Patents

Literature

968 results about "Cardanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

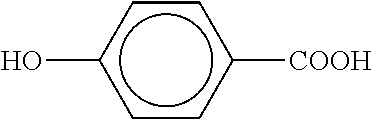

Cardanol is a phenolic lipid obtained from anacardic acid, the main component of cashew nutshell liquid (CNSL), a byproduct of cashew nut processing. Cardanol finds use in the chemical industry in resins, coatings, frictional materials, and surfactants used as pigment dispersants for water-based inks. It is used to make phenalkamines, which are used as curing agents for the durable epoxy coatings used on concrete floors. The name of the substance is derived by contraction from the genus Anacardium, which includes the cashew tree, Anacardium occidentale. The name of the genus itself is based on the Greek word for heart.

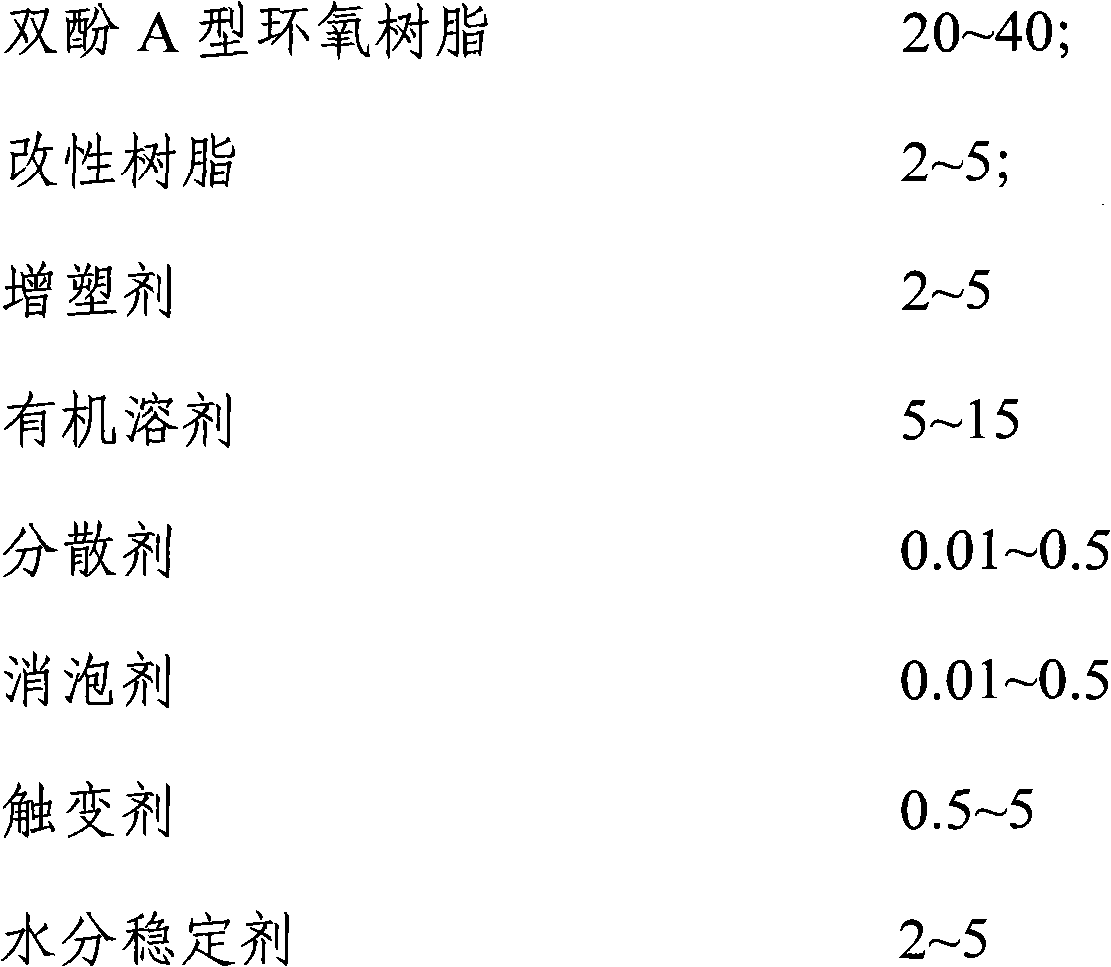

Epoxy coating and preparation method and application thereof

ActiveCN102618148AImprove the shortcomings of hard and easy to crack and poor flexibilityHigh mechanical strengthRosin coatingsAnti-corrosive paintsResin coatingPolyurethane coating

The invention provides a novel epoxy coating and a preparation method thereof. The coating not only has excellent corrosion resistance, but also has excellent compatibility with a base material or a lower coating film, particularly an epoxy coating, a polyurethane coating, a fluorocarbon coating or an alkyd resin coating. The epoxy coating comprises a main paint and a curing agent, wherein the main paint contains bisphenol A epoxy resin and modifying resin for modifying the bisphenol A epoxy resin; and the curing agent contains polyamino amide and cardanol modified phenolic amine.

Owner:北京红狮科技发展有限公司

Polyester Polymer Having Phenolic Functionality and Coating Compositions Formed Therefrom

A polyester polymer is provided that includes at least one pendant phenolic-containing group. In one embodiment, the polyester polymer is combined with an optional crosslinker and an optional carrier to form a coating composition suitable for use in coating articles such as packaging articles. The coating composition typically includes a resole phenolic crosslinker. In one embodiment, the polyester polymer has at least one phenolic-containing group that comprises an adduct of cardanol.

Owner:SWIMC LLC

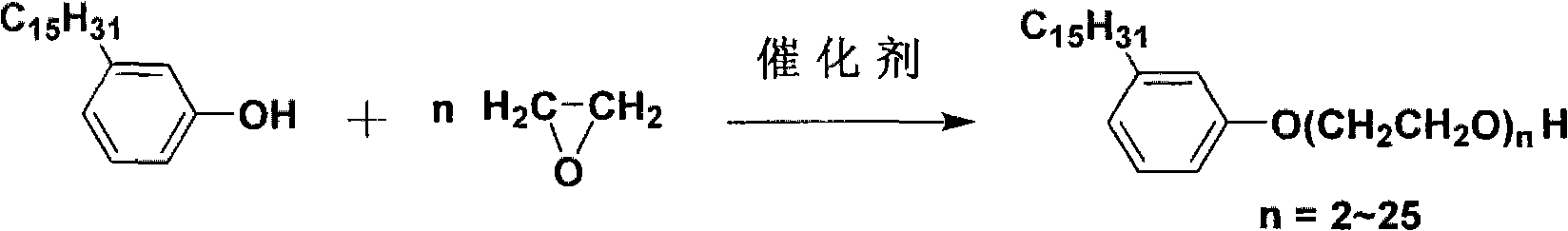

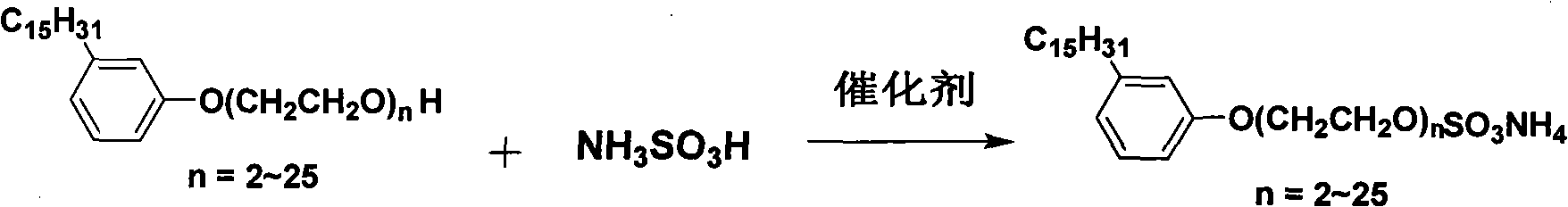

Cardanol polyoxyethylene ether and preparation method thereof

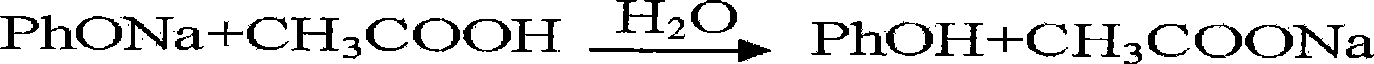

InactiveCN101941894ALow priceReduce adverse effectsEther preparation from oxiranesAcetic acidEthylene oxide

The invention provides cardanol polyoxyethylene ether and a preparation method thereof. The cardanol polyoxyethylene ether is prepared by reacting cardanol and epoxy ethane. The method comprises the following steps of: adding a catalyst and the cardanol into a reaction kettle during a reaction; fully stirring at the temperature of between 150 and 180 DEG C; introducing the epoxy ethane into the reaction kettle; performing polyreaction with stirring; adding acetic acid after the reaction for neutralization; and discharging after cooling so as to obtain the cardanol polyoxyethylene ether. The cardanol polyoxyethylene ether and the preparation method thereof have the advantages of a small number of side reactions, good color and luster of a product, mild reaction condition and low cost of raw materials. Natural cardanol is taken as a raw material for producing, so that the adverse effect of alkylpheol ethoxylates synthesized from petroleum on the environment is avoided. The cardanol polyoxyethylene ether belongs to linear chain alkylpheol ethoxylates and the hydrophile-lipophile balance (HLB) of a nonionic surfactant can be controlled by adjusting the adduct number of the epoxy ethane according to a process, so that the cardanol polyoxyethylene ether can be taken as an emulsifier, a lubricant, a washing agent, a solubilizing agent and the like.

Owner:BINZHOU MEIDONG RESIN

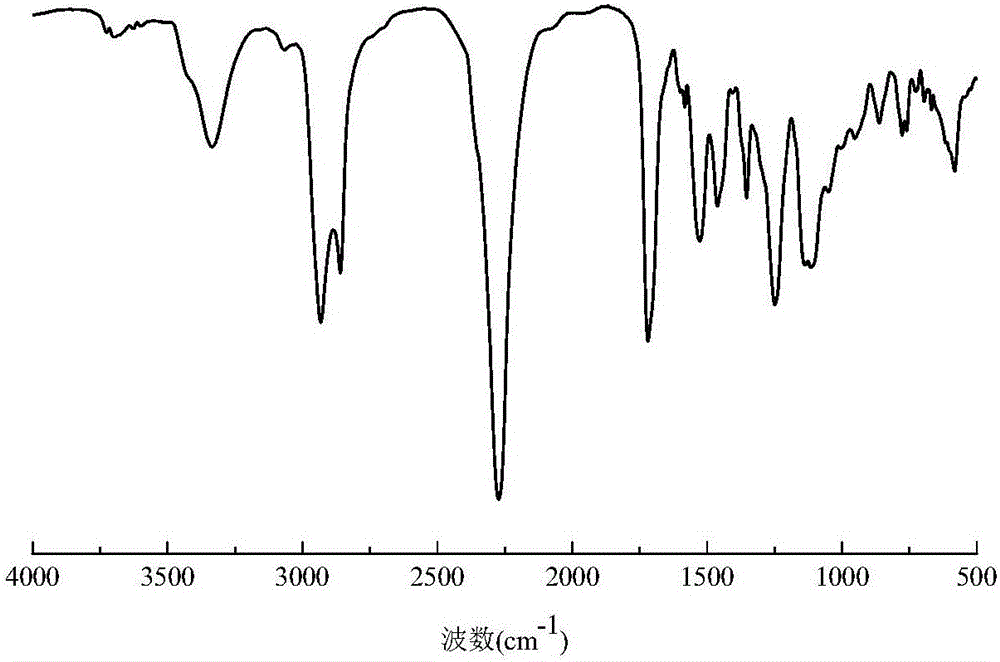

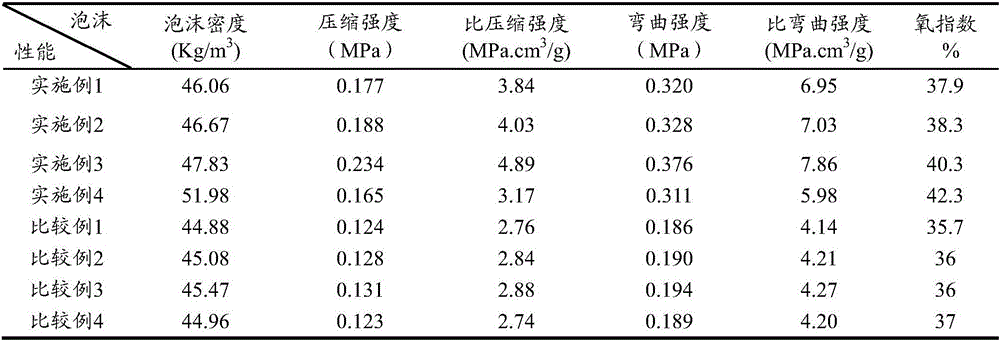

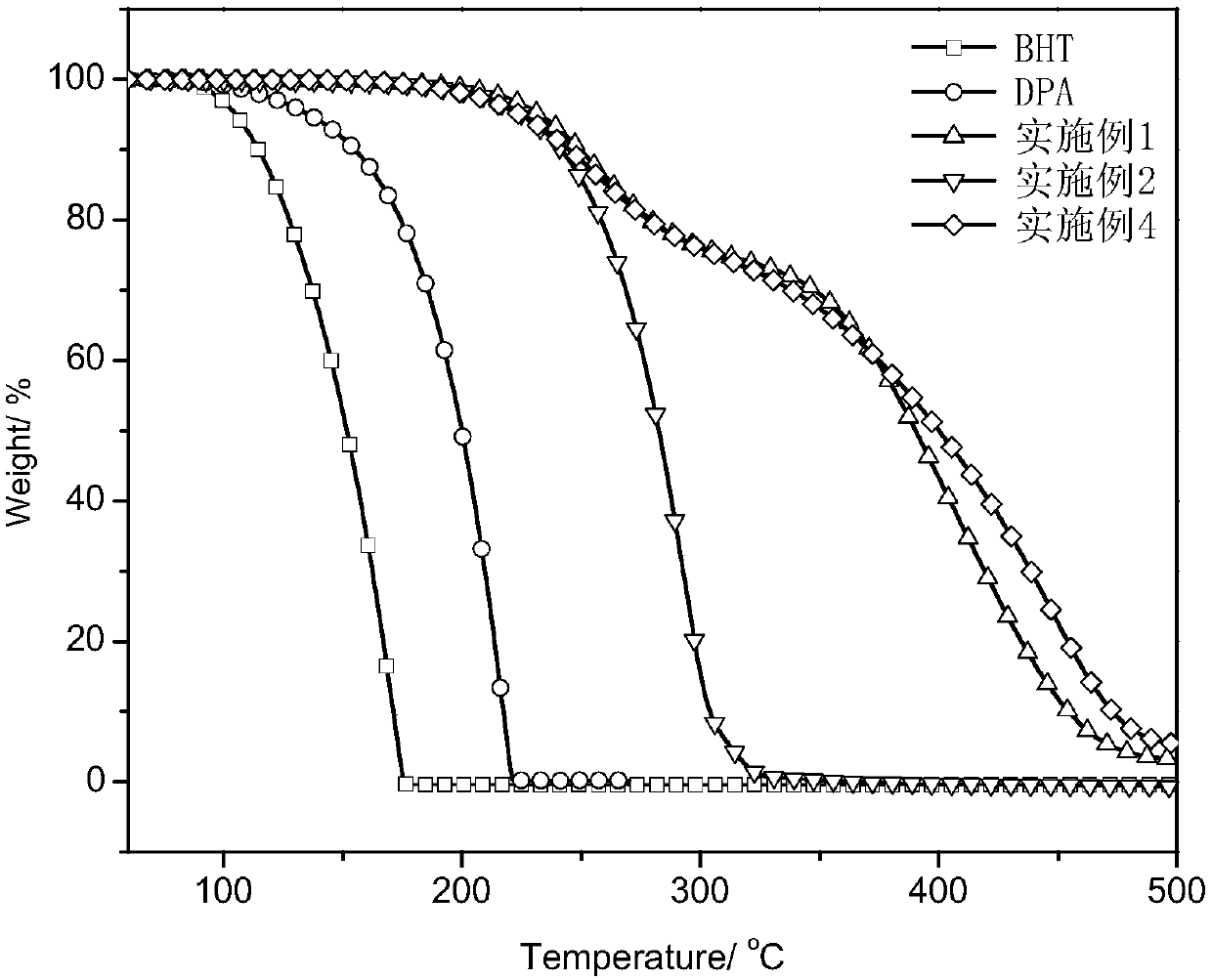

Phosphorus-containing cardanol-base polyurethane prepolymer modified phenolic foam plastic and preparation method thereof

The invention relates to a phosphorus-containing cardanol-base polyurethane prepolymer modified phenolic foam plastic and a preparation method thereof. The preparation method comprises the following steps: synthesizing cardanol glycidol ether from cardanol and epoxy chloropropane under alkaline conditions, and hydrolyzing under acidic conditions to generate cardanol-base dibasic alcohol; by using the cardanol-base dibasic alcohol as the raw material, dropwisely adding oxydol to react under acidic conditions to obtain the epoxy cardanol-base dibasic alcohol, carrying out reaction on the epoxy cardanol-base dibasic alcohol and a phosphorus-containing flame retardant to obtain phosphorus-containing cardanol-base polylol; carrying out reaction on the phosphorus-containing cardanol-base polylol and isocyanate to obtain a phosphorus-containing cardanol-base polyurethane prepolymer; and mixing the phosphorus-containing cardanol-base polyurethane prepolymer with a phenolic resin, and sequentially adding a surfactant, a foaming agent and a curing agent, thereby obtaining the phosphorus-containing cardanol-base polyurethane prepolymer modified phenolic foam thermal-insulation material. The mechanical properties of the phenolic foam thermal-insulation material are obviously enhanced. The flame-retardant element phosphorus is introduced into the polyurethane prepolymer, thereby solving the problem of degradation of foam flame retardancy due to the carbamate introduced into the phenolic foam.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

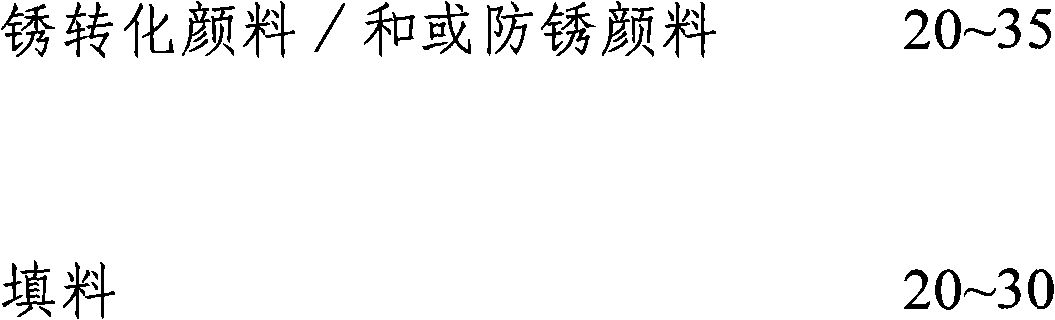

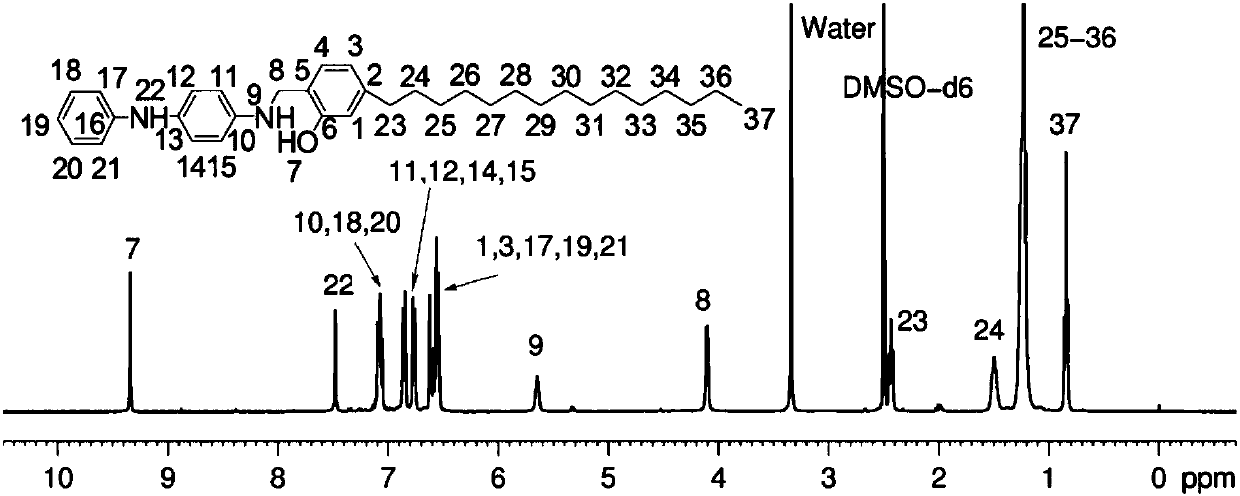

Cardanol-based antioxidant as well as preparation method and application thereof

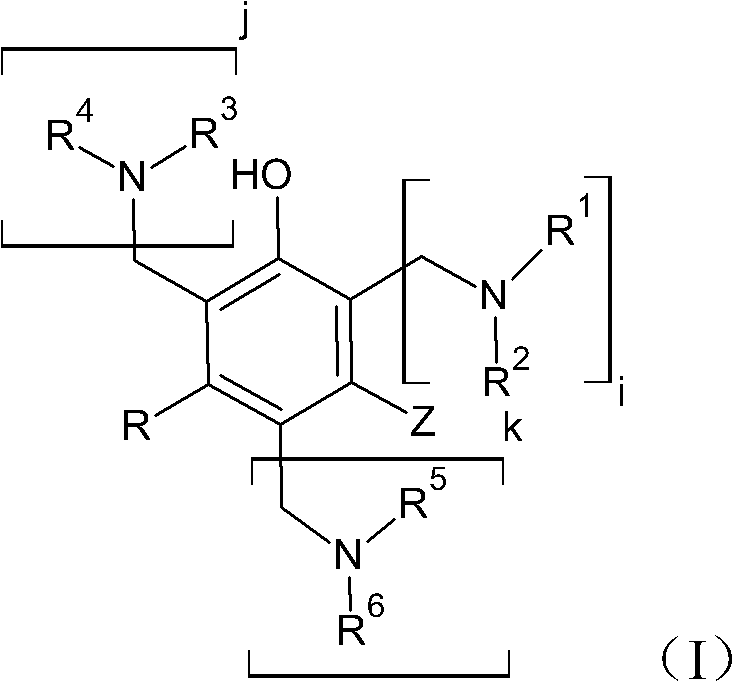

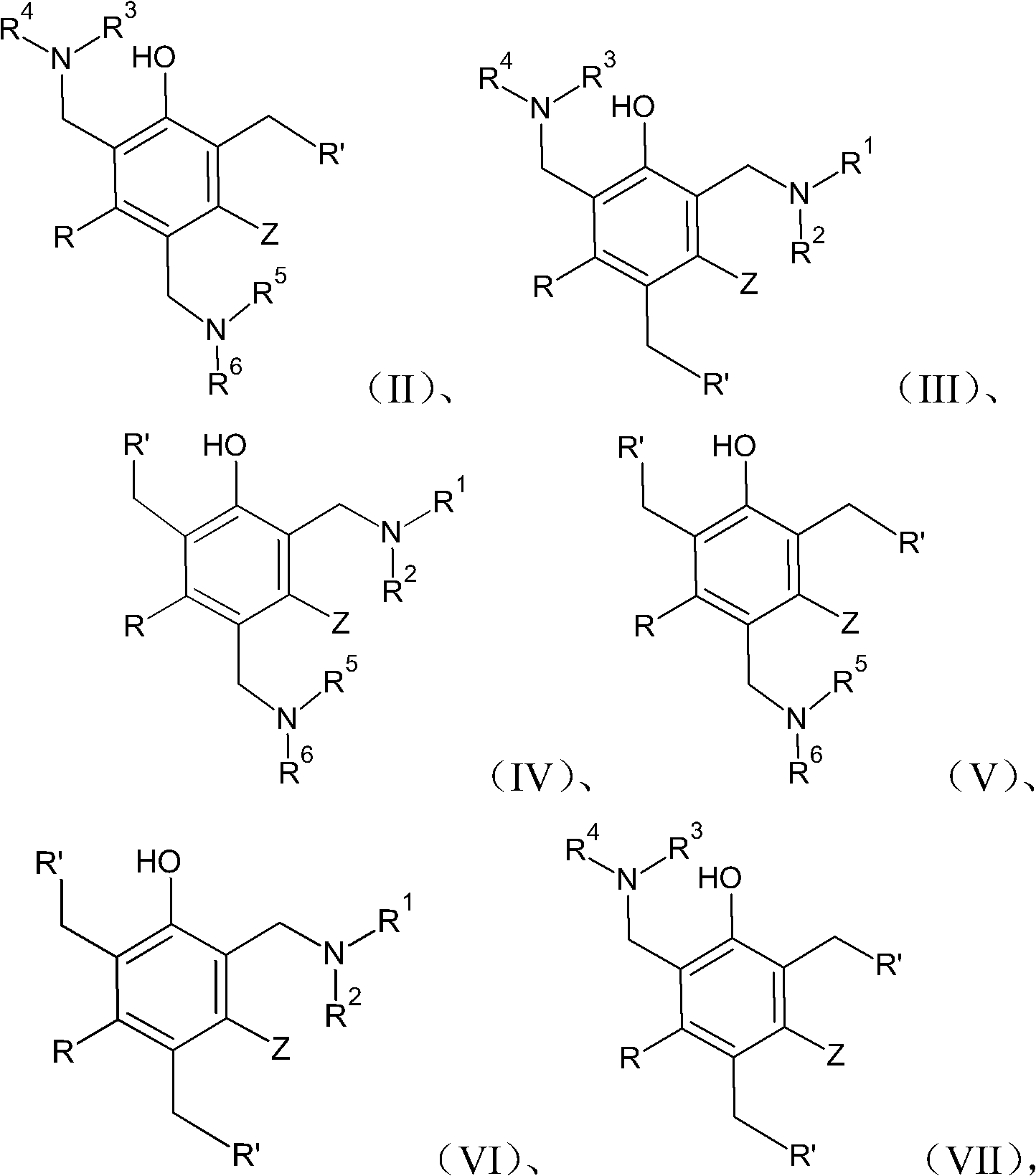

The invention discloses a cardanol-based antioxidant as well as a preparation method and application thereof. The cardanol-based antioxidant contains a compound with a structure shown as a formula (1): (shown in the description), wherein n ranges from 0 to 3; R1 and R2 are respectively and independently selected from H, alkyl, cycloalkyl, aryl, alkaryl or aralkyl; at least one of R3 and R4 has a structure shown as a formula (2) or (3): (shown in the description); R and R' are respectively and independently selected from H, alkyl, cycloalkyl, aryl, alkaryl or aralkyl; R5 is selected from -S-, -O-, -NH- or -(CH2)n'-; n' ranges from 0 to 3; Ra and Rb are respectively and independently selected from H, -OH, -SH, -NH2, alkyl, cycloalkyl, aryl, alkaryl or aralkyl; m and m' are any integer of 0 to 3 respectively. The cardanol-based antioxidant disclosed by the invention has the characteristics of greenness, environmental protection, antioxidation property, excellent thermal stability and extreme pressure resistance and the like; a preparation process has the advantages of simplicity, feasibility, mild conditions and wide application prospect in the fields of multiple oil products, fuel, plastic, rubber, fibers, coatings and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Single-component high/low-temperature-resistant epoxy resin composition

ActiveCN102827566AImprove performanceSimple preparation processNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkEther

The invention provides a single-component high / low-temperature-resistant epoxy resin composition which comprises the following ingredients in parts by weight: 100 parts of rubber cross-linked modified epoxy resin, 0-20 parts of cardanol-type glycidol ether, 80-120 parts of alicyclic acid anhydride curing agent, 0.5-10 parts of latent curing accelerator, 10-40 parts of polyacrylate core-shell compound particle toughener, 2-20 parts of thixotropic agent and 50-100 parts of filler. The epoxy resin composition has the advantages of high toughness, high / low-temperature alternation resistance, simple preparation technique, low viscosity and favorable flowability, and can greatly enhance the packaging reliability and durability of electronic devices.

Owner:GUANGDONG TGPM AUTOMOTIVE IND GRP

Cashew pnenolic aldehyde amine epoxide resin paint solidifying agent and method for producing the same

The invention relates to a curing agent used for epoxy resin coating and a preparation method thereof. The curing agent has the main component of cardanol-aldehyde amine, and is characterized in that the synthetic formulation of the cardanol-aldehyde amine comprises the following components based on the weight percentage: 60-70% of cardanol, 20-30% of polyamine, 10-20% of formaldehyde or paraformal-dehyde and 1-5% of 2, 4, 6ternary (dimethylamino methyl) phenol. Compared with common phenolic aldehyde amine curing agent, the curing agent has better water resisting property and flexility when being used for the epoxy resin coating, and generally does not affect the color mixing of finishing coat.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

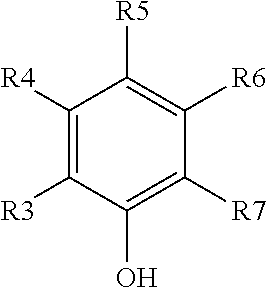

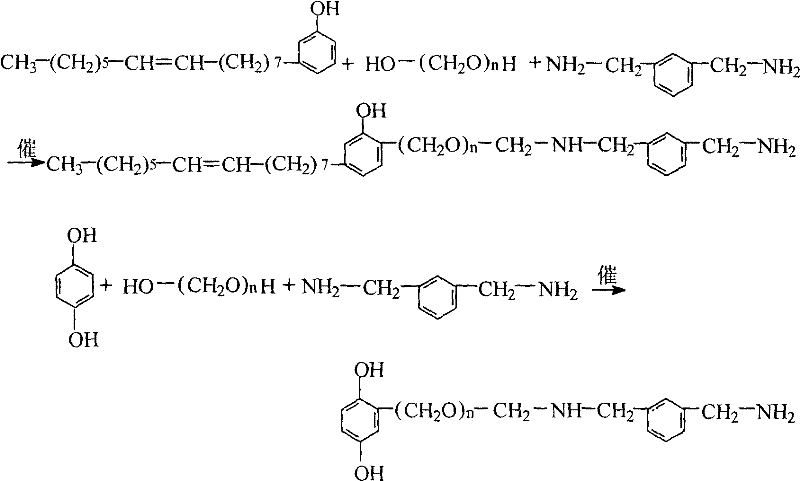

Low-viscosity cardanol solidifying agent of epoxy resin and preparation method thereof

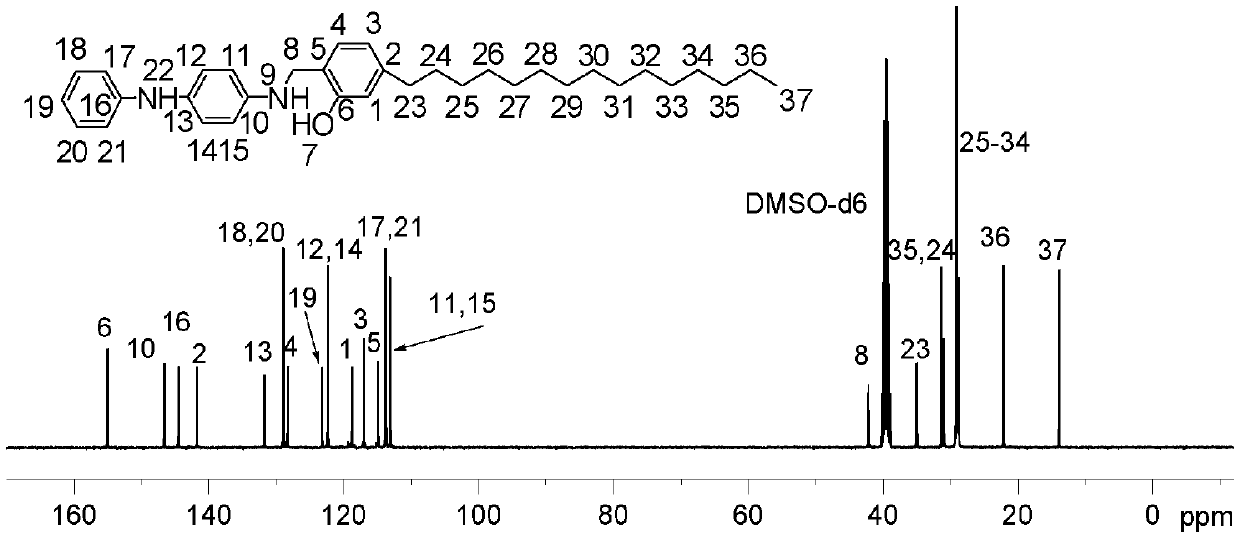

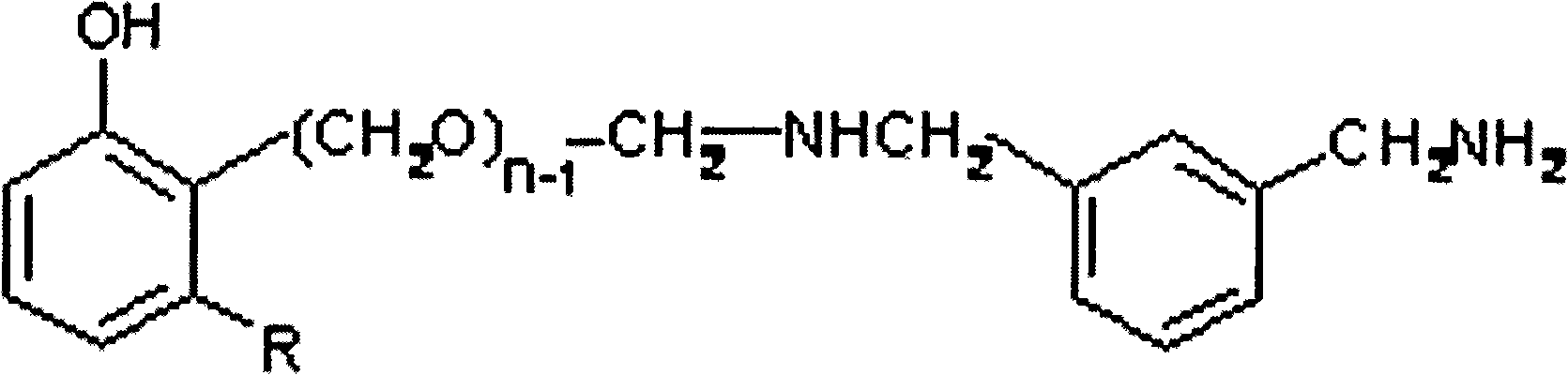

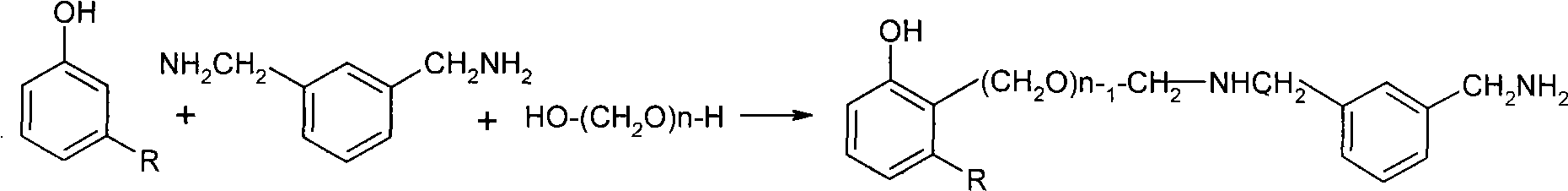

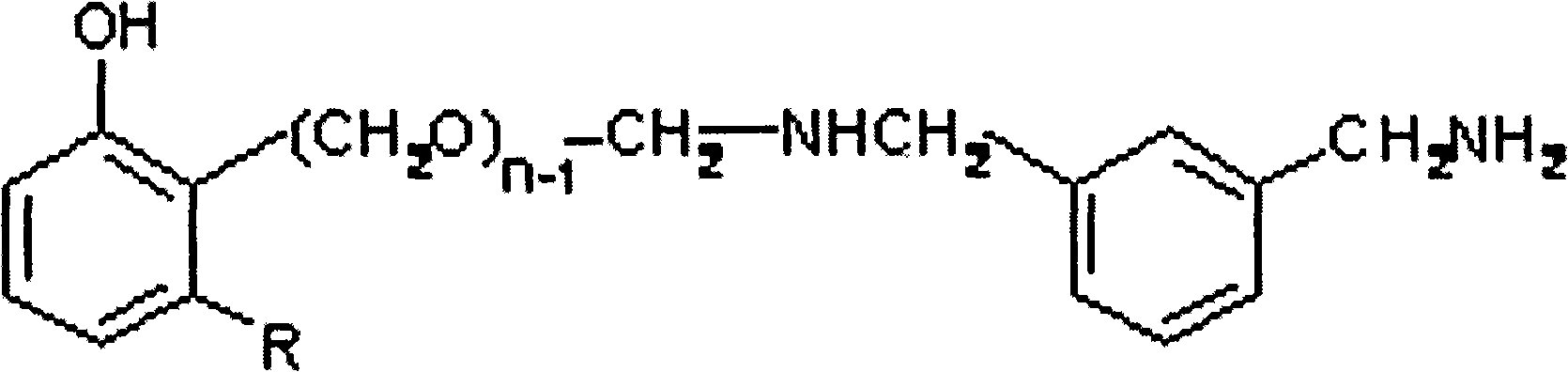

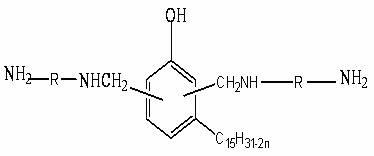

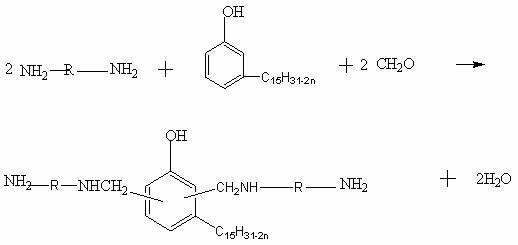

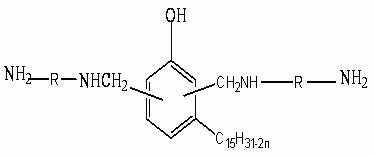

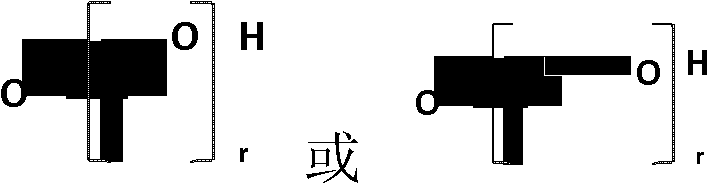

The invention relates to a low-viscosity cardanol epoxy resin curing agent which has a structural formula shown on the right. The method for preparing the low-viscosity cardanol epoxy resin curing agent utilizes reaction of cardanol, p / m-benzene dimethylamine and paraformaldehyde to prepare the low-viscosity cardanol epoxy resin curing agent. The low-viscosity cardanol epoxy resin curing agent has no solvent, has no irritation, is nontoxic and environment-friendly, is mild in heat release, low in color, low in viscosity, and moderate in curing speed, can be cured at a low temperature, and simultaneously has superior anti-corrosive and protective properties; and cured products have superior toughness, good strength, superior adhesion and invasive ability on substrates, and superior low surface construction performance, and are normally used on wet and rusty surfaces.

Owner:上海美东生物材料股份有限公司

Cardanol epoxy floor curing agent and preparation method thereof

InactiveCN102134306AImprove smoothnessAvoid disadvantagesOrganic compound preparationEpoxy resin coatingsNatural productMechanical property

The invention discloses a cardanol epoxy floor curing agent and a preparation method thereof. Cardanol extracted from cashew shell oil which is a natural product serves as a raw material, and the cardanol with 15 long-chain hydrocarbyl substituents of carbon is reacted with alicyclic amine and a formaldehyde solution to prepare the cardanol epoxy floor curing agent, wherein the molar ratio of the cardanol to the alicyclic amine to the formaldehyde solution is 1:(1-1.5):(1-1.5); in the reaction, the cardanol is firstly added into a reactor, the formaldehyde solution is then added into the reactor for reaction, the alicyclic amine is dropwise added in the reactor, and the cardanol epoxy floor curing agent can be obtained after the material is discharged. In the invention, the synthesis is performed at low temperature; synthetic products have a longer application period; and alicyclics with higher rigidity and better stability are introduced in molecular structures of the products, therefore, an epoxy resin curing product has excellent mechanical properties.

Owner:GUANGDONG UNIV OF TECH +1

Cardanol modified phenolic aldehyde foam and preparation method thereof

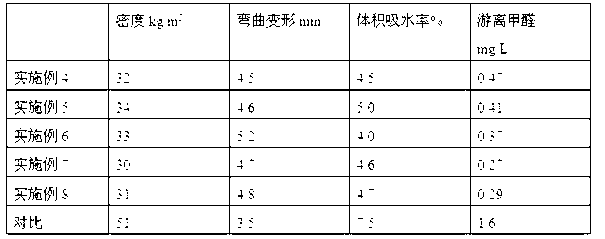

The invention discloses cardanol modified phenolic aldehyde foam and a preparation method of the cardanol modified phenolic aldehyde foam. The cardanol modified phenolic aldehyde foam is prepared by the following materials in parts by weight: 100 parts of a cardanol modified phenolic aldehyde resin, 4-7 parts of a surfactant, 6-10 parts of a foaming agent and 15-20 parts of a curing agent, wherein the cardanol modified phenolic aldehyde resin is a phenolic aldehyde resin obtained by performing a first step of reaction on cardanol and liquid formaldehyde under a basic catalyst condition, then, adding phenol and paraformaldehyde, and performing a second step of reaction under the basic catalyst condition, and at last, adding a hydroxymethylurea resin to react. According to the preparation method, on the basis of not affecting the heat conductivity coefficient and high fire resistance of the phenolic aldehyde foam, the density, water absorption and free formaldehyde of phenolic aldehyde foam plastic are reduced by the cardanol, the tenacity of phenolic foam is improved, and meanwhile, renewable plant resources are adequately used. The cardanol modified phenolic aldehyde foam can be used as a building heat-insulation, heat-preservation and fire-proof material, and is a product with good market prospect.

Owner:北京傲德新材料科技有限公司

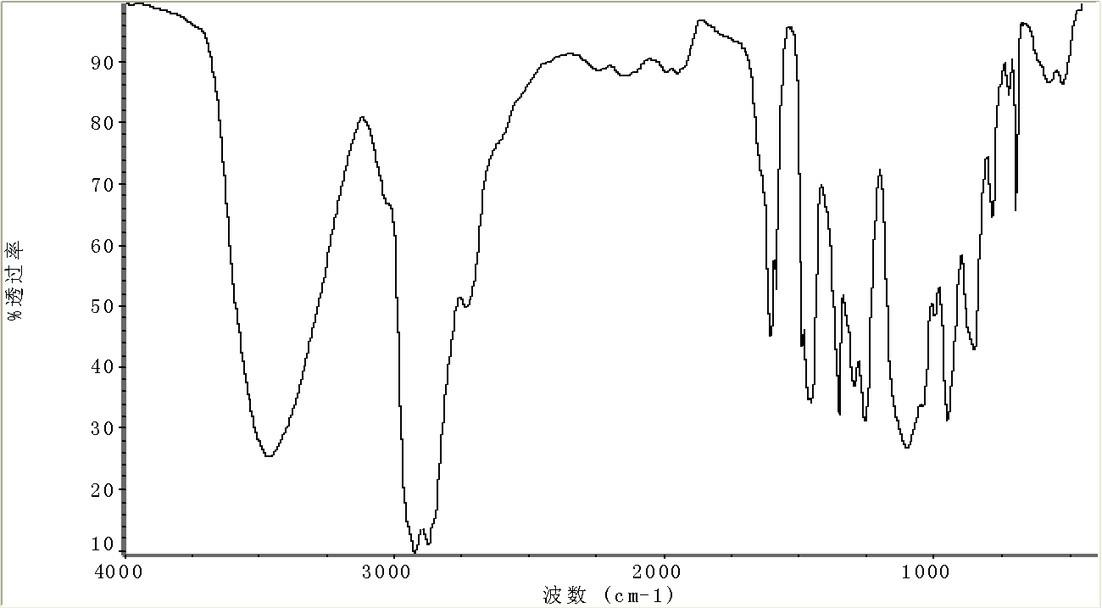

Method for preparing modified phenolic resin

The invention relates to a method for preparing a modified phenolic resin for a paper-base copper clad laminate substrate resin. In the method, cardanol is adopted together with an epoxide vegetable oil to modify a phenolic resin, the usage amount of tung oil is reduced considerably, the copper clad laminate manufactured by using the modified phenolic resin as a main resin has the advantages of excellent flexibility, low water absorptivity, high electrical insulation in wet state, low manufacturing cost and the like, and at the same time, a melamine resin is added to further modify the phenolic resin, so the drawback that the phenolic resin changes color due to the light is inhibited obviously and the modified phenolic resin prepared by the method can meet requirements on appearance color.

Owner:福建利豪电子科技股份有限公司

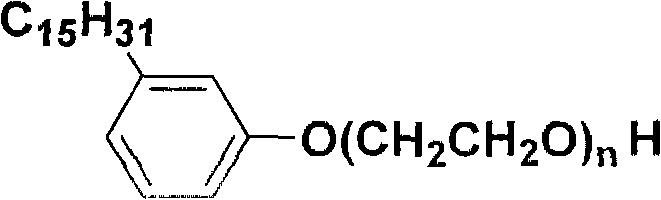

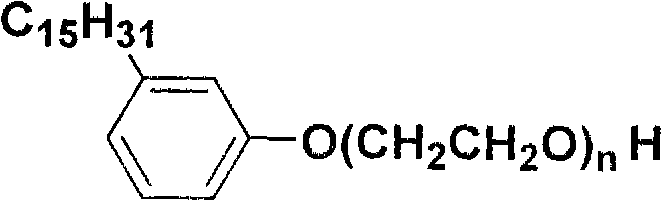

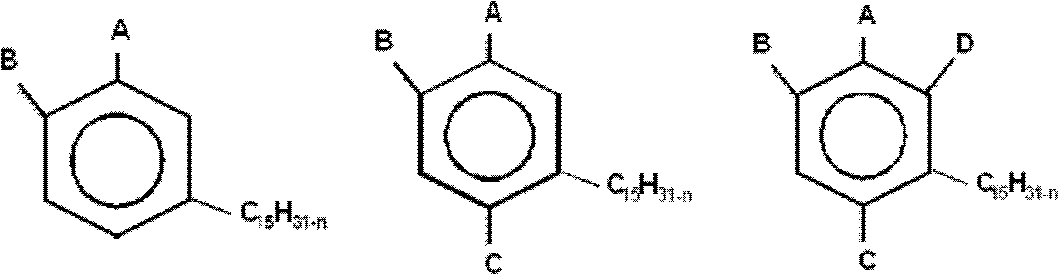

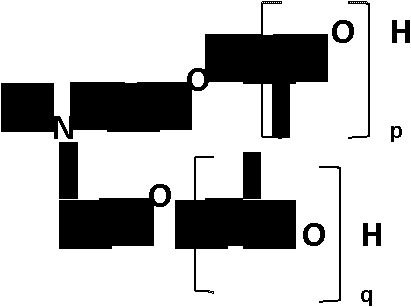

Saturated cardanol polyoxyethylene ether and preparation method thereof

The invention relates to saturated cardanol polyoxyethylene ether and a preparation method thereof, which belongs to the technical field of organic synthesis, and the structural formula of the saturated cardanol polyoxyethylene ether is as follows, wherein n=2-30. The preparation method comprises the following steps: performing a hydrogenation reaction of cardanol; performing filtration and distillation, and performing an addition reaction with ethylene oxide; adjusting the pH value, filtering, and performing reduced-pressure distillation; or performing an addition reaction of cardanol and ethylene oxide; adjusting the pH value, filtering, performing a hydrogenation reaction, filtering, and performing reduced-pressure distillation. The preparation method of the invention uses cardanol as a raw material, and prepares cardanol polyoxyethylene ether with different ethylene oxide adduct numbers and saturated side chains; the product does not contain mixed unsaturated double bond structures, has surface activity, and has stable using performance.

Owner:NORTHEASTERN UNIV

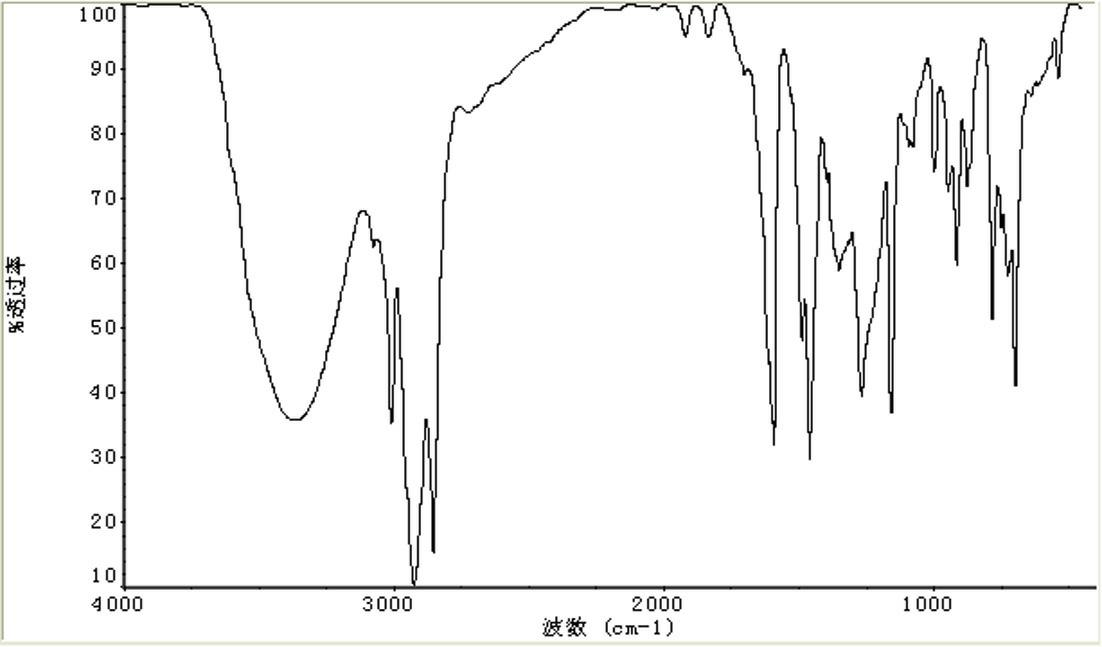

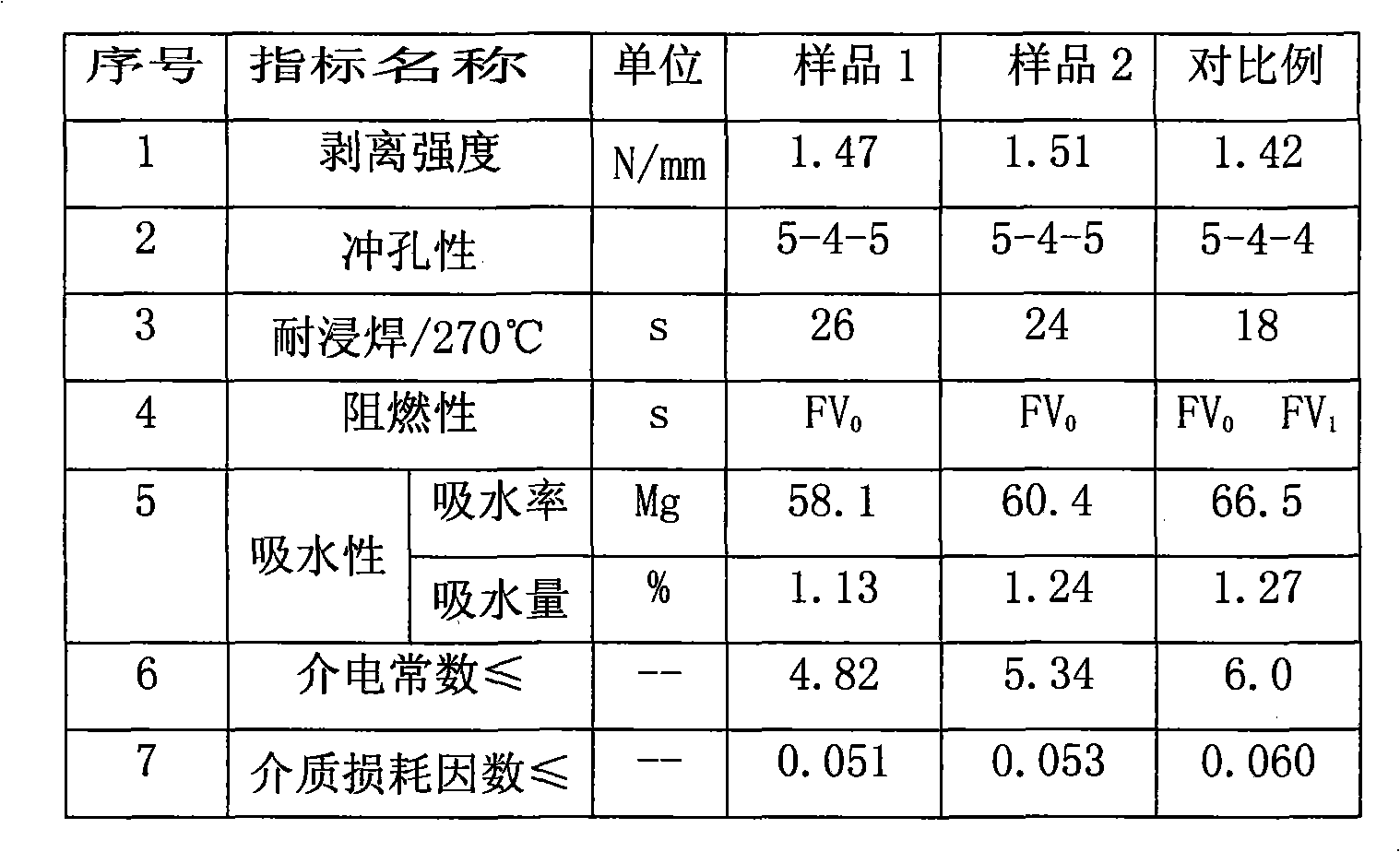

Cardanol modifying phenolic resin composition and method for producing environmental protection type flame-proof paper-base copper-coating board

ActiveCN101265352ALow costImprove heat resistanceCircuit susbtrate materialsFiberTetrabromobisphenol A

The invention relates to a cardanol modified phenol-formaldehyde resin and a method for producing an environmentally protective flame-retardant paper-based copper-covering plate by using the resin compound, and belongs to the technology field of the production method of the copper-covering plate. The cardanol modified phenol-formaldehyde resin is used for producing the copper-covering plate with cheap cardanol substituting for industrial phenyl hydroxide and tung oil partly. The cardanol is refined and abstracted from the raw oil extracted from fruits grown on a cashew which is a tropical plant. The modified resin compound contains flame retardants, such as nitride, phosphide, tetrabromobisphenol A and so on, and the flame retardants are free of such hazardous materials as polybrominated biphenyl, polybrominated diphenyl oxide and so on. Wood chip paper is dipped with the modified resin to form prepregs. Subsequently, a plurality of pieces of prepregs are stacked up, and are compressed into the copper-covering plate at a certain temperature and certain pressure. The copper-covering plate can reduce the product cost and ensure the performance, and is friendly to the environment.

Owner:SHANDONG JINBAO ELECTRONICS

Non-ionic self-emulsifying epoxy resin curing agent and preparation method thereof

The invention discloses a non-ionic self-emulsifying epoxy resin curing agent and a preparation method thereof. The method comprises that polyethylene glycol and epoxy resin of low molecular weight are adopted to pre-prepare a water-based chain segment under the function of a catalytic agent, the water-based segment is reacted with a mannich base which is prepared from cardanol, formaldehyde and polymine, and at the same time, organosilicone is added to conduct partial end blocking, compatibility of a system on an inorganic component is increased, and the non-ionic cashew phenol amine epoxy curing agent with the self-emulsifying capacity is obtained. The natural cardanol and the polyethylene glycol in the main raw materials of the curing agent have no adverse effect on environment. The prepared curing agent integrates the advantages of non-ionic emulsion and cashew phenol amine.

Owner:GUANGDONG UNIV OF TECH

High recycle content polyester polyols

ActiveUS20160053050A1Nice appearanceDesirable functionalityPolyurea/polyurethane coatingsParticulatesPolyester

Polyester polyols made from thermoplastic polyesters are disclosed. The polyols are reaction products of a thermoplastic polyester, a glycol, and a hydrophobe selected from ricinoleic acid, ethoxylated castor oil, saturated or unsaturated C9-C18 dicarboxylic acids, tung oil, soybean oil, sunflower oil, cardanol-based products, recycled cooking oil, isostearyl alcohol, hydroxy-functional materials derived from epoxidized, ozonized, or hydroformylated fatty esters or fatty acids, and mixtures thereof. In one process, the polyols are made by reacting the thermoplastic polyester with a glycol to give a digested intermediate, which is then reacted with the hydrophobe. In another process, the thermoplastic polyester, glycol, and hydrophobe are combined and reacted in a single step. These hydrophobes facilitate the production from recycled thermoplastics of polyols that have good transparency and little or no particulate settling or phase separation. High-recycle-content polyols having desirable properties and attributes for formulating polyurethane products, including aqueous polyurethane dispersions, can be made. The polyols provide a sustainable alternative to bio- or petrochemical-based polyols.

Owner:RESINATE MATERIALS GRP

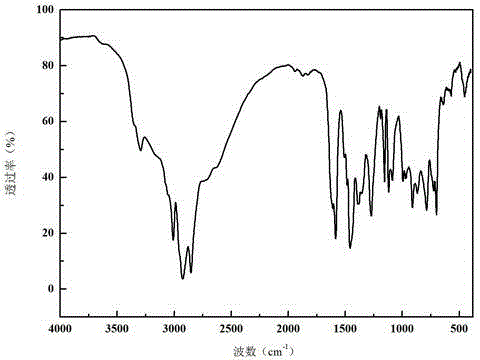

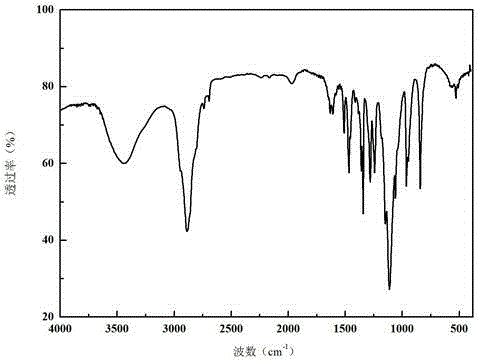

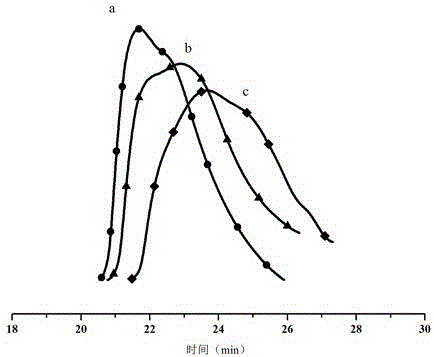

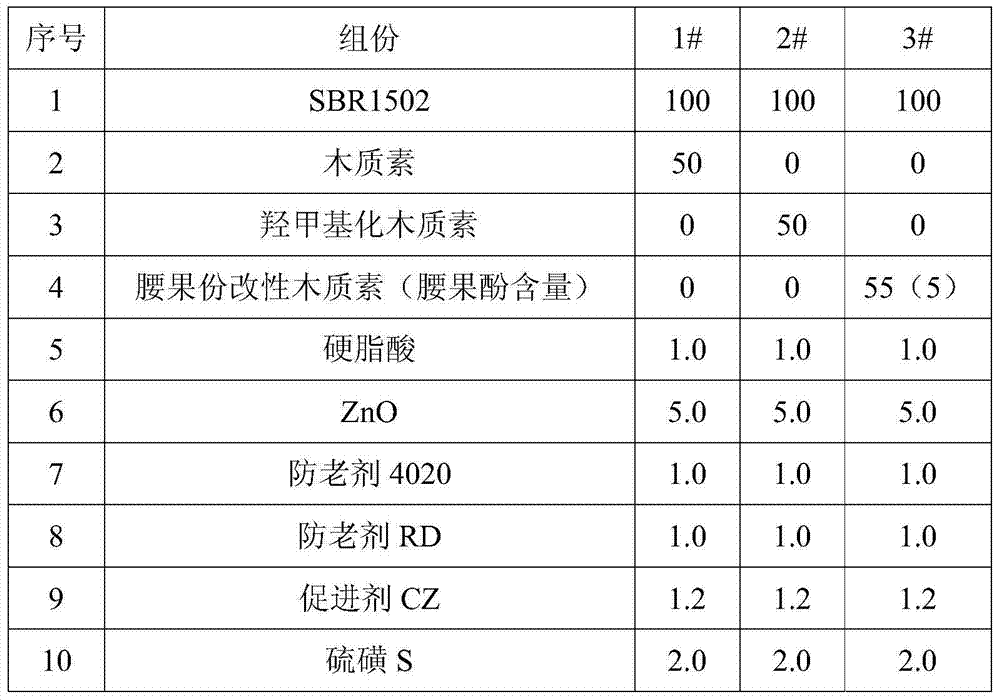

Rubber composite material filled by cardanol modified lignin and preparation method thereof

The invention relates to a rubber composite material filled by cardanol modified lignin and a preparation method thereof. The rubber composite material is characterized by being made of 100 parts by weight of rubber and 10-200 parts by weight of cardanol modified lignin. The rubber is natural rubber, polyisoprene rubber, styrene butadiene rubber, butadiene rubber, 1, 2 polybutadiene, an ethylene propylene diene monomer, butyl rubber, nitrile rubber or neoprene, or a combinationof two or more of natural rubber, polyisoprene rubber, styrene butadiene rubber, butadiene rubber, 1, 2 polybutadiene, an ethylene propylene diene monomer, butyl rubber, nitrile rubber and neoprene. The cardanol modified lignin contains hydroxymethyl and unsaturated alkyl long chain functional groups. The cardanol modified lignin is obtained by employing ormaldehyde and cardanol as modifiers to modify a black liquor or pure lignin. According to the invention, environment friendly and renewable lignin and cardanol are taken as the main raw materials, which can improve the mechanical properties of the rubber products and lower the rubber product cost. Thus, the rubber composite material filled by cardanol modified lignin has economic value and social significance.

Owner:SOUTH CHINA UNIV OF TECH +1

Environment-friendly braking friction material and preparation method thereof

The invention provides an environment-friendly braking friction material containing natural plant fiber, natural mineral fiber, natural mineral powder and cardanol-based benzoxazine modified phenolic resin and a preparation method thereof. The natural plant fiber is one or a plurality of flax, ramie, jute, hemp and sisal processed by a chemical method (alkali and acid) and a physical method (high-pressure steam), the natural mineral fiber comprises needle-like limestone and basalt fiber, and the natural mineral powder comprises zircon, barite, vermiculite and graphite. The invention also provides a preparation method of the natural mineral powder and cardanol-based benzoxazine pellet and a preparation method of cardanol-based benzoxazine in-situ toughening phenolic resin.

Owner:BEIJING UNIV OF CHEM TECH

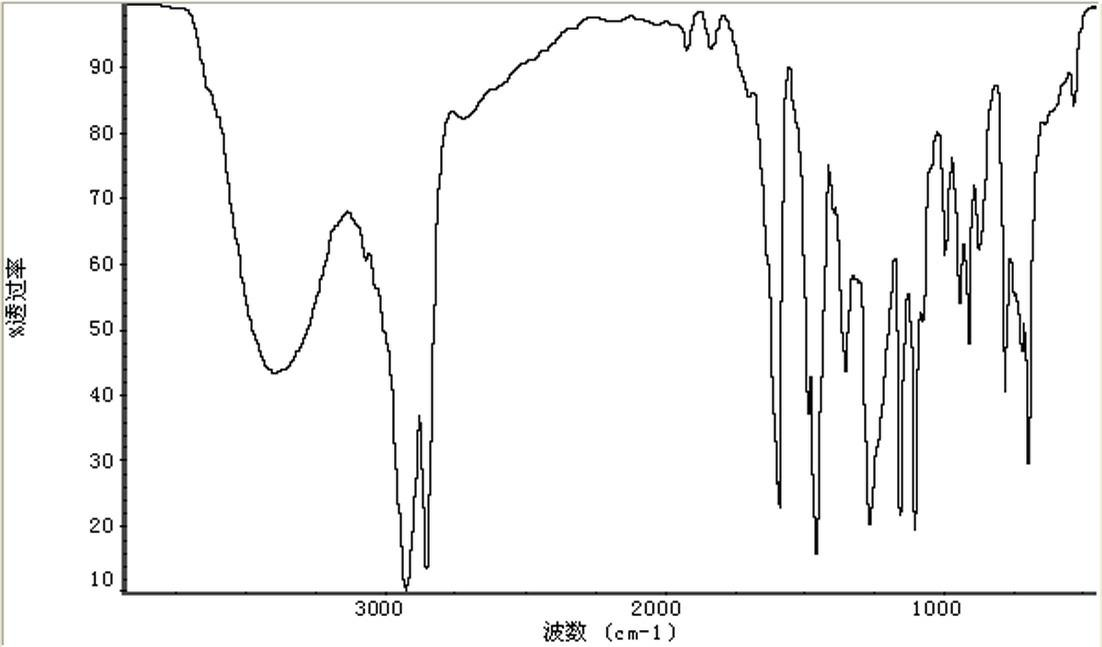

Production method for cardanol modified phenolic resin

The invention relates to a production method for cardanol modified phenolic resin, wherein the method comprises the following steps: 1, preparing modified phenolic resin solution, the raw materials for preparing the modified phenolic resin solution based on mass parts proportioning are as follows: 150-210 parts of phenol, 148-185 parts of cardanol, 230-260 parts of formaldehyde, 0.1-2.3 parts of triethylamine, 2.0-4.2 parts of ammonia water and 350-400 parts of methanol, wherein when preparing, adding the phenol, cardanol, formaldehyde, triethylamine and ammonia water based on the proportioning into a reaction kettle to react, and adding methanol as dissolvent to prepare phenolic resin solution; 2, preparing modified phenolic resin composite: taking 100 parts of phenolic resin solution and adding 11-18 parts of silicon micro-powder and 10-15 parts of epoxidized soybean oil into the solution, and fully mixing them to obtain the finished product. The invention is characterized by simple technology and low production cost. The prepared copper-clad plate has good flexibility.

Owner:JIANGSU SUNYUAN AEROSPACE MATERIAL

Method for preparing modified phenolic resin by adopting cardanol

InactiveCN101676311AReduce manufacturing costImprove antioxidant capacityPolymerizationPhenol formaldehyde resin

The invention provides a method for preparing modified phenolic resin by adopting cardanol. The method adopts phenol, methanal, the cardanol, auxiliary agent and hydrochloric acid to have reaction; the pH value of a reaction system is controlled to be within the range of 1.5-2.0, the temperature is slowly raised to 80-90DEG C, and then heating is stopped; the heat of the reaction is released untilthe temperature of the reaction system is 100 DEG C, and the reactant begins to boil; and after heat preservation reaction is stabilized for 2-3h, decompression dehydration can be carried out, so that the phenolic resin can be obtained. The performance of the modified phenolic resin can be measured under the experiment condition, the softening point is 82-90 DEG C, the flowing degree is 2.9-5.0cm, the polymerization speed is 60-90S, the viscosity is 12-15mpa*s, and the temperature is 25DEG C. The method can greatly reduce the manufacturing cost of the phenolic resin, so that the phenolic resin has good market prospect. The phenolic resin is environment-friendly and has no volatile component, thus being successfully applied to the coating industry by consumers. Furthermore, the method improves the inoxidizability and the heat resistance of the phenolic resin.

Owner:上海美东生物材料股份有限公司

Benzoxazine resin based on furfuryl amine, composition and preparation method thereof

The invention relates to a benzoxazine resin based on furfuryl amine, a composition and a preparation method thereof. The benzoxazine resin is prepared from phenol derived from renewable resources (for example, eugenol, guaiacol and cardanol), primary amine derived from renewable resources (for example, furfuryl amine) and an aqueous solution of paraformaldehyde or trioxymethylene or formaldehyde; and the relevant composition is a composition prepared from the benzoxazine resin and other thermosetting resins. The benzoxazine resin based on furfuryl amine and the composition thereof can be used in multiple fields of matrix resins of paint, thermosetting plastic, composite material and the like.

Owner:BEIJING UNIV OF CHEM TECH

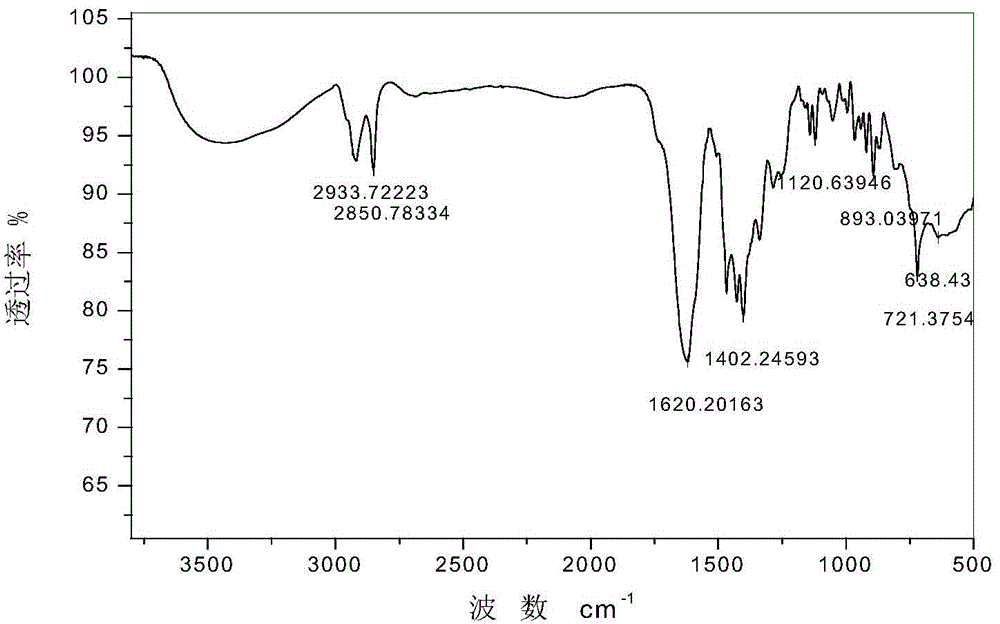

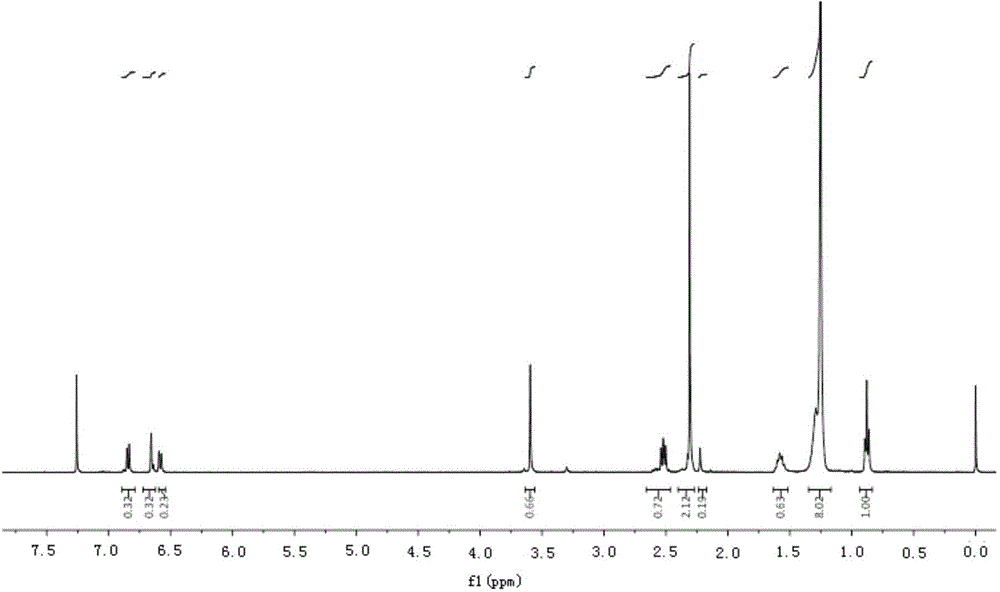

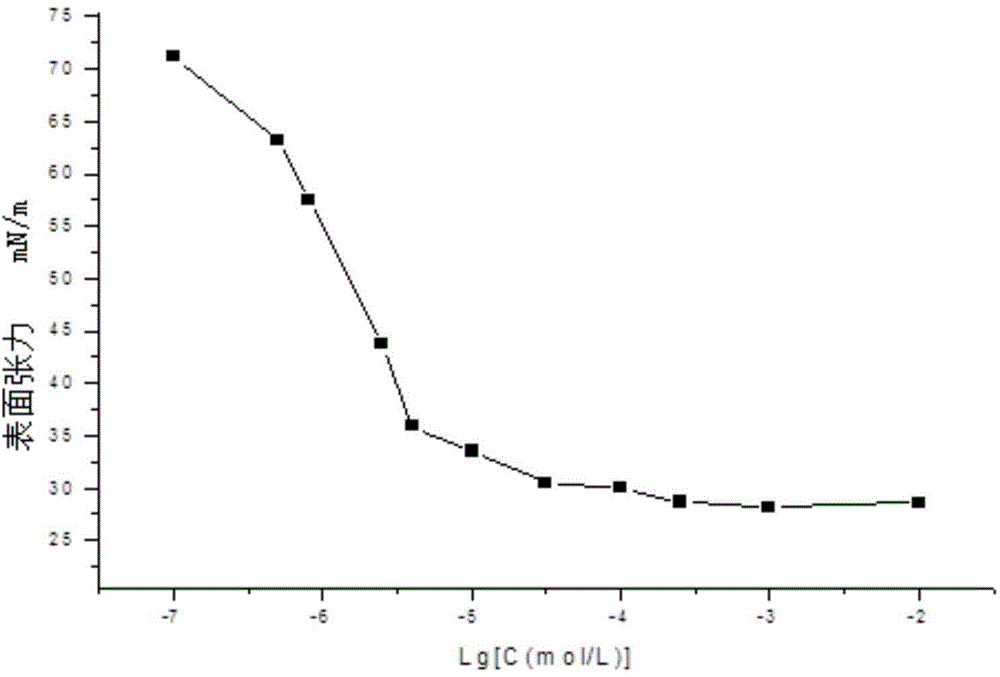

Saturated cardanol betaine surfactant, and preparation method and application thereof

ActiveCN105983370ALow toxicityBiodegradableOrganic compound preparationTransportation and packagingBetaineMannich reaction

The invention discloses a saturated cardanol betaine surfactant. The saturated cardanol betaine surfactant of a specific structure is prepared from saturated cardanol through a Mannich reaction and a quaterisation reaction. The saturated cardanol betaine surfactant has good interfacial performance; an aqueous solution of the saturated cardanol betaine surfactant and alkane or crude oil can form low or ultra-low interfacial tension; so the saturated cardanol betaine surfactant has good application prospects in a plurality of fields like mineral flotation, industrial washing and tertiary oil recovery. The saturated cardanol betaine surfactant has a structure as shown in a formula I which is described in the specification.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Cardanol polyether polyol and use thereof

InactiveCN102660014AGood internal adhesionSpecial physicsAnti-corrosive paintsPolyurea/polyurethane coatingsPolyethylene oxidePhenol

The invention relates to cardanol polyether polyol and a use thereof. The cardanol polyether polyol comprises cardanol aminal-based polyethylene oxide / propylene oxide polyether polyol and has a hydroxyl value of 220 to 550 and viscosity less than 4500CPS. The cardanol polyether polyol is environmentally friendly. Compared with other phenol-based Mannich polyols, the cardanol polyether polyol has specific physical and chemical properties, and can be used for preparation of polyurethane foam materials such as flame-retardant materials, energy-absorbing semi-rigid foam materials, high-resilience foam materials, polyurethane coatings and other polyurethane elastomeric materials.

Owner:常熟耐素生物材料科技有限公司

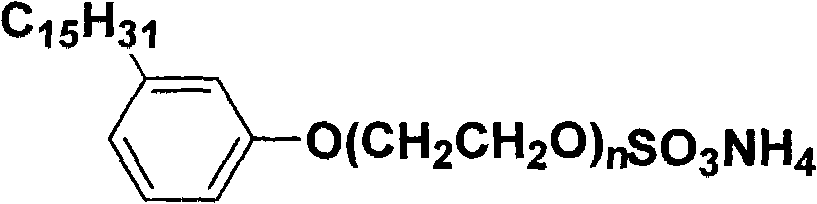

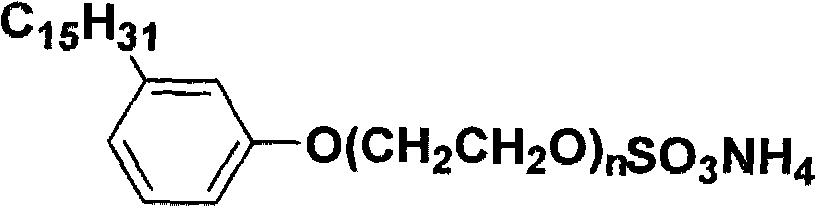

Cardanol polyoxyethylene ether ammonium sulfate and preparation method thereof

InactiveCN101941926AReduce adverse effectsOvercoming defects such as complex process control operationsSulfuric acid esters preparationSulfamic acidReaction system

The invention provides cardanol polyoxyethylene ether ammonium sulfate and a preparation method thereof. The preparation method comprises the following steps of: adding cardanol polyoxyethylene ether into a reactor provided with a stirrer, fully stirring at constant temperature and adding sulfamic acid and a catalyst; and stirring, reacting at constant temperature for 7 to 9 hours, neutralizing excessive sulfamic acid in the reaction system to a pH value of 8 to 10 by using sodium hydroxide, cooling, and filtering to prepare the cardanol polyoxyethylene ether ammonium sulfate. The cardanol polyoxyethylene ether which is prepared from natural cardanol is taken as a raw material for production, the negative influence of petroleum-synthesized cardanol polyoxyethylene ether ammonium sulfate on environment is avoided, the defects of more waste acid, high product saltness, complex technical control operation and the like in the technical route that the alkylpheol polyoxyethylene ether and a sulfating agent are directly reacted are overcome, and sulfated products is not needed to be neutralized by ammonia water or liquid ammonia.

Owner:BINZHOU MEIDONG RESIN

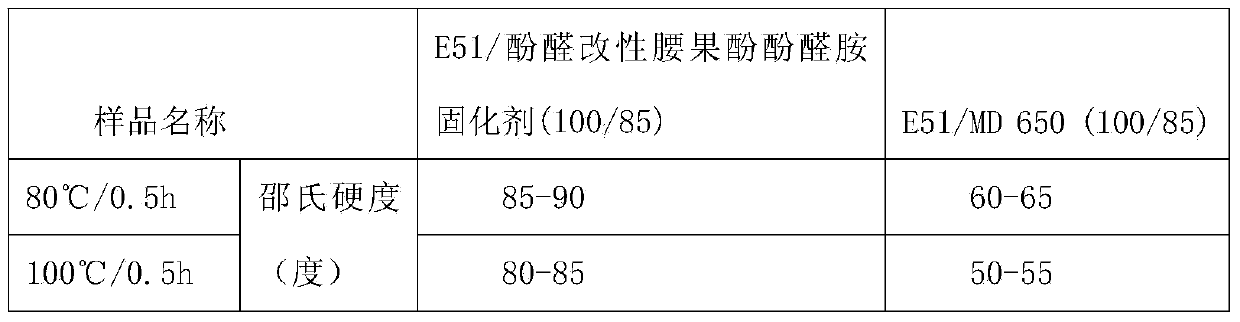

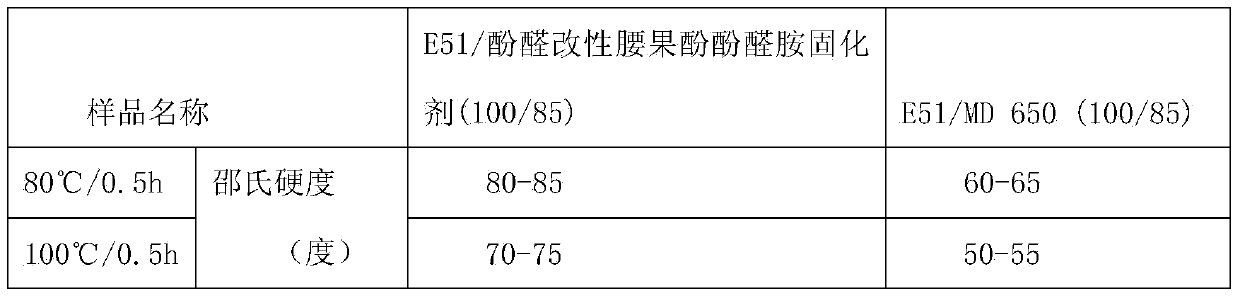

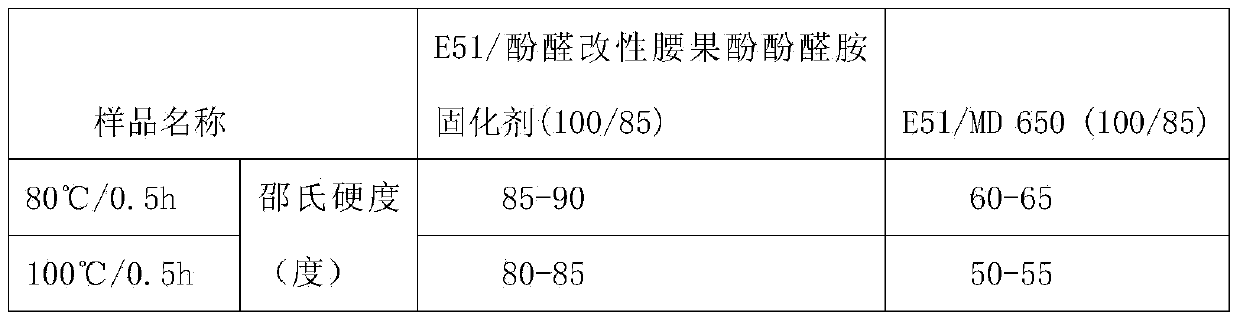

Preparation method of cardanol-based high temperature-resistant epoxy resin curing agent

The invention relates to a preparation method of a cardanol-based high temperature-resistant epoxy resin curing agent. The preparation method comprises the steps of firstly weighing cardanol, a phenolic compound, paraformaldehyde and diamine or polyamine according to weight, adding the cardanol, the phenolic compound and the paraformaldehyde into a reaction container, adding a catalyst, heating at the temperature of 75-100 DEG C for 2-6h to obtain an intermediate, then cooling the intermediate to 60-68 DEG C, adding the diamine or the polyamine, adding the remaining paraformaldehyde at the temperature in a stirring state, then heating till the temperature achieves 65-95 DEG C, reacting for 4-8h, and dehydrating in a vacuum state to obtain the cardanol-based high temperature-resistant epoxy resin curing agent provided by the invention. The synthesized curing agent has the advantages of great surface hardness and Shore hardness, excellent gloss, good high temperature resistance and low-temperature fast curing. According to the preparation method disclosed by the invention, the epoxy resin curing agent with a wide range of curing temperature, high temperature resistance and excellent surface performance is obtained and is suitable for requirements of primer paint and finish paint.

Owner:上海美东生物材料股份有限公司

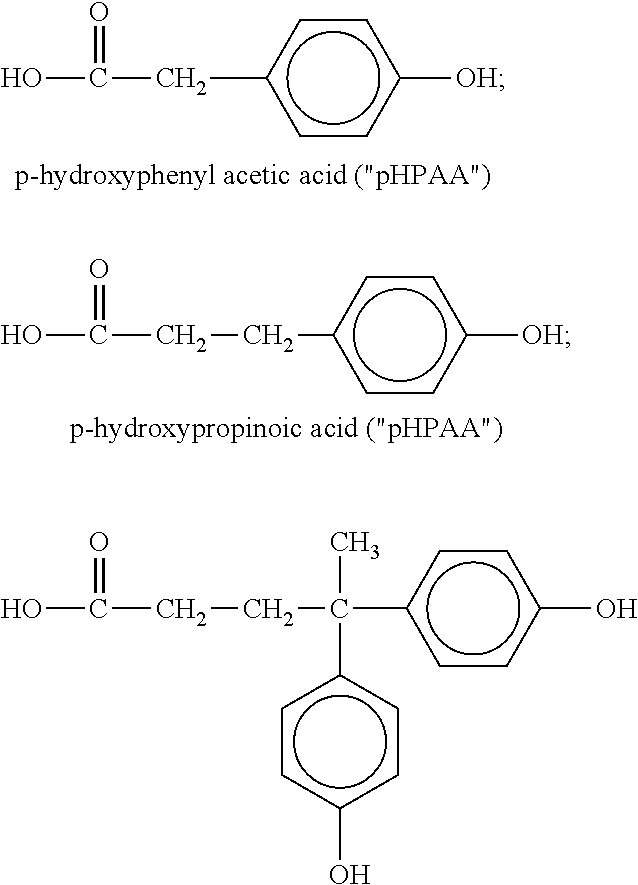

Novel accelerant and curing agent, preparation method and application thereof

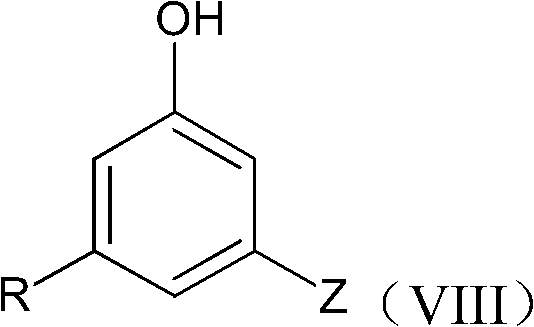

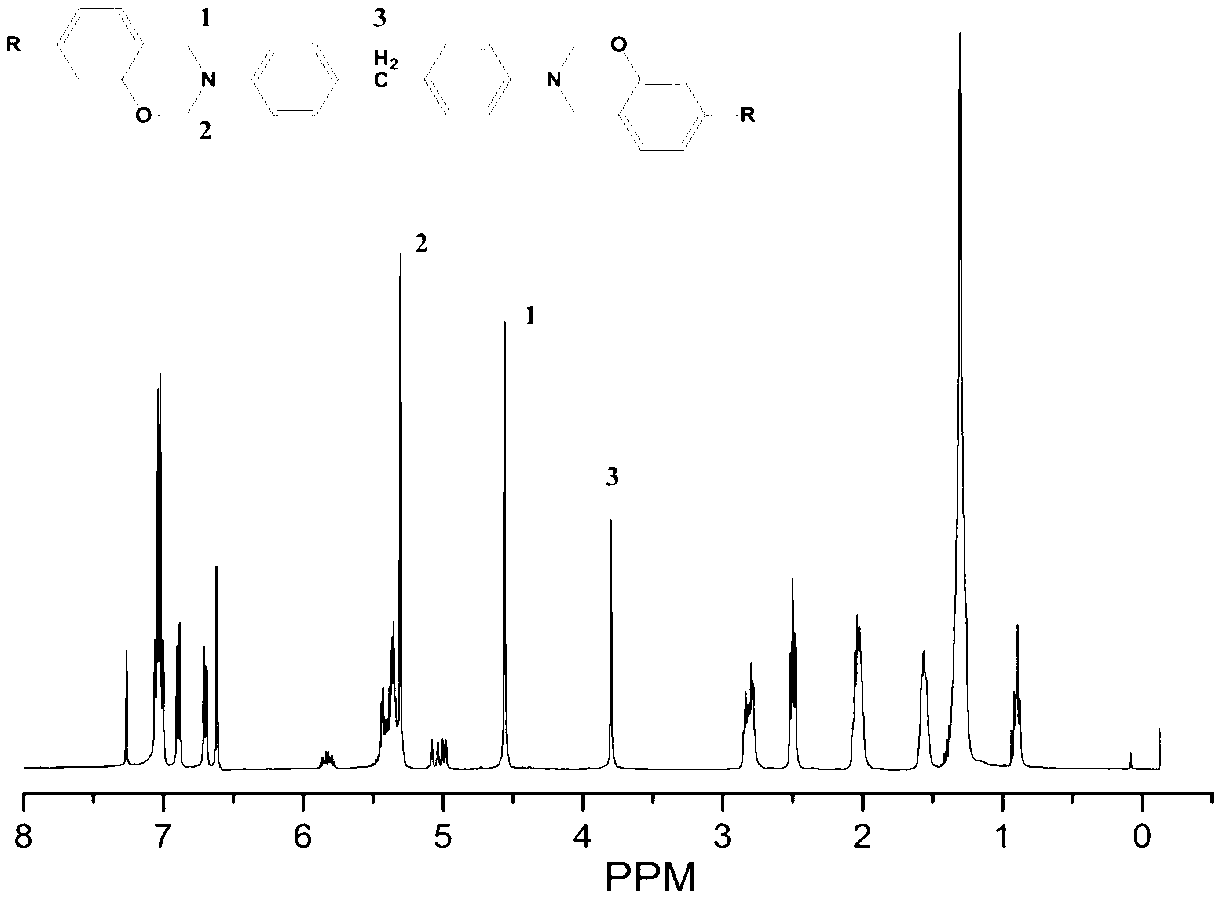

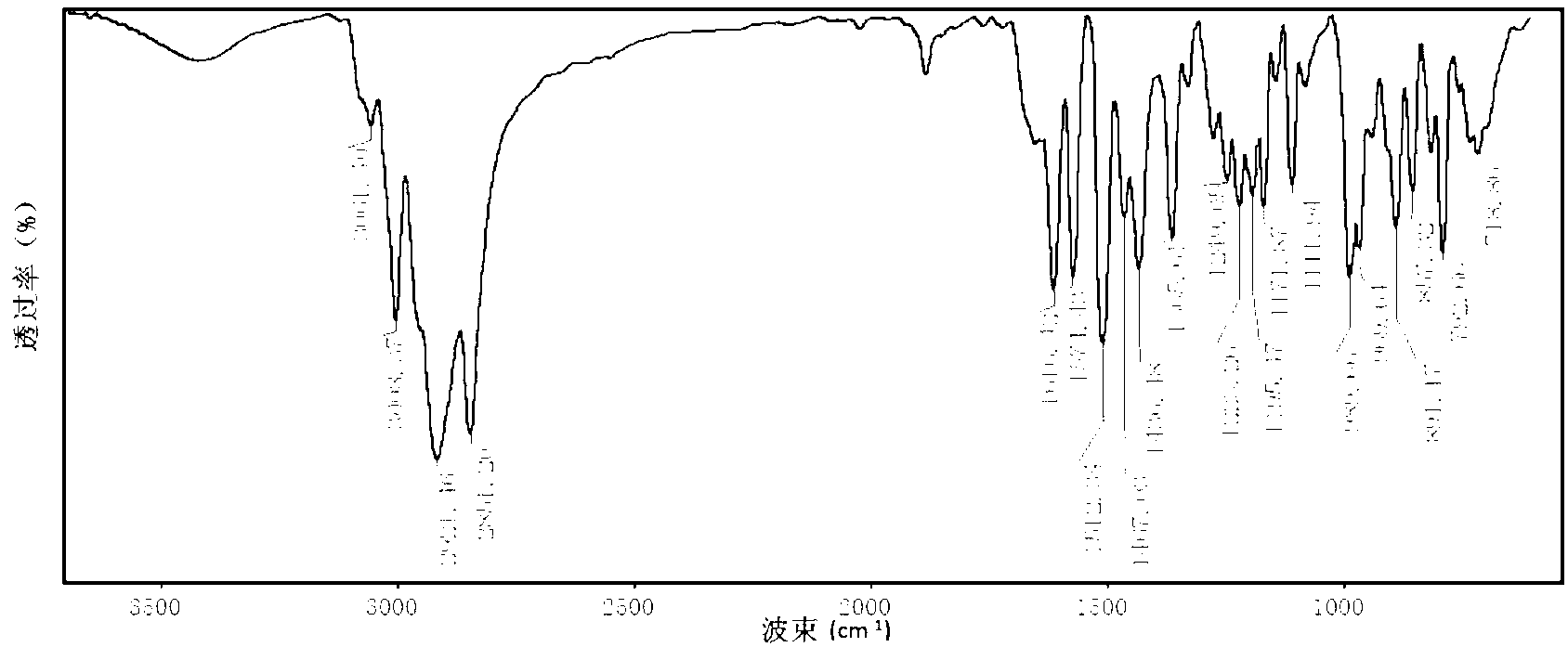

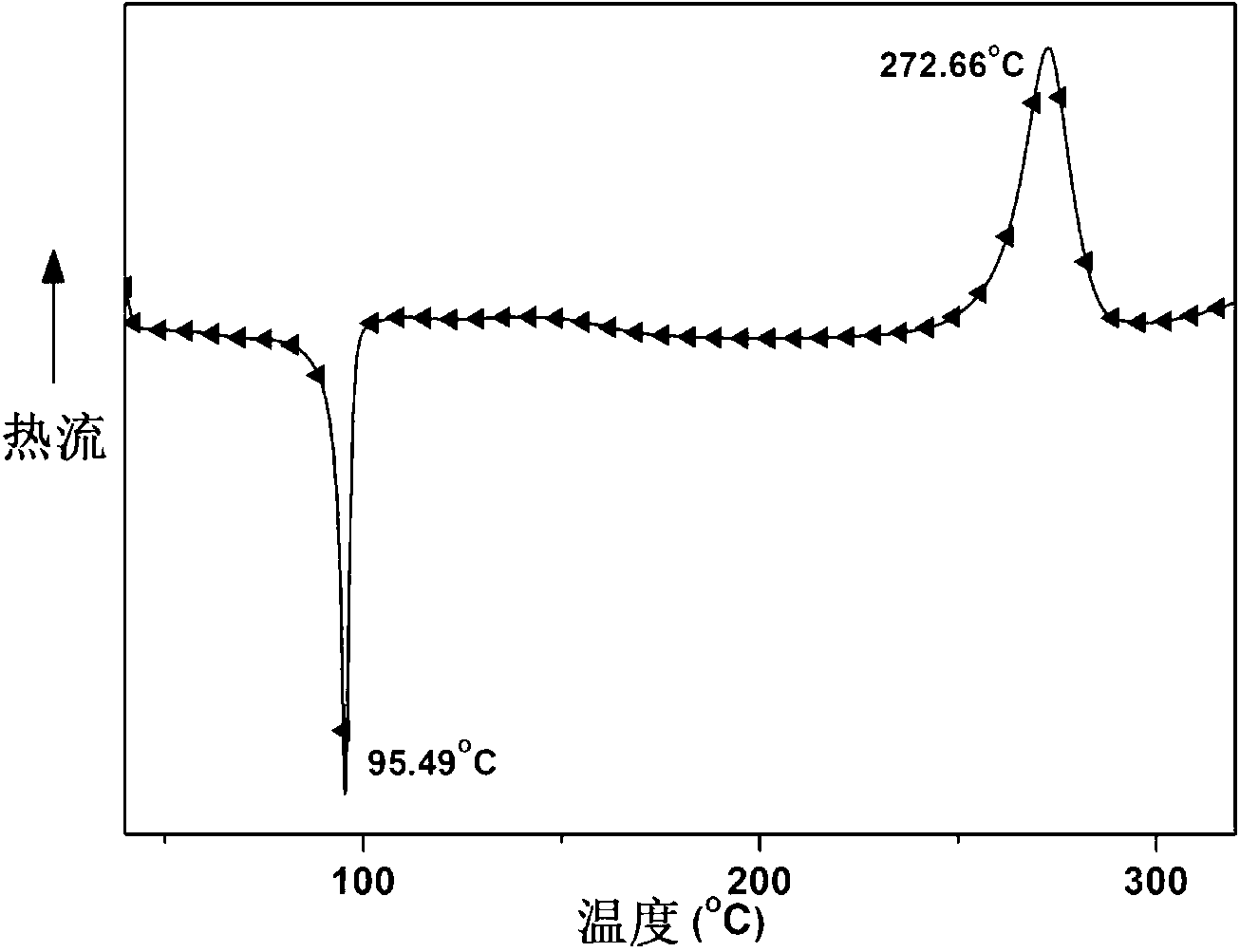

InactiveCN103102506AOrganic compound preparationAmino-hyroxy compound preparationMannich condensationStructural formula

The invention relates to a novel accelerant and a novel curing agent, a preparation method and an application thereof. The preparation method of the novel accelerant comprises: providing at least natural cardanol or artificial cardanol compound which has a chemical structural formula as shown in a formula VIII, wherein R is C15H2X+1, X is an integer between 12 and 15, and Z is H or OH; providing an aldehydes compound; providing an alkyl amine compound which has secondary amine; mixing the cardanol compound, the aldehydes compound and the alkyl amine compound, heating, and performing a mannich condensation reaction to form the accelerant. The invention further relates to the novel accelerant and the novel curing agent.

Owner:林登科 +1

Solvent-free cardanol epoxy heavy-duty antiseptic paint and method for producing the same

ActiveCN101508865AGood flexibilityImprove temperature resistanceAnti-corrosive paintsEpoxy resin coatingsSolvent freeFirming agent

The invention provides a solvent-free cardanol epoxy heavy anticorrosive paint, comprising 40-60 wt% of butyronitrile modified epoxy; 20-40 wt % of cardanol epoxy firming agent; 5-20 wt % of reactive diluent; 10-30 wt % of color filler and 5-8 wt% of additive. The invention further provides a preparation method of the solvent-free cardanol epoxy heavy anticorrosive paint, comprising the following steps: evenly mixing, stirring and milling the butyronitrile modified epoxy, the reactive diluent, the color filler and the additive so as to obtain component A according to mixture ratio of the solvent-free cardanol epoxy heavy anticorrosive paint; taking the cardanol epoxy firming agent as component B; and evenly mixing and stirring the component A and comment B when in use. The invention has the advantages of good high-temperature resistance property, good oil resistant property, strong chemicals corrosion resistance property, good construction matching property, good matching use property with the cathode protector of a storage tank, stable curing reaction in low-temperature moist environment, long service life, outstanding paint film insulating property, no environmental pollution, no irritating gas as well as simple, safe, environmental protection and healthy use.

Owner:湖北铁神新材料有限公司

Preparation method of mixed cresol modified meta-xylylene diamine epoxy resin curing agent

InactiveCN102532449AEfficient removalTemperature controlAnti-corrosive paintsEpoxy resin coatingsXylyleneIrritation

The invention provides a preparation method of a mixed cresol modified meta-xylylene diamine epoxy resin curing agent. The method comprises the following steps of: adding meta-xylylene diamine into an N2-charged reaction kettle; raising the temperature to 80-95 DEG C; adding hydroquinone; fully mixing; adding cardanol; keeping the temperature at 85-95 DEG C till a solution is clear and transparent; adding a catalyst; gradually adding polyformaldehyde in batches simultaneously; lowering the temperature to 70-80 DEG C; vacuumizing and dehydrating; after dehydrating, raising the temperature to 130-150 DEG C; undergoing a polymerization reaction; cooling to 70-85 DEG C; filtering the catalyst; diluting to 15-25 percent by using an organic solvent; and discharging to obtain the mixed cresol modified meta-xylylene diamine epoxy resin curing agent. A product prepared with the method has the advantages of stable performance, high curing speed, low toxicity, high transparency, unremarkable whitening phenomenon, nontoxicity and freeness of irritation, can be applied to underwater construction, and is a superior sea heavy-duty coating.

Owner:上海美东生物材料股份有限公司

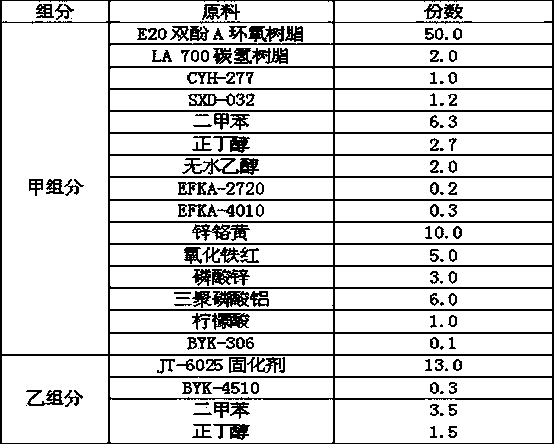

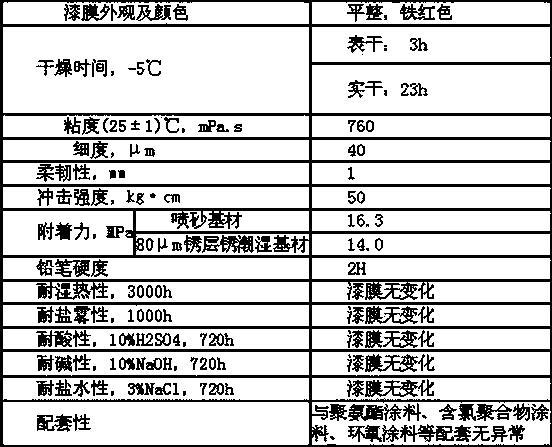

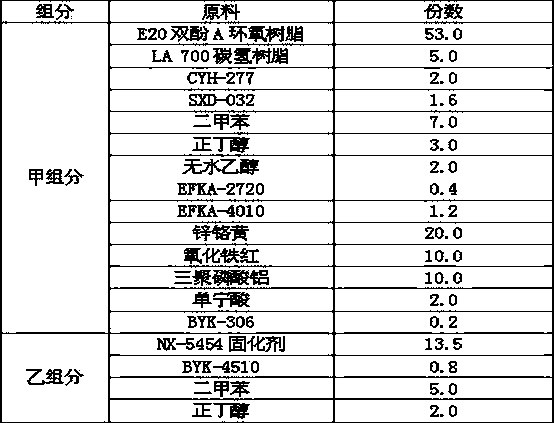

High-performance rust inhibiting primer for low surface treatment of mechanical equipment and preparation method of high-performance rust inhibiting primer

ActiveCN103351787AStrong adhesionImprove adhesionAnti-corrosive paintsEpoxy resin coatingsMechanical equipmentLayer thickness

The invention discloses a high-performance rust inhibiting primer for low surface treatment of mechanical equipment. The high-performance rust inhibiting primer is composed of a component A and a component B, wherein the component A comprises the following components in parts by mass: 50.0-57.0 parts of bisphenol A epoxy resin, 2.0-6.0 parts of modified resin, 1.0-3.0 parts of reactive toughening agent, 1.2-2.0 parts of penetrating agent, 9.0-11.0 parts of organic solvent, 2.0-5.0 parts of gradient alcohol solvent, 0.2-0.5 part of defoaming agent, 0.3-1.5 parts of wetting dispersant, 24.0-55.0 parts of rust inhibiting filler, 1.0-3.0 parts of rust converting agent and 0.1-0.3 part of substrate wetting agent; the component B comprises the following components in parts by mass: 13.0-14.0 parts of cardanol modified Mannich amide curing agent, 0.3-1.0 part of adhesive force promoter and 5.0-9.0 parts of organic solvent; and the mass ratio of the component A to the component B is 5:1 to 6:1. The primer has excellent adhesive force and favorable curing and film forming properties when coated on a wet substrate with the rust layer thickness of less than 80mum, so that the requirement for low surface treatment of the mechanical equipment is met.

Owner:洛阳双瑞防腐工程技术有限公司

Cardanol-aromatic diamine type benzoxazine flexibilizer as well as preparation method and purposes thereof

The invention discloses a cardanol-aromatic diamine type benzoxazine flexibilizer as well as a preparation method and purposes thereof. Cardanol, aromatic diamine and formaldehyde are used as raw materials, and are reacted under an alkali condition by adopting a solution synthesis method to obtain the cardanol-aromatic diamine type benzoxazine flexibilizer with high yield and high purity; in the structure, flexible aliphatic side chains of the cardanol can remarkably improve the toughness of condensates, can reduce the melt viscosity of resin systems, and can modify the forming processability; and rigid benzene ring structures of the aromatic diamine can retain high heat resistance and mechanical strength of the condensates. The benzoxazine flexibilizer is used for preparing high-performance structural materials, electric insulation materials or electronic packaging materials through lamination, mould pressing and RTM (Release to Manufacture) techniques after being mixed with epoxy resin, phenolic resin, cyanate ester resin, bismaleimide resin and other benzoxazine resin.

Owner:SICHUAN UNIV

Method for preparing cardanol modified phenolic paper-based copper clad plate

The invention relates to a method for preparing a cardanol modified phenolic paper-based copper clad plate. The method comprises the following steps: step 1), preparing a mixed solution of modified phenolic resin, namely, firstly, preparing cardanol modified phenolic resin, then preparing tung oil modified phenolic resin, then mixing the cardanol modified phenolic resin with the prepared tung oil modified phenolic resin according to a mass ratio of 1:1, then adding epoxidized soybean oil, and fully stirring to obtain the mixed solution of modified phenolic resin; and step 2), preparing the copper clad plate, namely, socking a wood fiber insulation paper in the mixed solution of modified phenolic resin prepared in the step 1), then drying and cutting to prepare a phenolic paper base, and then coating a copper foil on the surface of the phenolic paper base for compressing and molding so as to obtain the finished product. The method for preparing the cardanol modified phenolic paper-based copper clad plate is low in production cost, and the prepared copper clad plate has good flexibility.

Owner:江阴市明康绝缘玻纤有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com