Large-load last stage blade with steam exhaust area of 5.0 m<2>

A technology of last stage blade and large load, applied in the field of industrial steam turbine blades, can solve the problems of low aerodynamic efficiency, small steam exhaust area, large energy consumption, etc., achieve the effect of large steam exhaust area, meet the operation requirements, and improve the single unit capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

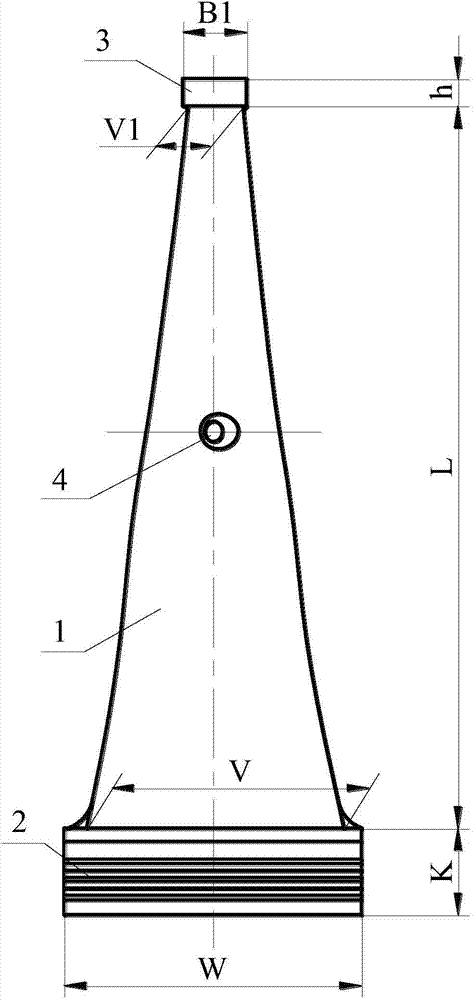

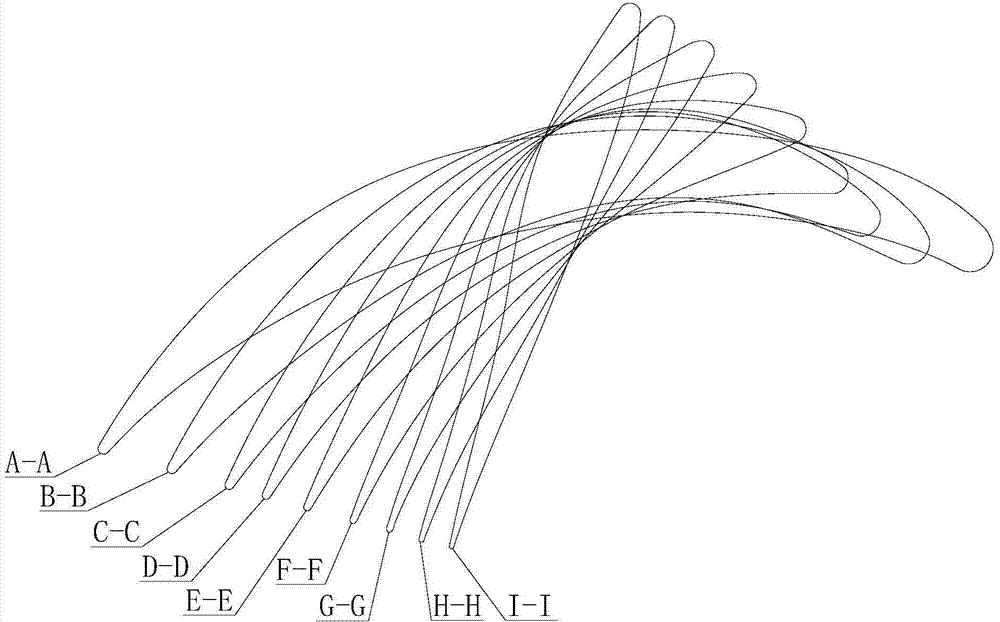

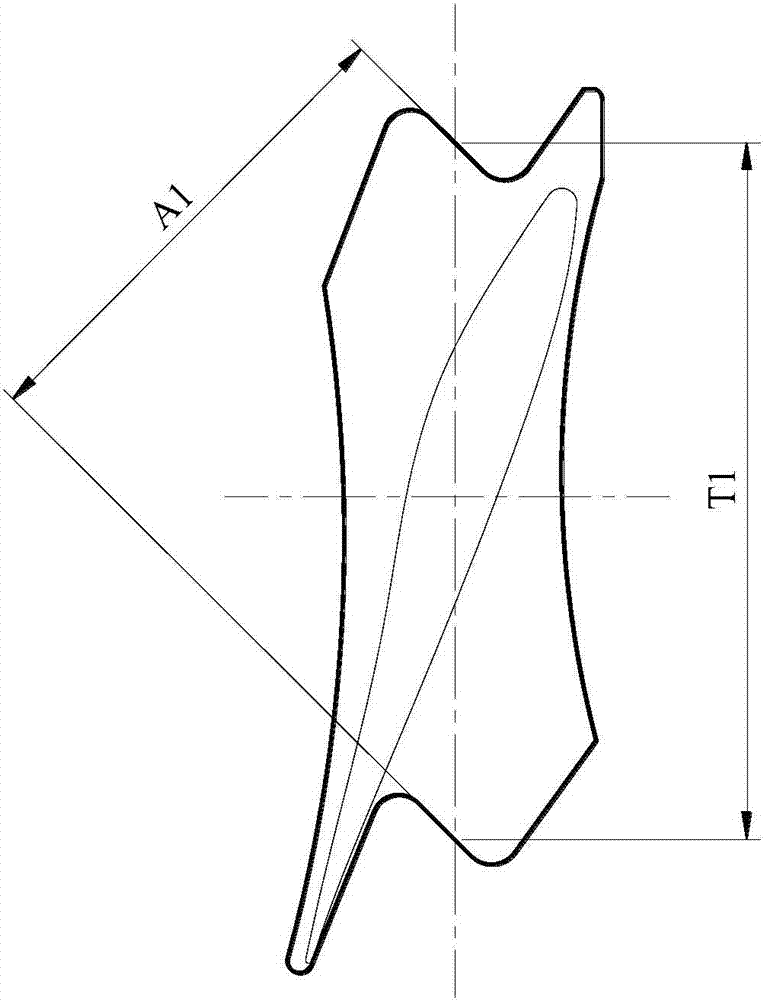

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, the steam exhaust area described in this embodiment is 5.0m 2 The final stage blade with heavy load is composed of blade working part 1, blade root 2, shroud 3 and boss tie bar 4. Tie bars 4 are located at 0.550 relative to the blade height of the working part 1 of the blade from bottom to top, and are integrated with the working part 1 of the blade. The profile of the working part 1 of the blade is a variable cross-section twisted blade, the cross-sectional area from the root to the top gradually decreases, and there is relative twist between two adjacent cross-sections. It is characterized in that the height L of the working part 1 of the blade is 661.92 mm, the axial width V of the root is 231.11 mm, the diameter of the root is 728 mm, the axial width V1 of the top is 47.37 mm, and the steam exhaust area of the working part 1 of the blade is 5.0 m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com