Multilayer and multi-strand wire twisting method and device implementing same

A multi-stranded wire and stranded wire technology, which is applied in the manufacturing of electrical components, circuits, cables/conductors, etc., can solve the problems of unsatisfactory splicing effect, inability to splicing wires in layers, and difficulty in ensuring product quality, etc. Achieve the effect of improving the competitiveness of enterprises, simple structure and low friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

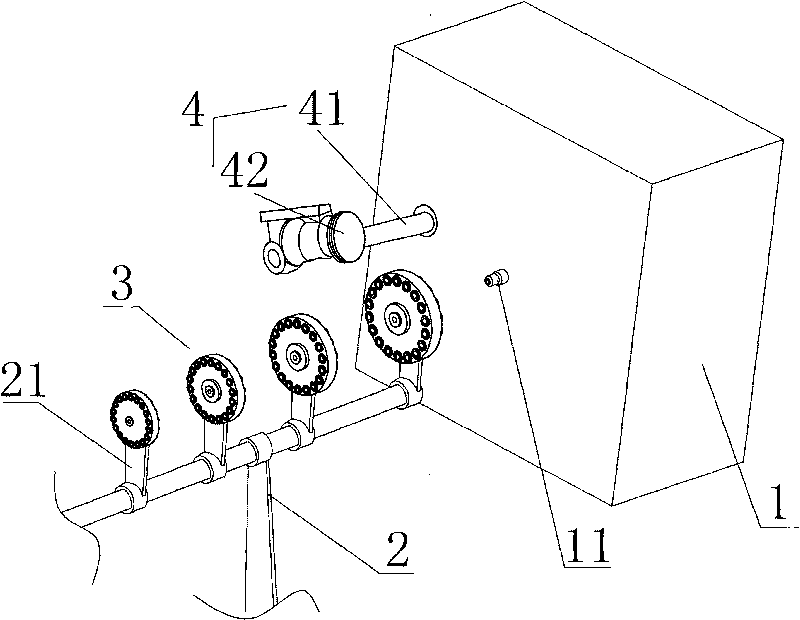

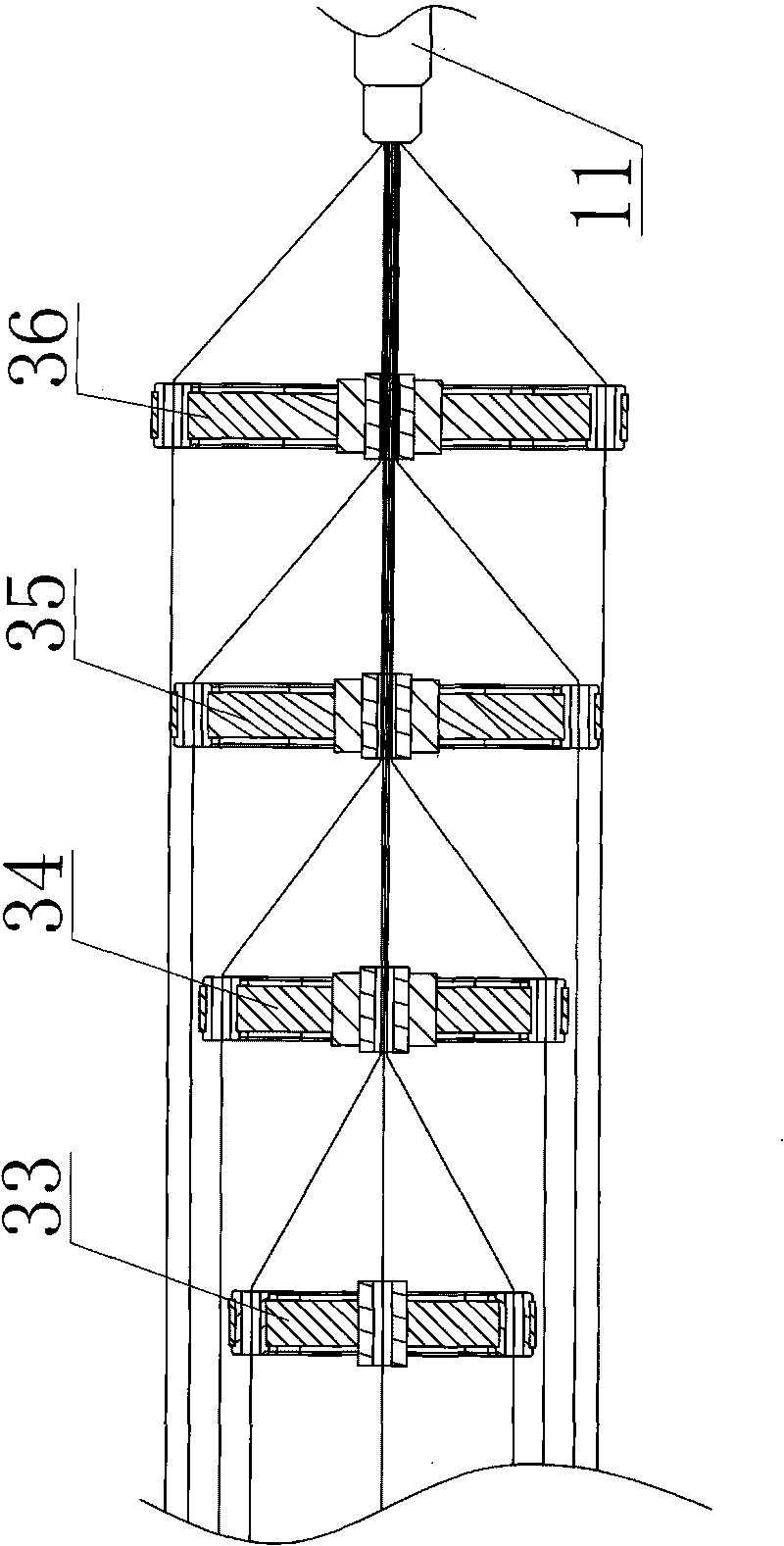

[0032] Example: see figure 1 , figure 2 and image 3 , a kind of multi-layer twisted wire method that the embodiment of the present invention provides, it comprises a twisting machine 1 and a support 2, and this support 2 is arranged near the twisting wire opening 11 place of described twisting machine 1, and it comprises Follow the steps below:

[0033] (1) Prepare the wire reel, select a plate-shaped metal body, because of the need to produce five layers of multi-strand twisted wires, four discs with different radii are cut and processed. In other embodiments, according to the required twisted wires The number of layers, correspondingly cutting and processing a corresponding number of discs with different radii;

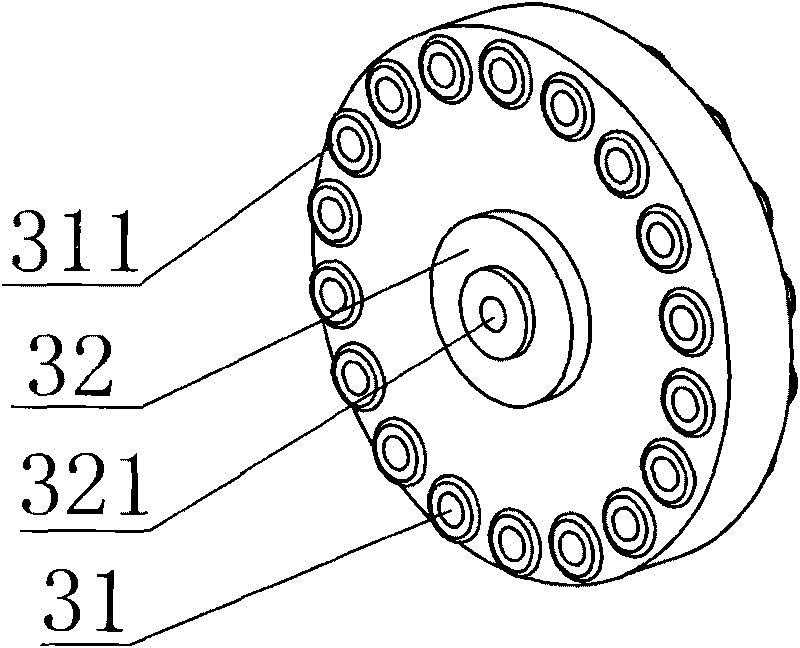

[0034] (2) prepare wire holes 31, according to the number of core wire strands in a certain layer of required stranded wires corresponding to the disk, correspondingly drill out the corresponding number of wire holes 31, the wire holes 31 are evenly and spaced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com