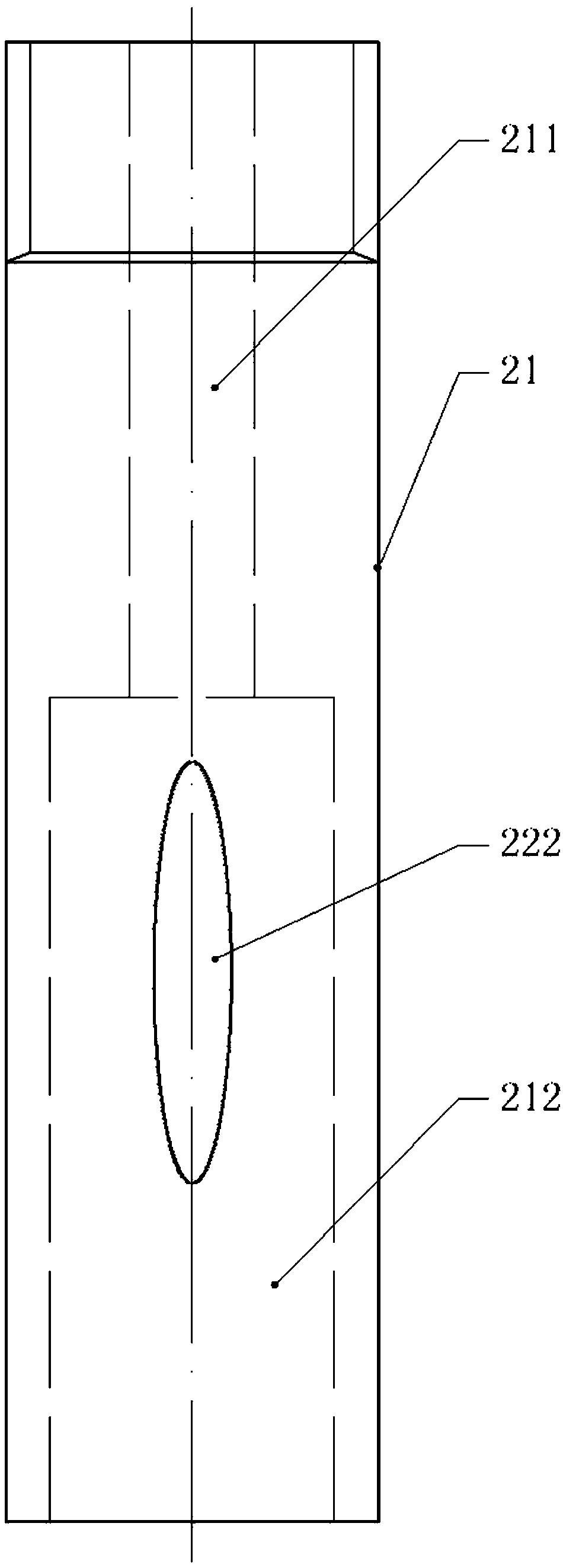

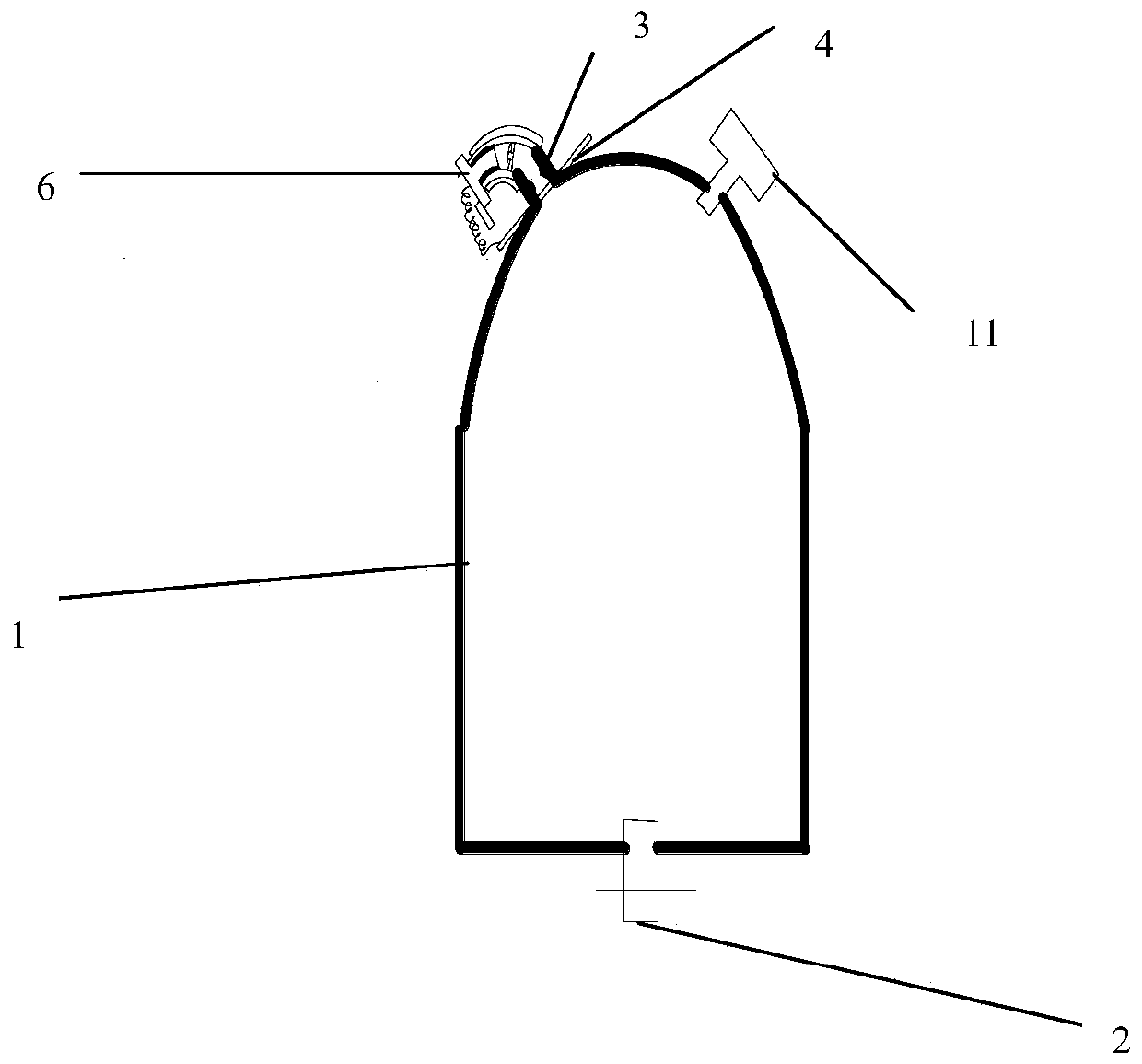

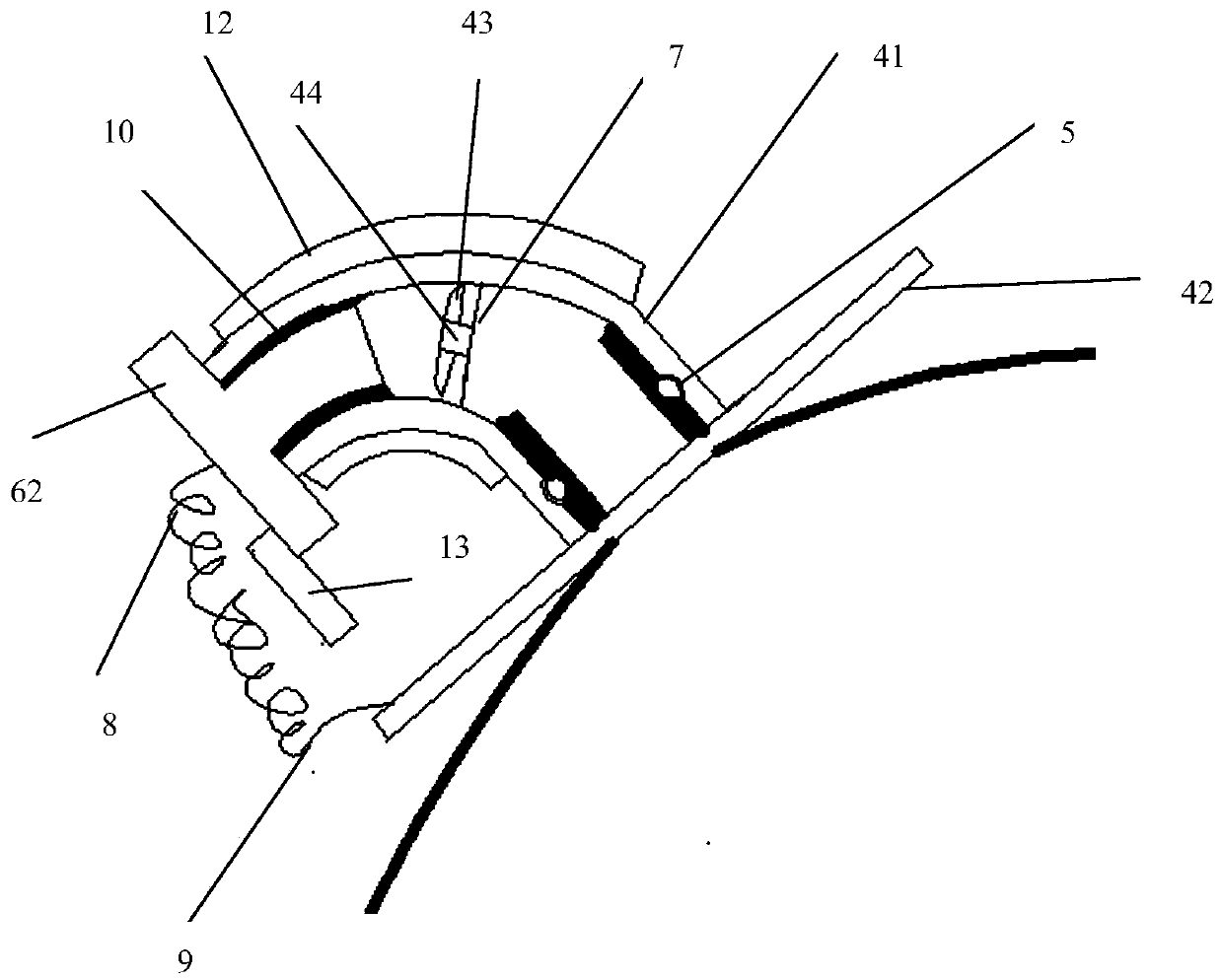

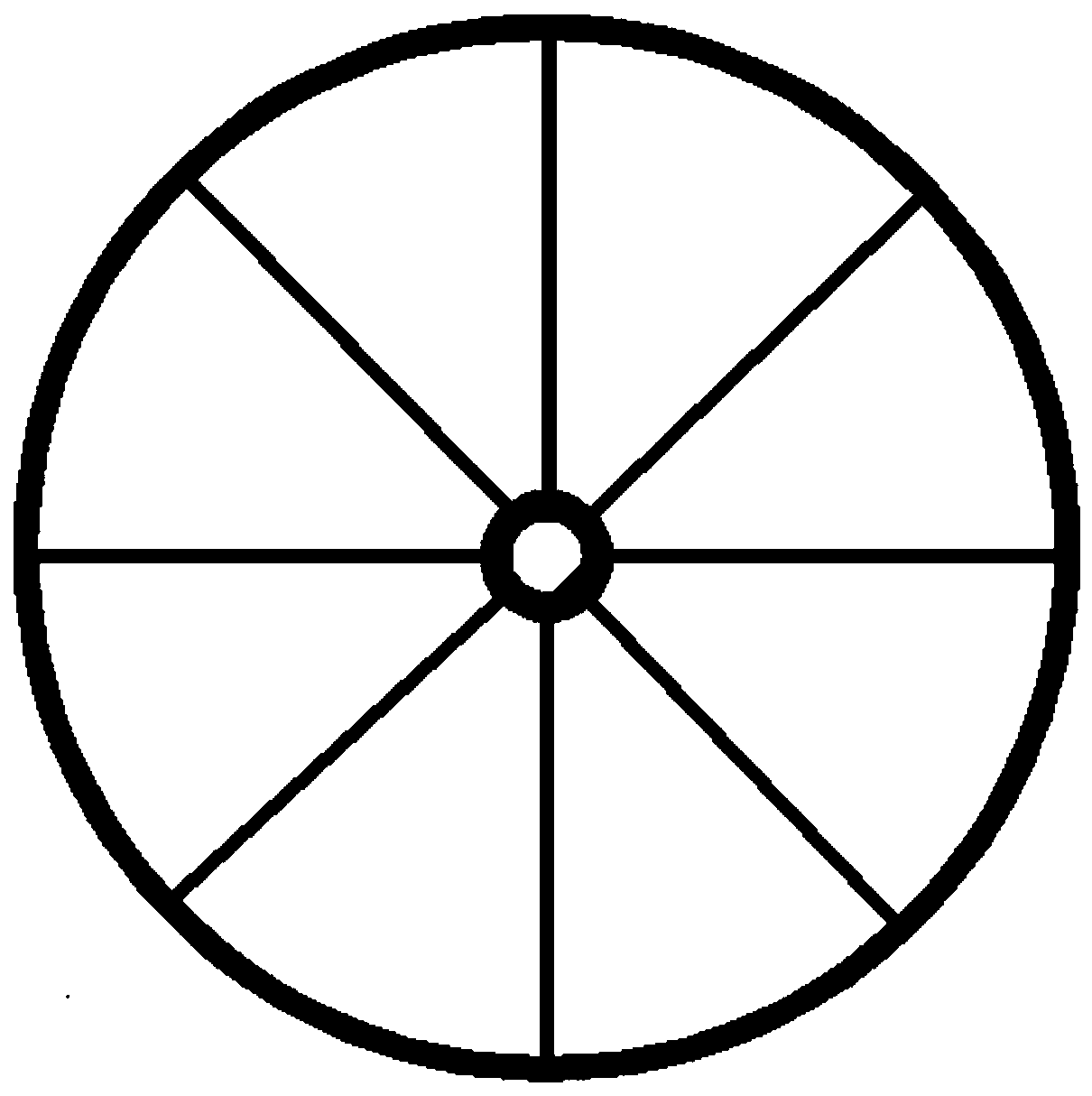

Gas exhaust device for aerostat

InactiveCN103711977AIncrease the exhaust areaSmooth dischargeOperating means/releasing devices for valvesLift valveAirbag deploymentEngineering

The invention provides a gas exhaust device for an aerostat. The gas exhaust device comprises a valve. The valve comprises a valve body and a valve cover, wherein the valve body is provided with a valve port, and the valve cover covers the valve port in an openable and closable mode. The valve body is fixed to a gas suction and exhaust port of a gas bag in the circumferential direction of the gas bag of the aerostat through a valve body installing mechanism, wherein the valve cover covers the valve port in the openable and closable mode through a control device with an opening and closing device. The opening and closing device comprises a drive mechanism and a valve cover reset mechanism, wherein the drive mechanism is connected with the valve cover and used for driving the valve cover to be vertically lifted at a preset height and driving the valve cover to tilt and be kept at a certain angle after the valve cover is vertically lifted at the preset height. The valve cover reset mechanism is connected with the valve cover and pushes the valve cover to reset to cover the valve port after the drive mechanism stops driving the valve cover. The valve cover can be vertically lifted and can tilt at the same time, the gas exhaust area is increased, collision between gas and the valve cover is reduced, and the gas exhaust speed is increased.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

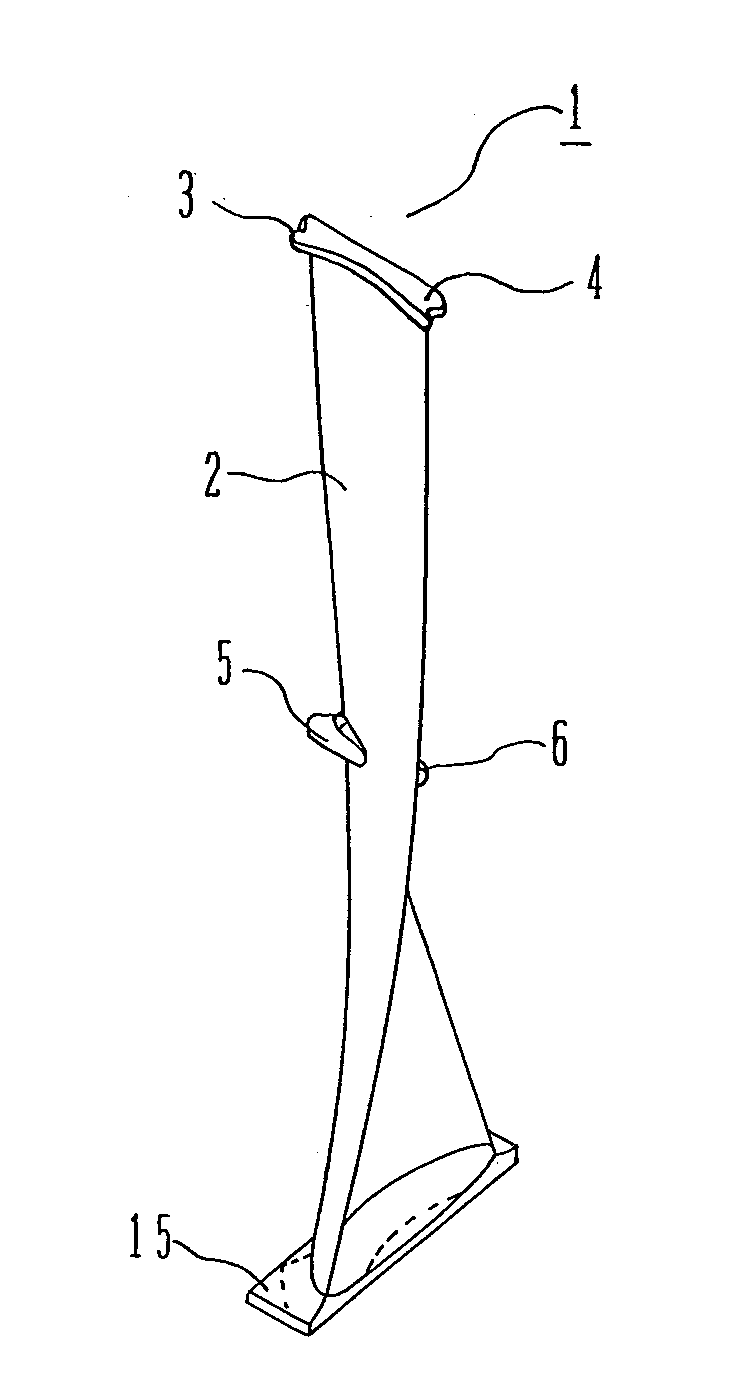

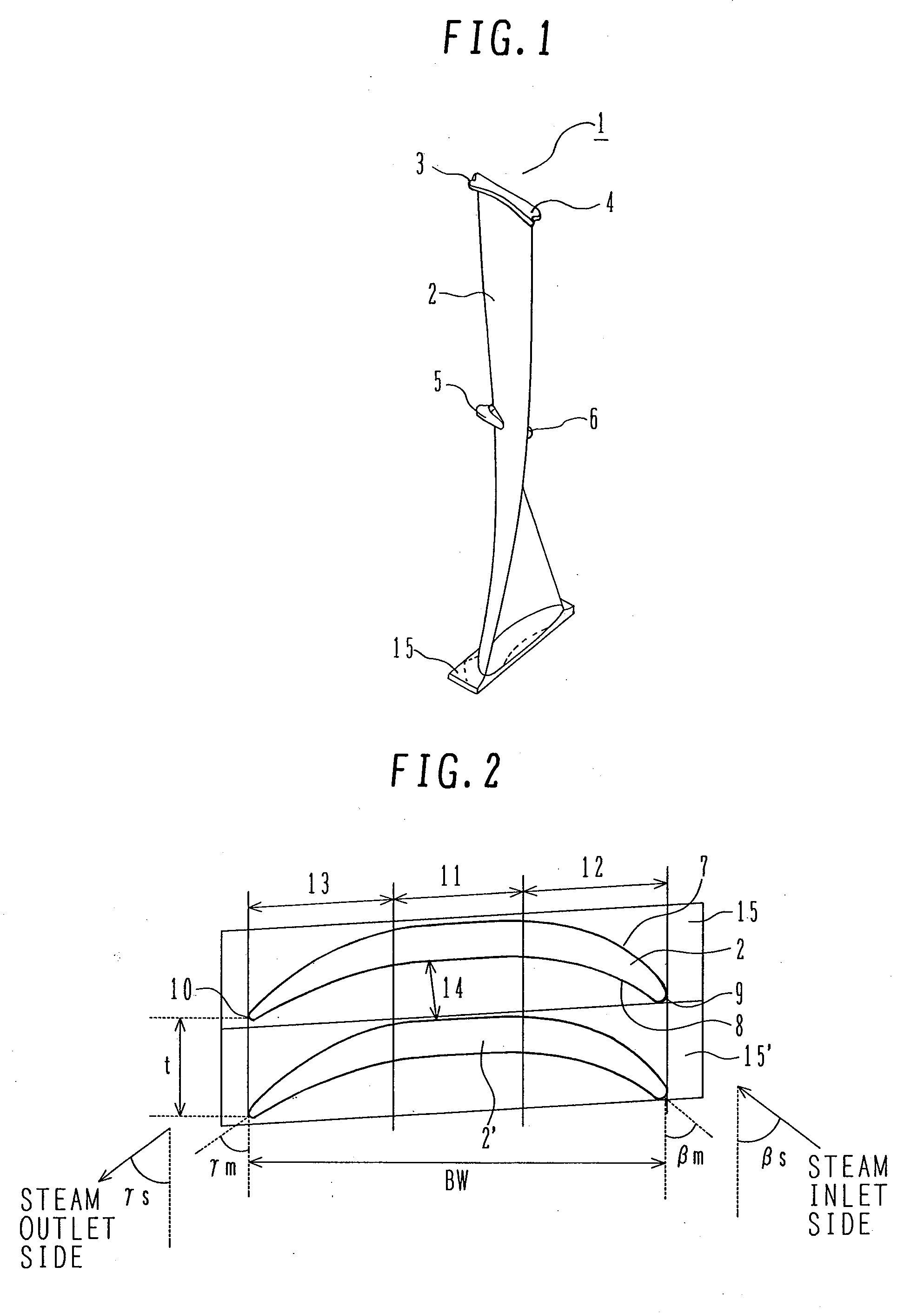

Turbine bucket

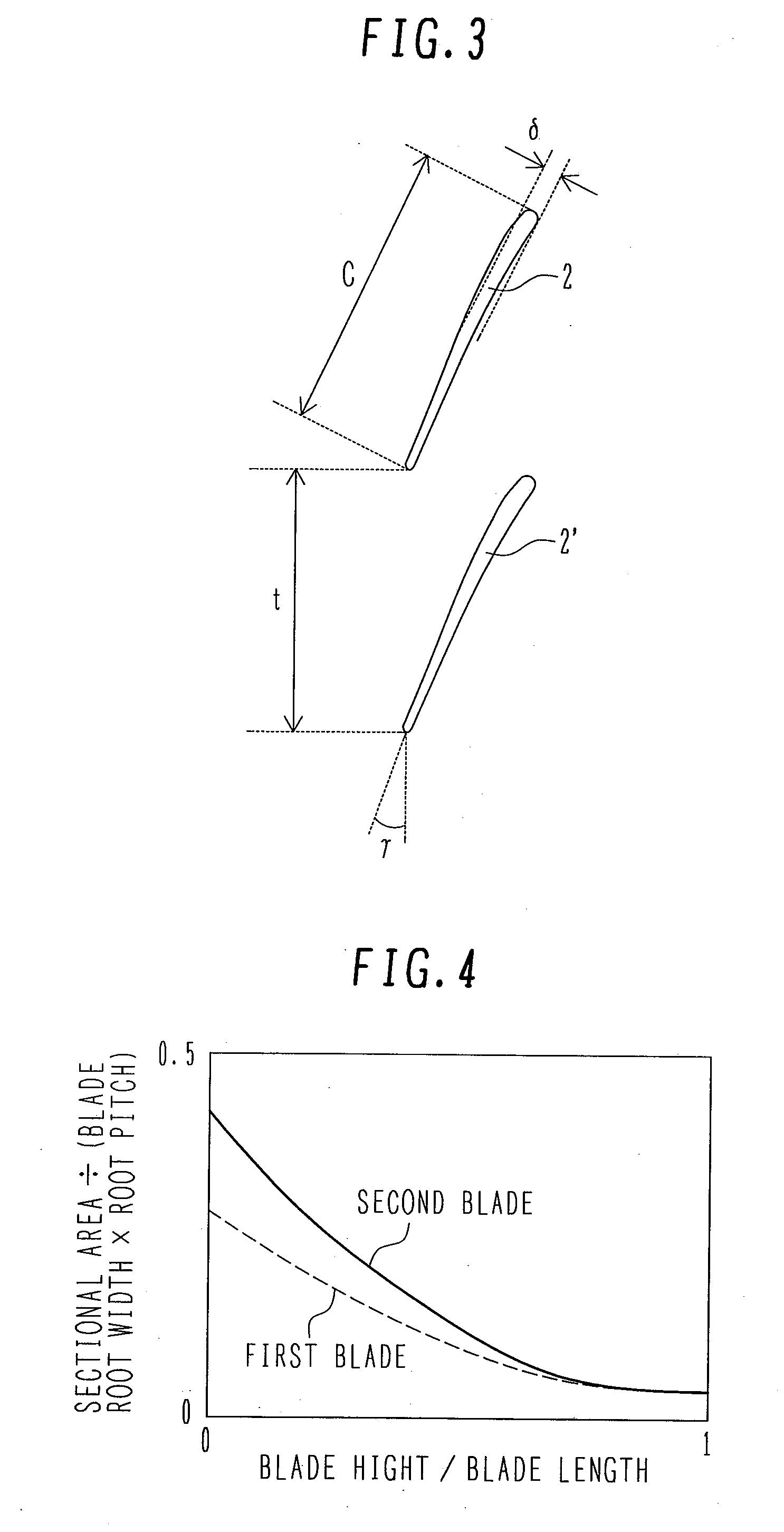

ActiveUS20080206065A1Reduce vibration responseIncrease the exhaust areaPropellersPump componentsImpellerTurbine wheel

A turbine bucket is provided that can make centrifugal stress acting on a blade or dovetail not greater than a limit value of a material and that is provided with a shape of a blade root that can ensure a steam passage even if the blade is increased in length in order to increase an exhaust area.The turbine bucket is for a steam turbine low-pressure final stage and has an exhaust area exceeding 9.6 m2 (13.8 m2) in steam-turbine final-stage buckets for a rated speed 3600 rpm (3000 rpm) machine. The turbine bucket is made of martensite steel. A blade portion of the turbine bucket has a suction surface 7 and a pressure surface 8 which are each formed, at a turbine blade root, of three areas consisting of a steam inlet side area 12 with curvature, a steam outlet side area 13 with curvature and an approximately straightly formed area put between the two areas. An airfoil of the turbine bucket root is formed such that the relationship between a blade pitch t and a turbine-axial width BW of the blade portion is BW / t≧5.

Owner:MITSUBISHI POWER LTD

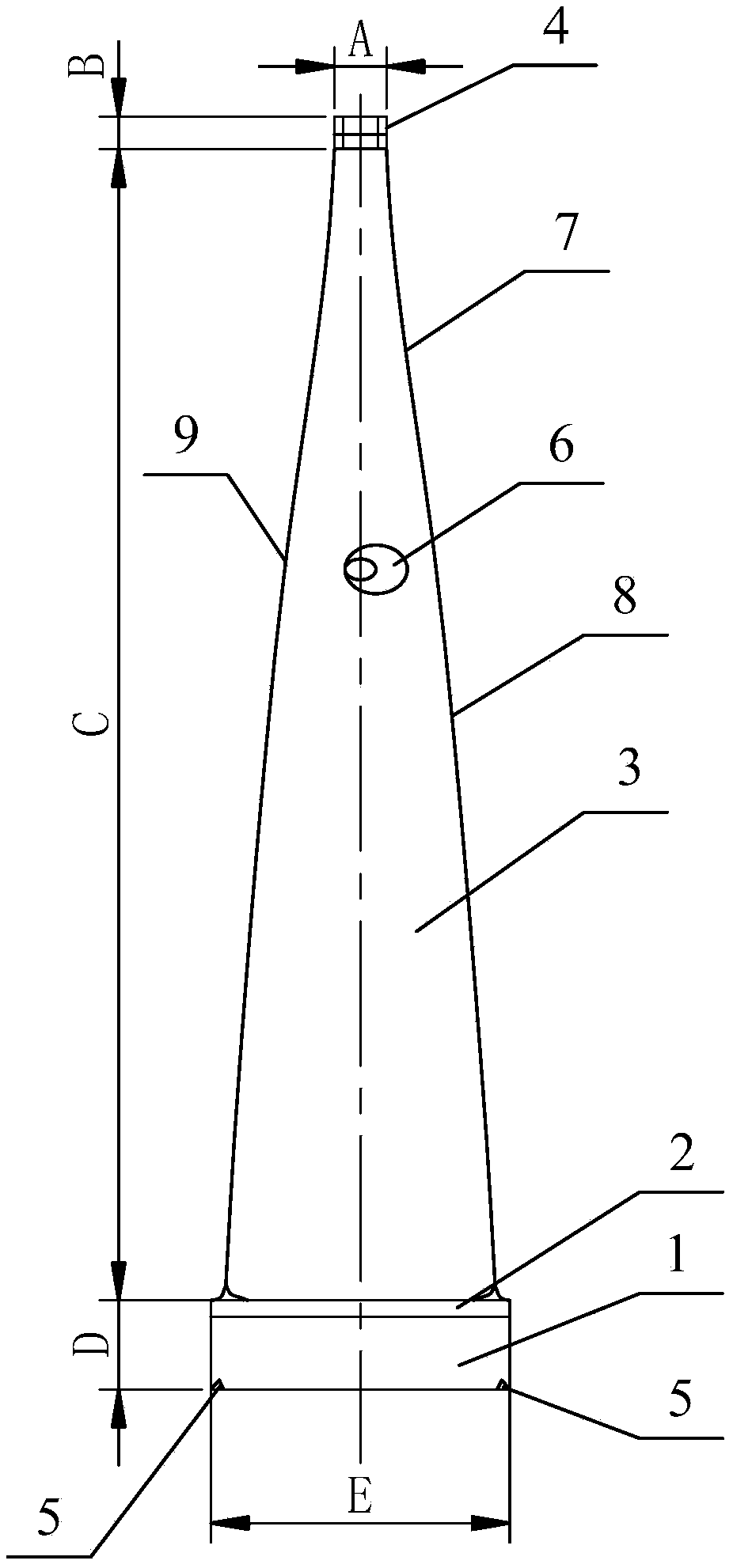

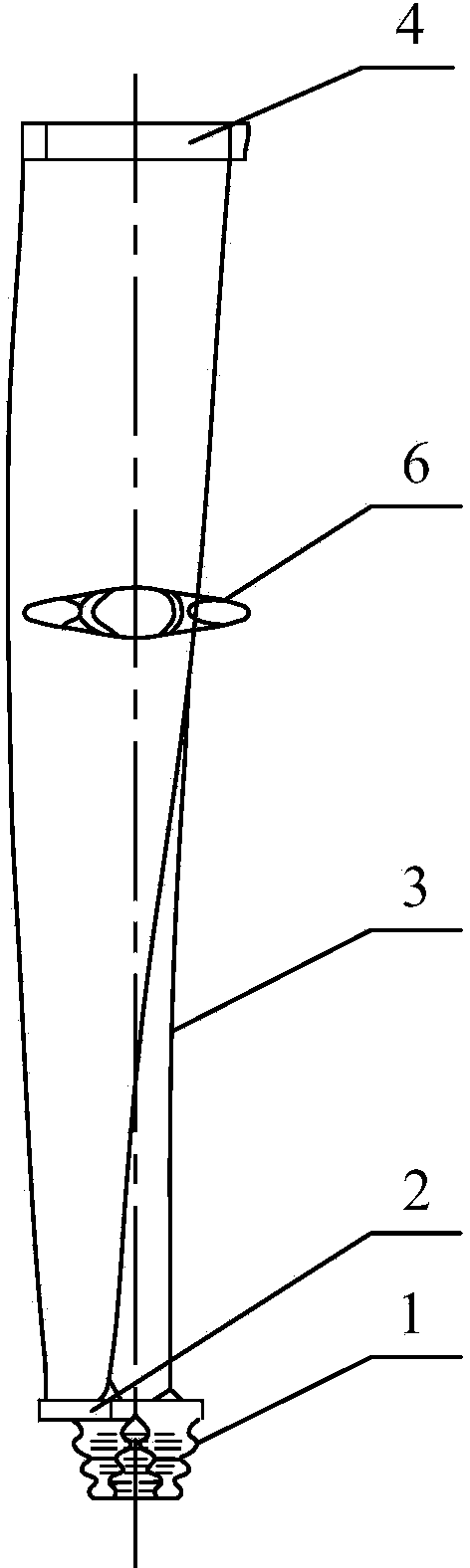

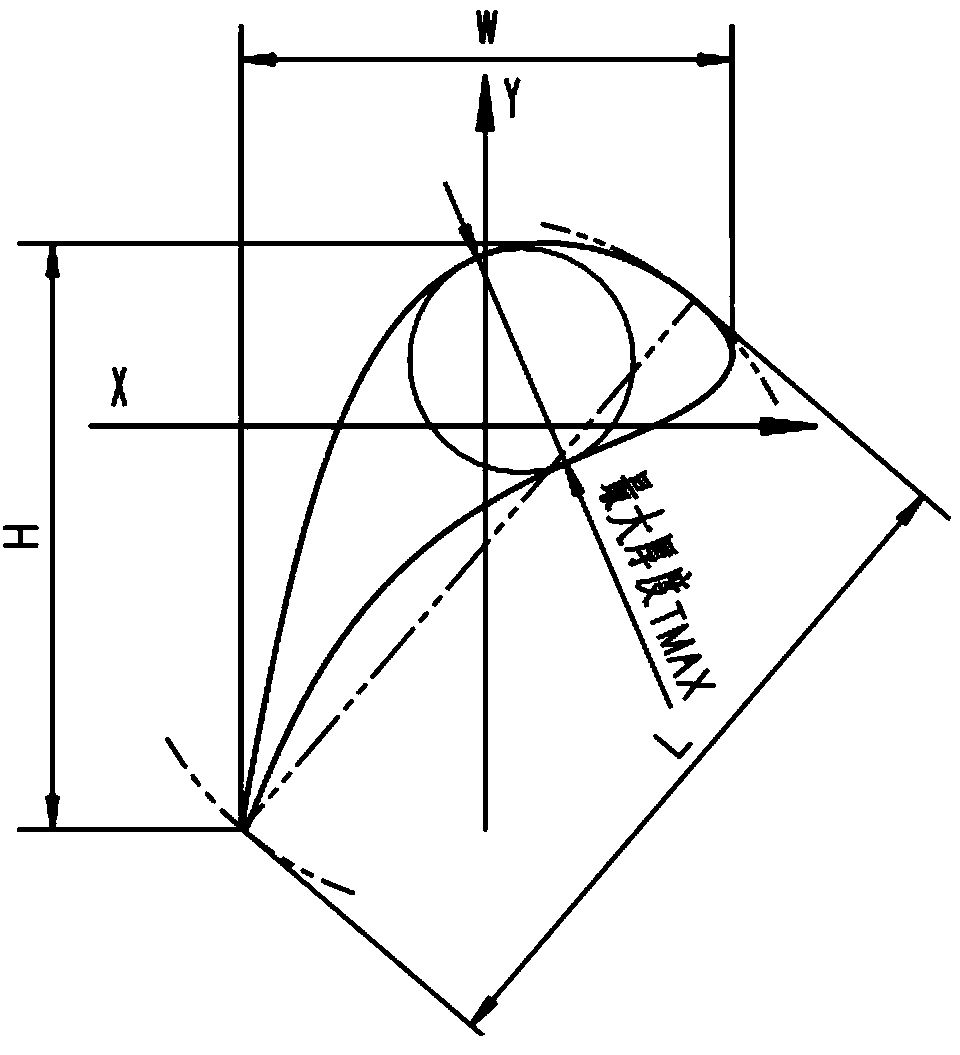

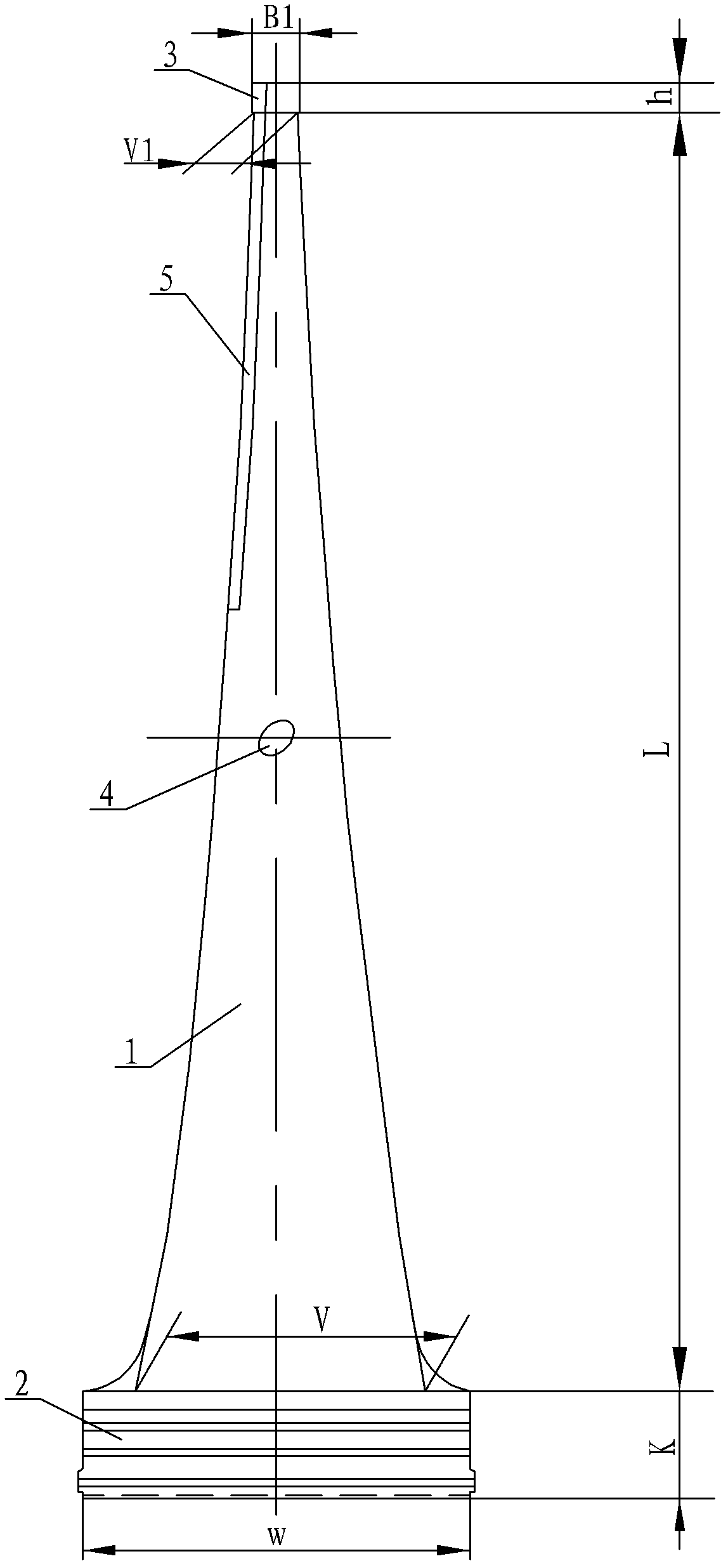

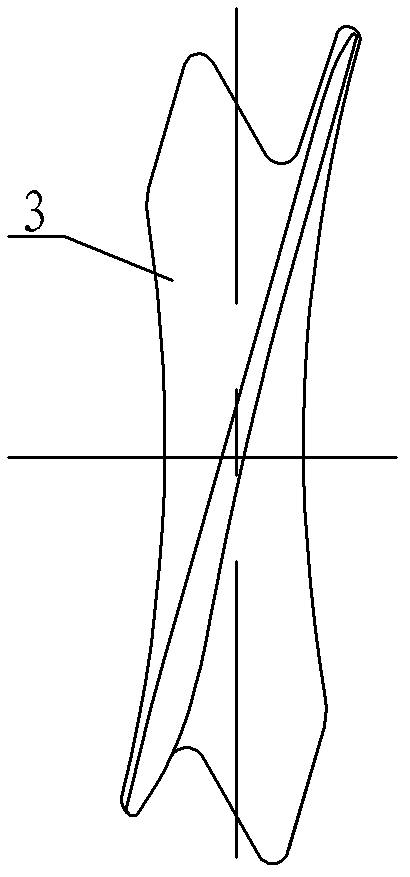

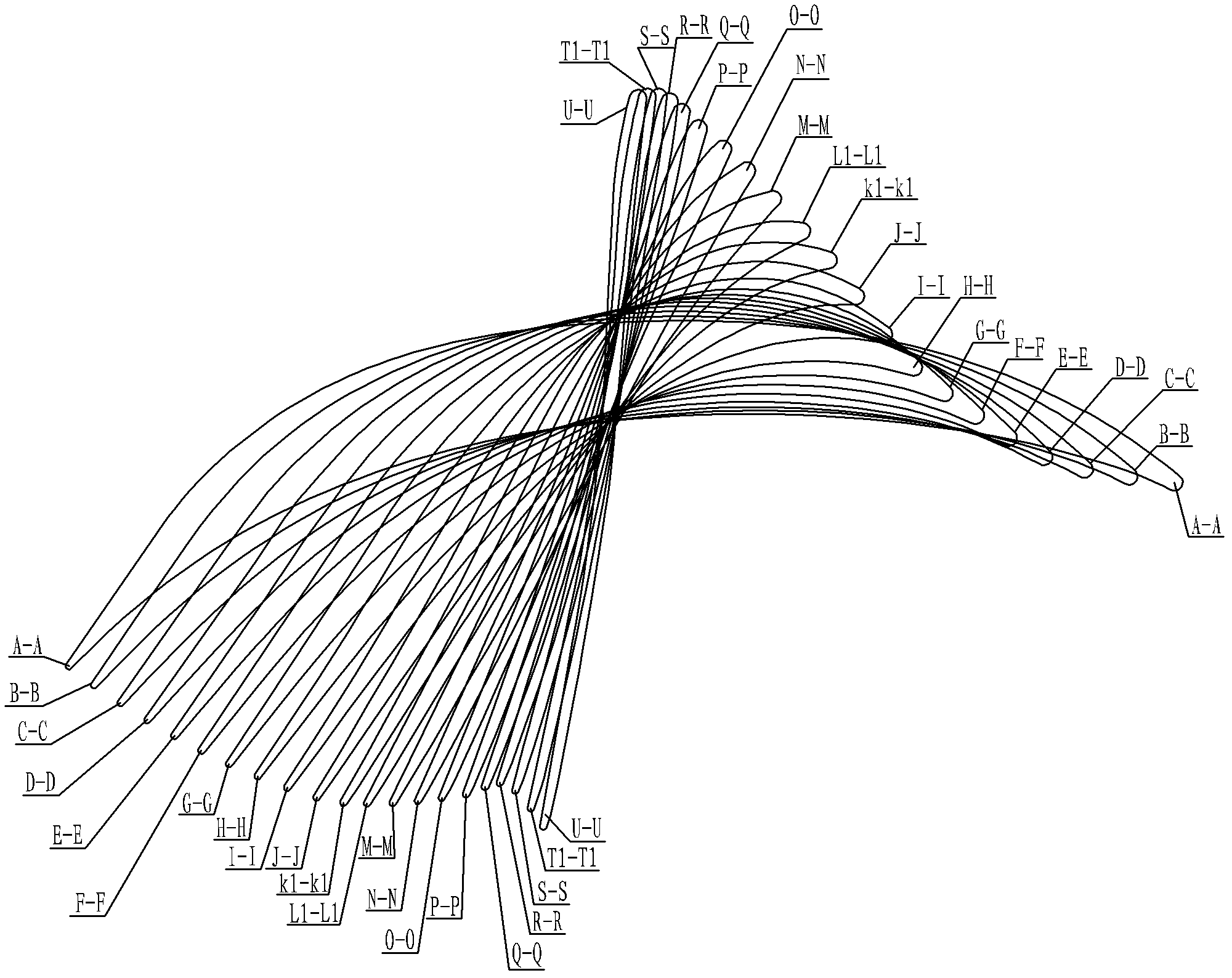

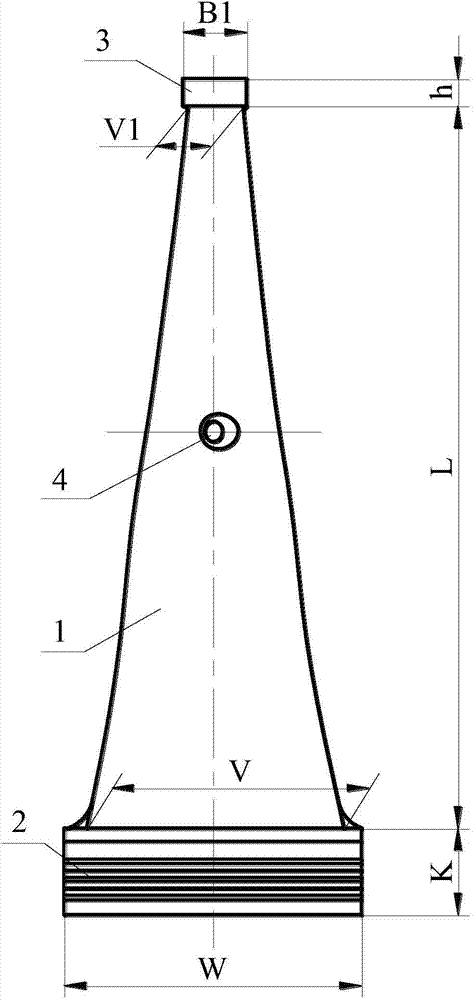

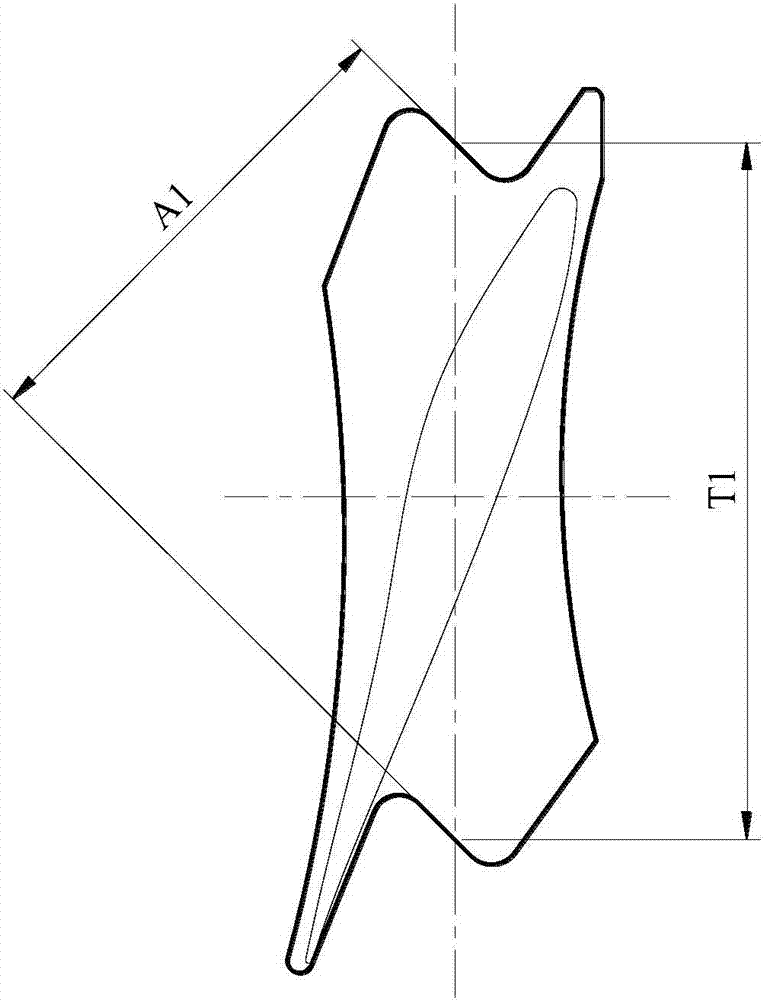

Final-stage long blade of steam turbine

ActiveCN103742203AIncrease the lengthIncrease the exhaust areaBlade accessoriesMachines/enginesPulp and paper industryTurbine

The invention provides a final-stage long blade of a steam turbine. The final-stage long blade comprises a blade root, a middle body, a blade body and a cover band which are connected in sequence, wherein the height C of the blade body is 1905mm; the relative value of the section area of the blade body is gradually reduced to 1.0 from 7.33 in the height direction of the blade body; the relative value of the molded line axial width W of the blade body is gradually reduced to 1.0 from 5.61; the relative value of the molded line circumferential width H of the blade body is gradually increased to 1.67 from 1.0; the relative value of the molded line chord length L of the blade body is gradually reduced to 1.0 from 1.40; the relative value of the maximum thickness TMAX of the blade body is gradually reduced to 1.0 from 5.89; a mounting angle alpha is gradually increased to 76 degrees from 12 degrees. The steam exhaust area of the final-stage blade is increased by increasing the length (namely the height) of a blade, and the steam exhaust area reaches 30m2 and can meet application requirements of nuclear turbines with different back pressures and unit levels, such as CAP1400 / CAP1700, and the like.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

1300mm moving blade of final stage for full-rotary-speed steam turbine

ActiveCN102359397AIncrease stand-alone capacityImprove economyBlade accessoriesMachines/enginesAlloyEngineering

The invention discloses a 1300mm moving blade of the final stage for a full-rotary-speed steam turbine, and relates to a moving blade of the final stage for a full-rotary-speed steam turbine, and the moving blade is used for solving the problems of less length, small steam exhaust discharge area, great energy source consumption of the moving blade of the final stage for the full-rotary-speed steam turbine, and incapability of reaching higher economy requirement. A shroud, a blade operation part and a blade root are subjected to die forging integrally from top to bottom; a boss tie piece is positioned at the middle part of the blade operation part, and is integrated with the blade operation part; a stelite alloy sheet is sticked to the steam inlet side at the upper part of the blade operation part; the height of the blade operation part is 1300mm, the axial width of the root part is 346.62mm, the diameter of the root part is 1850mm, the steam exhaust area of the blade operation part is 12.86m<2>, and the axial width of the blade root is 400mm. The moving blade of the final stage provided by the invention is used for the full-rotary-speed steam turbine with the power between 600MW and 1000MW.

Owner:HARBIN TURBINE +1

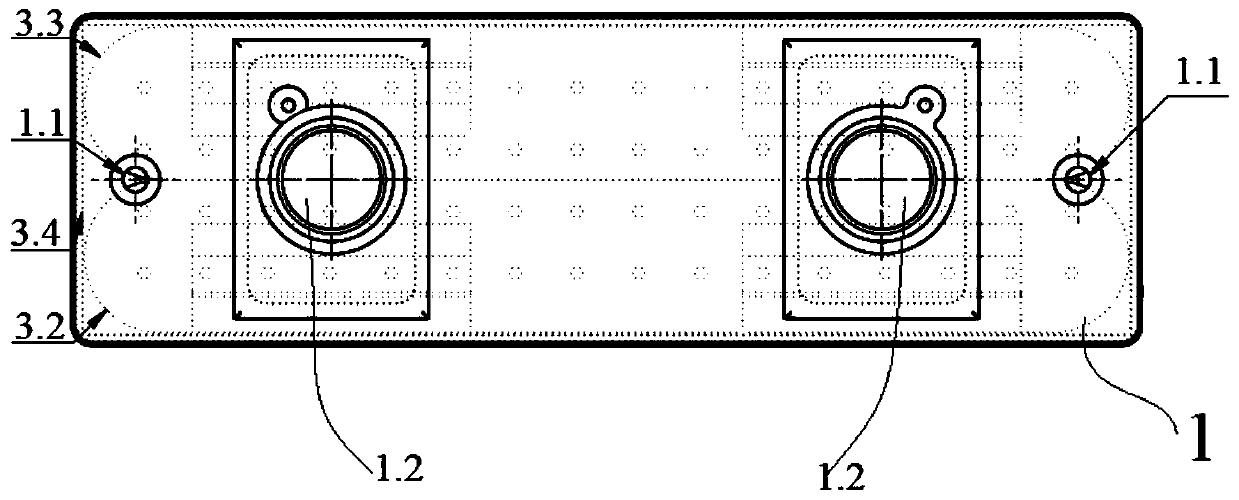

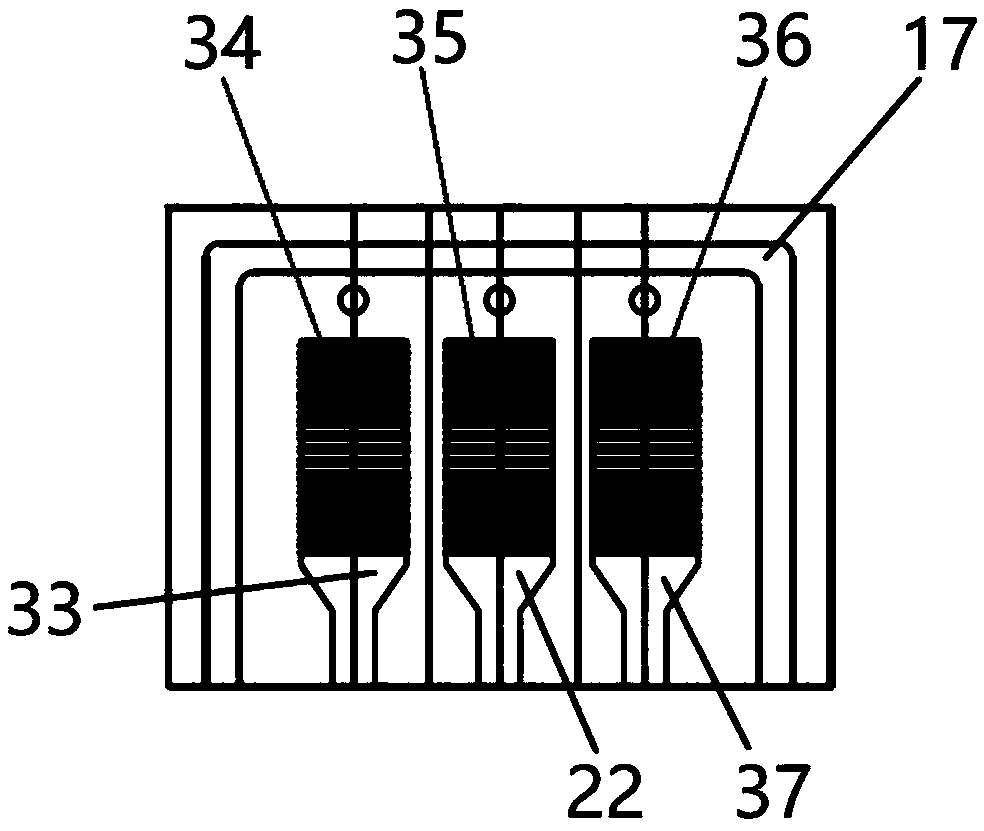

Double-hole lithium ion cover plate and rocking-chair type liquid injection device and method thereof

InactiveCN110416445ALower hair drumRapid infiltrationSecondary cellsCell lids/coversEngineeringLithium-ion battery

The invention discloses a double-hole lithium ion cover plate and a rocking-chair type liquid injection device and method thereof, and belongs to the technical field of lithium ion battery process preparation. The double-hole lithium ion cover plate comprises a first liquid injection hole and a second liquid injection hole which are formed in the two ends of the cover plate respectively, wherein each liquid injection hole is located above an r angle of an A pole core and a B pole core of a lithium ion battery. The cover plate is also provided with welding sites used for being fixedly connectedwith positive and negative lugs. During liquid injection, the double-hole lithium ion cover plate is arranged above the lithium ion battery body and welded and fixed together, and liquid is injectedthrough the liquid injection cups at the left end and the right end, enters the battery in a vacuum state, and can be dispersed in multiple directions and quickly infiltrated after entering a batterycell. The liquid injection time of a single battery is short, and the quick liquid injection requirement is met; and during formation and capacity grading, the internal produced gas can be divided anddischarged through the double liquid injection holes, so that the exhaust area is increased, the bulging of the battery is reduced, and the abnormal phenomenon of liquid overflow is eliminated.

Owner:湖北锂诺新能源科技有限公司

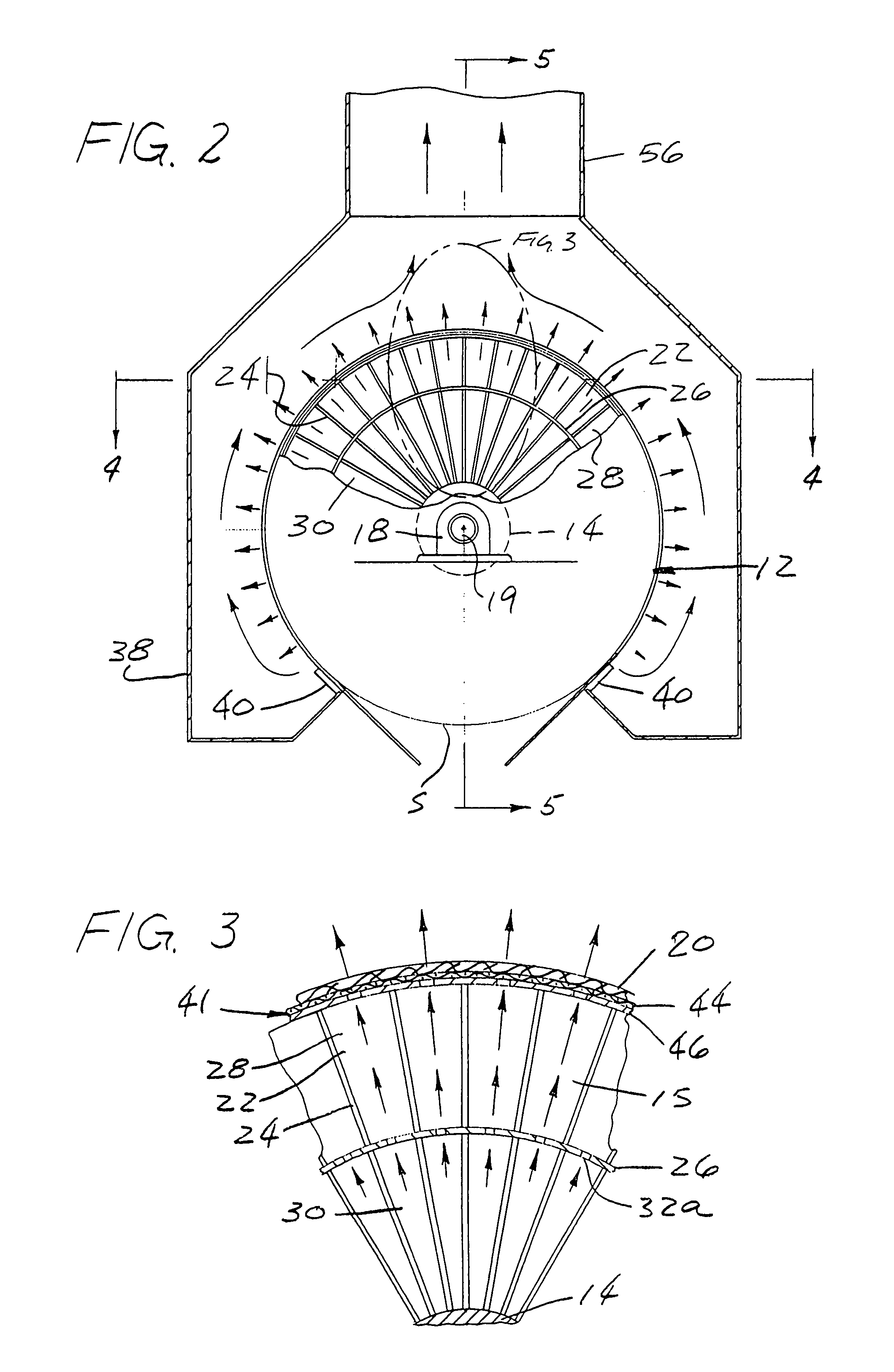

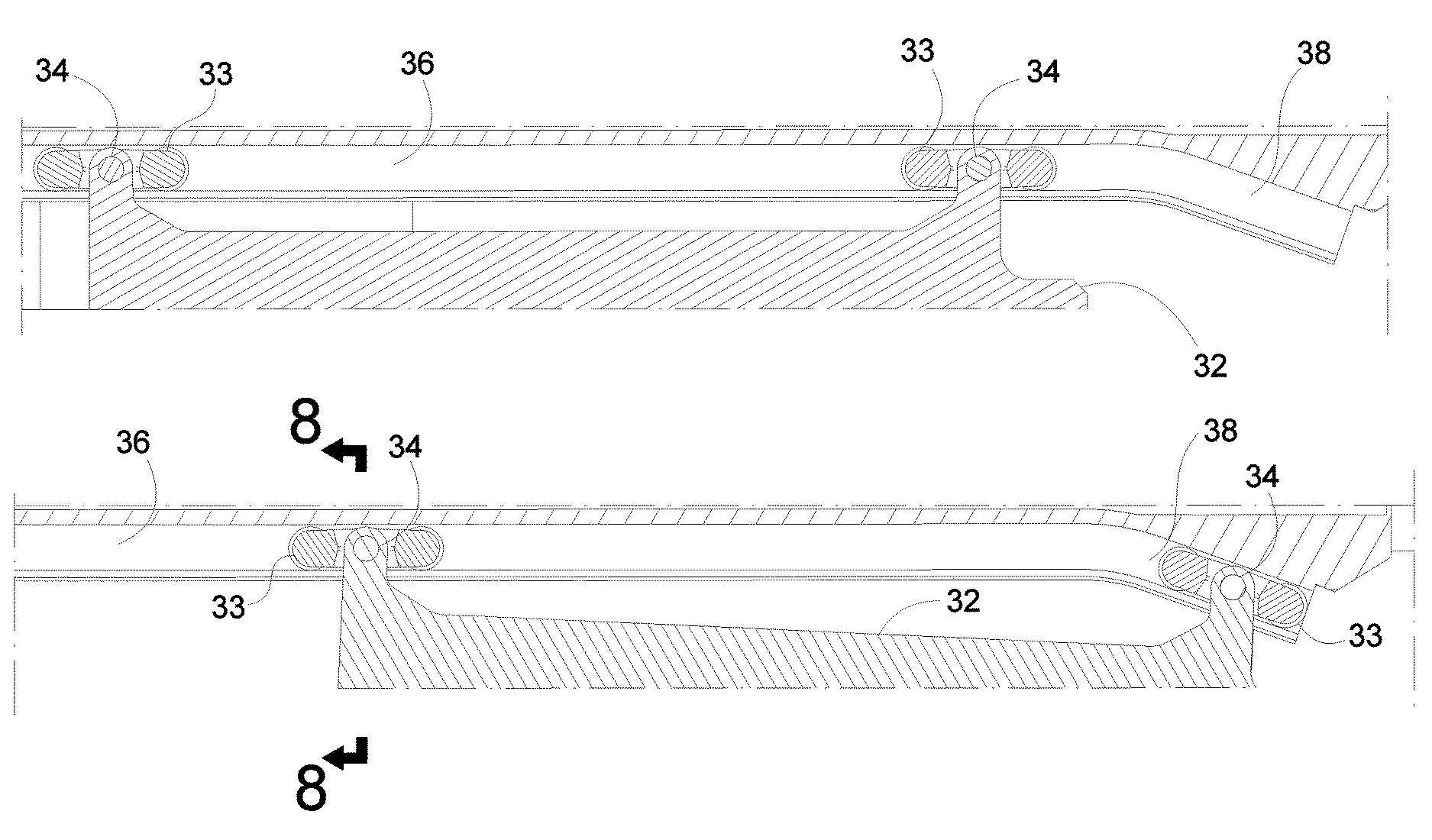

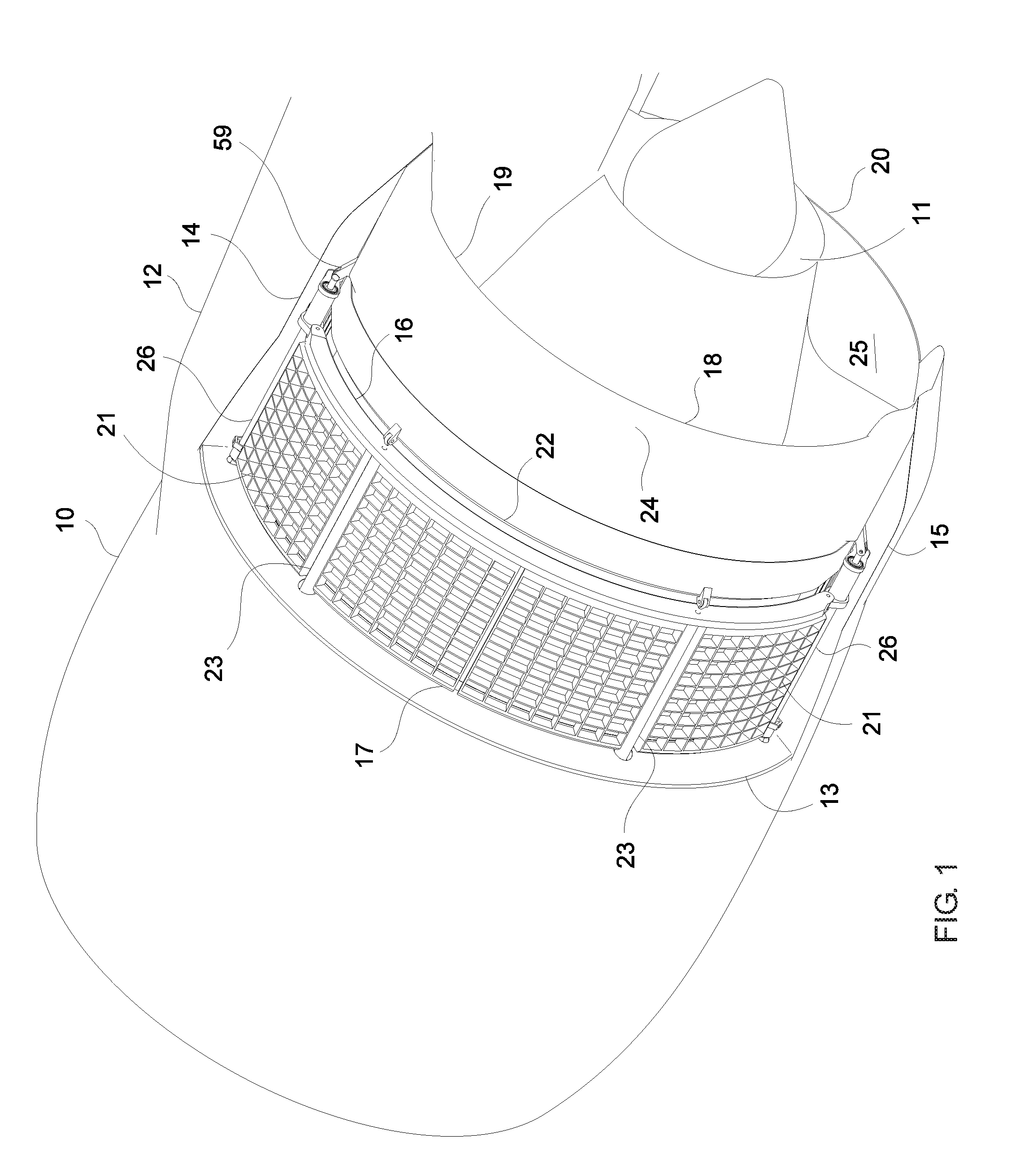

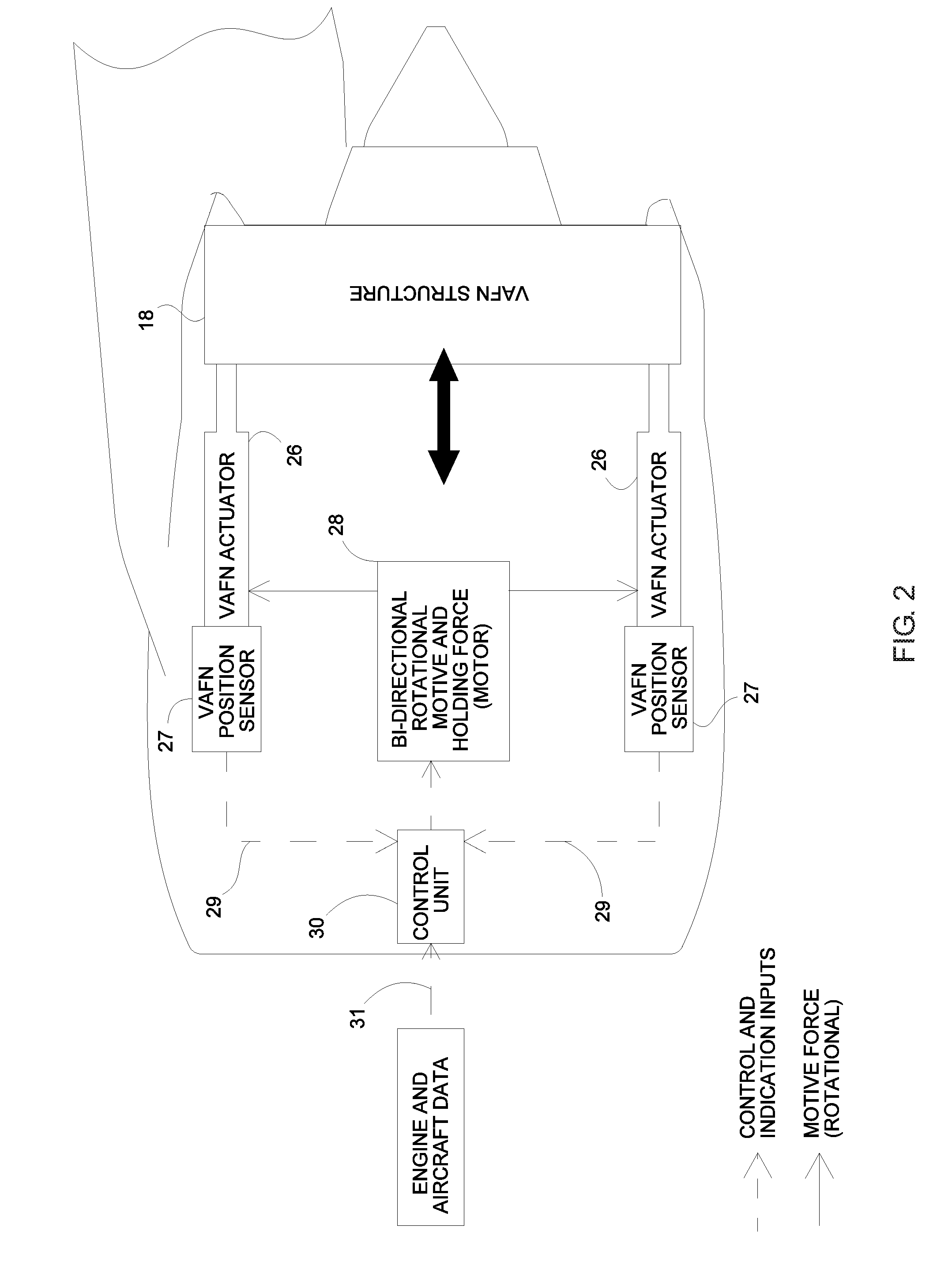

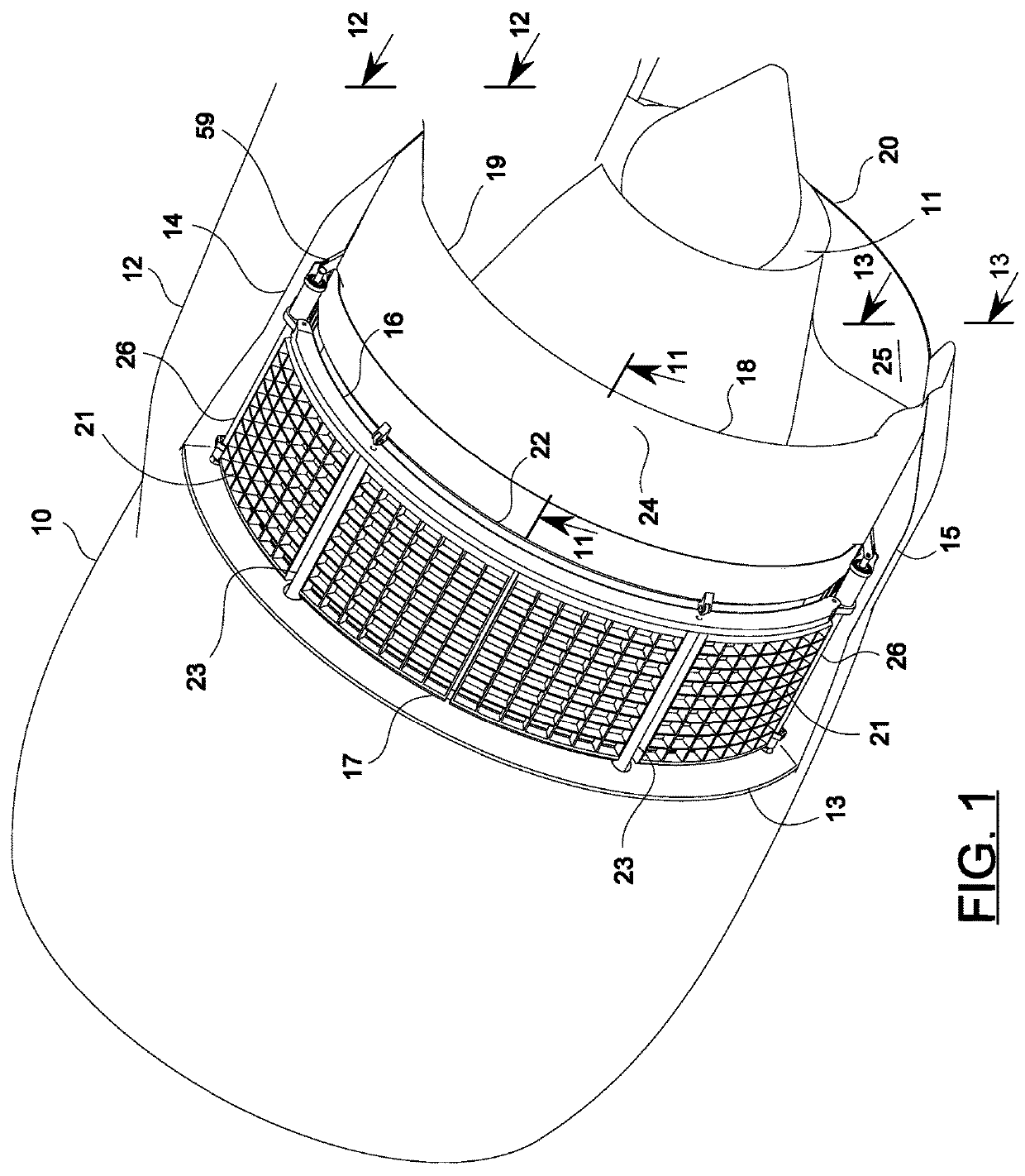

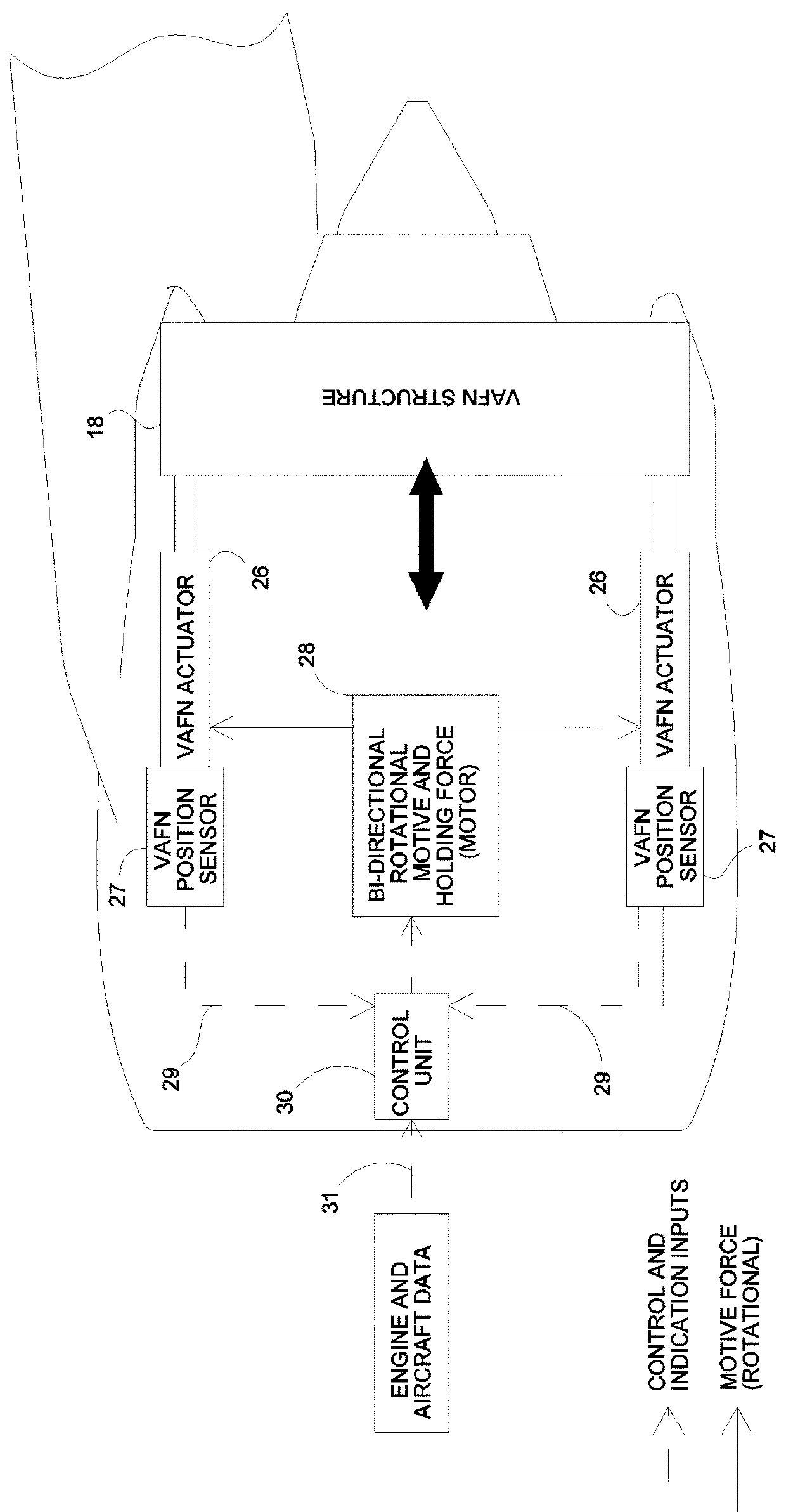

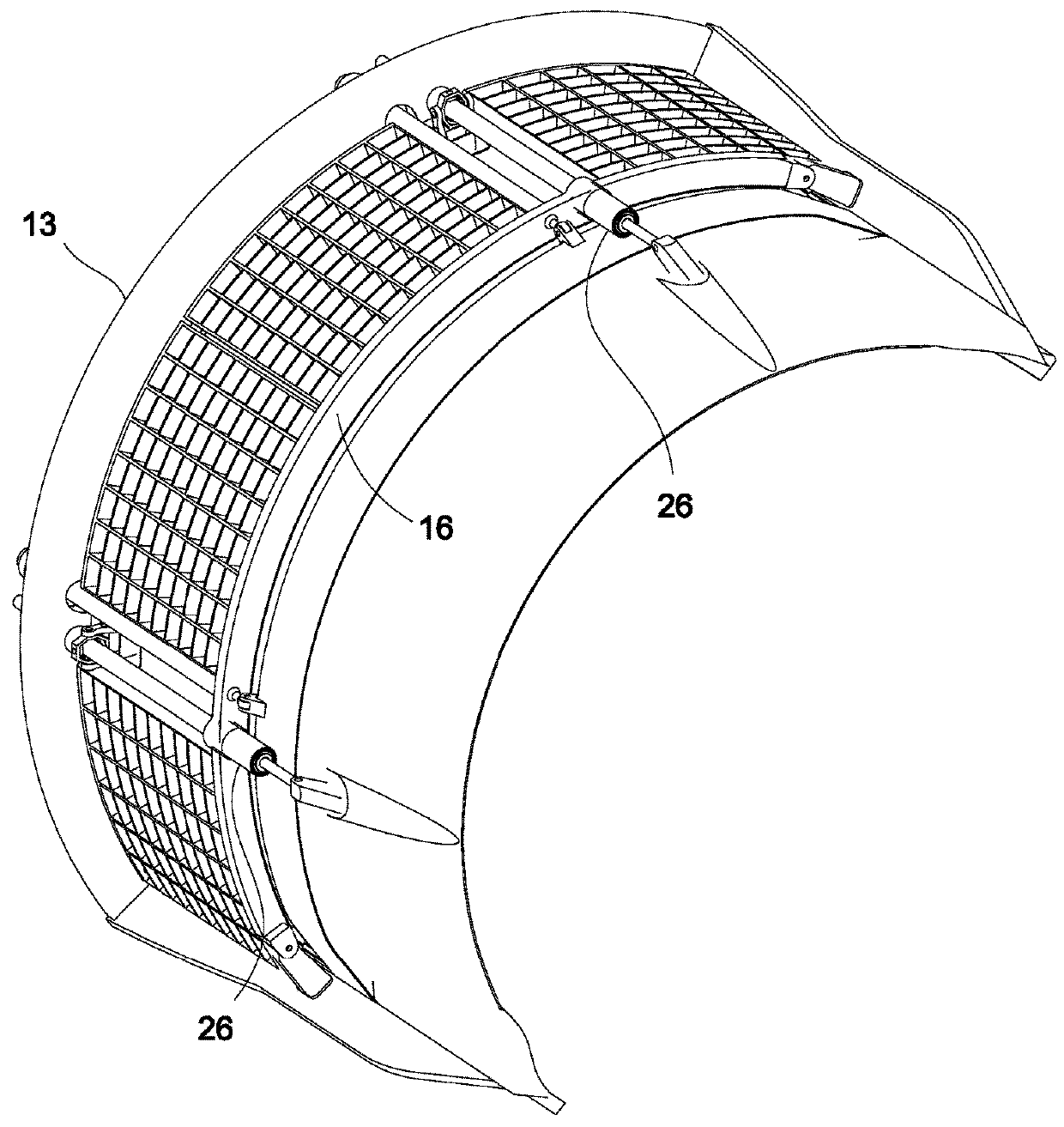

Axially translating and radially tilting fan nozzle segments with combined actuation and position sensing

ActiveUS9581109B1Increase the exhaust areaShort actuator strokePump componentsEngine fuctionsLinear variable differential transformerNacelle

An aircraft engine variable area fan nozzle structure disposed abaft a thrust reverser, including a sleeve translatable over a cascade array, comprises two semi cylindrical segments that can be axially translated and radially tilted to enlarge the fan duct exhaust area in order to optimize exhaust pressure and associated noise in high thrust circumstances such as on take-off, and to constrict that area under lower thrust conditions such as cruise. The segments are moved by actuators anchored to the fixed engine framework and independently of the thrust reverser translating sleeve. Each actuator incorporates a linear variable differential transformer acting as a fan nozzle position sensor. The tilting movement is imposed by the pivoting links of each segment to carriages that ride in a non-linear trackway secured to a thrust reverser translating sleeve slider. In an alternate embodiment of the invention, the thrust reverser sleeve actuator and the variable area fan nozzle actuator are coaxially mounted in a compact assembly anchored to stationary components of the nacelle.

Owner:PINTO GEOFFREY P

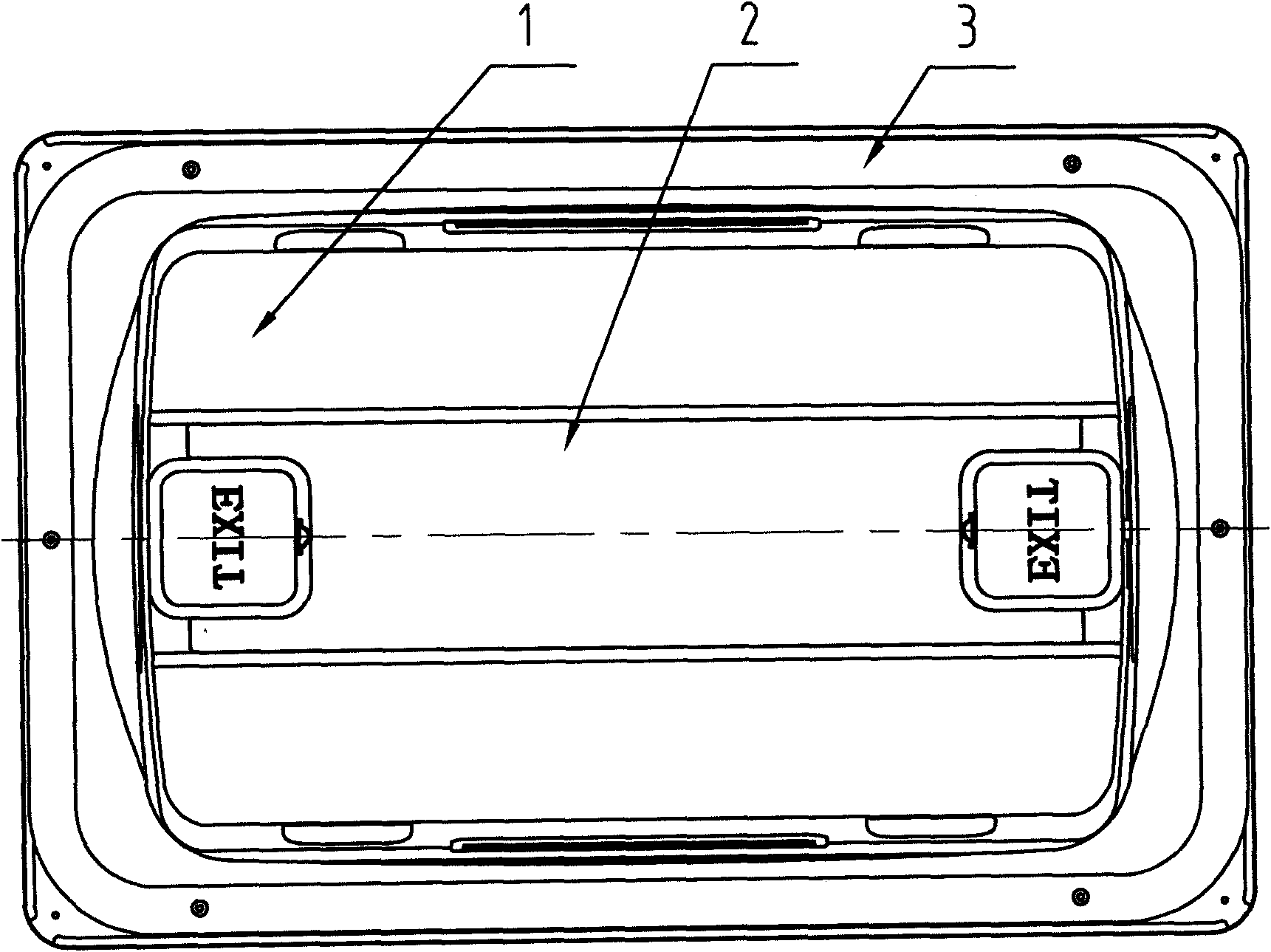

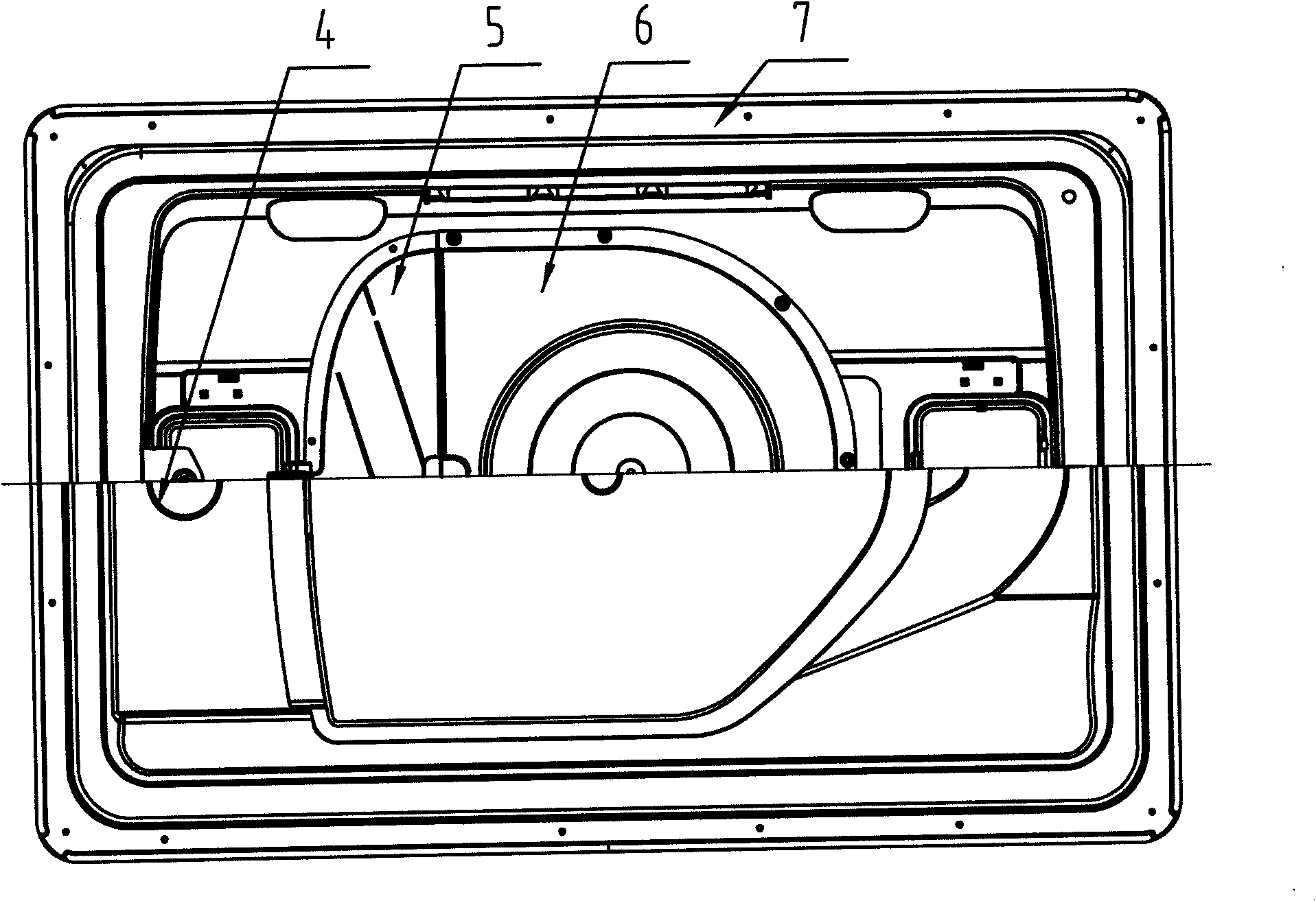

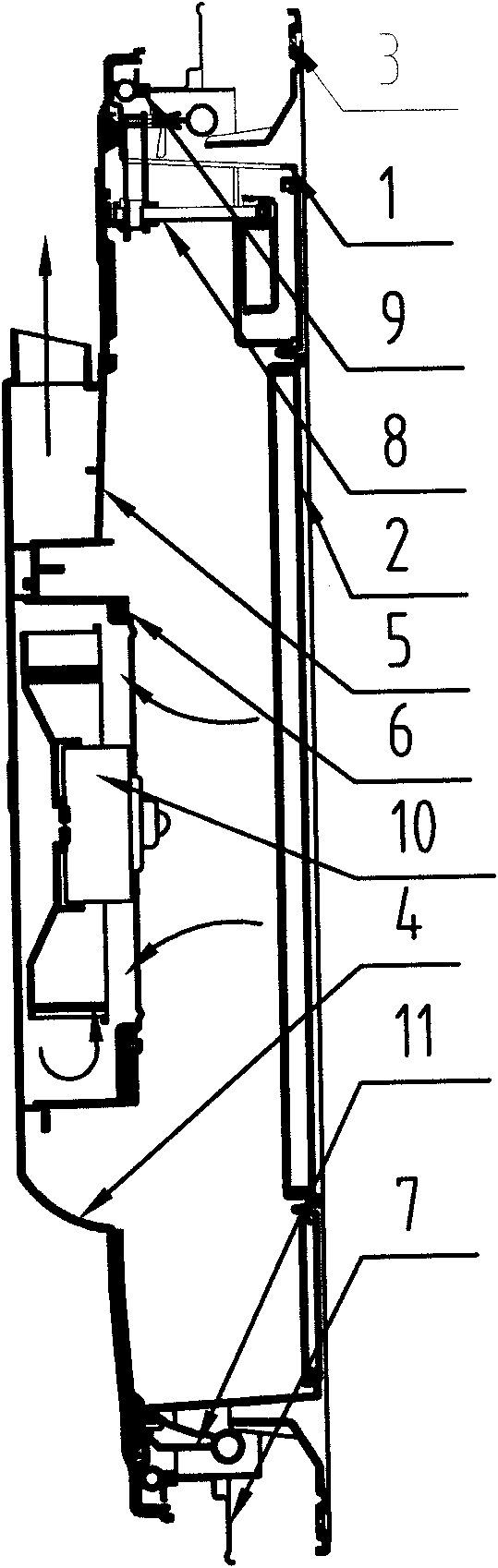

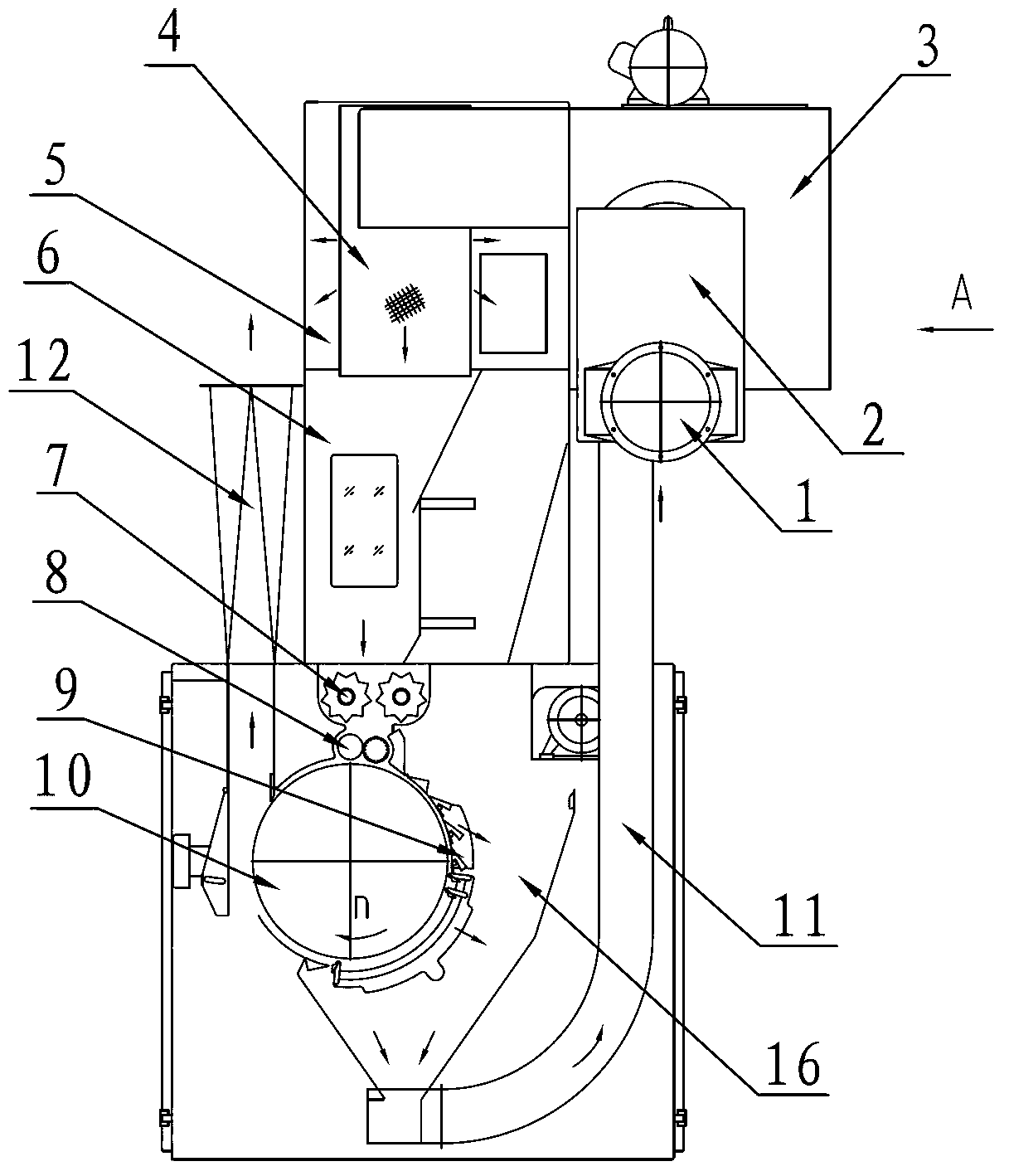

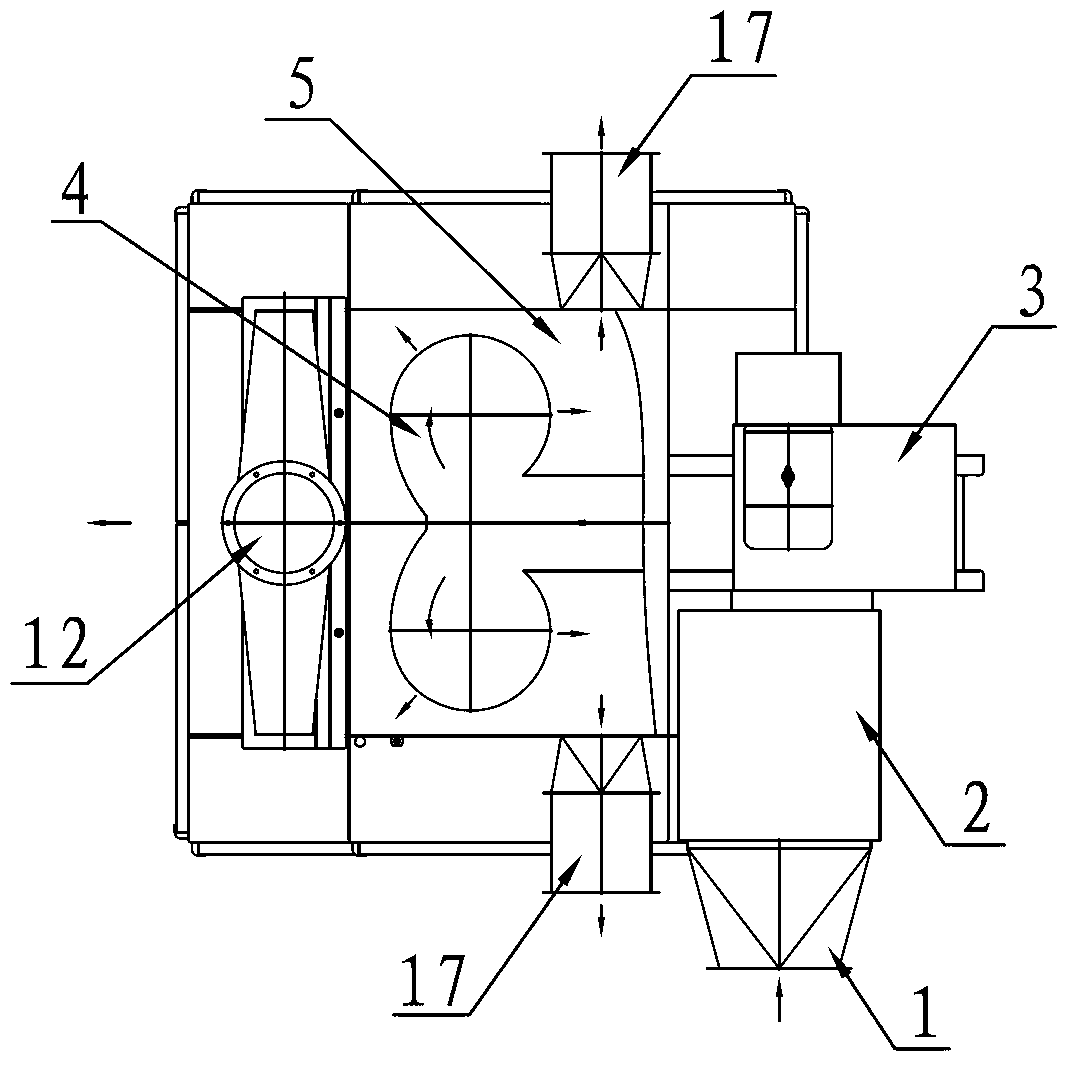

Automobile air window

InactiveCN101659196AIncrease the exhaust areaAvoid the effects of water ingressSuperstructure subunitsRoofsNatural ventilationPush pull

The invention relates to an automobile air window which comprises a top cover (4), a main frame part (9), an accessory frame (3), an air guide ring (8), a ventilator (12), an inner cover (1) and a decorative shield (2), wherein a push-pull device (13) and an opening device (11) are respectively fixed at the front end and the rear end of the top cover (4); the ventilator (12) is fixed in the middleof the air guide ring (8); the accessory frame (3), the inner cover (1) and the decorative shield (2) are arranged at an inner ring of the top cover (4); rain shields (5) are fixed at both sides of the top cover (4); the main frame part (9) is arranged between the accessory frame (3) and the rain shields (5); one end of the air guide ring (8) is connected with the inner cover (1), the other end is connected with the rain shields (5), and the air guide ring (8) is fixed in the middle of the top cover (4) by the inner cover (1) to form a complete automobile air window. The structure has the functions of forced ventilation, natural ventilation and escaping and the characteristic of strong air exchange and seal.

Owner:JIANGSU WENGUANG VEHICLE ACCESSORIES

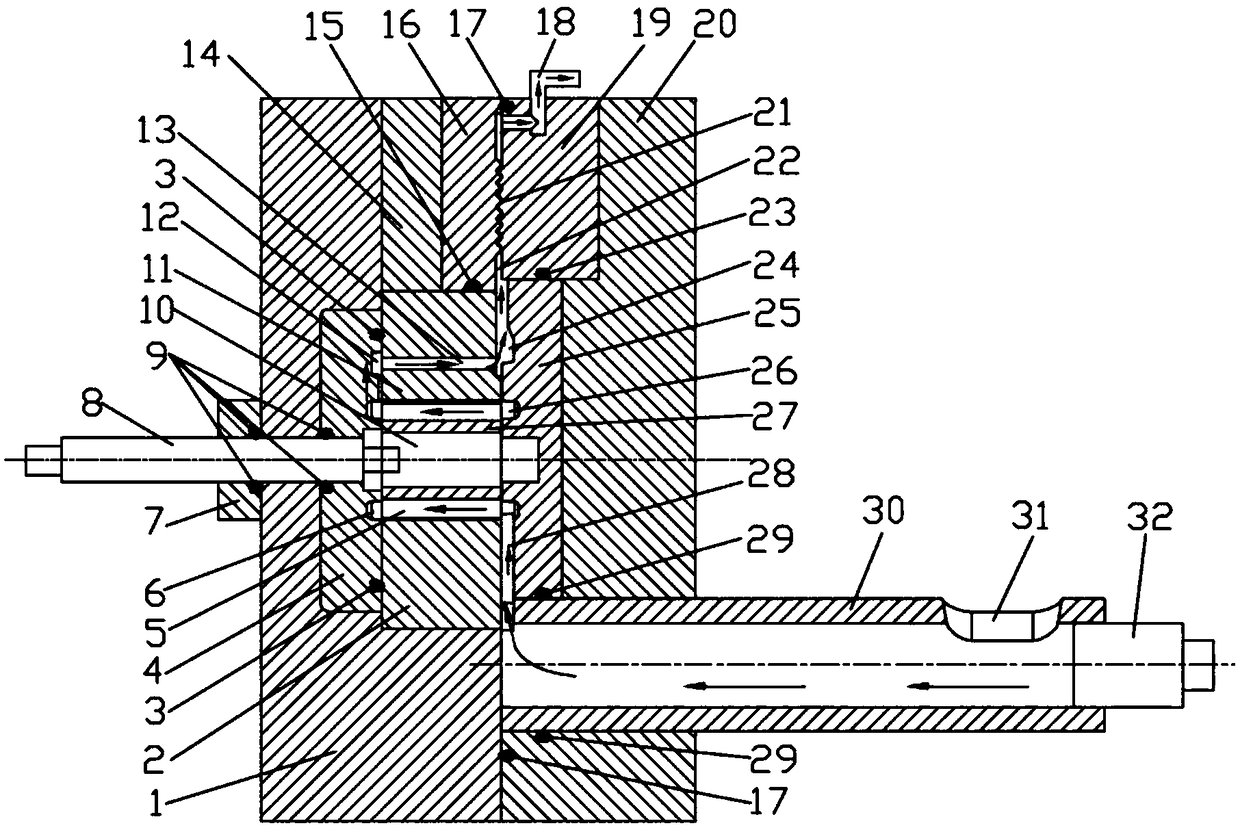

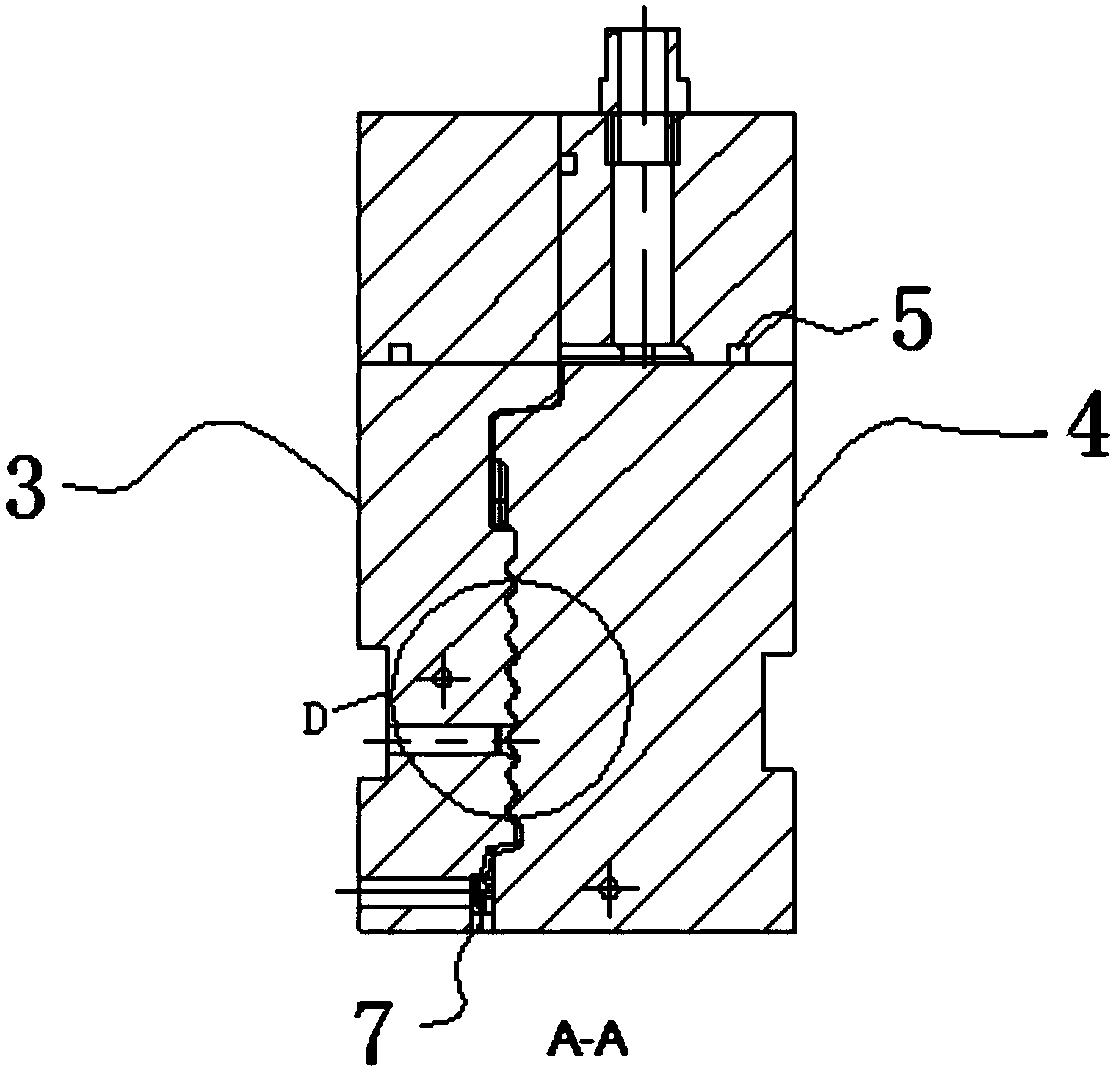

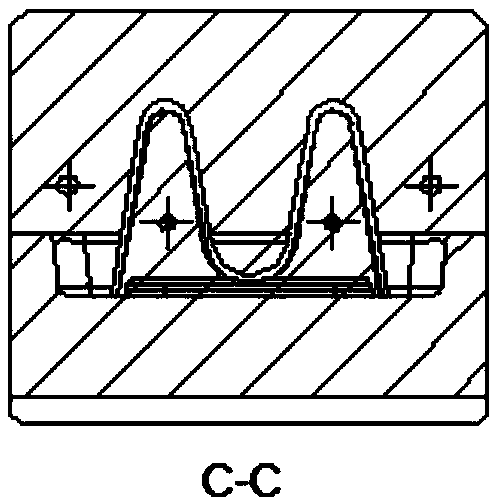

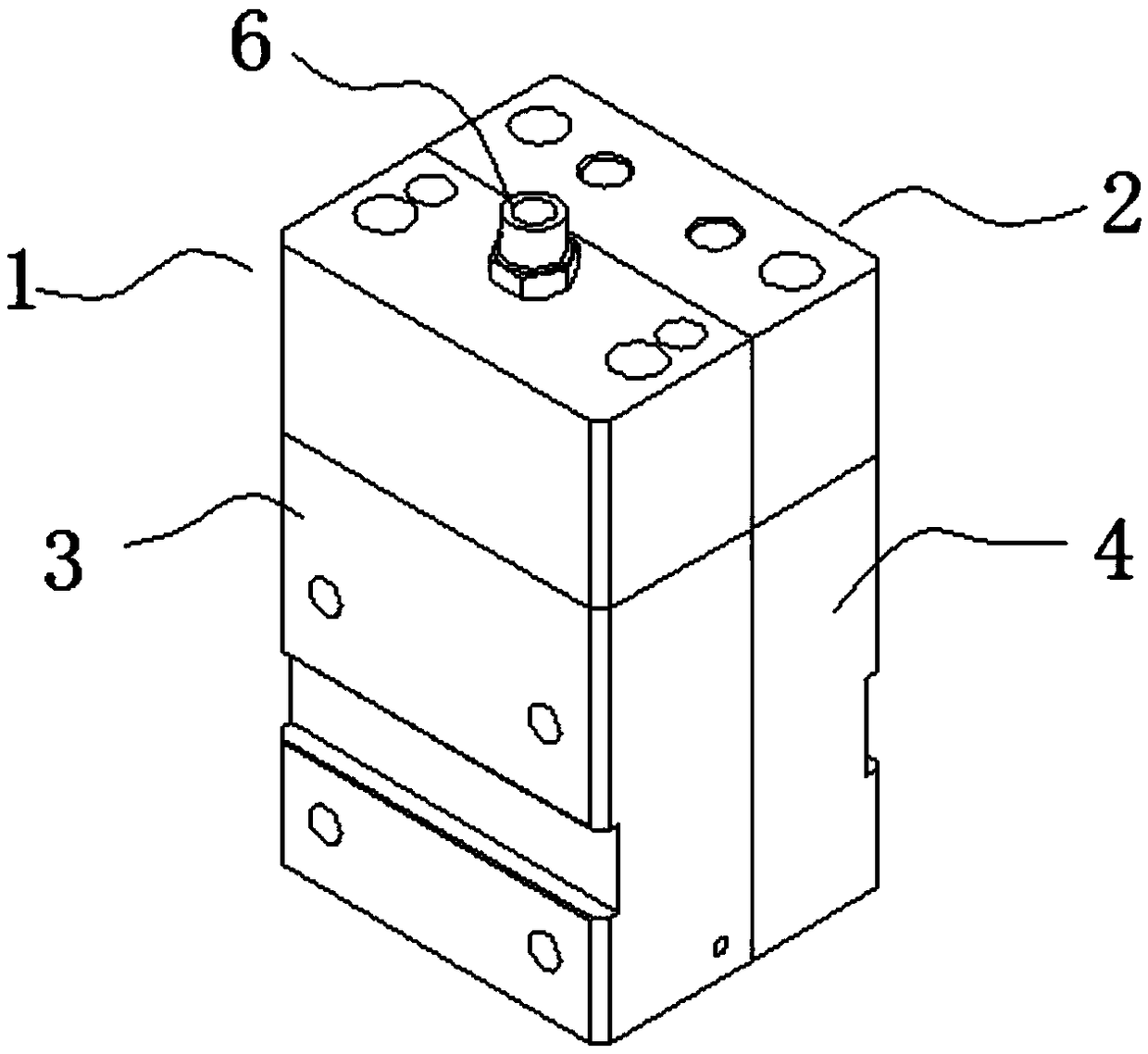

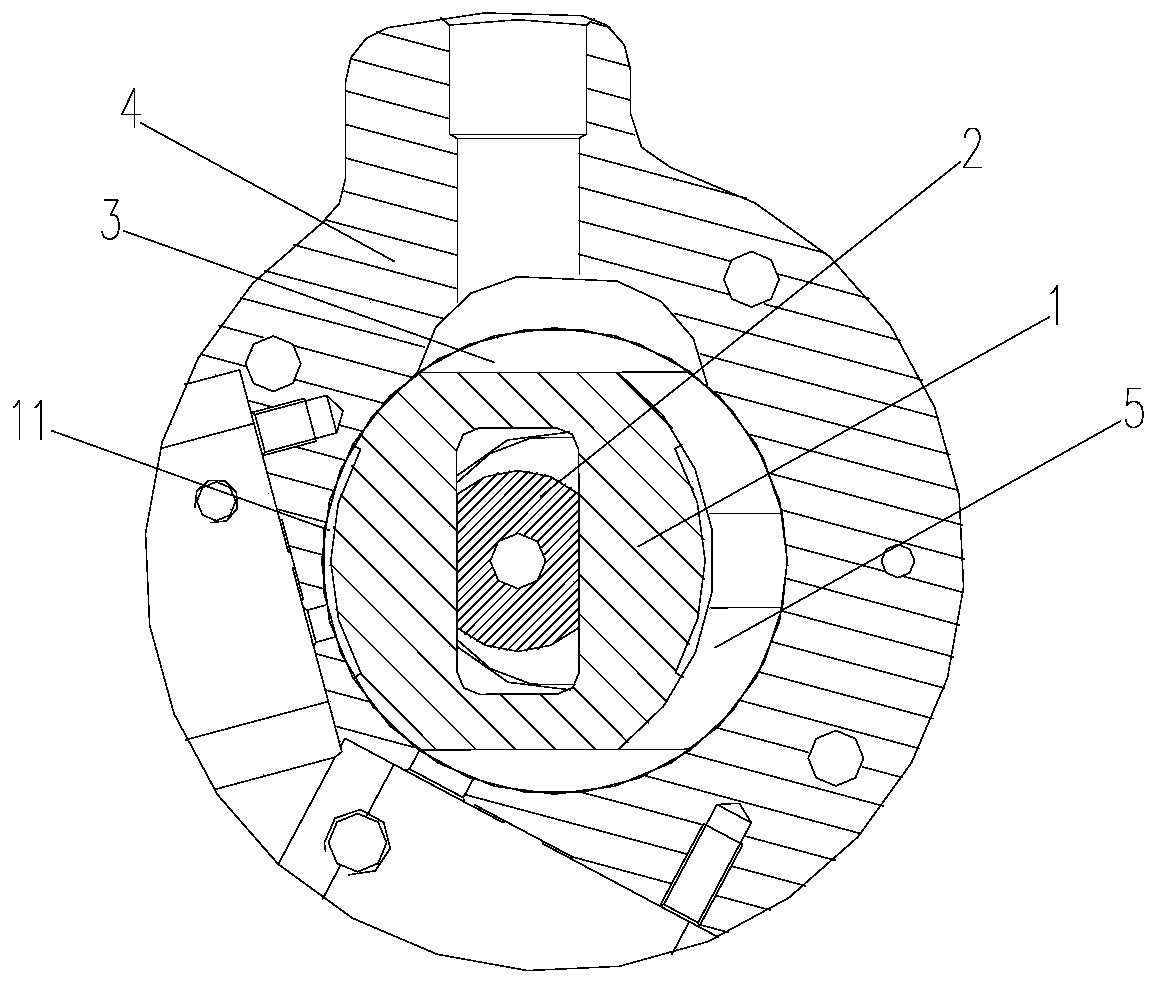

Copper rotor vacuum die-casting die

The invention relates to a copper rotor vacuum die-casting die which mainly comprises a movable formwork, a static formwork corresponding to the movable formwork, a core pulling sliding block mountedon the movable formwork, a moving die insert, a lower half block, an upper half block mounted on the core pulling sliding block, a static die insert and a pressing chamber, wherein the moving die insert and the lower half block are disposed on the movable formwork; and the static die insert and the pressing chamber are mounted on the static formwork. Exhaust blocks are arranged at the upper ends of the movable formwork and the static formwork respectively, each exhaust block is designed into three independent exhaust wave plates, and gaps of the exhaust wave plates on the two sides are smallerthan a gap of the middle exhaust wave plate. According to the copper rotor vacuum die-casting die, by the design of two exhaust channels, a mode of pumping out gas in the pressure casting process step by step is achieved, the exhaust area and the vacuumizing capability are improved, the exhaust capability is improved, the gas flow-out stroke is shortened, so that the gas is effectively pumped out, and the vacuum pressure of a cavity of the die-casting die is maintained at 10 KPa. The die is suitable for vacuum die casting of pure copper and copper alloy.

Owner:云南铜业压铸科技有限公司

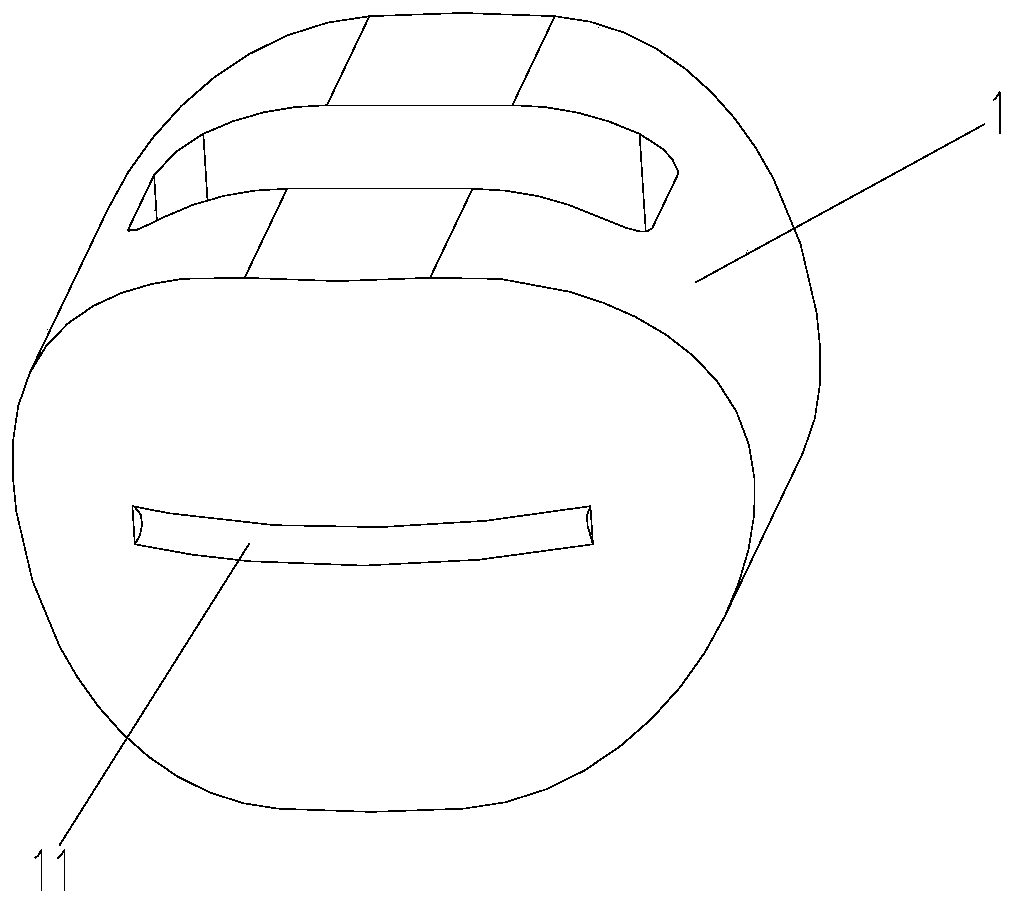

Novel anti-overflow pot cover

InactiveCN103892705AIncrease the exhaust areaGood anti-spill effectBoiling over preventionCooking-vessel lids/coversEngineeringBuoyant force

The invention relates to a novel anti-overflow pot cover. The novel anti-overflow pot cover comprises a pot cover body, an exhaust hole, standby holes, seal caps, connection rods and hard foam sheets. The novel anti-overflow pot cover is characterized in that the round exhaust hole with the diameter being 1 cm is formed in the pot cover body, the standby holes with the diameters being 4 cm are formed in the two ends of the pot cover body, each standby hole is sealed through the corresponding seal cap, each seal cap is connected with the corresponding hard foam sheet through the corresponding connection rod, each hard foam sheet is a cylinder with the diameter being 8 cm and the height being 0.2 cm, and the had foam sheets have good buoyant force; steam in a pot is exhausted through the exhaust hole of the pot cover body when normal heating is conducted, soup in the pot firstly arrives at the positions of the hard foam sheets when being about to overflow, the soup and the hard foam sheets ascend together when the soup continues ascending, the hard foam sheets push the seal caps out of the standby holes through the connection rods, the standby holes are also used for exhausting the steam at the moment, and therefore the very good anti-overflow effect can be achieved. The novel anti-overflow pot cover is simple in structure and easy to manufacture.

Owner:杨美英

Dual panel actuator system for jet engines

ActiveUS10040563B1Increase the exhaust areaShort actuator strokeAircraft power plant componentsEfficient propulsion technologiesJet engineTrackway

An aircraft engine variable area fan nozzle structure disposed abaft a thrust reverser, including a sleeve translatable over a cascade array, comprises two semi cylindrical segments that can be axially translated and radially tilted to enlarge the fan duct exhaust area in order to optimize exhaust pressure and associated noise in high thrust circumstances such as on take-off, and to constrict that area under lower thrust conditions such as cruise. A pair of angularly adjacent segments can be moved by an actuator anchored to the fixed engine framework and independently of the thrust reverser translating sleeve. The tilting movement is imposed by the pivoting links of each segment to carriages that ride in a non-linear trackway secured to a thrust reverser translating sleeve. The actuator can be of a dual concentric type which can independently drive the trust reverser and nozzle segments.

Owner:PINTO GEOFFREY P

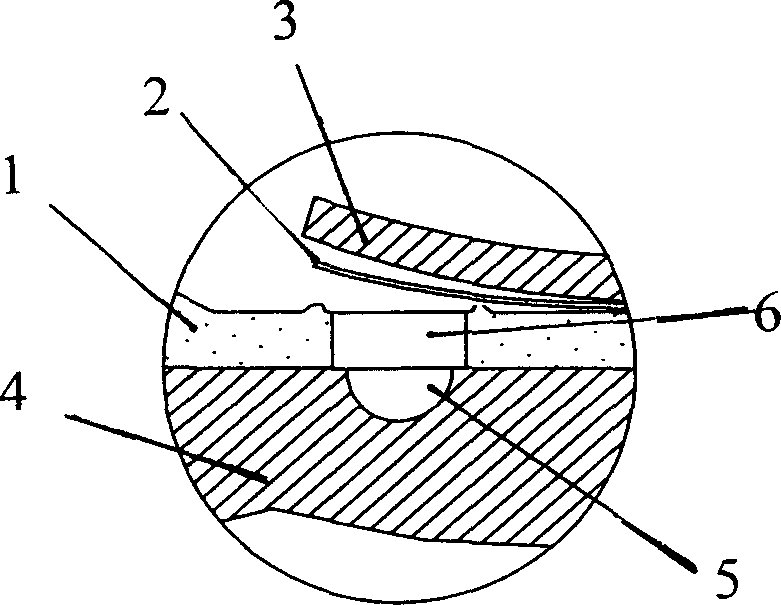

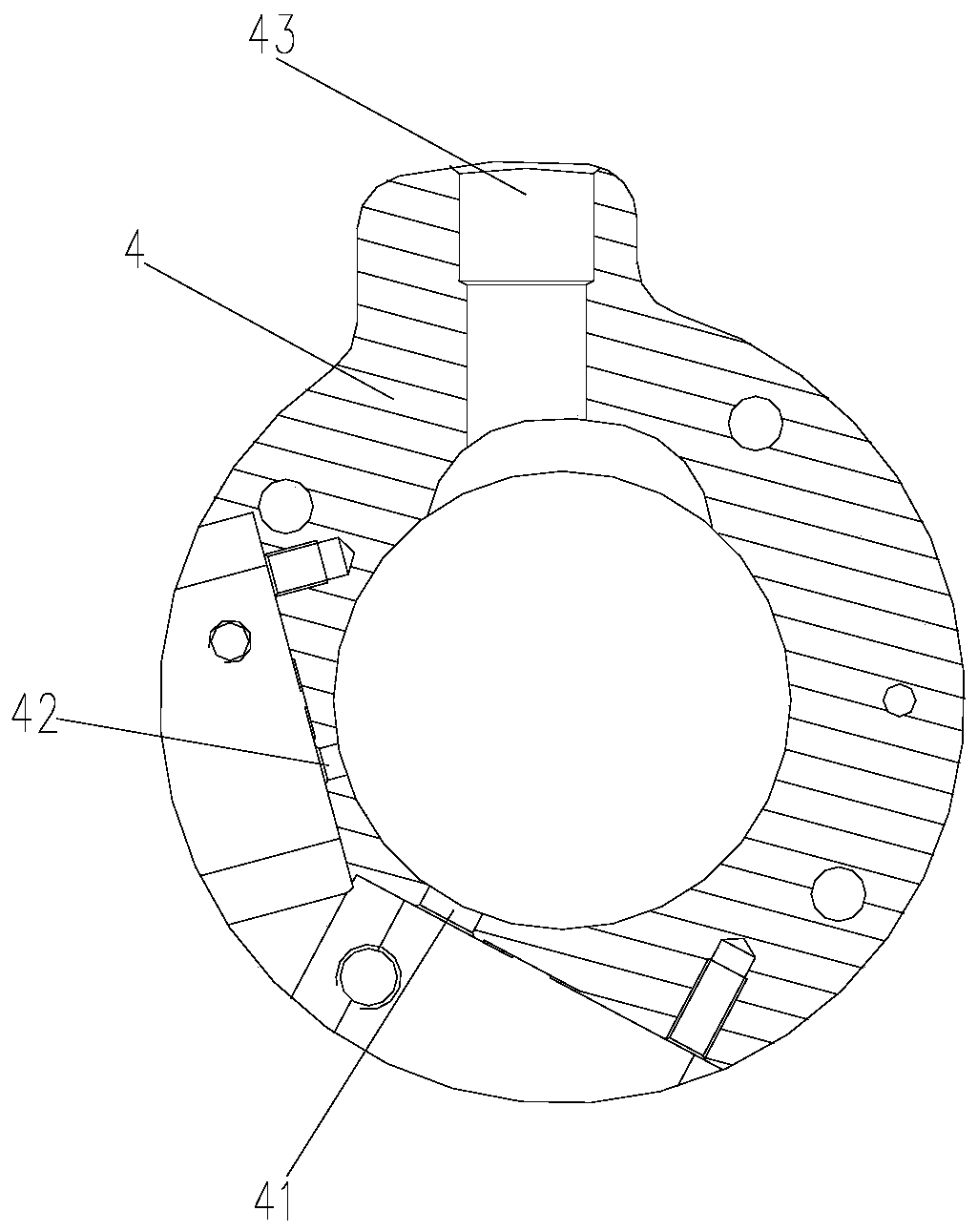

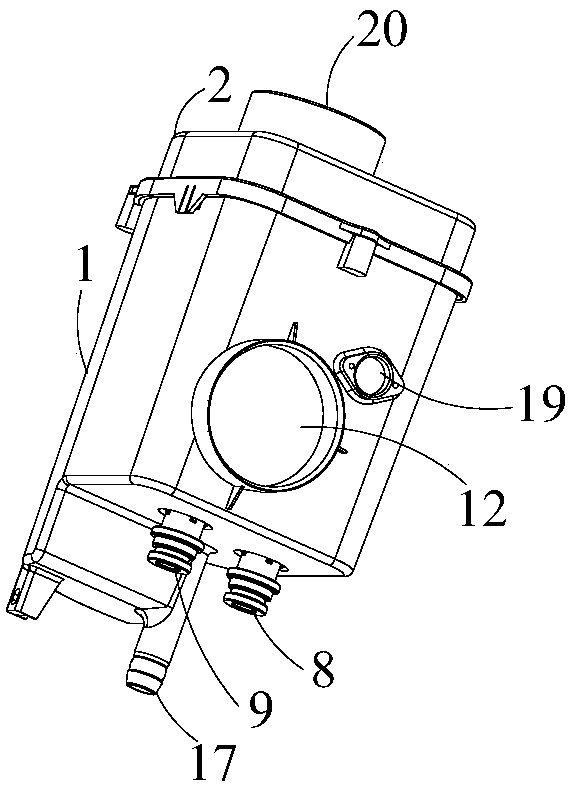

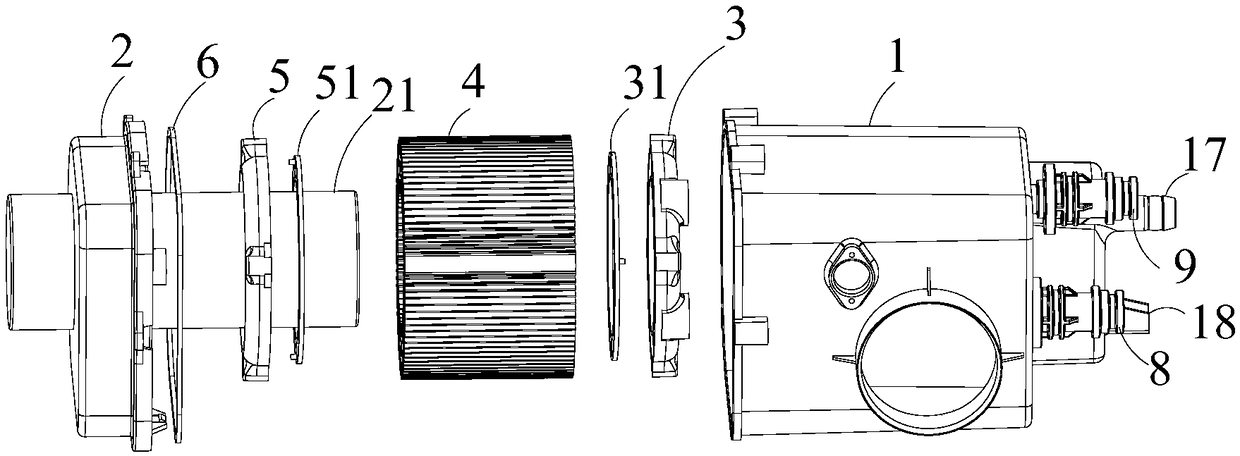

Rotary type compressor exhaust apparatus

InactiveCN1632320AImprove volumetric efficiencyIncrease the exhaust areaRotary/oscillating piston pump componentsLiquid fuel engine componentsExhaust valveSpherical shaped

The invention provides a rotary compressor exhaust device, which includes a compressor main bearing, a stopper, a compressor cylinder, a cylinder exhaust hole, a partially spherical exhaust valve plate and a conical exhaust hole. The main bearing is fixed on the compressor cylinder, and the compressor cylinder is provided with a cylinder exhaust hole. The above-mentioned partial spherical exhaust valve plate is fixed on the compressor main bearing, and a conical exhaust hole is arranged on the compressor main bearing. The local sphere of the partially spherical exhaust valve plate is aligned with the conical exhaust hole, and the above-mentioned limiter is arranged on the upper surface of the partially spherical exhaust valve plate and fixed on the main bearing of the compressor. The beneficial effects of the present invention are: the cylindrical exhaust hole is designed as a conical exhaust hole, which expands the exhaust area under the same circumstances, relatively reduces the clearance volume caused by the existence of the exhaust hole, and improves Improve the volumetric efficiency of the compressor and reduce noise.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

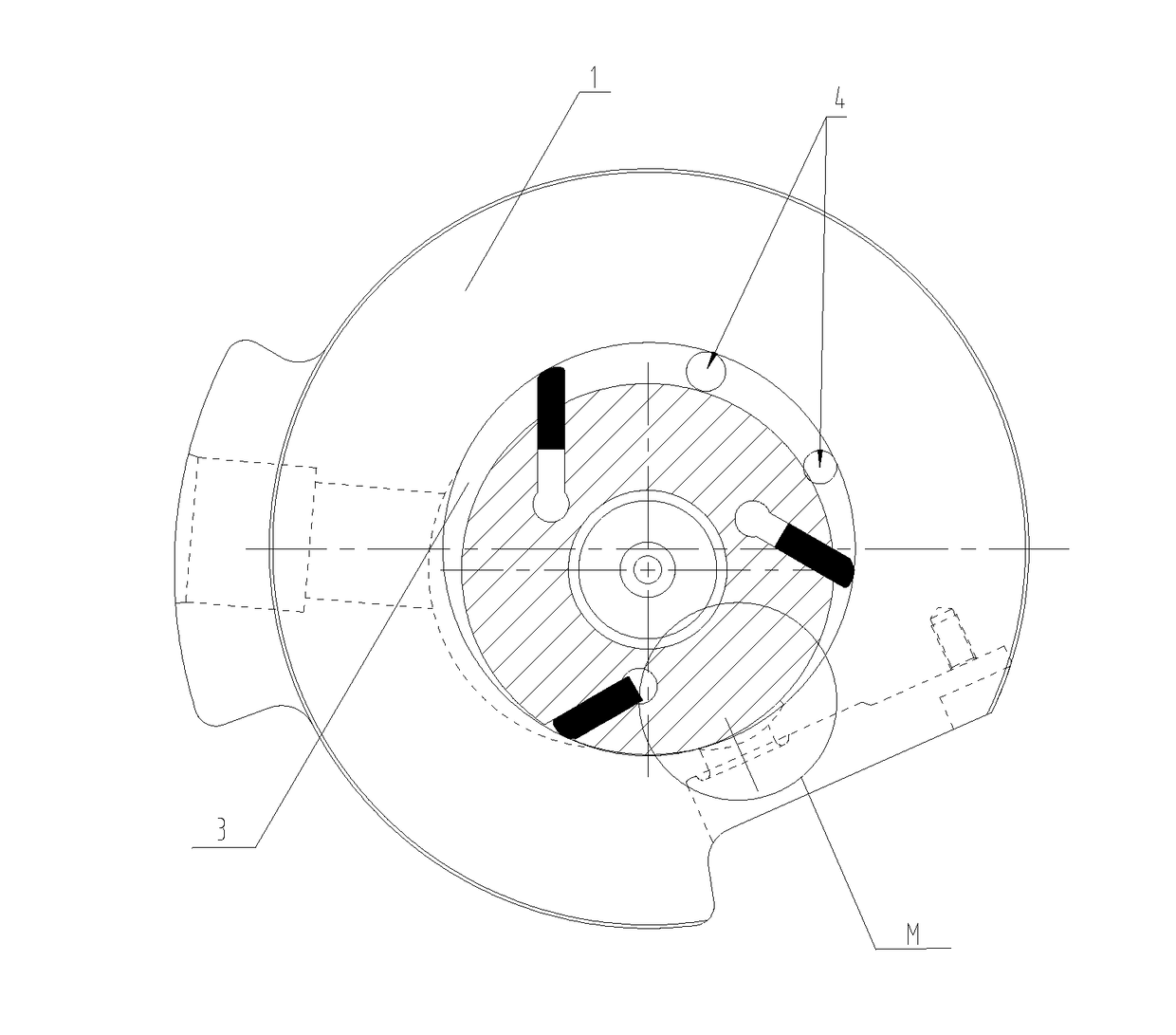

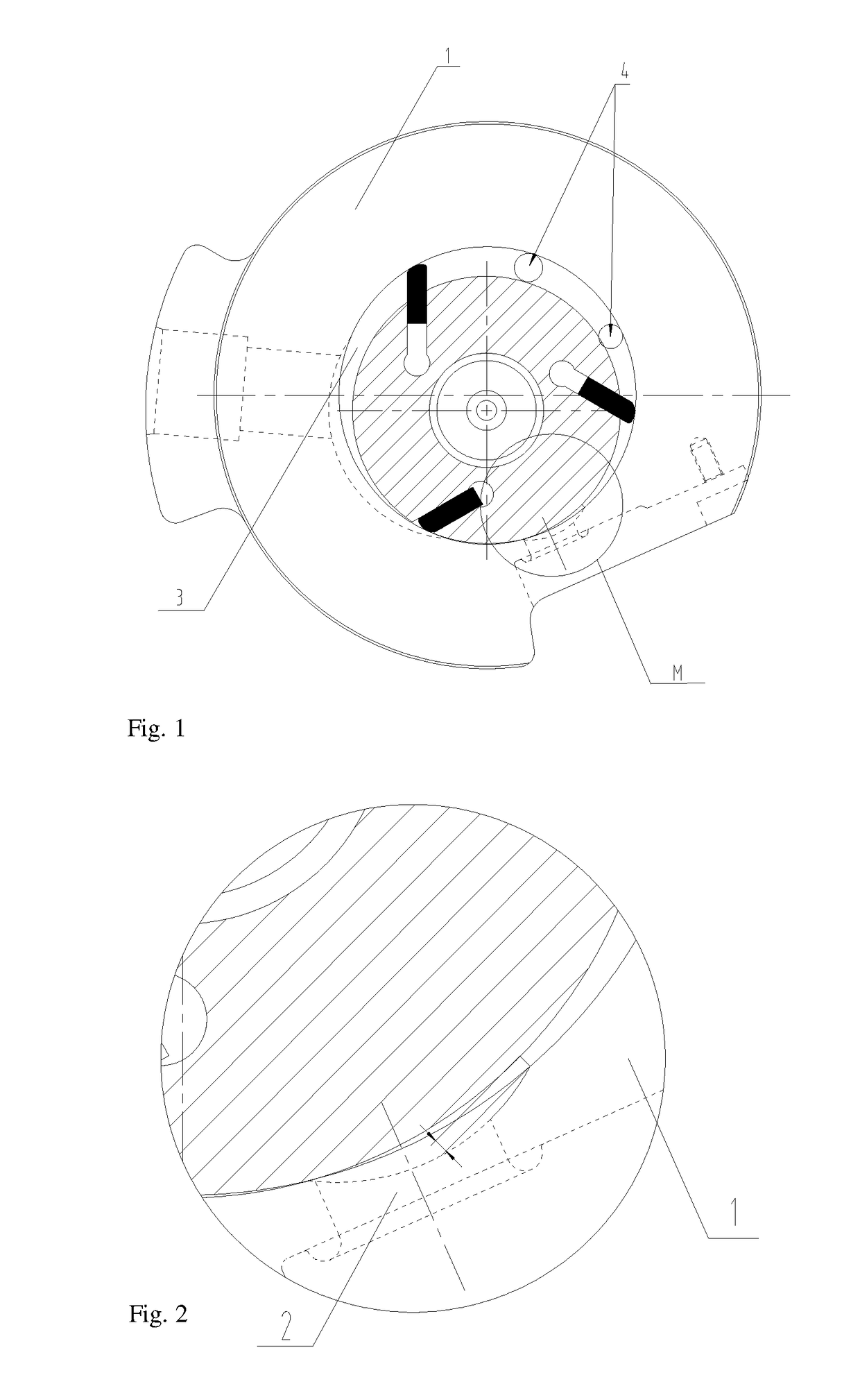

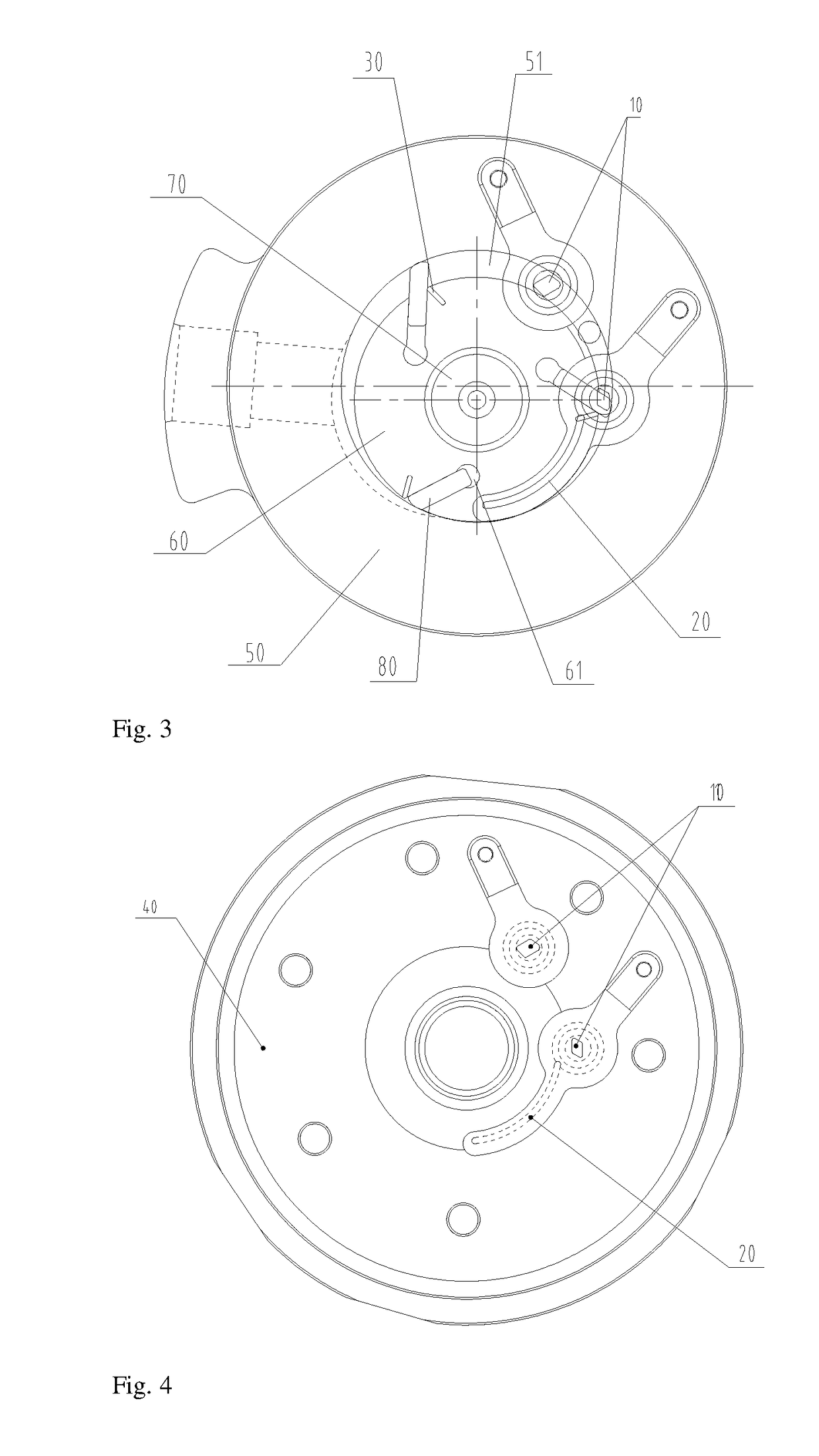

Sliding Vane Type Compressor and Exhaust Structure Thereof

ActiveUS20170342982A1Low production costReduce exhaust lossRotary piston pumpsRotary piston liquid enginesEngineeringFlange

Disclosed are a sliding vane compressor and an exhaust structure thereof. The exhaust structure of the sliding vane compressor includes: an exhaust hole, the exhaust hole being formed in a flange of the sliding vane compressor and being in communication with a compression cavity of a cylinder of the sliding vane compressor; a guide channel, the guide channel being formed on the flange and penetrating through the flange; and an exhaust channel, the exhaust channel being formed on an eccentric circle of the sliding vane compressor, and the exhaust channel being used for communicating the compression cavity with the guide channel using the rotation of the eccentric circle. The sliding vane compressor and the exhaust structure thereof have a small exhaust loss, thereby effectively reducing the power consumption and the production and manufacturing costs of the sliding vane compressor.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Vacuum air-exhausting device of pressure-casting mould

The invention discloses a vacuum air-exhausting device of a pressure-casting mould. The vacuum air-exhausting device is characterized by comprising a fixed mould air-exhausting block, and a movable mould air-exhausting block which are oppositely arranged in a clung mode, wherein an air-exhausting cavity is arranged between the fixed mould air-exhausting block and the movable mould air-exhausting block; one end of the fixed mould air-exhausting block is equipped with a vacuum interface; one end of the movable mould air-exhausting block is provided with an air suction hole; the air suction hole,the air-exhausting cavity and the vacuum interface are sequentially in communication to form an air-exhausting channel; the air-exhausting cavity extends in a wavy mode from the air suction hole to the vacuum interface; and a gap between the upper wall of the air-exhausting cavity and the lower wall of the air-exhausting cavity is gradually reduced in an extending direction. The vacuum air-exhausting device has the beneficial effects of being good in air-exhausting effect, not liable to have air hole blockage, easy to dismount and clear, great in air-exhausting area, and high in vacuum-pumping efficiency.

Owner:XIANGYANG MEILIXIN SCI & TECH

Large-load last stage blade with steam exhaust area of 5.0 m<2>

ActiveCN103806947AIncrease the exhaust areaIncrease stand-alone capacityBlade accessoriesMachines/enginesSteam turbine bladePulp and paper industry

The invention relates to a the field of industrial steam turbine blades, and particularly discloses a large-load last stage blade which has a steam exhaust area of 5.0 m<2>, is large in steam exhaust area and high in aerodynamic efficiency and can meet the operating requirements of large-load variable working conditions. A lashing strip, a blade working part and a blade root of the blade are forged into a whole from top to bottom, wherein a boss lacing wire is arranged in the position, 0.550 mm relative to a blade height from bottom to top, of the blade working part and integrated with the blade working part; a molded line of the blade working part adopts a variable cross-section twisted blade, the height of the working part is 661.92 mm, the axial width of the root of the working part is 231.11 mm, the diameter of the root is 728 mm, and the steam exhaust area of the blade working part is 5.0 m<2>; and the blade root adopts a fir-shaped oblique blade root, and the axial width is 272 mm. The large-load last stage blade with the steam exhaust area of 5.0 m<2> has the advantages of high aerodynamic efficiency, good strength performance, large steam exhaust area and the like, has the characteristics of convenience in assembly and stable structure, and can be widely applied to a large-load industrial steam turbine with a variable working condition.

Owner:HANGZHOU STEAM TURBINE

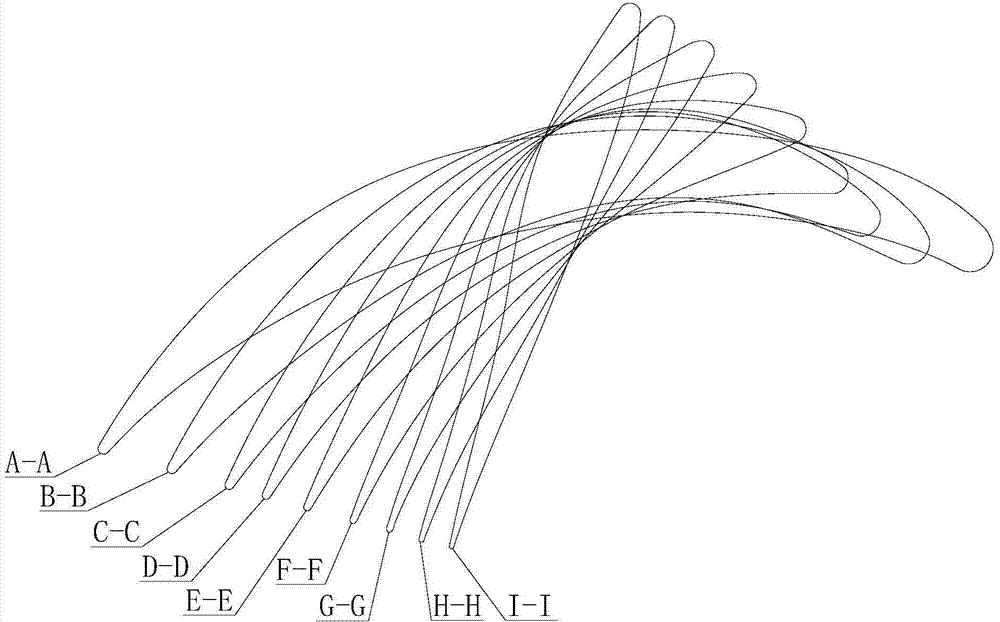

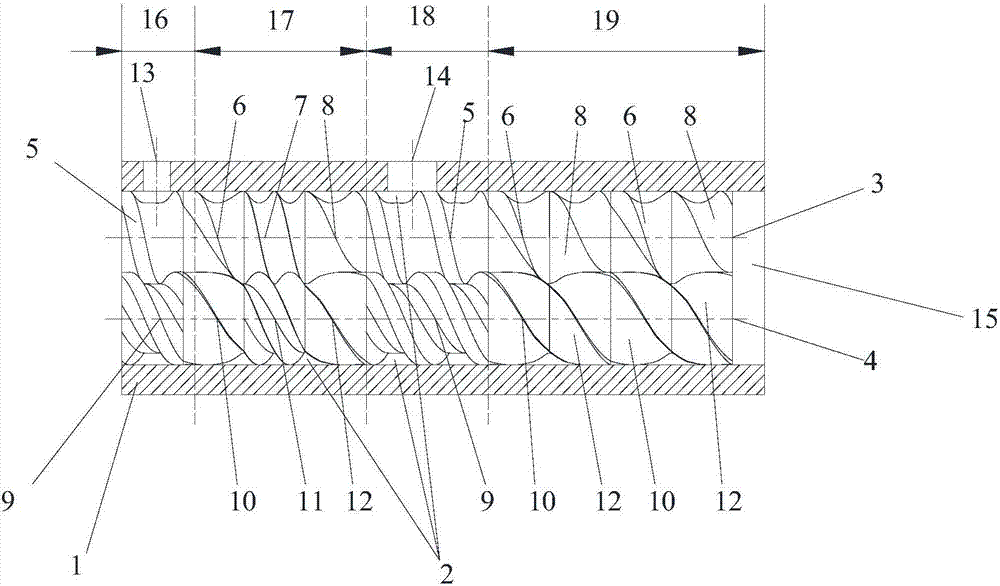

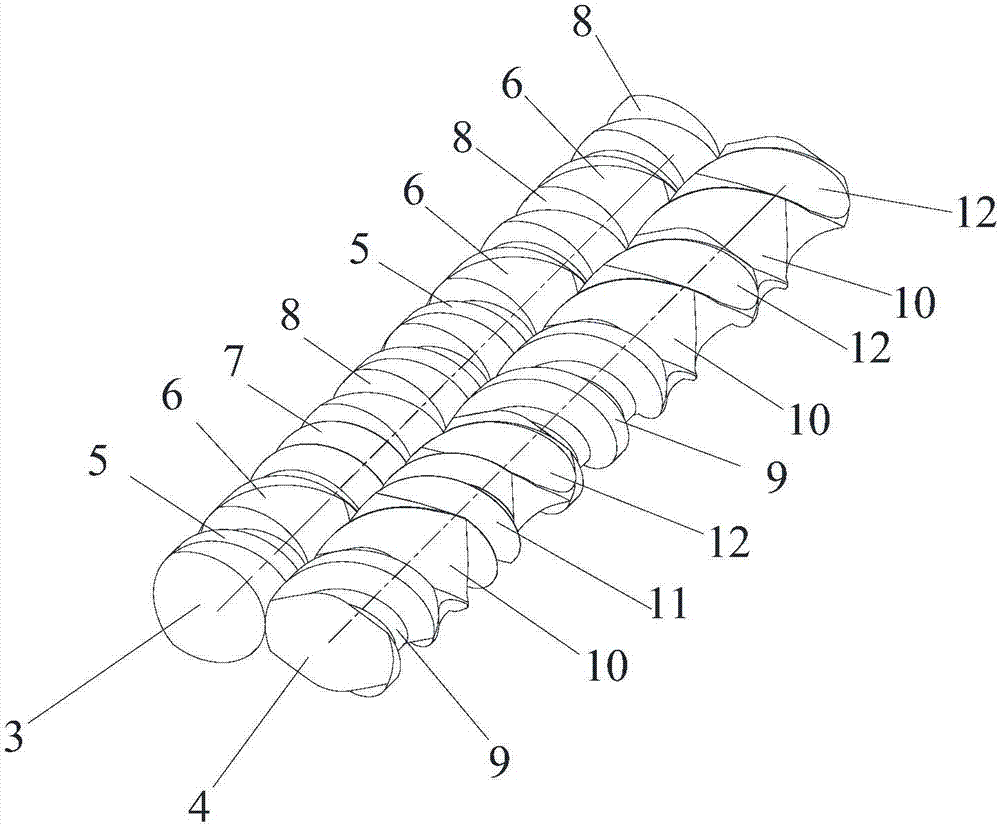

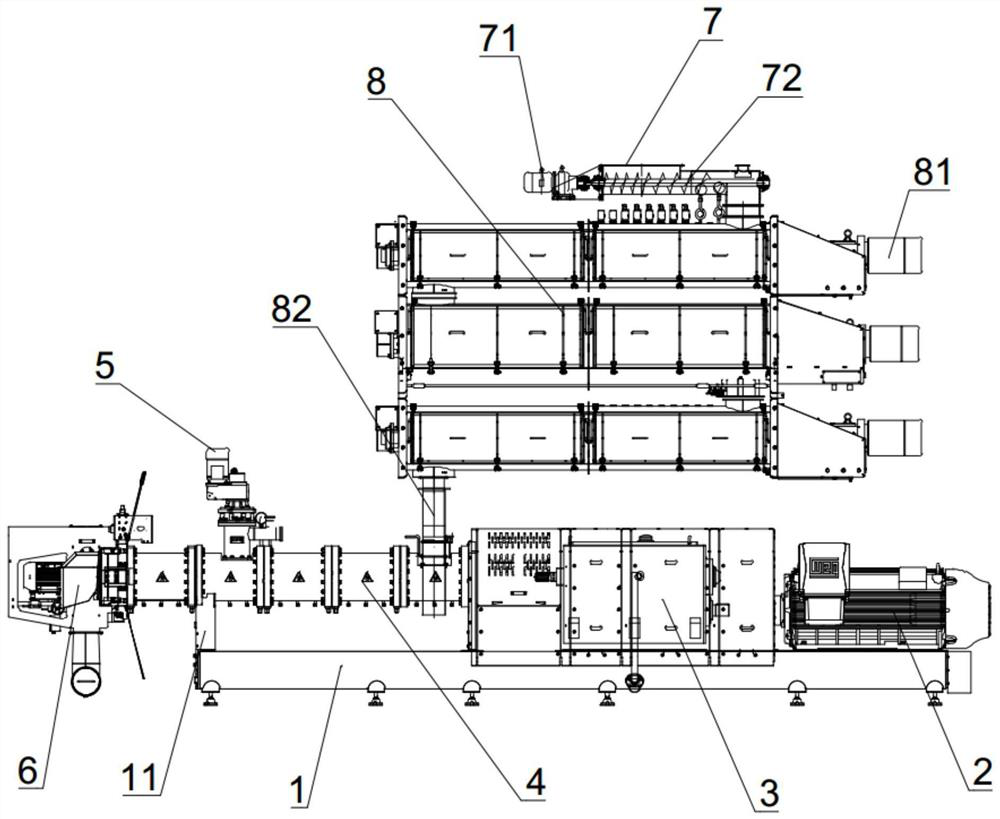

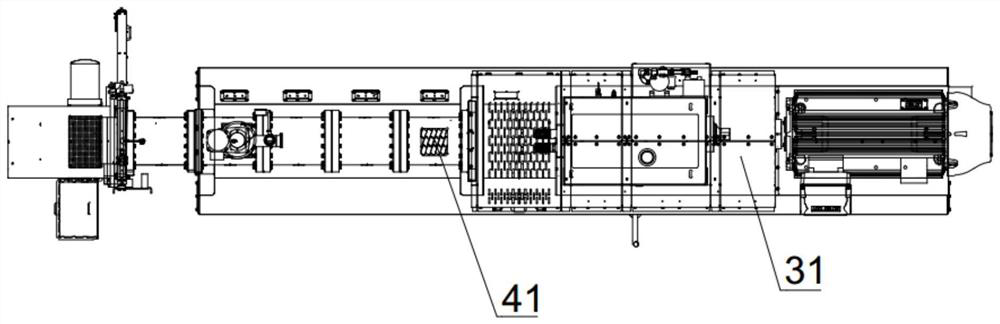

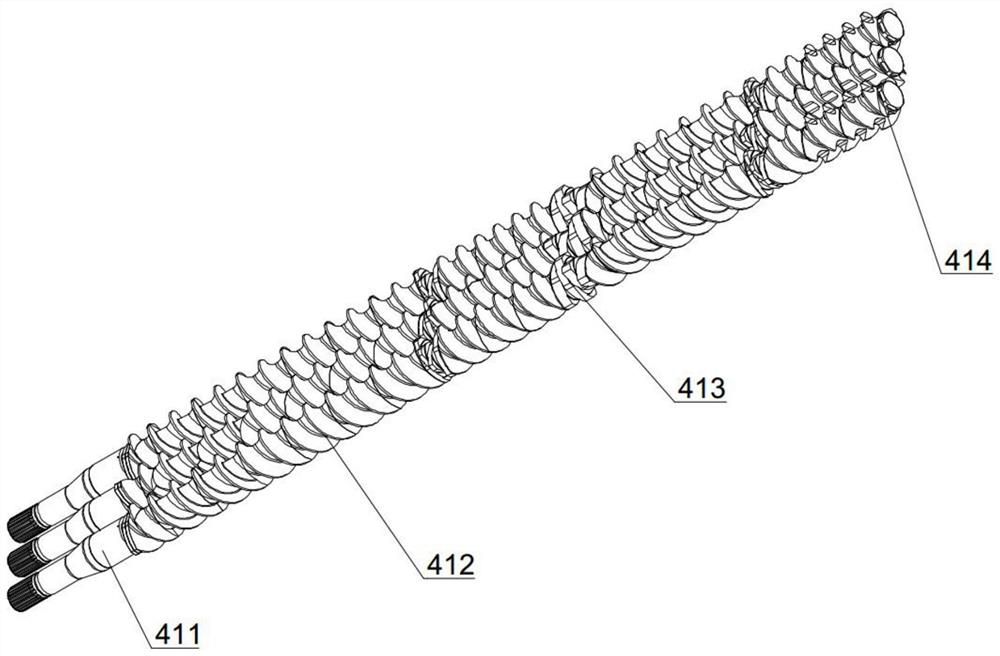

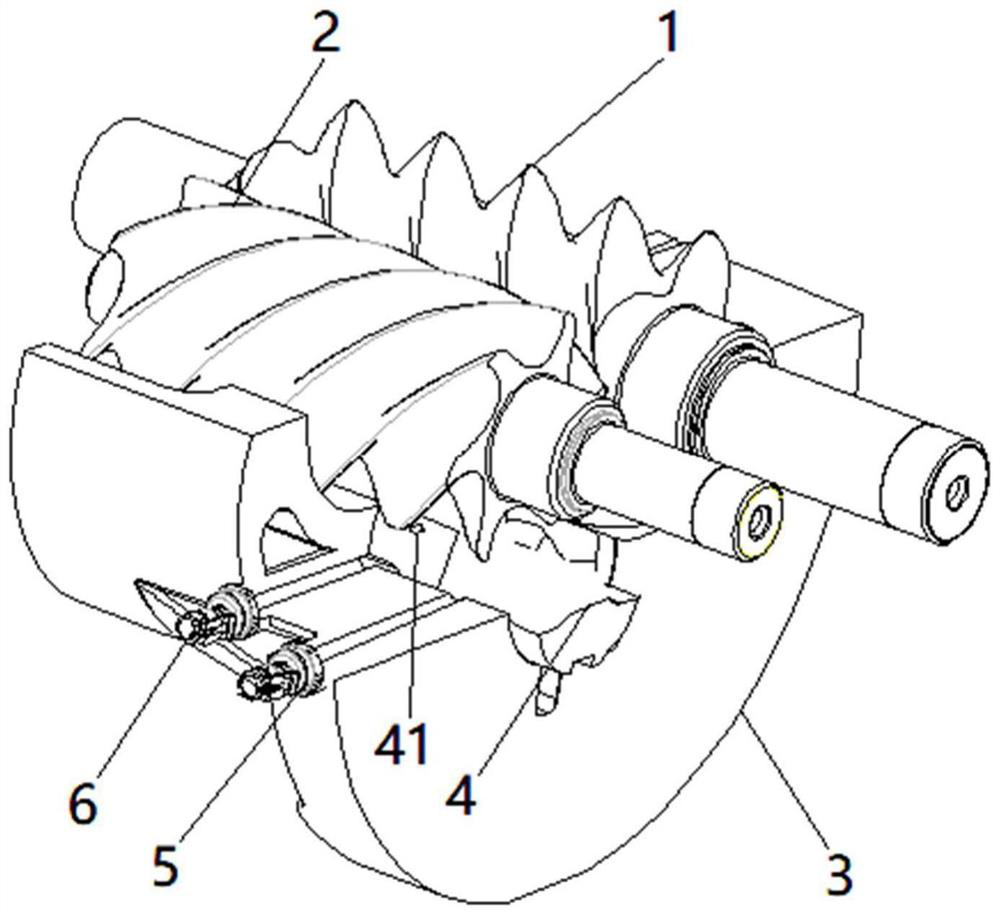

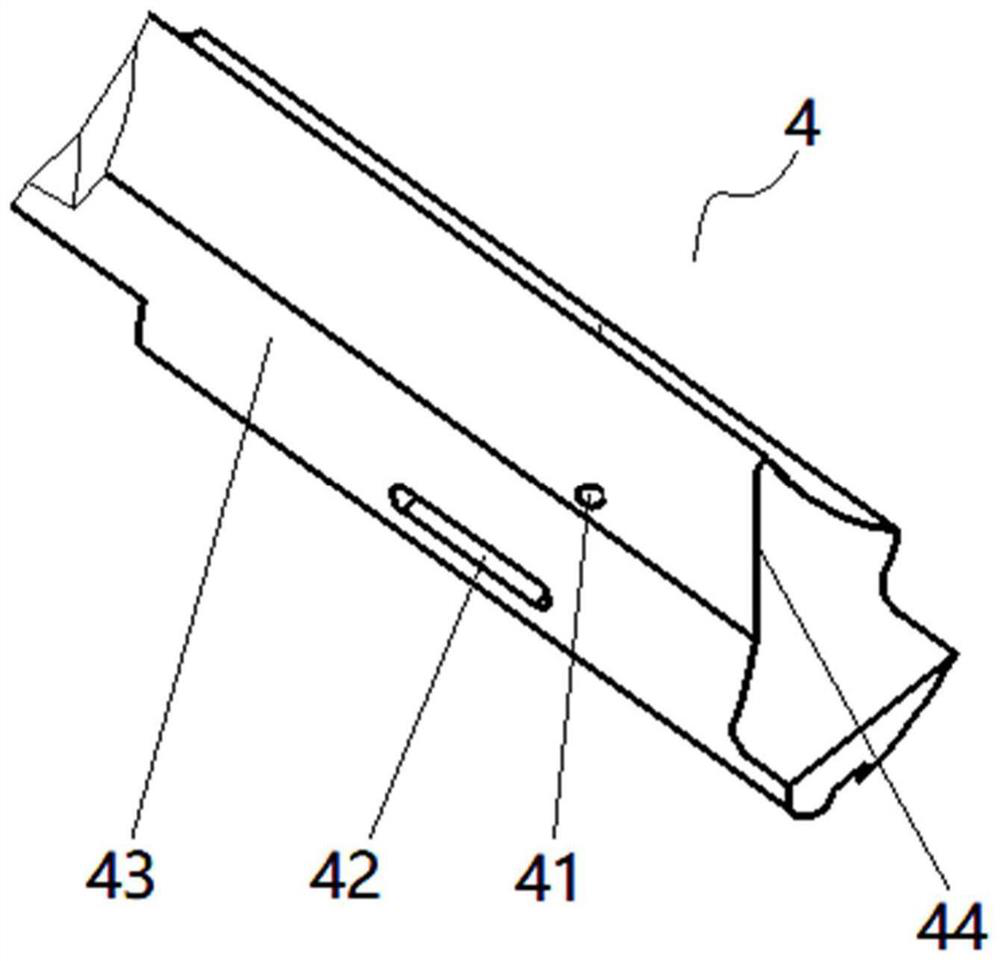

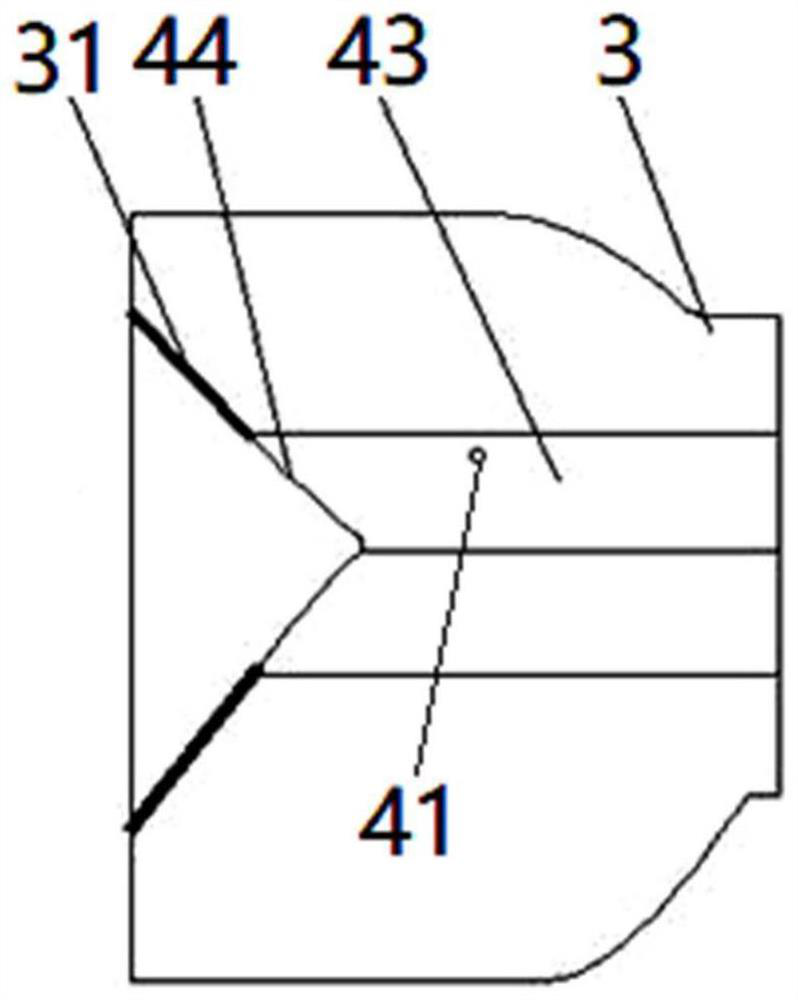

Co-rotating differential multi-screw extruding machine with gradually changing type thread number and machining method thereof

InactiveCN107031015AFacilitate interface updatesIncrease the exhaust areaDifferential equationEngineering

The invention discloses a co-rotating differential multi-screw extruding machine with the gradually changing type thread number and a machining method thereof. A first threaded rod in the extruding machine comprises two single-start thread elements, three single-start-gradually-changed-to-double-start transition thread elements, a double-start thread element and three double-start-gradually-changed-to-single-start transition thread elements; and a second threaded rod comprises two double-start thread elements, three double-start-gradually-changed-to-four-start transition thread elements, a four-start thread element and three four-start-gradually-changed-to-double-start transition thread elements. According to the machining method, a threaded rod mechanism achieves five enhancement mixing mechanisms by adopting the structure of the threaded rod mechanism, and conducts all-sided enhancement mixing on materials.

Owner:徐百平

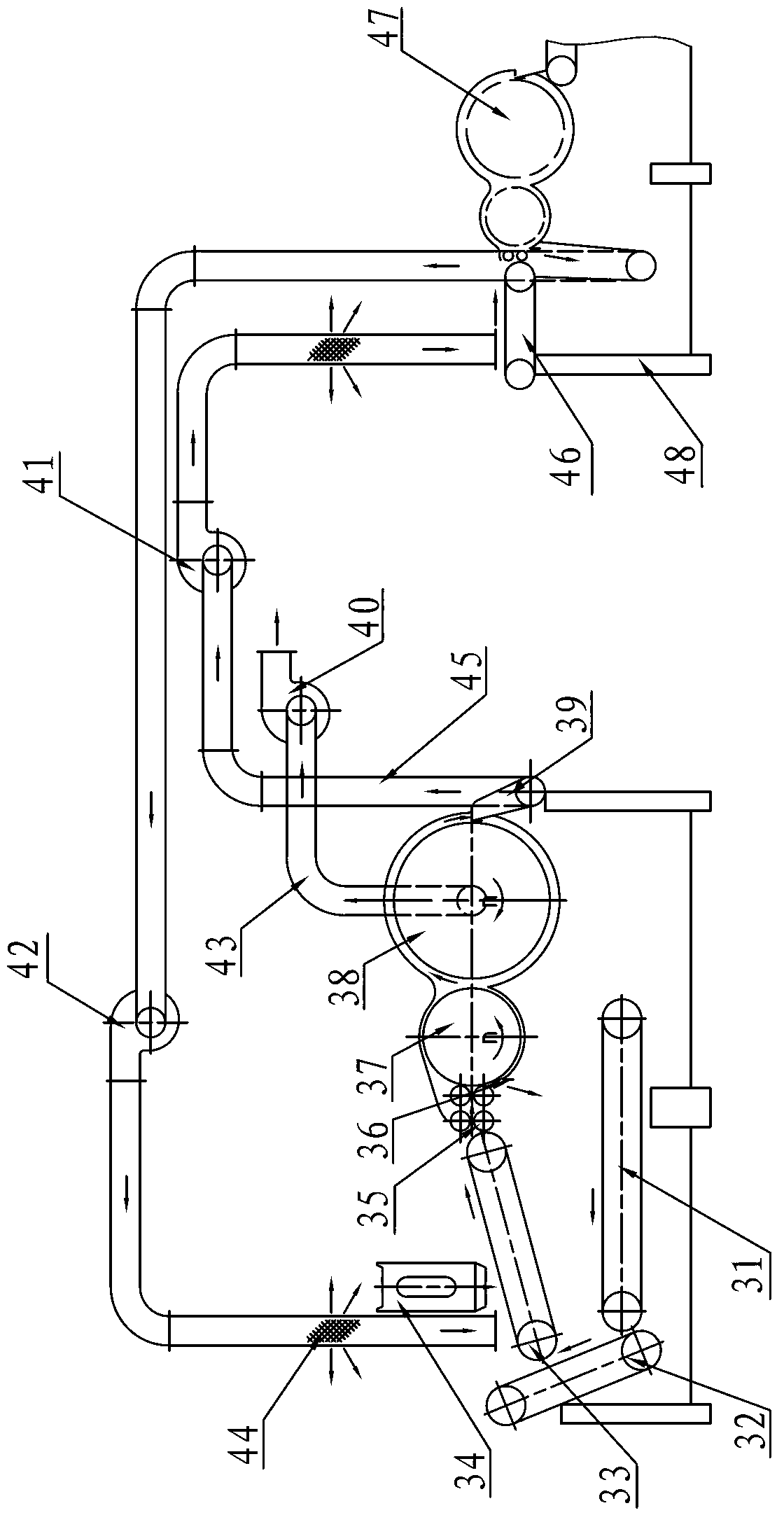

Single-roller opener for regenerated fibers of waste textiles

ActiveCN102797076AImprove uniformityIncrease the exhaust areaFibre cleaning/opening by air draught arrangementsFibre cleaning/opening machinesLow noiseFiber

The invention provides a single-roller opener for regenerated fibers of waste textiles. The single-roller opener comprises a cotton inlet, a multifunctional impurity removing box, a cotton inlet fan, a double-circle dust cage filter drum, a dust flock cavity, a cotton storage box, a star-like roller, front and back steel rollers, an adjustable dust grid, an opening roller, a cotton return pipe, a cotton outlet, a heavy impurity removing grid bar, a magnet, a heavy impurity box, a cotton return hopper and a dust filter port, wherein raw materials directly enter the multifunctional impurity removing box from the cotton inlet under an effect of the cotton inlet fan; first, the raw materials are collided with the heavy impurity removing grid bar, so as to remove heavy impurities, and metals and then enter the double-circle dust cage filter drum; dust and flocks are sucked by a dust filter of the system; after the pressure of the raw materials is released, the raw materials fall into the cotton storage box, are opened by the star-like roller, the front and back steel rollers as well as the opening roller, and are gradually torn and opened into fiber-shaped substances; average lengths of the opened fibers can reach more than 14 mm; the yield is 400-500 kg / h; and the installed power of the whole machine is only 16.5 kw; and the single-roller opener for the regenerated fibers of the waste textiles, provided by the invention, has the advantages of small volume, small power consumption, high yield, no dust and flock leakage as well as low noise.

Owner:卓郎新疆智能机械有限公司

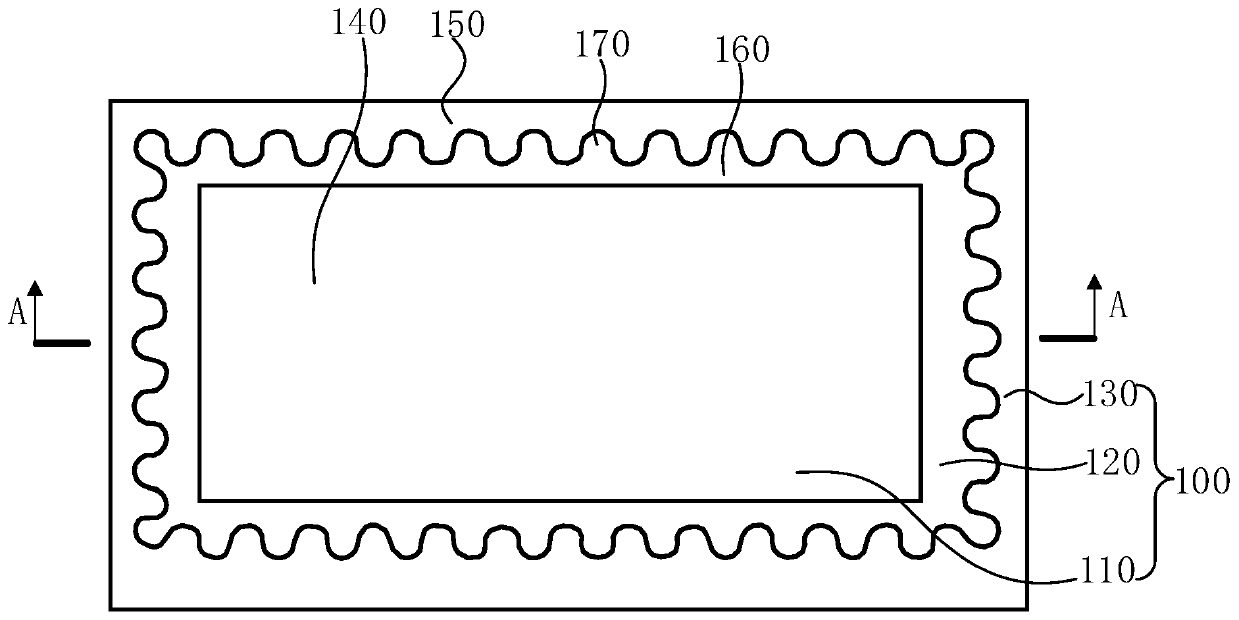

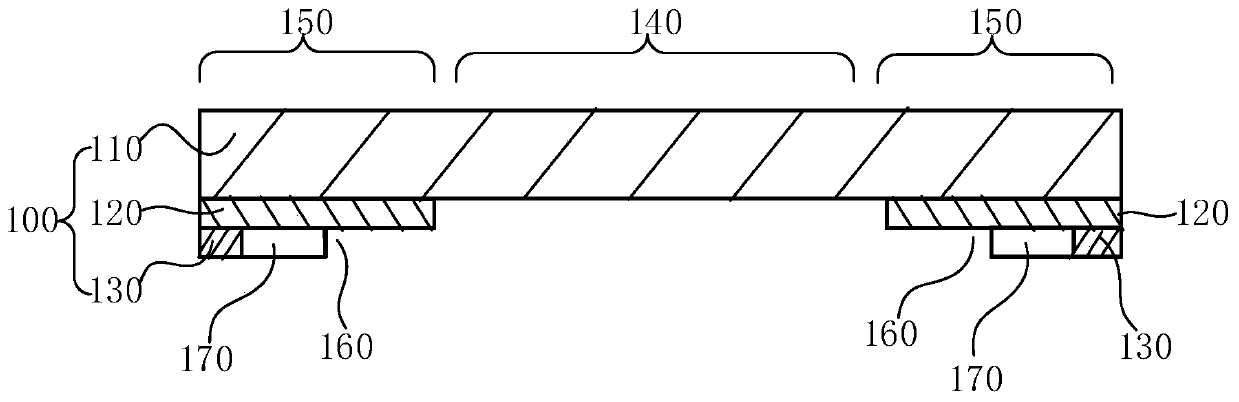

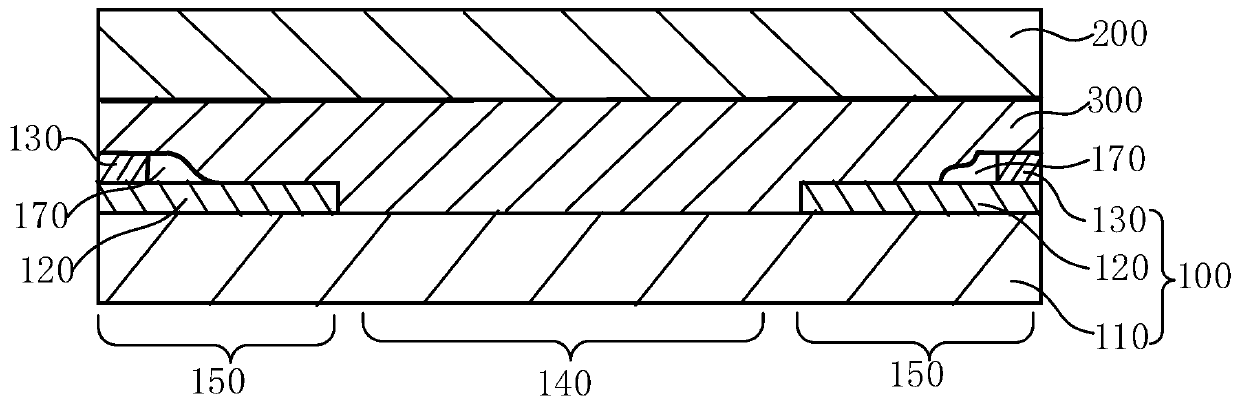

Display device and cover plate thereof

InactiveCN110728903AAvoid pinholesAvoid fit bubble problemsIdentification meansDisplay deviceEngineering

The invention discloses a display device and a cover plate thereof, wherein the cover plate of the display device comprises a transparent base plate, a first ink layer and a second ink layer; the transparent base plate comprises a display region positioned in the center and a non-display region surrounding the periphery of the display region; the first ink layer is arranged at the inner side surface of the non-display region of the transparent base plate; the second ink layer is arranged on one side, far away from the transparent base plate, of the first ink layer; the area of the second ink layer is smaller than the area of the first ink layer; a step part is formed between the second ink layer and the first ink layer; a hollow part is arranged at one side edge, near the display region, of the second ink layer; the hollow part communicates with the step part; and the hollow part is used for exhausting. The display device and the cover plate of the display device have the advantages that through the arrangement of the hollow part at one side, near the display region, of the second ink layer, the exhaust area can be increased; and the problem of display region attaching bubbles caused by ink misplacing can be solved.

Owner:INTERFACE TECH CHENGDU CO LTD +2

Pump body assembly, heat exchange equipment, fluid machine and operation method of fluid machine

PendingCN110905809AEasy to compressIncrease the exhaust areaRotary piston pumpsRotary piston liquid enginesReciprocating motionEngineering

The invention provides a pump body assembly, heat exchange equipment, a fluid machine and an operation method of the fluid machine. The pump body assembly comprises a piston, a rotating shaft, a piston sleeve and an air cylinder; the rotating shaft performs reciprocating motion in the piston sleeve while driving the piston to rotate; the piston sleeve are located in the air cylinder; a compressioncavity is formed between the outer circumferential wall of the piston and the inner wall of the air cylinder; a pressure relief concave part is arranged on the outer circumferential wall of the piston or the inner wall of the air cylinder; and the pressure relief concave part corresponds to the compression cavity. With the pump body assembly of the invention adopted, over-compression occurring during the air exhausting of a pump body assembly in the prior art is alleviated.

Owner:GREE ELECTRIC APPLIANCES INC

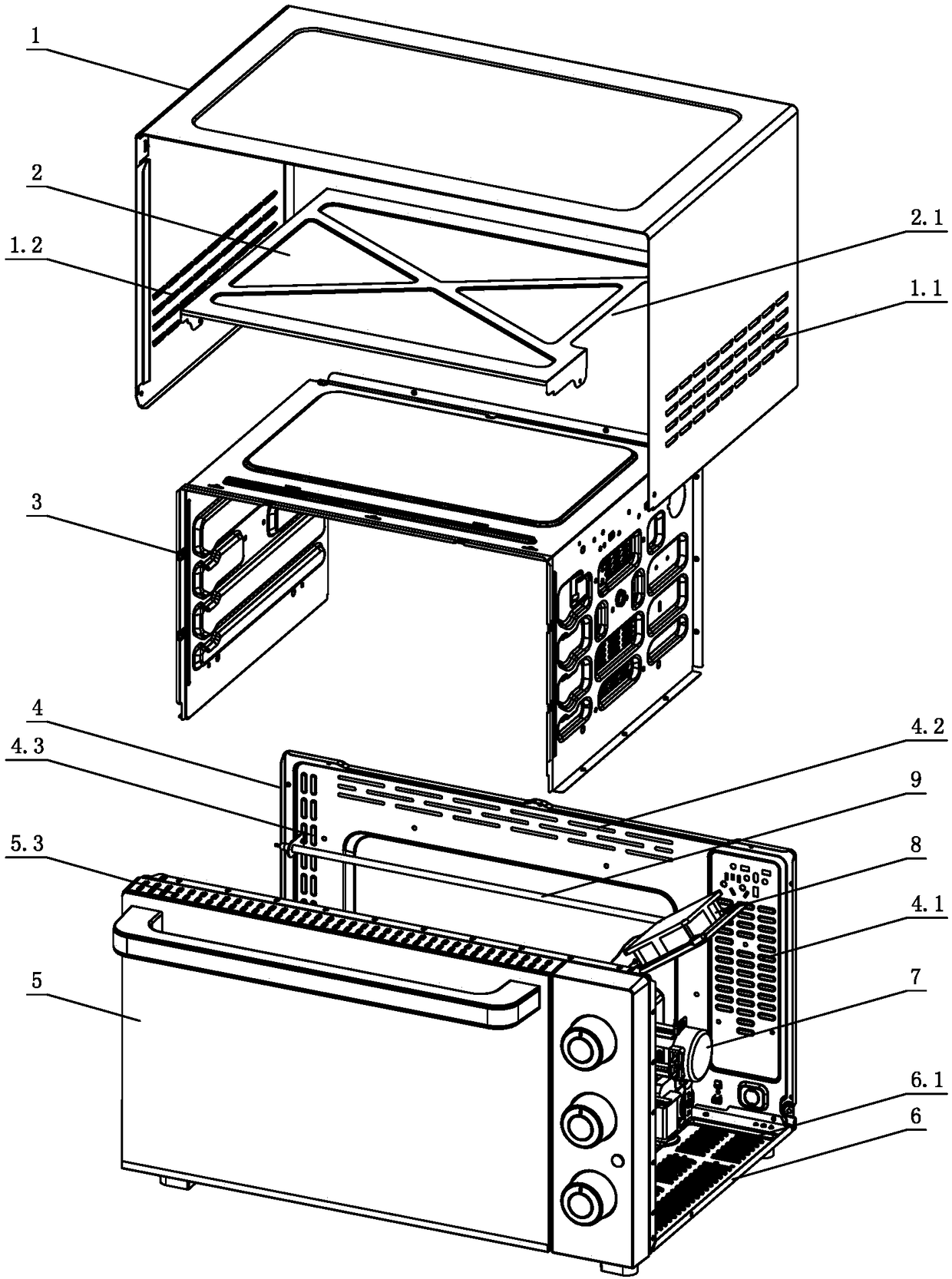

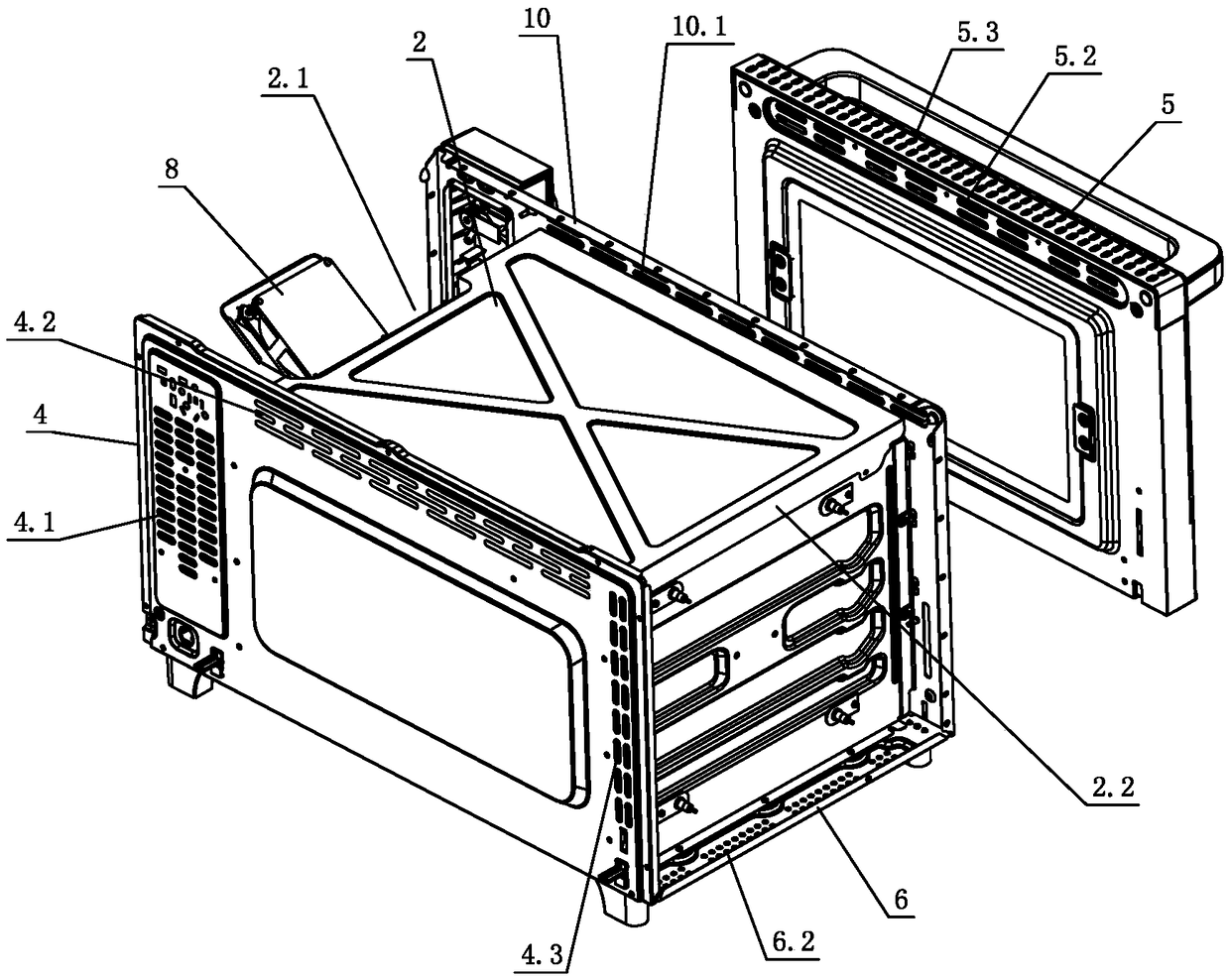

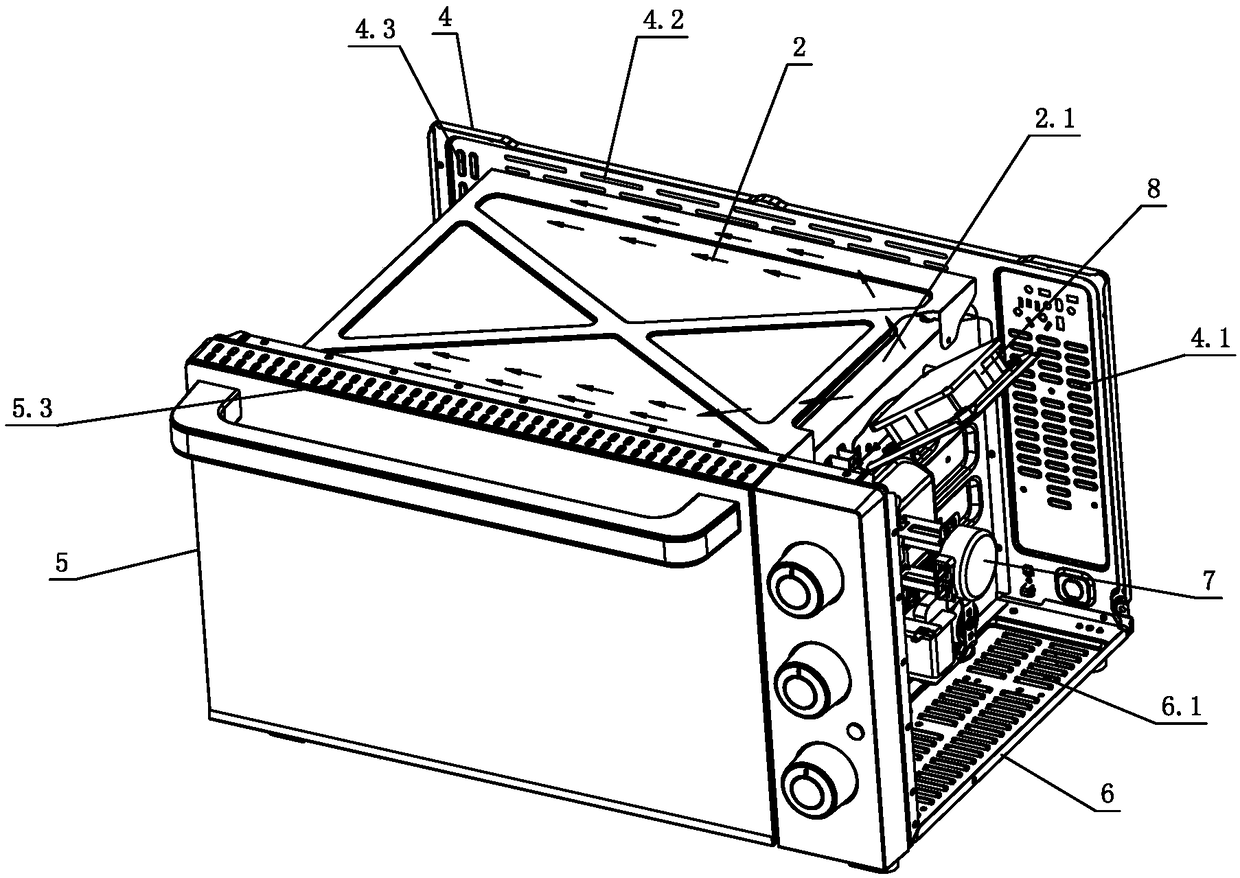

Dual-radiating structure of electric oven

A dual-radiating structure of an electric oven comprises an oven lining and an oven housing; the oven housing covers the oven lining; the oven lining is in spaced fit with the oven housing, and a radiating gap is formed between the oven lining and the oven housing; an insulation layer is arranged between the oven lining and the oven housing; the radiating gap is divided into a high-temperature zone and a low-temperature zone through the insulation layer; a cooling fan is arranged in the radiating gap; the back, side and / or top and / or top of the oven housing are provided with a plurality of vent holes communicated with the radiating gap; the high-temperature zone and the low-temperature zone are communicated with the vent holes in the back of the oven housing. When the cooling fan operates,external air is sucked into the radiating gap via corresponding vent holes in the oven housing; wind generated by the cooling fan is divided by the insulation layer to flow respectively into the high-temperature zone and the low-temperature zone, and the wind is discharged at least via the vent holes in the back of the oven housing. The dual-radiating structure is simple and reasonable in structure, low in manufacture cost and good in heat-radiating and cooling effect, enables oven core temperature to be ensured to ensure cooking effect, and has good market competitiveness.

Owner:GUANGDONG GALANZ GRP CO LTD

Adjustable constant-pressure safe exhaust valve

ActiveCN108980427AIncrease pressureOvercoming elasticityEqualizing valvesSafety valvesExhaust valvePressure reduction

The invention relates to the technical field of valves, and particularly discloses an adjustable constant-pressure safe exhaust valve. The adjustable constant-pressure safe exhaust valve comprises anexhaust assembly and a valve cap connected with the exhaust assembly; a stepped hole is formed in the exhaust assembly, the two ends of the stepped hole extend to the two end surfaces of the exhaust assembly correspondingly, the small end of the stepped hole is an air inlet hole, the large end of the stepped hole is an inner hole communicating with the outside, a shoulder portion is formed at thejoint between the air inlet hole and the inner hole, a valve plug capable of abutting against the shoulder portion of the stepped hole and plugging the air inlet hole is arranged in the inner hole, anexhaust groove is formed in the side wall of the inner hole, the length of the exhaust groove in the axial direction of the inner hole is larger than the height of the valve plug, and a spring whichwith two ends abutted against the valve plug and the valve cap correspondingly is arranged in the inner hole. According to the valve, the rapid pressure reduction can be achieved under the condition that the pressure is suddenly increased, so that the phenomenon that the phenomenon of tire burst caused by the fact that the pressure intensity inside a tire is rapidly increased is avoided.

Owner:李阳

Passive trigger gas fire-extinguishing device for electric power machine room

InactiveCN111298343ALarge fire extinguishing areaIncrease the exhaust areaFire rescueSprayerGaseous fire suppression

The invention relates to the field of fire extinguishers and discloses a passive trigger gas fire-extinguishing device for an electric power machine room. The passive trigger gas fire-extinguishing device for the electric power machine room comprises a high-pressure gas tank, an intake valve and an exhaust port. The left side of the top of the high-pressure gas tank is provided with the exhaust port, and a rotating sprayer is arranged at the exhaust port. The rotating sprayer is in an elbow shape. One end of the rotating sprayer is concentrically and rotationally connected with the exhaust port of the high-pressure gas tank, and a seal ring is arranged between the rotating sprayer and the exhaust port of the high-pressure gas tank. A metal plug is plugged into the other end of the rotary sprayer, a gap exists between the first end of the metal plug and an opening of the elbow of the rotary sprayer, and the gap is filled with a fusible material. The metal plug is connected with a connecting line. The bottom of the high-pressure gas tank is provided with the intake valve. One end of the intake valve is connected with a high-pressure flame retardant gas bin through a gas guide pipe, and the other end of the intake valve communicates with the high-pressure gas tank. The high-pressure gas tank is filled with high-pressure flame retardant gas. A pressure difference control valve capable of detecting the pressure difference between the inside and the outside of the high-pressure gas tank is arranged on the right side of the top of the high-pressure gas tank. The passive trigger gas fire-extinguishing device for the electric power machine room can rapidly and effectively conduct spontaneous fire extinguishing.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD JIAXING POWER SUPPLY CO +1

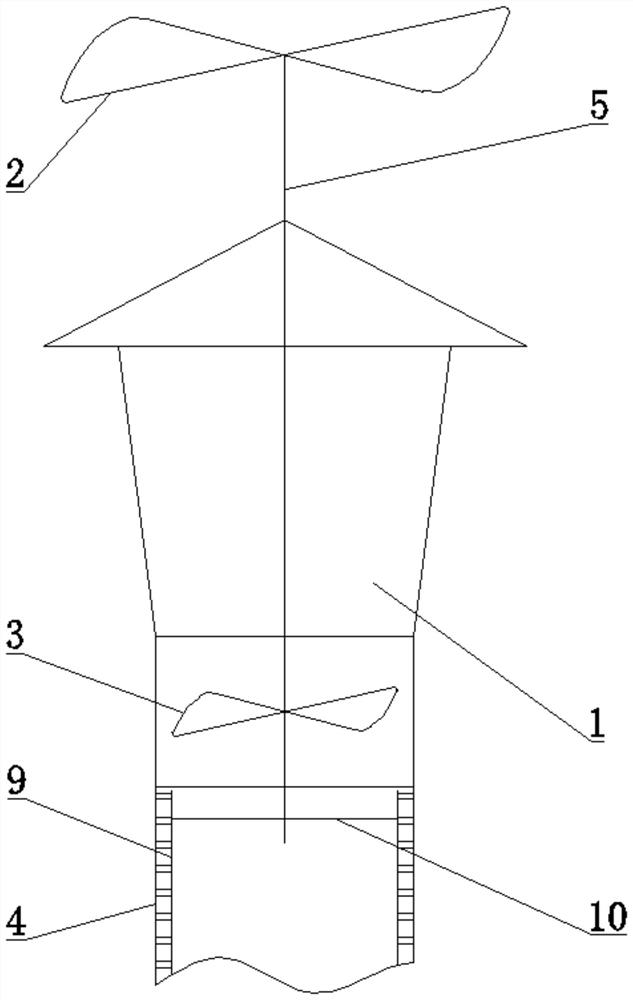

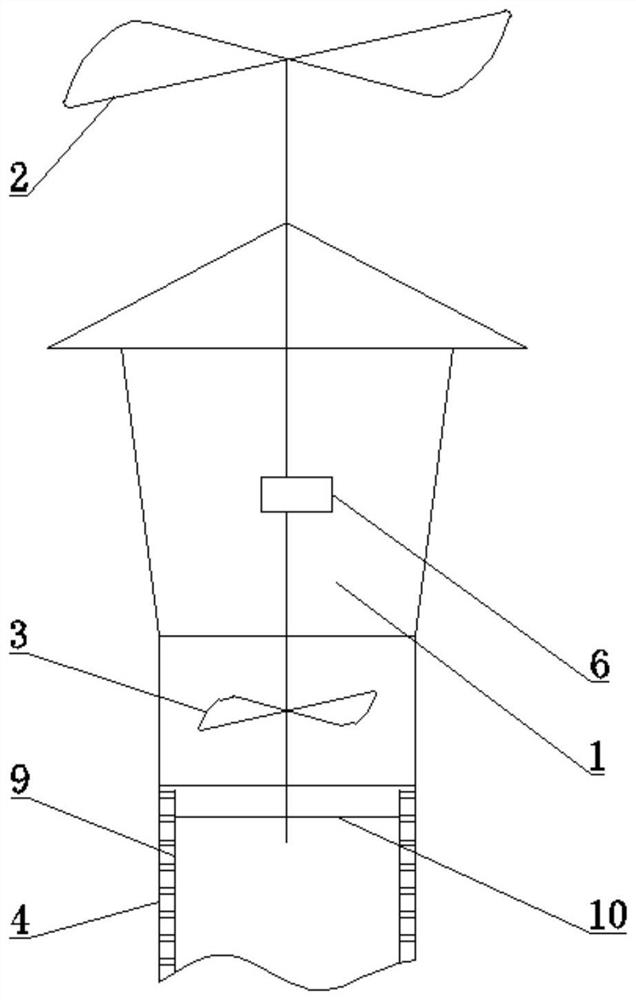

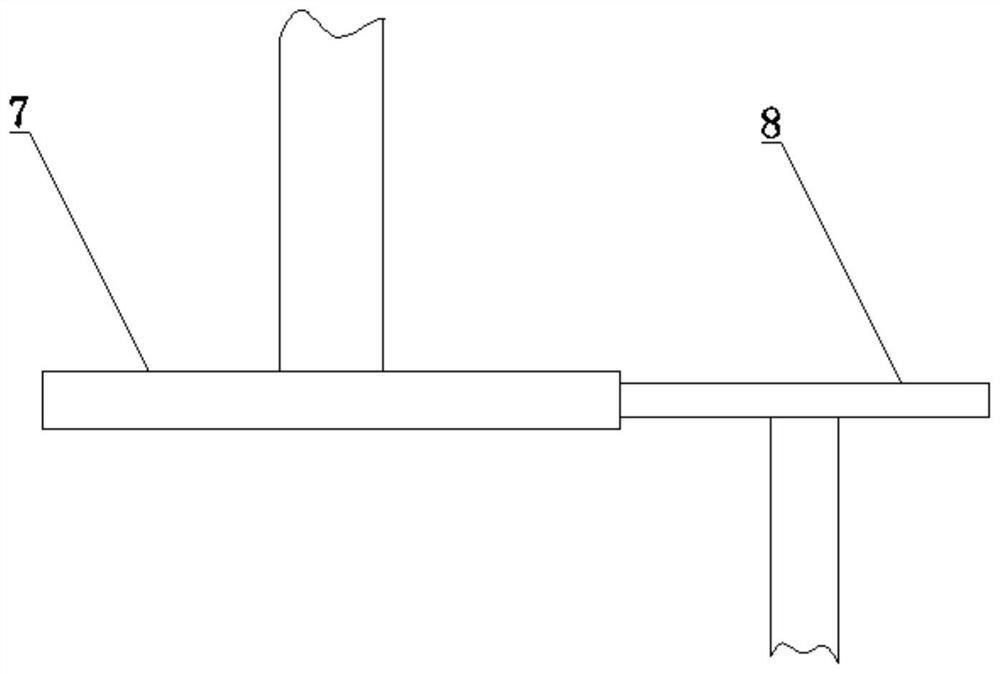

Fume exhaust funnel cap

PendingCN111964088AIncrease the exhaust areaSmall exhaust resistanceChimneysThermodynamicsEngineering

The invention is suitable for the technical field of environmentally-friendly exhaust equipment, and provides a fume exhaust funnel cap. The fume exhaust funnel cap comprises a funnel cap body, a fumeexhaust assembly and at least one wind power assembly. The fume exhaust assembly is arranged at the bottom of an inner cavity of the funnel cap body in a rotating mode. The at least one wind power assembly is arranged above the funnel cap body and driven by the wind power to rotate. The wind power assemblies drive the fume exhaust assembly to rotate through a transmission mechanism, and the fumeexhaust speed is increased. A sweeping mechanism is arranged below the funnel cap body, connected with the transmission mechanism and used for sweeping fume dust in a funnel. According to the fume exhaust funnel cap, the fume exhaust assembly is driven by the wind power assemblies to rotate, the fume exhaust efficiency can be improved by the wind energy under the windy condition, the fume exhausteffect is not affected or is slightly affected when no wind exists or a breeze exists, and the fume dust accumulated in the funnel can be cleaned away.

Owner:林森

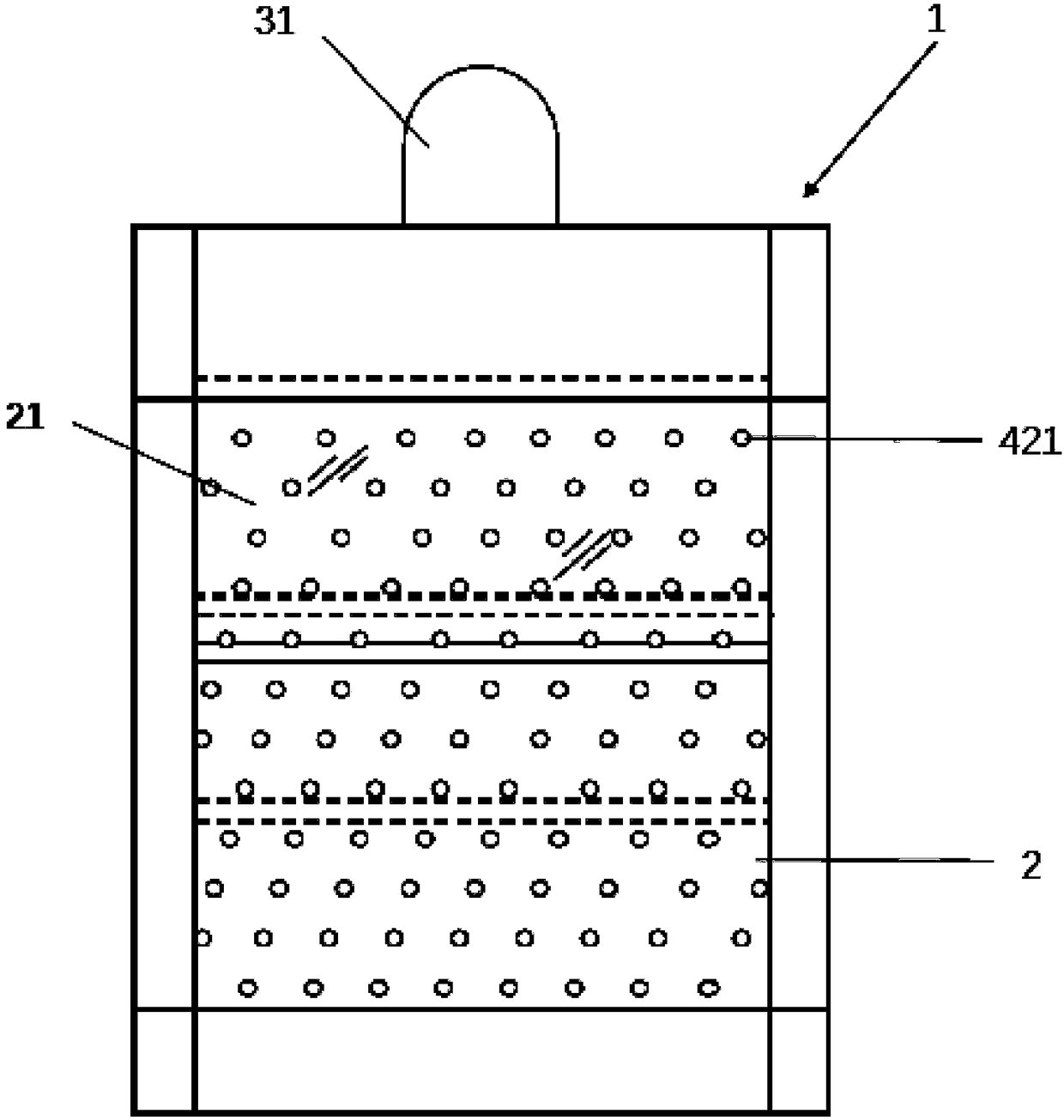

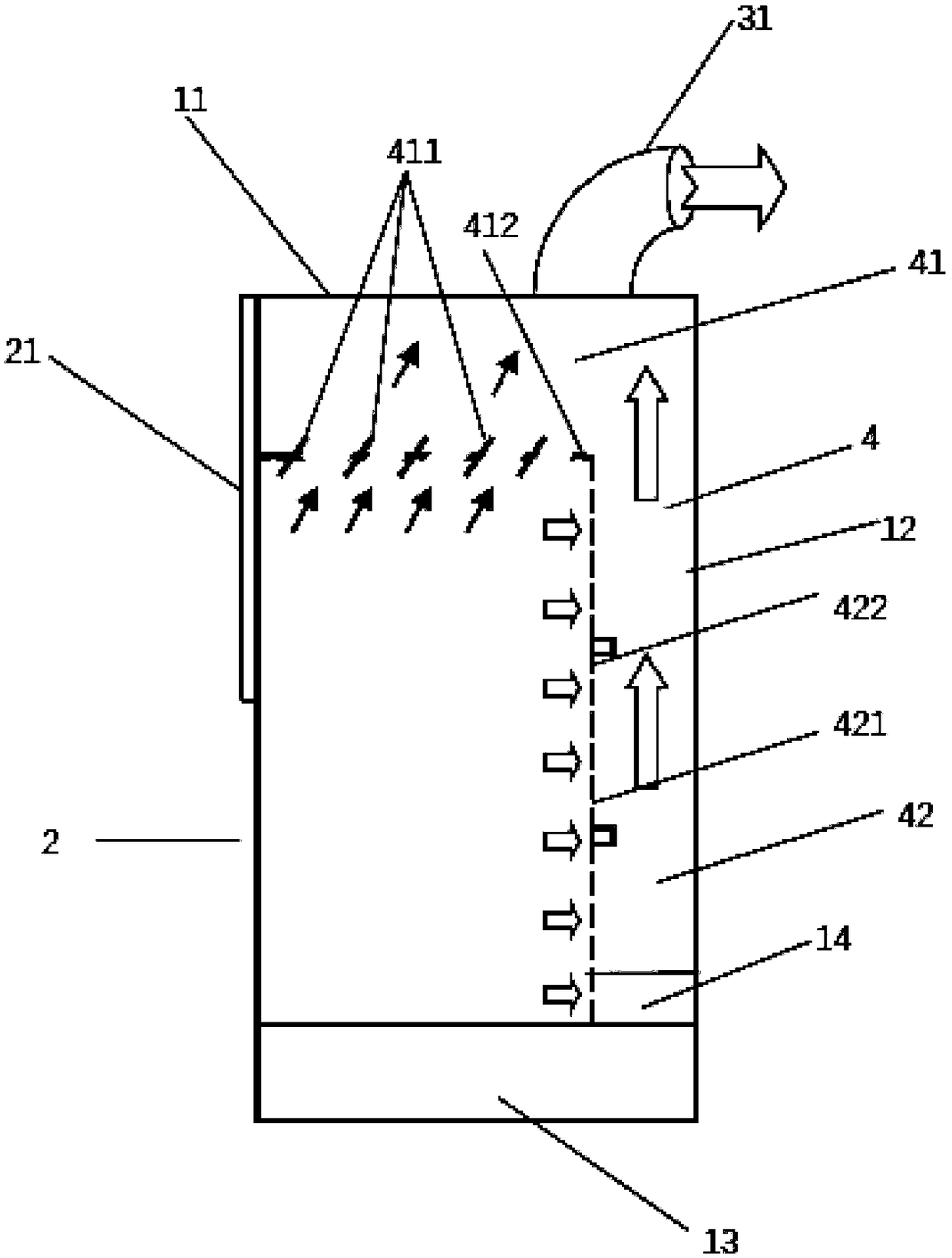

Device for purifying pollutants in operating area

The invention relates to a device for purifying pollutants in an operating area. The device for purifying the pollutants in the operating area is characterized in that the device comprises a body, andthe body is provided with a ventilating port; the body is internally provided with a ventilating cavity, and the ventilating cavity comprises a top ventilating cavity body and a vertical face ventilating cavity body; the top ventilating cavity body is composed of a top solid wall plate and a top plate; a gap-variable air door is arranged on the top plate; and the vertical face ventilating cavitybody is composed of a vertical face solid wall plate and a vertical plate, and the vertical plate is provided with a ventilating hole. The device for purifying the pollutants in the operating area provides a new air exhaust mode and an air volume adjusting mode for a fume cupboard, and under the condition that air disturbance in the cupboard is controlled, the granular dust pollutants produced inan experiment are effectively removed.

Owner:北京天辰昊桦科技有限公司

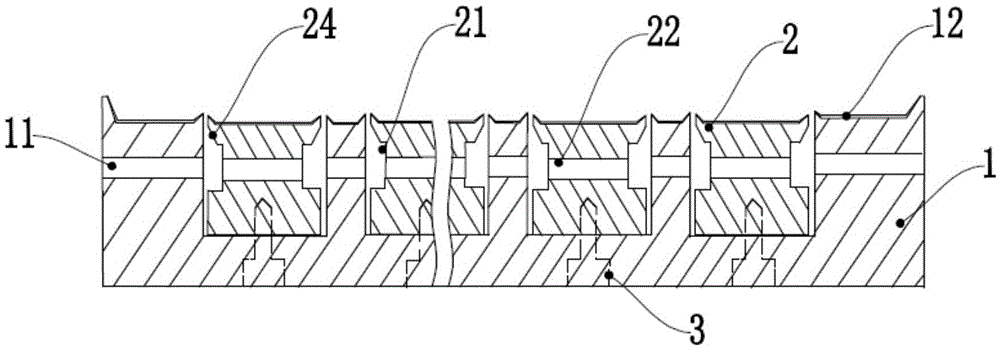

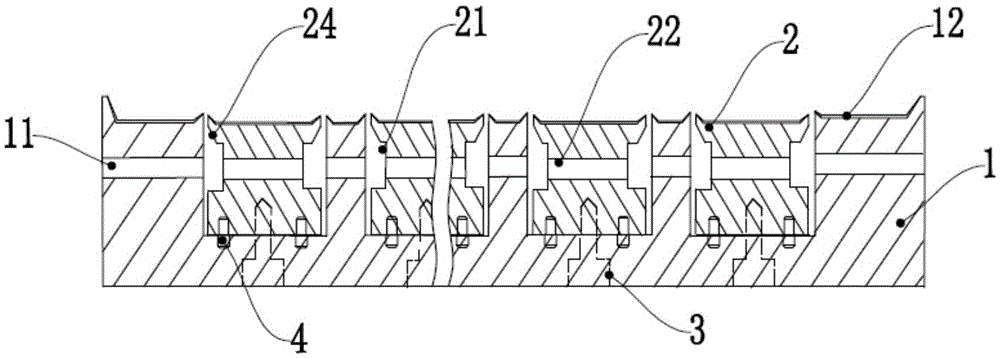

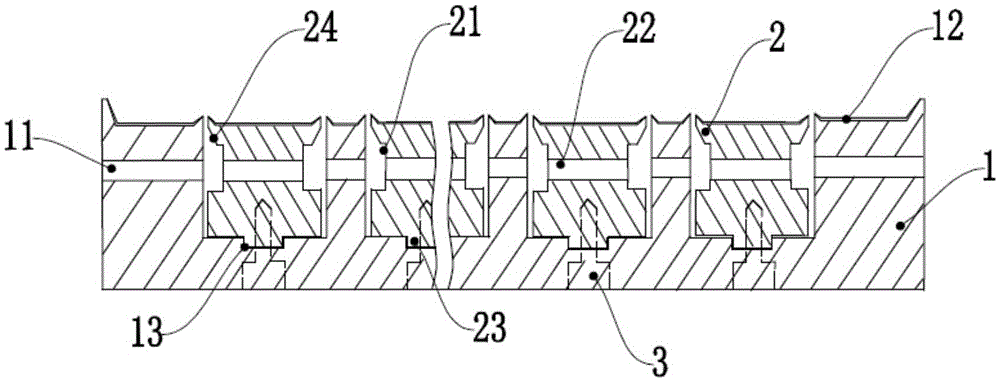

A high-efficiency exhaust tile mold

ActiveCN103847018BSimplify exhaust and powder removal structureIncrease the exhaust areaMould auxillary partsEngineeringPlunger

The invention discloses an efficient exhaust ceramic tile die. The efficient exhaust ceramic tile die comprises a base and plungers, wherein the base is provided with multiple blind holes, the blind holes are internally and fixedly provided with the plungers, exhaust gaps are reserved between the blind holes and the plungers, the base is also provided with air passages, and the air passages are communicated with the exhaust gaps; the plungers are provided with a passage penetrating through two sides of the plungers, and the passage is communicated with the air passages. The efficient exhaust ceramic tile die provided by the invention has the advantages that the structure is simple, the tile pressing speed can be increased, the exhaust area is enlarged, and the production efficiency is obviously increased.

Owner:佛山市石湾陶瓷工业研究所有限公司

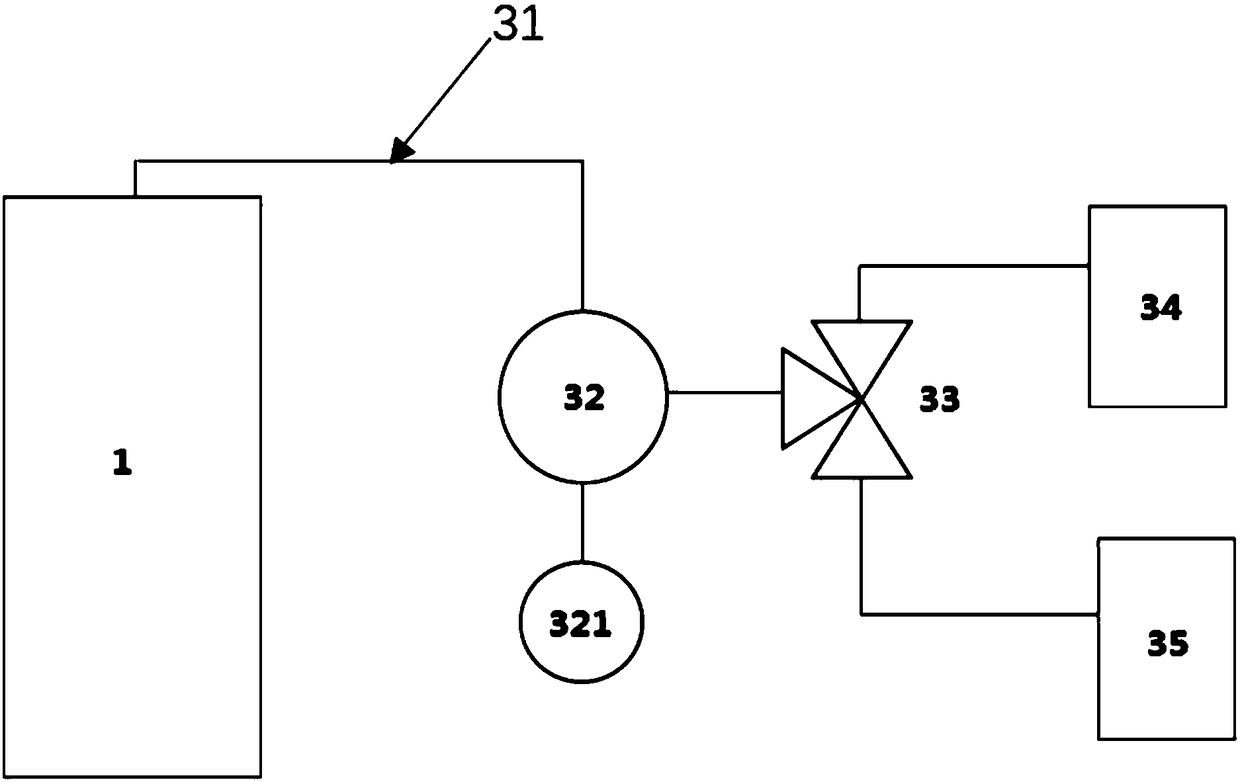

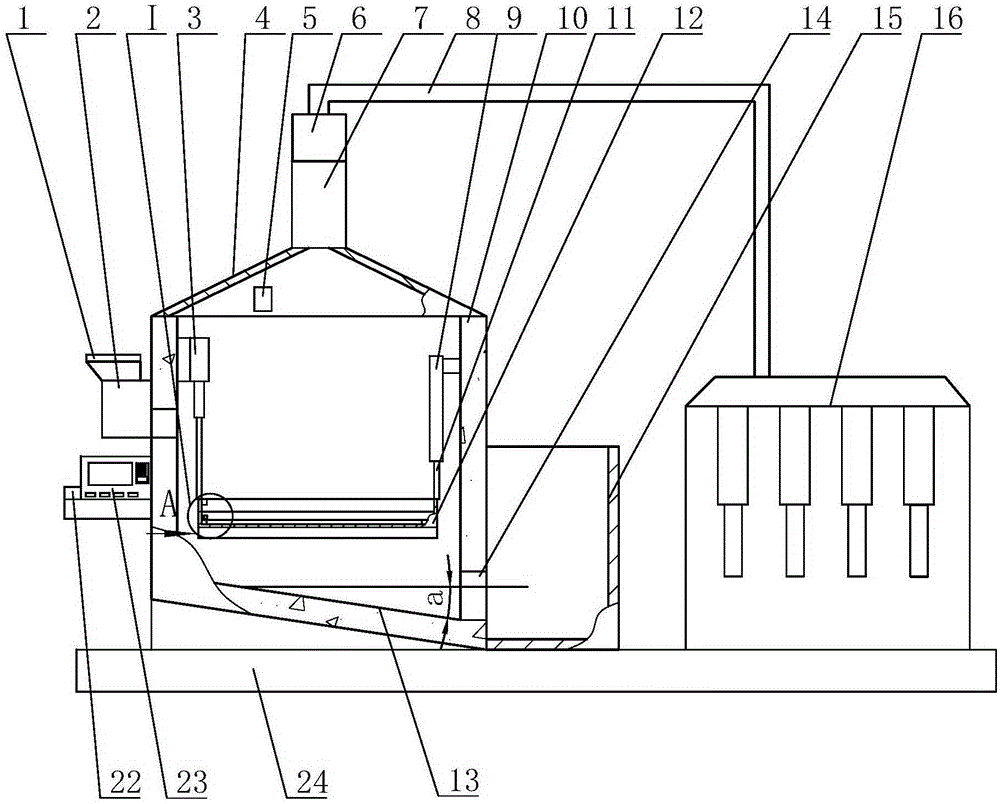

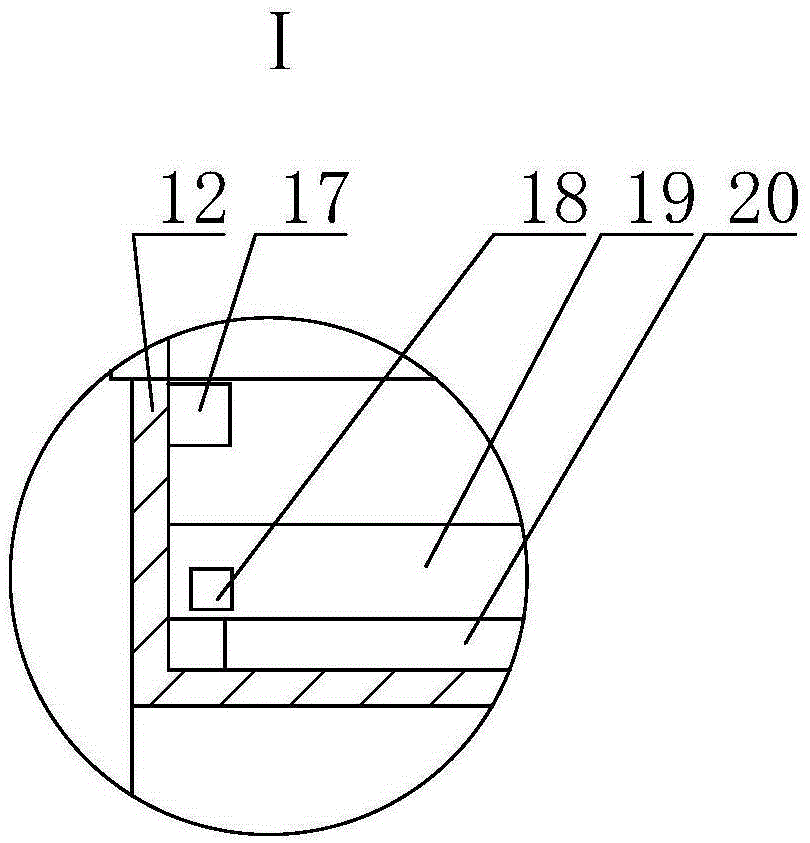

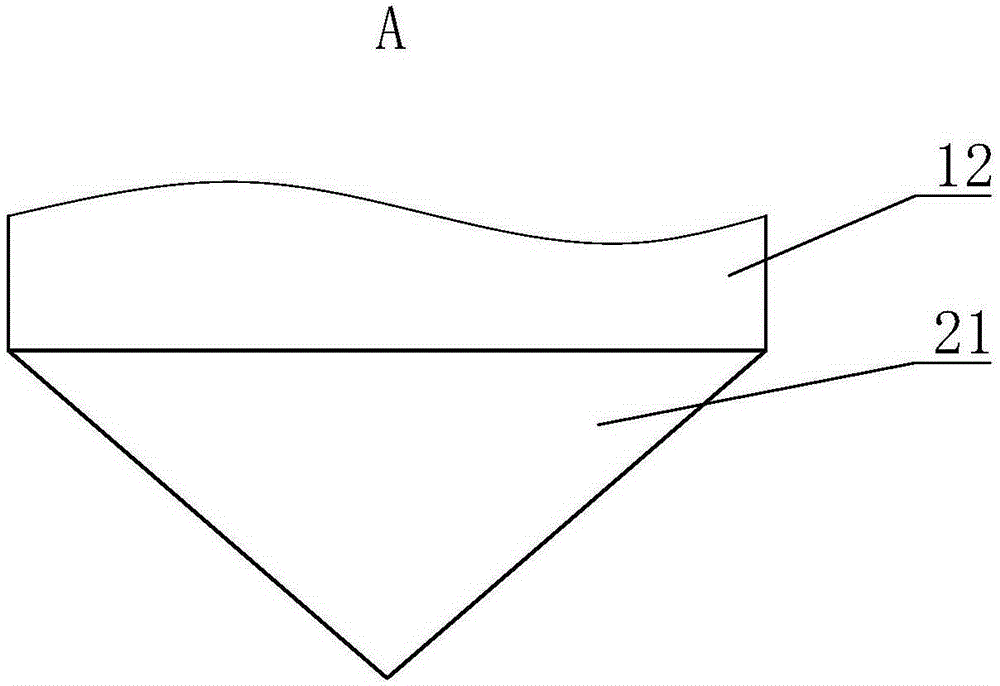

Biomass power generating equipment

InactiveCN105176800AQuick layeringEasy dischargeBioreactor/fermenter combinationsGas production bioreactorsEngineeringProcess engineering

The invention discloses biomass power generating equipment capable of producing biogas in a layered manner. The biomass power generating equipment comprises a base, wherein a methane tank and a gas-powered generator are mounted on the upper portion of the base, a guide cover is mounted on the upper portion of the methane tank, an oxygen content sensor is mounted on one side inside the guide cover, a gas pump is mounted on the upper portion of the guide cover, the gas outlet of the gas pump is connected with a gas pipe, one end of the gas pipe is connected with the gas pump, and the other end of the gas pipe is connected with the gas-powered generator. The biomass power generating equipment has the advantages that biomass can be layered fast through a simple process and structural design during methane producing, methane inside the biomass can be discharged fast, the methane producing efficiency of the biomass power generating equipment is increased by 10-15% as compared with existing biomass power generating equipment, and the power generating efficiency of the biomass power generating equipment is increased greatly.

Owner:SHANDONG HUANNENG DESIGN INST

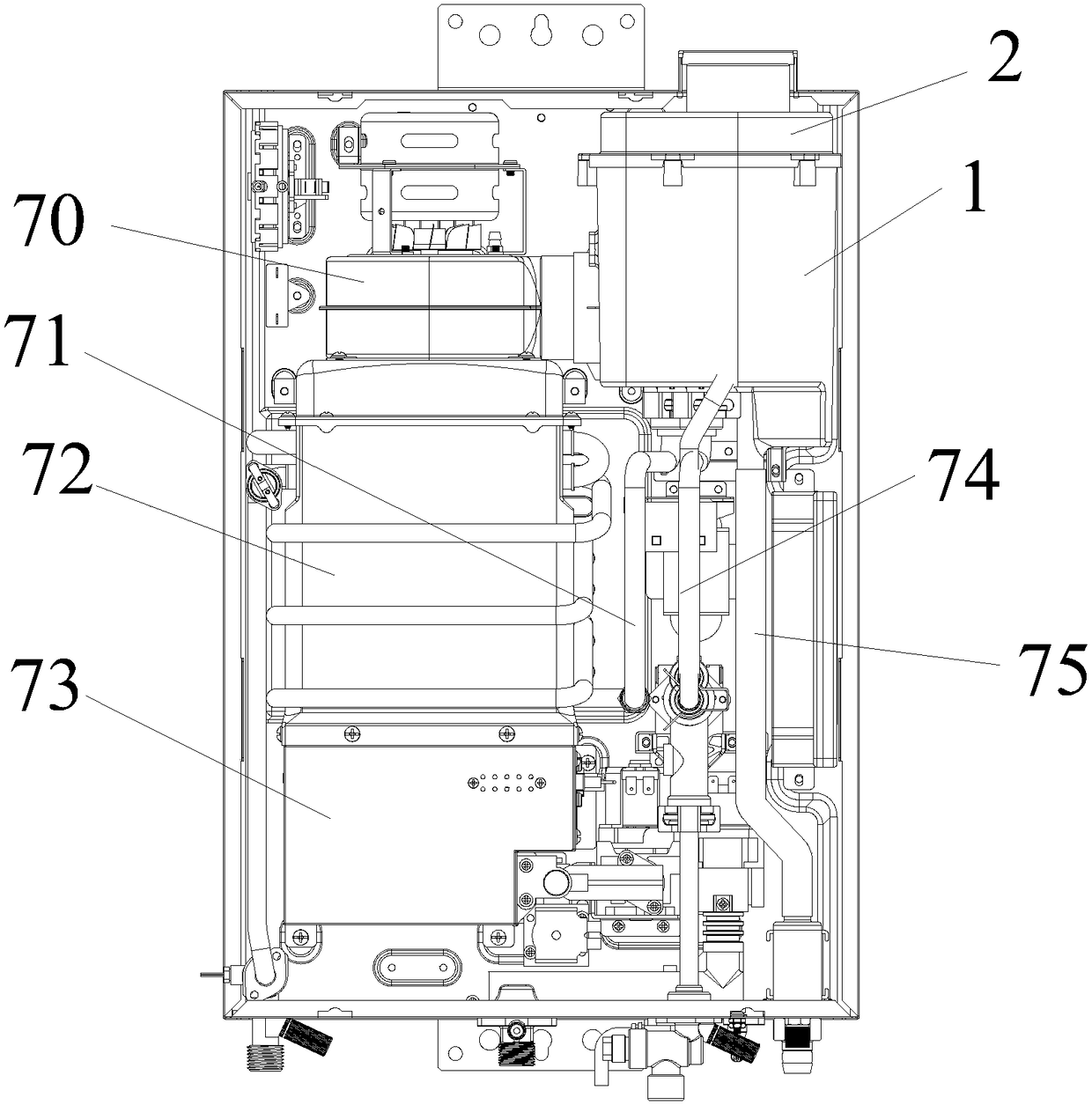

Condensate type fuel gas fast water heater

The invention relates to the technical field of fuel gas water heaters, in particular to a condensate water heater. The condensate type fuel gas fast water heater comprises a main heat exchanger, a fan and a condensate heat exchanger. The fan is arranged on the main heat exchanger, and the fan is connected with the condensate heat exchanger. A sealing pad is arranged between an upper water sealingcover and a lower water sealing cover of a heat exchange body and the heat exchange body, and the heat exchange body comprises a first water inlet flow channel, a second water inlet flow channel, a first water outlet flow channel and a second water outlet flow channel. Due to the fact that the upper water sealing cover is provided with a first water passing groove and a second water passing groove, water flow can flow to the first water outlet flow channel from the first water inlet flow channel and flows to the second water outlet flow channel from the second water inlet flow channel, and two ways of water flow flow into a water outlet groove of the lower water sealing cover from the first water outlet flow channel and the second water outlet flow channel and combined. The heat exchangebody is simple in waterway, end face sealing of the heat exchange body is achieved in a non-welding manner, and heat exchange body water inlet and outlet channels are provided.

Owner:VATTI CORP LTD

Linear equidirectional parallel three-screw extruder

PendingCN112223719AIncrease production capacityAvoiding the problem of sinking and deformation at one end with a large length-to-diameter ratioElectric machineEngineering

The invention provides a linear equidirectional parallel three-screw extruder which comprises a rack, a motor, a gear box and a screw sleeve arranged on the rack, wherein a screw assembly is arrangedin the screw sleeve and comprises three linear parallel screws, the adjacent screws are meshed with one another, the motor drives the three screws to rotate in the same direction through the gear box,each screw comprises a mandrel, a threaded conveying element and a threaded mixing element are arranged on each mandrel, the threaded conveying elements are arranged in a partitioned mode through thethreaded mixing elements. a cutting device is connected to the output ends of the screws, the thread sleeve is further in communication with a vacuumizing device and a conditioner, the conditioner isconnected with a feeder, and the feeder feeds materials into the thread sleeve through the conditioner. According to the three-screw extruder, the mixing performance and productivity of the existingextruder are improved, and the overall energy consumption is reduced.

Owner:BUHLER CHANGZHOU MASCH CO LTD

Screw compressor, control method thereof and air conditioning equipment

PendingCN114352523AIncrease the exhaust areaReduce power consumptionRotary piston pumpsRotary piston liquid enginesSpool valveEngineering

The invention relates to a screw compressor, a control method thereof and air conditioning equipment. The screw compressor comprises a machine body and a slide valve, the exhaust end of the slide valve is provided with a first exhaust port, and the exhaust end of the slide valve cavity of the machine body is provided with a second exhaust port. The exhaust port is formed in the machine body while the exhaust port is formed in the sliding valve, and the first exhaust port and the second exhaust port are communicated in the initial state that the exhaust end of the sliding valve slides to the exhaust end of the sliding valve cavity, so that the initial exhaust area of the exhaust ports is increased, the flow loss in the initial exhaust period is reduced, and the power consumption of the compressor is reduced. The control method comprises the steps that the slide valve is moved to change the position of an exhaust port of the slide valve, the internal compression final pressure is made to be equivalent to the condensation pressure, then the tooth space pressure of the tail section in the exhaust process is made to be equivalent to the condensation pressure, and the compressor operates in a high-efficiency area; meanwhile, the pressures of monitoring points of the slide valve at different positions are compared to judge whether the slide valve normally moves, the slide valve jamming fault is found in time, and long-term low-efficiency operation of equipment is avoided.

Owner:GREE ELECTRIC APPLIANCES INC

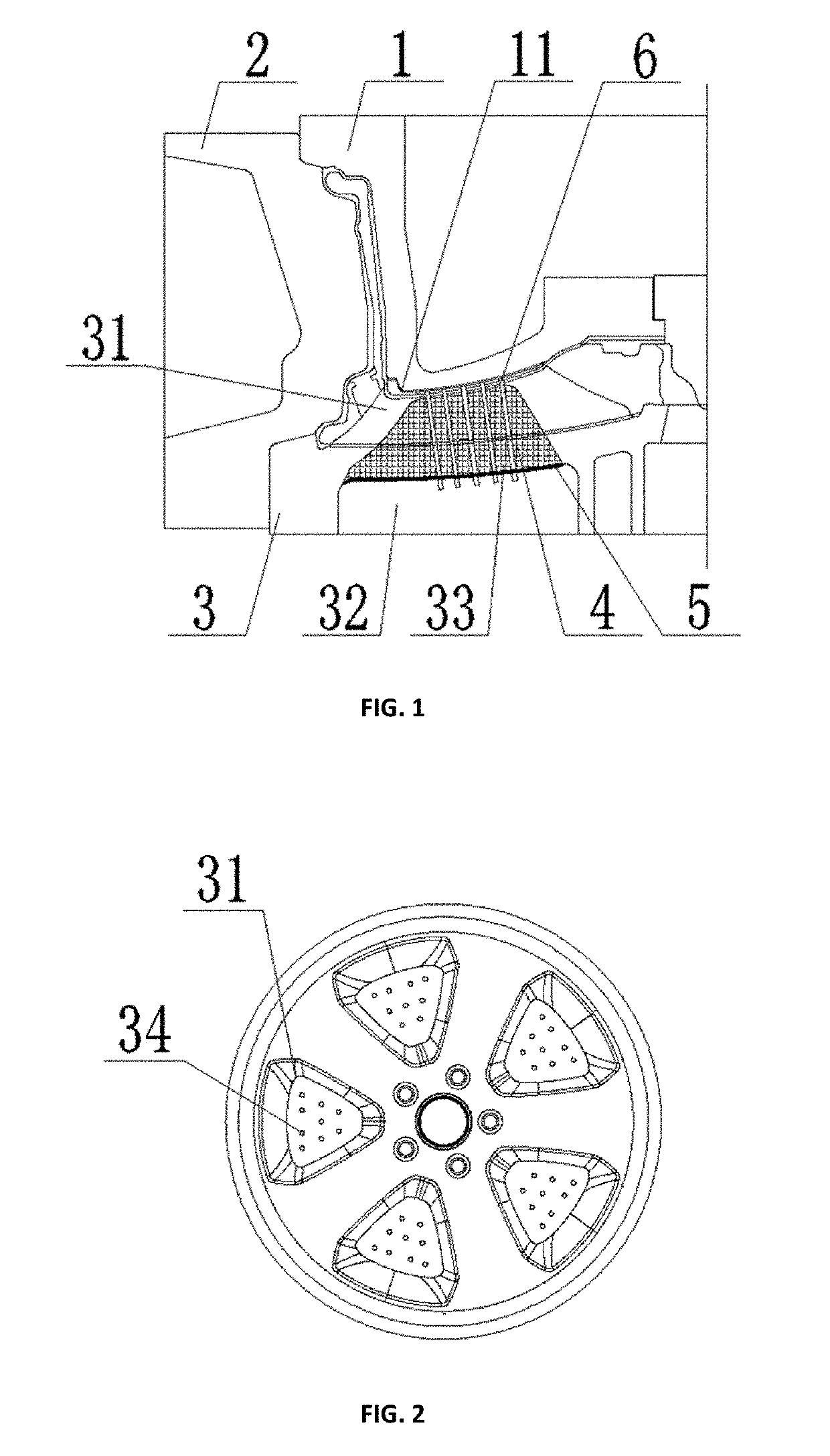

Mold for reducing defects in low pressure casting of aluminum alloy wheel

ActiveUS20190321878A1Reduced heat absorption capacityPrevent heat lossFoundry mouldsFoundry coresAlloy wheelMaterials science

A mold for reducing defects in low pressure casting of an aluminum alloy wheel includes a top mold, a side mold and a bottom mold, wherein the top mold is arranged above the bottom mold to mold a back cavity of a wheel, the bottom mold is arranged below the top mold to mold a front wheel disc of the wheel, the side mold is arranged on the side of the top mold and the bottom mold, and the top mold, the side mold and the bottom mold collectively surround a casting cavity of the aluminum alloy wheel, wherein the upper surface of the bottom mold includes a recessed portion configured to form a spoke and a boss portion configured to form a window and wherein the boss portion configured to form the window includes cooling ducts.

Owner:CITIC DICASTAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com