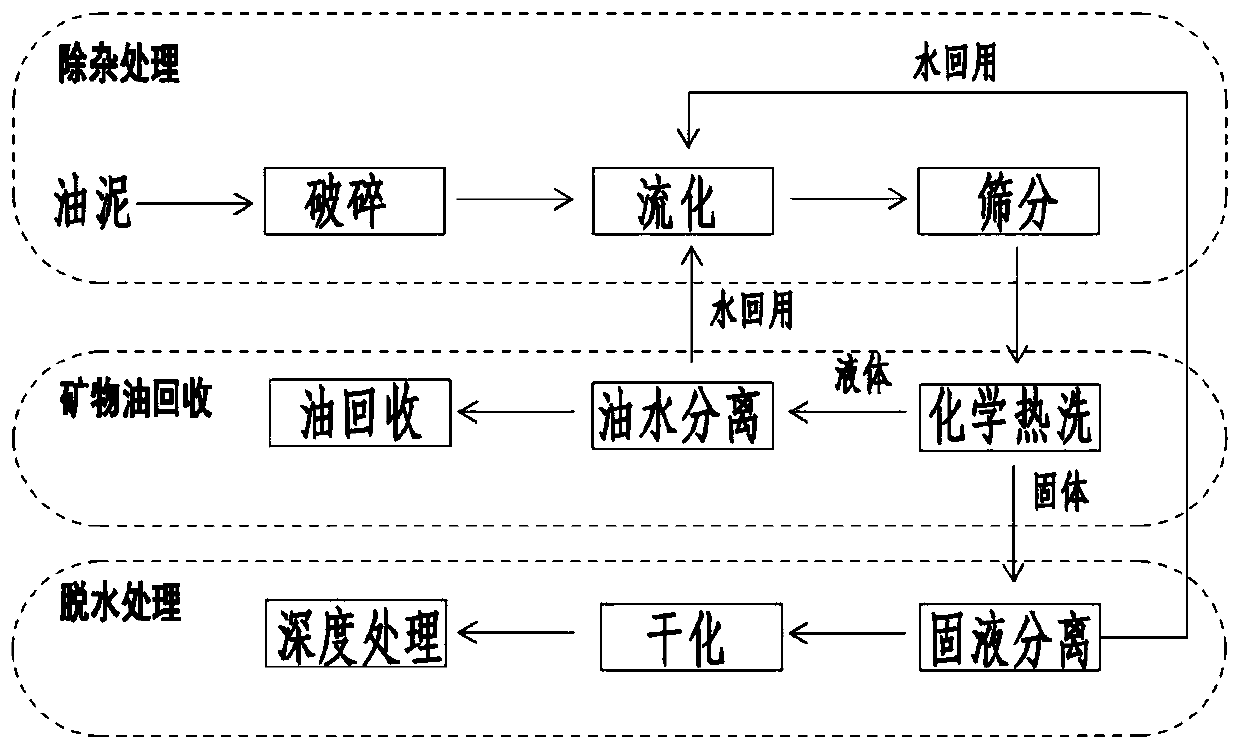

Oily sludge recycling and reduction treatment method and system

A treatment method and technology of a treatment system, which are applied in the field of oily sludge recycling and reduction treatment methods and treatment systems, can solve the problem of wasting heat energy of petroleum resources, high oil content and water content of oily sludge, limited treatment capacity, etc. problem, to achieve the effect of resource utilization and reduction, low mud water content, and high oil recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

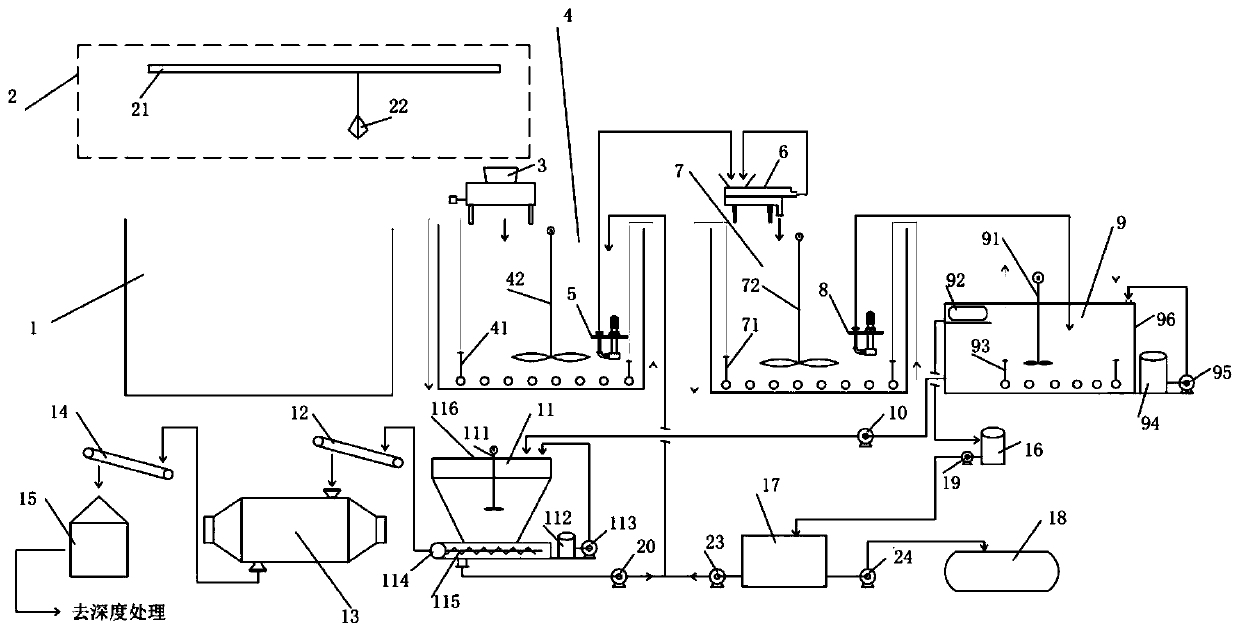

example 1

[0044] Taking the oily sludge from an oil field as the treatment object, its water content is 34%, oil content is 55%, and the soil particle size is less than 12mm. After the oily sludge is crushed, fluidized, screened and impurity removed according to the method of the present invention, chemical heat washing is carried out. The heat washing agent is a composition of sodium silicate and NP-10, and the dosage is 1% and 0.5% of the weight of the oil sludge respectively. %, the recovery rate of crude oil after cleaning is 92%, and the deoiled mud is dehydrated by a solid-liquid separator and a paddle dryer, and the moisture content of the sludge is reduced to 24%.

example 2

[0046] Taking the oily sludge at the bottom of an oilfield as the treatment object, its water content is 30%, oil content is 61%, and the soil particle size is less than 5mm. The oily sludge is subjected to chemical heat washing after crushing, fluidization, screening and impurity removal according to the method of the present invention. The heat washing agent is a composition of sodium silicate, sodium carbonate and cardanol polyoxyethylene ether, and the dosage is respectively 0.5%, 0.5% and 0.5% of the mass, the recovery rate of crude oil after cleaning is 89%, and the deoiled mud is dehydrated by a solid-liquid separator and a paddle dryer, and the moisture content of the sludge is reduced to 26%.

example 3

[0048] Taking the refining oily sludge of a petroleum refining enterprise as the treatment object, its moisture content is 89%, oil content is 10%, and the soil particle size is less than 5mm. The oily sludge is subjected to chemical heat washing after crushing, fluidization, screening and impurity removal according to the method of the present invention. The heat washing agent is a composition of sodium silicate and SP169, and the dosage is 1% and 0.5% of the weight of the oil sludge respectively. , The recovery rate of crude oil after cleaning is 92%, and the deoiled mud is dehydrated by a solid-liquid separator and a paddle dryer, and the moisture content of the sludge is reduced to 25%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com