Patents

Literature

94results about How to "Quick layering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

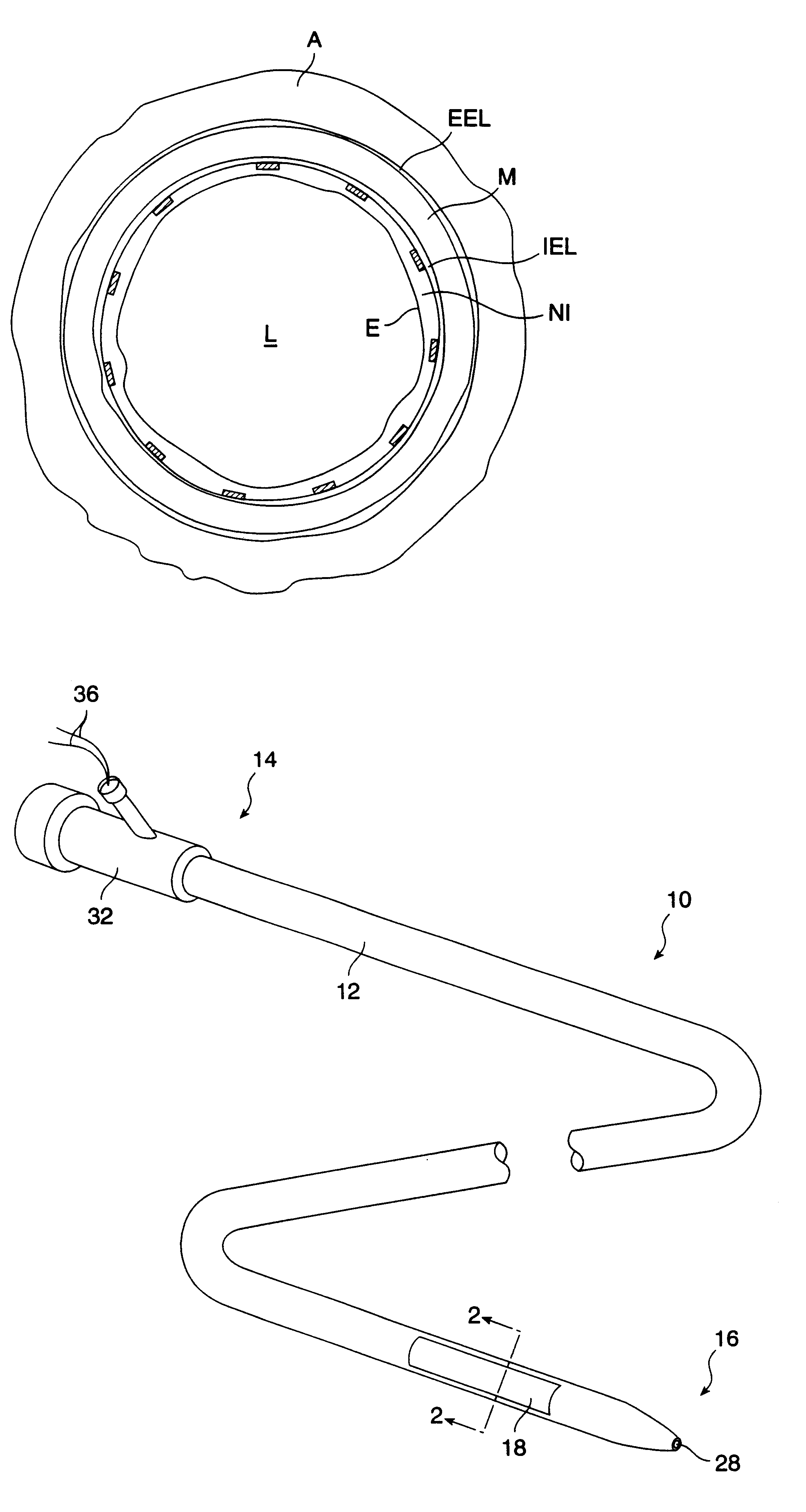

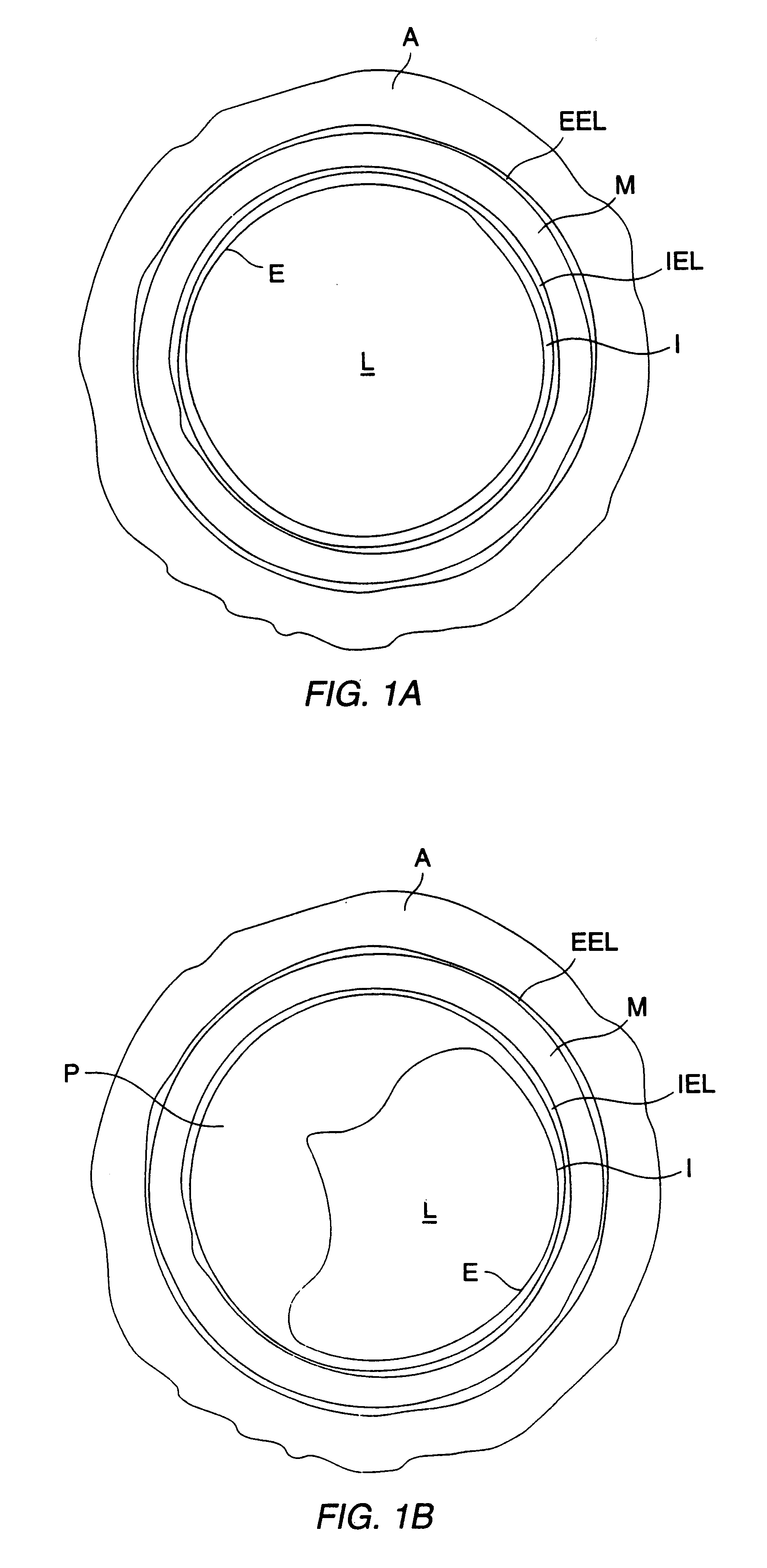

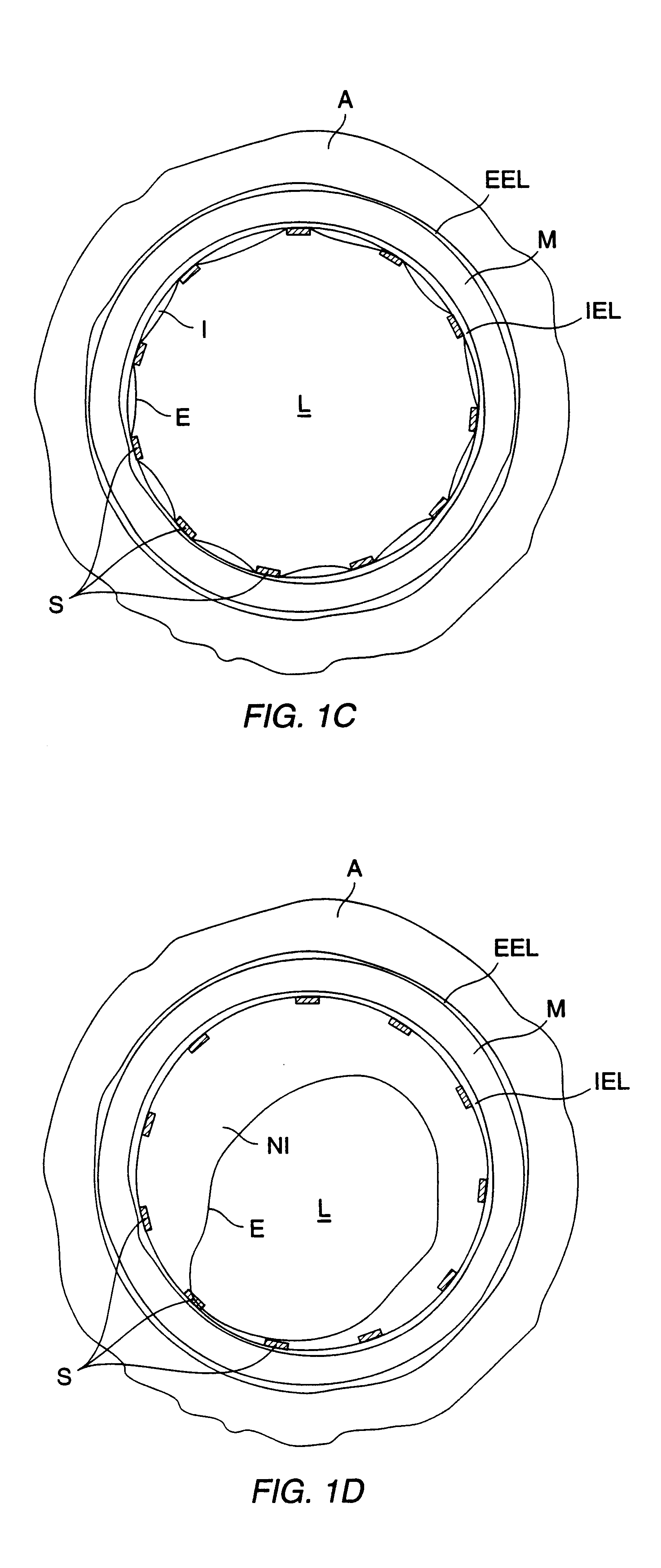

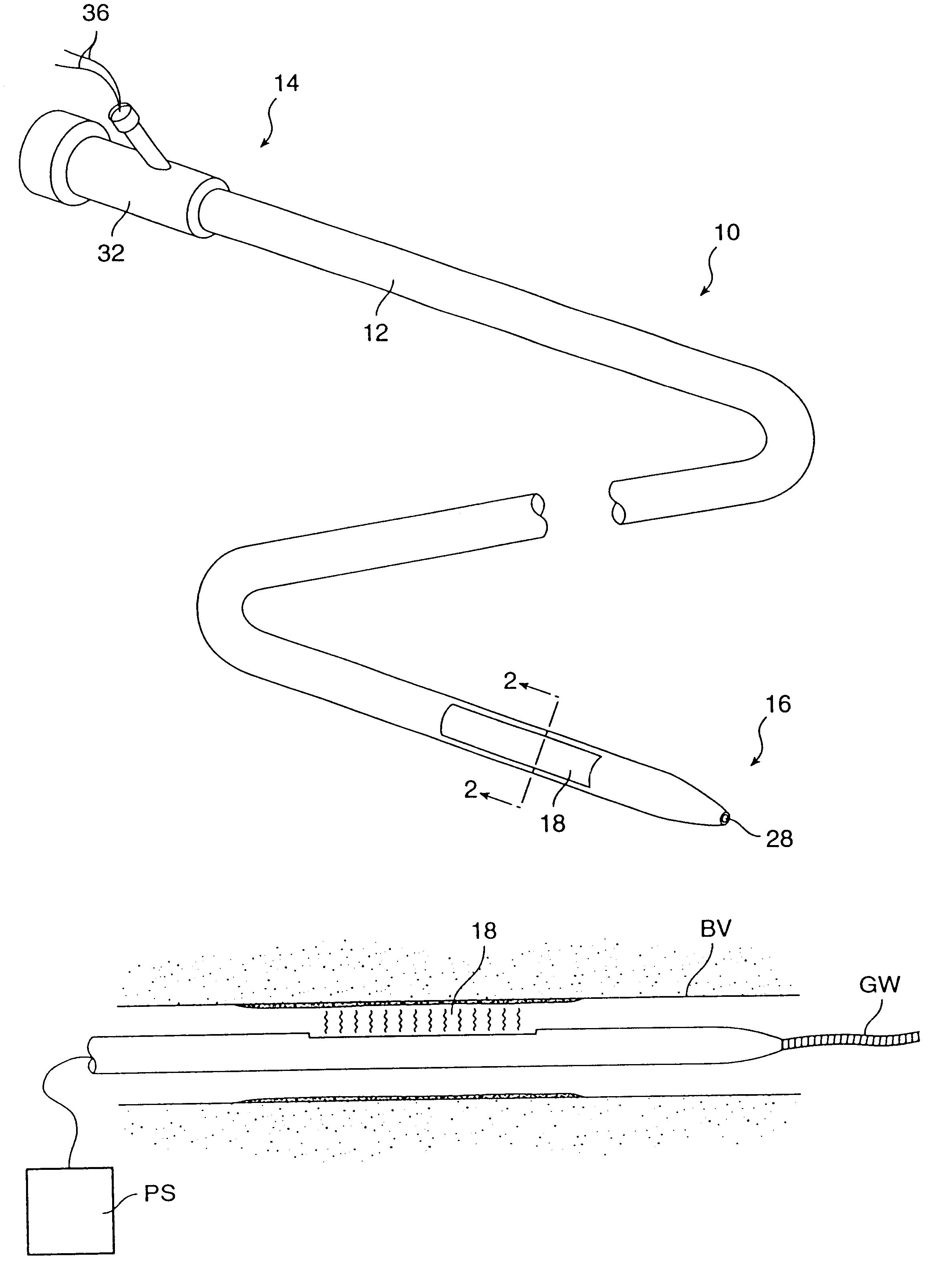

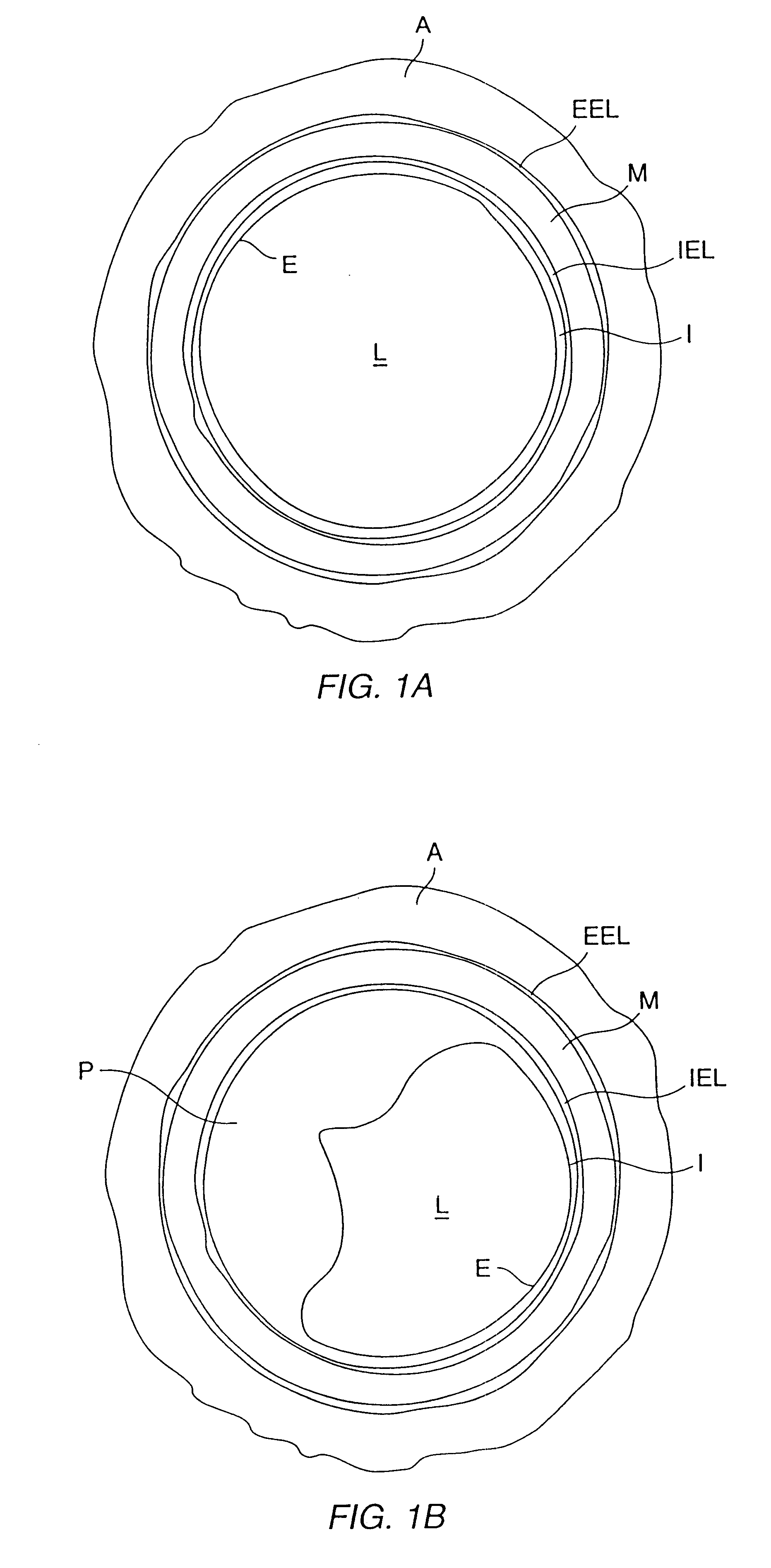

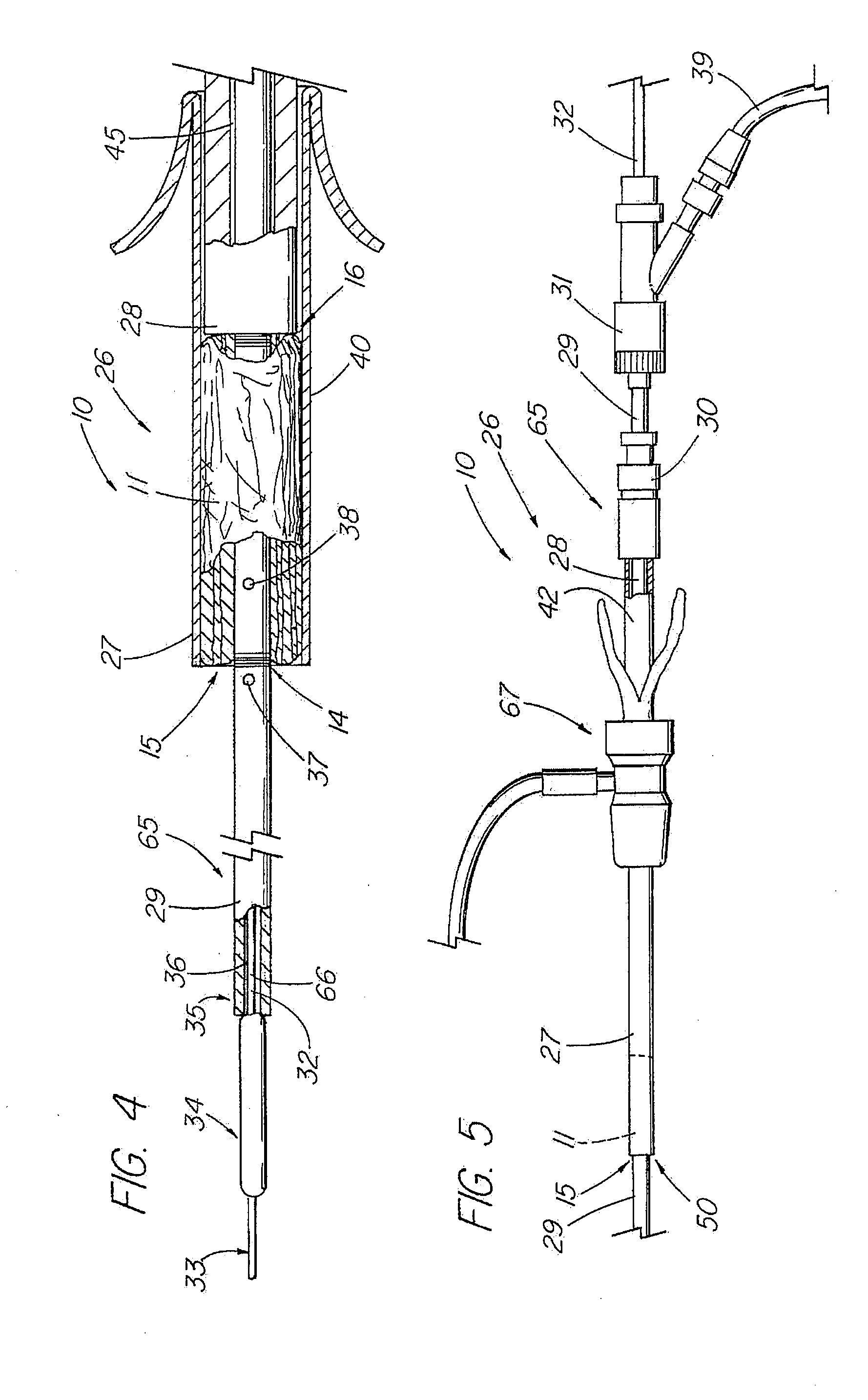

Methods and systems for the inhibition of vascular hyperplasia

InactiveUS6210393B1Limited extentQuick layeringUltrasound therapyStentsSmooth muscleVascular proliferation

Post-interventional neointimal hyperplasia in arteries is treated by the application of ultrasonic energy. Usually, an intravascular catheter having an interface surface is positioned at a target site in the artery which has previously been treated. The interface surface is vibrationally excited to apply energy to the arterial wall in a manner which inhibits smooth muscle cell proliferation in the neointimal layer.

Owner:PHARMASONICS

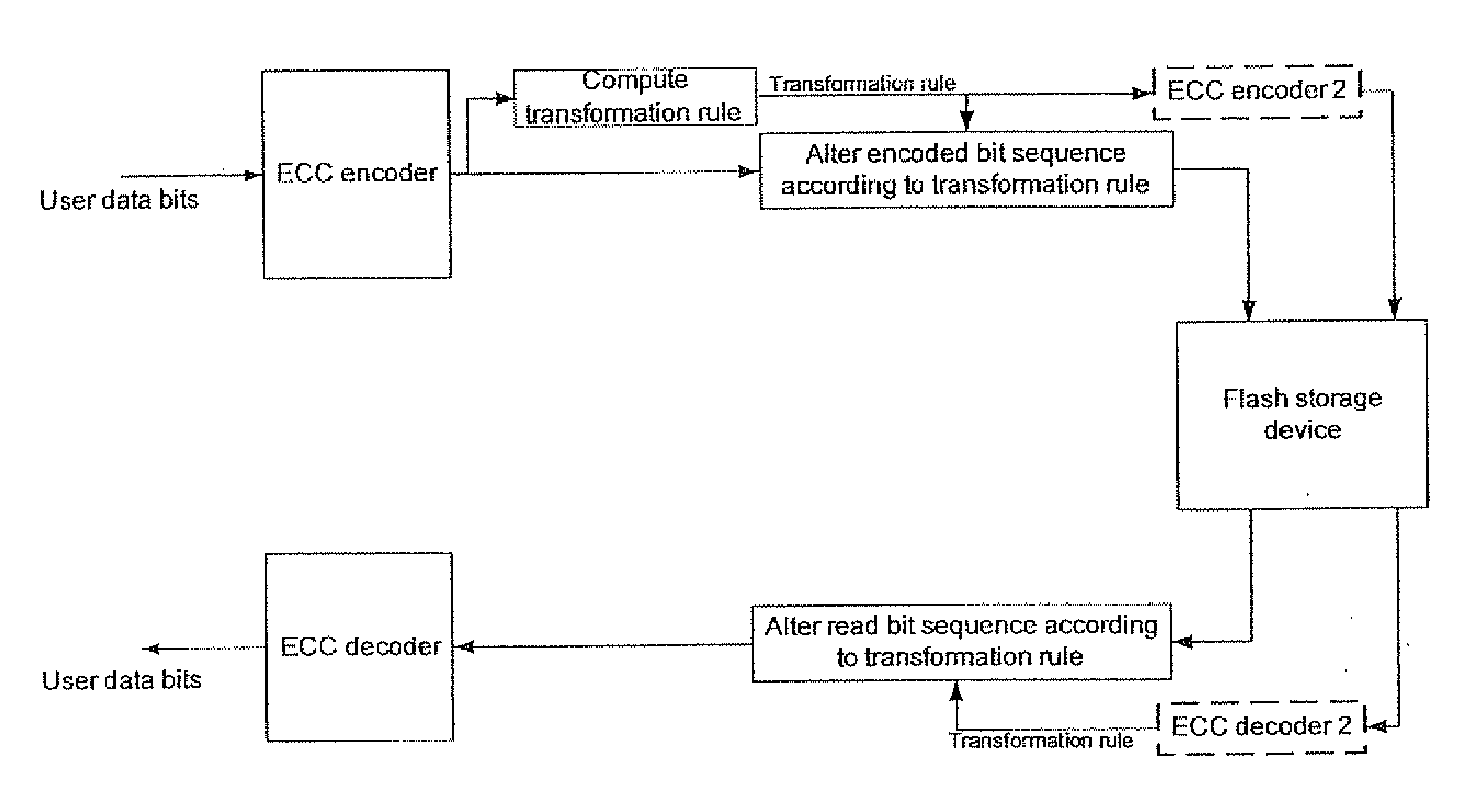

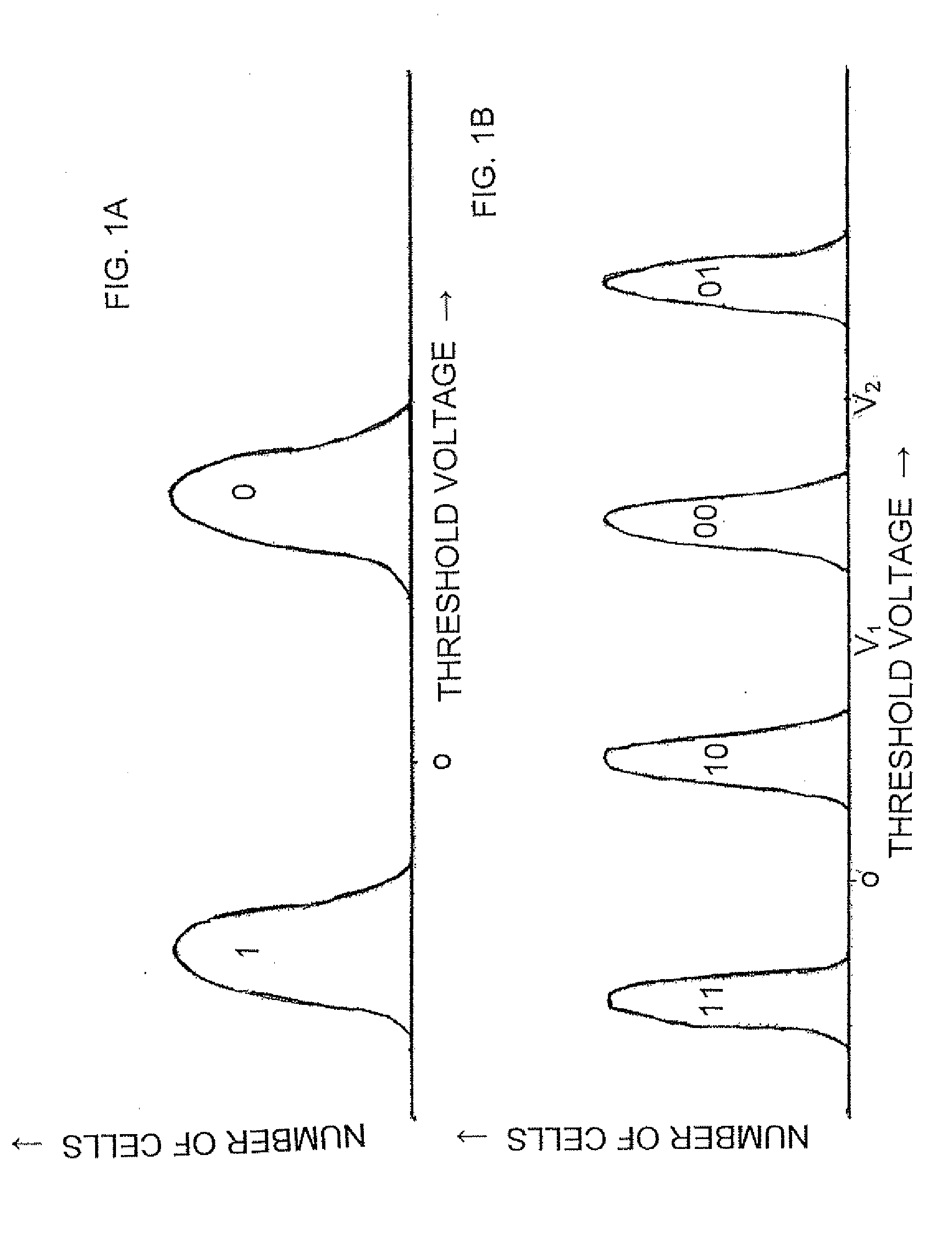

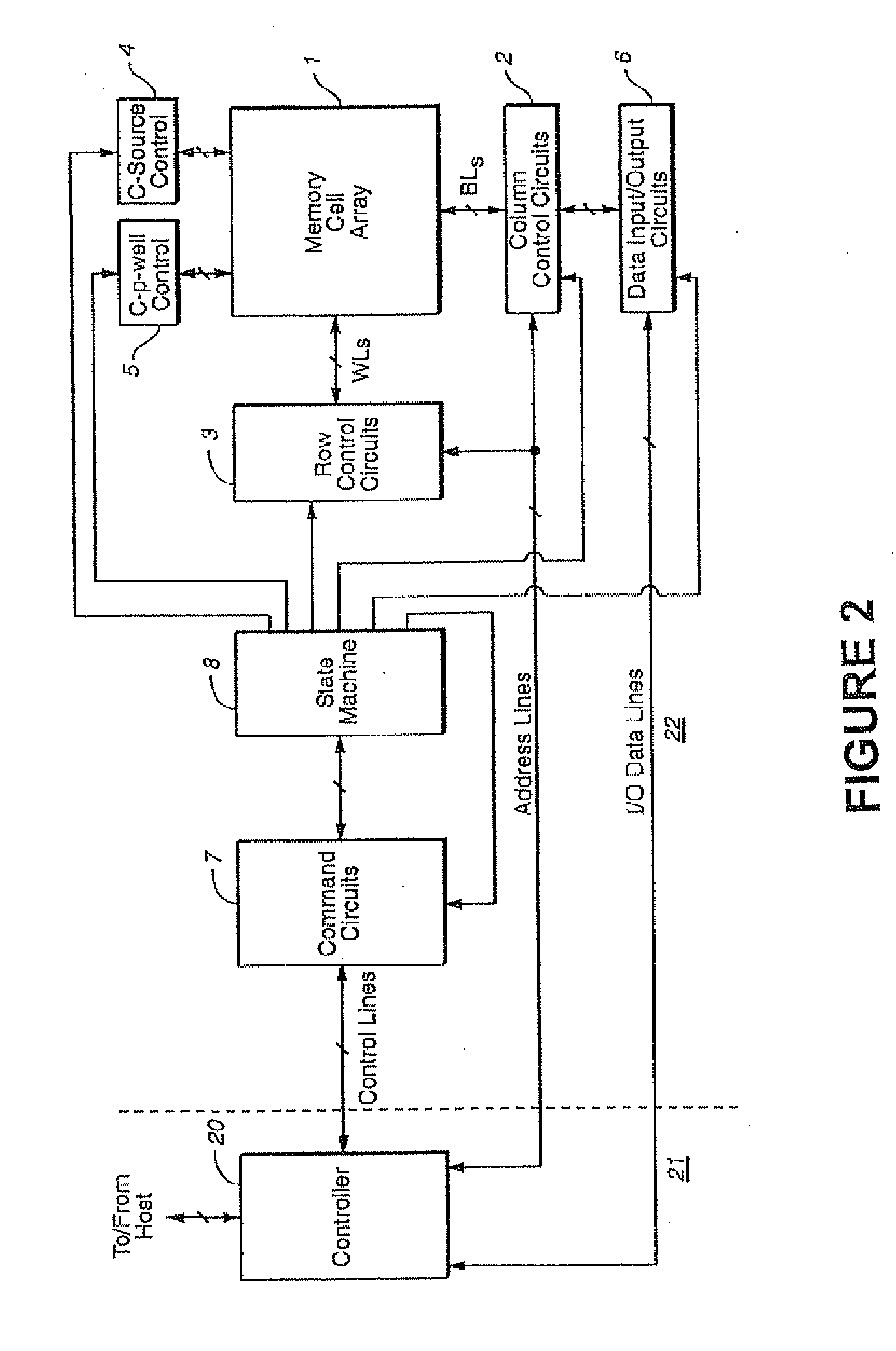

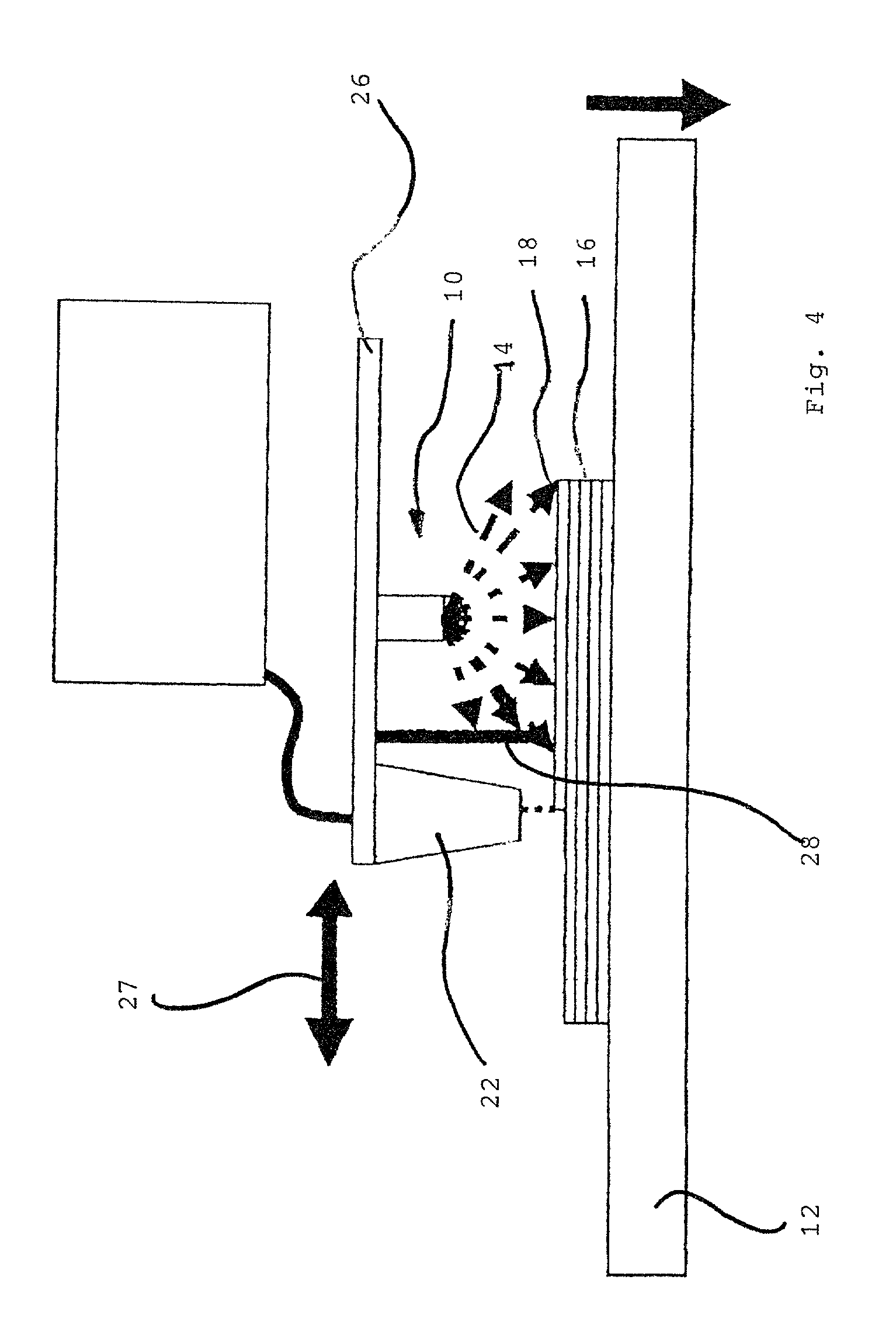

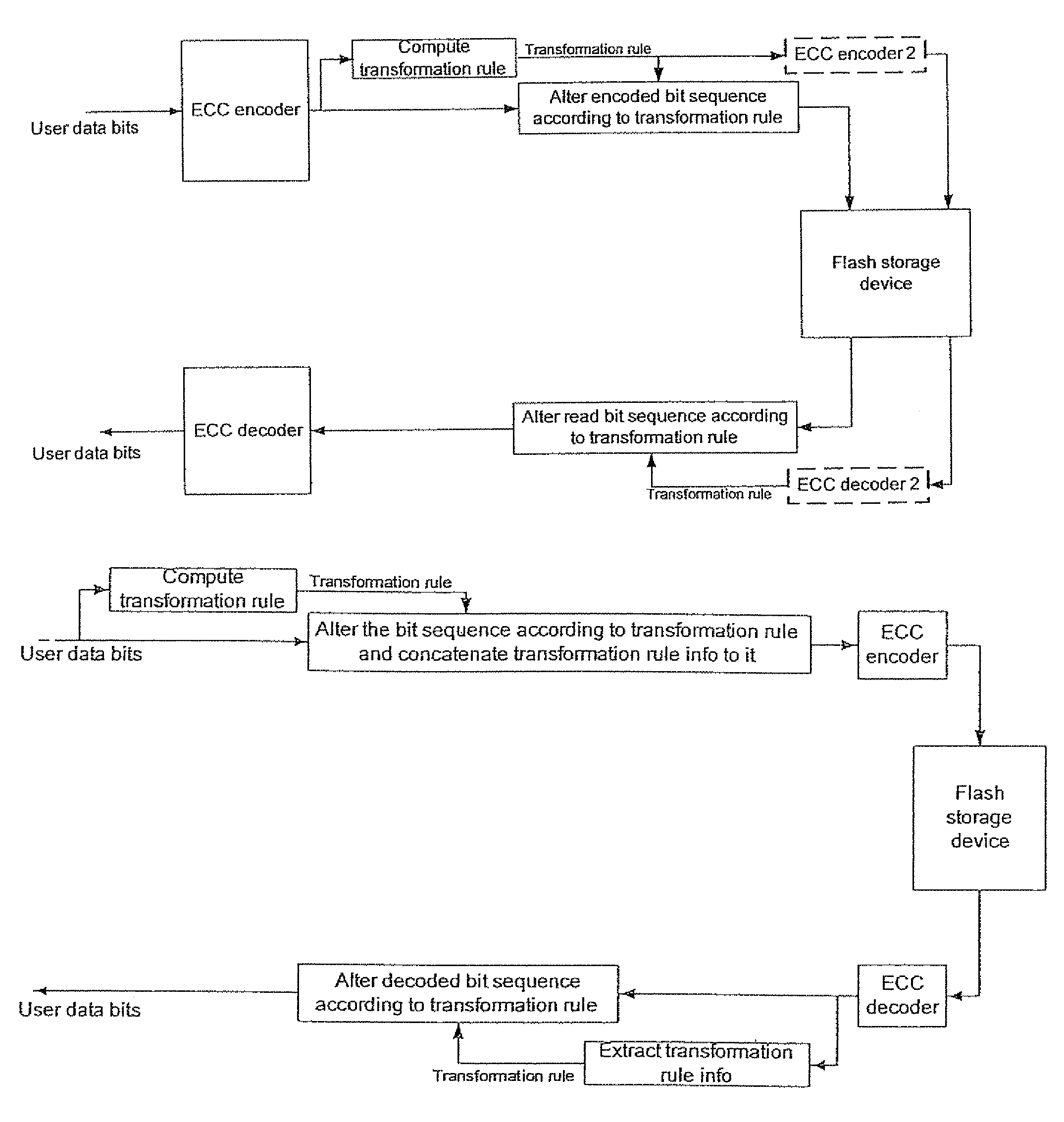

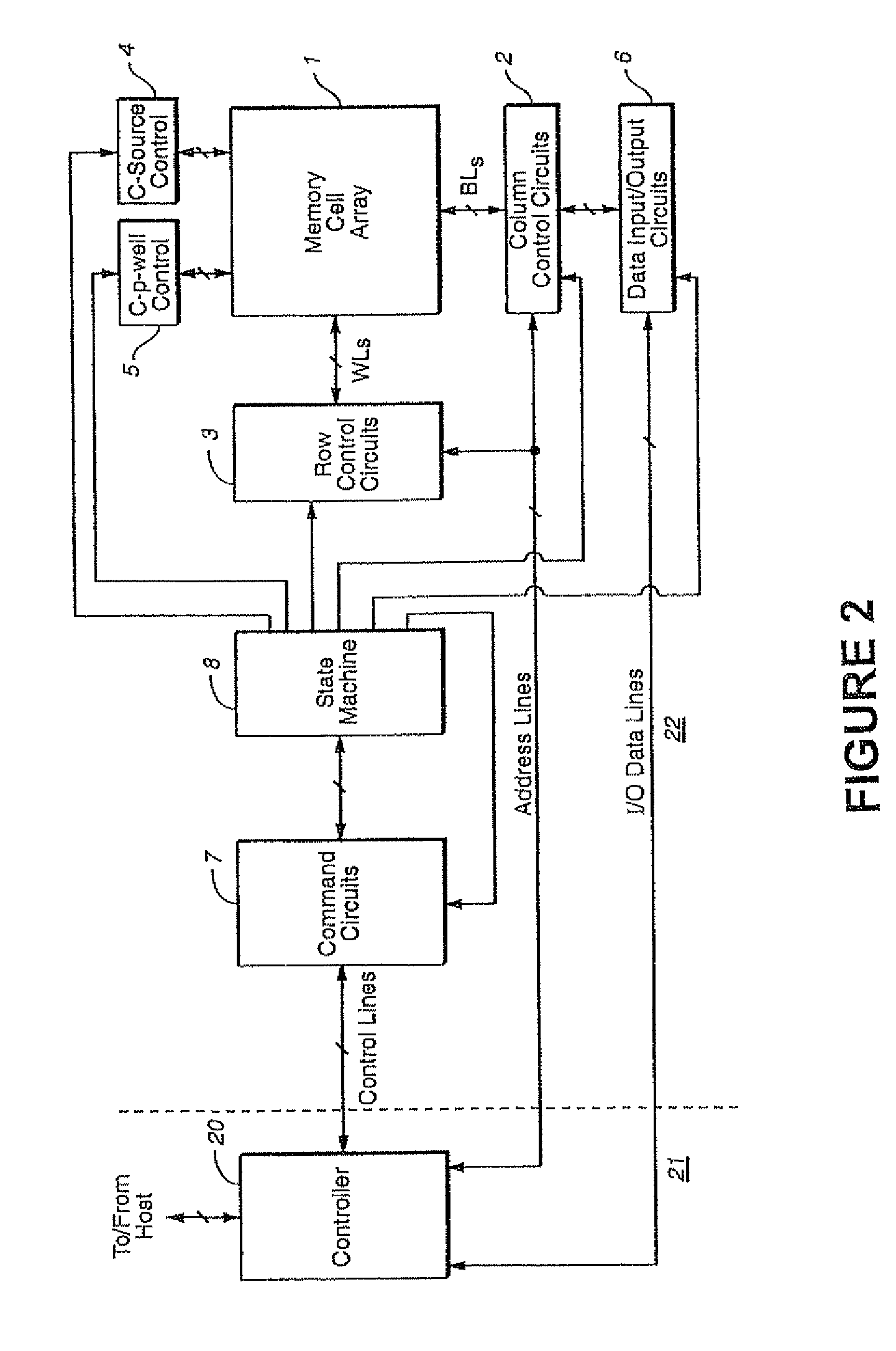

Avoiding errors in a flash memory by using substitution transformations

InactiveUS20080158948A1Reduce impactImprove reliabilityMemory loss protectionRead-only memoriesMemory cellAlgorithm

Owner:RAMOT AT TEL AVIV UNIV LTD

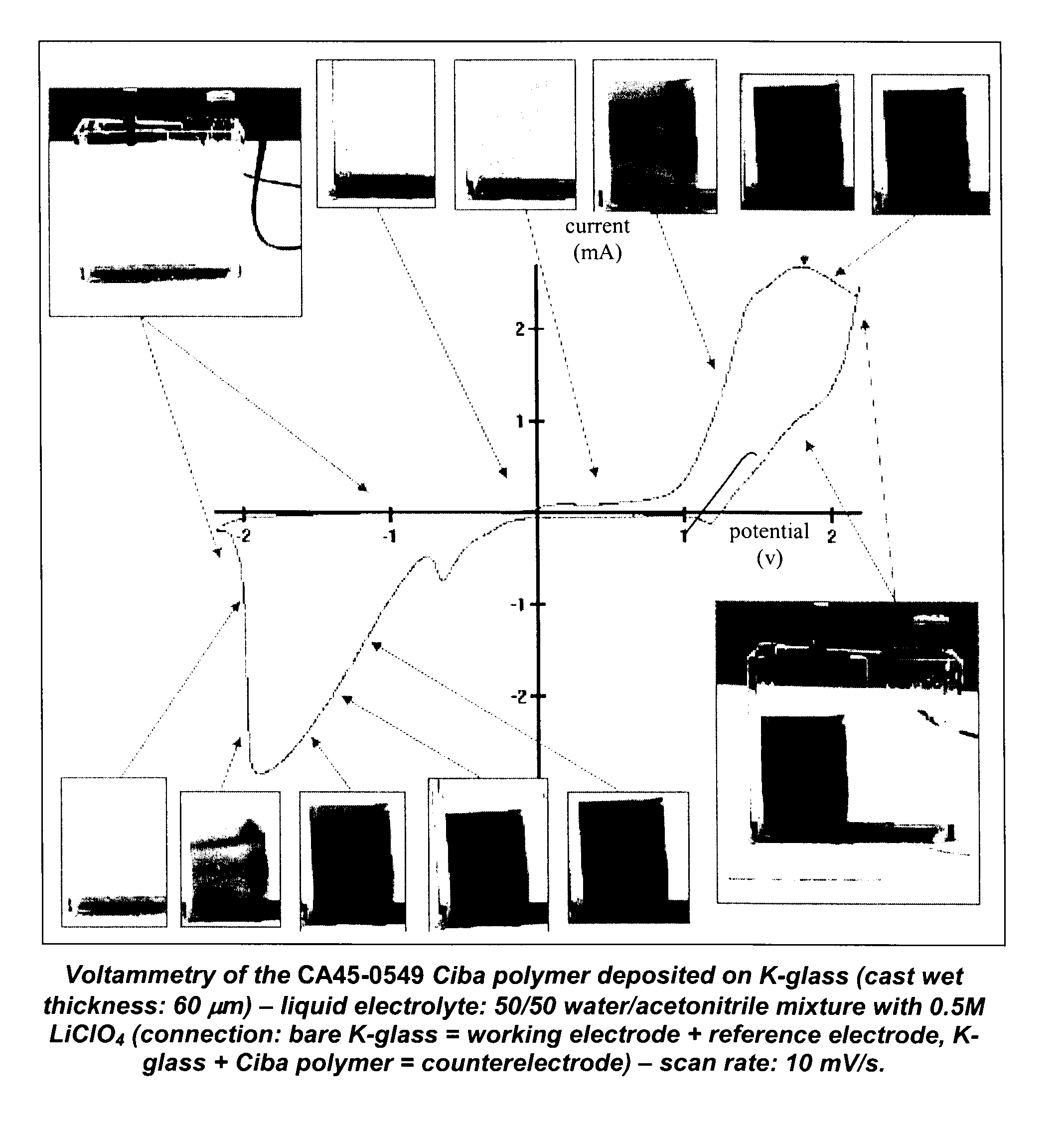

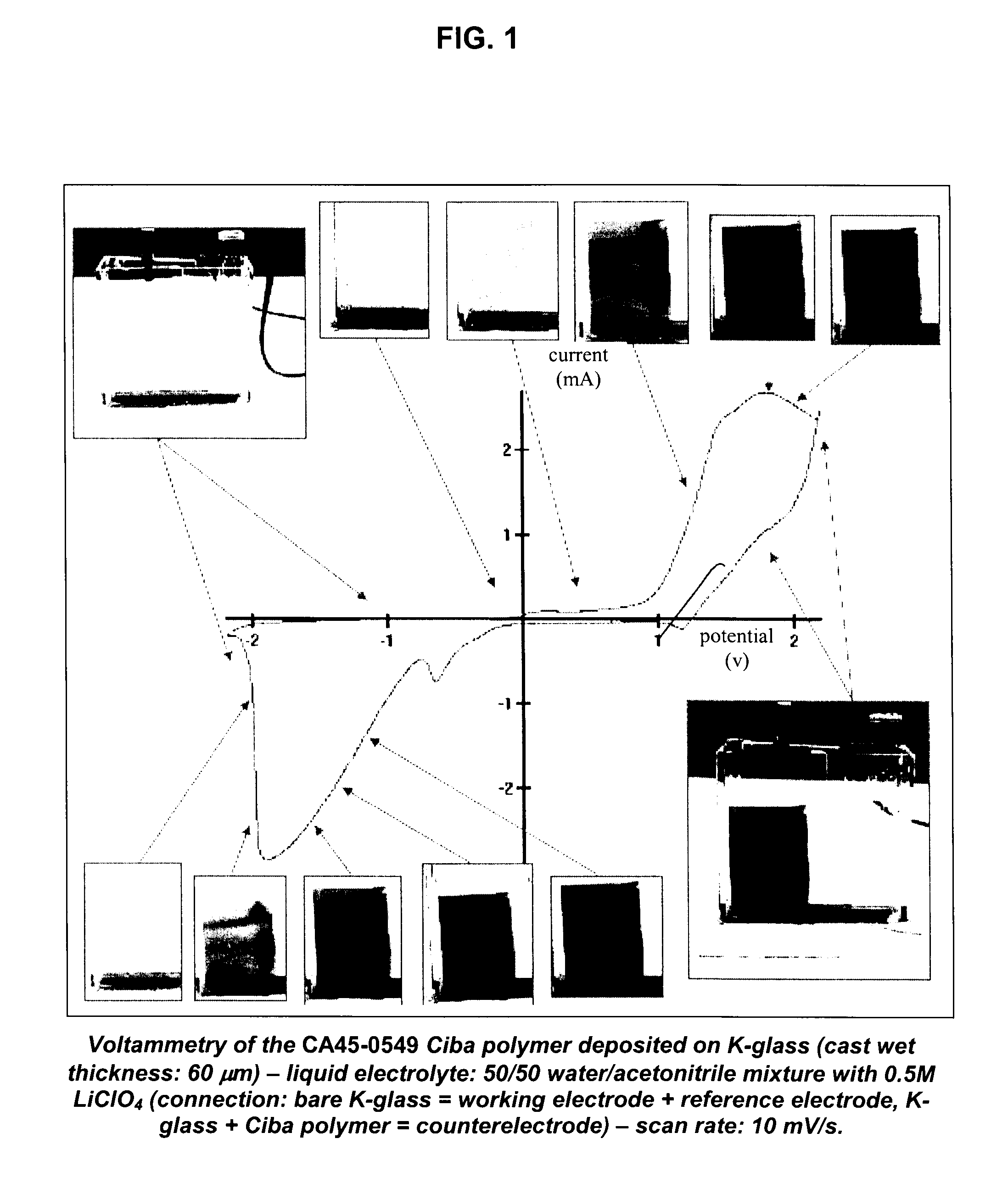

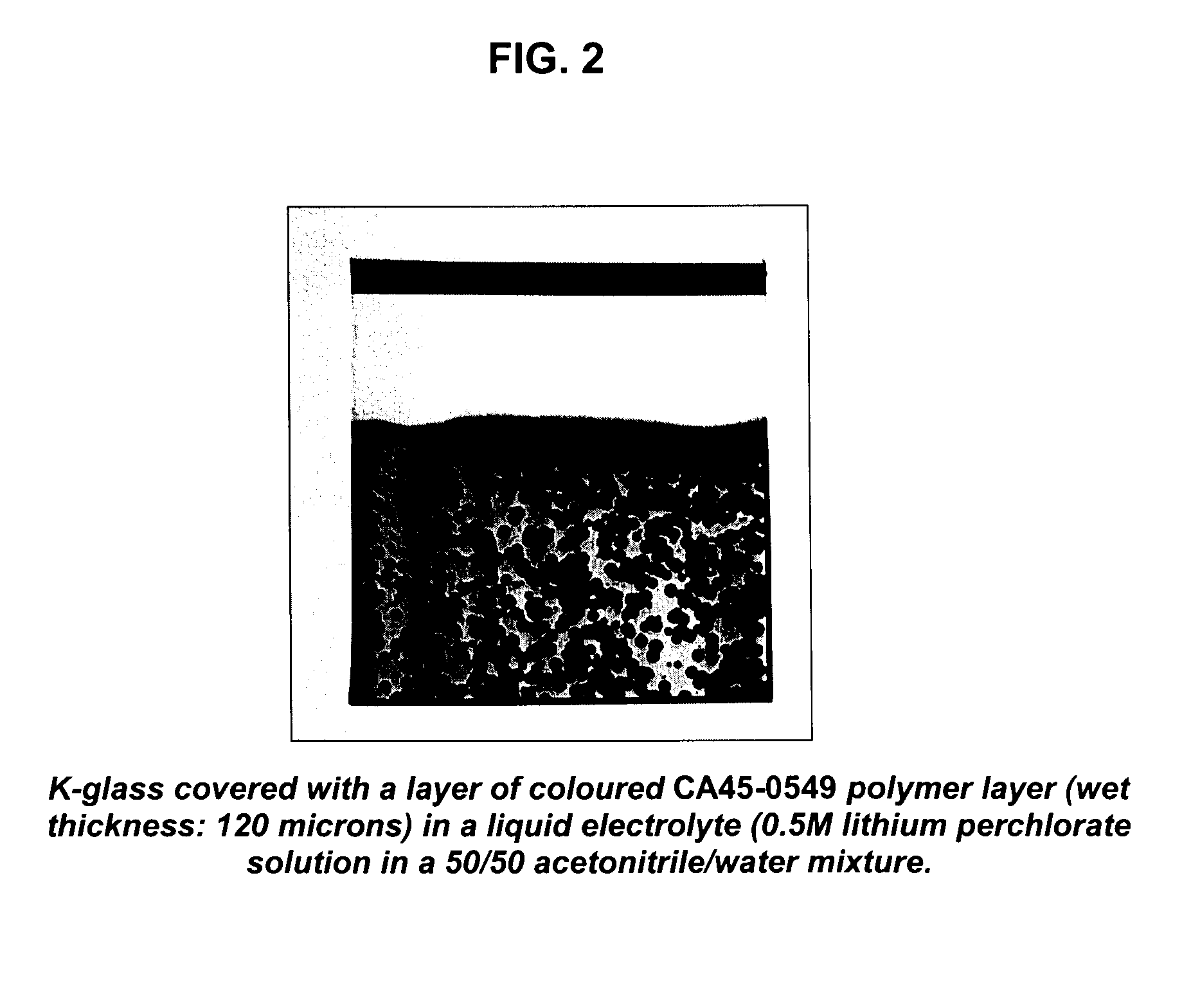

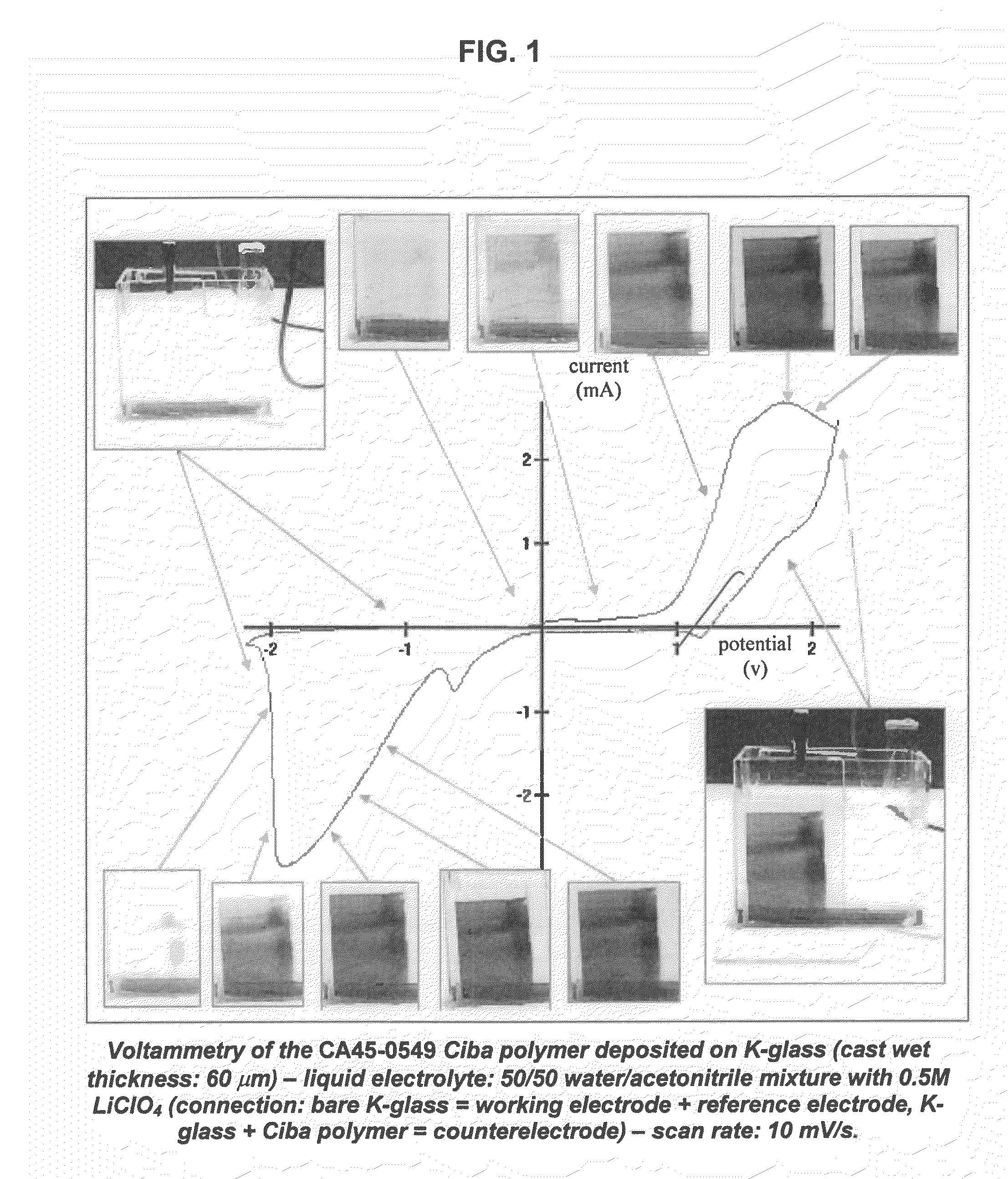

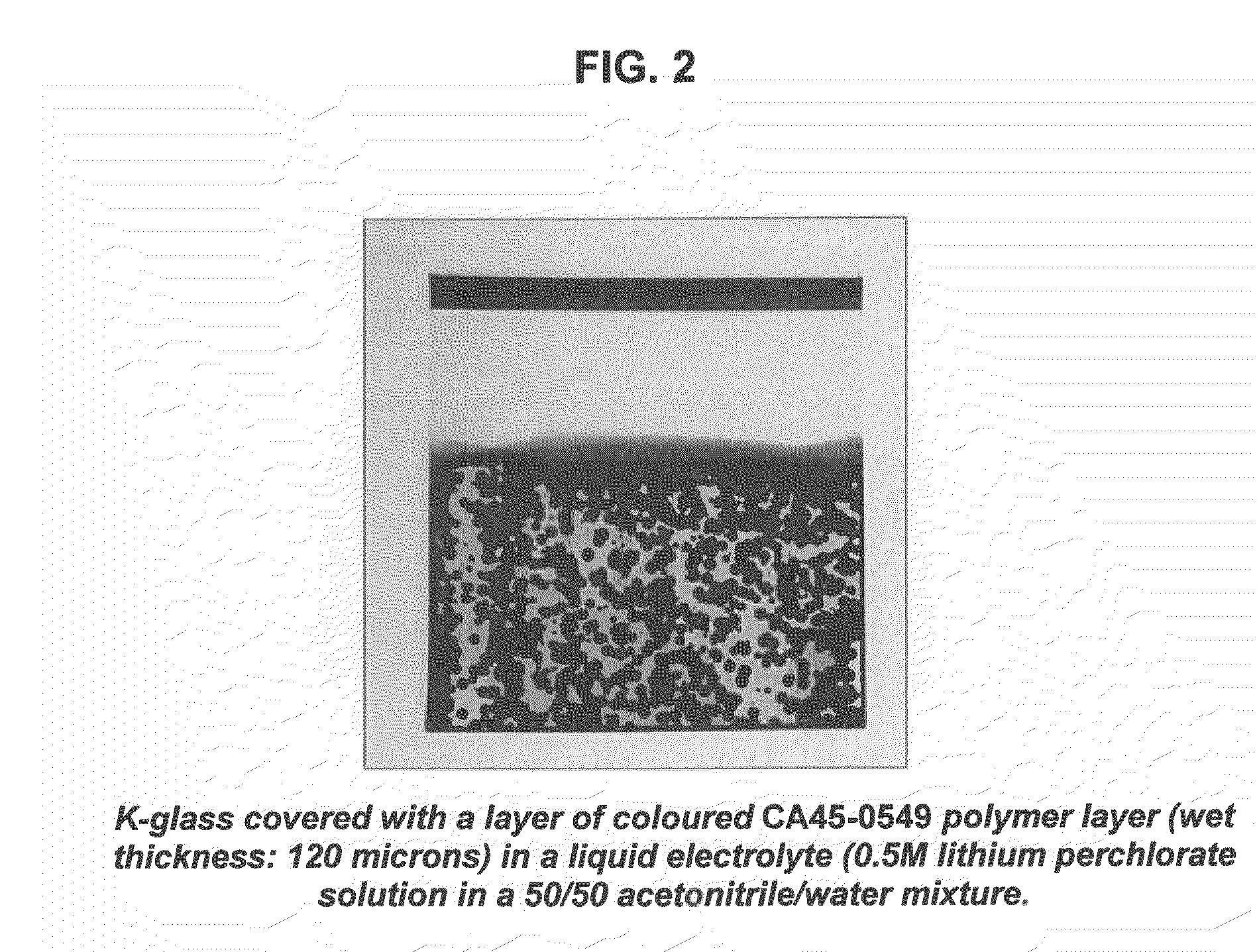

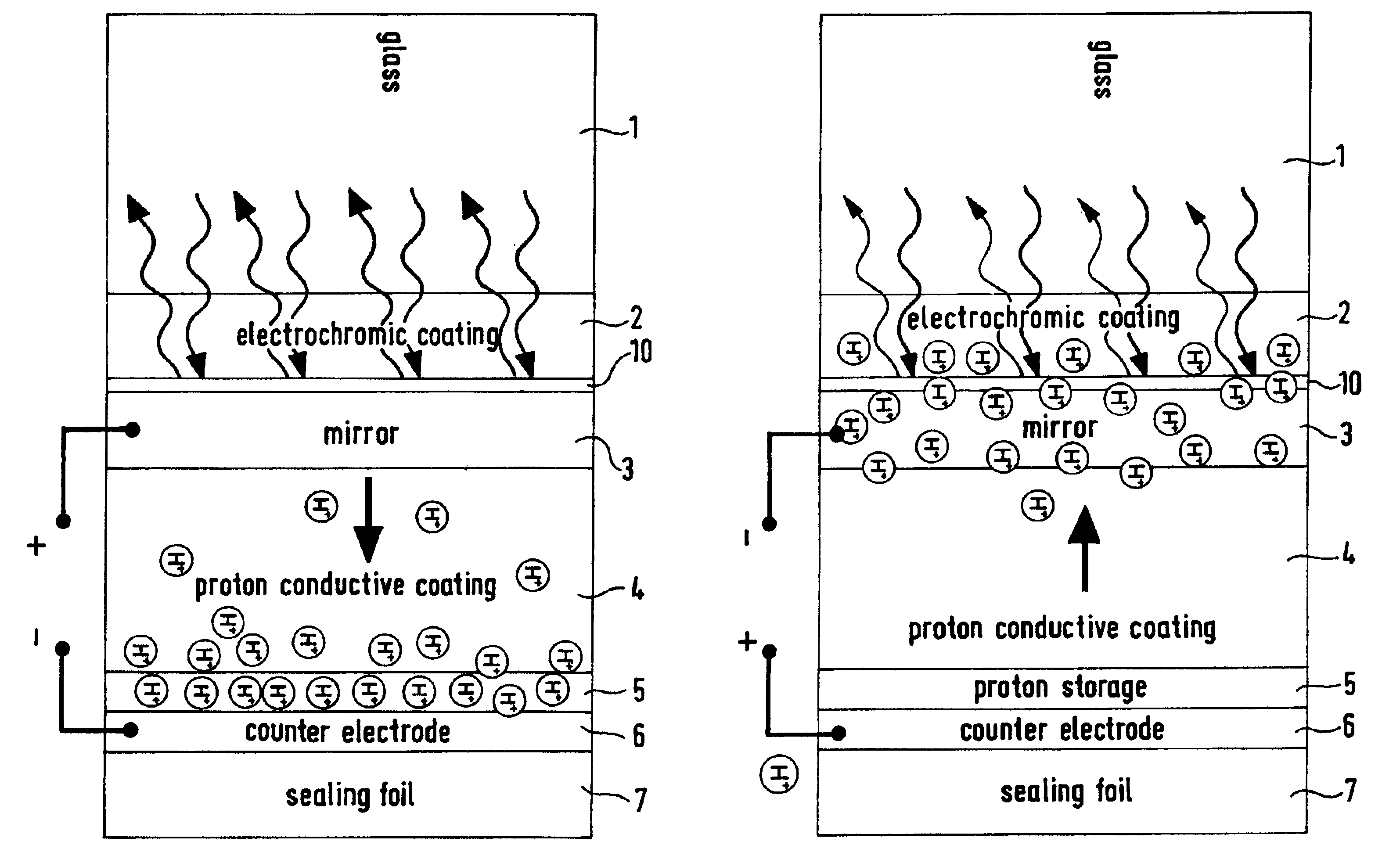

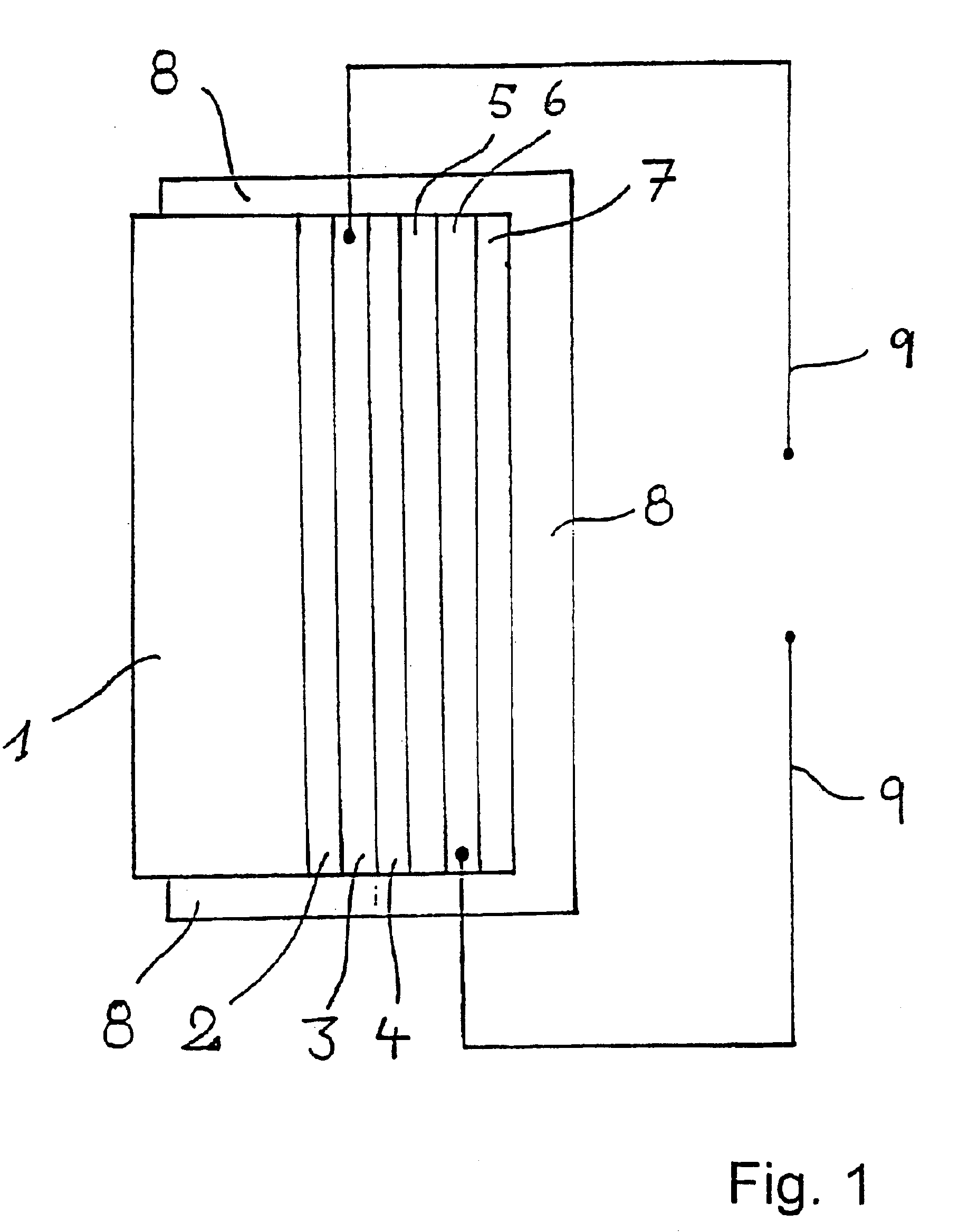

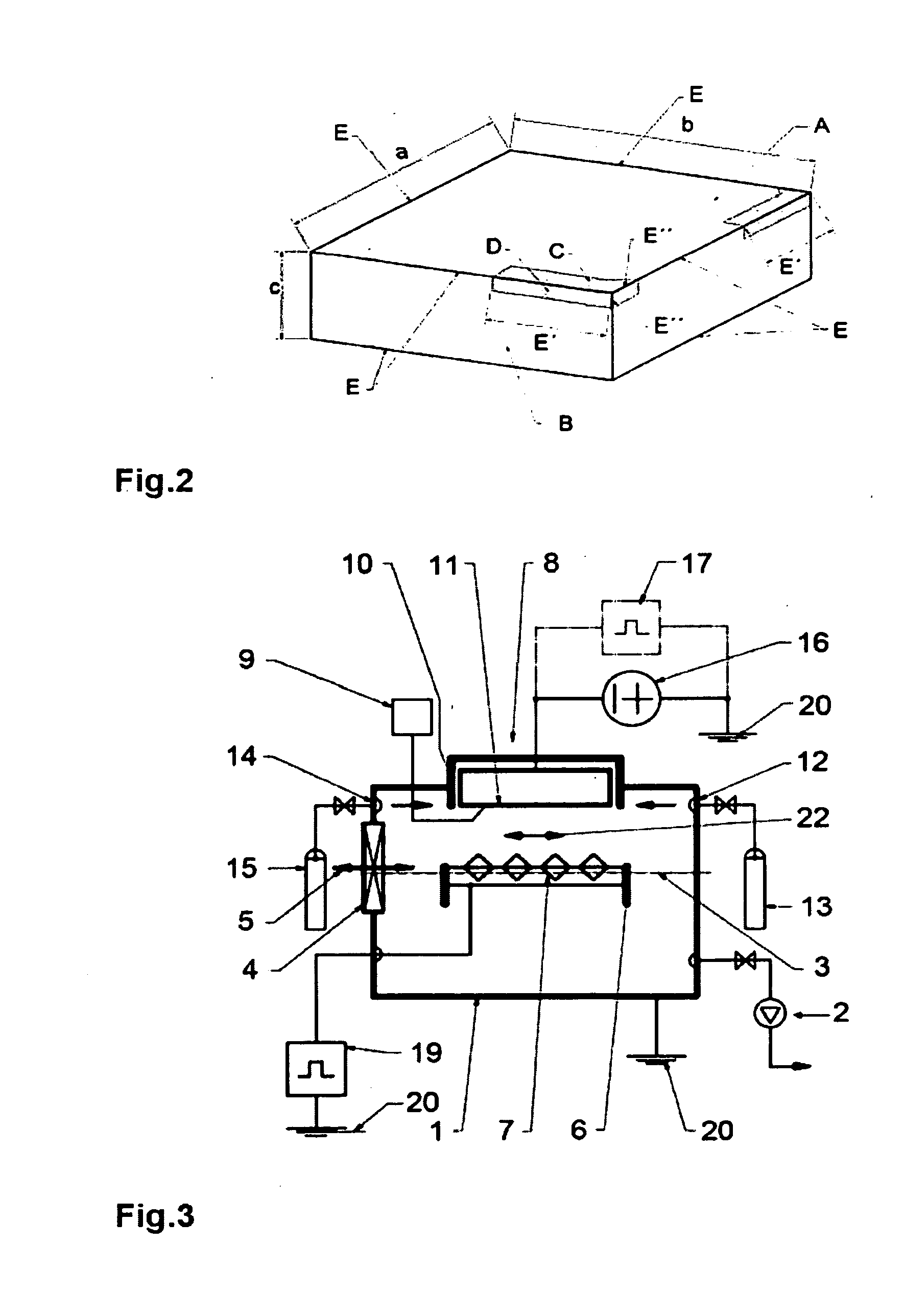

Electrochromic layers, device and process of producing same

InactiveUS20090097098A1Uniform color intensityQuick layeringLaminationLamination apparatusElectricityElectrochromism

Provided is an electrochromic device (ECD) that includes: a first transparent electrode having a first substrate having thereon a first electrically conductive layer; a second transparent electrode having a second substrate having thereon a second electrically conductive layer; a first polymeric layer on the first transparent electrode, wherein the first polymeric layer includes a cathodic electrochromic polymer and a first non-electrochromic polymeric matrix; a second polymeric layer on the second transparent electrode, wherein the second polymeric layer includes an anodic electrochromic polymer and a second non-electrochromic polymeric matrix; and an electrolyte layer disposed between the first polymeric layer and the second polymeric layer. Also provided is a process of producing the ECDs, as well as the electrochromic layers themselves.

Owner:SAINT-GOBAIN GLASS FRANCE

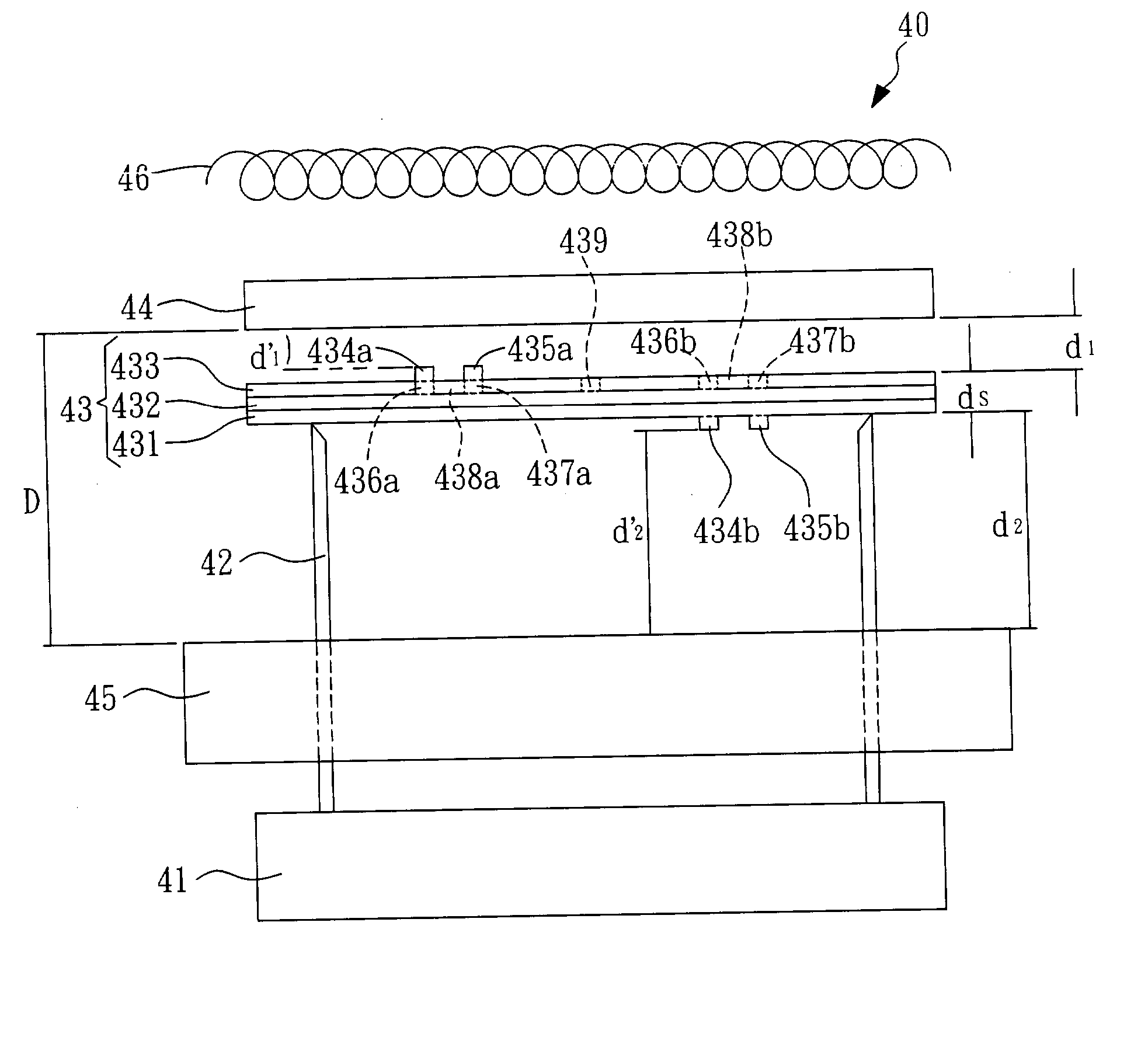

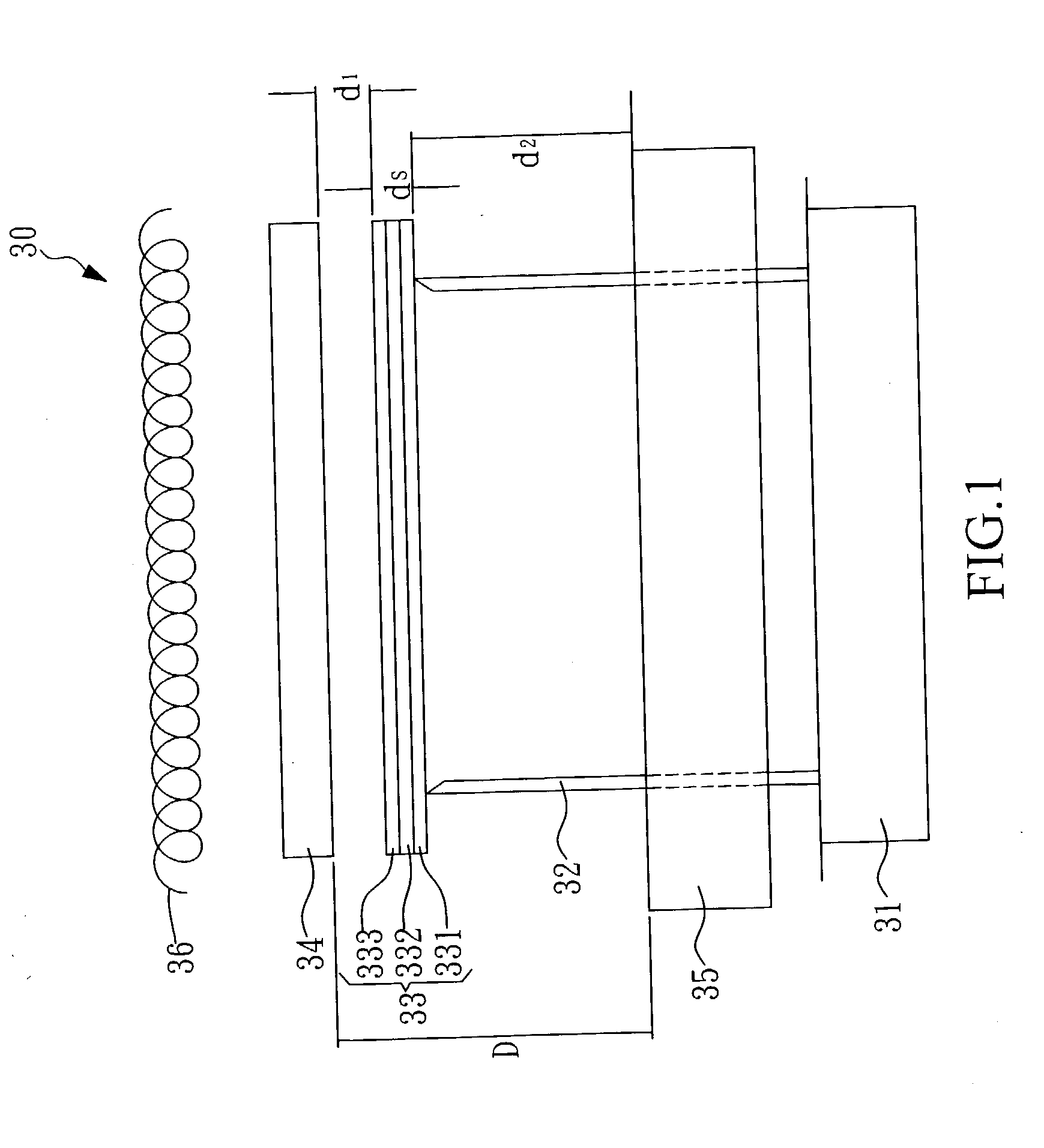

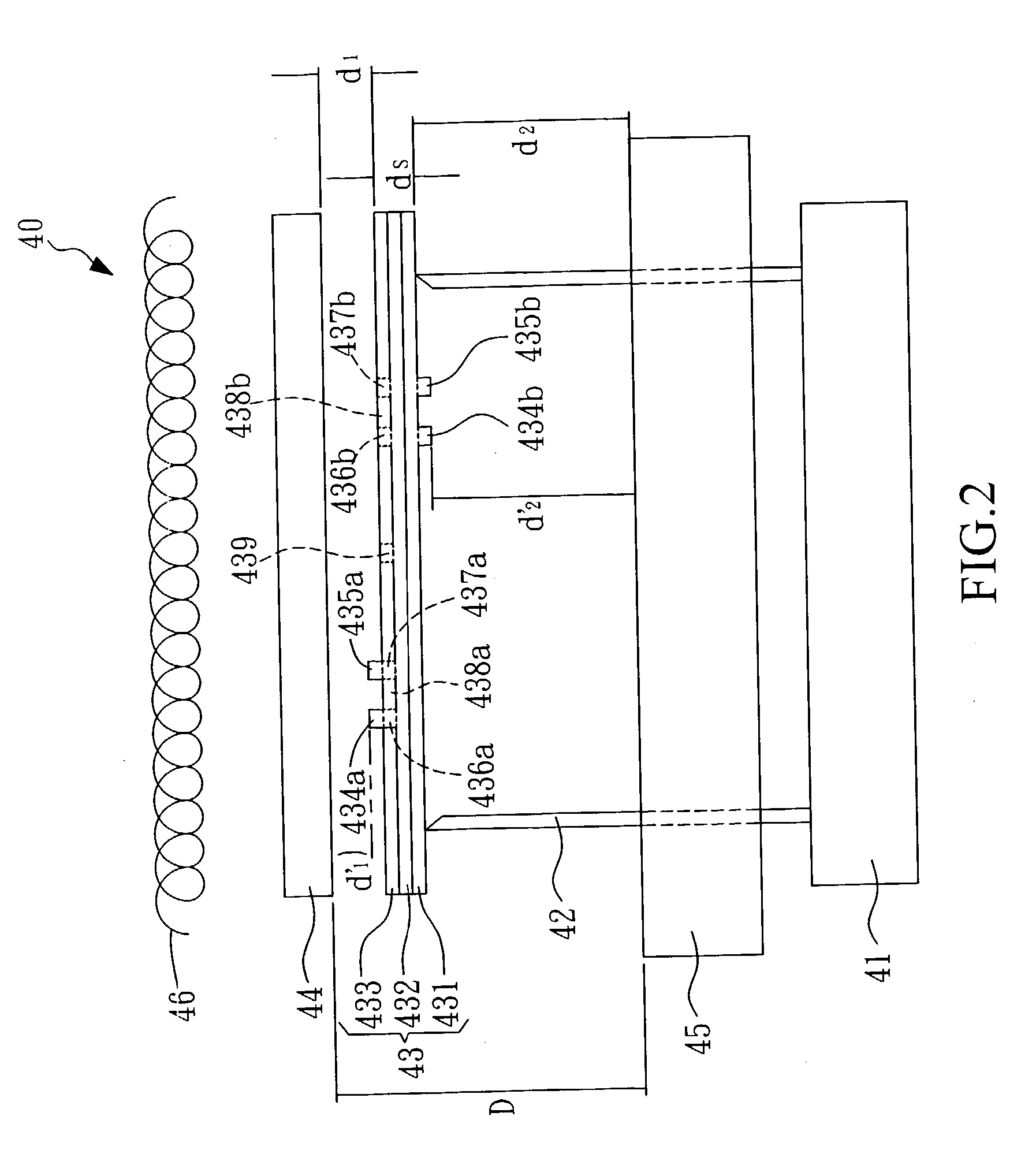

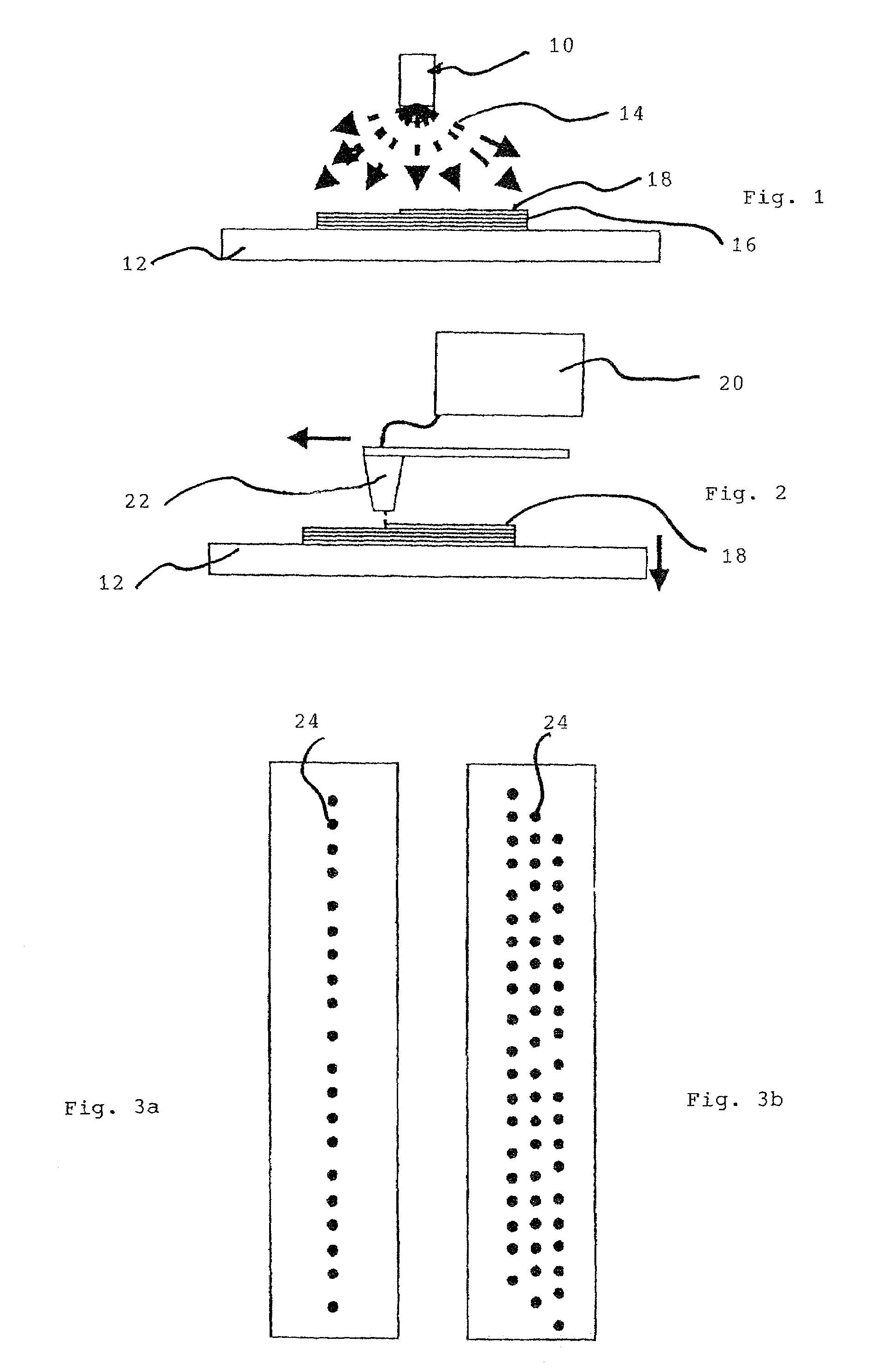

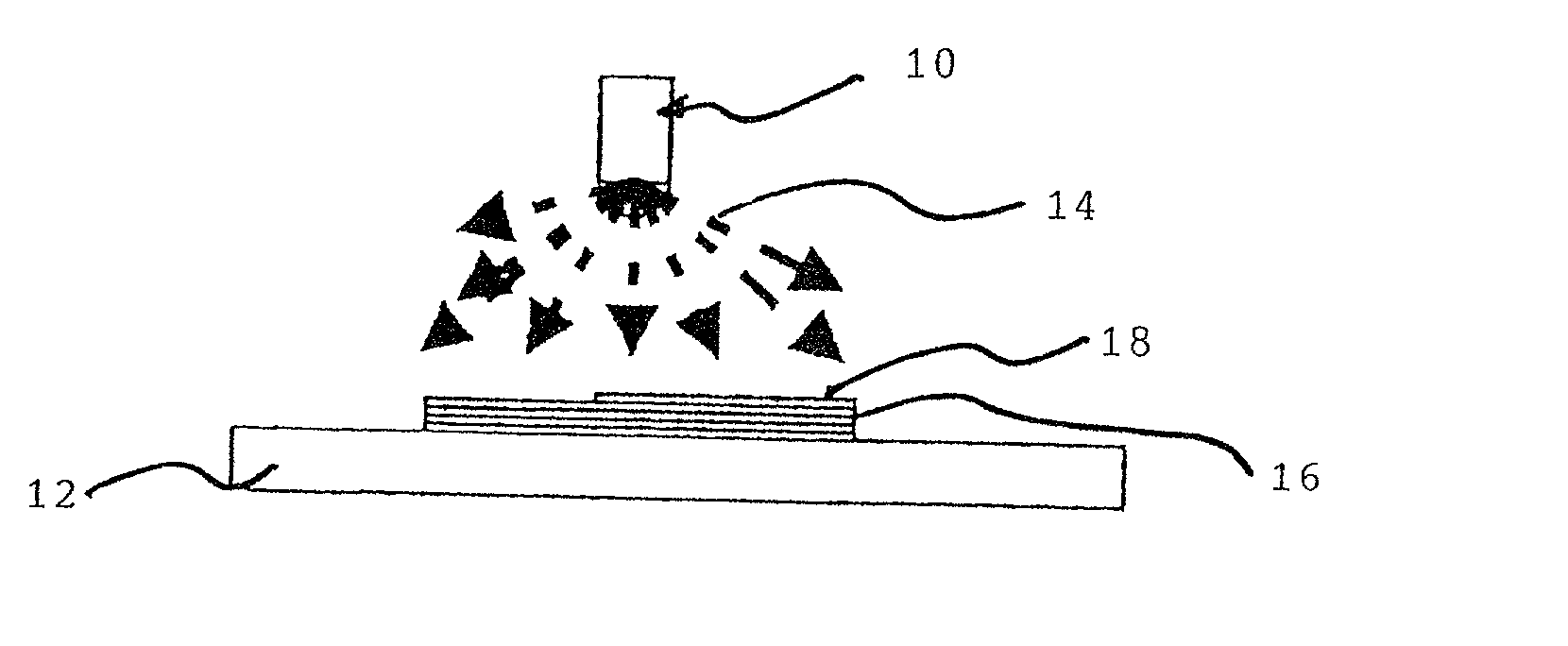

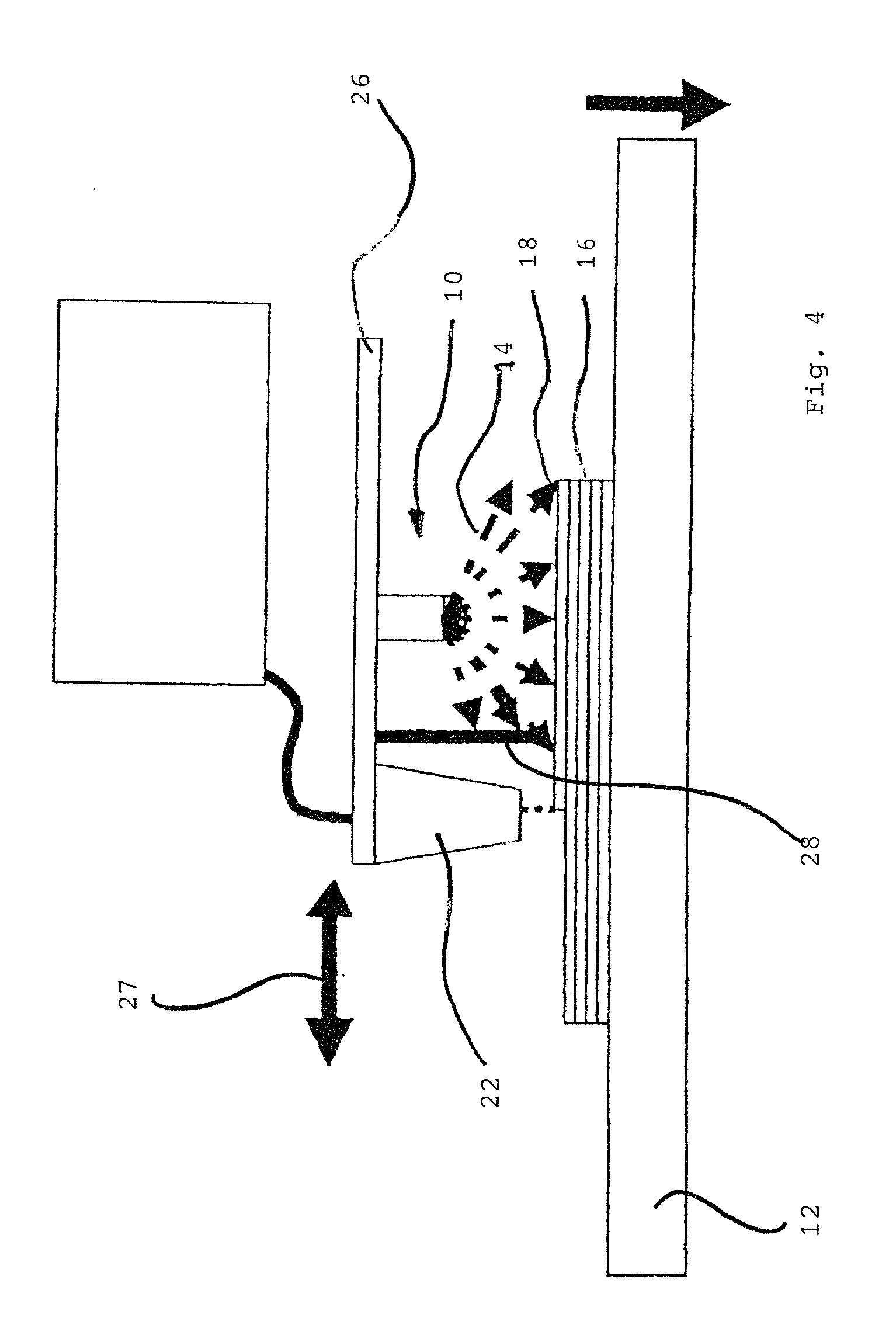

Rapid energy transfer annealing device and process

InactiveUS20040147139A1Easy to prepare in large areaQuick layeringFinal product manufactureSemiconductor/solid-state device manufacturingHeat sinkLight source

Disclosed is a rapid energy transfer annealing (RETA) device and process, where an energy plate is used to rapidly absorb the primary photonic energy of the light source, such as a tungsten halogen lamp (or an xenon Arc lamp), to allow temperature elevation. The energy plate faces an amorphous thin film deposited above a glass or plastic substrate and releases the heat energy transferred by a gas or solid medium to the amorphous thin film,, so as to heat the amorphous thin film for transforming the amorphous thin film into a polycrystalline film. On another side of the glass or plastic substrate may be further provided with a heat sink plate and a supporting plate. The heat sink plate absorbs energy of the glass substrate, protects glass substrate from damages due to overheating. The heat sink plate or the supporting plate may be moved to freely adjust distance between the amorphous thin film and the energy plate and that between the glass substrate and the heat sink plate, so as to control energy transferred to the amorphous thin film and energy released by the glass substrate transfer. The adjustment of distance may be fixed or varied as a function of time so as to randomly adjust the energy transfer. Further, between the glass substrate and the amorphous film may be provided with a heat conducting layer and a heat shielding layer. On another side of the glass substrate may be provided with a heat sink layer. On the amorphous thin film may be provided with a heat absorption layer to control and allow selective crystallization, or to control direction of heat transfer thereby guiding the crystallization to grow in a specific direction.

Owner:JIANG YEU LONG

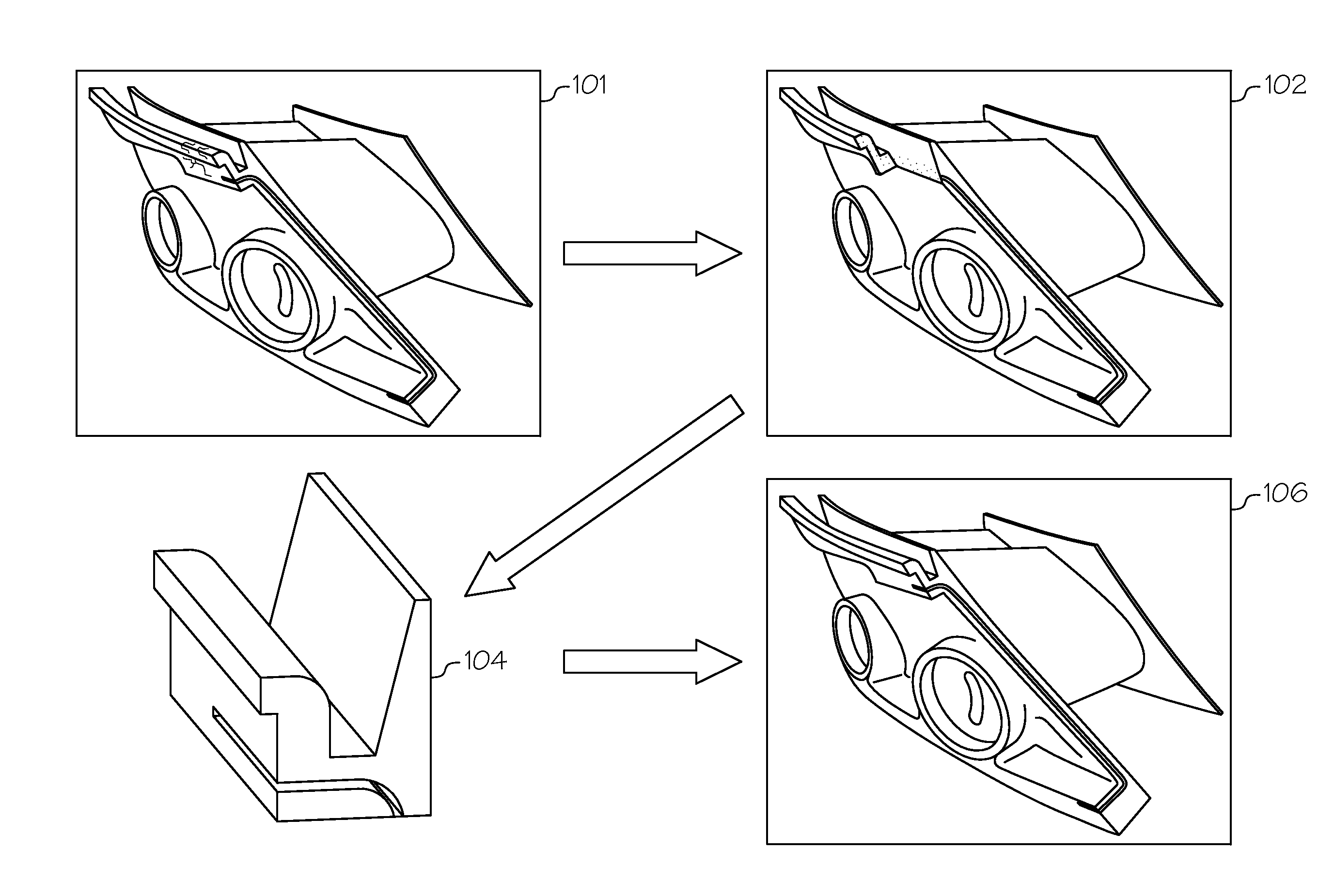

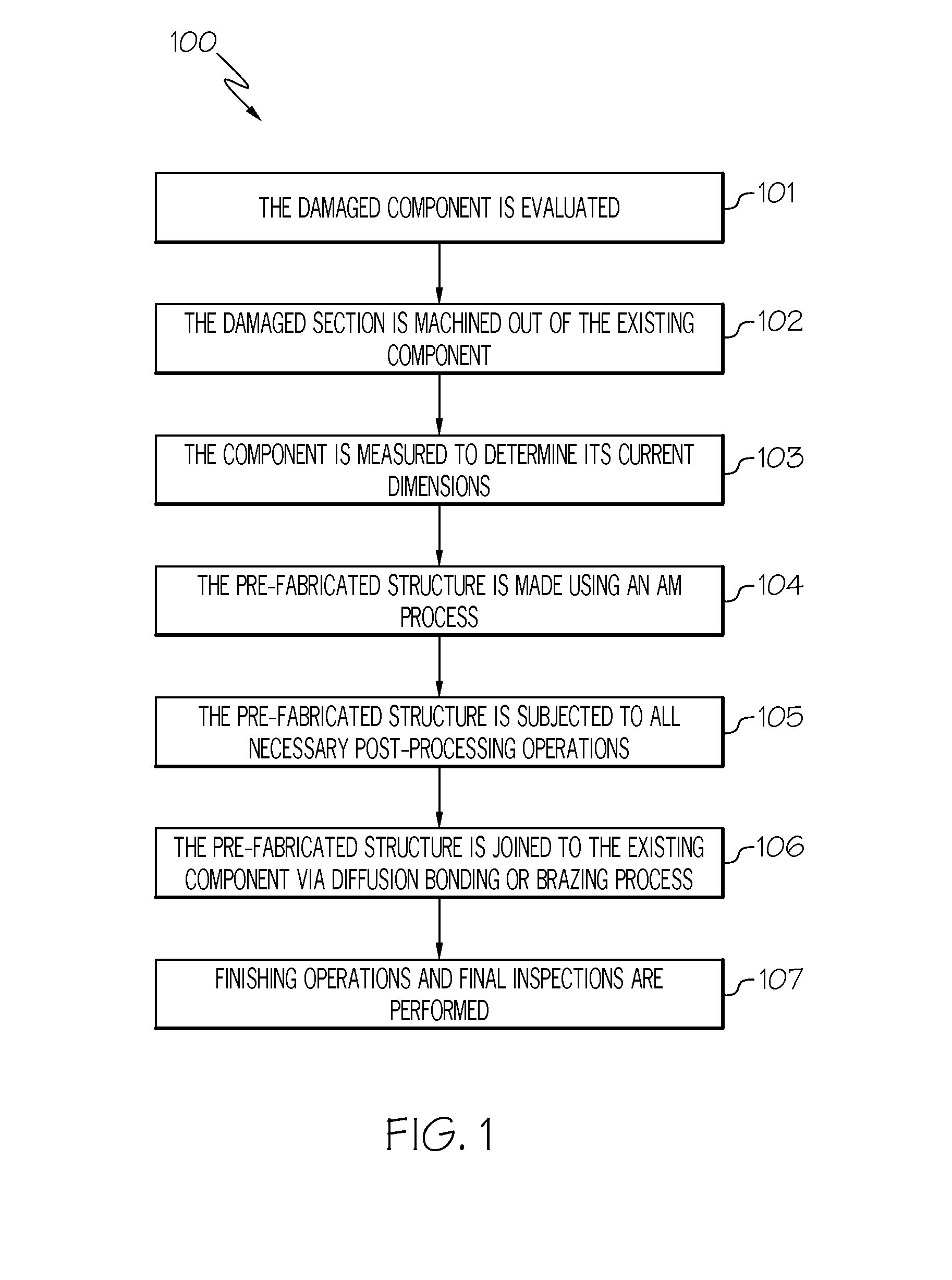

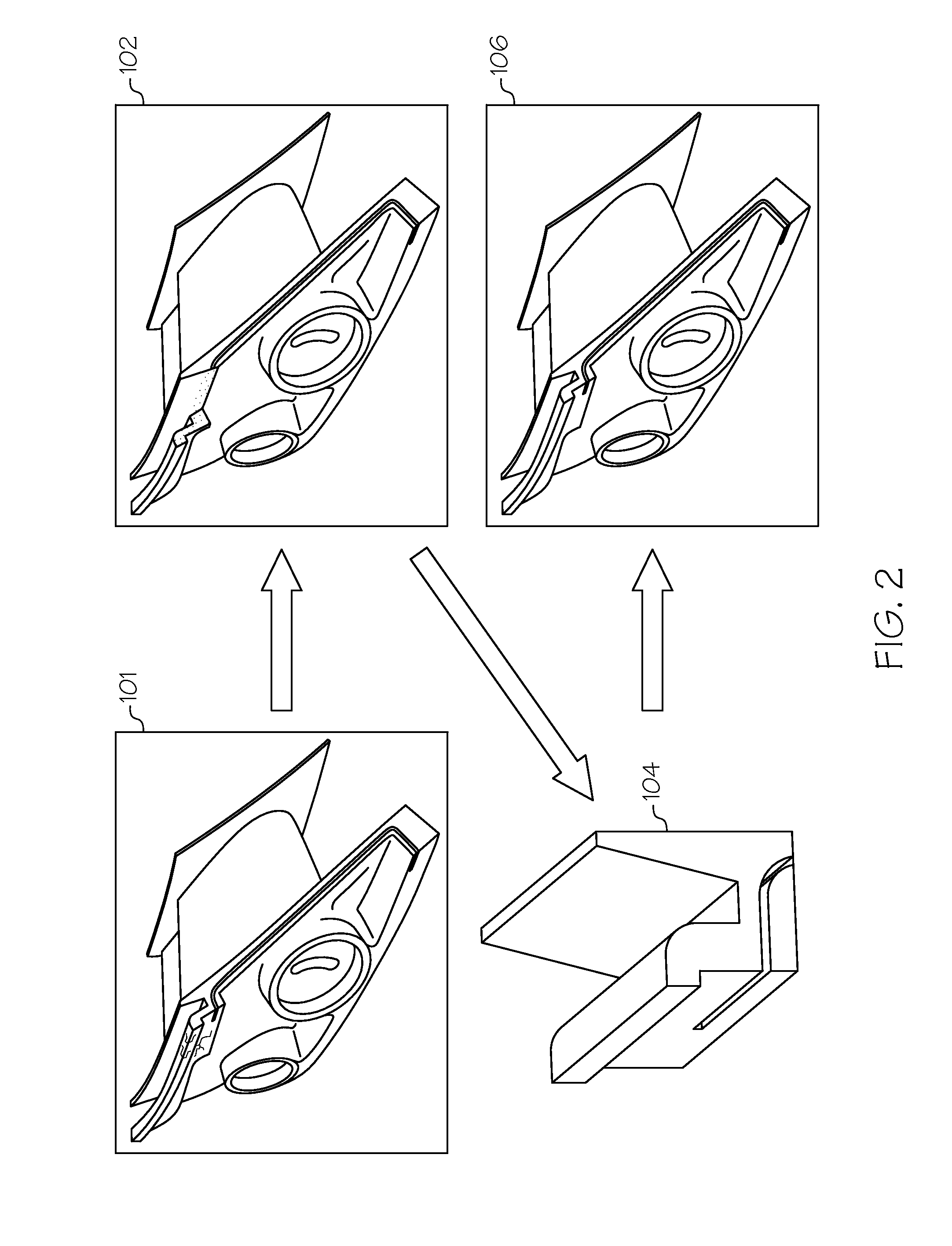

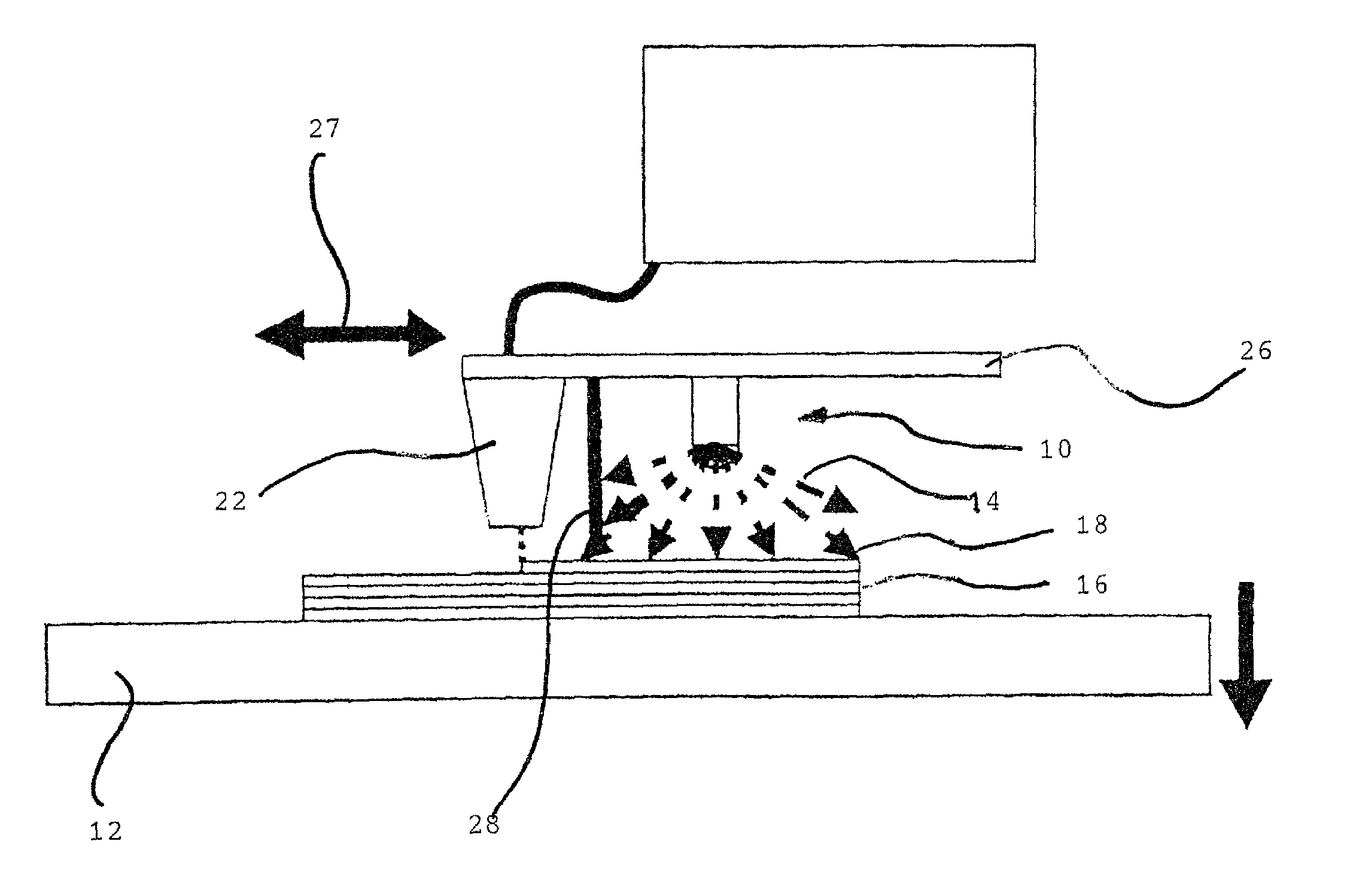

Methods for the repair of gas turbine engine components using additive manufacturing techniques

Owner:HONEYWELL INT INC

Method for producing a synthetic material part

InactiveUS7189344B2Rapid productionReduce capital investment costsImpression capsGum massageSynthetic materialsViscosity

A method for producing a synthetic material part such as, for example, a dental restorative part, is provided and includes spray applying with a spray device a material having at least a polymerizable synthetic material onto a base in succeeding layers. Each layer of the spray applied material is substantially continuously polymerized by the spray device and has a viscosity which permits working of the applied material in an unpolymerized condition thereof with the spray device. The method also includes hardening the one or more of the already applied layers prior to the application of subsequent layers.

Owner:IVOCLAR VIVADENT AG

Avoiding errors in a flash memory by using substitution transformations

InactiveUS7984360B2Reduce impactImprove reliabilityMemory loss protectionRead-only memoriesTheoretical computer scienceFlash memory

Owner:RAMOT AT TEL AVIV UNIV LTD

Method for producing a synthetic material part

ActiveUS20020127345A1High transparencyRapid productionImpression capsGum massageSynthetic materialsViscosity

A method for producing a synthetic material part such as, for example, a dental restorative part, is provided and includes spray applying with a spray device a material having at least a polymerizable synthetic material onto a base in succeeding layers. Each layer of the spray applied material is substantially continuously polymerized by the spray device and has a viscosity which permits working of the applied material in an unpolymerized condition thereof with the spray device. The method also includes hardening the one or more of the already applied layers prior to the application of subsequent layers.

Owner:IVOCLAR VIVADENT AG

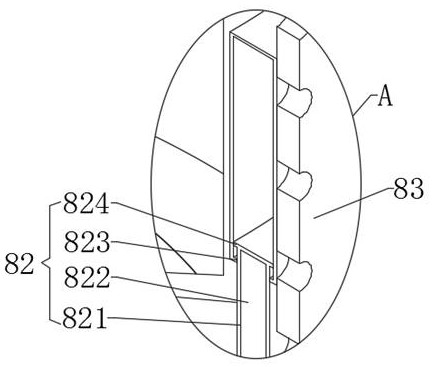

Mixed settler extractor

InactiveCN101219289AEliminate pollutionQuick layeringLiquid solutions solvent extractionSingle stagePhase ratio

The invention relates to a mixer settle extraction tank that is applicable to the extraction of high flow rate solvent, in particular to an extraction case combined by single-stage mixer settle extraction tanks. A two-phase mixer is stirred and driven by a turbine and the stirring has a pumping effect for two-phase fluid. Two phases are induced to a place below a stirring axial center by a diversion tube in a mixing chamber. The mixed phases are layered in a settling chamber, wherein, a light phase flows into a light phase box and enters a next stage mixing chamber through the diversion tube and a heavy phase gets across an overflow plate of a heavy phase box and enters a former stage mixing chamber and the two phases form an adverse current mode in a cascade stage device. The settling chamber is provided with a return line to be communicated with the mixing chamber to guarantee that the mixing phase ratio of the two phases in the mixing chamber is less than 4 when the flow rate of the two phases is high. A heat protection layer is coated around the extraction case, a cover board is arranged at the upper part and temperature in the tank body is constant. Water sealing is used at the top part of the mixing chamber of the extraction tank, thus organic gas evaporated from the extraction tank can be recovered.

Owner:GRIREM ADVANCED MATERIALS CO LTD

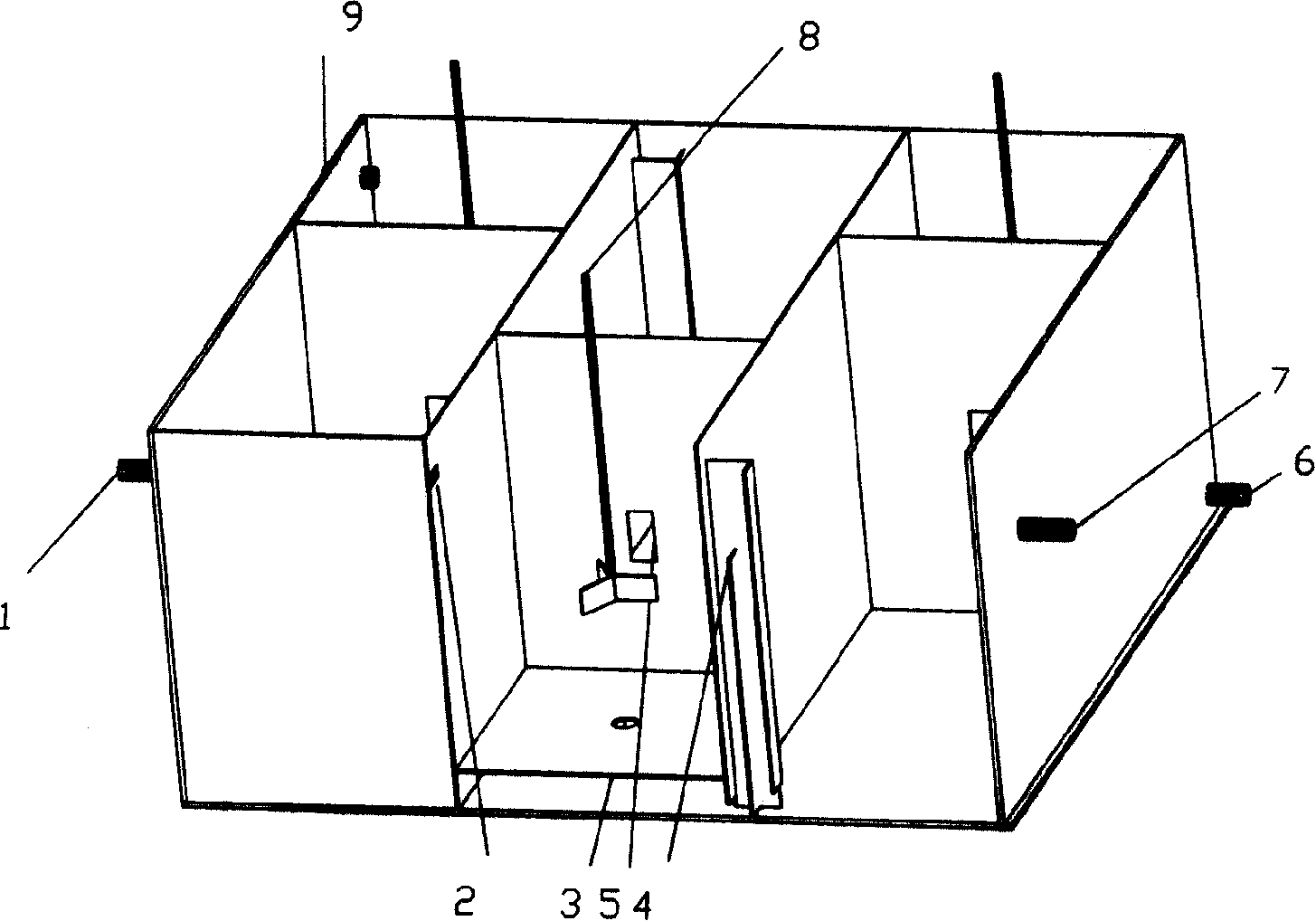

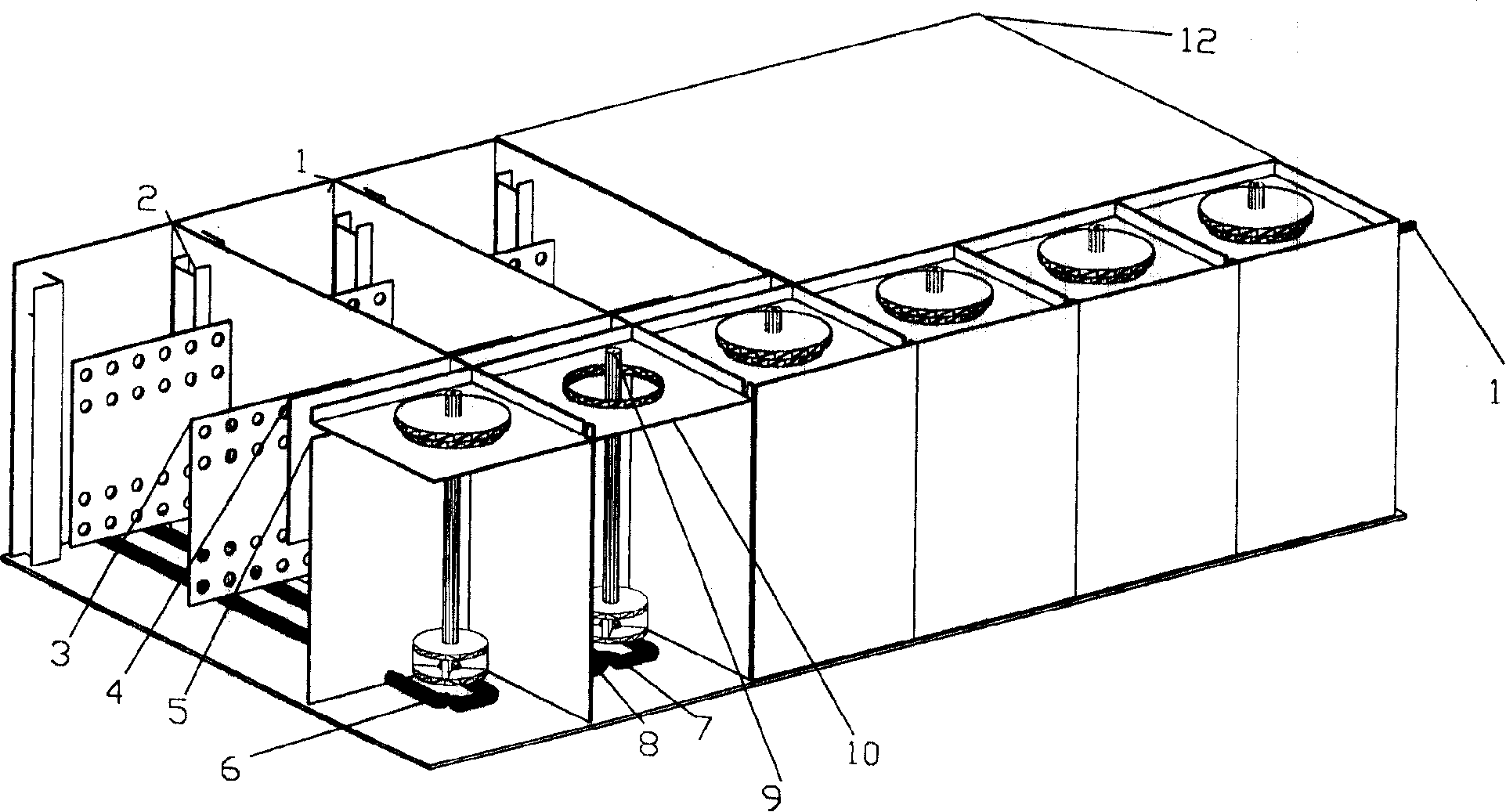

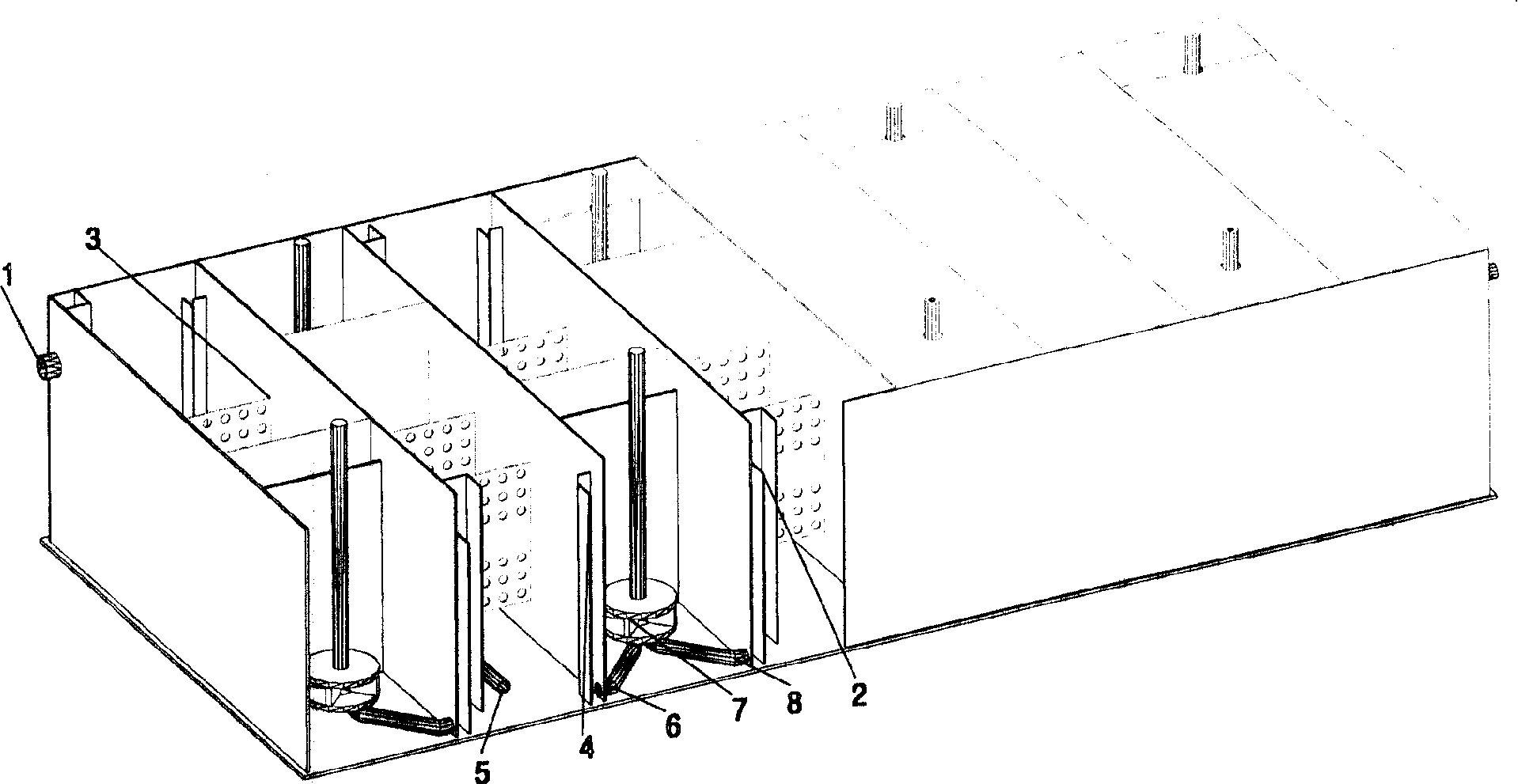

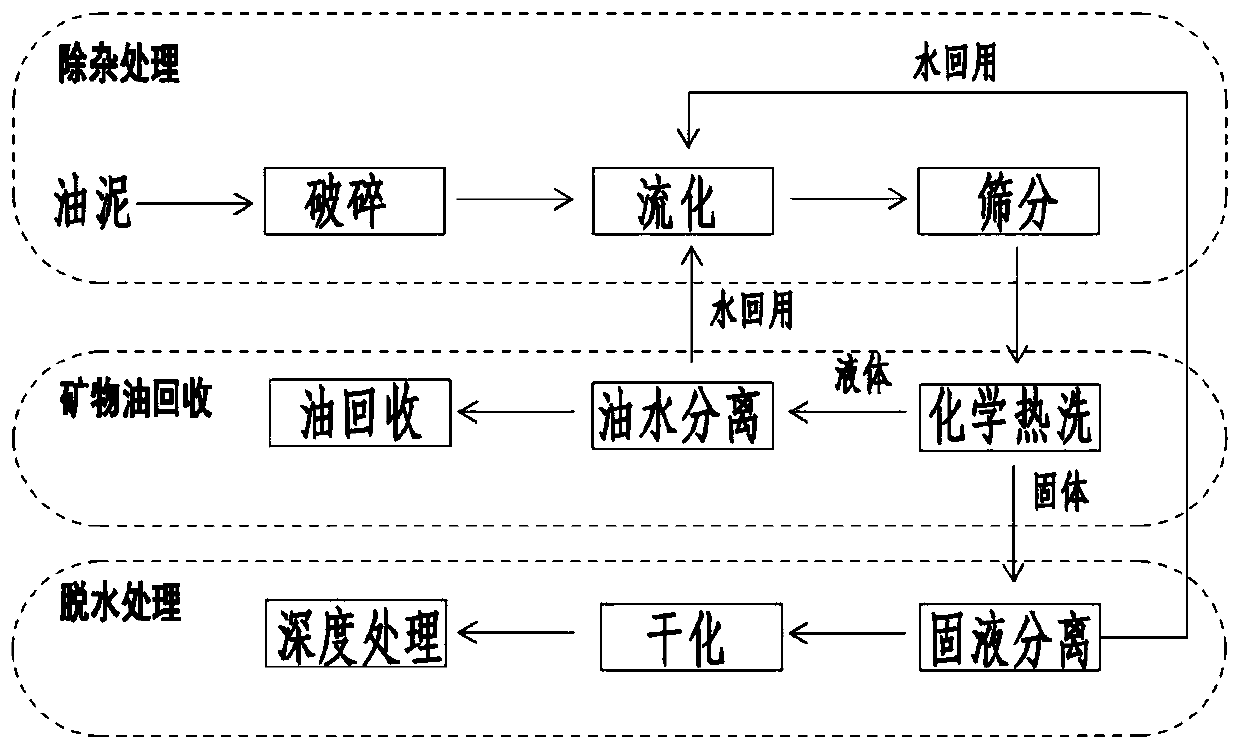

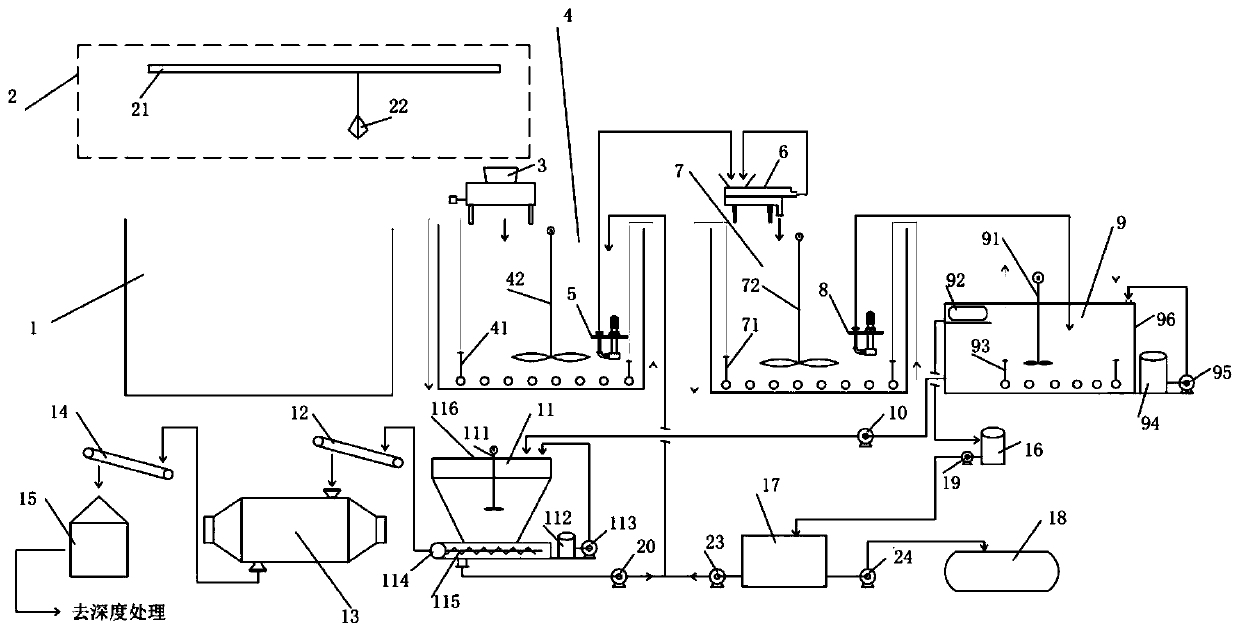

Oily sludge recycling and reduction treatment method and system

InactiveCN110606633AImplement resourcesAchieve reductionSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesReduction treatmentSlag

The invention discloses an oily sludge recycling and reduction treatment method and system. The treatment method comprises the steps of crushing, fluidization, screening and impurity removal, chemicalhot washing, solid-liquid separation, drying, deep treatment and the like. The treatment system mainly comprises an oily sludge storage tank, a feeding device, an impurity removal system, an oil recovery system and a dehydration system which are connected in sequence, wherein oily sludge in the oily sludge storage tank is conveyed to the impurity removal system through the feeding device to be subjected to crushing, fluidization and screening treatment, then the oil sludge treated by the impurity removal system is conveyed to the oil recovery system to collect crude oil, and isolated slag slurry is conveyed to the dehydration system to be subjected to solid-liquid separation, drying treatment and harmless deep treatment. By adopting the method and the treatment system provided by the invention, more than 80% of mineral oil in the oily sludge can be recycled, and meanwhile, the moisture content in the sludge is reduced to 30% or below, so that recycling and reduction of the oily sludgeare realized.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

Electrochromic layers, device and process of producing same

InactiveUS7884994B2Uniform color intensityQuick layeringLaminationLamination apparatusElectrochromismElectrolyte

Provided is an electrochromic device (ECD) that includes: a first transparent electrode having a first substrate having thereon a first electrically conductive layer; a second transparent electrode having a second substrate having thereon a second electrically conductive layer; a first polymeric layer on the first transparent electrode, wherein the first polymeric layer includes a cathodic electrochromic polymer and a first non-electrochromic polymeric matrix; a second polymeric layer on the second transparent electrode, wherein the second polymeric layer includes an anodic electrochromic polymer and a second non-electrochromic polymeric matrix; and an electrolyte layer disposed between the first polymeric layer and the second polymeric layer. Also provided is a process of producing the ECDs, as well as the electrochromic layers themselves.

Owner:SAINT GOBAIN VITRAGE SA

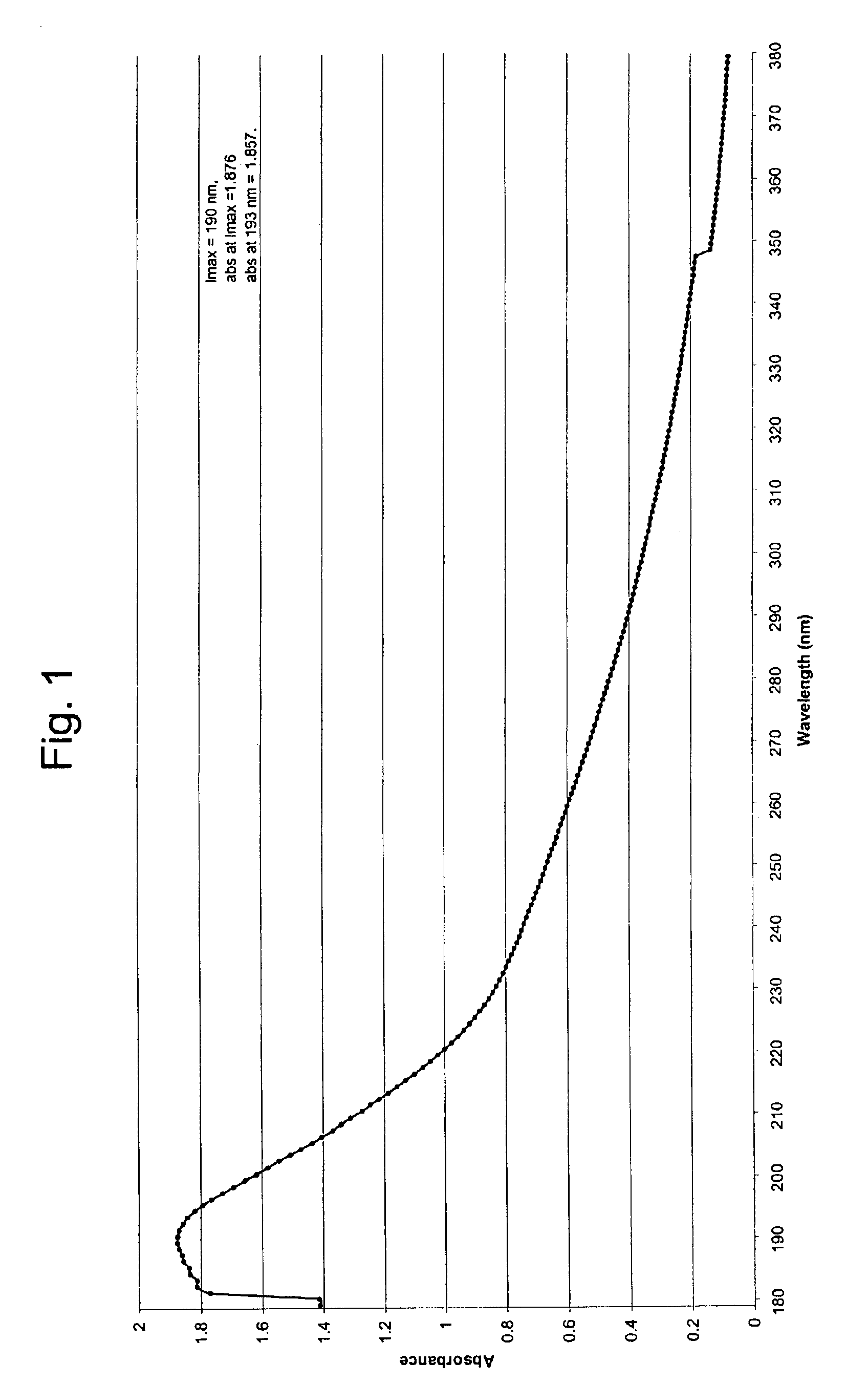

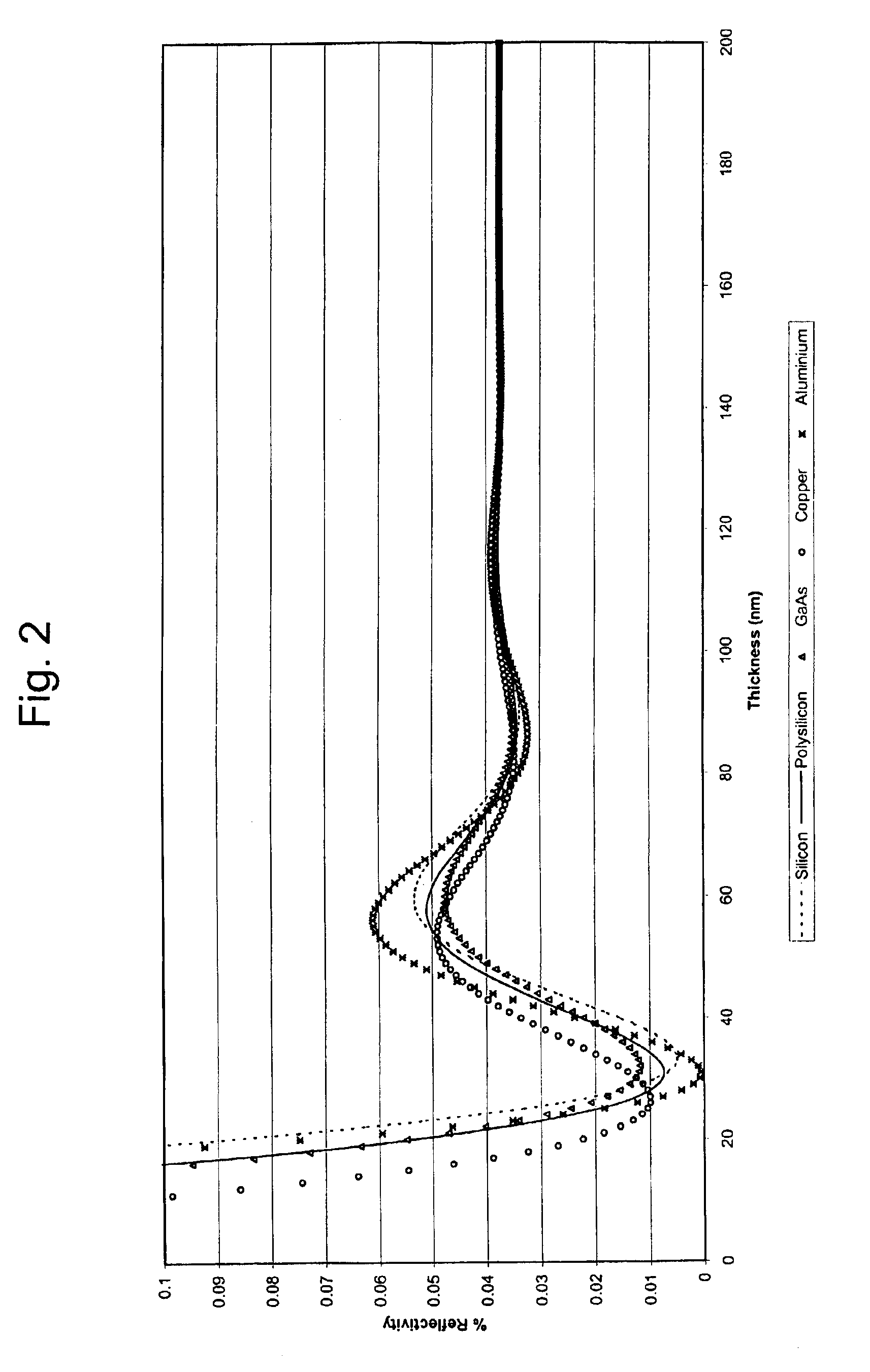

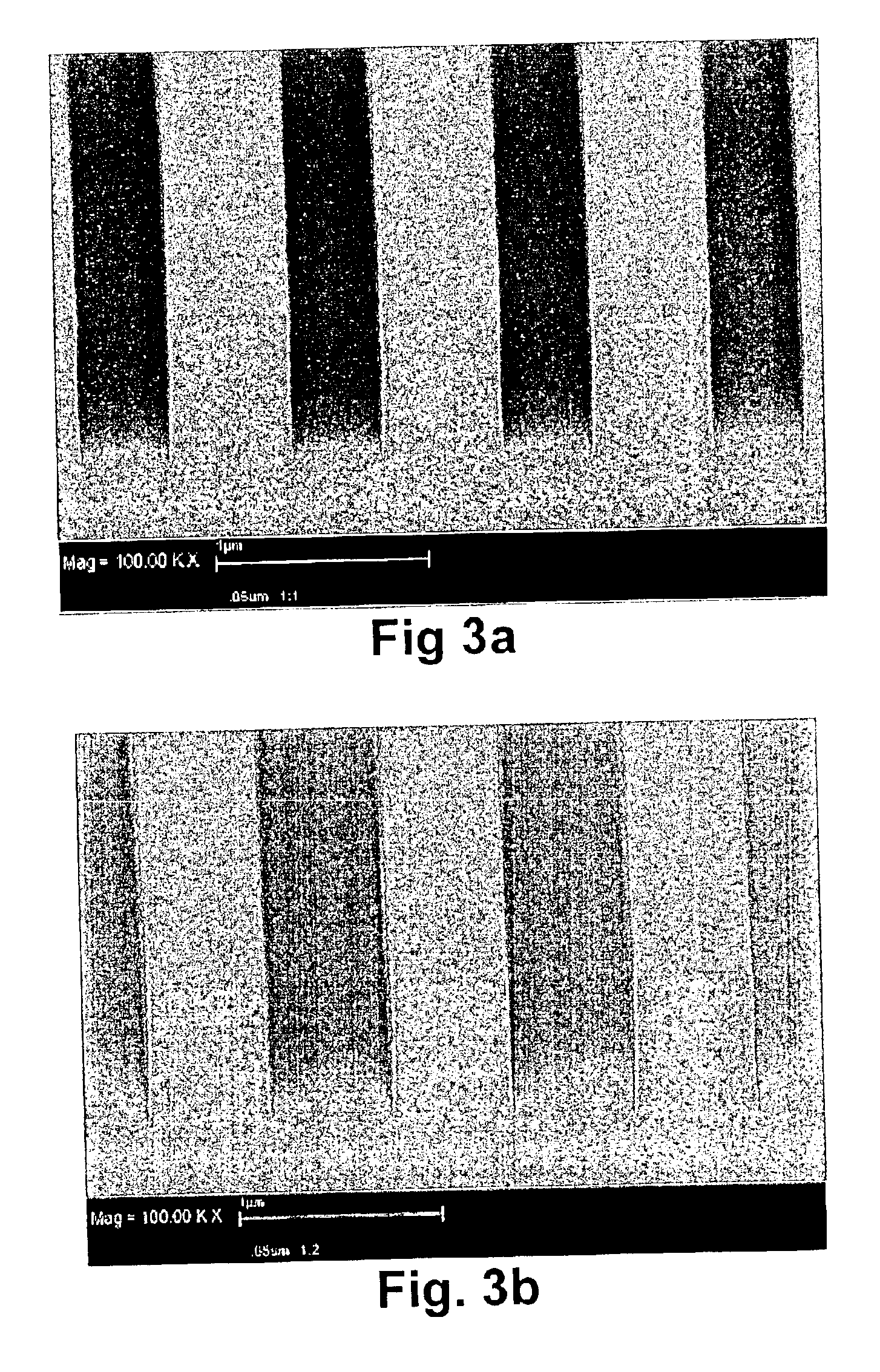

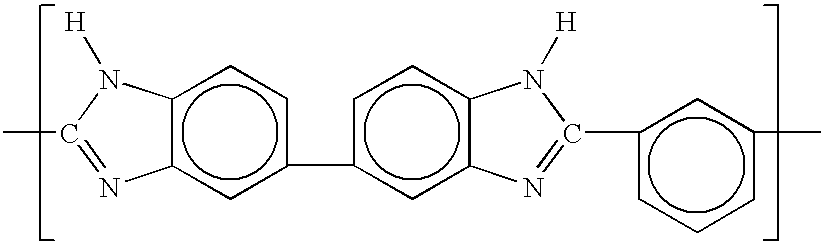

Polymeric antireflective coatings deposited by plasma enhanced chemical vapor deposition

InactiveUS6852474B2Negative effectReduce wastePhotosensitive materialsSemiconductor/solid-state device manufacturingGas phaseChemical vapors

An improved method for applying polymeric antireflective coatings to substrate surfaces and the resulting precursor structures are provided. Broadly, the methods comprise plasma enhanced chemical vapor depositing (PECVD) a polymer on the substrate surfaces. The PECVD processes comprise providing a quantity of a polymer generated by introducing monomer vapors into a plasma state followed by polymerization thereof, with assistance of plasma energy, onto the surface of a substrate. The most preferred starting monomers are phenylacetylene, 4-ethynyltoluene, and 1-ethynyl-2-fluorobenzene. The inventive methods are useful for providing highly conformal antireflective coatings on large surface substrates having super submicron (0.25 μm or smaller) features. The process provides a much faster deposition rate than conventional chemical vapor deposition (CVD) methods, is environmentally friendly, and is economical.

Owner:BREWER SCI

Methods and systems for the inhibition of vascular hyperplasia

InactiveUS6494874B1Limited extentQuick layeringUltrasound therapyStentsSmooth muscleVascular proliferation

Owner:PHARMASONICS

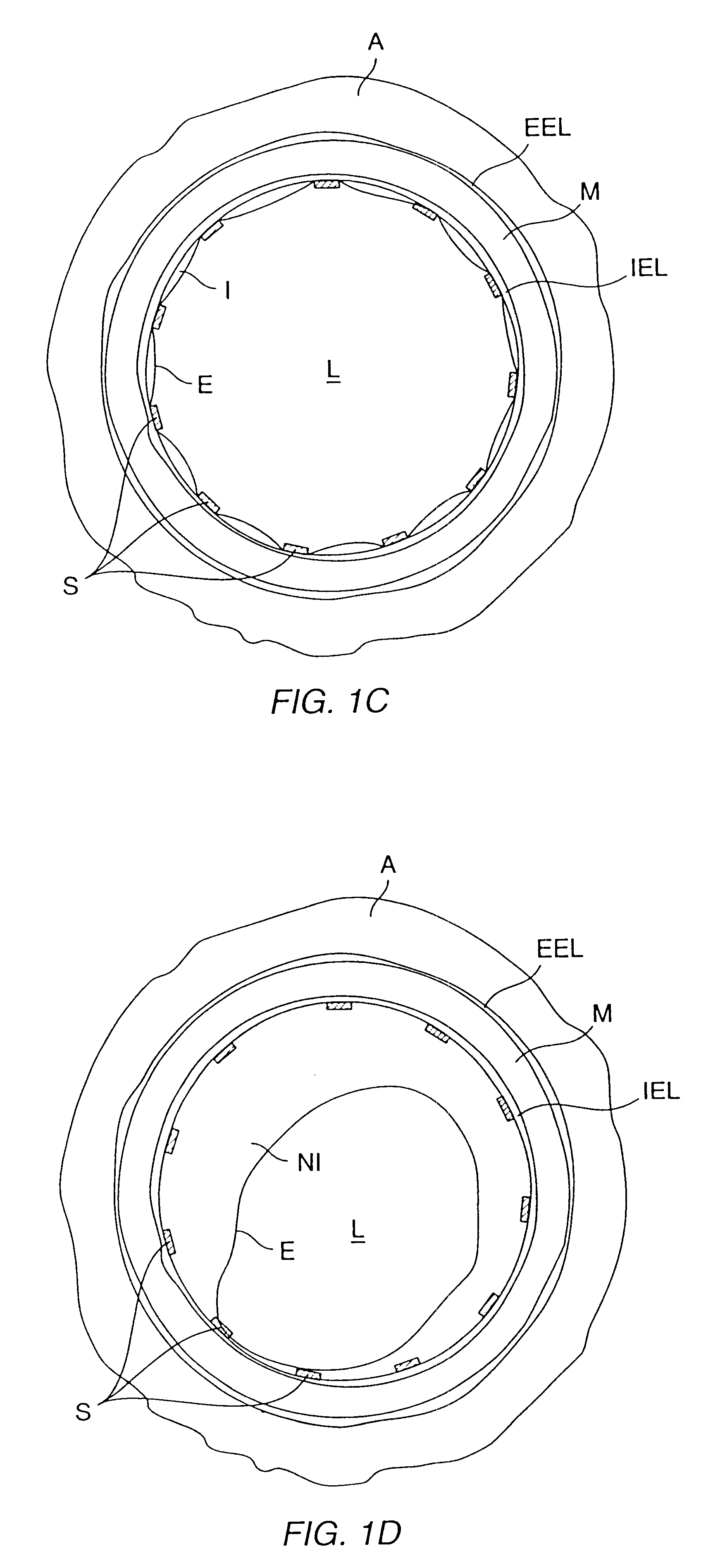

Sea buckthorn berry oil preparation method

InactiveCN102120945AReduce manufacturing costQuick layeringFatty-oils/fats refiningFatty-oils/fats productionPectinaseOrganic solvent

The invention provides a sea buckthorn berry oil preparation method which is implemented by the following steps: (1) cleaning sea buckthorn berries; (2) quickly freezing; (3) pulping; (4) hydrolyzing pectinase; (5) precipitating with alcohol; (6) freezing to stratify sea buckthorn berry oil; (7) extracting raw oil; (8) recovering ethanol by distillation; (9) carrying out secondary freezing and thawing to separate the sea buckthorn berry oil; and (10) refining to obtain the sea buckthorn berry oil. In the invention, poisonous and odorous organic solvents are not used, and the extraction process cost is low, thereby ensuring that the preparation method has a high use value.

Owner:HEILONGJIANG CHANGLESHAN DAGUO SHAJI DEV

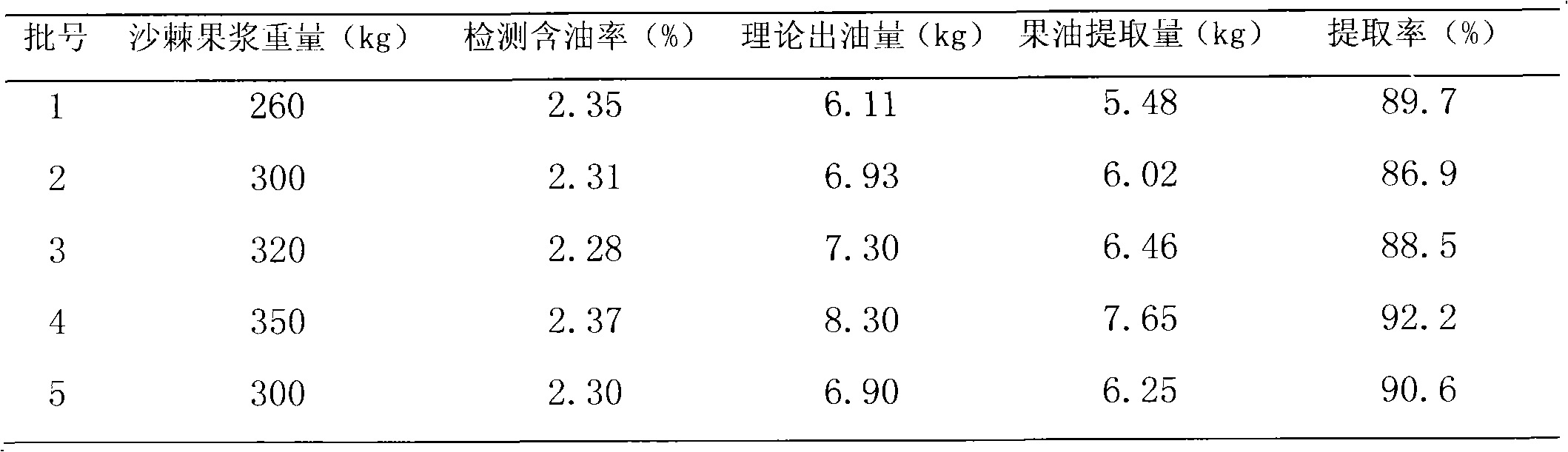

Electrochromic glass component

InactiveUS6563625B1Improve ionic conductivityQuick layeringNon-linear opticsOptical viewingPolyesterCoating system

The invention relates to an eclectrochromic glass component, particularly for motor vehicle mirrors, which contains a doped ion-conducting basic polymer (4) as the ion-conducting layer. The electrochromic glass component consists, for example of a glass substrate (1) as well as a layer system having an electrochromic layer (2), a mirror layer (3), a doped polymer membrane (4), for example of polybenzimidazole polymer, a proton store (5), a rear electrode (6) and a polyester film (7). The layer system is sealed by a seal (8) which closes the coating system towards the glass substrate (1).

Owner:MAGNA AUTECA ZWEIGNIEDERLASSUNG DER MAGNA HLDG +1

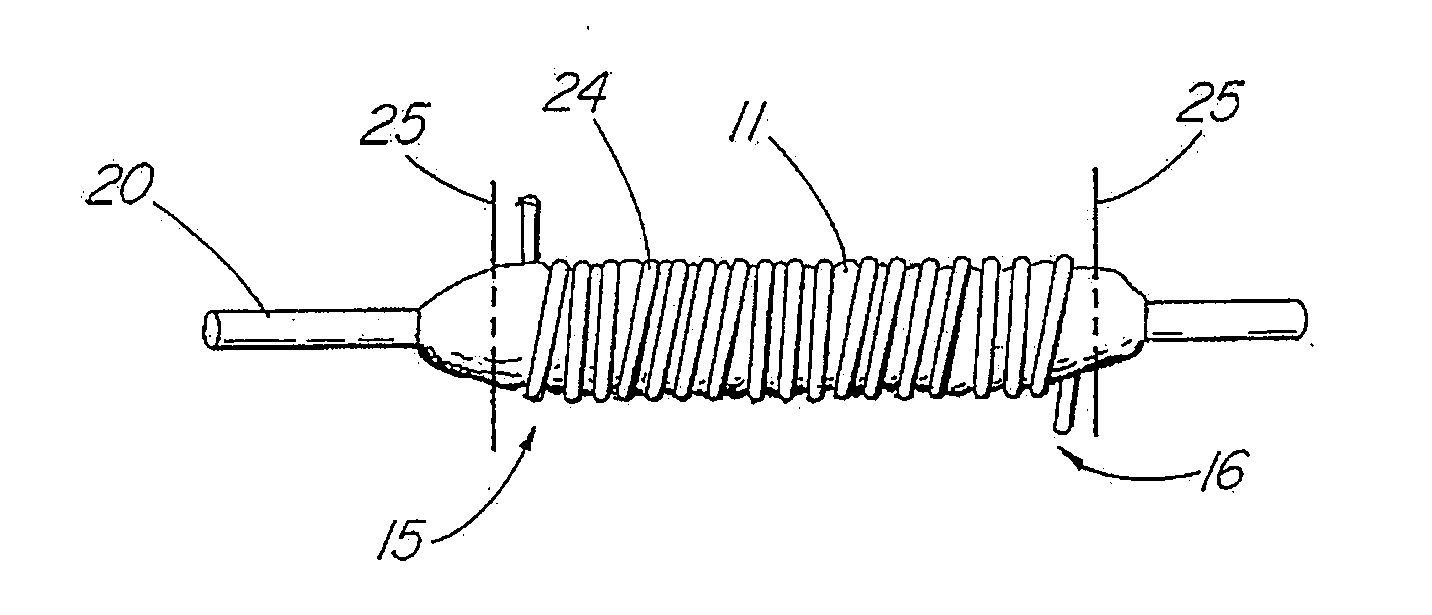

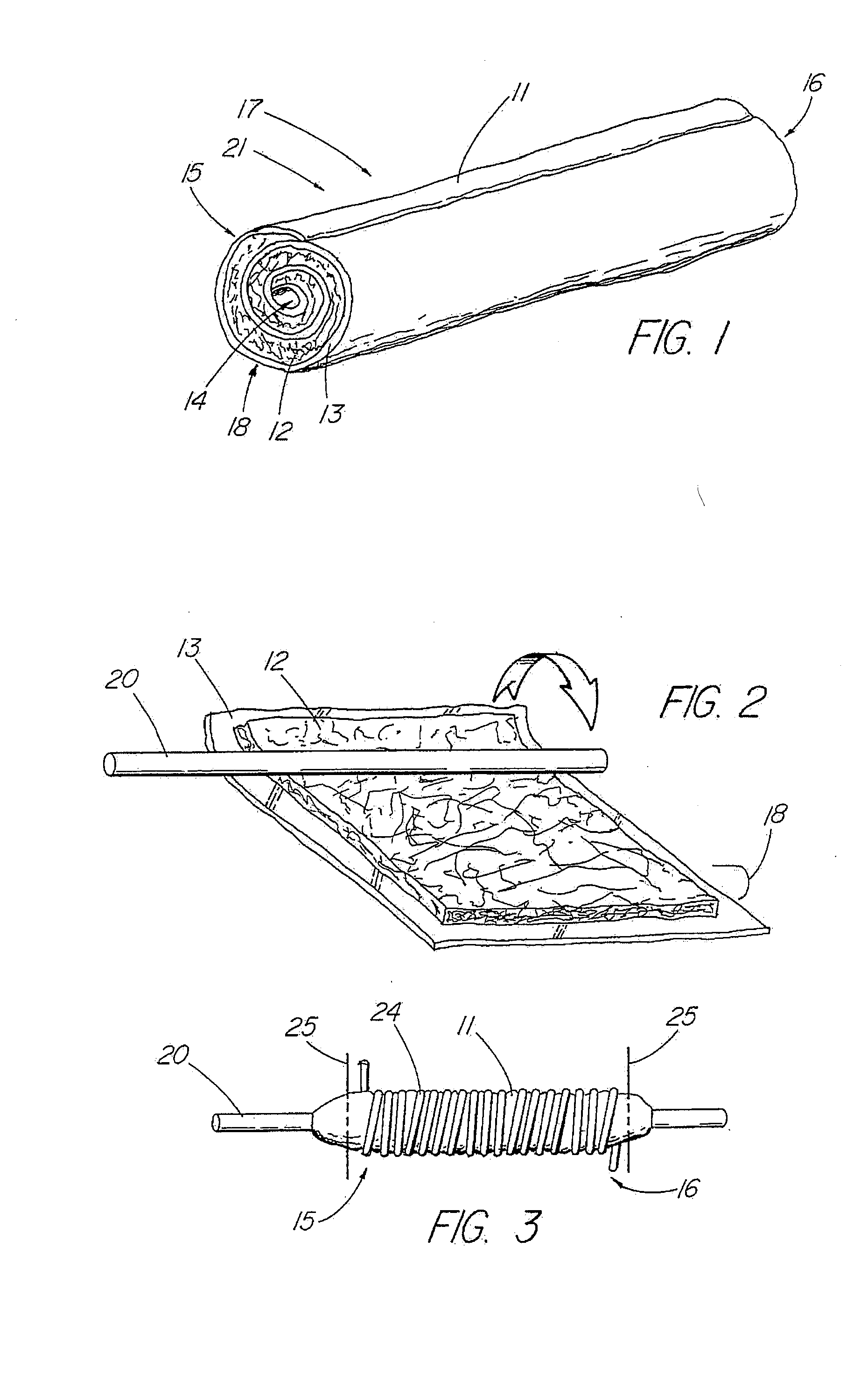

Bodily Lumen Closure Apparatus and Method

InactiveUS20140148839A1Avoid blood leakagePrevent leakageStentsFallopian occludersSource materialSmall intestine

An absorbable and expandable closure member used to occlude or exclude a body lumen or cavity, such as a blood vessel, fallopian tube, duct, aneurysmal sac, etc., comprising a closure member comprising one of more sheets of a biomaterial that are rolled, stacked, or folded to form a multilayer construct of a generally cylindrical configuration for deployment through a delivery system, either as a singularly or part of a multiplicity of closure members. The biomaterial is derived from a source material, such as small intestinal submucosa or another remodelable material (e.g., an extracellular matrix) having properties for stimulating ingrowth of adjacent tissue into the biomaterial deployed within the bodily lumen. The closure member is deployed to the bodily lumen from a delivery sheath, cartridge, and / or over a inner guiding member, such as a wire guide or catheter.

Owner:OREGON HEALTH & SCI UNIV

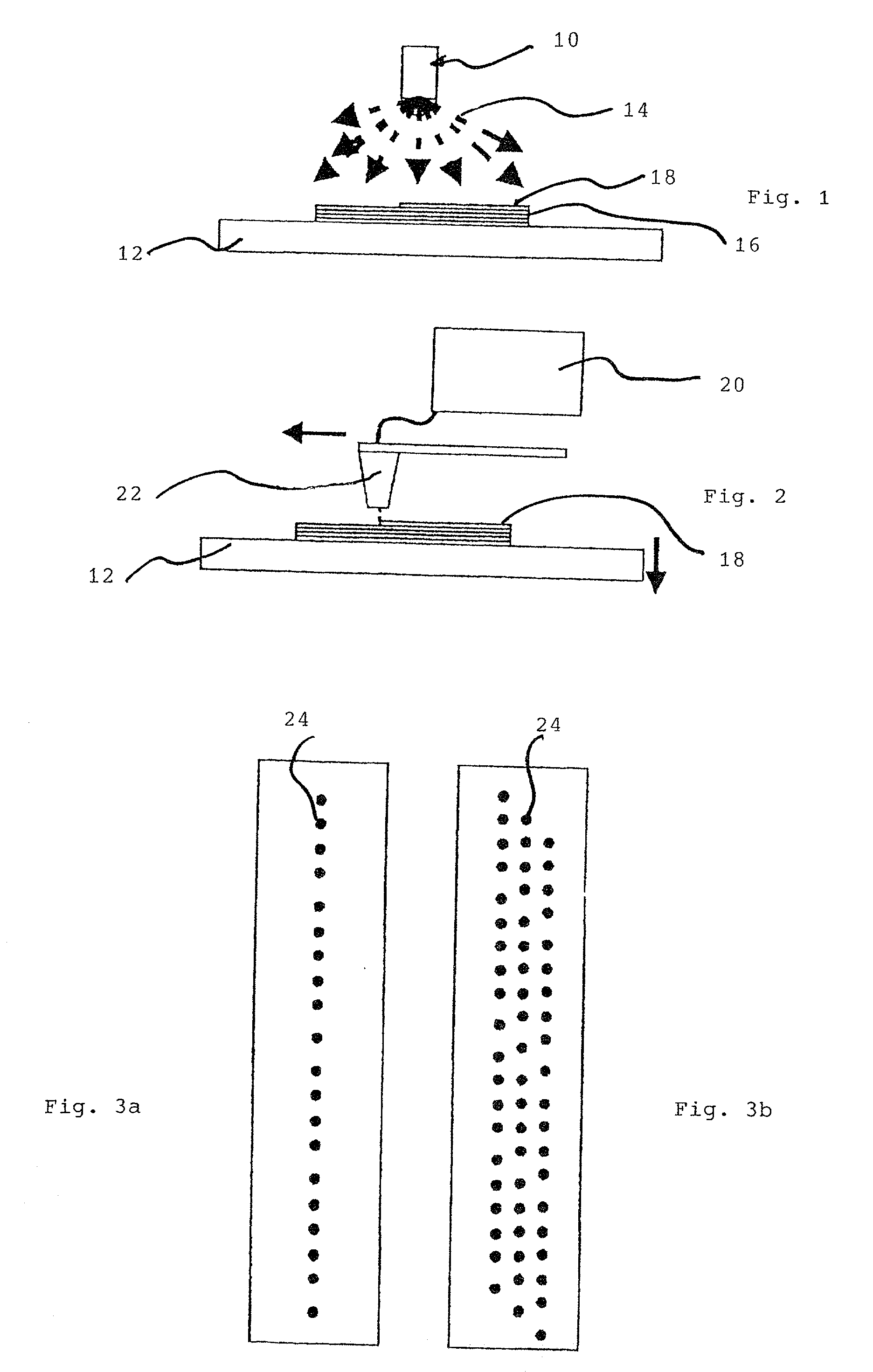

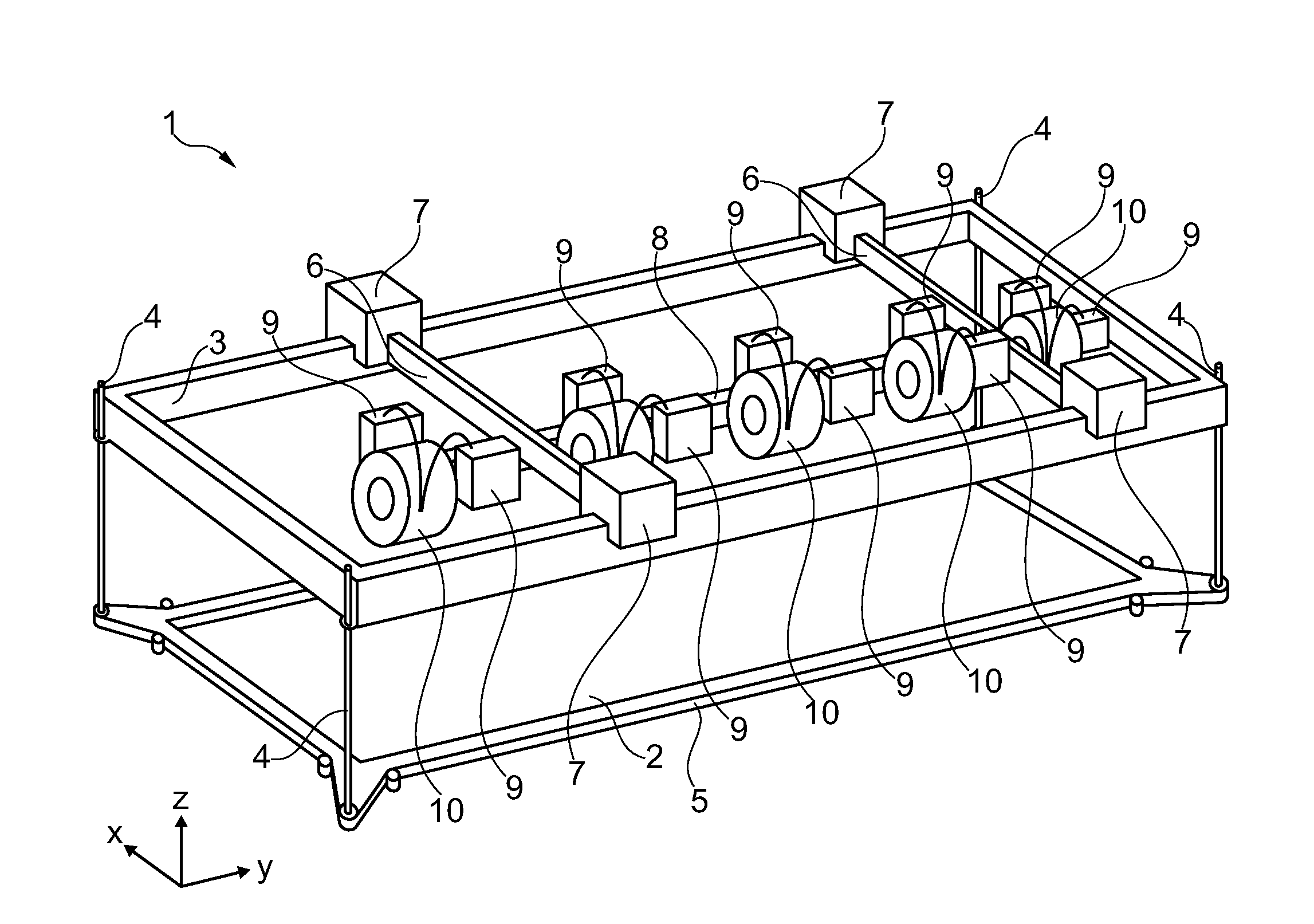

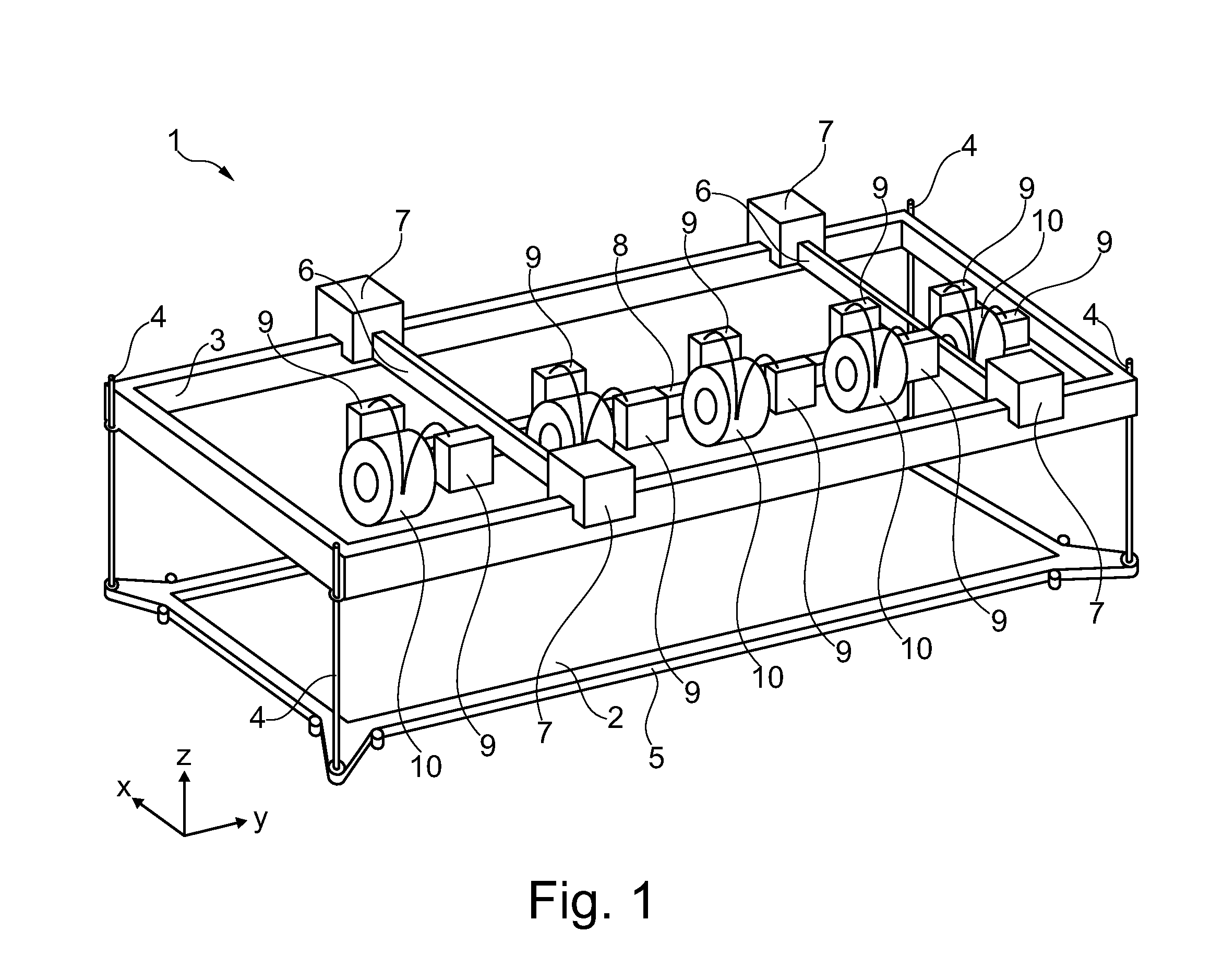

Device for Printing Simultaneously Three Dimensional Objects

InactiveUS20150079217A1Easy to disassembleLow melting pointConfectioneryTypewritersEngineeringSupport surface

A device for printing simultaneously three dimensional objects includes a support surface for supporting the object to be printed and a carriage arranged over the support surface. The carriage is movable along two axes of a Cartesian coordinate system parallel to the support surface the distance between the carriage and the support surface is adjustable. A number of printing heads are arranged at the carriage. The printing heads are positioned at a regular first pitch distance along the first axis of the Cartesian coordinate system and at a regular second pitch distance along the second axis of the Cartesian coordinate system.

Owner:SDD HLDG

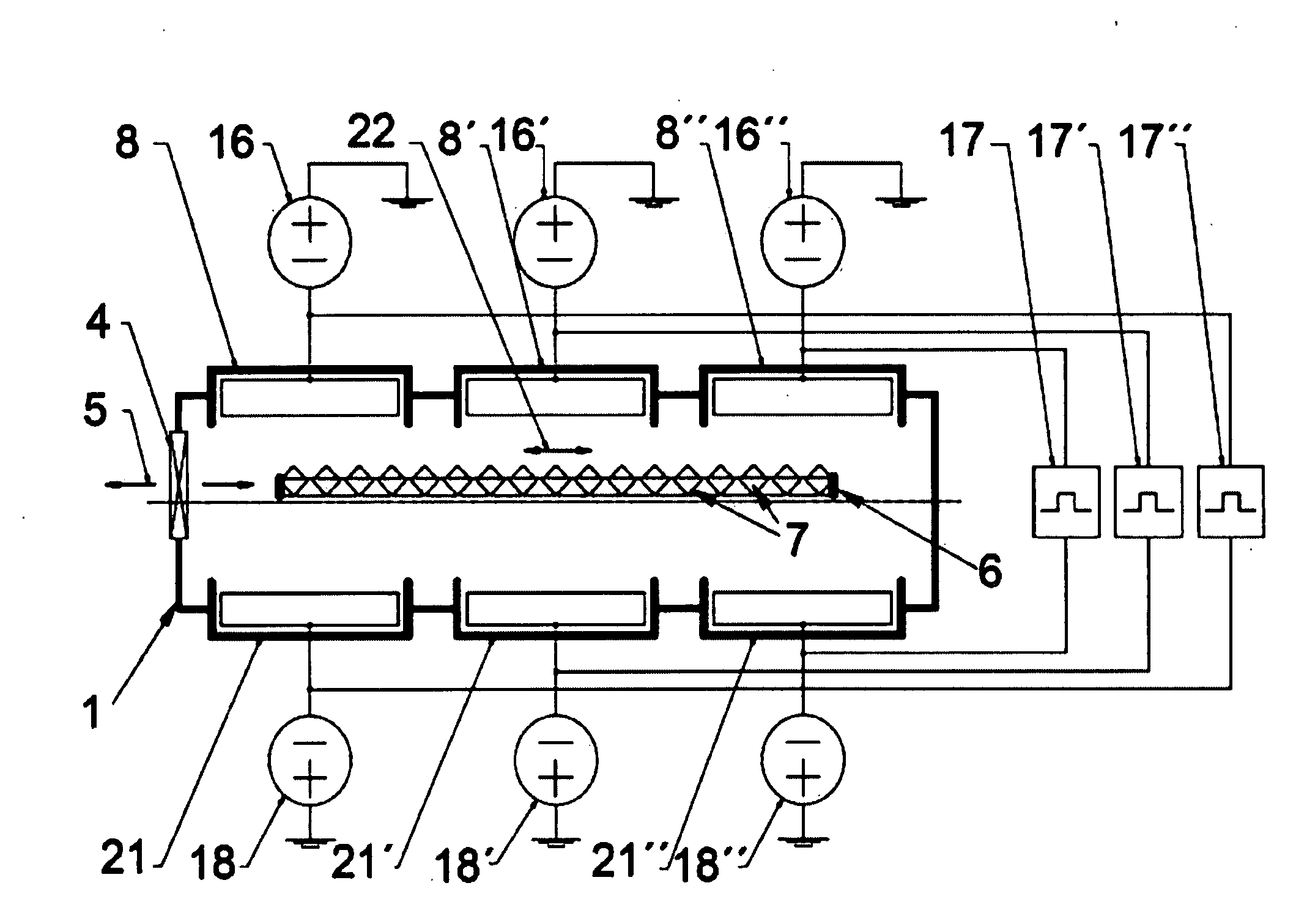

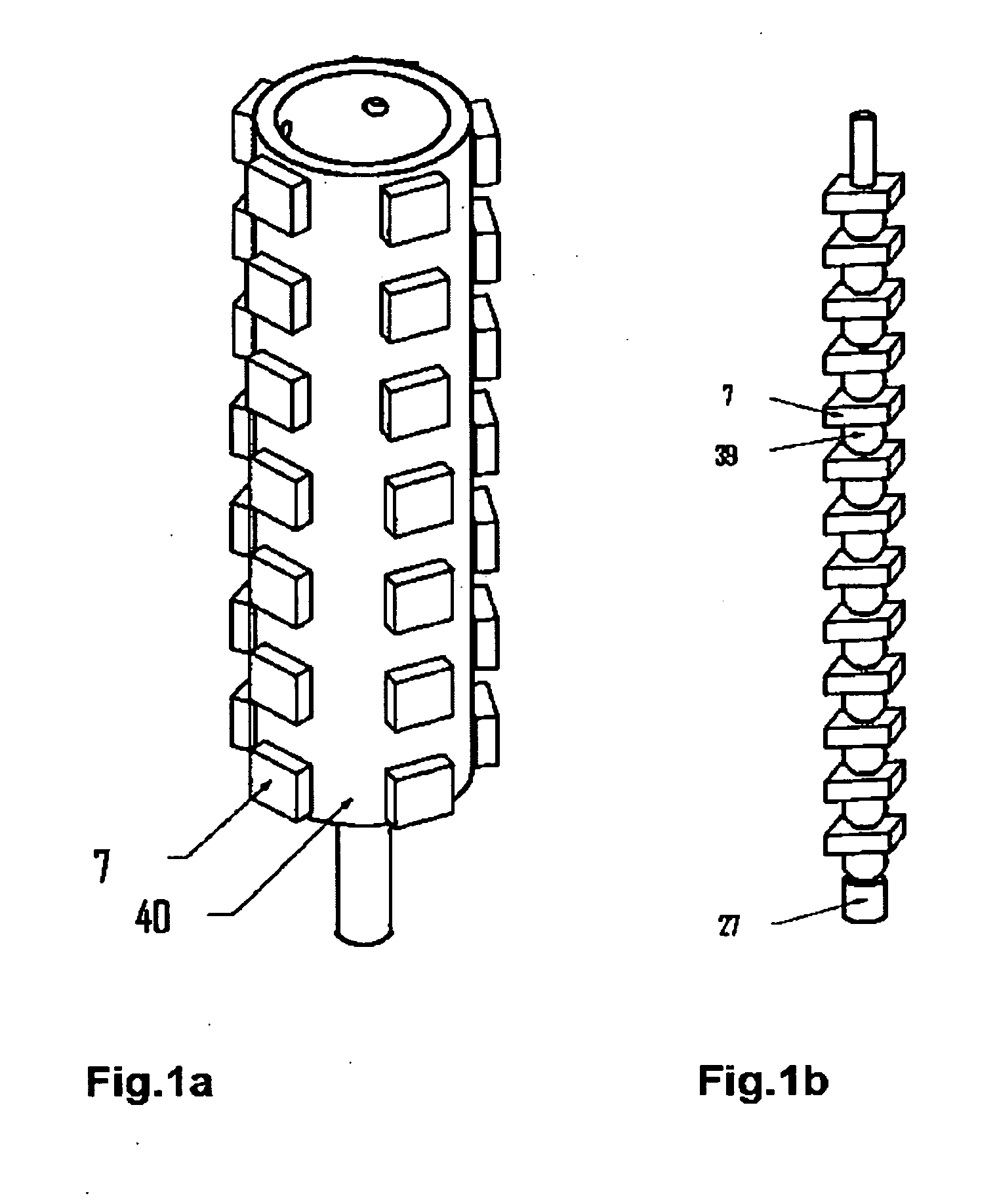

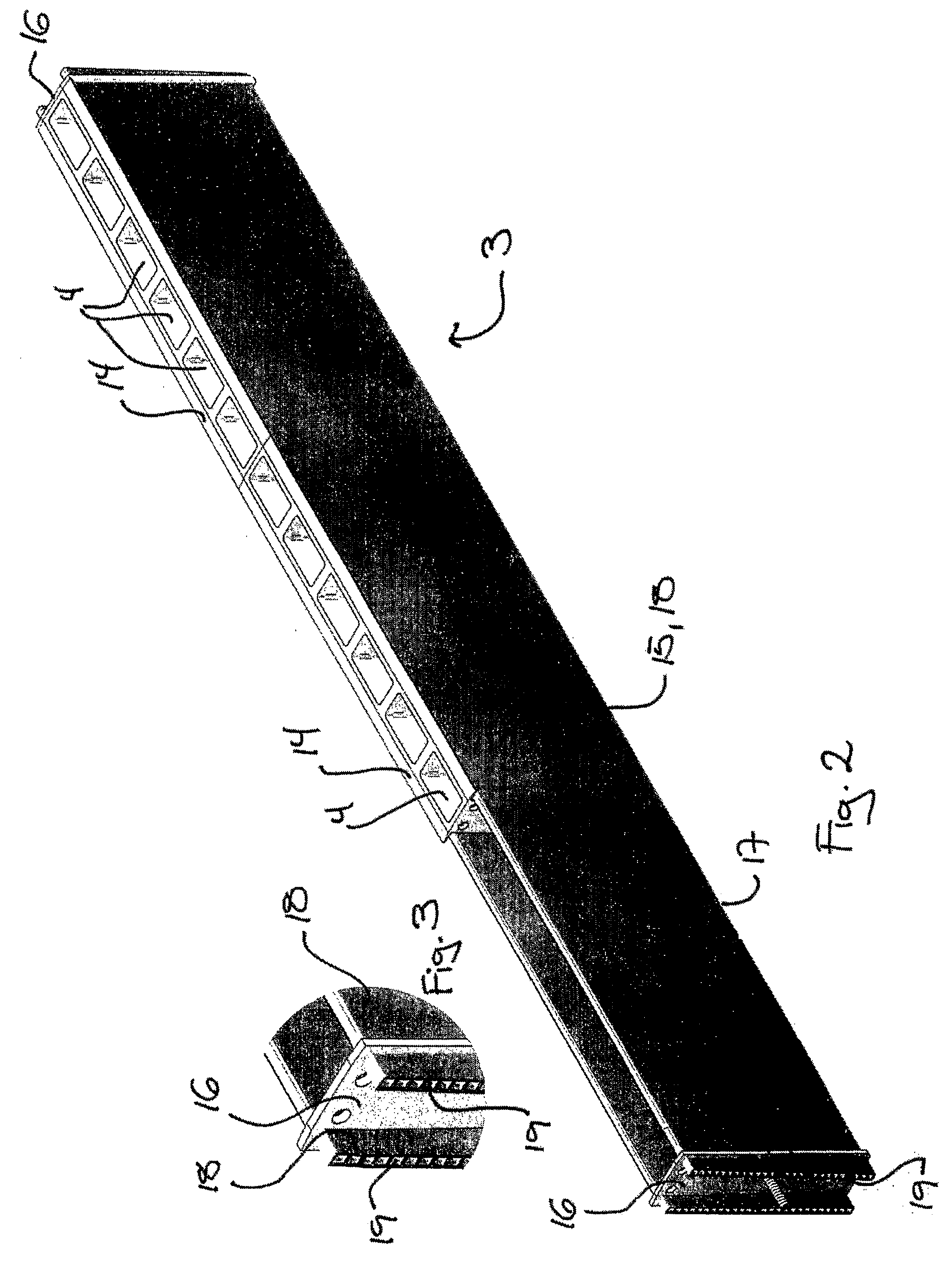

Pvd - vacuum coating unit

A vacuum coating unit includes a reactive gas inlet, at least one PVD coating source with a laminar cathode and a substrate carrier containing a multiplicity of substrates. The substrate carrier forms a two dimensional horizontal extent, and the carrier is between at least two PVD coating sources. The substrates are cutting tools with at least one cutting edge in their peripheral margin region, which are distributed in a plane of the two dimensional extent of the substrate carrier. The substrate carrier is in a horizontal plane in the vacuum process chamber spaced between the laminar cathodes of the PVD coating sources and positioned such that at least a portion of each of the at least one cutting edge includes an active cutting edge and this active cutting edge is oriented opposite at least one of the cathodes of the PVD coating sources exposed at any time along a line of sight.

Owner:OERLIKON TRADING AG TRUEBBACH

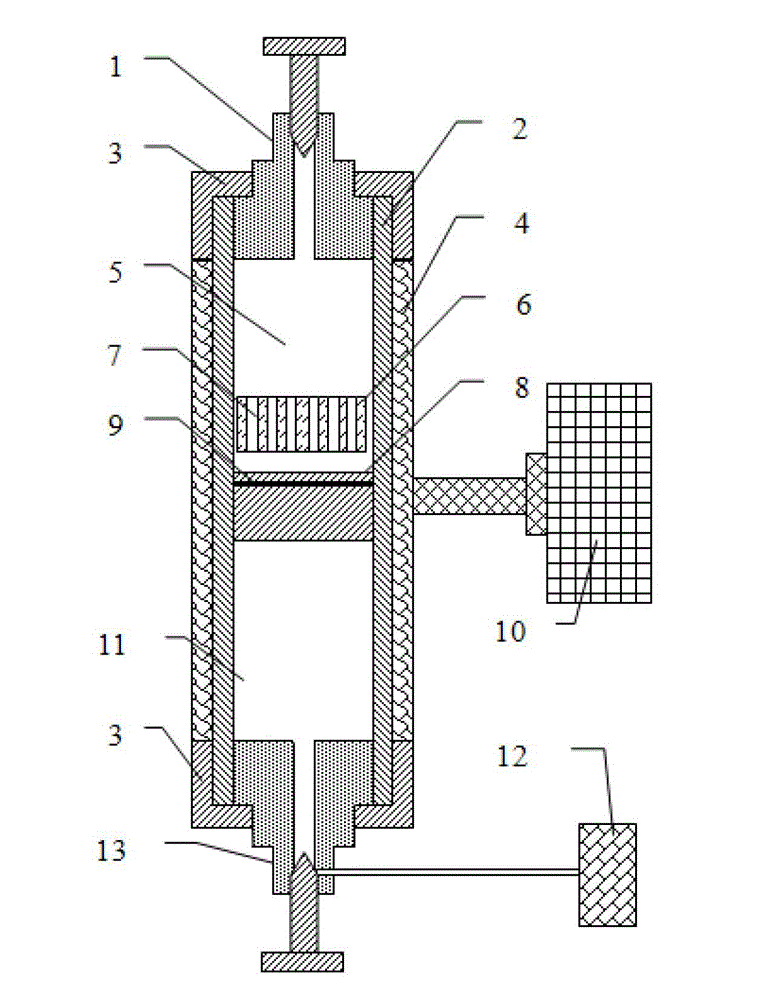

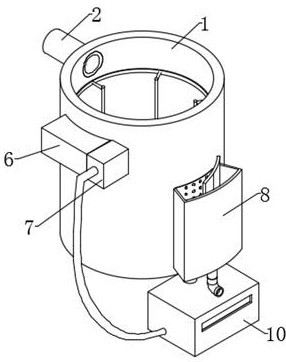

Device and method for dehydrating crude oil

InactiveCN102876354AFast layeringEasy to drainHydrocarbon oil dewatering/demulsificationControl systemReciprocating motion

The invention relates to a device and a method for dehydrating crude oil. The device mainly comprises a reaction kettle, a crude oil sample cavity, a stirrer, a piston and a pressure transferring liquid cavity; the reaction kettle is divided by the piston into the crude oil sample cavity and the pressure transferring liquid cavity; the stirrer is arranged in the crude oil sample cavity; a heating thermal insulation sleeve is arranged outside the reaction kettle; the reaction kettle is connected with a rotation and control system; and the pressure transferring liquid cavity is connected with a power system. According to the device, the crude oil to be treated is heated and pressurized by the reaction kettle; the reaction kettle rotates in the vertical direction to drive the stirrer to do reciprocating motion in the crude oil to be treated, so that the crude oil is subjected to mechanical demulsification and dehydrated; and the physical and chemical properties of the dehydrated crude oil cannot be influenced. A principle is reliable; the device and the method are convenient to operate; any chemical agent is not needed to be added; the phenomenon that the dehydrated crude oil hangs on a wall can be reduced; in-place oil compound composition experiment can be directly performed; the high temperature and high pressure physical characteristics of the crude oil can be kept; and the device and the method can be used for relative industry of performance test of the crude oil.

Owner:SOUTHWEST PETROLEUM UNIV

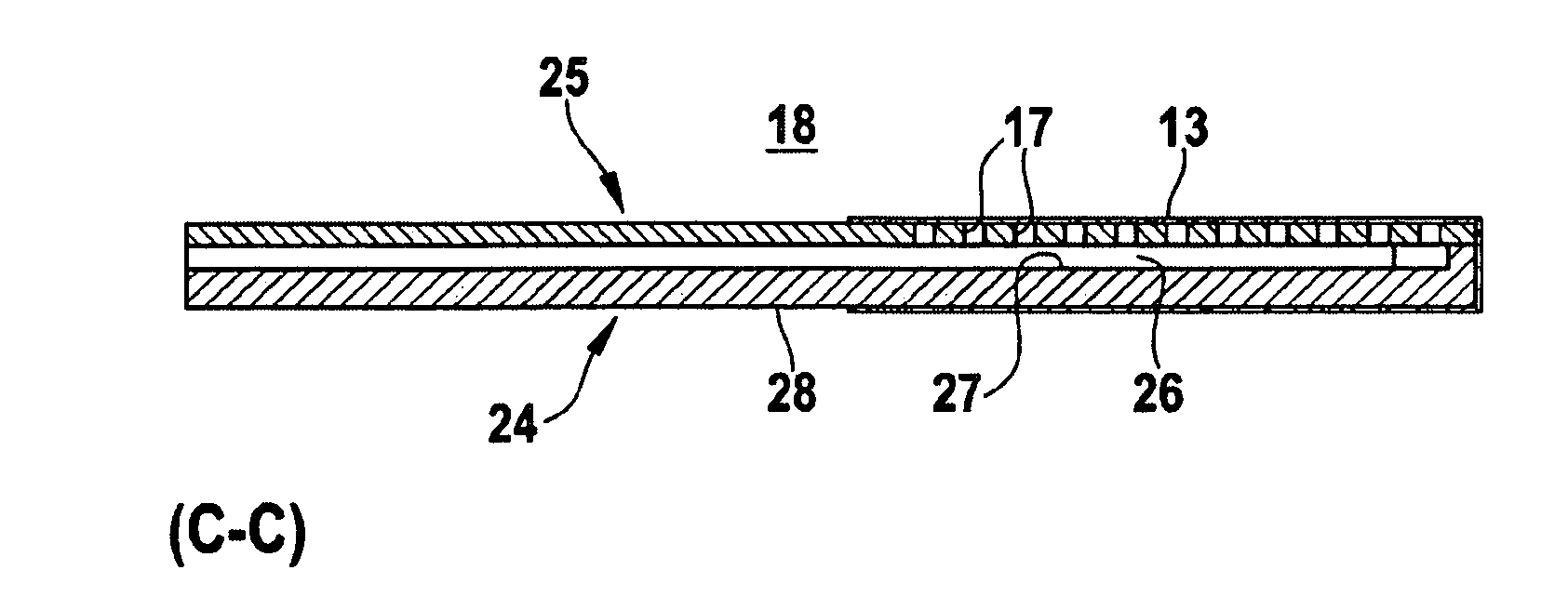

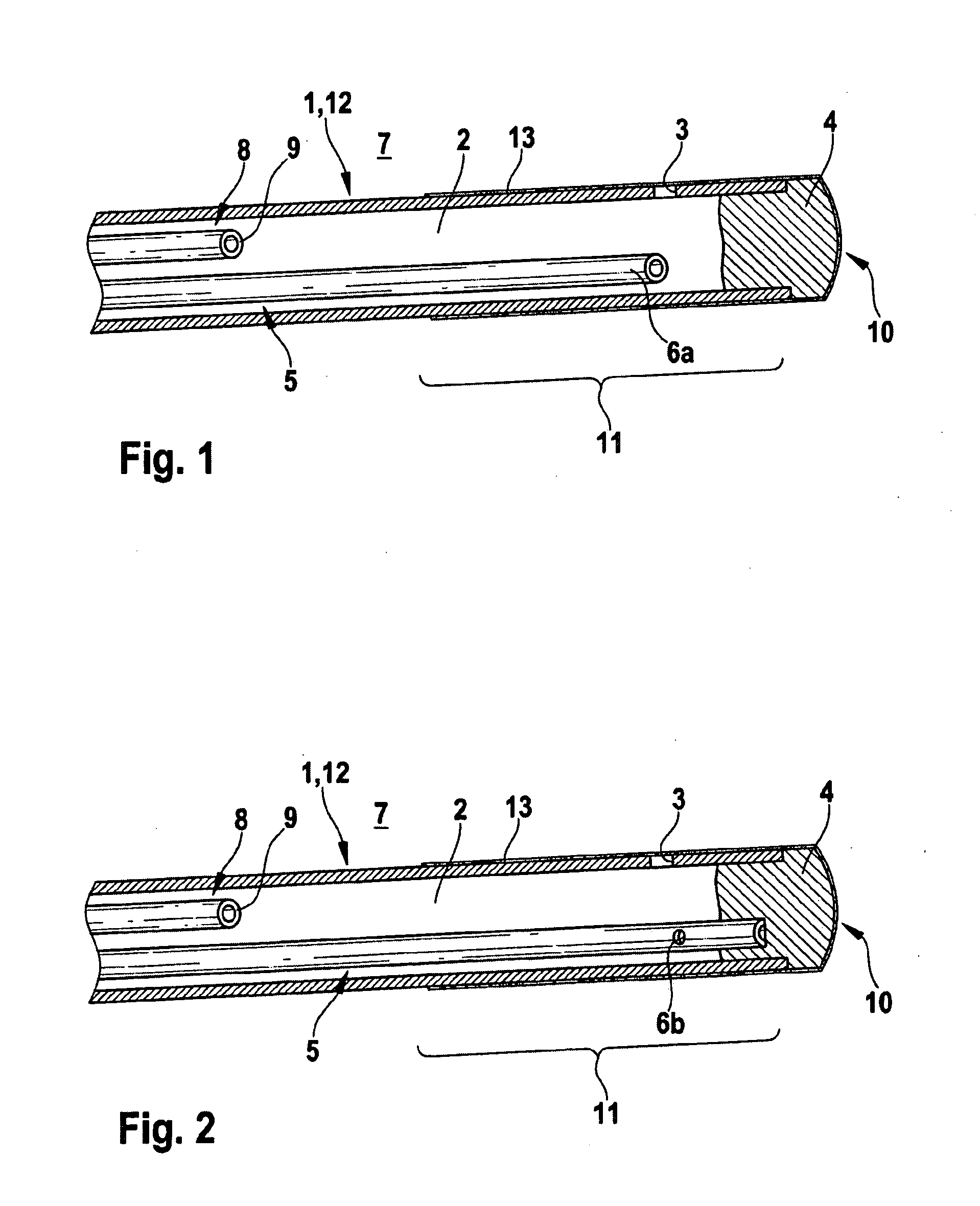

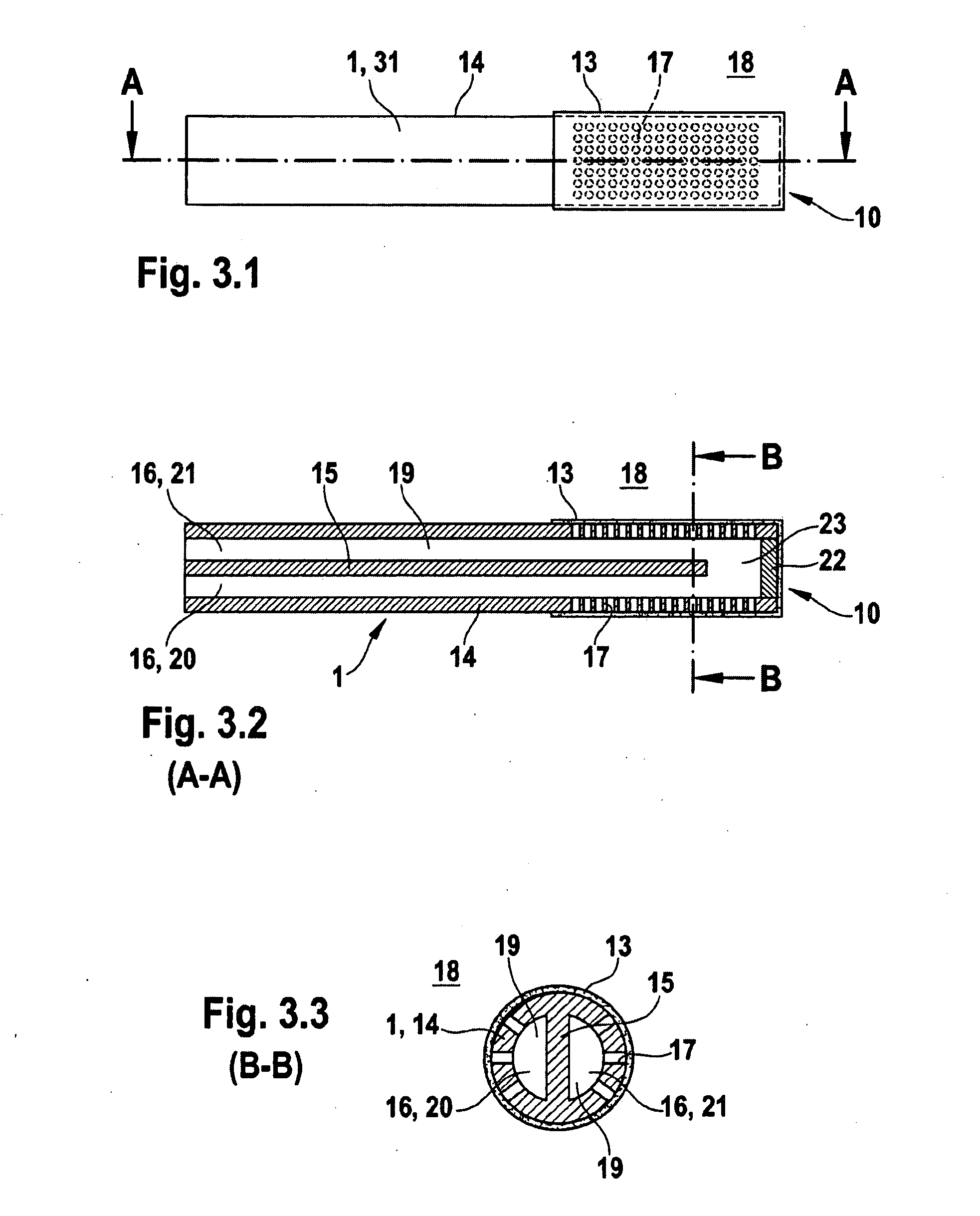

Microdialysis catheter and process for manufacture

InactiveUS20090054854A1Short diffusion timeGood biocompatibilityGlovesPretreated surfacesPorous coatingAnalyte

A microdialysis catheter for partial implantation is used to supply a perfusion fluid and remove a dialysate, such as glucose, and comprises a carrier, at least one opening in the carrier, and a non-porous coating over the opening. The carrier contains at least one channel for supplying a perfusion fluid and for removing a dialysate and an area intended for implantation. The opening on the carrier has a connection with the channel for the passage of fluid. The non-porous coating is externally bonded to the carrier. The non-poroous coating is diffusion-permeable to an analyte and covers the area intended for implantation and the opening. A process for manufacturing the microdialysis catheter is also disclosed.

Owner:ROCHE DIABETES CARE INC

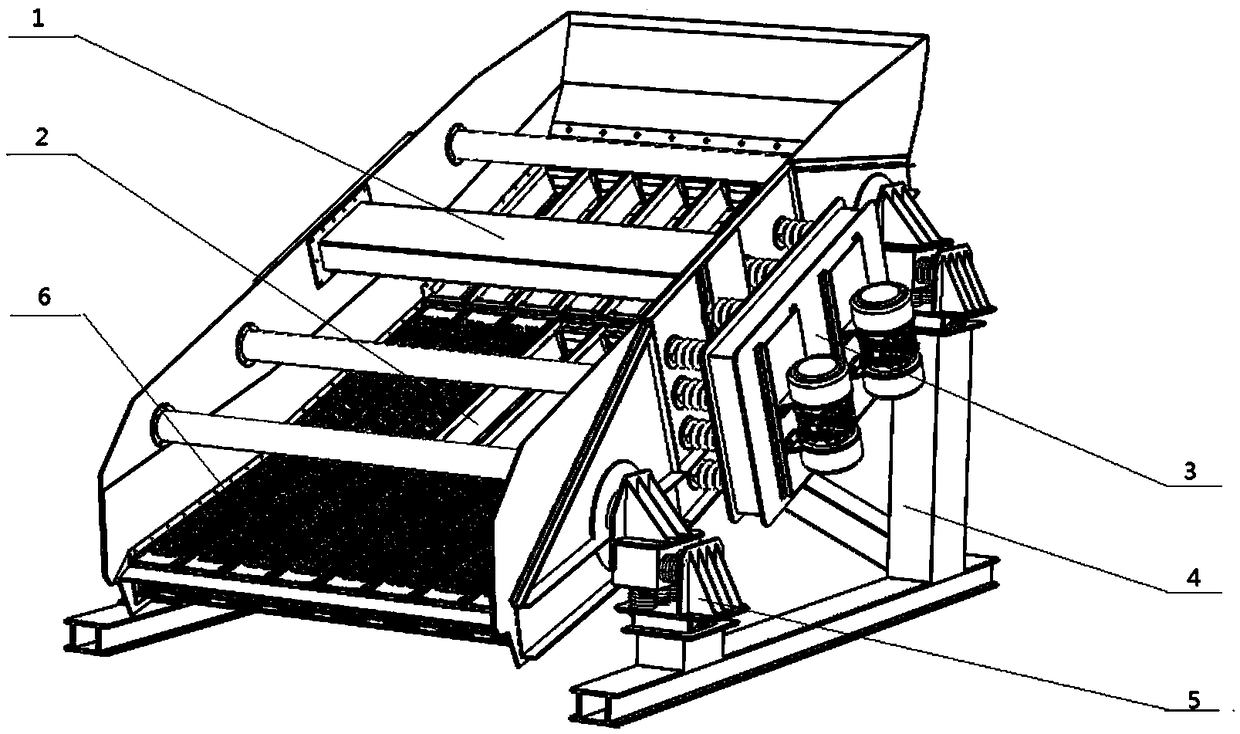

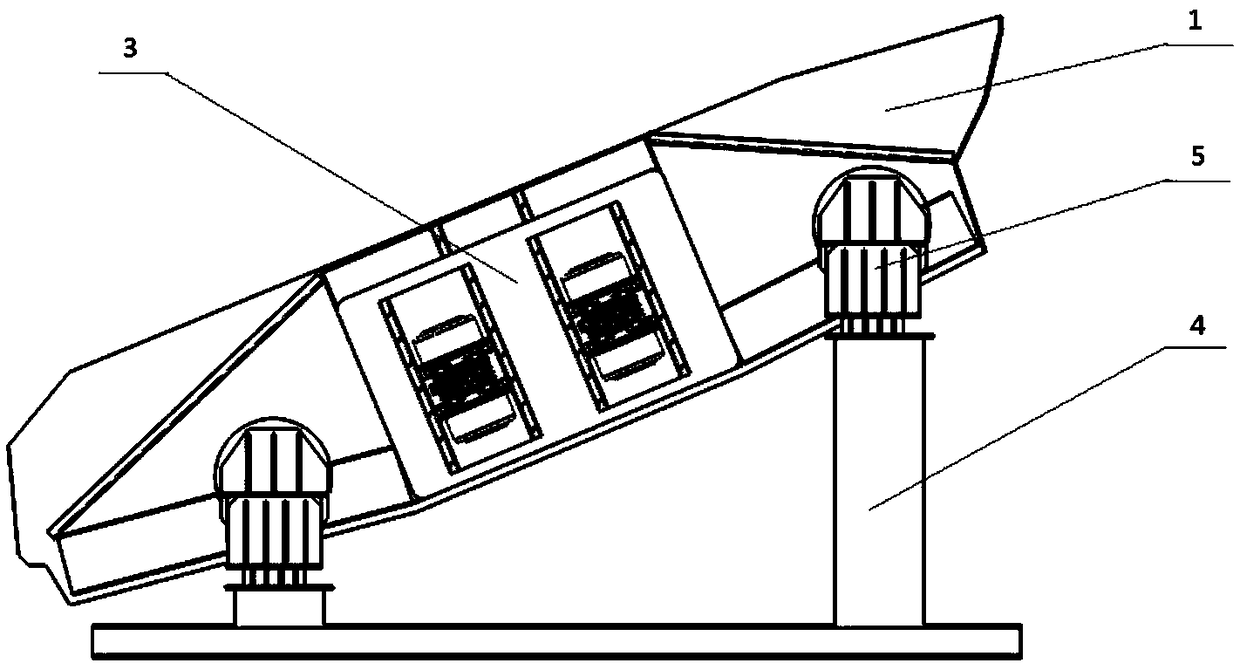

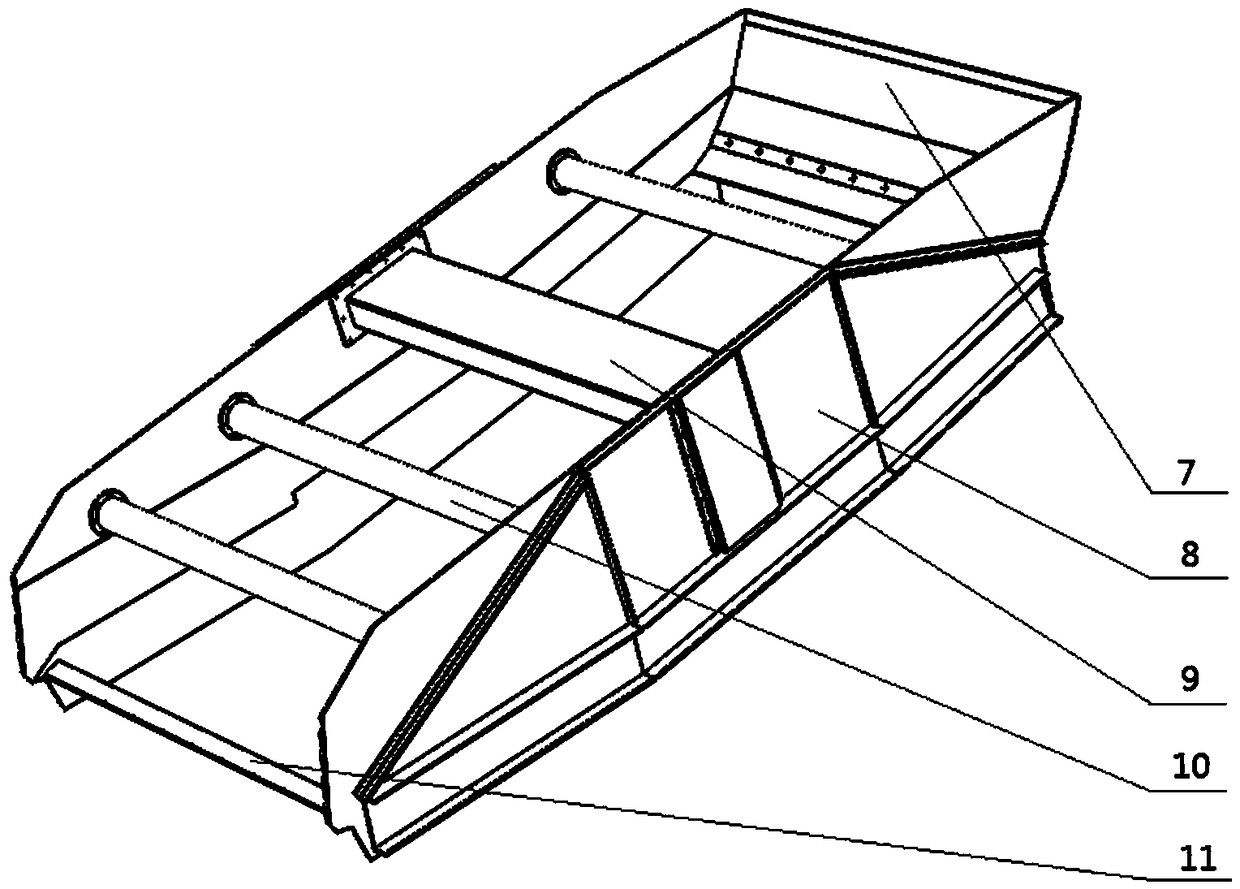

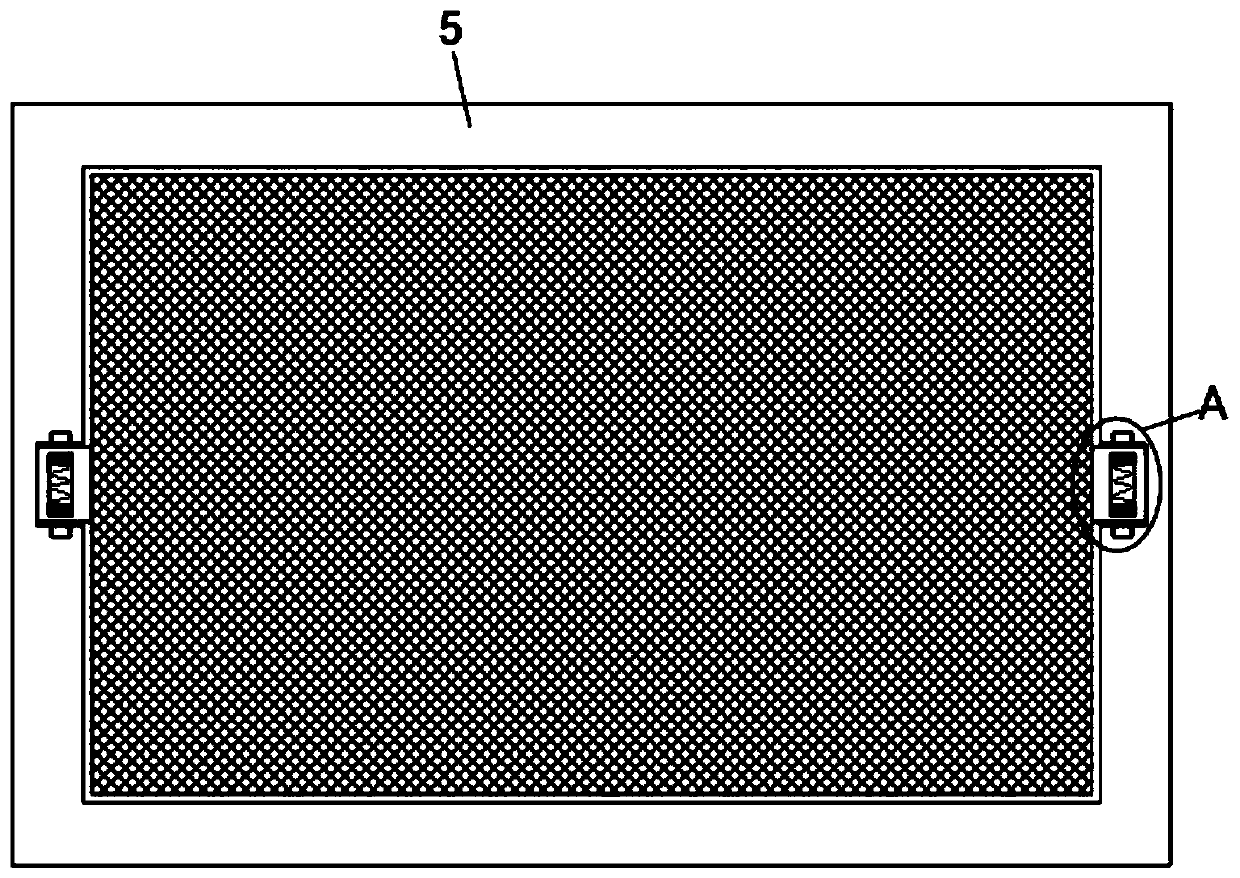

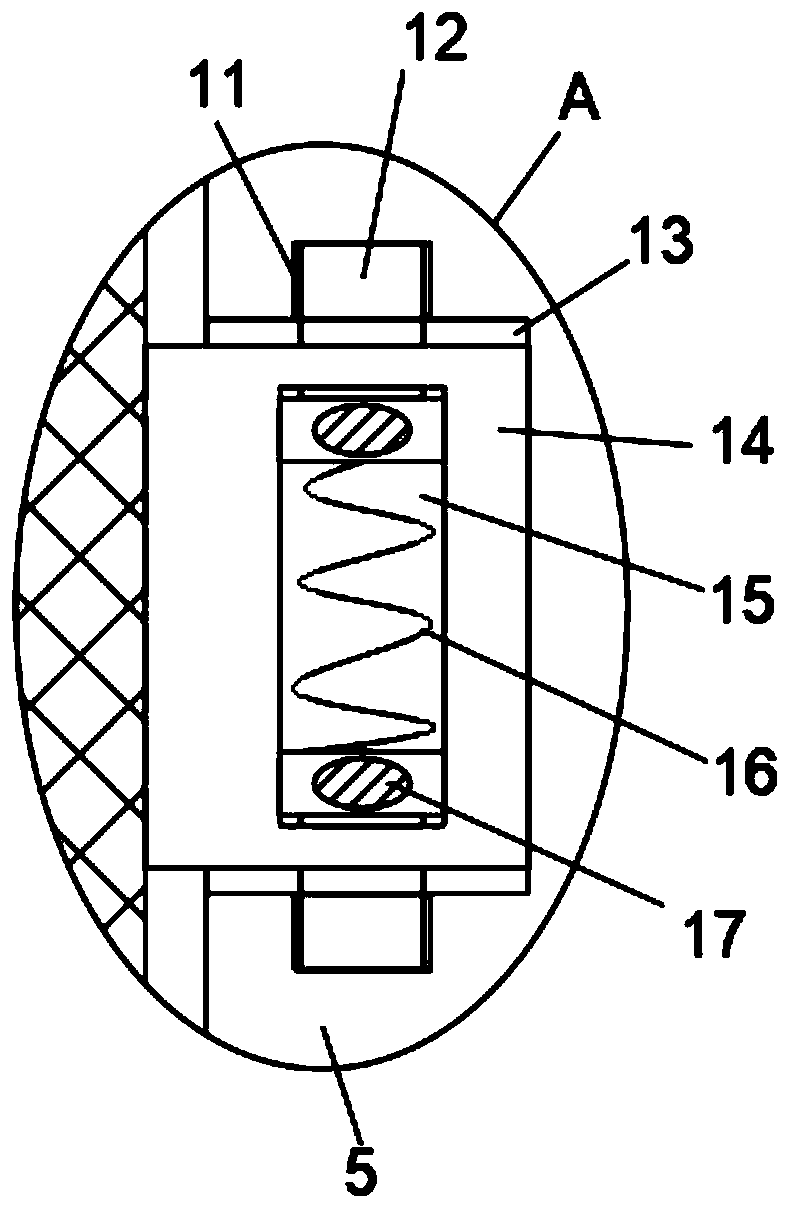

Vibrating equal-thickness flip-flow screen for multi-plastid activation

ActiveCN109453989AAvoid damageWith horizontal activationSievingScreeningEngineeringBiological activation

The invention discloses a vibrating equal-thickness flip-flow screen for multi-plastid activation. The flip-flow screen comprises an outer screen frame, a flip-flow body, an excitation device, a supporting frame, a T-shaped vibration isolation spring device and a screen plate, and the flip-flow body is fixedly arranged between two side plates of the outer screen frame to form a screen box; the excitation device is connected to the side face of the screen box through a main vibration spring; and the supporting frame and the outer screen frame are connected through the T-shaped vibration isolation spring device. The vibrating equal-thickness flip-flow screen for multi-plastid activation has the advantage that multi-plastid transverse vibration (which is beneficial to activating materials), equal-thickness screening and screen surface relaxation are achieved. The flip-flow screen only has transverse shearing dynamic load to the ground, a special vibration mode has a transverse activationeffect on materials, and the screening efficiency is high. The flip-flow screen surface makes the materials jump, and the hole blocking phenomenon is effectively eliminated. A motor is connected witha vibrating plastid small in amplitude, and the function of protecting the motor is achieved. The vibrating plastid and the screen box are flexibly connected through a plurality of sets of springs, sothat the stress of the whole structure is more reasonable.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Freezer segment for a freezer for confectionary with segments including channels for direct evaporation of CO.sub.2

ActiveUS8763420B2Increase capacityCross sectional areaDomestic cooling apparatusLighting and heating apparatusSaline waterEvaporation

The present invention concerns a freezer segment for a freezer of the type used for casting confectionery in molds which are cooled for freezing and subsequently supplied with heat for a short period, whereafter stripping occurs. Cooling of the molds is effected by using direct evaporation of CO2. The advantage of such a freezer segment is that there is no use for both a primary and a secondary cooling circuit. Another advantage in using a system according to the invention is that working with temperatures down to about minus 50° C. is enabled, compared to about minus 40° C. with brine systems. The low freezing temperature entails that the capacity of a given system is increased by about 40%.

Owner:GRAM EQUIP

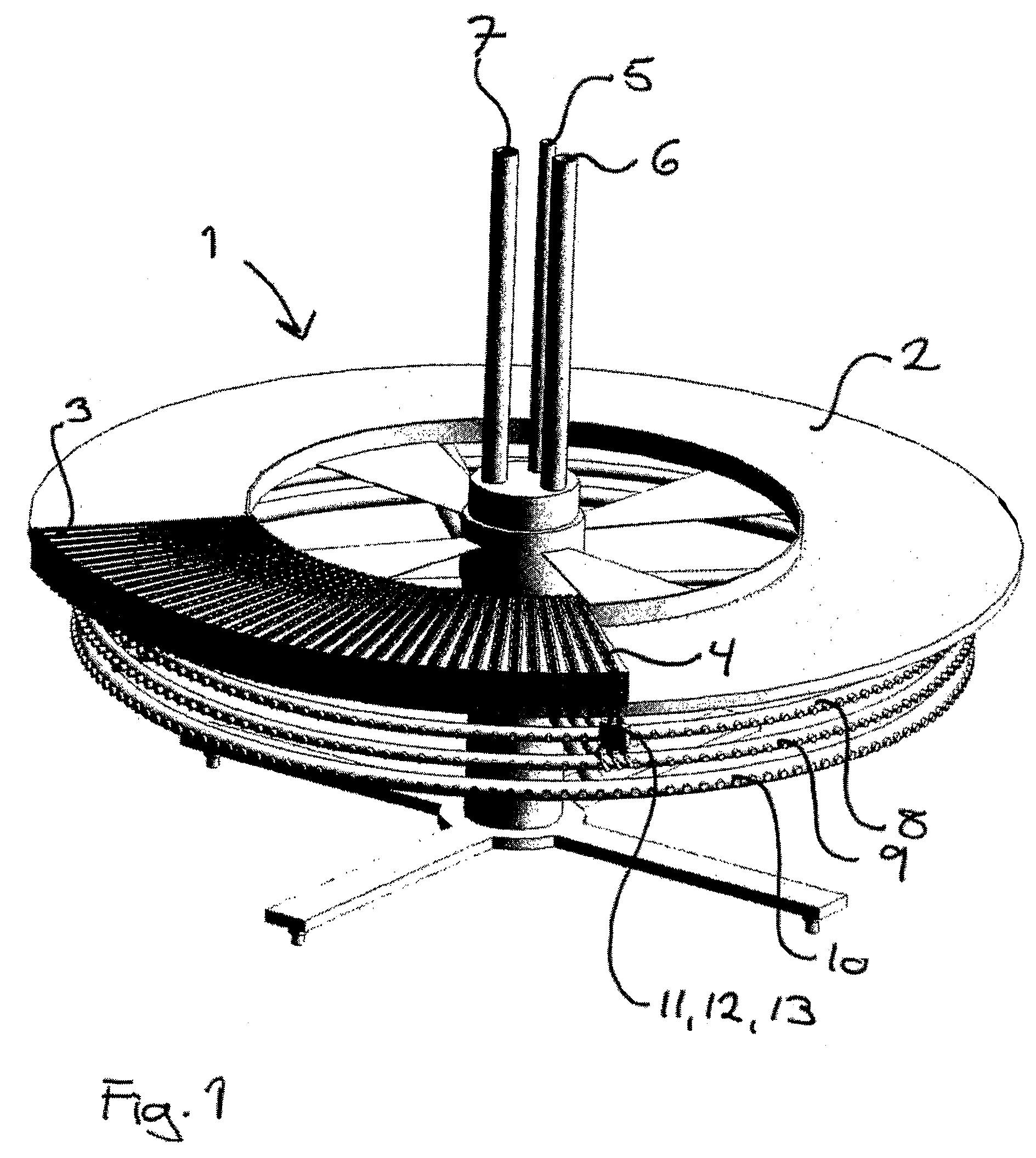

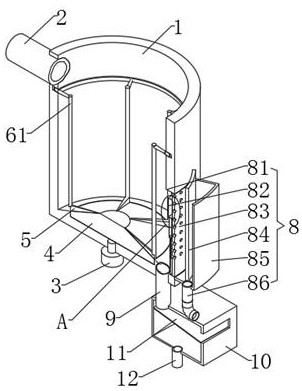

Petroleum separation device based on density separation method and separation method thereof

ActiveCN113617069AQuick layeringEasy dischargeLiquid degasificationLiquid separationWater dischargeElectric machine

The invention discloses a petroleum separation device based on a density separation method and a separation method of the petroleum separation device, and belongs to the technical field of petroleum exploitation. The petroleum separation device comprises a centrifugal barrel, the top of the centrifugal barrel is sleeved with a petroleum conveying pipe, and the bottom of the centrifugal barrel is sleeved with a rotating disc; a motor is arranged on the bottom surface of the centrifugal barrel, the motor is connected with the rotating disc, and a plurality of blades are arranged on the top surface of the rotating disc; a transmission mechanism is arranged between the top surfaces of the blades and the centrifugal barrel, the transmission mechanism is connected with a flushing mechanism, an oil collecting mechanism is arranged at the bottom of the centrifugal barrel, a bottom plate of the centrifugal barrel is sleeved with one end of a slag discharging pipe, the other end of the slag discharging pipe is sleeved with the top of one side of a water collecting tank, a filter plate is arranged in the water collecting tank, and a water discharging pipe is fixedly sleeved with the bottom of the water collecting tank. Petroleum enters the centrifugal barrel after being extracted, gas discharge and layering speed are accelerated through rotary centrifugation of the rotating disc, then an oil layer flows out through the oil collecting mechanism, a sediment layer and a water layer are discharged through the slag discharging pipe, the discharged water layer repeatedly flushes the centrifugal barrel through the transmission mechanism and the flushing mechanism, and self-cleaning is achieved.

Owner:江苏华普泰克石油装备有限公司

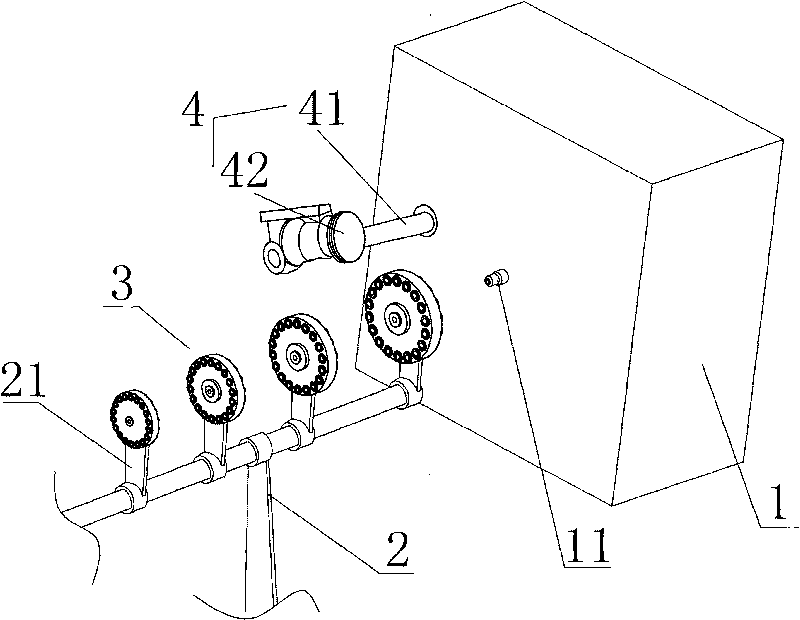

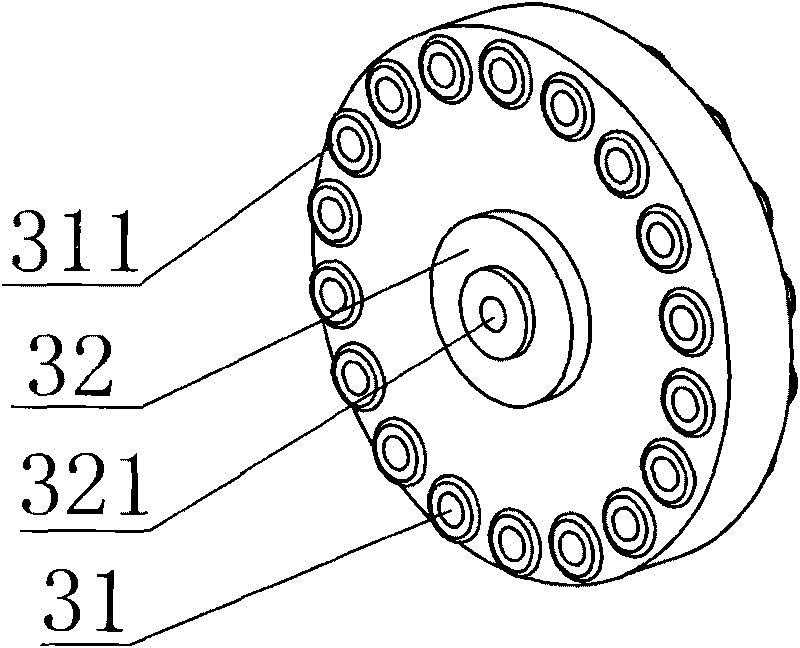

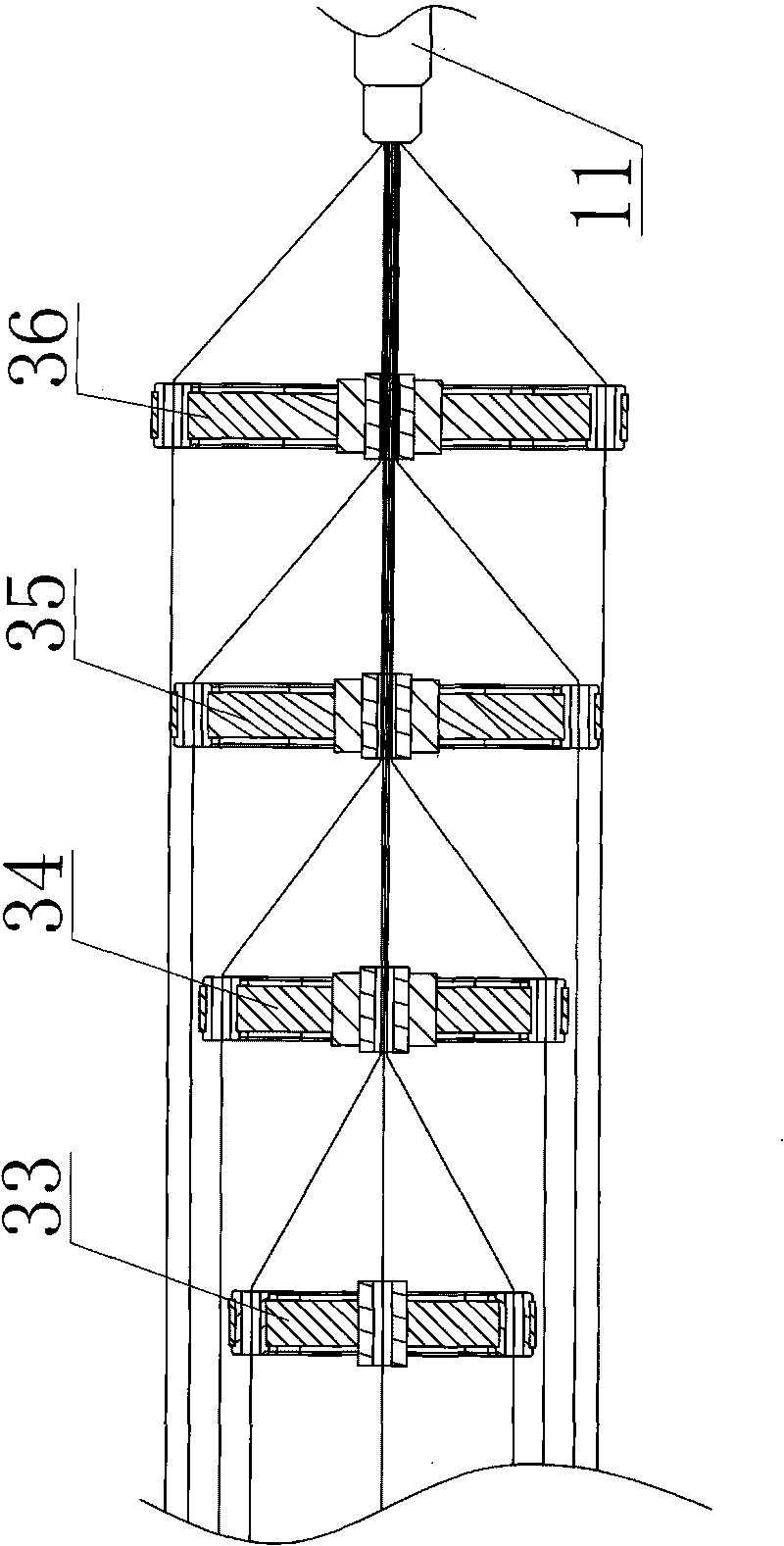

Multilayer and multi-strand wire twisting method and device implementing same

InactiveCN101728031AQuick layeringFast, even layeringCable/conductor manufactureEngineeringMechanical engineering

The invention discloses a multilayer and multi-strand wire twisting method. A device comprises a wire twisting machine and a bracket which is arranged at the wire twisting opening of the wire twisting machine. The method comprises the following steps: 1. preparing wire guide disks; 2. preparing wire guide holes; 3. preparing a wire collection hole; and 4. preparing a wire collection group: arranging the prepared wire guide disks in line according to the order from small radius to large radius and fixing the wire guide disks on the bracket, wherein the wire guide disk with the largest radius is arranged close to one end of the wire twisting opening of the wire twisting machine. The method provided by the invention can rapidly and uniformly twist and joint the multilayer and multi-strand wires of the same type or of different types in multiple layers. The device provided by the invention is simple in structure and convenient in operation and can automatically twist and joint the multilayer and multi-strand wires of the same type or of different types in multiple layers by only starting the wire twisting machine, thus greatly reducing the labor intensity, ensuring the product quality and being beneficial to improving the enterprise competitiveness.

Owner:LINOYA ELECTRONIC TECHNOLOGY CO LTD +1

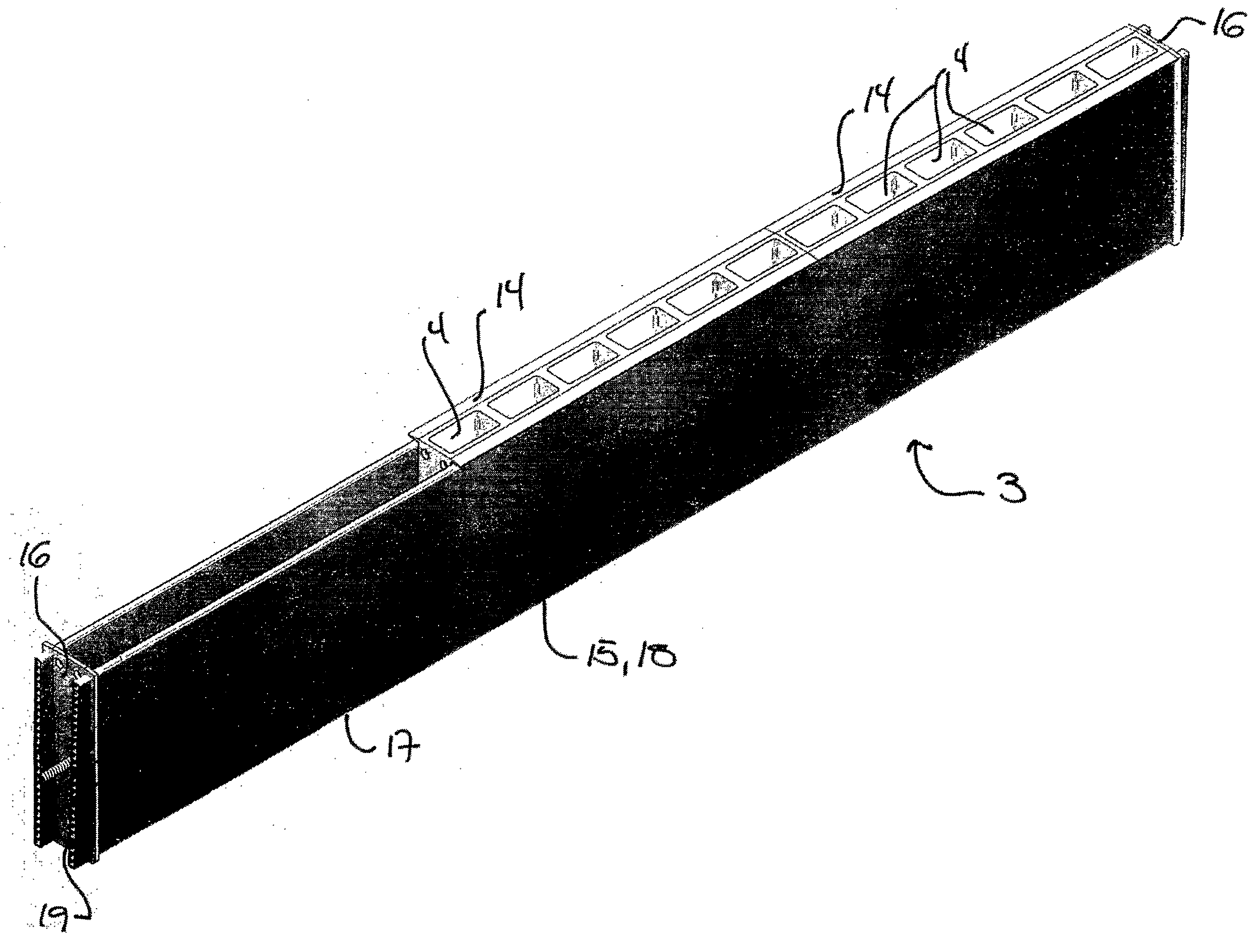

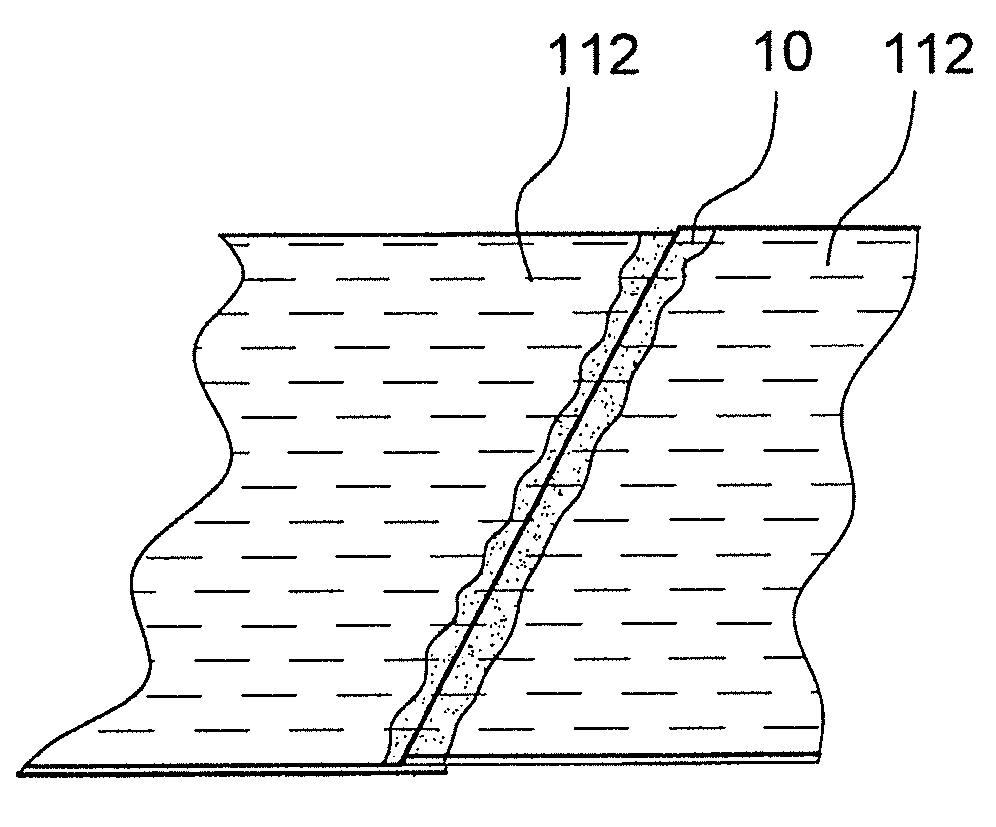

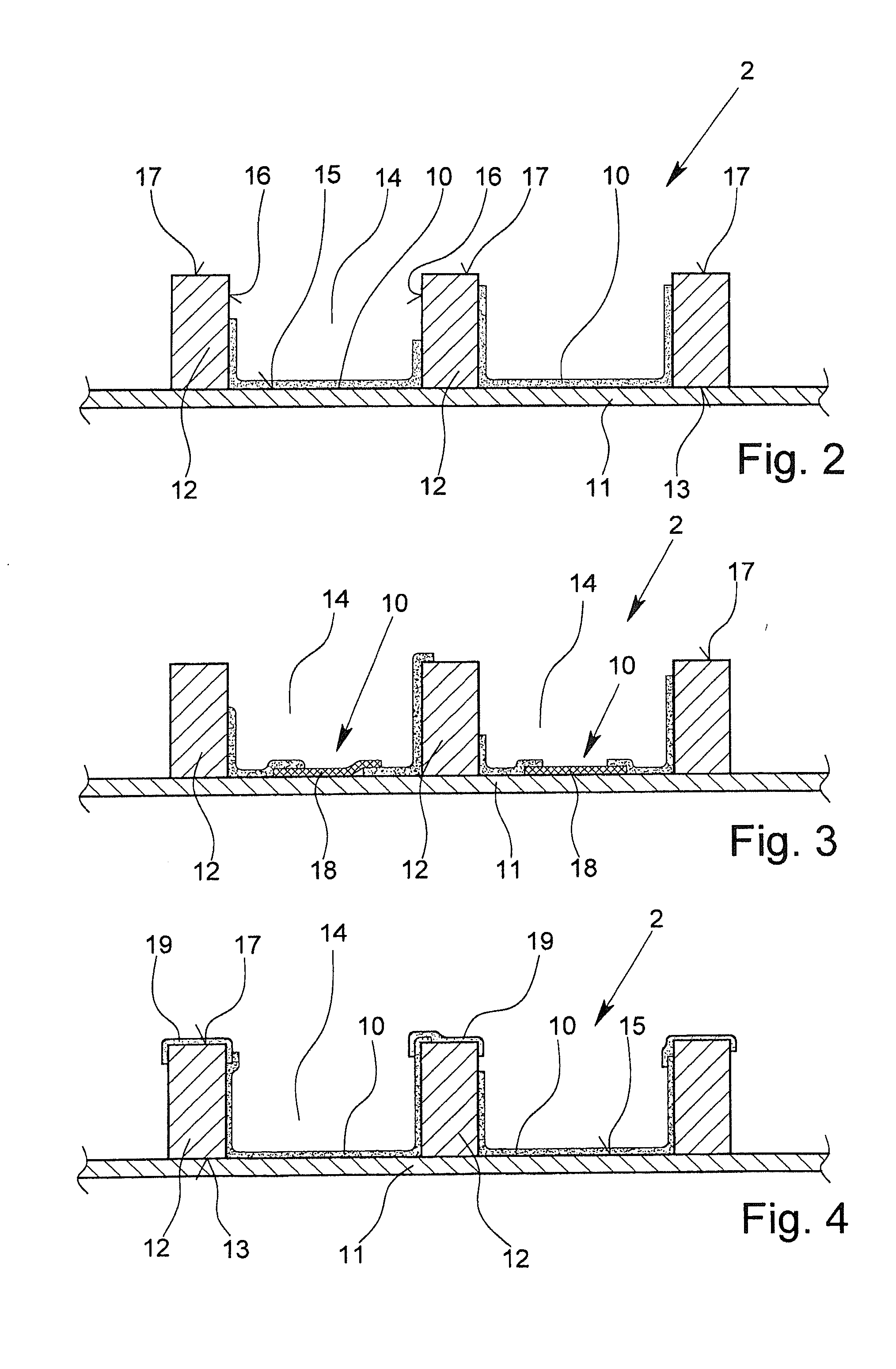

Method for Producing a Functional Layer of a Building Shell, and Building Shell and Functional Layer

ActiveUS20120055110A1Seal is necessaryQuick layeringRoof coveringBuilding repairsVapor barrierArchitectural engineering

A method for the production of a functional layer of a building shell (2), whereby the building shell (2) has a sheathing (11) on the inside of the building and a large number of rafters (12) with roof bays (14) provided between the rafters (12) and the sheathing (11). It is provided, in this case, that the functional layer is applied at least in some places by painting and / or spraying on the outside (15) of the sheathing (11), and an air-tight and / or water-tight foil (10), made especially as a vapor barrier, forms after application.

Owner:EWALD DORKEN

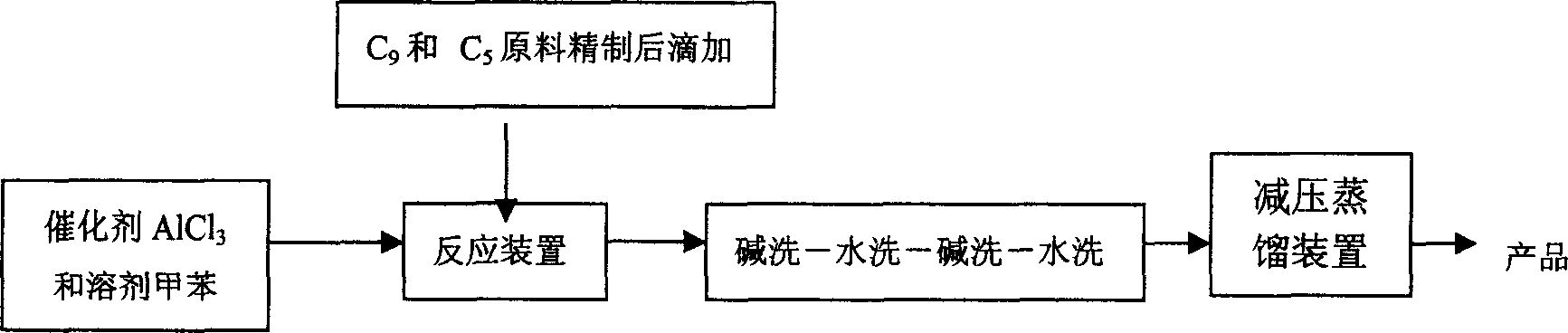

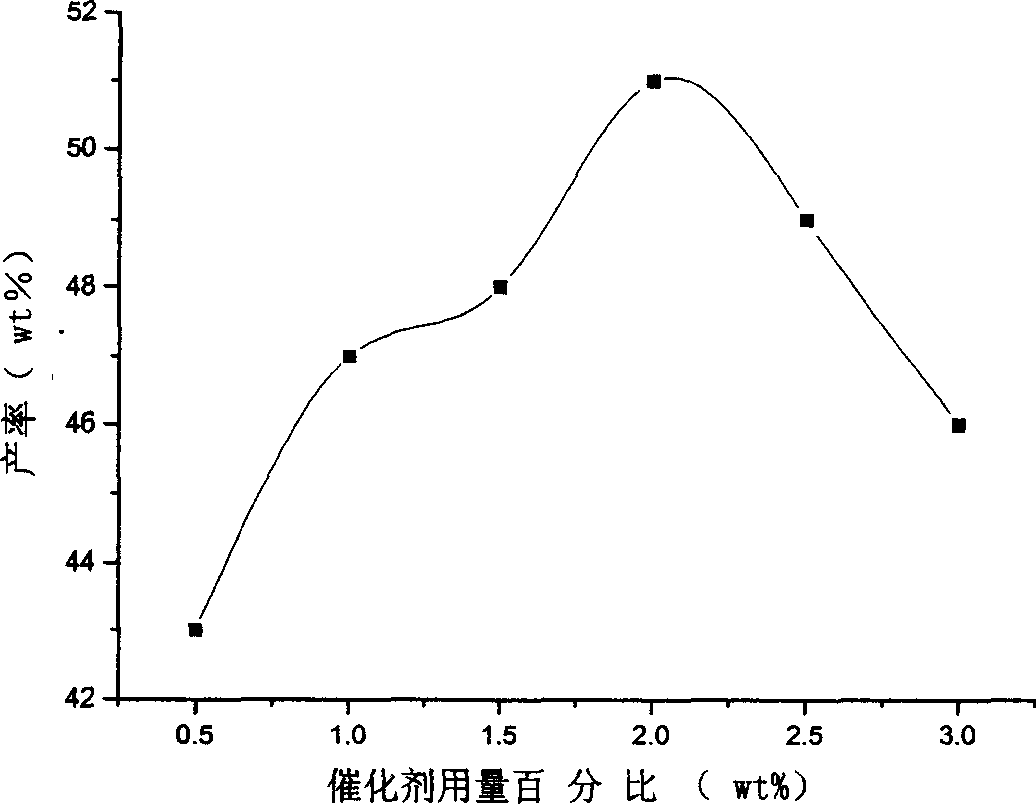

C5íóC9 copolymerized petroleum resin preparation method

Disclosed is a process for preparing C9 modified C5 petroleum resin, which comprises using C5 as the main raw material, using C9 as the modifying raw material, charging C9 active fraction into C5 active fraction, preparing C9 modified C5 petroleum resin, using AlCl3 as catalyst for copolymerizing C5, C9 petroleum resin.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

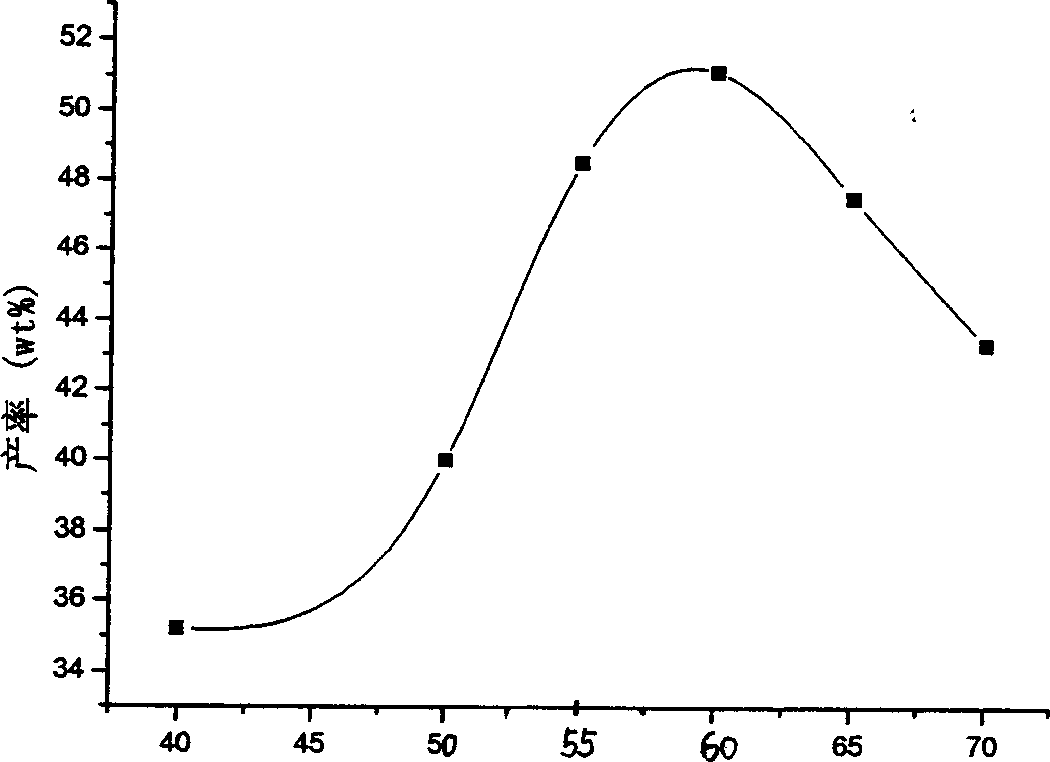

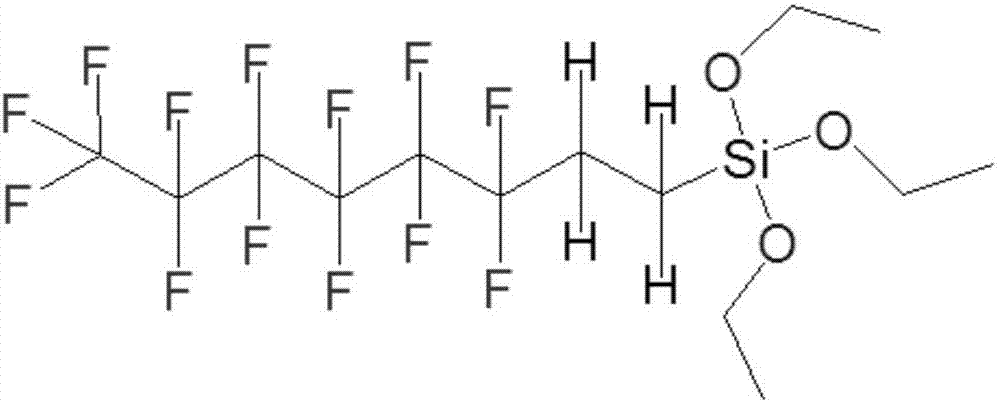

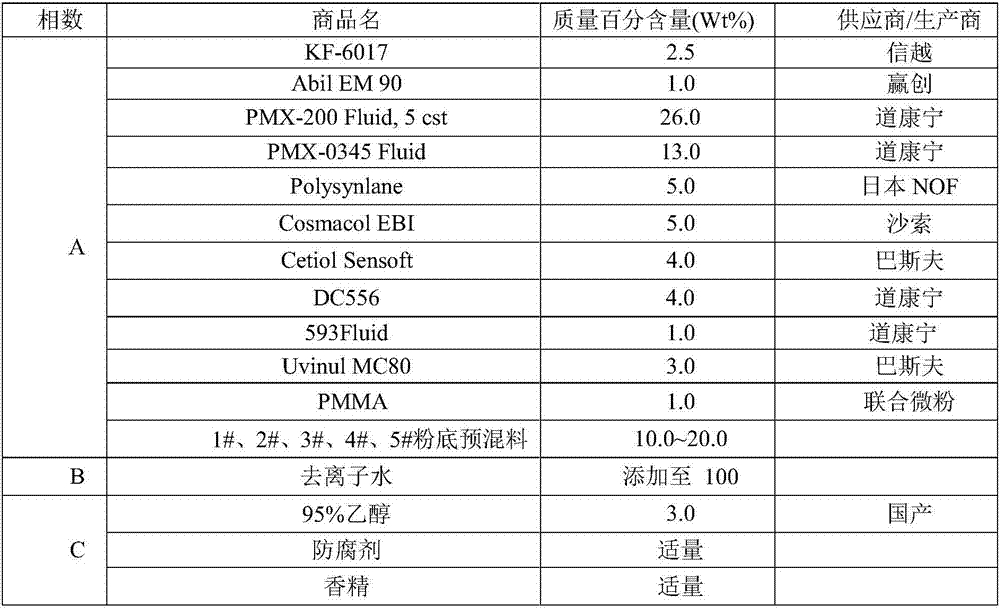

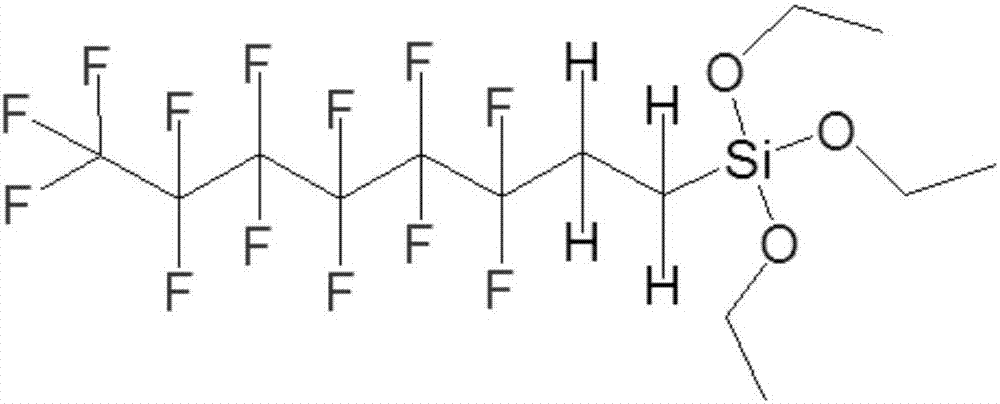

Liquid foundation with rapid layering and redispersion properties and preparation method thereof

InactiveCN106901992AQuick layeringRapid DispersionCosmetic preparationsMake-upWater in oilTitanium dioxide

The invention discloses a liquid foundation with rapid layering and redispersion properties and a preparation method thereof. The liquid foundation with the rapid layering and redispersion properties comprises a premix which is added at a weight percentage of 10%-20%. The preparation method of the premix comprises performing uniform surface treatment on inorganic powder of titanium dioxide and ferric oxide through perfluorooctyl triethoxysilane surface treating agent, wherein the perfluorooctyl triethoxysilane surface treating agent is, by weight, 1%-12% of the total weight of the inorganic powder of titanium dioxide and ferric oxide. The liquid foundation with the rapid layering and redispersion properties is a water-in-oil agent and accordingly can provide light skin feeling, achieve high water-resistance and avoid makeup meltdown, and meanwhile, can eliminate the risk of instability and enhance product utilization interestingness.

Owner:SCIENCOO BIOLOGICAL TECH CO LTD

Method for producing an Anti-corrosion coating for hardenable sheet steels and an Anti-corrosion coating for hardenable sheet steels

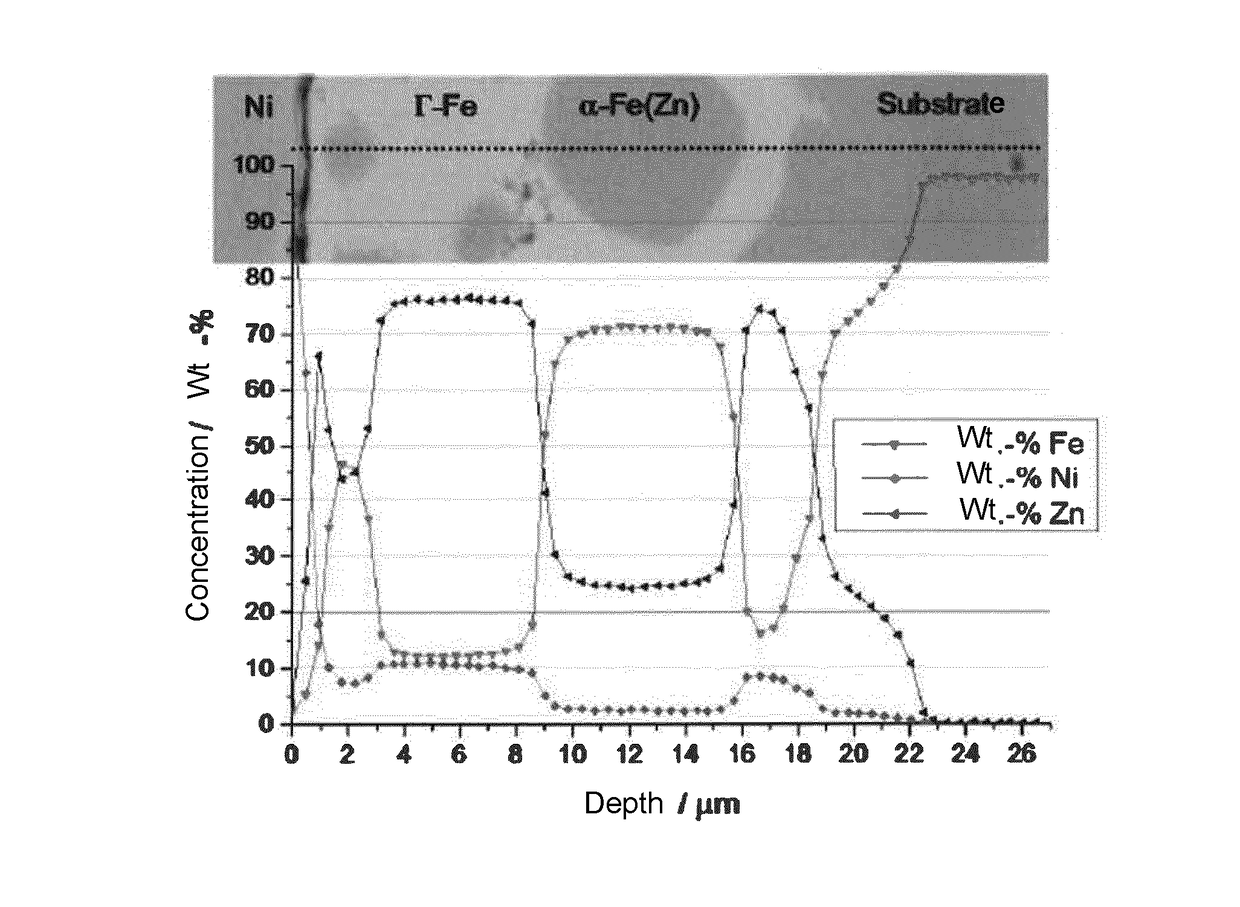

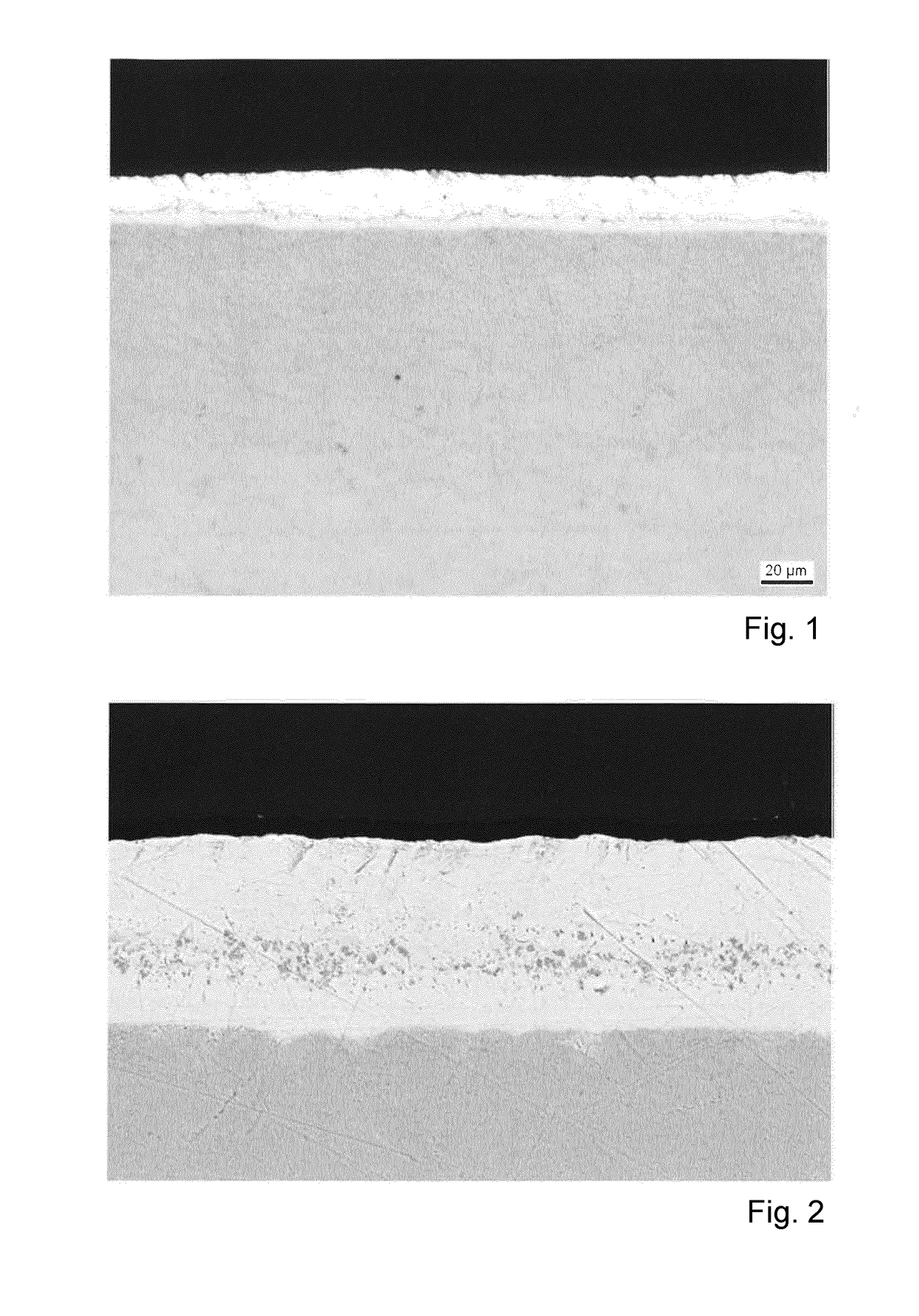

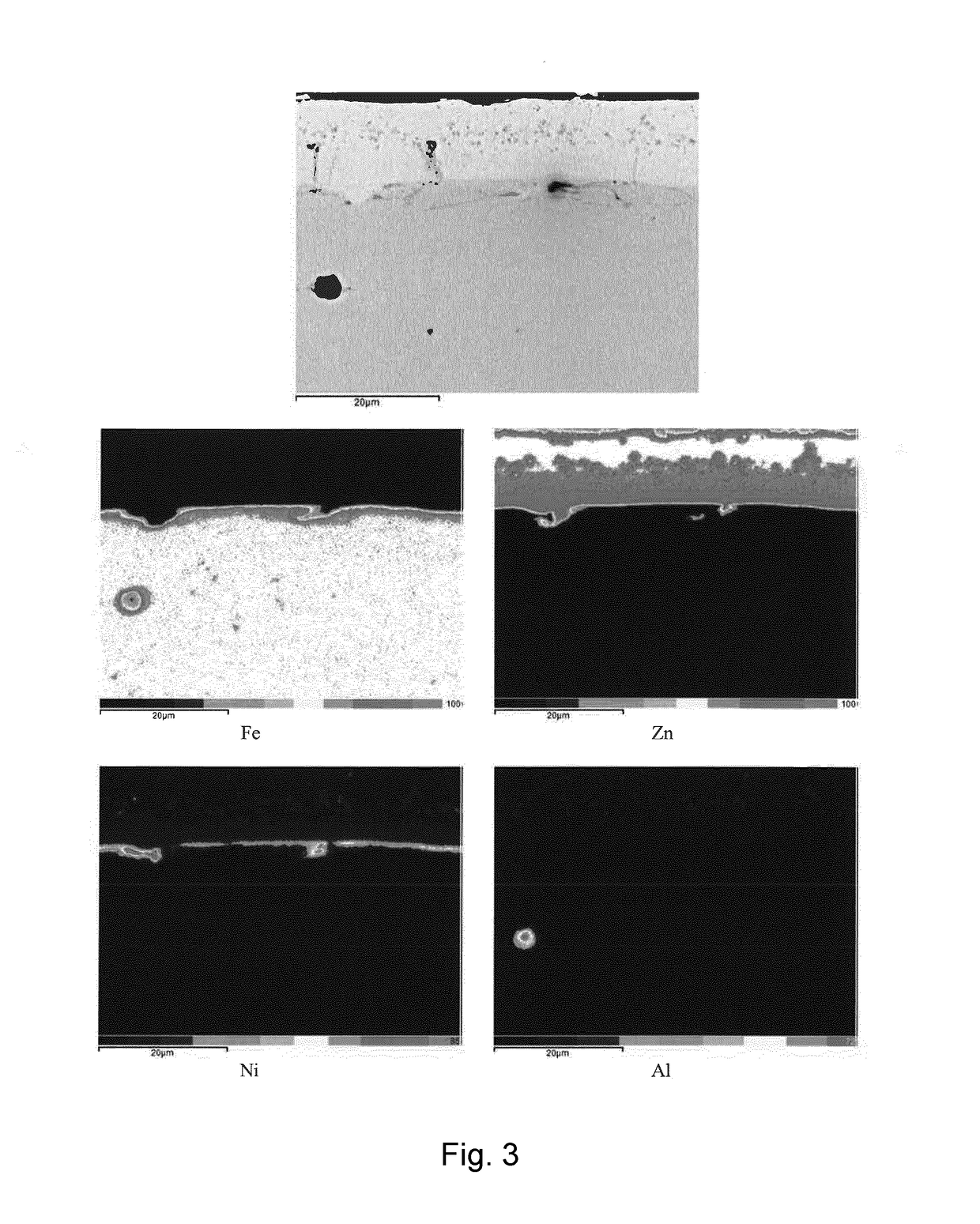

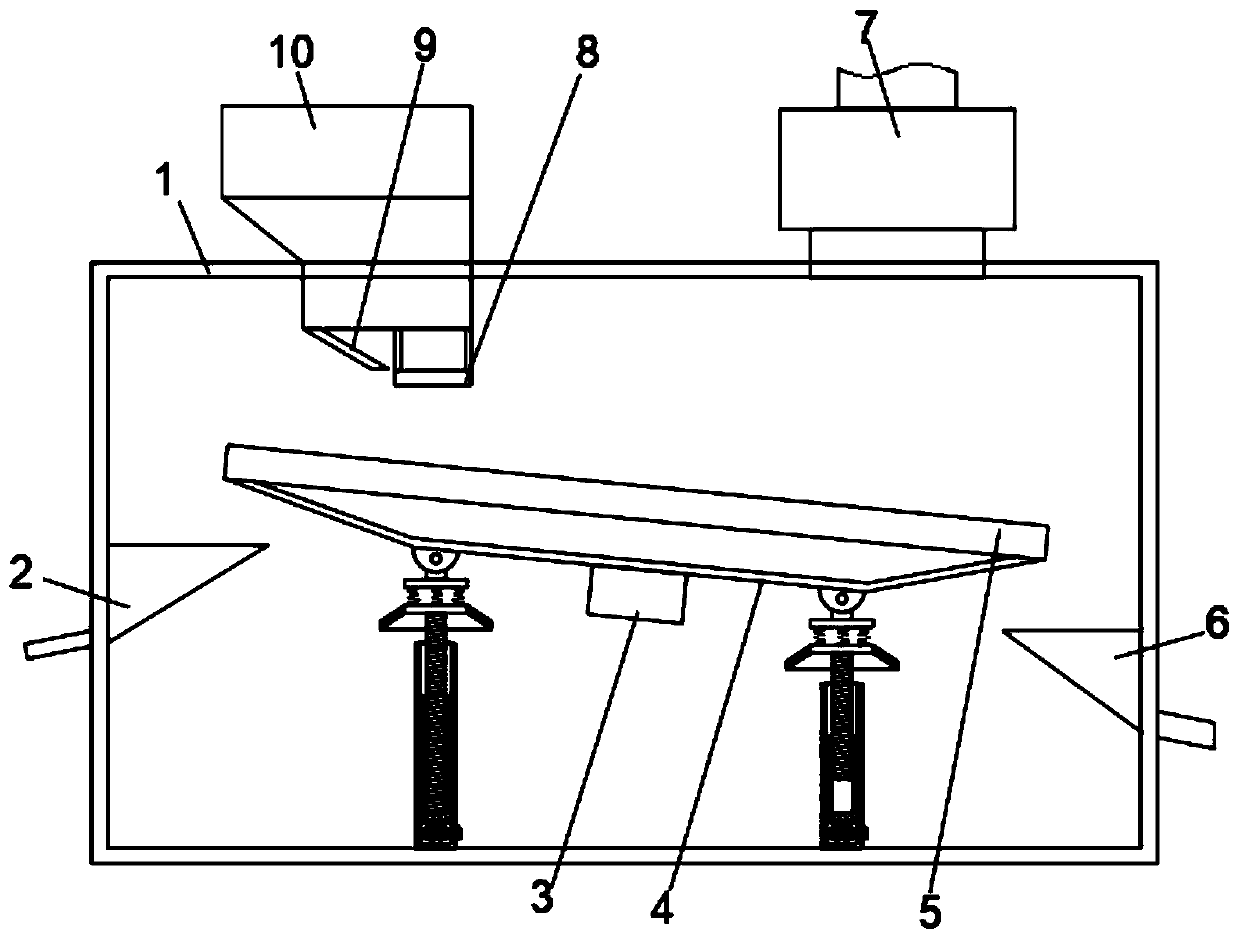

InactiveUS20170321314A1Reduction of formationHigh melting pointHot-dipping/immersion processesFurnace typesSheet steelZinc

The invention relates to a method for producing an anti-corrosion coating for hardenable sheet steels, wherein at least two metal layers are deposited one after another onto the steel substrate; the one metal layer is a zinc layer or zinc-based layer and the other layer is a layer composed of a metal that forms baser intermetallic phases with Zn or Fe and has a higher oxidation potential than Zn, namely Ni, Cu, Co, Mn, or Mo, or a layer based on these metals; and an anti-corrosion coating for hardenable sheet steels.

Owner:VOESTALPINE STAHL GMBH

Raw material stone removing device for feed production

ActiveCN110394299AEffective stone removalGuaranteed stone removal effectSievingFeeding-stuffFixed frameEngineering

The invention belongs to the field of feed production, and particularly relates to a raw material stone removing device for the feed production. The problems that material distribution is not uniformduring using an existing stone removing machine, materials are easy to be accumulated on a sieve, the separation efficiency is low, the inclination angle of the sieve is not adjustable and the applicability is poor are solved. According to a scheme, the device comprises a box body, wherein a mounting frame is arranged in the box body, the mounting frame is obliquely arranged, a fixing frame is fixedly connected to the lower end of the mounting frame, a supporting mechanism is connected to the lower end of the fixing frame, a sieve vibrating mechanism is arranged on the inner side of the mounting frame, and a vibrating motor is fixedly arranged at the lower end of the fixing frame. According to the device, the inclination angle of the sieve surface can be flexibly and conveniently adjusted,effective stone removal can be performed on feed with different weight ratios, the effect of stone removal is guaranteed, the feed and the stone are more quickly layered, so that the stone removal efficiency is improved, and the stone removal effect is improved.

Owner:徐州德诚饲料有限责任公司

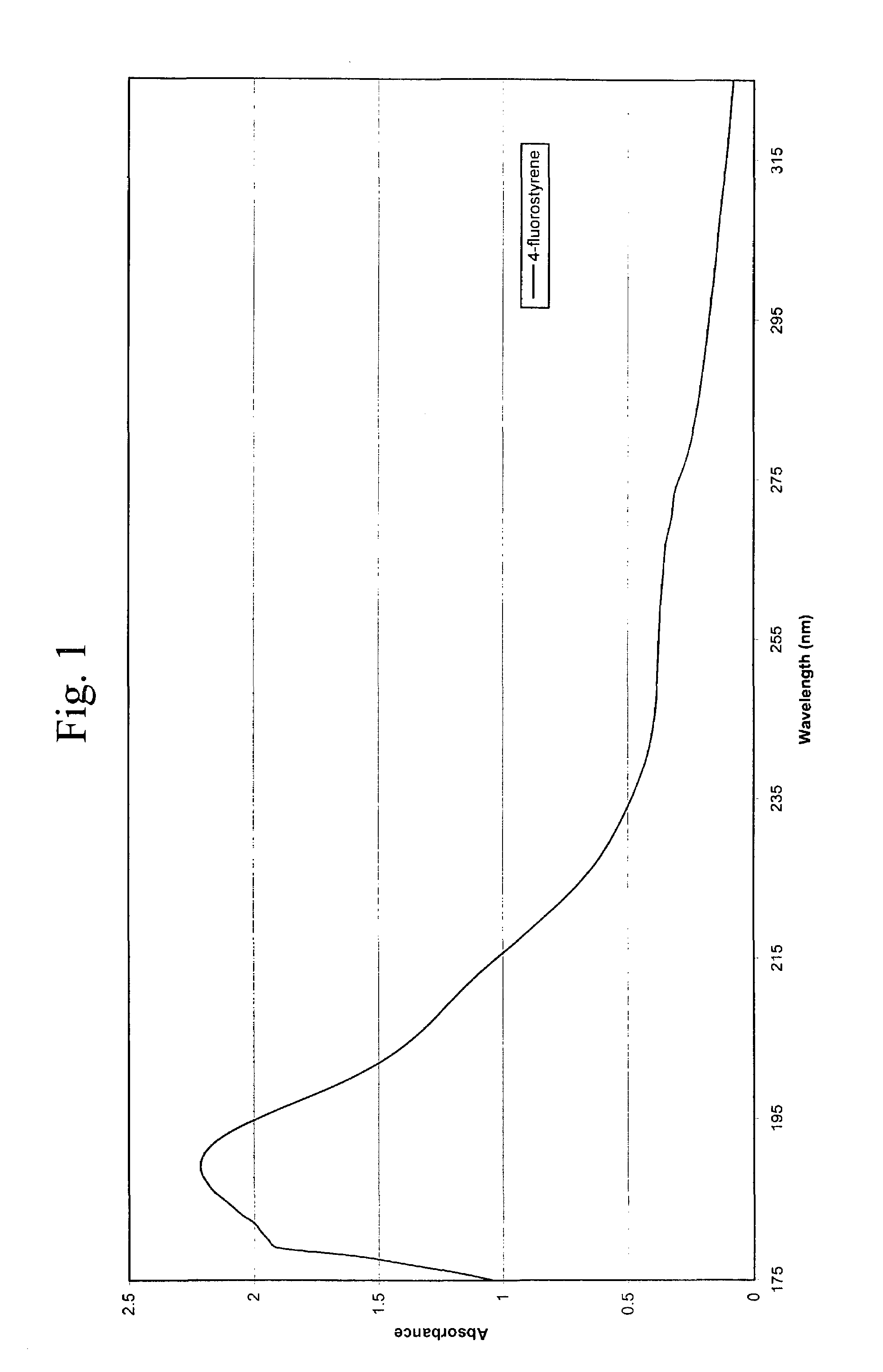

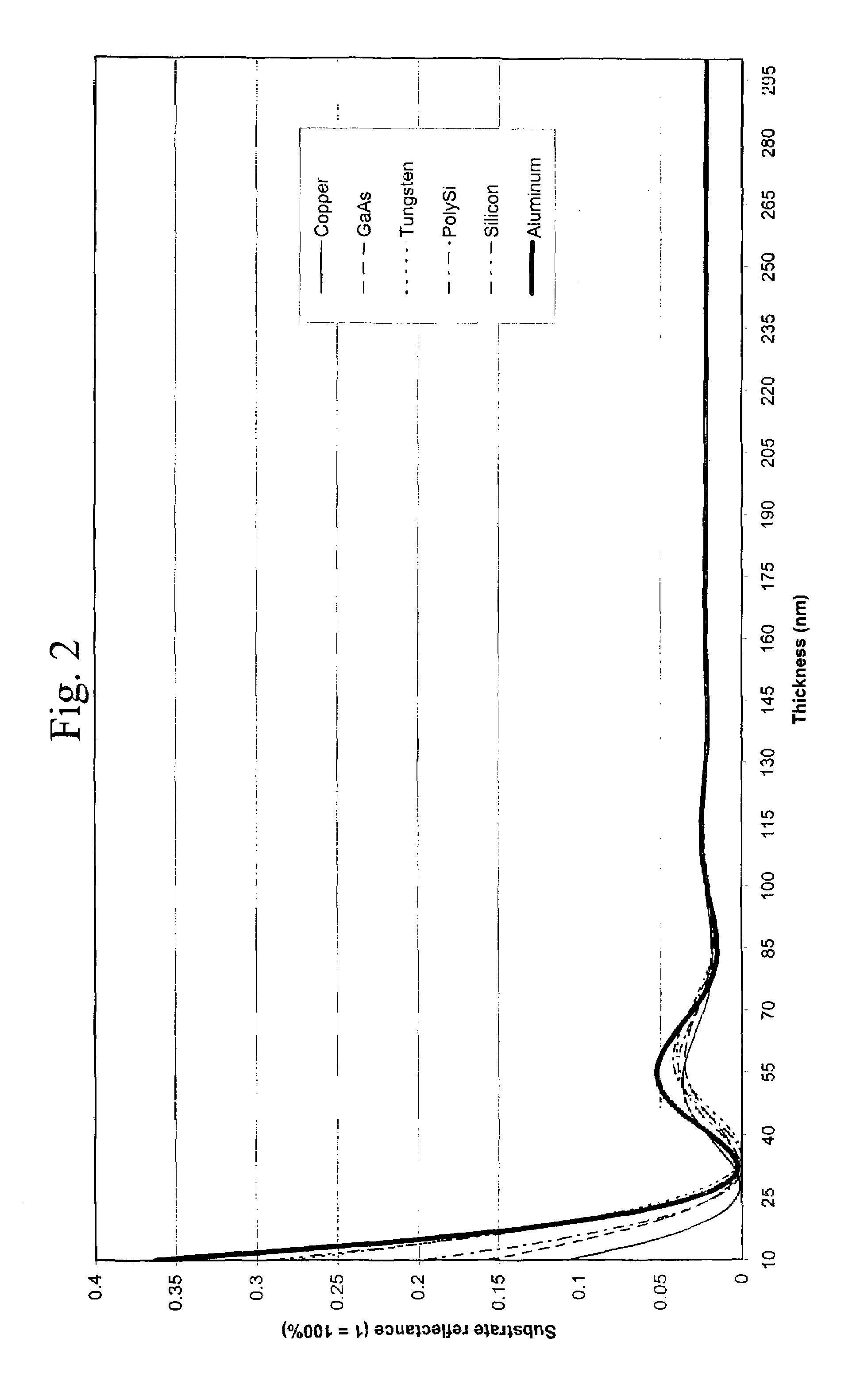

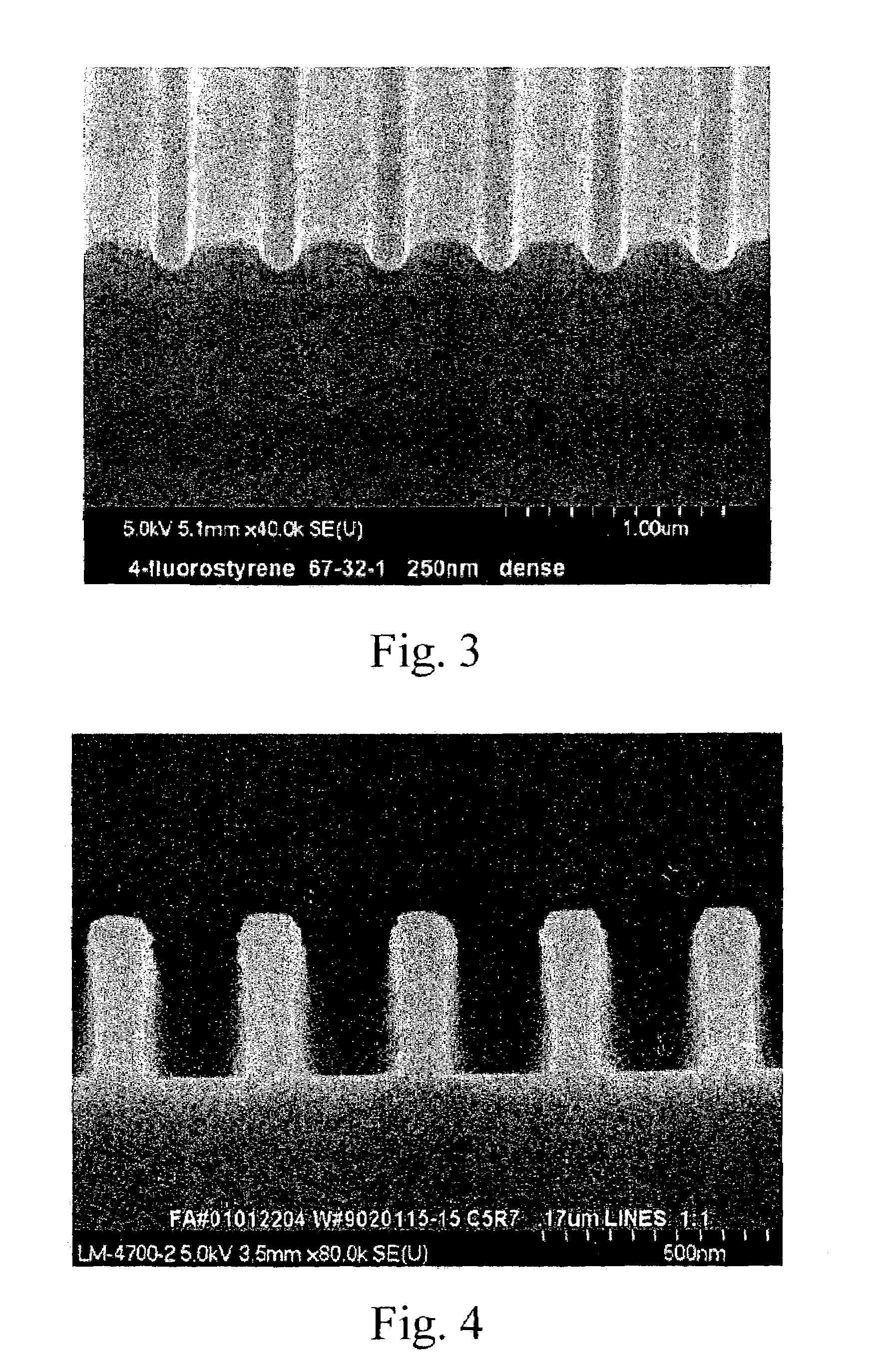

Polymeric antireflective coatings deposited by plasma enhanced chemical vapor deposition

InactiveUS7132219B2Negative effectReduce wastePhotosensitive materialsVacuum evaporation coatingGas phaseMonomer

An improved method for applying polymeric antireflective coatings to substrate surfaces and the resulting precursor structures are provided. Broadly, the methods comprise plasma enhanced chemical vapor depositing (PECVD) a polymer on the substrate surfaces. The most preferred starting monomers are 4-fluorostyrene, 2,3,4,5,6-pentafluorostyrene, and allylpentafluorobenzene. The PECVD processes comprise subjecting the monomers to sufficient electric current and pressure so as to cause the monomers to sublime to form a vapor which is then changed to the plasma state by application of an electric current. The vaporized monomers are subsequently polymerized onto a substrate surface in a deposition chamber. The inventive methods are useful for providing highly conformal antireflective coatings on large surface substrates having super submicron (0.25 μm or smaller) features. The process provides a much faster deposition rate than conventional chemical vapor deposition (CVD) methods, is environmentally friendly, and is economical.

Owner:BREWER SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com