Linear equidirectional parallel three-screw extruder

A three-screw, in-line technology, applied in the field of in-line co-directional parallel three-screw extruders, can solve the problems of large drying workshop area, difficult air discharge, large space occupation, etc., so as to reduce the workshop area and exhaust air. And the effect of improving the vacuuming capacity and increasing the production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

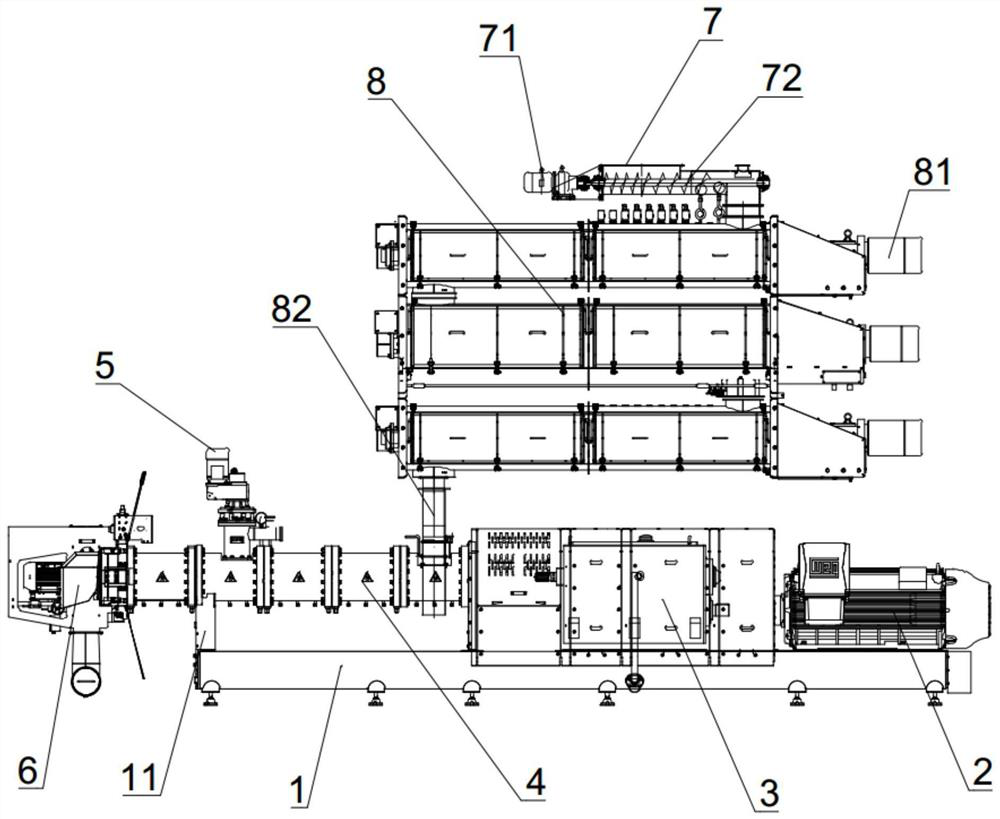

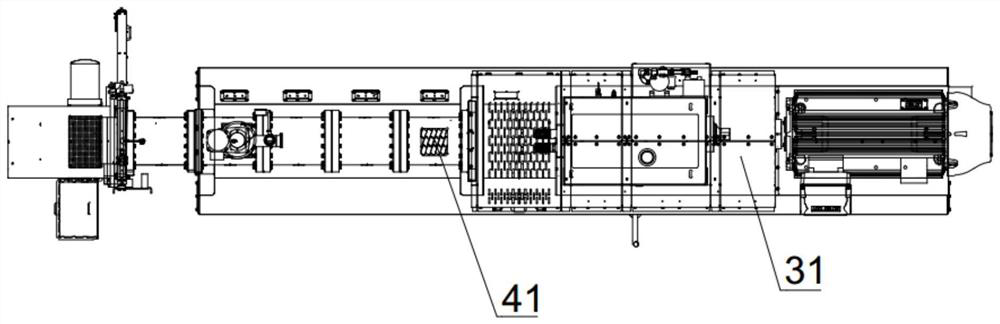

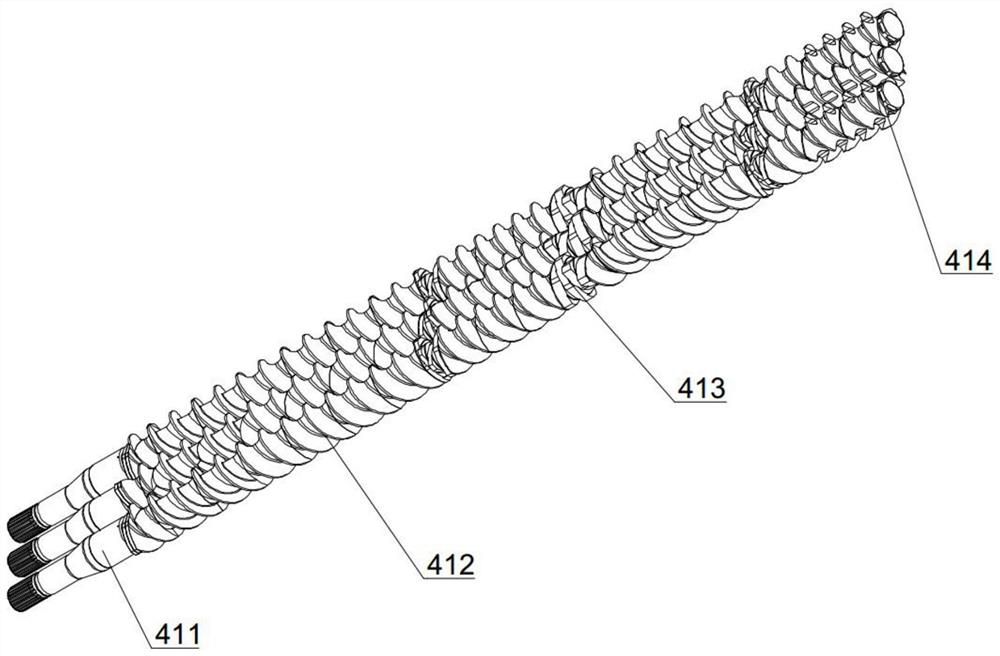

[0021] Such as Figure 1-Figure 2 As shown, a parallel three-screw extruder in the same direction includes a frame 1, a motor 2, a gear box 3 and a screw sleeve 4 arranged on the frame 1, and a screw sleeve 4 is arranged between the frame 1 and the screw sleeve 4. A support 11 is arranged to keep the overall machine stable. One end of the screw sleeve 4 is connected to the gear box 3, and the other end is connected to the cutting device 6. The gear box 3 is provided with a safety shield 31 for protecting the gear box 3. A screw assembly 41 is provided inside the screw sleeve 4, and the motor 2 drives the screw assembly 41 to rotate through the gear box 3; the output end of the screw is connected with a cutting device 6, and the screw sleeve 4 is also connected with a vacuum device 5 and a conditioner 8. The feeder 8 is connected with the feeder 7, and the feeder 7 feeds into the screw sleeve 4 through the conditioner 8. One end of the feeder 7 is provided with a feeding motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com