Non-ionic self-emulsifying epoxy resin curing agent and preparation method thereof

An epoxy resin curing, non-ionic technology, applied in the field of non-ionic self-emulsifying epoxy resin curing agent and its preparation, can solve the problems of increased cost, many operation steps, high viscosity of curing agent, etc., and achieve the overall coating film Improved performance, simple preparation equipment, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

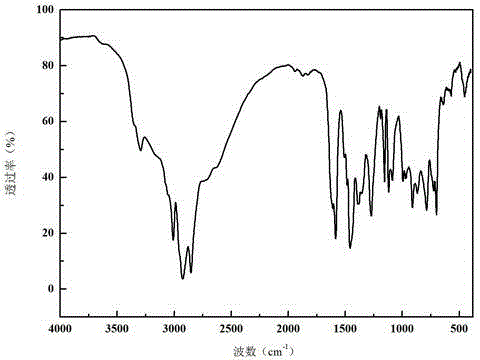

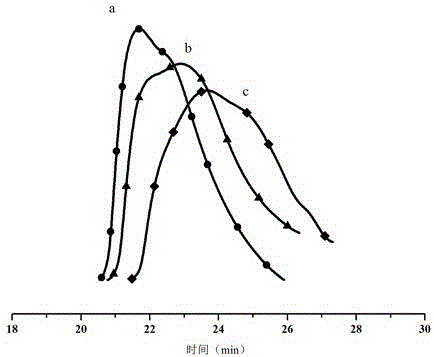

[0036] Add 100g of cardanol and 58.93g of m-xylylenediamine into a 250ml three-necked flask equipped with a stirrer, reflux condenser and constant pressure dropping funnel, heat to 70°C, and add 32.43g of 37wt% formaldehyde solution dropwise under stirring After 30 minutes of dropwise addition, the temperature was raised to 100°C for 3 hours, then washed with warm water, and the water layer was separated by standing. Then, at 70°C and -0.095MPa vacuum, the water was removed under reduced pressure for 30 minutes to obtain a brownish-red liquid with an amine value of 256mgKOH / g, the viscosity is 1765mPas, lowered to room temperature for use.

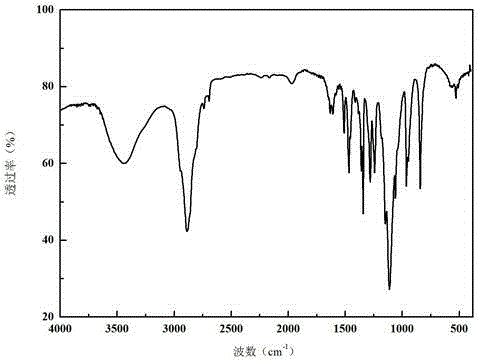

[0037] Add 100g of polyethylene glycol 6000 and 13.06g of epoxy resin E51 into a 250ml flask with a stirrer, raise the temperature to 90°C, and under stirring, add the catalyst boron trifluoride ether 0.27g in 6 times, each interval 20min, reacted for 120min, a white waxy solid was obtained.

[0038]Take 15g of the white waxy solid and 8...

Embodiment 2

[0043] Add 90g of cardanol and 66.3g of isophoronediamine into a 250ml three-neck flask equipped with a stirrer, a reflux condenser and a constant pressure dropping funnel, heat to 70°C, and dropwise add 37wt% formaldehyde solution 26.76 g, after 30 minutes of dropwise addition, warm up to 100°C for 3 hours, wash with warm water, let stand to separate the water layer, and then remove water under reduced pressure at 70°C and -0.095MPa vacuum for 30 minutes to obtain a brownish-red liquid with an amine value of 295mgKOH / g, viscosity 2256mPas, cooled to room temperature for use.

[0044] Add 100g of polyethylene glycol 6000 and 13.06g of epoxy resin E51 into a 250ml flask with a stirrer, raise the temperature to 90°C, and under stirring, add the catalyst boron trifluoride ether 0.27g in 6 times, each interval 20min, reacted for 120min, a white waxy solid was obtained.

[0045] Take 20g of the white waxy solid, 80g of the above-mentioned maroon liquid and 3g of γ-glycidyl ether p...

Embodiment 3

[0049] Add 100g of cardanol and 63.27g of triethylenetetramine into a 250ml three-necked flask equipped with a stirrer, a reflux condenser and a constant pressure dropping funnel, heat to 70°C, and add 32.43g of 37wt% formaldehyde solution dropwise while stirring, After 30 minutes of dropping, raise the temperature to 100°C for 2 hours, then wash with warm water, let stand to separate the water layer, and then remove water under reduced pressure at 70°C and -0.095MPa vacuum for 30 minutes to obtain a brownish-red liquid with an amine value of 268mgKOH / g, the viscosity is 1605mPas, lowered to room temperature for use.

[0050] Add 100g of polyethylene glycol 6000 and 13.06g of epoxy resin E51 into a 250ml flask with a stirrer, raise the temperature to 90°C, and under stirring, add a total of 0.27g of boron trifluoride ether as a catalyst in 6 times, each interval 20min, reacted for 120min, a white waxy solid was obtained.

[0051] Take 8g of the white waxy solid and 92g of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com