Liquid foundation with rapid layering and redispersion properties and preparation method thereof

A technology of redispersion and liquid foundation, applied in the field of water-in-oil type, liquid foundation and preparation thereof, can solve the problems of inability to satisfy the refreshing skin feeling at the same time, inability to apply makeup evenly, and difficult to adjust the stability, so as to eliminate the risk of instability. , The skin feels moist, light and no burden, and the effect of adding interest to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

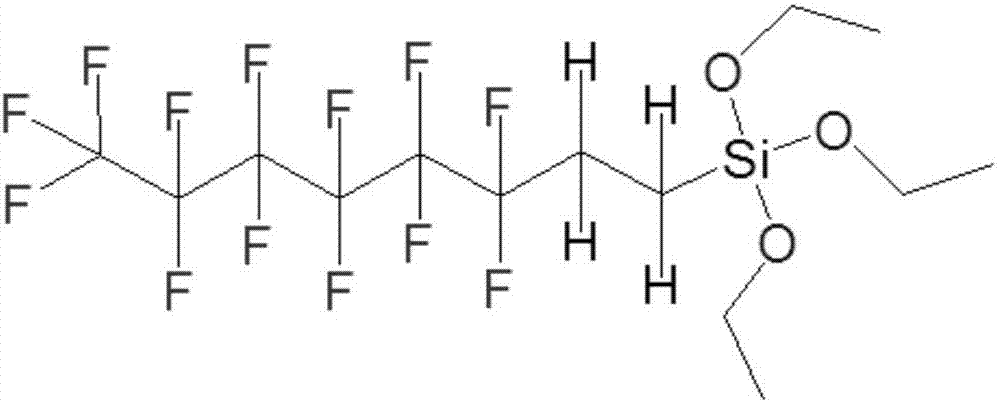

[0031] Mix 15g of perfluorooctyltriethoxysilane with 95% alcohol at a ratio of 1:1 to prepare a composite surface treatment solution, ready to use.

[0032] Add 900g of titanium dioxide, 70g of iron oxide yellow, 22g of iron oxide red, and 8g of iron oxide black into the high-speed mixer. Under high-speed stirring, spray the pre-prepared composite surface treatment liquid into the high-speed mixer through the oil spray tank. Stir well to make the reaction solution and the inorganic powder mix evenly.

[0033] The powder is discharged, immediately sent to an oven, baked at 105°C for 4 hours, cooled naturally and discharged to obtain 1# foundation premix.

Embodiment 2

[0035] Mix 30g of perfluorooctyltriethoxysilane with 95% alcohol evenly at a ratio of 1:1 to prepare a composite surface treatment solution, ready to use.

[0036] Add 900g of titanium dioxide, 70g of iron oxide yellow, 22g of iron oxide red, and 8g of iron oxide black into the high-speed mixer. Under high-speed stirring, spray the pre-prepared composite surface treatment liquid into the high-speed mixer through the oil spray tank. Stir well to make the reaction solution and the inorganic powder mix evenly.

[0037] The powder is discharged, immediately sent to an oven, baked at 105°C for 4 hours, cooled and discharged naturally, and the 2# foundation premix is obtained.

Embodiment 3

[0039] Mix 45g of perfluorooctyltriethoxysilane with 95% alcohol at a ratio of 1:1 to prepare a composite surface treatment solution, ready to use.

[0040] Add 900g of titanium dioxide, 70g of iron oxide yellow, 22g of iron oxide red, and 8g of iron oxide black into the high-speed mixer. Under high-speed stirring, spray the pre-prepared composite surface treatment liquid into the high-speed mixer through the oil spray tank. Stir well to make the reaction solution and the inorganic powder mix evenly.

[0041] The powder is discharged, immediately sent to an oven, baked at 105°C for 4 hours, cooled naturally and discharged to obtain 3# foundation premix.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com